Page 1

Prestige® IAQ

with Equipment Interface Module

Installation Guide

TM

RedLINK to Equipment Interface Module

TM

2 Wires for Power

OR

RedLINK to TrueZONE Wireless Adapter

TM

2 Wires for Power

Page 2

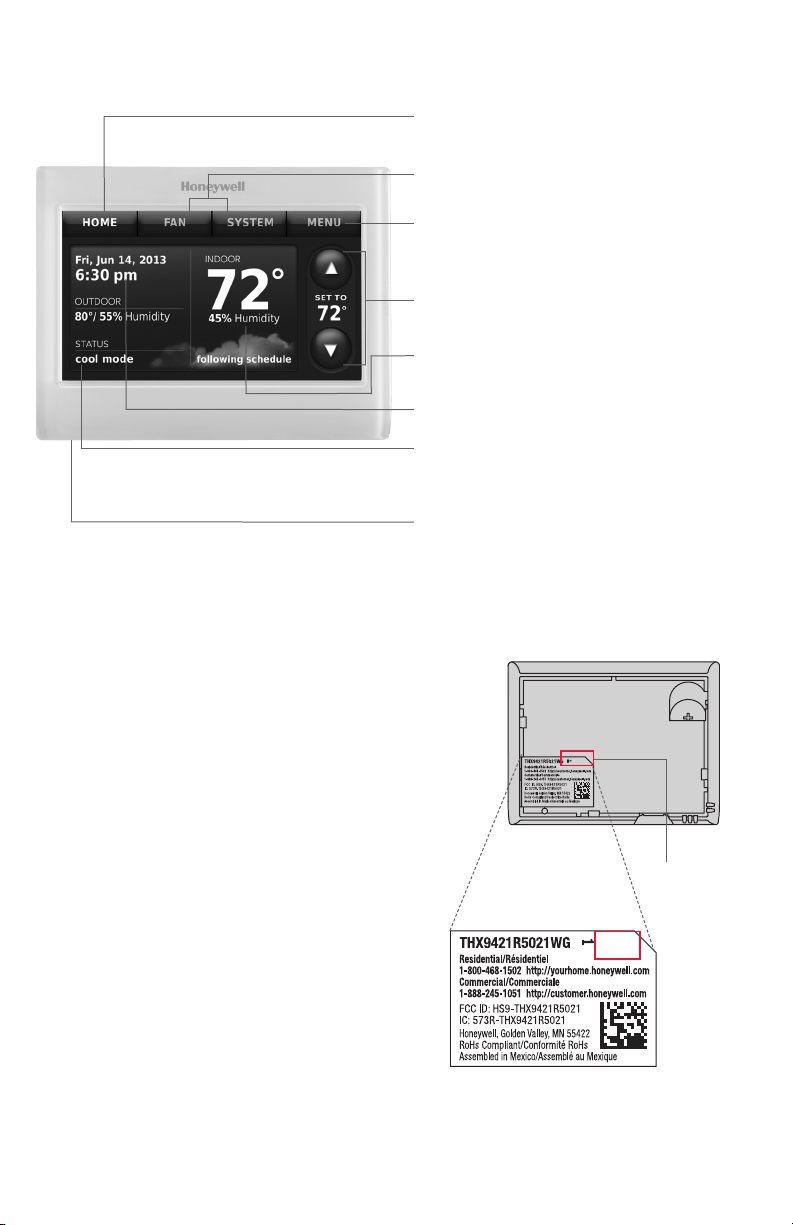

Reference to key features

* Password is date code.

Current display. Button pressed in

signifies current display

Mode control buttons. Use to change

settings for Fan or System Heat/Cool.

Menu. Select options to: set schedules,

view equipment status, change IAQ

settings, access installer options*, etc.

Current schedule. Shows desired

temperature and schedule status.

Indoor conditions. Shows indoor

temperature and humidity.

Current date and time.

Current status. Shows system mode

(heat/cool), outdoor temperature and

humidity (with optional outdoor sensor).

USB port. Use USB device to load

settings and dealer information.

Getting started

Follow these basic steps to install this

thermostat, link it with the equipment interface

module (EIM) and wireless accessories and

set installer options.

Installing the Equipment Interface

1

Module (EIM)

Installing the thermostat

2

Powering optional RedLINK accessories

3

Performing initial setup

4

Finding your password (Date Code)

5

• To add or remove RedLINK accessories

• To make changes to Installer Setup

• To perform an Installer Test

• To view Data Logs

2

Thermostat (back view)

1324

Password

(Date Code)

1324

Page 3

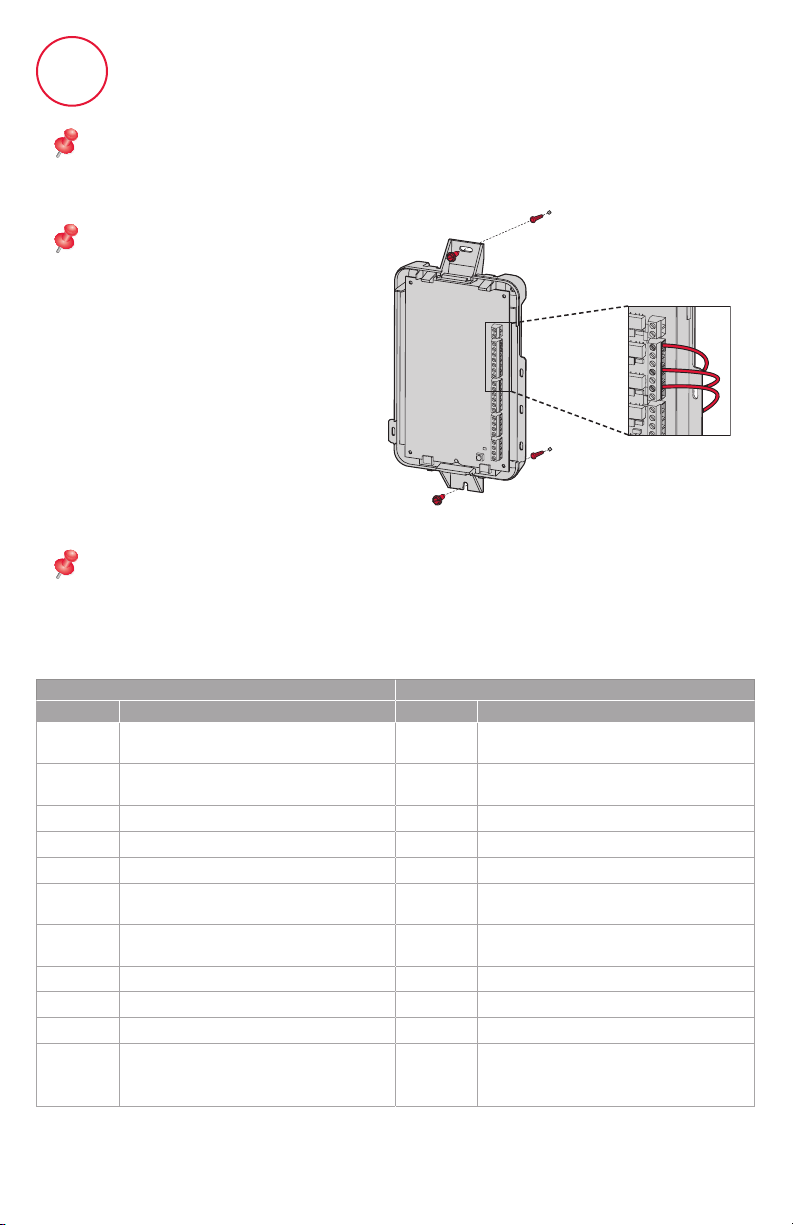

1

Installing the equipment interface module (EIM)

NOTE: If an EIM is mounted inside a metal cabinet, it is recommended to use

a THM4000R1000 Wireless Adapter for extended wireless range. Mount the

Wireless Adapter outside the metal cabinet and connect to the ABCD terminals at

the EIM.

NOTE: When installing multiple

thermostats and EIMs, mount the

EIMs at least 2 feet apart for best

RedLINK performance.

1.1 Mount EIM.

Mount the EIM near the HVAC

equipment or on the equipment

itself.

Use screws and anchors as

appropriate for the mounting

surface.

1.2 Wire EIM as shown.

Refer to the table and wiring diagrams on pages 3-5.

NOTE: If you are installing discharge and return air sensors, refer to the mounting

instructions in the Alerts and Delta T Diagnostics Installation Instructions packed

in the kit.

R

C

W

O/B

W2

AUX1

W3

AUX2

Y

Y2

G

A

L/A

Terminal Designations

Conventional System Heat Pump

Terminal Description Terminal Description

Common wire from 24 VAC

C

transformer.

Power wire from 24 VAC

R*

transformer.

Common wire from 24 VAC

C

transformer.

Power wire from 24 VAC

R

transformer.

RH* Heating power. RH Heating power.

RC* Cooling power. RC Cooling power.

W Heat Stage 1 O/B Changeover valve for heat pumps.

W2 Heat Stage 2 AUX 1

W3 Heat Stage 3 AUX 2

Backup Heat Stage 1/Emergency

Heat Stage 1

Backup Heat Stage 2/Emergency

Heat Stage 2

Y Compressor Stage 1 Y Compressor Stage 1

Y2 Compressor Stage 2 Y2 Compressor Stage 2

G Fan Relay G Fan Relay

Connect to Economizer Module or

A

Lighting Panel (TOD).

L/A

Connect to Compressor Monitor,

Zone Panel, Economizer Module or

Lighting Panel (TOD).

* Remove jumpers when separate transformers are used.

3

Page 4

Terminal Designations

ONE DRY CONTACT DEVICE

Conventional System Heat Pump

Terminal Description Terminal Description

U1 / U1**

U2 / U2**

U3 / U3**

S1 / S1***

S2 / S2***

S3 / S3***

S4 / S4***

Universal relay for humidification,

dehumidification, ventilation, or

a stage of heating/cooling. U

terminals are dry contacts that

require power.

Universal input for a wired indoor

sensor, outdoor sensor, discharge

sensor, return sensor, dry contact

device for alerts or dry contact

device for remote setback.

U1 / U1**

U2 / U2**

U3 / U3**

S1 / S1***

S2 / S2***

S3 / S3***

S4 / S4***

Universal relay for humidification,

dehumidification, ventilation, or

a stage of heating/cooling. U

terminals are dry contacts that

require power.

Universal input for a wired indoor

sensor, outdoor sensor, discharge

sensor, return sensor, dry contact

device for alerts or dry contact

device for remote setback.

A

Connect to THM4000R1000

B

Wireless Adapter for extended

C

wireless range.

D

** See wiring diagrams on pages 4-5.

*** See wiring diagram below for wiring Dry Contact Devices to display alerts.

A

Connect to THM4000R1000

B

Wireless Adapter for extended

C

wireless range.

D

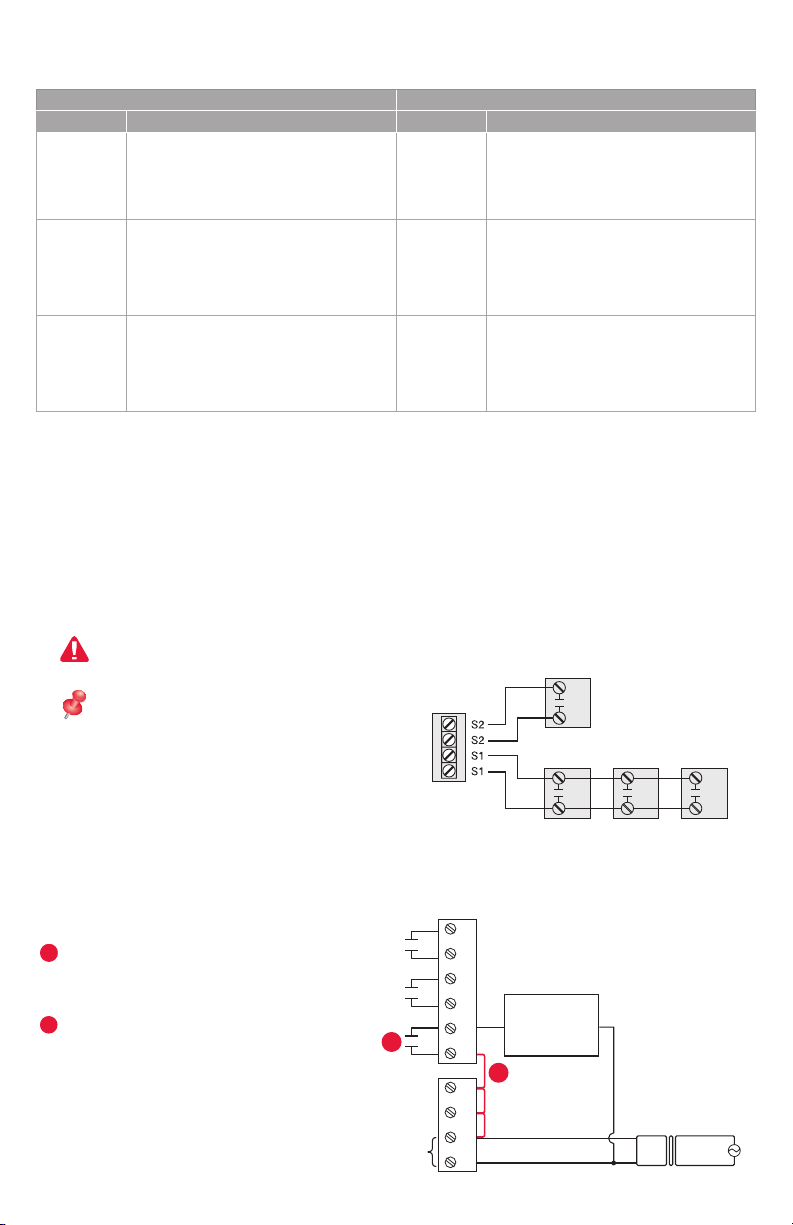

Wiring dry contact devices to display alerts

DISCONNECT POWER BEFORE INSTALLATION.

Do not apply power to S1, S2, S3 or S4 terminals.

NOTE: The dry contact device must

EIM

be rated for low voltage.

Connect a dry contact device such as a

water sensor to S1, S2, S3 or S4 terminals.

MULTIPLE DRY CONTACT DEVICES

ON ONE SET OF TERMINALS

The thermostat displays an alert when a

problem is detected.

Connecting a stage of heating or cooling to a universal relay

(U1, U2, U3)

U3

1

U1, U2, and U3 are normally

open dry contacts when set up

for a stage of heating or cooling.

2

Youmustinstallaeldjumperif

the stage of heating or cooling is

powered by the system trans-

former.DoNOTinstallaeld

jumper if the stage of heating has

its own transformer.

4

1

VAC

U3

U2

HEAT STAGE 3,

U2

COOL STAGE 3,

COOL STAGE 4 OR

U1

GEOTHERMAL

RADIANT HEAT

U1

2

RH

RC

R

24

C

TRANSFORMER

24

VAC

120

VAC

Page 5

VA

VA

VA

24

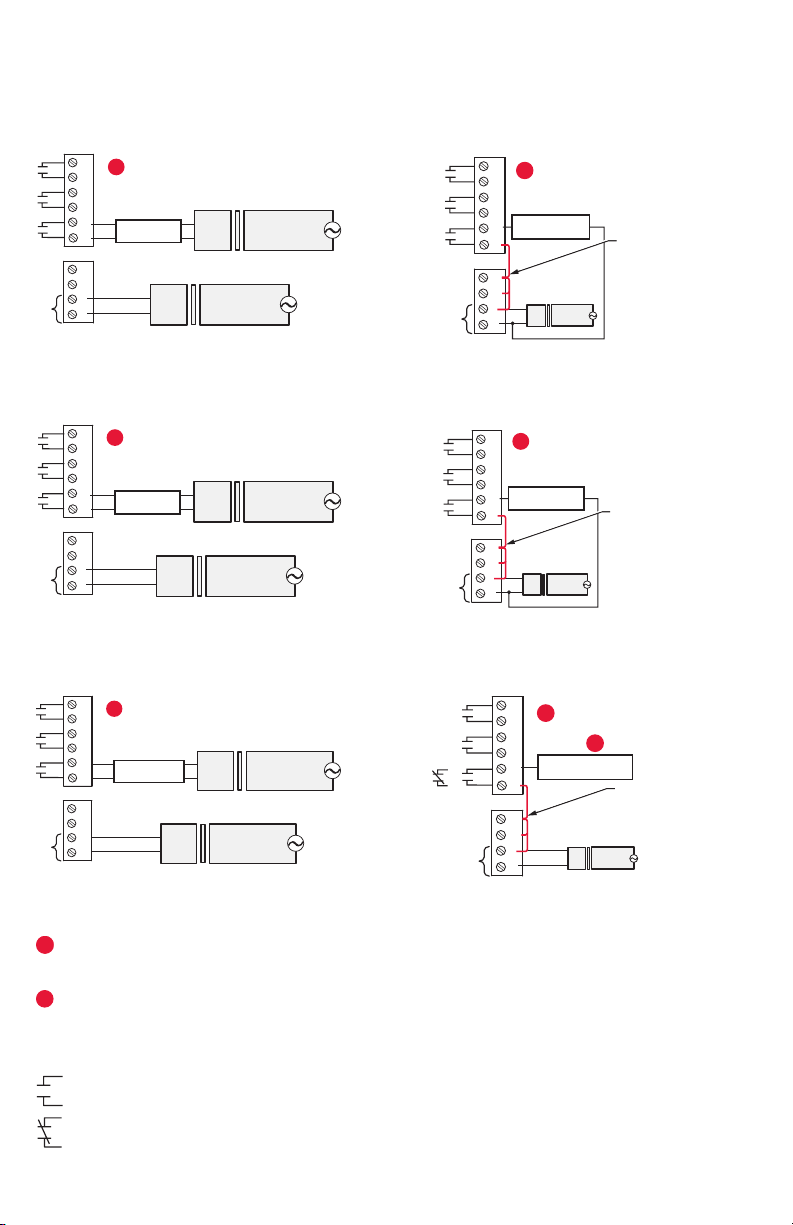

Wiring humidification, dehumidification and ventilation

Typicalhookupofpoweredhumidier Typical hookup of non-powered

humidier

U3

1

U3

U2

U2

U1

POWERED

HUMIDIFIER

U1

RH

RC

R

24

C

C

VAC

24

VAC

24

120

VAC

120

VAC

Typical hookup of powered ventilation

U3

1

U3

U2

U2

U1

POWERED

VENTILATOR

U1

RH

RC

R

24

C

C

VAC

24

VAC

24

120

VAC

120

VAC

Typicalhookupofpowereddehumidier

(whole house dehumidifer)

U3

1

U3

U2

U2

U1

POWERED

DEHUMIDIFIER

U1

RH

RC

R

24

C

C

VAC

24

VAC

24

VAC

120

VAC

120

U3

1

U3

U2

U2

NON-POWERED

U1

HUMIDFIER

24 VAC

U1

RH

RC

R

24

VAC

C

120

VAC

FIELD INSTALLED

JUMPER BETWEEN

R AND U1

Typical hookup of non-powered

ventilation

U3

1

U3

U2

U2

NON-POWERED

U1

VENTILATOR

U1

RH

RC

R

VAC

24

VAC

C

120

VAC

FIELD INSTALLED

JUMPER BETWEEN

R AND U1

Typical hookup of variable speed blower

fordehumidicationinlowspeed

U3

1

U3

OR

24 VAC

U2

U2

U1

U1

RH

RC

R

C

2

DEHUMIDIFICATION

WITH LOW SPEED FAN

120

24

VAC

VAC

FIELD INSTALLED

JUMPER BETWEEN

R AND U1

1

Any combination of universal relays (U1, U2, U3) can be used. They are set in the

thermostat installer setup.

2

WiretheuniversalEIMrelaytothelowspeedfanfordehumidicationcontrolat

the equipment. The EIM relay can be set to be normally open or normally closed

in the thermostat installer setup.

Normally open, dry contacts

Normally closed, dry contacts

5

Page 6

2

Installing the thermostat

2.1 Separate wallplate

from thermostat.

2.2 Mount wallplate as shown.

Mount new wallplate using

screws and anchors included

with the thermostat.

Drill 3/16-in holes for drywall.

Drill 7/32-in holes for plaster.

2.3 Connect power to

thermostat.

2.3a Connect thermostat to

the R and C terminals at

the EIM or to a separate

24 volt transformer (not

provided).

2.3b Push excess wire back

into the wall opening.

Thermostat (back view)

1324

R

C

Wallplate

Wallplate (back view)

Wallplate

2.4 Insert coin cell battery.

Place coin cell battery in

thermostat as shown with +

side up.

NOTE: Coin cell battery saves

time and date during a power

loss.

6

Coin cell

battery

1324

Thermostat (back view)

Page 7

2.5 Mount thermostat on

wallplate.

Align thermostat to wallplate

and snap into place.

Thermostat

Wallplate

R

C

3

Powering optional RedLINK accessories

3.1 Install batteries in RedLINK

accessories.

• Portable Comfort Control

• Wireless Outdoor Sensor*

• Wireless Indoor Sensor*

• Wireless Entry/Exit Remote*

• Wireless Vent and Filter Boost

Remote*

* Requires setup. See Installer

Setup options in Step 4.5.

3.2 Connect gateway to internet and

connect to power.

3.2a Connect RedLINK Internet

Gateway to router or modem

with Ethernet cable (RJ45).

3.2b Connect gateway’s power cord

to an electrical outlet that is not

controlled by a wall switch.

3.2a

3.2b

7

Page 8

CONNECT

CONNECTED

4

Performing initial setup

Initialsetupoptionsdenethetypeofsystemyouareinstalling:

• Residential or commercial

• Non-zoned or zoned

• Used with or without an Equipment Interface Module (THM5421)

• Used with or without the TrueZONE Wireless Adapter (THM4000)

4.1 Follow prompts on the screen to

select appropriate options.

NOTE: If you are connecting the

thermostat to the TrueZONE Wireless

Adapter (THM4000), refer to the

TrueZONE instructions to link the

thermostat and RedLINK accessories.

Then go to step 4.5.

4.2 Link the thermostat to the equipment

interface module.

4.2a Press and quickly release the

CONNECT button on the EIM.

Make sure the “Connected” light is

flashing green.

NOTE: If the “Connected” light does

NOT flash green, another system may

be in the listening mode. Please exit the

listening mode at the other system and

then try again.

• Green Flashing: In Listening

Mode - system is ready to add

RedLINK devices.

• Green Steady: RedLINK devices are

communicating.

• Red: RedLINK device(s) are NOT

communicating. Check EIM and

RedLINK devices.

Next

Next

4.2b While the “Connected” light is

flashing green on the EIM, press

Next on the thermostat. After a

short delay, the screen will display

Device Connected.

8

Next

Page 9

4.3 When you see the prompt Do you

have RedLINK accessories to

connect? Touch Yes or No.

• If you select Yes, you will be

prompted to Press Connect on all

new accessories. Continue to Step

4.4.

• If you select No, continue to Step 4.5.

4.4 Connect each RedLINK accessory.

NOTE: Make sure accessories are at

least 2 feet away from the EIM during

the linking process.

4.4a While the Add Device screen

is displayed (listening mode),

press and quickly release the

CONNECT button on each new

RedLINK accessory.

4.4b After a short delay (up to 20

seconds), check the thermostat

to confirm the connection of each

RedLINK accessory.

4.4c Touch Done at the thermostat after

all new RedLINK accessories are

connected.

NOTE: The thermostat displays a

countdown timer while in listening

mode. If it detects no activity for 15

minutes, it exits listening mode.

Listening mode

Done

Listening mode

4.5 Finish the initial setup.

Finish the setup by selecting the

desired options. Touch Done after

you select the last option you want to

change.

The thermostat now displays its Home

screen and the thermostat setup is

complete.

9

Page 10

5

Finding your password (Date Code)

• To add or remove RedLINK accessories

• To make changes to Installer Setup

• To perform Installer Test

• To view Data Logs

Finding your password

You can find the Date Code on the

back of the thermostat, or

1 Touch Menu.

2 Select Dealer Information.

Thermostat (back view)

1324

Password

(Date Code)

1324

10

Dealer Informa�on

OK

Page 11

Linking RedLINK accessories to the thermostat

1 Touch Menu.

2 Select Installer Options.

3 Enter password (date code) and

touch Done.

4 Select Wireless Device Manager.

Installer Op�ons

Done

Wireless Device Manager

5 Select Add Device to display the Add

Device screen. The thermostat is now

in listening mode.

NOTE: Accessories must be at least

2 feet away from the EIM during the

linking process.

5a Press and quickly release the

CONNECT button on each new

RedLINK accessory.

5b After a short delay (up to 20

seconds), check thermostat to

confirm the connection of each

RedLINK accessory.

5c Touch Done at the thermostat

after all new RedLINK

accessories are connected.

NOTE: Thermostat displays a

countdown timer while in listening

mode. If it detects no activity for 15

minutes, it exits listening mode.

11

Add Device

Listening mode

Done

Listening mode

Page 12

Making changes to Installer Setup and performing Installer Test

Follow these steps to set system options after initial installation.

NOTE: Use a USB device to save set up time. See page 14.

1 Touch Menu.

2 Select Installer Options.

Installer Op�ons

3 Enter password (date code) and

touch Done.

4 Select Create Setup or Installer Test.

Done

5 Follow prompts on the screen to

select the desired setup options or

to perform an equipment test.

Mounting outdoor and indoor sensors

Mounting an outdoor sensor

1 Mount the sensor on a vertical

exterior wall, at least 6 inches below

any overhang. Choose a location

protected from direct sunlight.

2 Place sensor securely in bracket,

facing away from wall.

12

Page 13

Mounting an indoor sensor

1 Remove the wallplate and mount

it 4 to 6 feet above the floor on an

interior wall. Drill 3/16-inch holes for

drywall, 7/32-inch for plaster.

2 Attach sensor securely to wallplate

as shown.

Indoor sensor operation

Temperature control

The thermostat can be set to respond to its

internal temperature sensor, or to an optional

remote indoor sensor. If multiple sensors are

selected, the thermostat will respond to an

average of temperatures detected at each

sensor.

Humidication control

If optional remote indoor sensors are

installed, you can choose which sensor you

wanttouseforhumidicationcontrol.You

can use a different sensor for

dehumidication.

Dehumidication control

If optional remote indoor sensors are

installed, you can choose which sensor you

wanttousefordehumidicationcontrol.For

example, you can use one sensor for

humidicationcontrol,andanotherfor

dehumidication.

13

Page 14

Using a USB device for setup, data logs and software upgrades

Use a USB device to save set up time by loading Installer Setup settings, Dealer

Information, Holiday Schedules, and Custom Reminders to multiple thermostats.

For troubleshooting help, you can save the thermostat Data Logs (Alerts Log, User

Interactions Log and Performance Logs) to a USB device - then view them on your

computer. Also use the USB device to upgrade the thermostat software.

• Visit http://thermostatsetup.honeywell.com to enter your dealer information

and contractor logo or load new thermostat software.

• After setup is complete, save Installer Setup, Holiday Schedules, and Custom

Reminders to a USB device.

To use the USB device in the thermostat:

1 Slide USB device into the bottom of

thermostat.

2 Select the item to load or save.

3 Follow the prompts on the screen for the

item you selected.

• To add information from the USB

device to the thermostat, select

Load into Thermostat.

• To put thermostat information on

the USB device, select Save to USB.

Load Installer Setup

into Thermostat

To replace a thermostat

When you replace a thermostat, you must reset the RedLINK accessories before

connecting them to the new thermostat. Follow the instructions below.

At the Portable Comfort Control:

Press and hold the blank space (or arrow) in the lower right corner

of the screen until the display changes (hold for about 4 seconds).

Press REMOVE, then YES to disconnect the old thermostats. To

reconnect the thermostat, go to Step 4.3.

At the Indoor Sensor, RedLINK Internet Gateway, Entry/Exit

Remote, Vent-Filter Boost Remote or TrueSteam Wireless

Adapter:

Press and hold the CONNECT button on the accessory until the

status light glows amber (hold for about 10 seconds). To reconnect

the thermostat, go to Step 4.3.

At the Equipment Interface Module (EIM):

Press and hold the CONNECT button on the EIM until the CONNECTED LED glows amber (hold for about 10 seconds). Follow the

prompts on the screen to connect the new thermostat to the EIM.

To reconnect the thermostat, go to Step 4.2.

14

Portable Comfort

Control

Press and hold

Page 15

Specifications and replacement parts

Operating Ambient Temperature

Thermostat: 32 to 120° F (0 to 48.9° C)

Portable Comfort Control: 32 to 120° F (0 to 48.9° C)

Wireless Outdoor Sensor: -40 to 140° F (-40 to 60° C)

Wireless Indoor Sensor: 0 to 120° F (-17.8 to 48.9° C)

-For Optimal Battery Life: 35 to 114° F (1.7 to 45.6° C)

Equipment Interface Module: -40 to 165° F (-40 to 73.9° C)

Return Air Sensor: 0 to 200° F (-17.8 to 93.3° C)

Discharge Air Sensor: 0 to 200° F (-17.8 to 93.3° C)

RedLINK Internet Gateway: 32 to 120° F (0 to 48.9° C)

Operating Relative Humidity

Thermostat: 5% to 90% (non-condensing)

Portable Comfort Control: 5% to 90% (non-condensing)

Wireless Outdoor Sensor: 0% to 100% (condensing)

Wireless Indoor Sensor: 5% to 90% (non-condensing)

Equipment Interface Module: 5% to 95% (non-condensing)

RedLINK Internet Gateway: 5% to 95% (non-condensing)

Physical Dimensions (height, width, depth)

Thermostat: 4-1/2 x 3-1/2 x 7/8 inches (115 mm x 88 mm x 22 mm)

Equipment Interface Module: 9-5/16 x 4-13/16 x 1-19/32 inches (91 x 147 x 42 mm)

Wireless Outdoor Sensor: 5 x 3-1/2 x 1-11/16 inches (127 x 89 x 43 mm)

Wireless Indoor Sensor: 2-7/8 x 1-7/8 x 15/16 inches (74 x 48 x 24 mm)

Portable Comfort Control: 6-1/4 x 3-1/8 x 1-5/8 inches (158 x 80 x 38 mm)

RedLINK Internet Gateway: 6 x 4-7/8 x 2-1/2 inches (152 x 124 x 64 mm)

RedLINK Communication

Frequency: 900 Mhz frequency range

Re-Sync Time: RedLINK devices re-establish communication within 6 minutes after AC power resumes.

Electrical ratings

W - OB 18 to 30 VAC and 750 mVDC 1.00A

Y (cooling) 18 to 30 VAC 1.00A

G (fan) 18 to 30 VAC 0.50A

W2 - Aux 1 (heating) 18 to 30 VAC 0.60A

W3 - Aux 2 18 to 30 VAC 0.60A

Y2 (cooling) 18 to 30 VAC 0.60A

A-L/A (output) 18 to 30 VAC 1.00A

U1 30 VAC max. 0.50A

U2 30 VAC max. 0.50A

U3 30 VAC max. 0.50A

Accessories and replacement parts

Equipment Interface Module THM5421R1021

Wireless Adapter for TrueZone, TrueSteam, or extend wireless range of EIM THM4000R1000

RedLINK Internet Gateway THM6000R1002

Wireless Entry/Exit Remote REM1000R1003

Wireless Vent and Filter Boost Remote HVC20A1000

Portable Comfort Control REM5000R1001

Wireless Outdoor Sensor C7089R1013

Wireless Indoor Sensor C7189R1004

Wireless Outdoor Sensor 10k ohm NTC C7089U1006

Wired Wall-mount Indoor Sensor 10k ohm NTC C7189U1005

Wired Flush-mount Indoor Sensor 20k ohm NTC C7772A1004, C7772A1012

Wired Wall-mount Indoor Sensor 20k ohm NTC TR21

Wired Wall-mount Indoor Sensor 10k ohm NTC TR21-A

Supply or Return Air Sensor 10k ohm NTC C7735A1000

Supply or Return Air Sensor 20k ohm NTC C7041

Supply or Return Air Sensor 20k ohm NTC C7770A1006

Occupancy Sensor for Remote Setback WSK-24

Cover Plate (covers marks left by old thermostats) THP2400A1027W, THP2400A1027G,

15

Terminal Voltage (50/60 Hz) Max. Current Rating

Accessories / Replacement Parts Part Number

THP2400A1027B

Page 16

DISCONNECT POWER BEFORE INSTALLATION. Can cause electrical shock or

equipment damage.

This thermostat contains a Lithium battery which may contain Perchlorate

material. Perchlorate Material—special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

MERCURY NOTICE: If this product is replacing a control that contains mercury in a

sealed tube, do not place the old control in the trash. Contact the Thermostat Recycling

Corporation at www.thermostat-recycle.org or 800-238-8192 for information on how and

where to properly and safely dispose of your old thermostat.

Must be installed by a trained, experience technician. Read these instructions

carefully. Failure to follow these instructions can damage the product or cause a

hazardous condition.

Need Help?

For assistance please visit

http://customer.honeywell.com,

or call toll-free:

1-800-468-1502 (residential installation)

1-888-245-1051 (commecial installation)

Automation and Control Systems

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

http://customer.honeywell.com

® U.S. Registered Trade mark.

© 2012 Honeywell International Inc.

69-27 39— 01 M.S. 11-12

Printed i n U.S.A .

Scan for more information

TM

69-2739-01

Loading...

Loading...