PEUGEOT XS1P37QMA-2 Workshop Manual

Direction commerciale

Animation technique réseau

WORKSHOP MANUAL

-

50 CC ENGINE 4 STROKE

2 VALVES

SYM

Workshop manual

Technical network leadership

Reproduction or translat ion, even partial, is forbi dden without the written co nsent of Peugeot Motocyc les

TABLE OF CONTENTS

1

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

TABLE OF CONTENTS

TABLE OF CONTENTS . ... ....................................... ... ... ... .... ... ....................................... ... ... ... ... ....................... 1

PRODUCTS DANGER SYMBOLS USED..... ... .... .......................................... ... ... ... ... .... ................................... 3

CHARACTERISTICS......................................................................................................................................... 5

Capacities..................................................................................................................................................5

SPECIAL IMPORTANT POINTS....................................................................................................................... 6

Oil and fuel.................................................................................................................................................6

TIGHTENING TORQUES ................................. .... ... ... ... ... .......................................... .... ... ................................ 7

SPECIAL TOOLS .............................................................................................................................................. 8

Standard tools............................................................................................................................................9

OPERATION....................................................................................................................................................10

Putting the engine on the stand...............................................................................................................10

Changing the engine oil ...........................................................................................................................10

PRIMARY TRANSMISSION............................................................................................................................ 11

Removal of the primary transmission cover.............................................................................................11

Removal of the drive pulley......................................................................................................................11

Removal of the driven pulley....................................................................................................................12

Changing the drive pulley bearings..........................................................................................................12

Checking the drive belt ............................................................................................................................12

Removal of the clutch lining assembly.....................................................................................................13

Refitting the clutch lining assembly..........................................................................................................14

Removal of the starter system .................................................................................................................15

Fitting the starter system .........................................................................................................................16

SECONDARY TRANSMISSION...................................................................................................................... 17

Removal of the secondary transmission ..................................................................................................17

Replacing the bearings of the relay box...................................................................................................18

Crankcase.........................................................................................................................................................18

Relay box cover .............................................. .................................... ... ...........................................................18

TABLE OF CONTENTS

2

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

CARBURETTOR ............................................................................................................................................. 19

Removal of the carburettor.......................................................................................................................19

Removal of the choke ..............................................................................................................................19

Removal of the starter holder and its gasket ...........................................................................................19

Removal of the throttle valve....................................................................................................................20

Removal of the float, needle valve and jets..............................................................................................20

Removal of the mixture screw..................................................................................................................22

Removal of the pick-up pump ..................................................................................................................22

Removal of the pick-up pump suction valve.............................................................................................22

Removal of the deceleration enrichment device ......................................................................................23

Removal of the carburetor heater ............................................................................................................23

Removal of the intake pipe.......................................................................................................................24

MAGNETO FLYWHEEL/FREEWHEEL........................................................................................................... 25

To remove the magneto flywheel .............................................................................................................25

Removal of the overrunning clutch...........................................................................................................26

Checking the overrunning clutch..............................................................................................................27

CYLINDER HEAD/CYLINDER/PISTON.......................................................................................................... 29

Removal of the cylinder head...................................................................................................................29

Removal of the camshaft and/or rockers .................................................................................................31

Removal of the valves or valve stem seals ..............................................................................................32

Removal of the cylinder / piston...............................................................................................................34

Checking the cylinder...............................................................................................................................35

Checking the piston .................................................................................................................................35

Checking the piston rings.........................................................................................................................35

Installing the piston rings on the piston......................... ... ........................................................................35

Fitting the piston.......................................................................................................................................36

Fitting the cylinder....................................................................................................................................36

Setting the timing .....................................................................................................................................38

Checking the timing .................................................................................................................................39

Installing the valve clearance........................ ... ... .......................................... ... ... .... ... ..............................40

Checking the valve clearance..................................................................................................................40

CRANKCASE .................................................................................................................................................. 41

Removal of the crankshaft .......................................................................................................................41

Checking the crankshaft and conrod assembly .......................................................................................42

Fitting the conrod and crankshaft assembly.............................................................................................43

PRODUCTS DANGER SYMBOLS USED

3

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

PRODUCTS DANGER SYMBOLS USED

Protection of individuals and of the environment.

Möbius band Recyclable.

Means that the product or the package

can be recycled. However, this does not

guarantee that the product will be

recycled.

Irritant

The product can irritate the

skin, eyes and repiratory

organs.

Avoid contact with skin and clothes. Wear

gloves, safety goggles and appropriate

clothes such as a cotton overall. Do not

breath fumes. If in contact, wash

thoroughly with water.

Flammable The product is flammable.

Keep it away from flames or any heat

source (barbecue, radiator, heater, etc.).

Do not leave the product in the sun.

Corrosive

The product can damage living

tissues or other surfaces.

Avoid contact with skin and clothes. Wear

gloves, safety goggles and appropriate

clothes such as a cotton overall. Do not

breath fumes.

Explosive

The product can explode under

certain circumstances (flame,

heat, impact, friction).

Avoid impacts, friction, sparks and heat.

Hazardous to

the environment

The product affects fauna and

flora. Do not dump it in

dustbins, sinks or in the

environment.

The ideal solution is to bring this product

to your nearest household waste recycling

centre.

Toxic

The product can seriously

affect health if it is inhaled,

ingested or in contact with skin.

Av oid direct contact with the body, even b y

inhalation. If you f ee l unwell, seek medical

advice immediately.

Do not throw

away into a

garbage can

One of the product's

component is toxic and can be

hazardous to environment. For

example: Used batteries.

This symbol informs the consumer that the

used product shall not be thrown awa y into

a garbage can, but shall be brought back

to the merchant or dropped at a specific

collection point.

Compulsory

gloves

Operation that can be

dangerous for people.

People's saf ety can be seriously aff ected if

the recommendations are not fully

respected.

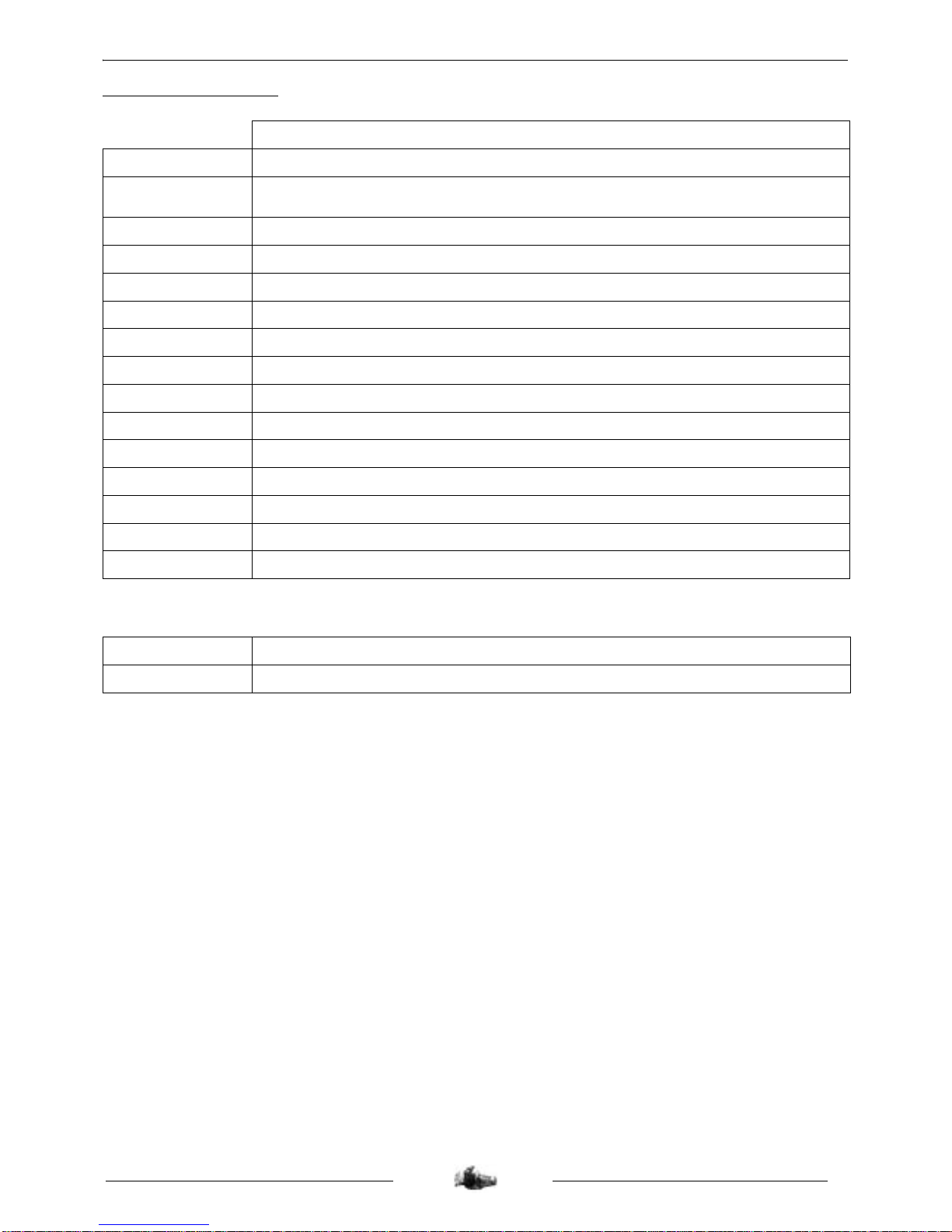

PRODUCTS DANGER SYMBOLS USED

4

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

People's safety

Operation that can be

dangerous for people.

People's saf ety can be seriously aff ected if

the recommendations are not fully

respected.

Important

Operation that can be

hazardous to the vehicle

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Good operating

condition of the

vehicle

The operation must be carried

out in strict compliance with the

documents.

Serious damage to the vehicle and in

certain cases a cancellation of the

warranty can be involved if the

recommendations are not fully respected.

Note Operation that can be difficult.

Indicate a note which gives key

information to make the procedure easier.

Lubricate

Lubricate the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Grease

Grease the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Glue

Glue the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

New part Use a new part.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

GLUE

N

CHARACTERISTICS

5

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

CHARACTERISTICS

Capacities

50 cc

Marking

XS1P37QMA-2

Type

4-stroke single-cylinder

2 valves per cylinder with chain driven overhead camshaft

Cooling By a circulation of forced air by means of a turbine on the flywheel magneto

Bore x stroke 37 x 46 mm

Cubic capacity 49.5 cc

Max. power output 2.8 kW at 8000 rpm

Max. torque rating 3.5 Nm at 6500 rpm

Lubrication Trochoid pump driven by a gear set from the crankshaft

Transmission By 2 variable pulleys and V-type belt

Clutch Centrifugal automatic

Exhaust Catalytic

Spark plug

NGK CR6HSA

Magneto flywheel 80 W

Fuel supply Carburettor Keihin NVC18 (c/d)

Standards Euro 3

Crankcase 0.7 l

Relay box 0.1 l

SPECIAL IMPORTANT POINTS

6

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

SPECIAL IMPORTANT POINTS

Oil and fuel

This engine is designed to run on 95 or 98 unleaded fuel only.

Never run the machine with a petrol/oil mixture.

Fuel pipes must absolutely be changed if there are any signs of wear, cracks, etc.

The clips are specific, they must always be changed each time they are removed and replaced

with new genuine parts clips.

Petrol is highly inflammable, do not smoke in the working area and avoid pr oximity to flames or

sparks.

TIGHTENING TORQUES

7

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

TIGHTENING TORQUES

Spark plug 12 Nm

Filler cap 20 Nm

Screen 15 Nm

Cylinder head

• Nut Ø 6 mm

• Screw Ø 6 mm

20 Nm

12 Nm

Camshaft gear cover 10 Nm

Camshaft gear 20 Nm

Valve clearance covers 15 Nm

Automatic tensioner 10 Nm

Automatic tensioner plug 8 Nm

Chain tensioner 10 Nm

Inlet manifold 10 Nm

Cylinder casings 12 Nm

RH casing cover 12 Nm

Freewheel 90 Nm

Oil pump 10 Nm

Transmission cover 10 Nm

Relay box cover 22 Nm

Relay box drain plug 10 Nm

Starter motor 10 Nm

Rotor 55 Nm

Turbine 10 Nm

Stator 10 Nm

Engine speed sensor 10 Nm

Drive pulley 55 Nm

Driven pulley 55 Nm

Clutch plate and shoes 55 Nm

SPECIAL TOOLS

8

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

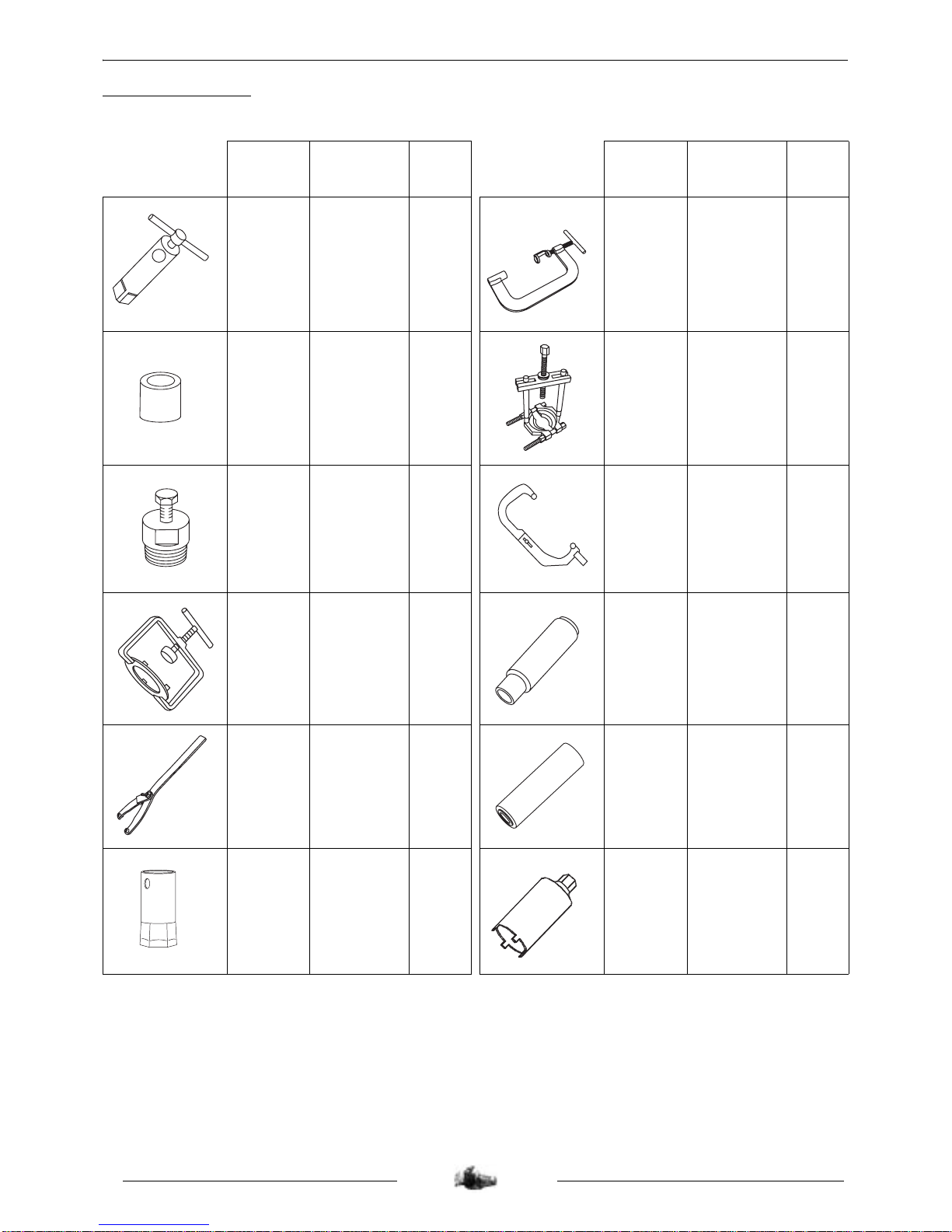

SPECIAL TOOLS

(*) New or modified tool

Tool N° Designation

Used

with

Tool N° Designation

Used

with

064765

Engine

mount

755982 754035 Valve lifter

068007

Protective

end-piece

small model

750806 755585

Bearing

extractor tool

750806

Flywheel

puller

68007 755982

Engine

mount

adapter

64765

752127

Clutch

compression

tool

752361 756668 Seal piston

752237

Adjustable

pin wrench

757990 Seal piston

752361

39 mm pipe

wrench

752127 800673

Freewheel

nut tool

SPECIAL TOOLS

9

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Standard tools

Heat gun

Automatic resetting type

torque wrench

5 to 25 Nm

Type:Facom R.306A25

Intertia type extractor

tool for bearings from 6

to 18 mm

Type: Facom U.49PJ3

Automatic resetting type

torque wrench

10 to 50 Nm

Type: Facom J.208A50

Automatic resetting type

torque wrench

40 to 200 Nm

Type: Facom S.208A200

OPERATION

10

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

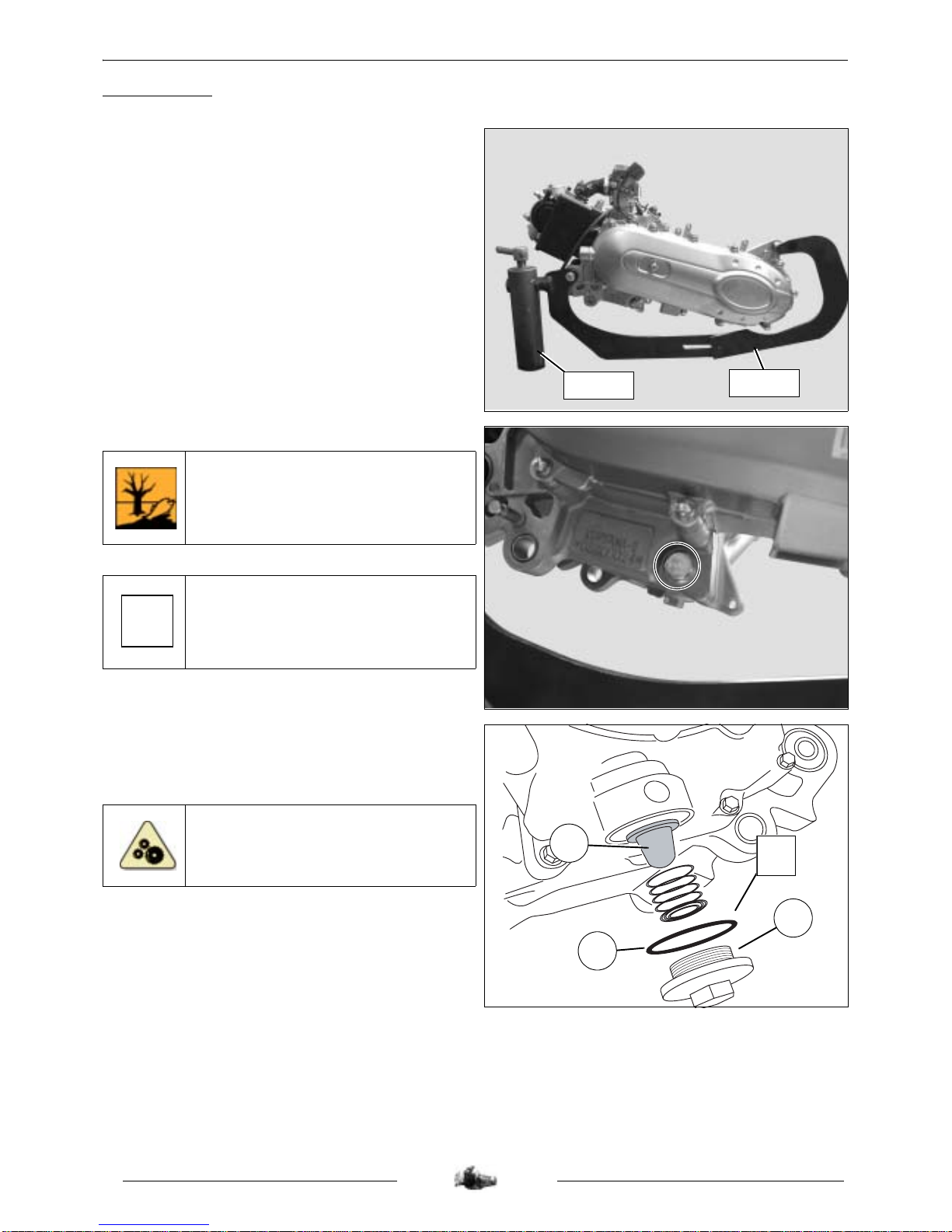

OPERATION

Putting the engine on the stand

- Fit the engine to adapter P/N 755982.

- Put the assembly on stand P/N 064765

clamped in the jaws of a vice.

Changing the engine oil

To drain the engine remove the cap and

let the oil drip.

Tightening torque: 20 Nm.

Replace the seal each time you change

the oil.

- Remove the strainer cap (1) and clean the

strainer (2).

Tightening torque: 15 Nm.

Every time oil is changed, the f ilter (2)

must be cleaned and the O-ring

changed (3).

755982

064765

N

1

2

3

N

PRIMARY TRANSMISSION

11

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

PRIMARY TRANSMISSION

Removal of the primary transmission

cover

- Remove the transmission cover (10 screw).

- Remove the paper gasket and the two 2

centering pins.

Tightening torque: 10 Nm.

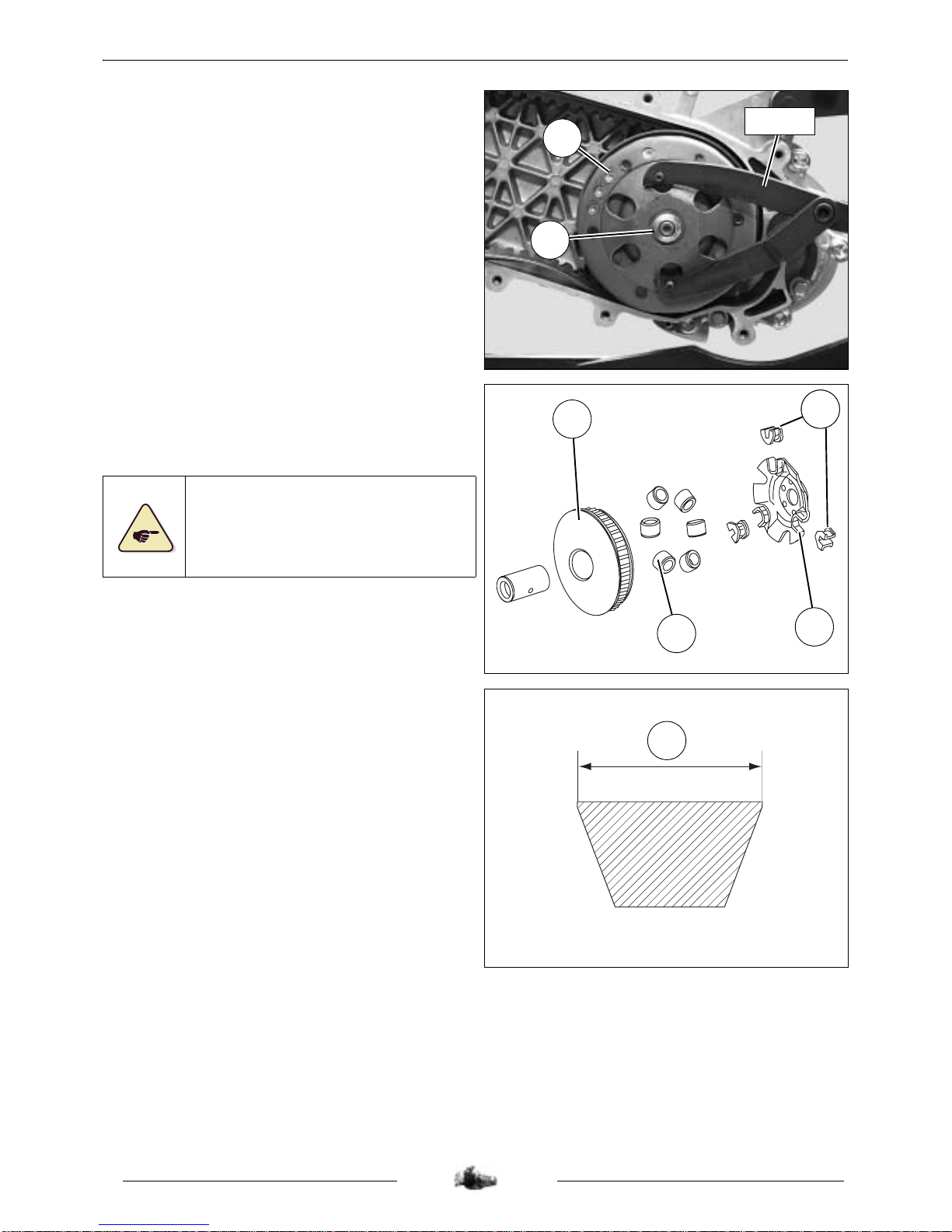

Removal of the drive pulley

- Hold the fixed flange with tool P/N 752237.

- Remove the nut (1) and washer (2) from the

fixed flange.

- Remove the fixed flange.

Tightening torque: 55 Nm.

- Remove the belt (3).

- Remove the plastic spacer (4).

- Remove the drive pulley (5) with the guide

hub (6).

752237

1

2

3

5

4

6

PRIMARY TRANSMISSION

12

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Removal of the driven pulle y

- Lock the clutch drum (1) with the pin wrench

P/N 752237.

- Remove the nut (2).

- Remove the clutch drum and the clutch and

drive pulley assembly.

Tightening torque: 55 Nm.

Changing the drive pulley bearings

- Remove the ramp (1) and its 3 guides (2).

- Remove the moving flange (4)

6 bearings (3).

The bearings must be changed if they

show major signs of wear.

The guides shall be replaced if they

show signs of wear.

Checking the drive belt

- Measure the width of the belt (A).

Minimum width: 17.2 mm.

- Make sure the belt is not cracked.

1

2

752237

4

3

212

A

PRIMARY TRANSMISSION

13

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Reassembly:

- Proceed in reverse order to disassembly

and do not grease the bearings.

- When refitting, respect the way the rollers

are installed.

- Grease the moving flange bore lightly (high

temperature grease).

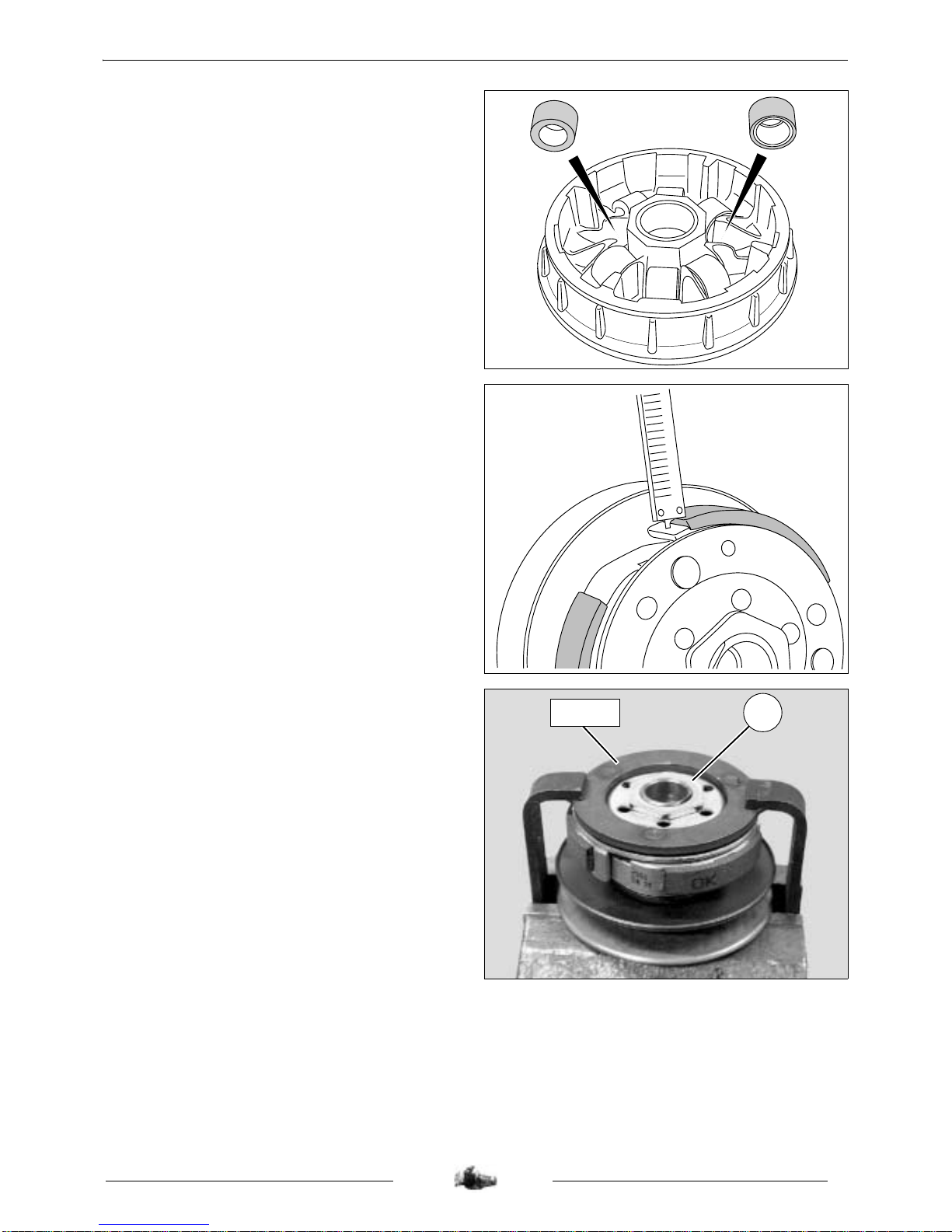

Removal of the clutch lining assembly

- Using the depth calliper, measure the

thickness of the clutch linings.

Mini. thickness: 2 mm.

- Compress the clutch drive pulley and driven

pulley assembly with the tool P/N 752127

clamped in the jaws of a vice.

- Remove nut (1) using spanner P/N 752361.

- Slacken tool P/N 752127.

1

752127

Loading...

Loading...