Page 1

• '>;V*v

C:iX-fJ,7K-s-..:.,''

*

•

iiWd

•

9.''-)

Page 2

rJ/

C

PFAFF)

Vfc^Oit

3334

-958/01

Automatic

for

making

measuring

7/8"

X 1

Lockstitch

tacks

up

7/16"

to

Instruction

and

Bartacker

Book

PFAFF

Manual

INDUSTRIEMASCHINEN

GMBH

KAISERSLAUTERN

Page 3

Foreword

This

instruction

matic

lockstitch

swering

the

construction,

interested

all

book

contains

bartacker.

questions

relatedtosewing

function

operatortoget

Though

and

to know

much

not

operation

quicklyaspossible.

The

instructions

be

much

the

best

serviced by an

for

appreciated

sewing

machine

expert

mechanics

by all

maintenance

will

We have

containedinthe

work

made

instructionsassimpleaspossible

to

affordabetter

We

welcome

illustrations

any

suggestions

in which

understanding.

round-belt

and

recommendations

drives

machines having V-belfdrive (-958/01).

valuable

intendedasa

information

exhaustively,itoffers

of

the

various

her

machine

second

men

servicing

satisfactorily

every effort to

and

have

included

aretobe

seen

about

the

full-scale

textbook

sufficient

mechanisms

and

attain maximum efficiency

only

which

partofthis

our

sewing

if it is

render

numerous

you

also

apply

Pfaff

book

machines

employed

the presentation of

illustrationsinorder

may

wishtomake.

to a limited

Industriemaschinen

Kaiserslautern

Pfaff

3334

capableofan

information

to

enable

willnodoubt

since

properly

extend

auto

on

every

as

even

and

these

to

GmbH

Page 4

A.

Instrudtions

1.

Brief

DescriptionofMachine

The Pfaff 3334 and 3334-958/01

for

Operators

are

equipped with centra! bobbin shuttle

and

link take-up

and designed for tacking bars of every description automatically. Their range of applica

tions

embraces

all

branchesofthe

sewing

industry.

The number of stitches per tack varies according to the purpose of employment of the

different

The

subclass

work is held

machines.

between

the

workclamp

and

the

feed

plate

and

moved

under

the

needle as required by the tack design. The needle bar moves up and down only and

does

not

swing

sideways.

The length and crosswise feed motion needed to produce the tack is derived from two

cams which are carried on a joint shaft on either side of the machine arm. The right

cam

has

two control

on the front controls the feed across

slots

milled into its front

motion,

and

back

sides.

While

the

channel

trade

the slot on the back controls the motion

of the work lengthwise of the machine arm. Another function of this cam is to stop the

machineatthe

When you depress the right treadle, the stop

endofthe

sewing

cycle.

motion

mechanism is disengaged, the

tripping lever engaged and the driving belt shifted from the loose to the driving pulley.

While the machine is in operation, the lifting lever is locked so that the work clamp

cannot

be

raised.

The-left cam operates the needle and bobbin thread knives and moves them from the

inoperative to

the

operative

position.

Whenyou depress the left treadle after the machine has been stopped automatically, the

work clamp is raised and both threads trimmed simultaneously.

T

I\!^

Rear

view

Fig. 1

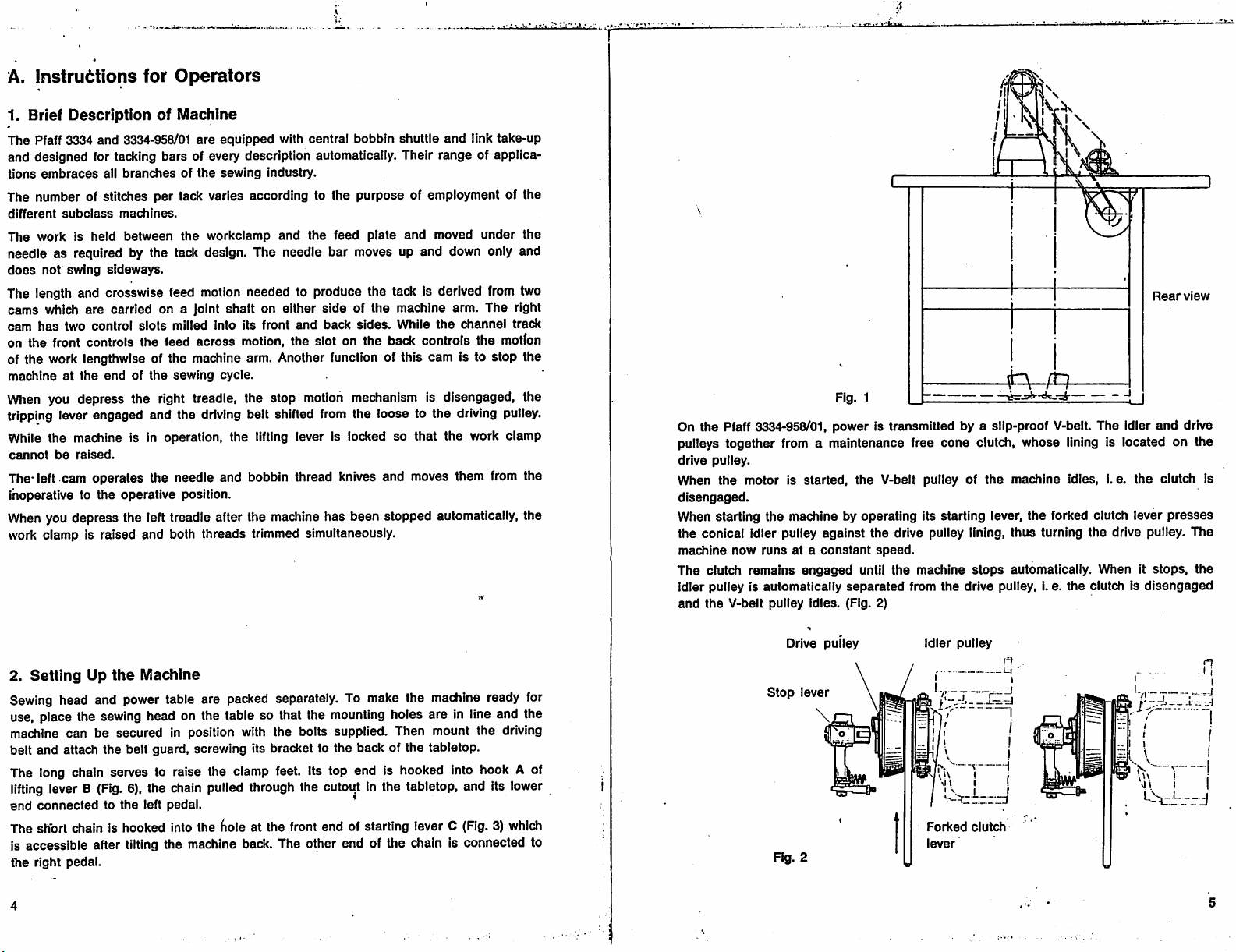

On

the

Pfaff 3334-958/01,

pulleys together from a maintenance free cone clutch, whose lining is located on the

drive

pulley.

When

the

motor is

disengaged.

When

starting

the

the conical idler pulley against the drive pulley lining, thus turning the drive pulley.

machine

now

runsata

The clutch remains

idler pulley is automatically

and

the

V-belt

pulley

power

started,

machine by

constant

engaged

idles.

Is transmitted by a slip-proof V-belt.

the

V-belt pulley of

operating

speed.

its starting lever,

until the machine

separated

(Fig. 2)

from the drive pulley, i. e. the clutch is

the

machine

stops

automatically. When it

The

idles,

the

forked clutch lever

i.e.

idler

and

the

stops,

disengaged

drive

clutch is

presses

The

the

2.

Setting

Up

the

Machine

Sewing head and power table are packed separately. To make the machine ready for

use, place the sewing head on the table so that the

mounting

holes are in line and the

machine can be secured in position with the bolts supplied. Then mount the driving

belt and attach the belt guard, screwing its bracket to the back of the tabletop.

The long chain serves to raise the clamp feet. Its top end is hooked into hook A of

lifting

lever B

end

connectedtothe

The

short

(Fig.

chain is

6), the chain pulled through the cutout in the tabletop. and its lower

left

pedal.

hooked

into the

lioieatthe

front

end

of starting lever C (Fig. 3) which

is accessible after tilting the machine back. The other end of the chain is connected to

the

right

pedal.

Drive pulley

Stop

lever

Idler

pulley

.=j

\

I

1

*

V \

^

—V

-I

i I

Forked

clutch

lever

Page 5

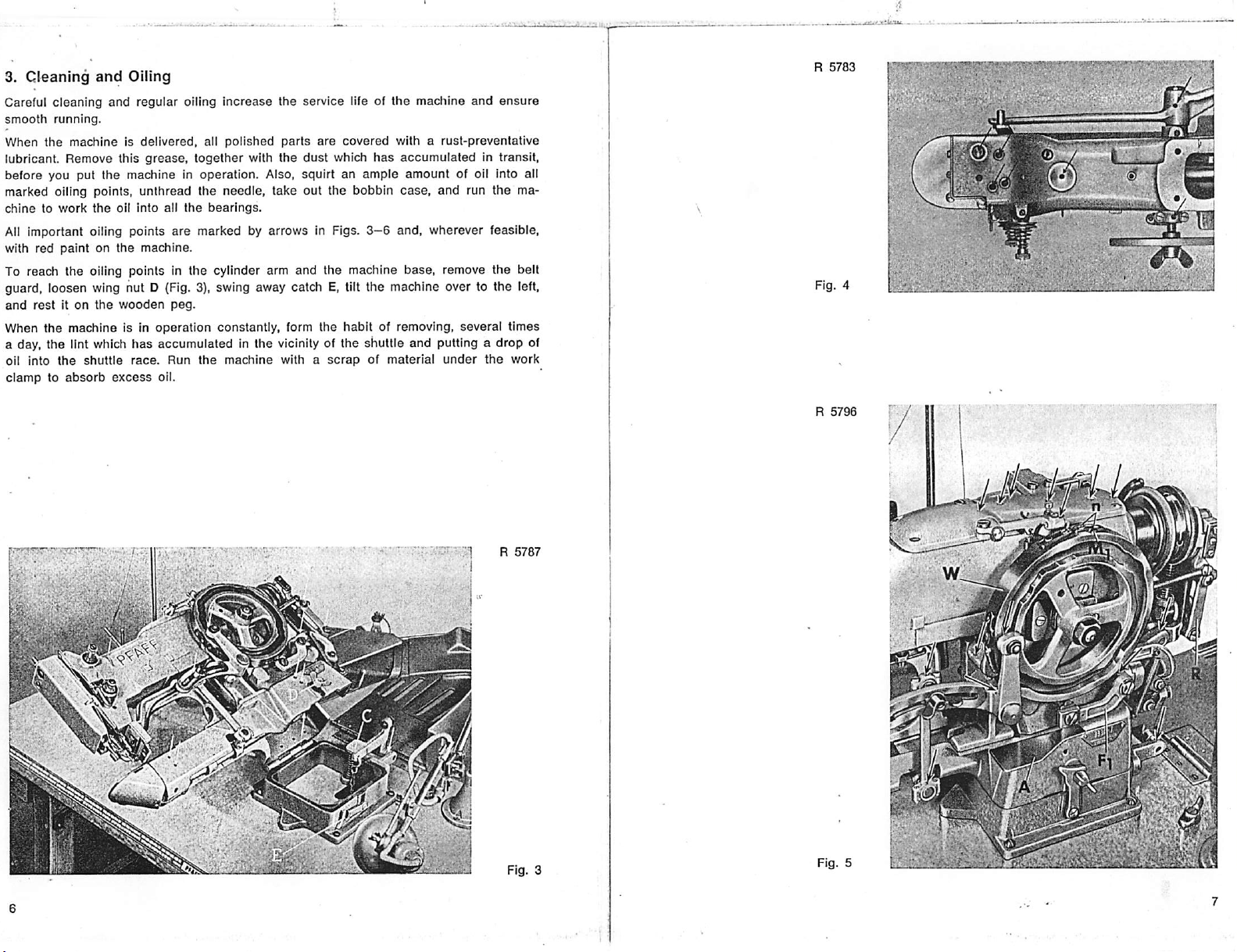

3.

Cleaning

Careful cleaning and regular oiling

smooth

When

the

lubricant.

before

marked oiling points, unthread the needle, take out the bobbin

chinetowork

All important oiling points

with

red

and

Oiling

running.

machineisdelivered,

Remove

you put

paintonthe

this

the

machineInoperation.

the

oil

into

machine.

grease,

all

are

all

together

the

increase

polished

bearings.

the service life of the machine and

parts

are

with

the

dust

Also,

squirtanample

marked by arrows in Figs.

covered

which

with a

rust-preventative

has

accumulatedintransit,

amount

case,

3-6

and, wherever feasible,

of oil into all

and run the ma

ensure

To reach the oiling points in the cylinder arm and the machine base, remove the belt

guard, loosen wing nut D (Fig. 3), swing away catch E, tilt the machine over to the left,

and

restiton

When

the

a day,

the

oil into

clamptoabsorb

machine

lint which

the

shuttle

the

wooden

is in

operation

has

accumulatedInthe

race.

Run

excess

oil.

peg.

the

constantly, form

vicinity of

machine

with a

the

habit of removing,

the

shuttle

scrapofmaterial

and

several

putting a

under

the

times

drop

work

of

R

5787

_ ,

&•••'

mi

m

Page 6

Certain

with

Therefore,

Since

andisnon-resinous,

sewing

mediedbylavish-oiling.

the

Pfaff

dirt

and

oil

sparingly

sewing

troubles,

lint in

machine

usenoother

suchasskippingofstitchesorthread

Excessive

the

but

regularlyl

quantities

machine

oil No. 280-1-120122

oil.

and

cause

of oil

hard

has

are

liable

running.

the

correct

breaking,

to soil

lubricating

cannotbere

the

workormix

properties

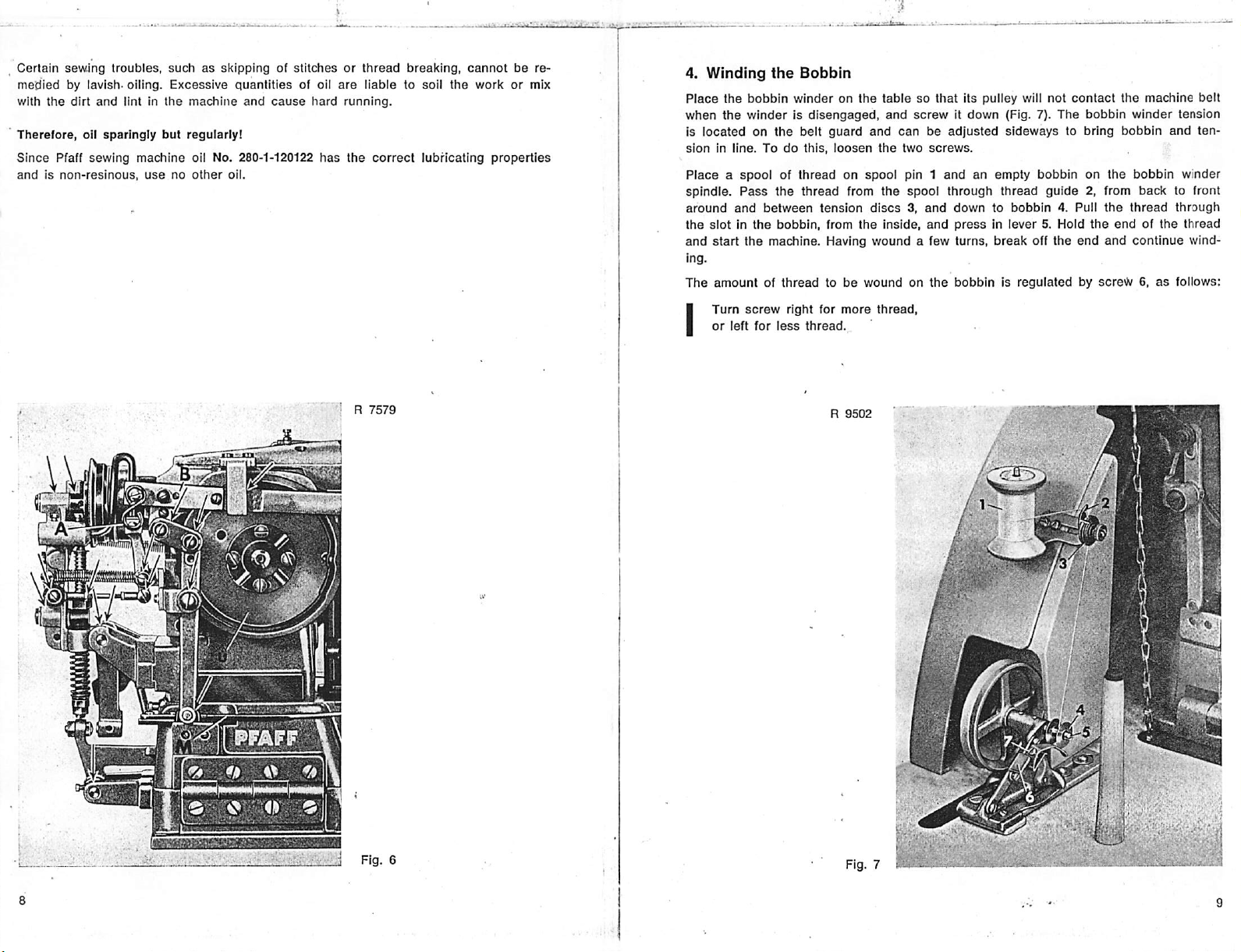

4.

Winding

Place

the

when

the

is

locatedonthe

sionInline.Todo

Placeaspoolofthreadonspool

spindle.

around

the

slotinthe

and

start

ing.

The

amountofthreadtobe

I

Turn

or

the

Bobbin

bobbin

winderonthe

winderisdisengaged,

belt

guard

this,

Pass

the

thread

and

between

the

machine. Having

screw

left

for

bobbin,

right

less

tension

from

for

thread.

and

loosen

from

discs3.and

the

wound

woundonthe

more

the

thread,

tablesothat

and

screwitdown

canbeadjusted

two

screws.

pin 1

and

the

spool

through

inside,

and

a few turns,

its pulley will not

(Fig. 7). The

sideways

an empty

thread

downtobobbin

pressinlever

break

bobbinisregulatedbyscre^6,as

contact

bobbin

to bring

bobbinonthe

guide

2, from

4. Pull

5. Hold

off

the

the

end

the

winder

bobbin

bobbin

back

the

thread

endofthe

and

continue

machine

tension

and

winder

to front

through

thread

wind

follows:

belt

ten

• J R

J

7579

Fig.

R

9502

; ^

' / .k'

6

Page 7

5. Threacflng

To remove

latch

bobbin

Next,

in

the

delivery

three

the

and

pull

drops

insert

the

case.

Puii

eye

2 (Fig. 10)

inchesofthread

the

Bobbin

empty bobbin,

out

bobbin

out

full

bobbin

the

thread

and

hanging

Case

open

the

cap

case

and

bobbin. When

into

the

bobbin

into

slot

1 (Fig. 9}

through hole 3 in

from

the

bobbin

on the cylinder arm. lift

you

release

case,asshown

and

drawitunder

the

position finger (Fig. 10). Leave

in Fig. 8,

the

case.

the

the

latch,

and

tension

bobbin

the

hold

spring

case

empty

it firmly

into

about

yv-j'JyCj

6.

Selecting

All Pfaff 3334

fabricsonModelCmachines,

standard

The

needle

weight, in

rule,

select

dense

and

\

For

best

Select

the

the

Correct

machines

needle.

size

should

any

case,

the

needleasthinaspossible,

resistant

results,

useasmooth,

proper

the

materials.

needle

are

be

thread

from

Needle

regularly fitted with

useaSystem

selected

must

supple

the

in

accordance

pass

thread

following

System34needles.

332

needle

with

freely

through

but

not

too

withamoderate

table.

whichisslightly

the

thread

size

the

needle

thintorisk

needle

twist.

eye.

To

longer

and

As a

breakage

sew

than

the

general

thicker

the

fabric

in

Fig. 8

When inserting

fn

the

shuttle

the

race

bobbin

ring

tween position finger and

hearitsnap

into

place.

and

case,

that

edge

make

the

loose

of slot.

Fig. 9 Fig. 10

sure

that

the

position finger

endofthread

Press

against the bobbin

does

not

enters

get

case

the

jammed

until you

slot

be

Needle

Size

70

80

90

100

110

120

insertanew

go. Make

sure

needle

the

Cotton

100/3

100/4

80/3

80/4

70/3-60/3

70/4-60/4

50/3-40/3

50/4-40/4

30/3

30/4

30/6

24/3

24/6

into

long

the

openingofthe

groove

faces

Silk

120/3

100/3

80/3

70/3

60/3

50/3

needle

toward you.

140/3-120/3

120/3-100/3

100/3-

clamp

Synthetic

80/3

70/3

60/3

50/3

and

push

Linen

70/3

60/3

50/3

40/3

it upasfarasit will

10

11

Page 8

7.

Threading

Lead

stand,

the

then

the

thread

from

downtospool

Needle

the

spoolupthrough

pin 1 on

hollow pin, from top to bottom,

left

around

and

4,

over

thread

check

to left through

between

the

thread

needle eye. Leave

between

nipper

tension

spring5,below

hole in

take-up

spring11and

about

three

the

thread

guideatthe

the

machine

thence

below

discs3,clockwise

thread

guide

lever 8. down

needle

thread

bar,

arm

guide2,over

around

6, up

and

and

through

and

from front to

(Fig. 11).

and

behind

inches of thread hanging from the

topofthe

PassItthrough

and

between

guide

thread

guides9and

back

needle

thread

from right to

tension

discs

7, from

through

eye.

the

right

10,

the

8.

Regulating

the

Thread

Tensions

The neat appearance of the finished bartack greatly depends on the correct regulation

of

tensions.

catenationofthreads

will not kink on

be

balanced.

Set

the

lower

tension

will not be visible on the top

the

underside.

Both

tensions

The bobbin threod pulls the needle thread to the underside of the fabric

OS

the stitch Is being formed.

Causei Needle thread tension too weolc, or bobbin thread tension too tight.

Remedy: Increase needle threod tension or decreose bobbin thread tension.

threads

are

a little

tighter

The

following illustrations

are

Interlocked

baloneed

correctly.

than

In the

the

upper

tensionsothat

side

of the material and

show

hov/

center

oF the

the

material

tensions

because

the

the

should

both

con

thread

The neede thread pulls the bobbin thread to the surface of the fabric

as the stitch is

Cause:

Remedy: Decrease needle thread tension or increase bobbin thread tension.

Regulating

Set

the

the bobbin

Bobbin

thread

Thread

teiislon so

correctly. Make sure, however,

thread

will

notbecut.

Needle

Tension

that

being

formed.

thread

tension too tight, or

that

the bobbin thread will be pulled into the fabric

the

tension is not too light as otherwise the bobbin

bobbin

threod

tension too

weak.

Page 9

The.bobbirf

I

thread

tensionIsregulatedbythe

TurnItright

or

left

for

for

looser

tighter

tension,

tension.

small

screw

S (Fig. 9),asfollows:

The tension Is correct If you have to overcome a noticeable resistance when pulling

the

thread.

10.

Stopping

Upon completion of the sewing action, tripping lever F 1 (Fig. 5) Is

stop

tripping

the stop cam by a tension spring. At the

the

driving to the loose pulley to slow down the machine before It stops. Then the stop

link

snaps

Is

absorbedbydouble

chanism Is releasedsothat, by depressing the left treadle,

th^e

threads

If any trouble

pressing

Into the

down

the

segment

cut.

should

hand

Machine

on the rim of feed cam W and

same

stop

cam which

buffer springs. After

occur

stop

lever

while

A (Fig. 5).

stops

the machine. The momentum of the machine

the

madilne

depressed

stop

motion lever R pulled against

time, the belt shifter shifts the belt from

the

machine

Is In operation,

has

the

stopped,

clamp

stop

the

locking me

can

be raised and

the

machine by

by the

Regulating

the

controls

the

sive

the

closetothe

The

se'tting phase. Begin by setting top tension

that

fabric willbecontractedbythe

bnecome

applies only to tacks

es). The main

sufficient

threads

9.

Don't start the machine

operation.

When you

loosetothe

the

Needle

Thread

Pfaff 3334-958/01

the

thread

threadIstrimmed

amountofthread

other

hand,

needle

lower, or main,

the

thread

has

tension

easily. If

through

the

tensionIstoo

eye.

tension

willbedrawn

operative until the machine

made

tensionIsreleased

amountofthread

are

trimmed.

Starting

the

Machine

unless

depress

the right treadle, the brake Is released and the belt shifted from the

driving pulley. This action

Tension

two needle thread tensions. The top tension Sp 1 (Fig. 11)

during

the

thread

the

the

Sp2

Into

first long

tensionIsset

tension

(Fig. 11)

tight,

and

the

controls

Spl

the

material

stitchesofthe

has

made three or four stitches. (This naturally

trimming

thread

action

and

shouldbesetsothat

too

light,

the

knives

will

drawanexces

the

needle

thread

will

notbecut.

willbetrimmed

the

needle

and

then

adjust

properly.Inordertoprevent

tack,

thread

main tension

the

lower

too

during

tension

early

the

and

Sp2

that

will

If,

too

stitch

on flimsy material and Involving extremely long Initial stitch

again

before

the

last

tying stitch Is

canbepulled

through

the

tension

you have thoroughly familiarized yourself with Its

starts

the

machine.

madesothat

mechanism

before

mode

To acquaint yourself with the operation of the machine, turn the driving pulley by hand

and study the Individual

stitching on a

piece

phases

of material.

of operation. Then thread the machine and try out the

Whife the machine Is In operation, a locking mechanism prevents the work clamp from

being raised and the knives from cutting the thread. Conversely, the machine cannot

be

started

while

the

work,

clampIsraised.

on

so

the

not

the

a

11.

Trimming

The

thread

before

the

cam

u (Fig. 6)

causes

the

the

of

needle

are

caughtbythe

upper

and

ing tack. On completion of

the

take-up

nipperIsclosed

When

the

lever

drops

to

the

knife

down

from

pulls

the

the

trimming

last

stitdiIsmade,

operates

knivestobe

descends

lower

lever

and

left

treadle

Into a

bar

the

knife

needle

thread

Threads

knives

are

locatedonthe

main

tensionSp2 Is

the

vertical knife

movedtothe

between

knife

tensionstoprovide

has

traps

Is,

recessInthe

and

the knives which swing forward.' As a result, the

tips

them

tips.

The

the

last

almost

reached

the

needle

depressed,

onto

endupthrough

for

knives

stitch,

the

control

the

cutting

operative

the

pullanadequate

sufficient

the

thread.

slotofthe

the

undersideofthe

bar

tripping lever

position.Asthe

last

stitch

thread

the

machine

highest

rolleratthe

edges

needle

released.Atthe

and

and

the

amountofthread

for

the

stops

point of Its

top

endofthe

knife

cam.

and

are

hole.

needle

plate.

same

time,

knife

barMand

knives

swing

upper

and

lower

through

first

stitchesofthe

automatically. At this

stroke

and

the

knife

bar

This

motion Is

transmitted

threads

trimmed.

The

thread

Shortly

knife

thereby

forward,

threads

the

follow

stage,

thread

tripping

slide

wiper

14

15

Page 10

.12.

Feeding

Since

this machine

rial is moved

The

feed

plate E (Fig. 12), between which the work is clamped. Depending on the

the

machine

pensating

The compensating work clamp (shown in Fig. 12) features two feet which yield inde

pendently

on

the

material,

needle

than

the

lengthwise

motion is

and

work

clampisused.

against

on

the

Material

derived

the

spring

it is

other.

has

used

a rigid

and

across

from

natureofthe

pressuresothat

for

conditions

needle

the

the

feed

worktobe

bar

which

arm to form

cam

and

performed,

each

foot

where

the

does

not swing

the

desired

conveyedtowork

eitherastandardora

exerts

the

materialisthickeronone

sideways,

tack

design.

clampDand

same

amountofpressure

the

mate

feed

subclass

com

sideofthe

Eyelet-end buttonholes look nicer and wear longer if their square end is closed together

before it Is barred. For this purpose the Pfaff 3334-958/01-5

are

work clamp whose feet

closed showing the fabric together toward the middle. The correct position of the

assured

clamp

by a guide entering the buttonhole slot. This guide is located

feet.

spread

apart

when they reach the material and then

has

been

fitted with a special

bar

between

are

the

13.

Regulating

The

amountofsideways

and

varies

(Fig. 13)

of

I

As a

together,

too

larly In

facilitate

accordance

is

and

MoveIttoward

or

over

resultofthis

while

far

apart,

leatherorplastic

correct

with

each

move ball

from

the

the

with

the

Feed

Across

travel of

subclass.

stud

G in

you

for

more

you

for

less.

adjustment,

total

tack

looks ugly. And conversely, if they

adjustment,

the

styleoftack

the

numberofstitches

material,

the

Motion

the

work

To

adjust

the

the

slot

of feed

sideways

stitches

the

thread

maximum width of

madebyeach

clamp

depends

feed

across

across

clamp

travel,

willbelengthenedorpacked

does

not

is likely to

sideways

subclass.

on

the

motion,

regulatorH,as

change.Ifthe

are

packed

cut

through

travel

designofthe

loosen

stitches

too

has

wing nut F

follows:

more

close,

the

material.

been

closely

are

placed

particu

limited in

tack

To

f

mm

R

5797

Fig. 12

Fig. 13

Page 11

14,

Regulating

The lengthwise clamp travel is derived from the control slot on the back

feed cam. This motion is conveyed to the work clamp by

(Fig. 14), feed regulator

the

Feed

Lengthwise

Motion

means

post

K. feed plate carrier b and arch clamp frame L.

side

of the

of feed regulator a

To adjust the feed lengthwise motion. loosen screw B and move hinge block J, as fol

lows.

Move it upasfarasIt will go to

clamp travel to zero, or down to

reduce

increase

lengthwise

travel.

Note that for certain tack designs which are not'actually bars, hinge block J must not

be moved if

the

proportionsofthe

design

are

to be

preserved.

^ R

7576

K-

15. Dismantling

If the machine is

Let the machine run until it

Open the cylinder bed cap. press down and

bobbin. Take out

shuttle by its center stud and

don't

get

lost.

the

used

screws

Shuttle

constantly,

Race

clean

stops.

h and I (Fig. 15)

pull

the shuttle

Tilt It over to the left, resting it on the

and.strip

race

pullitoff.

shuttle

from time to time.

Remove

the bobbin case and

race

ring d. Then, seize the

wooden

peg.

it out. Take care that the springs on screws h and I

The shuttle race proper need not be stripped for cleaning. Take a pair of tweezers and

remove pieces of thread that have accumulated In the area behind the shuttle race.

Then, with a toothpick or similar wooden instrument, clean the raceway of the shuttle.

Never

useametal

To

assemble

of the shuttle should point downward when you Insert it. Don't forget to

the

tool

shuttle

for

this

mechanism,

purpose.

reverse

the

above

procedure.

Note

that

replace

the

point

the

springs on screws h and i and to put a drop of oil into the shuttle race after it has

been

re-assembled.

The springs on screws h and I hold the shuttle race ring in elastic suspension and pre

vent damage to the machine if thread should jam in the raceway. Pieces of thread or

lint

that

should

have

entered

the

race

can

thusbeeasily

removed.

Fig. 14

R

5790

Fig. 15

-V-i-

h—^

Page 12

B.

Instructions

16.

Ceniering

Needle

screw

In

as

The

the

make

the

17.

The

form the loop) of

needle

Its

center

If

Ttie

Setting

See

has

the

adjustment

necting

To

and

the

same

shuttle

same

bar

frame

e, which

the

needle

hole,

appropriate.

needle

plate

two

set

screws

sure

the

needle

plate.

Timing

Pfaff 3334-958/01 Is fitted for a

In timing

stroke

adjustmentisrequired,

21),

which

shuttle

positiononthe

that

passed

point of

double

seeIfthe

latter

the

rise

gauge

the

shuttle,

and

lineofthe

canbereached

driver

the

Needle

the

pointofthe

the

the

is

studtothe

check

Is at Its right

whether

driver

time.

and

for

the

NeedleInthe

F (Fig. 12) is

passes

loosen

hasanInterchangeable

and

groove

on Its

Shuttle

V32",

No.

88013605

apply

risenVnof an Inch,

needle.

crankIspinnedtothe

shaft

cannot

BaratCorrect

lowest point of Us

shuttle

required

needle

the

above

bottomofthe

the

driving

the

Mechanics

Needle

hinged

to a

throughanelongated

screweand

press

the

undersideIsexactlyInline

move

InsertupoutofIts

needle

or 2.4 millimeters. To facilitate this adjustment,

whichIsavailableonspecial

this

rule:

When

the

pointofthe

This

setting

ensures

loosen

shuttle

driver

through

shuttleIsopposite

should

loosen

pointofreversal.

needle

holesaiandajon

be

adjusted.

Height

stroke

and

be Vu" (1.5 millimeter)

the

clamping

bar,

and

move

settings,

needle

pulleyIsturned

bar

bring

eye

should

Is flush with

Hole

studatits

holeInthe

the

Insert.Ifthe

bar

rise

the

needle

proper

screwsbiand

rear

endofthe

the

center

risen

screw,

the

latterupor

the

needletothe

Also

checkIfthe

clockwise

reach

their

upper

end

and

casting.Tocenter

needle

bar

frametothe

needle

holeIsdamaged,

seat.InInsertinganew

with

the

knife

(amountofneedle

request.

has

passed

shuttle

shouldbejust

loop

formation.

b: (only bi

the

undersideofthe

shuttle

driver

lineofthe

V22

of an Inch. When In

above

which

the

topofthe

or

pointsofreversalatexactly

needle

the

top of

fastens

down,asappropriate.

amountofneedle

counter-clockwise.

the

lowest

heldInplace

guide

rise

use

the

lowest

opposite

visible

cylinder

shaftsothat

after

this

the

needle

needle

point

of its

shuttle

the

needle

rightorleft,

loosen

Insert,

groove

required

the Pfaff

point

the

In Fig.

arm.

the

latter

position,

eye. If

bar

con

stroke

driver

when

riseIsthe

Both

the

the

Adjust the feed

across

motion so that the right and left hand

ends

of the feed plate slot

are equidistant from the needle hole when the feed plate Is at the extreme right or left

of Its throw. Check this setting for the longest and the

All

by

no further

If

readjustment

1. After

motions

roller

^

gulatorH.Tighten

In

to

of

2. Move ball

plate

3.

Push

4.

Turn

plate

rightorleft of Its throw. If

m (Fig. 16)

5. Move ball stud G (Fig. 13) over from you as farasit will go, setting

plate

6.

Repeat

I2

crosswise

its

this setting, move ball

other

If

Pi (Fig. 18) slightly to

H.

shouldbetimed very carefully.

adjustment

shouldbemade,

Is required,

the

stud

for

the

the

slot

for

and

n (Fig. 16)

machine

stud

the

belt

driving pulley

are

the

the

travel of

has

completed

Pi (Fig. 13)

the

and

nut

G (Fig. 13)

longest

shifter

crosswise

over

equidistant

and

set

the

feed

shortest

check

crosswise

outlinedInpar.4above.Ifadjustmentisrequired,

and

the

work

stud

and

make

sure

the

the

feed

plate

should

the

R

Once

unless

proceedasfollows;

the

sewing

center

the

studInthe

securely.

toward

from

and

from

adjustmentIsrequired,

move

G (Fig. 13) from

feed

move

rightorleft In

5782

youasfarasit will go,

travel.

youtorelease

chedt

whether

the

needle

plate,asappropriate.

travel.

studRlengthwiseofthe

clamp

Is exactly halved by

plate

does

sidewaysInspiteofthis

the

absolutely

the

hole

not

the

correct

cycle

elongated

the

right

when

loosen

Then

one

endofthe

move

elongated

shortest

necessary.

and

stopped,

brake.

and

the

feed

tighten

feed

the

sideways.

minute

hole of feed

feed

across

setting

has

been

loosen

holeoffeed

setting

clamp

left

hand

endsofthe

plate

is at

screwhand

both

screws

clamp

loosen

across

shaft

needle.Todouble

slotInregulator

adjustment,

across

motion.

obtained,

the

across

and

the

binding

securely.

and feed

move

nut on

re-

feed

feed

extreme

screw

screws

until

the

check

H to

the

stud

regulator

h, R

18.

Adjusting

The

feed

the

rolleronstudPifollows

As

curvatureofthe

feed

across

of

the

cylinder

the

Crosswise

across

motionIsderived

slotIsconveyedtofeed

shaftSand

arm.

feed

Clamp

from

the

plate

Travel

the

slotonthe

channel

carrierU,and

track,

across

frontoffeed

the

throw

whichIsInitiatedbythe

regulatorH,connection

causes

the

latter

to move

cam

Q, ball

W (Fig. 13).

stud

crosswise

R,

Fig.

• /

,'

I

m I2 n

16

Page 13

19.

Adjusting

the

feed lengthwise

W {Fig. 17). Motion is

block

J (Fig. 14),

To

adjust

Turn

the

driving

clamp

feet

If

the

machine

sign

are

correctly

paper

under

Foraprecise

17)

and

move

tighten

the

the

feed

the

lengthwise

pulleybyhand

slot

when

makesabar-type

centered

the

clamp

adjustmentofthe

the

studinthe

nut

securely.

Lengthwise

motion

is derived

transmitted

regulator

clamp

these

feet

over

and

examine

Clamp

from

from

the

postK,feed

travel,

move

and

check

reach

the

seam,

also

the

long

the

feed

lengthwise

elongated

Travel

the control slot on the back of feed cam

rolleronstud

plate

carrierband

hinge

blockJdownwardasfarasIt will

whether

extreme

check

stitches.Tocheck

stitch

pattern.

motion

holeoffeed

P2 to

the

the

needle

hole

positonsoftheir

whether

the

this,

loosen

regulator

plain

the

feed

regulatorV.hinge

work

clamp.

remains

stitchesInthe

placeapiece

nutonstudP2(Fig.

V,asrequired.

within

lengthwise

go.

the

travel.

de

of stiff

Then

20.

Timing

The

feed cam is located on the right hand

operator). It controls both the feed lengthwise and

motion

penetrates

the

Feed

Cam

side

of the machine arm (as

the

begins

after the

needle

has

risen

clear

of the fabric and

the material again. If the feeding begins too early or

ing motion is retimed by turning the cam on its shaft.

Todothis,

shaft

in

cam

loosen

nut

Y (Fig. 18)

(the

cam

canbeturned

positioning block 2). After

R

5793

within

r

and

studXand

the

the

adjustment,

limits

turn

setbystud

tighten

feed

across

the

feed

X riding in

studXand

seen

from the

motions. The feeding

ends

before the

ends

too late, the feed

camonthe

the

nut Y

transverse

elongated

securely.

W'

needle

hole

-01

•••Vx

• .

Fig.

17

Fig.

fell

Yt®fX

18

Page 14

21.

Timing

Shortly before the machine stops, the knife cam

the Inoperative to the operative position, and after the

tripping

in

turn,ispinnedtothe

lever t

the

(Fig.

Knife

19)

Cam

and

knife

transverse

barM.Knife

shaft.

causes

the knives to be moved from

machine

has stopped, operates

cam u is screwed to hub cover f

which,

The four screwholes in hub cover f are elongated so that the position of the knife cam

on the shaft can be adjusted after loosening the four screws q.

Set the

point of its stroke and begins to descend for the last stitch. Since gear ratios

each

deviations. If additional adjustment is required, reset the knife

following

tips when It

next

knife

subclass

cam so that

machine, no hard and fast rule can be given for the elimination of minor

knife

motion

begins

when

the needle has passed the

bar

as instructed in the

chapter..Note as a general rule that the needle should pass between the knife

descends

seam.

for the last stitch of

one

seam

and the first four stitches of the

highest

vary

with

22.

Adjusting

The

throw initiated by knife

platebymeansoftripping

the

Knife

Bar

cam

u (Fig. 19) Is

leverXand

transmittedtothe

knife

bar

l\A.

knives

below

the

needle

The knife bar carries a rack at its front end which meshes with the knife carrier pinion.

Its

rear

endisconnected

Loosen

Vaj"—Vii"

when

No

bobbin

Instructions

screwsrand

the

gauge

thread

(7—8

millimeters) between tip of bobbin

knife is

Inoperative

Is required for this setting. Simply adjust the knife bar until the tip of the

knife is in line with

giveninthe

to tripping lever t by

s (Fig. 19)

and

(Fig. 20).

preceding

set

knife

the

top

chapter.

means

barMso

left

edgeofthe

of an adjustable fork.

that

there

is a

thread

knife U and the

shuttle

clearanceofabout

needle

race.

Note

also

hole

the

msmmm

^-•Greiferbahn-kanle

i *

Page 15

23.

Changing

Th'e knives

used

-wooden

Next,

The knife

b (Fig. 22) in

needle

pullingitforward.

shouldbesharpened

constantly.

peg.

remove

assembly

plate

screws

Open

pinion

the

the

To

feed

Knives

strip

the

stud

can

and

cylinder

also

plate

from time to time, particularly

the

knives,

tilt

the

bed

cap,

bracket0and

machine

loosen

the

knife

overtothe

nut M (Fig. 21)

assembly.

be removed from above. To do this,

and

pull

the

plate

out

of its

remove

the

needle

plate

with

mount.

the

left

and

loosen

Then

attached

when

and

take

take

knife

the

machine

restiton

out

hexagon

out

assembly

screw

screw

the

the

four

by

N.

The

knives

are

securedtothe

screw

and

strip

the

Is

new

In

replacing

tighten

knives.

the

screwasecurely.

knives.

knives

make

(Fig. 21) so that the knife

replaced.Toreplace

dure.

the

knife

Sharpen

sure

The

meshing

bar

need

knife

assemblyinthe

carrier

them

they fit in

teethofthe

onlybyscrew

with a knife

the

knife

a (Fig. 22).

grinderorexchange

carrier

groove

rack

and

the

pinion

Take

correctly.

not be readjusted after the knife assembly

machine

simply

reverse

the

above

are

out

them

spotted

has

proce

this

for

Then

been

R

5952

•-

Fig.

21

Fig. 22

24.

Adjusting

When you

wardtothe

may swing slightly

edge

this

If

the

knife

depress

operative

when

protrudes

the

Knife

the

beyond

the

treadleisdepressed

from

of regulating block Gi in

left

treadle

position.

the

the

the

Motion

after

During

right

edgeofthe

edge,

slotofthe

the

this

completely.

loosen

lifting lever.

machine

operation

cylinder arm,

lock

nut

has

stopped,

the

tip of

H (Fig. 17)

the

knives swing for

the

bobbin

thread

knife

butitshouldbeflush with

and

adjust

the

position

Page 16

25. Adjusting

Stop

motion

vertically.

end.

Both

the

catch

Into

the upper

chine. To adjust, loosen the hexagon screws.

When

you

meters) between the face of the stop link

the

Stop

Motion Lever

leverp(Fig.

23)

carriesacatch,

Ei,atits

The spring-loaded tripping lever Fi carries an adjustable

and

the

latch

should

beso

make

notch

this

of catch Ei

adjustment

when

also

see

adjusted

the

that

(Fig.

that

right

treadle is depressed to start the ma

there

is a

24) and the highest point on the face of

the stop cam.Ifadjustment is required, loosen screw t

the

groove

of tripping lever Fi.

; R

lower

end,

which

latch,

latchGiwill

leap

clearanceofabout

(Fig.

23) and reset

5485

canbeadjusted

Gi at its rear

about

halfway

(2

milli

latchGiIn

26.

Adjusting

Adjust brake lever R (Fig. 23) so

between

machine

V«4"

To

Start

In

Loosen

resistance.

Stop

cam. Check whether the

meters)

If

back

I

hinged

is In

(2 millimeters) when the machine

adjust,

the

the

central

the

the

against

further

accordingly.

Make

surfaceofthe

the

Brake

brake

operation.

follow

this

procedure:

machinebyhand.

position

nut of

stop

Then

turn

the

machine

adjustmentIsrequired,

sure

completelysothat

spring

the

brake

driving

LeverofMachines

shoeKand

Also

Loosen

and

lighten

screwvand

screw

brake

pressure.

shoe

pulley

with

that

there

is a

clearanceofabout

the

braking

make

sure

has

the

two

both

screws

turn

in

oneortwo

the

lever

can

loosen

exertsasufficient

when

the

surfaceofthe

the

brake

lever

stopped.

screws

q (Fig. 23),

securely.

the

screw

out

turns.

stop

link

snaps

be pulled off the pulley

the

two

screwsqand

amountofpressureonthe

machineisbeing

Round-Belt

driving

can

be pulled off

set

until It

turns

Into

the

stopped.

Drive

V32"

(7 millimeters)

pulley

hinged

brake

freely, without

grooveofthe

about

move

the

Slop

when

the

shoe

V<4"

(2 milli

brake

braking

com

the

pulley

K

any

stop

shoe

Fig. 23

Fig.

24

Stop

segment

tripping

tripping

and

dog

Slop link

Stop motion lever

Tripping

lever

Page 17

27.

Adjusting

Tripping

adjusted vertically.

dogLi(Fig.

depresses the

rely.

As a general

ters) between the tripping dog and the rim of the feed cam when the machine

stopped

(Fig. 23).

28. Adjusting

the

Set

tripping

rule,

the

Tripping

23),

it so that the

Lever

which

is located at the

stop

tripping

front

segment

end of the

on the rim of the feed

dog far enough to ensure that the machine

there should be a clearance of aboutVbon an

Stop

Tripping

Segments

tripping

will

lever,

be stopped secu

inch

(3.5

can be

millime

cam

has

Although the

error,

I

The

without

The pressure Is regulated by stop screw d (Fig. 18). Some bartacks which feature very

long crosswise stitches (without Intermediate stitches) require a sufficiently long

of

thread

be

pushed

If

there

adjusted

the

correct

following

pressure

rule

maybehelpful:

pressureIscorrectifthe

breaking.

with which to begin

back

slightlysothatitcan

are

several

separately.

thread

nipper

of the thread nipper Is normally established by trial and

thread

can

the

tack. On

fall

segments

justbepulled

machines

earlier

arrangedonthe

into

making

the

through

such

tacks

recess

on

feed cam,

the

the

rimofthe

each

thread

nipper

finger f

should

has

end

cam.

to be

The number of stop tripping segments which are arranged on the rim of the feed cam

varies with each

To

adjust

Turn the

passed

stop cam. When the machine has stopped, tripping dog Li should be positioned just

behind

ping dog Li should contact the rim of the feed cam instantly.

If

move the segment back or forth on the

If

tripping

the stop

the stop

the

feed

29. Timing

The needle thread must be trapped when the machine stops. If this condition is not

met, adjust by loosening screw e

follows:

Toward

The

the

Another rule

the needle has reached the lowest point of its stroke when making the first stitch. As

the sewing cycle continues, the thread should remain loose until the take-up lever has

reached a point about Vu" (15 millimeters) below the highest point of its stroke. This

condition

sive

you

finger

recess

stitches

If the above condition is not

thread nipper tripping

Over

from

the

driving

tripping

cam

the

subclass

stop

pulley

dogLi(Fig.

tripping

has

Needle

and

tripping

segments,

until

the

23)

segment,

segment needs

more

than

Thread

Nipper

threadIstrapped

ranges

from 1 to 6.

proceedasfollows:

tripping

and the stop

without

adjustment,

rim

one

stop

tripping

(Fig.

18) and

segment to be adjusted

link

has snapped into the groove of the

touching

of the cam, as required.

earlier

it.

On restarting the

loosen

the

segment,

moving

two

each

finger f on tripping lever c as

(MiinFig.

screws n

has

to be set

5) has just

machine,

(Fig.

separately.

5) and

is positioned correctly if Its tapered side just slips over the front edge into

on the rim of the cam when the machine stops.

that

also

appliestothe

the

you

must be

thread

observedisthat

nipper

segment

Needle

threadIsreleased

the

needle

thread

mustbereleased

initial

phase

of the

second

remains

met,

h (Fig. 18), as follows:

inactive. i

adjust by loosening the two set screws and

earlier

stitch,

whereas

for all

before

succes

moving

trip

30.

Changing

A powerful buffer

the

momentumofthe

chine is

est point of its stroke and descended V8"-Vu"

slowed

the

Buffer

springislocatedinthe

down

first

machine

and

Fig. 25

Spring

whenItstops.Ifthe

stopped

hollow driving pulley

only when

and

servestoabsorb

spring

works

correctly,

the

needle

bar

has

passed

(3-5

millimeters) and the take-up lever

*•-

i'-'

the

the

ma

high

Page 18

has almost reached the top of Its stroke.

stress,

it may

becomes

become

evident

weakoreven

when

the

machine

the take-up lever do not always stop at the

stop

beforeithas

reached

the

top of Its

Since

break

after

ceasestostop

same

stroke

and

this spring is

some

time by fair

evenly or when

subjected

wear

the

positions. As a result, the

may be

brokenbythe

to excessive

and

tear.

needle

bar

needle

thread

This

and

may

wiper

upon lifting the work clamp. To correct this and similar conditions, exchange the buffer

spring,asfollows:

Remove tension

studQand

Next,

take

ken

buffer

Insertion of a new spring Is greatly facilitated by the

which will be

strip

out

the

spring.

supplied

springs

stop

N and 0 (Fig. 25), loosen

motion lever p (Fig. 25)

four

screwsb,strip

by us on

special

cap

request.

and

ring A

brake

and

screw

K (Fig. 26), pull out hinge

lever R.

remove

use

stop

camSand

of a special wrench (Fig. 27)

the

bro

Proceed,

as

shown

in Fig. 27, by

insertingasuitable

pulley. Then rotate the pulley until punch D rests

Insert

the

buffer

spring

into

the

the

wrench,

block

.

compress

sure

Then

lever

contacting

the

the

flat

replace

and

the

and

push

the

spring

sidesofthe

the

stop

stop

motion

the

loose

and

cam

wrench

endofthe

place

check

and

lever.

R'5788

receptacle,

over

the

Novotext

blocks

the

the

spring.

face

cap

place

endofthe

segment

toward

ring

against

the

Now, with

the

and

screw

punch

into

hole

the bearing bracket.

loose

check

blockonthe

arm shaft, with

the

wrenchinyour

between

segment.

them

both

down. Attach

I of

the

check

the

driving

stud

loose

check

left

hand,

blocks. Make

the

brake

of

v.'.usi

• -"-i

Fig. 26

Fig. 27

Page 19

31.

To

adjust

Adjusting

the

Cone

the clearance

ClutchofMachines

between

V-belt

pulley

(Idler

with

pulley)

V-belt

1 and

Drive

drive

pulley

7 after

the machine has stopped, loosen the nut of eccentric 5 aiid turn the eccentric to the

rightorleftbyhand

of the

V-belt

pulley

pntll

the

forked

clutch

against the arm shaft

lever

bearing.

3 has

pushed

Hold

the eccentric in this

the

ball-bearing

collar

position

with an open-ended spanner and tighten its nut.

32.

Trouble

Sewing

troubies

followed. If

the

fault.

Shooting

should

trouble

rarely

should

occur

if aii

nevertheless

the

instructions given in this

occur,

the

following hints wiii

book

heip

are

you

carefully

locate

Q

1 = V-belt pulley (idler pulley)

2 = Engaging

3 =

Forked

4 = Leaf

5 =

6 =

spring

Adjusting

Clutch

lining

clutch

eccentric

disengaging

lever

collar

and

7 = Drive puiiey (take-up spring housing)

Fig. 28

Machine

1.

2.

3.

4.

5.

Thread

1.

2.

3.

4.

5.

Needle

1.

2.

3.

4.

5.

6. Work

Machine

1.

2. Mechanism

3.

4.

Skips

^Needle

Needle

Needie

Needle

Shuttle

For

Needle

Thread

Poororknotty

Thread

Needie

Needle

Buffer

Knives

Machine

bent.

incorrectly

too

rise

set

Breaks:

anyofthe

point

caught

tensions

Breaks:

bent.

too

spring

improperly

clamp

sewn

on.

Works

Uck

of

oil.

Piecesofthread

Machineorline

Stitches:

inserted.

fine

for

the

thread.

inaccurately

too

far

causes

bluntorworn,orburrs

between

thread

too

fine

for

broken.

feeds

while

timed,orneedle

away

from

enumerated

tension

used.

looseortoo

the

fabric,ordeflectedbyhard

timed.

needleisdowninmaterial.

not in line with

Heavily:

clogged

by inferior

jammedinshuttle

shaft

belt

needle.

discs.

tight.

neediesothat

iubricants.

too

long.

above.

and

race.

set

sharp

too

highortoo

edges

needle

iow.

on

needle

spotsinthe

strikes

buckle or

plate.

material.

clasp

to be

34

35

Loading...

Loading...