PEERLESS GM, GM Series, GM-05, GM-06, GM-07 Installation, Operation & Maintenance Manual

...Page 1

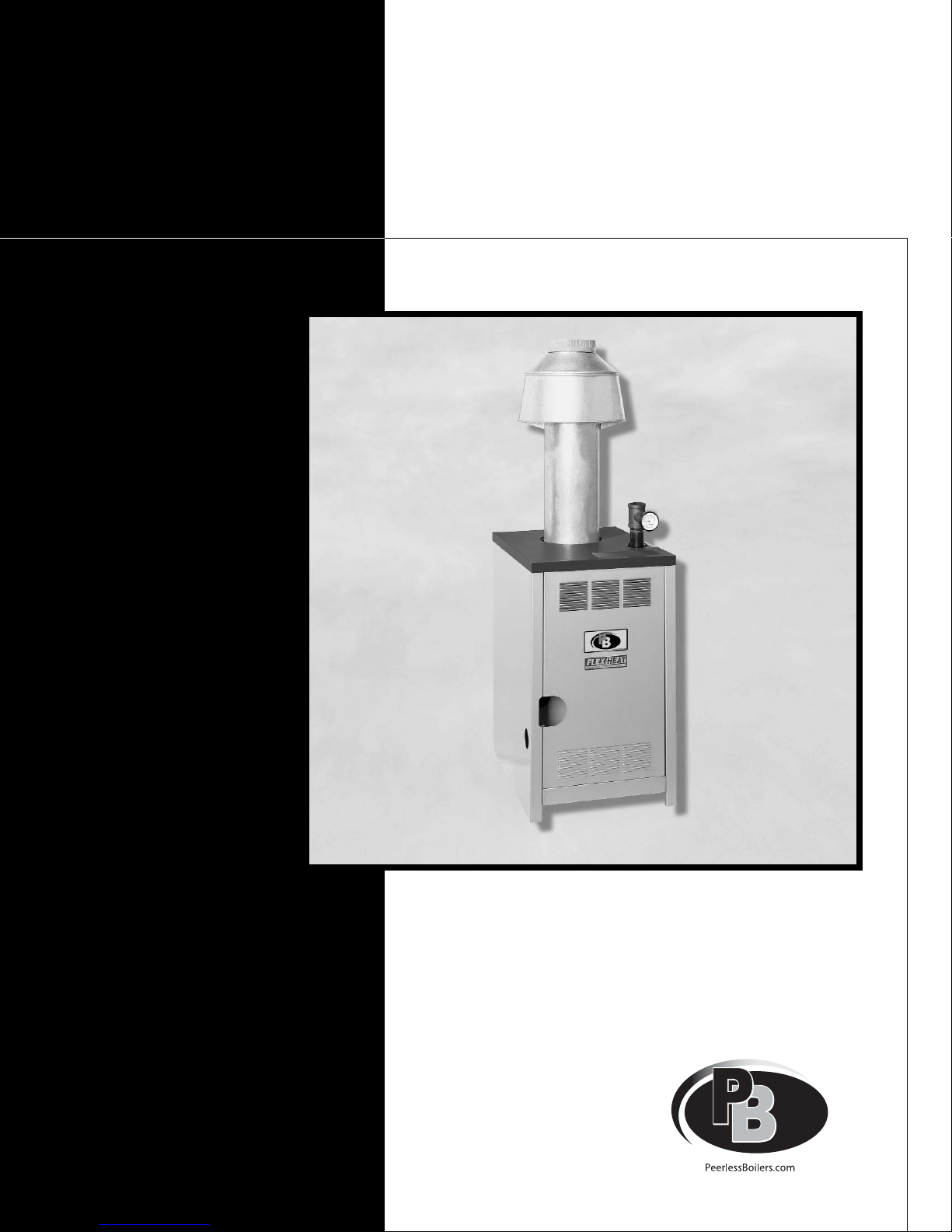

GM

Boilers

Series

Gas

Installation,

Operation &

Maintenance

Manual

Page 2

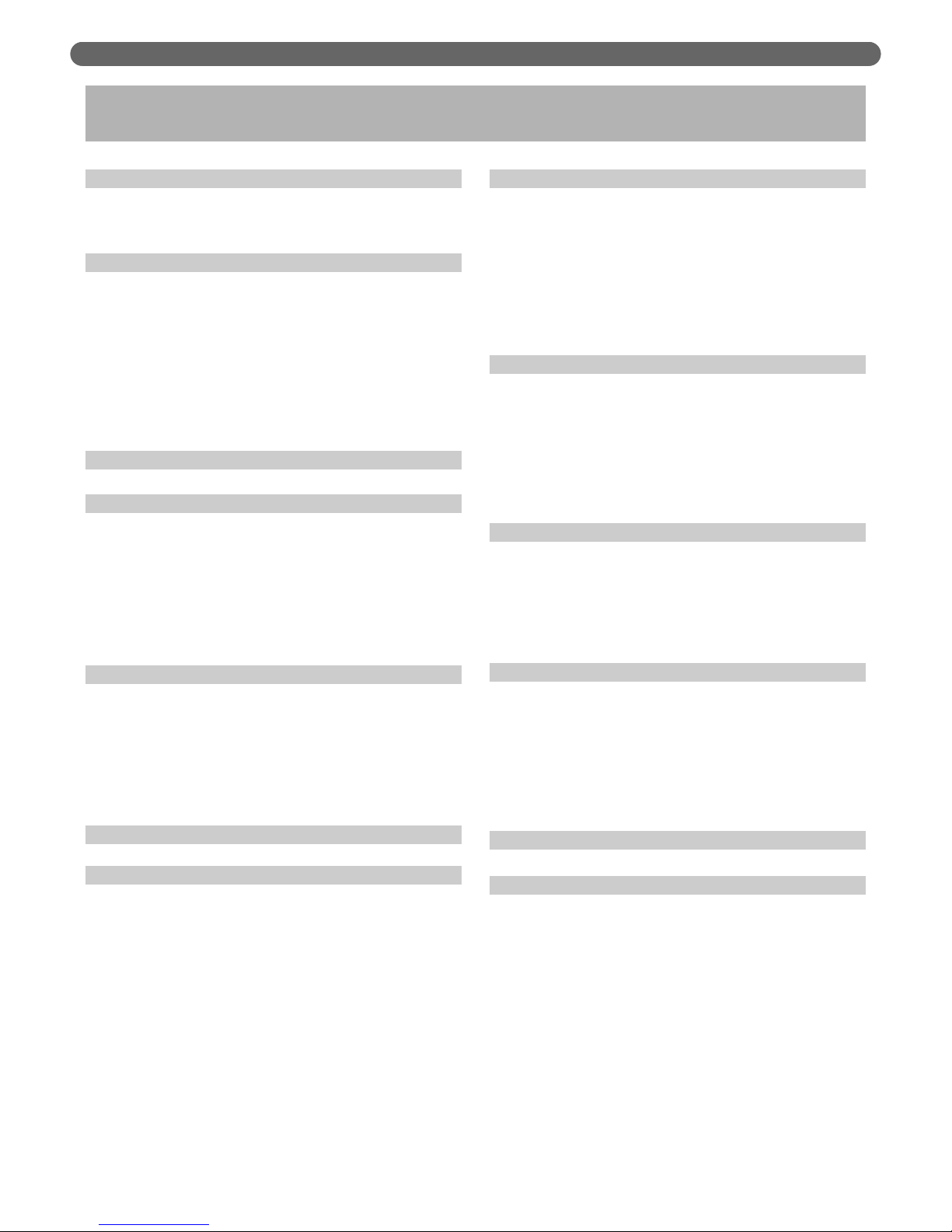

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. ACCESSIBILITY CLEARANCES . . . . . . . . . . .2

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .2

C. COMBUSTION AND VENTILATION AIR . . . .2

D. INSTALLATION SURVEY . . . . . . . . . . . . . . . .5

E. CIRCULATORS . . . . . . . . . . . . . . . . . . . . . . . .5

F. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .5

2. BOILER SET-UP 6

3. WATER PIPING AND CONTROLS 7

A. BOILER SUPPLY AND RETURN . . . . . . . . . . .7

B. SAFETY RELIEF VALVE . . . . . . . . . . . . . . . . .8

C. PIPING FOR ZONED SYSTEMS . . . . . . . . . . .9

D. EXPANSION TANK . . . . . . . . . . . . . . . . . . . .10

E. INDIRECT-FIRED WATER HEATER . . . . . . .10

F. FREEZE PROTECTION . . . . . . . . . . . . . . . . .10

4. VENTING 11

A. DRAFT HOOD . . . . . . . . . . . . . . . . . . . . . . .11

B. AUTOMATIC VENT DAMPER

INSTALLATION – GENERAL . . . . . . . . . . . .12

C. VENT PIPING AND CHIMNEY . . . . . . . . . . .12

D. BOILER REMOVAL FROM COMMON

VENTING SYSTEM . . . . . . . . . . . . . . . . . . .13

5. GAS PIPING 14

6. ELECTRICAL 16

A. WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

B. CIRCULATOR/ZONE VALVE WIRING . . . . . .16

C. LOW WATER CUTOFF . . . . . . . . . . . . . . . . .16

7. CSD CODE REQUIREMENTS 23

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .23

B. CSD PART CF REQUIREMENTS . . . . . . . . .23

C. CSD PART CW REQUIREMENTS . . . . . . . .23

D. CSD MODULAR AND MULTIPLE BOILER

REQUIREMENTS . . . . . . . . . . . . . . . . . . . . .23

E. CSD PART CE ELECTRICAL

REQUIREMENTS . . . . . . . . . . . . . . . . . . . . .24

8. START-UP PROCEDURES 25

A. COMPLETING THE INSTALLATION . . . . . . .25

B. CONTROL DESCRIPTIONS . . . . . . . . . . . . .30

C. ADJUSTMENT OF GAS PRESSURE

REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . .30

D. CHECKING BURNER INPUT . . . . . . . . . . . . .30

E. CHECK-OUT PROCEDURE . . . . . . . . . . . . . .31

9. TROUBLESHOOTING 32

A. SHUT-DOWN CAUSED BY PILOT OUTAGE,

VENT SAFETY SHUTOFF SWITCH OR

FLAME ROLLOUT SAFETY SHUTOFF

SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

B. TROUBLESHOOTING GUIDES . . . . . . . . . .32

10. MAINTENANCE 35

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .36

B. DAILY (WITH BOILER IN USE) . . . . . . . . . . .36

C. WEEKLY (WITH BOILER IN USE) . . . . . . . . .36

D. MONTHLY (WITH BOILER IN USE) . . . . . . .36

E. ANNUALLY (BEFORE START OF HEATING

SEASON) . . . . . . . . . . . . . . . . . . . . . . . . . . .37

11. BOILER DIMENSIONS & RATINGS 38

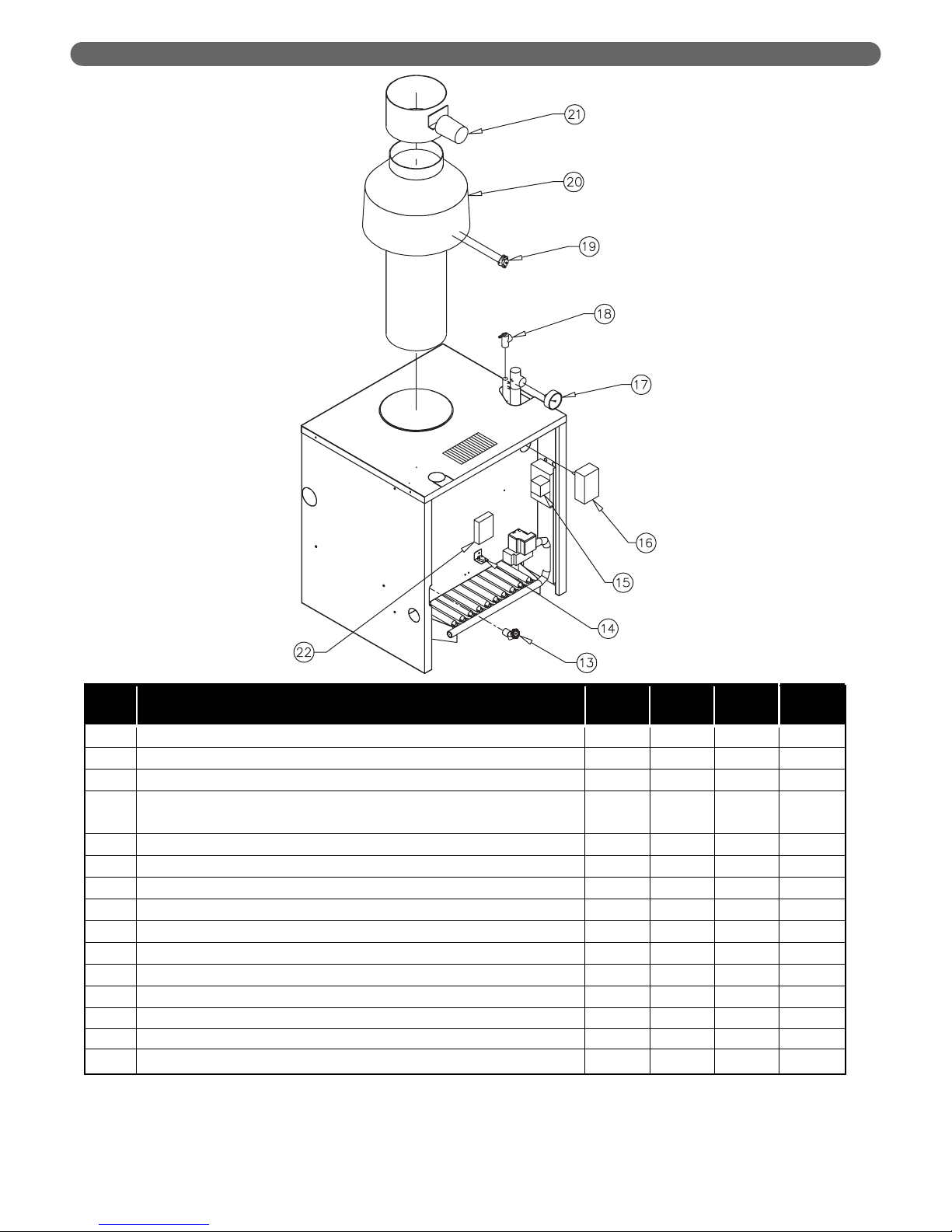

12. REPAIR PARTS 39

A. BASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

B. GAS MANIFOLD, ORIFICE SPUDS, AND

MAIN BURNERS . . . . . . . . . . . . . . . . . . . . . .40

C. BLOCK AND FLUE COLLECTOR . . . . . . . . .41

D. JACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

E. CONTROLS, DRAFT HOOD AND

AUTOMATIC VENT DAMPER . . . . . . . . . . .43

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

1

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this

manual in the order shown. The order of these

instructions have been set in order to provide the

installer with a logical sequence of steps that will

minimize potential interferences and maximize safety

during boiler installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of PB Heat, LLC:

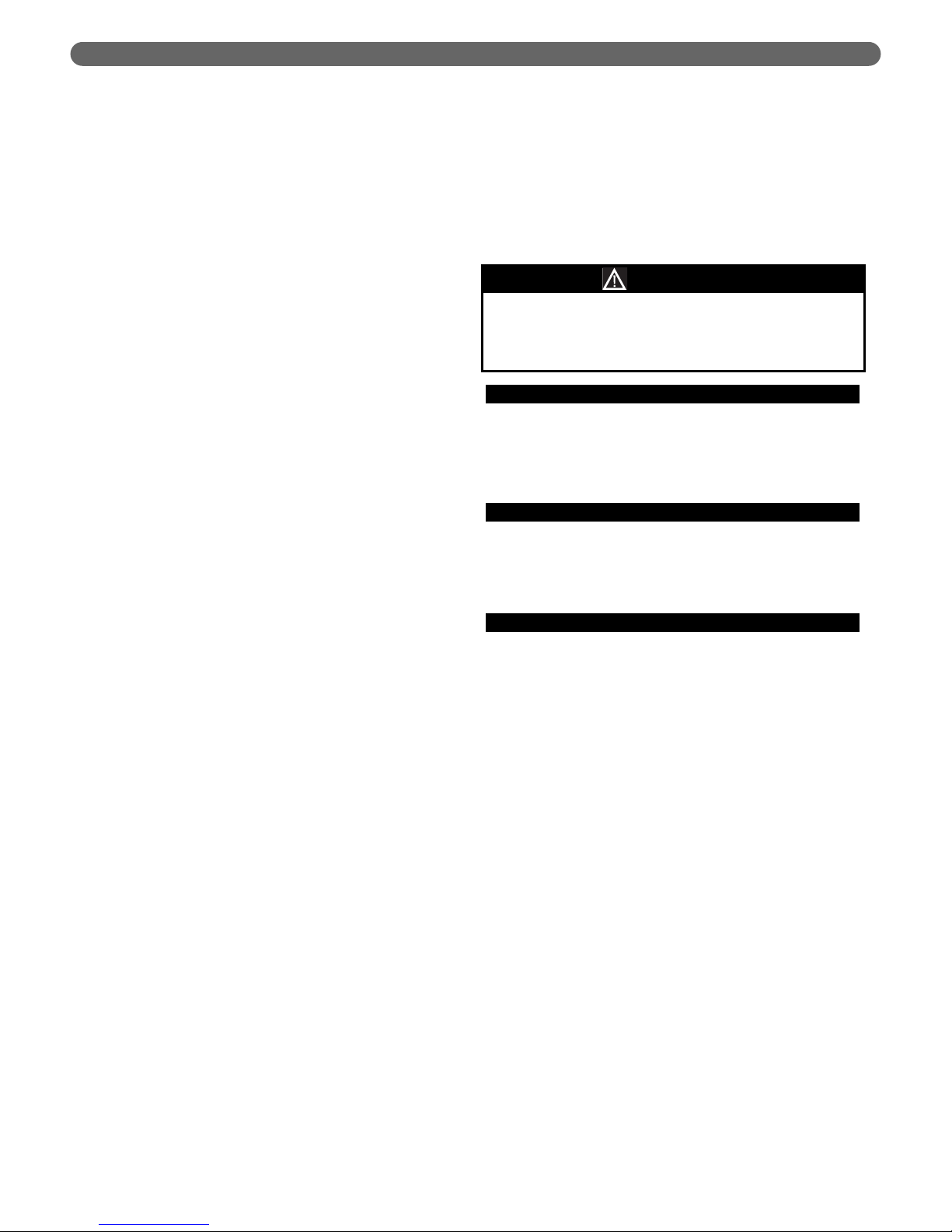

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

USING THIS MANUAL

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

Page 4

2

The equipment must be installed in accordance with installation requirements of the authority having

jurisdiction or, in the absence of such requirements, to the current edition of the

National Fuel Gas Code

, ANSI

Z223.1/NFPA 54 or CAN/CGA B149 Installation Codes.

Where required by the authority having jurisdiction, the installation must conform to

American Society of

Mechanical Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers,

ASME CSD-1.

NOTICE

A. ACCESSIBILITY CLEARANCES

Install boiler with not less than 24" (610 mm) between

the top and front of the boiler and adjacent wall or other

appliance, when access is required for servicing.

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION

The design of this boiler is certified for alcove installation

with the following clearances from combustible

construction:

1. Sides: 6" (152 mm)

2. Top of Jacket: 36" (914 mm)

3. Draft Hood: 6" (152 mm)

4. Vent Pipe: 6" (152 mm )[1" (25 mm) for Type B vent]

5. Rear of Jacket: 6" (152 mm)

6. Hot Water Pipes: 1" (25 mm)

7. If it is necessary to build a non-combustible floor pad

over top of an existing combustible floor, construct

pad as stated in the current edition of National Fuel

Gas Code Handbook under “Installation of Specific

Equipment”, or CAN/CGA B149 Installation Codes

under “General”.

C. COMBUSTION AND VENTILATION AIR

1. Provide adequate facilities for combustion and

ventilation air in accordance with current edition of

National Fuel Gas Code under “Air for Combustion

and Ventilation”, or applicable provisions of the local

building code, or CAN/CGA B149 Installation

Codes. Subsections 2 through 8 below are based on

National Fuel Gas Code requirements.

2. Requir

ed Combustion Air Volume: The total required

volume of indoor air is to be the sum of the required

volumes for all appliances located within the space.

Rooms communicating directly with the space in

which the appliances are installed and through

combustion air openings sized as indicated in

Subsection 3 are considered part of the required

volume. The required volume of indoor air is to be

determined by one of two methods.

a. Standard Method: The minimum required

volume of indoor air (room volume) shall be 50

cubic feet per 1000 BTU/Hr (4.8 m

3

/kW). This

method is to be used if the air infiltration rate is

unknown or if the rate of air infiltration is known

to be greater than 0.6 air changes per hour. As

an option, this method may be used if the air

infiltration rate is known to be between 0.6 and

0.4 air changes per hour. If the air infiltration rate

is known to be below 0.4 then the Known Air

Infiltration Rate Method must be used. If the

building in which this appliance is to be installed

is unusually tight, PB Heat recommends that the

air infiltration rate be determined.

b. Known Air Infiltration Rate Method: Where

the air infiltration rate of a structure is known,

the minimum required volume of indoor air for

appliances other than fan assisted and for the

Series GM Boiler shall be determined as follows:

PREINSTALLATION

1. PREINSTALLATION

Carefully read these instructions before beginning work. Understand all aspects of the installation. Contact your PB Heat sales

representative or customer service for help in answering questions.

This boiler must be installed by a qualified contractor. The boiler warranty can be voided if the boiler is not installed, maintained

and serviced correctly.

Do not install this boiler on combustible flooring.

Boiler installation on combustible flooring is a fire

hazard.

WARNING

Do not install boiler on carpeting. Boiler installation

on carpeting is a fire hazard.

WARNING

21 ft

3

I

other

ACH 1000

Btu

/

hr

Required Volume

other

=

⎛

⎜

⎝

⎛

⎜

⎝

Page 5

3

where:

I

other

= Input of appliances other than fan

assisted in Btu/hr

ACH = air change per hour (percent of the

volume of the space exchanged per

hour, expressed as a decimal)

For fan assisted appliances, calculate the required

volume of air using the following equation:

I

fan

= Input of the fan assisted appliances in

Btu/hr

Note: These calculations are not to be used for

infiltration rates greater than 0.60 ACH.

3. Indoor Air Opening Size and Location:

Openings

connecting indoor spaces shall be sized and located

as follows:

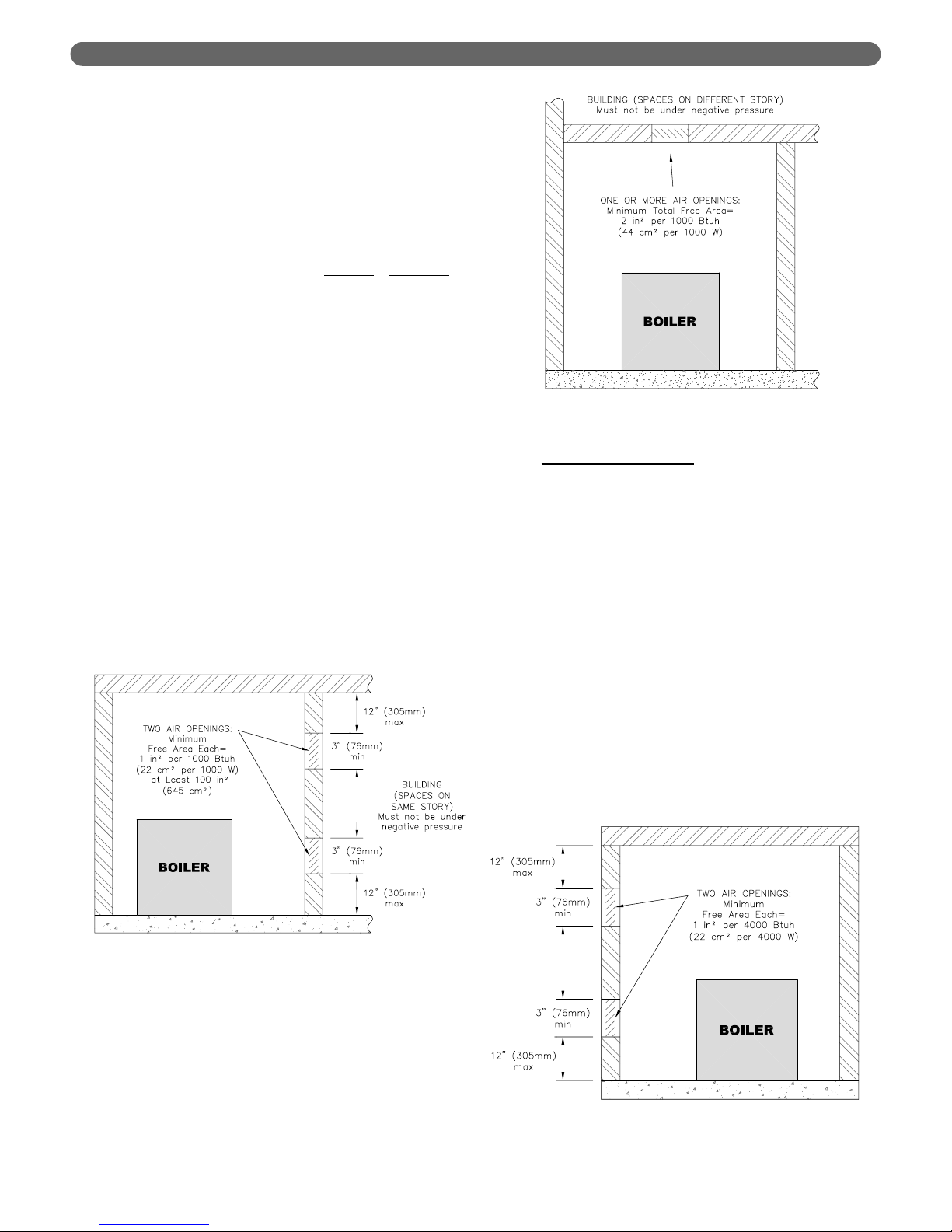

a. Combining spaces on the same floor:

Provide two permanent openings communicating

with additional spaces that have a minimum free

area of 1 in² per 1000 Btu/hr (22 cm² per 1000 W)

of the total input rating of all gas fired equipment

but not less than 100 in² (645 cm²). One

opening is to begin within 12 inches (305 mm)

of the top of the space and the other is to begin

within 12 inches (305 mm) of the floor. The

minimum dimension of either of these openings

shall be 3 inches (76 mm). See Figure 1.1 for an

illustration of this arrangement.

b. Combining spaces on different floors:

Provide one or more permanent openings

communicating with additional spaces that have

a total minimum free area of 2 in² per 1000

Btu/hr (44 cm² per 1000 W) of total input rating

of all equipment. See Figure 1.2 for an

illustration of this arrangement.

D.

LIQUEFIED PETROLEUM (LP) GAS

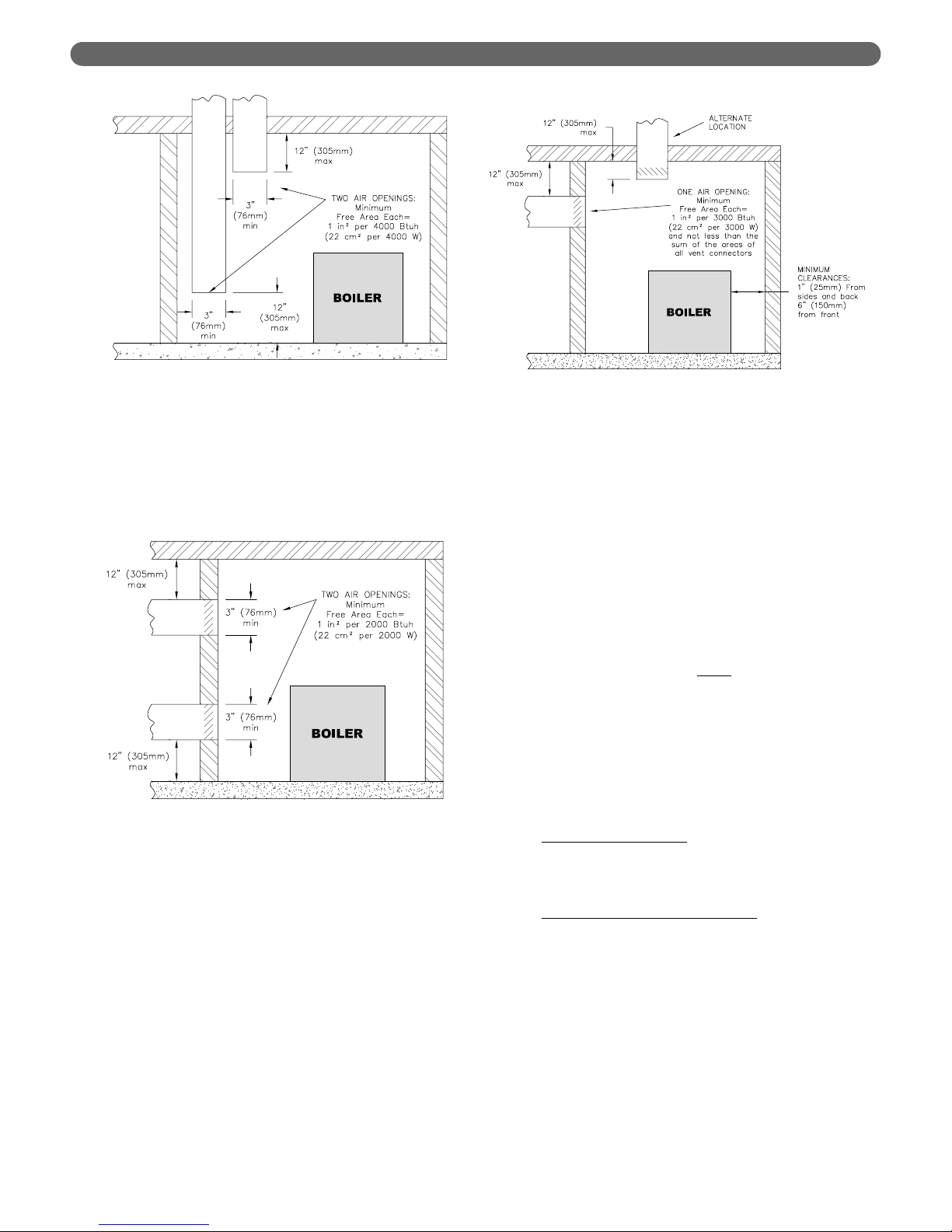

4. Outdoor Combustion Air: Outdoor combustion air is

to be provided through one or two permanent

openings. The minimum dimension of these air

openings is 3 inches (76 mm).

a. Two Permanent Opening Method: Provide

two permanent openings. One opening is to

begin within 12 inches (305 mm) of the top of

the space and the other is to begin within 12

inches (305 mm) of the floor. The openings are

to communicate directly or by ducts with the

outdoors or with spaces that freely communicate

with the outdoors. The size of the openings shall

be determined as follows:

i. Where communicating directly or through

vertical ducts with the outdoors each opening

shall have a minimum free area of 1 in² per

4000 Btu/hr (22 cm² per 4000 W) of total

input rating for all equipment in the space.

See Figure 1.3 for openings directly

communicating with the outdoors or Figure

1.4 for openings connected by ducts to the

outdoors.

PREINSTALLATION

15 ft

3

I

fan

ACH 1000

Btu

/

hr

Required Volume

fan

=

⎛

⎜

⎝

⎛

⎜

⎝

Figure 1.1: Air Openings – All Air from Indoors

on the Same Floor

Figure 1.2: Air Openings – All Air from Indoors

on Different Floors

Figure 1.3: Air Openings – All Air Directly from

Outdoors

Page 6

4

ii. Where communicating with the outdoors

through horizontal ducts, each opening shall

have a minimum free area of 1 in² per 2000

Btu/hr (22 cm² per 2000 W) of total rated

input for all appliances in the space. See

Figure 1.5.

b. One Permanent Opening Method: Provide

one permanent opening beginning within 12

inches (305 mm) of the top of the space. The

opening shall communicate directly with the

outdoors, communicate through a vertical or

horizontal duct, or communicate with a space

that freely communicates with the outdoors. The

opening shall have a minimum free area of 1 in²

per 3000 Btu/hr of total rated input for all

appliances in the space and not less than the

sum of the cross-sectional areas of all vent

connectors in the space. The gas-fired equipment

shall have clearances of at least 1 inch (25 mm)

from the sides and back and 6 inches (150 mm)

from the front of the appliance. See Figure 1.6

for this arrangement.

5. Combination Indoor and Outdoor Combustion Air: If

the required volume of indoor air exceeds the

available indoor air volume, outdoor air openings or

ducts may be used to supplement the available

indoor air provided:

a. The size and location of the indoor openings

comply with Subsection 3.

b. The outdoor openings are to be located in

accordance with Subsection 4.

c. The size of the outdoor openings are to be sized

as follows:

where:

A

req

= minimum area of outdoor openings.

A

full

= full size of outdoor openings calculated

in accordance with Subsection 4.

V

avail

= available indoor air volume

V

req

= required indoor air volume

6. Engineer

ed Installations: Engineered combustion air

installations shall provide an adequate supply of

combustion, ventilation, and dilution air and shall be

approved by the authority having jurisdiction.

7. Mechanical Combustion Air Supply

:

a. In installations where all combustion air is

provided by a mechanical air supply system, the

combustion air shall be supplied from the

outdoors at the minimum rate of 0.35 ft

3

/min per

1000 Btu/hr (0.034 m

3

/min per 1000 W) of the

total rated input of all appliances in the space.

b. In installations where exhaust fans are installed,

additional air shall be provided to replace the

exhaust air.

GAS

Figure 1.4: Air Openings – All Air from Outdoors

through Vertical Ducts

Figure 1.5: Air Openings – All Air from Outdoors

through Horizontal Ducts

Figure 1.6: Air Openings – All Air from Outdoors

through One Opening

V

avail

1 –

V

req

A

req

= A

full

x

⎛

⎜

⎝

⎛

⎜

⎝

PREINSTALLATION

Page 7

5

c. Each of the appliances served shall be

interlocked to the mechanical air supply to

prevent main burner operation when the

mechanical air supply system is not in operation.

d. In buildings where the combustion air is provided

by the mechanical ventilation system, the system

shall provide the specified combustion air rate in

addition to the required ventilation air.

8. Louvers & Grills:

a. The required size of openings for combustion,

ventilation, and dilution air shall be based on the

net free area of each opening.

i. Where the free area through a louver or grille

is known, it shall be used in calculating the

opening size required to provide the free area

specified.

ii. Where the free area through a louver or grille

is not known, it shall be assumed that wooden

louvers will have 25% free area and metal

louvers and grilles will have 75% free area.

iii. Nonmotorized dampers shall be fixed in the

open position.

b. Motorized dampers shall be interlocked with the

equipment so that they are proven in the full

open position prior to ignition and during

operation of the main burner.

i. The interlock shall prevent the main burner

from igniting if the damper fails to open

during burner startup.

ii. The interlock shall shut down the burner if

the damper closes during burner operation.

9. Combustion Air Ducts

a. Ducts shall be constructed of galvanized steel or

an equivalent corrosion- resistant material.

b. Ducts shall terminate in an unobstructed space,

allowing free movement of combustion air to the

appliances.

c. Ducts shall serve a single space.

d. Ducts shall not serve both upper and lower

combustion air openings where both such

openings are used. The separation between ducts

serving upper and lower combustion air

openings shall be maintained to the source of

combustion air.

e. Ducts shall not be screened where terminating in

an attic space.

f. Horizontal upper combustion air ducts shall not

slope downward toward the source of the

combustion air.

g. The remaining space surrounding a chimney

liner, gas vent, special gas vent, or plastic piping

installed within a masonry, metal, or factory built

chimney shall not be used to supply combustion

air.

h. Combustion air intake openings located on the

exterior of buildings shall have the lowest side of

the combustion air intake opening at least 12

inches (305 mm) above grade.

D. INSTALLATION SURVEY

For new and existing installations, a Water Installation

Survey is available from PB Heat. The survey will

provide information on how a hot water boiler works

with your specific system and will provide an overview

of hot water system operation in general.

E. CIRCULATORS

The Series GM boiler is not equipped with a circulator

or a means to control circulator operation. Provide

circulator and zone controls, such as Taco zoning

circulator or Honeywell R845.

F. PLANNING THE LAYOUT

Prepare sketches and notes of the layout to minimize the

possibility of interferences with new or existing

equipment, piping, venting and wiring.

Liquefied Petroleum (LP) is heavier than air and may

collect or “pool” in a low area in the event of a leak

from defective equipment. This gas may then ignite,

resulting in a fire or explosion.

WARNING

PREINSTALLATION

Page 8

6

BOILER SET-UP

1. Provide a sound, level foundation. Locate boiler as

near to the chimney or outside wall as possible and

centralized with respect to the heating system.

2. Locate boiler in front of installation position before

removing crate.

3. Separate the wood shipping pallet from the boiler

base by removing two (2) hold-down bolts at each

end of the boiler base.

4. Move boiler into final position.

2. BOILER SET-UP

Page 9

7

Design piping and size circulator(s) to suit the system. Refer to

the I=B=R - Residential Hydronic Heating Installation/Design

Guide and the PB Heat Water Survey for guidance.

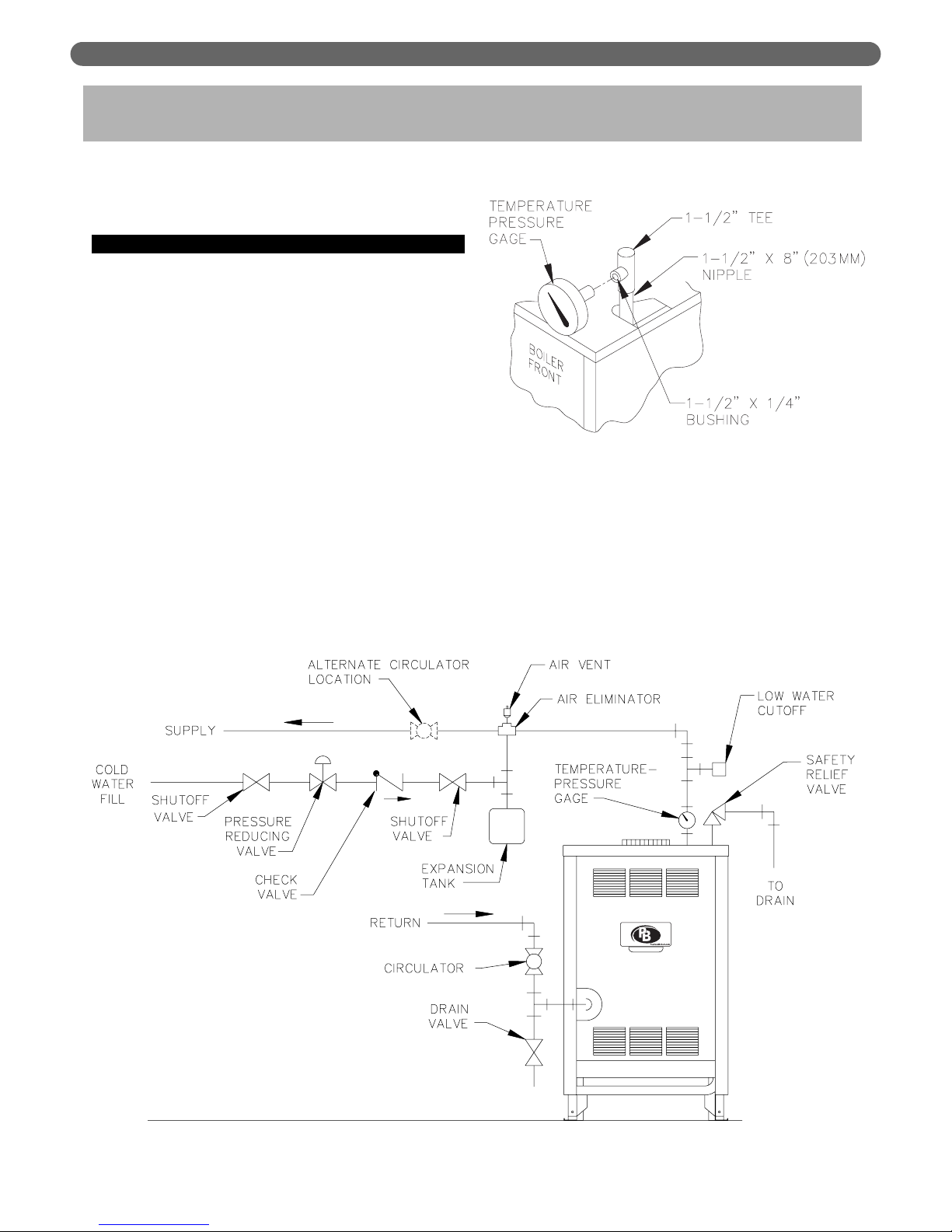

A. BOILER SUPPLY AND RETURN

Install boiler to protect the gas ignition system

components from water (dripping, spraying, etc.) during

appliance operation and service (circulator replacement,

condensate trap, control replacements, etc.).

1. Remove shipping nipple from supply tapping.

2. Install temperature-pressure gage with tee in

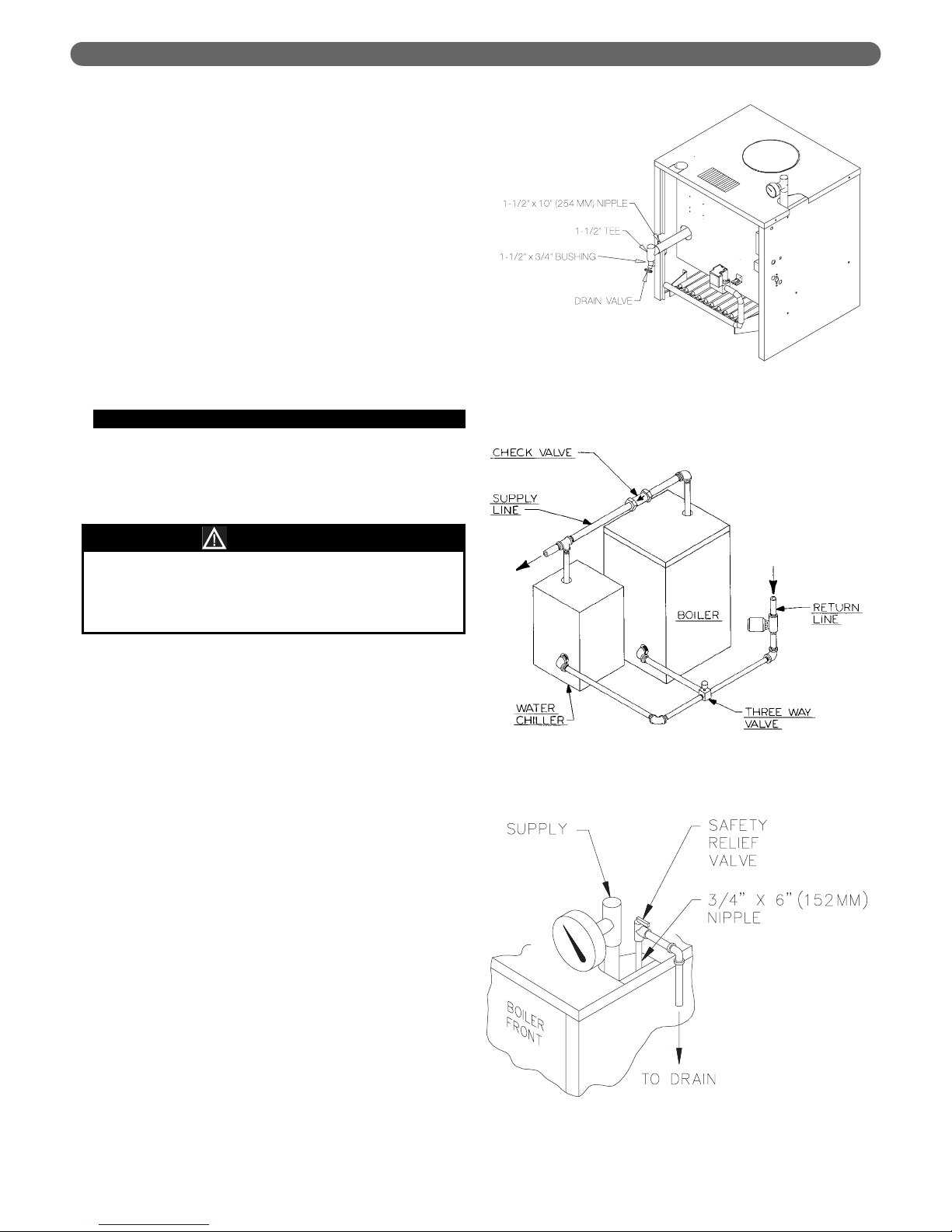

supply tapping. Nipple, tee, bushing and gage are

located in trim carton. See Figure 3.1.

3. Install drain valve. Remove jacket front panel.

Install drain valve with tee in return tapping. Nipple,

tee, bushing and drain valve are located in trim

carton. See Figure 3.3. Tee may be installed with run

in either horizontal or vertical orientation.

4. Install supply piping, return piping and circulator.

See Figure 3.2.

a. If boiler is installed above radiation level, provide

a low water cutoff device in the supply piping

above boiler. See Figure 3.2.

3. WATER PIPING AND CONTROLS

Figure 3.2: Typical Supply and Return Piping

Figure 3.1: Temperature-Pressure Gage Installation

WATER PIPING AND CONTROLS

Page 10

8

b. When system return water temperature will be

below 130°F (54°C), pipe the boiler with a

bypass arrangement to blend the system return

and hot supply to obtain at least 130°F (54°C)

entering the boiler. For more information on

bypass piping, consult the PB Heat Water

Installation Survey.

c. If this boiler and distribution system is used in

conjunction with a refrigeration system, pipe the

chilled medium in parallel with the boiler and

install the proper valve to prevent the chilled

medium from entering the boiler. See Figure 3.4.

d. When the boiler is connected to heating coils

located in air handling units where they may be

exposed to refrigerated air circulation, install flow

control valves or other automatic means to

prevent gravity circulation of the boiler water

during the cooling cycle.

B. SAFETY RELIEF VALVE

1. Locate safety relief valve and nipple in trim carton.

2. Install safety relief valve in 3/4 NPT tapping behind

supply tapping. Safety relief valve must be installed

with spindle in vertical position. See Figure 3.5.

Pipe the discharge of safety relief valve to prevent

injury in the event of pressure relief. Pipe the

discharge to a drain. Provide piping that is the same

size as the safety relief valve outlet.

CAUTION

Figure 3.5: Safety Relief Valve Installation

Figure 3.4: Parallel Hook-up with Water Chiller

WATER PIPING AND CONTROLS

Figure 3.3: Drain Valve Installation

Page 11

9

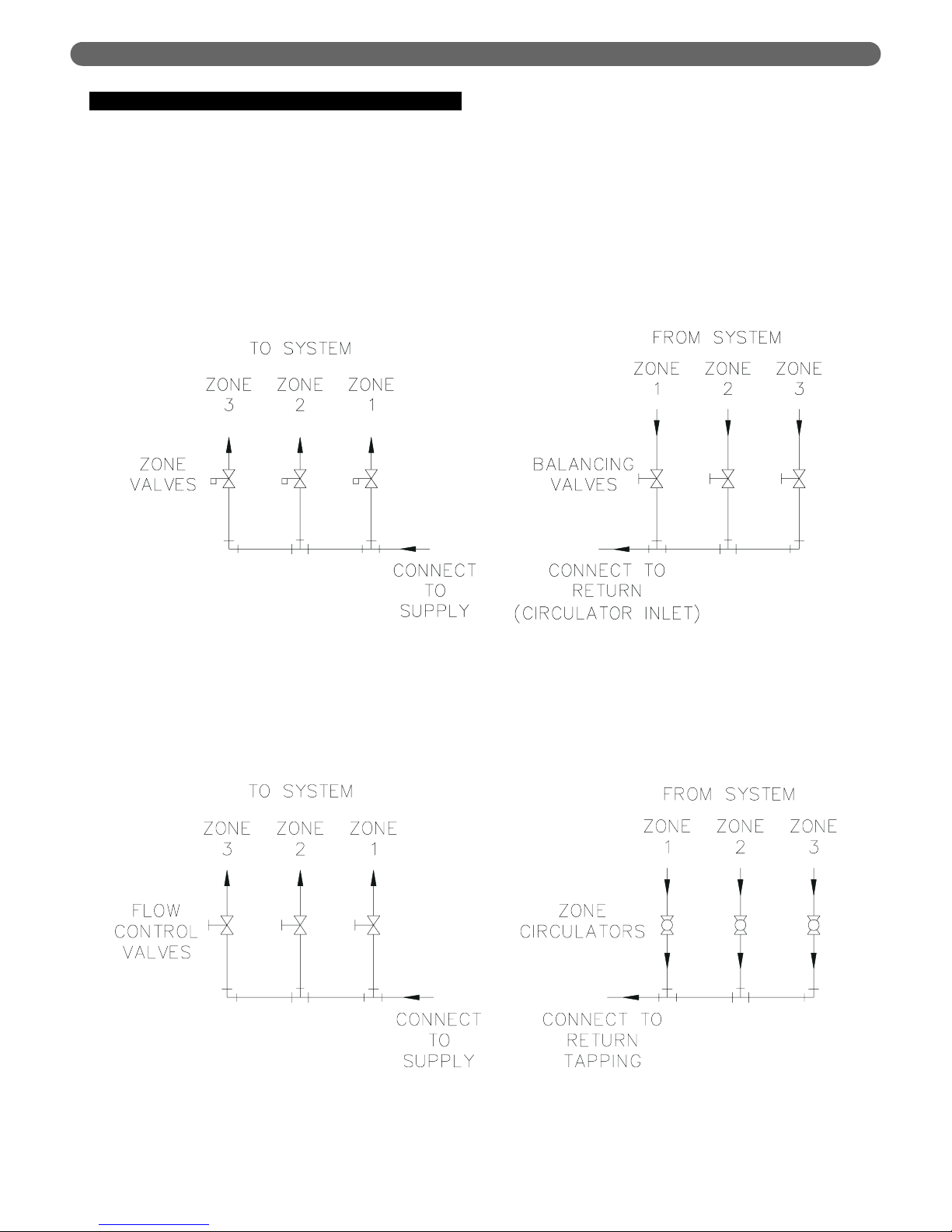

C. PIPING FOR ZONED SYSTEMS

1. See Figures 3.6 and 3.7 for basic zoned system

layouts. Circulators may be installed in either supply

or return piping. Refer to PB Heat Water Installation

Survey for additional information.

2. Run each zone pipe down then up to zone to

prevent air accumulation in piping.

3. If required, provide means to isolate and drain each

zone separately.

Figure 3.6: Zone Piping with Zone Valves

Figure 3.7: Zone Piping with Circulators

WATER PIPING AND CONTROLS

Page 12

10

D. EXPANSION TANK

1. Consult the tank manufacturer’s instructions for

specific information relating to tank installation. Size

the expansion tank for the required system volume

and capacity. See Table 11.1 for boiler’s water

content.

2. Expansion tanks are available with built-in fill valves

and check valves for reducing supply water pressure

and maintaining minimum system pressure. Check

the design features of the tank and provide valves as

necessary.

Refer to Figure 3.2 for typical expansion tank piping.

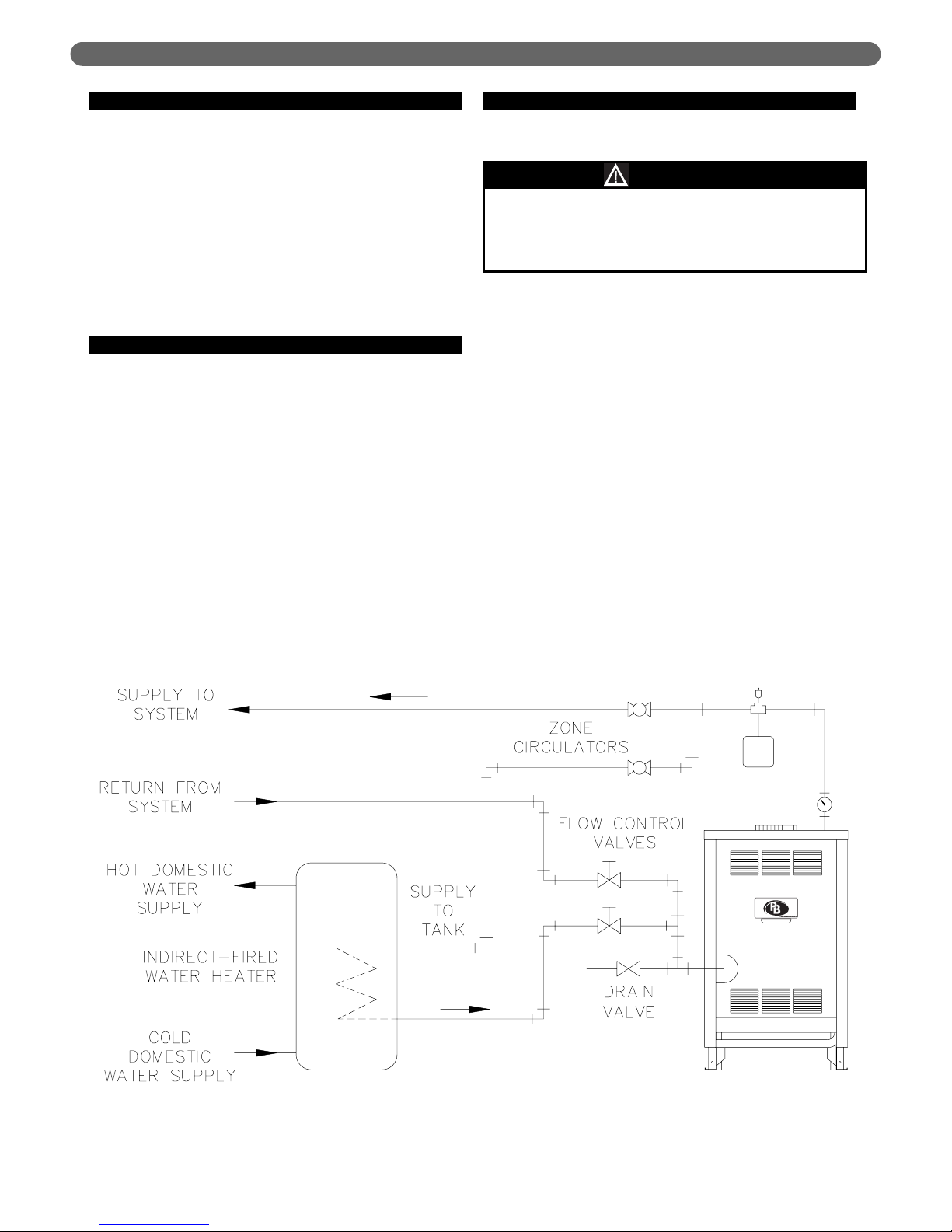

E. INDIRECT-FIRED WATER HEATER

Boiler may be used as heat source for indirect-fired

water heater. Refer to Figure 3.8 for typical piping.

Follow the instructions provided by the water heater

manufacturer. Pipe the water heater as if a separate

space heating zone.

F. FREEZE PROTECTION

For new or existing systems that must be freezeprotected:

1. Glycol for hydronic applications is specially

formulated with inhibitors which prevent the glycol

from attacking metallic system components. Make

certain that the system fluid is checked for the

correct glycol concentration and inhibitor level.

2. Antifreeze solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

in volume for a temperature increase from 32°F

(0°C) to 180°F (82°C), while water expands 3% with

the same temperature rise. Allowance must be made

for this expansion in system design.

3. For more information, consult the PB Heat Water

Installation Survey and the antifreeze manufacturer.

Figure 3.8: Typical Piping with Indirect-Fired Water Heater

WATER PIPING AND CONTROLS

Use only inhibited propylene glycol solutions of up to

50% by volume with water. Ethylene glycol is toxic

and can attack gaskets and seals used in hydronic

systems.

WARNING

Page 13

11

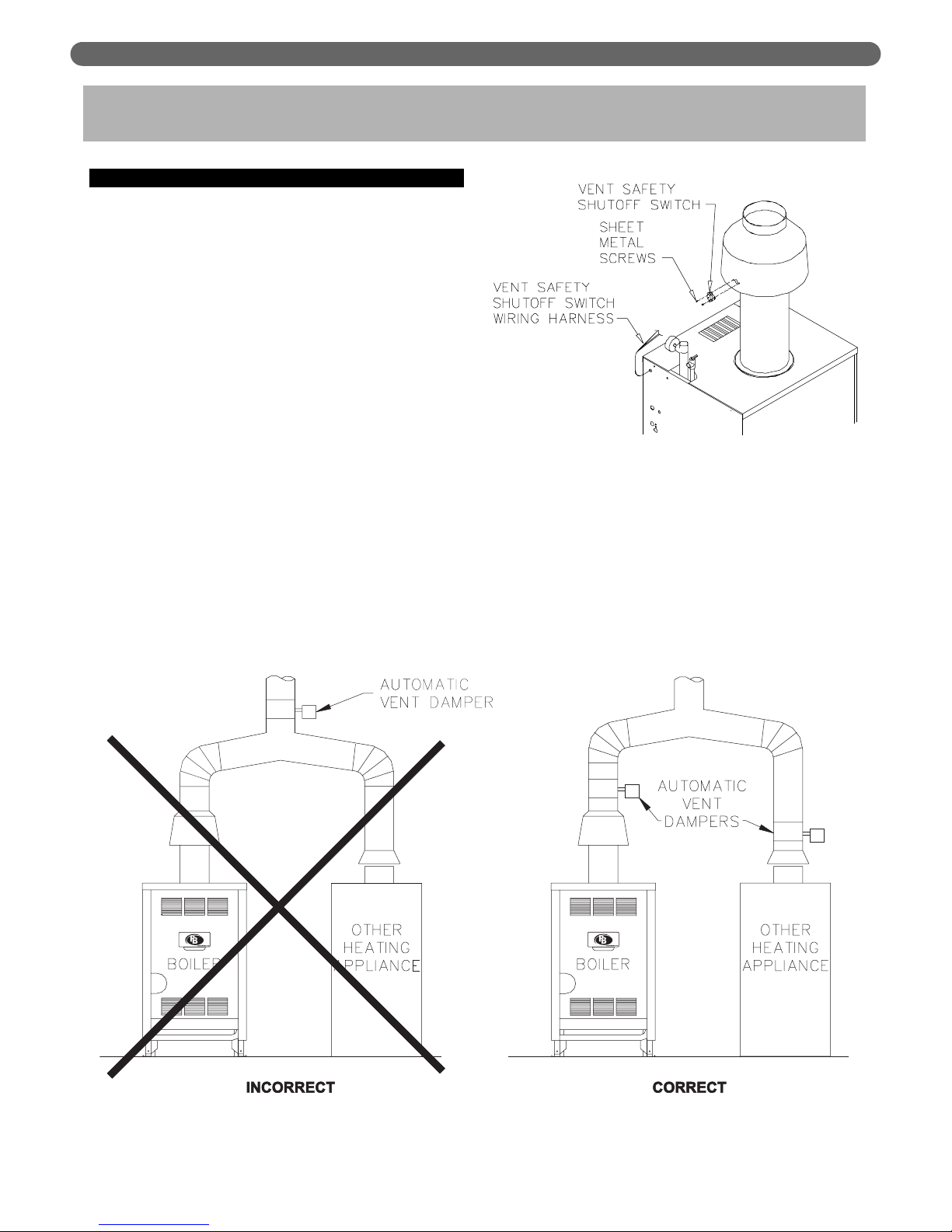

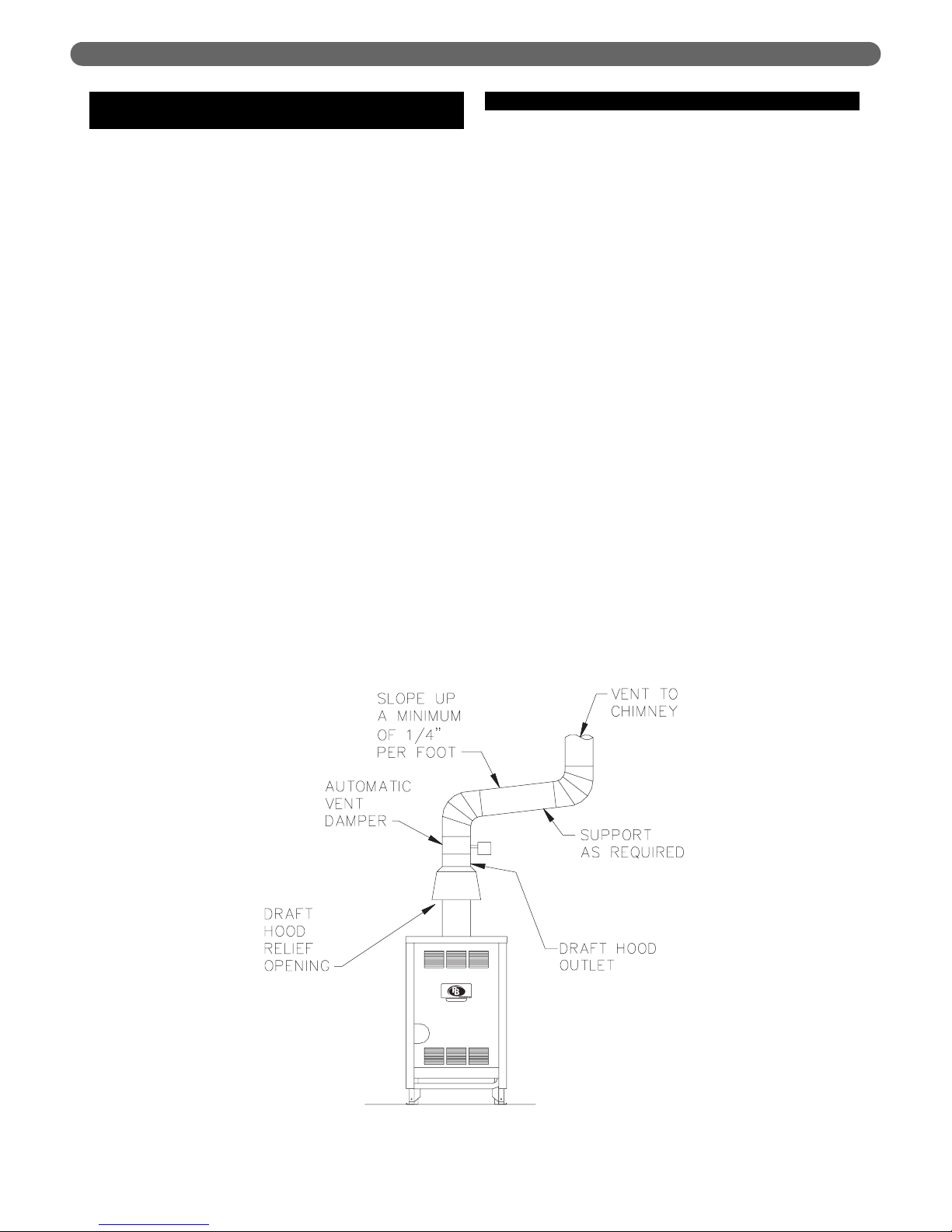

A. DRAFT HOOD

1. The boiler is equipped with a draft hood designed to:

a. provide for the ready escape of flue gases from

the boiler in the event of no draft.

b. prevent a backdraft from entering the boiler.

c. control stack draft during operation.

The draft hood must be installed without alteration.

Make certain there are no obstructions to airflow to

the relief opening.

2. Position draft hood with 1" (25 mm) diameter hole in

conical portion of draft hood (for vent safety shutoff

switch) towards front right corner of boiler. Secure to

flue collector with sheet metal screws. See Figure 4.1.

3. The boiler is equipped with a vent safety shutoff

switch. The switch is shipped in a cloth bag attached

to the harness on the exterior of the boiler. Attach

switch to holes in the conical portion of the draft

hood using the screws provided in bag. See

Figure 4.1.

Vent safety shutoff switch wiring harness must extend

to vent safety shutoff switch without excessive slack.

To adjust harness length, squeeze strain relief bushing

to release from jacket. Adjust harness to proper

length. Reinsert strain relief bushing.

4. VENTING

Figure 4.2: Venting Multiple Appliances

VENTING

Figure 4.1: Draft Hood and Vent Safety Shutoff

Switch Installation

Page 14

12

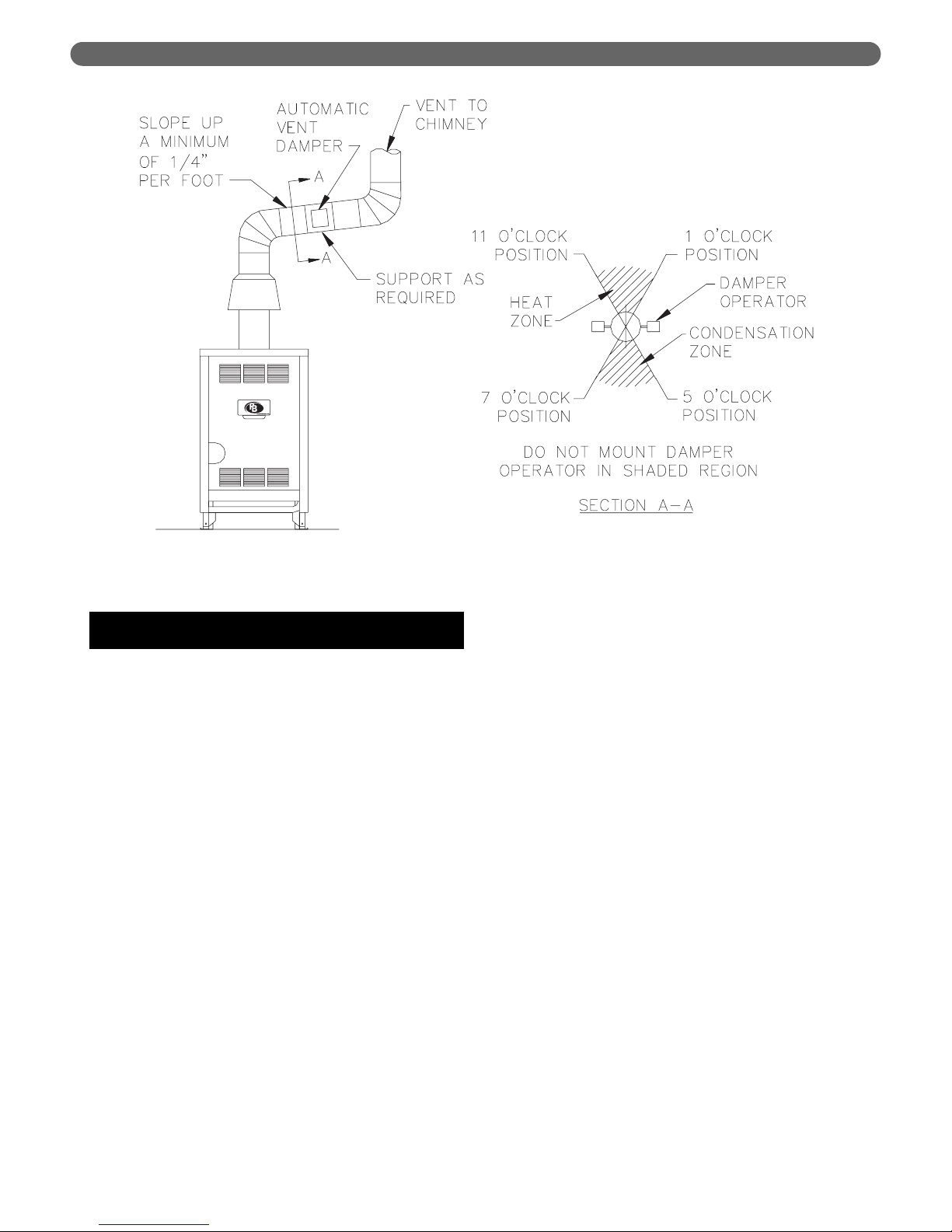

Figure 4.3: Venting with Vent Damper in Vertical Position

B. AUTOMATIC VENT DAMPER

INSTALLATION – GENERAL

1. Do not use one vent damper to control two or more

heating appliances. See Figure 4.2.

2. Follow these and the installation instructions included

with the vent damper. Observe the cautions and

warnings that accompany all instructions.

3. Provide minimum 6 inch (152 mm) clearance

between automatic vent damper and combustible

construction. Increase clearance if required by vent

damper manufacturer’s instructions. Provide

adequate space for vent damper access and service.

4. The automatic vent damper can be mounted directly

onto the draft hood outlet or in vent piping close to

the boiler.

See Figure 4.3 for installation with vent damper

mounted in vertical position. See Figure 4.4 for

installation with vent damper mounted in horizontal

position. Mount the unit to avoid excessive heat on

the operator or condensation drips into the operator.

a. Orient the vent damper operator to facilitate

connection of the vent damper harness to

knockout on right side of boiler. See Figure 6.1.

b. Orient vent damper direction arrow in direction

of vent gas flow. Direction arrow must be visible

from front of boiler.

C. VENT PIPING AND CHIMNEY

1. Install vent piping in accordance with current edition

of National Fuel Gas Code, ANSI Z223.1/NFPA 54

under “Venting of Equipment”, or applicable

provisions of the local building codes, or CAN/CGA

B149 Installation Codes.

2. Inspect the existing chimney and lining for structural

soundness, corrosion and perforations. Repair as

necessary.

3. Install vent pipe to slope upward at least 1/4" per

lineal foot (21 mm per meter) between the draft

hood outlet and the chimney.

4. Before connection of joints, inspect the vent pipe

interior for foreign objects such as tools, equipment,

rags, etc. and remove if present.

5. Insert vent pipe into but not beyond the inside wall

of the chimney flue.

6. Do not connect vent connectors serving appliances

vented by natural draft into any portion of

mechanical draft systems operating under positive

pressure.

7. Support horizontal portions of the venting system to

prevent sagging by use of metal strapping or

equivalent means. Locate supports at no more than

four (4) foot (122 cm) intervals, or in accordance with

vent system manufacturer’s installation instructions.

VENTING

Page 15

13

D. BOILER REMOVAL FROM COMMON

VENTING SYSTEM

At the time of removal of an existing boiler, follow these

steps with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation:

a. Seal any unused openings in the common venting

system.

b. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

c. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on any clothes dryers and any

appliance not connected to common venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

d. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

e. Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame

of a match or candle, or smoke from a cigarette,

cigar, or pipe.

f. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

conditions of use.

g. Any improper operation of the common venting

system should be corrected so that the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CAN/CGA B149 Installation

Codes. When resizing any portion of the common

venting system, the common venting system should

be resized to approach minimum size as determined

using the appropriate tables located in the chapter

“Sizing of Category I Venting Systems,” of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 or

CAN/CGA B149 Installation codes.

VENTING

Figure 4.4: Venting with Vent Damper in Horizontal Position

Page 16

14

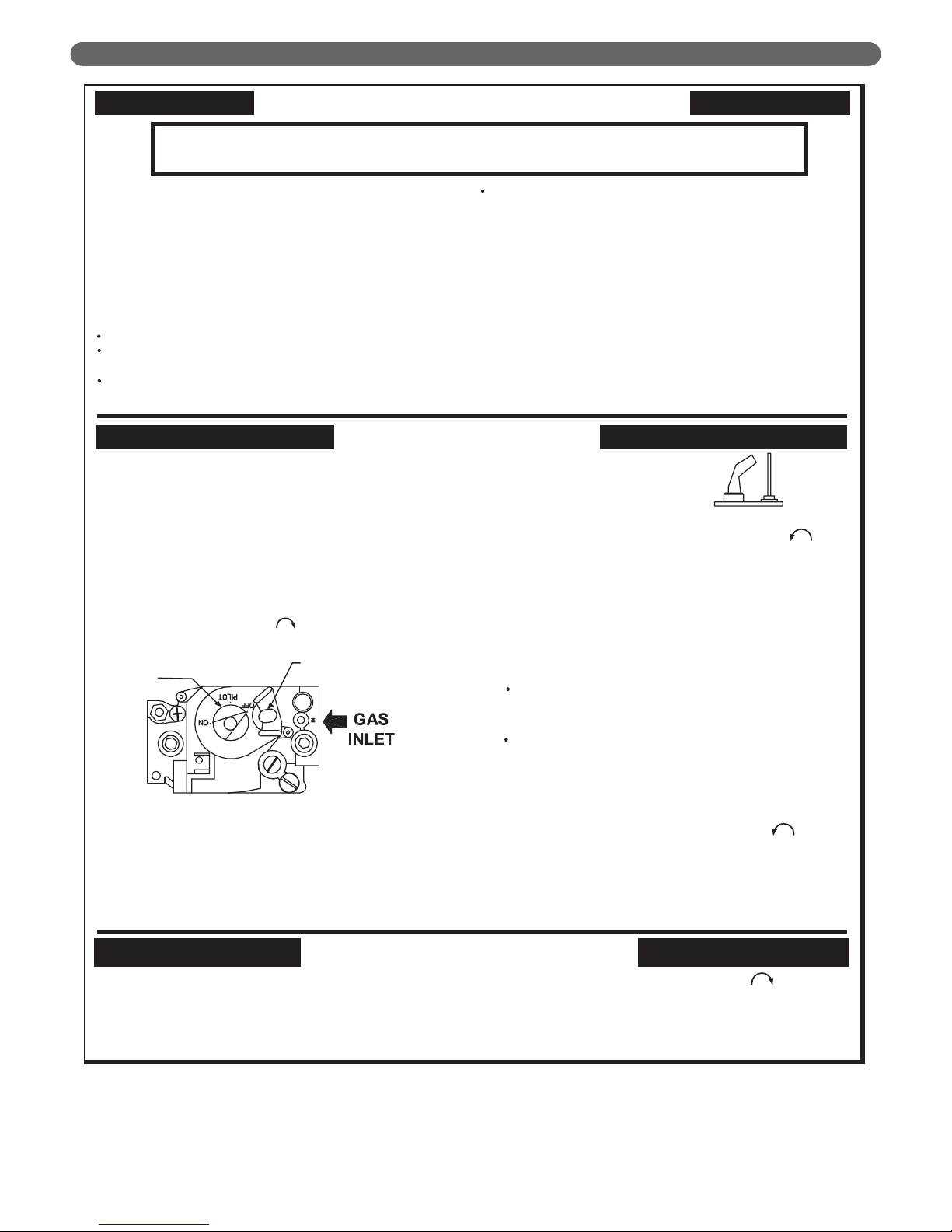

1. Size and install the gas supply piping to provide a

supply of gas sufficient to meet the maximum

demand of all appliances without undue loss of

pressure between the meter and the boiler.

Maximum permissible gas supply pressure to the

boiler is 13.5 inches (3.4 kPa) water column.

2. Determine the volume of gas to be provided to the

boiler. Obtain this value by dividing the Btu per hour

(Watts) rating (on the boiler rating plate) by the

heating value of the gas in Btu per cubic feet (Joules

per cubic meter). Obtain the heating value of the gas

from the gas supplier. As an alternative, use Table

5.1 to obtain the volume of gas to be provided to

the boiler.

3. Table 2 shows the maximum flow capacity of several

pipe sizes based on 0.3" w.c. (.08 kPa) of water

pressure drop. These values are based on a specific

gravity of 0.60. Apply the factors indicated in Table 3

for gas with specific gravity other than 0.60 to obtain

corrected capacities.

4. Connection of boiler to the gas piping system may

be made on the left side or top of the boiler. See

Figure 11.1 for jacket opening locations.

5. Install a sediment trap. See Figure 5.1. Locate a tee

in the drop pipe at same elevation as the gas inlet

connection to the boiler. Extend the drop pipe to a

pipe cap. As an alternate, the sediment trap may be

located in the boiler vestibule. See Figure 5.2.

6. Install a ground joint union ahead of the gas control

assembly to permit servicing of the control. Some

local codes require an additional equipment shutoff

valve when using the combination gas controls. If

your code requires such a valve, a suggested

location is shown in Figure 5.1 or 5.2.

7. Check piping for leaks. Use an approved gas

detector, a non-corrosive leak detection fluid or other

leak detection method. If leaks are found, turn off all

gas flow and repair as necessary.

5. GAS PIPING

Figure 5.1: Gas Connection to Boiler - External

When checking for leaks, do not use matches,

candles, open flames or other methods that provide a

source of ignition. This can ignite a gas leak,

resulting in fire or explosion.

WARNING

Use a pipe joint sealing compound that is resistant to

the action of liquefied petroleum gas. A non-resistant

compound may lose sealing ability in the presence of

this gas, resulting in a gas leak and fire or explosion

potential.

WARNING

GAS PIPING

10

20

30

40

50

60

Pipe

Length

Feet

278

190

152

130

115

105

3/4"

Pipe

520

350

285

245

215

195

1

"

Pipe

1,050

730

590

500

440

400

1-1/4

"

Pipe

1,600

1,100

890

760

670

610

1-1/2

"

Pipe

Capacity of Schedule 40 pipe [cu. ft. per hour (cu. m per

hour)] with pressure drop of 0.3 in. (75 Pa) and specific gravity

of 0.60. No allowance for an ordinary number of fittings is

required.

Table 5.1: Input

Model

Natural Gas LP Gas

(Cubic Feet

Per Hour)

(Cubic Meter

Per Hour)

(Cubic Feet

Per Hour)

(Cubic Meter

Per Hour)

GM-05 228 6.5 91 2.6

GM-06 285 8.1 114 3.2

GM-07 342 9.7 137 3.9

GM-08 399 11.3 160 4.5

Natural gas based on 1000 Btu/Cubic Foot (37,300 kJ/m³).

LP gas based on 2,500 Btu/Cubic Foot (93,145 kJ/m³).

Table 5.2: Capacity of Schedule 40 Pipe

7.8

5.4

4.3

3.7

3.3

3.0

15

9.9

8.1

6.9

6.1

5.5

30

21

17

14

12

11

45

31

25

22

19

17

m³ m³ m³ m³ft.³ ft.³ ft.³ ft.³

Table 5.3: Maximum Capacity Correction Factors

Specific Gravity other than 0.60

Specific Gravity 0.50 0.55 0.60 0.65 0.70 0.75

Correction Factor 1.10 1.04 1.00 0.96 0.93 0.90

Specific Gravity 0.80 0.85 0.90 1.00 1.10 1.20

Correction Factor 0.87 0.84 0.82 0.78 0.74 0.71

Specific Gravity 1.30 1.40 1.50 1.60 1.70 1.80

Correction Factor 0.68 0.66 0.63 0.61 0.59 0.58

Page 17

15

GAS PIPING

8. Disconnect the boiler and its individual shut-off valve

from the gas supply piping system during any

pressure testing of that system at test pressure in

excess of 1/2 psig (3.5 kPa).

Isolate the boiler from the gas supply piping system

by closing its individual service valve during any

pressure testing of the gas supply piping system at

test pressure equal to or less than 1/2 psig (3.5 kPa).

9. Minimum permissible natural gas supply pressure

Inches Water Column (kPa)]:

Minimum permissible LP gas supply pressure is

11.0" w.c. (2.7 kPa).

10. Maximum permissible supply pressure to the boiler

[Inches Water Column (kPa)]:

All models 13.5" (3.4 kPa)

Do not subject the gas valve to more than 1/2 psi

pressure (3.5 kPa). Doing so may damage the valve.

CAUTION

Figure 5.2: Gas Connection to Boiler - Internal

Standing Pilot

Intermittent

Ignition

4.8

4.5

GM-05

5.5

4.5

GM-06 GM-07

----

4.9

GM-08

In. In. In.

----

4.6

In.

1.2

1.1

kPa

1.4

1.1

kPa

----

1.1

kPa

----

1.2

kPa

Page 18

16

A. WIRING

1. See Figure 6.1 for location of wiring and controls.

use Figures 6.4 - 6.6 to connect the boiler to a

power supply and then connect components to the

boiler.

2. Connect the boiler to a separate, permanently live

electrical supply line with a fused switch.

3. Connect the vent damper harness to the polarized

connector in the boiler vestibule as shown in

Figure 6.1.

B. CIRCULATOR/ZONE VALVE WIRING

1. A zone control is required to operate circulator(s)

when using a low voltage thermostat.

2. Taco Zoning circulator(s) can be used instead of

mounting separate circulator relay(s) (Figure 6.2).

3. Figure 6.8 shows typical wiring for one or more

circulators.

4. Figure 6.9 shows typical wiring for zone valves.

C. LOW WATER CUTOFF

Wire low water cutoff to turn off power to boiler. See

Figure 6.3 for Hydrolevel 550 low water cutoff. Refer to

manufacturer’s instructions for other low water cutoffs.

ELECTRICAL

6. ELECTRICAL

This unit when installed must be electrically grounded in accordance with the requirements of the authority

having jurisdiction or, in the absence of such requirements, with the current edition of the

National Electrical

Code

, ANSI/NFPA 70 or the Canadian Electrical Code Part I, CSA C22.1, Electrical Code.

NOTICE

Figure 6.1: Wiring Details

Do not power zone valves directly from the boiler

transformer. Doing so will greatly reduce the life of

the transformer. Use a separate transformer sized to

handle the total of all zone valve electrical loads.

NOTICE

Page 19

17

Figure 6.2: Taco Zoning Circulator Wiring

ELECTRICAL

Figure 6.3: Hydrolevel 550 Low Water Cutoff Wiring

Page 20

18

ELECTRICAL

SEQUENCE OF OPERATION, INTERMITTENT

IGNITION:

1. Thermostat calls for heat.

2. Limit senses boiler water temperature. Prevents

operation until water temperature falls approximately

15°F (9°C) below the cut-out temperature.

3. Automatic vent damper (if used) opens. Damper

must be in open position when appliance main

burner(s) is operating.

4. Gas valve energizes.

a. Igniter on.

b. Pilot gas on, igniting pilot.

5. Pilot flame detected.

a. Igniter off.

b. Main gas on, igniting main burners.

Note: If pilot flame is not detected within 30 seconds,

the igniter is turned off for 30 seconds, and then turned

back on. If the pilot is not detected within 30 seconds,

the igniter and pilot gas are turned off for 5 minutes.

The sequence then resumes at Step 4a.

6. Call for heat ends.

a. Pilot and main gas off, extinguishing pilot and

main burners.

b. Automatic vent damper (if used) closes.

Figure 6.4: Connection and Schematic Diagram, Intermittent Ignition, Natural Gas

Page 21

19

SEQUENCE OF OPERATION, INTERMITTENT

IGNITION:

1. Thermostat calls for heat.

2. Limit senses boiler water temperature. Prevents

operation until water temperature falls approximately

15°F (9°C) below the cut-out temperature.

3. Automatic vent damper (if used) opens. Damper

must be in open position when appliance main

burner(s) is operating.

4. Gas valve energizes.

a. Igniter on.

b. Pilot gas on, igniting pilot.

5. Pilot flame detected.

a. Igniter off.

b. Main gas on, igniting main burners.

Note: If pilot flame is not detected within 30 seconds,

the igniter is turned off for 30 seconds, and then turned

back on. If the pilot is not detected within 30 seconds,

the igniter and pilot gas are turned off for 5 minutes.

The sequence then resumes at Step 4a.

6. Call for heat ends.

a. Pilot and main gas off, extinguishing pilot and

main burners.

b. Automatic vent damper (if used) closes.

Figure 6.5: Connection and Schematic Diagram, Intermittent Ignition, LP Gas

ELECTRICAL

Page 22

20

ELECTRICAL

Figure 6.6: Connection and Schematic Diagram, Standing Pilot

SEQUENCE OF OPERATION, STANDING

PILOT:

1. Thermostat calls for heat.

2. Limit senses boiler water temperature. Prevents

operation until water temperature falls approximately

15°F (9°C) below the cut-out temperature.

3. Automatic vent damper opens.

4. Gas valve energizes.

5. Pilot flame detected by thermocouple. Main gas on,

igniting main burners.

Note: If pilot flame is not detected, main and pilot

gas are automatically turned off. Pilot must be

manually relit. See Figure 8.7 for Lighting

Instructions.

6. Call for heat ends.

a. Main gas off, extinguishing main burners.

b. Automatic vent damper closes.

Page 23

21

ELECTRICAL

Figure 6.7: Intermittent Ignition System Operating Sequence

Page 24

22

ELECTRICAL

Figure 6.8: Circulator Wiring

Figure 6.9: Zone Valve Wiring

Page 25

23

A. GENERAL

This section is in regard to requirements of the ASME

CSD-1 Code, Controls and Safety Devices for

Automatically Fired Boilers, which may be in effect in

your area. Any omissions or discrepancies that may exist

between these instructions and the CSD-1 code itself,

the code itself takes precedence. The CSD-1 Code may

be ordered by calling 1-800-THE-ASME.

B. CSD PART CF REQUIREMENTS

The Series GM is CSA certified to ANSI Z21.13 (CSA

4.9) and as such meets all CSD-1 Part CF requirements

for combustion side controls for units under 400,000

btuh (117 kW) input. No other combustion side controls

are required to meet CSD-1.

C. CSD PART CW REQUIREMENTS

CSD-1 requires the following waterside controls to be

installed with the boiler:

1. Manual reset low water cut-off (LWCO), such as

Hydrolevel 550SV Probe (29028)

2. Manual reset high limit, such as Honeywell

L4006E1117 (50536).

Install these controls in the supply piping. Figures 7.1-

7.3 show typical piping using a probe style low water

cut-off.

See CSD-1 code for requirements when using a float

type low water cut-off.

No valves are allowed between these controls and the

boiler supply connection.

Low water cut-off must be positioned higher than the

top of the boiler. See Figure 7.4 for wiring details. Follow

all instructions furnished by the control manufacturers.

D. CSD MODULAR AND MULTIPLE BOILER

REQUIREMENTS

1. Modular Boilers

a. CSD-1 requires a manual reset low water cut-off

and manual reset high limit to control the

modular boiler system. The individual boiler

modules are not required to have a low water

cut-off or manual reset high limit.

b. To be considered a modular boiler system, the

individual boiler modules are not allowed to be

isolated from the main headers and controls with

stop valves.

2. Multiple Boilers

CSD-1 requires a manual reset low water cut-off and

manual reset high limit on each individual boiler.

For more information on modular and multiple boiler

systems, see the Flex-Heat manual or contact PB Heat.

CSD CODE REQUIREMENTS

7. CSD CODE REQUIREMENTS

Figure 7.1: CSD Piping, Using Cross Fitting

Figure 7.2: CSD Piping, Vertical Using Tee’s

Figure 7.3: CSD Piping, Horizontal

(51 MM)

(102 MM)

(51 MM)

(102 MM)

(51 MM)

(102 MM)

Page 26

24

E. CSD PART CE ELECTRICAL

REQUIRMENTS

Note the following electrical requirements per CSD-1

Section CE-110(a):

“A disconnecting means capable of being locked in

the open position shall be installed at an accessible

location at the boiler so that the boiler can be

disconnected from all sources of potential. This

disconnecting means shall be an integral part of the

boiler or adjacent to it.”

“A manually operated remote shutdown switch or

circuit breaker shall be located just outside the boiler

room door and marked for easy identification.

Consideration should be given to the type and

location of the switch to safeguard against

tampering. If the boiler room door is on the building

exterior, the switch should be located just inside the

door. If there is more than one door to the boiler

room, there should be a switch located at each

door.”

“The emergency shutdown switch or circuit breaker

must disconnect all power to the burner controls.”

CSD CODE REQUIREMENTS

Figure 7.4: CSD Low Water Cut-Off/Limit Wiring

Page 27

25

START-UP PROCEDURES

8. START-UP PROCEDURES

A. COMPLETING THE INSTALLATION

1. Confirm that all water, gas and electricity are

turned off.

2. Inspect the boiler combustion chamber for foreign

objects and remove if present.

3. Check physical condition of burners and pilot. Make

certain that there are no unusual bends or

perforations in the burners or pilot. Replace

components if necessary.

4. Verify that water piping, venting, gas piping and

electrical wiring and components are installed

properly. Refer back to previous sections of these

instructions as well as equipment manufacturer’s

instructions as necessary.

5. Fill the boiler and system with water, making certain

to vent all air from all points in the system. To check

water level in the system, open and close each vent

in the system. Water should exit from each vent when

it is opened.

6. The pressure reducing valve on the fill line will

typically allow the system to be filled and pressurized

to 12 psi (83 kPa). Consult the valve and expansion

tank manufacturer for more specific information.

7. Check joints and fittings throughout the system for

leaks. If leaks are found, drain the system and repair

as required.

8. Connect a manometer to 1/8 NPT tapping provided

on the manifold. See Figures 8.1 and 8.2.

9. Confirm that the gas supply pressure to the boiler is

above the minimum and below the maximum values

for the gas being used. See the end of Section 5 for

these values. If a supply pressure check is required,

isolate the boiler and gas valve before performing the

pressure check. If the supply pressure is too high or

too low, contact the gas supplier.

10. Turn on electricity and gas to boiler.

11. Light the boiler by following the Lighting/Operating

Instructions label mounted to the jacket panel. The

initial ignition may require several tries as the piping

is purged of air.

12. Use the sequence descriptions in Figures 6.4, 6.5 and

6.6 in Section 6 (Electrical) to follow light-off and

shutdown sequences and to assist in diagnosing

problems. If the boiler does not function properly,

consult Section 9, Troubleshooting.

13. The gas manifold and control assembly provided

with this boiler meet with all criteria regarding safe

lighting and performance as specified in ANSI

Z21.13 (CSA 4.9), Gas-Fired Low-Pressure Steam

and Hot Water Boilers. The gas manifold and control

assembly are made of gas-tight, completely factory

assembled and installed components of the base

assembly. See Figures 8.1 and 8.2.

Page 28

26

START-UP PROCEDURES

Figure 8.1: Gas, Valve, Manifold and Burner Assembly, GM-05/06 (Standing Pilot shown, Intermittent

Ignition similar)

Figure 8.2: Gas, Valve, Manifold and Burner Assembly, GM-07/08 (Intermittent Ignition)

Figure 8.3: Valve Tapping and Adjustment Screw

Locations, Intermittent Ignition,

Natural Gas

Figure 8.4: Valve Tapping and Adjustment Screw

Locations, Standing Pilot or LP Gas

Page 29

27

START-UP PROCEDURES

Figure 8.5: Operating Instructions, SmartValve Intermittent Ignition (boiler model suffix “SV”)

Page 30

28

Figure 8.6: Operating Instructions, Spark Intermittent Ignition (boiler model suffix “SPRK”)

START-UP PROCEDURES

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

A. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance

Do not touch any electric switch;

do not use any phone in your building.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Set the thermostat or operating control to lowest

setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

Gas Control Knob

(shown in "OFF"

position)

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier,

call the fire department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

5. If the gas valve is not visible, remove control access

panel.

6. If the gas control knob is not in the "OFF" postion,

turn the knob clockwise to "OFF".

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above on

this label. If you don't smell gas, go to the next step.

8. Turn the gas control knob counterclockwise to

"ON".

9. Replace control access panel, if applicable.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat or operating control to lowest

setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. If the gas valve is not visible, remove the control

10. Turn on all electrical power to the appliance.

11. Set thermostat or operating control to desired setting.

12. If the appliance will not operate, follow the

instructions "To Turn Off Gas To Appliance"

and call your service technician or gas supplier.

access panel.

4. Turn the gas control knob clockwise to "OFF".

5. Replace control access panel, if applicable.

HSP VR8204/VR8304 9181R REV.1 (MM/YY)

Page 31

29

START-UP PROCEDURES

Figure 8.7: Lighting Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these

instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance

Do not touch any electric switch;

do not use any phone in your building

Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instruction.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. If the gas valve is not visible, remove control access

panel.

5. If the gas control knob is not in the "OFF" position,

turn the knob clockwise to "OFF".

Gas Control Knob

(shown in "OFF"

position)

Red Reset Button

If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

8. Find pilot - follow metal tube

from gas valve. The pilot is

between two burner tubes

Pilot Burner

9. Turn the gas control knob counterclockwise to

"PILOT".

10. Push in red reset button all the way and hold in.

Immediately light the pilot with a match. Continue to

hold the reset button in for about one (1) minute after

the pilot is lit. Release button and it will pop back up.

Pilot should remain lit. If it goes out, repeat steps 5

through 10.

If button does not pop up when released, stop and

immediately call your service technician or gas

supplier.

If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service

technician or gas supplier.

6. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above on

this label. If you don't smell gas, go to the next step.

7. Remove the pilot access panel, if supplied, located

below and behind the gas valve directly above burner

tubes.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. If the gas valve is not visible, remove the control access

panel.

11. Replace pilot access panel, if applicable.

12. Turn gas control knob counterclockwise to "ON".

13. Replace control access panel, if applicable.

14. Turn on all electric power to the appliance.

15. Set thermostat to desired setting.

4. Turn the gas control knob clockwise to "OFF".

5. Replace control access panel, if applicable.

H24V VR8200/VR8300 9177R

Page 32

30

B. CONTROL DESCRIPTIONS

See Figure 8.8 for locations of these devices.

1. FLAME ROLLOUT SAFETY SHUTOFF SWITCH –

A thermally activated switch located above the

burners on the inner front jacket panel. The flame

rollout safety shutoff switch will sense excessive

temperature caused by continued flame rollout and

shut down main burner gas. This is a non-recycling

switch that must be replaced once activated.

2. VENT SAFETY SHUTOFF SWITCH – A thermally

activated, manually resetable switch located on the

draft hood. If venting system becomes partially or

totally blocked, the vent safety shutoff switch will

sense excessive temperature caused by flue products

exiting the draft hood relief opening and shut down

main burner gas.

3. LIMIT – A thermally activated, manually adjustable

switch located in the upper right side of boiler

vestibule. The limit senses supply water temperature

and will shut down main burner gas if the supply

water exceeds the preset temperature limit. This is a

recycling switch that will automatically reset when

the supply water falls below the preset temperature.

4. LOW WATER CUT-OFF (FOR GRAVITY SYSTEMS

OR HOT WATER BOILERS INSTALLED ABOVE

RADIATION LEVEL) – A level-sensing device (float

or probe) located in supply piping near the boiler. If

water level in the system drops below the control’s

position, it will shut down main burner gas. The

control will automatically reset once the water level

rises above its position.

C. ADJUSTMENT OF GAS PRESSURE

REGULATOR

1. Using the manometer setup installed in part 8A, set

manifold pressure.

2. To adjust gas pressure, turn adjusting screw of gas

pressure regulator counterclockwise to decrease

pressure, clockwise to increase pressure. Refer to

Figure 8.3 and 8.4 for location of gas pressure

regulator. Replace the cap screw when adjustment is

complete.

3. In no case should the final manifold pressure vary

more than ±0.3 inches (±75 Pa) water column from

the above specified pressures. Any necessary major

changes in the flow should be made by changing the

size of the burner orifice spuds.

4. When adjustment is complete, turn off boiler, gas

flow and electricity to boiler. Remove manometer

connection from valve and plug tapping with plug

provided. Turn utilities back on and resume

checkout.

D. CHECKING BURNER INPUT

1. Refer to rating label mounted on the jacket top panel

to obtain the rated BTU (kW) per hour input. In no

case shall the input to the boiler exceed the value

shown on the rating label.

2. Check input by use of the following formula [PB

Heat suggests reading meter for 2 Cu. Ft. (.05 Cu.

Meter)]:

BTU/Hr. Input=3600 x F x H

T

3600 – Seconds per hour

F – Cubic Feet of Gas Registered on Meter

H – Heat Value of Gas in BTU/Cubic Feet

T – Time in Seconds the Meter is Read

(Metric) Determine the input by multiplying

“F” – Meter Reading (Cubic Meters of Gas) times

“H” – Heating Value of Gas (Joules per Cubic

Meter). Divide by “T” – the time in seconds of the

meter reading.

Rate, Watts=F x H

T

3. As an alternative, use Table 8.1. Use the heating

value provided by gas supplier. Use a stopwatch to

record the time it takes for 2 cubic feet (.05 cubic

meter) of gas to pass through the meter. Read across

and down to determine rate.

START-UP PROCEDURES

Figure 8.8: Control Locations

Page 33

31

Burner inputs in Btu/hr for various meter timings and

heat values. (Table based on 2 cubic feet of gas through

meter).

(Metric) Burner inputs in Watts for various meter timings

and heat values. (Table based on .05 cubic meters of gas

through meter).

E. CHECK-OUT PROCEDURE

1. After starting the boiler, be certain all controls are

working properly. Check to be sure that the limit will

shut off the boiler in the event of excessive water

temperature. This can be done by lowering the limit

setting until the main burners shut down. When

proper limit function is confirmed, return the dial to

its previous setting.

2. To check operation of the ignition system safety

shut-off features:

a. Standing Pilot:

i) Turn the gas control knob counterclockwise

to “PILOT”. The main burner should go out

and the pilot should remain lit.

ii) Extinguish the pilot flame. Pilot gas flow

should stop within 2-1/2 minutes. Complete

shutdown is proven since the safety shut-off

valve has stopped main and pilot gas flow.

iii) Reset the boiler by following Lighting

Instructions.

iv) Observe boiler operation through one

complete cycle.

b. Spark Intermittent Ignition System:

i) Turn gas supply off.

ii) Set thermostat or controller above room

temperature to call for heat. Watch for

igniter glow at pilot burner.

iiia) SmartValve Intermittent Ignition - Igniter will

continue to glow for 30 seconds, de-energize

for 30 seconds, then re-energize and glow

for another 30 seconds. It will then deenergize for 5 minutes before restarting the

sequence.

iiib) Spark Ignition - Igniter will continue to spark

for 90 seconds and then de-energize for 5

minutes. It will then restart the sequence.

iv) Turn gas supply on.

v) Reset the boiler and control by following

Operating Instructions.

vi) Observe boiler operation through one

complete cycle.

3. Low Water Cut-Off (if used) – Consult the

manufacturer’s instructions for the low water cut-off

operational check procedure.

4. Check the system to make sure there are no leaks or

overfilling problems which might cause excessive

make-up water to be added. Make-up water causes

liming in the boiler and brings in oxygen. Oxygen

can cause severe damage to the boiler though

oxygen corrosion pitting.

5. Check the expansion tank and automatic fill valve (if

used) to confirm that they are operating correctly. If

either of these components causes high pressure in

the system, the boiler relief valve will weep or open,

allowing fresh water to enter the system.

6. Do not allow the system controls to subject the boiler

to excessively low water temperatures, which would

cause condensation of flue gases and corrosion of

the boiler. Operate the boiler at a temperature above

130°F (54°C). Adjust the boiler limit as required to

maintain boiler temperature above this level.

7. Check the general condition of the system including

piping support, joints, etc. Check cleanliness of the

radiators, baseboard units and/or convectors. Clean

them to the extent possible. If radiators do not heat

evenly, vent any remaining air from them.

8. Review operation and User’s Information Manual

with end-user.

9. Complete the Warranty Card and submit it to PB

Heat.

10. Hang the Installation, Operation and Maintenance

Manual and User’s Information Manual in an

accessible position near the boiler.

START-UP PROCEDURES

Table 8.1a: Meter Conversion – Natural Gas

480,000

360,000

288,000

240,000

205,714

15

20

25

30

35

492,000

369,000

295,200

246,000

210,857

504,000

378,000

302,400

252,000

216,000

Heat Value of Gas

(Btu/cubic foot)

1,000 1,025 1,050

Time that

meter is

read (sec)

124,333

93,250

74,600

62,167

53,286

15

20

25

30

35

127,333

95,500

76,400

63,667

54,571

130,333

97,750

78,200

65,167

55,857

Heat Value of Gas

(kJ/cubic meter)

37,300 38,200 39,100

Time that

meter is

read (sec)

Table 8.1b: Meter Conversion – Natural Gas

Page 34

32

A. SHUT-DOWN CAUSED BY PILOT

OUTAGE, VENT SAFETY SHUTOFF

SWITCH OR FLAME ROLLOUT SAFETY

SHUTOFF SWITCH

In the event of a shut-down caused by a pilot outage,

action of the vent safety shutoff switch or flame rollout

safety shutoff switch effecting a shut-down of the main

burners:

a. Refer to the Lighting/Operating Instructions in

Figures 8.5 - 8.7 to properly turn off the gas to the

boiler.

b. Turn off all electric power to the boiler.

c. Call a qualified heating service agency or local gas

company and have the cause of the shut-down

investigated and corrected.

d. Refer to Lighting/Operating Instructions to re-start

boiler.

B. TROUBLESHOOTING GUIDES

Use Table 9.1 to assist in determining causes and

providing corrective actions to boiler problems. Refer

also to Figure 9.1 to troubleshoot the Intermittent

Ignition System Control. These guides must be used

only by qualified service technicians. These individuals

must follow all applicable codes and regulations in repair

of any boiler problems.

TROUBLESHOOTING

9. TROUBLESHOOTING

Should overheating occur or the gas supply fail to

shut off, do not turn off or disconnect the electrical

supply to the pump. This may aggravate the problem

and increase the likelihood of boiler damage. Instead,

shut off the gas supply at a location external to the

appliance.

CAUTION

Do not use this appliance if any part has been under

water. Improper or dangerous operation may result.

Immediately call a qualified service technician to

inspect the boiler and to replace any part of the

control system and any gas control which has been

under water.

WARNING

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

CAUTION

When servicing or replacing items that communicate

with the boiler water, be certain that:

●●

There is no pressure on the boiler.

●●

The boiler is not hot.

●●

The power is off.

When servicing the gas valve or pilot, be certain that:

●●

The gas is off.

●●

The electricity is off.

DANGER

Page 35

33

TROUBLESHOOTING

Table 9.1: Boiler Troubleshooting Guide

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTIONS

1. No power.

2. Limit (Aquastat) not working.

3. Flame rollout switch open.

4. Blocked vent switch open.

5. Gas off at boiler gas valve.

6. Gas off external to boiler.

7. Plugged orifice spuds.

8. Defective gas valve.

9. Improper wiring.

10. Vent damper malfunctioning.

Burners not functioning.

1. Check line voltage wiring and fuses.

2. Check wiring and contacts, relay, temperature

setting. Clean and adjust as necessary.

3. Replace switch. Locate cause and correct.

4. Reset blocked vent switch. Locate cause and correct.

5. Start boiler using Lighting/Operating

Instructions.

6. Check any gas valves in the line.

7. Check, clean and re-install.

8. Use Figure 9.1 to troubleshoot intermittent

ignition gas valve. Replace if necessary.

9. Check and correct in accordance with wiring

diagrams in Section 6.

10. Refer to vent damper manufacturer’s instructions.

Replace if necessary.

1. Defective gas valve.

2. Short circuit.

Burners will not shut

down.

1. Use Figure 9.1 to troubleshoot intermittent

ignition gas valve. Replace if necessary.

2. Check and correct wiring.

1. Manifold gas pressure too low.

2. Improperly sized/drilled orifice spuds.

3. Leaking gas valve.

4. Burrs on orifice.

5. Low supply gas pressure.

6. Excessive downdraft or draft problems in

boiler room.

Flashback or burning

at orifice spuds.

1. Adjust to proper pressure.

2. Install correct spuds.

3. Replace valve.

4. Remove burrs.

5. Contact gas supplier.

6. Check air supply, ventilation and venting

system.

1. Insufficient pilot flame.

2. Pilot burner/orifice clogged.

3. Overfiring.

4. Misaligned burners or pilot.

5. Draft problem in boiler room.

Delayed ignition.

1. Increase pilot gas flow.

2. Clean pilot burner and orifice.

3. Reduce rate to input on rating label.

4. Realign burners or pilot.

5. Check air supply, ventilation and venting

system.

1. Underfiring.

2. Limit (aquastat) set too low.

3. Vent pipe too long.

4. Inadequate chimney or venting system.

Excessive condensation in

vent.

1. Increase rate to input on rating label.

2. Reset limit (aquastat) to higher setting.

3. Reposition boiler to reduce length.

4. Check chimney and venting recommendations.

1. Underfiring.

2. Limit set too low.

3. Air in system.

4. Circulator malfunctioning.

5. Circulation system clogged.

6. Incorrect thermostat heat anticipator setting.

Boiler not heating

properly.

1. Increase rate to input on rating label.

2. Reset limit (aquastat) to higher setting.

3. Vent air from all points in system.

4. Check circulator, replace if necessary.

5. Shut down and cool boiler, drain and flush

system.

6. Adjust heat anticipator.

1. Leaks in gas piping or fittings.

2. Leaks in gas service line or meter.

3. Obstructed chimney.

4. Obstructed flueways or vent.

5. Undersized chimney or vent, high draft loss

in vent.

6. Draft problem in boiler room.

7. Overfiring.

8. Vent damper malfunctioning.

Fumes or gas odors

1. Locate and repair or replace.

2. Shut down boiler and notify gas provider.

3. Check, repair and/or clean chimney.

4. Clean flueways or vent and remove obstructions.

5. Check National Fuel Gas Code ANSI

Z223.1/NFPA 54 and/or CAN/CGA B149

Installation Codes and vent manufacturer’s

recommendations.

6. Check air supply, ventilation and venting system.

7. Reduce rate to input on rating label.

8. Refer to vent damper manufacturer’s instructions.

Replace if necessary.

Page 36

34

TROUBLESHOOTING

Figure 9.1: SmartValve™ Intermittent Ignition System Troubleshooting Sequence

Page 37

35

10. MAINTENANCE

WARNING

Product Safety Information

Refractory Ceramic Fiber Product

This appliance contains materials made from refractory ceramic fibers (RCF). Airborne RCF,

when inhaled, have been classified by the International Agency for Research on Cancer

(IARC), as a possible carcinogen to humans. After the RCF materials have been exposed to

temperatures above 1800°F (982°C), they can change into crystalline silica, which has been

classified by the IARC as carcinogenic to humans. If particles become airborne during

service or repair, inhalation of these particles may be hazardous to your health.

Avoid Breathing Fiber Particulates and Dust

Suppliers of RCF recommend the following precautions be taken when handling these

materials:

Precautionar

y Measures:

Provide adequate ventilation.

Wear a NIOSH/MSHA approved respirator.

Wear long sleeved, loose fitting clothing and gloves to prevent skin contact.

Wear eye goggles.

Minimize airborne dust prior to handling and removal by water misting the material and

avoiding unnecessary disturbance of materials.

Wash work clothes separately from others. Rinse washer thoroughly after use.

Discard RCF materials by sealing in an airtight plastic bag.

Fir

st Aid Procedures:

Inhalation: If breathing difficulty or irritation occurs, move to a location with fresh clean air.

Seek immediate medical attention if symptoms persist.

Skin Contact: Wash affected area gently with a mild soap and warm water. Seek immediate

medical attention if irritation persists.

Eye Contact: Flush eyes with water for 15 minutes while holding eyelids apart. Do not rub

eyes. Seek immediate medical attention if irritation persists.

Ingestion: Drink 1 to 2 glasses of water. Do not induce vomiting. Seek immediate medical

attention.

MAINTENANCE

Page 38

36

A. GENERAL

1. Disconnect this boiler from the gas supply piping

during any pressure testing of the gas system.

2. Check pipes adjacent to cold walls or in unheated

spaces. Insulate and tape them if necessary to be

sure they can’t freeze up. Keeping the water moving

at all times will reduce the likelihood of freezing. See

Section 3 for antifreeze instructions.

3. If there is considerable foreign matter in the boiler

water, the boiler should be shut down and allowed to

cool, then drained and thoroughly flushed out. Use

the drain valve at the bottom of the return

connection to drain the boiler. Pipe the drain cock to

a suitable drain or containment device if antifreeze is

used. Flush the system to remove remaining matter.

If there is evidence that hard scale has formed on the

internal surfaces, the boiler should be cleaned by

chemical means as prescribed by a qualified water

treatment specialist.

4. There must not be signs of continuous wetness at the

chimney. If signs of continuous wetness are

observed, a qualified service agency must be

consulted to modify the vent configuration to prevent

the formation of condensate.

B. DAILY (WITH BOILER IN USE)

Daily boiler observation can be performed by the owner.

If any potential problems are found, a qualified installer

or service technician/agency must be notified.

1. Remove any combustible materials, gasoline and

other flammable liquids and substances that generate

flammable vapors from the area where the boiler is

contained. Make certain that the boiler area has

ample air for combustion and ventilation and that

there are no obstructions to the free flow of air to

and from the boiler.

2. Observe general boiler conditions (unusual noises,

vibrations, etc.)

3. Observe operating temperature and pressure on the

combination gauge located on the left side of the

boiler. Boiler pressure should never be higher than

5 psi (34 kPa) below the rating shown on the safety

relief valve [25 psig (172 kPa) maximum for a 30

psig (207 kPa) rating, 45 psig (310 kPa) maximum

for a 50 psig (345 kPa) rating]. The valve rating can

be found on the top of the safety relief valve (see

Figure 3.1 for location of the safety relief valve).

Boiler temperature should never be higher than

250°F (121°C).

4. Check for water leaks in boiler and system piping.

5. Smell around the appliance area for gas. If you smell

gas, follow the procedure listed in the

Lighting/Operating Instructions in Section 8.

C. WEEKLY (WITH BOILER IN USE)

1. Flush float-type low-water cut-off (if used) to remove

sediment from the float bowl as stated in the

manufacturer’s instructions.

D. MONTHLY (WITH BOILER IN USE)

1. Check boiler room floor drains for proper

functioning.

2. Check function of the safety relief valve (monthly

unless specified otherwise by manufacturer) by

performing the following test:

a. Check valve piping to determine that it is

properly installed and supported.

b. Check boiler operating temperature and pressure.

c. Lift the try lever on the safety relief valve to the

full open position and hold it for at least five

seconds or until clean water is discharged.

d. Release the try lever and allow the valve to close.

If the valve leaks, operate the lever two or three

times to clear the valve seat of foreign matter. It

may take some time to determine if the valve has

shut completely.

e. If the valve continues to leak, it must be replaced

before the boiler is returned to operation.

f. Check that operating pressure and temperature

have returned to normal.

g. Check again to confirm that valve has closed

completely and is not leaking.

3. Test low-water cut-off (if used) as described by the

manufacturer.

4. Test limit as described in Section 8E, “Check-Out

Procedure.”

5. Test function of gas safety shut-off features as

described by gas valve and ignition control

manufacturer.

6. Cycle the boiler at least once and check operation of

the vent damper.

MAINTENANCE

Page 39

37

MAINTENANCE

E. ANNUALLY (BEFORE START OF HEATING

SEASON)

1. Check flueways and burners for cleanliness and clean