4C

DRILL-POWERED WATER PUMP

KH 4125

DRILL-POWERED WATER PUMP

Operating instructions

ČRPALNI PRIKLJUČEK ZA VRTALNIK

Navodila za uporabo

KOMPERNASS GMBH · BURGSTRASSE 21 ·

D-44867 BOCHUM

www.kompernass.com

ID-Nr.: KH4125-06/08-V1

PUMPA ZA BUŠILICU

Upute za upotrebu

e

q

w

r

t

u

y

LIST OF CONTENTS PAGE

Safety instructions 2

Intended use 2

Technical data 3

Device overview 3

Required assembly material 3

Assembly and connection 3

Utilisation 4

Cleaning and care 5

Disposal 5

Service 6

Importer 6

Conformity Declaration 7

Preserve these operating instructions for future reference. Pass this manual on

to whoever might acquire the appliance at a future date.

- 1 -

Safety instructions

To avoid the risk of accidents:

• Only operate the pump when it is effectively secured against twisting,

wrenching or canting by correct use of the supplied mounting.

• Check the pump for faultless service-ability before every utilisation. The

pump may not be used if it shows signs of damage.

• Use only hoses certified as being able to withstand a pressure of at

least 3 bars (44 psi).

• Check the plug-in connectors on the hoses for firm seating.

• Ensure that fluids cannot come close to the electric drill being used to

drive the pump. Should it nonetheless occur, immediately remove the

power plug.

• This device is not suitable for children or for people whose physical,

sensorial or intellectual faculties prevent the safe usage of the appliance

without support or supervision. Children should be supervised to ensure

that they do not play with the appliance.

Intended use

This pump is intended for ...

– standard electric drills with a 43 mm spindle shaft and scroll chuck and

a rotation speed of up to 3,400 rpm,

– for the pumping of cold or up to 40° C warm fluids, as in the draining

or transfer of water in aquariums, ponds or large containers/barrels.

This pump is not intended ...

– for the pumping of inflammable, explosive, poisonous or caustic fluids or

foodstuffs.

- 2 -

Technical data

Capacity: max. 2.4 m3/h

Hose connection: 3/4” (19 mm)

Pressure: max. 3 bar

Delivery height: max. 30 m

Dry run time: max. 12 seconds

Rotation speed: max. 3400 rpm

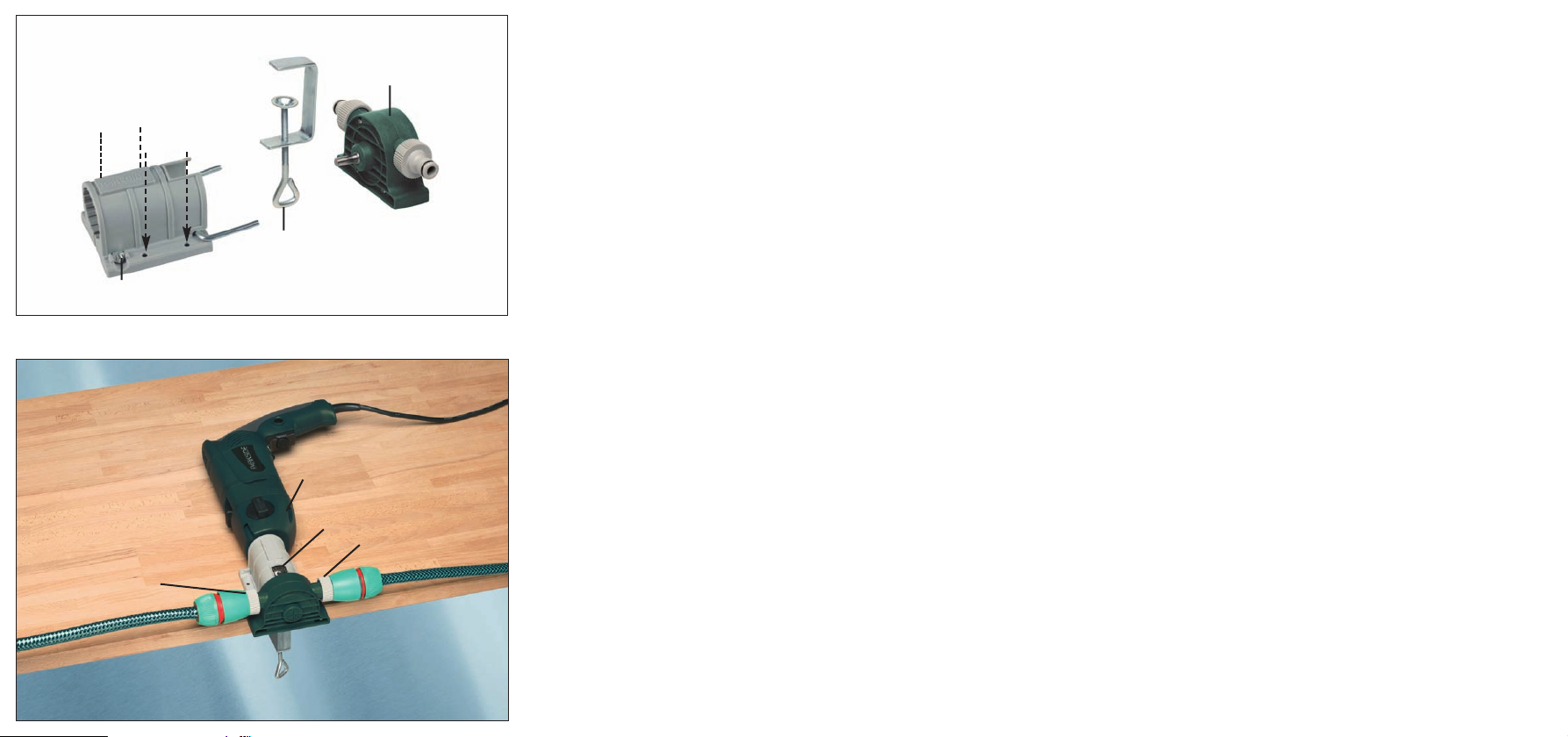

Device overview

Items supplied:

Pump

q

Fixing clamp

w

Mounting

e

Operating instructions

Required assembly material

Philips-type screwdriver

Assembly and connection

Assemble the mounting ewith the fixing clamp wonto a work surface

as shown in the diagramme.

Alternatively, the mounting

of screws (Assembly material not supplied).

can be fixed to a work surface by means

e

- 3 -

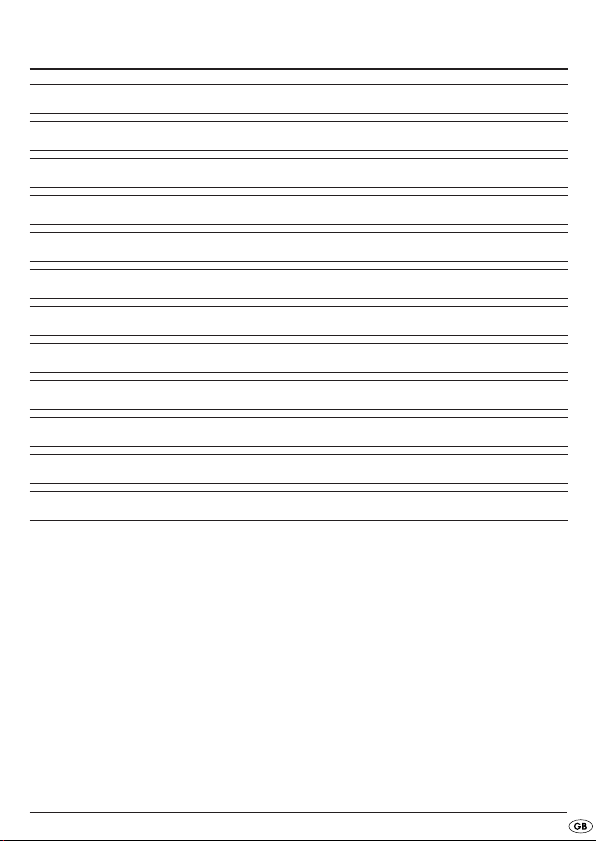

Insert the spindle shaft of the electric drill rinto the mounting e.

Now slide the pump

pump extends into the drill chuck, and the pegs of the mounting

inserted into the receptor holes on the pump

Through the recess

the pump cannot be detached from the mounting.

Securely tighten the cross-head screw on the mounting

is being firmly held .

Connect the suction hose to connection

connection

u

.

onto the mounting eso that the drive axle of the

q

e

.

q

, turn the drill chuck with the chuck key so tight that

t

so that the drill

e

and the pressure hose to

y

Utilisation

Insert the open end of the suction hose into the fluid to be drained/

transferred. Suction is only possible if ...

– the suction hose does not draw air and is not longer than 12 meters

(ca. 39 feet), and

– the pressure hose is open during suction.

Now allow the electric drill to drive the pump – but not without super-

vision, so as to be able to react quickly in the event of danger. Make

absolutely sure that the drill revolves to the right, just as in drilling. Should

the drill-speeds be adjustable, you can adjust the work capacity with

them.

are

- 4 -

Attention!

If the pump does not commence suction within 12 seconds, switch off immediately so as to avoid impeller seizure.For this same reason, do not allow the

pump to run if the hose on the discharge side is blocked.

Cleaning and care

To clean the pump, use only a dry or lightly moistened cloth. DO NOT use

solvents or abrasive cleaners, these will damage the plastic surfaces.

The pump is maintenance-free.

Disposal

Do not dispose of the appliance in your normal domestic waste.

Dispose of the appliance through an approved disposal centre or at your

community waste facility.

Observe the currently applicable regulations. In case of doubt, please

contact your waste disposal centre.

Dispose of the packaging materials in an environmentally responsible

manner.

- 5 -

Service

DES Ltd

Units 14-15

Bilston Industrial Estate

Oxford Street

Bilston

WV14 7EG

Tel.: 0870/787-6177

Fax: 0870/787-6168

e-mail: support.uk@kompernass.com

Irish Connection

Harbour view

Howth

Co. Dublin

Tel: 00353 (0) 87 99 62 077

Fax: 00353 18398056

e-mail: support.ie@kompernass.com

Importer

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 6 -

Conformity Declaration

We, Kompernass GmbH, Burgstrasse 21, D-44867 Bochum, hereby declare

on our own responsibility that the product described here; "Electric Drill Pump

KH 4125", to which this declaration refers, complies with the current requirements of the EU Guideline 98/37/EC (Machines) in the version brought into

circulation by ourselves. This declaration loses its validity in the event of a modification being made to the product and the modification not being first agreed to or approved by us.

Bochum, on 16.06.2008

Alexander Kompernaß

Managing Director

- 7 -

- 8 -

KAZALO VSEBINE STRAN

Varnostni napotki 10

Predvidena uporaba 10

Tehnični podatki 11

Pregled naprave 11

Potreben montažni material 11

Montaža in priključitev 11

Uporaba 12

Čiščenje in vzdrževanje 13

Odstranitev 13

Servis 14

Uvoznik 14

Izjava o skladnosti 15

Pred prvo uporabo ta navodila skrbno preberite in jih shranite za poznejšo

uporabo. Pri predaji naprave tretji osebi je treba izročiti tudi ta navodila.

- 9 -

Varnostni napotki

Za preprečevanje nezgod:

• Črpalko uporabljajte le, če je s priloženim držalom zavarovana pred

udarjanjem okrog sebe, zvijanjem ali zataknitvijo.

• Pred vsako uporabo črpalko preverite glede njenega brezhibnega stanja.

Črpalke ne smete uporabljati, če ima vidne poškodbe.

• Uporabljajte le gibke cevi, ki so tlačno odporne do najmanj 3 barov.

• Vtične povezovalne elemente na gibkih ceveh preverite glede trdnega

prileganja.

• Poskrbite za to, da v bližino vrtalnega stroja, s katerim poganjate črpalko, ne

morejo zaiti nobene tekočine. Če pride do tega, omrežni vtič takoj potegnite

iz vtičnice.

• Ta naprava ni namenjena za otroke ali druge osebe, čigar fizične, zaznavne

ali mentalne sposobnosti ne dovoljujejo varne uporabe brez podpore ali

nadzora. Otroke je treba nadzorovati, da preprečite igro z napravo.

Predvidena uporaba

Ta črpalka je predvidena za ...

– običajne desnosučne ročne vrtalne stroje s 43 mm evro grlom in

zobniško vpenjalno glavo, do števila vrtljajev 3400 obr./min,

– za črpanje hladnih ali toplih tekočin do 40 °C, kot npr. odpadno

ali umazano vodo iz akvarijev ali ribnikov.

Ta črpalka ni predvidena za ...

– črpanje gorljivih, eksplozivnih, strupenih ali jedkih tekočin ali živil.

- 10 -

Tehnični podatki

Količina črpanja: maks. 2,4 m3/h

Priključek gibke cevi: 3/4" (19 mm)

Moč tlaka: maks. 3 bar

Višina črpanja: maks. 30 m

Čas suhega teka: maks. 12 sekund

Število vrtljajev: maks. 3400 obr./min

Pregled naprave

Obseg dobave:

Črpalka

q

Zatično pritrdilo

w

Držalo

e

Navodila za uporabo

Potreben montažni material

Križni izvijač

Montaža in priključitev

Montirajte držalo

prikazano na sliki.

Držalo

(montažni material ni del obsega dobave).

pa lahko na delovno površino montirate tudi z vijaki

e

z zatičnim pritrdilom wna delovno površino, kot je

e

- 11 -

Vrtalni stroj

Sedaj črpalko

sega v vpenjalno vrtalno glavo, in nastavke držala

luknje na črpalki

Vpenjalno vrtalno glavo s ključem za glavo skozi odprtino

trdno, da se črpalke ne da več odstraniti z držala.

Potem trdno zategnite križni izvijač na držalu

udarjati okrog sebe.

Sesalno gibko cev priključite na priključek

priključek

z vpenjalno vrtalno glavo vtaknite v držalo e.

r

na držalo epotisnite tako, da pogonska os črpalke

q

e

.

q

, da vrtalni stroj ne more

e

in tlačno gibko cev na

y

.

u

vtaknite v sprejemne

privijte tako

t

Uporaba

Odprti konec sesalne gibke cevi položite v tekočino, ki jo želite črpati.

To je možno le, če ...

– sesalna gibka cev ne vleče zraka in ni daljša od 12 m, in

– če je med črpanjem odprta tlačna gibka cev.

Sedaj pustite, da vrtalni stroj poganja črpalko – vendar ne nenadzorovano,

da se lahko v primeru nevarnosti hitro odzovete. Obvezno pazite tudi, da

se vrtalni stroj vrti na desno, torej kot pri vrtanju. Če se število vrtljajev vrtalnega stroja da regulirati, lahko na ta način regulirate količino za črpanje.

- 12 -

Pozor!

Če črpalka ne začne črpati v 12 sekundah, jo takoj izklopite, da preprečite

njeno zataknitev. Iz tega razloga črpalke tudi ne pustite črpati, dokler je gibka

cev na iztočni strani zaprta.

Čiščenje in vzdrževanje

Črpalko čistite le s suho ali z rahlo navlaženo krpo. Ne uporabljajte topil ali

ostrih sredstev, da ne poškodujete površin iz umetne snovi.

Črpalka ni potrebna vzdrževanja.

Odstranitev

Naprave nikakor ne odvrzite v normalne hišne smeti.

Napravo odstranite pri registriranem podjetju za odstranjevanje odpadkov

ali pri svojem komunalnem podjetju za odpadke.

Upoštevajte trenutno veljavne predpise. V primeru dvoma se obrnite na svoje

podjetje za predelavo odpadkov.

Vse embalažne materiale oddajte v reciklažo.

- 13 -

Servis

Birotehnika

Tkalčec Zlatko Andrija s.p.

Lendavska ulica 23

9000 Murska Sobota

Slovenija

Phone: +386 (0) 2 522 16 66

Fax: +386 (0) 2 531 17 40

e-mail: support.si@kompernass.com

Uvoznik

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 14 -

Izjava o skladnosti

Mi, podjetje Kompernaß GmbH, Burgstrasse 21, D-44867 Bochum, izjavljamo

pod lastno odgovornostjo, da je tukaj opisani izdelek "črpalka za vrtalni stroj

KH 4125", na katerega se ta izjava nanaša, v izvedbi, kot jo dajemo v promet,

skladen z veljavnimi zahtevami Direktive ES 98/37 (stroji). V primeru spremembe tega izdelka, ki ni bila izvedena po dogovoru z nami, ta izjava

postane neveljavna.

Bochum, 16.06.2008

Alexander Kompernaß

- Poslovodja -

- 15 -

- 16 -

SADRĒAJ STRANA

Sigurnosne napomene 18

Uporaba u skladu sa namjenom 18

Tehnički podaci 19

Pregled uređaja 19

Potreban materijal za montažu 19

Montaža i priključak 19

Uporaba 20

Čišćenje i održavanje 21

Zbrinjavanje 21

Servis 22

Izjava konformiteta 23

Upute za rukovanje prije prve upotrebe pažljivo pročitajte i sačuvajte ih za

kasnije korištenje. Ukoliko uređaj dajete trećim osobama, priložite i ove upute.

- 17 -

Sigurnosne napomene

Da biste izbjegli opasnost od nezgode:

• Sa pumpom radite samo onda, kada je ona pomoću priloženog držača

osigurana od udaranja, uvrtanja ili zaglavljivanja.

• Prije svake uporabe prekontrolirajte besprijekorno stanje pumpe.

Pumpa ne smije biti korištena, ako postoje vidljiva oštećenja.

• Koristite isključivo crijeva, koja su otporna na tlak od 3 bara ili više.

• Kontrolirajte čvrstoću položaja bajonet-spojeva na crijevima.

• Pobrinite se za to, da tekućine ne mogu dospjeti do bušilice, sa kojom

pogonite pumpu. Ukoliko se to dogodi, odmah izvucite mrežni utikač.

• Ovaj uređaj nije prikladan za djecu ili druge osobe, čije fizičke, senzorične

ili mentalne sposobnosti bez pomoći ili nadzora ne dopuštaju sigurnu

uporabu. Djeca bi trebala biti pod nadzorom, čime treba biti osigurano

da se ne mogu igrati ovim uređajem.

Uporaba u skladu sa namjenom

Ova pumpa je predviđena za ...

– uobičajene ručne bušilice sa okretanjem u desnu stranu, sa normiranim

Euro-grlom od 43 mm i zupčastim kružnim steznikom, prikladne do broja

okretaja od 3400 U/min,

– pumpanje hladnih tekućina ili tekućina temperature do 40 °C, kao na

primjer uporabne ili otpadne vode iz akvarija ili jezeraca.

Ova pumpa nije predviđena za ...

– pumpanje zapaljivih, eksplozivnih, otrovnih ili agresivnih tekućina, niti za

pumpanje namirnica.

- 18 -

Tehnički podaci

Transportna količina: maks. 2,4 m3/h

Priključak crijeva: 3/4” (19 mm)

Pogonski tlak: maks. 3 bar

Transportna visina: maks. 30 m

Vrijeme suhog pogona: maks. 12 sekundi

Broj okretaja: maks. 3400 U/min

Pregled uređaja

Obim isporuke:

Pumpa

q

Stezno učvršćenje

w

Držač

e

Upute za uporabu

Potreban materijal za montažu

Križni odvijač

Montaža i priključak

Montirajte držač

je prikazano na slici.

Alternativno držač

za montažu nije sadržan u obimu isporuke).

sa steznim učvršćenjem wna radnoj ploči, kao što

e

može vijcima biti montiran na radnoj ploči (materijal

e

- 19 -

Postavite bušilicu

Sada gurnite pumpu

zahvata steznik bušilice, a klinovi držača

na pumpi

q

Okrenite steznik bušilice sa ključem kroz utor

više ne može osloboditi iz držača.

Zatim zavrnite križni vijak na držaču

Priključite usisno crijevo na priključnom mjestu

priključnom mjestu

sa steznikom u držač e.

r

tako na držač e, da pogonska osovina pumpe

q

.

.

u

stoje u prihvatnim otvorima

e

tako čvrsto, da se pumpa

t

, tako da bušilica ne može udarati.

e

i tlačno crijevo na

y

Uporaba

Umetnite otvoreni kraj usisnog crijeva u tekućinu, koja treba biti usisana.

To je moguće samo u slučaju, kada ...

– usisno crijevo ne uvlači zrak i nije duže od 12 metara, i

– kada je za vrijeme usisavanja tlačno crijevo otvoreno.

Pustite, da sada bušilica pogoni pumpu – ali ne bez nadzora, tako da

u slučaju opasnosti možete brzo reagirati. Osim toga obavezno obratite

pažnju na to, da bušilica okreće u desnu stranu, dakle kao kod bušenja

otvora. Ukoliko broj okretaja bušilice može biti podešavan, na taj način

možete regulirati transportiranu količinu.

- 20 -

Pažnja!

Ako pumpa ne počne usisavati u roku od 12 sekundi, odmah isključite

uređaj, kako biste spriječili oštećenje. Iz tog razloga ne dopustite da pumpa

transportira tekućinu, dok je crijevo na izlaznoj strani još zatvoreno.

Čišćenje i održavanje

Pumpu čistite isključivo pomoću suhe ili blago navlažene krpe. Ne koristite

ribajuća sredstva, kako ne biste oštetili plastične površine.

Pumpa je samoodržavajuća.

Zbrinjavanje

Uređaj nikako ne bacajte u obično kućno smeće.

Uređaj zbrinite preko autoriziranog poduzeća za zbrinjavanje otpada ili

preko Vašeg komunalnog poduzeća.

Obratite pažnju na aktualno važeće propise. U slučaju dvojbe se povežite

sa svojim mjesnim poduzećem za zbrinjavanje otpada.

Sve materijale ambalaže zbrinite na način neškodljiv za okoliš.

- 21 -

Servis

Ovlašteni servis: Microtec sistemi d.o.o.

Koprivnička 27 a

10000 Zagreb

Tel.: 01/3692-008

email: support.hr@kompernass.com

Proizvođač:

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM, Njemačka

Uvoznik

Lidl Hrvatska d.o.o. k.d.,

p.p. 61

10020 Novi Zagreb

- 22 -

Izjava konformiteta

Mi, Kompernaß GmbH, Burgstrasse 21, D-44867 Bochum, sa samostalnom

odgovornošću izjavljujemo, da ovdje opisani proizvod “Pumpa za bušilicu

KH 4125”, na koji se ova izjava odnosi, u izvedbi koju puštamo u trgovački

promet, odgovara važećim zahtjevima EG-smjernice 98/37/EG (strojevi). U

slučaju prerade proizvoda, koja nije sa nama usklađena, ova izjava gubi

svoju važnost.

Bochum, dana 16.06.2008

Alexander Kompernaß

- Poslovođa -

- 23 -

Loading...

Loading...