PEUGEOT Geopolis 250 Workshop Manual

Direction commerciale

Animation technique réseau

WORKSHOP MANUAL

-

Workshop manual

Technical network leadership

Reproduction or translat ion, even partial, is forbi dden without the written co nsent of Peugeot Motocyc les

TABLE OF CONTENTS

1

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

TABLE OF CONTENTS

TABLE OF CONTENTS . ... ....................................... ... ... ... .... ... ....................................... ... ... ... ... ....................... 1

CHARACTERISTICS......................................................................................................................................... 4

Engine........................................................................................................................................................4

Capacities..................................................................................................................................................4

Chassis......................................................................................................................................................5

Dimensions and weight.................................................... ... ... .... ... ... ..........................................................5

Tyres ..........................................................................................................................................................5

SERVICE SCHEDULE AND COMMISSIONING............................................................................................... 6

Check.........................................................................................................................................................6

Change ......................................................................................................................................................6

Check and lubricate ...................................................................................................................................7

Reading the ECU fault codes.............................................. .......................................... .............................7

Test machine..............................................................................................................................................7

Battery preparation (Except battery without maintenance)* ......................................................................8

Checks before handing over to the customer.............................................................................................8

SPECIAL IMPORTANT POINTS....................................................................................................................... 9

Oil and fuel.................................................................................................................................................9

Starting up after overhauling the engine....................................................................................................9

Electricity....................................................................................................................................................9

Special features ........................... .... ...................................... .... ... ... ... .... ...................................................9

TIGHTENING TORQUES ................................. .... ... ... ... ... .......................................... .... ... .............................. 10

Engine part ..............................................................................................................................................10

Body panels .............................................................................................................................................11

Cycle part.................................................................................................................................................11

Standard ..................................................................................................................................................11

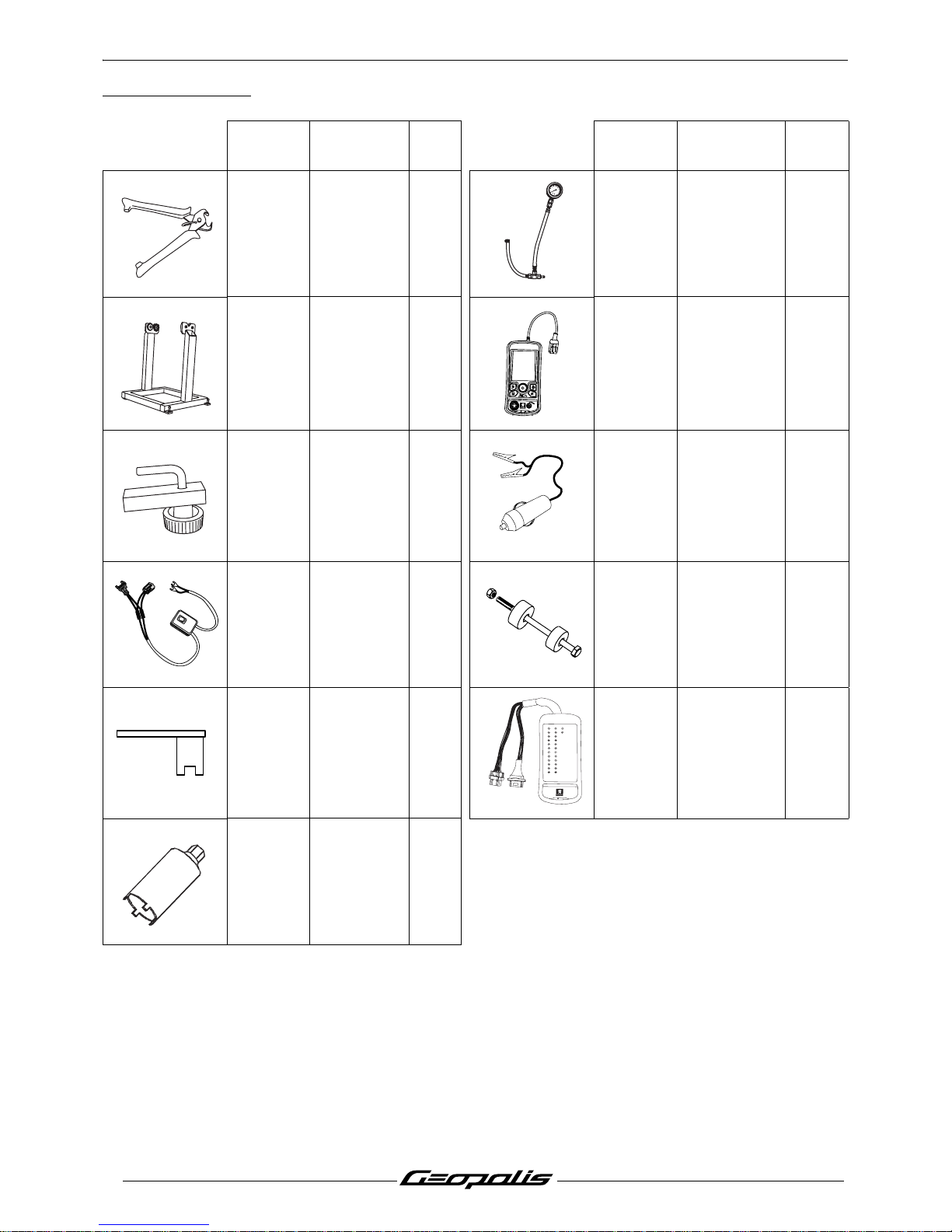

SPECIAL TOOLS ............................................................................................................................................ 12

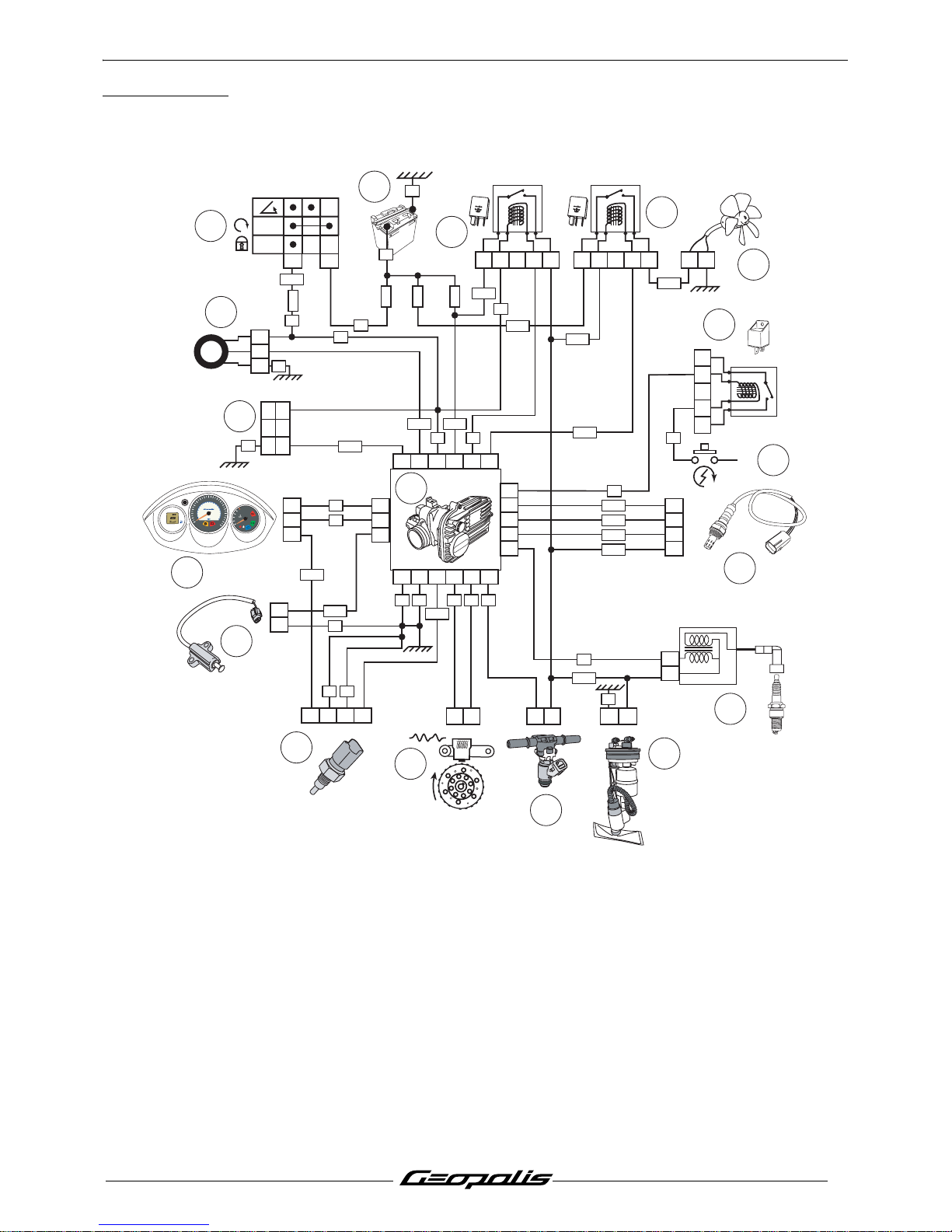

ELECTRICITY..................................................................................................................................................13

4 stroke indirect injection system functional diagram...............................................................................13

Fuses and energy distribution..................................................................................................................14

LOCATION OF COMPONENTS...................................................................................................................... 15

TABLE OF CONTENTS

2

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

BODY PANELS ............................................................................................................................................... 16

Location of body components..................................................................................................................16

Body component sequence of disassembly.............................................................................................17

Removal of the storage compartment......................................................................................................18

Removal of a RH or LH side cover...........................................................................................................18

Removal of the tank covers......................................................................................................................19

Removal of a RH or LH footboard............................................................................................................20

Removal of the front shield panel.............................................................................................................21

Removal of the rear shield panel .............................................................................................................22

Removal of the dirt shield ........................................................................................................................22

Removal of the instrument cluster ...........................................................................................................23

Removal of the battery holder..................................................................................................................23

SERVICE OPERATIONS................................................................................................................................. 24

Changing the engine oil and replacing the oil filter ....... ... ... ... .... ... ... .......................................... ..............24

Draining the relay box..............................................................................................................................25

Replacing the air filter ..............................................................................................................................26

Removal of the spark plug .......................................................................................................................27

Replacing the rollers and drive belt..........................................................................................................27

Draining the cooling circuit.......................................................................................................................28

Installing the valve clearance........................ ... ... .......................................... ... ... .... ... ..............................29

Replacing the brake pads ........................................................................................................................30

Front brake........................................................................................................................................................30

Rear brake............................................. ... .................................... ....................................................................30

SERVICING AN ABS/PBS SYSTEM .............................................................................................................. 31

Removal of the brake modulator..............................................................................................................31

TABLE OF CONTENTS

3

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

MISCELLANEOUS OPERATIONS ................................................................................................................. 32

Procedure for reducing the fuel circuit pressure .............................................. ... .... ... ..............................32

Checking fuel pressure ............................................................................................................................33

Removal of the fuel pump........................................................................................................................34

Removal of the fuel gauge.......................................................................................................................34

Removal of the throttle box......................................................................................................................35

Removal of the lambda sensor ................................................................................................................35

Removal of the thermostat.......................................................................................................................37

Removal of the temperature sensor.........................................................................................................37

Removal of the regulator..........................................................................................................................37

Removal of the radiator............................................................................................................................38

Removal of the engine mounting assembly .............................................................................................38

Installing the engine mounting assembly...... ... ... ... ... .... ............................................. ... ... .... ... ... ... ...........39

Removal of the cylinder head...................................................................................................................40

Removal of the cylinder / piston...............................................................................................................40

Removal of the fork..................................................................................................................................41

Replacing the bearings of the steering system........................................................................................41

Steering system tightening method..........................................................................................................43

Removal of the suspension arm ..............................................................................................................44

CHARACTERISTICS

4

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

CHARACTERISTICS

Engine

Capacities

GEOPOLIS 250 cc.

Type.

4-stroke single-cylinder.

4 valves per cylinder with chain driven overhead camshaft

Cooling. Liquid.

Bore x stroke. 2 x 60 mm.

Cubic capacity. 244 cc.

Max. power output. 16.5 kW at 8000 rpm.

Max. torque rating. 6250 rpm.

Fuel supply.

Indirect electronic injection.

Magneti-Marelli

Lubrication. Trochoidal pump.

Transmission. By 2 variable pulleys and V-type belt.

Clutch. Centrifugal automatic.

Spark plug.

Champion RG 4 PHP

Exhaust. Catalytic.

Standards. Euro 3.

Fuel tank. 13.2 l 95 or 98 lead-free.

Engine oil.

1.3 L SAE 5W40.

Minimum grade: API SJ.

Relay box. 0.25 L SAE 75W85.

Coolant. 1.4 l. Peugeot coolant part number 754614

Fork. 212cc by tube Esso Univis 46 or Agip H Lift 46.

CHARACTERISTICS

5

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Chassis

Dimensions and weight

Tyres

Chassis. Double cradle out of high-resistance steel tube.

Front suspension. Hydraulic telescopic fork. Ø37 mm.

Travel. 110 mm.

Rear suspension. 2 adjustable combined spring hydraulic shock absorbers.

Travel. 100 mm.

Overall length.

2170 mm.

Width at handlebar.

770 mm.

Height. (without rear-view

mirrors).

1425 mm.

Wheelbase. 1420 mm.

Ground clearance.

140 mm.

Saddle height.

784 mm.

Unladen weight.

159 kg.

Front wheel rim. 16 inch aluminium alloy.

Front tyre. .110/70 - 16.

Front tyre pressure. 2.1 bars.

Rear wheel rim. 16 inch aluminium alloy.

Rear tyre. .140/70 - 16.

Rear tyre pressure. 2.3 bars.

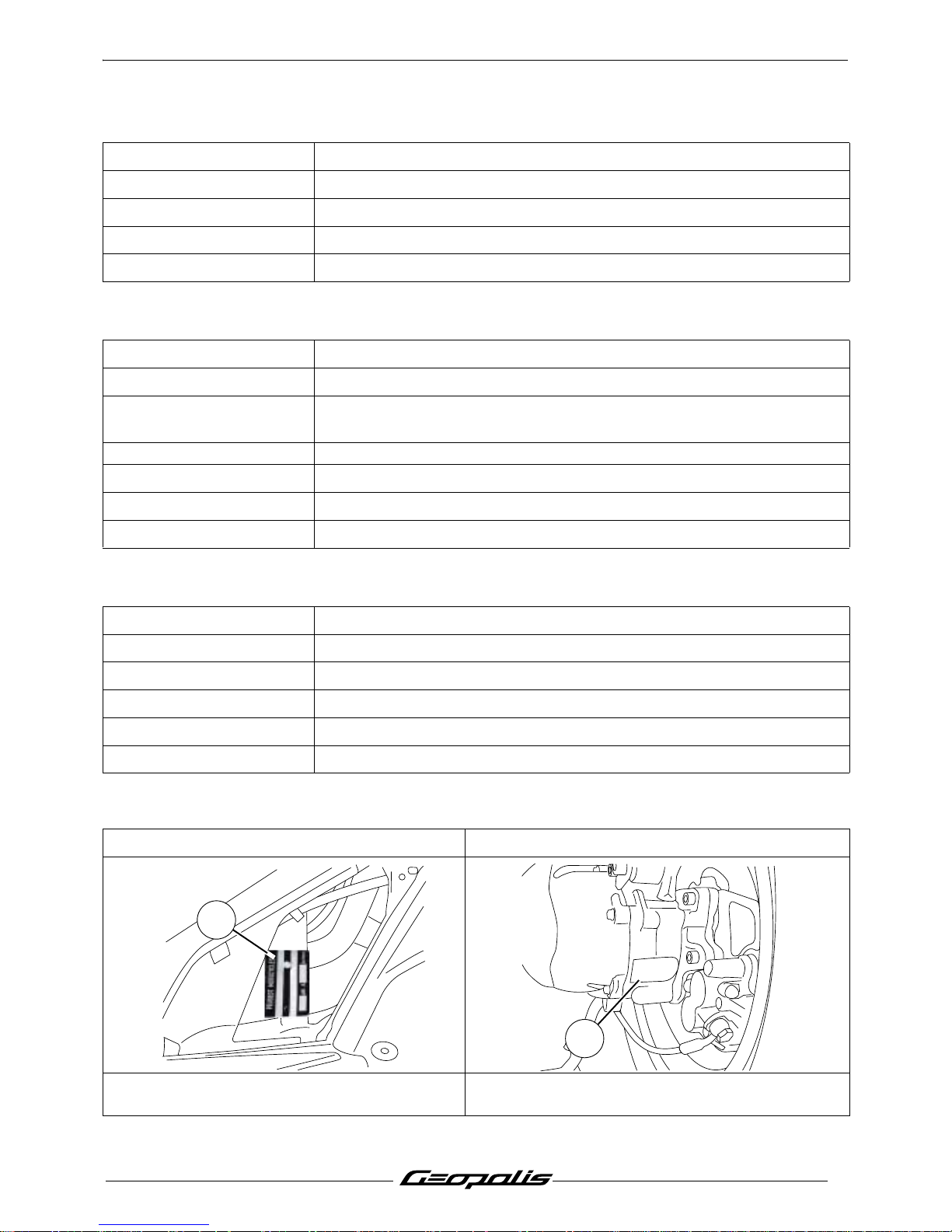

Chassis markings Engine marking

1. Manufacturer's plate. (Left side).

- VIN number of the RH side of the vehicle.

2. Engine number.

1

XXXXX

XXXXXXX

2

SERVICE SCHEDULE AND COMMISSIONING

6

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

SERVICE SCHEDULE AND COMMISSIONING

Heavy duty servicing is for vehicles used under "harsh" conditions: door-to-door deliveries, intensive

urban use (courier), short journeys with engine cold, dusty areas, ambient temperature over 30°C.

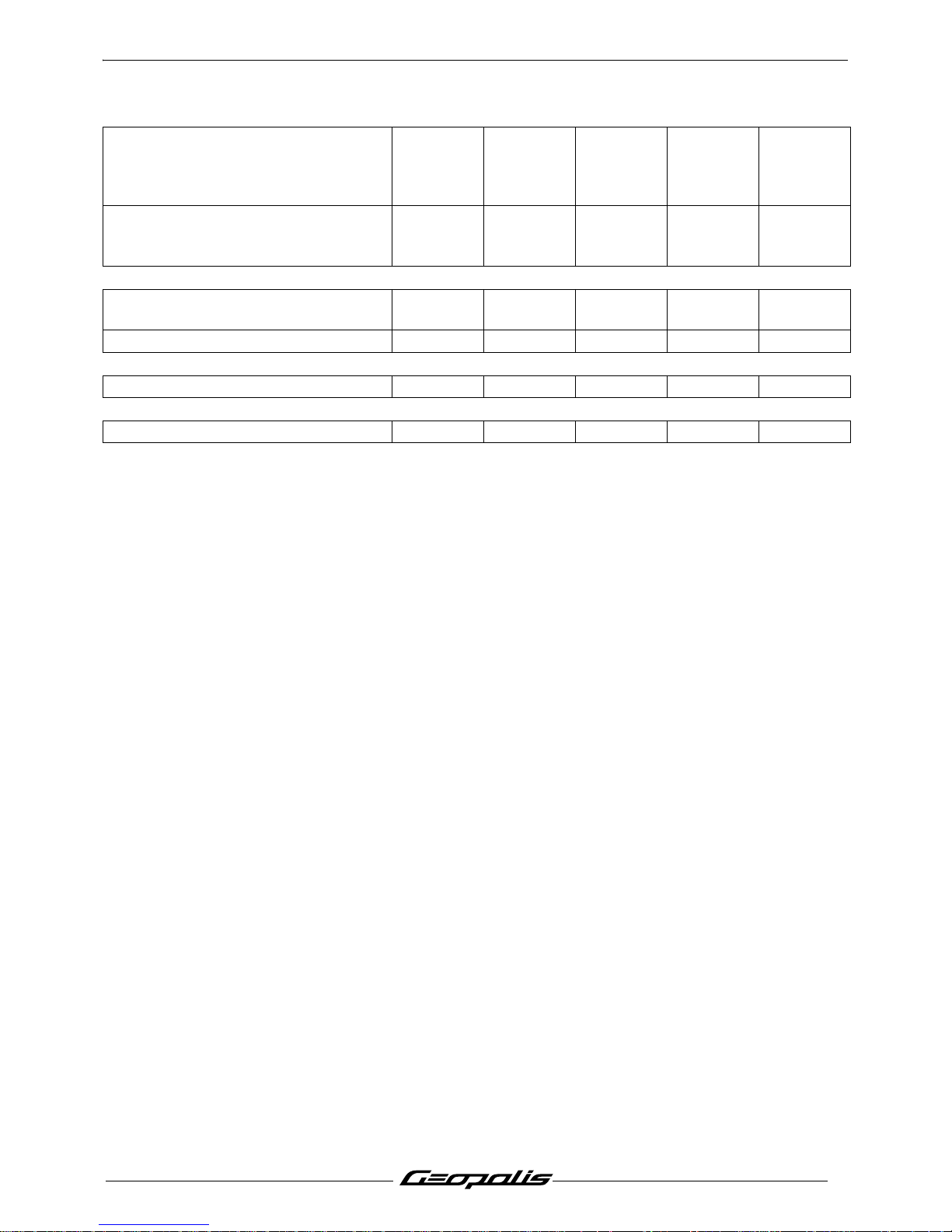

Service operations.

1000 kms

or

1 months

Every

5000 kms

or

12 months

Every

10000 kms

Every

15000 kms

Every

20000 kms

Heavy duty servicing. 500 kms

Every

2500 kms

Every

5000 kms

Every

7500 kms

Every

100000 k

ms

Check

Throttle cable play. C C C C

Steering column play. C C C C

Operation of electrical equipment. C C C C

Condition of front and rear brake

hydraulic controls.

CCC C

Condition of petrol pipes. C C C C

Condition of oil pipes. C C C C

Tyre pressures. C C C C

Tyre condition, pressure and wear. C C C C

Condition of the front suspension. C C C C

Condition of the rear suspension. C C C C

Brake fluid level. C C C C

Battery electrolyte level *. C C C C

Coolant level. CCCCC

Engine oil level. C

Tightening the engine mounting and

linkrod.

CCCC

Tightness of nuts and bolts. C C C C

Change

Spark plug. R

Inlet silencer/air filter. N N

Front brake pads #. C C C C

Rear brake pads #. C C C C

Drive pulley bearings and guides #. C C

Transmission belt. R

Belt anti-flapping roller #. C C

Engine oil (+ clean strainer). RCRCR

Engine oil filter. R R R

Relay box oil. R C R

Brake fluid and coolant. Once every 2 years

SERVICE SCHEDULE AND COMMISSIONING

7

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

C: Check.

N: Clean.

R: Change.

G: Check and lubricate.

* Depending on equipment.

# Change if necessary.

Service operations.

1000 kms

or

1 months

Every

5000 kms

or

12 months

Every

10000 kms

Every

15000 kms

Every

20000 kms

Heavy duty servicing. 500 kms

Every

2500 kms

Every

5000 kms

Every

7500 kms

Every

100000 k

ms

Check and lubricate

Driven pulley: Moving flange and

needle bush.

GG

Drive pulley/Movable face. G G

Reading the ECU fault codes

Injection and ABS/PBS* system. CCCCC

Test machine

On road CCCCC

SERVICE SCHEDULE AND COMMISSIONING

8

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Battery preparation (Except battery without maintenance)*

Remove the battery.

Remove the 6 filler caps and the vent plug.

Fill with electrolyte to the level marked "UPPER LEVEL".

Electrolyte: (35% sulfuric acid = 1.28g/cm3).1 litre can P/N 752740; 5 litre can P/N 752741.

Leave the battery to stand for around half an hour.

Top up if necessary.

Charge the battery for at least 2 hours with a current of 0.4A.

Refit the battery and connect the vapour vent pipe.

Connect the red wire lug to the battery's + terminal, and the green wire lug to the battery's - terminal.

Then, the battery level should be topped up if necessary, after fully charging, using distilled water only.

Checks before handing over to the customer

Check the wheel nuts are tight.

Check nuts and bolts are tight.

Check brake adjustment and efficiency.

Check the tyre pressures cold.

Check operation of the lights, flashers, horn, and brake light.

Check the different warning lights work.

Carry out a road test.

* Depending on equipment.

SPECIAL IMPORTANT POINTS

9

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

SPECIAL IMPORTANT POINTS

Oil and fuel

This engine is designed to run on 95 or 98 unleaded fuel only.

Fuel pipes must absolutely be changed if there are any signs of wear, cracks, etc.

The clips are specific, they must always be changed each time they are removed and replaced

with new genuine parts clips.

Petrol is highly inflammable, do not smoke in the working area and avoid pr oximity to flames or

sparks. Work in a clear and well-ventilated area.

Before carrying out any work, leave the engine to cool for at least 2 hours.

Starting up after overhauling the engine

When starting the engine hot or cold do not accelerate.

Check the coolant level in the header tank.

After road-testing the machine, check there are no fault codes left in the ECUs (using the diagnostic

tool).

Electricity

All components of the electrical system are powered with 12 volts DC.

The battery must not be disconnected while the engine is running and the voltage must be at least

7 volts for the ECU to function and enable engine starting.

Special features

An immobiliser built in the ECU provides the antitheft function by means of a transponder

The ECU features a diagnosis function which allows you to read memorized faults using th e diagnostic

tool.

TIGHTENING TORQUES

10

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

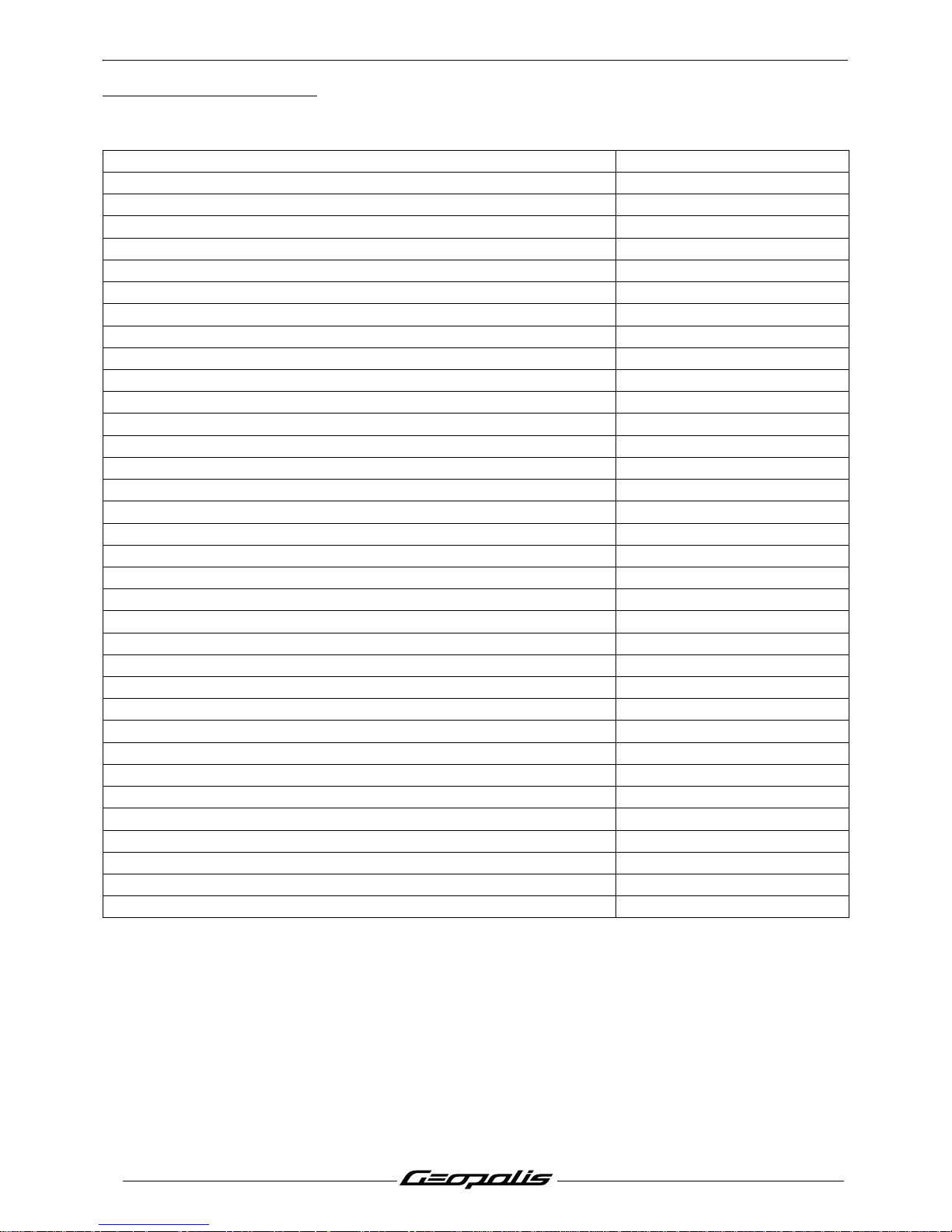

TIGHTENING TORQUES

Engine part

Drive pulley 8 m.daN

Driven pulley 5.5 m.daN

Clutch plate and shoes 4.8 m.daN

Belt anti-flapping roller 1.5 m.daN

Transmission cover 1.2 m.daN

Relay box cover 2.5 m.daN

Filler cap. Relay box 1.5 m.daN

Flywheel magneto cover 1.2 m.daN

Stator 1m.daN

Engine speed sensor 0.5 m.daN

Rotor 9.5 m.daN

Freewheel 1.4 m.daN

Starter motor 1.2 m.daN

Automatic tensioner 1.2 m.daN

Automatic tensioner plug 0.5 m.daN

Spark plug 1.2 m.daN

Decompressor valve balance weight 0.8 m.daN

Decompressor valve housing 1.2 m.daN

Chain tensioner 1 m.daN

Camshaft stop plat 0.5 m.daN

Cylinder head bolt 1.2 m.daN

Cylinder head Procedure

Cylinder head cover 0.7 m.daN

Inlet manifold 1.2 m.daN

Injection rail 0.7 m.daN

Oil pressure switch 1.2 m.daN

Oil pump 0.6 m.daN

Oil pump pinion 1.2 m.daN

Oil pump cover 0.8 m.daN

Oil pan 1.2 m.daN

Crankcase 1.2 m.daN

Filler cap. Engine oil 2 .5 m.daN

Water pump cap 0.7 m.daN

Thermostatic valve cover 0.4 m.daN

Cooling system bleeder screw 0.3 m.daN

TIGHTENING TORQUES

11

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

Body panels

Cycle part

Standard

Front mudguard. 0.8 to 1.2 m.daN

Handlebar cover. 0.2 to 0.4 m.daN

Front shield panels. 0.2 to 0.4 m.daN

Rear shield. 0.2 to 0.4 m.daN

Bottom panel. 0.2 to 0.4 m.daN

Floor panel. 0.4 to 0.6 m.daN

Saddle storage compartment. 0.8 to 1.2 m.daN

Rear panels. 0.2 to 0.4 m.daN

Grab handle. 2 to 2.5 m.daN

Rear mudguard. 0.4 to 0.6 m.daN

Front wheel spindle. 6.5 m.daN

Rear wheel bolt. 10 m.daN

Rear wheel spindle nut. 13.5 m.daN

Linkrod to engine pivot. 5.8 m.daN

Linkrod to frame pivot. 5.8 m.daN

Linkrod connecting pin 3.6 m.daN

Linkrod to frame adjustment locknut 10 m.daN

Linkrod to frame mounting bolt 6.8 m.daN

Shock absorber top mount. 4.5 m.daN

Shock absorber bottom mount. 4.5 m.daN

Exhaust to cylinder head mounting nut. 1.8 m.daN

Exhaust to casing mounting bolt. 2.5 m.daN

Exhaust clamp. 1.8 m.daN

Upper cone (in 2 operations). 4/2.2 m.daN

Upper cone locknut. Hand tightened

Steering locknut. 7.5 m.daN

Front brake caliper. 2.5 m.daN

Rear brake caliper. 2.5 m.daN

Front brake disc. 3 m.daN

Rear brake disc. 0.9 m.daN

Handle bar. 4 m.daN

Nut and bolt 5 mm diameter. 0.6 m.daN

Nut and bolt 6 mm diameter. 1 m.daN

Nut and bolt 8 mm diameter. 2.2 m.daN

Nut and bolt 10 mm diameter. 3.5 m.daN

Nut and bolt 12 mm diameter. 5.5 m.daN

SPECIAL TOOLS

12

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

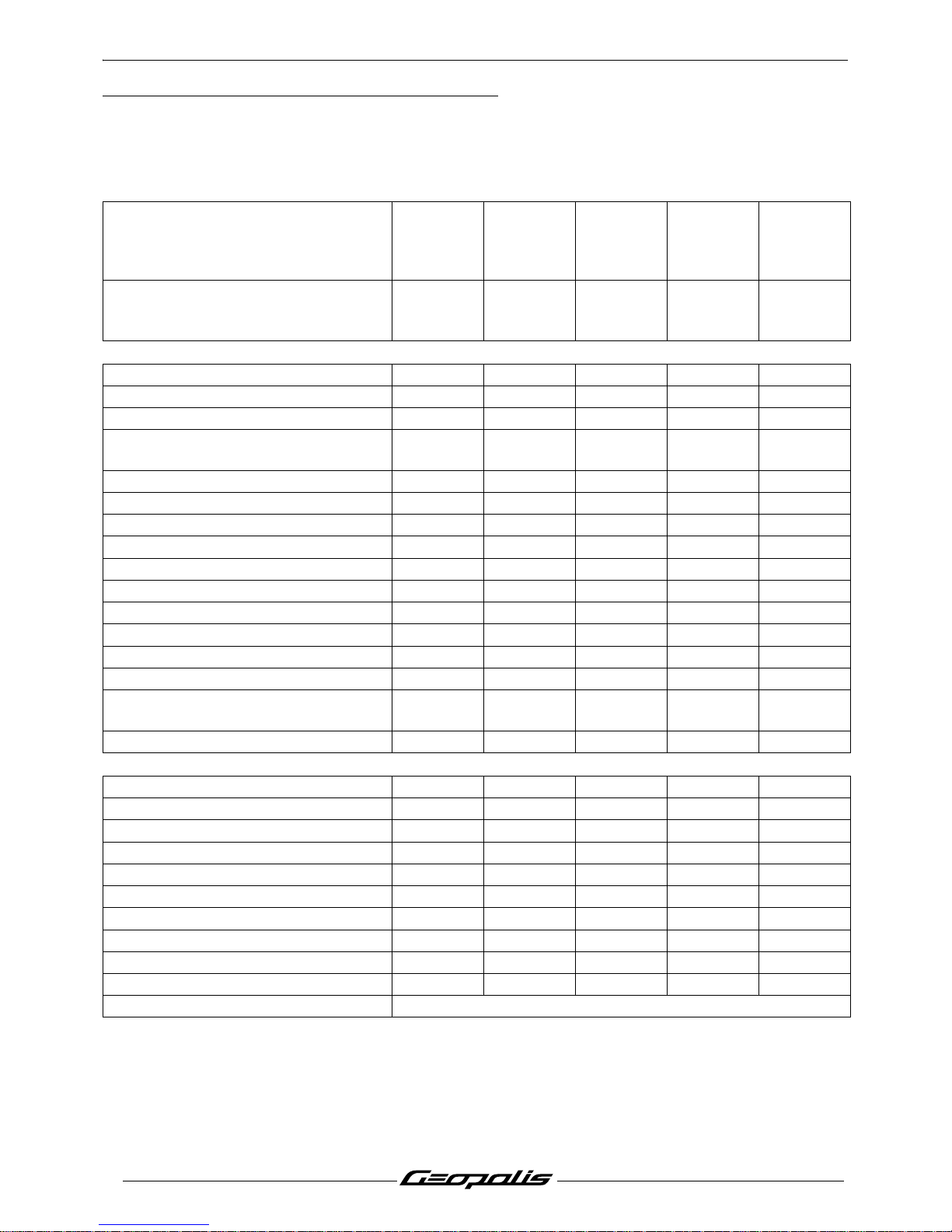

SPECIAL TOOLS

(*) New or modified tool.

Tool N° Designation

Used

with

Tool N° Designation

Used

with

750539

Tie-wrap

pliers

757877

Pressure

gauge

754278

Balance

support with

pins Ø15 and

Ø17 mm

758358 TEP 2005

755996 Hose clamp 758585

Power supply

cable tool

756017

Fuel injector

power supply

harness

758810

Steeing head

cup

installation

tool

756715

(*)

Tank gauge

spanner

758924

24 way

terminal block

(*)

757860 Steering tool

0

6

8

1

0

2

4

b

a

r

OK

TEP 2005

by

xxo

test

1

24

12

23

11

2210

21

9

20

8

197

186

175

16

15

141326

25

4

3

2

BM 426

b

y

xxo

t

e

s

t

ELECTRICITY

13

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

ELECTRICITY

4 stroke indirect injection system functional diagram

1. Injection ECU.

2. Engine speed and position sensor.

3. Petrol injector.

4. Petrol pump.

5. Ignition coil.

6. Lambda sensor.

7. Starter motor switch.

8. Starter motor relay.

9. Cooling fan.

10. Fan relay.

11. Injection relay.

12. Battery.

13. Ignition switch.

14. Transponder antenna.

15. Diagnostic plug.

16. Instrument panel.

17. Kickstand switch.

18. Engine temperature sensor.

1

2

V

-

2

5

A

21345

1

2

V

-

2

5

A

12345

2

1

3

4

5

1

2

6

3

OFF

ON

11

7

8

-

U

P

P

E

R

L

E

V

E

L

L

O

W

E

R

L

E

V

E

L

VE

B1A1

A3

VE

6

5

4

3

2

18

17

16

15

14

13

12

11

10

9

8

7

2

1

21

22

21

11

4

15 1413926 12

1

17

18

82420716 5 6

1

R

1

2

4

3

1

2

3

2

1

1

2

30A

F1

15A

F6

10A

F2

15A

F4

VE

VEVE

VE

JN

BCNR

NR

NR

RG

RG

VI

VE-NR

RG-BA

BA-BE

VE-NR

VE-NR

VE-JN

BE-NR

BA-VE

VI-BA

BE-NR

GR-RG

RG-NR

VI-NR

VE-NR

GR-RGMR-BA

BA-NR

12

+

BE

BA

VE

VE VE RG MR OR

VI

NR

Km

100

6

0

5

0

Km/h

40

30

20

10

70

8

0

9

0

1

0

0

120

140

160

80

60

40

80

40

120

20

0

M

Hrs

PEUGEOT

ELECTRICITY

14

Reproduction ou traduction, même partielle, interdite sans autorisation écrite de Peugeot Motocycles

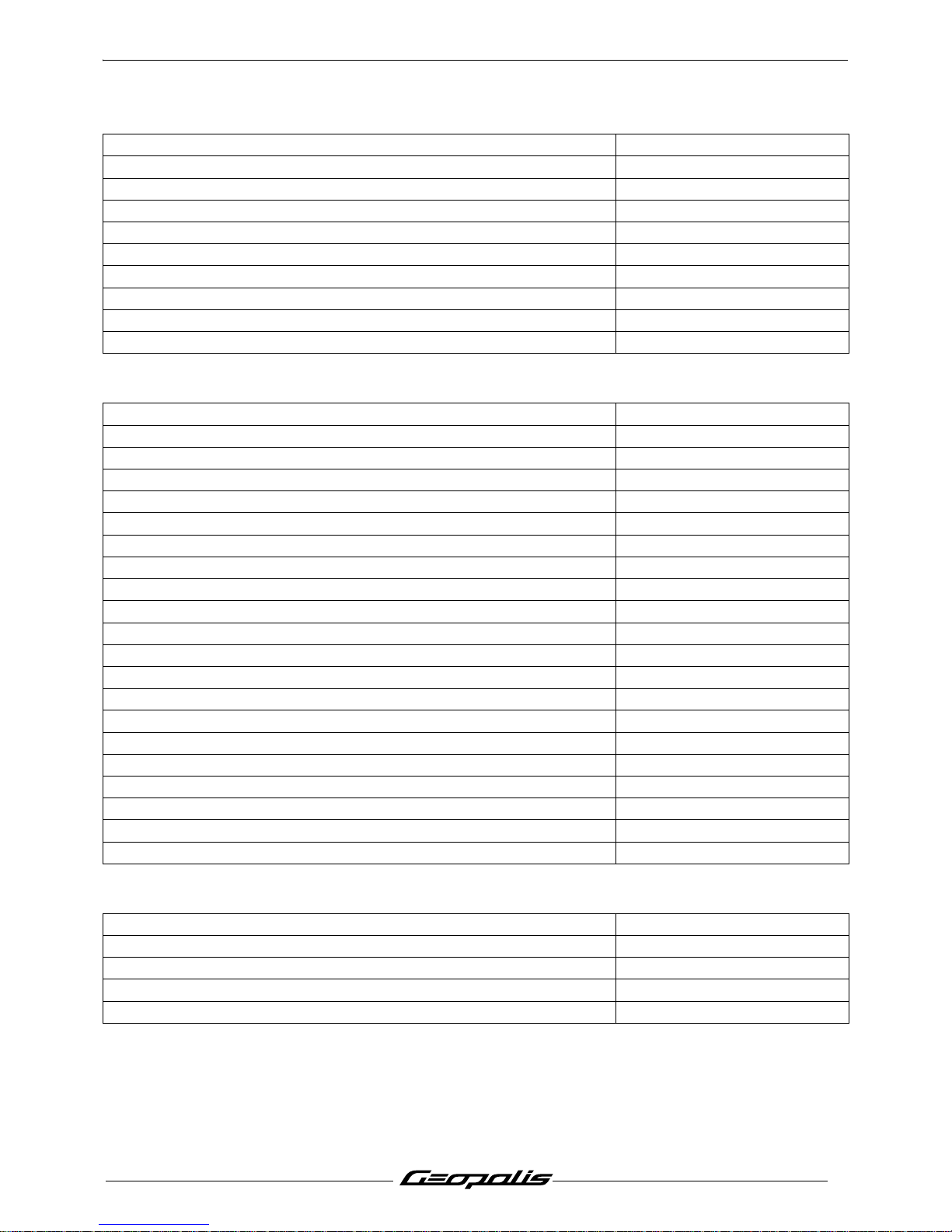

Fuses and energy distribution

Geopolis 250 cc

F1

Regulator.

Ignition switch.

F7.

F2

Injection ECU.

Injection relay:

HT coil.

Petrol injector.

Petrol pump.

Lambda sensor.

Fan relay.

F4

Instrument panel.

Lighting relay.

Fan relay.

F5

Instrument panel.

Dip switch (main/low headlight).

Horn.

Number plate light.

Sidelight.

Stop light contact.

F6

Injection ECU.

Transponder antenna.

Diagnostic plug.

Injection relay.

Lighting relay.

F7 Accessory socket.

RG

GR-BE

GR-RG

GR-RG

+B

-

UPPER LE

VEL

LOW

ER LE

VEL

RG

RG-NR

GR-NR

NR

6

5

1

2

4

7

F1-30A

F6-7,5A

F5-15A

F2-10A

F4-15A

F7-10A

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Loading...

Loading...