Panasonic TX-36PF10P, TX-32PF10P Service Manual

ORDER No. SM-98089

6HUYLFH0DQXDO

Colour Television

TX-36PF10P

TX-32PF10P

EURO5 Chassis

SPECIFICATIONS

(Information in brackets { } refer to TX-32PF10P)

Power Source: 220-240V AC, 50Hz

Power Consumption: 226W {229W}

Aerial Impedance: 75Ω unbalanced, Coaxial Type

Stand-by Power

Consumption: 1,9W

Receiving System: PAL B/G, H, D/K, PAL-525/60

SECAM B/G, D/K

M.NTSC

NTSC (AV only)

Receiving Channels:

VHF E2-E12 VHF H1-H2 (ITALY)

VHF A-H (ITALY) VHF R1-R2

VHF R3-R5 VHF R6-R12

UHF E21-E69 CATV (S01-S05)

CATV S1-S10 (M1-M10) CATV S11-S20 (U1-U10)

CATV S21-S41 (HYPERBAND)

Intermediate Frequency:

Video 38,9MHz

Audio 33,4MHz, 33,16MHz

32,4MHz, 33,05MHz

32,66MHz

Colour 34,47MHz (PAL)

34,5MHz, 34,65MHz (SECAM)

Video/Audio

Terminals:

AUDIO MONITOR OUT Audio (RCAx2) 500mV rms 1kΩ

AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin)

AV1 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV2 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21 pin) C: 0.3V p-p 75Ω

AV2 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

Selectable Output (21 pin)

AV3 IN S-Video IN Y: 1V p-p 75Ω

(4-pin) C: 0,3V p-p 75Ω

Audio (RCAx2) 500mV rms10kΩ

Video (RCAx1) 1V p-p 75Ω

AV4 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21 pin) C: 0.3V p-p 75Ω

AV4 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

High Voltage: 32kV ±1kV

Picture Tube: W86LPX555X05 {W76LPX555X05}

Audio Output: Front Left/Right 2 x 20W

(Music Power) Centre 14W (Speech mode only)

8Ω Impedance

Headphones: 8Ω Impedance

3,5 mm

Accessories

Supplied: Remote Control

2 x R6 (UM3) Batteries

Dimensions:

Height: 637mm {576mm}

Width: 874mm {777mm}

Depth: 588mm {537mm}

Net weight: 78kg {56kg}

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

NOTE: This Service Manual should be used in conjunction with

the EURO5 Technical Guide.

CONTENTS

SAFETY PRECAUTIONS..........................................................................................................................................................2

SERVICE HINTS.......................................................................................................................................................................3

SERVICE POSITION.................................................................................................................................................................4

ADJUSTMENT PROCEDURE AND SELF-CHECK ..................................................................................................................5

WAVEFORM PATTERN TABLE...............................................................................................................................................6

ALIGNMENT SETTINGS...........................................................................................................................................................7

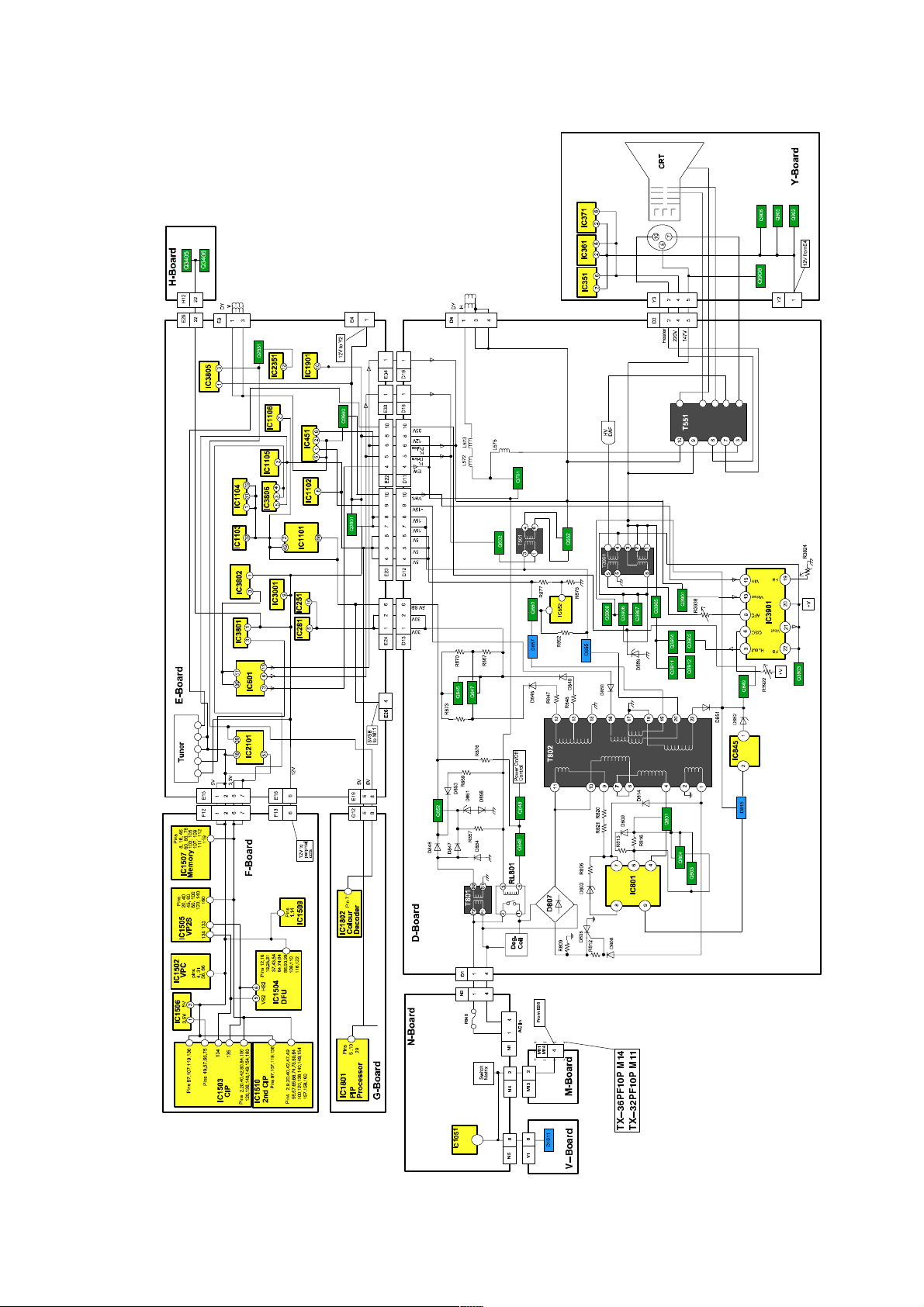

BLOCK DIAGRAMS..................................................................................................................................................................8

PARTS LOCATION.................................................................................................................................................................12

REPLACEMENT PARTS LIST................................................................................................................................................13

SCHEMATIC DIAGRAMS.......................................................................................................................................................30

CONDUCTOR VIEWS.............................................................................................................................................................39

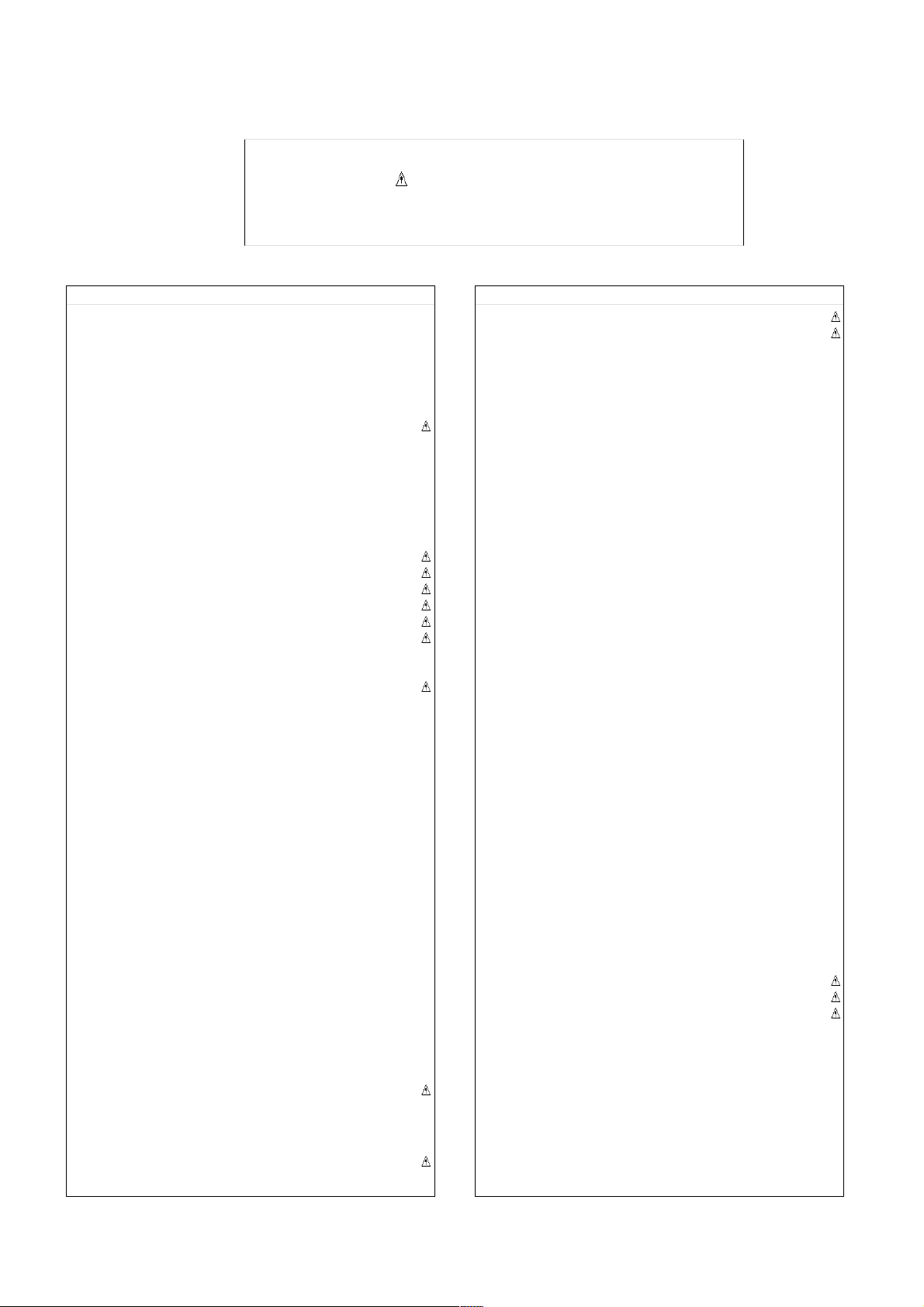

SAFETY PRECAUTIONS

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5. Potentials as high as 33kV are present when this

receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2. Connect a 2kΩ 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the a.c. plug at the outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed

1,4 Vrms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

HOT CHECK CIRCUIT

A.C. VOLTMETER

2kΩ 10 Watts

TO INSTRUMENT’S EXPOSED

METALLIC PARTS

Fig. 1.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 33kV without

causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should

indicate:- 32kV ± 1kV. If the meter indication is out of

tolerance, immediate service and correction is

required to prevent the possibility of premature

component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

WATER PIPE

(

EARTH)

2

SERVICE HINTS

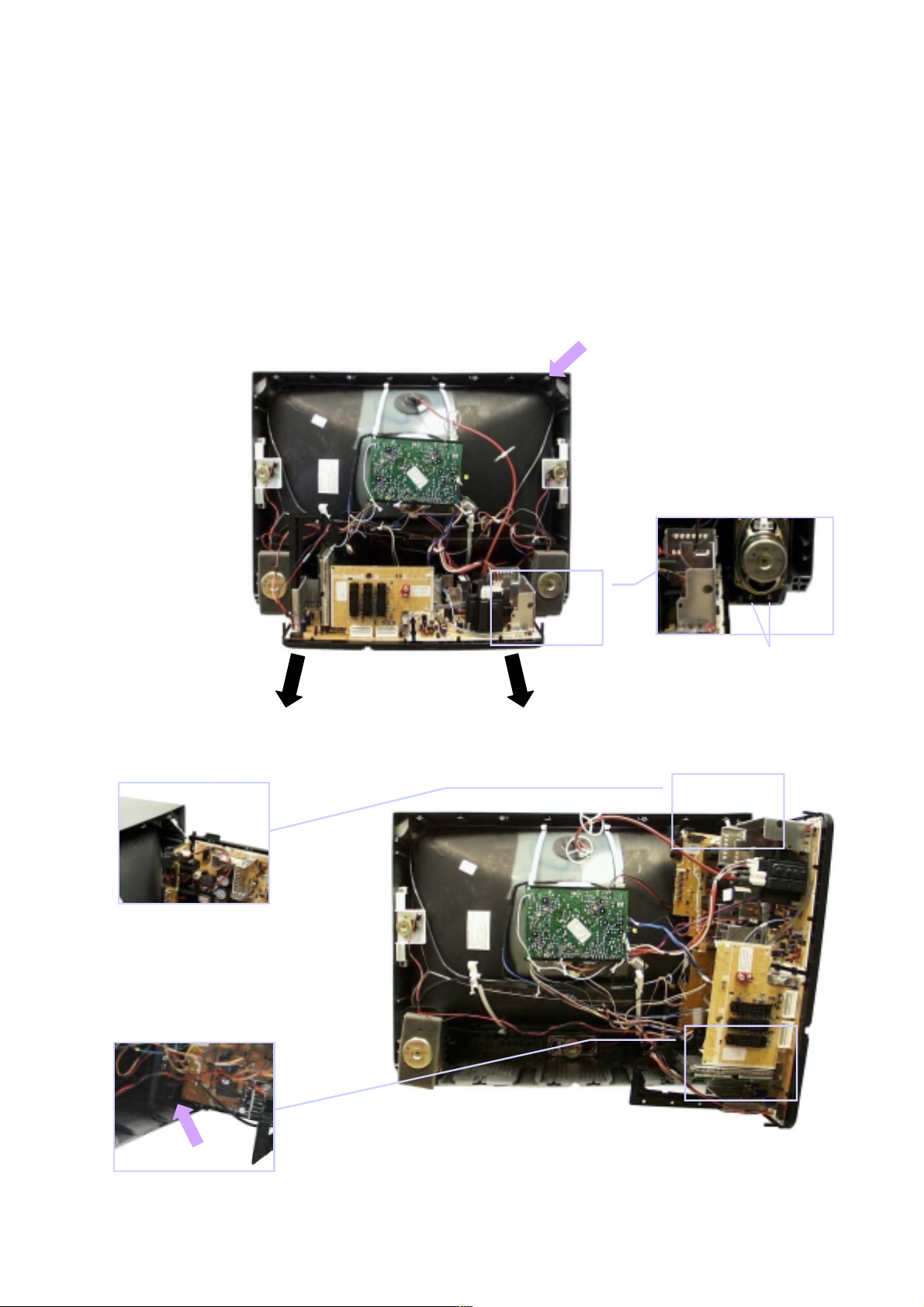

How to remove the rear cover

1. Remove the 10 screws as shown in Fig.2.

SCREWS

Fig.2.

LOCATION OF CONTROLS

M-Board

F-Board

E-Board

G-Board

Fig.3.

Y-Board

V-Board

N-Board

Focus

D-BoardH-Board

Screen

3

HOW TO MOVE THE CHASSIS INTO SERVICE POSITION

(A)

(

1. Remove the bead clamper from the mains lead and affix, using back cover screw, into top right-hand cabinet rib (A),

shown in Fig.4.

2. Remove 2 screws (B), as shown in Fig.5, and remove speaker assembly.

3. Hold and lift the rear of the chassis and gently pull the chassis toward you, as shown in Fig.4.

4. Release the respective wiring clips and rotate the chassis vertically through 90°, anti-clockwise.

5. Locate the base of the chassis frame into location (C), shown in Fig.6 / Fig.8.

6. Clip the chassis frame onto the bead clamper, shown in Fig.6 / Fig.7.

7. After servicing replace the bead clamper and speaker, and ensure all wiring is returned to its original position before

returning the receiver to the customer.

Fig.4.

Fig.5.

Fig.5.

Fig.7.

Screws

(B)

a

Fig.6.

C)

Fig.8.

4

ADJUSTMENT PROCEDURE

Item / Preparation Adjustments

+B SET-UP

1. Receive a Greyscale signal.

2. Set the controls :-

Brightness Minimum

Contrast Minimum

Volume Minimum

1. Confirm the following voltages.

D-Board E-Board

D3 PIN5 147V ± 3V U8A E19-PIN8 8V ± 0,5V

D12 PIN5 5V ± 0,3V U9 IC3801-PIN3 9V ± 0,5V

D13 PIN1 40V ± 4V U12 E22-PIN8 12V ± 0,5V

D3 PIN4 230V ± 10V STD5VE26-PIN4 5V ± 0,5V

D3 PIN4 205V ± 10V U15 E23-PIN8 15V ± 1V

D3 PIN4 190V ± 10V U15 E23-PIN9 -15V ± 1V

D3 PIN4 190V ± 10V U33 E22-PIN10 33V ± 4V

D14 PIN5 5V ± 0,5V U40 E24-PIN1 40V ± 3V

D12 PIN7 15V ± 2V U5B E19-PIN5 5V ± 0,5V

D12 PIN9 15V ± 2V

D11 PIN8 12V ± 2V

D11 PIN10 33V ± 3V

Cut Off

1. Receive a Greyscale signal.

2. Degauss the tube externally.

3. Set the TV into Service Mode 1.

4. Select Cut off mode.

Adjust the screen VR until the display shows "O.K."

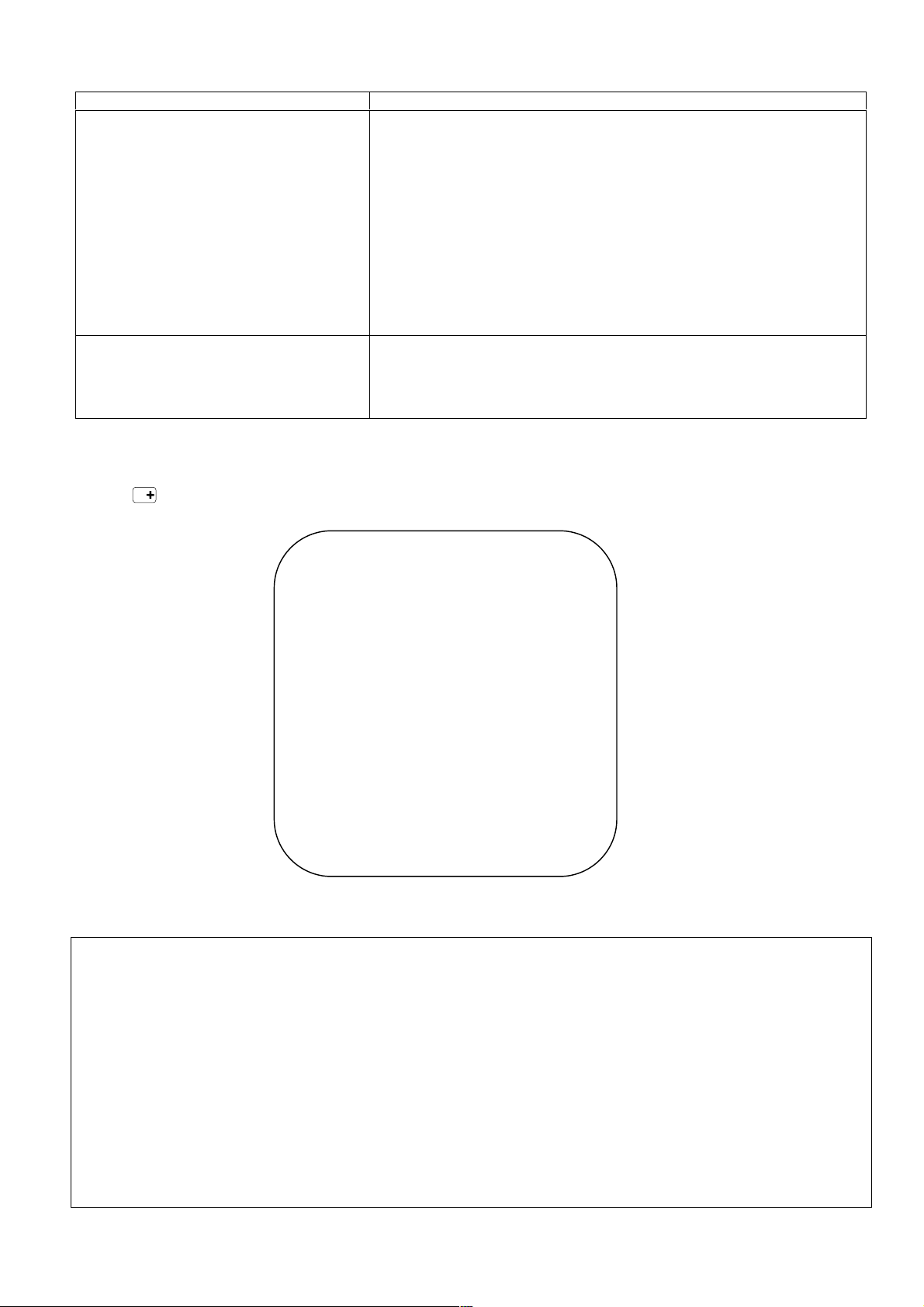

SELF CHECK

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set. To get into the Self-Check mode

press the down (-/v) button on the customer controls at the front of the set,at the same time pressing the STATUS

button on the remote control, and the screen will show :-

VPC O.K.

TUN O.K.

E2 O.K.

DPL - CIP1 O.K.

CIP2 O.K.

VP O.K.

DFU O.K.

COL O.K.

PIP O.K.

DIS O.K.

OPTION 1 BD

OPTION 2 FD

OPTION 3 1F

OPTION 4 20

OPTION 5 FF

Self Check is also used to automatically check the bus lines and hexadecimal code of the TV set. If the CCU ports have

been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.". For more in-depth TV

diagnostics use the LUCI interface as listed below.

PCB O.K.

Cab O.K.

Sum Factory use

only

Service Aids

To aid in the service of our current chassis there are a number of Service Aids which have been made available.

• LUCI interface kit (Linked Utility Computer Interface)

Part number: TZS6EZ002

This contains interface and cables for connecting TV service connector and a PC as well as diagnostic software. As new

models are introduced upgrade software will become available.

• VICI (Visual Interactive Computer Information)

These C.D.'s contain multimedia documentation providing quick access to service information.

Part No. TZS7EZ006 & TZS7EZ005

1. Service Manuals

2. Instruction Books

3. Technical Information

• TASMIN (Technically Advanced System for Multimedia Interactive Notes)

As well as providing a first step towards more interactive training this product also achieves quick access to Technical

Information.

5

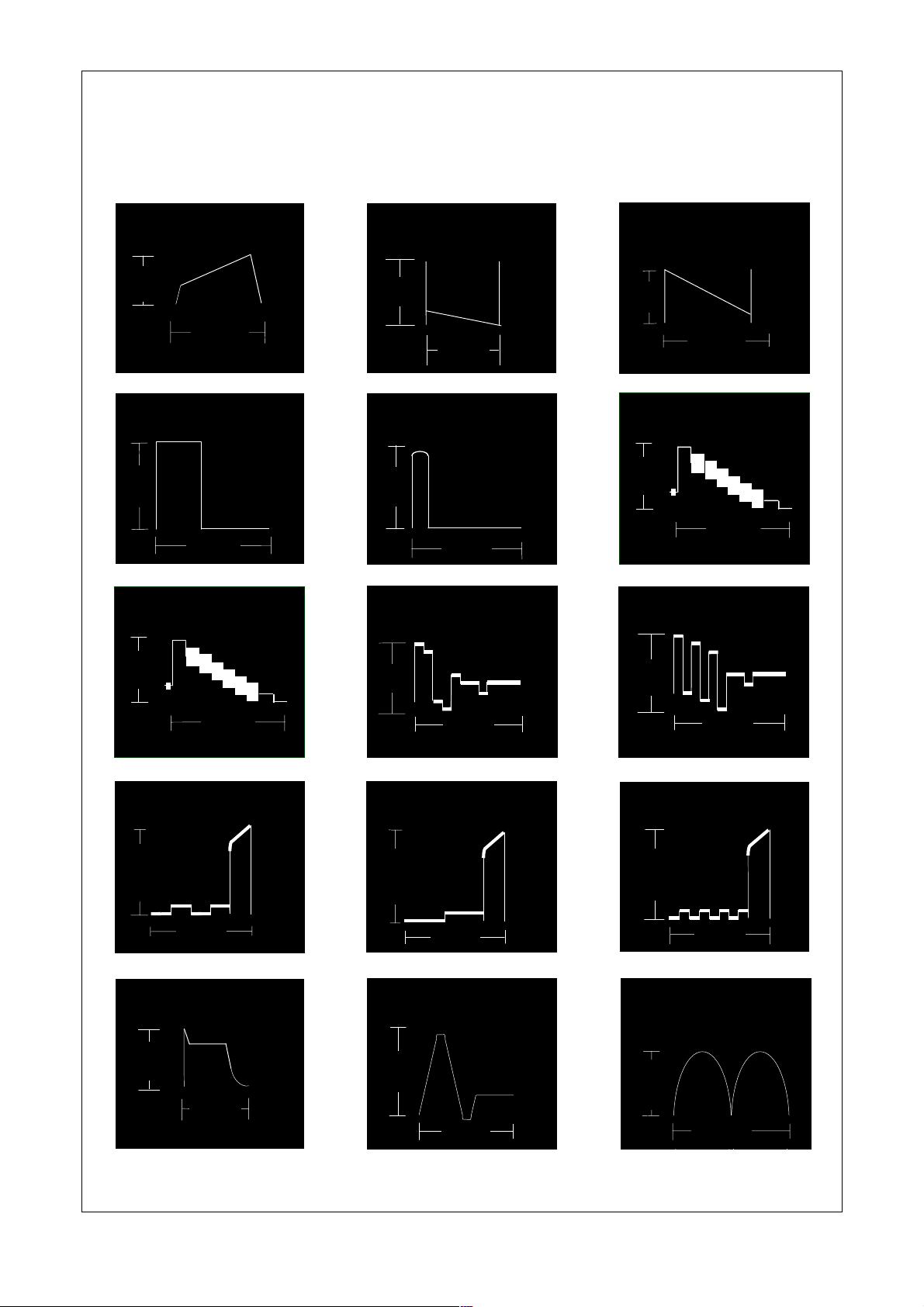

WAVEFORM PATTERN TABLE

NOTE: All waveforms have been taken using a standard colour bar pattern.

Vert Out

IC601 Pin 1

0.6V

H - Out

IC601 Pin 8

3.9V

Luminance In

IC601 Pin 28

8.6ms

32µs

Vert Drive

IC451 Pin 2

63V

HFLB

IC601 Pin 13

7V

R - Y

IC601 Pin 26

8ms

32µs

VFLB

IC451 Pin 5

1V

8.6ms

Video In

IC1101 Pin 68

0.9V

64µs

B - Y

IC601 Pin 27

0.9V

R - Out

IC601 Pin 40

2.2V

H - Out

IC3901 Pin 3

6V

32µs

28µs

32µs

1V

G - Out

IC601 Pin 41

2.2V

V - Out

IC3901 Pin 21

0.1V

32µs

32µs

32µs

1.3V

32µs

B - Out

IC601 Pin 42

2.2V

32µs

E/W - Out

IC601 Pin 3

280mV

8.5ms

6

ALIGNMENT SETTINGS:

(The figures below are nominal and used for representative purposes only.)

1. Set the Bass to maximum position, set the Treble to minimum position, press the down button (- / v) on the customer

controls at the front of the TV and at the same time press the INDEX button on the remote control, this will place the TV

into the Service Mode.

2. Press the RED / GREEN buttons to step up / down through the functions.

3. Press the YELLOW / BLUE buttons to alter the function values.

4. Press the STR button after each adjustment has been made to store the required values.

5. To exit the Service Mode, press the "N" button.

Alignment Function Settings / Special features

Horizontal Position

Vertical Position

Horizontal Amplitude

Vert. Amplitude

EW-amplitude

EW-amplitude

Trapezium-comp

H-Pos

+020

V-Pos

+024

H-Amp

+049

V-Amp

+029

E/W-Amp1

+022

E/W-Amp2

+000

Trapez-1

+033

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Horizontal-Parallel

Vertical Linearity

DVCO

Cut-off DC

Highlight High 0031 0031 0031

Sub-Brightness

H-Parallel

+032

V-Lin

+004

DVCO

000

Cut-off

O.K.

Sub-Brightness

000

Optimum setting.

Optimum setting.

Receive a PAL Colour Bar Pattern. For

DVCO alignment press "Blue" button, wait

until the colours are stable and press

"STR".

To adjust Cutoff adjust the screen VR until

the display shows "O.K."

Contrast Maximum

A.I. Off

Adjust for optimum setting.

Optimum setting.

7

32:(5 6833/ < '()/(&7,21 %/2&. ',$*5$0

1

)

&

,

(

P

R

U

)

1

0

0

0

1

G

U

1

D

R

%

9

9

0

0

3

3

)

)

3

3

;

;

7

7

17

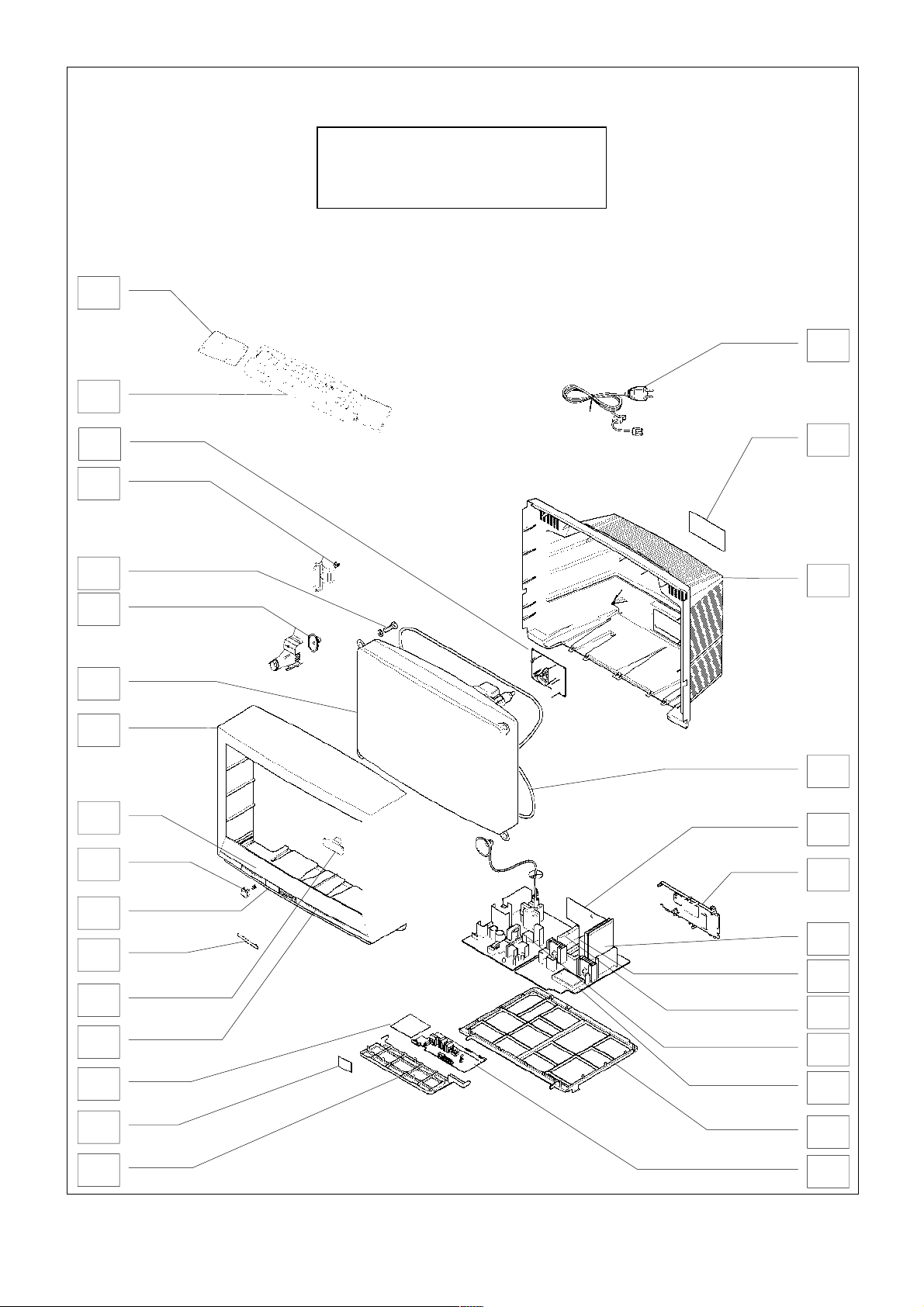

PARTS LOCATION

NOTE:

The numbers on the exploded view below

refer to the mechanical section of the

Replacement Parts List.

16

4

30

18

19

25

27

2

6

1

5

29

23

14

7

28

20

11

12

21

9

15

13

3

8

22

24

10

26

12

Components Identified by mark have spec ial characteristics important for safety.

* When replacing any of these components, use only manufacturers specified parts.

In case of ordering thes e spare parts, please always add the complete Model-Type

number to your order.

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COMMON PARTS

MECHANICAL PARTS

LOUD SPEAKER 1 EAB12146B

TWEETER SPEAKER 2 EAS13KH14E

TUNER 3 ENG29505G

REMOTE CONTROL 4 EUR511220

POWER BUTTON 5 TBXA19701

CRT FIXING SCREW 6 THTA006Z

REAR AV PANEL 7 TKP8E1253-3

RIGHT DOOR 8 TKPA27904

LEFT DOOR 9 TKPA28004

CHASSIS FRAME 10 TMX8E034

N P.C.B. 11 TNP8EN017AA

V P.C.B. 12 TNP8EV003AA

G P.C.B. 13 TNPA0877AB

H P.C.B. 14 TNPA1047AC

F P.C.B. 15 TNPA1068AA

POWER CORD 16 TSX8E0028

BATTERY COVER (REMOTE) 17 UR51EC904A

ANODE CABLE 18 ZTBZAD550A

F.B.T. 19 ZTFL77002A

MISCELLANEOUS COMPONENTS

IC SOCKET 832AG11D-ESL

84 PIN SOCKET PCS-084A-1

RUBBER TBL63413

AV PANEL LABEL TBM8E1940-1

LEFT INDICATION SHEET TBMU025-1

BADGE TBMU026

LID CATC H TEK6940

CRT EARTH SPRING TES2298

SCREW THT1062

SPEAKER NET SHEET TKNA005

SPEAKER NET TKNE020

INDICATOR PANEL TKPA27711

HANDLE TKRA13104

REMOTE CONTROL HOLDER TMWJ002

LED HOLDER TMWJ011

P.C.B. BRACKET TMX8E025

POWER BUTTON JOINT TMX8E035

BATTERY PACK UM-3DJ-2P

RELAY RL801 TSE1885-1

THERMISTOR R805 232266296706

FIX CLIP SOD1 31221212478

FIX CLIP SOD9 31221212478

INSTRUCTION BOOKS

BULG./ROMANIAN TQB8E2700MN2

REPLACEMENT PARTS LIST

Important Safety Notice

POLISH/HUNG. TQB8E2700PQ2

CZECH/ENGLISH TQB8E2700RU2

I.C.s

AUDIO OUTPUT IC251 LA4282

AUDIO AMPL IFIERIC281 TDA2030AV

RGB OUTPUT IC351 TDA6111Q-N4

RGB OUTPUT IC361 TDA6111Q-N4

RGB OUTPUT IC371 TDA6111Q-N4

REGULATOR IC381 TL431ACLPM

VERTICAL OUTPUT IC451 LA7845N

VIDEO PROCESSOR IC601 TDA9330HN1G

POWER SUPPLY IC801 AN8029

ERROR AMPLIFERIC845 SE140N

REGULATOR IC852 TL431ACLPM

LED RECEIVER IC1051 PNA4601M04TV

MICRO PROCESSOR IC1101 SDA5450C47-1

SRAM IC1103 M5M51008BP

EPROM * IC1104 27C2001-K03

RESET IC1105 MN1381-T(TA)

RESET IC1106 MN1381-R(TA)

VPC IC1502 VPC3215CB4TP

CIP IC1503 MB87F1720

DFU IC1504 FJB007S

VP2S IC1505 MB87F2131

3.5V REGULATOR IC1506 AN77L035M-E1

MEMORY IC1507 MB87H2010

CLOCK CONVERTOR IC1509 TLC2932IPWL

CIP IC1510 MB87F1720

PIP PROCESSOR IC1801 SDA9288XEGEG

COLOUR DECODERIC1802 TDA9143-N1

EARTH CORRECTION IC1901 LA6515

AUDIO PROCESSORIC2101 MSP3410DPPB4

H.P. AMPLIFIER IC2351 AN7108

VIDEO SWITCHIC3001 TEA6415C

9V REGULATOR IC3801 AN7809FLB

8V REGULATOR IC3802 AN7708FLB

8V REGULATOR IC3805 AN7808LB

3.5V REGULATOR IC3806 SI-3033C

DYNAMIC FOCUS IC3901 AN5422K

FUSES

FUSEF840 XBA2C50TH15

FUSE F845 TR5-T3150

FUSEF846 TR5-T1250

FUSE HOLDERF8401 EYF52BC

FUSE HOLDERF8402 EYF52BC

DIODES

DIODE D001 MA4020

DIODE D002 MA4020

DIODED252 MA165TA5

DIODE D253 MA700TA5

DIODE D254 MA700TA5

DIODED255 MA165TA5

13

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

DIODED282 MA165TA5

DIODED284 MA165TA5

DIODED285 MA165TA5

DIODED286 MA165TA5

DIODE D287 MA4200

DIODE D351 ERA15-04V3

DIODE D352 ERA15-04V3

DIODE D361 ERA15-04V3

DIODE D362 ERA15-04V3

DIODE D371 ERA15-04V3

DIODE D372 ERA15-04V3

DIODE D373 MTZJT-7715A

DIODE D374 MTZJT-7715A

DIODE D375 MTZJT-7715A

DIODE D387 MA2160LFS

DIODE D400 MA4104

DIODED401 MA165TA5

DIODED402 MA165TA5

DIODE D404 EU02AV1

DIODED405 MA165TA5

DIODED408 MA165TA5

DIODED502 1SS254T-77

DIODE D503 EU02

DIODE D504 EU02

DIODED505 ERA81004V3

DIODE D556 AU02V0

DIODE D559 MTZJT-7736A

DIODED560 1SS252T-77

DIODE D563 RH3GLF102

DIODE D571 FMV-3GULF730

DIODED575 1SS252T-77

DIODE D601 MA29TA5

DIODE D603 MA4075

DIODE D605 MA4062

DIODED607 MA165TA5

DIODE D610 MA4043

DIODED611 MA165TA5

DIODED612 MA165TA5

DIODED615 MA165TA5

DIODE D616 MA178TA5

DIODE D617 MTZJT-779.1C

DIODE D618 MTZJT-779.1C

DIODED620 MA165TA5

DIODED651 MA165TA5

DIODE D701 AU02V0

DIODE D803 MTZJT-7712C

DIODE D806 TF361MALF3

DIODE D807 RBV-608LF-B

DIODED808 MA165TA5

DIODE D809 ERA22-02V3

DIODE D810 MA2180BLFS

DIODE D812 MTZJT-775.6B

DIODE D813 MA700TA5

DIODE D814 AU01ZV0

DIODE D815 PC123FY2

DIODE D817 D5L60F4015

DIODE D818 TMPG10G3

DIODED819 ERA81004V3

DIODE D820 MA4100

DIODE D821 EU02AV0

DIODED845 MA165TA5

DIODE D846 EK04V0

DIODE D847 ERA15-01V3

DIODE D848 EU02

DIODE D849 FMGG26S

DIODE D850 ERB32-02E

TRANSISTORS

DIODE D851 FMGG2CSLF116

DIODE D852 MA4062

DIODE D853 1N4150T-77

DIODE D854 ERA15-01V3

DIODE D855 D10SC6MRL

DIODED856 MA165TA5

DIODE D857 FML22SLF610

DIODED860 1SS254T-77

DIODE D861 MTZJT-775.1C

DIODED901 1SS254T-77

DIODED902 1SS254T-77

DIODED903 1SS254T-77

DIODE D910 R2KNLFA1

DIODE D1011 LN81RPHL

DIODE D1102 MA4051

DIODE D1103 MA4051

DIODED1104 MA165TA5

DIODED1105 MA165TA5

DIODED1107 MA165TA5

DIODED1109 MA165TA5

DIODED1110 MA165TA5

DIODED1112 MA165TA5

DIODE D1501 MA151ATX

DIODE D1801 MA151ATX

DIODE D1802 MA151ATX

DIODE D2101 MTZJT-7712C

DIODE D2102 MTZJT-7712C

DIODE D2351 MTZJT-775.6B

DIODE D3006 MA4100

DIODE D3008 MA723TA5

DIODE D3009 MA170

DIODE D3011 MA858TA5

DIODED3351 1SS254T-77

DIODED3352 MA165TA5

DIODED3353 MA165TA5

DIODED3354 MA165TA5

DIODE D3401 MTZJT-7712C

DIODE D3402 MTZJT-7712C

DIODE D3803 MA4043

DIODE D3804 MTZJT-778.2A

DIODED3805 ERA81004V3

DIODE D3901 MTZJT-779.1C

DIODE D3907 ERA22-06V3

DIODE D3908 ERA22-06V3

DIODED3909 MA165TA5

DIODE D3910 RP1HLFA5

DIODE D3911 RP1HLFA5

DIODED3912 1SS254T-77

DIODE D3915 MTZJT-7710D

DIODED3917 MA165TA5

DIODE D3990 MTZJT-7724D

TRANSISTOR Q101 BC847B

TRANSISTOR Q103 BC847B

TRANSISTOR Q104 BC847B

TRANSISTOR Q251 2SD1328STX

TRANSISTOR Q252 2SD1328STX

TRANSISTOR Q253 BC847B

TRANSISTOR Q254 BC857B

TRANSISTOR Q281 2SD1328STX

TRANSISTOR Q282 BC857B

TRANSISTOR Q400 BC847B

TRANSISTOR Q401 BC847B

TRANSISTOR Q502 2SC2925STA

TRANSISTOR Q552 2SC5144LB230

TRANSISTOR Q553 2SC1473-RN

14

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

TRANSISTOR Q554 2SC1473-RN

TRANSISTOR Q601 BC857B

TRANSISTOR Q602 BC857B

TRANSISTOR Q603 BC857B

TRANSISTOR Q604 BC857B

TRANSISTOR Q607 BC857B

TRANSISTOR Q608 BC857B

TRANSISTOR Q701 2SK2538000LB

TRANSISTOR Q801 2SK1365LB106

TRANSISTOR Q803 2SD965-R

TRANSISTOR Q804 2SA719-TA

TRANSISTOR Q845 2SA684R

TRANSISTOR Q846 BC847B

TRANSISTOR Q847 BC857B

TRANSISTOR Q848 BC847B

TRANSISTOR Q849 2SA1018QTA

TRANSISTOR Q850 2SD1474PLB

TRANSISTOR Q852 2SC1318-S

TRANSISTOR Q853 BC857C

TRANSISTOR Q854 BC857C

TRANSISTOR Q902 BC847B

TRANSISTOR Q903 BC847B

TRANSISTOR Q904 BC857B

TRANSISTOR Q905 BC847B

TRANSISTOR Q906 BC847B

TRANSISTOR Q907 BC857B

TRANSISTOR Q908 2SA1535ARLB

TRANSISTOR Q909 2SC3944ARLB

TRANSISTOR Q1011 BC557B/126

TRANSISTOR Q1103 BC847B

TRANSISTOR Q1104 BC847B

TRANSISTOR Q1105 BC847B

TRANSISTOR Q1106 BC847B

TRANSISTOR Q1107 BC847B

TRANSISTOR Q1108 BC847B

TRANSISTOR Q1109 BC847B

TRANSISTOR Q1110 BC847B

TRANSISTOR Q1111 BC847B

TRANSISTOR Q1112 BC847B

TRANSISTOR Q1113 BC847B

TRANSISTOR Q1116 BC847B

TRANSISTOR Q1118 BC857B

TRANSISTOR Q1501 BC857B

TRANSISTOR Q1502 BC857B

TRANSISTOR Q1503 BC847B

TRANSISTOR Q1504 BC847B

TRANSISTOR Q1505 BC847B

TRANSISTOR Q1506 BC847B

TRANSISTOR Q1507 BC847B

TRANSISTOR Q1508 BC847B

TRANSISTOR Q1509 BC847B

TRANSISTOR Q1510 BC847B

TRANSISTOR Q1511 BC847B

TRANSISTOR Q1513 BC857B

TRANSISTOR Q1660 BC847B

TRANSISTOR Q1661 BC847B

TRANSISTOR Q1662 BC847B

TRANSISTOR Q1663 BC847B

TRANSISTOR Q1664 BC847B

TRANSISTOR Q1665 BC847B

TRANSISTOR Q1666 BC847B

TRANSISTOR Q1667 BC847B

TRANSISTOR Q1801 BC847B

TRANSISTOR Q1802 BC847B

TRANSISTOR Q1803 BC847B

TRANSISTOR Q1804 BC857B

TRANSFORMERS

COILS

TRANSISTOR Q1805 BC857B

TRANSISTOR Q1806 BC857B

TRANSISTOR Q1901 BC847B

TRANSISTOR Q2101 BC860B

TRANSISTOR Q2102 BC860B

TRANSISTOR Q2103 BC860B

TRANSISTOR Q2301 BC847B

TRANSISTOR Q2302 BC847B

TRANSISTOR Q2305 BC857B

TRANSISTOR Q2307 BC860B

TRANSISTOR Q2308 BC860B

TRANSISTOR Q2351 BC847B

TRANSISTOR Q2352 BC847B

TRANSISTOR Q3001 BC857B

TRANSISTOR Q3002 BC847B

TRANSISTOR Q3003 BC847B

TRANSISTOR Q3005 BC847B

TRANSISTOR Q3006 BC847B

TRANSISTOR Q3007 BC847B

TRANSISTOR Q3008 BC847B

TRANSISTOR Q3010 BC857B

TRANSISTOR Q3011 BC857B

TRANSISTOR Q3012 BC847B

TRANSISTOR Q3013 BC847B

TRANSISTOR Q3014 BC847B

TRANSISTOR Q3351 BC847B

TRANSISTOR Q3352 BC857B

TRANSISTOR Q3401 BC847B

TRANSISTOR Q3402 BC847B

TRANSISTOR Q3403 BC847B

TRANSISTOR Q3404 BC847B

TRANSISTOR Q3405 BC847B

TRANSISTOR Q3406 BC847B

TRANSISTOR Q3801 2SD1474PLB

TRANSISTOR Q3901 BC847B

TRANSISTOR Q3902 BC847B

TRANSISTOR Q3903 BC847B

TRANSISTOR Q3904 BC857B

TRANSISTOR Q3905 2SK1006RF122

TRANSISTOR Q3906 2SC4572RB

TRANSISTOR Q3907 BC847B

TRANSISTOR Q3908 BC847B

TRANSISTOR Q3911 BC847B

TRANSISTOR Q3912 BC847B

TRANSISTOR Q3990 BC847B

TRANSFORMER T501 ETH19Y187AY

TRANSFORMER T801 ETP35KAN619U

TRANSFORMER T802 ETS49AH1W7AD

TRANSFORMER T3901 ETF18L37B

COILJ361 EXCELSA39V

COILL002 EXCELDR35V

COILL003 EXCELDR35V

COILL004 EXCELSA35T

COILL005 TLT100K991R

COILL007 EXCELDR35V

COIL L008 ELJFC2R2KF

COIL L009 ELJFC2R2KF

COILL251 EXCELSA35T

COILL252 EXCELSA35T

COILL253 EXCELSA35T

COILL254 EXCELSA35T

COILL281 EXCELSA35T

COILL282 EXCELSA35T

DELAY LINE L351 TAXK0036

15

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COIL L353 TLT120K991R

DELAY LINE L361 TAXK0036

COIL L363 TLT120K991R

DELAY LINE L371 TAXK0036

COIL L373 TLT120K991R

COILL381 TLT220K991R

COILL383 EXCELSA35T

COIL L501 ELELN101KA

COILL554 EXCELSA35T

COILL555 EXCELDR35V

COILL556 EXCELDR35C

COILL557 EXCELDR35C

COILL572 ELHKLB025B

COIL L573 ELHKLB026B

COILL575 ELC18B331E

COILL601 EXCELDR25V

COILL602 EXCELDR35V

COILL603 TLT033K991R

COIL L604 ELEXT2R7KA

COIL L605 ELEXT2R7KA

COIL L606 ELEXT2R7KA

COIL L607 ELEXT2R7KA

COILL701 ELC18B801L

COILL806 EXCELSA39V

COILL808 EXCELSA39V

COILL809 EXCELDR35C

COILL810 EXCELSA39V

COILL811 EXCELSA39V

COILL812 EXCELDR35V

COILL813 EXCELDR35V

COILL817 EXCELDR35V

COILL819 EXCELSA39V

COILL840 ELF18D856A

COILL842 ELF18D856A

COILL843 ELF18D486D

COILL845 EXCELSA35T

COILL847 EXCELSA35B

COILL849 EXCELSA35T

COILL854 ELEIE150KA

COILL859 EXCELSA35T

COILL860 EXCELSA35T

COILL861 EXCELSA35T

COILL910 EXCELSA35T

COILL911 EXCELSA35T

COILL912 EXCELSA35T

COILL1101 EXCELDR35V

COILL1103 TLT047K991R

COILL1104 EXCELDR35V

COILL1105 EXCELDR35V

COILL1106 TLT047K991R

COIL L1507 TLT018K991R

COILL1508 TLT033K991R

COILL1509 EXCELDR35V

COILL1510 EXCELDR35V

COIL L1511 TLT018K991R

COILL1516 EXCELDR35V

COILL1519 EXCEMT103DTM

COILL1523 EXCEMT103DTM

COILL1525 EXCEMT103DTM

COILL1527 EXCEMT103DTM

COILL1528 EXCELDR35V

COILL1529 EXCELDR35V

COILL1532 EXCELDR35V

COILL1533 EXCELDR35V

COILL1534 EXCELDR35V

COILL1535 EXCELDR35V

FILTERS

CRYSTALS

RESISTORS

COILL1536 EXCELDR35V

COILL1537 TLT100K991R

COIL L1538 TLT018K991R

COILL1539 TLT033K991R

COIL L1540 TLT018K991R

COILL1541 TLT033K991R

COIL L1542 TLT018K991R

COILL1543 TLT033K991R

COILL1802 EXCELDR35V

COILL1803 EXCELDR35V

COILL1807 EXCELDR35V

COIL L1808 TLT470K991R

COILL1809 EXCELDR35V

COILL1811 EXCELDR35V

COILL1901 EXCELDR25V

COILL2101 TLT100K991R

COIL L2102 TLT039K991R

COILL2103 TLT100K991R

COILL2104 EXCELDR35V

COILL2106 TLT068K991R

COILL2381 EXCELSA35T

COILL2382 EXCELSA35T

COILL2412 EXCELSA35T

COILL2413 EXCELSA35T

COILL2505 EXCEMT103DTM

COILL2506 EXCEMT103DTM

COILL3001 TLT100K991R

COILL3205 EXCELDR35V

COILL3281 EXCELSA35T

COILL3282 EXCELSA35T

COIL L3401 TLT015K991R

COIL L3402 TLT015K991R

COIL L3403 TLT015K991R

COIL L3404 TLT015K991R

COIL L3405 TLT015K991R

COIL L3406 TLT015K991R

COIL L3407 TLT015K991R

COIL L3408 TLT015K991R

COILL3409 TLT100K991R

COIL L3410 TLT015K991R

COIL L3411 TLT015K991R

COIL L3412 TLT015K991R

COIL L3413 TLT015K991R

COILL3801 EXCELDR35V

COILL3901 EXCELSA35T

COIL L3902 ELC08D182E

LINE FILTER L841 ELF18D850C

LINE FILTER T803 ETQ24K37AY

FILTERX101 EFCT6504BF

CERAMIC FILTER X102 EFCT7004BF

CRYSTAL X601 TSSA010

CRYSTAL X1101 TSSA121

CRYSTAL X1501 TSS2169-B

CRYSTALX1801 TSSA009

CRYSTALX1802 TSSA025

CRYSTALX1803 TSSA024

CRYSTAL X2101 4730007158

CARBONJ101 ERD25TC0T 0.25W 5% 0

S.M.CARBJA1 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA1 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA2 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA2 ERJ8GEY0R00 .125W 5% 0

16

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CARBJA3 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA3 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA4 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA4 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA5 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA6 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA7 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA8 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA8 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA9 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA10 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA11 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA12 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA13 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA14 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA15 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA16 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA18 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA19 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA20 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA21 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA23 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA24 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA26 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA27 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA29 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA30 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA31 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA33 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA35 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA36 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA37 ERJ6GEY0R00 0.1W 5% 0

CARBONJSN002 ERD25TC0T 0.25W 5% 0

S.M.CARBJSF001 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF013 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF010 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF009 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF007 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF006 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF005 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE044 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE033 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE026 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE025 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE024 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE011 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE004 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF018 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSE009 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF032 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSY04 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSY03 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSH010 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSH002 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSG4 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSG2 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSG1 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF043 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF042 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF041 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF039 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF015 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF034 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF017 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF029 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF028 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF027 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF026 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF025 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF024 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF023 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF022 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF021 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF020 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF019 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSG13 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSF037 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSG3 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR001 ERJ6GEYJ223 0.1W 5% 22K

S.M.CARBR002 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR003 ERJ6GEYJ393 0.1W 5% 39K

S.M.CARBR101 ERJ6GEYJ561 0.1W 5% 560

S.M.CARBR102 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR103 ERJ6GEYJ563 0.1W 5% 56K

S.M.CARBR104 ERJ6GEYJ471 0.1W 5% 470

S.M.CARBR105 ERJ6GEYJ332 0.1W 5% 3K3

S.M.CARBR106 ERJ6GEYJ821 0.1W 5% 820

S.M.CARBR107 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR109 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR110 ERJ6GEYJ222 0.1W 5% 2K2

S.M.CARBR111 ERJ6GEYJ331 0.1W 5% 330

S.M.CARBR251 ERJ6GEYJ100 0.1W 5% 10

S.M.CARBR252 ERJ6GEYJ391 0.1W 5% 390

S.M.CARBR253 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR254 ERJ6GEYJ100 0.1W 5% 10

S.M.CARBR255 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR256 ERJ6GEYJ471 0.1W 5% 470

S.M.CARBR257 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR258 ERJ6GEYJ391 0.1W 5% 390

S.M.CARBR259 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR260 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR261 ERJ6GEYJ471 0.1W 5% 470

S.M.CARBR262 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR263 ERJ6GEYJ104 0.1W 5% 100K

S.M.CARBR264 ERJ6GEYJ473 0.1W 5% 47K

CARBONR265 ERDS1TJ2R2 0.5W 5% 2R2

CARBONR266 ERDS1TJ2R2 0.5W 5% 2R2

S.M.CARBR269 ERJ6GEYJ273 0.1W 5% 27K

S.M.CARBR270 ERJ6GEYJ273 0.1W 5% 27K

S.M.CARBR271 ERJ6GEYJ272 0.1W 5% 2K7

S.M.CARBR272 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR273 ERJ6GEYJ331 0.1W 5% 330

CARBONR276 ERDS1TJ2R2 0.5W 5% 2R2

S.M.CARBR281 ERJ6GEYJ272 0.1W 5% 2K7

S.M.CARBR282 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR283 ERJ6GEYJ471 0.1W 5% 470

S.M.CARBR284 ERJ6GEYJ223 0.1W 5% 22K

S.M.CARBR285 ERJ6GEYJ391 0.1W 5% 390

S.M.CARBR286 ERJ6GEYJ222 0.1W 5% 2K2

S.M.CARBR287 ERJ6GEYJ273 0.1W 5% 27K

CARBONR288 ERDS1TJ1R0 0.5W 5% 1

S.M.CARBR289 ERJ6GEYJ104 0.1W 5% 100K

S.M.CARBR290 ERJ6GEYJ104 0.1W 5% 100K

S.M.CARBR292 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR293 ERJ6GEYJ564 0.1W 5% 560K

S.M.CARBR294 ERJ6GEYJ331 0.1W 5% 330

WOUNDR295 ERF3AJ220H 3W 5% 22

WOUNDR296 ERF3AJ220H 3W 5% 22

CARBONR299 ERD25TJ225 0.25W 5% 2M2

METALR350 ERQ12AJ331P .125W 5% 330

S.M.CARBR351 ERJ6GEYJ911 0.1W 5% 910

S.M.CARBR352 ERJ6GEYJ102 0.1W 5% 1K

17

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

METALR354 ERO25CKF4122 0.25W 5% 1K2

METALR355 ERG2FG823H 2W 5% 82K

S.M.CARBR356 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR357 ERJ6GEYJ822 0.1W 5% 8K2

SOLIDR358 ERC12GK471C 0.5W 5% 470

METALR360 ERO50PKF8251 0.5W 5% 8M2

S.M.CARBR361 ERJ6GEYJ911 0.1W 5% 910

S.M.CARBR362 ERJ6GEYJ102 0.1W 5% 1K

METALR364 ERO25CKF4122 0.25W 5% 1K2

METALR365 ERG2FG823H 2W 5% 82K

S.M.CARBR366 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR367 ERJ6GEYJ822 0.1W 5% 8K2

SOLIDR368 ERC12GK471C 0.5W 5% 470

S.M.CARBR369 ERJ6GEY0R00 0.1W 5% 0

METAL R370 ERQ2CJP2R2 2W 5% 2R2

S.M.CARBR371 ERJ6GEYJ911 0.1W 5% 910

S.M.CARBR372 ERJ6GEYJ102 0.1W 5% 1K

METALR374 ERO25CKF4122 0.25W 5% 1K2

METALR375 ERG2FG823H 2W 5% 82K

S.M.CARBR376 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR377 ERJ6GEYJ822 0.1W 5% 8K2

SOLIDR378 ERC12GK471C 0.5W 5% 470

S.M.CARBR379 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR383 ERJ6GEY0R00 0.1W 5% 0

S.M. CARR394 ERJ6ENF1021 0.1W 5% 1K

S.M. CARR395 ERJ6ENF2370 0.1W 5% 37

S.M. CARR396 ERJ6ENF1021 0.1W 5% 1K

S.M. CARR397 ERJ6ENF2370 0.1W 5% 37

S.M. CARR398 ERJ6ENF1021 0.1W 5% 1K

S.M. CARR399 ERJ6ENF2370 0.1W 5% 37

S.M.CARBR401 ERJ6GEYJ272 0.1W 5% 2K7

S.M.CARBR402 ERJ6GEYJ682 0.1W 5% 6K8

S.M.CARBR403 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR404 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR416 ERJ6GEYJ682 0.1W 5% 6K8

S.M.CARBR418 ERJ6GEYJ682 0.1W 5% 6K8

METALR419 ERG3FJ471 3W 5% 470

S.M.CARBR420 ERJ6GEYJ563 0.1W 5% 56K

S.M.CARBR421 ERJ6GEYJ224 0.1W 5% 220K

S.M.CARBR441 ERJ6GEYJ393 0.1W 5% 39K

S.M.CARBR442 ERJ6GEYJ123 0.1W 5% 12K

S.M.CARBR443 ERJ6GEYJ222 0.1W 5% 2K2

CARBONR451 ERDS1TJ3R3 0.5W 5% 3R3

CARBONR452 ERDS1TJ3R3 0.5W 5% 3R3

S.M.CARBR453 ERJ6GEYJ393 0.1W 5% 39K

S.M.CARBR454 ERJ6GEYJ123 0.1W 5% 12K

S.M.CARBR457 ERJ6GEYJ682 0.1W 5% 6K8

S.M.CARBR458 ERJ6GEYJ302 0.1W 5% 3K

S.M.CARBR470 ERJ6GEYJ682 0.1W 5% 6K8

CARBON R471 ERDS1FJ1R0 0.5W 5% 1

CARBONR504 ERD25TJ271 0.25W 5% 270

CARBON R506 ERDS1TJ681 0.5W 5% 680

CARBON R507 ERDS1TJ681 0.5W 5% 680

METALR554 ERX3FJR39H 3W 5% R39

CARBONR556 ERDS1TJ223 0.5W 5% 22K

CARBON R557 ERDS1TJ683 0.5W 5% 68K

CARBONR558 ERDS1TJ273 0.5W 5% 27K

S.M.CARBR560 ERJ6GEYJ123 0.1W 5% 12K

S.M.CARBR562 ERJ6GEYJ273 0.1W 5% 27K

CARBONR564 ERDS1TJ394 0.5W 5% 390K

METALR567 ERG3FJ223 3W 5% 22K

CARBONR569 ERDS1TJ120 0.5W 5% 12

S.M.CARBR570 ERJ6GEYJ103 0.1W 5% 10K

METALR572 ERG3FJ821 3W 5% 820

METALR574 ERG3FJ151 3W 5% 150

S.M.CARBR579 ERJ6GEYJ274 0.1W 5% 270K

S.M.CARBR580 ERJ6GEYJ563 0.1W 5% 56K

S.M.CARBR581 ERJ6GEYJ104 0.1W 5% 100K

S.M.CARBR582 ERJ6GEYJ225 0.1W 5% 2M2

S.M.CARBR583 ERJ6GEYJ225 0.1W 5% 2M2

S.M.CARBR588 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBR601 ERJ6GEYJ153 0.1W 5% 15K

S.M.CARBR613 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR614 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR615 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR616 ERJ6GEYJ100 0.1W 5% 10

S.M.CARBR617 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR619 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR620 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR622 ERJ6GEYJ393 0.1W 5% 39K

S.M.CARBR623 ERJ6GEYJ153 0.1W 5% 15K

S.M.CARBR626 ERJ6GEYJ331 0.1W 5% 330

S.M.CARBR627 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR628 ERJ6GEYJ472 0.1W 5% 4K7

S.M.CARBR630 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR631 ERJ6GEYJ105 0.1W 5% 1M

S.M.CARBR632 ERJ6GEYJ223 0.1W 5% 22K

S.M.CARBR634 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR635 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR636 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR637 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR638 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR639 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR640 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR641 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR642 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR643 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR644 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR645 ERJ6GEYJ102 0.1W 5% 1K

S.M.CARBR646 ERJ6GEYJ821 0.1W 5% 820

S.M.CARBR647 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR648 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR649 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR650 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR651 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR652 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR653 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR655 ERJ6GEYJ224 0.1W 5% 220K

S.M.CARBR657 ERJ6GEYJ750 0.1W 5% 75

S.M. CARR658 ERJ6ENF2212 0.1W 5% 220

S.M.CARBR663 ERJ6GEYJ394 0.1W 5% 390K

S.M.CARBR664 ERJ6GEYJ682 0.1W 5% 6K8

S.M.CARBR666 ERJ6GEYJ222 0.1W 5% 2K2

S.M.CARBR667 ERJ6GEYJ473 0.1W 5% 47K

S.M.CARBR674 ERJ6GEYJ273 0.1W 5% 27K

S.M.CARBR675 ERJ6GEYJ562 0.1W 5% 5K6

S.M.CARBR676 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR677 ERJ6GEYJ273 0.1W 5% 27K

S.M.CARBR678 ERJ6GEYJ562 0.1W 5% 5K6

S.M.CARBR679 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR680 ERJ6GEYJ273 0.1W 5% 27K

S.M.CARBR681 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR682 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR683 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR684 ERJ6GEYJ101 0.1W 5% 100

S.M.CARBR685 ERJ6GEYJ103 0.1W 5% 10K

S.M.CARBR686 ERJ6GEYJ102 0.1W 5% 1K

S.M. CARR688 ERJ6ENF3162 0.1W 5% 1K6

METALR701 ERQ1CJP5R6 1W 5% 5R6

CARBON R702 ERDS1TJ683 0.5W 5% 68K

S.M.CARBR703 ERJ6GEYJ103 0.1W 5% 10K

CARBONR704 ERDS1TJ330 0.5W 5% 33

18

Loading...

Loading...