Panasonic omsr-ga281, omsr-ga421 Operation Manual

Service Manual

Order No. PHAT070510C3

Automatic Rice Cooker

SR-GA421/SR-GA281/SR-GA721

EXPORT

© 2007 Panasonic Home Appliance (Thailand) Co.,Ltd

All rights reserved. Unauthorized copying and distrbution

is a violation of law.

Specification

Specification subject to change without notice.

Model

SR-GA421 SR-GA281 SR-GA721

Detail

Country HK SIN-DBD SIN-RBD MALAYSIA HK MALAYSIA SIN-DBD SIN-RBD USA

Power Source

220 V / 50 Hz 230 V / 50 Hz 220 V / 50 Hz 240 V / 50 Hz 220 V / 50 Hz 240 V / 50 Hz 230 V / 50 Hz 220 V / 50 Hz 208 V / 60 Hz

Power

consumption

Cooking 1400 W 950 W 2500 W

Warming

47.5 W

Cooking capacity 5 ~ 23 L 5 ~ 15 L 3 ~ 7 L

Center thermostat

working temperature

140 °C

Keep warm temperature More than equal to 80 °C (After 1 Hr. keep warm)

Thermal fuse specification 113

169 °C

Dimension (mm)

Width x Depth x Height 429 x 369 x 300

367

x 295

x 305

248 x 247 x 255

Weight

5.5 kg 3.6 kg 10.1 kg

Power Cord (approx.) 1.0 m

Accessories Measuring cup, Steaming basket Rice scoop

COOK

WARM

Rice Cooking

Keep War

m

SR-928

SR-GA421/SR-GA281 SR-GA721

2

SR-GA421/SR-GA281/SR-GA721

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

There are special components used in this equipment which are important for safety. These parts are marked by

in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should

be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without

permission of manufacturer.

IMPORTANT SAFETY NOTICE

CONTENTS

1.SCHEMATIC DIAGRAM & WIRING DIAGRAM .....................................................................3-4

2.FUNCTION OF CENTER THERMOSTAT AND THERMAL FUSE .........................................

5-6

3.TROUBLE SHOOTING GUIDE ...............................................................................................7-8

4.TESTING PROCEDURE .........................................................................................................9-10

5.EXPLODED VIEW & PACKING VIEW (SR-GA421/SR-GA281) ............................................11-12

6.REPLACEMENT OF PARTS LIST & PACKING LIST

(SR-GA421/SR-GA281) ....................13-14

7.EXPLODED VIEW & PACKING VIEW (SR-GA721) ..............................................................15-16

8.REPLACEMENT OF PARTS LIST & PACKING LIST

(SR-GA721) .......................................17-18

Page

3

SR-GA421/SR-GA281/SR-GA721

L

N

MICA HEATER ASS’Y

CAST HEATER

LAMP RESIST

.

T.F.

INPUT

SWITCH

LAMP RESIST.

KEEP WARM NEON LAMP

(BIG)

(SMALL

)

E

Green

RICE COOKING NEON LAMP

Lamp Lead Wire A (Orange)

Lead Wire (Orange)

Lamp Lead Wire C (Brown)

Twist one time

Lamp Lead Wire B (Gray)

Lever Earth Lead Wire (Green)

Silicone Tube (Blue)

N

Twist two time

Thermal Fuse Wire (Gray)

Switch Lead Wire (Blue)

Cord Wire Earth (Green)

Silicone Tube (Green)

Silicone Tube (Brown)

Cord Bush

1

0

˚

±

5

˚

Thermal Fuse Wire (Brown)

N

Cord Bush

Silicone Tube (Blue)

Silicone Tube (Brown)

After ass’y, Mica Heater Ass’y must not overlie

the Outer Case of Center Thermostat

.

Water guard

Cord Wire Earth (Green)

Silicone Tube (Green)

Thermal Fuse Wire (Blue)

Lever Earth Lead Wire (Spiral Green)

Wiring Lead Wire (Brown

)

Lamp Lead Wire A (Red

)

Lamp Lead Wire C (Brown

)

Twist one time

Thermal Fuse Wire (Gray)

Lamp Lead Wire B (Gray)

After assembly Mica Heater case

Must no touch the terminal of cast heat

.

Glass tape 20 x 20 mm

.

After as

s’y, gap between terminal and mica heater case must be more than 4 mm.

1

0

˚

±

5

˚

Cast Heater

Lamp Resistor

Lamp Resistor

Switch

Keep Warm Neon Lamp

Rice Cooking Neon Lam

p

Gra

y

Input

Blue

Brown

N

L

E

Gree

n

Mica Heater Ass’y

T.F. T.F.

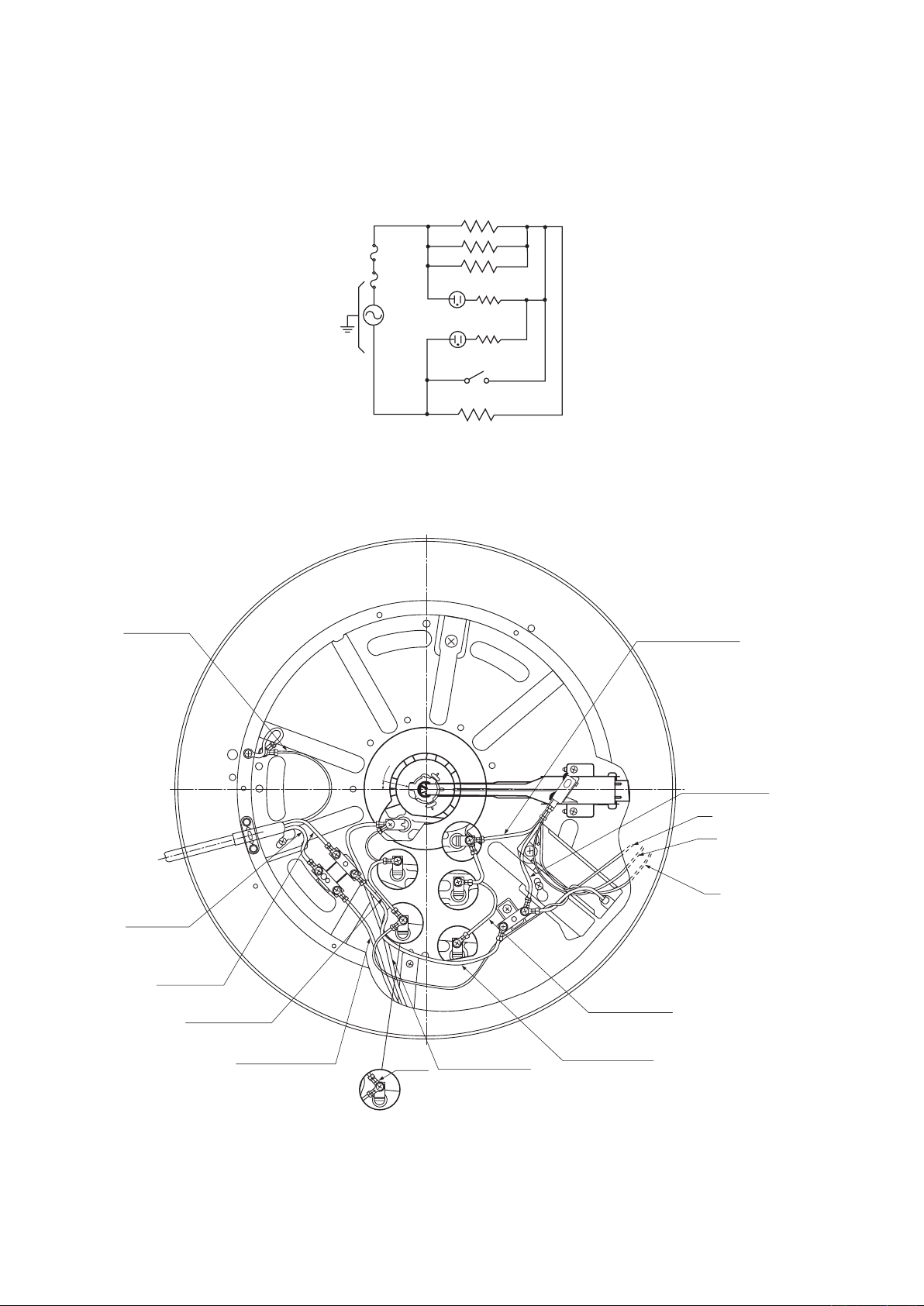

1. SCHEMATIC DIAGRAM & WIRING DIAGRAM

SCHEMATIC DIAGRAM (SR-GA421) WIRING DIAGRAM (SR-GA421)

SCHEMATIC DIAGRAM

(SR-GA281) WIRING DIAGRAM (SR-GA281)

4

SR-GA421/SR-GA281/SR-GA721

Cord Wire Earth (Green)

Cord Wire Blue (N)

Cord Wire Brown (L)

Heater lead wire B (grey)

Thermal fuse lead wire (Blue)

Thermal fuse lead wire (Grey

)

User positio

n

Heater lead wire C (Brown

)

Heater lead wire A (Red)

Grey

Brown

Red

Cathode lead wire (Brown

)

Keep warm lamp lead (Red

)

1

0

˚

±

5

˚

MICA HEATER ASS’Y

CAST HEATER

LAMP RESIST.

SWITCH

LAMP RESIST.

KEEP WARM NEON LAMP

RICE COOKING NEON LAMP

(SMALL)

(MIDDLE)

(BIG)

E

Green

INPUT

L

N

Brown

Blu

e

1

.

F.

T2.

F

.

T

1. SCHEMATIC DIAGRAM & WIRING DIAGRAM

SCHEMATIC DIAGRAM (SR-GA721)

WIRING DIAGRAM (SR-GA721)

5

SR-GA421/SR-GA281/SR-GA721

2.

FUNCTION OF CENTER THERMOSTAT AND THERMALFUSE

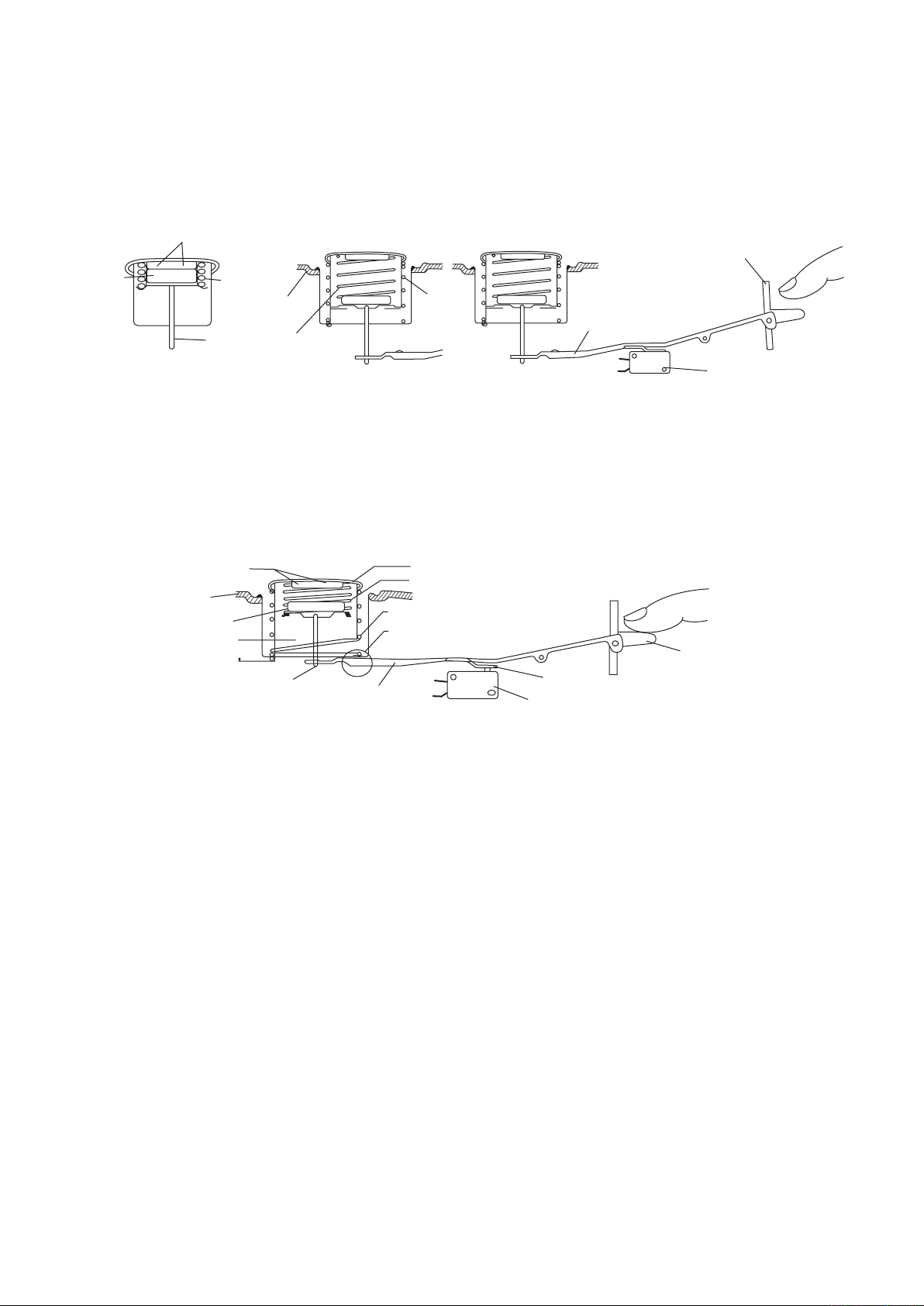

A. Center Thermostat

The center thermostat senses when the bottom of the rice cooker pan reach 134°C ± 6°C.

And it’s action turns off the cooking cycle, and starts the warming cycle.

Refer to these figures showing the center thermostat construction and cooking position. As

the metal is heated, its ability to be attracted by the magnet decreases.

Finally, the inner spring pressure becomes stronger than the magnetic pull and the metal

and magnet will pop apart. The rod activates the switch lever which causes the auxiliary lever to

press the micro-switch button into the warming cycle.

B. Switch-On Preventive System

This is design to prevent the rice cooker from being turned on without the pan placed into

position.

1) Normally when the pan is inserted properly into the rice cooker, the pan will depress the

center thermostat. The center thermostat outer spring will be compressed. In this case when

the switch button is depressed, the following will happen:

a. The auxiliary lever will release the micro-switch button. This puts the micro-switch in the

cook position.

b. The switch lever will push the rod which will allow the magnet to meet with the metal.

c. When the rice is cooked and the proper temperature has been reached 134°C ± 6°C, the

metal and magnet will pop apart as described in the center thermostat operation above.

d. The rod will push the switch lever and cause the auxiliary lever to depress the micro-

switch button. This puts the micro-switch in the warming position.

2) When the pan is not in place within the rice cooker, the center thermostat is not depressed.

a. In this condition, the outer spring is not compressed within the center thermostat

preventing the metal from reaching its normal operating position.

b. When the switch button is depressed, the switch lever and auxiliary lever work as above

but the magnet cannot come in contact with the metal to hold the switch lever in the cook

position. This happens because the switch lever hits the thermostat case and cannot push

the rod, with the magnet attached, all they way up to meet with the metal.

c. When the pressure is taken off the switch button, the switch lever releases immediately to

the open or warm positions.

Metal

Magnet

Inner spring

Cooking heater

Rod

10mm

Outer spring

Switch lever

Cook switch button

Micro switch

Thermostat case

Thermostat surface

Auxiliary lever

Metal

Magnet

Inner spring

Cooking heater

Rod

Inner spring

Outer

spring

Switch lever

Cook switch button

Micro switch

NC

C

Center thermostat construction

(Cooking Position) (Warming or Off Position)

Figure 1

6

SR-GA421/SR-GA281/SR-GA721

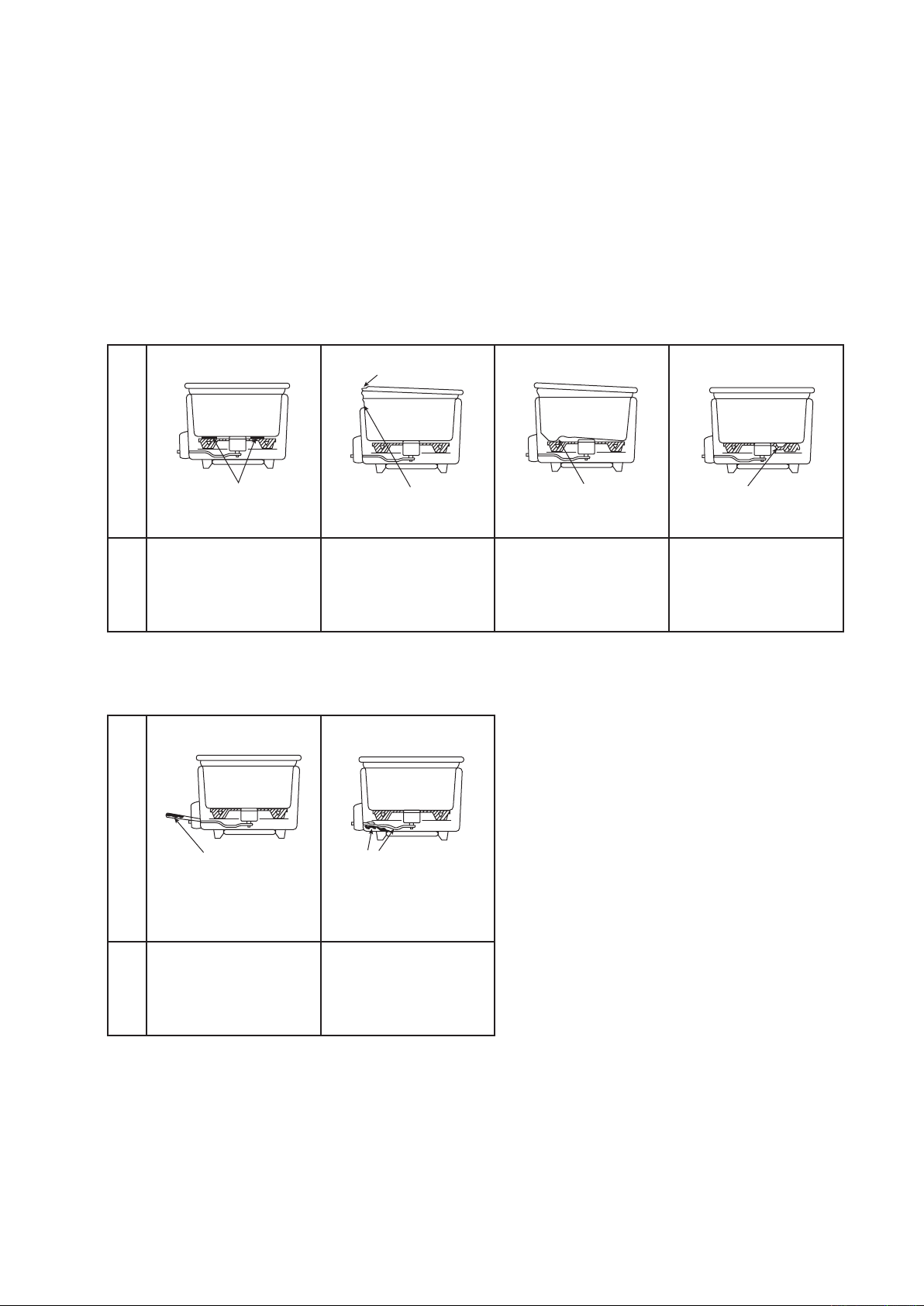

C. Thermal Fuse

The thermal fuse is used to open the circuit to the cooking heater when the temperature has

gone unusually high. This happens in cases such as incomplete contact between the heater

and pan or if the switch buttons is forced to stay on keeping the heater energized abnormally.

This fuse is not a resetting device and must be replaced after openning.

Whenever replacing the fuse make sure the protective cover is placed over all exposed wiring.

Cause of Fusion

[A] Improper contract between heater and pan

2.

FUNCTION OF CENTER THERMOSTAT AND THERMALFUSE

[B] Forced application of current

Cause

Pan collar or deformed

Foreign matter adhering Body dented or deformed Pan bottom dented or

deformed

Heater surface deformed

or corroded

Remedy

Remove foreign matter

by of (-) screw-driver,

etc., and then polish with

= 320 water paper while

wetting it with water.

Repair or replace body.

Replace pan. Replace cooking heater.

Cause

Chopstick, wooden

piece, etc. inserted onto

cooking button. (continuous application of current)

Switch lever deformed

or maladjusted, causing

continuous application of

current.

Remedy

Inserted to prevent earlier turning off? Refer to

cause in (a) above.

Repair or replace parts.

When fusion takes place, check the cause, set right the faulty section, and be sure to use

replacement parts.

Loading...

Loading...