Panasonic TX-15LT2M, TX-15LT2Q, TX-15LT2Z, TX-15LT2X, TX-15LT2T Service Manual

15.2” Diagonal LCD TV

TX-15LT2M

TX-15LT2Q

TX-15LT2Z

TX-15LT2X

TX-15LT2T

LH1 Chassis

ORDER NO. ITD0303001C2

Specifications

Power Source

AC 100~240V, 50/60Hz

Power Consumption

Average use: 49W

Stand-by condition: 4W

TV set: DC 15V, 2.8 A max.

LCD

15.2-inch (385mm), 16:9 aspect ratio LCD panel

Screen Size

13.21-inch (335.6mm) (W) x 7.43-inch (188.6mm)(H) x 15.2inch (385.0mm)(Diagonal)

Sound

Speaker

Tweeter (3 x 4cm 2pcs, 89), Woofer (Ø5cm, 89)

Audio Output

6.5W (2.0W+2.0W+2.5W (Woofer)), 10%THD

Headphones

M3(3.5 mm) Jack x 1 89 impedance

FEATURES

Aero-Hammer®Woofer System (2Way 3Speaker System)

Receiving System

Receiving Channels

Regular TV

VHF BAND

2-12 (PAL/SECAM B, K1)

0-12 (PAL B AUST.)

1-9 (PAL B N.Z)

1-12 (PAL/SECAM D)

1-12 (NTSC M Japan)

2-13 (NTSC M U.S.A)

UHF BAND

21-69 (PAL G, H, I/SECAM G, K, K1)

28-69 (PAL B AUST.)

13-57 (PAL D, K)

© 2003 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

13-62 (NTSC M Japan)

14-69 (NTSC M U.S.A)

14-69 (NTSC M U.S.A)

CATV

S1-S20 (OSCAR)

1-125 (U.S.A CATV)

C13-C49 (JAPAN)

S21-S41 (HYPER)

Z1-Z37 (CHINA)

5A, 9A (AUST.)

Aerial-Rear

UHF/VHF

Operating Conditions

Temperature: 5-40°C

Humidity: 5%-90% RH (non-condensing)

Connection Terminals

AV1

21 Pin socket

(Audio/ Video in, TV out, RGB in)

AV2

VIDEO

RCA PIN Type x 1

S-VIDEO

Mini DIN 4-pin

AUDIO L-R

RCA PIN Type × 2

AUDIO OUT

3.5mm, Stereo Jack 0.5Vrms

Dimensions (W x H x D)

Including TV Stand

413mm x 330mm x 180mm

TV Set Only

413mm x 295mm x 73mm

Weight (Mass)

5.6kg Net

Storage Conditions

Temperature: 55°C MAX

Note:

Design and Specifications are subject to change without notice.

Weight and Dimensions shown are approximate.

CONTENTS

1 Safety Precautions

1.1. General Guidelines

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 About lead free solder (PbF)

4SelfCheck

5 SERVICE HINTS

5.1. Hotel Mode

6 Chasis Board Layout

7 Servicing method

7.1. Removing tilt base

7.2. Removing rear panel

7.3. Removing speaker unit

7.4. Removing front panel

7.5. Removing LCD panel

7.6. Removing main A-Board

7.7. Removing B-Board (with tuner assembly)

7.8. Removing DG-Board

7.9. Removing H-Board

7.10. Removing P-Board

7.11. Removing K-Board

7.12. Pull out the flexible cable straight to the coupler.

7.13. Removing back-light

7.14. A-Board servicing

8 Service Mode Function

Page Page

4

4

5

6

7

7

7

8

9

9

10

10

11

11

12

13

14

14

15

15

15

16

16

17

8.1. How to enter SERVICE 1

8.2. How to enter SERVICE 2

8.3. Option Description

8.4. Option Code Setting

9 Adjustment

9.1. RF AGC Adjustment

9.2. DVCO Adjustment

10 Conductor Views

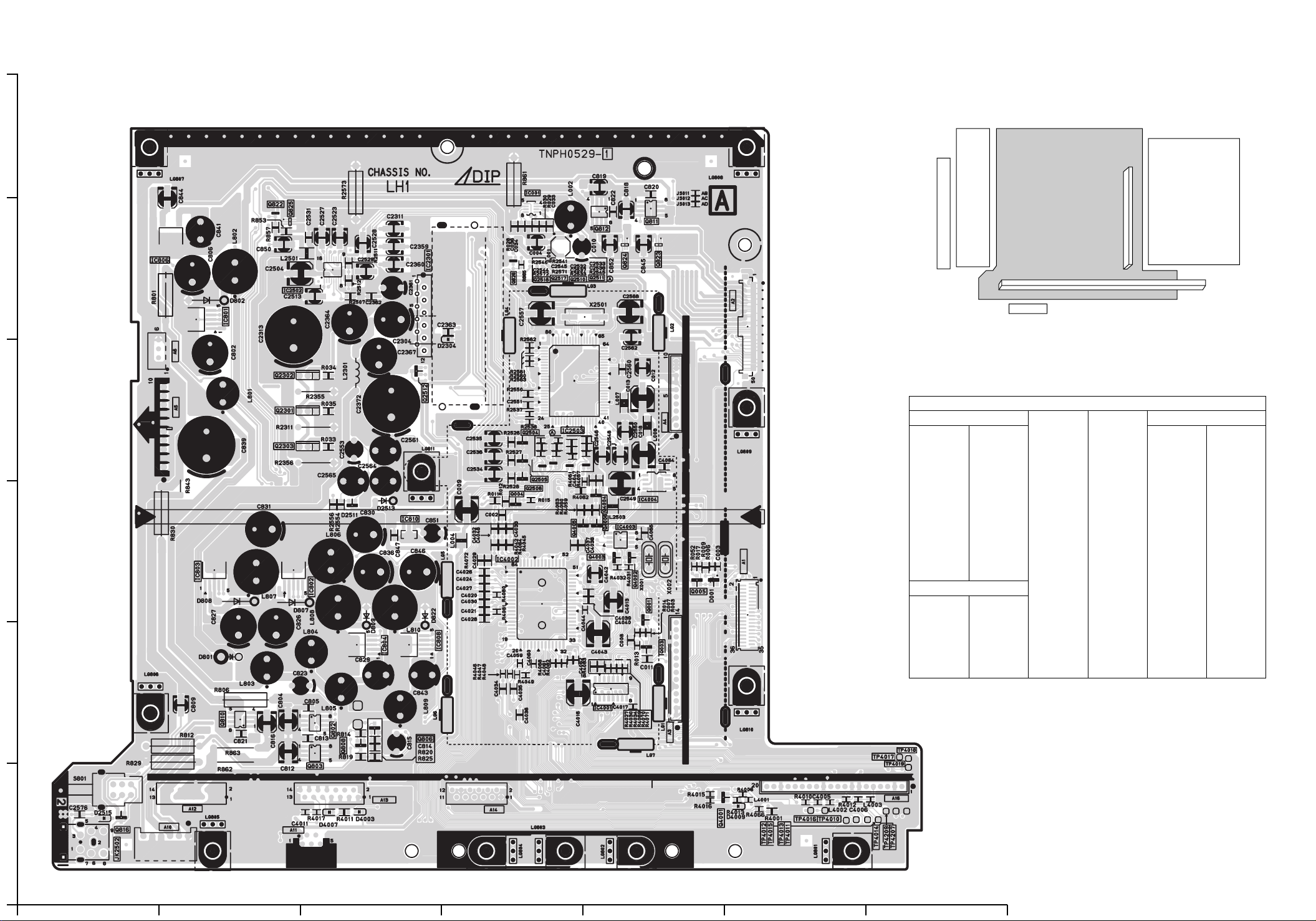

10.1. A-Board

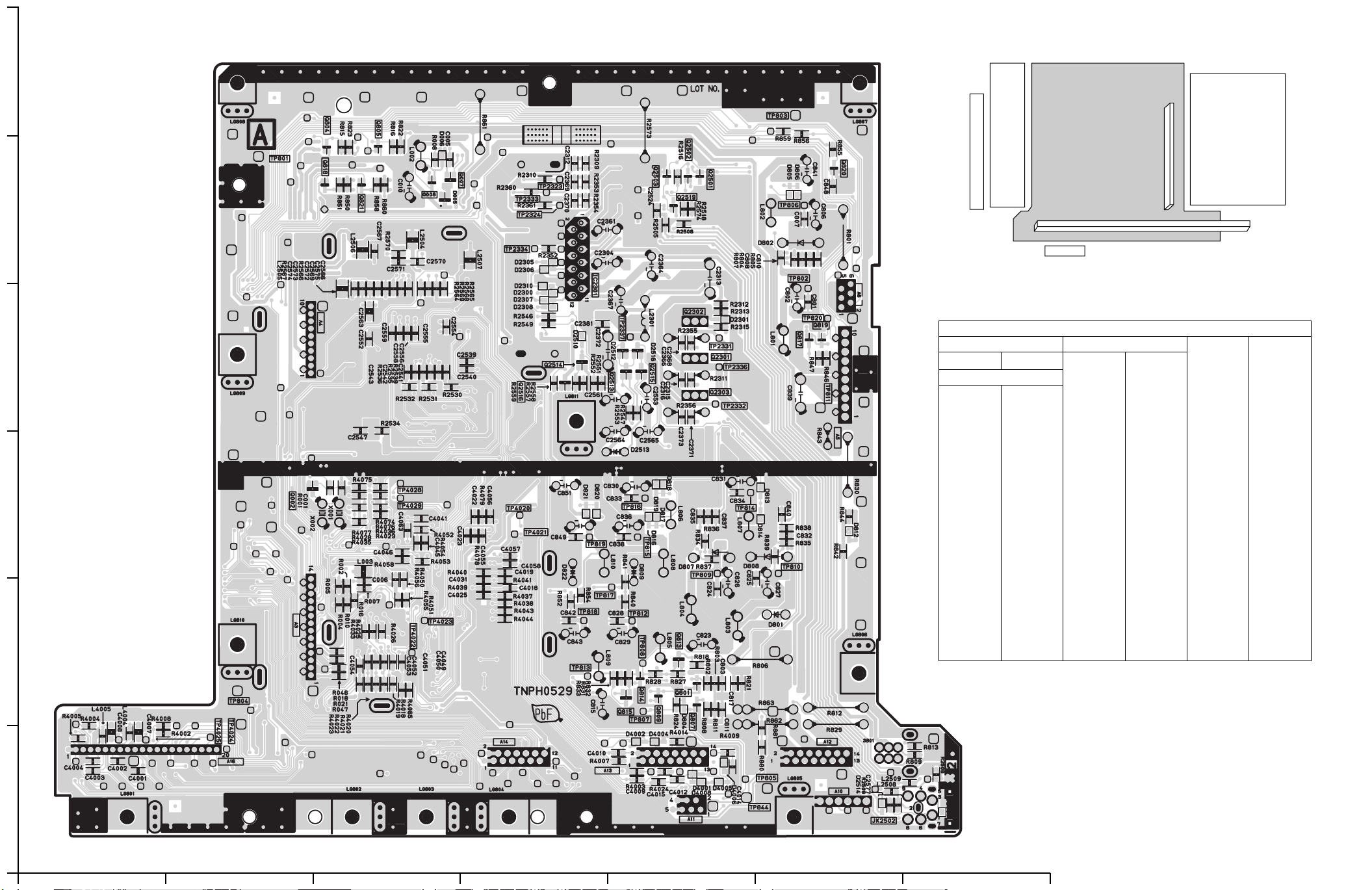

10.2. B, H, K, P and V-Board

10.3. DG-Board

11 Block and Schematic Diagrams

11.1. Schematic Diagram Notes

11.2. Power Block Diagram

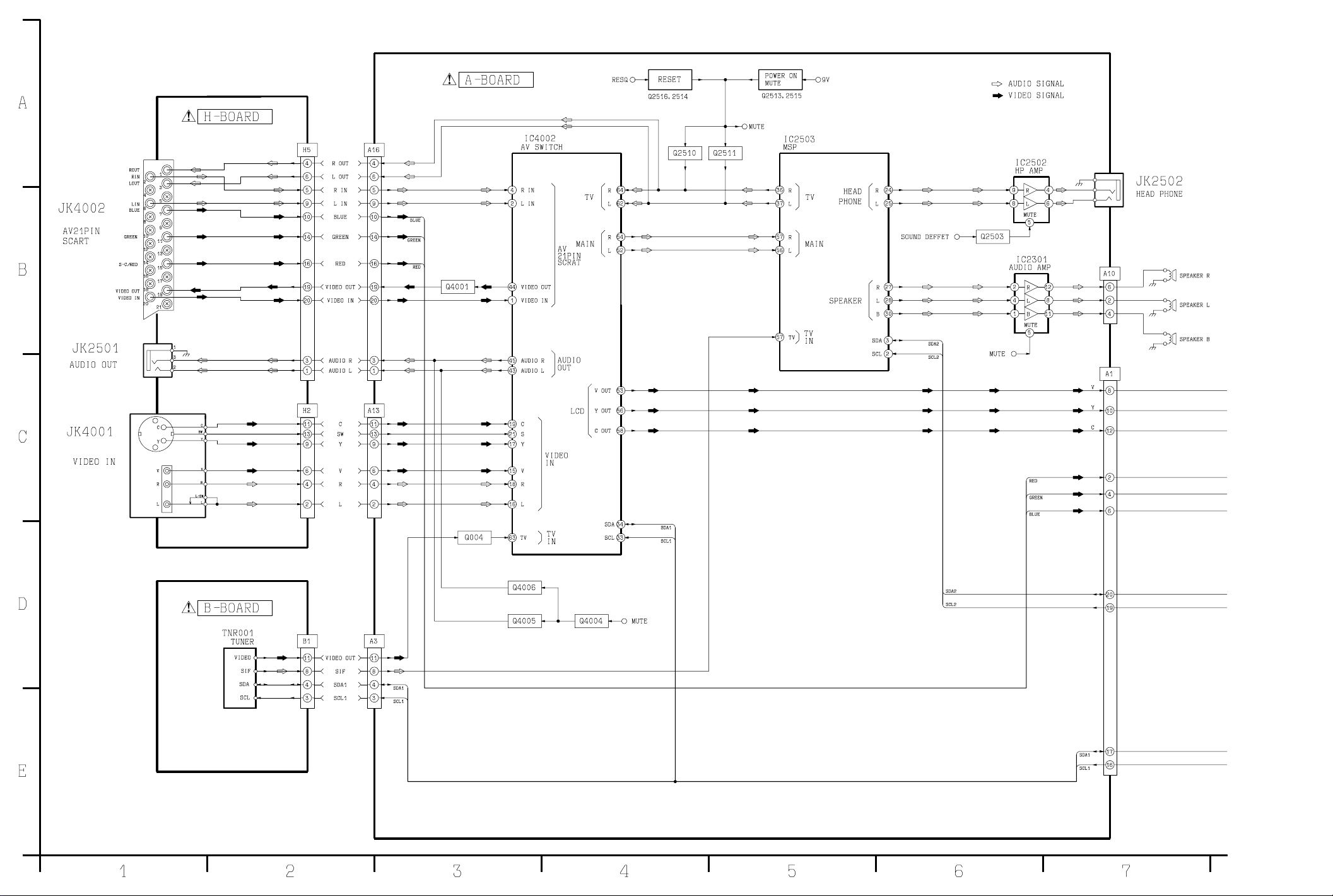

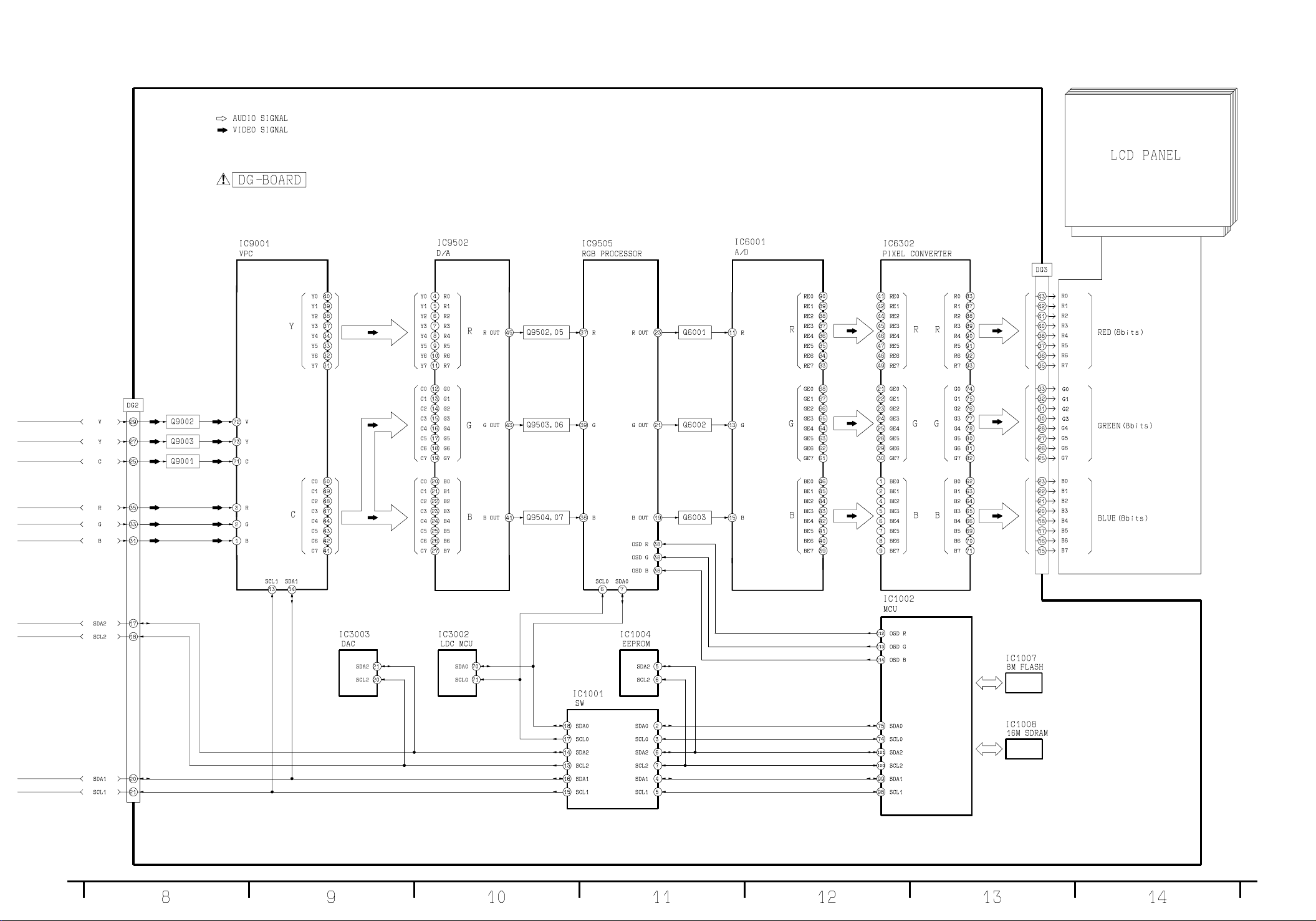

11.3. Signal Block Diagram

11.4. A-Board (1 of 4) Schematic Diagram

11.5. A-Board (2 of 4) Schematic Diagram

11.6. A-Board (3 of 4) Schematic Diagram

11.7. A-Board (4 of 4) Schematic Diagram

11.8. DG-Board (1 of 5) Schematic Diagram

11.9. DG-Board (2 of 5) Schematic Diagram

11.10. DG-Board (3 of 5) Schematic Diagram

11.11. DG-Board (4 of 5) Schematic Diagram

11.12. DG-Board (5 of 5) Schematic Diagram

11.13. B, H, K, and V-Board Schematic Diagram

17

17

19

21

22

22

22

23

23

25

27

29

29

30

32

34

35

36

37

38

39

40

41

42

43

2

11.14. P-Board Schematic Diagram 44

12 Parts Location & Mechanical Replacement Parts List

12.1. Parts Location

12.2. Packing Exploded View

12.3. Mechanical Replacement Parts List

45

13 Replacement Parts List

45

46

13.1. Replacement Parts List Notes

13.2. Electrical Replacement Parts List Notes

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

47

48

48

49

3

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

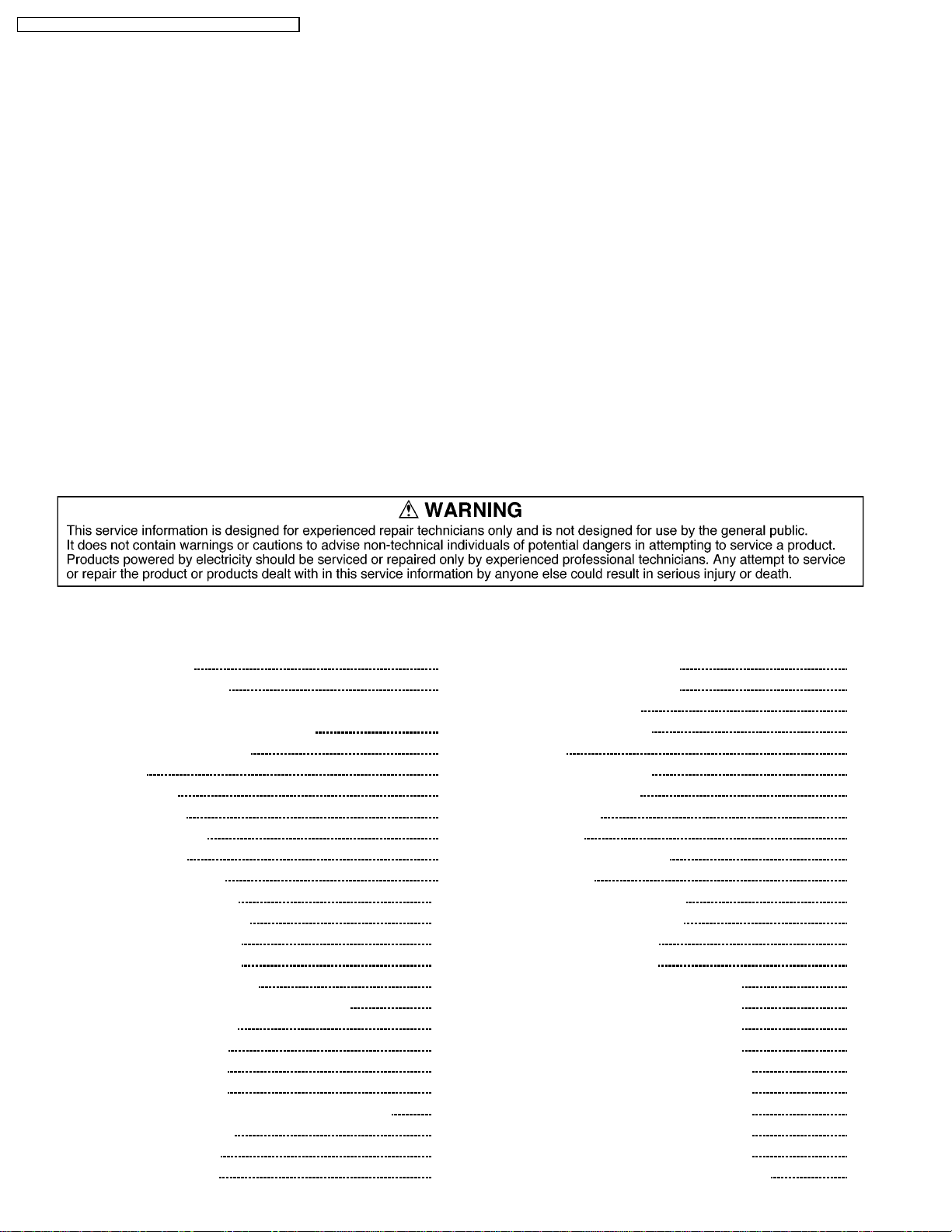

1 Safety Precautions

1.1. General Guidelines

1.When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1.Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2.Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1M9 and 5.2M9.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

1.1.2. Leakage Current Hot Check (See

Figure 1.)

1.Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2.Connect a 1.5k9, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3.Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4.Check each exposed metallic part, and measure the

voltage at each point.

5.Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6.The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

4

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

5

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

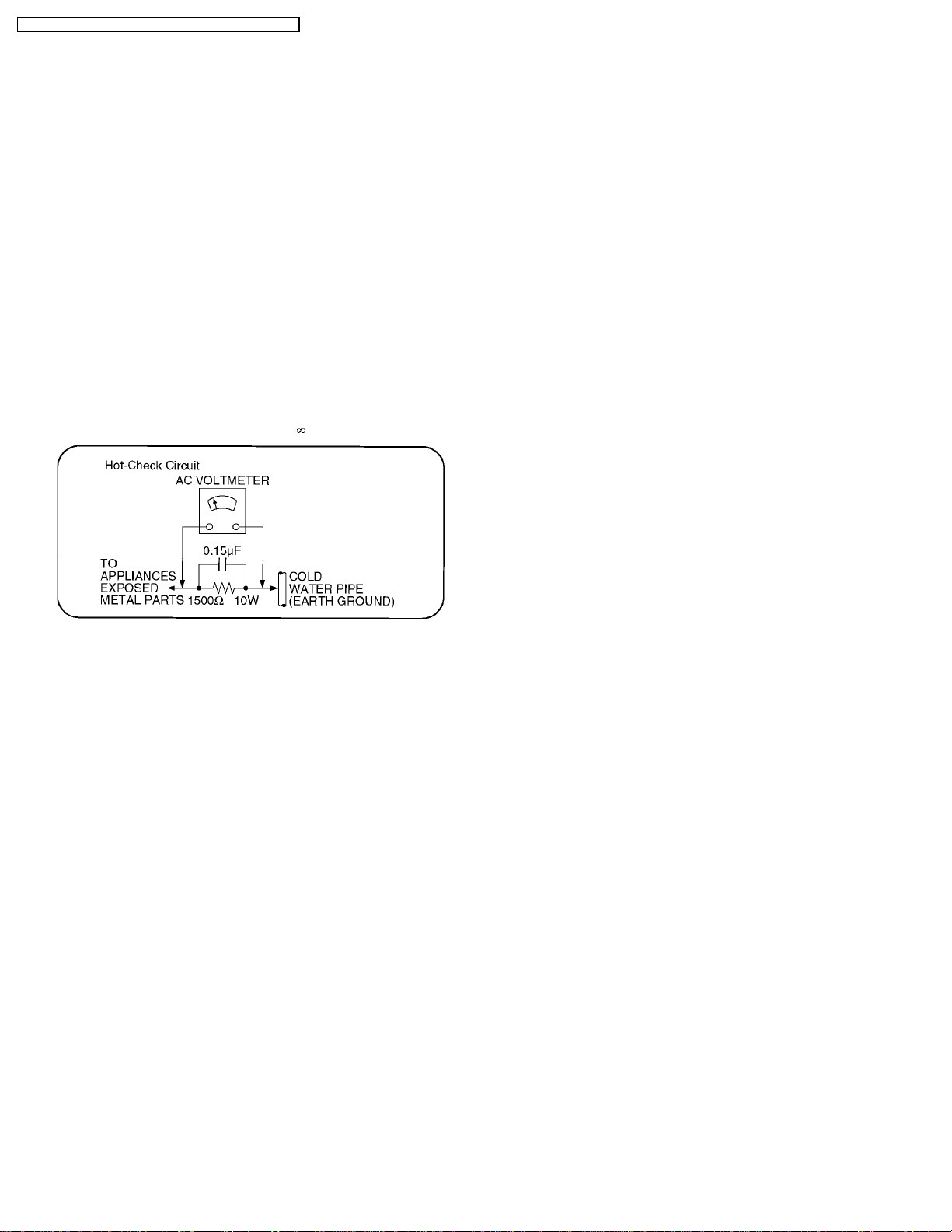

3 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30 ~ 40 °C) higher.

Please use a high temperature s oldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

6

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

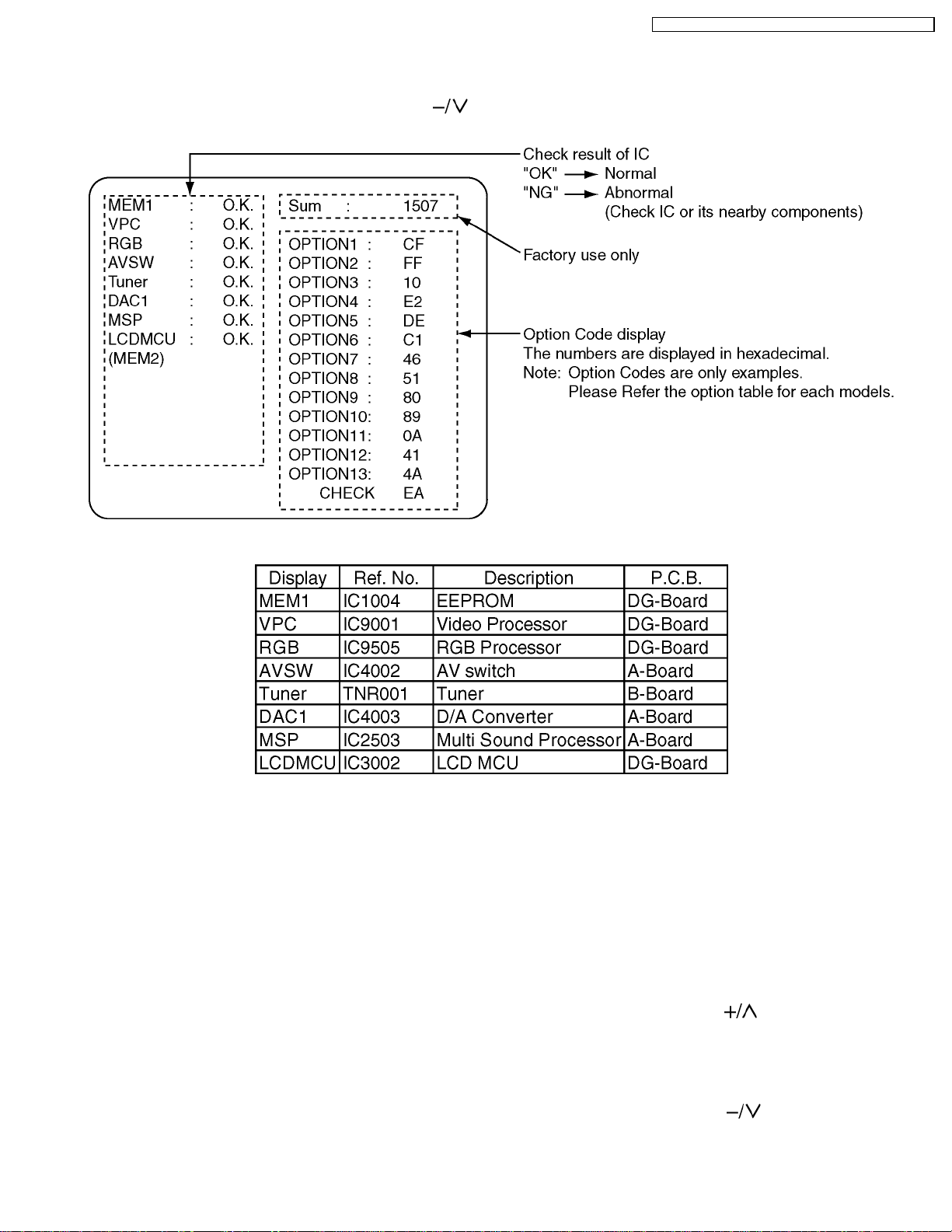

4SelfCheck

1.Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2.To get into the Self -Check mode press the [ Down (

time pressing the [ SET UP ] button on the remote control, and the screen will show :

) ] button on the customer controls at the front of the set, at the same

If the CCU ports have been checked and found to be incorrect or not located then “--” will appear in place of “O.K.”.

5 SERVICE HINTS

5.1. Hotel Mode

Purpose

1.At Hotels, this Mode prevent customer from changing the TV preset data, such as Channel preset data.

Note:

This Mode is useful for hotel, you should not get into “Hotel Mode” with Normal use.

Operation

1.To get into “ Hotel Mode”, press “Recall” button on the remote control and Channel up “[

simultaneously, after setting the “Off-Timer” mode.

2.In this mode, The Channel up and down Function will be able as normal Mode, and The maximum volume level for this

mode is set at the current volume level, that means setting at the level before entering the mode. However, other function

will be disable.

3.To exit This mode, press “SET UP” button on the remote control and the “Volume Down [

simultaneously.

* This Information is informed by Service Manual only.

]” key on the TV set

]” key on the TV set

7

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

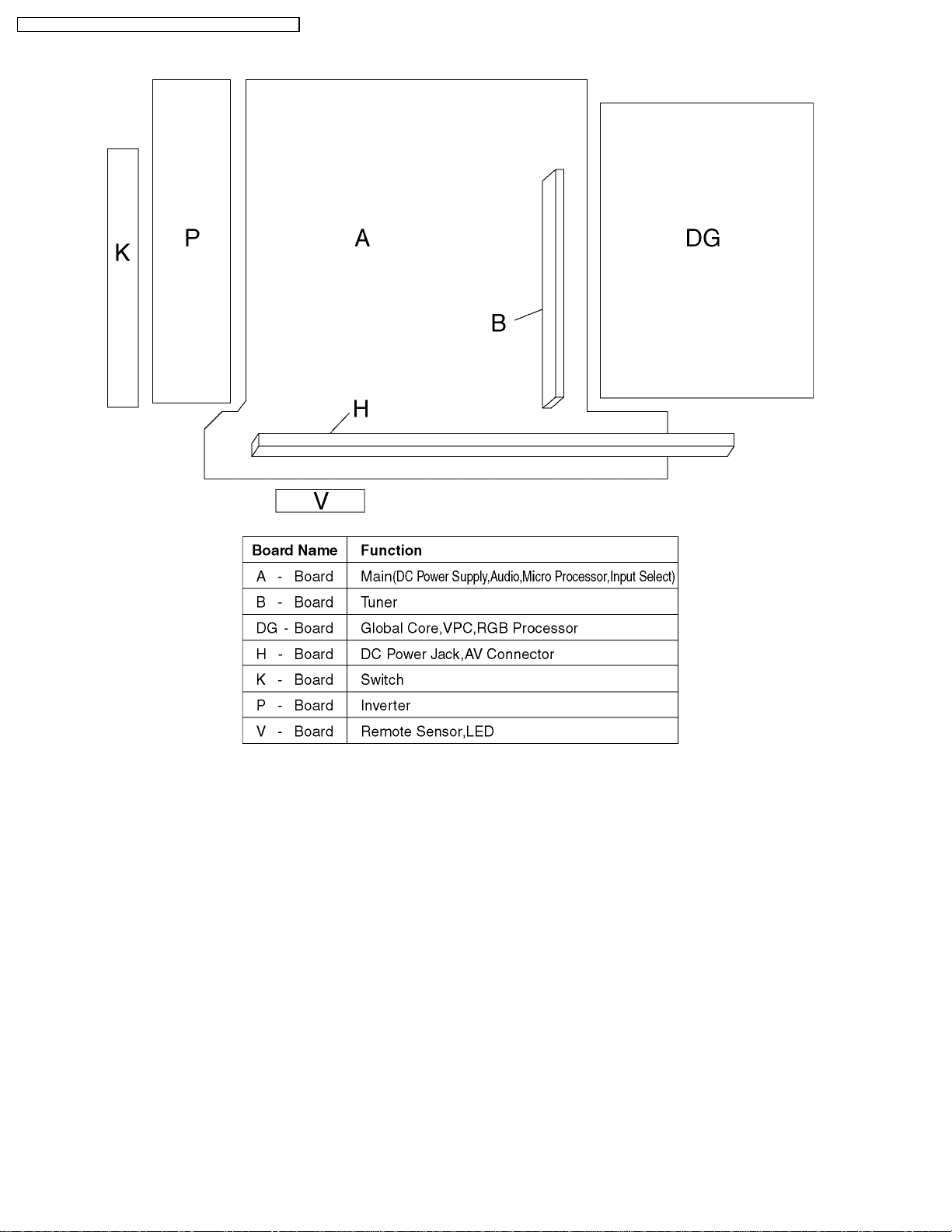

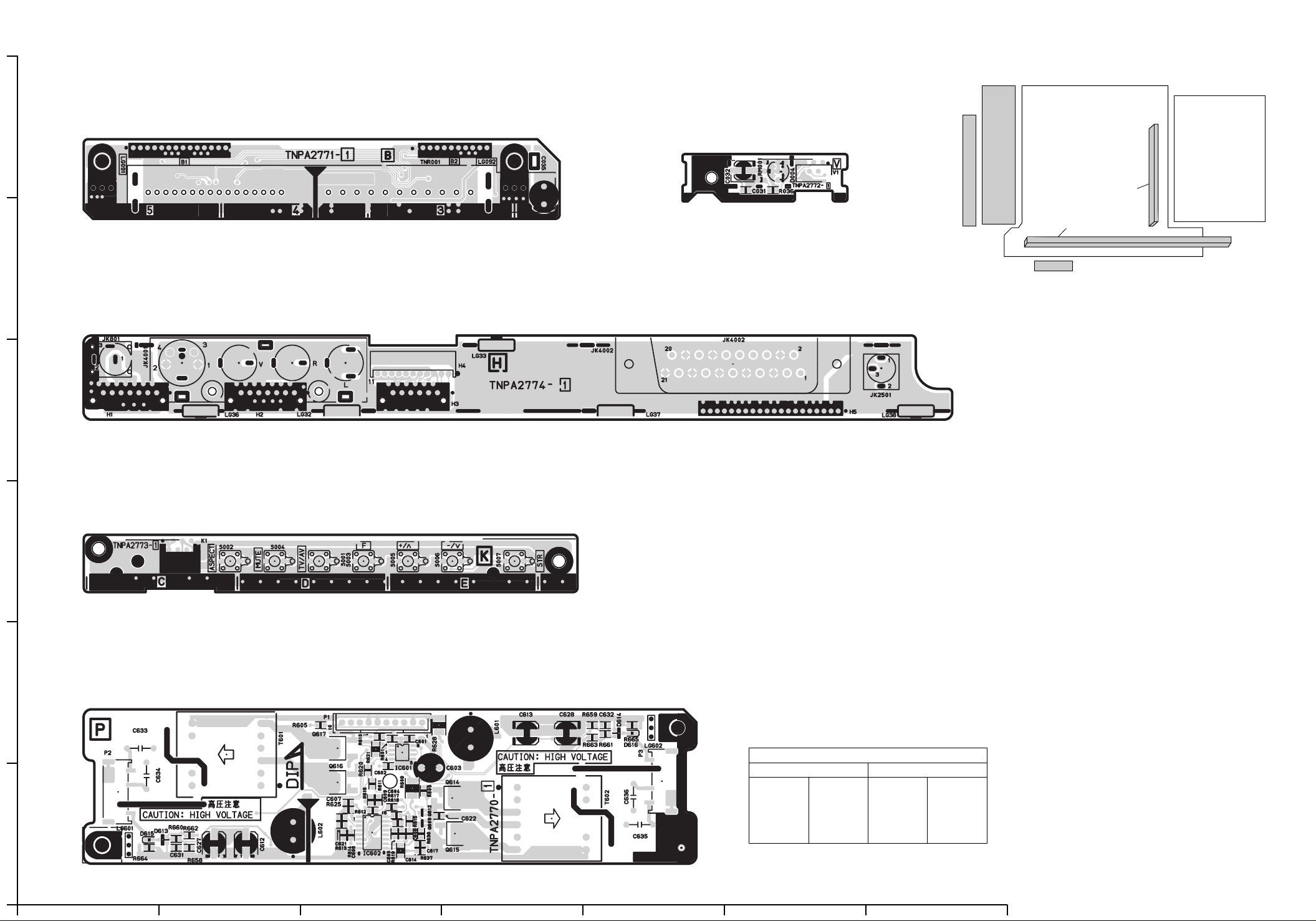

6 Chasis Board Layout

8

7 Servicing method

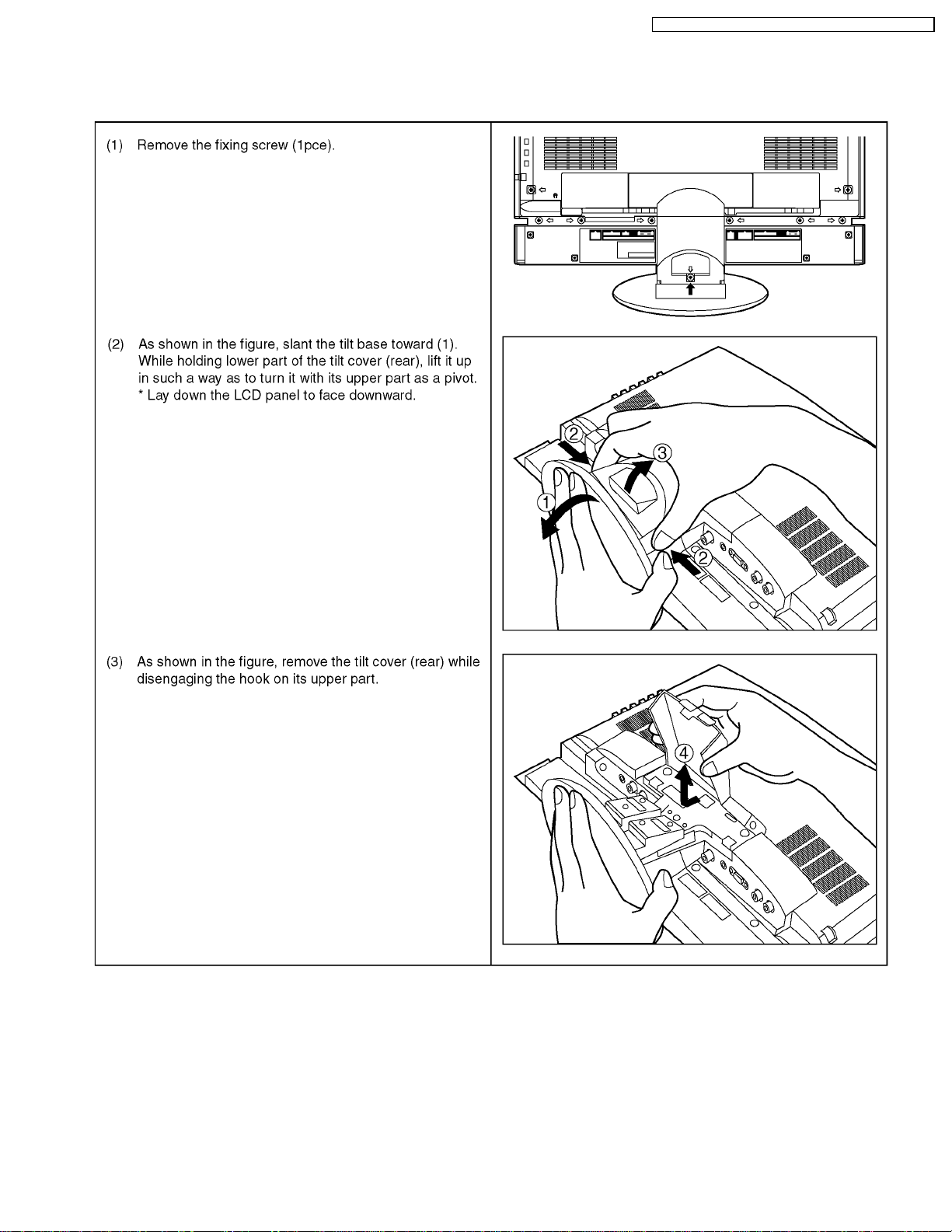

7.1. Removing tilt base

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

9

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

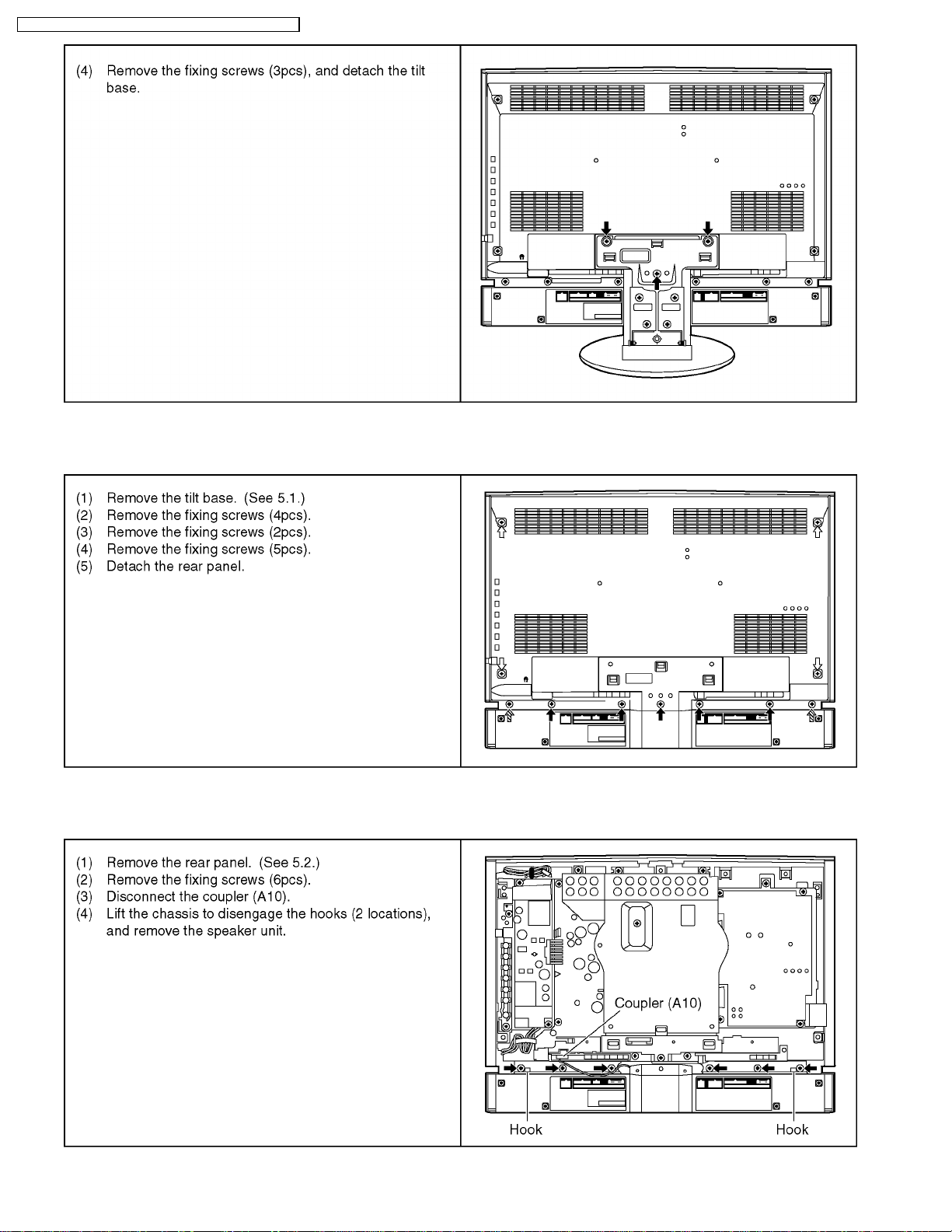

7.2. Removing rear panel

7.3. Removing speaker unit

10

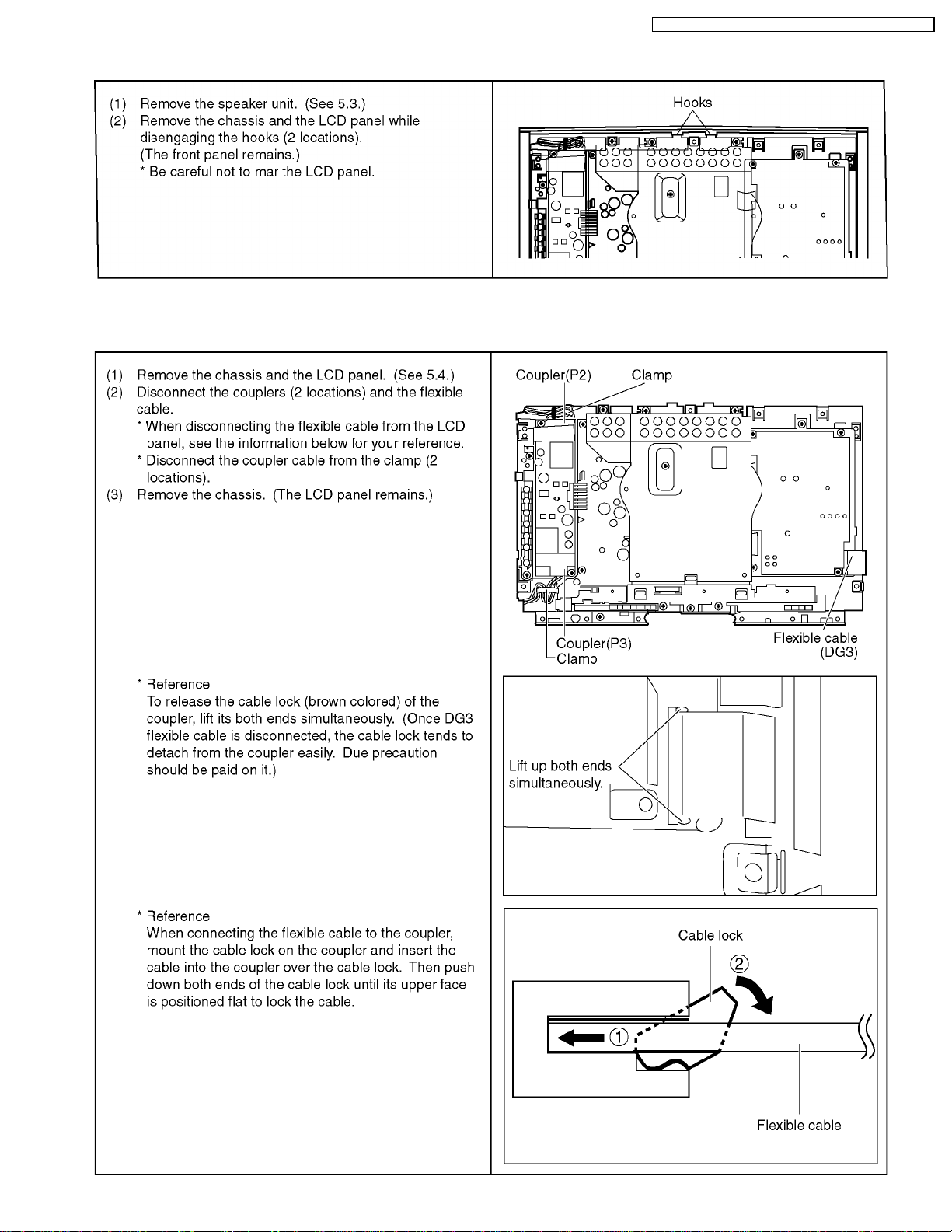

7.4. Removing front panel

7.5. Removing LCD panel

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

11

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

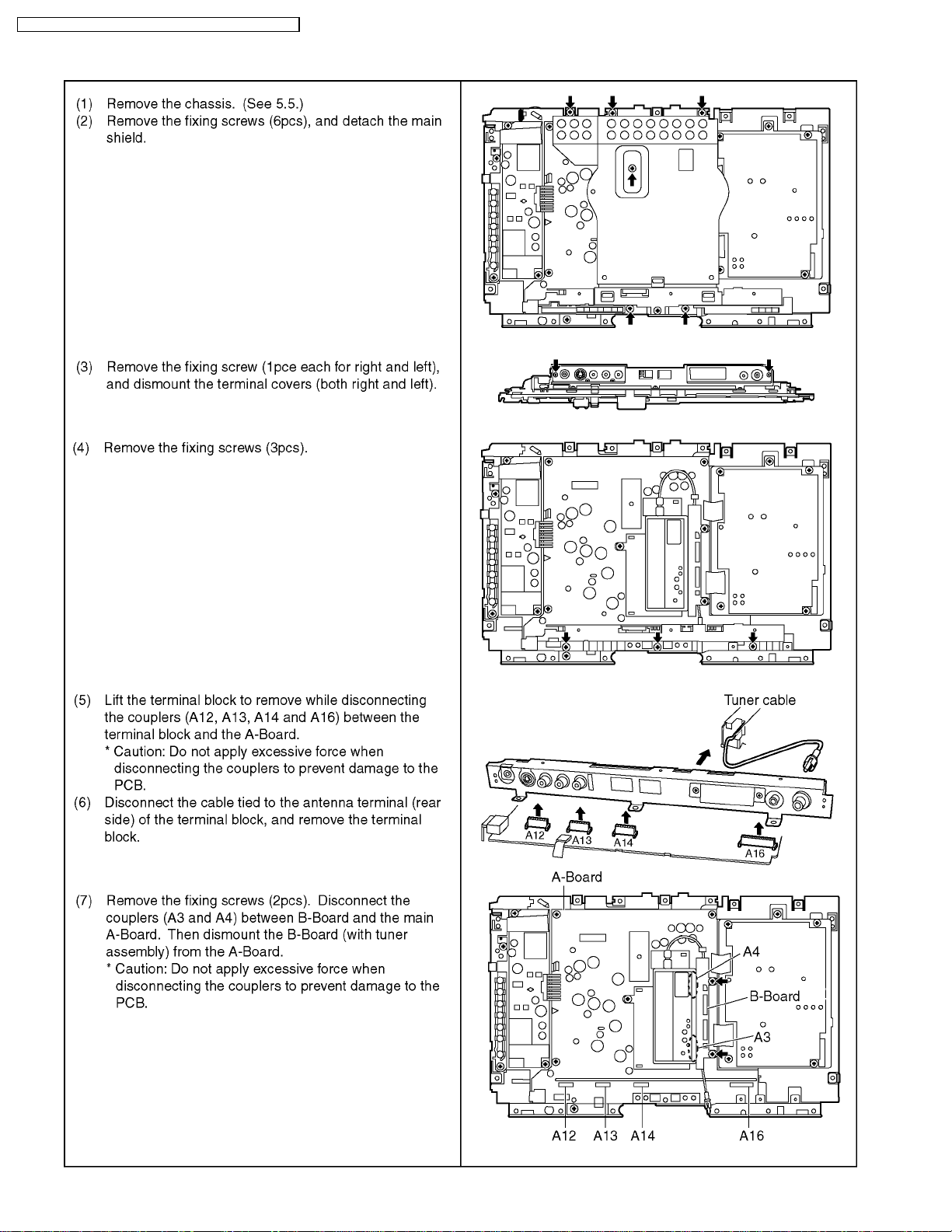

7.6. Removing main A-Board

12

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

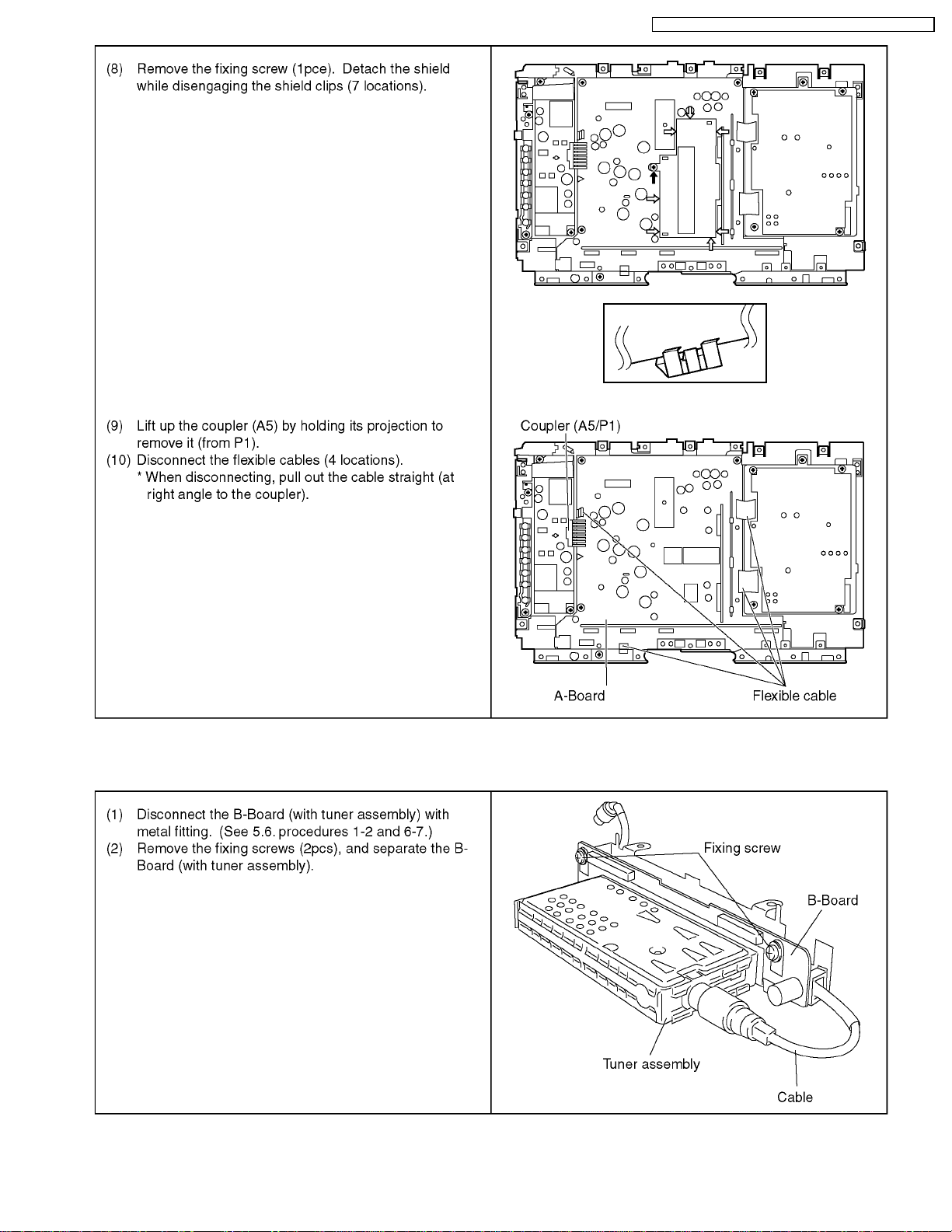

7.7. Removing B-Board (with tuner assembly)

13

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

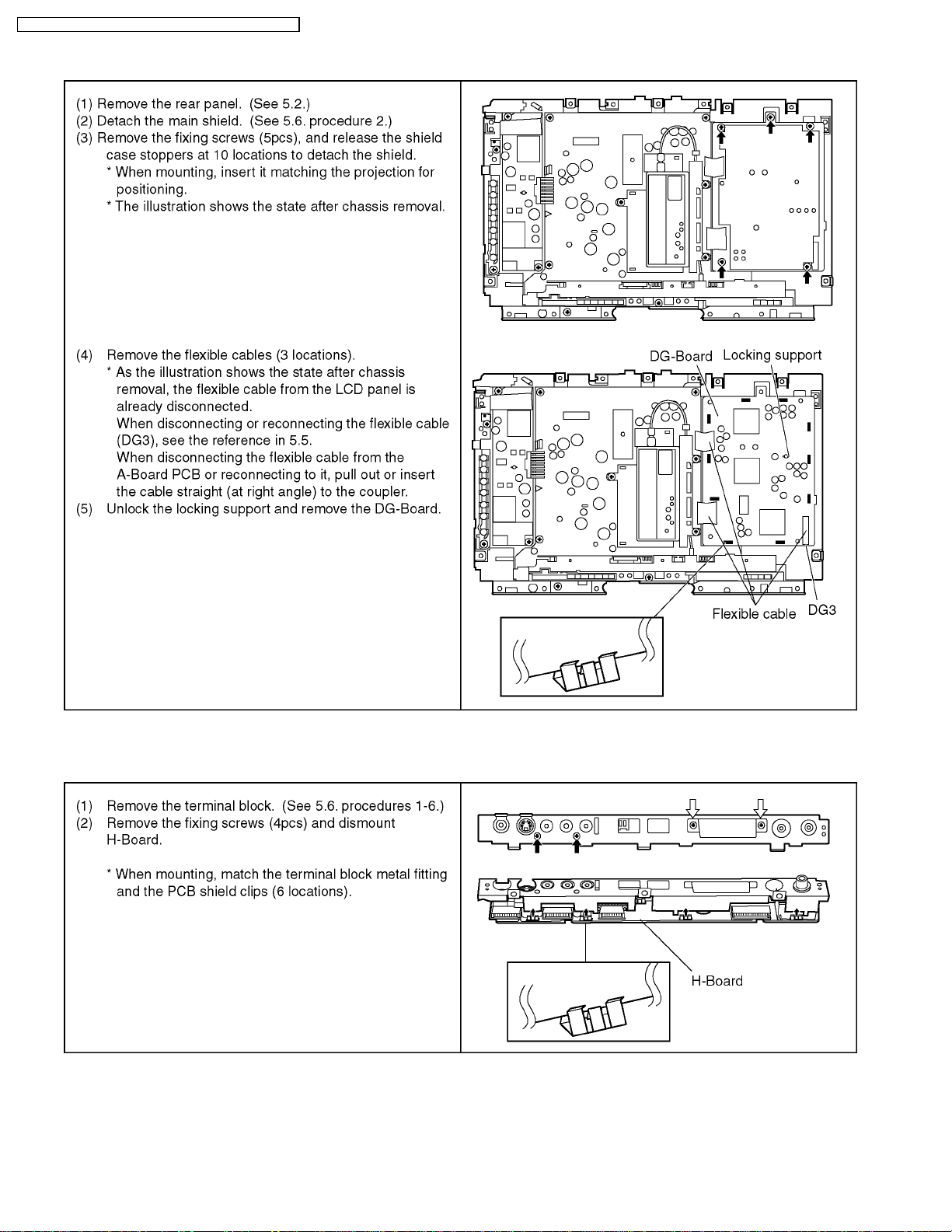

7.8. Removing DG-Board

7.9. Removing H-Board

14

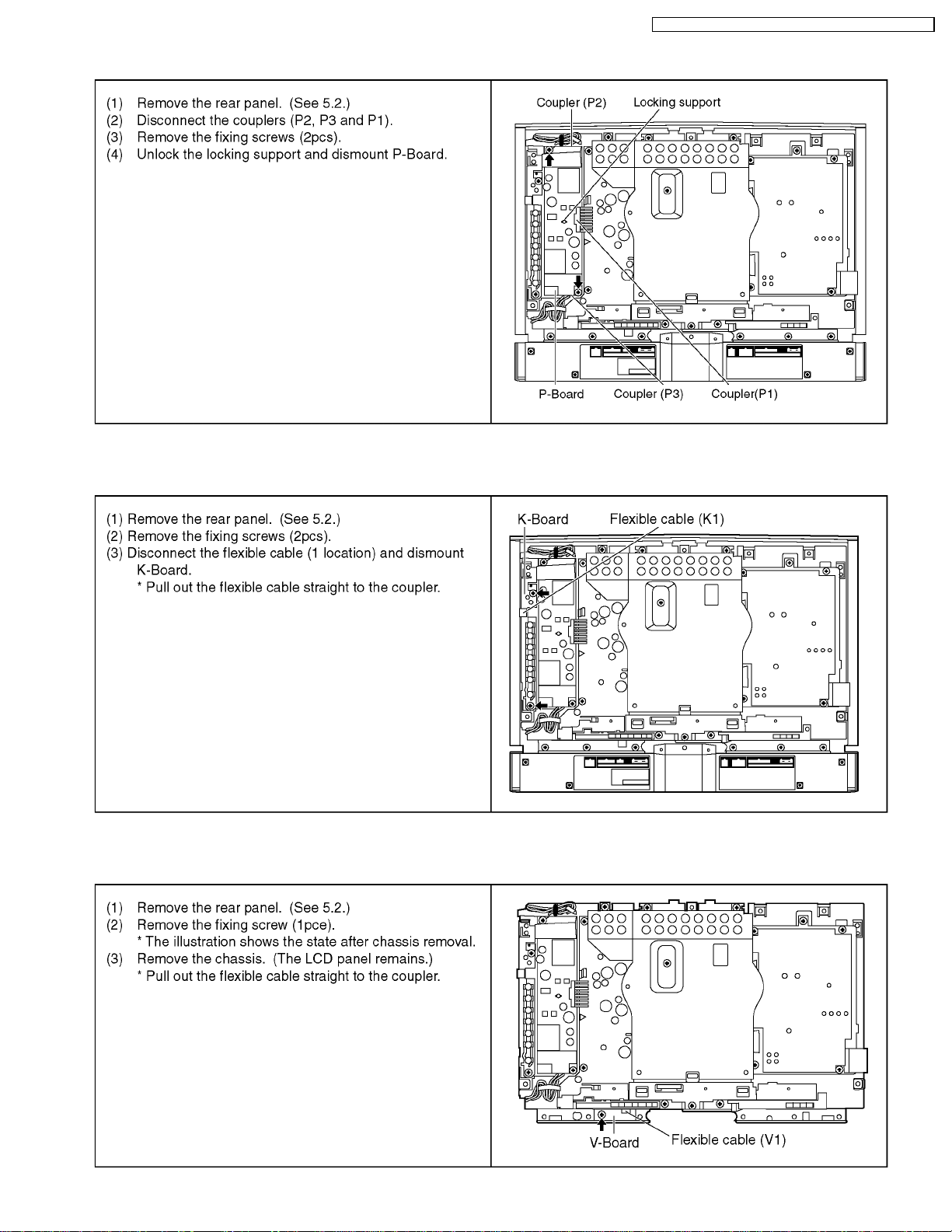

7.10. Removing P-Board

7.11. Removing K-Board

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

7.12. Pull out the flexible cable straight to the coupler.

15

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

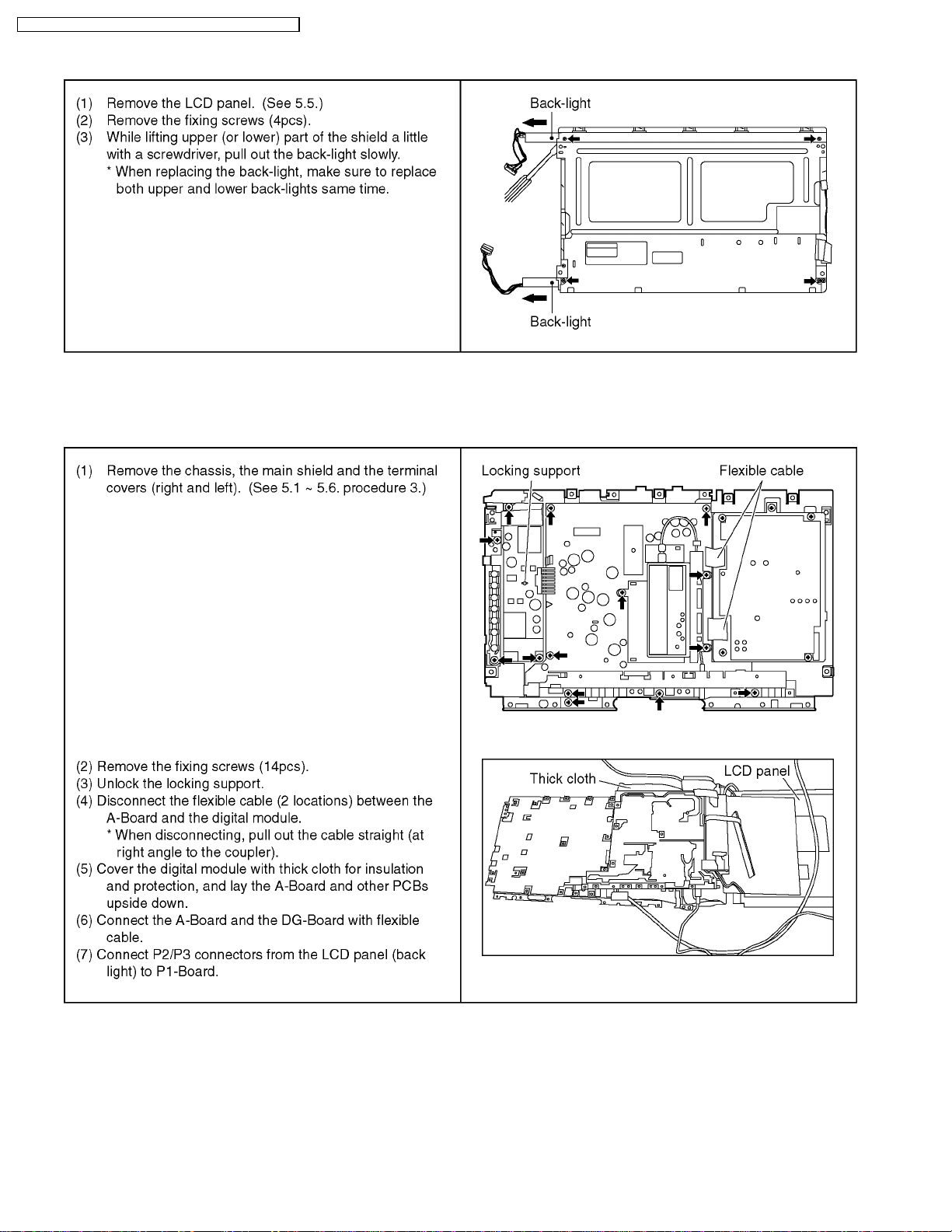

7.13. Removing back-light

7.14. A-Board servicing

* Follow the procedures described below when checking voltage on rear side of the A-Board.

16

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

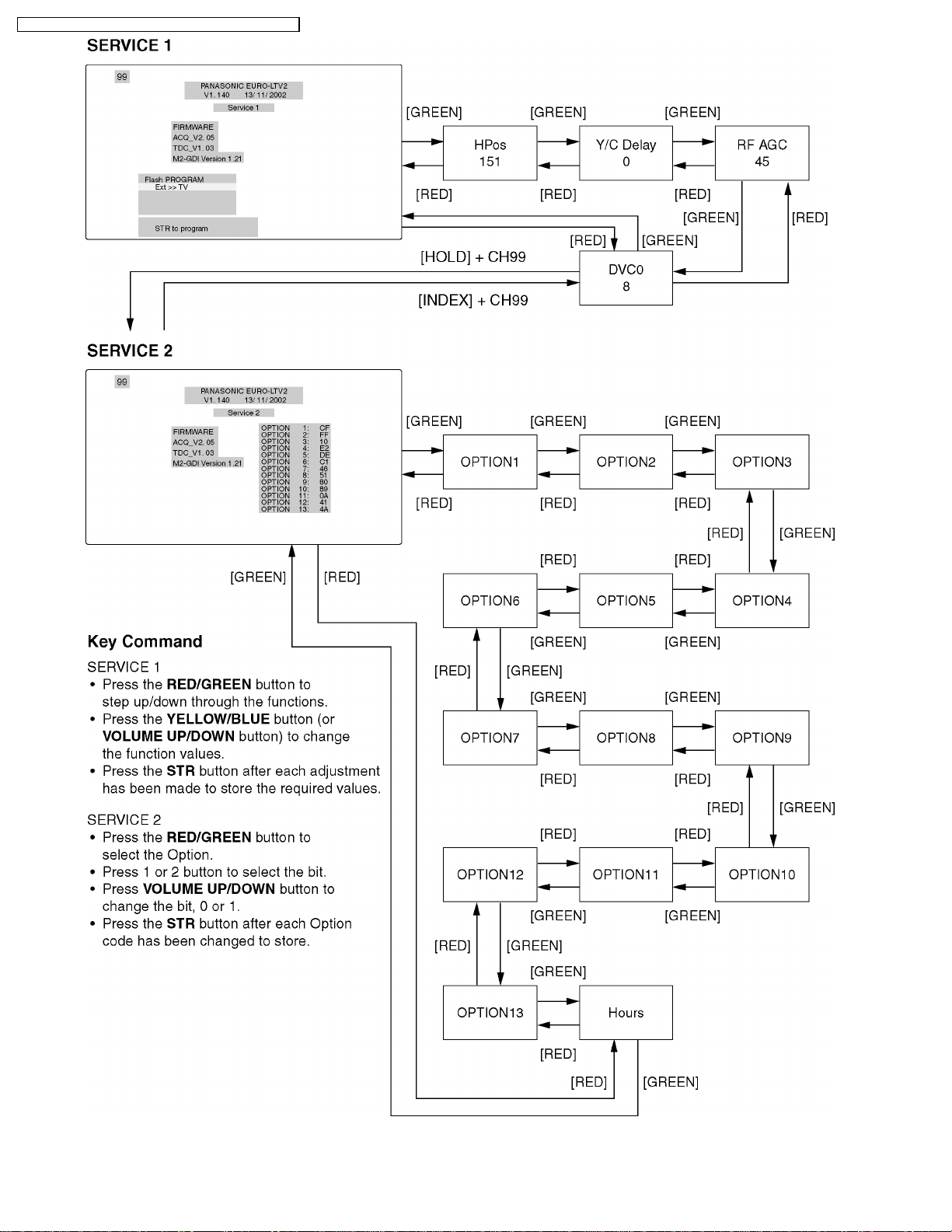

8 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment c an be

adjusted by remote control in Service Mode.

8.1. How to enter SERVICE 1

1.In sound menu, set BASS to MAXIMUM, and set TREBLE to MINIMUM.

2.Simultaneously press INDEX button on remote control and DOWN button [

8.2. How to enter SERVICE 2

1.Set the channel to CH99.

2.Press HOLD button on remote control.

Note:

To exit to Service mode, press N or Power button on remote control.

]ontheTVset.

17

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

18

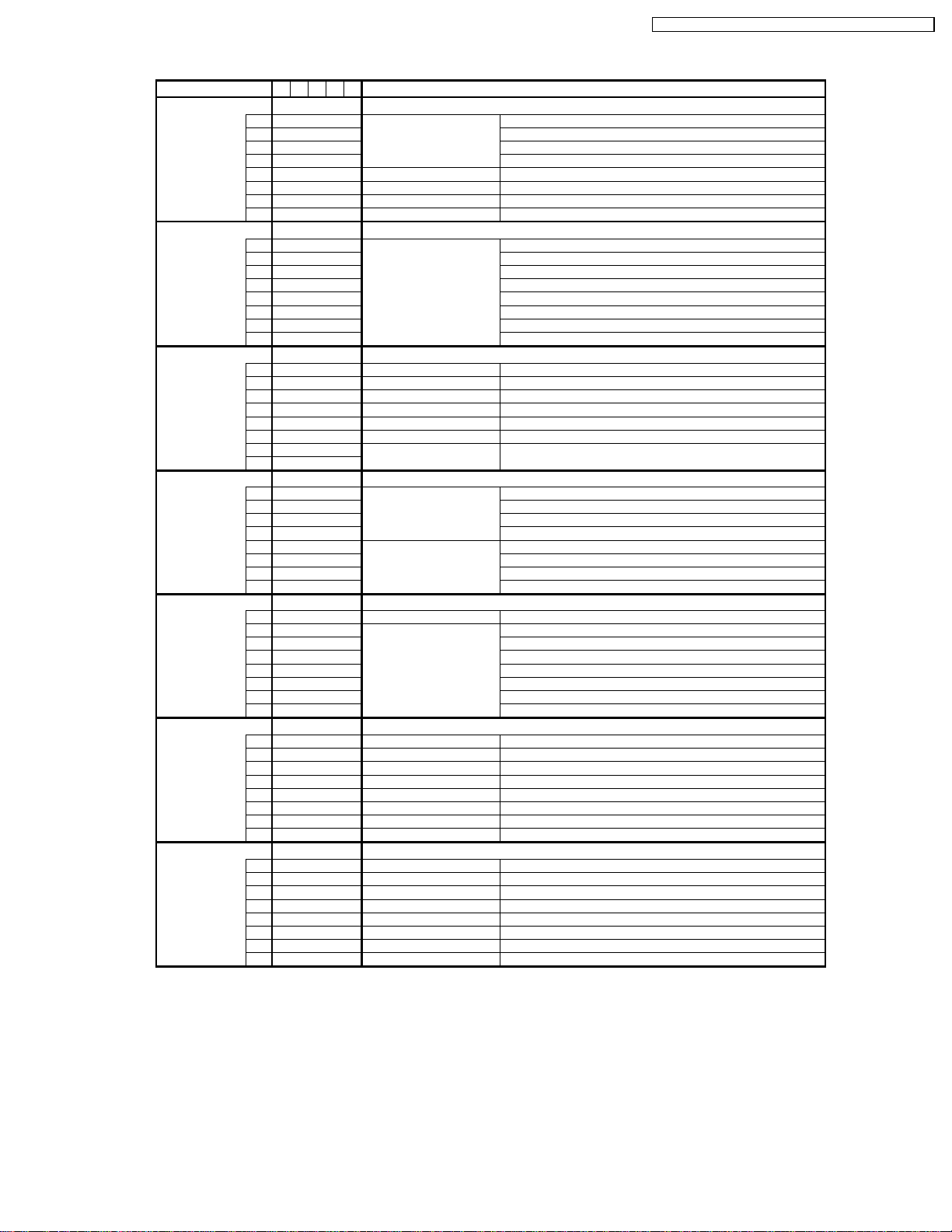

8.3. Option Description

ASIA / M.E. / HK / UK / CHINA (1)

AUSTRALIA (1)

E. EUROPE (1)

r

4.5 (1)

5.5 (1)

6.0 (1)

6.5 (1)

4.5 (1)

5.5 (1)

6.0 (1)

6.5 (1)

z

y

NZ / INDN (1)

AUSTRALIA (1)

E. EUROPE (1)

y

Auto(1)

NTSC(1)

not use

On (0), Off (1)

SASO enable (1)

set to 0

Q-Link on/off selectable in menu (1)

Display NICAM (0), Display MPX (1)

Description

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

Option Models

option1

option2

option3

option4

option5

option6

option7

MQZ X T

b0 Colour system

b1

b2

b3

b4 TV NTSC 50

b5 TV SECAM 60

b6 AV NTSC 50

b7 AV SECAM 60

b0 CH Plan

b1 NZ / INDES (1)

b2

b3

b4 SPECIAL (1)

b5 AMERICA (1)

b6 CATV (1)

b7 JAPAN (1)

b0 sub picture

b1 2tune

b2 VGA

b3 YUV

b4 Wide (16:9)

b5 HYPER

b6 SIF I only(0), BG only(1)

b7 I/BG/DK/L(2), BG/DK(3)

b0 A2 enable

b1

b2

b3

b4 NICAM enable

b5

b6

b7

b0 A2 select 6.5MHz 5.742 MHz (0), 6.742 MH

b1 NICAM priorit

b2 HK / UK (1)

b3 CHINA (1)

b4

b5

b6

b7 SPECIAL (1)

b0 VCR/GAME in search

b1 SASO enable

b2 Noise mute

b3 Monitor out AV1 mute

b4 AV SW 3/2AV out

b5 Tuner

b6 Child lock Child lock enable (1)

b7 TEXT VDEFEAT VDEFEAT ON (1), OFF (0)

b0 Power up EC-Mode

b1 CH Blanking

b2 AV Blanking

b3 Auto WIDE

b4 Volume correction

b5 AVLink

b6 MPX/NICAM displa

b7 free

CF

FF

10

E2

DE

C1

46

1

1

1

1

0

0

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

0

0

0

0

1

0

0

0

1

1

1

0

1

1

1

1

0

1

1

1

0

0

0

0

0

1

1

0

1

1

0

0

0

1

0

SECAM(1)

M.NTSC(1)

Reserved

Reserved

Reserved

Reserved

without sub-picture (0), with sub-picture (1)

2 tuner (1), 1 tuner (0)

enable (1)

enable (1)

16:9 (1), 4:3 (0)

ASIA / M.E. (1)

Noise mute enable(0)

Monitor out AV1 mute(1)

MACO tuner (0), ALPS tuner (1)

Power on EC enable (1)

Blanking enable (1)

Blanking enable (1)

WSS enable only in aspect Auto (0), WSS always enable (1)

TV Volume correction enable (1)

19

Description

r

y

y

y

y

A

(0),

)

(1)

(1)

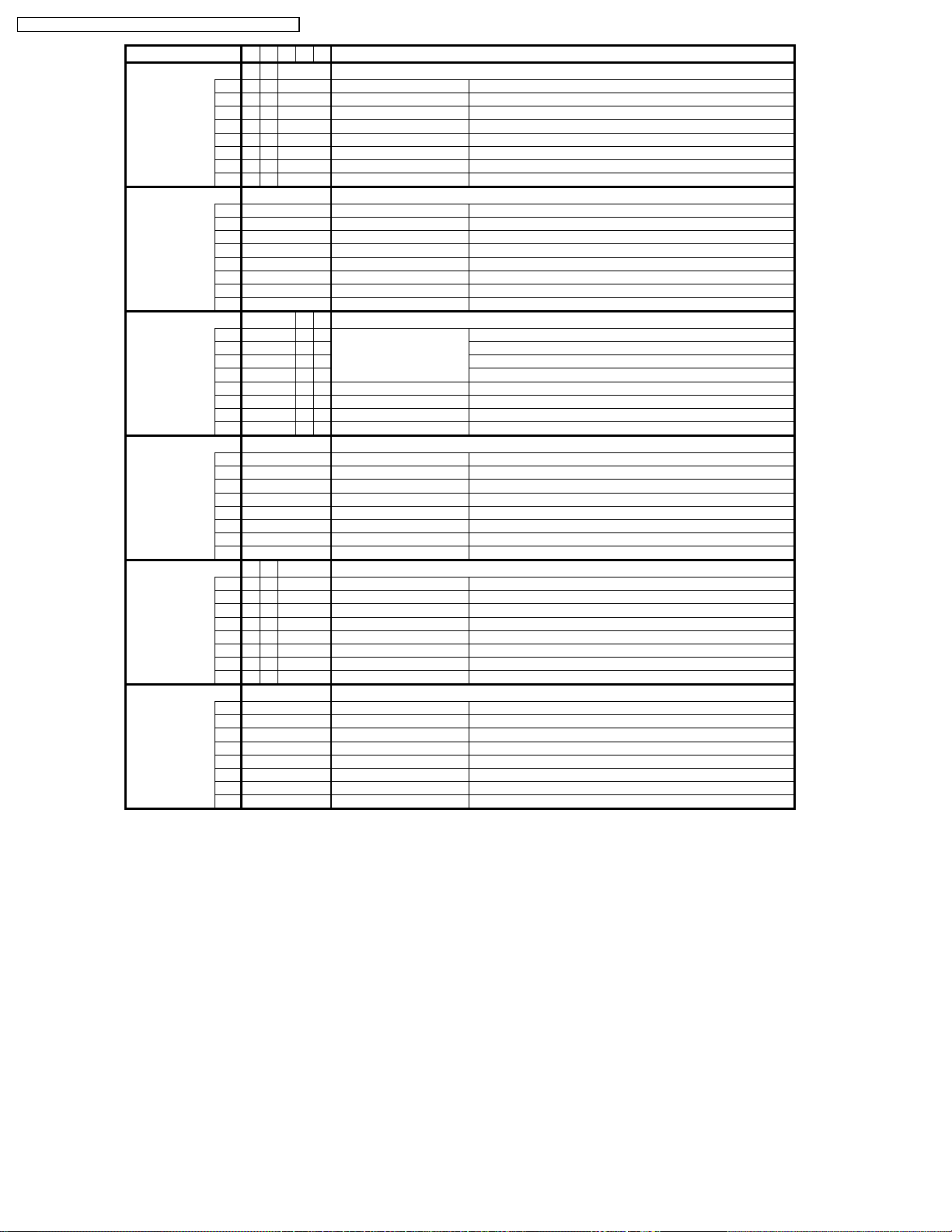

option13

option12

option11

option10

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

Option Models

option8

option9

MQZ X T

51 D0

b0 10 Teletext CH Refresh

00 Geomagnetic Senso

b1

b2 00 Geomagnetic Polarit

b3 00 RF Attenuation

11 Fine tuning

b4

00 Search speed

b5

11 TEXT FLOF

b6

b7

01 TEXT TOP

b0 free

b1 free

b2 free

b3 free

b4 free

b5 Surround SP polarit

b6 Volume curve

b7 Volume EXDAC

b0 1 1 OSD language English Only enable (1) : Top Prorit

b1 1 0

b2 0 1

b3 0 0

b4 0 0 Blue Back

b5 0 0 free

b6 0 0 free

b7 1 1 OVP

b0 Shop mode

b1 Full / 16:9 displa

b2 Sub Headphone

b3 Scan mode Blanking

b4 User aspect 14:9

b5 NICAM C4 bit

b6 ID-1

b7 1080i

41 43

11 Asia

b0

01 Australia Australia (1)

b1

00 Ireland Ireland(1)

b2

00 UK UK(1)

b3

00 MELCO

b4

00 28 inch

b5

11 Large size

b6

b7

00 PTV

b0 VDU Version

b1 GC Version

b2 UV Swap

b3 TEXT

b4 LT2 22inch

b5 free

b6 Picture Shift set to 1

b7 CIP2

89

51

1

0

0

0

1

0

1

0

Enable(1)

set to 0

set to 0

Enable(1)

Enable(1)

Slow(1) Fast(0)

Reserved

TOP enable

80

0

0

0

0

0

0

0

1

set to 0

Volume curve1(0), curve2(1)

Add Volume

83 85

1

0

0

1

0

Arabic enable (1)

Russian enable (1)

Chinese enable (1)

enable(0)

0

0

1

set to 1

0A

enable(1)

Reserved

enable (1)

Blanking enable (1)

enable (1)

enable (1)

enable (1)

enable

Asia (1), europe (0)

MELCOA (1)

Reserved for 28 inch etc.

set to 1

set to 0

A21 (0), A12(1)

ES5 (0), ES6 (1)

Swap (1)

Enable (1)

22inch (1), 15inch (0)

without CIP1

with CIP (1

4A

0

0

0

1

0

1

0

1

41

Area Option

1

0

0

0

0

0

1

0

Temporary

0

1

0

1

0

0

1

0

20

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

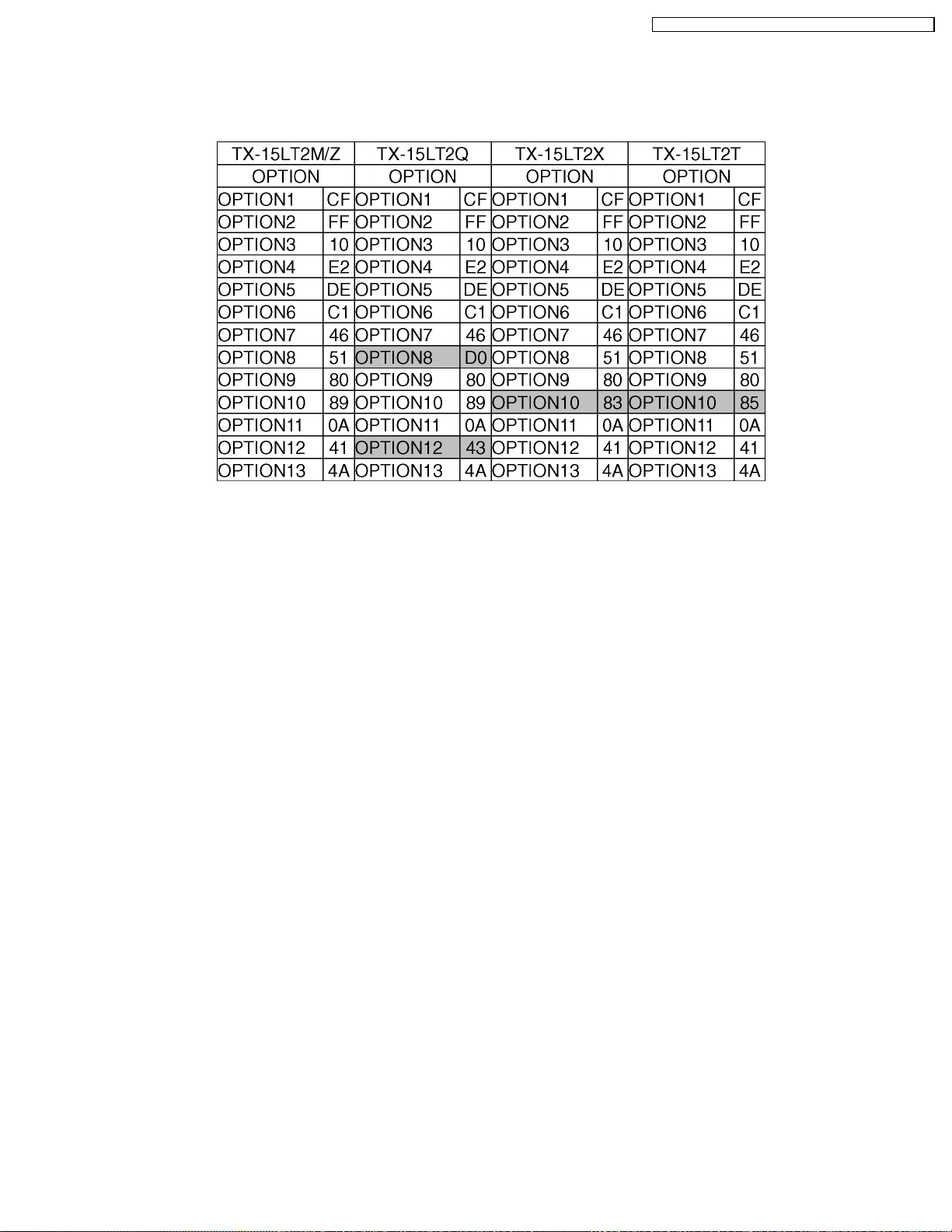

8.4. Option Code Setting

If the memory IC (IC1004) or DG Board is replaced, option code should be re-memorized.

Spare part of IC1004 is already memorized all Data for TX-15LT2M/Z.

If you use for other model, you should re-memorized the different option code in SERVICE 2 mode.

21

TX-15LT2M / TX-15LT2Q / TX-15LT2Z / TX-15LT2X / TX-15LT2T

9 Adjustment

9.1. RF AGC Adjustment

1.Connect RF signal generator to antenna terminal.

2.Receive a RF signal, Colour bar.

3.Enter service 1 mode, and select RF AGC.

4.Adjustment begins when the blue button of the remote controller is pushed.

5.It waits to become stable.

6.The STR button of the remote controller is pushed, and adjustment value is saved.

9.2. DVCO Adjustment

1.Connect PAL colour bar signal generator to AV1 (SCART) terminal.

2.Input a PAL Color bar.

3.Enter service 1 mode, and select DVCO.

4.Adjustment begins when the blue button of the remote controller is pushed.

5.It waits to become stable.

6.The STR button on remote controller is pushed, and adjustment value is saved.

22

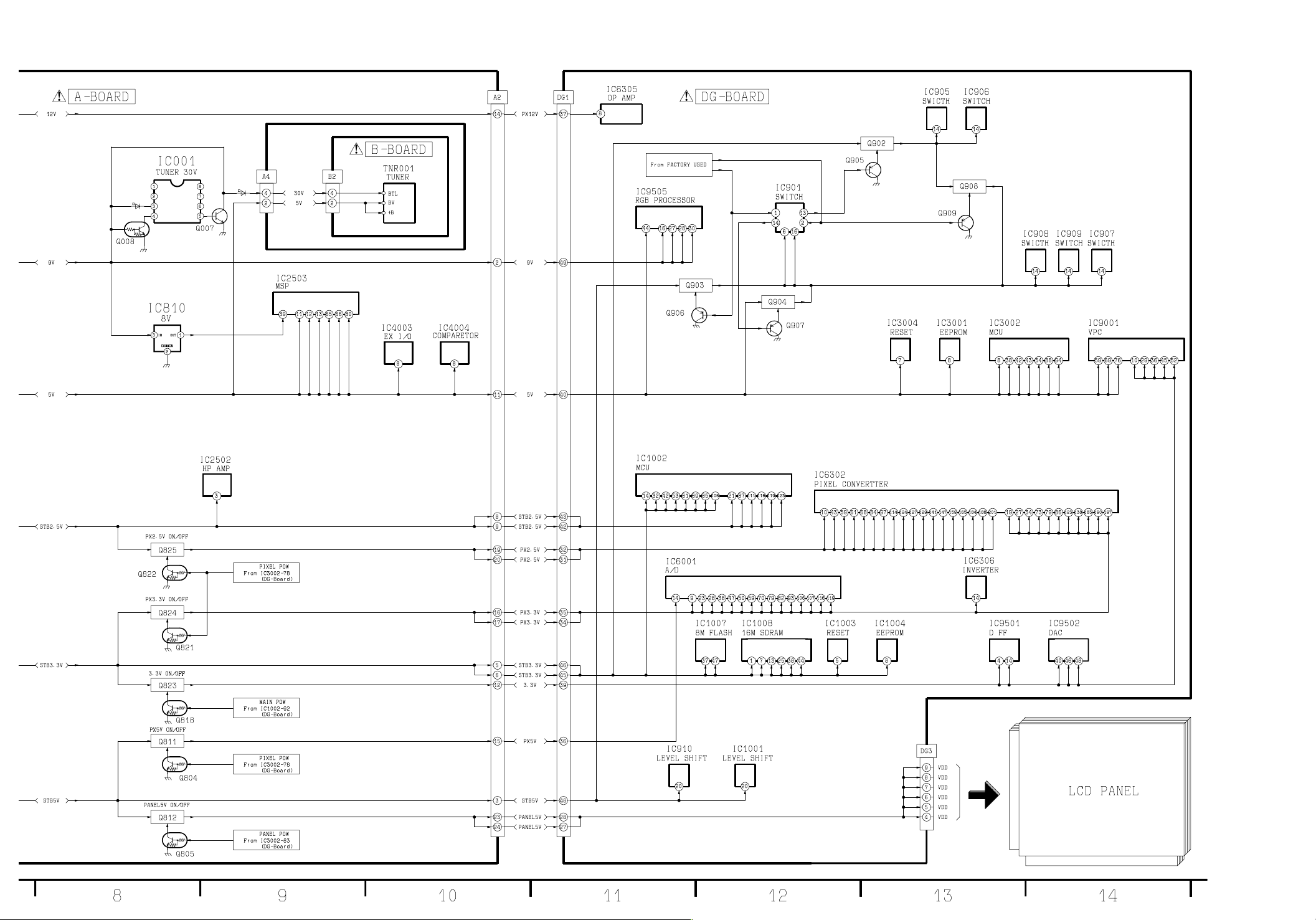

Remarks:

1. The Power Circuit contains a circuit area which uses a separate power supply to isolate the

earth connection.

The circuit is defined by HOT and COLD indications in the schematic diagram. Take the

follwing precautions.

All circuits, except the Power Circuit, are cold.

Precautions

a. Do not touch the hot part or the hot and cold parts at the same time or you may

be shocked.

b. Do not short- circuit the hot and cold circuits or a fuse may blow and parts may

break.

c. Do not connect an instrument, such as an oscilloscope, to the hot and cold

circuits simultaneously or a fuse may blow.

Connect the earth of instruments to the earth connection of the circuit being

measured.

d. Make sure to disconnect the power plug before removing the chassis.

2. Following diodes are interchangeable.

MA150- MA162 (Replacement part)

TX-15LT2M/Q/T/X/Z

Schematic Diagram Notes

TX-15LT2M/Q/T/X/Z Power Block Diagram TX-15LT2M/Q/T/X/Z Power Block Diagram

TX-15LT2M/Q/T/X/Z Signal Block Diagram TX-15LT2M/Q/T/X/Z Signal Block Diagram

TX-15LT2M/Q/T/X/Z Signal Block Diagram TX-15LT2M/Q/T/X/Z Signal Block Diagram

A-BOARD (COMPONENT SIDE)

6

5

4

3

2

TNPH0529

Parts Location

IC

IC001 D-6

IC801 B-5

IC802 C-3

IC803 B-3

IC804 C-2

IC806 B-5

IC808 C-2

IC810 C-3

IC2301 C-5

IC2502 B-5

IC2503 D-4

IC4001 E-2

IC4002 D-3

IC4003 E-3

IC4004 E-3

TRANSISTOR

Q001 E-3

Q003 E-2

Q004 D-3

Q005 E-3

Q802 C-2

Q803 C-2

Q806 C-2

Q808 C-2

A

A-BOARD (COMPONENT SIDE)

Q810 B-2

Q811 E-5

Q812 E-5

Q816 A-1

Q822 B-5

Q823 E-5

Q824 E-5

Q825 B-5

Q826 D-5

Q2301 B-4

Q2302 B-4

Q2303 B-4

Q2504 D-4

Q2505 D-4

Q2506 D-3

Q2510 E-5

Q2511 E-5

Q2512 C-4

Q2517 D-5

Q2518 D-5

Q4001 E-1

Q4002 E-3

Q4003 E-3

Q4004 E-3

Q4005 D-3

Q4006 E-3

TP

TP4010 F-1

TP4011 F-1

TP4012 F-1

TP4013 F-1

TP4014 G-1

TP4015 F-1

TP4016 F-1

TP4017 G-2

TP4018 G-2

TP4019 G-2

TP4207 G-1

TP4209 G-1

1

TX-15LT2M/Q/T/X/Z

A-BOARD TNPA0529

A

TX-15LT2M/Q/T/X/Z

A-BOARD TNPA0529

C EGBDF

A-BOARD (FOIL SIDE)

6

5

4

3

2

TNPH0529

Parts Location

IC

IC2301 D-4

TRANSISTOR

Q002 B-3

Q007 C-5

Q008 C-5

Q801 E-2

Q804 C-6

Q805 C-6

Q807 E-2

Q809 E-2

Q813 E-2

Q814 E-2

Q815 E-2

Q817 F-4

Q818 C-5

Q819 F-4

Q820 F-5

Q821 C-5

Q2301 E-4

Q2302 E-4

Q2303 E-4

Q2501 E-5

Q2502 E-5

Q2503 E-5

Q2513 E-4

Q2514 D-4

Q2515 E-4

A

A-BOARD (FOIL SIDE)

TP

Q2516 D-4

Q2519 E-5

TP801 B-5

TP802 F-5

TP803 F-6

TP804 B-2

TP805 F-1

TP806 F-5

TP807 E-2

TP808 E-2

TP809 E-3

TP810 F-3

TP811 F-4

TP812 E-2

TP813 D-2

TP814 E-3

TP815 E-3

TP816 E-3

TP817 E-2

TP818 D-2

TP819 D-3

TP820 F-4

TP844 F-1

TP2323 D-5

TP2324 D-5

TP2331 E-4

TP2332 E-4

TP2333 D-5

TP2334 D-5

TP2336 E-4

TP2337 E-4

TP4020 D-3

TP4021 D-3

TP4022 C-2

TP4023 C-2

TP4024 B-1

TP4025 B-1

TP4028 C-3

TP4029 C-3

1

TX-15LT2M/Q/T/X/Z

A-BOARD TNPA0529

A

TX-15LT2M/Q/T/X/Z

A-BOARD TNPA0529

C EGBDF

B-BOARD (COMPONENT SIDE)

6

TXN/B10HGK

V-BOARD (COMPONENT SIDE)

TNPA2772

P

K

B

H

5

V

H-BOARD (COMPONENT SIDE)

TNPA2774

4

K-BOARD (COMPONENT SIDE)

TNPA2773

3

P-BOARD (COMPONENT SIDE)

2

1

TX-15LT2M/Q/T/X/Z

B-BOARD TXN/B10HGK H-BOARD TNPA2774 K-BOARD TNPA2773

P-BOARD TNPA2770 V-BOARD TNPA2772

TNPA2770

A

Parts Location

P-BOARD (COMPONENT SIDE)

IC

IC601 C-2

IC602 C-1

TRANSISTOR

Q609 C-1

Q612 C-1

Q614 D-1

Q615 D-1

Q616 C-2

Q617 C-2

TX-15LT2M/Q/T/X/Z

B-BOARD TXN/B10HGK H-BOARD TNPA2774 K-BOARD TNPA2773

P-BOARD TNPA2770 V-BOARD TNPA2772

C EGBDF

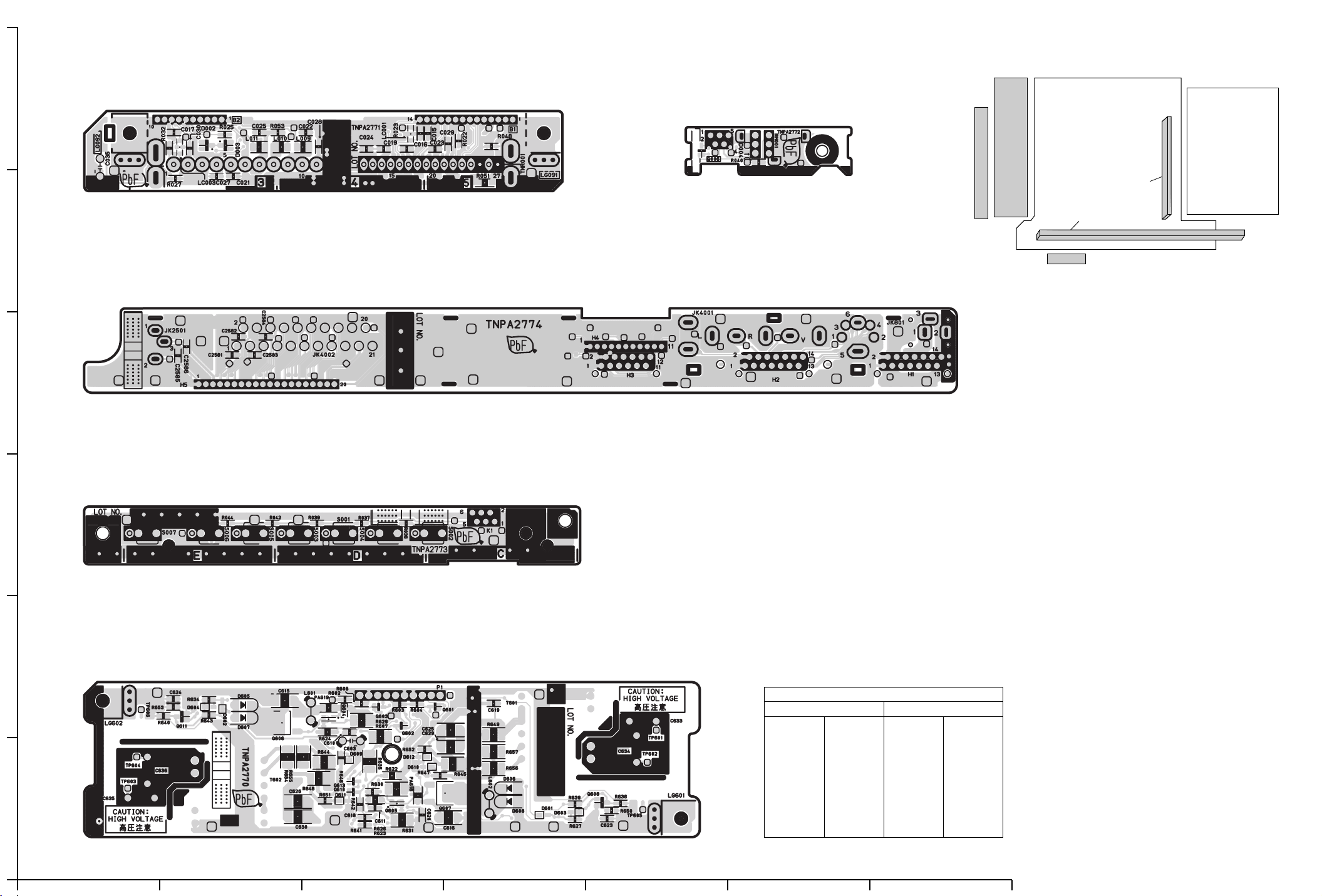

B-BOARD (FOIL SIDE)

6

TXN/B10HGK

V-BOARD (FOIL SIDE)

TNPA2772

P

K

B

H

5

H-BOARD (FOIL SIDE)

V

TNPA2774

4

K-BOARD (FOIL SIDE)

TNPA2773

3

P-BOARD (FOIL SIDE)

2

1

TX-15LT2M/Q/T/X/Z

B-BOARD TXN/B10HGK H-BOARD TNPA2774 K-BOARD TNPA2773

P-BOARD TNPA2770 V-BOARD TNPA2772

TNPA2770

A

Parts Location

P-BOARD (FOIL SIDE)

TRANSISTOR

Q601 C-2

Q602 C-2

Q603 C-2

Q604 C-2

Q605 C-1

Q606 B-2

Q607 C-1

Q608 E-1

Q610 C-1

Q611 B-2

Q613 C-1

TP

TP601 E-2

TP602 E-1

TP603 A-1

TP604 A-1

TP605 E-1

TP606 A-2

TX-15LT2M/Q/T/X/Z

B-BOARD TXN/B10HGK H-BOARD TNPA2774 K-BOARD TNPA2773

P-BOARD TNPA2770 V-BOARD TNPA2772

C EGBDF

Loading...

Loading...