Pfaff 145, 151, 153, 143, 541 Instruction Manual

...

R

6499

( PMff f

141;

143|

145;

151;

153

541; 543;

543-712;

545;

555

Single-needle

flatbed

sewing

machines

142;

144;

146

542;

542-748/01;

544; 546;

546-748/01

Two-needle

flatbed

sewing

machines

Instruction

Book

/

' •

Contents

, ^

Page

1.

General

®

2.

Fundamentalsofmachine

operation

3

3.

Cleaning

and

oiling

^

4.

Winding

the

bobbin

®

5.

Changing

the

bobbin

and

threading

the

bobbin

case 7

6.

Selecting

the

correct

needle

3

Needle

systems

®

Needle

point

styles

®

Needle

and thread sizes 8

7. Changing

the

needle

8.

Threading

the

needle

^

9. Drawing up the bobbin thread

10. Regulating the thread tensions

Adjusting the upper tension

Adjusting the lower tension

11. Regulating the stitch length

12.

Regulating

the

pressureonthe

material

''S

13. Cleaning

the

sewing hook

14.

The

safety

clutch

Additional

instructions

for

Pfaff

machines'141-705/03

and

141-705/03-725/01

. 16-18

15. Regulating the stitch length

16.

Changing

the

feed

gears

'•8

17. Adjusting

the

trimmer * *

^18.

Operating

the

trimmer

^

Additional

Instructions

for

Pfaff

machines

143-705/03

21

19.

Regulating

the

stitch

length

21

Additional

Instructions

for

Pfaff

machines

145

22-24

20.

Exchanging

the

alternating

pressers

22

21.

Lubricating

the

machine

24

0-22. Setting

the

foot lift

-

Additional

Instructions

for

Pfaff

machines

151

and

153

(

Additional

Instructions

for

Pfaff

machines

142,

542-748/01,

144

and

146

25-^

r23.

Threading

the

needles

25

.

24.

Adjusting

the

puller

feedofthe

Pfaff

542-748/01

26

Additional

Instructions

for

Pfaff

machines

543-712/01

and

543-712/02

...

27

"25. Threading the needle of the Pfaff

543-712

-.-Additional

Instructions

for

Pfaff

machines

546-748/01

28—29

^26.

Setting

the

foot

lift

. . . ; ^

't27.

Adjusting

the

puller

feed

29

^Additional

instructions

for

Pfaff

machines

4141

and

4145

. -

30

^^^28.

Threadingofthe

Pfaff

4141

and

4145

8®

^

Additional

Instructions

for

Pfaff

machines

fitted

with

thread

puller/trimmer

900/».31

"

'!'29.

Pedal

operation

Guards

Trouble

shooting

^

t

..

^i2

t.

General

•

Since

the

operationofthe

machines

listedonthe

title

pageismoreorless

the

same

the

general

instructions

compiledinthis

book

applytoallofthem.

Additional

instructions

for

the

Pfaff

141-705/03;

141-705/03-725/01;

142;

143-705

03-

144;

145;

146; 151;

153;

552-748/01;

543-712/..;

546-748/01;

4141;

4145

and

-900'..

appearatthe

backofthis

booklet.

We

reserve

the

righttomake

alterations

serving

progress.

The

illustrationsinthis

book

are also subject to change.

Itisrecommendedtorun

these

machinesatthe

following

top

speeds:

3

000

s.p.m.

Pfaff

4141

2

200

s.p.m.

Pfaff

141

and

144

2

900

s.p.m.

Pfaff

545

H3

2100

s.p.m.

2

800

s.p.m.

Pfaff

546

H2

1

300

s.p.m.

Pfaff

151

and

544

2

700

s.p.m.

Pfaff

546

H3

i

800

s.p.m.

Pfaff

153

and

542

2

600

s.p.m.

Pfaff

545

H4

i

700

s.p.m.

^ 2

500

s.p.m.

Pfaff

4145

1

600

s.p.m.

Pfaff

145

and

541

2

400

s.p.m.

Pfaff

546

H4

2

300

s.p.m.

and

543-712/..

1400

s.p.m.

When

sewing

tightly

woven

and

heavily

dressed

materials,

the

sewing

speed

should

be

reducedInorderto

prevent

overheating

of the

needle.

The

maximum

speedoftwo-needle

machines

decreasesasthe

needle

gauge

increases.

The

maximum

speeds

which

canbeattained

with

machines

fitted

with

special

attach

mentsortrimming

mechanisms

are

often

far

below

the

recommended

top

speeds

be

cause

the

natureofthe

work

and

the

thicknessofthe

material

tendtolimit

the

ma

chinescapacity.Ifthe

maximum

speedisexceeded,

trouble

may

develop

chieflyinthe

trimming mechanism.

To

avoid

troubleinthe

mechanism,

run

the

machineatabout75per

centofits

top

speed

until

the

parts

which

areinmovable

contact

have

become

thoroughly

glazed

by

their

action

upon

each

other.

This

should

normallybethe

case

after

about

two

weeks'

constant

use.

All

machines

are

regularly

equipped

withafixed

pulley

whichiscastinone

with

the

ba

ance

wheel.Ifdesired,

however,

these

machines

canbesupplied

withadisengage-

ible pulley.

If

fitted

with

the

latter

type

pulley,

the

machineisdispatched

with

the

sewing

mecha

nism

disengaged.Toengage

this

mechanism

for

sewing,

hold

the

balance

wheel

steady

with

your left hand and turn the large

lock

nut

clockwise.

2. Fundamentals of machine operation

Before

you

put

the

machineinoperation

for

the

first

time,

carefully

remove

all

dust

which

has

accumulatedintransit

and

oil

the

machine

thoroughly

(see

Chapter

3).

on

the

machine

only

with

Pfaff

sewing

machine

oil

whichIsnon-resinous

and

acid-free.

Checktomake

sure

the

finger,

take-up

lever

and

belt

guards

are

properly

fitted.

Never

runathreaded

machine

unless

you

have

fabric

under

the

presser

footorthe

vibrating

presser.

Before

you

start

sewing,

lay

both

threads

back

under

the

presser

foot

To

prevent

thread

jamming,

hold

both

thread

ends

until

the

machine

has

madeafew

stitches. . „

Do

not

pull

the

material

during

sewing:

the

machine

wiil

feed

the

fabric

automatically.

Use needlesofthe correct

system

only

(see Chapter

6).

Never

use

rusty

needles.

Use high-quality threads

only.

Always

bring

the

take-up

levertoits

highest

point

before

you

remove

the

material.

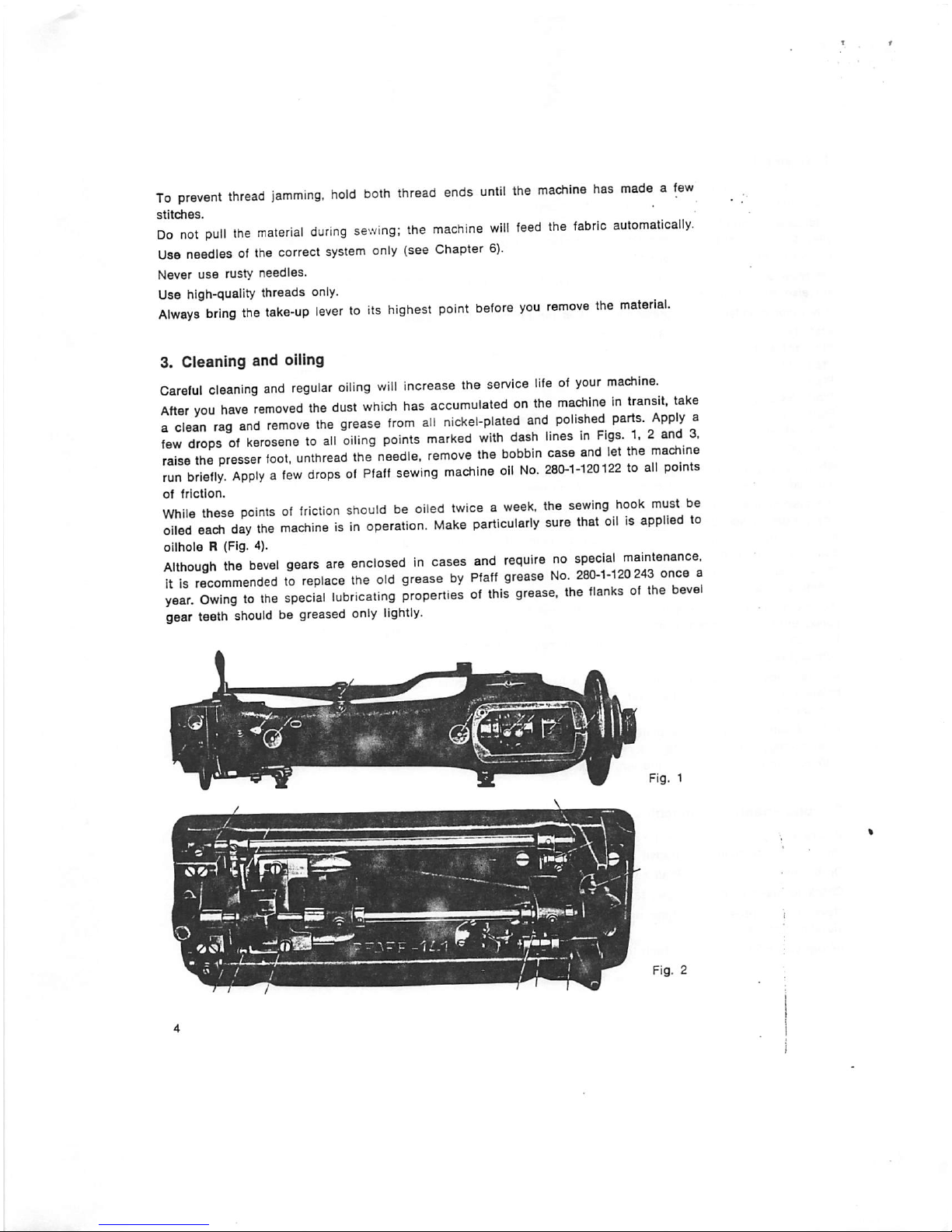

3. Cleaning

and

oiling

Careful

cleaning

and

regular

oiling

will

Increase

the

service

lifeofyour

machine.

After

you

have

removed

the

dust

which

has

accumulatedonthe

machineintransit,

take

a

clean

rag

and

remove

the

grease

from

all

nickel-plated

and

polished

Parts.

Apply

a

few

dropsofkerosenetoall

oiling

points

marked

with

dash

linesinFigs.1.2

and

3.

raise

the

presser

foot,

unthread

the

needle,

remove

the

bobbin

case

and

let

the

J^achine

run

briefly.

Applyafew

dropsofPfaff

sewing

machine

oil

No.

280-1-120122toall

points

of

friction.

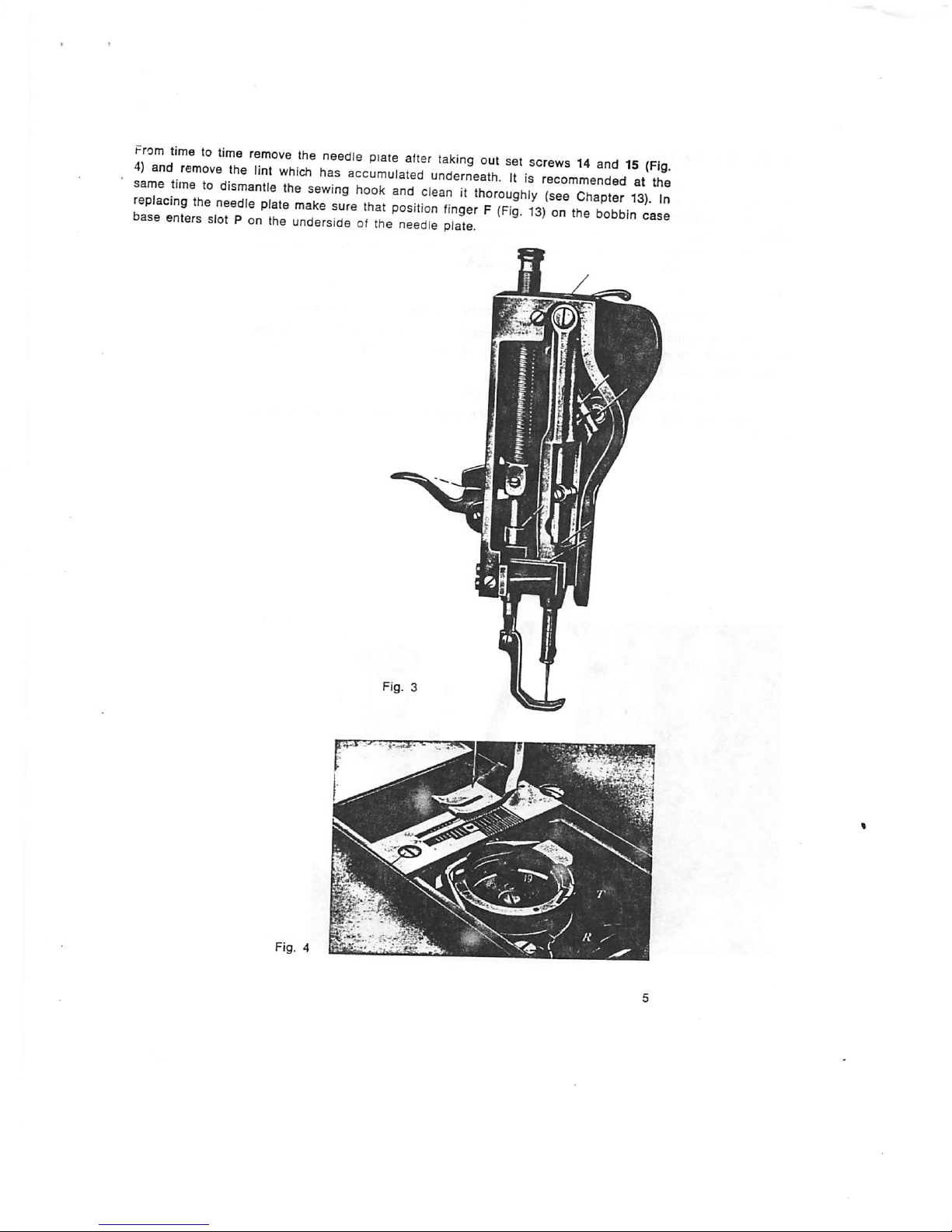

While

these

pointsoffriction

shouldbeoiled

twiceaweek,

the

sewing

hook

"lUSt

be

oiled

each

day

the

machineisin

operation.

Make

particularly

sure

that

oilisapplied

to

oilhoie R (Fig. 4).

Althougti

the

bevel

geers

ere

enclosedinceses

and

requirenospeclel

mamtenence.

itisrecommendedtoreplace

the

old

greasebyPfaff

grease

once

a

year.

Owingtothe

special

lubricating

propertiesofthis

grease,

the

flanksofthe

beve

gear teeth

shouldbegreased

only

lightly.

^rom

timetotime

remove

the

needle

plate

alter

taking

out

set

sorevvs14andisrpi.

repT

^-Tng'tortnd

dearnhTrougWy

(sarcTaTte?

13')

7n

jse::Lrs,rrhi\rr3ror.t~

^ -

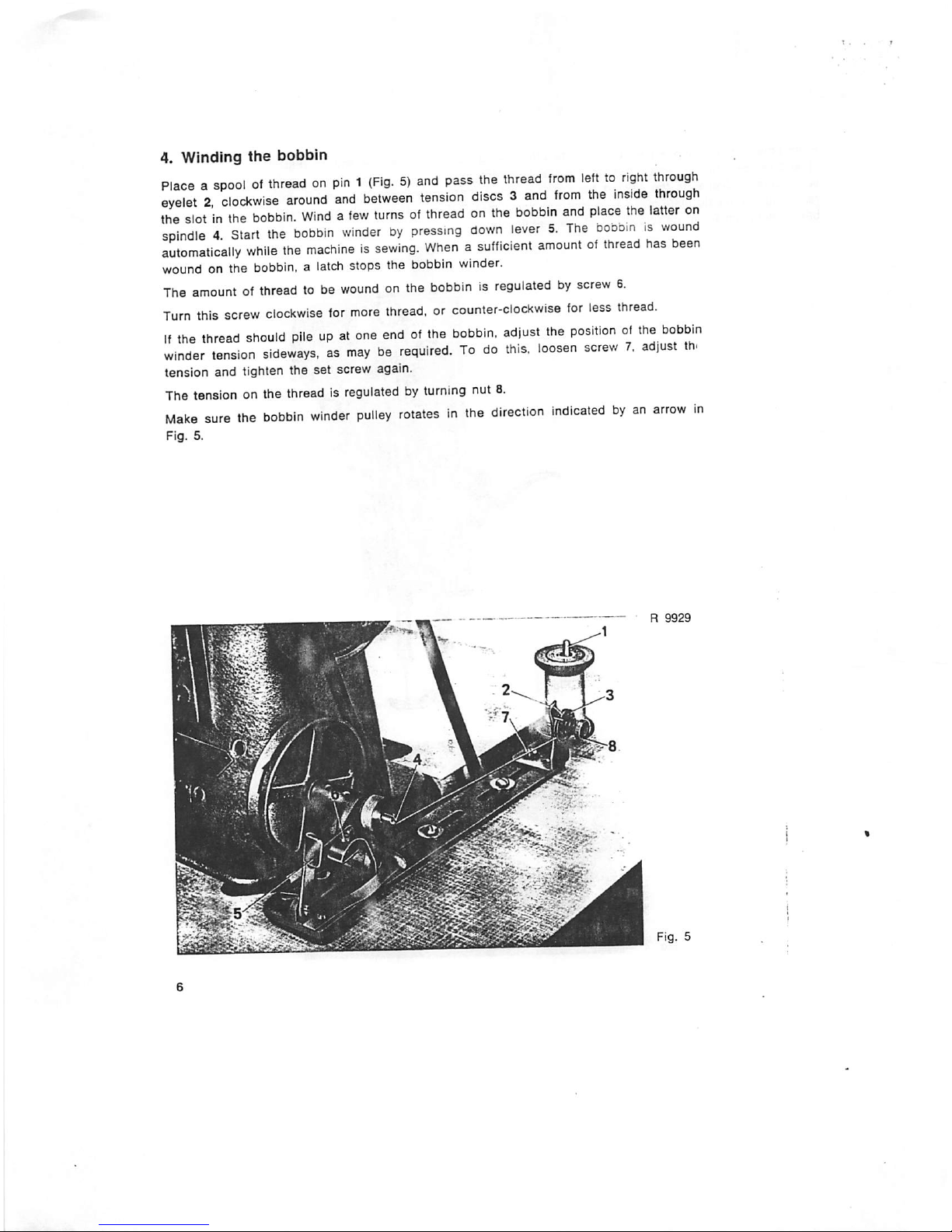

4. Winding

the

bobbin

Placeaspoolofttfreadonpin1(Fig.5)and

pass

the

thread

from

lefttoright

through

eyelet2,clockwise

around

and

between

tension

discs3and

from

the

inside

through

the

slotinthe

bobbin.

Windafew

turnsofthreadonthe

bobbin

and

place

the

latter

on

spindle4.Start

the

bobbin

winderbypressing

down

lever5.The

bobomiswound

automatically

while

the

machineissewing.

Whenasufficient

amountofthread

has

been

wound

on the

bobbin,alatch

stops the

bobbin

winder.

The

amountofthreadtobe

woundonthe

bobbinisregulatedbyscrew

6.

Turn

this

screw

clockwise

for

more

thread,orcounter-clockwise

lor

less

thread.

If

the

thread

should

pileupat

one

endofthe

bobbin,

adjust

the

positionofthe

bobbin

winder

tension

sideways,asmayberequired.Todo

this,

loosen

screw7,adjust

th.

tension and tighten the set screw again.

The tension on the thread is

regulatedbyturning

nut 8.

Maks

sure

the

bobbin

winder

pulley

rotatesinthe

direction

Indicatedbyan

arrow

in

Fig.

5.

R

9929

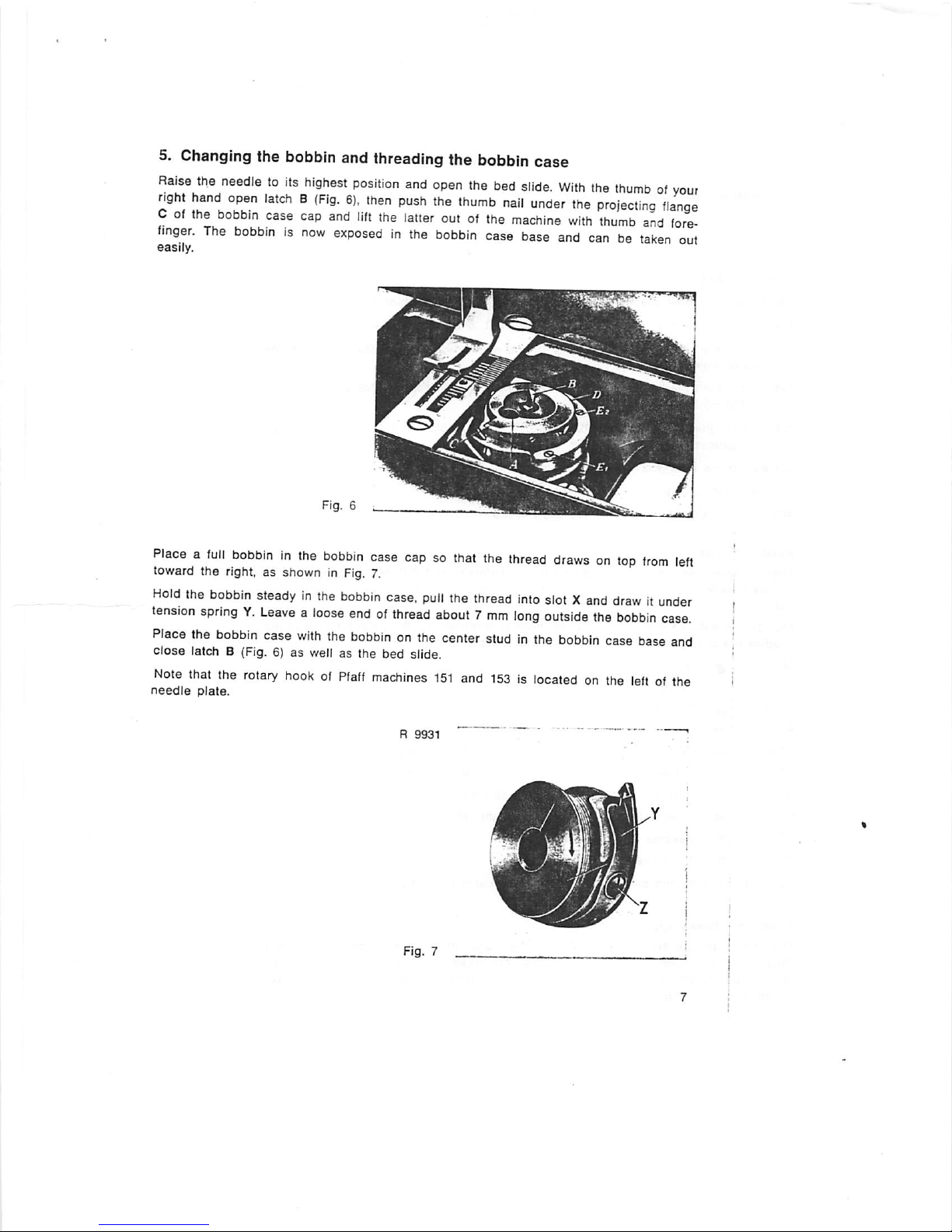

5. Changing the bobbin and threading the bobbin case

Raise

the

needletoits

highest

position

and

open

the

bed

slide.

With

the

thumbofyou:

right

hand

open

latchB(Fig.

6),

then

push

the

thumb

nail

under

the

projecting

flange

Cofthe

bobbin

case

cap

and

lift

the

latter

outofthe

machine

with

thumb

and

fore

finger.

The

bobbinisnow

exposedinthe

bobbin

case

base

and

canbetaken

out

easily.

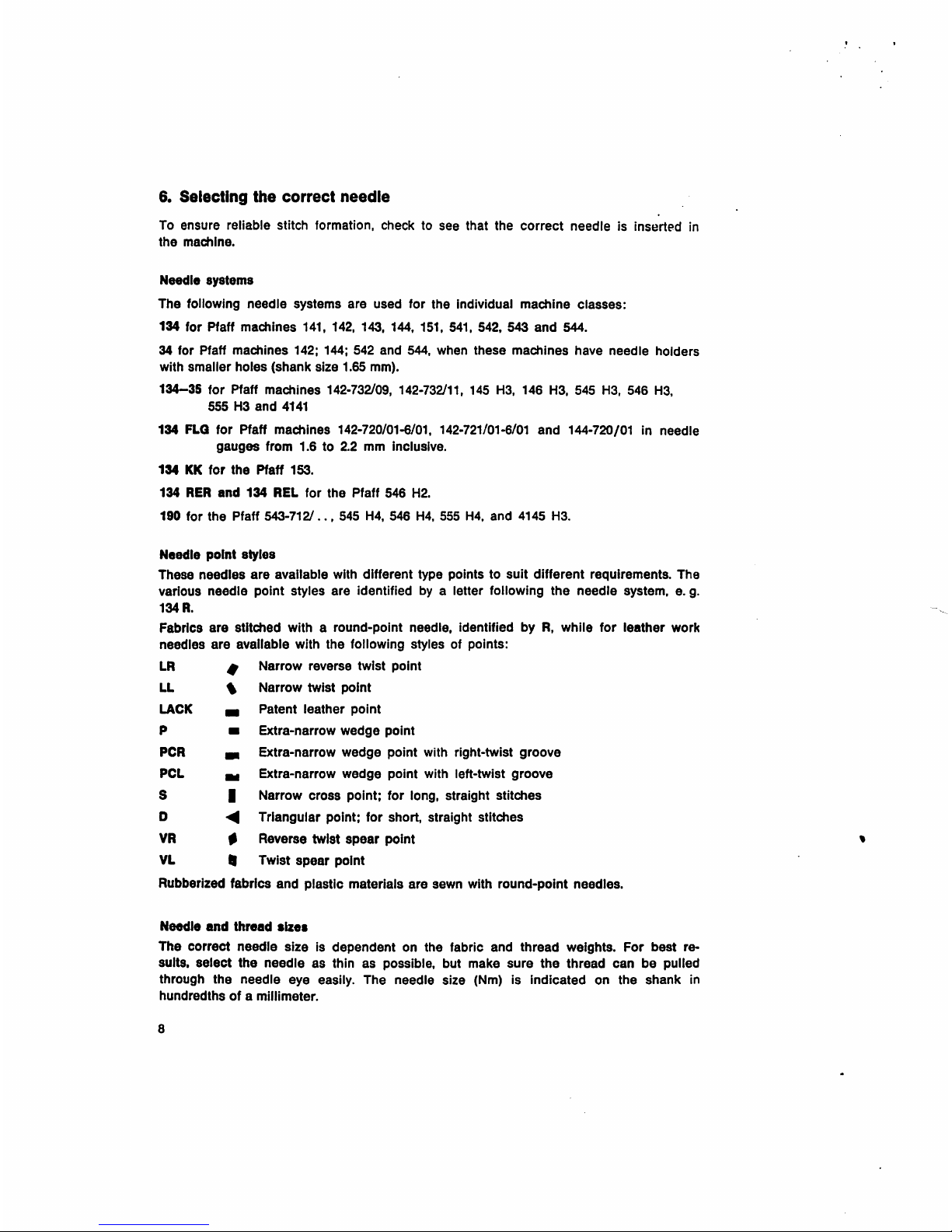

Placeafull

bobbininthe

bobbin

case

capsothat

the

thread

drawsontop

from

left

toward the right, as shown in

Fig.

7.

Hold

the

bobbin

steadyinthe

bobbin

case,

pull

the

thread

into

slotXand

drawitunder

tension

springY.Leavealoose

endofthread

about7mm

long

outside

the

bobbin

case.

Place

the

bobbin

case

with

the

bobbinonthe

center

studinthe

bobbin

case

base

and

close

latch B (Fig. 6) as well as the bed slide.

Note

that

the

rotary

hookofPfaff

machines

151

and

153islocatedonthe

leftofthe

needle

plate.

R

9931

6.

Selecting

the

correct

needle

To

ensure

reliable

stitch

formation,

checktosee

that

the

correct

needleisinserted

in

the

machine.

Needle

systems

The

following

needie

systems

are

used

for

the

individual

machine

classes:

134

for

Pfaff

machines

141, 142,

143,

144. 151. 541,

542,

543

and

544.

34

for

Pfaff

machines

142; 144;

542

and

544,

when

these

machines

have

needle

holders

with

smaller

holes

(shank

size

1.65

mm).

134-35

for Pfaff

machines

142-732/09, 142-732/11, 145 H3, 146 H3, 545 H3, 546 H3,

555H3and

4141

134 FLQ for Pfaff

machines

142-720/01-6/01, 142-721/01-6/01

and

144-720/01 in

needle

gauges

from

1.6to2.2

mm

inclusive.

134

KK

for

the

Pfaff

153.

134

RER

and

134

REL

for

the

Pfaff

546

H2.

190

for

the

Pfaff

543-712/...

545

H4.

546

H4.

555

H4.

and

4145

H3.

Needle

point

styles

These

needles

are

available

with

different

type

pointstosuit

different

requirements.

The

various

needle

point

styles

are

identified

by a

letter

following

the

needle

system,

e. g.

134

R.

Fabrics

are

stitched

witharound-point

needle,

identified

by R,

while

for

leather

work

needles

are

available

with

the

following

stylesofpoints:

LR

Narrow

reverse

twist

point

LL

%

Narrow

twist

point

LACK

m

Patent

leather

point

P

m

Extra-narrow

wedge

point

PGR

m

Extra-narrow

wedge

point

with

right-twist

groove

POL

m

Extra-narrow

wedge

point

with ieft-twist

groove

S

1

Narrow

cross

point;

for

long,

straight

stitches

D

Triangular

point;

for

short,

straight

stitches

VR

#

Reverse

twist

spear

point

VL

9

Twist

spear

point

Rubberized

fabrics

and

plastic

materials

are

sewn

with

round-point

needles.

Needle

and

thread

sizes

The

correct

needle

sizeisdependent

on

the

fabric

and

thread

weights.

For

best

re

sults.

select

the

needleasthinaspossible,

but

make

sure

the

thread

can

be

pulled

through

the

needle

eye

easily.

The

needle

size

(Nm) is

indicated

on

the

shank

in

hundredths

ofamillimeter.

a

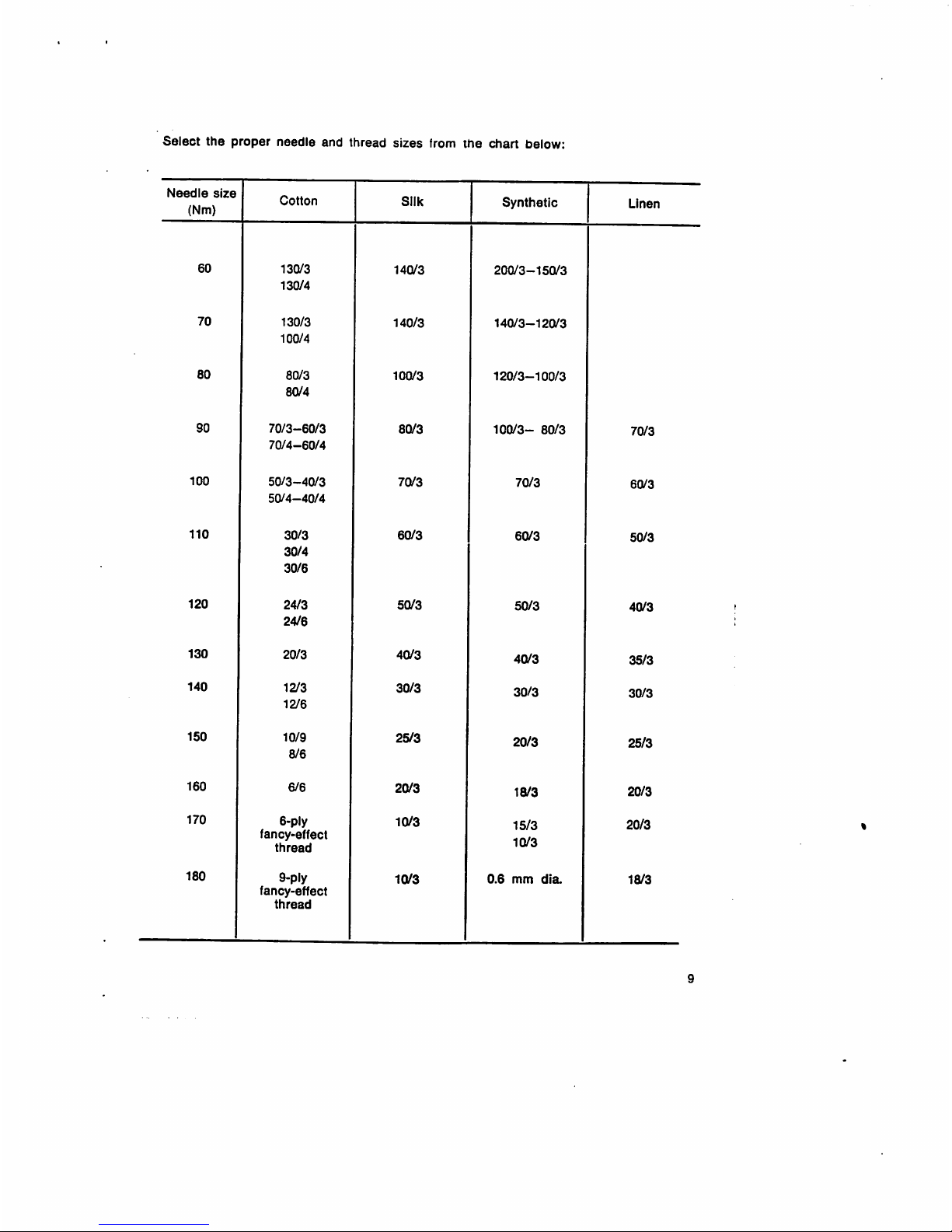

Select

the

proper

needle

and

thread

sizes

from

the

chart

below:

Needle

size

(Nm)

Cotton

Silk

Synthetic

Linen

60

130/3

130/4

140/3

200/3-150/3

70

130/3

100/4

140/3

140/3-120/3

60

80/3

80/4

100/3

120/3-100/3

SO

70/3-60/3

70/4-60/4

80/3

100/3-

80/3

70/3

100

50/3-40/3

50/4-40/4

70/3

70/3

60/3

110

30/3

30/4

30/6

60/3

60/3

50/3

120

24/3

24/6

50/3

50/3

40/3

130

20/3

40/3

40/3

35/3

140

12/3

12/6

30/3

30/3

30/3

150

10/9

8/6

25/3

20/3

25/3

160

6/6

20/3

18/3

20/3

170

6-ply

fancy>effect

thread

10/3

15/3

10/3

20/3

180

9-ply

fancy-effect

thread

10/3

0.6

mm

dia.

18/3

The

needle

size

should

be

selectedtomatch

not

only

the

thread

weight,

but

also

the

machine

model,asfollows:

ModelA:Needle

sizes

60—

70

Model

B:

Needle

sizes

80—100

Model

C:

Needle

sizes

110—140

Model

D:

Needle

sizes

160—180

The

needle

sizeisindicated

on

the

shankinhundredths

of

millimeters.

Thus,

a No.

100

needle

hasashaft

diameter

of

100/100

= 1

mm.

7.

Changing

the

needle

Raise

the

needle

bar

to its

highest

point,

loosen

the

needle

set

screw

half a turn, anc

pull

the

damaged

needle

outofthe

needle

clamp.

Insert a new

needle

into

the

clamp,

making

sure

that

its

short

groove

faces

toward

the

sewing hook.

Push

the

needle

up as far as it will go and tighten

the

needle

set

screw

securely.

Never

use

rusty

needles.

8.

Threading

the

needle

Pass

the

thread

from

spool

1 (Fig. 8)

through

the

holesinstud2and

thread

guide

3,

around

thread

retainer4,clockwise

around

between

te'"'ion

discs5,under

thread

controller

disc

6, through

thread

check spri up and th igh

thread

guide

8, from

right to left through the hole in take-up lever j. then down and through thread guides

10, 11

and

12,

and

from left to

right

through

the

eyeofthe

needle.

The spool

holder

on top of the machine arm w'

">6

suppli'^'f on

special

request

only

because

the

thread

stand

which is

supplied

the

m

le

regularly

ensures

a

smoother

passage

of

the

threadtothe

needle.

9,

Drawingupthe

bobbin

thread

HCd

t.e

endott.e

needle

thread

^ trne\V.~

rp;^rr:f.r:'.:e\r:.c.co..

r;:;Tr.rorHoTd".h?e:crr:;p°;'

.treads

un,,,

.he

.achma

has

.adea.a«

stitches.

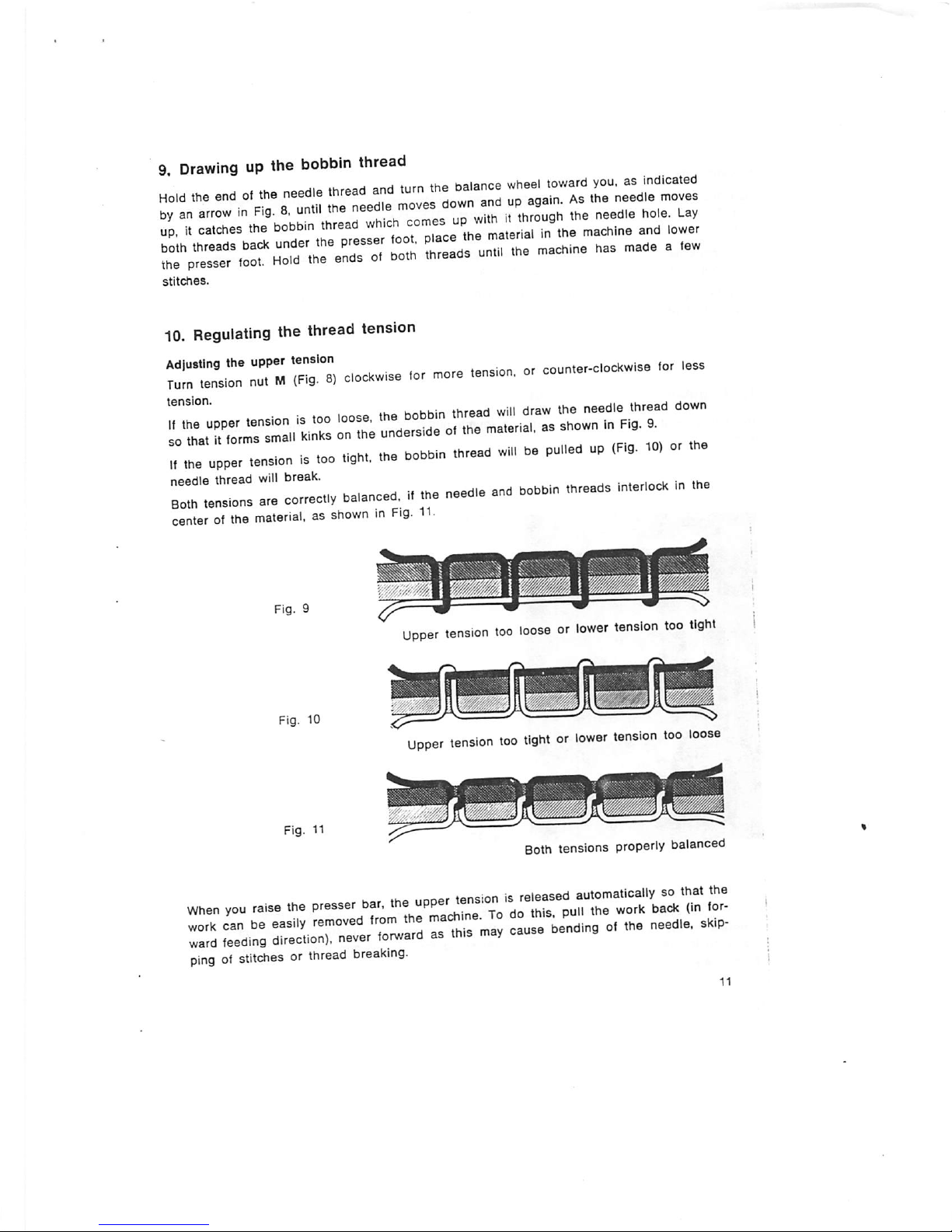

10.

Regulating

the

thread

tension

Adlustlng

the

upper

tension

counter-clockwise

tor

less

Turn

tension

nutM(Fig.8)clockw.se

for

more

tens.on,

K^Khin

thread

will

draw

the needle thread

down

^or

r.Tr:iv:.ra

re

unde.s.de

o.

.he

.a.eda,.

as

shown

,n

^.

„

,ne

upper

.ensionis.00

.iph.,

.he

hobbln

.hread

winbepu.ledup(Fig.

10)

:::r::

r.,—•

-

centerofthe

material,asshownmF.g.

11.

upper

tension

too

looseorlower

tension

too

tight

Fig. 10

tension

too

tightorlower

tension

too

loose

jliCZJ

Fig.

11

Both

tensions

properly

balanced

-:rsr,vrr."-r

=».s

rcrr

.r«s

r-™

™—•

«•

pingofstitchesorthread

breaking.

Loading...

Loading...