Page 1

R

6499

( PMff f

141;

143|

145;

151;

153

541; 543;

543-712;

545;

555

Single-needle

flatbed

sewing

machines

142;

144;

146

542;

542-748/01;

544; 546;

546-748/01

Two-needle

flatbed

sewing

machines

Instruction

Book

Page 2

/

' •

Contents

, ^

Page

1.

General

®

2.

Fundamentalsofmachine

operation

3

3.

Cleaning

and

oiling

^

4.

Winding

the

bobbin

®

5.

Changing

the

bobbin

and

threading

the

bobbin

case 7

6.

Selecting

the

correct

needle

3

Needle

systems

®

Needle

point

styles

®

Needle

and thread sizes 8

7. Changing

the

needle

8.

Threading

the

needle

^

9. Drawing up the bobbin thread

10. Regulating the thread tensions

Adjusting the upper tension

Adjusting the lower tension

11. Regulating the stitch length

12.

Regulating

the

pressureonthe

material

''S

13. Cleaning

the

sewing hook

14.

The

safety

clutch

Additional

instructions

for

Pfaff

machines'141-705/03

and

141-705/03-725/01

. 16-18

15. Regulating the stitch length

16.

Changing

the

feed

gears

'•8

17. Adjusting

the

trimmer * *

^18.

Operating

the

trimmer

^

Additional

Instructions

for

Pfaff

machines

143-705/03

21

19.

Regulating

the

stitch

length

21

Additional

Instructions

for

Pfaff

machines

145

22-24

20.

Exchanging

the

alternating

pressers

22

21.

Lubricating

the

machine

24

0-22. Setting

the

foot lift

-

Additional

Instructions

for

Pfaff

machines

151

and

153

(

Additional

Instructions

for

Pfaff

machines

142,

542-748/01,

144

and

146

25-^

r23.

Threading

the

needles

25

.

24.

Adjusting

the

puller

feedofthe

Pfaff

542-748/01

26

Additional

Instructions

for

Pfaff

machines

543-712/01

and

543-712/02

...

27

"25. Threading the needle of the Pfaff

543-712

-.-Additional

Instructions

for

Pfaff

machines

546-748/01

28—29

^26.

Setting

the

foot

lift

. . . ; ^

't27.

Adjusting

the

puller

feed

29

^Additional

instructions

for

Pfaff

machines

4141

and

4145

. -

30

^^^28.

Threadingofthe

Pfaff

4141

and

4145

8®

^

Additional

Instructions

for

Pfaff

machines

fitted

with

thread

puller/trimmer

900/».31

"

'!'29.

Pedal

operation

Guards

Trouble

shooting

^

t

..

^i2

Page 3

t.

General

•

Since

the

operationofthe

machines

listedonthe

title

pageismoreorless

the

same

the

general

instructions

compiledinthis

book

applytoallofthem.

Additional

instructions

for

the

Pfaff

141-705/03;

141-705/03-725/01;

142;

143-705

03-

144;

145;

146; 151;

153;

552-748/01;

543-712/..;

546-748/01;

4141;

4145

and

-900'..

appearatthe

backofthis

booklet.

We

reserve

the

righttomake

alterations

serving

progress.

The

illustrationsinthis

book

are also subject to change.

Itisrecommendedtorun

these

machinesatthe

following

top

speeds:

3

000

s.p.m.

Pfaff

4141

2

200

s.p.m.

Pfaff

141

and

144

2

900

s.p.m.

Pfaff

545

H3

2100

s.p.m.

2

800

s.p.m.

Pfaff

546

H2

1

300

s.p.m.

Pfaff

151

and

544

2

700

s.p.m.

Pfaff

546

H3

i

800

s.p.m.

Pfaff

153

and

542

2

600

s.p.m.

Pfaff

545

H4

i

700

s.p.m.

^ 2

500

s.p.m.

Pfaff

4145

1

600

s.p.m.

Pfaff

145

and

541

2

400

s.p.m.

Pfaff

546

H4

2

300

s.p.m.

and

543-712/..

1400

s.p.m.

When

sewing

tightly

woven

and

heavily

dressed

materials,

the

sewing

speed

should

be

reducedInorderto

prevent

overheating

of the

needle.

The

maximum

speedoftwo-needle

machines

decreasesasthe

needle

gauge

increases.

The

maximum

speeds

which

canbeattained

with

machines

fitted

with

special

attach

mentsortrimming

mechanisms

are

often

far

below

the

recommended

top

speeds

be

cause

the

natureofthe

work

and

the

thicknessofthe

material

tendtolimit

the

ma

chinescapacity.Ifthe

maximum

speedisexceeded,

trouble

may

develop

chieflyinthe

trimming mechanism.

To

avoid

troubleinthe

mechanism,

run

the

machineatabout75per

centofits

top

speed

until

the

parts

which

areinmovable

contact

have

become

thoroughly

glazed

by

their

action

upon

each

other.

This

should

normallybethe

case

after

about

two

weeks'

constant

use.

All

machines

are

regularly

equipped

withafixed

pulley

whichiscastinone

with

the

ba

ance

wheel.Ifdesired,

however,

these

machines

canbesupplied

withadisengage-

ible pulley.

If

fitted

with

the

latter

type

pulley,

the

machineisdispatched

with

the

sewing

mecha

nism

disengaged.Toengage

this

mechanism

for

sewing,

hold

the

balance

wheel

steady

with

your left hand and turn the large

lock

nut

clockwise.

2. Fundamentals of machine operation

Before

you

put

the

machineinoperation

for

the

first

time,

carefully

remove

all

dust

which

has

accumulatedintransit

and

oil

the

machine

thoroughly

(see

Chapter

3).

on

the

machine

only

with

Pfaff

sewing

machine

oil

whichIsnon-resinous

and

acid-free.

Checktomake

sure

the

finger,

take-up

lever

and

belt

guards

are

properly

fitted.

Never

runathreaded

machine

unless

you

have

fabric

under

the

presser

footorthe

vibrating

presser.

Before

you

start

sewing,

lay

both

threads

back

under

the

presser

foot

Page 4

To

prevent

thread

jamming,

hold

both

thread

ends

until

the

machine

has

madeafew

stitches. . „

Do

not

pull

the

material

during

sewing:

the

machine

wiil

feed

the

fabric

automatically.

Use needlesofthe correct

system

only

(see Chapter

6).

Never

use

rusty

needles.

Use high-quality threads

only.

Always

bring

the

take-up

levertoits

highest

point

before

you

remove

the

material.

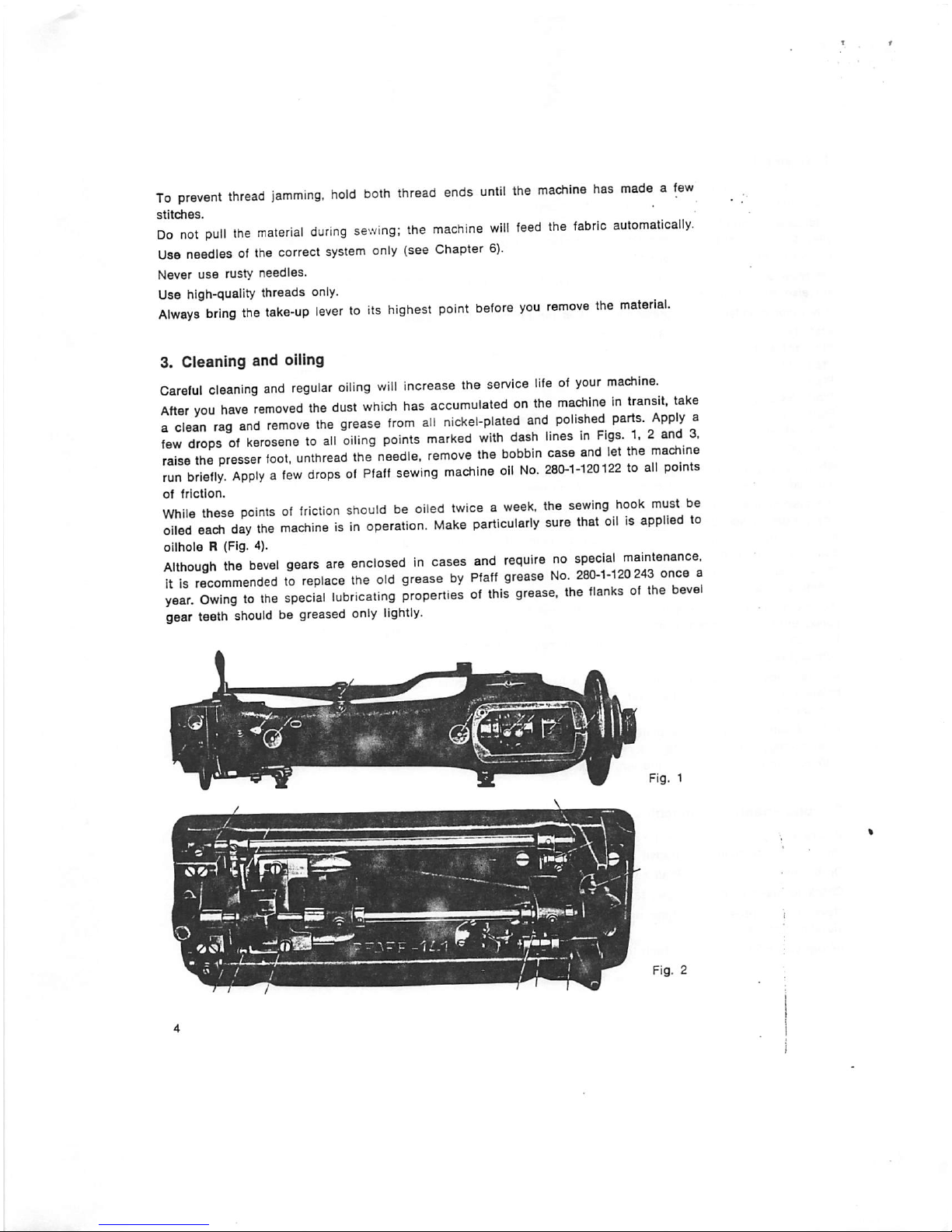

3. Cleaning

and

oiling

Careful

cleaning

and

regular

oiling

will

Increase

the

service

lifeofyour

machine.

After

you

have

removed

the

dust

which

has

accumulatedonthe

machineintransit,

take

a

clean

rag

and

remove

the

grease

from

all

nickel-plated

and

polished

Parts.

Apply

a

few

dropsofkerosenetoall

oiling

points

marked

with

dash

linesinFigs.1.2

and

3.

raise

the

presser

foot,

unthread

the

needle,

remove

the

bobbin

case

and

let

the

J^achine

run

briefly.

Applyafew

dropsofPfaff

sewing

machine

oil

No.

280-1-120122toall

points

of

friction.

While

these

pointsoffriction

shouldbeoiled

twiceaweek,

the

sewing

hook

"lUSt

be

oiled

each

day

the

machineisin

operation.

Make

particularly

sure

that

oilisapplied

to

oilhoie R (Fig. 4).

Althougti

the

bevel

geers

ere

enclosedinceses

and

requirenospeclel

mamtenence.

itisrecommendedtoreplace

the

old

greasebyPfaff

grease

once

a

year.

Owingtothe

special

lubricating

propertiesofthis

grease,

the

flanksofthe

beve

gear teeth

shouldbegreased

only

lightly.

Page 5

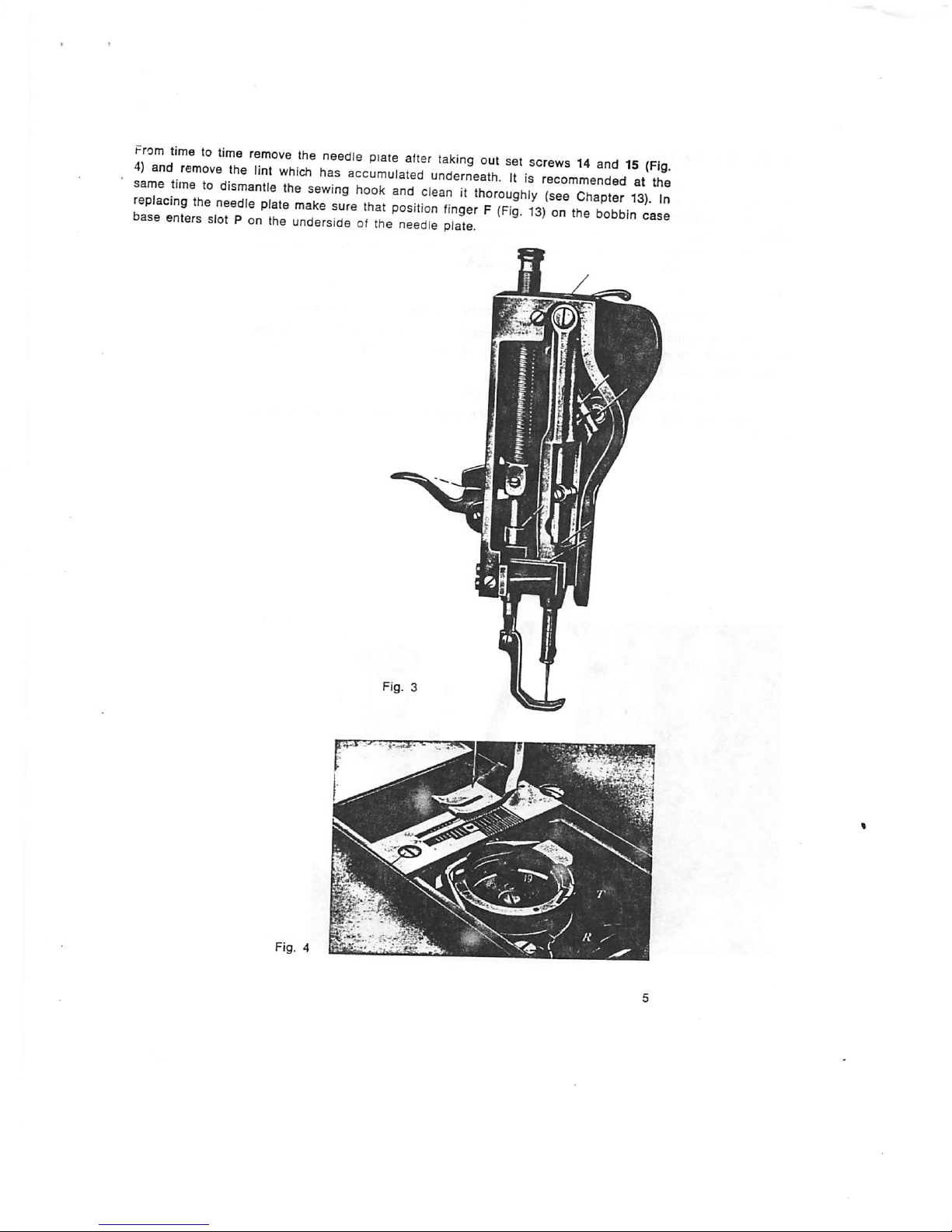

^rom

timetotime

remove

the

needle

plate

alter

taking

out

set

sorevvs14andisrpi.

repT

^-Tng'tortnd

dearnhTrougWy

(sarcTaTte?

13')

7n

jse::Lrs,rrhi\rr3ror.t~

^ -

Page 6

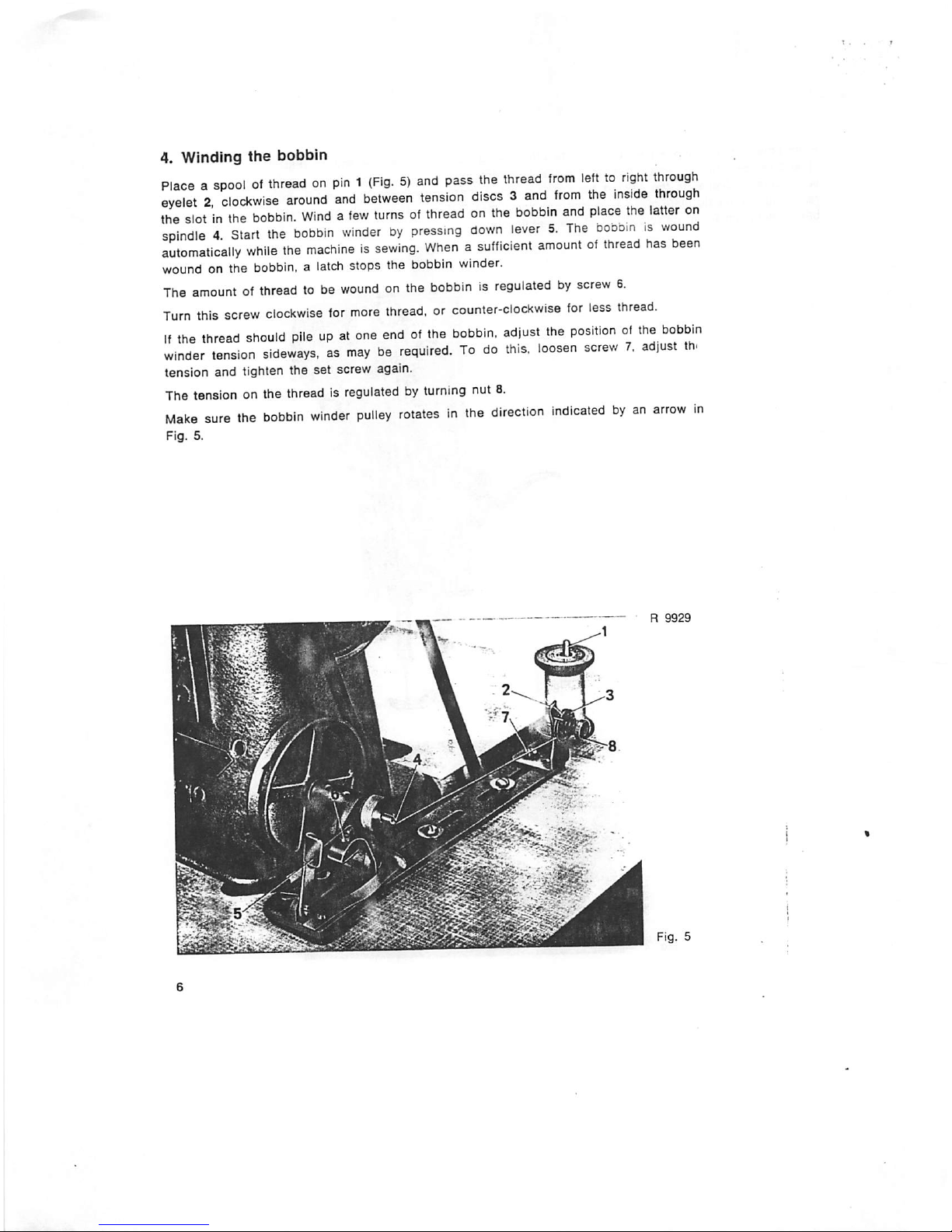

4. Winding

the

bobbin

Placeaspoolofttfreadonpin1(Fig.5)and

pass

the

thread

from

lefttoright

through

eyelet2,clockwise

around

and

between

tension

discs3and

from

the

inside

through

the

slotinthe

bobbin.

Windafew

turnsofthreadonthe

bobbin

and

place

the

latter

on

spindle4.Start

the

bobbin

winderbypressing

down

lever5.The

bobomiswound

automatically

while

the

machineissewing.

Whenasufficient

amountofthread

has

been

wound

on the

bobbin,alatch

stops the

bobbin

winder.

The

amountofthreadtobe

woundonthe

bobbinisregulatedbyscrew

6.

Turn

this

screw

clockwise

for

more

thread,orcounter-clockwise

lor

less

thread.

If

the

thread

should

pileupat

one

endofthe

bobbin,

adjust

the

positionofthe

bobbin

winder

tension

sideways,asmayberequired.Todo

this,

loosen

screw7,adjust

th.

tension and tighten the set screw again.

The tension on the thread is

regulatedbyturning

nut 8.

Maks

sure

the

bobbin

winder

pulley

rotatesinthe

direction

Indicatedbyan

arrow

in

Fig.

5.

R

9929

Page 7

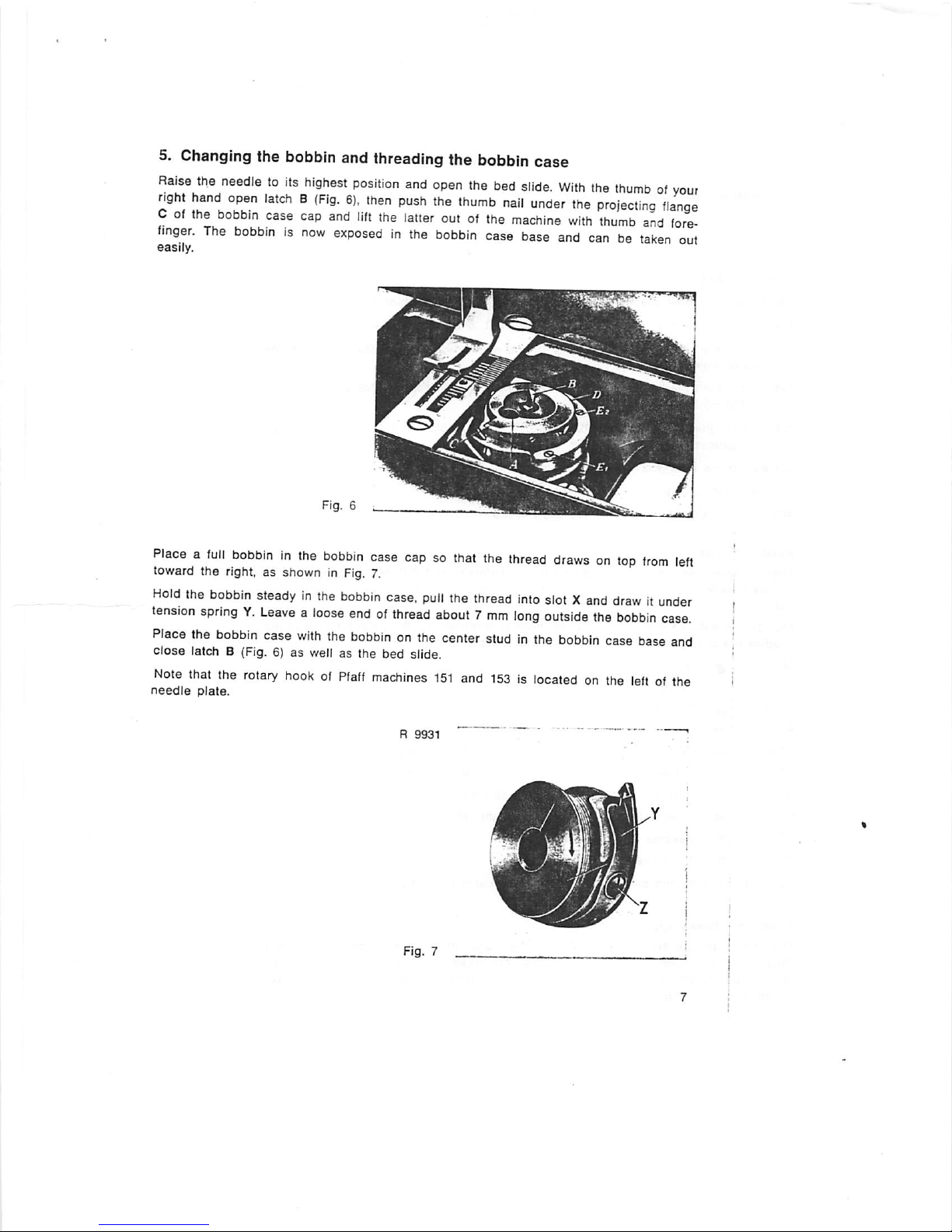

5. Changing the bobbin and threading the bobbin case

Raise

the

needletoits

highest

position

and

open

the

bed

slide.

With

the

thumbofyou:

right

hand

open

latchB(Fig.

6),

then

push

the

thumb

nail

under

the

projecting

flange

Cofthe

bobbin

case

cap

and

lift

the

latter

outofthe

machine

with

thumb

and

fore

finger.

The

bobbinisnow

exposedinthe

bobbin

case

base

and

canbetaken

out

easily.

Placeafull

bobbininthe

bobbin

case

capsothat

the

thread

drawsontop

from

left

toward the right, as shown in

Fig.

7.

Hold

the

bobbin

steadyinthe

bobbin

case,

pull

the

thread

into

slotXand

drawitunder

tension

springY.Leavealoose

endofthread

about7mm

long

outside

the

bobbin

case.

Place

the

bobbin

case

with

the

bobbinonthe

center

studinthe

bobbin

case

base

and

close

latch B (Fig. 6) as well as the bed slide.

Note

that

the

rotary

hookofPfaff

machines

151

and

153islocatedonthe

leftofthe

needle

plate.

R

9931

Page 8

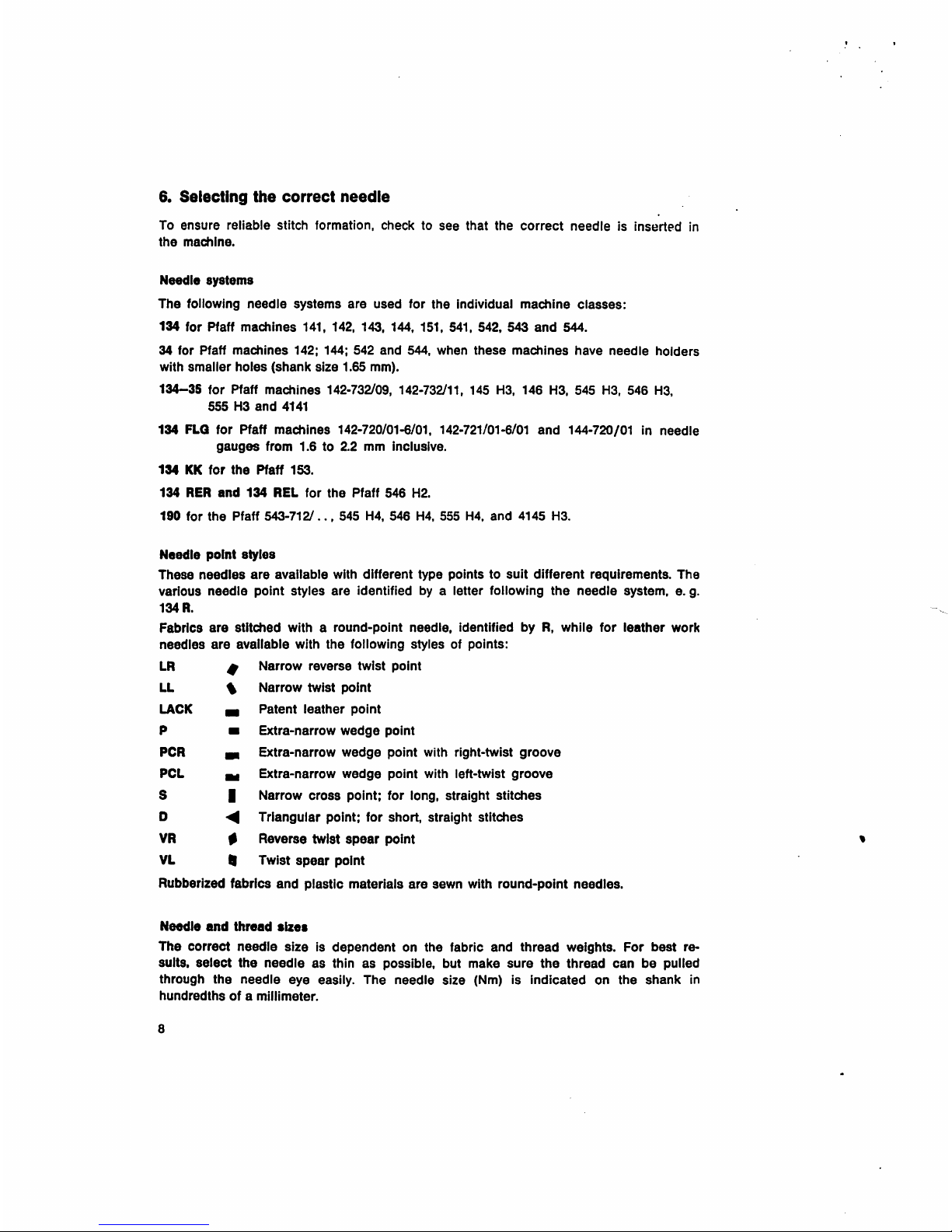

6.

Selecting

the

correct

needle

To

ensure

reliable

stitch

formation,

checktosee

that

the

correct

needleisinserted

in

the

machine.

Needle

systems

The

following

needie

systems

are

used

for

the

individual

machine

classes:

134

for

Pfaff

machines

141, 142,

143,

144. 151. 541,

542,

543

and

544.

34

for

Pfaff

machines

142; 144;

542

and

544,

when

these

machines

have

needle

holders

with

smaller

holes

(shank

size

1.65

mm).

134-35

for Pfaff

machines

142-732/09, 142-732/11, 145 H3, 146 H3, 545 H3, 546 H3,

555H3and

4141

134 FLQ for Pfaff

machines

142-720/01-6/01, 142-721/01-6/01

and

144-720/01 in

needle

gauges

from

1.6to2.2

mm

inclusive.

134

KK

for

the

Pfaff

153.

134

RER

and

134

REL

for

the

Pfaff

546

H2.

190

for

the

Pfaff

543-712/...

545

H4.

546

H4.

555

H4.

and

4145

H3.

Needle

point

styles

These

needles

are

available

with

different

type

pointstosuit

different

requirements.

The

various

needle

point

styles

are

identified

by a

letter

following

the

needle

system,

e. g.

134

R.

Fabrics

are

stitched

witharound-point

needle,

identified

by R,

while

for

leather

work

needles

are

available

with

the

following

stylesofpoints:

LR

Narrow

reverse

twist

point

LL

%

Narrow

twist

point

LACK

m

Patent

leather

point

P

m

Extra-narrow

wedge

point

PGR

m

Extra-narrow

wedge

point

with

right-twist

groove

POL

m

Extra-narrow

wedge

point

with ieft-twist

groove

S

1

Narrow

cross

point;

for

long,

straight

stitches

D

Triangular

point;

for

short,

straight

stitches

VR

#

Reverse

twist

spear

point

VL

9

Twist

spear

point

Rubberized

fabrics

and

plastic

materials

are

sewn

with

round-point

needles.

Needle

and

thread

sizes

The

correct

needle

sizeisdependent

on

the

fabric

and

thread

weights.

For

best

re

sults.

select

the

needleasthinaspossible,

but

make

sure

the

thread

can

be

pulled

through

the

needle

eye

easily.

The

needle

size

(Nm) is

indicated

on

the

shank

in

hundredths

ofamillimeter.

a

Page 9

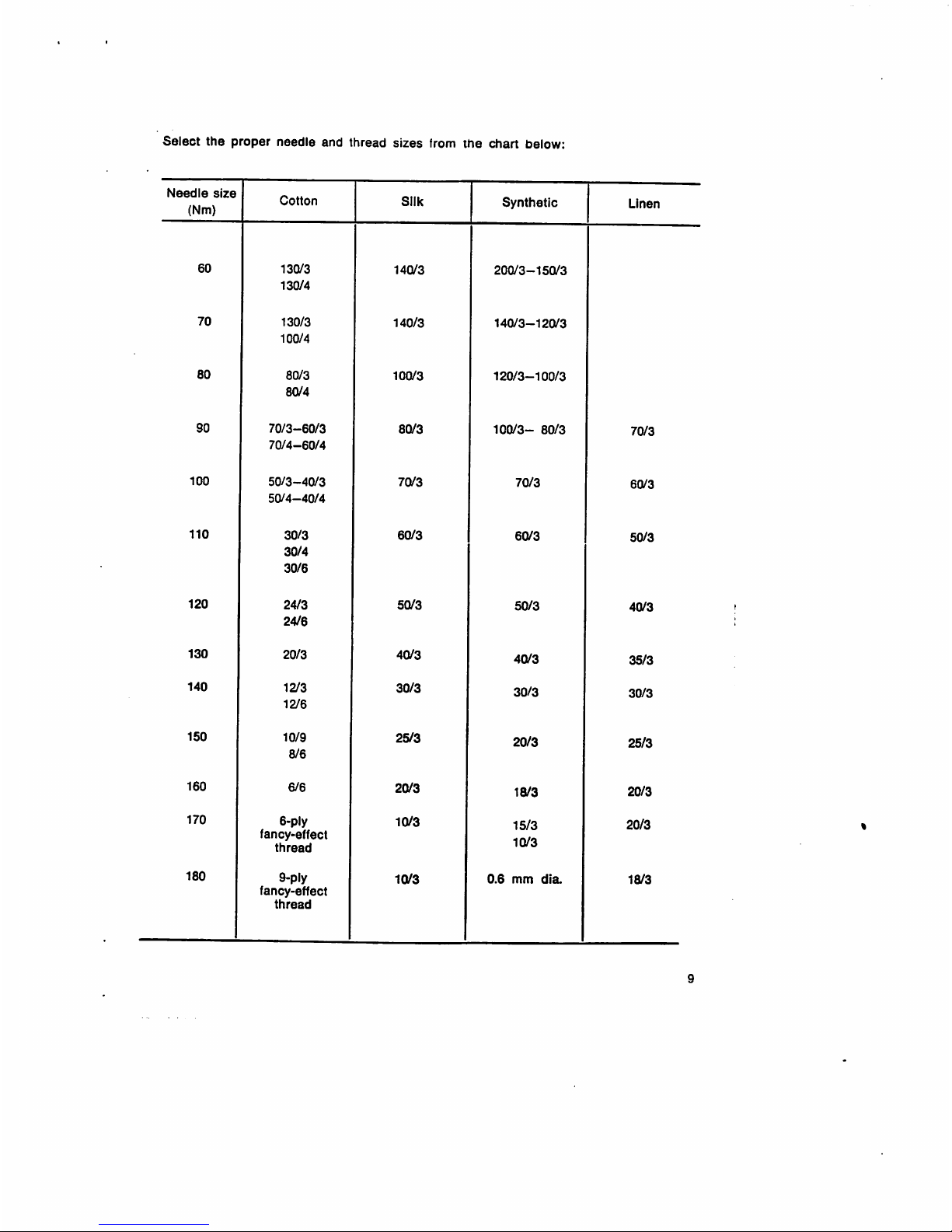

Select

the

proper

needle

and

thread

sizes

from

the

chart

below:

Needle

size

(Nm)

Cotton

Silk

Synthetic

Linen

60

130/3

130/4

140/3

200/3-150/3

70

130/3

100/4

140/3

140/3-120/3

60

80/3

80/4

100/3

120/3-100/3

SO

70/3-60/3

70/4-60/4

80/3

100/3-

80/3

70/3

100

50/3-40/3

50/4-40/4

70/3

70/3

60/3

110

30/3

30/4

30/6

60/3

60/3

50/3

120

24/3

24/6

50/3

50/3

40/3

130

20/3

40/3

40/3

35/3

140

12/3

12/6

30/3

30/3

30/3

150

10/9

8/6

25/3

20/3

25/3

160

6/6

20/3

18/3

20/3

170

6-ply

fancy>effect

thread

10/3

15/3

10/3

20/3

180

9-ply

fancy-effect

thread

10/3

0.6

mm

dia.

18/3

Page 10

The

needle

size

should

be

selectedtomatch

not

only

the

thread

weight,

but

also

the

machine

model,asfollows:

ModelA:Needle

sizes

60—

70

Model

B:

Needle

sizes

80—100

Model

C:

Needle

sizes

110—140

Model

D:

Needle

sizes

160—180

The

needle

sizeisindicated

on

the

shankinhundredths

of

millimeters.

Thus,

a No.

100

needle

hasashaft

diameter

of

100/100

= 1

mm.

7.

Changing

the

needle

Raise

the

needle

bar

to its

highest

point,

loosen

the

needle

set

screw

half a turn, anc

pull

the

damaged

needle

outofthe

needle

clamp.

Insert a new

needle

into

the

clamp,

making

sure

that

its

short

groove

faces

toward

the

sewing hook.

Push

the

needle

up as far as it will go and tighten

the

needle

set

screw

securely.

Never

use

rusty

needles.

8.

Threading

the

needle

Pass

the

thread

from

spool

1 (Fig. 8)

through

the

holesinstud2and

thread

guide

3,

around

thread

retainer4,clockwise

around

between

te'"'ion

discs5,under

thread

controller

disc

6, through

thread

check spri up and th igh

thread

guide

8, from

right to left through the hole in take-up lever j. then down and through thread guides

10, 11

and

12,

and

from left to

right

through

the

eyeofthe

needle.

The spool

holder

on top of the machine arm w'

">6

suppli'^'f on

special

request

only

because

the

thread

stand

which is

supplied

the

m

le

regularly

ensures

a

smoother

passage

of

the

threadtothe

needle.

Page 11

9,

Drawingupthe

bobbin

thread

HCd

t.e

endott.e

needle

thread

^ trne\V.~

rp;^rr:f.r:'.:e\r:.c.co..

r;:;Tr.rorHoTd".h?e:crr:;p°;'

.treads

un,,,

.he

.achma

has

.adea.a«

stitches.

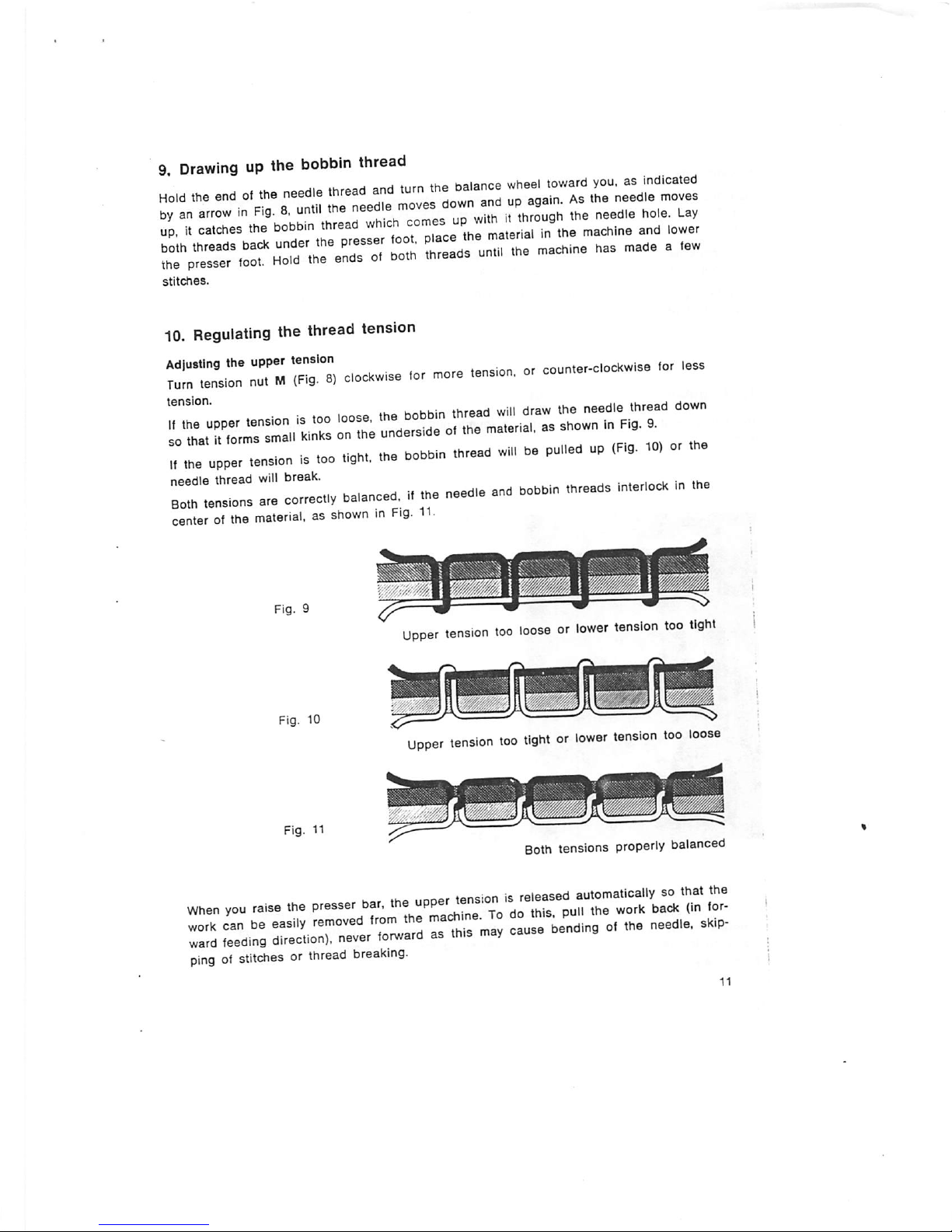

10.

Regulating

the

thread

tension

Adlustlng

the

upper

tension

counter-clockwise

tor

less

Turn

tension

nutM(Fig.8)clockw.se

for

more

tens.on,

K^Khin

thread

will

draw

the needle thread

down

^or

r.Tr:iv:.ra

re

unde.s.de

o.

.he

.a.eda,.

as

shown

,n

^.

„

,ne

upper

.ensionis.00

.iph.,

.he

hobbln

.hread

winbepu.ledup(Fig.

10)

:::r::

r.,—•

-

centerofthe

material,asshownmF.g.

11.

upper

tension

too

looseorlower

tension

too

tight

Fig. 10

tension

too

tightorlower

tension

too

loose

jliCZJ

Fig.

11

Both

tensions

properly

balanced

-:rsr,vrr."-r

=».s

rcrr

.r«s

r-™

™—•

«•

pingofstitchesorthread

breaking.

Page 12

Adjusting

the

lower

tension

Take

the

bobbin

case

outofthe

machine

and

regulate

the

tensionbyturning

screw

Z

(Fig.7)with

the

hook

screwdriver,asappropriate.

Turn

this

screw

clockwise

foratight

er

tension,orcounter-clockwise

foralooser

tension.

The

tensioniscorrectifa

noticeable

resistanceofspringY(Fig.7)has to be

overcome

when

pulling

the

thread

outofthe

bobbin

case.

If

puckering

occursondelicate

materials

although

the

tension

has

been

set

correctly,

ease

both

tensions

slightly.

11. Regulating the stitch length

The

stitch

lengthisregulatedbyturning

thumb

nutS(Fig.

12)onthe

feed

regulator

lever.

R

9933

s

Fig.

12

Turn

this

nut

clockwise

for

shorter

stitches,orcounter-clockwise

for

longer

stitches.

The

numerals on the left of the scale Indicate the

stitch

lengthinmillimeters.

The letters V

andRon

the

left

sideofthe

scale

(Fig.

12)

stand

for

forward

and

backward

sewing,

respectively.

Page 13

All machines with the exception of the Pfaff 141-705/03

and

143-705/03

are

regularly fitted

with

a spring-return feed regulator. This device incorporates a spring

which

permanently

holds the feed regulator lever down in forward feeding position. When the lever is

pushed up as far as it

will

go, the machine

will

sew in reverse. And conversely, when

the

leverisreleased,

forward

sewing

willberesumed

instantly.

If

desired,

the

machine

can

be fitted with a

pedal

which

makesitpossibletoreverse

the

directionoffeed

by foot

action.

12. Regulating the pressure on

the

material

The amount of pressure to be exerted by the

presser

foot must be adapted to the ma

terial to be sewn. The pressure is set correctly if the material is advanced through the

machine evenly without being injured by the teeth of the feed dog.

The pressure on the

material

is regulated by turning screw V

(Fig.

8).

Turn

this screw

in for

more

pressure,

or out for

less

pressure.

Depending

on the

version,

Pfaff

145,

146,

545.

546

and

555

machines

are

equipped

with

one or two leaf springs on the machine arm instead of the conventional presser bar

spring

with

pressure

regulating

screw.Onthese

machines

the

presser

foot

pressure

Is

increased by

turning

knurled

nut V

(Fig.

13)

upwards,

and decreased by

turning

It

downwards.

Fig.

13

Page 14

13.

Cleaning

the

sewing

hook

The

sewing

hookIsthe

most

essential

partofthe

whole

machine

and.

for

this

reason,

shouldbecleaned

thoroughly

from

timetotime.

To do

this,

raise

the

needle

bar

to its

highest

point,

open

the

bed

slide

and

remove

the

bobbin

case

with

the

bobbin.

Take

out

the

three

screws

Ei, Ej

and

Es (Fig. 6)

and

strip

the

hook

gib.

Turn

the

balance

wheel until point S of

the

bobbin

case

baseisabouttoenter

groove

N of

the

hook

(Fig. 14). When in this position, the

bobbin

case

base

canbetipped

out

easily by

seiz

ing

center

stud

Z with

thumb

and

forefinger while

turning

the

balance

wheel

back

and

forth

lightly.

Clean

hook

and

hook

raceway

thoroughly with

kerosene.Ifthe

cotton

wool in slot 0

(Fig. 14)

should

have

become

matted,itshouldbereplaced

and

the

new

cotton

wool

be

soaked

with

oil.

Fig. 14

To clean the parts in the vicinity of the sewing hook, take out set screw 20 (Fig. 4) and

pull the hook up out of the machine. When the hook is replaced, pin 19 (Fig. 4) ensures

proper positioning and eliminates the

need

of retiming the hook.

In replacing the bobbin case base, make sure that position finger F (Fig. 14) enters slot

P on the underside of the needle plate. Replace hook gib and tighten screws Ei-

Ej. Put a drop of oil Into the hook raceway, replace the bobbin

case

with the bobbin

and

close

latch B (Fig. 6).

Never run the machine

with

the needle plate removed as this may result in damage to

the bobbin

case

or the bobbin

case

opener.

The above Instructions also apply to all two-needle sewing machines covered by this In

struction

Book.

Page 15

14.

The

safety

clutch

ModelCandDmachines

are

equipped

withasafety

clutch

which

prevents

disturbance

of

the

hook

timing and

damagetothe

bobbin

case

baseincaseofthread

jamminginthe

hook

raceway.

If an irregularly

spun

needle

thread

should

jam in

the

hook

raceway

and

block

the

sew

ing hook,

the

safety clutch

automatically

disengages

the

hook drive.

After

the

jammed

thread

has

been

removed,

tilt

back

the

sewing

head

and

rotate

the

balance

wheel,

while

holding

the

hook

drive

shaft

steady,

until

the

tipofthe

latch

is

positioned

exactly

above

the

grooveinthe

clutch

bushing.

Now

push

back

the

spring-

loaded

pinsothat

the

latch

can

snap

Into

this

groove.

To

resume

sewing,

simply

let

down

the

sewing

head

again.

R

9343

Fig. 15

Page 16

Additional

instructions

for

Pfaff

machines

141-705/03

and

141-705/03-725/01

The

Pfaff

141-705/03

and

141-705/03-725/01

have

the

same

feed

regulator.

This

new

mechanism

makesitpossibletoselect

the

proper

stitch

length

outoftwelve

different

stitch

lengths

available.

These

twelve

stitch

lengths

are

divided

into

four

stitch

length

groups

(l-IV)

having

three

predetermined

stitch

lengths

each

(Fig.

16).

The

following

taoie

lists

the

stitch

lengthsinmillimetersaswellasthe

number

of

stitches

per

inch.

For

adjustment,aswellasengagement

and

disengagementofthe

trimming

mechanism

on the

Pfaff

141-705/03-725/01.

see pages 19 and 20.

Stitch

length

group

Stitches

per

inch

33 28

25V2

23 21 19 17 15 13 12 11 10

Stitch

lengthinmm

0.8 0.9 1.0

1.1

1-2 1.3 1.5 1.7 1.9

2.1

2.3 2.6

Stitches

per

cm

12'/?1110 9 8

Th

6Vj

5Vj

5

4V2

4 3'/?

R

6575

Fig.

16

Page 17

15.

Regulating

the

stitch

length

The

stitch

lengthisregulated

as

follows:

Beginbyselecting

the

proper

stitch

length

group

from

the

table

on p. 16

and

inter

change

the

feed

gearsasindicatedinthe

feed

gear

housing

(Fig.

18).

Press

down

button

K (Fig, 17)

and

turn

the

baiance

wheei

untii

the

button

snapsinpo

sition.

Again

rotate

the

balance

wheel

backwardsorforwards

until

notch

M (Fig. 17) on

the

baiance

wheeiisopposite

the

numberofthe

stitch

length

group

chosen

(I, II. IllorIV).

Release

buttonKand

turn

feed

regulator

lever

S (Fig. 16) to

the

desired

stitch

length.

R

8994

Fig. 17

Page 18

16.

Changing

the

feed

gears

Exchanging the feed gears is greatly facilitated by the wheel puller which Is supplied

with the machine. To pull the feed

gear

off its shaft, slip the fork of the wheel puller

under

the

projecting

rim of

the

hub

and

puli (Fig. 18),

Consult the diagram on the feed

gear

housing (Fig, 18) to

see

how the feed

gears

have

to be exchanged to obtain the stitch length group and stitch length desired. Exchange

the

feed

gears

accordingly.

For better Identification, the

outside

of the feed

gears

and the

corresponding

symbols

used in the diagram are painted yellow, green, red and blue. In slipping the feed gear

onto

its shaft,

see

that

the

key on

the

shaft

enters

the

notch in

the

feed

gear

and

that

the

mating

gears

are

meshed

properly.

For instructions on how to

adjust

the

trimmer of

the

Pfaff 141-705/03-725/01.

please

refer

to

Chapters17and

18.

m

R

6585

IPI

Fig. 18

Page 19

17.

Adjusting

the

trimmer

To

take

out

the

trimming

knife

for

sharpening,

loosen

set

screwC(Fig.

19)

swinq

the

knife

halfway

between

its

operative

and

inoperative

positions

and

pull

the

knife

out

of

Its

guide.Asyou

replace

the

knife,

make

sure

its

cutting

edge

bears

lightly

against

the

edgeofthe

needle

plate

slot

which

servesasa

guide.

However,

the

knife

must

neverbeset

too

closetothis

edgeasthis

might

cause

the

knifetojamasitisthrown

outofaction.

When

the

settingiscorrect,

tighten

set

screwCsecurely.

The

cutting

strokeofthe

knife

shouldbeexactly

halvedbythe

needle

hole.Toadjust

the

positionofthe

cutting

edgeinrelationtothe

needle

hole,

loosen

nutM(Fig

19)

and

move

the

knife

carrier

forwardorbackward,asappropriate.

This

setting

also

appliestoknives

which

have

been

resharpened

repeatedly.

After

the

adjustment

tighten

lut M securely. . y ci.

The

vertical

positionofthe

knifeisadjustedbyscrewS(Fig.

19).

Turn

this

screw

clock

wisetoset

the

knife

lower,orcounter-clockwisetosetithigher.

The

knife

isset

cor

rectly,IfIts

cutting

edgeispositioned

just

above

the

bottomofthe

needle

plate

guide

Fig. 19

Page 20

It

goes

without saying

tnat

only a

sharp

and

correctly

set

knife will

produceaclean

cut.

Blunt knives are either snarpened with a triangular oilstone by hand (Fig.

2C)

or with

the aid of a knife sharpener. In sharpening the

knife,

take care that the cutting angle

is

preserved

and

that

the

cutting

edgeissharpened

thoroughly up to its

innermost

cor

nerewhich

hastotake

most

of

the

strain.

18.

Operating

the

trimmer

To

engage

the trimmer, turn lever H (Fig. 19) to the right until it

catches

on lug K on th(

knife carrier. To

disengage

it. lift lever H up slightly and swing it forward.

With the trimmer thrown out of action, the machine

can

be used for ordinary sewing

operations.

R

5436

'si«'

•

Fig.

20

Page 21

Additional

Instructions

for

PfafI

machines

143-705/03

The

general

instructions

given

for

the

Pfaff

143

apply

alsotothe

Pfaff

143-705/03

wheel-

feed

machine.Inaddition,

however,

the

following

instructions

shouldbeheeded:

9. Regulating the stitch length

On

wheel-feed

machines

the

stitch

lengthisregulated

under

the

bedplate

instead

of

on the

machine

arm.

as is

customary.

The

feed

gear

assembly

(Fig.

21)

enables

selection

of three pre-determined stitch lengths.

To

change

the

stitch

length,

pull

out

pinP(Fig.

21)

and

move

leverHto

positiona,b

or c, as

desired,

while

turning

the balance

wheel.

Let

pin

P snap

into

position.

To

convert

the

mac^iinetoanother

stitch

length

group,

consult

the

Spare

Parts

Cata

-

logue

which

contains a list of all feed gears available for this

machine.

Page 22

Additional

instructions

for

Pfaff

machines

145

Pfaff machines 145 are fitted not only with compound feed like the Pfaff 141. but also

with

alternating

pressers

which

makes them

unison-feed

machines

capable of

feeding

materials

that

are

difficulttohandle.

Apart

from

the

general

instructions

given

for

Pfaff

machines

141

and

143

which

apply

to Pfaff machines 145 also, the following special instructions should be heeded;

20.

Exchanging

the

alternating

pressers

Raise presser bar

liftera(Fig.

22) and rotate the balance wheel to bring the needle to

its

highest

point.

Loosen

screw b and

pull

out the

vibrating

presser,

rotatingitslightly

to

the

right

and

left.

R

3503

Fig. 22

Page 23

In

replacing

the

vibrating

presser

make

sure

you

pushitupasfarasIt

willgoand

orientitso

that

the

needleiscenteredinits

needle

hole.

Then

tighten

screwb(Fig.

22)

securely.

The

lifting

presser

can be

removed

only

when

the

presser

bar is

raised.Todo

this,

take out screw c

(Fig.

22)

and

pull

out the

lifting

presser.

tiltingitback

and

forth

slightly.

When

replacing the

lifting

presser. push it up as far as it

will

go so that screw c can

be pushed through the hole in its shank and tightened securely.

R

6189

'

/ ^

mmi

F H

Fig.

23

Page 24

21.

Lubricating

the

machine

Since

Pfaff

machines

145

are

fitted with

alternating

pressers,

they

haveanum

ber of additional oiling points which are marked by arrows in Figs. 22 and 23. Of these,

particularly the points of friction at the needle-bar-end of the machine, such as the

needle bar (inside needle bar frame in Fig. 22) and the sleeve take-up with its round

shank (behind needle bar in Fig. 22), require thorough and regular lubrication.

All

moving and rotating parts should be oiled regularly. To prevent soiling of the work

through dripping oil, sew a few seams on a piece of scrap material to absorb all ex

cess

oil.

Never try to remedy certain faults by applying excessive quantities of oil. Excessive

oiling

will

merely soil the work. Tnerefore, oil the machine sparingly, but regularly.

22.

Setting

the

foot

lift

To

adapt

the

foot lift to the thickness of the material to be sewn, loosen wing nut F

(Fig. 23) and adjust the position of lifting eccentric connection H in the slot of the lift

ing crank. Move the connection upward for a higher foot lift, or downward for a lower

foot

lift.

Additional

instructions

for

Pfaff

machines

151

and

153

Pfaff machines 151

and

153

are

single-needle sewing machines fitted with compound

feed

and

ordinary

drop

feed, respectively. Both have the vertical rotary hook

arranged

on

the

left of

the

needle.

The

Instructions

given in

Chapters

1-14

appytothem

also.

24

Page 25

Additional

Instructions

for

Pfaff

machines

142,144,146

and

542-748/01

23.

Threading

the

needles

To thread the left needle, pass tne thread

from

tne spool on the tnread stand through

the two upper holes in stud 1 on the machine arm (not shown In Fig.

24),

through thread

guide2.around

thread

retainer3,around

and

between

tension

discs4,down

and

iround thread controller disc 5. through thread check spring 6, up and through thread

juide

7, from right to left through the hole in take-up lever 8. down and through thread

guides

9, 10

and

11,

and

from

right

to left

through

the

eyeofthe

left

needle

12.

To

thread

the

right needle,

pass

the

thread

from

the

second

spoolonthe

thread

stand

through the two lower holes in

stud

1 (not

shown

in Fig. 24).

thence

to 2, 14, 15, 5, 6,

7. 8, 9, 10

and

16.

and

from left to right

through

the

eyeofthe

right

needle

17.

Fig. 24

Page 26

24.

Adjusting the puller feed of the

Pfaff

542-/48/01

The

Pfaff

542-748/01isequipped

withanadditional

puller

feed

whichisarranged

bacif

of

the

presser

foot

and,

actinginsynchronization

with

the

drop

feed,

ensures

even

feedingofthe

material.

The

lower

feed

rollerispositively

drivenbythe

feed

rock

shaft

via a

connecting

link.

When

the

presser

bar

lifterislowered,

the

upper

feed

rollerislowered

onto

the

lower

feed

roller

and

the

materialisfirmly

gripped

between

them.Toincrease

the

rate

of

feedofthe

puller

feed

for

sewing

materials

that

are

difficulttohandle,

loosen

the

hexa

gon

nut

and

adjust

the

positionofthe

connectioninthe

elongated

holeofleverX(Fig.

25).

Then

tighten

the

hexagon

nut

securely

again.Asa

resultofthis

adjustment

a

stronger

pullisexerted

on the

material

back

of the

presser

foot.

To

remove

the

work,

the

top

feed

rollerisraisedbypushingupthe

lifting

lever.

Operation

and

maintenanceofthis

machineisgovernedbythe

general

instructions

giveninthis

book,

except

that

the

additional

oiling

points

shownInFig.25should

be

supplied

with

oil.

'

Fig.

25

Page 27

Additional

instructions

for

Pfaff

machines

543-712/01

and

543-712/02

The

Pfaff

543-712/02rsa

single-needle

sewing

machine

equipped

withatwo-speed

btop-motor

andaroller

thread

tension,

while

the

Pfaff

543-712/01isfitted

with

a

standard

motor

andadisc-type

thread

tension.

Both

these

machines

are

equipped

with

an extra-large vertical rotary hook.

T':

»he

Pfaff

543-712Isidentical

with

thatofthe

,1

flatbed

sewmg

machinesothat

all

operating

and

servicing

instructions

given

r

the

latter

also

applytothe

former,

the

only

exception

being

Chapters8and

11.

25.

Threading the needle ofthe

Pfaff

543-712/,

Pass

the

thread

from the

spoolupand

over

the

thread

guide

at the top of the

thread

stand, down and through the

hole of the angular thread

guide on the machine arm,

and

through

the

thread

re

tainer. making

sure

that the

thread

enters

the

slot

in the

thread

retainer

stud. Now

lead it clockwise around the

roller tension of subcl.-712/02

machines or the disc-type

insionofsubcl.

-712/01 ma

chines. Then

pass

it around

the thread controller disc,

through the

thread

check

spring, up and through the

thread guide, from right to

left through the eye in the

take-up lever, down

and

through both thread guides,

and

from

lefttoright

through

the needle eye.

Fig.

26

R

9697a

Page 28

Additional

Instructions

for Pfaff machines 546-748/01

The

Pfaff

546-748/01isa

two-needle,

flatbed

sewing

machine

fitted

with

unison

feed,

two

extra-iarge

vertical

rotary

hooks

and

additional

puller

feed

which

ensures

smooth

feeding of "problem" materials.

Fitted

withasubcl.

-368/01,

-369/01or-371/01

attachment

this

machineisprimarily

intended for attaching waistbands to trousers and skirts.

Other

than

that

the

Pfaff

546-748/01isidentical

with

our

standard

two-needle,

flatbed

sewing

machinesothat

the

general

operating

and

servicing

instructions

given

for

this

machine

applytothem

also.

The

only

exceptions

are

the

instructions

for

settin.

the

foot

lift

and

adjusting

the

puller

feed

which

are

given

below.

R

9680

26.

Setting

the

foot lift

To adapt the

f«

lift the

thickness

of

the

material

to

be sewn,

loosen

wing

nut

F

(Fig. 27) and adjust the posi

tion of lifting

eccentric

con

nection

H in

the

slotofthe

lifting crank. Move

the

con

nection upward for a higher

foot lift, or downward for a

lower

foot

lift.

Then

tighten

wing nut F

securely.

If

delicate

fabrics

should

con

tinuetopucker

when

sewn

on

a

subcl.

-368/01, -369/01 or

-371/01

machine,

although

the

foot

lift

was

adjusted

correct

ly, It Is recommended to re

place the rear swing-away

folder by one having a built-

in retaining mechanism and a

regulating screw (R in Fig.

28).

To

increase

the

pressure

ex

ertedcrthe

fabricbythe

re-

Page 29

taining

tongue,

turn

screw

R

.backward;

to

decrease

the

pressure,

turnitforwards.

For

easy

removalofthe

ma*

terial,

press

against

the

knee

lever

to

raise

the

vibrating

and

lifting

pressers

and

lock

the

latterInpositionbylever

St

(Fig. 27).

Fig.

28

27.

Adjusting

the

puller

feed

The Pfaff

546-748/01

is equipped

with

an additional puller feed

which

is arranged

behind the

presser

foot and, acting in synchronization with the unison feed,

ensures

even feeding of the material. The lower feed roller is positively driven by the feed rock

shaft

via a connection and

has

a buiit-in retaining mechanism.

By lowering

presser

bar lifterSj(Fig. 27),

the

upper

feed roller is lowered

onto

the

lower feed roller and both

advance

the

material together. To increase the

rate

of feed

of the puller feed so that It

exertsastronger

pull on the material at the

backofthe

needles,

adjust

the

position of

connection

Z (Fig. 27) in relation to

the

feed lever.

Then

tighten

the

hexagon

nut securely.

Page 30

Additional

instructions

for

Pfaff

machines

4141

and

4145

Pfaff

machines

4141

and

4145

closely

resemble

Cl.

141

and

145

machinesmtheir

mecha

nical

setup,

exterior

design

and

dimensions.

Insteadofa

vertical

rotary

hook,

however,

both

machines

are

equipped

withaconstant-motion

rotary

looper

which

moves

coun

ter-clockwise.inaddition,

they

are

fitted

withathread

nipper

whichisoperatedbythe

needle

bar

crank.

Apart

from

the

needle

threading

instructions,

the

general

instructions

given

for

Pfaff

ma

chines

141

and

145

applytoPfaff

machines

4141

and

4145

also.

(Since

the

latter

ma

chines

are

chainstitch

sewing

machines,

bobbin

winding

naturallyisomitted.)

R

6312

28.

Threading

of

the

Pfaff

4141

and

4145

Pass

the

thread

from

the

spool

up to the top thread guide of

the

thread

stand,

then

down

and through both holes in the

pin on the machine arm,

through the upper hole in the

thread

guide

on the machine

arm (as shown in Fig. 29),

around

the

pin.

through

tf\

lower

holeinthe

thread

guide,

clockwise

around

and

be

tween

the

tension

discs,

from

right to left through the hole

in

the

take-up

lever, below

the

leverofthe

automatic

ten

sion,

through

the lower

thread

guide and the thread guide

on

the

needle

clamp,

and

from left to right through the

needle

eye.

Page 31

Additional

Instructions

for Pfaff machines fitted with thread pulier/trimmer •900/..

Since

these

machines

are

equipped

with

Stop

motor

and

electro-magnetic

thread

puller/trimmer,

manual

needle

positioning

and

thread

trimming

are

completely

elimi

nated.

29.

Pedal

operation

When

you

depress

the

heelofthe

pedal

at the

completionofthe

sewing

action,

the

eedle is

raised

automatically,

the

needle

thread is

pulled

to the

underside

of the

ma-

teriaJ

and

both

threads

are

trimmed.

All

you

have

to do to

remove

the

work

is raisethe

presser

foot

The

thread

ends

remaining

on the

undersideofthe

material

are

long

enough to permit them to be pasted down reliabiy.

The pedal of these machinescontrols the

following

functions:

1.

When

you

depress

the

tipofthe

pedal,

the

machine

starts

sewing.

The

harder

you

press, the faster the

machine

will

run.

(If

it is

fitted

withaninching

device,

the

pedal

will

also control slow stitch-by-stitch sewing).

2.

When

you

relieve

the

pressure

and

allow

the

pedaltoreturntoits

neutral

posi

tion, the needle is lowered for turning comers.

3.

When

you

depress

the

heelofthe

pedal,

the

needleisraisedtoits

highest

point,

the needle thread

pulled

to the underside of the material, and both threads are

trimmed.

4. When the pedal is returned to its neutral position again, the needle

remains

at its

highest

point

The

various

pedal

positions

are

shown

below:

Forward

sewing

After

sewing:

needle

down

Neutral

position

Raising

needle

and

trimming

threads

After

thread

trimming:

needle

up

Ifthe machine is fitted

with

two pedals (subcl.

pedals are simultaneously pressed forward.

-911/01),

it will

sewinreverse

when

both

31

Page 32

Guards

irra^Tn^are'Tegularly

fitted

withaguard

which

protects

the

operator's

firtgers

rjlrgrorthTfingerguard

and

the

methodoffittingitdepend

on

the

matdtine

version.

vei

Please

make

sure

that

this

guardisalways

fitted

correctly.

R

11466

....

Fig. 30

Take-up lever guard (Fig.31)

All

machines

are

normally

equipped

withatake-up

lever

safety

regulations.Itis

imperative

that

this

safety

deviceisfittedatall

times.

Page 33

Belt

guardonbalance

wheel

(Fig. 32)

This

guard

covers

the

point

where

the

belt

runs

onto

the

balance

wheel.

The

belt

guardismountedasfollows:

Guard 1 is

secured

with two

screws

2 and positioned so

that

it covers the point of belt

entrance

completely.

R

11369

A

¥rv.--:-;iSws

Page 34

Belt guard below tabletop (Fig. 33)

This guard covers the belt below the tabletop.

Loosen

wing

nut 4, and

position

guard 5 so that

motor

puliey

and

V-belt

run

freely

in

the

guard.

"

f'-vj

\

R

10865

Page 35

• #

I

{

i •«

'

Troubfe

shooting

Machlrte

skips stitches

Cause

Wrong

needle

system.

Needle

bent

Needle

inserted

incorrectly.

i

Incorrect

threading.

^hread

breaks

Cause

For

anyofthe

reasons

indicated

above.

Thread

tensions

too tight

Knotty

thread.

Needle

point

bluntordamaged.

Thread snarled up.

Faulty stitch formation

Cause

Improper

tension.

"Wrong

needle

size

and/or

thread

used.

Piecesofthread

between

tension

discs

or

under

bobbin

case

tension

spring.

Needle

breaks

Cause

Wrong

needle

system.

Needle

bent

Needle

too

thin.

Machine

binds

'Cause

• ^

Lackofoil.

Remedy

For

correct

needle

system

see

Chapter

6.

Insert

new

needleasInstructedInChapter

7

Orient

needlesothat

its

short

groove

faces'

toward

the

sewing

hook.

In Chapters S.

8, 23, 25 and 28.

Remedy

See

remedies

listed

above.

Regulate

tensionsasInstructedInChapteria

Use

high-quality

thread

only.

Replace

needle.

Check

upper

threading

from

spoolofthread

to

needle.

Remedy"^

Regulate

tensionsasinstructedInChapter

ia

See

Chapter

&

Remove

thread

and

re-adjust

tensionasIn

structed In Chapter 10.

Remedy

.

Insert

needleofcorrect

systemasInstructed

in Chapter 6.

Insert

new

needle.

Insert thicker

needta

Wrong

lubricant

^

Hook

race

obstructedbypieces

of

thread.

'

.Remedy.'

Oil

machineasInstructedInChapters

3.-13

and'21.

- •

Use

only

non-reslnous

and

add-free

sewfno

machine-oil.

Trytofree

the

jammed

threadasyou

rock

the

balance

wheel

back

and

forth.Ifthis

action

should

fall,

dismantle

the

sewing

hookasIn

structedInChapter

ia

Page 36

\} :

I-

1 *

f':'

rsaPTf

Nr.

296-12-07

064/1275

engl. P.

« • 6

M

♦

C:

*1

Printed In

West

Germany

-•??.

vlT'

Loading...

Loading...