Page 1

®

--T-T'V

•

.'J::

PFAFF

High-Speed

Sewing

U.S.

Federal

Machine

Service

Two-Thread

Stitch

Type

5463

Chainstitch

401

Manual

G.M.

PFAFF

AG

KAISERSLAUTERN

BRANCH

,-v

•

Page 2

• . -•

a •

Ji.

R9430

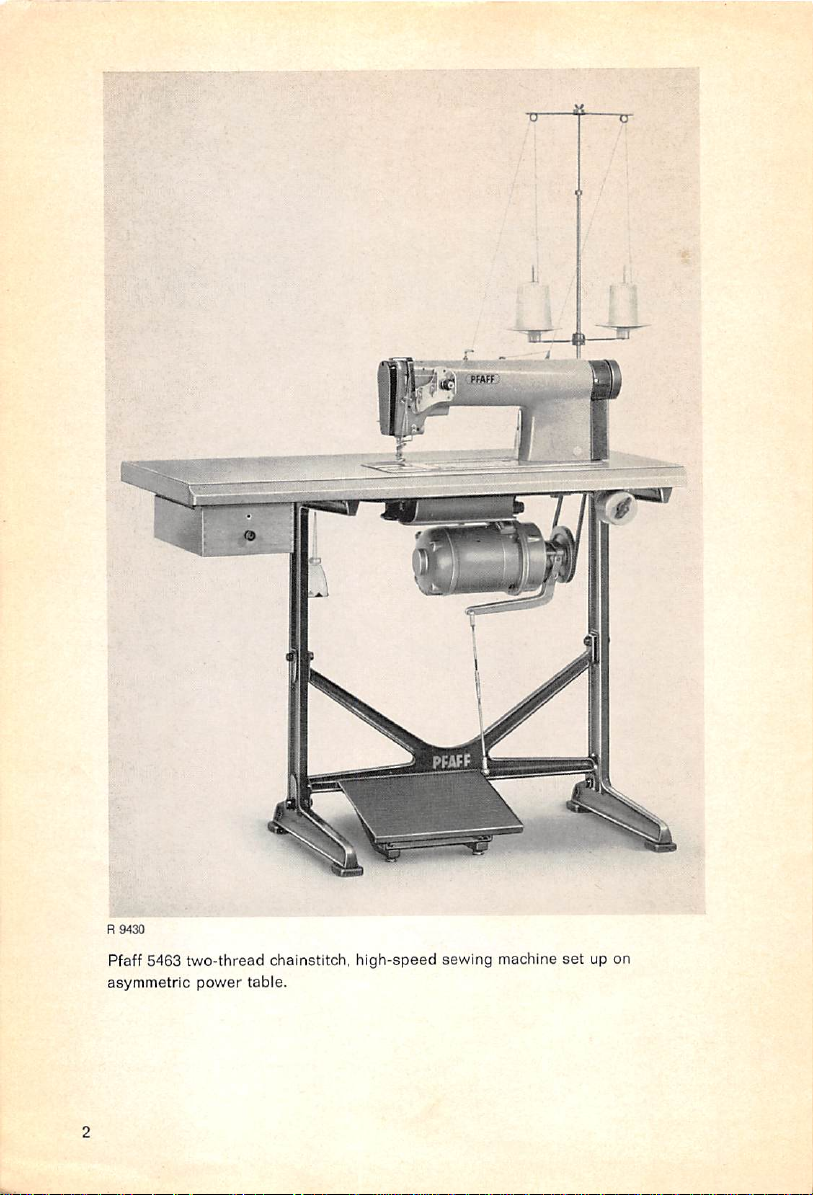

Pfaff 5463 two-thread chainstitch, high-speed sewing machine

asymmetric

power

table.

set

up on

Page 3

1.

General

The

which

new

makes

Pfaff

5463isa

the

two-thread

flat-bed

high-speed

chainstitch.U.S.

sewing

Federal

machine

Stitch

Type

fitted

withatransverse

401.

iooper

Equipped

built

size.

The

two-thread

regulator.Inaddition,itis

needle

6,000

For the time being, the machine is available in two varieties:

The

of two-thread chainstitching.

The

duces two lines of two-thread chainstitching, using four threads.

Thelatter

6.4

2.

Insert

as it

screw

with

ordinary

into

the

Pfaff

463

essential

difference

chainstitch

bar

and

replaces

s.p.m.and makes up to

Pfaff

5463-801isequipped

Pfaff

5463-802,

varietyisavailable

mm.

Inserting

the

needle

will

go.

securely.

the

into

Turn

on the other

Needle

it so that its

drop

feed,

this

machine

and

closely

resembles

between

sewing

the

the

both

machines

mechanism

fitted

withathread

conventional

5V2

stitches to the

with

one

hand,isfitted

at present in needle gauges of about

opening

ofthe

long

groove faces

follows

this

liesinthefact

andadisc-type

take-up

link

take-up.

inch.

needle

and

with

needle

bar or

the

latter

machineinits

lever

The

Ituses

one

two

needles

needle

toward

Pfaff

Iooper

same

basic

mechanical

exterior

that

the

Pfaff

rather

thanalink-type

whichisrigidly

5463

attainsatop

4463kKneedles.

and

producesasingle

and

two

Vw"

and

holder

and

you and

tighten

principle

design

5463

features

mounted

speed

loopers

pushitup

and pro

V4",

or 4.8 and

the needle set

and

a

feed

onthe

of

line

as far

3.

Adjusting

The needle bar frame should be positioned so that the needle

close

to its

To adjust the position of the needle bar frame in the direction of sewing, turn the eccentric

studatthe

Ifthe position of the needle bar frame requires adjustment crosswise of the direction of sew

ings, push it to the right or left in its bearings, as appropriate.

the

Needle

near

end, without actually touching it.

needle-bar-endofthe

Bar

machine

Frame

withascrewdriver.

will

enter the needle plate slot

Page 4

4.

Adjusting

The

lobeofthe

top

of its

point

down

the

feed

stroke.

At the

perpendicularly.

Feed

lifting

same

Dog

eccentric

time,

the

should

borehole

pointupwhen

in the

balancing

the

needle

collarofthe

bar

has

reached

eccentric

the

should

When the feed dog is at its highest point, its teeth should protrude from the surface of

the

needle

platebyabout

,or1.2 mm.

Timethe feed dog so that it

risen

clearofthe

4.1 Timing

To time

the

the

feed

needle

Feed

motion,

shaft, as may be appropriate (Fig. 1). If the feed

this guide backward; if it is supposed to begin earlier,

Motion

will

start to advance the material right after the needle point has

plate

slot.

loosen

set

screws

a in

the

dovetail

motion

guide

and turn

is supposed to begin later, turn

forward,

i.e. toward you. After this

this

guide

on its

adjustment, tighten set screws a securely. Anyretiming of the feed motion necessitates a re

timing of the looper motion in relation to the needle stroke.

4.2

Setting

the

Loopertothe

To do this, turn the balance wheel toward you

line of the needle as the looper moves toward the

of the

looper

point

and the edge of the

posite

direction

make

sure the

If

adjustmentisrequired,

regulator,asmay

Fig. 1

until

relative

be appropriate.

the

looper

vertical

Needle

pointisagain

positions

loosen

Then

until

needle

eye.

opposite

of the looper

set

screwsb(Fig.1)and

tighten

set screws b securely.

the looper point is opposite the center

left.

Note the relative vertical positions

Then

turn

the

balance

the

center

point

and the needle eye are the same.

rotate

wheelinthe op

lineofthe

the

gearonthe

needle

feed

and

s

a

;

i2

/

/

a =

Set

screws

on dovetail

b =

Set

a

screwsongear

guide

Page 5

5. Adjusting and

5.1 Setting the Looper at the Correct Height

The looper

face

5.2

with

Setting

should

the

the

thread

Timing

the Looper

be set so that its underside rests on the

grooveispositionedatright

Looper

Point

in Relation to

the

angles

Center

to the

Line of

looper

sewing

the

Needle

holder

and its inner sur

direction.

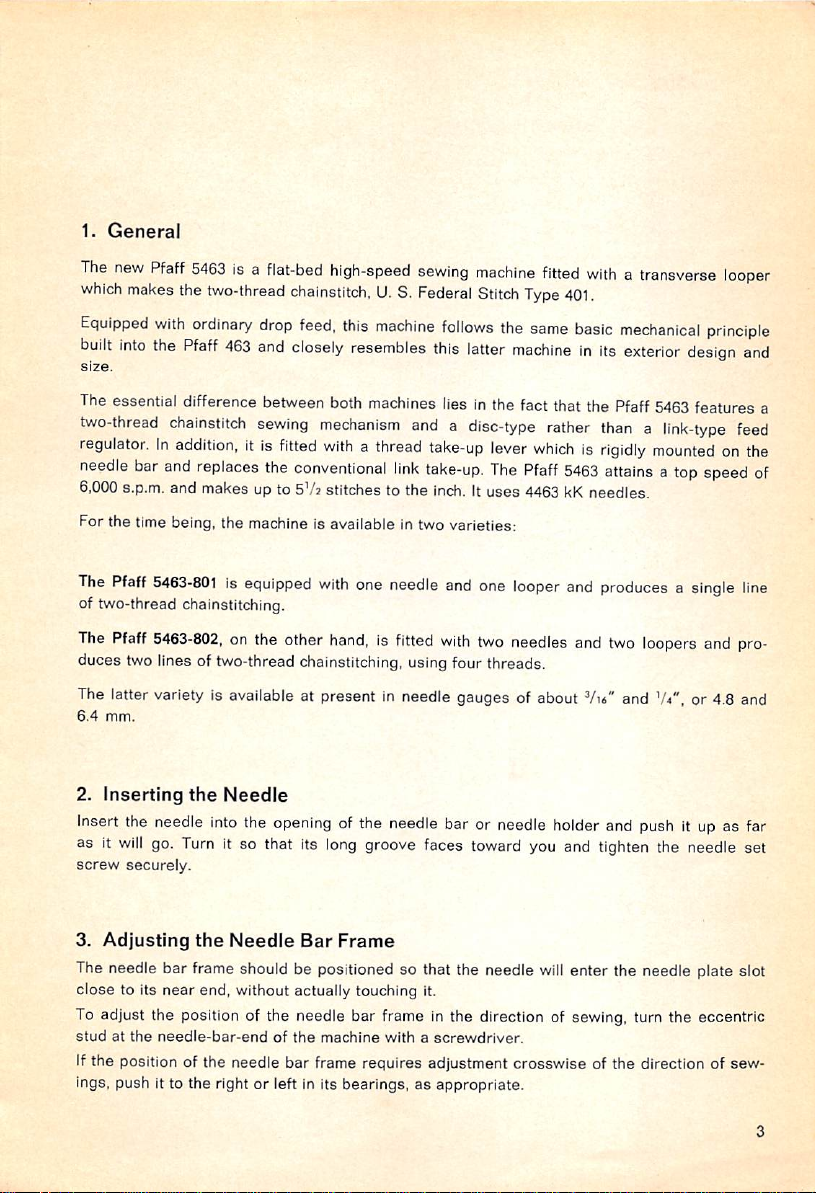

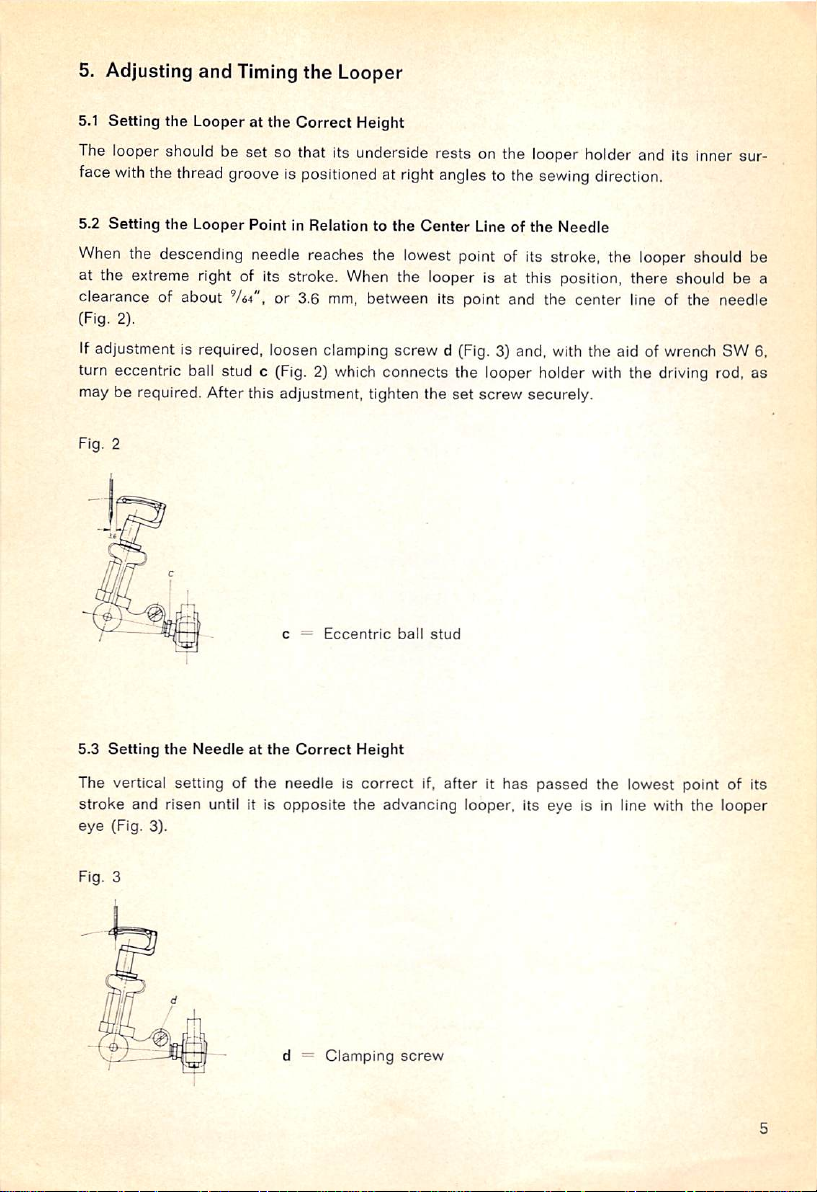

When the descending needle reaches the lowest point of its stroke, the looper should be

at the extreme right of its stroke. When the looper is at this position, there should be a

''U*",

or 3.6

rnm,

clearance of about

(Fig. 2).

between its point and the center line of the needle

Ifadjustment is required, loosen clamping screw d (Fig. 3) and. with the aid of wrench SW 6,

turn eccentric ball stud c (Fig. 2) which connects the looper holder with the driving rod. as

may be required. After this adjustment, tighten the set screw securely.

Fig. 2

c =

Eccentric

ball

stud

5.3

Setting

the

Needleatthe

The vertical setting of the

stroke

and risen until it is

eye

(Fig. 3).

Fig. 3

Correct

needleiscorrect

opposite

Height

the advancing looper, its eye is in line with the looper

Clamping

if,

screw

afterithas

passed

the lowest point of its

Page 6

5.4 Timing

the

Looper

Avoiding Motion

The looper avoiding motion is controlled by an eccentric which is carried on the main drive

shaft

under

the

bedplate.

Eccentric e (Fig. 4) is

front

set

screw

set

correctly if its lobe points to the right toward the needle and its

f points downward when the needle has reached the bottom of its stroke (g in

Fig- 4).

Fig. 4

e =

Eccentric

f =

g =

5.5

Setting

the

Turn

the

to

see

to

turn

between

the

looper

Loopertothe

balance

that

the

looper

wheel

the looper is at the extreme right of its stroke. If this setting is correct, continue

balance

point and

must

not

strike

NeedleinSewing

until

wheel

until

needle

the

needleihas

the

should

needle

If adjustment is required, loosen both

turn

this

bracket

around

its

fulcrum

until

looper is obtained. Then tighten both

Eccentric

Needleatlowest

looper

(Fig. 5).

set

the

set

screws I securely again (Fig. 5).

front

set

screw

point

Direction

reached

not

the

lowest

pointisopposite

exceed

.004",or0.1 mm. On the

point

the

of its

needle.

stroke

The

and

clearance

other

screws I on the looper mechanism bracket and

correct

amountofclearance

between

needle

check

hand,

and

Fig. 5

h =

1 =

k =

I =

Fulcrum

Needle

Bracket

Bracket

stud

set

screws

Page 7

6. Adjusting the Looper Thread Pull-Off Lever

Thread pull-off lever m is clamped onto a stud on the looper driving rod and should be ad

^U*",

justed so that there is a clearance of about

avoiding motion

of its throw (Fig. 6).

eccentric

and

Fig. 6

m =

n =

the

thread

Looper

Set

collar

thread

pull-off

or 2.0 mm, between collar n of the looper

lever

when

the

latter

is at

the

extreme

pull-off

lever

left

7. Regulating

The thread regulator arranged under

regulating

plate.

the

Looper Thread Pull-Off

the

bedplate

consists

of a bracket and an adjustable

Regulating plate o can be adjusted on its bracket and determines the amount of thread

tobepulled

over

from you (Fig. 7).

Any adjustment of the thread pull-off lever in relation to the regulating plate

off. To

increase

this

amount,

move

the

plate

toward

you,

andtodecrease

changes

the

time at which the thread is pulled through the looper thread tension. If the thread pull-off

lever

has

been

adjusted,

The regulating plate should be

thread

will be pulled

needleisat

When

the

other

automatically.

the

the

needle

phasesofthe

top

taut

of its

enters

regulating

the

stroke.

the

plateohas

set

in relation to the thread pull-off lever so that the looper

very

moment

thread

triangle,

the

to be

looper

the

adjusted

thread

begins

should

likewise.

its

return

become

stroke,

slack

i.e.

again. During

stitch forming cycle, the tension on the looper thread will be regulated

when

the

The curvature of the regulating plate controls the looper thread so that it will not be too slack

when the looper swings forward to pick up the needle thread, and

under

the

topofthe

looper.

Fig. 7

that

it will not be flung

it,

Regulating

plate

Page 8

8.

Adjusting

Thread

eyelet will be positioned about

the

needle

The

adjustable

regulator

bar

the

Needle

r (Fig. 8) on

is at its

thread

lowest

guide

Thread

the

tension

Va",

or 3.0 mm. below the top of the thread regulator when

point

(see

s (Fig. 8) on

Regulator

bracket

g in Fig. 8).

the

tension

that the thread runs in a horizontal line from its top

bar

needle

and

9.

Is at the top of its stroke. This setting should be

thread

being

used

(see

p in Fig. 8).

p =

Positionoftake-up

with

q =

Positionoftakeuplever

with

r =

Thread

s —

Adjustable

Adjusting

the

Looper

Swing-Back

needle

needle

Guide

shouldbesetsothat

bracket

shouldbeadjusted

edge

to the take-up lever eyelet when the

adapted

lever

barattopofstroke

baratbottomofstroke

regulator

thread

guide

the

take-up

to the type of material

eyelet

eyelet

vertically

lever

so

Looper swing-back guide u (Fig. 9) should besoadjusted that the looper

distanceof0.1or

When

looper

the spring-loaded

0.3 mm (Fig. 9).

t is at

the

base

extreme

right of its

stroke,itcanbeswung

catch (Fig. 9). With the looper swung out. Its

base

clears

outbypressing

base

should

bear

it at a

against

against

the swing-back guide so that the thread eyelet near its point clears the edge of the needle

plate on the right and the looper can be threaded without any difficulty (see Fig.14on page 12).

When

sewingisresumed,

Fig. 9

1

the

looper

t =

u =

returns

Looper

Looper

to its

operative

swing-back

position automatically.

guide

Page 9

10.

Adjusting

The rigid

it lightly,

To

guard

looperisopposite

the

proper

After this adjustment, tighten

Fig. 10

however

adjust

around

needle guard. In adjusting the needle guard, make

timing of

the

Needle

needle

guard w should be so adjusted that the

without

the

positionofthe

its fulcrum,asmay be

the

needle

the

loop

Guard

being

needle

on its

spreading

set

deflected

guard

reverse

action.

screwvsecurely

V =

w =

(Fig. 10).

vertically,

required

Needle

Needle

(Fig. 10).

side,

guard

guard

the

again.

descending

loosen

When

needle

sureitdoes

set

screw

needle

will chafe

set

screwvand

the

point of

shouldbeoutofcontact

turn

the

not interfere with the

against

the

needle

advancing

with

11. Regulating

the

Stitch Length

To regulate the stitch length, depress button x on the bedplate and turn the balance wheel

until this button

wheel

backorforth until

The stitch length

Fig. 11

snapsinplace

the

set

is indicated on scale y in the belt guard window (Fig. 11).

(Fig. 11). While keeping it

desired

stitch length

has

been

X =

y = Stitch

set.

Needle

depressed,

position

length

rotate the balance

knob

scale

Page 10

12.

Threading

upper

threading

Lead

the

thread

thread guide 2 on the machine arm.

guide3,clockwise

the

Needle

is illustrated In Fig. 12.

from

spool

1 up to

around

and

between

the

top

thread

guideofthe

Pass

it through the holes of this guide and of thread

tension

discs4and

through

thread

the

stand

center

and

down

holeofadjust

able thread guide 5. Passing above adjustable thread regulator 5a, the thread is then led

from right to left through the hole in take-up lever 6 which moves up and down with the

pass

needle bar. Then lead the thread down through guides 7, 8 and 9 and

back

through

the

eyeofneedle

10.

it from front to

to

10

Fig. 12

R943I

Page 11

13.

Threading

Pass

the thread from spool 11 on the thread

down

through

through hole 15 and thread guide 16 on the arm standard. Swing out thread guide z, insert the

thread into thread guide 17 near its lower end, and swing the guide back to its original posi

tion. Next, pull

the

Looper

holes12and

the

thread

into

13,

thread

clockwise

channel 18 In

stand

around

up and through the top thread guide and

and

the

between

bedplate,

tension

starting

discs

14.

at the arm

down

standard,

and

and draw it through thread guide 19, hole 20 of the thread pull-off lever, opening 21 of the

thread regulator, hole 22 of the thread pull-off lever, hole 23 at the heel of the looper and

then from front to back through hole 24 at the looper point.

Fig. 13

r;

R9432

11

Page 12

cm

Fig. 14

To draw the looper thread through guides 19 through 24, remove the right bedplate cover

by pulling back slide S (Fig. 12). Turn the

balance

wheel until holes 20 and 22 near the tips

R

9435

of the thread pull-off lever are in line with opening 21 of the thread regulator and the thread

can

be pulled from thread guide 19 through holes 20, 21 and 22.

To thread the looper, rotate the balance wheel until the looper is in its extreme right position.

Then swing out the looper by pressing against release latch k (Fig.14)with your finger.

12

Page 13

Contents

1.

General

2. Inserting the Needle

3. Adjusting

the

Needle

Bar

Frame

4. Adjusting the Feed Dod

4.1 Timing

4.2 Setting the Looper to

the

Feed Motion

the

Needle

5. Adjusting and Timing the Looper

5.1 Setting the Looper at the Correct Height

5.2 Setting the Looper Point inRelation to the Center Lineof the Needle

5.3 Setting the Needle at the Correct Height

5.4 Timing the Looper Avoiding Motion

5.5 Setting the Looper to the Needle in Sewing Direction

6. Adjusting the Looper Thread Pull-Off Lever

7.

Regulating

the LooperThread

Pull-Off

•

8. Adjusting the Needle Thread Regulator .

9.

Adjusting

the Looper

Swing-Back

Guide

10. Adjusting the Needle Guard

11. Regulating the Stitch Length

12.

13.

Threading

Threading

the

the

Needle

Looper

3

3

3

4

4

4

5

5

5

5

6

6

7

7

8

8

9

9

10

11

13

Page 14

mr

No. 12321

engl.

R 366

PrintedinGermany

Loading...

Loading...