Page 1

8320

8321

INSTRUCTION MANUAL

This instruction manual applies to machines

from software version 0332/010 and serial

number 2 708 363 onwards

296-12-18 585/002

Betriebsanleitung engl. 05.17

Page 2

This Instruction Manual is valid for all models and subclasses listed in the

chapter "Specifi cations".

The parts list for the machines can be downloaded free of

charge from the internet address

www.pfaff-industrial.com/pfaff/de/service/downloads.

As an alternative to the internet download the adjustment manual can also be

ordered in book form under part no.296-12-18 585.

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen GmbH

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Contents

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 6

1.01 Directives ............................................................................................................................... 6

1.02 General notes on safety ......................................................................................................... 6

1.03 Safety symbols ......................................................................................................................7

1.04 Important notes for the user .................................................................................................. 7

1.05 Operating and technical staff .................................................................................................8

1.05.01 Operating staff ....................................................................................................................... 8

1.05.02 Technical staff ........................................................................................................................ 8

1.06 Danger ...................................................................................................................................9

2 Proper use ..........................................................................................................................10

3 Specifi cations ..................................................................................................................... 11

3.01 Machine variants .................................................................................................................. 12

4 Disposal of Machine .......................................................................................................... 14

5 Transportation, packing and storage ............................................................................... 15

5.01 Transportation to customer‘s premises ............................................................................... 15

5.02 Transportation inside the customer‘s premises ................................................................... 15

5.03 Disposal of packing materials ..............................................................................................15

5.04 Storage ................................................................................................................................ 15

6 Explanation of symbols ..................................................................................................... 16

7 Controls ..............................................................................................................................17

7.01 Summary of controls ........................................................................................................... 17

7.02 Main switch ......................................................................................................................... 18

7.03 Pedal .................................................................................................................................... 18

7.04 Foot switch (optional) ........................................................................................................... 19

7.05 Triple foot switch (optional) .................................................................................................. 19

7.06 Adjustment wheel for the roller clearance ........................................................................... 20

7.07 Control panel ........................................................................................................................ 21

8 Installation and commissioning ....................................................................................... 22

8.01 Installation ............................................................................................................................ 22

8.02 Commissioning .................................................................................................................... 23

8.03 Switching the machine on/off ..............................................................................................24

8.04 Selecting the language and units ......................................................................................... 25

9 Preparation ......................................................................................................................... 26

9.01 Adjusting the feed roller clearance ...................................................................................... 26

9.02 Selecting the production type: .............................................................................................27

9.03 Entering the sealing parameters (Manual Heat Sealing) ...................................................... 29

9.03.01 Entering the sealing temperature ........................................................................................31

9.03.02 Entering the sealing speed .................................................................................................. 32

9.03.03 Stipulating the hot wedge type (only on the PFAFF 8320-010) ............................................ 34

9.03.04 Adjusting the contact pressure of the hot wedge (only on the PFAFF 8320-010) ................ 34

9.03.05 Stipulating the nozzle type and hot air volume (only on the PFAFF 8320-020) ....................35

9.03.06 Entering the roller pressure ................................................................................................. 36

Page 4

Contents

Contents ..................................................................................Page

9.04 Adjusting the control panel .................................................................................................. 37

10 Heat sealing ........................................................................................................................ 38

10.01 Heat sealing principle ........................................................................................................... 38

10.02 Manual heat sealing ............................................................................................................. 39

10.03 Creating/editing a heat sealing program .............................................................................. 41

10.03.01 Notepad ............................................................................................................................... 42

10.03.02 Basic functions for the program input .................................................................................. 43

10.03.03 Sealing parameters .............................................................................................................. 44

10.03.04 Functions for switching to other zones ................................................................................ 45

10.03.05 Entering further sealing parameters .................................................................................... 46

10.03.06 Concluding programming ..................................................................................................... 47

10.03.07 Example of how to enter a sealing program ........................................................................ 48

10.04 Programmed heat sealing with individual programs ............................................................ 52

10.05 Creating/processing sequences ........................................................................................... 53

10.06 Programmed heat sealing with sequences .......................................................................... 54

10.07 Error messages .................................................................................................................... 56

11 Input .................................................................................................................................... 57

11 .01 Summary of the functions in the input mode ...................................................................... 57

11 .02 Program management .........................................................................................................59

11 .03 Further settings ....................................................................................................................61

11 .03.01 Feed roller parameters ......................................................................................................... 63

11 .03.02 Rights of access .................................................................................................................. 64

11 .04 Installation and commissioning ............................................................................................ 66

11 .04.01 8320-010 (Hot wedge sealing machine) ............................................................................... 66

11 .04.02 8320-020 (Hot air sealing machine) ......................................................................................68

11.05 Advanced programming ....................................................................................................... 70

11 .05.01 Manual datasets (recipes) .................................................................................................... 70

11 .05.02 Stop with light barrier........................................................................................................... 73

11 .05.03 Start with light barrier .......................................................................................................... 73

11 .05.04 Connecting the external puller 95-256 400-90 with DC motor .............................................74

12 Care and Maintenance ....................................................................................................... 76

12.01 Servicing and maintenance intervals ................................................................................... 76

12.02 Cleaning ............................................................................................................................... 76

12.03 Checking/adjusting the air pressure .....................................................................................77

12.04 Cleaning the air fi lter of the air-fi lter/lubricator ..................................................................... 77

12.05 Grinding the hot wedge (only on the PFAFF 8390-010) ........................................................ 78

13 Adjustment ......................................................................................................................... 79

13.01 Notes on adjustment ........................................................................................................... 79

13.02 Tools, gauges and other accessories ...................................................................................79

13.03 Changing the feed rollers .....................................................................................................80

13.04 Adjusting the feed rollers .....................................................................................................81

13.05 Swinging the post into position ........................................................................................... 82

13.06 Changing the hot wedge (only on the PFAFF 8320-010)) ..................................................... 83

Page 5

Contents

Contents ..................................................................................Page

13.07 Adjusting the hot wedge on the PFAFF 8320-010 ................................................................84

13.07.01 Positioning the hot wedge crosswise to the feed direction ................................................. 84

13.07.02 Adjusting the height and counter-balancing the weight of the hot wedge .......................... 85

13.07.03 Hot wedge to feed roller clearance and contact pressure ................................................... 86

13.08 Adjusting the hot air nozzle on the PFAFF 8320-020 ........................................................... 87

13.08.01 Lateral adjustment and setting the angle of the hot air nozzle ............................................ 87

13.08.02 Adjusting the height and feed roller clearance of the hot air nozzle ................................... 88

13.09 Changing the heating cartridge (only on the PFAFF 8320-020) ............................................ 89

13.10 Changing the temperature sensor (only on the PFAFF 8320-020)) ......................................90

13.11 Protective switch and boot key ............................................................................................ 91

13.12 Service menu ....................................................................................................................... 92

13.12.01 Machine confi guration ......................................................................................................... 93

13.12.02 Loading/updating the operating program with SD-Card ...................................................... 95

13.13 Description of the error numbers......................................................................................... 97

13.13.01 General errors ...................................................................................................................... 97

13.13.02 Temperature control error .................................................................................................... 98

13.13.03 DC-motors error (Feed rollers) ............................................................................................. 99

13.14 List of outputs and inputs .................................................................................................. 100

13.14.01 Digital Outputs ................................................................................................................... 100

13.14.02 Digital Inputs ...................................................................................................................... 100

13.14.03 Analog Outputs ...................................................................................................................101

13.14.04 Analog Inputs ......................................................................................................................101

13.15 Parameter settings ............................................................................................................. 102

13.15.01 Selection and changing parameters ................................................................................... 102

13.15.02 List of parameters .............................................................................................................. 103

14 Circuit diagrams .............................................................................................................. 104

15 Pneumatic-circuit diagrams ............................................................................................ 109

Page 6

Safety

1 Safety

1

1.02 General notes on safety

.01 Directives

This machine is constructed in accordance with the European regulations indicated in the

conformity and manufacturer’s declarations.

In addition to this instruction manual, please also observe all generally accepted, statutory

and other legal requirements, including those of the user’s country, and the applicable pollu-

tion control regulations! The valid regulations of the regional social insurance society for oc-

cupational accidents or other supervisory authorities are to be strictly adhered to!

● The machine may only be operated by adequately trained operators and only after these

have read the appropriate Instruction Manual!

● The danger and safety instructions attached to the machine must be followed!

● The machine may only be used for the purpose intended and may not be operated wit-

hout its safety devices. All relevant safety regulations must be adhered to.

● When changing the feed rollers or the hot air nozzle, when leaving the machine unatten-

ded or during maintenance work, the machine must be disconnected from the power

supply by operating the main switch or by pulling out the plug!

● The daily maintenance work may only be carried out by appropriately trained personnel!

● During repair and maintenance work on pneumatic devices the machine must be discon-

nected from the pneumatic supply system! The only exceptions permitted are during ad-

justment work and function tests carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualifi ed service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

Exceptions to this rule are found in the regulations EN 50110.

● Modifi cations and alterations to the machine may only be carried out under observance

of all the relevant safety operations!

● Only spare parts which have been approved by us are to be used for repairs! We draw

special attention to the fact that spare parts and accessories not supplied by us have not

been subjected to testing nor approval by us. Fitting and/or use of any such parts may

cause negative changes to the design characteristics of the machine. We shall not accept

any liability for damage caused by the use of non-original parts.

6

Page 7

Safety

o

o

o

o

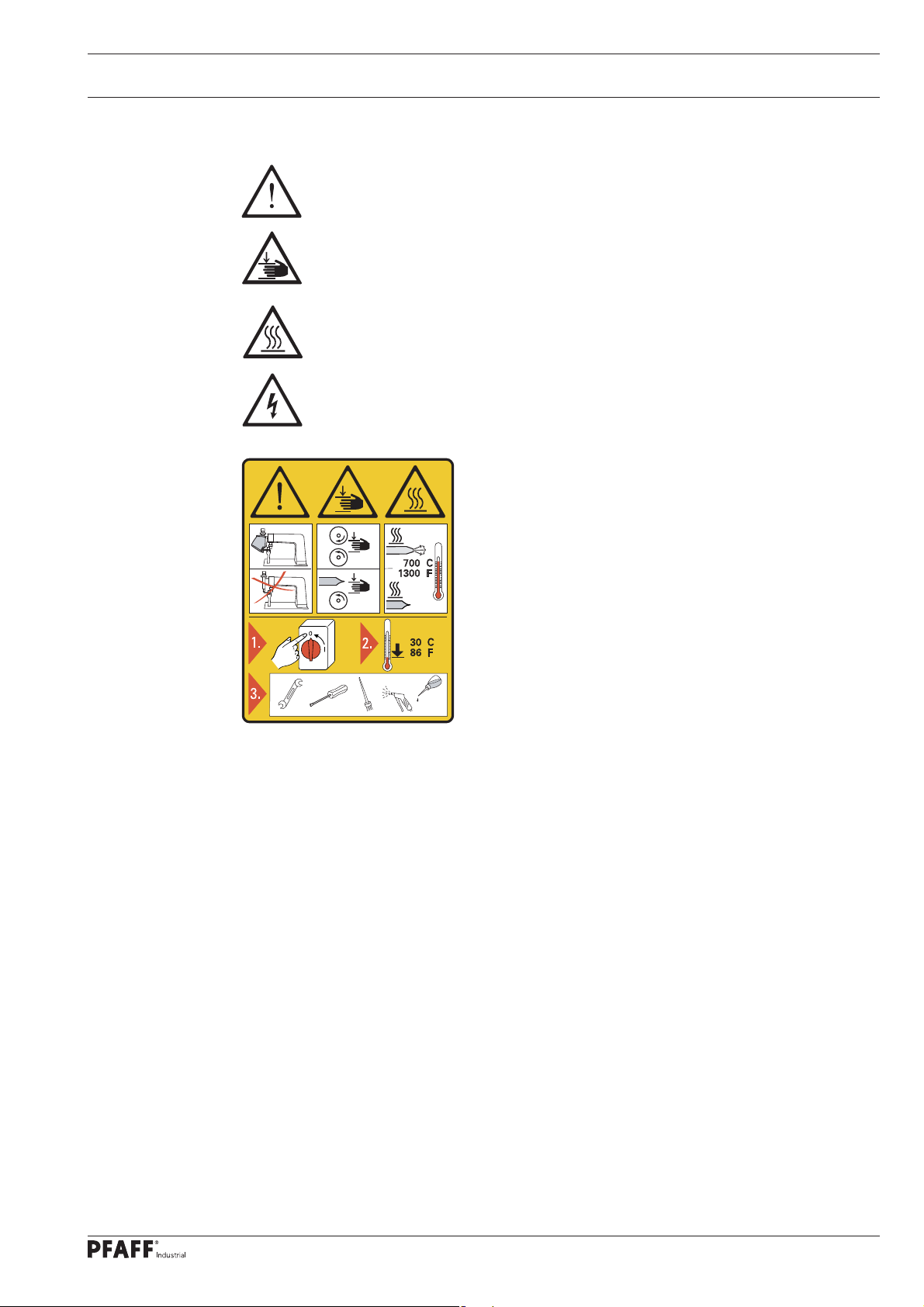

1.03 Safety symbols

Danger!

Special points to observe.

Danger of hands being crushed!

Danger of burns from hot surface!

Danger from electric voltage!

Caution

Do not operate without fi nger guard and safety

devices.

1.04 Important notes for the user

● This instruction manual belongs to the equipment of the machine and must be available

to the operating staff at all times.

● This instruction manual must be read before the machine is operated for the fi rst time.

● Both operating and technical staff must be instructed on the safety devices of the machi-

ne and on safe working methods.

● It is the duty of the user to operate the machine in perfect running order only.

● The user must ensure that none of the safety devices are removed nor put out of wor-

king order.

Turn off the main switch and let the machine cool

down before any setting up, maintenance or cleaning

work!

● The user must ensure that only authorized persons operate and work on the machine.

● The user must make sure there is no high-frequency welding equipment being operated

in direct proximity to the machine that exceeds the EMC limit values according to

EN 60204-31 for the machine.

For further information please refer to your PFAFF agency.

7

Page 8

Safety

1.05 Operating and technical staff

1

1.05.02 Technical staff

.05.01 Operating staff

Operating staff are the persons responsible for setting up, operating and cleaning the machi-

ne and for removing any disturbances in the sewing area.

The operating staff is obliged to observe the following points, and must:

● always observe the notes on safety in this instruction manual!

● avoid using any working methods which adversely affect the safety of the machine!

● avoid wearing loose-fi tting clothing or jewelry such as necklaces or rings!

● also ensure that only authorized persons are allowed near the danger area of the machine!

● immediately report to the user any changes to the machine that may affect its safety!

Technical staff are persons who have been trained in electrical engineering, electronics and

mechanical engineering. They are responsible for lubricating, servicing and repairing the ma-

chine.

The technical staff is obliged to observe the following points, and must:

● always observe the notes on safety in this instruction manual!

● switch off the on/off switch before carrying out any maintenance and repair work on the

machine!

● never work on parts or equipment still connected to the power supply! Exceptions to this

are only permissible according to regulations EN 50110.

● replace all safety covers after maintenance and repair work!

8

Page 9

Safety

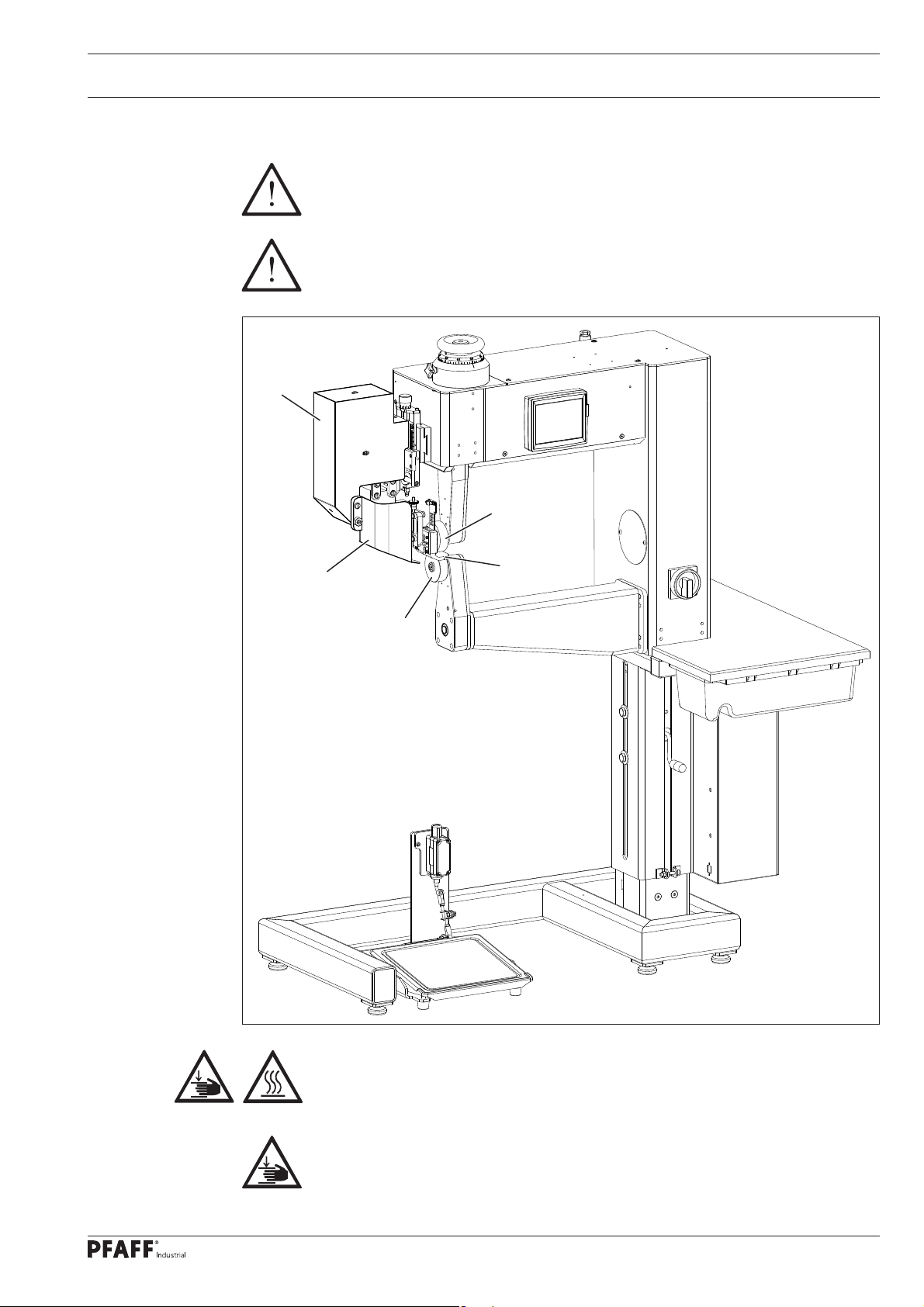

1.06 Danger

When the machine is in operation, a work area of 1 m must be kept free in

front of and behind the machine, so that access to the machine is possible at all

times without diffi culty.

If toxic vapours occur during processing, use extractor!

Danger to health if the toxic vapours are inhaled!

1

4

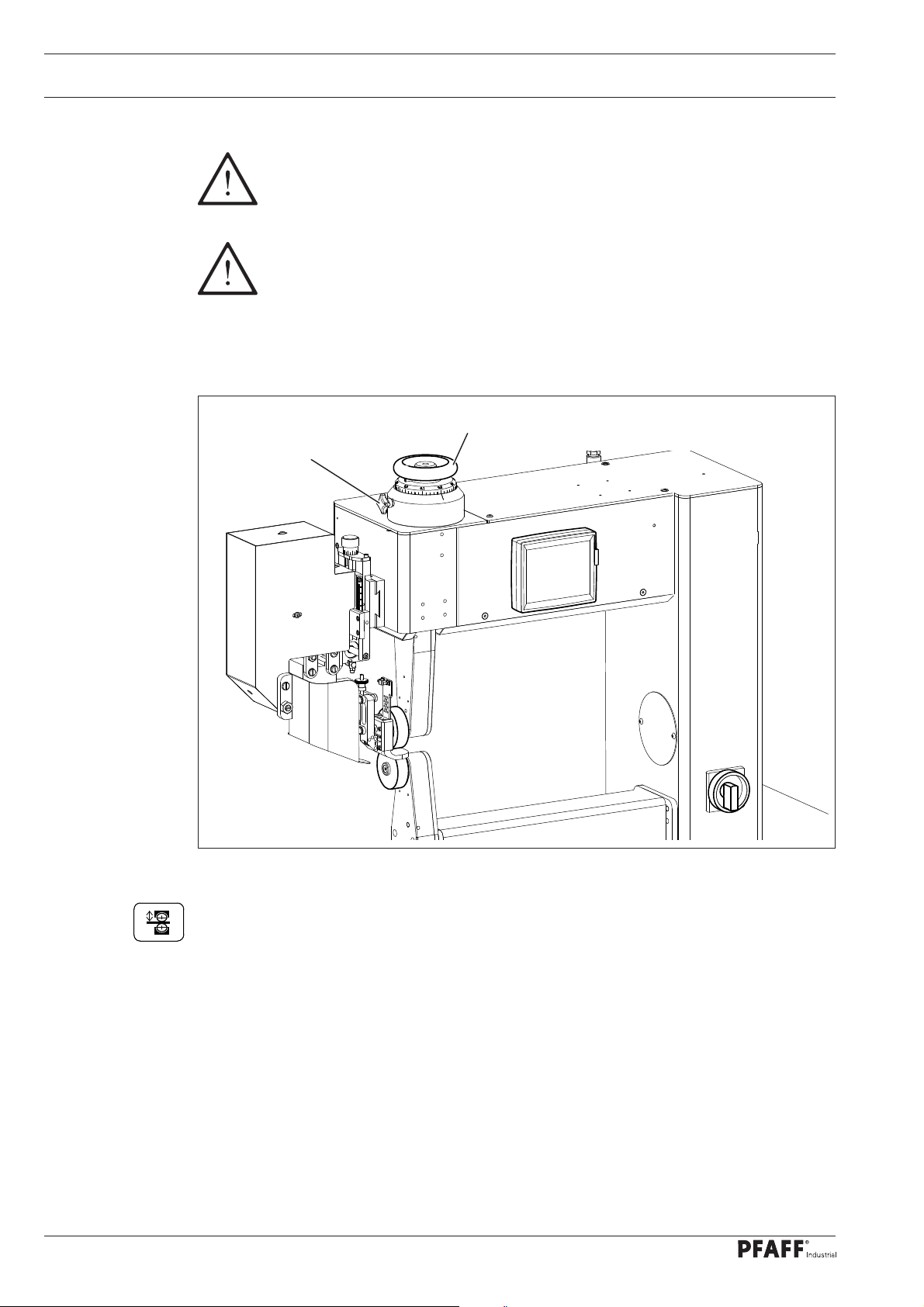

Fig. 1 - 01

2

3

4

Do not operate the machine without protective cover 1 and only operate the machine with protective cover 2 folded down. Danger of crushing when the heating

element 3 is engaged and disengaged, as well as a danger of burns if touched!

During operation do not place hands near the feed rollers 4!

Danger of crushing if the fi ngers are drawn between the rollers!

9

Page 10

Proper use

2 Proper use

The PFAFF 8320-010 is a hot-wedge sealing machine with swivel post.

The PFAFF 8320-020 is a hot-air sealing machine with swivel post.

The PFAFF 8321-014 is a hot-wedge sealing machine with vertical post.

The PFAFF 8321-024 is a hot-air sealing machine with vertical post.

The machines are used to seal fl exible thermoplastic materials such as e.g. covers, PVC

clothing, insulating and fi lter tubes, small tarpaulins and tents, motorcycle seats etc.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

10

Page 11

Specifi cation

3 Specifi cations▲

Dimensions and weight:

Length: ..................................................................................................................ca. 1100 mm

Width: ..................................................................................................................... ca. 620 mm

Height: ................................................................................................................. ca. 1400 mm

Clearance width: .................................................................................................... ca. 480 mm

Clearance between rollers: ...................................................................................... ca. 20 mm

Net weight: ...............................................................................................................ca. 140 kg

Mains voltage set for: .............................................................230 V ± 10%, 50/60 Hz, 1 phase

Leakage current ........................................................................................................... < 5 mA

Power input

8320-010 (hot-wedge version): ................................................................................ ca. 1500 W

8320-020 (hot-air version): ...................................................................................... ca. 3500 W

◆

Heating capacity

8320-010 (hot-wedge version): ................................................................................ ca. 1500 W

8320-020 (hot-air version): ...................................................................................... ca. 3300 W

Fuse: ..................................................................................................................................16 A

Working air pressure: ................................................................................................. min. 5 bar

Air consumption

8320-010 (hot-wedge version): ..................................................................................... 30 l/min

8320-020 (hot-air version): ..................................................................................30 – 150 l/min

Sealing speed: ............................................................................................... max. 10 m/min.*

Noise data:

Emission sound level at the workplace: .............................................................. LpA<70 dB(A)

(Noise measurement in acc. with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO 4871)

Ambient temperature

85% rel. humidity (condensation not permitted): ....................................................... 5 – 40°C

■

Sealing temperature

8320-010 (hot-wedge version): ............................................................................... max. 500°C

8320-020 (hot-air version): ..................................................................................... max. 650°C

▲

Subject to alterations

◆

Due to the use of network fi lters there is a nominal leakage current of < 5 mA.

* Depending on the equipment, up to 30 m/min

■

KpA = 2,5 dB

11

Page 12

Specifi cation

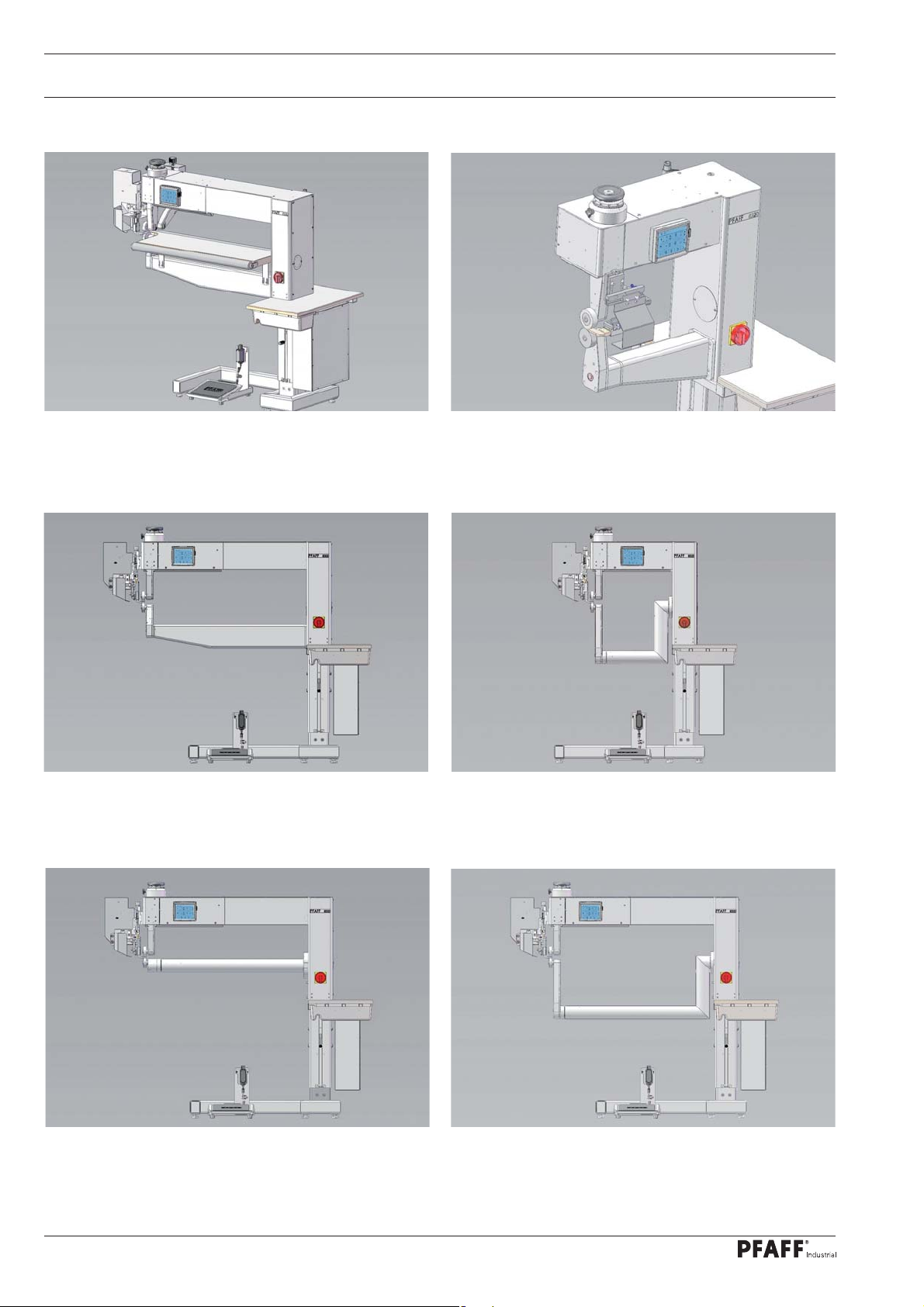

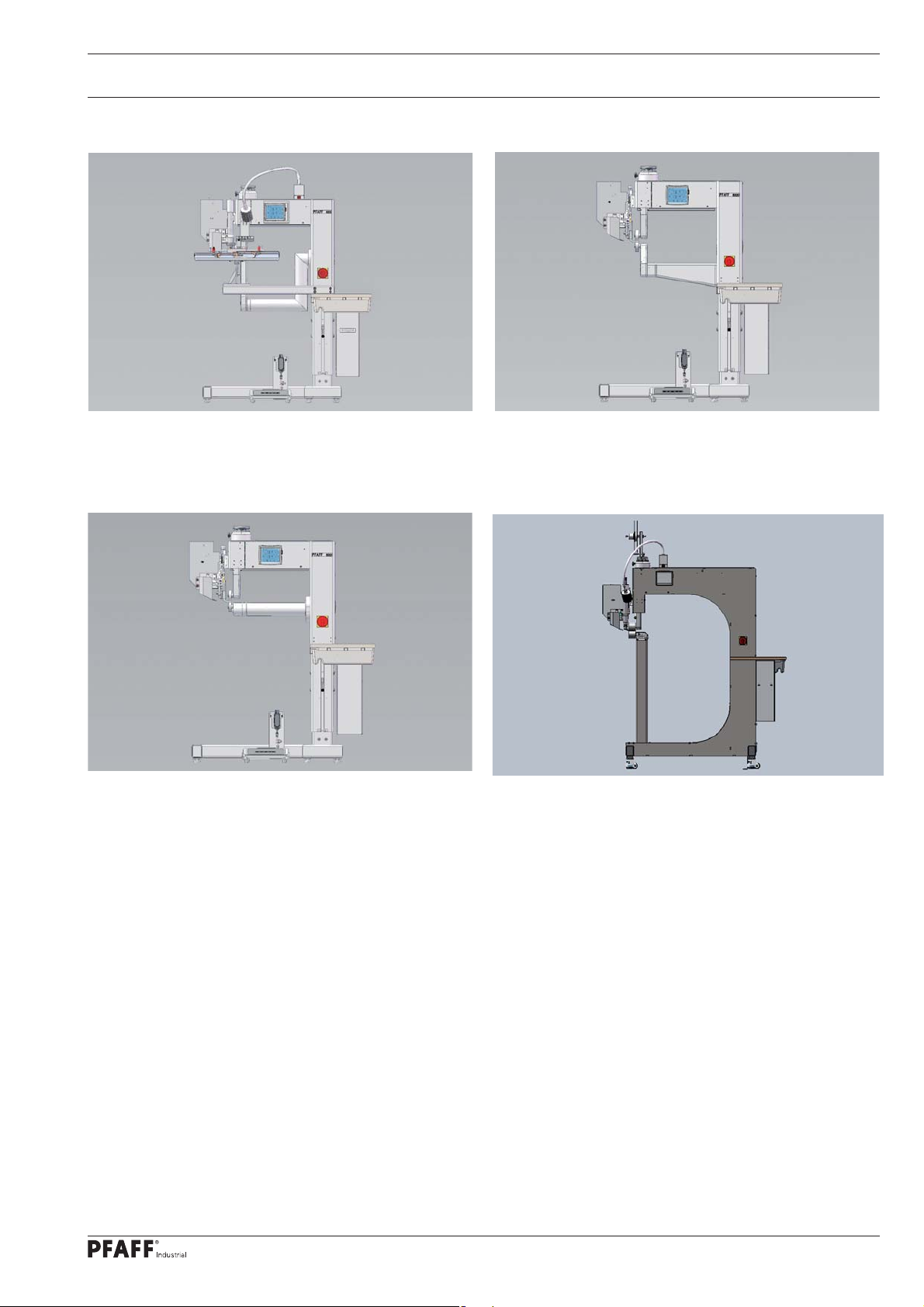

3.01 Machine variants

PFAFF 8320-111

PFAFF 8320-121

PFAFF 8320-111

PFAFF 8320-121

Long-arm version with

table, track rollers and

puller

Long-arm version,

vertical post

PFAFF 8320-011

PFAFF 8320-021

PFAFF 8320-010

PFAFF 8320-020

Standard machine housing,

vertical post, swinging unit

from the right

Standard machine housing,

swivel post

PFAFF 8320-112

PFAFF 8320-122

12

Long-arm version,

cylinder post

PFAFF 8320-110

PFAFF 8320-120

Long-arm version,

swivel post

Page 13

Specifi cation

PFAFF 8320-061

PFAFF 8320-061

PFAFF 8320-012

PFAFF 8320-022

Standard machine housing

for fi lter tube production

(hot-air)

Standard machine housing,

cylinder post

PFAFF 8320-011

PFAFF 8320-021

PFAFF 8321-014

PFAFF 8321-024

Standard machine housing,

vertical post

Standard machine housing,

vertical post

13

Page 14

Disposal of Machine

4 Disposal of Machine

● Proper disposal of the machine is the responsibility of the customer.

● The materials used for the machine are steel, aluminium, brass and various plastic

materials. The electrical equipment comprises plastic materials and copper.

● The machine is to be disposed of according to the locally valid pollution control regula-

tions; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

14

Page 15

Transportation, packing and storage

5 Transportation, packing and storage

.01 Transportation to customer‘s premises

5

The machines are delivered completely packed.

5.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fi bre. Proper dis-

posal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a fi lm of oil.

15

Page 16

Explanation of symbols

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

16

Page 17

Controls

7 Controls

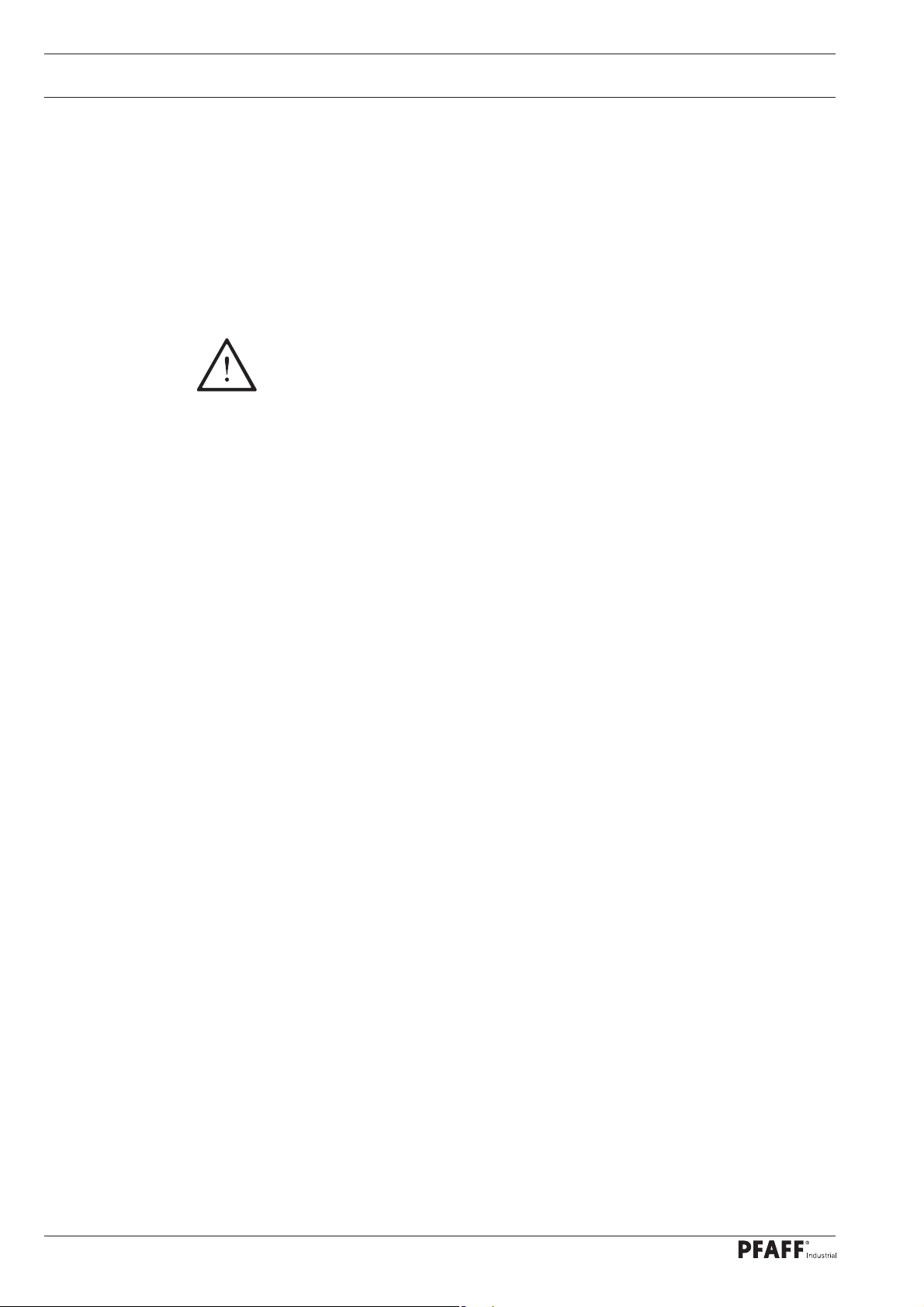

.01 Summary of controls

7

5

9

6

7

1

8

3

4

Fig. 7 - 01

1 Main switch, see Chapter 7.02

2 Pedal, see Chapter 7.03

3 Foot switch (available as an option), see Chapter 7.04

4 Triple foot switch (available as an option), see Chapter 7.05

5 Adjustment wheel for roller clearance, see Chapter 7.06

6 Control panel, see Chapter 7.08

7 Top feed roller

8 Bottom feed roller

9 Key-switch, see Chapter 11.03.02 Rights of access

2

17

Page 18

Controls

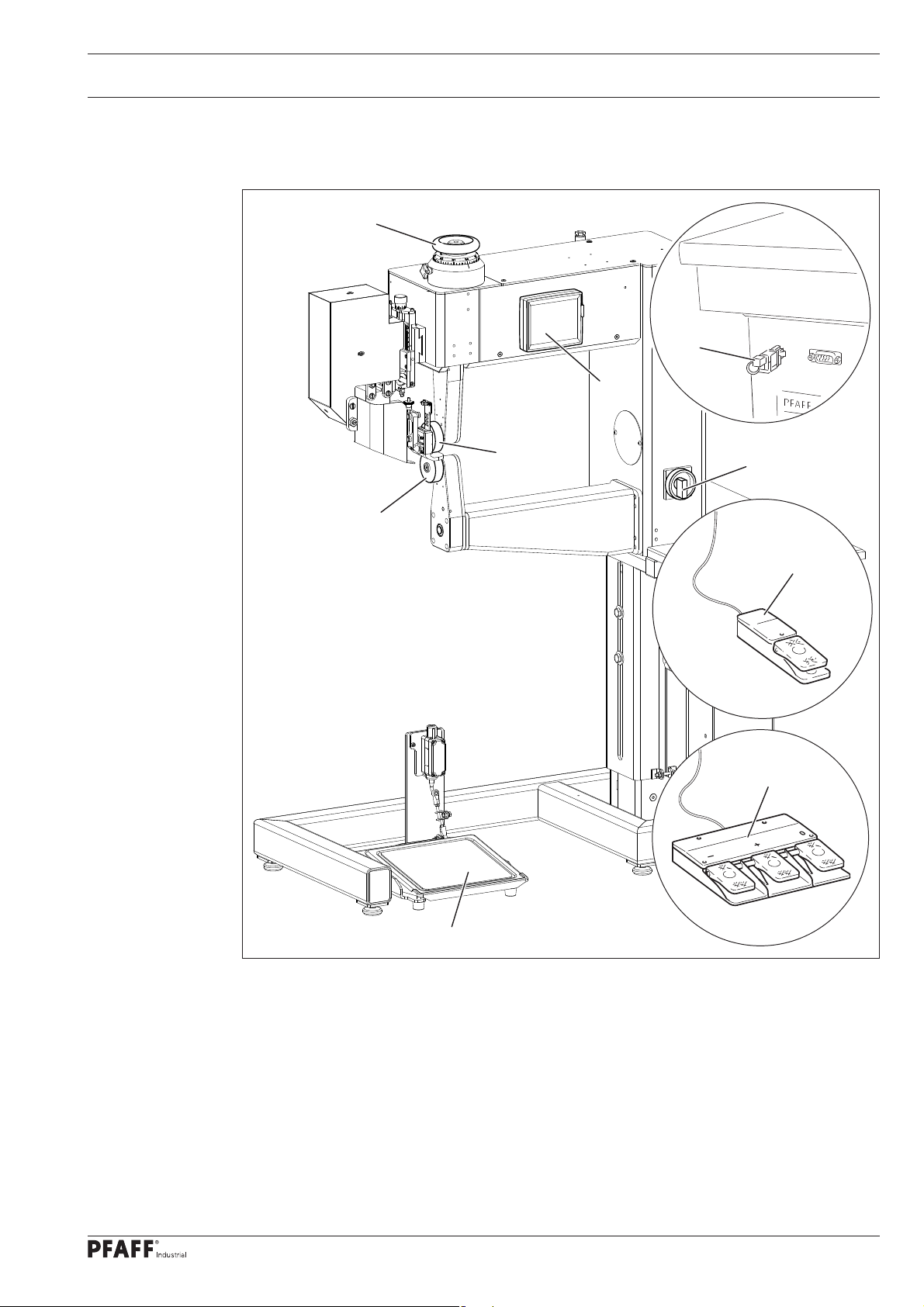

7.02 Main switch

● The machine is switched on or off by

turning main switch 1.

Position "0" : Machine is switched off

Position "1" : Machine is switched on

When switching the

machine on or off, please observe the notes in Chapter 8.03

Switching the machine on and

1

off!

Fig. 7 - 02

7.03 Pedal

The function method of the

pedal depends on the select-

ed pedal mode (level or fl ip-fl op

mode), see Chapter 11.03

Further settings

+1

0

+2

Sealing / level mode

0 = Rest position / Stop sealing process

+1 = Lower top feed roller

+2 = Engage heating element /

Sealing start

-1 = Interrupt sealing process / Raise top

feed roller

18

Fig. 7 - 03

-1

Sealing / fl ip-fl op mode

0 = Rest position

+1 = Lower top feed roller

+2 = Start / Stop sealing

-1 = Interrupt sealing process / Raise top

feed roller

Page 19

Controls

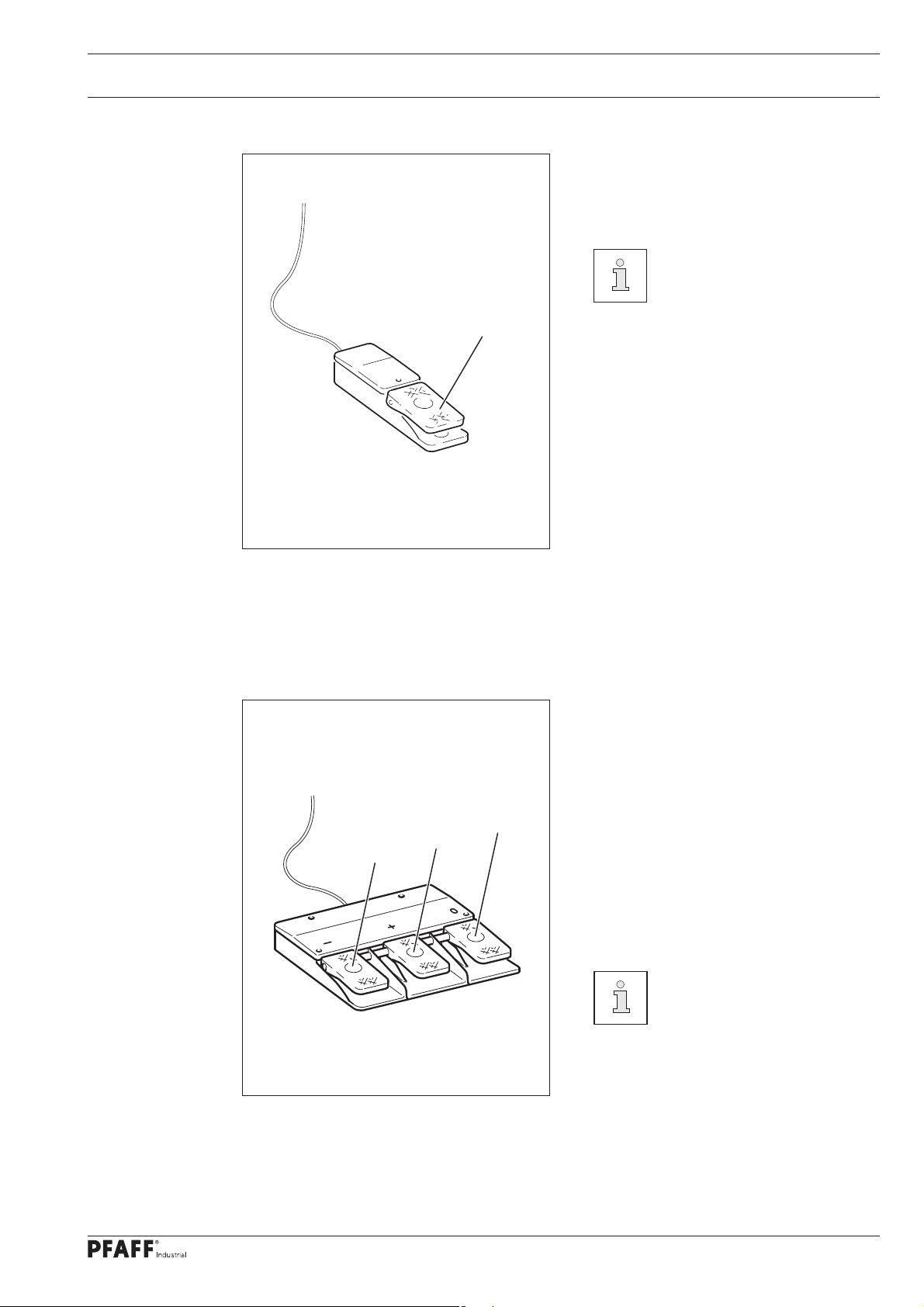

7.04 Foot switch (optional)

● Move to the next sealing section in the

programmed sealing operation by pres-

sing foot switch 1.

Alternatively, a knee switch can

be ordered for this function.

1

Fig. 7 - 04

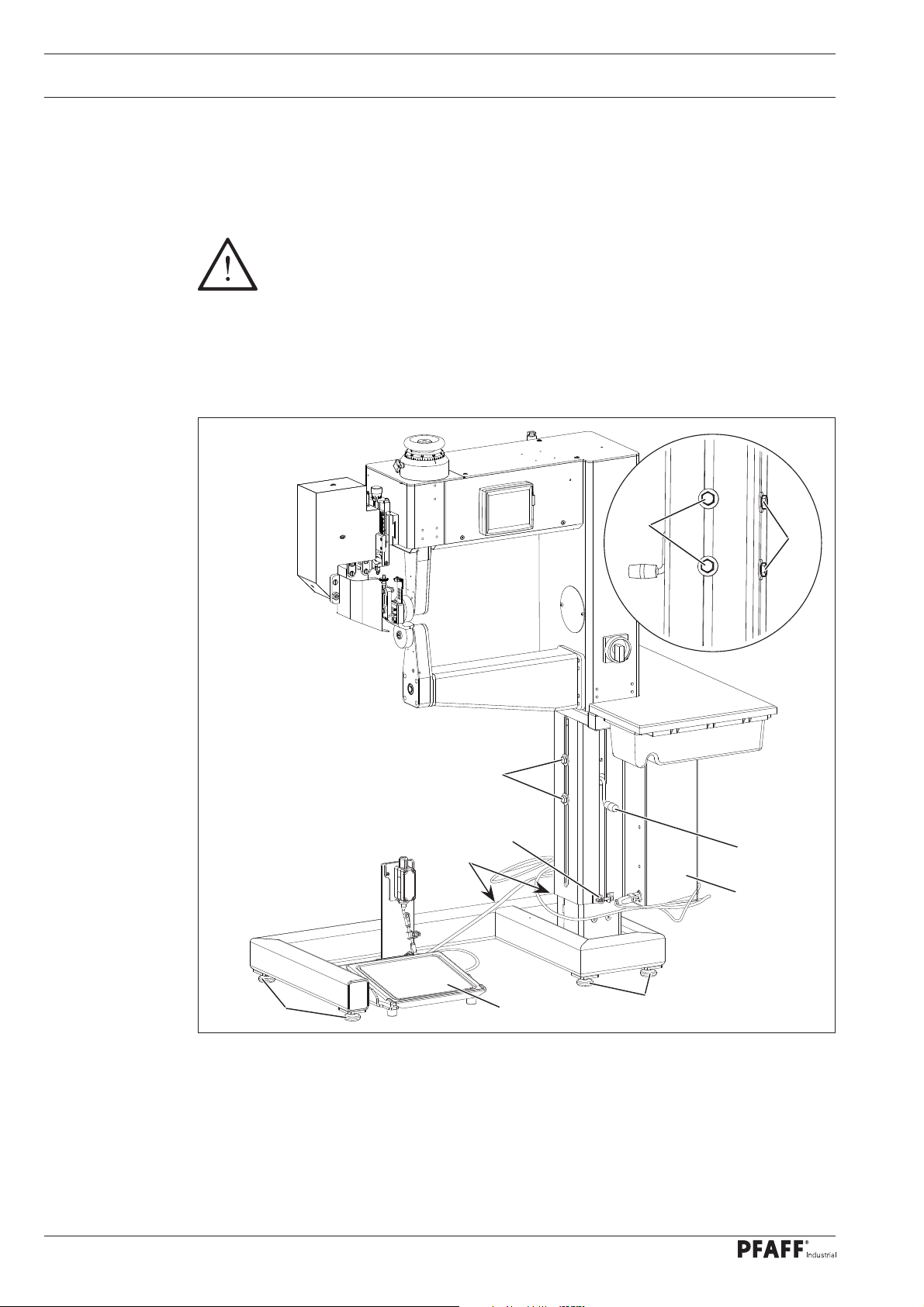

7.05 Triple foot switch (optional)

1

2

● If the foot switches 1 to 3 are pressed,

the value for the speed difference bet-

ween the top and bottom feed roller is

changed step by step or reset.

1 = Reduce speed of top feed roller

3

step by step

2 = Increase speed of top feed roller

step by step.

3 = Reset speed difference between

the top and bottom feed rollers.

The speed difference between

top and bottom feed rollers is

shown in % on the control

panel.

Fig. 7 - 05

19

Page 20

Controls

7.06 Adjustment wheel for the roller clearance

● After loosening clamp screw 1, the

2

1

clearance between the top and bottom

feed rollers is changed by turning adjustment wheel 2.

The clearance can be read on the scale.

Fig. 7 - 06

20

Page 21

Controls

7.07 Control panel

1

2 GB

max.

Fig. 7 - 07

The current operating conditions are displayed on control panel 1. Operation takes place in a

constant dialogue between the control unit and the operator. For this purpose, depending on

the operating condition of the machine, different symbols and/or texts are displayed. If the

symbols or texts are framed, these show functions which can be selected by pressing the

appropriate position on the monitor. By pressing the corresponding function this is carried

out or switched on or off immediately, or a further menu appears, e.g. for entering a value.

Activated functions are shown with inverted symbols. Unframed symbols or texts are only

used for display purposes and cannot be selected by pressing.

To read welding programs or install machine software, use the sd-card 2 in the control

panel.

2

Description of the functions

Normal symbol = function switched off (inactive)

Inverted symbol = function switched on (active)

21

Page 22

Installation and commissioning

8 Installation and commissioning

After the machine has been unpacked, check it for any damages caused during transportati-

on. If there are any damages, please notify the transport company and your

local PFAFF agency.

The machine must only be installed and commissioned by qualifi ed personnel.

All relevant safety regulations must be strictly adhered to!

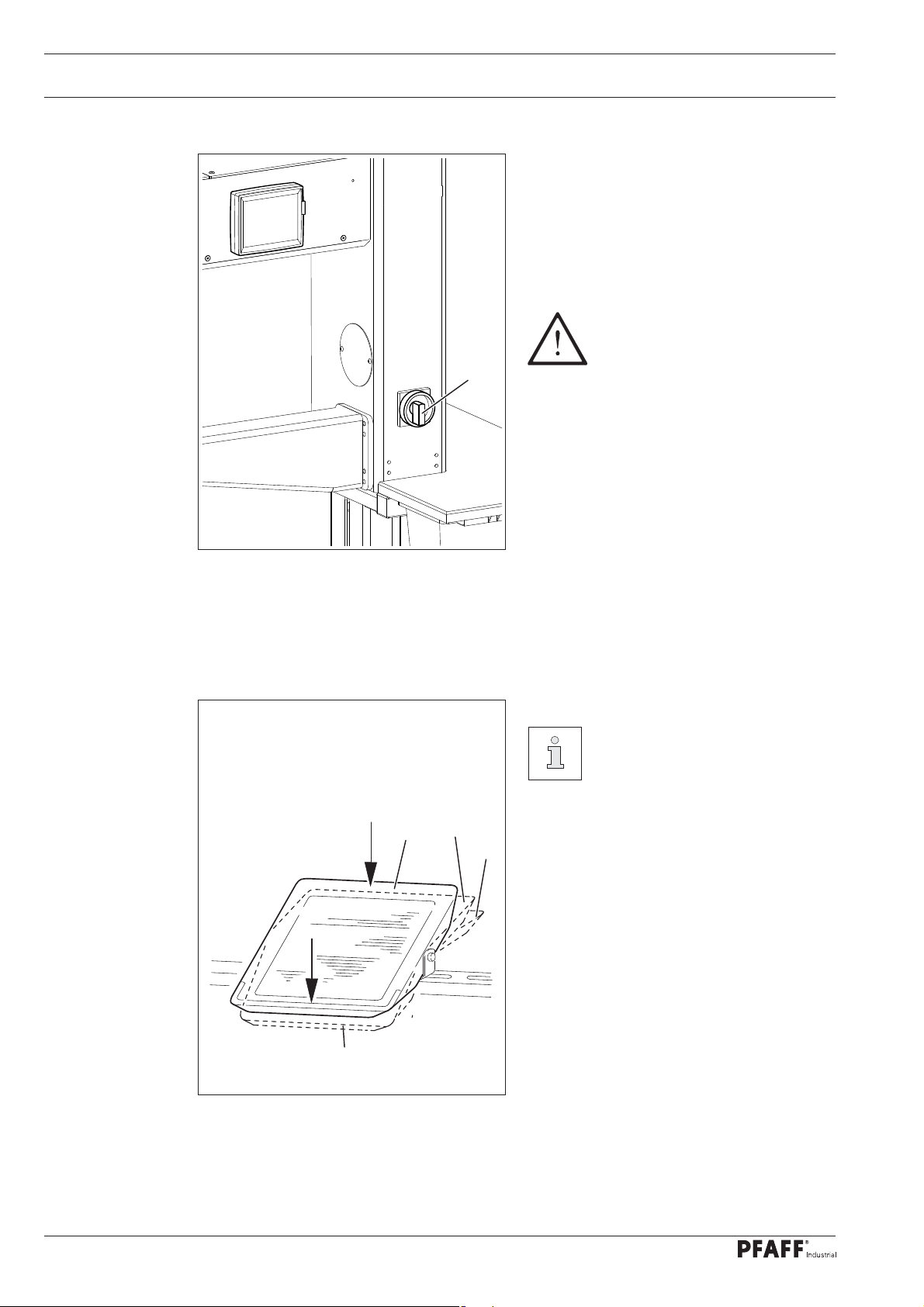

8.01 Installation

Suitable connections for electricity and compressed air must be available at the machine’s

location (see Chapter 3 Specifi cations).

4

4

4

5

1

6

3

22

Fig. 8 - 01

● Slide the machine from the transport pallet.

● Level the machine horizontally by turning the feet 1.

● Connect the plugs from pedal 2 and any existing foot switches to the control box.

● Loosen screws 4 and 5 and adjust the height of the machine by turning crank 6.

● Well tighten screws 4 and 5 again.

1

2

1

Page 23

Installation and commissioning

8.02 Commissioning

● Examine the machine, in particular the electric leads, for any damage.

● Clean the machine thoroughly, also see Chapter 12 Maintenance.

● Connect the machine to the electrical network and have specialists examine, whether the

machine can be operated with the available voltage and whether it is properly connected.

Do not operate the machine if there is any discrepancy!

The machine may only be connected to an earthed socket!

● Connect the machine to the compressed

air system. A pressure of 6 bar should

be displayed on the manometer. If necessary, set this value, see Chapter 12.02

Fig. 8 - 02

0.4 0.6

0.2 0.8

0

+

-

1

1

134-010

Checking / adjusting the air pressure.

The air must be completely oil-

free and dry.

The compressed air quality

influences the service life of the

heating cartridge in the air

heater. If the air is very damp,

a compressed air cold drier with

preliminary filter and secondary

fine filter must be installed in

front of the heat-sealing

machine

23

Page 24

Installation and commissioning

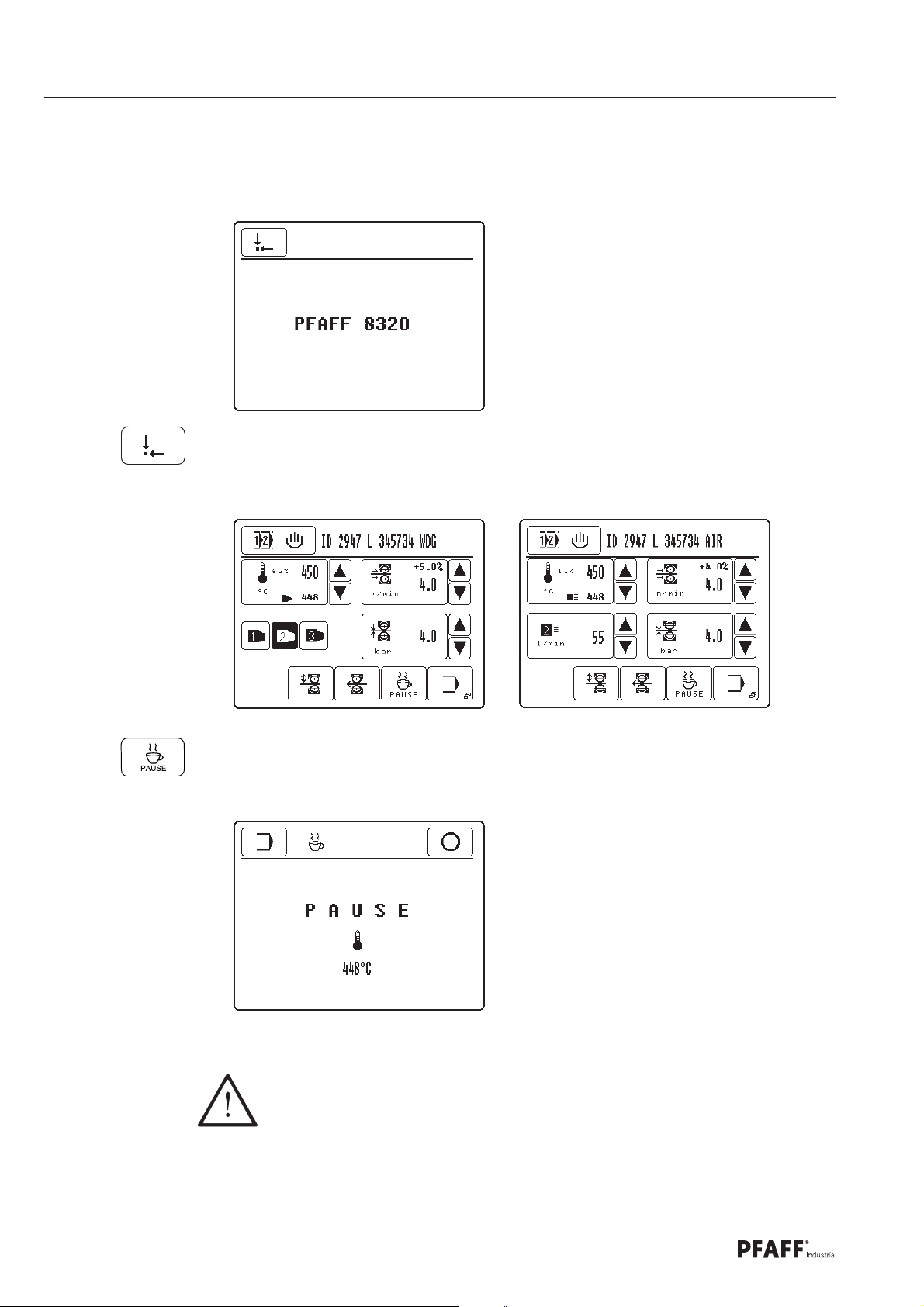

8.03 Switching the machine on/off

● To switch on the machine, turn the main switch to the "I" position, see Chapter 7.02 Main

switch.

● After the boot operation of the control unit, call up the "basic position" function.

PFAFF 8320-010

● To switch off the machine, call up the "pause" function and wait until the blast air

switches off automatically (approx. 1 - 2 min).

PFAFF 8320-020

24

Danger of damage to the heating cartridge!

The hot air temperature must not exceed 100°C when switched off!

Before switching off the compressed air system, wait until the blast air swit-

ches off automatically!

● Turn the main switch to the "0" position, see Chapter 7.02 Main switch.

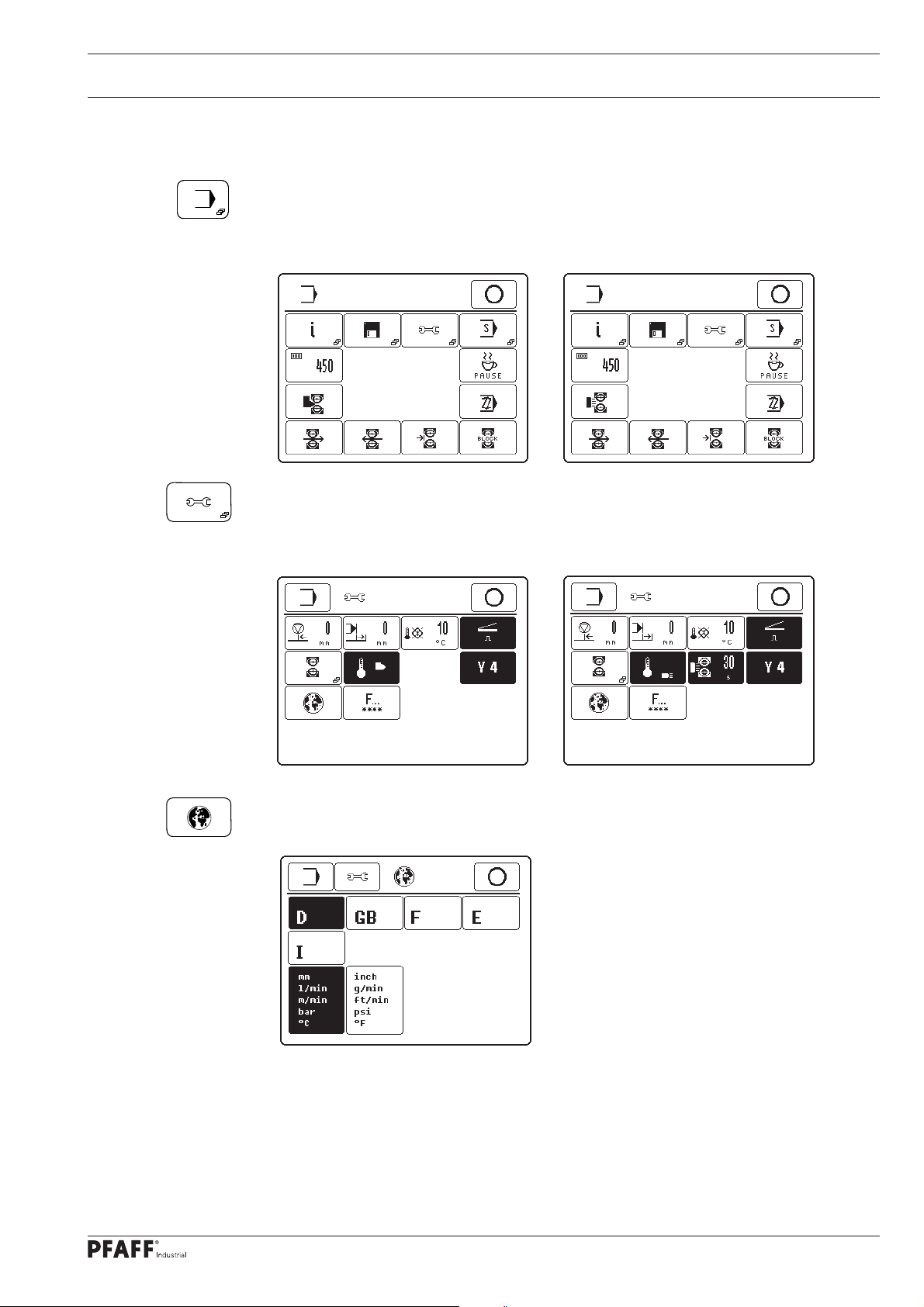

Page 25

Installation and commissioning

8.04 Selecting the language and units

● Switch on the machine.

● Call up the input menu.

PFAFF 8320-010

● Call up the settings menu.

PFAFF 8320-010

PFAFF 8320-020

PFAFF 8320-020

● Call up the "language setting" menu.

● Select the appropriate language and units.

25

Page 26

Preparation

9 Preparation

9.01 Adjusting the feed roller clearance

All regulations and notes in this Service Manual must be observed!

Special attention must be paid to the safety regulations!

All setting-up work must only be carried out by personnel with the appropriate

training!

2

1

26

Fig. 9 - 01

● Switch on the machine.

● Lower the top feed roller.

● Loosen clamp screw 1.

● Adjust the clearance between the rollers with adjustment wheel 2 depending on the

workpiece and sealing method, see Chapter 7.06 Adjustment wheel for roller

clearance.

● Tighten clamp screw 1.

Page 27

Preparation

9.02 Selecting the production type:

The program selection function is used to choose between the types of production

- Manual heat sealing (Chapter 10.02)

- Programmed heat sealing with individual programs (Chapter 10.04) and

- Programmed heat sealing with sequences (Chapters 10.06).

The types of production listed above, particularly their functions, are explained

in more detail in Chapter 10 Heat sealing.

● Switch on the machine.

● Call up program selection.

Example 1

● Call up manual heat sealing, the production type, "Manual Heat Sealing" is activated.

or

● Select the desired program number.

(Selection can also be made by entering the program number on the fi gure panel

directly.)

27

Page 28

Preparation

● Confi rm selection and quit selection menu, die production type "Programmed Heat

Sealing with individual program" is activated.

Example 2

or

● Call up sequence selection.

● Select desired sequence number.

(Selection can also be made by entering the sequence number on the fi gure panel

directly.)

● Confi rm selection and quit selection menu, die production type "Programmed Heat Seal-

ing with sequence program" is activated.

Example 1

28

Page 29

Preparation

9.03 Entering the sealing parameters (Manual Heat Sealing)

● Switch on the machine.

● Call up program selection.

● Call up manual heat sealing.

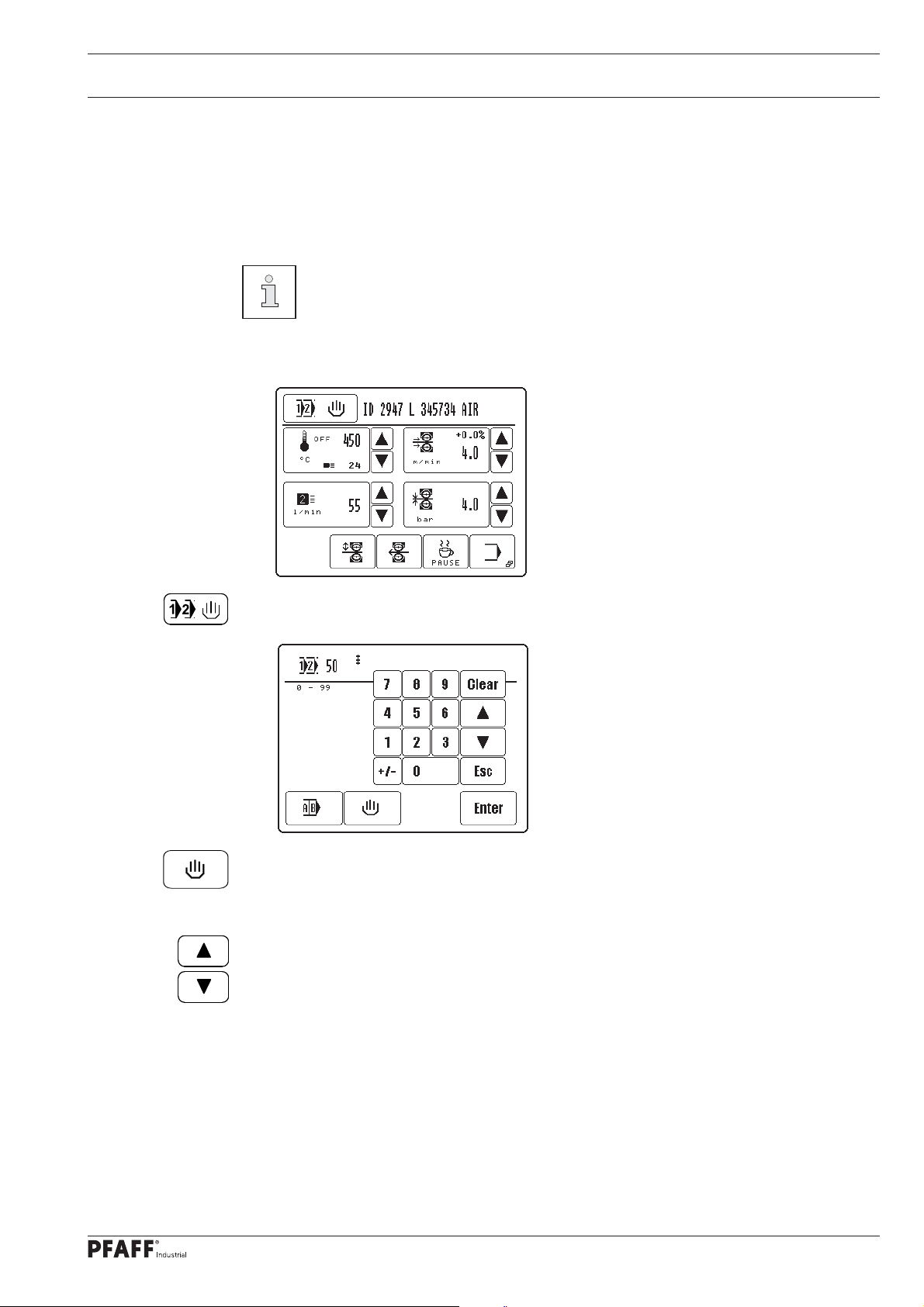

PFAFF 8320-010

Duty cycle

Set temperature

Actual temperature

Hot wedge type

Duty cycle

Set temperature

Actual temperature

Nozzle type

Air volume

Comment 20 indications

PFAFF 8320-020

Comment 20 indications

Differential

(top to bottom roller)

Sealing speed

Roller pressure

Differential

(top to bottom roller)

Sealing speed

Roller pressure

29

Page 30

Preparation

After selecting "Manual Heat Sealing", also see Chapter 9.02 Selecting the production

type:, following values can be entered depending on the sealing method:

- Sealing temperature

In addition to the set sealing temperature, the value for the parameter (off = heating off)

appears in the appropriate symbol as well as the actual sealing temperature.

- Sealing speed

In addition to the sealing speed, the value for the difference in speed in % between the

top and bottom feed rollers appears in the appropriate symbol.

- Type of heating wedge or heating nozzle with hot air volume

- Roller pressure

The values can be entered directly by pressing the appropriate key symbol.

In Programmed Heat Sealing the direct input of sealing parameters is not

possible. The alteration must be made in the appropriate sealing program,

see Chapter 10.03 Creating/altering a heat sealing program.

After switching the machine on, after the "pause" function or after detection of

an error, the heating element is switched off (parameter "OFF"). After changing

the sealing temperature, pressing the "start" function or after operating the

pedal, the heating element is switched on again.

30

Page 31

Preparation

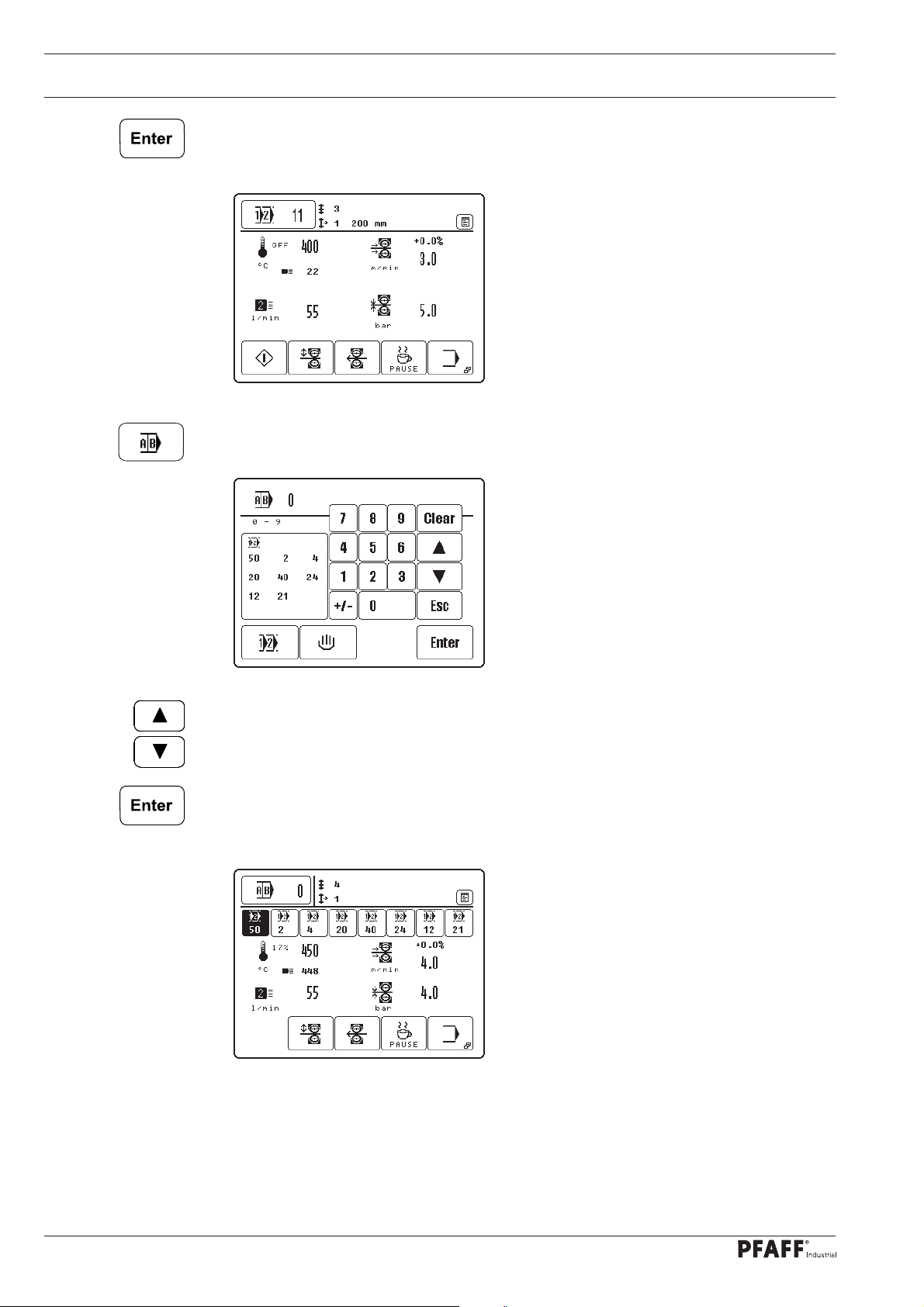

9.03.01 Entering the sealing temperature

PFAFF 8320-010

● Increase or reduce the value for the sealing temperature directly.

or

● Call up the fi gure panel to enter the sealing temperature.

__

● Enter the value for the sealing temperature within the permitted range.

● Conclude the input, permissible values will be taken over.

Description of further functions

Clear

● When this function key is pressed, the value is set at "0".

Arrow keys

● When these function keys are pressed, the value is increased or reduced.

Esc

When this function key is pressed, the input is cancelled without the value entered being ta

31

Page 32

Preparation

9.03.02 Entering the sealing speed

PFAFF 8320-020

● Increase or reduce the value for the sealing speed directly.

or

● Call up the fi gure panel to enter the sealing speed.

__

● Enter the value for the speed difference within the permitted range.

● If necessary call up the fi gure panel to enter the speed difference between the top and

bottom feed roller.

32

Page 33

Preparation

__

● Enter the value for the speed difference within the permitted range.

The speed difference results from the change in speed of the top feed roller, which ro-

tates either more quickly or more slowly than the bottom feed roller. The value for the

speed difference depends on the material and application.

● Further sealing parameters

● Select acceleration and brake profi le of the feed rollers, dependent on the material for

sealing. Each of the profi les selected is displayed as an inverse symbol. A fl at ramp

stands for slight acceleration of the feed rollers. The selection of a steep ramp means

high acceleration.

__

● Increase or reduce the start delay for the feed rollers directly.

or

● Call up the fi gure panel to enter the start delay.

Enter the start delay depending on the material being processed.

● Conclude the input, permissible values will be taken over

The start delay function is used to stipulate the amount of time which should

pass between the engaging of the heating element and the start of the feed

rollers.

33

Page 34

Preparation

9.03.03 Stipulating the hot wedge type (only on the PFAFF 8320-010)

● Select the hot wedge type in accordance with the width of the hot wedge installed.

The symbol for the selected hot wedge type appears as an inverse symbol.

Hot wedge

type

1

2

3

Hot wedge version

Heating cartridge with integrated temperature sensor and fast control

response (width 7 mm, 9 mm and 12 mm, 360 W)

Heating cartridge with external temperature sensor and medium control

response (width 15 mm, 20 mm and 30 mm, 500 or 1000 W)

Heating cartridge with external temperature sensor and slow control

response

(width 7 mm, 9 mm and 12 mm, 360 W)

(width > 30 mm, 1000 W)

9.03.04 Adjusting the contact pressure of the hot wedge (only on the PFAFF 8320-010)

● Loosen the locknut 1.

● Adjust the pressure by turning the nut 2

in accordance with the sealing operation,

also see Chapter 13.06.02 Hot wedge

pressure on and clearance to the feed

rollers.

34

● Tighten locknut 1.

1

2

Fig. 9 - 02

Page 35

Preparation

9.03.05 Stipulating the nozzle type and hot air volume (only on the PFAFF 8320-020)

● Increase or reduce the hot air volume directly

or

● Call up input menu to enter hot air volume.

__

● Select the nozzle type in accordance with the width of the nozzle installed.

The symbol for the selected nozzle type appears as an inverse symbol.

Nozzle type Width of nozzle

1 < 10 mm

2 10 mm - 30 mm

3 > 30 mm

● Using the number block, enter the value for the hot air volume within the permitted

range.

● Conclude the input, permissible values will be taken over.

Description of further functions

Clear

● When this function key is pressed, the value is set at "0".

Arrow keys

● When these function keys are pressed, the value is increased or reduced.

Esc

When this function key is pressed, the input is cancelled without the value entered being

taken over.

35

Page 36

Preparation

9.03.06 Entering the roller pressure

PFAFF 8320-010

● Increase or reduce the roller pressure directly.

or

● Call up the number panel to enter the roller pressure.

__

● Enter the roller pressure within the permitted range

● Conclude the input, permissible values will be taken over.

Roller pressure can be capped for specifi c application cases

(see chapter 11.03.01)

36

Page 37

Preparation

9.04 Adjusting the control panel

● Switch on the machine.

● Call up the input mode.

PFAFF 8320-010

● Select the service menu.

PFAFF 8320-020

● Select control panel functions.

● Switch the key tone off or on.

● Change the display contrast. (Function only on the control panel BDF T1).

Never reduce the display contrast to the extent, that the display can no

longer be read!

37

Page 38

Heat sealing

10 Heat sealing

The machine may only be operated by properly instructed personnel. The oper-

ating personnel must make sure that only authorised persons are in the danger

zone of the machine.

In particular for production, in addition to the input menu (see Chapter 11 Input), the „heat

sealing“ mode is available, in which, irrespective of the program selected and the machine

status, all functions and settings relevant for the sealing operation are shown on the display.

With the program selection function, following production types can be selected in the "heat

sealing" mode, see Chapter 9.02 Selecting the production type:

Manual heat sealing, see Chapter 10.02

Programmed heat sealing with individual programs, see Chapter 10.04

Programmed heat sealing with sequences, see Chapter 10.06

10.01 Heat sealing principle

To achieve optimum sealing results, certain conditions must be fulfi lled with regard to mate-

rial and machine setting.

The material must:

- be heat-sealable, and

- suitable for being processed by the machine with regard to thickness and structure.

In the seam area, the material to be heat sealed must be clean and free from separating

agents, such as e.g. oil or silicone.

The basic conditions depending on the sealing device are:

- correct working temperature of the hot wedge or hot air temperature (sealing temperature);

- correct contact pressure of the hot wedge and the correct position of the hot air nozzle;

- correct setting for the hot air volume;

- correct choice of feed rollers (silicone or steel);

- optimum pressure of the feed rollers on the material being sealed (roller pressure);

- correct distance between the feed rollers and

- correct sealing speed (feed stroke).

All the settings of the heat-sealing device are principally dependent on the ma-

terial being sealed and the ambient temperature. Due to the infl uence of the in-

dividual operating parameter on each other, it is only possible to determine the

optimum setting values by carrying out test sealing operations.

38

Page 39

Heat sealing

10.02 Manual heat sealing

In the "Manual heat sealing" mode, all relevant parameters for the sealing operation can be

entered or altered directly, see Chapter 9.02 Selecting the production type.

● Select "manual heat sealing", see Chapter 9.02 Selecting the production type

PFAFF 8320-010

Description of the functions

Selecting a program

This function opens the menu for entering the program number or for selecting the production type, see Chapter 9.02 Selecting the production type

Comment Field

This function opens the menu to allow the input of a comment (max. 20 chars.), e.g. material

assignment for the selected welding parameters.

PFAFF 8320-020

Heat sealing temperature

These functions are used to alter the heat sealing temperature, see Chapter 9.03.01

Entering the sealing temperature.

Feed stroke (sealing speed)

These functions are used to alter the feed stroke or to open the menu for entering the feed

stroke difference, the brake and acceleration profi les and the start delay for the feed rollers,

see Chapter 9.03.02 Entering the sealing speed.

Hot wedge type (only on the PFAFF 8320-010)

These functions are used to stipulate the hot wedge type, see Chapter 9.03.03 Stipulating

the hot wedge type… The selected function appears inverse.

Nozzle type / hot air volume (only on the PFAFF 8320-020)

These functions are used to alter the hot air volume or to open the menu for stipulating the

nozzle type, see Chapter 9.03.05 Stipulating the nozzle type and hot air volume …

Roller pressure

These functions are used to alter the roller pressure, see Chapter 9.03.06 Entering the roller pressure.

39

Page 40

Heat sealing

Start

(This function appears when the top feed roller is lowered.)

With this function the sealing start is called up, analog to the pedal function "+2", also see

Chapter 7.04 Pedal.

Feed roller up/down

With this function the top feed roller, depending on its position, can be raised or lowered,

analog to the pedal functions "-1" and "+1", also see Chapter 7.04 Pedal.

Feed rollers in reverse

This function makes it possible to call up the reverse running function of the feed rollers.

Break

This function is used to switch off the temperature control of the heating element.

The heating element cools down.

Input menu

This function is used to call up the "input" mode, see Chapter 11 Input.

Stop

(This function appears during the sealing operation.)

This function is used to stop the sealing operation, analog to pedal function "-1", also see

Chapter 7.04 Pedal.

During the sealing process, the machine is operated by pedal and foot switch,

see Chapter 7 Controls.

40

Page 41

Heat sealing

10.03 Creating/editing a heat sealing program

Up to 100 sealing programs (0 – 99) each with up to 20 sealing zones can be fi led and man-

aged in the machine memory.

● Call up the input menu.

● With the “programming” function from the input menu it is possible to enter the pro-

gramming function for sealing programs. A number block for entering the desired pro-

gram number appears.

Creating a new program

Altering a program

Example 1

If no program is fi led in the memory under the program number selected, the current seal-

ing parameter of the manual heat sealing function will be taken over and a new program cre-

ated.

As an alternative to the creation of a new program, the program number of an existing program (e.g. 10) can be selected, and this program can be changed or copied to create a new

program. In the case of existing programs, the number of zones and possibly a comment are

displayed next to the program number in the headline.

● Enter the program number, e.g. "10".

● Confi rm selection.

Example 1

The fi rst zone of the selected program is displayed on the screen with functions for enter-

ing sealing parameters, notes, switching to the next zone, as well as basic functions for the

program input. For further descriptions of the functions see Chapter 10.03.07 Example for

sealing program input.

41

Page 42

Heat sealing

10.03.01 Notepad

When creating a sealing program, this function is used to enter data about the sealing tools

for the program. The data serves as information for the operator and can be called up in the

programmed sealing mode.

● Press the relevant key panels to enter the data.

● Enter the relevant data.

● Conclude the input

42

Page 43

Heat sealing

10.03.02 Basic functions for the program input

The following functions are used to enter the basic information for the currently selected

program. In addition to functions for navigating in the different zones and functions for in-

serting and deleting zones, depending on the zone displayed, functions can be called up for

entering further parameters and comments as well as for concluding the program input.

● Call up the appropriate functions to process or conclude the program.

Description of the functions

Selecting a zone

These functions are used to switch forwards and backwards to other zones in the current

program.

Insert

This function inserts a new zone at the current location. The data of the current zone are

copied for the new zone and the following zones are moved one place back.

Delete

This function deletes the current zone.

Further sealing parameters

(This function only appears in the fi rst zone.)

This function opens a menu for entering further sealing parameters, for example, nozzle or

hot wedge type, see also Chapter 10.03.05 Further sealing parameters.

Comment

(This function only appears in the fi rst zone.)

With this function, when entering a note, see Chapter 10.03.01 Notepad, the analog entry

of a comment about the current program is possible. The comment is displayed as informa-

tion about the appropriate program in the program selection and program management func-

tions.

Add

(This function only appears in the last zone.)

This function is used to copy the data of the current zone and add it as a new zone.

Conclude programming

This function concludes the programming, see Chapter 10.03.06 Concluding the program-

ming.

43

Page 44

Heat sealing

10.03.03 Sealing parameters

● Enter sealing parameters for each zone as described in Chapter 9.03 Entering sealing

parameters (manual heat sealing).

Description of the functions

Heat sealing temperature

This function is used to alter the heat sealing temperature, see Chapter 9.03.01 Entering

the sealing temperature.

Feed stroke (sealing speed)

This function is used to open the menu for entering the feed stroke difference, the brake and

acceleration profi les and the start delay for the feed rollers, see Chapter 9.03.02 Entering

the sealing speed.

Roller pressure

This function is used to alter the roller pressure, see Chapter 9.03.04 Entering the roller

pressure.

Hot air volume (nur bei der PFAFF 8320-020

This function is used to alter the hot air volume.

44

Page 45

Heat sealing

10.03.04 Functions for switching to other zones

In addition to the sealing parameters, further functions can be allocated to each zone, which

serve to enable the automatic switch to other zones and a more exact setting of the sealing

operation sequence.

● Select appropriate functions for each zone, activated functions are displayed as inverse

symbols on the screen.

Description of the functions

Programmed section

mm

This function is used to determine the length of the current zone. The value in millimetres

is entered on the appropriate number block. When this function is activated, the machine

switches to the next sealing zone after processing the entered section.

Loop program command

When this function is switched on a loop is programmed into the program sequence.

Entering the return target position

Here, the number of a previous zone can be entered.

Entering the number of loop iterations 0 - 99

Input "0" = the loop runs endlessly

IN2

Programmed output

When this function is switched on, the current zone takes on an output switch function. Two

outputs can be stipulated with the appropriate menu. The sealing parameters entered for

this zone are not taken into account.

Programmed input

When this function is switched on, the machine does not switch to another zone until an

appropriate input signal is given or not given. The two different inputs can be set up with the

appropriate menu.

Sealing on/off

When this function is switched on, the current zone takes on a switching function. The seal-

ing operation is switched off or on and the machine moves to the next zone. For the follow-

ing zones, the sealing remains switched off or on until the setting is changed again.

Interrupt the loop with a high level (24V) on free input IN2 (X8/PIN3)

Zone forwarding with foot switch 1 at Stop (see chapter 7.04) skips the loop

command

Programmed Stop

Activating this function will transform the current range to a stop function. The welding

stop is executed and a transfer to the next range occurs. The welding parameters entered for that range will not be applied.

45

Page 46

Heat sealing

10.03.05 Entering further sealing parameters

Further sealing parameters can be entered either

● from the manual resp. dynamic sealing mode in conjunction with the sealing speed input

or

● when creating programs in conjunction with the input of the fi rst zone.

Input while

creating programs

with PFAFF 8320-010

Example

Example

● Select acceleration and brake profi le of the feed rollers, dependent on the material for

sealing. Each of the profi les selected is displayed as an inverse symbol. A fl at ramp

stands for slight acceleration of the feed rollers. The selection of a steep ramp means

high acceleration.

If the sealing result is unsatisfactory, the alteration of the acceleration or brake

profi le can lead to an improvement.

The values of the different acceleration and brake profi les can be stipulated in

the input mode, see Chapter 11.03.01 Feed roller parameters.

Input while

creating programs

with PFAFF 8320-020

46

__

● Increase or reduce the start delay for the feed rollers directly.

or

● Call up the fi gure panel to enter the start delay.

Enter the start delay depending on the material being processed.

● Conclude the input, permissible values will be taken over

The start delay function is used to stipulate the amount of time which should

pass between the engaging of the heating element and the start of the feed

rollers.

Page 47

Heat sealing

Further functions are available for creating programs:

● Select the sealing tool by switching between heating wedge and hot air nozzle. This

makes it possible e.g. to also create programs for hot air machines on hot wedge machi-

nes.

● Select the nozzle type in accordance with the width of the nozzle installed, see Chapter

9.03.05 Stipulating the nozzle type and hot air volume …

or

● Select the hot wedge type in accordance with the width of the hot wedge installed, see

Chapter 9.03.03 Stipulating the hot wedge type …

10.03.06 Concluding programming

Once all the details for the programming have been entered, the programming can be

concluded by pressing the appropriate function key.

Example

Example

Description of the functions

Esc

The input is interrupted and the machine moves back to the initial state of the programming

function.

Discard alterations

All program alterations are cancelled.

Save as...

If this function key is pressed, the number panel opens to enter any program number.

Enter

All program alterations are saved under the current program number.

47

Page 48

Heat sealing

10.03.07 Example of how to enter a sealing program

The following example should be fi led under program number "10" with the comment "example 1", and consists of three seam zones:

1. Seam zone 1 with switch to another zone after 200 mm seam length

- 2. Seam zone with reduced welding speed and speed difference between the upper and

lower transport roller and with zone forwarding after 100 mm

- 3. Seam zone back to original welding speed without speed difference between transport rollers and with zone forwarding after 400 mm

● Switch on the machine.

● Call up the programming function..

● Enter program number "10".

● Confi rm input.

The sealing parameters from the manual sewing mode are taken over for seam zone 1.

48

Page 49

Heat sealing

● Call up comment input.

● Enter the term "example" with the appropriate symbols.

● Change to number input.

Example

● Enter number "1" with the appropriate symbol.

● Conclude the comment input.

Example 1

mm

● Activate the switch to another zone using the seam length.

● Enter the value "200" as seam length with the number panel.

● Conclude the activated function for switching to another zone.

49

Page 50

Heat sealing

Example 1

● Add seam zone 2.

Example 1

● Change the values for sealing speed and speed difference.

● Activate the switch to another zone with the value "100" as seam length.

mm

Example 1

● Conclude the input of seam zone 2.

Example 1

50

Page 51

Heat sealing

● Add seam zone 3.

● Reset the values for sealing speed and speed difference.

mm

● Activate the switch to another zone with the value "400" as seam length.

● Conclude the input of seam zone 3.

Example 1

● Conclude programming.

Example 1

● Reconfi rm the sealing program input.

The programmed sealing function is called up to process the created sealing program.

Example 1

4

The entered program is automatically activated.

51

Page 52

Heat sealing

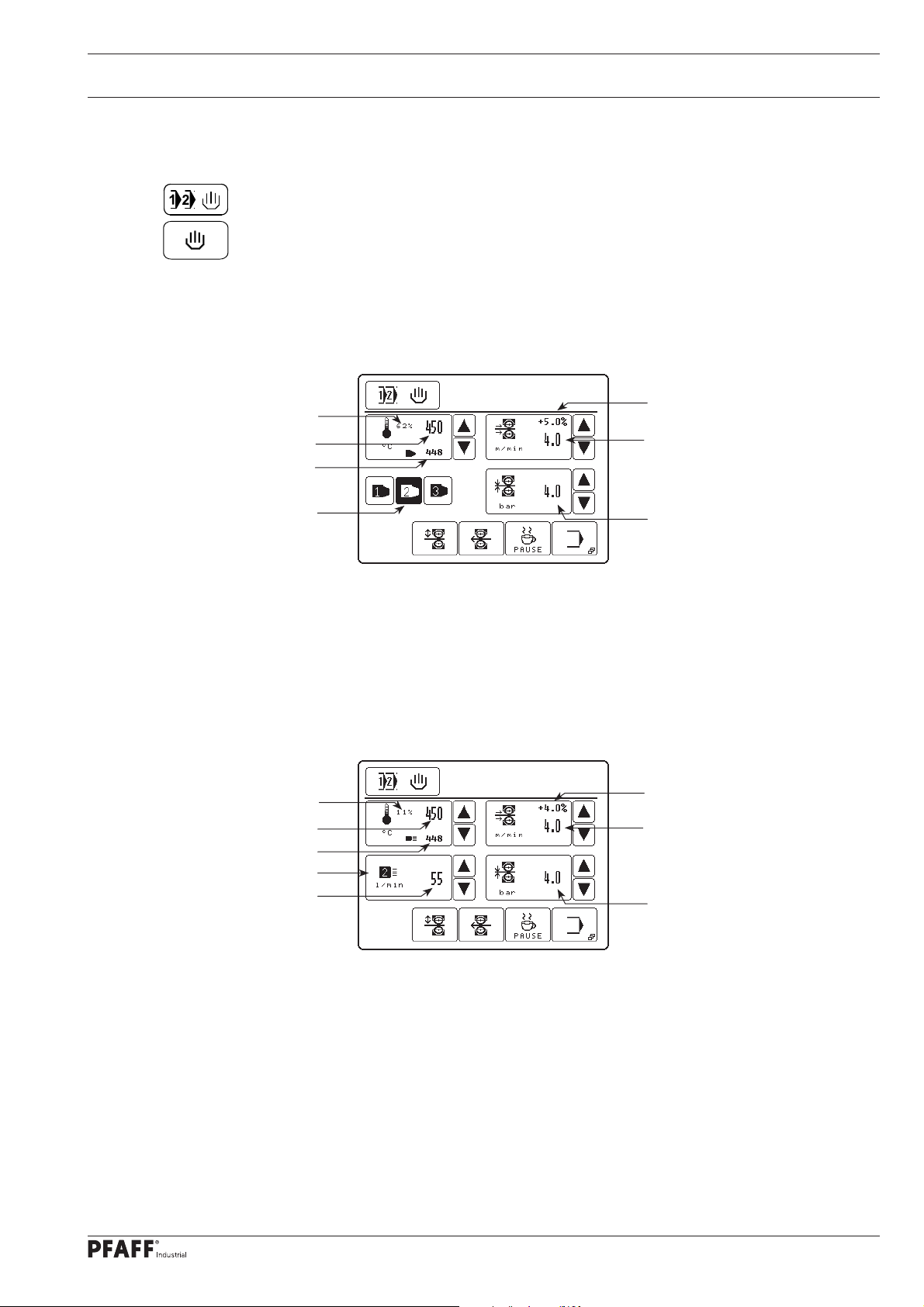

10.04 Programmed heat sealing with individual programs

In the headline, in addition to the program number of the selected program, the number

of zones, the current zone and the comment for the program are displayed. For the current

zone all heat-sealing parameters are displayed. The heat-sealing parameters have been

stipulated during programming and cannot be processed without changing the program.

● Select the desired program, see Chapter 9.02 Selecting the production type.

PFAFF 8320-010

Example 1

Description of the functions

Program selection

The function opens the menu for entering the program number or for choosing the

production type, see Chapter 9.02 Selecting the production type.

Notepad

This function opens the notepad with program details about the heat-sealing tools

to be used.

Start

(This function appears, when the top feed roller is lowered.)

This function is used to call up the sealing start, analog to pedal function "+2", also see

Chapter 7.03 Pedal.

PFAFF 8320-020

Example 2

52

Feed roller up/down

This function is use to raise or lower the top feed roller, depending on its position, analog to

the pedal functions "-1" and "+1", also, see Chapter 7.03 Pedal

Feed rollers in reverse

This function can be used to call up the reverse running function of the feed rollers

Break

This function is used to switch off the temperature control of the heating element.

The heating element cools down.

Input menu

This function is used to call up the "Input" mode, see Chapter 11 Input.

Stop

(This function appears during the heat-sealing operation.)

This function is used to stop the heat-sealing operation, analog to pedal function "-1", also

see Chapter 7.03 Pedal

Page 53

Heat sealing

10.05 Creating/processing sequences

In sequences up to 8 heat sealing programs are combined in any order whatever and fi led

under a sequence number. A total of up to 10 sequence programs can be fi led in the ma-

chine’s memory.

● To enter sequence programming, fi rst of all call up the Program selection function.

● Call up the Sequence selection function and select the desired sequence number.

● Call up sequence programming.

The cursor in the window shows which program is being deleted or at which point

a new program is being inserted.

Description of the functions

Arrow keys

These functions are used to move the cursor.

Insert

This function inserts or adds a program to the sequence at the place marked.

Delete

This function deletes the marked program from the sequence.

Conclude programming

This function concludes the sequence programming.

53

Page 54

Heat sealing

10.06 Programmed heat sealing with sequences

In the headline, in addition to the sequence number of the selected sequence, the num-

ber of zones, the current zone and the comment for the current program are displayed. For

the current zone all heat-sealing parameters are displayed. The heat-sealing parameters have

been stipulated during programming and cannot be processed without changing the pro-

gram. In addition, in the case of heat sealing with sequence programs, the individual pro-

grams belonging to the sequence are displayed, and the current program is shown here as

an inverse symbol.

● Select the desired sequence, see Chapter 9.02 Selecting the production type.

Example 1

Description of the functions

Program selection

The function opens the menu for entering the program number or for choosing the

production type, see Chapter 9.02 Selecting the production type.

Notepad

This function opens the notepad with program details about the heat-sealing tools

to be used.

Heat sealing program

Press this function to select the appropriate heat sealing program.

Start

(This function appears, when the top feed roller is lowered.)

This function is used to call up the sealing start, analog to pedal function "+2", also see

Chapter 7.03 Pedal.

Feed roller up/down

This function is use to raise or lower the top feed roller, depending on its position, analog to

the pedal functions "-1" and "+1", also, see Chapter 7.03 Pedal

Feed rollers in reverse

This function can be used to call up the reverse running function of the feed rollers.

54

Break

This function is used to switch off the temperature control of the heating element.

The heating element cools down.

Input menu

This function is used to call up the "Input" mode, see Chapter 11 Input.

Page 55

Heat sealing

Stop

(This function appears during the heat-sealing operation.)

This function is used to stop the heat-sealing operation, analog to pedal function "-1", also

see Chapter 7.03 Pedal.

Sequence programs are run as follows depending on the parameter setting

'Sequence continue':

Sequence continue = 1

The programs are executed in sequence according to the sequence

displayed. The currently executing program is shown inversely.

The sequence can be restarted at any point by pressing one of the program

buttons.

Sequence continue = 0

The selected program remains selected and is shown inversely. A different

program can be selected at any time by pressing one of the program buttons

(quick key selection).

55

Page 56

Heat sealing

10.07 Error messages

In case of a malfunction, an error code appears on the display. An error message may be

caused by incorrect handling, faults on the machine or by overload conditions.

For the explanation of the error code, see Chapter 13.13 Explanation of the

error numbers.

● Eliminate the error..

● Acknowledge the elimination of the error.

or

● Call up the input menu to eliminate the error with the service functions.

56

Page 57

Input

11 Input

Contained in the input mode are the functions for displaying information, for program ma-

nagement, for machine adjustment and confi guration (incl. choice of country and access

rights), as well as for supporting service and adjustment work.

11.01 Summary of the functions in the input mode

● Switch on the machine.

● Call up the input mode

PFAFF 8320-010

Description of the functions

Heat sealing mode

This function is used to change to the heat sealing mode.

Info

This function opens a menu to display the following information:

- Current software status of the machine

- Current fi rmware status of the machine

- Current fi rmware status of the control panel

- Regulation degree of the temperature control unit

- Number of operating hours (can be reset with the Clear function)

- Number of production hours (can be reset with the Clear function)

PFAFF 8320-020

Program management

This function is used to manage the data from the machine memory and disks,

see Chapter 11.02 Program management.

Further settings

This function is used to call up a menu for stipulating further machine settings,

the choice of country and the access rights, see Chapter 11.03 Further settings.

Service menu

This function is used to call up the menu for selecting various service functions,

see Chapter 13.11 Service menu.

57

Page 58

Input

450

Daily piece counter

This function is used to call up the daily piece counter. The daily piece counter can be reset

with the Clear function.

Break

This function is used to switch off the temperature control of the heating element.

The heating element cools down.

Grinding the hot wedge (only on the PFAFF 8320-010)

After this function has been called up, the hot wedge can be ground. The speed of the feed

rollers can be altered in the menu displayed. The grinding operation is controlled with the pedal function, see Chapter 12.05 Grinding the hot wedge…

Pre-heating the feed rollers (only on the PFAFF 8320-020)

This function is used to switch the manual pre-heating function of the feed rollers on or off.

When the function is activated, a menu opens for entering the pre-heating time.

Programming

These functions are used to enter the Creating or Altering Heat-Sealing Programs, see

Chapter 10.03 Creating/altering heat sealing programs.

Feed rollers forwards/backwards

This function makes it possible to turn the feed rollers forwards/backwards at a freely

selectable speed. For this purpose a menu is opened with functions for selecting the

speed of the feed rollers and rotational direction, as well as for stopping and starting

the feed rollers.

Positioning the heating element

With the use of this function, the heating element can be engaged manually to facilitate the

positioning of the heating element to the feed rollers. A menu is opened with functions for

carry out the engaging or disengaging operation.

Locking the feed rollers

This function is used to lock the feed rollers in order to facilitate a feed roller change. A menu

is opened with a function for releasing the lock again.

58

Page 59

Input

11.02 Program management

The program management function is used to manage sealing programs as well as confi gu-

ration and machine data. Files can be selected from the machine memory or from a disk and

be copied or deleted.

● Switch on the machine.

● Call up the input mode.

● Call up the program management function

If the machine is equipped with a

Floppy Disk drive, the operator can

switch between Floppy and SD-

Card with the button.

The directoryies of machine memory and SD-Card appear on the display:

- Left window: Machine memory ("C:\DATEN\" - is currently selected)

- Right window: SD-Card

The medium is selected by touching the appropriate fi eld. The selected medium and the se-

lected fi les are shown as inverse symbols:

Sealing programs are fi led at a different level to that for the confi guration and

machine data, in order to avoid the confi guration and machine data being pro-

cessed by mistake.

Description of the functions

Input menu

This function is used to call up the input menu.

Refresh directoryies

This function is used to refresh the directoryies of machine memory and SD-Card.

Sealing mode

This function is used to change to the sealing mode.

Data selection

With these functions the desired fi les are marked in the current drive. Individual fi les are se-

lected with the arrow keys. In combination with the Lock key (*) several fi les can be selected

at one time with the arrow keys.

Copy

This function is used to copy the selected fi les from the current storage medium onto the

second storage medium.

59

Page 60

Input

Delete

This function is used to delete the selected fi les.

MDAT/KONF

This function is used to call up the level for the confi guration and machine data. The

current settings and the machine confi guration are stored in the fi les „MDAT8320“ and

„KONF8320.BIN“. In this way the machine data can be copied on to a disk as a backup, or

several machines with the same designation can be confi gured quickly by reading the

machine data.

Format

This function is used to format the fl oppy disk inserted. In case of SD-Card, a folder P8320 is

created

In the course of the formatting operation, all data on the disk are deleted!

On SD-Card, only the contend of folder P8320 is deleted!

60

Page 61

Input

11.03 Further settings

The further settings are use for stipulating further machine settings, the choice of country

and access rights.

● Switch on the machine.

● Call up the input mode.

● Call up the input menu for further settings.

PFAFF 8320-010

Description of the functions

Input menu

This function is used to call up the input menu.

Sealing mode

This function is used to change to the sealing mode.

Feed unit backwards after stop

This function is used to enter the distance which the feed unit should move back after a

sealing stop.

PFAFF 8320-020

Feed unit forwards at end

The function can be switched on or off. When the function is switched on, the distance,

which the feed unit should continue moving after the end of sealing, can be entered.

Temperature window for sealing start

This function is used to enter the tolerance between the actual and the set temperature,

within which a sealing start is possible. If the actual temperature is outside the tolerance ,

the sealing start is blocked.

Flip-fl op mode (pedal)

This function is used to switch the fl ip-fl op mode for the pedal function on or off:

- Function switched on (symbol shown inverse)

The pedal function is only carried out as long as the pedal is held in the appropriate

position.

- Function switched off

The pedal function is carried out as soon as the pedal is brought into the appropriate posi-

tion and remains active after the pedal has been released.

61

Page 62

Input

Feed roller parameters

This function opens a menu for entering the feed roller parameters, see Chapter 11.03.01

Feed roller parameters.

Automatic heat-up

This function switches the automatic heat-up function on or off. With the function activated,

the heating element is slowly heated in a range between 20° and 120° to prevent damage to

the element due to abrupt temperature change.