Page 1

I

I

rr

t

‘I

I

p

I

it

t

4

“ft

Page 2

The

from

pressly

sold

sealed

-

clogs

Wheninneed

which,

PFAFF

durable

Apart

influence

in

your

The

stamped

packing

needles,

passed

able

with

contain

not

If

the

new

and

ask

The

ably

using

by

needle

ings.

name

for

oil

the

shop

for

both

in

with

often

proof

as

stamped

and

from

on

own

genuine

on

by

manufactured

quality

sewing

the

inscription

shuttle

one

which

for

PFAFF

for

suited

the

plate,

Buying

PFAFF

-

the

sewing

where

genuine

bottles

the

redPTrade

the

mechanism.

of

of

on

not

do

shuttle,

the

the

formation

interest

PFAFF

the

shank.

authorized

and

the

to

genuine

has

bears

the

engraved

High

Speed

Darning

attachments,

darning

these

proof

as

-

Useful

machine

machine

the

PFAFF

tins,

oil

can

genuineness,

its

The•

it.

rust.

the

of

use

only

needles

They

PFAFF

under

every

be

replaced,

the

Sewing

and

apparatus,

of

their

sewing

of

needles.

name

number

Embroidermg

and

an

to

offer

owners

“Needles

PFAFF

to

attachments

hints!

ought

was

machine

and

be

Mark.

Oil

buy

only

PFAFF

needles

the

stitches.

Pfaff

needles

bear

are

sold

agents.

control,

our

guarantee

PFAFF

for

PFAFF

take

PFAFF

below

Machine

embroidery

and

be

sure

genuineness.

be

to

bought.

sure

that

other

of

a

PFAFF

bears

oil

cans

have

It

is,

the

name

only

Only

these

are

of

machines.

machines”

care

stamped

that

131

ring,

darner

they

purchased

Ask

oil

which

they

quality

oil

the

are

-

the

greatest

therefore,

system

in

original

of

irreproach

Packets

buying

name.

is

favour-

auxiliary

for

bear

ex-

are

can

name

very

130.

PFAFF

PFAFF

unsur-

do

a

on

it

stock-

the

In

fr

ti

the

Sewing

131

the

treadle.

work

nor

with

rotating

is

does

wheel

the

uniform

disconnect

again.

it

/

the

balance

.

this

ns

the

in

at

the

fly-wheel

nor

as

seamstress.

but

the

balance

To

N

nut

.

time

Machine

handIng

not

Do

random.

when

move.

well

as

not

jerking

the

tighten

.

Disconnecting

in

the

wheel

with

a

or

get

discon

working

Take

the

Exercise

wheel

balance

it,

opposite

and

piece

the

any

SincD

care

stand

mo

fold

-

exer

of

is

or

using

Small

High

Speed

PFAFF

To

acquire

machine,

oarts

out

the

machines

nected,

the

that

wheel

slow

vements.

:

I

wheel,

l

the

‘

is

.

direction

cisc

work

treadle,

when

and

disconnect

To

When

wheel

achieved

.

the

inserted

only

are

.

when

treadle

a

begin

of

order,

the

the

treadling,

moving

quick

winding

sewing

with

b/

in

thoroug’

operating

by

are

supplied

hand

machine

treadling

and

the

your

unscrewing

.

Tighten

operation

the

oraclice

and

do

wheel

irself

hand

the

to-Nard

to

bobbin,

tighten

.

right

machine.

ii

-

tighten

hand

the

but

Page 3

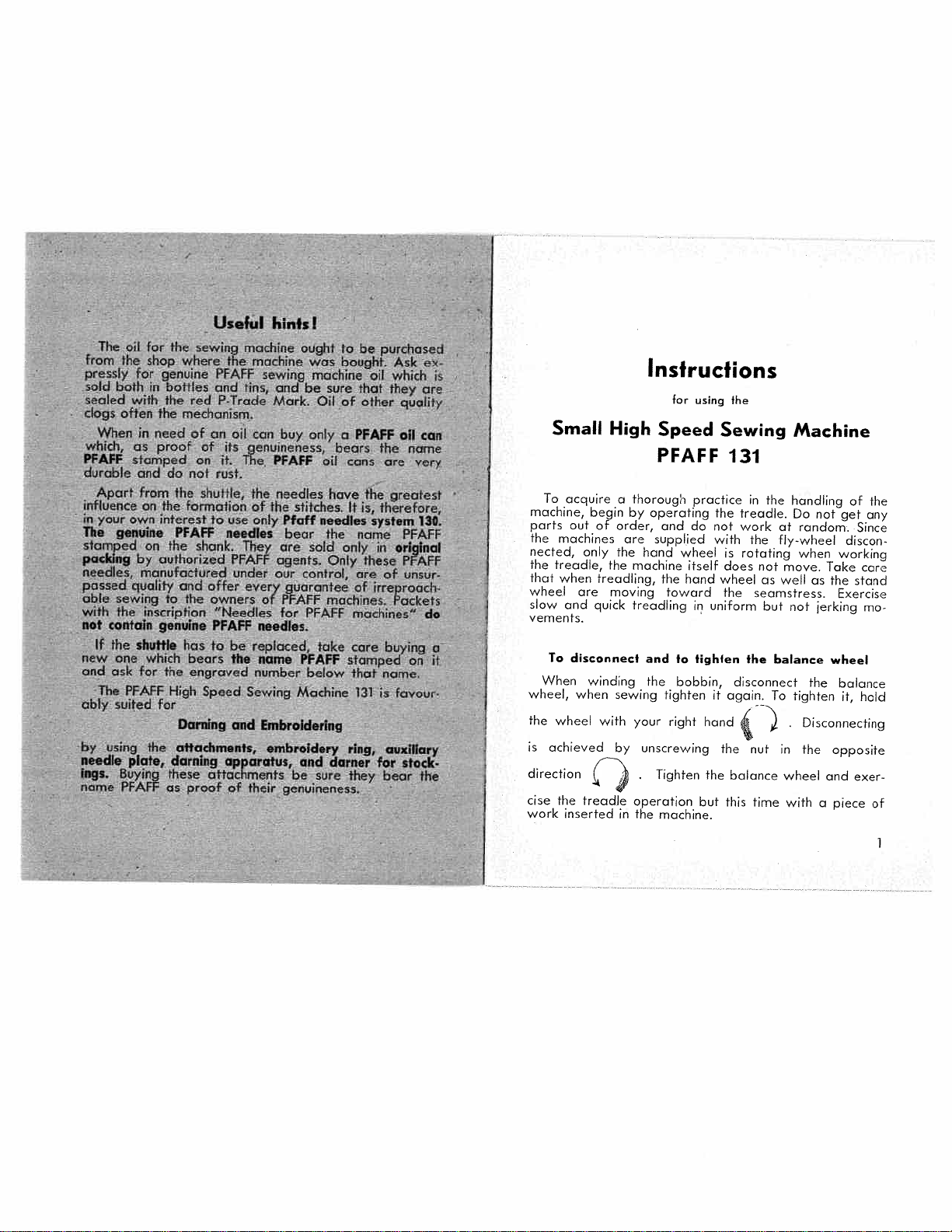

cated

draw

inch

This

of

the

latch

thumb

an

audible

and

bobbin

ing

the

follows:

and

through

3,

then

regulating

to

left,

must

through

thread

4

in

it

or

so

done,

lower

opened,

suffices

upper

Guide

over

through

be

raised

eyelet

the

fig.

3,

beneath

from

place

case,

sound.

case

thread

top

the

hook

needle

through

opening

and

to

ore

the

tension

5,

the

to

8,

the

bobbin

the

finally

have

This

likely

proceed

thread

thread

through

hole

its

the

from

slot

clamp

Y.

needle

release

the

is

between

2

controller

eyelet

of

highest

needle

left

X,

and

so

case

bar

bobbin

important

to

get

in

from

the

bar

to

right

while

that

it

with

bobbin

being

latch.

case

being

as

damaged.

accordance

the

spool

the

two

spring

6

and

take-up

point,

and

eyelet

through

holding

will

protrude

raised

Pressure

otherwise

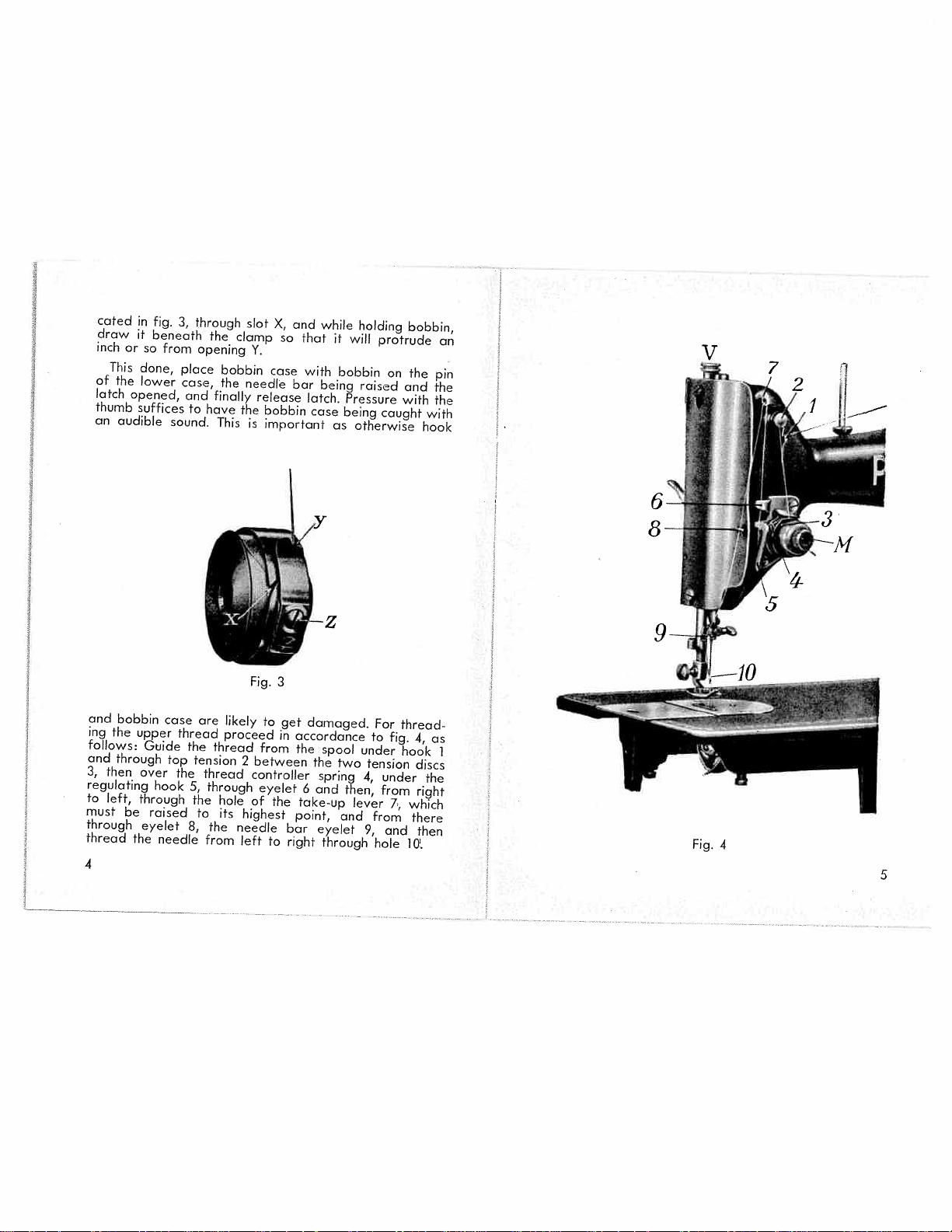

For

to

under

tension

4,

then,

lever

from

9,

hole

on

with

caught

thread

fig.

hook

under

from

7,

and

bobbin,

the

and

with

hook

4,

discs

the

right

which

there

then

1O

as

pin

the

the

an

1

Fig.

7

e!

2

c1

4

:1

1

ji

5

Page 4

To

Hold

wheel

needle

the

thread

needle

the

passing

presser

forward

presser

presser

behind

not

Do

jammed

ond

piece

a

effected

is

this

and

machine

If

thread,

behind

on

practice

figures

If

will

loops,

or

draw

end

the

with

will

screw

a

foot

feeding.

foot

foot

the

forget

in

feed

the

of

Regulation

a

screw

turned

note

the

disconnecting

the

is

and

upper

the

down

draw

as

the

up

of

your

goes

then

hole

and

by

is

presser

this

shuttle

the

dog,

fabric

with

few

in

set

is

the

nut,

obtained,

divisions,

tension

shown

under

the

hand

down

come

and

driver

the

Now

the

lowered

foot,

to

never

inserted.

the

of

the

turns

opposite

the

for

proper

its

in

the

upper

sewing

upper

the

in

once

up

to

is

or

needle

place

side

prevent

race.

tension

of

aid

right

figure

position

sleeve

one

of

too

is

fig.

in

thread

the

in

be

pair

a

of

ond

until

run

tension

tension

can

course.

thread,

5.

thread

direction

and

shape

drawn

of

plate

upper

the

under

the

the

some

upper

the

protect

To

machine

the

of

the

,

direction

on

to

the

in

get

loose,

and

and

up

scissors

in

thread

stitches

the

nut

tension

and

the

the

bell.

then

thus

to

turn

of

the

again.

of

up

direction

the

thread

thread.

thread

the

upper

M

certain

a

bell

divisions,

along

the

forming

commence

balance

the

arrow,

The

through

loop

a

completely,

between

under

Then

are

ends

formed.

ore

from

press.er

without

thread

4).

(fig.

will

be

grade

attached

is

that

stamped

After

a

without

shuttle

little

until

under

by

the

the

of

the

the

held

being

foot

having

Giving

tighter,

looser.

certain

these

thread

knots

tight

the

regulation

released

is

the

be

otherwise

causes

too

too

under

the

in

material

done

the

skipping

loose

thread

of

centre

the

auto

from

the

in

needle

of

tension

under

or

loose

tension

the

permitting

the

the

of

break

to

thread

and

too

too

tension

up,

the

as

presser

presser

forward

tight

Both

as

locking

result

or

breaking.

Fig.

tensions

too

is

shown

foot,

easy

foot

feeding,

be

or

Fig.

of

of

the

removal

bent

6

under

7

tight,

fig.

in

both

the

which

tension

equal

then

6.

threads

right

tension

of

should

as

which

tension

Upper

Upper

upper

the

if

drawn

be

will

shaws

of

of

tens

Fig.

the

7

material

ion.

Raising

matically,

underneath

direction

likely

is

stitches

6

Page 5

To

The

screw-driver,

the

the

if

tight

too

regulate

bobbin

tension

(see

case

is

fig.

the

is

tighten

too

3).

tension

taken

loose,

out

the

or

of

of

tension

the

the

under

machine

screw

if

,

thread

the

then,

Z

tension

with

Cotton

of

Cotton

Schappe

Real

Cotton

Schappe

Real

silk

silk

Sice

Linen

silk

silk

Silk

or

150—100

150

-1003

150—100/3

(000/001

100—80

100/3

100’3

(0)

I

Very

(cambric,

fine

Very

fine

fine

Class

thin

linen

fine

linen,

calicoes

Work

of

fabrics

tulle,

silk

goods,

underwear,

etc.

muslin)

of

No.

Needles)

70

t7)

is

regulate

To

For

found

thread

materials

lever

the

thread

the

is

a

is

b

is

c

The

direction

following

Use

thickness

the

table

In

order

highest

its

what

inserting

shank

long

the

as

up

8

the

embroidery

convenient

controller

tighter

a

the

of

controller

position

the

standard

the

position

the

marks:

needles

Pfaff

following

on

to

point,

take

and

needle,

a

fit

will

groove

possible,

tension

work

to

tension

for

turning

of

change

out

into

is

then

loosen

spring.

tension

spring

for

position

for

l=’loose

The

system

thread

page.

the

loosen

the

be

groove

the

pointing

tighten

the

of

when

or

somewhat

When

is

bushing,

darning

sewing

the

(light),

Needle

and

needle,

the

needle

careful

to

wanted,

being

is

for

lever

130

material

needle

with

of

the

the

thread

darning

working

the

and

sewing

thick

f=fast

in

raise

that

the

left.

needle

controller

it

the

By

desired

adjusted

embroidery

hard

or

designated

is

(tight).

appropriate

sizes

used,

the

clamp

left

your

flat

the

needle

Push

clamp

may

tension

thick

simply

needle

screw

hand,

side

bar

needle

spring

often

of

hard

or

turning

tension

4).

(fig.

work

materials.

by

consulting

bar

some

When

of

and

as

again.

be

the

the

the

that

far

Cotton

Schappe

)9

100

(10>

of

110

(11)

120

(121

Stitch

to

The

means

not

to

does

machine

beyond

stitches

retained.

accomplished

be

darning,

for

only

Real

Cotton

Schappe

Real

Cotton

Schappe

ReaLsilk

Linen

Cotton

Schappe

Real

Linen

regulation:

regulation

screw

of

move

is

sewing

it

0,

and

Changing

choose

tying

silk

silk

silk

sewing

is

vice

forward

silk

silk

silk

silk

of

M

at

versa,

whilst

the

80—60

80/3

80/3

60—40

70/3

70/3

40—30

60/3

60/3.

90—80

30—24

50/3

50/3

80—50

Forward

length

the

1).

(fig.

all.

Moving

forward,

backward.

the

length

the

sewing.

0-position,

seams.

(B)

IC)

(D)

(E)

M

I

and

the

of

pointing

screw

and

same

of

When

using

underwear,

Thick

light

knitted

Ladies’

hems

Gents’

corsets

Cloths,

etc.

backward

stitches

on

M

moving

Switching

length

stitches

the

embroidering

the

goods

clothings,

umbrellas

clothings,

etc.

winter

is

the

0,

upward,

downward,

it

backward

to

of

stitches

backward

clothing

sewing

done

feeder

can

by

the

is

also

and

stitch

9

Page 6

OC

000

00-0

,,

0

8g-

p

7’•

0(0

pressure

the

it,

respectively,

and/or

hands.

the

of

B,

(fig.

the

the

Pfaff

the

of

pressure

out.

Be

sure

Do

The

bobbin

The

8).

screws

guiding

The

not

131

hook

I,

plate

regulate

To

To

increase

decrease

screwed

C”

=

D

0-

D

0

0-

0000

CD0-O

,

0-

=0

CT

rr,

0

0

a

0

done

with

ing

The

,-<

‘iI

0

70

(0

(0

OCn0

0_0

0Q

D

0

C”OD

CD

0

(00

(0

C”

(5(0

0

0

CM

Q

0

CT

=

0

0

0

-,,

0

0-

Q

—

E_co

0

=<

Co

-h

the

case

body

serve

in

automatically.

your

both

of

the

needle.

hook

hook

bow

cap

0,

by

means

to

attach

the

presser

of

of

the

sewing

bushing

the

feeding

to

push

guide

of

the

or

pull

Hook

consistsofth3

case

II,

and

base

bow

M

III.

to

U

is

Three

the

foot

V

—fig.

the

material

to

avoid

hook

and

secured

screws

hook

foot

and

4—

machine

gently

break

body

bobbin

the

on

body.

to

is

is

C,

the

also

10

C’,

0CD

9

Fig.

8

Fig.

11

Page 7

Taking

To

clean

then

back,

bow

Then,

unscrewing

by

by

correlation

the

lower

finger

at

the

D

the

shoulder

index

case

Thus,

automatically

After

thoroughly

replace

fluff,

balance

assume

Rofthe

bobbin

the

and

together

the

caseinthe

hook

finally,

wheel

under

bow,

with the

12

hookapiece

the

the

hook

remove

the

the

turning

with

the

the

under

edgeofscrew

alignment

in

are

your

of

from

stud

of

R

nose

central

groove

cleaning

in

them

that

so

position

observed

bobbin

bodyofthe

fastening

the

insert

bobbin.

it

is

upper

three

balance

hole

left

Z

the

P

reverse

hook

case

it

upper

necessary

case

screws

wheel,

bobbin

S

(fig.

hand,

and

under

of

the

the

order.

and

in

holder

with

for

to

and

S

case

and

1

Then

9).

seize

lift

out

bobbin

bobbin

individual

Begin

under bobbin

9,

fig.

and

hook.

This

screws

bobbin

cleaning

tip

the

off

take

1,S2,

bring

the

the

to

the

lower

with

the under

hook

the

case

case

by

then,

push

insert

done,

S1,S

case

machine

the

and

hook

effect

edge

thumb

bobbin

body.

withdraws

holder.

parts

turning

groove

under

the

replace

2,

and

0

(fig.

hook

S

that

and

from

the

case

S

Directions

of

PFAFF

presser

the

supplied.

is

use

the

particularly

ruler

chosen

be

of

width

hemmer,

the

131

between

of an

of

as

foot

suitable

at

hem

shown

as

the

will.

inch

and

3

using

some

sewing

which

along

Edge

with

edges.

attachments

machine

use

work

machine

the

edge

the

stitcher

the ruler

is

for

high

all

ordinary

in

fig.4with

stitching

in

combination

speed

sewing

close

narrow

3.

in

of

For

shown

For

which

for

producing

3

8)

10

Fig.

The

seam

(fig.

When

of

guide

in

the

fig.

and

10).

ruler

edge

it

11.

being

the

starting

evenly

edge

of

Edge

adjustable,

of

a

hem,

the

into

stitcher

The

material

the

the

fold

curl

with

the

cloth

hemmer

a

to

of the

distance

may

length

the

Page 8

The

Fig.

hemmer

11

When

upon

1/6

inch

guide

described

under

Now

flatten

has

been

fell

it.

The

suspension

Unscrew

around

hole

c

little

with

to

reestablish

the

the

piece

open

the

the

on

felling,

other,

further

two

with

seam

formed,

the

head

the

your

the

with

to

pieces

the

is

folded

the

two

somewhat

of

of

embroidering

sewing

of

face

hand.

the

two

the

the

into

hemmer,

and

pieces

again

the

foot,

screw

plate,

Then

tension

k

The

pieces

edge

right

the

sewn

through

presser

b

of

feller

of

of

thon

feller

which

by

on

of

cloth

and

bar

and

place

and

insert

heavening

release

the

F

cloth

the

the

the

guide

the

darning

the

the

upper

in

as

for

bent

the

should

under

upper

the

the

upper

shown

the

feller

the

presser

thread

piece

piece.

some

edge

edge,

in

the

end

other

presser

be

laid

about

woy

of

piece.

in

fig.

which

order

purposes

of

hook

end

bar

bar

(fig.

one

Then

as

the

12,

to

a

into

a

lever

13).

14

____j

The

Fig.

12

feller

Fig.

13

15

Page 9

Open

rear

two

line g

come

To

slide

notch

angular

.

...

lie

to

apply

a,

into

parts

Close

beneath

insert

recess

slide

the

,d

auxiliary

L

tue

bof

will

a

the

auxi

the

close

oud

slide

ja

neecule

be

(See

sewing

sewinri

r

‘i

the

sur

ne

ig.

poe,

t,,no

plate

“late

e

so

c

hes

with

that

don

c

USEFUL

its

the

...

1.

When

But

plate

by

To

aarrnng

itisquite

(fig.

the

teeth

assure

must

recommend

we

Thread

Thread

Thread

Darning

threads,

tially

loosened

sewing

2.

For

Lustreless

moreover

ducing

when the

place

better

14>toovoid

of the

good

match

No.

No.

No.

thickness of

the

.—

40inconnection

30

50—60

80—100

threads

both upper- and

when

lustreless

use

a

thread

is

better

fabric

is

smoother and

drawn-in

-is

HINTS!

reguang

stitch

to

use

cutting of the

feed

dog.

darning

connection

in

connection

in

being

twined

under

darning.

thread—not

as

strong

washed.

the

supplied

the sizeofneedl

work

thread

with

with

with

lighter

tension

as

glazed

more

stitch,

flexible,

which

srewonpont

feed

soft

darning

Therefore

used.

needle

No.80(8

needle

No.70(7

needle

No.60(6

than

must

glazed

sewinç

be

cotton

cotton

thus

importani

is

c

cove

yaru

essen

anc

pro

16

Fig.

14

Skipping

1.

Needle

2.Ifother

This

our

3.

Needle

Thread

1.

For

2.

The

3.

Using

of

stitches may

not

set

than

needle

prescriptions

being

breaking

the

maybecaused:

above

tension being

badorknotty

Pfaff

produced

is

bent

three

be

according

Needles

examined.

and

thread

or

reasons.

too

thread.

caused:

instructions.

to

System

meticulously

used too

loose.

130

according

fine.

-

are

used.

to

17

Page 10

Ugly

1

2

Heavy

rust

clean

stitches

The

should

tension

Thickness

needle

be

Fluff

3

or

The

1.

therefore

shorten

Belt

2.

shortened

Shuttle

3.

inadvertance.

nickel

All

proof

all

at

raised

without

apply

friction.

from

after

and

Very

kerosene,

especially

after

The

the

dog.

18

may

tension

always

and

little

a

having

under

working

belt

being

Thereupon

rag.

points

presser

the

thread

drop

a

Make

time

a

important’

and

prolonged

a

needle

removed

lint

be

too

material

of

thread

finer

accumulated

tension

the

of

having

does

it.

too

too

race

oil

To

plated

grease

marked

of

it

time,

to

prolonged

thereafter

when

plate

caused

light

be

than

the

become

nat

tight.

much.

being

and

and

which

foot

wipe

Pfaff

habit

a

especially

Rinse

using

standstill.

from

too

or

little

a

not

under

The

the

spring

machine

pull

Therefore

obstructed

clean

polished

should

apply

figures

in

run

off

oil

to

standstill.

the

apply

machine

the

should

its

The

loose

looser

corresponding

thread

thread

upper

between

the

of

be

may

long

too

anymore,

it

by

Machine

the

parts

be

little

a

and

15

machine

the

dripping

the

points

all

at

be

underside

clean

when

shuttle

some

Keep

taken

and

for

the

under

than

should

the

bobbin

causd:

long

by

in

should

fluff

are

rubbed

kerosene

16

for

where

oil

using

race

sewing

the

oil

off

and

tension

upper

the

size

to

rather

tension

case

use

which

never

caused

treated

off

(paraffin)

After

short

a

kerosene

there

machine

the

permanently

it

thoroughly

machine

time

first

clean!

can

frequently

the

from

of

discs

and

case.

with

with

having

time

be

by

and

with

and

and

feed

a

oil,

is

15

Fig.

Page 11

requires

drop

a

the

to

The

is

man

consistent

lubrication

ing

long

a

necessary

ball-bearing

the

only

use

the

oil

sewing

your

ing

treadle

certain

play

to

bearings.

the

with

with

plied

screw

bearing

careful

Be

bearings

necessary,

If

screws

two

centre

tighten

Then

again.

adjusted

be

bearing

crank

Stand

little

but

oil

of

treadle

ball-bearing

at

filled

grease,

Should

time.

later

consistent

flung

is

high

at

dress.

work

of

time

having

Tighten

special

the

of

f

17).

(fig.

not

do

loosen

d

firmly

pin

the

crank

The

by

attendance.

and

now

stud

of

the

factory

thus

unnecessary

on

to

of the

grease,

speed,

Should

noisily

use,

arisen

the

wrench

machine,

treadle

the

the

that

become

and

the

to

fastening

points

tightening

a.

then

and

c

the

it

become

lubricate

pitman,

out

thus

after

this

bearing

and

one

press

treadle.

can

pit

with

render

since

when

soil

due

is

in

sup

stud

treadle

loose.

of

screw

also

It

to

the

for

the

a

the

e

the

the

the

the

Treadle

The

ball-bearing

with

will

the

treadle

I

sufficienttoapply

be

crank

points

bearings

pitman

and

a

(fig.

d

b,

18).

I

f

16

Fig.

20

17

Fig.

.

21

Page 12

Loading...

Loading...