Page 1

INSTRUCTION MANUAL

c

or

c

r

or

Photoelectric Sensor

Digital Laser Sensor Amplifier

LS-400 Series

Thank you very much for using SUNX products. Please read this Instruction Manual

carefully and thoroughly for the correct and optimum use of this product.

Kindly keep this manual in a convenient place for quick reference.

٨

Never use this product as a sensing device for personnel protection.

In case of using sensing devices for personnel protection, use

٨

products which meet standards, such as OSHA, ANSI or IEC etc.,

for personnel protection applicable in each region or country.

٨

WARNING

1

SPECIFICATIONS

Model

No.

Item LS-401P-C2LS-401P

Power consumption

Output

(Output1, Output2)

Short-circuit protection

External input

(Note 2)

Response time

Sensitivity

setting

Fine sensitivity adjustment function

Timer function

Interference prevention

function

Ambient temperature

Material

Weight

Notes: 1)

2)

3)

2

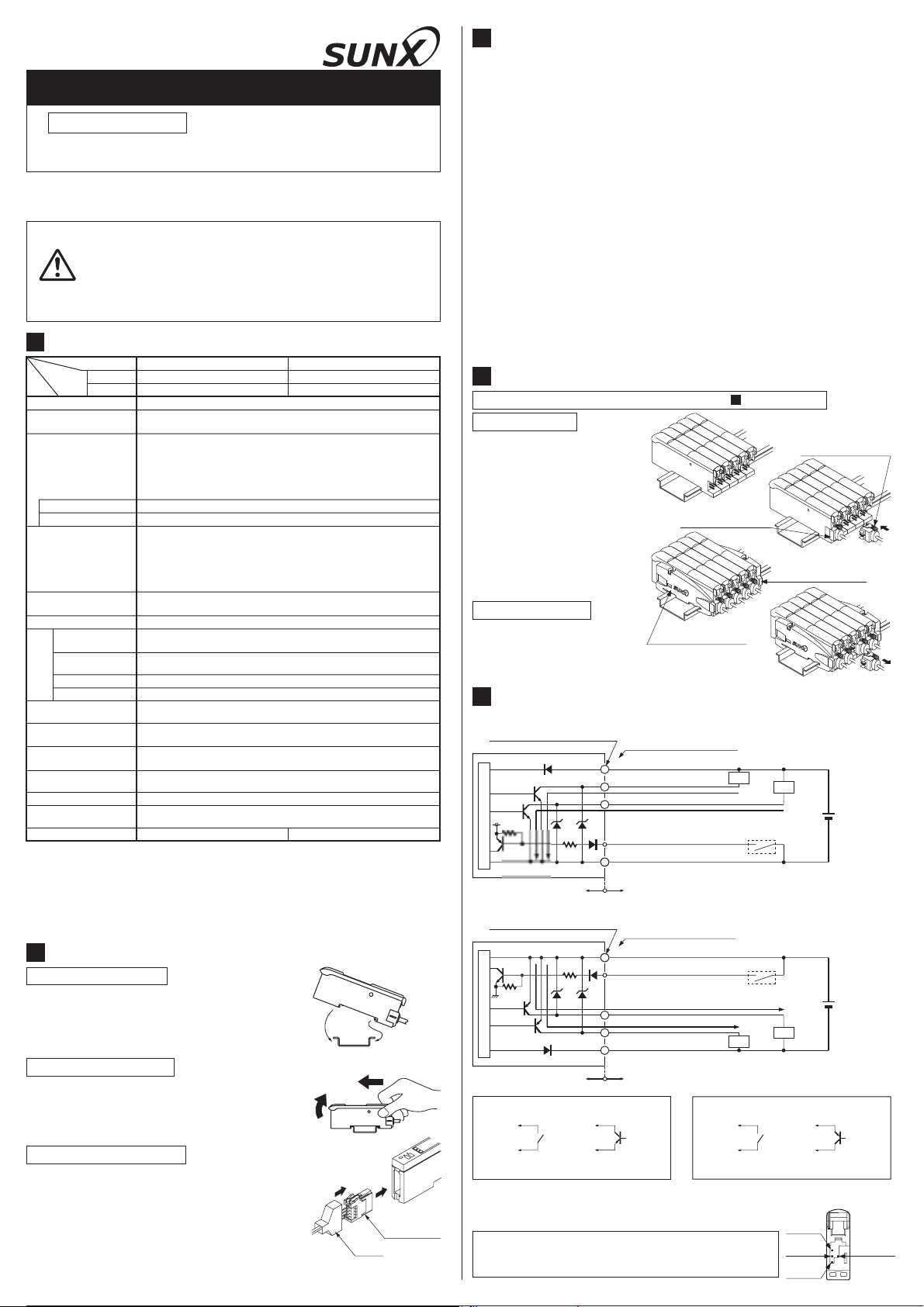

MOUNTING

How to mount the amplifier

ԘԙFit the rear part of the mounting section of the amplifier

on a 35mm width DIN rail.

Press down the rear part of the mounting section of

the unit on the 35mm width DIN rail and fit the front

part of the mounting section to the DIN rail.

How to remove the amplifier

ԘԙPush the amplifier forward.

Lift up the front part of the amplifier to remove it.

Take care that if the front part is lifted without pushing the

Note:

amplifier forward, the hook on the rear portion of the

mounting section is likely to break.

How to mount the sensor head

ԘԙInsert the sensor head connector into the inlet until it

clicks.

Fit the cover to the connector.

Use of control or adjustment or performance of procedures

other than those specified in this instruction manual may result

in hazardous rediation expose.

NPN Output

PNP Output

Normal operation: 950mW or less (current consumption 40mA or less at 24V supply voltage)

ECO mode: 780mW or less (current consumption 33mA or less at 24V supply voltage)

<NPN output type>

NPN open-collector transistor

Maximum sink current: 100mA (Note 1)

Residual voltage: 1.5V or less

ޓ[at 100mA (Note 1) sink current]

<NPN output type>

NPN non-contact input

Signal condition

Input impedance: 10kǡapprox

Normal mode

Window compa-

rator mode

50mA max. if 5 to 8 units are connected in cascade, and 25mA max. if 9 to 16 units are connected in cascade.

External input is not incorporated with the connector type LS-401(P).

The cable is not supplied as an accessory for connector type LS-401(P). Be sure to use

the optional quick-connection cables given below.

Main cable (4-core): CN-74-C1 (cable length 1m), CN-74-C2 (cable length 2m)

Sub cable (2-core): CN-72-C1 (cable length 1m), CN-72-C2 (cable length 2m)

CN-72-C5 (cable length 5m)

Manual adjustment

Incorporated with variable ON-delay/OFF-delay/ONE-SHOT timer, switchable either effective or ineffective (Timer period: 1ms㨪9999ms approx.)

Incorporated [Up to four sensor heads can be mounted adjacently (However,

in H-SP mode, the interference prevention function cannot be operated)]

-10 to +55 (If 4 to 7 units are mounted closely: -10 to +50, if 8 to 16 units are mounted

closely: -10 to +45) (No dew condensation or icing allowed), Storage: -20 to +70

12 to 24V DCr10% Ripple P-P 10% or lessSupply voltage

<PNP output type>

PNP open-collector transistor

Applied voltage: 30V DC or less

(between output and 0V)

Light-ON or Dark-ON, selectable with jog switchOutput operation

High: +5 to +V DC or open

Low㧦0 to 2V DC (source current 0.5mA)

H-SP: 80Ǵs or less, FAST: 150Ǵs or less, STD: 500Ǵs or less,

U-LG: 4ms or less, selectable with jog switch

Enclosure: Heat-resistant ABS, Transparent cover: Polycarbonate,

Mode key switch: Acrylic, Jog switch: ABS

CN-74-C5 (cable length 5m)

4 digit (green) + 4 digit (red) LED displayDigital display

2-level teaching / Limit teaching / Full-auto teaching /

Teaching (1, 2, 3 level) / Manual adjustment

Teaching (1, 2, 3 level) / Manual adjustmentHysteresis mode

35 to 85% RH, Storage: 35 to 85% RHAmbient humidity

Maximum source current: 100mA (Note 1)

Applied voltage: 30V DC or less

(between output and +V)

Residual voltage: 1.5V or less

ޓ[at 100mA (Note 1) source current]

Incorporated

<PNP

PNP non-contact input

Signal condition

High: +4 to +V DC (sink current 3mA or less)

Low㧦0 to 0.6V DC, or open

Input impedance: 10kǡ

Five-level settingsDifferential mode

Incorporated

CableType Connector type Cable type

LS-401-C2LS-401

output type>

65g approx.15g approx.

ԙ

35mm width DIN rail

Ԙ

ԙ

ԙ

Ԙ

Cover

approx

Ԙ

Sensor head

connector

3

CAUTIONS

٨

Make sure that the power supply is off while wiring.

٨

Verify that the supply voltage variation is within the rating.

٨

Take care that if a voltage exceeding the rated range is applied, or if an AC power

supply is directly connected, the sensor may get burnt or damaged.

٨

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity

of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

٨

The ultra long distance (U-LG) mode is more likely to be affected by extraneous noise since the

sensitivity of that is higher than the other modes. Make sure to check the environment before use.

٨

If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

٨

Do not use during the initial transient time (0.5 sec.) after the power supply is switched on.

٨

Take care that short-circuit of the load or wrong wiring may burn or damage the sensor.

٨

Do not run the wires together with high-voltage lines or power lines or put them in

the same raceway. This can cause malfunction due to induction.

٨

Make sure to use the optional quick-connection cable for the connector type LS-401(P).

٨

Extension up to total 100m is possible with 0.3mm2, or more, cable. However, in

order to reduce noise, make the wiring as short as possible.

٨

This sensor is suitable for indoor use only.

٨

Avoid dust, dirt, and steam.

٨

Take care that the product does not come in direct contact with water, oil, grease,

or organic solvents, such as, thinner, etc.

٨

This sensor cannot be used in an environment containing inflammable or explosive gases.

٨

Never disassemble or modify the sensor.

4

CASCADING CONNECTOR TYPE LS-401 (P)

For mounting and removing the amplifier, refer to ' MOUNTING'.

2

Cascading method

Ԙ

Mount each amplifier one by

one to 35mm width DIN rail

Sub cable

(CN-72-Cغ) (optional)

and set the amplifiers to

contact each other.

ԙ

Insert the connector of quickconnection cable into the

connector of the amplifier.

Ԛ

Mount the optional end plates

Main cable

(CN-74-Cغ) (optional)

(MS-DIN-E) at both the ends

to hold the amplifiers between

their flat sides.

ԛ

Tighten the screws to fix the

End plate

(MS-DIN-E) (optional)

end plates (MS-DIN-E).

Dismantling method

ԘԙPressing the projection at the top

of the quick-connection cable,

pull out the connector.

Remove the amplifier.

5

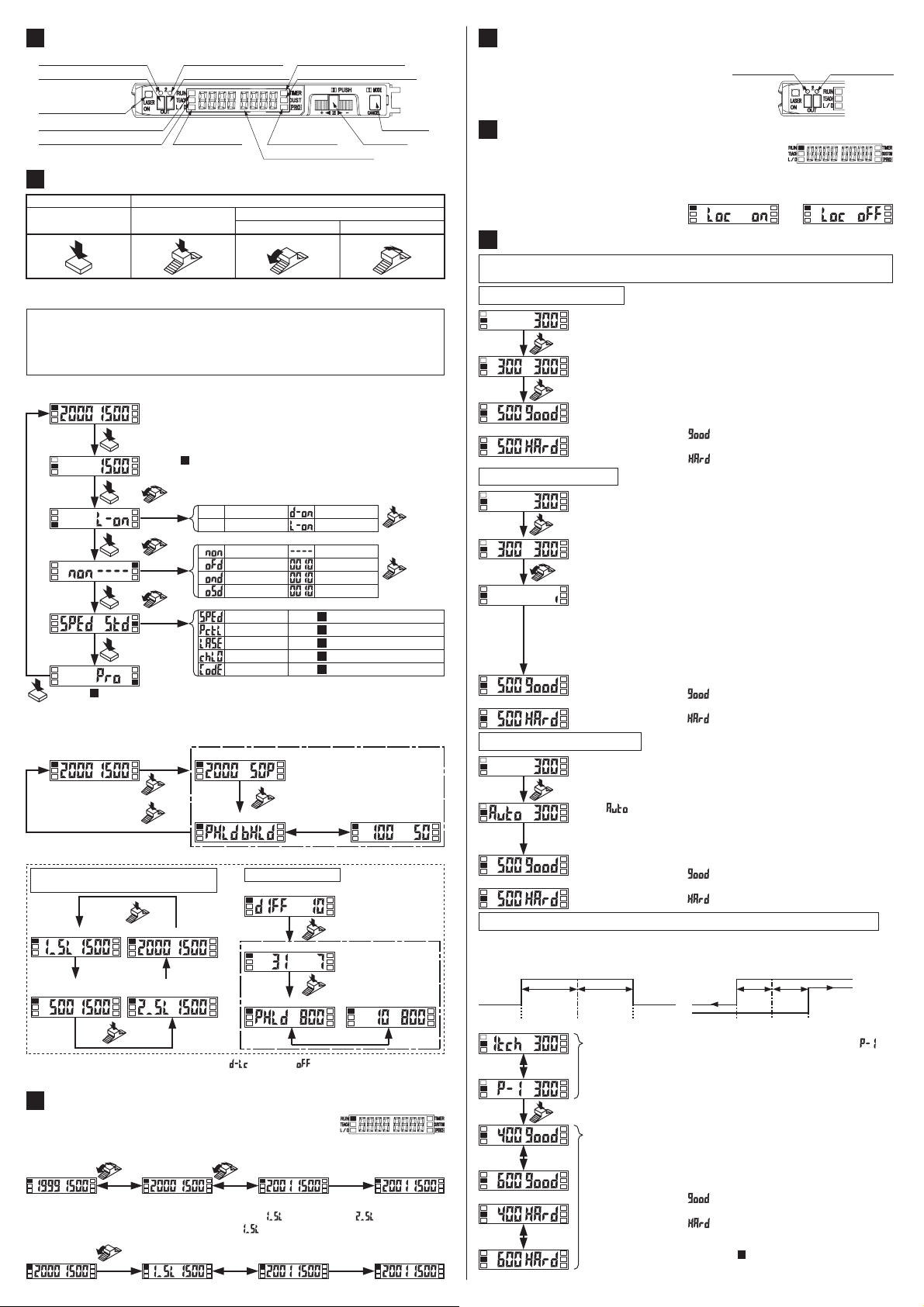

I/O CIRCUIT DIAGRAM

End plate

(MS-DIN-E) (optional)

٨ NPN output type

Terminal No. of connector type

D1

Tr1

Tr2

Z

5V

Sensor circuit

D2

Cable type / Color code of

quick-connection cable

(Brown) + V (Note 1)

1

(Black) Output 1

2

(White) Output 2

4

Z

D1

(Pink) External input (Note 2)

(Blue) 0 V (Note 1)

3

Users' circuitInternal circuit

Load

100mA max. (Note 3)

100mA max.Note3

*1

Load

㧗

12㨪24V DC

r10%

㧙

٨ PNP output type

Terminal No. of connector type

0V

Tr3

Sensor circuit

*1

Non-voltage contact or NPN transistor open

ollector

High㧦5V to +V, or open

Low㧦0 to 2V

Notes: 1)

The quick-connection sub cable does not have +V (brown) and 0V

(blue). The power is supplied from the connector of the main cable.

2)

External input is not incorporated with the connector type LS-401(P).

50mA max. if 5 to 8 units are connected in cascade, and 25mA max. if 9 to 16 units are connected in cascade.

3)

Symbols㨯㨯㨯 D1, D2:Reverse supply polarity protection diode

D3

Tr4

D2

D1, ZD2, ZD3, ZD4:Surge absorption zener diode

Z

r1, Tr2:NPN output transistor

T

r3, Tr4:PNP output transistor

T

Cable type / Color code of

quick-connection cable

(Brown) + V (Note 1)

1

(Pink) External input (Note 2)

D4

2

(Black) Output 1

4

(White) Output 2

3

(Blue) 0V (Note 1)

Users' circuitInternal circuit

*2

100mA max. (Note 3)

100mA max. (Note 3)

Load

*2

Non-voltage contact or PNP transistor open

ollecto

High㧦4V to +V

Low㧦0 to 0.6V, or open

㧗

㧙

Load

Layout of terminals of

connector type LS-401 (P)

Ԙ㧗V

ԙ

Output 1

Ԛ0V

12㨪24V DC

r10%

ԛ

Output 2

Page 2

6

PART DESCRIPTION

Select 1 indicator (Yellow)

Output 1 operation indicator (Orange)

Laser emission indicator

(Green)

MODE indicator / RUN (Green)

MODE indicator / TEACH (Yellow)

7

OPERATION PROCEDURE

MODE key

Press Press

1

When Jog switch is pressed, the setting is confirmed.

2

Cancellation is possible by pressing MODE key during setting.

٨

Be sure to set each item after selecting the output 1 or the output 2.

٨

The items that can be set in the output 1 and the output 2 respectively are only ԘThreshold value,

ԙOutput operation, ԚTimer operation and Timer period, and ԛDetection mode. The items other than

Select 2 indicator (Yellow)

Output 2 operation indicator (Orange)

MODE indicator /

L/D ON (Yellow)

MODE indicator /

PRO (Yellow)

Digital display (Green, Red)

Jog switch

'+' side '-' side

MODE indicator / TIMER (Yellow)

MODE indicator / CUSTOM (Yellow)

MODE key

Jog switch

Turn

those are common. (However, in case of setting with the direct code, a combination of the output1/2 can

be set only for output operation. The items other than output operation are valid only for the output 1.)

٨

Procedures for switching the NAVI mode

RUN mode

TEACH

mode

L/D

mode

TIMER

mode

CUSTOM

mode

PRO

mode

12

Refer to ' PRO MODE'.

Press

Refer to '٨Procedures for switching the display in RUN mode'.

Press

Press

Press

Press

Press

11

Refer to ' TEACHING MODE'.

Turn

Turn

Turn

No display

No display

No timer

OFF delay

ON delay

ONE-SHOT delay

Response time selection

M.G.S.

Emission halt

Data bank loading

Code setting

Dark ON

Light ON

㧙

Timer period

Timer period

Timer period

12

Refer to ' PRO MODE / PRO1 mode setting'.

12

Refer to ' PRO MODE / PRO1 mode setting'.

12

Refer to ' PRO MODE / PRO1 mode setting'.

12

Refer to ' PRO MODE / PRO3 mode setting'.

12

Refer to ' PRO MODE / PRO5 mode setting'.

㧦Confirmed

㧦Confirmed

٨ Procedures for switching the display in RUN mode

Threshold value

Displayed only in Window comparator mode or Hysteresis mode and Differential mode.

*

In Window comparator mode or Hysteresis

mode

Automatic

Threshold

value 1

Note: Can be displayed if the display switching ' ޓ' is set to ' ' to enable the display switching

Incident light

intensity

Incident light

intensity

Threshold value 2

Automatic

Incident light

intensity

Press

in PRO2 of PRO mode.

Press

Press

Press

Threshold value

Peak value Bottom value

Incident light

intensity

Incident light

intensity

Incident light intensity

Press

Blinking

by turns

In Differential mode

Differential value of incident light intensity

Threshold value

Incident light intensity

Incident light intensity

Blinking by turns

Incident light intensity

Press

Press

Hold value

(Note)

(Note)

Incident light

intensity

9

OUTPUT SWITCHING

٨

Press the MODE key for more than 2 seconds when in

NAVI mode. If Output 1 has been selected, the Select

Select 1 indicator

(Yellow)

Select 2 indicator

(Yellow)

1 indicator (yellow) lights up. If the output 2 is being

selected, the Select 2 indicator (yellow) lights up.

10

KEYLOCK FUNCTION

٨ If the jog switch and MODE key are press down

simultaneously for more than 3 seconds when the MODE

indicator / RUN (green) is on, the key operation is locked.

Press down for more than 3 seconds

again to unlock the key.

11

TEACHING MODE

<Key locked> <Key unlocked>

When teaching in Window comparator mode or Hysteresis mode, a setting has to be made in PRO6

beforehand. In case of 1-level teaching, a shift value (the initial value is 100 digit or 15%) has to be set as well.

In case of 2-level teaching

Ԙ Press the MODE key once to select 'TEACH mode'. Press

Press

the jog switch in the object present condition.

ԙ Press the jog switch in the object absent condition. The

Press

MODE indicator / TEACH (green) blinks.

Ԛ A threshold is set between Ԙandԙ.

or

In case stable sensing is possible:

' ' is displayed in the red digital display.

In case stable sensing is not possible:

' ' is displayed in the red digital display.

In case of Limit-teaching

Ԙ Press the MODE key once to select 'TEACH mode'. Press

Press

the jog switch in the object absent condition.

ԙ The MODE indicator / TEACH (green) blinks.

Turn

Ԛ Turn the jog switch to '+' or '-' side.

Turn to '+' side: The threshold level is shifted to a value

approx. 15% higher (low sensitivity) than that set at Ԙ. (Note 1)

Automatic

Turn to '-' side: The threshold level is shifted to a value approx.

15% lower (high sensitivity) than that set at Ԙ. (Note 1)

Note:

The approx. 15% amount of shift is an initial value. The amount of Shift can be

changed in a range of approx. 5% to 200% (increment of 1%) in PRO mode.

ԛ In case stable sensing is possible:

or

In case stable sensing is not possible:

' ' is displayed in the red digital display.

' ' is displayed in the red digital display.

In case of Full-auto teaching

Ԙ Press the MODE key once to select 'TEACH mode'.

Press

Run the workpiece on the line and hold down the jog switch.

ԙ ' ' is displayed on the green digital display and when the

workpiece passed through, release the jog switch.

Automatic

The MODE indicator / TEACH (green) blinks.

Ԛ In case stable sensing is possible:

or

In case stable sensing is not possible:

' ' is displayed in the red digital display.

' ' is displayed in the red digital display.

In case of 1-level teaching in Window comparator mode or Hysteresis mode

٨ This is the method to set the shift value to the desired value and set the threshold

range by using the single-point teaching.

<Window Comparator mode>

Set to desired value

1_SL P-1 2_SL 1_SL 2_SLP-1

Set to desired value

<Hysteresis mode>

Set to de-

Set to de-

sired value

sired value

Ԙ Press the MODE key once to select 'TEACH mode'. ' ' is

Blinking

by turns

displayed on the green digital display.

Press the jog switch in the object present condition.

8

THRESHOLD VALUE FINE ADJUSTMENT FUNCTION

٨

The threshold can be fine-adjusted when the MODE indicator

RUN (green) lights up.

/

Turn the jog switch to either '+' (left) or '-' (right) to increase / decrease the threshold value.

Turn Turn

When you turn the jog switch to '+' or '-' in Window comparator mode or Hysteresis mode, the

threshold will increase or decrease after the output 1 ' ' or the output 2 ' ' is displayed.

If you turn the jog switch to '+' when the output 1 ' ' is displayed, the following will be displayed.

Turn to '+'

Change

Automatic

AutomaticAutomatic

Confirmed

Confirmed

Or

Blinking

by turns

Blinking

by turns

Press

The threshold value (1_SL) that has been calculated by

ԙ

subtracting the shift value (100) from the incident light intensity

and the threshold value (2_SL) that has been calculated by

adding the shift value (100) to the incident light intensity are

alternatively blinks on the green digital display. (Note 1) (Note 2)

In case stable sensing is possible:

In case stable sensing is not possible:

' ' is displayed in the red digital display.

' ' is displayed in the red digital display.

Notes 1):

The shift value of 100 digit is an initial value. The shift value can be

set in PRO mode. Furthermore, 'digit' or 'percent' can be selected.

For setting method, refer to ' PRO MODE /PRO6 mode setting'.

2):

If the value after setting exceeds the maximum (minimum), the

maximum (minimum) sensitivity will be set.

12

Page 3

In case of 2-level teaching in Window Comparator mode or Hysteresis mode

٨ This method is to set the threshold range by using the 2-point teaching (P-1, P-2).

<Window comparator mode><Hysteresis mode>

1_SL

P-1

2_SL

P-2

1_SL

P-1

2_SL

P-2

Ԙ Press the MODE key once to select 'TEACH mode'. ' ޓޓ'

Blinking

by turns

Press

is displayed on the green digital display.

Press the jog switch in the object present condition for the

first point.

ԙ ' ' blinks on the green digital display.

Press the jog switch in the object present condition for the

second point.

Ԛ

The value of the first point (1_SL) and the second point (2_SL)

are alternatively blink on the green digital display. (Note)

In case stable sensing is possible:

' ' is displayed in the red digital display.

Blinking

by turns

Press

In case stable sensing is not possible:

Or

Blinking

by turns

' ' is displayed in the red digital display.

Note : If the value after setting exceeds the maximum (minimum), the

maximum (minimum) sensitivity will be set.

In case of 3-level teaching in Window comparator mode or Hysteresis mode

٨

This is the method to set the threshold range by setting the threshold (1_SL) of the

mid-point between 'A' and 'B' and the threshold (2_SL) of the mid-point between

'B' and 'C', using the 3-point teaching (P-1, P-2, P-3).

After teaching, P-1, P-2 and P-3 will be automatically relocated in ascending order:

٨

i.e. the lowest value is placed in 'A', the second lowest in 'B' and the highest in 'C'.

<Window comparator mode>

1_SL B CA 2_SL

<Hysteresis mode>

1_SL 2_SL

B CA

Ԙ Press the MODE key once to select 'TEACH mode'. ' ' is

Blinking

by turns

Press

displayed on the green digital display.

Press the jog switch in the object present condition.

ԙ ' ' blinks on the green digital display.

Or

Blinking

by turns

Blinking

by turns

Press

Press

Press the jog switch

second point.

Ԛ ' ' blinks on the green digital display.

Press the jog switch

third point.

ԛ

The threshold (1_SL) of the mid-point between 'A' and 'B'

and the threshold (2_SL) of the mid-point between 'B' and 'C'

blinks alternatively on the green digital display (Note)

n case stable sensing is possible:

I

' ' is displeyed in the red digital display.

In case stable sensing is not possible:

' ' is displayed in the red digital display.

Note: If the value after setting exceeds the maximum (minimum), the

maximum (minimum) sensitivity will be set.

in the object present condition for the

in the object present condition for the

Span adjustment in Differential mode

٨

If Differential mode is selected when in PRO mode, the maximum sensitivity will be set.

The span adjustment in Differential mode can be set as follows.

٨

The threshold can be set by using the threshold value fine adjustment function.

٨

For details, refer to ' THRESHOLD VALUE FINE ADJUSTMENT FUNCTION'.

Short span Long span

Incident light

intensity

8

Incident light

Tur n Tur n

intensity

Incident light

intensity

Incident light

intensity

Tur n

Incident light

Tur nTur n

intensity

12

PRO MODE

٨

When MODE indicator / PRO (yellow) lights up, PRO mode

can be set.

PRO1 mode setting

Response

Press

time

switching

function

Tur n

Hysteresis

function

Tur n

(Shift function)

Tur n

Tur n

(M.G.S. function)

Tur n

Emission

halt function

Notes: 1)

Display for laser amount can show the digit of max. 9,999 digits if ' ' for standard or ' ' for ultra long

distance is selected in the response time switching function ' ', but will display the digit of max. 4,000 digits

if ' ' for ultra high speed or ' ' for high speed is selected.

2)

This can be selected only if ' ' for ultra long distance (response time of 4ms or less) is selected in the

response time switching function ' '.

PRO2 mode setting

Tur n

PRO3 mode setting

Tur n

Display

Press

switching

function

Tur n

Display turning

function

Tur n

ECO mode

function

Tur n

Time period

holding function

Tur n

Present value

storage function

Tur n

Stored value

comparison function

Data bank

Press Press Press

loading

function

Tur n

Data bank saving function

Press

(Note1)

Tur n

Press

Tur n

Press

Tur n

Press

Press

Tur n

Press

Tur n

Press

Tur n

Press

Tur n

Press

Tur n

Press

Press

(1 unit only)

Tur n

Press

(1 unit only)

Tur n

(Ultra high speed) Response time: 80Ǵs or less

(High speed) Response time: 150Ǵs or less

(Standard) Response time: 500Ǵs or less

(Ultra long distance) Response time: 4 ms or less

Hysteresis: Small

Hysteresis: Standard

Hysteresis: Large

Shift amount: 15% approx. (default)

The shift amount can be set in a range of

about 5 to 200% (increment of 1%).

Turn

Sensitivity adjustment: High (Note 2)

Sensitivity adjustment: Rather high

Sensitivity adjustment: Rather low

Sensitivity adjustment: Low

Laser emission: ON

Laser emission: OFF

Digital display switching on

Digital display switching off

Digital display turning: OFF

Digital display turning: ON

ECO mode: OFF

ECO mode: ON

Hold: OFF

Hold: ON

Stored

value

Press

Tur n

Press

(All)

Tur n

Press

Tur n

Press

(All)

Tur n

Incident light intensity

Press

<Example>

For 1CH setting

Press

<Example>

For 1CH setting

Press

<Example>

For 1CH setting

Press

<Example>

For 1CH setting

Page 4

PRO4 mode setting

Press

(Copy function)

Tur n

Transmission change

To permit / Not to

permit function

Tur n

External input switch

setting function

Tur n

Tur n

Backup

function

Note: This indication is not shown on the connector type LS-401(P).

(Note)

(Note)

Press

Setting copy: OK

Press

Transmission enable

Transmission disable

Tur n

Press

Emission halt

Full-auto teaching

Limit teaching / plus side

Limit teaching / minus side

Tur n

Press

Backup: OFF

Backup: ON

Tur n

PRO5 mode setting

Press

Code setting

function

Tur n

(0-ADJ function)

Tur n

13

Reset

function

Tur n

CUSTOM

mode display

function

Tur n

Refer to ' LIST OF CODE SETTING' when using the code setting function.

Note:

Press

Press

Press

Press

Tur n

Tur n

(Note)

Turn: Code selecting

Press down: Confirmed

0-ADJ: OFF

0-ADJ: Set

Reset: OK

Response time

M.G.S.

Emission halt

Data bank loading

Code setting (Note)

PRO6 mode setting

٨ Output 1

Press

(Normal mode)

(Rising differential mode)

Tur n

(Trailing differential mode)

Tur n

Window comparator mode

Tur n

Tur n

Press

Tur n

Press

Tur n

Press

Press: Confirmed

Change by

increment

of 1 digit

Change by

increment

of 1 %

٨ Output 2

13

LIST OF CODE SETTING

Press

(Normal mode)

Turn

Turn

Green digital display Red digital display

٨ Green digital display

First digit Second digit Third digit Fourth digit

Direct

L/D switching

code

(Output 1, Output 2)

L-ON㨯L-ON

L-ON㨯D-ON

D-ON㨯L-ON

D-ON㨯D-ON

㧙

㧙

㧙

㧙

㧙

㧙

Direct

Timer operation Response time

code

Off

On delay

Off delay

One-shot delay

㧙

㧙

㧙

㧙

Direct

code

STD

H-SP

FAST

U-LG

㧙

㧙

㧙

㧙

㧙㧙

㧙㧙

Direct

Sensitivity setting

code

^^^^^^

^^^^

^^

^^^^^^^^

㧙

㧙

㧙

㧙

㧙

㧙

٨ Red digital display

First digit Second digit (Note) Third digit Fourth digit

Direct

Hyster-

code

esis

H-02

H-02

H-03

H-03

H-01

H-01

㧙

㧙

㧙

㧙

: The highlighted line indicates the default code (factory setting).

Connector type LS-401 (P) shows only ' '.

Note:

14

ERROR DISPLAY

Copy

lock

OFF

ON

OFF

ON

OFF

ON

㧙

㧙

㧙

㧙

Direct

code

External

Backup

input

Laser emis-

sion halt

Laser emis-

sion halt

Auto teaching

Auto teaching

Limit +

Limit +

㧙

Limit

Limit

㧙

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Direct

code

Response time

M.G.S.

Data bank loading

Emission halt

D code

Direct

Detection modeCustom

code

Normal 2 output

Window comparator

Rising differential

Trailing differential

Hysteresis

㧙

㧙

㧙

㧙㧙㧙

㧙㧙㧙

Output 2 OFF

㧙

㧙

㧙

㧙

٨ Take the following actions in case of errors.

Description of error

Overcurrent has been applied due to

short-circuited load.

Disconnection error of sensor head.

Transmission error during connection.

15

OPTICAL COMMUNICATION

٨

When the collective data bank load / save function or copy function is used via optical communication, loading / saving or copy of the setting can be carried out only to the amplifiers (sub

units) connected on the right side of the amplifier (main unit), as shown in the figure below.

Turn off the power supply and check the

load.

Check the connection of sensor head.

Verify that there is no loose or clearance

between amplifiers.

ActionDisplay

However, if the amplifier (sub unit) is being connected (the indicator blinks), PRO mode is being set or the transmission enable / disable function is set to 'disable', loading / saving or copy

is not carried out. Furthermore, the sensing operation stops during optical communication.

Communication direction

Tur n

Hysteresis

mode

Press

Tur n

Press

Tur n

Press

Press: Confirmed

Main unit

Sub unit

SUNX Limited

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

http://www.sunx.co.jp/

PRINTED IN JAPAN

Loading...

Loading...