Page 1

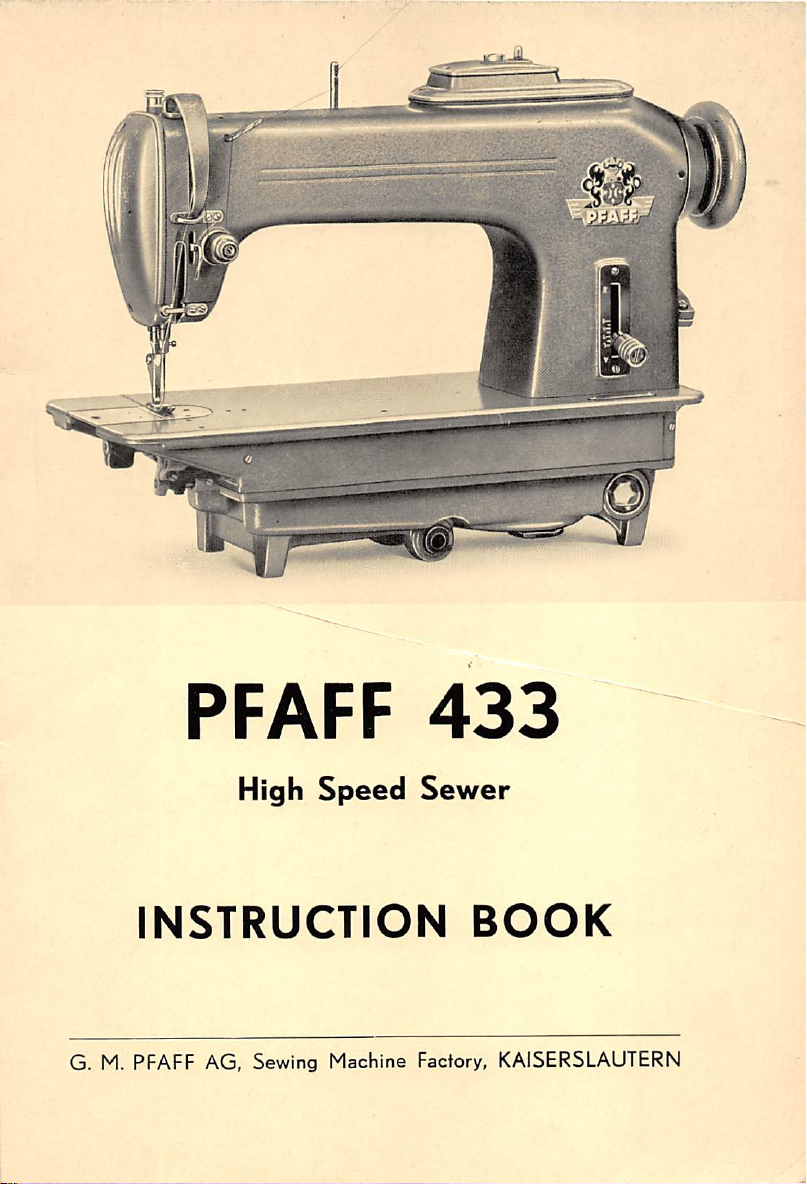

PFAFF

433

G. M.

High

Speed

INSTRUCTION

PFAFF

AG, Sewing Machine

Sewer

BOOK

Factory,

KAISERSLAUTERN

Page 2

r

Page 3

Insfruction

Book

PFAFF

Single-Needle Flaf-Bed Loclcstifch

with

Automatic

433

Lubrication

Sewer

Page 4

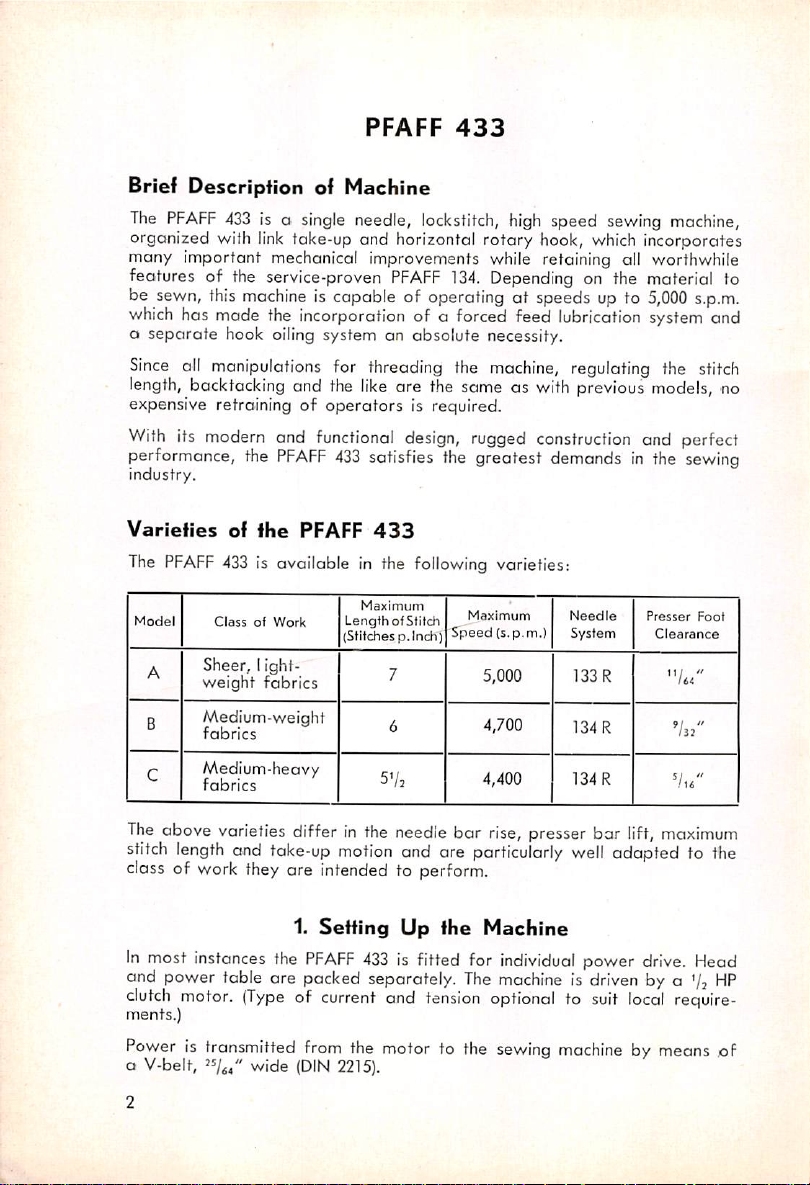

PFAFF

Brief

Description

The

PFAFF

433

organized with

many important mechanical improvements while retaining oil worthwhile

features of the service-proven

be sewn, this

which

has made the incorporation of a forced feed

o

separate

Since

all manipulations for threading the

length,

expensive retraining of operators is required.

With

its

machine

hook oiling system an absolute necessity.

backtacking and the

modern

performance, the

industry.

of

Machine

is o

single

needle,

link

take-up and horizontal rotary hook,

PFAFF

is capable of operating at speeds up to

like

and

functional

PFAFF

433

satisfies the greatest demandsinthe

433

lockstitch,

high

134.

Depending on the material to

machine,

are the same as

design,

rugged

speed

sewing

which

lubrication

regulating the

with

previous

construction

machine,

incorporates

5,000

s.p.m.

system and

stitch

models,

no

and perfect

sewing

Varieiies

The

PFAFF

Model

A

B

C

The

above varieties differinthe needle bar rise, presser bar lift,

stitch

of

the

433

is available in the following varieties:

ClassofWork

Sheer, ight-

weight

Medium-weight

fabrics

Medium-heavy

fabrics

length

and take-up

fabrics

PFAFF

Lengfhof

(Stitchesp.Inch)

motion

433

Maximum

7

6

5V.

Sfitch

Maximum

Speed

(s.p.m.)

5,000

4,700

4,400

Needle

System

and are particularly well adapted to the

class of work they are intended to perform.

1.

Setting

In

most

instances

the

PFAFF

and power table are packed separately.

clutch

motor.

ments.)

Power

a V-belt, wide

(Typeofcurrent

is transmitted

from

(DIN

2215).

Up

the

433

is fitted for

The

and

tension

the motor to the

Machine

individual

machineisdriven

optional

sewing

to suit

machine

133

134R

134

power

Presser

Clearance

R

R

drive.

by a '/i

local

by means of

Foot

^/u"

maximum

Head

HP

require

Page 5

For

50-cycle

currenta2,800

r.p.m. motor is appropriate for

The

motor

pulley

speed

of the machine.

The below

numberofstitches which

diameters.

Balance

Wheel

dm ^

3"

2^'/64"

2^-/64"

2^V64"

2^V^4"

dm=effective

3"

3"

3"

3"

3"

can be easily exchanged to alter the

table

should be consulted for all

DiameterofMotor

dm D Order No.

3

"/u"

4"/44"

4'V3:"

4^V.4"

4"/»"

diameter;

canbeobtained

50 Cycles

'

3

4'/.4'

4^8"

'

4"/84

'

4"/3=

S'/b"

r.p.m.

60-cycle

Pulley

99089

99090

99091

99092

99093

99094

D =

total

motor

shouldbeused,

current.

with

Stitches

per

Minute

3,800

4,000

4,2C0

4,400

4,700

5,000

diameter

whilea3,400

maximum

data

regarding the maximum

motor

pulleysofdifferent

60

Cycles

DiameterofMotor

dm D OrderNo.

3^/s2"

31-/3/'

3"/84"

3"/84"

3'V.6"

4"/m"

3-/32

3"/84

3^V84

3

4'/64'

4^/8-

-/,8

'

'

'

'

Pulley

99086

99087

99088

99089

99090

99091

sewing

Stitches

per

Minute

3,800

4,000

4,300

4,600

4,800

5,000

Unpack

After

the head

taking

cautiouslyinorder to

off

the

lidofthe

box,

avoid

unscrew

damage to the

the

wood

screws

machine.

which

hold

the cushioned wooden blocks that support the machine head in the box.

Cautiously

pads on the

on the

the

The

run

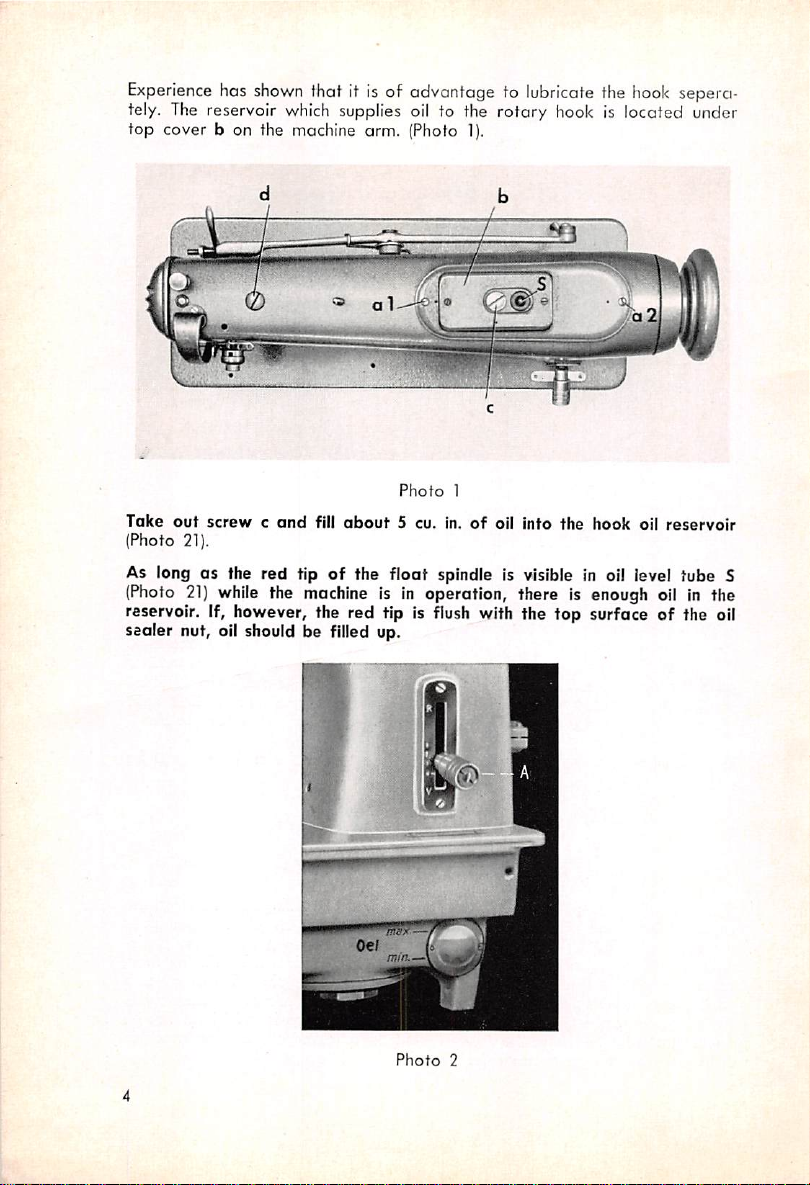

The amount of oil

machine in o can. The oil used in the

viscosityof110S/70»F

factory for the

reservoir take out screw d (Photo

wait

the

lift out the head,

machine

motor

pulley.

machine

whileinthis

table.Tofacilitate the

pulley,

Adjusting

is dispatched

condition.

2. Filling

which

lubricationofhigh

wipe

off the dust and

mounting

slightly

(US)or95R/70°F

tilt back the

the

V-belt

without

the

oilInthe reservoirs and must not be

machine

tensionisinstructedinSection

Oil

Reservoirs

is needed for the first two

PFAFF

(Br.)

speed

1),

which

sewing

fill

in about one pint

mount

of the

it on the rubber

V-belt,

and

pull

fillings

comes with the

slip

the belt onto

433 is a spindle oil with o

has

proved

machines.Tofill

(.5I)of oil obd

a few minutes until it has drained down into the reservoir. Then

oil

level

gauge to see if the

amountofoil

filled

up is

sufficient.

the belt

very

the

20.

satis

main

-check

The

level should be between the "max." and "min." marks when the machine

is inoperative.

Never

remove

the top cover to

fillupoil

there.

oil

Page 6

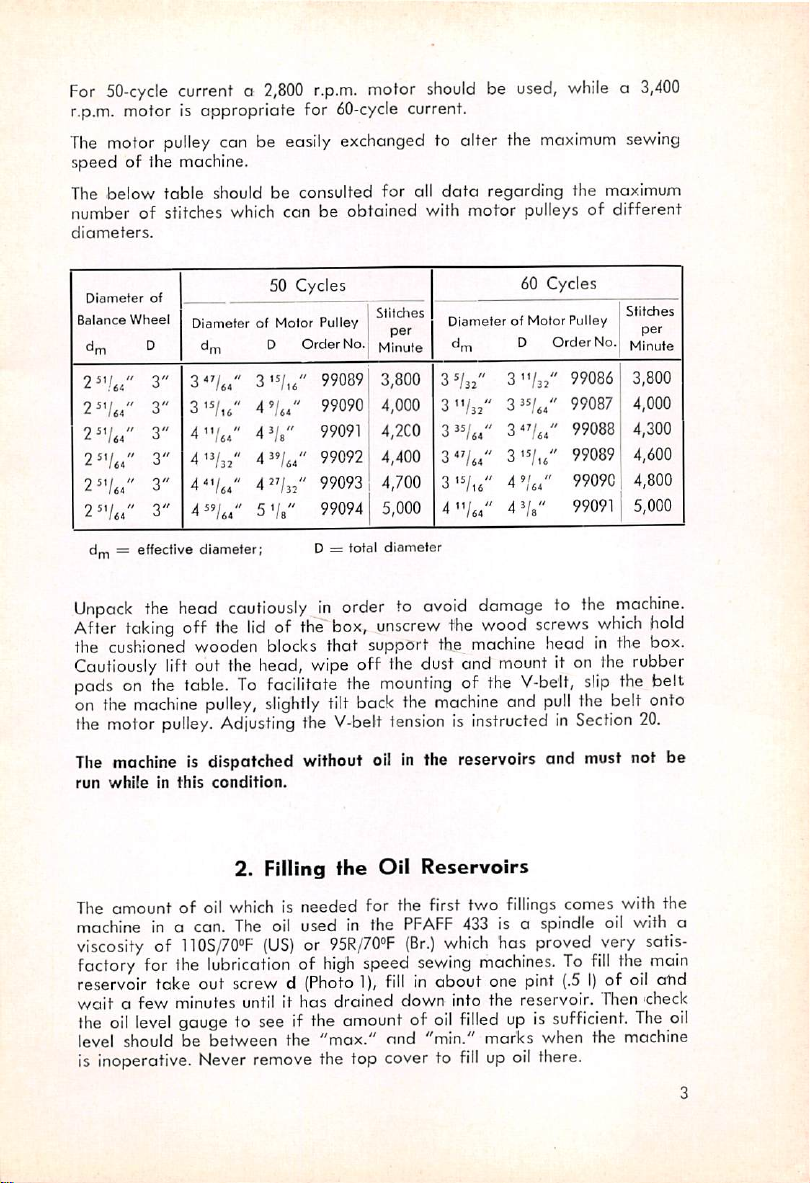

Experience

has

shown

fhof

It is of advantage to

lubricate

the

hook

sepero-

tely. The reservoir which supplies oil to the rotary hook is located under

top

cover b on the machine arm. (Photo 1).

Photo

1

Take

out

(Photo 21).

screwcend

fill

about

5 cu. In.ofoil Into

the

hook

oil

reservoir

As long as the red tipofthe float spindle is visible In oil level tube S

(Photo

21)

while

the

machineisIn

operation, there Is enough oil in the

reservoir. If, however, the red tip Is flush with the top surface of the oil

sealer nut, oil should be filled up.

mm—V

Photo

2

Page 7

3.

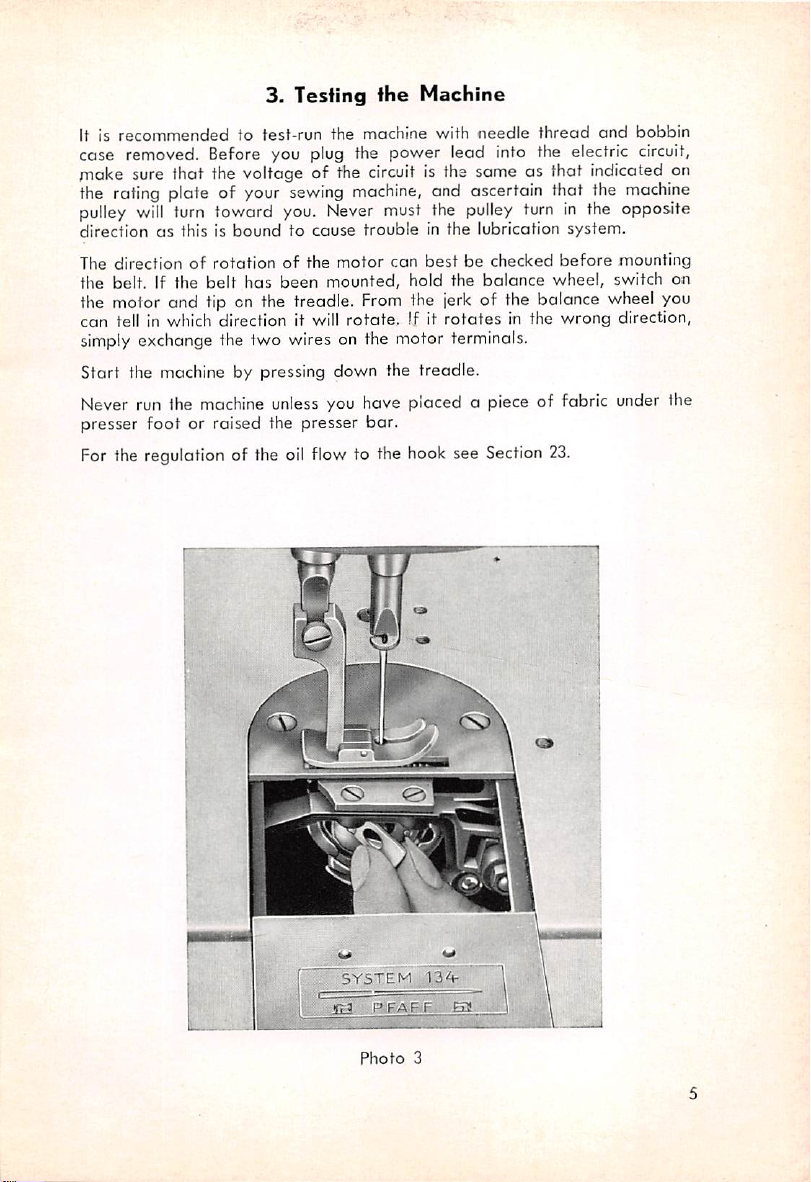

It is

recommended

to

Testing

test-run

the

the

machine

Machine

with

needle

thread

and

bobbin

case removed. Before you plug the power lead into the electric circuit,

niake sure that the voltage of the circuit is the same as that indicated on

the

rating

pulley

will

turn

directionasthis is

The direction of

the belt. If the

toward

rotationofthe

belt

the motor and tip on the treodle.

can

tell In which direction it will

simply

exchange the two wires on the motor terminals.

Start the machine by pressing down the treadle.

plate of your

Never run Ihe

presser

For

the regulation of the

machine

foot

or raised the presser

sewing

you.

boundtocause

has

Never

been

mounted,

unless

you have placed a piece of fabric

oil

flow

machine,

must

troubleinthe

motor

can

From

rotate.

bar.

to the

and ascertain that the

the

pulley

turninthe opposite

lubrication

best

be checked

hold the

balance

wheel,

system.

before

machine

mounting

switch on

the jerk of the balance wheel you

If it

rotates

hook

see

in the

Section

wrong

23.

direction,

under

the

SYSTEM

Photo

3

Page 8

4.

Taking

Raise fhe take-up lever to its highest position, lift the latch of the bobbin

Out

fhe

Bobbin

Case

case with thumb and forefinger of your left hand and pull the bobbin case

out of the machine as shown in photo 3.

As long as you hold the latch open, the bobbin cannot fall out.

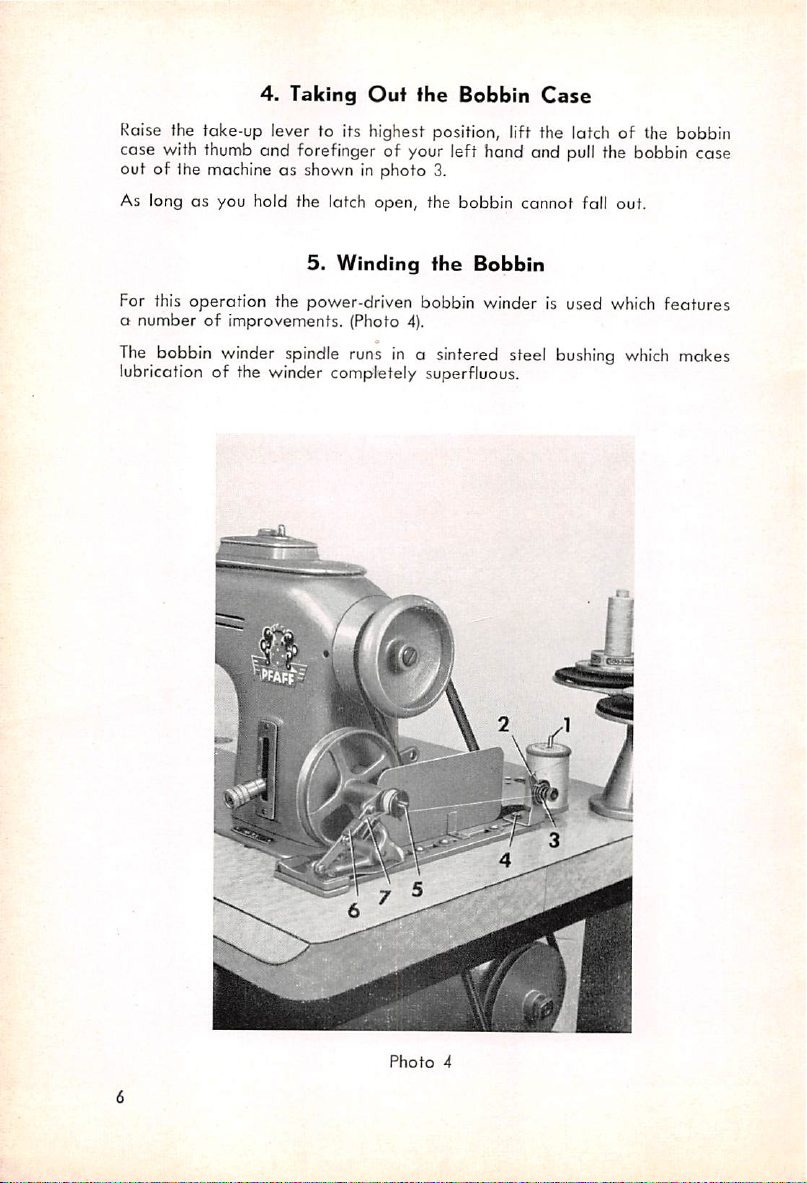

5.

Winding

For this operation the power-driven bobbin winder is used which features

a

numberofimprovements. (Photo 4).

The

bobbin winder

lubrication of the winder completely superfluous.

spindle

runs in a sintered steel

fhe

Bobbin

bushing

which

makes

Photo

4

Page 9

In

order

of the bobbin winder pulley

to reduce

somewhot

the high

has

speed

been Increased to

of the machine, the

diameter

The V-groove in the rim of the pulley has been designed with an obtuse-

angled profile so that the V-belt

even

o round

belt

may

be used.

will

fit into it perfectly and, if necessary,

The bobbin winder is quietly stopped by means of an adjustable leather

pad.

A windshield which is mounted on the winder

being dragged over

toward

the belt by air suction.

base

prevents the

thread

from

Fasten the bobbin winder to the table with Its driving pulley far enough

from

the

is

disengaged.

machine

beltsothat

it will

not

touch

the

belt

when

the

winder

Pass the thread from spool 1 through thread guide 2, clockwise around and

between tension discs 3, and to the bobbin.

Pull

the thread through the

slot in the bobbin, from the inside. Place the bobbin on spindle 5 and hold

the

endofthe

the winder by pressing down engaging lever 6.

thread

until

the

winder

has

madeafew

When

revoilutions.

sufficient thread has

Start

been wound on the bobbin, the winder will stop automatically. The amount

of

thread

to be

wound

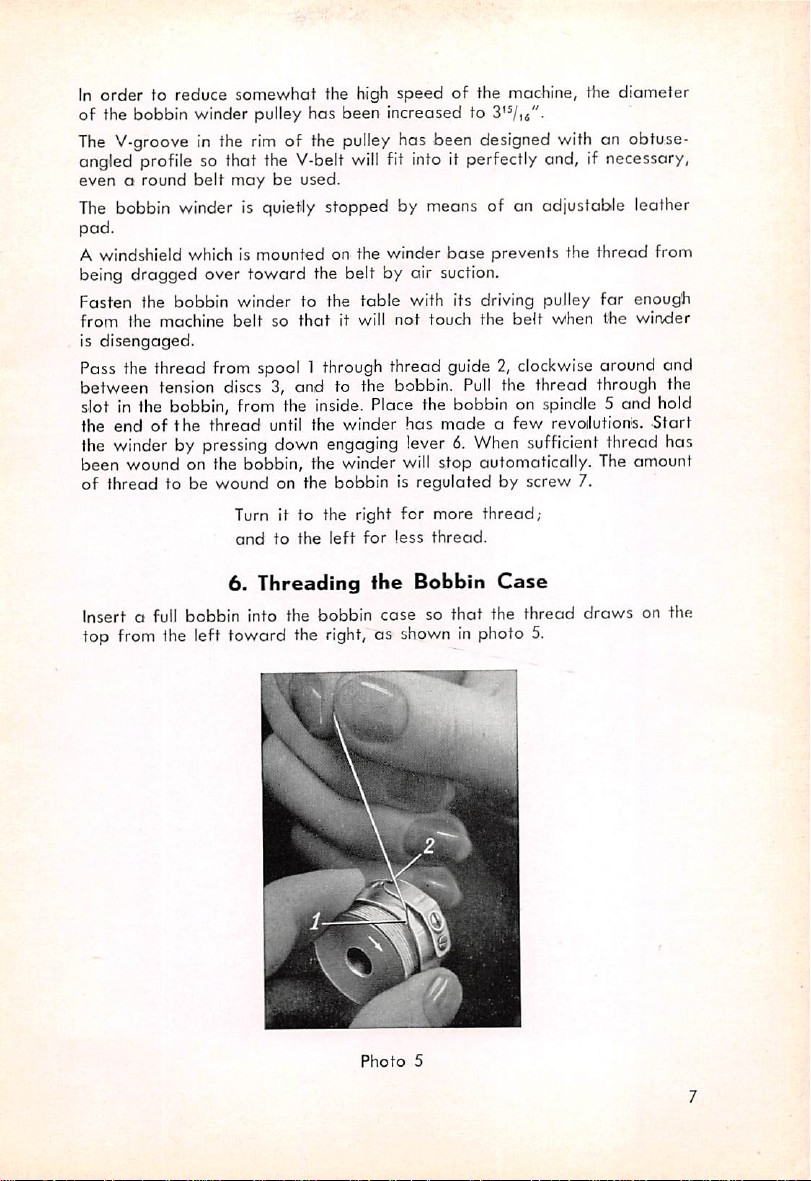

Insert a full bobbin into the bobbin

top from

1he

left toward the

on the

bobbinisregulatedbyscrew

Turn it to the right

endtothe

6.

Threading

left

right,

for

more

thread;

for

less

thread.

ihe

Bobbin

casesothat

Case

the

as shown in photo 5.

thread

7.

draws

on the

Photo

5

Page 10

Pull

the thread into slot 1 end draw it under the

eye2.Place

the

bobbin

case

with

the

bobbin

tension

on

the

spring into delivery

center

studinthe

bobbin case base and moke sure that the end of the latch points toward

you. Press the bobbin case all the wayinuntilitclicks

This

is very important as, otherwise, needle or bobbin case breakage may

result.

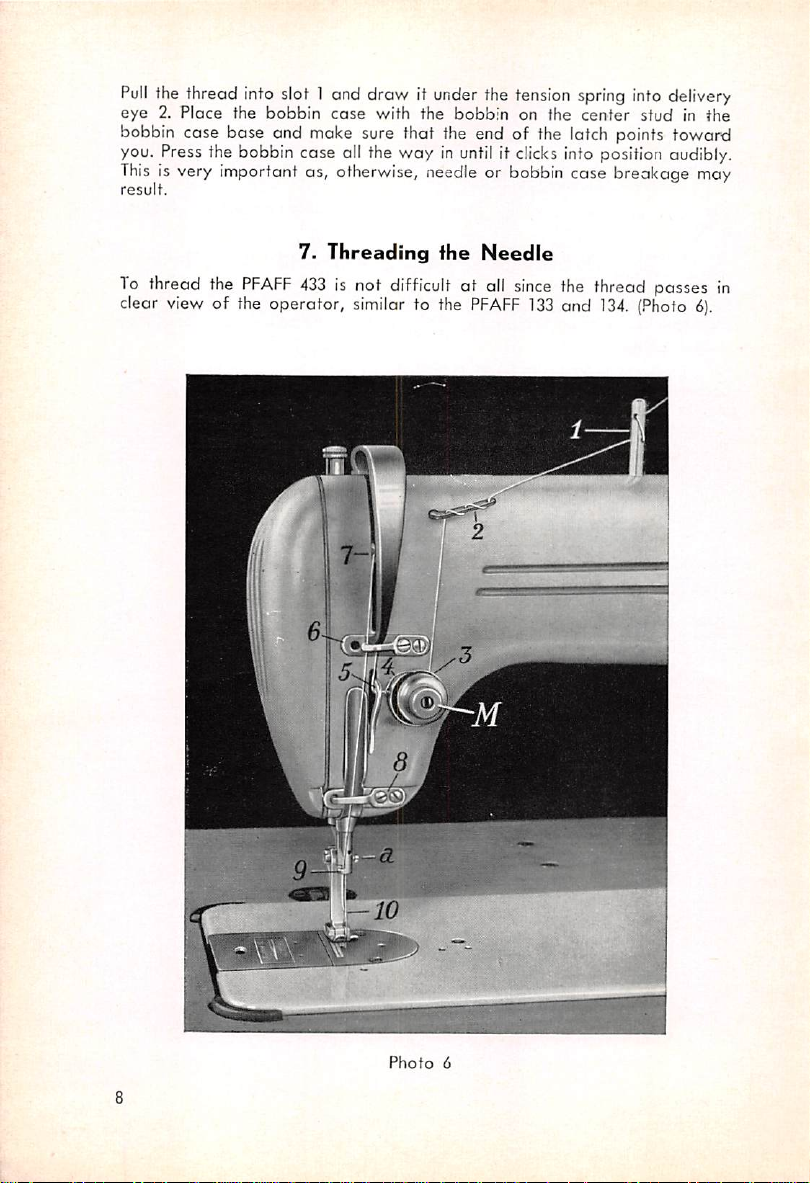

7.

To

thread the

clear

view

of the operator,

PFAFF

Threading

433

is not

similar

difficult

to the

the

Needle

at all

PFAFF

info

position audibly.

since

the thread passes in

133

and

134.

(Photo

6).

Photo

6

Page 11

Pass

the

thread

from the

thread

unwinder to

thread

guide pin 1

and

through

both holes in order to keep the thread from whippingathigh speed.Bythe

same token, pass it through all three holes in thread retainer 2 as shown

in photo 6, then between tension discs 3, through thread check spring 4,

under thread regulator 5, through guide 6, up and from right to left through

eyelet 7 in the take-up lever, down and through thread guides 8 and 9, and

from left to right through need'le eye 10.

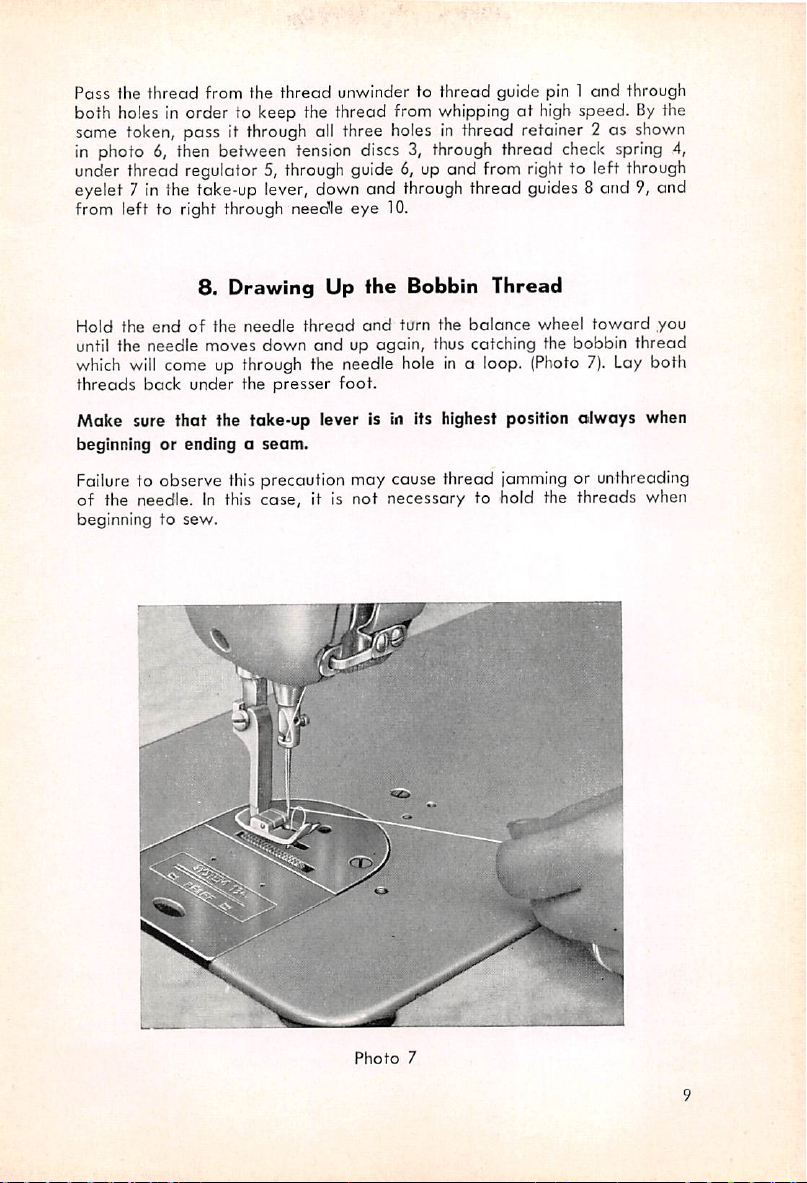

8.

Drawing

Up

fhe

Bobbin

Thread

Hold the

endofthe

needle

thread

and

turn the

balance

wheel

toward

you

until the needle moves down and up again, thus catching the bobbin thread

which

will

threads

come up through the needle holeina loop. (Photo 7). Lay both

back under the

presser

foot.

Moke sure that fhe take-up lever is in Its highest position olwoys when

beginningorendingaseam.

Failure to observe this precaution may cause thread

of the needle. In this

beginning to

sew.

case,

it is

not

necessary

jamming

to hold the

or unthreading

threads

when

4^

Photo

7

Page 12

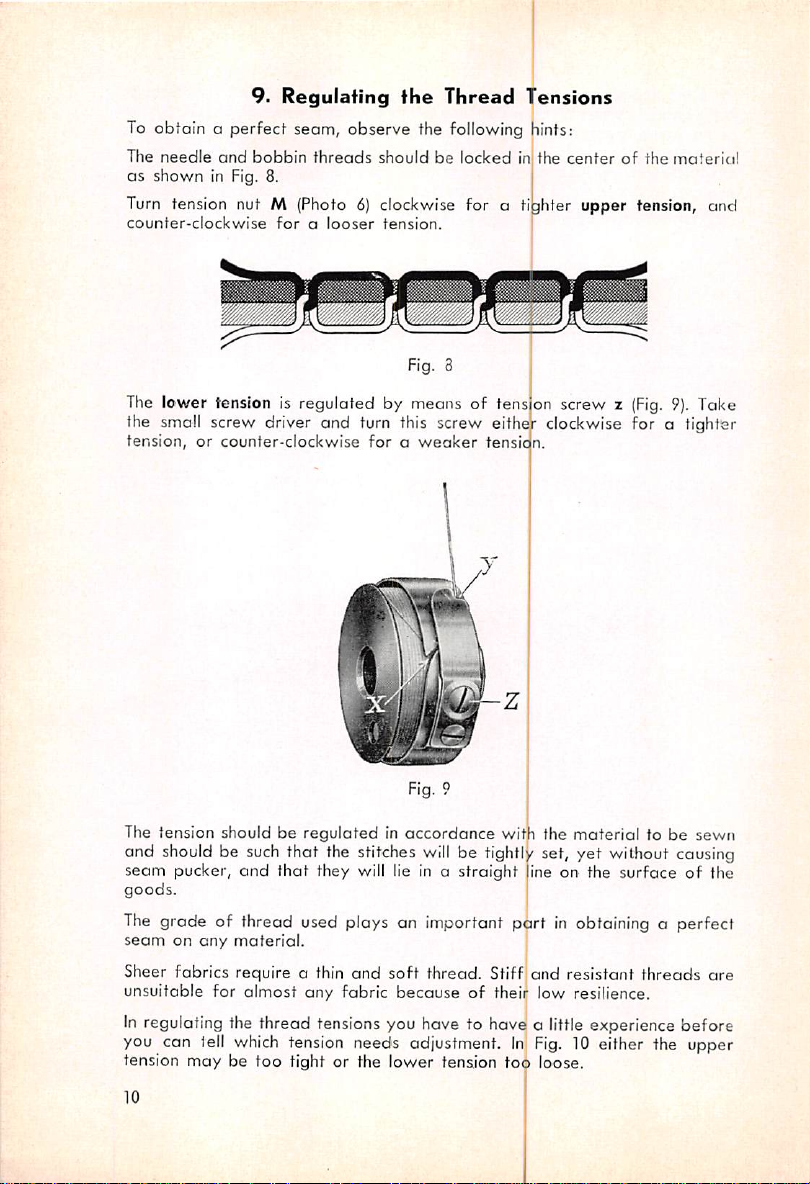

9. Regulating the Thread Tensions

To

obtain o perfect seam, observe the

The

needle

and

as

shown

bobbin

in Fig. 8.

Turn tension nut M (Photo6}clockwise for a

counter-clockwise

threads

foralooser

shouldbelockedinthe

tension.

following

hints:

tijhter

centerofthe

material

upper tension, and

The lower tension is

the

small

tension,orcounter-clockwise

The tension should be

screw

and should be such that the stitches

seam pucker,

goods.

The grade of thread used plays an important

seamonany

Sheer fabrics require a thin

unsuitable for

In

regulating the thread tensions you have to have a little experience before

you can lell

tension

material.

which

maybetoo

regulated

driver

and

turn

foraweaker

regulatedinaccordance

and

that

they will lie in a straight ine on the surface of the

and

almost

any

tension

fabric

neecis

tight or the lower tension

by means of tens

this

screw

will

be tightly set, yet without causing

soft

thread. Stiff and resistant

becauseoftheir low resilience.

adjustment.

on

eithe

tensia

screw

' clockwise for a

n.

with the

part

in obtaining a perfect

In

Fig. 10

too

loose.

material

either

z (Fig. 9).

to be

threads

the

Take

tighter

sewn

are

upper

10

Page 13

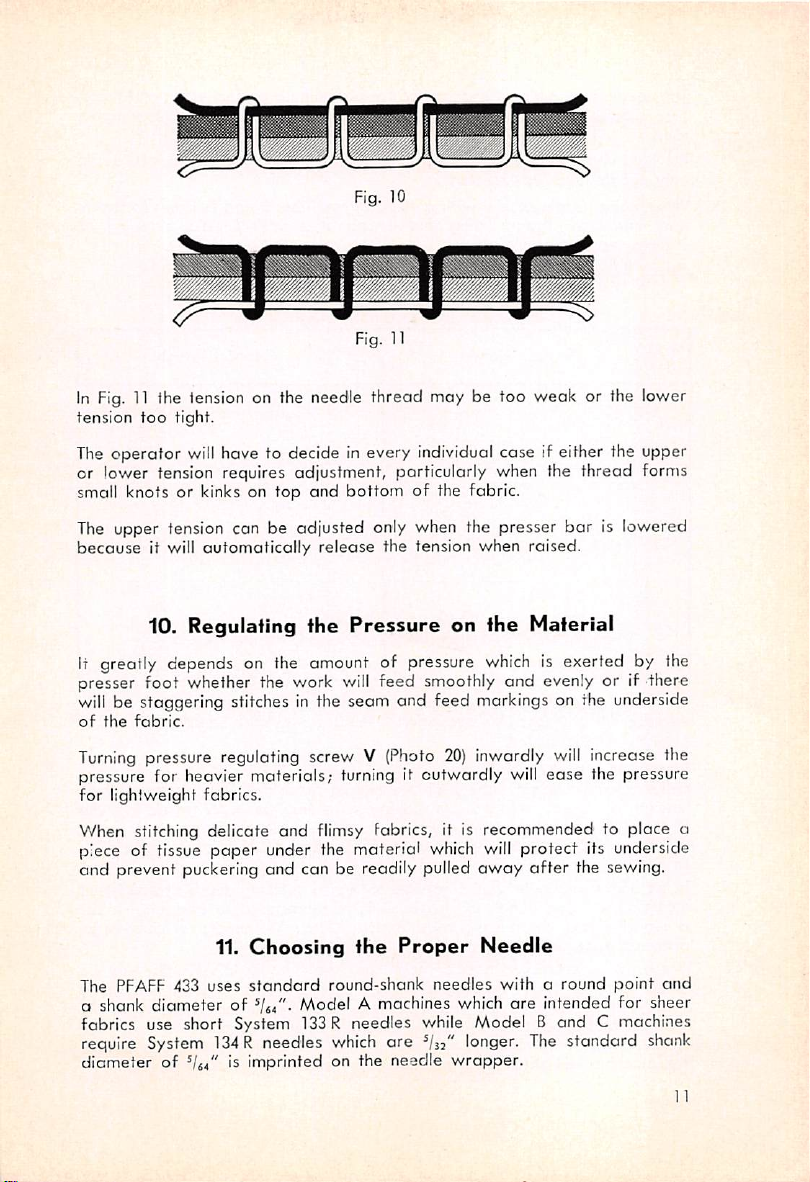

In

Fig.11Ihe

tension

too

tension

tight.

Fig. 10

Fig. 11

on the needle thread may be too weak or the lower

The operator

will

have to decide in every individual case if either the upper

or lower tension requires adjustment, porticularly when the thread fornts

small knots or kinks on top

The upper tension can be adjusted only when the presser

because

it will

automatically

10. Regulating

it greatly depends on the amount of pressure

presser foot whether the work

will

be staggering stitches in the seam and feed markings on ihe underside

of

the

fabric.

Turning

pressure for heavier materials;

for lightweight fabrics.

When stitching delicate and

piece of tissue paper under the material

and prevent puckering and can be readily pulled

The PFAFF 433

o

fabrics use short System 133 R needles while Model B and C machines

require

diameter

pressure regulating screw V

11.

uses

shank

diameter

System

of is imprinted on the needle

standard

of

134

R needles

and

release

the

flimsy

Choosing

round-shank

ModelAmachines

bottom

of the fabric.

bar

the tension

Pressure

will

feed smoothly and evenly or if there

(Photo

turning

it outwardly

when

raised.

on the Material

which

is exerted by the

20)

inwardly

will

will

ease the pressure

fabrics, it is recommended to place a

which

will

protect its underside

away

after

the sewing.

the

which

Proper

are

needles

which

longer.

wrapper.

Needle

witharound

are

intended

The

standard

is lowered

increase tlie

point

atid

for

sheer

shank

11

Page 14

The

needleisof

fore

should be

eminent

choseninproper

used.

For

lightweight

ugly

needle

When

using a thin

and,

conversely, when using thin

stitches

Select

may

the

fabrics, a

holes in the fabric.

needle

occurasa

correct

needle

importance

thin

needle

with a thick

result.

from

the

for

obtainingaperfect

relation

to the

thread

and

seam

fabric

and

j

shouldbeemjployedinorder to avoid

thread,

thread

chart

in a

below:

the

thread

is likelytobreak

thick needle, skipping

there

weights

of

Needle

Needle

Size

70

75

80

85

90

We

warn

wrapper

plus

the

Never use rusty

Cotton

Silk

Cotton

Silk

Cotton

Silk

you

should

needle

Thread

against

bear

system.

needles!

Weight

using needles of unknown

the inscription "Needles for

Only the exceptional quality of the needle

sewing

PFAFF

the thread.

to

and

prevent

thread

433, o needle with a rough surface will quickly

This

heat

and fuses easily. |

is particularly true of nylon thread which is highly sensitive

If the ordinary needle should get

100-80

100 (0)

80-60

80

(B)

60-40

70 (C)

and

Thread

Needle

Size

100

110

120

breaking.

Due

Ch

Cot'ton

Silk

Line n

Cotton

Silk

Linen

Col

Silk

Linen

finisl^

to

arf

Thread

ton

origin

Pfaff

will

Weight

even

Sewing

ensure trouble-free

get

too

hot when stitching dense and resistant

40-30

60 (D)

90-80

30

50(E)

80-50

30

40

60-40

if the

needle

Machines"

hot and scorch

materials or long panels of fabric, it is recommended to exchange it for

o superfinished, chromium-coated System 133 or

[134

needle which may be

procured from us. |

If even o superfinished needle should get too hot, the

fitted with a "Schmetz needle cooling device".

ideally suited to solve the problem since it requires no

machine

and

does

not disturb the

operator.

The

draft

PFAFF

This

efficient device is

attachments

of air which is

433 may be

to the

caused

by the needle motion is not noticeableatall. When fitted with this device,

the machine

will

stitch also resistant fabrics with appreciable speed.

12

Page 15

1. Raise the

2. Take the small

3.

Pull

out

needle

the

needle.

12.

Changing

bar

to its highest position.

screw

driver

and

fhe

loosen

Needle

needle

set

screw

I

a (Photo

•6).

Photo

12

13

Page 16

4.

InserfaSystem

and

push it upasfar

faces

to the right.

5. Tighten needle

The

PFAFF

which

canbeset

(Photo

2).

Once set, a special device will lock the, length of stitch so

133

Ror

134Rneedle

as it will

set

screw

a securely.

13.

Regulating

433 is fitted with a job-proven, spring-loaded stitch regulator

for the length of stitch

the

go.

into

the

Make

Length

desired

ojiening

sure

df

of the

the

needle

short

that

Stitch

,by turning thumb nut A

bar

groove

that

it cannot inadvertently be changed while sewing. 1|he numbers on the scale

indicate

up

Switching the machine to

by

the stitch length in millimeters. By pushing

as

farasit will

foot

control. When letting goofthe stitch

go,

the machine can be

reverse

stitching can be

the

set

tar

regulator

stitch

feeding

done

regulator

reverse.

either by

lever it will

lever

hand

auto

matically return to its initial position.Inorder to relieve the right leg which

or

/

Photo

13

14

Page 17

actuates

arranged

both

The

moniously

The presser

or by actuating the knee lifter with the right knee. The knee lifter

be

loosen screw b and

screw c (Photo 13). To permit the machine to be tilted back, pull out pin d,

which

(Photo 18),

The

tion rotary hook.

one is

The hubofthe

and ensures an absolutely vibrationless

the

knee

on the left. The foot-controlled reverse

hands

free to

PFAFF

connected

adjusted

can

end

PFAFF

433 is organized with the trade-tested

lifter, the

manipulate

433 is equipped with a knee lifter mechanism which is har

with the

foot

is lifted either by raising the presser

horizontallyaswell as vertically. For horizontal adjustmenf,

be easily

adjustatscrew O; for vertical adjustment, loosen

strip the knee lifter

The

that

the

PFAFF

hook

carriesanoil

treadle

the

work.

14.

The

headofthe machine.

reached

through an opening in the dress

15.

The

only difference between previous models and this

433 hook is provided with centrifugal lubrication.

for

actuating

Knee

Lifter

shaft

with the knee lifter lever.

Hook

feed

PFAFF

retainer

which is

running

of the hook.

the stitch

regulator

mechanism leaves

bar

lifter by hand

134double-revolu

meticulously

Emerging

pad

can

guard

balanced

from

o jet in the hook shaft bushing the oil is atomized by centrifugal force and,

through a second borehole, enters the hook race where it effects a depend

able

and

permanent

lubrication.

After removing the needle plate, the amount of oil, which is set for

ordinary sewing requirementsatthe factory, can be regulated as instructed

in Section 23. If this adjustment should become necessary, it should be

performed

only by a mechanic.

is

16.

The

All varieties of the

PFAFF

Bobbin

433

are

Case

fitted with a positive mechanical opener.

Opener

Since the advantages of this mechanism are not generally known, a few

explanations will be given here.

The interlocking of the needle and bobbin threads

which

is necessary to

form a lockstitch seam is accomplished in two different ways, depending

In

on the class of machine.

are

locked

thread loop

by passing the shuttle with the bobbin thread

which

is formed as the needle rises after

long or vibrating shuttle machines the threads

through

having

the needle

passed the

lowest point of its stroke. Another method consists in passing the needle

thread loop around the bobbin

position.

case

while the latter is in a stationary

16

Page 18

In machines with oscillaUng

shuttle mochines, the loop forming

the needle

a

centeroroff-center

With the double-revolution horizontal rotary hook, the type of loop

which is generally used in high

PFAFF

case at every other revolution of the

In

rotary

hoving

in

ordertomakeanopening

The

the

against

result,

passing between position finger and edge of slot and may break. The

only

The

in

most cases, has to be eased to an extent

setting of stitches impossible when the machine is operated at o reduced

speed.Toeliminate

are organized with a mechanical bobbin case opener whose finger,

is

carriedonthe

the bobbin case at the right time and contrary to the direction of rotation

of the

the

position

high

First of all, as the needle thread is not subjected to additional or fluctuant

strain,

speed. For this reason, the thread tensions may .be so set os to ensure

an even setting of stitches and prevent

speed and alsoinsheer

breaking has been greatly eliminated, it is possible to use threads of

low

will

sew

hook

All

of the above

case opener have lead to its incorporation not

in the heavy styles of the

Timing

as

instructed

thread

loop around the bobbin

433,

the

needle

hook machines which have no mechanical opener, the needle thread,

passed

friction

sewing

the

remedytothis

drawback of this remedy lies in the fact that the needle thread

around

between

speed.Bythe

the

position

needle

hook

thread

conditionisto

these

opener

sewing

speed

tensile

are

the

flimsy

not

of the

hook.Inthis

finger

sewers

upper

and the

are

tension

strength

even

fabrics at top speed

completely

advantages

mechanical

in

Section

loop

takers,

suchascentral

part,

in moving back and forth,

cose

position.

speed

thread

loop

the

bobbin

through

race

and

same

slot

token,

inc/"easasasthe

hastoovercomeastronger

disadvantages,

shaft,

case the

position

manifold.

need

not be

fabrics.

for

high

smooth

which are inherent in the mechanical bobbin

PFAFF

opener

29.

sewing machines

is passed

case,

arourid

hook.

hastoturnl

whichitcan

bobbin

case

the

pressureofthe

sewing

ease

the

threap

PFAFF

assumes

the

needle

thread can pass

slot.

The

advantages of

changed,

puckering

Secondly,

speed operations.

even

sincd

when

yet.

433.

should

be performed

bobbinorbeak

which is carried either In

passes

|

end

the stationary

'

the

bobbin

fiass.

trjcreasesinproportion

position

speed

goes

resistance

tension.

which

will

make the proper

higji

speed

sewing

functionofslightly

freely

this

regardless

of the material at

the danger of thread

the bearing surfaces of the

|

onlyinthe

|

Thirdly,

only

of the

light

by o

taker

also in tlie

bobbin

case

slightly

finger

up.Asa

when

tension,

machines

which

rotating

between

device

tsewing

the

machine

but also

mechanic

for

aniy

io

ci

To

facilitate the

dog,

strip

16

the

17. Tilting

removal

knee

lifter

the

of packed

and

tilt the machine

Machine

lint

between

bad

Back

sewing

hook

and feed

Page 19

To do this, reach through the hole in the middle of the dress

the table

and

pull out pin d (Photo

18).

Now pull the knee lifter with its

guard

under

shaft forward out of its bearings. This done, tilt the machine back and resi

it on the

light

Skilled

with the take-up lever in its highest position or to lay the threads

wooden

bracket.

machine

18.

rest

pin or on the

Dismantling

the

base

Hook

of the

operators who make it a routine olways to begin or

swung-away

Finishasean>

sew-

(boick

under the presser foot when commencing to sew will hardly ever encounter

thread

jamming in the hook race.

If thread should happen to jam in the hook race, try to get a hold of the

end of the thread tind to pull it out while turning the balance wheel back

and forth slightly. If this action fails to free the jammed thread, dismantle

the

hook

os

instructed

below:

Photo

14

17

Page 20

1. Tilt the machine bockasdescribed

2. Raise needle

still

be turned. If not, remove position

3. Loosen

the

parts,

be found since the

4. Pull

out

thumb

bar

and

take-up lever, provided the balance wheel con

set

screw c and pull

the correct position of the finger

shaftismarked

the

and

bobbin

forefinger.

case

with

off

the

opener

bobbin,

in Section l7.

finger

finger b. When reassembling

with a grc

5. Return the machine to its upright position o

and

feed

dog.

6. Take

sure

out

that

screws

youdonot

e,,

and

ej (Photo 15)

confuseitwith

and

thread

Bracket a first.

on

the

ove.

se

zing it by the latch witfi

nd

remove

shaft

{Photo

can

needle

remove hook gib d. Be

3ull-off

flange

f.

14).

easily

plate

7. Turn the

opposite

is

case

components

base

flange.

18

Photo

15

balance

base

wheel until the first

slot

i in the

can

be

taken

in the

same

bobbin

out

position.

of

screw

f, in

case.

When ih this position, the

the

hook.

Note

Photo

that

thread

tip 1ofthe

puil-off flange f

17

shows

bobbin

bobbin

the

hook

case

should be positioned between hook point g and tip f of the

Page 21

8. Seize Ihe bobbin cose

left

end

down,

and

9. Clean hook and bobbin

pointed wooden instrument, never with o screw driver.

10. It is recommended to screw on position finger bracket a before replac

ing

Ihe

sure that

bobbin

is a clearance of

the

bottom

11. Reploce hook gib d and tighten screws e,,Ojand

12.

Push

the opener finger onto its shaft. Take care that screw c

in the

lengthwise

case base.

position

of

slot

aboutVjof the projection on the

screw

c securely. (Photo 14).

base

take

finger

about

I.

with thumb

iit

outofthe machine.

case

base

When

inserting

h engagesinslot Iinits

between the tip of position finger h and

and

thoroughly

the

forefinger, pull it to the

and

remove lint with a

bobbin

case base, make

rim

and that there

e^.

ride:s

groove of the shaft and that the opener finger covers

rim

of the

bobbin

cose base.

Tighten

Photo

16

19.

Care

Since

the

PFAFF

433

any

maintenance

check the automatic lubrication system regularly and clean the machine

thoroughly.

be replenished.

It is

fluff which have accumulated between needle plate and feed dog and on

From

urgently

is provided with automatic lubrication there

be

required

timetotime

recommendedtomake

and

while

the

Maintenance

the

machineisin

oilinthe

it a

daily

hook

lubrication

routinetobrush

operation.

system

off

will

hardly

Merely

should

lint

and

19

Page 22

the hook when the machine is In

high percentage of dressing which has an abrasive effect on the sewing

mechanism, in time excessive

including

r"

the

bottom,

shouldbecleaned

permanent

wear

would develcp. The whole machine,

use. As the fluff contains a

withasotit

rag.

Oi

62

(?3

a

a

Photo

17

Great emphasis has been placed on making the oil rdservoirs in the

as leak-proof as possible.

knows that the capillary attraction of the oil cannot be completely over

come with machines which contain large quantises of oil—and sewing

machines are no exception. Capillary ottroction denotes the property of

thin-bodied oil to spread in every direction and seap even through the

tightest packings, covering the

oil

film.

The

greatly

of the

that a minor leakage may occur when the maihine has been idle for

several

important

result in insufficient lubrication once the temperature has dropped to nor

mal.

This

functional

contributedtoeliminating

oil.

But

even

days

or the

that

youdonot

temporary

preventedbywiping

outside of the machine and, particularly, the needle and presser

the

underside

There are many people who prefer, for sewing machines, a clear, colorless

oil in

ordertoavoid

should

particles as any other brand and that its

result

of optical refraction

yellow,

The

flow of oil to all lubricating points

mechanic.

of

the

like

to point out that yellowish oil is as pure and free of color

greenorblue.

But

everybody who is familiar with the problem

outer

surface of the machine with a thin

arrangementofvent

excess

rises

the

flowofoil

pressure

given

above

rag,

yellowish

should

so, for the

temperature

reasons

throttle

nuisance

head.

can best be remedied and

off,

withaclean

yellowish spots on the work. In this connection we

which

makes olso the cut edges of glass appear

I

PFAFF

holetonthe

l^nd

abdve,

normal. In this case it is

PFAFF

attendant

the

possibility

433

expansion

Idrasticallyasthis

soiling

the

|oil

film

color is

of the work

that

covers

nothing

bars

|

^be

regulated only by a

has

exists

might-

the

and

but the

433

20

Page 23

Insfrucfions

20.

The

for

V-Belt

Mechanics

Drive

When mounting the V-belf for the first time, remember

mounted

pulley.

The

motors

motor

or a nut, can be

the belt. (See PKA

It

avoid excessive pressure on the

heoting

belt

will

wear

more

various

which

motors

meet

which

German

bracketbymeansofa hinge

readily

motor

takes

some experience to

and

seizingofthe machine.

quickly. Hence,donot

are

used

DIN 42691

to

requirements.

stud

swung to

any

desired

picturedinphoto

set

the tension on the belt correctly so as to

top

shaft

drive

and,

18).

bearings

the

PFAFF

They

after

loosening a

position in

force

and

that

a crookedly

the

beltonthe

433

are

are

hingedonthe

order

attendant

standard

set

screv/

to tension

over-

Photo

18

The belt is correctly tenstoned if you con readily compress it

ofoninch

midway

between

the

pulleys.

cuboui

^'4

21

Page 24

Securely lighlen either the hinge siud nut or

so

thot

it will

not

get

loose while sewing. r

sat

sc'ew

k (on

PKA

motors)

If you foil to tighten this screw securely, the motor will be held only by

the

V-belt

in turn, will

The flow of oil to the sewing hook, the

parts

the machine

oil flow to specific

in to

balesoffabric, a

Sudden

o

temporary

Arm

Through a hole in this tube a jet of oil squirts up

reverberates

leadtooverhaating

con be regulated

leaves

do

the

job.

changes,

adjustment

end head parts are

and

and exert c

one-sided

21.

Regulafing

separately

the

factory.

operating

When

used

more

liberal supply of oil is reqi.

particularly

of

pressure on the tdp shaft bearings

and

andisset

If it should

requirements,

for

permanent

abrupt

the

oil

supplied

sprays

the

bevel

seizingofthe machine.

the

Flow of

top

shaft

Oil

bearings

for normal requirements when

rises, in

flow.

with

gears,

become

oilbymei^j

connect

necessarytoadapt

a me

rhanic

oper

ationinseaming

red

temp

erature

ns of line 1 (Photo 19).

against

ng

than

rods

and

has

tobecalled

for

may

the

and

which,

the heacl

the

whole

short

runs,

necessitate

top

cover,

eccentrics.

197

Photo

19

maintaining a

constant

filmofoil

between

all

parts

in moving

Of the two valves in line 1, one regulates the flow of oil to the

and

the

top

shaft

front

and

oil supply for the

22

top

shaft

center bearings wh"

rear

bearing.

e

the

other

contocf.

head

controls

parts

the

Page 25

When slots n and o (Photo 19) point lengthwise of the arm, the valves

open.

By turning them

or shut

valvenopen

both

top

off

shaft

22.

completely. It is

and

Regulating

thus to

bearings.

either

the

woy,

recommended,

ensure

proper

Flow of

the oil flow

lubricationofthe

Oil

canberegulatedasdesired

however,

to

the

normally to

head

Head

Parts

parts

are

leave

ond

As may be seen from

photo

20, the hollow top

shaft

end with regulating stud o which is held in position by

stud serves to regulate the

hollow

top

shaft

to the

amount

take-up

turning it clockwise. When the + symbol is

needle

Whei'i turning the

opposite

bar

crank,anunrestricted

stud

either

the red mark, the flow of oil is restricted accordingly. (Fig. 20a).

of oil which is pressure-fed from .the

crank.Toadjust,

loosen

opposite

oil flow

to the right

passes

or

to the fake-up crank.

left until the — symbol is

is closedatits one

set

screw p. This

set

screw

p by

the red mark on the

Photo

Fig.

20

20a

23

Page 26

There is no hard

OS

to ensure

amount

Hold a piece of

the machine

that

of oil, however, can be easily established by the following tes't:

cardboard

and

may be required to

which

should

be

the

To

ensure

adequate

heavy strain, an

wound

bushing,

Ground

wound

the

around

and

fosf rule for properly regulofing the flow of oil so

the

head

ports

will be

between the presser

run the machineattop

obtain

case

after

two

10

lubricationofthe

oil

wick

has been passed

needle

the

bar

needle

upper

adequately

thin lines of

speed.

seconds.

needle

bushing,

bar

and

secured

lubricated. The correct

bar

and

Turn regulating stud o

spray

bar

|/hichisconstantly

throudh

ta|<en

the rear wall

oil on the

the take-up

downtothe

by a clip. (Photo 20).

cardboard

under

link

stud,

lower

of

as

second

A

is

secured

fakeup

The

feed

This

the

and

delicate

Becauseofthe fine grit which mixes with the lubri

feed

it

does

for

For instructions about

Section

Oil is

tubes2and

which is

stops,

oil wick connects the

inside

the

link

rotary

lubrication

feature

sewing

clean

oilofexcellent

fabrics.

lubrication

not

the

lubrication

wheneveritbrushes

23.

hook

has

hookasthe

impair its lubricity in the

machine

Regulafing

of

the PFAFF 433 is oiled

systemofthe machine.

proved

system

of

the

filling

2. i

conducted

generatedinpumppand

the

to the

3. When the machine runs,

valveisclosedbyspring

take-up

head

past.

fhe

very

advantageous

most

sensitive

lubricity. This is

will

soon

assume

hook.

the hook

rotary

hook by

conveyed

link

withascrew

Hook

part

least,

action.

stud

Lubrication

indepedentlyofthe

becauseitpermitstosupply

in a sewing machine with

particularly

a dark

migh

oil

reservbir in the top cover see

means

valve

v is

through

(Photo

w

th a small oil

and

delivers

importantinhandling

:ant,

the

er

soil

of the

opened

22).

oil in

color

which,

the

thread

transparent

by oil

tube

1. As the machine

pad

which

oiltothe

forced

fresh,

the

forced

although

if

used

plastic

pressure

Tube 3

conducts

bearing

photo

ing the needle

for

24

less

which

23, this

oil.

the oil from

regulates

screw

canbereached

plate.

Turn the

the

valve

v to regulating

oil

flow

screw

to

the

withasmall

to the left for

sewing

screw

screw

more

q in the hook

hook.

As

driver

after

oil

and

to the right

shown

remov

shaft

in

Page 27

Phofo

Photo

21

22

25

Page 28

Tube 5

plies

which

oil

onlytothis

connects the oil pump with hook shdft front bearing G

bearing.

Photo

23

sup>

Having

retainer,

hole

The oil flow must be

correct

as

Placeapiece

ten

inch

ticles which

After

regulating screw q in case the oil marks should foil to appear.

The amount of oil which is to be fed to the sewing hook greatly depervds

on

Since

dressed materials require a lavishoil flow to the

tends not only to choke the oil conduits but also to

andto"blacken"

All this con be avoided by permitting the oil to flow more profusely. This

will

and,

26

passed

and

amount

follows:

seconds,

apart,

sewing

the

material

the

keep

instead,

regulating screw q, the oil drips

is flung

away

of

oil

by centrifugal

adapted

required

enters the annular groove in the hook.

of stiff paper over the

check

are perceptible on the paper. These lines are

are

flung

for

about

tobesewn.

particlesofthe

the

the dressing particles from absorbing enough oil to settle down

will

wash

whether

two

away

from the roce and Ihe front

fifteen minutes,

dressing

sewing

them

thread.

away

force,

to specific operating requirements. The

under

ordinary

needle

thin

linesofSfiray

repeat

mix

with

outofthe

drains

ope

plate

the

the

hook.

i

ito

the

down

rating

jopening

oil,

above

i)il

and

dewing

wear

|

grooveofthe

throughanoblique

conditionsisfound

and, after about

about of on

made

edge

check

thicken

hook.

the hook unduly

oil

by oil

and

it,

par

slacken

heavily

mixture

of the hook.

This

Page 29

The

operator

correctly

heavily

bath

towels)

will not encounter any difficulties in regulating the oil flow

when

dressed

materials

and

she

that

for sewing flimsy ond

all

undressed.

remembers

that

or for long runsathigh

the

normal

delicate

oil

flow,oreven

materials

more

which,

oil is

required

speed

a little

(bed

less,

withoutanexception,

for stitching

sheets

will

or

suffice

ore

For short runs

fhe oil

flow

and

speeds

to the hook

below

may

4,000 s.p.m. in the

be shut

off

completelyinfavorofmanual

garment

manufacture,

oiling.

If

the

hook

should

either

cannot

touch it with your

there

other

is an

On the

that

soilingofthe

hand,

excessive

material

if oil

may

blacken

hand,

spots

flowofoil

the

thread,

or

this is a sure indication of

appear

on the

passing

to the

result.

becomesohot

inadequate

bobbin

case

sewing

this

hook

that

you

oiling.

indicates

and

that

These signs greatly help in keeping the oil flow to the hook at the correct

level ond in

adapting

it to specific

24.

Changing

operating

the

requirements.

Oil

As with any other high speed sewing machine with automatic lubrication,

regular changing of the oil will do much to increase the service life

of

the

machine. Particularly during the break-in period, the oil should be changed

This

more frequently.

particularly while a new machine is being broken

Of

the oil

in

ordertocorrect

does

To comply with the

First change

Second change

Third change

and

is necessary in order to remove the grit which occurs

in.

not

affect

this

above

thereafter

its lubricity, it is not

condition.

necessarytochange

requirement, follow the schedule given below.-

after

one week's operation

after

four week's

after

three months' operation

every

three

months

As the overheating

operation

the pil

Of

course, this schedule applies only to the

The oil which is used up in the

replenishedatshorter

To

drain

the

oil

while the machine is idle.

in

the

reservoir.

from

intervals.

the

bed

Take

separate

oil

reservoir,

care

thatnoused

automatic

lubrication system.

hook lubrication system has to be

take

out

the

large

drain

oil, mud or

grit

screw

remains

The drained oil may be reused for other lubricating purposes after it has

been

filtered through several lays of linen.

New

oil is filled inasinstructedinSection

2.

27

Page 30

25.

Regulating

The check spring assists the take-up lever in takirig up the balance of the

needle

in setting the stitch to the desired tightness ond in controlling the slack of

the

the

thread

needle

thread

after

the loop has

thread

from the spool until the needle

from

the

passed

the time the

Check

around

descending

reaches

Spring

the bobbin,

t|ake-up

the

Action

and

lever has drawn

goods.

further

Photo

24

The check spring is checked in its downward motion by a stop on its bushing

which

canbeadjusted

insertoscrew

driver

Since thread regulator R (Photo

bracket,

passes

amount

material

not

Vertical

ing

turning the check spring bushing. For

coordinate

it moves up

over

irregularities in thickness. With this motion it regulates the

of

thread

and

havetotakeupexcess

screw

complements the action of the check spring so that it

adjustment

u (Photo 20). It

both

the correct balance of the thread but also

cularly.

28

as required. To do this, loosen

into

the

slotoftension

20)

and

down with the presser

which

varies

slack

of the

thread

has

adjustmentssothat

is mounted on the presser

with the inequalities in thickness

thread.

regulator is

the

same

the

effect

best

check

set

studtand

made

on

results, it is

spjring

draw

screw

turn

barasthe sewing

possible

the

thread

recommended

will

not

up the thread perpendi

s (Photo 24),

the

stud.

bar

of

after

loosen

control

only

take

lifting

foot

the

does

as

to

up

Page 31

Once

you

are

familiar with the functionsofboth

thread

right

The check spring is correctly

of

of

regulator,

away,

without

the

thread

travelofthe

you will be in a position to

first having to try

set

when

take-up

the

needle

lever is

if it

stitches

somewhat

out

has

into

completed

is normal, it may be necessary to allow the

of

play

at

the time the

thanisusualsothat

needle

reaches

26.

SelHng

fhe

it will

the

Needle

exert

goods.

BaratCorrect

the check spring

perform

different

proper

settings.

taking up the

the

material.

lorger

check

still a slight pull on

Since

with the PFAFF 433

spring a larger amount

Height

and

the

adjustmetit

balance

the

amount,

than

the

thread

To facilitate setting the needle

about

bar

be flush with the

of

this

form the loop. In

wide

has

been

has reached the lowest point of its stroke, the

bottom

mark

coincides

with

other

baratthe correct height, a small depression

milled into

edge

the

words,

the

of the lower needle

amountofneedle

when the

bar.

needle

(Photo

top

bar

rise which is

bar

25).

When

the

needle

of this mark should

bushing. The widtti

risen

required

about

has

to

^1^"

Photo

25

29

Page 32

from the lowest point of its stroke, the point of tf

site

the

center

line

of

the

needle

eye.

enter Ihe loop

This is the position in which the

needle

afterithas

been

and

about

.04''

point

sufficiently enlarc

5

hook

above

Df

ed.

the

shouldbeoppo-

the

top

hookisabout

of

the

to

To

correctly

special

set

gauge

the

which will be supplied by us upon re

Begin by lowering the

onto

the

bar

so

Slip the

screw

clamp

it on. (Photo 26).

slowly until the

in this position,

thatiftouches

onto

clamp

proceed

amountofneedle

needle

the needle

Now

contacts

bar

the

bar

remove

the

to its

bottom

immediately

the

needle

to time the sewing hook.

rise, it is r

lowest

surfac

gauge

an<t

bar

bust

Bcommended

quest.

position,

eofthe

beneath

turn

the

ing. With the

slip

lower

the

balance

to

use

the

bushing,

gauge

needle

the

gauge

and

wheel

bar

Photo

26

30

Page 33

27.

Timing

the

Sewing

Hook

Remove the

then

ceding

above

great

Use

clearonce

When

that

the hook

o

clearance

canbeeasily

The

clearance

and

the hook

solutely

1. Remove

2. Loosen

3. Slacken hook

4. Turn

5.

Pull

needle

turn the

section

hook

on the hook

(pointofhook

topofneedle eye).

care

in setting the

of

about

making

the

above

shaft

of

.012"-.016"

measured

of

.008"-.012"

shaft

necessaryinorder

28.

fhe

the

needle,

set

balance

hook

needle

screw c

set

off

plate

and

slacken

opposite

.004"

between

adjustment

front

bushing is

between

between

bushing

which

after

to ensure

Exchanging

plate

and

pull

screwsvand

wheel

until

its

shaft.

hook

set

shaft

hook

the

to the position

center

to the

both.

or

moved

its

pointofthe

will

exist

screwsvand

lineofneedle

needlesothot

inserting a

well enough

face

and

hook

between

described

new

hook,

forwardtoensure

the

hook.

and

the

setting the hook to the needle is

proper

fhe

and

position finger

off

mechanical

lubricationofthe

Sewing

Hook

bracket.

opener

b.

w. (Photo 21).

the

feed

dog

is in its

highest

w (Photo 21),

end

there

This

the

hubofthe

position.

6. With the feed dog in its highest position, push the new hook

hook

shaft

and

replace the position finger bracket.

7. Time fhe

securely.

8. Replace

Section

9. Screw on

hookasinstructedinSection27and

and

screw on the mechanical

18.

feed

dog

and

needle

plate.

opener

tighten

set

screwsvand

as instructed in par. 12,

in the

about

will be a

make

distance

needle.

hook.

onto

pre

.04"

sure

hook

ob-

the

w

29.

Timing

fhe

Bobbin

Case

Opener

Despite the fact that many mechanics find it rather difficult to lime

mechanical opener correctly, it is of

adjustment meticulously in order to ensure that the

the bobbin cose

There

are

two

opener

different

may

take

adjustments

full

effect.

required:

great

importance to perform this

advantages

afforded

th©

by

31

Page 34

1. The odjusfment of the mechanical

2. the timing of the mechanical

The oscilloting motion of the

nical

opener

To

adjust the motion of this

clamp

halved

The

point

shaftbymeansofa. link.

crank

on the

by the

of the

feed

center

opener

line. (Photo 27).

grooveinthe opener shaft.

opener

replacing the opener finger

should

link (Photo 14)

To

time,

the

the hook

i.e.atnortheast.

Since the

we

finger on the

shaftsothatnoadjustment

become necessary, loosen

and

turn the

set

the

opener

finger so

turn ttie opener shoft so that the

bobbin

recommendtopush

cose

and

pointisabout

motionofthe

begin to

one-eightofa revolution

opener

the

lifting

finger

This

after

opener

thot

bobbin

opener

feed

link,

shaft

set

groove

it will

open

finger is

opener

drive,

and

finger.

lifting

shaft

loosen

until the thrci

screw

marks

is tr

the bini

should

ansmitted

ing

wofits

«ngoge

thk

correct

to

the

screw

and

turn

jointisexactly

in the lengthwise

position

mecha-

the

of the

will be required when

hoving removed, the hook.IFadjustment

binding

screw Q on the bottom of the

shaftasmay

rotate

finger

the

clearance

very

case

over

be required.

obbin

the b

wil

gap

shortofits

slov

' ond

the

caseatthe

reach

the

for the

hardly

rightatthe

correct

projection

thread

top

position,

perceptible,

bottom

on

when

and

Photo

27

32

Page 35

to

place

a pieceofthin

paper

between

the finger

the bobbin case. When the finger begins to hold the

has

reached

the

position

where

it will begin to

rotate

and

the

paper

the

bobbin

projection

on

in position, it

case.

When timing the mechanical opener,

and

lower

further,

jawsofthe link will not be

that

the mechanical opener shaft will not be allowed any end play.

care

should be taken

moved

sideways

If existent, it should be corrected by adjusting either the

or the

set

collar, (Photo 14).

30.

1. Remove

2.

Take

slacken

the

presser

3. Loosen

screw

clip

and

Disassembling

face

cover,

presser

out

the

pressure

set

screw

bar

outofthe machine.

set

screw

D (Photo 20) in the needle

oil wick

regulating

B (Photo 30) in

C (Photo 30) in

and

pull the needle

foot

ihe

and

screw

presser

needle

bor

bar

Link

Take-Up

needle.

and

the

bar

bar

upper

presser

lifting

connecting

bushing,

out of its bearings.

that

on the

opener

bracket

remove

bar

stud

the

shaft,

link

and

and

oil wick

upper

and

jaw

spring,

pull

set

Photo

28

33

Page 36

he

4. Toke out screw E (Photo

5. Turn

the

balance

wheel

28)atthe back

until

the

set

screw

of

for*

machine,

the

take-up

crank, whicli

is positioned in the needle bar crank, can be reached through hole G.

(Photo 28).

6. Loosen the

7.

Loosen

8. Unscrew the

stud

9. Ploce the

Vifi"x28

hinge stud of the take-up

stud.

10.

Carefully

the

needle

Do

not

are

apply

precision-engineered

parts as this would dislocate the press-fitted bedring rings.

Honed needle bearings

and

the

To

loosen

take-up

crank

set

screw.

the set screw for the take-up

top

cover ond pull the packing

of the

take-up

bar

screw

pull

bar

force when removing the take-up c

top

end of the needle

end

screw

link.

(Photo 29)

through its hole

out

the

connecting link, all in

L, turn it to the right. (Phot

across

link

take-up

and

meticulously fitted

are

provided in the

bar

and, in this manner,

lever

connecting

ond

the

with

link

head

screw

one.

stijd.

it

its

rear

linl<

outofthe

sf

the

into

the

ijik,

the

ssembly

and

endofthe

0 29).

machine,

hollow,

pull

out the

take-up

because

do

not

takeuplever

hollow

tap

hinge

insert

threaded

ihinge

crank

all

on the

o

and

parts

Photo

29

34

Page 37

When stripping the link take-up

noneofthe tiny

To

facilitate

that

the

tweezerstoinsert

bearing

insertionofthe

needles

will be held in

the

needles

needles

and

gets

needles,

position

into the

needle

lost. Each

the

bearings

by the

bearings.

bar

bearing

assembly,

contains 18

are

grease.

take

care

needles.

grease-packed

Use a poir of

that

so

Reverse the

toke-up

to

take

end

a thin

above

needle

wire

procedure

bar

assembly

whose

one

and

use

in the

endisbent

proper

head

caution

of the machine. It is

into a hook to

when

lace

replacing

advisable

the

packing

the

through the hollow hinge stud of the toke-up link. When fastening this

packing

it clears the

accumulote

soil

to the needle

the

work.

presser

bar

on the spring

bar

top

bushing (Photos 20

spring

as,

would

seep

otherwise, the

through the

and

30),

excess

presser

moke

sure

that

oil which would

bar

bearing

and

Photo

30

35

Page 38

31. Adjusting

•pFAFF

433 A

the same length when sewing forward or backward.

andBmachines

and

the

Stitch Length

Reverse

canbeso

Sewing

sefasfo:

lor

Forward

make

stitchesofexactly

This

means that the

needle will stitch through the same hole twice, otice when sewing forward

and again when sewing reverse

With

ModelCmachines,

OS

the stitch length for

forward

about

stitchofabout

long.

forward

whichismuch

the

reverse

sewing increases,

the

desired for backtacking.

stitch

becor^es

correspondi

proportionally

When

set

ig

reverse

foramaximum

shorter

stitch will be

To

adjust

the stitch length for both

forward

and

backward

sewing,

loosen

binding screw N, which is visible in the stitch regiilotor slot (Photo 31), and

turn

the

clamp

crank

on the

stitch

Hold lever A (Photo 31) in its

stitch

it

downward.

regulator

spindle. To

position

increase

regulator

the length

and

spindle.

by turning lever O on the

adjust

f

the

forward

stitch,

turn

Photo

31

36

Page 39

Having

tighten

cdiusted

screw

the

forward

N securely.

in relation to the

backward

stitch length,

The longer the maximum

corresponding

As all

settings

canbeperformed

hook

no

need

hastobe

stitch length for

32.

Dismantling

of the feeding mechanism, the mechanical

to strip the oil reservoir. If the oil

removed,

forward

reverse

Oil

on the

proceedasfollows:

1. Drain the oil completely.

2. Unscrew pinch nuts y (Photo 28)

on

the

bottom

3.

Tilt

the

machine

trough,

loosened.

4. Remove the

all

gritisremoved.

5.

Disconnect

6. Take

out

7. Unscrew the four

8. Rinse the

9. Clean the

end

mount

positioned.

10. Insert all position screws

except

all oil

both

pump

packing

it on

of

the

back

for

bottom

tubes

screws

set

with gasoline

the

oil

and

two

trough

from

No. 855

screws

surfaces

machine.

reservoir.

take

screws

and

stitch is

set,

the

sewing.

Reservoir

and

outsideofthe machine,

pump

should

and

strip the

out

all

screwsinthe

at

the

and

rinse it tharoughly with

the

pump.

and

strip the

and

dismantle

and

replace

along

the rim

Make

sure

knee

corners

cover

the oil pump.

it.

of

the

packings

tighten them crosswise.

shorter

Oil

will

Pump

opener

thereisnormally

cause

trouble

lifter mechani&m

oil

reservoir

which

need

kerosene

plates.

the

(Photo 27).

bottom

are

be

the

and

ithe

and

bottom

only be

.until

trough

correctly

As the machine is provided with a speciol type

gasket

which is located

between the bed plate and the oil reservoir, be cautious that this

will

notbedamaged

damaged

gasket

when removing or replacing the

is completely useless.

bottom

trough. A

gasket

37

Page 40

Skippingofstitches

1. Incorrect

2.

Wrong

3.

Needle

4.

Needle

5.

Needle

6.

Needle

7.

Needleatincorrect height

8.

Too

9.

Needle

10. Processing

11.

Thread

threading

needle

used

inserted

too

thin

too

thick

bent

wide o clearance between

rise

insufficient

adhesive

twisted

33.

incorrectly

for

thread

for

thread

or heavily

too

much

Trouble

used

used

Shooting

needle

dressed

and

pjointofhook

mate

iais

(.004'

Thread

Breaking

1. For

anyofthe

2.

Thread

3. Knotty

4.

Thread

5. Inferior

6.

Thread

7. Rough

tensions

thread

has

jamming in the

edgesofneedle

become

quality

above

too

thread

reasons

tight

unserviceable

hook

hole

8. Thread has slipped from spool

race

because

and

snarled u^

9. Incorrect setting of check spring

10. Point of needle blunt as a result of hitting th

Needle

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Breakage

Needle

Thread

Timing

Needle

Needle

Needle

Machine

Hook

Needle

Thread

bent

and

struckbypointofhook

too

thick

for

needle

of hook disturbed after thread

thread

deflectedbyhard

bent

set

too

snarled

tension

because

feeds

while

too

closetoneedle

thin

up on

for

material

used

jamming

too

tight

spotsinmaterial

materialispushedorbulled

needleisdowninmaterial

sewn

spool

pin

of

extensive

e

around

hook,

and

dry

spool pin

etc.

storage

38

Page 41

Improper Feeding

1.

Feed

dog

set

too

low

2. Tooth

patternonfeed

dog

too

fine for material sewn

3. Type of feed dog unfit for work to be performed

4. Insufficient

5.

Lint

amountofpressure

exertedbypressar

accumulated between teeth of feed dog

foot

6. Blunt feed points

Overhecriing

1. Oil hole in hook choked up causing overheating of hook

2. Oil regulating screw q (Photo 21)

3. Oil flow for

head

parts

(stud o in Photo 20) insufficient

too

tight

4. V-belt too tense, causes excessive pressure on arm shaft bearings

5.

Full

weight of motor presses on V-belt because belt take-up hanger

has

become

6. Improper oil used. (Viscous oil cannot

when

loose

the machine is cold).

penetrate

the

narrow

conduits

39

Page 42

Inde

Section

Brief Descriptionofthe Machine . .

Varieties

1. Setting Up the Machine

2. Filling

3. Testing Ihe Machine

4. Taking Out the Bobbin

5.

6. Threading the Bobbin

7.

8.

9. Regulating the

10. Regulating the Pressure on the Maleriol

11. Choosing the

12. Changing the

13. Regulating ihe Length of Stitch . . .

14.

15.

16. The Bobbin

17. Tilting Ihe Machine Back

18. Dismantling the Hook

19.

20.

21.

22. Regulating the Flow of Oil to the

23.

24.

25. Regulating ihe Check Spring Action

26. Setting the Needle BaratCorrect Height .

27. Timnig the

28. Exchanging

29. Timing the Bobbin

30.

31. Adjusting the Stitch Length for

32. Dismantling Oil Reservoir

33.

of

the

the

Oil

Winding

Threading

Drawing

The

The

Care

The

the Bobbin

the

Up the Bobbin

Knee

Litter

Hook

and

Maintenance

V-Belt

Regulating