Page 1

Installation and Assembly:

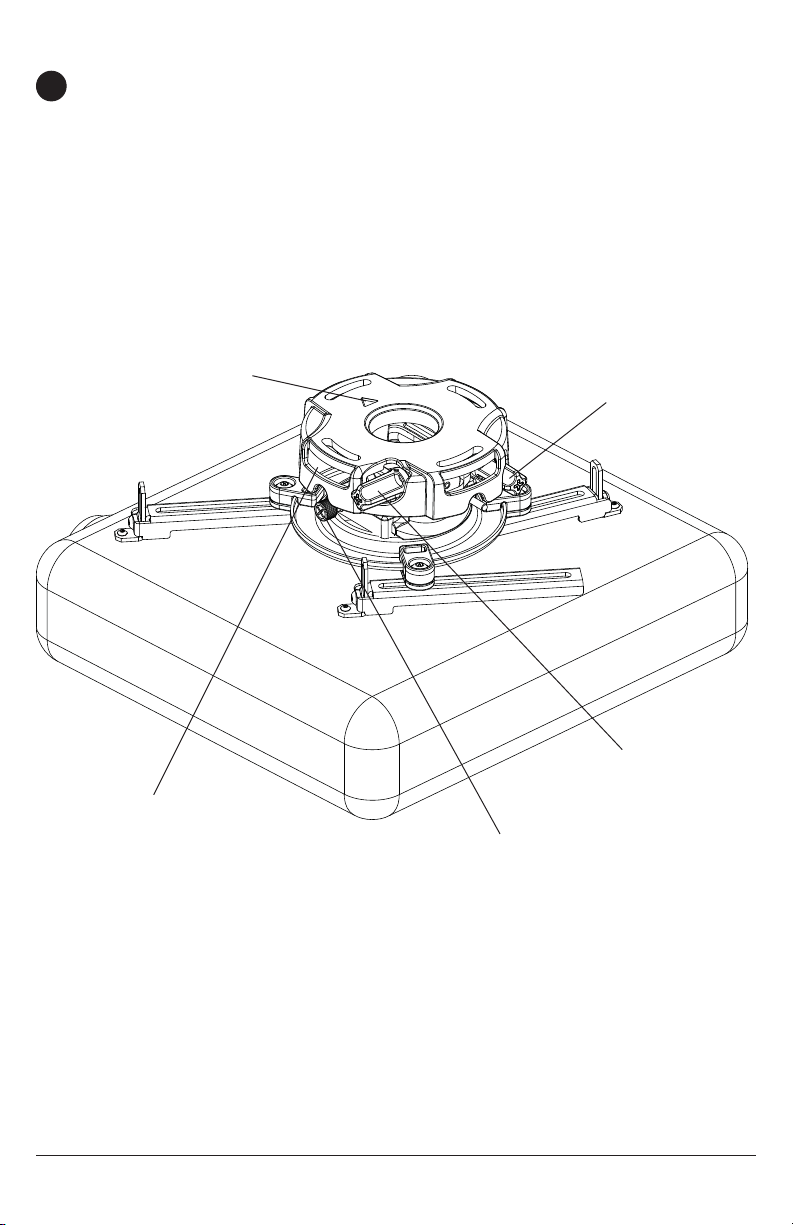

PRG Precision Gear Projector Mount with Universal

Adapter Plate

Models: PRG-UNV, PRG-UNV-S, PRG-UNV-W

Features:

• ImageLockTM alignment prevents picture sag or

drift

• Exclusive aluminum track quick release

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Max UL Load Capacity:

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

50 lb (22.7 kg)

Page 2

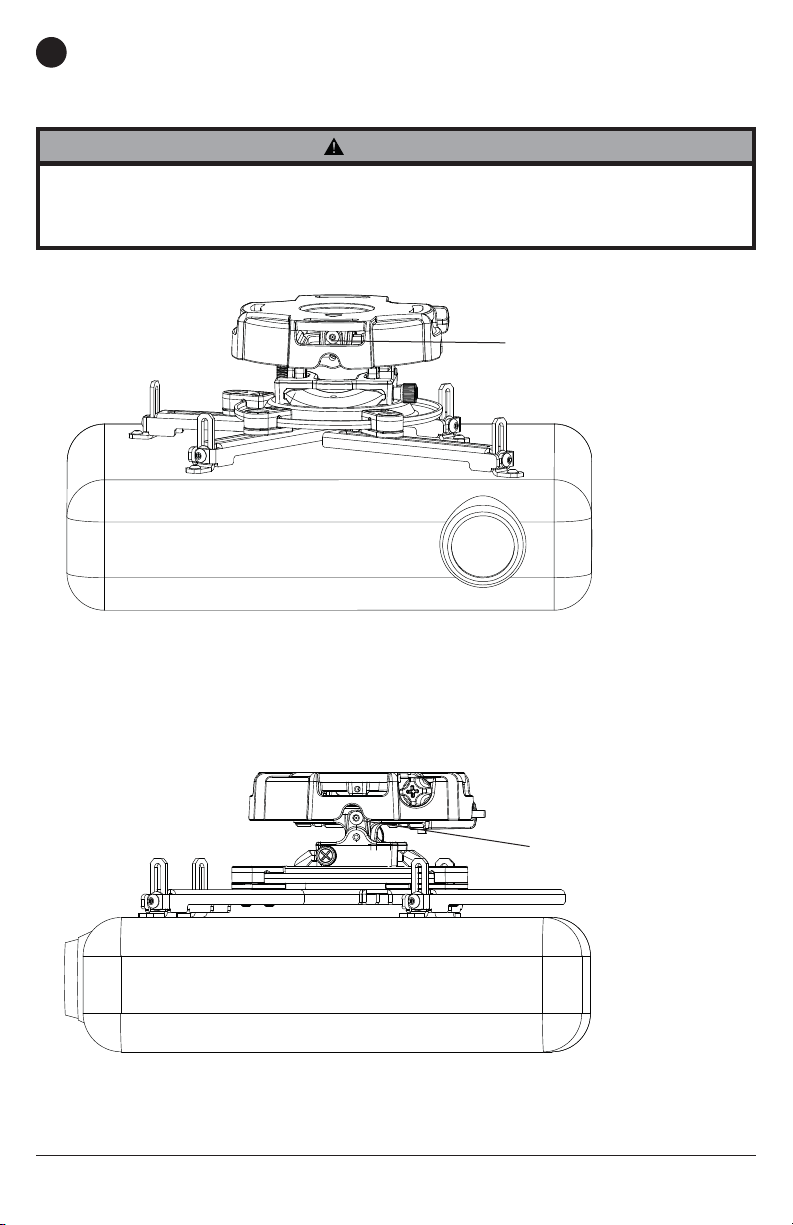

NOTE: Read entire instruction sheet before you start installation and assembly.

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions

and warnings contained in this Installation Sheet. If you have any questions regarding any of the

instructions or warnings, for US customers please call Peerless customer care at

1-800-865-2112, for all international customers, please contact your local distributor.

• This product should only be installed by someone of good mechanical aptitude, has experience

with basic building construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and

all attached hardware and components.

• Never exceed the Maximum UL Load Capacity. See page one.

• If mounting to wood joists ceilings, make sure that mounting screws are anchored into the center

of the studs. Use of an "edge to edge" stud fi nder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws fi rmly, but do not overtighten. Overtightening can damage the items, greatly

reducing their holding power.

• This product is intended for indoor use only. Use of this product outdoors could lead to product

failure and personal injury.

• This product was designed to be installed on the following wall construction only;

WALL CONSTRUCTION HARDWARE REQUIRED

• Wood Stud Included

• Wood Joist Included

• Solid Concrete Included

• Brick Contact Qualifi ed Professional (Not Evaluated By UL)

• Other or unsure? Contact Qualifi ed Professional

Tools Needed for Assembly

• stud fi nder ("edge to edge" stud fi nder is recommended)

• phillips screwdriver

• drill

• 5/16" bit for solid concrete surface

• 5/32" bit for wood studs

• open end wrench

• level

Table of Contents

Parts List................................................................................................................................................3

Projector Mount Assembly Installation................................................................................................4-7

Attaching Adapter Plate to Projector......................................................................................................9

Accessories ...................................................................................................................................15, 16

2 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 3

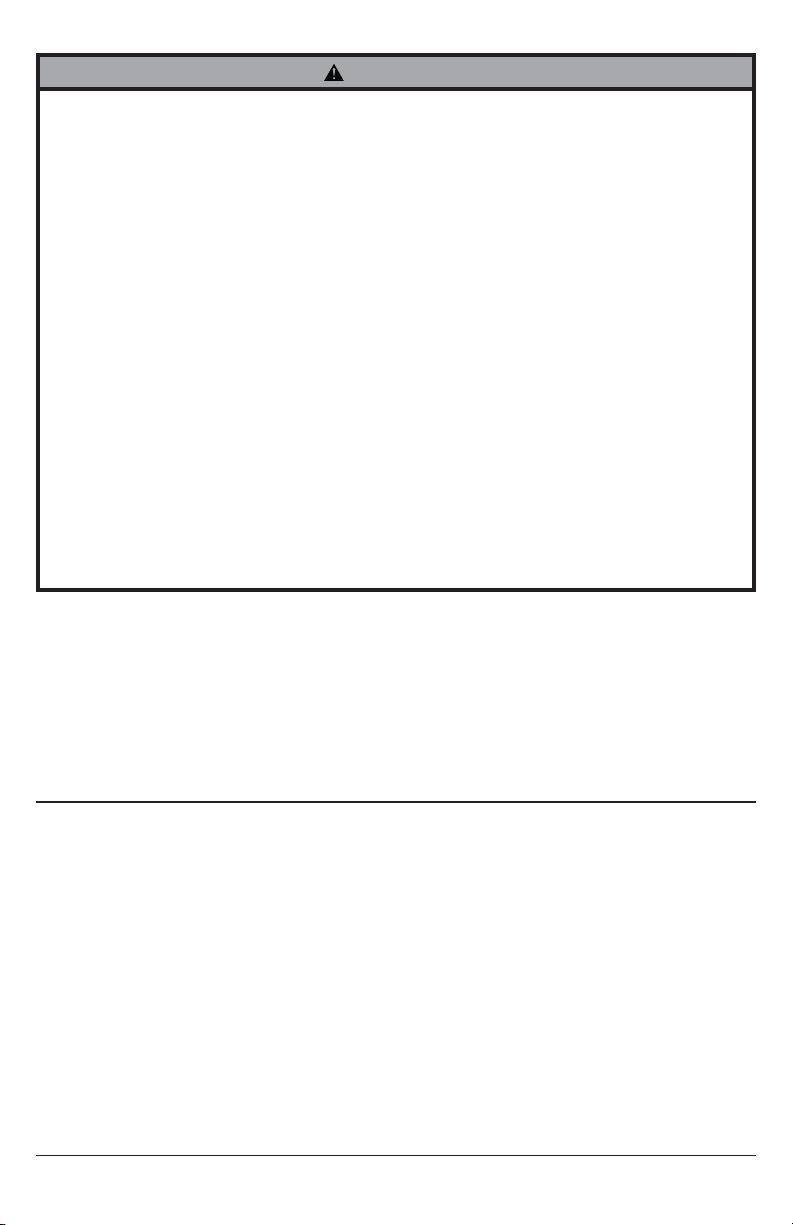

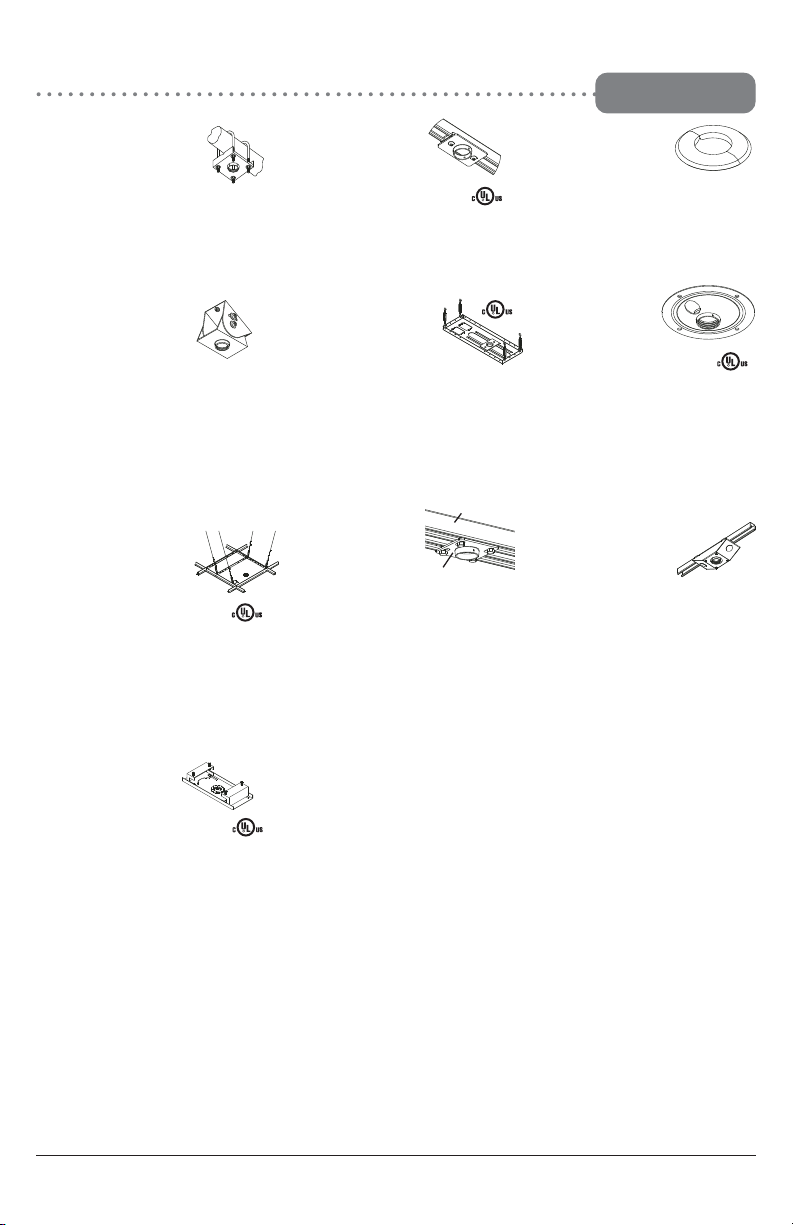

PRG-UNV PRG-UNV-S PRG-UNV-W

Description Qty. Part # Part # Part #

A projector mount assembly 1 054-1171 054-4171 054-2171

B adapter plate 1 055-1938 055-4938 055-2838

C concrete anchor 2 590-0320 590-0320 590-0320

D #14 x 2-1/2" phillips hex head wood screw 2 5S1-015-C03 5S1-015-C04 5S1-015-C04

E #10-32 x 1/4" socket pin screw 1 520-1196 520-2196 520-2196

F 1/4" flat washer 2 540-1078 540-1078 540-1078

G #6 flat washer x 1/2" OD 4 540-1025 540-2025 540-2025

H 2 mm security allen wrench 2 560-1097 560-1097 560-1097

I 4 mm security allen wrench 1 560-9646 560-9646 560-9646

J M3 x 8 mm serrated washer head socket pin screw 4 510-1004 510-2004 510-2004

K M4 x 10 mm serrated washer head socket pin screw 4 510-1060 510-2060 510-2060

L M5 x 10 mm serrated washer head socket pin screw 4 510-1126 510-2063 510-2063

M M6 x 10 mm serrated washer head socket pin screw 4 510-1066 510-2066 510-2066

Parts List

Before you start check the parts list to insure all of the parts shown are included.

NOTE: Actual parts may appear slightly different than illustrated.

A

B

CD

I

E

J

F

K

G

L

3 of 51

H

M

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 4

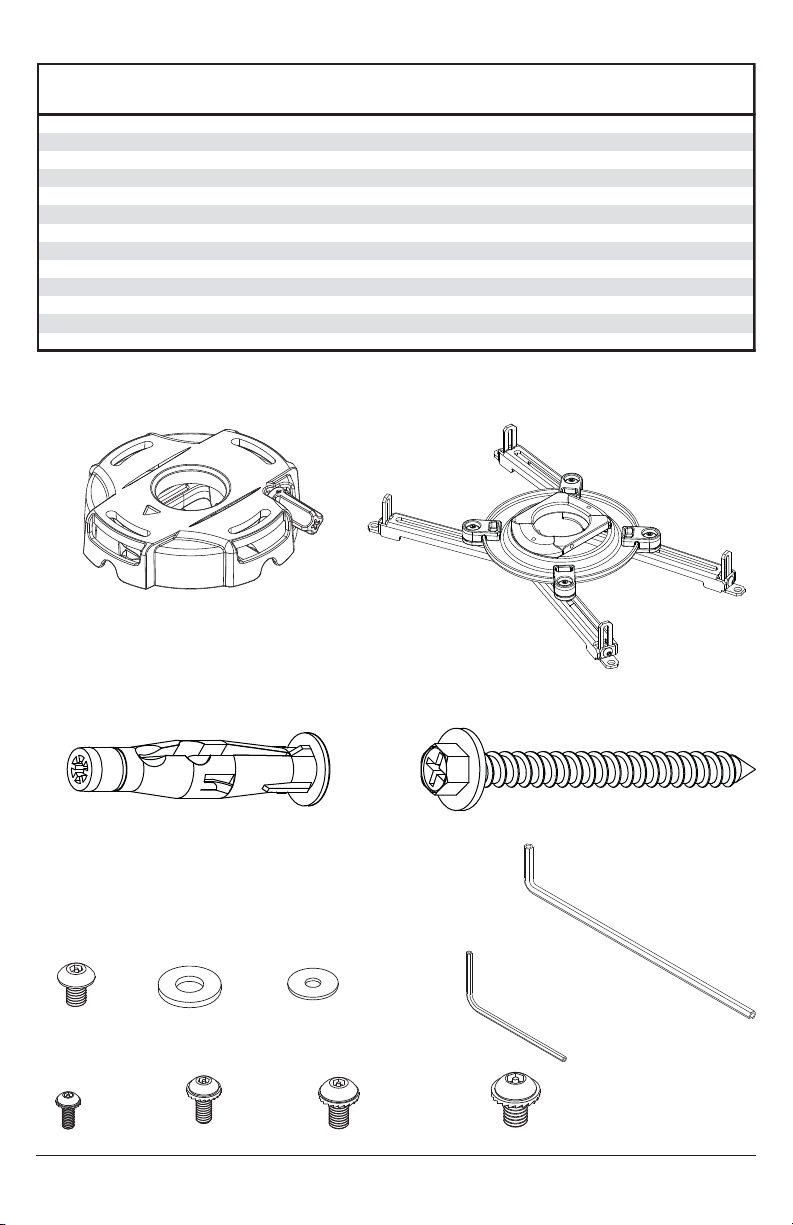

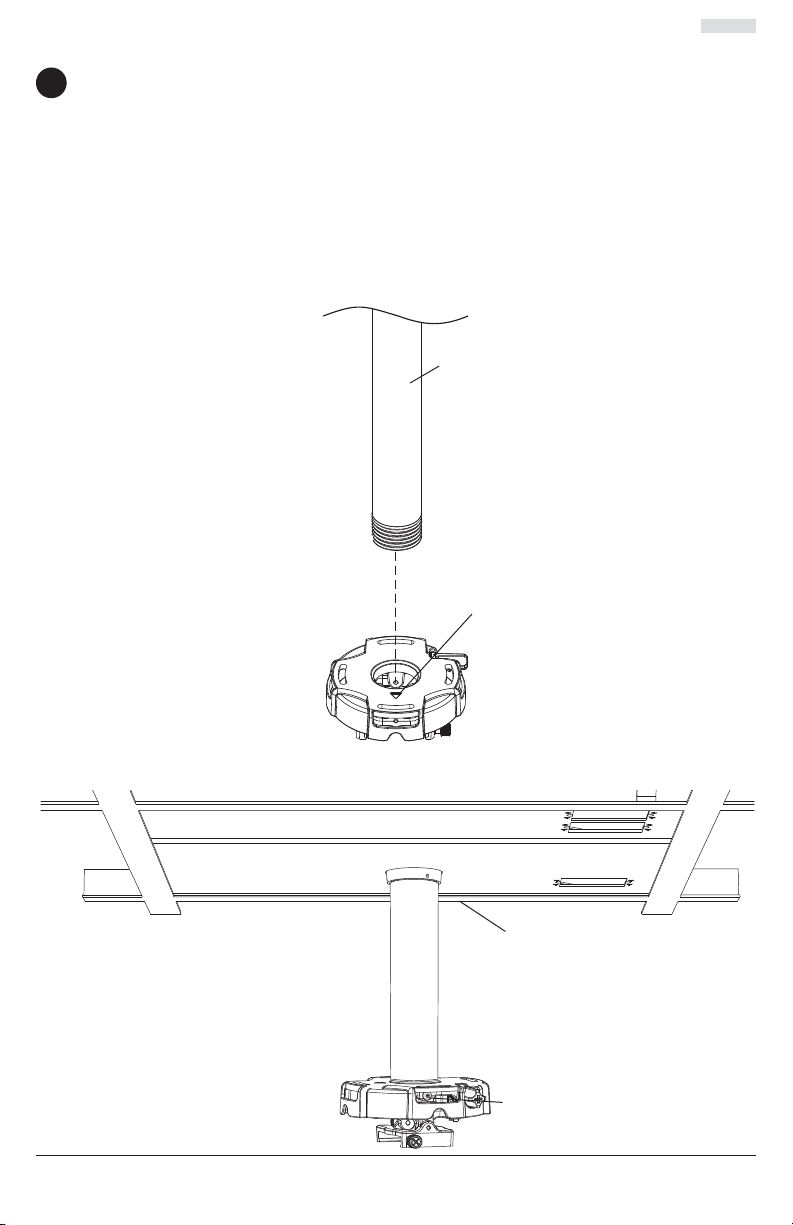

Installation to Extension Column/Ceiling Plate

NOTE: Refer to accompanying instructions with ceiling plates (sold separately) for installing

1

these models to ceiling.

Screw projector mount assembly (A) onto extension column as shown in fi gure 1.1.

Tighten swivel stop screw against extension column, fl ush mount tube or reducer using 4mm

security allen wrench (I) as shown in fi gure 1.2.

NOTE: Swivel stop screw is used to jam against threads of extension column, fl ush mount tube

or reducer to prevent any excess movement of projector mount assembly (A). Do not overtighten

screw; overtightening screw will damage threads making it diffi cult to separate products.

Skip to step 5.

1-1/2" EXTENSION COLUMN

(SOLD SEPARATELY)

(UL LISTED EXT OR AEC SERIES)

ARROW INDICATES

FRONT OF MOUNT

A

fi g. 1.1

fi g. 1.2

4 of 51

CMJ 455

(SOLD SEPARATELY)

SWIVEL STOP SCREW

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 5

Installation to Wood Joist Ceilings

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the

equipment and all attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening

can damage the screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to

edge" stud fi nder is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into

wood studs. Installers are responsible to provide hardware for other types of mounting situations

(not evaluated ny UL).

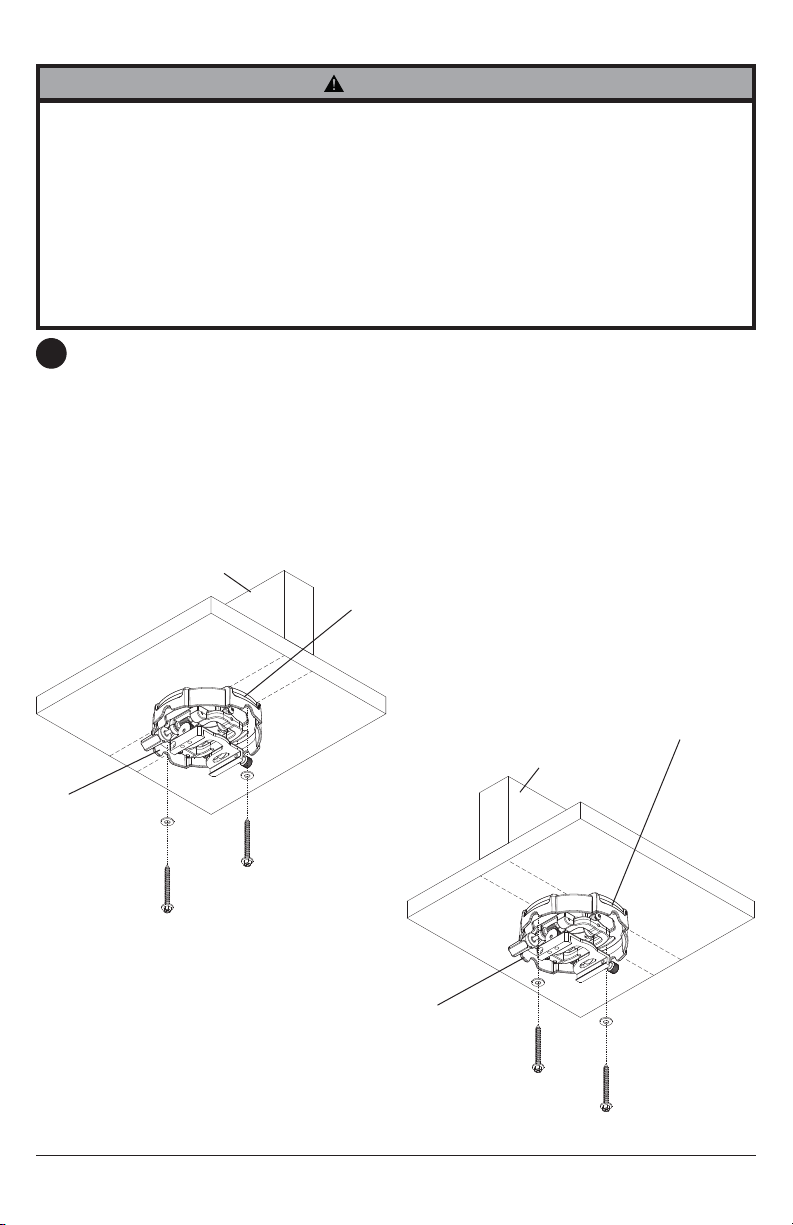

Place projector mount assembly (A) on ceiling as a template and mark the center of the two

2

mounting holes. Make sure that the mounting holes are in the center of the wood joist. Drill two

5/32" (4mm) dia. holes to a minimum depth of 2-1/2" (64mm). Attach projector mount assembly

(A) with two #14 x 2-1/2" (6mm x 64mm) wood screws (D) and two fl at washers (F) as shown in

fi gure 2.1 or fi gure 2.2 depending on joist orientation.

Tighten wood screws (D) using 3/8" (10mm) socket wrench or phillips screwdriver until projector

mount assembly (A) is fi rmly attached.

Skip to step 5.

fi g. 2.1

A

WOOD JOIST

F

D

ACCESS SLOT FOR

OPEN END WRENCH

ALLOWS TIGHTENING

OF WOOD SCREW (D).

fi g. 2.2

A

ACCESS SLOT FOR

OPEN END WRENCH

ALLOWS TIGHTENING

OF WOOD SCREW (D).

WOOD JOIST

F

D

5 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 6

Installation to Concrete Ceilings

WARNING

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete

anchor.

• Make sure that the wall will safely support four times the combined load of the equipment and all

attached hardware and components.

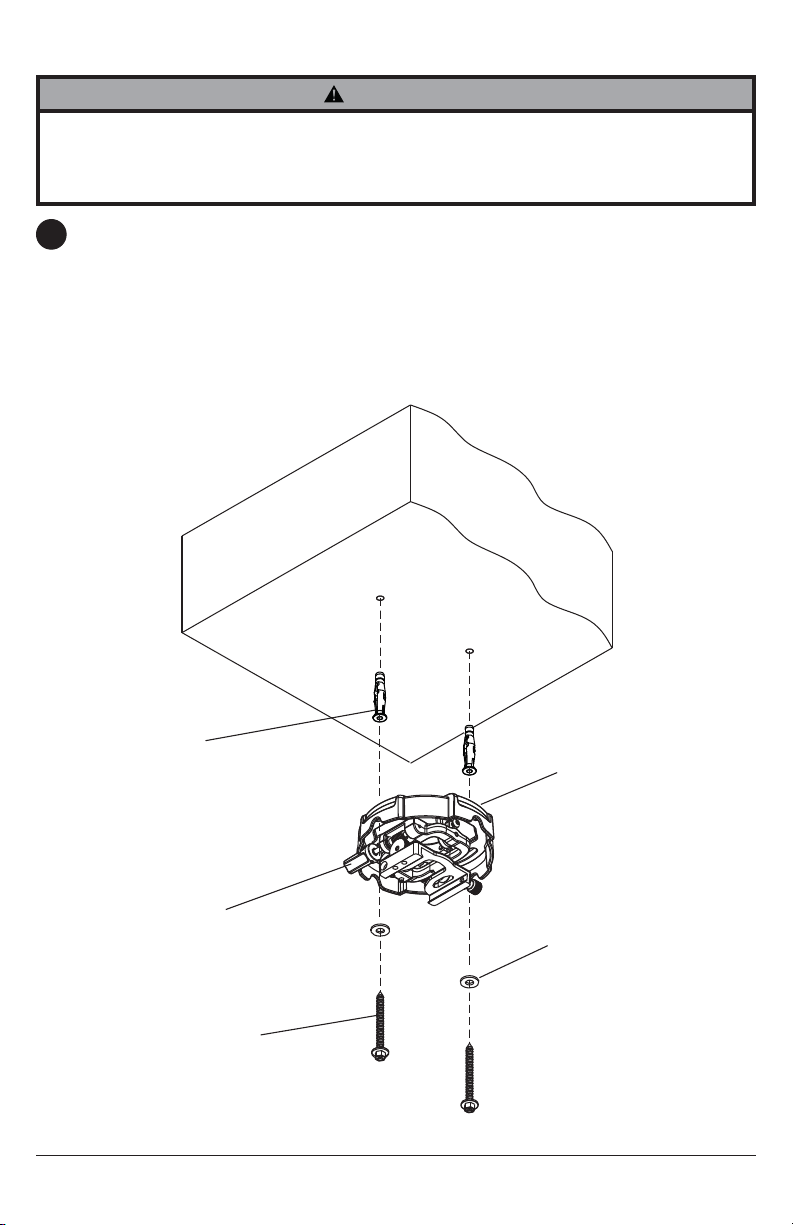

Place projector mount assembly (A) on ceiling as a template and mark the center of the two

3

mounting holes. Drill two 5/16" (8mm) dia. holes to a minimum depth of 2-1/2" (64mm).

Attach projector mount assembly (A) using two concrete anchors (C), two fl at washers (F),

and two #14 x 2-1/2" wood screws (D) as shown. NOTE: Mounting slots on projector mount

assembly allow for 30° (±15°) of rotation before fully securing wood screw. Tighten wood screws

(D) using 3/8" (10mm) socket wrench, phillips screwdriver or 10mm open end wrench until

projector mount assembly (A) is fi rmly attached.

Skip to step 5.

CONCRETE CEILING

C

ARROW ON TOP OF

PROJECTOR MOUNT

ASSEMBLY INDICATES

FRONT OF MOUNT

A

F

D

6 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 7

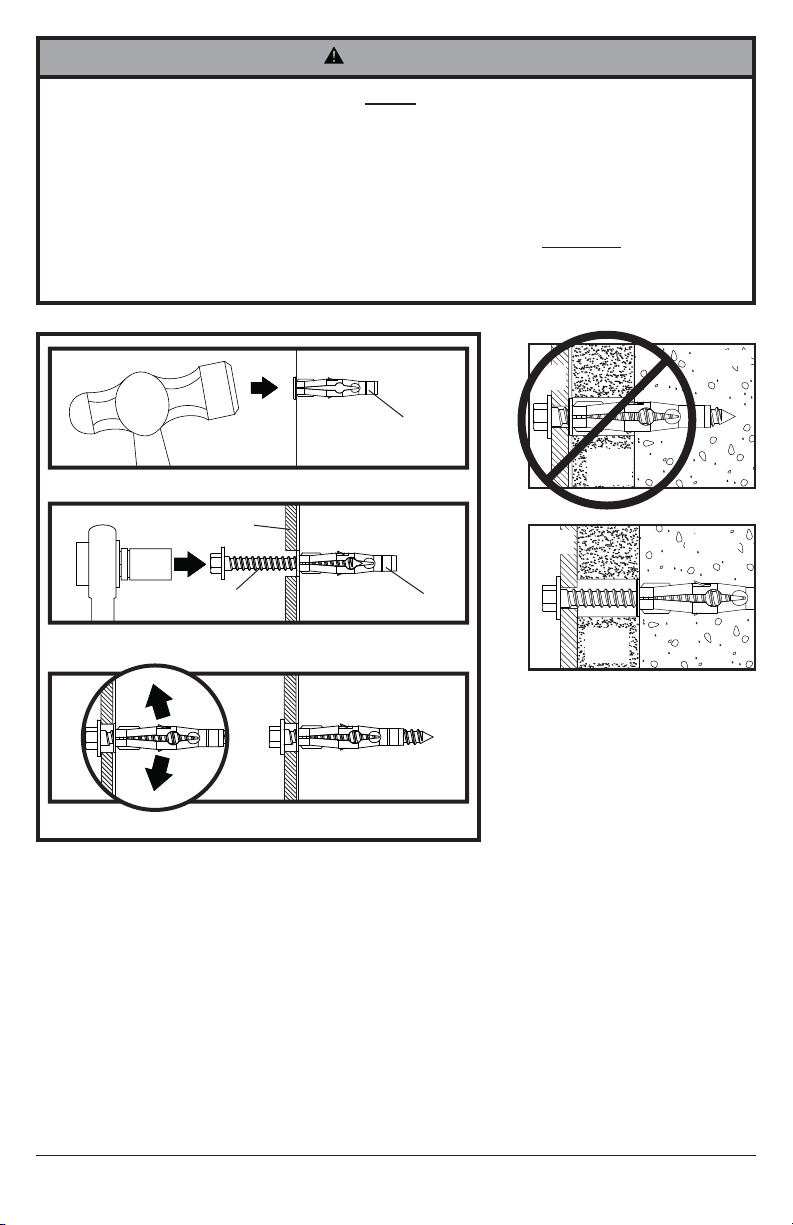

WARNING

• Always attach concrete expansion anchors directly to load-bearing concrete.

• Never attach concrete expansion anchors to concrete covered with plaster, drywall, or

other fi nishing material. If mounting to concrete surfaces covered with a fi nishing surface is

unavoidable (not evaluated ny UL), the fi nishing surface must be counterbored as shown below.

Be sure concrete anchors do not pull away from concrete when tightening screws. If plaster/

drywall is thicker than 5/8" (16mm), custom fasteners must be supplied by installer (not evaluated

by UL).

• Tighten screws so that projector mount is fi rmly attached, but do not overtighten. Overtightening

can damage screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

INCORRECT

1

Drill holes and insert anchors (C).

concrete

surface

C

A

plaster/

dry wall

concrete

2

A

D

Place plate (A) over anchors (C) and secure with

screws (D).

3

Tighten all fasteners.

CORRECT

A

concrete

CUTAWAY VIEW

C

plaster/

dry wall

7 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 8

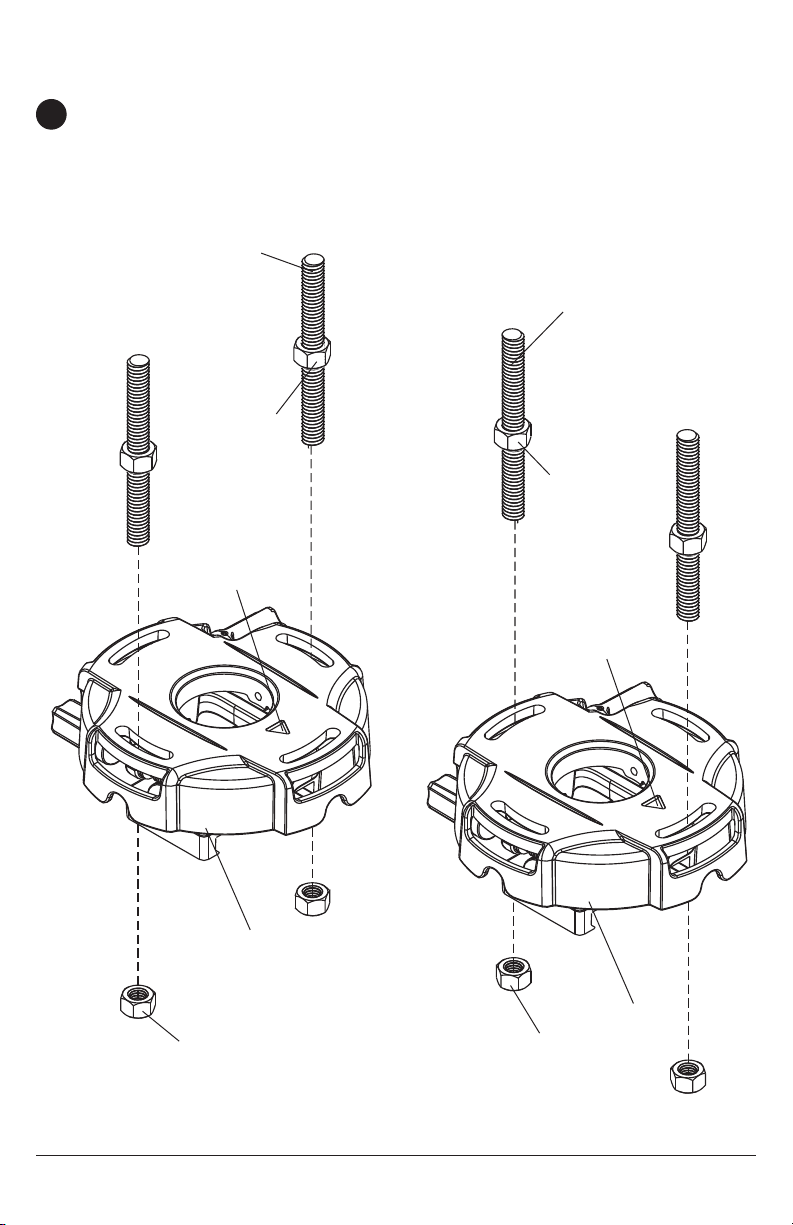

Installation to Threaded Rod

(Not evaluated by UL - Professional installation only)

Thread two 1/4-20 hex thin nylon-insert locknuts (not included) on two 1/4-20 threaded rods (not

4

included) to the desired height of projector mount assembly. Attach projector mount assembly

(A) to the two 1/4-20 threaded rods using two 1/4-20 hex thin nylon-insert locknuts as shown in

fi gure 4.1 or fi gure 4.2.

1/4-20 THREADED

ROD (NOT

INCLUDED)

1/4-20 HEX THIN

NYLON-INSERT

LOCKNUT (NOT

INCLUDED)

ARROW

INDICATES

FRONT OF

MOUNT

fi g. 4.1

fi g. 4.2

1/4-20

THREADED

ROD (NOT

INCLUDED)

1/4-20 HEX

THIN NYLONINSERT

LOCKNUT

(NOT

INCLUDED)

ARROW

INDICATES

FRONT OF

MOUNT

A

1/4-20 HEX THIN

NYLON-INSERT

LOCKNUT (NOT

INCLUDED)

8 of 51

A

1/4-20 HEX

THIN NYLONINSERT

LOCKNUT (NOT

INCLUDED)

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 9

Attaching Adapter Plate to Projector

NOTE: The projector you are installing may differ in appearance from the sample illustrated

5

below.

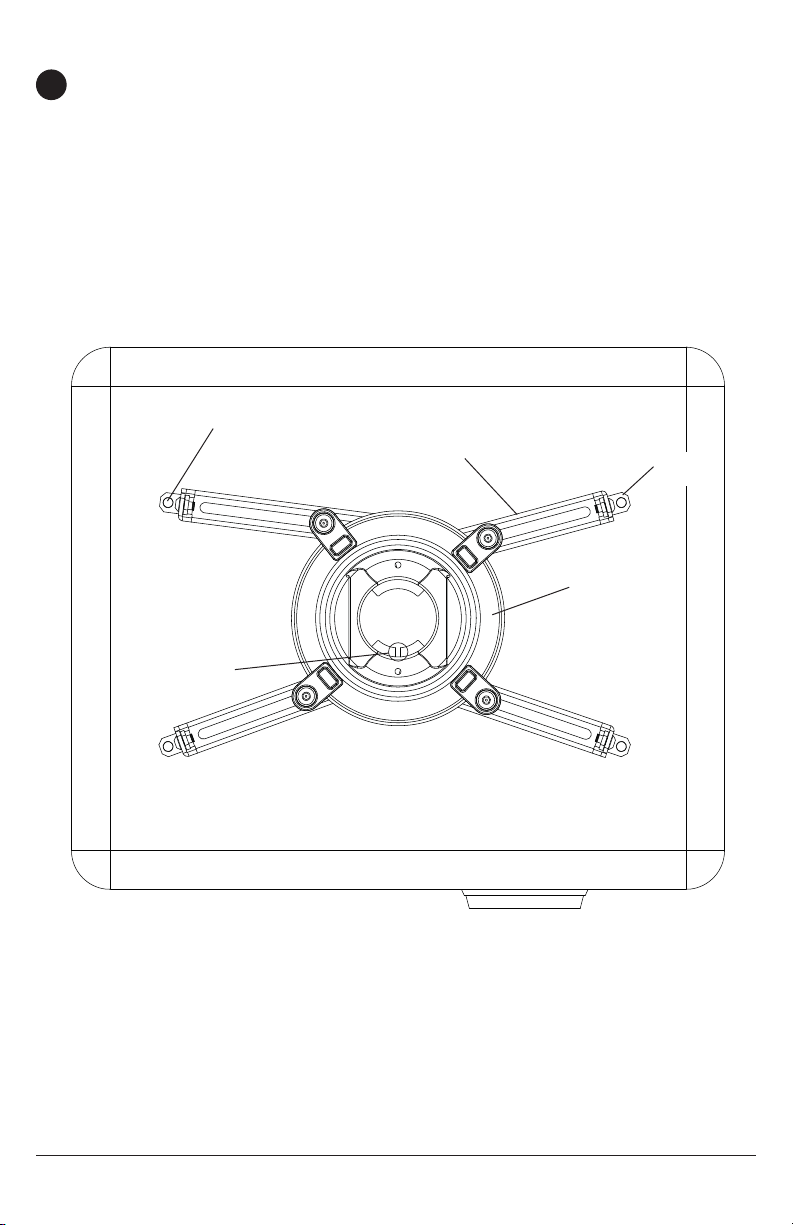

Place projector upside down. Locate adapter plate (B) with notch facing forward as close to

projector center of gravity as possible without covering any mounting holes. Loosen channels

with 4mm security allen wrench (I), and if there are only three mounting holes remove fourth

channel. Using one channel for each mounting hole, position feet of channels over mounting

holes as shown below. IMPORTANT: If projector does not have at least three mounting holes,

do not use this adapter plate.

NOTE: Some projectors have feet which can be removed and the corresponding threaded insert

can be used for a mounting hole.

NOTE: Once channels are in position retighten fasteners.

*Notch indicates front of projector.

MOUNTING HOLE

CHANNEL

B

FOOT OF

CHANNEL

*

GENERIC PROJECTOR

9 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 10

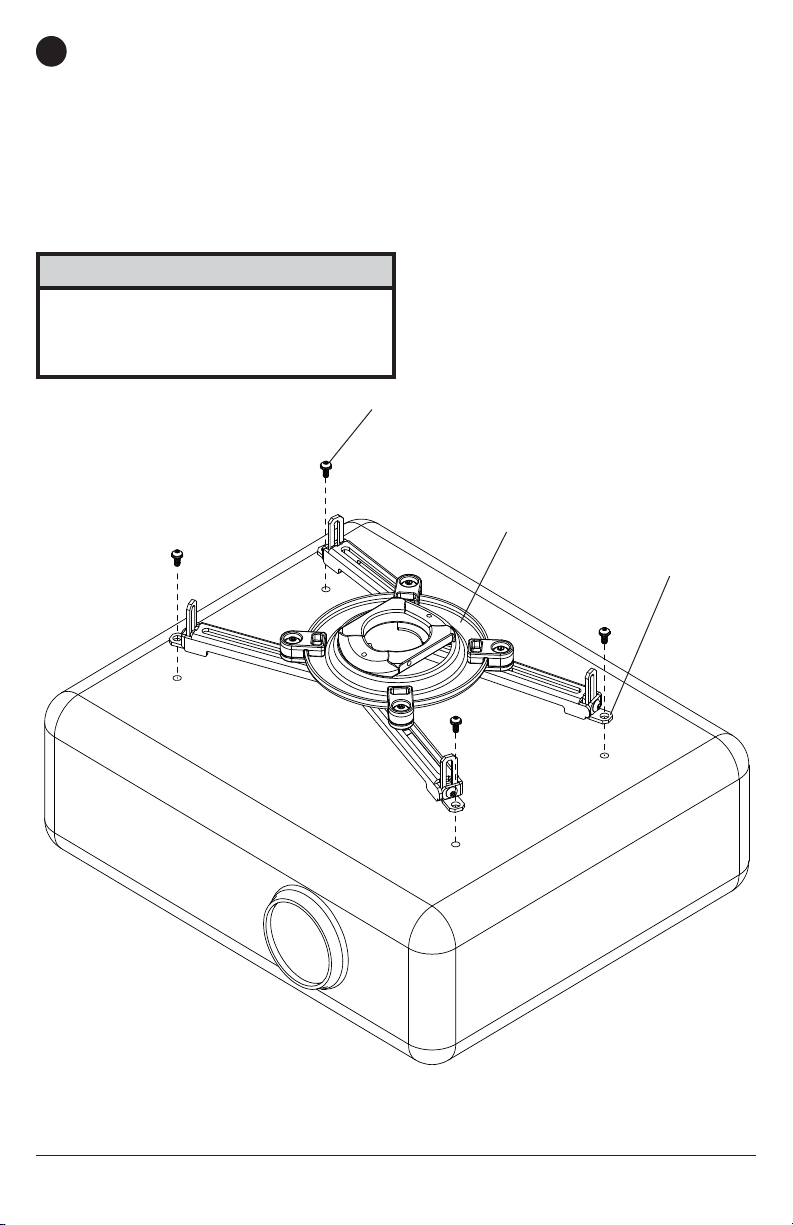

Attach adapter plate (B) to projector using one screw (J, K, L or M) for each channel as shown

6

below. Tighten all screws, while keeping the center of gravity. Be sure that adapter plate (B) is

straight. Adjust the feet of the channels to keep the adapter plate level. Tighten all screws with

4mm security allen wrench (I) while keeping the center of gravity. If M3 screws (J) are used,

tighten using 2mm security allen wrench (H).

NOTE: Projectors will require different size screws for mounting. Use a combination of screws

(J, K, L or M) and foot adjustment that will result in channels of adapter plate (B) fi tting tightly

against projector. IMPORTANT: In order to properly engage the threads in the mounting holes,

the screw must be turned at least 3 full turns.

NOTE: If using screw (J), place washer (G) between screw (J) and foot of channel.

CAUTION

• It is the responsibility of the installer to ensure

that the projector is properly ventilated. Feet

of channels are used to raise the mount off the

projector surface.

J, K, L or M

B

FOOT OF

CHANNEL

10 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 11

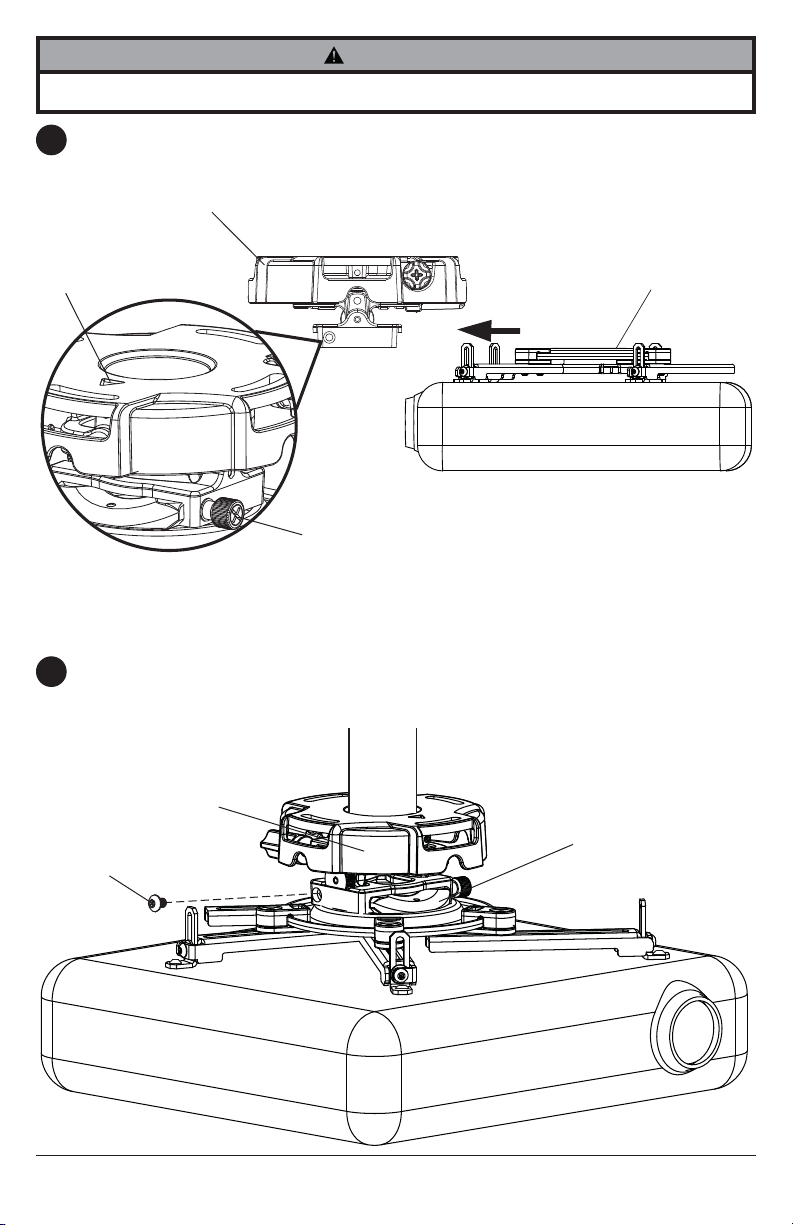

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the projector.

Slide connection block with projector into projector mount assembly (A) as shown. Push in and

7

tighten captive screw to secure projector to projector mount assembly (A).

FRONT OF MOUNT

ARROW INDICATES

FRONT OF MOUNT

CAPTIVE SCREW

IMPORTANT: For security installations, insert one #10-32 x 1/4" socket pin screw (E) through

8

projector mount assembly (A) and into connection block as shown. Tighten screw with 4mm

security allen wrench (I).

A

CONNECTION BLOCK

A

CONNECTION

BLOCK

E

11 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 12

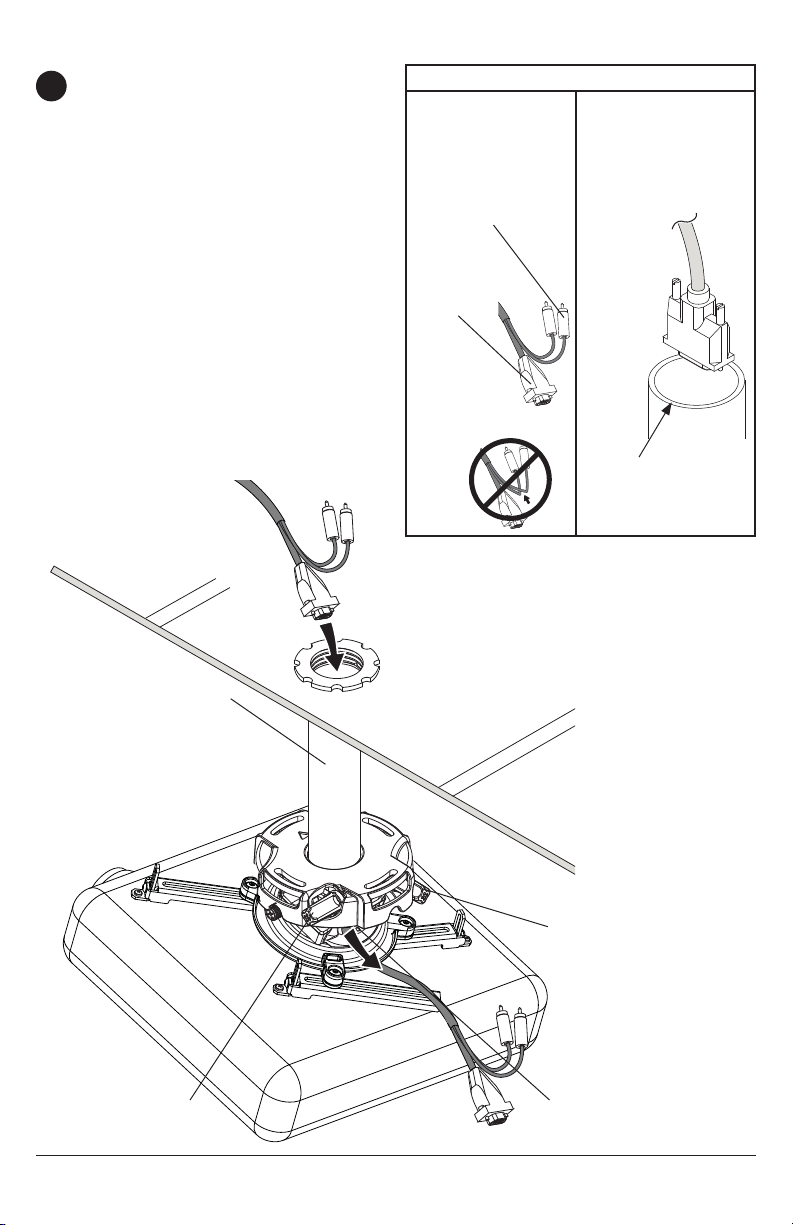

Cable Management

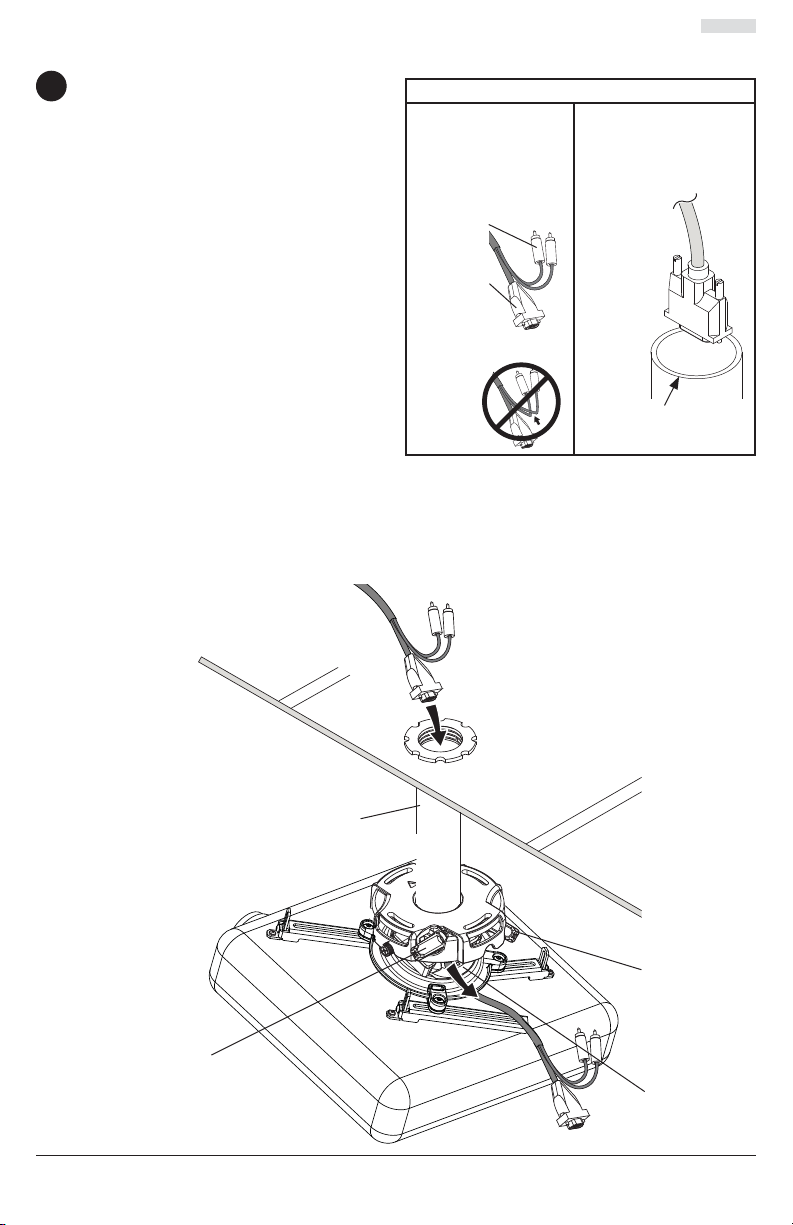

To make an opening to route cables through

9

projector mount assembly, adjust projector

mount assembly to full upward tilt position

by turning knob for tilt adjustment as shown

in fi gure 9.2. Left or right roll position can be

adjusted if more space is required.

NOTE: Be certain tamper resistant

screws are not engaged before making

adjustments (see step 11).

Route cables through top of extension

column as shown in fi gure 9.1 and fi gure

9.2.

NOTE: A method for assisting cables

through extension column may be required

(example: string tied to connector to help

pull through extension column).

Route cables through projector mount

assembly as shown in fi gure 9.2 and

connect to projector.

fi g. 9.2

fi g. 9.1

CABLES WITH

COMBINATION OF VGA

CONNECTOR

AND RCA PLUGS

BEND WIRES OF RCA

PLUGS IN OPPOSITE

DIRECTION

ROUTE

CONNECTOR

THROUGH

FIRST

DO NOT CRIMP

WIRES

NOTE: INNER

DIAMETER OF

EXTENSION COLUMN

MAY NOT ALLOW

PASSAGE FOR ALL

CONNECTOR TYPES.

CABLE

CONNECTOR

INNER DIAMETER

OF EXTENSION

COLUMN

EXTENSION

COLUMN

KNOB FOR TILT

ADJUSTMENT

12 of 51

KNOB FOR ROLL

ADJUSTMENT

OPENING FOR

ROUTING CABLES

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 13

Projector Alignment

To adjust yaw (swivel) for threaded rod mounting applications: Loosen locknuts for

10

threaded rods (step 4) until projector mount can be rotated. Rotate mount to desired position

and retighten locknuts.

To adjust yaw (swivel) for extension column applications: Loosen screw on projector mount

assembly (A) indicated below until projector mount can be rotated. Rotate mount to desired

position and retighten screw.

To adjust pitch (forward and backward tilt): Turn knob on back of mount as shown below.

Pull knob out and turn by hand for easy adjustment or insert #2 phillips screwdriver in end of

knob and turn.

To adjust roll (side to side tilt): Turn knob on side of mount as shown below. Pull knob out and

turn by hand for easy adjustment or insert #2 phillips screwdriver in end of knob and turn.

ARROW INDICATES FRONT OF

MOUNT

ACCESS SLOT FOR

OPEN END WRENCH

ALLOWS TIGHTENING

OF LOCKNUTS WITHOUT

REMOVING PROJECTOR

A

KNOB FOR PITCH

ADJUSTMENT

KNOB FOR ROLL

ADJUSTMENT

SCREW FOR YAW (SWIVEL) STOP

(REFER TO STEP 1, FIG. 1.2)

13 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 14

To prevent tampering with the pitch and roll adjustments: Tighten the two tamper resistant

11

security screws on the projector mount assembly using 4mm security allen wrench (I) to lock the

pitch and roll adjustments as shown below.

NOTE: Tighten screws fi rmly, but do not overtighten. Overtightening can damage the mount.

WARNING

• Do not adjust pitch or roll while tamper resistant security screws are fully engaged.

• Loosen the two tamper resistant security screws one complete turn before adjusting the projector

mount assembly or damage may occur.

TO LOCK ROLL, TIGHTEN

TAMPER RESISTANT SECURITY

SCREW

FRONT VIEW

SIDE VIEW

14 of 51

TO LOCK PITCH, TIGHTEN

TAMPER RESISTANT

SECURITY SCREW

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 15

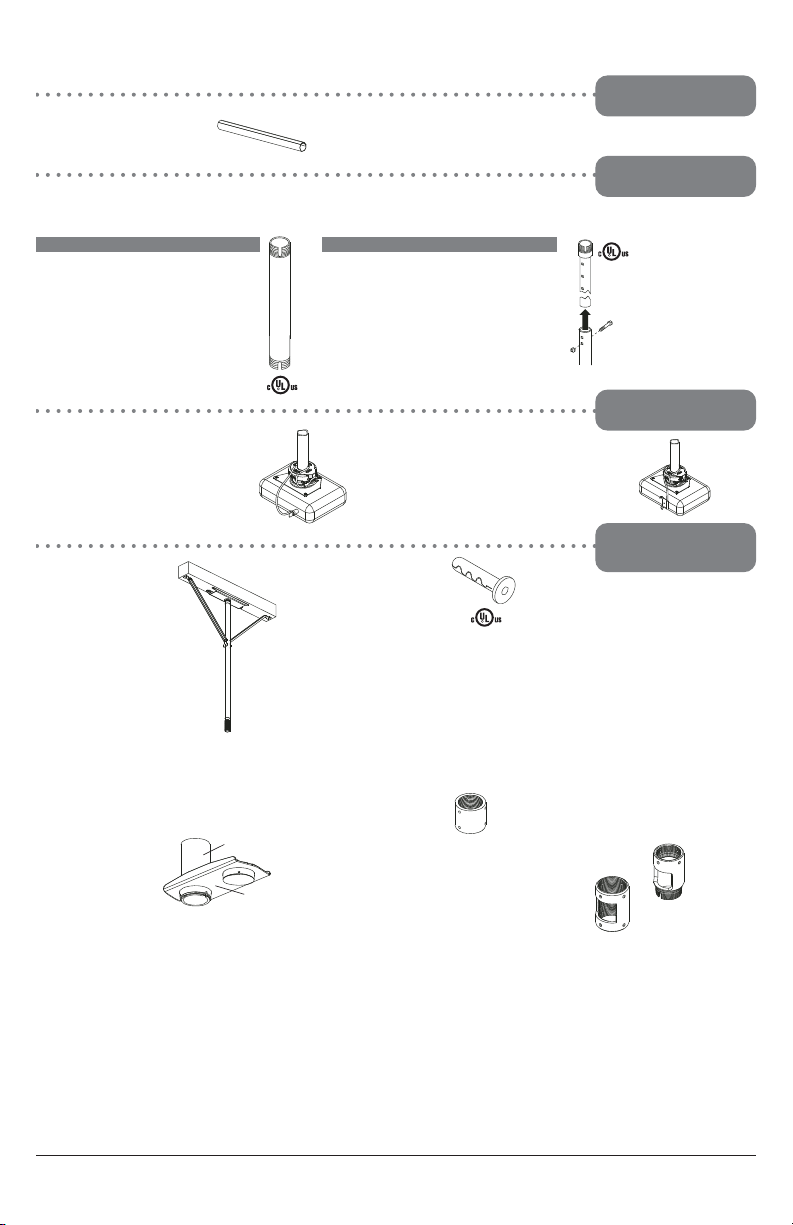

PRG Series Projector Mount Accessories

I-Beam Clamps

M

ODELS

:

ACC 558, ACC 559

M

AX LOAD

:

250 lbs. (113.4 kg.)

C

OLOR

:

Black

• ACC 558 clamps onto 4"-8" I-Beam

• ACC 559 clamps onto 7"-12" I-Beam

Unistrut® Adapter

M

ODEL

: ACC 550

M

AX LOAD

:

250 lbs. (113.4 kg.)

C

OLOR

:

Black

• Designed for use with

1 5/8" x 1 5/8" 12 gauge Unistrut

Accessory Pack for CMJ 455

M

ODEL

: ACC 455*

This pack includes 4 hanger brackets and

4 hanger clamps for additional stability. For

use with model CMJ 455.

M

ODEL

: ACC 557*

M

AX LOAD

:

250 lbs. (113.4 kg.)

C

OLOR

:

Black

• Attaches to a square, round,

rectangular, or I-Beam truss up to 3" in

diameter

Escutcheon Ring

M

ODEL

: ACC 640

• Covers hole where extension

column passes through ceiling

• Hinged ring wraps around extension column

• Included with CMJ 500

Lightweight Cathedral

Ceiling Plate

M

ODEL

: ACC 912*

M

AX LOAD

:

60 lbs. (27.2 kg.)

C

OLOR

:

Black

• Designed specifically for projectors

• Allows a projector to be mounted

on an angled ceiling

New!

Lightweight Adjustable

Suspended Ceiling Kit

M

ODEL

: CMJ 500

M

AX LOAD

:

60 lbs. (27.2 kg.)

C

OLOR

:

White

• Mounts above 2’ x 4’ or 2’ x 2’ false

ceiling tile

• Includes tie wire supports, flush mount

tube, and offers two knockout panels

for outlet boxes

• Offers unlimited adjustment for

projector placement

New!

Lightweight Suspended Ceiling Kit

M

ODEL

: CMJ 455

M

AX LOAD

:

50 lbs. (22.7 kg.)

C

OLOR

:

White

• Five different projector

mount attachment points

• Includes tie wire supports,

flush mount tube, and

offers two knockout panels

for outlet boxes

• May either replace a 2’ x 2’ false

ceiling tile or mount above an existing

2’ x 2’ or 2’ x 4’ ceiling tile

Anti-Vibration Ceiling Plates

M

ODELS

:

ACC 840*, ACC 845*

M

AX LOAD

:

60 lbs. (27.2 kg.)

C

OLOR

:

Black

• ACC 840 was designed for

a structural ceiling (wood only)

• ACC 845 was designed for

a Unistrut ceiling (1 5/8" x 1 5/8"

12 gauge Unistrut)

• Reduces unwanted vibrations

that may cause internal damage

to the equipment and/or cause the

screen image to vibrate

• Features two cord management

access holes

• Patent pending

Unistrut or Structural

Ceiling Plates

M

ODELS

:

CMJ 300*, CMJ 310*

M

AX LOAD

:

250 lbs. (113.4 kg.)

C

OLOR

:

Black

• CMJ 300 is a 4" x 4" ceiling plate

• CMJ 310 is a 8" x 8" ceiling plate

• Designed for a Unistrut ceiling

(1 5/8" x 1 5/8" 12 gauge Unistrut)

or a solid structural ceiling

(mounting hardware not included)

Unistrut

Ceiling plate

R

Ceiling Plates

R

*

= Not UL Listed

Round Ceiling Plate

M

ODEL

:

ACC570(S)(W)

C

OLOR

:

Black, silver or white

MAX L

OAD

:

150 lb (68 kg)

S

HIP WEIGHT

:

1.7 lb (.8 kg)

• Designed for finished or

structural ceilings (wood or

concrete)

• Features a cord management

R

R

R

15 of 51

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 16

PRG Series Projector Mount Accessories

ALLIGATOR

®

Concrete Anchors

M

ODELS

: ACC 203, 204

• ACC 203 contains 3 anchors

• ACC 204 contains 4 anchors

• Used for attachment to

concrete, concrete block,

or brick

• Used in conjunction with wood

screws (supplied with

projector mount and/or

ceiling plate)

• Expands in length and binds to

the contours of the hole and

the screw

Cord Wrap

M

ODELS

: ACC 852(W)(S)*

C

OLOR

:

Black, White, or Silver

M

ODEL

: ACC 830*

C

OLOR

:

Black

• Provides 4" of radial

adjustment side to side

• Includes Flush Mount

Tube, EXT 002

TM

Plus Security Cables

M

ODEL

: ACC 021*

• With 1/4" security cable and fasteners

• Includes adhesive for non-fastener applica

tions

M

ODEL

: ACC 020*

• With security lock

• For use with projectors that have a built-in

security slot

Extension

column

Extension Columns

Security Accessories

Additional Projector

Mount Accessories

Cord Management

Fixed Length 1 1/2"

Extension Columns

C

OLOR

:

Black

R

= Not UL Listed

• Includes, four, 2' sections

• Designed to externally route cords along the

outside of an 1/2" extension column

• Sections can be stacked to create longer lengths

or cut to desired length

M

ODEL

: ACC 050*

C

OLOR

:

Black

• Can be used to reduce

unwanted swaying that may

occur with extension

column installations

• Includes a hose clamp, two

stabilizer column supports,

& hardware for mounting to

wood joists

• For use with extension

columns over 21"

MODEL Drop Le ngth Ship Weight

EXT 006 8"

(20 cm)

2.5 lbs

(1.13 kg)

EXT 018 20"

(51 cm)

5 lbs

(2.27 kg)

EXT 101 14"

(36 cm)

3.5 lbs

(1.59 kg)

EXT 102 26"

(66 cm)

6 lbs

(2.72 kg)

EXT 103 38"

(97 cm)

9.25 lbs

(4.2 kg)

EXT 104 50"

(127cm)

12 lbs

(5.44 kg)

EXT 105 62"

(158 cm)

14.75 lbs

(6.69 kg)

EXT 106 74"

(188 cm)

18 lbs

(8.16 kg)

EXT 107 86"

(219 cm)

20.75 lbs

(9.41 kg)

EXT 108 98"

(249 cm)

23.25 lbs

(10.55 kg)

EXT 109 110"

(279 cm)

26.5 lbs

(12.02 kg)

EXT 110 122"

(310 cm)

29 lbs

(13.15 kg)

Side to side

adjuster

Extension Column

Connector

M

ODEL

: ACC 109*

C

OLOR

:

Black

• Can be used to join two

1-1/2" extension columns to

create a maximum length

of 20’

• Secures to columns with

Armor Lock

TM

Security

screws

Extension Column Connector

with Cord Management

M

ODEL

: ACC800, ACC850(S)

C

OLOR

: ACC800

Black

ACC850

Black or Silver

• 1-1/2" access hole for internal cord

management

• Unit has 1-1/2"-11.5 NPT fitting for

attachment of extension column

• Security screws included

• ACC800: One male and one female

connection to provide internal cord

management between extension

column and mount or ceiling plate

• ACC850: Two female connectors to

join two extension columns to

create maximum length of 20’

ACC850

ACC800

Adjustable Length 1 1/2"

Extension Columns

C

OLOR

:

Black

MODEL Drop Length Ship Weight

ADJ 006009 8"-11" 4 lbs.

ADJ 012018 14"-20" 4.75 lbs.

ADJ 018024 20"-26" 6.25 lbs.

ADJ 0203 26"-38" 8 lbs.

ADJ 0305 38"-62" 13.5 lbs.

ADJ 0406 50"-74" 16.25 lbs.

ADJ 0507 62"-86" 18.5 lbs.

ADJ 0608 74"-98" 21.75 lbs.

ADJ 0709 86"-110" 24.5 lbs.

ADJ 0810 98"-122" 27 lbs.

ADJ 0911 110"-134" 29 lbs.

ADJ 1012 122"-146" 31 lbs.

R

16 of 51

(1.81 kg)

(2.15 kg)

(2.83 kg)

(3.63 kg)

(6.12 kg)

(8.39 kg)

(11.11 kg)

(12.25 kg)

(13.15 kg)

(14.06 kg)

(7.37 kg)

(9.87 kg)

R

ISSUED: 09-30-09 SHEET #: 056-9024-5 07-18-11

Page 17

Instrucciones para la instalación y el ensamblaje:

Soporte para proyectores PRG Precision Gear con

placa adaptadora universal

Modelos: PRG-UNV, PRG-UNV-S, PRG-UNV-W

Características:

• El alineamiento ImageLockTM evita que haya

descenso o desvío de la imagen.

• Destrabe rápido del tornillo imperdible que

fi ja el bloque de conexión al exclusivo riel de

aluminio.

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Capacidad máxima de soportar carga:

50 lb (22.7 kg)

PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 18

NOTA: Lea toda la hoja de instrucciones antes de iniciar la instalación y el montaje.

Español

ADVERTENCIA

• No comience a instalar su producto de Peerless hasta haber leído y entendido las instrucciones

y las advertencias contenidas en la Hoja de Instalación. Si tiene alguna pregunta acerca de cualquiera de las instrucciones o las advertencias, por favor, llame a Servicio al Cliente de Peerless

al 1-800-865-2112 si está en EE. UU. Si es un cliente internacional, por favor, comuníquese con

su distribuidor local.

• Este producto sólo debe ser instalado por una persona que tenga una buena aptitud mecánica,

que tenga experiencia en construcción básica de edifi cios y que entienda estas instrucciones en

su totalidad.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

• Nunca sobrepase la capacidad máxima de soportar carga Underwriters Laboratories.

página 17.

• Si va a instalar el producto en una pared con montantes de madera, asegúrese de que los

tornillos de montaje estén anclados en el centro de los montantes. Se recomienda utilizar un

localizador de montantes de "borde a borde".

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para levantar

y colocar el equipo con más seguridad.

• Apriete los tornillos con fi rmeza, pero no en exceso. Apretarlos en exceso puede dañar los

artículos y puede disminuir signifi cativamente su fuerza de fi jación.

• Este producto está diseñado para uso en interiores solamente. Utilizar este producto en exteriores podría causar fallas del producto y lesiones a individuos.

• Este producto fue diseñado para ser instalado en paredes con la siguiente construcción solamente:

CONSTRUCCIÓN DE LA PARED ACCESORIOS NECESARIOS

• Montante de madera Incluido

• Viga de madera Incluido

• Concreto macizo Incluido

• Ladrillo Comuníquese con un profesional califi cado

(No evaluados por UL)

• ¿Otra superfi cie o no está seguro? Comuníquese con un profesional califi cado

Vea la

Herramientas necesarias para el ensamblaje

• localizador de montantes (se recomienda uno de “borde a borde”)

• destornillador phillips

• taladro

• broca de 5/16" para superfi cies de concreto

• broca de 5/32" para montantes de madera

• llave plana o tipo Crescent

• nivel

Tabla de contenido

Lista de piezas.....................................................................................................................................19

Instalación unidad del soporte para proyectores ............................................................................20-23

Fijar la placa adaptadora al proyector ................................................................................................. 25

Accesorios .....................................................................................................................................31, 32

18 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 19

Antes de comenzar, coteje la lista de piezas para asegurarse de que se han incluido todas las piezas.

PRG-UNV PRG-UNV-S PRG-UNV-W

Descripción Cant.

N.

o

de pieza N.o de pieza N.o de pieza

A unidad del soporte para proyectores 1 054-1171 054-4171 054-2171

B placa adaptadora 1 055-1938 055-4938 055-2838

C anclaje para concreto 2 590-0320 590-0320 590-0320

D

tornillos de cabeza hexa

g

.

o

14 x 2-1/2"

2 5S1-015-C03 5S1-015-C04 5S1-015-C04

E

6

6

6

Lista de piezas

E

tornillo pasador de cabeza hueca N.

10x-32x1/4

1

520 1196

520 2196

520 2196

p

.

o

6 x 1/2" OD

4 540-1025 540-2025 540-2025

H llave allen de seguridad de 2 mm 2 560-1097 560-1097 560-1097

I llave allen de seguridad de 4 mm 1 560-9646 560-9646 560-9646

J

tornillo pasador de cabeza hueca con arandela dentada de

M3 x 8 mm

4 510-1004 510-2004 510-2004

K

tornillo pasador de cabeza hueca con arandela dentada de

M4 x 10 mm

4 510-1060 510-2060 510-2060

L

tornillo pasador de cabeza hueca con arandela dentada de

M5 x 10 mm

4 510-1126 510-2063 510-2063

M

tornillo pasador de cabeza hueca con arandela dentada de

M6 x 10 mm

4 510-1066 510-2066 510-2066

Español

onalpara madera N

o

-

F arandela plana de 1/4" 2 540-1078 540-1078 540-1078

G

arandela

lana N

”

1 520-119

520-219

520-219

NOTA: Las piezas pueden verse un poco distintas a la ilustración.

A

B

CD

I

E

J

F

K

G

L

19 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

H

M

Page 20

Instalación en columnas de extensión / placas de techo

NOTA: Lea las instrucciones de las placas de techo (que se venden por separado) para ver

1

cómo instalar estos modelos en los techos.

Fije la unidad del soporte para proyectores (A) a la columna de extensión utilizando los tornillos,

como se muestra en la fi gura 1.1. Apriete el tornillo de tope, que impide el giro, a la columna de

extensión, al tubo de montaje empotrado o al reductor utilizando la llave allen de seguridad de

4mm (I), como se muestra en la fi gura 1.2.

NOTA: El tornillo de tope, que impide el giro, se utiliza para que trabe contra las columnas de

extensión, el tubo de montaje empotrado o el reductor para evitar que la unidad del soporte para

proyectores (A) se mueva más de lo necesario. No apriete el tornillo en exceso; apretarlo en

exceso dañará las roscas y hará que sea difícil separar las piezas.

Pase al paso 5.

COLUMNA DE EXTENSIÓN DE 1 1/2"

(SE VENDE POR SEPARADO)

(CLASIFICACIÓN DE UL EXT O SERIE AEC)

Español

fi g. 1.2

fi g. 1.1

A

LA FLECHA INDICA LA

PARTE DELANTERA DEL

SOPORTE

CMJ 455

(SE VENDE POR SEPARADO)

TORNILLO DE

TOPE QUE

IMPIDE EL GIRO

20 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 21

Instalación en techos con vigas de madera

ADVERTENCIA

• El instalador tiene que asegurarse de que la superfi cie de apoyo sostendrá, con seguridad, la

carga combinada del equipo y todos los fi jadores y componentes.

• Apriete los tornillos para madera de manera que la unidad del soporte para proyectores se

fi je fi rmemente, pero no en exceso. Apretarlos en exceso puede dañar los tornillos y puede

disminuir signifi cativamente su fuerza de sujeción.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje estén anclados en el centro del montante. Se

recomienda utilizar un localizador de montantes de “borde a borde”.

• Los accesorios para la instalación que se proveen son para fi jar el soporte a montantes de

madera a través de tabique de yeso-cartón o yeso de espesor estándar. Los instaladores son

responsables de suministrar los accesorios necesarios para otros tipos de instalaciones (no

evaluados por UL).

Coloque la unidad del soporte para proyectores (A) contra el techo a manera de plantilla y

2

marque el centro de los dos agujeros de montaje. Asegúrese de que los agujeros de montaje

estén en el centro de la viga de madera. Taladre dos agujeros de 5/32" (4mm) de diámetro a

una profundidad mínima de 2-1/2" (64mm). Fije la unidad del soporte para proyectores (A) con

dos tornillos para madera de 14 x 2-1/2" (6mm x 64mm) (D) y dos arandelas planas (F), como

se muestra en la fi gura 2.1 o en la fi gura 2.2, dependiendo de la orientación de la viga.

Apriete los tornillos para madera (D) utilizando una llave de copa de 3/8" (10mm), un

destornillador phillips o una llave plana o tipo Crescent de 10mm hasta que la unidad del

soporte para proyectores (A) se fi je fi rmemente.

Pase al paso 5.

Español

VIGA DE MADERA

A

F

D

fi g. 2.1

LA RANURA DE ACCESO

PARA LA LLAVE PLANA O

TIPO CRESCENT PERMITE

APRETAR EL TORNILLO

PARA MADERA (D)

A

21 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

VIGA DE

MADERA

fi g. 2.2

LA FLECHA EN LA

PARTE SUPERIOR

DE LA UNIDAD DEL

SOPORTE PARA

PROYECTORES

INDICA LA PARTE

DELANTERA DEL

SOPORTE

F

D

Page 22

Instalación en techos de concreto

ADVERTENCIA

• El concreto tiene que tener una densidad mínima de 2,000 psi. Es posible que un concreto de

menos densidad no sostenga el anclaje para concreto.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

Coloque la unidad del soporte para proyectores (A) contra el techo a manera de plantilla

3

y marque el centro de los dos agujeros de montaje. Taladre dos agujeros de 5/16" (8mm)

de diámetro a una profundidad mínima de 2-1/2" (64mm). Fije la unidad del soporte para

proyectores (A) utilizando dos anclajes para concreto (C), dos arandelas planas (F) y dos

tornillos para madera de 14 x 2-1/2" (D), como se muestra. NOTA: Las ranuras de montaje de la

unidad del soporte para proyectores permiten una rotación de 30° (±15°) antes de fi jar el tornillo

para madera completamente. Apriete los tornillos para madera (D) utilizando una llave de copa

de 3/8" (10mm), un destornillador phillips o una llave plana o tipo Crescent de 10mm hasta que

la unidad del soporte para proyectores (A) se fi je fi rmemente.

Pase al paso 5.

TECHO DE

CONCRETO

Español

C

LA FLECHA INDICA LA

PARTE DELANTERA

DEL SOPORTE

A

F

D

22 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 23

Español

ADVERTENCIA

• Siempre fi je los anclajes para concreto directamente en la pared que sostiene la carga.

• Nunca fi je los anclajes para concreto a una pared de concreto recubierta con yeso, tabique de

yeso-cartón u otro material de acabado. Si es inevitable hacer la instalación en una superfi cie

de concreto recubierta con una superfi cie de acabado (no evaluado por UL) , la superfi cie de

acabado tiene que ser escariada, como se muestra abajo. Asegúrese de que los anclajes para

concreto no se separen del concreto cuando apriete los tornillos. Si el grosor de la capa de

yeso o tabique de yeso-cartón tiene un grosor mayor de 5/8" (16mm), el instalador tiene que

suministrar las fi jaciones especiales (no evaluado por UL).

• Apriete los tornillos para madera con fi rmeza, pero no en exceso. Apretarlos en exceso puede

dañar los tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

INCORRECTO

1

concrete

surface

A

C

concreto

Taladre los agujeros e inserte los anclajes (C).

2

Coloque la placa (A) sobre los anclajes (C) y fíjela con los

tornillos (D).

A

D

C

3

Apriete todas las fi jaciones.

yeso / tabique de

yeso-cartón

A

VISTA EN CORTE

yeso / tabique de

yeso-cartón

CORRECTO

concreto

23 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 24

Instalación en varillas roscadas

(No evaluado por UL – Instalación profesional solamente)

Pase dos contratuercas hexagonales delgadas de nilón de 1/4-20 (no incluidas) por dos varillas

4

roscadas de 1/4-20 (no incluidas) a la altura que quiere instalar la unidad del soporte para

proyectores. Fije la unidad del soporte para proyectores (A) a las dos varillas roscadas de

1/4-20 utilizando las dos contratuercas hexagonales delgadas de nilón de 1/4-20, como se

muestra en la fi gura 4.1 o en la fi gura 4.2.

VARILLA ROSCADA DE

1/4-20 (NO INCLUIDA)

VARILLA ROSCADA DE

CONTRATUERCA

HEXAGONAL

DELGADA

DE NILÓN DE

1/4-20

(NO INCLUIDA)

LA FLECHA

INDICA LA

PAR TE

DELANTERA

DEL SOPORTE

fi g. 4.1

fi g. 4.2

1/4-20 (NO INCLUIDA)

CONTRATUERCA

HEXAGONAL

DELGADA

DE NILÓN DE

1/4-20

(NO INCLUIDA)

LA FLECHA

INDICA LA

PAR TE

DELANTERA

DEL SOPORTE

Español

A

CONTRATUERCA

HEXAGONAL

DELGADA DE

NILÓN DE 1/4-20

(NO INCLUIDA)

A

CONTRATUERCA

HEXAGONAL

DELGADA DE

NILÓN DE 1/4-20

(NO INCLUIDA)

24 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 25

Fijar la placa adaptadora al proyector

NOTA: El proyector que usted va a instalar puede tener una apariencia distinta al que se

5

muestra en la ilustración de abajo.

Coloque el proyector al revés. Coloque la placa adaptadora (B) de manera que la muesca

quede hacia el frente y tan cerca del centro de gravedad del proyector como sea posible sin

obstruir los agujeros de montaje. Afl oje los rieles con una llave allen de seguridad de 4mm (I)

y, si el proyector sólo tiene tres agujeros de montaje, quite el cuarto riel. Utilizando un riel para

cada agujero de montaje, coloque las patas de los rieles sobre los agujeros de montaje como se

muestra abajo.

IMPORTANTE: Si el proyector no tiene, por lo menos, tres agujeros de montaje, no utilice esta

placa adaptadora.

NOTA: Algunos proyectores tienen patas que se pueden quitar y entonces el inserto roscado

correspondiente se puede utilizar como un agujero de montaje.

NOTA: Una vez los rieles estén en la posición adecuada, apriete las fi jaciones.

*La muesca indica la parte delantera del proyector.

Español

Agujero de

montaje

*

Pata del riel

Riel

B

Proyector Genérico

25 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 26

Fije la placa adaptadora (B) al proyector utilizando un tornillo (J, K, L o M) para cada riel, como

6

se muestra abajo. Apriete todos los tornillos, sin cambiar el centro de gravedad. Asegúrese de

que la placa adaptadora (B) esté derecha. Ajuste las patas de los rieles para mantener el nivel

de la placa adaptadora. Apriete todos los tornillos, con una llave allen de seguridad de 4mm (I),

sin cambiar el centro de gravedad. Si utiliza tornillos M3 (J), apriételos utilizando una llave allen

de seguridad de 2mm (H).

NOTA: Necesitará tornillos de tamaños diferentes para instalar diferentes proyectores. Utilice

la combinación de tornillos (J, K, L o M) que sea necesaria y ajuste las patas de los rieles de

manera que los rieles de la placa adaptadora (B) queden fi rmes contra el proyector.

IMPORTANTE: Para que las roscas entren bien en los agujeros de montaje, tiene que darle, por

lo menos, tres vueltas completas al tornillo.

NOTA: Si utiliza un tornillo (J), coloque una arandela (G) entre el tornillo (J) y la pata del riel.

PRECAUCIÓN

• El instalador es responsable de asegurarse de que el proyector tenga una

ventilación adecuada. Las patas de los

rieles se utilizan para separar el soporte de

la superfi cie del proyector.

J, K, L o M

B

Español

PATA DE L RIEL

26 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 27

ADVERTENCIA

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para

levantar y colocar el proyector con más seguridad.

Deslice el bloque de conexión junto con el proyector ya instalado para que entre en la unidad

7

del soporte para proyectores (A), como se muestra. Empuje el tornillo imperdible hacia adentro

y apriételo para asegurar la unidad del soporte para proyectores (A).

Español

LA FLECHA

INDICA LA PARTE

DELANTERA DEL

SOPORTE

IMPORTANTE: Para una instalación segura, inserte un tornillo pasador de cabeza hueca de N.o

8

10 x 1/4" (E) a través de la unidad del soporte para proyectores (A) que entre en el bloque de

conexión como se ilustra. Apriete el tornillo usando una llave allen de seguridad de 4mm (I).

PARTE DELANTERA DEL SOPORTE

TORNILLO IMPERDIBLE

A

BLOQUE DE CONEXIÓN

A

E

BLOQUE DE CONEXIÓN

27 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 28

Manejo de cable

Para hacer una apertura para acomodar

9

los cables por la unidad del soporte para

proyectores, ajuste la unidad en una

posición totalmente hacia arriba dándole

vuelta a la perilla de ajuste de la inclinación,

como se muestra en la fi gura 9.2. Se puede

ajustar la posición de rotación hacia la

izquierda o hacia la derecha si hace falta

más espacio.

NOTA: Afl oje los dos tornillos de seguridad

a prueba de cambios no autorizados una

vuelta completa antes de ajustar la unidad

del soporte para proyectores o se puede

dañar.

Acomode los cables por la parte superior de

la columna de extensión, como se muestra

en la fi gura 9.1 y en la fi gura 9.2.

NOTA: Es posible que necesite una manera

de ayudar a pasar los cables por la columna

de extensión (por ejemplo: amarrar un

cordón para ayudar a tirar del conector por

la columna de extensión).

Acomode los cables por la unidad del

soporte, como se muestra en la fi gura 9.2 y

conéctelos al proyector.

fi g. 9.1

CABLES CON

COMBINACIÓN DE

CONECTOR VGA Y

ENCHUFES RCA

DIRIJA LOS CABLES DE

LOS ENCHUFES RCA EN

LA DIRECCIÓN OPUESTA

ACOMODE EL

CONECTOR

PRIMERO

NO DOBLE

LOS CABLES

Español

NOTA: ES POSIBLE QUE EL

DIÁMETRO INTERIOR DE LA

COLUMNA DE EXTENSIÓN

NO SEA SUFICIENTE COMO

PARA QUE PASE TODO

TIPO DE CONECTOR.

CONECTOR

DEL CABLE

DIÁMETRO INTERIOR

DE LA COLUMNA DE

EXTENSIÓN

PERRILLA PARA

EL AJUSTE DE

LA ROTACIÓN

COLUMNA DE

EXTENSIÓN

fi g. 9.2

PERRILLA PARA

EL AJUSTE DE

LA INCLINACIÓN

ABERTURA PARA

ACOMODAR

CABLES

28 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 29

Alinear el proyector

Para ajustar la desviación (el giro) después de una instalación en varillas roscadas:

10

Afl oje las contratuercas de las varillas roscadas (paso 4) hasta que pueda rotar el soporte para

proyectores. Rote el soporte hasta la posición deseada y vuelva a apretar las contratuercas.

Para ajustar la desviación (el giro) después de una instalación en columnas de extensión:

Afl oje el tornillo de la unidad del soporte para proyectores (A) que se indica abajo hasta que

pueda rotar el soporte para proyectores. Rote el soporte hasta la posición deseada y vuelva a

apretar el tornillo.

Para ajustar el cabeceo (la inclinación hacia adelante o hacia atrás): Gire la perilla que está

en la parte trasera del soporte como se muestra abajo. Hale la perilla hacia afuera y gírela con

la mano para hacer el ajuste con facilidad o inserte un destornillador phillips N.o 2 en el extremo

de la perilla y déle vuelta.

Para ajustar la rotación (la inclinación hacia un lado u otro): Gire la perilla que está en el

lado del soporte, como se muestra abajo. Hale la perilla hacia afuera y gírela con la mano para

hacer el ajuste con facilidad o inserte un destornillador phillips N.o 2 en el extremo de la perilla y

déle vuelta.

Español

LA RANURA DE

ACCESO PARA LA

LLAVE PLANA O TIPO

CRESCENT PERMITE

APRETAR LAS

CONTRATUERCAS

SIN TENER

QUE QUITAR EL

PROYECTOR

TORNILLO DE TOPE, QUE IMPIDE

LA DESVIACIÓN (EL GIRO)

(REFIÉRASE AL PASO 1, FIG. 1.2)

LA FLECHA INDICA LA PARTE

DELANTERA DEL SOPORTE

A

PERILLA PARA

EL AJUSTE

DEL CABECEO

PERILLA PARA

EL AJUSTE DE

LA ROTACIÓN

29 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 30

Para evitar cambios después de ajustar la inclinación y la rotación: Apriete los dos tornillos

11

de seguridad a prueba de cambios no autorizados de la unidad del soporte para proyectores

utilizando una llave allen de seguridad de 4mm (I) para fi jar los ajustes de inclinación y rotación,

como se muestra abajo.

NOTA: Apriete los tornillos con fi rmeza, pero no en exceso. Apretarlos en exceso puede dañar

el soporte.

PRECAUCIÓN

• No ajuste la inclinación ni la rotación mientras los tornillos de seguridad a prueba de cambios

no autorizados estén completamente apretados.

• Afl oje los dos tornillos de seguridad a prueba de cambios no autorizados una vuelta completa

antes de ajustar la unidad del soporte para proyectores o se puede dañar.

PARA AJUSTAR EL TORNILLO

DE SEGURIDAD A PRUEBA DE

CAMBIOS NO AUTORIZADOS DE

LA ROTACIÓN

Español

VISTA DELANTERA

VISTA LATERAL

30 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

PARA AJUSTAR EL TORNILLO

DE SEGURIDAD A PRUEBA DE

CAMBIOS NO AUTORIZADOS DE

LA INCLINACIÓN

Page 31

Accesorios del Soporte para Proyectores – Serie PRG

Placas de techo

Español

Pieza adaptadora de techo para cerchas

M

ODELO

: ACC 557*

ARGA MAXIMA

C

C

OLOR

• Se fija a cerchas con vigas

cuadradas, redondas, rectangulares o

metálicas de 3” de diámetro

:

Negro

:

250 lbs. (113.4 kg.)

¡Nueva!

Placa de peso liviano para

techos tipo catedral

M

ODELO

: ACC 912*

C

ARGA MAXIMA

C

OLOR

• Diseñada especialmente para proyectores

• Hace posible instalar proyectores en techos

angulares

Juego de techo suspendido de peso

liviano

M

ODELO

C

ARGA MAXIMA

50 lbs. (22.7 kg.)

C

OLOR

• Cinco puntos para fijar el soporte para

proyectores

• Incluye cables de seguridad y tubo de montaje

empotrado y tiene dos paneles removibles

para cajas de distribución eléctrica

• Puede reemplazar una loza de falso techo

de 2’ x 4’ ó 2’ x 2’ o puede instalarse sobre

una loza de falso techo de 2’ x 4’ ó 2’ x 2’

Abrazaderas para vigas de metal

M

ODELOS

ACC 558, ACC 559

ARGA MAXIMA

C

250 lbs. (113.4 kg.)

C

OLOR

• ACC 558 se acopla a vigas de metal de 4”-8”

• ACC 559 se acopla a vigas de metal de 7”-12”

:

Negro

: CMJ 455

:

Blanco

:

:

Negro

:

60 lbs. (27.2 kg.)

:

:

R

R

Pieza adaptadora Unistrut®

M

ODELO

: ACC 550

ARGA MAXIMA

C

250 lbs. (113.4 kg.)

C

OLOR

• Diseñada para uso con Unistrut de

:

:

Negro

12 ga de 1 5/8” x 1 5/8

¡Nueva!

Juego ajustable de techo suspendido

de peso liviano

M

ODELO

: CMJ 500

C

ARGA MAXIMA

60 lbs. (27.2 kg.)

C

OLOR

• Se instala sobre una loza de falso techo de

• Incluye cables de seguridad y tubo de

• Ofrece un ajuste ilimitado para la colocación

Placas de techo Unistrut o para

techos estructurales

M

ODELOS

CMJ 300*, CMJ 310*

ARGA MAXIMA

C

250 lbs. (113.4 kg.)

C

OLOR

• CMJ 300 es una placa de techo de 4" x 4"

• CMJ 310 es una placa de techo de 8" x 8"

• Diseñadas para uso con techado Unistrut

Juego de accesorios para el CMJ 455

M

Este paquete contiene cuatro soportes

colgantes y cuatro abrazaderas colgantes

para ofrecer mayor estabilidad, para uso

con el modelo CMJ 455

:

:

Blanco

2’ x 4’ ó 2’ x 2’

montaje empotrado y tiene dos paneles

removibles para cajas de distribución eléctrica

:

:

:

Negro

(de 12 ga de 1 5/8” x 1 5/8) o con techos

estructurales sólidos (no se incluyen los

fijadores para la instalación)

ODELO

: ACC 455*

R

Unistrut

Placa de techo

Aro Escutcheon

M

ODELO

R

Placa de techo

circular

Placas de techo antivibraciones

M

ACC 840*, ACC 845*

C

60 lbs. (27.2 kg.)

C

• ACC 840 fue diseñada para techos

• ACC 845 fue diseñada para uso con

• Disminuye las vibraciones no deseadas

• Tiene dos agujeros de acceso para el

• Patente en trámite

: ACC 640

• Cubre el agujero por el cual la columna

de extensión entra en el techo

• El aro abisagrado se cierra alrededor

de la columna de extensión

• Se incluye con el CMJ 500

M

ODELO

:

ACC570(S)(W)

C

OLORES

:

N

EGRO

, B

:

Negro

LANCO O PLATEADO

:

150 lb (68 kg)

:

1.7 lb (.8 kg)

:

C

ARGA MÁXIMA

P

ESO ENBARQUE

• Diseñado para techos con superficies

de acabado o techos estructurales

• Techos (Madera o concreto)

• Incluye un sistema de manejo de cables

ODELOS

ARGA MAXIMA

OLOR

:

estructurales (madera solamente)

techado Unistrut

(de 12 ga de 1 5/8” x 1 5/8)

que pueden causar daños internos al

equipo o causar movimiento de la

imagen de a pantalla

manejo de los cables

R

= No clasificado por UL

*

31 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 32

Accesorios del Soporte para Proyectores – Serie PRG

Español

Envoltura para cables

M

ODELOS

: ACC 852(W)(S)*

C

OLOR

:

Negro, Blanco o Plateado

Fixed Length 1 1/2"

Extension Columns

C

OLOR

:

Negro

MODELO Extensión Peso embarque

EXT 006 8"

EXT 018 20"

EXT 101 14"

EXT 102 26"

EXT 103 38"

EXT 104 50"

EXT 105 62"

EXT 106 74"

EXT 107 86"

EXT 108 98"

EXT 109 110"

EXT 110 122"

(20 cm)

(51 cm)

(36 cm)

(66 cm)

(97 cm)

(127cm)

(158 cm)

(188 cm)

(219 cm)

(249 cm)

(279 cm)

(310 cm)

2.5 lbs

5 lbs

(2.27 kg)

3.5 lbs

6 lbs

(2.72 kg)

9.25 lbs

12 lbs

14.75 lbs

18 lbs

20.75 lbs

23.25 lbs

26.5 lbs

29 lbs

(1.13 kg)

(1.59 kg)

(4.2 kg)

(5.44 kg)

(6.69 kg)

(8.16 kg)

(9.41 kg)

(10.55 kg)

(12.02 kg)

(13.15 kg)

Cables de seguridad Armor LockTM Plus

M

ODELO

: ACC 020*

• Con dispositivo de seguridad

• Para uso con proyectores que tienen una

ranura de seguridad integrada

Juego estabilizador de las

columnas de extensión

M

ODELO

: ACC 050*

OLOR

:

Negro

C

• Se puede utilizar para

disminuir la oscilación que

puede ocurrir después de

una instalación en columnas

de extensión

• Incluye una abrazadera

cremallera, dos soportes

estabilizadores para

columnas y las fijaciones

para instalación en vigas de

madera

• Para uso con columnas de

extensión de más de 21”

Pieza de ajuste hacia

ambos lados

M

ODELO

: ACC 830*

C

OLOR

:

Negro

• Ofrece ajuste radial de

4” de un lado a otro

• Incluye tubo de montaje

empotrado, EXT 002

= Not UL Listed

*

Columna de

extensión

Pieza de ajuste

hacia ambos lados

Manejo de cables

• Incluye, cuatro secciones de 2’

• Diseñado para que los cables pasen por el exterior de una columna de extensión de 1/2”

• Las secciones se pueden apilar para aumentar o disminuir la longitud

Columnas de extensión

Adjustable Length 1 1/2"

Extension Columns

C

OLOR

:

Negro

MODELO Extensión Peso embarque

ADJ 006009 8"-11" 4 lbs.

ADJ 012018 14"-20" 4.75 lbs.

ADJ 018024 20"-26" 6.25 lbs.

ADJ 0203 26"-38" 8 lbs.

ADJ 0305 38"-62" 13.5 lbs.

ADJ 0406 50"-74" 16.25 lbs.

ADJ 0507 62"-86" 18.5 lbs.

ADJ 0608 74"-98" 21.75 lbs.

ADJ 0709 86"-110" 24.5 lbs.

ADJ 0810 98"-122" 27 lbs.

R

ADJ 0911 110"-134" 29 lbs.

ADJ 1012 122"-146" 31 lbs.

(1.81 kg)

(2.15 kg)

(2.83 kg)

(3.63 kg)

(6.12 kg)

(8.39 kg)

(11.11 kg)

(12.25 kg)

(13.15 kg)

(14.06 kg)

(7.37 kg)

(9.87 kg)

R

Accesorios para la

seguridad

M

ODELO

: ACC 021*

• Con cable de seguridad de 1/4" y sujetadores

• Incluye pegamento para aplicaciones que no

se pegan

Accesorios adicionales para

el Soporte para Proyectores

Anclajes para concreto

ALLIGATOR

M

• ACC 203 contiene tres anclajes

• ACC 204 contiene cuatro anclajes

• Se usa para fijación en concreto,

• Se usa en combinación con tornillos

• Se expande y se ajusta al contorno

Conector de columnas

de extensión

®

ODELOS

: ACC 203, 204

bloque de concreto o ladrillo

para madera (proporcionados con el

soporte para proyectores o con la

placa de techo)

del agujero y del tornillo

M

ODELO

: ACC 109*

OLOR

:

Negro

C

• Se puede usar para unir dos columnas

de extensión de 1 1/2“ para darles una

longitud máxima de 20’

• Se fija a las columnas con tornillos de

seguridad Armor Lock

TM

Conector de columnas de

R

extensión con manejo de cable

M

ODELO

: ACC800, ACC850(S)

C

OLORES

: ACC800

ACC850

negro o plateado

• Agujero de acceso de 1-1/2" para

el manejo interno de cables

• La unidad tiene un aditamento de

1-1/2"-11.5 NPT para instalar la

columna de extensión

• Incluye tornillos de seguridad

• ACC800: Un conector macho y un

conector hembra para proporcionar

manejo interno de cables de la

columna de extensión a la unidad

del soporte o a la placa de techo

• ACC850: Dos conectores hembra

para unir dos columnas de

extensión para alcanzar una

longitud máxima de 20'

ACC850

negro

ACC800

32 de 51 PUBLICADO: 09-30-09 HOJA #: 056-9024-5 07-18-11

Page 33

Instructions d’installation et de montage:

Monture de projecteur à éléments de précision PRG

(Precision Gear) avec plaque d’adaptation universelle

Modèles: PRG-UNV, PRG-UNV-S, PRG-UNV-W

Caractéristiques :

• L’alignement ImageLockTM prévient

l’affaissement ou le déplacement de l’image

• Levier de blocage rapide du rail exclusif en

aluminium

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Capacité de charge maximale:

50 lb (22.7 kg)

PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 34

REMARQUE: Lisez entièrement la fi che d’instructions avant de commencer l’installation et l’assemblage.

Français

AVERTISSEMENT

• Ne commencez pas à installer ce produit avant d’avoir lu et assimilé les instructions et les avertissements contenus dans cette fi che d’installation. Pour toute question concernant les instructions

ou les avertissements, veuillez appeler le service à la clientèle au 1-800-865-2112.

• Ce produit doit être installé uniquement par quelqu’un possédant une bonne aptitude à la mécanique, une expérience de la construction immobilière et ayant bien compris ces instructions.

• Assurez-vous que la surface de support puisse soutenir sans danger la charge totale de

l’équipement ainsi que des pièces et composants qui y sont attachés.

• Ne dépassez jamais la capacité UL de charge maximum. Reportez-vous à la page 33.

• Si le montage est effectué sur des plafonds à solives de bois, assurez-vous que les vis de montage sont ancrées au centre des solives. L’utilisation d’un localisateur de montants « bord à bord »

est fortement recommandée.

• Pour lever et positionner l’équipement en toute sécurité, faites-vous toujours aider par une autre

personne ou utilisez un dispositif de levage mécanique.

• Serrez fermement les vis, mais sans excès. Un serrage excessif peut endommager les composants et en réduire considérablement la capacité de support.

• Ce produit est conçu uniquement pour un usage intérieur. L’utilisation de ce produit à l’extérieur

peut causer une défaillance du produit et des blessures corporelles.

• Ce produit a été conçu pour être installé uniquement sur les constructions de plafond suivantes :

CONSTRUCTION PLAFOND VISSERIE SUPPLÉMENTAIRE REQUISE

Montant en bois Aucune

Poutre en bois Aucune

Béton plein Aucune

Brique Adressez-vous au service clientèle (Non évalué par l’UL)

Autre, ou vous n’êtes pas sûr ? Adressez-vous au service clientèle

Outils nécessaires au montage

• localisateur de montants (un localisateur de

montants « bord à bord » est recommandé.)

• tournevis Phillips

• perceuse

• foret de 5/16 po pour surface en béton

• foret de 5/32 po pour montants en bois

• clé à fourches

• niveau

Table des matières

Liste des pièces ................................................................................................................................... 35

Installation assemblage du support de projecteur .......................................................................... 36-39

Fixation de la plaque d’adaptation au projecteur ................................................................................. 41

Accessoires ...................................................................................................................................47, 48

34 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 35

Avant de commencer, veuillez vous assurer que toutes les pièces énumérées sont incluses.

PRG-UNV PRG-UNV-S PRG-UNV-W

Description Qté Pièce no Pièce no Pièce no

A assemblage du support de projecteur 1 054-1171 054-4171 054-2171

B plaque d’adaptation 1 055-1938 055-4938 055-2838

C cheville d’ancrage pour béton 2 590-0320 590-0320 590-0320

D vis à bois Phillips no 14 x 2-1/2 po 2 5S1-015-C03 5S1-015-C04 5S1-015-C04

E vis à tête creuse no 10-32 x 1/4 po 1 520-1196 520-2196 520-2196

F rondelle plate de 1/4 po 2 540-1078 540-1078 540-1078

G rondelle plate no 6 x DE 1/2 po 4 540-1025 540-2025 540-2025

H clé hexagonale de sécurité de 2 mm 2 560-1097 560-1097 560-1097

I clé hexagonale de sécurité de 4 mm 1 560-9646 560-9646 560-9646

J vis à tête creuse à embase crantée M3 x 8 mm 4 510-1004 510-2004 510-2004

K vis à tête creuse à embase crantée M4 x 10 mm 4 510-1060 510-2060 510-2060

L vis à tête creuse à embase crantée M5 x 10 mm 4 510-1126 510-2063 510-2063

M vis à tête creuse à embase crantée M6 x 10 mm 4 510-1066 510-2066 510-2066

Liste des pièces

REMARQUE : Les pièces peuvent différer légèrement de l’illustration.

Français

A

B

CD

I

E

J

F

K

G

L

35 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

H

M

Page 36

Installation à une colonne d’extension / plaque de plafond

REMARQUE : veuillez vous reporter aux instructions accompagnant les plaques de plafonds

1

(vendues séparément) pour l’installation de ces modèles au plafond.

Visser l’assemblage du support de projecteur (A) à la colonne d’extension comme illustré à

la fi gure 1.1. Serrez la vis butée orientable sur la colonne d’extension, le tube pour montage

encastré ou le raccord réducteur à l’aide d’une clé hexagonale de sécurité de 4mm (I) comme

illustré à la fi gure 1.2.

REMARQUE : la vis butée orientable doit se caler contre le fi letage de la colonne d’extension,

le tube pour montage encastré ou le raccord réducteur pour empêcher tout mouvement excessif

du support de projecteur (A). Ne serrez pas trop les vis, car cela pourrait endommager le

fi letage et rendre diffi cile le démontage du produit.

Passez à l’étape 5.

COLONNE D’EXTENSION DE 1 ½ PO

(VENDUE SÉPARÉMENT)

(SERIES EXT. OU AEC. HOMOLOGUÉES UL)

Français

fi g. 1.2

A

LA FLÈCHE INDIQUE

L’AVANT DU SUPPORT

fi g. 1.1

CMJ 455

(VENDUE SÉPARÉMENT)

VIS DE BUTÉE ORIENTABLE

36 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 37

Français

Installation sur des plafonds à solives de bois

AVERTISSEMENT

• L’installateur doit s’assurer que la surface de support pourra soutenir sans danger la charge

combinée de l’équipement, de toute sa visserie et de tous ses composants.

• Serrez les vis à bois fermement, mais sans excès de manière que la monture de projecteur soit

solidement fi xée. Un serrage excessif peut endommager les vis et en réduire considérablement

le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L’usage d’un

localisateur de montants « bord à bord » est fortement conseillé.

• La visserie est fournie pour fi xer la monture à travers une cloison sèche ou du plâtre d’épaisseur

standard et dans des montants en bois. Il appartient aux installateurs de fournir la visserie

nécessaire pour d’autres types de situations (non évalué par l’UL)

Installez au plafond la monture de projecteur (A) qui servira de gabarit et marquez le centre des

2

deux trous de montage. Assurez-vous que les trous de montage se trouvent bien au centre de

la solive de bois. Percez deux trous de 5/32 po (4mm) de diamètre à une profondeur minimale

de 2-1/2 po (64mm). Fixez la monture de projecteur (A) à l’aide de deux vis à bois (D) nº14 x

2-1/2 po (6mm x 64mm) et de deux rondelles plates (F), comme illustré fi gure 2.1 ou fi gure 2.2,

suivant l’orientation de la solive.

Serrez les vis à bois (D) à l’aide d’une clé à douille de 3/8 po (10mm), d’un tournevis cruciforme

ou d’une clé à fourche jusqu’à ce que la monture de projecteur (A) soit fermement fi xée.

Passez à l’étape 5.

fi g. 2.1

A

SOLIVE DE BOIS

F

D

LA FENTE D’ACCÈS POUR

CLÉ À FOURCHE PERMET

LE SERRAGE DE LA VIS À

BOIS (D).

LA FLÈCHE SUR LE DESSUS

DE LA MONTURE DE

PROJECTEUR INDIQUE LE

SOLIVE DE BOIS

DEVANT DE LA MONTURE.

fi g. 2.2

A

F

D

37 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 38

Français

Installation à un plafond en béton

AVERTISSEMENT

• Le béton doit avoir une densité minimale de 2 000 psi. Un béton de densité moindre risquerait de

ne pas retenir un ancrage de béton.

• Assurez-vous que la surface de support pourra soutenir sans danger la charge combinée de

l’équipement, de toute sa visserie et de tous ses composants.

Installez au plafond la monture de projecteur (A) qui servira de gabarit et marquez le centre des

3

deux trous de montage. Percez deux trous de 5/16 po (8mm) de diamètre à une profondeur

minimale de 2-1/2 po (64mm). Fixez la monture de projecteur (A) à l’aide de deux ancrages pour

béton (C), de deux rondelles plates (F), et de deux vis à bois nº 14 x 2-1/2 (D), comme illustré.

REMARQUE : les fentes de montage se trouvant sur la monture de projecteur permettent une

rotation de 30º (±15º) avant le serrage complet des vis à bois.

Serrez les vis à bois (D) à l’aide d’une clé à douille de 3/8 po (10mm), d’un tournevis cruciforme

ou d’une clé à fourche jusqu’à ce que la monture de projecteur (A) soit fermement fi xée.

Passez à l’étape 5.

AVANT DU SUPPORT

C

PLAFOND EN BÉTON

A

F

D

38 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 39

Français

AVERTISSEMENT

• Fixez toujours des ancrages de béton directement sur du béton porteur.

• Ne fi xez jamais d’ancrages sur du béton recouvert de plâtre, une cloison sèche ou autre matériau

de fi nition. Si vous ne pouvez pas éviter d’effectuer le montage sur du béton recouvert d’une

surface de fi nition (non évalué par l’UL), celle-ci doit être chambrée, comme indiqué ci-dessous.

Assurez-vous que les ancrages de béton ne se séparent pas du béton lorsque vous serrez les

vis. Si l’épaisseur du plâtre / de la cloison sèche dépasse 16mm (5/8 po), des fi xations adaptées

devront être fournies par l’installateur (non évalué par l’UL).

• Serrez fermement les vis à bois, mais sans excès. Un serrage excessif peut endommager les vis

et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

1

surface

en béton

C

Percez des trous et insérez les ancrages (C).

2

Placez la plaque (A) sur les ancrages (C) et fi xez avec des

vis (D).

A

D

C

3

Serrez toutes les fi xations.

A

plâtre / cloison

sèche

A

VUE EN COUPE

plâtre / cloison

sèche

INCORRECT

concrete

CORRECT

concrete

39 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 40

Installation à des fi xations fi letées

(Non évalué par l’UL – Installation professionnelle uniquement)

Faites passer deux écrous de blocage hexagonaux avec insert en nylon 1/4-20 (non compris)

4

sur deux fi xations fi letées (non comprises) à la hauteur souhaitée du support de projecteur.

Fixez le support de projecteur (A) aux deux fi xations fi letées de 1/4-20 à l’aide de deux écrous

de blocage hexagonaux avec insert en nylon 1/4-20 comme illustré à la fi gure 4.1 ou à la fi gure

4.2.

FIXATION FILETÉE

1/4-20 (NON

COMPRISE)

ÉCROU DE

BLOCAGE AVEC

INSERT EN

NYLON 1/4-20

(NON COMPRIS)

LA FLÈCHE

INDIQUE

L’AVANT DU

SUPPORT

fi g. 4.1

FIXATION

FILETÉE

1/4-20 (NON

COMPRISE)

ÉCROU DE

BLOCAGE AVEC

INSERT EN

NYLON 1/4-20

(NON COMPRIS)

LA FLÈCHE

INDIQUE

L’AVANT DU

SUPPORT

fi g. 4.2

Français

A

ÉCROU DE

BLOCAGE AVEC

INSERT EN

NYLON 1/4-20

(NON

COMPRIS)

A

ÉCROU DE BLOCAGE

AVEC INSERT EN

NYLON 1/4-20

(NON COMPRIS)

40 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 41

Fixation de la plaque d’adaptation au projecteur

REMARQUE : Il se peut que le projecteur que vous installez ne ressemble pas tout à fait à celui

5

qui est illustré ci-dessous.

Placez le projecteur à l’envers. Repérez la plaque d’adaptation (B), encoche tournée vers

l’avant, aussi près que possible du centre de gravité du projecteur, sans recouvrir les trous de

montage. Desserrez les rails à l’aide d’une clé hexagonale de sécurité de 4mm (I), et s’il n’y a

que trois trous de montage, enlevez le quatrième rail. En utilisant un rail par trou de fi xation,

placez les pattes des rails sur les trous de fi xation comme illustré ci-dessous.

IMPORTANT : Si le projecteur ne dispose pas d’au moins trois trous de fi xation, n’utilisez pas

cette plaque d’adaptation.

REMARQUE : Certains projecteurs sont munis de pieds amovibles et l’insert fi leté

correspondant peut servir de trou de fi xation.

REMARQUE : Une fois les rails en place, serrez les fi xations.

*L’encoche indique l’avant du projecteur.

Français

TROU DE FIXATION

*

RAIL

PROJECTEUR GÉNÉRIQUE

PATTE DU RAIL

B

41 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 42

Fixez la plaque d’adaptation (B) au projecteur à l’aide d’une vis (J, K, L ou M) pour chaque rail,

6

comme indiqué ci-dessous. Serrez toutes les vis, tout en maintenant le centre de gravité. Veillez

à ce que la plaque d’adaptation (B) soit droite. Réglez les pattes des rails afi n de maintenir la

plaque d’adaptation à l’horizontale. Serrez toutes les vis à l’aide d’une clé hexagonale de sécurité de 4mm (I) tout en maintenant le centre de gravité. Si vous utilisez des vis M3 (J), serrez

celles-ci à l’aide d’une clé hexagonale de sécurité de 2mm (H).

REMARQUE : Le montage des projecteurs nécessitera des vis de tailles différentes. Combinez

les vis (J, K, L ou M) et un réglage des pattes approprié afi n de bien caler les rails de la plaque

d’adaptation (B) contre le projecteur. IMPORTANT : Afi n d’insérer correctement les fi letages

dans les trous de fi xation, vous devez serrer la vis d’au moins trois tours complets.

REMARQUE : Si vous utilisez la vis (J), placez la rondelle (G) entre la vis (J) et la patte du rail.

MISE EN GARDE

• Il incombe à l’installateur de s’assurer que le

projecteur est correctement ventilé. Les pattes

des rails servent à soulever le support de la

surface du projecteur.

Français

B

J, K, L ou M

PATTE DU RAIL

42 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 43

Français

AVERTISSEMENT

• Pour lever et positionner le projecteur en toute sécurité, faites-vous toujours aider par une autre

personne ou utilisez un dispositif de levage mécanique.

Faites glisser le bloc raccord fi xé au projecteur dans le support du projecteur (A) tel qu’illustré.

7

Enfoncez et serrez la vis imperdable pour fi xer le projecteur au support de projecteur (A).

AVANT DU SUPPORT

LA FLÈCHE INDIQUE

L’AVANT DU SUPPORT

VIS IMPERDABLE

IMPORTANT : Pour les installations de sécurité, insérez une vis à tête creuse no 10-32 x ¼ po

8

(E) dans le support de projecteur (A) et dans le bloc raccord tel qu’illustré. Serrez la vis à l’aide

d’une clé hexagonale de sécurité de 4mm (I).

A

BLOC RACCORD

A

BLOC

E

RACCORD

43 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 44

Gestion des câbles

Pour pratiquer dans la monture de

9

projecteur une ouverture permettant

d’acheminer les câbles, réglez la monture

de projecteur sur la position d’inclinaison

totale vers le haut en tournant le bouton de

réglage d’inclinaison comme illustré fi gure

9,2 Le roulis droit ou gauche peut être réglé

si vous avez besoin de plus d’espace.

REMARQUE : Desserrez les vis de

sécurité inviolables d’un tour complet avant

de régler le support de projecteur, sinon

vous risquez de l’endommager.

Acheminez les câbles par le dessus de la

colonne d’extension comme illustré fi gure

9,1 et fi gure 9,2

REMARQUE : une méthode pour passer

les câbles dans la colonne d’extension peut

être nécessaire (par exemple : fi celle reliée

à un connecteur pour aider à guider le câble

au travers de la colonne d’extension).

Acheminez les câbles dans la monture

de projecteur comme illustré fi gure 9,2 et

reliez-les au projecteur

fi g. 9.1

CÂBLES AVEC

COMBINAISON DE

PORT VGA

ET PRISES RCA

PLIEZ LES FILS DES

PRISES RCA DANS LE

SENS INVERSE

ACHEMINEZ

LE PORT

EN PREMIER

NE PAS PINCER

LES FILS

Français

REMARQUE : LE

DIAMÈTRE INTÉRIEUR

DE LA COLONNE

D’EXTENSION PEUT

NE PAS PEMETTRE

LE PASSAGE DE

TOUS LES TYPES DE

CONNECTEURS

CÂBLE

CONNECTEUR

DIAMÈTRE INTÉRIEUR

DE LA COLONNE

D’EXTENSION

fi g. 9.2

COLONNE

D’EXTENSION

BOUTON POUR

LE RÉGLAGE DU

PIVOTEMENT

LATÉRA

BOUTON POUR

LE RÉGLAGE DE

L’INCLINAISON

OUVERTURE DE

CHEMINEMENT DES

CÂBLES

44 sur 51 PUBLIÉ LE: 09-30-09 FEUILLE No: 056-9024-5 07-18-11

Page 45

Alignement du projecteur

Pour régler l’orientation (pivotement) dans les applications à montage à tige fi letée:

10

desserrez les contre-écrous des tiges fi letées (étape 4) jusqu’à ce que la monture de projecteur

puisse être tournée. Tournez la monture jusqu’à la position désirée et resserrez les contreécrous.

Pour régler l’orientation du projecteur lorsque celui-ci est monté sur une colonne

d’extension: Desserrez la vis du support de projecteur (A) comme indiqué ci-dessous jusqu’à

ce que vous puissiez faire pivoter le support de projecteur. Faites pivoter le support dans la

position souhaitée, puis resserrez la vis.

Pour régler l’inclinaison du projecteur (vers l’avant ou vers l’arrière): Tournez le bouton

situé à l’arrière du support comme illustré ci-dessous. Tirez sur le bouton et faites-le tourner à

la main pour un réglage facile ou insérez un tournevis Phillips no 2 à l’extrémité du bouton et

tournez.

Pour régler le pivotement latéral (de gauche à droite et vice versa): Tournez le bouton

situé sur le côté du support comme illustré ci-dessous. Tirez sur le bouton et faites-le tourner à

la main pour un réglage facile ou insérez un tournevis Phillips no 2 à l’extrémité du bouton et

tournez.

Français

LA FLÈCHE INDIQUE L’AVANT

DU SUPPORT

LA FENTE D’ACCÈS POUR

CLÉ À FOURCHE PERMET

LE SERRAGE DES CONTREÉCROUS SANS QU’IL SOIT

NÉCESSAIRE D’ENLEVER

LE PROJECTEUR.

A

BOUTON POUR

LE RÉGLAGE DE

L’INCLINAISON

BOUTON POUR

LE RÉGLAGE DU