TX-80P250Z

TX-34P250T

EURO7 Chassis

ORDER NO. ITD0012018C3

Colour Television

Specifications

Power Source

Power Consumption

Receiving System

AC 230-240 V, 50 Hz (TX-80P250Z)

AC 220 V, 50/60 Hz (TX-34P250T)

218 W

Stand-by condition 3.0 W

21 Systems Function

1 PAL B, G, H Reception of broadcast transmissions

2 PAL I

3 PAL D, K

4 SECAM B, G

5 SECAM D, K

6 SECAM K1

7 NTSC M (NTSC 3.58/4.5 MHz)

8 NTSC 4.43/5.5 MHz Playback from Special VCR´s

9 NTSC 4.43/6.0 MHz

10 NTSC 4.43/6.5 MHz

11 NTSC 3.58/5.5 MHz

12 NTSC 3.58/6.0 MHz

13 NTSC 3.58/6.5 MHz

14 SECAM I

15 PAL 60 Hz/5.5 MHz Playback from Special Disc Players

16 PAL 60 Hz/6.0 MHz

17 PAL 60 Hz/6.5 MHz

18 SECAM 60 Hz/5.5 MHz

19 SECAM 60 Hz/6.0 MHz

20 SECAM 60 Hz/6.5 MHz

21 NTSC 50 Hz/4.5 MHz

and Playback from Video Cassette

Tape Recorders

and Special VCR´s

© 2000 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TX-80P250Z / TX-34P250T

Receiving Channels Regular TV

VHF BAND UHF BAND

2-12 (PAL/SECAM B, K1) 21-69 (PAL G, H, I/SECAM G, K, K1)

0-12 (PAL B AUST.) 28-69 (PAL B AUST.)

1-9 (PAL B N.Z) 13-57 (PAL D, K)

1-12 (PAL/SECAM D) 13-62 (NTSC M Japan)

1-12 (NTSC M Japan) 14-69 (NTSC M U.S.A.)

2-13 (NTSC M U.S.A.)

CATV

S1-S20 (OSCAR)

1-125 (U.S.A. CATV)

C13-C49 (JAPAN)

S21-S41 (HYPER)

Z1-Z37 (CHINA)

4A, 9A (AUST.)

Receiving Stereo System NICAM I, NICAM B/G, NICAM D, A2 (German)

Tuning System Frequency synthesizer

Auto Search Tunin g POSITION : 100 Position

DIRECT : 125 Position

High Voltage 31.0 ± 1.0 kV at zero beam current

Picture Tube

Audio Output 36 W [ 2-way, 4-speakers ; 12 W + 12 W, AFB woofer ; 12 W] (10% THD)

Headphones

Aerial Impedance

Video/Audio/Component

Terminals

Overall Picture tube measured diagonally 86 cm

Viewable Picture tube measured diagonally 80 cm

CRT Deflection 104°

3.5 mm Plug

75Ω Unbalanced coaxial

AV 1, 2, 3, 4 S-Video In Y:1 Vp-p, 75Ω

C:0.3 Vp-p, 75Ω

DVD (Y/PB/PR)

Video In 1 Vp-p, 75Ω

Audio In Approx. 0.4 V 47KΩ

Monitor Out Video Out 1 Vp-p, 75Ω

Audio Out Approx. 0.4 V 1KΩ

AV1 IN(Rear) : S-Video, Video, Audio L/R terminals

AV2 IN(Rear) : Video or Y/PB/PR, Audio L/R terminals

AV3 IN(Front) : S-Video, Video, Audio L/R RGB terminals

AV4 IN(Rear) : Video or Y/PB/PR, Audio L/R terminals

RGB input High-DENSITY D-sub 15 pin

31.5 kHz / 60 Hz (640 × 480 dot) and 31.5 kHz / 70 Hz (640 × 400 dot)

Remote control Transmitter R6 (AA) Battery × 2

75Ω coaxial aerial plug

Dimensions (W × D × H) 762 mm × 558 mm × 706 mm

Weight (Mass) 74 kg (Net)

Note:

Design and Specifications are subject to change without notice. Weigh t and Dimensions shown are approximate.

2

TX-80P250Z / TX-34P250 T

CONTENTS

Page Page

1 Safety Precautions 5

1.1. General Guide

1.2. Leakage Current Cold Check

1.3. Leakage Current Hot Check

1.4. X-Radiation

2 SERVICE HINTS

2.1. HOW TO REMOVE THE REAR COVER

2.2. LOCATION OF CONTROLS

2.3. HOW TO MOVE THE CHASSIS INTO SERVICE

POSITION

2.4. Hotel Mode

2.5. Service positio n For DG-Board.

3 Self Check

4 Service Mode Function

4.1. How to enter SERVICE 1

4.2. How to enter SERVICE 2

4.3. Option Descrition

5 Adjustment Procedure

5.1. Voltage Confirmation

5.2. E.H.T Check

5.3. Sub Contrast

5.4. Sub Tint

5.5. Sub Colour

5.6. SECAM BLACK LEVEL

5.7. VRS Adjustment

5.8. Colour Purity

5.9. Convergence

5.10. CUT OFF

5.11. White Balance

5.12. Foucus

5.13. Geomagnetic

5.14. Sub Bright

6 Deflection Adjustment

6.1. V-ADJUSTMENT/CONFIRMATION (4:3 MODE)

6.2. H-DEFLECTION CONFIRMATION/ADJUSTMENT (4:3

MODE)

6.3. PINCUSSION ADJUSTMENT/CONFRMATION (4:3

MODE)

6.4. V LINIALITY ADJUSTMENT / CONFIRMATION (4:3

MODE)

6.5. DEFLECTION (16:9 MODE) ADJUSTMENT /

CONFIRMATION

6.6. 525p DEFLECTION ADJUSTMENT / CONFIRMATION

6.7. 625p DEFLECTION ADJUSTMENT

6.8. VGA480 / 60Hz DEFLECTION ADJUSTMENT /

CONFIRMATION

10

10

10

11

14

14

14

14

15

16

16

17

18

18

19

20

20

20

20

21

21

22

23

25

25

26

26

27

5

5

5

6

7

7

7

7

8

8

9

6.9. VGA400 / 70Hz DEFLECTION ADJUSTMENT /

CONFIRMATION

6.10. Table 1

7 Location of Lead Wring

8 Conductor Views

8.1. A-Board

8.2. D-Board

8.3. H-Board

8.4. DG-Board

8.5. L-Board

8.6. GK-Board

8.7. DF-Board and GM-Board

8.8. U-Board

9 Block Diagram

9.1. Power Block Diagram

9.2. Control Block Diagram

9.3. Video Block Diagram

9.4. Audio Block Diagram

9.5. IC Block Diagram

10 Schematic Diagrams

10.1. Schematic Diagram Notes

10.2. A-Board (1/5) Schematic Diagrams

10.3. A-Board (2/5) Schematic Diagrams

10.4. A-Board (3/5) Schematic Diagrams

10.5. A-Board (4/5) Schematic Diagrams

10.6. A-Board (5/5) Schematic Diagrams

10.7. D-Board (1/2) Schematic Diagrams

10.8. D-Board (2/2) Schematic Diagrams

10.9. DF-Board Schematic Diagrams

10.10. DG-Board (1/4) Schematic Diagrams

10.11. DG-Board (2/4) Schematic Diagrams

10.12. DG-Board (3/4) Schematic Diagrams

10.13. DG-Board (4/4) Schematic Diagrams

10.14. GK-Board Schematic Diagrams

10.15. GM-Board Schematic Diagrams

10.16. H-Board Schematic Diagrams

10.17. L-Board (1/2) Schematic Diagrams

10.18. L-Board (2/2) Schematic Diagrams

10.19. U-Board (1/2) Schem atic Diagrams

10.20. U-Board (2/2) Schem atic Diagrams

11 Parts Location

12 Mechanical Replacement Parts List

13 Replacement Parts List

13.1. Replacement Parts List Notes

13.2. Electrical Replacement Part List

28

29

30

33

33

36

37

38

39

40

41

42

43

43

45

46

47

48

53

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

75

76

3

1 Safety Precautions

1.1. General Guide

1. It is advisable to insert an isolation transformer in the AC

supply before servicing a hot chassis

2. When servicing, observe the original lead dress, especially

the lead dress in the high voltage circuits.

If a short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

3. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers, shields, and

isolation R-C combinations, are properly installed.

4. When the receiver is not to be used for a long period of

time, unplug the power cord from the AC outlet.

TX-80P250Z / TX-34P250 T

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screw heads, aerials,

connectors, control shafts, etc. When the exposed metallic

part has a return path to the chassis, the reading should be

4M

between

When the exposed metal does not have a return path to the

chassis, the reading must be.

and 20 M

ΩΩΩΩ

ΩΩΩΩ.

1.3. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect a 2 kΩ, 10W resistor, in series with an exposed

metallic part on the receiver and an earth such as a water

pipe.

3. Use an AC voltmeter, with high impedance type, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Potential, as high as

is in operation. Operation of the receiver without the rear

cover involves the danger of a shock hazard from the

receiver power supply. Servicing should not be attempted

by anyone who is not thoroughly familiar with the

precautions necessary when working on high voltage

equipment. Always discharge the anode of the picture tube

to the receiver chassis before handling the tube.

6. After servicing make the following leakage current checks to

prevent the customer from being exposed to shock

hazards.

32.0 kV

, is present when this receiver

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Turn on the receiver’s power switch.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed

case a measurement is outside of the limits specified, there

is a possibility of a shock hazard, and the receiver should

be repaired and rechecked before it is returned to the

customer.

1.0 V rms.

In

5

TX-80P250Z / TX-34P250 T

1.4. X-Radiation

Warning :

1. The potential sources of X-Radiation in TV sets are the

High Voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that jig is capable of handling

Radiation.

Note :

It is important to use an accurate periodically calibrated high

voltage meter.

1. Set the brightness to minimum.

2. Measure the High Voltage. The meter reading should

indicate

tolerance, immediate service and correction is required to

prevent the possibility of premature component failure.

3. To prevent an X-Radiation possibility, it is essential to use

the specified picture tube.

31.0 ± 1 kV

. If the meter indication is out of

without causing X-

32.0kV

6

2 SERVICE HINTS

TX-80P250Z / TX-34P250 T

2.1. HOW TO REMOVE THE REAR

COVER

1. Remove the 9 screwsas shown in Fig. 1.

Fig. 1.

2.2. LOCATION OF CONTROLS

2.3. HOW TO MOVE THE CHASSIS

INTO SERVICE POSITION

1. Hold and lift the rear of the chassis and gently pull the

chassis toward you, as shown in

2. Release the respective wiring clips and rotate the chassis

vertically through 90°, anti-clockwise.

3. After servicing replace the bead clamper and ensure all

wiring is returned to its original position before returning the

receiver to the customer.

Fig. 3.

Fig. 2.

Fig. 3.

Fig. 4.

7

TX-80P250Z / TX-34P250 T

2.4. Hotel Mode

Purpose

1. At Hotels, this Mode prevent customer from changing the TV preset data, such as Channel preset data.

Note:

This Mode is useful for hotel, you should not get into “Hotel Mode” with Normal use.

Operation

1. To get into “ Hotel Mode”, press the remote control “Recall” button and Channel up “[

simultaneously, after setting the “Off-Timer” mode.

2. In this mode, The Channel up and down Function will be able as normal Mode, and The maximum volume level for this

mode is set at the current volume level, that means setting at the level before entering the mode. However, other function

will be disable.

3.

To exit This mode,

* This Information is informed by Service Manual only.

exit “off-timer” mode and the “Volume Down [

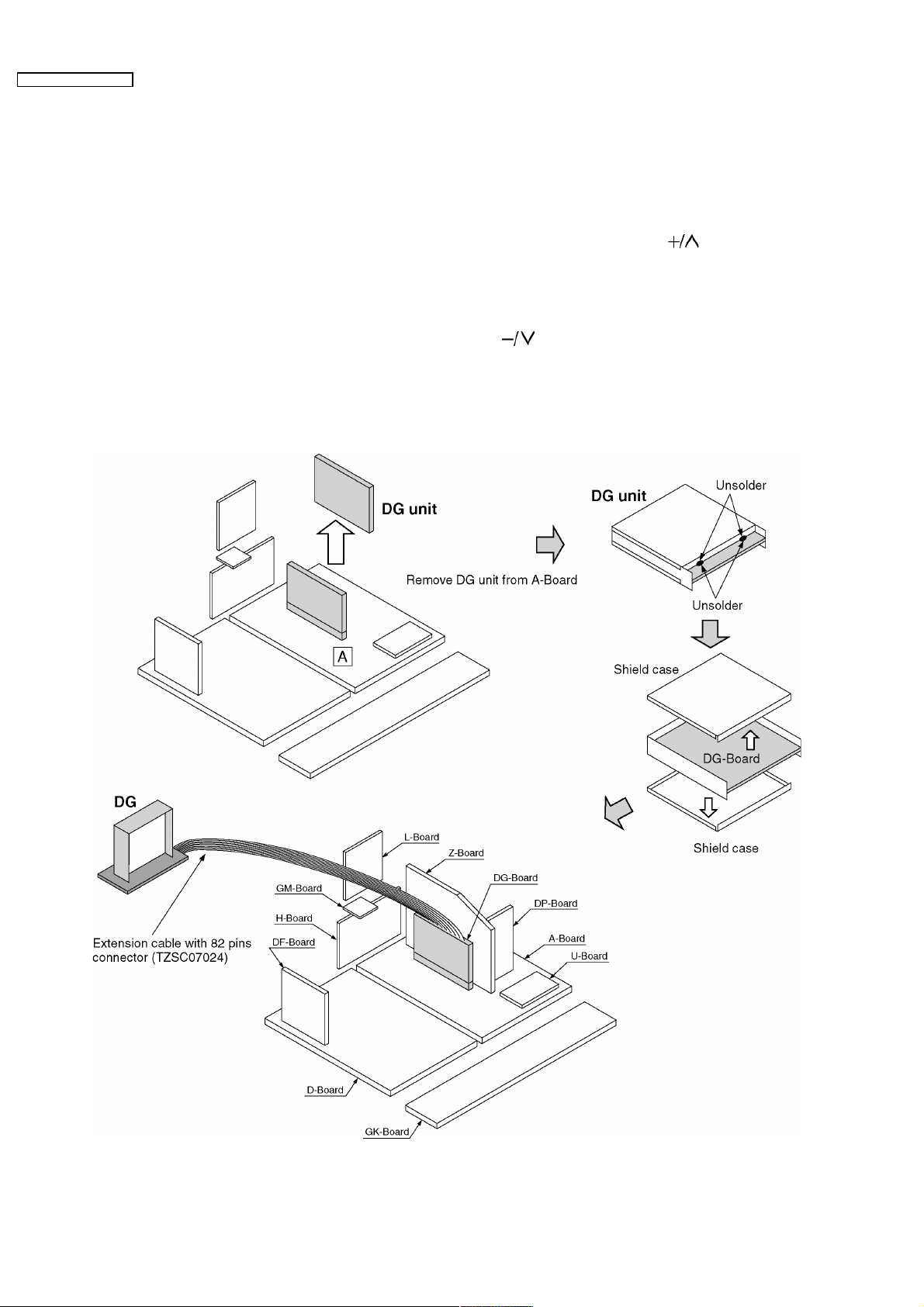

2.5. Service position For DG-Board.

Note:

Extension cable kit for DG Board is supplied as service fixtures and tools. (Part No. TZSC07024)

]” key on the TV set

]” key simultaneously.

8

3 Self Check

1. Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2. To get into the Self -Check mode press the down (

time pressing the HELP button on the remote control, and the screen will show :

) button on the customer controls at the front of the set, at the same

TX-80P250Z / TX-34P250 T

If the CCU ports have been checked and found to be incorrect or not located then “--” will appear in place of “O.K.”.

9

TX-80P250Z / TX-34P250 T

4 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Mode.

4.1. How to enter SERVICE 1

1. In sound menu, set BASS to MAX, and set TREBLE to MINIMUM.

2. Simultaneously press INDEX button on remote control and VOLUME DOWN button [ - ] on the TV set.

4.2. How to enter SERVICE 2

1. Set the channel to CH99.

2. Press HOLD button on remote control.

Note:

To exit to Service mode, press N or Power button on remote control.

10

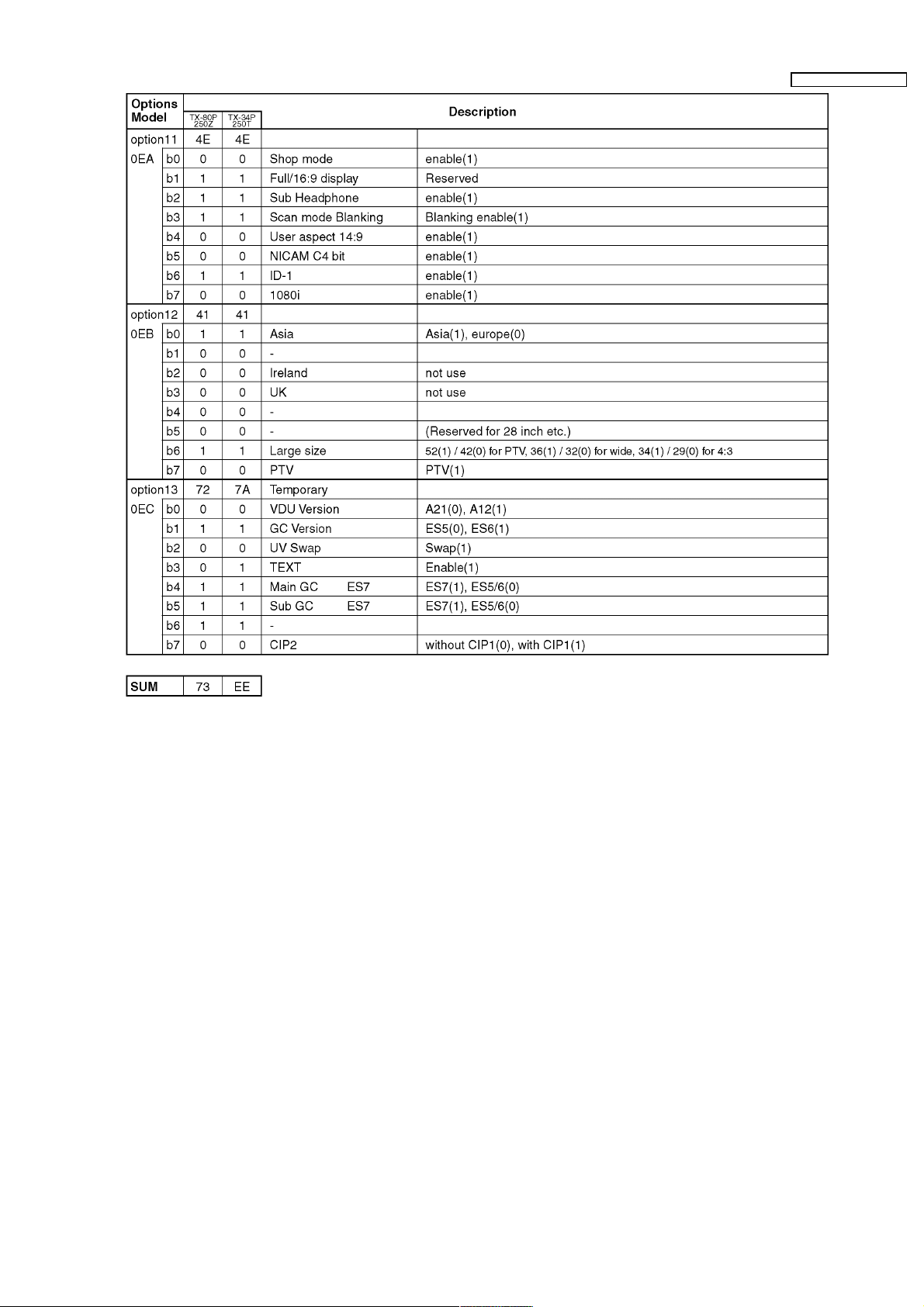

4.3. Option Descrition

TX-80P250Z / TX-34P250 T

11

TX-80P250Z / TX-34P250 T

12

TX-80P250Z / TX-34P250 T

13

TX-80P250Z / TX-34P250 T

5 Adjustment Procedure

5.1. Voltage Confirmation

Item/Preparation Adjustment Procedure

1. Operate the TV set.

2. Set controls :

Bright Minimum

Contrast Minimum

Volume Minimum

1. TPD15 : 144.8±1V (D-Board)

2. TPD 13 : 14.6±1V (D-Board)

3. TPD8 : 7.4±0.5V (D-Board)

4. TPD9 - TPD11: 34.0±1.5V (D-Board)

5. TPD10 : 15.5±1V (D-Board)

6. C864 (-) : -15.7±1V (D-Board)

7. Pin 15 of connector D2 : 31±2V (D-Board)

8. TPD32 : 224±10V (D-Board)

9. Pin 2 of IC1252 : 2.5±0.25V (A-Board)

10. Pin 3 of IC1251 : 3.3±0.3V (A-Board)

11. Pin 3 of IC3302 : 12±0.6V (A-Board)

12. Pin 2 of IC2708 : 9.0±0.4V (A-Board)

13. Pin 3 of IC2707 : 8.0±0.4V (A-Board)

14. Pin 2 of IC2706 : 5.0±0.4V (A-Board)

15. Pin 2 of IC2705 : 3.5±0.2V (A-Board)

16. Pin 2 of IC2709 : 3.5±0.2V (A-Board)

5.2. E.H.T Check

Item/Preparation Adjustment Procedure

1. Receive an RF signal, window or crosshatch pattern.

2. Set the Brightness and the Contrast to minimum (0 Beam).

3. Connect the High-Voltage Voltmeter to the CRT ANODE CAP.

4. The set should be switched to AV (no input) contrast & brightness

minimum.

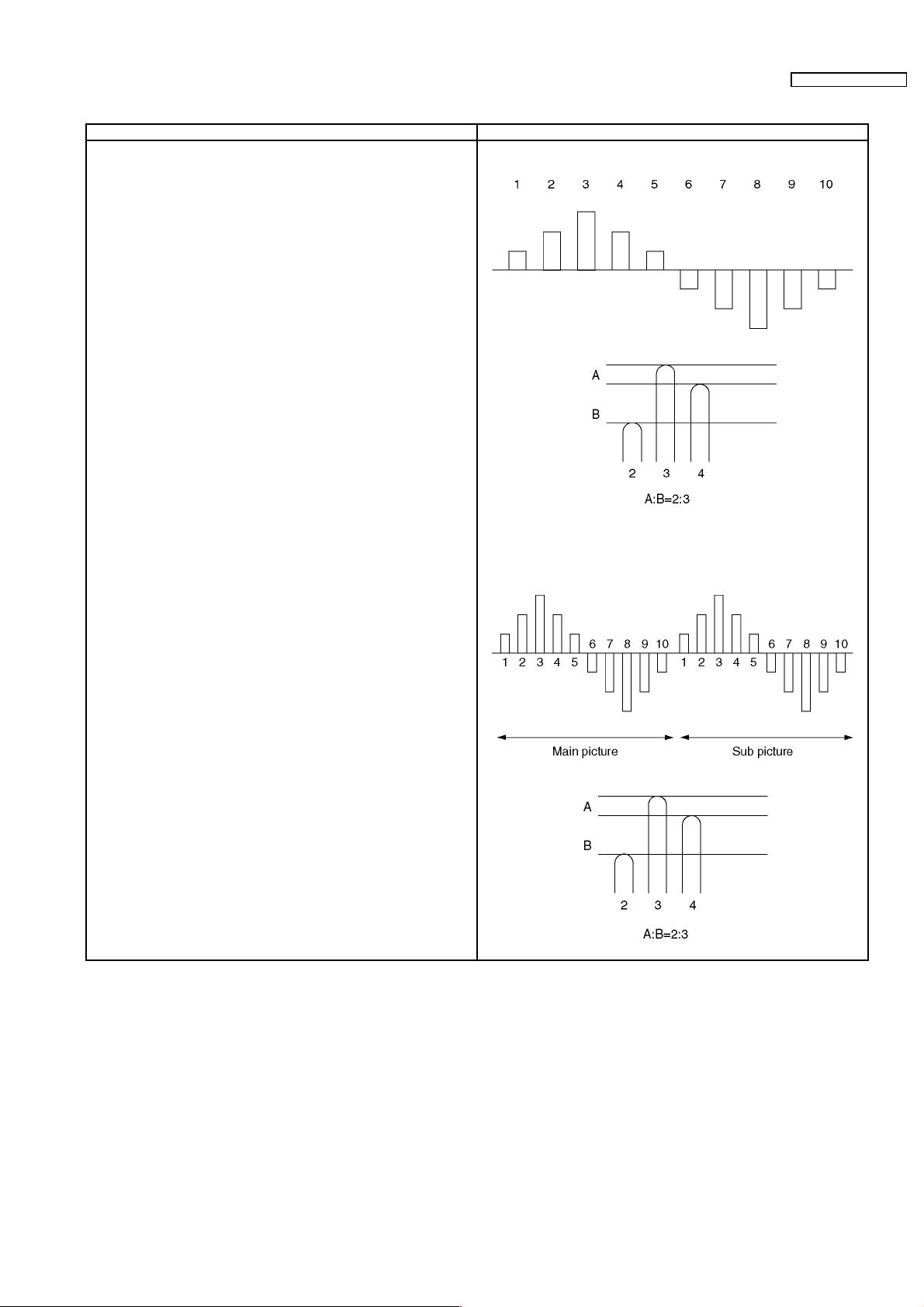

5.3. Sub Contrast

Item/Preparation Adjustment Procedure

1. Receive PAL colour bar pattern.

2. Connect osilloscope to A21 pin 3.

3. Set controls :

BRT...................CENTER

COLOUR..........CENTER

CONTRAST......MAX

AI......................OFF

1. Check the EHT voltage is (32.0±1.0) KV.

2. Switch from AV mode to TV.

3. With the Brightness and the contrast controls MAX, check that the

high voltage does not drop more than 3.0KV from the above

measurement with R.F. signal.

1. Adjust Sub Contrast (Service 1) :

A=3.85±0.1V

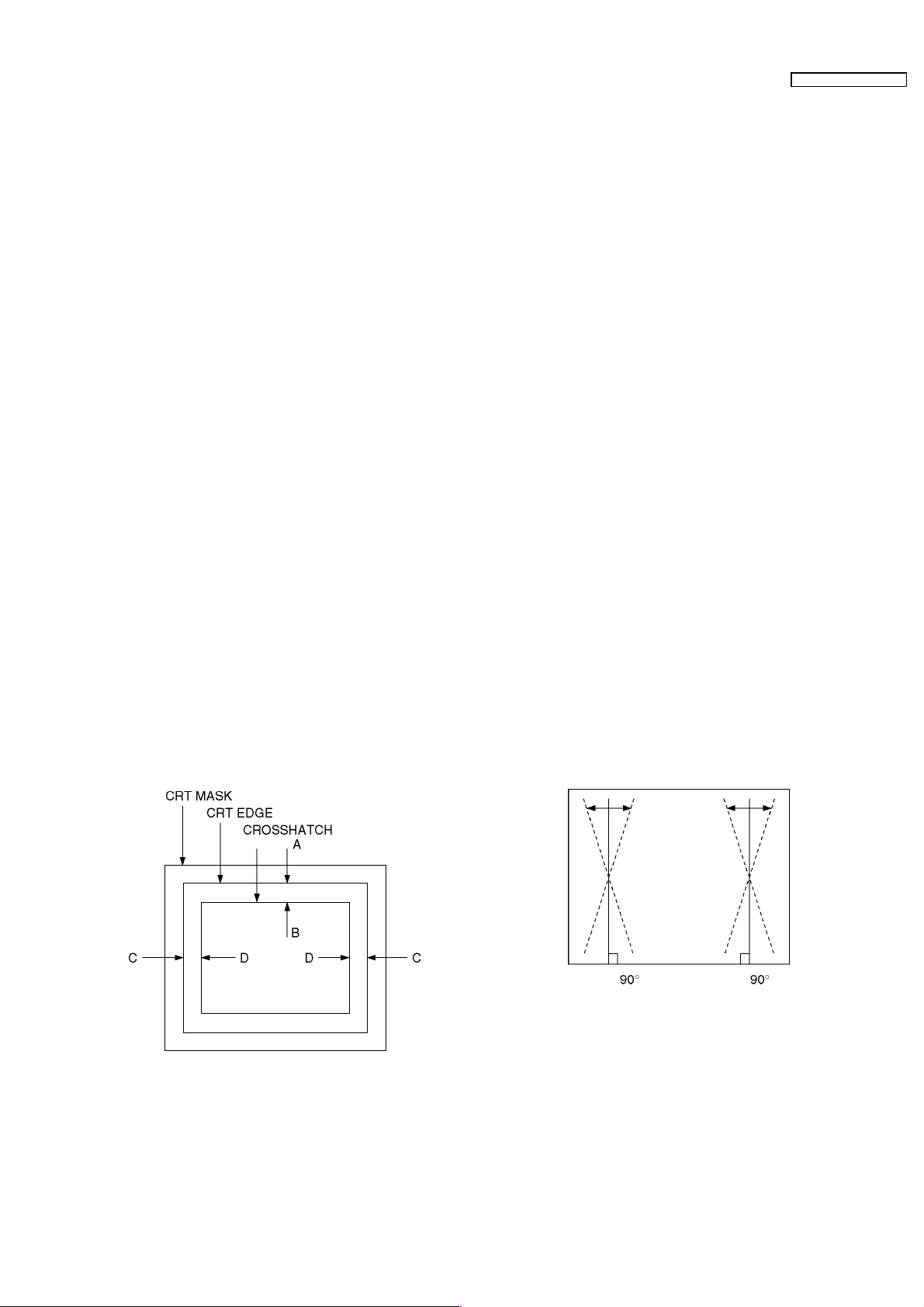

Fig. 1.

2. Adjust Video gain 2 (Service 1) so that Sub picture level B becomes

as same as Main picture level A.

14

Fig. 2.

5.4. Sub Tint

Item/Preparation Adjustment Procedure

1. Receive 3.58MHz NTSC rainbow parttern.

2. Connect oscilloscope to A21 pin 6.

3. Set controls :

BRT...................CENTER

COLOUR..........CENTER

CONTRAST......MAX

NTSC TINT.......CENTER

AI......................OFF

TX-80P250Z / TX-34P250 T

1. Adjust Sub NTSC Tint so that the peak of level of waveform is

similiar to Fig. 3.

Fig. 3.

2. Receive the Rainbow patter (3.58MHz NTSC) on both of Main and

Sub pictures.

3. Adjust Sub NTSC Tint 2 so that the peak of level of waveform is

similiar to Fig. 4.

15

Fig. 4.

TX-80P250Z / TX-34P250 T

5.5. Sub Colour

Item/Preparation Adjustment Procedure

1. Receive PAL colour bar pattern.

2. Connect osilloscope to A21 pin 3.

3. Set controls :

BRT...................CENTER

COLOUR..........CENTER

CONTRAST......MAX

AI......................OFF

5.6. SECAM BLACK LEVEL

Item/Preparation Adjustment Procedure

1. Receive SECAM white pattern.

2. Connect osilloscope to A44 pin 39.

3. Set controls :

BRT...................CENTER

COLOUR..........CENTER

CONTRAST......MAX

AI......................OFF

1. Adjust Sub Colour :

A=3.3±0.5V

Fig. 5.

1. Adjust SECAM B-Y so that H-blanking time and colour center are

equal level.

Fig. 6.

2. Connect oscilloscope to A44 pin 41.

3. Adjust SECAM R-Y OUT so that H-blanking time and colour center

are equal level.

Fig. 7.

4. Connect oscilloscope to A44 pin 39.

5. Receive SECAM white parttern on both of Main and Sub picture.

6. Adjust Sub SECAM B-Y so that H-blanking time and colort center

are equal level.

Fig. 8.

7. Connect osilloscope to A44 pin 41.

8. Adjust Sub SECAM R-Y so that H-blanking time and colour center

are equal level.

Fig. 9.

16

5.7. VRS Adjustment

1. PREPARATION

a. Set DY to CRT not to tilt up and down and left and right

deflection. (Fig. 1)

b. Set CY to CRT and set CY magnet primarily.

Pur Mg : Set Pur Mg that 2magnets are vertical position.

VRS Mag : Set VRS Mg that 2magnets are side

position.

c. Set geomagnetic correction DAC [0]

2. ADJUSTMENT

a. Receive the white balance pattern.

b. Adjust V-CENTER

c. Set R,B CUT OFF to minimum(0), and set G CUT OFF

to center(511).

d. Receive the aging pattern.

e. Set 2 magnet of vertical position to up and down equally

so that center part of CRT. (Fig. 3)

TX-80P250Z / TX-34P250 T

Fig. 2

Fig. 1

Fig. 3

17

TX-80P250Z / TX-34P250 T

5.8. Colour Purity

1. Operate the TV set over 60 minutes.

2. Receive a purity pattern signal. (white pattern)

3. Set Bright and Contrast controls to their maximum

positions.

4. Set V-POS to 128.

5. Adjust roughly the static convergence magnets.

6. Fully degauss the picture tube by using an external

degaussing coil.

7. Loosen a clamp screw for the deflection yoke and move the

deflection yoke as close to the purity magnet as possible.

8. Adjust the purity magnet so that a vertical green field is

obtained at center of the screen.

d. Set DY to CRT not to tilt (up and down and left and

right).

3. ADJUSTMENT

a. Static convergence Adjustment

a. Make sure that magnets are positioned shown in

Fig. 1.

b. Adjust 4-pole magnets (Fig. 1.) to align center dots

of R and B and adjust 6-pole magnets to align center

dots to G.

c. After adjustment, secure magnets with magnet lock

of white lacquer.

*Beams move with rotating when static magnets

are turned.

Rotational reduce of beams differs by angle of

two magnets.

Therefore, repeat magnet adjustments several

time so that all aligned completely.

9. Slowly press the deflection yoke and set it where a uniform

green field is obtained.

10. Adjust roughly the Low Light controls and make sure that a

uniform white field is obtained.

11. Tighten the clamp screw.

5.9. Convergence

1. INSTRUMENT

a. Helmhortz device

2. PREPARATION

a. Set the Helmhortz device to local magnetic field.

Hrizontal : 0 ± 0.03 × 10-4 T

b. Received the cross hatch pattern.

c. Picture menu : DYNAMIC Normal and adjust BRIGHT

DAC until gray portion of cross hatch.

Fig. 1.

b. YHC, YV, XV, Adjustment (Fig. 2.)

a. Adjust that Static and Dynamic convergence is best

with YHC VR, YV VR and XV coil.

In case of static convergence is tilted, repeat (1)

Static converegnce Adjustment.

Fig. 2.

c. Dynamic convergence Adjustment

a. When dynamic convergence is bad, fixing permalloy

between neck and DY so that dynamic convergence

is best.

4. Confirm that left upper side line is straight.

When left upper side line isn’t straight, put magnet on DY

and adjust the left upper scide line to straight.

18

5.10. CUT OFF

Preparation

1. Receive a colour bar signal with colour “OFF”, and operate

the TV set more than 15 minutes.

2. Set the picture menu to “DYNAMIC NORMAL” and the AI to

off.

3. Connect an oscilloscope to TPL7 with DC mode.

4. Set the TV set to Service Mode 1 .

5. Screen VR : Min

6. Set the data level of SUB BRIGHT, R, G, B-CUTOFF and

R, G, B-DRIVE to the table values.

Display Date Level

R High (R-CUT OFF) 128

G High (G-CUT OFF) 128

B High (B-CUT OFF) 128

R Low (R-DRIVE) 175

G Low (B-DRIVE) 175

B Low (G-DRIVE) 175

SUB BRIGHT 128

Adjustment

1. Select G-CUTOFF adjustment mode and collapse vertical

scan.

2. Adjust G-CUTOFF control to become the DC=0V to video

level at 180V as shown in.

TX-80P250Z / TX-34P250 T

7. Confirm correct B/W rendition and greyscale tracking or

repeat CUTOFF and drive control set up.

Note:

White down the original value for each address

adjustment before adjusting anything.

3. Slowly turn the screen control clockwise until a green colour

horizontal line appears on the picture tube. This is the

setting point for the screen control.

Note that do not adjust the G-CUTOFF setting in the

following procedure.

4. Adjust the remained R and B-CUTOFF controls so as to get

a white horizontal line on the screen.

5. Return to full field SCAN by pushing the position 5 key on

the remote control.

6. Adjust the R-Drive and B-Drive controls as to obatain

uniform white on the white bar of the greyscale pattern.

8. Wedge A shown in Fig. 1 should be fixed within a range of

45° to the left of the vertical line as shown.

9. After inserting wedge A, insert wedges B, C and D.

The wedges should be set 90° apart from each other.

10. Be certain that the four wedges are firmly fixed and the

Deflection Yoke is tightly clamped in place. Otherwise the

Deflection Yoke may shift its position and cause a loss of

convergence and purity.

19

TX-80P250Z / TX-34P250 T

5.11. White Balance

Item/Preparation Adjustment Procedure

1. Select Service Mode 1.

2. Aging should have been performed over 30 minutes.

3. Receive the white balan ce pattern.

4. Picture menu : DYNAMIC NORMAL.

AI : OFF

5. Degauss the CRT face.

6. Connect the photo sensors of the Colour Analyser to the CRT.

Note:

CRT cut off adjustment is completed.

1. Adjustment of Low Light.

a. Adjustment SUB BRIGHT, so that “Y“ axis indicates 6.5.

b. Adjustment R-CUT OFF, so that y axis indicates 0.293.

c. Adjustment B-CUT OFF, so that x axis indicates 0.273.

2. Adjustment of High Light.

a. Adjust SUB BRIGHT, so that “Y“ axis indicates 150.

b. Adjust R-DRIVE, so that y axis indicates 0.277.

c. Adjust B-DRIVE, so that x axis indicates 0.271.

5.12. Foucus

Item/Preparation Adjustment Procedure

1. Receive a cross-hatch pattern signal. 1. Adjust the Focus to thin all the Lines by Focus 1 Control.

(Prefer to thin the Vertical Lines than Horizontal Line.)

2. Adjust the Focus to thin the Horizontal Lines by Focus2 Control.

5.13. Geomagnetic

Item/Preparation Adjustment Procedure

1. Demagnetize the GM-Board around its perimeter with the

Demagnetizer.

2. Set to control;

Geomagnetic..........Auto

5.14. Sub Bright

Item/Preparation Adjustment Procedure

1. Receive the sub bright pattern.

2. Picture Menu :

BRT...................CENTER

COLOUR..........CENTER

CONT................MAX

3. Connect the photo sensor of the Colour Analyzer to the center of

CRT.

1. Connect a DC voltage meter to TPGM1-2pin (GM-Board)

2. Adjust the R4863 (GM-Board) so that the Vx Out at TPGM1-2pin

becomes

3. Connect a DC voltage meter to TPGM1-1pin (GM Board).

4. Adjust the R4861 (GM-Board) so that the Vy Out at TPGM1-1pin

becomes

1. Adjust Sub Bright so that brightness level became 1 ± 0.2 cd/m

4.9 ± 0.05 V

4.9 ± 0.05 V

.

.

2

20

6 Deflection Adjustment

6.1. V-ADJUSTMENT/CONFIRMATION (4:3 MODE)

6.1.1. V-HOLD CONFIRMATION

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Set aspect to 4:3.

4. Confirm that V-hold is normal.

5. Set the fix data in the table 1.

6.1.2. V-CENTER ADJUSTMENT (4:3 MODE)

6.1.2.1. 100i V-POS ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust V-POS (100i / 4:3) so that the scale of the top and bottom side is equal.

6.1.2.2. 120i V-POS ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust V-POS (120i / 4:3) so that the scale of the top and bottom side is equal.

TX-80P250Z / TX-34P250 T

6.1.2.3. 50p V-POS ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust V-POS (50p / 4:3) so that the scale of the top and bottom side is equal.

6.1.2.4. 60p V-POS ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust V-POS (60p / 4:3) so that the scale of the top and bottom side is equal.

Fig. 1

21

TX-80P250Z / TX-34P250 T

6.1.3. V-HEIGHT ADJUSTMENT (4:3 MODE)

6.1.3.1. 100i V-AMP ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust V-AMP (100i / 4:3) so that

B, D (Fig. 2) is 2.1 ± 0.1

6.1.3.2. 120i V-AMP ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust V-AMP (120i / 4:3) so that

B, D (Fig. 2) is 2.1 ± 0.1

6.1.3.3. 50p V-AMP ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust V-AMP (50p / 4:3) so that

B, D (Fig. 2) is 2.1 ± 0.1

6.1.3.4. 60p V-AMP ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust V-AMP (60p / 4:3) so that

B, D (Fig. 2) is 2.1 ± 0.1

Fig. 2

6.2. H-DEFLECTION CONFIRMATION/ADJUSTMENT (4:3 MODE)

6.2.1. H-HOLD CONFIRMATION

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Set aspect to 4:3.

4. Confirm that H-hold is normal.

6.2.2. H-CENTER ADJUSTMENT (4:3 MODE)

6.2.2.1. 100i H-POS ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust H-POS (100i / 4:3) so that the horizontal position is center of CRT.

22

6.2.2.2. 120i H-POS ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust H-POS (120i / 4:3) so that the horizontal position is center of CRT.

6.2.3. H-WIDTH ADJUSTMENT (4:3 MODE)

6.2.3.1. 100i H-AMP ADJUSTMENT

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust H-AMP (100i / 4:3) so that the both of edges are within A, B = 2.5 ± 0.2.

6.2.3.2. 120i H-AMP ADJUSTMENT

1. Receive NTSC monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust H-AMP (120i / 4:3) so that the both of edges are within A, B = 2.5 ± 0.2.

TX-80P250Z / TX-34P250 T

Fig. 3

6.3. PINCUSSION ADJUSTMENT/CONFRMATION (4:3 MODE)

6.3.1. 100i SIDE PINCUSSION ADJUSTMENT (4:3 MODE)

1. Receive PAL crosshatch pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust the vertical line to straight line by Parabola (100i / 4:3).

4. Adjust the vertical line to straight line of bothside vertical line in Fig. 4 by Trapezoid (100i / 4:3).

5. Confirm there is no H-parallel distortion.

If there is distortion, adjust by H-Pallalel (100i / 4:3).

In that case, repeat 4. and 5. so that there is no trapezoid / pararell distortion.

6. Confirmation vertical pincussion of the corner side.

If need, adjust Top-Corner (100i / 4:3) and Bottom-Corner (100i / 4:3).

7. Confirm bow level of the both side.

If it is not symmetrical, adjust C-Correct (100i / 4:3).

6.3.2. 120i SIDE PINCUSSION ADJUSTMENT (4:3 MODE)

1. Receive NTSC crosshatch pattern.

2. Set scan mode to 100Hz by remote control key.

3. Adjust the vertical line to straight line by Parabola (120i / 4:3).

4. Adjust the vertical line to straight line of bothside vertical line in Fig. 4 by Trapezoid (120i / 4:3).

5. Confirm there is no H-parallel distortion.

If there is distortion, adjust by H-Pallalel (120i / 4:3).

In that case, repeat 4. and 5. so that there is no trapezoid / pararell distortion.

6. Confirmation vertical pincussion of the corner side.

If need, adjust Top-Corner (120i / 4:3) and Bottom-Corner (120i / 4:3).

23

TX-80P250Z / TX-34P250 T

7. Confirm bow level of the both side.

If it is not symmetrical, adjust C-Correct (120i / 4:3).

Fig. 4

6.3.3. 50p SIDE PINCUSSION ADJUSTMENT (4:3 MODE)

1. Receive PAL crosshatch pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust the vertical line to straight line by Parabola (50p / 4:3).

4. Adjust the vertical line to straight line of bothside vertical line in Fig. 5 by Trapezoid (50p / 4:3).

5. Confirm there is no H-parallel distortion.

If there is distortion, adjust by H-Pallalel (50p / 4:3).

In that case, repeat 4. and 5. so that there is no trapezoid / pararell distortion.

6. Confirmation vertical pincussion of the corner side.

If need, adjust Top-Corner (50p / 4:3) and Bottom-Corner (50p / 4:3).

7. Confirm bow level of the both side.

If it is not symmetrical, adjust C-Correct (50p / 4:3).

6.3.4. 60p SIDE PINCUSSION ADJUSTMENT (4:3 MODE)

1. Receive NTSC crosshatch pattern.

2. Set scan mode to progressive by remote control key.

3. Adjust the vertical line to straight line by Parabola (60p / 4:3).

4. Adjust the vertical line to straight line of bothside vertical line in Fig. 5 by Trapezoid (60p / 4:3).

5. Confirm there is no H-parallel distortion.

If there is distortion, adjust by H-Pallalel (60p / 4:3).

In that case, repeat 4. and 5. so that there is no trapezoid / pararell distortion.

6. Confirmation vertical pincussion of the corner side.

If need, adjust Top-Corner (60p / 4:3) and Bottom-Corner (60p / 4:3).

7. Confirm bow level of the both side.

If it is not symmetrical, adjust C-Correct (60p / 4:3).

Fig. 5

24

6.4. V LINIALITY ADJUSTMENT / CONFIRMATION (4:3 MODE)

6.4.1. 100i V-linear ADJUSTMENT

1. Recive PAL monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Confirm V-linear (100i / 4:3) as to the balance of circle.

If need, adjust V-linear (100i / 4:3).

6.4.2. 120i V-linear ADJUSTMENT

1. Recive NTSC monoscope pattern.

2. Set scan mode to 100Hz by remote control key.

3. Confirm V-linear (120i / 4:3) as to the balance of circle.

If need, adjust V-linear (120i / 4:3).

6.4.3. 50p V-linear ADJUSTMENT

1. Recive PAL monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Confirm V-linear (50p / 4:3) as to the balance of circle.

If need, adjust V-linear (50p / 4:3).

TX-80P250Z / TX-34P250 T

6.4.4. 60p V-linear ADJUSTMENT

1. Recive NTSC monoscope pattern.

2. Set scan mode to progressive by remote control key.

3. Confirm V-linear (60p / 4:3) as to the balance of circle.

If need, adjust V-linear (60p / 4:3).

Fig. 6

6.5. DEFLECTION (16:9 MODE) ADJUSTMENT / CONFIRMATION

6.5.1. DATA SETTING (16:9)

1. Copy the adjusted data of 100i / 4:3 mode to 100i / 16:9 in the table. 1 (Except H-POS, V-S-Correct).

2. Copy the adjusted data of 120i / 4:3 mode to 120i / 16:9 in the table. 1 (Except H-POS, V-S-Correct).

3. Copy the adjusted data of 50p / 4:3 mode to 50p / 16:9 in the table. 1 (Except H-POS, H-AMP, V-S-Correct, C-Correct) and copy

the data of 100i / 4:3 to 50p / 16:9 about H-AMP and C-Correct.

4. Copy the adjusted data of 60p / 4:3 mode to 60p / 16:9 in the table. 1 (Except H-POS, H-AMP, V-S-Correct, C-Correct) and copy

the data of 120i / 4:3 to 60p / 16:9 about H-AMP and C-Correct.

25

TX-80P250Z / TX-34P250 T

6.5.2. V-AMP (16:9) ADJUSTMENT

1. Recive PAL monoscope pattern.

2. Set the aspect to 16:9.

3. Set scan mode to 100 Hz.

4. Confirm that A, B in the Fig. 7 is 6.0cm ± 1cm, if not, adjust V-AMP (100i / 16:9).

5. Set scan mode to progressive.

6. Confirm that A, B in the Fig. 7 is 6.0cm ± 1cm, if not, adjust V-AMP (50p / 16:9).

7. Receive NTSC monoscope pattern.

8. Set scan mode to 100Hz.

9. Confirm that A, B in the Fig. 7 is 6.0cm ± 1cm, If not, adjust V-AMP (120i / 16:9).

10. Set scan mode to progressive.

11. Confirm that A, B in the Fig. 7 is 6.0cm ± 1cm, If not, adjust V-AMP (60p / 16:9).

Fig. 7

6.6. 525p DEFLECTION ADJUSTMENT / CONFIRMATION

6.6.1. V,H-HOLD CONFIRMATION

1. Recive 525p signal.

2. Confirm V,H-hold is normal.

6.6.2. H-CENTER (525p) CONFIRMATION / ADJUSTMENT

1. Recive 525p signal.

2. Copy the data of 00h to EEROM ADRESS [333] (525p / H-POS).

3. Copy the data of F5h to EEROM ADRESS [332] (525p / H-POS).

4. Confirm H-center and if need, adjust H-POS (525p).

6.7. 625p DEFLECTION ADJUSTMENT

6.7.1. H-CENTER (625p) ADJUSTMENT

1. Recive 625p signal.

2. Copy the data of EEROM ADRESS [332] (525p / H-POS) to EEROM ADRESS [330] (625p / H-POS).

3. Copy the data of EEROM ADRESS [333] (525p / H-POS) to EEROM ADRESS [331] (625p / H-POS).

26

6.8. VGA480 / 60Hz DEFLECTION ADJUSTMENT / CONFIRMATION

6.8.1. V,H-HOLD CONFIRMATION

1. Receive VGA480 (60Hz) crosshatch pattern with border line.

2. Copy the data of 60p / 4:3 mode to VGA480 / 60Hz mode in the table 1.

3. Confirm V,H-hold is normal.

4. Set user control H-SIZE to “0”.

6.8.2. V-CENTER ADJUSTMENT

1. Adjust V-POS (VGA) so that center of the crosshatch pattern is center of the CTR.

6.8.3. V-HEIGHT ADJUSTMENT

1. Adjust V-AMP (VGA) so that A=B in the Fig. 8.

6.8.4. H-CENTER ADJUSTMENT

1. Adjust H-POS (VGA) so that horizontal position is center of CRT.

6.8.5. H-WIDTH ADJUSTMENT

1. Adjust H-AMP (VGA) so that C=D in the Fig. 8.

6.8.6. SIDE PINCUSSION ADJUSTMENT

TX-80P250Z / TX-34P250 T

1. Adjust the vertical line to straight line by Parabola (VGA).

2. Adjust the vertical line to straight line of bothside vertical line in Fig. 9 by Trapezoid (VGA).

3. Confirm there is no H-parallel distortion.

If there is distortion, adjust by H-Pallalel (VGA).

In that case, repeat 2. and 3. so that there is no trapezoid / pararell distortion.

4. Confirmation vertical pincussion of the corner side.

If need, adjust Top-Corner (VGA) and Bottom-Corner (VGA).

5. Confirm bow level of the both side.

If it is not symmetrical, adjust C-Correct (VGA).

6. Set H-SIZE in the user control to NORMAL.

(No need, if SELF CHECK is done before shipping.)

Fig. 9

Fig. 8

27

Loading...

Loading...