Panasonic MHE-UN4025CW User Manual

MHE-PF4025CW

MHE-UN4025CW

Integrated Cell

Processing Work

Station

CPWS Features:

• Cost effective, space-saving solution

for GMP and GTP compliant regenerative

medicine and cell therapy research.

• Minimizes the expense of a cleanroom laboratory

Panasonic… the new name for SANYO

www.panasonic.com/biomedical

MHE-PF4025CW

MHE-UN4025CW

Panasonic CPWS Integrated Cell Processing Work Station

Minimizes Cleanroom Expense

Self-Contained

Space-Saving

Quick to Acquire and Install

GMP Compliant for Aseptic Process

User Friendly

Energy Efcient, Green Design

The Essential Work Station for Cell Therapeutics

Continued worldwide development of new methods and processes in cell therapy and

regenerative medicine research requires renewed emphasis on tools and technologies

required to establish and maintain aseptic conditions demanded of the clinical environment.

Panasonic has met that challenge.

In designing the industry’s rst viable alternative to a conventional Class 10,000 cleanroom for

both Class 100 air quality and barrier isolation, Panasonic has introduced the Cell Processing

Work Station (CPWS) to bring the potential of cell therapeutics to more facilities while

mitigating acquisition and operation costs and protracted time lines.

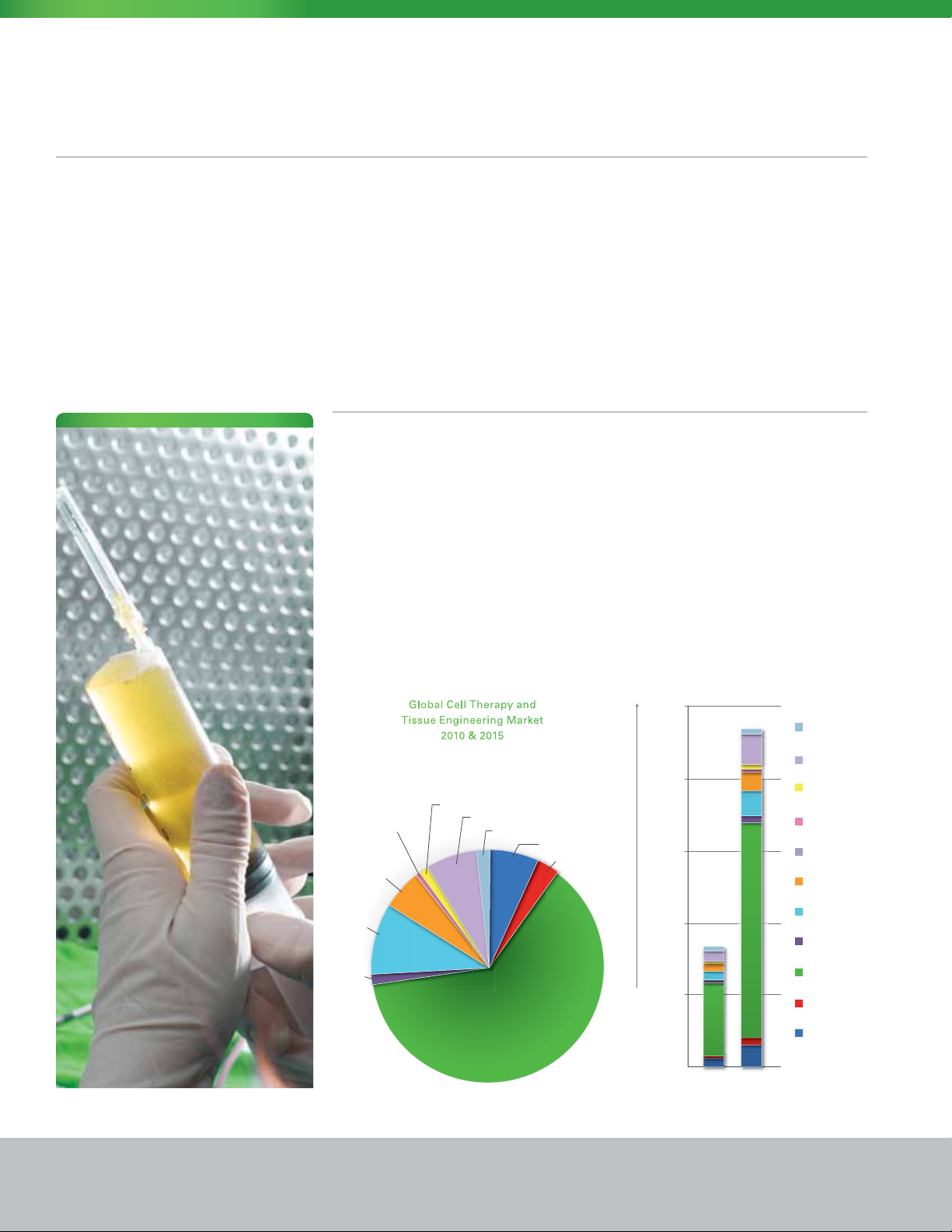

Ophthalmalogy and

Organ Replacement/

Preservation

Dental/Oral

Skin

Urology

Global Cell Therapy and

Tissue Engineering Market

2010 & 2015

General

Cancer

Cord Blood and Cell Banking

Cardiology

Neurology

Orthopedics/Spine

$25,000

$20,000

$15,000

$10,000

$5,000

Cell/Tissue

Banking

Cancer

General Surgery,

GI, Gyn, Others

Ophthalmalogy

Organ

Dental

Skin

Urology

Ortho

Neuro

Cardio

2 CWPS Integrated Cell Processing Work Station www.panasonic.com/biomedical

Millions of Dollars

$0

2010 2015

The Market

Immediate beneciaries of the Panasonic

CPWS include both private and public

institutions serving the life science,

clinical, biotechnology and pharmaceutical

markets. These include mainstream

and scale-up pharmaceutical companies

focused on drug and medical device

development related to human cells,

medical researchers applying cellular

therapies in clinical trials, and hospitals

now deploying approved cellular therapeutics to treat a broad range

of diseases.

As the science progresses and results

are propagated throughout the medical

and scientic community, the need for

bench-level research and production is

expanding exponentially. As a result, the

availability of the Panasonic free-standing,

self-contained work station apart from

the conventional layered cleanroom

approach to containment and protection,

is bringing the capability for on-site

cellular therapeutics to more facilities

more quickly and at a lower capital and

operational cost, all within the GMP

performance envelope required of the

cell technology itself.

Self-Contained System,

Small Footprint

The Panasonic concept of a self-contained work station is enabled by the

company’s demonstrated prociency

for in situ decontamination required to

separate processes from one patient

to the next, or one protocol to another.

By using a highly effective H

tamination process, the CPWS can be

completely decontaminated without heat

and prepared for the next protocol within

two hours as compared to a cleanroom

decontamination function can take days

or weeks.

By increasing throughput within the

compliant parameters of GMP criteria,

the CPWS is deployed for both research,

cellular manipulation and growth, cell

product extraction and emerging processes that fall within similar guidelines.

Current and future applications of the

CPWS include organ and tissue regeneration such as skin, cartilage, alveolar bone,

2O2

decon-

cornea, cardiac muscle, nerve, liver and

pancreas regeneration. Immunotherapy

applications may extend to dendritic cells,

T-cells and more.

Making it Work

Improving efciency in human interaction

is a primary design attribute of the CPWS.

All work must be performed without

human error, in an aseptic environment

with detailed documentation to assure

quality and compliance. Gown-up time,

expense and inconvenience is minimized

or eliminated altogether. Integrated

systems within the CPWS permit cellular

extraction, preparation, culturing and

administration with aseptic assurance as

well as economic practicality.

Because conventional autoclaving is

not possible, the Panasonic H

2O2

decontamination process diminishes both time

and labor associated with this critical step

between patients, positioning the CPWS

squarely in the equation for cost/benet

justication associated with investment

decision-making. Allowances for integrated centrifuge, microscopy, data acquisition and incubation functions are important considerations in the CPWS design;

a unique docking station permits interface

and exchange with unlimited number

of cell culture incubators dedicated to

individual patients or cell lines.

On the Work Surface

Since humans remain the single most

common source of contamination, the

CPWS provides both physical and

process benets to minimize contamination and cross-contamination in the

work area. Within the four-port glove

box the CPWS delivers more than a

conventional Class II, Type A2 biological

safety cabinet typically installed within a

cleanroom to achieve the same objective.

Here, the manually initiated, automatically

deployed H

supplements continuous HEPA ltration.

As 0.3 micron particles are removed

from the fresh air exchange, H

contamination neutralizes contaminants

brought forth by instrumentation or

equipment. A number of decontamination

sequences are available to protect the

aseptic environment.

decontamination process

2O2

2O2

de-

The glove box design offers barrier isolation protection for the operator and the

work inside. User comfort and ergonomics are inherent to the CPWS design, including a sloped front for ease of access

and glare reduction.

What You Don’t Need

The relatively small footprint permits

installation into existing or new Class

100,000 lab space with conventional

utilities and minimal site preparation.

Multi-layered airlocks in multiple treated

rooms are avoided. Capital intensive

expenses are lowered and lead times

from decision to operation are shortened.

Once in place, operational costs are

highly contained and predictable, with decontamination available more frequently

and at a fraction of conventional cost.

The Panasonic Difference

For over forty years, Panasonic has

established a reputation as a premier

manufacturer of precision biomedical and

laboratory equipment. Known throughout

the world as a leading brand in consumer

electronics and appliances, Panasonic

addresses global needs such as energy,

food, housing, healthcare and information

technology.

As a part of the Panasonic product line

worldwide, the Cell Processing Work

Station exemplies our unique Vertical Component Integration approach to

product development, combining ideas

and innovations from our global industrial

and consumer products network into an

integrated product featuring advanced

technology, controls, construction and

performance attributes.

The CPWS and subcomponent systems

have been extensively tested to meet the

toughest quality standards for performance, ergonomics and cost of ownership. The CPWS is designed to minimize

its carbon footprint through energy savings and environmental stewardship.

3

Panasonic CPWS Series Technical Attributes

The Panasonic CPWS work station is

designed to deliver efcient, costeffective and GMP compliant cell therapy

and manufacturing capability without the

expense and inconvenience of a class

10,000 cleanroom. The CPWS offers

signicant advantages over conventional

hard wall cleanroom construction.

• The CPWS is less expensive than a

cleanroom.

• It is quicker to acquire and place

into operation.

• The small footprint increases options

for location and orientation.

• The user-friendly glove box design

eliminates gowning and improves

operator comfort and convenience.

• Operating costs are lower than

cleanroom costs

• Work is easily suspended and resumed

without the need to de-gown and regown, improving user comfort.

• Fast decontamination and changeover improve productivity, increase

throughput and deliver quicker return

on investment.

• Recordkeeping and process

documentation are easier to manage.

Components and operating systems are

congured around a central work station

with a HEPA ltration and air management

system designed to deliver Class 100 air

to the work surface within the glove box.

• Central barrier isolator

• Pass box interchange

• Integrated H

decontamination

2O2

system

• Optional cell observation system with

microscope and monitor

• Optional centrifuge integrated into the

work surface

• Optional CO

incubator with

2

docking collar

• The optional incubator and optional

centrifuge operate within a Class 100

environment.

CPWS Work Station

The Panasonic CPWS work station is a

component-based design that permits

long-term or quick turnover self-contained

protocols with efciency and safety for

the product as well as personnel. As an

integrated system, all functions associated with good laboratory technique,

environmental control and ergonomic

comfort are selected for compatibility

and complementary functional performance.

1. Modular CO

cart, docked to barrier isolator.

2. Incubator cart with locking casters;

offset casters nest with

frame assembly when docked.

3. Lid cam latch

4. Centrifuge controller

5. Centrifuge module accessible

for the aseptic work area.

6. Glove port

incubator, shown on

2

1

2

14

18

15

3

7. Hinged front access assembly;

front lifts up when total interior

access is required.

8. Interchange pass box with manually

initiated, automatic sequence H

2O2

decontamination system.

9. System controller

10. H

liquid supply cartridge

2O2

11. HEPA supply and exhaust ltration

blower motor assembly

12. Electrical compartment

13. Interior uorescent lamps

14. Electropolished interior surfaces

15. Angled 6° front for user comfort,

reduced glare

16. Locking screws to secure

hinged front.

17. Adjustable leveling feet

18. Optional cell monitor LCD

11

7

13

6

5

16

4

17

9

8

10

12

4 CWPS Integrated Cell Processing Work Station www.panasonic.com/biomedical

Panasonic CPWS Series Applications

Clinical Applications of Cell Therapies

Disease States Cell Therapies

Cancer

Hematopoietic Stem Cell

(HSC) Transplantation

Immunotherapy

Orthopedic

Neurodegenerative Disorders/Trauma

Cardiovascular Disease

Organ Replacement

Pancreas (diabetes)

Liver (failure, metabolic disorders) Bioarticial liver; Isolated hepatocy tes; Hepatocyte stem cells

Kidney (failure) Bioarticial kidney

Wound Healing

Infectious Diseases

Genetic Deciencies

Hemophilia Gene Therapy

SCID Gene Therapy

Cystic Fibrosis Gene Therapy

Autologous and allogeneic HSC; Ex vivo expansion of HSC;

‘Suicide’ T-cells – gene transfer; Stem cell transportation

Dendritic cells; NK /T cells; Macrophage -activated killer cells;

T-cell expansion; NK cells; Co- stimulatory molecules (gene transfer)

Expanded chondrocytes; Mesenchymal stem cells

Adult stem cell-derived cells; Embryonic stem cell- derived neural cells

Infusion of marrow/blood- derived angio blasts;

CD34 stem cells; cardiac cells*

Pancreatic islet cells; Embryonic stem cell-derived islet cells;

Adult stem cell-derived islet cells

Keratinocytes; Skin stem cells

Antigen -loaded dendritic cells; Lymphocyte expansion; Macrophages

Applications

The Panasonic CPWS enables a broader

access to cellular therapeutic research

related to both minimally manipulated

and non-minimally manipulated cell

products by lowering the cost of entry,

extending the process to the widest

range of applications, and minimizing

operating expenses when compared to a

conventional cleanroom environment.

• Minimally manipulated products

are associated with cell washing,

enrichment, selection, HSC (PB,

BM, CB), cancer therapies and

other under GTP requirements.

• Non-minimally manipulated

products are associated with

expanded, differentiated or

transformed cells (DC, MSC, ESC,

TC) in cancer centers, biotech labs,

stem cell institutes and contract

manufacturing facilities operating

under GMP requirements.

• GMPs (Good Manufacturing Practices)

are mandated by the United States

Food and Drug Administration to

ensure that drug development

and manufacturing is safe, quality

controlled for repeatability and

thoroughly documented.

• GMPs typically require expensive

hard wall laboratories and laboratory

suites using biological safety cabinets

in Class 10,000 cleanrooms surrounded

by a Class 100,000 room.

Autoimmune Diseases

Immunotherapy

HSC, hematopoietic stem cells; NK, Natural Killer; SCID, severe combined immunodeciency

* Currently in clinical studies.

Dendritic cells; T-cells, Mesenchymal stem cells*;

Lymphocy te expansion; Natural Killer cells

5

Loading...

Loading...