Page 1

5463

High-Speed Two-Thread Chainstitch

Sewing

U.S.Federal

Instructions

G.M.

PFAFF

Machine

Stitch

Type

AG,

KAISERS

401

LA

UTERN

BRANCH

Page 2

Instructions

1.

The

Needle

Pfaff 5463

matching

two-thread

the

material

for

chainstitch

being

sewn

Operators

sewing

machines

(available in

sizes

use

System

70 to 120).

4463 KK

needlesinsizes

Insert the needle Into the opening of the needle bar and push it up as far as it will go.

set

Turn it so that its long groove faces toward you and tighten the needle

2.

Threading

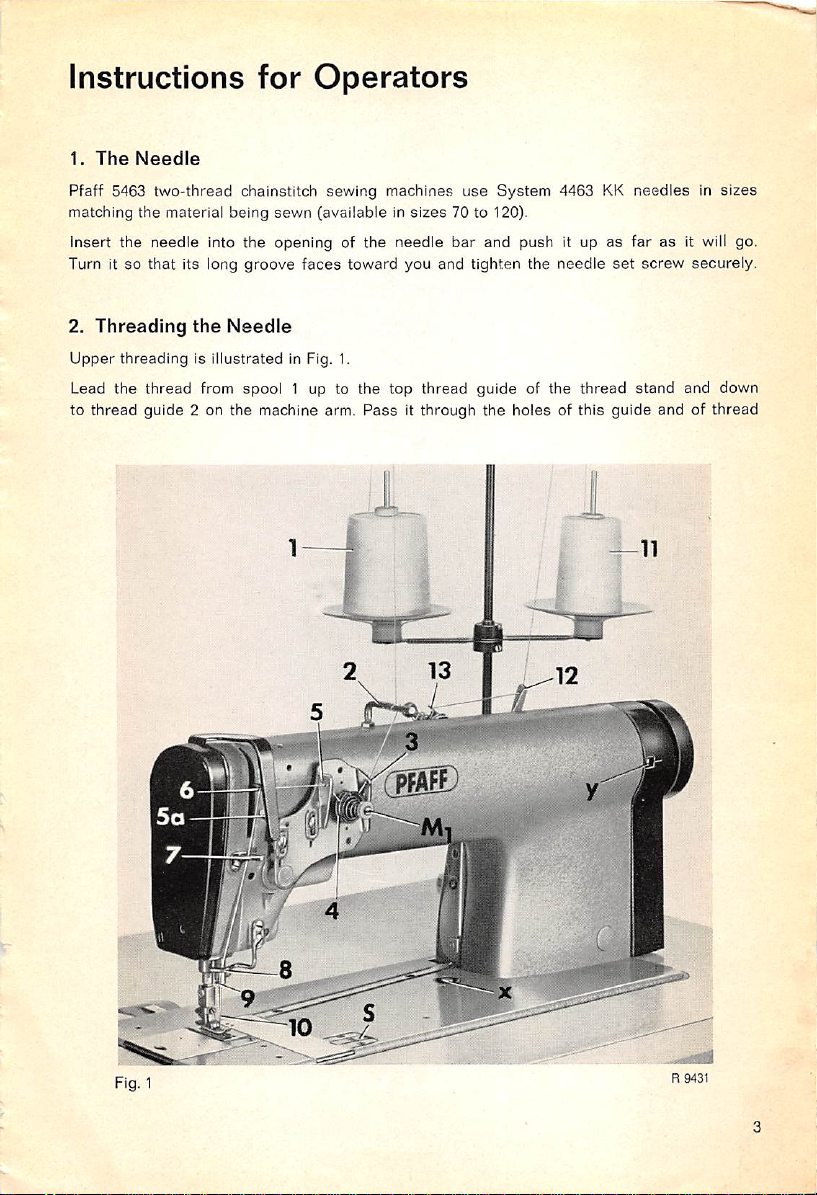

Upper

threading

Lead the thread from spool 1 up to the top thread guide of the thread

to thread guide 2 on the machine arm.

the

Needle

is illustrated in Fig. 1.

Pass

it through the holes of this guide and of thread

screw securely.

stand

and down

Fig. 1

R9431

Page 3

guide 3, clockwise around and between tension discs 4 and through the lower hole of ad

justable thread guide 5. Passing above adjustable thread regulator 5a, the thread is then led

from right to left through the hole in take-up lever 6 which moves up and down with the

needle bar. Then lead the thread down through guides 7, 8 and 9, and

back

through

3.

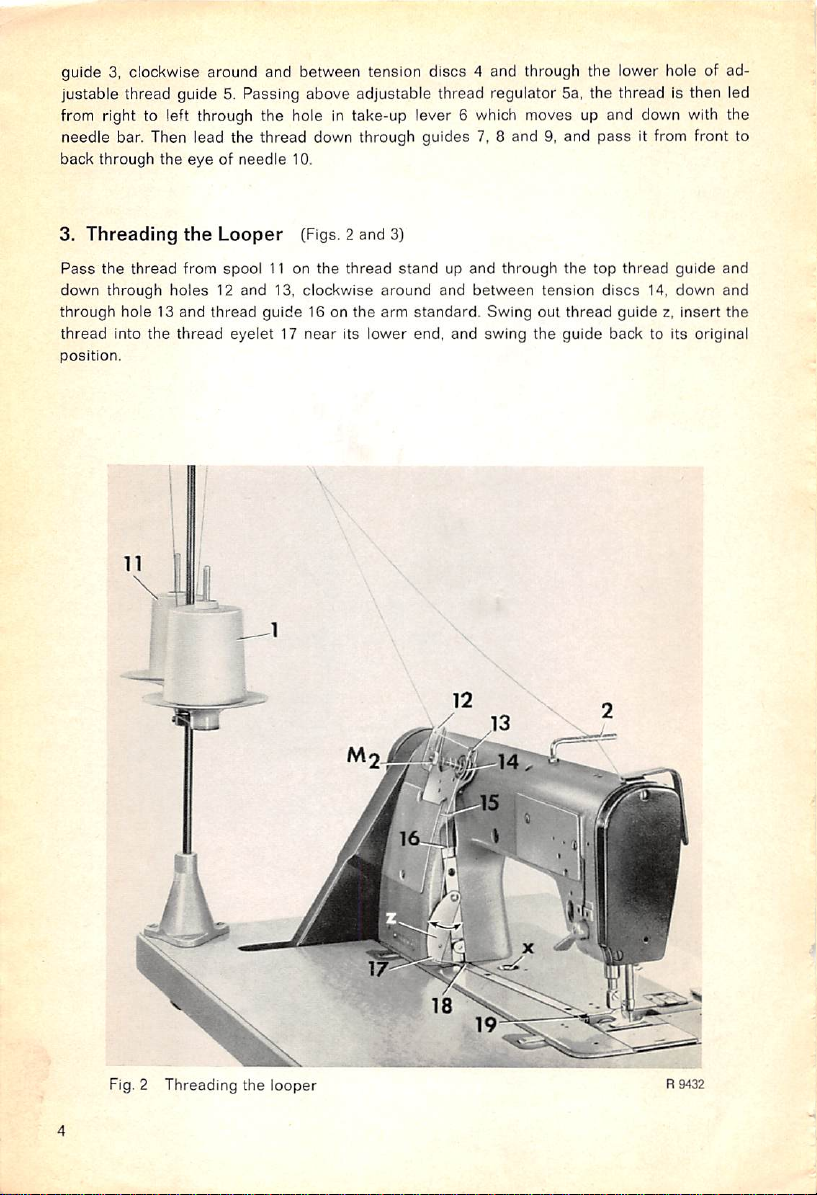

Threading

Pass

down

through

the

thread

through

hole 13 and

the

eyeofneedle

the

from

holes

thread

Looper

spool

11 on

12 and 13.

guide

10.

(Rgs. 2and3)

the

thread

clockwise

16 on

the

stand

around

arm

up and

and

standard.

through

between

Swing

the

tension

out

thread

pass

it from front to

top

thread

discs

14,

guidez,insert

guide

down

and

and

the

thread into the thread eyelet 17 near its lower end, and swing the guide back to its original

position.

J

'•S

Fig. 2 Threading the looper

R9432

Page 4

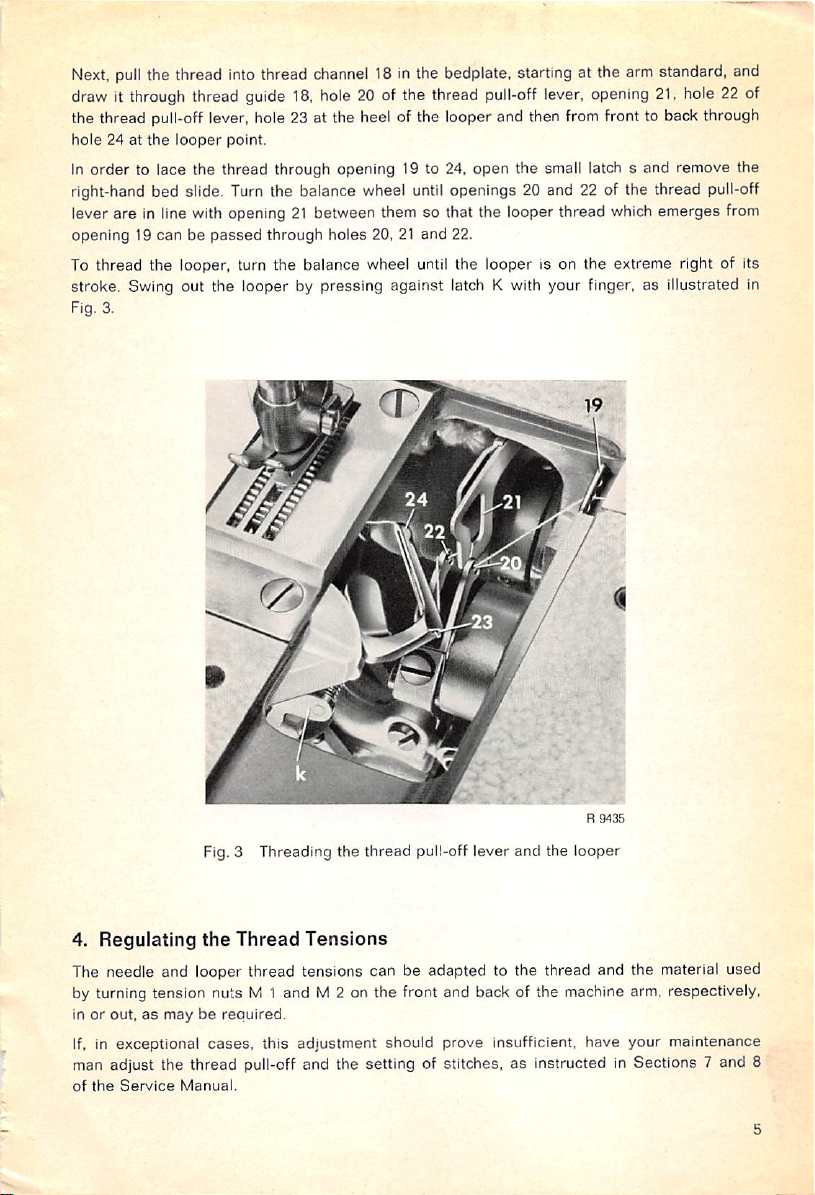

Next,

pull

the thread

drawitthrough

into

thread

thread guide

18.

channel

18in the bedplate,

hole

20 of the thread

starting

puil-off

at the armstandard, and

lever,

opening

21. hole 22 of

the thread pull-off lever, hole 23 at the heel of the looper and then from front to back through

hole

24 at

the

looper

point.

In order to lace the thread through opening 19 to 24. open the small latch s and remove the

right-hand bed slide.

Turn

the balance wheel

until

openings 20 and 22 of the thread

pull-off

lever are in line with opening21between them so that the looper thread whichemerges from

opening 19 can be

To thread the looper, turn the balance wheel until the looper is on the extreme right of its

passed

through holes 20, 21 and 22.

stroke. Swing out the looper by pressing against latch K with your finger, as illustrated in

Fig. 3.

Rg435

Fig. 3 Threading the thread pull-off lever and the looper

4.

Regulating

The needle and looper thread tensions can be adapted to the thread and the material used

the

Thread

Tensions

by turning tension nuts M 1 and M 2 on the front and back of the machine arm, respectively,

in or out.asmay be

If. in

exceptional

required.

cases,

this

adjustment

should

prove

insufficient,

have

your

maintenance

man adjust the thread pull-off and the setting of stitches, as instructed In Sections 7 and 8

of

the

Service

Manual.

Page 5

5. Regulating

The machine can be

the

Stitch Length

set

for a maximum stitch length of 5V2

(Fig.

i)

per

inch.

To regulate the stitch length, depress button x in the bedplate and turn the balance wheel

until

the

button

snapsinplace.

The stitch length is indicated in window y in the belt guard.

set

the machine for the desired stitch length, turn the balance wheel back or forth, while

To

button X Is

meters)

6.

Sewing

Since

into

lockstitch sewing machine, provided the

regulated

A

considerable

obtained

sewn

7.

Machine

Since

to a

Once

snapped

is in line with

this

two-thread

our

high-speed

correctly,

because

continously

in place, until

the

markinthe

chainstitch

lockstitch

amount of time is

there is no

at high

speed

Care

the

number indicating the desired stitch length (in milli

window.

seamer

seamers,

need

without any interruption.

its

proper

saved

on many sewing

follows

the

same

basic

operationisjustassimpleasthat

needle is

used

jobs

to change the bobbin and the individual

mechanical

and the tension

and a higher output of work

the Pfaff 5463 incorporates maintenance-free anti-friction bearings, its

few

manipulations.

a week, remove the face

cover

and put a few

drops

of oil into the oil dents on the

principle

of an

has

pieces

care

is limited

built

ordinary

been

can be

needle bar bearings.

All the

other

bearings are

solve

the

grease.

For the

same

reason, no

such non-sealed anti-friction bearings, it will dissolve the

The

only

implements

is important

that

the

ticularly when sewing fluffy or heavily

are

likely to

absorb

grease-packed

kerosene

that

shouldbeusedtoclean

lint which

the

greaseinthe

has

and must not be oiled

must be

used

in cleaning the machine. If

accumulatedinthe

dressed

bearings.

materials

grease.

the

machine

areabrush

machineberemoved

because

because

the

kerosene

andaduster.

the particles of

oil would dis

enters

regularly,

dressing

par

To clean the machine, take out the knee lever and tilt the sewing head back. This makes

the

looper

has

accumulated

easyofaccess.

between

From time to time,

the

tooth

rowsofthe

strip

feed

the

needle

dog

plate

and

with a pointed

remove

wooden

the

lint which

instrument.

It

Page 6

b-

y:

Nr. 12319

engl.

R 1264

PrintedinGermany

Loading...

Loading...