Page 1

PSG1302028CE

CD Stereo System

Model No. SA-AKX36PH

SA-AKX36PN

Product Color: (K)...Black Type

Please refer to the original service manual for:

O

O CD Mechanism Unit , Order No. PSG1102001CE

OO

O

O Speaker system SB-AKX36PN-K, Order No. PSG1302023CE

OO

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Before Use (For PH only)-------------------------------- 4

1.3. Before Repair and Adjustment------------------------- 4

1.4. Protection Circuitry----------------------------------------4

1.5. Power Supply using SMPS ----------------------------- 5

1.6. Safety Parts Information--------------------------------- 6

2 Warning-------------------------------------------------------------- 7

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 7

2.2. Precaution of Laser Diode------------------------------- 8

2.3. Service caution based on Legal restrictions-------- 9

2.4. Handling Precautions for Traverse Unit-------------10

2.5. Grounding for electrostatic breakdown

prevention-------------------------------------------------- 11

3 Service Navigation ---------------------------------------------12

3.1. Service Information--------------------------------------12

3.2. Firmware Update Procedure-------------------------- 13

4 Specifications ----------------------------------------------------14

5 General/Introduction-------------------------------------------15

5.1. Media Information---------------------------------------- 15

6 Location of Controls and Components------------------ 16

6.1. Remote Control Key Button Operation -------------16

6.2. Main Unit Key Button Operation----------------------17

7 Installation Instructions -------------------------------------- 18

7.1. Speaker and A/C Connection-------------------------18

© Panasonic Corporation 2013. All rights reserved.

Unauthorized copying and distribution is a violation

of law.

Page 2

8 Service Mode-----------------------------------------------------19

8.1. Cold-Start---------------------------------------------------19

8.2. Doctor Mode Table---------------------------------------20

8.3. Reliability Test Mode (CD Mechanism Unit)------- 23

8.4. Self-Diagnostic Mode -----------------------------------24

8.5. Self-Diagnostic Error Code Table--------------------24

8.6. Sales Demonstration Lock Function ---------------- 25

9 Troubleshooting Guide----------------------------------------26

10 Disassembly and Assembly Instructions---------------27

10.1. Screw Types-----------------------------------------------27

10.2. Disassembly Flow Chart--------------------------------28

10.3. Main Components and P.C.B. Locations-----------29

10.4. Disassembly of Top Cabinet---------------------------30

10.5. Disassembly of Front Panel Unit---------------------31

10.6. Disassembly of Panel P.C.B., LED P.C.B. and

Mic P.C.B.--------------------------------------------------32

10.7. Disassembly of Remote Sensor P.C.B.-------------34

10.8. Disassembly of USB P.C.B. ---------------------------35

10.9. Disassembly of CD Lid----------------------------------35

10.10. Disassembly of Rear Panel----------------------------36

10.11. Disassembly of Main P.C.B.---------------------------37

10.12. Disassembly of Digital Amplifier IC (IC6000)------38

10.13. Disassembly of SMPS Module and Voltage

Selector P.C.B.--------------------------------------------39

10.14. Disassembly of CD Mechanism Unit----------------40

10.15. Disassembly of CD Interface P.C.B.-----------------41

10.16. Disassembly of Fan Unit -------------------------------42

11 Service Position -------------------------------------------------43

1 1.1. Checking of Panel P . C.B., LED P.C.B. and Mic

P.C.B.--------------------------------------------------------43

11.2. Checking of Main P.C.B. (Side B)--------------------43

11.3. Checking of Main P.C.B. (Side A)--------------------44

12 Block Diagram ---------------------------------------------------45

12.1. Servo & System Control--------------------------------45

12.2. IC Terminal Chart-----------------------------------------47

12.3. Audio --------------------------------------------------------48

12.4. Power Supply ---------------------------------------------49

13 Wiring Connection Diagram---------------------------------51

14 Schematic Diagram---------------------------------------------53

14.1. Schematic Diagram Notes-----------------------------53

14.2. MAIN (CD Servo/Micon/Damp) Circuit -------------55

14.3. Panel Circuit-----------------------------------------------63

14.4. USB, Music Port, Memory LED, Remote

Sensor & CD Interface Circuit ------------------------65

15 Printed Circuit Board ------------------------------------------66

15.1. Main P.C.B. ------------------------------------------------66

15.2. Panel, USB, Music Port & Memory LED

P.C.B.--------------------------------------------------------68

15.3. Remote Sensor & CD Interface P.C.B. -------------69

16 Appendix Information of Schematic Diagram --------- 71

16.1. Voltage & Waveform Chart ----------------------------71

17 Exploded View and Replacement Parts List-----------77

17.1. Exploded View and Mechanical replacement

Part List-----------------------------------------------------77

17.2. Electrical Replacement Part List ---------------------83

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which a re important for safety. These parts are marked by in the

Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify

the original design without permission of manufacturer.

2. An Isolation Transformer should always be used during the servicing of AC Adaptor whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal

injury from electrical shocks. It will also protect AC Adaptor from being damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

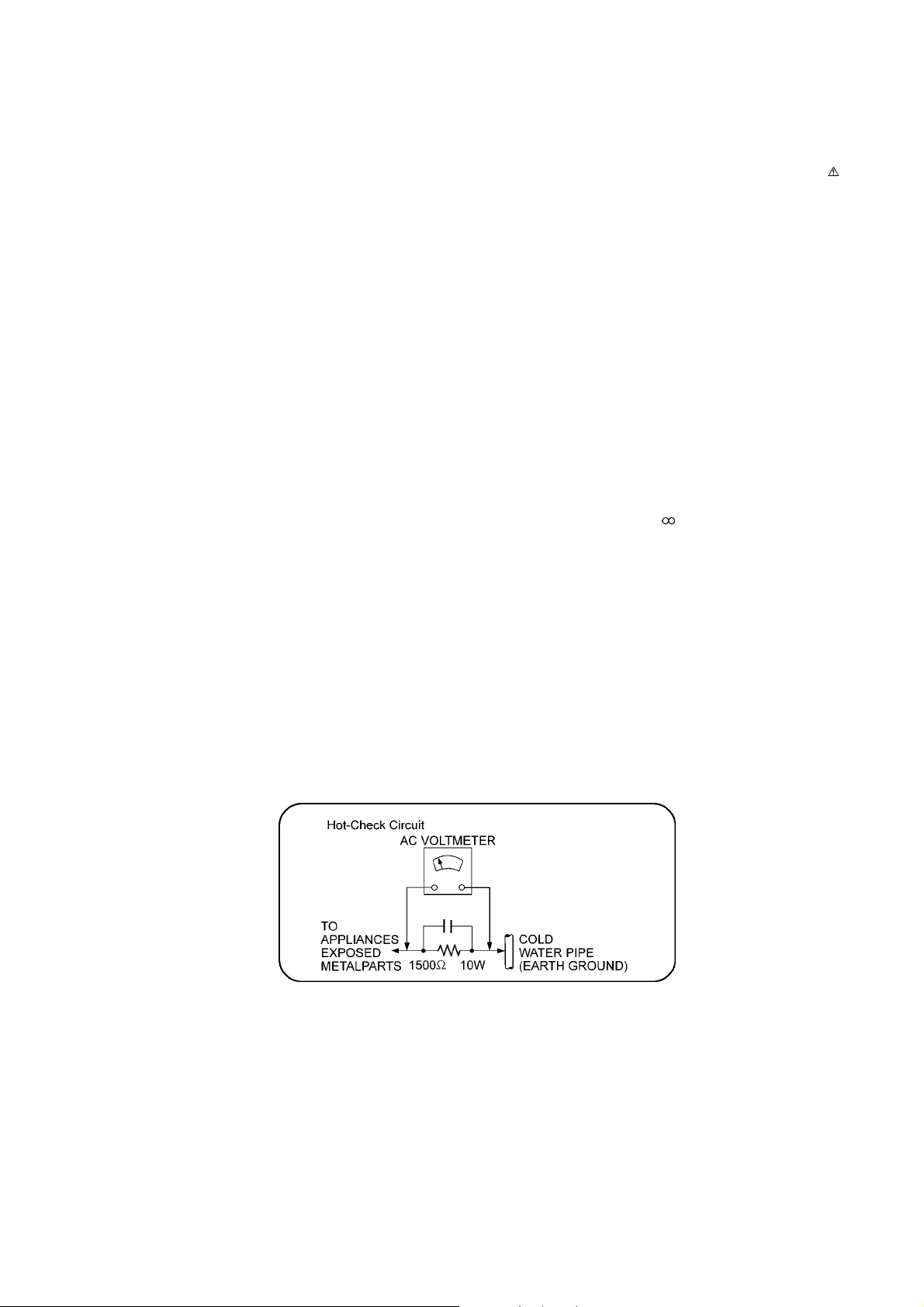

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1-1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equiva lent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

Figure 1-1

3

Page 4

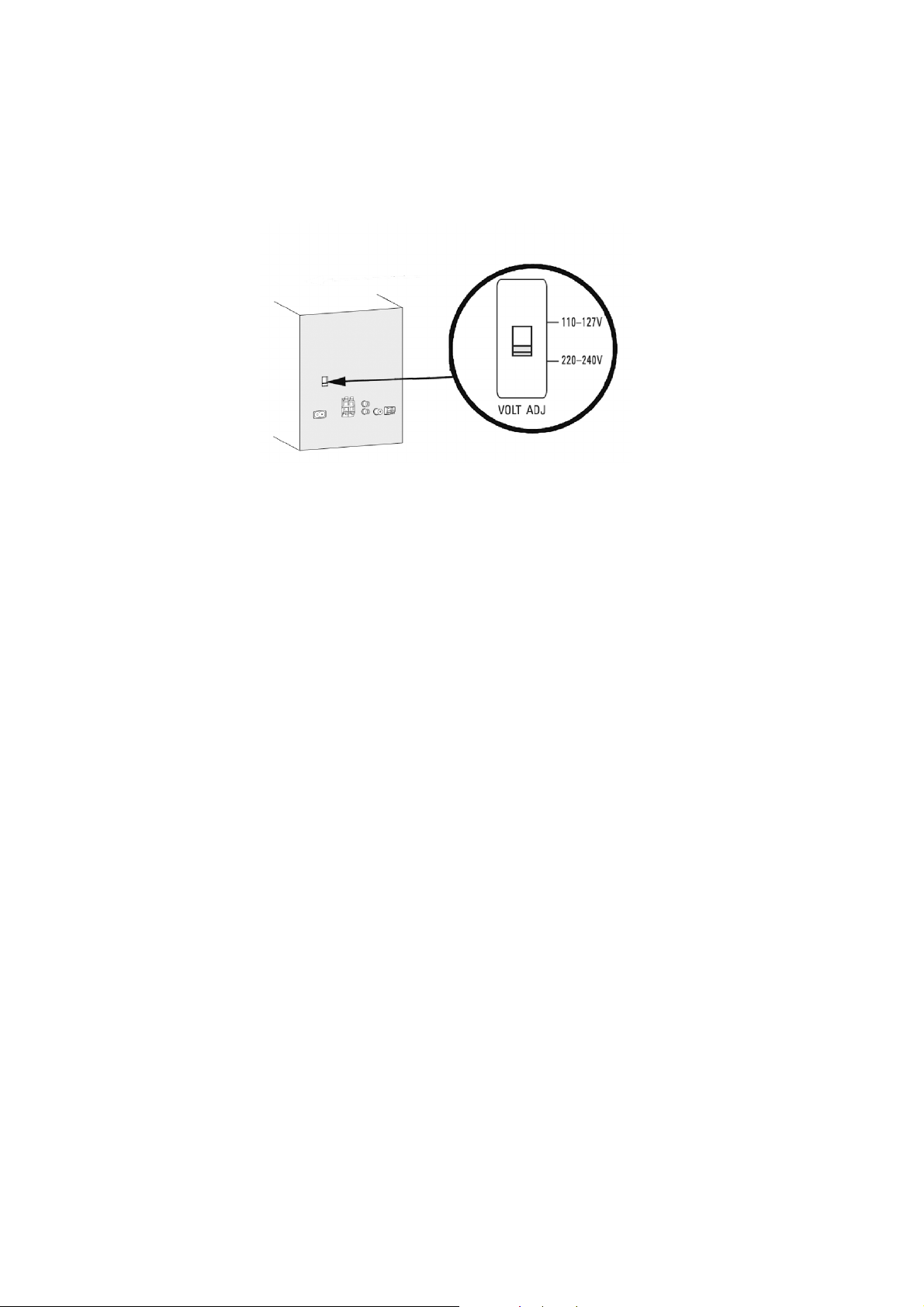

1.2. Before Use (For PH only)

Be sure to disconnect the mains cord before adjusting the voltage selector as shown in Figure 1-2

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will be

used.

Note that this unit will be seriously damaged if this setti ng is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

Figure 1-2

1.3. Before Repair and Adjustment

Caution:

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 110~127 V / 220~240 V, 50/60 Hz in FM Tuner at volume minimum mode should be ~ 500 mA (PH).

Current consumption at AC 120 V, 60 Hz in FM Tuner at volume minimum mode should be ~ 500 mA (PN).

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4

Page 5

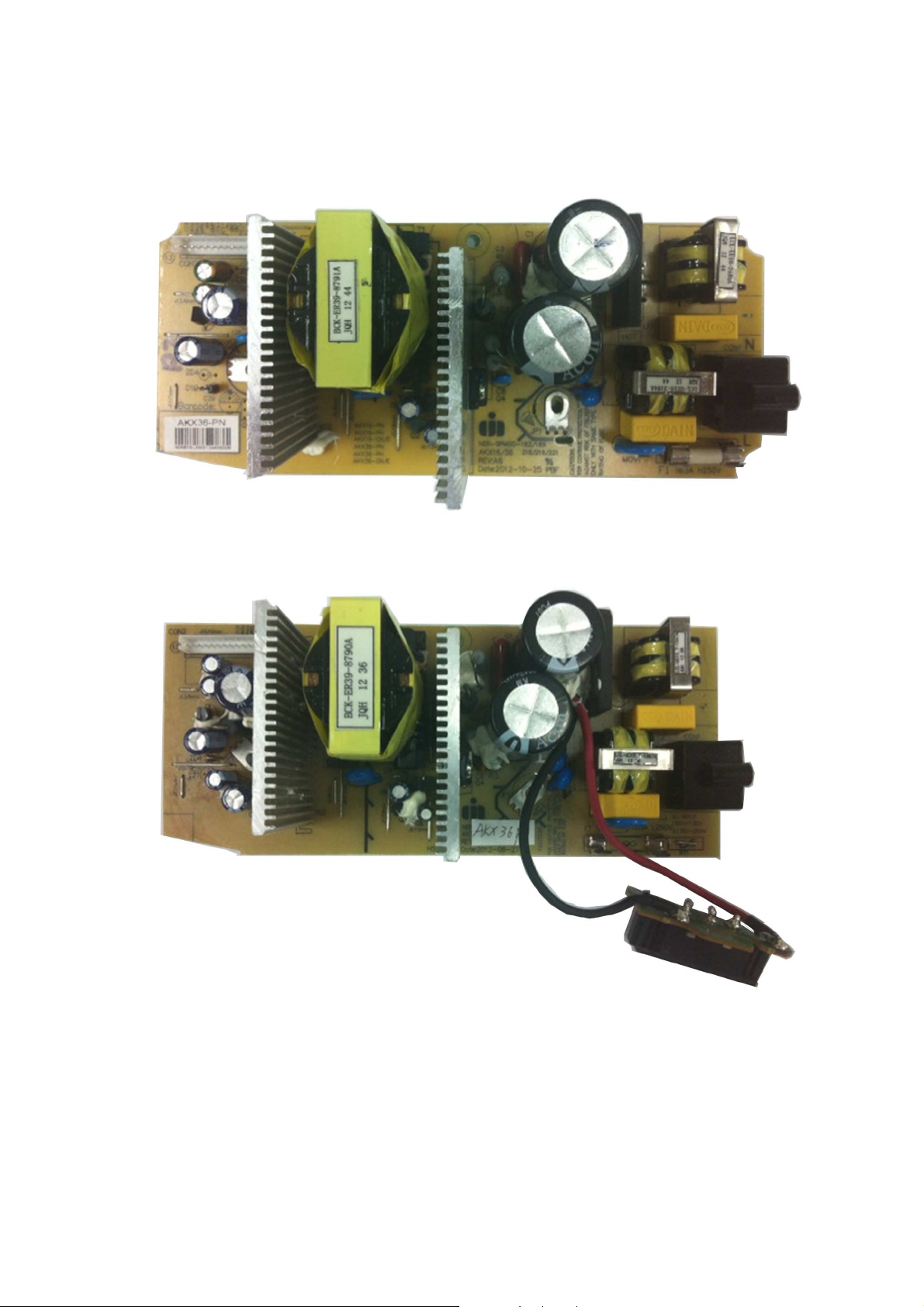

1.5. Power Supply using SMPS

This model uses SMPS Module to Power up the unit. Below is the part number of the SMPS Model.

N0AB3GL00001 (PN)

N0AD3GL00001 (PH)

1.5.1. For SA-AKX36PN

Figure 1-3

1.5.2. For SA-AKX36PH

Figure 1-4

5

Page 6

1.6. Safety Parts Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams, Exploded View & Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

Safety Ref No. Part No. Part Name & Description Remarks

16 RGR0443C-A1 REAR PANEL PH

16 RGR0443D-A1 REAR PANEL PN

17 RKM0713-K TOP CABINET

301 RAE1036Z-V TRAVERSE ASS'Y

A2 K2CB2CB00022 AC CORD PN

A2 K2CQ2YY00119 AC CORD PH

A3 RQT9796-M O/I BOOK (Sp)

PCB9 N0AB3GL00001 SMPS MODULE PN

PCB10 N0AD3GL00001 SMPS MODULE PH

T6000 G4DYA0000214 TRANSFORMER

6

Page 7

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by ele ctrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as al uminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

7

Page 8

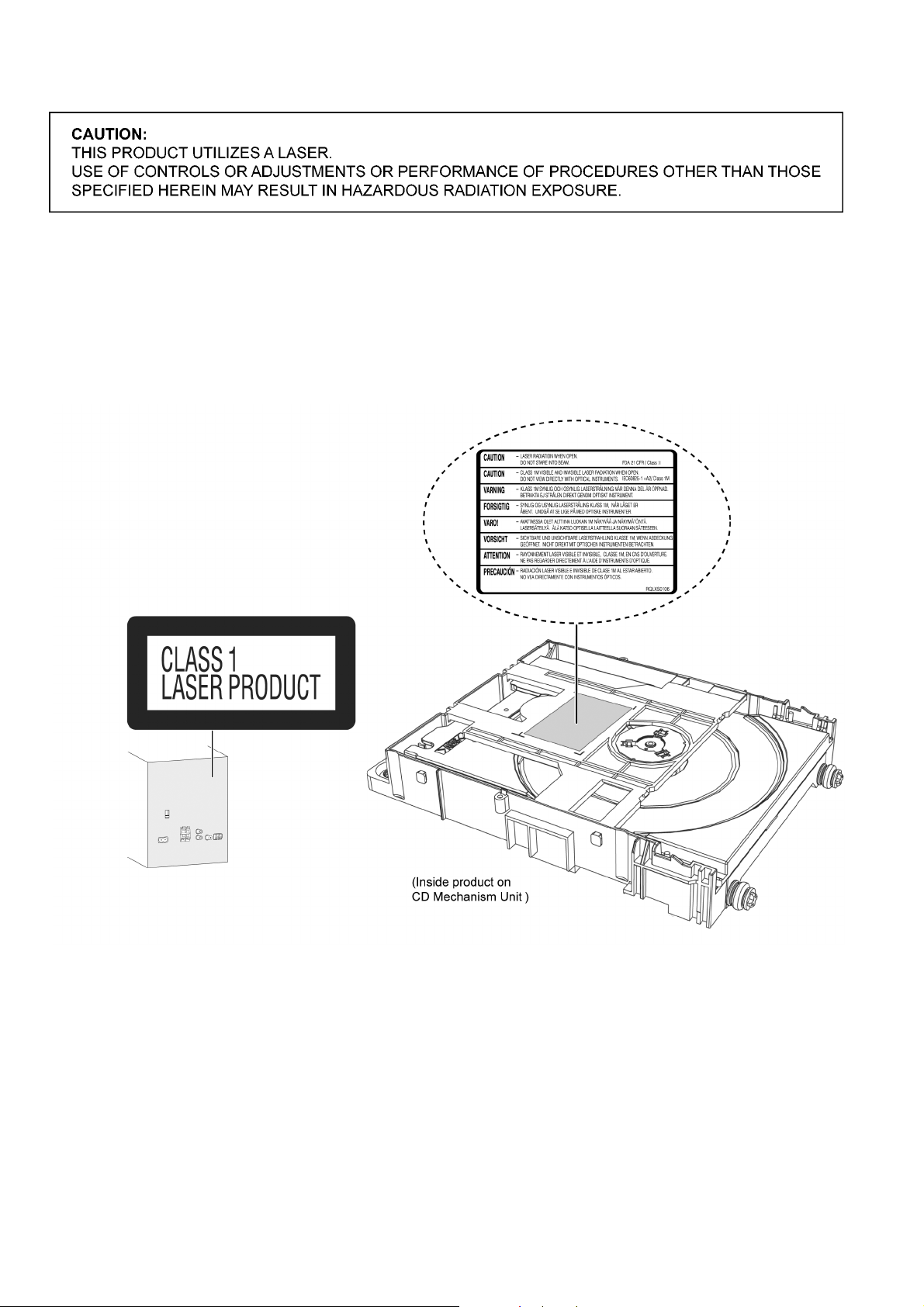

2.2. Precaution of Laser Diode

Caution:

This product utilizes a laser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Wavelength: 790 nm (CD)

Maximum output radiation power from pick up : 10 0 µW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

Figure 2-1

8

Page 9

2.3. Service caution based on Legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical comp onents on the printed circui t boa rds used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature con trol after setting the temperatu re at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

9

Page 10

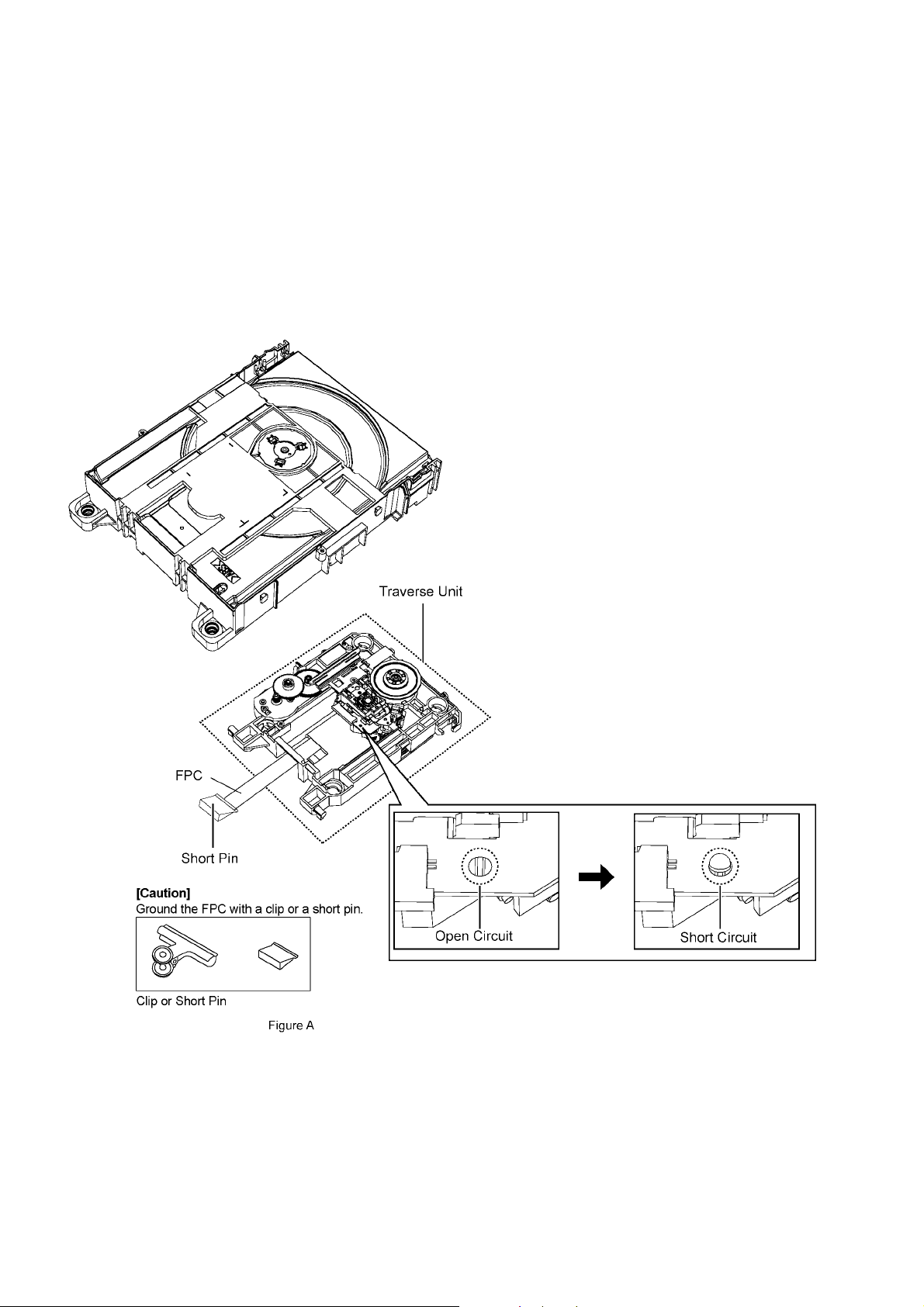

2.4. Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothe s or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To p revent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit remo ved

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible cable, cut off the antistatic FPC.

Figure 2-2

10

Page 11

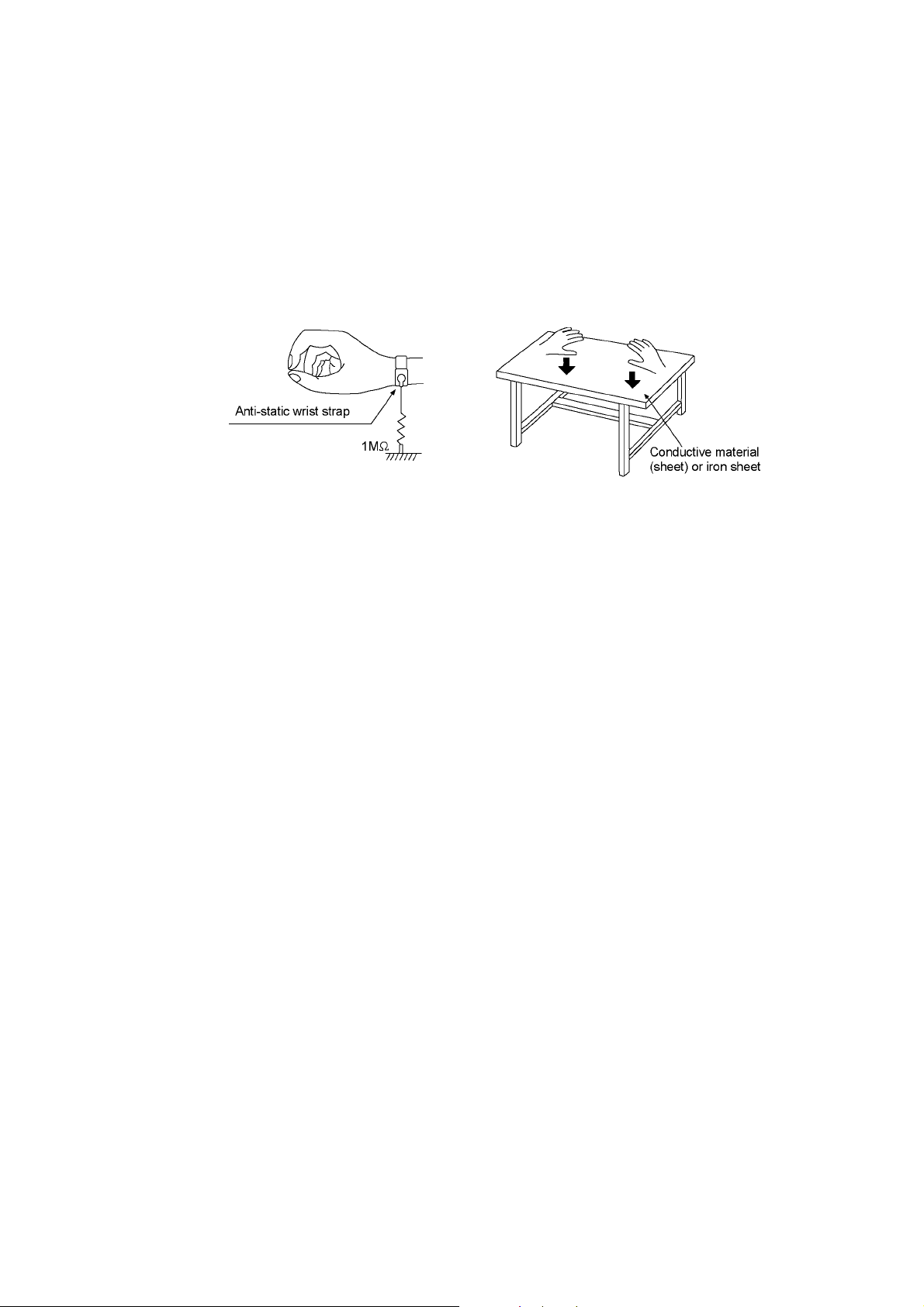

2.5. Grounding for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.5.1. Worktable grounding

• Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed and ground the sheet.

2.5.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity form your body Figure 2-3

Figure 2-3

11

Page 12

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

• CD Mechanism Unit:

1) This model uses CD Mechanism Unit.

• Micro-processor:

1) The following components are supplied as an assembled part.

- Micro-processor IC, IC2006 (RFKWMAKX36LM)

12

Page 13

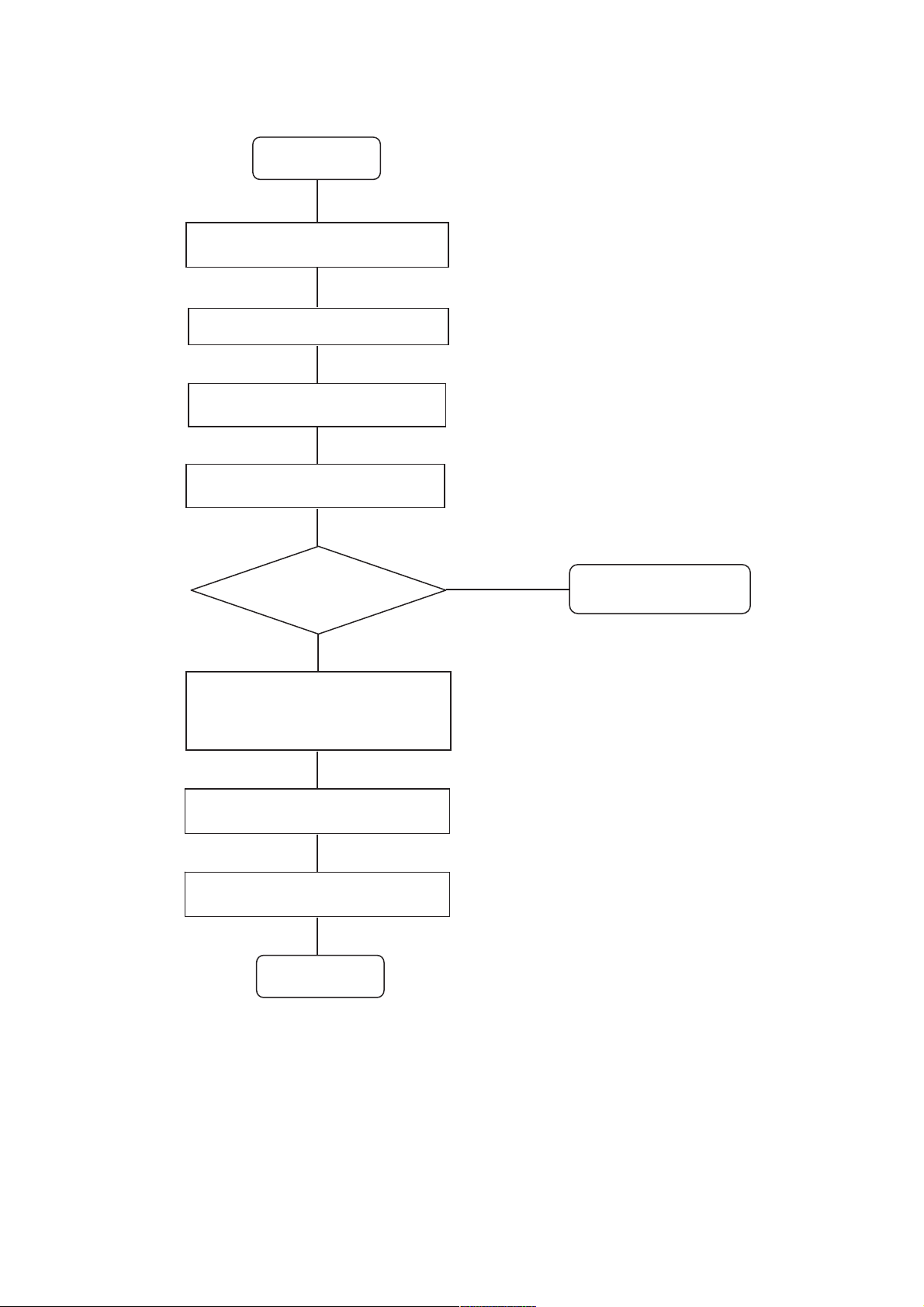

3.2. Firmware Update Procedure

Start

Write encrypted UPD bin to CD-R

Turn On main set

Insert CD-R (with UPD bin) and

close

TOC reading

"CHECKING"

Writing starts:

"0%" -> "20%" -> "40%" ->

"60%" -> "80%" -> 100%"

"GOOD" display 3 sec

Set auto turn Off -> Cold Start

End

NG

"NO PLAY"

process end

13

Page 14

4 Specifications

Q Amplifier section

RMS output power stereo mode

Front Ch (both ch driven) 275 W per channel (3 Ω),

1 kHz, 30% THD

Total RMS stereo mode power 550 W (30% THD)

Q

Q Tuner, terminals section

QQ

Preset memory FM 30 stations

AM 15 stations

Frequency modulation (FM)

Frequency range 87.50 to 108.00 MHz

(50 kHz step) (for PH)

87.5 to 108.0 MHz

(100 kHz step) (for PN)

87.9 to 107.9 MHz

(200 kHz step) (for PN)

Antenna terminals 75 Ω (unbalanced)

Amplitude modulation (AM)

Frequency range 522 kHz to 1629 kHz

(9 kHz step) (for PH)

520 kHz to 1630 kHz

(10 kHz step) (for PH)

520 kHz to 1710 kHz

(10 kHz step) (for PN)

Music port (front)

Sensitivity 100 mV, 4.7 kΩ

Terminal Stereo, 3.5 mm jack

Q General

Power supply AC 110 to 127/220 to 240 V,

50/60 Hz (for PH)

AC 120 V, 60 Hz (for PN)

Power consumption 73 W

Dimensions (W x H x D) 220 mm x 334 mm x 250 mm

Mass 3 kg

Operating temperature range 0 °C to +40 °C

Operating humidity range 35% to 80% RH

Power Consumption in

standby mode

Note:

1. Specifications are subject to change without notice.

Mass and dimension are appropriate

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

Q System: SC-AKX36PH-K

Main Unit: SA-AKX36PH-K

Front Speakers: SB-AKX36PN-K

Q System: SC-AKX36PN-K

Main Unit: SA-AKX36PN-K

Front Speakers: SB-AKX36PN-K

(no condensation)

0.5 W (approximate)

Aux Input RCA pin jack

Q

Q Disc section

QQ

Discs played (8 cm or 12 cm) CD, CD-R/RW(CD-DA, MP3*)

Pick up

Wavelength 790 nm(CD)

Audio output

Number of channels 2 ch (FL, FR)

FL = Front left channel

FR = Front right channel

*MPEG-1 Layer 3

Q

Q Internal memory section

QQ

Memory

Memory size 2 GB

Media file format support MP3 (*.mp3)

Memory recording

Bit rate 128 kbps

Memory recording speed 1x, 3x max (CD only)

Recording file format MP3 (*.mp3)

Capacity of total songs recorded 510 songs

(use 128 kbps, approximately 1 song = 4 mins)

Q

Q USB section

QQ

USB port

USB standard USB 2.0 full speed

Media file format support MP3 (*.mp3)

USB device file system FAT12, FAT16, FAT32

USB port power 500 mA (max)

Bit rate 16 kbps to 320 kbps (playback)

USB recording

Bit rate 128 kbps

USB recording speed 1x, 3x max (CD only)

Recording file format MP3 (*.mp3)

14

Page 15

5 General/Introduction

5.1. Media Information

15

Page 16

6 Location of Controls and Components

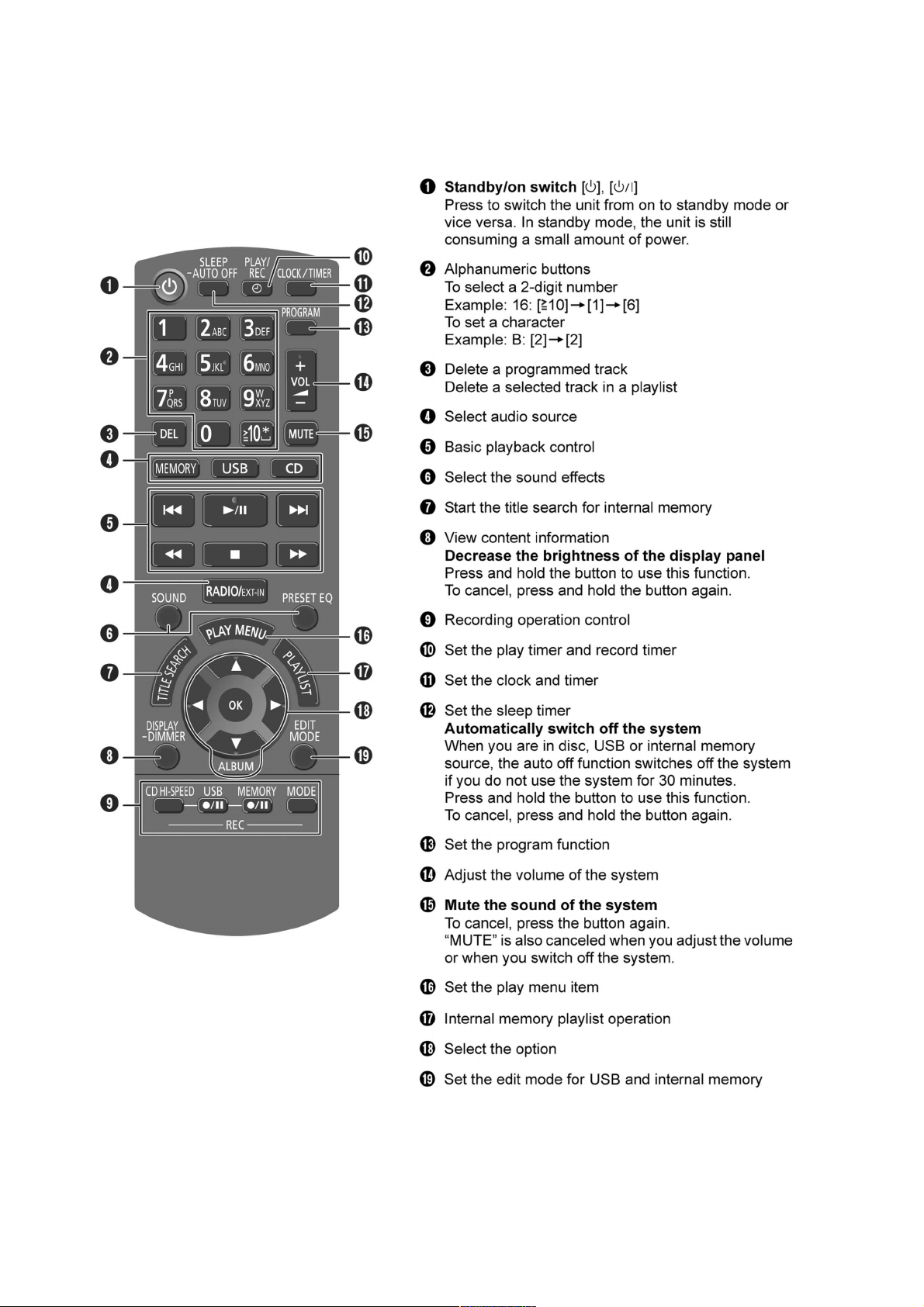

6.1. Remote Control Key Button Operation

16

Page 17

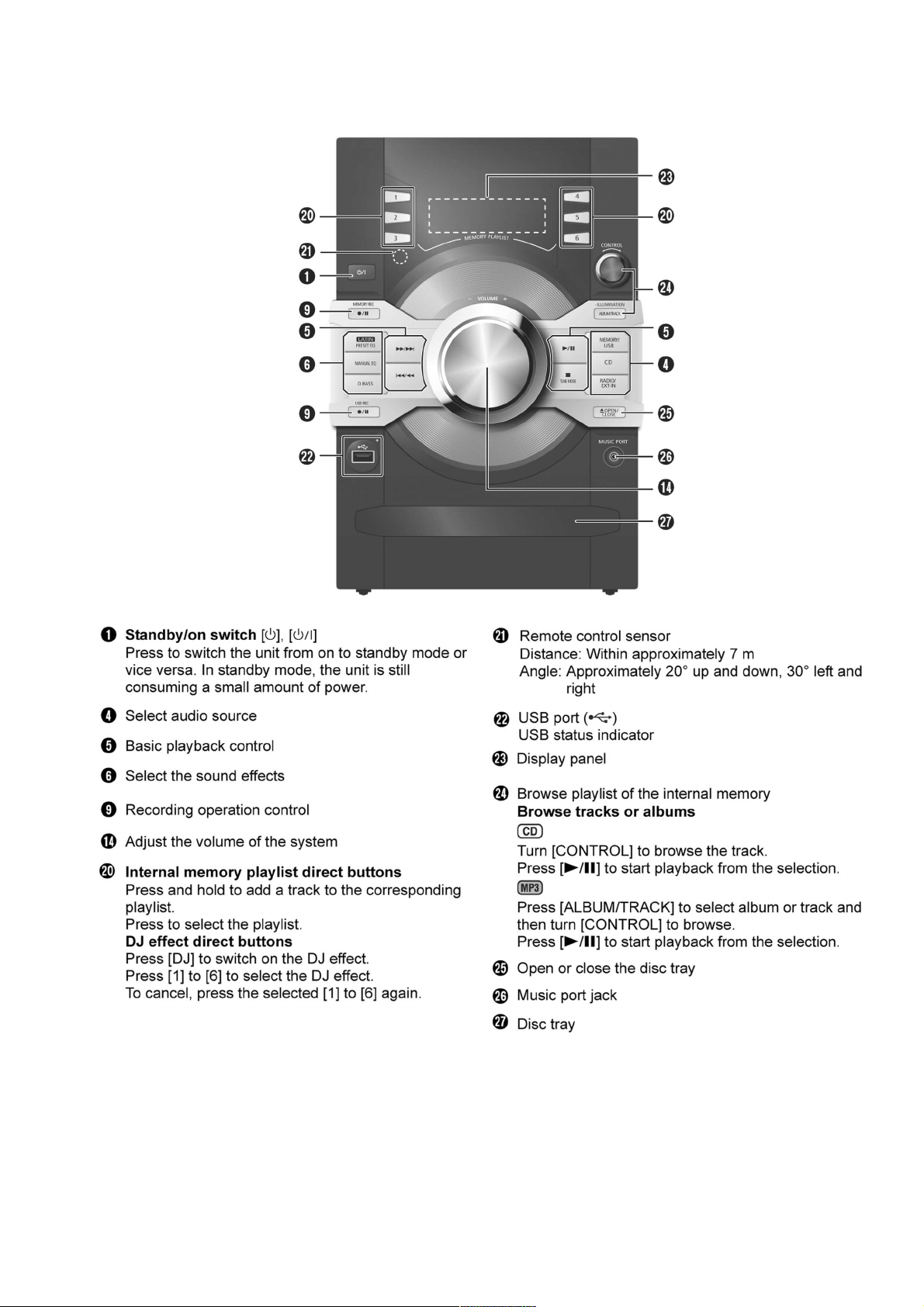

6.2. Main Unit Key Button Operation

17

Page 18

7 Installation Instructions

7.1. Speaker and A/C Connection

18

Page 19

8 Service Mode

8.1. Cold-Start

Here is the procedure to carry out cold-start or initialize to shipping mode.

1. Unplug AC power cord

2. Press & hold [POWER] button

3. Plug AC power cord while [POWER] button being pressed

FL Display will show “_ _ _ _ _ _ _ _”

4. Release [POWER] button

19

Page 20

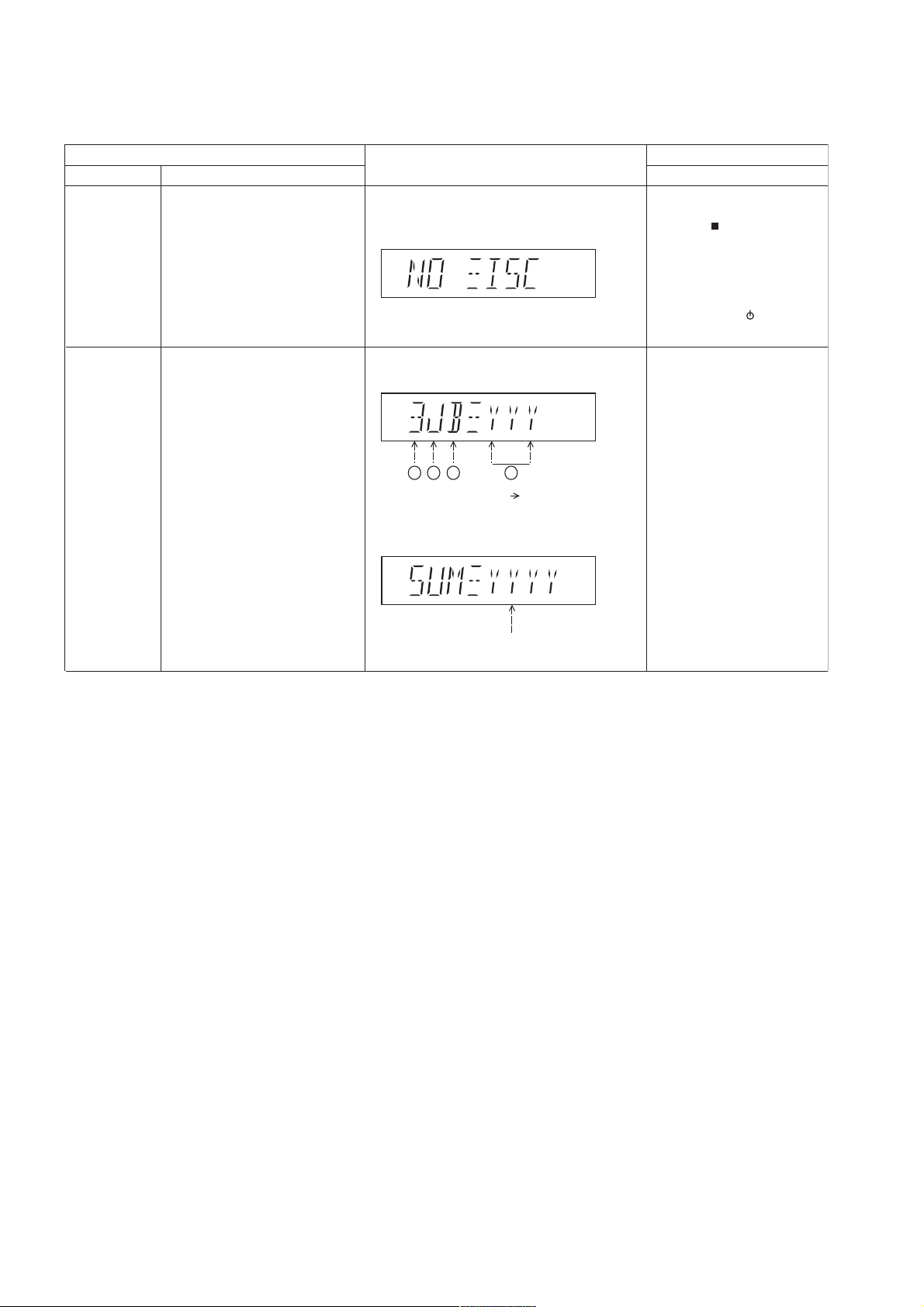

8.2. Doctor Mode Table

8.2.1. Doctor Mode Table 1

Doctor Mode

EEPROM

checksum

check

Item

DescriptionMode Name

To enter into Doctor Mode In CD Mode:

Displaying of

1. Year Develop.

2. Model Type.

3. ROM Type.

4. Firmware Version.

(Display 1)

Version No. (001 ~ 999) specific for each

firmware

(Display 2)

FL Display

(Decimal)1 2 3 4

Key Operation

Front Key

1. Press [ ] button on

main unit follow by [4]

and [7] on remote control.

2. To exit, press [DELETE]

button on remote control or,

press [POWER, /I] button on

Main Unit

In CD mode:

1. Enter into Doctor Mode

Checksum (Hex)

20

Page 21

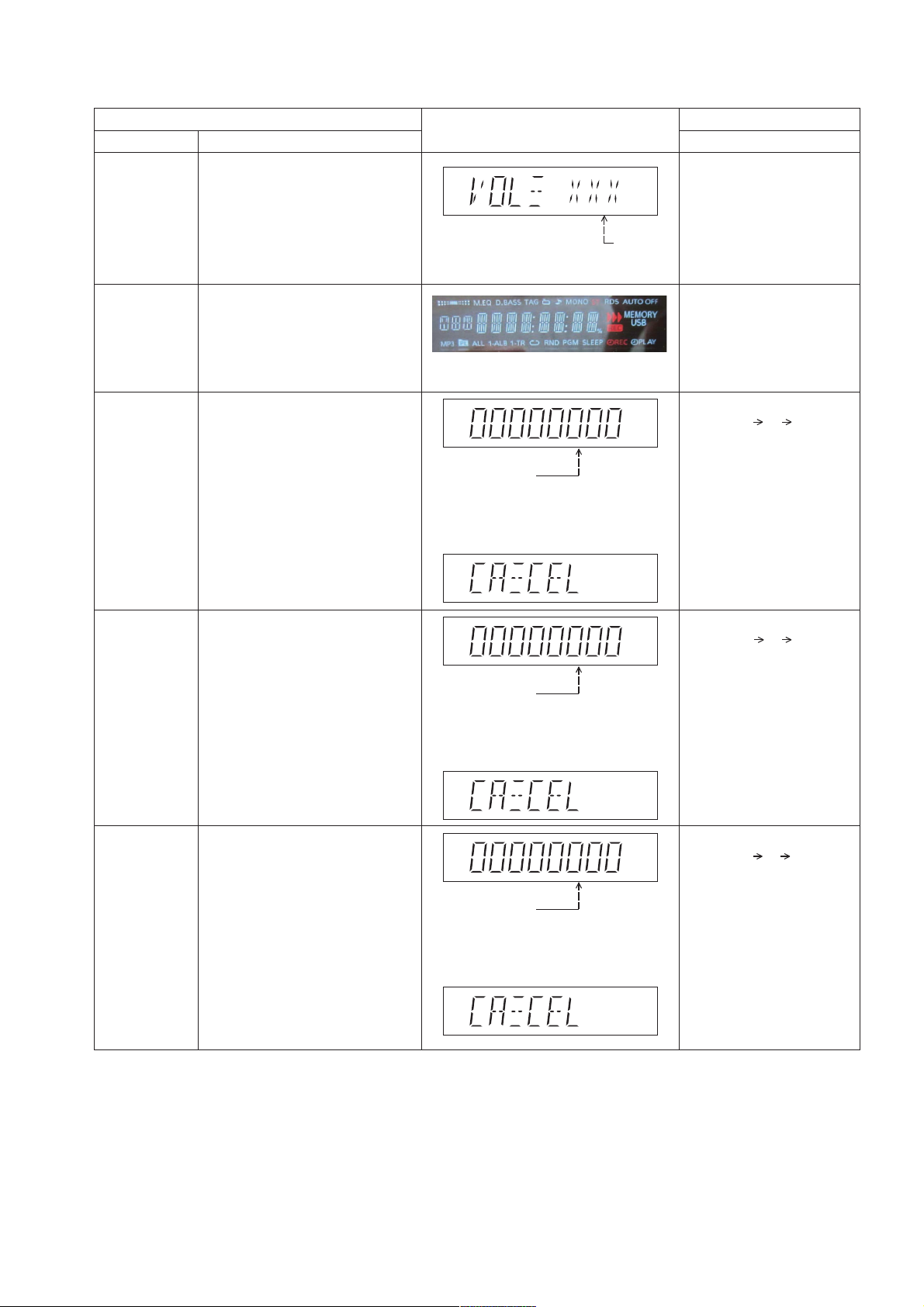

8.2.2. Doctor Mode Table 2

Item

DescriptionMode Name

Volume Setting

Check

FL Display Check

Traverse Test To determine the traverse unit

To check the volume setting of the

main unit.

To check the FL segment display.

All segments will light up while all LED

blink at 0.5s intervals.

operation for inner & outer access track.

In this mode,ensure the CD is in the

main unit.

FL Display

Press [7]: VOL50

Press [8]: VOL35

Press [9]: VOL0

The counter will

increment by one.

When reach 99999999

will change to 00000000

Cancellation Display

Key Operation

Front Key

In Doctor Mode:

1. Press [7], [8], [9] button on

the remote control.

Volume

In Doctor mode:

1. Press [1] button on the

remote control.

2. To cancel this mode, press

[0] button on the remote control.

In Doctor Mode:

1. Press [10] [1] [2] button

on the remote control.

Note: Refer to Section 8.3 Figure 8-2

.

for process flow

Reliability Test

(Combination)

Loading Test To determine the open & close

To determine the traverse unit

operation & open/close operation of the

mechanism.

In this mode,ensure the CD is in the

main unit.

Note: Refer to Section 8.3 Figure 8-3

for process flow

operation of the CD Mechanism Unit.

In this mode, the tray will open & close

automatically.

Note: Refer to Section 8.3 Figure 8-1

for process flow

2. To cancel this mode, press

[0] button on the remote control.

In Doctor Mode:

1. Press [10] [1] [5] button

on the remote control.

The counter will

increment by one.

When reach 99999999

will change to 00000000

Cancellation Display

2. To cancel this mode, press

[0] button on the remote control.

In Doctor Mode:

1. Press [10] [2] [1] button

on the remote control.

The counter will

increment by one.

When reach 99999999

will change to 00000000

Cancellation Display

2. To cancel this mode, press

[0] button on the remote control.

21

Page 22

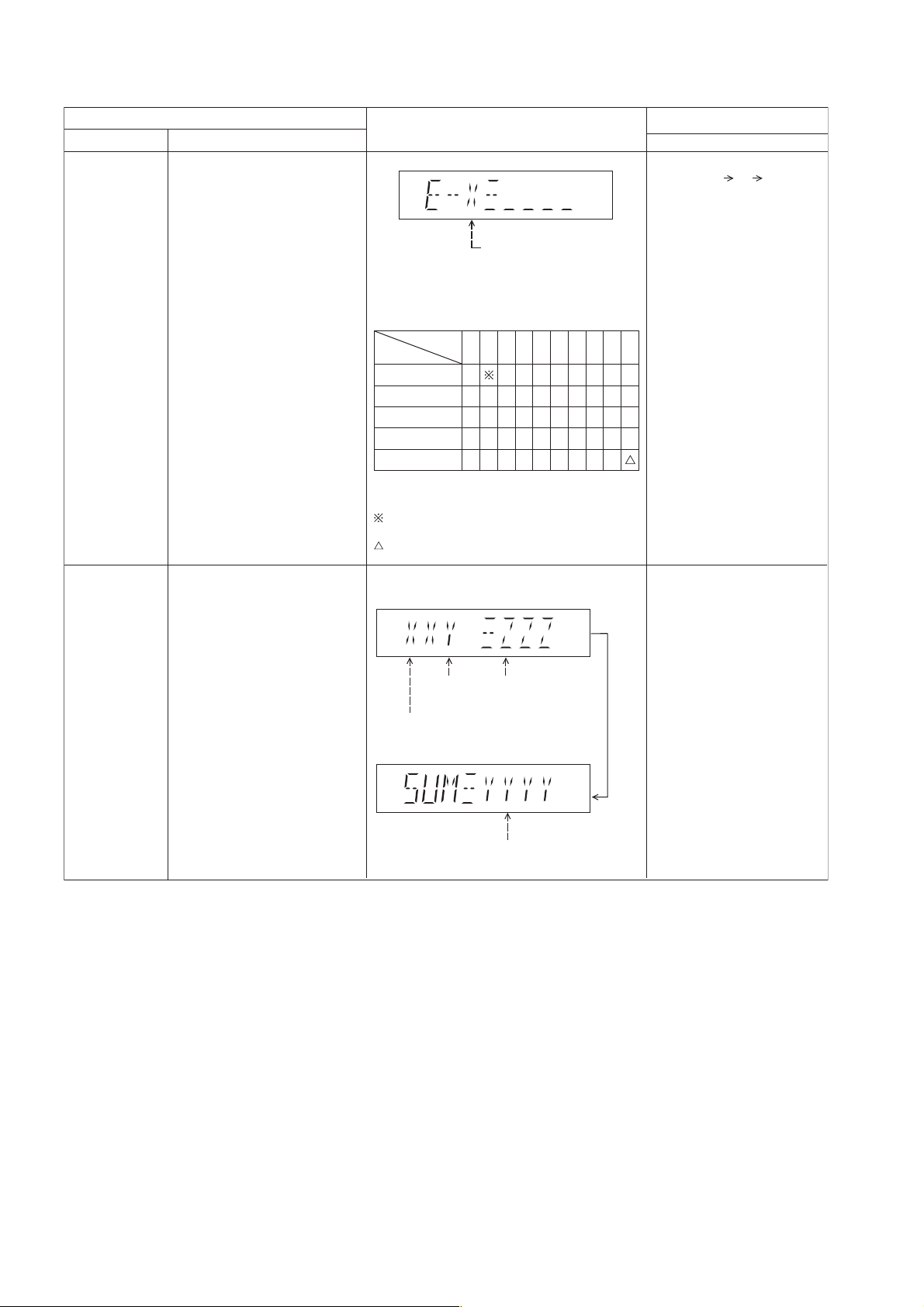

8.2.3. Doctor Mode Table 3

CD

Self- Adjustment

Test

Item

DescriptionMode Name

To display result of

self-adjustment for CD.

FL Display

Display of auto adjustment

result

Reference table:

ERROR Code

Status

Condition

0 1 2 4 6 8 A C E F

AOC1/AOC2 O O O O O O O O -

ABC2/ABC1 O - X O X O X O X -

nd

AOC1 O - O X X O O X X -

2

FAGC/TAGC O - O O O X X X X -

AGC2 O - O O O O O O O

O : OK;

X : NG (In case that time out happens.)

: Either one of FO AOC, TR AOC and FO

coarse AGC is NG.

: If the AGC is NG (ignore others).

Key Operation

Front Key

In Doctor Mode

:

1. Press [10] [1] [4] button

on the remote control.

To cancel this mode, press [0]

button on the remote control.

CD LSI Version

Check

For checking CD LSI Version and

checksum information.

(Display 1)

Year Develop

(Display 2)

ROM

Type

Checksum (Hex)

In Doctor Mode:

1. Press [4] button on the

remote control.

Version (Decimal)

after

2 sec

To cancel this mode, press [0]

button on the remote control.

22

Page 23

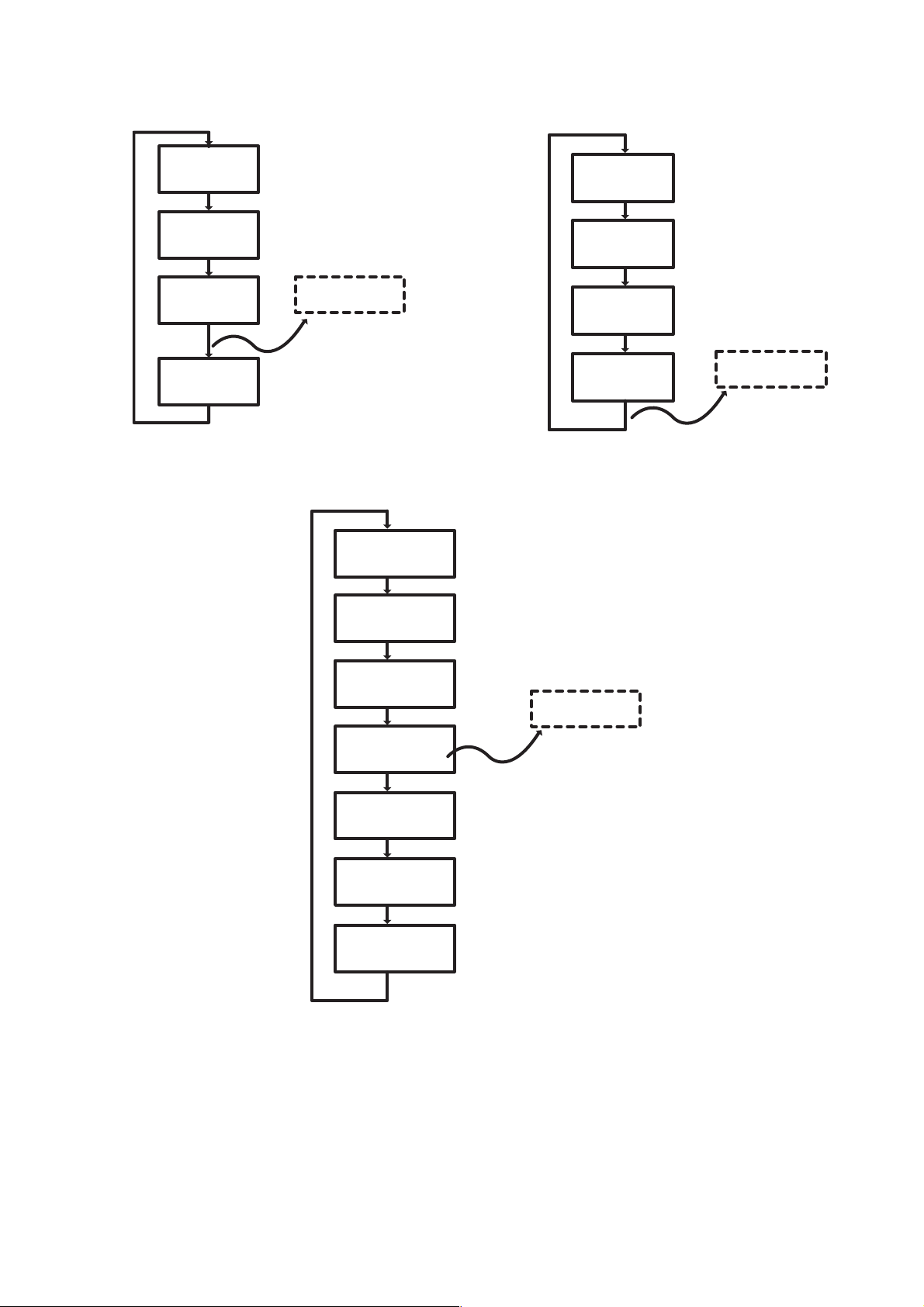

8.3. Reliability Test Mode (CD Mechanism Unit)

Below is the process flow chart of the aging test for the CD Mechanism Unit .

OPEN

Operation

OPEN wait

for 1 s

CLOSE

Operation

CLOSE wait

for 4 s

Fig. 1. Reliability Test (Loading)

Count up

First Track

Access

First Track

Play 10 s

First Track

Access

First Track

Play 5 s

Last Track

Access

Last Track

Play 5 s

Fig. 2. Reliability Test (Traverse)

Count up

Last Track

Access

Last Track

Play 10 s

Open

Operation

Open wait

for 1 s

CLOSE

Operation

Fig. 3. Reliability Test (Combination)

Count up

23

Page 24

8.4. Self-Diagnostic Mode

Item

Mode Name

Self Diagnostic

Mode

Error code

information

Delete error

code

Cold Start To active cold start upon next AC

To enter into self diagnostic checking

System will perform a check on any

unusual/error code from the memory

To clear the stored in memory

(EEPROM IC)

power up when reset start is

execute the next time.

Description

Example:

FL Display

Key Operation

Front Key

Step 1: Select CD mode

(Ensure no disc is inserted).

Step 2: Press & hold [ ] button

follow by [ ] on

main unit for 2 seconds.

Step 1: In self diagnostic mode,

Press [ ] on main unit.

To exit, press [^/I] on main

unit or remote control.

Step 1: In self diagnostic mode,

Press [0] on remote control.

To exit, press [^/I] on main

unit or remote control.

In self diagnostic mode:

1. Press [3] button on

the remote control.

/

8.5. Self-Diagnostic Error Code Table

Self-Diagnostic Function (Refer Section 8.4. Self-Diagnostic Mode) provides information on any problems occurring for the unit and

its respective components by displaying the error codes. These error code such as U**, H** and F** are stored in memory and held

unless it is cleared.

The error code is automatically display after entering into self-diagnostic mode.

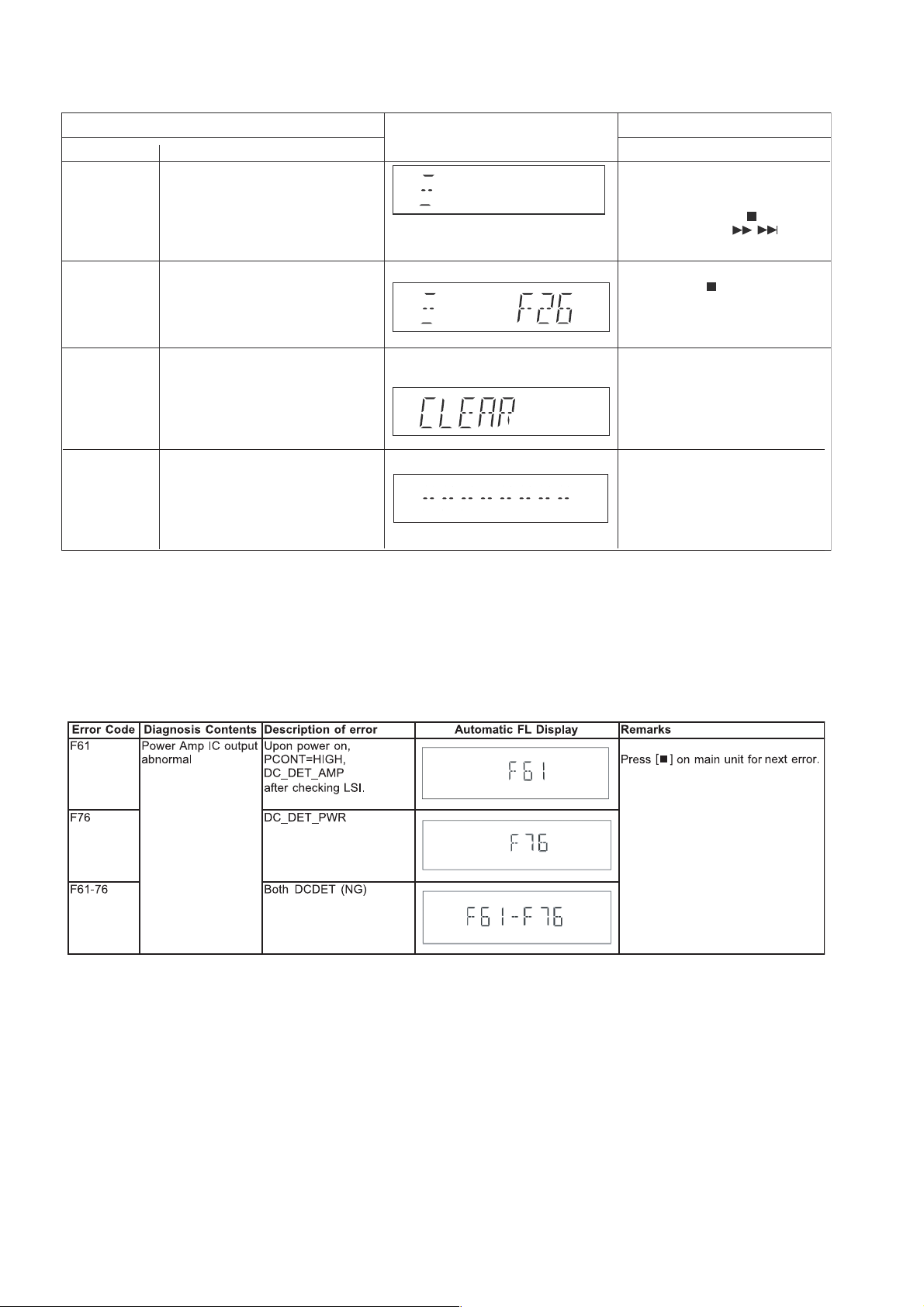

8.5.1. Power Supply Error Code Table

24

Page 25

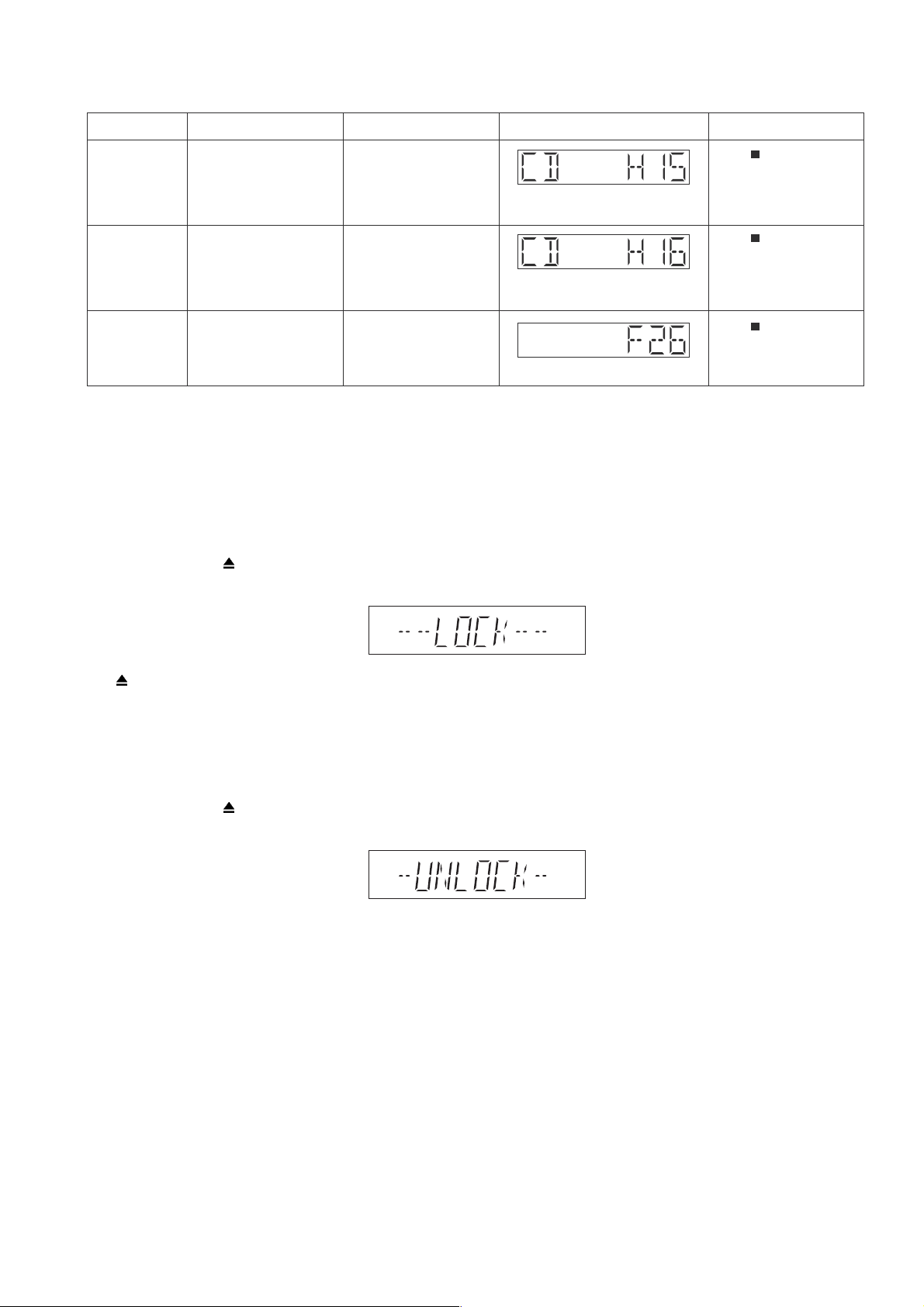

8.5.2. CD Mechanism Error Code Table (CD Mechanism Unit)

Error Code Diagnostic Contents Description of error Automatic FL Display Remarks

CD H15 CD Open Abnormal During operation

CD H16 CD Closing Abnormal During operation

F26 Communication between

CD servo LSI and micro-p

abnormal.

POS_SW_R On fail to be

detected with 4 sec. Error

No. shall be clear by force

or during cold start.

POS_SW_CEN On fail to

be detected with 4 sec.

Error No. shall be clear by

force or during cold start.

During switch to CD function, if SENSE = “L” within

failsafe time of 20ms.

8.6. Sales Demonstration Lock Function

8.6.1. Entering into Sales demonstration lock mode

Here is the procedures to enter into the Sales demonstration lock mode.

Step 1: Turn on the unit.

Step 2: Select to any mode function.

Step 3: Press and hold [

The display will show upon entering into this mode for 2 sec..

OPEN/CLOSE] and [CD] keys for 5 sec or more.

Press [

next error.

Press [

next error.

Press [

next error.

] on main unit for

] on main unit for

] on main unit for

Note: [ OPEN/CLOSE] button is invalid and the main unit displays “LOCKED” while the lock function mode is entered.

8.6.2. Cancellation of Sales demonstration lock mode

Step 1: Turn on the unit.

Step 2: Select to any mode function.

Step 3: Set volume to Vol 19.

Step 4: Press and hold [

The display will show upon entering into this mode for 2 sec..

OPEN/CLOSE] and [CD] keys for 5 sec or more.

25

Page 26

9 Troubleshooting Guide

"Contents for this section is not available at time of issue"

26

Page 27

10 Disassembly and Assembly Instructions

• Illustration is based on SA-AKX36PH-K.

Caution Note:

• This section describes the disassembly and/or assembly procedures for all major printed circuit boards & main components for the unit. (You may refer to the section of “Main components and P.C.B Locations” as described in the service

manual)

• Before carrying out the disassembly process, please ensure all the safety precautions & procedures are followed.

• During the disassembly and/or assembly process, please ha ndle with care as there may be chas sis components with

sharp edges.

• Avoid touching heatsinks due to its high temperature after prolong use. (See caution as described below)

• During disassembly and assembly, please ensure proper service tools, equipments or jigs is being used.

• During replacement of component parts, please refer to the section of “Replacement Parts List” as described in the service manual.

• Select items from the following indexes when disassembly or replacement are required.

• Disassembly of Top Cabinet

• Disassembly of Front Panel Unit

• Disassembly of Panel P.C.B., LED P.C.B. and Mic P.C.B.

• Disassembly of Remote Sensor P.C.B.

• Disassembly of USB P.C.B.

• Disassembly of CD Lid

• Disassembly of Rear Panel

• Disassembly of Main P.C.B.

• Replacement of Digital Amplifier IC (IC6000)

• Disassembly of SMPS Module and Voltage Selector P.C.B.

• Disassembly of CD Mechanism Unit

• Disassembly of CD Interface P.C.B.

• Disassembly of Fan Unit

10.1. Screw Types

27

Page 28

10.2. Disassembly Flow Chart

10.4.

Top Cabinet

10.5.

Front panel Unit

10.6.

Panel P.C.B.,

LED P.C.B. and

Mic P.C.B.

10.7.

Remote Sensor

P.C.B.

10.8.

USB P.C.B.

10.9.

CD Lid

10.14. CD Mechanism

Unit

10.15.

CD Interface

P.C.B.

10.16. Fan Unit

10.10. Rear Panel

10.11. Main P.C.B.

10.12.Digital Amplifier

IC (IC6000)

10.13.SMPS Module

and Voltage

Selector P.C.B.

28

Page 29

10.3. Main Components and P.C.B. Locations

29

Page 30

10.4. Disassembly of Top Cabinet

Step 1 Remove 2 screws on each side.

Step 2 Remove 5 screws.

Step 3 Slightly pull both side of Top Cabinet outwards as arrow

shown.

Step 4 Slightly lift up both sides of Top Cabinet in an outward

direction as shown.

Step 5 Remove the Top Cabinet.

Caution: During assembling, ensure that the Top Cabinet

catches are properly inserted into Front Panel Unit.

30

Page 31

10.5. Disassembly of Front Panel Unit

• Refer to “Disassembly of Top Cabinet”.

Step 1 Detach 5P Cable at the connector (CN2002) on Main

P.C.B..

Step 2 Detach 30P FFC at the connector (CN2000) on Main

P.C.B..

Step 3 Release tab at the left side of Front Panel Unit.

31

Page 32

Step 4 Release tabs at bottom.

Step 6 Remove the Front Panel Unit as arrow shown.

10.6. Disassembly of Panel P.C.B.,

Step 5 Release tab at the right side of Front Panel Unit.

LED P.C.B. and Mic P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

Step 1 Remove the Volume Knob.

Step 2 Remove the Control Knob.

32

Page 33

Step 3 Remove 7 screws.

Step 4 Release catches by following the sequences (1-8).

Step 5 Lift up the Panel P.C.B. and LED P.C.B. from Front

Panel Unit.

Caution: During assembling, ensure that LED P.C.B. is

properly insert to Front Panel Unit.

33

Page 34

Caution: During assembling, ensure that Panel P.C.B. is

seated properly through the located & fully catched.

Caution: During assembling, ensure that Mic P.C.B. is

seated properly through the located & fully catched.

10.7. Disassembly of Remote Sensor P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

• Refer to “Disassembly of Panel P.C.B., LED P.C.B. and

Mic P.C.B.”.

Step 1 Remove the Remote Sensor P.C.B..

Caution: During assembling, ensure that Remote Sensor

P.C.B. is properly inserted & fully connected to Panel

P.C.B..

Step 6 Remove 1 screw.

Step 7 Release 1 catch.

Step 8 Remove the Panel P.C.B., LED P.C.B. and Mic P.C.B..

34

Page 35

10.8. Disassembly of USB P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

Step 1 Remove 1 screw.

Step 2 Release 1 catch.

Step 3 Remove the USB P.C.B..

10.9. Disassembly of CD Lid

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

Step 1 Remove the spring as arrow shown in order of

sequence (1) to (3).

Caution: During assembling, ensure that the spring is

assembly at correct position.

Caution: During assembling, ensure that USB P.C.B. is

seated properly through the located & fully catched.

Step 2 Remove CD Lid as arrow shown.

35

Page 36

10.10. Disassembly of Rear Panel

• Refer to “Disassembly of To p Cab in et”.

Step 1 Remove 10 screws.

Step 5 Lift up Inner Chassis Unit to release the catch between

the Inner Chassis Unit and the Rear Panel.

Step 6 Release 2 tabs.

Step 7 Remove Rear Panel.

Step 2 Detach Voltage Selector P.C.B. from Rear Panel as

arrow shown.

Step 3 Release 1 catch at the Fan Unit .

Step 4 Remove the Fan Unit .

36

Page 37

10.11. Disassembly of Main P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Rear Panel”.

Step 1 Detach 5P Cable at the connector (CN2002) on Main

P.C.B..

Step 2 Detach 30P FFC at the connector (CN2000) on Main

P.C.B..

Step 3 Detach 13P Cable at the connector (CON2) on SMPS

Module.

Step 4 Detach 10P FFC at the connector (CN8251) on Main

P.C.B..

Step 5 Detach 24P FFC at the connector (FP8201) on Main

P.C.B..

Step 6 Detach 2P Wire at the connector (CN1001) on Main

P.C.B..

Step 7 Remove 2 screws.

Step 8 Remove the Main P.C.B..

Caution: During assembling, ensure that Main P.C.B . is

seated properly through the located & fully guided.

37

Page 38

10.12. Disassembly of Digital Amplifier IC (IC6000)

• Refer to “Disassembly of Main P.C.B.”.

10.12.1. Disassembly of Digital Amplifier IC

(IC6000)

Caution: Handle the Main P.C.B. with caution due to it’s

high temperature after prolonged use. Touching it may

lead to injuries.

Step 1 Place the Main P.C.B. on an insulated material.

Step 2 Remove 2 screws.

Step 4 Desolder the pins of the Digital Amplifier IC (IC6000).

Step 5 Remove the Digital Amplifier IC (IC6000).

10.12.2. Assembly of Digital Amplifier IC (IC6000)

Step 1 Fix the Digital Amplifier IC (IC6000) onto the Main

P.C.B..

Step 2 Solder the pins of the Digital Amplifier IC (IC6000).

Cautions: Ensure that the pins of the Digital Amplifier IC

(IC6000) is positioned correctly on the Main P . C.B. before

soldering.

Step 3 Lift up the Main P.C.B. as arrow shown.

Caution: Keep the Heatsink Spacers in safe place. Avoid

denting it, place it back during assembling.

38

Page 39

Step 3 Fix Heatsink spacers onto Main Heatsink..

Caotion: Ensure that the Heatsink Spacers are properly

located and seated flatly onto Main Heatsink.

Step 4 Apply grease to the Main Heatsink as indicate in the dia-

gram.

Caution: Ensure Grease thickness is about 0.2mm.

10.13. Disassembly of SMPS Module and Voltage Selector P.C.B.

• Refer to “Disassembly of Top Cabinet.”.

• Refer to “Disassembly of Rear Panel”.

Step 1 Detach 13P Cable at a connector (CON2) on the SMPS

Module.

Step 2 Remove 2 screws.

Step 3 Remove the SMPS Module and the Voltage Selector

P.C.B..

Step 5 Upset the Main P.C.B..

Step 6 Fix 2 screws.

Caution: During assembling, ensure that SMPS Module is

seated properly through the located & fully guided.

39

Page 40

10.14. Disassembly of CD Mechanism Unit

• Refer to “Disassembly of To p Cab in et”.

• Refer to “Disassembly of Front Panel Unit”.

Step 1 Remove 8 screws.

Step 2 Detach Voltage Selector P.C.B. from the Rear Panel.

Step 3 Detach 10P FFC at a connector (CN8251) on Main

P.C.B..

Step 4 Detach 24P FFC at a connector (FP8201) on Main

P.C.B..

Step 5 Detach 2P Wire at a connector (CN1001) on Main

P.C.B..

Step 6 Remove 1 screw.

Step 7 Remove 1 screw.

40

Page 41

Step 8 Release 2 catches.

Step 9 Lift up and remove the Inner Chassis Unit.

Step 10 Remove 2 screws.

Step 11 Remove the CD Mechanism Unit.

10.15. Disassembly of CD Interface

Caution: During assembling, ensure that Inner Chassis

Unit is catched onto Rear Panel properly.

P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

• Refer to “Disassembly of CD Mechanism Unit”.

Step 1 Remove 3 screws.

Step 2 Desolder pins of the motor (M7301).

Step 3 Desolder pins of the motor (M7302).

Step 4 Remove the CD Interface P.C.B..

41

Page 42

10.16. Disassembly of Fan Unit

• Refer to “Disassembly of To p Cab in et”.

Step 1 Remove 1 screw.

Step 2 Detach 2P Wire at a connector (CN1001) on the Main

P.C.B..

Step 3 Release 1 catch.

Step 4 Remove the Fan Unit.

Caution: During assembling, ensure that Fan Unit is

catched onto Rear Panel properly.

42

Page 43

11 Service Position

Note: For description of the disassembly procedures, see

the Section 10.

11.1. Checking of Panel P.C.B., LED P.C.B. and Mic P.C.B.

Step 1 Remove Top Cabinet.

Step 2 Remove Front Panel Unit.

Step 3 Remove the Panel P.C.B., the LED P.C.B. and Mic

P.C.B..

Step 4 Positioned the Panel P.C.B., the LED P.C.B. and Mic

P.C.B. on the insulated material as shown.

Step 5 Attach 30P FFC at a connector (CN2000) on the Main

P.C.B..

Step 6 Panel P.C.B., the LED P.C.B. and Mic P.C.B. can be

checked at diagram shown.

11.2. Checking of Main P.C.B. (Side B)

Step 1 Remove Top Cabinet.

Step 2 Remove Rear Panel.

Step 3 Remove Main P.C.B..

Step 4 Remove 2 screws.

Step 5 Lift up the Main P.C.B. as arrow shown.

43

Page 44

Step 6 Attach 13P Cable at a connector (CON2) on the SMPS

Module.

Step 7 Attach 30P FFC at a connector (CN2000) on the Main

P.C.B..

Step 8 Attach 10P FFC at a connector (CN8251) on the Main

P.C.B..

Step 9 Attach 24P FFC at a connector (FP8201) on the Main

P.C.B..

Step 10 Attach 2P FFC at a connector (CN1001) on the Main

P.C.B..

Step 11 Side B Main P.C.B. can be checked at diagram shown.

11.3. Checking of Main P.C.B. (Side A)

Step 1 Remove Top Cabinet.

Step 2 Remove Front Panel Unit.

Step 3 Remove Rear Panel.

Step 4 Remove Main P.C.B..

Step 5 Remove SMPS Module and Voltage Selector P.C.B..

Step 6 Positioned the Main P.C.B., SMPS Module and the Volt-

age Selector P.C.B. on the insulated material.

Step 7 Attach 13P Cable at a connector (CON2) on the SMPS

Module.

Step 8 Attach 10P FFC at a connector (CN8251) on the Main

P.C.B..

Step 9 Attach 24P FFC at a connector (FP8201) on the Main

P.C.B..

Step 1 0 Attach 30P FFC at a connector (CN20 00) on the Main

P.C.B..

Step 11 Attach 2P FFC at a connector (CN1001) on the Main

P.C.B..

Step 12 Side A Main P.C.B. can be checked at diagram shown.

44

Page 45

12 Block Diagram

12.1. Servo & System Control

: CD AUDIO INPUT SIGNAL LINE

CD MECHANISM UNIT

BRS11C

OPTICAL

PICKUP UNIT

LOADING P.C.B.

: AUDIO OUTPUT SIGNAL LINE

FP8201

16

FP8201

15

FP8201

20

FP8201

19

FP8201

14

FP8201

10

MD/LPD

FP8201

5

CD-LD

FP8201

6

Q8201

LASER DRIVE

+3.3V

FP8201

F+

23

FP8201

F-

24

FP8201

T+

22

FP8201

T-

21

M7302*

SPINDLEMOTOR

+

SPM-

SPM+

TRV+

+

TRV-

M7301*

TRAVERSE MOTOR

CN7001

CN7001

CN7001

CN7001

LDM+

5

LDM-

4

OPEN SW

3

CLOSE SW

1

LDM+

LDM-

S7201

RESET

REST SW REST SW

OPEN SW

CLOSE SW

CD TRACKING SIGNAL

CN7002 CN8251

92

CN7002 CN8251

10 1

CN7002 CN8251

110

CN7002 CN8251

29

CN7002 CN8251

38

CN7002 CN8251

47

CN7002 CN8251

74

CN7002 CN8251

56

CN7002 CN8251

83

: USB SIGNAL LINE

IC7704

C3ABMY000027

16M SDRAM

IC8401

C3FBMY000309

16M FLASH

MEMORY

SCLK

SI

SO

IC8501

C3FBXY000042

2GB NAND

FLASH MEMORY

IC8251

C0GBY0000117

5CH MOTOR DRIVER

VOFC+14

VOFC-13

VOTK-16

VOTK+

15

SPM-

VOSP-18

SPM+

VOSP+17

TRV+

VOSL+12

TRV-

VOSL-11

LDM+

VOLD+10

LDM-

VOLD-9

OPEN SW

CLOSE SW

TC - 1

A0 ~ A11

TC - 2

D0 ~ D7

6

5

2

X8101

3DAT0 MSDDAT038

4DAT1

5DAT2 MSDDAT240

2DAT3

16DAT3

1VINFC

26VINTK

23VINSP

4VINSL

7REV

6FWD

IC8001

MN6627992AB

SERVO

PROCESSOR

123

USBDM1

125

USBDP1

CLKSF33

IO0SF34

IO1SF30

XI190

XO189

MSDDAT137

MSDDAT339

A60

B58

C59

D57

E55

F56

PD61

LD62

FOP48

TRP49

SPOUT50

TRVP51

135

P33 AMUTE55

112

SCL5 USB IN62

113

SREQ/BLKCK CD BLKCK54

106

SO/STAT CD STAT (SYS TXD)73

107

SI/MDATA CD MDATA (SYS RXD)72

108

MCLK

105

IRQ1A/MLD CD MLD71

104

NRST CD RESET61

133

USBNOC

132

USBPP

52

TRVP2

118

AUDIOCLK

117

SRDAT

116

BCLK

115

LRCK

114

SRDATAIN

137

P31

136

P32

P30

134

CD I2S MCLK

CD I2S SDO

CD I2S BCLK

CD I2S LRCK

DAP I2S OUT

DAP I2S LRCKO

DAP I2S BCKO

CD I2S MCLK

CD I2S SDO

CD I2S BCLK

CD I2S LRCK

DAP I2S OUT

DAP I2S LRCKO

DAP I2S BCKO

FROM/TO AUDIO

IC2007

C3EBEY000037

EEPROM

6SCL

5SDA

X2001

X2002

MAIN P.C.B.

IC2006

RFKWMAKX36LM

MICROPROCESSOR

USB REC LED 65

EE CLK29

EE DATA28

XI

15

XO

16

XTIN

13

XTOUT12

CD MCLK74

EMMC/USB2 DET33

BOOT FILE ANALYSIS32

BOOT FILE DET31

LOAD CCW59

LOAD CW60

CD REST SW58

CD OPEN SW57

CD CLOSE SW56

NRST 19

ANALOG SEL1

ANALOG SEL 2

EMO1

EMO2

TU CLK

TU RST

TU SDA

TU INT

DAP RESET

DAP PDN

DAP MUTE

DAP CLK/DSP CLK

DAP SDA/DSP SDA

/DAMP OTW

/DAMP CLIP

/DAMP FAULT

AUTO BASS

BKND ERR

DAP VALID

MPORT SW 79

DAMP RESET

TEMP DET

SMPS ID

SYNC

DC DET2

SMPS BP

ECO CTNRL

PROTECT

POWER

PCONT

USB P.C.B.

CN6400

USB PORT

+5V

D6400

1 VBUS

2D-

3D+

TO SERVO & SYSTEM CONTROL

BLOCK (2/2)

D-

D+

D-

ZJ6400*CN2002

22

D+

ZJ6400*CN2002

33

Q2500

CN2002 ZJ6400*

+5V

SWITCH

D5V

55

D5V

QR2500

LED DRIVE

Q2001

RESET

+3.3V

D2002

5

7

26

27

9

10

8

25

46

47

48

36

34

41

42

43

93

49

50

44

97

95

88

53

70

51

22

23

90

EN

76

OC

75

ANA SEL1

ANA SEL2

TU SDA

TU INT

DAP RESET

DAP PDN

DAP MUTE

DAP SCL

DAP SDA

DAMP OTW

DAMP CLIP

DAMP FAULT

AUTOBASS

BKND ERR

DAP VALID

MPORT SW

DAMP RESET

TEMP DET

SMPS-ID

SYNC

DC DET PWR

ECO CTR

EMO1

EMO2

TU SCL

TU RST

AM-BP

PROT

POWER

PCONT

OC

EN

ANA SEL1

ANA SEL2

EMO1

EMO2

TU SCL

TU RST

TU SDA

TU INT

DAP RESET

DAP PDN

DAP MUTE

DAP SCL

DAP SDA

DAMP OTW

DAMP CLIP

DAMP FAULT

AUTOBASS

BKND ERR

DAP VALID

MPORT SW

DAMP RESET

TEMP DET

SMPS ID

SYNC

DC DET PWR

AM BP

ECO CTR

PROT

POWER

PCONT

EN

OC

FROM/TO AUDIO

FROM/TO POWER SUPPLY

CD INTERFACE P.C.B.

NOTE: “ * ” REF IS FOR INDICATION ONLY

SA-AKX36PH/PN SERVO & SYSTEM CONTROL (1/2) BLOCK DIAGRAM

45

Page 46

: CD AUDIO INPUT SIGNAL LINE

: AUDIO OUTPUT SIGNAL LINE

: USB SIGNAL LINE

TO SERVO & SYSTEM CONTROL

BLOCK (1/2)

FAN

MAIN P.C.B.

FAN

DC DET AMP FAN

+16V

QR2001

SWITCH

FROM AUDIO

+

-

POSITIVE

CN1001

-

2

-

CN1001

-

NEGATIVE

-

1

DC DET AMP FAN

IC1001

C0ABBB000067

FAN CONTROL

Q1001,Q1002,Q1003,

Q1004,Q1005,QR1001

CIRCUIT

IC2006

RFKWMAKX36LM

MICROPROCESSOR

LED DIMMER 78

LED RED 82

LED GREEN 83

DC DET1

40

21

FAN OUT120

FAN OUT2

FL DATA 1

FL CS 2

FL CLK 3

VOL JOG A 80

VOL JOG B 81

ROTARY JOG A 67

ROTARY JOG B 68

KEY1 99

LED DIMMER

RED LED

GREEN LED

FL DOUT

FL CS

FL CLK

JOG VOLA

JOG VOLB

JOG ROTA

JOG ROTB

KEY2

S6207

USB

ZJ6700*CN6003

ZJ6700*CN6003

MEMORY LED P.C.B.

LED CALED CA

11

D6700

LED AN

22

S6201

REWIND

S6204

MEMORY

REC/PAUSE

PANEL P.C.B.

QR6001,

S6000

PLAYLIST 2

S6107

CD

OPEN/CLOSE

QR6003,QR6004

LED

LIGHTING

CIRCUIT

D6102,D6103,

D6104,D6105,

DIN

7

STB

9

8

CLK

IC6000

C0HBB0000057

FL DISPLAY

DRIVER

S6001

PLAYLIST 3

S6012

STOP/TUNE MODE

SG1 ~ SG16

GR1 ~ GR12

PLAYLIST 4

PRESET EQ

S6002

S6200

LATIN

CN6001CN2000

LED DIMMER

283

CN6001CN2000

RED LED

427

CN6001CN2000

GREEN LED

328

CN6001CN2000

FL DOUT

1912

CN6001CN2000

FL CS

2011

CN6001CN2000

FL CLK

2110

JOG VOLA

CN6001CN2000

1516

JOG VOLB

CN6001CN2000

1615

JOG ROTA

CN6001CN2000

1318

JOG ROTB

CN6001CN2000

1417

KEY2

CN6001CN2000

247

S6003

PLAYLIST 1

S6203

POWER

VR6100

VOLUME

VR6200

ALBUM/TRACK

+5V

FL6000

FL DISPLAY

F-

F+

S6004

PLAYLIST 5

S6202

MANUAL EQ

LED AN

F-

44

F+

1

S6006

PLAYLIST 6

S6206

D.BASS

REC/PAUSE

NOTE: “ * ” REF IS FOR INDICATION ONLY

KEY2 98

KEY3 94

RMT 86

KEY1

KEY3

KEY1

CN6001CN2000

238

S6103

ALBUM/TRACK

KEY3

CN6001CN2000

256

S6104

MEMORY/USB

S6100

CD

S6101

RADIO/EXT-IN

S6105

PLAY/PAUSE

S6208

FORWARD

REMOTE SENSOR P.C.B.

CN6001CN2000

229

RMTRMT

CN6500CN6002

3,43,4

+3.3V

IR6500

REMOTE SENSOR

SA-AKX36PH/PN SERVO & SYSTEM CONTROL (2/2) BLOCK DIAGRAM

46

Page 47

12.2. IC Terminal Chart

IC7704

16M SDRAM

SIGNAL NAMETC

IC8001

SERVO PROCESSOR

PIN NOPORT NAME PIN NO PORT NAME

A0

A1

A2

A3

A4

1

A5

A6

A7

A8

A9

A10

BA0

16M SDRAM

IC7704

A021

A122

A223

A324

A427

A528

A629

A730

A831

A932

A1020

A1119 A1126

SIGNAL NAMETC

14

15

16

17

20

21

22

23

24

25

13

IC8001

SERVO PROCESSOR

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

PIN NOPORT NAME PIN NO PORT NAME

DQ0 / DQ15

DQ1 / DQ14

DQ2 / DQ13

DQ3 / DQ12

2

DQ4 / DQ11

DQ5 / DQ10

DQ6 / DQ9

DQ7 / DQ8

D02 / 49

D13 / 48

D25 / 46

D36 / 45

D48 / 43

D59 / 42

D611 / 40

D712 / 39

142

143

144

2

3

4

5

6

D0

D1

D2

D3

D4

D5

D6

D7

47

SA-AKX36PH/PN IC TERMINAL CHART

Page 48

12.3. Audio

MUSIC PORT

JK6002

AUX IN

JK51

FM ANT

JK52

AM ANT

JK6301

: AUX/TUNER/MUSIC PORT AUDIO INPUT SIGNAL LINE : AUDIO OUTPUT SIGNAL LINE: CD AUDIO INPUT SIGNAL LINE

: AM SIGNAL LINE : FM SIGNAL LINE

MAIN P.C.B.

IC6100

C0JBAR000367

AUDIO SELECTOR

ANA SEL2

ANA SEL2

QR6100

FROM/TO

SERVO & SYSTEM CONTROL

ANA SEL1

MPORT SW

5

4

R

3

L

2

1

6

7

AUX-L

L

2

AUX-R

R

3

1

MUSIC PORT P.C.B.

MPORT SW

MPORT R

MPORT L

PANEL P.C.B.

IC52

VUEALLPT056

FM/AM

RADIO RECEIVER

2 FMI

RIN 15

LIN 16

ANA SEL1

MPORT SW

ZJ6000*ZJ6300*

11

ZJ6000*ZJ6300*

44

ZJ6000*ZJ6300*

22

SWITCH

CN2000CN6001

MPORT SW

1912

MPORT R

CN2000CN6001

229

MPORT L

CN2000CN6001

2011

L52

2

1

4

3

2

6

1

4 AMI

DCLK 17

DFS 14

DOUT

SDIO 8

SCLK 7

RST 5

GCGPIO2 18

13

9 A(LSB)

10 B(MSB)

R114

L15

1L0

12 R0

13 RCH

3 LCH

FROM/TO

SERVO & SYSTEM CONTROL

TO SERVO & SYSTEM CONTROL

AUTOBASS

EMO2

EMO1

DAP RESET

DAP PDN

DAP MUTE

DAP SCL

DAP SDA

BKND ERR

CD I2S MCLK

CD I2S SDO

CD I2S BCLK

CD I2S LRCK

DAP I2S OUT

DAP I2S BCKO

DAP I2S LRCKO

AUTOBASS

EMO2

EMO1

DAP RESET

DAP PDN

DAP MUTE

DAP SCL

DAP SDA

BKND ERR

CD I2S MCLK

CD I2S SDO

CD I2S BCLK

CD I2S LRCK

DAP I2S OUT

DAP I2S BCKO

DAP I2S LRCKO

D6501

IC6500

C1AB00003993

DIGITAL AUDIO

PROCESSOR

PWM M 1 38

49 PWM P 4

43 PWM P 3

PWM P 1 39

PWM M 2 40

PWM P 2 41

10 ASEL EMO2

15 EMO1

16 /RESET

18 /PDN

19 /MUTE

21 SCL

20 SDA

34 /BKND ERR

11 MCLK

24 SDIN1

23 SCLK

22 LRCLK

25 SDIN2

29 SDOUT

31 LRCLKO

30 SCLKO

VALID 37

IC6000

C1AB00003986

POWER AMPLIFIER

44

BST A

INPUT B

6

INPUT A

5

INPUT D

15

INPUT C

14

OUT A

OUT A

OUT B

BST B

BST D

OUT D

OUT D

OUT C

BST C

40

39

35

43

23

27

28

32

24

16/FAULT

17/OTW

18/CLIP

4/RESET

DC DETECT

CIRCUIT

Q6001,Q6002

Q6007,Q6300

+12V

DC DET AMP FAN

DAMP FAULT

DAMP OTW

DAP CLIP

DAMP RESET

DAP VALID

JK6000

4

JK6000

3

JK6000

1

JK6000

2

DC DET AMP FAN

DAMP FAULT

DAMP OTW

DAMP CLIP

DAMP RESET

DAP VALID

SPEAKERS

-

LEFT

+

+

RIGHT

-

FROM/TO

SERVO & SYSTEM CONTROL

NOTE: “ * ” REF IS FOR INDICATION ONLY

FROM/TO

SERVO & SYSTEM CONTROL

TU INT

TU RST

TU SCL

TU SDA

TU INT

TU RST

TU SCL

TU SDA

SA-AKX36PH/PN AUDIO BLOCK DIAGRAM

48

Page 49

12.4. Power Supply

MAIN P.C.B.

AC INLET

SMPS MODULE

SWITCHING MODE

POWER SUPPLY

CIRCUIT

PW +32.5V

PCONT

PW +16V

PW +5V

EN

+32.5V

+3.3V

PW SYS3R3V

1

PW +6V

2

+5V

PW +5V

3

VBUS

OC

OC

4

EN

FROM/TO

SERVO & SYSTEM CONTROL

PCONT

PW +16V

5

+16V

PW SYS3R3V

SYS3V3

CN1000*-

6-

IC2030

C0DBZYY00311

HIGH SIDE

SWITCH

PW +5V

1 VIN

IC1003

C0DBAYY01594

+6V DC-DC

CONVERTER

PW +6V

10 PH

1 BOOT

7 VSENSE

PW +16V

2 VIN

IC1002

C0DBAYY01594

+12V DC-DC

CONVERTER

PW +16V

10 PH 3EN

1 BOOT

7 VSENSE

32.5V

CN1000*-

1,2-

PW +32.5V

2 VIN

VBUS

5VOUT

4/OC

3EN

3EN

NOTE: “ * ” REF IS FOR INDICATION ONLY

- CN1000*

-12

- CN1000*

-7

- CN1000*

-13

- CN1000*

-9

CN1000*-

11-

CN1000*-

8-

CN1000*-

10-

POWER

PROT

ECO CTR

AM-BP

SYNC

SMPS-ID

TEMP DET

POWER

PROT

ECO CTR

AM-BP

SMPS-ID

TEMP DET

SYNC

POWER

PROT

ECO CTR

AM BP

SYNC

SMPS ID

TEMP DET

FROM/TO

SERVO & SYSTEM CONTROL

TO POWER SUPPLY

BLOCK (2/2)

SA-AKX36PH/PN POWER SUPPLY (1/2) BLOCK DIAGRAM

49

Page 50

MAIN P.C.B.

PW 6V

+6V

IC1000

C0DBGYY03909

+3.3V VOLTAGE

REGULATOR

PW +6V

2

D1001

PW +16V

5

3 VIN

VOUT 2

PW 3V3PW 6V

D1002

QR1000

DC DETECT

Q1000

+12V VOLTAGE

REGULATOR

PW 12VPW 16V

D1005

PW 3V3,PW 3R3V DIG,PW 3R3V DAC,PW 3R3V CD

DC DET PWR

PW 12V

+3.3V

DC DET PWR

+12V

3

1

4

TO POWER SUPPLY

BLOCK (1/2)

VP DET

+16V

CD3.3V

+5VPW +5V

SYS3.3VPW SYS3R3V SYS3.3V PW SYS3R3V

VP DET

CN6001CN2000

625

+16V

CN6001CN2000

823

CD3.3V PW CD3R3V

CN6001CN2000

292

+5V

CN6001CN2000

301

CN6001CN2000

274

T6000

SWITCHING

TRANSFORMER

Q6001

PW +16V

FL DISPLAY

VOLTAGE SUPPLY

CIRCUIT

-VP

F-

F+

REMOTE SENSOR P.C.B.

VBUSVBUS VBUS

ZJ6400*CN2002

11

SYS3.3V SYS3.3V

CN6500CN6002

22

PW SYS3R3V

-VP

F-

F+

PW +5V

VBUS

PANEL P.C.B.

-VP

F-

F+

+3.3V

+5V

+3.3V

+3.3V

USB P.C.B.

+5V

NOTE: “ * ” REF IS FOR INDICATION ONLY

SA-AKX36PH/PN POWER SUPPLY (2/2) BLOCK DIAGRAM

50

Page 51

13 Wiring Connection Diagram

JK6000

1

JK6002

1

JK51

2

3

4

3

2

4

TO SPEAKERS

AUX IN

A

MAIN P.C.B.

(SIDE B)

TO SMPS MODULE P.C.B.

113

CN1000*

CN2000

1

30

2

29

CN6003

2

1

14

CN6002

B

PANEL P.C.B.

(SOLDER SIDE)

VR6100

132

CN6001

2

30

1

29

VOLUME

FM ANT

AM ANT

G

(SOLDER SIDE)

1

JK52

1

2

CD INTERFACE P.C.B.

1

CN1001

12

TO FAN UNIT

M7301*

(TRAVERSE

2

MOTOR)

FP9003

15

FOR DEBUG

TO OPTICAL PICKUP UNIT

(CD MECHANISM UNIT BRS11C)

M7302*

(SPINDLE

MOTOR)

CN7002

10

9

2

1

CN7001

TO LOADING P.C.B.

(CD MECHANISM

UNIT BRS11C)

FP8201

1

1245

CN2001

1

2

5

6

24

2

23

2

PbF

CN8251

10

2

9

1

1

1

9

2

10

FOR MICRO-P DOWNLOADER

CN6400

5

1

USB PORT

PbF

C

USB P.C.B.

(SOLDER SIDE)

ZJ6400*

15

4

6

29

CN2002

5

1

2

1

30

T6000

(SWITCHING TRANSFORMER)

PbF

PbF

15

JK6301

2

7

654

3

1

MUSIC PORT

D

MUSIC PORT P.C.B.

(SOLDER SIDE)

ZJ6300*

PbF

VR6200

132

ALBUM/TRACK

E

(SOLDER SIDE)

876

9

5

4

321

12

ZJ6700*

PbF

MEMORY LED P.C.B.

14

CN6500

PbF

IR6500

321

SENSOR

F

REMOTE SENSOR P.C.B.

(SOLDER SIDE)

ZJ6000*

5

1

NOTE: " * " REF IS FOR INDICATION ONLY.

SA-AKX36PH/PN WIRING CONNECTION DIAGRAM

51

Page 52

52

Page 53

14 Schematic Diagram

14.1. Schematic Diagram Notes

• This schematic diagram may be modified at any time

with the development of new technology.

Notes:

S6000: Playlist 2 switch.

S6001: Playlist 3 switch.

S6002: Playlist 4 switch.

S6003: Playlist 1 switch.

S6004: Playlist 5 switch.

S6006: Playlist 6 switch.

S6012: Stop ( ) /Tune Mode switch.

S6100: CD switch.

S6101: Radio/EXT-IN switch.

S6103: Album/Track switch.

S6104: Memory/USB switch.

S6105:

S6107: CD Open switch.

S6200: Latin/Preset EQ switch.

S6201: Rewind ( / ) switch.

S6202: Manual EQ switch.

S6203:

S6204: Memory Rec switch.

S6206: D.Bass switch.

S6207: USB Rec switch.

S6208:

S7201: Reset switch.

VR6100: Volume Jog.

VR6200: Control Jog.

• Important safety notice:

Components identified by mark have special characteris-

tics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high quality sound (capacitors), low-noise

(resistors), etc are used.

When replacing any of components, be sure to use only

manufacturer’s specified parts shown in the parts list.

• Resistor

Unit of resistance is OHM [Ω] (K=1,000, M=1,000,000).

• Capacitor

Unit of capacitance is µF, unless otherwise noted. F=Farads,

pF=pico-Farad.

• Coil

Unit of inductance is H, unless otherwise noted.

•

*

REF IS FOR INDICATION ONL Y.

• Voltage and signal line

Play/Pause ( / ) switch.

Power ( ) switch.

Forward ( / ) switch.

: +B signal line

: -B signal line

: CD Audio input signal line

: AUX/Tuner/Music Port Audio input signal line

: Audio output signal line

: USB signal line

: AM signal line

: FM signal line

53

Page 54

54

Page 55

14.2. MAIN (CD Servo/Micon/Damp) Circuit

1

A

SCHEMATIC DIAGRAM - 1

MAIN (CD SERVO) CIRCUIT

A

B

C

D

E

F

G

H

2 3 4 5 6 7 8 9 10 11 12 13 14

: AUDIO OUTPUT SIGNAL LINE

A2

A3

A1

A0

A10

NRAS

NCAS

A3

A1

A0

A2

A10

NRAS

RDACVSS

AOUT1L

RDACVDD

AOUT1R

SRAMVDD

SREGVDD

0.1C8048

4.7

C8033 0.1

C8044

R8043 0

R80041KR8003

1K

C8025

C8026

4.7

4.7

TP

TP

67

69

NWE

NCAS

TEST2

3300PC8069

3300PC8068

NWE

TEST1

R8044 0

DVSS1

TEST0

R8045 0

0.1C8012

DVDD1

DVDD4

C8043 0.1

D7D5D6

0.1C8059

IOVDD2

[144] D2

[143] D1

[142] D0

[111] P80

[110] P25

[109] P24

DVSS7

C8046 0.1

5631241314 111218 16 1517 9 8 710

D6

D7

NRST

IOVDD7

105101102100 104103 106 108

D3

D4

D4D5D3

USBNOC

USBPP

IOVDD9

DVSS9

USBDM2

USBAVDD2

USBDP2

USBAVSS

USBDP1

USBAVDD1

USBDM1

DVSS8

DVDD5

IOVDD8

REGON

AUDIOCLK

SRDAT

BCLK

LRCK

SRDATAIN

SREQ/BLKCK

SCL5

SI/MDATA

SO/STAT

IRQ1A/MLD

107

0.1C8058

IOVDD1

BA0

BA1

P85

P84

P31

P32

P33

P30

MCLK

P1

AMUTE

USB_D+

USB_D-

USB_IN

CD_MLD

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

MI

TO MAIN (CD SERVO)

CIRCUIT (2/3)

BOOT_MODE_DET

1C8060

0.1C8031

R8032

0

C8076 10

R8031 10K

1C8050

0R8001

C8049 10

10KR8046

R8302 0

R8301 0

0.1C8032

0R8033

0.1C8039

0R8034

R9001 30

0.1C8028

0.1C8041

R8021

R8022 10

R8000 0

R8002 10K

30R9002

R9003

R9004

15K 15K

LB8002

33R8029

33

0

144

143

142

141

R8047

140

10K

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

CD_INNER_SW

DGND

NRST

D2

D1

D0

DAP_I2S_LRCKO

DAP_I2S_BCKO

EMMC_USB2_DET

BOOT_FILE_ANA

CD_I2S_MCLK

CD_I2S_SDO

CD_I2S_BCLK

CD_I2S_LRCLK

DAP_I2S_OUT

CD_BLKCK

CD_MCLK

CD_MDATA

CD_STAT

CD_RESET

MI: MAIN (MICON) SCHEMATIC DIAGRAM - 4 ~ 7

C8515 0.1

3/32/31/3

SA-AKX36PH/PN MAIN (CD SERVO) CIRCUIT

PW_3V3

DAT1_SD

DAT0_SD

DAT3_SD

DAT2_SD

NRST_EMMC

CLK_EMMC

CMD_EMMC

FOP

TRP

SPOUT

TRVP

VREF

F

E

D

B

C

A

PD

LD

PW_3R3V_CD

PW_3R3V_DAC

PW_3R3V_DIG

SERVO_GND

LB8402

J0JHC0000045

LB8201

J0JHC0000045

R8209

2.2M

6.3V100

C8065

C801710C8013

: CD AUDIO INPUT SIGNAL LINE: +B SIGNAL LINE : USB SIGNAL LINE

A7

A6

A8

MN6627992AB

SERVO PROCESSOR

TRCST

DVDD3

TRCCLK

10C8075

0.1C8045

0.1C8011

R8005

1M

X8101

H0J338300002

A5

IOVDD6

0.1C8034

C8016

12P

A4A6A5

A4

DVSS2

IC8001

XI1

XO1

0.1C8035

IOVDD3

DVSS6

IO1SF

SDATA

SCLK

IO2SF

IO1SF

SCLK

R8010

R8011

K8206

K8202

0.1C8036

IO2SF

IOVDD4

TRCD3

EXTRGO

100K

100K

0

0

A11

CLK_SDRAM

R7158 33

2728 25 23 21 20 19222426

A11

CLK

TRCD2

TRCD1

84 8580 817776 787473 75 79 8382 93 9492 969589 9087 88 91 9997 9886

C8067 10

R8006

220

C8015

12P

A9

TRCD0

IO3SF

IO0SF

CLKSF

NCSSF

10

C8070

C8029 0.1

36393435

DVSS3

FIOVDD

MSDDAT2

MSDWP

MSDCD

MSDCDCLK

MSDCMD

IOVDD5

DVSS4

DVDD2

FOP

TRP

SPOUT

TRVP

TRVP2

OSCIN

VREF

E

F

D

B

C

A

PD

LD

CDAVSS

CDAVDD

CTCENV

RFENV

RFOUT

RFIN

ARFDC

ARFOUT

PLLF

DSLF

C8018 0.33

IO0SF

PLLFO

C8021 0.082

32 30 293133

IO3SF

CLKSF

[37] MSDDAT1

[38] MSDDAT0

[39] MSDDAT3

[71] ARFFB

[72] ARFIN

VCOF

DVSS5

C8019 1000P

SDATA

NCSSF

37

38

40

41

10KR8042

42

0R8025

0.1C8037

0.1C8038

C8047

0.015

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

68PC8009

66

67

68

4.7C8022

69

70

0.1C8010

71

680PC8020

72

R8210

820

R8211

2.7K

1000PC8027

R8026 0

TP

TP

R8214 10K

C8008 0.022

50

C8007 0.33

51

10

C8014 0.01

A9A7A8

1 2 3 4 5 6 7 8 9 10 11 12 13 14

55

Page 56

15 16 17 18 19 20 21 22 23 24 25 26 27 28

SCHEMATIC DIAGRAM - 2

MAIN (CD SERVO) CIRCUIT

A

P1 P1

: CD AUDIO INPUT SIGNAL LINE: +B SIGNAL LINE : USB SIGNAL LINE

: AUDIO OUTPUT SIGNAL LINE

G

TO

CD INTERFACE

CIRCUIT (CN7002)

IN SCHEMATIC

DIAGRAM - 11

TO MAIN (CD SERVO)

CIRCUIT (1/3)

FF+

T+

TC

D

A

B

F

LB8204 J0JBC0000134

MI

PW_5V

CN8251

1

10

MI

CD_CLOSE_SW

MI

CD_INNER_SW

MI

CD_OPEN_SW

MI

MI

MI

TRV+

LDM+

OPEN_SW

DGND

REST_SW

CLOSE_SW

SPMSPM+

LD_CW

LD_CCW

PW_6V

TRV-

LDM-

10

9

8

7

6

5

4

3

2

1

LB8251

J0JHC0000045

K8209

0

C8071

0.1 16V47

C8251

TRV+

TRV-

LDM+

LDM-

CD_INNER_SW

SPM-

SPM+

C8252

0.01

VREF

FOP

TRVP

DGND

LDMLDM+

TRVTRV+

FF+

R8254

5.6K

C8254

0.015

R8258

27K

R8260

47K

C0GBY0000117

C8255

1800P

R8259

4.7K

R8255

3.3K

29

10

11

12

13

14

IC8251

5CH MOTOR DRIVER

VINFC

MUTE

1

2

TRB1

BIAS

3

REG02

VINTK

TRB2

4

VINSL

REG01 NC

5

FWD

VINSP

6

GND

REV

7

GND

GND

VCC

8

VCTL

9

VOLDVOLD+

PVCC

VOSP-

VOSL-

VOSP+

VOSL+

VOTK-

VOFC-

VOTK+

VOFC+

J0JBC0000134

28

27

26

25

24

23

22

30

21

20

NC

19

18

17

16

15

LB8203

R8262

R8257 5.6K

C8261

R8256 100

R8263

C8256

C8258 C8253

10

1

SPMSPM+

1200P

1K

1000P

T+

TP

61

0.15

R8261

100

R8265

100K

R8252

1K

R8264

1.2K

LB8252

J0JHC0000045

C8262

T-

6.3V100

C8072

0.1

C8073

0.1

PW_3R3V_CD

TRP

SPOUT

LB8202 J0JHC0000045

E

PD

SERVO_GND

K8207

0

LD

K8205

C8204 10

C8203 0.01

C8202 0.1

C8201 10

D8250

0

DZ2J056M0L

C8260

0.01

0R8201

0R8202

0R8203

0R8204

0R8205

0R8206

LB8205

J0JHC0000045

C8259

10

FP8201

F-

24

F+

23

T+

22

T-

21

C

20

D

19

CD/DVD SW

18

RF

17

A

16

B

15

F

14

PD_GND

13

VREF

12

VCC(5V)

11

E

10

NC

9

GND

8

NC

7

CD-LD

6

MD/LPD

5

NC

4

NC

3

DVD-LD

2

GND-LD

1

TP

64

R8215

5.6

TP

63

Q8201

B1ADCF000001

LASER DRIVE

R8212

4.7

TO OPTICAL PICKUP UNIT

(CD MECHANISM UNIT BRS11C)

TO MAIN (CD SERVO)

CIRCUIT (3/3)

MI

DGND

PW_3V3

MI

C8263

0.01

C8101

1000P

MI: MAIN (MICON) SCHEMATIC DIAGRAM - 4 ~ 7

C8102

0.1

K8208

0

CHASSIS GND

C8074

0.1

C8064

6.3V220

LB8003

LB8004 R8027

0

NRST

PW_3R3V_DIG

PW_3V3

SDATA

SCLK

3/32/31/3

SA-AKX36PH/PN MAIN (CD SERVO) CIRCUIT

C8061

0.1

0

10

C8402

6.3V100

C8040

0.1

PW_3R3V_DAC

1

VSS

2

NRST

3

STBY3.3V

4

SDATA

5

SCLK

FP9003

FOR DEBUG

15 16 17 18 19 20 21 22 23 24 25 26 27 28

56

Page 57

29 30 31 32 33 34 35 36 37 38 39 40 41 42

SCHEMATIC DIAGRAM - 3

MAIN (CD SERVO) CIRCUIT

A

PW_3R3V_DIG

IO3SF

CLKSF

IO0SF

LB8052

TO MAIN (CD SERVO)

CIRCUIT (2/3)

IC7704

C3ABMY000027

16M SDRAM

DGND

A

: CD AUDIO INPUT SIGNAL LINE: +B SIGNAL LINE : USB SIGNAL LINE

LB8501

J0JHC0000045

LB8401

J0JHC0000045

R8017 0

R8016

J0JCC0000301

0R8015

C8403

C8401

0.01

0

A9

A7

A4

A5

A8

CLK_SDRAM

0.01

0.1

C7157

C7158

38

NC

CLK

CKE

UDQM

/WE

/LDOM

/CS

/RAS

/CAS

13

0.1

C7160

C7155

1

28

A4A6A5

VSS

A2A3VDD

2425 22 20 18 16 1415171921

23

3029 3433 36 373531 32

A7

A0A1A10/AP

A9NCA8

BA0

VDD

81

HOLD# SO

7

SCLK

6

SI

5

10

VDDQ

VDD

12 10 911

D7

C3FBMY000309

16M FLASH MEMORY

D4

D6

D5

4039 41

DQ8

DQ9

DQ10

VSSQ

DQ7

DQ6

DQ5

VSSQ

IC8401

D3

0.1

C7154

45 47464342 442726

DQ11

VDDQ

DQ4

VDDQ

0.1

C7159

DQ12

DQ3

D2

5

WP#

VSS

DQ2

CE#

DQ13

2

3

4

D1

48 50

VSSQ

VSSQ

3124678

D0

49

DQ14

DQ1

R8014 0

R8013 0

R8012 0

C7150

VSS

DQ15

VDD

DQ0

1

C8042

C7156

NCSSF

IO1SF

IO2SF

0.1

0.1

: AUDIO OUTPUT SIGNAL LINE

NRST_EMMC

CLK_EMMC

R8502

47K

R8503

47K

CMD_EMMC

C8510

0.1

R8501

C8512

0.1

C8514

4.7

0

C8511

0.1

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104