Page 1

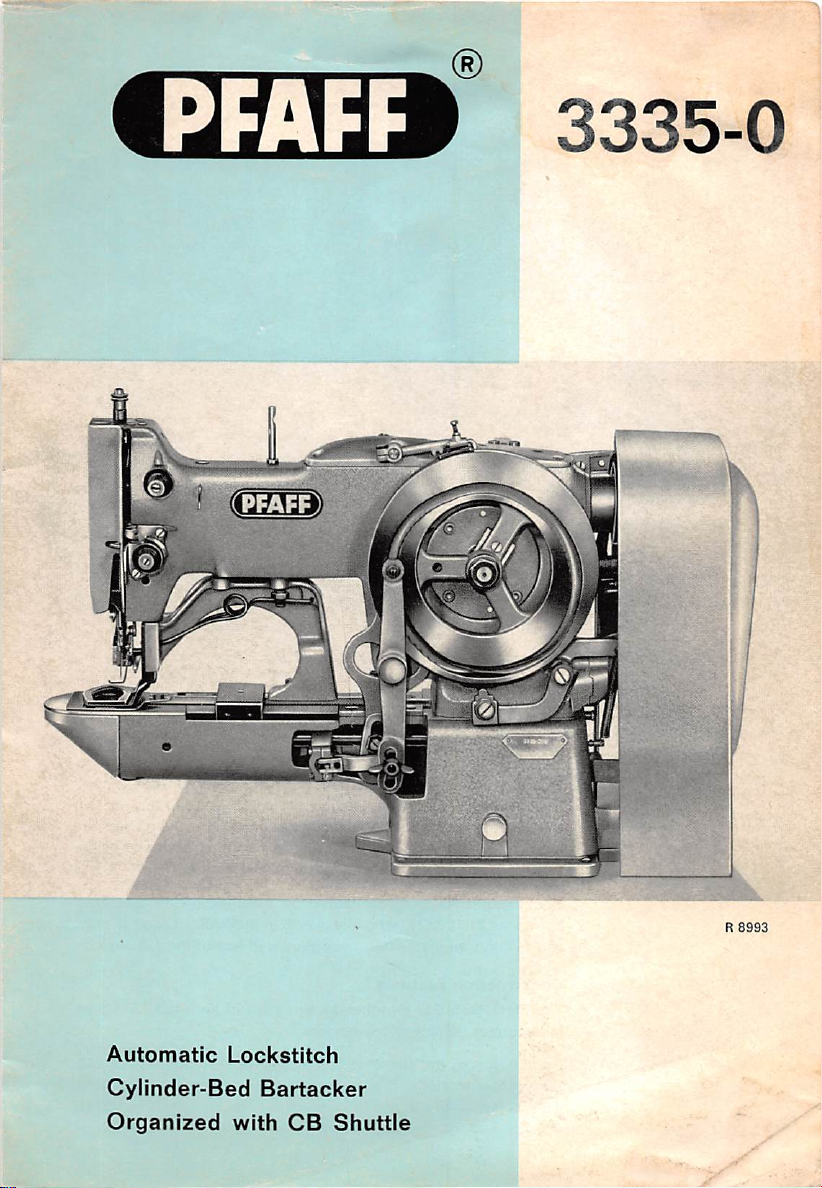

®

3335-0

.^•1

Automatic

Cylinder-Bed

Organized

Lockstitch

Bartacker

with

OB

Shuttle

R

8993

Page 2

©

R

8786

Pfaff

This

bobbin

sizes

light and

1^/i6"x2",or30x50

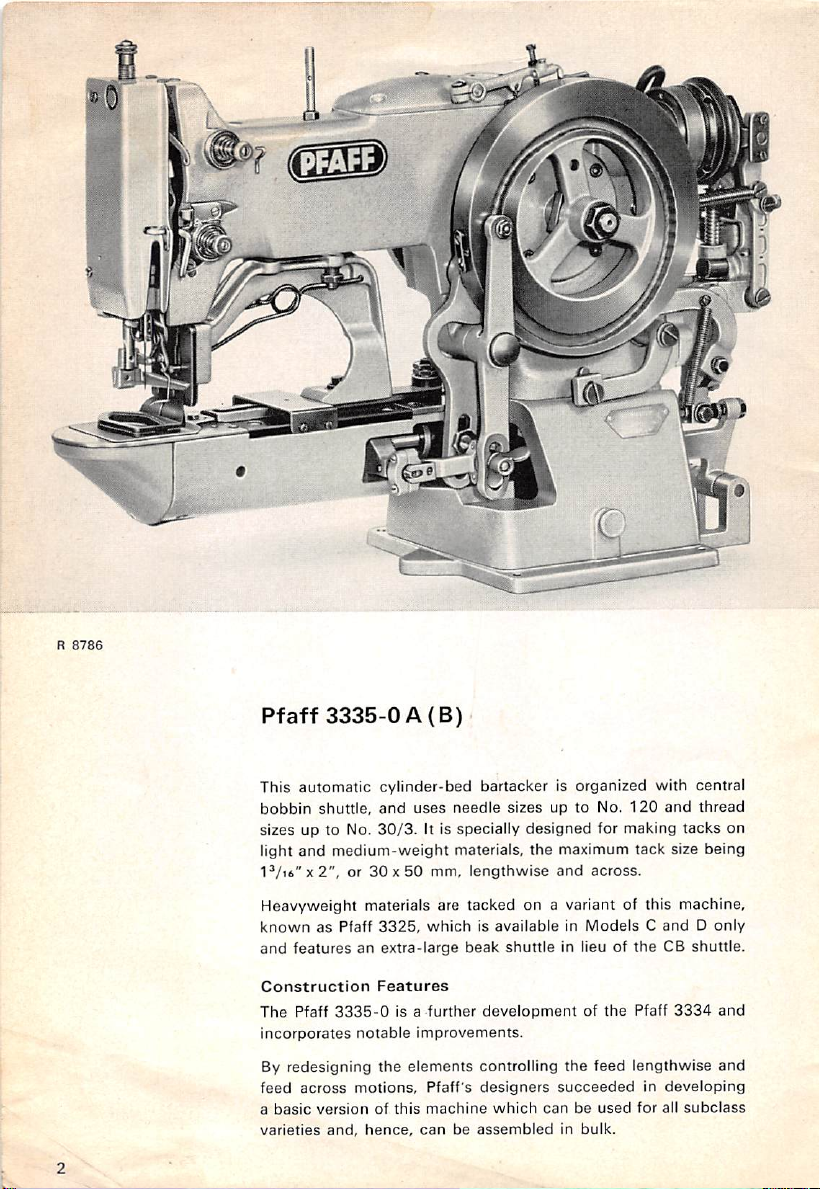

3335-0A(B)

automatic

shuttle,

up to No.

cylinder-bed

and

30/3.

medium-weight

bartackerisorganized

uses

needle

sizes

It is

specially

up to No.

designed

for

120

making

materials, the maximum tack size being

mm,

lengthwise

and

across.

with

and

central

thread

tacks

on

Heavyweight materials are tacked on a variant of this machine,

knownasPfaff

and

featuresanextra-large

Construction

The

Pfaff

incorporates

By

redesigning

feed

across

3

basic

versionofthis

varieties

3335-0

and,

3325,

Features

is a further

notable

the

motions,

hence,

whichisavailableinModelsCandDonly

beak

shuttle

in lieu of

developmentofthe

improvements.

elements

controlling

Pfaff's

designers

machine

canbeassembledinbulk.

which

the

succeededindeveloping

canbeused

theCBshuttle.

Pfaff

feed

lengthwise

for

3334

all

subclass

and

and

Page 3

R

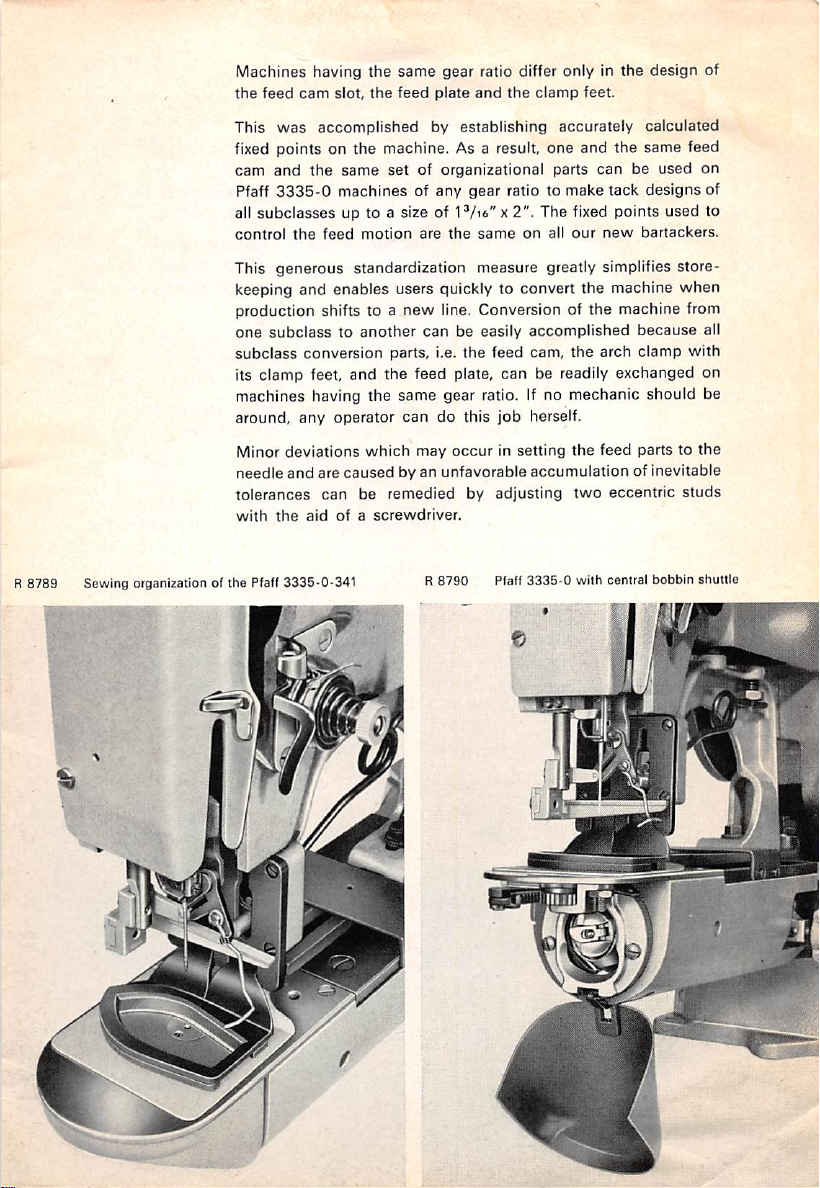

8789

Sewing organization of the Pfaff

Machines having the same gear ratio differ only in the design of

the

feed

cam

slot,

the

feed

plate

and

the

clamp

feet.

This

was

accomplished by establishing accurately calculated

fixed points on the machine. As a result, one and the same feed

cam

and

the

same

Pfaff

all

subclasses

control

This

3335-0

the

feed

generous

setoforganizational

machines of any

gear

up to a size of l^/i6" x 2". The fixed points used to

motion

are

the

sameonall

standardization measure greatly simplifies store-

parts

ratio to make

our

canbeused

tack

designs

new

bartackers.

keeping and enables users quickly to convert the machine when

production shifts to a

one

subclasstoanother

subclass

conversion

its clamp feet, and

new

line. Conversion of

can

be easily

parts, i.e.

the

the

feed

feed plate, can be readily exchanged on

the

accomplished

cam,

the

arch

machine from

because

ciamp

with

machines having the same gear ratio. If no mechanic should be

around, any operator can do this job herself.

which

Minor deviations

needle and are

caused

may occur in setting

by an unfavorable accumulation of inevitable

tolerances can be remedied by adjusting

with

the

aidofa

3335-0-341

screwdriver.

R

8790

Pfaff

3335-0

the

feed parts to

two

eccentric

with

central

bobbin

the

studs

shuttle

on

of

all

1

Page 4

Operation

The

needle

produce

moved

The

feed

The

the

cams

of

the

The

the

the

Both

cylinder

The

on

the

cylinder

of

the

emanates

cam

armbythe

the

Except

connections

underside.

carries

of

the

Machine

machineisstartedbydepressing

is of

the

rigid

the

different

under

the

workisheld

plate.

principal

seam

which

right, or

and

machine

motions

the

are

arm.

feed,

grooveonthe

oneonthe

motions

lengthwise

feed

are

bedbymeansofvertical

back

sideofthe

armbymeansofthe

cam.

from

tack

needle.

between,

required

trimmingofthe

carriedona

cam

outside

inside

produces

conveyed

feed

motionistransmitted

The

crosswise

the

channel

andisconveyedtothe

two-armed

outside

for a

The

merely

of

the

large

pass,

topofthe

the

feed

holeonthe

the

cylinder

feed

bar

type,itdoes

designs,

and

guided

for

joint

has

two

pattern-forming

controls

the

to

the

feed

camtothe

two-armed

feed

track

feed

driving

lever

and

cam.

right

armiscompletely

cylinder

fulcrum

the

right

not

swing

therefore,

by,

the

the

automatic

threads

transverse

the

are

shaftoneither

crosswise

lengthwise

feeding

two-armed

from

driving

lever

motion,onthe

on

the

front

mechanisminthe

two

ball-joint

side

through

armiscovered

stud.

treadle.

Since

the

sideways.

the

material

clamp

feet

and

the

production

derived

grooves.

feed

feed

from

motion,

motion.

two

side

While

mechanisminthe

levers.

the

channel

track

blockinthe

locatedatthe

sideofthe

other

back

hand,

feed

cylinder

connections

which

the

feed

enclosedonthe

by a

plate

which

To

is

of

on

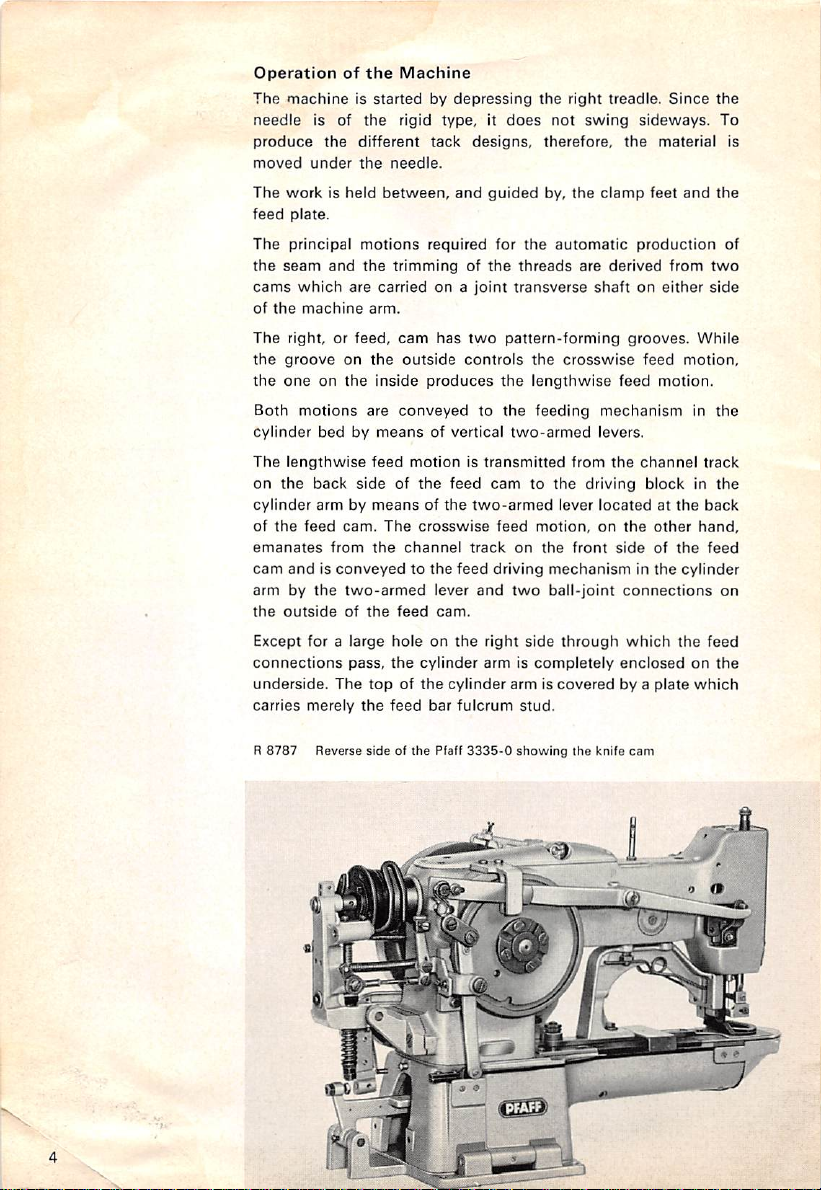

R

8787

Reverse

sideofrhe

Pfaff

3335-0

showing

the

knife

cam

Page 5

The

feed

cam.inaddition,

ference

thread

threads

The

knives

last

of

to

backsofthe

At

which

nipper

when

are

trimmedatthe

left, or knife,

and

swings

stitchisbeing

thread

to be pulled off

start

the

next

knives,

the

completionofthe

servetostop

stitch,

matically. Only after

operator press

trim

both

down

threads.

cam

them

formed.

carries

the

additional

thread

completionofeach

operates

forwardtothe

This

the

spool

both

threads

ready

for

trimming.

sewing

the

machine

the

left treadle to raise

tripping

machine

is pulled

the

needle

operative

action

causesasufficient

and

being

action,

the

has

come

pointsonits

andtoactuate

through

sewing

and

bobbin

positionasthe

the

bobbin

pulled

machine

to a

the

work clamp

taut

stop

and

with

stops

circum

cycle.

thread

amount

which

over

auto

can

the

both

the

the

and

During the sewing action, the lifting lever is interlocked by the

knife

camsothat

Double

sudden

The

Pfaff

motor

which

Machines

driving

Best

results

buffer

stops.

and,ifdesired,

greatly

belt.

the

work

springs

absorb

3335-0isdriven

canbefitted

fitted

are

simplifies

obtained

the

withabelt

clamp

cannot

the

momentumofthe

by a

constant-speed,

withabelt

regulationofbelt

take-up

with

the

Pfaff

be raised inadvertently.

machine

14-HP

take-up

tensions.

hanger

may

useanendless

3335-0,ifequipped

electric

hanger

with

electromagnetic control. On this machine the operator has merely

to

operate

When

a foot control switch

the

switchispressed

which

downtothe

has

first

two

switch

position,

positions.

the

two-

at

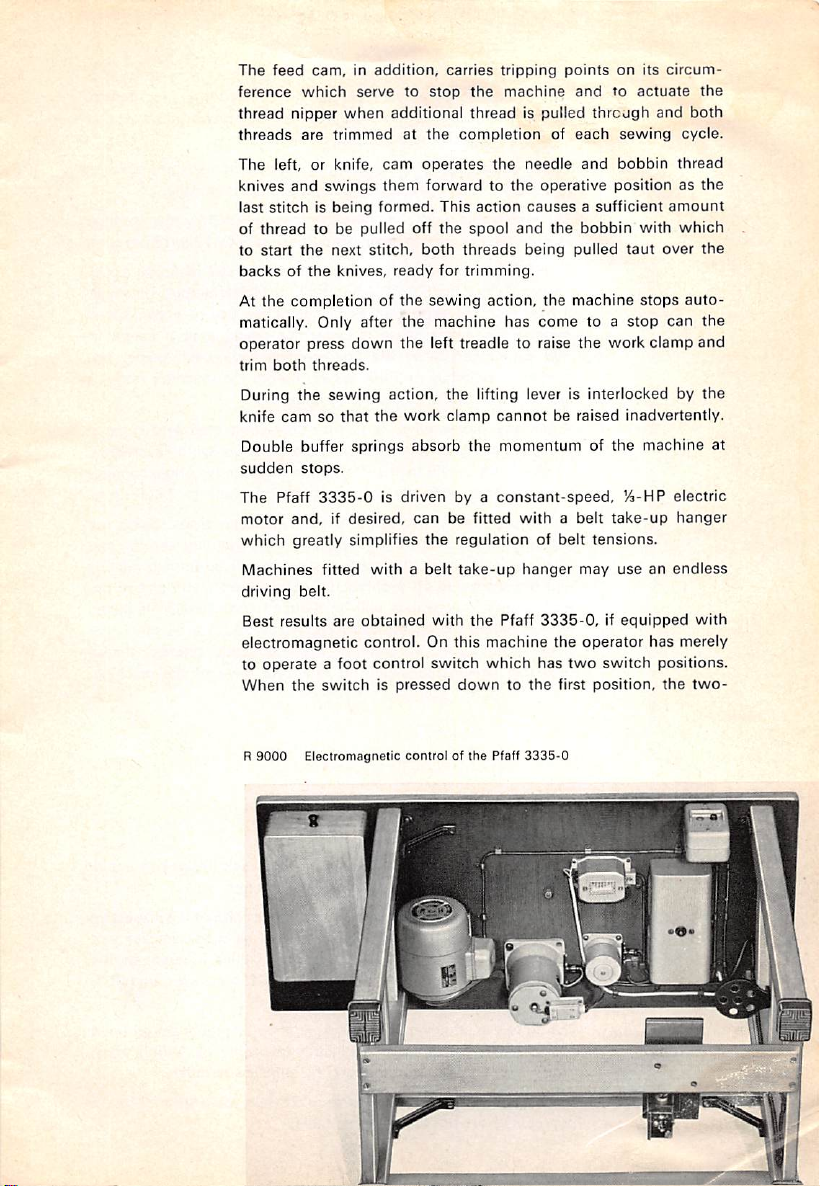

fl

9000

Electromagnetic

controlofthe

Pfaff

3335-0

Page 6

part

work

clampislowered

work

can

still

be

repositioned

again.

When

the

switchispressed

position,

At

and

The

enables

the

machineIsstarted.

the

completionofthe

the

work

clamp

remarkable

the

operatortoboost

is raised

work

simplification

All Pfaff bartackers normally

To

enable

the

Pfaff

3335-0toobtainahigher

it has

been

redesigned so as to permit the use of a

motor.

This

motor

starts

900

s.p.m.

and,

after

mediately

slows

When

1,400

mechanically

switchesto1.800

down

againtothe

the

motor

idles, it is

r.p.m.

When

which

the

then

tion and, thus, instantly accelerates

This

procedureisreversed

machine runs at half

the

onto

the

sewing

completely

her

operate

goods.Atthis

after

releasing

all

the

way

downtothe

cycle,

both

threads

automatically.

accomplishedbythis

output

easily by10to15per

at a

speedof1.200

the

output,

stage,

foot

are

however,

the

control

second

trimmed

machine

cent.

s.p.m.

two-speed

to drive

the

starting

the

machine

first

stitches

s.p.m.

have

Before

speed.

four-pole-connected

the

at a

been

machine

and

speed

made,

stops,

runs

im

machineisstarted,acontactorisactuated

switches

top

the motor to

the

when

the

speedatthe

two-pole

connec

machine to 2,800 r.p.m.

machine

stops.

Since

beginning and the

the

end

of the sewing cycle, the starting stitches will be formed reliably

and

the

seam

tied

off properly. In

stop

motion mechanism will be reduced considerably. If driven

byastandard

than

1,200

breaking,

motor,

the

Pfaff

s.p.m.inordertoavoid

needle

breakage

and

addition,

3335-0

excessive

wear

should

skipped

wearofthe

and

tearofthe

notberun

stitches,

machine.

faster

thread

of

it

at

Pfaff

3335-0

Subclasses

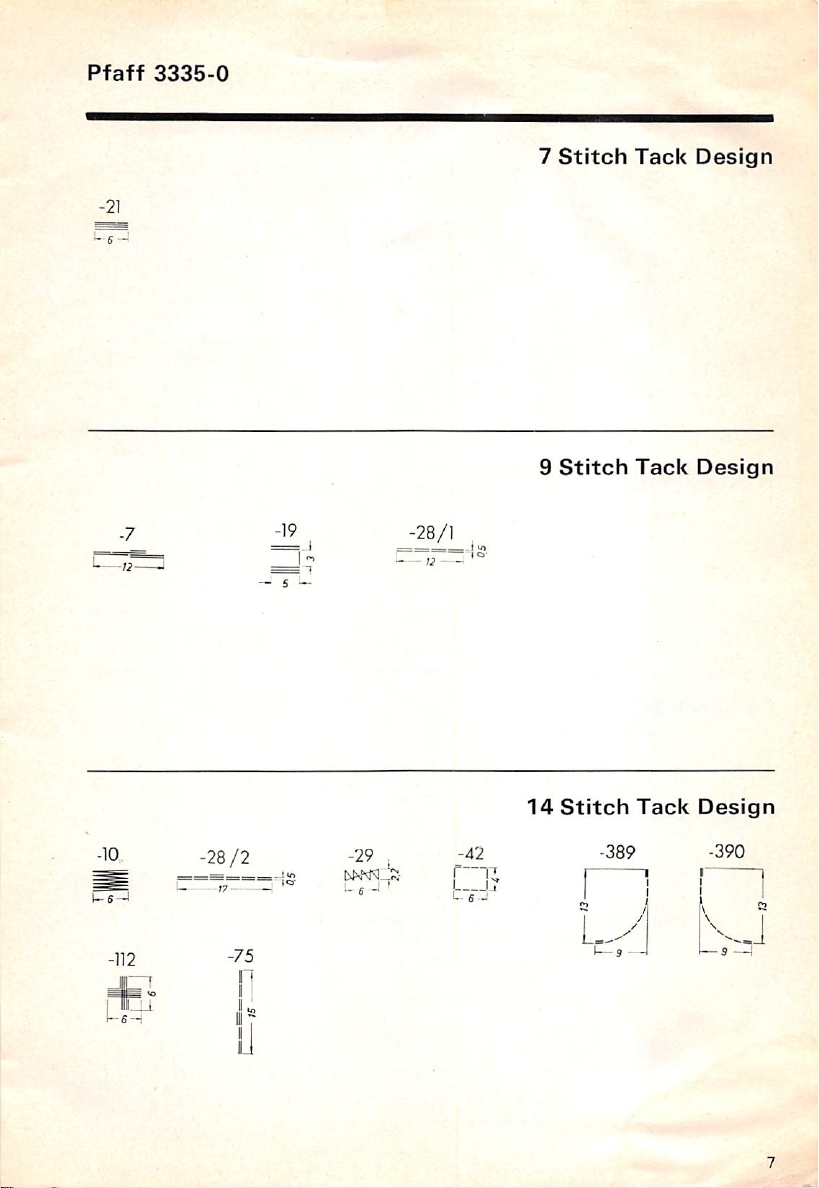

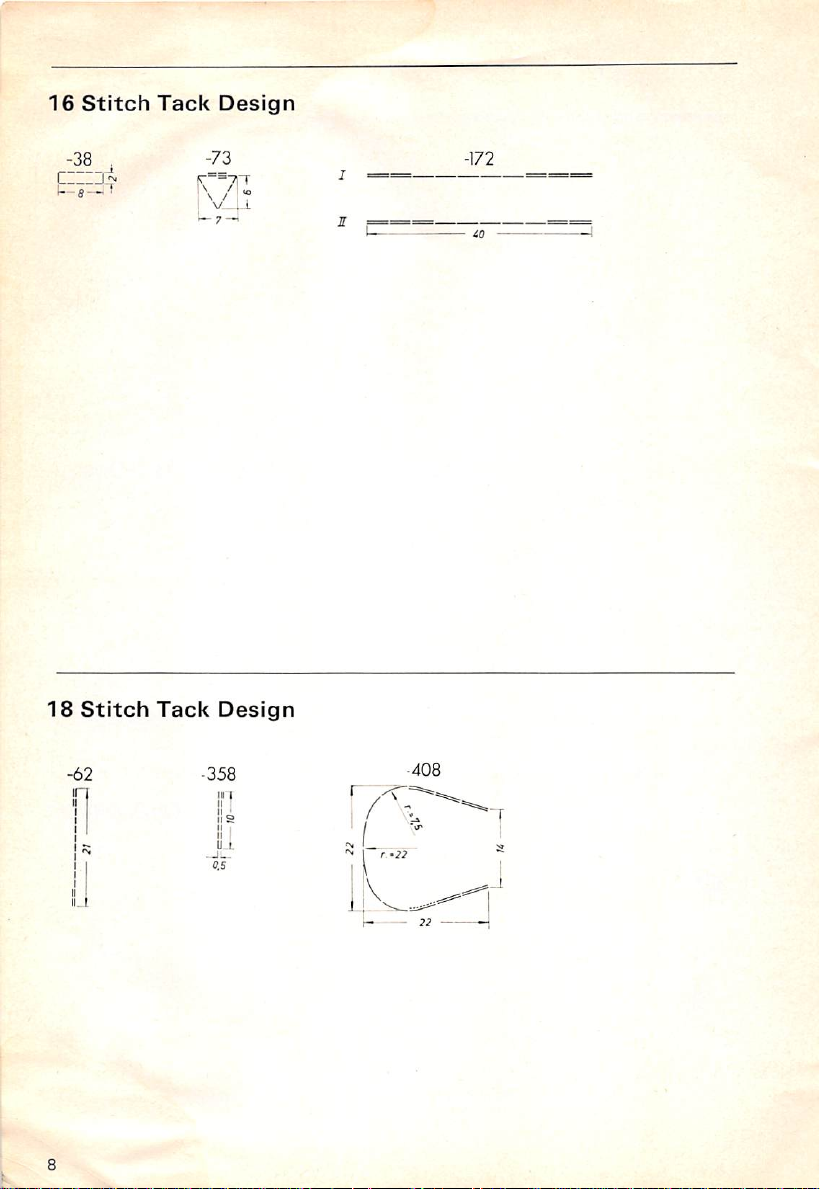

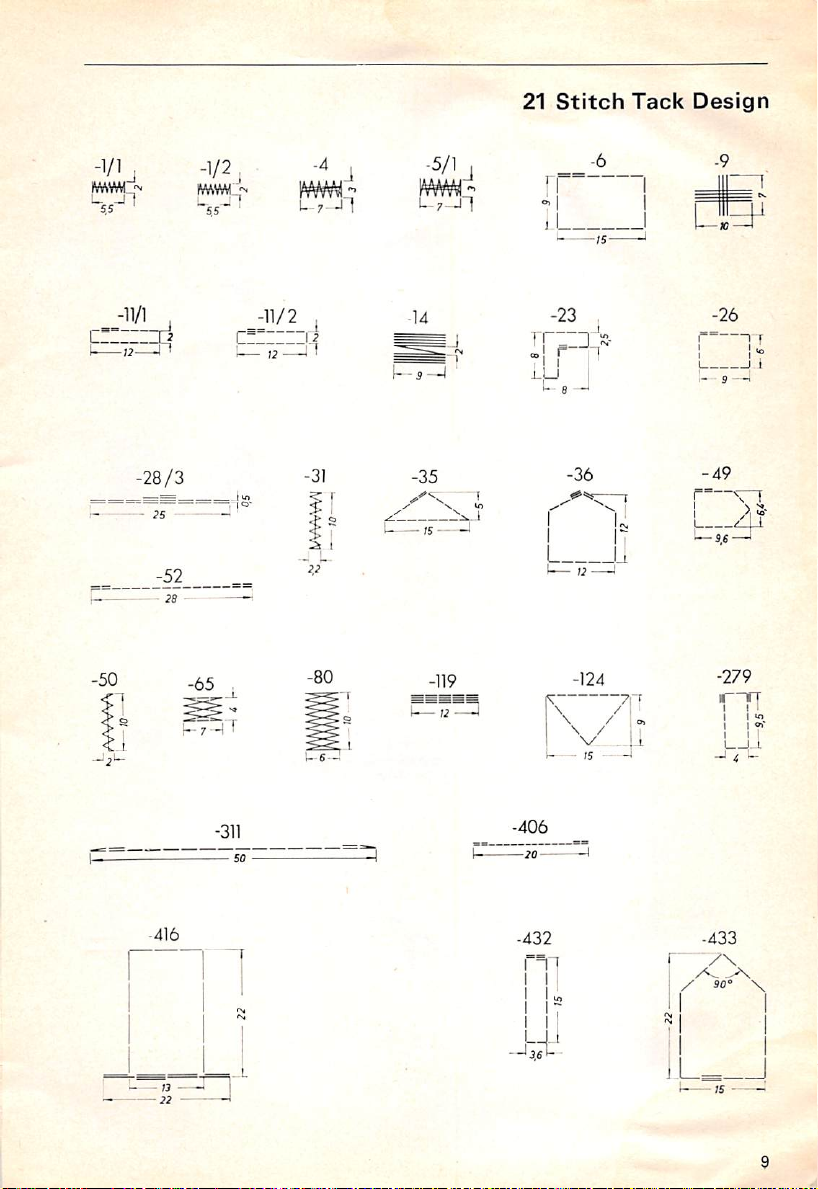

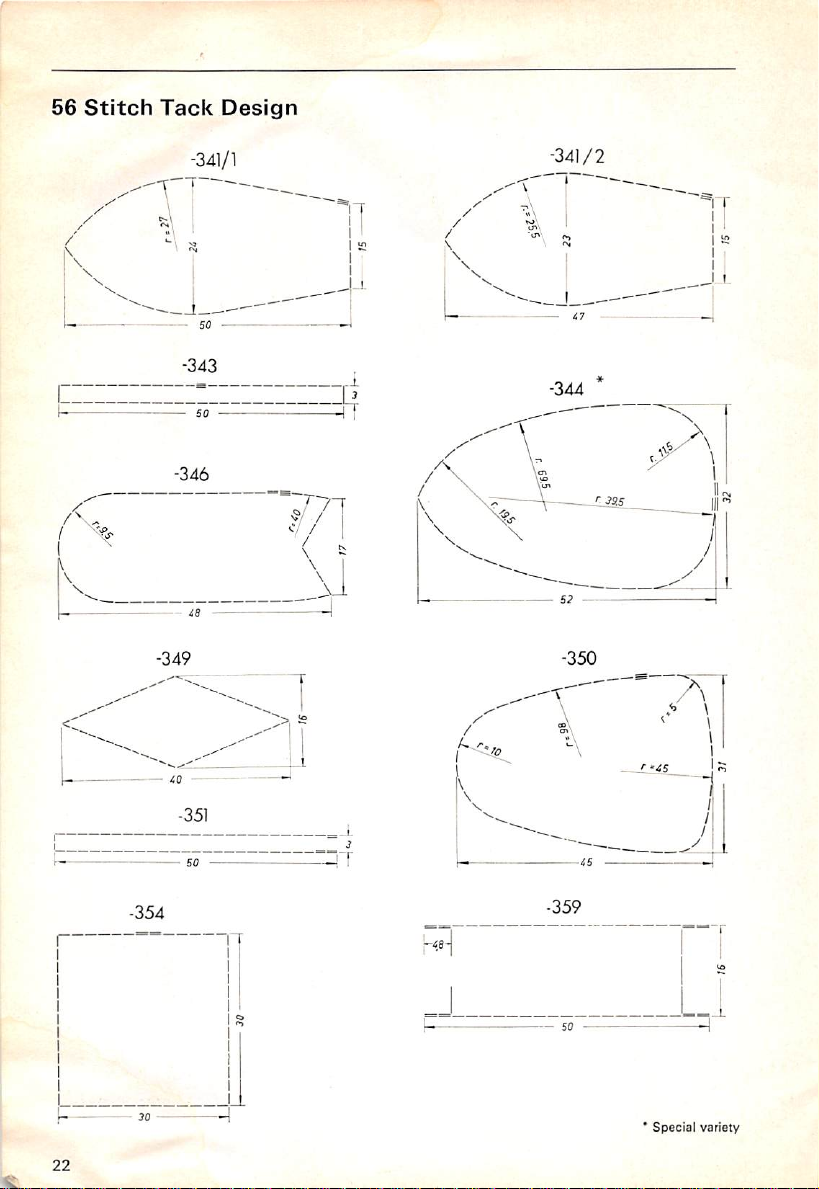

The following diagrams

size,

indicating

their

The dimensions given represent

tack. This

larger. With

machine,

lengthwiseofthe

means

the

they

canbereduced

show

the various tack designs in actua

dimensionsinmillimeters.

the

maximum size of

that

the tacks can only be made smaller, not

the

respective

aid of adjustment possibilities inherent in the

cylinder

by up to

arm.

30%

crosswise,

and

20%

Owing to the large variety of designs, their diagrams are grouped

accordingtothe

group,

the

Since

each

possibilities

numberofstitchesineach

diagrams

are

arrangedbysubclass

tack.

Within

numbers.

each

tack can be used in many different ways, its application

are

not

listedinthis

table.

Page 7

Pfaff

-21

3335-0

7

Stitch

9

Stitch

Tack

Tack

Design

Design

-10

-ti-

-112

-sH

-7

-28/2

-19

-29

~ 6 -I '

-75

n

,

-28/1

-42

p]}

L

s-J

14

Stitch

L..

-389

Tack

Design

-390

— 9 1

Page 8

16

Stitch

Tack

Design

18

-38

C—

,

Stitch

Tack

-73

v_U

Design

-172

-62

II

N i ,

' \

-408

•7

I

1

J

in

•358

- J —

0.5

U_L

Page 9

21

Stitch

Tack

Design

-1/1

-11/i

-1/2,

, -11/2 ,

cr:ziii|4

-28/3

==

I •

P 28 - ^

-50

-52

-65

^

^_L

1—7—1

.

1"

mm-

L.?^l

-31

5 r

-80

'--5—1

T"

9,

•6

•5/1

J

mm-

L.7—

,

-9

ll.

-26

'

I-.. 5 —I

-49

I—9

•14

-35

—4

-23

rrr-^f

-36

.

[""V-

IS 1

t:,-#

L____Q

-119

t 12

—-J

\

-124

/I.

V--U

;s i

7,-r

-279

TT!

I I «>

1 r

-311

—

50

-416

r

-406

-432

-433

~

V\

/

90'

\

ij

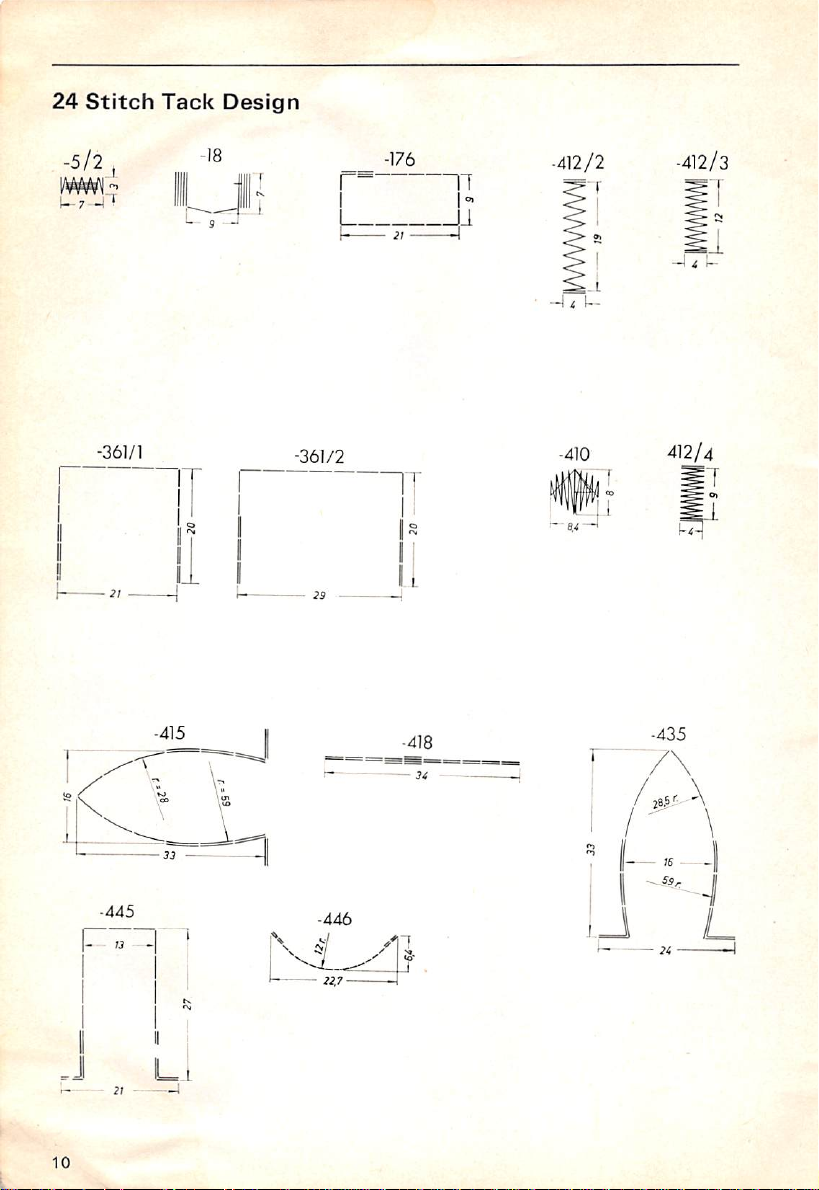

Page 10

24

Stitch

Tack

Design

-5/2

1^7

-J'V

-361/1

-415

-)8

L-

-361/2

-176

-j.

-410

"W

-412/3

u-

412/4

-435

r

y\

^1

-445

J

10

Li

21 1

-446

22.7-

/

U 24 d

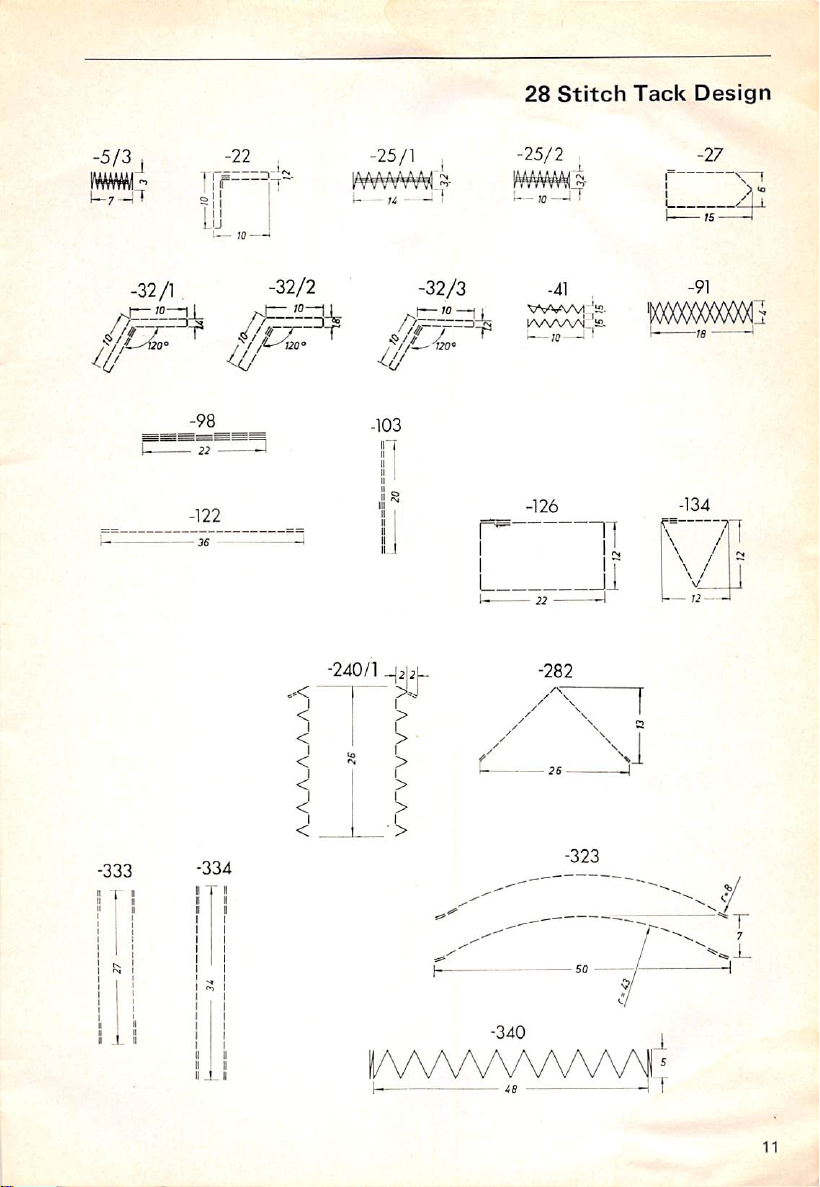

Page 11

28

Stitch

Tack

Design

-5/3 ,

pwi-

r^-7

'

1 22 1

—

s|l

-98

-122

3B-

n=":

-22

-32/2

-240/1

-25/1

-32/3 -41

I—

,0 ,

///

-103

-I

-25/2

-

wwvi:

vwwvj.a

-126

-282

,/X

-27

a.

-134

12 1

w

-333

-334

y J

< ^

<

IVv\WAA/V\i/

1 is 1T

-340

-323

:4i

T

7

i

11

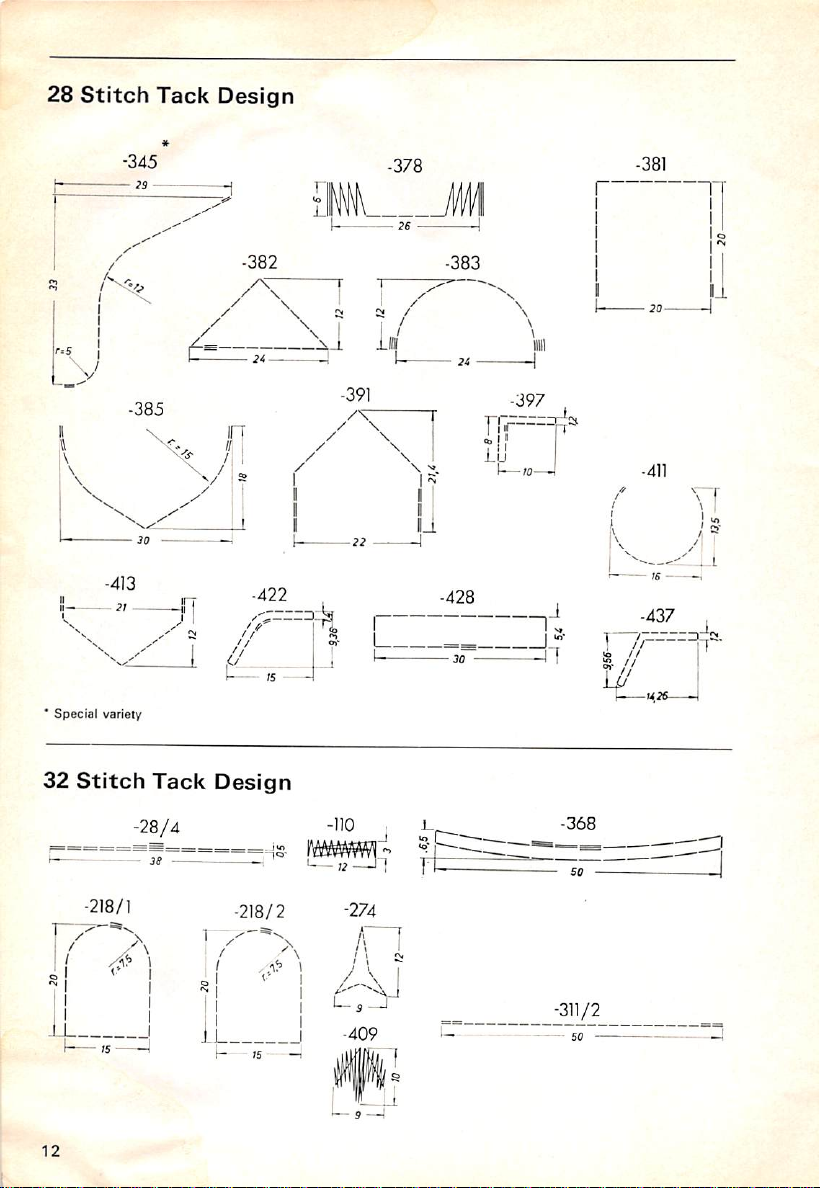

Page 12

28

Stitch

Tack

Design

Special

-345

-29-

/

-413

variety

-385

30

^ /

V

/

-382

/ \

/

-422

,4'

/ MI

'

T T

JS

"

J.

-391

-22 -J

-378

2S ——A

/

3 '

CS

/

1/

U.

iA

T

-383

-428

-381

r

2i

-397

I

r-

1^

-411

TI

41

—i

•n*i

-437

VTr

-//

32

.4 A

12

Stitch

-218/1

Tack

-28/4

—38—

Design

-218/2

/

i I

i I

iJ

4^

''

- rs- J

-110 J—

-274

/ \

1 J \

I

-409

L

J

«[;-

<o-

-368

so

-1V3

—so—

-rr::!

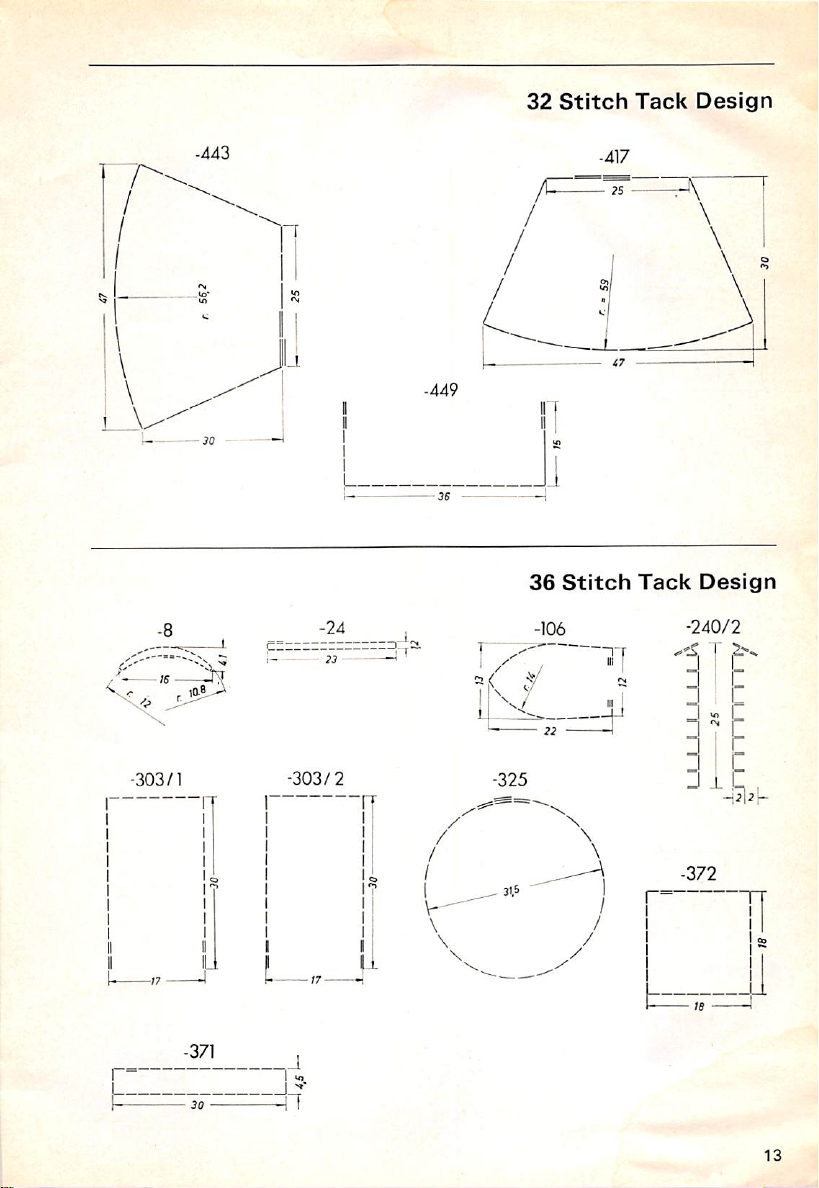

Page 13

32

Stitch

Tack

Design

7--

_\/'

-443

-417

F

\

\

A

-449

L.

< C

36

-106

j

Stitch

22

Tack

Design

-240/2

J.

fV

r

t

^

r

r"

-303/1

-371

30

lli

-303/

"n"i.

2

TT

-325

/

3t,5

\

\

/

" [-

-372

13

Page 14

36

Stitch

Tack

Design

-396

-384

-395

I

X /

30-

•405

I

IT

|_

I

/

•425

-420

-20

_BS

30

17

-421

r

_L

1 20 -

-429

IT

i

^

42

14

Stitch

-2

Tack

-442

Design

-3/1

Kxxxxxxxxxxxxxxxxxi-

• 30 II :

/

^

wmmmM"

-3/2

20

-440

^

-n I j u

-3/3

wmmm

.J

_L

,

"

Page 15

42

Stitch

Tack

Design

-17

U 30 • I

'20—

-55

i

/'

- " • • • • •

-240/3

~

\ K

-272

> <

$ .

\ ,

Z !

I I

-30

I

I 30 - - - 1

-67

:7ii

s/

30

~j

I I

I I I

|_ ,5 1

114/1

r~c."iT

78

r

-34 -46

-114/2

fx/ii

1 75

—1

-273

-276

nA

dr

:_L

A.

x~

-277

-301/1

-301/2

\

5

j4

I

15

Page 16

42

Stitch

Tack

Design

\

A

A

\

'••AS

-301/3

\

I

-309

/

-310/2

/

/

/

/

\

\

\

\

\

h

N

\

\

\

\

-301/4

—a

-310/1

%

\ /

\i/

-339

X

\

\

\

\ /

\ /

Viz

-342

\.

\

X

'i?/

W \

1.Z

/

-347

X

/

/

/

/

/

/

/

4^,.

/

/

/

/

16

/

/

X

\

X

\

\

•42-

Page 17

42

Stitch

Tack

Design

-348

•419

\l/

:z)

-374

I

-431

--rfi

I

13

1

-360

-373

L„..

-403/1

\

LJi

^5-i

-424

rc

/

I

\

-426

2S

Special

variety

A ,

V

-33^-

-441

/

/

/

\

\

\

3<6 '

1

.i

/

\.

V

-423

A1

i

-444

22

17

Page 18

48

Stitch

Tack

Design

•379

-392

-364

-380

T!

LuY

A

-363

_L

2.B

4B

-387

\

-393

\

I

I !3

*

Special

18

-407

—4

varlasy

il

i_L

-450

t—•»—ij

J-r

,

,'0

/,"

I0S3

/

rn-'D"

35

.1

A.

_-40_2/l

324

•438

-

r-

I

1

I

—

30

IT

/ "•

I ,

I

I

-—

35

^

fT

-402/2

324

?//-

.J.

Page 19

56

Stitch

Tack

Design

II

li

-114/3

><

I I

=

-56

-148

r"

-190

"il

I

-275

f

- 38,5

JJ

\

JO

-278

-304

n

"il

'N

/

JI

i-<:

-305

/

4

-307

\

:>

/

h-r.A

f-z'l®—1-

u>

-.\

'

L

-306

-315

—26—

\ / /

\y

\ /

/

-US—

19

Page 20

56

Stitch

Tack

Design

-317/23

-208-

Y'c

19

/

-316

-320

/

/

<—«-

\

\

-317/30

/

\

\

T

t

3.5',

-317/21

-319

It

-321/1

/

\

-321/2

/

TT

/

-U

20

-322

Ai

Page 21

56

Stitch

Tack

Design

i !

-327

-324

•so

•329

//

r

/ /

-326

\ \

\

\

\

L

-328

-330

71

/

/

/

\

\

\

\

-335

7

-336

::3T

-337

3.S

rr

•338

mmNwmNwmm^

1-

-u

-3s.e

21

Page 22

56

Stitch

Tack

Design

-341/1

"T"

/

-341/2

\

-J_,

so

-343

-344

jf

-346

/

/V

/

M

-349

/

A I

-350

•351

.J.

j

rr

-354

r"

W8-

-359

J.

t-

22

*

Special

variety

Page 23

56

Stitch

Tack

Design

-i

A

11

/ /

/ /

-366

/

/

\ \ ^

\ \

Vi

-29.i-

-J

-369

"~IT

-370

-367

I 1

u

^2

I—

A

i7

-376

N-

\

-377

special

394

•us

-430

variety

23

Page 24

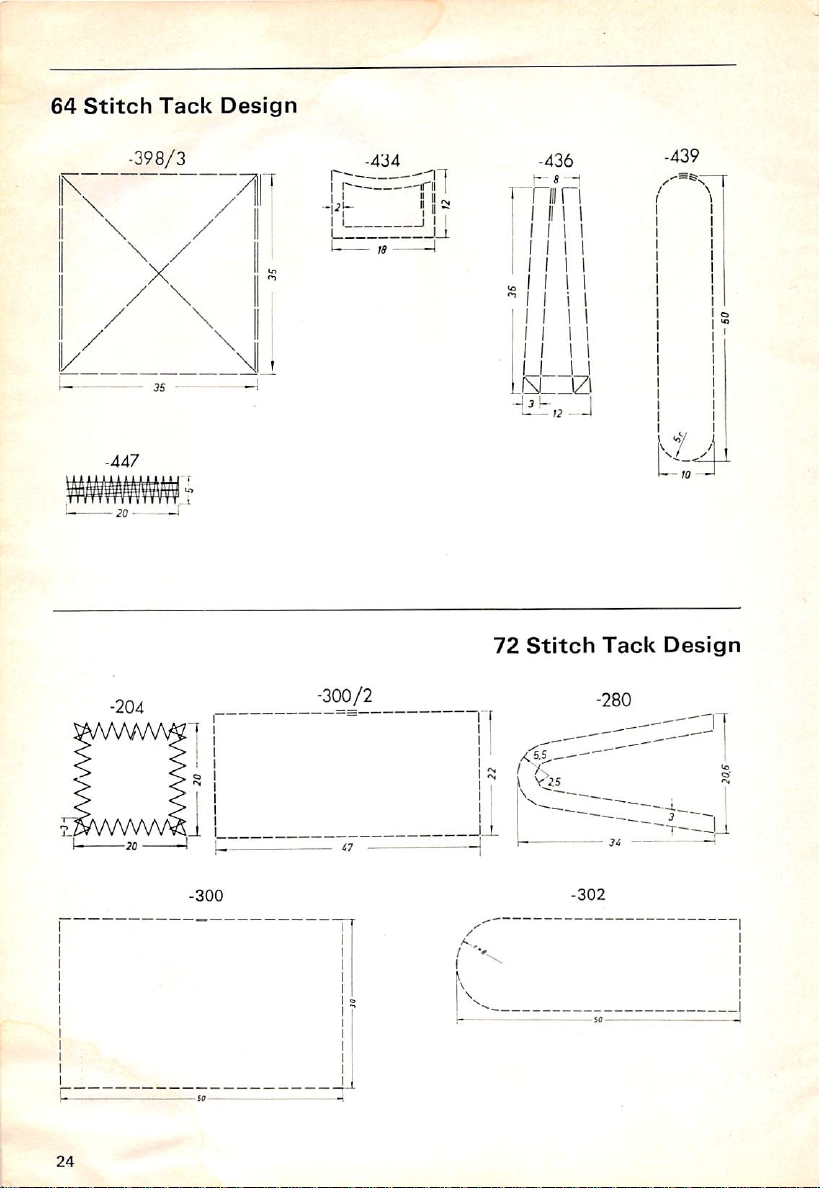

64

Stitch

Tack

Design

/

•398/3

\ /

\ /

/\

/ \

3S

-447

•204

\

:^i

nJI

•434

r--

I I

' ' a 0

it

I

-300/2

--ni

-J

I • &

I I

U

-436

-439

"nfl

!

I I j

_S__0

•

72

Stitch

"~l'

Tack

•280

Design

I- 20

24

-300

5.S_

25

as

L.

.J_L

H

/ >

3i

-302

Page 25

72

Stitch

Tack

Design

n

L

-308

-317/1

-317/6

J-r

^.01

-312

65-

•

-313

so-

j7

T"T

i3

4S

-317/3

I

-317/14

-317/15

_j..i

25

Page 26

72

Stitch

Tack

Design

-317/29

-30

-317/26

•2i

1-

Ji

-317/24

I

1-

.Jj.

-317/28

-30

._)_l

-317/27

•33-

-317/31

3B

!

b=-

I

I

h

*

special

26

-317/32

variety

-J-

-318

-352

Page 27

72

Stitch

Tack

Design

-357

32

-388

•355

.J_L

-356

•n"

<&•

/

/

. /

jj.

L...

I I I

LL

y

-375

-LL.

1

"T

-399/1

-399/2

\

V.

-404

j

1 30

a.

"^7

1

I

I

I

I

—J_l

•414

11

KJJ

-401

r'

II

II

II

L.

•IT

II

u

I

27

Page 28

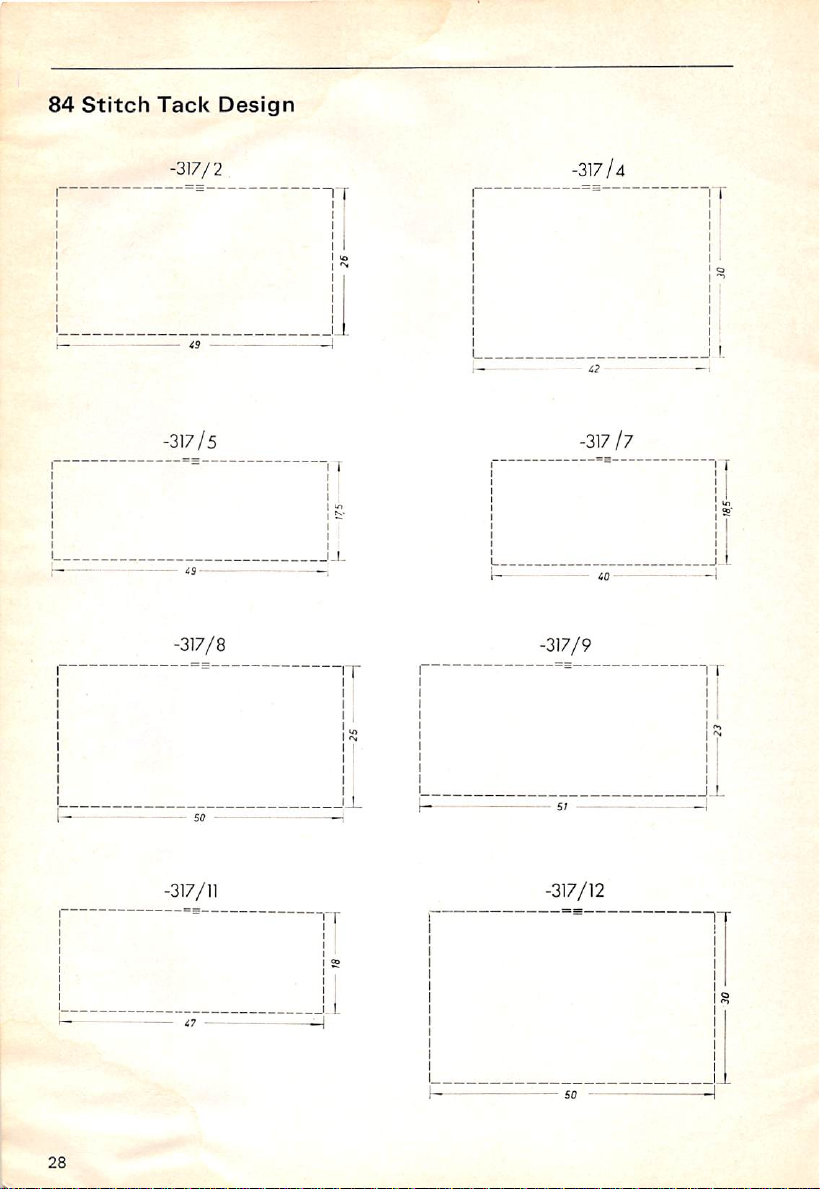

84

Stitch

Tack

Design

-317/2

HT

-317/5

T

.J-L

-317/8 -317/9

-317/4

-317

IT

/7

-317/n -317/12

28

Page 29

84

Stitch

Tack

Design

tF

L

-317/19

•50

-

-331

—

ii.3

-362

-317/20

1^

-39

-332

u.

-365

jJ.

TF"-:

\U:

Special

variety

-398/1

.X.

-398/2

29

Page 30

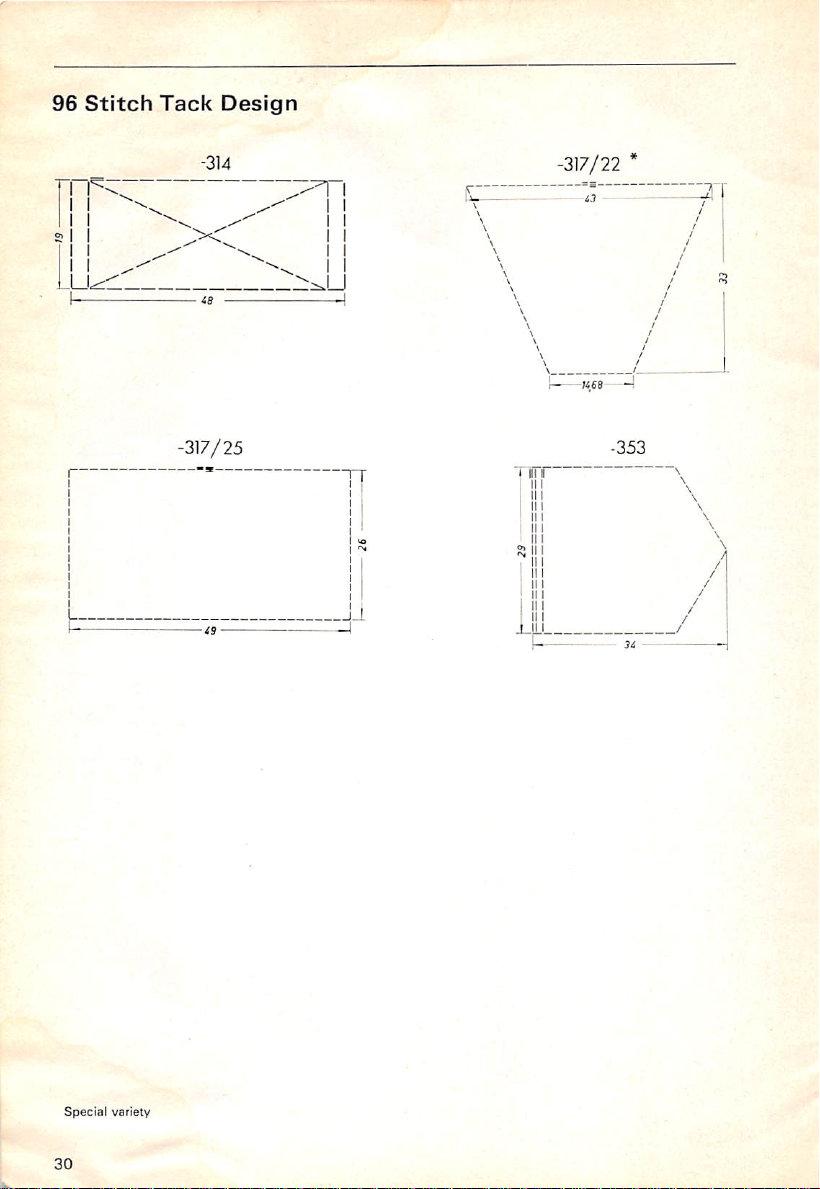

96

Stitch

Tack

Design

-314

-317/25

-2\7l22

-"n-

j

-W68-

-353

—\

Special

30

variety

Page 31

Subclass

Stitches

per

Tack

Numerical

Tack

on

Page

Design

List

of

Subclasses

Subclass

Stitches

per

Tack

Tack

on

Page

Design

-1/1

-1/2

-2

-3/1

-3/2

-3/3

-4

-5/1

-5/2

-5/3

-6

•7

-8

-9

-10

-11/1

-11/2

-14

-17

-18

-19

-20

-21

-22

-23

-24

-25/1

-25/2

21

21

42

42

42

42

21

21

24

28

21

9

36

21

14

21

21

21

42

24

9

42

7

28

21

36

28

28

9

9

14

14

14

14

9

9

10

11

9

7

13

9

7

9

9

9

15

10

7

15

7

11

9

13

11

11

-26

-27

-28/1

-28/2

-28/3

-28/4

-29

-30

-31

-32/1

-32/2

•32/3

-34

-35

-36

-38

-41

-42

-46

-48

-49

-50

-52

-55

-56

-62

-65

-67

21

28

9 7

14

21

32

14

42

21

28

28

28

42

21

21

16

28

14

42

56

21

21

21

42

56

18

21 9

42

19

15

9

11

7

9

12

7

15

9

11

11

11

15

9

9

8

11

7

15

19

9

9

9

15

8

31

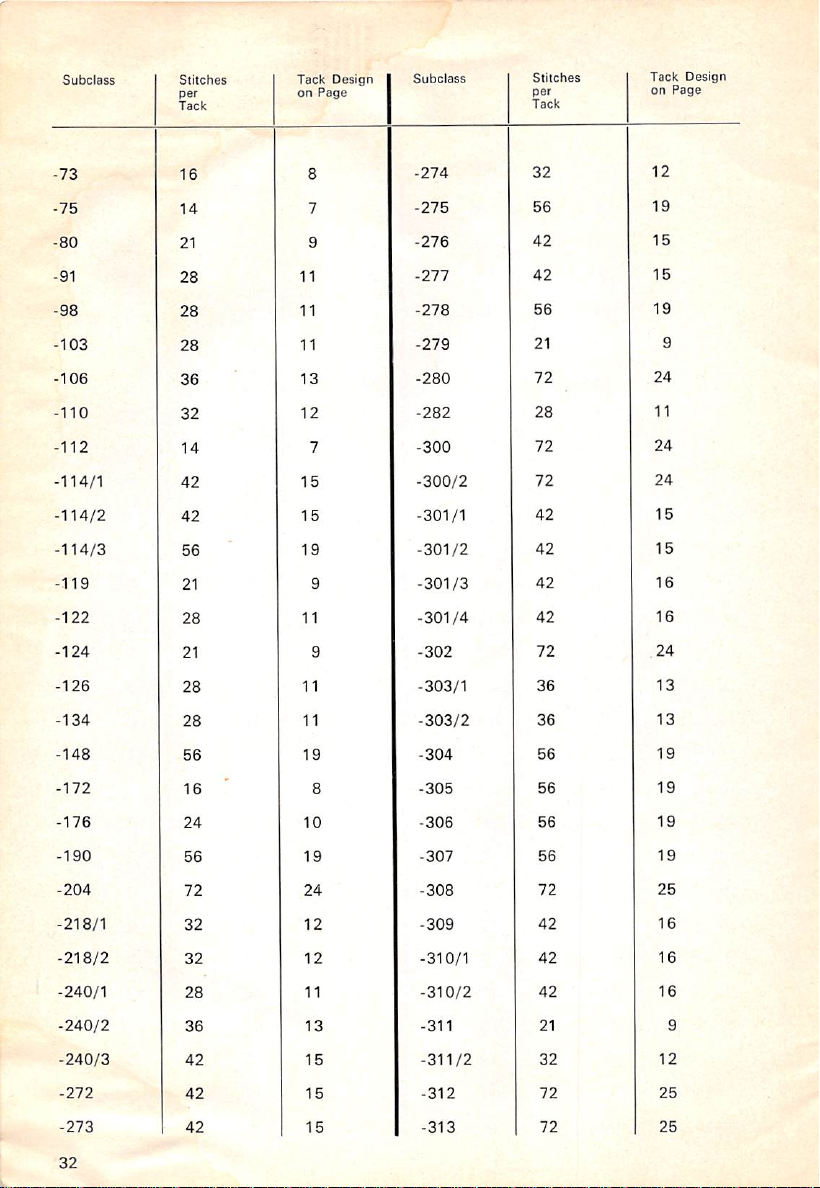

Page 32

Subclass

Stitches

per

Tack

Tack

on

Page

Design

Subclass

Stitches

per

Tack

Tack

on

Page

Design

-73

-75

-80

-91

-98

-103

-106

-110

-112

-114/1

-114/2

-114/3

-119

-122

-124

-126

-134

-148

-172

-176

-190

-204

-218/1

-218/2

-240/1

-240/2

-240/3

-272

-273

16

14

21

28

28

28

36

32

14

42

42

56

21

28

21

28

28

56

16

24

56

72

32

32

28

36

42

42

42

8

7

9

11

11

11

13

12

7

15

15

19

9

11

9

11

11

19

8

10

19

24

12

12

11

13

15

15

15

-274

-275

-276

-277

-278

-279

-280

-282

-300

-300/2

-301/1

-301/2

-301/3

-301/4

-302

-303/1

-303/2

-304

-305

-306

-307

-308

-309

-310/1

-310/2

-311

-311/2

-312

-313

32

56

42

42

56

21

72

28

72

72

42

42

42

42

72

36

36

56

56

56

56

72

42

42

42

21 9

32

72

72

12

19

15

15

19

9

24

11

24

24

15

15

16

16

24

13

13

19

19

19

19

25

16

16

16

12

25

25

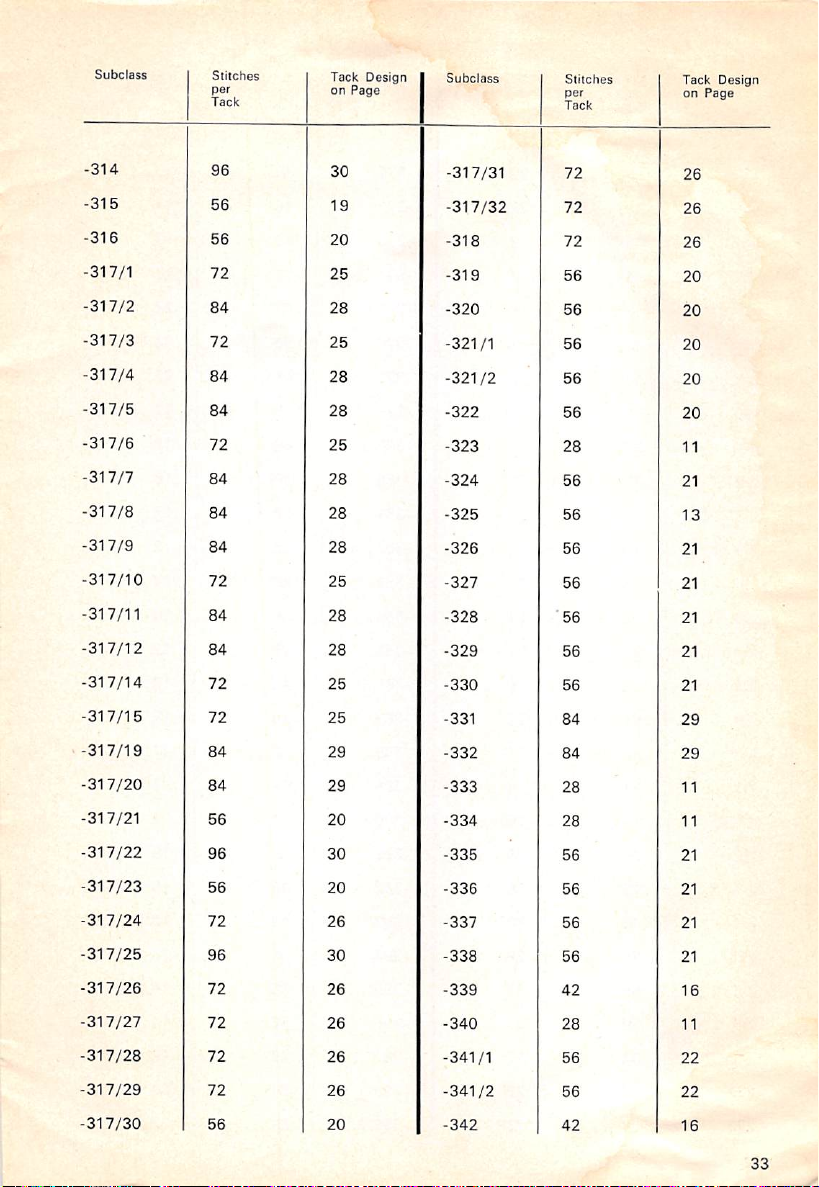

Page 33

Subclass

Stitches

per

Tack

Tack

on

Page

Design

Subclass

Stitches

per

Tack

Tack

on

Page

Design

-314

-315

-316

-317/1

-317/2

-317/3

-317/4

-317/5

-317/6

-317/7

-317/8

-317/9

-317/10

-317/11

-317/12

-317/14

-317/15

-317/19

-317/20

-317/21

-317/22

-317/23

-317/24

-317/25

-317/26

-317/27

-317/28

-317/29

-317/30

96

56

56

72

84

72

84

84

72

84

84

84

72

84

84

72

72

84

84

56

96

56

72

96

72

72

72

72

56

30

19

20

25

28

25

28

28

25

28

28

28

25

28

28

25

25

29

29

20

30

20

26

30

26

26

26

26

20

-317/31

-317/32

-318

-319

-320

-321/1

-321/2

-322

-323

-324

-325

-326

-327

-328

-329

-330

-331

-332

-333

-334

-335

-336

-337

-338

-339

-340

-341/I

-341/2

-342

72

72

72

56

56

56

56

56

28

56

56

56

56

56

56

56

84

84

28

28

56

56

56

56

42

28

56

56

42

26

26

26

20

20

20

20

20

11

21

13

21

21

21

21

21

29

29

11

11

21

21

21

21

16

11

22

22

16

33

Page 34

Subclass

Stitches

per

Tack

Tack Design 1

on Page 1

Subclass

Stitches

per

Tack

Tack

on

Page

Oesi

-343

-344

-345

-346

-347

-348

-349

-350

-351

-352

-353

-354

-355

-356

-357

-358

-359

-360

-361/1

-361/2

-362

-363

-364

-365

-366

-367

-368

-369

-370

56

56

28

56

42

42

56

56

56

72

96

56

72

72

72

18

56

42

24

24

84

48

48

84

56

56

32

56

56

22

22

12

22

16

17

22

22

22

26

30

22

27

27

27

8

22

17

10

10

29

18

18

29

23

23

12

23

23

-371

-372

-373

-374

-375

-376

-377

-378

-379

-380

-381

-382

-383

-384

-385

-386

-387

-388

-389

-390

-391

-392

-393

-394

-395

-396

-397

-398/1

-398/2

i

36

36

42

42

72

56

56

28

48

48

28

28

28

36

28

42

48

72

14

14

28

48

48

56

36

36

28

84

84

13

13

17

17

27

23

23

12

18

18

12

12

12

14

12

17

18

27

7

7

12

18

18

23

14

14

12

29

29

Page 35

Subclass

Stitches

per

Tack

Tack

on

Page

Design

Subclass

Stitches

per

Tack

Tack

on

Page

Design

-398/3

-399/1

-399/2

-401

-402/1

-402/2

-403/1

-404

-405

-406

-407

-408

-409

-410

-411

-412/1

-412/2

-412/3

-412/4

-413

-414

-415

-416

-417

-418

-419

-420

64

72

72

72

48

48

42

72

36

21

48

18

32

24

28

56

24

24

24

28

72

24

21

32

24

42

36

24

27

27

27

18

18

17

27

14

9

18

8

12

10

12

23

10

10

10

12

27

10

9

13

10

17

14

-421

-422

-423

-424

-425

-426

-428

-429

-430

-431

-432

-433

-434

-435

-436

-437

-438

-439

-440

-441

-442

-443

-444

-445

-446

-447

-449

-450

36

28

42

42

36

42

28

36

56

42

21

21

64

24

64

28

48

64

36

42

36

32

42

24

24

64

32

48

14

12

17

17

14

17

12

14

23

17

9

9

24

10

24

12

18

24

14

17

14

13

17

10

10

24

13

18

35

Page 36

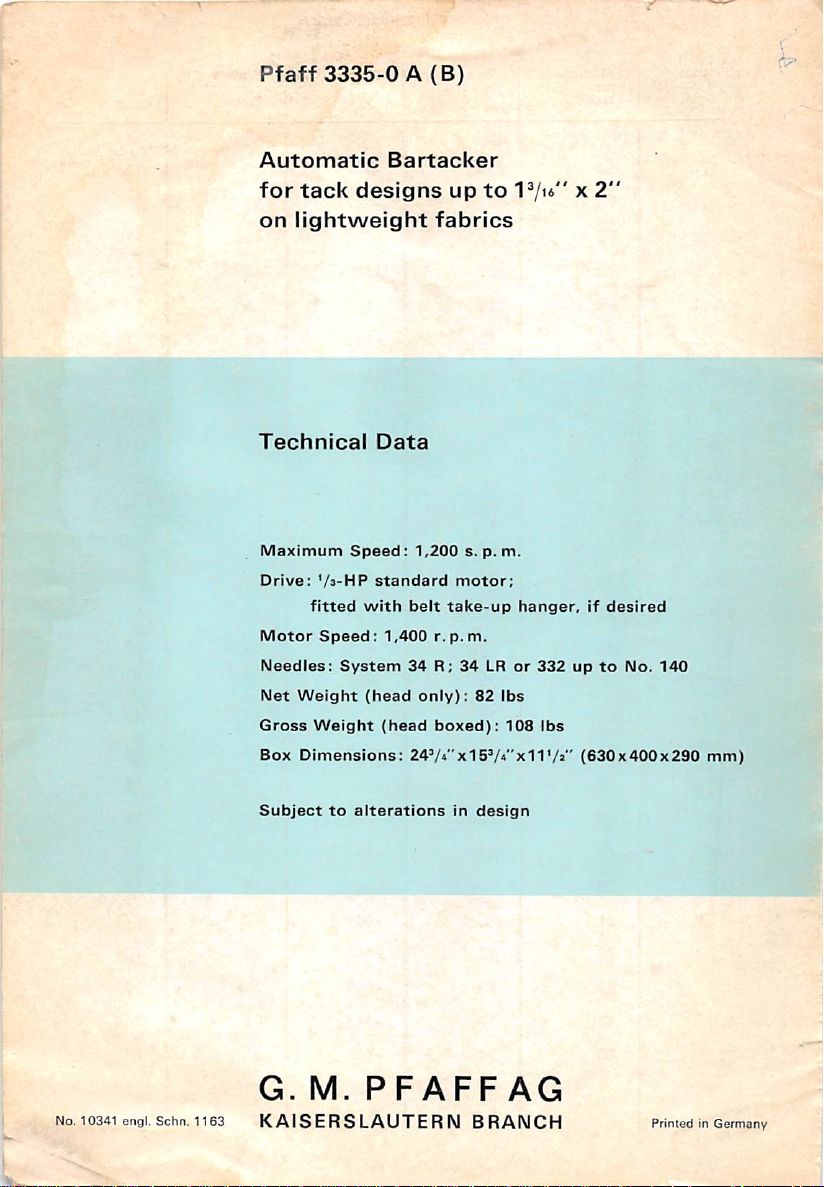

Pfaff

3335-0A(B)

h'

Automatic

for

tack

on

lightweight

Technical

Maximum

Drive:

'/a-HP

fitted

Motor

Speed:

Needles:

Net

Weight

Gross

Weight

Box

Dimensions:

designs

Data

Speed:

standard

with

System

(head

Bartacker

up

to

fabrics

1,200s.p.

motor;

belt

take-up

1,400

r.p.m.

34R;34LRor

only):

82

(head

boxed):

24V4"x15®/4"x11Va"

x2"

m.

hanger,ifdesired

332upto

lbs

108

lbs

(630x400x290

No.

140

mm)

Subject

G.

No.10341 engl.Schn. 1163 KAlS

M.

ERS

to

alterations

LAUTE

PFAFF

R N

in

design

BRANCH

AG

PrimedInGermany

Loading...

Loading...