Panasonic TX-20LB5F, TX-20LB5P Service manual

LCD Television

TX-20LB5F(WEST EUROPE)

TX-20LB5P(EAST EUROPE)

SL-115P Chassis

SPECIFICATIONS

Power Source

“AC 100-240V, 50/60Hz”

Power Consumption

Average use : 50W

Stand-by condition : 2.5W

“TV set DC 15V, 3.5A max”

LCD

“20-inch(510.54mm),

4:3 aspect ratio LCD panel”

Screen Size

408.0mm(H) * 306.0mm(V)

Sound

Speaker

5cm * 9cm, 2pcs, 4

Audio Output

5W(2.5W+2.5W), 10%THD

Headphones

M3(3.5mm) Jack * 1

Receiving Systems / Band name

“PAL B, G, H, SECAM B, G, SECAM L/L’

VHF E2-E12

VHF H1-H2(ITALY)

VHF A-H(ITALY)

UHF E21-E68(UK only)

CATV(S01-S05)

CATV S1-S10 (M1-M10)

CATV S11-S20 (U1-U10)

CATV S21-S41 (Hyperband)

PAL 525/60

Playback of NTSC tape from

some PAL video recorders

(VCR)

M.NTSC

Playback From M.NTSC video

recorders (VCR)

NTSC (AV input only)

Playback From NTSC video

recorders (VCR)

Aerial-ear

UHF / VHF

Operating Conditions

Temperature : 5-35°…

Humidity : 5%-90% RH (noncondensing)

Connection Terminals

AV1 (Scart connecter)

21 Pin socket (Audio/Video in,

Audio/Video out, RGB in)

AV2

VIDEO

RCA PIN Type * 1

S-VIDEO

Mini DIN 4-pin

AUDIO L-R

RCA PIN Type * 2

Dimensions (W * H * D)

Including TV Stand

608mm * 215mm * 457.5mm

TV Set Only

608mm * 73.7mm * 403mm

Weight (Mass)

10.1Kg NET

Note :

Specifications are subject to

change without notice.

Weights and dimensions

shown are approximate.

ORDER No. PCZ0511109C2

2005 Matsushita Electric Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

1. Safety Precautions 2

1.1 General Guidelines 2

1.2 Touch-Current Check 2

2. Prevention of Electro Static Discharge(ESD) to

Electrostatically Sensitive(ES) Devices 3

3. Chasis Board Layout 4

4. Servicing method 5

4.1 Removing the tilt base 5

4.2 Removing the rear cover 5

4.3 Removing the Switch Unit 6

4.4 Removing the E-Board 6

4.5 Removing the C-Board 6

4.6 Removing the IR/LED unit 6

4.7 Removing the D-Board 7

4.8 Removing the Speaker Unit 7

4.9 Removing the Shield pcb assy 7

4.10 Removing the Shield case 7

4.11 Removing the A-Board, B-Board 8

4.12 Removing the LCD panel 8

5. Service Mode Function 9

5.1 How to enter SERVICE 1 9

1

Design and Specifications are subject to change without notice.

Weight and Dimensions shown are approximate.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

6. Conductor Views 10

6.1 MAIN PCB(TOP) 10

6.2 MAIN PCB(BOTTOM) 11

7. Block and Schematic Diagrams 12

7.1 Schematic Diagram Notes 12

7.2 Signal Block Diagram 13

7.3 Power Schematic Diagram 14

7.4 VCTI Schematic Diagram 15

7.5 Memory AMP Schematic Diagram 16

7.6 AD9883 Schematic Diagram 17

7.7 Deinterlace Schematic Diagram 18

7.8 Image Processor Schematic Diagram 19

7.9 LVDS, KEY, Input Schematic Diagram 20

8. Parts Location & Mechenical Replacement

Parts List

21

8.1 Part Location

21

8.2 Packing Exploded View

22

9. Service Parts List

23

Contents

and 2

2

1. Safety Instruction

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all part

which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers,

insulation papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

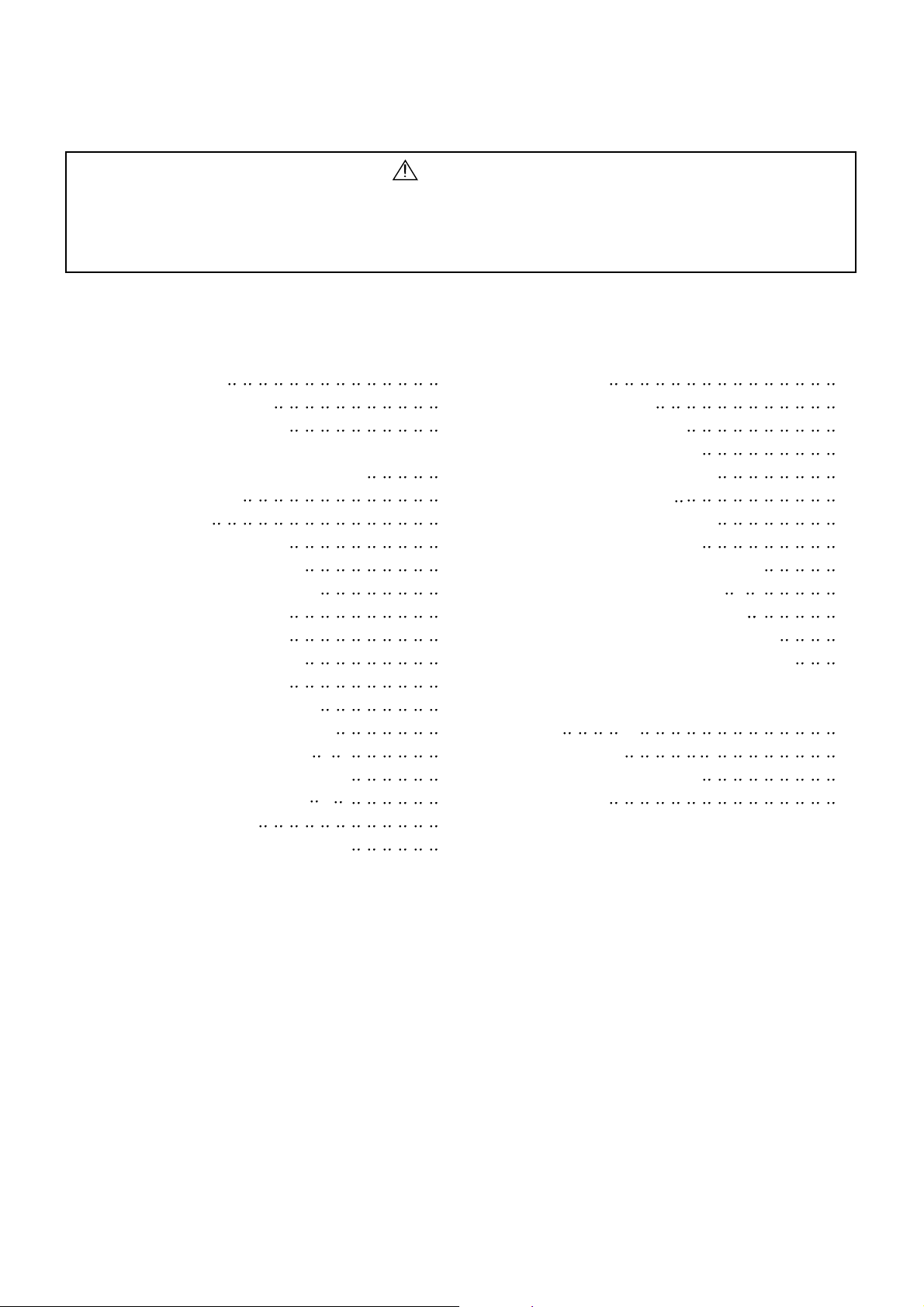

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this chack.

2. Connect a measuring network for touch currents between each exposed matallic part on

the set and a good earth ground such as a water pipe, as shown in Figure1.

3. Use Leakage Current Tester(Simpson 228 or equivalent) to measure the potential across

the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

6. The potential at any point (TOUGH CURRENT) expressed as voltage U1 and U2, does not

exceed the following values:

For a. c.: U1 = 35V(peak) and U2 = 0.35V(peak);

For d. c.: U1 = 1.0V,

Note:

The limit value of U

2 = 0.35V(peak) for a. c. and U1

= 1.0V for d. c. correspond to the

values 0.7 mA (peak) a. c. and 2.0 mA d. c.

The limit value U

1 = 35V(peak) for a. c. correspend to the value 70 mA(peark) a. c. for

frequencies greater than 100kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the

equipment should be repaired and rechecked before it is returned to the customer.

Measuring network for TOUCH CURRENTS

Resistance values in ohms( )

V: Voltmeter or oscilloscope(r.m.s. or peak reading)

Input resistance: 1M

Input capacitance: 200 pF

Frequency range: 15Hz to 1 MHz and d.c. respectively

NOTE - Appropriate measures should be taken to obtain the correct value in case of non-

sinusoidal waveforms.

Figure 1

COLD

WATER PIPE

(EARTH

GROUND

TO

APPLIANCES

EXPOSED

METAL PARTS

3

2 Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive(ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical

E

S d

evices are integrated circuits and some field-effect transistors and semiconductor “chip”

components. T

he following techniques should be used to help reduce the incidence of

component damage caused by electro static discharge(ESD).

1. I

mmediately before handling any semiconductor component or semiconductor-equipped

assembly, drain off any ESD on your body by touching a known earth ground. Alternatively,

o

btain a

nd wear a commercially available discharging ESD wrist strap, which should be

removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a

conductive surface such as alminum foil, to prevent electrostatic charge buildup or exposure

of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as

“anti-static(ESD protected)” can generate elec

trical charge sufficient to damage ES devices.

5. D

o not use freon-propelled chemicals. These can generate electrical chages sufficient to

damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before

y

ou a

re ready to install it.(Most replacement ES devices are packaged with leadse

electrically s

horted together by conductive foam, alminum foil or comparable conductive

material).

7. Im

mediately before removing the protective material from the leads of a replacement ES

device, touch the protective material to the chassis or circuit assembly into which the device

will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety

precautions.

8. M

inimize bodily motions when handling unpackaged replacement ES devices. (Otherwise

hamless motion such as the brushing together of your clothes fabric or the lifting of your foot

f

rom a c

arpeted floor can generate static electricity (ESD) sufficient to damage an ES

device).

There are special components used in this equipment which are imporant for safety.

These parts are maked by in the schematic diagrams, Exploded Views and replacement parts list. lt is

essential that these critical parts should be replaced with manufacturer’s specified parts to prevent shock,

fire, or other hazards. Do not modify the original design witho

ut permission of manufacturer.

IMPORTANT SAFETY NOTICE

4

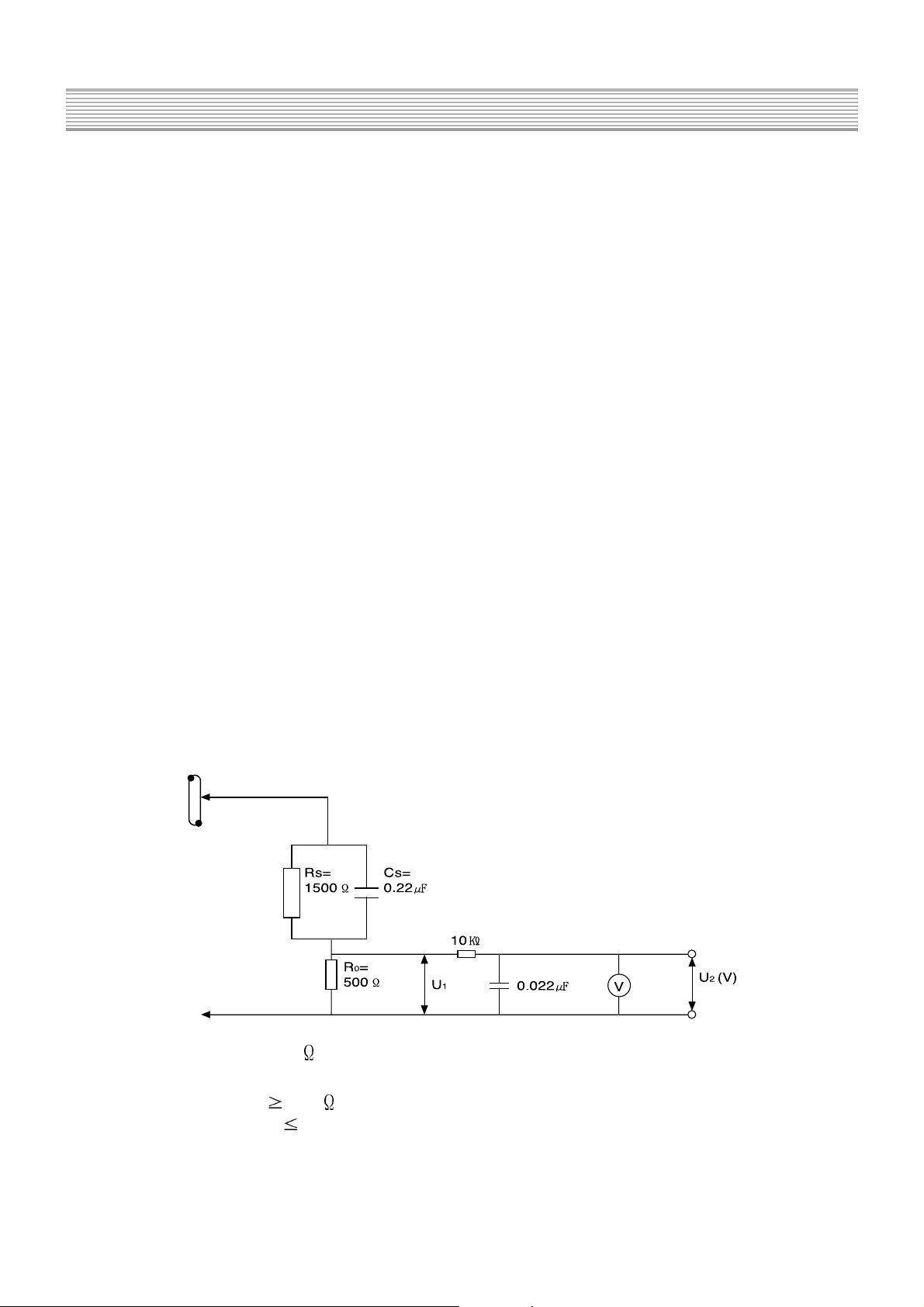

3. Chassis Board Layout

Board Name Function

A-Board MAIN PCB

B-Board INVERTER PCB

C-Board AV PCB

D-Board IR/LE D PCB

E-Board CONTROL PCB

5

4. Servicing method

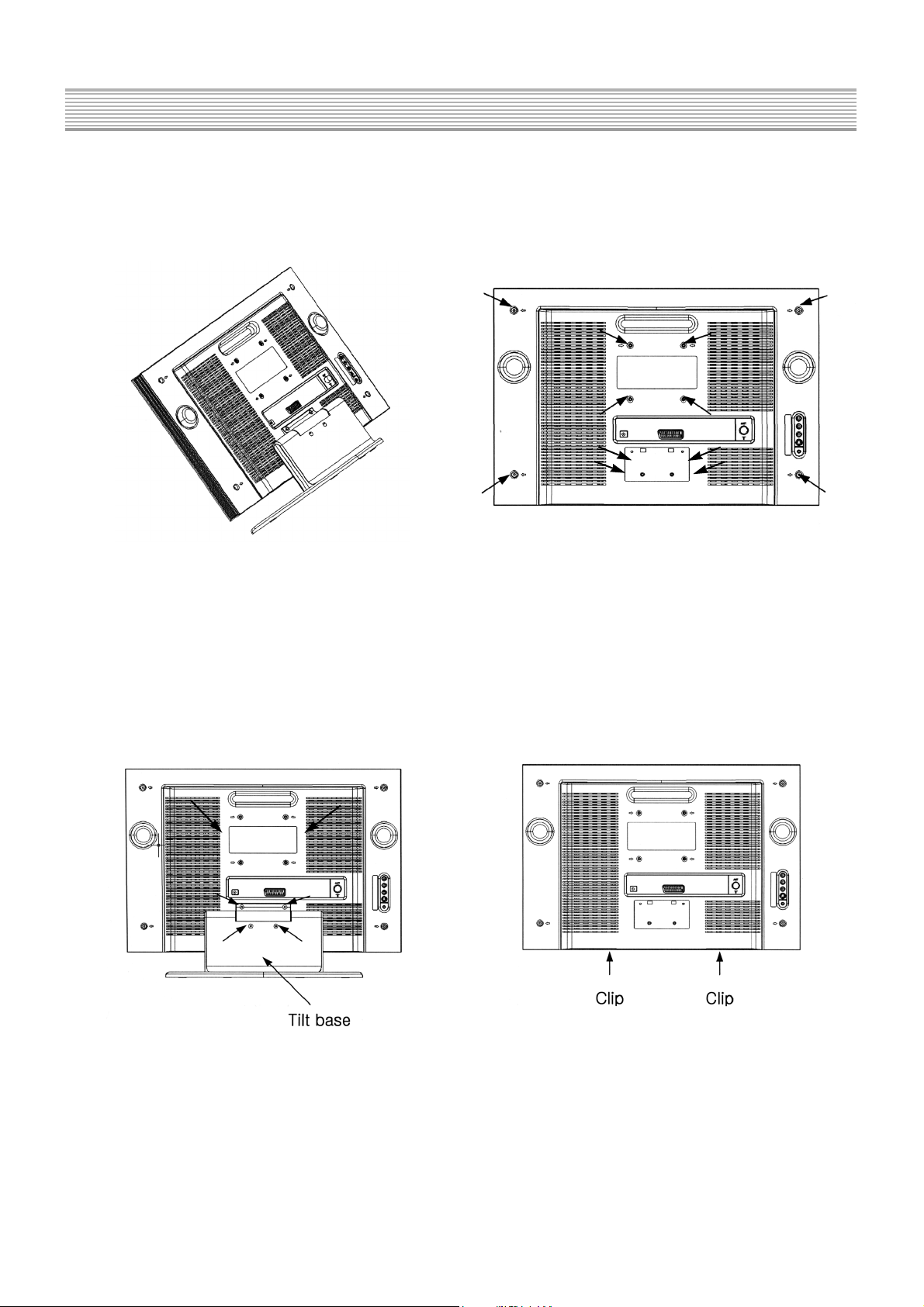

4.1. Removing the tilt base

1. Lay down the main unit so that the rear

cover faces upward.

2. Remove the fixing screw(4pcs).

3. Remove the hinge cover.

4.2. Removing the rear cover

1. Remove the tilt base.(See 4.1.)

2. Remove the fixing screw(8pcs)

3. Remove the rear cover as pushing clips.

(2 point clip)

6

Servicing method

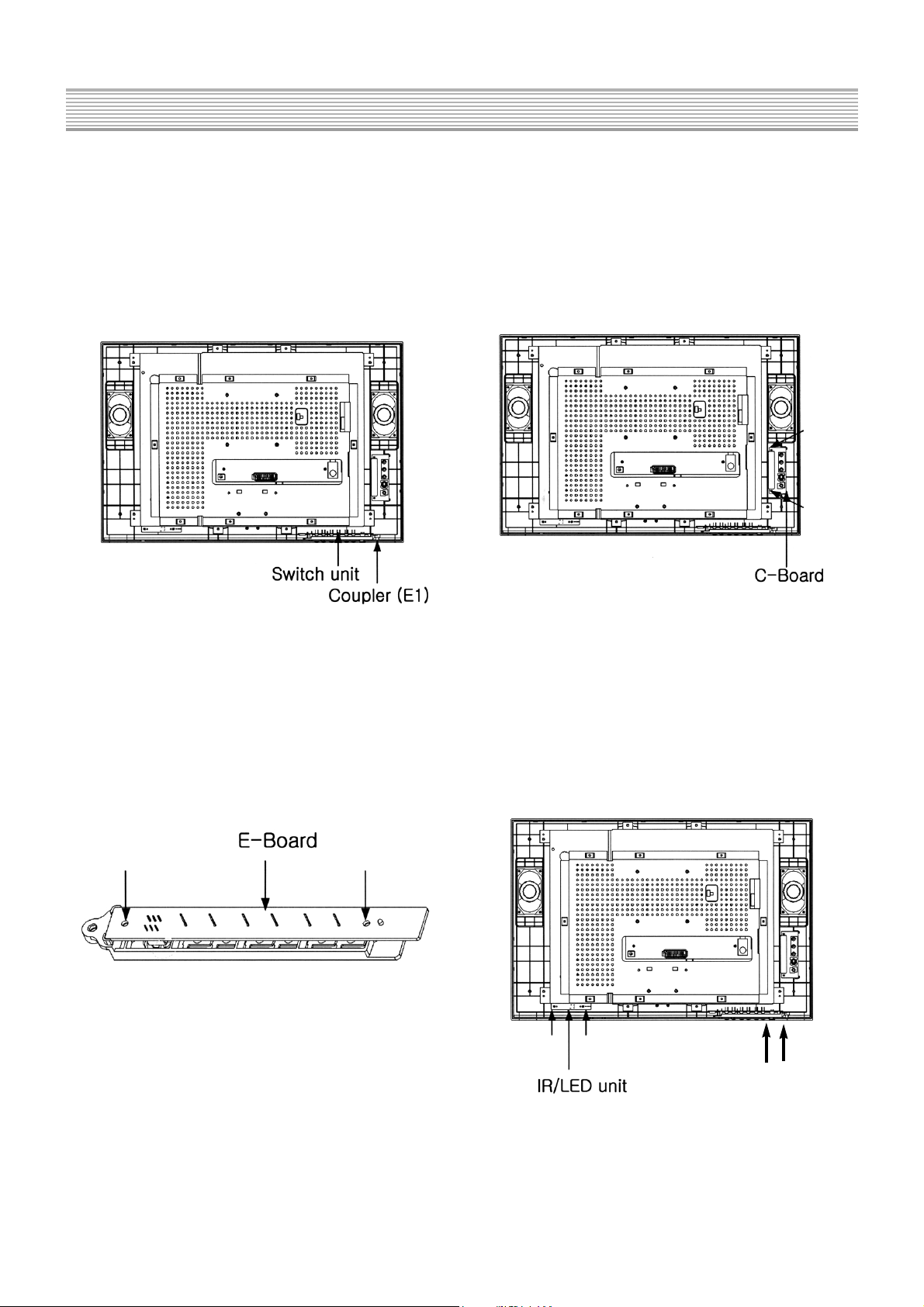

4.3. Removing the switch unit

1. Remove the rear cover. (See 4.2.)

2. Disconnect the coupler. (E1)

3. Remove the fixing screw. (1pcs)

4. Remove the switch unit.

4.4. Removing the E-Board

1. Remove the switch unit. (See 4.3.)

2. Remove the fixing screws. (2pcs)

3. Remove the E-Board.

4.5. Removing the C-Board

1. Remove the rear cover. (See 4.2.)

2. Disconnect the coupler. (C1)

3. Remove the fixing screws. (2pcs)

4. Remove the C-Board.

4.6. Removing the IR/LED unit

1. Remove the rear cover. (See 4.2.)

2. Disconnect the coupler. (D1)

3. Remove the fixing screws. (2pcs)

4. Remove the D-Board.

7

Servicing method

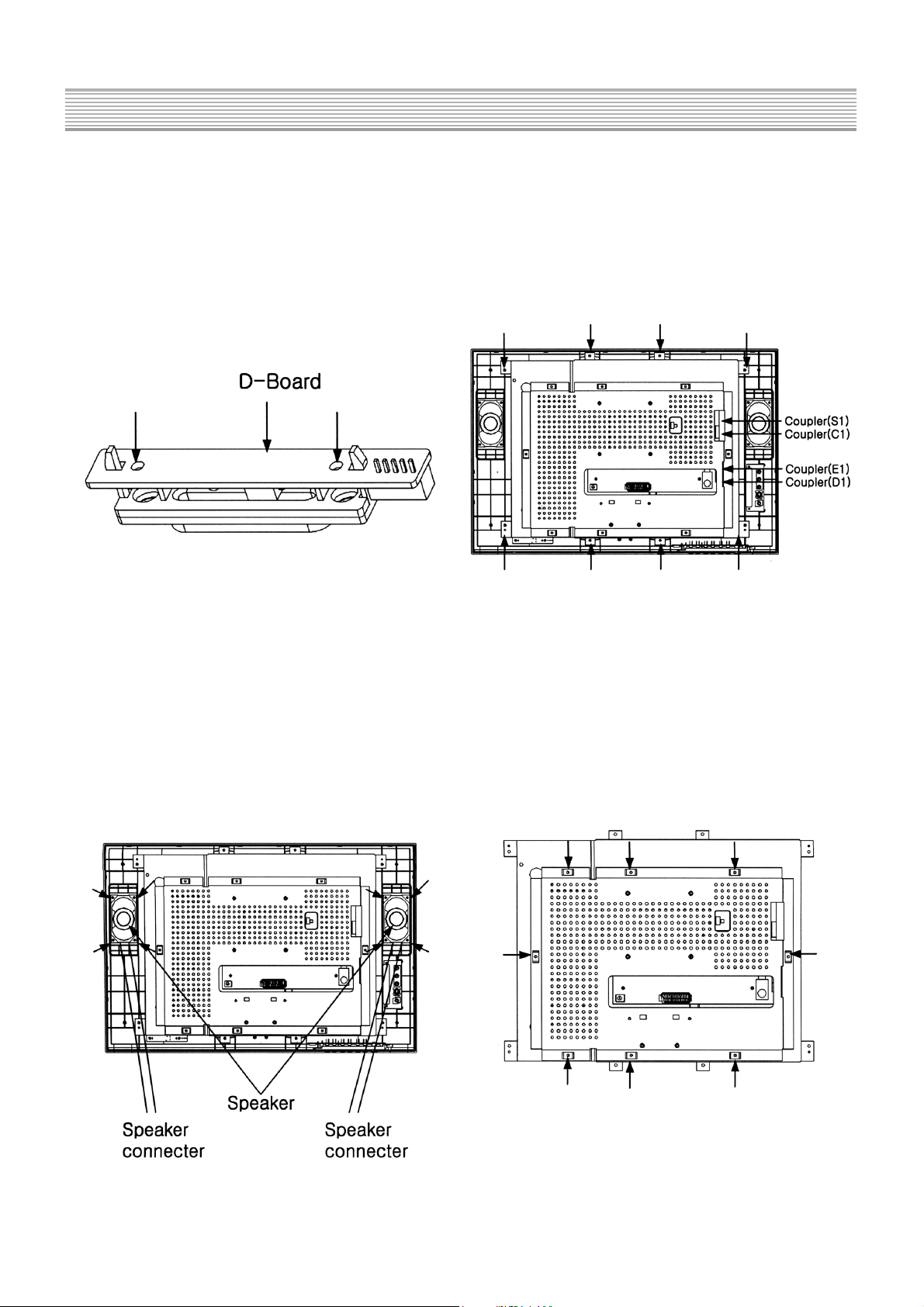

4.7. Removing the D-Board

1. Remove the IR/LED unit. (See 4.6.)

2. Remove the fixing screws. (2pcs)

3. Remove the D-Board.

4.8. Removing the Speaker unit

1. Remove the rear cover. (See 4.2.)

2. Remove the fixing screws. (8pcs)

3. Disconnect the Speaker connecters.

(S1, 4pcs).

4. Remove the speaker units.

4.9. Removing the Shield pcb assy

1. Remove the fixing screws. (8pcs)

2. Disconnect the coupler.

(C1), (D1), (E1), (S1)

3. Remove the Shield pcb assy.

4.10. Removing the Shield case

1. Remove the Shield pcb assy. (See 4.9.)

2. Remove the fixing screws. (8pcs).

3. Remove the Shield case.

8

Servicing method

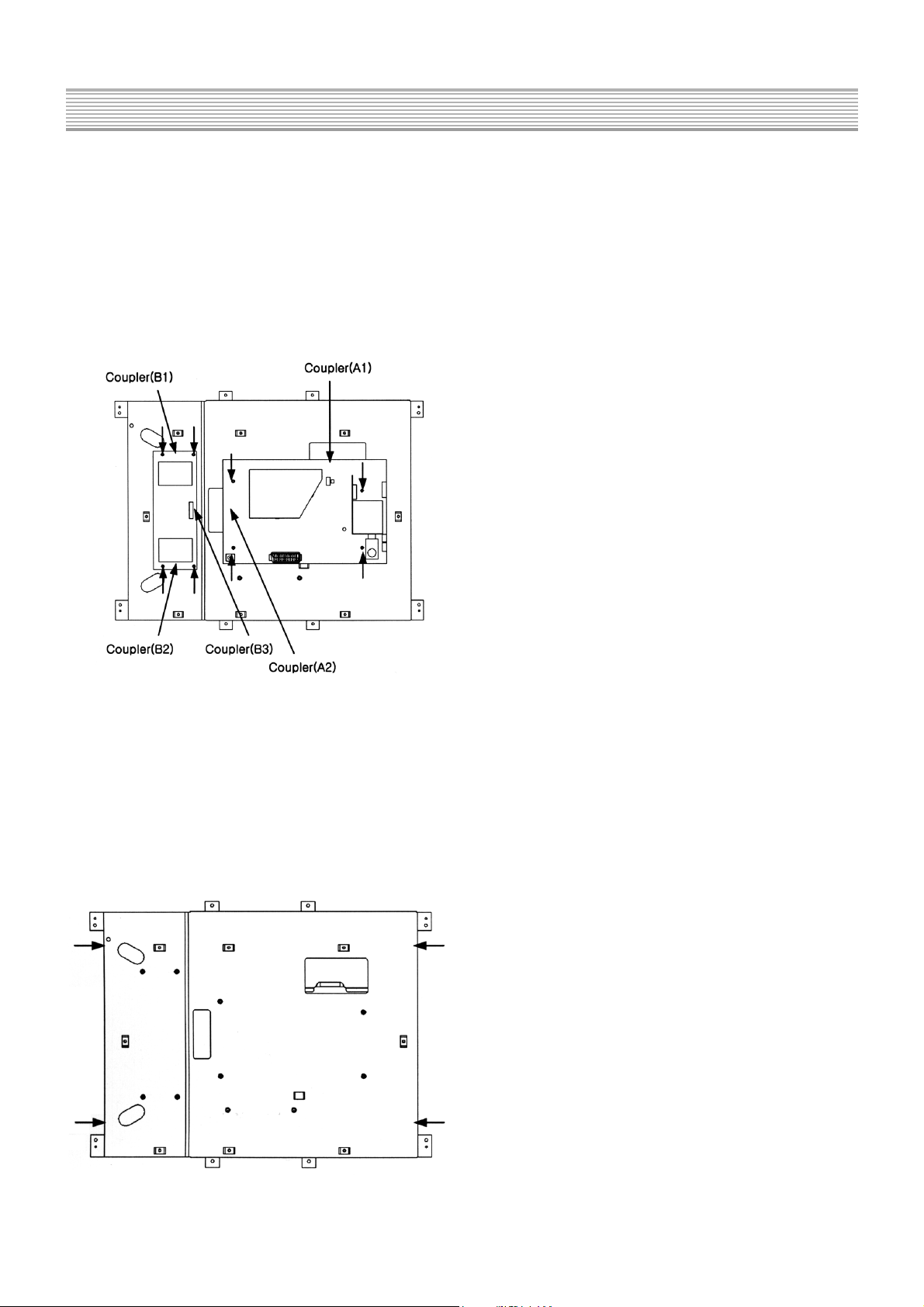

4.11. Removing the A-board, B-board

1. Remove the Shield pcb assy. (See 4.10.)

2. Disconnect the coupler.

(A1), (A2), (B1), (B2), (B3)

3. Remove the fixing screws. (8pcs)

4. Remove the A-Board, B-Board.

4.12. Removing the LCD panel

1. Remove the A-Board, B-Board. (See 4.11.)

2. Remove the fixing screws. (4pcs)

3. Remove the LCD Panel.

Loading...

Loading...