PFAFF

coverlock

4872

I

‘F

U

U

482

coe10Ck

PFAFF

Instruction

Manual

N

Parts

of

the

coverlock

4872

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

23

24

Upper

Upper

Carry

Thread

Thread

Thread

cover

Tension

needle-thread

needle-thread

handle

tension/upper

tension/lower

tension/two

stich

keys

display

LCD

sewing

for

Slide

Tension

Program

release

selection

MemorykeyM

Memory

Looper

Blade

Looper

Standard

Needle

Swivel

selection

cover

guard

disengaging

presser

plate

plate

Adjusting

Seam

Needle

Sewing

width

holder

light

Adjusting

looper

+

knob

viewing

cover

knob

and

key

for

for

thread

—

speed

keys

key

foot

seam

the

tension

tension

looper

looper

chainstitch

pre-selecfion

and

EE

P

lever

width

window

pressure

thread

thread

e

foot

looper!

pressure

25

26

27

28

29

30

31

32

33

34

35

36

37

Upper

Lower

overedge

overedge

Swiveling

Two-thread

Threading

cover

stitch

Movable

Fixed

Clamp

Needle

lower

spring

plate

Handwheel

Tweezers

Converter

Allen

key

stitch

chainstitch

for

aid

looper

upper

blade

for

disengaging

for

looper

looper

width

two

the

blade

serging

lowering

latch

looper

thread

thread

the

lever

upper

chainstitch

chains

blade

looper!

For

pease

easier

f&d

Safety

the

For

eads

The

terminal

wires

The

following

Blue:

the

As

may

your

in

The

terminal

The

terminal

Cut-off

immediately.

of

pletely.

Only

according

with

The

covers

agencies.

Please

understanding

this

out

ru’es

Kingdom

United

must

to

nor

the

in

code:

Neutral

of

colors

correspond

not

wire

wire

plug

plug,

which

which

which

which

mains

spare

A

3

to

corresponding

the

must

are

also

proceed

plugs

BS

available

observe

the

and

definitely

plug

a

mains

Brown:

wires

the

with

colored

is

marked

is

colored

is

marked

is

are

Defective

fuses

1362

never

from

the

of

only

with

lead

follows:

as

definitely

must

and

color

used

be

general

this

bst

be

not

three

are

Live

the

in

color

the

blue

with

brown

with

mains

be

the

code.

electrical

instruction

page

connected

pins.

colored

mains

coding

must

letter

the

must

letter

the

not

leads

as

used

cover

fuse

without

suppliers

safety

when

according

lead

connected

be

N

be

L

be

to

must

approved

fuse

notes

book

reading.

the

to

this

of

the

of

colored

or

connected

colored

or

used,

be

be

must

cover.

or

on

safety

the

to

appliance

terminals

to

but

replaced

ASTA

by

marked

Spare

PFAFF

the

page

lead

the

black.

the

to

red.

disposed

com

fuse

2.

or

A

3

You

wiN

Important

For

If

•

manufacturer

person

The

•

•

•

•

find

Australia

the

appliance

infirm

Young

play

not

Switch

Before

machine.

the

safety

only

supply

order

in

persons

children

with

or

off

servicing

contents

instructions

is

cord

or

its

avoid

to

not

is

without

should

appliance.

the

unplug

the

on

damaged,

service

a

intended

supervision.

be

machine

the

appliance

page

must

it

agent

hazard.

for

supervised

or

and

4

be

similarly

a

or

by

use

to

when

replacing

5.

replaced

young

ensure

leaving

lamps,

by

qualified

children

they

that

it

unattended.

unplug

the

or

do

the

DANGER

sewing

The

1.

appliance

2.

3.

4.

this

Always

Do

Do

Do

not

not

not

unplug

reach

place

place

V!ARNNG

allow

not

Do

1.

used

only

2.

Only

Never

3.

properly,

ce

mechanical

Never

4.

openings

dust

Never

5.

Do

6.

7.

Do

administered.

To

8.

9.

blocked.

10.

11.

12.

13.

14.

15.

16.

17.

Please

by

use

use

the

to

and

not

not

disconnect,

Never

not

Do

Keep

machine

Always

not

Do

not

Do

Switch

such

etc.

Always

ting,

manual.

Hold

also

or

this

attachments

operate

if

nearest

operate

of

loose

drop

use

operate

operate

unplug

fingers

needle.

use

use

pull

the

threading

as

unplug

when

or

plug

observe

To

reduce

machine

from

before

a

for

store

or

or

in

To

be

to

children.

near

sewing

this

been

has

it

authorized

adjustment.

the

sewing

the

cloth.

insert

or

of

out

where

turn

on

by

away

proper

the

or

bent

push

or

sewing

sewing

making

rewinding

when

the

mportant

For

This

HOLD

wing

Read

the

should

electric

the

relamping.

sewing

sewing

a

into

drop

reduce

used

machine

recommended

sewing

dropped

sewing

anything

doors.

aerosol

controls

all

soft

a

pulling

from

needle

blunt

fabric

machine

needle,

any

general

the

sewing

risk

never

machine

water

the

toy.

a

as

machine

dealer

machine

machine

surface

on

moving

all

needles.

while

off

changing

machine

other

into

United

use

basic

instructions

all

of

outlet

machine

risk

Great

for

or

and

into

(spray)

to

such

cord.

plate.

stitching.

(“0”)

from

user

cord

safety

machine

only.

safety

electric

left

be

immediately

Replace

that

other

or

burns,

of

intended

its

by

it

if

damaged,

service

or

with

foot

any

products

off

(“0”)

as

unplug,

To

parts.

The

Only

when

needle,

servicing

reel.

notes

safety

States

When

precautions

shock:

unattended

bulb

has

where

liquid.

care

the

has

any

control

opening.

position,

bed

a

Special

wrong

use

It

electric

the

Do

on

only

designed

is

use

you

before

after

same

with

into

fallen

can

it

electric

fire,

necessary

is

purpose

manufacturer

damaged

a

or

dropped

center

openings

air

free

being

are

couch

or

the

hold

care

plate

needles

deflect

may

threading

outlet

adjustments

allow

not

Page

any

2.

making

instructions

manufactured

and

electric

an

should

using

when

using

type

water.

or

tall

shock,

when

described

as

as

cord

into

examination,

for

blocked.

from

used

remove

then

where

plug,

is

required

cause

can

recommended

the

adjustments

bobbin,

when

plug

always

sewing

this

plugged

and

rated

Unplug

pulled

be

or

this

contained

or

water.

the

or

the

not

needle,

oi

removing

mentioned

whip

to

appliance,

before

injury

plug,

accumulation

where

plug

the

around

the

changing

be

machine.

Always

in.

Watts.

5

immediately.

into

to

sewing

this

in

in

itisnot

if

Return

repair,

ventilation

Keep

oxygen

from

openings

air

cord.

needle

the

by

causing

the

in

covers,

in

when

HOUSE

for

follo

the

adhered

unplug

cleaning.

or

tub

a

persons:

machine

manual.

manual.

this

working

applian

the

electrical

lint,

of

is

socket.

may

sewing

the

break.

to

manufacturer.

break.

to

it

needle

presser

lubrica

instruction

the

rewinding.

to:

sink.

is

or

being

be

area,

foot,

KEEP

THESE

1NSTRUC11ONS

N

A

SAFE

PLACE

Notes

Notes

according

The

1.

tion

movement

observe

When

2.

tenance

ical

nect

by

wall

The

3.

the

The

4.

adjusted

The

5.

according

fication

Do

6.

the

Do

7.

there

—

its

—

it

—

can

brought

Do

8.

socket

If

9.

pose

operated,

for

10.To

open

inside

repair.

of

11.Be

The

12.

on

safety

on

EN

to

must

user

regard

with

the

leaving

work

or

parts

machine

the

unplugging

outlet.

maximum

sewing

tension

by

machine

plate.

place

not

machine.

use

not

is

function

wet,

is

occur

into

pull

not

by

appliance

this

than

damage

any

avoid

the

the

This

qualified

our

to

sure

machine

safety

domestic

for

60335-2-28

exercise

the

of

sewing

the

or

accessories,

the

permissible

lamp

the

of

PFAFF

a

must

the

to

any

sewing

the

visible

is

with

e.g.

when

warm

a

the

cord.

its

that

cannot

we

risk

the

machine.

machine

the

is

use

is

the

to

needle

area

machine,

when

from

lead

watts.

5

is

belt

mechanic.

be

indications

objects

damage,

defective,

condensation

cold

a

room.

mains

used

is

intended

caused.

electric

of

There

which

exclusive

service

original

only

designated

sewing

IEC

or

adequate

up

and

during

changing

always

the

cord

drive

into

put

in

machine

machine

plug

for

or

accept

are

staff.

machines

335-2-28.

and-down

constantly

work.

during

mechan

discon

power

main

from

wattage

must

operation

the

on

openings

if:

is

of

out

another

is

it

if

liability

any

shock,

no

user

the

responsibility

PFAFF

a

for

cau

main

the

for

only

speci

on

which

the

pur

wrongly

do

parts

can

parts.

mains

be

not

supply

and

10

%

When

13.

outer

the

nically

85°

to

up

therefore

is

damage,

avoid

Environment

recommended

The

Ambient

(40°

Humidity

Storage

+

The

but

vicinity

radios,

etc.

C)

140°

machine

it

This

temperature

20

temperature

F

)60°

should

of

televisions,

machine

nic-mechanical

supervised

operated

dust,

to:

ted

sunlight,

permit

be

even

corrosive

kept

objects,

To

must

and

Treatment

Always

make

machine

Cleaning

Housing

the

clean

To

cloth

soft

stubborn

any

paraffin.

or

hol

Notel

Please

use

Never

such

petrol

as

housing.

the

an

with

a

rated

a

properly,

used

components

controlled

C.

not

to

%

C).

is

not

electronic

use

such

in

severe

static

adequate

unblocked

surface.

sure

knocking

by

display:

and

housing,

which

dirt,

insecticides

nominal

frequency

foot

Constant

permitted

environment

50°

%.

80

-

insensitive

used

be

appliances

PCs,

high

is

a

appliance,

home.lt

the

in

a

way

dampness,

electricity,

chemicals

ventilation

not

free

is

use

or

(gas)

voltage

temperature

the

a

of

control

use

F

(10°

F

13°

1-

to

the

in

radio

quality

is

it

that

t

heat-producing

or

and

damage

to

dropping

or

a

dry,

use

lint.

of

soft

a

chemical

or

chemic,tls

thin

+1—

of

4%.

of

+1—

non-electro

can

low

a

at

in

order

is:

104

to

C)

to

25°

C)

interference,

direct

such

as

transmitters,

electro

machine

a

should

subjec

is

not

direct

liquids.

machine

the

on

used

your

st.

clean

remuv”

To

with

cloth

products

reach

speed

to

be

firm

a

ml

.1

to

of

°F

for

cle

Simpe,

Congratulations!

coverlock

PFAFF

as

you

certainly

is

to

make

you

help

now

that

and

and

this

now

find

have

dealer.

will

technology,

instruction

take

manual

full

or

let’s

hours

product

new

stride

Your

design

use

If

instruction

It

way

and

If

PFAFF

any

So

enjoyable

ideas!

up4odate

have

You

provides

can

4872

through

sew

coverlock

of

bit

a

nothing

well

time

what

just

out

of

further

is

happy

started

creating

all

use

any

He

advice.

get

bought

unique

take

features

and

manual

time

spent,

your

its

questions,

to

We

I

your

sewing

advantages.

any

thick

the

just

is

it

to

is

study

to

go

can

since

machine

features.

of

be

wish

very

highquality

a

material

thin

and

very

as

follow.

the

wrong.

it

just

service

you

own

is

ask

many

Your

for

latest

easy

the

can

fashion

in

your

with

its

you.

in

to

only

do

3

Contents

Accessories

Accessories,

Accessory

Adjusting

Changing

spring

Clamp

Cleaning

thread

Cone

Converter,

stitch,

Cover

Differential

Differential

Electrical

Electrical

Error

control,

Foot

functions

Key

Language,

Display

LCD

bulb

Light

Loopercover

Lubricating

Machine

Maintenance

Needle

Needle

Needle

Needle

Needle

Needle

Needle,

Power

Presser

Presser

Presser

Presser

Program

Programmable

Programmable

.

special

box

the

spool

a

machine

the

adapter

attaching

important

feed

feed

connection

power

choice

(sewing

the

cover

holder

inserting

plate

plate,

position

threader

changing

table

foot

foot

foot

foot,

overview

machine

on

setting,

master

connecting

lamp),

machine

tool

disengaging

removing

lifter

pressure

changing

memories,

memories,

to

threaded

a

notes

switch

Prog.

on

changing

changing

lever

deleting

notes

2,

1,

machine

sewing

and

on

3,

all

storing

4

storing

Page

6

68,

6

36,

24

30

65

10

33

51,

38,

42

7

7

44

7

40

41

40

67

8

65

6

65-

13

13

64

64

12

25

13

37

11

10

29

29

69

37

52

39

67

-

48

46

44

44

4

Contents

feet,

Rubber

Safety

Seam

Seam

Seam

Sewing

Sewing

Sewing

cleaning

instructions

adjusting

width

width

viewing

width,

setting

light

cover

probiems

speed

window

and

pre-se(ection

Specifications

disc

5

pooi

holder

Spool

formation

Stitch

Stitch

length

length

Stitch

Stitch

length,

Stitch

programs

width

Stitch

Telescoping

Tension

settings,

Thread chain

Thread

chart

Thread

guide,

Thread

Thread

Thread

net

tension,

unreeling

Threading

adjustment

setting,

adjusting

latch,

thread

cutter

Clip-on

aid

for

correction

changing

programmable

swiveling

guide

changing

setting

disc

the

Threading paths/overview

lower

needle(s)

two

thread

upper

overedge

overedge

Threading the

Threading the

Threading the

Threading

the

Threading,

important

Threading/Thread guides

blade,

blade,

blade,

container

changing

disengaging

securing

Upper

Upper

Upper

Waste

...,.,....,...,...,......................

knob

their

solutions

measures

knob

and

storing

memories,

and

storing

thread

two

chainstitch looper/cover

looper

(yellow>

chainstitch looper cover

looper

(pink)

note

activating

stitch

stitch

looper

looper.

(violet)

...

. .

Page

65

1,

34

34

34

67

70,

29

72

10

7

49

35

42

35

41

32

9

43

30

63

10

9

45

9

19,

26-28

16,

22,

.

18

15

24

14

66

31

35

8

2

71

62

21

17

23

-

21

5

Accessory

the

Open

sing

the

lowing

1

Overlock

no.

2

Thread

Thread

3

Screw

4

Needle

5

Wrench

6

Needle

7

Replacement

8

Clip-on

9

Transparent

10

stitch

Machine

11

Cleaning

12

Edge

13

box

accessory

bottom

accessories

needle

2002

nets

unreeling

driver

threader

inserting

thread

two-thread

and

oil

brush

guide

box56by

the

of

can

(5>

upper

guide

presser

box

be

system

discs

tool

blade

inwards.

found

EL

(5>

foot

(F>

chainstitch

gently

in

X

705,

for

The

the

cover

pres

fol

box:

cat.

lock

Further

following

The

hind

Converter

1

Tweezers

2

Allen

3

Machine

The

from

process

thread

must

41

machine,

attached.

machine.

the

in

behind

accessories

swivel

the

key

cover

machine

dust

is

guide

be

accessory

the

accessories

plate

cover

dirt.

and

finished,

39

pushed

regardless

the

Place

accessories

The

swivel

19:

protects

When

push

together.

to

of

cover

or

box

plate.

be

can

the

sewing

the

telescoping

the

spool

The

extent

full

its

whether

the

over

should

compartments

found

machine

stand

into

spool

a

stored

be

be

the

is

6

I

(/____•S\

1I1!II!!IIII

/

III11I1

Operating

Electrical

Connect

45

of

I

Master

When

sewing

The

machine

the

the

switch

you

lamp

instructions

connection

lead

machine

turn

on

illuminated.

is

now

is

cord

and

the

operational.

between

wall

the

master

the

outlet.

switch

socket

Ii

Connecting

Connect

connection

The

page

control.

Notes

This

blade

To

plug

let

fully

still

trician

Do

For

troller

46

the

the

the

socket

pre-selected

is

regulated

29)

on

safety

appliance

wider

reduce

is

intended

only

one

in

the

does

not

install

to

not

modify

control

type

foot

plug

of

47

sewing

has

than

risk

the

to

way.

outlet,

fit,

contact

the

the

sewing

F8VC-485

control

the

of

by

polarized

a

the

other).

of

electric

fit

If

the

reverse

proper

plug

machine,

foot

the

speed

pressing

in

polarized

a

plug

the

a

in

has

control

machine.

range

the

plug

shock,

does

plug.

qualified

outlet.

way.

any

foot

to

be

to

not

con

used.

(see

foot

(one

this

out

If

elec

the

fit

it

7

cjr

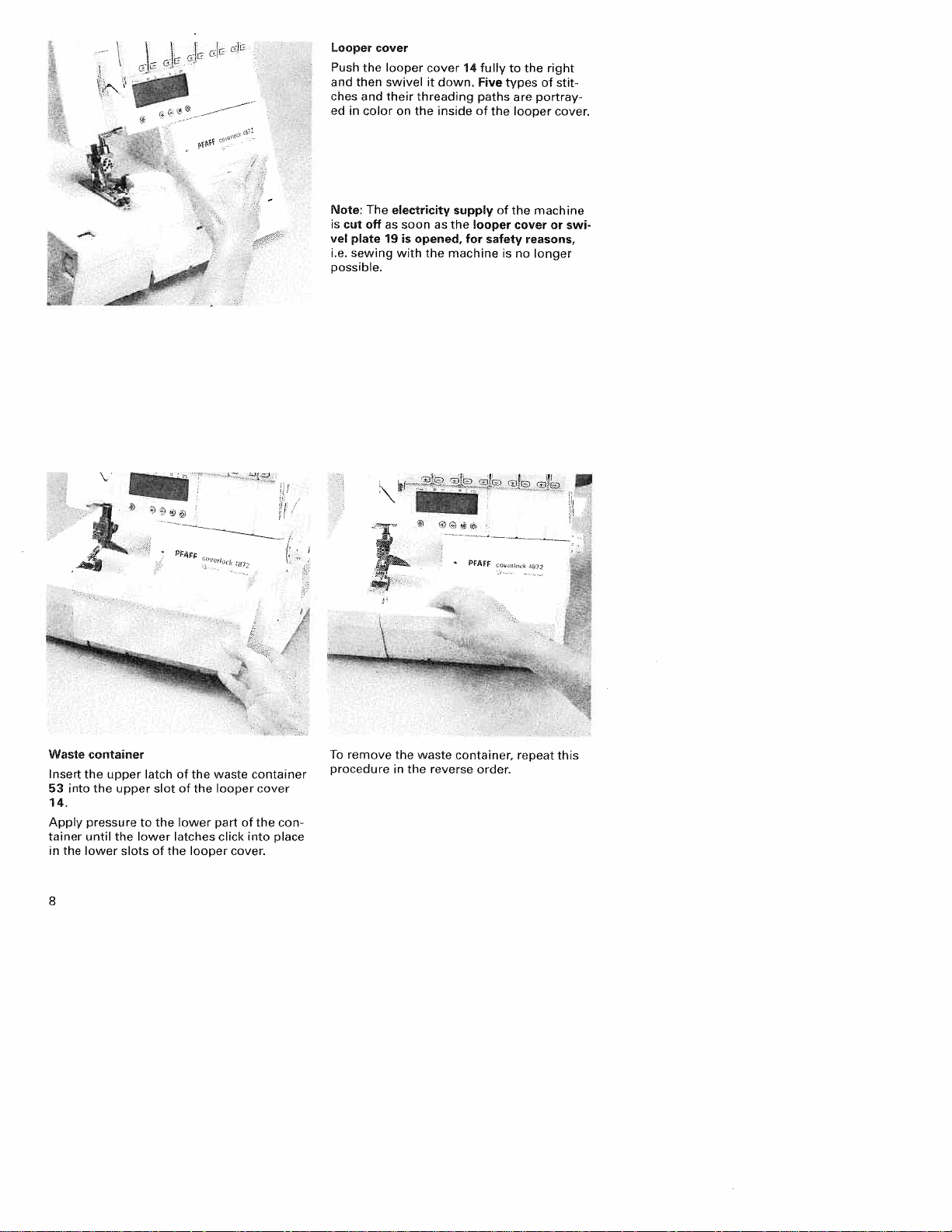

Looper

Push

and

then

ches

and

ed

in

Note:

is

cut

vel

plate

i.e.

sewing

possible.

cover

the looper

swivel

their

color

on

The

electricity

offassoon

19 is

with

cover14fully

it

down.

threading

the

insideofthe

supply

as

the

opened,

the machine

Five

paths

looper

for

to

types

are

looper

of

the machine

cover

safety

isnolonger

the

right

of

portray

reasons,

stit

cover.

or

swi

Waste

Insert

53

14.

Apply

tainer

in

the

8

into

container

the

upper

the

pressure

until

the

lower

latchofthe

upper

slot

to

the

lower

slotsofthe

of

the

lower

latches

looper

waste

looper

part

click

of

into

cover.

container

cover

con

the

place

To

remove

procedure

-‘

!

PFAFF

the

waste

in

the

container,

reverse

order.

repeat

this

Spool

Before

machine

fully

holder

away

placing

you

from

must

—

—

thread cones/spools

pull

the

the

spool holder

backofmachine.

_1

Pcnrc

Telescoping

on

Pull

41

the

upwards

To

ensure

telescoping

locking

thread

telescoping

to

its

optimum

parts

balls

click

highest

slowly

into

guide

thread

thread

place.

guide

position.

feed,

until

you

39

turn

hear

the

the

Thread

Synthetic

quickly

have been

se

threads.

the

accessory

low.

Place

ching

the

pin.

spool

net

threads

from

the

thread

includedtoallow

Pull

the

box)

the

spool

bottomofthe

generally

thread

over

on

the

&

unwind too

spool.

net

the

spool

spool

thread

Thread

easy

(located

net

use

from

holder

with

nets

of

Thread

unre&ing

The

thread

used

is

box)

the

cat

notchedorrough

spool

the

discontop

disc44is

spool

in

be

unreeling

for small

pin

42.

of

the

disc

ends.

Place

spool.

used

disc

(in

the

spools/spools

Place

the

the

thread

Make

under

the

accessory

spool

unreeling

sure the

spool.

with

on

the

9

Spool

It

is

advantageous

ling

disc

(5,000

cone

42.

With

take

up

and

guarantee

disc/cone

44

—

10,000

thread

synthetic

any

when

m).

adapter

play

excellent

thread

to

sewing

To

threads,

or

surplus

/

43

use

do

ill!

adapter

the

with

this,

onto

the

in

thread

thread

large

place

the

spool

the

feed.

spool

thread

unree

spools

the

discs

pin

Clip-on

Use

the

when

this

onto

and

thread

lustration.

unreeling

thread

clip-on

sewing

the

with

telescoping

the

Use

disc.

guide

thread

decorative

machine

the

thread

\

guide

thread

as

accessory

shown

net

thread.

guide

and

the

Clip

39

the

in

il

thread

Presser

The

presser

using

mum

foot

for

achieved

towards

10

foot

the

presser

vertical

particularly

by

the

lifter

foot

can

lift

of

pressing

rear.

foot

be

6.5

thick

lifter

the

raised

mm

51.

for

fabrics

presser

and

The

the

can

foot

lowered

maxi

presser

be

lifter

Once

ted,

to

be

the

same

cient

ser

foot

under

fabric

The

into

control.

the

to

the

an

presser

raised

gently

using

the

machine

initial

if

thread

raised

is

automatically

thread

foot

you

lift

your

continue

and

the

thumb.

part

when

chain

lifter

presser

front

of

the

you

has

longer

no

working

foot,

part

Slide

presser

taken

activate

been

of

the

up

It

the

crea

needs

with

is

fabric

foot.

and

the

suffi

pres

fed

foot

•\

‘4

Presser

With

setting

foot

(Progs.

(Prog.

(Prog.

seam

The

\

‘

accessories

stitch

chainstitch

For

presser

spring-loaded

foot

the

standard

“A”

latch

for

1,

2,

the

4),

191

and the

(Prog.

transparent

(Prog.1,2,

all

other

foot10and

the

of

the

the

3),

4-thread

20)-

can

(Prog.

programs

presser

presser

spring-loaded

cover

stitch

two-thread

safety-stitch

5-thread

presser

also

be

and the

3)

4).

use

the

foot

foot

safety-stitch

foot

used

two-thread

the

setting

latch.

10

presser

programs

chainstitch

F

from

for

the

standard

“B”

use

seam

the

for

the

cover

the

I

Changing

Switch

off

To

remove:

highest

towards

press

foot

until

holder

from

To

perpendicular

Pivot

the

presser

presser

necessary,

place.

Check:

ensure

locked

the

holder.

the

you

attach:

the

pin

position

you.

front

and

of

foot

foot

Please

that

into

the

presser

the

eectricaI

Raise

Raise

lever

A

Pivot

half

remove

towards

Place

the

to

presser

footisdirectly

the

holder

lever and

until

the

lift

the

presser

place.

foot

the

needle(s)

turning

by

presser

the

rearofthe

at

the

presser

the

of

presser

sliding

by

of

back

presser

the

sewing

foot

counterclockwise

clamp.

press

then

foot

presser

the

foot

power

the

machine.

foot

Lower

is

to

the

handwheel

foot and

presser

foot

clockwise

foot

clears

foot

away

behind and

foot

holder.

under

the

the

leverA,if

clicks

into

foot

lever

properly

until

to

11

o

1L2R2

1L21R2

0

EU

12

1R2

0

Need’e

position

one

above

with

time.

are

needles

the

has5needle

a

left

This

machine

can

sew

any

at

concerned

tightening/fastening

directly

Note:Ifthe

inserted,

the

three.

maximum

The

Li,

LO,

screw

the

corresponding

LO,

needle

positions

of

three

positions

needle

L2,

Ri

and

is

located

Li

andL2have

willbethe lowest

needles

R2.

needle.

and

The

been

of

needle

The

different

inaschematic

manual.

and

the

Note:Ifboth

been

mewhat

If

the

the

If

the

right

Also

Insert

below.

display.

LCD

inserted,

higher

1L21fl2

0

EILU

the

needles

left

needle

right

needle.

the needle

left

needle

needle.

positions

drawinginthe

refertothe

the

needles

the

than

L1

and

willbesomewhat

LO

andL2have

will

examples

the

needle(s)

R2

left

needle

right

the

1R2

1L2

0

o

1L2

1R2

UJ’EJ

1L21R2

have

L2

alsobelower

are

instruction

as

Ri

and

willbeso

needle.

V

been

lower

been

than

depicted

above

shown

have

inserted,

inserted,

the

on

than

12

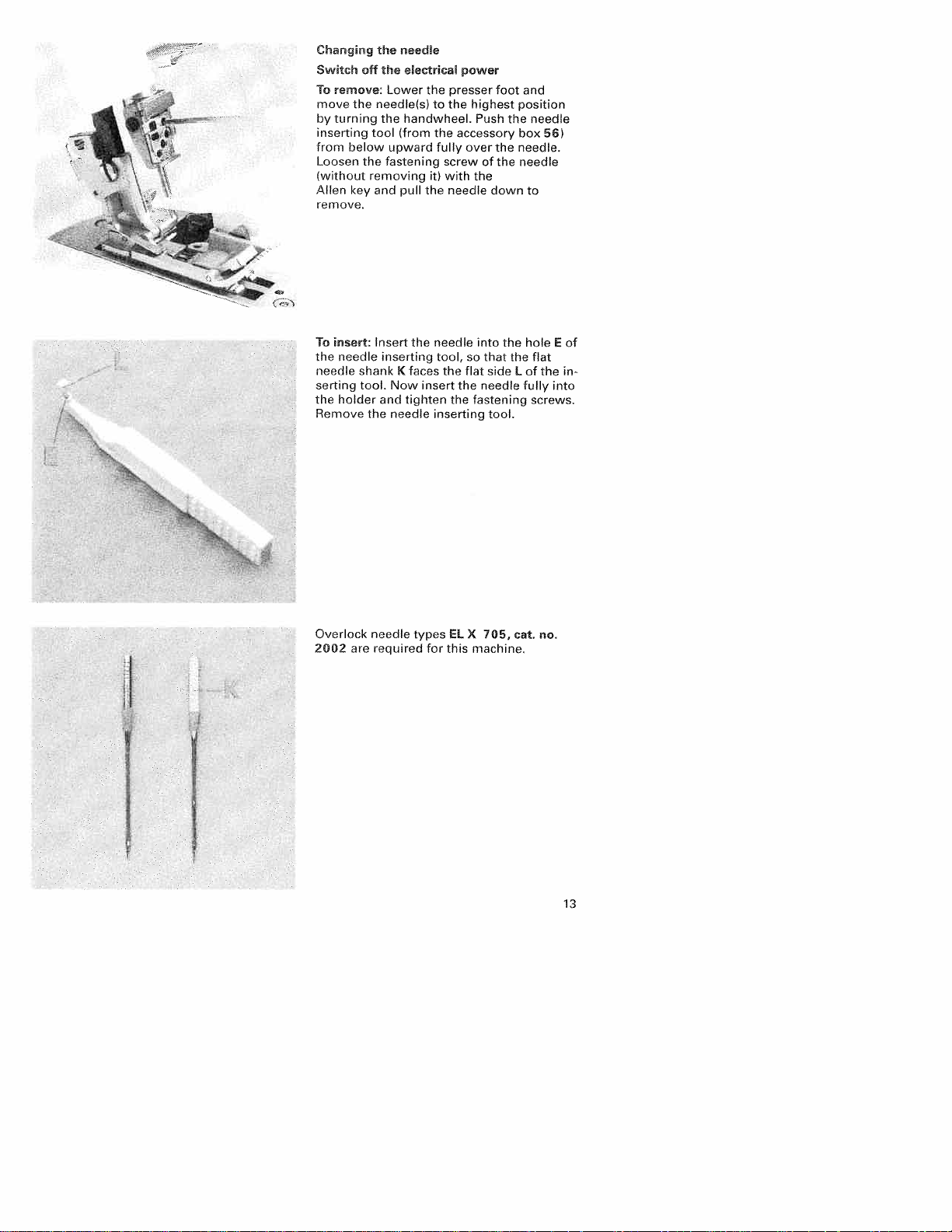

Changing

Switch

To

remove:

move

the

by

turning

inserting

from

below

Loosen

(without

Allen

key

remove.

To

insert:

the

needle

needle

serting

the holder

Remove

the

needle

the

eectrica

off

Lower

needle(s)tothe

handwheel.

the

tool

(from

upward

the

fastening

removing

and

pull

Insert

the

inserting

the

and

needle

K

Now

laces

tighten

shank

tool.

the

the

fully

it)

the

needle

tool,

insert

inserting

power

presser

accessory

screw

with

needle

the

the

the

highest

Push

over

of

the

into

so

that

flat

side

needle

fastening

tool.

foot

the needle

the

the

down

the

the

L

and

position

box

56)

needle.

needle

to

hole

flat

of

the

fully

screws.

E

into

of

in

I

I

I

Overlock

2002

are

needle

required

types

for

EL

this

705,

X

machine.

cat.

no.

13

Threading

I

‘tj

11

r

Place

will

ad

adapter

the

front

the

the

spoolsonthe

information

find

unreeling

on

pages9and

thread guides

following

disc,

thread

the

reel

38

colored

guides

spool

on

disc

from

the

10.

the

pins

thread

and

cone

Thread

backtothe

threading

42.

You

net,

thread

through

paths.

thre

Pull

the carry

through

through

and

both

hands

slips

under

thread

down

the

tension

its

original

\\

I

handle3upwards.

the

underside

the

to

the

through

untilitis

discs.

position.

of

thread guides52using

rear

pull

the

thread

thread

guide.

tension

the

positioned

Return

the

carry

Guide

discs and

firmly

carry

the

down

Thread

handle

until

the

between

handle

pull

it

it

to

ria-

Note:

Threadina

sequenceof1to5.

14

(pink)

overedge

upper

the

make

the

handwhe&

overedge

Thread

this

be

can

task

found

looper

in

a

easier,

towards

sequence

behind

Threading

i

If

—

11

Turn

upper

position.

Note:

To

which

‘ooper

until

highest

its

1

of

tweezers

swivel

the

to

9.

plate.

you

in

25

is

the

use

the

3I

I

L

—

5-.

I

;___

4

4

5

6

.1

1.

Thread

which

I

through

are

marked

the

thread

with

guides1to

pink

a

dot.

of

through

from

overedge

(10

cml

the

looper9.Pull

thread

of

left

the

under

8,

Thread

upper

4”

ly

and

foot.

placeitto

front

through

the

approximate

the

presser

the

eye

looper

the

15

Threading

(yeflow)

Turn

7

1

lower

right.

the

handwheel

overedge

the

‘ower

looper 26

overedge

towards

‘ooper

you

until

the

the

extreme

is

on

Threadinasequenceofi

,-

in

2

JJL

Note:

To

make

which can

this

task

found behind

be

easier,

use

to

10.

tweezers

the

the

swivel

plate.

5

—

16

Thread

marked

I

—

through

yellow.

5

thread

6

guides

I

I

1

to

8,

Press

thread

the

Note:

The

tion

the

into

drawing

lever

as

soon

lever

the

below.

returns

as

A

downwards

guide

B.

automatically

you

start

Please

sewing.

and

also

to

hook

refer

its

the

to

posi

7

the

Thread

lower

10>.

from

overedge

the

front

looper

through

C

1=

the

threading

eyeofthe

point

Pull

approximately

through

under

the

the

presser

looper

4”

and

foot.

>10

cm)ofthread

place

it

to

the

left

17

r

Threadng

ooper

Turn

the

two

thread

extreme

Thread

the two

and

handwheel

right.

in

a

thread

cover

sttch

chainstitch looper28isonthe

sequenceof1to11.

baper

towards

chanstftch

you

(vioet)

until

the

U

U

U

1

Note:

To

make

which canbefound

this task

easier,

behnd

use

the

the

tweezers

swivel

plate.

ji!

I

4

6

18

4

Thread

with

a

the

violet

rt

guides

thread

squareina

which

sequence

—5

are

marked

of

refer

and

hook

to

Push

to

1

9.

into

ad

below.

the

slot

Also

B.

upward

A

lever

the

the

thre

the

drawing

Note:

its

posi

The

tion

lever

as

soon

returns

as

automatically

start

you

to

sewing.

Thread

two

the

cover

from

thread

stitch

the

chainstitch

looper.

front

through

looper

the

and

eye

the

Pull

of

C

approximately

through

under

the

the

presser

looper

4”

and

foot.

(10

cm)

place

of

it

the

left

to

19

thread

11

‘Ic

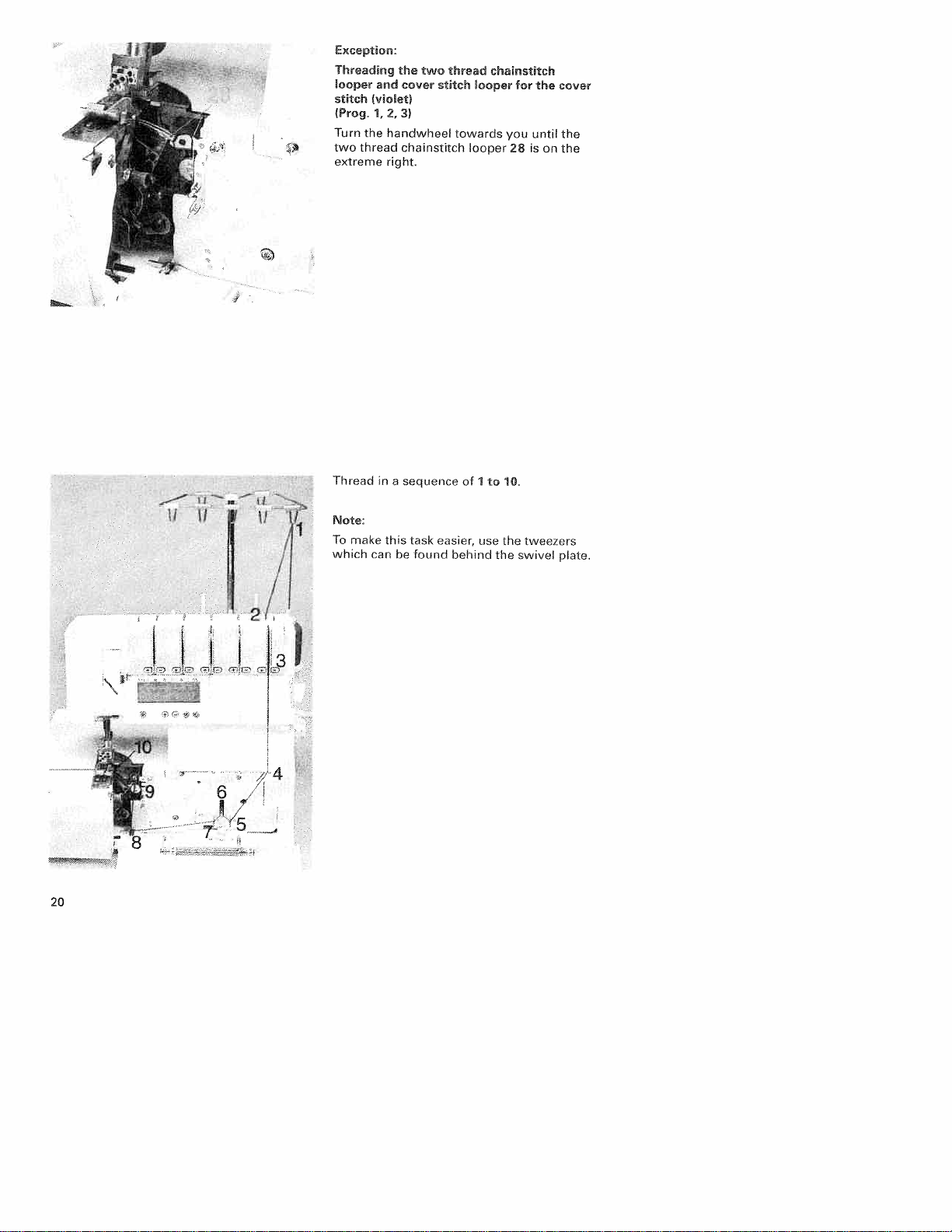

Exceptwn:

Threading

looper

stitch

(Prog,

Turn

two

extreme

Thread

Note:

To

make

/

which

the

and

cover

(violet)

1,

2,

3)

the

handwheel

thread

chainstitch looper

right.

in

sequence

a

this

canbefound

task

two

thread

stitch

towards

easier,

behind

looper

of

chainstitch

you

1

to

10.

use

the

the

for

28

tweezers

swivel

the

until

is

cover

the

on

the

plate,

2

,j

J

JF.

I

LEJ

//4

6

20

Thread

diagram,

the

threads

square.

the

8,

in

thread

a

sequence

guides

guides,

are

as

of

1

marked

shown

Some

to

8.

withaviolet

/

in

the

of

Press

into

slot

Note:

position

lever

The

A

upward

B.

Also

refer

lever

returns automatically

as

soon

as

you

and

to

the

start

hook

drawing

sewing.

the

thread

below.

to

its

Thread

twothread

stitch

looper

from

the

front

chainstitch

C.

through

looper

the

and

eyeofthe

the

cover

Pull

approximately

through

under

the

the

presser

looper

4”

and

foot.

(10

cm)

placeitto

/

(..

of

thread

the

left

21

‘iri

Threading

Thread

Note:

To

which

j

3

mc’,

I

cnr

Pl’AF

mm

inasequence

make

can

this

the

be

needles

task

found

easiet

behind

of

1to8.

use

the

the

tweezers

swivel

plate.

The

lower

22

thread

slot

7

must

of

5

thread

be

guided

guide

through

5.

the

Pull

approximately

through

under

tension

the

release

the

presser

F

looper

key

and

foot

4”

10,

(10cm>

place

necessary

(if

also

see

of

thread

it

to

the

left

activate

page

40>.

Exception:

;Z

Threading

ad

safety-stitch

chainstitch

Thread

needie

safety-stitch

in

a

seam

seam

(Prog.

sequence

L2

(Prog.

4)

when

(Prog.

of

19)

1

sewing

20),

and

to

8.

a

4-thread

a

2-thread

a

5-thre

Note:

To

make

this

task

easier,

use

the

which

can

be

found

behind

the

tweezers

swivel

plate.

5

The

upper

thread

slot

must

of

jw

the

be

guided

thread

guide

through

5.

the

Pull

approximately

through

under

tension

the

the

presser

release

looper

key

and

foot

4”

10,

(10cm>

place

necessary

(if

also

see

of

thread

it

to

the

left

activate

page

40>.

23

mportant

The

so

the

instead

in

drawing2.Should this

followed,

stitches

needle(s)

that

looper

the

over

can

noteonthreading

must

needle

thread

the

looper

thread

breakageormissed

occur.

alwaysbethreaded

threads

as

do

not

in

drawing

seen

threadasdepicted

sequence

run

not

under

1,

but

be

last

If

the

the

needle

rethread

rethread

looper

the looper

the

threads

threads

needle

break,

outofthe

thread

threads.

you

and

must

needle,

then

pull

Changingaspo&

Cut

the

threads

place

with

ads

which

new

threads,

needles,

(also

threads

(15

the

threads

The

ously

left

24

Activate

refer

until

past

cm)

needles.

through the

looper

past

underneath

off

new

spools.

are

stillinthe

and

tension release

to

page

the

knots

the

last

Cut

the

threads

the looper

the

on

threaded

a

closetothe

Tie

together

machine

pull

the

threads

Pullonthe

40).

are

about6inches

thread

knots

off

respective

canbepulled

eye

and

presser

machine

spool

with

outofthe

key

needle

guide

in

and

pull

needle

continu

placedtothe

foot.

the

front

and

10

re

thre

the

of

the

eyes.

I

Need!e

Move

the

and lower

from

right

threader

of

One

wards.

threader

needle(s)

the

to

(to

the

two

presser

left

be

into

in

notch

found

triangles

foot.

in

the

Aofthe

the

must

highest

Place

accessory

point

the

needle

position

thread

boxi.

up

Place

groove

threader

it

lightly

small

A

needle

threaded.

the

back.

the

of

down

against

metal

eye

threader

needle

the needle.

to

the needle.

pin

the needle

and

Thread

the

is

loops

Slide

needle

pushed

must

onto

the

the

needle

eye

through

is

automatically

be pulled

and

front

press

the

to

25

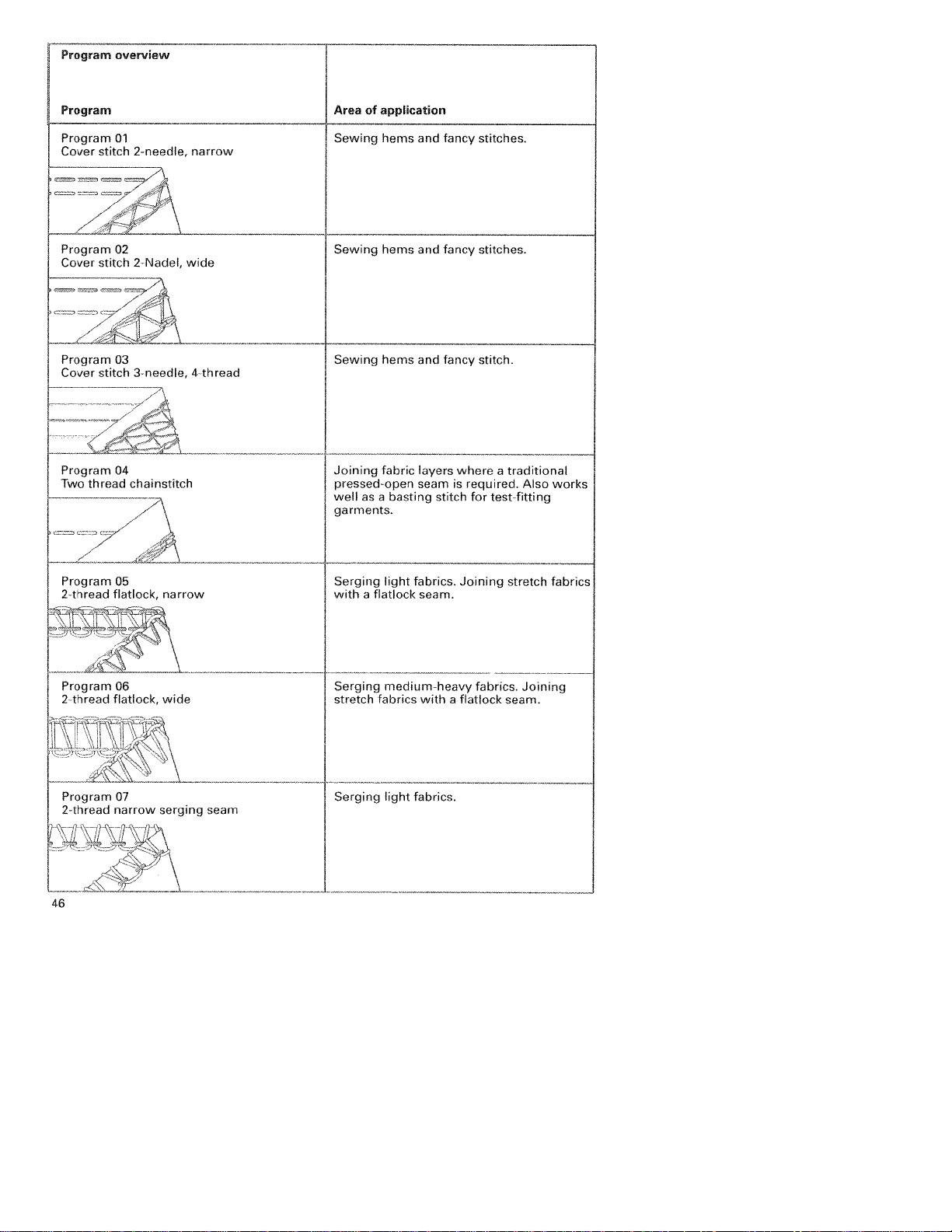

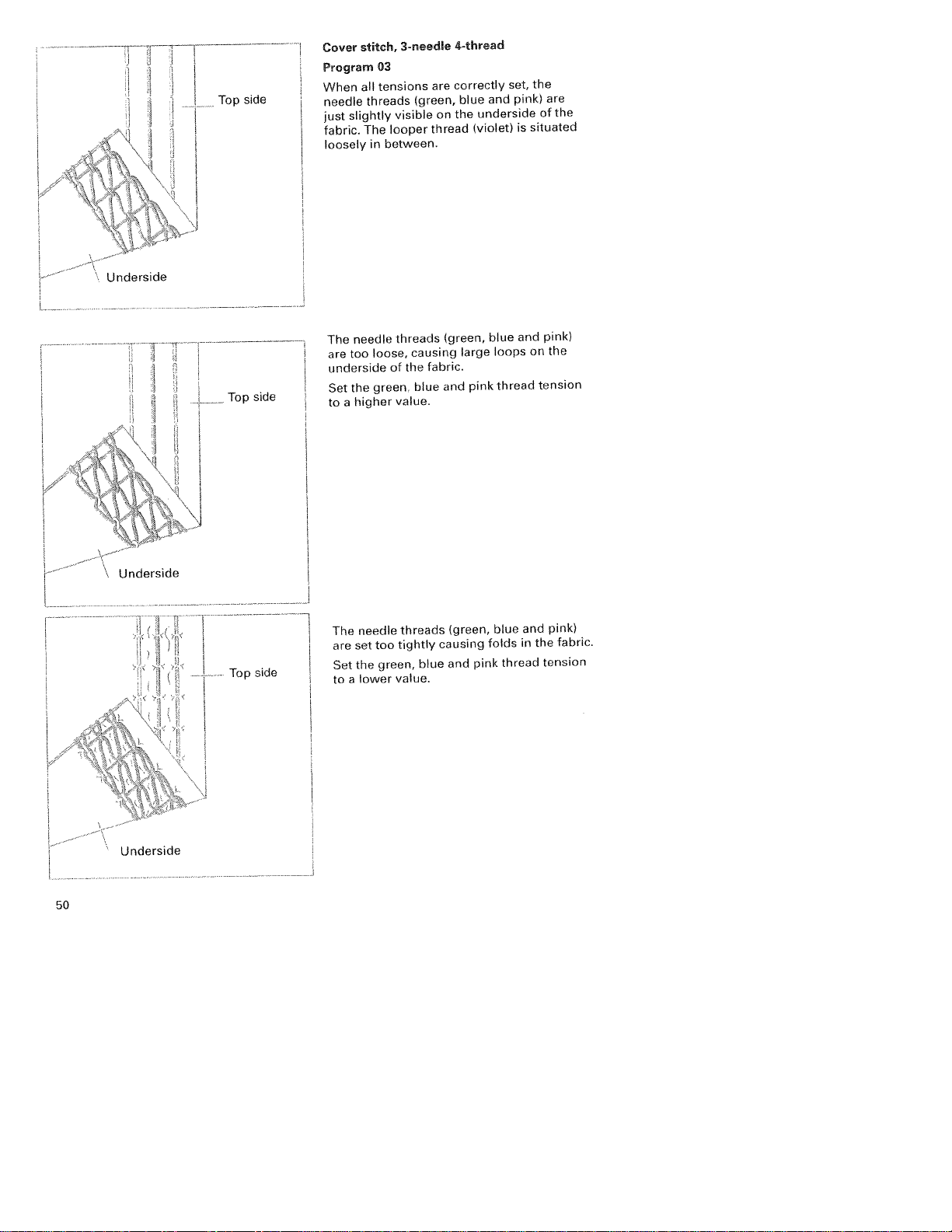

Overview

Program

cover

stich,

of

01:

2-needle,

the

threading

narrow

paths

and

threading

—

sequences

Program

cover

stitch,

02:

2-needle,

wide

Program

cover

26

stitch,

03:

3-needle

4-thread

Ei

Program

2-thread

i)

v

04:

chainstitch

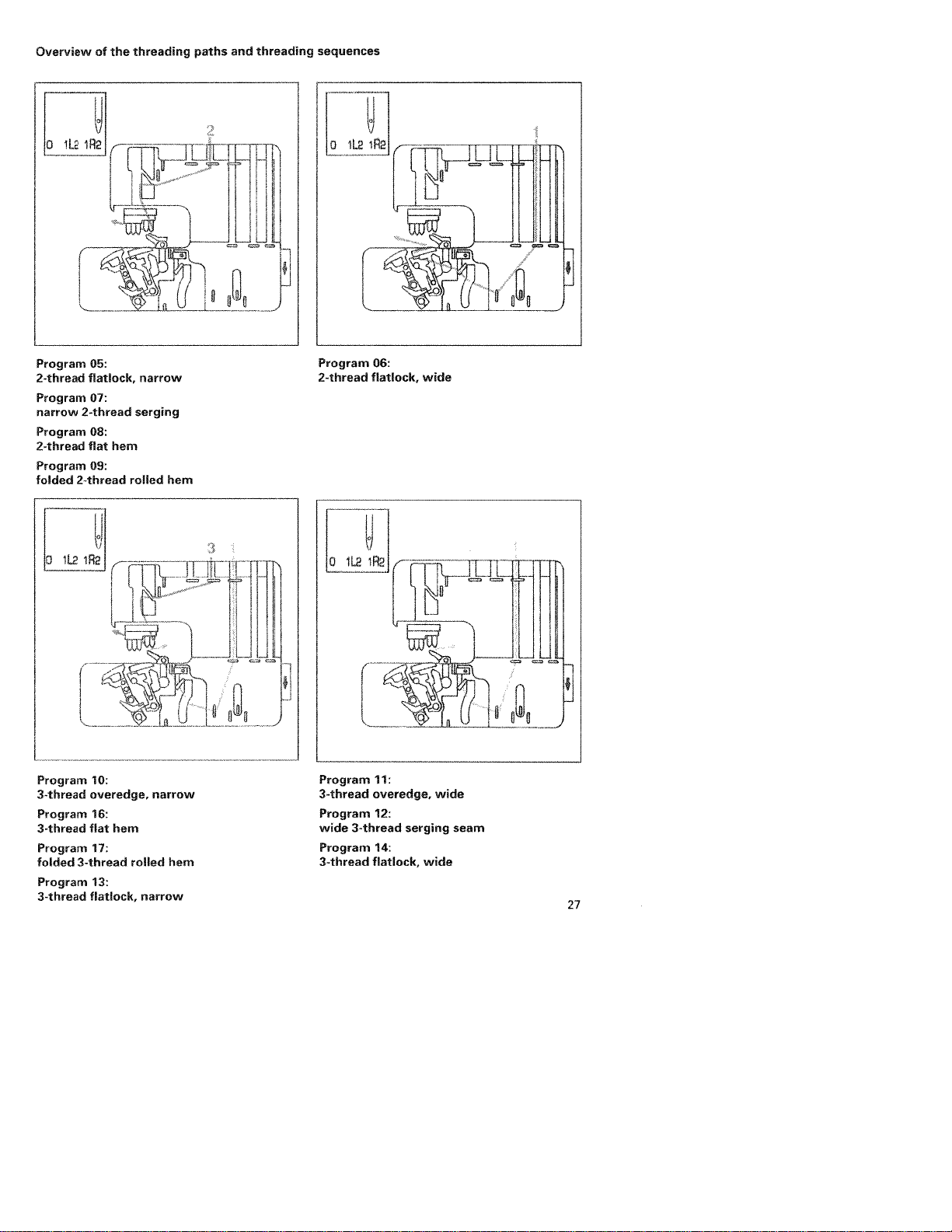

Overview

threading

of

the

paths

and

threading

sequences

Program

2-thread

Program

narrow 2-thread

Program

2-thread

Program

folded

Program

3-thread

Program

3-thread

Program

folded

Program

3-thread

05:

flatlock,

07:

08:

flat

09:

2-thread

10:

overedge,

16:

flat hem

17:

3-thread

13:

flatlock,

hem

narrow

serging

rolled

rolled

narrow

hem

narrow

hem

Program

2-thread

Program

3-thread

Program

wide

Program

3-thread

06:

flatlock.

11:

overedge,

12:

3-thread

14:

flatlock,

wide

serging

wide

wide

seam

27

Overviewofthe

threading

paths

and

threading

sequences

Program

2-needle 3-thread

Program

4-thread

15:

19:

safety-stitch

overedge

seam

seam

Program

4-thread

Program

5-thread safety-stitch

18:

overedge seam

20:

seam

28

4

A’

Sewing

Using

the

maximum

anywhere

rev/mm.

1500

pre-seection

speed

sewingspeed

speed

between

pre-selection

canbeadjusted

700

rev/mm.

slide 9,

and

Presser

pre-set

The

machine

fabrics.

need

are

working

may

‘

you

case,6setting

you

can

the

presser

setting

I

pressure

foot

pressure

presser

with

to

positions

using

foot

for

foot

for

light or

adjust

the

pressure

medium-heavy

pressure

most

heavy

the

are

adjusting

24.

presser

is

suitable

The

adjusted

to

be

need

select

foot

is

“N”.

fabrics,

fabrics

pressure.

available

The

on

the

does

If

In

which

knob

standard

not

you

then

this

for

29

Thread

chain

After

finishing

6”

-8”

(15

thread

the

the

the

cm>

from

Pull

thread

thread

spring

this

seam.

long

foot.

the

-20

chain

feature

the

the

over

off

Cbmp

Using

chainatthe

into

(10

presser

fully

27.

clampitunder

cutter

the

seam,

long

cm>

from

chain

chain.

for

serging

you

start

of

Stitch

thread

Remove the

swiveling

thread

chain

spring.

the

sewanapprox.

thread

the

backtothe

cutter

40.

thread

can

serge

the

fabric,bypulling

offaminimum

chain

and raise

thread

stitch width

forwards

chain.

This

chain

the

chain

and

Pull

front

will

thread

4”

the

latch

cut

32

it

care

Place

the

fabric

I

30

needle(s).

1.5”

(3cm>

cut-line

presser

chain

pulls

the

seam.

Note:

This

feature

five-thread safety-stitch

thread

safety-stitch

chainstitch

If

necessary,

cut

using

a

foot

and

automatically

cannot

or for

rightinfront

into

the

pairofscissors.

start

be

seam,

the

of

into

seam,

the

the

along

The

the

for

either the

the

two-thread

hem.

Lower

makeanapprox.

fabric

sewing.

used

rolled

the

thread

inside

four-

the

of

Disengaging

Switch

off

Move

the

highest

Remove

looper cover

the

upper

positionbyturning the

the

handwheel

blade

the

&ectrical

the

movable

waste

and

34.

upper

upper

container

swivel

the

fullytothe

bbde

power

blade30into

handwheel.

and

plate.

right

to lower

open

Now

its

the

turn

the

Turn

the

blades

bladeisnow

knob

clicks

towards

into

place

disengaged.

you

below.

until

The

the

upper

upper

1

Engaging

Push

to

clicks

Close

and

the

the

knob

the

right

and

into

the operating

the looper cover

remount

upper

for

lowering

swivel back

waste

the

bbde

and

the

the

position

the

container.

upper

blade

again.

swivel

blade

until

plate

it

31

stitch

width

to

width

width

when

seams

the

latch

seams:

right

latch

latch

27

sewing

lexception:

and

27

downwards.

remains

all

swivel

types

the

Swiveling

For

standard

The

swiveling

in

the

of

standard

Program

‘

For

rolled

the

Pull

swiveling

basic

knob

Position

overlock

1,

2,3,4),

hems:

stitch

overlook

stitch

(A)

This

rolled

setting

hems.

allows

you

all

to

types

of

sew

32

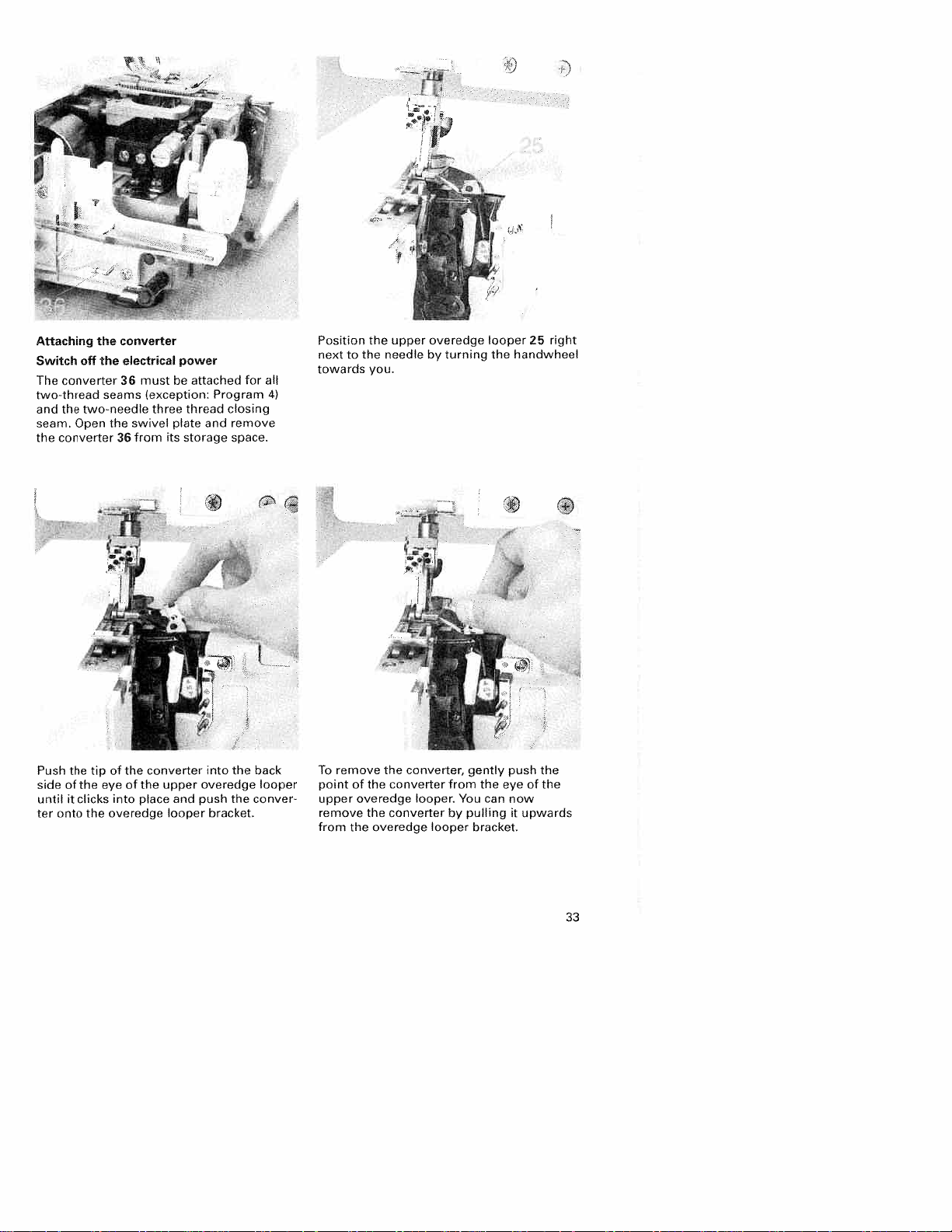

Attaching

Switch

The

twothread

and

seam.

the

Push

sideofthe

until

ter

the

off

the

converter

twoneedle

the

Open

converter36from

the

tip

clicks

it

onto

the

converter

eIectrcaI

36

seams

swivel

the

of

the converter

of

eye

into

overedge

must

be

(exception:

three

plate

its

the

upper

place and

looper

power

attached

thread

storage

push the

Program

closing

and

remove

space.

01

into

the

overedge

bracket.

for

back

conver

all

4)

I

looper

remove

the

the

needle

you.

the

overedge

Position

nexttothe

towards

To

pointofthe

upper overedge

remove the

from

overedge

upper

by

turning

converter, gently

converter

converter

from

looper.

by

looper

looper25right

the

handwheel

push

the

of

eye

You

can

now

pullingitupwards

bracket.

the

the

33

the

required

seam

seam

Setting

The

anywhere between

adjusting

the

setting

The

21.

clearance

a

Note:

The

seam

is

increased

completely

knob

canbeseen

two-thread

of

6.5

width

by

adjustable

width

width

3.5

for

at

chainstitch

to9mm.

settings

mm

2.0

can

and6mm

seam

the

viewing

nm

3

5

mm

ftO

3.5

when

from

be

adjusted

by

width

20.

window

sewn

is

mm

and

using

5.5mmto

turning

The

with

6.0

needle

8.0

mustration

the

workpiece,

blade 30

width

IllustrationB:Should

tight,

left

by

knob

are

Ri,

mm.

i.e.

only

you

mm

A:

the

to

adjusting

move

the

turning

downwards.

relevant

haveaseam

loops

Should

move

the

rightbyturning

upwards.

knob

the

movable

the seam

needle

for

width

project

the

out

upper

seam

movable

stitchingbetoo

upper

bladetothe

adjusting

width

R2.

This

which

set-value

is

of

Securing

Switch

Itisrecommended

upper

brics.

tion

screw

should

ter

blade

Raise

and

fully

sewing

the

off

the

open

always

heavy

upper

30

the

using

Note:

The

seam

width

the

upper

once

blade

master

switch

to

secure

before

sewing

needle(s)

the

the

be

can

bladeissecured.

to

swivel

plate.

Allen

slightly

fabrics.

loosened

longerbeadjusted

no

its

key.

the

heavy

highest

Tighten

movable

This

fa

screw

again

posi

the

af

*3

lb.

Adjusting

You

can

ween

0.5

stitch

length

Note:

For

the

should

stitch

the

set

the desired

mm

to

adjustment

two-thread

be

3.0

or

length

stitch

4.0

mmbyturning

knob

chainstitch, the

higher.

length

50.

bet

the

setting

35

Adjusting

(Prog.

/

/

S

(Prog.

This

trim

according

Open

blade

Lower

page

(see

is

disengaged

is

the

the

guard

32)

page

1,

4)

only

the

the

2,

3)

necessary

fabric

to

looper

swiveling

and

31).

machine

and

edge.

LCD

the

cover

15

by

disengage

Ensure

turning

by

two

Insert

pulling

stitch

to

thread

if

you

display

and

the

that

the

cover

the

chainstitch

do

the

(see

remove

it

towards

width

upper

the

handwheel.

want

not

needle(s)

page

the

latch

blade

upper

stitch

to

13).

you.

Isee

blade

Disengage

Move

lowest

Move

the

gaged

f

Thread

and

21)

23).

left.

the

and

the

position

the

Ensure

by

the

cover

then

the

upper

looper

turning

two

the

upper

overedge

by

turning

disengaging

that

the

thread

stitch

needle(s)

overedge

the

looper

handwheel.

chainstitch

looper

looper

the

(see

(see

looper.

25

hdndwheel.

lever

16

is

disen

looper

pages

page

into

22

its

to

18

to

and

36

k

PFAFF

Press

the

Close

Note:

Please

looper

power

To

return the

settings

two

Open

power

the power

designated

looper

ensure

is

disengaged

table

after

thread

the looper

table.

table

slot

on

cover.

that

the

57.

machinetoits

sewing

chainstitch.

cover

57

the

upper

before

with

and

downwards

looper

overedge

attaching

previous

the

cover

remove

cover.

stitch

the

into

the

or

lv

LJ

the

thus

the

basic

upper

the

close

looper

re-engaging

swiveling

position

blade

blade

guard

it.

disengaging

the

stitch width

page

(see

page

(see

into

lever

upper

latch

32)

and

31).

the looper

to

the

overedge

into

engage

cover

Move

right,

looper.

Bring

the

the

Push

and

I

Differential

The

dogs

feed

feed

material

the

between

The

movementofthe

synchronized

This

same

Note:

The

independent

type

differential

+

B),

(A

fabric.

the

dog

(A)

to

regulator

0.5

standard

means

amount

function

of

fabric

feed

one

and

be

wheel

and

setting

with

that

of

of

being

feed

consists

behind

The

movement

thus

the

canberegulated

fed

49.

2.0.

is

front

feed

the

rear

front

the

of

fabric

as

the

differential

stitch

the

set

used.

the

amount

The

10,

feed

the

where

feed dog

feed

of

two

other, which

the

of

of

using

range

setting

the

dog

rear

feed

length

(A)

is

feeds

feed

is

and

dog

front

is

(B).

the

dog.

the

Set

feed

half

that

much

the

38

the

49

as

the

fabric

fabric

regulator

0.5.

to

fast

as

front

to

Here

the

feed

as

the

stretch.

wheel

the

rear

dog

rear

for

front

feed

feeds

feed

the

differential

feed

dog.

only

dog,

dog

This

half

causing

feeds

means

as

Here

when

as

(A)

You

with

the

A

you

working

and

silk

will

can

the

wavelike

avoid

will

taffeta.

achieved.

be

achieve

also

differential

effect

ruffling

with very

Instead,

feed

when

in

light

smooth seam

a

fashionable

dog,

using

the

fabrics,

effects

for

example

rib

a

seam

knit

such

(B).

A

B,

the

Set

49to2.0.

feed

Here

the

the

as

feed

front

rear

the

gather.

The

following

should

Type

Very

Normal

fine

Light

tricot,

Heavy

fabrics,

Stretch

jerseys,

skirt

Gathering:

for

curves,

flaps,

(shoulders>,

regulator

front

rear

dog

feed

always

of

fabnc

light

fabrics:

cords,

knitwear:

fine

knitwear:

heavy

-

knitwear,

hems,

stretching

wheel

feed

dog.

feed

feeds

causing

dog,

table

test

.

effect

I

fabrics:

light

thermal-wear,

jerseys,

knitwear

sweatshirt

knitwear.

wavelike

dense

ruffling

arches

or

sleeve

dog

This

twice

contains

your

silk,

and

and

effect:

ruffled

stitch

light

on

gentle

widths

for

the

feeds

twice

means

much fabric

as

the

rnformation

setting

satin,

medium-heavy

polo

gathered

fleece,

medium

sleeve

lengths.

materials

blouses,

ruffling

for

differential

as

that

material

on

first

poplin,

fabrics,

fabrics.

heavy

and

and collar

and

shirts,

of

cuffs

fast

the

to

a

taffeta,

cut-pile

light

lace,

skirts,

arched

or

gathered

as

on

the

piece

cottons,

gathered

edges,

Here

when

jerseys

smooth

You

with

the

fabrics

differential

of

scrap

linings.

pullovers,

knitwear,

seam

round

sleeves

fabrics.

will

you

working

gathered

or

seam

can

also

differential

the

gathering

(B).

fabric.

allowances

pockets,

stretchinginthe seam

avoid

knitwear,

with

fabrics.

be

will

(A)

effect

fashionable

feed

when

settings.

gather

——

9

9

Differential

2

achieve

feed

such

Instead,

achieved.

for

dog,

using

However,

normal

very

feed

1’-

9

as

a

effects

example

light

you

setting

stretch

9

39

Prog

•

3F

LCD

1

2

3

4

5

6

7

8

9

Display

Program

Name

Stitch

Differential

Needle

Swiveling

—-—

.

3

Upper

Thi

Power

with

without

Upper

blade

upper

no.

of

stitch

length

feed

position

stitch

stitch

position

stitch

width

overedge

looper

looper

Converter

table

position

power

position

blade

in

mm

setting

width

width

looper

engaged

lowered

engaged

power

latch

latch

table

table

engaged

latch

in

lowered

position

position

basic

Key

10

11

12

13

10

functions

Tension

1

For

tension

Tension

When

thread

lows

from

leased,

programm

Program

The

with

preset

pressed

matically

switched

gram

Memory

for

stitch

thread

key.

Memory

you

can

ii

a

d

the

programmable

C.

keys

increasing

release

this

tensions

the

thread

the

machine.

the

selection

desired

these

for

your

down,

run

off

sewn

key

length,

tension

selection

activate

+

and

key

is

thread

selected.

program

keys.

use.

the

on.

and

will

appear.

M:

can

11

and

-

reducing

key

pressed

are

released.

chain

When

tensions

key

can

There

If

the

programs

When

back

The

adjusted

differential

be

stored

key

the

program

memories

to

+

are

on,

P:

and

be

the

and

be

keys

the

the

With

1213

thread

held,

This

easily

key

reset

—

selected

20

programs

are

will

machine

last

settings

feed

using

this

memory

A,

B

al

pulled

is

for

kept

auto

pro

and

this

key,

and

the

re

the

is

upper

10

11

2_.

Seam

Setting

A

or

display,

from

B

the

width

of

spring

—

As

the

accessories

blade

in

mm

presser

long

as

transparent

disengaged

foot

appears

E

presser