Page 1

ORDER NO.ITD1308048CE

FULL HD LCD Display

Model No. TH-42LFE6W

LA45 Chassis

© Panasonic Corporation 2013

Unauthorized copying and distribution is a violation

of law.

Page 2

TH-42LFE6W

TABLE OF CONTENTS

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Touch-Current Check--------------------------------------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

3.1. Service Hint--------------------------------------------------6

3.2. Applicable signals ------------------------------------------7

4 Specifications ------------------------------------------------------8

5 Service Mode -------------------------------------------------------9

5.1. CAT (Computer Aided Test) mode ---------------------9

5.2. IIC mode structure (following items value is

sample data)----------------------------------------------- 13

6 Troubleshooting Guide---------------------------------------- 14

6.1. Self Check ------------------------------------------------- 14

6.2. No Power--------------------------------------------------- 17

6.3. No Picture -------------------------------------------------- 17

7 Disassembly and Assembly Instructions --------------- 18

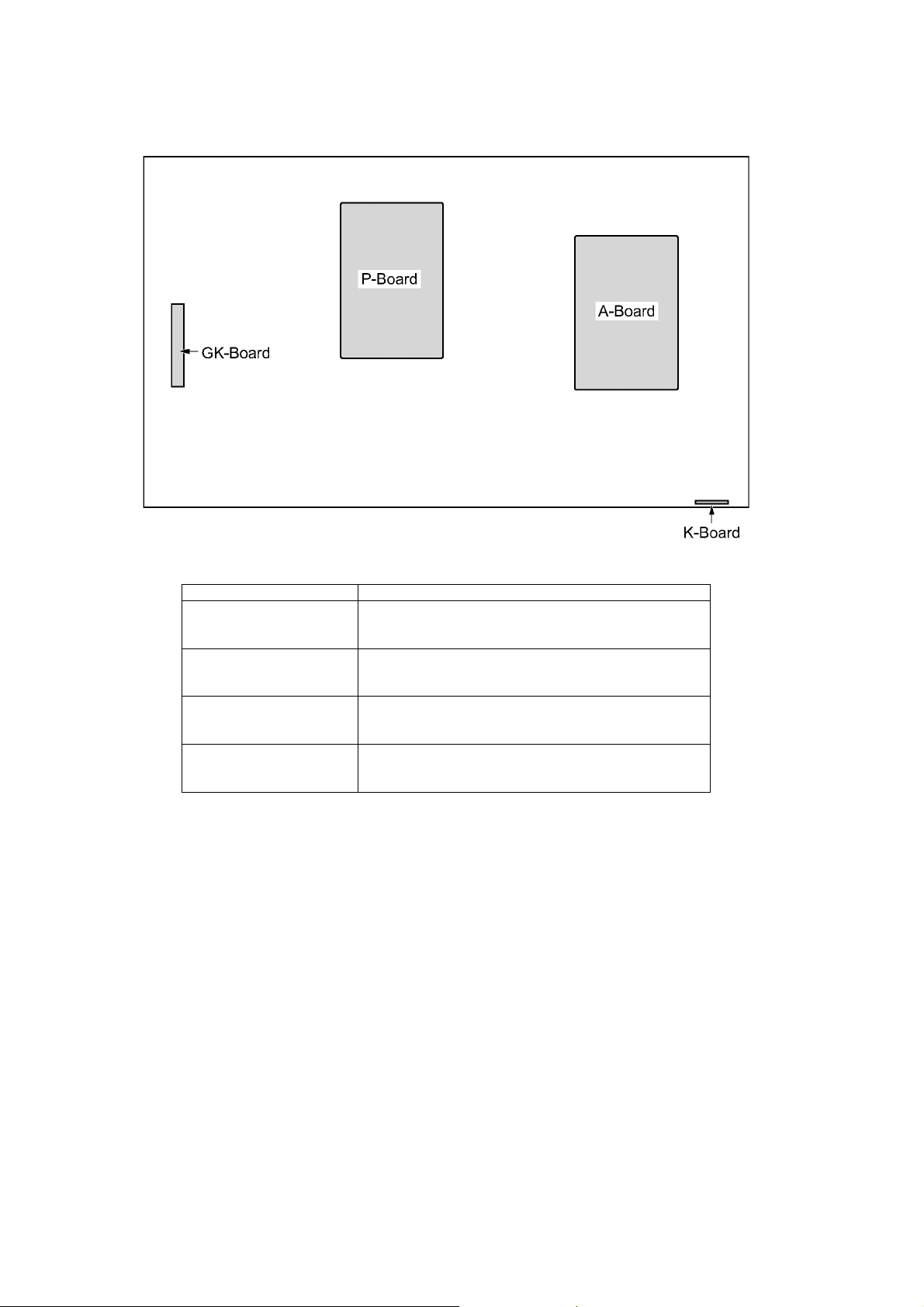

7.1. PCB Layout ------------------------------------------------18

7.2. Preparation ------------------------------------------------ 18

7.3. About disassembly and replacement --------------- 18

7.4. Back Cover removal ------------------------------------- 19

7.5. A-Board replacement------------------------------------ 19

7.6. P-Board replacement------------------------------------ 20

7.7. GK-Board and Key Button Bracket

replacement ----------------------------------------------- 21

7.8. Speaker Unit L/R replacement------------------------ 21

7.9. K-Board, LED Panel and LED Panel Case

replacement ----------------------------------------------- 22

7.10. Rear Panel BTM Assy replacement ----------------- 22

7.11. Rear Panel Top/L/R Assy replacement------------- 22

7.12. Rear Panel Metal Bot L/R replacement------------- 23

7.13. Metal Bracket Bottom replacement ------------------ 23

7.14. Rear Panel Metal Top/L/R replacement ------------ 24

7.15. LCD Panel replacement -------------------------------- 24

7.16. Caution about the sticking parts of LCD Panel --- 26

8 Block Diagram --------------------------------------------------- 29

8.1. Diagram Notes -------------------------------------------- 29

8.2. Main Block Diagram ------------------------------------- 30

8.3. Block (1 of 2) Diagram ---------------------------------- 31

8.4. Block (2 of 2) Diagram ---------------------------------- 32

9 Wiring Connection Diagram --------------------------------- 33

9.1. Wiring Connection Diagram --------------------------- 33

PAG E PAG E

2

Page 3

TH-42LFE6W

1 Safety Precautions

1.1. General Guidelines

1. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

2. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

3. When conducting repairs and servicing, do not twist the Fasten connectors but plug them straight in or unplug them straight

out.

4. When servicing, observe the original lead dress.If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

5. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

6. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

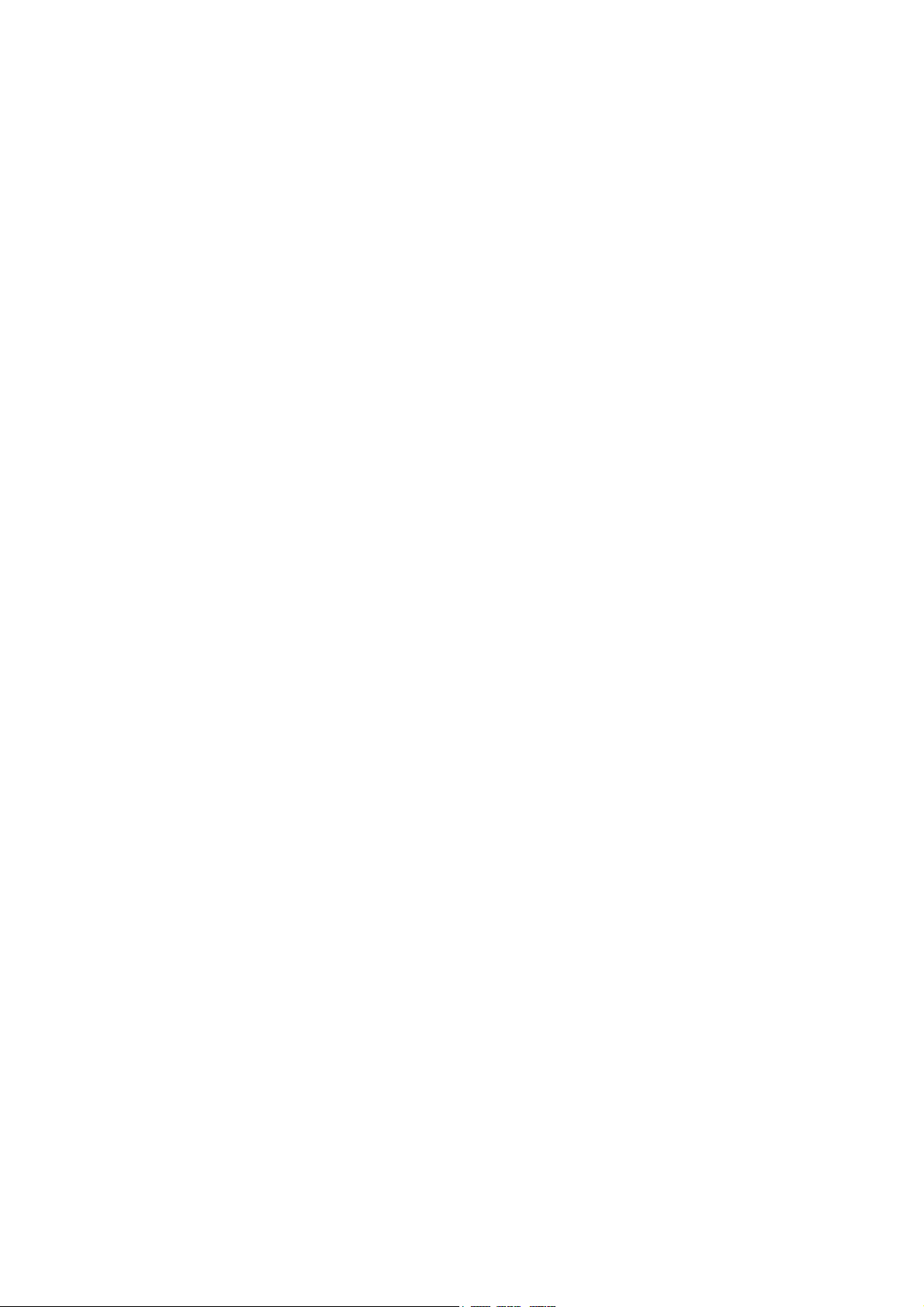

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground

such as a water pipe, as shown in Figure 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U

Note:

The limit value of U

mA d. c.

The limit value U

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

= 1.0 V,

1

= 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and 2.0

2

= 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100 kHz.

1

and U2, does not exceed the following values:

1

Figure 1

3

Page 4

TH-42LFE6W

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

4

Page 5

TH-42LFE6W

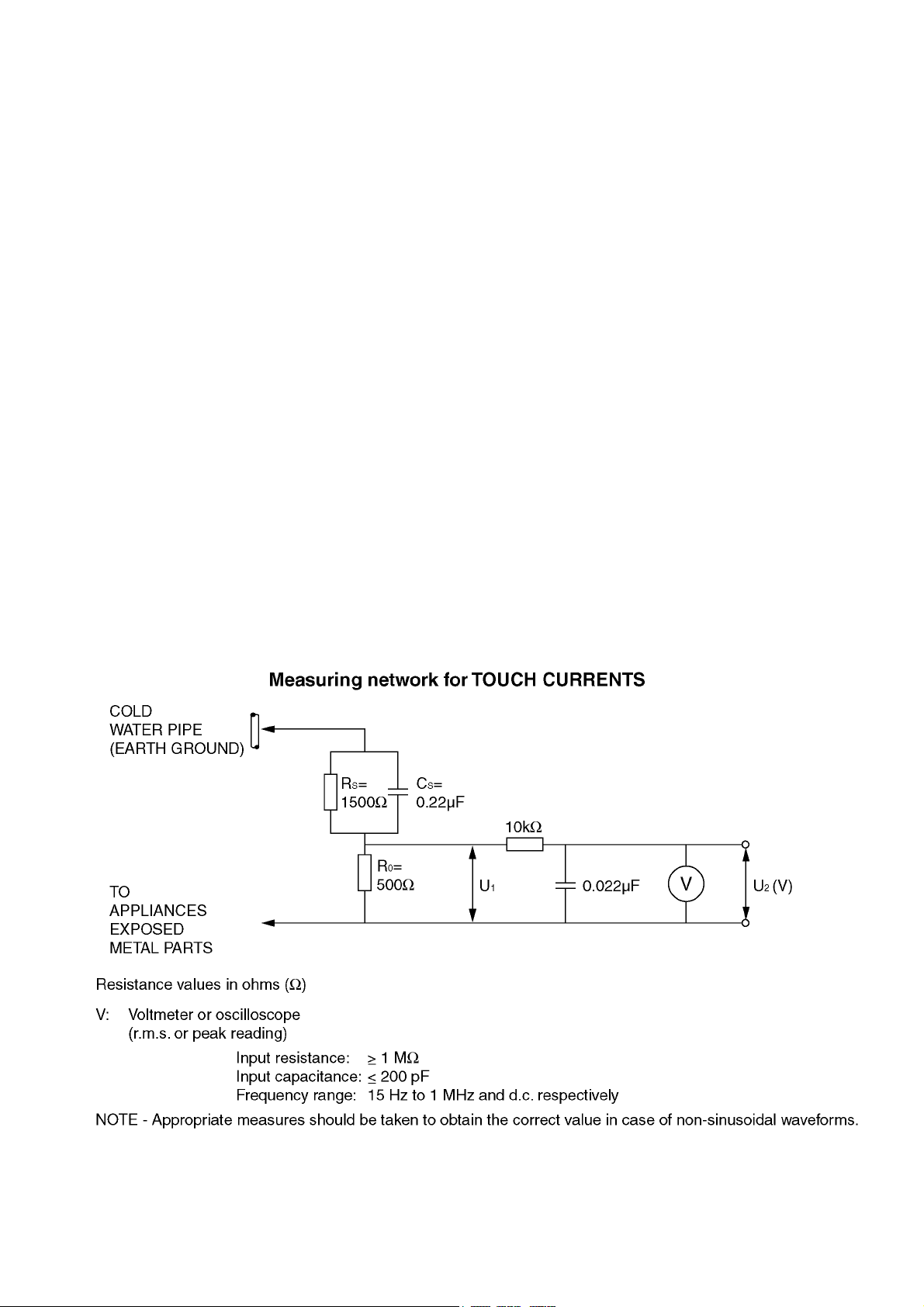

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

5

Page 6

TH-42LFE6W

3 Service Navigation

3.1. Service Hint

Board Name Function

P-Board Power supply

Non serviceable.

P-Board should be exchanged for service.

A-Board Digital core signal processor

Non serviceable.

A-Board should be exchanged for service.

GK-Board Switch

K-Board Power LED, Remote receiver, C.A.T.S. sensor

Non serviceable.

GK-Board should be exchanged for service.

Non serviceable.

K-Board should be exchanged for service.

6

Page 7

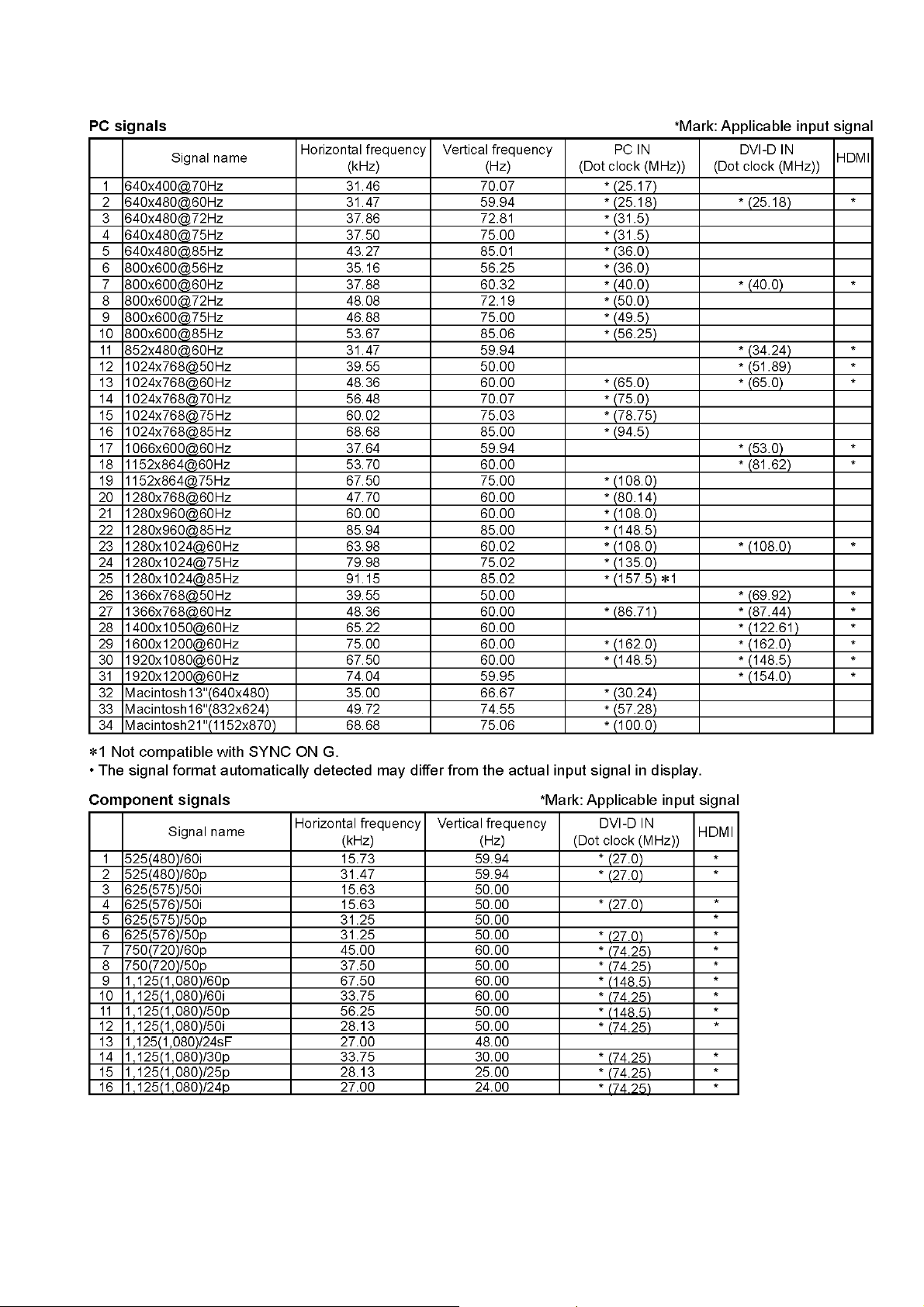

3.2. Applicable signals

TH-42LFE6W

7

Page 8

TH-42LFE6W

4 Specifications

Power Source 220-240 V AC, 50/60Hz

Power Consumption

Rated Power Consumption 65 W

Stand-by condition 0.5 W

Power off condition 0.5 W

Sound

Speakers 22 mm × 90 mm × 2 pcs

Audio Output 10 W [5 W + 5 W] (10 % THD)

LCD Display panel 42-inch VA panel (LED backlight), 16:9 aspect ratio

Screen size 930 mm (W) × 523 mm (H) × 1,067 mm (diagonal)

(No. of pixels) 2,073,600 (1,920 (W) × 1,080 (H))

[5,760 × 1,080 dots]

Operating condition

Temperature 0 °C - 40 °C

Humidity 20 % - 80 %

Applicable signals

Scanning format

PC signals VGA, SVGA, XGA, SXGA

Connection terminals

HDMI TYPE A Connector

DVI-D IN DVI-D 24 Pin Compliance with DVI Revision 1.0

AUDIO Stereo mini jack (M3) × 1 0.5 Vrms, Shared with PC IN

PC IN High-Density Mini D-sub 15 Pin G with sync 1.0 Vp-p (75 Ω)

AUDIO Stereo mini jack (M3) × 1 0.5 Vrms, Shared with DVI-D IN

LAN

SERIAL IN External Control Terminal

AUDIO OUT Stereo mini jack (M3) × 1 0.5 Vrms

Accessories Supply

Remote Control Transmitter N2QAYB000691

Batteries R6 Size × 2

Cable tie TMM17499 × 2

Ferrite core J0KG00000014 × 2

Dimensions (W × H × D) 957 mm × 564 mm × 49 mm

Mass (weight) approx. 13.5 kg

Note:

• Design and specifications are subject to change without notice. Mass and dimensions shown are approximate.

525 (480) / 60i 60p, 625 (575) / 50i 50p, 750 (720) / 60p 50p, 1125 (1080) /

60i 60p 50i 50p 24p 25p 30p 24sF

UXGA ..... (compressed)

Horizontal scanning frequency 30 - 110 kHz

Vertical scanning frequency 48 - 120 Hz

Content Protection Compatible with HDCP 1.1

G without sync 0.7 Vp-p (75 Ω)

B: 0.7 Vp-p (75 Ω)

R: 0.7 Vp-p (75 Ω)

HD / VD:1.0 - 5.0 Vp-p (high impedance)

RJ45 10BASE-T/100BASE-TX, compatible with PJLink

D-sub 9 Pin RS-232C compatible

Output level: Variable (- — 0 dB)

TM

[INPUT 1 kHz / 0 dB, 10 kΩ Load]

8

Page 9

5 Service Mode

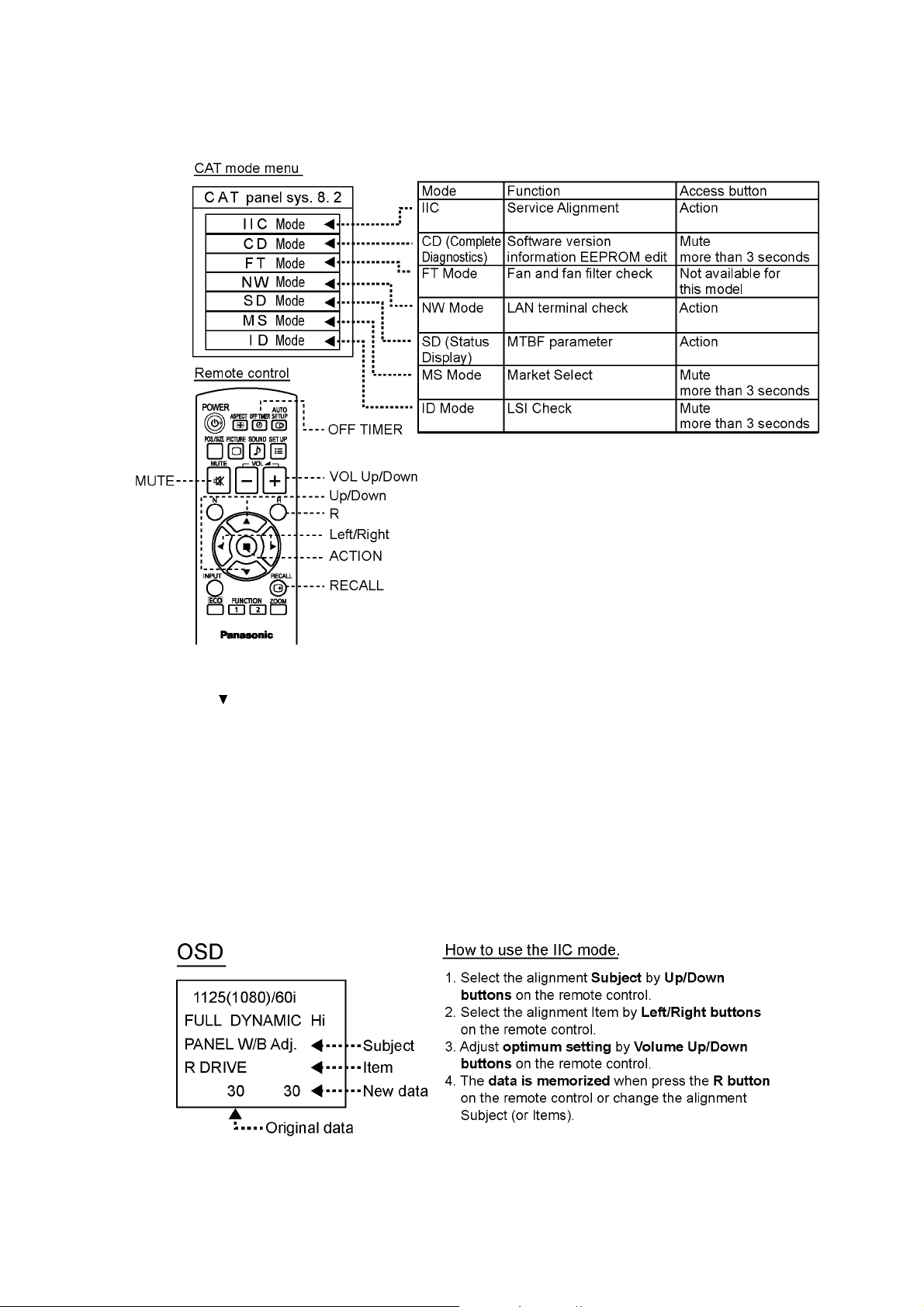

5.1. CAT (Computer Aided Test) mode

TH-42LFE6W

How to access the CAT mode.

Method A Main unit + remote control operation

Press and hold the button on the right side of the unit and press the RECALL button on the remote control 3 times quickly

within 2 second, this will place the unit into the CAT mode.

Method B Remote control operation only

1. Set the OFF timer except for [0] minute by OFF TIMER button. (30 minutes, 60minutes, 90 minutes)

2. Set the volume level of sound to 0 by VOL down button / -button.

3. Press the RECALL button more than 3 seconds before a volume display disappears.

To exit the CAT mode, turn the power off by the main unit or a remote control.

5.1.1. IIC mode

Select the IIC mode by Up/Down button on the remote control at the front page of CAT mode and then press the Action button on

the remote control.

Subject and item are mentioned on “IIC mode structure”.

To exit the IIC mode, press the R button on the remote control.

9

Page 10

TH-42LFE6W

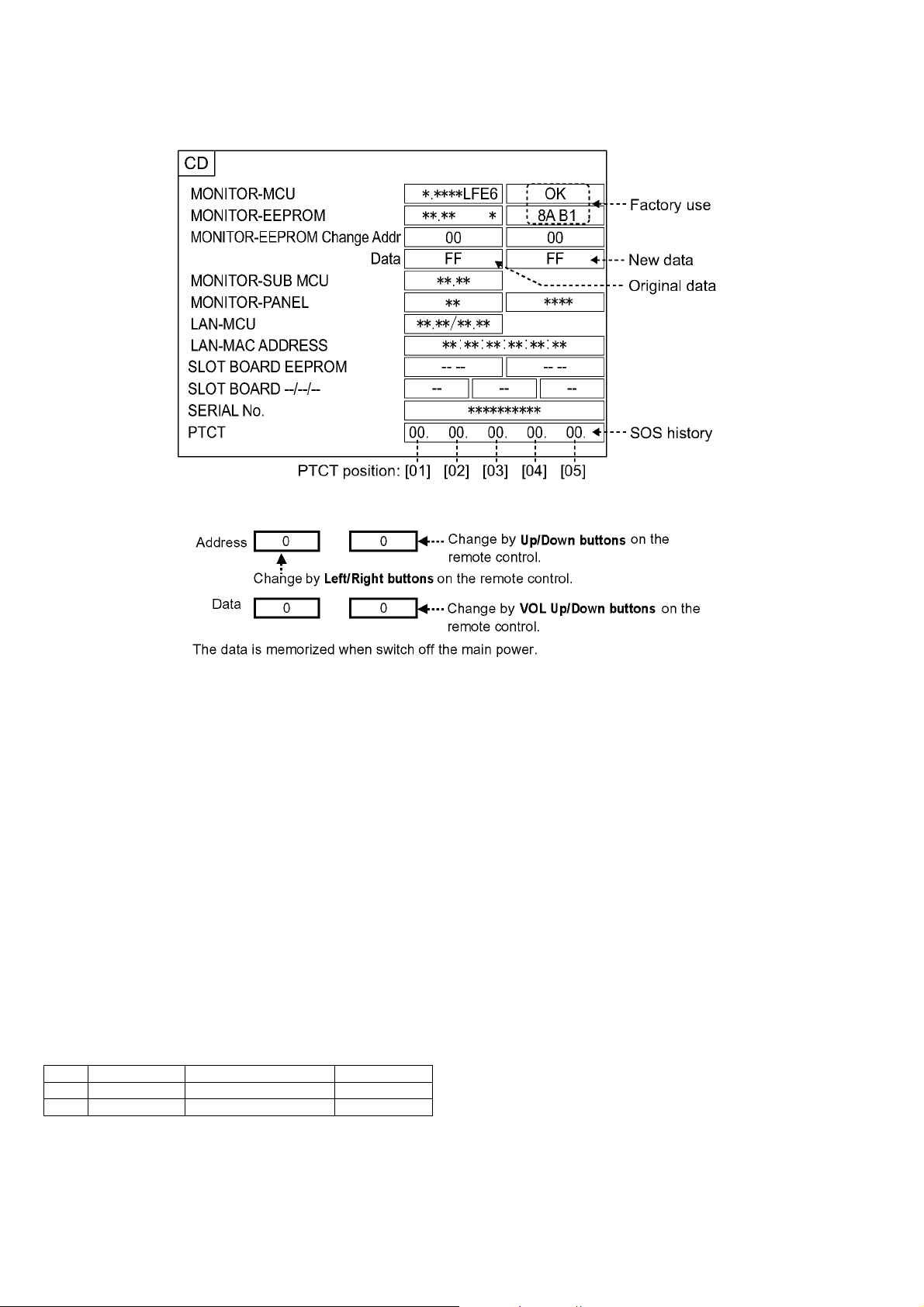

5.1.2. CD mode

Select the CD mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute button on

the remote control more than 3 seconds.

Memory data change

To exit the CD mode, press the R button on the remote control.

About the serial number display

As for the serial number of A-module for repair, a dummy value is displayed.

* By the set for which A-module was exchanged, a serial number is displayed as [-----].

About the history display of SOS for the power supply system

• This unit adds the history display (5 times) of power supply failure to the CD mode as PTCT.

• By the self check of a signal system, only one history is displayed (After a self check disappears). But PTCT displays 5 times of

histories (Abnormality of the latest 3 times, first time and second time after shipment) and after a self check does not disappear.

You can see a detailed history of power failure sometimes.

* About the display contents of PTCT

PTCT : The position of [05] is the first time after shipment.

PTCT : The position of [04] is the second time after shipment.

PTCT : The position of [03] is second from last time.

PTCT : The position of [02] is last time.

PTCT : The position of [01] is the latest.

In [Contents & Check point] of [6.1.2. Power LED Blinking timing chart], the two-digit following PTCT are displayed by a hexadecimal number.

Blinking times Contents & Check point Display contents

ex.1 2 times PTCT 02 H 09 02

ex.2 9 times PTCT 09 H 09 09

10

Page 11

TH-42LFE6W

5.1.3. SD mode

Select the SD mode by Up/Down button on the remote control at the front page of CAT mode and then press the Action button on

the remote control.

To exit the SD mode, press the R button on the remote control.

5.1.4. MS mode

Select the MS mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute button on

the remote control more than 3 seconds.

To exit the MS mode, press the R button on the remote control.

Caution:

Market Select should be set after exchange of A-Board.

Destination number

Number Model (Destination)

0 42/50LFE6J (Japan)

1 42/50LFE6U (North America)

2 42/50LFE6E (Europe)

3 42/50LFE6W (Asia, Oceania, ME, Africa)

18 42/50LFE6C (China)

11

Page 12

TH-42LFE6W

5.1.5. NW mode

Note :

To use the network function, set each "Network Setup" setting and make sure to set the "Control I/F Select" to "LAN".

Select the NW mode by Up/Down button on the remote control at the front page of CAT mode and then press the Action button

on the remote control.

To exit the NW mode, press the R button on the remote control.

5.1.6. ID mode

Select the ID mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute button on

the remote control more than 3 seconds.

To exit the ID mode, press the R button on the remote control.

12

Page 13

5.2. IIC mode structure (following items value is sample data)

TH-42LFE6W

13

Page 14

TH-42LFE6W

6 Troubleshooting Guide

6.1. Self Check

6.1.1. Display Indication

1. Self-check is used to automatically check the bus line controlled circuit of the LCD display.

2. To get into the Self-check mode, press the volume down button on the right side of the unit, at the same time pressing the

OFF-TIMER button on the remote control, and the screen will show.

Method A Self-check only (A shipment setup is not carried out).

• Select the ID mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute button

on the remote control more than 3 seconds.

Method B Self-check+Shipment setup

• Press and hold the button on the right side of the unit and press the OFF-TIMER button on the remote control.

If the IIC ports have been checked and found to be incorrect

Or not located then “ - - ” will appear in place of “ OK ”

“ 02 ” in the line of the “ PTCT ” means the number of blinks of the Power LED is 2. (Reference to 6.1.2)

“ H09 ” in the line of the “ PTCT ” is the error code.

To exit the CAT mode switch off the main power.

Note:

The line of the “ PTCT ” displays when you get into the Self-check mode for the first time only after the Power LED blinks.

6.1.2. Power LED Blinking timing chart

1. Subject

Information of LED Blinking timing chart.

2. Contents

When an abnormality has occurred to the unit, the protection circuit operates and resets to the stand by mode. At this time,

the defective block can be identified by the number of blinks of the Power LED on the front panel of the unit.

* Refer to 6.1.1 Display Indication

14

Page 15

6.1.3. LCD Panel test mode

A-Board

The failure-diagnosis by LCD Panel test mode

To find the possible failure point where in LCD Panel or Printed Circuit Board when the

abnormal picture is displayed.

[How to display the test pattern]

(A) Main unit + remote control operation

1. While pressing [VOLUME ( - )] button of the main unit, press [R] button of the

remote control three times within 2 seconds.

2. Test pattern is displayed and Power LED lights red and orange alternately.

How to Exit: Turn off the unit.

(B) Remote control operation only

1. Press [Recall] button of the remote control.

2. Press [R] button of the remote control.

3. Press [N] button of the remote control for over 3 seconds.

4. Test pattern is displayed and Power LED lights red and orange alternately.

TH-42LFE6W

How to Exit: The unit automatically turns off after around 10 seconds.

[Display pattern]

It is unfixed from which color it starts.

White Magenta Yellow Cyan Black

[Test pattern output image]

A-Board

IC

Input

switching

Video signal processing

IP conversion

OSD synthesis

LCD Panel

T-CON

Test pattern

LCD

Test pattern

Output test pattern from A-Board

15

Page 16

TH-42LFE6W

[Diagnostic flow chart]

Is a test pattern

displayed normally?

Is a part abnormal

even in a test pattern?

Yes

It displays.

No

It is still abnormal.

Yes

It is abnormal.

Failure of A-Board

Failure of LCD Panel

(rarely failure of A-Board or FR-Board)

Vertical line/

Vertical bar

No

This is not an abnormality

of part

Is the whole abnormal

even in a test pattern?

or

A test pattern is not

displayed but is the state

of LED blink of red and

orange?

Vertical line/

Vertical bar

Horizontal line/

Horizontal bar

Yes

It is abnormal.

Yes

It is blinking.

An image is

not displayed.

LED blinking

Color

unevenness

Failure of A-Board or LCD Panel

(rarely failure of FR-Board)

No

- The whole is not abnormal.

- It is not blinking.

A test pattern is not

displayed but is the state

of LED green lighting?

Yes

It is green lighting.

Failure of A-Board

An image is

not displayed.

LED lighting

16

Page 17

6.2. No Power

First check point

There are following 3 states of No Power indication by power LED.

1. No lit.

2. Green is lit then turns red blinking a few seconds later.

3. Only red is lit.

TH-42LFE6W

6.3. No Picture

17

Page 18

TH-42LFE6W

7 Disassembly and Assembly Instructions

7.1. PCB Layout

7.2. Preparation

Please pull soft cloth etc. not to damage a screen and please

turn the front of a main part down and lay it down

7.3. About disassembly and replacement

Cautions when replacing each component

• When you replace each component, please be sure to carry

out according to the following procedure.

• When you attach each module, please do not bolt a screw

strongly.

• The part without the statement of tightening torque, please

tighten a screw 50 - 70 [N cm].

• To disassemble P.C.B., wait for 1 minute after power was off

for discharge from electrolysis capacitors.

• When tightening a screw, retention structures are required

not to deform the LCD Panel.

• Please remove a clamper and a wire processing tape if

needed in the repaire.

• Hold the specified parts to stand the monitor up. (Prevent

from the curvature and deformation of a set)

18

Page 19

TH-42LFE6W

7.4. Back Cover removal

1. Remove the screws, and then remove the Back Cover.

7.5. A-Board replacement

1. Disconnect the connectors and remove the screws.

Caution when attaching the Back Cover

• Please tighten 4 screws fixing Back Cover of the following

figure, pressing down the dotted line part (A, B) of a rear

panel in the direction of an arrow.

Please do not press down the Back Cover.

2. Remove the screws, and then remove the A-Board from

the Terminal Metal.

19

Page 20

TH-42LFE6W

Caution when replacing the A-Board

• Gaskets are enclosed in the A-Board for repaire. Please

stick the gaskets on the position of the following figure

when replacing the A-Board.

Caution after replacing the A-Board

• Since the electronic switch is adopted as a power switch

of main unit, how the rise of the power of the initial state

is different from the case of a mechanical switch in the

past.

• After replacing the A-Board, it will be in an initial state.

When you connect the AC code to a wall outlet, a power

supply state turns into a standby state, and it can turn on

the power supply of the main unit by pressing the power

button on the remote control.

* Please note that a main power supply will be in an OFF

state if a power button of main unit is pressed after connecting the AC code to a wall outlet.

Please press a power button of main unit again and turn

on the main unit.

(Since the power supply state is saved in EEPROM of ABoard, when remove/insert an AC plug, it start in the last

state after an initial state.)

7.6. P-Board replacement

1. Disconnect the connectors and remove the screws, and

then remove the P-Board.

20

Page 21

TH-42LFE6W

Caution when replacing the P-Board

• A Heat Rubber is attached between the P-Board and

Barrier P PCB LCD.

• Please check the back side of the P-Board and Barrier P

PCB LCD when replacing.

• When the back side of P-Board has the Heat Rubber,

please remove the Heat Rubber from the P-Board, and

stick it along the guide line of the Barrier P PCB LCD.

Cautions when removing/attaching the GK-Board

• When removing the GK-Board from the Key Button

Bracket, please remove it carefully to five hooks.

• The hooks are locked certainly when assembling.

7.7. GK-Board and Key Button Bracket replacement

1. Disconnect the connector and remove the screw, and

then remove the GK-Board and Key Button Bracket.

7.8. Speaker Unit L/R replacement

1. Disconnect the speaker terminal, and then remove the

Speaker Unit L/R.

21

Page 22

TH-42LFE6W

7.9. K-Board, LED Panel and LED Panel Case replacement

1. Disconnect the connector, and remove the K-Board, LED

Panel and LED Panel Case.

7.11. Rear Panel Top/L/R Assy replacement

1. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

2. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

3. Remove the Rear Panel BTM Assy.

(Refer to “7.10. Rear Panel BTM Assy replacement”)

4. Remove the screws, and then remove the Rear Panel

Top/L/R Assy.

7.10. Rear Panel BTM Assy replacement

1. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

2. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

3. Remove the screws, and then remove the Rear Panel

BTM Assy.

Caution when reolacing the Rear Panel L/R Assy

• Felt is enclosed in the Rear Panel L Assy and Rear

Panel R Assy for repaire. Please stick the felt on the

position of the following figure when replacing the Rear

Panel L Assy or Rear Panel R Assy.

22

Page 23

TH-42LFE6W

Caution when attaching the Rear Panel Top/L/R Assy

• As shown in the following figure, please insert the part of

A correctly.

Please tighten a screw, pressing down Rear Panel L/R

Assy and Rear Panel Top Assy by hand and fixing.

Caution when attaching the Rear Panel Metal Bot L/R

• Please check that the hooks (positioning) of metals are

inserted firmly when assembling.

7.13. Metal Bracket Bottom replacement

1. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

2. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

3. Remove the Rear Panel BTM Assy.

(Refer to “7.10. Rear Panel BTM Assy replacement”)

4. Remove the Rear Panel L/R Assy.

(Refer to “7.11. Rear Panel Top/L/R Assy replacement”)

5. Remove the Rear Panel Metal Bot L/R.

(Refer to “7.12. Rear Panel Metal L/R replacement”)

6. Remove the screws, and then remove the Metal Bracket

Bottom.

7.12. Rear Panel Metal Bot L/R replacement

1. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

2. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

3. Remove the Rear Panel BTM Assy.

(Refer to “7.10. Rear Panel BTM Assy replacement”)

4. Remove the Rear Panel L/R Assy.

(Refer to “7.11. Rear Panel Top/L/R Assy replacement”)

• When removing the Rear Panel Metal Bot L, remove

the Rear Panel L Assy.

• When removing the Rear Panel Metal Bot R, remove

the Rear Panel R Assy.

5. Remove the screws, and then remove the Rear Panel

Metal Bot L/R.

23

Page 24

TH-42LFE6W

7.14. Rear Panel Metal Top/L/R replacement

1. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

2. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

3. Remove the Rear Panel BTM Assy.

(Refer to “7.10. Rear Panel BTM Assy replacement”)

4. Remove the Rear Panel Top/L/R Assy.

(Refer to “7.11. Rear Panel Top/L/R Assy replacement”)

5. Remove the Rear Panel Metal Bot L/R.

(Refer to “7.12. Rear Panel Metal Bot L/R replacement”)

• When removing the Rear Panel Metal L, remove the

Rear Panel Metal Bot L.

• When removing the Rear Panel Metal R, remove the

Rear Panel Metal Bot R.

6. Remove the screws, and then remove the Rear Panel

Metal Top/L/R.

Caution when attaching the Rear Panel Metal Bot L/R

• Please check that the hooks (positioning) of metals are

inserted firmly when assembling.

7.15. LCD Panel replacement

Caution about the sticking parts of LCD Panel

• The sticking parts for LCD Panel are enclosed.

When replacing the LCD Panel, please replace the sticking

parts simultaneously.

* Attachment specifications are subject to change without notice and parts may remain.

* Please stick on the same place as before.

Precautions when replacing the LCD Panel

• Please be sure to remove metal fittings and a clampers and

to attach them to the LCD Panel for repair. (Please check a

wiring diagram)

1. Remove the A-Board.

(Refer to “7.5. A-Board replacement”)

2. Remove the P-Board.

(Refer to “7.6. P-Board replacement”)

3. Remove the Key Button Bracket.

(Refer to “7.7. GK-Board and Key Button Bracket replacement”)

4. Remove the Speaker Unit L/R.

(Refer to “7.8. Speaker Unit L/R replacement”)

5. Remove the LED Panel Case.

(Refer to “7.9. K-Board, LED Panel and LED Panel Case

replacement”)

6. Remove the Rear Panel BTM Assy.

(Refer to “7.10. Rear Panel BTM Assy replacement”)

7. Remove the Rear Panel Top/L/R Assy.

(Refer to “7.11. Rear Panel Top/L/R Assy replacement”)

8. Remove the Rear Panel Metal Bot L/R.

(Refer to “7.12. Rear Panel Metal Bot L/R replacement”)

9. Remove the Metal Bracket Bottom.

(Refer to “7.13. Metal Bracket Bottom replacement”)

10. Remove the Rear Panel Metal Top/L/R.

(Refer to “7.14. Rear Panel Metal Top/L/R replacement”)

11. Remove the Barrier P PCB.

12. Remove the flexible cable, connector and tape, and then

replace the LCD Panel.

24

Page 25

Caution when replacing the LCD Panel

• Please stick the Model Name Sheet on the position of the

following figure when replacing the LCD Panel.

About the wire arrangement after replacing the LCD Panel

• Please refer to the “Wiring Connection Diagram”.

TH-42LFE6W

Precaution when connecting the LVDS FFC

• Please insert the LVDS FFC firmly to the back.

The shortage of plugs causes failure.

25

Page 26

TH-42LFE6W

7.16. Caution about the sticking parts of LCD Panel

• Please remove the Barrier P PCB from the old LCD Panel and stick it on the new LCD Panel for repair.

• Please stick the tapes according to the sticking position of the LCD Panel for repair after connecting the LVDS FFC.

* Attachment specifications are subject to change without notice and parts may remain.

* Please stick on the same place as before.

(Please refer to the "Wiring Connection Diagram".)

26

Page 27

TH-42LFE6W

27

Page 28

TH-42LFE6W

28

Page 29

8 Block Diagram

8.1. Diagram Notes

TH-42LFE6W

29

Page 30

TH-42LFE6W

(LED:2TIMES)

(LED:2TIMES)

(LED:4TIMES)

(LED:4TIMES)

(LED:13TIMES)

(LED:13TIMES)

(LED:1TIMES)

8.2. Main Block Diagram

A

DIGITAL CORE SIGNAL PROCESSOR

LAN TERMINAL

LAN DATA

EEPROM

MII DATA

POWER LINE

VIDEO LINE

AUDIO LINE

LAN

CONTROL

NETWORK

CONTROL

FLASH

MEMORY

REMOTE IN

C.A.T.S. SENSOR

DCDC

1.8V

LED_R

LED_G

K

LAN3.3V

LDO

3.3V

POWER LED

REMOTE RECEIVER

C.A.T.S. SENSOR

STB+5V/D3.3V

PWR5V

RS232C IN

K10

PC/DVI

AUDIO IN

A10

DVI

HDMI

PC

PC/DVI

R,G,B-PC

HD,VD-PC

L,R

RXD/TXD

STB+5V/D3.3V

PC/DVI AUDIO IN

STB3.3V_SW

D3.3V

D1.2V

RTC

UART SW

(LAN OR RS232C)

REMOTE

POWER LED_R

POWER LED_G

C.A.T.S.

MAIN CPU

+3.3V

+1.2V

SUB CPU

RTC_INT

RXD/TXD

UART_SW

REMOTE IN

LED_R

LED_G

C.A.T.S. SENSOR

AUDIO

PROCESSOR

VIDEO

PROCESSOR

(LED:2TIMES)

(LED:13TIMES)

(LED:4TIMES)

(LED:1TIMES)

+1.8V

LVDS

PWR_SOS

REG_SOS

PNL12V_SOS

SOUND_SOS

BL_SOS

MUTE

BL_ON

SOUND15V

AUDIO

SOS DET

PWM1

KEY

SERIAL AUDIO SIGNAL

+9V

LINE AMP

L/R

FLASH

MEMORY

DDR2

STB5V

+5V

PWR_SOS

(LED:2TIMES)

REG_SOS

(LED:13TIMES)

PNL12V_SOS

(LED:4TIMES)

5VD_POWER

P15V_24V_EN

MAIN_EN

LINE_OFF

P24_EN

DDR1.8V

BL_SOS

D3.3V

+9V

PANEL12V

POWER_ON

LINE_OFF

PWR5V

PWR15V

D3.3V

LAN3.3V

DDR1.8V

AMP

R

L

R+/-

L+/-

SPEAKER(R)

A13

SPEAKER(L)

LINE OUT

P

AC CORD

POWER SUPPLY

INPUT

FILTER

NEUTRAL

LIVE

JK7101

PFC

AC

DETECT

LLC

CONVERTER

DCDC

PNL12V

DCDC

SOUND15V

DCDC

STB5V

SOUND15V

PWR5V

D5V

STB5V

LDO

9V

DCDC

D3.3V

DCDC

DDR1.8V

DCDC

D1.2V

+9V

D3.3V

DDR1.8V

D1.2V

PANEL12V

A1

PANEL

CONTROL

PANEL

BACK LIGHT

LVDS DATA

LCD PANEL

PWR15V

5VD_POWER

PWR15V

P15V

DCDC

PWR5V

LINE_OFF

LINE_OFF

SUB_ON

A2

BL_SOS

P2

GK

GK4

P5

P15V

SWITCH

POWER SW

CONTROL PANEL KEY

16V

24V

BL_PWM

BL_ON

KEY

POWER_ON

P15V24V_EN

PWR15V

MAIN_EN

BL_SOS

BL_PWM

BL_ON

POWER_ON

KEY

P4

30

Page 31

8.3. Block (1 of 2) Diagram

(LED 2TIMES)

(LED

4TIMES)

(LED

13TIMES)

COLDHOT

TH-42LFE6W

LAN TERMINAL

F7101

JK7101

AC CORD

JK2701

P

POWER SUPPLY

**

LINE

FILTER

NO

HOLDER

2

1

A

DIGITAL SIGNAL PROCESSOR

LAN

DATA

LAN3.3V

D7106

RECTIFIER

CF7103

CF7104

LF7103

LF7104

LF7105

IC2701

LAN CONTROL

+3.3V

IC2706

EEPROM

WP

VCC

IC7201

T7201,

Q7201

PFC

CLK

MII_TXD/

MII_RXD

RESET

SDA/

SCL

IC7301

GK

CONTROL PANEL KEY

CONTROL IIC

Q7301,

Q7302

LLC

CONVERTER

AC

DETECT

KEY,Power SW

SW2851-2855

SW2857

POWER SW

25MHZ

MII DATA

PC7301

PC7302

PC7303

X2701

25MHZ

T7301

PHOTO

COUPLER

PHOTO

COUPLER

PHOTO

COUPLER

GK4

2

3

IC2704

MII_MDC

MII_TXD

MII_RXD

RESET

IIC_IF

EDID_WP

(IC4501)

DVI_DET

SHORT SOS

STB5V_SW

HDMI_DET

Q4094

PNL12V_SOS

JK3505

PC/DVI

AUDIO IN

PC/DVI_R

4TIMES)

(LED

PC/DVI_L

13TIMES)

(LED

REG_SOS

1

2

3

4

5

6

7

8

9

10

11

12

NETWORK

CONTROLER

UART

10/100

EtherMAC

w/FIFO

+1.8V

IC2703

+1.8V

TXD1

RXD1

+3.3V

Q2706

SPIO_SS

SPIO_MISO

SPIO_MOSI

SPIO_SCLK

IC2705

SPI

FLUSH

MEMORY

IC2708

SPI_CS

SPI_SO

SPI_SI

SPI_SCK

LAN3.3V

Q2719

5V->3.3V

IC2709

Q2714,15

Q2716

RXD_LAN

TXD_LAN

SPI_LAN_WP

SPI_CS_LAN

SPI_SO_LAN

SPI_SI_LAN

SPI_SCLK_LAN

SPI_LAN_SW

NT_RST

Q2717,18

RXD_PC

TXD_PC

IC3504

VCC

RS232C_IN

(SEIRIAL IN)

RS232C

DRIVER

RXD_232C

TXD_232C

JK3503

3

TXD

2

RXD

JK4002

DVI-D IN

DVI_5V

DVI_HPD

DDC IIC

TMDS DATA CLOCK

IC4806

POWER LED

K

REMOTE RECEIVER

C.A.T.S. SENSOR

COLDHOT

D7408,9

D7401,2

Q7402

RM2800

REMOTE

RECEIVER

SN2800

C.A.T.S.

SENSOR

D2802

REMOTE

G

R

POWER LED

IC7401

ERROR

DETCT

Q7401

PA7401

+24V

+24V

1

7

2

3

P5

P4

3

8

4

PA7402

SUB_ON

KEY

POWER_ON

LINE_OFF

BL_SOS

BL_ON

BL_PWM

K10

REMOTE

1

G_LED_ON

6

R_LED_ON

7

C.A.T.S

4

STB5V_SW

5

3

P2

1

2

3

SUB_ON

8

10

POWER_ON

9

LINE_OFF

6

BL_SOS

11

BL_ON

12

PWM1

13

D3.3V

+16V

+16V

+16V

KEY

PWM1

BL_ON

STATUS

24V

A10

1

6

7

4

5

3

A2

1

3

5

2

6

4

11

8

10

12

+3.3V

Q4129

IC5201

Q5201

BACK LIGHT

INVERTER

CIRCUIT

Q4128

Q4030

LAN3.3V_ON/OFF

LIGHT_DET

STB5V_SW

KEY_MUTE

KEY_LOCK

+5V

P15V_24V_EN

KEY_POWER

LINE_OFF

BLON_EN

PANEL

IR_IN

LED_G

LED_R

BL_SOS

KEY0

PWM1

LAN3.3V_ON/OFF

5VD_POWER

MAIN_EN

Q5102

PWR5V

IC5102

+5V

P5V_EN

PANEL

CONTROL

Q4138

Q5101

Q4602

D5V

STB5V

PWR5V

LAN3.3V

IC4904

PWR15V

D4165

12VPAN_EN

LVDS DATA

+12V

VCC12V

IC4901

(SHORT SOS)

PWR5V SOS

HDMI_I2C

D+3.3V

+3.3V

PANEL12V

IC4712

D3.3V

IC4905

A1

1

4

11

41

JK4004

HDMI IN1

HDMI DATA CLOCK

PANEL12V

DDC IIC

HDMI_5V

HDMI_HPD

SHORT SOS

9V

LVDS DATA

Q4300

Q4301

Q4088

IC4703

EEPROM

IC4706

EEPROM

HDMI_I2C

PWR_SOS

(LED 2TIMES)

IC4711

PWR5V

HDMI/DVI_SW

"L": IC4711 ON

Q4711

PWR5V

D4169

9V

Q4380,4100

SHORT SOS

D5V

D4187

Q4091,93

Q4087

D4161,64

D4400

OVP DET

PWM5V

DDR1.8V

STB5V_SW

D4174,4402

D4401

Q4024

Q4019

D5V

Q4099

31

LCD PANEL

Page 32

TH-42LFE6W

(LED:4TIMES)

(LED:2TIMES)

(LED:13TIMES)

(LED:1TIMES)

8.4. Block (2 of 2) Diagram

JK4001

PC

PC-R

PC-G

PC-B

H_SYNC

V_SYNC

3V_RXD3

3V_TXD3

IC4714

IC4715

VGA_R/PR

VGA_-G/Y

VGA_B/PB

1

PWM5V

2

3

4

5

IC4906

6

7

8

9

3.3V

D5V

IC4903

IC4902

10

DDR1.8V

D1.2V

STB3.3V_SW

D3.3V

D1.2V

+1.2V

DDR1.8V

+1.8V

VGA_SCL

VGA_SDA

PC_V_DET

PC_H_DET

STB5V_SW

TXD_PC

TXD_LAN

RXD_PC

RXD_LAN

X3120

PC_V_DET

PC_H_DET

LAN OR RS232C

Q2713

IC4702

EEPROM

IC4502,03

ANALOG VIDEO DATA

(R/G/B/H/V )

IC3120

REAL

TIME

CLOCK

IC2707

UART SW

3.3V

VGA_5V

Q4132

PC_DVI_L/R

DDR2

5V_I2C1

Q3120,Q3121

X4801

20MHz

Q2707

Q2712

A

DIGITAL SIGNAL PROCESSOR

IC4501

EDID_WP

DDR_SDRAM

I/F

MUX

+1.2V

+1.8V

+3.3V

AUD3.3V

MUX

HDMI/DVI_SW

HDMI_I2C

DVI_HPD

HDMI_HPD

DVI_DET

HDMI_DET

3V_RXD3

3V_TXD3

H_SYNC

V_SYNC

IC4801

RTC_INT

PC_V_DET

PC_H_DET

STB+5V

UART_SW

TXD0

Q4802

RXD0

LED_R

MAIN CPU

Analog

Capture

SUB CPU

R_LED_ON

LED_G

INPUTS

DVI/

HDMI

G_LED_ON

Q4801

SOUND15V

I2C2

RC

Q4805

Q4806

IIC2

Q4106

Q4109

I2C

5V->3V

Q4766

Q4114

VCC

VCC

IC4763

SPI_CS_LAN

IC5202

IC4761

Q4762

Q4105

Q4130,31

UART SW

5V->3.3V

UART SW

3.3V->5V

CS_FL

SPI_DI_S

SPI_DO_S

CLK2

SPI_SI_LAN

SPI_SO_LAN

IC4506

TEMP SENSOR

+15V

5V_I2C1

Q4058

SPI_CLK

SPI_SW2

SPI_SCLK_LAN

SERIAL AUDIO SIGNAL

IC4504

EEPROM

CS#

SPI_DI

SPI_DO

SPI_SW

IC4762

5V<->3.3V

Q4765

Q4763

X4004

19.6608MHz

CLOCK

GENARATION

AUDIO

PROCESSOR

DSP

AUDIO

A/D

3D VIDEO

DECORDER

TO JK3503

REMOTE

RXD0

5V_TXD

5V_RXD

TXD0

STB5V_SW

MUX

MUX

MUX

SUB_MAIN

SPI_LAN_WP

SPI_LAN_SW

LAN3.3V_ON/OFF

MOTION DETECTION

DCDI MOTION

ADAPTIVE

De-interlacing

Scaling

Shaping Filtter

MAIN_SUB2

NT_RST

POWER KEY_LOCK

KEY_POWER

P5V_EN

MEMORY

CONTROLER

VIDEO

PROCESSOR

5VD_POWER

P15V_24V_EN

MAIN_ON

2nd Channel

Processing

Enhancer ADCII

ACM-3D

3x3 Matrix

OSD Blend

SOUND_SOS

LINE_OFF

3x3

Matrix

(LED:4TIMES)

(LED:1TIMES)

BL_SOS

PNL12V_SOS

OSD

CONTROLER

(LED:13TIMES)

(LED:2TIMES)

PWR_SOS

REG_SOS

SPI_SW2

D/A

I2C_CONT

C.A.T.S_SENSOR

Q4112

IR_IN

RXD_PC

TXD_PC

Q4116

LAN3.3V_ON/OFF

SPI_LAN_WP

SPI_LAN_SW

NT_RST

P5V_EN

KEY_LOCK

KEY_POWER

5VD_POWER

MAIN_EN

P15V_24V_EN

LINE_OFF

SOUND_SOS

BL_SOS

PNL12V_SOS

REG_SOS

PWR_SOS

I2C_CONT

SPI_SW2

I2C_INT

AMP_STBY

SP_MUTE

BUS

CONTROL

SERIAL

I/F

OUTPUT

Formater

LVDS

Tx

LINE_OFF

IIC_CONT

12VPAN_EN

FLASH_WP_SUB

I2C_INT

FLASH_WP_SUB

PWM1

BL_ON

KEYSCAN

3V_TXD1

3V_RXD1

5V_TXD1

5V_RXD1

WP_SUB

SERIAL

I/F

CS_FL

PWR15V

OUT_R/L

MUTE

3V_I2C1

WP_MAIN

RC

5V_I2C1

SOUND15V

IC2001

LINE AMP

PWR5V

Q4057

FLASH_WP_SUB

IC4505

PWM1

BLON_EN

LINE_OFF

KEY0

LIGHT_DET

IR_IN

IIC_CONT

12VPAN_EN

SPI_SW2

SP_MUTE

SLEEPN

9V

Q4118

SERIAL

FLASH

KEY_MUTE

WP_SUB

Q4764

CS#

SO/SI01

SI/SI00

SCLK

Q4125

SPI_SW2

IC5103

AUDIO

OUT

AUDIO AMP

IC2002

SPI_SW

D3.3V

SPI_SW

Q2042

STB5V

SOUND_SOS(IC4801)

LINE MUTE

Q2052

Q2054

Q4761

Q2051

Q2053

SPI_SW

5V_I2C1

5V_I2C2

R(+)

R(-)

L(-)

L(+)

I2C_INT

I2C_CONT

STB5V

MODE

RESET

STB5V

R OUT

L OUT

D3.3V

A13

1

2

3

4

JK3506

LINE OUT

A40

FOR

FACTORY

USE

A48

FOR

FACTORY

USE

SPEAKER_R

SPEAKER_L

9V

11

12

LVDS DATA

9V

32

Page 33

9 Wiring Connection Diagram

9.1. Wiring Connection Diagram

TH-42LFE6W

33

Loading...

Loading...