Page 1

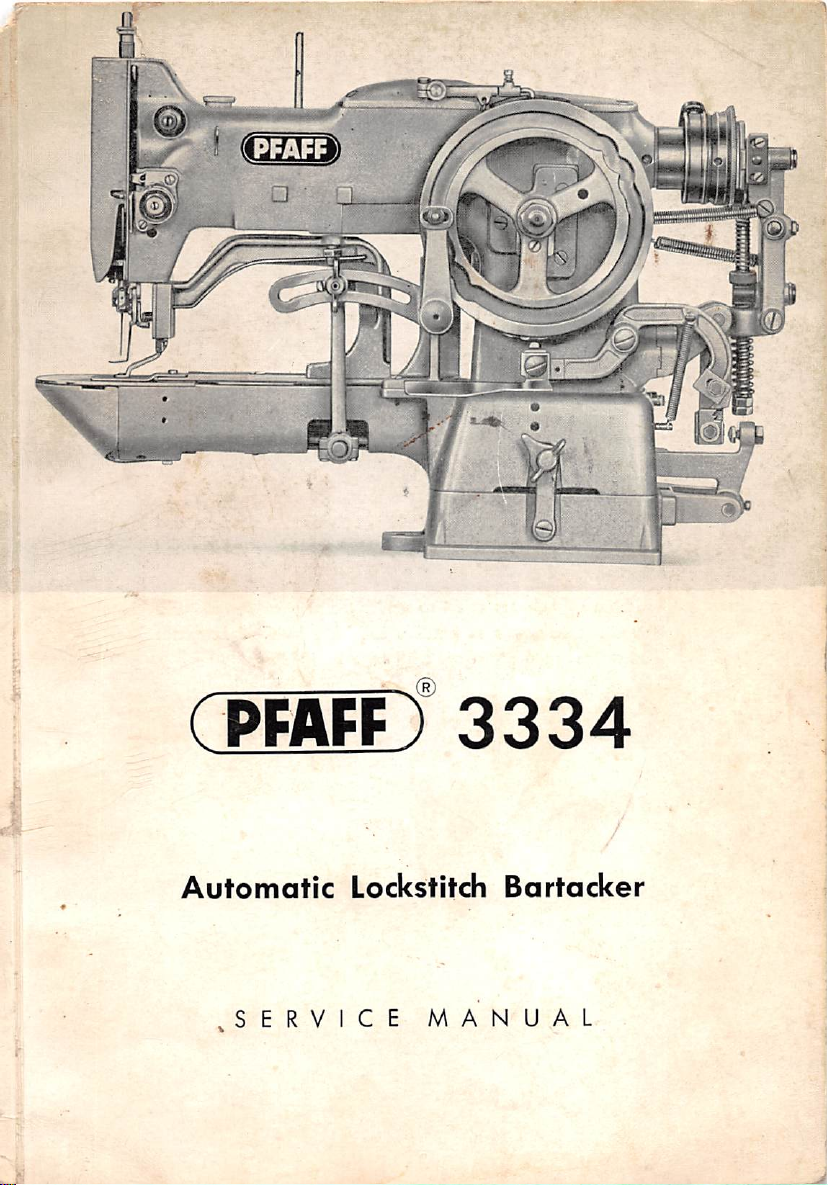

IS'

' " (D

(TOFF)

Automatic

SERVICE

Lockstitch

3334

Bortocker

MANUAL

Page 2

Foreword

Pfaff sewing machines

are

quality products. Constant checks ore

being made throughout the production process to ensure that o

But

high quality standard is maintained.

machine

results

has to be operated and serviced

aretobe

obtained.

even the best sewing

skillfuify

if satisfactory

This book has been compiled cs a source of information for all

Pfaff mechanics servicing Pfaff 3334 automatic bartackers and

will serve as a valuable guide in performing minor repairs and

adjustments.

We have made every effort to render the presentation of these

instructions as simple as possible and have included numerous

illustrations inordertoafford a better understanding.

G.M.PFAFF

Kaiserslautern

AG

Branch

Page 3

SERVICE

MANUAL

Automatic

PFAFF

Lockstitch

3334

Bortocker

Page 4

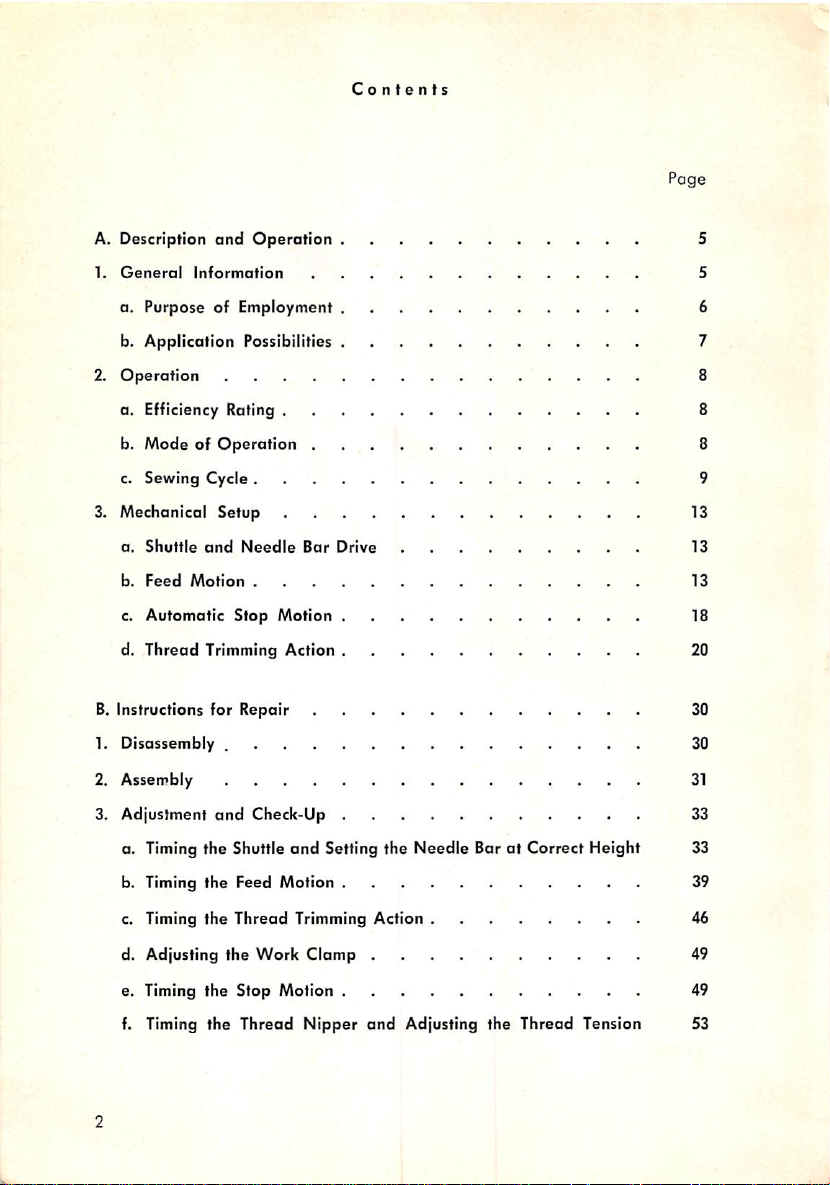

Contents

A.

Description

1.

General

and

Information

Operation

a. Purpose of Employment 6

b.

Application

Possibilities 7

Page

5

5

Operation

2.

a. Efficiency Rating 8

ModeofOperation

b.

c. Sewing Cycle 9

3. Mechanical Setup . 13

a.

Shuttle

b.

c.

d.

Thread

B. Instructions for

ond

Feed

Motion

Automatic

Trimming Action 20

Needle

Stop

Repair

Bar

Motion

Drive

.

13

13

18

30

1. Disassembly , 30

2. Assembly 31

3. Adjustment

a. Timing the Shuttle

and

Check-Up 33

and

Setting the Needle Bar ot Correct Height 33

b. Timing the Feed Motion 39

c. Timing the Thread Trimming Action 46

Work

d. Adjusting the

Clamp 49

8

8

e. Timing the Stop Motion 49

f. Timing the Thread

Nipper

and

Adjusting the Thread Tension 53

Page 5

4. Stitching-Off 60

a. Sewing

b.

Needle

Thread

c. Bobbin Winding 61

Needle

d.

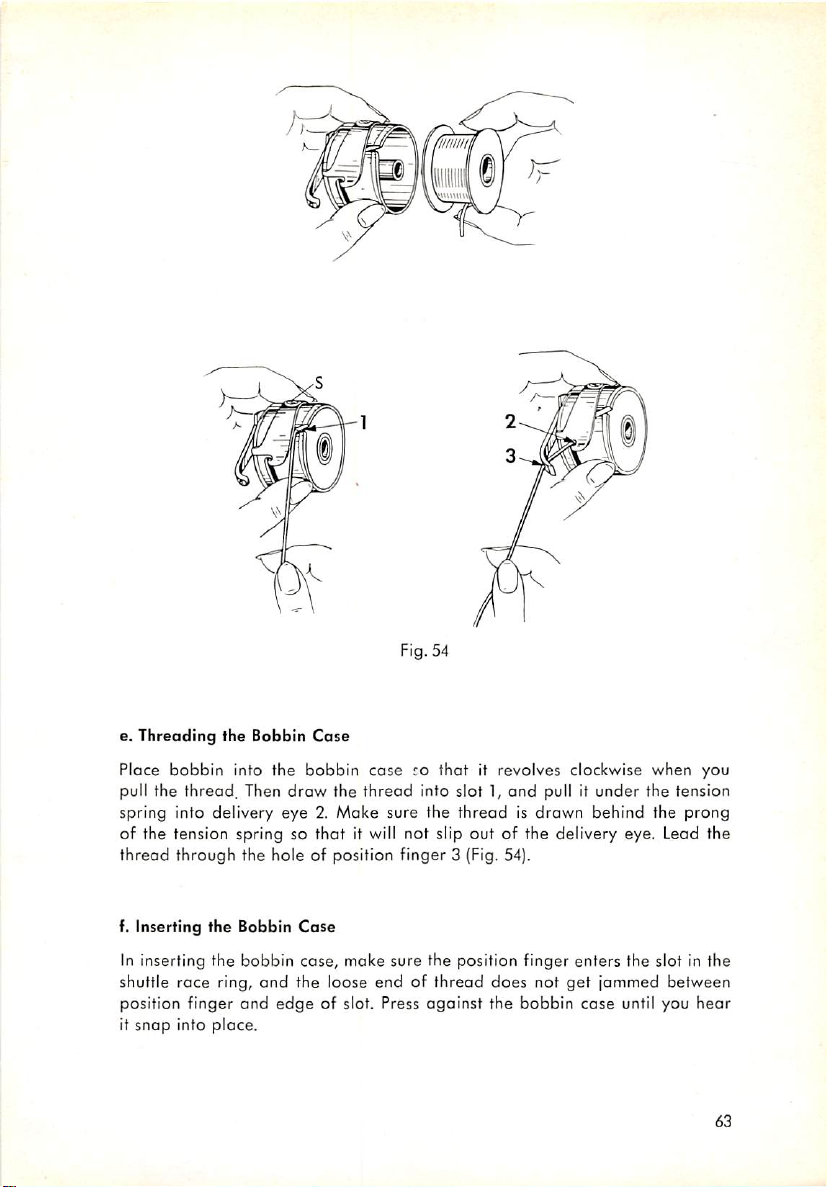

e. Threading the Bobbin

f. Inserting the Bobbin

5.

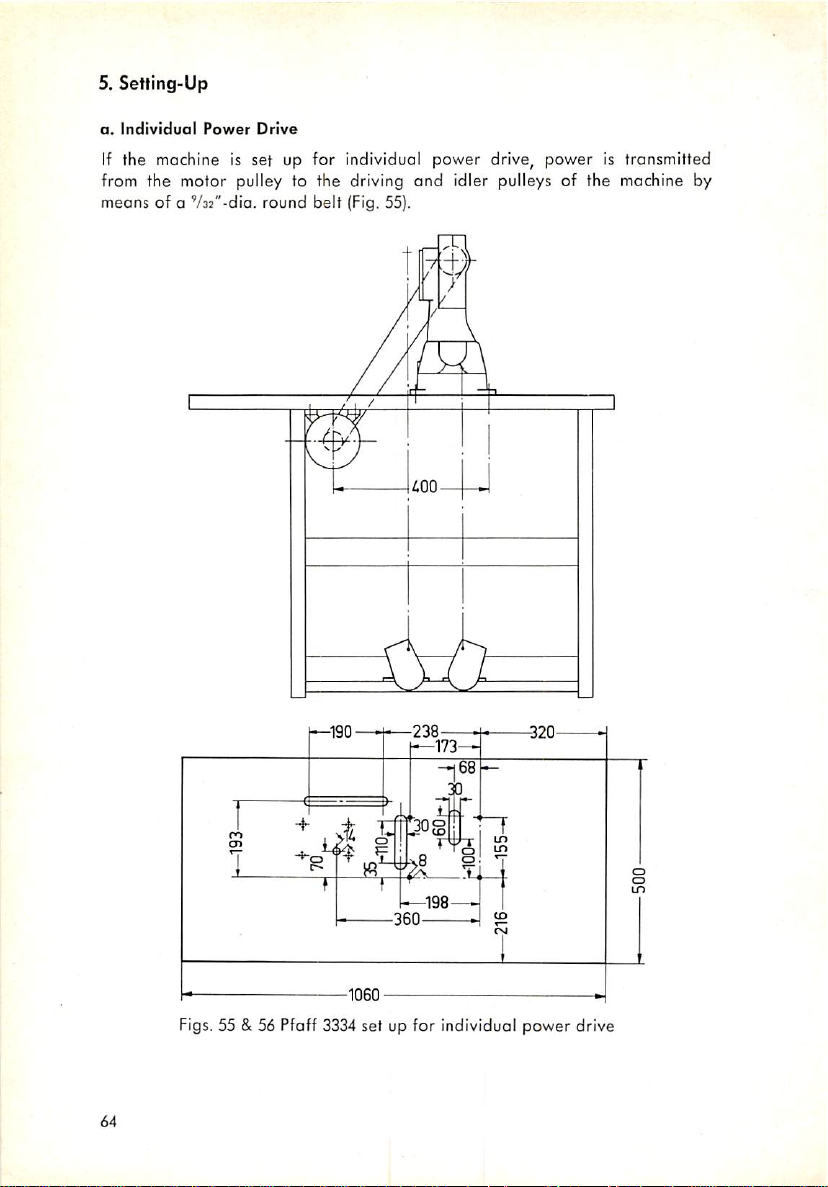

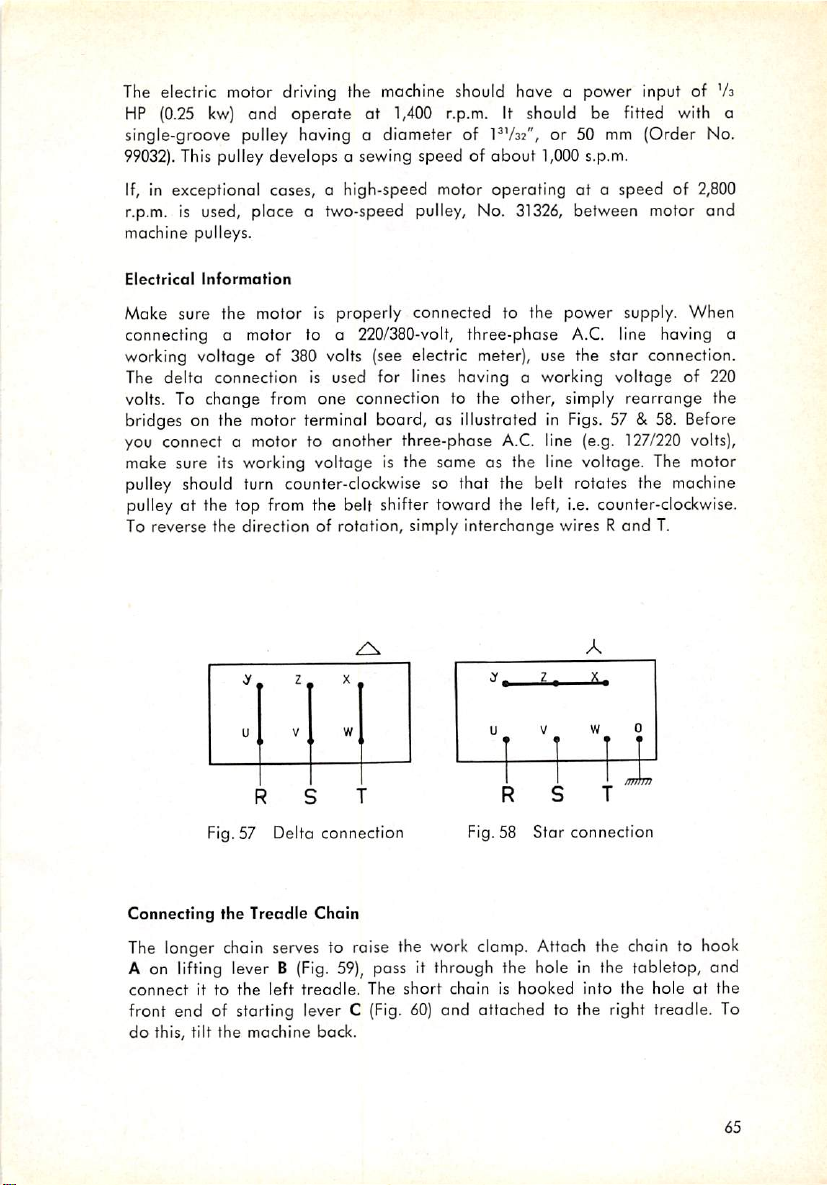

Setting-Up

a.

Individual

b.

Bench

c. Individually Powered Machine on Power Benching

6.

Subclass

Threading 62

Case

Case

Power

Power

Drive

Drive

.

....

Conversion

a. Changing the Feed Cam 69

b. Changing the Knife Cam 70

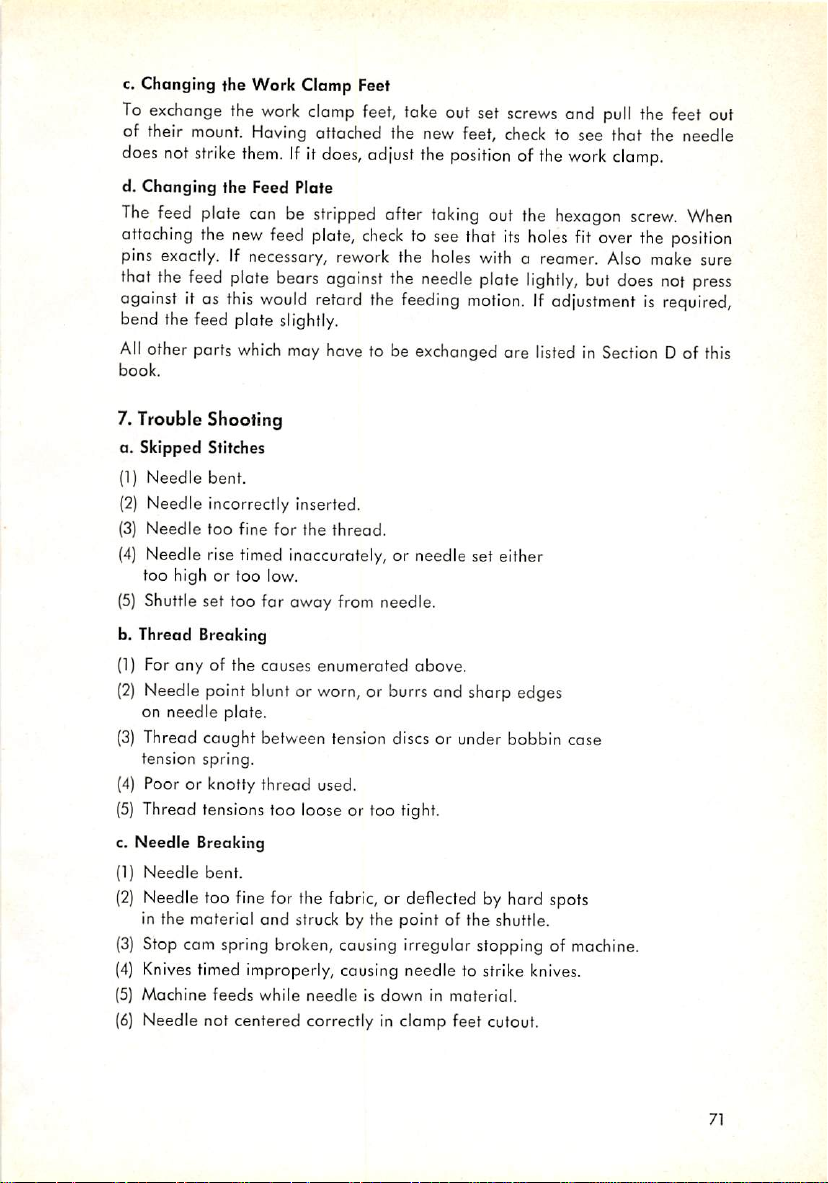

c. Changing the Work Clamp Feet 71

d. Changing the Feed Plate 71

60

60

63

63

64

64

67

68

69

7. Trouble Shooting 71

a. Skipped Stitches 71

b. Thread Breaking

71

c. Needle Breaking 71

d. Heavy Working 72

e. Irregular Stopping 72

8.

Machine

Care

75

a. Cleaning and Oiling 75

b. Dismantling the Shuttle Race 77

Page 6

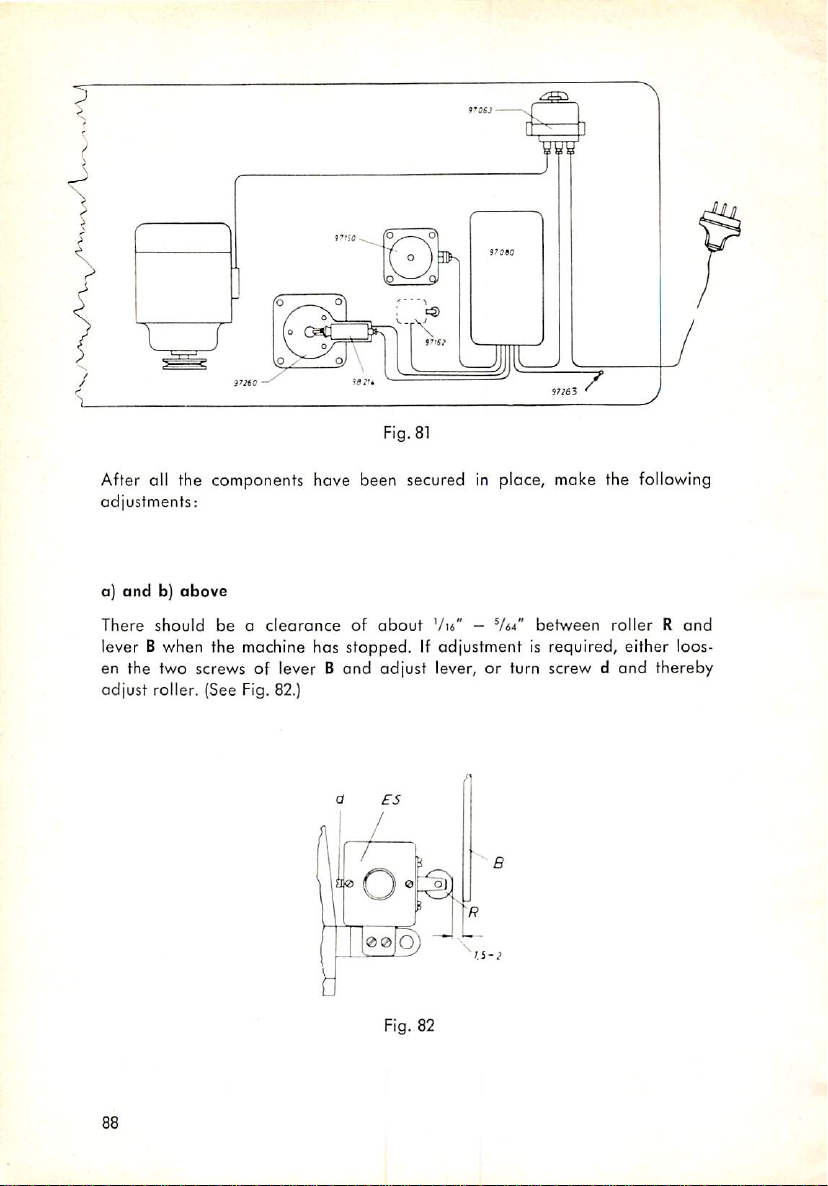

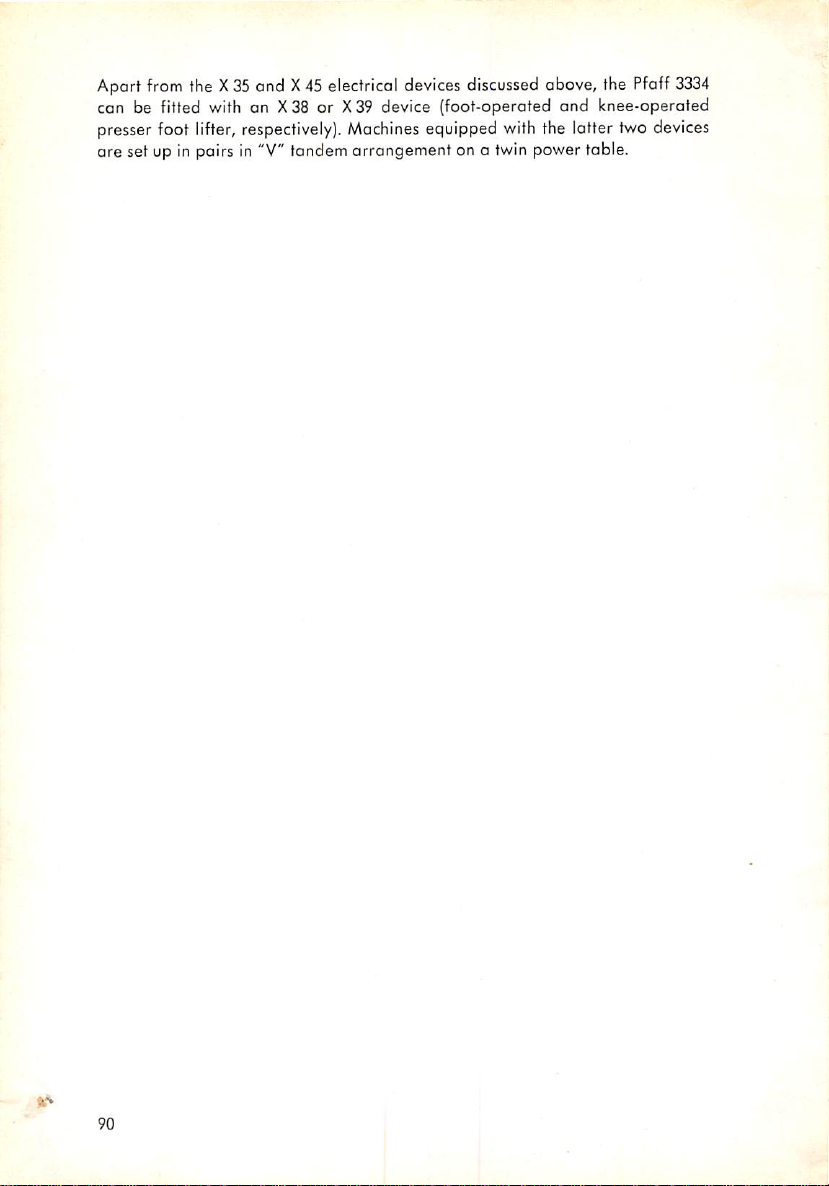

C. Electromagnetic Control 78

1.

General

a.

Information

78

Brief Description 78

b. Key to Symbols Used 79

Operating

2.

Instructions for X35

and

X45 Devices 80

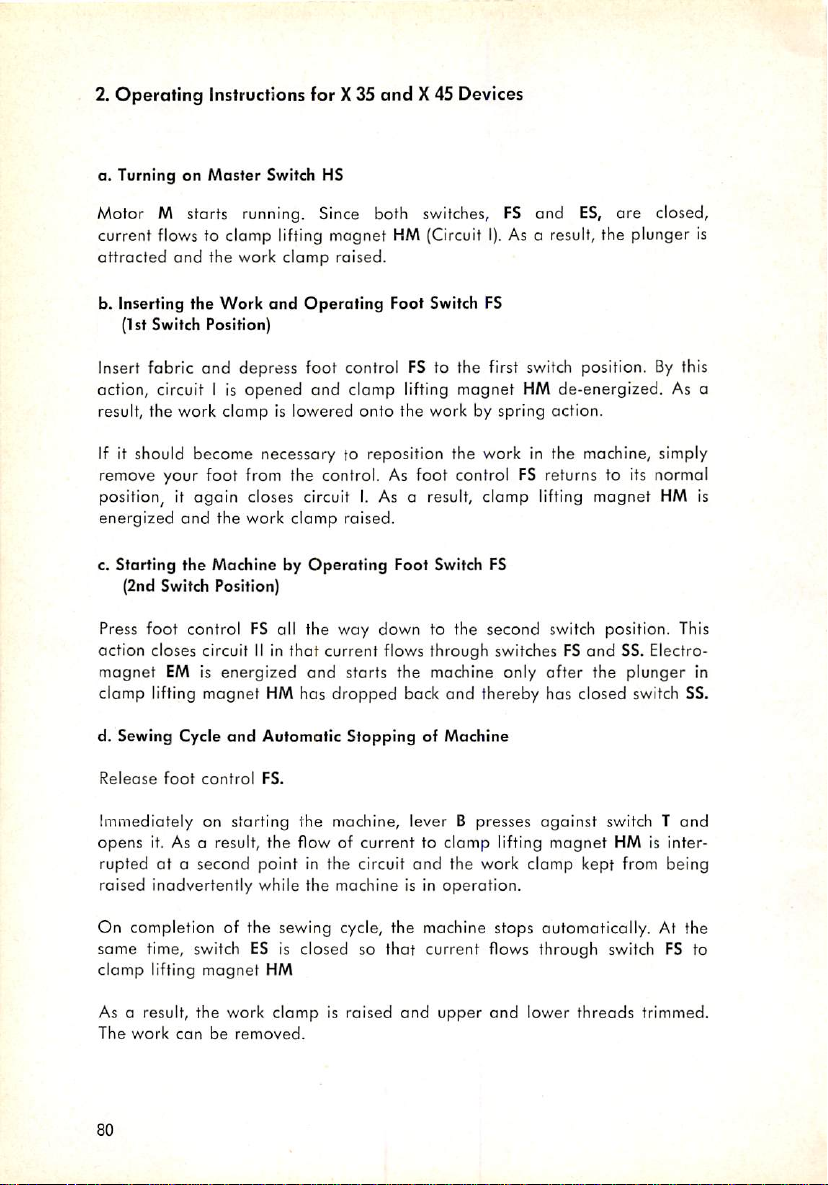

a. Turning on Master Switch HS 80

b. Inserting the

Work

and

Operating

Foot Switch FS (1st Switch Position) 80

c. Starting the Machine by Operating

Foot Switch FS (2nd Switch Position) 80

d. Sewing Cycle

and

Automatic Stopping of Machine

....

3. Working of Device 84

a.

Master

Switch

HS

b.

Foot

Switch

FS 84

c.

Solenoid

d.

Solenoid

e.

Switch

4. Mounting

a.

Switch

b.

Lever

c.

Solenoid

d.

Switch

e.

Solenoid

EM

HM

and

Switch

ES

SS

and

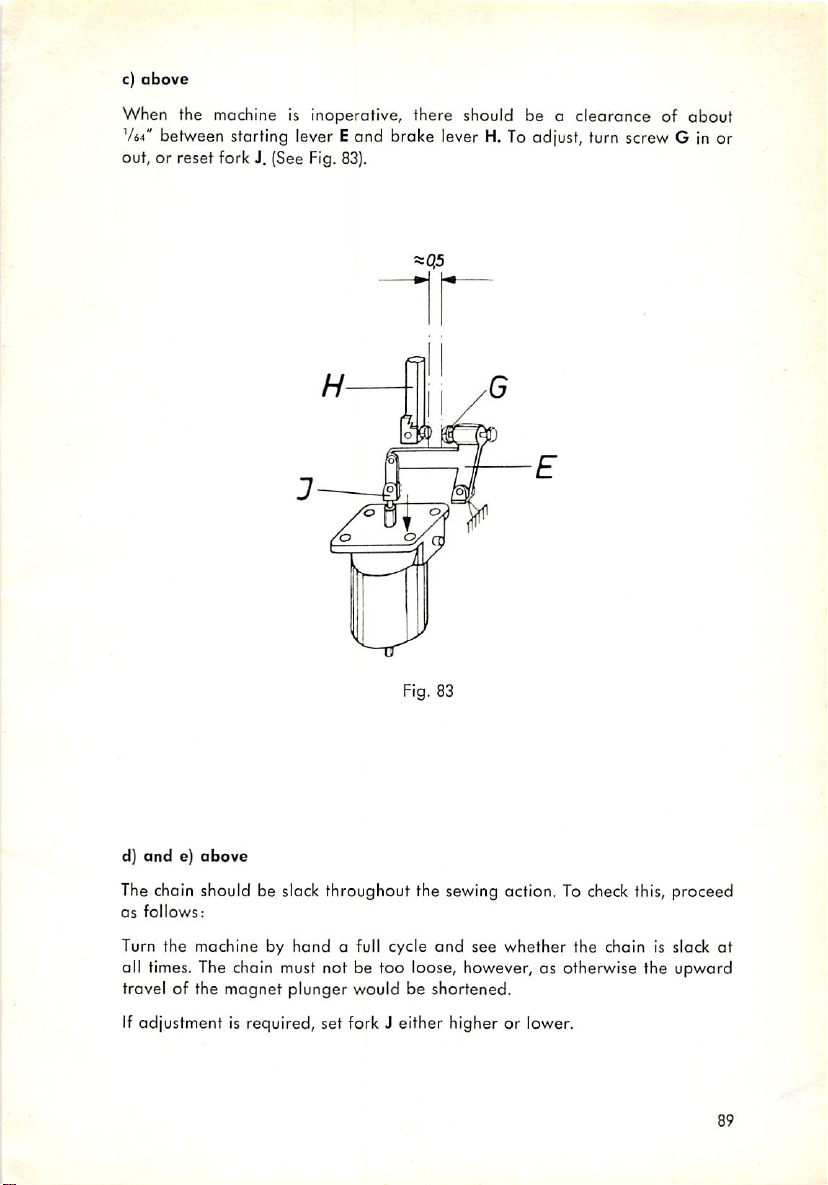

Adjustment Procedures 87

ES

B

EM

SS

HM

80

84

84

86

86

87

87

87

87

87

D.

Subclass

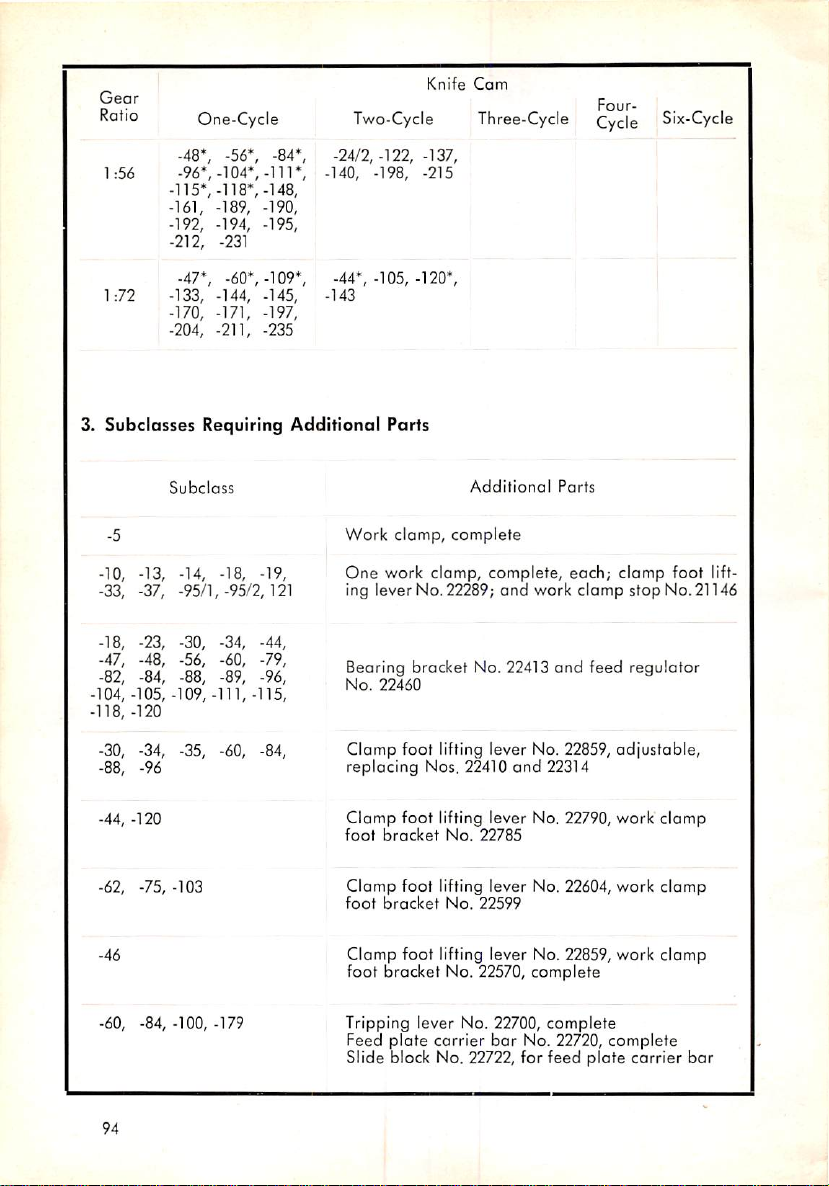

1. Subclasses Having the

2.

Subclasses

Information

Having

the

Same

Same

Gear

Ratio 92

Knife

Cam

91

93

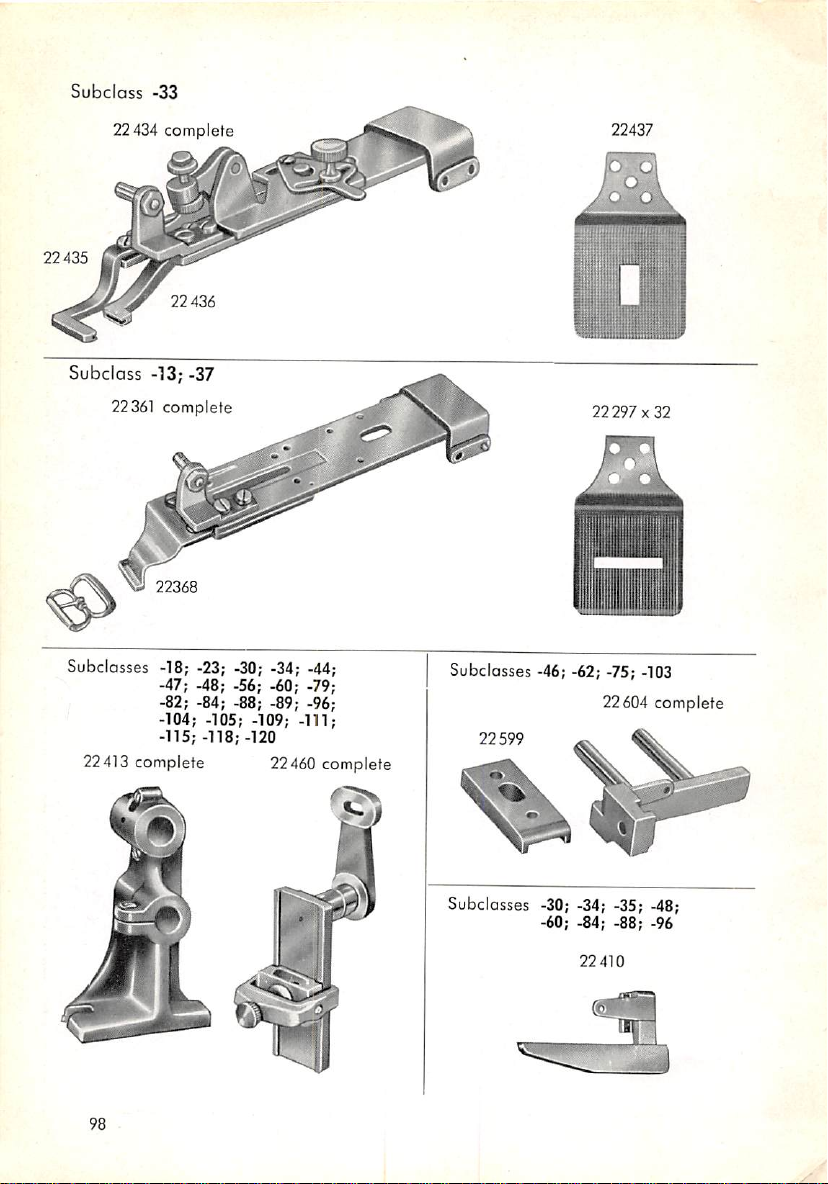

3. Subclosses Requiring Additional Parts 94

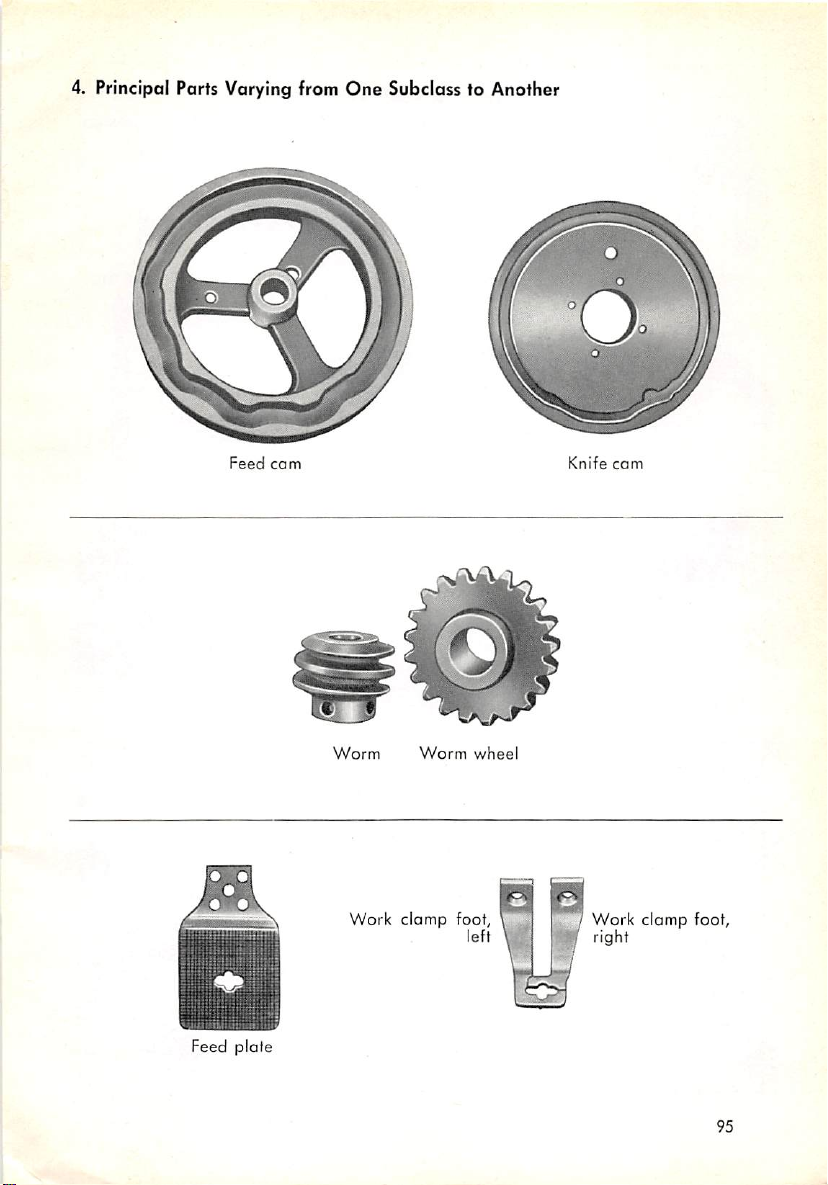

One

4. Principal Parts Varying from

5. Special

lock

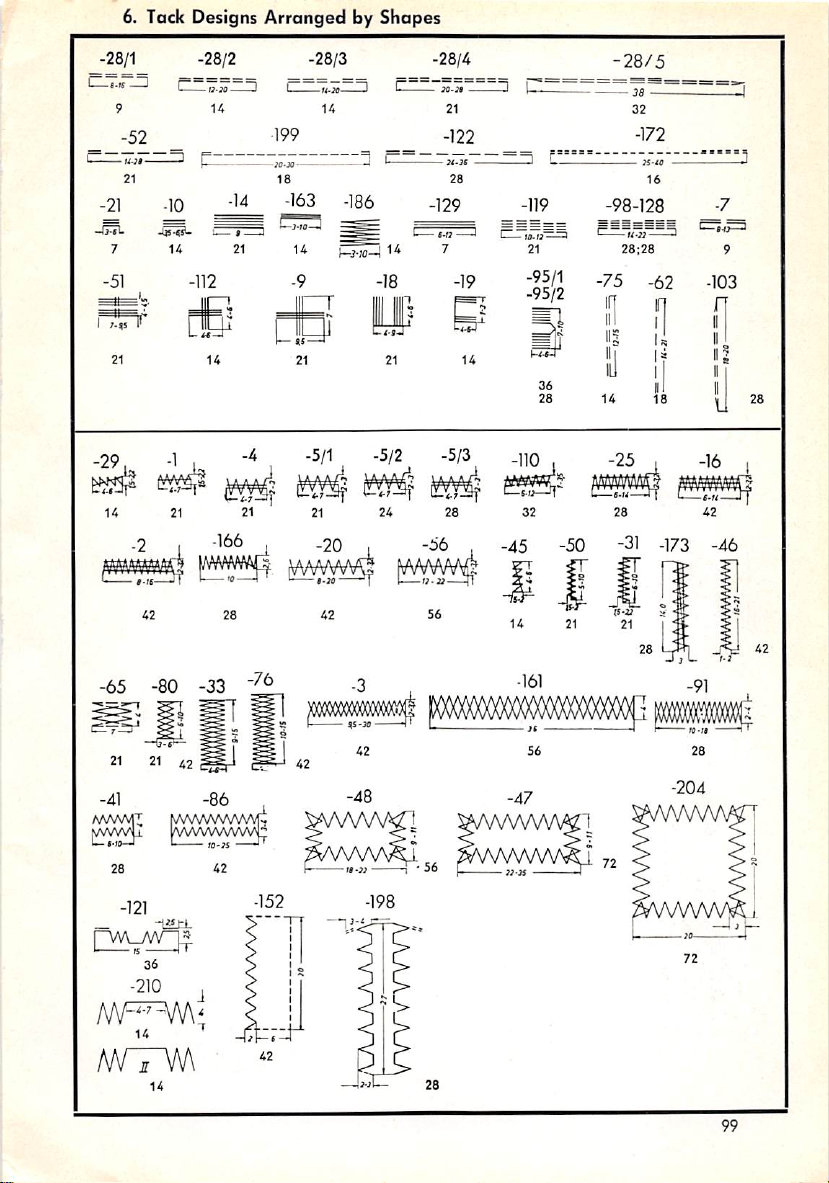

6.

Organizational

Designs

Arranged

Parts 96

by Shapes 99

Subclass to

Another

....

95

Page 7

A. Description

1.

General

and

Operation

Information

Stitch Type:

LoopTaker System;

Bobbin Capacity:

Needle System:

Foot

Lift:

Maximum

Length of Tack:

Maximum

WidthofTack:

ClassesofWork:

Lock

stitch

Oscillating (central bobbin) shuttle

66 yds No. 40/3 cotton

Model A and B machines use System 34 R needles for

Lr

110).

or 34 D

Model C

sewing

ordinary sewing operations, and System 34

needles for leather work (needle size up to

machines

use

System

332Rneedles

for ordinary

operations, and System 332Lror 332 D needles for

leather

work.

(Additional needle

on

page

60).

'V32"

to Vb", or 15 to 16 mm (on

foot lift ranges from "/as" to

1Vib",or36 mm

Va",

or

22 mm

ModelsAand Bare used for

materials.

systems

thot may be used are listed

earlier

machines the

'V32",

or 9 to 10

light-

to medium-weight

mm).

Model C is used for heavyweight materials (machine

features higher needle bar rise and larger take-up

motion).

Page 8

a. Purpose of Employment

The

Pfaff

seaming

3334isspecially

operationsofevery

designed

description.

for

While

automatic

both

bartacking

the

shape

and short

of the

tack

and the number of stitches per tock ore predetermined for each subcloss, the

sizeofmost

tacks

canbevaried

within

certain

limits.

The machine's field of application embraces oil branches of the sewing indus

try.

Thus,

opart

from

bartacking, it may be

seams,

attaching

justa few additional applications. (See ill.on page 7).

belts

and straps, and

employed

stitching

for

arnamentol

stitching

tacks,

staying

to name

The Pfaff

greatly facilitates the

cles

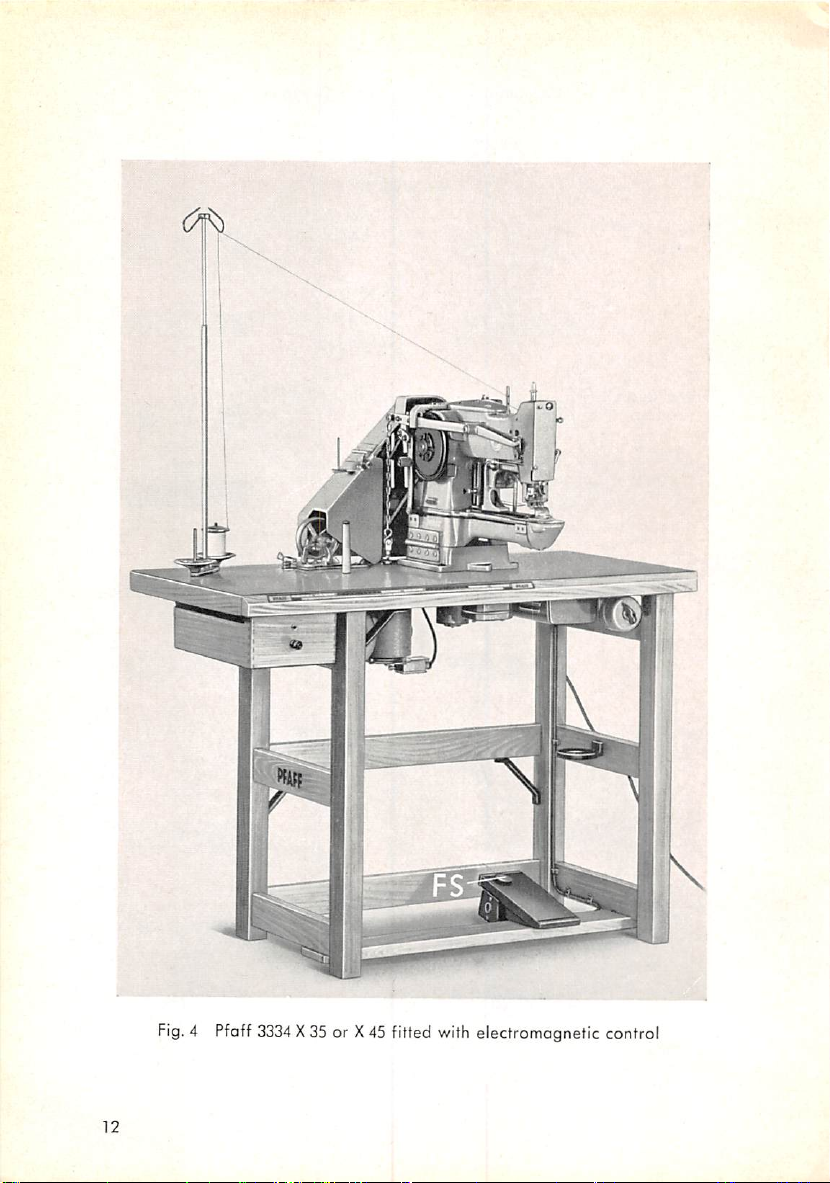

If desired, the Pfaff 3334 automatic bartacker can be fitted with electro

magnetic

or Pfaff 3334X45 in Model C. On this machine, the functions of raising the

work clomp and storting the

treadles of the standard model ore replaced by a foot switch (Fig. 4).

Feed

The work is held between, and guided by, the work clamp and the feed

plate. To produce the desired

machine bed while the needle moves up and down. The feed motion is deriv

ed

The Pfaff 3334 attains a speed of up to

thickness of the material as well os the size

the machine from one subclass to another, it

exchange the feed plate and the clamp feet rather than the complete work

clamp.

are

being stitched.

control,

Motion

from

the

3334

is of the cylinder-bed construction.

feed

this

com.

handling

version

of the

being

machine

tack,

knownasPfaff

are performed by solenoids, and the two

the material is

work,

Its

slender cylinder arm

particularly

when

3334X35inModels

moved

up and across the

1,200

s.p.m., depending on the

and

shape

of the tack. To convert

will

be sufficient normally to

tubular arti

Aand

B,

If,

however, the shape and size of the tack or the number of stitches in the

design

ore to be changed, the feed cam,

have

to be exchanged.

knife

cam,

worm

and

worm

wheel

Page 9

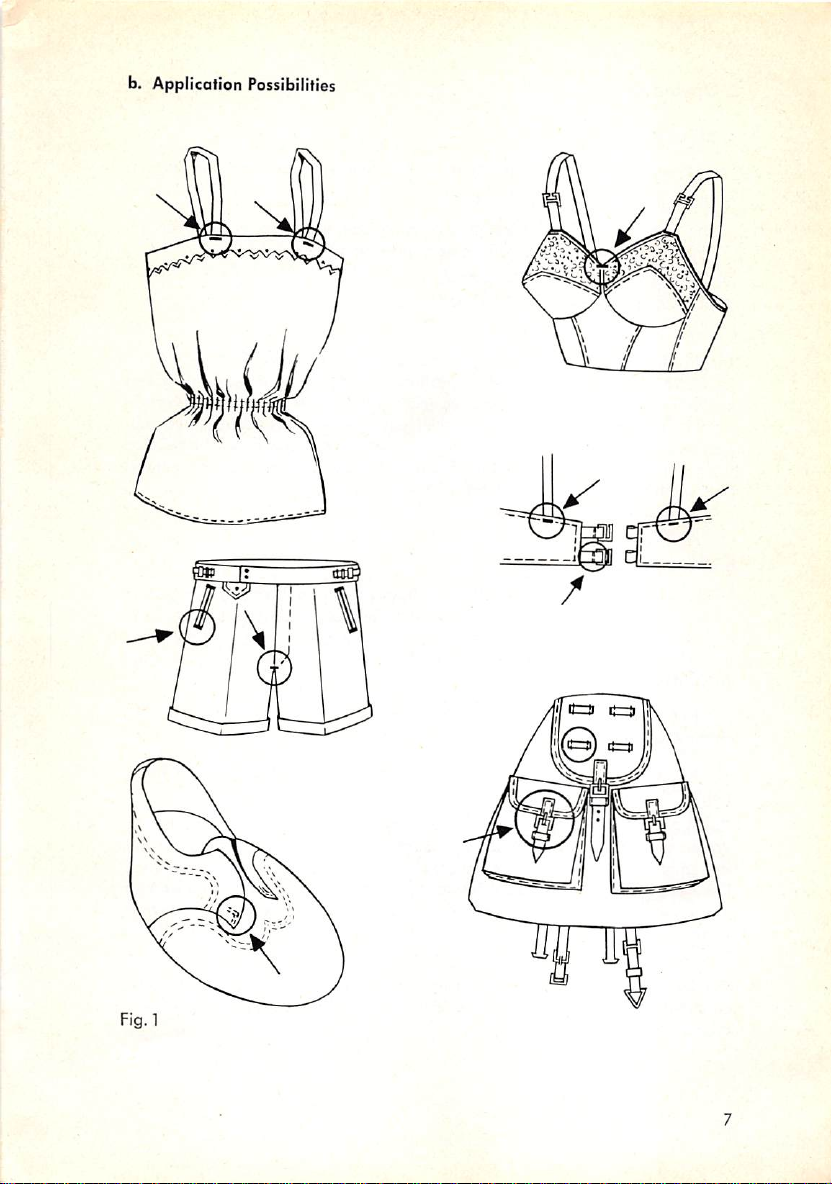

b. Application Possibilities

Fig. 1

Page 10

2.

Operation

a. Efficiency Rating

The output of on automatic bartacker is determined by the following factors:

(1)

the number of stitches

(2)

the

handling

times

per

involved

tack,

in a

given

operation

(which,inturn,

are de

termined by the size and bulkineess of the workpiece),

(3)

the quality of material

(4}

the handy arrangement of the work, and

(5)

the

speed

of the machine.

The

Pfaff

3334

automatic

21, 24, 28,

32, 36,

42,

contained in the Subclass Catalogue (Form No.

lity

of this efficient

and

thread,

48,

bartacker

56,

and 72

can

stitches

machine.Inspecial

be

fittedtomoke

per

tack.

The

tack

10080)

illustrate the versati

coses,

it may be advisable to sub

7, 9, 14, 16, 18,

design

diagrams

mita sample of the moterial to be sewn as wellas a specimen of the finished

work

eithertothe

Pfaff industrial

Kaiserslautern

sewing

machine

BranchofG.M.

representative.

Pfaff

AGorthe

nearest

b. Mode of

Operation

While both the length and width of a bartack con be varied within certain

limitsbysimply

adjusting a lever, its shape as well as the number of

stitch

es it comprises can be varied only by exchanging the feed cam.Inmany

instances, the worm gear assembly and the knife cam must be exchanged

in

addition.

The entire sewing action, including the stopping of the

automatically.

The machine is equipped with two cams which ore corried on a joint trans

verse

shaftoneither

sideofthe

machine

arm.

machine,

is controlled

The right, or feed, cam has two pattern-forming grooves, one on each side.

While the groove on its outside face controls the crosswise feed

motion,

the lengthwise feed motion emanates from the groove on its inside face.

The feed cam, in addition, carries

one

or several stop tripping segments as

well as one or several thread nipper tripping segments. Whereas the former

serve to stop the machine at the completion of a sewing cycle, the latter

actuate

The number of stop tripping segments and thread nipper tripping segments

the

thread

nipper.

provided on the rim of the feed cam depends on the number of tacks pro

duced

per

cam revolution.

Page 11

The left,or knife, cam operates the needle and bobbin thread

knives.

As the knives swing forward from the inoperative to the stand-by position,

a sufficient

whichtostart

amountofthread

the

next

tack.

is pulled from the spool

and

the bobbin with

As the machine makes the last stitch of the tack, the

couses the lower, or main, tension to be

releasedsothat

groove

in the knife cam

the

last

stitch knot

is pulled ino the material.

The main tension will not by reactivated until the machine, depending on the

subclass, has completed

three

to four stitches

after

starting a new tack. In

this way, puckering of the fabric is successfully eliminated. This is particularly

important for stitching

The machine is

delicate

started

the stop motion lever to swing back

interlocked.

The locking lever prevents the

clamp

while the machine is in

knivestotrim

By the

roised.

When

the

threads.

same

token, the machine

the machine is

started,

fabrics or sewing with long stitches.

by depressing the right treadle. This action causes

and

the tripping

operator

operation

from inadvertently raising the work

since this action would cause the

cannotbestarted

and

locking levers to be

while the work clamp is

the driving belt is shifted from the idler to the

driving pulley and, conversely, when the machine stops, it is returned from

the driving to the idler pulley.

All the

operator

has to do to start the sewing cycle is to press down the right

treadle. After the machine has stopped automatically, she raises the work

clompbydepressing

the

left

treadle.

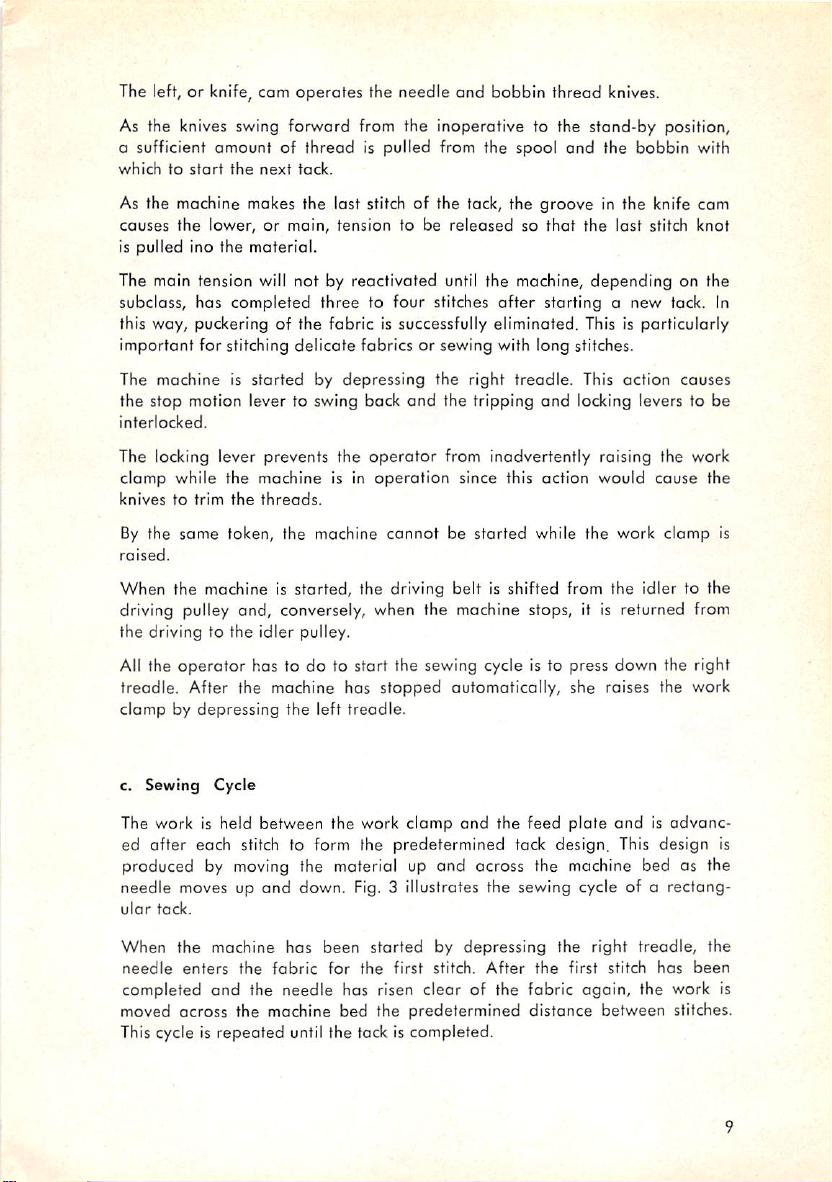

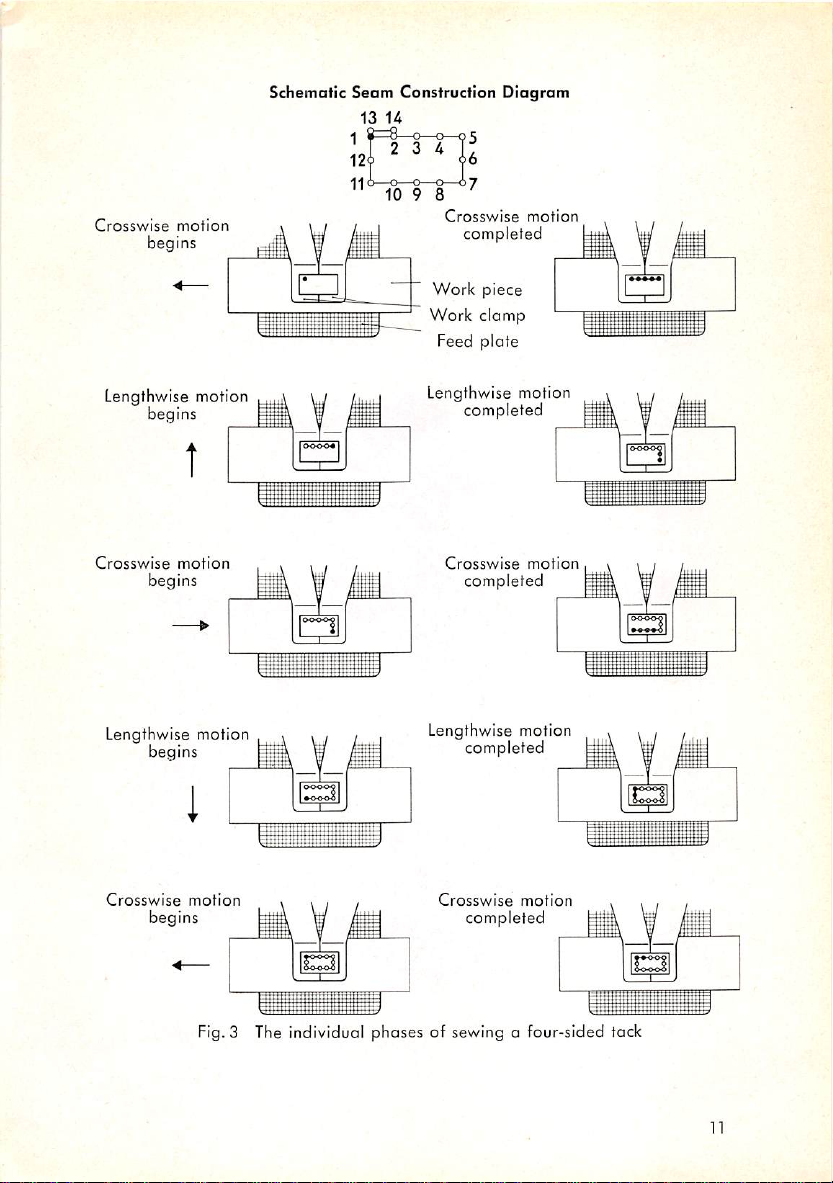

c. Sewing

The work is held between the work clamp

ed

after

Cycle

each stitch to form the

and

predetermined

the feed

plate

andisadvanc

tack design. This design is

produced by moving the material up and across the machine bed as the

needle moves up and down. Fig. 3 illustrates the sewing cycle of a rectang

ular

tock.

When the machine has been started by depressing the right treadle, the

needle

enters

the

fobric

for

the

first

stitch.

After

the

first

stitch

has

been

completed and the needle has risen clear of the fabric again, the work is

moved across the machine bed the predetermined distance between stitches.

This cycle is

repeated

until the tack is completed.

Page 12

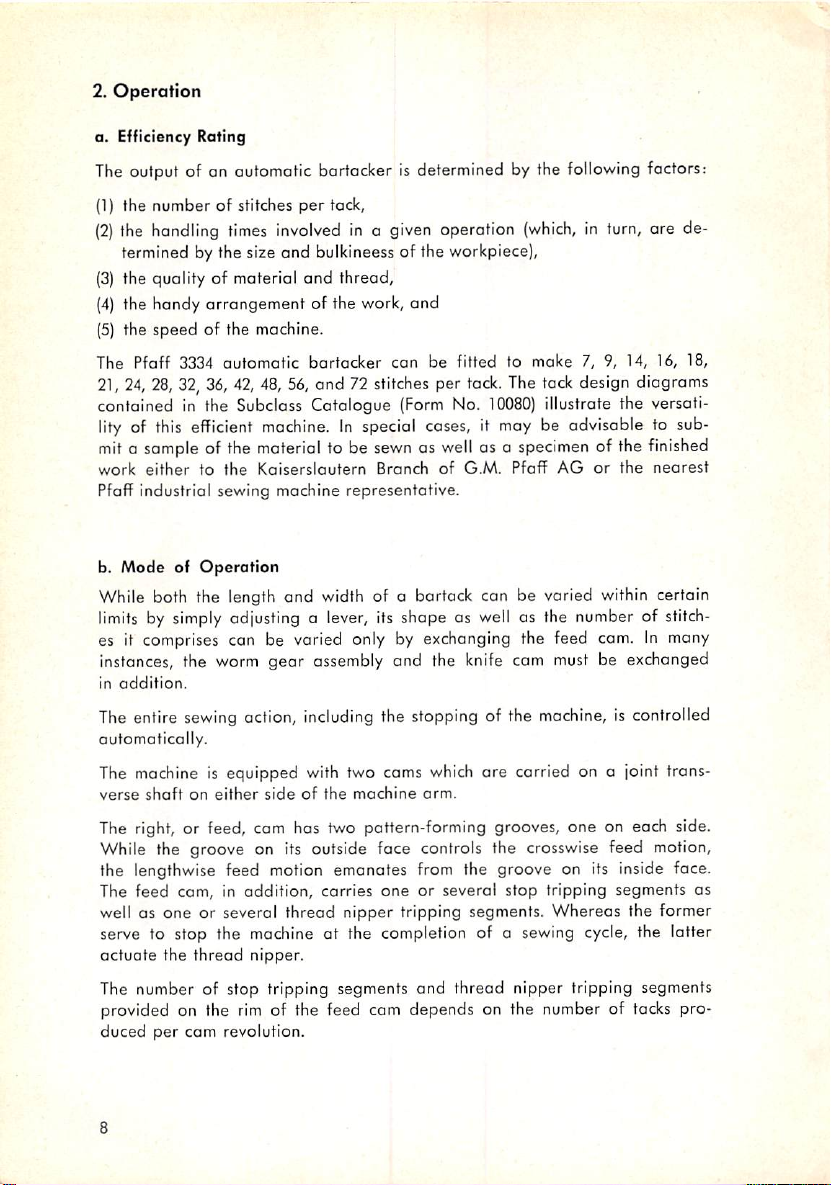

1 ==

Needle

2 =

Needle

3 =

Work

4 = Clamp foot lifting lever

5 = Thread wiper wire

6 = Feed plote

7 = Work clomp feet

8 =

Presser

9 — Presser bar lifting bracket

bar

bar

clamp

bar

frame

Fig. 2 Feed

While the last

the

machine

the

last

stitch.

When the left treadle is depressed, the needle

med and the work clomp raised for easy removal of the work.

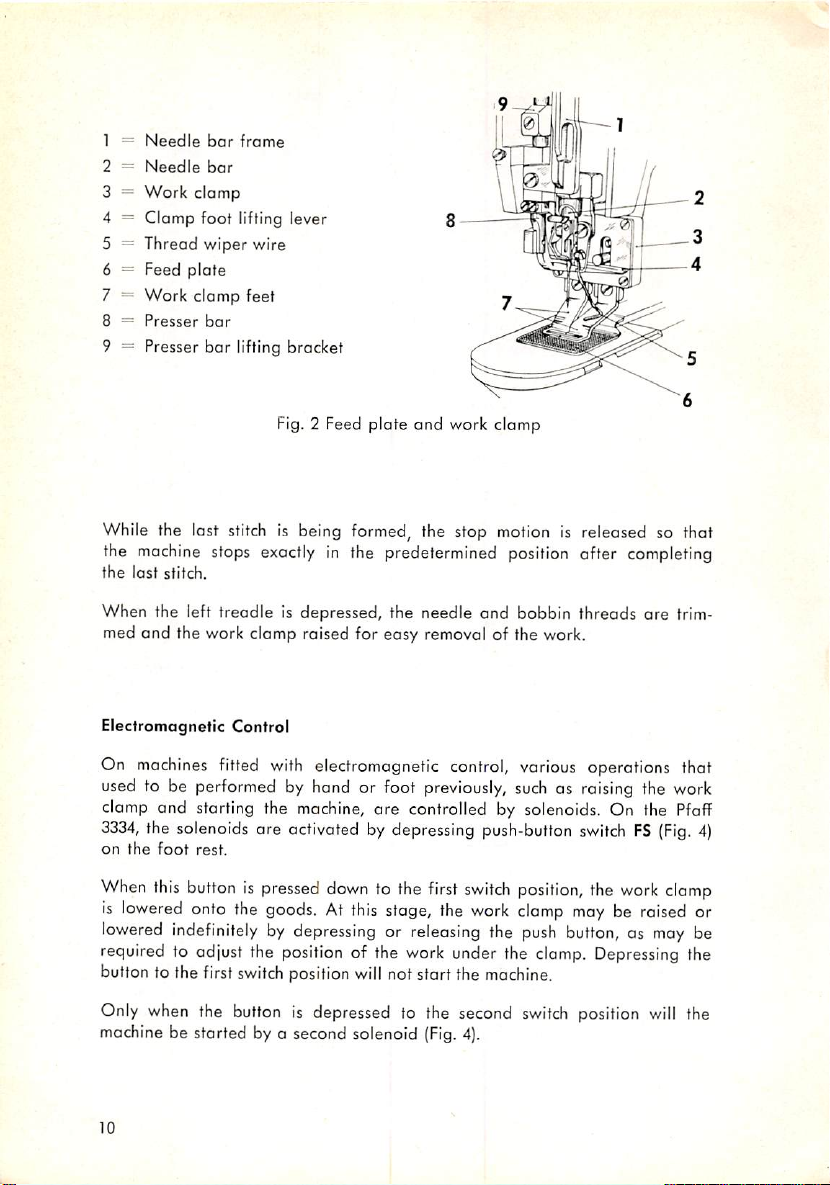

Electromagnetic Control

stitch

stops

is being

exactly

plate

and

work

formed,

the stop

in the predetermined

clamp

motion

position

and

bobbin threads

is released so that

after

completing

are

trim

On machines fitted with electromagnetic control, various operations that

used to be performed by hand or foot

clomp and starting the

3334,

the

solenoids

on

the

foot

rest.

When

this

buttonispressed

is

lowered

lowered

onto the

indefinitelybydepressingorreleasing

machine,

ore

activatedbydepressing

down

goods.Atthis

previously,

suchasraising

the work

are controlled by solenoids. On the

to the

first

stage, the

push-button

switch

position,

work

clamp

the

switchFS(Fig.

mayberaised

push

button,asmay

the

work

Pfoff

clamp

or

be

required to odjust the position of the work under the clamp. Depressing the

button to the first switchposition will not start the machine.

4)

Only

when

the

button

is depressed to the second

machine be storted by a second solenoid

10

(Fig.

4).

switch

position

will

the

Page 13

Crosswise

motion

begins

Schematic Seam Construction

13

U

11<^^2r-2-^7

10

9 8

Crosswise

completed

Work

Work

clomp

Feed

Diagram

motion

piece

plate

Lengthwise motion

begins

Crosswise

motion

begins

Lengthwise motion

begins

Crosswise

motion

begins

Fig.3 The individual phases of sewing a four-sided tack

Lengthwise motion

completed

Crosswise

motion

completed

Lengthwise motion

completed

Crosswise

motion

completed

1

—1—1

lall

iiaHiiiH;HiK|^88|i88s

g

11

Page 14

12

Fig.4Pfaff

3334

X35or X45fitted

with

electromagnetic control

Page 15

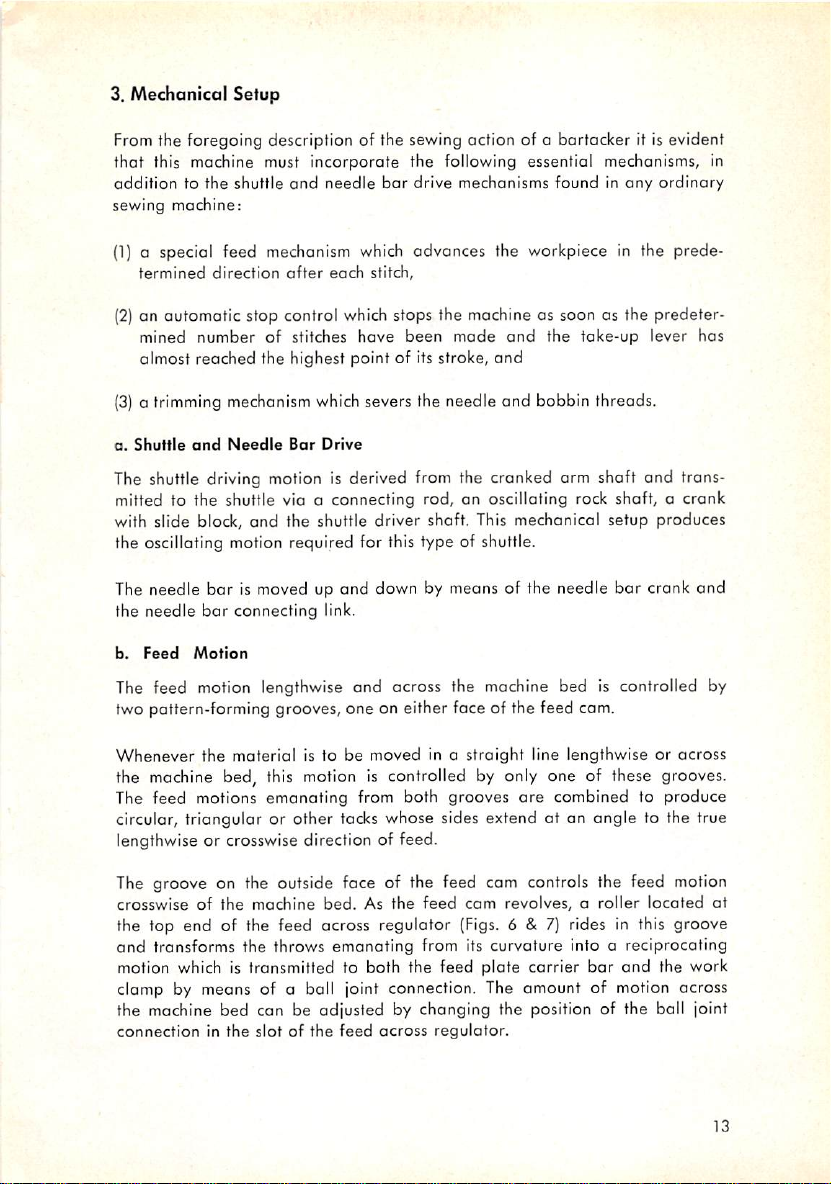

3.

Mechanical

Setup

From the foregoing description of the sewing action of a bortocker it is evident

that this machine must incorporate the following essential mechanisms, in

addition

to the shuttle

and

needle

bar

drive mechanisms found in

any

ordinary

sewing machine:

(1)

a special feed

termined

(2)

an automatic stop control which stops the machine as soon as the predeter

mined number of stitches

direction

mechanism

offer

each

which

advances the workpiece in the prede

stitch,

have

been

mode

and

the take-up lever has

almost reached the highest point of its stroke, and

(3)

a trimming mechanism whichsevers the needle and bobbin threads.

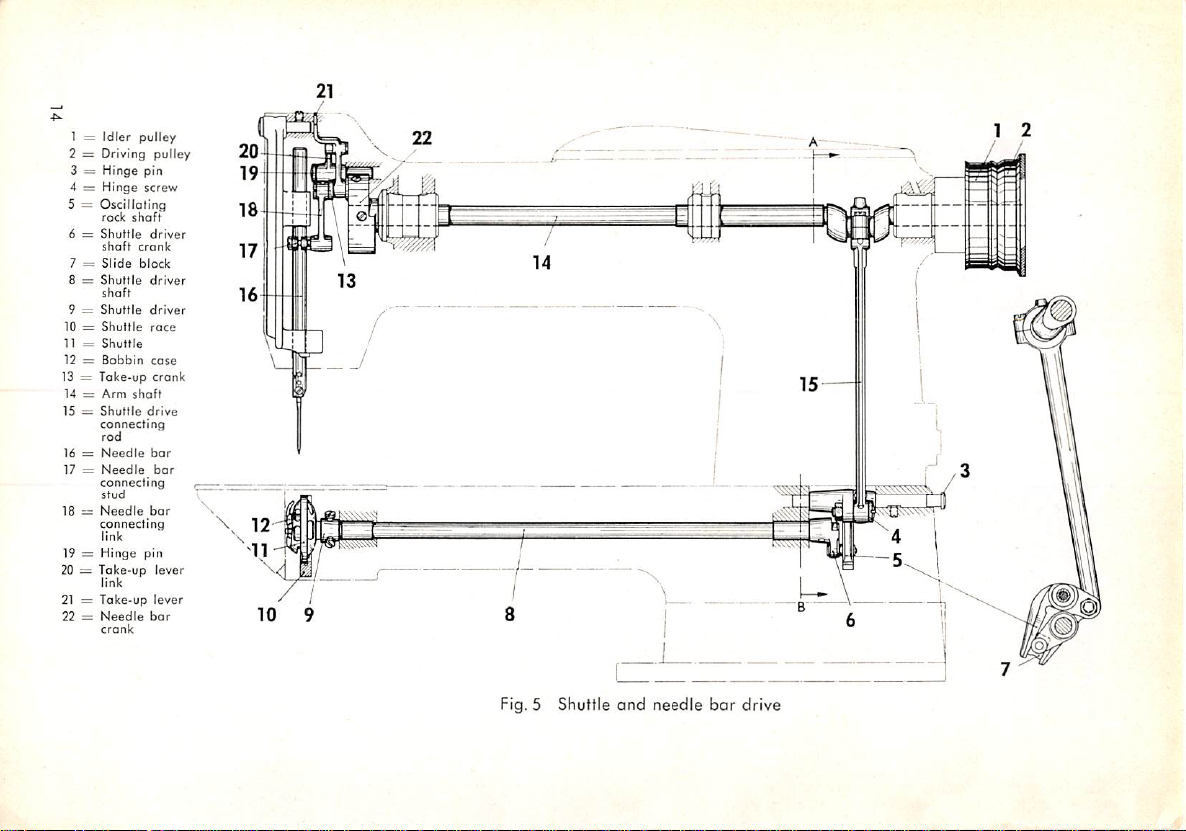

a.

Shuttle

and

Needle

Bar

Drive

The shuttle driving motion is derived from the cranked arm shaft and trans

mitted to the shuttle via a connecting rod, an oscillating rock shaft, a crank

with slide block, end the shuttle driver shaft. This mechanical setup produces

the oscillating motion required for this type of shuttle.

The needle

the needle

b.

Feed

bar

is moved up and down by means of the needle

bar

connecting link.

Motion

bar

crank and

The feed motion lengthwise and across the machine bed is controlled by

two pattern-forming grooves, one on either face of the feed cam.

Whenever the material is to be moved in a stroight line lengthwise or across

the machine bed, this motion is controlled by only one of these grooves.

The feed motions emanating from both grooves

are

combined to produce

circular, triangular or other tacks whose sides extend at on angle to the true

lengthwise or crosswise direction of feed.

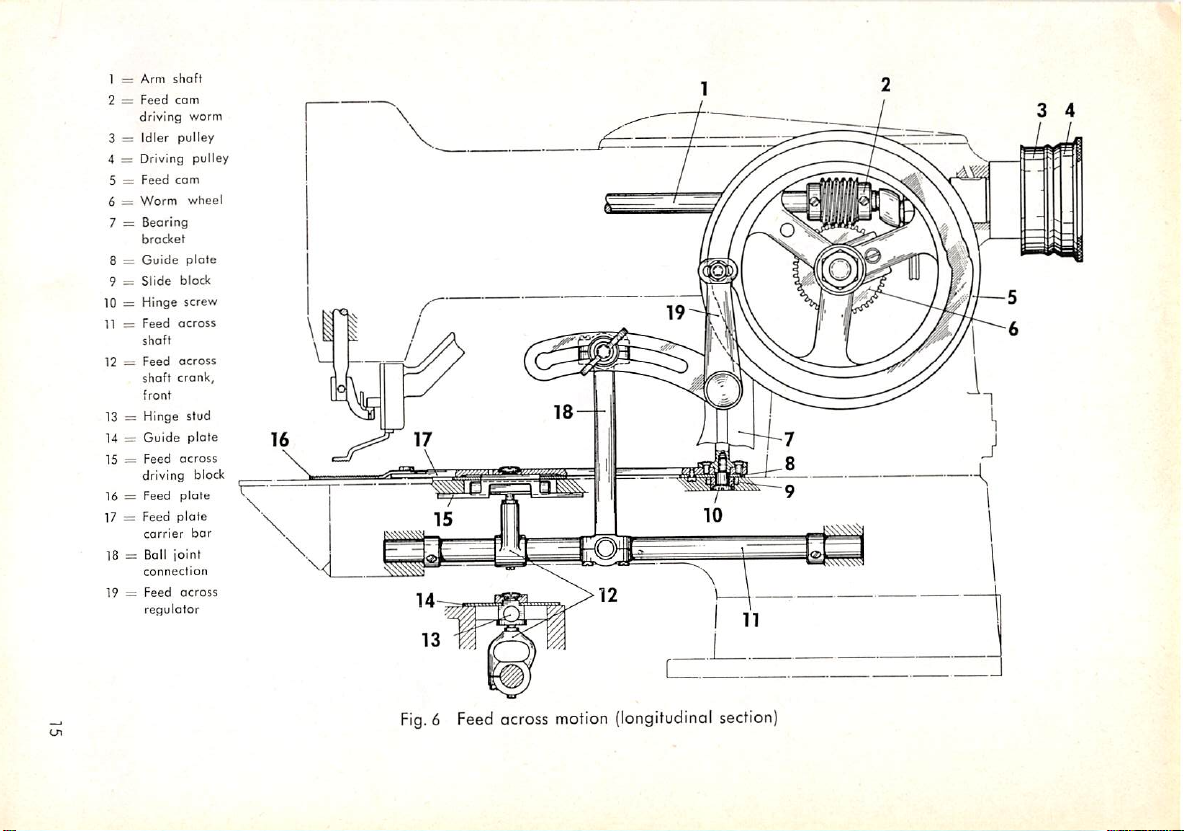

The groove on the outside face of the feed cam controls the feed motion

crosswise of

the top end of the feed across regulator

and

transforms the throws

the

machine

bed.Asthe

emanating

feed

cam

revolves, o

(Figs.

6 &7}rides in this groove

roller

located

from its curvature into a reciprocating

motion which is transmitted to both the feed plate carrier bar and the work

clomp by means of a ball joint connection. The amount of motion across

the machine bed can be adjusted by changing the position of the ball joint

connectioninthe

slot of

the

feed

across

regulotor.

at

13

Page 16

1 =

Idler

2 = Driving

3 =

Hinge

4 =

Hinge

5 =

Oscillating

rock

6 =

Shuttle

shaft

7 =

Slide

8 =

Shuttle

shoft

9 =

Shuttle

10 =

Shuttle

11 =

Shuttle

12 =

Bobbin

13 =

Take-up

14 =

Arm

15 =

Shuttle

connecting

rod

16 =

Needle

17 =

Needle

connecting

stud

18=Needle

connecting

link

19 =

Hinge

20 = Take-up

link

21 = Take-up

22 =

Needle

crank

pulley

shaft

crank

block

shaft

pulley

pin

screw

driver

driver

driver

race

case

crank

drive

bar

bar

bar

pin

lever

lever

bar

nsi

1 4 1

—

'-^1

\ 1

1

6 ;

1

Fig. 5 Shuttle

and

needle

bar

drive

Page 17

1 =

Arm

shaft

2 =

Feed

cam

driving

worm

3 =

Idler

pulley

4 = Driving pulley

5 =

Feed

com

6 —

Worm

wheel

7 =

Bearing

bracket

8 =

Guide

plate

9 =

Slide

block

10 =

Hinge

screw

11 =

Feed

across

shaft

12 =

Feed

across

shaft

crank,

front

13 = Hinge stud

14 =

Guide

plate

15 =

Feed

across

driving block

plote

carrier

connection

Feed

regulator

plate

bar

across

16 = Feed

17 = Feed

18 = Ball joint

19 =

V

\

\ 1

\

V

\

Fig.6Feed

across

motion

(longitudinal

section)

Page 18

] =

2 =

Roller

Roller

stud

3 ~ Feed across

4 = Boll screw stud,

5 =

Hinge

6 = Ball joint connection

7 = Boll stud,

8 =

Feed

9 = Feed across shaft crank,

rear

stud

across

regulator

lower

shaft

Fig.7Feed

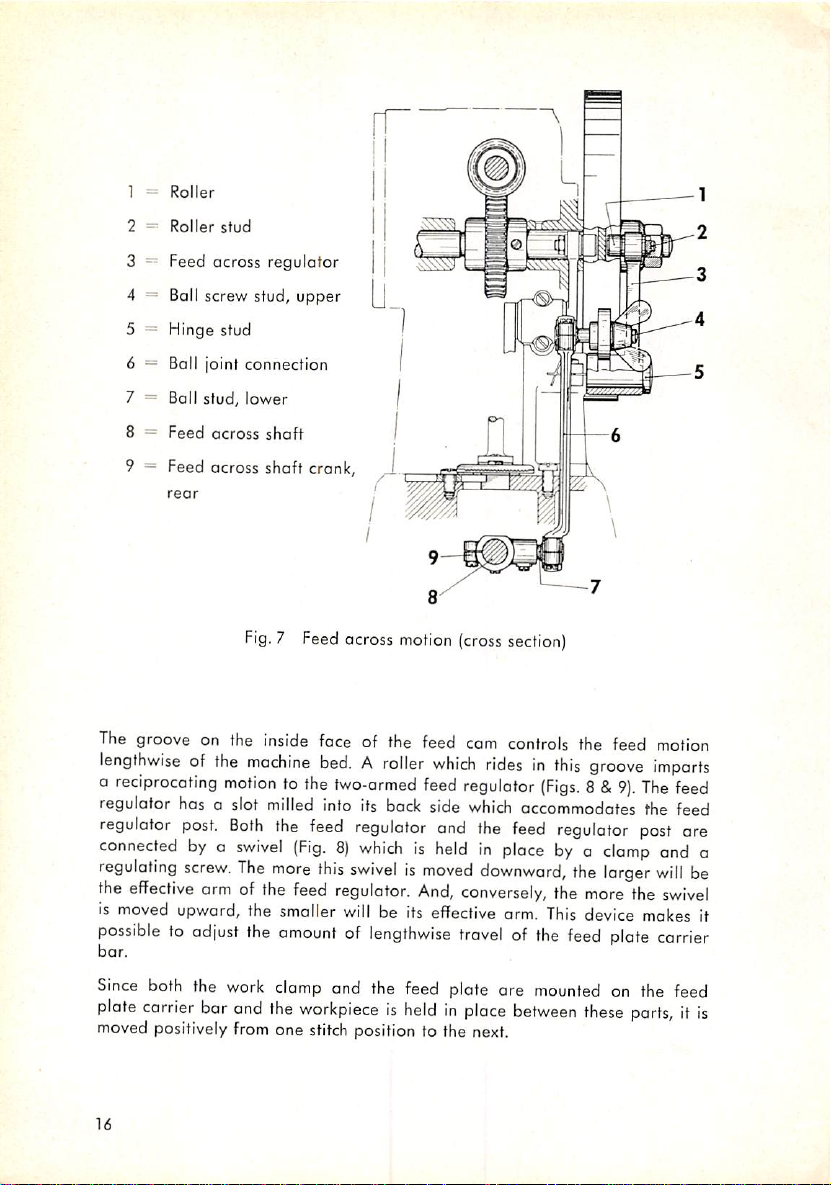

The

groove

lengthwiseofthe

a

reciprocating

regulator has a slot

regulator

connectedbyo

regulating

the

effective

is

moved

possibletoadjust

bor.

on the

post.

screw.

armofthe

upward,

inside

machine

motiontothe

milled

Both

the

swivel

The

more

the smaller

the

amountoflengthwise

upper

across

motion

(cross

section)

face

of the

feed

cam

controls

bed.Aroller

fwo-ormed

into

its

feed

regulator

back

which

feed

side

and

ridesinthis

regulator

which

the

(Figs.8&9).

accommodates the feed

feed

regulator

(Fig.8)whichisheldinplacebya

this

swivelismoved

feed

regulator.

willbeits

And,

downward,

conversely,

effective

travelofthe

orm.

the

This

feed

the feed

groove

clamp

the

larger

more

device

plate

imparts

The

post

will

the

makes

carrier

motion

feed

are

and

be

swivel

a

it

Since

both

the

plate

carrier

bor

moved positively

16

work

and

from

clomp

and the feed plate are

the

workpieceisheldinplace

one

stitch

position to the next.

mounted

between

on the feed

these

parts,itis

Page 19

1 = Feed

2 =

plate

Feed

across

driving

block

3 =

Slide

block

4 =

Feed

plate

carrier

bar

5 = Feed regulator post

6 = Work

clamp

7 = Feed regulator

swivel

8 = Swivel

9 =

10=Worm

11 =

Feed

Worm

clamp

cam

wtieel

wheel

12 = Driving pulley

13

Idler pulley

Feed cam driving

14

worm

Arm

15

16

shaft

Feed regulotor

Fig.

8 Feed lengthwise motion (longitudinal section)

Page 20

1 —

Feed

cam

2 =

Roller

stud

3 =

Roller

4 = Feed regulotor

5 = Bearing bracket

6 =

Slide

block

7 =

Guide

plate

8 ~ Feed plate

9 = Swivel

10 =

11

= Feed regulator swivel

12 =

13=Worm

14=Worm

Thumb

Feed

clamp

screw

regulator

wheel

wheel

post

shaft

15 = Feed cam driving worm

16 =

Arm

shaft

Fig.9 Feed lengthwise motion (cross section)

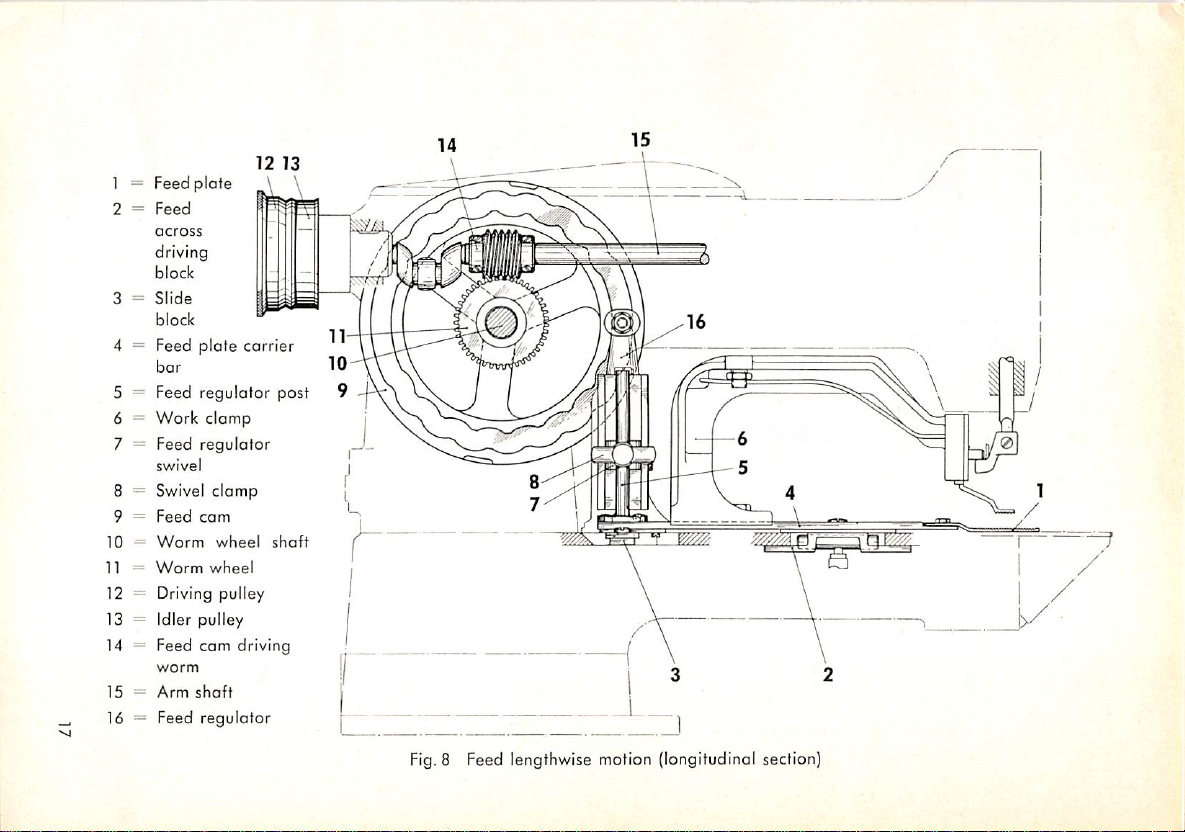

The adjustment possibilities inherent in the feed regulator and feed across

regulator ore not sufficient to produce larger tacks. Such tacks, however,

can be made with the aid of special organizational parts

which

provide for

a larger amount of work clomp travel lengthwise and ocross the machine bed.

c.

Automatic

Stop

Motion

The machine is stopped automatically in order to ensure that all tacks will

be sewn with exatly the some number of stitches and that the machine will

always

be in the same

position

whenanew

needle

cycle

begins.

The

shape

of the pattern-forming groove and the gear ratio of the worm gear ossem-

bly are determined by the number of stitches per tack.

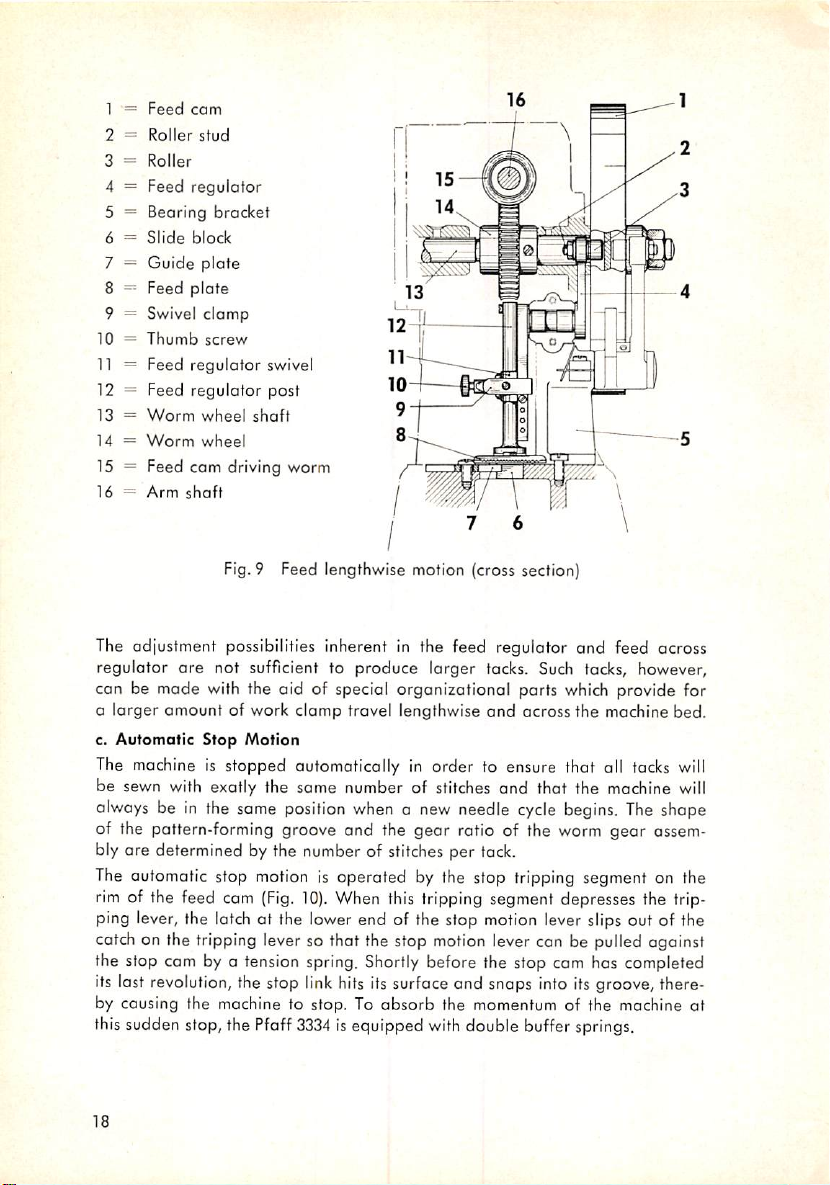

The automatic stop

rim of the feed cam

motion

(Fig.

is operated by the stop tripping segment on the

10).

When this tripping segment depresses the trip

ping lever, the latch at the lower end of the stop motion lever slips out of the

catch on the tripping lever so that the stop

motion

lever can be pulled against

the stop com by a tension spring. Shortly before the stop com has completed

its last revolution, the stop link hits its surface and snaps into its groove, there

by causing the machine to stop. To

thissudden stop, the Pfaff

3334

absorb

isequipped

the momentum of the machine at

with

double buffer springs.

18

Page 21

t.

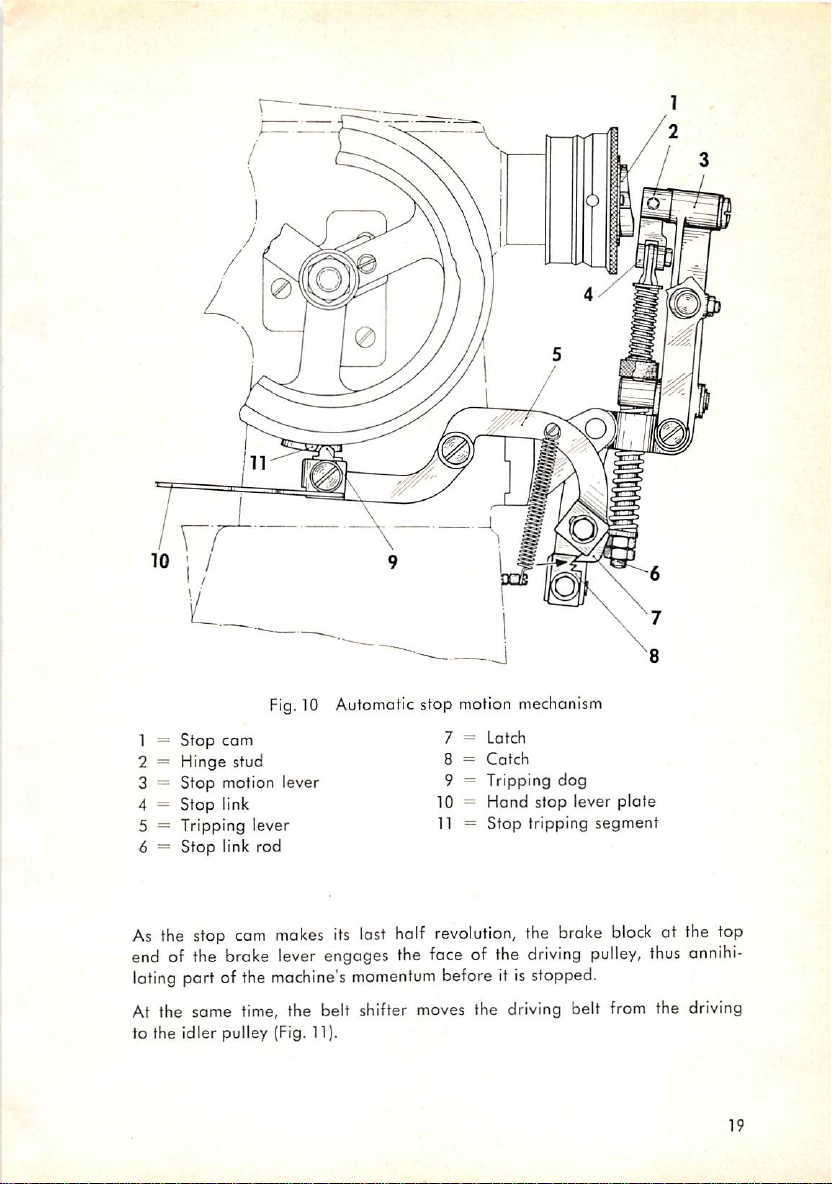

Fig.10 Automatic stop motion mechanism

1 =

Stop

cam

2 = Hinge stud

3 = Stop motion lever

4 = Stop link

5 = Tripping lever

6 = Stop link rod

7 =

Latch

8 =

Catch

9 = Tripping dog

10 = Hand stop lever plate

11 =

Stop

tripping

segment

As the stop cam

end of the broke lever engages the face of the

lating port of the

makes

machine's

its last half

momentum

revolution,

the broke

driving

before it isstopped.

At the same time, the belt shifter moves the driving belt

to the idler pulley (Fig. 11).

block

pulley,

from

at the top

thus

annihi

the driving

19

Page 22

If trouble should occur while the machine is in operation, it can be stopped

instantly by depressing the hand stop lever (Fig. 10). This is important in

case of needle or thread breakage.

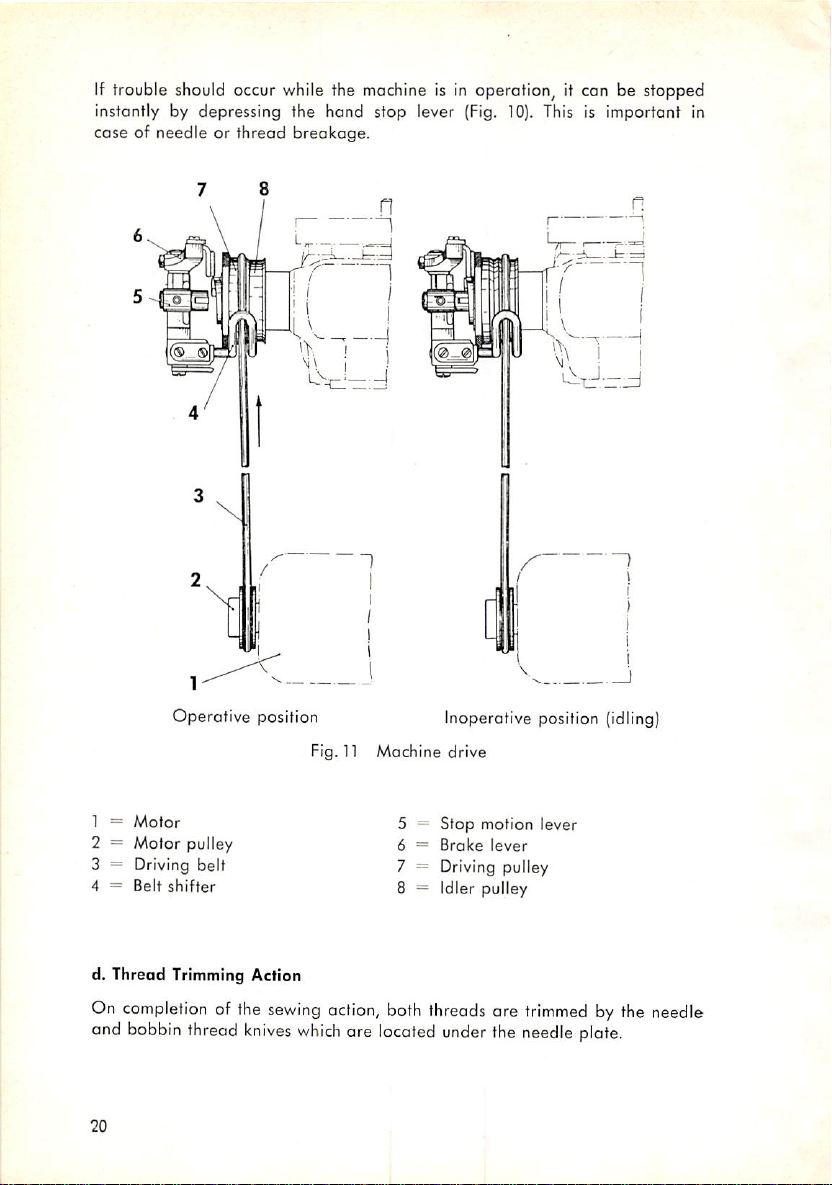

Operative

1 =

Motor

2 = Motor pulley

3 = Driving belt

4 =

Belt

shifter

d.

Thread

On

and

20

Trimming Action

completion

bobbin

thread

of the

knives

position

sewing

which

Fig. n

action,

Machine

5 -

6 =

7 = Driving pulley

8 = Idler pulley

both

threads

are

located

Inoperotive

drive

Stop

motion

Broke

lever

are

under

the

position

lever

trimmed

needle

(idling)

by the needle

plate.

Page 23

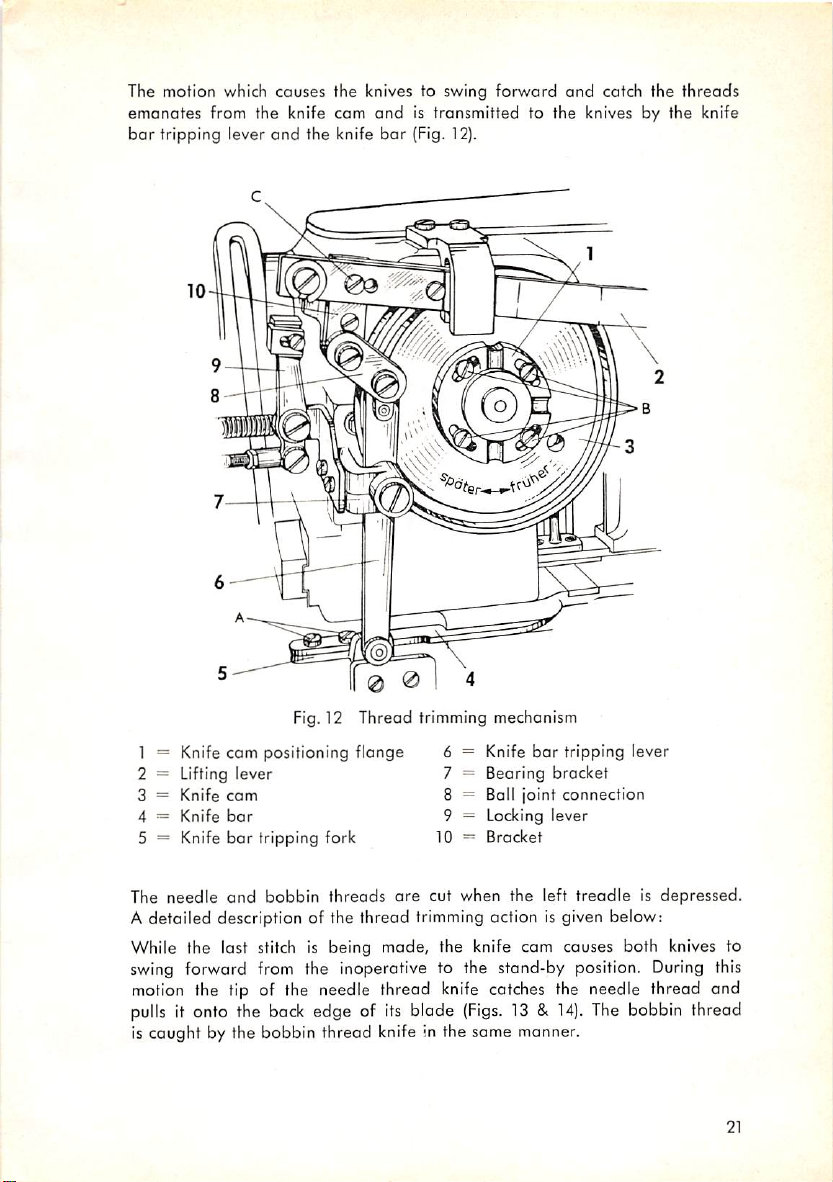

The motion which causes the knives to swing forward and catch the threads

emanates from the knife cam

bar

tripping lever

and

the knife

and

is transmitted to the knives by the knife

bar

(Fig. 12).

Fig.12 Thread trimming mechanism

bar

1 = Knife cam positioning flange 6

2 = Lifting lever 7

3 =

Knife

cam

4 =

Knife

bar

5 = Knife

The

needle

bar

tripping fork 10

and

bobbin

threads

are

Knife

Bearing bracket

Ball joint connection

8

Locking lever

9

Bracket

cut when the left

tripping lever

treadleisdepressed.

A detailed description of the thread trimming action is given below:

While the last stitch is being made, the knife cam causes both knives to

swing

forward from the inoperative to the stand-by position.

motion

pulls

the tip of the needle thread knife catches the needle thread and

it onto the

back

edge of

its

blade

(Figs.

13 &

14).

The

During

bobbin

this

thread

Is caught by the bobbin thread knife in the same manner.

21

Page 24

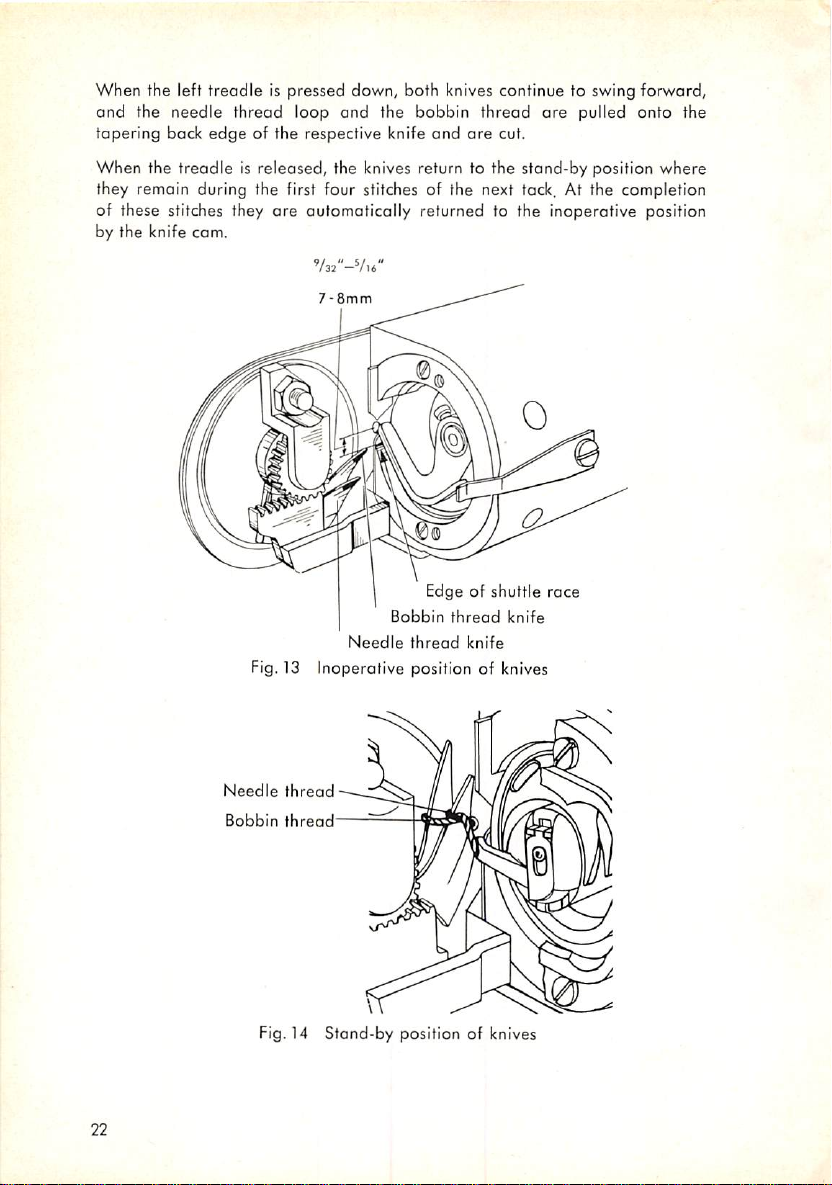

When the left treadle is pressed down, both knives continue to swing forward,

and

the

needle

tapering back

thread

edge

loop

and

of the respective knife and

the

bobbin

thread

are

cut.

are

pulled

onto

the

When the treadle is released, the knives return to the stand-by position where

they remain during the first four stitches of the next tack. At the completion

are

of these stitches they

by the knife

cam.

automatically returned to the inoperative position

'/32"-Vl6"

7-8mm

Needle

Edge of

Bobbin

thread

thread

knife

shuttle

knife

race

Fig. 13 Inoperotive position of knives

Needle

22

Bobbin

thread

thread

Fig. 14

Stand-by

position of knives

Page 25

18 19

20

21

63

22

62

23 24

58

61

60

57

56

55

54

53

52

51

50

49

0

29

25

26 27 28

30

Fig. 15

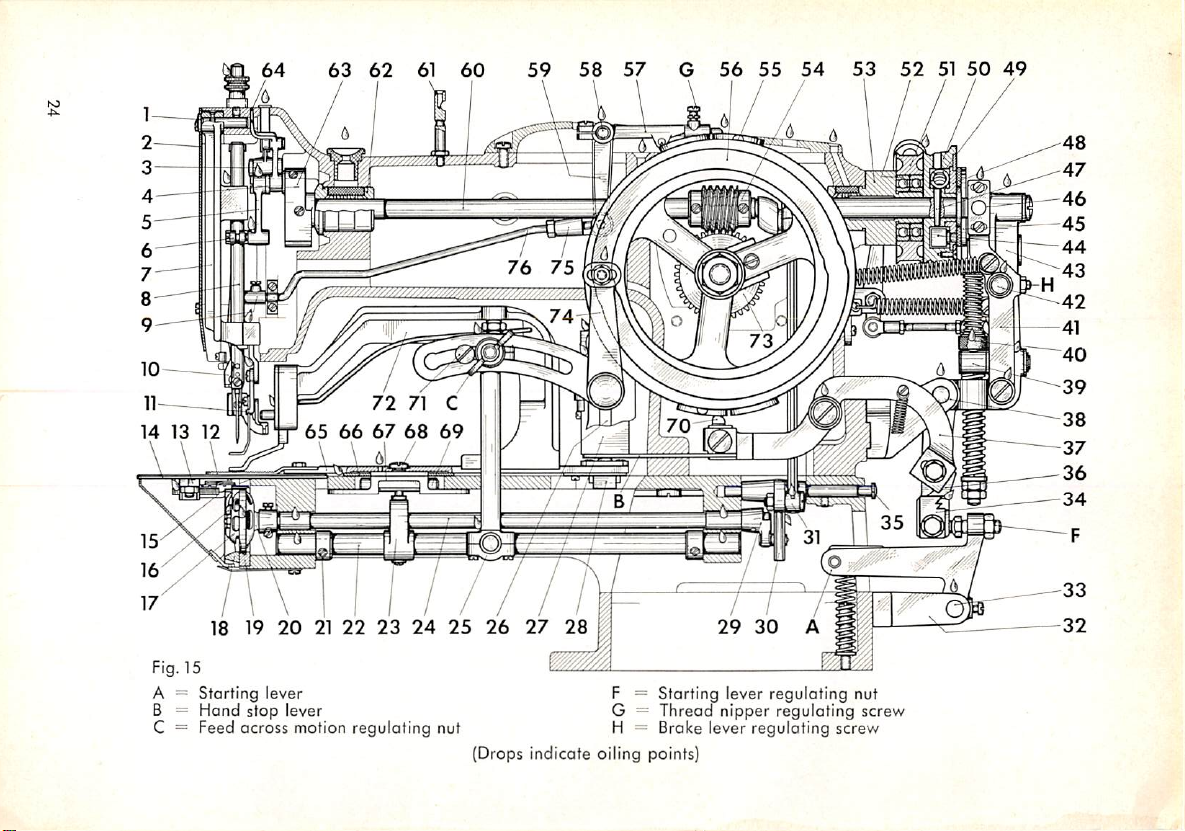

A = Starting lever F = Starting lever regulating nut

B = Hand stop lever G = Thread

nipper

regulating screw

C = Feed across motion regulating nut H = Brake lever regulating screw

(Drops indicate oiling points]

Page 26

-

1

Hinge

stud

2 = Face

=

3

4

:

5

=

6

=

7

8 =

=

9

=

10

11

=

12

=

13

=

14

=:

15

16

17

—

18

—

19

=

20

21=Set

22

=

23

=

=

24

=

25

plate

Take-up

Take-up

Needle

Needle

Needle

Needle

lever link

crank

bar

connecting link

bar

connecting

bar

frame

bar

Thread nipper rod extension

Thread

Thread

Feed

nipper

wiper

plate

Thread trimming mechanism

Needle

Knife

Bobbin

Shuttle

Shuttle

Shuttle

Shuttle

Feed

Feed

Shuttle

collar

across

across

bar

race

race

driver

driver

plate

case

ring

shaft

shaft

Ball joint connection

lever

wire

shaft

crank,

stud

front

Bearing bracket

26

-

27

= Feed

=

28

=

29

30

=

31

32

= Bearing bracket

33

=

=

34

35

=

36

37

38

= Bearing bracket

-

39

=

40

=

41

=

42

43

=

44

=

45

46

=

47

=

48

49

=

50

regulator

Slide

block

Shuttle

driver

Oscillating

rock

Shuttle drive connecting rod

Hinge

stud

Stop

motion

Oscillating

rock

Tripping lever latch

-

Tripping lever

Hinge

stud

Felt

washer

Brake

lever

Hinge

stud

Stop

motion lever

Check

block

Brake

•

block

Brake regulating bracket

Positioning pin

Stop

com

Stop

com

spring

Driving pulley

shaft

lever

shaft

catch

shaft

crank

hinge

pin

51 =

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

=

=

=

_

=

=

=

=

=

=

=

•

Thread

Arm

nipper

shaft

w/ position pin

hinge stud

Page 27

55

54

53 52

51

50

49

48 47 46

45

44

15

16

43

17

62

61

58

18 19

59.60

20

40

39

21

22

23

24

25

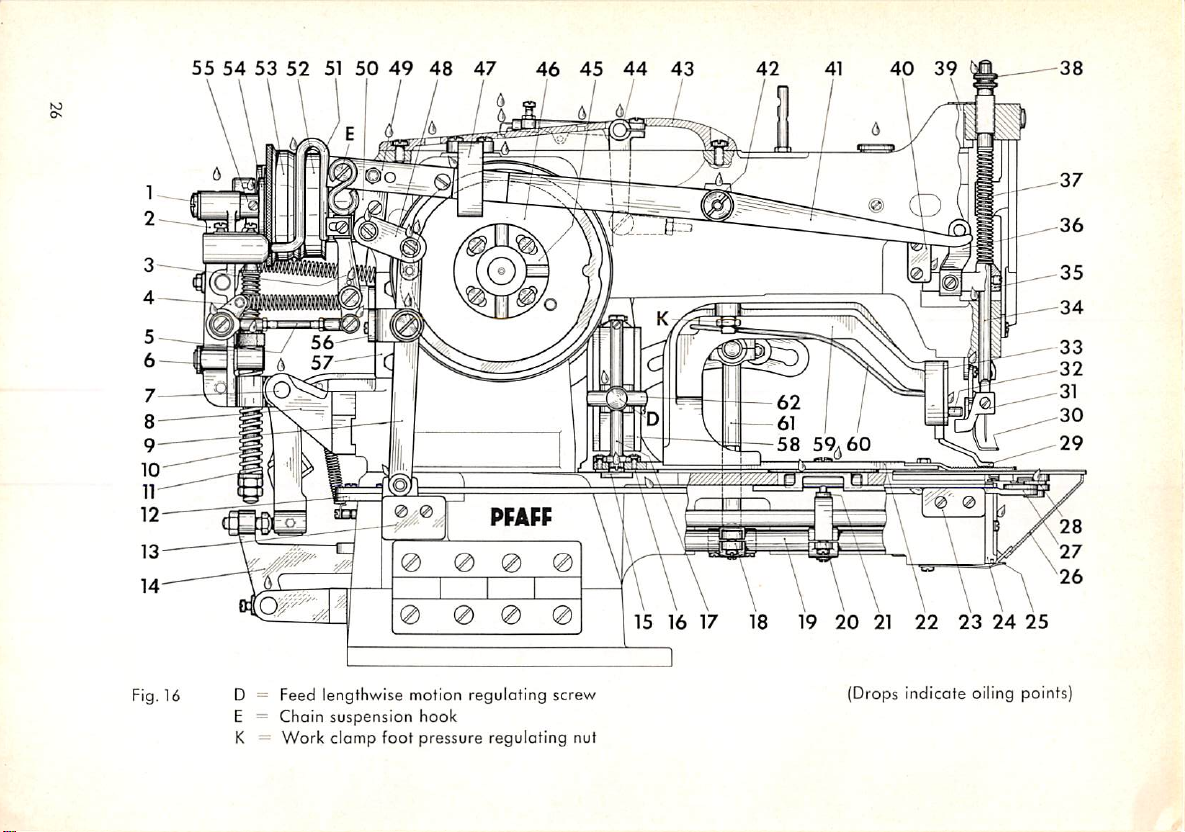

Fig.16 D = Feed lengthwise motion regulating screw

E = Chain suspension hook

Work

clomp

foot

K =

pressure reguloting nut

(Drops indicate oiling points)

Page 28

1

End

screw

=

2

Stop

motion

connection

w/circiip

bar

tripping

spring

bar

tripping fork

bracket

plate

plate

regulator

across

shaft

across

shaft

across

shaft

lever

lever

post

crank,

crank,

=

=

3

Locking lever

4 Spring suspension bracket

:

5

Boll joint

=

6

Washer,

7 =

Hinge stud

=

8

Bearing bracket

=

9

Knife

=

10

Stop link rod

=

11

Pressure

_

12

Knife

—

13

Position

14

Starting lever

15

Guide

16

=

Guide

17

Feed

18

Feed

19

Feed

=

20

Feed

=

21

Driving stud

=

rear

front

22

Feed

=

plate

w/position

23

Position bracket, front

=

24

Shuttle

race

25

Cylinder arm

26

Cylinder

-

27

Knife

=

28

Thread

29

Work

=

30

Thread

=

31

Clamp

.

32

Work

=

33

Work

=

34

Presser

35

Presser

36

Lifting

=

37

Presser

=

38

Pressure regulating screw

=

39

Oil

40

Lifting bracket

=

41

Lifting lever

arm

bar

trimming mechanism

clamp

wiper wire

foot

clamp

clamp

bar

bar

brocket

bar

tube

corrier bar.

pin

ring

cap

spring

cap

foot

lifting lever

foot lifting stud

face

plate

lifting bracket

link

spring

guide

42

=

Hinge

stud

43

Top

cover

=

=

44

Thread nipper hinge stud

45

= Knife cam positioning flange.

adjustable

=

46

Knife

cam

=

47

Lifting lever

48

Ball joint

=

49

Lifting lever

=

50

Bracket

51

Belt

=

52

= Idler pulley

53

=

54

55

56

57

58

=

59

=

60

61 Ball joint connection

62

shifter

Driving pulley

=

Stop

Hinge

Bracket

=

Bearing bracket

—

Feed

Work

Pressure spring

Swivel

guide

connection

extension

com

stud

regulator

clamp

clamp

Page 29

37 36

32

31

30

29

28

27 26

25

24

23 22

12

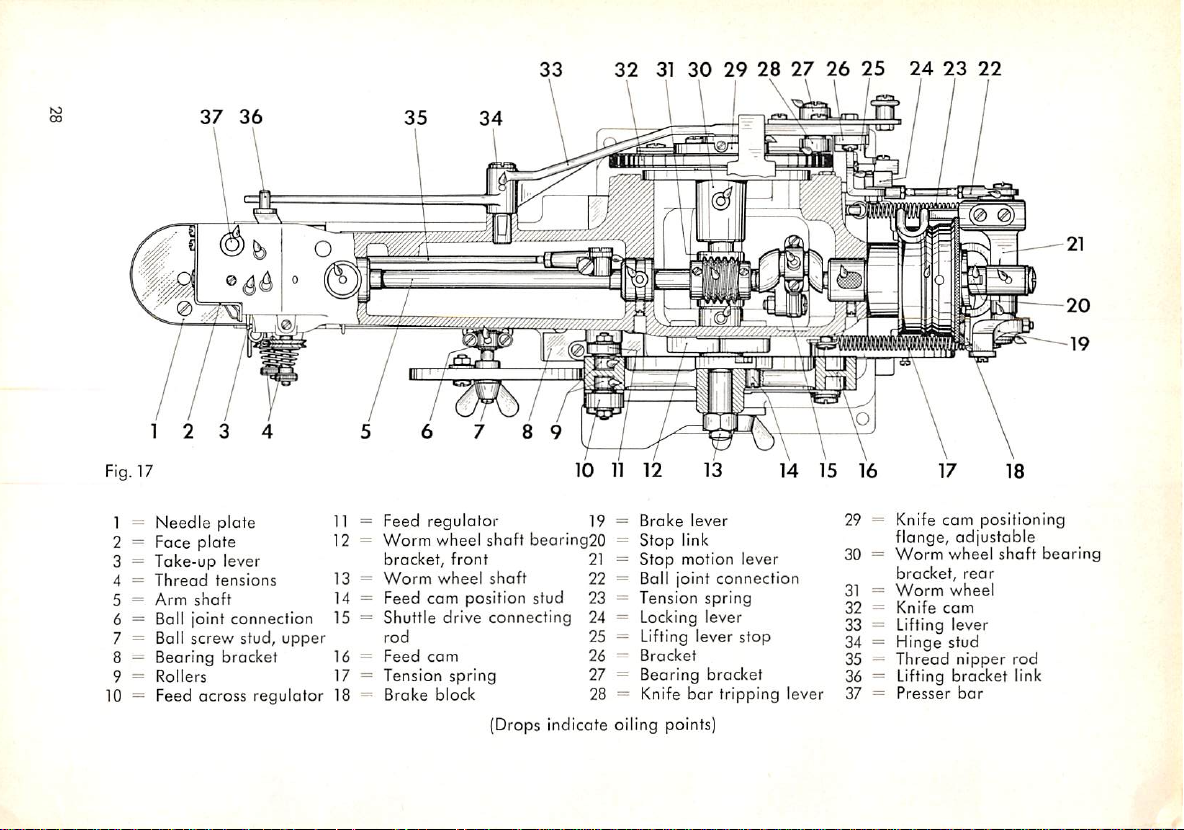

Fig. 17

1 =

Needle

2 = Face

3 =

Take-up

4 =

Thread

5 =

Arm

6 = Ball joint

7 = Ball screw stud,

8 — Bearing brocket 16 =

9 =

Rollers

10 = Feed across

3 4

plate

plate

tensions

shaft

lever

connection

upper

regulator

Feed

11 =

12 =

13 =

14 =

15 =

17

18 =

=

regulator

Worm

wheel

bracket,

Worm

shaft

front

wheel

Feed cam position stud 23

Shuttle

drive

rod

Feed

Tension

Brake

cam

connecting

spring

block

shaft

10

bearing20

11

12

19

Broke

Stop

21

Stop motion lever

22

Ball joint

Tension

Locking lever

24

Lifting lever stop

25

Bracket

26

Bearing bracket

27

Knife

28

13

lever

link

connection

spring

bar

tripping lever

14

15

{Drops indicate oiling points)

16 17 18

29 = Knife

30 =

31 =

32=Knife

flange,

Worm

bracket,

Worm

cam

positioning

adjustable

wheel

rear

wheel

cam

shaft

33 = Lifting lever

34 = Hinge stud

35 —

Thread

nipper

rod

36 = Lifting bracket link

37=Presser

bar

bearing

Page 30

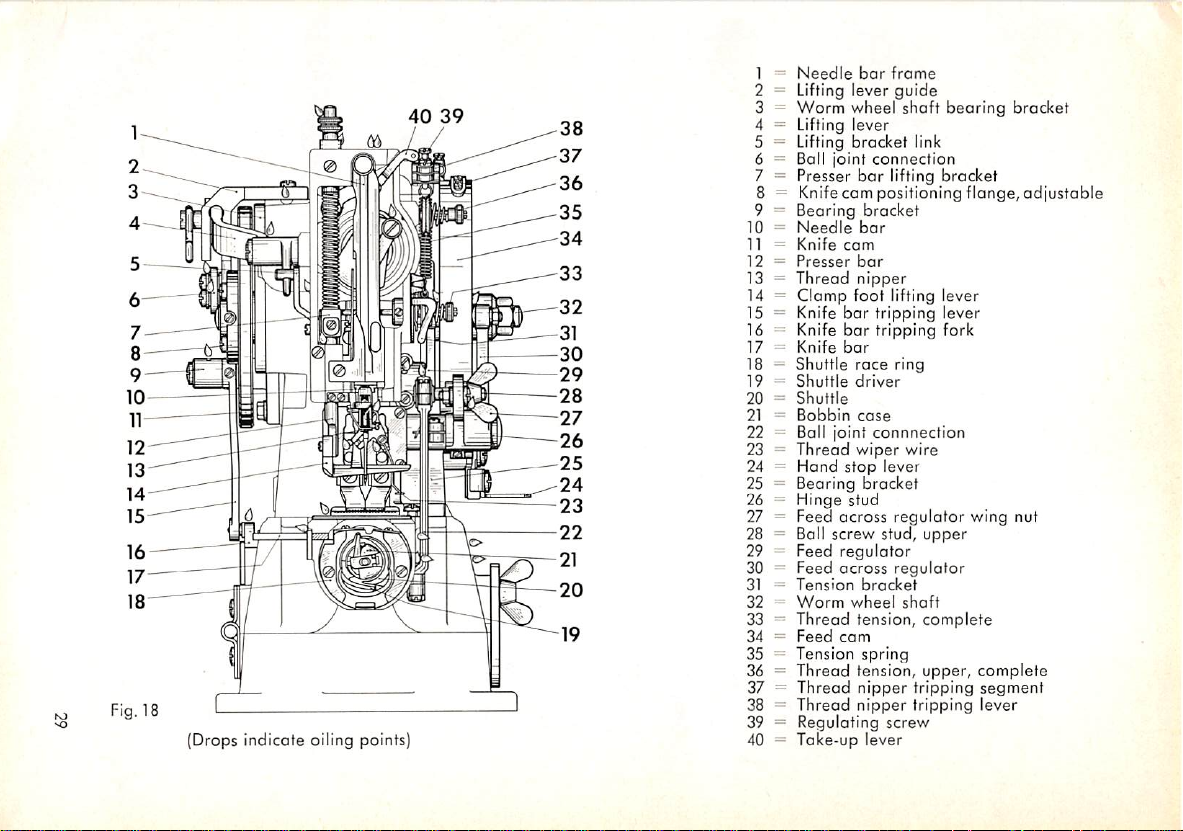

Fig. 18

(Drops indicate oiling points]

40

39

-^38

-37

-36

-35

"34

"33

-32

-31

30

-29

-28

-27

-26

-25

-24

-23

-22

-21

-20

-19

=

Needle

1

=

2

Lifting lever

=

3

Worm

-

Lifting lever

4

Lifting

5

----

6

Boll

7

Presser

=

8

=

9

Bearing

=

10

Needle

11

Knife

12

Presser

13

Thread

Clamp

14

--

15

Knife

--

16

Knife

=

17

Knife

—

18

Shuttle

19

Shuttle

20

Shuttle

-

21

Bobbin

22

Ball joint

23

Thread

24

Hand

Bearing

25

26

Hinge stud

-

27

Feed

=

28

Ball screw stud,

--

29

Feed

30

Feed

-

Tension

31

32

Worm

33

Thread tension, complete

=

34

Feed

=

Tension

35

=

36

Thread

37

Thread

-

38

Thread

=

39

Regulating screw

Take-up

40

bar

frame

guide

wheel

bracket

joint

connection

bar

lifting

Knifecam positioning flange,

bracket

bar

cam

bar

nipper

foot

lifting lever

bar

tripping lever

bar

tripping

bar

race

ring

driver

case

connnection

wiper

stop

lever

bracket

across

regulator

regulator

across

regulator

bracket

wheel

cam

spring

tension,

nipper

nipper

lever

shaft

bearing

link

bracket

fork

wire

wing nut

upper

shaft

upper,

tripping

complete

segment

tripping lever

bracket

adjustable

Page 31

B. Instructions

for

Repair

1. Disassembly

Strip the

intended. This rule applies particularly to dismantling the worm

bly.

plant.

machine

All

major repair and

only as far as is absolutely necessary for the repair job

conversion

jobs

should

be performed at the

gear

assem

Pfaff

It is advisable to strip complete ossemblies

and

reassembled as a unit. In

order

which

to avoid

can be easily disassembled

that

screws will be misplaced

or get lost, replace them in the screwholes immediately after the respective

port has been

removed,

if not

morked

previously,

spot the

positionofcranks

on shafts and the meshing teeth on both the worm and the worm wheel.

These

position

machine

To dismantle the machine completely, strip the ports in the following se

later.

marks

greatly facilitate the assembly and adjustment of the

quence (see illustrations on pages 24 through 29):

Needle, Work Clamp

Remove these ports first.

Stop Motion

Unscrew brake lever tension spring

Loosen

screw on stop motion lever hinge stud

Strip both the stop motion and broke levers, and dismantle

(22530).

Front

Ports

Turn out needle

on needle

bar

the machine cautiously. Dismantle presser bar

pressure regulating screw

foot lifting lever

take-up

Feed

lever.

Cam

Unscrew wing nut

(22394),

pull out feed across regulator

wheel shaft

loosen

(22009),

and

Face Plate

bar

frame set screw

frame hinge stud.

(392),

(22861).

(701578)

binding

and

Unscrew

on boll screw stud of boll joint connection

screw

pull the feed cam off this shaft.

(9624)

and boll joint connection

(11126),

(700073),

Pull

needle bar frame and hinge stud out of

presser bar lifting bracket

thread wiper wire

(700297)

(22017).

on bearing

Unscrew hexagon nut

and push out this stud.

and loosen set screw

(6523)

with presser bar spring,

(22037),

(22104),

bracket

(701638)

(22772).

locking

(700152)

and clamp

and strip

(21060),

on worm

lever

and

Knife

cam

Strip knife bar tripping lever

mantle

com

30

lifting

positioning

lever and knife cam (cautiously drive toper pin out of knife

flange).

(22239)

and lifting lever guide

(22004).

Dis

Page 32

Top Cover

Pull out thread nipper hinge stud

well as worm wheel shaft

Feed Regulator Bearing Bracket

Take both set screws

loosen thumb screw

Pull

and

Cylinder

and

Worm Wheel Shaft Bearing Bracket

rear

(700252)

(700293),

(22332),

bearing

out of feed regulator bearing bracket

and

and unscrew top cover

bracket

move swivel clamp

(22016).

(22467)

(22333)

(21060),

downward.

bearing bracket to the right and up, end strip feed plate carrier bar

feed

regulator

Bed Parts

post.

Unscrew needle plate and shuttle race ring. Take out shuttle, and strip

shuttle race. Cautiously drive pin out of shuttle driver shaft crank

pull out shuttle driver shaft. Dismantle feed across shaft

Arm

Parts

Strip

shuttle

crank ond worm, slacken set screws

(21195),

points

Worm

Loosen set screws im worm wheel,

bearing bracket

you drive out taper pin

drive connecting rod

(22059).

Loosen

(700150)

and cautiously drive out arm shaft, making sure its cranked portion

downward.

Wheel

Shaft

and

attach

(22016)

so that the worm wheel shaft

(1848).

Now

pull

worm wheel shaft out of

(22020).

set

screws

in arm shaft rear bushing

worm wheel shaft

will

(6568),

and

in needle bar

rear

not be bent when

machine.

2. Assembly

Examine

or replace damaged parts.

oil parts for wear before you assemble

Make

sure to

remove

them.

If necessary,

rework

burrs and dents on shafts

so as to ensure that gears, eccentrics, set collars and other parts can be

moved

are

on them

likely

eosily.

to cause

All

binding

shafts

and

must

be perfectly straight because bent shafts

noisy

running

of the

machine.Tofacilitate

subsequent adjustment, it is recommended to replace all parts in close

proximity to their previous positions.

Worm

Wheel

Shaft

Replace both the worm wheel and the worm wheel shaft. Again screw on

worm

wheel shaft rear bearing bracket

when you drive home taper pin

Arm

Ports

Replace

arm shaft

with

driving

(1848).

pulley

(22016)

(20658),

so that the shaft

arm shaft rear

will

not be bent

bushing

(21195)

and worm. Push needle bar crank onto arm shaft, and screw down. Rotate

arm

shaft

to make sure it revolves freely. Mesh worm

and

worm wheel

as

31

Page 33

in

accordance

with

position

marks.

Both

the

arm

ond

worm

wheel

shafts

must revolve freely, without having any end play. The only gears that may

have a scarcely perceptible amount of play

are

the worm and worm wheel.

Place machine on

be too noisy, correct this condition by setting the worm as close to the

worm wheel as possible

hove any

end

pulley as close to arm shaft

screws securely. Re-ream pin hole with a

taper

pin to pin driving pulley on arm shaft. Make sure the

stand

play, drive

and

test-run it. If the worm

and

relapping

taper

rear

both parts. If the

pin

(2056)

bearing as possible,

gear

arm

out

of the driving pulley, set

taper

reamer,

and

assembly should

shaft

should

and

tighten set

take

a thicker

taper

pin does

not protrude from the hub of the pulley, as this would interfere with the

proper functioning of the stop cam spring.

If a new arm shaft must be installed in the machine, drill the toper pin

hole in the driving pulley only

after

the

latter

has

been

mounted on the

shaft. The driving pulley is screwed onto the arm shaft only until the front

ports have been installed. Rotate the driving pulley on the arm shaft until

the groove in the stop com extends vertically. Check to see that the machine

stops when the ascending take-up lever has reached a position about

^Ua",

or 2.0 mm, below the highest point of its stroke. To make whatever adiust-

ment may be necessary, insert stop com spring, Novotex segment

and stop cam

Insert shuttle drive connecting rod

(20062)

into the driving pulley.

(22059)

and oscillating rock shaft

(20275),

(6674),

and check to see that both parts move freely without having any end ploy.

Mount thread nipper components in machine arm.

Front

Parts

Screw on needle plate, and odd take-up lever. Insert needle bor frame

with needle bar, and align so that needle is correctly centered in the needle

hole. Mount presser

Cylinder

Bed Ports

Insert feed plate carrier

to the feed plate carrier

without having ony lateral play. Screw feed across driving block

guide plate

parts

move

freely. Install

and rear cranks. Adjust the front crank so that driving stud

in the cutout of the feed across driving block when both feed motions

set on

zero.

Add shuttle driver

(22391)

bar

with guide, spring and pressure regulating screw.

bar

and

bearing bracket. Set guide plate as close

bar

as possible so that the latter moves freely

to feed plate carrier bar, making sure the attached

feed

across

shaft

with

set

shaft

with crank

collarsaswell as

(22025)

(6568).

front

is centered

and

are

Feed

Com

Attach feed cam,

and

tighten hexagon nut on worm wheel shaft. Make sure

the machine runs smoothly and the roller does not chafe

32

against

the bottom

Page 34

of

plate

l"he

pattern-forming groove. Add feed across regulator, and screw feed

onto

feed

plate

carrier

bar.

prevent

To

loosen the set screws in the

by hand. This action will cause the rollers to

grooves automatically.

Knife

Attach bearing bracket for knife

the rollers from becoming

Com

bearing

bar

wedged

bracket,

tripping lever

and

odopt

in the grooves,

turn the driving pulley

the best position in the

(22239).

Push knife cam

again

with positioning flange onto worm wheel shaft, pin down, and tighten set

screws securely. Install knife

of rack and pinion mesh. Mount lifting lever

bar

tripping lever by means of ball joint connection

Stop Motion

Attach stop motion lever, brake lever, tripping lever, and locking lever.

Other

Ports

Attach remaining parts while you adjust the machine, or

has

been

completed.

3. Adjustment

To focilitate the use of this manual, all adjustments discussed in the follow

ing chapter,

and

Check-Up

wherever

for instance, all adjustments pertaining to the shuttle

the heading

"Timing

the Shuttle and Setting the Needle Bar at Correct

bar

(22088),

making sure that spotted teeth

(22003)

and connect with knife

(22512).

feasible, hove been grouped by

will

after

adjustment

assemblies.

Thus,

be found under

Height". For best results, it is recommended to perform the adjustment

and check-up of a machine in the sequence given below.

Important

Always

size in accordance with the material to be sewn. Unless specified otherwise,

insert a new needle before you adjust a

machine.

Select the needle

the adjustments discussed below apply to all subclasses. Certain materials,

however, necessitate minor deviations from the standard settings given here.

a.

Timing

Insert a new needle,

the Shuttle and Settingthe Needle Barat CorrectHeight

and

screw on the needle plate. Loosen the set screw

in the needle bar frame, and adjust the latter so that the needle is centered

in the needle hole. (Needle plate inserts are available in various needle hole

sizes).

33

Page 35

(1)

Needle

Bar Rise

The amount of needle

mm. This means that the point of the shuttle should be opposite the center

bar

rise required to form the loop is

V35",

or 2.4

line of the needle when the letter has passed the lowest point of its stroke

V32".

and risen

as

viewed

rise can be set easily with the aid of

Make sure you turn the driving pulley counter-clockwise,

from

the

backofthe

machine.

gauge

The

correct

No. Z 70.67-2 (Fig.

amount

19}.

of

needle

bar

Fig. 19 Setting the

omountofneedle

bar

rise

To moke this adjustment, turn driving pulley to bring needle bar to its

lowest

the

shuttle

the

gouge

and the

gauge,

34

position.

and

When

the needle has reached the

should

bottom

be at

its

left

point of reversal. Slip both the clamp and

onto the

tighten the clamp screw. To moke sure the needle

needle

bar,

of the needle bar

positioning

frame.

the latter

Push

the

lowest

clamp

point of its

between

up against the

barisat

the

stroke,

clamp

the

Page 36

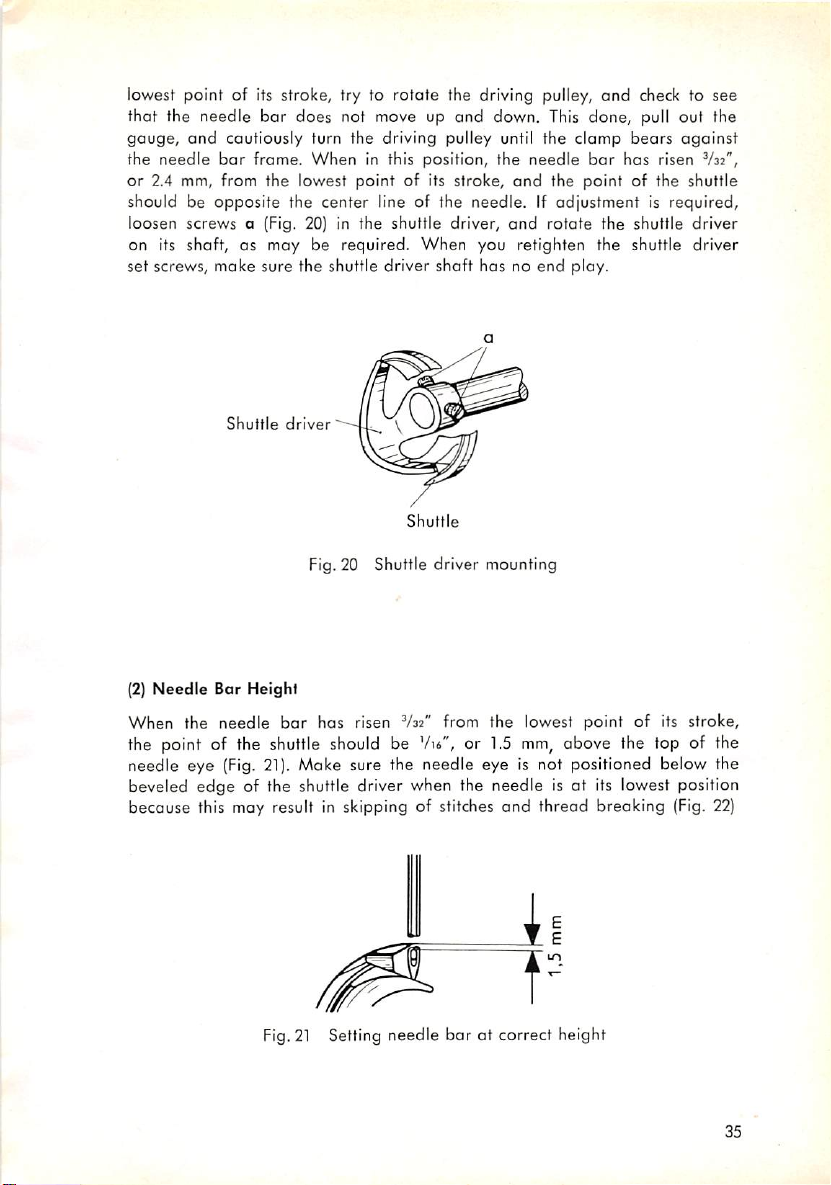

lowest point of its stroke, try to rotate the driving pulley,

and

check to see

that the needle bar does not move up and down. This done, pull out the

gauge,

the

or

should be

and

cautiously turn the driving pulley until the clomp

needle

bor

frame.

When

in this position,

2.4 mm, from the lowest point of its stroke,

opposite

the

center

line of the needle. If adjustment is required,

the

needle

bar

and

the point of the shuttle

bears

has

risen

against

V32",

loosen screws a (Fig. 20) in the shuttle driver, and rotate the shuttle driver

on its shaft, as may be required.

When

you retighten the shuttle driver

set screws, make sure the shuttle driver shaft has no end play.

Shuttle

driver

Shuttle

Fig.20 Shuttle driver mounting

(2)

Needle

When the needle

Bar Height

bar

has risen

V32"

from the lowest point of its stroke,

the point of the shuttle should be Vii", or 1.5 mm, above the top of the

(Fig.

21).

needle eye

beveled

edge

becouse this may result in skipping of stitches

Make sure the needle eye is not positioned below the

of the shuttle driver when the needle is at its lowest position

and

thread breaking (Fig. 22)

Fig.21Setting needle bar at correct height

35

Page 37

Fig.

22 Setting the needle bar at correct height

36

Page 38

To

adjust,

higheror

loosen

screw

lower,

as may be required

a on needle bar

(Fig.

connecting

22).

stud,

and set needle bar

(3)Setting

When the needle has risen

Needle

to Shuttle

V32"

should be a clearance of about

the point of the

shuttle.

This

settingispredeterminedbythe

shuttle race and cannot be changed

Shuttle

Needle

0,1

from the lowest point of its stroke, there

.004",or0.1

(Fig.

mm

23).

mm,

between the needle ond

position

of the

Fig. 23 Setting needle to shuttle

The only way adjustment can be made is by exchanging the shuttle race.

Shuttle races

.012",or0.1, 0.2

recent machines, this adjustment

thickness.

(4) Setting

order

In

are

Needle

to avoid

available

and

to Shuttle Driver

that

for this purpose which

0.3 mm,

the point of the shuttle hits the

thicker

than

canbemadebyadding

the

ore

standard

.004", .008"

shuttle

spacers

needle

race.

of varying

if the

letter

and

On

is deflected by hard spots in the material, the shuttle driver has been design

ed as a

needle

guide. The needle should

bear

lightly

against

the shuttle

driver when the point of the shuttle passes it. If adjustment is required,

bend the shuttle driver coutiously (Fig. 24).

37

Page 39

Needle

guide

Shuttle

Fig. 24 Setting

(5)

Clearance

The

clearance

to permit the heaviest

pass

through it freely. A

Between

gap

between

Shuttle

gradeofthread

normally will be sufficient for this purpose. To

and

Shuttle Driver

shuttle

clearance

needle

to shuttle driver

and

shuttle driver should be wide enough

used on this

of

obout

V64",

allow

used on this machine, it may be necessary to make this

or

0.6 to 0.7 mm,

wide.

driver

particular

machine to

or 0.4 to 0.5 mm,

heavier

gap

threads

about

to be

V32",

If adjustment is required, bend the driver fingers cautiously, making sure,

however,

top finger is positioned exactly

(Fig. 25).

1 =

2 = Shuttle driver top finger

3 =

4 = Shuttle driver bottom finger

5 =

that

the bottom finger

Clearance

V64",or0.4 to 0.5 mm

opposite

Shuttle

lines up with heel of shuttle

(must not

gap

center of neck

driver

contact

shuttle

race)

Shuttle

does

opposite

not

contact

the

the shuttle

center

of the shuttle neck

m

race

and

the

Fig. 25 Clearance gap between shuttle and shuttle driver

38

Page 40

b.

Timing

the Feed Motion

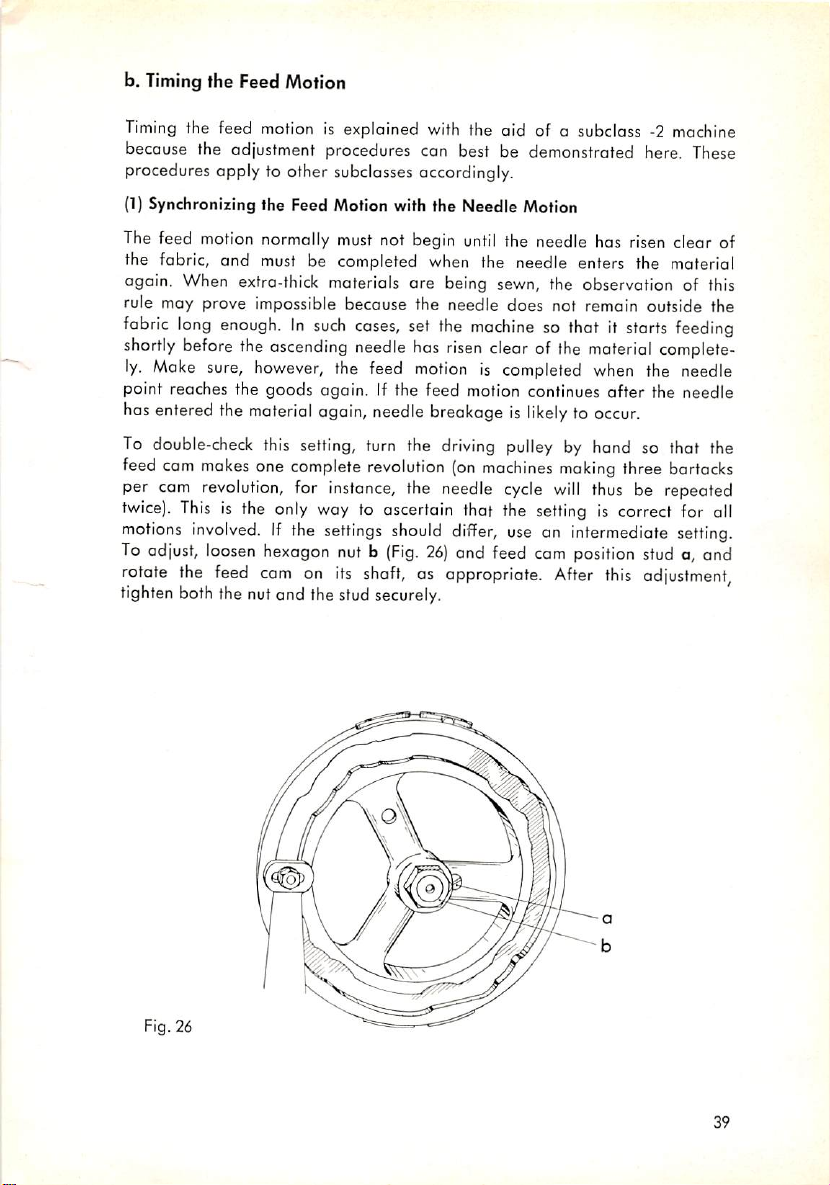

Timing

procedures apply to other subclasses accordingly.

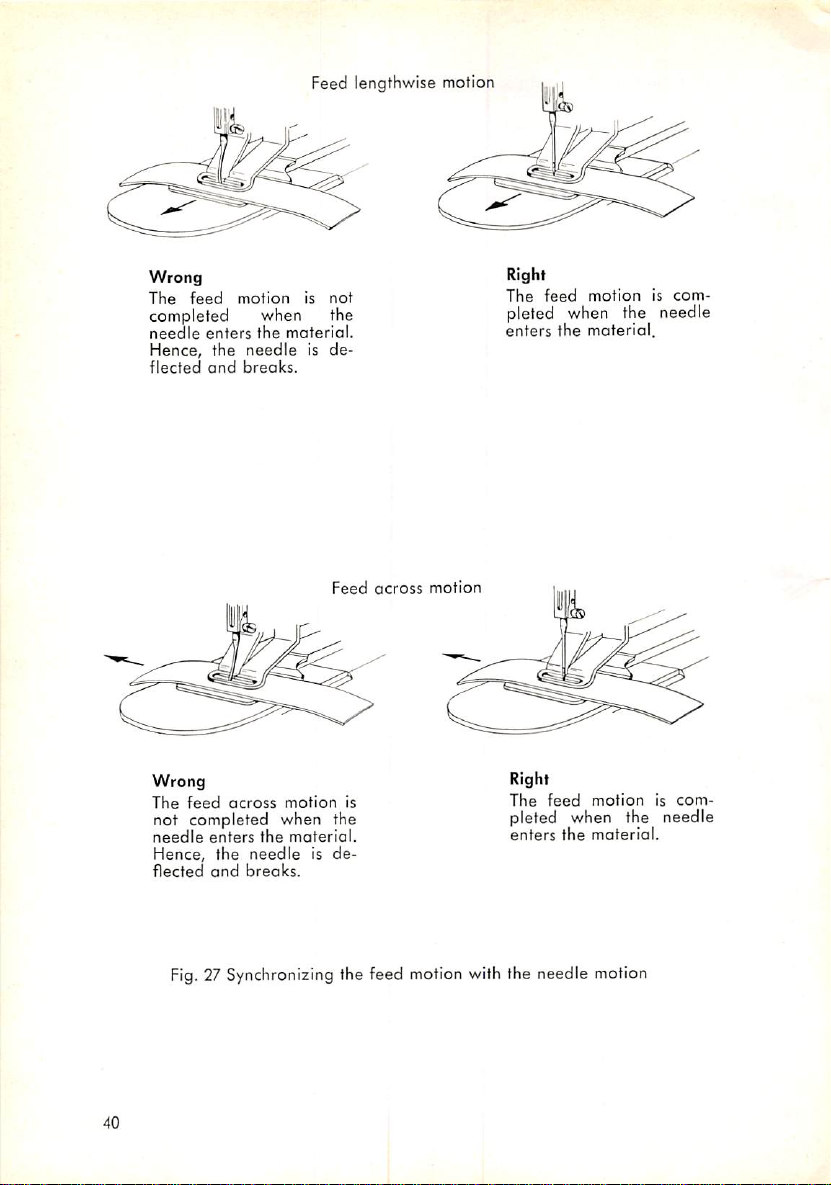

(1}

The feed motion normally must not begin

the fabric, and must be completed when the needle enters the materiel

again. When extra-thick materials are being sewn, the observation of this

rule may prove impossible because the needle does not remain outside the

fabric

shortly

ly.

point reaches the goods again. If the feed motion continues

has

To

feed

per

twice).

motions

To adjust,

rotate

tighten

the feed motion is explained with the aid of o subclass -2 machine

because the adjustment procedures can best be demonstrated here. These

Synchronizing the Feed Motion with the Needle Motion

until

the needle has risen clear of

long

enough.Insuch

before

the

Make

sure,

however,

entered

double-check

com

the

material

this setting, turn the

cam

makes

one

revolution,

This

is the only way to ascertain that the

involved.Ifthe

loosen

hexagon nut b

the

feed

cam

boththe nutand the

ascending

complete

for

again,

settings

on

cases,

set the

needle

has

risen

the feed

instance,

its

stud

motioniscompleted

needle

breakageislikelytooccur.

driving

revolution

should

(Fig.

(on

the needle

differ,

26)

and feed cam

shaft,asappropriate.

securely.

machine

so that it

clearofthe

pulley

by hond so that the

machines

cycle

making

will

setting

useanintermediate

position

After

starts

feeding

moterial

when

thus

is correct for all

complete

the needle

after

the needle

three

be repeated

bartacks

setting.

stud a, and

this

adjustment,

Fig. 26

39

Page 41

Feed lengthwise motion

Wrong

The

feed

motion

is

not

completed when the

needle

enters

the

Hence,

flected

the

and

needle

breaks.

material.

is de

Wrong

The

feed

across

motion

not completed when the

needle

enters

the

Hence,

flected

the

and

needle

breaks.

materiel.

is de

Feed

is

across

motion

Right

The

feed

motioniscom

pleted when the needle

enters

the

material.

Right

The

feed

pleted when the needle

enters

motioniscom

the

material.

Fig.

27 Synchronizing the feed motion with the needle motion

40

Page 42

(2)

Timingthe Feed Lengthwise Motion

When

the roller stud is positioned in the middle of the

in the feed

regulator

A in Fig. 28), the

elongated

screws a

as

appropriate.

hole in the work

and

b (Fig. 28),

and

needle

the swivel

must be centered in the feed

and

Wrong

clamp

move the

clampisat

its highest position (marked

feet. If adjustment is

bearing

bracket

forwardorbackward,

elongated

plate

needed,

hole

cutout or the

loosen

1 =

Feed

2 = Bearing

3 = Feed

4 =

Feed

5 =

Needle

6 =

Workpiece

7 = Adjust

8 =

Work

cam

bracket

plate

carrier

bar

plate

clomp

feet

Fig. 28 Timing the feed lengthwise motion

9 = Feed

10 =

Thumb

11 = Swivel

12=Thrust

13 = Feed

14 =

Feed

15=Roller

16 =

Pattern-forming

regulator

screw

clamp

washer

regulator

regulator

stud

post

swivel

groove

41

Page 43

When the swivel clamp is moved down to position B, the feed plate should

move the some distance from the middle both ways so that the needle will

hit neither the work clamp feet nor the feed plate. Adjustment can be

made by loosening nut c (Fig. 29) and moving the roller stud in the elongated

hole of the feed regulator, as may be appropriate.

Wrong

4'

« I

Wrong

42

Work

clamp feet

Adjust

Workpiece

Needle

Roller

stud

Right

Fig. 29 Timing the feed

6 = Feed

regulator

7 = Bearing bracket

8 = Thumb screw for adjusting

the feed lengthwise motion

9 =

Feed

plote

10 =

lengthwise

Feed

motion

carrier

plate

bar

Page 44

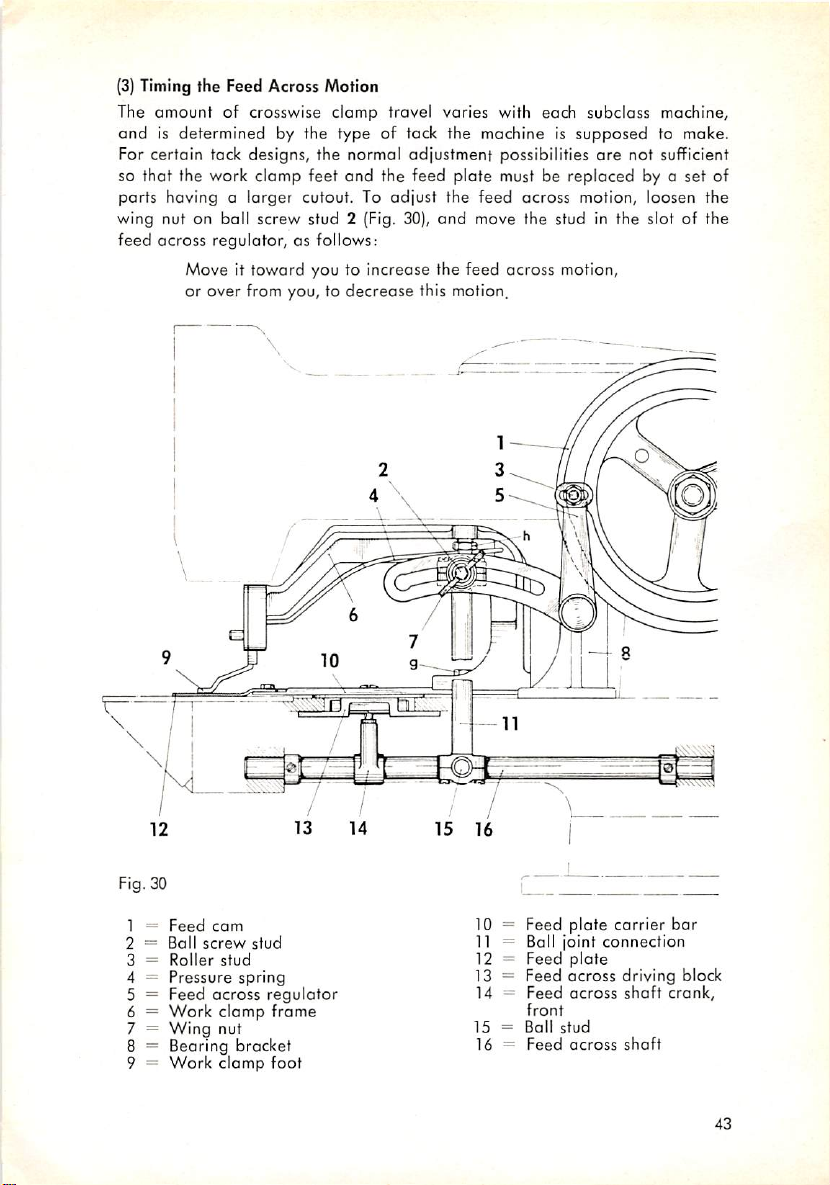

(3)

Timing the Feed Across Motion

The

amount

andisdetermined

For certain tack designs, the normal adjustment possibilities

of crosswise clamp travel varies with each subclass machine,

by the type of tack the machine is

supposed

are

not sufficient

to make.

so that the work clamp feet and the feed plate must be replaced by o set of

parts having a larger cutout. To

wing nut on ball screw stud 2 (Fig. 30),

across

feed

regulator, as follows:

Move it

toward

you to increase the feed across motion,

adjust

the

feed

across motion, loosen the

and

move the stud in the slot of the

or over from you, to decrease this motion.

Fig. 30

1 =

Feed

2 =

3 =

4 =

com

Ball

screw

Roller

Pressure

stud

stud

spring

5 = Feed across

6 =

Work

Wing

clamp

nut

7 =

8 = Beoring bracket

9 =

Work

clomp

regulator

frame

foot

10 = Feed plate carrier

11 = Ball joint

12 = Feed

13 =

Feed

14 =

Feed

front

15=Ball

16 =

Feed

plate

across

across

stud

across

connection

driving block

shaft

shaft

bar

crank,

43

Page 45

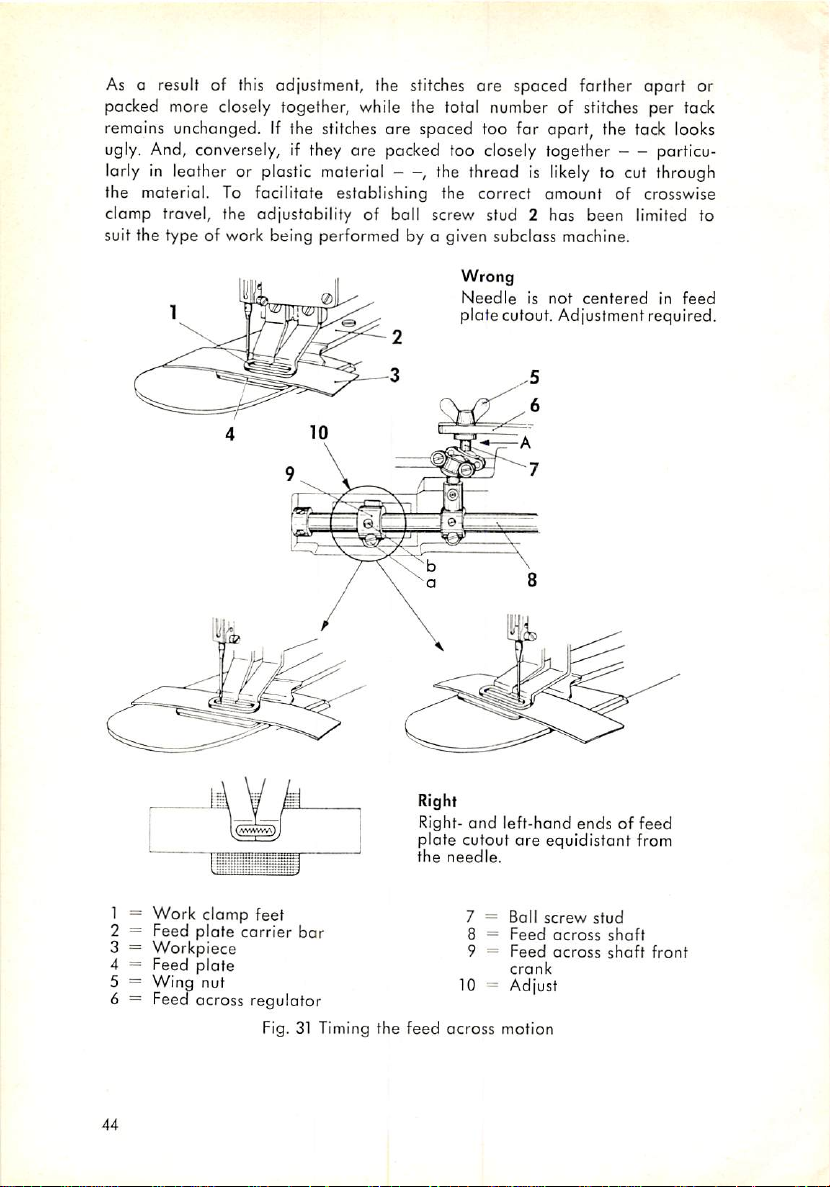

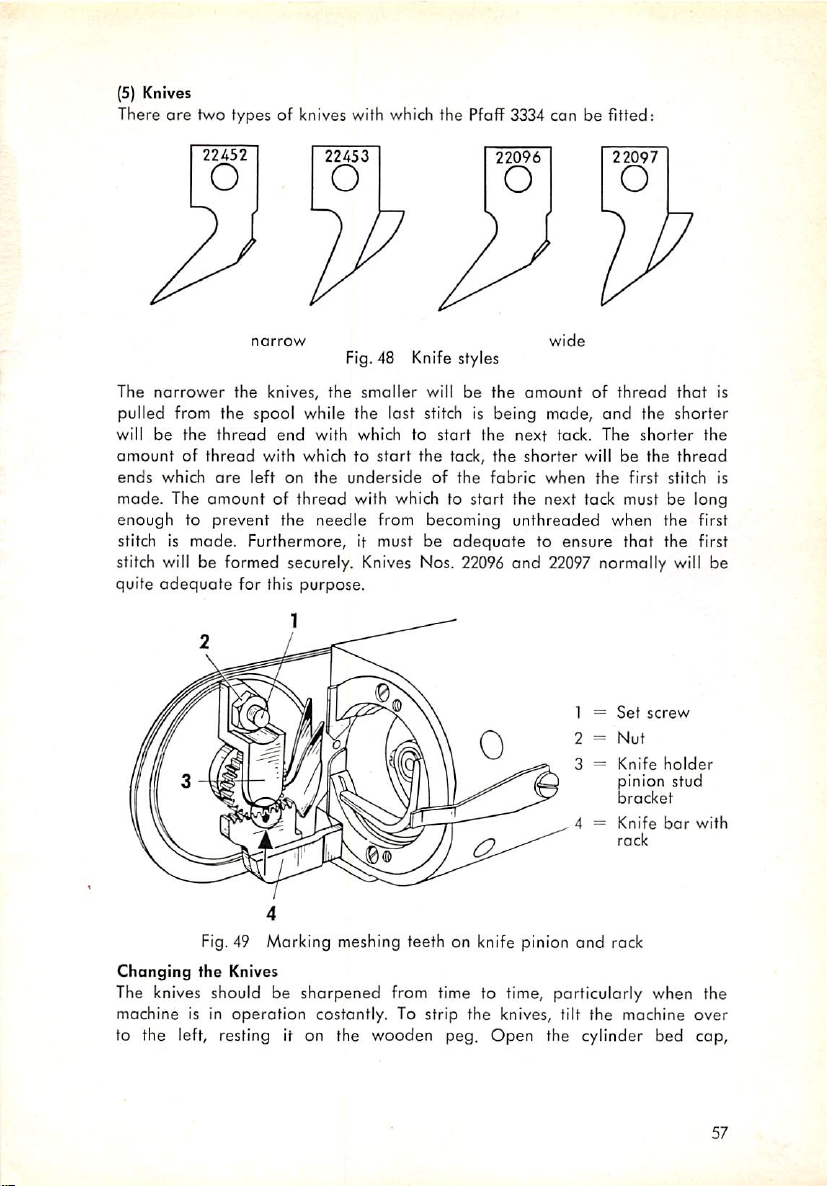

As a result of this adjustment, the stitches are spaced farther

apart

packed more closely together, while the total number of stitches per tack

remains

unchanged.

If the

stitches

are spaced too for opart, the

tack

looks

ugly. And, conversely, if they are packed too closely together particu

larly in leather or plastic material , the thread is

the material. To facilitate establishing the correct

likely

amount

to cut through

of crosswise

clamp travel, the adjustability of ball screw stud 2 has been limited to

suit the type of work being performed by a given subclass mochine.

Wrong

Needleisnot

platecutout. Adjustment required.

centered

in

feed

or

1 =

Work

clamp

2 =

3 =

Feed

Workpiece

plate

feet

carrier

4 = Feed plate

Wing

5 =

nut

6 = Feed across regulator

Fig. 31 Timing

44

bar

the

Right

Right-

plate

the

feed

and

left-hand

cutout

needle.

across

ore

7 =

Ball

8 =

Feed

9 =

Feed

crank

10 - Adjust

motion

endsoffeed

equidistant

screw

stud

across

shaft

across

shaft

from

front

Page 46

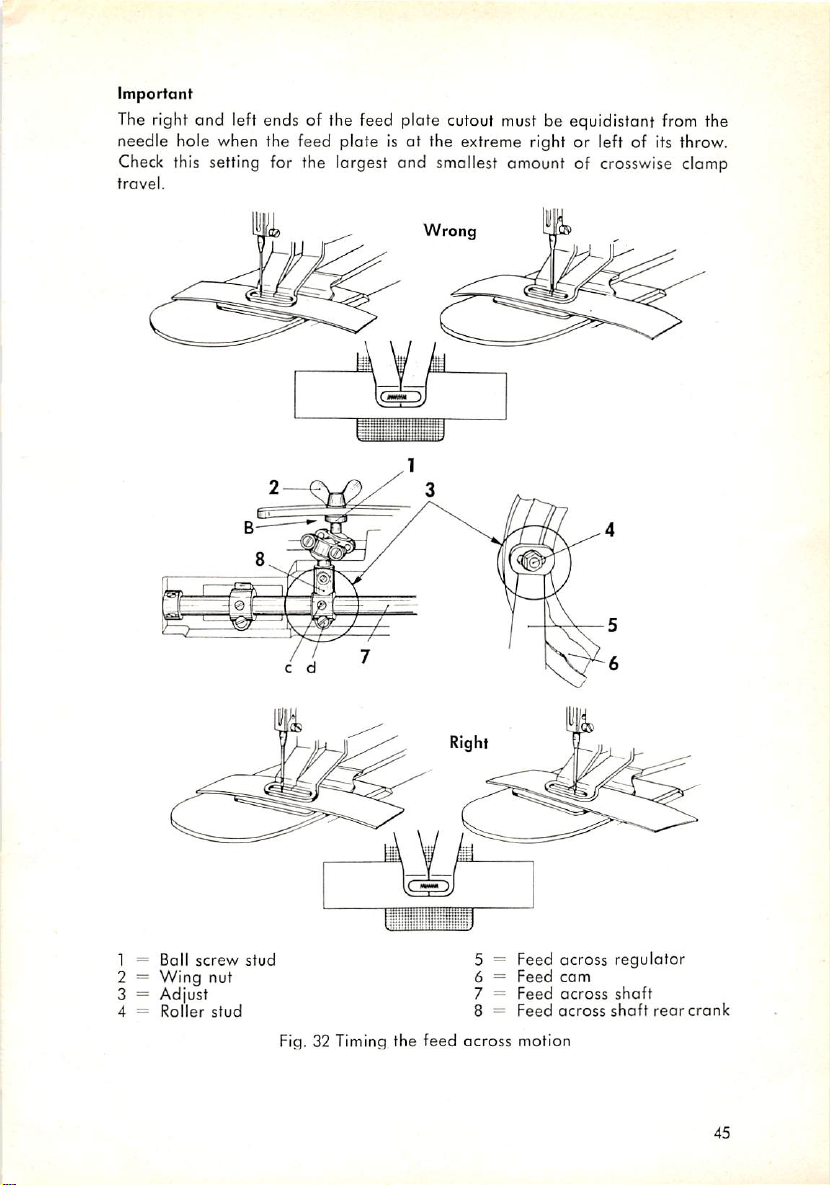

Important

The right

and

left ends of the feed plate cutout must be equidistant from the

needle hole when the feed plate is at the extreme right or left of its throw.

Check

this setting for the largest and smallest amount of crosswise clamp

travel.

Wrong

1 =

Ball

2 =

Wing

3 = Adjust

4 =

Roller

screw

nut

stud

stud

Fig. 32 Timing

the

5 = Feed across regulator

6 =

Feed

Feed

Feed

motion

com

across

across

feed

7 =

8 =

across

shaft

shaft

rear

crank

45

Page 47

To odjust, set the roller stud in the middle of the

feed

across

regulator

(Fig. 32). Loosen wing nut 5 (Fig. 31),

elongated

hole in the

and

move

boll screw stud 7 to its extreme left position in the slot of the feed across

regulator (marked A in Fig.

amount

the right-

of crosswise clamp travel. Turn the driving pulley,

and

left-hand ends of the feed plate cutout

31).

The machine is now set for the largest

and

check whether

are

equidistant from

the needle hole when the feed plate is at the extreme right or left of its

throw. To adjust, loosen screws a

and

b on the feed

across

shaft

front

crank and adjust the position of the feed plate, as appropriate.

Move ball screw stud 7 to the right in the slot of the feed across regulator

as f»f as it will go, thus setting the machine for the smallest

crosswise clomp travel.

the driving pulley, check to see

This

position is marked B in

that

the short tack side is centered within

Fig,

amount

32. As you turn

the long tack side produced with the previous setting. If adjustment is

required, loosen screws c and d on the feed across shaft rear crank, and

move the crank slightly to the right or left on the shaft until the correct

setting is obtained (Fig. 32).

Again set the machine for the largest amount of crosswise clamp travel,

and check whether the left- and right-hand ends of the feed plate cutout

are equidistant from the needle when the feed plate is at the extreme right

or left of its throw. If necessary, adjust as instructed obove.

Provided the adjustment hos been made conscientiously, tacks of all sizes

will be correctly centered in the feed plate cutout.

If the

small

tack

is positioned to the left of the center

line

of the large

tack,

move the feed across shaft rear crank slightly to the left. And, conversely,

if it is positioned too far to the right, move the crank slightly to the right.

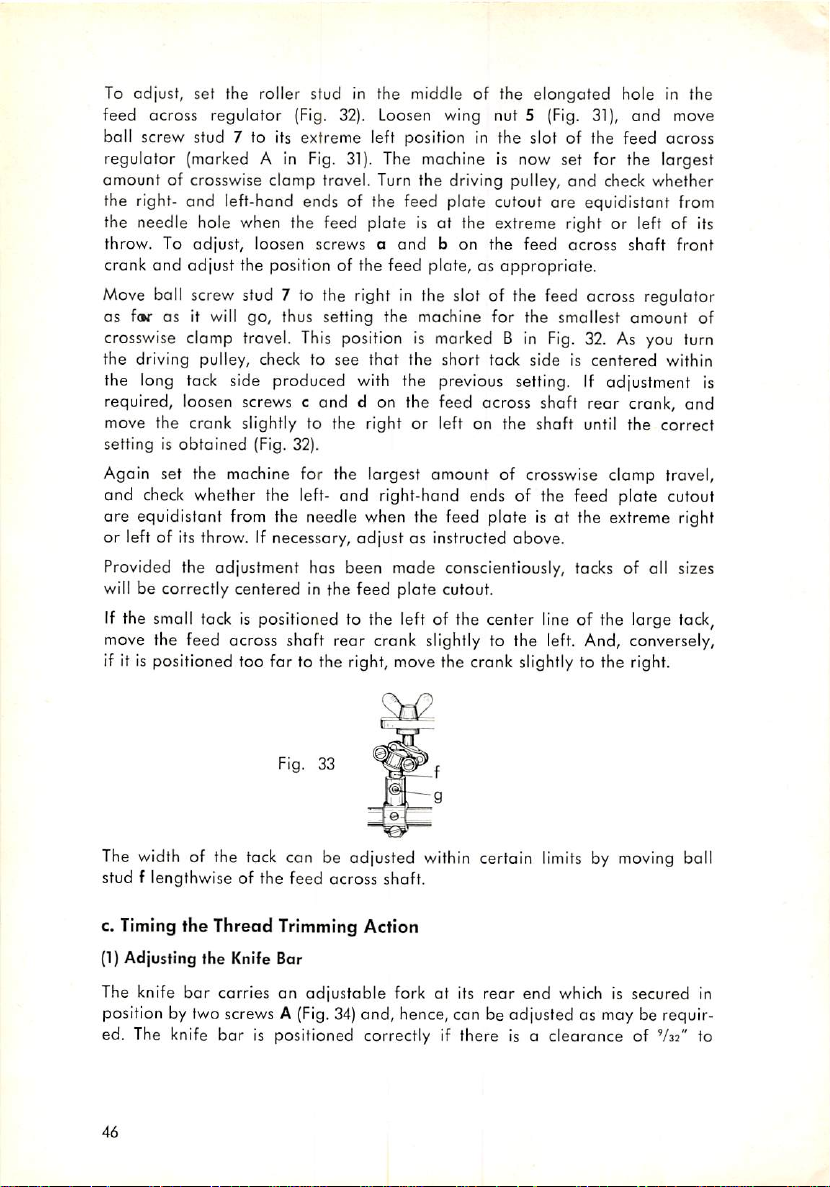

of

Fig. 33

The width of the tack can be odjusted within certain

stud f lengthwise of the feed across shaft.

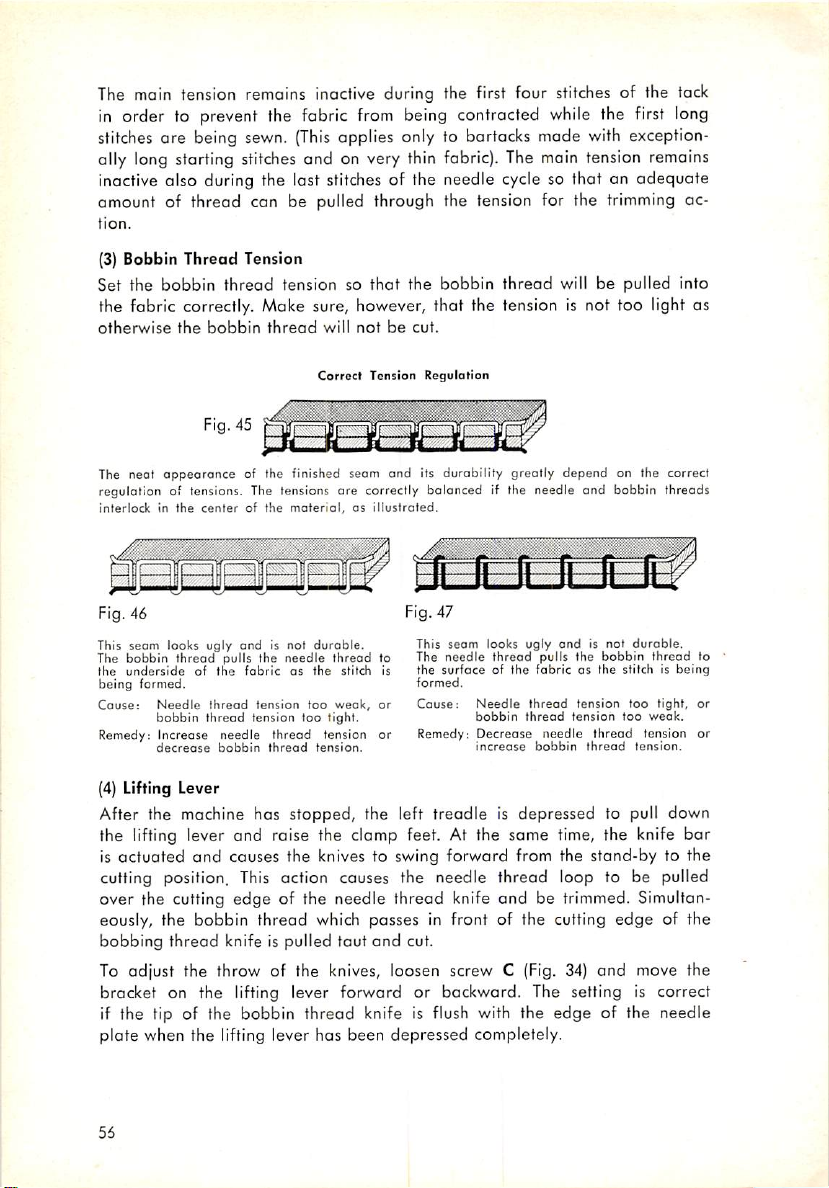

c. Timing the Thread Trimming Action

(1)

Adjusting the Knife Bar

bar

The knife

carries an

position by two screws A

ed. The knife

46

bar

adjustable

(Fig.

forkatits

34)

and, hence, can be adjusted as may be requir

rear

is positioned correctly if there is a clearance of

limits

by moving ball

end

which is secured in

V32"

to

Page 48

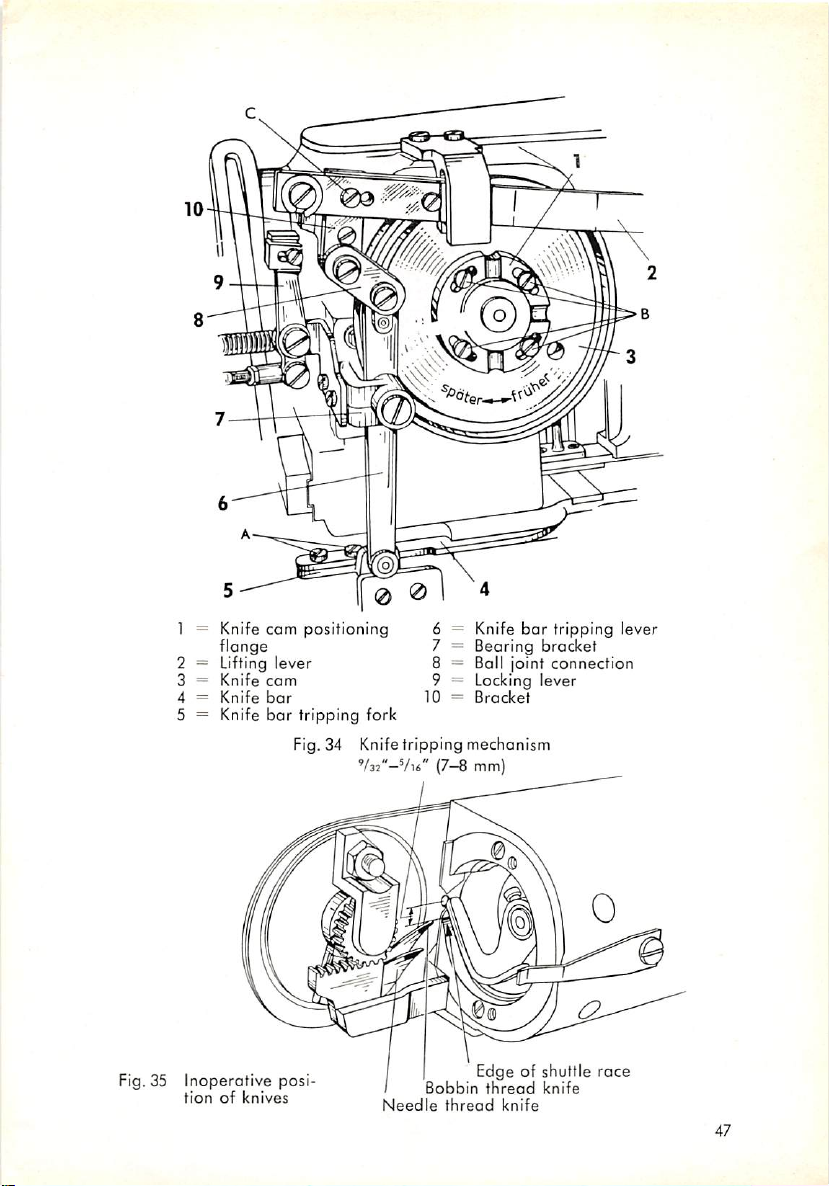

1 = Knife

cam

flonge

2 = Lifting lever

3 =

Knife

Knife

com

bar

bar

4 =

5 = Knife

Fig. 34 Knifetripping mechanism

positioning

tripping fork

V32"-Vu"

6 = Knife

7 =

Bearing

bar

tripping

bracket

8 = Ball joint connection

9 = Locking lever

10=Bracket

{7—8

mm)

lever

Fig. 35

Inoperative

tionofknives

posi

Needle

Bobbin

thread

Edge of shuttle

thread

knife

knife

race

47

Page 49

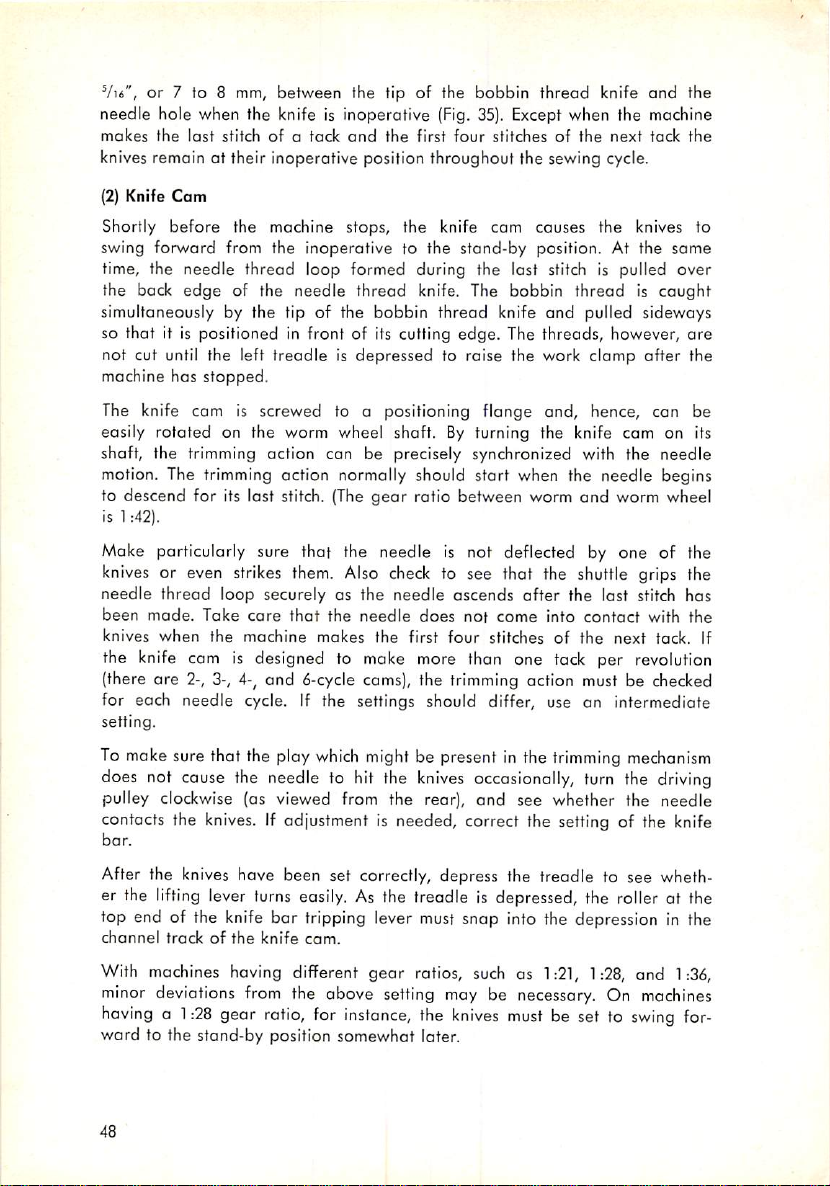

Vu", or 7 to 8 mm,

between

the tip of the

bobbin

thread

knife

and

the

needle hole when the knife is inoperative (Fig. 35). Except when the machine

makes

the

last

stitchofo

tack

and

the

first

four

stitchesofthe

next

tack

the

knives remain at their inoperative position throughout the sewing cycle.

(2)

Knife Cam

Shortly

before

the machine stops, the knife com causes the knives to

swing forward from the inoperative to the stand-by position. At the same

time, the needle thread loop formed during the lost stitch is pulled over

the back

simultaneously by the tip of the

so that it is positioned in front of its cutting edge. The threads, however,

edge

of the needle thread knife. The bobbin thread is caught

bobbin

thread

knife

and

pulled sideways

are

not cut until the left treadle is depressed to raise the work clamp after the

machine has

stopped.

The knife com is screwed to a positioning flange and, hence, can be

easily rotated on the worm wheel shaft.

By

turning the knife cam on its

shaft, the trimming action can be precisely synchronized with the needle

motion. The trimming action normally should stort when the needle begins

to descend for its last stitch. (The

is 1:42).

gear

ratio between worm

and

worm wheel

Make particularly sure that the needle is not deflected by one of the

knives

or even strikes them. Also

needle

thread

loop securely as the

been

made.

Take

care

knives

when

the

machine

that

the

makes

check

to see that the shuttle grips the

needle

ascends

needle

does

the

first four stitches of

not

come

after

the last stitch has

into

contact

the

with

the

next tack. If

the knife cam is designed to make more than one tack per revolution

(there ore 2-, 3-, 4-, and

6-cycle

cams), the

trimming

action must be

checked

for each needle cycle. If the settings should differ, use an intermediate

setting.

To make sure that the play

does not cause the needle to hit the

which

might be present in the

knives

trimming

mechanism

occasionally, turn the driving

pulley clockwise (as viewed from the rear), and see whether the needle

contacts the

bar.

knives.

If adjustment is needed, correct the setting of the knife

After the knives have been set correctly, depress the treadle to see wheth

er the

lifting

lever turns easily. As the treadle is depressed, the roller at the

top end of the knife bar tripping lever must snap into the depression in the

channel

With machines having different gear ratios,

minor

havinga1:28

ward to the stand-by position somewhat later.

48

trackofthe

deviations

gear

knife

from

ratio,

cam.

the above

for

instance,

setting

suchas1:21, 1:28,

maybenecessary.

the

knives

must

On

be set to

and 1:36,

machines

swing

for

Page 50

d. Adjusting the

Adjust

the work clamp frame on the feed plate carrier bar so that the

needle

will neither be deflected by, nor strike against, the work

feet, regardless

Work

Clomp

how

large the tack may be.

The

work

clomp

spring

clamp

pres

sure can be regulated by nut h (Fig. 30).

The clamp foot lifting lever (Fig. 2) must not contact the lifting studs pro

truding

will not press the material against the feed plate

has completed the last stitch and stopped, adjust the presser

from

the work clamp face plate as, otherwise, the work clamp feet

firmly.

After the machine

bar

and the

clomp foot lifting lever so that the top edge of the latter is positioned

just below the work clomp foot lifting studs.

e. Timing the Stop Motion

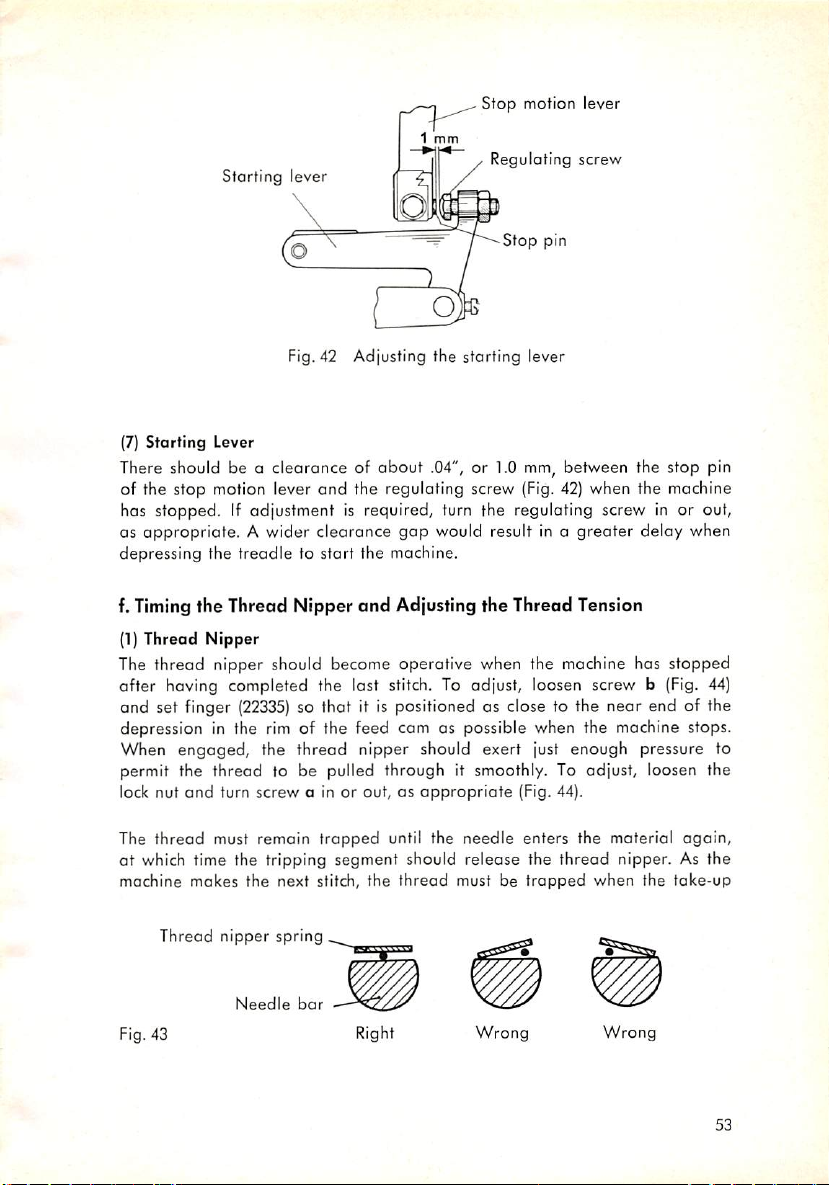

(1) Stop Motion Lever

Adjust both the tripping lever latch

so that the latch will leap about holfway into the upper notch of the catch

and

the stop motion lever catch

about

(Fig.36)

Hinge stud

Stop

motion lever

Stop

link

Stop

link rod

Stop

cam

Brake

lever

7 = Tripping lever

8 =

9 =

10 = Tripping

11 = Hand stop lever plate

12 =

Fig.36 Stop motion

Latch

Catch

Stop

dog

tripping

segment

49

Page 51

when the right treadle is depressed to start the machine. Also see that

gap

about

^U*",

there is a clearance

edge of the stop

link

and the lobe on the foce of the stop cam

or 2.0 mm, wide between the front

(Fig.

when the machine is in operation.

Brake lining

Brake

block

Set

screws

a

Brake

lever

Lock

nut

Driving pulley

(stop cam spring housing)

Regulating

Hinge

stud

screw

b

36)

(0 0)

K

(

i

•

Stop

Hinge

Stop

-

Brake

Brake

motion lever

stud

link

lever

block

OJ

Brake lining

Fig. 37 Adjusting the

brake

lever

Make particularly sure that the stop link snaps into the groove of the stop