Page 1

TOTAL STATION

V-325 | V-325N | V-335N | V-323N

QUICK

REFERENCE

GUIDE

BASIC PROCEDURES

FOR V-300

AND POWERTOPOLITE

OPERATING PROCEDURE

FOR V-300

V-300

SERIES

PENTAX Industrial Instruments Co.,Ltd.

2-36-9, Maeno-cho

Itabashi-ku, Tokyo 174-0063 Japan

Tel. +81 3 3960 0502

Fax +81 3 3960 0509

E-mail: international@piic.pentax.co.jp

Website: www.pentaxsurveying.com

Page 2

Electronic T otal Station

Quick Reference Guide

Basic Procedures

for V-300

and

Po werTopoLite

Operating Procedure

PENTAX Industrial Instruments Co.,Ltd.

Page 3

Page 4

5

CONTENTS

General 8

Instruction Manuals 8

Precautions regarding safety 8

Warning 8

Usage Precautions 9

I Basic Procedures for V-300

1 Basic Operation 10

1.1 Removing the Battery 10

1.2 Attaching the Battery 10

1.3 Turning the Power On and Off 10

1.4 Angle Measurement 10

1.4.1 Horizontal Angle 10

1.4.2 Vertical Angle 11

1.5 Distance Measurement 11

1.5.1 Select your target 11

1.5.2 Distance Measurement 11

1.5.3 Changing Target constants 11

1.5.4 Input Temperature and Atmospheric pressure 12

1.5.5 Laser pointer 12

1.5.6 Adjusting LCD contrast 12

1.5.7 Adjusting Illumination brightness 13

2 Changing Instrument Settings 13

3 Basic Field Checking Procedures 15

3.1 Laser Pointer 15

3.2 Warning and Error Messages 16

3.3 Atmospheric Correction 17

4 Specifications 18

Notice to the user of this product 19

>>

Page 5

6

CONTENTS

>>

II PowerTopoLite Operating Procedure

1 Starting Special Function 21

2 Creating / Selecting a Job File 21

3 Input a Known Point Coordinate 21

4 Rectangular Coordinate Measurement 22

4.1 Station Point Setup 22

4.2 Orientation (Station Point H.Angle Setup) 23

4.3 Measurement 24

4.4 Offset Measurement 25

4.5 Remote Measurement 25

5 Polar Coordinate Measurement 26

5.1 Station Point Setup 26

5.2 Orientation (Station Point H.Angle Setup) 27

5.3 Measurement 27

5.4 Offset Measurement 28

6 Free Stationing 29

6.1 Known Point Setup 29

6.2 Measurement 29

6.3 Calculation 29

7 Stake Out 30

7.1 Station Point Setup 30

7.2 Orientation (Station Point H.Angle Setup) 30

7.3 Stakeout Point Setup 31

7.4 Stakeout Measurement 31

8 Stake Out (Point to Line) 32

8.1 Station Point Setup 32

8.2 Orientation (Station Point H.Angle Setup) 32

8.3 Point A Setup 33

8.4 Point B Setup 33

8.5 Point to Line Measurement 33

>>

Page 6

7

CONTENTS

>>

9 Traverse Measurement 34

9.1 Measurement at the Start Point 35

9.2 Measurement at a Corner Point 36

9.3 To Finish the Traverse Measurement 37

9.4 Traverse Calculation 37

10 Cogo 38

Calculation Parameters and Output 39

11 Area Calculation 40

12 3D Surface and Volume Calculation 40

13 REM (Remote Element Measurement) 41

14 RDM (Remote Distance Measurement) 42

15 VPM (Virtual Plane Measurement) 42

16 Changing Preference 43

Preference List 44

Page 7

8

Instruction Manuals

Quick Reference Guide is intended to provide a quick referenc e in the

field.For ease of use in the field,the following Quick Reference Guide

booklets are provided in the carrying case.

1. Basic procedure

2. PowerTopoLite Operating procedure

The complete instruction manuals are contained on the CD that is

attached to each V-300.

This guide uses the symbol “

xN

”as an expression of repeating times

of key operation. For example. “ x2” means that [ESC] key is

pressed two times.

The symbol “+”expresses that multiple keys are pressed simultaneously.

PRECAUTIONS REGARDING SAFETY

Before using this product, be sure that you have thoroughly read

and understood the instruction manual that is included in the

attached CD-ROM to ensure proper operation.

WARNING

Solar Observation

Never view the sun directly using the telescope as this may result

in loss of sight.

Laser Safety

V-300 is a class-II (2) Laser product.Avoid direct eye

exposure.Do not stare into laser beam.

V-325 is Class II(2) and V325N/V335N/V323N are Class IIIR

Laser product. Avoid direct eye exposure.Do not stare into

laser beam.

Page 8

9

Electro-Magnetic Compatibility (EMC)

This instrument complies with the protection requirement for

residential and commercial areas.If this instrument is used close to

industrial areas or transmitters,the equipment can be influenced

by electromagnetic fields.

Risk of Explosion

Do not use this product in a location where there is coal dust, or

near flammable material as there is a risk of explosion.

USAGE PRECAUTIONS

Target Constant

Confirm the Target Constant of the instrument before measurement.

Reflectorless and Reflecting sheet

The reflectorless measurement range may vary depending on the

target and surrounding brightness.

In case the reflectorless measurement results in low accuracy,

perform the distance measurement by Prism.

Battery & Charger

Use the battery charger that is suitable to the battery you are using.

If water should happen to splash on the instrument or the battery,

wipe it off immediately and allow it to dry in a dry location.

Page 9

10

I Basic Procedures for V-300

1.Basic Operation

1.1 Removing the Battery

(1) Rotate the knob above the battery pack counter-clockwise.

(2) Lift up the batter y pack and remove it from the instrument.

1.2 Attaching the Battery

(1) Place the channel on the bottom of the battery pack,onto the

protrusion of the instrument and push the battery pack down

into place.

(2) Turn the knob clockwise.

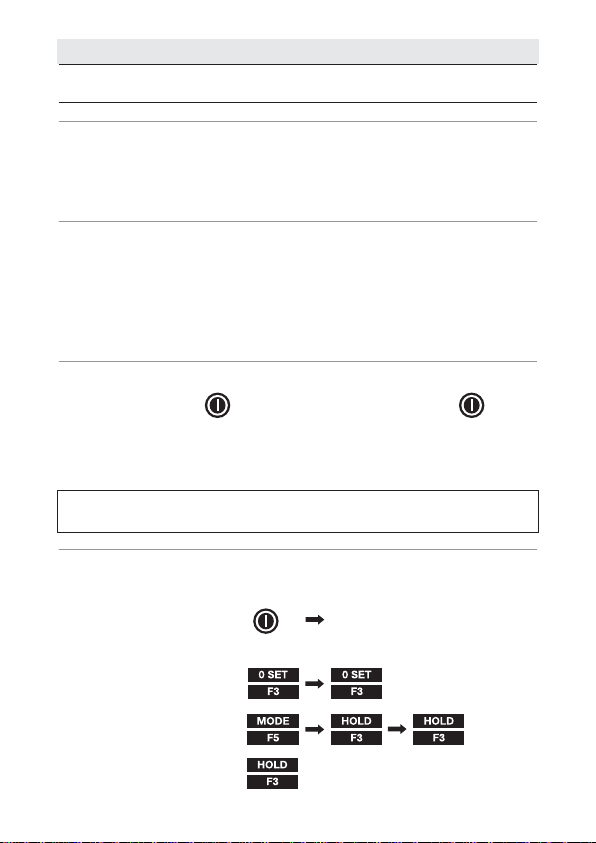

1.3 Turning the Power On and Off

To set power on : To shut down :

To turn the power supply off,press the I/O key for more than

1 second and then release it.Power turns OFF.

NOTE: The power is automatically turned off after 10 minutes

of inactivity (Factory default setting).

1.4 Angle Measurement

1.4.1 Horizontal Angle

Set the screen MODE A :

MODE A screen

Control keys for measuring horizontal angle:

To set the angle to 0 :

To hold the angle :

To release HOLD :

Page 10

11

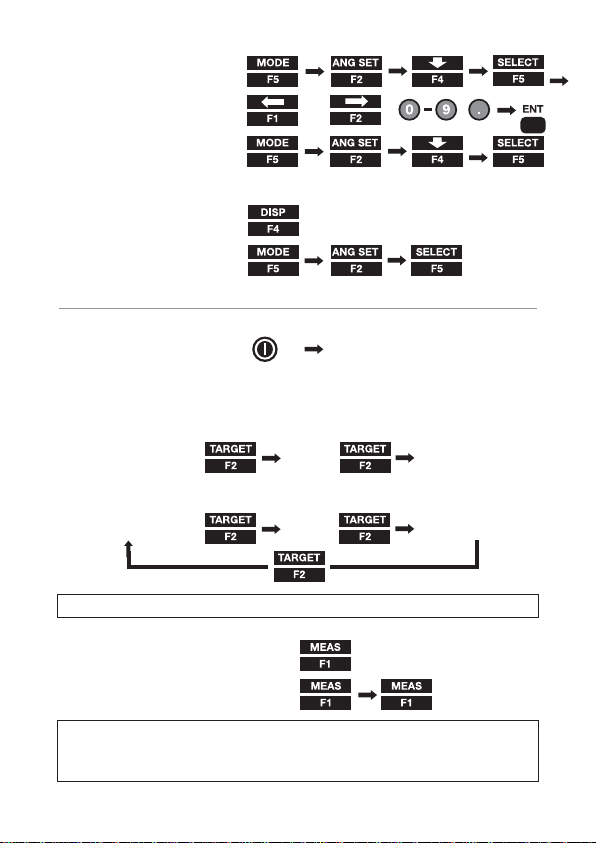

To input an angle :

To read clockwise angle :

1.4.2 Vertical angle

To display vertical angle :

To read the slope % :

1.5 Distance Measurement

Set the screen MODE A:

MODE A screen

1.5.1 Select your target

Select target type (measurement mode):

In case of V-325:

(Reflecting sheet) (Prism) (Reflecting Sheet)

In case of V-325N/V-335N/V323N:

(Reflecting sheet) (Prism) (Reflectorless)

NOTE:The selected target is maintained until next time you change.

1.5.2 Distance measurement

For a single shot measurement:

For tracking measurement :

NOTE: The number of shots can be defined.The default is

“one time”.The measuring modes activated by the above operations

can be also changed.

,

,

,

input value by using:

x2

Page 11

12

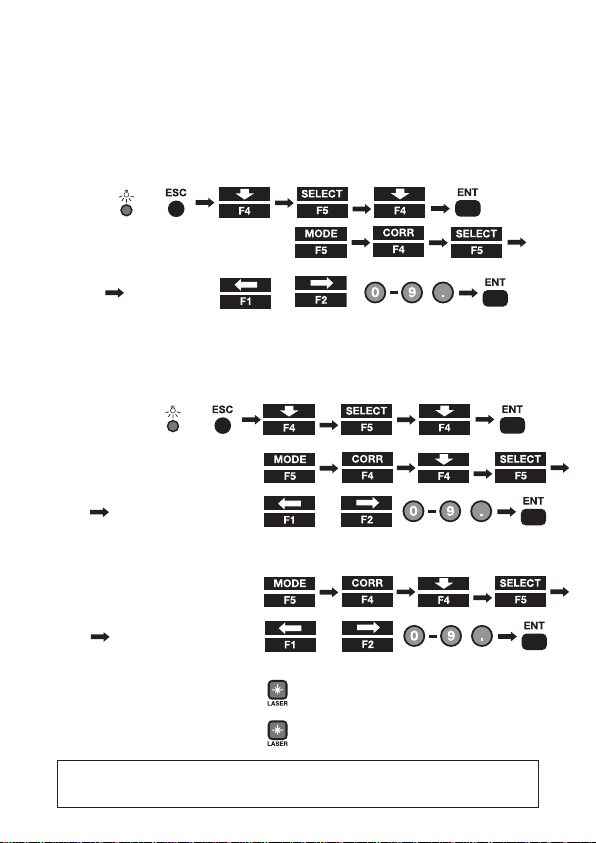

1.5.3 Changing Target constants

The default constants are:

Prism : -30mm

Reflector-less : always 0mm (V-323N,V-325N,V-335N)

Sheet :0mm

Before changing the constants, set Target Constant in the Initial

Setting to“INPUT”mode:

To change Prism constant:

1.5.4 Input Temperature and Atmospheric pressure

The default atmospheric correction mode is “ATM INPUT”.

Before manual input,change the default mode to “ppm INPUT”:

To Input temperature :

To Input atmospheric pressure:

1.5.5 Laser pointer

To activate Laser pointer :

To quit Laser pointer :

NOTE: The laser pointer is kept activated until it is deactivated by

the above procedure.

x2

x3

+

input value

by using:

,

,

,

x2

x2

x2

x2

input value by using:

,

,

,

x2

x3

input value by using:

,

,

,

x2

+

x2

Page 12

13

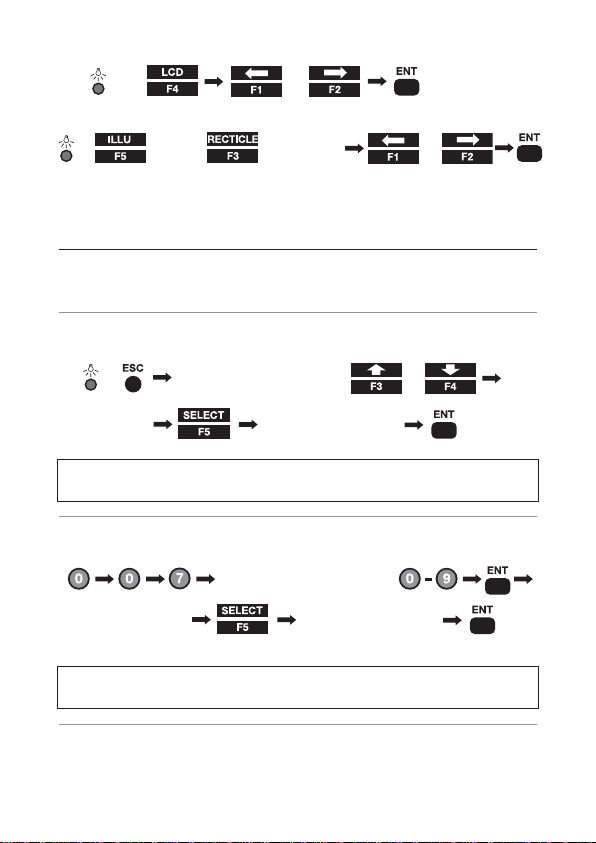

1.5.6 Adjusting LCD contrast

or

1.5.7 Adjusting Illumination brightness

for LCD (for Reticle) or

2.Changing Instrument Settings

You can change the instrument settings by “HELP”menu or by

inputting “007”code.

2.1 Help menu

While the screen is in MODE A or MODE B,

Select a desired item by or

NOTE: Some items have sub-menus where the selecting

procedure by using F1 - F4 is again repeated.

2.2 “007”code

While the screen is in MODE A or MODE B,

Input 007 code by using

NOTE: Some items have sub-menus where the selecting

procedure by using F1 - F4 is again repeated.

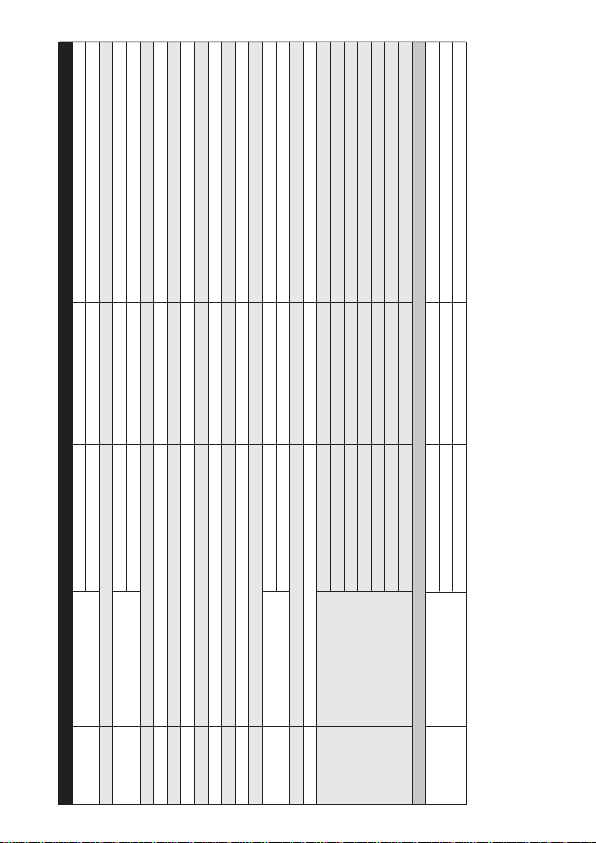

2.3 Instrument setting items

See chart on page 14

+

+

Change the setting

Change the setting

x2

+

Page 13

14

007 code HELP menu list Default Other options

401 TARGET CONST PRISM CONST -30mm 0mm,INPUT

SHEET CONST 0 mm INPUT

402 ATM CORR ATM INPUT ppm INPUT,NIL

502 SHOT COUNT SHOT CONT 1 time 3 times,5 times, INPUT

SHOT INPUT 01 times (input)

503 CRV/REF CORR 0.14 0.2,NIL

504 MIN UNIT ANG. COARSE FINE

505 V.ANG. STYLE Z.0 H.0,COMPASS

509 QUAD BUZ OFF ON

510 AUTO OFF 10 MIN 20 MIN, 30 MIN, NIL

511 EDM OFF ON OFF

517 COMPENSATOR ON OFF

522 QUICK MEASURE OFF ON

523 ATM CORR DISP ON OFF

701 ATM UNIT TEMP.UNIT Centigrade Fahrenheit

PRESS UNIT hPa mmHg,inchHq

702 DIST.UNIT m ft+inch,ft

703 ANG.UNIT DEG DEC,GRD,MIL

801 SET UP COM. BAUD RATE 1200 2400 4800 9600

DATA LENGTH 8

PARITY BITS NIL EVEN, ODD

STOP BITS 1 2

SIGNAL CONTROL ON OFF

XON/XOFF ON OFF

THROUGHT COMMAND NIL a,b,c,d,e,f

V-325N,V-335N,V-323N

521 REF.LESS RANGE REF.LESS RANGE NORMAL LONG

LONG RANGE MES. ON OFF

LONG RANGE SETUP EACH TIME PERMANENT

Page 14

15

3.Basic Field Checking Procedures

Checks and Adjustments should be performed before and during

measurement.

3.1 Laser Pointer

To activate the laser pointer:

Check if the projected laser spot points at the same position that is

aimed by the center of the cross-hair line of the telescope.

To adjust the laser pointer:Consult your local dealer.

Page 15

16

3.2 Warning and Error Messages

Warning Message

Meaning What to do

Displayed when the instrument is tilted beyond the vertical compensation

range (±3’) in case 1 axis or 2 axis

automatic compensation is selected.

This message may be temporarily displayed if the instrument is turned too

fast.

The input data exceeds the allowable

range.

• This message is displayed if a long

distance which is a far beyond

measurable distance of V-300

series is measured with a wrong

target mode.

Please select a correct target then

measure.

If a wrong target is selected,a

correct distance cannot be

measured.

• The measurement distance is less

than 1.5m in Reflector sheet mode.

• The measurement distance is less

than 1.5m in Prism mode.

• Under too strong sun light.

• Unstable light value owing to

shimmer or obstacles.

• Target and Prism do not face

the instrument.

• Target and Prism are not correctly

sighted.

• Measurement range is over in

Reflectorless mode.

• Sufficient signal does not return by

sighting sharp edge etc. at

Reflectorless mode.

Re-level the instrument.

Repair is needed if the

message is displayed

when it is properly

leveled.

Press the [ESC] key and

enter the correct data.

Select the correct target

mode.

Select a longer point,

or use a tape measure.

Change the object

that has much better

reflectivity,or wait until

the sun activity

has weakened.

Out of tilt range

Excess data

Mismatched

Target

Target is too

close.

Unsuitable

Condition

Page 16

17

ERROR!! EDM ERROR

04 -05,34-39,50-53

ERROR!!

ETH ERROR 70-76

ERROR!!

MEMORY ERROR 19

ERROR PS DATA of EDM

ERROR P DATA of EDM

ERROR ETH DATA

Distance measurement system problem

Angle measurement system problem

Memory problem

Problem of the internal EDM parameters

Problem of the internal ETH parameters

Turn the power

off,and then turn on

again.Repair is

needed when the

message appears

consistently.

Error Message Meaning What to do

3.3 Atmospheric Correction

The speed at which light travels through the air varies depending

on the temperature and atmospheric pressure.The V-300 is

designed to measure distances at the speed of light in order to

measure accurately, atmospheric correction needs to be used.

The instrument is designed to correct for weather conditions

automatically if the temperature and pressure are input.

Correction is then carried out based on the following formula.

Calculation formula:

K= (276.26713 -

78.565271 • P

) x10

-6

K:Atmospheric Correction Constant

P:Atmospheric pressure (hPa)

t:Temperature(°C)

Distance after Atmospheric Correction D = Ds (1+K)

Ds:Measured distance when no Atmospheric Correction is used.

273.14941 + t

Page 17

18

4.Specificaties

V-325 V-325N V-335N V-323N

Telescoop

Image Erect

Magnification 30X

Effective aperture 45mm

Field of view 1°30'(2.6%)

Minimum forcus 1.0m

Resolving power 3.0"

Focus Manual

"Distance measurement"

Laser class

Visible Laser:Class II

Visible Laser:Class IIIR (Reflectorless),Class II (Prism)

Measure Range Reflectorless No 1.5~300m

Reflector sheet 600m (800m)

Mini Prism 1,100m (1,600m)

1prism 3,400m (4,500m)

3prisms 4,500m (5,600m)

Accuracy Prism 1.5m~10m:±(3+2ppmxD)mm 10m~ ±(2mm+2pmxD)mm

Reflector sheet 1.5m~10m:±(3+2ppmxD)mm 10m~ ±(2mm+2pmxD)mm

Reflectorless No 1.5~200m:±(5+2ppmxD)mm,200m~:±(7+10ppmxD)mm

Minimum Reading Normal 1mm

Tracking mode 10mm

Measure Time-Rep. Normal Mode 2.0 Seconds(1mm)

Tracking Mode 0.4 Seconds(1cm)

Quick Mode 1.2 Seconds(1mm)

Angle measurement

Method Absolute Rotary Encoder

Minimum Display 5"/1"

Accuracy 5" 3"

Compensator

Type Single Axis

Range ±3'

Leveling

Plate Vial 40"/2mm

Circular Vial 8'/2mm

Optical plummet Magnification 3X

Base section Type Detachable Shifting Detachable

Display

Quantity 2

Graphic LCD 8 lines x 20 characters

Numeric Keys 12 Standard-Dedicated

Alpha keys Standard-Non Dedicated

Function Keys 5

Special Keys 5

Backlight 10 step adjustable

Environmental

Operating Range -20°C ~ +50°C

Water Protection IP55

Internal memory Size 16000 points 30000 points

Motions Tangent 1 Speed(H & V)

Battery

Voltage DC6V

Type Ni-Mh

Dimension 172mm x 343mm x 177mm

Weight

Instrument w/Battery 5.7kg 5.6kg 5.7kg

Carrying Case 2.6kg

Page 18

19

NOTE:

* The measurement range may vary by measurement conditions.

* Normal conditions: 20km visibility with slight shimmer.

* G ood conditions: 40km visibility,overcast,no heat,no shimmer

and moderate wind.

* EDM Measuring time varies according to distance to be

measured and conditions of the environment.

* Reflectorless V-323N ,V-325N,V-335N:

- The measurement range and accuracy of Reflec torless are based

on the condition that laser beam is emitted perpendicular to the

white side of the Kodak Gray Card.

- The measurement range may be influenced by the shape

of the target and its environment.

- The measurement range at TRACK mode is over 5m.

- I t takes time, longer than usual,

to measure the distance to the

object that is hard to measure.

- The measurement range,accuracy of distance measurement and

time required to measure may be influenced by the shape, size of

surface area and reflection rate of the target and its environment.

* The operating time becomes shorter under the low temperature,

due to the temperature dependence of the battery performance.

* Quick mode,which is effective only under Normal mode(1mm)

setting,functions with Prism and Reflector Sheet.

NOTICE TO THE USER OF THIS PRODUCT

To assure compliance with the Safety standard 21 CFR, Chapter 1.

Subchapter J. The U.S. bureau of Radiological Health requires the

following information to be provided to user.:

It can be dangerous to look into the beam with optical equipment such as binoculars and telescopes.

1. Specifications of Laser Radiation

A) The EDM module of the V-300 produces a visible light beam,

which is emitted from the telescope objective lens and the center

hole of the instrument base plate.The V-300 is designed and built

to have a laser diode radiating at 620-690nm.

Page 19

20

B) Radiant power

The V-300 is designed and built to radiate a maximum average

radiant power of 4.75mW (0.95mW for the model without"N")

from the telescope,and 0.95mW from the center hole of the

base plate.The user may be subject to this radiation as a beam

while operation until such time that the instrument is turned off.

2. The following labels are affixed to and must remain

attached to this laser product.

A) For V-300 model:

The following Certification label is located near the Plate level:

“This laser product is complied with the provisions of 21 CFR

1040.10 and 1040.11.For a Class II laser product.”

B) For V-300N models:

"This laser product is complied with the provisions of 21 CFR

1040.10 and 1040.11.For a Class IIIa laser product."

C) Caution label is located near the exit aperture:

“AVOID EXPOSURE.Laser radiation is emitted from this aperture.”

D) Warning logotype is located on the surface of the telescope:

“CAUTION LASER RADIATION DO NOT STARE INTO BEAM”

E) Warning label is Located near the exit aperture.

3. Caution to maintain the safety in compliance with the standard

A) To maintain the safety standard,refrain from any operation,

maintenance,or adjustment other than described in this

instruction manual.

B) Operation,maintenance or adjustment other than those specified in

this instruction manual may result in hazardous radiation exposure.

C) Maintenance and repair not covered in this manual must be

done by an authorized Pentax dealer.

D) The Laser beam emission by the Distance measurement

can be terminated by pressing key.

E)

Pressing keys can terminate the laser beam emission

by the laser pointer.

Page 20

II PowerTopoLite Operating Procedure

1.Starting Special Function

2.Creating / Selecting a Job File

To create a new job file:

Or to select a job file:

NOTE: Once a job file is created or selected, it is effective until a

new job file is created or another job file is selected.

The default job file "PENTAX" is provided permanently

so that data is stored even when no user defined

job file exists.

3.Input a Known Point Coordinate

To input and store a known point coordinate;

21

MODE A SCREEN

MODEF5S. FUNC

F1

POWER TOPO LITE

MAIN MENU

ENT

POWER TOPO LITE

MAIN MENU

FILE

F1

F4

input a new job name by using

F1

TO 123

F5

0.9

DEF

,

ENT

POWER TOPO LITE

MAIN MENU

FILE

F1

F4

x2

x2 select a job file by

ENT

F1

F4

ENT

POWER TOPO LITE

MAIN MENU

VIEW

F3

F4

input a Point Name by using

F1

TO 123

F5

0.9

DEF

,

x2

ENT

repeat to input value

ESC

SAVE

F1

ESC

to quit

x2

ENT

input PC (point code)

ENT

Page 21

NOTE: There are other functions in VIEW menu;Graphical View,

Edit Rectangular Data,and Edit Polar Data.For detail of

these functions,please refer to the instruction manual of

PowerTopoLite.

To input PC (point code):

NOTE: PC list is displayed only when point codes are stored in

the job named “PointCodeList”. “PointCodeList”job can be

created by the procedure described in the section 2,and

PC can be stored by inputting PN and PC as a point

coordinate data.PC list can be also transferred from a

computer. For more detail,refer to the instruction manual

of PowerTopoLite.

A new point code can be input and memorized as a point

coordinate data,but it is not stored as the data of

“PointCodeList”.If a new PC need to be added to the list,

select “PointCodeList”job and add a PC as a new

Rect.Coord.Data.

4.Rectangular Coordinate Measurement

4.1 Station Point Setup

To select from the memory:

22

ENT

select a PC

from the list by

input a new PC by

move cursor to PC

F1

F4

ENT

F1

TO 123

F5

0.9

DEF

POWER TOPO LITE

MAIN MENU

MEAS

F2

ENT

STATION POINT

SETUP

H. ANGLE

SETUP

LIST

F2

F5

ACCEPT

select

the point by

F2

FIND PN

F4

ENT

ENT

x2

Page 22

23

Or to input the station point information:

NOTE: The input item (cursor position) may be selected by

To input PC (point code):

NOTE:

Input items are PN (point name), X, Y, Z, IH (instrument

height),and PC (point code).

If the input PN already exists in the memory,then the corresponding

point information

(coordinate & point code) is displayed in the screen.

The result of Free Station, prior to stakeout, is automatically

set in each field of Station Setup.

4.2 Orientation (Station Point H.Angle Setup)

To input a given angle:

Or to set the angle 0°:

Or to calculate by the Back Sight Point:

STATION POINT

SETUP

0.9

DEF

input Point

Name by

F1

TO 123

F5

ENT

,

H. ANGLE

SETUP

repeat to

input value

ENT

ESC

SAVE

F1

to quit

ENT

input PC (point code)

or

F5

ACCEPT

F3

F4

ENT

,

move cursor to PC

ENT

select a PC from the list by

input a new PC by using

F1

F4

ENT

F1

TO 123

F5

0.9

DEF

,

MEASUREMENT

SCREEN

0.9

DEF

input value by using

INPUT

F2

ENT

x2

MEASUREMENT

SCREEN

0 SET

F1

ENT

x2

MEASUREMENT

SCREEN

input value or select from the list

BSP

F5

ENT

LIST

F2

F5

ACCEPT

aim Back Sight Point

ENT

ENT

x2

Page 23

24

4.3 Measurement

To select the Target type:

NOTE: You can check the selected target type at the left side

of the Battery mark in the top line of the screen.

To measure:

Or to start tracking:

NOTE: EDM measurement mode can be changed by

To input the point information:

To save the point information:

Or to measure and save:

NOTE: the Point number is automatically incremented or

decremented to make rapid continuous measurements

possible.

press

PAGE

F5

TARG ET

F2

PAGE

F5

x2 to select the desired target type

MEASF1MEAS

F1

x2

PAGE

F5

x2

EDM

F1

select and change the EDM mode

0.9

DEF

move cursor by

F3

F4

ENT

,

RETURN TO THE

MEASUREMENT

SCREEN

repeat to input value

ENT

ESC

to quit

ENT

input point code

F5

ACCEPT

EDIT

F4

,,

F1

TO 123

F5

input values by using

SAVE

F2

(next measurement)

ME/SAVE

F3

(next measurement)

Page 24

25

4.4 Offset Measurement

For Radial Offset (the horizontal distance offset along the line of

measurement):

For T angential Offset:

For Distance Offset (slope distance):

NOTE: The Offset values are cleared once the measurement is

saved.

4.5 Remote Measurement

To enter the Remote mode:

or

MEASUREMENT

SCREEN

0.9

DEF

input value

by using

PAGE

F5

OFFSET

F2

ENT

ENT

ESC

F5

ACCEPT

RETURN TO THE

MEASUREMENT

SCREEN

MEASUREMENT

SCREEN

0.9

DEF

x3

PAGE

F5

OFFSET

F2

ENT,ENT

RETURN TO THE

MEASUREMENT

SCREEN

F4

input value by using

MEASUREMENT

SCREEN

0.9

DEF

x2

PAGE

F5

OFFSET

F2

ENT

,

ENT

RETURN TO THE

MEASUREMENT

SCREEN

F4

input value by using

ESC

F5

ACCEPT

MEASUREMENT

SCREEN

x2

PAGE

F5

REMOTE

F1

PAGE

F5

x2

MEAS

F1

RETURN TO THE MEASUREMENT

VALUES ARE UPDATED BY

TURNING THE TELESCOPE

EDIT

F4

Input PN,PH

ESC

F5

ACCEPT

SAVE

F2

(next measurement)

ENT

input PC

MEASUREMENT

SCREEN

MEAS

F1

PAGE

F5

REMOTE

F1

x2

REMOTE MODE

MEASUREMENT VALUES ARE

UPDATED BY TURNING THE

TELESCOPE

EDIT

F4

Input PN,PH

ESC

F5

ACCEPT

SAVE

F2

(next measurement)

ENT

input PC

PAGE

F5

Page 25

26

NOTE: Remote values are calculated based on the assumption of

the reference plane.Three types of the reference plane are

available in PowerTopoLite;Cylindrical surface,Fixed plane

(default) and Rotated plane.

To change the reference plane type:

To quit the Remote mode:

5.Polar Coordinate Measurement

5.1 Station Point Setup

To input the point information:

NOTE: Input items are PN (point name), IH (instrument height),

PC (point code),TEMP (temperature), PRESS (atmospheric

pressure) and ppm."TEMP" and "PRESS" can be input only

when "Atmospheric Correction" is set to "ATM INPUT".

"ppm" can be input only when "Atmospheric Correction"

is set to "ppm INPUT".

The input item (cursor position) may be selected by

POWER TOPO LITE

MAIN MENU

x2

PAGE

F5

PREF

F4

F4

x3

F4

ENT

select by using

F3

,

ENT

PAGE

F5

REMOTE

F1

x2

MEASUREMENT

SCREEN

F5

ACCEPT

MEAS

F2

F4

STATION POINT

SETUP

POWER TOPO LITE

MAIN MENU

ENT

ENT

input Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

repeat to input value

H. ANGLE

SETUP

ESC

SAVE

F1

to quit

ENT

or confirm “ppm”

F4

F3

,

ENT

Page 26

27

5.2 Orientation (Station Point H.Angle Setup)

Only when the orientation of the horizontal angle is required,

proceed according to the following procedure.

Otherwise,just pass this step by

To input a given angle:

Or to set the angle 0°:

Or to calculate by Inverse:

5.3 Measurement

To select the Target type:

NOTE: You can check the selected target type just at the left of the

Battery mark in the top line of the screen.

To measure:

Or to start tracking:

NOTE: EDM measurement mode can be changed by

input value by using

0.9

DEF

INPUT

F2

ENT

MEASUREMENT

SCREEN

x2

0 SET

F1

ENT

MEASUREMENT

SCREEN

x2

INVERS

F5

ENT

MEASUREMENT

SCREEN

select Start Point from the List

LIST

F2

ENT

F5

ACCEPT

LIST

F2

select End Point

from the List

ENT

F5

ACCEPT

ENT

x2

PAGE

F5

x2 press to select the desired target type

TARG ETF2PAGE

F5

MEAS

F1

MEAS

F1

x2

PAGE

F5

x2

EDM

F1

select and change the EDM mode

ENT

Page 27

28

To input the point information:

To save the point information:

Or to measure and save:

NOTE: The point number is automatically incremented or

decremented for rapid continuous measurements.

5.4 Offset Measurement

For Radial Offset (horizontal distance offset along with the line of

measurement):

For Distance Offset (slope distance offset):

NOTE: The O ffset values are cleared once the measurement

is saved.

ENT

input

Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

repeat to input value

RETURN TO THE

MEASUREMENT

SCREEN

ESC

to quit

ENT

Input PC

EDIT

F4

F5

ACCEPT

(next measurement)

SAVE

F2

(next measurement)

ME/SAVE

F3

input value

by using

MEASUREMENT

SCREEN

ENT

PAGE

F5

RETURN TO THE

MEASUREMENT

SCREEN

OFFSET

F2

0.9

DEF

ENT

ESC

F5

ACCEPT

input value by using

MEASUREMENT

SCREEN

ENT

PAGE

F5

RETURN TO THE

MEASUREMENT

SCREEN

OFFSET

F2

0.9

DEF

ENT

ESC

F5

ACCEPT

(point

code)

Page 28

29

6.Free Stationing

6.1 Known Point Setup

Select the point from the stored data:

Or input PN which is already stored in memory to call and display the

known coordinate.

6.2 Measurement

Select the target type and measure:

NOTE: You can check the selected target type just at the left of the

Battery mark in the top line of the screen.

To proceed to the next point:

Repeat "6.1 Known Point Setup" and "6.2 Measurement" for all known points.

6.3 Calculation

input Inst.Height (IH) by using

0.9

DEF

ENT

FREE

F4

POWER TOPO LITE

MAIN MENU

KNOWN POINT

SETUP

select the point by

LIST

F2

MEASUREMENT

SCREEN

F2

FIND PN

F4

ENT

F5

ACCEPT

press

TARG ET

F2

to select until the desired target type

MEAS

F1

KNOWN POINT

SETUP

ENT

ADD

F1

input

Point Name

CALC

F5

MEASUREMENT

SCREEN

RETURN TO

POWER TOPO LITE

MAIN MENU

ENT

F5

ACCEPT

ENT

ENT

ENT

select Point Code from the list or input

ESC

to quit

F5

ACCEPT

Page 29

30

NOTE: The result of Free Station is automatically carried

forward to the station setup of Rectangular coordinate

measurement and stakeout.

7.Stake Out

7.1 Station Point Setup

Select from the stored data:

Or input PN which is already stored in the memory to call and display

the known coordinate.

NOTE: The result of Free Station,prior to stakeout, is

automatically set in each field of Station Setup.

7.2 Orientation (Station Point H.Angle Setup)

To input a given angle:

Or to set the angle 0°:

Or to calculate by the Back Sight Point:

POWER TOPO LITE

MAIN MENU

ENT

PAGE

F5

STAK

F1

STATION POINT

SETUP

H. ANGLE

SETUP

ENT

LIST

F2

F2

FIND PN

select the point by

F4

F5

ACCEPT

STAKEOUT

COORD. SETUP

ENT

INPUT

F2

input the value x2

STAKEOUT

COORD. SETUP

ENT

0 SET

F1

x2

STAKEOUT

COORD. SETUP

ENT

BSP

F5

select the point by

F2

FIND PN

F4

F5

ACCEPT

ENT

LIST

F2

Page 30

7.3 Stakeout Point Setup

Select the point from the stored data:

7.4 Stakeout Measurement

Check the designed value.If “COMPARE METHOD”is set to

“LARGE CHARACTER”, press to proceed to the Stakeout screen

Turn the instrument until "DH.Angle" reads to "0".

Select the Target type:

NOTE: You can check the selected target type just at the left of the

Battery mark in the top line of the screen.

To measure in Tracking mode:

To confirm the position of the stake:

To proceed to the next point:

31

STAKEOUT

MEASUREMENT

ENT

select the

point by

F2

FIND PN

F4

F5

ACCEPT

repeat

TARG ET

F2

until the desired target type is selected

MEAS

F1

x2 (move the target until “DH.dist”reads “0”)

MEAS

F1

To quit measurement

(position the target accurately)

PAGE

F5

F1

RECT. M

MEAS

F1

EDIT

F4

Input PN,PH and PC

SAVE

F2

ESC

RETURN TO STAKE-

OUT MEASUREMENT

SCREEN

NEXT

F4

STAKEOUT

MEASUREMENT

(repeat from “Stakeout Point Setup)

SCROLL

F3

LIST

F2

Page 31

32

8.Stake Out (Point to Line)

"Point to Line" gives the distances between SOP and Int.P,A and Int.P,

B and Int.P.

8.1 Station Point Setup

Select the point from the stored data:

NOTE: The result of Free Station,prior to stakeout, is

automatically set in each field of Station Setup.

8.2 Orientation (Station Point H.Angle Setup)

To input a given angle:

Or to set the angle 0°:

Or to calculate by the Back Sight Point:

POWER TOPO LITE

MAIN MENU

ENT

STAK

F1

F4

PAGE

F5

STATION POINT

SETUP

A Int. P

SOP

B

H. ANGLE

SETUP

ENT

LIST

F2

select the point by

F2

FIND PN

F4

F5

ACCEPT

POINT A SETUP

ENT

INPUT

F2

input the value x2

POINT A SETUP

ENT

BSP

F5

select the point by

F2

FIND PN

F4

F5

ACCEPT

POINT A SETUP

ENT

0 SET

F1

x2

ENT

LIST

F2

Page 32

33

8.3 Point A Setup

To input values:

Or to select from the memory:

8.4 Point B Setup

To input values:

Or to select from the memory:

8.5 Point To Line Measurement

To select the Target type:

NOTE: You can check the selected target type just at the left of the

Battery mark in the top line of the screen.

ENT

input Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

repeat to

input value

POINT B SETUP

ESC

to quit

ENT

Input PC (Point Code)

SAVE

F1

or

F5

ACCEPT

POINT B SETUP

ENT

LIST

F2

select the

point by

F2

FIND PN

F4

F5

ACCEPT

ENT

input Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

repeat to

input value

MEASUREMENT

ESC

to quit

ENT

Input PC (Point Code)

SAVE

F1

or

F5

ACCEPT

MEASUREMENT

ENT

LIST

F2

select the

point by

F2

FIND PN

F4

F5

ACCEPT

press

TARG ET

F2

to select the desired target type

Page 33

34

To measure in Tracking mode:

To confirm the position of the stake:

9.Traverse Measurement

Traverse Measurement is based on the following assumptions:

• The current station is the foresight point of the previous station.

• The back sight point of current station is the previous station.

Limitations are:

• More than one traverse route can not be measured at the same

time.

• Do not store other data while you are measuring the traverse route.

• When one traverse route is finished,perform the traverse calcula-

tion before you store other data.

• Do not turn the power supply off until all the measurement at one

start point or at one corner point is completed.

• Do not escape from the MEASURE screen.

• The same PN should not be used in one Job.And the PN can not

be overwritten in the traverse.

• The same traverse route can not be calculated again.

• Polar coordinates data of back sight and station points can not be

seen in the POLAR EDIT function, but it is sent properly in SEND

POLAR DATA function.

MEAS

F1

x2 (move the target to the desired position)

MEAS

F1

To quit measurement

(position the target accurately)

PAGE

F5

F1

RECT. M

MEAS

F1

EDIT

F4

Input PN,PH and PC

SAVE

F2

ESC

RETURN TO STAKE-

OUT MEASUREMENT

SCREEN

x2

Page 34

35

To start Traverse:

9.1 Measurement at the Start Point

Start the traverse from the start point measurement.

Station Setup:

Orientation (Station Point Setup):

or to set the angle 0°:

or to calculate by the known points (Start point and End point):

Side shot measurement:

POWER TOPO LITE

MAIN MENU

PAGE

F5

TRAV

F1

TRAVERSE

MENU

x2

TRAVERSE

MENU

ENT

STATION SETUP

ENT

input Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

repeat to input value

H. ANGLE

SETUP

ESC

to quit

or confirm “ppm”

input value by using

0.9

DEF

ENT

INPUT

F2

x2

SIDE SHOTS

x2

ENT

0 SET

F1

SIDE SHOTS

LIST

F2

select Start Point from the List

F5

ACCEPT

select End Point

from the List

INVERS

F5

ENT

ENT

F5

ACCEPT

LIST

F2

ENT

ENT

x2

SIDE SHOTS

EDIT

F4

for all side shots

MEAS

F1

repeat

,

SAVE

F2

,

MEAS

F1

finish measurements by

EDIT

F4

,

,

ENT

at the

Corner Point

ESC

TRAVERSE

MENU

F5

ACCEPTF5ACCEPT

Page 35

NOTE: The corner point is the foresight of the traverse,which is the

next instrument point and must be ended by

If required,select the target by before each

measurement.

9.2 Measurement at a Corner Point

Station Setup:

NOTE: Input Instrument Height (IH), if necessary.

Orientation:

Side shot:

NOTE: The corner point is the foresight of the traverse,which is the

next instrument point and must be ended by .

If required,select the target by before each

measurement.

ENT

x2

TRAVERSE

MENU

ENT

F4

(the last corner point is displayed as Station)

(sight the back sight point)

ENT

ACCEPT

F5

EDIT

F4

for all side shots

MEAS

F1

repeat

,

SAVE

F2

,

MEAS

F1

finish measurements by

EDIT

F4

,

,

ENT

at the

Corner Point

ESC

TRAVERSE

MENU

PAGE

F5

TARG ET

F2

PAGE

F5

x2

TARG ET

F2

ENT

36

Page 36

37

9.3 T o Finish the Trav erse Measurement

Fixed traverse: Measure the known point and press at the last

corner point.

Closed traverse: Measure the star t point and press at the last

corner point with the different Point Name.

NOTE: Use the different point name (PN) when you measure the

start point as the last corner point.For example,change “T1”

to “T1-1”etc.

Open traverse: The closing errors are not calculated.No need to end

the measurement by pressing .

9.4 Tra verse Calculation

To Start Fixed traverse calculation:

NOTE: To select CLOSE TRAVERSE CALC.:

To select OPEN TRAVERSE CALC.:

Start Point Coordinate setup:

or to input the known coordinate;

ENT

ENT

ENT

TRAVERSE

MENU

ENT

F4

F4

F4

x3

x4

END POINT SETUP

ENT

LIST

F2

select the

point by

F2

FIND PN

F4

F5

ACCEPT

ENT

input Point Name by

0.9

DEF

,

F1

TO 123

F5

ENT

input the next value or

END POINT SETUP

ESC

to quit

F5

ACCEPT

x2

Page 37

End Point Coordinate setup: the same operation as in the above.

NOTE: The End Point Coordinate Setup is required only in the fixed

traverse.

Result of Traverse Calculation:

To see the result of each corner point:

To see all points in order:

To save all results:

10.Cogo

To access COGO menu and select calculation type:

Input required parameters:

Save the result:

The required calculation parameters and the output are as follows

(page 39):

38

F2

F1

or

F4

F3

or

F5

ACCEPT

TRAVERSE

MENU

PAGE

F5

POWER TOPO LITE

MAIN MENU

CALC

F2

ENT

select calc.

type by

F4

F3

or

ENT

input parameters by

terminating with

F5

ACCEPT

or

ENT

each time

RESULT SCREEN

ENT

input point name and point code

F5

ACCEPT

RETURN TO

PARAMETER SCREEN

ENT

Page 38

39

Direction Angle (SP->EP)

H,V,S Distance

Coordinate of the

unknown point

Coordinate of centerpoint

of the arc,Radius of the arc

Coordinates of intersect

points (P1,P2)

Coordinate of the

intersect point

Coordinates of intersect

points (P1,P2)

Coordinate of the

intersect point of the line

and a perpendicular line

from the offset point.

Distance of the intersect

point from the SP of the

line

Coordinate of the offset

point

Coordinate of the offset

point

1

2

3

4

5

6

7

8

9

Inverse

Point

Coordinate

Circle Radius

Line-Arc

Intersection

Line-Line

Intersection

Arc-Arc

Intersection

Distance

Offset

Point Distance

Offset

ARC Distance

Offset

SP (Start Point)

EP (End Point)

CO (Known point coordinate)

DI (Distance to the unknown point)

BE (Direction Angle to the unknown point)

Coordinates of three points (P1,P2,P3)

SP (Start point of the line)

EP (End point of the line)

CP (Center point of the circle)

R (Radius of the circle)

S1 (Start point of the 1st line)

E1 (End point of the 1st line)

S2 (Start point of the 2nd line)

E2 (End point of the 2nd line)

C1 (Center Point of the 1st circle)

R1 (Radius of the 1st circle)

C2 (Center Point of the 2nd circle)

R2 (Radius of the 2nd circle)

SP (Start point of the line)

EP (End point of the line)

OP (Offset Point)

SP (Start point of the line)

EP (End point of the line)

DI (Distance on the line from SP)

OD (Offset distance from the line)

SP (Start Point of the arc)

EP (End point of the arc)

R (Radius of the arc)

DI (Distance on the arc from SP)

OD (Offset distance from the arc)

Page 39

11.Area Calculation

To start area calculation:

To return to the calculation menu screen:

NOTE: This func tion calculates the length of 2D and 3D contour of

a polygon,and the 2D surface (area) of the polygon.

The polygon is defined by selecting points in such a way

that the contour segments of the polygon do not intersect.

The last selected point is automatically tied to the first

selected point to form the closed figure.

There are several function keys for point selection,such as

"ALL", "FIND PN", FROM", "TO", and "ORDER". Refer to the

instruction manual on the CD-R.

12.3D Surface and Volume Calculation

To start Volume calculation:

PAGE

F5

POWER TOPO LITE

MAIN MENU

CALC

F2

ENT

select points of the polygon by repeating select (

F4

F3

or

ENT

F4

) and

F1

ACCEPT

RESULT SCREEN

ESC

x2

RESULT SCREEN

CALCULATION

MENU SCREEN

PAGE

F5

POWER TOPO LITE

MAIN MENU

CALC

F2

ENT

select points of the polygon by repeating select (

F4

F3

or

ENT

F4

) and

F1

ACCEPT

RESULT SCREEN

VOLUME

input the reference height by

0.9

DEF

ENT

RESULT SCREEN

CONTOUR

SURFACE AREA

ENT

x2

40

Page 40

To return to the calculation menu screen:

NOTE: This func tion calculates the contour, the 2D and 3D sur face

area,and the volumes (positive,negative and total.)

The order of point selection is not important.The number of

points must be less than 350.The 3D polygon is automatcally

defined by the element triangles that are formed by

connecting neighboring points. The positive and negative

volumes are calculated based on the reference height.

13.REM (Remote Element Measurement)

To start REM:

Measure the Reference point:

Measure the elevation of the remote point:

To return to Calculation menu:

41

ESC

x2

RESULT SCREEN

CALCULATION

MENU SCREEN

PAGE

F5

POWER TOPO LITE

MAIN MENU

CALC

F2

F4

ENT

x3

MEAS

F1

ENT

input prism (or reference) height

ENT

aim the point to be measured

REM VALUE IS

DISPLAYED AT THE

BOTTOM OF THE SCREEN

ESC

CALCULATION

MENU SCREEN

x2

Page 41

42

14.RDM (Remote Distance Measurement)

To start RDM:

Measure the Reference point:

Measure the 2nd point (Target Point):

Measure the 3rd point (Target Point):

To change the reference to the present point:

To return to PowerTopoLite Main menu:

15.VPM ( Virtual Plane Measurement)

To start VPM:

Station point setup:

RESULT SCREEN

ENT

POWER TOPO LITE

MAIN MENU

PAGE

F5

POWER TOPO LITE

MAIN MENU

VPM

F3

STATION POINT

SETUP

select the

point by

LIST

F2

H. ANGLE

SETUP

ENT

F2

FIND PN

F4

F5

ACCEPT

PAGE

F5

POWER TOPO LITE

MAIN MENU

RDM

F4

MEASURE THE

REFERENCE POINT

EDIT

F4

input the target height by

0.9

DEF

ENT

MEAS

F1

(select target if necessary)

MEAS

F1

RESULT SCREEN

DISTANCE FROM THE

REFERENCE POINT

MEAS

F1

RESULT SCREEN

DISTANCE FROM THE

REFERENCE POINT

VER.

F5

RESULT SCREEN

DISTANCE FROM THE

PREVIOUS TARGET POINT

RESULT SCREEN

DISTANCE FROM THE

PREVIOUS TARGET POINT

ENT

x2 (repeat reference point measurement)

Page 42

43

H.angle setup:

To input a given angle:

Or to set the angle 0°:

Or to calculate by the Back Sight Point:

Measure three points to define the plane:

Virtual plane measurement:

To return to PowerTopoLite Main menu:

16.Changing Preference

To access Preference menu:

Preference List (page 44)

input the value by

0.9

DEF

INPUT

F2

ENT

x2

THREE POINTS

MEASUREMENT

0 SET

F1

ENT

x2

THREE POINTS

MEASUREMENT

LIST

F2

Input value or select from the List

BSP

F5

F5

ACCEPT

ENT

SAVE

F1

or

THREE POINTS

MEASUREMENT

if necessary,

MEAS

F1

SAVE

F2

ENT

(repeat measurements

of remaining two points)

VPM SCREEN

if necessary,

SAVE

F2

aim a point on the plane

ESC

VPM SCREEN

POWER TOPO LITE

MAIN MENU

PREF

F4

select an item by

PAGE

F5

F4

ENT

F3

or

POWER TOPO LITE

MAIN MENU

POWER TOPO LITE

MAIN MENU

x2

select an option by

F4

F3

or

ENT

F5

ACCEPT

Page 43

44

Preference List

10 KEY SYTEM (123),FULL TEMPLATE,DIVIDED TEMPLATE,

MATRIX SYSTEM

Item

Default

Options

Remark

1

2

3

4

567

8

9

10

11

LANGUAGE

COORD.AXIS

INPUT METHOD

ACTION METHOD

REMOTE METHOD

COMPARE METHOD

REQUEST AIMING

EDM SETTINGS

ELEV.FACTOR

DUPLICATE PN CHK

MEAS DISPLAY

DISP.1 NAME

DISP.2 NAME

DISP.3 NAME

DISP.1 AXIS

DISP.2 AXIS

DISP.3 AXIS

ROT ATION

PRIM.MEAS KEY

SEC.MEAS KEY

MEAS.MIN DISP.

SHOT COUNT

SHOT INPUT

AVE.ELEV.

SCALE FACT.

ENGLISHXYZBASE DIRECT.

RIGHT ANGLE

HEIGHTCW10 KEY SYSTEM

(ABC)

PROCESS TYPE

FIXEDPLANE

ALL IN ONE INFO.

OFF

MEAS SHOT

TRACK COUNT

COARSE

1 time

01 times

0m

1.0

OFF

POLAR DATA

YOUR LANGARGE

Any alpha-numeric character

Any alpha-numeric character

Any alpha-numeric character

HEIGHT,RIGHT ANGLE

BASE DIRECTION,HEIGHT

BASE DIRECTION,RIGHT ANGLE

CCW

STRUCTURE TYPE

CYLINDER FACE,ROTATED PLATE

LARGE CHARACTERONMEAS CONT,TRACK SHOT,TRACK CONT

TRACK SHOT,MEAS CONT,MEAS SHOT

FINE

3 times,5 times,INPUT

01-99 times

-9999.998 - +9999.998m

0.00000001 - 1.99999998

ON

RECT.DATA

Axis labels that are

displayed in 1st line,2nd

line,and 3rd line.

Orientation direction of

each axis.

Direction of H.angle

measurement

Operational procedure

type

Stake Out screen

"AIM" message ON/OFF

Dist.Meas.mode for 1st

MEAS key

Dist.Meas.mode for 2nd

MEAS key

Page 44

45

AVOID EXPOSURE

Laser radiation

is emitted from

this aperture

Aperture label

Warning label

Laser beam is transmitted

from this aperture

Identification label

V-323N

V-325N

V-335N

V-325

Page 45

46

Warning logotype Warning logotype

Laser beam is transmitted

from this aperture

For North America Certification

LASER

R

ADI

A

T

I

O

N

AVO

I

D

D

I

R

E

C

T

E

Y

E

E

X

P

O

S

UR

E

CL

A

SS

3

R

L

A

SE

R

PR

O

D

UCT

LASER RADIATION

AVOID DIRECT EYE

EXPOSURE

CLASS 3R LASER PRODUCT

CAUTION

D

A

N

GE

R

LED is turned on at the time of emission

For V-300N model For V-300N model

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

For V-300 model

D

A

NGER

For V-300 model

For V-300N model

For V-300 model

Page 46

N

Laserclass II,conform FDA 21 CFR

Ch.1 § 1040

CAUTION

LASER RADIATION - DO NOT

STARE INTO BEAM

620-690nm/0.95mW max.

CLASS II LASER PRODUCT

DANGER

LASER RADIATION-AVIOD

DIRECT EYE EXPOSURE

PEAK POWER 4.75mW

WAVELENGTH 620-690nm

CLASS IIIa LASER PRODUCT

O

I

T

E

Y

A

I

E

T

T

D

C

C

U

A

E

E

D

R

R

R

O

I

U

R

D

S

P

R

O

D

I

E

P

S

X

A

E

L

LASER

AVO

R

3

S

S

A

L

C

Page 47

48

Page 48

Printed in Belgium

010908

Member symbol of the Japan Surveying

Instruments Manufacturers’

Association representing the high quality

surveying products.

PENTAX Industrial Instruments Co.,Ltd.

2-36-9,Maeno-cho

Itabashi-ku, Tokyo 174-0063 Japan

Tel.+81 3 3960 0502

Fax +81 3 3960 0509

E-mail:international@piic.pentax.co.jp

Website:www.pentaxsurveying.com

Japan Surveying Instruments Manufacturers’ Association

Loading...

Loading...