Page 1

Supplement to the instruction

manual and parts list for the

series 1050, 1180

-926/06

296-12-18 770/002

engl. 09.03

Page 2

Reprinting, copying or translation of PFAFF instruction manuals, whether in whole or in part,

is not permitted without our prior permission and not without written indication of the

source.

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Editing/illustrations

HAAS-Publikationen GmbH

D-53840 Troisdorf

Page 3

Index

Contents ................................................................................. Chapter - Page

1 Safety ........................................................................................................................... 1 - 1

1.01 Regulations ................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................ 1 - 1

1.03 Safety symbols ............................................................................................................. 1 -2

2 Bedienungselemente .................................................................................................. 2 - 1

2.01 Spulenfadenrestanzeige................................................................................................ 2 - 1

2.02 Pedal ....................................................................................................................... ...... 2 - 1

3 Preparation .................................................................................................................. 3 - 1

3.01 Winding the bobbin thread, adjusting the thread tension .............................................. 3 - 1

3.02 Inserting the bobbin case / Adjusting the bobbin thread tension................................... 3 - 2

4 Sewing ......................................................................................................................... 4- 1

4.01 Sewing with bobbin thread monitoring ......................................................................... 4 - 1

4.02 Sewing with remaining bobbin thread count ................................................................. 4 - 2

5 Adjustment .................................................................................................................. 5 - 1

5.01 Notes on adjustment..................................................................................................... 5 - 1

5.02 Function control and adjustment of the bobbin thread monitor..................................... 5 - 1

5.03 Parameter settings........................................................................................................ 5 - 3

5.03.01 Selecting and altering parameters................................................................................. 5 - 3

5.03.02 Selecting the user level................................................................................................. 5- 4

5.03.03 List of parameters.........................................................................................................5- 5

6 Parts list ....................................................................................................................... 6 - 1

Page 4

Safety

1 - 1

1 Safety

1.01 Regulations

This machine is constructed in accordance with the European regulations indicated in the

conformity and manufacturer's declarations.

In addition to this instruction manual, please also observe all generally accepted, statutory

and other legal requirements, including those of the user's country, and the applicable pollution control regulations!

The valid regulations of the regional social insurance society for occupational accidents or

other supervisory authorities are to be strictly adhered to!

1.02 General notes on safety

● The machine must only be operated by adequately trained operators and only when the

instruction manual has been fully read and understood!

● All notices on safety and the instruction manual of the motor manufacturer are to be read

before the machine is put into operation!

● All notes on the machine concerning danger and safety must be observed!

● The machine must be used for the purpose for which it is intended and must not be

operated without its safety devices; all regulations relevant to safety must be adhered to.

● When part sets are changed (e.g. needle, presser foot, needle plate, feed dog or bob-bin),

during threading, when the workplace is left unattended and during maintenance work,

the machine must be isolated from the power supply by turning off the on/off switch or

removing the plug from the mains!

● Daily maintenance work must only be carried out by appropriately trained persons!

● Repairs and special maintenance work must only be carried out by qualified technical

staff or persons with appropriate training!

● During maintenance or repairs on the pneumatic system the machine must be isolated

from the compressed air supply! The only exception to this is when adjustments or

function checks are carried out by appropriately trained technical staff!

● Work on the electrical equipment must only be carried out by technical staff who are

qualified to do so!

● Work on parts or equipment connected to the power supply is not permitted! The only

exceptions to this are specified in regulations EN 50110.

● Conversion or modification of the machine must only be carried out under observation of

all relevant safety regulations!

Page 5

Safety

1 - 2

● Only spare parts which have been approved by us are to be used for repairs! We draw

special attention to the fact that spare parts and accessories not supplied by us have not

been subjected to testing nor approval by us. Fitting and/or use of any such parts may

cause negative changes to the design characteristics of the machine. We shall not accept any liability for damage caused by the use of non-original parts.

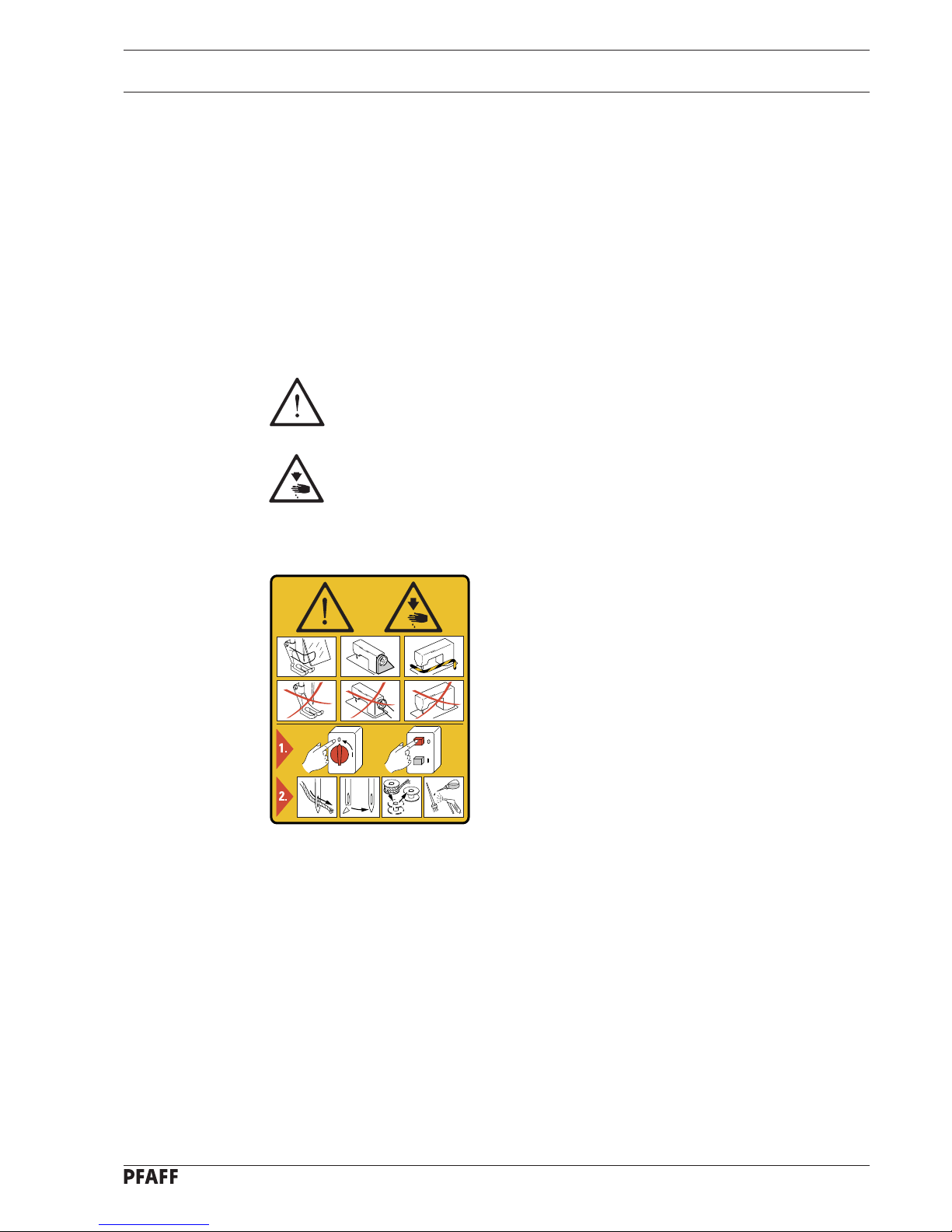

1.03 Safety symbols

Danger!

Special points to observe.

Danger of injury to operating or technical staff!

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

Page 6

Bedienungselemente

2 - 1

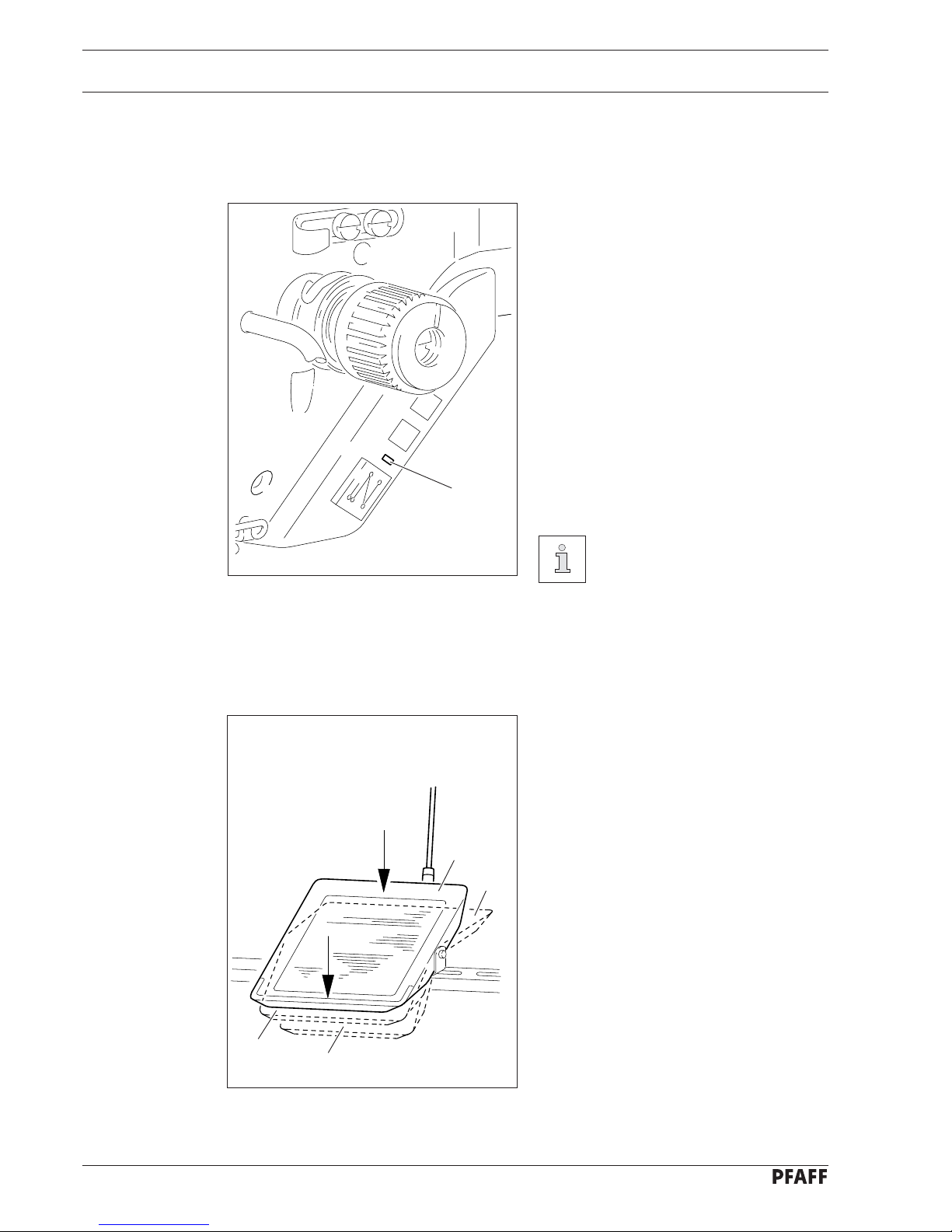

Fig. 2 - 01

2 Control elements

2.01 Control device for remaining bobbin thread

Bobbin thread monitor

● When the use of the last amount of

the remaining thread supply begins, the

LED 1 starts flashing.

● When the remaining thread supply has

been used up, the LED 1 lights up

permanently until the bobbin has been

changed.

Bobbin thread counter

● When the thread counter reaches its end,

the LED 1 starts flashing.

● If sewing continues without the bobbin

being changed, the LED 1 remains on

permanently until the bobbin is changed.

To select thread monitoring or

thread counting see Chapter

5.03 Parameter settings.

2.02 Pedal

0 = Neutral position

1 = Sewing

2 = Raise presser foot

3 = Trim sewing threads / reset

bobbin thread monitor or bob

bin thread counter

Fig. 2 - 02

0

+ 1

- 1

- 2

1

Page 7

Preparation

3 - 1

3 Preparation

All regulations and instructions in this Instruction Manual are to be observed!

Special attention is to be paid to the safety regulations!

All preparation work is only to be carried out by appropriately trained personnel.

Before all preparation work, the machine is to be separated from the electricity

supply by removing the plug from the mains or switching off the On/Off switch!

3.01 Winding the bobbin thread, adjusting the thread tension

81-095

81-094

Fig. 3 - 01

4

-

3

2

1

+

81-096

6

5

1

● Fit empty bobbin 1 onto bobbin winder spindle 2 with the rest thread chamber on the

outside.

● Thread the thread as shown in the above illustration and wind it round the bobbin 1 a few

times in an anti-clockwise direction.

● Switch on the bobbin winder by pressing bobbin winder spindle 2 and lever 3

simultaneously.

Page 8

Preparation

3 - 2

3.02 Inserting the bobbin case / Adjusting the bobbin thread tension

Fig. 3 - 03

5 cm

1

+

-

● Insert bobbin 1 into the bobbin case 2 as shown in Fig. 3-02.

● Place the bobbin in the bobbin case.

● Pass the thread through the slot under the spring as shown in Fig. 3-03. When the thread

is drawn off, the bobbin must turn in the direction shown by the arrows.

● Adjust the thread tension by turning screw 1.

-

Fig. 3 - 02

2

1

The bobbin fills up during sewing.

If the machine is only run for bobbin winding (without sewing), a hook

base must be fitted in the hook.

Otherwise a jammed thread may damage the hook!

● The tension of the thread on bobbin 1 can be adjusted with knurled screw 4.

● The bobbin winder stops automatically when bobbin 1 is full.

If the thread is wound unevenly:

● Loosen nut 5.

● Turn thread guide 6 accordingly.

● Tighten nut 5..

Page 9

Sewing

4 - 1

4 Sewing

4.01 Sewing with bobbin thread monitoring

The bobbin thread monitoring function is activated, when parameter "660" is set

at value "1". The number of stitches remaining after the bobbin thread monitor

has reacted is entered under parameter "760". More information about the

parameter setting is contained in Chapter 5.03 Parameter settings.

● If the bobbin thread monitor recognises

during sewing that the remaining

amount of thread has been started, LED

1 starts flashing.

Sewing can be continued without changing the bobbin, and from this point on

the pre-set number of remaining stitches

are counted.

● If the number of remaining stitches after

recognition of the bobbin thread monitor

have been sewn, the machine stops

automatically with the needle lowered

and LED 1 remains lit up permanently.

● Set the pedal at its neutral position (pedal

position "0").

● Complete the seam (pedal position "+1").

● Carry out the thread trimming function

(pedal position "-2").

● The bobbin thread monitor is reset.

● Change the bobbin.

The bobbin thread monitor can be reset at any time by pressing key 2 and at

the same time operating the pedal in position "-2".

2

Fig. 4 - 01

1

Page 10

Sewing

4 - 2

2

1

4.02 Sewing with remaining bobbin thread count

The remaining bobbin thread count function is activated, when parameter "660"

is set at value "2". The total number of stitches for the bobbin is entered under

parameter "760". More information about the parameter setting is contained in

Chapter 5.03 Parameter settings.

● If the total number of stitches have been

sewn, the machine stops automatically

with the needle lowered and LED 1

flashes.

● If sewing is continued without a bobbin

change, LED 1 remains lit up

permanently.

● Set the pedal at its neutral position (pedal

position "0").

● Complete the seam (pedal position "+1").

● Carry out the thread trimming function

(pedal position "-2").

The bobbin thread monitor is reset.

● Change the bobbin.

The bobbin thread monitor can be reset at any time by pressing key 2 and at

the same time operating the pedal in position "-2".

Fig. 4 - 02

Page 11

Adjustment

5 - 1

5 Adjustment

5.01 Notes on adjustment

All adjustments in this instruction manual apply to a completely assembled machine and may

only be carried out by suitably trained staff.

Machines covers which are removed for control and adjustment work and then set back in

place again are not mentioned in the text.

5.02 Function control and adjustment of the bobbin thread monitor

Requirement

The value of parameter "382" should correspond to the average value of the top and

bottom threshold value of the thread monitor.

● Insert a full bobbin in the bobbin case and place the bobbin case in the hook.

● Switch on the machine.

● Press the TE/Speed key to call up the parameter input function.

● By pressing the corresponding +/- keys, set parameter "797" at "ON" (displaying the

inputs).

● By pressing the corresponding +/- keys, set parameter "798" at value "1" (selecting the

mechanic level).

No / VAL

No VAL

B 797 ON

TE

No VAL

A 101 ON

TE

No / VAL

No VAL

B 798 1

TE

Page 12

Adjustment

5 - 2

E 1 X 5: 5 0

● By pressing the corresponding +/- keys, select sub-menu "Fw" (thread monitor menu).

Fw 63%

● Draw the bobbin thread by hand and note the top or bottom threshold value

(e.g. 63% or 3% => average value: 30%)

● Press the TE/Speed key to call up the parameter input function.

● By pressing the corresponding +/- keys, select parameter "382" and enter the

corresponding average value (e.g. "30").

No / VAL

● Press the TE/Speed key to conclude the parameter input function.

● Switch off the machine.

No VAL

B 382 30

TE

Page 13

Adjustment

5 - 3

5.03 Parameter settings

5.03.01 Selecting and altering parameters

● Switch on the machine.

● Press the TE/Speed key to call up the parameter input function.

● By pressing the corresponding +/- keys, select the desired parameter, e.g. "660" for the

bobbin thread monitoring function.

No

● By pressing the corresponding +/- keys, select the desired parameter group, e.g. "600".

No

No

600

TE

No VAL

A 101 ON

TE

No VAL

A 660 1

TE

● By pressing the TE/Speed key the value is taken over and the machine changes to the

sewing mode.

● By pressing the corresponding +/- keys, set the desired value for the selected parameter,

e.g. "2" for the "bobbin rest thread counter on" function.

No VAL

A 660 2

TE

VAL

Page 14

Adjustment

5 - 4

5.03.02 Selecting the user level

● Switch on the machine.

● Press the TE/Speed key to call up the parameter input function.

● By pressing the corresponding +/- keys, select parameter "798".

No

● By pressing the corresponding +/- keys, select the parameter group "700".

No

No

700

TE

No VAL

A 101 ON

TE

No VAL

A 798 0

TE

● By pressing the corresponding +/- keys, select the desired user level:

"0" = operator lever A

"1" = mechanic level B

"11" = service level C

● By pressing the TE/Speed key the value is taken over and the machine changes to the

sewing mode.

VAL

Page 15

Adjustment

5 - 5

3 382 Average value for switching threshold B 0 – 100 15

bobbin thread monitor

6 660 Bobbin thread monitor A 0 – 2 0

0 = off

1 = bobbin thread monitor on

2 = bobbin thread reverse counter on

7 760 Number of stitches A 0 – 250 5

for remaining thread after reaction of

bobbin thread monitor

(for bobbin thread monitoring)

No. of stitches (x 200)

(for remaining bobbin thread count)

797 Hardware test C ON-OFF OFF

798 User level A 0 – 255 0

0 = operator level A

1 = mechanic level B

11 = service level C

5.03.03 List of parameters

Parameter

The standard values listed in the table are basic settings. When required,

deviations are possible.

Group

Description

Standard value

Adjustment

range

Access level

Page 16

Parts list

6 - 1

40/13

11-130 092-25

12-305 084-25

95-774 460-91

95-774 459-25

91-056 193-25

91-174 879-05

91-056 192-25

12-024 191-25

95-774 466-91

11-330 952-15

11-250 084-25

95-774 464-25

91-266 397-01

91-118 685-05

95-774 467-05

95-774 465-25

12-640 130-55

99-137 151-45

91-174 783-05

91-700 996-15

91-118 940-05

14-602 901-01 (2x)

91-171 049-05

91-100 281-25

91-171 042-05

91-118 683-05

Page 17

6 - 2

Parts list

95-774 525-91 (PFAFF 1051;1181)

11-210 084-25 (2x)

95-774 524-91 (PFAFF 1053;1183)

11-210 084-25 (2x)

95-774 407-91

91-004 181-05

91-262 806-05

95-774 409-25

91-100 076-15 (2x)

91-000 621-15 (2x)

95-784 334-91

95-774 361-05

95-774 408-91

95-774 419-25

95-784 334-91

Page 18

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Telefon: (0631) 200-0

Telefax: (0631) 17202

E-Mail: info@pfaff-industrial.com

Gedruckt in der BRD

Printed in Germany

Imprimé en R.F.A.

Impreso en la R.F.A.

Loading...

Loading...