Page 1

(

r

315$

CPFAFFD

)

C-

aFardz

‘132

Page 2

Dear

Housewife,

At

last

you

are

the

proud

owner

of

this

Sewing

Mochinel

The

machine

was

fully

explained

to

you

and

you

were

delighted

with

the

many

useful

and

wonder

ful

things

performed

on

this

true

wonder

of

en

gineering.

Although

everything

is

quite

cleartoyou

now,

it

is

possible

that

in

time

some

of

the

directions

given

to

you

for

making

the

various

adjustments

may

escape

your

memory

—

because,itis

unlikely

that

you

will

immediately

try

your

handatall

the

different

kinds

of

sewing

your

machine

can

do.

We

have

therefore

prepared

this

informative

in

struction

book

and

hope

you

will

find

it

a

useful

guide.

Before

putting

the

machine

to

work

we

vise

you

to

glance

briefly

at

the

pages

of

fhis

book,

so

that

you

will

hove

a

rough

idea

of

the

contents.

This

will

help

you

when

reverting

later

on

to

any

one

of

the

chapters.

It

is

a

good

plan

to

open

out

to

the

left

page

1,

for

the

information

given

on

that

page

should

be

read

in

conjunction

with

the

directions.

The

same

appliestopage

2.

Your

attention

is

drawn

particularlytosections

1,

2

and

4.

After

reading

the

information

contained

in

those

three

chapters

you

will

be

thoroughly

ac

quainted

with

the

working

of

your

sewing

machine;

it

will

becomealiving

thing

to

you,

placed

under

your

care

and

protection.

The

more

you

understand

your

machine,

the

greater

willbeyour

appreciation

of

its

scope

and

capacity.

Page 3

The

following

accessories

are

available

at

slight

additional

charge

1

box

for

housing

accessories,

No.

1466

a

1

edger

with

guide

Z—153a

5

1

feller

No.

823

1

hemmer

No.

Z—824,

4

mm

•

“

bobbins

No.

970

6

sewing

machine

needles,

System

No.

130

R

1

threader,

No.

188

•

11

1

screwdriver,

No.

140

c

(medium

size)

1

screwdriver,

No.

533

(small

size)

•

14

1

oil

can

(plastic),

with

oil,

No.

132

a

18

1

quilter

guide,

No.

101

1

quilter

guide

holder,

complete

with

screws,

No.

Z—1016

24

1

hemmer

2

mm

No

827

4

1

ruffler,

No.

116

1

guide

No

535

1

thumb

screw,

No.

410

1

hemmer

No.

Z—827

(2

mm)

Contents

I

Important

Hints

Choice

of

Needle

Sizes

and

Thread

Numbers

1.

To

Prepare

for

Sewing

2.

Sewing

3.

Cleaning

and

Oiling

4.

Cause

of

Faults

and

Simple

Home

Service

The

Electric

Motor

3

Page 4

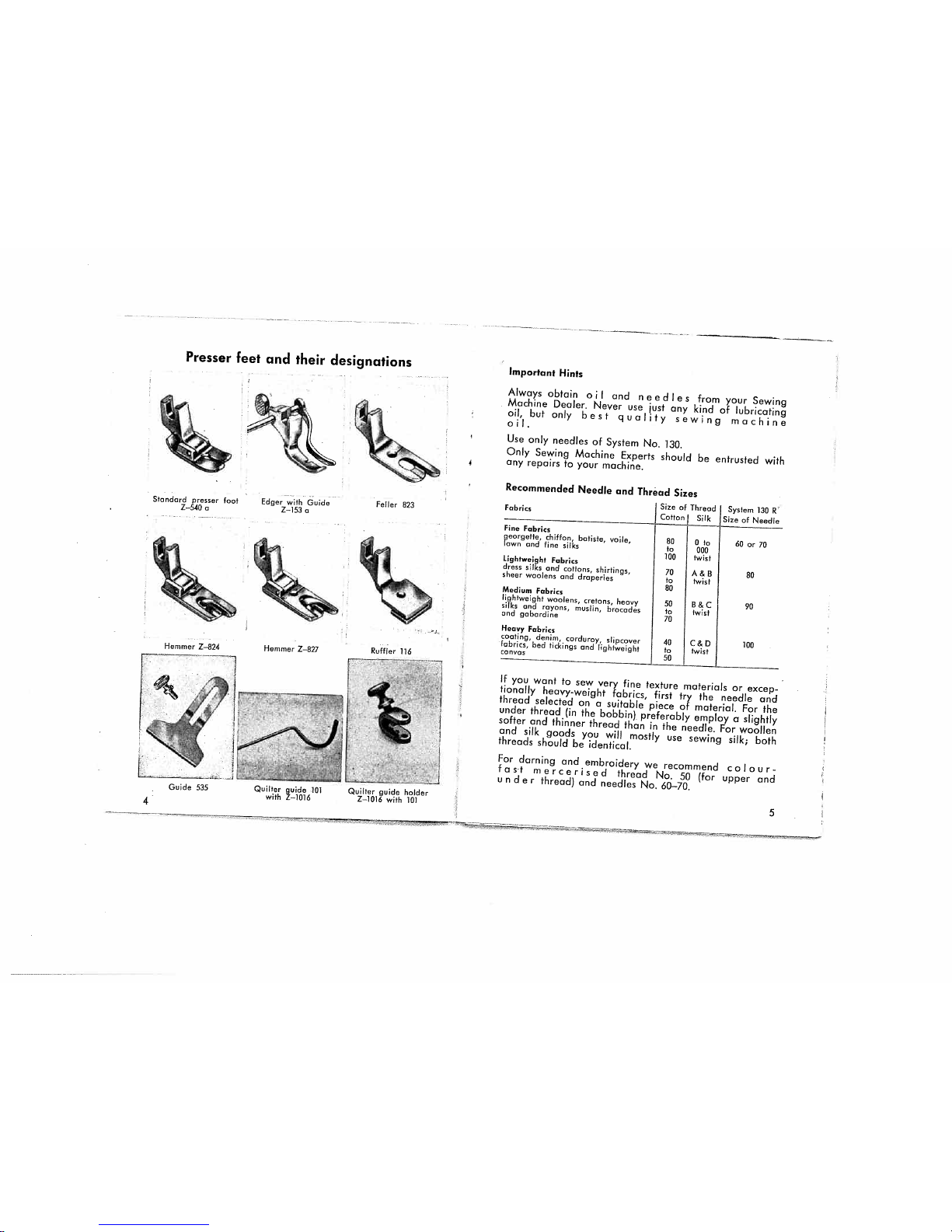

Presser

feet

and

their

designations

Important

Hints

Always

obtain

a

I

and

n

eed

I

e

s

from

your

Sewing

Machine

Dealer.

Never

use

just

any

kind

of

lubricating

oil,

but

only

best

quality

sewing

machine

oil.

Use

only

needles

of

System

No.

130.

Only

Sewing

Machine

Experts

should

be

entrusted

with

any

repairs

to

your

machine.

Recommended

Needle

and

Thread

Sizes

Size

of

Thread

System

130

R

Cotton

Silk

Size

of

Needle

Fine

Fabrics

georgette,

chiffon

botiste,

voile,

80

0

to

60

or

70

lawn

and

fine

silks

to

000

100

twist

LighIweyhi

Fabrks

dress

silks

and

cottons,

shirtings,

70

A

&

B

80

sheer

woolens

and

draperies

to

twist

80

Medium

Fabrics

lightweight

woolens,

cretons,

heavy

50

B

&

C

90

silks

and

rayons,

muslin,

brocades

to

twist

and

gabardine

70

Heavy

Fabrics

coating,

denim,

corduroy,

slipcover

40

C&D

100

fabrics,

bed

tickings

and

lightweight

to

twist

anvos

50

For

darning

and

embroidery

we

recommend

c

o

I

o

u

r

-

f

a

st

m

e

r

Ce

r

i

s

e

d

thread

No.

50

(for

upper

and

u

n

d

e

r

thread)

and

needles

No.

60—70.

Standard

presser

foot

Edger

with

Guide

Feller

823

Z—540

a

Z—153

a

Fabrics

Hemmer

Z—824

Hemmer

Z—827

RuttIer

116

Guide

535

If

you

want

to

sew

very

fine

texture

materials

or

excep

tionally

heavy-weight

fabrics,

first

try

the

needle

and

thread

selected

on

a

suitable

piece

of

material.

For

the

under

thread

(in

the

bobbin)

preferably

employ

a

slightly

softer

and

thinner

thread

than

in

the

needle.

For

woollen

and

silk

goods

you

will

mostly

use

sewing

silk;

both

threads

should

be

identical.

Quilter

guide

holder

Z—1016

with

101

4

Quilter

guide

101

with

Z—1016

5

Page 5

Under

Threading

To

prepare

for

sewing

I

‘

I

Before

despatch

from

the

works,

each

machine

is

subjected

to

a

severe

test

run.

Therefore,

should

you

experience

any

trouble

with

the

machine,

the

cause

may

well

be

due

to

wrong

manipulation.

Do

not

interfere

with

any

settings

without

first

carefully

checking

the

upper

and

under

thread

ing,

the

tensions,

the

needle

and

the

position

of

the

feed

dog,

the

control

of

which

should

be

set

at

“Sewing”.

Inserting

the

Needle

Raise

the

needle

bar

to

its

highest

point.

With

thumb

and

forefinger

of

your

left

hand

insert

the

needle

into

the

clomp.

Push

the

needle

up

as

far

as

it

will

go.

T

h

e

fIa

side

of

the

needle

shank

must

be

to

the

right.

Then

tighten

the

thumb

screw.

Attaching

the

Presser

Foot

Slide

the

foot

on

to

the

presser

bar,

right

up

against

the

screw

and

firmly

tighten

the

latter

with

a

screwdriver.

All

other

types

of

presser

feet

supplied

for

use

with

the

machine

ore

attached

and

secured

in

the

same

manner

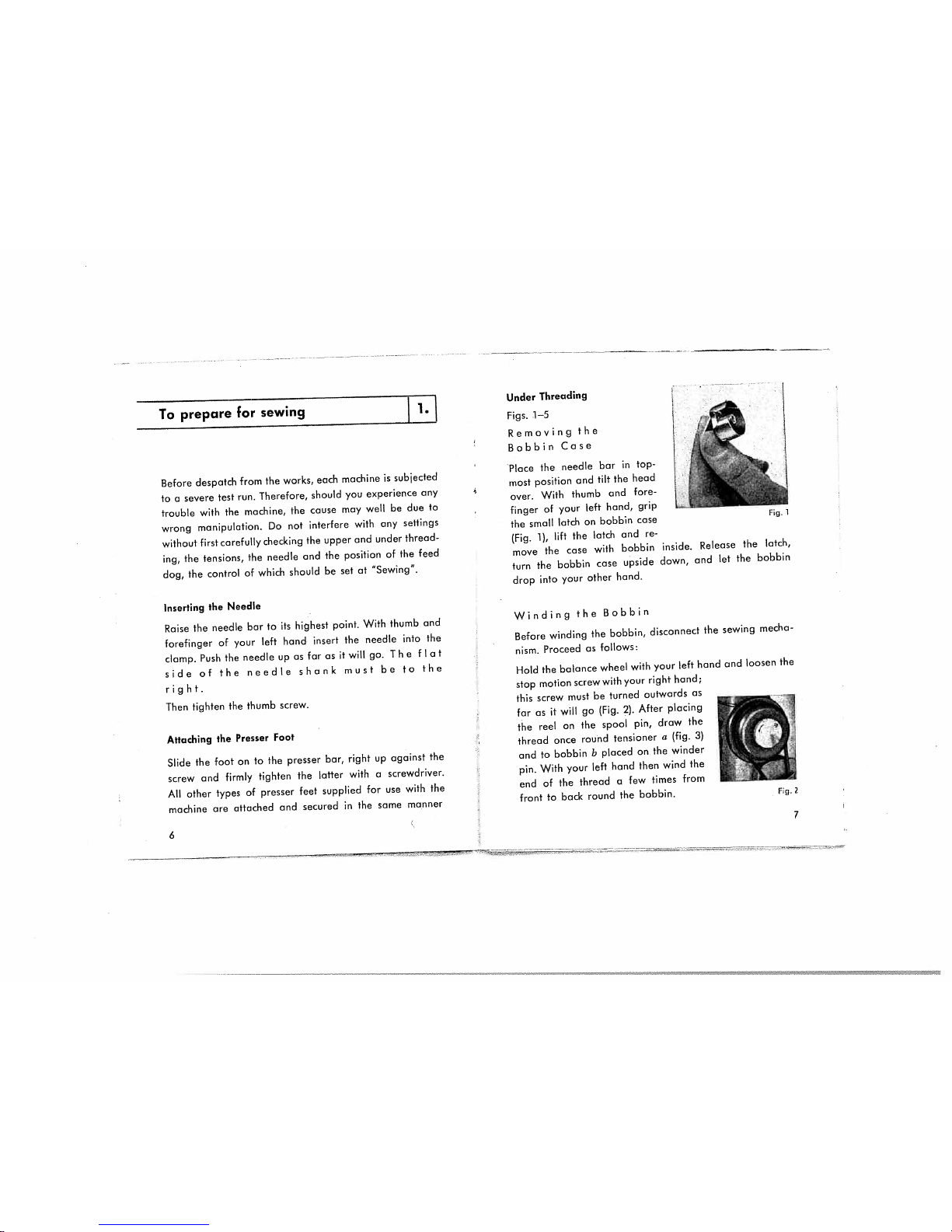

Place

the

needle

bar

in

top

most

position

and

tilt

the

head

over.

With

thumb

and

fore

finger

of

your

left

hand,

grip

the

small

latch

on

bobbin

case

(Fig.

1),

lift

the

latch

and

re

move

the

case

with

bobbin

inside.

Release

the

latch,

turn

the

bobbin

case

upside

down,

and

let

the

bobbin

drop

into

your

other

hand.

Winding

the

Bobbin

Before

winding

the

bobbin,

disconnect

the

sewing

mecha

nism.

Proceed

as

follows:

Hold

the

balance

wheel

with

your

left

hand

and

loosen

the

stop

motion

screwwith

your

right

hand;

this

screw

must

be

turned

outwards

as

far

as

it

will

go

(Fig.

2).

After

placing

the

reel

on

the

spool

pin,

draw

the

thread

once

round

tensioner

a

(fig.

3)

and

to

bobbin

b

placed

on

the

winder

pin.

With

your

left

hand

then

wind

the

end

of

the

thread

a

few

times

from

front

to

back

round

the

bobbin,

Fig.

2

Figs.

1—5

Removing

the

Bobbin

Case

Fig.

1

6

7

Page 6

Upper

Threading

Fig.

6

Place

the

spool

of

thread

on

the

spool

pin

and

bring

the

thread

below

the

guide

and

to

the

left,

then

from

left

to

right

into

the

upper

slot

in

guide

b

and

from

right

to

left

through

the

lower

slot.

From

there

pass

the

thread

down

and

from

right

to

left

through

the

slot

in

thread

tensioner

and

take-up

spring

c,

then

up

again

and

from

right

to

left

through

the

take-up

leverd,then

down

and

through

the

guideinnee

dle

bar

a

and

finally

from

lefttoright

through

the

eyeofthe

needle.

Replacing

the

Bobbin

Case

With

thumb

and

forefinger

of

your

left

hand

hold

the

bobbin

case

(complete

with

bobbin)

by

its

latch

(Fig.

1)

and

slide

the

caseonto

the

small

stud

in

the

center

of

the

hook

(Fig.

5).

Now

press

that

the

latch

clicks

into

pa-

Fig

5

the

bobbin

case

down

so

sition.

Fig.3

Now

press

on

the

winder

by

means

of

latch

and

turn

the

free

balance

wheel

over

towards

you

to

set

it

in

motion

as

you

start

treadling.

The

winder

action

stops

automatically

when

the

bobbin

is

fully

loaded.

Finally,

the

stop

motion

screw

is

firmly

retightened

by

screwing

it

inwards

against

the

balance

wheel.

Threading

the

Bobbin

Case

Fig.

4

Hold

the

case

with

its

open

side

up

and

insert

the

bobbin

as

indicated

by

the

arrow,

i.

e.

so

that

the

thread

un

winds

from

left

to

right

(Fig.

4).

Pass

the

thread

through

slot

a,

along

and

underneath

the

spring

b

and

out

through

opening

c

in

the

side

of

the

bobbin

case.

Fig.

6

8

9

Page 7

Picking

up

the

Lower

Thread

—

Fig.

7

General

Turn

the

balance

wheel

to

move

the

thread

take-up

lever

to

its

highest

point.

Place

the

material

under

the

presser

foot,

lower

the

presser

bar

and

commence

to

sew.

When

4

making

the

first

few

stitches,

hold

the

ends

of

bath

threads

in

your

hand,

so

that

they

do

not

get

sewn

down

or

get

drawn

into

the

race.

Never

force

the

material

along

by

either

pushing

or

pulling

it,

but

merely

guide

the

work;

otherwise

the

needle

may

break.

It

is

best

to

always

make

a

short

practice

run

on

a

remnant

before

commencing

on

your

work.

When

sewing

hard

or

thick

pieces

of

material,

or

when

stitching

across

seams,

assist

the

needle

by

carefully

turning

the

balance

wheel

with

your

hand.

This

practice

will

guard

against

the

needle

bending

or

breaking.

Before

sewing

the

corner

of

a

seam,

with

a

hand

sewing

needle

draw

a

thread

through

the

fabric

and

sew

along

one

edge.

At

the

corner

leave

the

needle

in

the

fabric

to

act

as

a

pivot,

turn

the

material

and

continue

to

sew

while

holding

both

ends

of

the

tacking

thread.

This

way

you

will

prevent

stoppages

at

corners

which,

otherwise,

easily

occur.

Setting

the

Length

of

Stitch

—

Fig.

8

The

machine

has

in

front,

on

the

r

i

g

h

I,

a

stitch

regulating

lever

a

with

thumb

screw

b,

with

which

the

required

stitch

length

may

be

selected

on

the

scale

c.

Before

you

can

make

any

adjustment

the

thumb

screw

must

be

turned

to

the

left.

The

more

you

loosen

this

screw,

the

greater

the

up

and

down

movement

of

the

regulating

lever

will

be,

and

the

stitches

will

increase

or

decrease

accordingly.

For

re

verse

sewing

you

must

move

the

lever

to

the

top.

[

2.

Sewing

With

your

left

hand

hold

the

end

of

the

upper

thread

above

the

bed-

plate,

leaving

the

thread

slack.

Turn

the

balance

wheel

towards

you

to

allow

the

needle

to

travel

down

and

up

again

to

its

high

est

point;

the

lower

thread

will

be

brought

up

in

a

loop

through

the

needle

plate.

Place

the

ends

of

both

threads

under

the

presser

foot

to

the

back.

Do

not

move

the

threaded

needle

unlessa

piece

of

ma

terial

has

been

placed

beneath

it.

Fig.

7

4i

Fig.

8

—a

—b

10

11

Page 8

Regulating

the

Thread

Tensions

—

Figs.

9—li

The

Upper

Thread

Tension

is

regulated

by

turning

the

setting

flange

of

upper

thread

tensioner

a

(Fig.

6).

—

Clockwise

turning

increases

the

tension;

anti-

clockwise

turning

loosens

the

tension.

The

U

n

d

erT

h

r

e

a

d

T

e

nsI

o

n

is

regulated

by

turn

ing

the

small

screw

a

(Fig.

4)

with

a

screwdriver.

Here

too

the

tension

is

increased

by

clockwise

adjustment

and

decreased

by

anti-clockwise

adjustment.

It

is

generally

only

necessary

to

adjust

the

upper

thread

tension.

Satisfactory

stitching

is

possible

only

if

upper

and

under

thread

tensions

are

correctly

set.

After

you

have

sewn

an

inch

or

two,

inspect

the

stitching

on

top

and

underneath.

The

tensions

are

satisfactory

if

both

threads

are

drawn

into

the

material

e

q

u

a

II

y

and

lock

in

the

center

of

the

work

(see

Fig.

9).

If,

however,

loops

have

formed

on

the

underside,

the

upper

thread

is

too

slack

and

must

be

given

more

tension

by

turning

the

setting

flange

a

(Fig.

6)

to

the

right

(Fig.

10).

If

loops

continue

to

be

formed

on

the

u

n

d

ers

i

d

e

of

the

work,

it

is

possible

that

the

under

thread

has

been

tensioned

too

severely

and

this

must

be

corrected

by

turning

the

small

screw

a

(Fig.

4)

a

little

to

the

left.

If,

on

the

other

hand,

the

thread

is

lying

fIat

o

n

to

p

of

h

e

m

a

t

eri

a

I

(Fig.

ii),

or

if

loops

hove

formed,

the

upper

thread

may

be

too

tight

and

you

must

loosen

the

Regulating

the

Presser

Foot

The

presser

foot

must

exert

on

the

material

sufficient

pressure

to

ensure

satisfactory

feeding

of

the

material.

The

presser

barisset

for

oIl

regular

sewing

work

on

light

and

medium

weight

goods.

Heavy

or

hard

texture

materials

require

more

pressure.

To

increase

the

pressure,

turn

the

setting

screw

to

the

right;todecrease

the

pressure,

turn

the

screw

to

the

left,

I.

e.

upwards.

Removing

the

Work

from

the

Machine

Raise

the

take-up

lever

to

its

highest

and

lift

the

presser

foot.

Draw

the

work

to

the

back

of

the

machine,

away

from

the

needle.

The

ends

of

the

thread

should

be

cut

approx.

3’

from

the

needle

and

be

placed

under

the

foot

to

the

back,

thus

leaving

the

machine

ready

for

the

next

run.

b

-J

tension

by

turn

ing

the

flange

a

—

Fig.

6

—

to

the

left.

If

this

adjustment

does

not

improve

the

stitch

forming,

the

under

thread

must

then

re

ceive

more

ten

sionbyturning

__

the

screw

a

—

Fig.

4

—

to

the

right.

F;g.

9

Fg.

10

Fig.

11

12

13

Page 9

[

After

cleaning

apply

a

few

drops

of

high-grade

sewing

I

machine

oil

to

all

working

parts.

Do

not,

however,

apply

too

much

oil;

a

few

drops

at

the

right

places

will

prove

ode

(

quote.

After

oiling

run

the

machine

rapidly

for

a

short

while

and

then,

before

you

start

to

sew,

wipe

all

parts

]

clear

of

any

surplus

oil.

If

the

machine

has

not

been

used

for

some

time,

or

if

it

has

been

used

continuously,

a

few

drops

of

paraffin

should

be

applied

to

all

lubrication

points

and

the

mach

ine

worked

rapidly

for

a

minute

or

two.

Then

clean

the

mochine

with

a

soft

rag

and

oil

the

mechanism.

Fig.

12

Machine

Head

The

following

points,

which

ore

marked

thus

0

in

the

illu

with

open

stration

must

be

cleaned

and

oiled

in

proper

sequence:

Face

Cover

Plate

Regular

oiling

is

essential

for

the

smooth

running

of

the

machine.

Lint

and

thread

ends

settle

in

the

working

me

chanism

ond

eventually

impede

the

free

running

of

the

machine.

It

is

necessary,

therefore,

to

give

all

parts

specified

here

after

a

regular,

thorough

cleaning.

Never

use

a

screw

driver

or

other

metal

instrument

for

cleaning,

not

even

a

needle,

but

only

a

small

pointed

stick,

so

that

no

damage

is

done

to

the

sewing

mechanism.

Cleaning

and

oiling

Fig.

13

Machine

Head

with

removed

Arm

Cover

Plate

14

15

Page 10

1.

The

Head

(Fig.

12).

Open

the

hinged

face

cover

plate.

2.

The

Arm

(Fig.

13).

Lubricate

all

points

marked

thus

0.

3.

The

Needle

Plate.

Take

out

the

screws

and

remove

the

plate.

4.

The

Hook

(Fig.

14).

Move

the

needle

bar

to

its

high

est

and

tilt

the

head

over

on

its

hinges.

With

a

small

brush

dust

the

hook.

Apply

a

few

drops

of

paraffin

to

the

race

between

the

hook

II

and

the

bobbin

carrier

IV;

then

work

the

mach

ine

rapidly

for

a

short

while.

Now

apply

a

few

drops

of

oil.

Should

this

prove

inef

fective

in

dislodging

any

dirt

from

the

hook,

or

should

thread

ends

impede

the

free

move

ment,

then

the

hook

must

be

carefully

dis

mantled.

This

is

done

by

removing

the

race

guide

Ill,

after

the

small

screws

1,

2

and

3

have

been

taken

out.

Now

the

bobbin

carrier

IV

can

be

removed.

All

dismantled

parts

should

be

carefully

wiped

with

a

clean

rag.

Before

reassembling

the

parts

move

the

thread

take-up

lever

to

•

•

.

.

Fig.

16

its

highest

point

so

that

the

point

I

of

the

hook

is

on

the

left,

and

on

top,

as

shown

in

Fig.

14.

Then

re

place

the

bobbin

carrier

IV

into

the

hook

II,

and

let

the

retaining

key

engage

into

the

groove

n

—

see

Fig.

14.

Finally,

replace

the

guide

Ill

and

fix

it

down

with

screws

1,

2

and

3.

You

must

also

lubricate

all

Fig.

17

other

points

indicated

in

the

illustrations,

making

sure

that

after

oiling

oIl

ports

ore properly

replaced.

Ii’

Fig.

14

Fig.

15

Fig.

18

View

of

Underside

of

Machine

Bedplote

16

17

Page 11

2.

Certain

working

ports

of

the

machine

are

dry

—

apply

Cause

of

faults

and

simple

home

service

4.

___________________________________________________

a

few

drops

of

oil.

3.

A

component

part

has

worked

itself

loose

—

retighten

it

with

a

screwdriver

Please

always

remember:

many

machine

troubles

may

be

caused

by

your

not

carefully

following

these

working

instructions.

In

many

cases,

faulty

working

of

your

mach-

The

upper

thread

breaks

me

canberemedied

merely

by

cleaning

and

oiling.

1.

Inferior

quality,

knotty

sewing

thread

breaks

easily

—

use

a

better

quality.

Machine

works

heavily

2.

The

needle

selected

is

too

fine

for

the

thread

or

ma

terial

used

—

use

a

thicker

needle

(see

page

5:

“Relat

1.

Thread

ends

have

become

entangled

in

the

hook

race

—

ive

Needle

and

Thread

Sizes”).

remove

all

obstructions.

2.

Certain

working

parts

of

the

machine

are

dry

—

apply

The

upper

thread

tension

is

too

severe

—

loosen

the

a

few

drops

of

oil,

setting

flange

on

tensioner

(see

page

12:

“Regulating

the

ThrecidTensions”)

3.

The

machine

is

dirty

—

thoroughly

clean

it.

4.

The

needle

is

wrong

inserted,

or

it

is

bent

—

change

4.

The

wrong

kind

of

oil

has

been

used

—

clean

the

mach

ine

with

paraffin.

the

needle

(see

page

6:

Inserting

the

Needle)

5.

The

eye

of

the

needle

has

a

knife

edge

—

change

the

needle.

The

machine

is

noisy

1.

Thread

ends

have

become

entangled

in

the

hook

race

—

6.

Thread

ends

or

dirt

are

interfering

with

the

free

move

remove

all

obstructions.

ment

of

the

feed

dog,

resulting

in

bad

feeding

of

the

18

19

i.

.

Page 12

material

—

remove the

needle

plate

and

thoroughly

thread

used

—

change

the

needle

or

the

thread

to

give

clean

the

feed

dog.

the

correct

relation

between

the

two;

(see

page

5:

“Re-

7.

The

bobbin

case

has

developed

a

rough

edge,

causing

lative

Needle

and

Thread

Sizes”).

the

thread

to

break

—

remove

the

case

and

consult

a

4.

The

thread

curls,

because

it

is

unsuitable

for

machine

sewing machine

specialist.

sewing

—

use

a

different

thread.

5.

The

needle

used

is

not

of

the

correct

system

—

obtain

The

under

thread

breaks

correct

needles

from

the

suppliers

of

your

machine.

1.

Inferior

quality,

knotty

sewing

thread

breaks

easily

—

use a

better

quality.

The

needle

breaks

2.

The

bobbin

thread

tension

is

too

severe

—

loosen

the

1.

The

needle

is

wrongly

inserted

—

reset

the

needle.

tension

screw

(see

page

12:

“Regulating

the

Thread

The

needle

isbentorblunt

change

the

needle

(see

p.6:

Tensions”).

“Inserting

the

Needle”).

3.

The

bobbin

thread

tension

is

too

weak

—

tighten

the

2.

The

needle

used

is

too

fine

for

the

thread

or

material

—

screw

with

a

screwdriver

(see

page

12:

“Regulating

the

use

a

thicker

needle;

(see

page

5:

“Relative

Needle

and

Thread

Sizes”).

Thread

Tensions”).

3.

The

upper

thread

tension

is

too

severe

—

loosen

the

setting

flange

on

tensioner;

(see

page

12:

“Regulating

Stitches

are

missed

the

Thread

Tensions”).

1.

The

needle

has not

been

set

high

enough

—

change

the

needle,

(see

page

6:

“Inserting the

Needle”>.

Faulty

feeding

2.

The

needle

is

bent

or

blunt—change

the

needle.

1.

Thread

ends

or

dirt

are

interfering

with

the

free

move

3.

The

needle

selected

is

too

fine

or

too

thick

for

the

ment

of

the

feed

dog,

resulting

in

bad

feeding

of

the

20

21

Page 13

material

—

remove

the

needle

plate

and

thoroughly

clean

the

feed

dog.

The

material

puckers

1.

Both

tensions

are

too

severe

—

loosen

the

setting

flange

on

upper

thread

tensioner

and

the

screw

on

bobbin

case;

(see

page

12:

“Regulating

the

Thread

Tensions”).

2.

The

presser

foot

exerts

too

much

pressur

on

the

work

—

reduce

the

pressure

by

adjusting

the

regulating

screw

13

—

see

page

1.

Uneven

stitching

1.

The

thread

is

uneven

or

too

thick

—

change

the

thread.

2.

The

tension

is

wrong

—

regulate

the

tension

(see

p.

12:

“Regulating

the

Thread

Tensions”).

3.

Upper

and

under

thread

are

drawing

off

unequally

from

reel

or

bobbin

respectively,

owing

to

a

dirty

set

ting

flange

or

bobbin

—

remove

all

obstructions.

4.

The

needle

is

blunt

or

bent

—

use

a

new

needle.

5.

The

bobbin

is

wrongly

positioned

—

remove

the

bobbin

case

and

make

sure

the

bobbin

is

properly

inserted

in

the

case;

(see

page

9:

“Replacing

the

Bobbin

Case”).

22

In

all

cases

where

faulty

working

of

your

sewing

machine

cannot

be

rectified

by

your

following

the

above

directions,

please

consult

your

Sewing

Machine

Dealer.

He

will

al

ways

be

glad

to

advise

you.

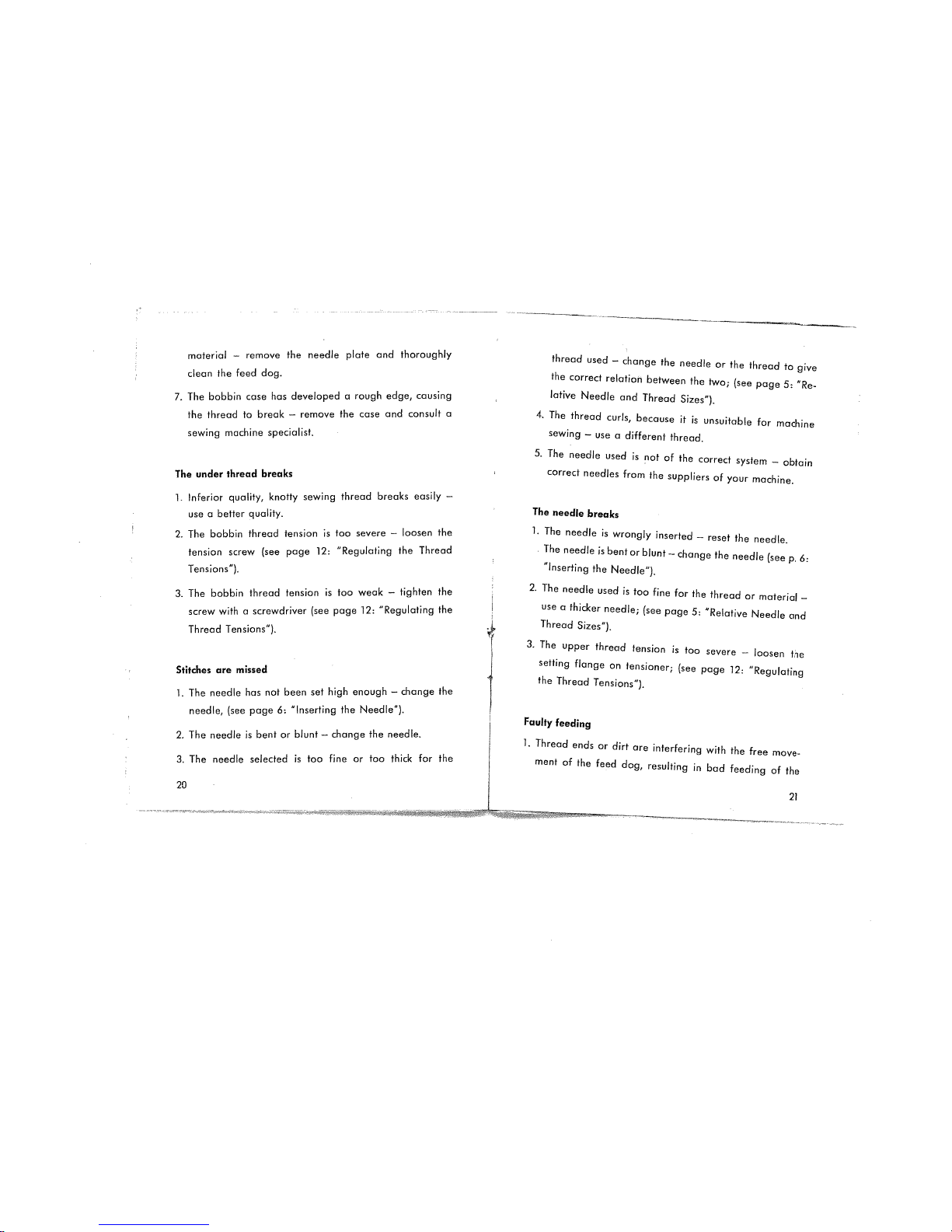

Fig.

W

Rear

View

of

machine

showing

support

opened

23

Page 14

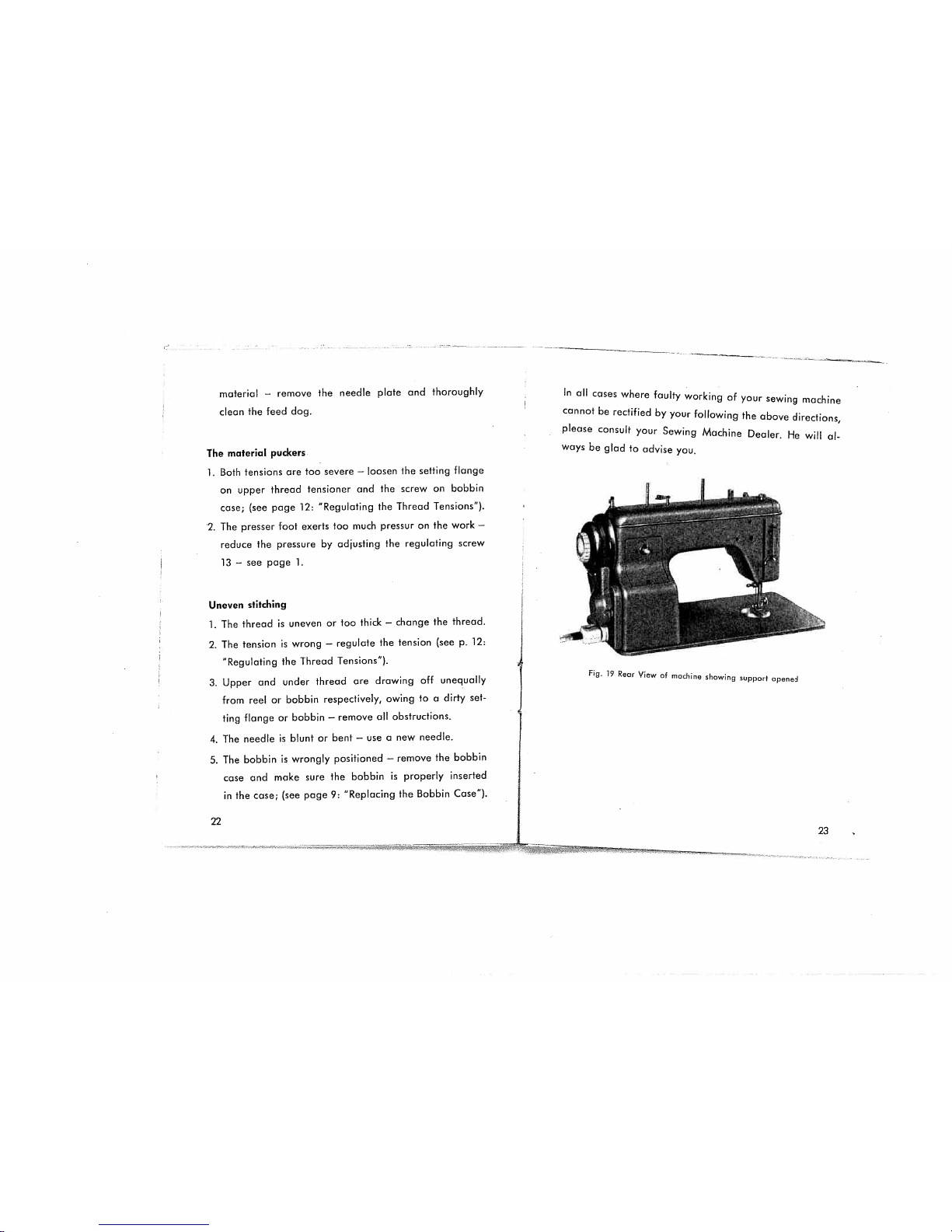

The

E’ectric

Motor

1.

Line

Voltage

The

motor

works

on

115

volts.

2.

Tensioning

the

Drive

Belt

a)

Loosen

both

screws

holding

the

guard

to

motor

and

remove

the

guard.

Fig.

20

shows

Motor

Housing

with

Guard

removed.

b)

Loosen

the two

screws

b

which

are

now

visible

—

see

Fig.

20.

c)

By

moving

the

motor

up

or

down,

the

correct

belt

tension

may

be

obtained.

Retighten

both

screws.

3.

Changing

the

Carbon

Brushes

a)

Remove

the

Vbelt.

b)

Take

out

the

4

screws

c

in

motor

end

shield

plate

—

see

Fig.

20.

The

motor,

complete

with

plate,

can

now

be

drawn

from

the

motor

housing,

to

give

free

access

to

the

carbon

brushes

—

see

Fig.

20.

24

c

Fig.

20

End

shield

plate

with

screws

for

regulating

the

belt

tension

and

with

fixing

screws

for

access

to

carbon

brushes

25

Page 15

-e

-

9?

paq

Id,

II)

paq

black

0

0

DC

Jo

012

6)

CC

WnJUOfQ

6

U!4!M

a

a

0

a

Loading...

Loading...