Page 1

3371-1/..

Instruction Manual

This instruction manual applies to machines from software

version 0335/013 and serial number 60 801 005 onwards

296-12-18 631/002

Betriebsanleitung engl. 08.06

Page 2

This Instruction Manual is valid for all models and subclasses listed in the

chapter " Specifications ".

The adjustment manual for the machines can be downloaded free of charge

from the internet address

www.pfaff-industrial.de/pfaff/de/service/downloads

As an alternative to the internet download the adjustment manual can also be

ordered in book form under part no. 296-12-18 632/002.

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 6

1.01 Directives .............................................................................................................................. 6

1.02 General notes on safety ......................................................................................................... 6

1.03 Safety symbols ......................................................................................................................7

1.04 Important points for the user ................................................................................................. 7

1.05 Operating and specialist personnel ........................................................................................ 8

1.05.01 Operating personnel .............................................................................................................. 8

1.05.02 Specialist personnel ...............................................................................................................8

1.06 Danger ................................................................................................................................... 9

2 Proper use .......................................................................................................................... 10

3 Specifi cations ..................................................................................................................... 11

3.01 General specifi cations .......................................................................................................... 11

3.02 Versions and subclasses ...................................................................................................... 12

4 Disposal of Machine .......................................................................................................... 13

5 Transportation, packing and storage ................................................................................ 14

5.01 Transportation to customer‘s premises ............................................................................... 14

5.02 Transportation inside the customer‘s premises ................................................................... 14

5.03 Disposal of packing materials ..............................................................................................14

5.04 Storage ................................................................................................................................ 14

6 Explanation of symbols ..................................................................................................... 15

7 Controls .............................................................................................................................. 16

7.01 On/off switch ....................................................................................................................... 16

7.02 Key on the machine head ..................................................................................................... 16

7.03 Pedal .................................................................................................................................... 17

7.04 Lever for lifting the presser foot ........................................................................................... 17

7.05 Knee lever ............................................................................................................................ 18

7.06 Reverse feed key ................................................................................................................. 18

7.07 Stitch length adjustment wheel ........................................................................................... 19

7.08 Adjustment key for limiting the reverse stitch length .......................................................... 19

7.09 Thread wiper switch (only on machines with thread wiper -909/93) ...................................20

7.10 Control panel ........................................................................................................................ 20

7.10.01 Screen displays .................................................................................................................... 21

7.10.02 Display symbols ...................................................................................................................21

7.10.03 Function keys ....................................................................................................................... 21

8 Installation and commissioning ....................................................................................... 24

8.01 Installation ............................................................................................................................24

Page 4

Index

Contents ..................................................................................Page

8.01.01 Adjusting the table height .................................................................................................... 24

8.01.02 Assembling the oil pan ........................................................................................................ 25

8.01.03 Mounting the sewing head .................................................................................................. 26

8.01.04 Mounting the spool holder .................................................................................................. 26

8.01.05 Connecting the plug-in connections and earth cables ......................................................... 27

8.02 Commissioning .................................................................................................................... 28

8.03 Switching the machine on/off .............................................................................................. 28

8.04 Basic position of the machine drive unit ............................................................................. 29

8.05 Checking the function of the start inhibitor ..........................................................................30

9 Preparation ........................................................................................................................ 31

9.01 Inserting the needle ............................................................................................................. 31

9.02 Winding the bobbin thread / adjusting the preliminary thread tension ................................32

9.03 Removing / Inserting the bobbin case ................................................................................. 33

9.04 Threading the bobbin case / adjusting the bobbin thread tension ....................................... 33

9.05 Threading the needle thread / Adjusting the needle thread tension .................................... 34

9.06 Setting the stitch length ....................................................................................................... 35

9.07 Adjusting the width of the zigzag stitch ............................................................................... 36

9.08 Adjusting the stitch position ............................................................................................... 37

9.09 Changing the stitch position reference point .......................................................................38

9.10 Entering the start and end backtacks ...................................................................................39

9.11 Inserting and removing the SD-memory card ...................................................................... 40

10 Sewing ................................................................................................................................ 41

10.01 Manual sewing .................................................................................................................... 41

10.02 Standard patterns ................................................................................................................. 42

10.02.01 Straight stitch ....................................................................................................................... 42

10.02.02 Zigzag stitches ..................................................................................................................... 43

10.02.03 Shell stitches ........................................................................................................................ 43

10.02.04 Blind stitches ....................................................................................................................... 44

10.03 Sewing programmed seam patterns ................................................................................... 45

10.03.01 Altering/creating seam patterns ........................................................................................... 46

10.04 Mirror imaging shell stitches and programmed seam patterns ........................................... 47

10.05 Program Management .........................................................................................................48

10.05.01 Calling up the program management .................................................................................. 48

10.05.02 Display of the data in the machine memory ........................................................................ 49

10.05.03 Display of the data on the SD-memory card ........................................................................ 50

10.05.04 Copying data onto the SD-memory card ............................................................................. 51

10.05.05 Copying data into the machine memory .............................................................................. 52

10.05.06 Deleting data in the machine memory ................................................................................. 53

10.05.07 Deleting data from the SD-memory card ............................................................................. 54

10.05.08 Formatting the SD-memory card ......................................................................................... 55

10.06 Error messages .................................................................................................................... 56

10.07 Explanation of the error messages ...................................................................................... 57

Page 5

Contents

Contents .................................................................................... Chapter - Page

11.07 List of parameters ................................................................................................................ 54

11.08 Error messages on the display .............................................................................................61

11.09 Sewing motor errors ............................................................................................................ 63

11.10 OTE-errors ............................................................................................................................63

12 Care and maintenance ....................................................................................................... 64

12.01 Maintenance intervals ..........................................................................................................64

12.02 Cleaning the machine ..........................................................................................................64

12.03 Cleaning the hook compartment .........................................................................................65

12.04 Oiling the needle head parts ................................................................................................ 65

12.05 Oiling the hook .....................................................................................................................66

12.06 Oiling the bearing points in the arm ..................................................................................... 67

12.07 Oil disposal ..........................................................................................................................67

13 Circuit diagrams ................................................................................................................. 68

14 Wearing parts ..................................................................................................................... 73

Page 6

Safety

1 Safety

1.01 Directives

1.02 General notes on safety

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations.

In addition to this Instruction Manual, also observe all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations are to be strictly adhered to!

This machine may only be operated by adequately trained operators and only after having

●

completely read and understood the Instruction Manual!

All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read be-

●

fore operating the machine!

The danger and safety instructions on the machine itself are to be followed!

●

This machine may only be used for the purpose for which it is intended and may not be

●

operated without its safety devices. All safety regulations relevant to its operation are to

be adhered to.

When exchanging sewing tools (e.g. needle, needle plate and bobbin), when threading

●

the machine, when leaving the machine unattended and during maintenance work, the

machine is to be separated from the power supply by switching off the On/Off switch or

by removing the plug from the mains!

Everyday maintenance work is only to be carried out by appropriately trained personnel!

●

Repairs and special maintenance work may only be carried out by qualified service staff

●

or appropriately trained personnel!

Work on electrical equipment may only be carried out by appropriately trained personnel!

●

Work is not permitted on parts and equipment which are connected to the power supply!

●

The only exceptions to this rule are found in the regulations EN 50110.

Modifications and alterations to the machine may only be carried out under observance

●

of all the relevant safety regulations!

Only spare parts which have been approved by us are to be used for repairs! We express-

●

ly point out that any replacement parts or accessories which are not supplied by us have

not been tested and approved by us. The installation and/or use of any such products can

lead to negative changes in the structural characteristics of the machine. We are not liable

for any damage which may be caused by non-original parts.

6

Page 7

Safety

I

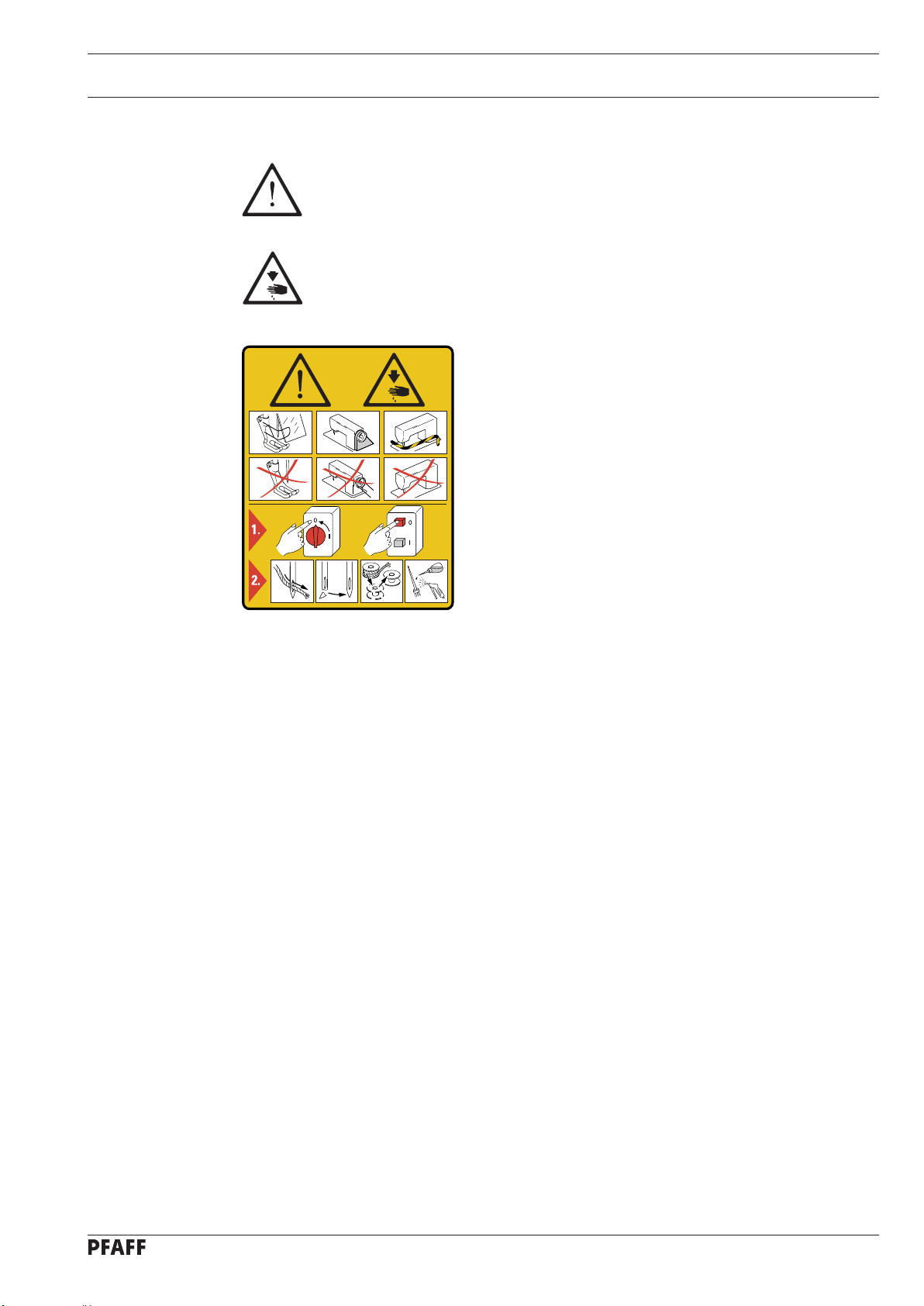

1.03 Safety symbols

Danger!

Points to be observed..

Danger of injury for operating and specialist personnel!

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

1.04 Important points for the user

This Instruction Manual is an integral part of the machine and must be available to the

●

operating personnel at all times.

The Instruction Manual must be read before operating the machine for the first time.

●

The operating and specialist personnel is to be instructed as to the safety equipment of

●

the machine and regarding safe work methods.

It is the duty of the user to only operate the machine in perfect running order.

●

It is the obligation of the user to ensure that none of the safety mechanisms are removed

●

or deactivated.

It is the obligation of the user to ensure that only authorized persons operate and work

●

on the machine.

Further information can be obtained from your PFAFF agent.

7

Page 8

Safety

1.05 Operating and specialist personnel

1.05.01 Operating personnel

Operating personnel are persons responsible for the equipping, operating and cleaning of

the machine as well as for taking care of problems arising in the sewing area.

The operating personnel is required to observe the following points and must:

always observe the Notes on Safety in the Instruction Manual!

●

never use any working methods which could adversely affect the safety of the machine!

●

not wear loose-fitting clothing or jewelery such as chains or rings!

●

also ensure that only authorized persons have access to the potentially dangerous area

●

around the machine!

always immediately report to the person responsible any changes in the machine which

●

may limit its safety!

1.05.02 Specialist personnel

Specialist personnel are persons with a specialist education in the fields of electrics, electronics and mechanics. They are responsible for the lubrication, maintenance, repair and adjustment of the machine.

The specialist personnel is obliged to observe the following points and must:

always observe the Notes on Safety in the Instruction Manual!

●

switch off the On/Off switch before carrying out adjustments or repairs, and ensure that

●

it cannot be switched on again unintentionally!

wait until the luminous diode on the control box is no longer blinking or on before begin-

●

ning adjustment or repair work.

never work on parts which are still connected to the power supply! Exceptions are explai-

●

ned in the regulations EN 50110.

replace the protective coverings and close the electrical control box afer all repairs or

●

maintenance work!

8

Page 9

Safety

1.06 Danger

A working area of 1 meter is to be kept free both in front of and behind the machine while it is in operation so that it is always easily accessible.

Never reach into the sewing area while sewing!

Danger of injury by the needle!

Never leave objects on the table while adjusting the machine settings!

Objects can become trapped or be slung away! Danger of injury!

3

4

Fig. 1 - 01

1

5

2

Do not operate the machine without its take-up-lever guard 1!

Danger of injury due to the motion of the take-up lever!

Do not operate the macine without finger deflector 2!

Danger of injury by the needle!

Do not operate the machine without eye shield 3!

Danger of injury from flying needle fragments!

Only operate the machine with cover 4 closed!

Danger of injury from rotating hook!

Do not operate the machine without cover 5!

Danger of injury from moving parts!

9

Page 10

Proper use

2 Proper use

The Pfaff 3371-1/.. is an automatic sewing machine for sewing lockstitch bartacks and short

seams in the sewing industry..

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

10

Page 11

Specifications

3 Specifications

Max. sewing speed: ............................................................................................... 2700 spm

Feed type: .............................................................................................................. intermittent

Stitch length: ...................................................................................................... 0.1 – 10.0 mm

Stitch type: ........................................................................................................ 301 (lockstitch)

Needle size in 1/100 mm:

for fine materials: ......................................................................................................... 70 - 100

for medium-weight materials: .................................................................................... 100 - 120

for medium-heavy materials: ..................................................................................... 120 - 140

Needle system

Subclass -1/01, -1/21, -1/31 ............................................................................................... DPx5

Subclass -1/11 ..................................................................................................................DPx17

Needle bar stroke: ...........................................................................................................41mm

Fabric clearance: ................................................................................................... max. 17 mm

Max. size of sewing area: ......................................................................................40 x 20 mm

Power supply: .................................................................220 V ± 10%, 50/60 Hz, single phase

Power consumption: ...................................................................................................0.55 kVA

Electrical power rating: ................................................................................................1,2 kVA

Fuse protection: ................................................................................................... 1x 16 A, inert

▲

-1

Noise data:

Noise emission level at workplace

with a sewing cycle of 1 sec. on and 2 sec. off: ...............................................LpA = 74 dB(A)

(Noise measurement in accordance with DIN 45 635-48-B-1, ISO 11204, ISO 3744, ISO

4871)

Sewing head dimensions:

Length: ............................................................................................................approx. 700 mm

Width: ..............................................................................................................approx. 220 mm

Height: ............................................................................................................approx. 380 mm

Dimensions of standard base:

Length: .......................................................................................................... approx. 1060 mm

Width: ..............................................................................................................approx. 600 mm

Height: ............................................................................................................approx. 820 mm

Weights

Sewing head: ................................................................................................... approx. 42 kilos

Base incl. control box: ...................................................................................... approx. 45 kilos

■

▲

Subject to alterations

■

KpA = 2,5 dB

11

Page 12

Disposal of Machine

4 Disposal of Machine

Proper disposal of the machine is the responsibility of the customer.

●

The materials used for the machine are steel, aluminium, brass and various plastic

●

materials. The electrical equipment comprises plastic materials and copper.

The machine is to be disposed of according to the locally valid pollution control regula-ti-

●

ons; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

12

Page 13

Transportation, packing and storage

5 Transportation, packing and storage

5.01 Transportation to customer‘s premises

The machines are delivered completely packed.

5.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fibre. Proper disposal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a film of oil.

13

Page 14

Explanation of symbols

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

14

Page 15

Control elements

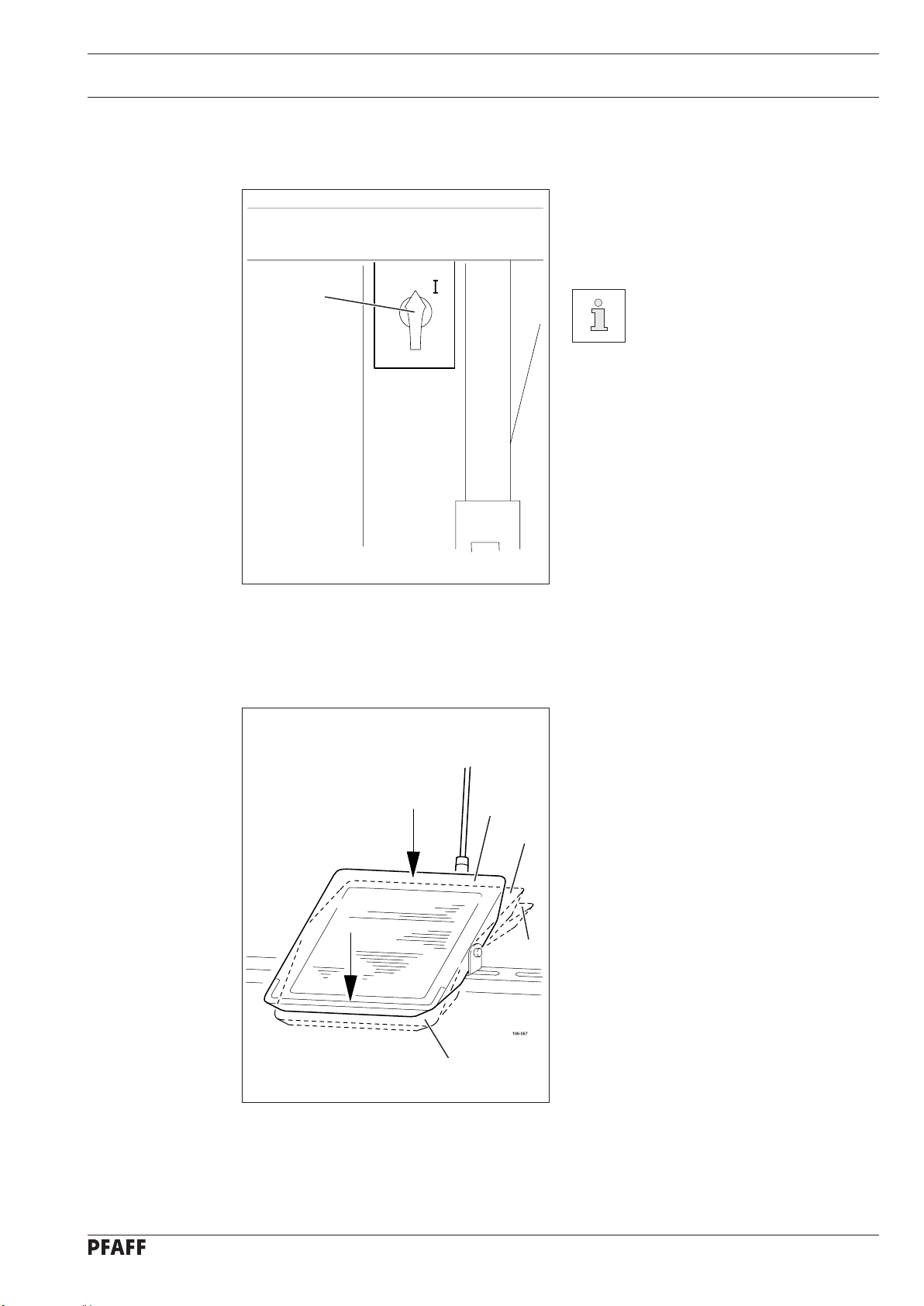

0

56-067

7 Control elements

7.01 Main switch

Switch the machine on or off by turning

●

main switch 1.

Fig. 7 - 01

7.02 Pedal

1

The pedal is used to lower and raise

●

the work clamp, and to start the sewingprogram.

After switching the machine on,

first press the "TE" key to bring

the machine into its neutral position.

0

+1

-1 = sewing interruption

0 = neutral position

+1 = lower work clamp

+2 = sewing

+2

-1

Fig. 7 - 02

15

Page 16

Control elements

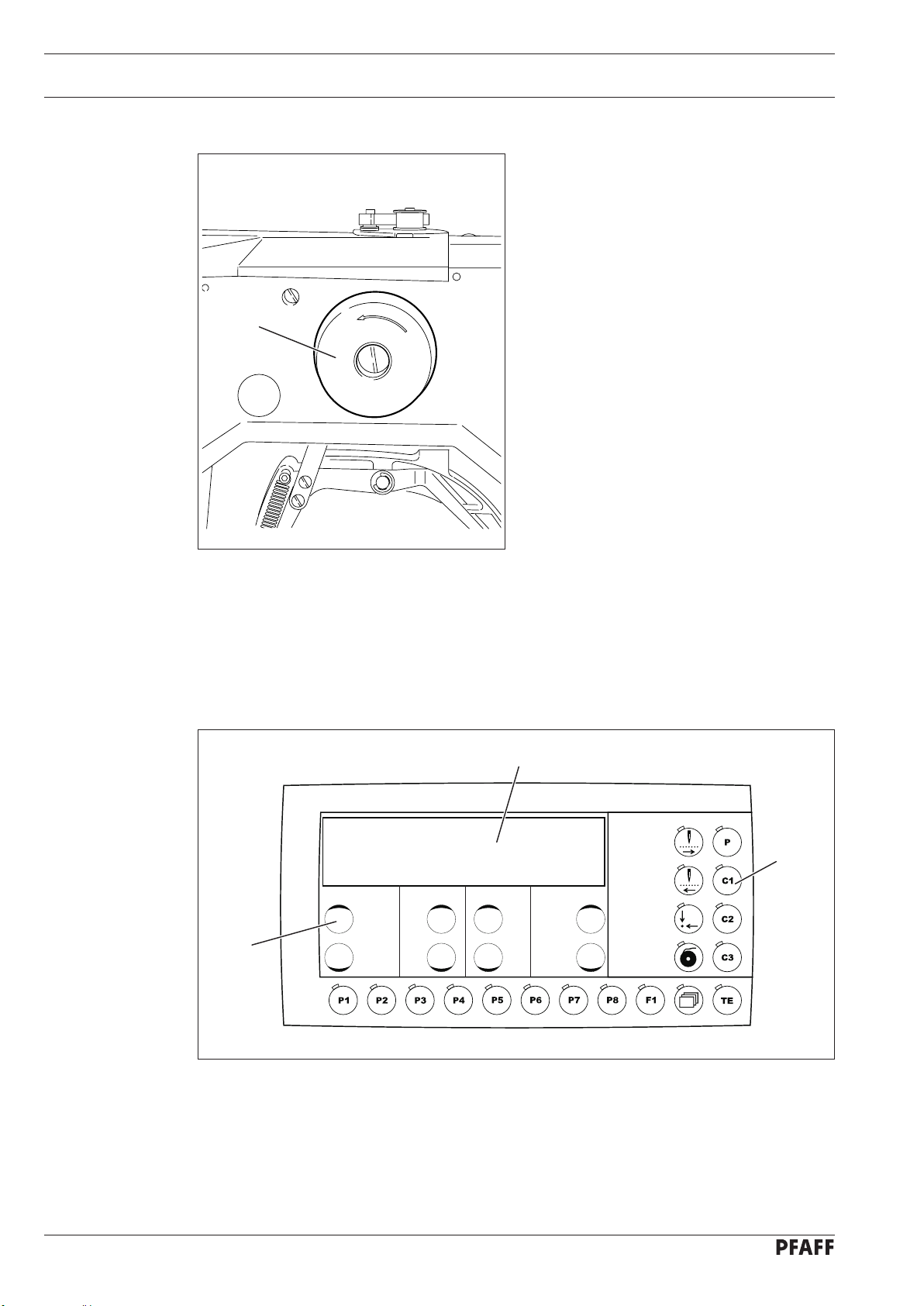

7.03 Balance wheel

By pressing and holding down balance

●

wheel 1, it is possible to adjust the needle bar manually.

1

Fig. 7 - 03

7.04 Control panel

The control panel is used to select seam programs, call up machine functions, change

parameters, control the different operating modes, as well as for reading error signals and

service settings.

3

1

2

16

Fig. 7 - 04

The control panel consists of display screen 1 with the function keys described below. The

display 1 consists of a two-row alphanumerical LCD display with 16 symbols per row. The

function keys 2 are located below and to the right of the display screen. The status of the

function keys and the machine operating modes are shown with LEDs in the corresponding

keys. Every time the function keys 2 are operated, a key tone sounds as confirmation of the

Page 17

Control elements

input. If the input required is invalid, e.g. because the max. permissible value for the

parameter input has been reached, a double tone is audible. An SD-card reader for data

transfer is integrated.

7.04.01 Screen displays

Depending on the operating mode, on the screen 1 information is shown about the machine

status, program selection, sequence program progress, input parameters, as well as error signals (also see Chapter 11 Input).

Depending on the operating mode, relevant data is displayed in combination with the ap-

●

propriate symbol or text, and can be altered directly.

When the parameters are entered, the number of the parameter selected is shown with

●

the corresponding parameter value, see Chapter 11.03 Parameter input.

If faults occur in the sewing operation, a corresponding error signal appears in the display,

●

see Chapter 11.08 Error messages on the display.

7.04.02 Display symbols

Program number

Speed

X Size factor X-direction (crosswise) in %

Y Size factor Y-direction (lengthwise) in %

Bobbin thread counter / piece counter

Enter

Machine memory

SD-memory card

7.04.03 Function keys

The functions keys described below are used essentially to switch machine functions on and

off. When the function is switched on, the diode in the key is illuminated.

If a corresponding value has to be fixed for the activated function, this can be carried out

with the corresponding +/- keys 3.

By pressing and holding the corresponding +/- key, firstly the numerical value displayed above it is altered slowly. If the +/- key is pressed longer, the numerical value changes more

quickly. The respective +/- keys shown opposite are described below.

17

Page 18

Control elements

Menü

This function is used in the respective operating mode to scroll within the existing menus.

Wind

The bobbin thread winding function is called up, see Chapter 9.03 Winding the bobbin

thread.

Basic position

Work clamp and needle are positioned in the basic position and , if necessary, the thread

trimming function is activated.

Tacting backwards

Each time the key is pressed, the selected seam program is sewn stitch by stitch in reverse,

and the coordinates for each stitch are shown on the control panel.

Tacting forwards

Each time the key is pressed, the selected seam program is sewn forwards stitch by stitch,

and the coordinates for each stitch are shown on the control panel.

to

to

Program stations

The function keys P1 to P8 are used to enter and select seam programs, see Chapter

9.06.02 Selecting the program station.

Direct program selection

This function is used to select a seam pattern. After selection, speed and size can be altered, see Chapter 9.06.01 Selecting and altering the seam pattern.

Sequences

The function keys C1 to C3 are used to enter and select sequences, see Chapter 9.06.03

Selecting a sequence.

TE

In the sewing mode, this key is used to change to the input mode. In the input mode this

key is used to acknowledge the input of program stations and sequences, and to change

into the sewing mode.

18

Page 19

8 Installation and commissioning

The machine must only be installed and commissioned by qualified personnel!

All relevant safety regulations must be strictly adhered to!

If the machine is delivered without a table, be sure to use a stand and table top

that can hold the weight of the machine with its motor.

It is very important to ensure that the stand of the machine is firm and steady,

also during sewing.

8.01 Installation

The site where the machine is installed must be provided with suitable connections for the

electric current, see Chapter 3 Specifications.

It must also be ensured that the standing surface of the machine site is firm and horizontal,

and that sufficient lighting is provided.

For packing and transportation reasons the table top is in the lowered position.

The table height is adjusted as described below.

Installation and commissioning

If the machine is delivered with stand, the transit lock must be removed before

commissioning, see Chapter 8.01.02 Removing the transit lock.

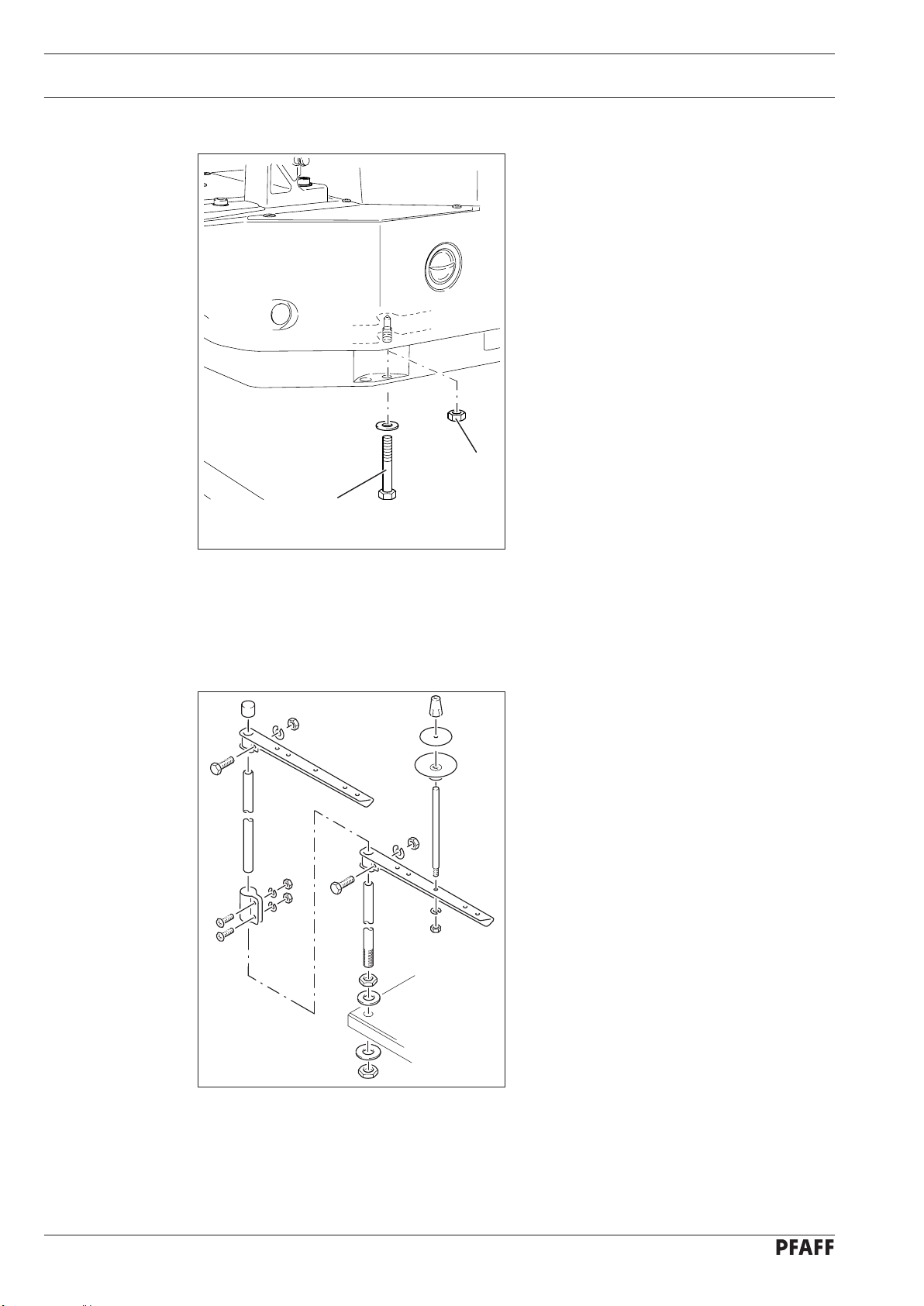

8.01.01 Adjusting the table height

1

1

2

Fig. 8 - 01

Loosen screws 1 and 2 and set the table height as required.

●

Firmly tighten screw 1.

●

Set the required pedal position and tighten screw 2.

●

19

Page 20

Installation and commissioning

8.01.02 Removing the transit lock

2

Loosen nut 1.

●

Remove screw 2.

●

1

Fig. 8 - 02

8.01.03 Fitting the reel stand

Fit the reel stand as shown in Fig. 8 - 03.

●

Afterwards insert the stand in the hole in

●

the table top and secure it with nuts provided.

20

Fig. 8 - 03

Page 21

Installation and commissioning

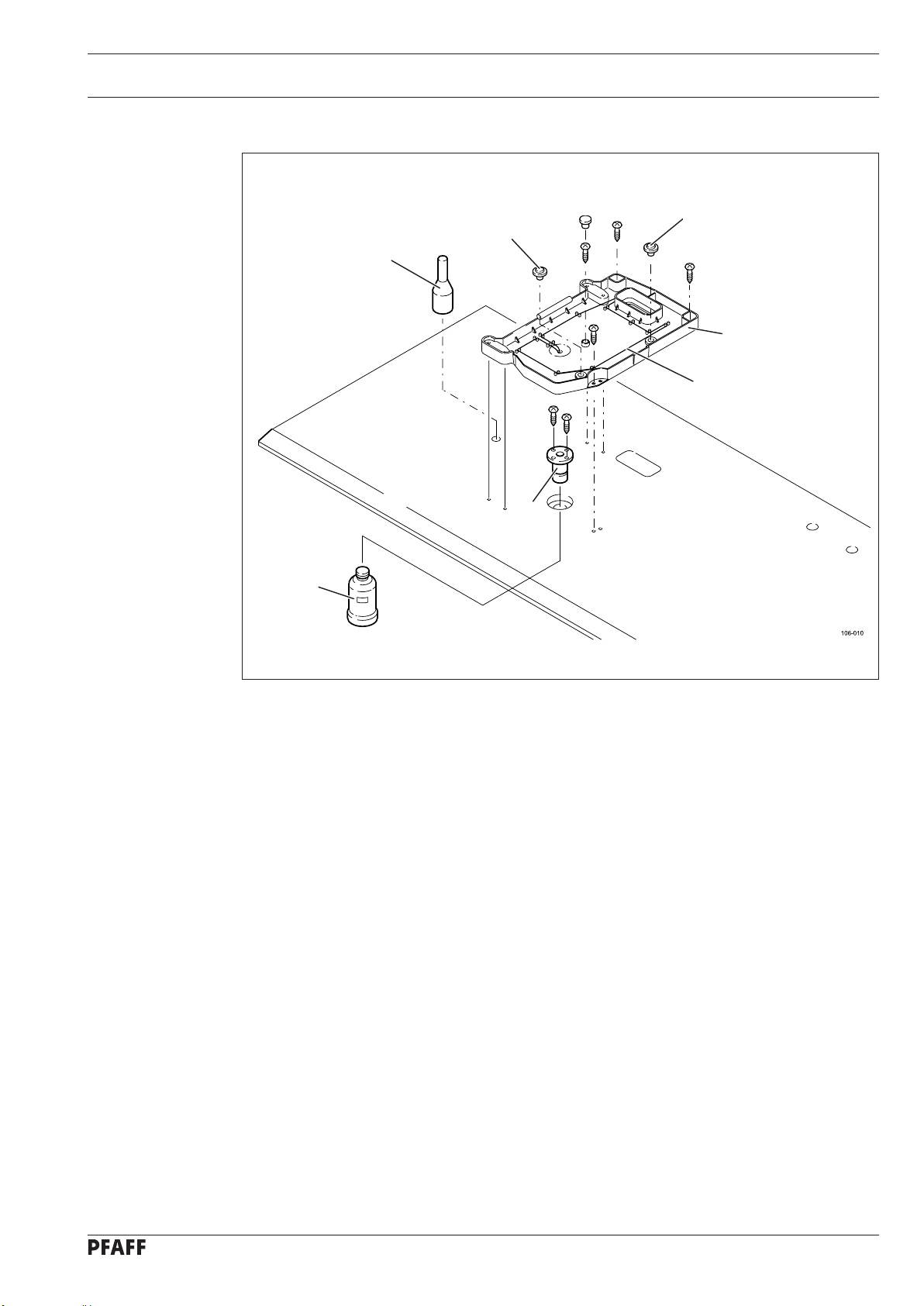

8.01.04 Mounting the table top (for deliveries without stand)

3

5

1

3

4

6

2

Fig. 8 - 04

Drill holes in the table top as shown in the drawing, see Chapter 8.01.05 Table top drill

●

hole plans.

Screw on the oil outlet 1.

●

Screw the oil tank 2 to oil outlet 1.

●

Set the rubber pads 3 in the fastening holes of the oil pan 4 and screw oil pan 4 to the

●

table top.

Set support 5 in the appropriate hole.

●

Place wick 6 iin the holders of oil pan 4.

●

21

Page 22

Installation and commissioning

8.01.05 Table top drill hole plans

Top view

22

Control panel holdersr

Transit lock

Page 23

Bottom view

Installation and commissioning

Drawer

Gestell 906-3550-005/895

Controller

Speed control unit

Stand 906-3550-005/895

Main switch

23

Page 24

Installation and commissioning

106-051

8.01.06 Connecting the plug-in connections and earth cable

A

1

B

Fig. 8 - 05

Connect all plugs as labelled in the control box.

●

Screw the earth cable from the machine and the main switch to earth point A.

●

Connect earth point A and earth point B with an earth cable.

●

Screw the earth cable of plug 1 to earth point B.

●

8.02 Commissioning the machine

Clean the machine thoroughly.

●

Check the oil level, see Chapter 12 Care and Maintenance.

●

Check the machine, especially the electric wires, for any damage.

●

Have specialists check, whether the machine’s motor can be used with the existing

●

mains voltage.

Circuit diagrams, see Chapter 13.

24

8.03 Switching the machine on/off

Switching the machine on/off, see Chapter 7.01 Main switch.

●

Page 25

Setting up

9 Setting up

All instructions and regulations in this instruction manual must be observed.

Special attention must be given to all safety regulations!

All setting-up work must only be done by personnel with the necessary

training. For all setting-up work the machine must be isolated from its powe

supply by turning off the on/off switch or removing the machine plug from the

electric power socket!

9.01 Inserting the needle

Switch off the machine!

Danger of injury if the machine

is started accidentally!

Only use needles from the sys-

2

tem intended for the machine,

see Chapter 3 Specifications.

1

Fig. 9 - 01

Loosen screw 1.

●

Insert the needle as far as possible. The

●

long needle groove (see arrow) must be

facing forwards.

Tighten screw 1.

●

Through hole 2 it is possible to check whether the needle has been inserting

as far as possible.

Broken needles can be removed by inserted suitable tools in hole 2.

25

Page 26

Setting up

9.02 Threading the needle thread / adjusting the needle thread tension

1

2

Fig. 9 - 02

Switch off the machine!

Danger of injury if the machine is started accidentally!

Thread the needle thread as shown in Fig. 9-02.

●

Adjust the needle thread tension by turning milled nuts 1 and 2.

●

26

Page 27

Setting up

9.03 Winding the bobbin thread

3

6

2

1

5

4

Fig. 9 - 03

Place the empty bobbin 1 on the bobbin winder spindle 2.

●

Thread the thread as shown in Fig. 9-03 and wind it round bobbin 1 a few times in the

●

anti- clockwise direction.

Set the preliminary thread tension by turning milled screw 3.

●

Press lever 4 in the direction of the arrow until it clicks into place.

●

The bobbin is filled during sewing.

Winding is also possible as follows:

●

Switch on the machine and press the key for winding.

●

Remove the thread from the needle and take-up lever.

●

Operate the pedal to carry out winding, the bobbin winder stops automatically as soon as

●

the bobbin is adequately full.

Press the key for winding, the machine stops.

●

Thread the machine again.

●

Adjusting the amount of thread on the bobbin

Loosen screw 5.

●

Set stop 6 so that the bobbin winder switches off automatically when the thread is

●

still ca. 1 mm from the edge of the bobbin.

Tighten screw 5.

●

27

Page 28

Setting up

9.04 Removing / replacing the bobbin case

Switch off the machine.

Danger of injury if the machine

starts accidentally!

2

1

Fig. 9 - 04

Removing the bobbin case

Open the hook cover

●

Pull out latch 1

●

Remove bobbin case 2

●

Replacing the bobbin case

Push bobbin case 2 into the bobbin case

●

base until you feel it click into place

Close the hook cover.

●

9.05 Threading the bobbin thread / adjusting the bobbin thread tension

Fig. 9 - 05

Place the bobbin into the bobbin case,

●

so that this turns in the direction shown

1

by the arrow when the thread is pulled.

Insert the thread as shown in Fig. 9-05.

●

Set the thread tension by turning

●

screw 1.

28

Page 29

Setting up

9.06 Selecting a seam program

To avoid the machine starting accidentally, to begin with the TE key must be pressed, after the machine has been switched on. The machine is then in its basic position and offers a

number of possibilities for selecting seam programs.

- Direct selection of the seam pattern and its individual adaptation by changing the speed

and size factors.

- Selection of the seam program via a program station. For this purpose a seam pattern with

its respective speed and corresponding size factors must have been stored previously.

- With the selection of a sequence several seam programs are sewn after each other. For

this purpose a sequence must have been compiled beforehand from individual seam pro

grams (program stations).

9.06.01 Selecting and changing the seam pattern.

X

Y

With the machine in the basic position, select the direct seam pattern.●

X Y

11 2 700 100 10 0

With the corresponding +/- key select the desired seam pattern, e.g. 11. The seam pat-

●

terns are stored in the machine under program numbers, see Chapter 11.05 Summary of

the seam patterns.

Select the desired speed with the corresponding +/- key.

●

Enter the desired size factor (in %) (X-direction) with the corresponding +/- key.

●

Enter the desired size factor (in %) (Y-direction) with the corresponding +/- key.

●

Conclude the input by pressing the TE key. (The machine changes to the sewing mode).

●

The enlargement of the seam pattern is limited by the size of the machine’s sewing area.

The altered speed and size factors entered are not stored when the machine

changes to another seam program. If you wish to store these values, a station

key must be reserved with the corresponding seam program, see Chapter 11.01

Reserving program stations.

29

Page 30

Setting up

9.06.02 Selecting a program station.

With the machine in its basic position, select the desired program station, e.g. P3.●

X Y

20 2 200 90 110

Only those program stations can be selected, which have been reserved previously with a seam pattern with its respective speed and size factors, see

Chapter 11.01 Reserving program stations.

Speed and size factors cannot be changed directly in a seam program selected

via a program station.

9.06.03 Selecting a sequence

With the machine in its basic position, select the desired sequence, e.g. C2.●

A 3 - 3 - 3 - 3 - 3 - 3 - 8

8 - 8 - 8 - 4 - 4

The next seam program waiting to be sewn is depicted by the relevant flashing

entry.

Sequences can only be called up if they have been created beforehand (see

Chapter 11.02.01 Enter sequences).

30

Page 31

Setting up

9.07 Adjusting the size of the sewing area

A comparison between the sewing area

size entered and the actual sewing area size

of the work clamp ensures that seam programs, which are not within the sewing area

1

size, cannot be sewn.

If the actual and the entered sewing area size do not concur

with each other, severe damage

can be caused to the machine!

Measure the sewing area size of work

●

clamp 1.

Fig. 9 - 06

With the machine in its basic position, select the input mode. (LED is illuminated).●

No VAL

023 -2 0 0 20 0

With the corresponding +/- key select parameter "023".

●

If required, enter the access code, see Chapter 11.04.01 Entering the access code.

●

With the corresponding +/- key enter the measured value (in 1/10 mm) for the

●

X-axis.

With the corresponding +/- key select parameter "024".

●

With the corresponding +/- key enter the measured value (in 1/10 mm) for the

●

Y-axis.

Conclude the input by pressing the TE key. (Machine changes to the sewing mode).

●

31

Page 32

Setting up

9.08 Setting up the bobbin thread counter

With the machine in its basic position, select the input mode.

●

With the corresponding +/- key select parameter "004".

●

If required, enter the access code, see Chapter 11.04.01 Entering the access code.

●

No VAL

0 04 O N 800

With the corresponding +/- key switch on the bobbin thread counter.

●

With the corresponding +/- key enter the number of workpieces to be sewn.

●

Conclude the input by pressing the TE key. (Machine changes to the sewing mode).

●

9.09 Resetting the piece counter

In the sewing mode (basic position of the machine) the piece counter or the bobbin thread

counter can be displayed by pressing the menu key. (When the bobbin thread counter is

switched off, the piece counter is displayed - Selection under parameter 004) .

20 SET 0

32

The piece counter counts from 0 onwards and differs from the bobbin thread counter in the

display through the upwards pointing arrow.

Reset the piece counter with the corresponding +/- keys. ●

Page 33

Setting up

9.10 Shifting the seam pattern

To adapt the seam patterns to formed workpiece holders, selected seam patterns can be

shifted.

From the basic position of the machine select the desired program station, e.g. P1.

●

Tact through the seam pattern, e.g. forwards.

●

The actual coordinates are shown together with the shift values for each stitch.

X: Y:

169+0 -99+ 10

With the corresponding +/- keys it is possible to enter a shift value for the entire seam

●

pattern in X- or Y-direction at each seam pattern coordinate.

The seam pattern shift is allocated to the respective actual program station and

is deleted when the program number is changed.

33

Page 34

Setting up

9.11 Inserting and removing the SD-memory card

Inserting the SD-memory card

Open cover 1.

●

1

2

Insert SD-memory card 2 into the card

●

slot with the label at the front.

Close cover 1 again.

●

Removing the SD-memory card

Open cover 1.

●

Press the edge of the SD-memory card 2

●

lightly – the SD-card is ejected.

Close cover 1 again.

●

3

Fig. 9 - 08

By moving slide 3 it is possible to activate (position "LOCK") or deactivate

the write protection function of the SD-memory card. To store, process or

delete data on the SD-memory card, the write protection function must be

deactivated.

34

Page 35

Sewing

10 Sewing

The machine must be installed, connected and set up as described in Chapter 8

Installation and Commissioning.

The machine must not be operated without the safety devices 1 to 5, see Chapter 1.06 Danger warnings! Danger of injury!

1

5

3

4

Fig. 9 - 02

2

10.01 Operating cycle

Carry out all steps in accordance with Chapter 9 Setting up.

●

Place the material properly under the work clamp.

●

Lower the work clamp and start the sewing cycle, see Chapter 7.02 Pedal.

●

10.02 Sewing in the "Direct program selection" mode

In this function, a seam pattern is selected. After selection, the speed and size can be altered, see Chapter 9.06.01 Selecting and changing the seam pattern.

10.03 Sewing in the "Program stations" mode

Program stations can be selected, which have been reserved beforehand with a seam pattern with relevant speed and size factors, see Chapter 11.01 Reserving program stations.

35

Page 36

Sewing

10.04 Sewing in the "Sequences mode".

10.04.01 Interrupting a sequence

Sequences, which have been created beforehand, can be called up with the function keys

C1 to C3 (see Chap. 11.02.01 Entering sequences)

If an interruption occurs during a sequence cycle (e.g. broken thread), it is possible to

continue at the same sequence point after the error has been eliminated.

The procedure is as follows:

A 3 - 3 - 3 - 3 - 3 - 3 - 8

8 - 8 - 8 - 4 - 4

The activated sequence point flashes.

●

Select the sequence A, B or C by pressing the left +/- key.

●

Press the corresponding +/- key to move to the sequence point to be repeated.

●

Conclude input by pressing the TE key.

●

10.05 Error messages

When an error occurs, the text "ERROR" appears on the display together with an error

code and short instructions. In addition the diode in the memory card slot lights up red

(see arrow). An explanation of the error codes can be found in the Chapter 11.07 Error

messages on the display.

ERRO R: 003

RESE T

36

Correct the error.

●

Acknowledge the correction of the error by pressing the corresponding +/- key or by

●

switching the machine off and on.

The diode in the memory card slot (see arrow) turns yellow again

●

Page 37

Input

11 Input

After the machine has been switched on, it is in the input mode. The LED in the "TE" key is

illuminated. The input mode is used to reserve program stations, to enter sequences and to

change machine parameters. In addition information and input possibilities for the service

area are available in this mode.

11 .01 Reserving program stations

to

to

The station keys P1 to P8 are used to enter and select seam programs. A complete seam

program is confi gured from the following parameter:

- seam pattern

- speed

- size factor in X-direction

- size factor in Y-direction

Call up the input mode by pressing the TE key (LED is illuminated).

●

Press a station key to call up the direct seam pattern selection function.

●

X Y

20 2200 90 110

With the corresponding plus/minus key select the desired seam pattern, e.g. 20. The

●

seam patterns are stored in the machine under program numbers, see Chapter 11.05

Summary of the seam patterns.

Select the desired speed with the corresponding +/- key.

●

Enter the desired size factor (in %) (X-direction) with the corresponding +/- key.

●

X

●

Y

Enter the desired size factor (in %) (Y-direction) with the corresponding +/- key.

The enlargement of the seam pattern is limited by the size of the machine’s

sewing area.

●

Conclude the input by pressing the TE key. (The machine changes to the sewing mode).

37

Page 38

Input

11 .02 Sequences

11

.02.01 Entering sequences

to

2x

The sequence program keys C1 to C3 are used to enter and select sequence programs. The

sequence programs are put together from seam programs, which have been deposited under the station keys P1 to P8.

A sequence can consist of up to 3 segments (A, B + C). In each segment up to

14 entries can be made.

Call up the input mode by pressing the TE key (LED is illuminated).

●

In the input mode, select the desired sequence program key, e.g. C2.

●

Enter the desired seam programs in any order by using the station keys, e.g. P3 six times ,

●

P8 four times,

P4 twice

Press the TE key input twice (machine changes to the sewing mode).

A 3 - 3 - 3 - 3 - 3 - 3 - 8

8 - 8 - 8 - 4 - 4

The station keys for selection must have been reserved beforehand, see

Chapter 11.01 Reserving program stations.

In the "Input" mode it is possible to scroll between the sequence zones

A, B and C by pressing the Menu key.

11 .02.02 Checking the sequence contents

With the machine in its basic position, select the desired sequence, e.g. C2.

●

The activated sequence point fl ashes.

●

38

Press the corresponding +/- key to move to the sequence point to be checked (e.g. 8).

●

Page 39

Input

A 3 - 3 - 3 - 3 - 3 - 3 - 8

8 - 8 - 8 - 4 - 4

Press the TE key (LED is not illuminated).

●

The parameters, such as number of the seam pattern, speed and size factors of the fl as-

●

hing sequence entry are shown if the Menu key is pressed.

2x

Quit the check mode by pressing the Menu key twice.

●

11 .02.03 Deleting sequences

Call up the Input mode by pressing the TE key (LED is illuminated).

●

Call up the sequence to be changed by pressing the C1, C2 or C3 keys.

to

to

●

Deleting individual entries

Press a +/- key to set the cursor beneath the entry to be deleted and delete the entry by

●

pressing the reverse tacting key twice.

Inserting individual entries

Press a +/- key to set the cursor beneath the position for the insertion.

●

Insert the desired entry by pressing the corresponding station key.

●

Deleting a complete sequence

Press a +/- key to set the cursor at the beginning of the sequence. Press the reverse

●

tacting key as often as necessary to delete all entries on the display.

Press the TE input key twice (machine changes to the sewing mode).

2x

●

11

.02.04 Combining sequences

Several sequences can be combined to one seam program. To carry out the adjustment,

enter the corresponding value for parameter 005 (see Chapter 11.07 List of parameters).

39

Page 40

Input

11 .03 Parameter input

After the machine has been switched on, it is in the input mode..

With the corresponding +/- key select the desired parameter, e.g. 003 lock seam

●

patterns.

No VAL

001 2700

No VAL

003 1: ON

With the corresponding +/- key select the desired seam pattern.●

No VAL

003 3: OFF

With the corresponding +/- key lock the desired seam pattern.

●

Conclude the input by pressing the TE key. (The machine changes to the sewing mode).

●

There is a list explaining all the parameters in Chapter 11.06 List of parameters.

40

Page 41

Input

11 .04 Access codes

The selection of seam patterns, the reservation of the program stations, the input of

sequences and the selection of individual parameter levels can be locked with a 4-fi gure

access code. The access code can be changed as desired. The factory set access code

is "3371".

11 .04.01 Entering the access code

If, in the input mode, a function is selected, which has an access code, the demand for

entering the access code appears on the display.

PINCODE:

3 3 7 1

Enter the access code with the corresponding +/- keys.

●

Conclude the input by pressing the TE key (machine changes to the sewing mode).

●

Once the access code has been entered, all functions with access protection

are freely accessible, until the machine is switched off.

11 .04.02 Changing the access code

In the input mode, select parameter "811"

●

Enter the access code, see Chapter 11.04.01 Entering the access code

●

No VAL

811 3371

Change the access code with the corresponding +/- keys.

●

Conclude the input by pressing the TE key (machine changes to the sewing mode).

●

41

Page 42

Input

11 .04.03 Granting access rights

In the input mode select the corresponding parameter ("801" to "806"), see

●

Chapter 11.07 List of parameters.

If required, enter the access code, see Chapter 11.04.01 Entering access codes.

●

No VAL

801 OFF

With the corresponding +/- key approve (on) or lock (OFF) access..

●

Conclude the input by pressing the TE key (machine changes to the sewing mode).

●

42

Page 43

Input

11 .05 Summary of the seam patterns

No. Seam pattern Size of sewing area [mm] No. of stitches

P1 16,0 x 2,0 42

P2

P3 16,0 x 2,5 42

P4 24,0 x 3,0 42

P5 10,0 x 2,0 27

P6 16,0 x 2,5 30

P7 10,0 x 2,0 35

P8 16,0 x 2,5 38

P9 24,0 x 3,0 53

10,0 x 2,0 39

P10 24,0 x 3,0 61

P11 6,0 x 2,5 20

P12 6,0 x 2,5 25

P13 6,0 x 2,5 34

P14 8,0 x 2,0 15

P15 8,0 x 2,0 22

P16 8,0 x 2,0 29

P17 10,0 x 0,0 21

P18 10,0 x 0,0 28

43

Page 44

Input

No. Seam pattern Size of sewing area [mm] No. of stitches

P19 25,0 x 2,0 28

P20 25,0 x 2,0 36

P21 25,0 x 0,0 41

P22 25,0 x 0,0 44

P23 4,0 x 20,0 27

P24 4,0 x 20,0 35

P25 4,0 x 20,0 41

P26 4,0 x 20,0 56

P27 0,0 x 20,0 18

44

P28 0,0 x 10,0 21

P29 0,0 x 20,0 21

Page 45

Input

No. Seam pattern Size of sewing area [mm] No. of stitches

P30 0,0 x 20,0 28

P31 10,0 x 10,0 28

P32 10,0 x 10,0 28

P33 15,0 x 15,0 28

P34 15,0 x 15,0 28

P35 14,0 x 2,0 21

P36 36,0 x 19,0 74

P37 6,5 x 9,0 34

P38 6,5 x 9,0 34

P39 11,0 x 11,0 72

P40 31,7 x 6,0 32

45

Page 46

Input

11 .06 Program Management

IIn the program management the programs fi led in the machine memory or on connected

SD-memory cards are displayed and can be deleted or copied. Commercially available

SD-memory cards with a storage capacity of max. 512 MB can be inserted in the control

panel. The data is stored in machine-relevant sub-directories. The way to insert or remove the

SD-memory card is described in Chapter 9.07

The programs 50 – 99 are stored in the fi les 50 – 99 and

●

the machine data in the fi le MD.

●

Should the SD-memory cards need to be formatted by the PC, they must be formatted

in the format “FAT16”. Alternatively the SD-memory cards can also be formatted on the

corresponding machine with the formatting function, see Chapter 11.10.08 Formatting the

SD-memory card.

11 .06.01 Calling up the program management

Switch on the machine.

●

Call up the program management

●

DIR

After the program management has been called up, the fi rst menu item appears (display of

data in the machine memory).

Confi rm the selection of the menu item with the "Enter" function by pressing the right plus

key. In this example the contents of the machine memory are then displayed.

It is possible to scroll through the other menu points by pressing the left +/- key (see following chapters).

46

The following menu items are available in the program management:

●

Display data in the machine memory

●

Display data on the connected SD-memory card

●

Copy data to the SD-memory card

●

Copy data to the machine memory (from the SD-memory card)

●

Delete data in the machine memory

●

Delete data on SD-memory card

●

Format SD-memory card

Page 47

Input

11 .06.02 Display of the data in the machine memory

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

DIR

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

DIR

01 02 40 42 END

By pressing the right +/- keys it is possible to scroll through the display of the machine

●

memory.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up.

47

Page 48

Input

11 .06.03 Display of the data on the SD-memory card

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

DIR

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

DIR

01 02 40 END

By pressing the right +/- keys it is possible to scroll through the display of the

●

SD-memory card.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up.

48

Page 49

Input

11 .06.04 Copying data onto the SD-memory card

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

COPY

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

COPY 01 02

Press the corresponding +/- keys to select the data to be copied from the

●

machine memory onto the SD-memory card:

MD = machine parameters

50 - 99 = programs

ALL = all programs

The copying process is started with the "Enter" function by pressing the right plus key.

●

If the data for copying already exists, a safety enquiry appears before overwriting the data. Press the right plus key to confi rm the copying process. The copying process can be stopped by pressing the right minus key.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up.

49

Page 50

Input

11 .06.05 Copying data into the machine memory

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

COPY

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

COPY 01 02

Press the corresponding +/- keys to select the data to be copied from the

●

SD-memory card into the machine memory:

MD = machine parameters

50 - 99 = programs

ALL = all programs

The copying process is started with the "Enter" function by pressing the right plus key.

●

If the data for copying already exists, a safety enquiry appears before overwriting the data. Press the right plus key to confi rm the copying process. The copying process can be stopped by pressing the right minus key.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up.

50

Page 51

Input

11 .06.06 Deleting data in the machine memory

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

DEL

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

DEL 01

Press the corresponding +/- keys to select the data to be deleted from the

●

machine memory:

50 - 99 = programs

ALL = all programs

Machine data cannot be deleted.

The deleting process is started with the "Enter" function by pressing the right plus key.

●

Before the data is deleted, a safety enquiry ensues.

Press the right plus key to confi rm the deleting process.

The deleting process can be stopped by pressing the right minus key.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up

51

Page 52

Input

11 .06.07 Deleting data from the SD-memory card

Call up the program management, see Chapter 11.06.01 Calling up the program

●

management.

DEL

Press the left +/- keys until the corresponding menu item appears.

●

Confi rm the selection of the menu item with the "Enter" function by pressing the right

●

plus key.

DEL ALL

Press the corresponding +/- keys to select the data to be deleted from the SD-memory

●

card:

MD = machine parameters

50 - 99 = programs

ALL = all programs

The deleting process is started with the "Enter" function by pressing the right plus key.

●

Before the data is deleted, a safety enquiry ensues.

Press the right plus key to confi rm the deleting process.

The deleting process can be stopped by pressing the right minus key.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up

52

Page 53

Input

11 .07.08 Formatting the SD-memory card

Call up the program management, see Chapter 11.07.01 Calling up the program

●

management.

FORMAT

Press the left +/- keys until the corresponding menu item appears.

●

The formatting process is started with the "Enter" function by pressing the right plus key.

●

Before formatting begins, a safety enquiry ensues.

Press the right plus key to confi rm the formatting process.

The formatting process can be stopped by pressing the right minus key.

When the left +/- keys are pressed, the other menu items of the program management

●

are called up

53

Page 54

Input

11 .07 List of parameters

The parameter setting values my only be altered by appropriately trained staff!

Group

Gruppe

000 001

Parameter

Parameter

Description

Bedeutung

Maximum speed

This parameter is used to fi x the max.

sewing speed (upper limit).

002 Sewing speed for start stitches

With this parameter the speeds for

the 5 start stitches are fi xed.

Speed (spm) for start stitch no. 1

Speed (spm) for start stitch no. 2

Speed (spm) for start stitch no. 3

Speed (spm) for start stitch no. 4

Speed (spm) for start stitch no. 5

003 Locking/releasing seam patterns

This parameter is used to release (ON)

or lock (OFF) the individual seam

patterns (0 to 99) to be carried out in

the sewing mode.

Setting

range

500 - 2700 2700

500 - 2700

500 - 2700

500 - 2700

500 - 2700

500 - 2700

ON - OFF ON

Set value

500

900

2700

2700

2700

004

005

Switch bobbin thread counter on/off

Standard value (pieces per bobbin)

In the sewing mode, the bobbin thread

counter counts the pieces sewn backwards from the standard value. If the

bobbin thread counter is

switched on, in the sewing mode a

signal is given when the value 0 is reached.

Sequence combination

This parameter is used to combine several sequences with each other.

0 = no combination

1 = C1 with C2

2 = C2 with C3

3 = C1 with C3

4 = C1 with C2 and C3

ON - OFF

1 - 9999

0 - 4 0

OFF

11

54

Page 55

Input

Group

Gruppe

000

Parameter

Parameter

006

007

008 Speed for the "winding" function

Description

Bedeutung

Reversing after thread trimming

Reverse position [°]

With this parameter it is possible to

switch the automatic reversing function after thread trimming on or off. If

the reversing function is switched on,

the reverse position can be set by turning the balance wheel. The access

code is necessary for this adjustment.

Starting point = scale reference

point

With this parameter it is possible to

choose whether the scale reference

point is the starting point (ON) or the

zero point (OFF).

This parameter is used to fi x the

speed for the winding operation.

Setting

range

ON - OFF

0 - 14

ON - OFF OFF

200 - 2700 1500

Set value

ON

11

009

010

011 Pedal mode

Via zero point to starting point after

end of sequence

With this parameter it is possible to

choose that, after the end of the

sequence, the X-, Y-drive moves to the

seam starting point via the reference

initiators.

Via zero point to starting point after

number of program cycles Number

of program cycles

With this parameter it is possible to

choose that, after a certain number of

program cycles, the X-, Y-drive moves

to the seam starting point via the reference initiators.

Switchover between level mode (0)

and fl ip fl op mode (1).

ON - OFF OFF

ON - OFF

1 - 100

0 - 1 0

OFF

012

Needle or balance wheel position

in degrees

0 - 360 11

55

Page 56

Input

Group

Gruppe

000 013 NIS "needle in material" [°]

Parameter

Parameter

014

015 Reduced current for stepping motors

Description

Bedeutung

This parameter is used to set the NIS

signal. If the function is executed, the

position can be entered by turning the

balance wheel. If the position is altered, the result is a change in the point

of time when the carriage is moved.

The access code is necessary for this

adjustment.

Thread trimming speed [min-1]

This parameter is used to fi x the

speed for thread trimming.

The reduction function of the holding

current at rest with closed work clamp

is switched on or off.

Setting

range

65 -166 107

100 - 700 300

ON - OFF ON

Set value

016 Key tone

The key tone, as reaction to a key on

the control panel being pressed, is

switched on or off. The double tone

for incorrect inputs always remains

switched on.

017 Clamp solenoid Operating time [10 ms]

The time, for which the solenoid is under full current, is entered.

018 Clamp solenoid duty-cycle [%]

At the end of the clamp solenoid operating time (Parameter "017") the so-

lenoid is clocked. The relationship between duration of operation and nonoperation is entered here.

019

Thread trimming solenoid operating

time [10 ms]

The time, for which the solenoid is under full current, is entered.

ON - OFF ON

5 - 100 10

5 - 100 20

5 - 100 25

56

020 Thread trimming solenoid duty-cycle

At present without a function

5 - 100 100

Page 57

Input

Group

Gruppe

000 021 Thread take-up lever t.d.c. [°]

Parameter

Parameter

022

023 Sewing area size X [1/10 mm]

Description

Bedeutung

The position for the t.d.c. thread takeup lever is entered here. If the function is executed, the position can be

set by turning the balance wheel. The

access code is necessary for this adjustment.

Thread trimming position (in relation to t.d.c. needle) [°]

The position, at which the thread trimming solenoid is switched on, is entered here. The adjustment is set by turning the balance wheel. The access

code is necessary for this adjustment.

To avoid mechanical collisions, the

sewing area size of the clamp in use

is entered. The control unit checks

the path and, if necessary, issues an

error message.

Setting

range

45 - 53 51

180 - 253 180

± 200 -100/ +100

Set value

024 Sewing area size Y [1/10 mm]

To avoid mechanical collisions, the

sewing area size of the clamp in use

is entered. The control unit checks the

path and, if necessary, issues an error

message.

025

026 Thread wiper solenoid, ratio on-time

027 Basic position / loading point = zero

100 101 Software version main processor

102 Software version sewing drive unit

Thread wiper solenoid

operating time [10 ms]

to off-time in % (Duty-Cycle)

point

The software version of the main processor is displayed

The software version of the sewing

drive module is displayed.

± 100 -15/ +15

ON - OFF OFF

0335/xxx

V.xx

103

Software version control panel

The soft- and hardware version of the

control panel are displayed.

V.xxx/ H.xxx

57

Page 58

Input

Group

Gruppe

600 601 Display inputs

Parameter

Parameter

Description

Bedeutung

With this function the digital inputs

can be checked. "IN" shows the input

numbers (1 - 16). Under "VAL" the respective switch status is displayed.

IN VAL

1 IN1, programmable input 1

2 IN2, programmable input 2

3 E3, work clamp raised

4

5

6

7

8

9

10

11

12

13

14

15

16

Setting

range

Set value

58

602 Display special inputs

With this function it is possible to

check the special inputs pedal,

reference X (SM1) and reference Y

(SM2). "IN" shows the inputs (PED,

REFX, REFY). Under "VAL" the

respective switch status is displayed.

IN VAL

PED Pedal (speed control unit

-1; 0; +1; 2)

REFX Reference input X

REFY Reference input Y

Page 59

Input

Group

Gruppe

600 603 Connect outputs

Parameter

Parameter

Description

Bedeutung

With this function the outlets can be

connected. "OUT" shows the outlet

selected (1-16). Under "VAL" the

selected output is set (S) with the

plus/minus key (+), and reset (R) with

the plus/minus key. Interlocks are

checked. Non-assigned outlets are not

connected.

OUT VAL

1 S/R Solenoid for work

clamp open

2 S/R

3 S/R Solenoid for

thread trimming

4 S/R

5 S/R

6 S/R Program outlet

7 S/R Program outlet

8 S/R

9 S/R

10 S/R

11 S/R

12 S/R

13 S/R

14 S/R

15 S/R

16 S/R

Setting

range

Set value

604

605 Turn sewing motor

Move stepping motors

The stepping motors SM1 (X-axis) and

SM2 (Y-axis) are moved individually

with the respective plus/minus keys.

Interlocks are not checked.

500 -2700 500

The sewing motor can be operated

with a selectable set speed by pressing the pedal. After the sewing motor

has been started, the current speed is

also displayed.

59

Page 60

Input

Group

Gruppe

600 606 Thread trimming sequence

Parameter

Parameter

607 Cold start (RESET)

608 Setting zero points

Description

Bedeutung

The sequence for a complete thread

trimming cycle is started with the +/key (+) below CUT and below THR.

With this function the control unit

carries out a cold start (RESET) with

which the data is reset. After this function has been selected, the machine must be switched off and then on

again.

With this function and the adjustment

gauge, the zero points for the X/Y-drive

unit can be set. (stepping motor correction values for the reference points

REFX, REFY). The access code is

required for this adjustment.

Setting

range

Set value

609 Setting the clamp centre X

This function is used to set the centre of the clamp in X-direction. When

entering the function, the machine

moves to the current clamp centre,

after which it is possible to move to

the right or left edge of the clamp,

depending on the set limits (param.

"023"). A correction can be made with

the plus/minus keys. The relocation value is displayed.

610 Setting the clamp centre Y

This function is used to help set the

centre of the clamp in Y-direction. After entering this function, the machine

moves to the current clamp centre,

after pressing a key to the front or the

rear limit (param. "024"). The clamp

must be shifted manually.

60

Page 61

Input

Group

Gruppe

600 611 Automatic clamp opening off

800 The function groups and the functions

Parameter

Parameter

612

Description

Bedeutung

With this function the automatic opening of the clamp after thread trimming can be switched off. After the

machine has been switched off, the

automatic clamp opening function

is always activated.

Test function continuous start

Programming the Function Keys P, P1P8 and C1-C3 can be released for mani-

pulation (ON) or locked (OFF). If a function group is suppressed, its parameters cannot be changed until a valid access code has been entered. Once a

valid access code has been entered,

the suppression is cancelled until the

machine is switched off.

Setting

range

ON - OFF OFF

ON - OFF OFF

Set value

801

802 Right of access function group 100 ON - OFF ON

807 Right of access function group 600 ON - OFF OFF

808 Right of access function group 700 ON - OFF OFF

809 Right of access function group 800 ON - OFF OFF

810 Right of access to keys "P",

811

Right of access function group 000

"P1" - "P8" and "C1" - "C3"

Access code

This parameter is used to alter the access code. Upon delivery the

machine is set with the access code

"3371".

11 .08 Error messages on the display

Following error messages are shown on the control panel display

ON - OFF ON

ON - OFF ON

3371

ERROR: 1 Processor error STACK_OVERFLOW

ERROR: 2 Processor error STACK_UNDERFLOW

ERROR: 3 Processor error UNDEF_OPCODE

ERROR: 4 Processor error PROTECTION_FAULT

61

Page 62

Input

ERROR: 5 Processor error ILLEGAL_WORD_OPERAND

ERROR: 6 Processor error ILLEGAL_INSTRUCTION

ERROR: 7 Processor error ILLEGAL_BUS_ACCESS

ERROR: 8 Processor error NMI

ERROR: 10 OTE (Sewing head recognition unit) not attached

ERROR: 11 OTE not programmed (new)

ERROR: 12 OTE check sum error

ERROR: 13 OTE header invalid

ERROR: 14 OTE user data invalid

ERROR: 30(#) (OTE error see cap. 11.10)

ERROR: 31(#) (Error Sewing motor see cap. 11.09)

ERROR: 50 Incorrect control panel

ERROR: 51 Incorrect machine class in OTE