Page 1

ORDER NO.MTNC110216CE

B34 Canada: B62

55 inch Class 1080p Plasma HDTV

Model No. TC-P55VT30

GPF14DU Chassis

© Panasonic Corporation 2011.

Unauthorized copying and distribution is a violation

of law.

Page 2

TABLE OF CONTENTS

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

2 Warning --------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

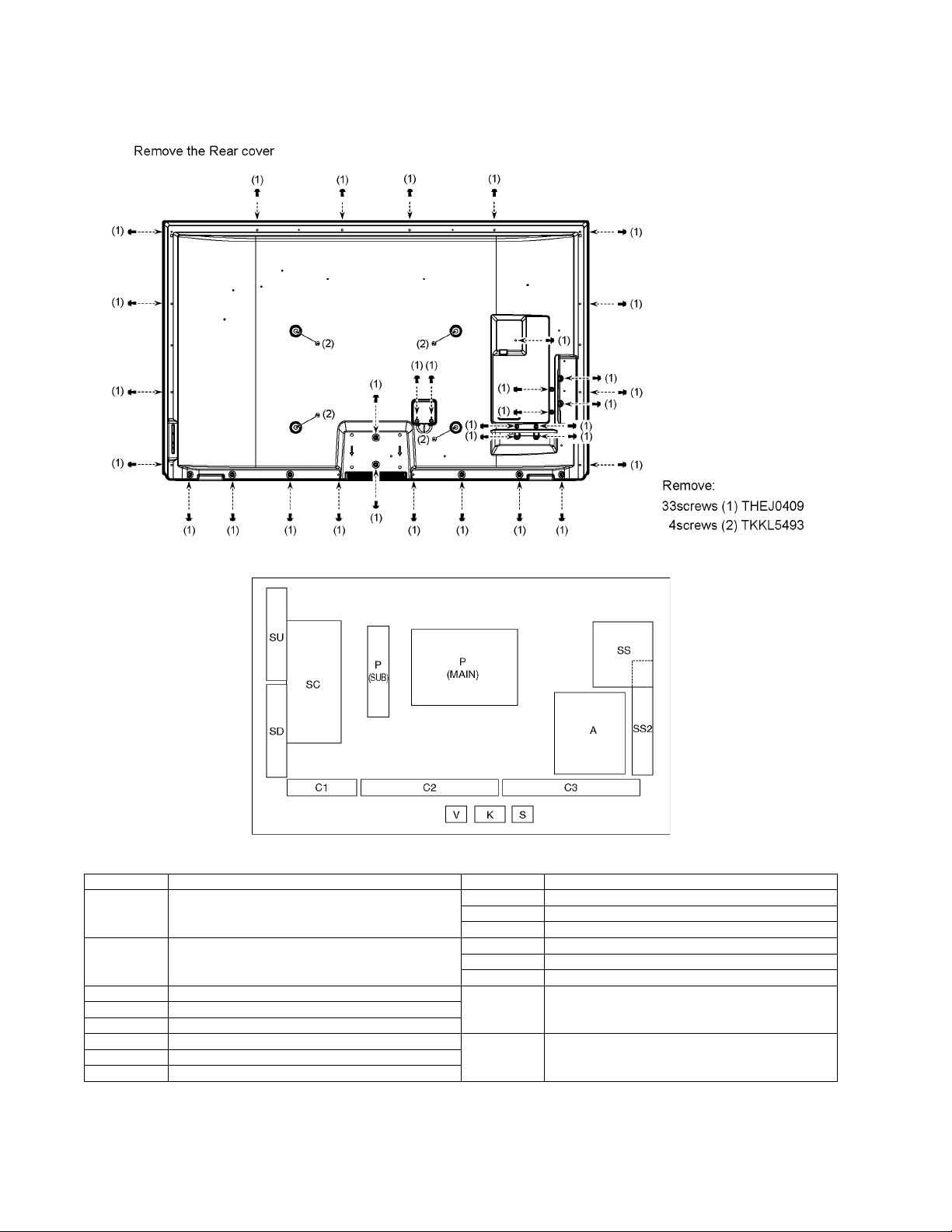

3 Service Navigation------------------------------------------------6

3.1. PCB Layout--------------------------------------------------6

3.2. Applicable signals------------------------------------------7

4 Specifications------------------------------------------------------8

5 Technical Descriptions----------------------------------------10

5.1. Specification of KEY for DTCP-IP, WMDRM

and Widevine----------------------------------------------10

5.2. Service port (M3 mini Jack) Specifications --------11

6 Service Mode-----------------------------------------------------14

6.1. How to enter into Service Mode----------------------14

6.2. Option - Mirror---------------------------------------------16

6.3. Service tool mode---------------------------------------- 16

6.4. Hotel mode-------------------------------------------------17

6.5. Data Copy by SD Card ---------------------------------18

7 Troubleshooting Guide---------------------------------------- 21

7.1. Check of the IIC bus lines------------------------------21

7.2. Power LED Blinking timing chart-------------- -------22

7.3. No Power--------------------------------------------------- 22

7.4. No Picture--------------------------------------------------23

7.5. Local screen failure--------------------------------------24

8 Service Fixture & Tools---------------------------------------25

8.1. SC jig------------------------------------- -------------------25

9 Disassembly and Assembly Instructions---------------26

9.1. Remove the Rear cover --------------------------------26

9.2. Remove the AC inlet ------------------------------------26

9.3. Remove the P(MAIN)-Board -------------------------- 26

9.4. Remove the P(SUB)-Board----------------------------26

9.5. Remove the Terminal covers and the shield

metals-------------------------------------------------------27

9.6. Remove the A-Board------------------------------------27

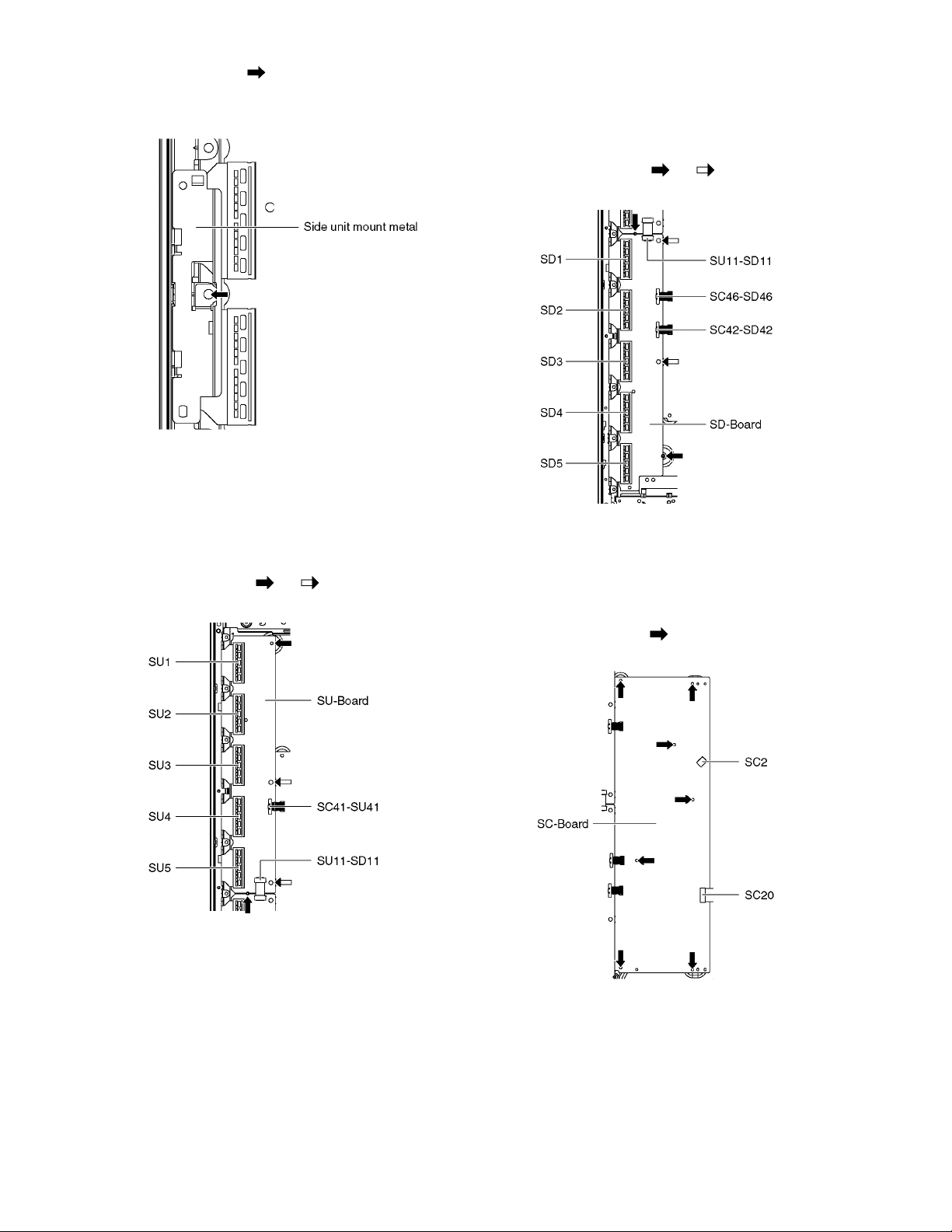

9.7. Remove the Side unit assy ----------------------------27

9.8. Remove the SU-Board----------------------------------28

9.9. Remove the SD-Board----------------------------------28

9.10. Remove the SC-Board----------------------------------28

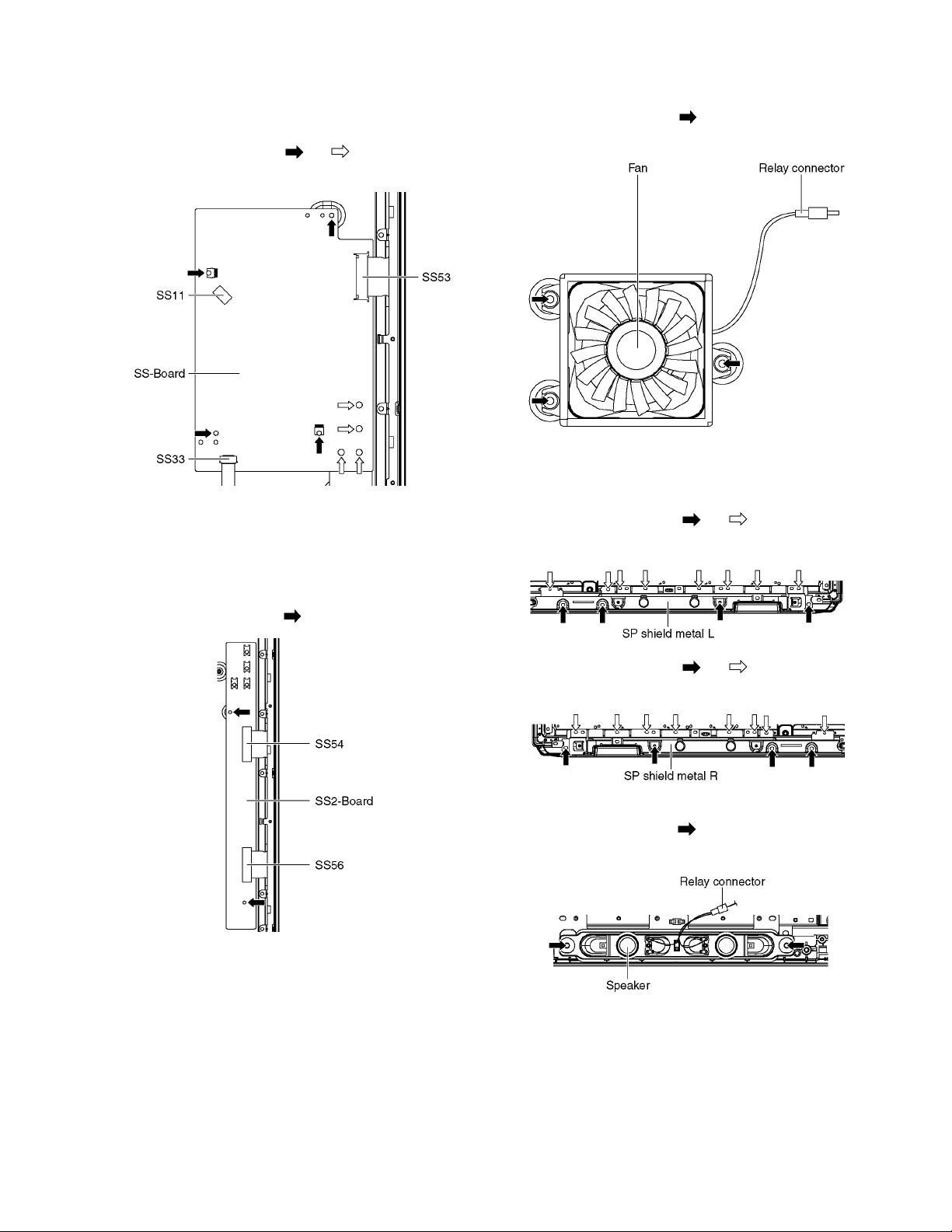

9.11. Remove the SS-Board----------------------------------29

9.12. Remove the SS2-Board --------------------------------29

9.13. Remove the Fan------------------------------------------29

9.14. Remove the Speakers ---------------------------------- 29

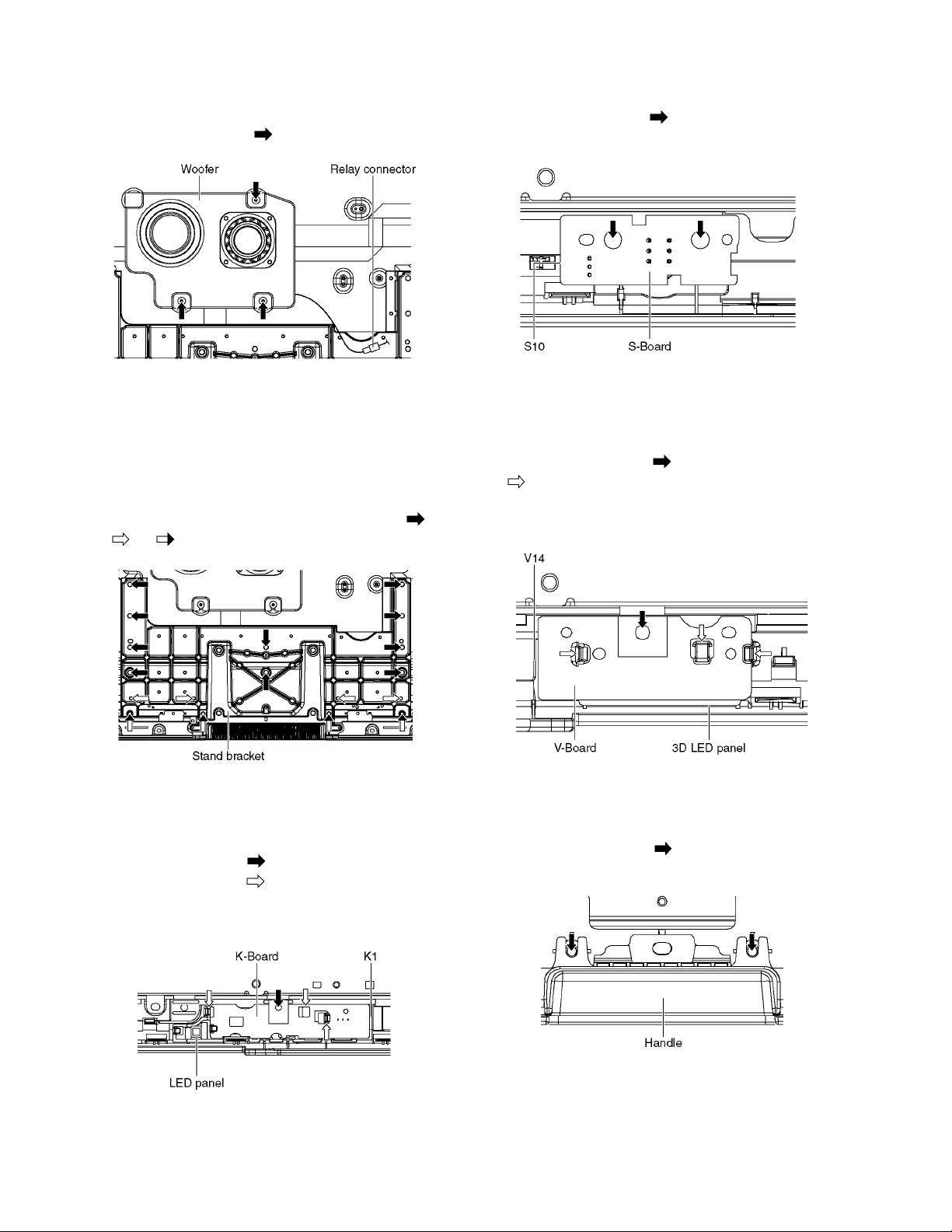

9.15. Remove the Woofer -------------------------------------30

9.16. Remove the Stand bracket-----------------------------30

9.17. Remove the K-Board------------------------------------30

9.18. Remove the S-Board------------------------------------30

9.19. Remove the V-Board------------------------------------30

9.20. Remove the Handles------------------------------------30

9.21. Remove the Bottom cabinet assy-------------------- 31

9.22. Remove the Plasma panel section from the

Cabinet assy.---------------------------------------------- 31

9.23. Remove the Contact metals--------------------------- 31

9.24. Remove the C1-Board ----------------------------------31

9.25. Remove the C2-Board ----------------------------------31

9.26. Remove the C3-Board ----------------------------------32

9.27. Remove the AL frames ---------------------------------32

PAGE PAGE

9.28. Replace the Plasma panel ---------------------------- 32

10 Measurements and Adjustments-------------------------- 33

10.1. Adjustment ------------------------------------------------ 33

11 Block Diagram--------------------------------------------------- 39

11.1. Main Block Diagram------------------------------------- 39

11.2. Block (1/4) Diagram ---------- -------------------------- 40

11.3. Block (2/4) Diagram-------------------------------- -- --- 41

11.4. Block (3/4) Diagram-------------------------------- -- --- 42

11.5. Block (4/4) Diagram-------------------------------- -- --- 43

12 Wiring Connection Diagram -------------------------------- 45

12.1. Caution statement. -------------------------------------- 45

12.2. Wiring (1) - ------------------------------------------------- 45

12.3. Wiring (2) - ------------------------------------------------- 45

12.4. Wiring (3) - ------------------------------------------------- 46

12.5. Wiring (4) - ------------------------------------------------- 47

12.6. Wiring (5) - ------------------------------------------------- 48

12.7. Wiring (6) - ------------------------------------------------- 49

12.8. Wiring (7) - ------------------------------------------------- 50

13 Schematic Diagram

14 Printed Circuit Board

15 Exploded View and Replacement Parts List

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

2. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

3. When conducting repairs and servicing, do not twist the Fasten connectors but plug t hem straight in or unplug them straight

out.

4. When servicing, observe the original lead dress. If a sh ort circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

5. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shield s are properly

installed.

6. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplu g the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1Mohm and 5.2Mohm.

When the exposed metal does not have a return path to

the chassis, the reading must be .

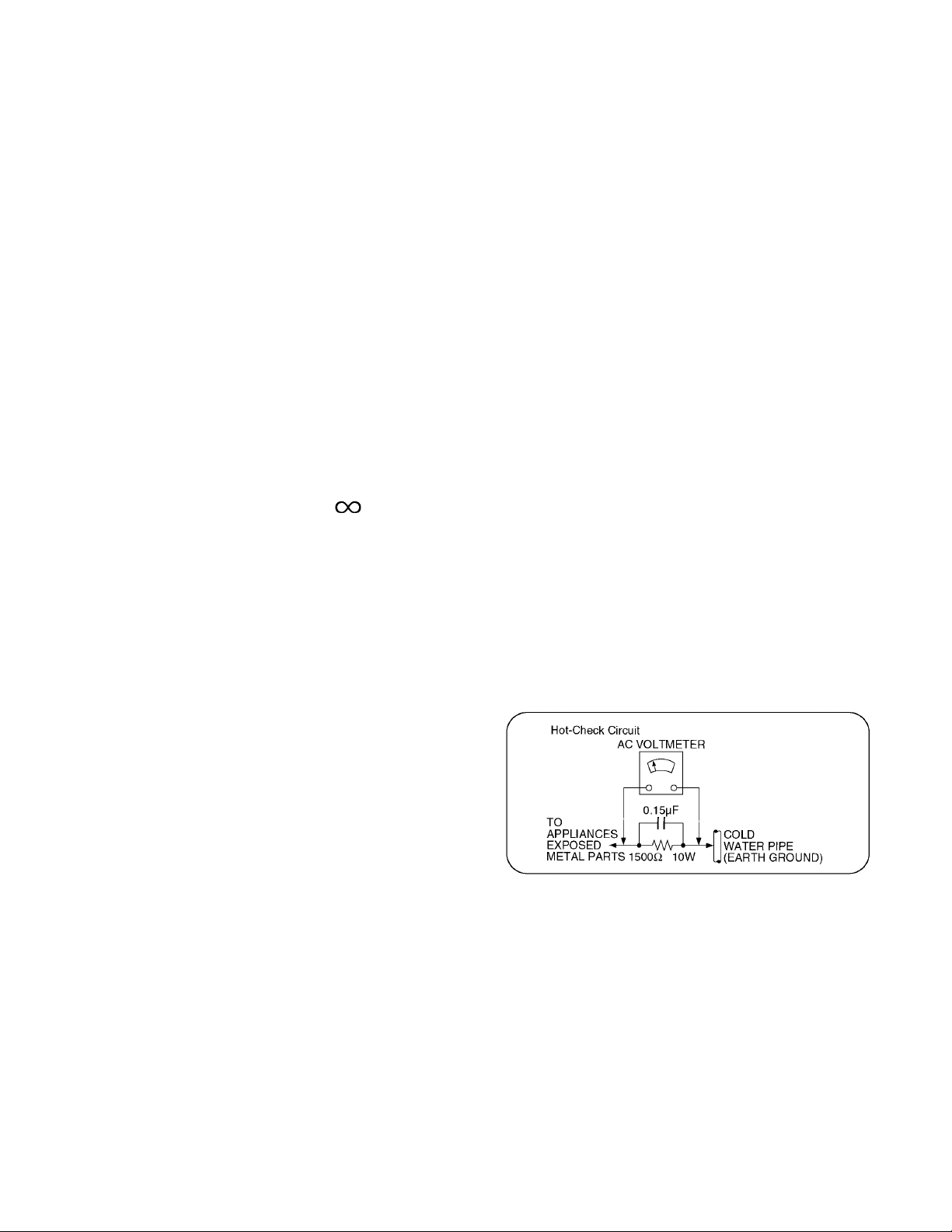

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a measurement is outside of the limits specified, there is a possibility

of a shock hazard, and the equipment should be repaired

and rechecked before it is returned to the customer.

Figure 1

3

Page 4

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrica l assembly equ ipped with ES devices, place the assembly on a conductive su rface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

4

Page 5

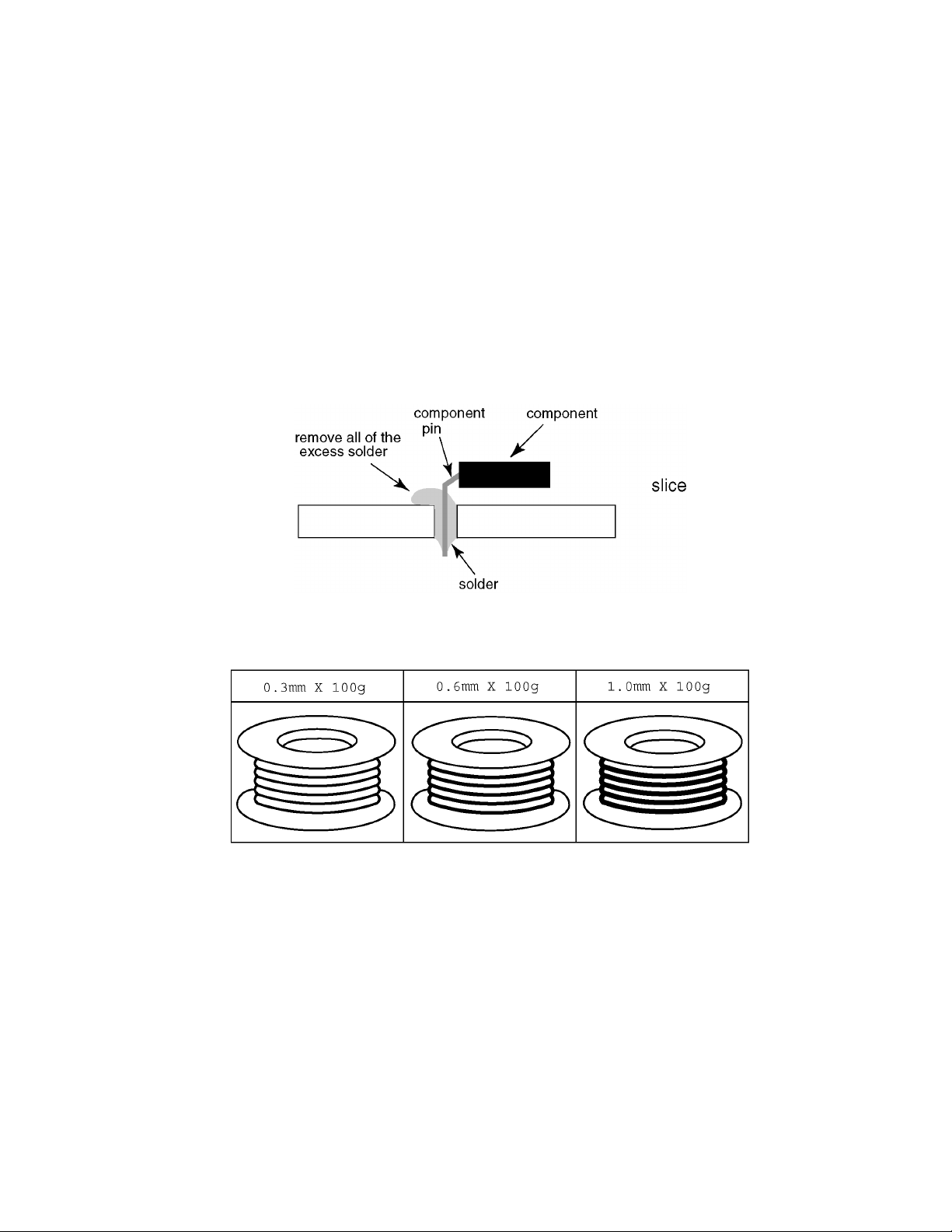

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it's manufacture due to environmental conservation issues. For service and repair work, we'd

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (37 0 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

5

Page 6

3 Service Navigation

3.1. PCB Layout

Board Name Function Board Name Function

P(MAIN) Power Supply

Non serviceable.

P(MAIN)-Board should be exchange for service.

P(SUB) Power Supply

Non serviceable

P(SUB)-Board should be exchange for service

A Main AV input, processing SU Scan out (Upper)

K Remote receiver, Power LED, C.A.T.S sensor

SPower Switch

V 3D Eyewear transmitter SD Scan out (Lower)

C1 Data Driver (Lower Right)

C2 Data Driver (Lower Center)

C3 Data Driver (Lower Left)

SC Scan Drive

SS Sustain Drive

SS2 Sustain out (Lower)

Non serviceable.

SU-Board should be exchanged for service.

Non serviceable.

SD-Board should be exchanged for service.

6

Page 7

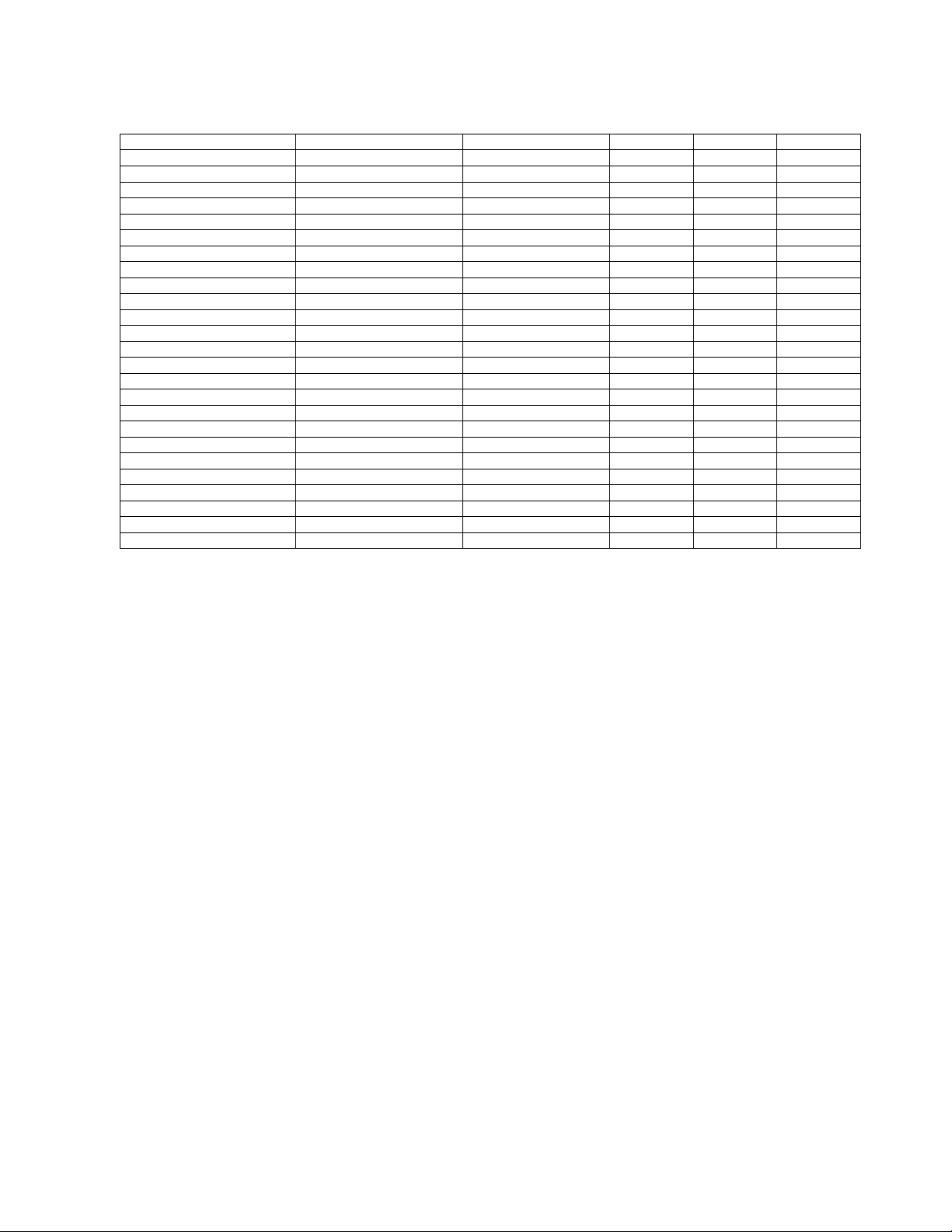

3.2. Applicable signals

* Mark: Applicable input signal for Component (Y, PB, PR), HDMI and PC

horizontal frequency (kHz) vertical frequency (Hz) COMPONENT HDMI PC

525 (480) / 60i 15.73 59.94 * *

525 (480) /60p 31.47 59.94 * *

750 (720) /60p 45.00 59.94 * *

1,125 (1,080) /60i 33.75 59.94 * *

1,125 (1,080) /60p 67.43 59.94 *

1,125 (1,080) /60p 67.50 60.00 *

1,125 (1,080) /24p 26.97 23.98 *

1,125 (1,080) /24p 27.00 24.00 *

640 × 400 @70 31.47 70.08 *

640 × 480 @60 31.47 59.94 *

Macintosh13 inch (640 × 480) 35.00 66.67 *

640 × 480 @75 37.50 75.00 *

852 × 480 @60 31.44 59.89 *

800 × 600 @60 37.88 60.32 *

800 × 600 @75 46.88 75.00 *

800 × 600 @85 53.67 85.08 *

Macintosh16 inch (832 × 624) 49.73 74.55 *

1,024 ×768 @60 48.36 60.00 *

1,024 ×768 @70 56.48 70.07 *

1,024 ×768 @75 60.02 75.03 *

1,024 ×768 @85 68.68 85.00 *

Macintosh21 inch (1,152 × 870) 68.68 75.06 *

1,280 ×768 @60 47.78 59.87 *

1,280 ×1,024 @60 63.98 60.02 *

1,366 ×768 @60 48.39 60.04 *

Note

• Signals other than above may not be displayed properly.

• The above signals are reformatted for optimal viewing on your display.

• Computer signals which can be input are those with a horizontal scanning frequency of 15 to 110 kHz and vertical scanning frequency of 48 to 120 Hz. (However, the image will not be displayed properly if the signals exceed 1,200 lines.)

7

Page 8

4 Specifications

Q TV

Power Source AC 120 V, 60 Hz

Power Consumption

Rated Power Consumption 438 W

Standby condition 0.2 W

Plasma Display panel

Drive method AC type

Aspect Ratio 16:9

Visible screen size 55 inch class (55.1 inches measured diagonally)

(W × H × Diagonal) 48.0 inch × 27.0 inch × 55.1 inch (1,221 mm × 686 mm × 1,401mm)

(No. of pixels) 2,073,600 (1,920 (W) × 1,080 (H)) [5,760 × 1,080 dots]

Sound

Audio Output 22 W [ 6 W + 6 W + 10 W ] ( 10 % THD )

PC signals VGA, SVGA, XGA, WXGA, SXGA

Horizontal scanning frequency 31 - 69 kHz

Vertical scanning frequency 59 - 86 Hz

Channel Capability (Digital/Analog) VHF/ UHF: 2 - 69, CATV: 1 - 135

Operating Conditions

Temperature: 32 °F - 104 °F (0 °C - 40 °C)

Humidity: 20 % - 80 % RH (non-condensing)

Connection Terminals

VIDEO IN VIDEO: RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

AUDIO L-R: RCA PIN Type × 2 0.5 V [rms]

COMPONENT IN Y: 1.0 V [p-p] (including synchroniz ation)

PB, PR: ±0.35 V [p-p]

AUDIO L-R: RCA PIN Type × 2 0.5 V [rms]

HDMI 1-4 TYPE A Connector × 4

This TV supports [HDAVI Control 5] function.

USB 1-3 USB 2.0 Type A connector x 3 (DC 5 V MAX500mA)

PC D-SUB 15 PIN: R, G, B / 0.7 V [p-p] (75 Ω)

LAN (for VIERA Connect) RJ45 (10BASE-T/100BASE-TX)

Card slot SD CARD slot × 1

RS232C (Serial) D-sub 9pin for external control

DIGITAL AUDIO OUT PCM / Dolby Digital, Fiber Optic

FEATURES 3D Y/C FILTER

CLOSED CAPTION V-Chip

VIERA Connect Media player

3D IMAGE VIEWER HDAVI Control 5

Dimensions (W × H ×

luding pedestal 52.4 inch × 33.4 inch × 15.3 inch (1,329 mm × 847 mm × 387 mm)

Inc

TV Set only 52.4 inch × 31.9 inch × 1.5 (2.2) inch (1,329 mm × 810 mm × 37 (55) mm)

Mass

Including pedestal 98.2 lb. (44.5 kg)

TV Set only 84.9 lb. (38.5 kg)

D)

HD, VD / 1.0 - 5.0 V [p-p] (high impedance)

Note

• Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

Q 3D Eyewear

Lens type Liquid Crystal Shutter

Usage temperature range 32 °F - 104 °F (0 °C - 40 °C)

Charging power supply DC 5 V (supplied by USB terminal of a Panasonic TV)

Battery Lithium-ion polymer rechargeable battery

DC 3.7 V, 70 mAh

Operation time*

Viewing range*

Materials Main body: Resin

Dimensions Width 6.70 inch (170.1 mm)

(not including nose pad part) Height 1.63 inch (41.2 mm)

2

Charging time*

Transmitter for 3D Eyewear

Within 10 feet 5 inch (3.2 m) from front surface

(Within ± 35° horizontal, ± 20° vertical)

Lens section: Liquid crystal glass

Overall length 6.69 inch (169.8 mm)

1

: Approx. 30 hours

1

: Approx. 2 hours

8

Page 9

Mass Approx. 0.09 lb. (Approx. 39 g)

*1 Operation time/charging time

• The battery deteriorates after repeated use, and the op eration time eventually be comes short. The figures above are at shipping from the

factory, and are not a guarantee of performance.

*2 Viewing range

• The location of the 3D Eyewear transmitter.

• There are differences in the viewing range of the 3D Eyewear among individuals.

• The 3D Eyewear may not operate correctly at the outside of the viewing range.

Q Wireless LAN Adaptor

Power supply DC 5 V (USB powered) 500 mA

Antenna Tx 1, Rx 2

Interface USB 2.0

Standard Compliance IEEE802.11n / IEEE802.11a / IEEE802.11g / IEEE802.11b

Transmission system MISO-OFDM system, OFDM system, DSSS system

Frequency Range IEEE802.11n / IEEE802.11a:

5.150 GHz - 5.725 GHz for EU Countries

5.150 GHz - 5.850 GHz for USA, Canada

5.250 GHz - 5.850 GHz for Taiwan

IEEE802.11g / IEEE802.11b / IEEE802.11n:

2.412 GHz - 2.472 GHz for EU countries

2.412 GHz - 2.462 GHz USA, Canada, Taiwan

Transfer rate (standard)* IEEE802.11n: Tx Max. 150 Mbps, Rx Max. 300 Mbps

IEEE802.11g / IEEE802.11a: Max. 54 Mbps

IEEE802.11b: Max. 11 Mbps

Access Mode Infrastructure mode

Security WPA2-PSK (TKIP/AES)

WPA-PSK (TKIP/AES)

WEP (64 bit / 128 bit)

Dimensions (W × H × D) 1.18 inch × 0.42 inch × 3.73 inch (30.00mm × 10.72 mm × 94.85 mm)

Mass 0.88 oz (25g) Net

*Transfer rates are theoretical values; however, actual communication rate will vary according to communication environment or

connected equipment.

9

Page 10

5 Technical Descriptions

5.1. Specification of KEY for DTCP-IP, WMDRM and Widevine

5.1.1. General information:

1. EEPROM (IC8902 ) for spare parts has the seed of KEY for each DTCP-IP for DLNA, WMDRM for Netflix and Widevine for

CinemaNow.

2. The fin al KEY data will be generated by Peaks IC (IC8000) when SELF CHECK was done and are stored in both Peaks IC

(IC8000) and EEPROM (IC8902).

5.1.2. Replacement of ICs:

When Peaks IC is replaced, EEPROM should be also replaced with new one the same time.

When EEPROM is replaced, Peaks IC is not necessary to be replaced the same time.

After the replacement of IC, SELF CHECK should be done to generate the final KEY data.

How to SELF CHECK: While pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote control for

more than 3 seconds.

TV will be forced to the factory shipment setting after this SELF CHECK.

10

Page 11

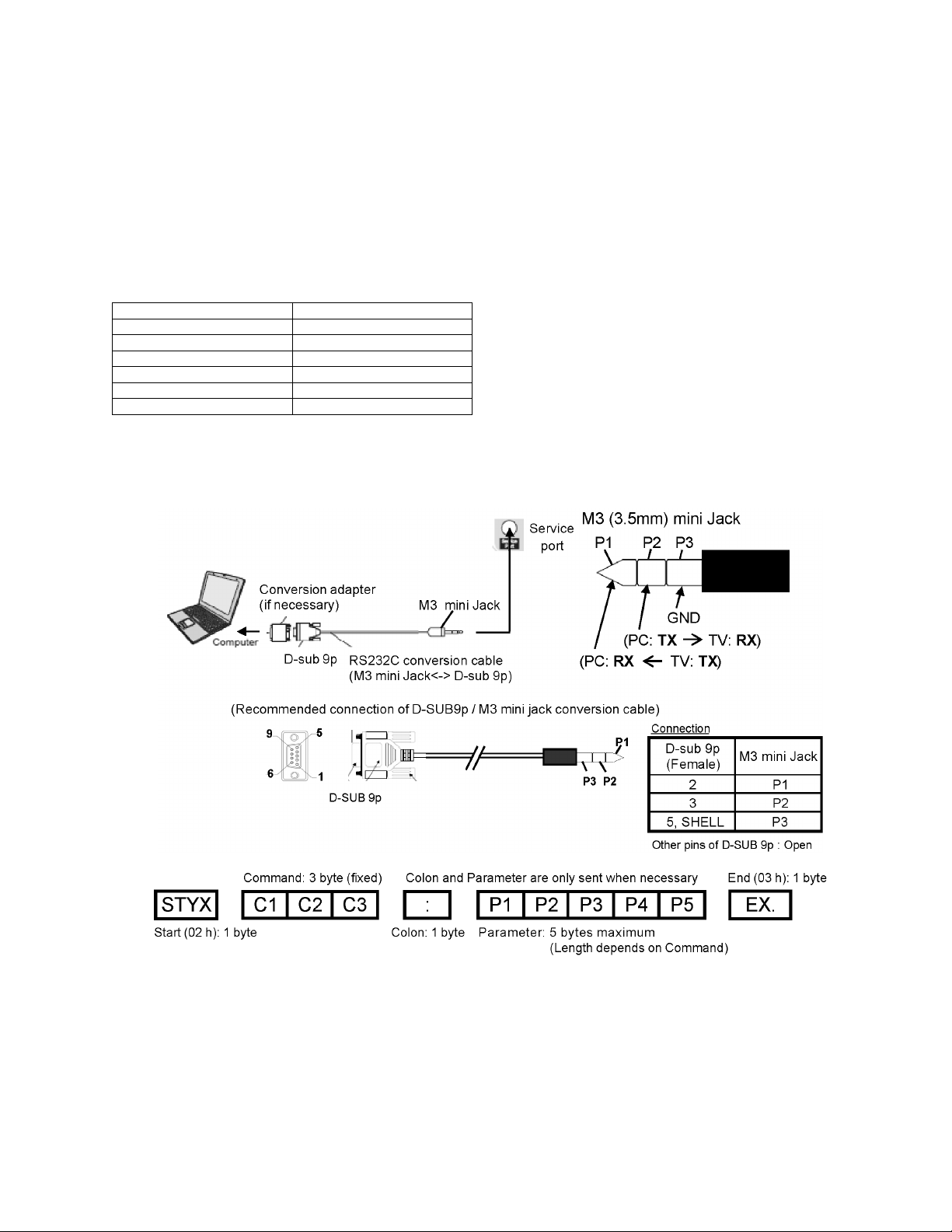

5.2. Service port (M3 mini Jack) Specifications

The Service port (M3 mini Jack) on the following TVs can use as the RS232C terminal which is a standard computer SERIAL interface.

*This operation system should be used by the certified professional dealer.

PC Control of the TV

• The TV can be controlled by a personal computer when connected through an RS232C/ M3 mini jack conversion cable (not supplied).

• The computer will require software which allows sending and receiving of control data through its SERIAL port.

Please see required parameters and commands below.

Communication parameters

Signal level RS-232C compliant

Synchronization method Asynchronous

Baud rate 9600 bps

Parity None

Character length 8 bits

Stop bit 1 bit

Flow control -

Basic format for control data

The transmission of control data from the PC starts with a STX signal, followed by the command, the parameters, and lastly an

EXT signal in that order. If there are no parameters, then the parameter signal does not need to be sent.

*Please see other side regarding Commands and Parameters.

Connection

Notes:

• With standby mode, this TV responds to "PON" and "QPW" commands only.

• Wait for the response of the first command to come from this unit before sending the next command.

• If multiple commands are transmitted, be sure to keep intervals of 250 m sec.

Send the command again when the call back command is unusual.

• If an incorrect command is sent by mistake, this TV will send an "ER401" or "ER402" command back to the computer.

• This TV does not respond for 15 seconds when "PON" or "POF" commands are transmitted.

• Send "EXT" commands before sending "IMS:**" commands.

• MUTE commands ("AMT: 0" and "AMT: 1") and "AVL: ***" command are invalid in case of HDMI (CECIL) cooperation.

However AMT, AUK, AUDI commands is effective. (MUTE rotation (toggle), VOLUME UP and VOLUME DOWN controls are

possible.)

11

Page 12

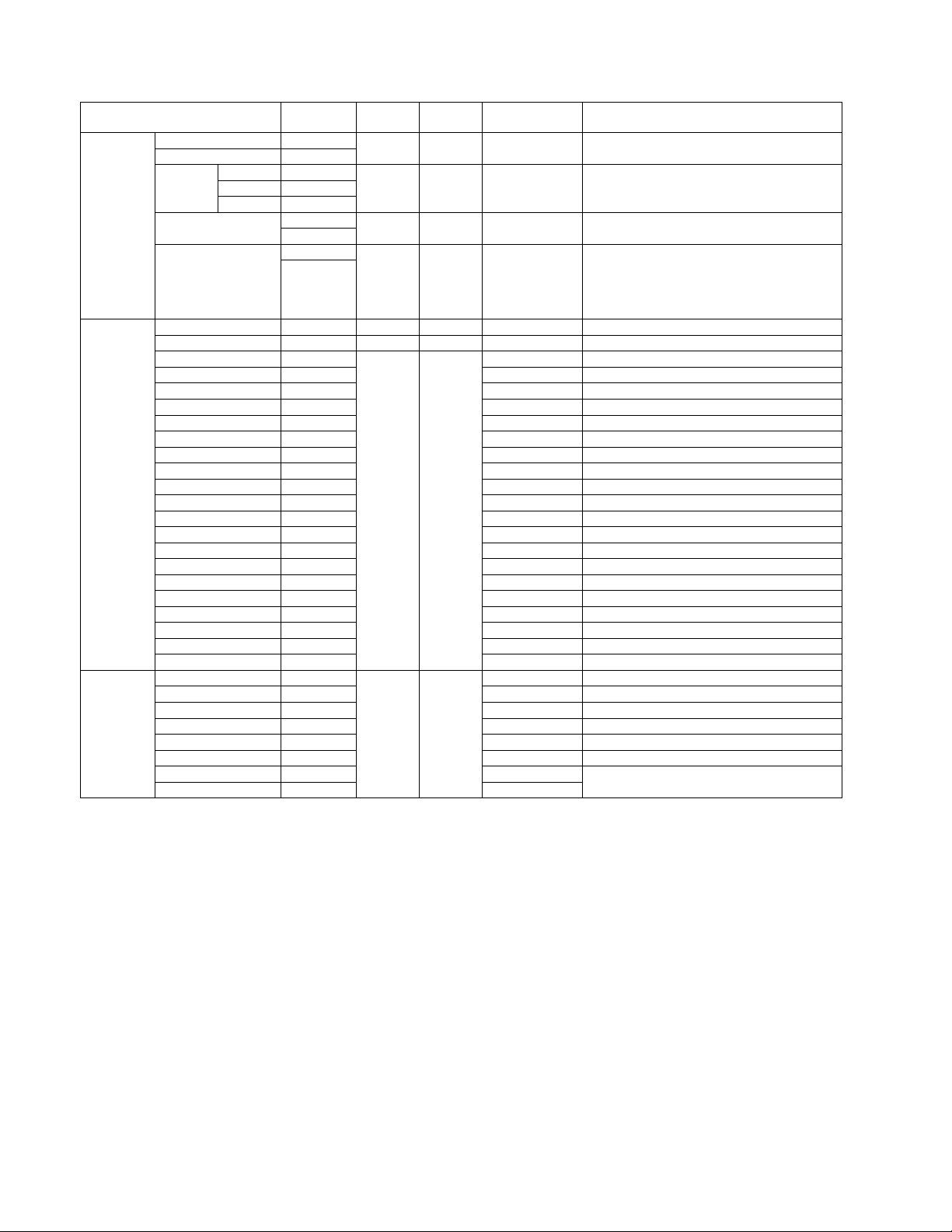

Main, Input & Picture Control Command

STANDARD

CONTROL

INPUT

SELECT

PICTURE

MODE

Control

Command

POWER ON PON QPW QPW : * "0"(OFF)/ "1"(ON)

POWER OFF POF

VOL (level) AVL: *** QAV QAV : *** "000" - "100"

(up) AUU

(down) AUD

MUTE AMT (Toggle) QAM QAM : * "0"(NO MUTED)

AMT: *

ASPECT DAM: **** QAS QAS : **** "ZOOM"/"FULL"/

DAM (Tog-

gle)

CH UP CHU -- -- -CH DOWN CHD -- -- -TV IMS : TV QMI QMI : ** "TV" TV network (Toggle)

Analogue TV IMS : TVA "TVA"

DVB-T IMS : TVD "TVD"

DVB-S/Other Sat IMS : BS1 "BS1"

Freesat IMS : BS2 "BS2"

DVB-C IMS : CAB "CAB"

Component 1 IMS : C1 "C1"

Component2 IMS : C2 "C2"

Video 1 IMS : V1 "V1"

Video 2 IMS : V2 "V2"

Video 3 IMS : V3 "V3"

S-Video 1 IMS : S1 "S1" SCART Cable

S-Video 2 IMS : S2 "S2" SCART Cable

HDMI 1 IMS : H1 "H1"

HDMI 2 IMS : H2 "H2"

HDMI 3 IMS : H3 "H3"

HDMI 4 IMS : H4 "H4"

PC IMS : PC "PC"

SD (photo viewer) IMS : SP "SP"

VIERA CAST IMS : VC "VC"

Vivid (Dynamic) VPC : VVT QPC QPC : *** "VVT"

Standard VPC : STD "STD"

THX/ True Cinema VPC : THX "THX" THX : Except PC, JPEG, MOVIE & VIERA CAST

Cinema VPC : CNM "CNM"

Game VPC : GAM "GAM"

Photo VPC : CST "CST" Only HDMI, JPEG, MOVIE & VIERA CAST

Pro1 VPC : PR1 "PR1" When Advance (isfccc) menu is On.

Pro2 VPC : PR2 "PR2"

Inquiry

Command

Call back

Command

Parameter note

/ "1"(MUTED)

Except SD mode

"JUST"/"NORM"/

"SELF"/"ZOM2"/

"ZOM3"/"SFUL"/

"14:9"

Except VIERA CAST

12

Page 13

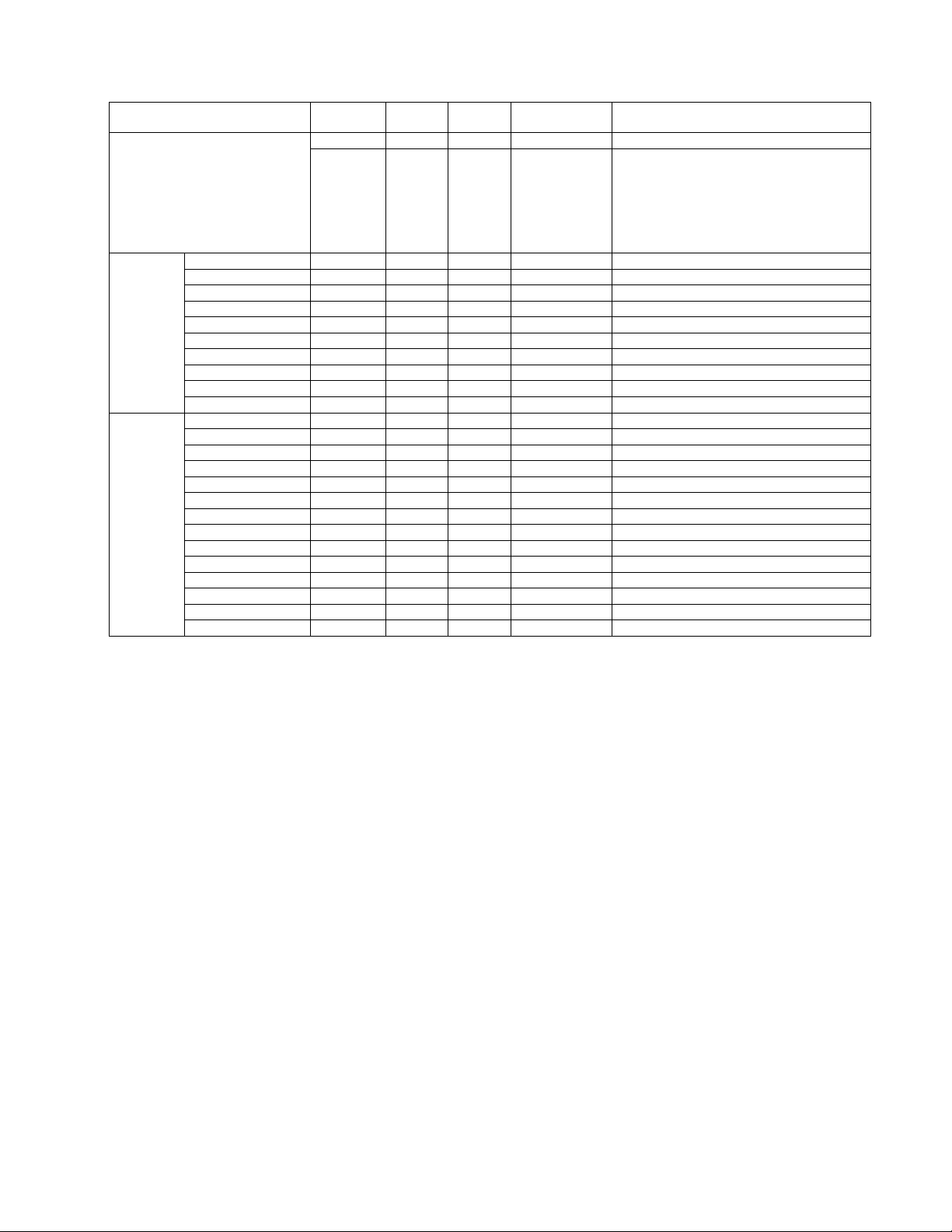

Else & Remote Controller Key Command

DIRECT CH

INPUT

MENU

FUNCTION

Control

Command

Information INF

-- QIF QIF : ***** 480i

0 ICH : 0 - - 1 ICH : 1 - - 2 ICH : 2 - - 3 ICH : 3 - - 4 ICH : 4 - - 5 ICH : 5 - - 6 ICH : 6 - - 7 ICH : 7 - - 8 ICH : 8 - - 9 ICH : 9 - - MENU MEN - - SELECT SEL - - RETURN RTN - - EXIT EXT - - ARROW LEFT ARL - - ARROW RIGHT ARR - - ARROW UP ARU - - ARROW DOWN ARD - - OPTION (SUB MENU) SUB - - RED RED - - GREEN GRN - - YELLOW YEL - - BLUE BLU - - VIERA TOOLS VTL - - -

Inquiry

Command

Call back

Command

Parameter note

480p

576i

576p

720p

1080i

1080p

13

Page 14

6 Service Mode

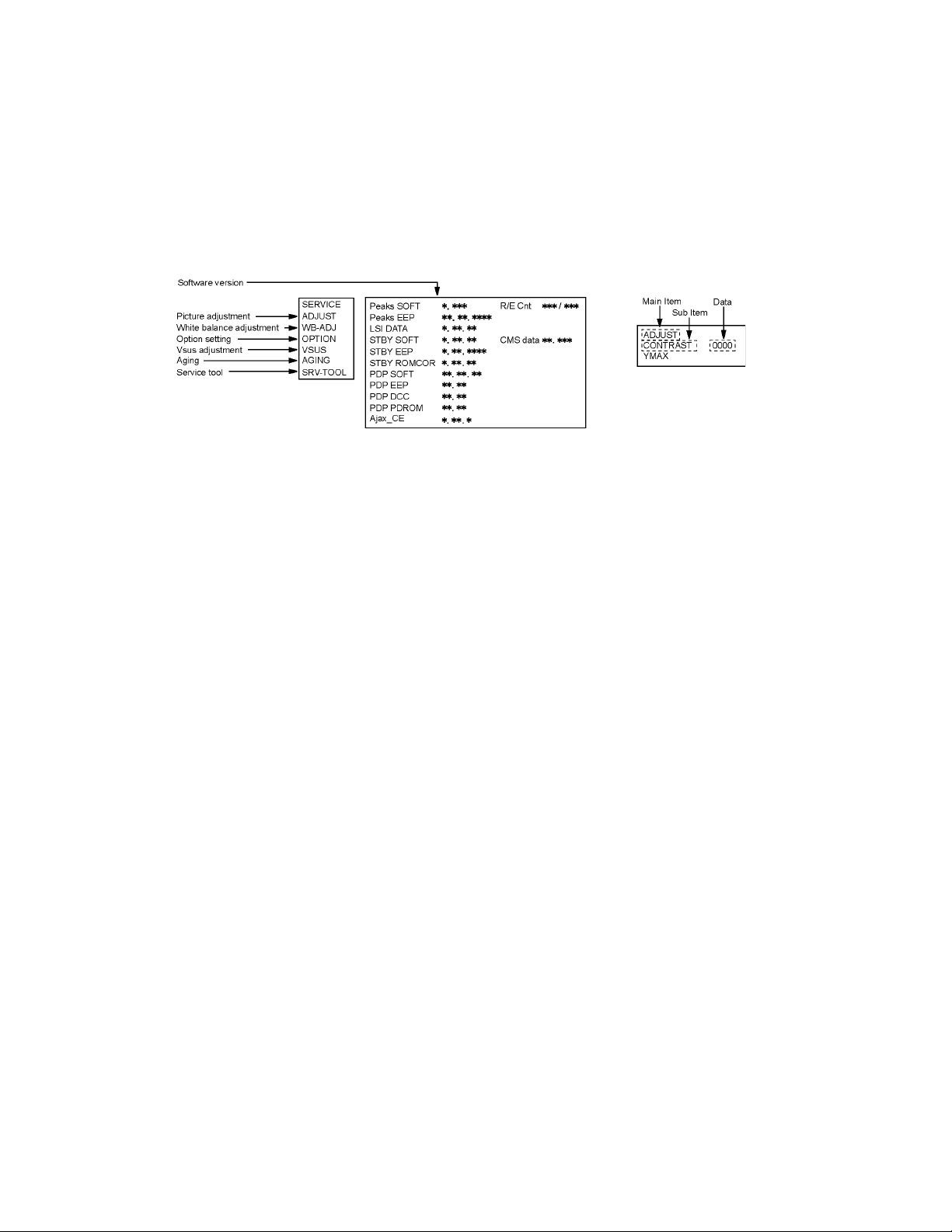

6.1. How to enter into Service Mode

6.1.1. Purpose

After exchange parts, check and adjust the contents of adjustment mode.

While pressing [VOLUME ( - )] button of the main unit, press [INFO] button of the remote control three times within 2 seconds

Note:

Service Mode can not be entered when 3D signal input.

Input 2D signal to enter Service Mode.

6.1.2. Key command

[1] button...Main items Selection in forward direction

[2] button...Main items Selection in reverse direction

[3] button...Sub items Selection in forward direction

[4] button...Sub items Selection in reverse direction

[VOL] button...Value of sub items change in forward direction ( + ), in reverse direction ( - )

6.1.3. How to exit

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

14

Page 15

6.1.4. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value in each item before starting adjustment.

Main item Sub item Sample Data Remark

ADJUST CONTRAST 000

COLOR 3C

TINT 00

SUB-BRT 800

WB-ADJ R-CUT 80

G-CUT 80

B-CUT 80

R-DRV DF

G-DRV FF

B-DRV 7C

ALL-CUT 80

ALL-DRV FF

OPTION Boot ROM Factory Preset

STBY-SET 00

EMERGENCY OFF

CLK MODE 00

CLOCK 000

EDID-CLK HIGH

MIRROR 00 (See Option-Mirror)

VSUS LOW See Vsus selection

AGING ALL WHITE Built-in test patterns can be

ALL BLUE WITH WHITE OUTSIDE FRAME

ALL GREEN

ALL RED

LOW STEP WHITE

LOW STEP BLUE

LOW STEP GREEN

LOW STEP RED

WHITE DIAGONAL STRIPE

RED DIAGONAL STRIPE

GREEN DIAGONAL STRIPE

BLUE DIAGONAL STRIPE

A-ZONE & B-ZONE

1% WINDOW

COLOR BAR

9 POINTS BRIGHT MEASURE

2 DOT OUTSIDE FRAME

ALL BLUE

DOUBLE FIXED 1% WINDOW

VERTICAL LINE SCROLL

ON/OFF OR WHITE

R/G/B/W ROTATION

HALF FIXED ALL WHITE

ALL WHITE WITH COUNT DISPLAY

SRV-TOOL - See Service tool mode

displayed.

15

Page 16

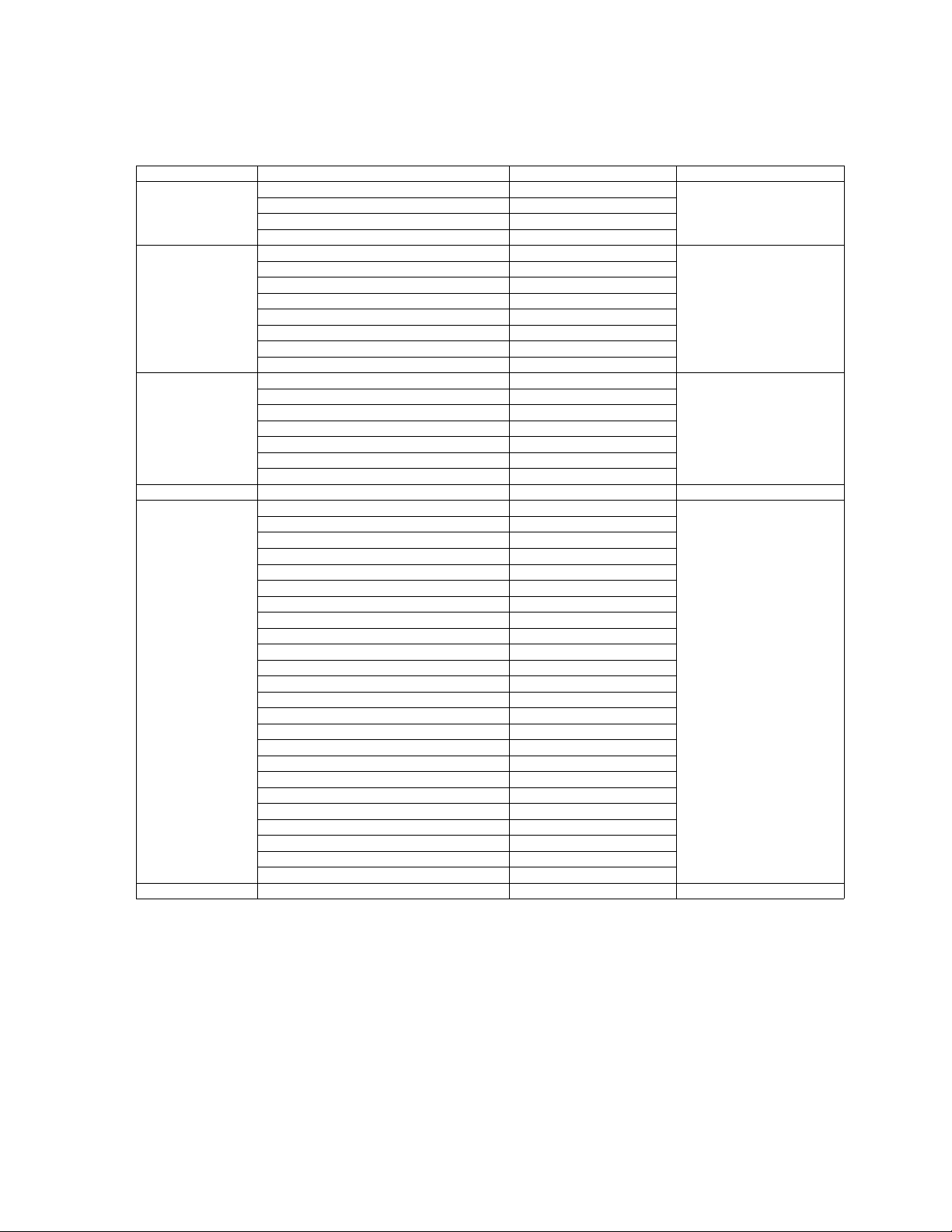

6.2. Option - Mirror

Picture can be reversed left and right or up and down.

00 : Default (Normal picture is displayed)

01 : Picture is reversed left and right.

02 : Picture is reversed up and down.

Hint : If the defective symptom (e.g. Vertical bar or Horizontal bar) is moved by selection of this mirror, the possible cause is in

A-board.

6.3. Service tool mode

6.3.1. How to access

1. Select [SRV-TOOL] in Service Mode.

2. Press [OK] button on the remote control.

6.3.2. Display of SOS History

SOS History (Number of LED blinking) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication except 2nd and 1st occurrence after shipment will be cleared by [Self-check indication and forced to factory shipment setting].

6.3.3. POWER ON TIME/COUNT

Note : To display TIME/COUNT menu, highlight position, then press MUTE for 3 sec.

Time : Cumulative power on time, indicated hour : minute by decimal

Count : Number of ON times by decimal

Note : This indication will not be cleared by either of the self-checks or any other command.

6.3.4. Exit

1. Disconnect the AC cord from wall outlet.

16

Page 17

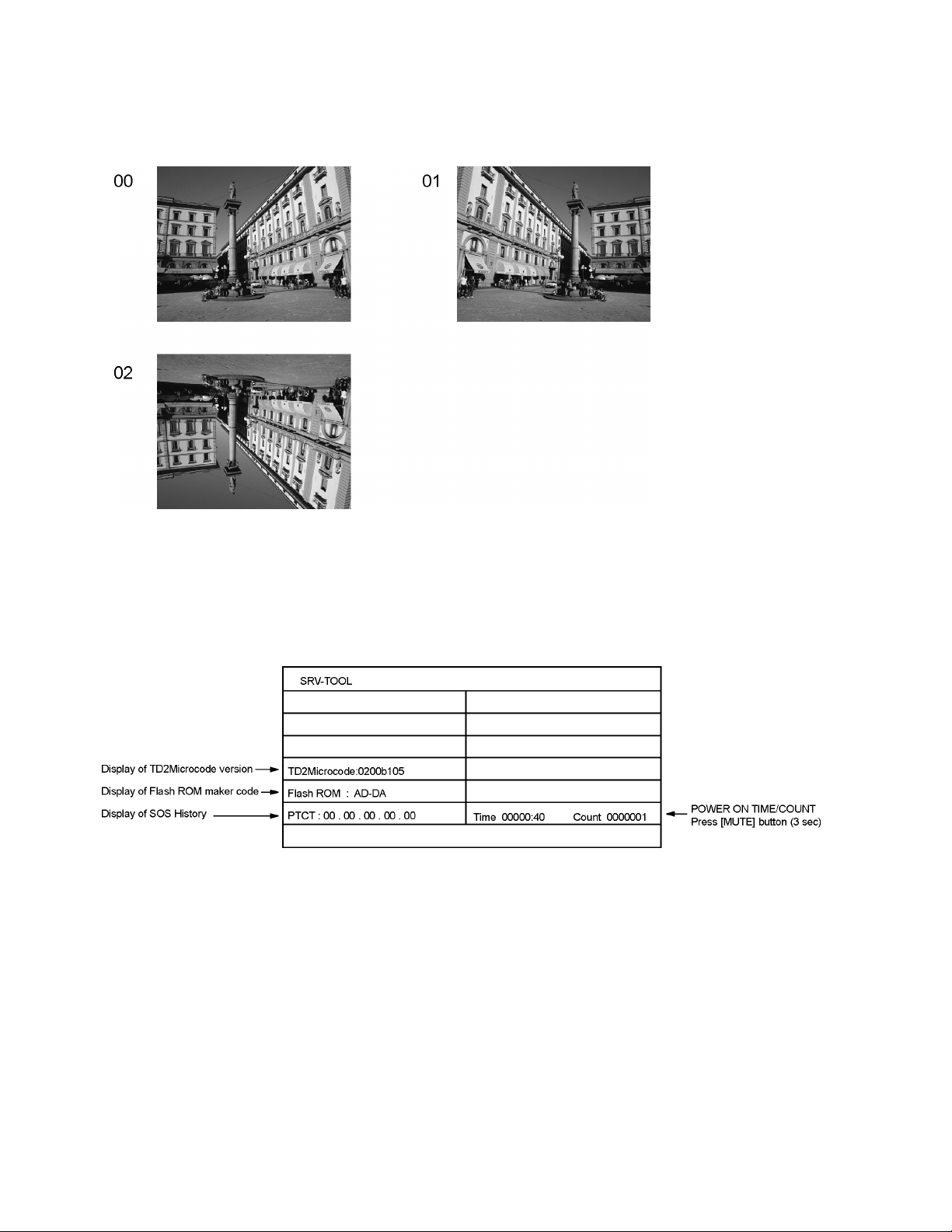

6.4. Hotel mode

1. Purpose

Restrict a function for hotels.

2. Access command to the Hotel mode setup menu

In order to display the Hotel mode setup menu:

While pressing [VOLUME (-)] button of the main unit,

press [INPUT] button of the remote control three times

within 2 seconds.

Then, the Hotel mode setup menu is displayed.

3. To exit the Hotel mode setup menu

Disconnect AC power cord from wall outlet.

4. Explain the Hotel mode setup menu

Item Function

Mode Select hotel mode On/Off

Input Select input signal modes.

Set the input, when each time power is

switched on.

Selection:

-/RF/HDMI1/HDMI2/HDMI3/HDMI4/Component/Video/PC

• Off: give priority to a last memory.

Channel Select channel when input signal is RF.

Set the channel, each time power is switched

on.

Selection:

Any channel number or [-].

[-] means the channel when turns off.

Volume Adjust the volume when each time power is

switched on.

Range:

0 to 100

Vol. Max Adjust maximum volume.

Range:

0 to 100

OSD Ctrl Restrict the OSD.

Selection:

Off/Pattern1

• Off: No restriction

• Pattern1: restriction

FP Ctrl Select front key conditi ons .

Selection:

Off/Pattern1/All

• Off: altogether valid.

• Pattern1: only input key is valid.

• All: altogether invalid.

Pow Ctrl Select POWER-On/Off condition when AC

power cord is disconnected and then connected.

Off: The same condition when AC power

cord is disconnected.

On: Forced power ON condition.

17

Page 18

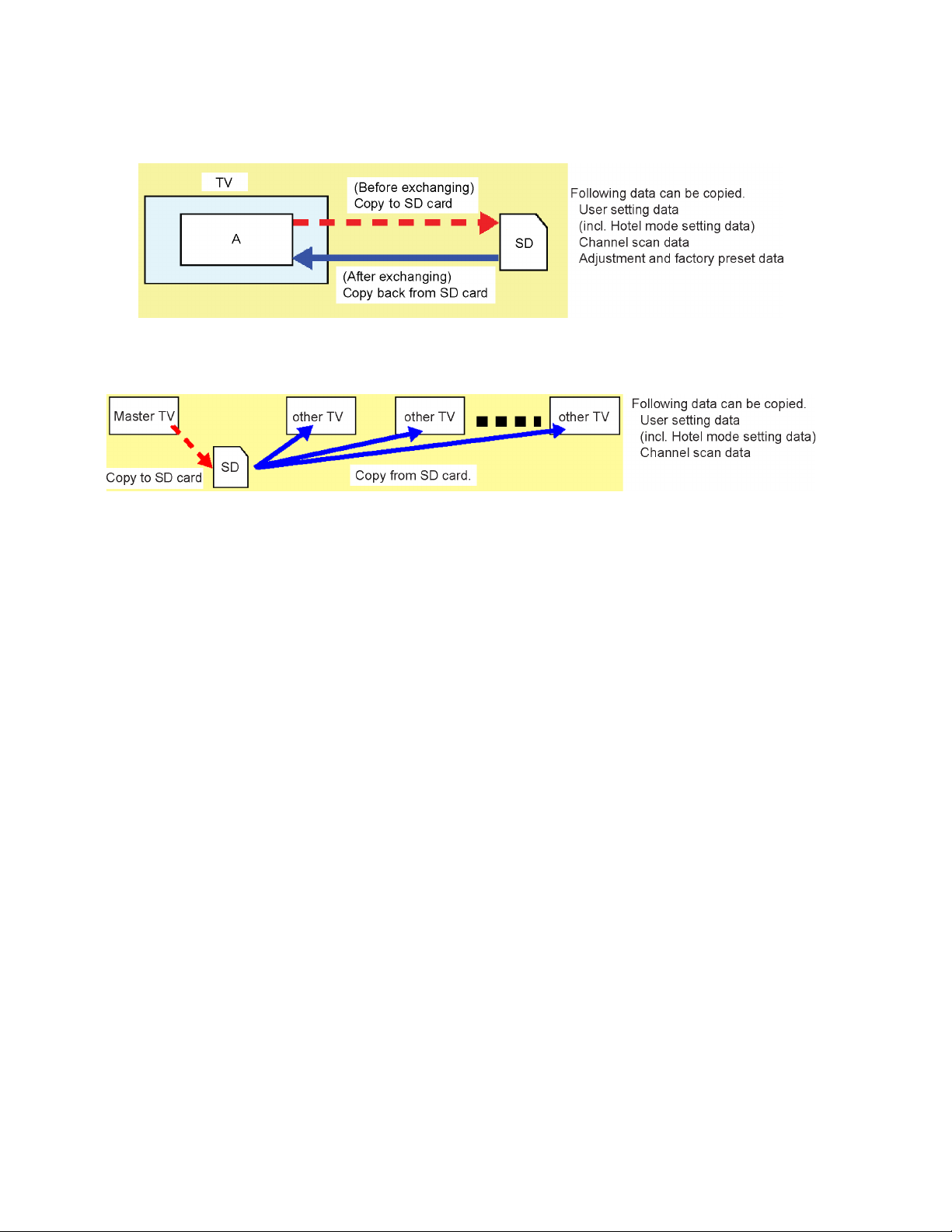

6.5. Data Copy by SD Card

6.5.1. Purpose

(a) Board replacement (Copy the data when exchanging A-board):

When exchanging A-board, the data in original A-board can be copied to SD card and then copy to new A-board.

(b) Hotel (Copy the data when installing a number of units in hotel or any facility):

When installing a number of units in hotel or any facility, the data in master TV can be copied to SD card and then copy to other

TVs.

6.5.2. Preparation

Make pwd file as startup file for (a) or (b) in a empty SD card.

1. Insert a empty SD card to your PC.

2. Right-click a blank area in a SD card window, point to New, and then click text document. A new file is created by default

(New Text Document.txt).

3. Right-click the new tex t document that you just created and select rename, and then change the name and extension of the

file to the following file name for (a) or (b) and press ENTER.

File name:

(a) For Board replacement : boardreplace.pwd

(b) For Hotel : hotel.pwd

Note:

Please make only one file to prevent the operation error.

No any other file should not be in SD card.

18

Page 19

6.5.3. Data copy from TV set to SD Card

1. Turn on the TV set.

2. Insert SD card with a startup file (pwd file) to SD slot.

On-screen Display will be appeared according to the startup file automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2770

(b) For Hotel : 4850

Data will be copied from TV set to SD card.

It takes around 2 to 6 minutes maximum for copying.

4. After the completion of copying to SD card, remove SD card from TV set.

5. Turn off the TV set.

Note:

Following new folder will be created in SD card for data from TV set.

(a) For Board replacement : user_setup

(b) For Hotel : hotel

19

Page 20

6.5.4. Data copy from SD Card to TV set

1. Turn on the TV set.

2. Insert SD card with Data to SD slot.

On-screen Display will be appeared according to the Data folder automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2771

(b) For Hotel : 4851

Data will be copied from SD card to TV set.

4. After the completion of copying to SD card, remove SD card from TV set.

(a) For Board replacement : Data will be deleted after copying (Limited one copy).

(b) For Hotel : Data will not be deleted and can be used for other TVs.

5. Turn off the TV set.

Note:

1. Depending on the failure of boards, function of Data copy for board replacement does not work.

2. This function can be effective among the same model numbers.

20

Page 21

7 Troubleshooting Guide

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

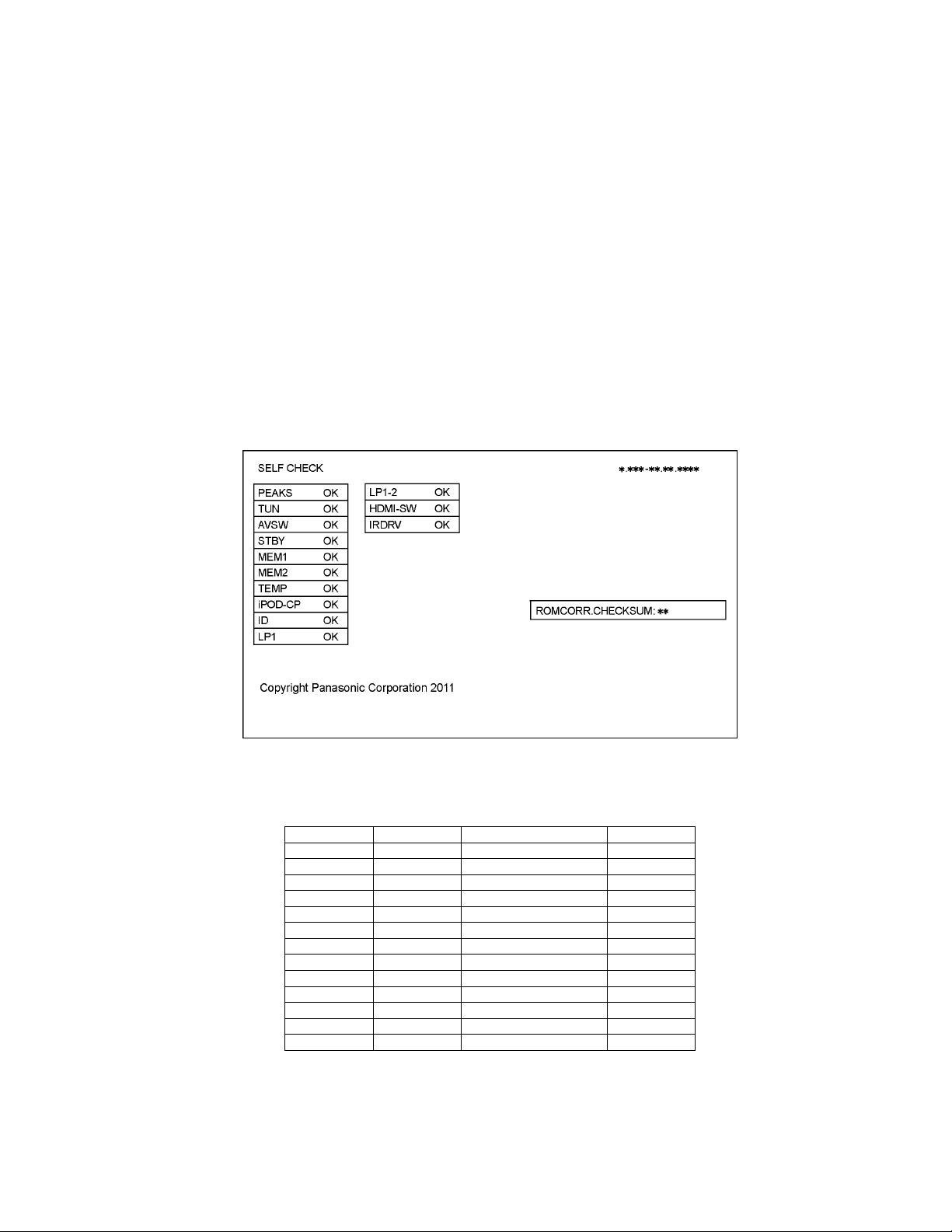

7.1. Check of the IIC bus lines

7.1.1. How to access

7.1.1.1. Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [OK] button on the remote control

for more than 3 seconds.

7.1.1.2. Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote control for more than 3 seconds.

7.1.2. Exit

Disconnect the AC cord from wall outlet.

7.1.3. Screen display

7.1.4. Check Point

Confirm the following parts if NG was displayed.

DISPLAY Check Ref. No. Description Check P.C.B.

PEAKS IC8000 PEAKS-LDA3 A-Board

TUN TU4801 TUNER A-Board

AVSW IC3001 AUDIO/VIDEO SW A-Board

STBY IC8000 PEAKS-LDA3 (STM) A-Board

MEM1 IC8902 PEAKS EEPROM A-Board

MEM2 IC8901 STM EEPROM A-Board

TEMP IC3753 TEMP SENSOR A-Board

iPOD-CP IC3900 iPOD-CP A-Board

ID A-Board

LP1 IC9300 LP1 A-Board

LP1-2 IC9500 LP1-2 A-Board

HDMI-SW IC4700 HDMI SW A-Board

IRDRV IC5901 IR LED DRIVER A-Board

21

Page 22

7.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinks of the Power LED on the front panel of the unit.

Blinking Times Contents Check point

1 Panel information SOS

LP1 Start SOS

3 P+ 3.3V SOS A-Board

4 Power SOS P(MAIN)-Board

5 P+ 5V SOS A-Board

6 Driver SOS1

(SC Energy recovery circuit)

(A-SC FPC DET)

7 Driver SOS2

(SU/SD Connector DET)

(SU/SD Scan and Logic IC)

8 Driver SOS3

(SS FPC DET)

(SS Energy recovery circuit)

9 Discharge Control SOS A-Board

10 Sub 5V SOS

Sub 3.3V SOS

Tuner power SOS

11 FAN SOS A-Board

12 Sound SOS A-Board

13 Emergency SOS A-Board

14 IR LED SOS A-Board

-

P(SUB)-Board

SC-Board

A-SC FPC

SU-Board

SD-Board

*

SS-Board

SS2-Board

SS FPC

SS2 FPC

A-Board

SC-Board

SS-Board

P(MAIN)-Board

P(SUB)-Board

FAN

Speaker

Woofer

*Use SC jig to isolate the board.

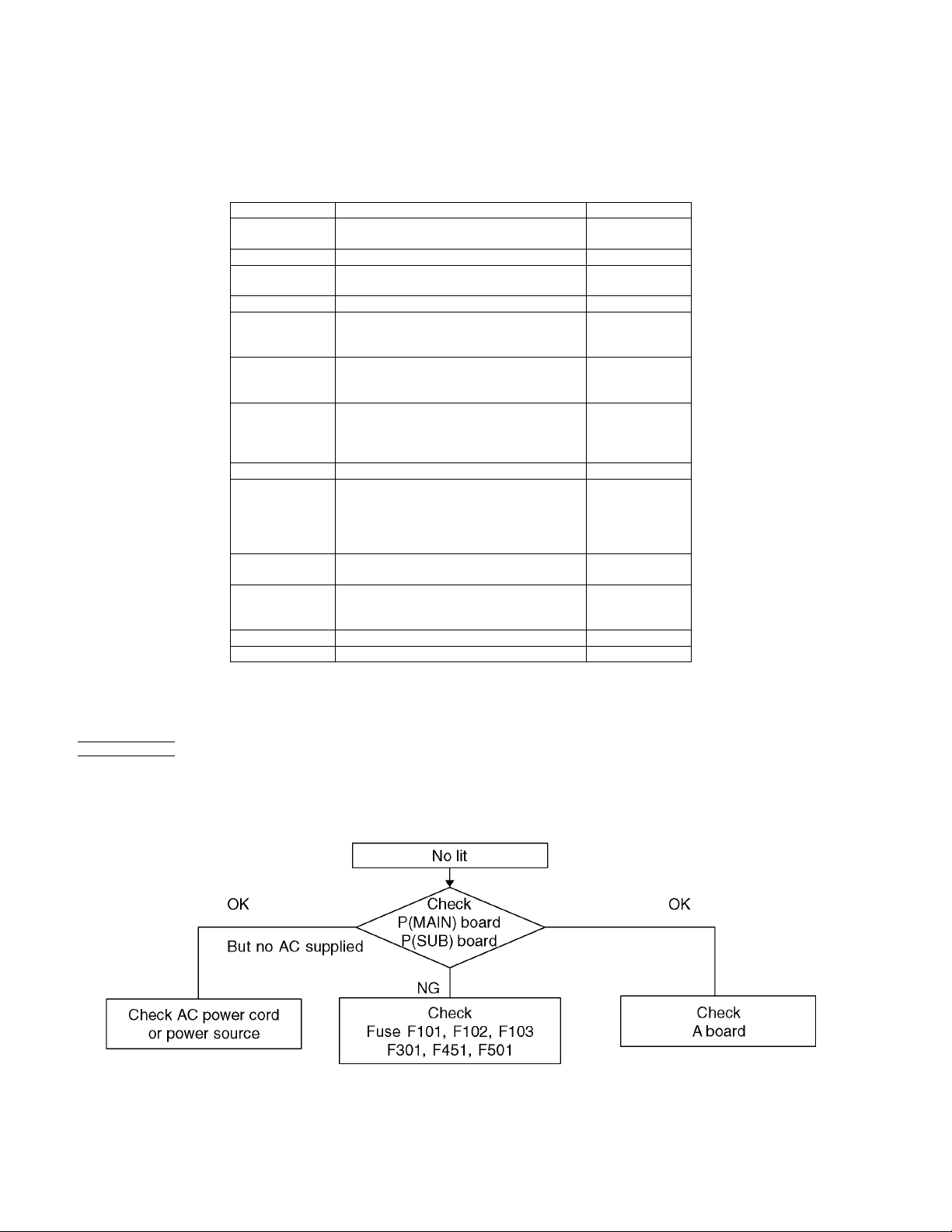

7.3. No Power

First check point

There are following 2 states of No Power indication by power LED.

1. No lit

2. Red is lit then turns red blinking a few seconds later. (See 7.2.)

22

Page 23

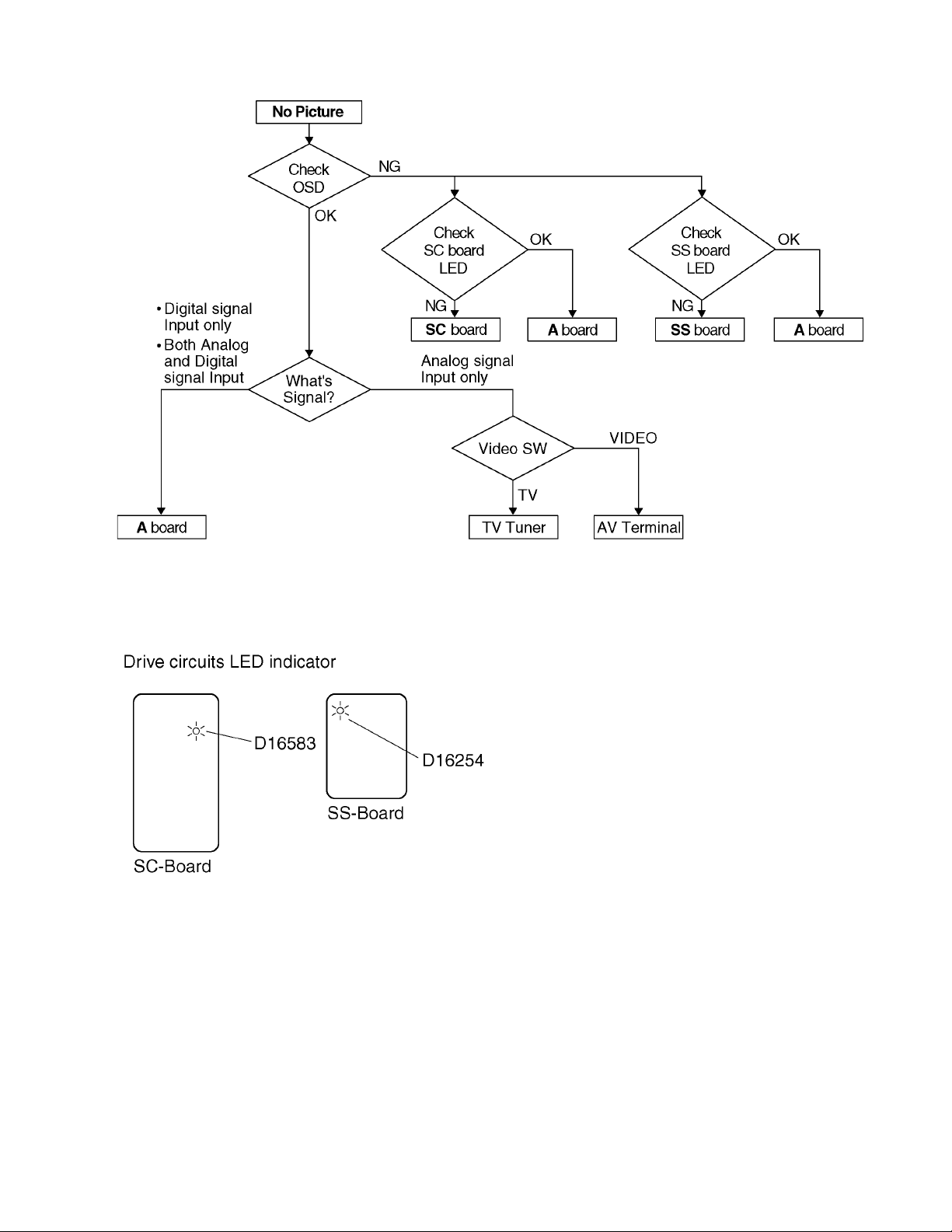

7.4. No Picture

23

Page 24

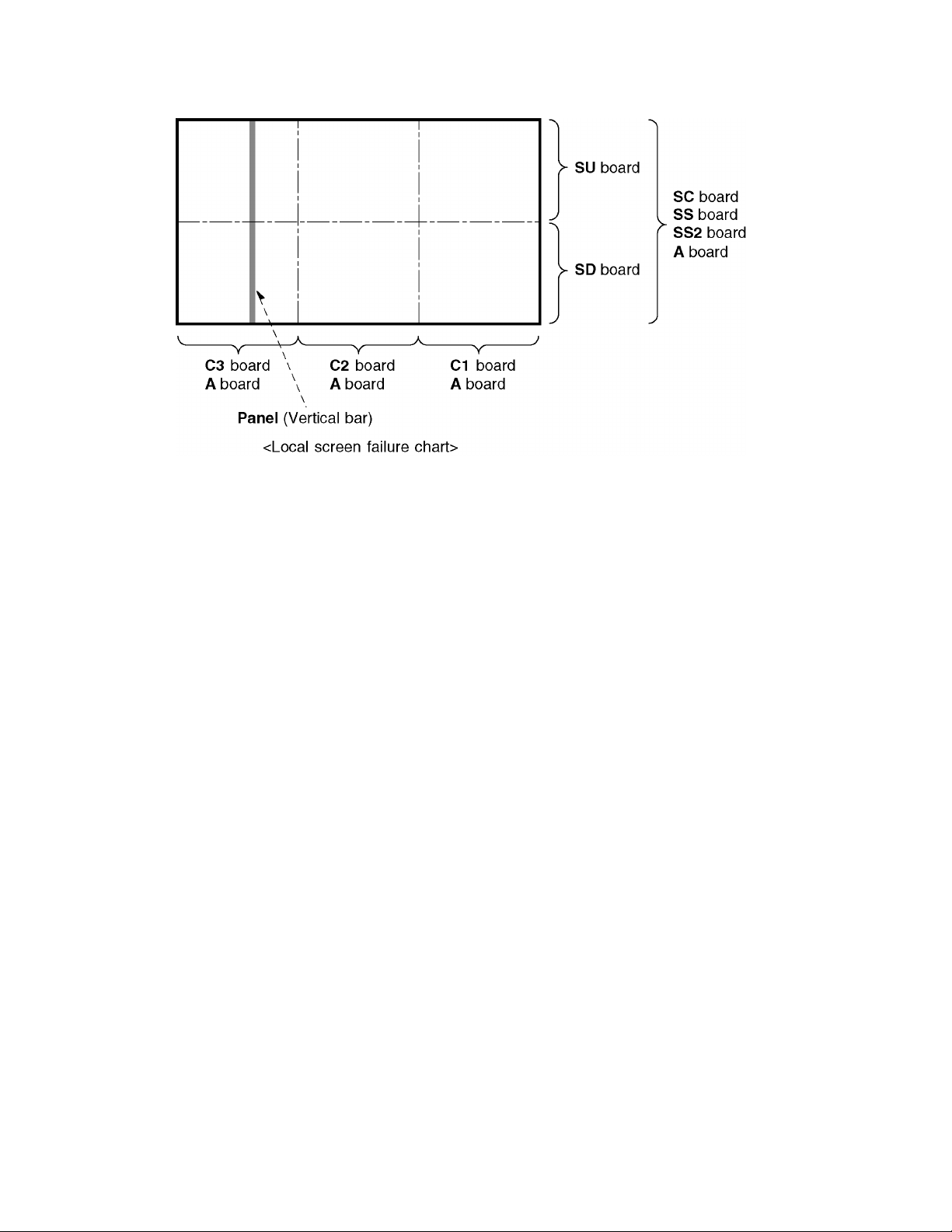

7.5. Local screen failure

Plasma display may have local area failure on the screen. Fig-1 is the possible defect P.C.B. for each local area.

Fig-1

24

Page 25

8 Service Fixture & Tools

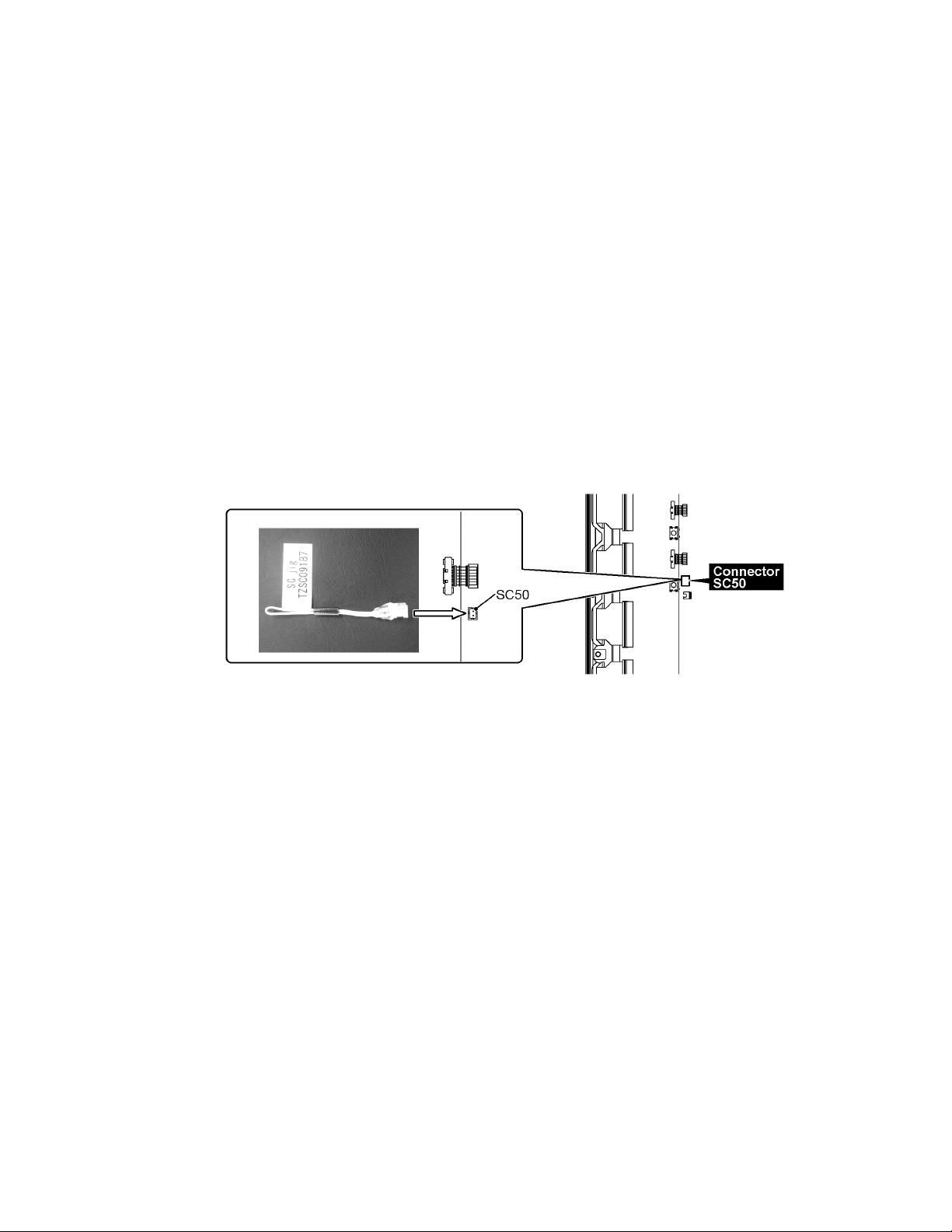

8.1. SC jig

Purpose:

To find the failure board (SC or SU/SD) when the power LED is blinking 7 times.

SC jig:

Jumper connector to connect to SC50 connector on SC board

Part number:

TZSC09187

How to use:

Caution: Remove SC jig from SC board after inspection.

1. Remove all connector between SC board and SU/SD board to isolate SC board from both SU and SD board electrically.

Note: The board will be damaged if all connector is not removed (for example; remove connector only for SU b oard and s tay

connecting with SD board. The board will be damaged.)

2. Connect SC jig to connector SC50 at left bottom side of SC board

3. Turn on the TV/Display Unit and confirm the power LED blinking.

LED blinking: Possible cause of failure is in SC board

No LED blinking (Lighting or no lighting): Possible cause of failure is in SU or SD board

4. After inspection, turn off the TV/Display Unit and wait a few minutes to discharge.

5. Remove SC jig from SC board.

Remark: This SC jig can be used for all 2011 Plasma TV and Plasma Display.

25

Page 26

9 Disassembly and Assembly Instructions

9.1. Remove the Rear cover

1. See PCB Layout (Section 3)

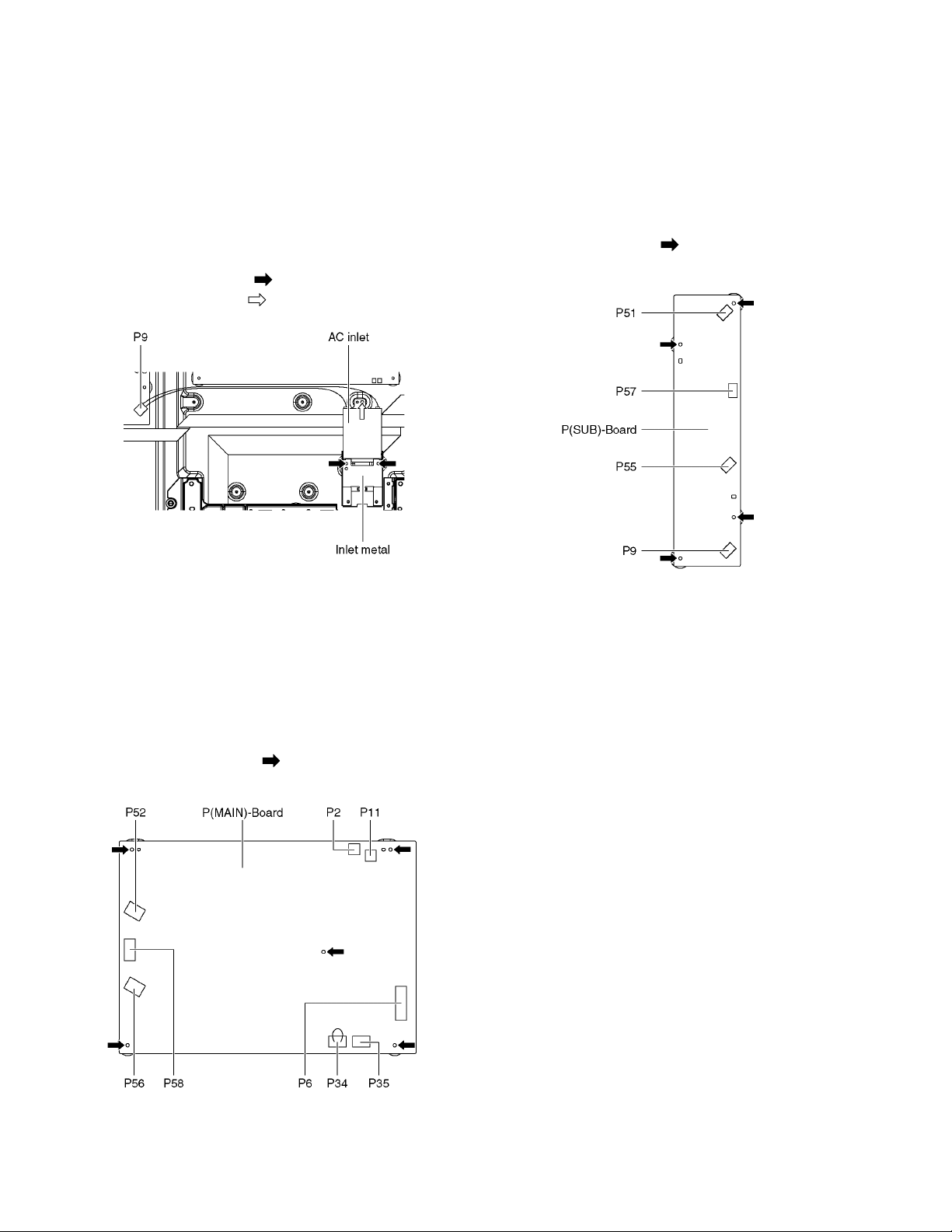

9.2. Remove the AC inlet

Caution:

To remove P.C.B. wait 1 minute after power was off for discharge from electrolysis capacitors.

1. Unlock the cable clampers to free the cable.

2. Disconnect the connector (P9).

3. Remove the screws (×2 ) and remove the Inlet metal.

4. Remove the screw (×1 ) and remove the AC inlet.

9.4. Remove the P(SUB)-Board

Caution:

To remove P.C.B. wait 1 minute after power was off for discharge from electrolysis capacitors.

1. Unlock the cable clampers to free the cable.

2. Disconnect the connectors (P51, P55 and P57).

3. Disconnect the connector (P9).

4. Remove the screws (×4 ) and remove the P(SUB)Board.

9.3. Remove the P(MAIN)-Board

Caution:

To remove P.C.B. wait 1 minute after power was off for discharge from electrolysis capacitors.

1. Unlock the cable clampers to free the cable

2. Disconnect the connectors (P52, P56 and P58)

3. Disconnect the connectors (P2, P6, P11 and P35).

4. Discon nect a short-jumper connector P34 and re-use for

new P(MAIN)-Board.

5. Remove the screws (×5 ) and re move the P(MAIN)-

Board.

26

Page 27

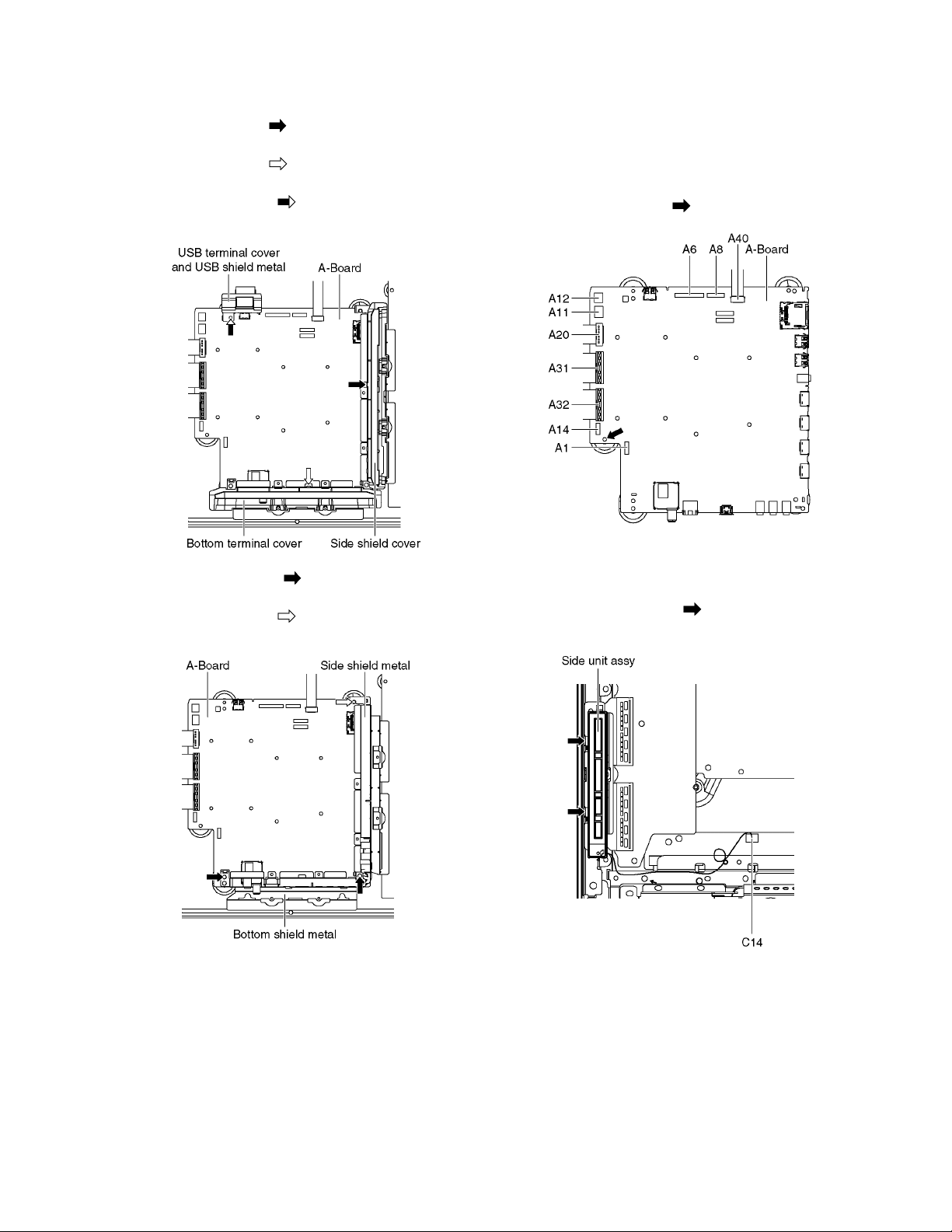

9.5. Remove the Terminal covers and the shield metals

1. Remove the claw (×1 ).

2. Remove the Side terminal cover.

3. Remove the claw (×1 ).

4. Remove the Bottom terminal cover.

5. Remove the screw (×1 ).

6. Remove the USB terminal cover and USB shield metal.

9.6. Remove the A-Board

1. Remove the Terminal covers and the Shield metals. (See

section 9.5.)

2. Unlock the cable clampers to free the cable.

3. Disconnect the connectors (A1, A6, A8, A11, A12, and

A14).

4. Disconnect the flexible cables (A20, A31, A32 and A40).

5. Remove the screw (×1 ) and remove the A-Board.

7. Remove the screws (×2 ).

8. Remove the Bottom shield metal.

9. Remove the screw (×1 ).

10. Remove the Side shield metal.

9.7. Remove the Side unit assy

1. Disconnect the connector (C14).

2. Remove the claws (×2 ) and remove the Side unit

assy.

27

Page 28

3. Remove the screw (×1 ).

4. Remove the Side unit mount metal.

9.8. Remove the SU-Board

1. Discon nect the flexible cab les (SU1, SU2, SU3, SU4 and

SU5) connected to the SU-Board.

2. Disconnect the flexible cable (SU11-SD11) and the bridge

connector (SC41-SU41).

3. Remove the screws (×2 , ×2 ) and remo ve the SU-

Board.

9.9. Remove the SD-Board

1. Disconnect the flexible cables (SD1, SD2, SD3, SD4 and

SD5) connected to the SD-Board.

2. Disconnect the flexible cable (SU11-SD11) and the bridge

connectors (SC42-SD42 and SC46-SD46).

3. Remove the screws (×2 , ×2 ) and remove the SD-

Board.

9.10. Remove the SC-Board

1. Remove the SU-Board and SD-Board. (See section 9.8.

and 9.9.)

2. Disconnect the connector (SC2).

3. Disconnect the flexible cable (SC20).

4. Remove the screws (×7 ) and remove the SC-Board.

28

Page 29

9.11. Remove the SS-Board

1. Disconnect the connector (SS11).

2. Disconnect the flexible cable (SS33).

3. Disconnect the flexible cable (SS53).

4. Remov e the screws (×4 , ×4 ) and remove the SS-

Board.

9.12. Remove the SS2-Board

1. Remov e the Terminal metals and the Shield metals. (See

section 9.5.)

2. Remove the SS-Board. (See section 9.11.)

3. Disconnect the flexible cables (SS54 and SS56).

4. Remove the screws (×2 ) and remove the SS2-Board.

9.13. Remove the Fan

1. Unlock the cable clampers to free the cable.

2. Remove the screws (×3 ).

3. Remove the Relay connector and remove the Fan.

9.14. Remove the Speakers

1. Unlock the cable clampers to free the cable.

2. Remove the screws (×4 , ×8 ) and remove the SP

shield metal L.

3. Remove the screws (×4 , ×8 ) and remove the SP

shield metal R.

4. Disconnect the Relay connector.

5. Remove the screws (×2 each) and remove the Speakers (L, R).

29

Page 30

9.15. Remove the Woofer

1. Unlock the cable clampers to free the cable.

2. Disconnect the Relay connector.

3. Remove the screws (×3 ) and remove the Woofer.

9.18. Remove the S-Board

1. Remove the SP shield metal L. (See section 9.14.)

2. Remove the screws (×2 ).

3. Disconnect the connector (S10) and remove the S-Board.

9.16. Remove the Stand bracket

1. Remove the Plasma panel section from the servicing

stand and lay on a flat surface such as a table (covered

by a soft cloth) with the Plasma panel surface facing

downward.

2. Unlock the cable clampers to free cable.

3. Remove the Stand bracket fastening screws (×10 , ×4

, ×4 ) and the Stand bracket.

9.17. Remove the K-Board

1. Remove the SP shield metal L. (See section 9.14.)

2. Remove the Stand bracket. (See section 9.16.)

3. Remove the screw (×1 ).

4. Remove the claws (×3 ).

5. Disconnect the connector (K1) and remove the K-Board

from the LED panel.

9.19. Remove the V-Board

1. Remove the SP shield metal R. (See section 9.14.)

2. Remove the Stand bracket. (See section 9.16.)

3. Remove the screw (×1 ) and remove the claws (×3

).

4. Disconnect the connector (V14) and remove the V-Board

from the 3D LED panel.

9.20. Remove the Handles

1. Remove the SP shield metal (L, R). (See section 9.14.)

2. Remove the screws (×2 each) and remove the Han-

dle (L, R).

30

Page 31

9.21. Remove the Bottom cabinet assy

1. Remove the Speakers. (See section 9.14.)

2. Remove the Stand bracket. (See section 9.16.)

3. Remove the K, S and V-Board. (See section 9.17 - 19.)

4. Remove the screws (×2 ) and remove the Bottom cabinet assy.

9.22. Remove the Plasma panel section from the Cabinet assy.

1. Remove the Plasma panel section from the servicing

stand and lay on a flat surface such as a table (covered

by a soft cloth) with the Plasma panel surface facing

downward.

9.23. Remove the Contact metals

1. Remove the Cabinet assy. (See section 9.22.)

2. Remove the Tape from the Contact metals.

3. Remove the screws (×6 ).

4. Remove the Contact metal side (L, R).

5. Remove the screws (×6 ).

6. Remove the Contact metal top.

7. Remove the screws (×15 ).

8. Remove the Contact metal bottom.

2. Remove the Bottom cabinet assy. (See section 9.21.)

3. Remove the screws (×4 , ×14 ).

4. Remove the Plasma panel section from the Cabinet assy.

9.24. Remove the C1-Board

1. Remove the Contact metal bottom. (See section 9.23.)

2. Disconnect the flexible cables (CB1, CB2 and CB3).

3. Disconnect the flexible cable (C10).

4. Disconnect the connector (C14).

5. Remove the screws (×3 ) and remove the C1-Board.

9.25. Remove the C2-Board

1. Remove the Contact metal bottom. (See section 9.23.)

2. Disconnect the flexible cables (CB4, CB5, CB6, CB7,

CB8 and CB9).

3. Disconnect the flexible cables (C20, C21 and C26).

4. Remove the screws (×4 ) and remove the C2-Board.

31

Page 32

9.26. Remove the C3-Board

1. Remove the Contact metal bottom. (See section 9.23.)

2. Disconnect the flexible cables (CB10, CB11, CB12,

CB13, CB14 and CB15).

3. Disconnect the flexible cables (C31 and C36).

4. Disconnect the connector (C35).

5. Remove the screws (×4 ) and remove the C3-Board.

9.27. Remove the AL frames

1. Remove the screws (×4 each) and remove the Corner

fixing metals.

2. Remove the screws (×14 ) and remove the AL frames.

3. Attach the Cabinet assy and each P.C.Board and so on,

to the new Plasma panel.

*When fitting the Cabinet assy, be careful not to allow any

debris, dust or handling residue to remain between the

Front glass and Plasma panel.

9.28. Replace the Plasma panel

Caution:

Remove the Plasma panel section from the servicing

stand and lay on a flat surface such as a table (covered

by a soft cloth) with the Plasma panel surface facing

downward.

A new Plasma panel itself without Contact met als is fragile.

To avoid the damage to new Plasma panel, carry a new

Plasma panel taking hold of the Cont act metals.

1. Place a carton box packed a new Plasma panel on the

flat surface of the work bench.

2. Open a box and without taking a new Plasma panel.

32

Page 33

10 Measurements and Adjustments

10.1. Adjustment

10.1.1. Vsus selection

Caution:

When Plasma panel or A-board is replaced, Vsus should be set to LOW or HIGH.

Procedure

1. Go into main item [VSUS] in Service Mode. LOW or HIGH will be displayed.

2. Press [OK] button to go to TEST stage.

White pattern without On-Screen Display will be displayed during TEST and CONF stage. Press [5] button to display the

On-Screen Display .

3. Press [VOL (-)] button to set to LOW.

4. In LOW setting

a. If no several dead pixel is visible remarkably in white pattern, press [3] button to go to CONF stage.

b. If the several dead pixels are visible remarkably in white pattern, Set to HIGH by press [VOL (+)] button. Press [3] button

to go to CONF stage if the symptom is improved.

5. Press [OK] button in CONF stage to store LOW or HIGH.

6. Exit Service Mode by pressing [Power] button.

33

Page 34

10.1.2. RF video sub contrast adjustment

Instrument Name Remarks

1. REMOTE TRANSMITTER

2. RF analog signal (Sprit color bar. The pattern for adjustment must contain 100% white part.)

Adjustment or Inspection Procedure Remarks

1. Receive the sprit color bar with RF analog signal.

(ASPECT FULL, Picture menu: Vivid)

2. Enter Service mode menu, and select ADJUST -- CONTRAST.

Pushing the remote controller [OK] key for about 3 seconds, GAIN is suited to the adjustment value automatically.

34

Page 35

10.1.3. White balance adjustment

Name of measuring instrument Remarks

Color analyzer

(Minolta CA-100 or equivalent)

Note:

The CA-100 which was calibrated to less than +-0.001 with CS-1000.

Steps Remarks

• Make sure the front panel to be used on the final set is fitted.

• Make sure a color signal is not being shown before adjustment.

• Put the color analyzer where there is little color variation.

1. Set to Service mode, WB-ADJ.

2. Select [VIVID] for picture menu.

3. Select [Cool] for color temperature.

4. Push [5] key of remote controller to display window pattern.

5. Confirm the brightness. The following is the confirmation value.

TC-P55VT30 101cd/m2 or more

6. Select [Cinema] for picture menu.

7. Select [Warm] for color temperature.

8. Set [R-CUT] [G-CUT] [B-CUT] the values written in table 1.

9. Attach the sensor of color analyzer to the center of window pattern.

10. Fix [G drive] at [C0] and adjust [B-DRV] and [R-DRV] so x, y value of color analyzer

become the [Color temperature Low] in table 2.

11. Increase RGB together so the max imum drive value in RGB becomes [FF]. That is, se t

[ALL DRIVE] to [FF].

Execute adjustment again. When that, the max imu m va lue of R /G/ B DRV should be [FF ],

and either R/G/B DRV should be [FF].

12. The average of the adjusted values i n co lor te mper at ure Coo l, Mid , a nd Warm is shown in

Table 4.

The setting value for color temperature Cool will be calculated by multiplying the adjusted

value of color temperature Warm to the ratio of the valu e o f Warm and Coo l in ea ch GBR

value in Table 4.

Write that values to the data area of color temperature Cool in EEPROM.

13. The setting value for color temperature Mid will be calc ulated by multiplyin g the adjusted

value of color temperature Warm to the ratio of the value of Warm and Mid in each GBR

value in Table 4.

Write that values to the data area of color temperature Mid in EEPROM.

14. Select [Vivid] for picture menu when you check the adjusted data of Cool and Normal.

Note:

When white balance adjustment is executed, The TV set should be display some

video signal, or select VIDEO input (with no

signal) or select component input (with no

signal).

WB adjustment function will not be worked

when digital TV (with no signal) or HDMI

input (with no signal) is selected.

Note:

Adjusted value must be written to both SD

data area and HD data area of the

EEPROM.

35

Page 36

363738

Page 37

Page 38

Page 39

(LED:7 TIMES)

(LED:4TIMES)

(LED:8 TIMES)

(LED:6 TIMES)

(LED:6TIMES)

(LED:14TIMES)

(LED:9TIMES)

(LED:11TIMES)

(LED:12TIMES)

(LED:7TIMES)

(LED:11TIMES)

(LED:3TIMES)

(LED:8TIMES)

(LED:10TIMES)

(LED:10TIMES)

(LED:5TIMES)

(LED:4TIMES)

P

P

DATA

DRIVER

P+15V

ZA16112

VSCAN GEN.

SCAN

DRIVER

DATA

DRIVER

SS-BOARD

SOS DETECT

F15V

SD42

SC SCAN DRIVE

DATA

DRIVER

(LOWER)

P56

F15V

CONTROL

PULSE

SCAN CONTROL

VAD GEN.

SUSTAIN DRIVESS

ZA16111

ZA16101

AC CORD

C1

SU11

DATA

DRIVER

SC46

C2

VIDEO DATA

SC-BOARD

ENERGY RECOVERY

SOS DETECT

VE GEN.

SC-BOARD

FLOATING PART

SOS DETECT

SC42

SS11

VDA

OUT

C14

C21

P9

P6

VIDEO DATA

DATA

DRIVER

VDA

C31

P+3.3V

VIDEO DATA

RELAY

DATA

DRIVER

P+15V

DATA

DRIVER

P11

P+15V

ENERGY RECOVERY

P2

SUSTAIN CONTROL

P+3.3V

DATA

DRIVER

SUB

SC2

LOGIC

SUSTAIN

VOLTAGE

CONVERTER

DATA DRIVER (RIGHT)

C3

SCAN

DRIVER

SOS8_SS

P+5V

POWER SUPPLY

DATA

DRIVER

STB5V

SOS8_SS

SUSTAIN CONTROL

SCAN OUT (LOWER)

KEY1

SOS4_PS

SUSTAIN

P-BOARD

SOS DETECT

SCAN OUT (UPPER)

P51P55

KEY1

P58

SOS7_SC2

VSUS

KEY1

SOUND15V

C36

VIDEO DATA

DATA DRIVER (CENTER)

P

P35

P52

P+3.3V

VDA

ZA16102

P+5V

DATA

DRIVER

SU41

P+3.3V

PANEL MAIN ON

SS2

DATA

DRIVER

SC20

P57

STB5V

MAIN

DATA

DRIVER

C20

P+5V

P+15V

POWER

FACTOR

CONTROL

SOUND15V

P+3.3V

P+15V

SC41

DATA

DRIVER

STANDBY

VOLTAGE

CONVERTER

VIDEO DATA

VSUS

DATA

DRIVER

DATA

DRIVER

VSUS GEN.

SS33

DATA DRIVER (LEFT)

Vda

Vda

SU

C26

SD

SD11

C10

PROCESS

VOLTAGE

CONVERTER

P+3.3V

VSUS

SD46

RECTIFIER

SOS6_SC1

VSUS VSUS

C35

SOS6_SC1

POWER LED(R)

AV SW

SCAN CONTROL

SUB1.8V

SPEAKER(R)

P+2.5V

A14

LED1-4

TMDS DATA

SOS8_SS

ANALOG-ASIC

FAN CONT.

REMOTE RECEIVER

SD CARD DATA

P+1.1V

C.A.T.S. SENSOR

LAN

DDR3 I/F

PWM L/R

DCDC

SUB1.2V

VIDEO INPUT

SUB5V

AUDIO INPUT

F15V

DIGITAL AUDIO OUT

VIDEO (PC) INPUT

SUB1.2V

TUNER I/F

SUB5V

P+3.3V

SUB3.3V

PEAKS-LDA3

LP1-2

DCDC

LP1

DCDC

DDR3

PC

REMOTE IN

IEC OUT

P+5V

L/R

COMP

SBO1/SBI1

STB3.3V

SPEAKER(L)

SUB9V

DCDCIN

P+5V

SUB5V

P+3.3V DET

V

SUB1.5V

IR_LED_SOS

3D EYEWEAR

SUB1.5V

F15V

FAN ON

LVDS DATA

S10

K

AUDIO

SD CARD

NAND FLASH I/F

POWER SWITCH

A6

IIC

P+15V

S

KEY3

K1

CPU BUS I/F

PANEL MAIN ON

P+5V

ON

STM

PEAKS

EEPROM

P+15V

L

V14

NAND

FLASH

P+2.5V

FAN_SOS DET

RS232C SBO1/SBI1

SOS7_SC2

AUDIO PWM

USB

RS-232C

DRIVER

SIF I/F

LVDS I/F

SOS4_PS

SOUND SOS

RS-232C

TRANSMITTER

TXD/RXD

R

SOUND SOS

P+1.1V

VIDEO DATA

WOOFER

STB5V

WO

FAN SOS

STB5V

HDMI I/F

REMOTE RECEIVER

AUDIO

CVBS/Y,PR/C,PB

AMP

STB1.2V

AUDIO

A12

P+3.3V

IFD_OUT

SUB3.3V

SD CARD I/F

SPI

FLASH

3D EYEWEAR

SOS8_SS

P+1.1V_M

USB I/F

STM IIC

A1

KEY1

A8

F15V

PANEL SOS

PANEL MAIN ON

SUSTAIN

CONTROL

V

FAN_A,B

V

LAN CON I/F

F15V

SOUND15V

P+3.3V

SUB+5V SENSE

C.A.T.S SENSOR

ARC

(HDMI4)

TRANSMITTER

SOS4_PS

SUB5V

P+5V

SIF_OUT

DCDC

IR LED

DRIVER

SOS6_SC1

DCDC

TUNER

P+1.1V_S

L/R

DIGITAL

P+3.3V

SOUND SOS

VDDSD

18V33V

ETHERNET DATA

A

ARC

(HDMI4)

SUB5V

AMP

A20

SOS_DCC

SOS7_SC2

VIDEO

POWER LED

A11

SUB1.8V

PWMW

STM

EEPROM

PC_H/V

IPOD_CP_XRST

P+3.3V

DCDC

iPOD-CP

PANEL SOS

SUB3.3V

OUT

LED R

IR_LR

Y/PB/PR

R/G/B

FAN ON

SUB+3.3V SENSE

ETHERPHY

HDMI1-4

STB3.3V

L/R

TUNER_POWER_SOS

TUNER_POWER_SOS

SUB3.3V

KEY1

USB_1-3

C.A.T.S SENSOR

STB3.3V

VIDEO

DATA

MAIN AV INPUT,PROCESSING

P+5V DET

A31

A40A32

SUSTAIN

CONTROL

(LED:7 TIMES)

(LED:4TIMES)

(LED:8 TIMES)

(LED:6 TIMES)

(LED:6TIMES)

(LED:14TIMES)

(LED:9TIMES)

(LED:11TIMES)

(LED:12TIMES)

(LED:7TIMES)

(LED:11TIMES)

(LED:3TIMES)

(LED:8TIMES)

(LED:10TIMES)

(LED:10TIMES)

(LED:5TIMES)

(LED:4TIMES)

SIDE UNIT ASSY

OPERATION KEYS

11 Block Diagram

11.1. Main Block Diagram

39

Page 40

11.2. Block (1/4) Diagram

(LED:14TIMES)

(LED:11TIMES)

(LED:3TIMES)

(LED:4TIMES)

(LED:5TIMES)

(LED:12TIMES)

(LED:10TIMES)

COMP

JK3000

VIDEO

JK3002

JK3003

JK3004

PC

JK3005

RS-232C

SOUND15V

PANEL_MAIN_ON

SOS4_PS

STB5V_SW_ON

TUNER_SUB_ON

STB5V

P+15V

P_S1

P_S0

F15V

F15V

IC4901

AUDIO

SOUND15V

WOOFER

3

1

A12

WO(-)

WO(+)

OUT

WOOFER

PWM

SOS

USB I/F

AUDIO PWM

SOUND SOS

(LED:12TIMES)

JK8533

IC8531

USB1

JK8532

USB2

IC8532

USB0VBUS

JK8531

USB3

IC8607

USB1VBUS

PEAKS-LDA3

USB2VBUS

IC8000

JK8301

LAN

VCC

DDR3 I/F

CPU BUS I/F

IPOD_CP_XRST

HDMI3.3V

SUB3.3V

SUB1.8V

SUB1.5V

SUB1.2V

IC3900

IIC1

iPOD-CP

SUB3.3V

IIC1

IC8601

ETHERPHY

X8600

25MHz

HDMI_SW3.3V

X8300

24.576MHz

LAN CON I/F

SBO1

SBO1

AXO

RS-232C

SBI1

SBI1

JK3007

DIGITAL

AUDIO

OUT

AXI

PANEL_MAIN_ON

PANEL MAIN ON

TUNER_SUB_ON

Q4500

IEC OUT

TUNER_SUB_ON

SOS4_PS

(LED:4TIMES)

SOS4_PS

ARC_OFF

KEY1

KEY1

JK4600

HDMI1

ARC

HDMI_CEC

HDMI_CEC

HDMI_CEC_

PULL_ON

STM

KEY3

XRSTSTM

XRSTSTM

KEY3

+5V

DDC_IIC0

TMDS DATA

RX0

DDC_IIC0

HDMI_5VDET0

DRVRST

XRST

LP1_XRST_SYS

PDP_DRVRST

XRST

JK4601

HDMI2

+5V

HDMI_CEC

CLOCK

HDMI_5V_DET1

REMOTE_IN

SDVOLC

LP1_XRST_SYS

C.A.T.S

SDVOLC

REMOTE IN

JK4602

HDMI3

DDC_IIC1

TMDS DATA

CLOCK

RX1

DDC_IIC1

R_LED_ON

PANEL_SOS

C.A.T.S_SENSOR

POWER_DET

R_LED_ON

PANEL SOS

+5V

DDC_IIC2

HDMI_CEC

DDC_IIC3

HDMI_5V_DET2

MAIN_FAN_ON

SW_OFF_DET

POWER_DET

SW_OFF_DET

MAIN_FAN_ON

TMDS DATA

CLOCK

HDMI I/F

FAN_MAX

FAN_MAX

FAN_SOS

JK4603

HDMI4

ARC

HDMI_CEC

HDMI_5V_DET3

FAN_SOS

IR_DCDC_ON

(LED:11TIMES)

IR_LED_SOS

IR_DCDC_ON

+5V

DDC_IIC3

TMDS DATA

DDC_IIC4

IR_LED_SOS

(LED:14TIMES)

CLOCK

STB1.2V

HDMI MUX

DDC_IIC3

DDC_IIC2

RX4

RX5

3.3V

STB3.3V

D8725

USB5V

IC4700

SEL2

SEL1

(LED:10TIMES)

TUNER_POWER_SOS

D8719

IIC3

SUB3.3V_SENSE

SUB5V_SENSE

D8726

P

VJ9805

RX2

DDC_IIC2

P+5V DET

P+3.3V DET

(LED:5TIMES)

SD DATA:4bit

SD CARD I/F

LVDS I/F

IIC0

IIC1

IIC3

DMD_

IIC0

SBI0

SBO0

STM

IIC

(LED:3TIMES)

SUB3.3V

LEDDRV_5V

JK8650

SD CARD

VDDSD18V33V

VDDSD1.8V3.3V

LVDS DATA

P+3.3V

P+5V

IC3753

TEMP SENSOR

STB3.3V

STB1.2V

STB5V

SUB9V

SUB5V

F15V

P+15V

IIC0

IIC1

IIC3

DMD_

IIC0

SBI0

SBO0

STM

IIC

IC8901

STM

EEPROM

1

2

STB3.3V

3

4

IIC3

5

6

7

8

9

10

11

12

13

SPEAKER_L

SPEAKER_R

TU4801

MAIN AV INPUT,PROCESSING

A

DMD_IIC0

IC3001

AV SW

V1_R

V1_V

V1_L

D1_PR

D1_PB

D1_Y

D1_R

D1_L

PC_R

PC_G

PC_B

PC_H

PC_V

IC3002

RS232C

RXD

TXD

DRIVER

SBI1

SBO1

R

VIDEO

V

L

PR

PB

Y

COMP

R

L

PC

R

G

B

H

V

IIC3

TUNER

MAIN

CVBS/Y,PR/C,PB

PC_H/V

L/R

3.3V

5V

9V

ANT IN

TUNER

VIDEO

FE_XRST

3.3V

SIF_OUT

IFD_OUT1

IFD_OUT2

IF_AGC

1.8V

TV_V

V

A11

IC4900

AUDIO

AMP AMP2

SOUND15V

USB5V

HDMI_SW3.3V

SUB3.3V

IFD2

IFD1

IF_AGC

FE_XRST

SIF I/F

CVBS/YPbPr/RGB/YC

L/R

H/V

4

L(+)

SPEAKER

3

L(-)

L_OUT

SUB1.5V

PWM L/R

SUB3.3V

2

R(+)

SOS

AV IN

1

R(-)

R_OUT

SPEAKER

IC8200,01

DDR3

IC8902

PEAKS

EEPROM

IC8900

NAND

FLASH

STB3.3V

A6

P6

15

6

PANEL_MAIN_ON

1

2

3

4

5

7

10

11

13

SOS4_PS

STB5V_SW_ON

TUNER_SUB_ON

PA5601

P_S1

P_S0

VJ1001

DCDCEN

P

F15V

SOUND15V

PA5440

DCDCIN

STB5V

IC5350

IC8701

IC8100

USB5V

+5V

SUB5V

+5V

SUB1.5V

SUB1.2V

+1.5V

+1.2V

USB5V

SUB1.5V

SUB1.2V

F15V

P+15V

IC8706

HDMI3.3V

HDMI_SW3.3V

3.3V

IC8702

+1.8V

HDMI3.3VSUB5V

SUB1.8V

40

Page 41

11.3. Block (2/4) Diagram

(LED:14TIMES)

(LED:8TIMES)

(LED:7TIMES)

(LED:6TIMES)

(LED:9TIMES)

(LED:11 TIMES)

(LED:9TIMES)

S

SUB_AI3.3V

SUB5V

STB1.2V

D5704

SUB5V

D2851

SUB9V

D5616

STB5V

D2850

SUB5V

F15V

D5622

D2852

STB3.3V

P+3.3V

P+5V

VJ5000

STB3.3V

D5614

VDDSD18V33V

LEDDRV_5V

D5615

D5703

D5624

STB5V

D5621

STB3.3V

D5613

P+3.3V

F15V

VDDSD18V33V

D2820

SUB9V

STB1.2V

D2853

P+15V

D5625

P+3.3V

P+1.1V_S

P+3.3V

P+15V

D9806

P+5V

F15V

P+3.3V

X9300

P+2.5V

P+2.5V

P+1.1V_M

P+3.3V

PA5900

LEDDRV_5V

C.A.T.S

A18

STB+3.3V

7

KEY3

IC5251

POWER LED

3D EYEWEAR

REMOTE_IN

FAN CONTROL

IR_LED_SOS

8

REMOTE RECEIVER

IC5607

KEY3

IR_DCDC_ON

IIC0

IIC3

DMD_IIC0

MAIN_FAN_ON

3D EYEWEAR

UHZ

3

12

2

IC5900

5

9

SUB9V

REMOTE_IN

FAN_MAX

IR_LR

8

1

BUFF_EN

DCDC_CTL

R_LED_ON

DTV_RST

V

PWM

TRANSMITTER

IR LED DRIVER

RESET

2

3

REMOTE

RECEIVER

10

C.A.T.S

SOS7_SC2

SDVOLC

STBRST

C.A.T.S SENSOR

LED1

POWER_DET

LEDDRV5V

POWER LED

C.A.T.S. SENSOR

V14

4

ANALOG-ASIC

6

LVDS DATA

LED4

3

SUB_AI3.3V

DTV_15V

10

2

TRANSMITTER

3

2

STB3.3V

5

SD_VCC

FOR

FACTORY

USE

4

D_UHZ

K1

7

5

A17

1

4

5

SOS7_SC2

SW_OFF_DET

DRVRST_

IN

STB5V_SW_ON

FAULT

A8

IC5606

PANEL_SOS

+5V

SN2810

6

A1

SOS_DCC_M

SC_UHZ

6

SOS_DCC_M

XRST

+3.3V

XRSTSTM

FOR

FACTORY

USE

3

RM2810

12

10

LED4

SUB_AI3.3V

A14

DCDCEN

5

SOS6_SC1

4

POWER_DET

PANEL SOS

9

8

R_LED_ON

DRVRST

LED3

STB+1.2V

3

SOS8_SS

IC5000

IIC0

IIC1

STM_IIC

SBO0/SBI0

DRVRST_

OUT

2

LED3

1

LED1

LED2

SUB5V

SOS6_SC1

FAN A,B

FAN_SOS

6

MAIN AV INPUT,PROCESSING

13

1

K

KEY3

PDP_DRVRST

SOS8_SS

LED2

VBAT

IC5901

SD_UHS

A

14

IC9501

3.3V

52

DATA DRIVER CONTROL

P_S0

OFF_FLAG

SS33

XRST

SOS_DCC_S

DRVRST

PLASMA AI

CPG

H/V Sync Control

Sub Filed Processor

P_S0

D_UHZ

IC9820

LVDS DATA

A31

4

LP1

1.1V_S

P+3.3V

VIDEO DATA

VIDEO DATA

C21

XRST_SYS

SOS8_SS

C31

IC9400-02

KEYSCAN

1

P_S1

P_S1

SI/SO

UHZ

SPI

FLASH

KEY1

SCAN DATA

BUFFER

2.5V

P+3.3V

IC9300

SOS_DCC_S

DRVRST

SCAN CONTROL

FLASH I/F

IC9304

2

SUSTAIN DATA

BUFFER

DISCHARGE CONTROL

LP1_XRST_SYS

IIC0

SUSTAIN CONTROL

IC9830

P+5V

A32

SUSTAIN CONTROL

P+5V

DATA DRIVER CONTROL

1

A40

40

55

VIDEO DATA

2

SOS8_SS

19

P+5V

20

IC9500

IIC0

2.5V

VIDEO DATA

XRSTSYS

XRST1.1V_M

3.3V

LP1-2

PLASMA AI

CPG

H/V Sync Control

Sub Filed Processor

LVDS DATA

IR_LR

X0

20MHz

X1

P+15V

SC_UHZ

SOS6_SC1

16

SC20

30

UHZ

15

SCAN CONTROL

SOS7_SC2

1

18

29

SOS7_SC2

SOS6_SC1

A20

P+5V

P+15V

SOS_DCC_S

SOS_DCC_S

SOS_DCC_M

IR_LR

XRST_SYS_A

SOS_DCC_M

P+2.5V

+2.5V

P+3.3V

+3.3V

DCDCEN

DCDCEN

+1.1V

IC9860

+1.1V

DCDCEN

P+1.1V_S

P+1.1V_M

DATA DRIVER CONTROL

S

POWER SWITCH

ON

2

S10

SW2890

POWER

SWITCH

SBI1

SBO1

11

XRST_SYS_A

(LED:14TIMES)

(LED:8TIMES)

(LED:7TIMES)

(LED:6TIMES)

(LED:9TIMES)

(LED:11 TIMES)

(LED:9TIMES)

41

Page 42

11.4. Block (3/4) Diagram

COLDHOT

COLD

HOTHOT

COLD

P(MAIN)

POWER SUPPLY

P(SUB)

NEUTRAL

POWER SUPPLY

FILTER

F101F102

LIVE

2

1

P9

AC CORD

RECTIFIER

R103

L101

L104

RELAY

1

2

RELAY

2

1

S101

S102

COLD

4

3

3

4

D352

RECTIFIER

Q354

ZD352

Q201,02

Q203,04

CONTROL

FET

DRIVER

D201

D202

Q501

Q301,Q302

F301

RESONANCE

VGH

VGL

I301

RESONANCE

CONTROL

FB

CSS

VCC

I401

STB

CONTROL

F501

D501

D404

AC DET

T301

T302

L301

PHOTO COUPLER

PHOTO COUPLER

PHOTO COUPLER

T401

PHOTO COUPLER

PHOTO COUPLER

PHOTO COUPLER

I302

I602

I501

I402

I603

I101

Q374

D351

RECTIFIER

Vsus

VR251

I351

Vsus

ERROR DET

COLDHOT

D451

D459

I451

F_STBY

ERROR DET

ZD652

Q701,Q702

Vsus Adj

F_STBY(F15V)

F451

STB+5V DET

Q457

Q451

I455

STB+5V

I352

Vda

CONTROL

P52

P51

3

3

L201,02

P56

P55

3

3

P57

P58

1

1

2

2

4

4

HOTHOT

COLD

I201

PFC

F103

Q565

Q375

Q376

Q377

ERROR DET

ERROR DET

CONTROL

I651

P+15V

Q454

I453

FET

DRIVER

D354

Q459,60

VR600

Vda

Q458

P35

1

Vda

2

Vda

P2

1

Vsus

P11

1

Vsus

4

P+15V

P25

7

S0

8

S1

1

P+15V

2

P+15V

5

STB+5V

9

PANEL_MAIN_ON

10

SOS_P4

P6

4

SOS4_PS

1

PANEL_MAIN_ON

2

S1

3

S0

6

STB+5V

13

P+15V

15

SOUND+15V

10

F+15V

11

F+15V

7

F_STABY_ON

5

STBY5V_ON

C35

SC2

SS11

NO USE

A6

Q555

Q462

31

P34

42

Page 43

(LED:6 TIMES)

(LED:8 TIMES)

(LED:7 TIMES)

A40

TPVFG

TPSS1

ZA14902

D16473

TPSOS8

TPSOS6

ZA16422

TPVSUS

ZA16112

TPVSUS

D16583

ZA14952

ZA14901

ZA16111

ZA14951

ZA16421

ZA16102

D16476

D16475

ZA16412

D16255

D16493

ZA16106

ZA16101

ZA16105

ZA16116

D16618

TPSOS7

D16282

ZA16411

ZA16115

D16254

D16825

TPSC1

D16728

D16791

TPVAD

TPVE

IPD CIRCUIT

C2

OC2

CPH1

Q16600

SC

50

1

15

CB3

SC JIG

CHA

1

VIDEO DATA

VSET DET

C21

VFG

8

16

2

USL

VIDEO DATA

1

CRC1

IC16243

IC16502

DRIVER

BUFFER

CB6

6

BUFFER

SC2

CSH

13

CB8

1

SU

BUFFER

AND

UMH

BUFFER

SOS6

VFG

C10

SUSTAIN L

CERS

OR

SC

4

CIS

SU1-SU5

SD

42

CB5

22

C20

LOGIC IC

VFG

VFO

VIDEO DATA

SCAN

CONTROL DATA

9

Q16001

Q16002

Q16003

CB1

6

IC17201,02

CHA

+5V

Q16451

Q16452

Q16021

Q16022

Q16023

6

IC14804-06

SU

11

CML

IC16132

SOS7

Vsus

SU

41

IC16521

8

SCAN

VOL

VF5V

VDA

VSCN-F

55

SD

UEH

CEL

IC16563

P35

Q16601

Q16441

Q16442

DATA DRIVER

SCNR_PRO

IC16564,65

54

1

DATA DRIVER

7

VDA

CLK

CB7

DATA DRIVER

2

P+5V

2

Q16401

Q16402

Q16403

PLASMA PANEL

CPH1

CB

12

SCAN

CML

SEPA

P+15V

A32

Q16421

Q16422

Q16423

CB

15

2

CHA

IC16684

CB

11

Q16607

BUFFER

Q16101

Q16102

PLASMA PANEL

IC16151

VDA

OC1

CB9

IC16244

IC14601-03

NAND

LED(G)

MAIN H

1

CIS

SEL

DATA DRIVER (RIGHT)

26

P+15V

CSL

Q16051

Q16053

BUFFER

RECOVERY H

C1

BUFFER

52

35

SCAN CONTROL

SUSTAIN DRIVE

23

C35

SHUNT REG

5V_F

VF5V

PC16301

MAIN L

PLASMA

PANEL

IC16131

DRIVER

SS2

SD1-SD5

SC

42

CEL

OC1

24

SCAN OUT (UPPER)

IC16691

1

C14

VE GEN.

2

USL

C3

RECOVERY H

18

42

SCAN OUT (LOWER)

SEL

SIU

SCNR_PRO

VDA

CSL

DATA DRIVER (LEFT)

8

C31

CRC2

2

RECOVERY L

CONTROL DATA

SC

41

30

1

IC14604-06

VIDEO DATA

IC16471

VIDEO DATA

VSCN-F

6

9

IC16522

SCAN DRIVE

LED(G)

VFO

IC16724

BUFFER

27

CMH

C26

IC17301

ELECTRODE

P2

SC

46

SIU

25

CB

14

SUSTAIN H

1

MID

CB

10

22

BUFFER

P+3.3V

5

4

IC16501

CB

13

5

P11

9

20

SHUNT

REG

IC16241

P+3.3V

P+3.3V

FPC PROTECTOR

IC14801-03

P+3.3V

USH

P+3.3V

C36

2

8

26

1

P+15V

BUFFER

BUFFER

PANEL

SUSTAIN

ELECTRODE

DRIVER

Q16621

Q16622

Q16623

38

UML

1

SCAN

13

Q16041

Q16043

4

1

CERS

UMH

VDA

BUFFER

IC16490,91

RECOVERY L

CONTROL DATA

CMH

VIDEO DATA

21

6

SS

53

CB2

32

SD

46

14

8

CLK

IC16561,62

16

DRIVER

UEH

BUFFER

Q16471

54

BUFFER

UHZ

UML

CSH

CB4

IC16191

SCAN

CONTROL

3

(SC)

(LOWER)

PANEL SCAN

40

IC16304,12

INVERTER

IC16152

SS

54

13

37

Vsus

SS

SS

56

VSCN_F

6

SC

20

SUSTAIN OUT

INV

SD

11

VDA

A31

IC14901,02,04

A20

USH

1

DATA DRIVER (CENTER)

SS

11

OC2

5

KEY1

36

2

KEYSCAN

SS

33

SUSTAIN CONTROL

SOS8_SS

2

20

P+5V

1

P+5V

MID

IC16786,87

CEL

SHUNT REG

D16714

VSCN GEN.

D16713

IPD CIRCUIT

PC16723

T16472

Q16660

IC16795

F15V

Q16661

IGBT CONTROL

IC16921

PC16897

CRC2

CRC1

CEL

SHUNT REG

T16471

VAD GEN.

IPD CIRCUIT

IC16784,85

(LED:6 TIMES)

(LED:8 TIMES)

(LED:7 TIMES)

OPERATION KEYS

SIDE UNIT ASSY

-

+

VOL

CH

MENU

INPUT/

OK

11.5. Block (4/4) Diagram

43

Page 44

44

Page 45

12 Wiring Connection Diagram

12.1. Caution statement.

Caution:

Please confirm that all flexible cables are assembled correctly.

Also make sure that they are locked in the connectors.

Verify by giving the flexible cables a very slight pull.

12.2. Wiring (1)

12.3. Wiring (2)

45

Page 46

12.4. Wiring (3)

46

Page 47

12.5. Wiring (4)

47

Page 48

12.6. Wiring (5)

48

Page 49

12.7. Wiring (6)

49

Page 50

12.8. Wiring (7)

50

Page 51

Model No. : TC-P55VT30 Schematic Diagram Note

S-1

Page 52

Model No. : TC-P55VT30 Replacement Parts List Note

S-2

Page 53

Model No. : TC-P55VT30 A-Board (1/17)

S-3

Page 54

Model No. : TC-P55VT30 A-Board (2/17)

S-4

Page 55

Model No. : TC-P55VT30 A-Board (3/17)

S-5

Page 56

Model No. : TC-P55VT30 A-Board (4/17)

S-6

Page 57

Model No. : TC-P55VT30 A-Board (5/17)

S-7

Page 58

Model No. : TC-P55VT30 A-Board (6/17)

S-8

Page 59

Model No. : TC-P55VT30 A-Board (7/17)

S-9

Page 60

Model No. : TC-P55VT30 A-Board (8/17)

S-10

Page 61

Model No. : TC-P55VT30 A-Board (9/17)

S-11

Page 62

Model No. : TC-P55VT30 A-Board (10/17)

S-12

Page 63

Model No. : TC-P55VT30 A-Board (11/17)

S-13

Page 64

Model No. : TC-P55VT30 A-Board (12/17)

S-14

Page 65

Model No. : TC-P55VT30 A-Board (13/17)

S-15

Page 66

Model No. : TC-P55VT30 A-Board (14/17)

S-16

Page 67

Model No. : TC-P55VT30 A-Board (15/17)

S-17

Page 68

Model No. : TC-P55VT30 A-Board (16/17)

S-18

Page 69

Model No. : TC-P55VT30 A-Board (17/17)

S-19

Page 70

Model No. : TC-P55VT30 K, S and V-Board

S-20

Page 71

Model No. : TC-P55VT30 C1-Board

S-21

Page 72

Model No. : TC-P55VT30 C2-Board (1/2)

S-22

Page 73

Model No. : TC-P55VT30 C2-Board (2/2)

S-23

Page 74

Model No. : TC-P55VT30 C3-Board (1/2)

S-24

Page 75

Model No. : TC-P55VT30 C3-Board (2/2)

S-25

Page 76

Model No. : TC-P55VT30 SC-Board (1/4)

S-26

Page 77

Model No. : TC-P55VT30 SC-Board (2/4)

S-27

Page 78