Page 1

PFAFF

436

One

G. M. PFAFF AG, Sewing Machine Factory, KAISERSLAUTERN

y

>/-

•

Needle

with

Locksfifch

Automatic

INSTRUCTION

Superspeed

Lubrication

BOOK

Sewer

Page 2

Ind

ex

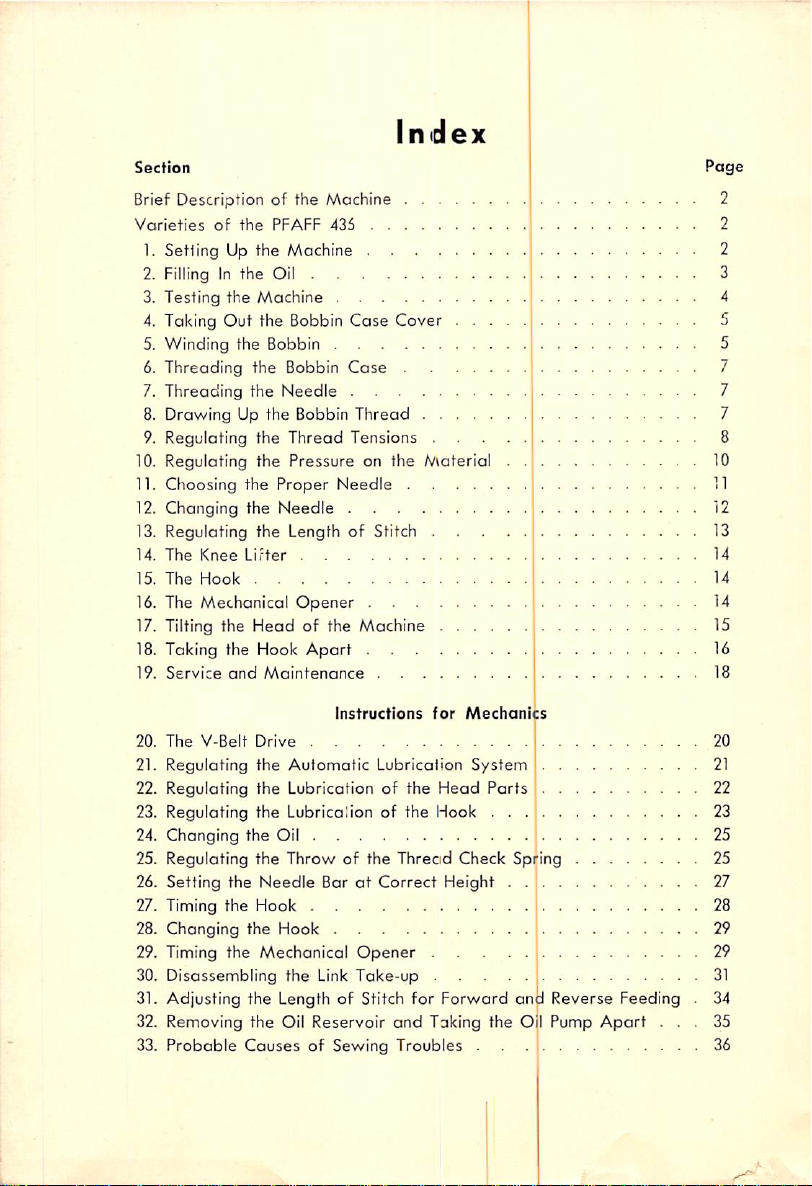

Section

Brief Description of the Machine

Varieties

1.

of

the

SettingUpthe

PFAFF

Machine

435

2. Filling In the Oil

3.

Testing

4. Taking

5.

Winding

Threading

6.

7.

Threading

8. Drawing Up the Bobbin

9.

Regulating

the

Qjt

the

the

the

Machine

the Bobbin

Bobbin

Bobbin

Needle

the

Thread

Case

Cover

Case

Thread

Tensions

. . .

.

10. Regulating the Pressure on the Material

11. Choosing the

12. Changing the

13.

Regulating

14.

The

Knee

15.

The

Hook

16. The

Mechanical

17. Tilting the

18. Taking

19.

Service

Lifter

the

and

Proper

Needle

Needle

the

LengthofStitch .

Opener

Head

of the Machine . . . .

Hook

Apart

Maintenance

Page

2

2

2

3

10

11

12

13

14

14

14

15

16

18

Instructions

20.

The

V-Belt

Drive

21.

Regulating

the

Automatic

22. Regulating the Lubrication of the

23. Regulating the Lubricalion of the Hook . . .

24.

Changing

the

Oil

for

Lubrication

Head

Mechanics

System

Parts

20

21

22

23

25

25. Regulating the Throw of the Threcid Check Spring 25

the

Needle

Hook

26. Setting the

27. Timing

28. Changing the Hook

29. Timing

30.

Disassembling

the

Mechanical

31. Adjusting the Length of Stitch for Forward and Reverse Feeding

32. Removing the Oil Reservoir

33.

Probable

Causes

BaratCorrect

Opener

the

Link

Take-up

and

of Sewing Troubles .

Height .

....

....

Taking the Oil Pump

Apart

27

28

29

29

31

34

35

36

Page 3

Instruction

Book

One

This

operators

made

Needle

Instruction

available to both

PFAFF

Lookstifch

with

Automatic

Book

contains

and mechanics alike and therefore should be

rather

436

Superspeed

Lubrication

useful

than

instructions

put away In your files.

Sewer

for

Page 4

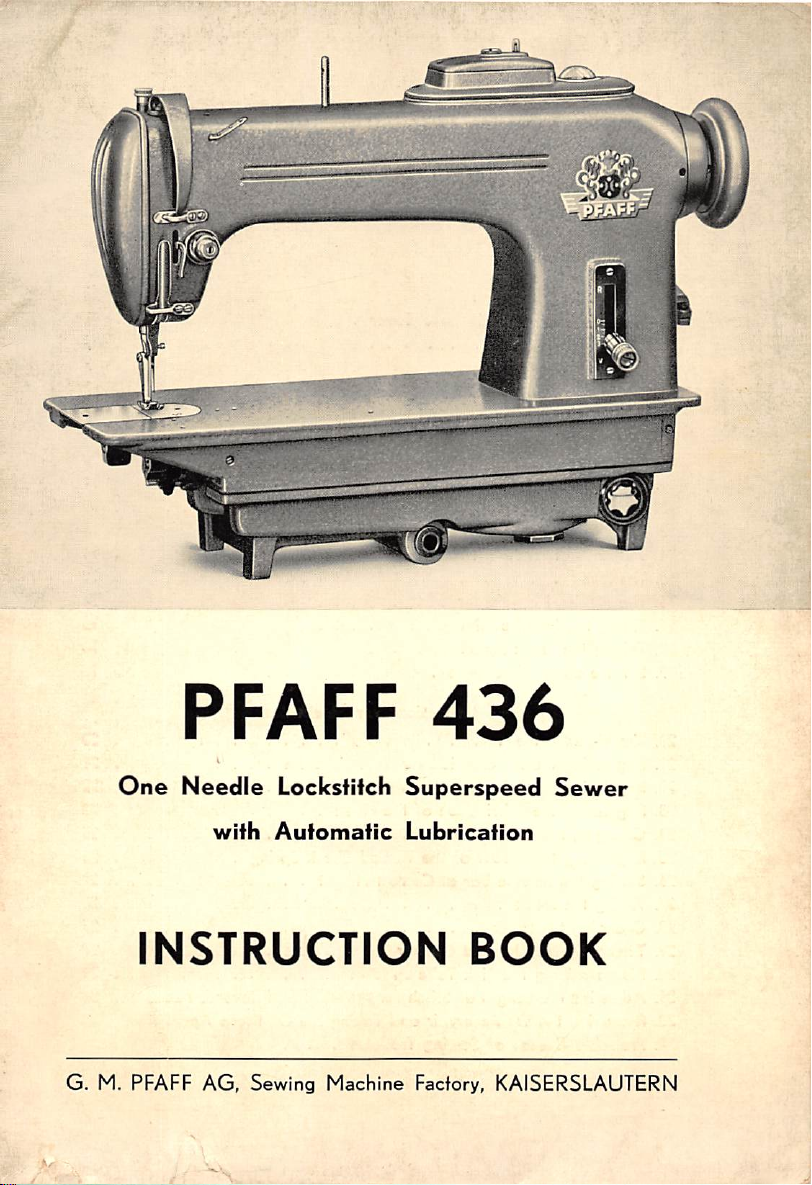

PFAFI=

Brief

Descrlpfion

The PFAFF436

with link

take-up

One

and

of

the

Needle

horizontal

Machine

Lockstitch

be regarded as an improved model of the

of this machine, ranging

on the

grade

withaforced

of material sewn, has mode it

feed

from

lubrication

4,000 to 5,000 stitches

system.

436

Superspeed

rotary

hook, in its mechanical set-up

PFAFF

mandatory

Sewing Machine,

134.

The high sewing speed

per

minute

that

it be provided

depending

Since the manipulations required for this machine, such as for threading

the needle, regulating the length of stitch,

been

changed,

training

With its

properties

branchesofthe

are

eliminated.

modern,

of highest

operators

functional design,

perfection,

sewing

industry.

need not bs retrained

this machine

sturdy

and

tying

and

construction,

satisfies

off

seams,

expenses

any

for such re

and

its

demand

have

fitted

may

not

sewing

in all

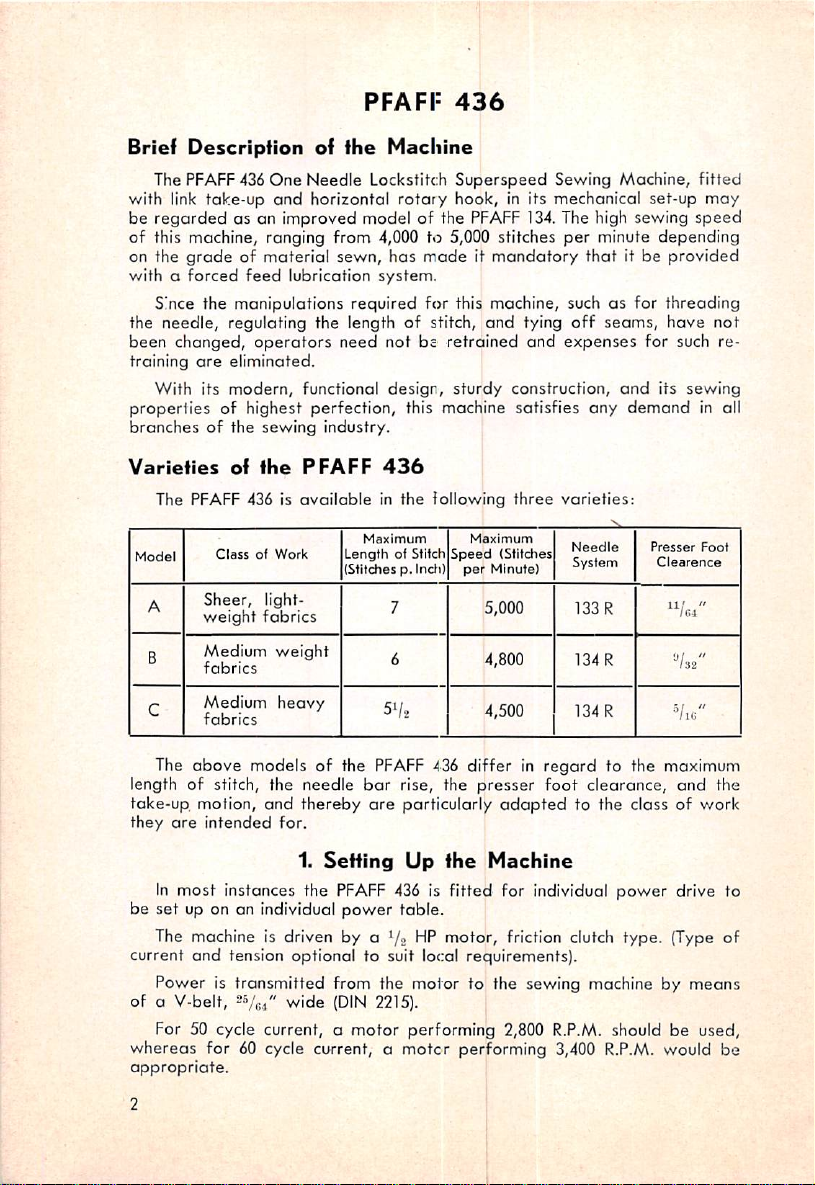

Variefies

The PFAFF 436 is

Model

A

B

C

The

length of stitch, the

take-up motion,

they

In

be

set

off

the

PFAFF

availoble

ClassofWork

Sheer,

weight

Medium

fabrics

Medium

fabrics

above

light

fobrics

weight

heavy

models of the

needle

and

are

intended

thereby

for.

1.

most

instances the PFAFF 436 is

up on on individual

Maximum

Length

(Stitches p.

bar

are

Setting

power

436

in the following

of Stifch

7 5,000

6 4,800

5'/,

PFAFF

Maximum

Speed

Indit

per

436 differ in

rise, the

particularly

Up

the

fitted

table.

three

(Stitches

Minute)

4,500

presser

adapted

Machine

for individual

varieties:

Needle

System

133

134

134

regard

foot

clearance,

Presser

Clearence

R

R

R

to the maximum

to the class of work

power

''Ua"

The machine is driven by a '/» HP motor, friction clutch type. (Type of

current

and

tension

optional

to suit local requirements).

Power is transmitted from the motor to the sewing machine by

of a V-belt,

For 50 cycle current, a

whereas

appropriate.

2V0.1"

wide

(DIN 2215).

motor

for 60 cycle current, a

performing 2,800 R.P.M. should be used,

motcr

performing 3,400 R.P.M. would be

Foot

"/ic '

and

drive to

means

the

Page 5

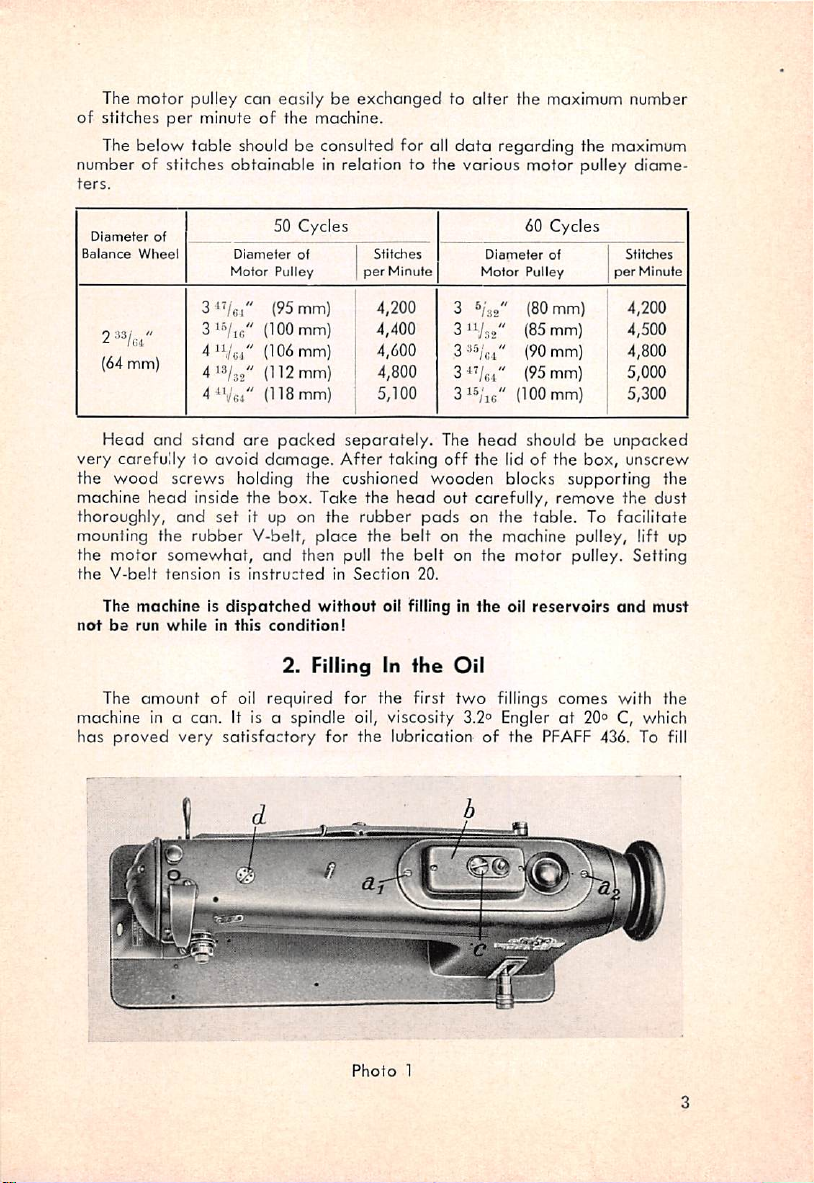

The

motor

pulley

per

of stitches

The below

minute of the machine.

table

number of stitches

ters.

can

easilybeexchangedtoalter

should be consulted for all

obtainable

in relation to the

the maximum number

data

regarding the maximum

various

motor

pulley

diame

Diameter

Balar^ce

(64 mm)

Head

very

of

Wheel

and

carefully lo

50 Cycles 60

Diameter

Motor

Pulley

3'Vei"

3'"/ic"

(95 mm)

(100mm)

4'Vg4" (106 mm)

4%2"

(112mm)

4 (118 mm)

stand

are

avoid

packed

damage.

of

Stitches

per

Minute

4,200

4,400

4,600

4,800

5,100

separately.

After

taking

Diameter

Motor

3 (80 mm)

3'Vn2"

3

35/^,,"

3^'/c.i" (95 mm)

3";ic"

The

head

off

the lid of the

Cycles

of

Pulley

(85 mm)

(90 mm)

(100 mm)

should be

box,

Stitdies

per

Minute

4,200

4,500

4,800

5,000

5,300

unpacked

unscrew

the wood screws holding the cushioned wooden blocks supporting the

machine

thoroughly,

mounting the

the motor

the

not

machine in a can. It is a spindle oil, viscosity 3.2° Engler

has

head

inside the box. Take the

and

set

rubber

somewhat,

V-belt

tensionisinstructed

The

machineIsdispatched

be

run

whileinthis

The

amount

proved

of oil

very

it up on the

V-belt,

and

condition!

2.

required

satisfactory

head

rubber

place

the

than pull the

in

Section

without

oil filling in

Filling In

for the first

out carefully,

pads

belt

on the machine pulley, lift up

belt

on the motor pulley. Setting

20.

ihe

Oil

two

for the lubrication of the

on the

the

fillings

table.

oil

reservoirs

remove

To

comes

at

20° C, which

PFAFF

the

dust

facilitate

and

must

with the

436. To fill

Photo

1

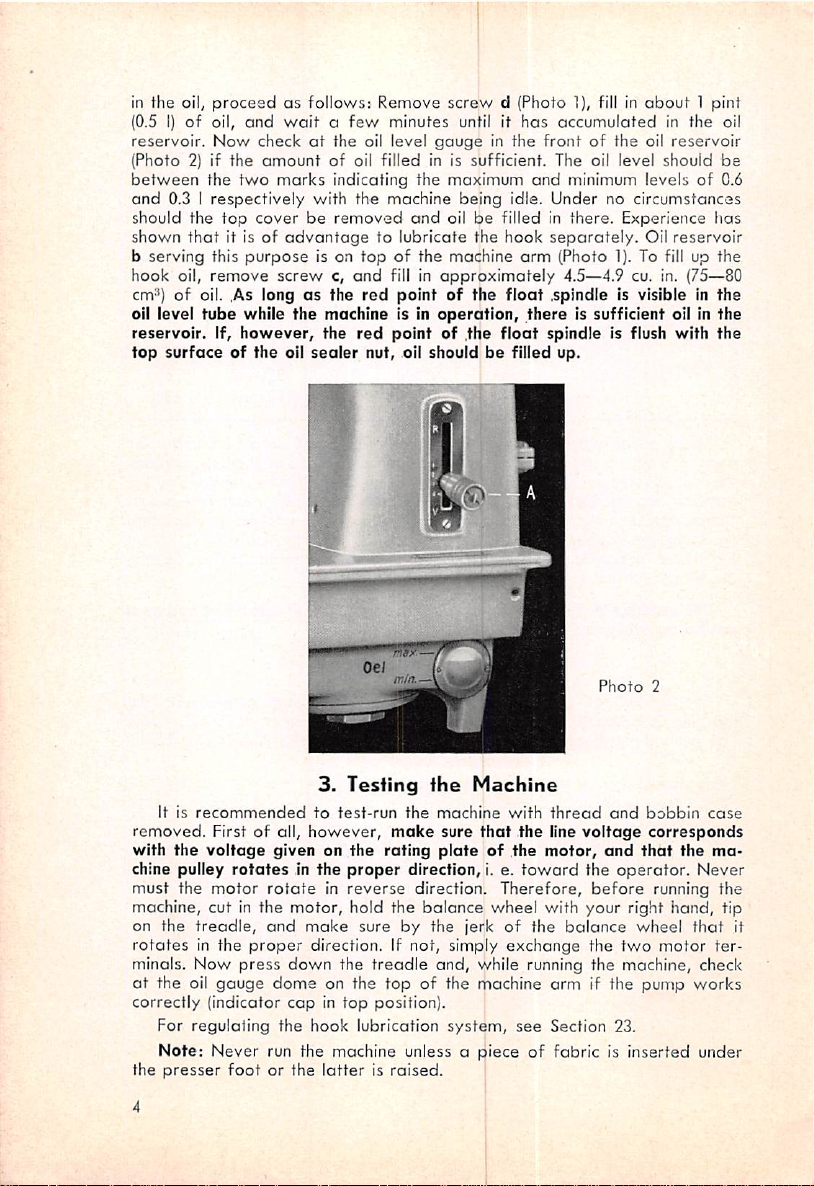

Page 6

in the oil,

(0.51)of

reservoir.

(Photo 2) if

between

and

should the

shown

b

serving

hook oil,

proceedasfollows: Remove

oil,

and

Now

checkatthe

the

amountofoil filled in is sufficient. The oil level

the

0.3 I

two

respectively

top

that

coverberemoved

it isofadvantagetolubricate

this

purpose

remove

cm^) of oil. ,As long

oil level

reservoir.

top

tube

surface

while

If,

however,

of the oil

waitafew

marks

with

is on

screwc,and

as

the

machine is in

the

sealer

minutes

oil level

indicating the maximum

the

machine

topofthe

fill in

the

red

red

pointof.the

nut, oil should be filled up.

screw

d (Photo 1), fill in

until it

gaugeinthe

being

and

oil be filled in there. Experience fias

machine

approximately

point

of the

operation,

the

has

accumulatedinthe

frontofthe

and

minimum levels of 0.6

idle.

Undernocircumstances

hook

separately.

arm

(Photo

1). To fill up

4.5—4.9 cu. in. (75—80

float

.spindle is visible in

there

float

is sufficient oil in the

spindle

is flush

about

oil

should

Oil

1 pint

reservoir

reservoir

the

the

with

the

oil

be

3.

Testing

It Is

removed.

with the

chine pulley

must the

recommended

First of all,

voltage

rotates

motor

machine, cut in the

on the

rotates

minals.

ot the oil

treadle,

in the

Now

gauge

proper

press

correctly (indicator

to

test-run

however,

given on the

in the

proper

rotateinreverse

motor,

and

hold the

make

sure by the jerk of the

direction. If not, simply

down

the

dome on the top of the machine arm if the pump

capintop

For regulating the hook lubrication

Note:

the

Never run the machine unless a piece of fabric is inserted under

presser

footorthe

latterisraised.

the

Machine

the

machine

make

sure

rating

plateofthe

direction, i. e.

direction. Therefore,

balance

treadle

and,

while running the machine, check

position).

system,

Photo

with

that

thread

the

line

motor,

toward

and

voltage

and

the

operator.

before

wheel with your right

balance

exchange

see

the

Section 23.

two

2

bobbin

corresponds

that

the

Never

running the

hand,

wheel

that

motor

works

case

ma

tip

it

ter

Page 7

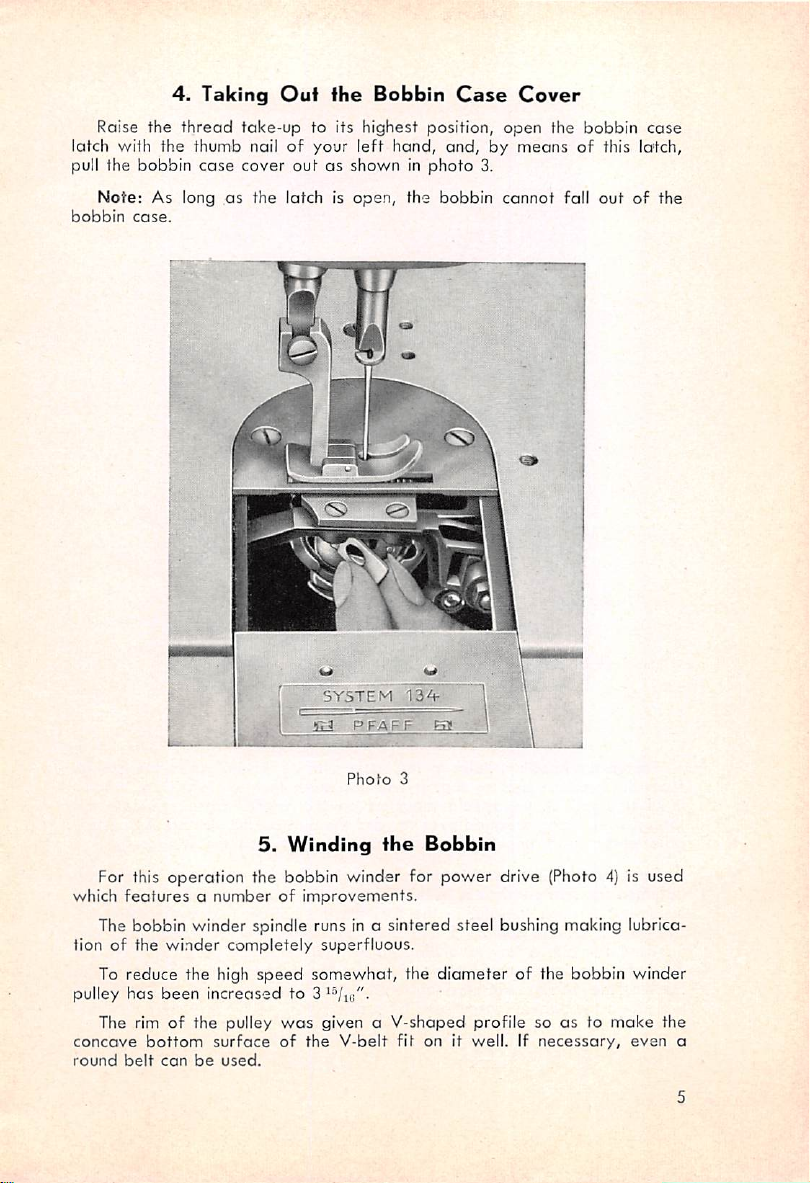

4.

Raise the

Taking

thread

Ouf

take-up

fhe

to its highest position,

latch with the thumb nailofyour

bobbin

case

cover

pull the

Note:

bobbin

As long as the latch is

case.

outasshown in

Bobbin

left

open,

Case

hand,

and,bymeansofthis lotch,

photo

the bobbin

iilTiTIM

3.

Cover

open

cannot

the

fall

bobbin

out

case

of the

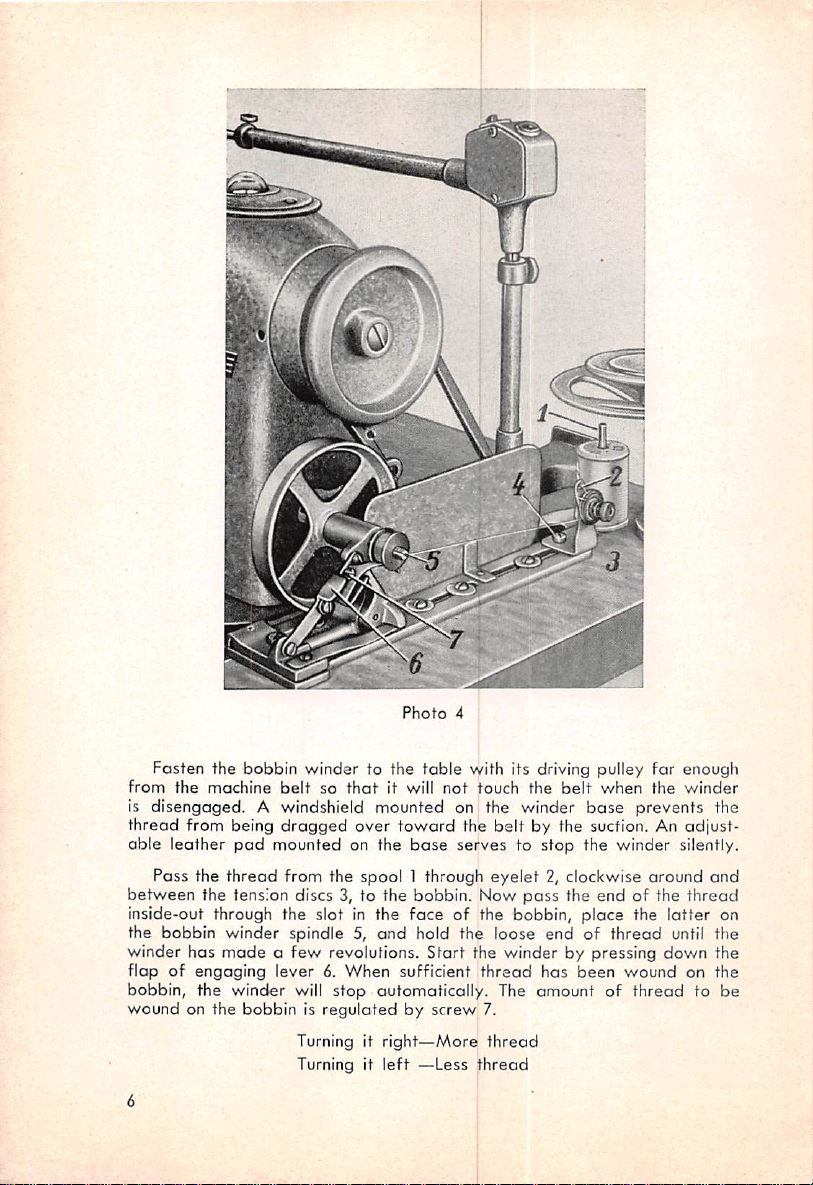

5.

Winding

For this

which

operation

featuresanumberofimprovements.

the bobbin winder for

SYSTEM

Photo

the

ISA-

3

Bobbin

power

drive (Photo 4) is used

The bobbin winder spindle runs in a sintered steel bushing making lubrica

tion of the

To reduce the high

pulley

The rim of the pulley

concave

round

has

been

bottom

belt

canbeused.

winder

completely

speed

increased

surface

superfluous.

somewhat,

to

was

given a V-shaped profile so as to

of

the

V-belt

the

fit

diameter

on it

well.Ifnecessary,

of the bobbin winder

make

even

the

a

Page 8

hjLv

Photo

4

Fasten

the

from

the

bobbin

machine

belt

winder

so

to the

thatitwill

table

with its driving pulley for enough

not

touch

the

is disengaged. A windshield mounted on the winder

thread

from being

oble leather

Pass

between

the

the tension discs 3, to the bobbin. Now

inside-out through the slot in the

the

bobbin

winder has

flap of engaging lever 6. When sufficient

bobbin, the wincier will

wound

on the

dragged

pad

mounted on the

thread

from the spool 1 through

over

toward

base

face

winder

madeafew

spindle 5,

revolutions.

stop

and

hold the loose

automatically. The amount of

bobbinisregulatedbyscrew

Turning it

Turning it

right—More

left

—Less

the belt by the suction. An adiust-

serves to

eyelet

stop

2, clockwise

pass

of the bobbin, place the

endofthread

Start

the winder by pressing down the

thread

has

7.

thread

thread

belt

when

base

the

prevents the

the winder silently.

around

the end of the

latter

until the

been

wound on the

thread

winder

and

thread

on

to be

Page 9

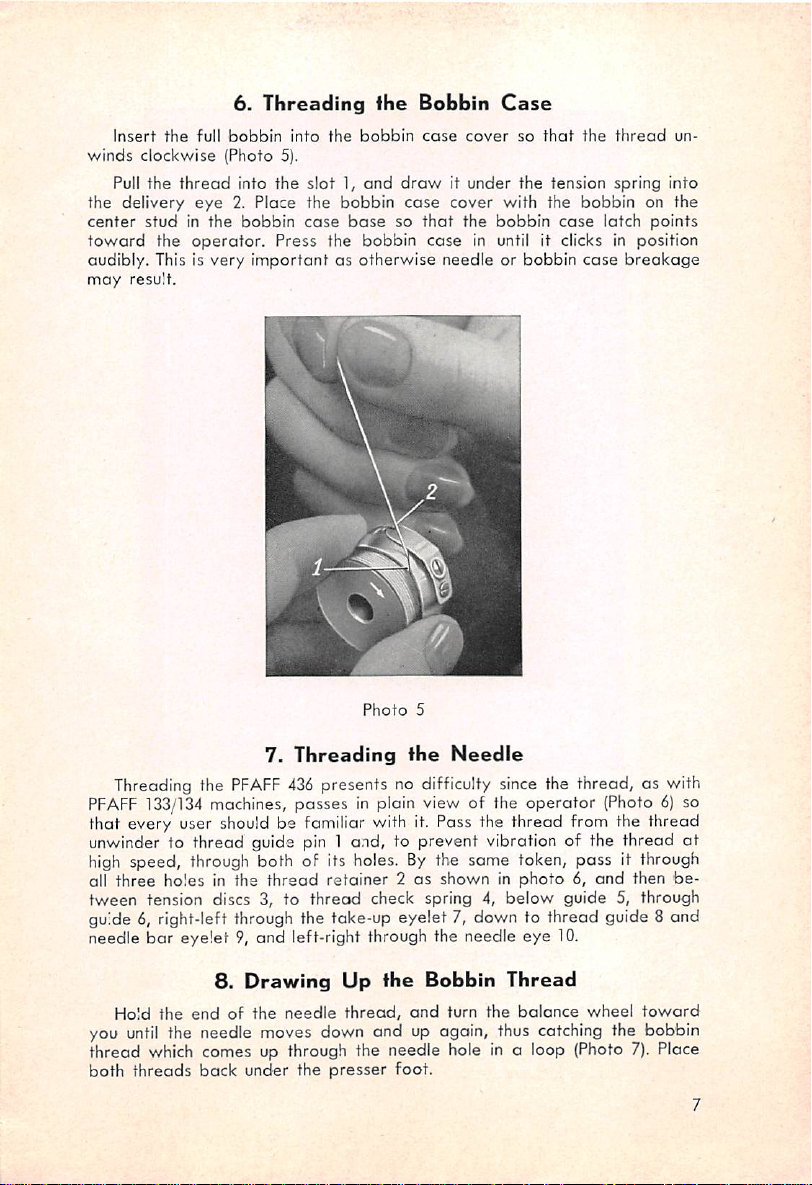

6.

Threading

Insert

the

full

winds

clockwise

Pull

the

the delivery

center

stud

toward

audibly. This is very innportant

may

the

result.

bobbin

(Photo 5).

thread

eye

in the

operator.

into

into the slot 1,

2. Place the bobbin

bobbin

case

Press the

ihe

the

bobbin

and

basesothat

bobbin

as

otherwise

Bobbin

case

draw

case

case

Case

cover

so

that

it under the tension spring into

cover with the bobbin on the

the

bobbin

in until it clicks in position

needle or

case

bobbin

the

case

thread

latch

breakage

un

points

Photo

5

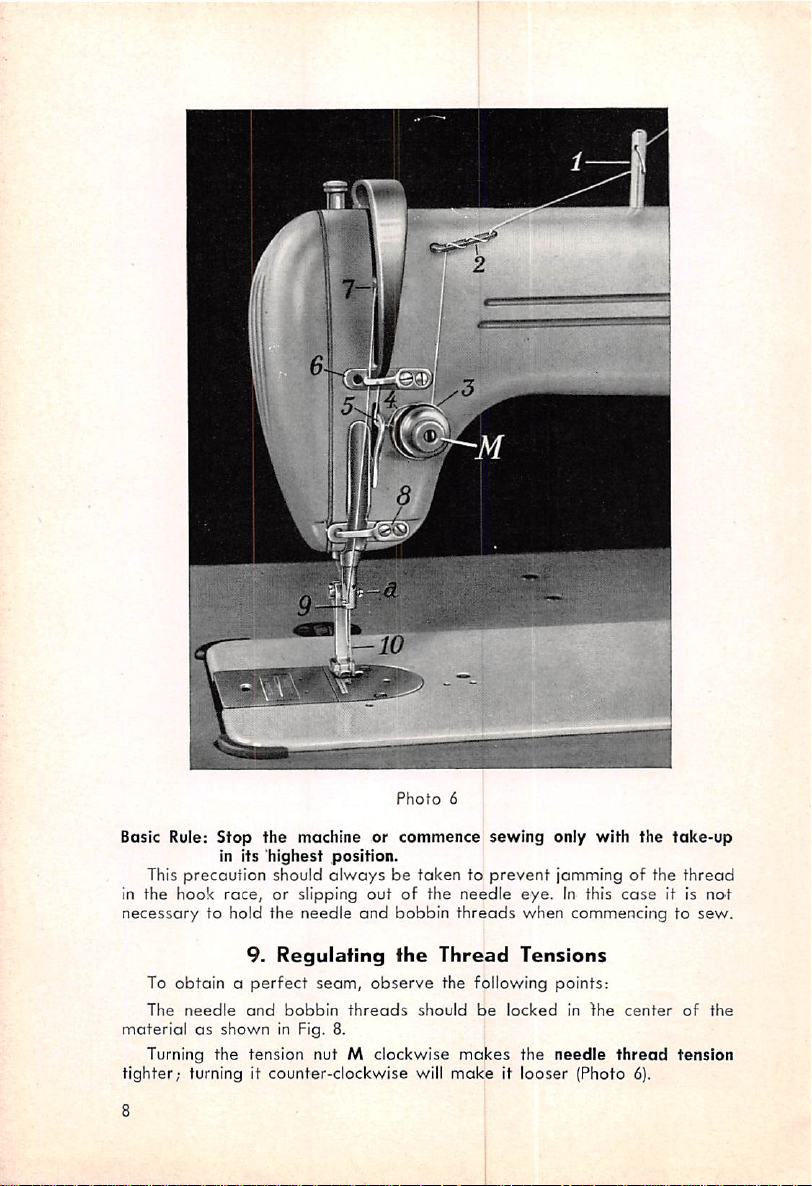

7.

Threading the

PFAFF

133/134

Threading

PFAFF

436

machines, passes in plain view of the operator (Photo 6) so

presents no difficulty since the thread, as with

fhe

Needle

that every user should be familiar with it. Pass the thread from the thread

unwinder to thread guide pin 1 and, to prevent vibration of the thread

high

all

speed,

three

through

holes in fhe

both of its holes.Bythe same token, pass it

thread

retainer2as

showninphoto6,and

through

then

be

tween tension discs 3, to threod check spring 4, below guide 5, through

guide 6, right-left through the take-up eyelet 7, down to thread guide 8 and

needle

bar

eyelet

you

9, and left-right through the needle

8.

Drawing

Hold

the

until

endofthe

the needle moves down and up again, thus catching the bobbin

needle

Up

thread,

the

Bobbin

and

turn

Thread

the

eye

balance

10.

wheel

toward

thread which comes up through the needle hole in a loop (Photo 7). Place

both

threads

back

under the

presser

foot.

at

Page 10

Photo

6

Basic Rule:

This

in the hook

necessary

To

The

materialasshown

Stop

the machine or

in its

race,

highest

should

or slipping

precaution

to hold the

9.

Regulating

obtainaperfect

needle

and

bobbin

in Fig. 8.

position.

alwaysbetakentoprevent

out

needle

and

seam,

observe

threads

Turning the tension nut M clockwise

tighter;

8

turning it

counter-clockwise

commence

of the

bobbin

the

sewing

needle

threads

Thread

the following points:

should

be

makes

will

makeitlooser

only with the

jamming of the

eye.

when

Tensions

locked

the

needle

In this

case

commencing to

in

fhe

center

thread

(Photo

6).

take-up

thread

it is no't

sew.

of

the

tension

Page 11

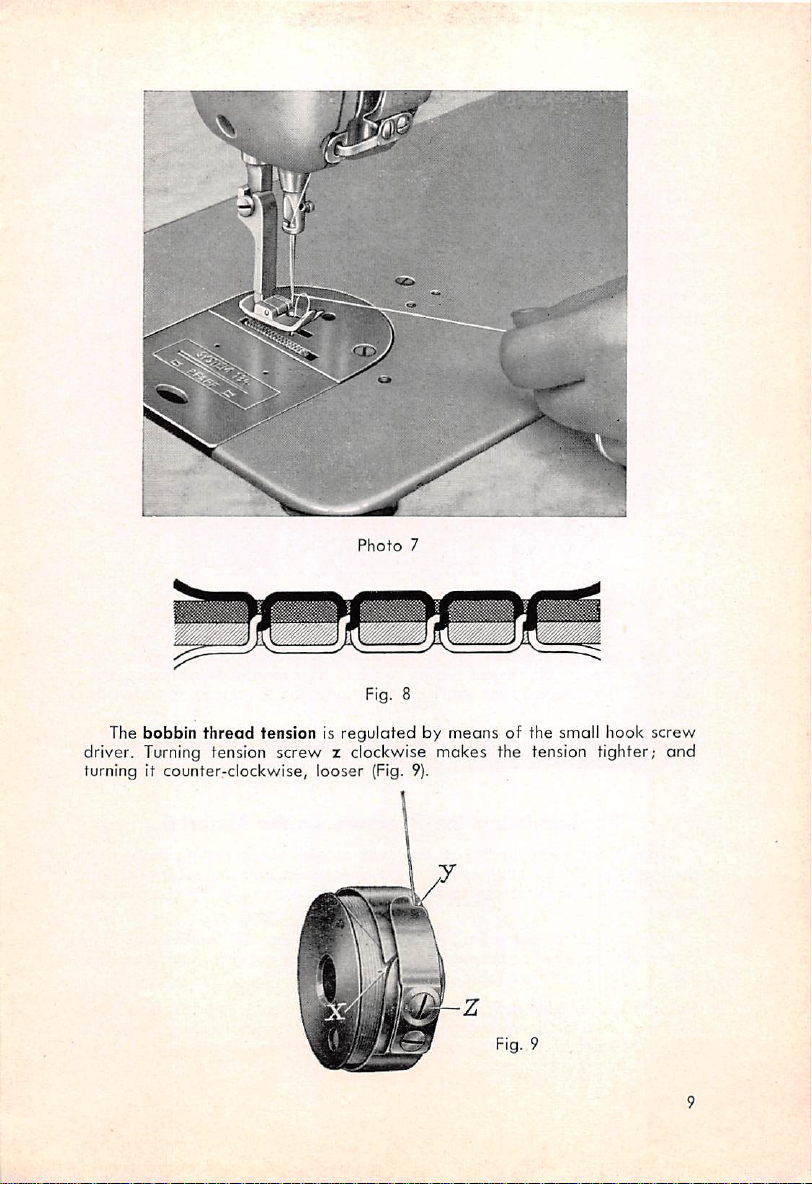

Photo

Fig. 8

7

The bobbin

thread

tension is regulated by means of the small hook screw

driver. Turning tension screw z clockwise mokes the tension tighter;

turning it

counter-clockwise,

looser

(Fig. 9).

Fig. 9

and

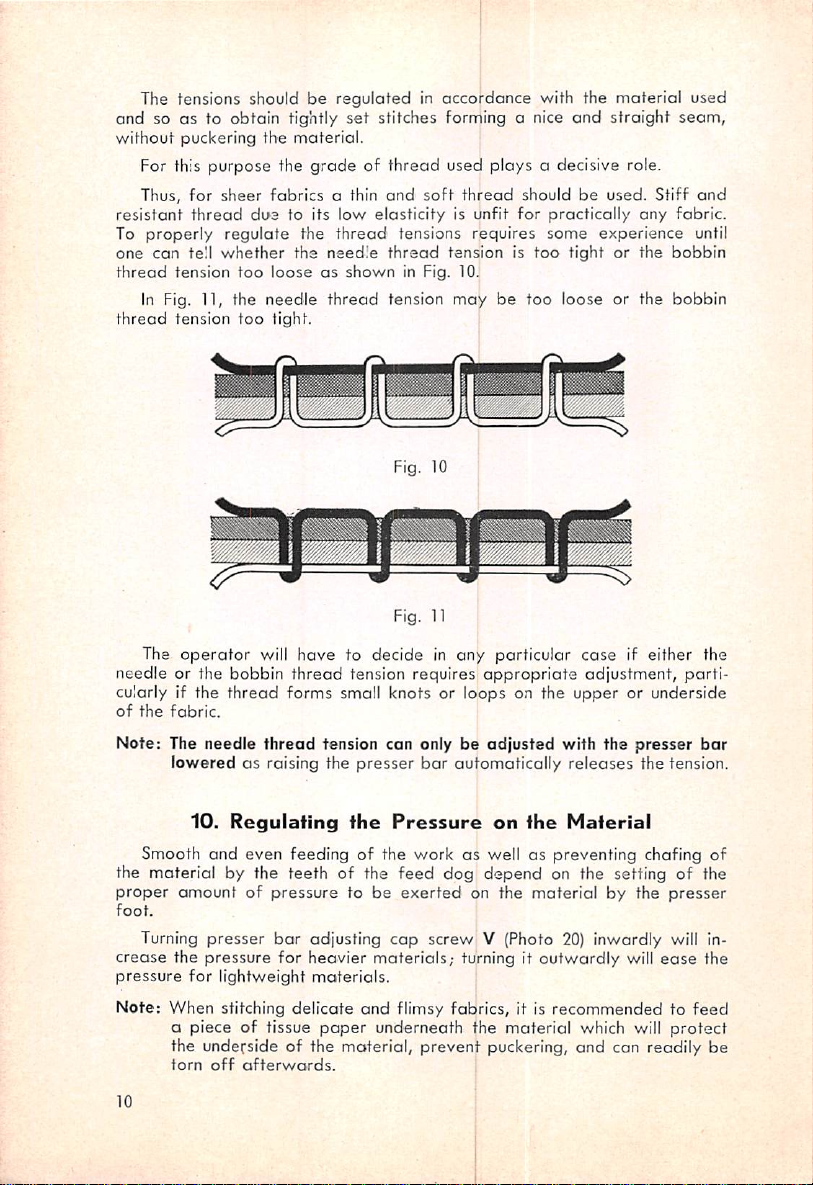

Page 12

The tensions should be reguloted in accordance with the material used

and so as to obtain tightly set stitches forming a nice and straight seam,

without

resistant

To

one

thread

thread

needle

cularly if the

of

Note: The needle

puckering the

For this purpose the

Thus, for

properly

can

In Fig. 11, the

The

sheer

thread

tell

whether

tension

tension

operator

or the

fabrics

due

regulate

too

looseasshown

needle

too

tight.

will

bobbin

thread

the

fabric.

thread

loweredasraising the

material.

gradeofthread

a thin

low

thread

needle

and

elasticity

to its

the

the

thread

have

to decide in any particular

thread

tension

used plays a decisive role.

soft

thread

should be used. Stiff

for

requires

be

appropriate

tensions

thread

in Fig. 10.

tension

Fig. 10

Fig. 11

requires

is unfit

tensionistoo

may

practically

some

tightorthe

too

loose or the

any

experience

case

if either the

adjustment,

and

fabric.

until

bobbin

bobbin

parti

forms small knots or loops on the upper or underside

tension can only be

presser

bar

adjusted

automatically

with the presser

releases

the tension.

bar

10.

Smooth

Regulating

and

even

feeding

the

of the

Pressure

work

on

the

Material

as wellaspreventing

chafing of

the material by the teeth of the feed dog depend on the setting of the

proper

foot.

crease

pressure

Note:

10

amountofpressure

Turning

presser

bar

the pressure for heavier

for

lightweight

When

stitching

a piece of tissue

adjusting

materials.

delicate

paper

to be

exerted

cap

materials;

and

flimsy fabrics, it is

underneath the material which will

the underside of the moterial, prevent

torn

off

afterwords.

on the

material

by the

presser

screw V (Photo 20) inwardly will in

turning it outwardly will

ease

the

recommendedtofeed

protect

puckering,

and can readily be

Page 13

11.

Choosing

Standard

are

used with the

short

System 134R, which

is imprinted on the needle

needles,

round-shank

PFAFF

System

133 R,

are

needles

436. Model A mochines for sheer fabrics require

wropper.

fhe

with round point

whereos

ModelBand

longer. The

Proper

standard

Needle

and

C machines use

shank

diameter

shank

The needle is of eminent importance for obtaining a perfect seam

therefore should be chosen in

weights

used.

proper

relation to the

thread

and

For lightweight fabrics, a thin needle should be used to prevent ugly

needle

marksinthe

When using a thin needle with a thick thread, the

to breok, ond, conversely, when using thin

pingofstitches

Select the

may

proper

fabric.

occurasa

needle

result.

from the

chart

thread

below:

thread

in a thick needle, skip

diameter

needles,

of

and

fabric

is likely

Needle

Size

Cotton

70

Silk,

75

Silk,

Cotton

80

Silk,

85

Silk, genuine 80/3

Cotton

90

Silk,

Silk, genuine 70/3 (C)

Note:

We

wrapper

Machines"

Never

use

Only fhe

free

sewing

PFAFF 436, a

thread.

the

to

heat

and

Needle

Thread

short

genuine

short

short

warn

Weight

fiber 100/3

fiber 80/3

fiber

youtouse

should

bear

plus the

rusty

needles!

exceptional

and

needle

quality

prevents

with a rough

This is particularly

melts

easily.

and

Thread

Needle

Size

100-80

100

100/3(0)

80-60

110

(B)

60-40

70/3

120

needlesofunknown

the inscription

needle

system.

of the finish of the

thread

breaking.

surface

true

of Nylon

Chart

Thread

Cotton

Silk,

short

fiber

Silk, genuine 60/3

Linen

thread

Cotton

Silk,

short

fiber

Silk, genuine 50/3

Linen

thread

Cotton

Silk,

short

fiber 40/3

Silk, genuine 40/3

Linen

thread

origin

"Needles

evenifthe

for

needle

Due to the high

gets

hot

quickly

thread

which is

Weight

40-30

60/3

90-80

30-24

50/3

80-50

30-16

60-40

Pfaff

ensures

speed

and

very

(D)

(E)

needle

Sewing

trouble-

of the

thus burns

sensitive

11

Page 14

If the

rial or

standard

running

needle

shoyld

get

too hot

when

stitching in

dense

mate

the machine for a longer time, it is recommended to ex

change the ordinary needle for a mirror-finished, chromium-coated high

efficiency needle, Systems 133 or

12.

Changing'the

1.

Raise

the

needle

bar

to its

2. Loosen the

3.

Pull

out

the

needle

needle.

set

screw

134,

which

may be procured from us.

Needle

highest

position.

o (Photo 6) with the small

screw

driver.

•,^i

Photo

12

12

Page 15

4. Insert

5. Tighten the

which con be

(Photo 2). A special device locks the length of stitch

be

the length oF stitch in miLimeters. Through pushing the stitch

up

by

tically return to its initial position. The

new

needle,

right

end

push it upasfarasit will go.

The PFAFF 436 is

changed

as

Shifting the machine to

foot

set

inadvertently

farasit will go, the machine is

control.

Systems

needle

set

screw

13.

Regulating

fitted

for the length of stitch

After

with the

while sewing. The numbers on the scale

reverse

letting go of the stitch

133 R or 134 R, with the

a firmly.

ihe

Lengfh

proved

desired

set

stitching can

treadle

of

spring-activated

by turning the thumb nut A

for

reverse

eitherbedonebyhand

regulator

for the stitch reversing device

short

Stitch

setsothat

feeding.

lever, it will

groove

stitch

regulator

it cannot

regulator

facing

indicate

lever

or

automa

Photo

/

13

13

Page 16

is arrangedatthe left to relieve the right leg which has to

actuate

the knee

lifter. Through this device both hands are free to manipulate the work

(Photo

12}.

14.

The

Knee

The PFAFF 436 is

connected

with

the

heodofthe

fitted

withaknee

machine.

The presser foot is either lifted by raising the

or by actuating the knee lifter with the right knee. The knee lifter

be

adjusted

screwband

(Photo 13). To permit tilting the

knee

lifter can be pulled

can

easilybereached

The

twice

is

that

The hub of the hook

being properly

horizontally

adjustatscrew

through an opening in the

PFAFF

per

436 is fitted with the

cycle. The only difference

the

PFAFF

436 hook is provided with centrifugal lubrication.

shaft

balanced,

and

vertically. For horizontal

a;

for

head

off

after

pulling

15.

The

is provided with an oil

ensures an absolutely vibrationless running of the

hook. The oil emerging from a hole in the hook

by centrifugal force

and

then enters the hook race through a second

Lifter

lifter

device

presssr

vertical

adjustment,

back, the knee lifter

out

piston pin d (Photo 18) which

dress

Hook

proved

between

hook of Model 134, rotating

previous models and this one

shaft

which is

bar

adjustment,

guard.

retainer

bushing is

harmoniously

lifter by hand,

pad

loosen

shaft

loosen

screw

with the

ring which,

atomized

can

bore

where it effects a dependable and permanent lubrication.

The amount of oil,

can be regulated

This

job, however,

set

after

for

removing the needle

should

only

average

sewing requirementsatthe factory,

plate

be performed by a

as instructed in Section 23.

mechanic.

c

16.

The

Mechanical

All varieties of the

Since the

like to

advantages

addafew

With a lockstitch machine the locking of the needle

is

doneintwo

as with oscillating or vibrating shuttle machines, the

PFAFF

of this device

explanations here.

different

ways,

436

are

depending

fitted with positive mechanical opener.

Opener

are

not generally known,

and

on the class of machine. Either,

threads

bobbin

are

we

should

threads

locked by

passing the bobbin thread in a shuttle through the needle thread loop which

has

been

formed while the needle, having

passed

the lowest point of its

downward stroke, is rising, or by passing the needle thread loop around

the bobbin case with the latter being in a stationary position.

14

Page 17

In

machines having oscillating loop takers, such as central bobbin ma

chines,

needle thread loop around the

the loop

forming

part,

while

bobbin

moving

back and forth, passes the

case with the latter being mounted

in a cenfral or eccentric position.

With

horizontal hook rototing twice per cycle,

which

the needle thread loop ispassed around the stationary

other

the type of loop taker generally used for

revolutionofthe

hook.

high

speed sawers, the

isalso usedinthe

bobbin

case at every

PFAFF

436,

With rotary hook machines, having no mechanical opener, the needle

thread, after having been passed around the bobbin case, has to turn the

bobbin case slightly making an opening through

With the increasing

sewing

speed

the friction

which

between

it can pass.

the hook

race

and the bobbin case increases accordingly and causes the bobbin case stop

to increase its pressure on the bobbin case position finger. As a result, the

needle thread has to overcome a stronger resistance when passing between

the stops.

This

intensified strain, in turn, can only be overcome by easing

the thread tension to prevent thread breaking.

The

needle thread tension has to be

drawback

setting of stitches impossible if the machine is

To eliminate

o mechanical

opener

at

This

finger

speed

changed,

exposed

shaft

the

proper

way

the needle

and

sewers

irregardless

to additional or evar-changing strain. As a result,

fabrics the

stitches

threads

high sewing

eliminated.

become

top

of

mechanical

as

and

of a low tensile strength

completely

speed.

All of the

the PFAFF 436

Timing of the mechanical

instructed

of this remedy lies in the

eased

fact

that

in most

cases

to an extent which makes proper

operatedatreduced speed.

these

disadvantages,

opener,

whereby

PFAFF High

a small lever

Speed

mounted

Sewers

are

on the mechanical

fitted

assumes the function of moving the bobbin case back sligthly

moment

the

bobbin

are

thread

and

thread

manifold.

contrary

is permitted to

case

stop.

of the

First

sewing

tensions can be

to the

rotating

pass

The

advantages

the

needle

spead,

set

since the

so as to ensure even setting of the

direction of the hook.

freely

between

of this device for high

thread

tension

needle

need

threadisnot

also

the position

not

for

to prevent puckering of the materialatall speeds. Second,

may

be

used

speeds

Third,

above

opener.

in

Section

since the

also

smooth

advantages

intended

dangerofthread

while

the

yet,

account

for heovier

opener

29.

bearing

the

should only be

surfaces

machins

for the

materials

on this machine

breaking

will

fact

are

performed

has

of

the

sew

flimsy

that

also

fitted

with the positive

even

greatly

hook

have

fabrics

the

varieties

by a mechanic

the

with

be

sheer

for

been

not

at

dog

knee

17.

Tilfing

To

facilitate

and

lifter.

the

the hook, the machine can be tilted

removaloflint

fhe

Head

having

of

the

accumulated

Machine

back

after

between

taking

the,feed

off

the

15

Page 18

For

this

under

purpose,

the table and

lifter with the knee lifter shaft can be pulled out at the front. Having done

reach

through

pull

back the piston

the

holeinthe

middle

pind(Photo

of the dress guard

18).

Then

the knee

this, the head can be tilted back and rested on the wooden machine rest

or on the sew light bracket

after

the latter has been swung off.

18. Taking

Skilled

operators who make it a routine to start or

the

Hook

Apart

finish

a seam only

with the take-up in its highest position, or to place the threads back under

the presser foot when commencing to sew,

jamming in the hook

Should thread jamming occur, however, first try to get a hold of the

loose end and to

If this

attempt

race.

pu-l

it out while jerking the balance wheel back and forth.

fails,

take

the hook

will

hardly ever encounter thread

apart,

proceeding as follows:

Photo

14

16

Page 19

1.

Tilt

the

head

backasinstructedinSection

2. Raise

the

needle

still be turned. If not,

(Photo 14) first.

3. Loosen

set

screw c and pull off the mechanical opener lever b. When

reassembling the

on the

shaft

groove.

4. Pull

out

with

thumb

5. Raise the

6. Loosen

can easily be reestablished since the

the bobbin

and

head

screws,

bar

and

the

remove

parts,

the

cose

forefinger.

cover

of the machine

e„

e®,

and

O;)

take-up,

the

bobbin

proper

with the bobbin, seizing it by the latch

and

(Photo 15)

17.

provided

case

position finger

position of the mechanical

remove

needle

and

take

which, however, should not be confused with the hook

the

balance

shaftismarked

plate

and

off

the hook gib d

body

wheel

bracket

opener

feed

guard

can

a

by a

dog.

f.

Photo

15

7. Turn the

balance

wheel

until the

first

screw

is opposite notch I in the bobbin case (Photo

the

bobbin

case

base

canbetaken

outofthe

hook components in the some position

point 1 of the bobbin case

and

point

f of the

body

base

guard.

should be between point g of the hook

f, in the hook

16).

whereby

When in this position,

body

hook.

Photo17shows

it should be

noted

guard

f

the

that

17

Page 20

8. Seize the bobbin cose base with thumb and forefinger, pull it to the

left

and

down,

and

take

it out.

9. Clean the hook and the bobbin case

with o pointed

10. Before replacing the

the bobbin

base

but

case

base

the tip of the finger h and the

n.

Replace hook g'b d

case

make

and

wooden

position finger

sure

that

instrument, never with a screw driver.

bobbin

that

case

the finger h

a clearance about .019" wide is preserved between

and

tighten screws Oj, e^, and e;,.

base,

bracket

bottom

base

thoroughly, and remove fluff

it is

recommendedtoscrew

a. Then insert the bobbin

engages

of the notch I.

in notch i in the bobbin

on

case

12. Push the mechanical opener lever on its shaft whereby screw c should

engage

obout

tighten screw c securely (Photo 14).

in the lengthwise

'/a of the projection on the rim of the bobbin

groove

in the

shaft

and

the lever should

case

base.

cover

Then

!r

Photo

19.

Service

Due to the

PFAFF

436 being provided with automatic lubrication, there

ishardly any maintenancerequired

the automatic

machine

cleaned

lubrication

regularly.

system

and

while

should

Mainfenance

the

machineisin

be checked, oil

operation. Merely

filled

up, and the

When the machine is in constant use, it is urgently recommended to moke

it a daily routine to

18

remove

with a brush the lint

and

fluff

that

have

16

accu-

Page 21

mulated beKveen the needle

Since this fluff contains a high

sive

effect

on the sewing mechanism, the

plate

and

percentage

the

feed

of dressing which has an

parts

would be worn

The whole machine, including the bottom, should be

rag

regularly.

Photo

17

Great

emphasis

PFAFF 436

as

with no machine containing

are

no exception—can the capillarity of the oil be

Capillarityorcapillary

in all directions

the

outer

holes,

greatly

surface

the

been

vent

has

the possibility exists

been

idle

this

this might

dropped

for

case,

however,

easily

to normal. This

wiping this film

and

presser

work.

In

prevent

connection

other

optical

green,orblue.

many

yellowish

that

brand

refraction,

bars

instances,

and

has

been

tightasthey

possibly can be. But

larger

attraction

placed

andtoleak

with

occuranceofexcess

eliminated,

that

several

we

through

a thin filmofoil. Through a functional

but

a minor

days,

or if

urge

you

on making the oil

quantities

designatesapropertyofthin oil to

even

pressure

even

so, for the

leakage

the

nottochoke

of oil—and sewing machines

the

tightest

causinganexpansionofthe

reasons

occurs

temperature

the

result in insufficient lubrication once the

off

the machine with a

and

under the

clear,

temporary

spots

yellowish

that

in the work.

oil isaspure

the

only

similaraswith cut

white

nuisance can simply be remedied by

dry

head,

oil is

reasonitappears

rag,

and

thus to

preferred

We

should like to

and

free

from

edgesofglass

every

particularly on the

The oil supply for all lubricating points should only be

mechanic.

dog

and

on the hook.

abra

off

wiped

off

reservoirs

expert

completely

unduly.

with a

soft

in the

knows

that

eliminated.

spread

packings, covering

distribution

enumerated

after

rises

oil

flow

the machine

above

temperature

above,

normal.

drastically

has

as

has

needle

prevent

soiling of the

for sewing machines to

point

out

color

yellowisthe

particlesasany

which

appear

regulated

in this

effect

yellow,

by a

of

oil

In

of

19

Page 22

Instructions

20.

When mounting the belt for the first time, core should be taken

is not forced on the motor pulley as a crookedly stretched

The

for

V-Belt

Mechanics

Drive

belt

weors

that

out

more quickly. Instead, the belt should be placed in the groove of the pulley

rim

after

regulated very conscientiously. As

lifting the motor

is

mounted

to a hinged

mitting adjustment of the

the

motor

somewhat

moved up or down with stud m sliding in

give the belt the

so

that

the full

proper

weight

excessive pressure on the

might

easily

of

the

damage

machine.

somewhat.

bracket

belt

and

loosen wing

Then the tension of the

may

andisprovided

be seen from photo 18, the motor

with a simple device

tension without tools. For this purpose, lift

screwk.Now

bracket

I, as may be required to

tension. The tension should never be

of the

motor

the

bottom

arm

presses

surface of the arm

shaft,

on the

beltasthis

or result in binding

the

shaft

and

belt

should be

motor

set

too tight

would

bearings

overheating

per

can be

cause

and

ii

Note:

20

After

rely so

regulating the

thatitcannot

proper

get

Photo

belt

loose

18

tension,

while

tighten

sewing.

wing

screwksecu

Page 23

21.

Regulating

The oil

parts

for normal requirements. To

readjustment

is used for permanent

flowtothe

can be regulated

by a mechanic

the

Automatic

hook,

the

individuol

separately

adapt

heavy

and,

the oil flow to

may

become

duty operations, such as the seaming of whole

Lubrication

arm

shaft

when leaving the factory, is

necessary.

bearings,

any

specific

Thus, if the machine

System

and

the

requirements,

head

set

bales of fabric, a more liberal supply of oil is required than would be

necessary if the machine is used for short seaming operations. Sudden

changes

call for a

(Photo

of

Arm and

19).

temperature,

temporary

head

particularly

abrupt

adjustment of the oil supply.

parts

are

supplied with oil by means of oil tube 1

rises in

temperature,

Through a hole in this tube a jet of oil squirts up, hits the

may

indicator cap in the oil gauge dome and thus indicates that the oil pump

is functioning properly. The oil having bounced back from the

cap

then

sprays the bevel gears, pitman rods, and eccentrics so that a constant film

parts

of oil is provided between all

provided in the oil tube 1, one regulating the oil supply for the front

center arm

arm

shaft

shaft

bearing.

bearings

and

the

mem

in moving contact. Two valves are

head

parts,

and the second for the

and

rear

Photo

19

If the valve slots n

open.

When

turning

and

them, the

o (Photo

oil

supply

19}

point lengthwise, the valves

can be regulated as required or

are

shut off completely. We recommend, however, to leave valve n open and

thus to ensure proper lubrication of both arm shaft bearings and the head

parts.

21

Page 24

22.

Regulating

As can be seen from

the

Lubrication

photo

20, the hollow

of

the

Head

arm

shaftisclosedatthe

Parts

end with center stud o which is secured in Its position by screw patthe

right of the former. This stud serves to regulate the amount of oil being

pressed

loosen

is

turning the stud right or left so

the oil flow is diminished accordingly (Fig. 20a).

cient lubrication of the

by the following test: Hold a piece of cardboard between the presser

and the

turn the oil regulating stud o until two thin stripes of spray oil

the

from

the hollow

screwpby

opposite

the symbol+/the oil flow to the

turning it right. If

There is no hard and

rear

of the machine

cardboard

which

arm

fast

head

should

shaft

into the

that

the

the

arm

shaft

red

markonthe

arm

red

shaft

markisopposite

crank. For

arm

crank

adjustment,

shaft

is open. When

crank

symbol —.

rule for the amount of oil required for suffi

parts.

This,

head

however,

and

run the machineattop speed. Now

con

easily

be found

appear

be

the

case

afteramaximum

of10seconds.

out

bar

on

0 ®^

Photo

20

22

Fig. 20a

Page 25

To ensure

strain constantly, an oil packing

odequate

lubrication of the needle

has

been

up link stud, wound around the upper needle

down

to the

lower

needle

bar

secured

A

pad

screwed

to the

by a clip

second

take-up

23.

strap.

oil wick is

passed

on in the upper

link

whenever

Regulating

bushing,

part

the

the

wound

from

the

of the machine

latter

brushes

Lubrication

bor

passed

take-up

through the

bar

bushing (Photo 20),

around

link stud to a small oil

head

past.

of

which is under heavy

thread

take-

passed

the

needle

bar,

and

which delivers oil

the

Hook

Before the machine is

lubrication

plate

hook.

system

to gain

This

accesstoscrew

screwistobeturned

hastobe

Turning the

Turning

i

put

in use, the

checked. For this

q (Photo 21) regulating the oil flow to the

withasmall

screw

the

screw

Photo

proper

left

right—Less oil

21

functioningofthe hook

purpose,

screw

—More

oil

remove

driver

as

the

follows:

needle

23

Page 26

Hook

12 11 9 B 7

1.

Oil reservoir,

2.

Valve

3. Four-segment centrifugal

governor

4.

Arm

shaft

5.

Oil

tube

6.

Hook

shaft

upper

bearing,

Lubrication

Fig. 22

7.

Oil

8.

Hook

9.

Oil

10.

Oil

11.

Oil

Hook

12.

front

13.

Bobbin

Diagram

regulating

shaft

retainer

retainer

retainer

oil

bore

case

screw

bearing

ring

groove

ring

ring

bore

base

oil conduit

race

ring

If the hook should become so hot thot you cannot touch it with your

hand, or if the

indicate

case

indicate

the

work.

thread

that

the hook is lubricated inadequately. Oil

that

should be blackened by the hook, these symptoms

there is too much oil fed to the hook which is

spots

on the bobbin

apt

to soil

The drip oil lubricalion system used for the hook is shown in Figg. 22.

The hook lubrication oil

reservoir

1 in the

top

cover

on the machine

arm

has a valve 2 in its bottom. The oil flow is regulated In proportion to the

sewing

octuates

the

more

speed

by meons of governor 3 on arm

the

four

pressure is

segments

exerted

of

the

by these segments on the lower end of o

governor.

The

shaft

4. Centrifugal force

faster

the

machine

runs,

plastic connecting lever which, in turn, transmits the pressure to the valve

plunger. This plunger effects the opening of the volve to a higher or lesser

24

Page 27

degree,

segments.

ing 6. Prior to

which is

for fine

retainer

and,

ring in

it can

depending

Via

enclosed

adjustment

ring 10 is flung

finally,

the

hook.

After

the oil flow to the

easilybeadopted

oil

passing

bore

on the amount- of

tube5the

in the hook

of the oil flow. The oil dripping into

12 in

oil

the

oil

conduit

shaft

outbycentrifugal

the

hook

which

heed

to specific requirements.

24.

Changing

travels

bearing

parts

pressure

thentothe

8, it

lubricates

and

exerted

passes

in an oblique position

force

the

the hook

fhe

Oil

the

and

by the govertior

front

hook

oil

regulating

groove

thus

has

enters

case

been

bobbin

shaft

screw

and

9 of oil

bore

base

checked,

bear

7

serves

11

race

As with any high

importance also for the

the oil

are

not

speed

sewing machine, changing the oil is of utmost

PFAFF

lessenedasa resultofoverheating

436. Although the lubricating

the oil in the machine, it

properties

is nevertheless very important and will serve to increase the service life of

your machine considerably, if, particularly in the beginning, the oil is chang

ed frequently

new

machine—is

Therefore,

This

schedule, of course, only applies to the automatic lubrication system,

abrasive

thereby

we

recommendtochange

change

First

Second change

Third change

and

thereafter

effect

diminished.

of metal grit—inevitable with every

the oilasfollows:

after1week's

after4weeks'

after

3 months' operation

every

6 months

operation

operation

and

fhe

whereas the oil required for the hook lubrication has to be replenished

currently.

To drain the oil, remove the large oil drain screw on the bottom of the

bed

oil

reservoir

oil, mud, or grit remains in the reservoir.

The

used

several plies of linen) and reused for

Fresh

oil is

25.

Regulating the Throw of

while

oil is

not

filledinas

the

machineisidle.

useless

but

instructedinSection

Care

shouldbetaken

can

be

other

filtered mechanically (through

lubrication purposes.

2.

the

Thread

Check

thatnoused

Spring

of

The thread check spring assists the thread take-up in taking up the slack

of the needle thread

after

the loop has passed around the bobbin, in setting

the stitch to the desired tightness, and in checking the slack of the needle

thread

after

thread

has

been

up

until

the needle has penetrated the material.

drown from the spool by the descending take-

25

Page 28

VT^T,

Photo

23

The trip made by the thread check spring during this operation is limited

by a stop on its bushing, and can be adjusted as required by turning this

set

bushing. For this purpose, loosen

pin t

withascrew

driver.

The thread regulator R (Photo

screw s (Photo

20)

is mounted to the presser bar guide

collar which causes it to follow the motion of the presser

23),

and turn tension

bar

when passing

over irregularities in thickness of the material and to compensate for the

higher amount of

thread

required for thicker

spots

in the material so

that

the thread check spring need not take up so much slack of the thread.

The thread regulator can be adjusted vertically after loosening screw u

(Photo

20).

This

adjustment serves the same purpose as that effected by

turning the check spring bushing. We recommend to coordinate both adjust

ments so that, in addition to a

proper

control of the amount of thread, the

check spring takes up the thread slack by drawing in a vertical plane.

Note: Once you know the functions performed by the thread check spring

and the thread take-up, you will be in a position to perform proper

adjustment without trying out different settings first.

The thread check spring is correctly adjusted if it has completed taking

up

the

with the

slockofthe

PFAFF

thread

when

the

436

the trip of the take-up is somewhat longer than normal,

needle

stitches

into

the

material.

Since

it may be necessary to allow the thread check spring somewhat more play

than usual so that it is still slightly tenseatthe time the needle stitches

into

the

material.

26

Page 29

26.

Setting

the

Photo

Needle

24

Bar

at

Correct

Height

To facilitate setting the needle

sion has

been

milled in it (Photo 24). When the needle

lowest point of its downward stroke, the upper

be in line with the lower

is .070" (1.8 mm) wide which distance corresponds to the needle

(to form the loop). With the

edge

[ust opposite the center line of the needle and

of the needle

eye

when the needle on its

baratthe correct height, a small depres

bar

has

of the

lower

needle

bor

PFAFF

436, the point of the hook should

.039"(1mm)

edge

upward

stroke has risen .070" from

of this mark should

reached the

bushing. This

above the top

bar

mark

rise

be

the lowest point of the stroke, which is the position in which the point of

the hook is

sufficiently.

Timing

toasadjusting the

For adjusting the needle

willbesupplied

abouttoenter

the loop

after

the needle bor rise and the hook

needle

bar

rise.

bar

by us

upon

rise, we recommend to use the gauge which

request.

the

motion

latter

has

been

is generally referred

enlarged

27

Page 30

Photo

25

Begin by lowering the needle

the

gauge

bor

remove the

the needle

meet

(.070" thick) on the needle

bushing. Posilion the

the

gauge,

bar

above

and turn the

bushing. When in this position, the hook should be

requirements.

27.

To turn the hook on the hook

clamp

bar

to the lowest point of its stroke, place

bar

beneathitand

balance

Timing

shaft

immediately under the lower needle

screw

if on (Photo 25).

Now

wheel slowly until the clamp strikes

adjusted

fhe

Hook

until it is in the position described

in the preceding section (point of hook .039" above top of needle eye), first

remove

(Photo 21).

ensure

hook

28

The

the

needle

sideways

that

there is a clearance of .004"

and

the

plate,

adjustment should be

needle.

and

then loosen the hook

made

(0.1

set

with particular

mm)

between

screwsvand

care

so as to

the point of the

to

w

Page 31

Note: When making the

sure

that

tween

be

After

hook .004"

(0.2—0.3 mm)

bushing must be

a maximum

the hook

measured

having

between

made

apart

between

above

and

the hook

the

from

preserved

28.

Changing

adjustment or inserting a new hook moke

play

of .012"—.016" (0.3—0.4 mm)

shaft

the

point

sideways

needle), a minimum

the

to ensure

of the hook

adjustment

hub

of

ihe

bushing. This

the

hook

proper

Hook

distance

and

the

of the hook (point

play

and

lubrication of the hook.

exists

can easily

needle.

of .008"—.012"

the

hook

be

of

shaft

1. Remove the

bracket.

2. Loosen

3. Loosen the hook

4. Turn the

5. Pull

off

6. With the

shaft,

7. Time the hookasinstructed in Section 27

andwsecurely.

8. Replace

12,

Section

9.

Screw

set

balance

the

feed

and

and

on the

replace

needle,

screwcand

hook

18,

29.

the

needle

plate,

pull

off

set

screwsvand

wheel

until the

from

the

dog

in its highest position, push the

the

bobbin

screw

on the mechanical

feed

dog

and

Timing

feed

hook

case

the

needle

the

Mechanical

and

the

bobbin

the mechanical

w (Photo 21).

dog

has

risen to its highest position.

shaft.

position finger

and

tighten the

openerasinstructed in

plate.

Opener

case

opener

b.

new

hook on the hook

bracket.

position

set

poragraph

Mony mechanics find it rather difficult to properly time the mechanical

opener.

in

There

1.

2. the timing of the mechanical

sleeve

mechanical

shaft

joint on both sides of the center line (indicated by

This

very

order

to preserve the

are

two

Adjustmentofthe mechanical

adjustment,

stepstobe

The oscillating motion of the

joint to the mechanical

opener

After

loosening the binding screw, the binding collar on the

should

lever to

be

turned soasto ensure an

however,

odvontages

observed:

opener

opener

feed

opener

make

an oscillating motion.

should be

of this device outlined in Section 16.

drive,

motion.

lifting

shaft

equidistant

made

very

and

shaft

is transmitted via a

which, in turn,

throwofthe

dotted

lines in Photo 26).

meticulously

causes

feed

finger

screws

lifting

sleeve

v

the

29

Page 32

The point of the mechanical opener

set

screw should engage in the

lengthwise groove in the mechanical opener shaft which eliminates the

necessity of adjusting the mechanical

removed

for taking

apart

the hook.

opener

laterally whenever it

has

been

In case sideways adjustment should become necessary, this is dona

after

by turning the mechanical opener shaft

at

the

lower

jawofthe

sleeve

joint (Photo 14).

loosening the binding screw Q

To properly time the mechanical opener the mechanical opener shaft

should be turned so

that

the mechanical

opener

lever strikes the projection

on the bobbin case and just starts opening the bobbin caseatthe time the

point of the hook is

i.e.atnorth-east,

Since the motion of the mechanical

about

after

one-eighth of a revolution short of its top position,

the

loop

has

passed

opener

around

the

bobbin

case.

lever is very slow and hardly

perceptible, we recommend to push the bobbin case over to the right at

the

bottom

opener

easily be established In which the lever begins to hold the

I.e. in which it

and to place a thin piece of

paper

between

the mechanical

lever and the projection of the bobbin case. Thus the position can

paper

starts

opening the

bobbin

cose.

in position,

Photo

26

30

Page 33

Note:

When timing the mschanicol

upper

and

on

shaft

the

shaft.

be

lower

Under

allowed

by adjusting the

30.

Disassembling

1. Remove face

plate,

2. Loosen the presser

spring, loosen the presser

pull

out

the

presser

3. Loosen needle

upper needle

bar

bar

and pull out the needle

4. Loosen locking

5.

Turn

the

shaft

crank

6.

Loosen

7. Loosen

the

the

screwEat

balance

wheel

canbereached

needle

take-up

jaws

no

any

jaw

or the

presser

bar

baratthe top.

binding screw C

bushing, remove the oil wick clip and the oil wick,

baratthe top.

until

bar

link

link

stud

opener,

of the

circumstances

end

play.Ifexistent,

set

Photo

foot,

care

sleeve

joint

must

should be

ore

the

collar s (Photo 27).

27

fhe

Link

Take-up

and

needle.

token

not

moved

mechanical

it should be

that

sideways

opener

corrected

adjusting cap screw, pull out the presser

bar

guide collar

the

backofthe machine (Photo 28).

the

needle

through hole G.

crank

screw.

set

screw.

and

set

screw B (Photo 30), and

set

screw D (Photo 20) in the

bar

link

crank

screwinthe

8. Unscrew the top cover and pull out the packing in the hollow hinge stud

of the

take-up

9. Place

barKacross

screw ^/,6"x28 in its hole,

link.

the

head

of the machineasshowninphoto

and

screw it into the hollow,

29, insert

threaded

hinge

stud, turning it toward the take-up link, and thus pull out the hinge stud.

(In

lieu of

bar

maybeused).

10. Carefully pull out the link take-up with its link, the needle

crank,

and

the

needle

K any iron

bar

bar

about

link, all in

4" long with a (5 mm) hole

bar

one.

the

bar

arm

link

31

Page 34

Photo

28

Photo

29

32

Page 35

Note: Don't use force when removing the take-up components since oil

ports

are

precision-made

and

meticulously fitted. Also avoid any

blows so as not to dislocate the pressed-in bearing rings.

The

upper

bar

link

right

are

(Photo 29).

When taking the assembly

bearing

ing

needles

inserting the

gets

needles,

lost. Each

making the needles stick. Use a

needles.

Reassembling the

verse

sequence,

using

honed

the

take-up

utmost

of the

needle

bearing

bearings

and

care.

take-up

apart,

and

bearings.

take

care

contains18bearing

are

provided

pair

of pincers for inserting the bearing

head

components

the

To

lower

bearing

loosen

end

that

none of the tiny

needles. To

with

some

should be

of the

screw

clean

L, turn it

facilitate

dona

needle

bear

grease

in re

Photo

30

33

Page 36

To puil Ihe oil packing through the take-up link stud, it is advisable to

use a thin

link slud to the upper needle

(Photos 29

wire

and

with its

30) so

that

one

end

bent.

bar

the wick

The oil wick leading

bushing should be

does

not

contact

from

fastened

the

presser

the

to the

bar

take-up

as the excessive oil supplied by the wick might leak through the presser

bearing

stitches of equal length when sewing

the

some

desired

the longer the length of stitch is

maximum

stitch

and

soil

the

work.

31.

Adjusting

ModelAandBmachinesofthe

needle,

With

when

hole

for

ModelCmachines,

for

reverse

stitching

thatithas

tying

off

forward

feedingisabout

the

Length

and

Reverse

reverse,

made

seams.

stitch length

while

the

reverse

of Stitch

PFAFF 436

forward

will

penetrate

sewing

stitch

set

for

of

'•'/oj".

for

Forward

Feeding

canbesetsoastoproduce

or reverse. This means

the

forward.

grows

forward

the

fabricinexactly

This

feature

proportionally

feeding so

corresponding

that

is much

shorter,

with a

length

latter

spring

bar

that

the

of

Photo

31

34

Page 37

To regulate the length of stitch for

loosen the binding screw N, visible in the slot

forward

and

backward

above

the stitch regulator

feeding,

lever (Photo 31), and turn the stitch regulator lever joint on the stitch regu

lator

axis.

Now hold the stitch regulator lever A

the stitch regulator axis. When turning the lever O

stitch for

it up, will

feeding can be

should be

Note:

forward

grow

longer.

Thus the relation

set

tightened

The

larger

smaller will be the

32.

Removing

sewing will

between

very exactly

firmly.

the maximum length of stitch for

grow

the stitch lengths

after

corresponding

the

Oil

the

Oil

and

adjust by turning lever O on

shorter,

downward,

and

conversely, when turning

for

forward

the length of

and

which adjustment binding screw N

forward

for

rever.se sewing.

and

Taking

Reservoir

Pump

stitch length

Apart

reverse

sewing;

the

Due to

opener,

it hardly

of trouble with the oil

1. Drain the oil thoroughly.

2. Loosen the pinch nuts y (Photo 28),

rod components which

3. Tilt

the

4.

Remove

is

5. Disconnect all oil

6. Loosen

(Photo 27).

7. Loosen the four

8. Rinse the pump with gasoline

the

fact

and

the timing of the hook

ever

becomes

the

machine

oil

reservoir.

the

both

oil

screws

removed.

that

all

settings

necessarytoremove

pump,

it hos tobetaken

are

mounted on the

over

and

unscrew

reservoir

tubes

screws

and

and

from

remove

and

remove

rinse it

the oil pump.

and

for

the

canbedone

the

the

ond

take

all

position

out

two

the oil pump.

replace it.

feed

motion,

outsideofthe oil reservoir,

latter.

off,

off

bottom

screws

with

kerosenesothat

oil

reservoir

the

mechanical

If,

however,incase

proceedasfollows:

the

knee

lifter

of the oil reservoir.

all

the

way

top

cover

pitman

around

all

plates

9. Clean the gasket rim of the oil reservoir and replace the reservoir. Make

sure

that

the oil wicks

areinproper

position.

10. Insert all position screws and tighten them crosswise.

Note: As the machine is provided with a special

between

be

reservoir. An injured

taken

the

that

bed

plate

it is

and the oil reservoir, meticulous

not

injured

gasketiscompletely

when

type

gasket

positioned

care

removing or replacing

useless.

should

the

grit

oil

35

Page 38

33.

Probable

Causes

Skipping of Stitches

1. Incorrect

2.

Wrong

3.

Needle

4.

Needle

5.

Needle

6.

Needle

7.

Needleatincorrect height

8. Too

9.

Needle

threading

needle

bent

inserted

too

thin

too

thick

used

incorrectly

for

for

wideaclearance

bar

rise

insufficient

thread

thread

used

between

10. Processing adhesive or heavily

11.

Thread

twisted

too

much

used

of

needle

dressed

Sewing

and

pointofhook

materials

Troubles

(.004").

Thread

Breaking

1. For

anyofthe

2. Thread tensions

3. Knotty

thread

reasons

too

above

tight

4. Thread having turned resistant due to extensive and dry storage

5. Inferior quality

6. Thread jamming in the hook

7. Rough

edgesofneedie

thread

race

hole

8. Thread having slipped from the spool and snarled up around the spool

pin

9. Incorrect setting of thread check spring

10. Point of needle blunt due to bumping

Needle

Breakage

1. Needle bent and struck by point of hook

2.

3.

Thread

Timing

too

thick

for

of hook upset

needle

used

after

thread jamming

4. Needle thread tension too tight

5. Needle deflected by hard

spots

in material

6. Needle bent due to pushing or drawing the material

7. Feed motion in progress while needle stitches into material

8.

Hook

set

too

closetoneedle

9. Needle too thin for material processed

10.

Thread snarled up on spool pin

36

Page 39

Improper Feeding

1.

Feed

dog

positioned

Feed

dog

2.

3. Type of

tooth

feed

4. Insufficient amount of pressure

5. Lint

accumulated

6.

Points

of

teeth

pattern

dog

blunt

too

unfit for

between

low

too

fine for

material

teethoffeed

exerted

Overheating

1. Oil hole in hook

2. Oil regulating

3. Oil flow for

4. Excessive

5.

Full

weight of motor

having

become

choked

screw

q (Photo 21)

head

parts

pressureonarm

presses

loose

up causing

(stud o in Photo 20) insufficient

shaft

bearings

on V-belt due to motor position device

6. Improper oil used. (Viscous oil cannot

the

machine

Is cold)

material

processed

by presser

dog

overheating

too

tight

due

penetrate

processed

foot

of hook

to V-belt

being

the narrow conduits if

too

tense

Page 40

G.

SEWING

M.

PFAFF

MACHINE

AG,

KAISERSLAUTERN

FACTORY

V

Cerfificafe

For every PFAFF

TRADE

and

fhe

name

Sewing

Founded

of

Machine

1862

Guarantee

bearing this

MARK

the factory assumes

and durability.

The

Trade

All rights reserved.

No. 8843 engl. P 855

Mark and the name PFAFF are registered.

PFAFF

full

guarantee for first-class quality, efficiency,

Printed in

Germany

Loading...

Loading...