Page 1

PFAFF

coverlock

4772

I:.t

i:i

cover10

I

Instruction

L.

4772

manual

Page 2

For

please

easier

understanding

fold

out

rules

Safety

For

the

United Kingdom only

leads

The

terminal

The

wing code:

As

may

your

The

nal

The

minal

Cut-off

of

pletely.

Only3A

dingtoBS

the

The plug

covers are

cies.

Please

I

wiresinthe

Blue:

Neutral

the

colorsofthe

not

correspond

plug,

wire whichiscolored

whichismarked

wire whichiscolored

whichismarked

mains

immediately.

spare

corresponding

must

also

of

and

this

must

nor

proceedasfollows:

1362

available

observe

the

definitely

plug

a

mains

wiresinthe

with

with

are

Defective

mustbeused

and

the

color

from

with

lead

with

definitely not tobeused,

the

to

plugs

fuses

neverbeused

the

the

mains

fuse cover

code.

electrical

instruction

this

page

when

last

notbeconnected

three

pins.

are

colored

color

blue

mustbeconnected

letterNor

brown

the

letterLor

without

general safety

accordingtothe

Brown:

mains

leadofthis appliance

coding

colored

mustbeconnectedtothe

leads

mustbereplaced

approved

as

mustbemarked

fuse

suppliersorthe

reading.

to

Live

of

the

colored

cover.

notes

book

the

terminals

black.

red.

but

by

Spare

on

safety

lead

follo

to

the

termi

disposed

com

ASTA

accor

3 Aorwith

fuse

PFAFF

page

in

ter

agen

2.

will

Important safety instructions

For

find

Australia

•Ifthe supply

manufacturer

soninordertoavoidahazard.

•

The

infirm

•

Young

not play with

•

Switch

ded.

•

Before

the

Contents

the

only

applianceisnot

persons

children

offorunplug the machine when

servicing

machine.

cordisdamaged,itmustbereplaced

or

its

service

agent

intended

without

the

on

supervision,

shouldbesupervised

appliance.

applianceorreplacing

the

pages4and

for

similarly

or

a

usebyyoung

to

ensure

leavingitunatten

lamps,

by

qualified

children

that they

unplug

the

per

or

do

Page 3

Page 4

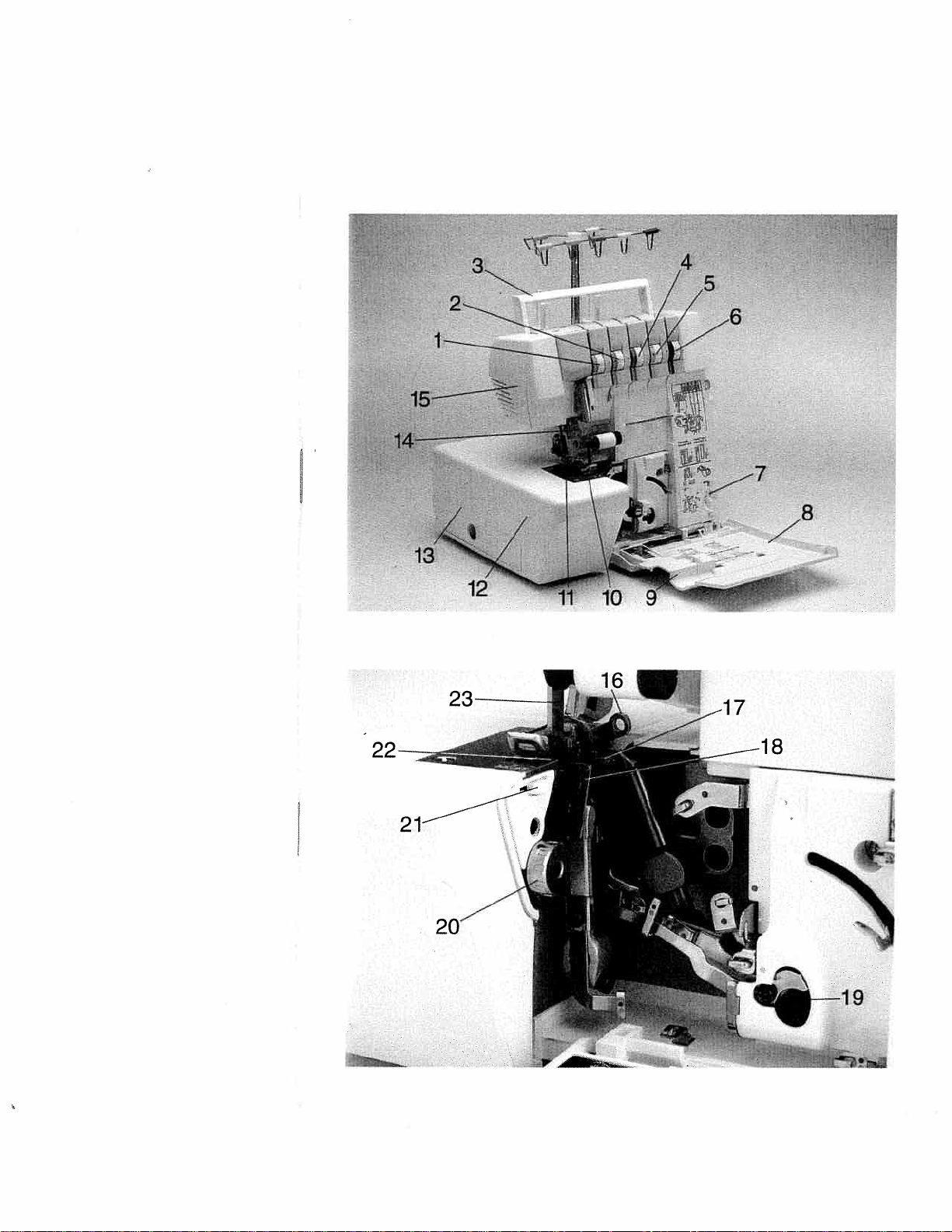

Parts

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

of

(1)

Upper

(2)

Upper

(3)

Carrying

(4)

Thread

Thread

Thread

Converter

Looper

Blade

Standard

Standard

Detachable

Accessory

Needle

Sewing

the

coverlock

thread

thread

handle

tension/upper

tension/lower

tension/Two-thread

cover

guard

presser

needle

work

box

holder

light

cover

4772

tension

tension

foot

plate

support

looper

looper

thread

thread

chainstitch

looper

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

Upper

Lower

Two-thread

Retaining

Adjusting

Bed

Fixed

Movable

overedge

overedge

slide

lower

chainstitch

screw

knob

for

stitch

blade

upper

looper

looper

for

for

blade

upper

seam

width

looper

overedge

width

latch

looper

Page 5

Important

United

For

the

This

sewing

EHOLD

wing

Read

use

basic

all

instructions

only.

safety

States

machine

When

safety

only

is

designed

you

precautions

before

instructions

and

manufactured

electric appliance,

use

an

always

should

using

this

sewing

adhered

be

machine.

for

the

HOUS

follo

to:

DANGER

1,

The

sewing

this

appliance

2.

Always

3.Donot reach

4.Donot

Do

unplug

placeorstore

placeinor

not

NARNING

1.Donot allow

used

2.

Only

Only

3.

Never

properly,

ce

mechanical

4.

Never

nings

and

5.

Never

6.

Do

7.

Do

administered.

To

8.

9.

Never

blocked.

10.

Do

11.

Keep

machine

12.

Always

13.

Do

14.

Do

15.

Switch

such

etc.

Always

16.

ting,

manual.

Hold

17.

Please also

or

by

this

use

use

attachments

operate

if

the

nearest

to

operate

the

of

loose

droporinsert

not

use out

not

operate

disconnect,

operate

unplug

not

fingers

needle.

use

not

use

not

pullorpush

the

as

threading

unplug

or

when

plug

when

observe

near

it

cloth.

bent

sewing

reduce

To

machine

from

before

forasewing

To

tobeused

sewing

this sewing

has

adjustment.

the

sewing machine

of

where

turn

onasoft

by

away

the proper

sewing machine

making

the

should

the

electric

relamping.

sewing

a

into

drop

reduce

children.

as

machine

recommended

been

dropped

authorized

sewing

anything

doors.

aerosol

all

controls

surface

pulling

all

from

needle

or

blunt

fabric

machine

needle, changing

any

rewinding

general

the

risk

never

machine

water

the

risk

a

toy.

for

machine

dealer

machine

and foot

into

(spray)

on

cord.

moving

plate.

needles.

while

off

other user

into

safety

electric

of

left

be

immediately

outlet

Replace bulb

that

machine

or

other

burns,

of

careisnecessary

Great

intended

its

by

ifithas

or

damaged,

or

service

with

control

opening.

any

products

off

to

(“0”)

asabedorcouch

such

To

unplug,

parts.

The

Only

use

stitching.

when

(“0”)

needle,

from

the

servicing

cord

reel.

notes

shock:

unattended

fallen

has

where

liquid.

fire,

manufacturer

the

a

damaged

or

center

any

air

free

position,

hold

Special

wrong

needles recommended

It

may

making any

threading

electric

not

Do

on

Page

when

after

with

same

into

water. Unplug

fall

it

can

electric

purpose

dropped

for

openings

from

are being

then

the

plug,

careisrequired

plate

can

deflect

bobbin,

outlet

adjustments

allow

plug

2.

as

plugged

using

type

or

shock,

when this

described

as

cord or

into

examination,

blocked.

the

used

remove

where

cause

the

adjustments

when removing

before

and

rated15Watts.

be

pulled into

or

injurytopersons:

sewing machine

contained

plug,

water.

Keep

accumulation

where

or

plug from

air

the

the

cord.

not

around

the

by

needle, causing

or

changing

mentioned

to whip

in,

Always

cleaning.

immediately.

a

tub

in

this manual.

in

this

not

ifitis

the

Return

repair,

ventilation

of

oxygenisbeing

socket.

openings

the

needle

to

the

manufacturer.

it

in

the

needle

presser

covers,

in

the

rewinding.

when

unplug

or sink.

manual.

working

applian

electrical

dust

lint,

may

sewing

break.

break.

to

area,

lubrica

instruction

is

or

ope

be

foot,

KEEP

THESE

INSTRUCTIONS

IN

A

SAFE

PLACE

Page 6

Notes

Notes

machines

IEC

1.

2.

3.

4.

5.

tion

6.

the

7.

Do

-

-

-

can

brought

8.

Do

cket

9.Ifthis

pose

gly

bility

10.

To

open

side

pair.

our

11.

Be

parts.

12.

The

cal

10

2

on

safety

according

335-2-28.

The

user

tion

with

vement

wing

area

while

working.

When

leaving

maintenance

mechanical

disconnect

tric

power

The

maximum

the

sewing

The

tension

be

adjusted

The

machine

as

indicated

plate.

Do

not

place

machine.

not

use

there

is

its

function

it

is

wet,

occur

into

not

pull

by

its

appliance

than

operated,

for

any

avoid

the

the

the

machine

This

qualified

sure

to

machine

supply

and

%

on

for

must

regard

of

the

under

work

parts

the

by

lamp

of

by

should

any

the

visible

is

e.g.

with

when

a

warm

the

cord.

that

intended

we

damage

risk

machine.

the

exclusive

service

use

only

is

with

rated

a

safety

domestic

to

EN

exercise

to

the

needle

constant

the

machine,

or

or

accessories,

machine

pulling

permissible

is

15

the

drive

a

PFAFF

be

on

the

objects

sewing

damage,

defective,

condensation

a

cold

room.

mains

plug

is

used

cannot

caused.

of

electric

There

which

staff.

original

designated

nominal

a

frequency

sewing

60

335-2-28

adequate

up

and

and

down

keep

observation

during

when

changing

from

the

the

plug.

out

wattage

Watts.

belt

should

mechanic.

put

into

specification

in

openings

machine

machine

out

of

for

another

or

if

it

is

accept

shock,

are

no

the

user

responsibility

PFAFF

for

an

voltage

of

+1-

the

opera

if:

which

is

the

wron

any

parts

can

electri

of

4%.

or

cau

se

always

elec

for

only

so

pur

lia

do

not

re

of

+/-

mo

on

in

When

13.

the

outer

nically

up

to

is

therefore

avoid

Environment

The

recommended

Ambient

Humidity

Storage

The

temperature

machine

interference

lations;

however

near

electronic

PCs,

broadcasting

This

sewing

tro-mechanical

supervised

operated

posed

to:

sunlight,

objects,

To

must

and

permit

be

even

corrosive

kept

Treatment

Always

chine

make

by

knocking

Cleaning

Housing

To

soft

clean

cloth

and

the

stubborn

or

paraffin.

Please

Note!

Never

use

such

an

the

petrol

as

housing.

used

components

controlled

85°

C.

damage.

temperature

20%

to

is

suppressed

according

devices

machine

appliance;

use

in

in

such

dust,

severe

static

electricity,

adequate

unblocked

surface.

sure

display:

housing,

that

is

free

dirt,

use

insecticides

(gas)

properly,

foot

Constant

not

permitted

environment

10°C

80%

-25°C

it

should

transmitters

is

the

home.

way

a

dampness,

chemicals

ventilation

not

to

or

dropping

use

of

fluff.

a

soft

or

or

thin

the

temperature

of

a

control

use

at

in

40°C

to

to

+60°C

and

international

to

not

be

such

as

a

high-quality

it

is

a

It

should

that

it

is

heat-producing

or

the

and

used

damage

it.

a

dry,

To

cloth

with

chemical

chemicals

non-electro

can

a

low

order

is:

immune

operated

radios,

etc.

machine

not

ex

direct

liquids.

machine

on

a

your

clean

and

remove

alcohol

products

to

of

reach

speed

to

to

regu

TVs,

elec

for

be

firm

ma

any

cle

Page 7

that

and

PFAFF

and

this

now

find

it

have

dealer.

help

any

let’s

up-to-date

will

coverlock

technology,

instruction

take

out

to

any

hours

Simple,

Congratulations!

product

coverlock

new

stride

Your

design

as

use

If

you

manual

tion

certainly

is

It

to

way

put

and

If

you

PFAFF

with

now

So

enjoyable

ideas.

You

provides

4772

sew

bit

a

nothing

time

just

use.

full

further

They

or

advice.

started!

get

creating

can

for

well

what

are

have

unique

take

you

features

and

manual

of

time

go

can

spent,

questions,

happy

We

sewing

bought

advantages.

any

through

the

is

it

is

to

amiss.

since

machine

your

to

wish

very

your

a

material

very

just

to

study

just

be

you

high-quality

Your

in

and

thick

latest

easy

as

follow.

instruc

the

the

it

is

can

your

ask

service

of

many

fashion

own

its

thin.

in

to

only

do

3

Page 8

Contents

Accessories

Accessories,

Accessory

Adjusting

Bed

slide for

Blade

guard

.

special

box

the

machinetocover

stitch

width

Changingaspoolona

Chainstitch

Converter,

Cover

Cover

Differential

Edge

Foot

Free

Light

Looper

Lower

Lower

Lubricating

Machine

stitch,

stitch

guide

control,

arm

bulb

cover

blade,

overedge

cover

looper

(violet),

attaching

important notesonsewing

and

2-thread chainstitch,

feed

connecting

(sewing

lamp),

changing

looper

the

machine

Maintenance

Master

switch

Needle

changing

Needle

holder

Needle plate,

Needle

position

Needle(s),

Needle,

Power

Presser

Presser

changing

table

foot

foot

Presserfoot

Presser

foot,

Program

overview

Rubber feet,

Safety

instructions

width,

Seam

aid

changing

threading

lifter

pressure

changing

cleaning

setting

latch,

threaded

threading

changing

(yellow),

stitch

setting

machine

threading

and

2-thread chainstitch

setting

the

machine

Page

6

59-69

6

30-33

25

32

20

17

16,

24

34,

35

30-33

28,

29

35

7

27

58

8

57

14,

15

56

6

56-58

7

11

11

30

10,

11

18,

19

11

32, 34

22

21

21

22

36-41

56

1,2,7

26

4

Page 9

Contents

Serging

problems

Specifications

Spool

centering

Spool

holder

Spool

net

Stitch

length,

Stitch

width

Telescopic

Thread

chain

Thread

changing

Thread

chart

Thread

guides,

Thread

tensions,

Thread

unreeling

Threading,

Trimming

Trouble

shooting

Two-thread

Upper

blade,

Upper

overedge

and

their

piece

setting

latch,

setting

thread

guide

trimmer

onathreaded

threading

setting

disc

important

waste

chainstitch

note

container

looper

disengaging/engaging

looper

(pink),

solutions

machine

(violet),

threading

threading

Page

72,

74

9

9

9

27

25

9

22

20

70

12

42

10

20

8

72,

16,

23

13

73

-

55

73

17

5

Page 10

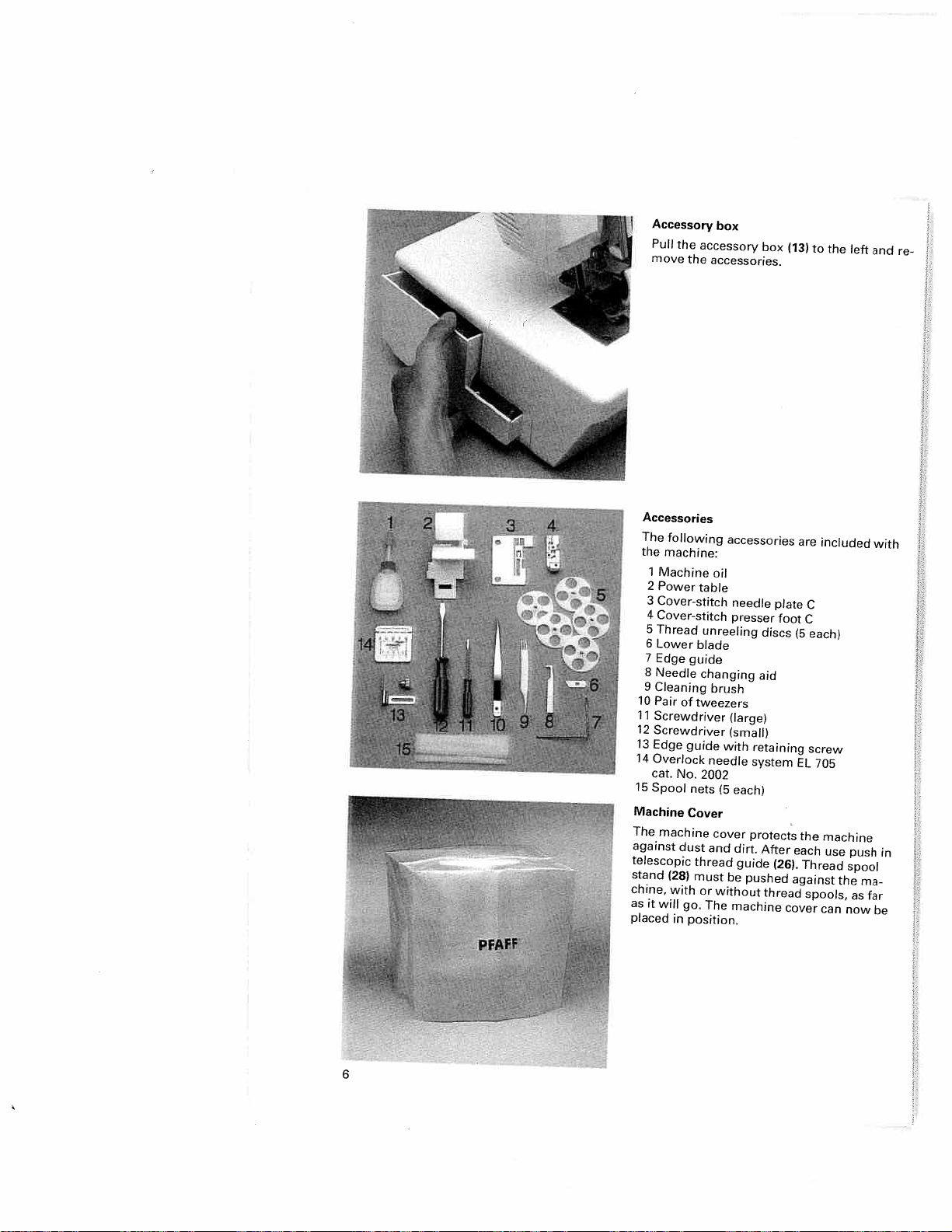

Accessory

Pull

move

Accessories

The

the

machine:

1

Machine

2

Power

3

Cover-stitch

4

Cover-stitch

Thread

5

6

Lower

7

Edge

8

Needle

9

Cleaning

10

Pair

11

Screwdriver

12

Screwdriver

13

Edge

14

Overlock

cat.

15

Spool

Machine

The

machine

against

telescopic

stand

chine,

as

will

it

placed

the

accessory

the

following

table

unreeling

blade

guide

changing

of

tweezers

guide

No.

2002

nets

Cover

dust

thread

(28)

must

with

or

go.

in

position.

box

accessories.

accessories

oil

needle

presser

brush

(large)

(small)

with

needle

(5

each)

cover

and

dirt.

guide

be

without

The

machine

box

discs

aid

retaining

system

protects

After

pushed

thread

plate

foot

(26).

(13)

are

(5

EL

each

against

cover

to

C

C

eachl

screw

705

the

Thread

spools,

the

left

included

machine

use

push

spool

the

as

can

now

ma

far

and

with

be

re

in

6

Page 11

Connecting

Plug

the

ting

bush

socket.

The

activating

gulate

the

slide

on

foot

(31)

the

the

the

control

sewing

foot

sewing

front

of

foot

the

control

plug

machine

speed

control.

speed

of

the

by

foot

into

and

is

regulated

You

adjusting

control.

the

may

connec

the

also

plug

by

the

Master

switch

When

you

turn

on

the

master

switch

the

sewing

lamp

is

illuminated.

The

re

machine

is

now

operational.

(32)

Setting

Setting

Notes

This

To

one

fit,

in

USA

used.

Australia:

41

on

appliance

reduce

way.

contact

anyway.

and

=

=

safety

risk

If

the

qualified

a

Canada:

For

control

reduced

full

final

has

of

electric

plug

For

speed

a

polarized

does

electrician

control

sewing

final

speed

shock,

not

plug

this

fit

fully

to

sewing

machine,

(one

plug

in

install

machine,

foot

blade

the

intended

is

outlet,

the

controller

wider

proper

foot

than

to

reverse

outlet.

controller

type

the

other),

fit

in

polarized

the

AE

Do

a

plug.

not

type

034

If

modify

AE

has

it

033

to

outlet

still

be

the

has

does

used.

only

plug

to

not

be

7

Page 12

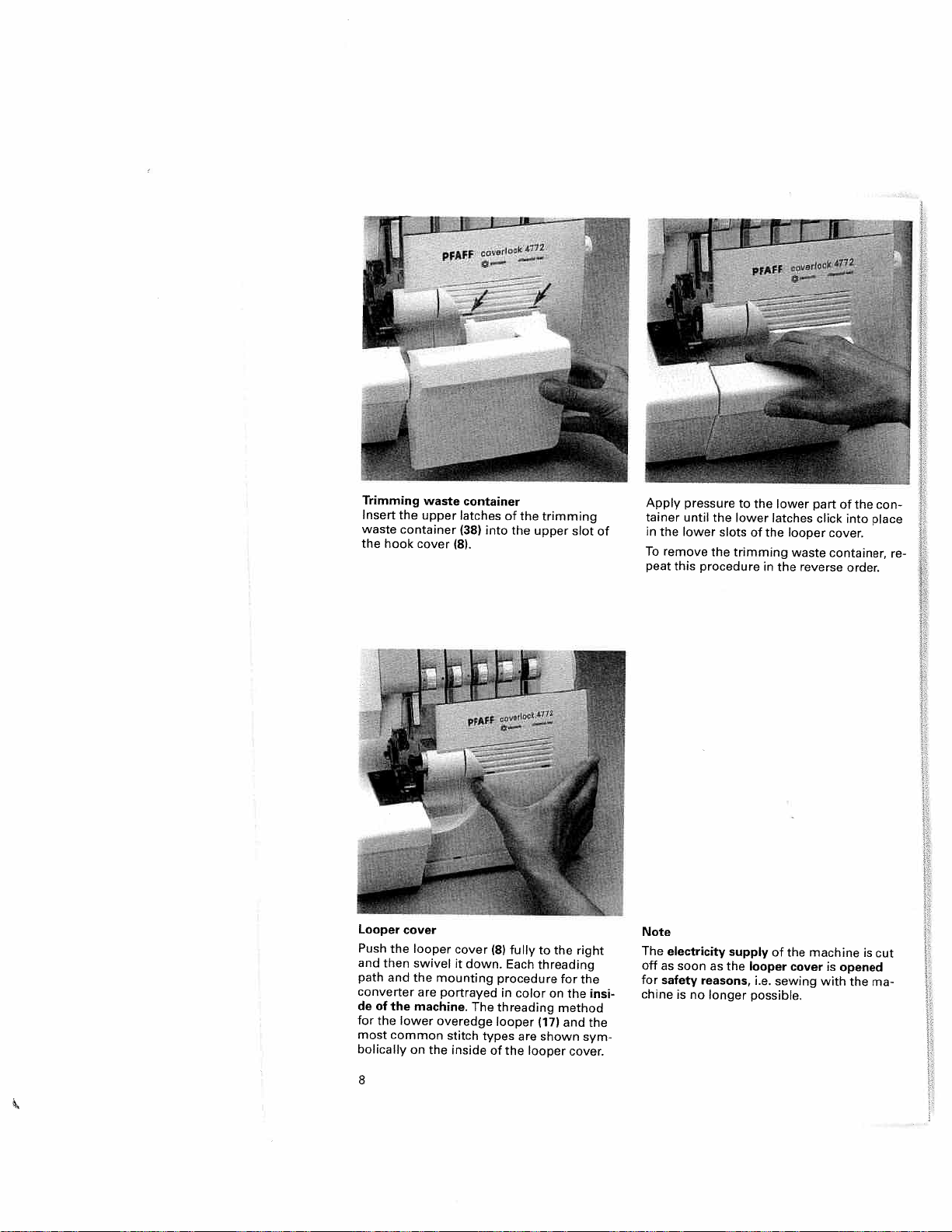

Trimming

Insert

waste

the

hook

Looper

Push

the

and

then

path

and

converter

de

the

of

for

the

most

common

bolically

waste

the

upper

container

cover

cover

looper

swivel

the

are

machine.

lower

on

the

container

latches

(38)

18).

cover

it

down.

mounting

portrayed

The

overedge

stitch

inside

of

into

<8)

Each

procedure

in

threading

looper

types

of

the

the

the

fully

color

are

trimming

upper

the

to

threading

on

117)

shown

looper

slot

right

for

the

the

method

and

sym

cover.

insi

the

Apply

pressure

tainer

of

in

To

peat

Note

The

off

for

chine

until

the

lower

remove

this

electricity

as

soon

safety

is

no

the

lower

slots

the

trimming

procedure

supply

as

the

reasons,

longer

to

the

of

looper

i.e.

possible.

lower

latches

the

in

the

of

sewing

looper

waste

reverse

the

cover

part

click

cover.

container,

machine

is

opened

with

of

into

order.

the

the

is

con

place

re

cut

ma

S

Page 13

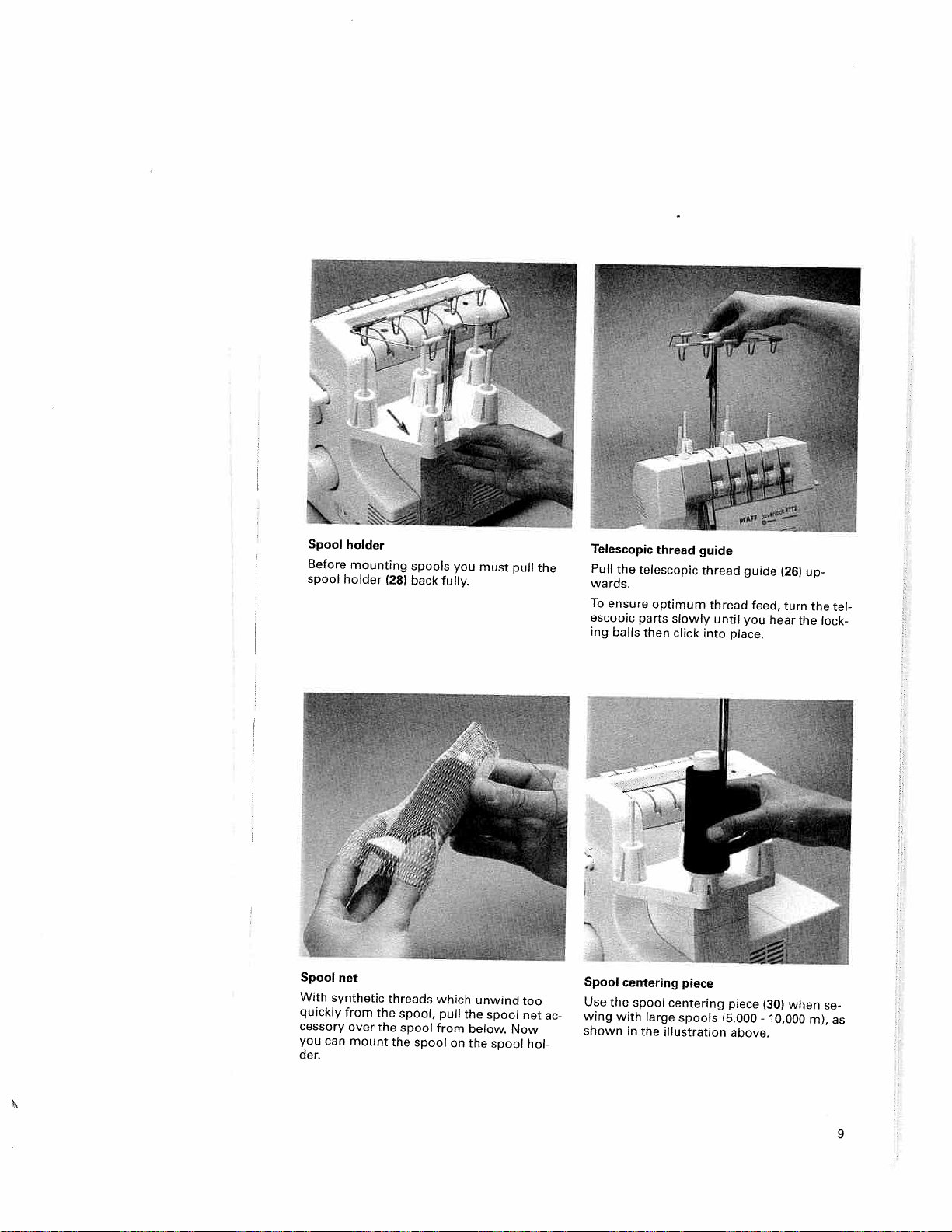

Spool

Before

spool

Spool

With

quickly

cessory

you

can

der.

holder

mounting

holder

net

synthetic

from

over

mount

(28)

threads

the

the

spool,

spool

the

spoois

back

spool

you

fully.

which

pull

from

on

must

unwind

the

below.

the

spool

spool

pull

too

net

Now

hol

the

ac-

Telescopic

Pull

the

wards.

To

ensure

escopic

ing

balls

Spool

Use

the

wing

with

shown

thread

telescopic

optimum

parts

then

centering

spool

large

in

the

guide

thread

slowly

click

into

piece

centering

spools

illustration

thread

until

piece

(5000

guide

feed,

you

place.

above.

hear

(30)

10,000

(26)

turn

when

the

up

the

ml,

tel

lock

se

as

9

é

Page 14

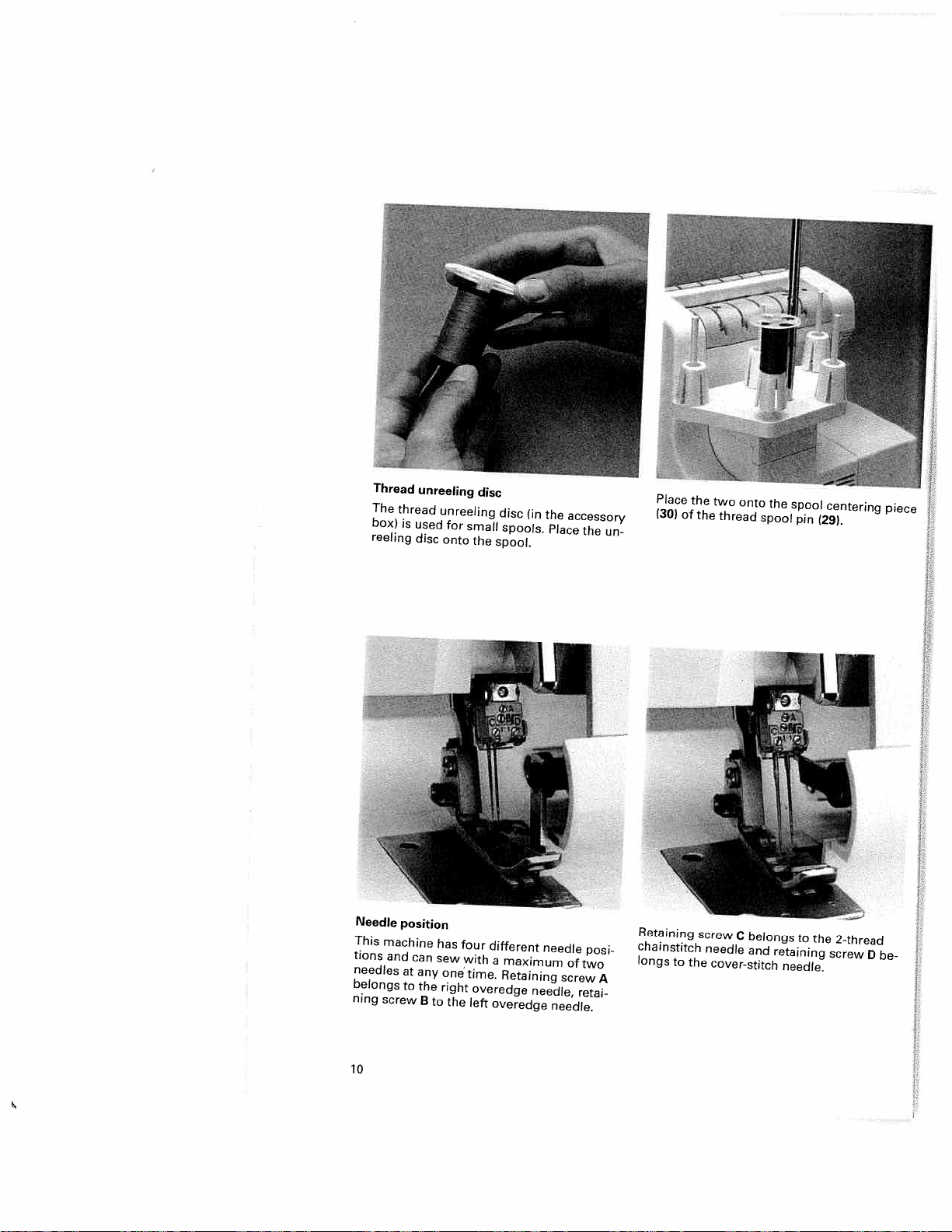

Thread

The

box)

reeling

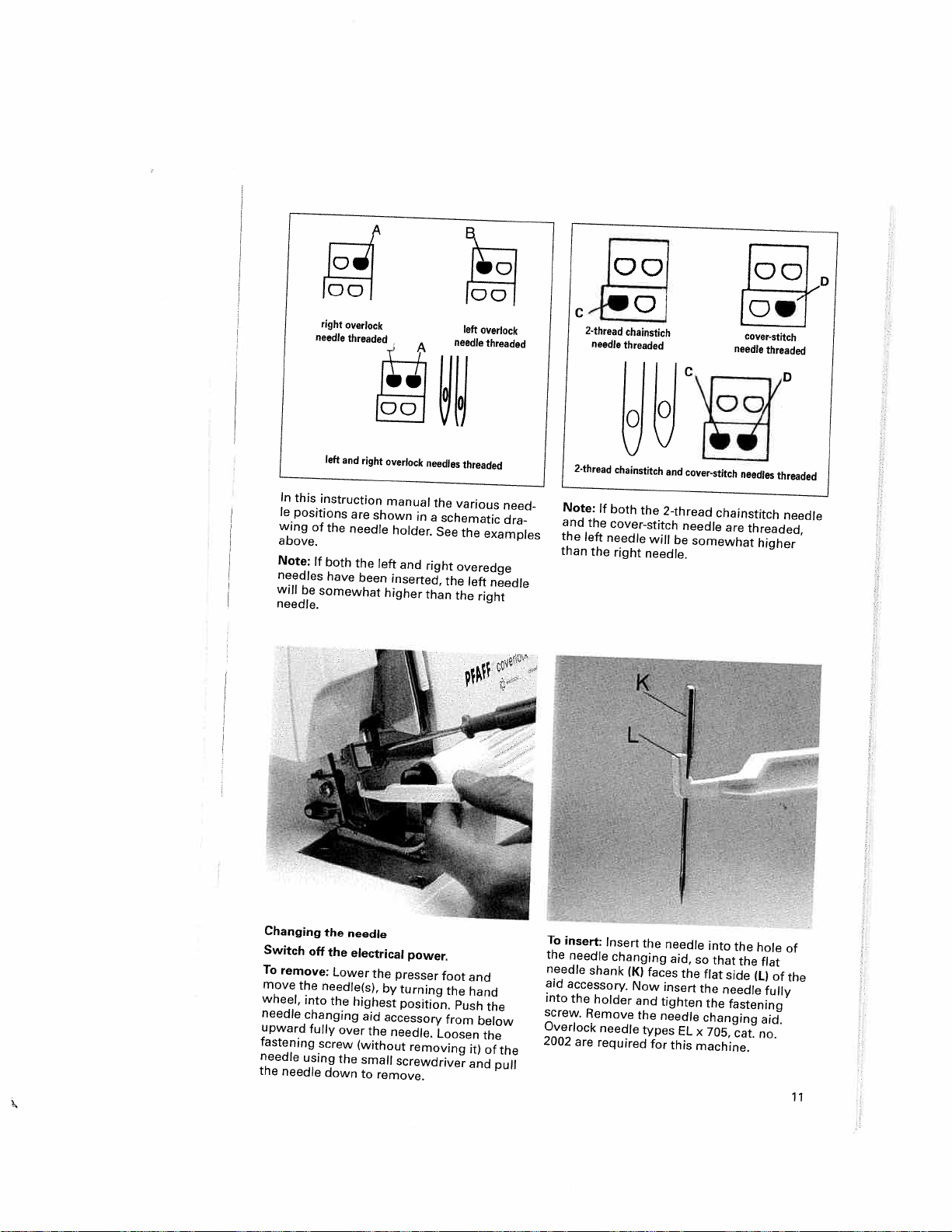

Needle

This

tions

needles

belongs

ning

thread

is

position

machine

and

at

to

screw

unreeling

unreeling

used

disc

has

can

sew

any

the

B

to

for

onto

one

right

the

disc

small

the

four

with

time.

overedge

left

disc

spools.

spool.

different

a

maximum

Retaining

overedge

(in

the

needle

needle,

accessory

Place

of

screw

needle.

the

posi

two

retai

A

un

Place

(30)

Retaining

chainstitch

longs

to

of

the

the

screw

the

two

onto

thread

C

belongs

needle

and

cover-stitch

the

spool

retaining

spool

pin

to

needle.

centering

(29).

the

screw

2-thread

piece

0

be

10

Page 15

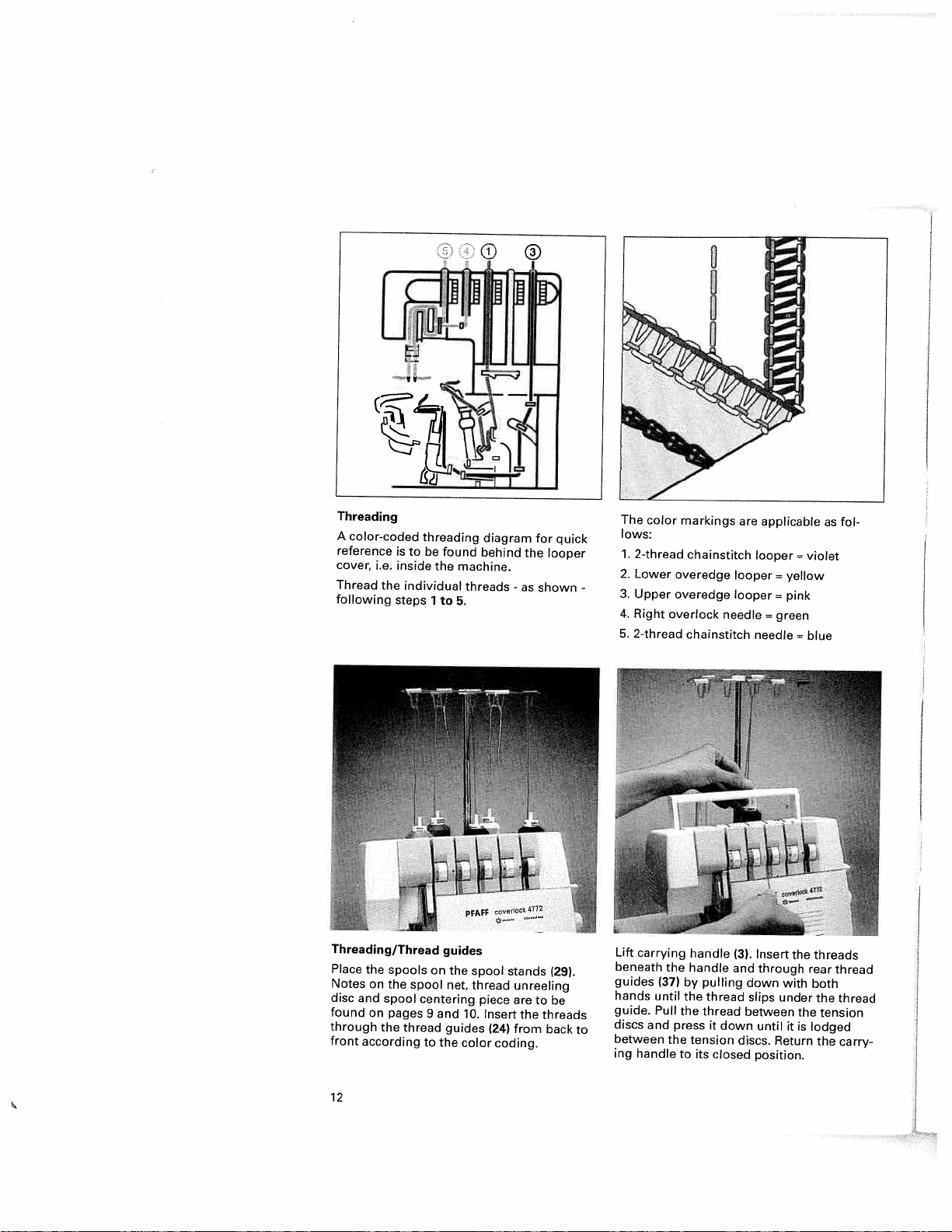

cLD

In

this

le

positions

wing

above.

Note:

needles

will

needle.

right

needle

left

instruction

of

If

both

be

somewhat

the

have

overlock

threaded

and

right

are

needle

the

been

!I

SI

Ioöl

overlock

manual

shown

holder.

left

and

inserted,

higher

A

needles

in

right

than

needle

the

various

a

schematic

See

overedge

the

the

left

overlock

threaded

threaded

the

examples

left

right

need

dra

needle

C-I—c

2-thread

Note:

and

the

than

2-thread

needle

If

both

the

cover-stitch

left

needle

the

chainstich

threaded

chainstitch

the

will

right

needle.

and

cover-stitch

2-thread

needle

be

somewhat

os]

cover-stitch

needle

needles

chainstitch

are

threaded,

higher

threaded

threaded

needle

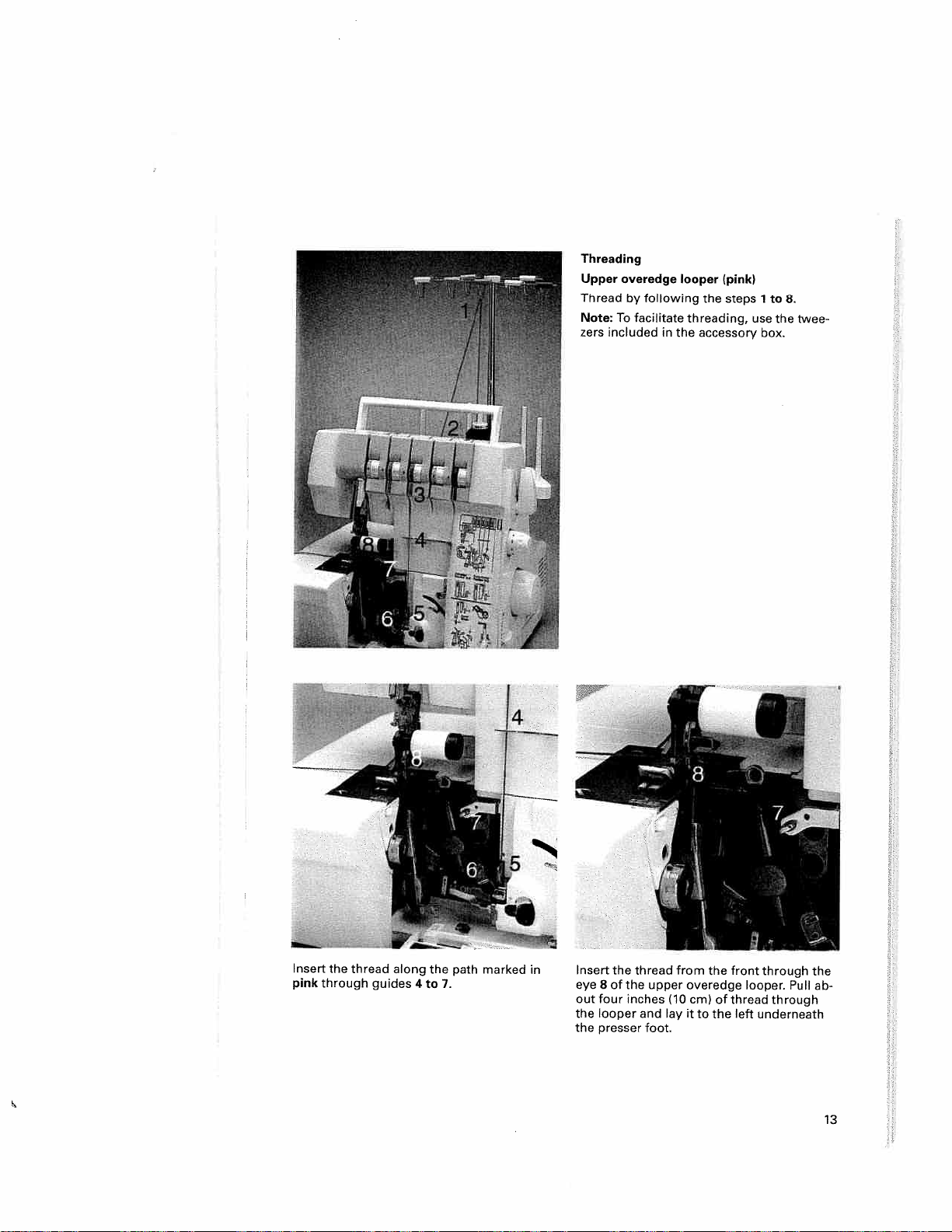

Changing

Switch

To

remove:

move

wheel,

needle

upward

fastening

needle

the

needle

the

off

the

the

needle(s),

into

changing

fully

screw

using

down

needle

electrical power.

Lower

the

over

the

highest

aid

the

(without

small

to

remove.

by

accessory

the

presser

turning

position.

needle.

removing

screwdriver

foot

the

Push

from

Loosen

and

hand

below

it)

and

the

the

of

the

pull

To

insert:

the

needle

needle

aid

accessory.

into

the

screw.

Overlock

2002

are

Insert

changing

shank

holder

Remove

needle

required

(K)

Now

and

the

faces

the

types

tighten

needle

for

needle

aid,

the

insert

EL

this

into

so

that

flat

side

the

needle

the

fastening

changing

x

705,

machine.

the

the

cat.

hole

(LI

no.

flat

fully

aid.

of

of

the

11

Page 16

Threading

A

color-coded

reference

cover,

Thread

following

i.e.

the

threading

is

tobefound

inside

individual

steps

1

the

to

diagram

behind

machine.

threads

5.

PFArF

The

color

for

quick

the

looper

-

as

shown

lows:

1.

2-thread

2.

-

Lower

3.

Upper

4.

Right

5,

2-thread

chainstitch

overedge

overedge

overlock

chainstitch

markings

are

looper

looper

needle

applicable

looper

=

yellow

=

pink

=

green

needle

=

=

violet

blue

as

fol

Threading/Thread

Place

the

Notes

disc

found

through

front

spools

on

the

and

spool

on

pages

the

according

spool

thread

12

guides

on

the

net,

centering

9

and

guides

the

to

spool

thread

10.

color

piece

Insert

(24)

stands

unreeling

are

the

from

coding.

(29).

to

be

threads

back

Lift

carrying

beneath

guides

hands

guide.

discs

to

between

ing

handle

and

(371

until

Pull

the

the

by

the

the

press

to

handle

handle

pulling

thread

thread

it

tension

its

down

closed

(3).

and

down

slips

between

discs.

Insert

through

with

under

until

it

Return

position.

the

the

is

threads

rear

both

the

tension

lodged

the

thread

thread

carry

Page 17

Threading

Upper

overedge

looper

Threadbyfollowing

Note:Tofacilitate

zers

included

in

the

(pink)

the

steps

threading,

accessory

use

1

to

box.

the

8.

twee

Insert

pink

the

through

thread

along

guides

the

4

to

7.

path

marked

in

Insert

the

8

of

eye

out

the

the

four

looper

presser

the

inches

thread

upper

and

foot.

from

(10

lay

the

overedge

cml

of

it

to

the

front

looper.

thread

left

through

Pull

through

underneath

the

ab

13

Page 18

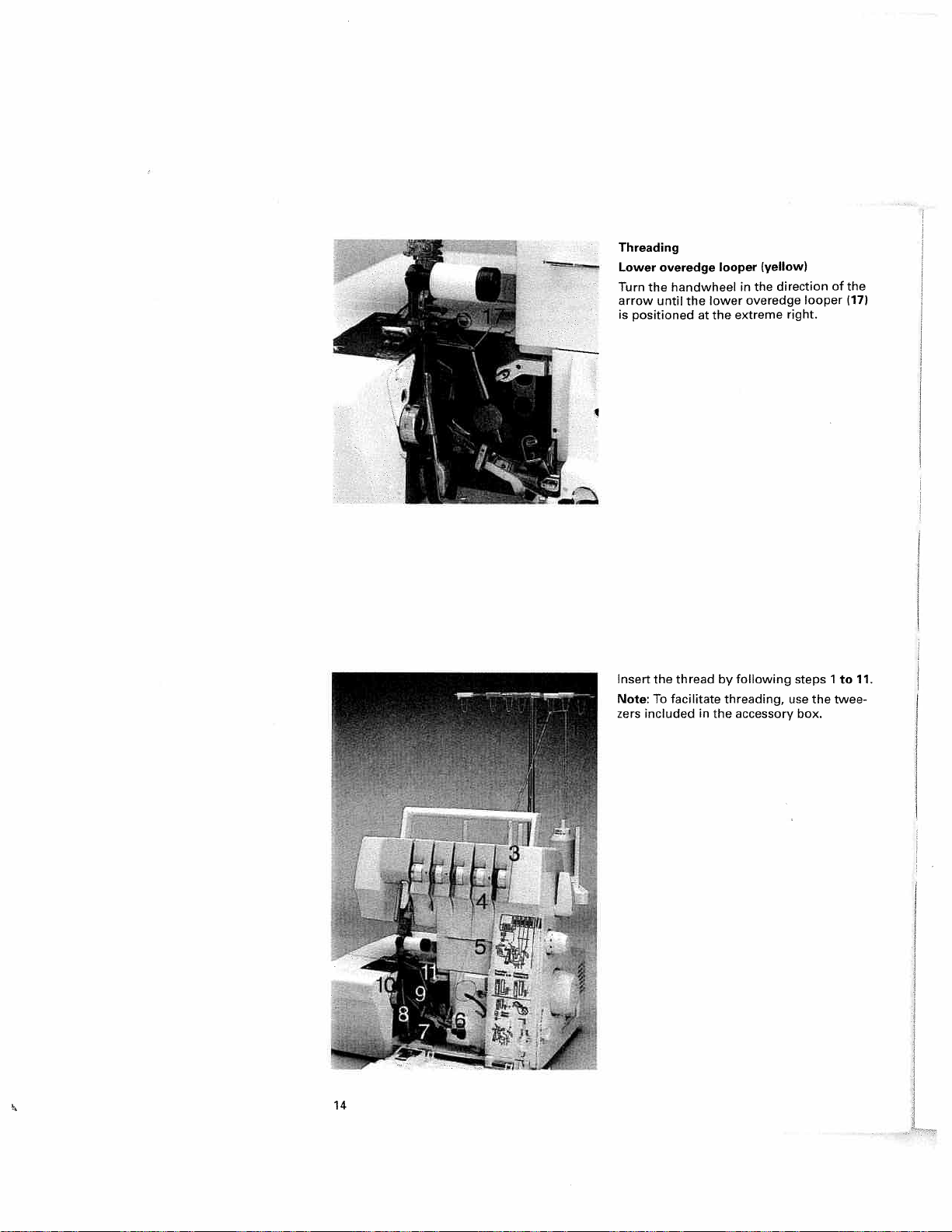

1

Threading

overedge

Lower

Turn

arrow

is

Insert

Note:

zers included

the

until

positioned

the

To

hanc(wheel

facilitate

the

thread

looper

in

lower

extreme

at

the

following

by

threading,

the accessory

in

(yellow)

direction

the

overedge

right.

steps

use

box.

looper

the

of

1

to

twee

the

(17)

11.

14

Page 19

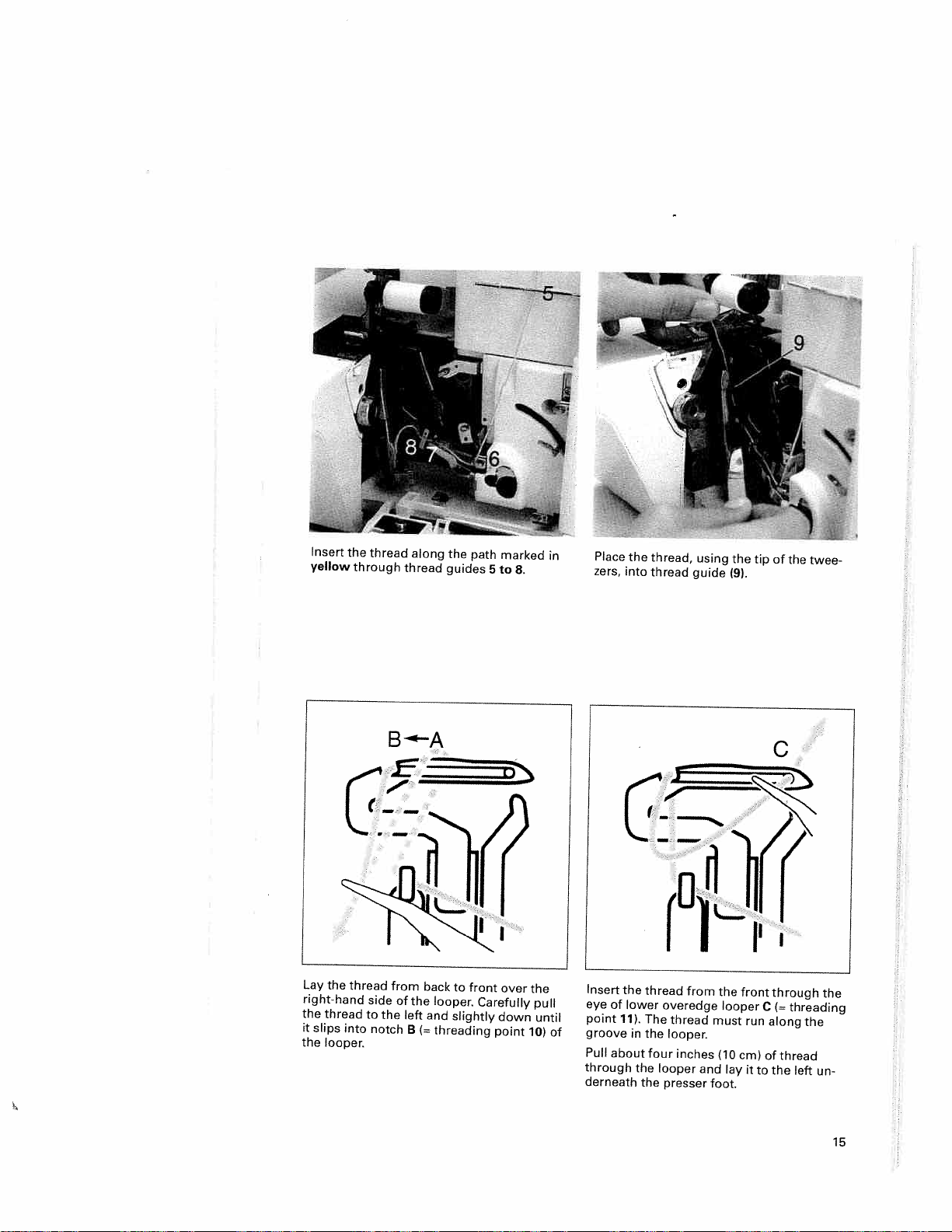

Insert

yellow

thread

the

through

along

thread

the

guides

path

marked

5

to

in

Place

the

thread,

using

the

tip

of

the

8.

zers,

into

thread

guide

(9).

twee

Lay

the

right-hand

the

thread

it

slips

the

looper.

thread

into

side

to

notch

the

B---A

from

back

of

the

left

and

B

(=

to

front

looper.

slightly

threading

over

Carefully

down

point

the

10)

pull

until

C

Insert

the

thread

from

the

front

lay

run

it

C

of

to

through

(=

along

the

eye

lower

of

point

of

groove

Pull

about

through

derneath

11).

in

the

The

the

four

the

overedge

thread

looper.

inches

looper

presser

looper

must

(10cm)

and

foot.

threading

the

thread

left

the

un

15

Page 20

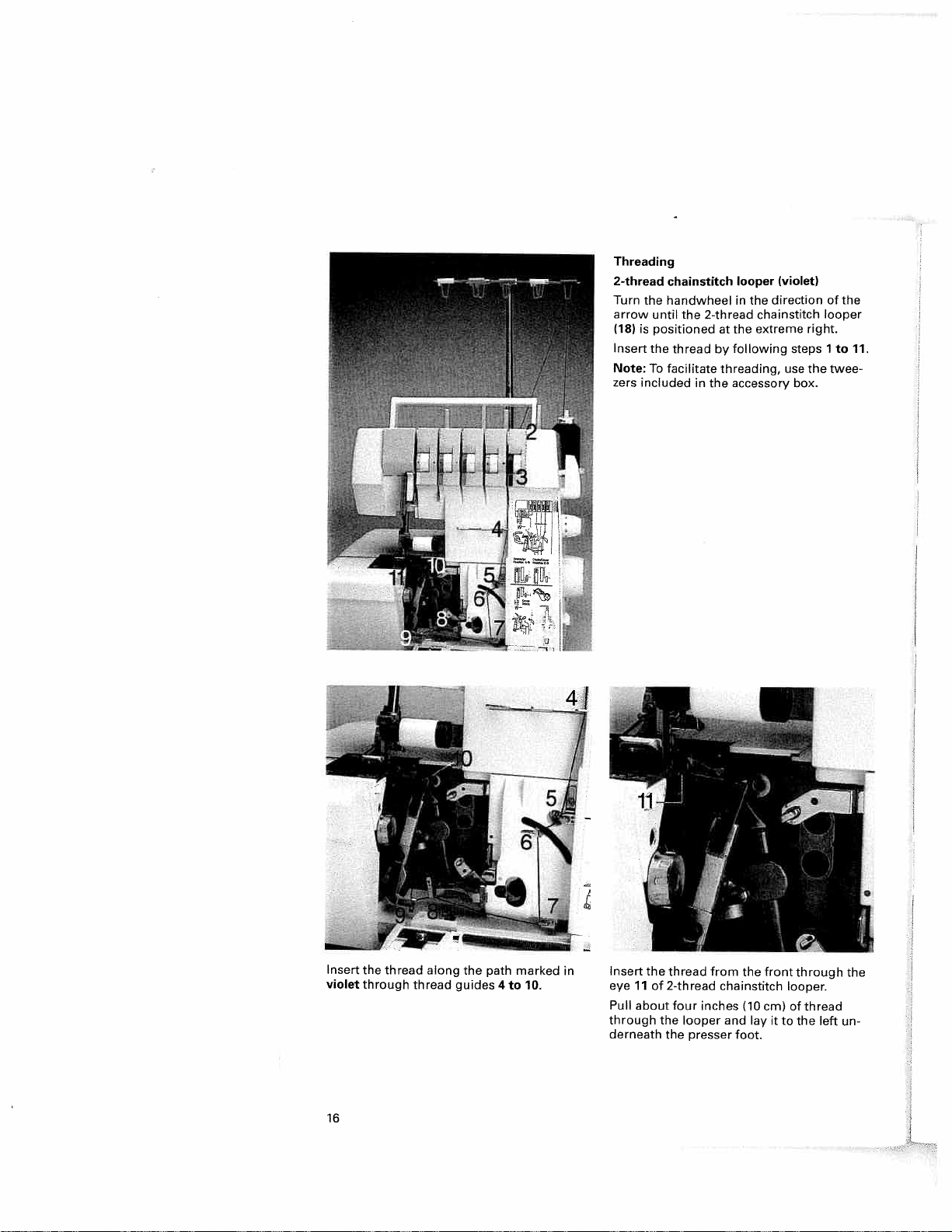

Threading

2-thread

Turn

the

arrow

is

(18)

Insert

the

Note:

To

zers

included

chainstitch

handwheel

until

the

positioned

thread

facilitate

2-thread

by

in

the

looper

the

in

extreme

at the

following

threading,

accessory

(violet)

direction

chainstitch

steps

use

box.

right.

the

of

the

looper

1

to

twee

11.

Insert

violet

16

the

thread

through

along

thread

the

guides

path

4

marked

to

10.

Insert

in

eye

11

Pull

about

through

derneath

the

of

thread

2-thread

four

the

the

inches

looper

presser

from

chainstitch

and

foot.

the

front

(10cm)

lay

it

through

looper.

of

to

the

thread

left

the

un

Page 21

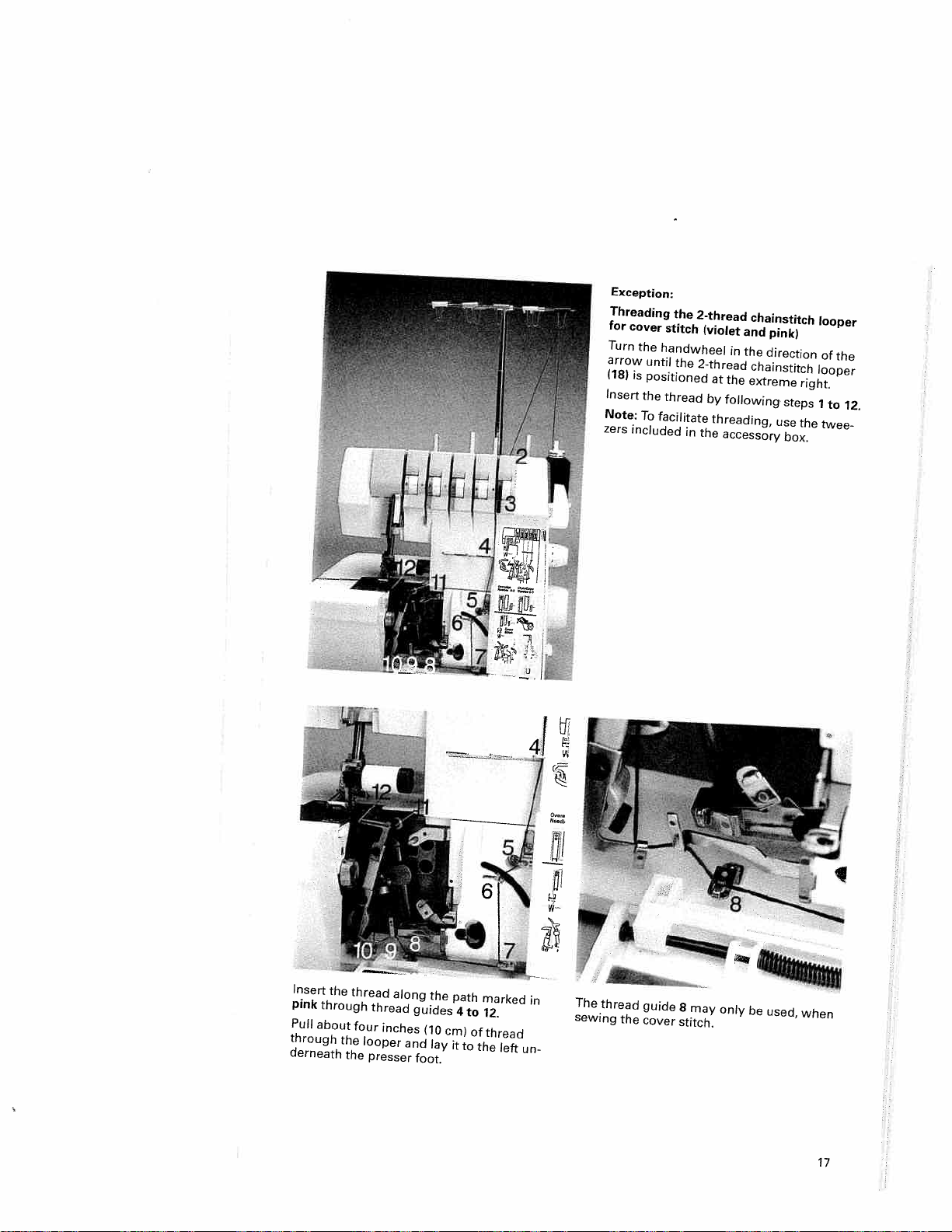

Exception:

Threading

for

cover

Turn

the

arrow

(18)

is

Insert

Note:

zers

included

the

stitch

handwheel

until

the

positioned

the

thread

To

facilitate

2-thread

(violet

2-thread

in

the

in

at

the

by

following

threading,

accessory

chainstitch

and

pink)

the

direction

chainstitch

extreme

use

steps

box.

right.

the

looper

of

the

looper

1

to

twee

12.

Insert

pink

through

Pull

about

through

derneath

the

the

the

thread

thread

four

looper

presser

along

inches

guides

and

foot.

(10

the

lay

cm)

path

4

it

to

to

of

marked

12.

thread

the

left

un

0

in

The

thread

guide

8

may

sewing

the

cover

only

stitch.

-

be

used,

when

17

Page 22

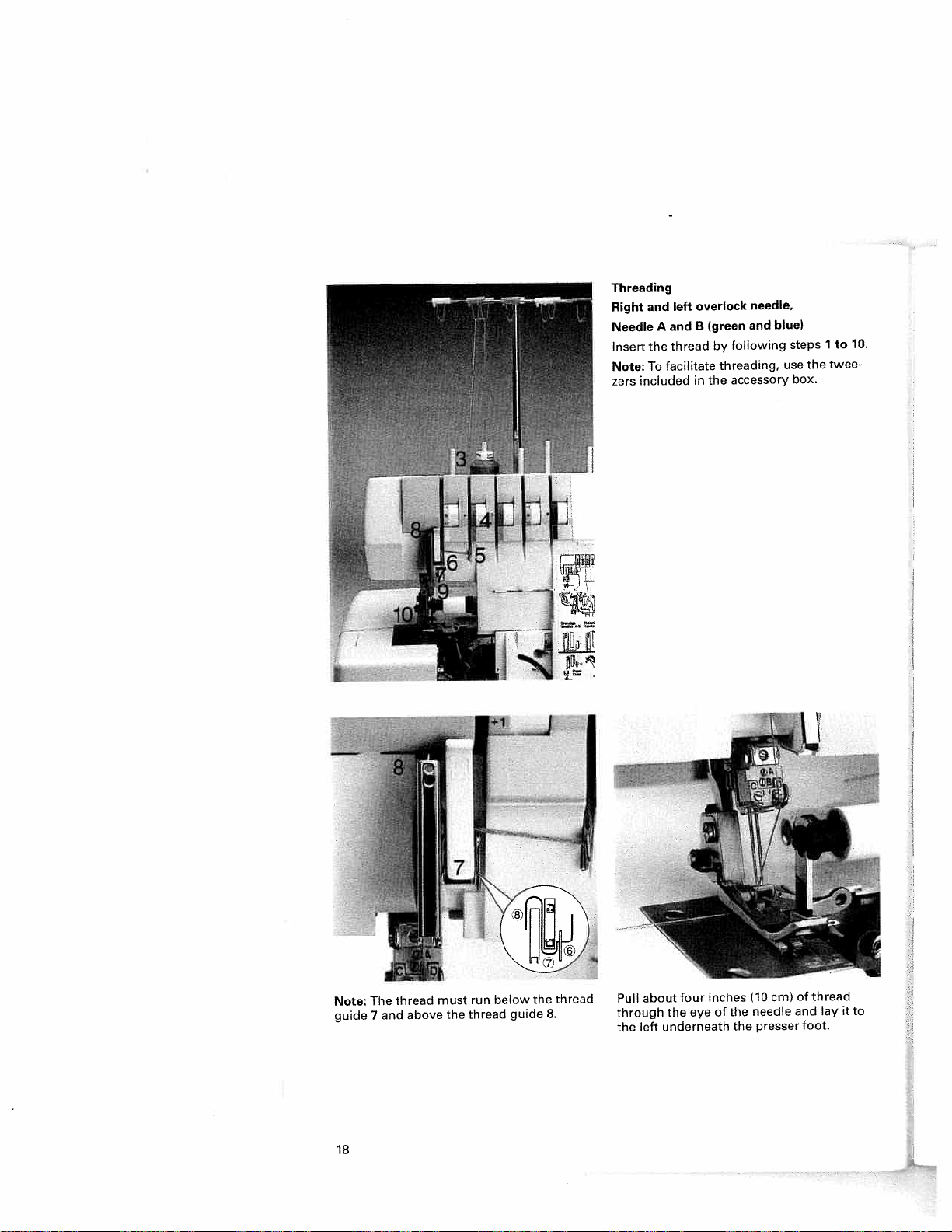

Threading

and

Right

Needle

the

Insert

To

Note:

included

zers

left

and

A

thread

facilitate

overlock

(green

B

by

threading,

in

the

needle,

and

following

accessory

blue)

use

steps

box.

the

1

twee

10.

to

Note:

guide

18

The

7

and

thread

above

must

the

run

thread

below

guides.

the

thread

about

Pull

through

left

the

four

eye

the

underneath

inches

of

the

the

(10

needle

presser

cm)

of

and

foot.

thread

lay

it

to

Page 23

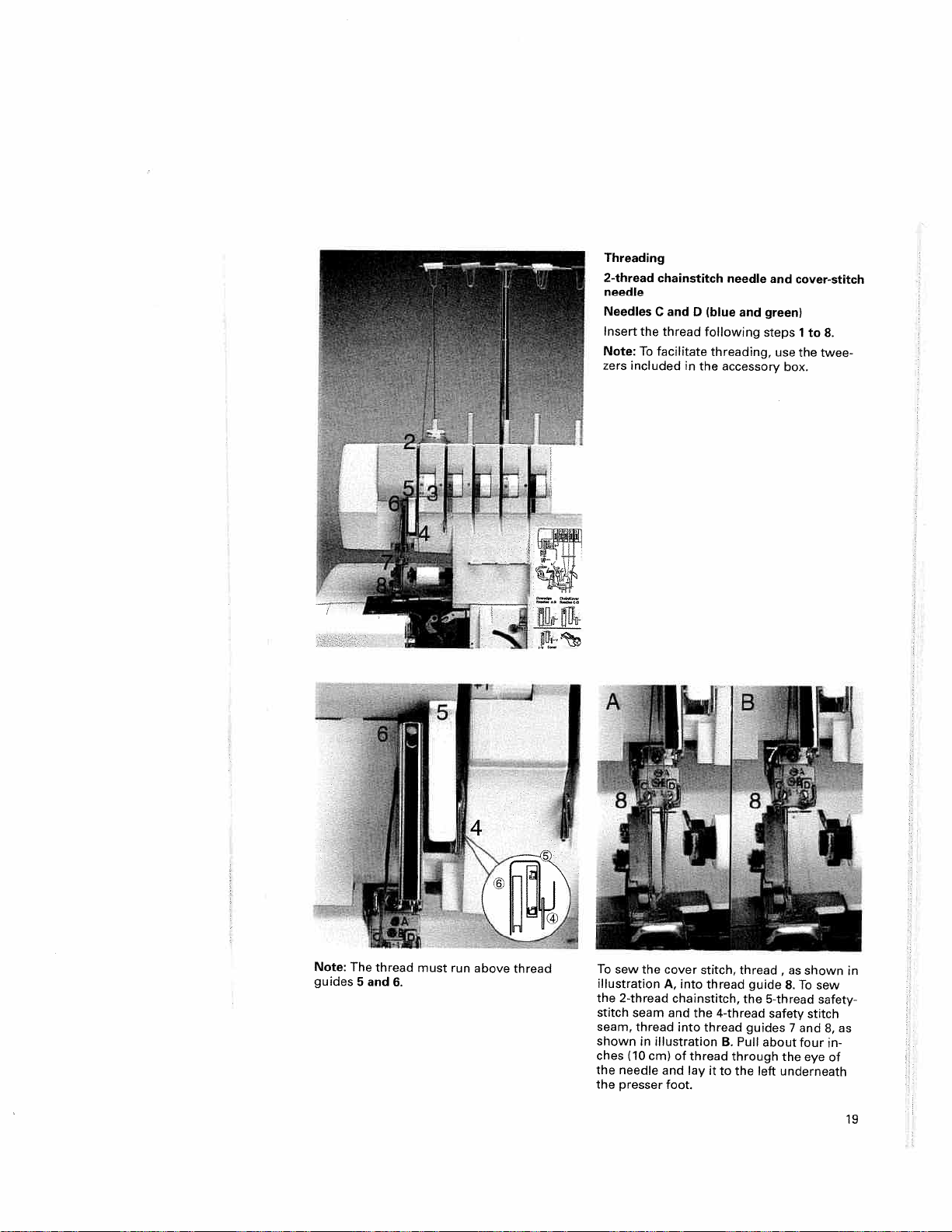

Threading

2-thread

needle

Needles

Insert

the

Note:

To

zers

included

chainstitch

and

C

D

thread

facilitate

in

needle

(blue

following

threading,

accessory

the

and

and

green)

steps

use

cover-stitch

1

to

the

twee

box.

8.

Note:

guides

The

5

thread

and

run

must

6.

above

thread

To

sew

illustration

the

2-thread

stitch

seam

seam,

thread

shown

ches

(10

the

needle

the

presser

cover

the

A,

and

in

illustration

cml

and

foot.

stitch,

into

thread

chainstitch,

the

4-thread

into

thread

of

thread

it

lay

B.

through

to

the

thread

guide

the

guides

Pull

,

5-thread

safety

about

left

underneath

8.

the

as

7

shown

To

stitch

and

four

eye

sew

safety-

8,

in

of

in

as

19

Page 24

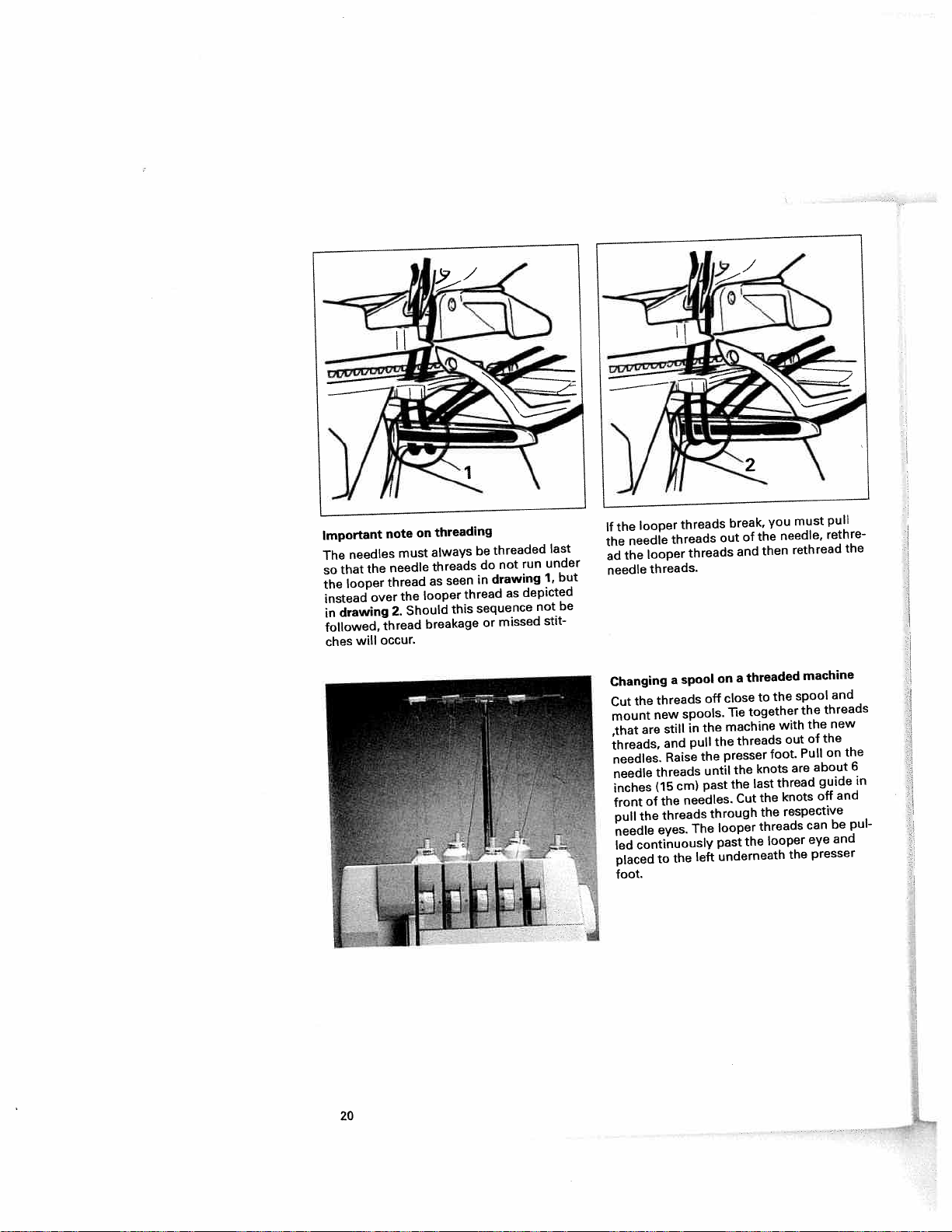

Important

needles

The

that

so

looper

the

instead

in

drawing

followed,

will

ches

the

over

note

must

needle

thread

the

2.

thread

occur.

on

as

looper

Should

breakage

threading

always

threads

seen

thread

this

threaded

be

not

do

in

drawing

as

sequence

missed

or

last

under

run

1,

depicted

not

stit

but

be

If

the

the

ad

needle

looper

needle

the

looper

threads.

threads

threads

threads

break,

out

and

you

needle,

the

of

then

rethread

rethre

the

pull

must

20

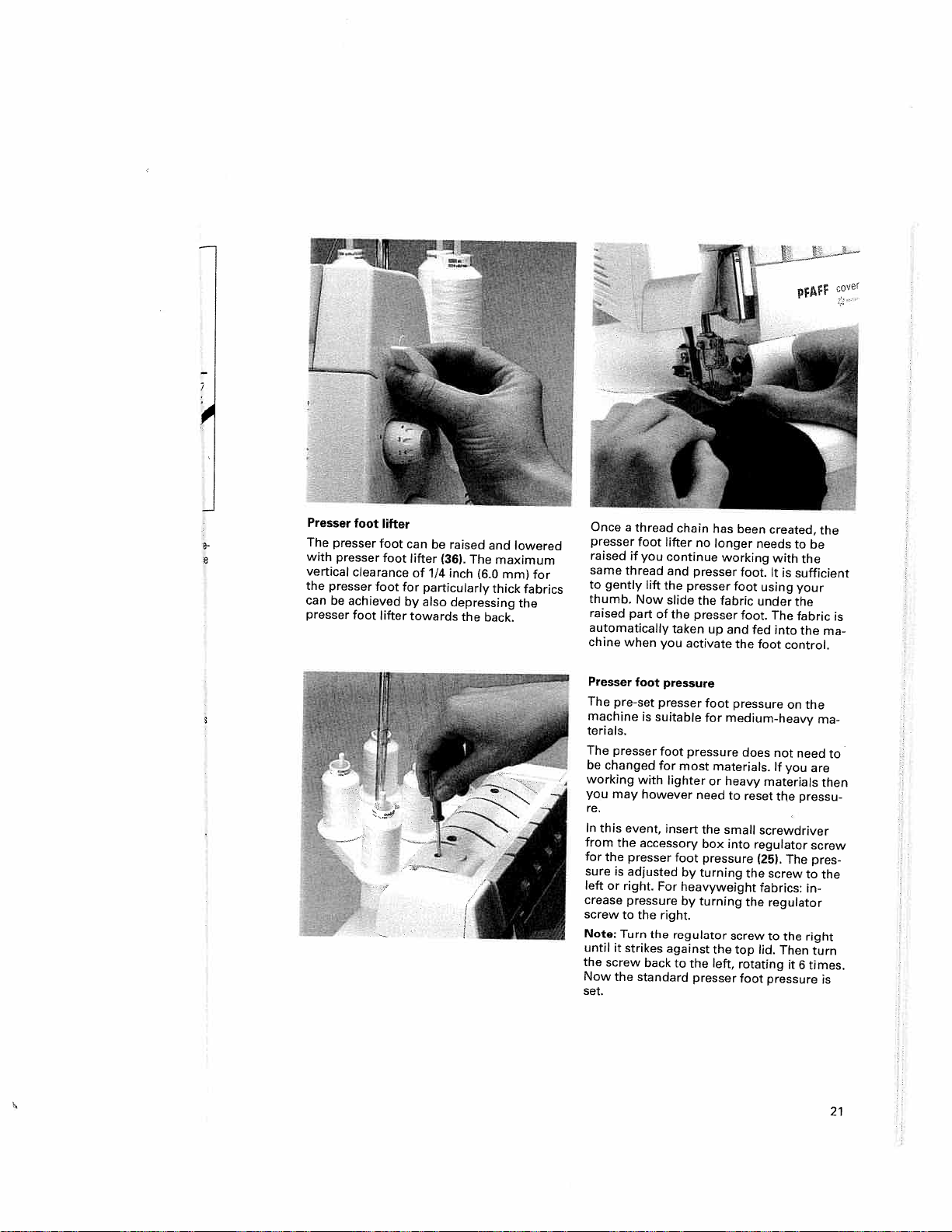

Changing

the

Cut

mount

are

,that

threads,

needles.

needle

inches

of

front

the

pull

needle

continuously

led

placed

foot.

a

threads

new

still

and

Raise

threads

cm)

(15

the

threads

eyes.

the

to

spool

off

spools.

the

in

pull

the

until

past

needles.

through

The

left

threaded

a

on

close

together

lie

machine

threads

the

presser

the

last

the

Cut

looper

the

past

underneath

the

to

foot.

knots

thread

the

the

threads

looper

machine

spool

the

the

with

of

out

Pull

about

are

knots

respective

can

eye

presser

the

and

threads

new

the

on

guide

off

be

and

the

6

in

and

pul

Page 25

Presser

The

with

vertical

the

presser

can

be

presser

foot

presser

presser

clearance

achieved

foot

lifter

foot

foot

foot

lifter

can

lifter

of

for

particularly

by

also

towards

be

(36).

1/4

raised

The

inch

(6.0

depressing

the

back.

and

lowered

maximum

mm)

thick

the

for

fabrics

Once

a

thread

presser

raised

if

same

thread

gently

to

thumb.

raised

part

automatically

chine

when

Presser

foot

The

pre-set

machine

terials.

The

presser

changed

be

working

you

may

re.

In

this

event,

from

the

for

the

presser

sure

is

adjusted

left

or

right.

crease

pressure

screw

to

Note:

Turn

until

strikes

it

the

screw

Now

the

set.

foot

lifter

you

continue

and

lift

the

Now

slide

of

you

pressure

presser

is

suitable

foot

for

with

lighter

however

insert

accessory

For

the

right.

the

against

back

standard

chain

has

no

presser

presser

the

the

presser

taken

up

activate

foot

for

pressure

most

materials.

or

need

the

box

foot

pressure

turning

by

heavyweight

turning

by

regulator

the

to

the

left,

presser

been

longer

created,

needs

working

foot.

foot

using

fabric

under

foot.

and

fed

the

foot

pressure

medium-heavy

does

heavy

materials

to

reset

small

screwdriver

into

regulator

(25).

the

screw

fabrics:

the

regulator

screw

to

top

lid.

rotating

foot

pressure

with

It

The

into

not

If

the

is

the

Then

to

be

the

sufficient

your

the

fabric

the

control.

on

the

need

you

are

pressu

screw

The

to

in

right

it

6

times.

the

is

ma

ma

to

then

pres

the

turn

is

21

Page 26

foot

presser

off

remove:

position

white

holder.

insert:

sewing

the

the

of

Please

that

into

the

the

lever

to

Lift

presser

foot

place.

Raise

and

The

from

the

the

foot

the

electrical

the

lift

the

at

sewing

the

left.

spring

under

foot

locks

lift

the

presser

power

needle(s)

presser

the

rear

foot

holder

do

To

slightly

the

lever

the

into

presser

toot

the

of

will

this,

holder

is

presser

is

the

to

foot.

presser

be

and

lift

and

so

lowered,

foot

properly

hig

released

can

the

insert

that

foot

lever

Press

be

spring

the

to

lock

Changing

Switch

To

hest

the

foot

automatically

removed

slightly.

To

the

when

pin

holder.

Check:

ensure

\

ed

Presser

Use

cessory

Use

further

the

On

extension

the

le(s)

used

Thread

After

8

to

Pull

front

This

foot

cover-stitch

box

standard

the

programs

presser

istobe

aid

an

as

chain

finishing

(15

inch

the

thread

over

the

will

cut

presser

sewing

when

presser

(see

feet,

which

of

positioned.

when

trimmer

seam,

the

cm)

—20

chain

thread

off

the

page

there

is

sewing.

long

from

chain

thread

foot

cover

foot

are

where

These

sew

the

chain.

from

C

stitch.

1O)

36-

41).

markings

the

markings

an

thread

back

trimmer

the

all

for

need

approx.

chain.

to

(27).

ac

A,

can

6

the

22

Page 27

an

Disengaging

Switch

S

Raise

sition

ad

trimming

per

vable

Turn

you

zontal

cover.

upper

the

until

position.

off

upper

by

head

the

the

the

blade

rotating

waste

Now

blade

of

upper

upper

electrical

(23)

the

container

slide

fully

the

upper

blade

blade

power

to

its

handwheel.

and

the

holder

towards

blade

locks

uppermost

Detach

open

of

the

the

right.

away

into

a

hori

the

from

po

the

loo

mo

Engaging

Slide

towards

until

it

the

looper

waste

the

the

holder

the

locks

cover

container.

upper

right

into

of

and

its

and

blade

the

movable

swing

working

re-attach

upper

the

blade

position.

the

trimming

blade

back

Close

23

Page 28

Fitting

Switch

converter

The

seams,

closing

stitch

container

verter

chine

Insert

ture

of

converter

the

the

off

the

for

seam

seam.

and

is

(7)

housing.

hub

the

must

and

Detach

open

located

of

A

upper

electrical

be

2-needle,

for

the

the

in

it

Pull

the

converter

overedge

power

fitted

3-thread

the

trimming

looper

the

out.

for

4-thread

front

into

looper.

all

overedge

waste

cover.

the

of

2-thread

safety-

Con

ma

A

aper

the

Rotate

arrow

positioned

is

blade.

per

Rotate

press

that

eye

The

der.

handwheel

the

until

the

upper

the

the

tip

of

the

converter

upper

the

the

to

converter

the

of

looper.

can

right

part

converter

be

the

in

overedge

of

towards

slightly

removed

direction

looper

movable

the

the

the

to

locks

in

of

and

left

rear

into

reverse

the

(16)

up

so

the

or

24

Page 29

Setting

latch

For

Set

to

For

Set

to

standard

the

position

rolled

the

position

bed

the

bed

hems

slide

R.

bed

overlock

slide

S.

and

for

slide

for

stitch

the

stitch

for

seams:

cover

the

width

width

stitch

stitch

latch

latch

width

(21)

(21)

Stitch

All

with

Stitch

ward.

can

width

standard

this

width

All

be

sewn

setting.

rolled

latch

overlock

latch

with

A

hems

this

A

will

will

and

be

seams

be

the

setting.

pushed

can

pushed

cover

forward.

be

back

stitch

sewn

25

Page 30

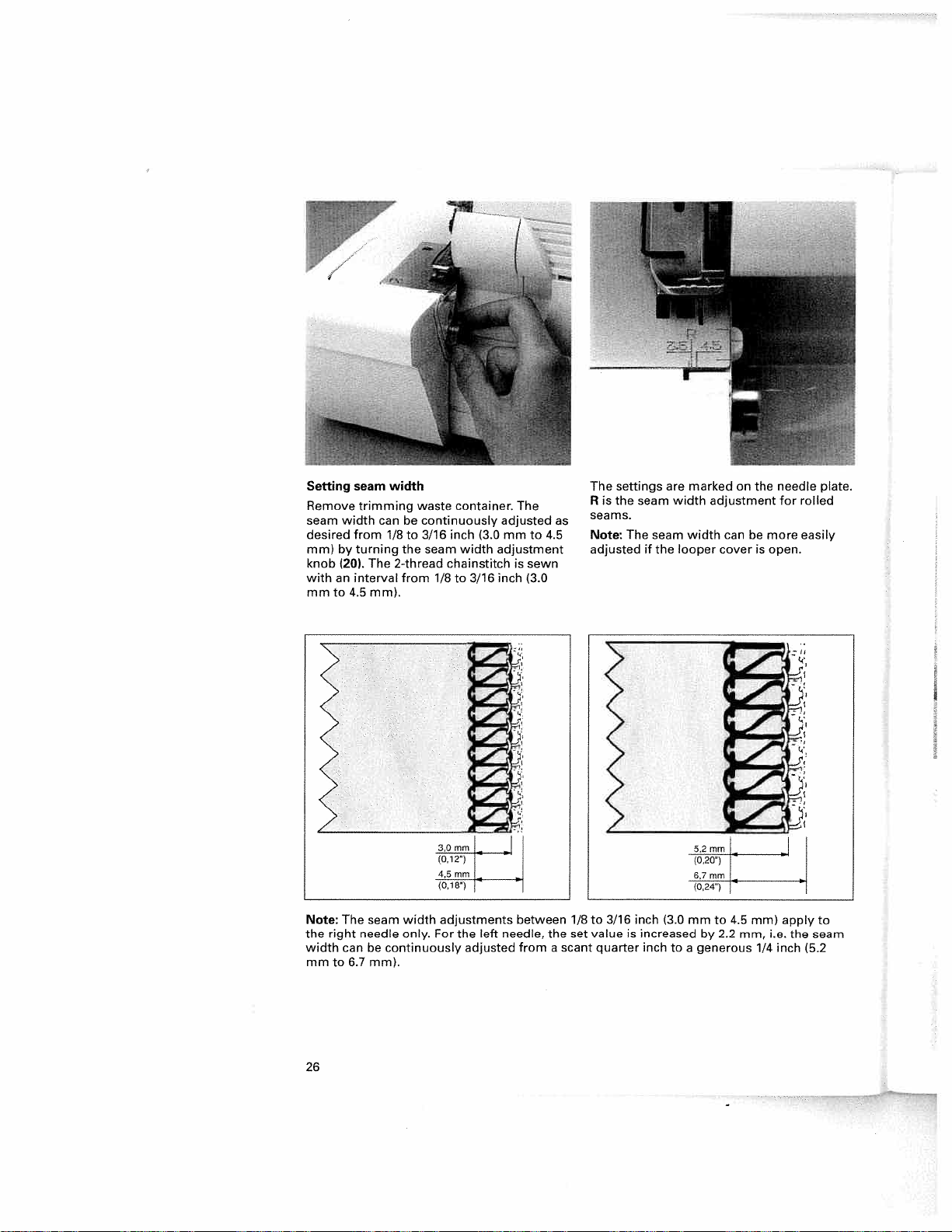

Setting

Remove

seam

desired

mm>

knob

withaninterval from

mm

Note:

the

by

(20).

to

right

seam

width

trimming

width

canbecontinuously

from

1/8to3/16

turning

The

2-thread

4.5

mm>.

The

seam

needle

waste

the

seam

1/8to3/16

width

only. For

3,0mm

(0.12’)

4,5

(0,18)

width canbecontinuously

mmto6.7

mm>.

container.

inch

(3.0

width

chainstitch

—

•

mm

adjustments

the

left

adjusted

The

adjusted

mmto4.5

adjustment

is

sewn

inch

(3.0

between

needle, the

fromascant

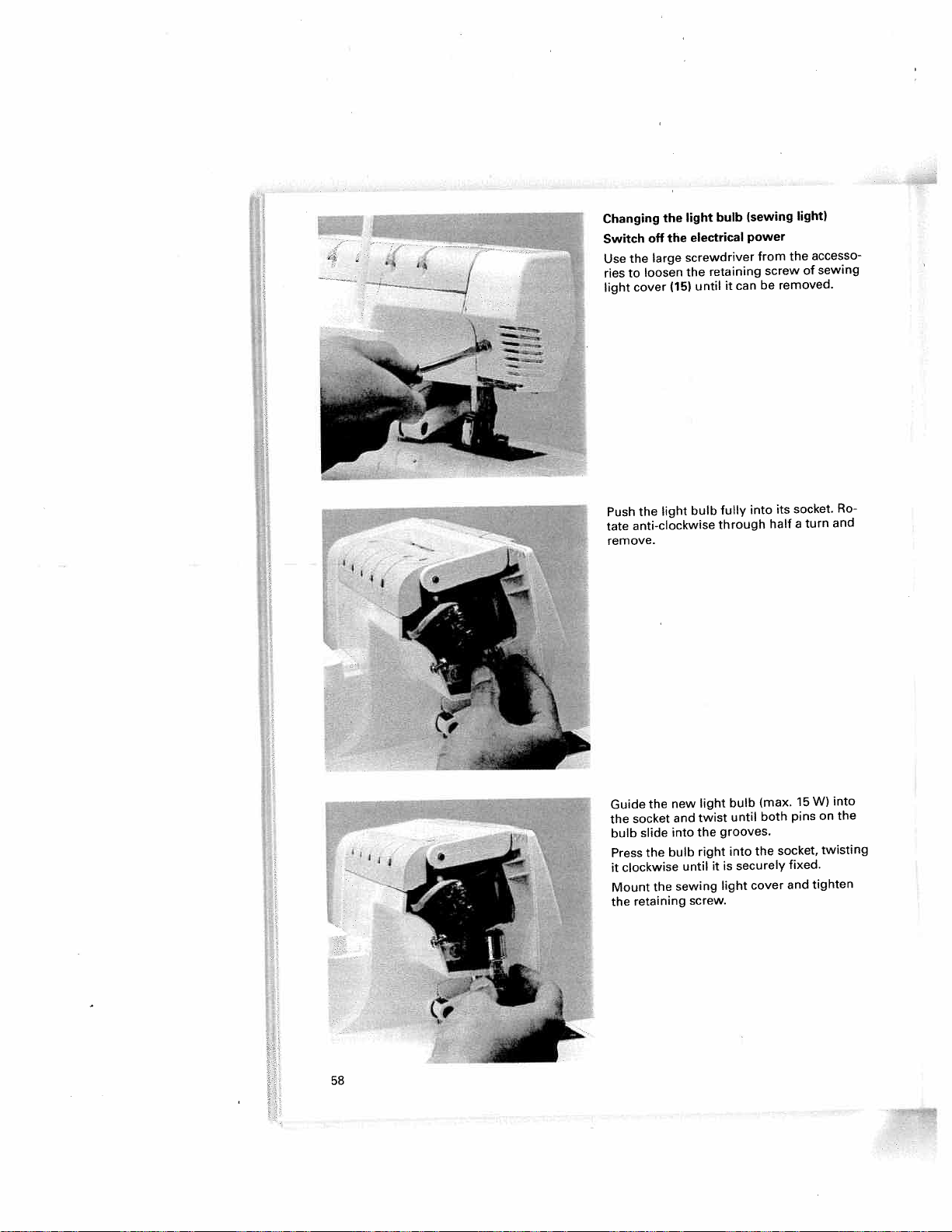

The

Risthe

seams.

as

Note:

adjustedifthe

1/8to3/16

set

valueisincreased

quarter

settings

seam

The

inch

marked

are

width

adjustment

seam

width canbemore easily

looper cover

mmto4.5

(3.0

by

inch

toagenerous

2.2

on

mm,

the

is

mm)

1/4

needle

for

open.

apply

i.e.

inch

the

plate.

rolled

to

seam

(5.2

26

Page 31

Setting

The

it

the

stitch

1

F

mm>

(4

adjustment

most

For

justment

working

with

justment

the

the

slightly,

with

detachable

Sewing

Detach

Pull

ward

Note:Ifyou

tainer

beforehand,

detachable

length

to

knob

sewing

knob

knob

work

work

can

mm

4

(35).

work,

should

close-knit

to

4

free

the

support

and

detach

support.

be

by

be

mm.

arm

work

remove

the

is

it

as

set

turning

stitch

the

at

set

fabrics,

support

this

trimming

easier

desired

stitch

mm.

3

set

to

remove

to

length

the

(12)

the

waste

from

length

ad

When

ad

for

left.

con

the

length

stitch

free

The

tubular

wing

sleeves.

Reattaching

Position

it

is

that

it

to

slide

tion.

arm

Insert

the

level

the

particularly

is

such

items

article

the

work

the

detachable

the

with

until

right

as

over

support

work

machine

it

locks

useful

trouser

the

support

for

free

cover,

into

legs

posi

se

and

arm.

so

then

27

Page 32

Differential

differential

The

dogs

(A

move

which

regulates

(34)

dog

feed

fed

be

to

range

the

standard

The

feed

front

the

with

feed

rear

fabric.

of

The

Note:

feed

also

and

ted

feed

arranged

B),

+

the

the

and

(A),

through.

and

0.5

setting

dog

feed

rear

dogs

effectiveness

depends

type

the

feed

fabric.

movement

thus

It

2.0.

moves

(A)

dog

both

on

of

consists

one

Adjustment

the

can

1.0,

is

(B),

move

the

fabric

two

of

behind

the

of

amount

adjusted

be

which

by

synchronously

the

i.e.

same

the

differential

of

the

length

stitch

used.

the

lever

front

of

front

feed

other,

fabric

within

the

and

amount

selec

differential

If

0.5,

to

set

fastasthe

feeds

dog

rear

the

as

Asaresult,

28

/

feed

front

the

rear

through

feed

the

adjustment

feed

feed

only

dog.

fabric

dog,

is

lever

moves

dog

the

i.e.

half

as

stretched.

front

much

(34)

half

is

feed

fabric

fabrics

a

is

when

ga

when

silk

seam

way,

rib

knit

the

sewing

and

(A).

touches

such

(B).

taffeta.

as

delicate

very

result

The

alsobeintroduced

can

wave

the

effect

as

as

such

smooth

Fashionable

this

in

using

prevents

This

thered

becoming

from

seam

Page 33

ther

Inc

(tin

tnd

nt

iu

al

alec-

Set

2.0

as

feed

bric

As

fast

differential

so

that

as

dog

as

the

a

result,

the

the

feeds

rear

the

feed

front

rear

through

feed

fabric

adjustment

feed

feed

dog,

dog.

is

gathered.

dog

twice

moves

i.e.

as

lever

the

much

twice

front

(34)

fa

to

This

prevents

stretched

as

Jersey

a

smooth

Fashionable

in

this

way,

using

very

when

and

seam

touches

such

delicate

the

sewing

rib

(C).

seam

stitch

as

can

the

fabrics

from

knitted

goods.

also

gather

(D).

becoming

fabrics

The

result

be

introduced

effect

such

is

when

ted

The

following

should

Type

always

of

fabric

table

test

I

effect

contains

your

setting

information

first

on

a

on

piece

the

Very_light_fabrics:_silk,_satin,_poplin,_taffeta,_linings.

Normal

thermal-wear.

Light

fine

Heavy

heavy

Stretch

sleeve

Gathering:

for

flaps,

sleeve

kniwear:

knitwear

knitwear:

knitwear.

and

curves,

stretching

widths

fabrics:

-

wavelike

collar

ruffling

arches

light

jerseys,

and

or

for

and

polo

gathered

sweatshirt

effect:

edges,

light

on

blouses,

gentle

cuffs

or

medium-heavy

fabrics,

materials.

fleece,

medium

skirt

hems,

materials

shirts,

ruffling

gathered

heavy

and

dense

and

of

arched

fabrics.

cut-pile

light

lace,

skirts,

cottons,

pullovers,

gathered

knitwear

stitch

seam

round

sleeves

differential

of

scrap

fine

materials,

ruffled

lengths.

allowances

pockets,

(shoulders),

fabric.

cords,

tricot,

teed

settings.

gather

<2.0>

•

However,

Differential-feed

normal

<1.0?-

you

setting

stretch

<0.5>

29

Page 34

Adjusting

and

Switch

For

cover

Turn

arrow

position.

(see

container

gage

the

stitch

For

cover

Remove

screwing

ver

from

of

the

plate

slightly.

the

two-thread

off

eIectrica

stitch:

the

handwheel

until

the

Remove

page

22).

and

the

upper

width

stitch:

the

standard

screw

the

accessory

needle

machine

needle(s)

Detach

open

blade.

latch

A

plate.

Then

to

chainstitch.

power

in

the

the

standard

the

the

looper

Set

to

R

needle

using

the

box.

This

raises

remove

the

direction

in

is

the

trimming

the

bed

(see

page

plate

large

Press

the

it

to

cover

presser

cover.

screwdri

on

the

stitch

of

highest

waste

Disen

slide

25).

by

un

area

needle

left.

the

foot

for

B

30

For

cover

Raise

the

sert

cover

“C”)

from

Re-tighten

needle

C

(see

foot

(marked

box

(see

D

page

stitch:

finger

stitch

the

the

and

page

protection

needle

accessory

screw.

two-thread

11).

Attach

with

“C”)

22).

slightly

plate

box.

Insert

cover-stitch

chainstitch

cover-stitch

from

(marked

the

accessory

and

with

needle

presser

in

I

Page 35

handwheel

the

needle(s)

two-thread

Insert

11).

page

trimming

the

looper

latch

chainstitch:

the

in

waste

cover

(the

is

at

set

direction

in

are

chainstitch

container

bed

Disengage

S).

the

slide

the

of

highest

need

for

and

the

the

two-thread

For

the

Turn

until

arrow

position.

le

C(see

Remove

the

open

width

ot

stitch

upper

blade.

cover

For

Disengage

Move

position

west

direction

the

cover

For

the

Turn

redge

out

mes

the

that

looper

ge

handwheel

Thread

pages

(see

needle(s)

upper

looper

upper

the

stitch

upper

overedge

by

of

stitch

retaining

(19)

the

of

disengaged

are

in

two-thread

16

(see

two-thread

and

overedge

turning

arrow.

the

two-thread

and

screw

anti-clockwise,

looper’s

blade

and

direction

the

and

17)

page

19).

looper

looper

handwheel

the

of

the

drive

the

by

of

chainstitch

then

and

chainstitch:

into

(16)

chainstitch:

upper

until

lever.

upper

turning

arrow.

the

the

(16).

Ensure

overed

the

looper

its

ove

it

lo

in

co

31

Page 36

pFAF

For

Remove

power

above

Screw

table

Note:

the

the

For

cover

The

units

left

are

inches.

the

needle,

mm.

3.5

interval

fabric.

the

lv,

cover

blade

table,

into

the

beforehand.

It

is

upper

power

stitch

power

of

measurement.

in

mm,

These

This

between

stitch

guard

from

the

slot

edge

absolute

overedge

table.

table

and

values

when

is

an

Adjust

two-thread

and

upward.

(9)

accessory

the

looper

of

the

tight

guide

Close

necessarytodisengage

and

is

marked

those

the

aid

the

the

looper

looper,

two-thread

with

The

figures

on

show

the distance

stitch

width

to

determine

needle

edge

guide

onto

when

the

and

chainstitch:

Push

from

box,

cover.

the

power

cover.

attaching

chainstitch:

various

on

the

right

are

is

set

at

the

the

edge

according

the

in

to

of

32

Page 37

stitch:

the

ro

ower

gage

thing

For

cover

stitch

and

two-thread

On

m

completing

set

the

machine

lows:

Open

the

wer

table

F

looper

upward.

cover

in

cover

the

stitch

basic

and

or

chainstitch,

position

remove

chainstitch:

as

fol

the

po

stitch:

the

are

e

to

t

at

ge

rding

For

cover

stitch

and

two-thread

Turn

the

arrow,

handwheel

until

the

push

looper

stitch:

bed

page

position

the

needle

retaining

looper

screw.

slide

25).

cover-stitch

the

in

overedge

Tighten

(9)

For

Set

S

into

and

the

cover

the

(see

of

highest

Remove

the

cover-stitch

standard

foot.

Close

needle.

the

cover.

needle

looper

is

blade

for

Bring

and

foot

in

the

screw

in

its

Engage

guard

the

the

raise

plate.

and

cover.

stitch

presser

standard

direction

A

highest

the

needles

the

Attach

Remove

chainstitch:

of

the

position.

upper

from

width

presser

foot

of

upper

blade

above

latch

into

foot.

and

the

presser

the

the

to

the

33

Page 38

I

Important

stitch

The

units

left

inches.

These

le,

when

To

start

Raise

under

the

fabric

onto

of

the

fabric

because

sew,

34

power

of

measurement.

are

in

values

sewing:

the

presser

the

the

power

seam.

taut

the

feeds

notes

table

mm

the

stitch

presser

for

the

When

towards

machine,

the

and

show

first

table

fabric

on

is

marked

those

width

foot

foot

starting

the

slowly.

sewing

The

on

the

distance

is

and

place

so

the

stitch.

according

rear

when

with

with

figures

the

set

needles

Place

to

and

you

to

sew,

sew

the

various

right

to

at

3.5

the

the

the

start

on

the

mm.

fabric

pierce

fabric

width

pull

slowly,

to

cover

the

are

need

the

in

Preparing

It

is

hemming

the

seam

press

Note:

ble

as

fabric

press

Finishing

1.

When

Hold

the

tightly

which

wards

Note:

to

be

useful

under

The

special

with

under

sewing

sewing

threads

and

sew

the

thread

the

rear.

In

most

adjusted.

the

fabric:

to

press

it.

Depending

must

be

1/4

inch

cover-stitch

accessory.

it

at

ease,

the

fabric

to

at

slowly

should

cases

Sew

under

stitched

(0.5

without

the

the

off

the

trial

a

the

on

as

down,

cm)

guide

set

You

can

beforehand.

edge

of

end

of

the

the

fabric

pulled

be

differential

seam

fabric

how wide

to

wider.

is

having

the

seam

first.

before

you

obtaina

hem

to

fabric:

during

lightly

feed

must

your

to

has

2.

bric,

Sew

ring

wards

and

(just

position)

Edge

Push

box,

can

de

the

left

If

into

A

you

i.e.

4

the

you

heft

K

guid

the

he

or

-

y

c

Page 39

I

st

a

sr

2.

If

you

bric,

i.e.

Sew

4

ring

the

wards

and

you

(just

before

position).

A<

-

you

are

by

5

stitches

last

have

not

tubular

stitch,

until

heard

the

to

sew

fabrics:

on

turn

the

needles

to

top

the

needles

each

are

the

edge

of

each

handwheel

pierce

needle

in

the

of

other.

the

“click”

lowest

the

Du

to

fabric

fa

After

the

second

“click”

turn

the

back,

sition.

ads.

knot

the

until

Pull

them.

fabric

Raise

the

the

the

needle

Hold

tightly

needles

presser

the

and

are

foot.

threads

threads

remove

in

to

the

Cut

the

at

the

the

handwheel

highest

the

thre

back

and

end

of

fabric.

po

Edge

guide

Push

the

edge

guide,

from

the

box,

into

the

guide

de

can

be

10

10-

as

the

left

set

or

right.

as

holder

required

A.

by

accessory

The

moving

edge

gui

it

to

The

edge

at

regular

two-thread

guide

is

intervals

chainstitch.

useful

with

the

for

serging

cover

seams

stitch

or

35

Page 40

Thread

The

values

normal

blue

-

1.5

tension

refer

polyester

preen

-1.5

to

medium-heavy

thread

pink

fabrics

yellow

and

violet

-1.5

Stitchlength

3-4

Stitchwidth

4.5

of

for

Position

bed

slide

stitch

latch

R

width

Converter

•

=

with

E

=

with-

out

-1.5

N

N

-1.5

-1.5

-1.5

-4

-2

-3

-2

-3

-2

-1.5

-3

-1

÷3

+3

÷3

3-4

3

3

3

3

3.5

3.5

3.5

3.5

S

5

S

S

5

C

I

C

C

C

N

-1.5

-1.5

3

3.5

S

C

37

Page 41

Program

summary

Programs

Cover-stitch

5-thread

4-thread

w\

2-thread

seam

safety-stitch

safety-stitch

chainstitch

seam

seam

seam

Application

Sewing

stitches

Joining

woven fabrics

Joining

woven

Joining

fabrics

and

hems

and

and

fabrics

pieces

for

denim,

and

serging

simultaneously

serging

simultanously

of

tightly

upholstery

without

ornamental

of

tightly

of

tightly

woven

covers

serging