Page 1

3307-3/..

Industrial

®

3307-9/..

INSTRUCTION MANUAL

This instruction manual applies to machines from the

following serial numbers 2 752 431 and software

version 0366/001 onwards:

296-12-19 035/002

Betriebsanleitung engl. 06.09

Page 2

This Instruction Manual is valid for all models and subclasses listed in the

chapter "Specifications ".

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 7

1.01 Regulations ............................................................................................................................7

1.02 General notes on safety .........................................................................................................7

1.03 Safety symbols ......................................................................................................................8

1.04 Important notes for the user .................................................................................................. 8

1.05 Notes for operating and technical staff ..................................................................................9

1.05.01 Operating staff .......................................................................................................................9

1.05.02 Technical staff ........................................................................................................................9

1.06 Danger warnings .................................................................................................................. 10

2 Proper use .......................................................................................................................... 11

3 Specifi cations ..................................................................................................................... 12

3.01 General information ............................................................................................................ 12

3.02 Seam pattern sizes .............................................................................................................. 13

4 Disposal of Machine .......................................................................................................... 14

5 Transportation, packing and storage ................................................................................ 15

5.01 Transportation to customer‘s premises ............................................................................... 15

5.02 Transportation inside the customer‘s premises ................................................................... 15

5.03 Disposal of packing materials ..............................................................................................15

5.04 Storage ................................................................................................................................ 15

6 Explanation of symbols ..................................................................................................... 16

7 Controls .............................................................................................................................. 17

7.01 Main switch ......................................................................................................................... 17

7.02 Pedal .................................................................................................................................... 17

7.03 Balance wheel ..................................................................................................................... 18

7.04 Special operating elements of the PFAFF 3307-3/.. ............................................................. 18

7.04.01 Adjusting the button clamp .................................................................................................. 18

7.04.02 Lock lever of the blind stitching guide .................................................................................. 19

7.04.03 Setting the stem lengths ..................................................................................................... 19

7.04.04 Setting the penetration depth .............................................................................................. 20

7.04.05 Missed stitch detection key .................................................................................................20

7.05 Special operating elements of the PFAFF 3307-9/01 ........................................................... 21

7.05.01 Setting the stem length ....................................................................................................... 21

7.06 Control panel ........................................................................................................................21

7.06.01 Screen displays ....................................................................................................................22

7.06.02 Display symbols ...................................................................................................................22

7.06.03 Function keys .......................................................................................................................22

8 Mounting and commissioning the machine .................................................................... 25

8.01 Installation ............................................................................................................................25

Page 4

Index

Contents ..................................................................................Page

8.01.01 Adjusting the table height .................................................................................................... 25

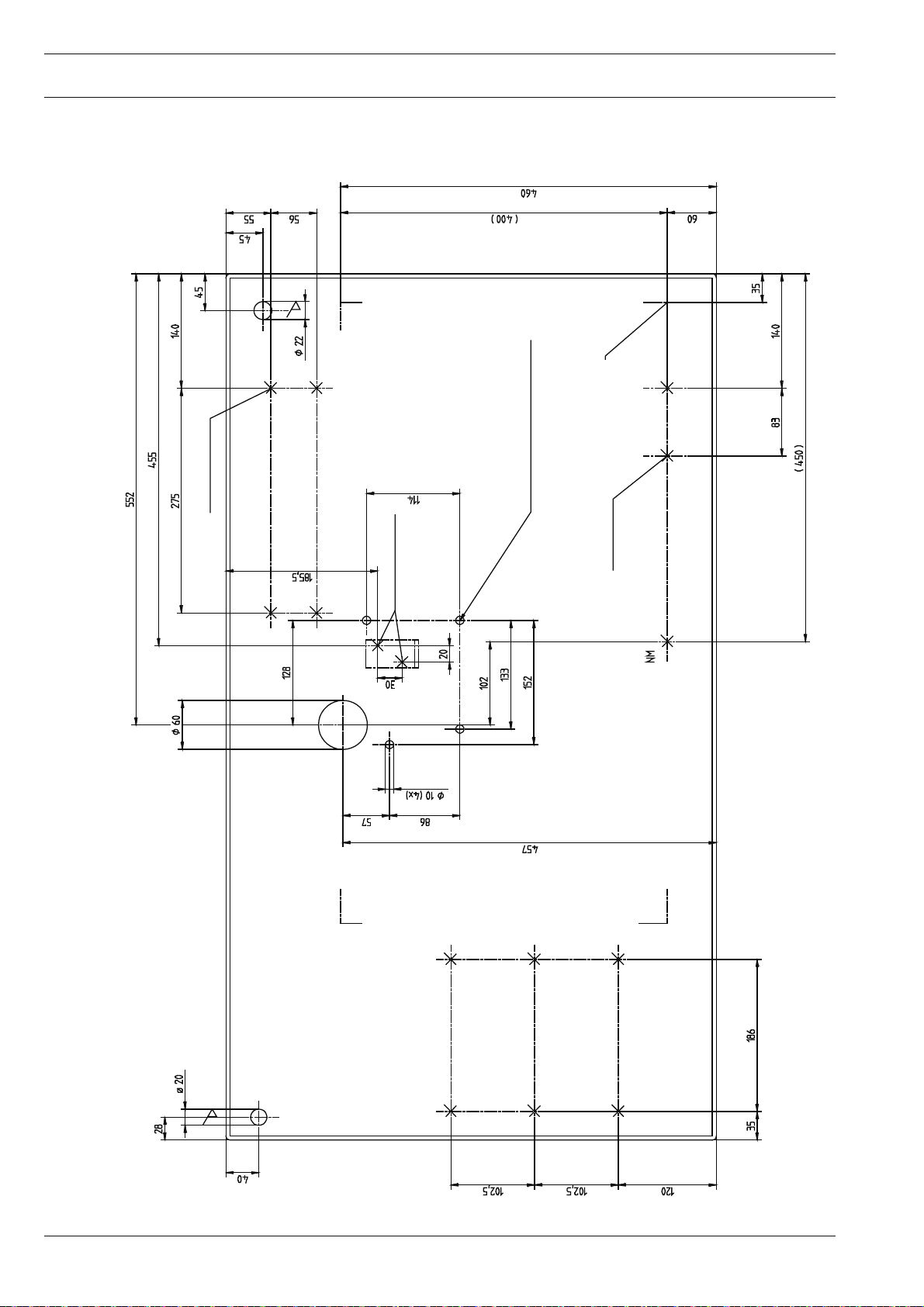

8.01.02 Drilling template for the table-top ........................................................................................ 26

8.01.03 Connecting the plug-in connections and earth cable ........................................................... 27

8.01.04 Fitting the reel stand ............................................................................................................ 28

8.02 Commissioning .................................................................................................................... 28

8.03 Switching the machine on / off ............................................................................................ 28

8.04 Setting the seam pattern size ..............................................................................................29

8.04.01 Establishing the value for parameter "204" .......................................................................... 29

8.04.02 Altering parameter "204" ......................................................................................................30

9 Setting up ...........................................................................................................................31

9.01 Inserting the needle ............................................................................................................. 31

9.02 Threading the sewing thread ............................................................................................... 32

9.03 Special setting-up work on the PFAFF 3307-3/.. ..................................................................33

9.03.01 Selecting the button type and program number ................................................................. 33

9.03.02 Adjusting the button clamp to the button size .....................................................................34

9.03.03 Selecting the stem length ................................................................................................34

9.03.04 Setting the stem length for the short stem .........................................................................35

9.03.05 Setting the stem length for the long stem ........................................................................... 35

9.03.06 Selecting/setting the "sew-through button attachment" function .........................................36

9.03.07 Selecting/setting the "blind sewing" function .......................................................................36

9.03.08 Selecting/setting the "blind sewing through the facing" function ......................................... 37

9.03.09 Allocating the stem length to the seam version .................................................................. 38

9.03.10 Loading plate for loading stay button ...................................................................................38

9.04 Special setting-up work on the PFAFF 3307-9/.. ..................................................................39

9.04.01 Setting the stem length ....................................................................................................... 39

9.05 Inserting and removing the SD-memory card ...................................................................... 39

9.06 Activating the sequence mode ............................................................................................ 40

10 Sewing ................................................................................................................................ 42

10.01 Sewing with the PFAFF 3307-3/.. .. .....................................................................................43

10.02 Sewing with the PFAFF 3307-9/.. .. .....................................................................................45

10.03 Error messages ....................................................................................................................46

11 Input .................................................................................................................................... 47

11 .01 Seam pattern input on machines from subclass -3/.. .. .......................................................47

11 .01.01 Seam pattern input for two-hole and self-shank buttons ..................................................... 47

11 .01.02 Seam pattern input for three-hole buttons ........................................................................... 48

11 .01.03 Seam pattern input for four-hole buttons .............................................................................49

11 .01.04 Seam pattern input for six-hole buttons ............................................................................... 50

11 .02 Seam pattern input on sub-class -9/.. machines ..................................................................53

11 .03 Sequence input ....................................................................................................................54

11 .04 Program Management .......................................................................................................55

11 .04.01 Calling up the program management ..................................................................................56

11 .04.02 Displaying programs in the machine memory ..................................................................... 57

Page 5

Index

Contents ..................................................................................Page

11 .04.03 Displaying programs on the SD-memory card ..................................................................... 58

11 .04.04 Copying programs to the SD-memory card ......................................................................... 59

11 .04.05 Copying programs to the machine memory ....................................................................... 60

11 .04.06 Deleting programs in the machine memory ........................................................................ 61

11 .04.07 Deleting programs on the SD-memory card ........................................................................ 62

11 .04.08 Formatting the SD-memory card ......................................................................................... 63

12 Care and maintenance ....................................................................................................... 64

12.01 Maintenance intervals ..........................................................................................................64

12.02 Cleaning the machine .......................................................................................................... 64

12.03 Cleaning the hook compartment .........................................................................................65

12.04 Cleaning the air fi lter/lubricator ............................................................................................65

12.05 Checking/adjusting the air pressure ..................................................................................... 66

12.06 Top up the oil for needle drive ..............................................................................................66

12.07 Topping up oil for the gears ..................................................................................................67

12.08 Lubricating the gear shaft .................................................................................................... 67

13 Adjustment ......................................................................................................................... 68

13.01 Notes on adjustment ........................................................................................................... 68

13.02 Tools, gauges and other accessories ..................................................................................68

13.03 Abbreviations ....................................................................................................................... 68

13.04 Toothed belts of the main drive ...........................................................................................69

13.05 Top needle bar position (reference position) ........................................................................ 70

13.06 Pre-adjusting the needle height ........................................................................................... 71

13.07 Position of the needle to the needle hole ............................................................................ 72

13.08 Basic position „button clamp raised“ ..................................................................................73

13.09 Sensor board of the needle drive (in dismantled condition) ................................................. 74

13.10 Basic setting of the needle drive .......................................................................................... 76

13.11 Position of the hook shaft to the needle ..............................................................................77

13.12 Adjusting the drag link mechanism ......................................................................................78

13.13 Needle rise and hook clearance ........................................................................................... 79

13.14 Readjusting the needle height ............................................................................................. 81

13.15 Adjusting the loop spreader ................................................................................................. 82

13.16 Position of the loop spreader to the needle ......................................................................... 83

13.17 Adjusting the thread trimmer on the PFAFF 3307-3/.. .........................................................84

13.18 Manual cutting test (only on the PFAFF 3307-3/..) ............................................................... 85

13.19 Adjusting the thread catcher (only on the PFAFF 3307-3/..) ................................................. 86

13.20 Adjusting the thread loop support on the PFAFF 3307-3/.. ..................................................87

13.21 Adjusting the spreader (only on the PFAFF 3307-9/..) .......................................................... 88

13.22 Adjusting the thread loop support on the PFAFF 3307-9/.. ..................................................89

13.23 Aligning the button holder (only on the PFAFF 3307-9/..) .....................................................90

13.24 Basic position of the button holder (only on the PFAFF 3307-9/..) ....................................... 91

13.25 Adjusting the thread trimmer on the PFAFF 3307-9/.. .........................................................92

13.26 Basic position of the button clamp drive on the PFAFF 3307-3/.. ........................................93

13.27 Basic position of the button clamp drive on the PFAFF 3307-9/.. ........................................94

Page 6

Index

Contents ..................................................................................Page

13.28 Aligning the button clamp (only on the PFAFF 3307-3/01) ................................................... 95

13.29 Adjusting the clamp pressure (only on the PFAFF 3307-3/..) ...............................................96

13.30 Basic setting of the end knotting equipment .......................................................................97

13.31 Adjusting the retaining fi nger of the end knotting equipment .............................................98

13.32 Adjusting the lifting lever of the end knotting equipment .................................................... 99

13.33 Adjusting the reed switch ..................................................................................................100

13.34 Setting the angle for the end knotting ...............................................................................101

13.35 Adjusting the moment tension .......................................................................................... 102

13.36 Adjusting the thread puller ................................................................................................. 103

13.37 Adjusting the thread clamp ................................................................................................ 104

13.38 Adjusting the thread regulator ........................................................................................... 105

13.39 Adjusting the thread wiper ................................................................................................ 106

13.40 Adjusting the thread air jet ................................................................................................. 107

13.41 Aligning the holder of the blind stitching guide (only on the PFAFF 3307-3/01) ................. 108

13.42 Basic position of the blind stitching guide (only on the PFAFF 3307-3/01) ......................... 109

13.43 Adjusting the height of the mounting plate (only on the PFAFF 3307-3/01) ........................110

13.44 Basic position of the stay button plate (only on the PFAFF 3307-3/01) ...............................111

13.45 Adjusting the insert plate (only on the PFAFF 3307-3/01) ...................................................112

13.46 Adjusting the reed switch for the insert plate (only on the PFAFF 3307-3/01) ....................113

13.47 Insert plate pressure (only on the PFAFF 3307-3/01) ..........................................................114

13.48 Adjusting the stem fi nger (only on the PFAFF 3307-3/01) ...................................................115

13.49 Detaching/fi tting the blind stitching unit (only on the PFAFF 3307-3/01)

13.50 Parameter settings ..............................................................................................................118

13.50.01 Selecting the function group and altering the parameter ...................................................118

13.50.02 Entering / altering the access code .....................................................................................119

13.41.03 Allocating access rights ..................................................................................................... 120

13.50.04 Parameter list ..................................................................................................................... 121

13.51 Description of the error messages .................................................................................... 128

13.52 Sewing motor errors .......................................................................................................... 130

13.44 Internet update of the machine software .......................................................................... 131

13.44.01 Update with null modem cable .......................................................................................... 131

13.44.02 Update with SD-card .......................................................................................................... 132

14 Wearing parts ...................................................................................................................134

15 Pneumatics-switch diagram ........................................................................................... 135

16 Circuit diagrams ............................................................................................................... 138

Page 7

Safety

1 Safety

1

.01 Directives

The machine has been constructed in accordance with the requirements listed in the

EC Declaration of Conformity and the Declaration of Incorporation.

In addition to this Instruction Manual, also observe all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations are to be strictly adhered to!

1.02 General notes on safety

● This machine may only be operated by adequately trained operators and only after having

completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read be-

fore operating the machine!

● The danger and safety instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All safety regulations relevant to its operation are to

be adhered to.

● When exchanging sewing tools (e.g. needle, roller presser, needle plate and bobbin),

when threading the machine, when leaving the machine unattended and during maintenance work, the machine is to be separated from the power supply by switching off the

On/Off switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualifi ed service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

The only exceptions to this rule are found in the regulations EN 50110.

● Modifi cations and alterations to the machine may only be carried out under observance

of all the relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We express-

ly point out that any replacement parts or accessories which are not supplied by us have

not been tested and approved by us. The installation and/or use of any such products can

lead to negative changes in the structural characteristics of the machine. We are not liable

for any damage which may be caused by non-original parts.

7

Page 8

Safety

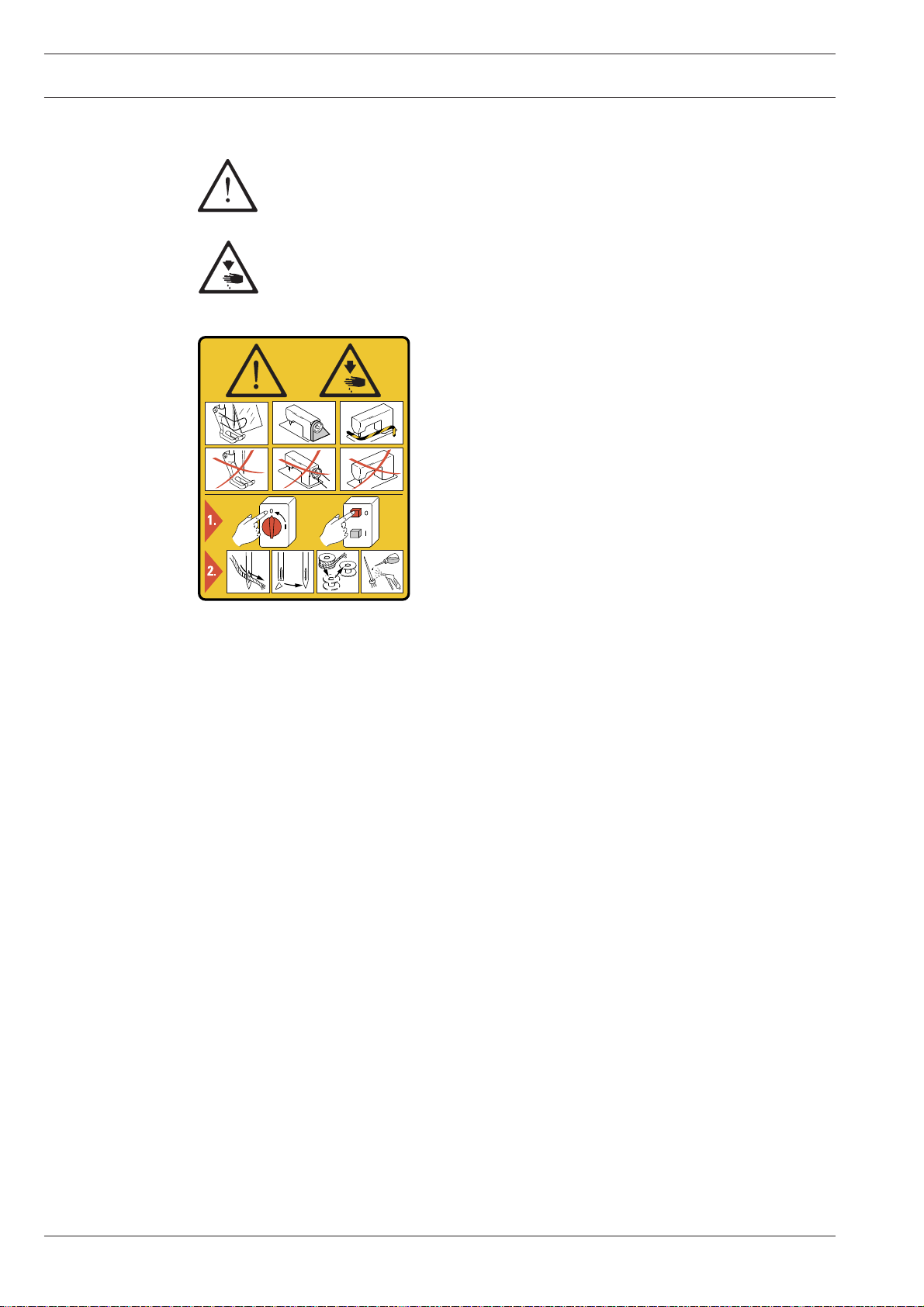

1.03 Safety symbols

Danger!

Special points to observe.

Danger of injury to operating or technical staff!

Caution

Do not operate without fi nger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

1.04 Important notes for the user

This instruction manual belongs to the equipment of the machine and must be available

●

to the operating staff at all times.

●

This instruction manual must be read before the machine is operated for the fi rst time.

●

Both operating and technical staff must be instructed on the safety devices of the machine and on safe working methods.

●

It is the duty of the user to operate the machine in perfect running order only.

The user must ensure that none of the safety devices are removed nor put out of work-

●

ing order.

The user must ensure that only authorized persons operate and work on the machine.

●

For further information please refer to your PFAFF agency..

8

Page 9

Safety

1.05 Notes for operating and technical staff

1

.05.01 Operating staff

Operating staff are the persons responsible for setting up, operating and cleaning the machine and for eliminating any malfunctioning in the sewing area.

The operating staff is obliged to observe the following points:

The notes on safety in this instruction manual must always be observed!

●

Any working methods, which adversely affect the safety of the machine, must be avoi-

●

ded.!

Loose-fi tting clothing should be avoided. No jewellery, such as chains and rings, should

●

be worn!

●

Ensure that only authorised persons enter the danger area of the machine!

●

Any changes occurring on the machine, which may affect its safety, must be reported to

the user immediately.

1.05.02 Technical staff

Technical staff are persons who have been trained in electrical engineering/electronics and

mechanical engineering. They are responsible for lubricating, servicing, repairing and adjusting the machine.

The technical staff is obliged to observe the following points:

The notes on safety in this instruction manual must always be observed!

●

Before carrying out any adjustment or repair work the main switch must be switched off

●

and measures taken to prevent it from being switched on again!

●

Never work on parts or equipment still connected to the power supply! Exceptions are

only permissible in accordance with the regulations EN 50110.

●

All safety covers must be replaced after the completion of maintenance or repair work!

9

Page 10

Safety

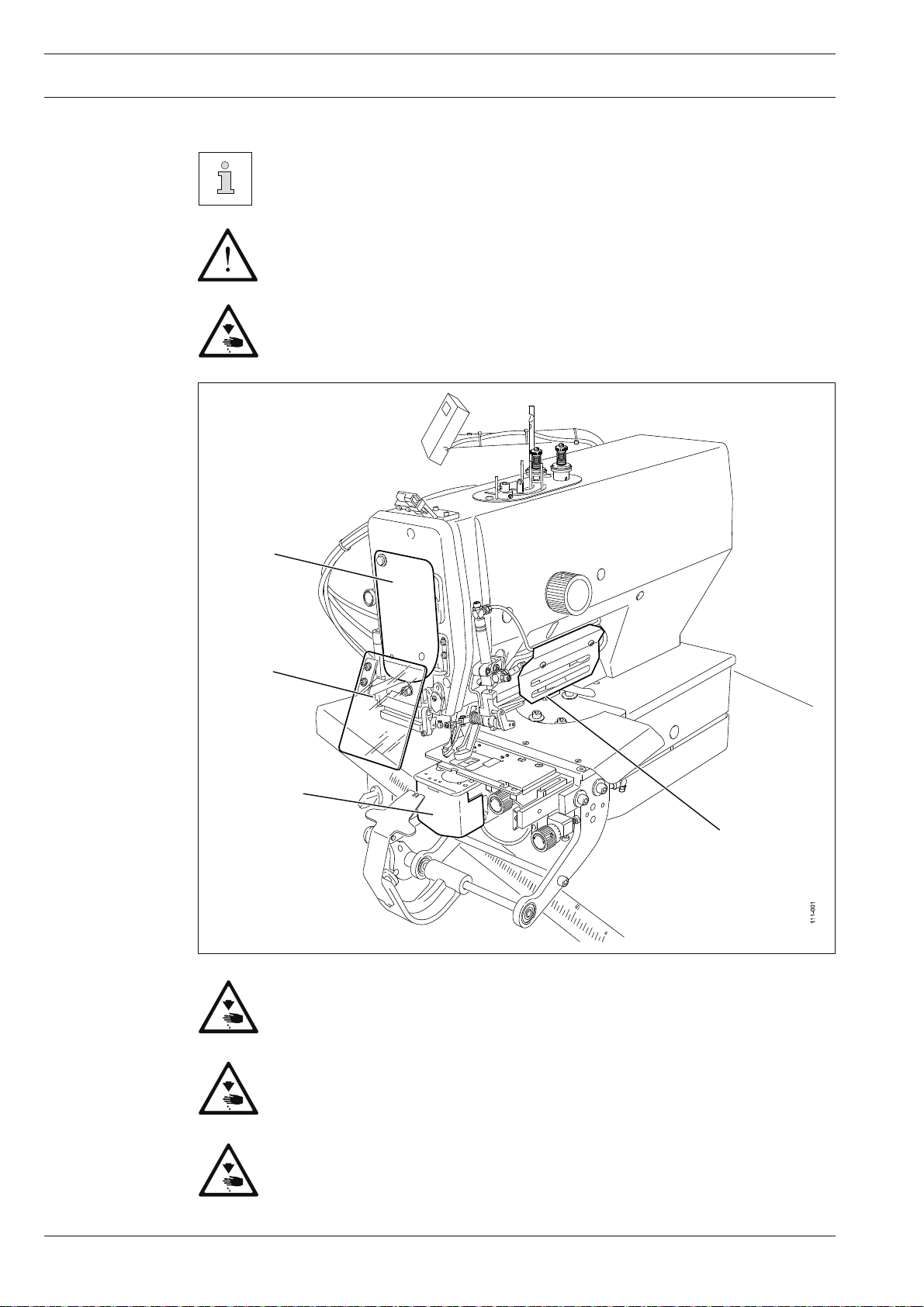

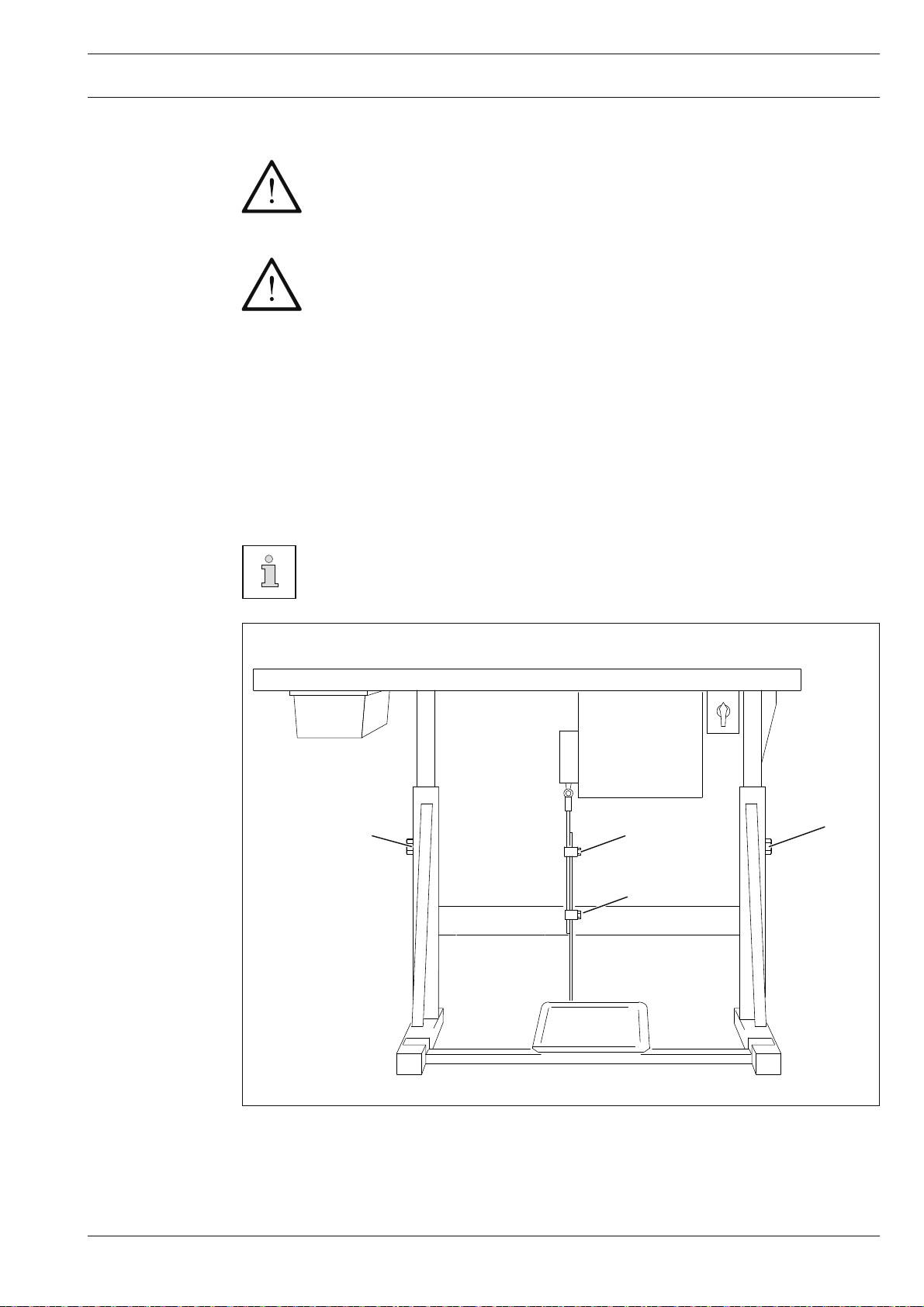

1.06 Danger warnings

Fig. 1-01 shows the PFAFF 3307-3/01, which has the same safety appliances

as the PFAFF 3307-9/02.

A working area of 1 m must be kept free both in front of and behind the

mach-ine, so that easy access is possible at all times.

Never put your hands in the sewing area during sewing!

Danger of injury by the needle!

Fig. 1 - 01

1

3

2

4

Only operate the machine with covers 1 and 2 closed!

10

Danger of injury from the movement of the take-up lever and the hook!

Do not operate the machine without eye shield 3!

Danger of injury from fl ying needle or button fragments!

Do not operate the machine without protective cover 4 (only on the

PFAFF 3307-3/01)! Danger of injury from clamp drive!

Page 11

2 Proper use

The PFAFF 3307-3/01 is used for the automatic attachment of buttons in the clothing

industry.

The PFAFF 3307-9/01 is used to wrap button stems in the clothing industry.

Proper use

Any use of these machines which is not approved by the manufacturer shall be

considered as improper use! The manufacturer shall not be liable for any damage arising out of improper use! Proper use shall also be considered to include

compliance with the operation, adjustment, service and repair measures specifi ed by the manufacturer!

11

Page 12

Specifi cations

3 Specifi cations

▲

3.01 General information

Max. sewing speed:

PFAFF 3307-3/01 ...................................................................................................... 2000 min

PFAFF 3307-9/02 ...................................................................................................... 1600 min

Stitch type: ........................................................................................................................... 107

Needle bar stroke: ..........................................................................................................46 mm

Max. thickness of workpiece: ...........................................................................................4 mm

Max. work clamp clearance: ...........................................................................................17 mm

Fabric clearance (crosswise to sewing arm): ................................................................235 mm

Fabric clearance (lengthwise to sewing arm): .................................................................30 mm

Max. size of sewing area: ........................................................................................8 x 12 mm

Number of stitches: ..................................................................................freely programmable

Feed type: ............................................................................................................... intermittent

Power supply: ...................................................................................... 230 V ±10%, 50 / 60 Hz

Power consumption: ............................................................................................. max. 1,3 kVA

Fuse protection: ................................................................................................... 1 x 16 A, inert

-1

-1

◆

Working air pressure: ......................................................................................................... 6 bar

Air consumption: ...........................................................................................~1,2 l / work cycle

Noise data:

Noise emission level at workplace with a sewing speed of 1800 spm

Sewing cycle 2.5 sec. on and 2.5 sec. Off: ..................................................... LpA = 68,5 dB(A)■

(Noise measurement in accordance with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO

4871)

Sewing head dimensions:

Length: ............................................................................................................. approx. 514 mm

Width: .............................................................................................................. approx. 200 mm

Height: .............................................................................................................approx. 450 mm

Weight of sewing head: ........................................................................................approx. 65 kg

Needle system:

PFAFF 3307-3/01 .................................................................................................................. 190

PFAFF 3307-9/02 ................................................................................................. 332 LG HK SP

Needle size for fi ne materials: ...................................................................................... 70 - 100

Needle size for medium-weight materials: ................................................................. 100 - 120

12

▲

Subject to alterations

◆

Depending on cut-out size of bed plate

■

KpA = 2,5 dB

Page 13

Specifi cations

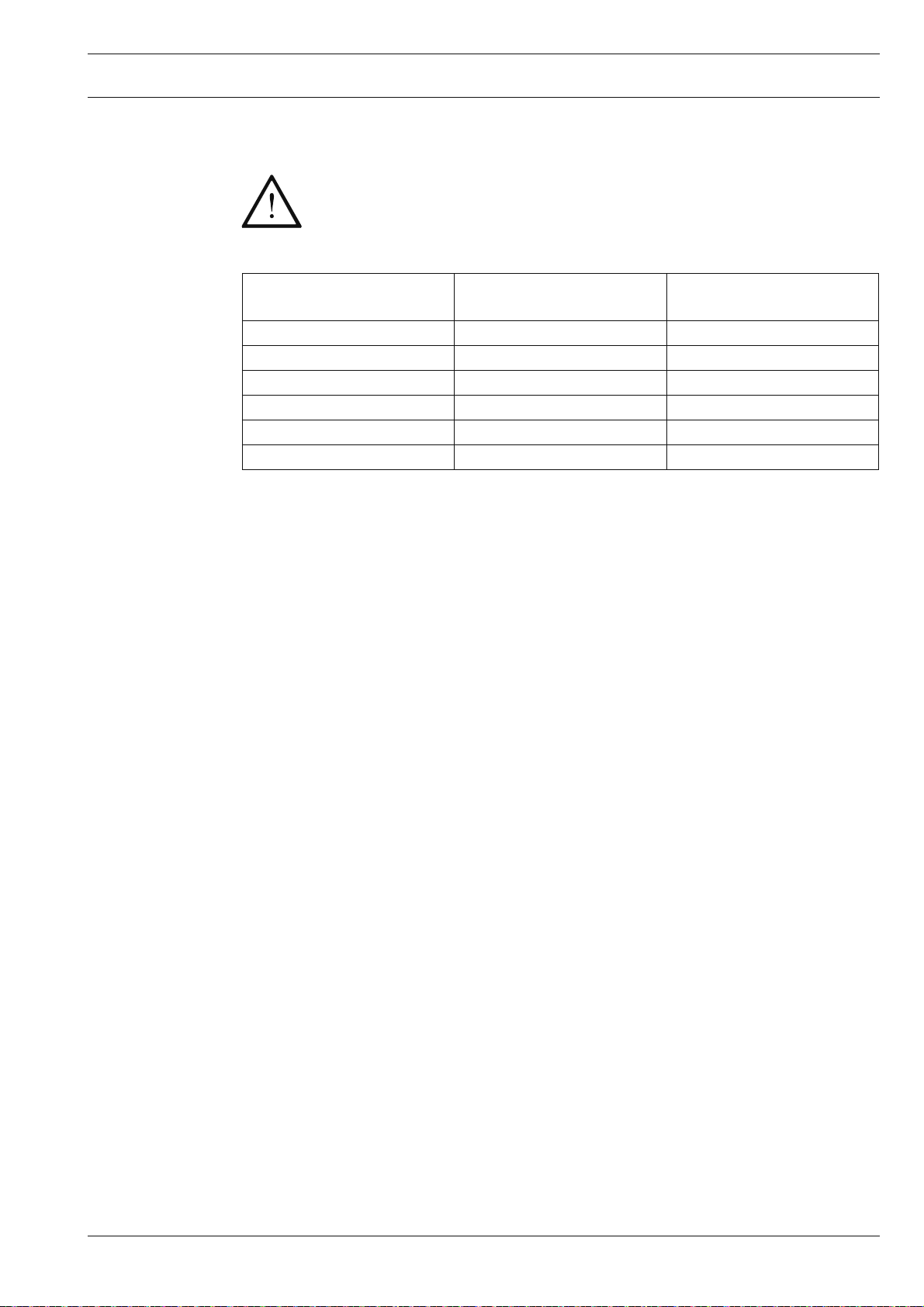

3.02 Seam pattern sizes

When changing part sets parameter "204" must be adapted to the cut-out

size of the bed plate, see Chapter 8.04 Setting the seam pattern size.

If this instruction is not observed there is a risk of severe damage to the

machine!

Value for

parameter "204"

1 7 mm x 7 mm 5 mm x 5 mm

2 8 mm x 8 mm 6 mm x 6 mm

3 9 mm x 9 mm 7 mm x 7 mm

4 10 mm x 10 mm 8 mm x 8 mm

5 11 mm x 11 mm 8 mm x 9 mm

6 10 mm x 14 mm 8 mm x 12 mm

Cut-out size of the

bed plate

Size of seam pattern

13

Page 14

Disposal of Machine

4 Disposal of Machine

Proper disposal of the machine is the responsibility of the customer.

●

The materials used for the machine are steel, aluminium, brass and various plastic

●

materials. The electrical equipment comprises plastic materials and copper.

●

The machine is to be disposed of according to the locally valid pollution control regula-tions; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

14

Page 15

Transportation, packing and storage

5 Transportation, packing and storage

5

.01 Transportation to customer‘s premises

The machines are delivered completely packed.

5.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fi bre. Proper disposal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a fi lm of oil.

15

Page 16

Explanation of symbols

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

16

Page 17

Controls

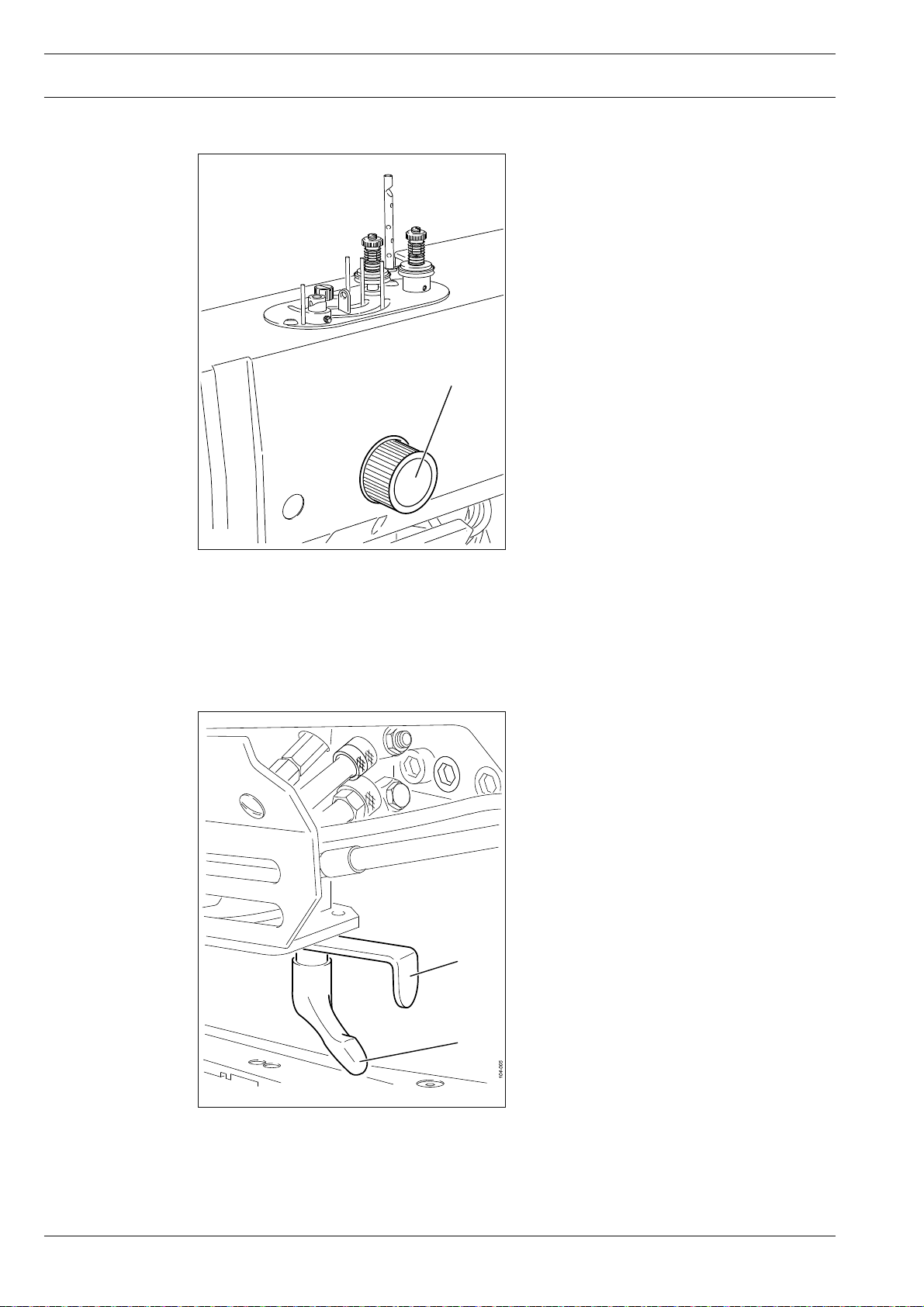

56-067

7 Controls

7

.01 Main switch

The machine is switched on or off by tur-

●

ning the main switch 1.

Fig. 7 - 01

7.02 Pedal

1

0

-1 = change stem height

(only on sub-class -3/01)

Fig. 7 - 02

0 = Neutral position

0

+1

+1 = Lower button clamp

+2 = Sewing

+2

-1

17

Page 18

Controls

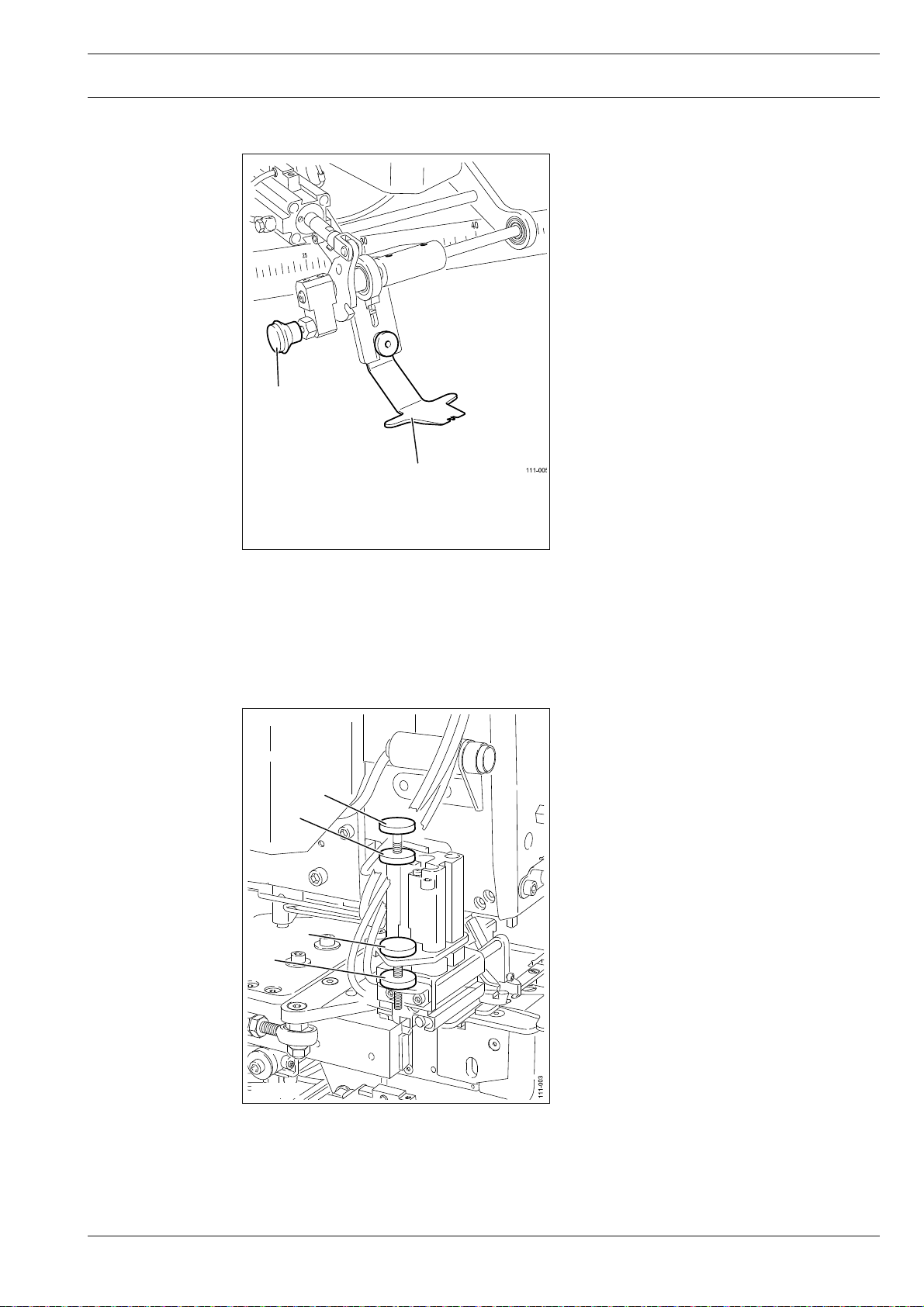

7.03 Balance wheel

By pressing and holding down balance

●

wheel 1, it is possible to adjust the needle bar manually.

1

111-002

Fig. 7 - 03

7.04 Special operating elements of the PFAFF 3307-3/..

7

.04.01 Adjusting the button clamp

After loosening T-screw 1, with sliding

●

bar 2 the button clamp is adjusted to

match the button size, see Chapter

9.03.02 Adjusting the button clamp to

the button size..

2

18

1

Fig. 7 - 04

Page 19

Controls

7.04.02 Lock lever of the blind stitching guide

Lock lever 1 is used to retract the blind

●

stitching guide 2 when sewing without it.

Blind stitching guide 2 is retracted and locked.

1

2

Fig. 7 - 05

7.04.03 Setting the stem lengths

2

1

4

3

fter loosening locknut 1, the stem

●

height for the long stem is set by turning

screw 2.

After loosening locknut 3, the stem

●

height for the short stem is set by turning screw 4.

Fig. 7 - 06

19

Page 20

Controls

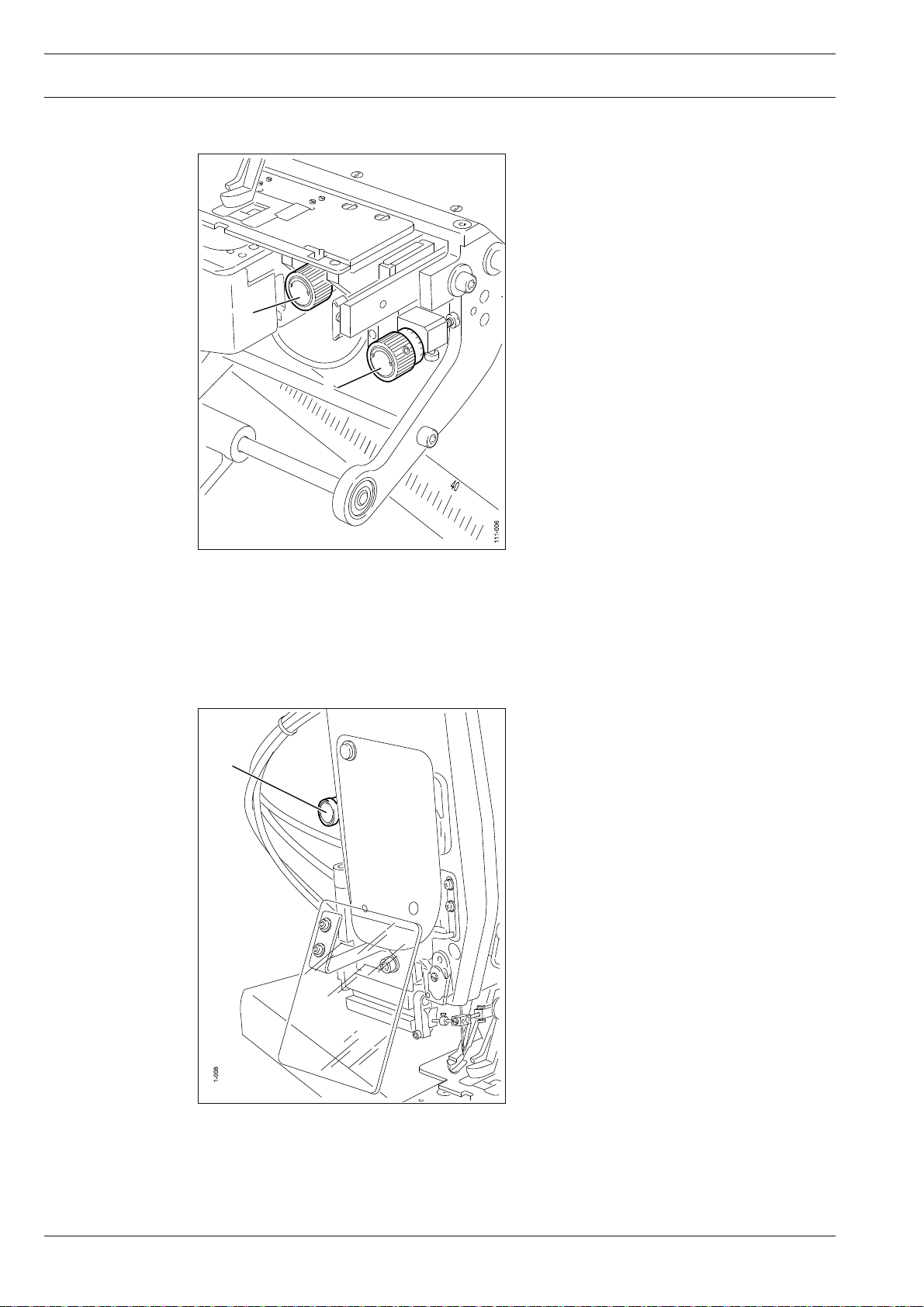

7.04.04 Setting the penetration depth

To set the penetration depth (visible

●

seam), turn adjustment wheel 1.

To set the penetration depth for blind stit-

●

ching, turn adjustment wheel 2.

1

2

Fig. 7 - 07

7.04.05 Missed stitch detection key

1

●

Key 1 lights up, when an error is detec-

ted in the sewing process.

Acknowledge the error signal by pressing

●

key 1.

By pressing key 1 in addition the thread

●

can be tightened as required

20

Fig. 7 - 08

Page 21

Controls

7.05 Special operating elements of the PFAFF 3307-9/01

7

.05.01 Setting the stem length

After loosening screw 1, the appropriate

●

stem length is set by turning screw 2.

1

If the stem length setting is altered, the seam pattern input

2

must be checked.

Fig. 7 - 09

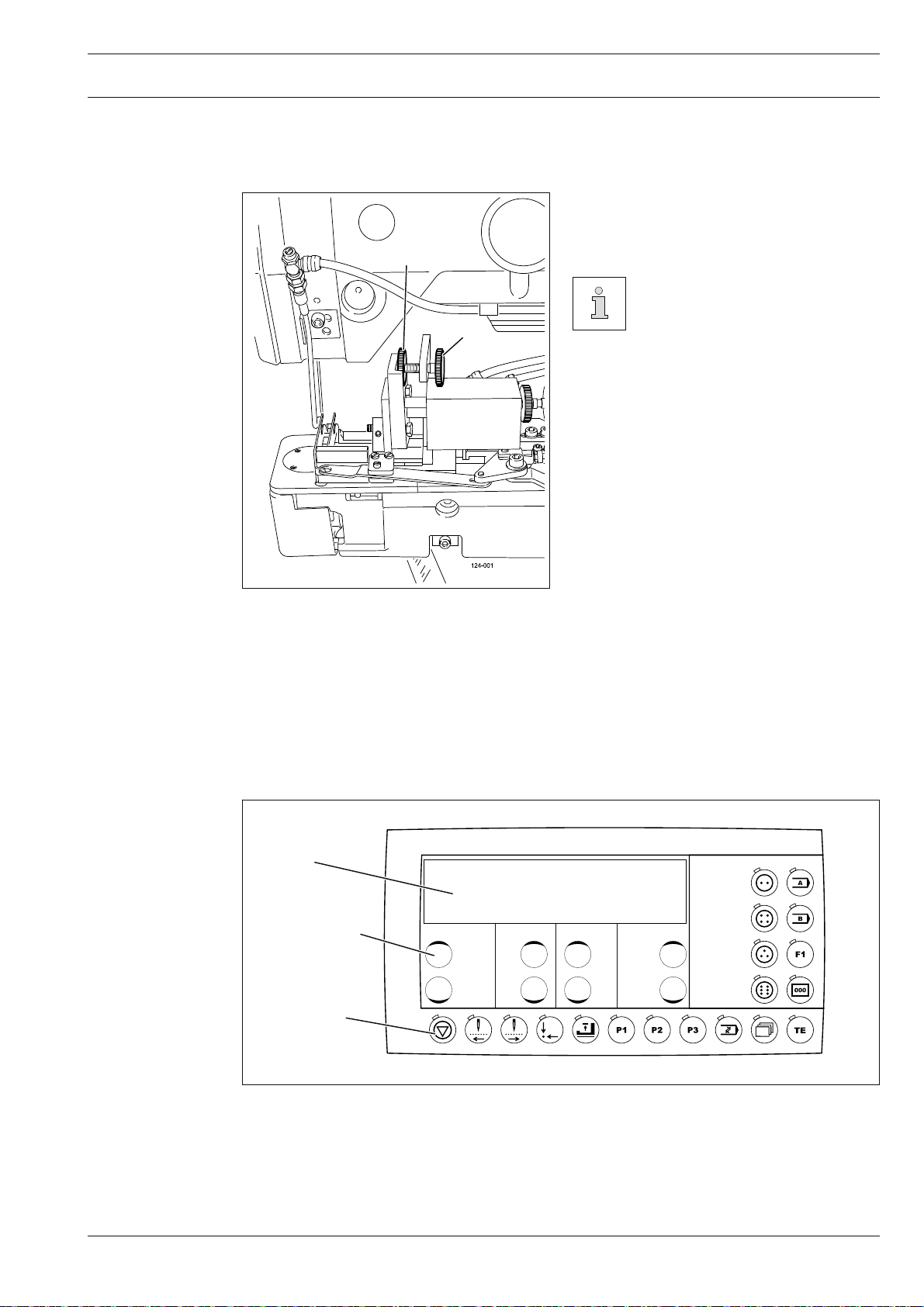

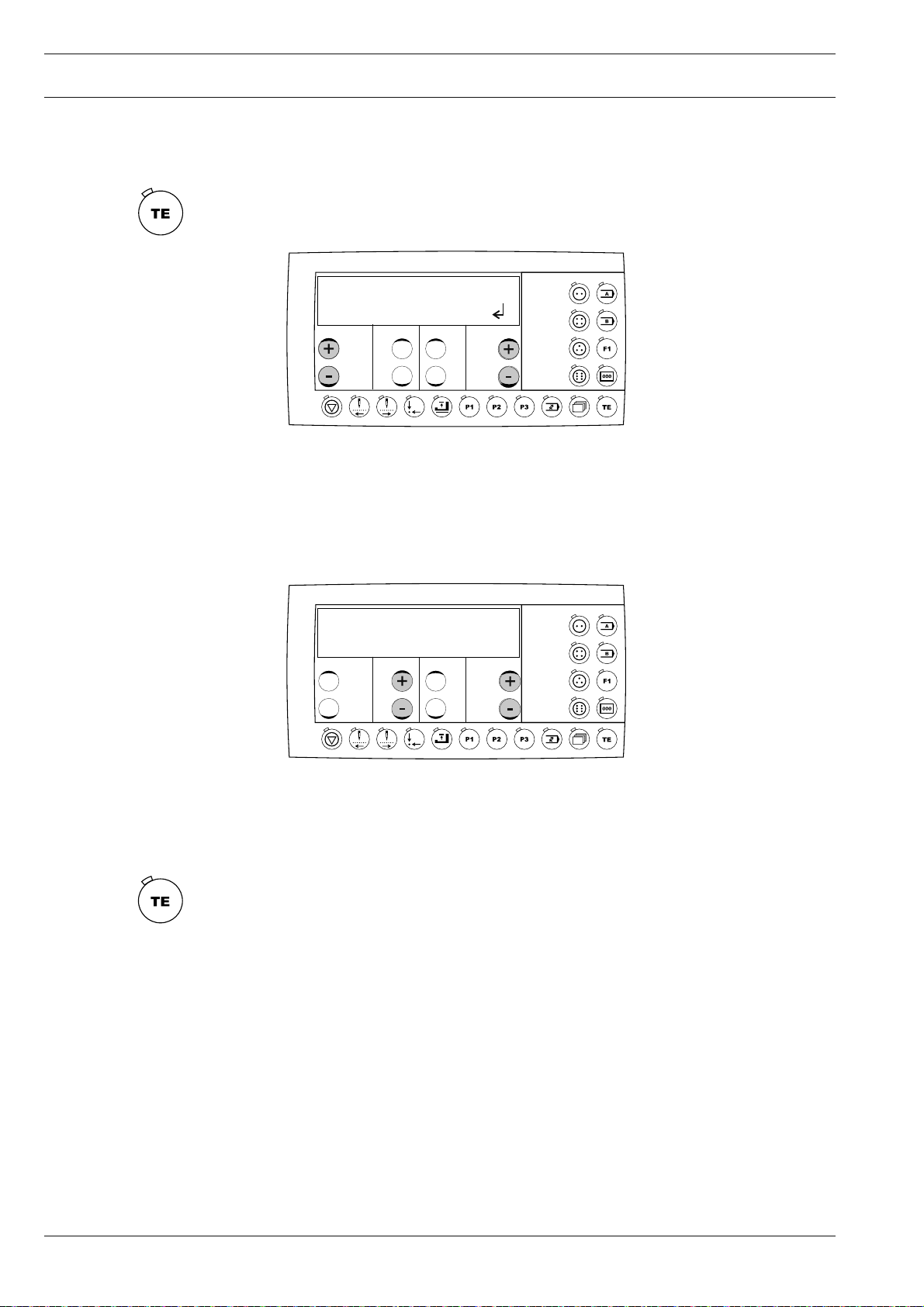

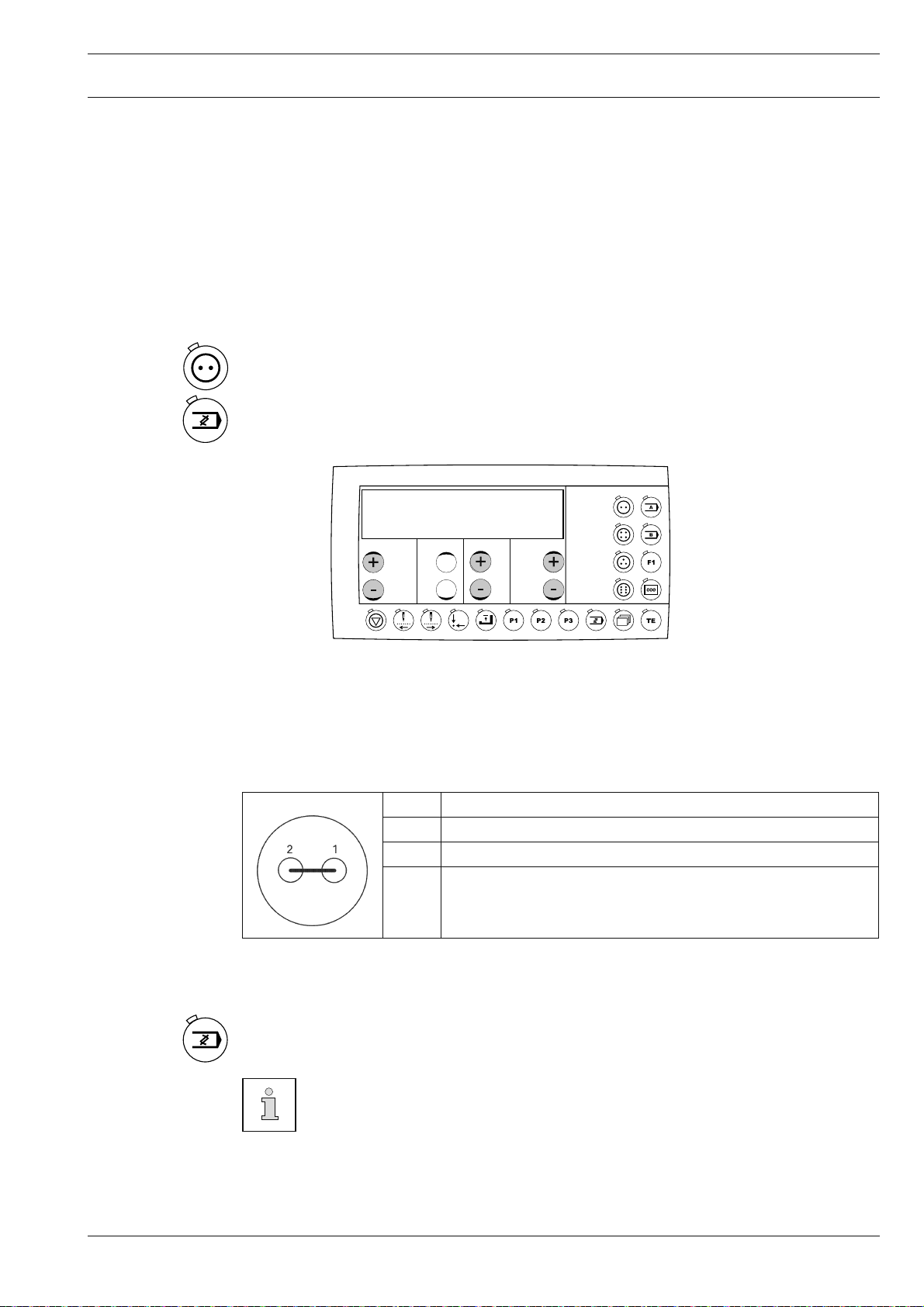

7.06 Control panel

The control panel is used to call up machine functions for setting up the machine and for

sewing operation, for entering parameter values and for reading error messages and service

settings.

1

3

2

Fig. 7 - 10

The control panel consists of the display 1 and the function keys described below. The display 1 consists of a two-line alphanumerical LCD display with 16 symbols per line. The function keys 2 are located below and to the right of the display. The status of the function keys 2

and the operating status of the machine are shown by LEDs in the respective keys.

21

Page 22

Controls

7.06.01 Screen displays

7.06.02 Display symbols

Every time the function keys 2 are operated, a key tone sounds as confi rmation of the

input. If the input required is invalid, e.g. because the max. permissible value for the

parameter input has been reached, a double tone is audible. An SD-card reader for data

transfer is integrated.

●

In the sewing mode all relevant sewing data is displayed and can be changed directly, depending on the status of the machine, see also Chapter 10 Sewing.

●

During the parameter input the selected parameter number with the corresponding value

is displayed, see Chapter 13.50 Parameter settings.

Speed Stem length

Piece counter SD-memory-card

Program number Machine memory

"Enter" function"

7.06.03 Function keys

The functions keys described below are used essentially to switch machine functions on and

off. When the function is switched on, the diode in the key is illuminated.

If a corresponding value has to be fi xed for the activated function, this can be carried out

with the corresponding +/- keys 3.

By pressing and holding the corresponding +/- key, fi rstly the numerical value displayed above it is altered slowly. If the +/- key is pressed longer, the numerical value changes more

quickly. The respective +/- keys shown opposite are described below.

Stop

●

When operated during a sewing cycle, the machine is stopped.

●

When entering the code number this key corresponds to the fi gure 1.

22

Tacting forwards

●

This key is used to tact forwards through the entire sewing cycle step by step.

●

When entering the code number this key corresponds to the fi gure 2.

Danger of needle breakage!

Before tacting move the needle to its t.d.c. using the balance wheel.

Page 23

Controls

Tacting in reverse

●

This key is used to tact in reverse through the entire sewing cycle step by step.

●

When entering the code number this key corresponds to the fi gure 3.

Danger of needle breakage!

Before tacting move the needle to its t.d.c. using the balance wheel.

Basic position

●

In the sewing mode the machine moves to the basic position.

●

When entering the code number this key corresponds to the fi gure 4.

Button clamp raised/lowered

●

In the sewing mode the button clamp (or work clamp or button holder) is raised/lowered.

●

When entering the code number this key corresponds to the fi gure 5.

Direct fetch key P1

●

The direct fetch key can be allocated to a button seam pattern or a sequence. The currently selected seam pattern or the currently selected sequence is allocated to the key by

pressing this for approx. 2 sec.

●

When entering the code number this key corresponds to the fi gure 6.

Direct fetch key P2

●

The direct fetch key can be allocated to a button seam pattern or a sequence. The currently selected seam pattern or the currently selected sequence is allocated to the key by

pressing this for approx. 2 sec.

●

When entering the code number this key corresponds to the fi gure 7.

Direct fetch key P3

●

The direct fetch key can be allocated to a button seam pattern or a sequence. The currently selected seam pattern or the currently selected sequence is allocated to the key by

pressing this for approx. 2 sec.

●

When entering the code number this key corresponds to the fi gure 8.

Programming

●

This key is used to enter the seam pattern programming mode for different button types.

●

When entering the code number this key corresponds to the fi gure 9.

Piece counter

●

Press this key to reset the piece counter (LED has no function).

23

Page 24

Controls

Further functions can be selected with the keys described below, which are

each equipped with an LED. When the LED lights up, the corresponding function is activated / switched on.

Button type

●

With these keys the type of button required (two-, four-, three- or six-hole button) can be

selected.

●

On stem-wrapping machines the keys are locked.

Key A

●

This key is reserved for special functions.

●

On stem-wrapping machines the LED lights up (stem-wrapping programs are activated)

●

On blind sewing machines the sew-through with blind sewing function is activated (LED

on) or deactivated (LED off).

Key B

●

This key is reserved for special functions.

●

On blind sewing machines the blind sewing function without sewing through is activated

(LED on) or deactivated (LED off).

Key F1

●

This key is reserved for special functions.

●

On blind sewing machines the blind sewing function with material shift is activated (LED

on) or deactivated (LED off).

TE

●

This key can be used to switch between sewing operation (LED off) and input mode (LED

on). It is also used to acknowledge error messages.

24

Page 25

Mounting and commissioning the machine

8 Mounting and commissioning the machine

The machine must only be mounted and commissioned by qualifi ed personnel!

All relevant safety regulations are to be observed!

If the machine is delivered without a table, be sure that the frame and the table

top which you intend to use can hold the weight of the machine and the motor.

It must be ensured that the supporting structure is suffi ciently sturdy, even during sewing operations.

8.01 Installation

The site where the machine is installed must be provided with suitable connections for the

electric current, see Chapter 3 Specifi cations.

It must also be ensured that the standing surface of the machine site is fi rm and horizontal,

and that suffi cient lighting is provided.

8.01.01 Adjusting the table height

For packing reasons the table top is in the lowered position. The table height is

adjusted as described below..

1

2

1

2

56-058

Fig. 8 - 01

●

Loosen screws 1 and 2 and set the table height as required.

●

Firmly tighten screw 1.

●

Set the required pedal position and tighten screws 2.

25

Page 26

Mounting and commissioning the machine

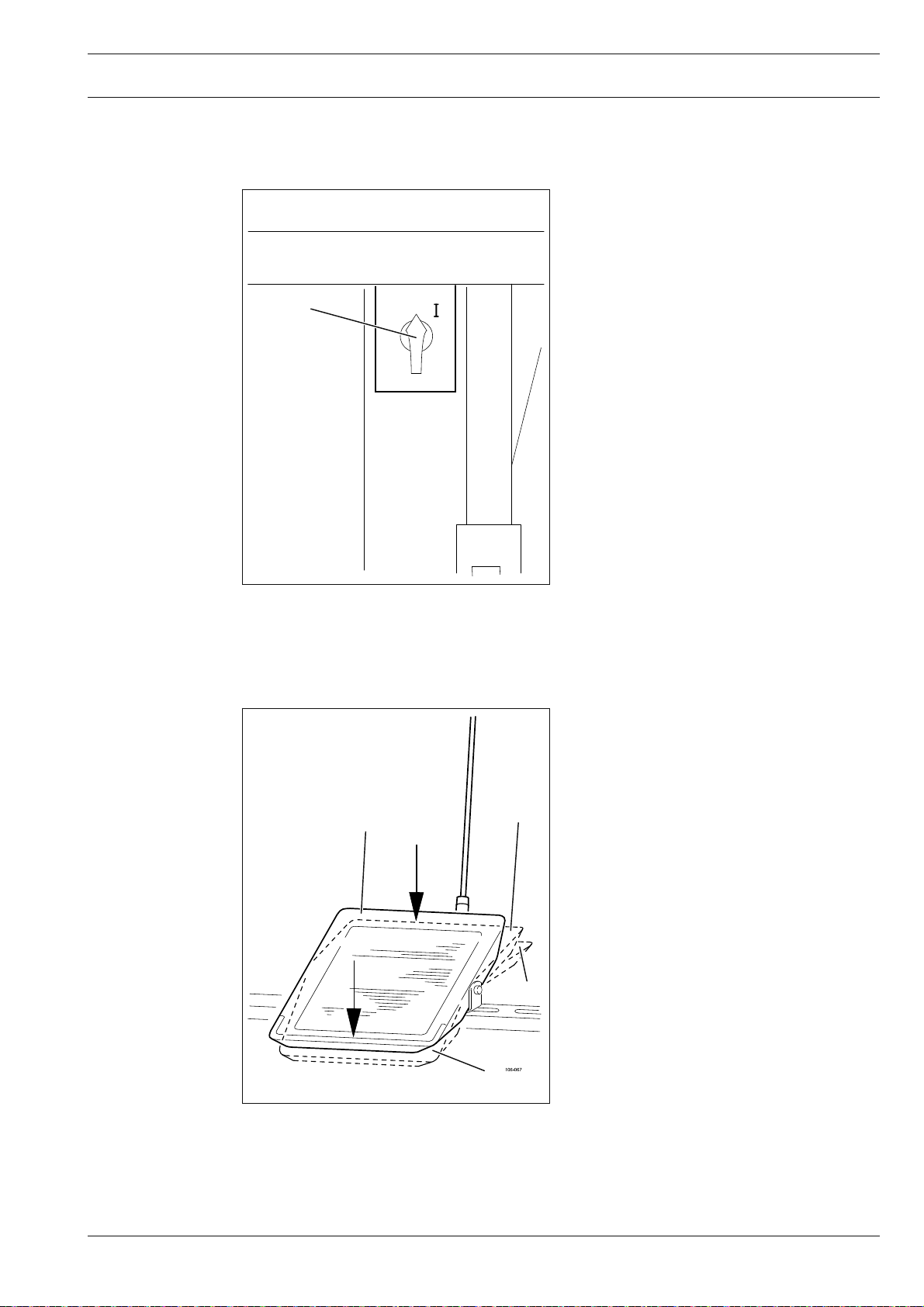

8.01.02 Drilling template for the table-top

mounting

Hole for cradle

Controlbox

unit

Speedcontrol

906-3750-000

Stand position

0 / I

26

Page 27

Mounting and commissioning the machine

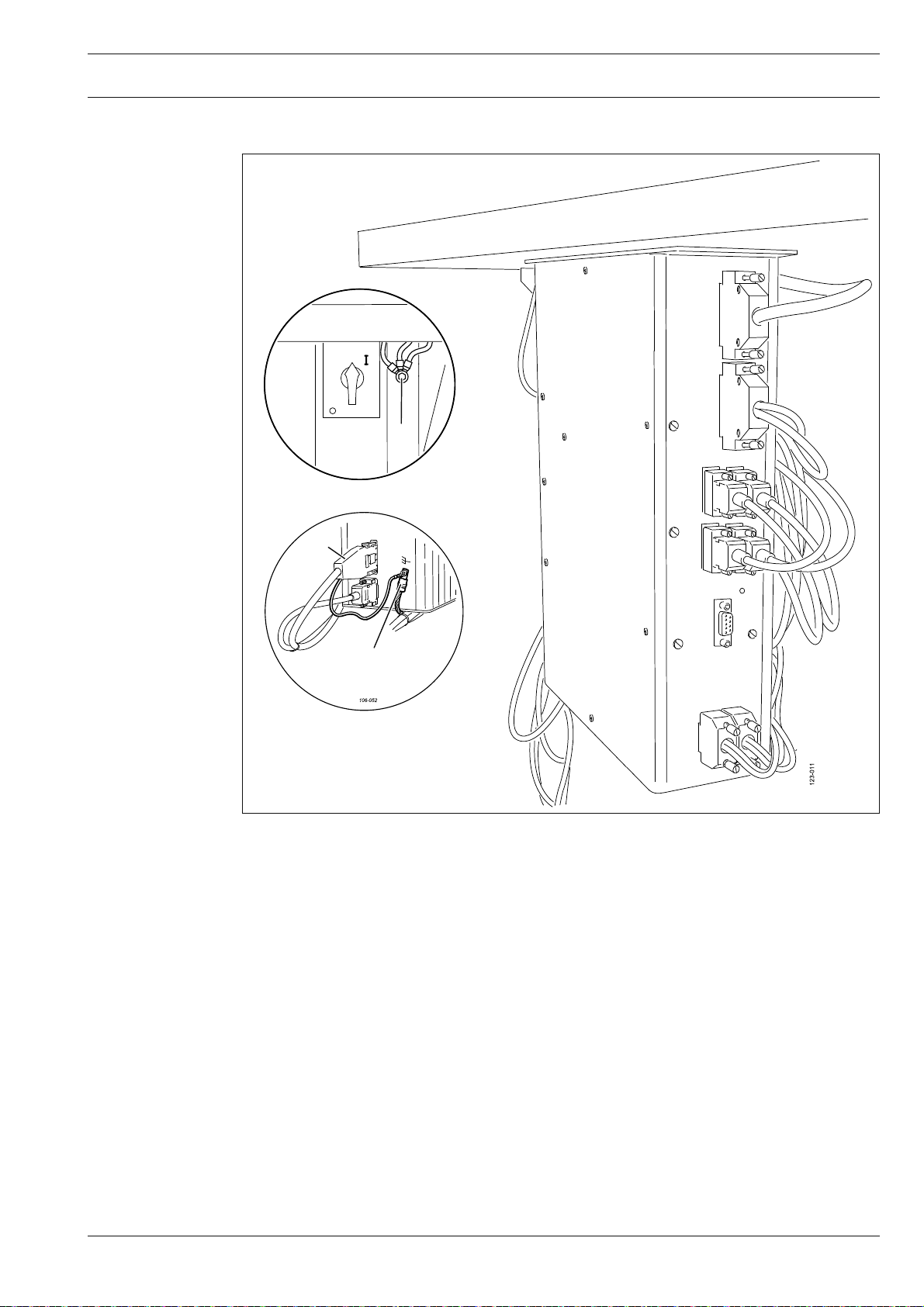

8.01.03 Connecting the plug-in connections and earth cable

106-051

A

1

B

Fig. 8 - 03

●

Connect all plugs as labelled in the control box.

●

Screw the earth cable from the machine and from the main switch to earth point A.

●

Connect earth points A and B with an earth cable.

●

Screw the earth cable of plug 1 to earth point B.

27

Page 28

Mounting and commissioning the machine

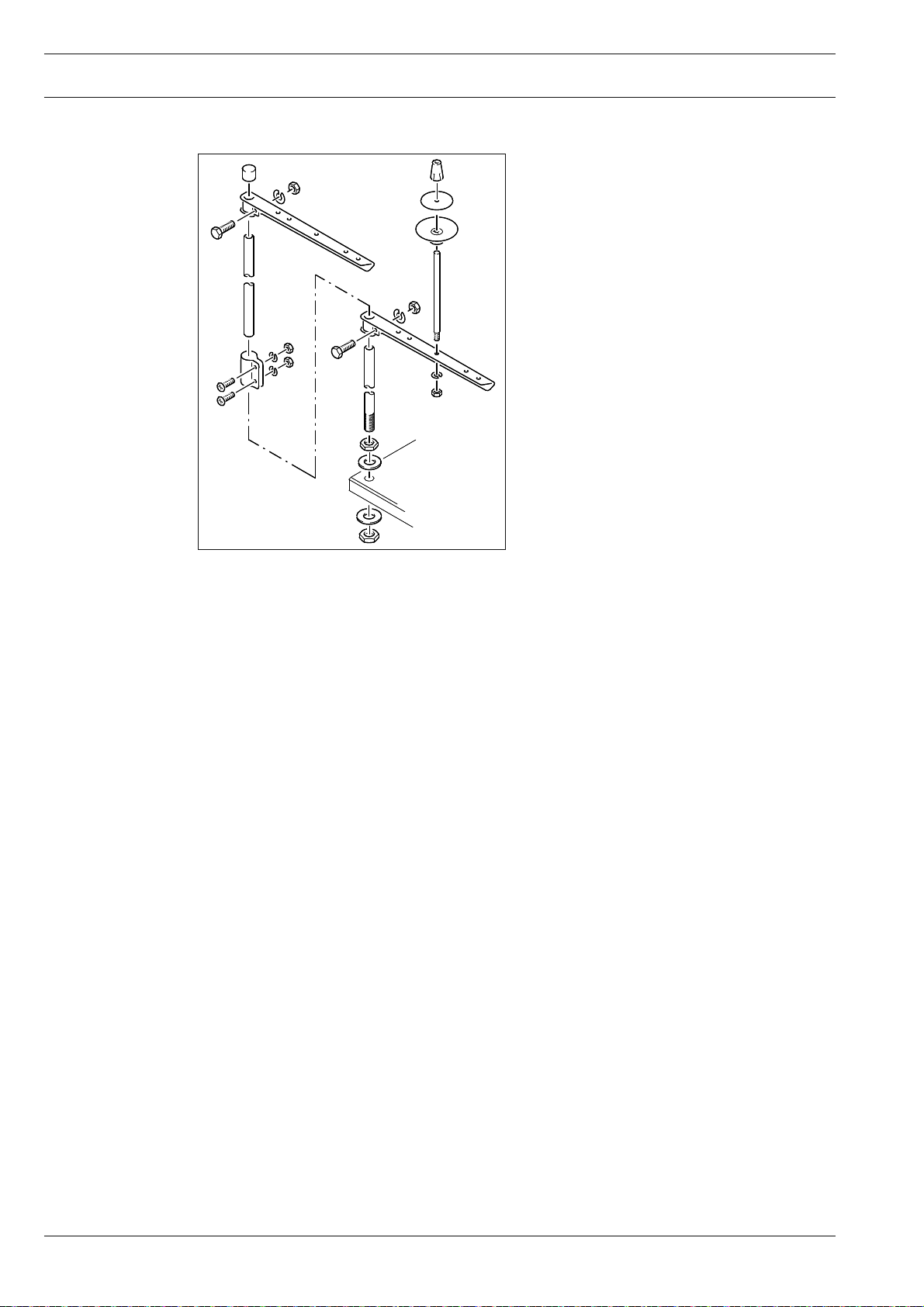

8.01.04 Fitting the reel stand

●

●

Fit the reel stand as shown in Fig. 8 - 04.

Afterwards insert the stand in the hole in

the table top and secure it with nuts provided.

Fig. 8 - 04

Fig. 8 - 04

8.02 Commissioning

●

Clean the machine thoroughly and then check the oil level ( see Chapter 12 Care and

Maintenance ).

●

Check the machine, in particular the electric leads and pneumatic connection tubes, for

any damage.

Have mechanics ensure that the machine’s motor can be operated with the available

●

electricity supply.

Connect the machine to the compressed air system. The manometer should show a

●

pressure of 6 bar.

If necessary, set this value ( see Chapter 12.05 Checking / adjusting the air pressure ).

●

Before the machine is commissioned, the seam pattern sizes set in the machine control

●

unit must be checked, see Chapter 8.04 Setting the seam pattern size.

8.03 Switching the machine on / off

28

●

Switch the machine on or off ( see Chapter 7.01 Main switch ).

Page 29

Mounting and commissioning the machine

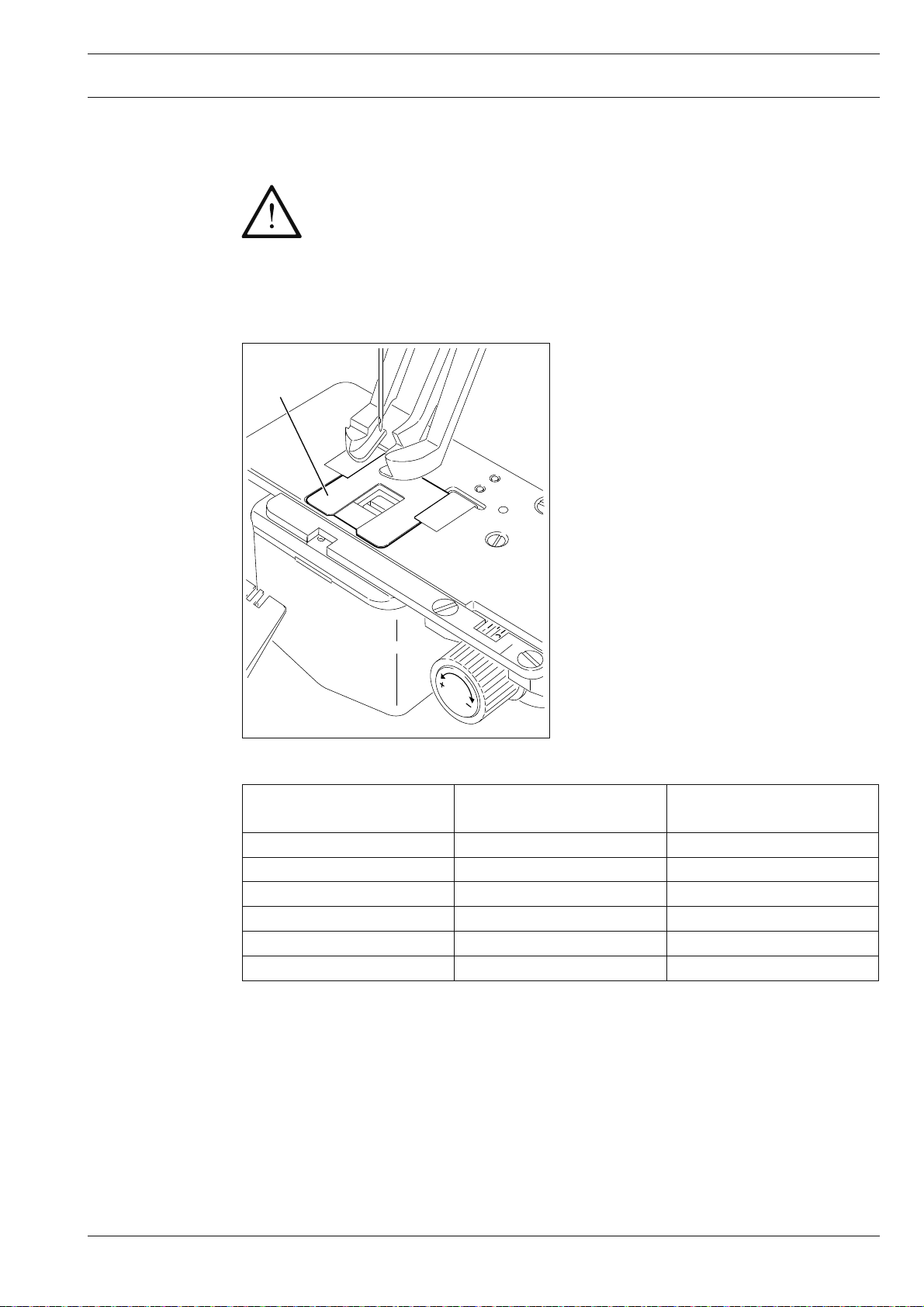

111-009

8.04 Setting the seam pattern size

After the machine has been switched on for the fi rst time, fi rst of all the seam

pattern sizes set in the machine control unit must be checked and corrected if

necessary. The seam pattern size depends on the cut-out size of the bed plate

and is set with parameter "204". If these instructions are not observed there is

a risk of severe damage to the machine!

8.04.01 Establishing the value for parameter "204"

●

1

●

●

Measure the size of the cut-out in bed

plate 1.

With the use of the table below determine the value for parameter "204".

Set „parameter "204", which is the seam

pattern size, in accordance with Chapter

8.04.02 Changing parameter "204".

Fig. 8 - 05

parameter "204"

Value for

1 7 mm x 7 mm 5 mm x 5 mm

2 8 mm x 8 mm 6 mm x 6 mm

3 9 mm x 9 mm 7 mm x 7 mm

4 10 mm x 10 mm 8 mm x 8 mm

5 11 mm x 11 mm 8 mm x 9 mm

6 10 mm x 14 mm 8 mm x 12 mm

Bed plate

cut-out size

Seam pattern size

29

Page 30

Mounting and commissioning the machine

8.04.02 Altering parameter "204"

Switch on the machine.

●

Press the "TE" key to select the input mode (LED in the key is on).

●

No

200

●

Select the function group "200" by pressing the left +/- keys.

●

Confi rm the selection by pressing the right plus key.

●

If necessary enter the access code, see Chapter 13.41.02 Entering/altering the access

code.

No VAL

204 1

●

Select parameter "204" by pressing the left +/- keys.

●

Select the value calculated for the seam pattern size by pressing the right +/- keys, see

Chapter 8.04.01 Calculating the value for parameter "204".

●

By selecting the sewing mode, the altered value is taken over and the machine changes

to the sewing mode (LED in the key goes off).

30

Page 31

Setting up

9 Setting up

All instructions and regulations in this instruction manual must be observed.

Special attention must be given to all safety regulations!

All setting-up work must only be done by personnel with the necessary

training. For all setting-up work the machine must be isolated from its power

supply by turning off the on/off switch or removing the machine plug from the

electric power socket!

9.01 Inserting the needle

Switch off the machine!

Danger of injury if the machine

is started accidentally!

Fig. 9 - 01

2

1

●

Loosen screw 1.

●

Insert the needle as far as possible. The

long needle groove (see arrow) must be

facing forwards.

●

Tighten screw 1.

Through hole 2 it is possible to check whether the needle has been inserting as

far as possible.

Broken needles can be removed by inserted suitable tools in hole 2.

Only use needles from the system intended for the machine,

see Chapter 3 Specifi cations.

31

Page 32

Setting up

9.02 Threading the sewing thread

3307-3/..

1

2

3307-3/..

32

3307-9/..

3307-9/..

Fig. 9 - 02

Switch off the machine!

Danger of injury if the machine is started accidentally!

● Thread needle thread as shown in Fig. 9-02.

Page 33

Setting up

● By turning milled screws 1 and 2 adjust the tension of the needle thread to avoid material

puckering or thread breakage.

For thin, soft materials a lower thread tension is required, for thicker fabrics a

higher thread tension.

Thread the needle from the front!

9.03 Special setting-up work on the PFAFF 3307-3/..

9

.03.01 Selecting the button type and program number

To select a button type and program number, a program for the corresponding

button must already have been entered with the seam pattern input, see Chapter 11 .01 or 11.02 Seam pattern input.

● Switch on the machine.

● The sewing mode is activated automatically.

● Select the desired button type with the corresponding key.

2000 1 10 1500

● Select the desired program number (1-99), (e.g. "10"), by pressing the corresponding

+/- key.

33

Page 34

Setting up

9

.03.02 Adjusting the button clamp to the button size

●

Loosen T-screw 1.

●

Open the button clamp with sliding bar 2

and insert the button.

Move sliding bar 2 to the right and

●

tighten T-screw 1.

The button must fi t easily into

the button clamp, but without

play.

2

1

Fig. 9 -03

9.03.03 Selecting the stem length

Switch on the machine.

●

The sewing mode is switched on automatically.

2000 1 10 1500

Select the desired stem length with the corresponding +/- key:

●

Value "1" = "without stem"

Value "2" = "short stem"

Value "3" = "long stem"

34

When the short or long stem are selected, the corresponding pre-set stem

length is called up. The setting of the stem lengths is described below.

Page 35

Setting up

9

.03.04 Setting the stem length for the short stem

●

Switch on the machine.

●

Select the short stem (value "2") with the

corresponding +/- key.

●

Loosen nut 1.

●

Set the desired stem length by turning

nut 2.

●

Tighten nut 1.

2

1

Fig. 9 - 04

9.03.05 Setting the stem length for the long stem

2

1

●

Switch on the machine.

●

Select the long stem (value "3") with the

corresponding plus/minus key.

●

Loosen nut 1.

●

Set the desired stem length by turning

nut 2.

●

Tighten nut 1.

Fig. 9 - 05

35

Page 36

Setting up

9.03.06 Selecting/setting the "sew-through button attachment" function

●

Switch on the machine.

●

Call up the "sew through button attachment" function.

●

1

Set the desired penetration depth by turning adjustment wheel 1.

Fig. 9 - 06

9.03.07 Selecting/setting the "blind sewing" function

Switch on the machine.

●

Call up the "blind sewing" function.

●

●

Set adjustment wheel 1 in accordance

with the thickness of the workpiece.

36

1

Fig. 9 - 07

Page 37

Setting up

9.03.08 Selecting/setting the "blind sewing through the facing" function

Switch on the machine.

●

Press the "TE" key to call up the operating mode (LED in the key lights up).

●

No

100

●

Select the function group "100" by pressing the left +/- keys.

●

Confi rm the selection by pressing "+" on the right +/- keys.

●

If necessary enter the access code, see Chapter 13.50.02 Entering / altering the access

code.

No VAL

106 1

●

Select parameter "106" by pressing the left +/- keys.

●

Select the number of sew-through stitches by pressing the left +/- keys.

●

By calling up the sewing mode, the altered value is taken over and the machine changes

to the sewing mode (LED in the key goes off).

●

Switch on the "blind sewing through the facing" function.

To achieve the correct operation of the "blind sewing through the facing" function, the value for parameter "503/attaching stitches" must be set at "3".

37

Page 38

Setting up

111-044

9.03.09 Allocating the stem length to the seam version

Switch on the machine.

●

The sewing mode is automatically activated.

2000 1 10 1500

Select the required stem length with the corresponding +/- key:

●

Value "1" = "without stem"

Value "2" = "short stem"

Value "3" = "long stem"

Allocate the required seam version by pressing the corresponding key.

●

"sew-through button attachment"

"blind sewing"

"blind sewing through the facing"

9.03.10 Loading plate for loading stay button

1

When working with stay buttons, ex-

●

change the needle plate for an appropriate loading plate 1.

Loading plate 1 is manufactured

in accordance with customer

requirements.

38

Fig. 9 - 08

Page 39

Setting up

9.04 Special setting-up work on the PFAFF 3307-9/..

9

.04.01 Setting the stem length

Switch off the machine!

Danger of injury if the machine

is started accidentally!

1

●

Insert the button.

●

2

Loosen screw 1.

●

Turn screw 2 until the button stem is

slightly under tension.

●

Tighten screw 1.

The programmed stem length

must correspond to the actual

stem length of the button, see

Chapter 11 Input!

Fig. 9 -09

9.05 Inserting and removing the SD-memory card

Inserting the SD-memory card

●

Open cover 1.

1

●

Insert SD-memory card 2 into the card

slot with the label at the front.

●

Close cover 1 again.

2

Removing the SD-memory card

●

Open cover 1.

●

Press the edge of the SD-memory card 2

lightly – the SD-card is ejected.

●

Close cover 1 again.

3

Fig. 9 - 10

By moving slide 3 it is possible to activate (position "LOCK") or deactivate

the write protection function of the SD-memory card. To store, process or

delete data on the SD-memory card, the write protection function must be

deactivated.

39

Page 40

Setting up

9.06 Activating the sequence mode

To activate the sequence mode, the sequence must have been entered beforehand, see Chapter 11 .03 Entering a sequence.

Switch on the machine

●

Select the input mode ( LED in the key is on).

●

No

100

Call up the function group "100" by pressing the left +/- keys.

●

Confi rm the selection by pressing "+" on the right +/- keys.

●

No VAL

114 I I

●

Select parameter "11 4 " (sequence mode) by pressing the left +/- keys.

●

By pressing the right +/- keys select value "II" to switch on the sequence mode.

●

Conclude the parameter input (LED in the key goes off) by switching to the sewing

mode.

SEQ

2000 1 12 / 1 2

40

Page 41

Setting up

Screen displays:

2000: Maximum speed

The value can be changed directly with the corresponding +/- keys.

1: Stem length

The value can be changed directly with the corresponding +/- keys.

(1 = no stem; 2 = short stem; 3 = long stem)

12/1: Number of seam patterns / current seam pattern

The current seam pattern can be selected directly with the corresponding +/- key.

2: Current sequence

The current sequence can be selected directly with the corresponding +/- key.

When working through the sequences, the machine switches automatically to

the next seam pattern in the sequence after fi nishing the current seam pattern.

After the last seam pattern the machine switches back to the fi rst seam pattern

of the sequence.

41

Page 42

Sewing

10 Sewing

The machine must be installed, connected and set up in accordance with

Chapter 8 Installation and Commissioning.

The screen display on the control panel and consequently the operation of the

machine is dependent among other things on the subclass and the sequence

mode being activated, see Chapter 9.06 Activating the sequence mode.

Switch on the machine.●

2000 1 10 1500

Screen displays:

2000: Maximum speed

The value can be changed directly with the corresponding +/- keys.

1: Stem length (not on stem wrapper)

The value can be changed directly with the corresponding +/- keys.

(1 = no stem; 2 = short stem; 3 = long stem)

10: Program number

The seam pattern can be selected directly with the corresponding +/- key. In

conjunction with the four keys for button type (two-hole button, four-hole button,

three-hole button and six-hole button), for each button type 99 stored seam patterns can be selected. On the stem wrapper the stem length is selected with the

program number. Seam patterns with uneven program number have a short stem,

seam patterns with even program numbers have a long stem.

1500: Piece counter

The value can be changed directly with the corresponding +/- keys.

To set the counter at "0", press the "piece counter" key.

42

The function of the other keys and symbols is explained in Chapter

7.06 Control panel.

Page 43

Sewing

10.01 Sewing with the PFAFF 3307-3/..

Only operate the machine with

covers 1 and 2 closed!

4

Danger of injury from the movement of the take-up lever and

the hook!

1

Do not operate the machine without eye shield 3!

Danger of injury from fl ying

needle or button fragments!

3

Do not operate the machine

2

without protective cover 4!

Danger of injury from clamp

Fig. 10 - 01

drive!

Fig. 10 - 02

●

Switch on the machine, see Chapter 8.03 Switching the machine on/off.

●

Setting up the machine, see Chapter 9 Setting up.

●

Insert the button in the button clamp as shown in Fig. 10.02, and position the workpiece

as shown in Fig. 10-03.

●

Start the sewing operation, see Chapter 7.02 Pedal.

Fig. 10 - 03

43

Page 44

Sewing

Fig. 10 - 04

Danger of needle breakage!

Make sure that the button is

placed in a level position in the

button clamp!

If the button cannot be placed in a level

●

position, the button guide 1 must be appropriately re-machined.

1

Fig. 10 - 05

The machine is equipped with a missed

stitch detection function, which helps to

control the sewing process. If an error occurs, key 1 lights up. The machine start function is blocked.

Following work steps must be carried out:

●

Remove the workpiece.

●

Press key 1 (lamp goes off).

●

Cut off the button, reinsert button and

material.

●

If necessary, draw thread by pressing key

1 again.

●

Restart the sewing process.

An error signal can be caused

e.g. by an incorrectly positioned

button or by an incorrectly set

needle. If key 1 still lights up,

the machine adjustment must

be checked by qualifi ed staff.

44

Page 45

Sewing

111-048

10.02 Sewing with the PFAFF 3307-9/..

Only operate the machine with

covers 1 and 2 closed!

Danger of injury from the

1

movement of the take-up lever

and the hook!

Do not operate the machine

without eye shield 3!

3

Danger of injury from fl ying

needle or button fragments!

2

Fig. 10 - 06

●

Switch on the machine, see Chapter

8.03 Switching the machine on/off.

Setting up the machine, see Chapter

●

9 Setting up.

Insert the button as shown in Fig. 10-07.

●

Start the sewing operation, see Chapter

●

7.02 Pedal.

Fig. 10 - 07

45

Page 46

Sewing

10.03 Error messages

If a malfunction occurs, an error code appears on the display together with short instructions. In addition the diode in the memory card slot lights up red. An error message may be

caused by incorrect settings, defective elements or seam programs, as well as by overload

conditions.

For a description of the error codes see Chapter 13.51 Description of the error messages.

E009

PRESS TE

Eliminate the error.

●

Acknowledge the elimination of the error by pressing the "TE" key.

●

The diode in the memory card slot lights up yellow.

46

Page 47

Input

11 Input

11

.01 Seam pattern input on machines from subclass -3/..

For each button type (two-hole, four-hole or three-hole button) 99 programs (seam patterns)

can be entered and stored. The seam pattern input is carried out by calling up or entering

certain seam parameters. The seam pattern input is described below for each button type.

11 .01.01 Seam pattern input for two-hole and self-shank buttons

●

Switch on the machine.

●

Select the program number and button type, see Chapter 9.03.01 Selecting the button

type and program number.

Call up the programming mode

●

No X Y

P01 -10 20

Select the desired parameter (P01, P02 etc.) with the left +/- keys.

●

With the two corresponding +/- keys move to or select the desired positions (X and Y) or

●

values.

Parameter input two-hole button

P01 First needle entry position

P02 Second needle entry position

P07 Total number of stitches (1-99).

P10 End knotting function: I = off, II = on

●

Operate the left +/- keys to take over the values entered and to call up the next or

previous parameter.

Press the "programming" key to take over the values entered and to call up the sewing

●

mode.

To achieve the best results, cutting should take place at the left needle entry

position. This is achieved through the number of stitches and the location of the

needle entry positions.

47

Page 48

Input

11 .01.02 Seam pattern input for three-hole buttons

● Switch on the machine.

● Select the program number and button type, see Chapter 9.03.01 Selecting the button

type and program number.

● Call up the programming mode

No X Y

P01 -10 20

● Select the desired parameter (P01, P02 etc.) with the left +/- keys.

● With the two corresponding +/- keys move to or select the desired positions (X and Y)

or values.

Parameter input three-hole button

P01 First needle entry position

P02 Second needle entry position

P03 Third needle entry position

P07 Total number of stitches (2-99)

P09 Seam pattern:1 = seam cycle, 2 = point, 3 = basting

P10 End knotting function: I = off, II = on

● Operate the left +/- keys to take over the values entered and to call up the next or

previous parameter.

● Press the "programming" key to take over the values entered and to call up the sewing

mode.

To achieve the best results, cutting should take place at the left needle entry

position. This is achieved through the number of stitches and the location of the

needle entry positions.

Seam pattern for the three-hole button

1

Seam cycle

(P09 = 1)

3

2

48

1

Point

(P09 = 2)

2

3

1

2

Basting

(P09 = 3)

3

Page 49

Input

11 .01.03 Seam pattern input for four-hole buttons

● Switch on the machine.

● Select the program number and button type, see Chapter 9.03.01 Selecting the button

type and program number.

● Call up the programming mode

No X Y

P01 -10 20

● Select the desired parameter (P01, P02 etc.) with the left +/- keys.

● With the two corresponding +/- keys move to or select the desired positions (X and Y)

or values.

Parameter input four-hole button

P01 First needle entry position

P02 Second needle entry position

P03 Third needle entry position

P04 Fourth needle entry position

P07 Total number of stitches (2-99)

P08 Intermediate trimming: I = off, II = on

P09 Stitch formation: 1 = normal, 2 = seam cycle, 3 = arrow, 4 = Z

P10 End knotting function: I = off, II = on

● Operate the left +/- keys to take over the values entered and to call up the next or

previous parameter.

● Press the "programming" key to take over the values entered and to call up the sewing

mode.

To achieve the best results, cutting should take place at the left needle entry

position. This is achieved through the number of stitches and the location of the

needle entry positions.

49

Page 50

Input

Seam pattern examples for the four-hole button

Seam patterns with intermediate cutting (P06 = II),

without seam cycle (P09 = 1).

Seam patterns witouth intermediate cutting (P06 = I),

and without seam cycle (P09 = 1).

Seam patterns with seam cycle (P09 = 2),

the intermediate cutting function is switched off automatically.

Seam pattern "arrow" (PO9 = 3)

the intermediate cutting function is switched off automatically.

Stitch formation "Z" (P09 = 4)

the intermediate trimming function is switched off automatically.

11 .01.04 Seam pattern input for six-hole buttons

● Switch on the machine.

● Select the program number and button type, see Chapter 9.04 Selecting the button

type and program number.

● Call up the programming mode

No X Y

P01 -10 20

● Select the desired parameter (P01, P02 etc.) with the left +/- keys.

● With the two corresponding +/- keys move to or select the desired positions (X and Y)

or values.

50

Page 51

Input

Parameter input six-hole button

P01 First needle entry position

P02 Second needle entry position

P03 Third needle entry position

P04 Fourth needle entry position

P05 Fifth penetration position

P06 Sixth penetration position

P07 Total number of stitches (2-99)

P08 Intermediate trimming: I = off, II = on

P09 Seam pattern: 1 - 17 (see seam example)

P10 End knotting function: I = off, II = on

● Operate the left +/- keys to take over the values entered and to call up the next or

previous parameter.

● Press the "programming" key to take over the values entered and to call up the sewing

mode.

To achieve the best results, cutting should take place at the left needle entry

position. This is achieved through the number of stitches and the location of the

needle entry positions.

Seam pattern examples for the six-hole buttons

2

1

4

3

6

5

6

5

1

3

4

2

3

1

4

2

6

5

Stitch formation 1 (P09 = 1)

Stitch sequence 1 – 2; 3 – 4; 5 – 6

Seam patterns with intermediate cutting (P08 = II)

5

1

2

3

6

4

2

1

4

3

6

5

Stitch formation 1 (P09 = 1)

Stitch sequence 1 – 2; 3 – 4; 5 – 6

Seam patterns without intermediate cutting (P08=I)

1

4

5

2

3

6

2

1

4

3

6

5

1

2

4

3

5

6

Stitch formation 2 (P09 = 2)

Stitch sequence 1 – 2 – 3; 4 - 5 – 6

Seam patterns with intermediate cutting (P08 = II)

1

2

4

3

5

6

1

2

3

4

5

6

1

6

5

2

3

4

2

1

3

4

6

5

1

6

5

2

3

4

Stitch formation 3 (P09 = 3)

Stitch sequence 1 – 2 - 3 – 1; 4 - 5 – 6 - 4

Seam patterns with intermediate cutting (P08 = II)

Stitch formation 4 (P09 = 4)

Stitch sequence 1 – 2 – 3 – 4 – 5 – 6 – 5 – 4 – 3

– 2– 1

3

6

5

2

1

4

2

1

6

3

4

5

2

1

4

3

6

5

2

1

3

6

4

5

1

2

3

6

5

4

1

2

6

5

4

Stitch formation 5 (P09 = 5)

3

Stitch sequence 1 – 2 - 3 – 4 - 5 – 6 –1

51

Page 52

Input

Seam pattern examples for the six-hole buttons

2

3

4

1

6

5

Stitch formation 6 (P09 = 6)

Stitch sequence 1 – 2 - 3 – 4 - 5 – 4 – 1 – 6 – 1 –

4 -3 – 2 -1

2

3

4

1

6

5

Stitch formation 7 (P09 = 7)

Stitch sequence 1 – 2 - 3 – 4 – 1 - 5 – 6 – 4 – 1 –

2 - 3 – 4 – 6 – 5 - 1

2

1

6

3

4

5

2

1

4

3

5

6

2

1

3

6

4

5

1

2

3

4

6

5

Stitch formation 8 (P09 = 8)

Stitch sequence 1 – 2 - 3 – 4 – 5 – 4 – 3 – 2 -1

Stitch formation 9 (P09 = 9)

Stitch sequence 1 – 2 - 3 – 4 – 3 - 5 – 6 – 5 - 3 – 2

-1

2

1

4

3

5

6

2

1

6

3

4

5

1

4

3

2

6

5

5

4

3

6

1

2

Stitch formation 10 (P09 = 10)

Stitch sequence 1 – 2 - 3 – 4 – 3 - 5– 3 – 2 -1

Stitch formation 11 (P09 = 11)

Stitch sequence 1 – 2 - 3 – 4 - 5 – 6 – 3 – 6 - 5 – 4

– 3 – 2 -1

1

4

3

2

6

5

Stitch formation 12 (P09 = 12)

Stitch sequence 1 – 2 - 3 – 4 – 3 - 5 – 3 – 2 – 6 - 2

-1

1

3

6

2

5

4

Stitch formation 13 (P09 = 13)

Stitch sequence 1 – 2 - 3 – 2 - 4 – 2 - 5 – 2 -1

3

4

5

2

1

6

Stitch formation 14 (P09 = 14)

Stitch sequence 1 – 2 - 3 – 4 – 5 - 2 – 6 - 2 – 5 – 4

– 3 – 2 -1

1

4

3

2

6

5

Stitch formation 15 (P09 = 15)

Stitch sequence 1 – 2 - 3 – 4 – 3 - 5 – 6 – 5 – 3 –

2 -1

1

3

4

2

6

5

Stitch formation 16 (P09 = 16)

Stitch sequence 1 – 2 - 3 – 2 - 4 – 2 - 5 – 2 - 6 – 2

-1

2

1

5

3

4

3

1

4

5

2

Stitch formation 17 (P09 = 17)

Stitch sequence 1 – 2 - 3 – 4 - 5 –1

Pfaff does not guarantee that all selectable stitch formations can be sewn

reliably in all the possible needle penetration point combinations.

To achieve the best possible sewing result, the fi rst penetration point should

be at the back and the fi rst tack should be sewn in the X-direction. If necessary use the soft start function (parameter 501) for a better sewing start and add

extra stitches (parameter 503) at the seam start, or change the direction of the

formation! A reduction of the maximum speed can also improve the sewing

result.

52

Page 53

Input

11 .02 Seam pattern input on sub-class -9/.. machines

●

Switch on the machine.

●

Select the program number and button type, see Chapter 9.03.01 Selecting the button

type and program number.

Call up the programming mode

●

No X Y

P01 -10 20

●

Select the desired parameter (P01, P02 etc.) with the left +/- keys.

●

With the two corresponding +/- keys move to or select the desired positions (X and Y)

or values.

Parameter input for stem wrapping

P01 Cross stitch position material side

P02 Cross stitch position button side

P07 Total number of stitches (1-99)

●

Operate the left +/- keys to take over the values entered and to call up the next or

previous parameter.

●

Press the "programming" key to take over the values entered and to call up the sewing

mode.

To achieve the best results, cutting should take place at the left needle entry

position. This is achieved through the number of stitches and the location of the

needle entry positions.

53

Page 54

Input

11 .03 Sequence input

In one sequence up to 99 seam patterns can be stored in any order. When working with

the sequence (sequence mode) the seam patterns are processed one after the other in

the order specifi ed. After the last seam pattern in the sequence, the fi rst seam pattern is

repeated again. Below is a description of a sequence input with two seam patterns.

Switch on the machine.

●

Call up the input mode (LED in the key lights up).

●

No

100

Select the function group "100" by pressing the left +/- keys.

●

Confi rm the selection by pressing "+" on the right +/- keys.

●

No

113

Select parameter "113" by pressing the left +/- keys.

●

Confi rm the selection by pressing "+" on the right +/- keys.

●

SEQ1 SEQ

111EXIT

54

●

Select the required seam pattern by pressing the middle +/- keys.

●

Select the next position by pressing "+" on the left +/- keys.

●

Select the next seam pattern by pressing the middle +/- keys.

●

After entering the seam patterns, conclude the sequence input by pressing the right +/keys ("EXIT").

Page 55

Input

11 .04 Program Management

In the program management the program numbers of the programs fi led in the machine

memory or on the inserted SD-memory card are displayed. The programs (seam patterns)

can be deleted or copied. Commercially available SD-memory cards with a storage capacity

of max. 2 GByte can be inserted in the control panel. The machine data is stored in the

fi le "MD" in the sub-directory \P3307. The button-hole programs are fi led as follows:

The 2-hole button programs are in directory \P3307\P2 in the fi les 01 – 99.

The 3-hole button programs are in directory \P3307\P3 in the fi les 01 – 99.

The 4-hole button programs are in directory \P3307\P4 in the fi les 01 – 99.

The 6-hole button programs are in directory \P3307\P6 in the fi les 01 – 99.

The stem-wrapping programs are in directory \P3307\PU in the fi les 01 – 99.

The desired button type is selected by pressing the corresponding key. A description of how

to insert or remove the SD-memory card is given in Chapter 9.08 Inserting/removing the

SD-memory card.

Should the SD-memory cards need to be formatted on the PC, they must be formatted

in the format "FAT16". Alternatively the SD-memory cards can also be formatted on the

corresponding machine with the formatting function, see Chapter 11.04.08 Formatting the

SD-memory card.

55

Page 56

Input

11 .04.01 Calling up the program management

Switch on the machine.

●