Page 1

rrrr

electronic

6250

PFAFF

.‘

eiectro

20

-

Instruction

book

Page 2

I

easier

For

-

please

understanding

fold

this

page

open

of

when

this

instruction

reading

it.

book

I

I

LL

Safety

For

the

The

leads

with

plug

The

wiresinthe

As

the

with

the

wire

The

marked

The

wire

marked

rules

United

must

three

Blue:

Brown:

colours

colour

which

with

which

with

Kingdom

definitely

pins.

mains

Neutral

Live

the

of

coding

is

the

lettter

is

the

letter

lead

wires

of

coloured

N

coloured

L

or

only

not

are

in

the

blue

or

coloured

brown

coloured

be

connected

coloured

the

mains

terminals

must

must

red.

lead

in

be

black

be

to

the

according

of

this

your

plug,

connected

connected

safety-lead

the

to

appliance

proceed

to

the

to

the

following

terminal

may

as

follows:

terminal

terminal

I

nor

code:

correspond

not

which

which

I

:

to

a

I

I

I

is

is

i

I

Cut-oft

Defective

Only

3

and

the

plug

The

electrical

froiii

Please

mains

mains

A

spare

fuse

must

also

plugs

leads

fuses

cover

never

suppliers

observe

are

definitely

must

must

must

be

used

be

or

the

general

Contents

be

be

used

marked

without

the

PFAFF

on

-

not

to

replaced

as

3

safety

pages

-

be

used,

complete.

approved

A

or

with

fuse

cover.

agencies.

notes

and

4

on

but

ASTA

by

the

corresponding

Spare

page

5

-

disposed

according

fuse

2.

immediately.

of

covers

to

BS

colour

are

1362

code.

available

I

I

I

I

i

I

I

I

I

I

I

Page 3

Important

the

For

Li

This

appliance,

Read

Li

DANGER

L

L

LI

L

1

2.

3.

4.

AIARNING

I

1

2.

3.

I

1

4

5

6

7.

8

9

0.

l

I

11.

1

2.

3.

1

1

4

15.

1

6

7.

1

U

k

U

L

L

United

sewing

The

the

Always

Do

Do

or

machine

basic

instructions

all

sewing

electnc

unplug

reach

not

place

not

into

drop

allow

not

Do

children.

near

this

Use

recommended

operate

Never

dropped

been

service

or

operate

Never

sewing

drop

Never

not

Do

not

Do

To

disconnect

operate

Never

riot

Dv

lingers

Keep

Always

not

Do

not

Do

Switch

needle,

Always

making

plug

Hold

States

safety

To

machine

outlet

for

or

water

sewing

center

machine

or

out

use

operate

unplug

the

use

bent

use

or

pull

sewing

the

changing

unplug

any

when

safety

only

designed

is

precautions

before

reduce

should

irrirriediately

before

sewing

a

stoie

other

or

reduce

To

used

be

to

machine

the

by

sewing

this

damaged,

or

examinatron.

for

sewing

the

and

mnsett

doors.

of

where

all

turn

soft

on

a

pulling

by

from

away

proper

blunt

or

push

machine

needle,

sewing

user

othei

rewinding

instructions

manufactured

and

should

sewing

this

using

electric

of

risk

the

be

never

after

machine

machine

liquid.

risk

the

toy.

a

for

only

machine

dropped

or

machine

control

(spray>

cord.

on

rnovmnq

plate.

needles

while

of[(”O’>

threading

into

Replace

Close

its

repair.

free

into

to

such

stitching.

from

adjustments

cord

relamping.

sewing

a

as

manufacturer

foot

object

any

aerosol

controls

suttace

all

needle

fabric

machine

servicing

always

left

usiiig

that

burns,

of

intended

as

if

with

any

off

(“0”)

To

patts

The

Use

when

bobbin,

machine.

shock:

unattended

and

bulb

has

where

attention

contained

has

it

into

electrical

any

from

opening.

products

position,

bed

a

as

unplug,

Special

wrong

needles

It

making

electric

the

reel.

for

adhered

be

before

with

fallen

can

it

electric

tire,

use

damaged

a

water,

air

openings

accumulation

the

are

or

grasp

plate

recommended

niay

changing

or

mentioned

not

Do

HOUSEHOLD

into

is

as

in

Return

or

being

then

couch

care

deflect

any

outlet

allow

as

to

plugged.

when

cleaning.

type

same

water

or

be

fall

shock,

necessary

described

manual.

this

cord

the

mnechirncal

blocked.

used

remove

where

pIng,

the

required

is

cause

can

the

adjustments

presser

when

in

plug

the

use

follows

rated

Unplug

pulled

or

when

ii

plug,

or

appliance

adjustment.

lint,

of

where

or

plug

the

not

the

by

needle,

foot,

removing

instruction

whip

to

only

Always

5

1

immediately.

into

injury

this

manual.

tIns

it

it

Keep

dust

horn

openings

air

cord.

the

around

needle

nianufacturer

the

causing

the

in

etc.

when

When

unplug

Watts.

tub

a

persons

to

sewing

not

is

the

to

ventilatmon

loose

and

oxygen

outlet

sewing

the

to

it

needle

covers,

manual.

rewinding.

you

this

sink.

or

machine

Use

oilli

working

nearest

openings

cloth

being

is

be

may

break.

only.

break

to

area,

lubricating,

an

use

appliance

not

Do

used

is

attachments

pioperly,

authorized

administered.

blocked.

machine

such

or

electric

place

of

needle

threading

as

when

by

if

the

from

in

or

it

has

dealer

notes

general

observe

also

Please

the

safety

on

page

2.

SAVE

THESE

INSTRUcTIONS

Page 4

22

1

2345

6

7

8

9

37

16

p;16

J

27

12

PFAFF

26

23

,

24

I

F

25

26

!i

ertronic

29

6250

—10

‘i

14

—15

V

4

1W

38

I

PFAFF

-_

electro

•

30

cc

6250

Page 5

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

(29)

(30)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

(38)

(39)

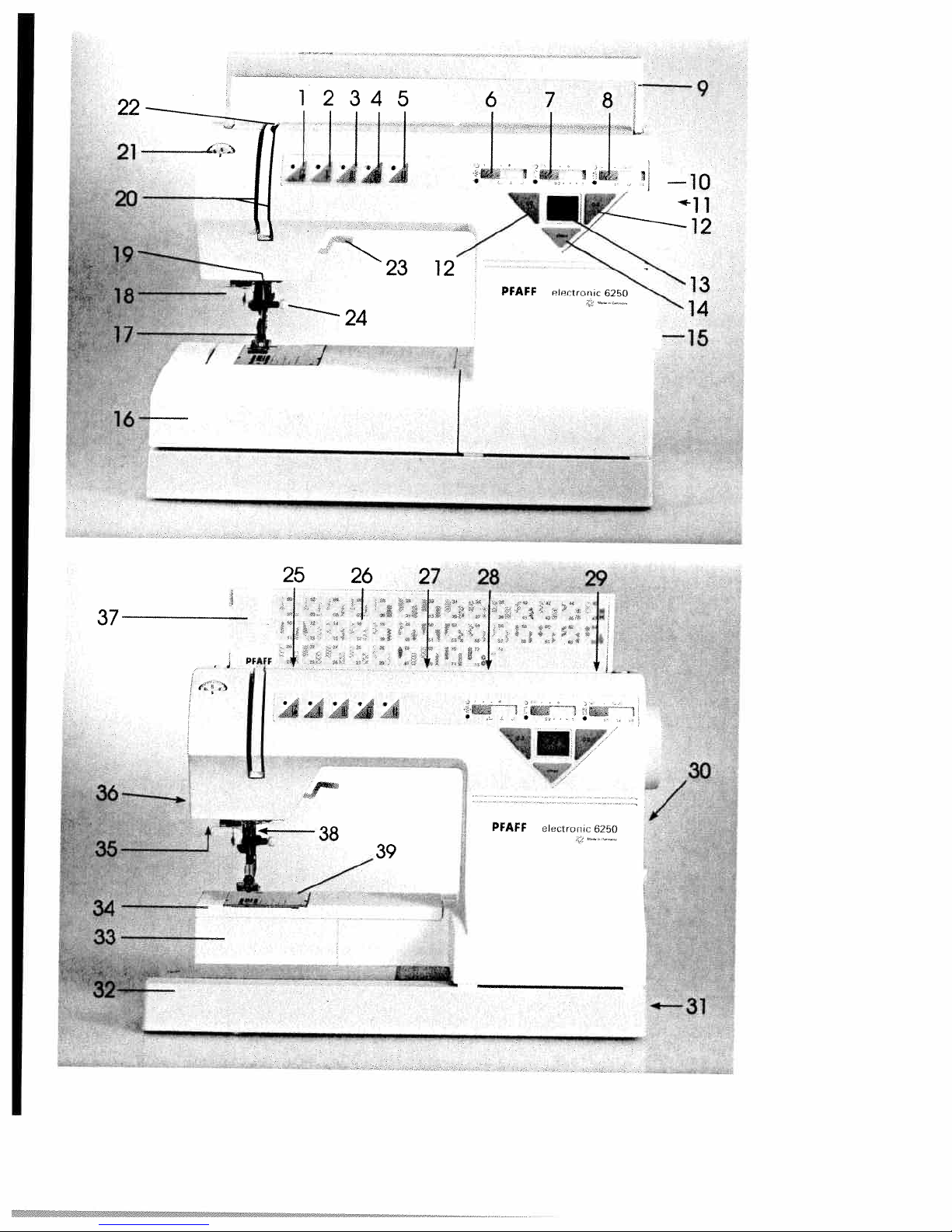

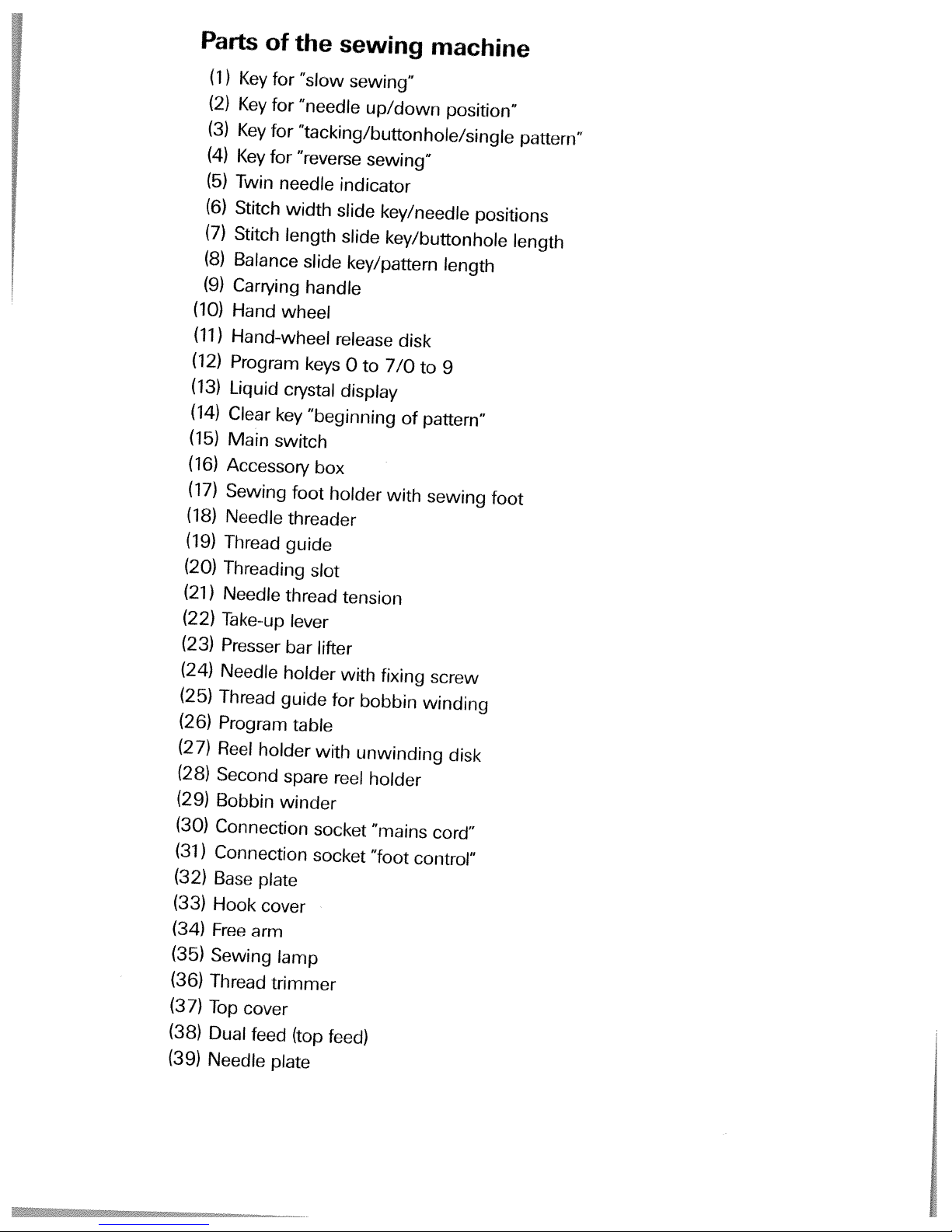

Parts

(1)

(2)

(3)

(4)

(5)

Twin

Stitch

(6)

Stitch

(7)

(8)

Balance

(9)

Carrying

(10)

Hand

(11)

Handwheel

(12)

Program

(13)

Liquid

(14)

Clear

(15)

Main

(16)

Accessory

(17)

Sewing

Needle

Thread

Threading

Needle

Takeup

Presser

Needle

Thread

Program

Reel

Second

Bobbin

Connection

Connection

Base

Hook

Free

Sewing

Thread

Top

Dual

Needle

Key

Key

Key

Key

arm

cover

feed

of

the

sewing

for

“slow

for

“needle

for

“tacking/buttonhole/single

for

“reverse

needle

width

length

wheel

crystal

key

switch

foot

threader

guide

thread

lever

bar

holder

guide

table

holder

spare

winder

plate

cover

lamp

trimmer

(top

plate

sewing”

up/down

sewing”

indicator

slide

slide

slide

key/pattern

handle

release

keys

0

to

display

“beginning

box

holder

slot

tension

lifter

with

for

bobbin

with

unwinding

reel

socket

socket

feed)

key/needle

key/buttonhole

disk

7/0

with

fixing

holder

“mains

“foot

machine

to

9

of

pattern”

sewing

screw

winding

cord”

control”

position”

pattern”

positions

length

length

foot

disk

Page 6

I.

/

Notes

Notes

machines

Section

1.

2.

3.

4.

5

The

according

specification

6.

Do

the

7.

Do

—

—

—

8

Do

socket

If

9.

purpose

wrongly

liability

1

0.

To

open

inside

repair,

our

11.

Be

on

on

safety

according

28

or

The

user must

with

regard

needle

area

When

maintenance

mechanical

disconnect

by

The

sewing

The

adjusted

this

during

pulling

maximum

tension

machine

not

machine

not

there

its

function

it

is

wet,

not

appliance

avoid

the

the

qulified

sure

and

leaving

lamp

by

place

use

is

pull

by

than

operated,

for

the

machine.

This

to

safety

for

IEC

to

the

constantly

work

work

parts

the

out

permissible

is

the

of

a

Ptaff

must

to

the

plate.

any

the

visible

is

e.g.

with

the

its

cord.

that

any

damage

risk

machine

is

solely

service

use

only

domestic

to

DIN

335,

Section

exercise

up-

the

machine,

or

or

accessories,

machine

the

mains

1

5

Watts.

drive

mechanic.

be

put

indications

objects

sewing

damage,

disturbed,

condensation.

mains

plug

is

used

intended

we

will

of

electric

There

which

the

staff.

original

sewing

57

700,

28

adequate

and

down

observe

the

during

when

changing

from

the

plug.

wattage

belt

must

into

operation

on

in

openings

machit

for

out

another

or

not

te

of

if

it

accept

caused.

shock,

are

rio

the

user

responsibility

PFAFF

caution

moving

only

the

if:

the

is

do

parts

can

sewing

always

mains

for

the

be

on

any

not

of

parts.

Environment

The

recommended

Ambient

Humidity

This

sewing

temperature

20%

machine

electronicmechanical

for

supervised

operated

to:

dust,

static

corrosive

rhe

machine

for

ventilation

electricity,

in

such

severe

chemicals

must

purposes,

use

even.

Treatment

Always

hitting

protect

or

dropping.

the

Cleaning

onsi

H

ii

g:

To

clean

the

housing,

cloth

which

stubborn

paraffin.

Please

Do

not

products

for

cleaning

dirt,

Note!

use

such

is

free

use

any

insecticides

as

the

environn

1

0

to

80%

is

appliance;

in

the

a

way

that

dampness,

heat-producing

or

be

used

machine

use

of

fluff

a

soft

cloth

petrol

(gas)

housing.

ient

to

C

40

a

high-quality

home.

it

is

direct

liquids.

on

a

which

is

against

a

dry,

To

remove

with

or

chemical

or

thin

is.

it

It

not

free

both

clean

alcohol

should

objects,

C

is

a

machine

be

subjected

sunlight,

surface,

firm

damage

and

soft

any

or

cheniicals

and

by

Page 7

Modern,

uncomplicated

Sewing

—

control

by

—

touch-key

Congratulations!

high-quality

advantages.

take

can

sew

will

features

It

technology,

as

just

sewing

If

the

wrong.

After

the

make

If

no

at your

you

So

you

your

now

you

instruction

all,

things

full

have

you

problem!

need.

now

many

fashion

product

Your

any

through

the

and

uncomplicated

machine.

take

this

is

the

use

any

service

you

can

enjoyable

ideas.

You

new

material

thick

ver’

latest

this

time

book,

the

only

machine

them.

of

further

PFAFF

Your

with

get

have

offers

that

sewing

in

its

stride

thin

and

in

desgin

instruction

your

as

enough

nothing

way

can

questions,

dealer

help

any

started!

hours

of

bought

unique

machine

for

book

PFAFF

study

to

can

learn

to

and

do,

will

or

advice

We

creating

a

and

you.

and

go

to

that

wish

is

all

is

be

Page 8

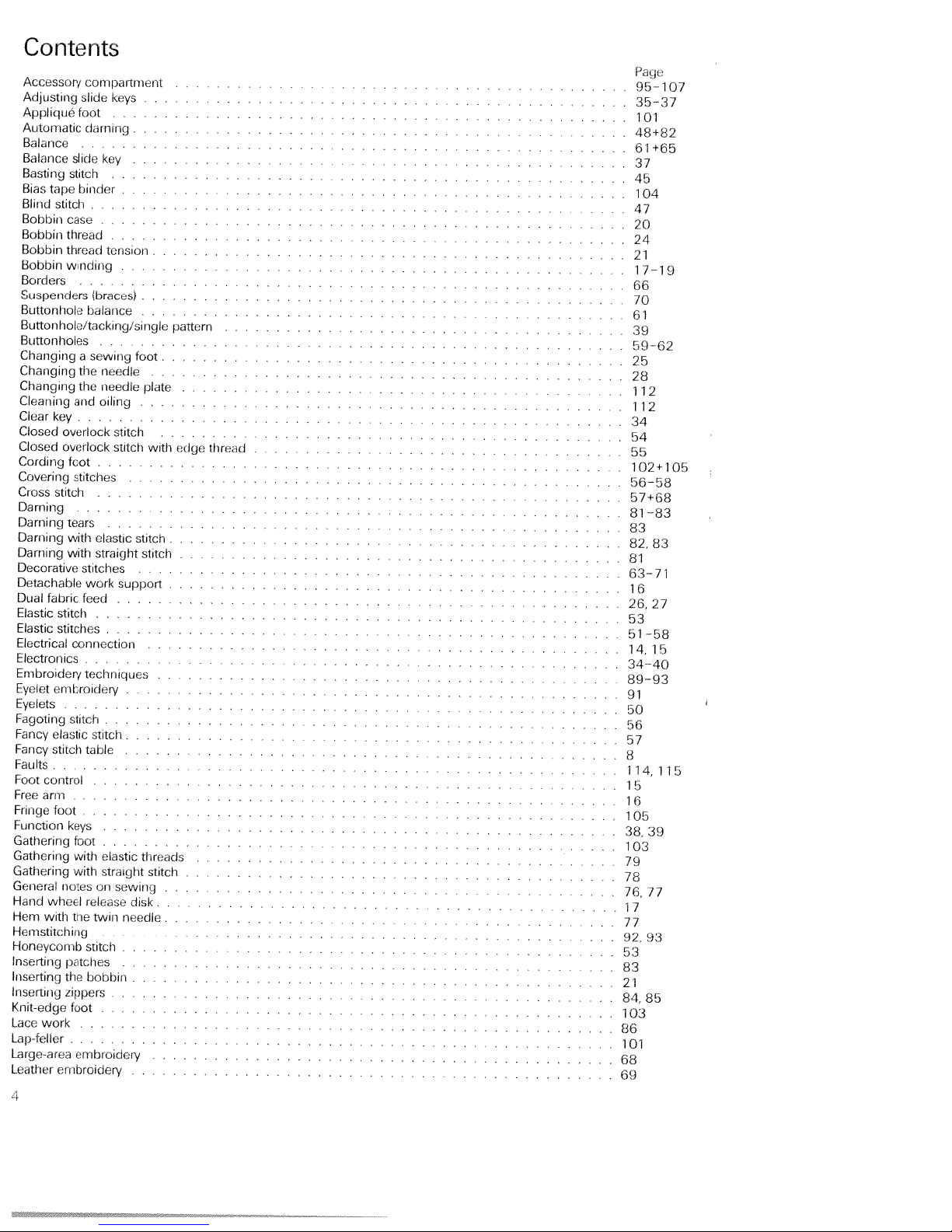

Contents

Accessory

Adjusting

Applique

Automatic

compartment

,lide

keys

foot

dirning

Balance

Balance

Basting

Bias

Blind

Bobbin

Bobbin

Bobbin

Bobbin

tape

stitch

slide

stitch

binder

case

thread

thread

winding

key

.

tension

Borders

Suspenders

Buttonhole

Ibraces)

balance

Buttonhole/tacking/single

Buttonholes

Changing

Changing

Changing

Cleaning

Clear

Closed

Closed

Cordingfoot

Covering

Cross

and

key

overlock

overlock

stitches

stitch

a

the

the

sewing

needle

needle

oiling

stitch

stitch

.

.

Darning

Darning

Darning

Darning

Decorative

Detachable

Dual

Elastic

Elastic

Electrical

Electronics

Embroidery

Eyelet

tears

with

with

stitches

fabric

feed

stitch

stitches

connection

techniques

embroidery

elastic

straight

work

.

support

Eyelets

Fagoting

Fancy

Fancy

stitch

eldstic

stitch

stitch

table

Faults

Foot

control

Free

arm

Fringe

foot

Function

Gathering

Gathering

Gathering

General

Hand

Heni

wheel

with

keys

foot

with

with

notes

the

elastic

straight

on

relcise

twin

sewing

Hemstitching

Honeycomb

Inserting

Inserting

Inserting

Knit-edge

Lace

work

stitch

patches

the

bobbin

zippers

foot

Lap-feller

Large-area

Leather

embroidery

eribroidery

.

.

foot

plate

.

stitch

stitch

.

threads

disk...

needle.

.

. .

with

.

.

stitch

pattern

edge

.

.

.

thread

.

.

95

.

.,...,....

.....

.

.

35—37

107

101

48+82

61

+65

.

.

.

.

.

.

.

.

37

45

104

.

.

.

47

20

24

21

1

.

.

.

7—19

66

70

61

.

.

39

59—62

25

28

112

.

11

2

34

54

55

102+105

.

.

.

56—58

.

57+68

81

83

83

82,

83

81

63—11

16

.

.

. .

.

. .

.

.

26,

2/

53

51

—58

4,

1

.

1

5

.

34

-40

89—93

.

.

.

.

.

.

.

91

.

50

56

57

.

.

8

.

114,115

.

1

5

1

6

1

05

38,

. .

.

39

103

79

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

78

76,

71

1

7

.

77

.

.

92,

93

.

53

.

83

21

.

84,

85

1

03

86

.

.

.

.

1

01

68

69

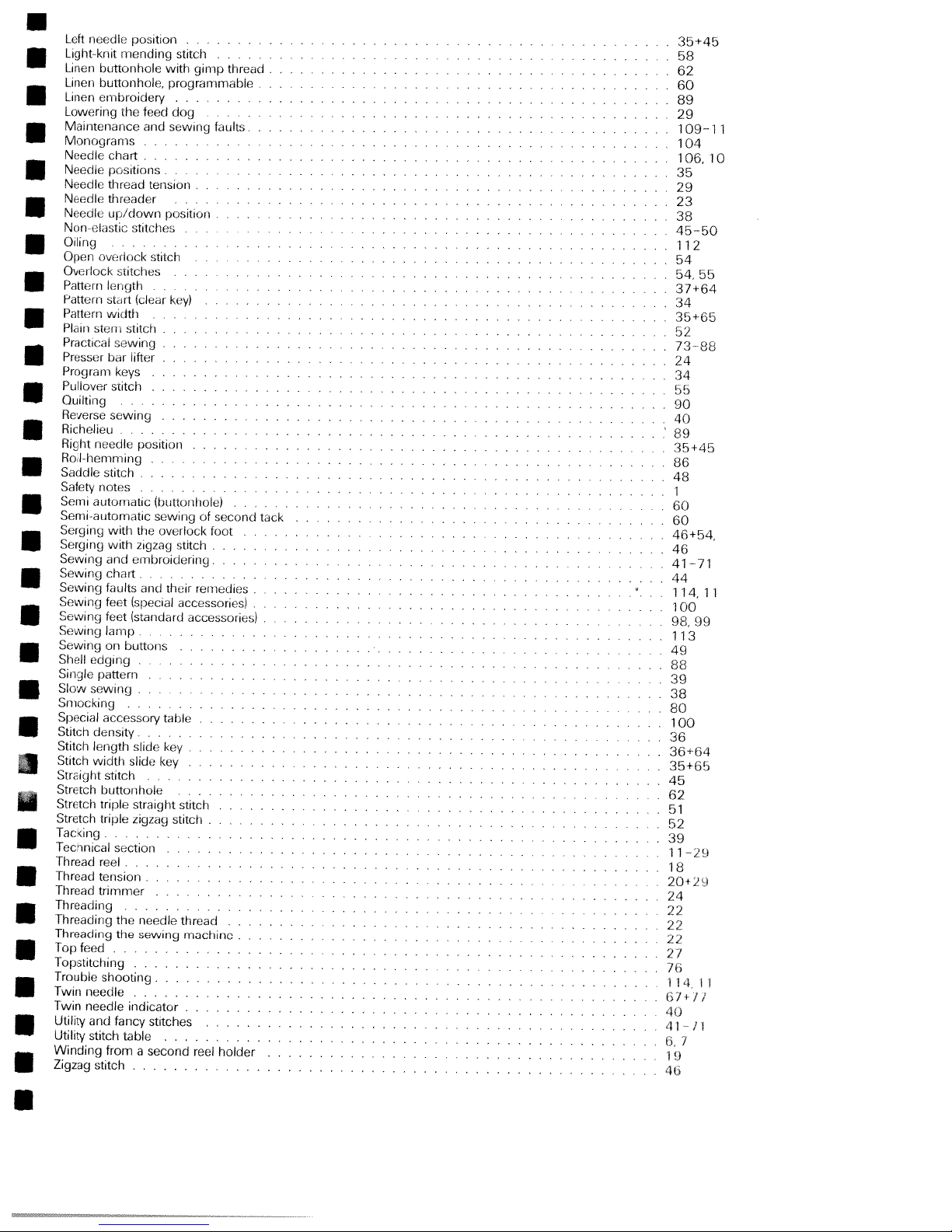

Page 9

I

I

I

I

a

I

U

a

I

a

a

a

a

I

a

a

a

a

I

a

a

I

a

a

a

a

a

a

Left

needle

Light—kiit

butiunhole

Linen

buttonhole,

Linen

Linen

embroidery

Lowering

Maintenance

Monograms

Needle

chart

Needie

Needle

thredd

Needle

threader

Needle

up/down

Non

elastic

Oiling

Ovui

Open

Overlock

Pattern

Iuigth

Pattern

sldfl

Pattern

width

Plain

stcni

Practical

Presser

bar

Progiam

Pullover

Quilting

Reverse

Richelieu

Right

needle

Roll

hemming

Saddle

stitch

Safety

notes

Semi

automatic

Semiautomatic

Serging

Serging

Sewing

Sewing

Sewing

Sewing

Sewing

Sewing

Sewing

Shell

Single

Slow

with

with

and

chart

taults

feet

feet

Limp

on

edging

pattern

sewing

Smocking

Special

accessory

Stitch

density

Stitch

length

Stitch

width

Straight

Stretch

Stretch

Stretch

stitch

buttonhole

triple

triple

Tacking

Technical

Thread

reel

Fhread

tension

Thread

trimmer

Threading

Threading

Threading

Top

feed

Topstitching

Trouble

shooting

Twin

needle

Twin

needle

Utility

anrl

Utility

stitch

Winding

Zigzag

from

stitch

position

nending

the

pcsitions

stitches

.

luck

stitches

fclcar

stitch

sewing

lifter

keys

stitch

sewing

position

.

the

zigzag

emhroidenng

and

(special

(stdnddrd

buttons

slide

slide

straight

zigzag

section

the

needle

the

sewing

indicator

fancy

table

a

stitch

with

progran

dog

feed

sewing

and

. .

tension

position

stitch

key)

.

.

(buttonhole)

sewing

ovuriock

stitch

their

accessoriesl

.

.

.

.

table

.

. .

.

key

key

...

stitch

stitch

threarh

stitches

second

.

ginip

i

mable

faults

of

second

foot

. .

remedies

occessones)

...

.

.

machine

reel

holder

thread

.

.

tack

...

.

•

.

.

.

35+45

58

62

.

.

60

89

29

109—il

104

106,10

35

29

23

38

112

54

54.55

37+64

.

34

35+65

73-88

.

24

90

40

.

.

86

48

.

.

60

60

46+54,

.

46

71

44

‘

.

114,11

.

.

.

.

.

.

.

.

.

.

100

.

.

98,

.

99

.

.

113

88

39

38

80

100

.

36

3664

5+65

45

52

39

11

.

29

18

4

.

2

lb

.

Il

41

I

9

4t,

I

Page 10

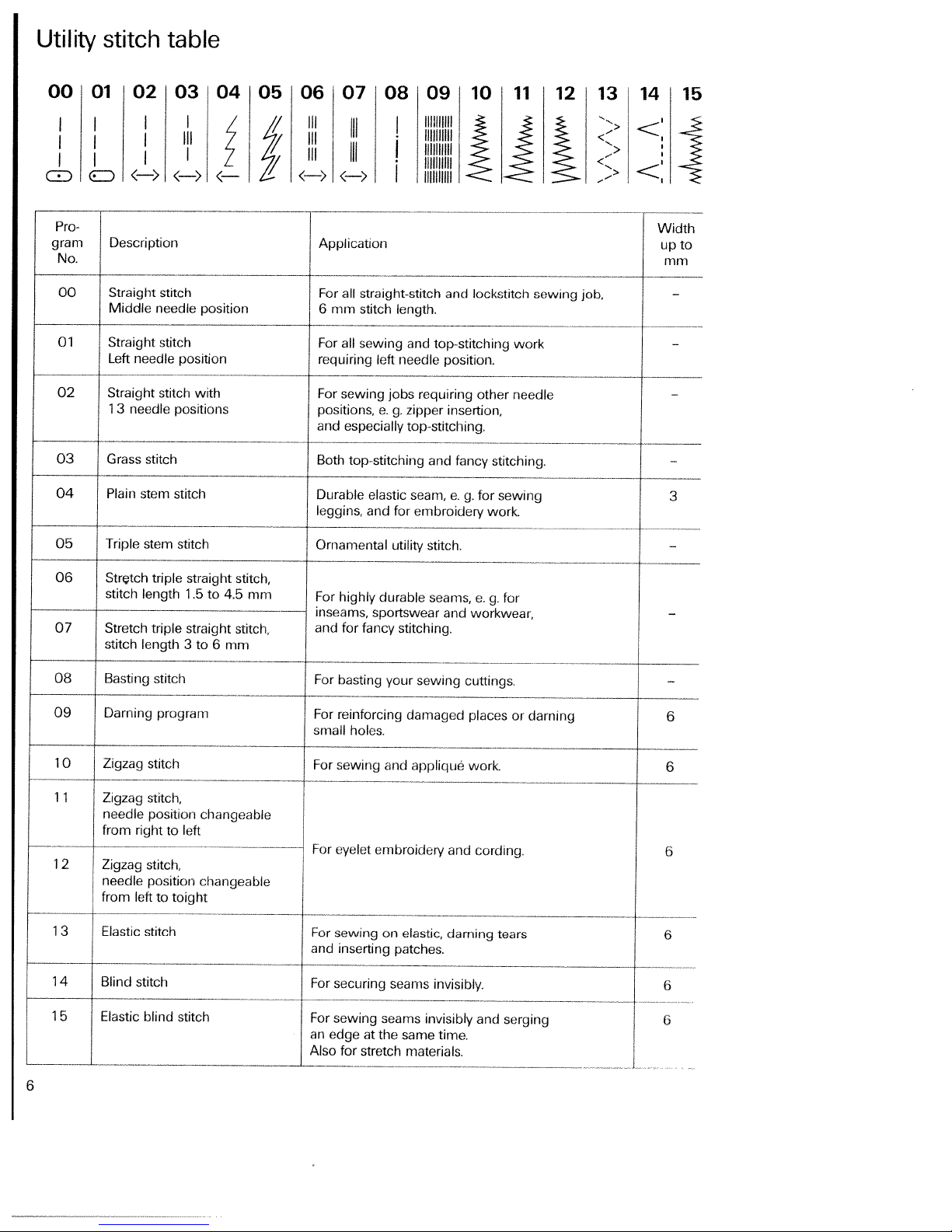

Utility

stitch

table

11

1213i14

15

Pro-

gram

No.

00

01

02

03

04

05

I

Description

Straight

Middle

Straight

Left

Straight

1

3

needle

Grass

Plain

Triple

I

needle

needle

stitch

stem

stem

stitch

stitch

position

stitch

positions

stitch

stitch

I

position

with

i

length.

and

needle

jobs

zipper

e.

g.

top-stitching.

seam,

for

utility

IIIIIIIIH

Bllllll

lockstitch

and

top-stitching

position.

requiring

insertion,

and

fancy

e.

embroidery

g.

stitch.

other

stitching.

for

sewing

work.

sewing

work

needle

ii>

job,

<>

><:

Width

to

up

mm

—

—

—

—

3

—

III

//

/

‘

I

Application

For

all

straight-stitch

mm

stitch

6

For

all

sewing

requiring

For

positions,

and

Both

Durable

leggins,

Ornamental

left

sewing

especially

top-stitching

elastic

and

—-

1

1

1

1

06

07

08

09

10

1 1

triple

length

triple

length

stitch

program

stitch

stitch,

position

to

stitch,

position

to

stitch

blind

straight

1

straight

3

left

toight

stitch

Stretch

stitch

Stretch

stitch

Basting

Darning

Zigzag

Zigzag

needle

from

right

——--—---

2

Zigzag

needle

from

left

3

Elastic

Blind

4

5

stitch

Elastic

stitch,

to

4.5

.5

stitch,

mm

to

6

changeable

changeable

mm

For

highly

inseams,

and

For

basting

For

reinforcing

small

For

sewing

For

eyelet

For

sewing

and

inserting

For

securing

For

sewing

an

edge

Also

for

for

holes.

stretch

durable

sportswear

fancy

stitching.

your

and

embroidery

on

patches.

seams

seams

at

the

seams,

sewing

damaged

appliqué

elastic,

invisibly.

invisibly

same

time.

materials.

and

cuttings.

and

darning

a

for

g.

workwear,

places

or

work

cording.

tears

and

serging

darning

—

—

6

6

6

6

6

(3

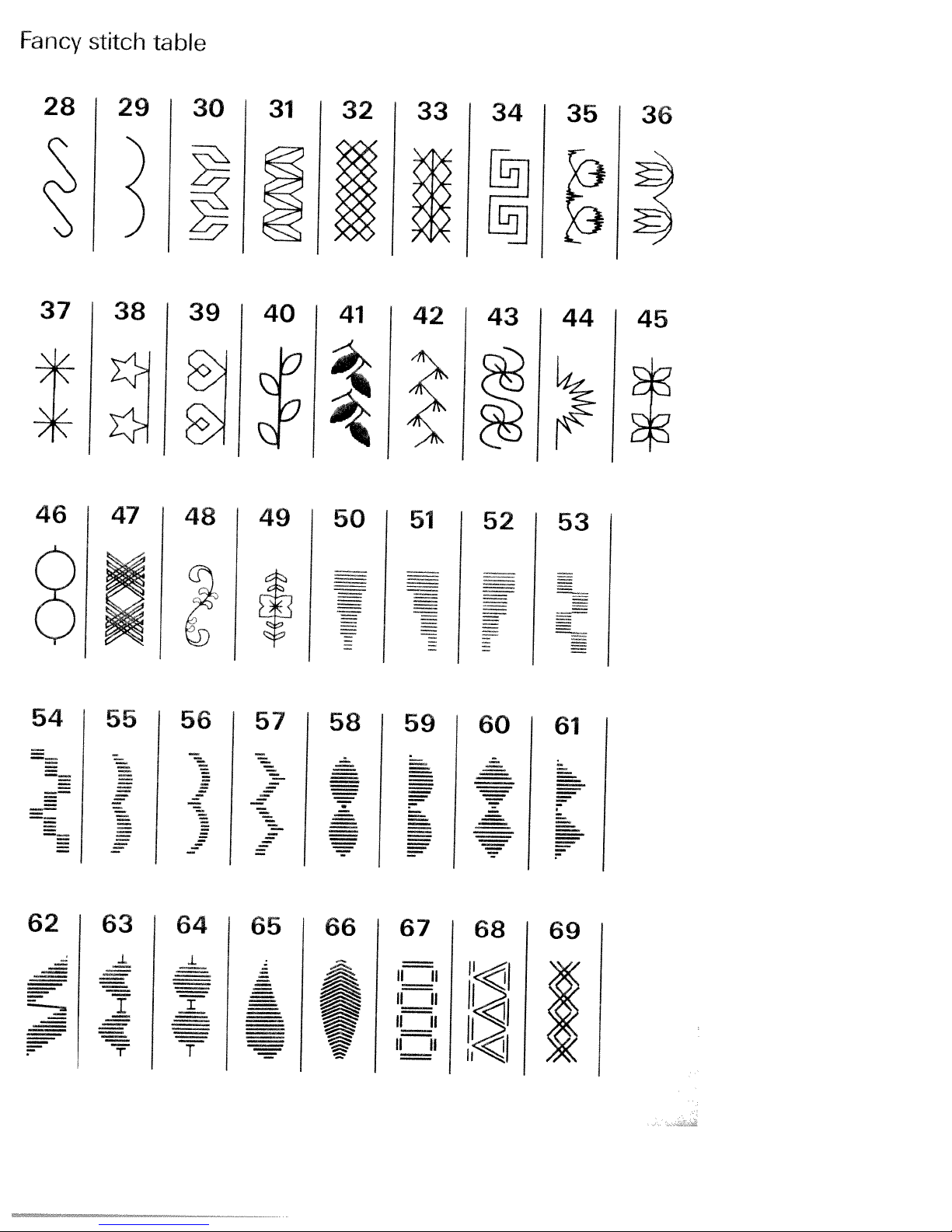

Page 11

Utility

stitch

table

:

16

Pro-

gram

No.

1

1

1

1

20

21

L._

22

6

7

8

9

17

Description

Shell-eding

Blind

Fancy

Stretch

Open

losed

with

Light-knit

18 19

stitch

elastic

triple

overlock

overlock

edge

thread

patchwork

stitch

stitch

zigzag

20

stitch

stitch

21

stitch

stitch

22 23

Application

For

e.g.for

j

Needle

For

of

For

materials.

For

For

oneorseveral

Lthat

For

Alsoasa

24

decorative

underwear.

position

over

stitching

fabric,

sewing

elastic

closing

simultaneously

sewing

materials.

comes

fancy-stitch

and

next

light-knit

25

26

hemsonlight

changeabletothe

two

butt

tape

onto

simultaneously

closing

labric

plies.Anoverlock

industrial

to

an

fabrics

seamonknitted

27

70

fabrics,

right.

joined

plies

elastic

serging

and serging

seam.

71

seam

fabrics.

72

73

V

23

24

25

26

27

70

71

72

—

73

74

Pullovei

Honeycomb

ft

Closed

Fagoting

Cross

1

Fully

buttonhole

Linen

-

Stretch

f

Fully

I

Button

stitch

stitch

-

overlock

stitch

automatic

buttonhole

buttonhole

automatic

sewing program

stitch

stitch

linen

eyelet

Elastic

closing

for

open

For

sewingonelastic

terry-cloth

-

-

For

materials

For

joining

overstitching

Flat

fabric

Also

The

pro

set

underwear

Stitch

thus

suchassilkorviscous

For

stretch

Canbere-called

Fully

in

various

closing

joining

plies.

suitable

buttonholeisstored

lengths,

length

very

automatic

and

knit

materials.

seams

and serging

that

fray

corsetry

that

seam

as

e.

and

blouses

and

suitable

materials,

sewing

sizes.

and

easily.

fray

for

a

fancy

g.

width

for

in

serging

threads,

for

seams

pans

easily

elastic

hem

in

for

bed

adjustable,

difficult

fabrics

different

of

seam

fancy

and

butt

three

linen,

matendls

sizes

bullons

covering

hems

-

for

for

joined

Page 12

01

L1JFi

1

rriw

Ill(1

Ill

0

hulk

a,

z

a,

g5

101

IIIHmp

IIi

-€4_

01

%%J

il

lIiJ

III

1

I

a

0,

II

liii!

II

‘I II

111111!

jJIil’’hiiIIIih

‘iIIIIIui’’iiIIIIIii

g

a,

P%J

‘‘liii

11101

11111

11111

111111

a,

qr

II

qr—’ip

‘qi

a,

.•.•

.•.•.•

.•.

Ii

hI’’’I’’J

—iIIIIIilI—ihiIIIIitI—

IIIfIIIHIIIjIIIF

tilillihi

‘‘‘II’’1V’’’’

)*)))

----

Page 13

S

S

S

S

S

S

S

S

S

S

S

S

I.....

5

S

S

I..’

I..’.’

•iI....

5:

a’

S..

I.’

5:

U..’

S

II

S

S

Page 14

..-

/

Page 15

Operating

the

sewing

machine

Tedmb&

Pages

11

secdon

to29

Page 16

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Page 17

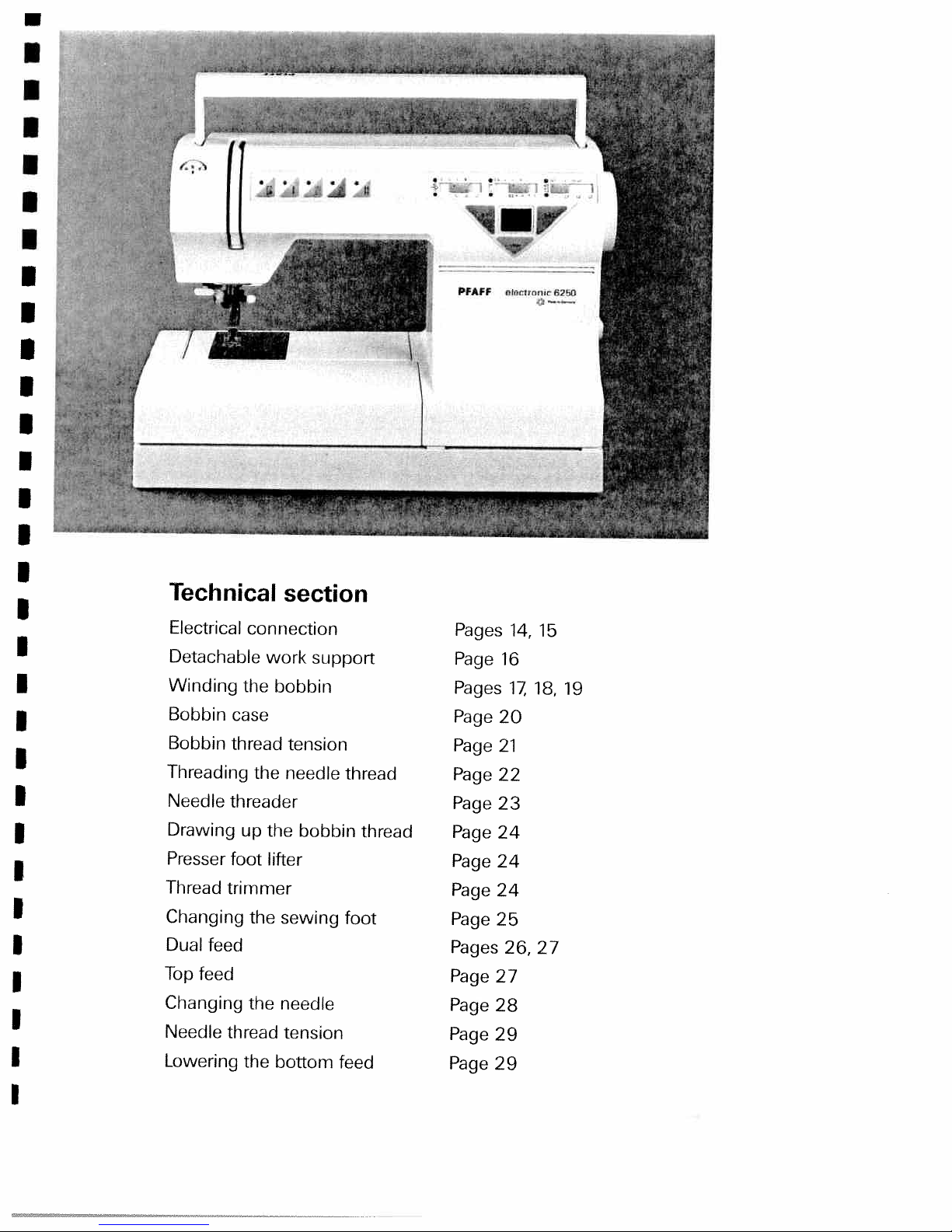

Technical

section

Electrical

Detachable

Winding

Bobbin

Bobbin

Threading

Needle

Drawing

Presser

Thread

Changing

Dual

Top

Changing

Needle

Lowering

threader

trimmer

feed

feed

thread

connection

work

the

bobbin

case

thread

the

the

up

foot

lifter

the

sewing

the

needle

the

bottom

support

tension

needle

bobbin

tension

thread

thread

foot

feed

Pages

Page

Pages

Page

Page

Page

Page

Page

Page

Page

Page

Pages

Page

Page

Page

Page

20

21

22

23

24

24

24

25

27

28

29

29

16

17

26,

14,

15

18,

27

19

Page 18

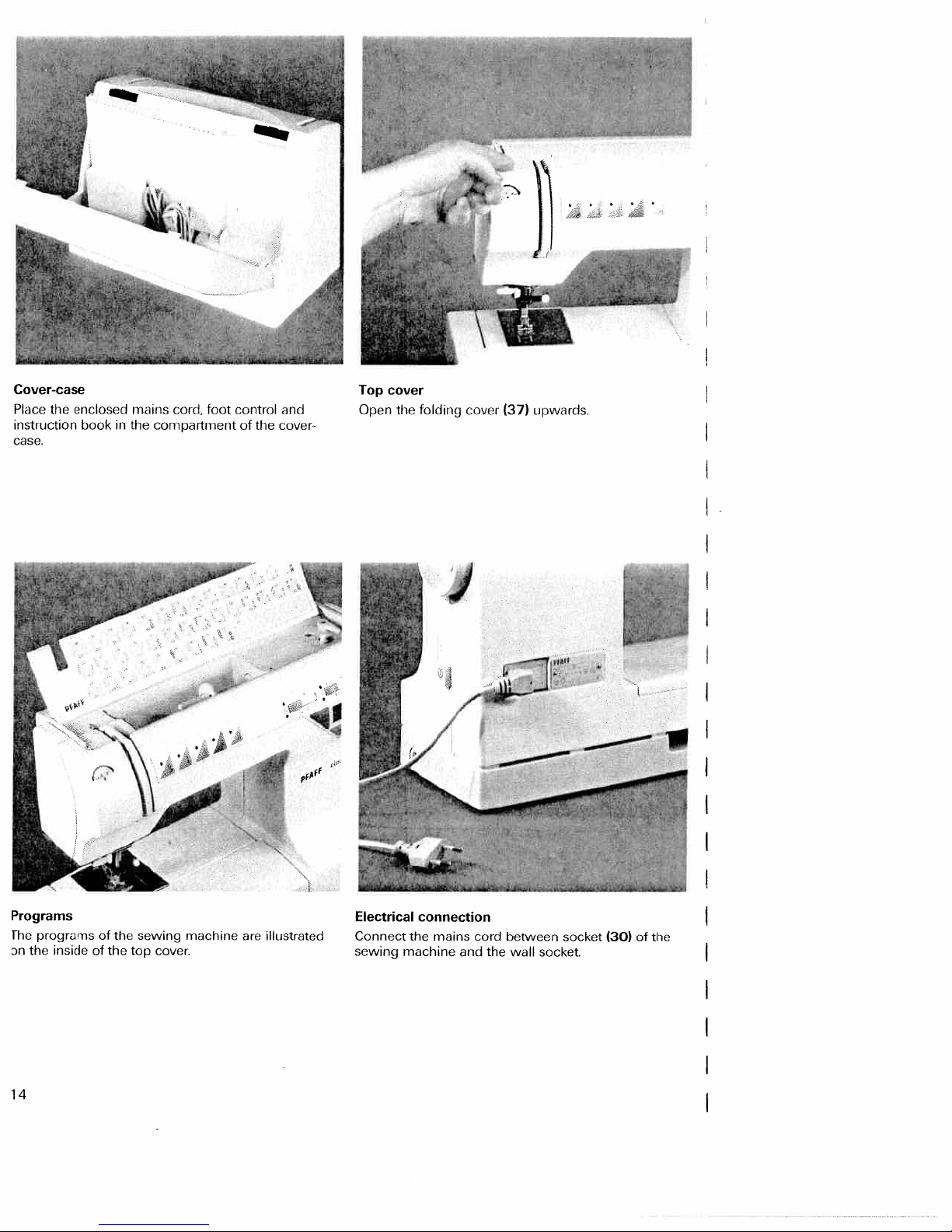

Cover-case

Place

the

instruction

case.

enclosed

bookinthe

mains

compartment

cord,

foot

control

of

the

and

cover-

I

Top

cover

Open the

folding

cover

(37)

upwards.

Programs

rhe

programsofthe

n

the

inside

of

the top

sewing

cover.

machine

are

illustrated

Electrical

Connect

sewing

connection

the

mains

machine

and

cord

the

between

wall

socket

socket

(30)

of

the

Page 19

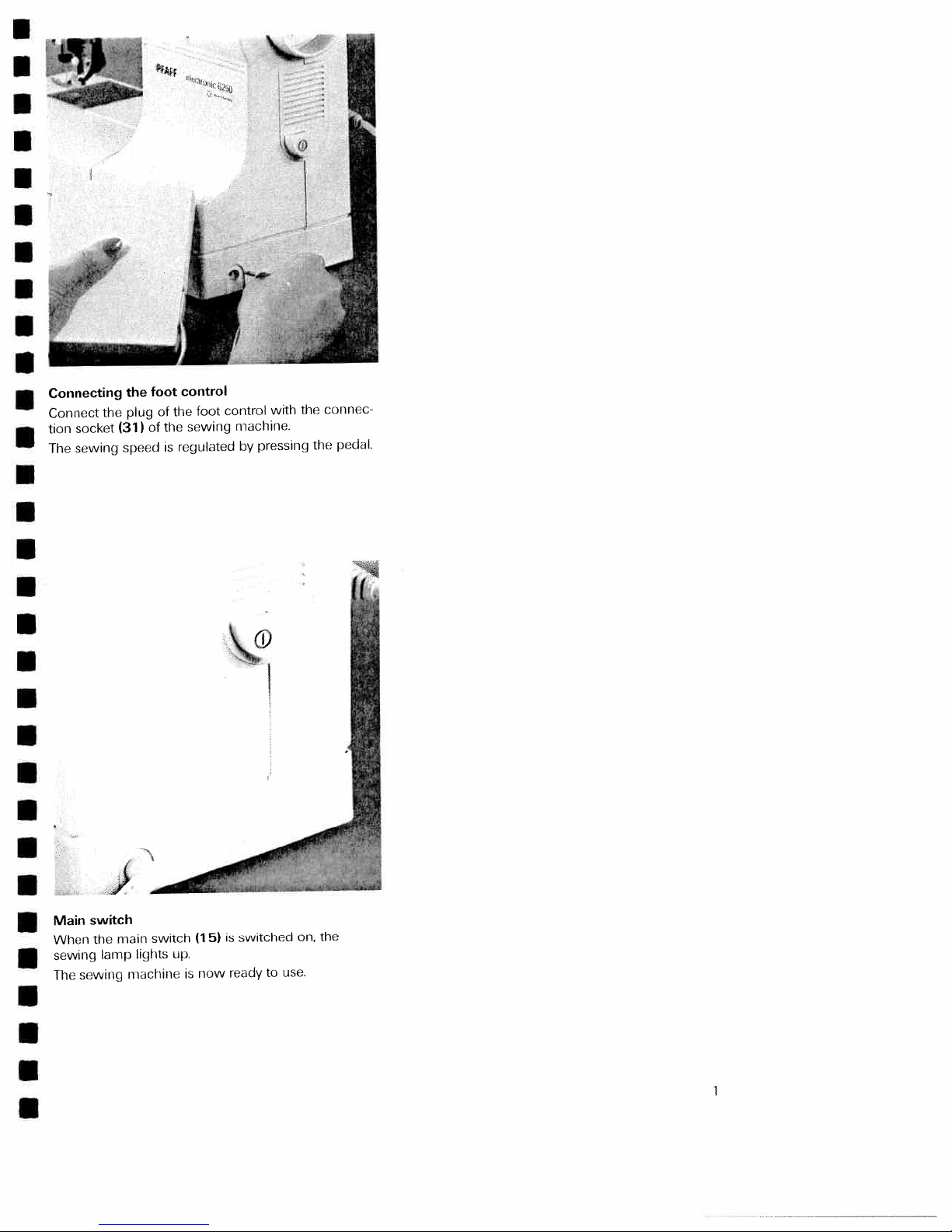

Connecting

Connect

socket

tion

sewing

The

the

the

plug

(31)of

speed

foot

of

control

the

sewing

the

regulated

is

foot

control

machine.

by

with

pressing

the

connec

the

pedal.

switch

Main

the

is

(1

now

5)

switched

ready

When

sewing

The

lamp

sewing

lights

machine

up

i

switch

main

the

on,

use.

to

Page 20

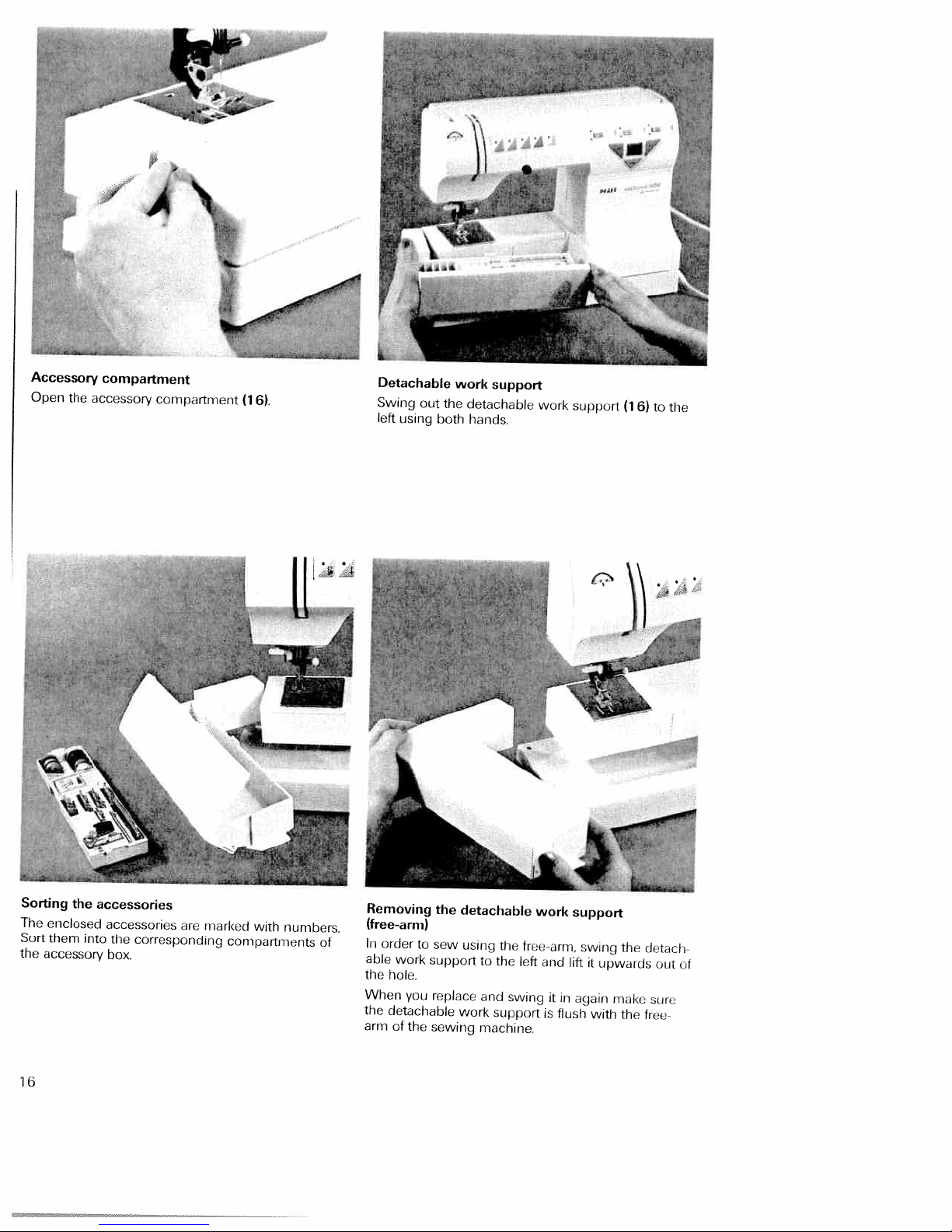

A

Accessory

Open

the

compartment

accessory

compartment

(16).

Detachable

Swing

out

left

using

work

the

both

support

detachable

hands.

work

support

to

(1

6)

the

Sorting

The

Sort

the

the

enclosed

them

into

accessory

accessories

accessones

the

corresponding

box.

are

marked

compartments

with

numbers.

of

Removing

(free-arm)

In

order

able

work

the

hole.

When

you

the

detachable

arm

of

the

to

support

sewing

the

sew

replace

detachable

using

the

to

the

and

work

support

machine

free-arm,

left

swing

work

and

it

is

lift

in

flush

support

swing

it

upwards

again

with

the

make

the

clutch

out

u1:

tree

of

Page 21

I

I

a

a

I

a

a

a

I

I

a

a

a

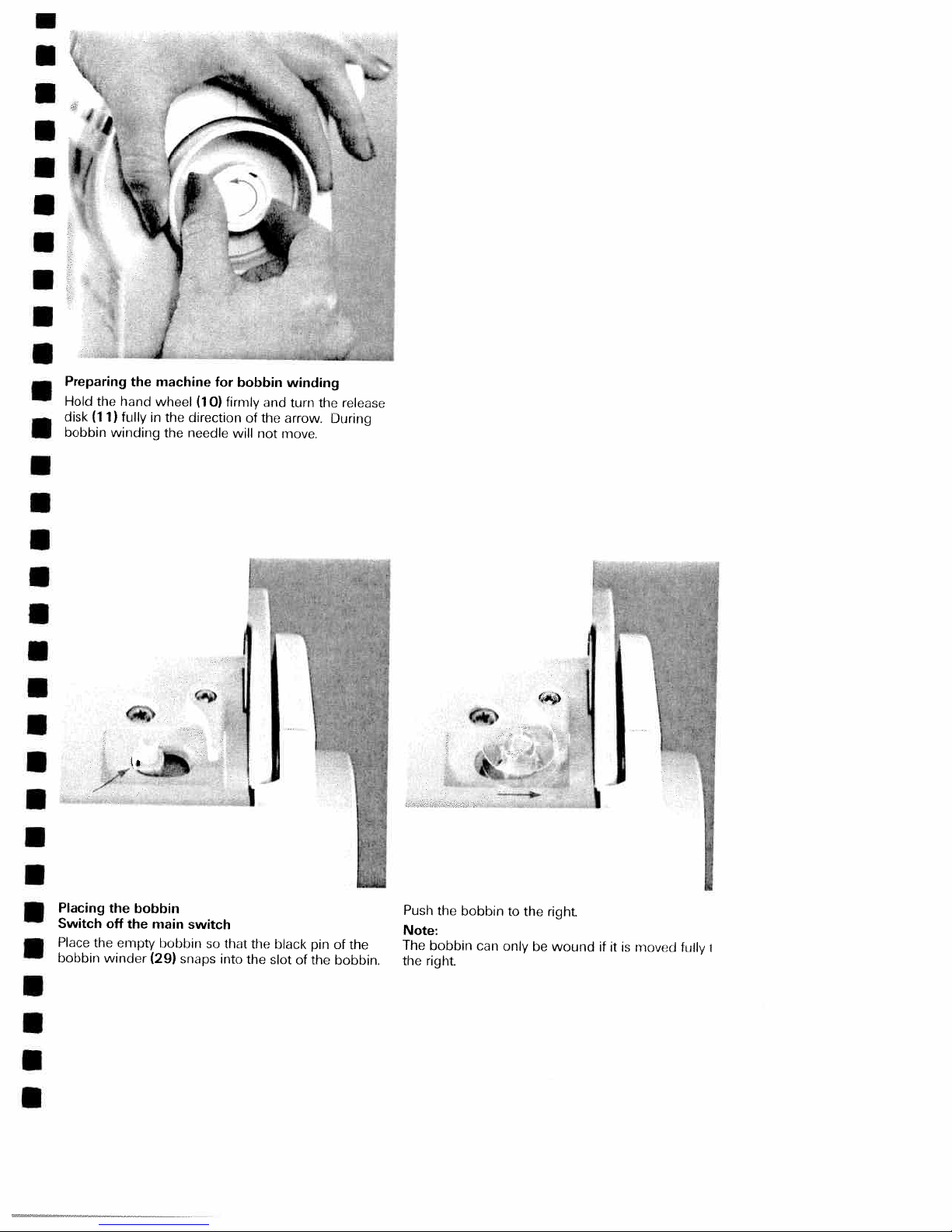

Preparing

Hold

the

disk

(11)

bobbin

the

hand

fully

winding

machine

wheel

in

the

the

for

firmly

(1

0)

direction

needle

bobbin

of

will

and

the

not

winding

turn

arrow.

move.

the

During

release

a

a

a

a

a

a

a

a

a

a

Placing

Switch

Place

bobbin

off

the

winder

the

empty

bobbin

the

main

bobbin

(29)

switch

snaps

so

that

into

the

the

black

slot

I’

Push

the

bobbin

to

the

right

pin

of

the

the

bobbin.

of

Note:

The

the

bobbin

right

can

only

be

wound

if

it

is

moved

fully

I

Page 22

L

e

holder

reel

the

thread

fit

an

reel.

from

on

the

of

unwinding

the

thread

reel

holder

and

disk

hold

of

(27).

the

To

the

right

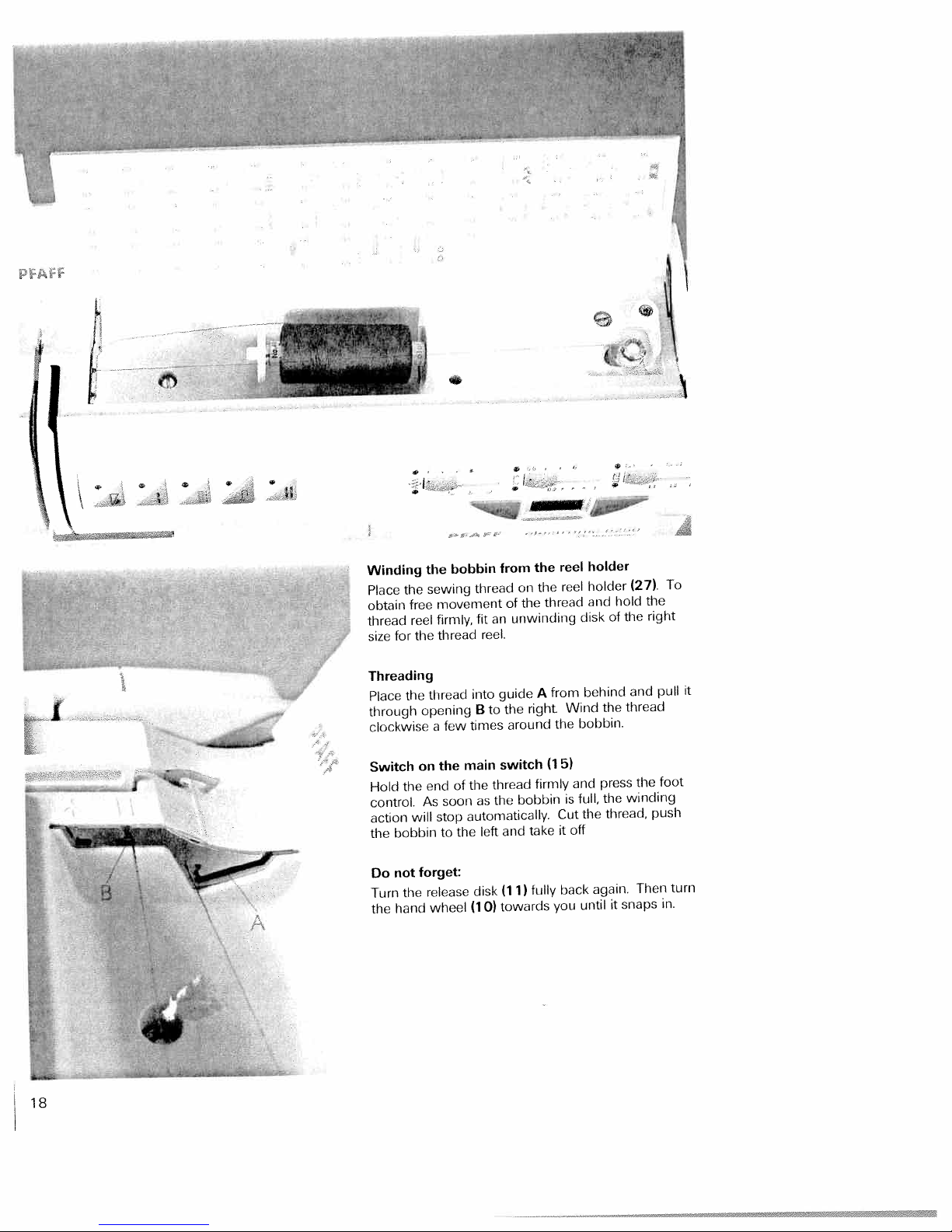

Winding

the

Place

obtain

thread

for

size

the

free

reel

the

bobbin

sewing

movement

firmly,

thread

Threading

Place

through

clockwise

Switch

Hold

control.

action

the

I

Do

Turn

the

on

the

will

bobbin

forget:

not

the

hand

opening

few

a

the

end

soon

As

stop

to

release

wheel

of

the

the

B

to

around

times

switch

main

thread

the

automatically.

(1

as

left

disk

the

towards

0)

bobbin

and

(11)

right

firmly

take

fully

(1

the

5)

Cut

it

back

you

Wind

bobbin.

and

full,

is

off

the

until

the

press

the

thread,

again.

it

thread

the

winding

Then

snaps

foot

push

turn

in.

it

pull

and

behind

from

A

guide

into

thread

the

0

Page 23

fr

4iIi

,

41

3

I

I

S

S

I

I

I

S

I

S

I

S

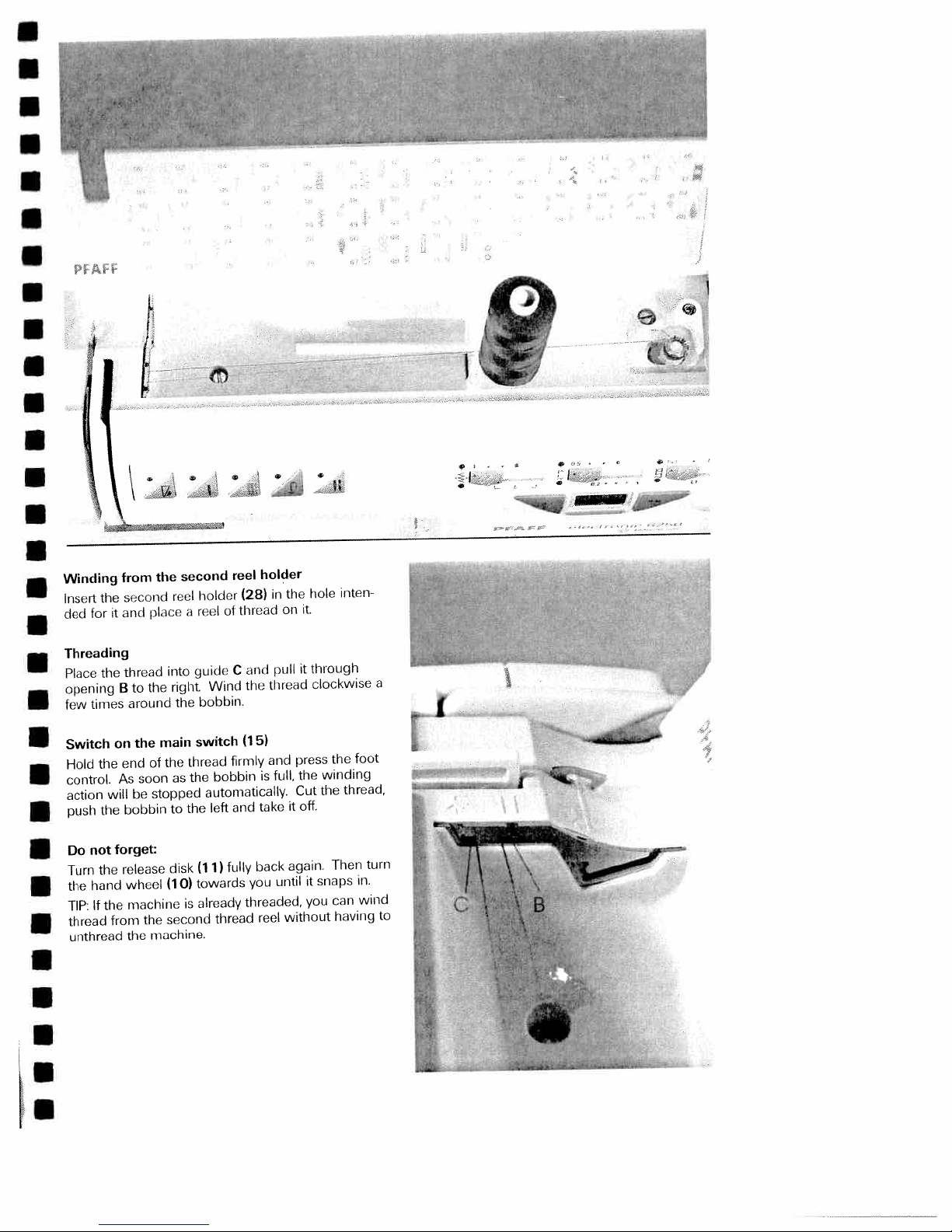

Winding

the

Insert

for

ded

Threading

the

Place

opening

times

few

Switch

the

Hold

control,

action

the

push

not

Do

the

Turn

hand

the

the

If

TIP:

thread

unthread

from

second

and

it

thread

B

on

end

As

will

bobbin

forget:

release

from

the

place

to

the

around

main

the

of

soon

stopped

be

wheel

machine

the

machine.

the

second

reel

a

into

right

the

thread

the

the

as

the

to

disk

(1

0)

is

second

reel

(28)

holder

thread

of

reel

and

C

guide

bobbin.

switch

(11)

towards

already

the

Wind

(1

firmly

bobbin

automatically.

and

left

fully

you

threaded,

thread

holder

in

pull

thread

5)

and

full,

is

take

back

reel

the

on

it

press

the

Cut

off

it

again.

until

without

hole

it.

through

clockwise

the

winding

the

Then

snaps

it

can

you

having

inten

foot

thread,

in.

wind

a

turn

ri

I

43

I

I

I

to

I

S

S

I

Page 24

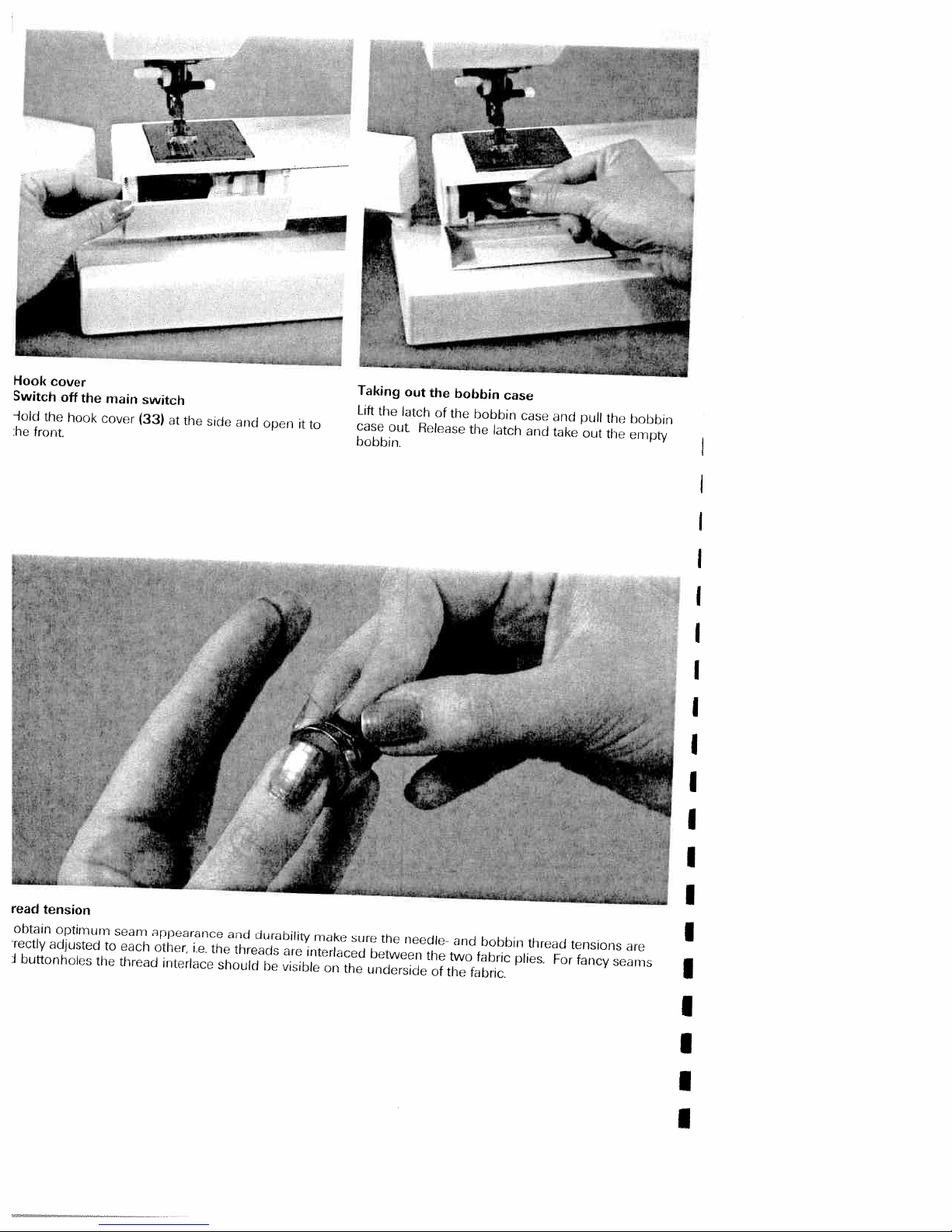

Hook

Switch

—loki

he

front.

cover

the

off

hook

the

main

cover

switch

(33)

Taking

at

the

side

and

open

it

to

Lift

case

bobbin

the

out

out

latch

the

of

Release

bobbin

the

bobbin

the

case

latch

case

and

and

take

pull

out

the

the

bobbin

empty

I

I

I

I

I

I

read

tension

obtain

optimum

rectly

adjusted

buttonholes

I

the

to

seam

each

thread

appearance

other.

ic.

interlace

and

tne

shoulrl

durability

threads

be

are

visible

make

interlaced

on

sure

the

the

needle

between

underside

tIre

of

two

the

and

bobbin

fabric

fabric.

thread

plrvs.

For

tensions

fancy

seaiTrs

are

I

I

I

I

I

I

I

1

Page 25

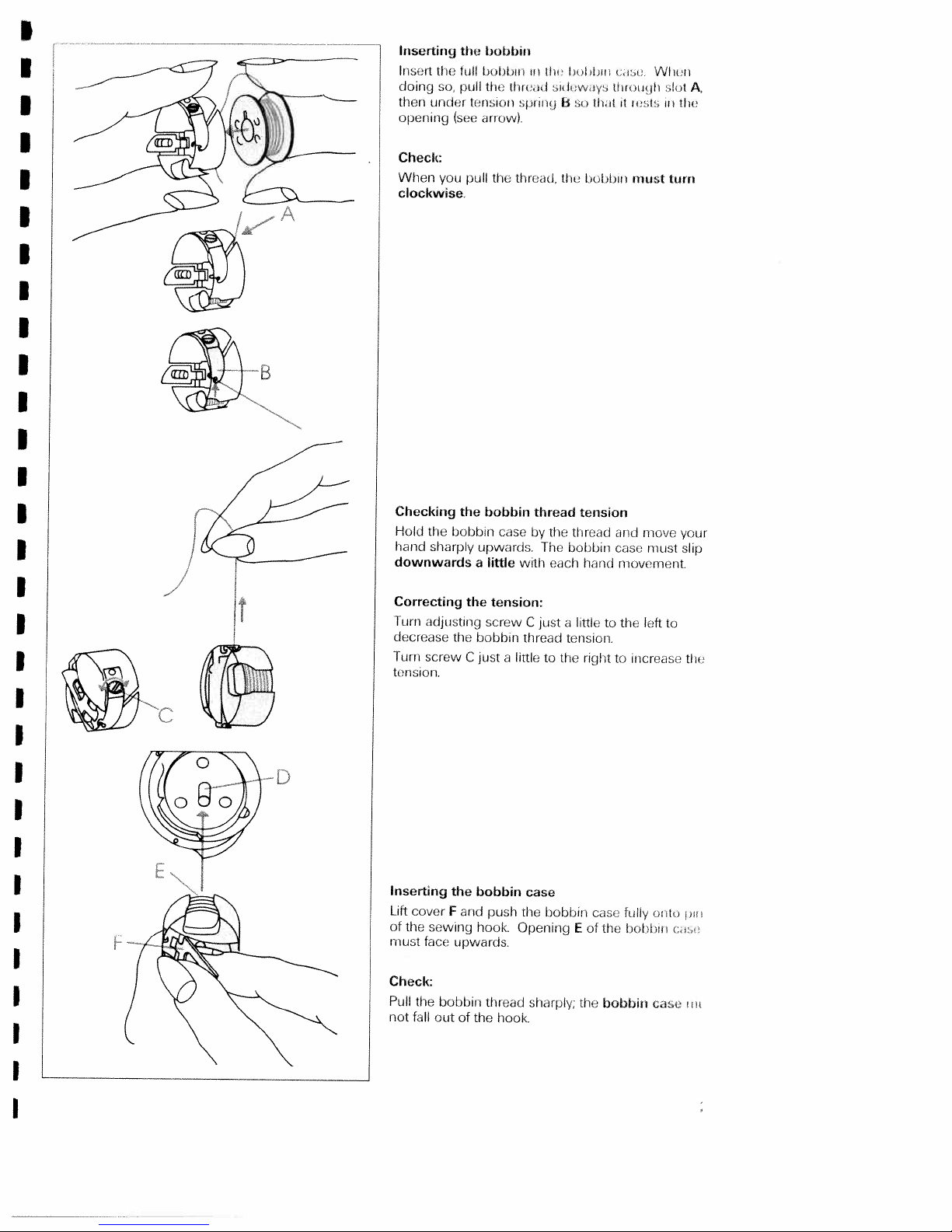

lnsertinj

Iris(3rt

tli(

doing

50,

iri(1(r

ther

opening

Check:

you

When

clockwise.

the

lull

pull

(see

pull

bobbin

Inibtun

tire

tt’risrcnr

arrow)

tho

tIm

iriii(j

thread

iii

l,ll,ir

ii

il

11ri

b

the

lrln

When

ririi

,iul

ii

i”t’

niust

A,

iii

turn

it

Checking

Hold

the

hand

sharply

downwards

Correcting

Turn

adjusting

decrease

Turn

screw

tension.

Inserting

Lift

cover

of

sewing

the

must

face

the

bobbin

upwards.

a

the

the

bobbin

C

just

the

bobbin

F

and

hook

upwards.

bobbin

case

little

tension:

screw

a

push

thread

by

The

with

C

just

thread

little

to

case

the

bobbin

Opening

the

eucti

the

tension

thread

uobbn

baud

a

little

tension.

right

E

of

to

cac

the

and

move

case

must

movement.

the

left

to

increase

oiili

fully

bobbin

your

slip

to

thu

pu

Ce

Check:

Pull

not

fall

the

bobbin

out

threud

of

the

sharply,

hook.

the

bobbin

can

Page 26

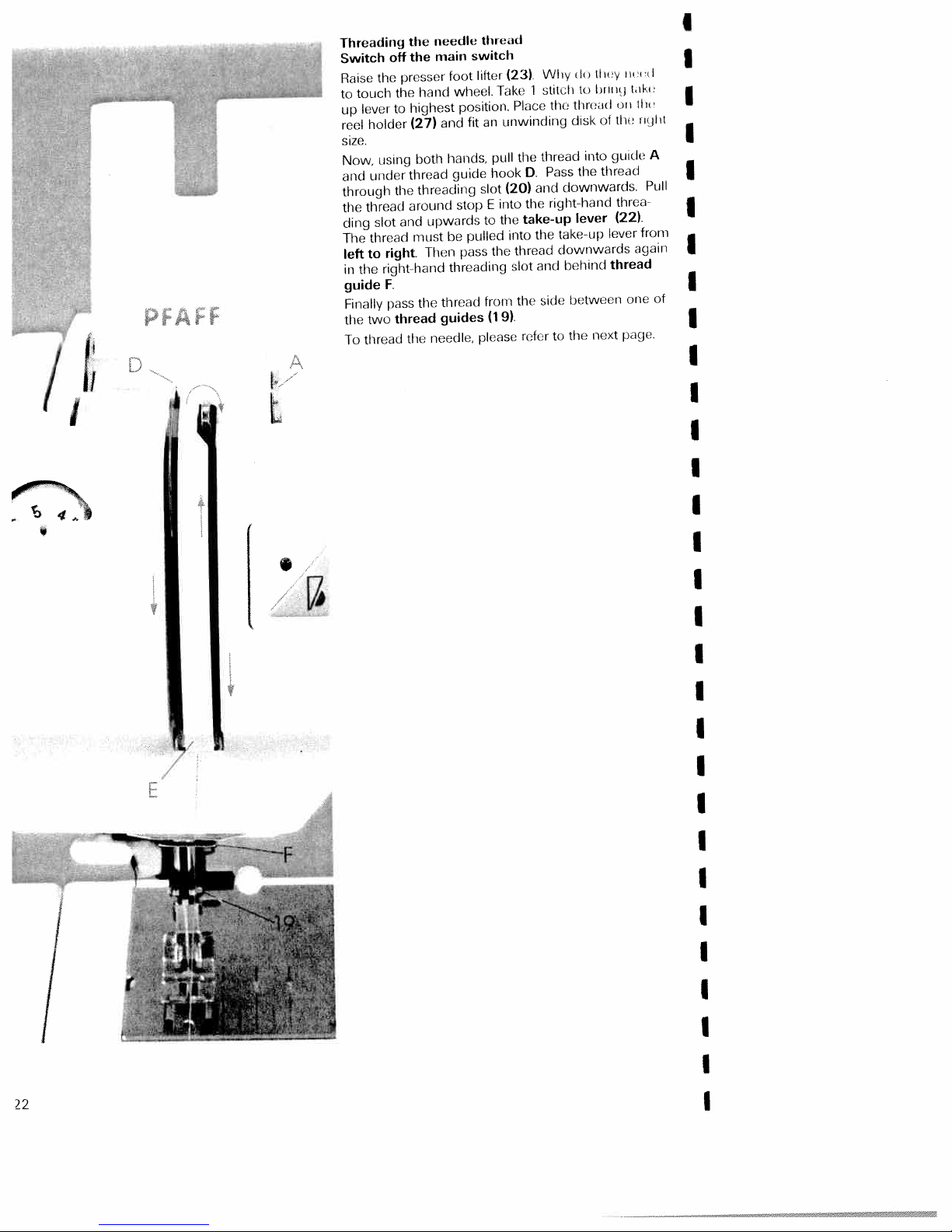

Threading

Switch

the

Raise

touch

to

lever

up

holder

reel

size.

using

Now,

under

and

through

thread

the

slot

ding

thread

The

to

left

right-hand

the

in

F.

guide

Finally

two

the

thread

Jo

off

presser

the

to

the

and

right.

pass

thread

needle

the

main

the

hand

highest

(27)

both

thread

threading

around

upwards

must

Then

the

needle,

the

loot

wheel.

position.

fit

and

hands,

guide

stop

pulled

be

pass

threading

thread

guides

th,e.id

switch

lifter

an

pull

hook

slot

E

to

the

from

(19).

please

(23>

1

Take

Place

unwinding

the

D.

(20)

the

into

take-up

the

the

into

thread

slot

the

refer

\Nliv

stitoli

the

thread

Pass

downwards.

and

right

take-up

downwards

and

side

to

do

u

rood

tI

disk

into

the

hand

lever

behind

between

next

the

LI

ma

of

guide

thread

lever

thread

y

RI

to

tin

threa

(22).

one

page.

t,11

ill

from

again

it

jI

a

A

Poll

I

it

I

I

of

I

I

/

I

Page 27

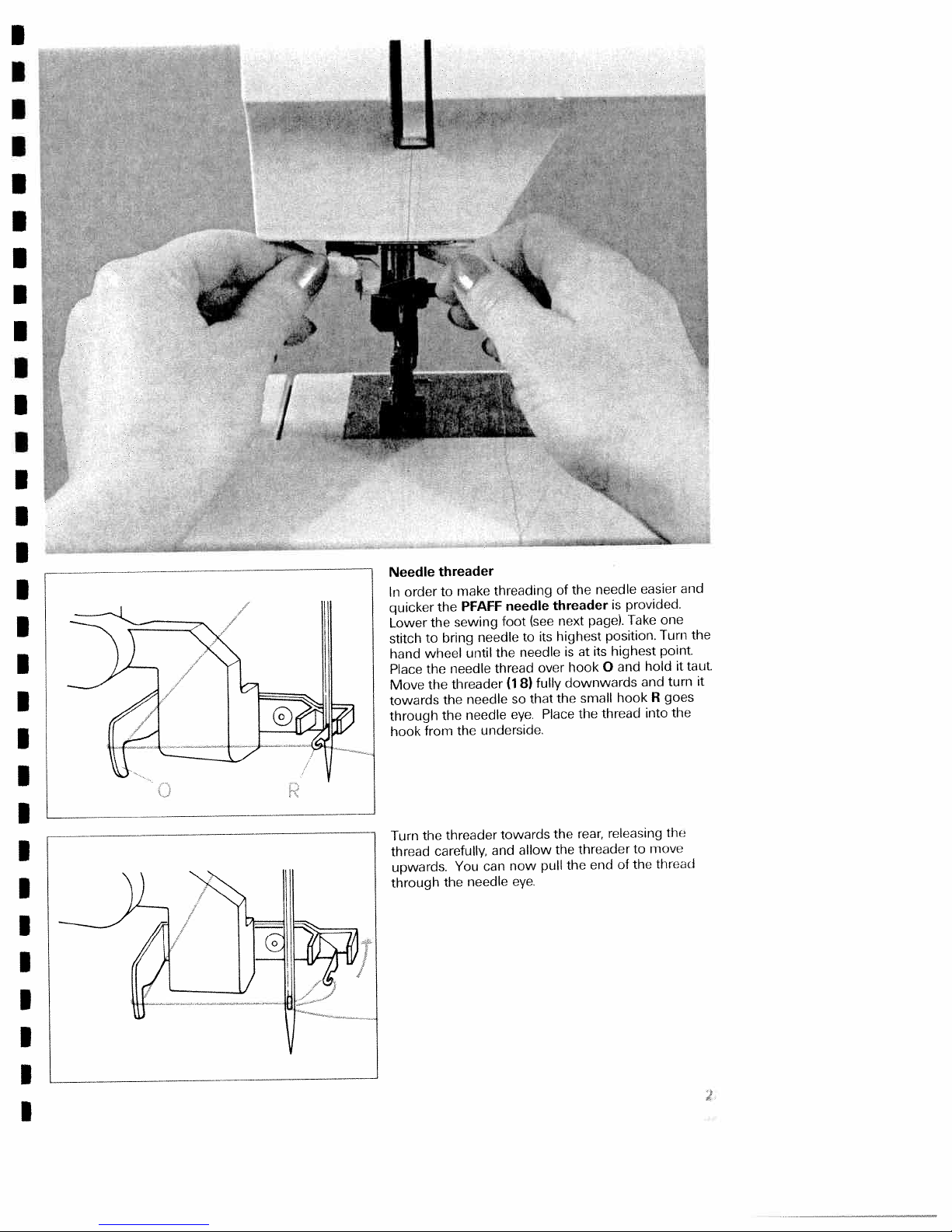

Needle

order

In

quicker

Lower

stitch

hand

Place

Move

towards

through

hook

threader

to

the

the

bring

to

wheel

the

the

the

the

from

make

PFAFF

sewing

needle

until

needle

threader

needle

needle

underside.

the

threading

needle

foot

(see

to

needle

the

thread

8)

(1

that

so

eye.

threader

its

over

fully

Place

of

next

highest

the

needle

the

is

page).

position.

highest

its

at

is

hook

and

0

downwards

hook

small

thread

the

easier

provided.

one

Take

Turn

point.

hold

and

goes

R

into

it

turn

the

and

the

taut.

it

the

Turn

thread

upwards.

through

threader

carefully,

You

needle

the

and

can

towards

allow

now

eye.

pull

the

the

rear,

threader

the

releasing

end

the

move

to

threud

the

of

Page 28

I

I

I

—

.

I

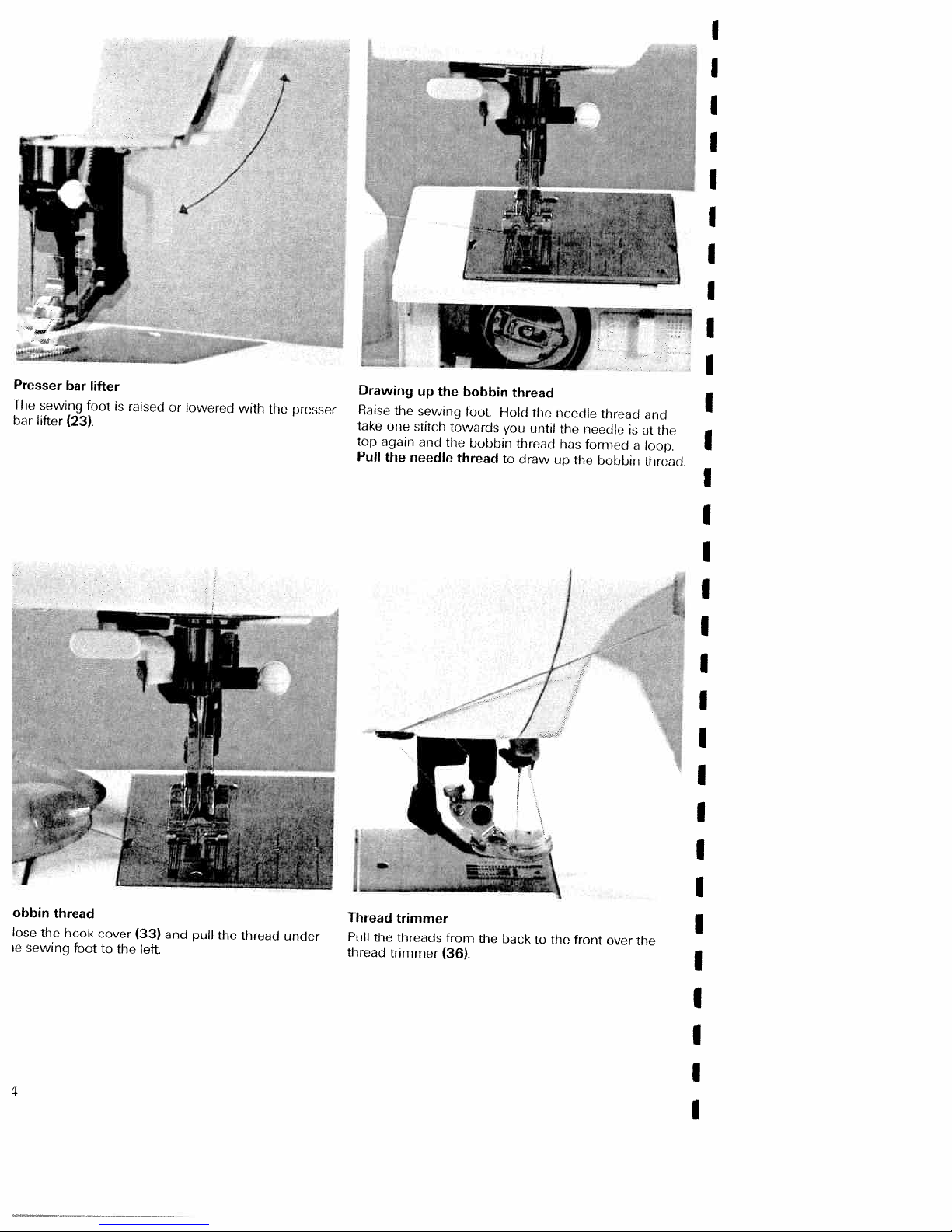

Presser

The

sewing

bar

lifter

bar

(23).

lifter

foot

is

raised

or

lowered

with

the

presser

Drawing

Raise

take

one

top

again

Pull

the

the

up

sewing

stitch

and

needle

the

towards

the

I

bobbin

foot.

bobbin

thread

I

thread

Hold

you

to

the

until

thread

draw

needle

the

has

up

the

thread

needle

formed

bobbin

is

a

and

at

the

loop.

thread.

I

I

I

I

I

I

I

I

I

I

I

I

I

obbin

lose

sewing

e

the

thread

hook

foot

cover

the

to

(33)

left

and

pull

the

thread

under

Thread

Pull

thread

the

trimmer

trimmer

threads

from

(36).

the

back

I

I

I

I

I

I

I

to

the

front

over

the

I

I

I

I

I

I

Page 29

A.

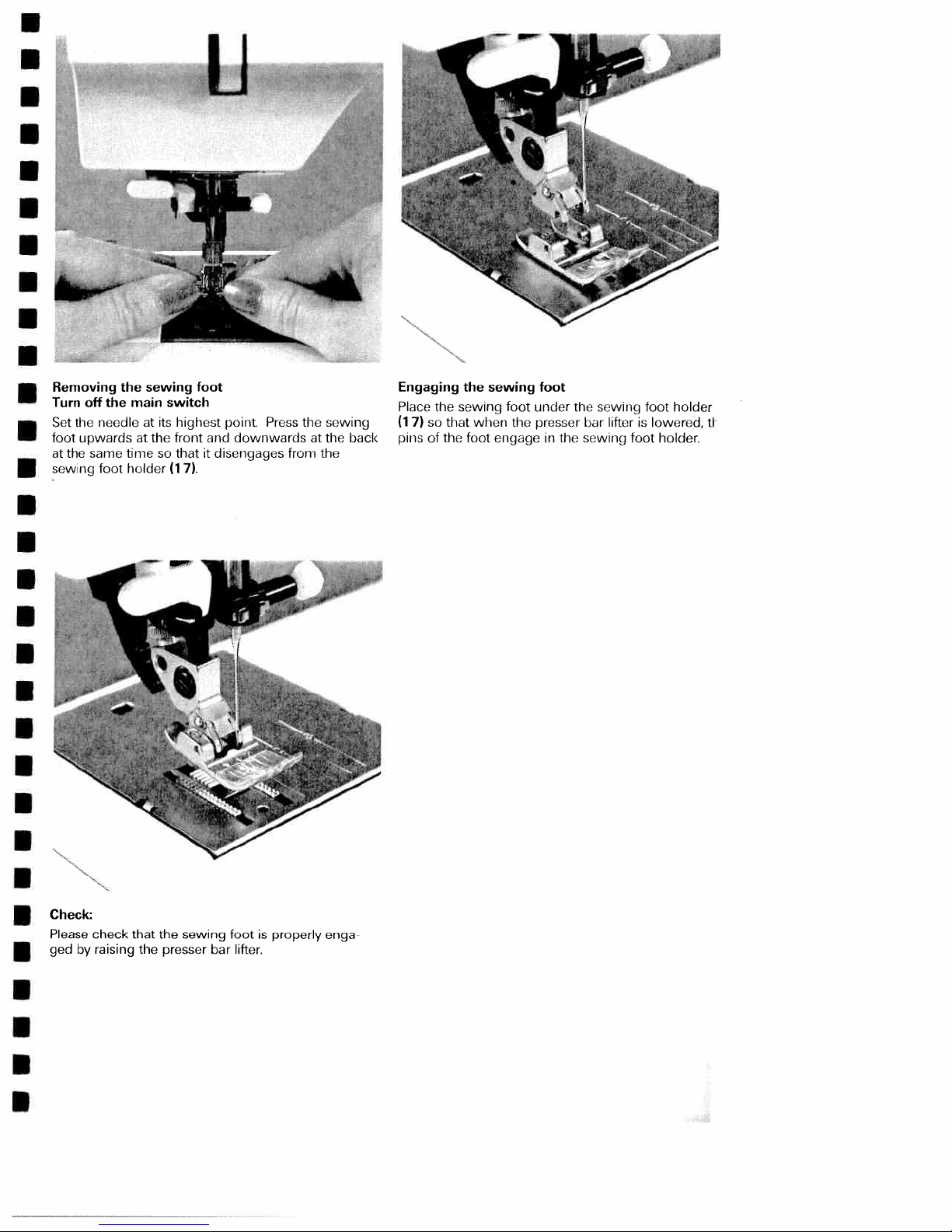

Removing

Turn

off

Set

the

foot

upwardsatthe

at

the

same

sewing

the

the

needle

timesothat

foot

holder

sewing

main

at

switch

its

front

(1

toot

highest

7).

point

and

downwards

it

disengages

Press

the

from

at

the

sewing

the

back

Engaging

Place

the

so

(1

7)

pins

of

the

sewing

sewing

that when the

the

foot

foot

engageinthe

foot

under

presser

the sewing

bar

lifterislowered,

sewing

holder

foot

foot holder.

tl

Check:

Please

check

gedbyraising

that the

the

sewing

presser

footisproperly

lifter.

bar

enga

Page 30

I

I

I

I

I

I

I

I

i

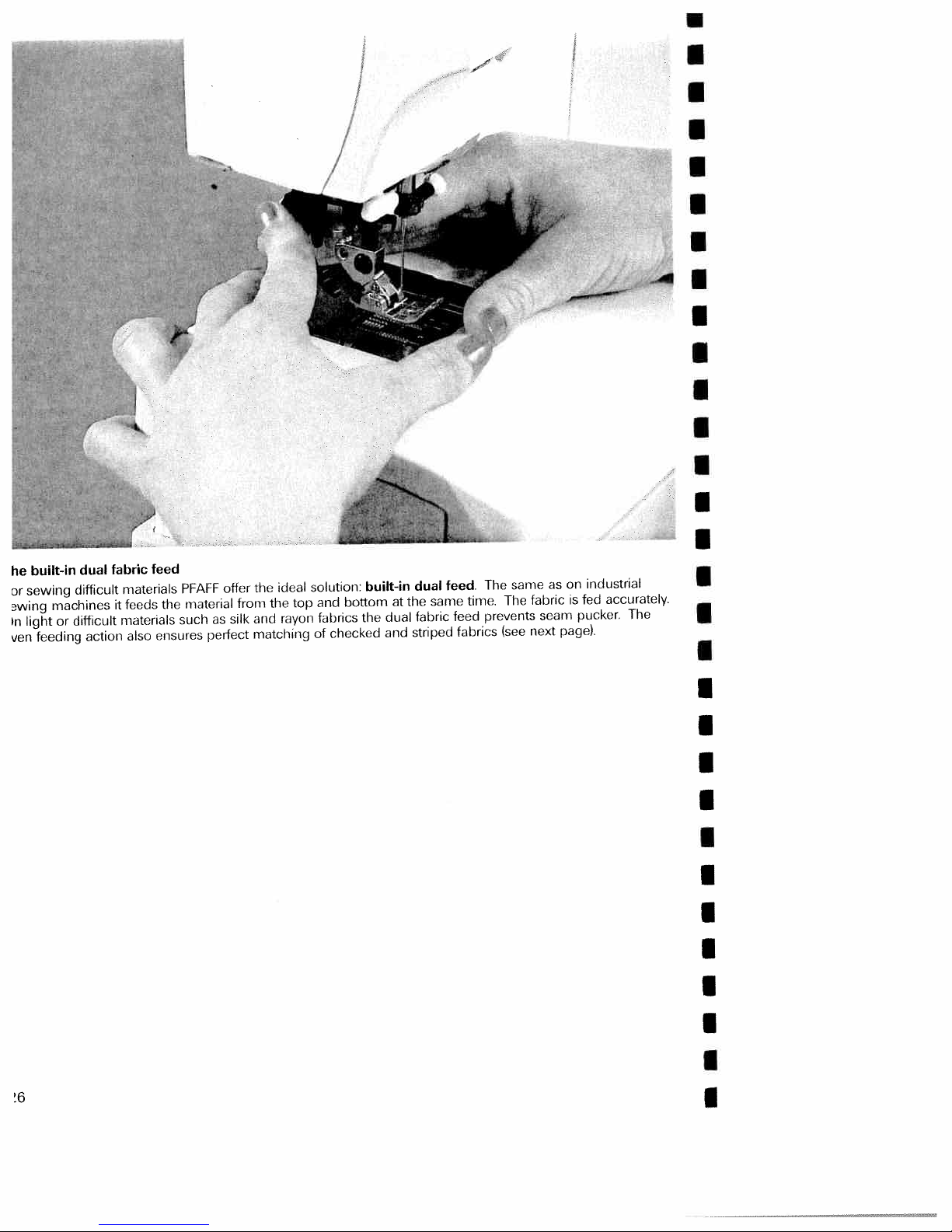

built-in

he

sewing

or

ewing

light

n

yen

machines

or

feeding

dual

difficult

difficult

action

fabric

materials

feeds

it

materials

also

feed

the

ensures

PEAFF

material

such

offer

silk

as

perFect

the

from

and

matching

the

ideal

rayon

solution:

top

and

fabrics

checked

ol

built-in

bottom

the

at

dual

and

dual

the

fabric

striped

same

feed.

feed

fabrics

time.

same

The

The

prevents

(see

fabric

seam

next

as

on

is

pucker,

page).

industrial

accurately.

fed

I

I

The

I

I

I

I

I

I

I

I

I

I

I

I

I

Page 31

Engaging

the

Raise

that

so

sewing

snaps

it

the

top

in

feed

foot

place.

Now

push

the

top

feed

(38)

Disengaging

top

the

Hold

places.

to

the

Push

rear,

the

illustration

and

the

teed

the

on

let

top

with

top

page

it

feed

two

feed

move

26>.

fingers

(38)

slowly

down

upwards

marked

the

at

little

a

and

(see

out

also

important!

feed,

top

the

with

jobs

sewing

all

For

only

use

sewing

feet

with

cutout

back

the

at

2/

Page 32

$ø

Changing

Switch

/

/

/

/

/

/

To

needle

screw

To

insert:

the

needk:,

needle

off

remove:

at

(24)

rear.

pushing

and

the

main

Lower

its

and

The

Lower

tightet

needle

highest

pull

flat

the

it

switch

thc

point.

the

side

sewing

rip

tire

sewing

A

as

fixing

Now

needle

of

foot

tar

as

II

te

screw

foot

out

tiedIe

and

it

will

dnd

loosen

downards.

insert

gu.

(24)

set

the

must

Hold

fit

th

fixing

the

ily.

n

face

tu

thu

Page 33

I

I

I

I

I

I

I

U

I

I

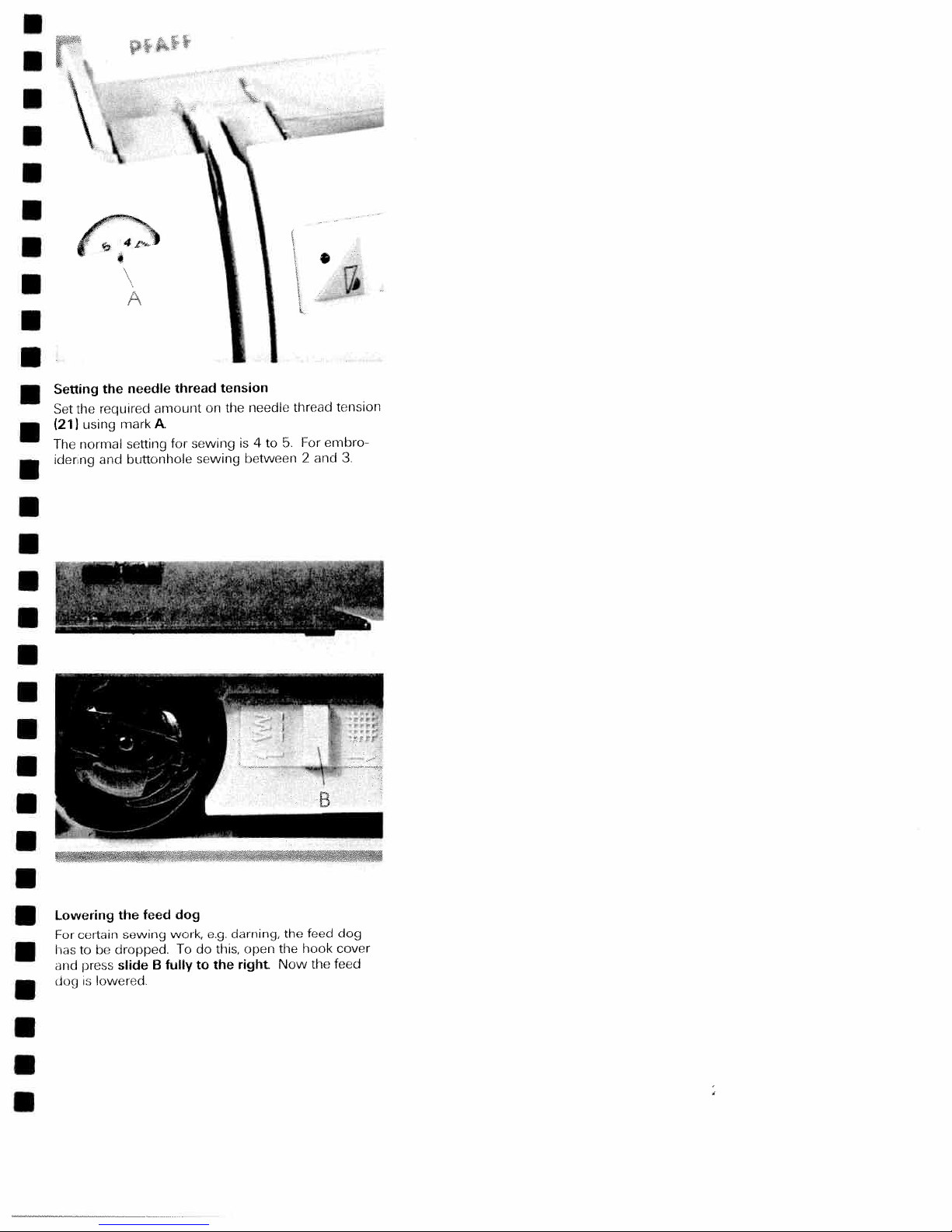

Setting

Set

the

(21)

The

idering

the

required

using

normal

and

needle

amount

A.

mark

setting

buttonhole

thread

for

on

sewing

sewing

tension

the

is

between

needle

4to5.

thread

For

and

2

tension

embro

3.

I

U

I

I

U

I

I

U

U

I

U

U

U

I

Lowering

For

ccrtain

tobedropped.

ii,s

arid

press

lowered

dog

is

the

sewing

slide

feed

B

dog

work,

Todothis,

fully

to

e.g

the

darninq,

open

right

the

the

Now

teed

hook

the

dog

cover

feed

I

B

B

Page 34

——

——————

——

—

—

—

—————

————

————

———

—

Page 35

Operating

the

sewing

machine

Program

Function

Control

Pages

31

keys

keys

slide

to

keys

40

Page 36

Page 37

S

S

S

S

S

S

S

1

:-

:--

:

S

•

•

•

5

•

U

5

S

S

S

S

S

S

S

Elektronic

Program

Clear

Needle

Stitch

Stitch

Balance

Slow

Needle

Buttonhole/tacking!

single

Reverse

Twin

keys

key

positions

width

length

slide

sewing

position

patterns

sewing

needle

section

slide

slide

key

key

key

up/down

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

PFAFF

34

34

35

35

36

37

38

38

39

40

40

electronic

6250

S

S

S

S

Page 38

_______

•

•

I

PFAFF

automatically

the

automatically

machine

the

from

keys

electronic

left

29

program

to

rogram

rhe

appear

Jse

return

9

e.g.

1

LL

does

20).

--—

PFAFF

6250

liquid

the

in

key

(12)

number

to

jump

not

selected

The

—-—

has

to

to

two

crystal

select

0.

the

program

Use

•Ob

l

•

program

display

tens

the

next

L-

right

tens

cannot

6

—---

electronic

When

keys.

3).

(1

from

digits

program

(e.g.

be

from

changed

digit

Li

•

—

LL

•

Li

L2

LS

J

6250

Geemany

in

Made

will

machine

After

9.

digit

00

number

stays

will

as

is

it

program

number

from

selected

on,

0

7

to

tens

the

switched

30).

you

units

is

reach

digits

the

but

sewing.

machine

the

After

7.

to

0

key

to

29

select

to

during

Clear

The

1.

2.

34

clear

You

You

key

can

can

key

(14)

a

set

cancel

two

has

program

previously

a

functions.

have

you

saved

started

buttonhole-

back

at

the

darning

or

beginning

program.

again.

Page 39

_____

0

Setting

The

When

1

0

Please

stitch

to

stitch

the

width

you

6

mm;

observe

•

width

slide

move

infinitely

the

I

key

the

note

L

has

(6)

key

slide

variable.

concerning

4.

two

the

•0.5_V

•

.J

functions:

upper

slide

diode

key

lights

(6).

r

O2’’1

up

and

you

can

•

La

L2

13

Ii

from

width

set

the

required

stitch

Setting

2.

‘

I

Note

Whenever

‘

program

The

I

moved

the

When

is

This

concerning

green

back

needle

you

possible

the

setting.

diode

to

,c

move

slide

machine

does

the

position

the

programs

in

not

basic

L

slide

key

switched

is

light

setting

key

(6):

J

(6)

02,

up

again.

the

03,

on

until

lower

06

or

the

.0.5

•

and

program

a

slide

diode

07.

key

O2’i

lights

selected,

is

moved.

is

6

and

up

the

It

•

you

electronic

goes

L.1

•

set

can

again

out

Li

to

up

system

as

L2

1

soon

needle

3

will

make

as

positions.

the

basic

a

slide

key

is

Page 40

4’

*

ioddn

“1

90

-

:suorpun4

poip

lUeJJ4!p

sq6i

9

‘

dii

stii6uai

JC)

pun

!/

Lvvv•O

-

nbA

P9•

i

1

tr’

•

ueo

os

SOOqUOfli1q

UI

‘

.z_

11

oqi

L2

‘c

tI

paiinhoj

01

itii’iiioid

El

qiis

l15ui

F

so

woij

*

-

ii+

-

111!1S

a’\Ow

qi6u

(L)

Op!(S

eqi

A1ovu!ju

jo

LflfiU0

Aoi

noA

(L)

apils

ajq?IJeA

uco

Olli

li

u

g

01

‘!flS

qi

1(lItliOi

ii

nutS

:ww

n

npi;

A

seq

Aa

7

os

r

00J41

oq

oquonq

is

ttu

0ON

cro

1htIflI

1

A

iII(I

oft

p

o

I

II)

GIl)

B

L

3110’)

1

1(1

I

iusqo

-

.

OP!IS

I-

f5U!UJOUOO

-

so.

aou

ooq

‘

-

*

T:_

U)

Aj

9

.

I

. .

i.

Li

-I

i

/4

A3!suap

epijs

:(L)

iq6ij

613111BS

Aa

pOqOl!Ms

dii

(L)

OqI

UO

iun

uin6n

n

pop

1OMO

e

Jo

oq

opis

6

si

iuei6njd

Ao(

si

dn

‘p0130(05

ii

paAbLu

jue

noA

soo6

i’o

pio

lOS

D!uOJjDcI(a

SC

u!C6C

uioisAs

ji

UbOS

piiflbw

SC

O)(eUi

Olfl

qDlils

Aieuip

oiouo

wu’

0[II

(W1

fiuiIiJ

0111

oqi

opqs

O1ftJ3’

SO()()

Aovuiui

Aoj

!

TOU

DISPq

I

I

I

I

I

B

)J

I

I

__

I

Page 41

C

Setting

The

1

The

wi!

The

wilt

the

buleuce

When

stitcl

res.

farther

he

r

larthoryon

he

loss

you

you

rore

dense

Please observe

•

bldnce

slide

move

move[Iin

iSe.

do

0ev:

the

key

II

note

(8)

s

the

hos

ol!(i

key

key

be’ow

two

key

right,

ieft,

functions

the

upper

the

longer

shorter

[he

concerning

0-7

diode

the

slide

the

0.2

lights up

reverse

reverse

key

stitches

shtches

(8).

rind

-

•

1

H

Li

0-9

11w

II

liflC311

htclIoS

otitches

of

of

otthe

tho

pork

poh’IH

you

will

will

con

he

ho

detso

soWn.

sewn.

ii:

:o

Setting

2.

When

seven

Note

concerning

Wliiiiover

qroei(

hi’

iv’!

the

hoik

pattern

you

steps

the

setting.

diode

move

frour

machurt’

Ici

the basic

length

the slide l’j’

Li

slide

does

not

In

L3

key

swtr’h’:l

light

selling

(8):

up

again.

(8)

on

until

rh:

07

[lie

lwe

Ii)

-

I

I

09

—

ii

I)

I)

I

l:hits

diojo

-

P0(11)

key

slide

is

:slectt’rh,

is

moved.

up

arid

It

the

goes

you

can

eheCtiOflic

out

set

apron

he

SWO

0)

eWili’

1’:

‘i”

‘l

‘I

Page 42

I

I

I

I

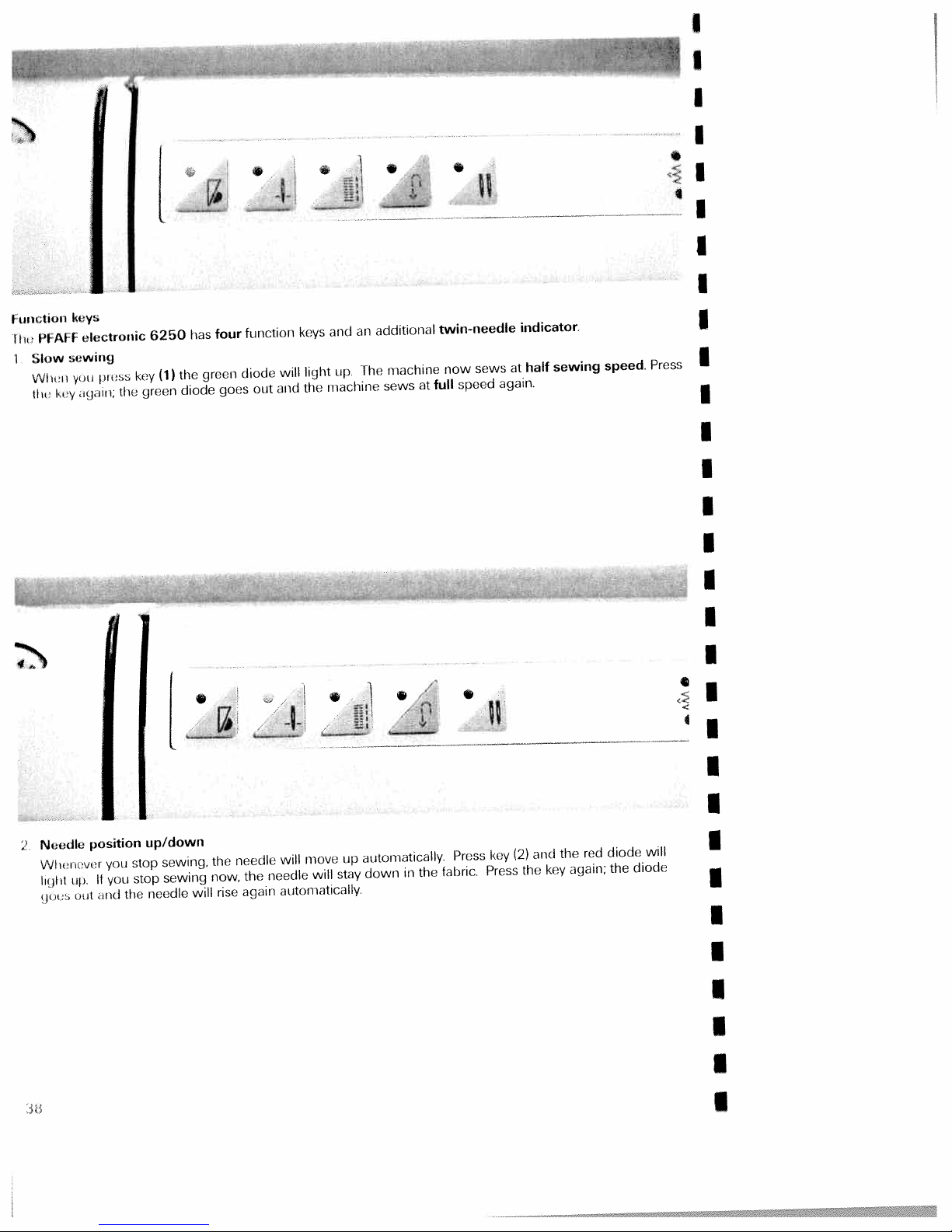

unction

F

lh

1

PFAFF

Slow

WIeu

h

sewing

ky

keys

electronic

pius

you

dgdlu;

tIm

key

green

6250

(1)

has

the

diode

four

green

goes

function

diode

out

-

will

and

keys

light

the

.1

and

up.

machine

additional

an

The

machine

sews

twin-needle

now

full

at

sews

speed

at

again.

indicator.

sewing

half

speed.

Press

I

I

I

I

I

I

I

I

I

I

I

I

I

Needle

WIii’,u’vt’i

tip.

light

uut

;o,s

position

you

you

If

iiid

stop

stop

the

up/down

sewing,

sewing

needle

will

a

V

the

now,

rise

needle

the

again

-

-

move

will

will

needle

automatically.

__

up

stay

‘

automatically.

down

the

in

Press

fabric.

key

Press

(2>

the

and

key

the

again;

red

diode

the

will

diode

I

I

I

I

I

I

I

I

I

I

I

S

I

Page 43

___

___

Buttonholes/tacking/single

3.

three

has

(3)

Key

Buttonholes

1.

2.

3,

With

Tacking

this

If

the

Single

If

pattern

pattern,

this

this

key

patterns

key

is

key

is

is

sewn

pressed

is

pressed

functions:

can

you

tacked

the

at

1

•

17’

vu

patterns

determine

sewing

before

automatically,

sewing,

during

The

end.

and

green

+

save

is

then

the

ft

begun,

the

green

diode

your

own

the

diode

diode

goes

buttonhole

green

goes

out

will

again.

a

diode

out

light

will

again.

rip.

a

lengths

light

A

seam

in

up.

programs

seam,

The

is

sewn

/2.

/

71

beginning

or

immedidlely,

l

dud

Page 44

I

I

I

I

4.

Reverse

Before

As

soon

again.

hold

sewing,

If

the

sewing

as

you

you

key.

press

Then

press

press

the

the

key

the

key

green

(4);

key

during

ri

11a

the

again,

diode

green

sewing,

does

the

-,-

diode

green

not

the

lights

diode

PFAFF

light

up.

will

up.

The

machine

go

out

electronic

n

and

6250

now

the

sews

machine

will

sew

backwards.

forwards

sews

backwards

I

4

I

I

I

long

as

as

you

I

I

I

I

I

I

Twin

In

some

the

twin

needle.

needle

indicator

of

the

needle.Ifyou

programs

t.

the

reduce

diode

the

of

stitch

the

*

twin

width

needle

and

v

the

indicator

diode

goes

•/‘

lights

out,

up.

I

This

means

that

you

must

not

it

is

then

possible

to

sew

with

nsc

twin

I

I

I

I

I

I

Page 45

Sewing

and

embroidering

Utility

Pages

and

41

fancy

to

stitches

71

41

Page 46

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

S

Page 47

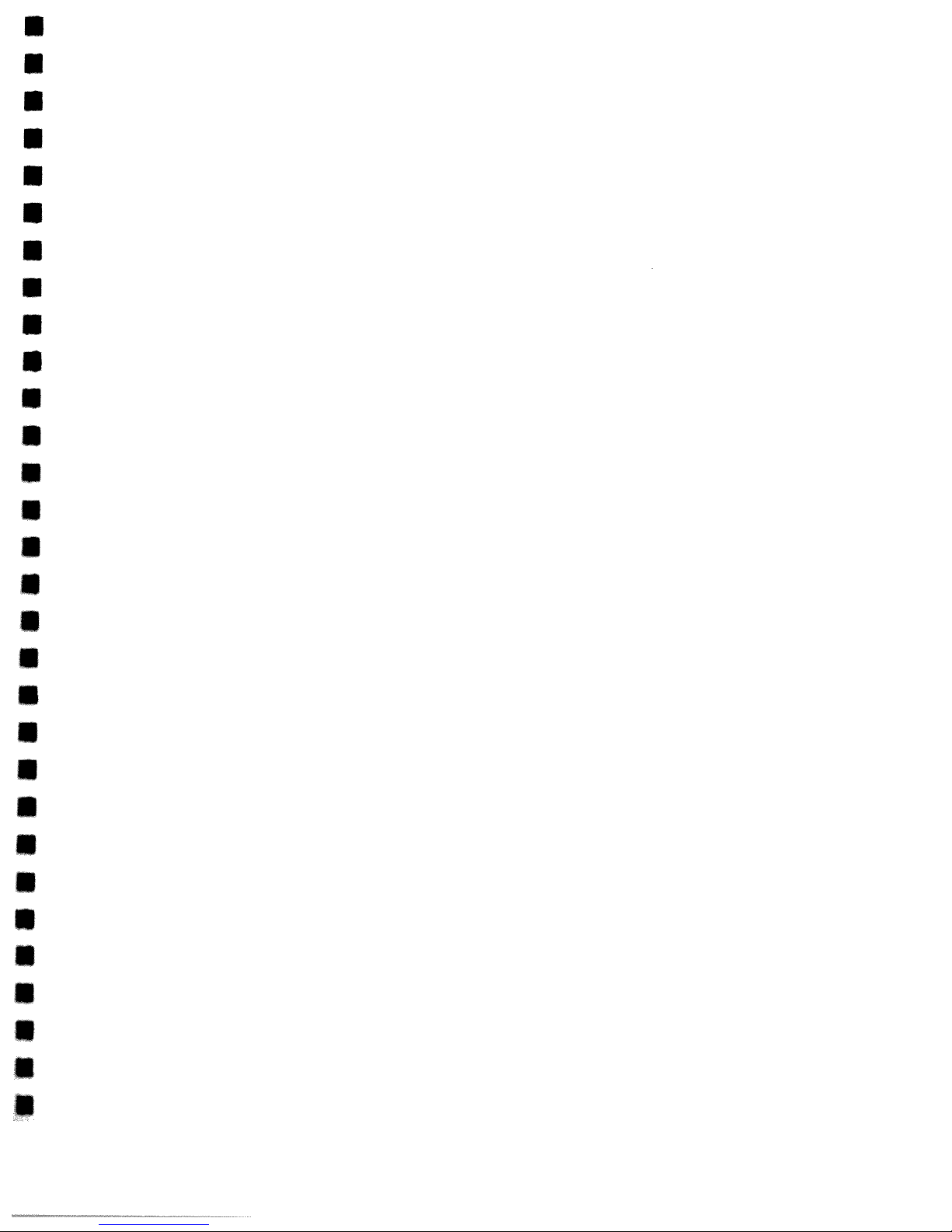

Utility

Non-elastic

Elastic

Overlock

Covering

Buttonholes

Fancy

Sewing

stitches

stitches

table

and

stitches

stitches

stitches

fancy

stitches

Pages

Pages

Pages

Pages

Pages

Pages

Page

45

51

54

56

44

59

63

to

to

to

to

to

to

50

53

55

58

62

71

Page 48

I

I

I

I

I

S

Explanation

recommendations

Whenever

basic

automatically.

You

and

the

following

recommend

These

sewing

foot

and

engaged

rog

p

A

stitch

can

change

sewing

tables

the

you

need,

whether

a

selected

or

Program

Stitch

Stitch

Top

tables

of

program

length,

purpose

for

disengaged.

tables

give

the

you

feed

stitch

these

using

you

different

you

programs:

needle

should

number

length

width

engaged

disengaged

for

is

selected,

settings

will

sewing

further

thread

sew

in

mm

in

mm

sewing

width

according

slide

keys

find

the

purposes.

information

the

with

the

machine

and

6,7and

settings

type

tension

the

top

•

0

balance

to

required

of

sewing

setting,

feed

sets

material

In

8,

we

for

a

I

I

I

a

I

U

I

I

U

I

I

I

a

I

Needle

thread

tension

E.1

Sewing

44

foot

number

I

S

a

I

I

S

Page 49

Basting

With

trying

machine

stitch

Lower

—

feed.

Place

—

Sew

—

the

Repeat

—

the

To

TIP:

dress

fabrics

mm).

(6

feed.

stitch

program

on.

it

will

have

you

the

the

one

required

work.

prevent

pins

are

Then

08

When

only

to

bottom

fabric

stitch,

amount

as

this

the

crosswise

easier

you

you

you

make

press

under

then

many

material

to

baste

do

can

press

feed

to

not

one

the

and

the

pull

times

the

with

need

baste

the

stitch.

foot

sewing

the

plies

basting

/

garment

a

toot

For

control

disengage

fabric

you

as

from

dirction.

long

lower

to

/

control

each

each

loot

to

need

shifting,

straight

the

the

the

before

the

further

time.

rear

finish

to

Light

stitches

bottom

top

insert

by

LLzi

6

to

needle

with

left

stitch

00

position.

mm

sewing

in

a

use

always

You

slide

needle

Straight

Program

needle

up

Some

the

sewing

position,

position,

point.

ens

with

the

is

required.

as

jobs

position,

fastener.

zip

program

make

can

set

key

position

The

(6).

basic

stitch

can

e.g.

up

02.

sure

to

straight

length

done

be

top-stitching

change

To

Before

the

different

3

1

Program

cannot

that

stitch

can

easier

you

needle

01

LL

1

with

increased

be

changing

by

collar

a

needle

the

change

isatits

needle

straight

a

is

changed.

be

middle

or

its

highest

positi

stitch

Page 50

1

\

ZI

1O-12

L_L_.

Zigzag

Zigzag

edges

all

of

the

Sure

alternately

edge

oqr

pr

In

tInt’

from

I)osltionl

toward

2

1

one

to

work

stitch

stitch

needle

ml

muddle

hanges

side,

1—2

10

Whilo

10

left,

e.g.

3—6

L

cart

set

(JUl’’

width

tIre

outwards.

toward

the

i.e.

eyelet

for

=rJ

ht

11110

tisl

qu

stitch

ig

of

the

•

fur

ar

II)aterial

the

zhgiag

prograni

In

right,

width

ennibrondt’ry

trouble

dge,

stitcl

,ind

can

3

always

Slid

m

11

in

Is.

anal

h

free

nkike

ilvIl

changes

the

program

regulated

trdnmrtj

i

Ii

sergirig

the

needle

.EW

LFlJ

For

very

thu’

1

[Is’

You

A.

Important:

11.

a

i

serging

‘

nst’lnl

JtrVvl’miJlIi(J

sm

iii

edge

raw

adjust

can

—?J

materials,

hea

has

this

limIlllI(J

in

tim

to

iii’

n

st’wmnrg,

I

he

etlrjm

flit’

difficult

linnnnmntj

‘w

Only

l\

j_L_J.IJ

is

No.

over

In

grade

rg

program

this

pin

screw

3

C,

way

B.

tIme

ol

smooth

guided

u

‘

blind

flit

blind

ihre,nd

tabrnc

seams.

It’

will

.tik