Panasonic TX-20LB5FG, SL-120PPP Schematic

ORDER NO. PCZ0602001CE

Service Manual

LCD TV

TX-20LB5F/G

TX-20LB5P/G

SL-120PP Chassis

Power Source

AC 100-240V, 50/60Hz TV set DC 15V, 4.67A Max.

Power Consumption

Average use: 50W

Standby condition: 2.5W

LCD

VGA (640 × 480 pixels)

4:3 aspect ratio LCD panel

Screen Size

408 mm(W) × 306 mm(H)

Sound

Speaker

9 cm × 5cm, 2pcs, 4Ω

Audio Output

4W (2W + 2W), 20% THD

Headphones

M3 (3.5 mm) Jack x 1

Receiving Systems/ Band name

VHF BAND I: CH2-CH4

BAND II: CH5-CH12

UHF HYPER BAND :SI’-S3’, S1-S20

BAND IV, V : CH21-CH68

PAL-B/G, D/K, SECAM-L/L’, NTSC(AV input only)

Aerial-Rear

UHF/VHF

Operating Conditions

Temperature: -10°C ~ 40°C

Humidity: 0% ~ 90% RH (non-condensing)

Connection Terminals

AV1 (Scart connecter)

21 Pin terminal (Audio/Video in, Audio/Video out,

RGB in)

AV2

VIDEO

RCA PIN Type × 1

S-VIDEO

Mini DIN 4-pin

AUDIO L-R

RCA PIN Type × 2

Dimensions (W x H x D)

Including TV Stand

608mm(W) × 215mm(D) × 457.5mm(H)

TV Set Only

608mm(W) × 73,7mm(D) × 403mm(H)

Weight

10.1kg Net

Note:

Design and Specifications are subject to change without

notice.

Weight and Dimensions shown are approximate.

© 2006 Matsushita Electric Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

TX-20LB5F/G

TX-20LB5P/G

CONTENTS

Page

1. Safety Precautions ----------------------------------------------- 3

1.1. General Guidelines -------------------------------------- 3

1.2. Touch-Current Check ------------------------------------ 3

2. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices ------------------ 4

3 About lead free solder (PbF) --------------------------------- 5

4. Self Check ---------------------------------------------------------- 6

5. Chasis Board Layout -------------------------------------------- 7

6. Before servicing -------------------------------------------------- 8

6.1. Wire dressing ---------------------------------------------- 8

7. Disassembly for service --------------------------------------- 9

7.1. Stand ass´y ------------------------------------------------ 9

7.2. Back cover ------------------------------------------------- 9

7.3. CTRL ass´y -----------------------------------------------10

7.4. LED ass´y -------------------------------------------------10

7.5. AV ass´y ----------------------------------------------------11

7.6. INVERTER ------------------------------------------------11

7.7. TTL ass´y -------------------------------------------------- 11

7.8. Speaker (left and right) --------------------------------- 11

7.9. Main ass´y -------------------------------------------------12

7.10.Panel LCD -------------------------------------------------12

Page

8 Service Mode Function ----------------------------------------13

8.1. How to enter SERVICE 1 ------------------------------13

8.2. How to enter SERVICE 2 ------------------------------13

8.3. Option Description --------------------------------------14

9. Conduct Views ---------------------------------------------------16

9.1. Foil Side ---------------------------------------------------16

9.2. Component Side -----------------------------------------18

10. Block and Schematic Diagrams --------------------------20

10.1. Schematic Diagram Notes ---------------------------20

10.2. Block Diagram ------------------------------------------21

10.3. Schematic Diagram -----------------------------------22

11. Parts Location & Replacement Parts List -------------28

11.1. Different parts List -------------------------------------28

11.2. Exploded View ------------------------------------------29

11.3. Stand Assy Exploded View --------------------------30

11.4. Packing Exploded Views -----------------------------31

11.5. Electrical Replacement Parts List ------------------32

2

TX-20LB5F/G

TX-20LB5P/G

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

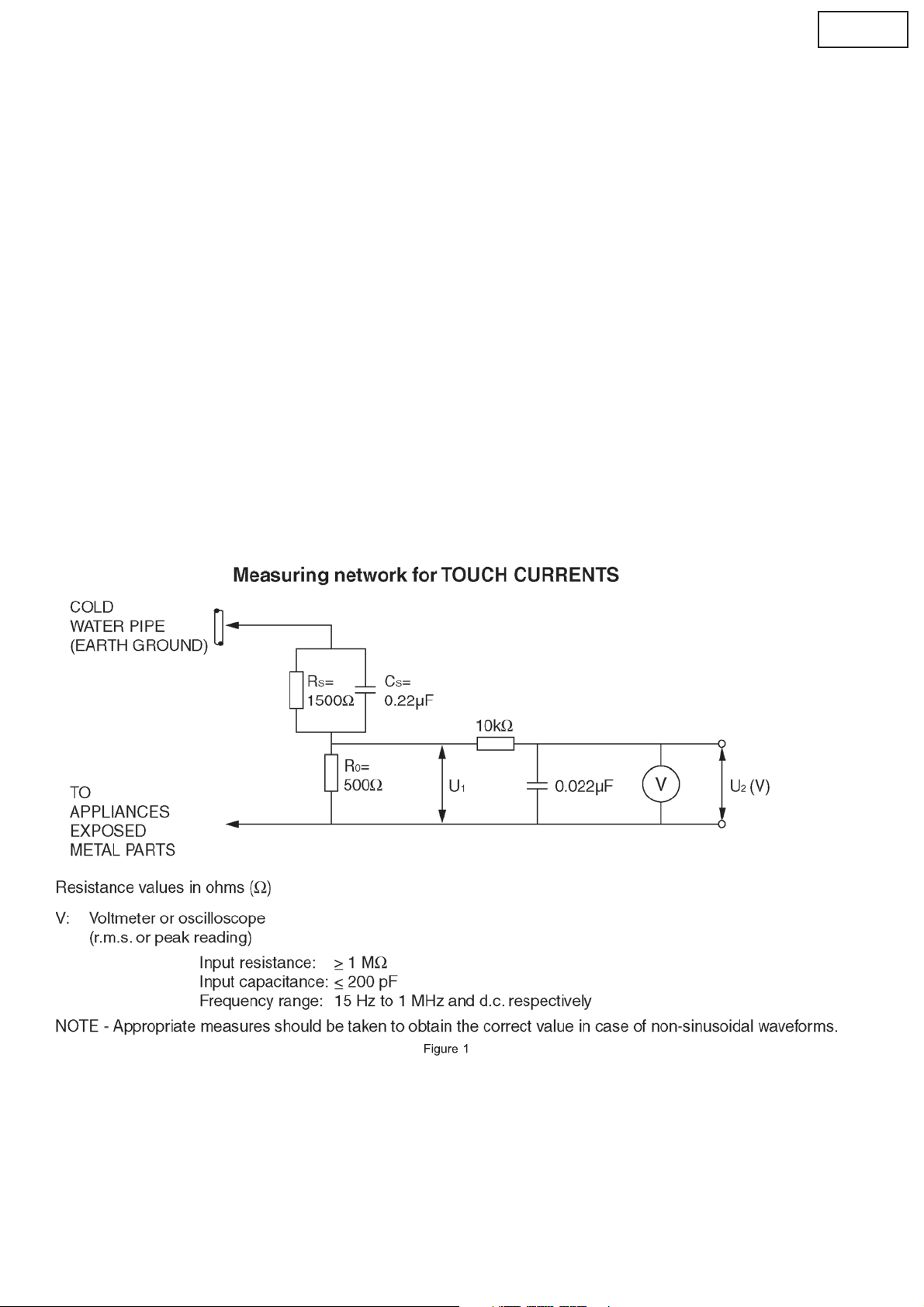

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground such

as a water pipe, as shown in Figure 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUGH CURRENT) expressed as voltage U1 and U2, does not exceed the following values:

For a. c.: U

For d. c.: U

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and 2.0

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

1 = 35 V (peak) and U2 = 0.35 V (peak);

1 = 1.0 V,

mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100 kHz.

3

TX-20LB5F/G

TX-20LB5P/G

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor „chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as almi-

num foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as „anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brush-

ing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

4

TX-20LB5F/G

TX-20LB5P/G

3 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

5

TX-20LB5F/G

TX-20LB5P/G

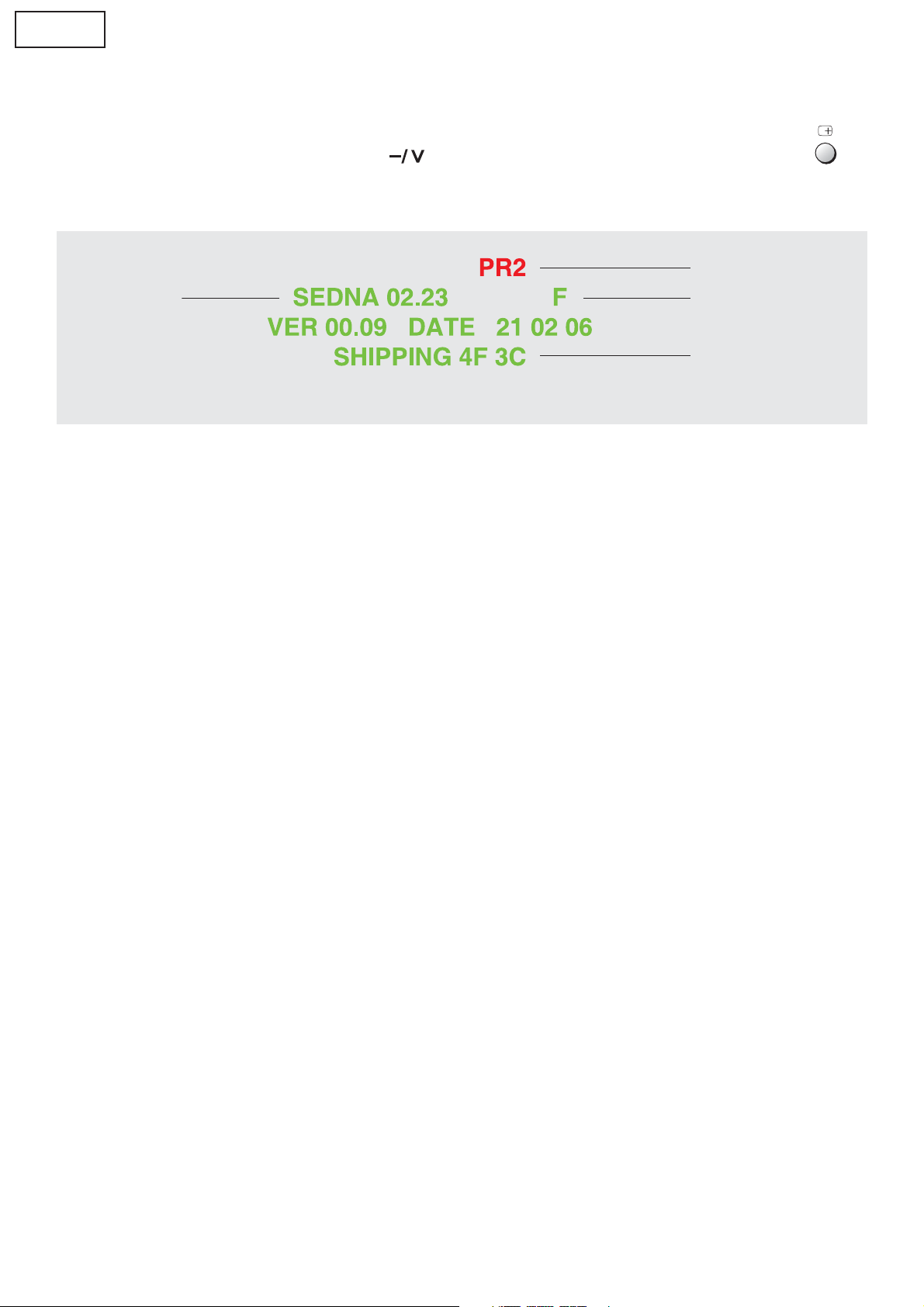

4 Self Check

1. Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2. To get into the Self -Check mode press the Down (

button on the remote control, and the screen will show when the self Check is finished:

SEDNA VERSION

3. Turn off the TV to reset after SELF-CHECK menu.

) button on the TV set, at the same time pressing the Recall ( )

Programm number

Software Type

When Self Check is

finished you have this line

within the option definition.

6

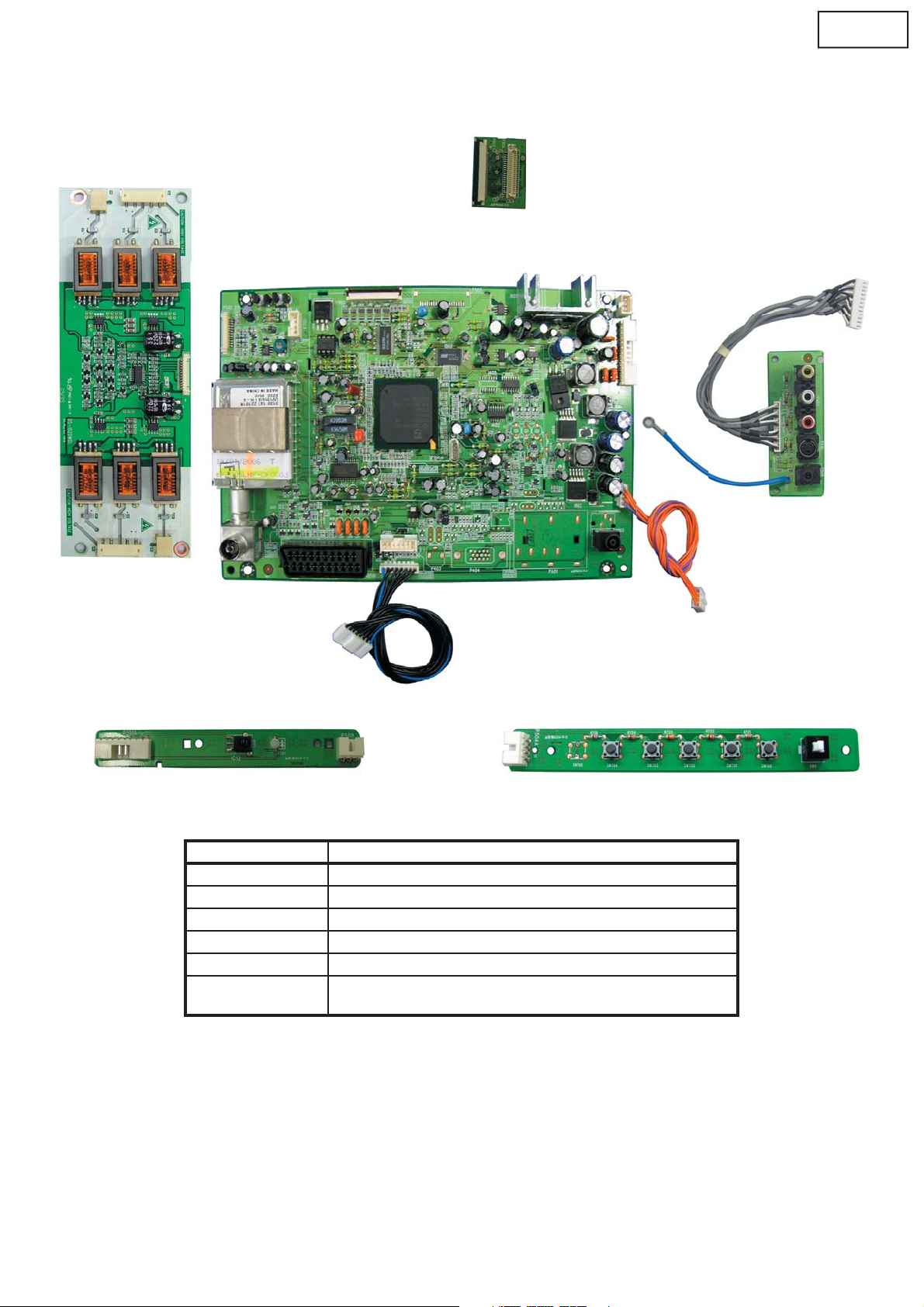

5. Chassis Board Layout

TX-20LB5F/G

TX-20LB5P/G

TTL ASSY

INVERTER

AV ASSY

MAIN ASSY

LED ASSY CTRL ASSY

Board Name Function

MAIN ASSY Main Board

CTRL ASSY Power Switch, Select Switch

AV ASSY AV, Headphone

LED ASSY Remote Receiver, LED, Speaker(R) connection

TTL ASSY Transistor-Transistor Logic circuit

INVERTER Inverter

None serviceable and should be exchanged for service.

7

TX-20LB5F/G

TX-20LB5P/G

6. Before servicing

6.1. Wire dressing

Check a wire dressing is same as illustrated below;

3

P508

4850712S01

A B

P502-INVERTER Coupler Wire

P502

P902

3

P501A

P504A

4859004560

P902-LCD PANEL FFC Cable

P601

PA09 A

2

P504

1

PA09

A

4850703S50

C

P601-Speaker(L) Coupler Wire

4850712N12

D

PA09-PA09A Coupler Wire

4850703S51

E F G

P508-Speaker(R) Coupler

6.1.1 Connection

1. Conect every connector surely as ilustrated above photo (

2. Manage wires not to touch any sharp edge of the metal parts.

3. Manage wires not to have too much tension.

6.1.2 Clamping

Clamp

Wire

P501 - P501A

connection wire

P502 - INVERTER

connection wire

P504 - P504A

connection wire

P508 - Right speaker

connection wire

P601 - Left speaker

connection wire

PA09 - PA09A

connection wire

Wire

CLAMP WIRE

4850708S02

P501-P501A Coupler Wire

1

A

2

TIE CABLE

~ G).

4850704G06

P504-P504A Coupler Wire

3

FILAMENT TAPE

Remark

No clamping

8

TX-20LB5F/G

TX-20LB5P/G

7. Disassembly for service

7.1 Stand Ass’y

1. Lay down the main unit so that the back cover faces

upward.

stand ass’y back cover

2. Remove the fixing screws (4pcs

3. Remove the stand ass’y

)

7.2. Back cover

1. Remove stand ass’y (see 7.1.)

2. Remove the fixing screws (4pcs

3. Remove the Back cover as pushing clips as illustrated

below (2 point clip

)

)

9

TX-20LB5F/G

TX-20LB5P/G

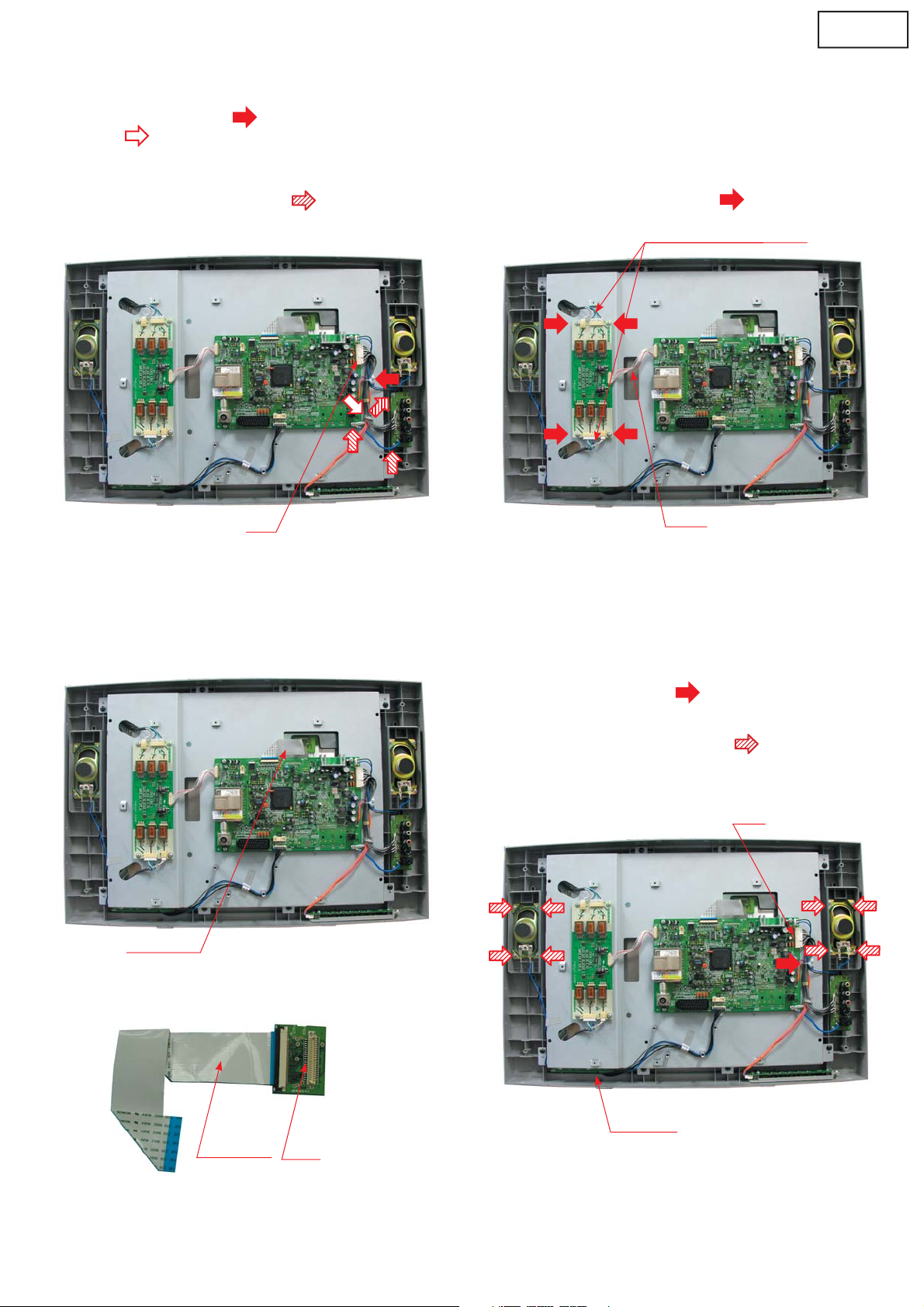

7.3. CTRL Ass’y

1. Remove the back cover (see. 7.2.)

2. Remove the fixing screw (1pcs

3. Remove the CTRL Ass’y with cable

4. Disconnect the coupler (conncector P504)

P504

5. Remove the fixing screws (2pcs

Power (1pcs

)

)

) and Button

7.4. LED Ass’y

1. Remove the back cover (see. 7.2.)

2. Remove the tapes (2pcs

3. Remove the fixing screws (2pcs

4. Remove the LED Ass’y with cable

SP02A P501

5. Disconnect the couplers.

(connector P501 and CONN As SP02A)

)

)

6. Remove the CTRL PCB.

SP02A P501

6. Remove the LED PCB.

10

TX-20LB5F/G

TX-20LB5P/G

7.5. AV Ass’y

1. Remove the back cover (see. 7.2.)

2. Remove tie cable(1pcs

(1pcs

3. Disconnect the coupler (connector PA09)

4. Remove the fixing screws (3pcs

5. Remove the AV Ass’y

) to free the cable.

) and unlock the clamp wire

)

7.6. INVERTER

1. Remove the back cover (see. 7.2.)

2. Disconnect the coupler(connector P502A)

3. Disconnect the backlight interface connectors which

are introduced from LCD panel.

4. Remove the fixing screw (4pcs

backlight interface connector

)

PA0 9

7.7. TTL Ass’y

1. Remove the back cover (see. 7.2.)

2. Unlock the coupler(CONN WAFER P902) to free the

FFC cable(P902A).

3. Remove the TTL Ass’y with FFC cable.

FFC CABLE

P502A

5. Remove the INVERTER.

7.8. Speaker (left and right)

1. Remove the back cover (see. 7.2.)

2. Remove the LED Ass’y (see 7.4.)

3. Remove tie cable(1pcs

pler (CONN AS SP01A)

4. Remove the fixing screws (8pcs

5. Remove the speaker (left and right).

) and disconnect the cou-

)

SP02

4. Unlock the coupler(CONN WAFER P905) and remove

FFC cable.

FFC CABLE

5. Remove the TTL Ass’y.

P905

LED Ass’y

11

TX-20LB5F/G

TX-20LB5P/G

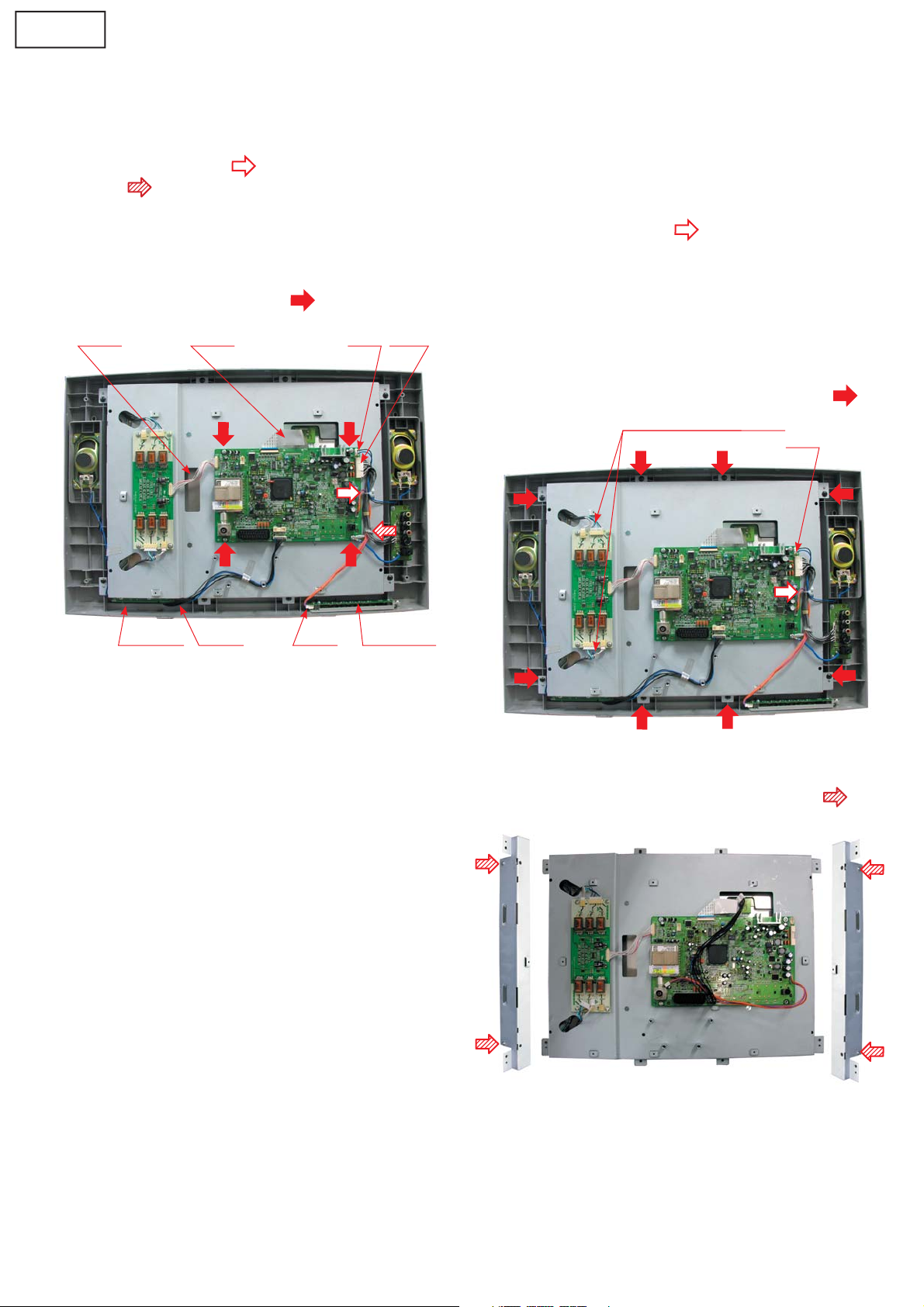

7.9. Main Ass’y

1. Remove the back cover (see. 7.2.)

2. Remove the LED Ass’y, CTRL Ass’y

(see 7.3., 7.4.)

3. Remove tie cable(1pcs

(1pcs

4. Disconnect the couplers (connector P902A, SP01A,

PA09A, P504A, P501A)

5. Disconnect the FFC cable(P902A)

6. Remove the fixing screws (4 pcs

P502A P902A SP01A PA09A

) to free the cable.

) and unlock the clamp wire

)

7.10. Panel LCD

1. Remove the back cover (see. 7.2.)

2. Remove the TTL Ass’y (see 7.7.)

3. Disconnect the backlight interface connectors which

are introduced from LCD panel

4. Remove the LED Ass’y (see 7.4.)

5. Remove tie cable (1pcs

6. Disconnect left speaker wire (connector SP01A)

7. Remove the fixing screws from AV Ass’y

(3 pcs, see 7.5.4.)

8. Remove the fixing screw from CTRL Ass’y

(1 pcs, see 7.3.2.)

9. Remove the fixing screws from Frame Main (8 pcs

backlight interface connector

)

)

SP01A

CTRL Ass’yP504AP501ALED Ass’y

10. Take out Frame Main with Panel.

11. Remove screws from Frame Main PCB (4 pcs

)

12

Loading...

Loading...