Page 1

PFAFF

.STOCK

DESC.

"

UNIT

ii^^JouANTITY

GUST

NO

jSysT.

OF^

SeryjceJMaiuiaJ

MAHUai.:

1 , j

*J

3337

date

PICKED

ORDER

PFAFF

INDUSTRIEMASCHINEN

GMBH

KAISERSLAUTERN

Page 2

Service

and

Illustrated

Manual

Guide

for

the

for

Tape-Recorded

Pfaff

3337

Instructions

Tools, gauges and sundry materials required for adjusting the Pfaff 3337:

1

setofscrewdrivers

1

setofspanners

1

set

of hexagon socket

1

Seeger

1

hammer

1

brass

circlip pliers

punch

with

with

openings

screw

blades

from

2—10

mm

wide

from

7-14

mm wide

keys ranging from 1.5 to 6 mm

1

metal

1

universal

1

needle

1

C-clamp,

1

wrapper

1

stripofwhite

sewing

ruie,

0.3 mm

gauge.

rise

gauge,

No.

880137/00

with

System34needles

paper,

thread

thick

No. 91-129604-91

2.4 mm,

Order

and

No.

880136/00

Page 3

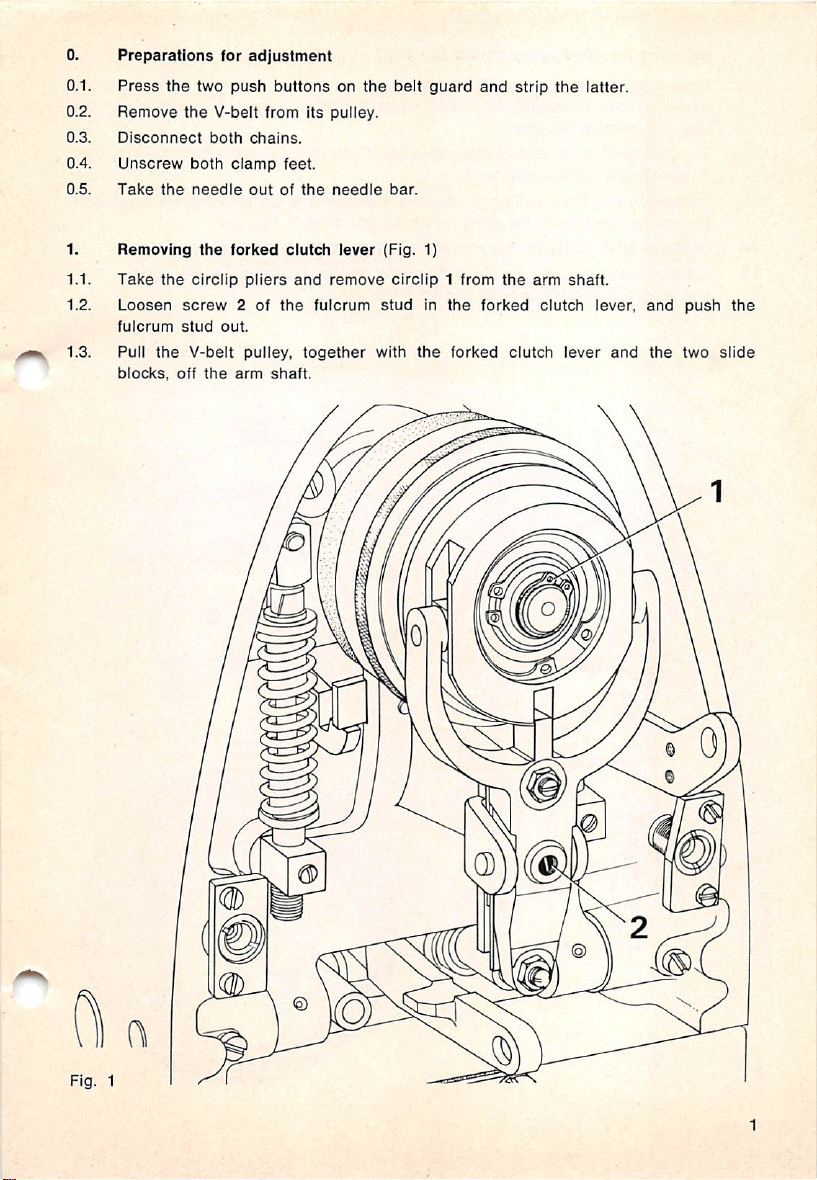

0.

Preparations

0.1.

Press

0.2. Remove

0.3.

Disconnect

0.4.

Unscrew

0.5.

Take

1.

Removing

Take

1.1.

1.2.

Loosen

fulcrum

1.3. Pull

the

blocks,

for

adjustment

the

two

push

the

V-belt from its puiiey.

both

chains.

both

ciamp

the

needle

outofthe

the

forked

the

circlip

pliers

screw

2 of

stud

out.

V-beit pulley,

off

the

arm

buttonsonthe

feet.

needle

clutdi

lever

and

remove

the

fulcrum

together

shaft.

belt

guard

bar.

(Fig.

1)

circiip1from

studinthe

with

the

and

forked

the

forked

strip

arm

clutch

the

clutch

lever

iatter.

shaft.

lever,

and

and

the

push

two

the

slide

Fig.

0

w

1

Page 4

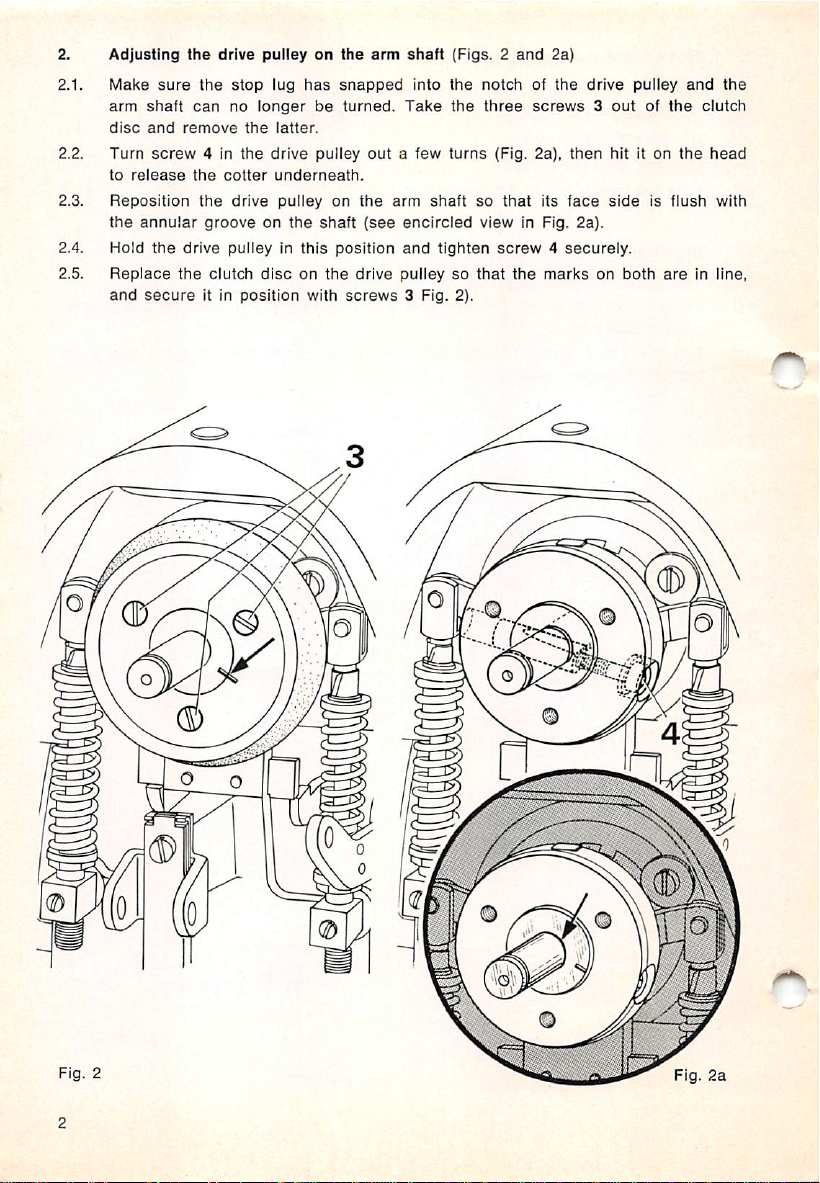

2.

Adjusting

2.1.

Make

arm

disc

2.2.

Turn

to

2.3.

Reposition

the

2.4. Hold

2.5.

Replace

and

sure

shaft

and

screw

release

annular

the

secure

the

drive

the

stop

can

no

remove

4 In

the

cotter

the

drive

grooveonthe

drive

pulley in

the

clutch

it In

pulleyonthe

lug

has

snapped

longerbeturned.

the

latter.

the

drive

pulley

underneath.

pulleyonthe

shaft

this

position

disconthe

position

with

arm

out

(see

drive

screws

shaft

(Figs.2and

Into

the

Take

the

a few

turns

arm

shaftsothat

encircled

and

tighten

pulleysothat

3 Fig. 2).

2a)

notchofthe

three

screws3outofthe

(Fig. 2a),

view

its

in Fig.

then

face

2a).

screw4securely.

the

marksonboth

drive

pulley

hit it on

sideisflush

are

and

the

in line,

the

clutch

head

with

o

o

o

Qb

©

©

Page 5

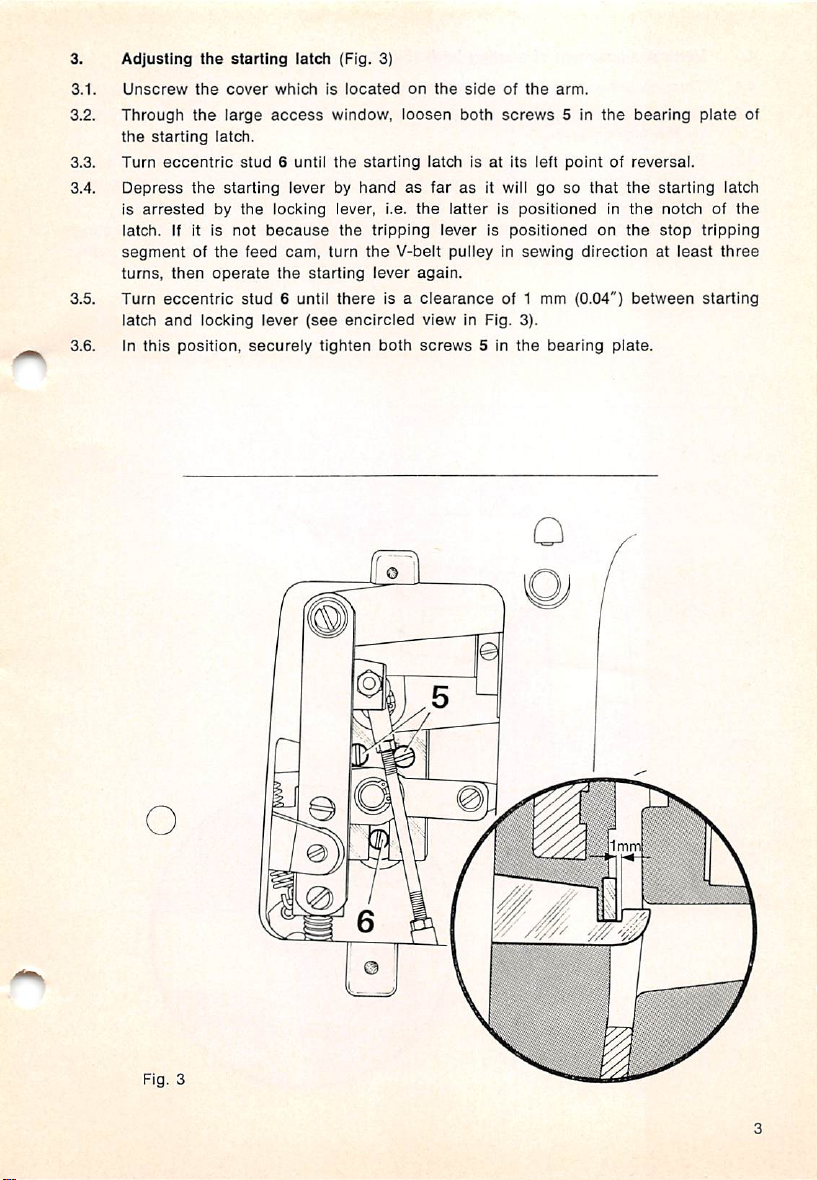

3.

3.1.

3.2.

3.3.

3.4.

3.5.

3.6.

Adjusting

Unscrew

Through

the

Turn

Depress

is

latch,

starting

eccentric

arrested

if it is

the

the

the

latch.

the

by

segmentofthe

turns,

then

operate

Turn

eccentric

iatch

and

locking

in

this

position,

starting

cover

whichislocated

large

access

stud

6 until

starting

leverbyhandasfarasit will gosothat

the

locking lever, i.e.

not

because

feed

cam,

the

stud

6 until

lever

securely

iatch

starting

(see

tighten

(Fig. 3)

window,

the

starting

the

turn

the

there

encircled

on

ioosen

tripping

V-belt

lever

is a

both

the

sideofthe

both

iatchisat

the

iatterispositionedinthe

ieverispositioned

screws

its ieft

arm.

5 in

pointofreversai.

pulleyinsewing

again.

clearance

viewinFig.

screws

of 1 mm (0.04")

3).

5 in

the

bearing

the

bearing

the

starting

notchofthe

on

the

stop

directionatleast

between

plate.

piate

latch

tripping

three

starting

of

O

Fig. 3

Page 6

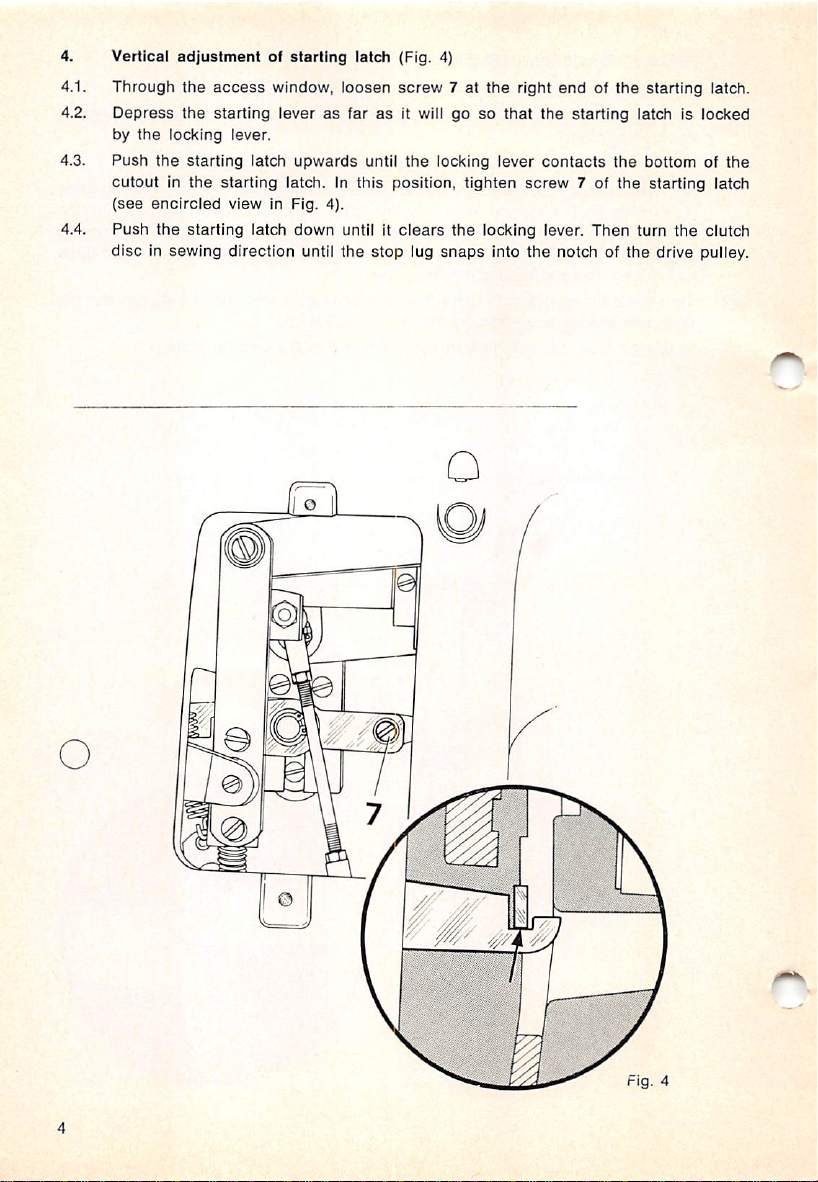

4. Vertical

Through

4.1.

4.2.

Depress

by

4.3.

Push

cutoutinthe

(see

4.4.

Push

adjustmentofstarting

the

access

the

starting leverasfarasIt will gosothat

the

locking lever.

the

starting

starting latch. In this position,

encircled

the

view

starting latch

disc in sewing direction until the

window,

latch

in Fig. 4).

upwards

down

latcfi (Fig. 4)

loosen

screw

until

the

until it

clears

stop

7 at

locking lever

tighten

the

lug

snaps

the

right

endofthe

the

contacts

screw

locking lever.

starting

7 of

latch is locked

the

the

Then

turn

starting

bottom of

starting latch

the

latch.

clutch

into the notch of the drive pulley.

the

O

Fig.

4

Page 7

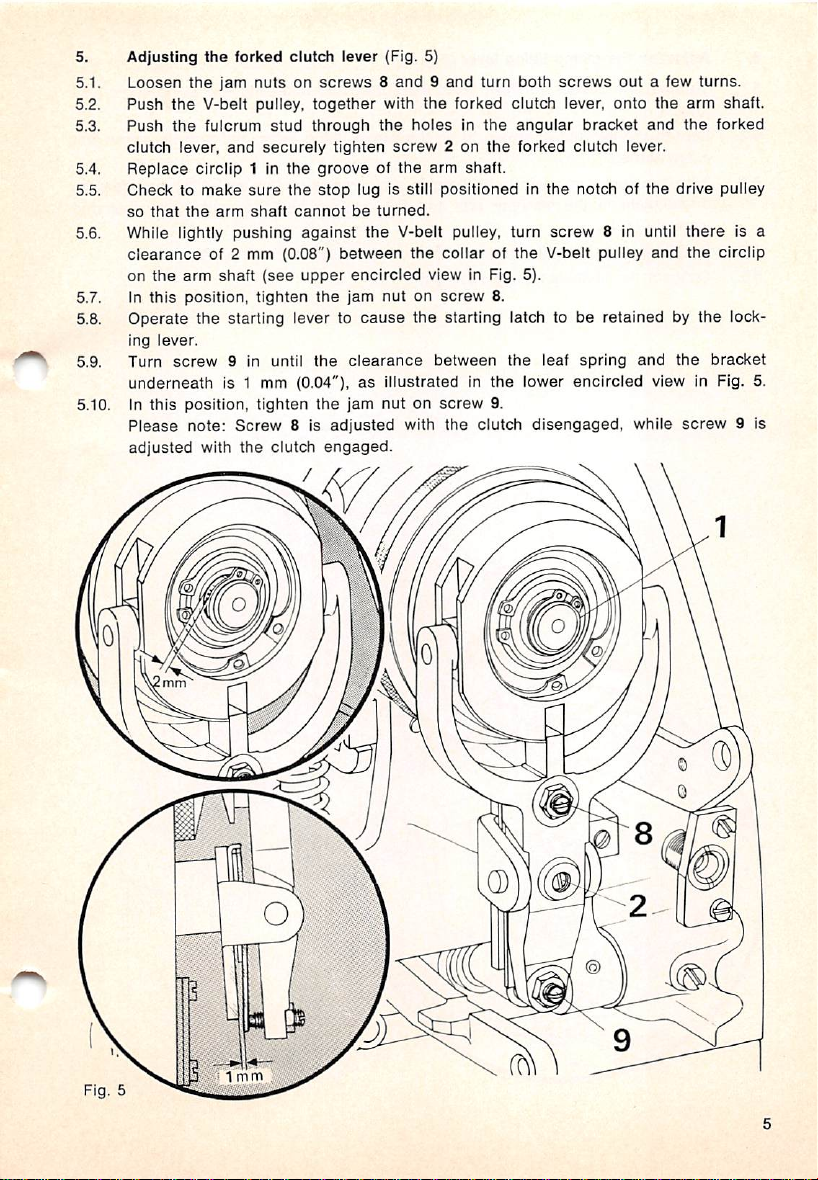

5.

Adjusting

5.1.

Loosen

5.2.

Push

Push

5.3.

clutch

Replace

5.4.

Checktomake

5.5.

so

5.6.

While lightly pushing against the V-belt pulley, turn

clearance

on

In

5.7.

5.8.

Operate the starting lever to

ing

5.9.

Turn

the

the

lever,

that

the

this

lever.

screw

the

forked clutch lever (Fig. 5)

the

jam

nutsonscrews8and9and

V-belt pulley,

fulcrum

and

clrcllp 1 in

sure

the

arm

shaft

stud

securely

the

the

cannot

together

through

of 2 mm (0.08")

arm

shaft

(see

upper

position,

tighten

9 in until

the

the

with

the

tighten

screw2on

grooveofthe

stop

lug is still

be

turned.

between

encircled

jam

nutonscrew

cause

clearance

turn

both

the

forked clutch lever,

holesInthe

the

screws

angular

forked

brad<et

clutch

out

onto

lever.

arm shaft.

positionedinthe

the

collarofthe

notch of

screw

8 in until

V-belt pulley

view in Fig. 5).

8.

the starting latch to be retained by the lock

between

the

leaf

spring

and

underneath is 1 mm (0.04"), as illustrated in the lower encircled view in Fig. 5.

In this position, tighten

5.10.

Please

adjusted

note:

with

Screw

the

8 is

clutch

the

adjusted

engaged.

/

jam nut on

with

screw

the

9.

clutch

disengaged,

while

a few

the

arm shaft.

and

the

the

drive pulley

there

and

the

the

screw

turns.

forked

Is a

clrcllp

bracket

9 is

Page 8

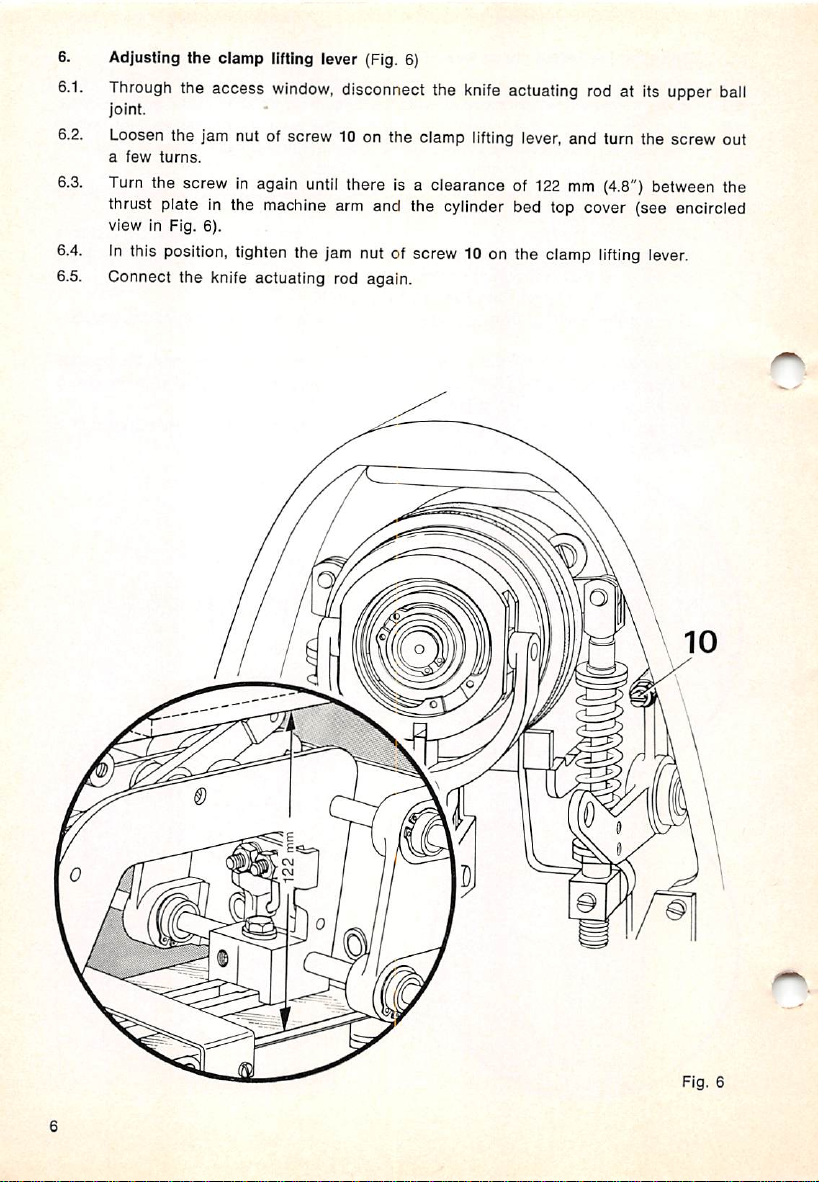

6. Adjusting the clamp lifting lever (Fig. 6)

6.1.

Through

joint.

6.2. Loosen the jam nut of screw 10 on the clamp

a

6.3.

Turn

the access

few

turns.

the screw in again

window,

until

disconnect the

knife

lifting

there is a clearance of

actuating rod at its upper

lever, and turn the screw out

122mm(4.8")

thrust plateInthe machine arm and the cylinder bed top cover (see encircled

view in Fig. 6).

6.4.

In

this

position,

6.5. Connect the knife actuating rod again.

tighten

the

jam

nut of screw 10 on the

clamp

lifting

o

between

lever.

ball

the

Fig.

6

Page 9

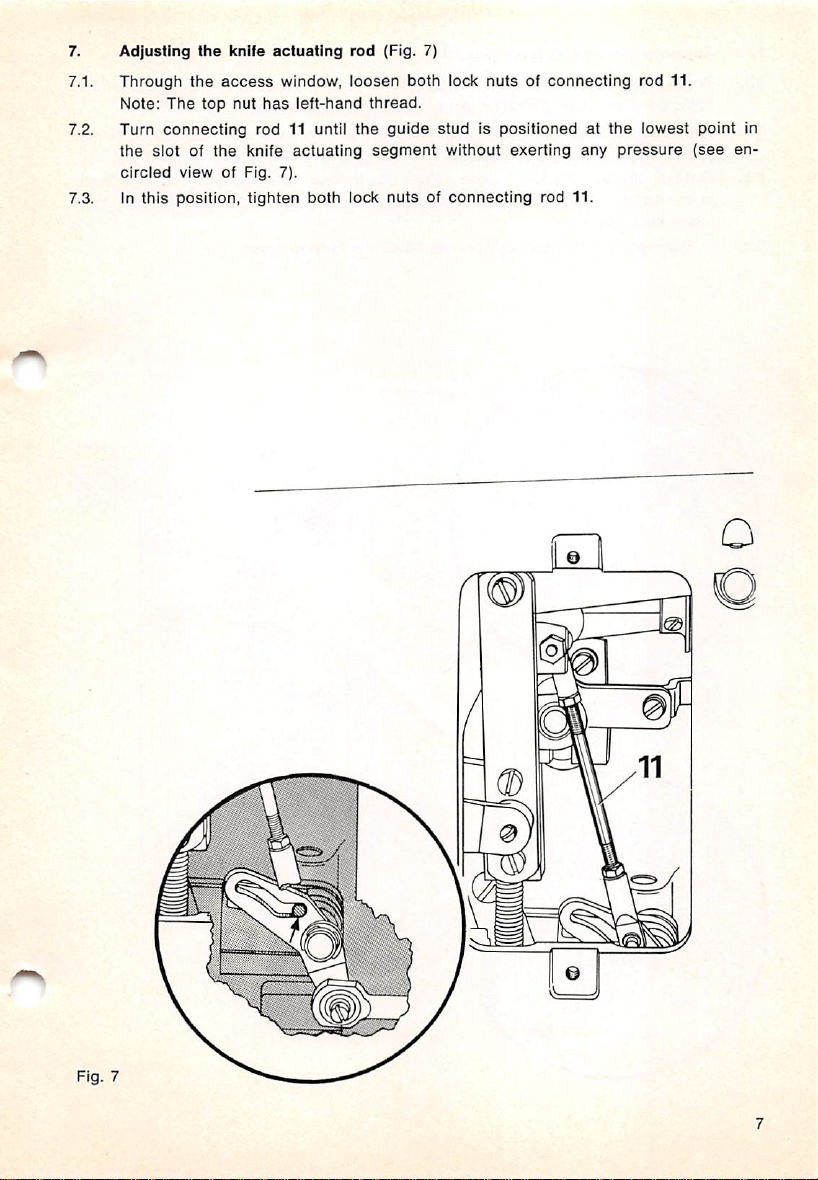

7.

Adjusting

Through

7.1.

Note:

7.2. Turn

the

circled

7.3. In

the

knife

actuating

the

access

window,

The

top nut

connecting

slot of

view

this

position, tighten both lock

has

rod 11 until

the

knife

of Fig. 7).

left-hand

actuating

rod

(Fig. 7)

loosen

both

thread.

the

guide

segment

nutsofconnecting

lock

nutsofconnecting

studispositionedatthe

without exerting

any

rod 11.

rod 11.

lowest point in

pressure

(see

en

O

Fig.

0)

7

Page 10

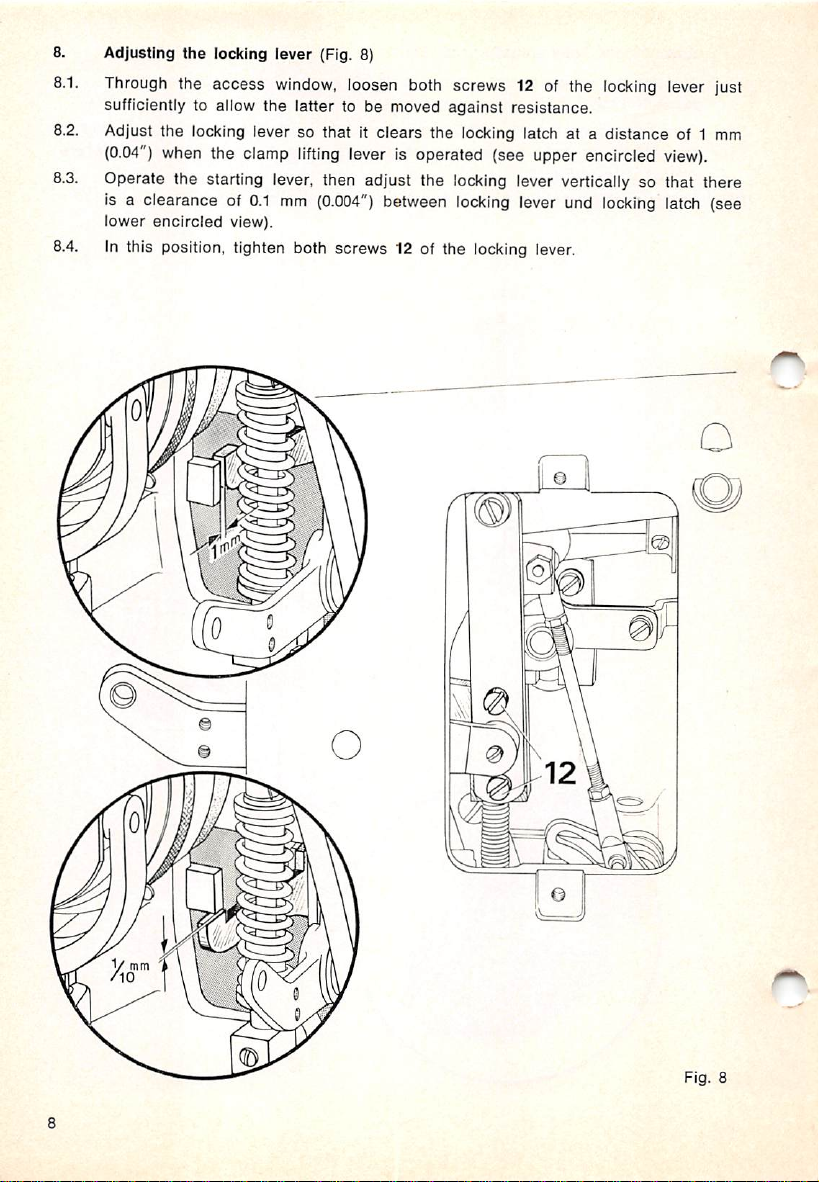

8.

Adjusting the locking lever (Fig. 8)

8.1.

Through

sufficiently to allow the latter to be moved against resistance.

8.2.

Adjust the locking lever so that it clears the locking latch at a distance of 1 mm

(0.04")

8.3.

Operate the starting lever, then adjust the locking lever vertically so that there

Is a clearance of

lower

8.4.

In this position, tighten both screws 12 of the locking lever.

the access

when

encircled

the

clamp

0.1

view).

window,

lifting

mm

(0.004")

loosen

lever

both

screws 12 of the

Is operated (see upper encircled

between

locking

lever und

locking

locking

lever

just

view).

latch (see

o

Q

m

Fig.

8

Page 11

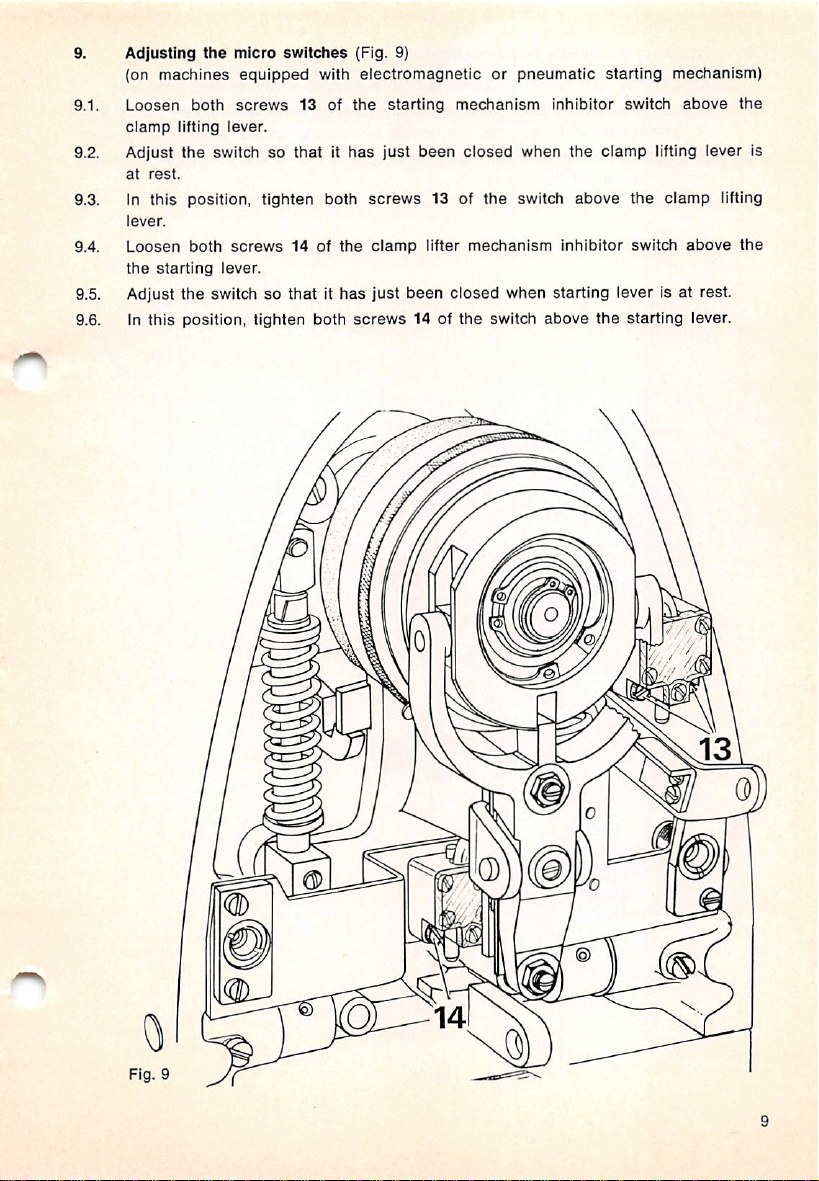

9.

Adjusting

(on

9.1.

Loosen

clamp

9.2. Adjust

at

9.3. In

lever.

9.4.

Loosen

the

machines

both

lifting

the

rest.

this

position,

both

starting

the

micro

equipped

screws

lever.

switchsothatithas

tighten

screws

lever.

9.5. Adjust the switch so

9.6. In

this

position, tighten

switches

with

13 of

both

14 of

the

thatithas

both

(Fig. 9)

electromagnetic

the

starting

just

been

screws

screws

clamp

just

13 of

lifter

been

14 of

or

pneumatic

mechanism

closed

the

mechanism

closed

the

switch

inhibitor

when

the

switch

above

inhibitor

when starting lever is at rest.

above

the

starting

switch

clamp

lifting lever is

the

switch

starting lever.

mechanism)

above

clamp

lifting

above

the

the

Fig.

Q

6)

w

9

Page 12

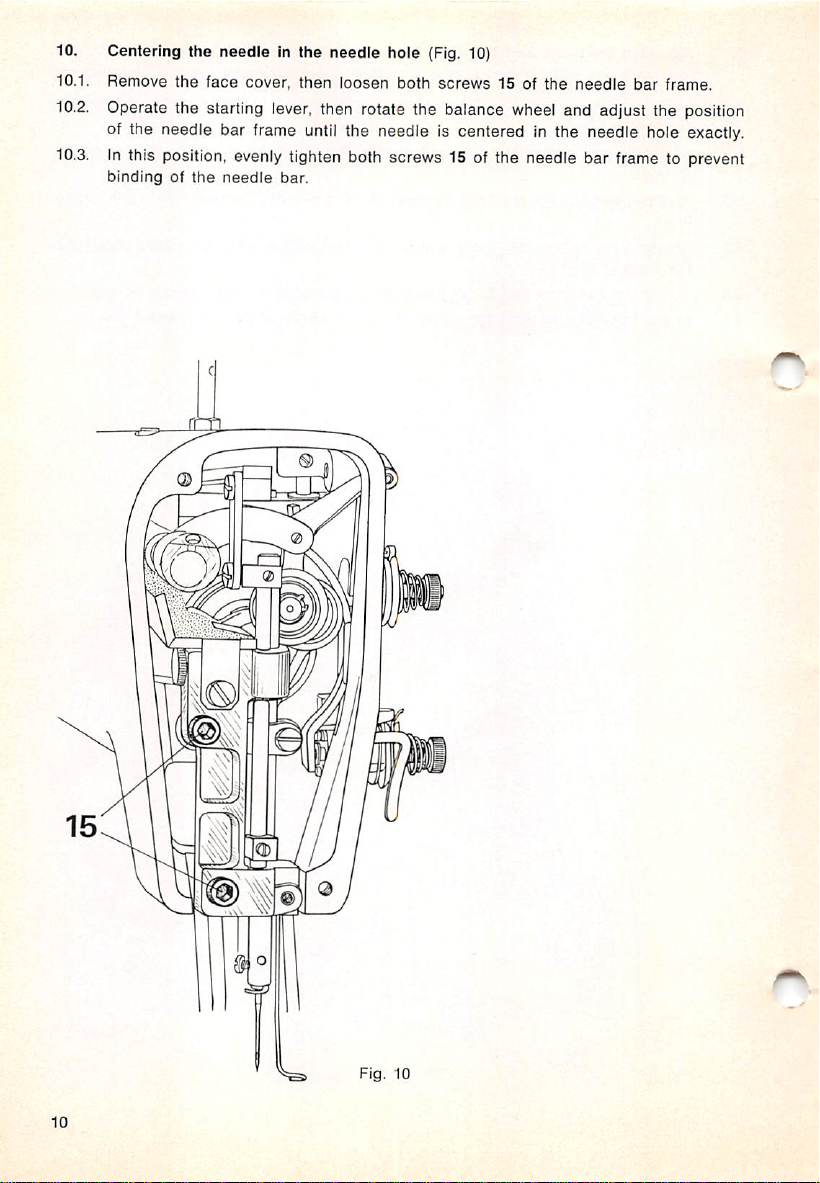

10. Centering the needle in the needle hole (Fig. 10)

10.1. Remove

10.2.

Operate the starting lever, then rotate the balance wheel and adjust the position

the

face

cover, then

loosen

both

screws

15 of

the

needle

of the needle bar frame until the needle Is centered in the needle hole exactly.

10.3.Inthis position,

bindingofthe

evenly

needle

tighten both screws 15 of the needle bar frame to prevent

bar.

bar

frame.

Fig. 10

10

Page 13

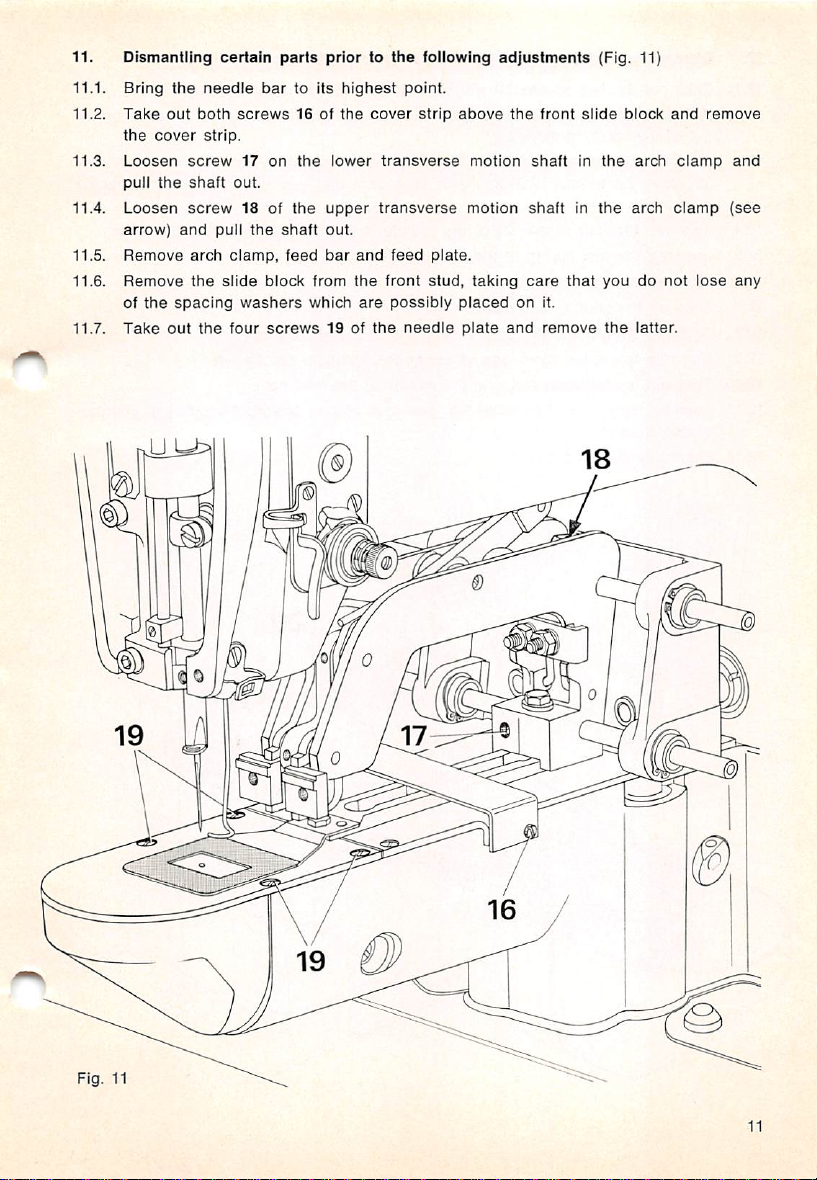

11. Dismantling

11.1. Bring

11.2.

11.3.

11.4.

11.5.

11.6.

11.7.

Take

the

cover

Loosen

pull

the

Loosen

arrow)

Remove

Remove

of

the

Take

the

out

screw

shaft

screw

and

arch

the

spacing

out

certain

needle

both

strip.

pull

slide

the

screws

17

out.

18 of

the

clamp,

washers

four

parts

bar

on

shaft

feed

block

screws

to Its

16 of

the

the

from

which

prior to

highest

the

lower

upper

out.

bar

and

the

are

19 of

the

point.

cover

transverse

transverse

feed

front

possibly

the

needle

following

strip

above

plate.

stud,

placedonit.

plate

adjustments

motion

motion

taking

and

the

front

shaftInthe

shaftinthe

care

remove

(Fig. 11]

slide

that

block

and

arch

arch

youdonot

the

latter.

clamp

clamp

lose

remove

and

(see

any

Fig.

U

17

19

11

11

Page 14

12. Dismantling certain parts prior to the following adjustments (Fig. 12)

12.1.

Take

out

the

two

screws

20

which

are

locatedinthe

trunnion

block.

12.2. Pull the trunnion block forward as farasit will go, then remove it by pulling it

outofthe

12.3. Remove

stripping

washers.

12.4.

Take

12.5.

Unscrew

12.6.

Unscrew

12.7.

Take

12.8.

Take

12.9.

Unscrew

Take

12.10.

12.11. Turn

clockwise,

12.12.

Then

out

off

the

out

the

strip

machine

slide

the

the

the

the

the

shuttle

the

the

eccentric

and

the

sideways.

block

guide

trunnion block. Again

four

screws

leaf

springofthe

cylinder

shuttle

roller

hexagon

and

race

the

lever

bed

screwinthe

bushinginthe

pull it

out.

feed

cam.

together

21 of

cap.

cover.

bobbin

located

with

take

the

cylinder

cylinder

case

under

middleofthe

feed

the

slide

care

bed

bed

cap.

outofthe

the

bedplateonthe

cam

slightly

block which

that

you do

top

shuttle

feed

cover

race.

cam.

toward

and

dot

the

left.

are

lose

strip

left,

exposed

any

the

latter.

i.e.

counter

aftei

spacing

12

Page 15

13.

13.1.

13.2.

13.3.

13.4.

13.5. In

13.6. In

13.7.

Setting

Turn

hititon

Operate

driver

Then

the

Loosen

clamp

screw

the

Replace

the

the

is

exactlyinthe

this

position,

race

lengthwiseofthe

between

this

the

position,

shaft

take

shuttletothe

screw

22 of

23 on

the

right-hand

head

to

release

shuttleInits

starting

middleofthe

move

race.

lever

the

cylinder

pointofthe

securely

bearinginposition.

the

shuttle

shuttle

tighten

out

needle

the

the

and

shuttle

of its

(Fig. 13)

shuttle

sideofthe

cotter

turn

the

clearance

driver

bed

and

screw

race

driver

underneath.

V-belt

until

the

23 of

again.

and

cylinder

pulley

cutofthe

shaft

there

needle

the

pull

needle.

bearing

is a

clearance

(see

cotter

the

latter

bed

until

the

together

encircled

which

off its

shaft.

out

a few

turns,

pointofthe

with

the

of 0.1 mm (0.004")

view

of Fig. 13).

secures

the

then

shuttle

shuttle

shuttle

Fig.

10mm

13

13

Page 16

14.

Setting the shuttle driver

14.1.

Loosen

14.2.

Loosen

Turn the V-belt pulley to bring the

14.3.

Pull the shuttle driver shaft forward as far as it

14.4.

14.5.

Turn the

both

both

rear

screws

screws

collar so that

shaft

24inthe

25 in

the

longitudinally (Fig. 14)

front

collarofthe

rear

collarofthe

needle

to its highest point.

one

of its

screws

shuttle

driver

shaft.

shuttle

driver

shaft.

wili

go.

points to the right —as

above —and the other faces upwards. Then push the collar up against the shuttle

driver

shaft

bearing

14.6.

Push

the

shuttle

(0.05")

between the rear collar and the bearing.

14.7.

In

this

position,

wards and the

shaft

bearing.

14.8.

Loosen

screw 25 in the rear collar tightened

against the shuttle driver shaft bearing, while

and

tighten

the

accessible

driver

shaft

toward

the

turn

the

front

collarsothat

other

to the upper left, and push it up against the shuttle driver

Tighten

the

lower

screw.

back

screw

25.

until

there

Is a

clearanceof1.3

one

of its

screws

previously,

lightly

and press this collar up

pushing against the front end

24

of the shaft. In this way, a clearance of 1.3 mm (0.05") is provided between the

wall of the arm standard and the spur gear on the shuttle driver shaft (see en

circled

view of Fig. 14).

14.9.

In this position, securely tighten both

14.10.

Then

securely

tighten

Please note: The shuttle

any

end

play.

the

second

driver

screw

shaft

screws

24 on

should

25 on the rear collar.

the

front

collar.

turn

lightly,

however

seen

faces

without

from

mm

down

having

Fig. 14

14

Page 17

15.

Adjusting

15.1.

Prize

15.2. Bring

15.3.

Place

the

the

circliponthe

the

needle

the

shuttle

shuttle

driver

bar

to its lowest point.

driver

shuttle

on its

(Fig. 15)

driver

shaft

and

shaft

push

forward.

it up

against

the

circlip.

15.4. Tap both parts - the shuttle driver and the circlip —back until, when you turn the

shuttle

needleaspossible,

15.5. In

this

driver, its finger with

without

position, lightly

tighten

the

needle

deflecting

the

clamp

deflecting

it.

screwofthe

surface

shuttle

passesasclosetothe

driver.

Fig.

15

15

Page 18

16. Adjusting the radial play of the shuttle driver (Fig. 16)

16.1.

Unscrew both nuts of the bobbin winder on the back of the machine, and strip

the

bobbin

winder.

16.2. Take out the eight screws of the bearing plate underneath and remove the plate.

16.3.

Loosen the three screws 27 in the eccentric bearing bushing exposed now.

16.4.

Turn

the

longer

eccentric

has

any radial play, but light running of the machine is still ensured.

stud

with

the

aid

of a

screwdriver

until

the

shuttle

driver

no

16.5. Evenlytighten all three screws 27 of the eccentric bearing bushing.

Fig. 16

17.

Timing

the shuttle

17.1.

Check to make sure that the first screw (in sewing direction) of all parts located

on the arm shaft, e.g.

in the groove, and that all

17.2.

Loosen the clamp screw of the shuttle driver just sufficiently to allow the latter

to be

turned

17.3.

Replace

17.4. Bring the

the

needle

driver

motion

spur

gear,

screws

on its

shaft

against

shuttleinthe

bar to its lowest point.

shuttle

and adjusting the needle rise

eccentric

are

resistance.

race.

and worm. Is positioned on the flat or

securely tightened.

(Fig.

17)

17.5. Set the machine for a needle bar rise of 2.4 mm (0.09"). Turn the shuttle and the

shuttle driver so that the shuttle point is exactly behind the needle.

17.6.

Rotate the

again contacts the needle bar

be

positioned

16

V-belt

pulley backwards until the C-clamp screwed to the needle bar

frame.Inthis position, the shuttle point must again

exactly

behind

the needle (see encircled

viewinFig.

17).

Page 19

17.7. If

17.8.

17.9. In

the

pointofthe

and

loosen

accessible

tobeturned

Turn

the

until

the

needle

bar

then

backwards.

this

position,

the

latter

the

through

against

belt

sprocket

shuttle

contacts

contacts

shuttleisnot

three

screws

the

access

resistance.

on

point is

the

securely

its

bearingonthe

the

exactly

needle

tighten

17.10. Remove the C-cIamp from the

tighten

the

clamp

screwofthe

17.11.

Loosen

17.12.

Replace

amountofplay

17.13.

Securely

both

screwsofthe

the

shuttle

tighten

in its

between

both

shuttle

race

shuttle

screwsofthe

exactly

28 of

window)

arm

bar

screw

needle

shuttle

and

and

the

shaft

behind

frame

right.

race.

adjust

shuttle

shuttle

behind

the

belt

sprod<et

just

sufficientlytoallow

just

slightly

the

needle

after

turning

28 on

the

belt

bar,

take

the shuttle out of its race, and

driver

securely.

the

lattersothat

driverinboth

race.

needle,

on

the

and

when

the

sprocket,

remove

arm

shaft

the

belt

repeat

this

the

C-clamponthe

V-belt pulley

making

thereisthe

ultimate

positions.

the

C-olamp

(which

sprocket

adjustment

forwards,

sure

are

that

same

O

Fig.

17

17

Page 20

18.

Setting the needle bar at the correct height (Fig. 18)

18.1.

Turn the

site

18.2.

Loosen clamp screw 29 on the needle bar connecting stud.

18.3.

Move

V-belt

pulley in sewing direction until the shuttle point is exactly oppo

the

center

lineofthe

needle.

the needle bar up or down until there is a clearance of 1.5 mm

between the lower edge of the shuttle point and the top of the needle eye (see

encircled

18.4.

In this position, securely tighten clamp screw 29 on the needle bar connecting

view of Fig. 18).

stud, making sure the thread guide screw on the needle bar points toward the

rear.

18.5.

Screw

on the shuttle

18.6.

Push the starting latch out of the locking lever and turn the clutch disc in sewing

race

cover, making

sureItdoes

not lose its resilience.

direction until the stop lug has snapped into the notch of the drive

(0.06")

pulley.

—i.o

mm

Fig.

18

18

Page 21

19.

Adjusting

Loosen

19.1.

the

19.2.

Loosen

tobemoved

19.3.

Operate

forward

19.4. Adjust

53 mm (2.09")

and

the

clamp

left,

and

screw30just

the

pointofreversal.Inthis

the

the

tip of

38 mm (1.5")

knife

(see

encircled

this

19.5. In

position,

puller. Make

positionedasclosetothe

contacting

It.

bobbin

screw

lightly

against

clamp

bobbin

between

the

between

sure

thread

puller

31 of

the

tighten

the

sufficientlytoallow

resistance,

lifting

levertobring

thread

puller

the

left

bobbin

thread

the

left

view

of Fig. 19).

securely

as

you tighten

tighten

shuttle

and

the

movable

needle

clamp

position,

edgeofthe

puller,inaddition,

edge

screw

and

the

of this hole

screw

the

race

thread

the

knife

block

knife so

30 of

screw

as

again.

right

possible

catcher,

knife

and

the

screwhole

there

the

that

knife (Fig. 19)

swing

the

latter

and

the

bobbin

clamp

that

and

knife

the

bobbin

thread

lifting lever.

there

shouldbea

the

and

bobbin

is a

on

the

cutting

the

thread

thread

pullertotheir

clearance

needle

clearance

edgeofthe

bobbin

vertically, without actually

toward

puller

of

plate

of

thread

puller is

Fig. 19

o

38

mm

53

mm

19

Page 22

20. Mounting

20.1.

Loosen

cam.

20.2. Turn the eccentric bushing of the feed cam so that its lobe points upwards,

toward

20.3.

fvlount

the

cam.

20.4. Insert the pin of the

in

20.5.

Turn

spur

20.6. In this position,

the

feed

cam

(Fig. 20)

screws

Set

the

the

all

tripping

feed

these

32, 33, 34, 35

screwsinthe

segment

camsothat

and36and

middle of

on

the

the

cutoutinits

rim of

right-hand roller lever is positioned in

cap

the

hexagon

the

gears,

washer

srewbyhandasfarasit will go.

eccentric

but

bushing

the

machine

securely

tighten

into the hole of the

clockwise

still

turns

the

hexagon

their

the

until

easily.

the

three

slots

cam.

rim isonthe

the

channelonthe

there

is no

screwofthe

alien

screws

and

tighten

eccentric

backlash

37 of

them again.

left

and

the

upper

bushing and turn

between

feed

cam.

the

feed

i.e.

roller

sideofthe

both

20.7. Mount the roller lever on the left-hand feed motion segment, and adjust the latter

so

that

the

20.8.

Securely

rollerispositionedinthe

tighten

the

two

screwsofthe

channelofthe

roller

lever.

cam.

of

Fig.

20

20

Page 23

21.

Timing

the

feed

motion

(Fig. 21)

21.1.

Operate

and

motion

point. (Only

21.2.

If adjustment is required, loosen the three

the

21.3.

Securely

the

the

feed

before,

camonits

tighten all

starting lever

motion

leversinthe

and

the

one

lever moves at

shaft

accordingly.

three

and

second

screws

turn

cylinder

half

any

37 of

the

V-belt pulley while watching

bed.

Each

lever

after,

the

needle

bar

given time).

the

feed cam.

screws

37 in the feed cam and turn

has

should

reached

the

make

Its

needle

half its

highest

Fig.

21

21

Page 24

22. Adjusting

the

stop

tripping

segment

(Fig. 22)

22.1. Turn the V-belt pulley in sewing direction until the machine has completed Its

sewing

15 mm (0.6")

22.2. if it is not, check to

22.3.

Operate

22.4. Loosen

22.5. If the machine stops too late,

it

22.6. Check again to

(0.6")

ment

cycle

and

above

stopped.

the

The

take-up

bottom

of Its stroke.

see

whether the machine

lever

should

has

the starting lever and turn the V-belt pulley backwards

the

three

screws

33 of

the

segmentonthe

set

the segment earlier, if it stops too early,

later.

Then

securely

above the

until

this

tighten

the

three

screws

see

if the machine stops with the take-up lever exactly 15 mm

bottom

condition

of its stroke. If it does not, repeat the foregoing adjust

is

met.

33.

now be

stopped

feed cam.

positioned

about

too early or too late.

about

two turns.

set

22.7. Turn the clutch disc in sewing direction until the machine has completed its

sewing cycle and stopped. The machine Is now in its starting position.

Fig.

22

22

Page 25

23.

Adjusting

Checktomake

23.1.

of

this

23.2.

Setaclearance

catcher

23.3. In

actuating

the

position,

this

the

needle

crank

position,

rod.

thread

catcher

sure

the

machine

thread

catcherisat

loosen

both

of 0.3 mm (0.01")

(see

encircled

securely

crank

screws

view

tighten

(Fig. 23}

is in its

the

highest

38 of

the

between

of Fig, 23),

first

the

starting

two-part

the

front,

position

point

thread

cylinder

then

of its

bed

the

and

tripping

catcher

wall

rear

the

and

screw

tripping

segment.

actuating

the

38ofthe

stud

In

rod.

thread

Page 26

24.

24.1.

Adjusting

Operate

the

the

its lowest point. During this

ping

stud

must

24.2. Loosen

thread

24.3.

Press

as

bed,

24.4. Swing

and,

When

starting

24.5. Adjust

bobbin

24.6. Loosen

24.7. Turn

thread

(see

24.8.

Press

clamp

catchertobe

the

thread

It will go, i.e. until

and

hold

the

needle

in this position,

you

release

position.

the

thread

thread

the

screw

catcher

encircled

the

starting

V-belt pulley

needle

thread

starting lever

catcher

and

turn

(Fig. 24)

the

V-belt pulley to bring

phaseofthe

have

screw

catcher

it in

cleared

31 of

turned

this

thread

securely

the

catcher

the

tripping

the

needle

thread

on its

shaft

against

actuating

the

thread

position.

catcher

actuating

catcher

inwards

tighten

rod in

clamp

rod,

the

verticallysothatitpasses

puller, i.e. without touching any of

lock nut of

39 until

and

view at right). In

backwards

there

the

latch

screw

is a

needle

outofthe

until

the

39 on

clearance

when

this

machine

the

left

the

position,

cutoutofthe

machine

segment.

the

crank

until it

of 4 mm (0.16")

thread

cycle,

catcher

resistance.

cylinder

just

bed

contacts

contacts

screw31(see

thread

catcher

these

sideofthe

catcher

tighten

the

locking iever,

the

thread

sufficiently to allow

toward

the wall of

the

encircled

should

freely

between

parts.

cylinder arm.

between

is in its

lock

nutonscrew

is in its starting position.

the

the

needle

starting

and

needle

the

bar

catcher

trip

the

leftasfar

the

cylinder

just

lightly

view at left).

return

to its

knife

and

tip of

the

position

39,

rotate

the

to

Fig. 24

24

Page 27

25.

Timing

Operate

25.1.

25.2.

Then

exactly

25.3. in

and

25.4. Now

lever

25.5. In

25.6.

Turn

this

the

25.7.

Turn

notchofthe

rotate

this

move

move

contacts

this

the

latter

shuttle

the

the

thread

the

starting

the

behind

the

position,

the

segment

the

tripping

the

position,

V-belt

phase,

pointisexactly

clutch

drive pulley.

catcher

V-belt

loosen

motion

lever

and

puiieyinsewing

rising

needie.

both

ali

the

segment

inclined

tighten

puiiey

the

surfaceofthe

both

backwards

needle

opposite

discinsewing

The

(Fig. 25)

turn

the

V-beit

direction

screws

32ofthe

waytothe

toward

screws

32 of

one

thread

catcher

the

rising

direction

machineisthus

ieft.

the

tripping

half

untii

puiley

until

thread

right untii

the

thread

turn,

should

needle.

the

in its

backwards

the

pointofthe

catcher

the

studofthe

segment.

catcher

then

slowly

begintomove

stop

lug

has

starting

one

turn.

tripping

tripping

forwards.

forward

snapped

position

shuttle

segment

actuating

segment.

During

when

into

again.

is

the

Fig. 25

25

Page 28

26.

Adjusting

26.1.

Loosen both

sideofthe

26.2.

Set

the needle hole and the cutting

26.3.

In this position, tighten both

26.4.

Replace and screw on the needle plate.

26.5.

To make a cutting test, pull two threads through the needle hole and operate the

lifting

26.6.

If they

its cutting

to

after the

26.7.

Screw on the cylinder bed lop cover, insert the trunnion block into the bearing

bushing of the machine and push it toward the rear as far as it

the

stationary

screws

needle

the knife so that

knife (Fig. 26)

40 of

plate.

there

the

stationary

is a

clearance

edge

screwsofthe

knife which

are

locatedonthe

of 1 mm (0.04") between the

of the knife

(see

encircled view of Fig. 26).

knife again.

lever by hand. As you do this, both threads should be trimmed perfectly.

are

not, remove the needle plate and adjust the knife so that the left

edge

—as

seen

from the front —is a little higher than the right. This is

ensure

a perfect shearing action between the movable and the stationary knife

needle

plate

has

been

screwed on again.

will

two slide blocks on their studs, making sure that their smooth surfaces are facing

upwards. Take

care

that the spacing washers are replaced, if any. Turn the rear

slide block on its stud so that its long side faces toward the right.

26.8.

Place

the

slide

block

guide

over

the

rear

slide

block

and

screw

it to

block with

26.9.

Replace the arch clamp, together with the feed bar and the feed plate, so that the

front

slide

the

block

aid of

enters

the

two

the

pan-head

channelinthe

screws.

feed

bar.

Push

both

transverse

through the holes in the trunnion block and the arch clamp so that their

protrude

equally on both

sides.

Then

tighten both

transverse

shaft

under

edge

end

go. Place the

the

trunnion

shafts

screws.

of

of

ends

Fig.

26

26

Page 29

28.

28.1.

28.2.

28.3. In

28.4. if

Setting

Open

the

cylinder

Loosen

as

farasthey

this

the

suitable

the

the

two

both

position,

largest

limiting

machine

covers

bed.

hexagon

will

tighten

tack

brackets

for Its

iargest

which

are

nuts43which

go.

both

nuts43securely.

shouldbebigger

under

tack

size

locatedonthe

are

now

than

both

nuts.

(Fig. 28)

bedplatetothe

exposed

the

cutoutofthe

and

push

clamp

right

them

and

feet,

left of

inwards

place

28

Page 30

29.

Centering

29.1.

Loosen clamp screw 44 in the left

blocktobe

29.2.

Also loosen clamp

trunnion

Operate the starting lever by hand. Then turn the V-bell pulley in sewing direction,

29.3.

the

tack

moved

blocktobe

designinthe

crosswise

screw

45 in the right crank just sufficiently to allow

moved

lenghtwise

cutoutofthe

crank

against

clamp

feet (Fig. 29)

just sufficiently to allow the trunnion

resistance.

against

resistance.

while simultaneously adjusting the position of the arch clamp until the needle at

the extreme right and left of the tack design clears both clamp feet at the same

distance.

Tighten clamp

29.4.

Continue turning the V-belt pulley In sewing direction until the machine starts

29.5.

feeding

29.6.

Adjust the position of the arch clamp until the needle while stitching the near

and far

cutout

29.7.

Tighten clamp screw 45 of the right clamp.

29.8.

Continue turning the V-belt pulley until the machine has completed its sewing

cycle and stopped. Then rotate the

screw

lengthwiseofthe

side

of the tack design

at

the

same

distance.

44 of the left crank.

cylinder

bed.

clears

clutch

the

near

disc

and far

until

edge

of the clamp feet

the stop lug has snapped

into the notch of the drive pulley, and the machine is in its starting position again.

the

29

Page 31

30. Timing the tension

30.1.

Operate the starting lever by hand, and turn the

until

the

take-up

30.2.

Loosen both screws 36 of the tension release tripping segment on the feed cam

and push them down as far as they will go.

30.3.

Then push the tension release tripping segment back as far as it

it

contacts

the feeler lever. In this position, tighten both

release

lever Is at its

mechanism (Fig. 30)

lowest

point.

V-belt

pulley in sewing direction

will

screws

36.

go, i.e.

until

30.4. To check this adjustment, turn the V-belt pulley backwards until the needle bar is

at its lowest point. In this position,

the

lower

tension

must be

released.

30.5. Then again bring the machine to its starting position.

Fig.

30

30

Page 32

31.

31.1.

31.2.

31.3.

31.4.

31.5.

31.6.

31.7.

Adjusting

Operate

direction

In

Turn

slack

The

the

downwards

In

Turn

this

screw

thread

thread

tension

this

the

the

until

position,

position,

nowbefully

46

and

the

Then

bring

the

tension

starting

screw46of

loosen

46 until

regulator

tension

release

slightly.

tighten

V-belt

pulleyinsewing

activated

actuating

the

machine

release

lever by

the

the

thread

and

should

lever

the

and

lever.

the

lock

both

still

toward

lock

there

to its

iever

(Fig. 31)

hand

and

tension

release

nutofscrew

check

spring

tension

haveasmall

the

right,

nutofscrew

direction

must

starting

position

slightly

discs

be a

46.

is in

amount

the

46.

a few

small

rotate

the

V-belt pulley in sewing

leverisaccessible.

line

with

the

are

separated

of play, i.e.

thread

check

turns.

The

amountofplay

again.

bottom

(see

spring

thread

edgeofthe

encircled

when

should

tension

between

you

view).

press

move

must

screw

Fig.

31

31

Page 33

32.

Timing

32.1.

Checktomake

screwsofthe

chine

32.2. Adjust

between

the

32.3. In

32.4. Briefiy

32.5. If

32.6.

32.7.

this

front

the

Make

Operate

As you

stitch.

32.8. If

32.9.

32.10.

32.11.

the

outer

Set

Repeat

first

Turn

low

the

32.12. If

the

inner

32.13.

Set

35

again.

32.14. Bring

the

motor

pole-changing

base).

the

switch vertically so

the

horizontal

actuating

endofthe

motor

sure

switch-over

the

stitch.

the

speed.

machine

plungerofthe

position,

switchonthe

tighten

machine,

rotates

the

V-beltisstill

the

starting

do

this,

the

motor

switches

switch-over tripping

this

adjustment

V-belt pulley in

Continue

makes

motor

switches

switch-over

the

inner

switch-over tripping

the

machine

speed

changes

sure

the

machine

actuating

switch.

the

three

motor

and

the

counter-clockwise,

removed,

leverbyhand,

motor

shouid

over

too

tripping

segment

segment

until

sewing

turning

another

tripping

to its

the

four

over

too

segmentonthe

starting

(Fig. 32)

is in its

switch (on

that

there

lever

screwsofthe

ched<

motor

should

exchange

and

and

switch

earlyortoo

on

the

earlierorlater,

the

motor

direction

V-belt pulley. As

stitches

earlyortoo

segment

position.

starting

the

right-hand

is a

(see

arrow)

its

directionofrotation.Asseen

turn

switchonthe

turn

the

from low to high

late,

feed

switches

until

beforeitswitches

late,

feed

somewhat

position.

outer

clearanceofabout

inside

the

switch

again.

clockwise.

the

wiresinthe

motor.

V-beit

pulleyinsewing

speed

loosen

both

cam.

then

tighten

from low to

the

motor

youdothis,

high

switches

checktomake

off

loosen

both

cam.

earlier,

Loosen

the

surfaceofthe

4 mm (0.16")

machine

base

from

plug.

direction.

after

the

screws

34 of

screws34again.

speed

after

from

mechanically.

screws

and

35 of

tighten

high

screw

three

ma

and

the

first

the

the

to

sure

the

32

Page 34

Fig.

32

33

Page 35

33.

Adjusting

33.1.

Replace

ciently to allow

33.2. Reposition

reiiably by

in

33.3. in

33.4. Mount

winder

winder.

33.5.iftoo

stop

33.6. Adjust

contact

this

position,

the

spindle,

muchortoo

latch.

the

the

bobbin

winder

the

mounting

the

the

friction wheel when

the

bobbin

bearing

plate

platesothat

with this wheei when

tighten

both

V-beit,

repiace

thread

the

little

threadiswound

studonthe

stop

(Fig. 33)

and

the

winder

plate

the

the

nuts

47.

the

beit

guard,

machine

latchsothat

bobbin winder, tightening

to be moved

the

bobbin

bobbin

bobbin

place

for

bobbin

on

the

bobbin

winderisdisengaged.

the

against

winder

puliey wiii be driven

winderisengaged,

an empty

winding,

bobbin,

winder

bobbinonthe

and

loosen

stops

nuts47just

resistance.

start

screw

when

wound on the bobbin is 1 mm (0.04") below its rim (see encircled view of Fig. 33).

33.7. in this position, tighten

33.8. if the thread on the bobbin has

thread

guideonthe

belt

screw

guard.

48 of

been

the

stop

latch stud.

wound unevenly, adjust the position of the

suffi

but wiil not be

bobbin

the

bobbin

48 of

the

the

thread

34

Page 36

34.

34.1.

34.2.

34.3. In

34.4.

34.5.

34.6.

35.

35.1.

Adjusting

Checktomake

of

Reposition

between

Now

Adjust

at a

circled

Tighten

Adjusting

Loosen

the

thread

the

vertical

the

thread

thread

needle

this

position,

loosen

screw50of

the

thread

distanceofabout

viewatright).

screw50of

the

eye

screw

51 of

sure

and

tighten

wiper

guard

wiper

(Fig. 34)

the

machine

wiper

rodatthe

wiper

rodsothat

thread

wiper

screw

49.

the

thread

wire

verticallysothatitpasses

1 mm (0.04") when

the

thread

wiper

(Fig. 34)

the

lifting

bracketonthe

35.2. Adjust the lifting bracket so that

between

35.3.Inthis

35.4.

Replace

swung

the

position,

the

toward

needle

face

the

tighten

cover

left at

bar

frame

screw

and

the

and

51 of

operate

same

Is in its

needfe-bar

wire.

wiper

wire.

there

the

the

the

moment

starting

there

is a

wire.

the

lifting lever is

vertical

is a

clearanceofabout

bracket.

lifting

bracket

lifting lever to

when

the

0X49

position,

endofthe

and

machine.

clearanceofabout

below

the

operated

thread

wiper

again.

seeifthe

clamp

feet

are

loosen

screw

15 mm (0.6")

needle

(see

rod.

1 mm (0.04")

eye

guard

raised.

49

point

en

is

Fig.

34

mm

35

Page 37

36.

36.1.

36.2.

36.3.

36.4.

36.5.

36.6.

36.7.

36.8.

Final

worksieps

Replace

the

cover

Screwonthe

Screw

on

the

Reconnect

Replace

both

the

threadispulled

about

3 cm (1.2").

Thread

Regulate

the

thread

the

machine

the

loopispassed

Switchonthe

strip

cylinder

cover

chains.

bobbin

through

upper

machine

above

the

bed

cap

and

on

the

sideofthe

case

with a full

the

holeinthe

and

place

material

tensionsothat,

smoothly

and

make

front

slide

the

cap

machine

bobbininthe

position

under

when

around

a few

sewing

block.

retaining

the

the

bobbin

the

spring.

arm.

shuttle,

fingersothat

clamp

thread

shuttle.

and

trimming

making

sure

its

end

feet.

tensionisreleased,

tests.

that

protrudes

the

36

Page 38

37.

Conversiontoother

37.1. Make

sure

the

subclasses

machine

is at its

having

starting

different

gear

position, i.e. at

ratios

the

sewing

cycle

end

position. Take out both screws of the roiler lever located under the bedplate

near

its

left

front

corner.

37.2. Take out the hexagon

washer

underneath.

Then

strip

the

roller

lever.

screw

in the middle of the feed cam and remove the

cap

37.3. Turn the eccentric bushing slightly toward the left, i.e. counter-clockwise, and

37.4.

strip both

Take

of

the

out

machine

the

the

feed

three

and

cam

alien

remove

and

the

bearing

screwsonthe

the

spur

bushing.

gear.

driving

spur

gear

on

the

vertical

shaft

37.5. Insert the spur gear having another gear ratio, and secure it in position with

the

three

alien

screws.

37.6. Now make the adjustment described In Chapters 21 through 32 inclusive.

37

Page 39

38. Explanation of circuit

Original

Switch

position:

Cur

rent

Path

master

*) 6

s

w

switch

diagram

Unit

No. 91-095418-95

a1 off.

Cur

rent

Path

2yl.

Function

a 1

54

b 1

51

56

51

56

52

*) 6 =

s =

w =

3-5

15

15

16

7+8

16

1+2

15

normally

closed

contact

normally

open

contact

change

over

contact

s m 1

o

6 s 1

3

s m 1

0

s m 1

s s 1

^ €

*

Motor

runs

3-5

si

15

Work

Connection

15

s2

$2

16

4

16

Work

Low-speed

After

High-speed

Solenoidisde-energized

Machine

At

4

15

fourthtolast

Low-speed

Machine

Work

slowly

clampisraised

tosinow

clampislowered

sewing

1st

stitch

sewing

remains

stitch

sewing

switches

clampIsraised

SrAfiT

via

r3

on (mechanically)

off mechanically

Nah4n

8»t$hfS9*t9r

38

g^schclttf

Siho/tonj

fuf HOV

Fur

iiOV.

firwAo

*»rjse/i»n7uJVvort

L9iiurig vortAfpnocA Z

t»i

99Z9iehr>9t

ot

Circuit

diagram

No.

91-095418-95

for

the

Pfaff

3337

Page 40

39. Explanation of

Original

position:

master

pneumatic

switch a1 off,

diagram

No. 91-130460-95

compressed

air

on.

a1

V 1

VI

be

V1

be

V2

V5

V4

Switch

Central

Ultimate

Starting

Cur

rent

Path

3-5

position

position

7+8

position

1+2

*)o

s

w

s

8

S m 1

Unit

m 1

V6

m 1 4

V5

V6

V6

Cur

rent

Path

3-5

2yl.

Function

Motorisrunning

Z1-

22

+

Work

clampislowered

Quick

exhausting

Low-speed

After

1st

stitch

High-speed

2

2-

Machine

+

At

Low-speed

Machine

Work

4

21

remains

fourthtolast

switches

clampisslowly

After work

Work

clampisraised

sewing

sewing

sewing

clamp

slowly

action

on

(mechanically)

stitch

of

mechanically

raised

has

risen

quickly

V3

6 =

s =

w =

normally

closed

contact

normally

open

contact

change

over

contact

11

0——10

KlQfrtntr

'MEin

Pneumatic

ffl

*

'C

AM

•M

lifMi

diagram

32IZ})

U(Vil

noO\

ua lUaneiarli^ut^

^ I ytetisi

No. 91-130460-95 for

vW

JH

Z

the

Pfaff 3337

39

Page 41

Contents

0.

Preparations

1.

Removing

2.

Adjusting

3. Adjusting

4. Vertical

5.

Adjusting

6.

Adjusting

7.

Adjusting

8. Adjusting

9.

Adjusting

10.

Centering

11.

Dismantling

12.

Dismantling

13.

Setting

14.

Setting

15.

Adjusting

16.

Adjusting

17. Timing

18. Setting the needle bar at the correct height

19.

Adjusting

20.

Mounting

21.

Timing

22.

Adjusting

23.

Adjusting

24.

Adjusting

25.

Timing

26.

Adjusting

27.

Centering

28.

Setting

for

adjustment

the

forked

clutch

the

drive

pulley on

the

starting

latch

adjustmentofstarting

the

forked

clutch

the

clamp

lifting

the

knife

actuating

the

locking lever

the

micro

switches

the

certain

certain

the

shuttletothe

the

shuttle

the

shuttle

the

radial

the

shuttle

the

bobbin

the

feed

the

feed

the

stop

the

thread

the

needle

the

thread

the

stationary

the

the

machine

needle

clamp

in

the

parts

parts

(continued)

driver

driver

playofthe

driver motion

thread

cam

motion

tripping

catcher

thread

catcher

knife

feetinthe

for its

lever

the

lever

lever

rod

needle

needle

shaft

puller

segment

crank

catcher

motion

largest

arm

shaft

latch

hole

longitudinally

shuttle

driver

and

adjusting

and

the

feed

plate

tack

size

....

....

the

....

movable

cutout

needle

knife .

.

29. Centering the tack design in the cutout of the clamp feet .

30.

Timing

the

tension

31.

32.

33.

34.

35.

36.

Adjusting

Timing

Adjusting

Adjusting

Adjusting

Final

the

the

motor

the

the

the

worksteps

37. Conversion to

38.

Explanationofcircuit

39.

Explanationofpneumatic

tension

bobbin

thread

eye

other

release

release

speed

winder

wiper

guard

subclasses

diagram

mechanism

lever

changes

No.

diagram

having different

91-095418-95

No.

91-130460-95

gear

ratios .

rise

40

Page 42

Page 43

(PFAFF)

-*

Nr. 296-12-13087 engl. P 1170 Printed in Germany

V . >

Loading...

Loading...