Page 1

471

474

Instruction Manual

296-12-18 398/002

Betriebsanleitung engl. 12.99

491

This instruction manual applies to machines from the

following serial numbers onwards:

PFAFF 471 # 2560474

PFAFF 474 # 2561194

PFAFF 491 # 2561421

Page 2

This instruction manual applies to all versions and subclasses listed under

"Specifications".

Reprinting, copying or translation of PFAFF instruction manuals, whether in whole or in part, is

not permitted without our prior permission and not without written indication of the source.

G.M. PFAFF KAISERSLAUTERN

INDUSTRIEMASCHINEN AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Editing/illustrations

Verlag TD

D-77901 Lahr

Page 3

Index

Contents ..................................................................................Chapter - Page

1 Safety............................................................................................................................ 1 - 1

1.01 Directives ...................................................................................................................... 1 - 1

1.02 General notes on safety................................................................................................. 1 - 1

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important points for the user.......................................................................................... 1 - 2

1.05 Operating and specialist personnel ................................................................................ 1 - 3

1.05.01 Operating personnel....................................................................................................... 1 - 3

1.05.02 Specialist personnel....................................................................................................... 1 - 3

1.06 Danger ........................................................................................................................... 1 - 4

2 Proper use.................................................................................................................... 2 -1

3 Specifications .............................................................................................................. 3 - 1

3.01 PFAFF 471, 474, 491 ..................................................................................................... 3 - 1

3.02 Needles and threads...................................................................................................... 3 - 2

3.03 Possible models and subclasses ................................................................................... 3 - 2

4 Disposal of Machine.................................................................................................... 4 - 1

5 Transportation, packing and storage ......................................................................... 5 - 1

5.01 Transportation to customer's premises ......................................................................... 5 - 1

5.02 Transportation inside the customer's premises ............................................................. 5 - 1

5.03 Disposal of packing materials........................................................................................ 5 - 1

5.04 Storage .......................................................................................................................... 5 - 1

6 Explanation of symbols............................................................................................... 6 - 1

7 Controls........................................................................................................................7- 1

7.01 On / off switch on machines with mini-stop motor

without edge trimmer -725/.. or -726/.. .......................................................................... 7 - 1

7.02 On / off switch on machines with mini-stop motor

and edge trimmer -725/.. or -726/.. ................................................................................ 7 - 1

7.03 Button on machine head (only on machines with -911/..) ............................................. 7 - 2

7.04 Pedal ............................................................................................................................. 7 - 2

7.05 Lever for lifting roller presser.......................................................................................... 7 - 3

7.06 Knee lever ..................................................................................................................... 7 - 3

7.07 Key for setting stitch length ........................................................................................... 7 - 4

7.08 Swing out roller presser ................................................................................................. 7 - 4

7.09 Edge trimmer -725/04 for 471 ....................................................................................... 7 - 5

7.10 Edge trimmer -725/04 for 474 and 491.......................................................................... 7 - 6

7.11 Edge trimmer -726/05 for 491 ........................................................................................ 7 - 7

8 Installation and commissioning ................................................................................. 8 - 1

8.01 Installation..................................................................................................................... 8 - 1

8.01.01 Adjusting the table height .............................................................................................. 8 - 1

8.01.02 Fitting the tilt lock .......................................................................................................... 8 - 2

8.01.03 Tensioning the v-belt (does not apply to machines with mini-stop motor)...................... 8 - 2

8.01.04 Fitting the v-belt guard ................................................................................................... 8 - 3

8.01.05 Fitting the bottom v-belt guard (does not apply to machines with mini-stop motor) ....... 8 - 3

8.01.06 Fitting the synchronizer.................................................................................................. 8 - 4

8.01.07 Fitting the reel stand ...................................................................................................... 8 - 4

8.02 Commissioning ............................................................................................................. 8 - 5

Page 4

Index

Contents ..................................................................................Chapter - Page

8.03 Switching the machine on / off ...................................................................................... 8 - 5

9 Setting up..................................................................................................................... 9- 1

9.01 Inserting the needle on model 471 and 491.................................................................... 9 - 1

9.02 Inserting the needle on model 474................................................................................. 9 - 2

9.03 Winding the bobbin thread; adjusting the primary thread tension ................................... 9 - 3

9.04 Removing / Inserting the bobbin case............................................................................ 9 - 4

9.05 Threading the bobbin case / Adjusting the bobbin thread tension ................................... 9 - 4

9.06 Threading the needle thread and regulating its tension on model 471/491 ...................... 9 - 5

9.07 Threading the needle thread and regulating its tension on model 474............................. 9 - 6

9.08 Setting the stitch length ................................................................................................. 9 - 7

10 Care and maintenance................................................................................................10 - 1

10.01 Cleaning .......................................................................................................................10 - 1

10.02 Oiling the hook .............................................................................................................10 - 2

10.03 Filling the oil reservoir of the thread lubrication unit.......................................................1 0 - 3

10.04 Lubricating the bevel gears...........................................................................................10 - 3

10.05 Checking / adjusting the air pressure............................................................................10 - 4

10.06 Cleaning the air filter of the air-filter / lubricator.............................................................10 - 4

11 Adjustment..................................................................................................................11 - 1

11.01 Notes on adjustment ....................................................................................................1 1 - 1

11.02 Tools, gauges and other accessories............................................................................1 1 - 1

11.03 Abbreviations................................................................................................................11 - 1

11.04 Adjusting the basic machine .....................................................................................1 1 - 2

11.04.01 Adjusting the synchronizer............................................................................................11 - 2

11.04.02 Needle position in sewing direction on the PFAFF 471 and 491.....................................1 1 - 3

11.04.03 Needle position in sewing direction on the PFAFF 474 ..................................................1 1 - 4

11.04.04 Preliminary adjustment of the needle height .................................................................1 1 - 5

11.04.05 Needle rise, hook clearance, needle height and needle guard on the PFAFF 471...........1 1 - 6

11.04.06 Needle rise, hook clearance, needle height and needle guard on the PFAFF 474...........1 1 - 8

11.04.07 Needle rise, hook clearance, needle height and needle guard on the PFAFF 491...........1 1 - 10

11.04.08 Needle position crosswise to sewing direction on the PFAFF 471.................................1 1 - 12

11.04.09 Needle position crosswise to sewing direction on the PFAFF 474.................................1 1 - 13

11.04.10 Needle position crosswise to sewing direction on the PFAFF 491.................................1 1 - 14

11.04.11 Height of the bobbin-case opener..................................................................................1 1 - 15

11.04.12 Bobbin-case opener stroke ...........................................................................................11 - 16

11.04.13 Height of the feed wheel on the PFAFF 471 ..................................................................11 - 17

11.04.14 Height of the feed wheel on the PFAFF 474 ..................................................................11 - 18

11.04.15 Height of the feed wheel on the PFAFF 491 ..................................................................11 - 19

11.04.16 Stitch length control eccentric....................................................................................... 11 -20

11.04.17 Stitch length scale disk.................................................................................................1 1 - 21

11.04.18 Shaft crank to feed wheel drive ....................................................................................11 - 22

11.04.19 Shaft crank to roller presser drive .................................................................................11 - 23

11.04.20 Clearance between roller presser and feed wheel.........................................................1 1 - 24

11.04.21 Roller presser ...............................................................................................................11 - 25

11.04.22 Stitch length on stitch length scale ...............................................................................11 - 26

11.04.23 Synchronization of roller presser and feed wheel ..........................................................11 - 27

11.04.24 Retainer (only on model 474) ........................................................................................11 - 28

11.04.25 Knee lever ....................................................................................................................11 - 29

Page 5

Index

Contents ..................................................................................Chapter - Page

11.04.26 Needle thread tension release.......................................................................................11 -30

11.04.27 Thread check spring .....................................................................................................11-31

11.04.28 Bobbin winder ..............................................................................................................1 1 - 32

11.04.29 Pressure of roller presser..............................................................................................11-33

11.04.30 Re-engage safety coupling ...........................................................................................11 - 34

11.05 Adjusting the edge trimmer -725/04...........................................................................11 - 35

11.05.01 Position knife holder on model 471 ...............................................................................11 - 35

11.05.02 Position knife holder on models 474 and 491................................................................11 - 36

11.05.03 Knife stroke on model 471 ............................................................................................11 - 37

11.05.04 Knife stroke on models 474 and 491.............................................................................11 - 38

11.05.05 Cutting stroke on model 471........................................................................................11 - 39

11.05.06 Cutting stroke on models 474 and 491..........................................................................11 - 40

11.05.07 Knife position................................................................................................................1 1 - 41

11.06 Adjusting the thread trimmer -726/05 on model 491................................................11 -42

11.06.01 Position of the knife to the needle plate ........................................................................1 1 - 42

11.06.02 Knife position crosswise to sewing direciton ................................................................11 - 43

11.06.03 Knife height ..................................................................................................................11 -44

11.06.04 Cutting stroke ...............................................................................................................11 - 45

11.06.05 Knife stroke ..................................................................................................................11 - 46

11.07 Adjusting the thread trimmer -900/53 ........................................................................11 -47

11.07.01 Removing the cutter .....................................................................................................11 - 47

11.07.02 Control cam with respect to bobbin opener and tripping lever .......................................11 - 48

11.07.03 Radial position of the tripping lever ...............................................................................11 - 49

11.07.04 Engaging solenoid.........................................................................................................1 1 - 50

11.07.05 Cutter drive lever ..........................................................................................................11 -51

11.07.06 Control cams for bobbin opener and cutter (using adjustment gauge) ...........................11 - 52

11.07.07 Radial position of the control cam in relation to the bobbin opener................................11 - 53

11.07.08 Control cam for cutter (adjustment without gauge) .......................................................11 - 54

11.07.09 Cutter control lever for the control cam of the cutter .....................................................11 - 55

11.07.10 Cutter return lever .........................................................................................................1 1 - 56

11.07.11 Cutter return control......................................................................................................1 1 - 57

11.07.12 Fitting the cutter............................................................................................................1 1 - 58

11.07.13 Eccentric sleeve ...........................................................................................................11 -59

11.07.14 Cutter driving rod ..........................................................................................................11 - 60

11.07.15 Cutter function test .......................................................................................................11 - 61

11.08 Tension release (only on machines with thread tension control -906/10)...............11 -63

11.09 Adjustment of backtacking mechanism -911/.. .........................................................11 -64

11.09.01 Needle in needle hole (only for PFAFF 471 and 491) .....................................................1 1 - 64

11.09.02 Coupling for roller presser drive ....................................................................................1 1 - 65

11.09.03 Bevel gears for feed wheel drive (on the PFAFF 471 and 474) ......................................1 1 - 66

11.09.04 Bevel gear play (on the PFAFF 471 and 474) ................................................................1 1 -67

11.09.05 Bevel gears for feed wheel drive (on the PFAFF 491)....................................................1 1 - 68

11.09.06 Bevel gear play (on the PFAFF 491)..............................................................................1 1 - 69

11.10 Parameter settings for the Quick-Ministop Motor.....................................................11 - 70

Page 6

Safety

1 - 1

1 Safety

1.01 Directives

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations.

In addition to this Instruction Manual, observe also all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organisations are to be strictly adhered to!

1.02 General notes on safety

● This machine may only be operated by adequately trained operators and only after the

Instruction Manual has been completely read and understood!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read

before operating the machine!

● The danger and safety instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All safety regulations relevant to its operation are to

be adhered to.

● When exchanging sewing tools (e.g. needle, roller presser, needle plate or bobbin), when

threading the machine, when leaving the machine unattended and during maintenance

work, the machine is to be separated from the power supply by switching off the On/Off

switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualified service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

Exceptions to this are only to be found in the regulations EN 50110.

● Modifications and alterations to the machine may only be carried out under observance

of all the relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We

expressly point out that any replacement parts or accessories, which are not supplied by

us, have not been tested and approved by us. The installation and/or use of any such

products can lead to negative changes in the structural characteristics of the machine.

We shall not be liable for any damage which may be caused by non-original parts.

Page 7

Safety

1 - 2

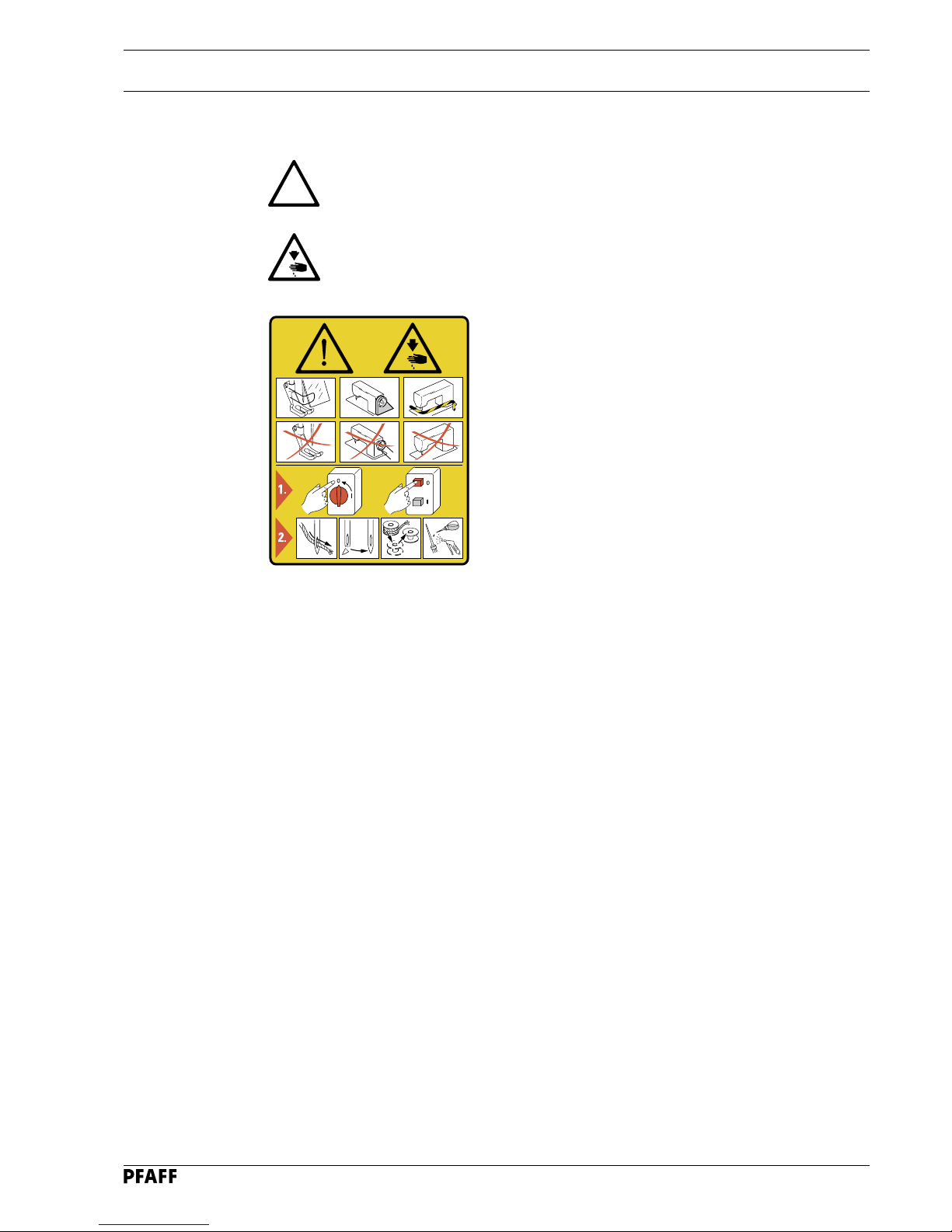

1.03 Safety symbols

Danger!

Points to be observed.

Danger of injury for operating and specialist personnel!

!

1.04 Important points for the user

● This Instruction Manual is a component part of the machine and must be available to the

operating personnel at all times.

● The Instruction Manual must be read before operating the machine for the first time.

● The operating and specialist personnel is to be instructed as to the safety equipment of the

machine and regarding safe work methods.

● It is the duty of the user to only operate the machine in perfect running order.

● It is the obligation of the user to ensure that none of the safety mechanisms are removed

or deactivated.

● It is the obligation of the user to ensure that only authorized persons operate and work on

the machine.

Further information can be obtained from your PFAFF agent.

I

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

Page 8

Safety

1 - 3

1.05 Operating and specialist personnel

1.05.01 Operating personnel

Operating personnel are persons responsible for the equipping, operating and cleaning of the

machine as well as taking care of faults arising in the sewing area.

The operating personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● never use any working methods which could limit the level of safety in using the machine!

● not wear loose-fitting clothing or jewellery such as chains or rings!

● also ensure that only authorized persons have access to the potentially dangerous area

around the machine!

● always immediately report to the person responsible any changes in the machine which

may limit its safety!

1.05.02 Specialist personnel

Specialist personnel are persons with a specialist education in the fields of electrics,

electronics and mechanics. They are responsible for the lubrication, maintenance, repair and

adjustment of the machine.

The specialist personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● switch off the On/Off switch before carrying out adjustments or repairs and ensure that it

cannot be switched on again unintentionally!

● never work on parts which are still connected to the power supply! Exceptions are

contained only in the regulations EN 50110.

● replace the protective coverings and close the electrical control box after all repairs or

maintenance work!

Page 9

Safety

1 - 4

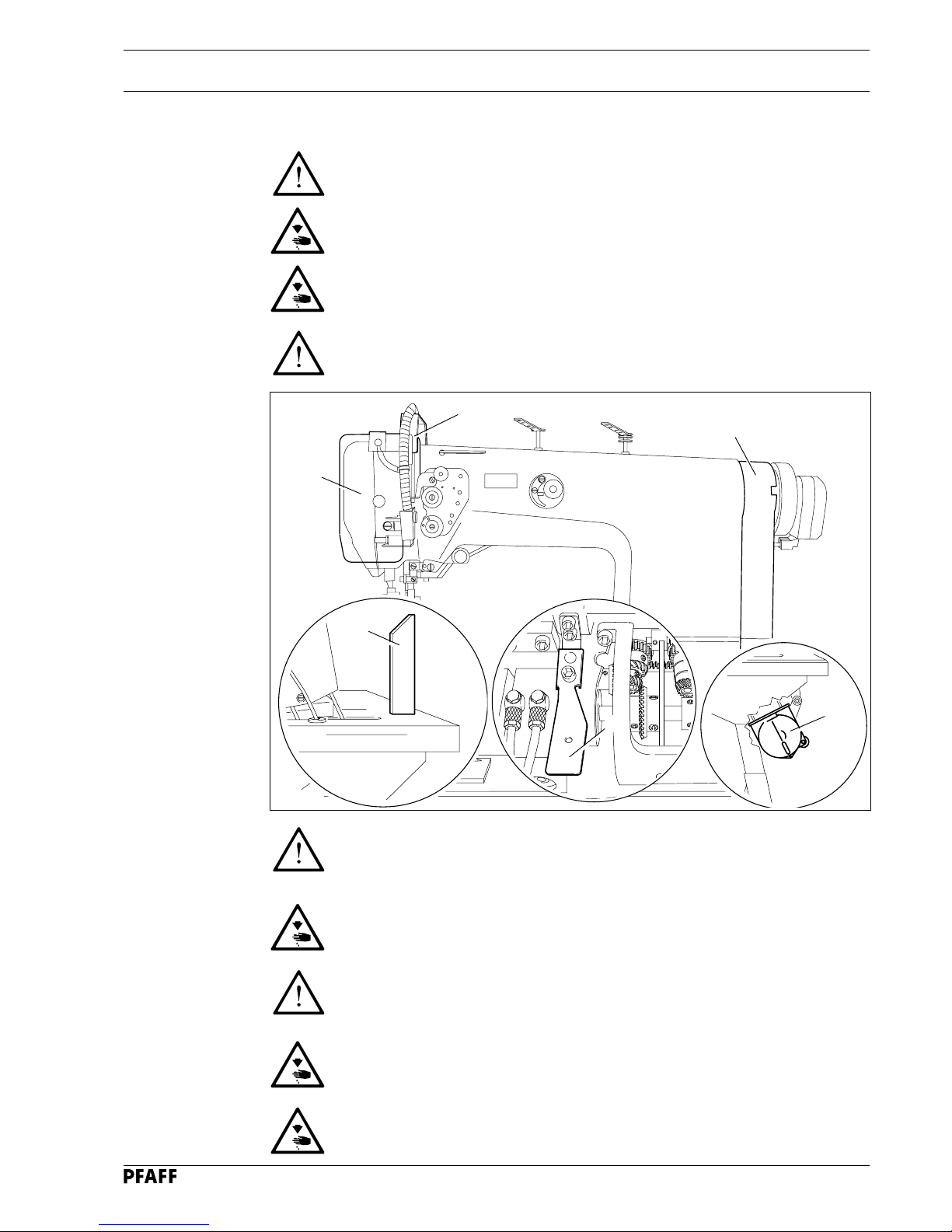

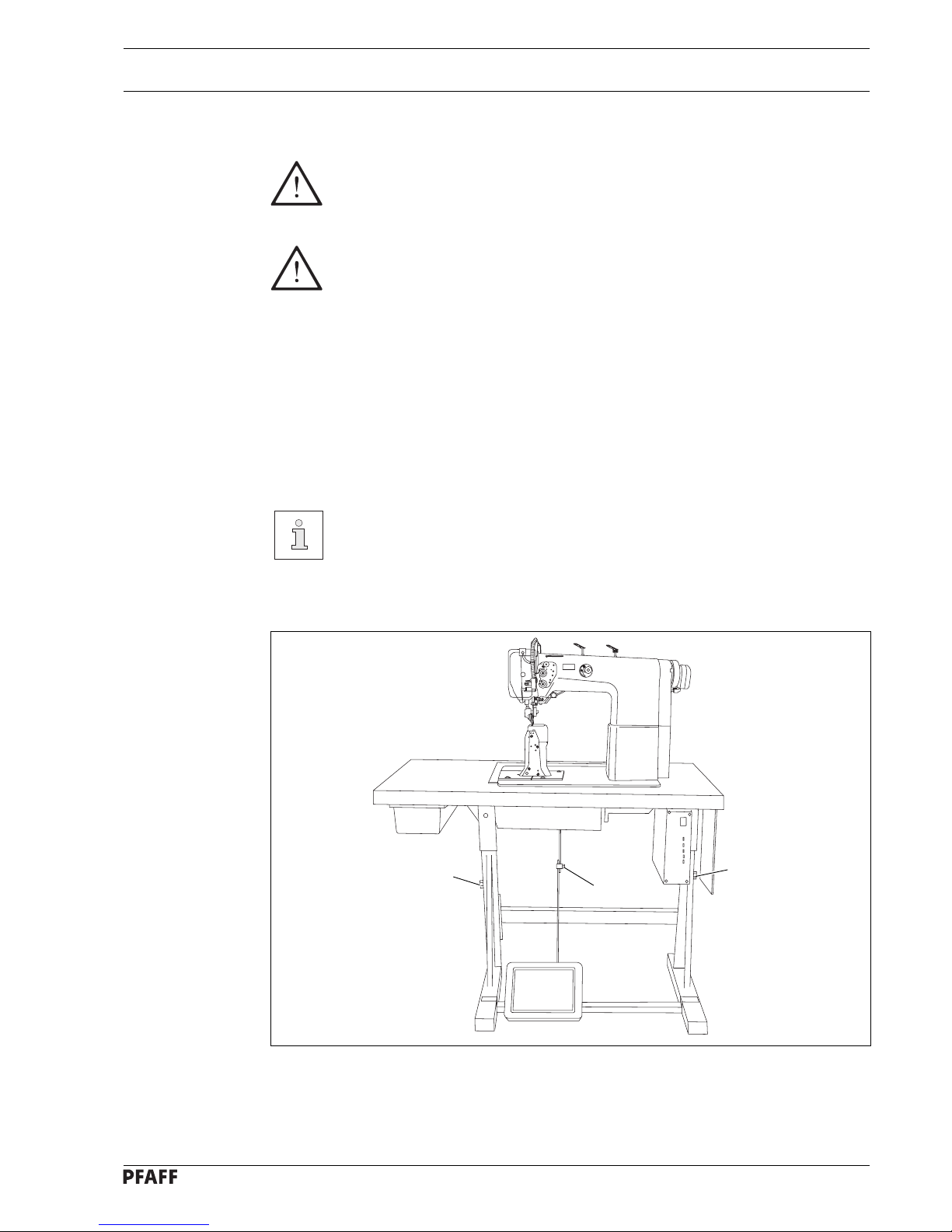

1.06 Danger

A working area of 1 meter is to be kept free both in front of and behind the

machine while it is in operation so that it is always easily accessible.

Never reach into the sewing area while sewing! Danger of injury by the needle!

Never leave objects on the table while adjusting the machine settings!

Objects can become trapped or be slung away! Danger of injury!

Switch the machine off before tilting it backwards!

Danger of injury if the machine is started accidentally!

Do not operate the machine without support 1! Danger due to top-heavy sewing

head! Machine can tip over backwards when tilted!

Do not operate the machine without its take-up-lever guard 2!

Danger of injury due to the motion of the take-up lever!

On machines with thread lubricator, only operate the machine with the eye

guard 3 lowered!

The eye guard 3 protects the eyes from oil particles from the thread lubrication.

Do not operate the machine without belt guard 4 and 5!

Danger of injury by rotating drive belt!

Do not operate the machine without tilt lock 6!

Danger of crushing between sewing head and table top!

2

4

Fig. 1 - 01

1

6

5

3

Page 10

Proper use

2 - 1

2 Proper use

The PFAFF 471 is a single needle, high-speed post bed sewing machine (post to the left

of the needle) with driven feed wheel and roller presser and synchronized

needle.

The PFAFF 474 is a two-needle, high-speed post bed sewing machine with driven feed

wheel and roller presser

The PFAFF 491 is a single needle, high-speed post bed sewing machine (post to the right

of the needle) with driven feed wheel and roller presser and synchronized

needle.

The machines are used for sewing lockstitch seams in the leather and upholstery industries.

Any use of these machines which is not approved by the manufacturer shall be

considered as improper use! The manufacturer shall not be liable for any damage arising out of improper use! Proper use shall also be considered to include

compliance with the operation, adjustment, service and repair measures specified by the manufacturer!

Page 11

Specifications

3 - 1

3 Specifications

3.01 PFAFF 471, 474 , 491

▲

Stitch type: .................................................................................................. 301 (lockstitch)

Balance wheel eff. diameter:.................................................................................... 65 mm

Fabric clearance (roller presser raised): ......................................................................7 mm

Clearance width: .................................................................................................... 245 mm

Clearance height:.................................................................................................... 115 mm

Post height: ............................................................................................................ 180 mm

Dimensions of sewing head:

Length: .......................................................................................................approx. 615 mm

Width:.........................................................................................................approx. 240 mm

Height (above table):...................................................................................approx. 450 mm

Size of bedplate: ............................................................................................518 x 177 mm

Max. speed:

Model A + B.........................................................................................2800 stichtes/min

◆

Model B/C ............................................................................................ 2500 stichtes/min

◆

Trimming margin (for -725/.. and -726/..): ....................................................... 0.8 - 2.5 mm

Trimming speed (for -725/.. and -726/..): ...................................................... 2800 cuts/min

Connection data:

Operating voltage: ........................................................................... 230 V ± 10%, 50/60 Hz

Max. power consumption:....................................................................................... 1.2 kVA

Fuse protection: ..............................................................................1 x 16 A, delayed action

Working noise level:

Emission at workplace

PFAFF 471 and 491 models A + B n = 2200 spm: ............................................... 80 dB(A)

PFAFF 471 and 491 models B/C n = 2000 spm:.................................................. 78 dB(A)

PFAFF 474 model B n = 2200 spm: ..................................................................... 81 dB(A)

PFAFF 474 model B/C n = 2000 spm: .................................................................. 79 dB(A)

( Noise measurement in accordance with DIN 45 635-48-A-1 )

Net weight of sewing head:............................................................................ approx. 53 kg

Gross weight of sewing head: ........................................................................ approx. 61 kg

▲

Subject to alteration

◆

Dependent on material, working cycle and stitch length

Page 12

Specifications

3 - 2

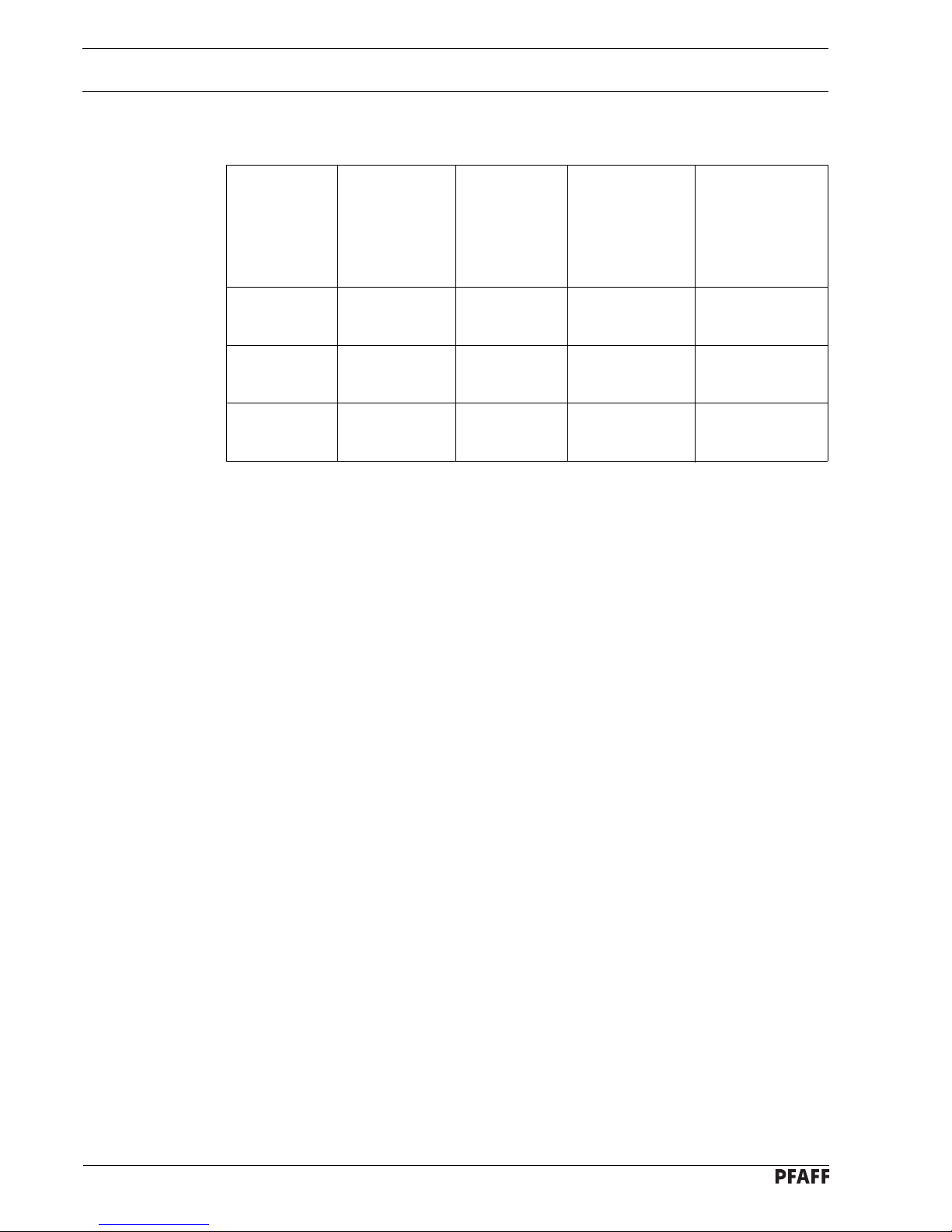

3.02 Needles and threads

Thread strength

▲

(Nm) max.

synthetic

Model

B 40/3 100 134 134 - 35

B/C 20/3 120 134 134 - 35

A 60/3 70 134 -

Needle size

in

1/100 mm

Needle system

for

PFAFF 471

and 491

▲

or similar strengths of other types of thread

3.03 Possible models and subclasses

Model A.............................................................................For sewing lightweight materials

Model B..................................................................... For sewing medium-weight materials

Model B/C ............................................... For sewing medium- to medium-heavy materials

Additional equipment:

Subclass -725/04 ............................................................................................ Edge trimmer

Subclass -726/05 ............................................................................................ Edge trimmer

Subclass -900/53 ......................................................................................... Thread trimmer

Subclass -906/10 ........................................................................................Thread tensioner

Subclass -910/15 ...................................................................... Automatic presser foot lifter

Subclass -911/35 .................................................................................................. Bartacker

Needle system

for the

PFAFF 474

Page 13

Disposal of Machine

4 - 1

4 Disposal of Machine

● Proper disposal of the machine is the responsibility of the customer.

● The materials used for the machine are steel, aluminium, brass and various plastic mat-

erials.

The electrical equipment comprises plastic materials and copper.

● The machine is to be disposed of according to the locally valid pollution control regulations; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

Page 14

Transportation, packing and storage

5 - 1

5 Transportation, packing and storage

5.01 Transportation to customer's premises

Within the Federal Republic of Germany, complete machines (with table and motor) are

delivered without packing.

Machines without table (only sewing heads) and machines intended for export are packed.

5.02 Transportation inside the customer's premises

The manufacturer cannot be made liable for transportation inside the customer's premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fibre. Proper disposal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a film of oil.

Page 15

Explanation of symbols

6 - 1

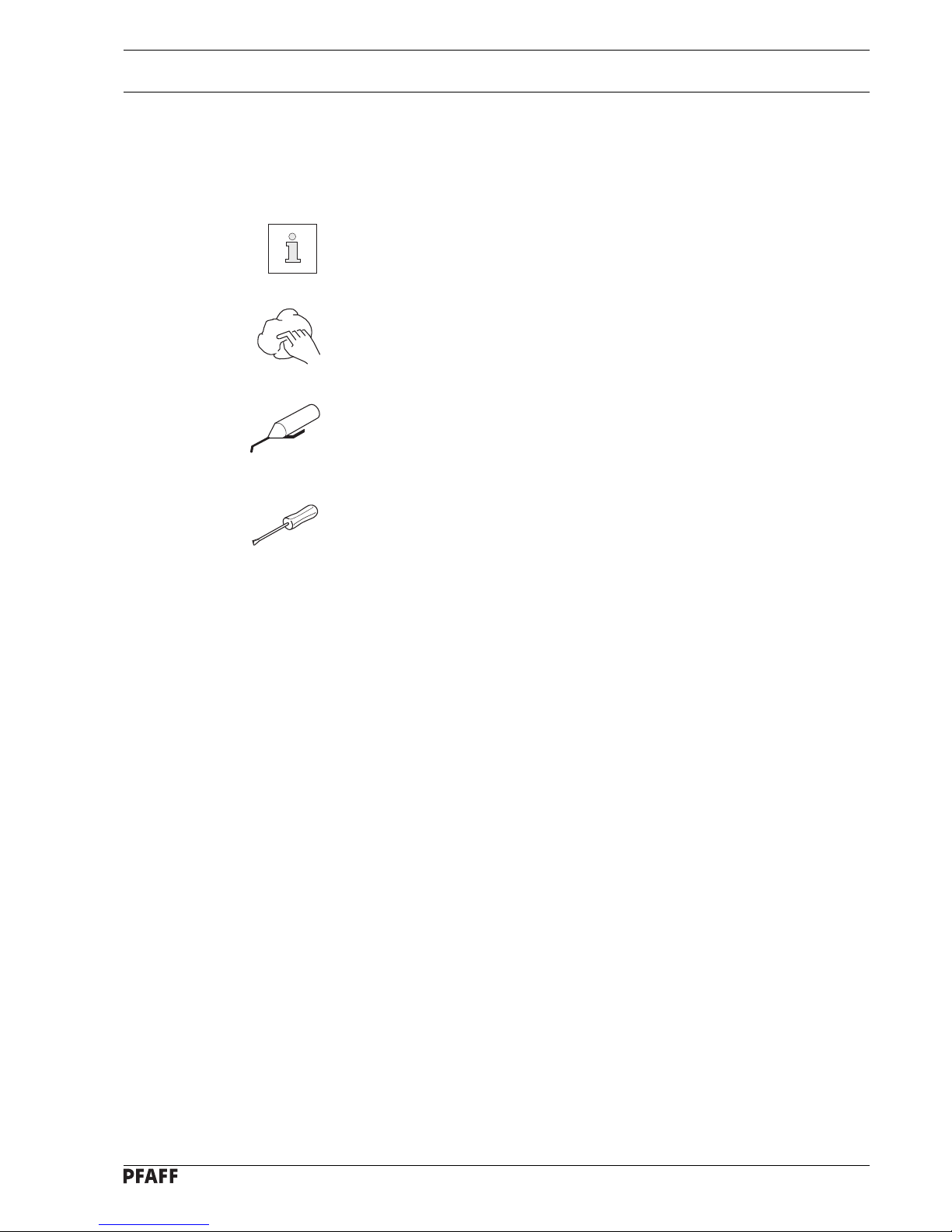

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

Page 16

Controls

7 - 1

7 Controls

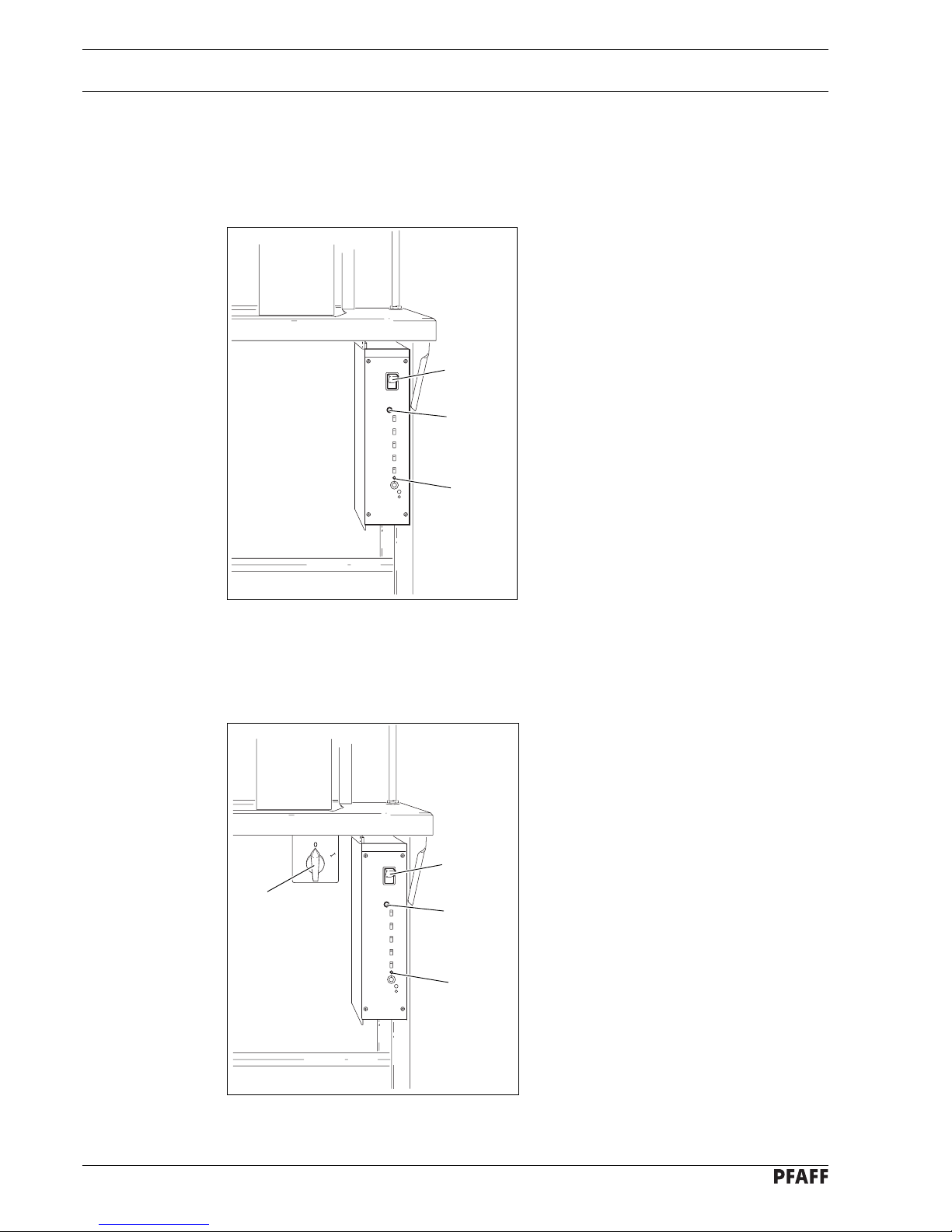

7.01 On/off switch on machines with mini-stop motor

without edge trimmer -725/.. or -726/..

● The machine is switched on or off by

pressing the on/off switch 1.

● The illuminated diode 2 controls the

machine operation

Switch 1 on:

Diode on = Machine ready for

operation

Diode flashes = Fault

Switch 1 off:

Diode flashes = Machine still

under electric

current for about

4 sec.

Diode out = Machine off

● The machine speed can be adjusted on

potentiometer 3.

7.02 On/off switch on machines with mini-stop motor

and edge trimmer -725/.. oder -726/..

● The machine is switched on or off by

turning the on/off switch 1.

● The illuminated diode 2 controls the

machine operation

Switch 3 on:

Diode on = Machine ready for

operation

Diode flashes = Fault

Switch 3 off:

Diode flashes = Machine still

under electric

current for about

4 sec.

Diode out = Machine off

● The machine speed can be adjusted on

potentiometer 4.

Fig. 7 - 02

1

Fig. 7 - 01

1

2

3

3

2

4

Page 17

Controls

7 - 2

7.04 Pedal

0 = Neutral position

1 = Sewing

2 = Raise roller presser (on

machines with -910/..)

3 = Trim sewing threads (on

machines with -900/..)

Fig. 7 - 04

0

1

2

3

7.03 Button on machine head (only on machines with -911/..)

● If button 1 is operated during sewing, the

machine switches to reverse sewing.

Fig. 7 - 03

1

Page 18

Controls

7 - 3

7.05 Lever for lifting roller presser

● The roller presser can be raised by turning

lever 1.

Fig. 7 - 05

1

7.06 Knee lever

● The roller presser can be raised by

pressing the knee lever 1 in the direction

of the arrow.

1

Fig. 7 - 06

Page 19

Controls

7 - 4

7.07 Key for setting stitch length

Fig. 7 - 07

● The stitch length is set by pressing key 1

and turning the balance wheel (see

Chapter 9.08 Setting the stitch length).

7.08 Swing out roller presser

● When the roller presser is raised, it can

be swung out by pulling it lightly

downwards.

Fig. 7 - 08

1

1

Page 20

Controls

7 - 5

7.09 Edge trimmer -725/04 for 471

Keep your hands away from the

moving knife! Danger of injury!

Switch on knife drive:

● Move lever 1 backwards. The knife

moves into operating position.

Switch off knife drive:

● Press lever 1. The knife swings

backwards.

Switch on edge guide:

● Swing edge guide 2 into position by hand

and press lever 3. The edge guide 2

moves into its operating position.

Switch off edge guide:

● Raise edge guide 2 and let it click into

position. The edge guide 2 is out of

operation.

● Raise lever 4. The edge guide swings

backwards.

Changing the knife:

The following work may only be carried out by technical staff or by persons who

have been properly instructed.

● Switch off the machine.

● Loosen screw 5 and remove knife 6.

● Insert new knife and slightly tighten screw 5.

● Adjust the knife according to Chaper 11.05.05 Cutting stroke and tighten screw 5.

Fig. 7 - 09

3

2 4

1

6

5

Page 21

Controls

7 - 6

7.10 Edge trimmer -725/04 for 474 and 491

Keep your hands away from the moving knife! Danger of injury!

Switch on knife drive:

● Move lever 1 backwards. The knife moves into operating position.

Switch off knife drive:

● Press lever 1. The knife swings backwards.

Switch on edge guide:

● Swing edge guide 2 into position by hand and press lever 3. The edge guide 2 moves into

its operating position.

Switch off edge guide:

● Raise edge guide 2 and let it click into position. The edge guide 2 is out of operation.

● Raise lever 4. The edge guide swings backwards.

Changing the knife:

The following work may only be carried out by technical staff or by persons who

have been properly instructed.

● Switch off the machine.

● Loosen screw 5 and remove knife 6.

● Insert new knife and push it close to needle plate insert 7.

● Slightly tighten screw 5.

● Adjust the knife according to Chaper 11.05.07 Knife position and tighten screw 5.

Fig. 7 - 10

1

2

4

3

6

5

7

Page 22

Controls

7 - 7

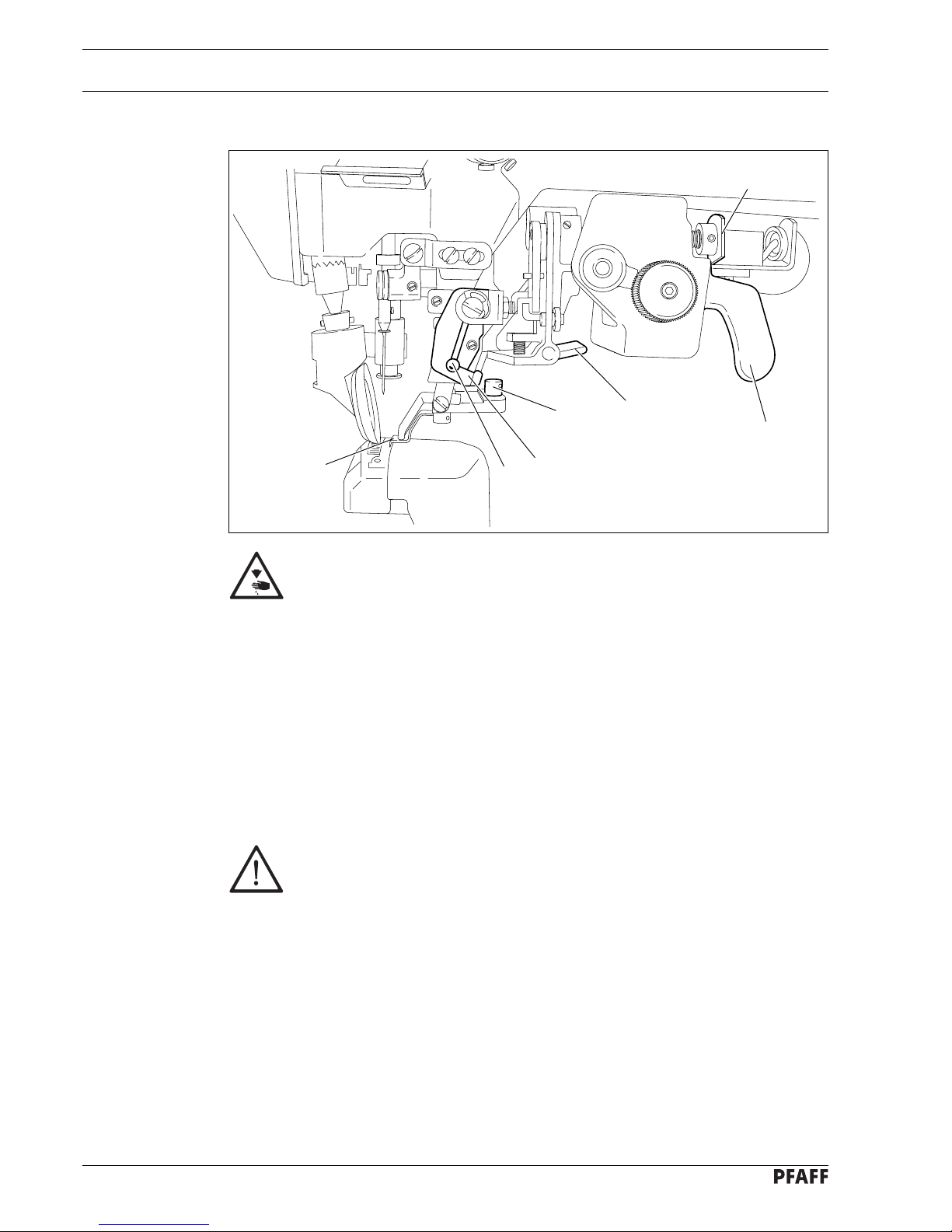

7.11 Edge trimmer -726/05 for 491

5

4

Fig. 7 - 11

Keep your hands away from the moving knife! Danger of injury!

Switch on knife drive:

● By turning lever 1 the knife is moved into its operating position.

Switch off knife drive:

● By pressing lever 2 or key 3 the knife is put out of operation.

Switch on edge guide:

● After lever 4 has been pressed, the edge guide moves into its starting position.

Switch off edge guide:

● By raising lever 5, the edge guide is put out of operation.

Changing the knife:

The following work may only be carried out by technical staff or by persons who

have been properly instructed.

● Switch off the machine.

● Loosen screw 6 and remove knife 7.

● Insert new knife and push it close to needle plate insert.

● Tighten screw 6.

● Adjust the knife according to Chapter 11.06.01 Position of the knife to the needle plate

and Chapter 11.06.02 Knife crosswise to sewing direction.

1

2

3

6

7

Page 23

Installation and commissioning

8 - 1

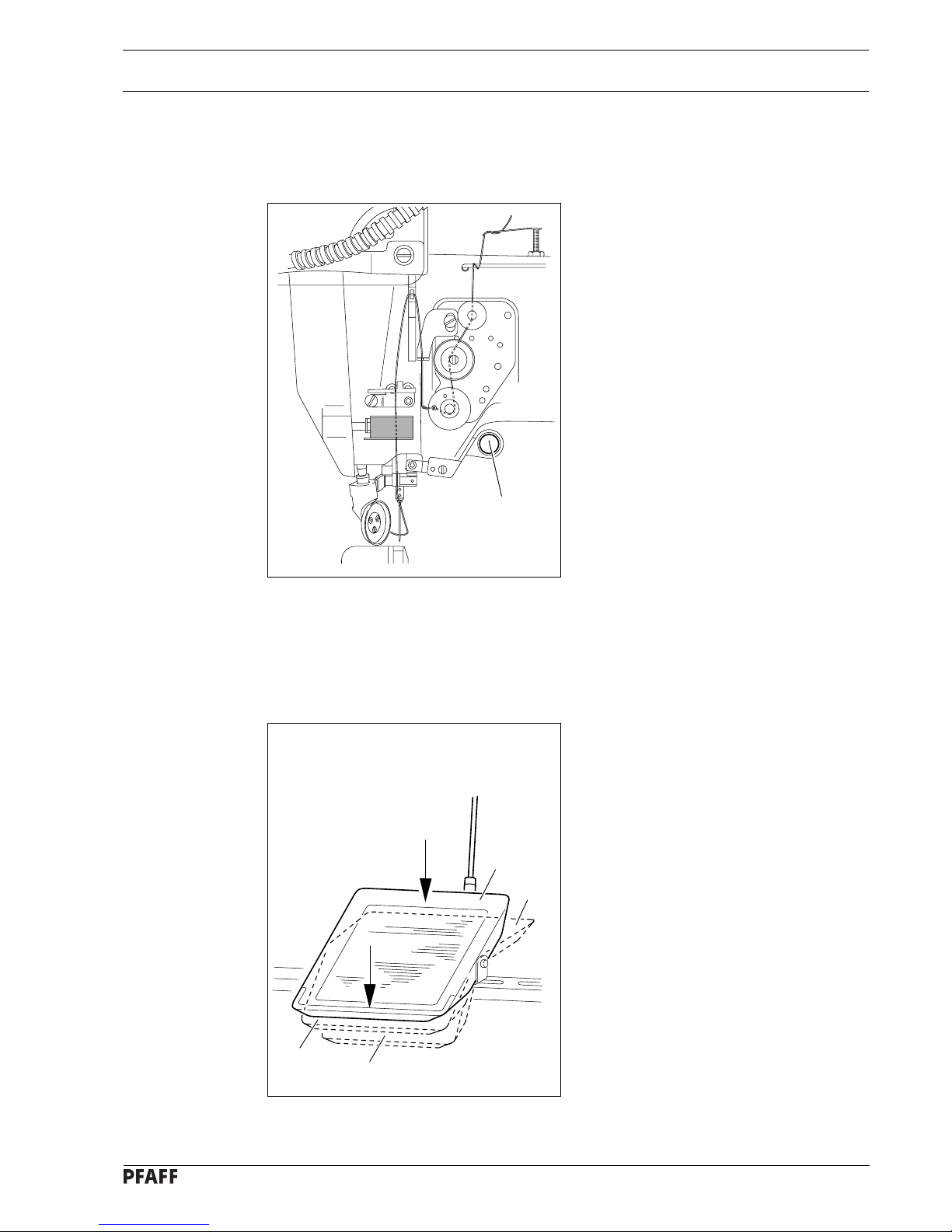

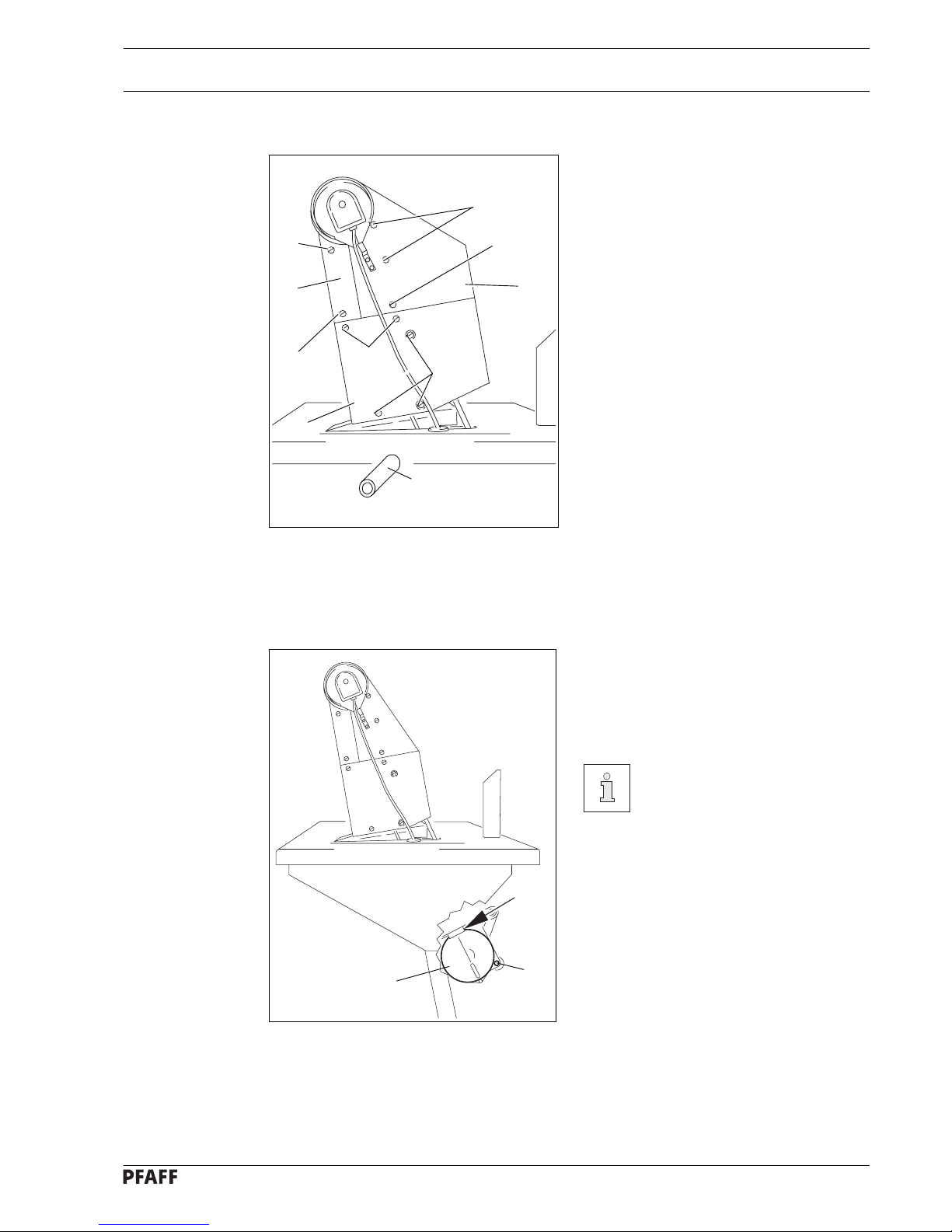

Fig. 8 - 01

1

2

1

8 Installation and commissioning

The machine must only be installed and commissioned by qualified personnel!

All relevant safety regulations must be strictly adhered to!

If the machine is delivered without a table, be sure to use a stand and table top

that can hold the weight of the machine with its motor.

It is very important to ensure that the stand of the machine is firm and steady,

also during sewing.

8.01 Installation

The site where the machine is installed must be provided with suitable connections for electric current.

It must be ensured that the standing surface of the machine site is firm and horizontal, and

that sufficient lighting is provided for.

For packing and transportation reasons the table top is in the lowered position.

The table height is adjusted as described below.

8.01.01 Adjusting the table height

● Loosen screws 1 and 2 and set the table height as required.

● Firmly tighten screw 1.

● Set the required pedal position and tighten screw 2.

Page 24

Installation and commissioning

8 - 2

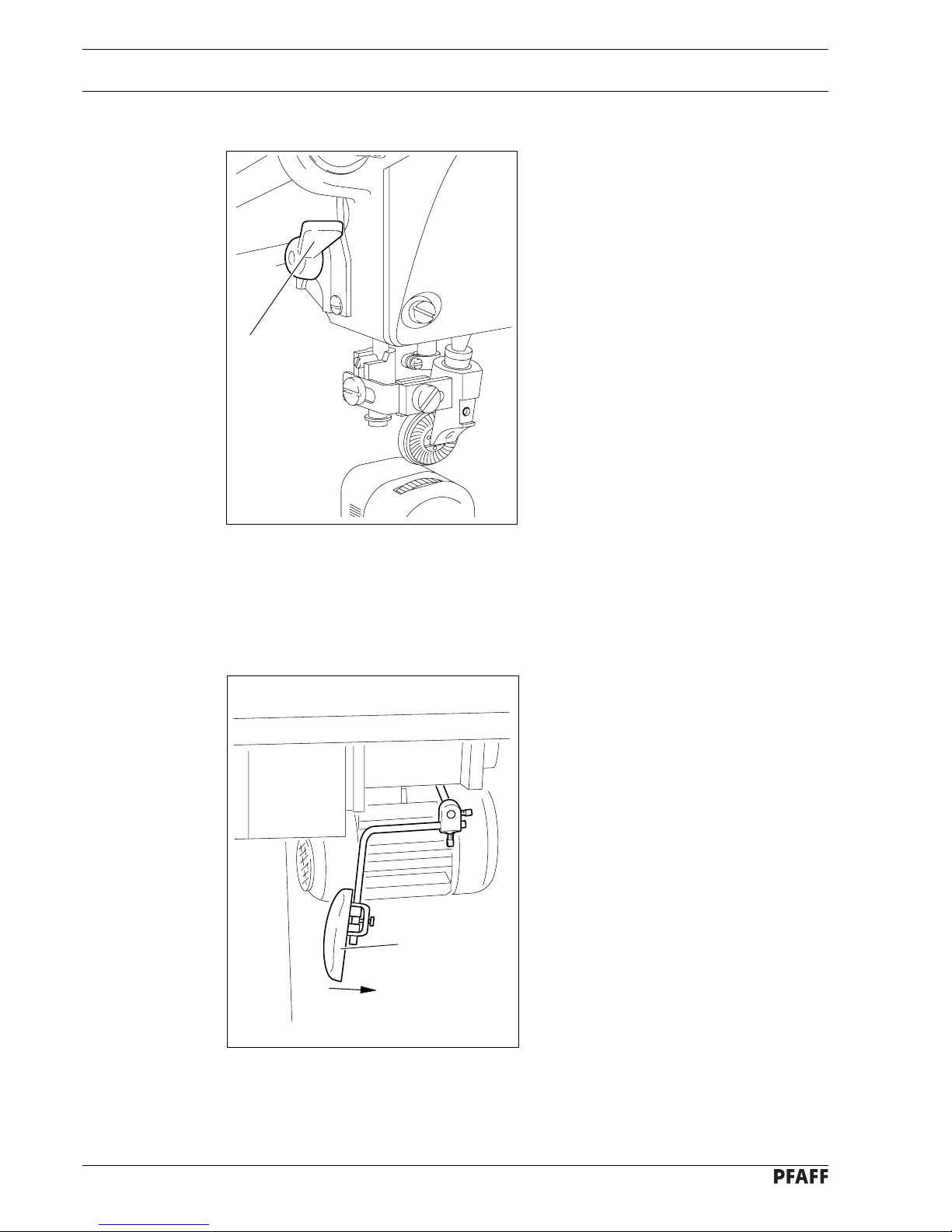

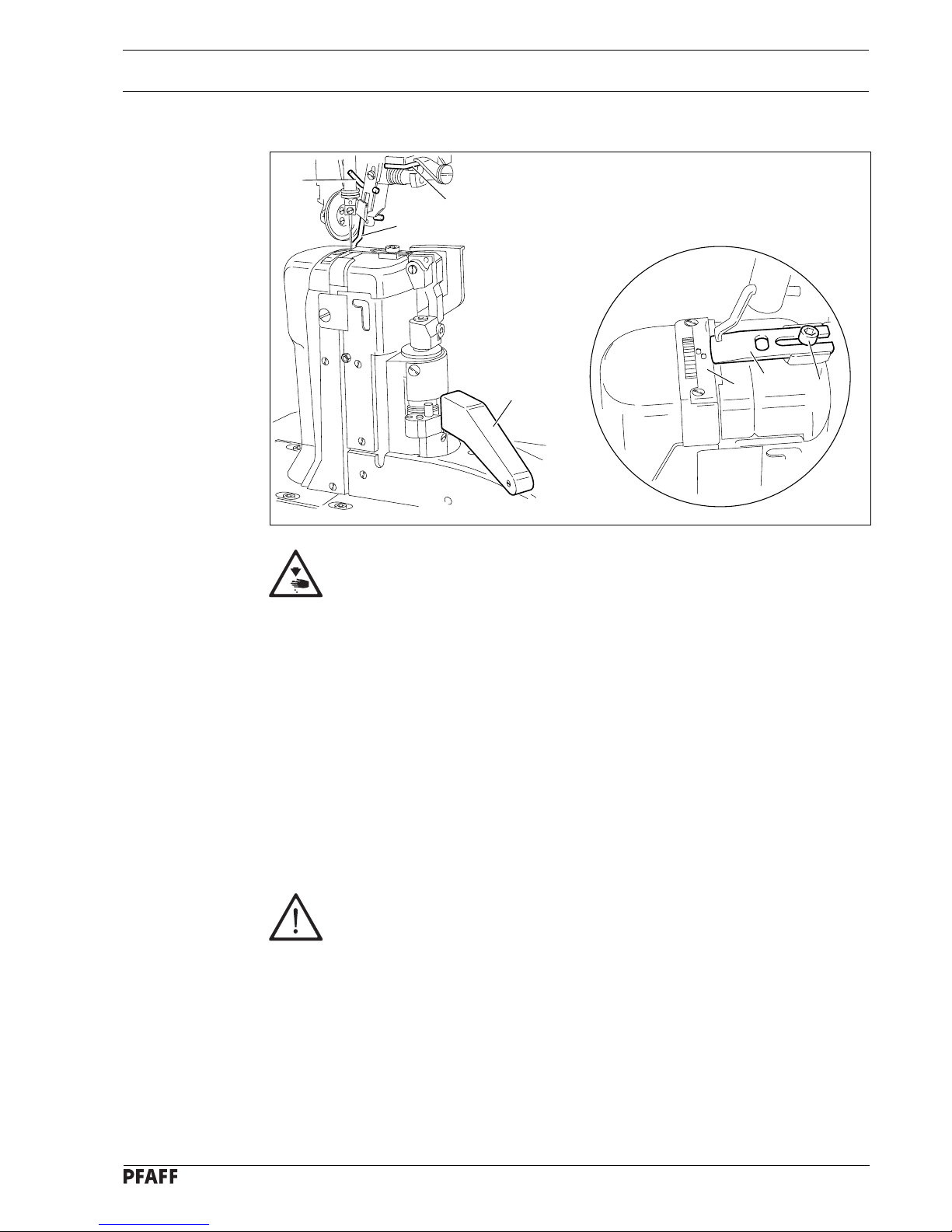

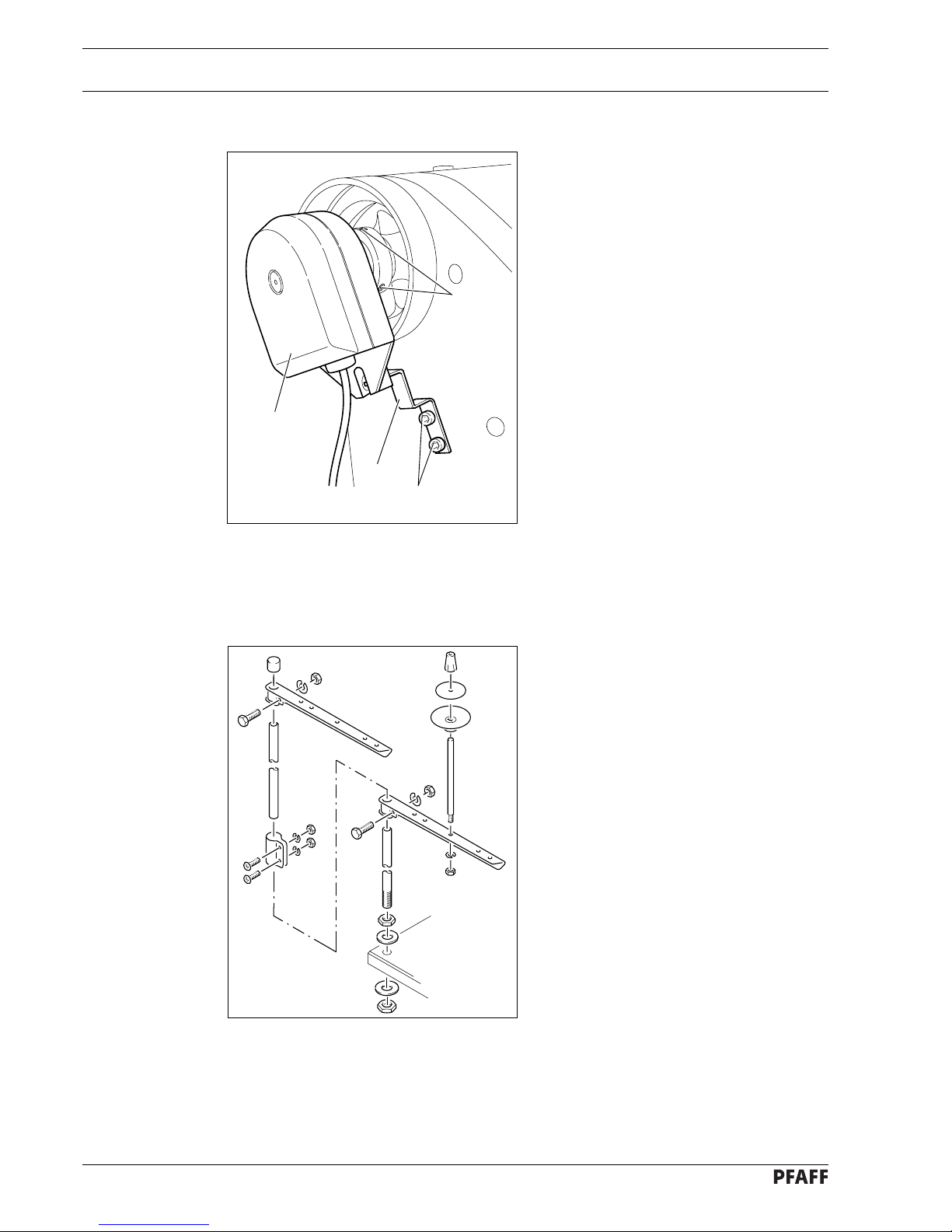

Switch off the machine!

Danger of injury if the machine

is the machine is started

accidentally!

● Screw on the tilt lock 1, provided in the

accessories, using screw 2.

Do not operate the machine

without tilt lock 1. Danger of

crushing between sewing head

and table top!

8.01.03 Tensioning the v-belt (does not apply to machines with mini-stop motor)

● Loosen the nuts 1.

● Set tension of v-belt using motor bracket 2

.

● Tighten nuts 1.

Fig. 8 - 03

1

2 cm

2

8.01.02 Fitting the tilt lock

Fig. 8 - 02

1

2

Page 25

Installation and commissioning

8 - 3

Fig. 8 - 04

2

7

1

3

6

9

9

4

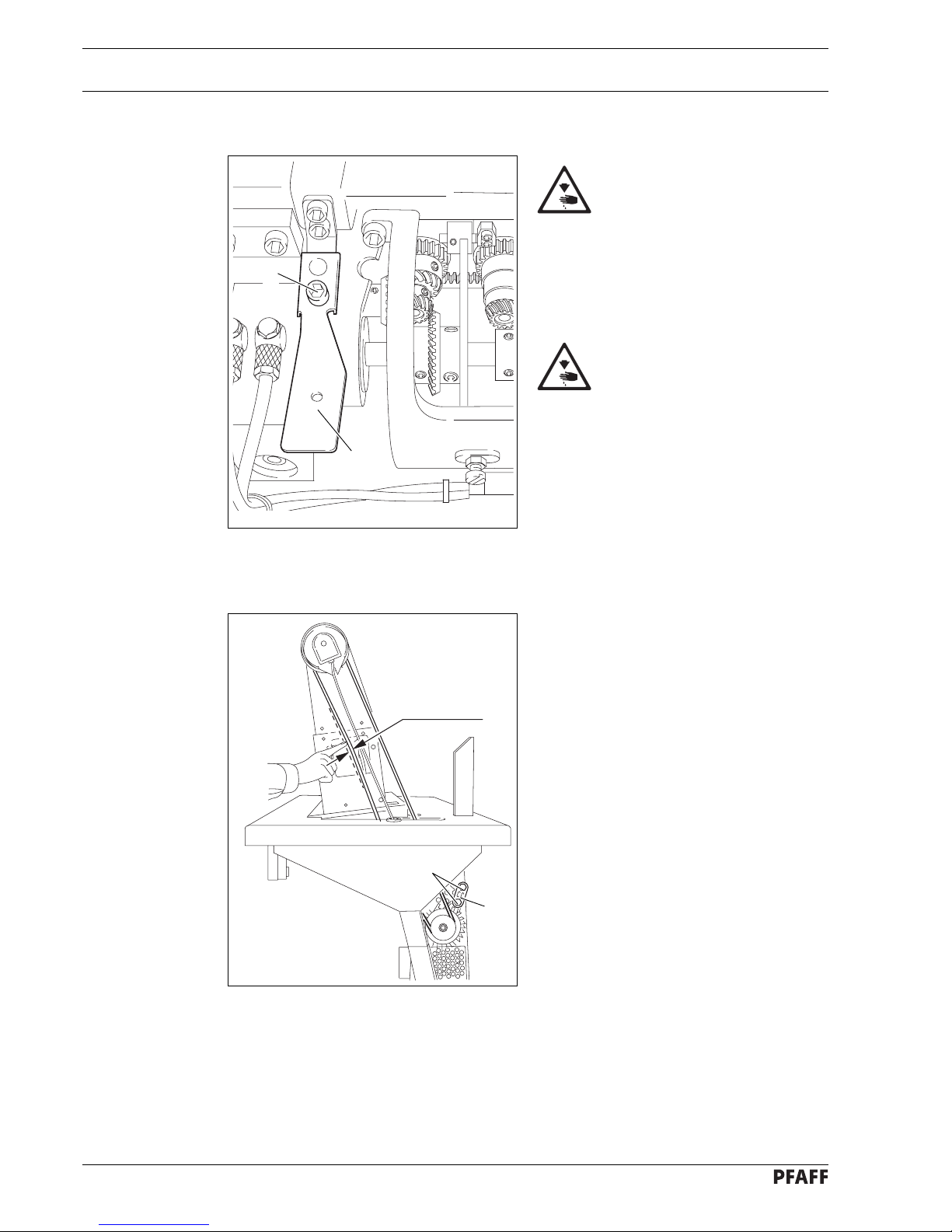

8.01.05 Fitting the bottom v-belt guard (does not apply to machines with mini-stop motor)

Fig. 8 - 05

● Adjust the v-belt guard 1 so that the

motor pulley and v-belt run freely.

● Tighten screws 2. Fig. 8-05 shows a

Quick motor.

If another motor is used, the

instruction manual of the motor

must be complied with.

1

2

2

5

8

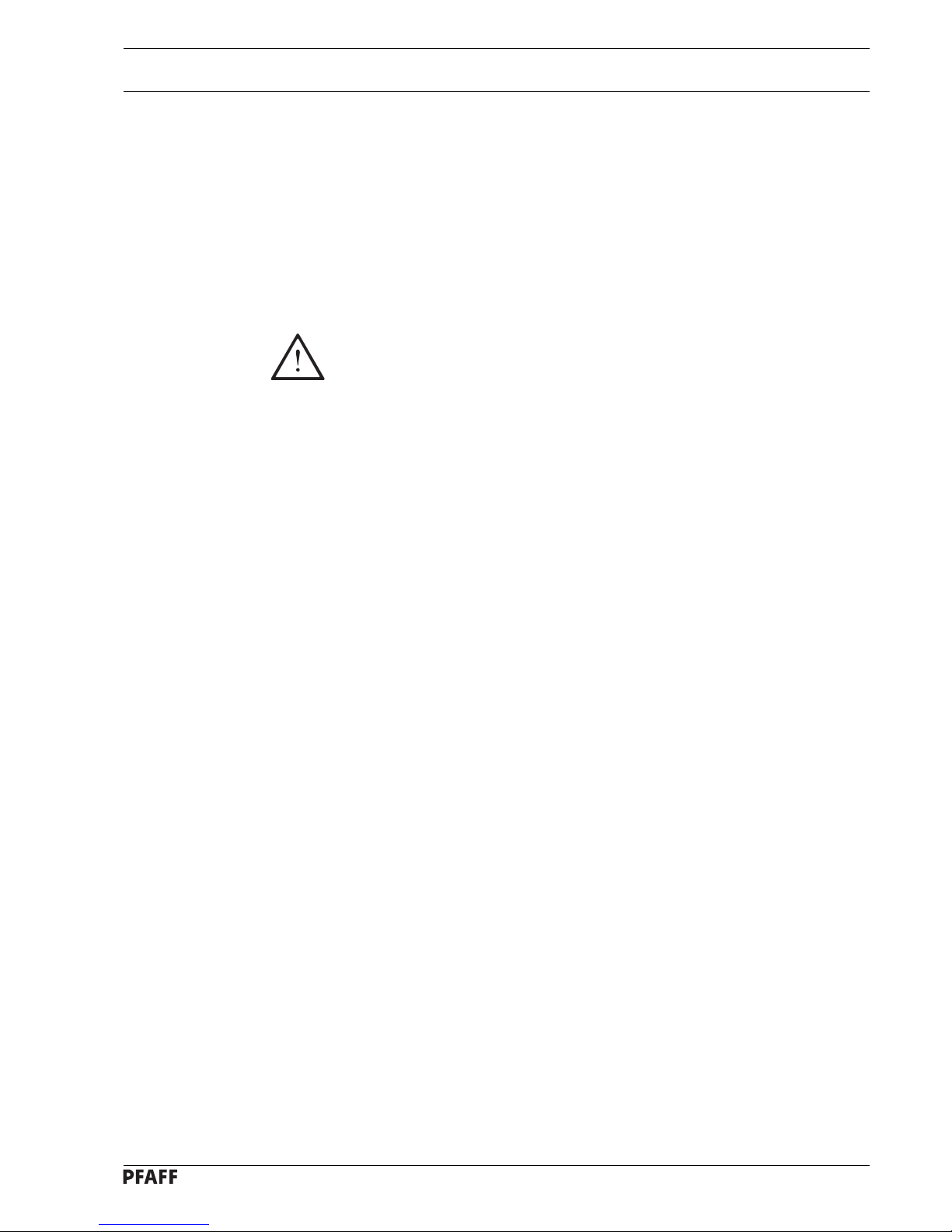

8.01.04 Fitting the top v-belt guard

● Attach belt guard 1 with screws 2 and 3.

● Place spacing sleeve 4 between belt

guard 1 and the machine housing.

● Attach belt guard 5 with screws 6 and 7.

● Place spacing sleeve 4 between belt

guard 5 and the machine housing.

● Attach belt guard 8 with screws 9.

Page 26

Installation and commissioning

8 - 4

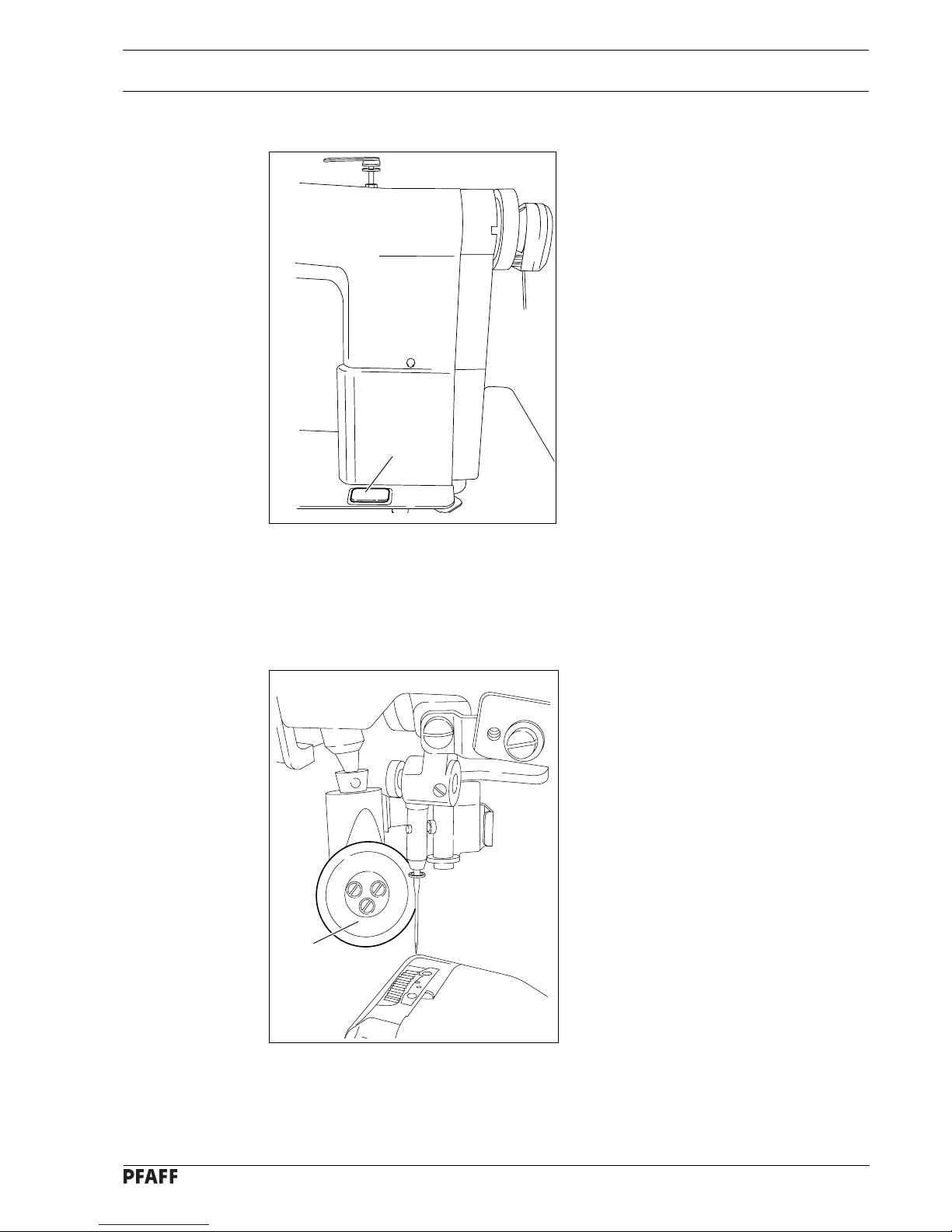

8.01.06 Fitting the synchronizer

● Attach position stop 1 using screws 2.

● Push synchronizer 3 onto the shaft so that

the position stop 1 is in the groove of the

synchronizer (see arrow).

● Slightly tighten screws 4.

● Insert the synchronizer plug in the

connection socket of the control box.

● Adjust the synchronizer 3 (see Chapter

11.04.01 Adjusting the Synchronizer).

Fig. 8 - 06

2

1

8.01.07 Fitting the reel stand

● Fit the reel stand as shown in Fig. 8-07.

● Afterwards insert the stand in the hole in

the table top and secure it with the nuts

provided.

Fig. 8 - 07

4

3

Page 27

Installation and commissioning

8 - 5

8.02 Commissioning

● Check the machine, particularly the electrical wiring, for any damage.

● Clean the machine thoroughly and then oil it or fill in oil (see Chapter 10 Care and

maintenance).

● Have a mechanic check whether the motor of the machine can be operated with the

available power supply, and that the motor is correctly connected in the junction box. If

there are any discrepancies the machine must not be operated under any

circumstances.

The machine may only be connected to an earthed socket!

● When the machine is running, the balance wheel must turn towards the operator. If it does

not, have the motor connection changed by a mechanic.

● Machines with pneumatic equipment must be connected to the compressed air supply.

The pressure gauge should indicate a pressure of 6 bar. If necessary, adjust to the correct

setting (see Chapter 10.05 Checking adjusting the air pressure).

8.03 Switching the machine on/off

● Switch the machine on or off (see Chapter 7.01 On/off switch).

Page 28

Setting up

9 - 1

9 Setting up

All instructions and regulations in this instruction manual must be observed.

Special attention must be paid to all safety regulations!

All setting-up work must only be carried out by personnel with the appropriate

training. For all setting-up work the machine must be disconnected from its

power supply by turning off the on/off switch, or removing the plug from the

electric power socket.

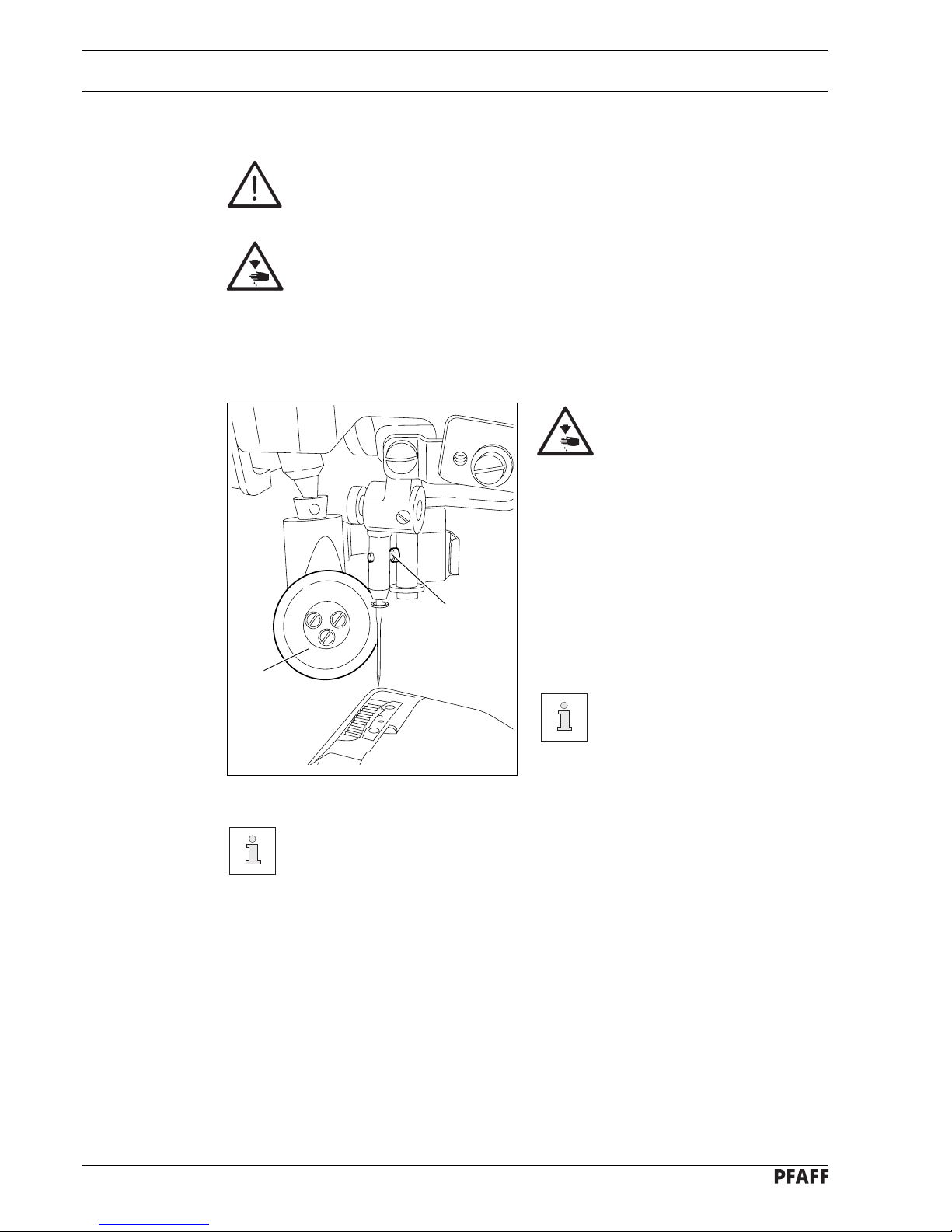

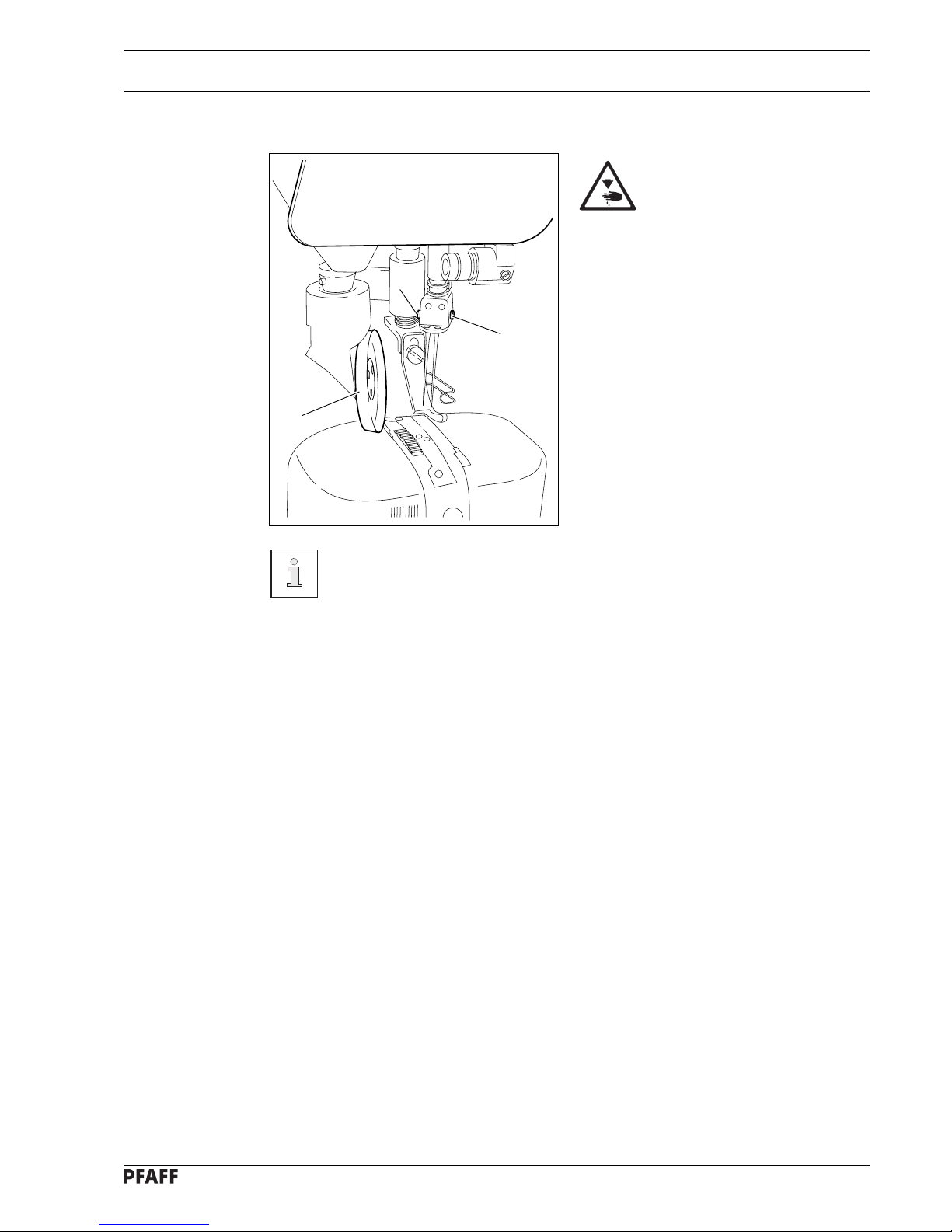

9.01 Inserting the needle on model 471 and 491

Switch the machine off!

Danger of injury if the machine

is started accidentally!

Only use needles of system 134.

● Raise the roller presser 1 and swing it

out.

● Loosen screw 2 and insert the needle as

far as possible. The long groove must

face to the right on model 471 and to the

left on model 491.

● Tighten screw 2 and swing roller presser 1

back into position.

Fig. 9-01 shows model 491.

1

The choice of needle depends on the model of the machine and the thread and

material used (see Chapter 3.02 Needles and threads).

Fig. 9 - 01

2

Page 29

Setting up

9 - 2

9.02 Inserting the needle on model 474

Switch the machine off!

Danger of injury if the machine

is started accidentally!

Only use needles of system 134-35.

● Raise the roller presser 1 and swing it

out.

● Loosen screws 2 and insert the needles

so that the long groove of the left needle

is facing right, and that of the right needle

is facing left.

● Tighten screws 2 and swing roller

presser 1 back into position.

Fig. 9 - 02

The choice of needle depends on the model of the machine and the thread and

material used (see Chapter 3.02 Needles and threads).

1

2

2

Page 30

Setting up

9 - 3

2

1

4

_

+

Fig. 9 - 03

5

6

3

9.03 Winding the bobbin thread; adjusting the primary thread tension

● Place an empty bobbin 1 onto bobbin winder spindle 2.

● Thread the bobbin as shown in Fig. 9 - 03 and wind it clockwise around bobbin 1 a few

times.

● Switch on the bobbin winder while at the same time pressing bobbin winder spindle 2 and

lever 3.

The bobbin is filled up during sewing.

● The thread tension on bobbin 1 can be adjusted using knurled screw 4.

● The bobbin winder stops automatically when bobbin 1 is full.

If the thread is wound unevenly:

● Loosen nut 5.

● Turn thread guide 6 accordingly.

● Tighten nut 5.

Page 31

Setting up

9 - 4

Fig. 9 - 04

2

3

-

+

1

5 cm

Fig. 9 - 05

1

2

Turn the machine off!

Removing the bobbin case:

● Open the post cap.

● Raise latch 1 and remove bobbin case 2.

Inserting the bobbin case:

● Insert bobbin case 2.

● Close the latch and close the post cap.

474 is shown in Fig. 9 - 04.

9.04 Removing/Inserting the bobbin case

9.05 Threading the bobbin case/Adjusting the bobbin thread tension

● Insert the bobbin into the bobbin case 1.

● Pass the thread through the slot under

spring 2.

● Pass the thread through the notch.

● Adjust the thread tension by turning

screw 3.

When the thread is pulled, the

bobbin must rotate in the

direction of the arrow.

Page 32

Setting up

9 - 5

9.06 Threading the needle thread and regulating its tension on model 471/491

1

Fig. 9 - 06

Switch the machine off!

Danger of injury if the machine is started accidentally!

● Tilt up the eye guard 1.

● Thread the needle thread as shown in Fig. 9-06.

● On model 471 the needle is threaded from the right to the left, and on model 491 from the

left to the right.

● Adjust the needle thread tension by turning milled screw 2.

2

Page 33

Setting up

9 - 6

9.07 Threading the needle thread and regulating its tension on model 474

Fig. 9 - 07

Switch the machine off!

Danger of injury if the machine is started accidentally!

● Tilt up the eye guard 1.

● Thread both needle threads as shown in Fig. 9-07.

● The left needle is threaded from the right to the left, and the right needle from the left to the

right.

● Adjust the needle thread tensions by turning milled screws 2.

1

2

Page 34

Setting up

9 - 7

9.08 Setting the stitch length

Fig. 9 - 08

3

2

1

● Press key 1 and at the same time turn the balance wheel until the stitch setter clicks into

position.

● Hold down key 1 and turn the balance wheel to and fro until the stitch length required is

shown on the scale 2 opposite the bottom edge 3 of the belt guard recess.

Page 35

Care and maintenance

10 - 1

10 Care and maintenance

Clean........................................................daily, more frequently if in continuous operation

Oil level (thread lubrication) ............................................................. daily, before operation

Oil the hook ..................................................................................... daily, before operation

Lubricate the bevel gears................................................................................. once a year

Check/adjust air pressure ................................................................ daily, before operation

Clean air filter of air-filter/lubricator .............................................................. when required

Fig. 10 - 01

5 mm

2

1

These maintenance intervals are calculated for the average running time of a single shift operation. If the machine is operated more than this, shorter intervals

are recommended.

10.01 Cleaning

Clean the hook and hook compartment daily, more often if in continuous operation.

Switch the machine off!

Danger of injury if the machine

is started accidentally!

● Bring the needle bar to its highest

position.

● Open the post cap and remove the bobbin

case cap and the bobbin.

● Unscrew hook gib 1.

● Turn the handwheel until the point of bob-

bin case 2 penetrates into the groove of

the hook race approx. 5 mm.

● Remove bobbin case 2.

● Clean the hook race with paraffin.

● When inserting the bobbin case 2, ensure

that the horn of the bobbin

case 2 engages in the groove of the

needle plate.

● Screw hook gib 1 back on and close the

post cap.

Page 36

Care and maintenance

10 - 2

10.02 Oiling the hook

Switch the machine off!

Danger of injury if the machine

is started accidentally!

● Pour 1-2 drops of oil into hole 1 of the

hook gib daily.

● Before commissioning the machine, and

after long periods out of operation, pour a

few drops of oil into the hook race (see

arrow).

Fig. 10 - 02

1

10.03 Filling the oil reservoir of the thread lubrication unit

Control the oil level before each

use.

There must always be oil in the

reservoir.

● If necessary, fill oil up to mark 2 through

hole 1.

We recommend

PFAFF thread lubricating oil,

Order No. 280-1-120 217.

Fig. 10 - 03

1

2

Page 37

Care and maintenance

10 - 3

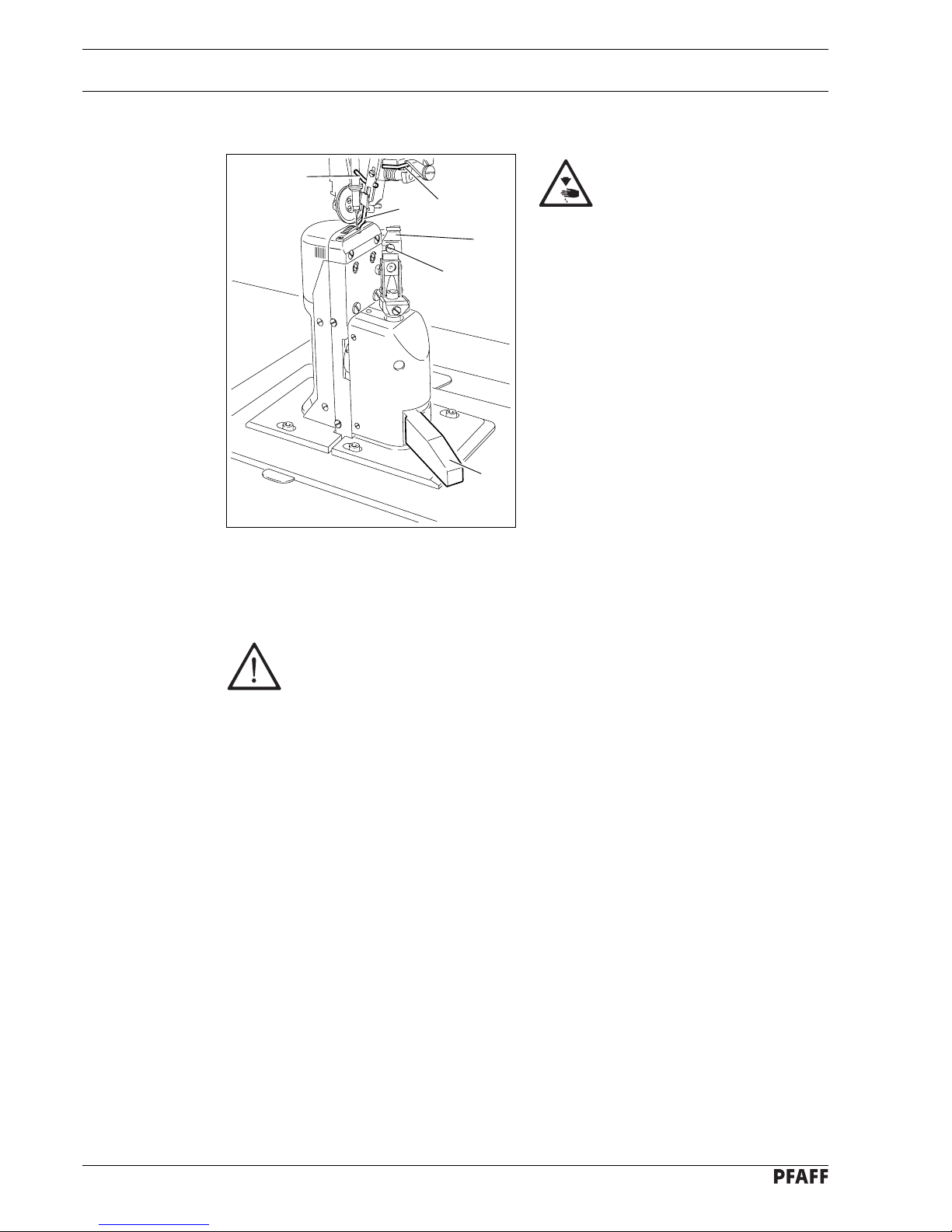

Switch the machine off!

Danger of injury if the machine is started accidentally!

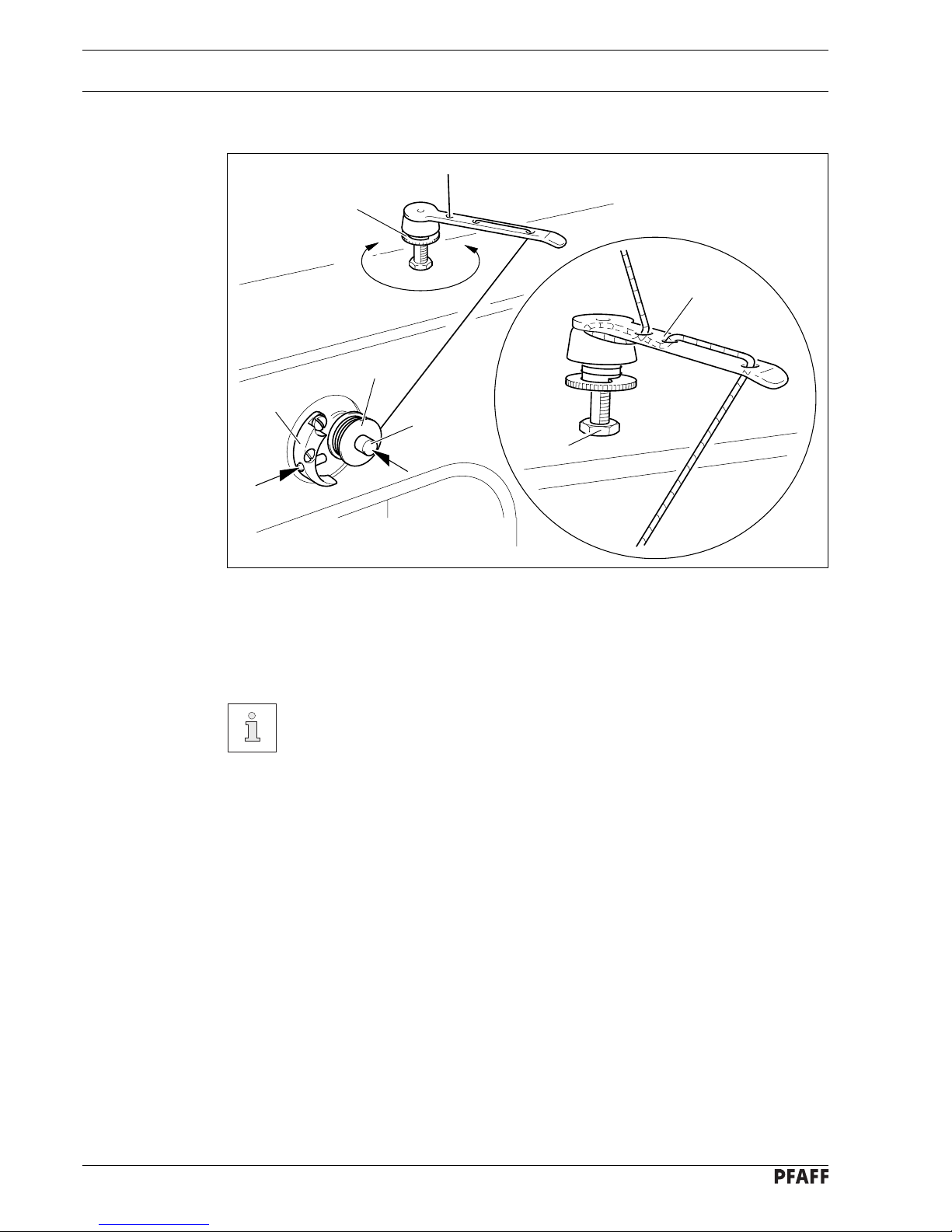

● Once a year new grease must be applied to the bevel gears, which drive the hook and the

toothed rack.

● Tilt the sewing head back onto the support.

Fig. 10-04 shows the bevel gears of the 474.

● Apply grease to all the tooth flanks and the rack (see arrows).

● To set the sewing head upright, press tilt lock 1 backwards and set the sewing head

upright using both hands.

Use both hands to set the sewing head upright!

Danger of crushing between the sewing head and the table top!

We recommend PFAFF sodium grease with a dripping point of approx. 150C,

Order No. 280-1-120 243.

Fig. 10 - 04

10.04 Lubricating the bevel gears

1

Page 38

Care and maintenance

10 - 4

10

12

0

6

4

2

8

16

14

100

50

150

0

200

230

Fig. 10 - 05

Fig. 10 - 06

2

1

10

12

0

6

4

2

8

16

14

100

50

150

0

200

230

1

2

10.04 Cleaning the air filter of the air-filter/lubricator

Switch the machine off!

Disconnect the air hose at the

air-filter/lubricator.

To drain water bowl 1:

● Water bowl 1 drains itself automatically

when the compressed-air hose is disconnected from the air-filter/lubricator.

Cleaning filter 2:

● Unscrew water bowl 1.

● Take out filter 2.

● Clean filter 2 with compressed air or iso-

propyl alcohol (part No. 95-665 735-91).

● Screw in filter 2 and screw on water

bowl 1.

10.03 Checking/adjusting the air pressure

● Before operating the machine, always

check the air pressure on gauge1.

● Gauge 1 must show a pressure of 6 bar.

● If necessary adjust to this reading.

● To do so, pull knob 2 upwards and turn it

so that the gauge shows a pressure of 6

bar.

Page 39

Adjustment

11 - 1

11 Adjustment

11.01 Notes on adjustment

All adjustments in these adjustment instructions are based on a completely installed machine

and must only be carried out by appropriately trained specialists. Covers on the machine,

which have to be removed and replaced for checks and adjustment work, are not mentioned

here.

The screws and nuts in brackets ( ) are attachments of machine parts which are to be

loosened before making the adjustment and tightened again after the adjustment has been

carried out.

The machine must be switched off for all adjustment work!

Danger of injury if the machine is started accidentally!

11.02 Tools, gauges and other accessories

● 1 set of screwdrivers with blade widths from 2 to 10 mm

● 1 set of open-ended wrenches with opening sizes from 7 to 13 mm

● 1 set of allen keys from 1.5 to 6 mm

● 1 clamp (Order No. 08-880 137-00)

● 1 metal rule (Order No. 08-880 218-00)

● 1 gauge (Order No. 08-880 136-01)

● Sewing thread and test material

11.03 Abbreviations

TDC = top dead center

BDC = bottom dead center

Page 40

Adjustment

11 - 2

11.04 Adjusting the basic machine

11.04.01 Adjusting the synchronizer

Requirements

1. When sewing is interrupted, the machine must be in a position 5 mm before BDC of

the needle bar.

2. After thread trimming the machine must be in the position TDC of the take-up lever.

Fig. 11 - 01

● Carry out adjustments according to the motor instruction manual.

● See also Chapter 11.10 Parameter settings.

Page 41

Adjustment

11 - 3

11.04.02 Needle position in sewing direction on the PFAFF 471 and 491

Requirement

With the stitch length set at its minimum, the needle should be positioned in the centre of

the needle hole, as seen in the direction of sewing.

Fig. 11 - 02

● Set the minimum stitch length.

● Adjust needle bar (screw 1) according to the requirement.

1

Page 42

Adjustment

11 - 4

11.04.03 Needle position in sewing direction on the PFAFF 474

Requirement

The needle should be positioned in the centre of the needle hole as seen in the direction of

sewing.

Fig. 11 - 03

1

● Adjust needle bar (screws 1 and 2) according to the requirement.

Screw 2 is accessible through a hole on the rear side of the case.

2

Page 43

Adjustment

11 - 5

11.04.04 Preliminary adjustment of the needle height

Requirement

When the needle bar is at TDC, there must be a clearance of approx. 22 mm between the

needle point and the needle plate.

Fig. 11 - 04

1

2

22 mm

● Adjust needle bar 1 (screw 2), without turning it, according to the requirement.

Page 44

Adjustment

11 - 6

4

11.04.05 Needle rise, hook clearance, needle height and needle guard on the PFAFF 471

Requirement

With the needle bar positioned 1.8 mm after BDC and the stitch length set at "0.8"

1. the hook point must be at needle centre with a hook-to-needle clearance of

0.05 to 0.1 mm;

2. the top of the needle eye must be 0.8 to 1.0 mm below the hook point;

3. the needle guard 6 must touch the needle lightly.

0.8 - 1 mm

6

5

● Set stitch length at "0.8".

● Loosen both screws 1, 2, 3, 4 and 5.

● Bring needle bar to 1.8 mm past BDC:

● Set hook point at needle centre, making sure that the needle is not deflected by needle

guard 6.

● Adjust needle height according to Requirement 2.

● Adjust hook post according to Requirement 1 and tighten screws 4 and 5.

Fig. 11 - 05

2

3

5

7

8

3

1

Page 45

Adjustment

11 - 7

● Making sure that there is some play in the bevel gear, tighten screws 1.

● With retaining collar 7 touching bevel gear 8 tighten screws 2 and 3.

● Adjust needle guard 6 according to Requirement 3.

10

When the hook is replaced, care

must be taken to see that markings 9

and 10 are on the same side.

9

Page 46

Adjustment

11 - 8

11.04.06 Needle rise, hook clearance, needle height and needle guard on the PFAFF 474

Requirement

With the needle bar positioned 1.8 mm after BDC on both hooks

1. the hook point must be at needle centre with a hook-to-needle clearance of

0.05 to 0.1 mm;

2. the top of the needle eye must be 0.8 to 1.0 mm below the hook points;

3. the needle guard 9 must touch the needle lightly.

● Loosen screws 1, 2, 3, 4, 5, 6 and 7.

● Loosen screws 8 slightly.

● Bring needle bar to 1.8 mm past BDC:

● Set both hook points at needle centre, making sure that the needles are not deflected by

needle guard 9.

● Adjust needle height according to Requirement 2.

● Adjust both hook posts according to Requirement 1 and tighten screws 8.

Fig. 11 - 06

7

7

8

8

9

5

2

11

10

12

13

0.8 - 1 mm

3

4

6

1

Page 47

Adjustment

11 - 9

● Tighten screws 1 and 6.

● Making sure that there is some play in the bevel gear, tighten screws 3 and 5.

● With retaining collar 10 touching bevel gear 11 tighten screws 2.

● With retaining collar 12 touching bevel gear 13 tighten screws 4.

● Tighten screws 7 on both sides of the post.

● Adjust needle guard 9 on both hooks according to Requirement 3.

When the hook is replaced, care must

be taken to see that markings 14 and

15 are on the same side.

15

14

Page 48

Adjustment

11 - 10

11.04.07 Needle rise, hook clearance, needle height and needle guard on the PFAFF 491

Requirement

With the needle bar positioned 1.8 mm after BDC and the stitch length set at "0.8"

1. the hook point must be at needle centre with a hook-to-needle clearance of

0.05 to 0.1 mm;

2. the top of the needle eye must be 0.8 to 1.0 mm below the hook point;

3. the needle guard 6 must touch the needle lightly.

4

5

5

4

● Set stitch length at "0.8".

● Loosen screws 1, 2, 3, 4 and 5.

● Bring needle bar to 1.8 mm past BDC:

● Set hook point at needle centre, making sure that the needle is not deflected by needle

guard 6.

● Adjust needle height according to Requirement 2.

● Adjust hook post according to Requirement 1 and tighten screws 4.

● Making sure that there is some play in the bevel gear, tighten screws 2.

● With retaining collar 7 touching bevel gear 8 tighten screws 1.

● Screws 5 remain loosened for further adjustments.

6

0,8 - 1 mm

Fig. 11 - 07

1

2

3

7

8

Page 49

Adjustment

11 - 11

● Adjust needle guard 6 according to Requirement 3.

When the hook is replaced, care must

be taken to see that markings 9 and 10

are on the same side.

10

9

Page 50

Adjustment

11 - 12

11.04.08 Needle position crosswise to sewing direction on the PFAFF 471

Requirement

When the stitch length is set at its maximum, the needle must be positioned in the centre

of the needle hole when entering and coming out of the needle plate.

Fig. 11 - 08

2

2

1

● Turn screws 1 (screws 2, on both sides of the post) according to the requirement.

Page 51

Adjustment

11 - 13

11.04.09 Needle position crosswise to sewing direction on the PFAFF 474

Requirement

As seen crosswise to the sewing direction, the needles must penetrate in the centre of

their needle holes.

● Adjust feed wheel post 1 (screws 2, on both sides of the post) according to the

requirement.

Fig. 11 - 09

2

2

1

Page 52

Adjustment

11 - 14

11.04.10 Needle position crosswise to sewing direction on the PFAFF 491

Requirement

As seen crosswise to the sewing direction, the needle must penetrate in the centre of the

needle hole.

Fig. 11 - 10

● Adjust feed wheel post 1 (screws 2, 3 and 4) according to the requirement.

1

2

2

4

4

4

4

3

Page 53

Adjustment

11 - 15

11.04.11 Height of the bobbin-case opener

Requirement

The top edges of the bobbin-case opener 1 and the bobbin case base 3 must be level.

Fig. 11 - 11

● Adjust the bobbin-case opener 1 (screws 2) according to the requirement.

Repeat the adjustment on the right-hand post for the 474.

1

3

2

1

Page 54

Adjustment

11 - 16

11.04.12 Bobbin-case opener stroke

Requirement

When the bobbin-case opener has pushed the bobbin case down as far as possible, the tip

of the bobbin case must be 0.3 - 0.5 mm from the rear edge of the needle plate recess.

● Turn the balance wheel until the bobbin-case opener has pushed the bobbin case down as

far as possible.

● Adjust the bobbin-case base (screw 1) according to the requirement.

Repeat the adjustment on the right-hand post for the 474.

This setting may differ according to the thread thickness.

Fig. 11 - 12

1

0.3 - 0.5 mm

Page 55

Adjustment

11 - 17

11.04.13 Height of the feed wheel on the PFAFF 471

Requirement

1. When pressure is applied to the feed wheel 4, it should protrude from the needle plate

by tooth height (approx. 0.8 mm)

2. When no pressure is applied to the feed wheel 4 , it should have a vertical play of

approx. 0.3 mm.

Fig. 11 - 13

● Swing out the roller presser.

● Loosen screws 1 and 2.

● Adjust drive wheel 3 according to requirement 1, taking care to see that the teeth of drive

wheel 3 and feed wheel 4 lock into each other properly.

● Tighten screws 1.

● Adjust guide 5 according to requirement 2 and tighten screws 2.

2

3

0.8 mm

0.3 mm

5

4

1

1

Page 56

Adjustment

11 - 18

11.04.14 Height of the feed wheel on the PFAFF 474

Requirement

1. When pressure is applied to the feed wheel 4, it should protrude from the needle plate

by tooth height (approx. 0.8 mm)

2. When no pressure is applied to the feed wheel 4 , it should have a vertical play of

approx. 0.3 mm.

Fig. 11 - 14

● Swing out the roller presser.

● Loosen screws 1 and 2 (two screws).

● Adjust drive wheel 3 according to requirement 1, taking care to see that the teeth of drive

wheel 3 and feed wheel 4 lock into each other properly.

● Tighten screws 1.

● Adjust guide 5 according to requirement 2 and tighten screws 2.

3

0.8 mm

0.3 mm

5

4

1

1

2

Page 57

Adjustment

11 - 19

11.04.15 Height of the feed wheel on the PFAFF 491

Requirement

The feed wheel should protrude from the needle plate by tooth height (approx. 0.8 mm)

1

2

3

● Swing out the roller presser.

● Loosen screws 1.

● Adjust eccentric 3 (fastening screw accessible through hole 2) according to the

requirement.

● Tighten screws 1.

Fig. 11 - 15

0.8 mm

Page 58

Adjustment

11 - 20

11.04.16 Stitch length control eccentric

Requirement

When the needle (with maximum stitch length set), coming from TDC, is 3 mm above the

needle plate, the crank 3 must have reached its front point of reversal.

2

● Set the maximum stitch length.

● Turn stitch length control device 1 (screws 2) according to the requirement.

Fig. 11 - 16

1

3

Page 59

Adjustment

11 - 21

11.04.17 Stitch length scale disk

Requirement

When the stitch length control device is locked in position, and the maximum stitch length

is set, the marking line of the highest number on the scale disk 1 must be opposite the

lower edge 3 of the belt guard recess.

3

● Set the maximum stitch length.

● Turn the scale disk 1 (screws 2) according to the requirement.

Fig. 11 - 17

2

1

Page 60

Adjustment

11 - 22

11.04.18 Shaft crank to feed wheel drive

Requirement

When the maximum stitch length is set, the linkage rod 3, or linkage rods 3 and 4 on the

models 471 and 491, must be able to move freely when the balance wheel is turned.

● Set the maximum stitch length.

● Twist or shift the shaft crank 1 (screw 2) according to the requirement.

Fig. 11 - 18

PFAFF 471

PFAFF 491

PFAFF 474

2

1

2

1

3

3

4

Page 61

Adjustment

11 - 23

11.04.19 Shaft crank to roller presser drive

Requirement

When the maximum stitch length is set, the linkage rods 3 and 4 must be able to move

freely at their left and right point of reversal when the balance wheel is turned.

● Set the maximum stitch length.

● Twist clamp crank 1 (screw 2) according to the requirement.

Fig. 11 - 19

2

1

3

4

Page 62

Adjustment

11 - 24

11.04.20 Clearance between roller presser and feed wheel

Requirement

When the presser bar lifter is raised, the clearance between the roller presser and the feed

wheel must be 7 mm.

● Raise the presser bar lifter.

● Adjust the presser bar 1 (screws 2) according to the requirement. Make sure that the

roller presser is parallel to the feed wheel.

Fig. 11 - 20

7 mm

1

2

Page 63

Adjustment

11 - 25

4

11.04.21 Roller presser

Requirements

When the roller presser 1 is touching the feed wheel 5 it must

1. be parallel to feed wheel 5, as seen in the direction of sewing,

2. be in the centre of the needle (on model 474 the left needle), as seen in the direction of

sewing,

3. be as near as possible to the needle (on model 474 the left needle), as seen crosswise

to the direction of sewing.

● Raise the roller presser.

● Always observe requirement 1 for subsequent adjustments.

● Adjust roller presser 1 (screw 2) according to requirement 2.

● Lower roller presser 1 to rest on feed wheel 5.

● Adjust roller presser bracket 3 (screw 4) according to requirement 3.

When sewing very tight curves, the roller presser 1 must be moved a little

towards the operator.

Fig. 11 - 21

3

2

1

5

Page 64

Adjustment

11 - 26

11.04.22 Stitch length on stitch length scale

Requirement

When the stitch length is set at "3", and after the needle has entered a strip of leather 11

times, the total length from the first to last needle penetration must be 30 mm.

● Set stitch length "3".

● By turning the balance wheel, let the needle enter 11 times and measure the total length.

● Adjust clamp 1 (screw 2) according to the requirement.

Clamp 1 must not be positioned diagonally to the rock shaft!

Fig. 11 - 22

PFAFF 471

PFAFF 491

PFAFF 474

1

1

2

2

2

Page 65

Adjustment

11 - 27

11.04.23 Synchronization of roller presser and feed wheel

Requirement

After 21 needle penetrations in a strip of leather the total length from the first to the last

penetration should be the same, both in the lower and the upper leather layer.

● Set stitch length "3".

● By turning the balance wheel, let the needle enter 21 times.

● Compare the total sewn length of the lower and upper leather layer.

● Adjust clamp 1 (screw 2) according to the requirement.

Clamp 1 must not be positioned diagonally to the rock shaft.

Fig. 11 - 23

1

2

+

-

Page 66

Adjustment

11 - 28

11.04.24 Retainer (only on model 474)

Requirements

The retainer 1 must

1. be as close as possible to the needle, as seen in the direction of sewing and

2. be in the centre of the needle, as seen crosswise to the direction of sewing.

3. When the roller presser is lowered, the distance between the retainer 1 and the

workpiece must be 0.2 - 0.3 mm.

● Adjust retainer 1 (screw 2) according to requirement 3.

● Adjust bracket 3 (screw 4) according to requirement 1 and 2.

Fig. 11 - 24

1

2

3

4

Page 67

Adjustment

11 - 29

11.04.25 Knee lever

Requirements

1. Before the roller presser rises, the knee lever must still have a slight play.

2. When the knee lever is raised as far as possible, the lever for the roller presser must

drop automatically.

3. Knee lever bar 5 must be at an angle of approx. 75° to the bedplate.

4

6

2

5

75°

● Adjust screw 1 (nut 2) according to requirement 3.

● Adjust screw 3 (nut 4) according to requirement 2.

● Set bar 5 (Screws 6) according to requirement 3.

Fig. 11 - 25

1

3

Page 68

Adjustment

11 - 30

11.04.26 Needle thread tension release

Requirements

1. When the presser bar lifter is raised, the tension discs 3 should be pressed at least

0.5 mm apart.

2. When the roller presser is lowered, the tension must be fully effective.

● Align tension mounting plate 1 and pressure plate 2 according to the requirement.

Fig. 11 - 26

1

2

3

0.5 mm

Page 69

Adjustment

11 - 31

11.04.27 Thread check spring

Requirement

1. The movement of thread check spring 5 must be completed when the needle point

enters the material ( spring stroke approx. 7 mm).

7 mm

1

Fig. 11 - 27

● Position rest 1 (screw 2) according to requirement 1.

● To adjust the spring tension, turn screw 3 (screw 4).

For technical sewing reasons it may be necessary to deviate from the indicated

spring stroke or spring tension.

3

5

4

2

Page 70

Adjustment

11 - 32

11.04.28 Bobbin winder

Requirements

1. When the bobbin winder is engaged, the winding spindle must be driven reliably. When

the bobbin winder is disengaged, the friction wheel 5 must not be moved by drive wheel 1.

2. The bobbin winder must switch itself off, when the filled thread is about 1 mm from the

edge of the bobbin.

2

1

5

Fig. 11 - 28

● Position drive wheel 1 (screws 2) according to requirement 1.

● Position bolt 3 (screw 4) according to requirement 2.

1 mm

4

3

Page 71

Adjustment

11 - 33

11.04.29 Pressure of roller presser

Requirement

The material must be fed smoothly. No pressure marks should be visible on the material.

Fig. 11 - 29

● Adjust roller presser pressure with screw 1 according to the requirement.

1

Page 72

Adjustment

11 - 34

11.04.30 Re-engage safety coupling

The coupling 1 is set by the manufacturer. When the thread jams, the coupling 1

disengages in order to avoid damage to the hooks.

A description of how to engage the coupling follows.

Fig. 11 - 30

● Remove jammed thread.

● Hold coupling 1 with screw 2 and turn the balance wheel, until you feel coupling 1 snap

back into place again.

1

2

Page 73

Adjustment

11 - 35

11.05 Adjusting the edge trimmer -725/04

11.05.01 Position of the knife holder on model 471

Requirements

When the thread trimmer is engaged and the adjusting wheel has been turned to its highest

position

1. the knife holder 2 must be parallel to the post and

2. the top edge of the needle plate must be in the centre of the angular knife opening.

● Turn the adjusting wheel 1 to its highest position and engage edge trimmer.

● Adjust knife holder 2 (screw 3) according to the requirements.

Fig. 11 - 31

1

2

3

Page 74

Adjustment

11 - 36

11.05.02 Position of the knife holder on models 474 and 491

Requirement

When the thread trimmer is engaged, the centre of the angular knife opening must be level

with the top edge of the needle plate.

Fig. 11 - 32

● Switch off the machine and engage the edge trimmer.

● Loosen screw 1.

● By turning sccentric 2, position the knife in the centre of its adjustment range.

● Adjust knife holder 3 according to the requirement and tighten screw 1.

● Position locking ring 4 on the knife holder 3.

Depending on the material thickness, changes in the basic setting of eccentric 2

are possible.

4

3

1

2

Page 75

Adjustment

11 - 37

3,5

Fig. 11 - 33

● Turn eccentric 1 (screws 2) so that the marking of the desired cutting stroke is opposite

the marking on clamp collar 3.

11.05.03 Knife stroke on model 471

Requirement

The knife stroke can be adjusted over a range from 1.0 to 3.5 mm, allowing the best

possible adaption to all materials used.

1

2

3

Page 76

Adjustment

11 - 38

11.05.04 Knife stroke on models 474 and 491

Requirement

The knife stroke can be adjusted over a range from 2.0 to 3.5 mm, allowing the best

possible adaption to all materials used.

1

3

2

-

+

Fig. 11 - 34

● Adjust crank 1 (nut 2) in slotted lever 3 according to the requirement.

Page 77

Adjustment

11 - 39

11.05.05 Cutting stroke on model 471

Requirement

When the edge trimmer is engaged and the needle is in the needle hole, the stroke of

knife 1 should be half in front of and half behind the needle, when the motor shaft is turned

by hand.

● Switch off the machine and engage the edge trimmer.

● Adjust knife 1 (screw 2) according to the requirement.

Fig. 11 - 35

1

2

1

½

½

Page 78

Adjustment

11 - 40

11.05.06 Cutting stroke on models 474 and 491

Requirement

When the edge trimmer is engaged and the needle is in the needle hole, the stroke of

knife 3 should be half in front of and half behind the needle, when the motor shaft is turned

by hand.

1

2

3

½

½

Fig. 11 - 36

● Switch off the machine and engage the edge trimmer.

● Adjust knife holder 1 (screw 2) according to the requirement.

Page 79

Adjustment

11 - 41

11.05.07 Knife position

Requirement

When the edge trimmer is engaged, the knife should rest lightly on the needle plate insert,

but no whistling sound should occur during trimming.

471

● Adjust screw 1 (screw 2) according to the requirements.

● Carry out a cutting test and repeat adjustment if necessary.

474 and 491

● Adjust knife 3 (screw 4) according to the requirements.

● Carry out a cutting test and repeat adjustment if necessary.

Fig. 11 - 37

1

2

4

3

Page 80

Adjustment

11 - 42

11.06 Adjusting the thread trimmer -726/05 on model 491

11.06.01 Position of the knife to the needle plate

Requirement

When the edge trimmer is engaged, the knife 2 must be parallel to the needle plate insert.

Fig. 11 - 38

● Switch off the machine and engage the edge trimmer.

● Loosen screw 1 and push back knife 2 slightly.

● Turn milled screw 3 until its top edge is flush with the top edge of the cylindrical guide 4.

● Loosen screw 5, position guide 6 in the centre of guide 7 and slightly tighten screw 5.