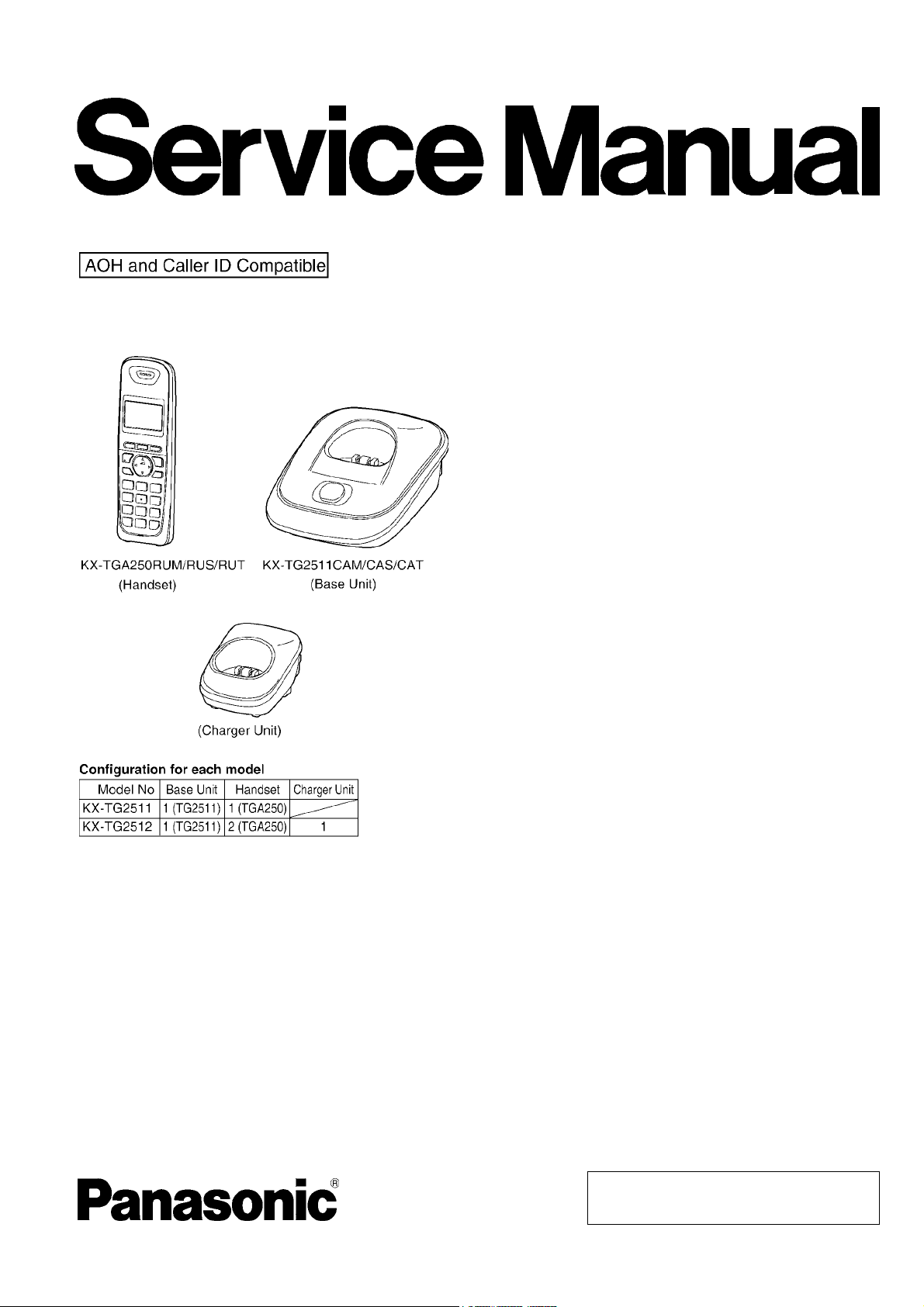

Page 1

ORDER NO. KM41006113CE

Telephone Equipment

Model No. KX-TG2511CAM

KX-TG2511CAS

KX-TG2511CAT

KX-TG2512CAM

KX-TG2512CAT

KX-TGA250RUM

KX-TGA250RUS

KX-TGA250RUT

Digital Cordless Phone

M: Metallic Grey Version

S: Silver Version

T: Titanium Black Version

(for Kazakhstan)

(for Tajikistan)

(for Uzbekistan)

(for Turkmenistan)

(for Kyrgyzstan)

© Panasonic System Networks Co., Ltd. 2010

Unauthorized copying and distribution is a

violation of law.

Page 2

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

2

Page 3

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions----------------------------------------------- 4

1.1. For Service Technicians --------------------------------- 4

2 Warning-------------------------------------------------------------- 4

2.1. Battery Caution--------------------------------------------- 4

2.2. About Lead Free Solder (Pbf: Pb free)--------------- 4

2.3. Discarding of P.C. Board--------------------------------- 5

3 Specifications ----------------------------------------------------- 6

4 Technical Descriptions----------------------------------------- 7

4.1. Block Diagram (Base Unit)------------------------------ 7

4.2. Circuit Operation (Base Unit)--------------------------- 8

4.3. Block Diagram (Handset)-------------------------------11

4.4. Circuit Operation (Handset)----------------------------12

4.5. Circuit Operation (Charger Unit)----------------------13

4.6. Signal Route -----------------------------------------------14

5 Location of Controls and Components ------------------15

6 Installation Instructions---------------------------------------15

7 Operating Instructions-----------------------------------------15

7.1. For Service Hint-------------------------------------------15

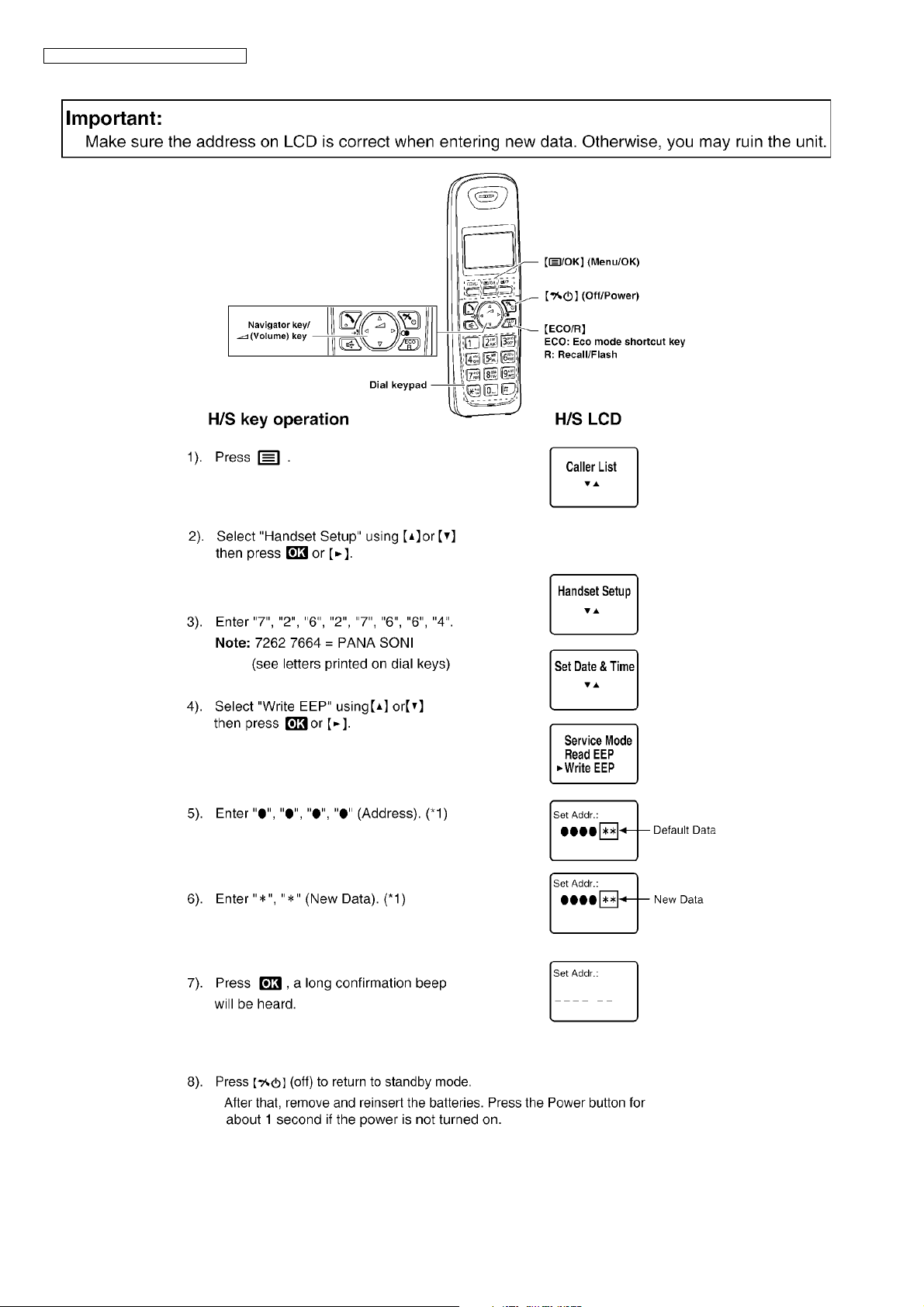

8 Service Mode -----------------------------------------------------16

8.1. Engineering Mode----------------------------------------16

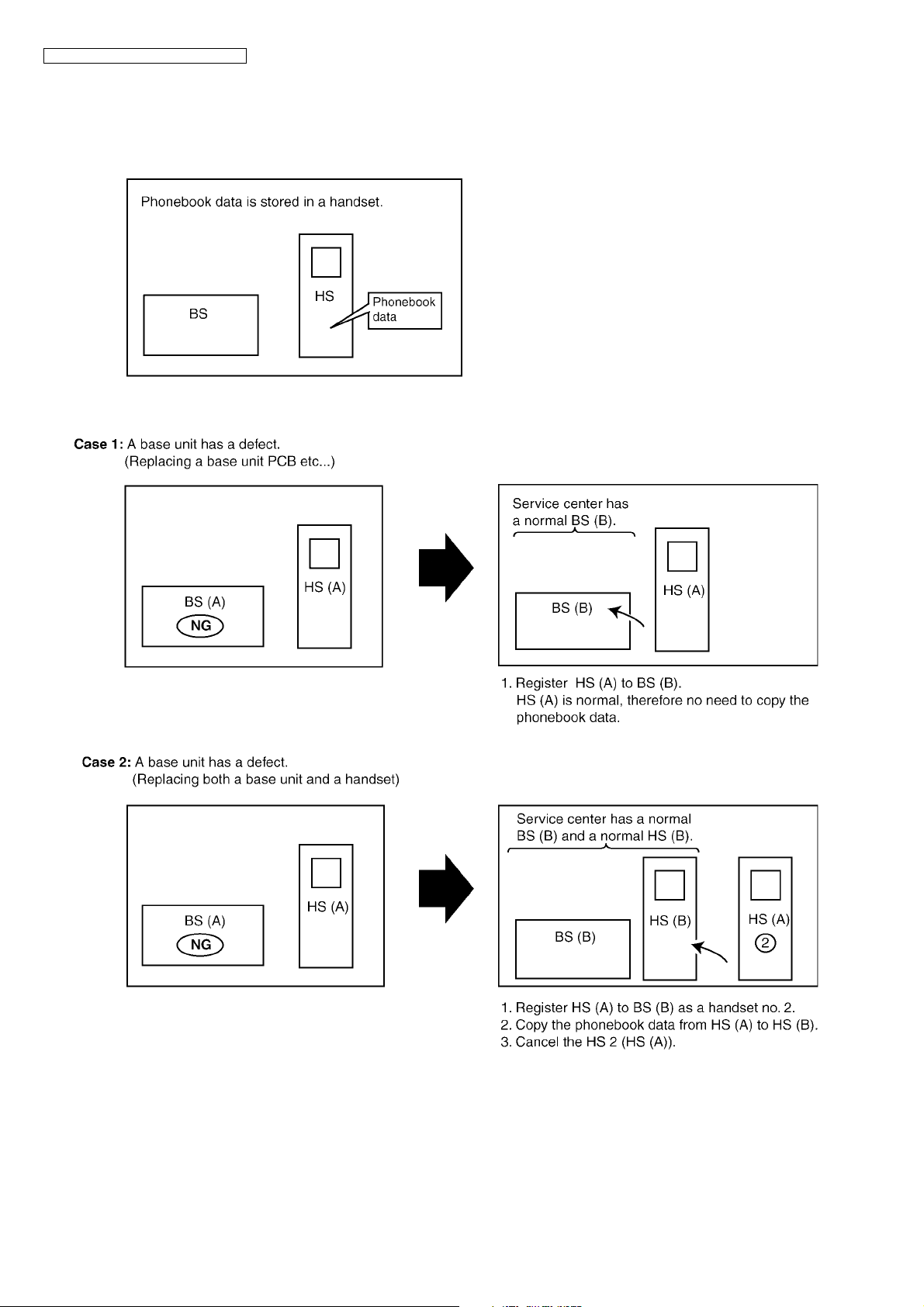

8.2. Copying Phonebook Items when Repairing -------20

8.3. How to Clear User Setting------------------------------22

9 Troubleshooting Guide----------------------------------------23

9.1. Troubleshooting Flowchart -----------------------------23

9.2. Troubleshooting by Symptom (Base Unit and

Charger Unit) ----------------------------------------------35

9.3. Troubleshooting by Symptom (Handset) -----------39

10 Disassembly and Assembly Instructions ---------------43

10.1. Disassembly Instructions-------------------------------43

10.2. How to Replace the Handset LCD -------------------46

11 Measurements and Adjustments---------------------------47

11.1. Equipment Required -------------------------------------47

11.2. The Setting Method of JIG (Base Unit) -------------47

11.3. Adjustment Standard (Base Unit)---------------------49

11.4. Adjustment Standard (Charger Unit)-----------------50

11.5. The Setting Method of JIG (Handset) ---------------51

11.6. Adjustment Standard (Handset) ----------------------53

11.7. Things to Do after Replacing IC or X'tal ------------54

11.8. RF Specification-------------------------------------------56

11.9. How to Check the Handset Speaker or

Receiver ----------------------------------------------------57

11.10. Frequency Table (MHz) ---------------------------------57

12 Miscellaneous ----------------------------------------------------58

12.1. How to Replace the Flat Package IC ----------------58

12.2. How to Replace the Shield Case---------------------60

12.3. Terminal Guide of the ICs, Transistors and

Diodes and Electrolytic Capacitors-------------------62

13 Schematic Diagram ---------------------------------------------63

13.1. For Schematic Diagram---------------------------------63

13.2. Schematic Diagram (Base Unit) ----------------------64

13.3. Schematic Diagram (Handset) ------------------------66

13.4. Schematic Diagram (Charger Unit) ------------------68

14 Printed Circuit Board-------------------------------------------69

14.1. Circuit Board (Base Unit_Main)-----------------------69

14.2. Circuit Board (Handset)---------------------------------71

14.3. Circuit Board (Charger Unit) ---------------------------73

15 Exploded View and Replacement Parts List -----------74

15.1. Cabinet and Electrical Parts (Base Unit) -----------74

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

15.2. Cabinet and Electrical Parts (Handset)------------- 75

15.3. Cabinet and Electrical Parts (Charger Unit) ------- 76

15.4. Accessories------------------------------------------------ 77

15.5. Replacement Part List ---------------------------------- 78

3

Page 4

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

1 Safety Precautions

1.1. For Service Technicians

• Repair service shall be provided in accordance with repair technology information such as service manual so as to

prevent fires, injury or electric shock, which can be caused by improper repair work.

1. When repair services are provided, neither the products nor their parts or members shall be remodeled.

2. If a lead wire assembly is supplied as a repair part, the lead wire assembly shall be replaced.

3. FASTON terminals shall be plugged straight in and unplugged straight out.

• ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

2Warning

2.1. Battery Caution

1. Danger of explosion if battery is incorrectly replaced.

2. Replace only with the same or equivalent type recommended by the manufacturer.

3. Dispose of used batteries according to the manufacture’s Instructions.

2.2. About Lead Free Solder (Pbf: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder.

Caution

• PbF solder has a melting point that is 50 °F ~ 70 °F (30 °C ~ 40 °C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700 °F ± 20 °F (370 °C ± 10 °C).

• Exercise care while using higher temperature soldering irons.:

Do not heat the PCB for too long time in order to prevent solder splash or damage to the PCB.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100 °F (600 °C).

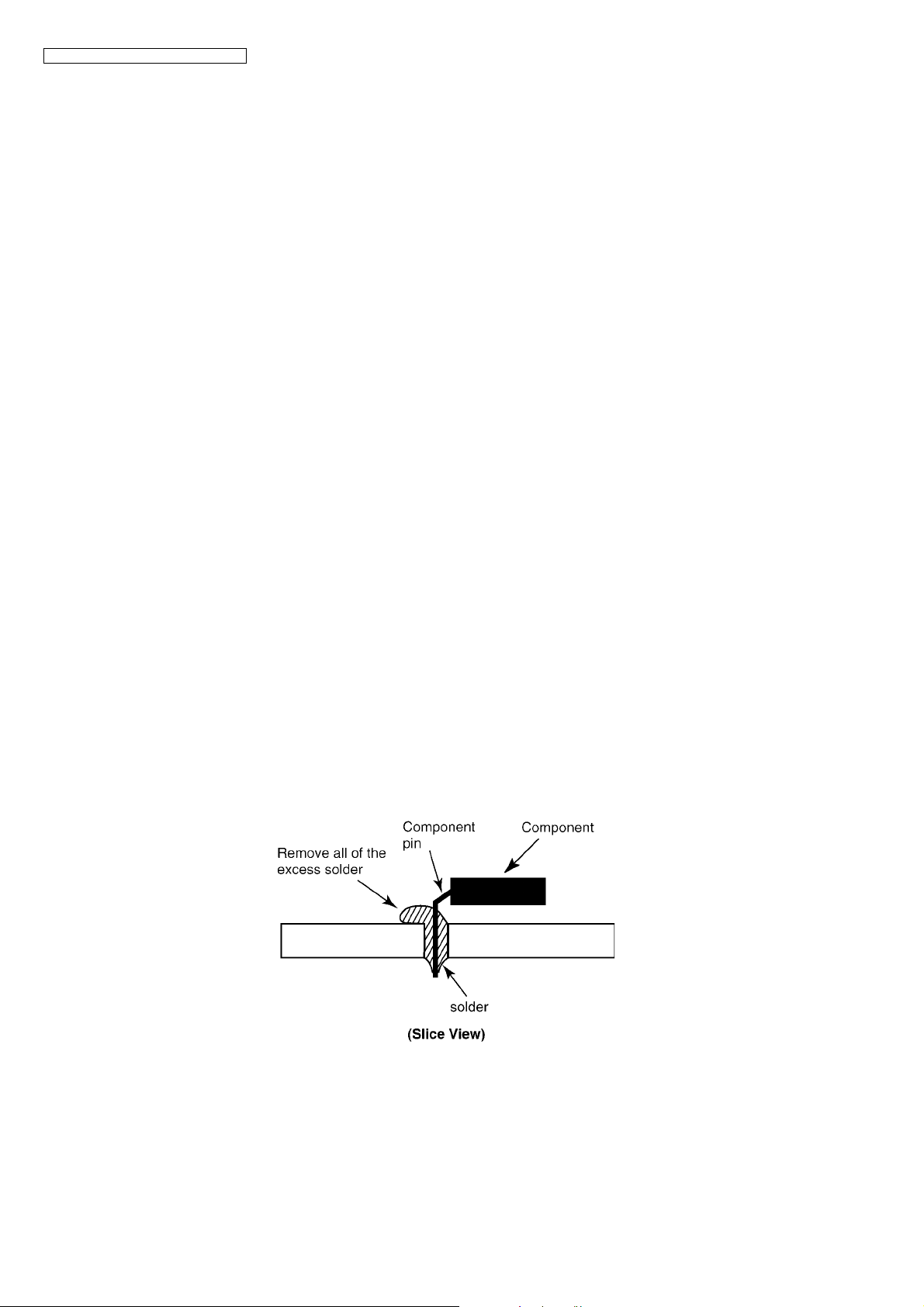

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See the figure below).

4

Page 5

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

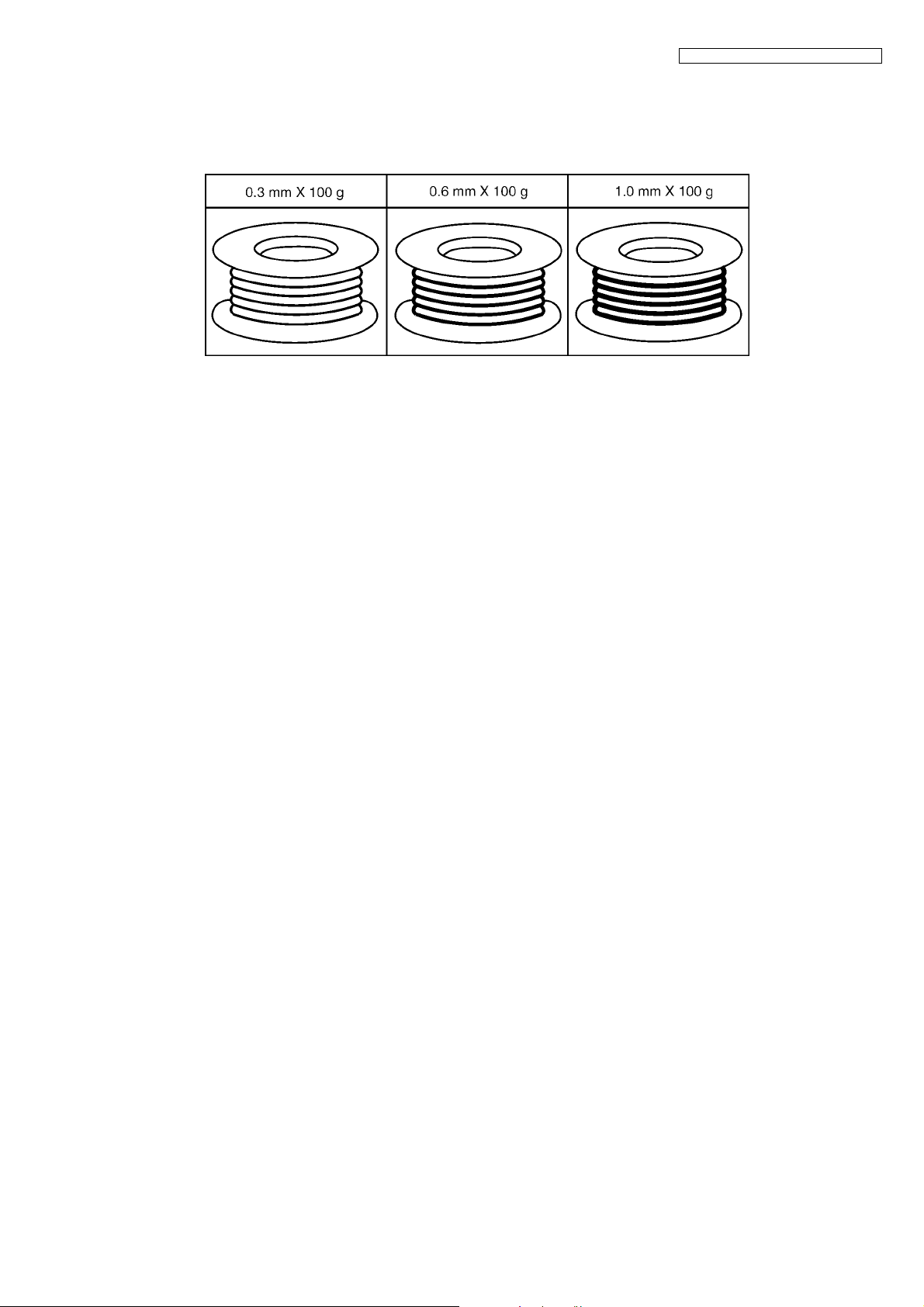

2.2.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu) or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the manufacturer’s

specific instructions for the melting points of their products and any precautions for using their product with other materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3 mm, 0.6 mm and 1.0 mm.

2.3. Discarding of P.C. Board

When discarding P. C. Board, delete all personal information such as telephone directory and caller list or scrap P. C. Board.

5

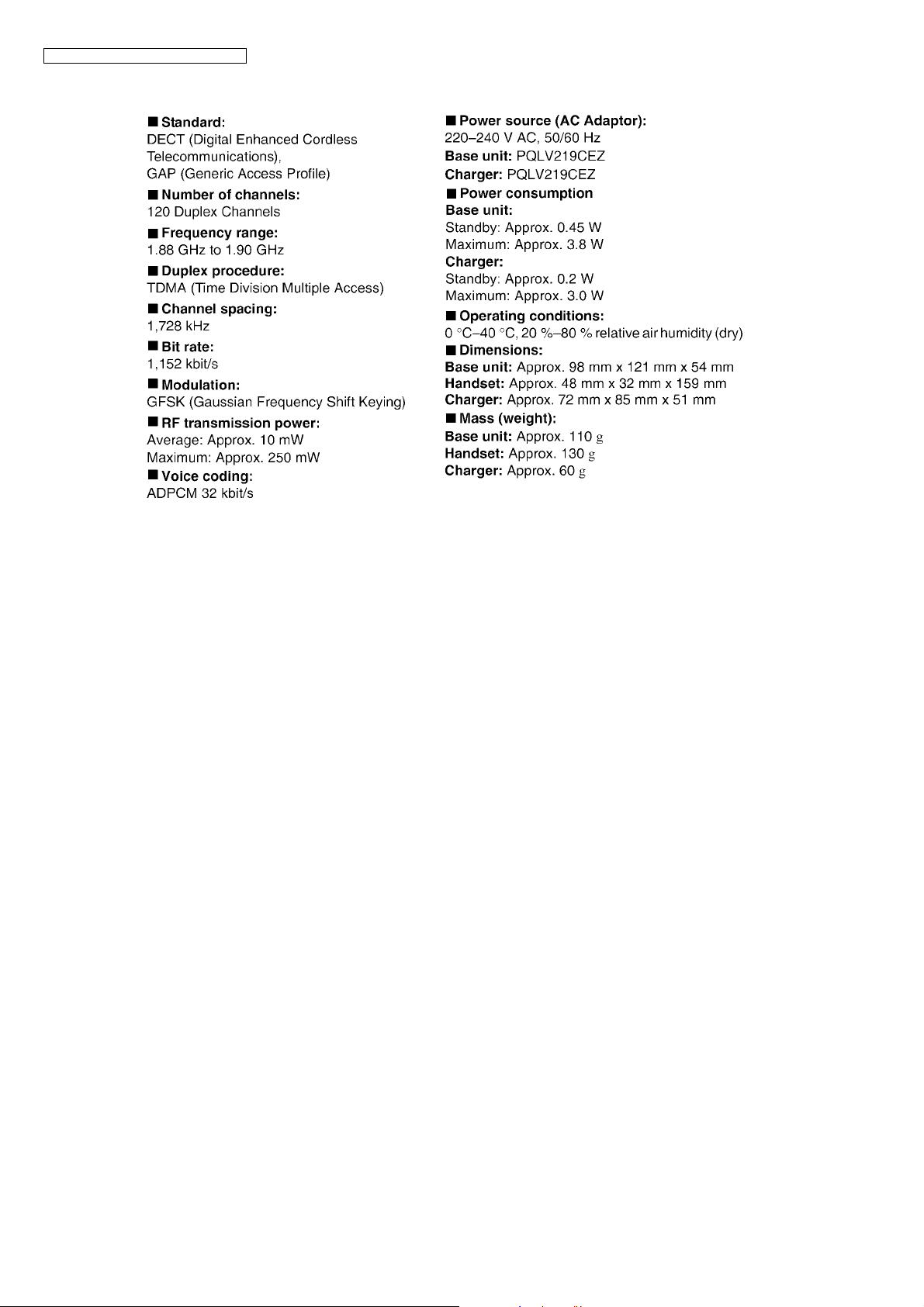

Page 6

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

3 Specifications

Note:

• Design and specifications are subject to change without notice.

Note for Service:

• Operation range: Up to 300 m outdoors, Up to 50 m indoors, depending on the condition.

• Analog telephone connection: Telephone Line

6

Page 7

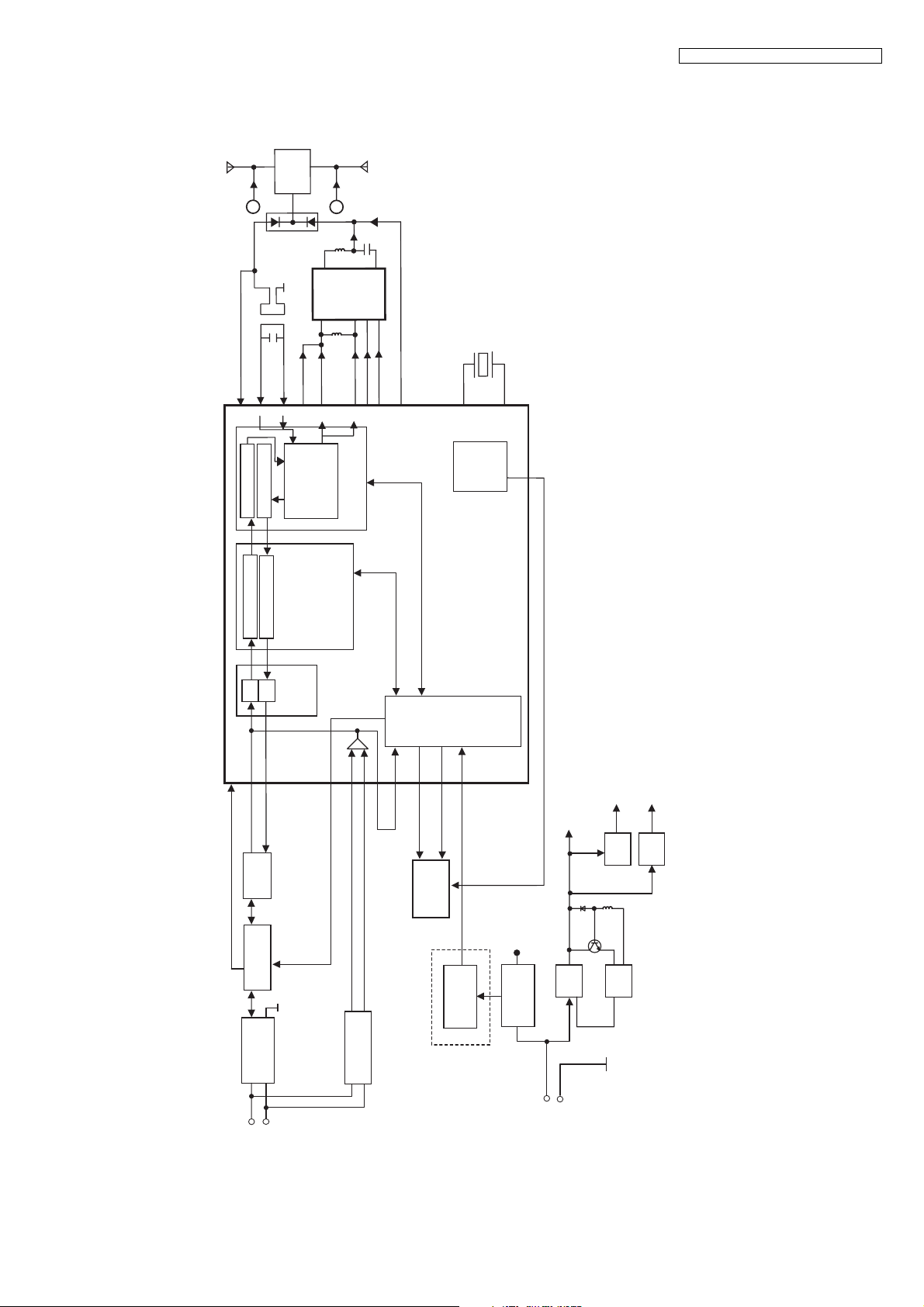

4 Technical Descriptions

D3

X1

4.1. Block Diagram (Base Unit)

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

T1

AN

T1

AN

on

X

R

5

Burst Encoding

Speech Encoding

T2

ANT1

AN

6

801

D

V

R

D

A

-P

p

n

X

DD

X

R

V

R

3

2

RF

Burst Decoding

Speech Decoding

T2

AN

72

9

A

P

F

R

4

p

X

T

77

75

PLL

MOD/DEMOD

DSP

ADPCM

Codec Filter

IC801

6

3

n

on

X

P

T

787374

BMC

ANT2

8

7

L

E

S

P

68

z

H

M

10.3

L

1

A

T

X

on

X

T

X

9

Pump

Charge

10

43

KX-TG2511/2512 BLOCK DIAGRAM (BASE UNIT)

80

IC7

BBIC

A/D

D/A

Analog

25

18

16

Audio

Off-Hook Line Voltage

Q4,Q5

Hook Switch

Bridge

Rect D3

2

L

L1

o TEL_LINE

End

Front

23

HOOK

20

211924

Interface

Bell/Caller ID

CPU

57

BELL

SCL

(Optional)

44

58

SDA

IC401

EEPROM

Charge

Detector

2.5V

CHARGE

CONTACT

Limit

Resistor

P

C

D

To AC Adaptor

3.0 V

IC2

M

C

D

Q9

2.4 V

2.4V

IC3

Reg.

1.8 V

1.8V

Reg.

Q8

7

Page 8

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

4.2. Circuit Operation (Base Unit)

4.2.1. Outline

Base Unit consists of the following ICs as shown in Block Diagram (Base Unit) (P.7).

• DECT BBIC (Base Band IC): IC7

- Handling all the audio, signal and data processing needed in a DECT base unit

- Controlling the DECT specific physical layer and radio section (Burst Module Controller section)

- ADPCM code filter for speech encoding and speech decoding (DSP section)

- Echo-cancellation and Echo-suppression (DSP section)

- Any tones (tone, sidetone, ringing tone, etc.) generation (DSP section)

- DTMF receiver (DSP section)

- Clock Generation for RF Module

- ADC, DAC, timer, and power control circuitry

- PLL Oscillator

-Detector

- Compress/Expander

- First Mixer

- All interfaces (ex: RF Power Amp, EEPROM, LED, Analog Front End, etc.)

• RF Power Amp.: IC801

- Amplifier for transmission and reception

• EEPROM: IC401

- Temporary operating parameters (for RF, etc.)

• Additionally,

- Power Supply Circuit (+3.0 V, +2.4 V, +1.8 V output)

- Crystal Circuit (10.368 MHz)

- Charge Circuit

- Telephone Line Interface Circuit

8

Page 9

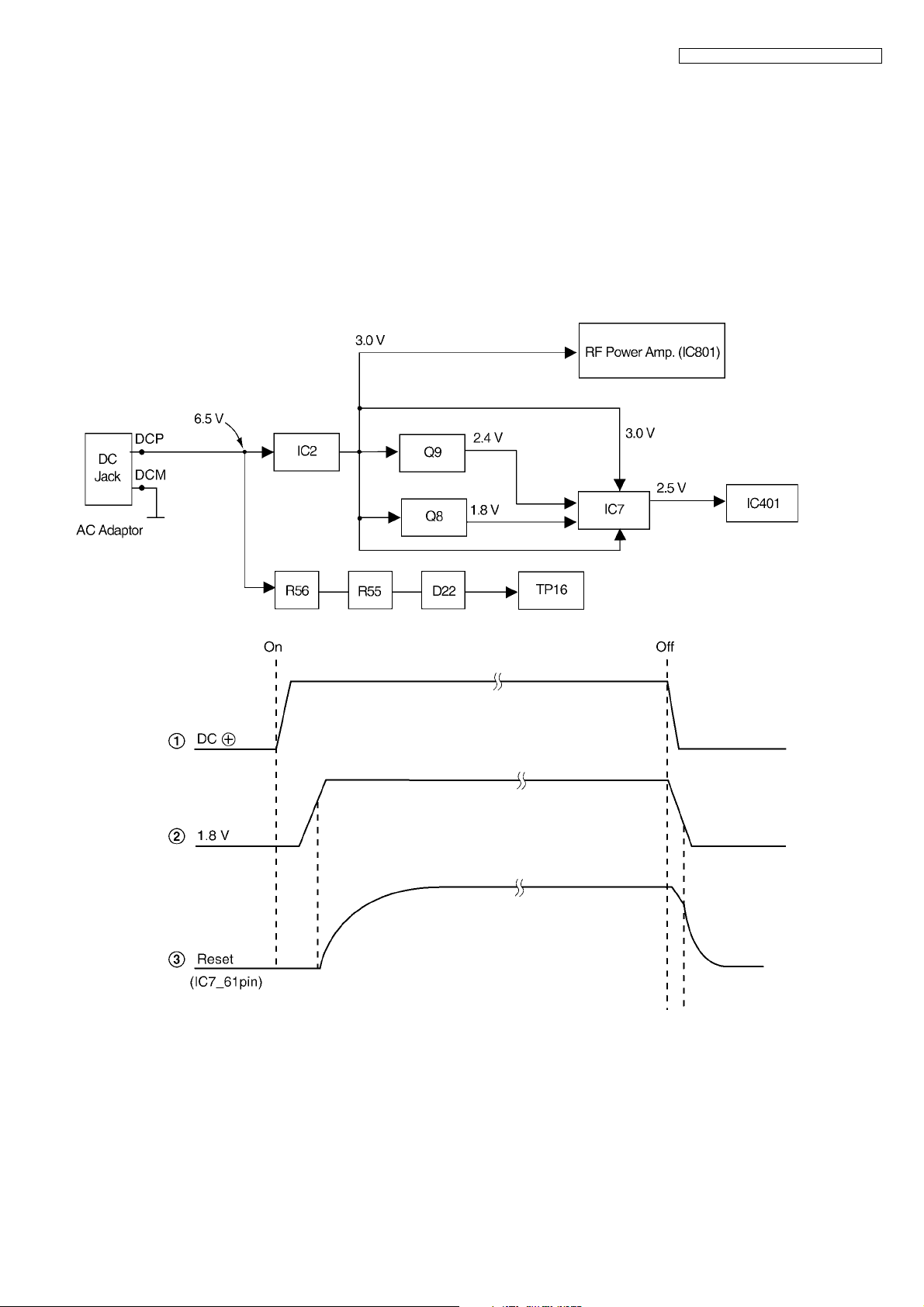

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

4.2.2. Power Supply Circuit

The power is supplied to the DECT BBIC, RF Module, EEPROM and Charge Contact from AC Adaptor (+6.5 V) as shown in

Fig.101. The power supply is as follows;

• DECT BBIC (IC7):

DC Jack (+6.5 V) → IC2 → IC7

DC Jack (+6.5 V) → IC2 → Q9 → IC7

DC Jack (+6.5 V) → IC2 → Q8 → IC7

• RF Power Amp. (IC801):

DC Jack (+6.5 V) → IC2 → IC801 (Power AMP)

• EEPROM (IC401):

DC Jack (+6.5 V) → IC2 → IC7→ IC401

• Charge Contact (TP16):

DC Jack (+6.5 V) → R56 → R55 → D22→ TP16

<Fig.101>

9

Page 10

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

4.2.3. Telephone Line Interface

<Function>

• Bell signal detection

• Clip signal detection

• ON/OFF hook circuit

Bell & Clip (: Calling Line Identification Presentation: Caller ID) signal detection:

In the standby mode, Q3 is open to cut the DC loop current and decrease the ring load.

When ring voltage appears at the L1T (A) and L1R (B) leads (when the telephone rings), the AC ring voltage is transferred as

follows;

•B → L2 → C4 → R6 → R33 → IC7 Pin 21 (CID INp)

•A → L1 → C3 → R4 → R35 → IC7 Pin 20 (CID INn)

ON/OFF hook circuit:

In the standby mode, Q3 is open, and connected as to cut the DC loop current and to cut the voice signal. The unit is

consequently in an on-hook condition.

When IC7 detects a ring signal or press the TALK Key onto the handset, Q4 turns on and then Q3 turns on, thus providing an

off-hook condition (DC current flows through the circuit) and the following signal flow makes the loop current.

•B → L2 →D3 → Q3 → Q5 → R21 → R22 → D3 → L1 →A [OFF HOOK]

4.2.4. Transmitter/Receiver

• Audio Circuits and DTMF tone signal circuits.

Base Unit and Handset mainly consist of RF Module and DECT BBIC.

Base Unit and Handset transmit/receive voice signal and data signal through the antenna on carrier frequency.

Signal Path:

*Refer to Signal Route (P.14).

4.2.4.1. Transmitter Block

The voice signal input from the TEL LINE interface goes to RF Power Amp. (IC801) through DECT BBIC (IC7) as shown in

Block Diagram (Base Unit) (P.7)

The voice signal passes through the analog part of IC7 where it is amplified and converted to a digital audio stream signal. The

burst switch controller processes this stream performing encryption and scrambling, adding the various other fields to produce

the GAP (Generic Access Profile) standard DECT frame, assigning to a time slot and channel etc.

In IC7, the carrier frequency is changing, and frequency modulated RF signal is generated.In IC801,RF signal is amplified, and

radiated from antenna. Handset detects the voice signal or data signal in the circuit same as the following explanation of

Receiver Block.

4.2.4.2. Receiver Block

The signal of 1900 MHz band (1881.792 MHz ~ 1897.344 MHz) which is input from antenna is input to IC7 as shown in Block

Diagram (Base Unit) (P.7).

In IC7, the signal of 1900 MHz band is downconverted to 864 kHz signal and demodulated, as GAP (Generic Access Profile)

standard DECT frames. It passes through the decoding section burst switch controller where it separates out the frame

information and performs de-encryption and de-scrambling as required. It then goes to the DSP section where it is turned back

into analog audio. This is amplified by the analog front end, and goes to the TEL LINE Interface.

4.2.5. Pulse Dialling

During pulse dialling the hookswitch (Q3, Q4) is used to generate the pulses using the HOOK control signal, which is set high

during pulses. To force the line impedance low during the “pause” intervals between dial pulses, the PULSE_DIAL signal turns

on Q2.

10

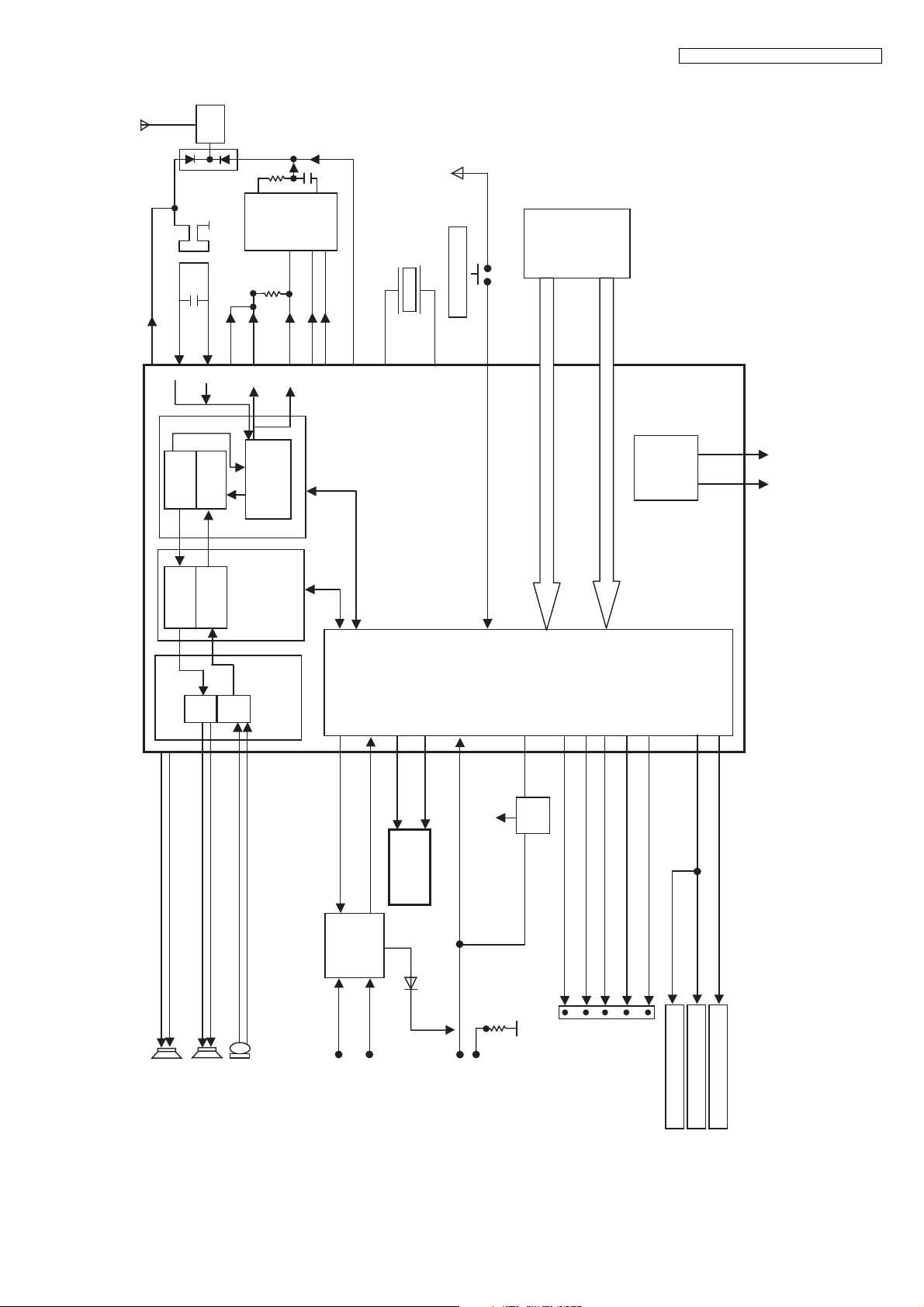

Page 11

4.3. Block Diagram (Handset)

Q4, Q9, R7

ANT1

ANT1

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

RXon

5

RXn

3

Burst

Decoding

Speech

Decoding

DA801

VDD-PADRY

RXp

TXp

2

75

Burst

Encoding

ADPCM

Speech

Encoding

9

RF PA

4

TXn

77

RF

PLL

MOD/DEMOD

Filter

Codec

IC801

367

Pon

78

737480

BMC

DSP

8

PSEL

TXon

X1

XTAL

9

10.368

MHz

10

BATTERY

ON SWITCH

44

KEYPAD

ROWS

COLUMNS

48, 49, 50, 51

22, 23, 24, 25, 26

Pump

Charge

IC1

BBIC

43 42

CP3.0V CP4.0V

KX-TGA250 BLOCK DIAGRAM (HANDSET)

33

35

SPEAKER

D/A

A/D

19

15

16

RECEIVER

MIC

Analog

20

End

Front

32

31

CHARGE

CHARGE_CTRL

CHARGE

CIRCUIT

Q4, Q9, R7

CHARGE(+)

CHARGE

CONTACTS

57

58

SCL

SDA

IC3

EEPROM

D7

CHARGE(-)

BATT+

CPU

36

VBAT

BATTERY

TERMINAL

13

1.8 V

R45

BATT-

LDO_CTRL

66

56

Q2

1.8 V

CD

RESET

635455

CSB

SDA

SCL

LCD

52

68

KEY LED

BELL LED

LCD-BACK LIGHT

11

Page 12

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

4.4. Circuit Operation (Handset)

4.4.1. Outline

Handset consists of the following ICs as shown in Block Diagram (Handset) (P.11).

• DECT BBIC (Base Band IC): IC1

- All data signals (forming/analyzing ACK or CMD signal)

- All interfaces (ex: Key, Detector Circuit, Charge, DC/DC Converter, EEPROM, LCD, RF Power Amp.)

- PLL Oscillator

-Detector

- Compress/Expander

- Reception

• RF Power Amp: IC801

- Amplifier for transmission

• EEPROM: IC3

- Temporary operating parameters (for RF, etc.)

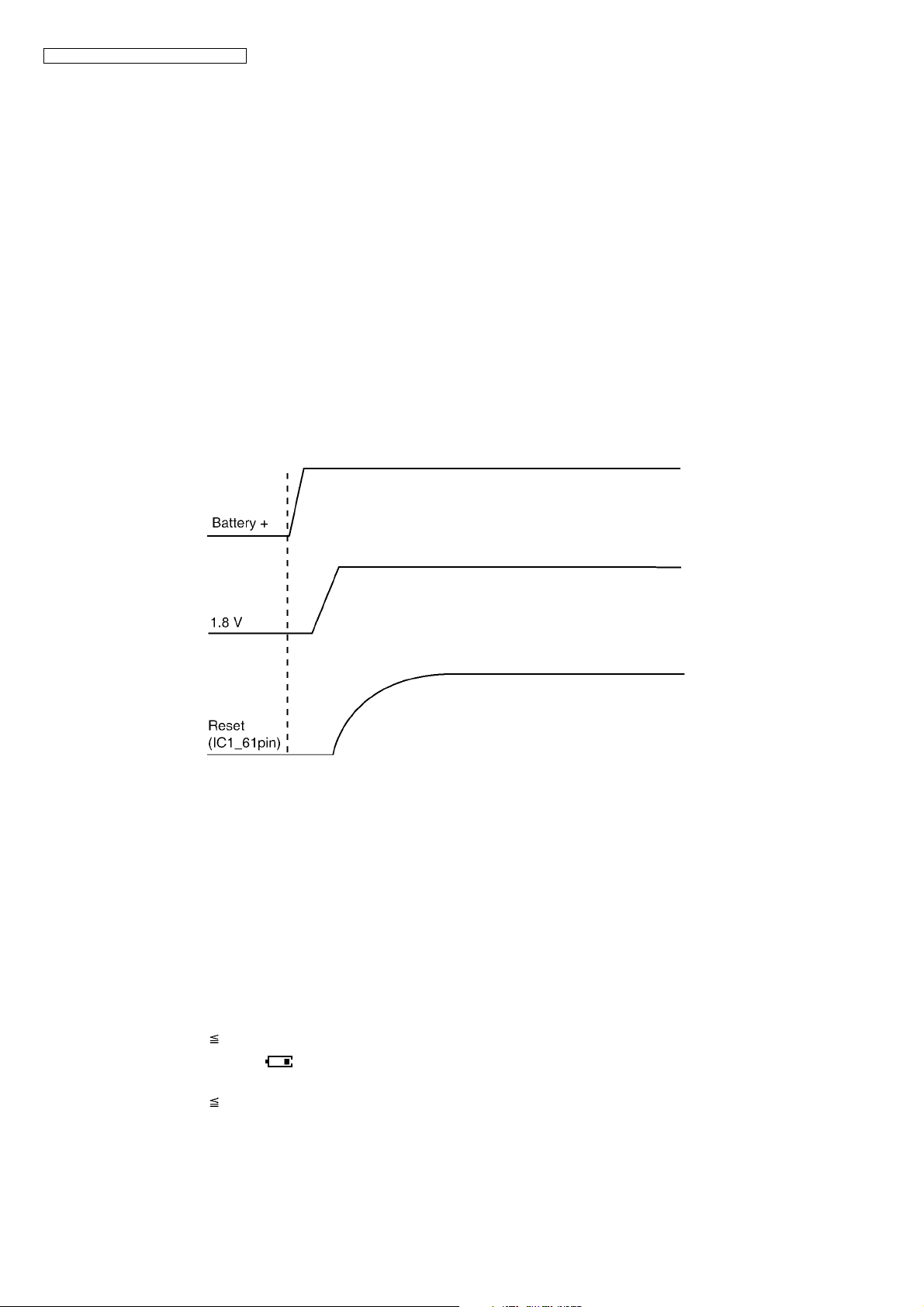

4.4.2. Power Supply Circuit/Reset Circuit

Circuit Operation:

When power on the Handset, the voltage is as follows;

BATTERY(2.2 V ~ 2.6 V: BATT+) → F1 → Q2 (1.8 V), IC1-43pin (2.5V)

The Reset signal generates IC1 (61 pin) and 1.8 V.

4.4.3. Charge Circuit

Circuit Operation:

When charging the handset on the Base Unit, the charge current is as follows;

DC+(6.5 V) → R56 → R55 → D22 → CHARGE+(Base) → CHARGE+(Handset) → Q4 → D7→ F1 → BATTERY+... Battery...

BATTERY- → R45 → GND → CHARGE-(Handset)→ CHARGE-(Base) → GND → DC-(GND)

In this way, the BBIC on Handset detects the fact that the battery is charged.

The charge current is controlled by switching Q9 of Handset.

Refer to Fig.101 in Power Supply Circuit (P.9).

4.4.4. Battery Low/Power Down Detector

Circuit Operation:

“Battery Low” and “Power Down” are detected by BBIC which check the voltage from battery.

The detected voltage is as follows;

• Battery Low

Battery voltage: V(Batt) 2.25 V ± 50 mV

The BBIC detects this level and " " starts flashing.

• Power Down

Battery voltage: V(Batt) 2.0 V ± 50 mV

The BBIC detects this level and power down.

4.4.5. Speakerphone

The hands-free loudspeaker at SP+ and SP- is used to generate the ring alarm.

12

Page 13

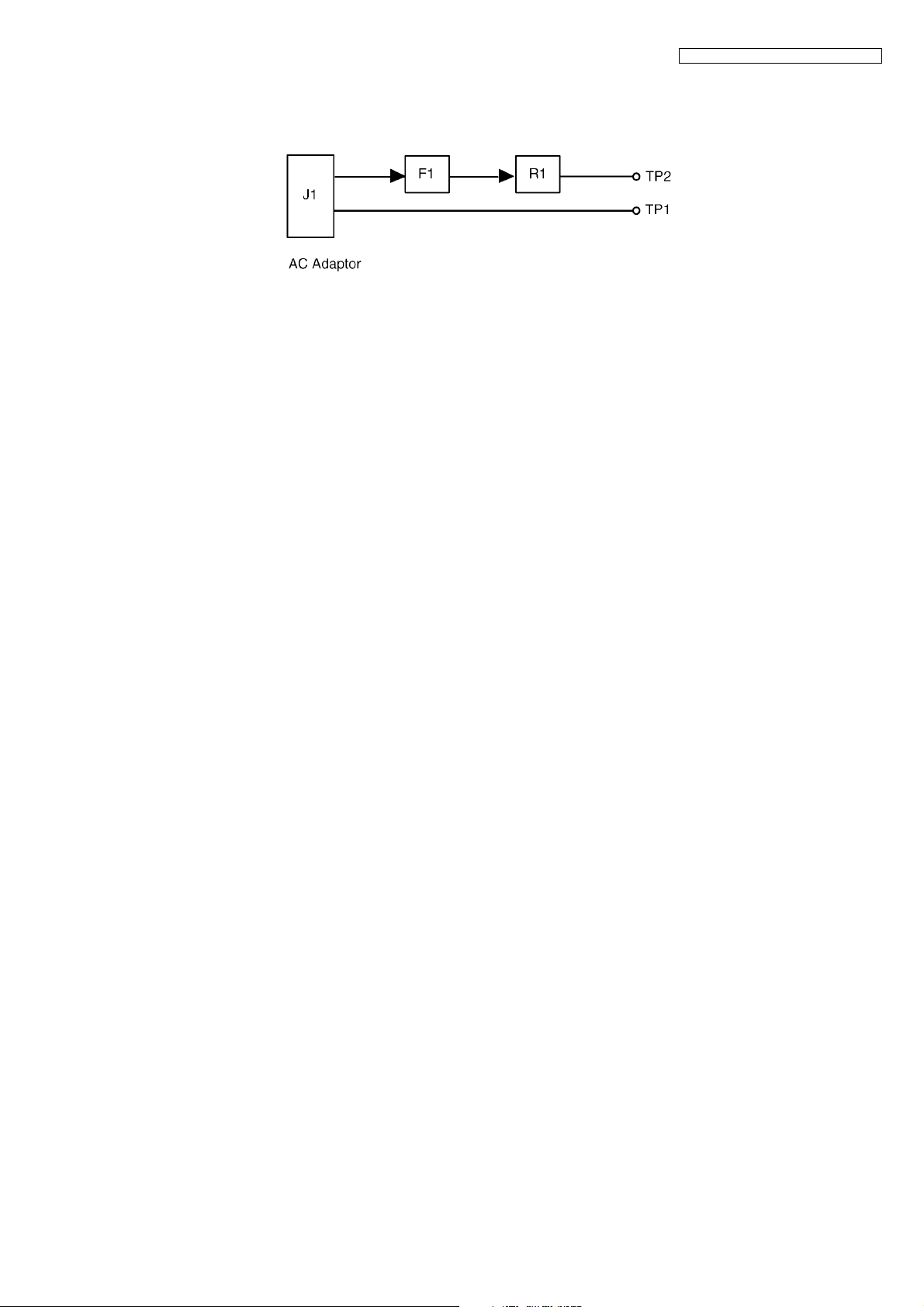

4.5. Circuit Operation (Charger Unit)

4.5.1. Power Supply Circuit

The power supply is as shown.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

13

Page 14

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

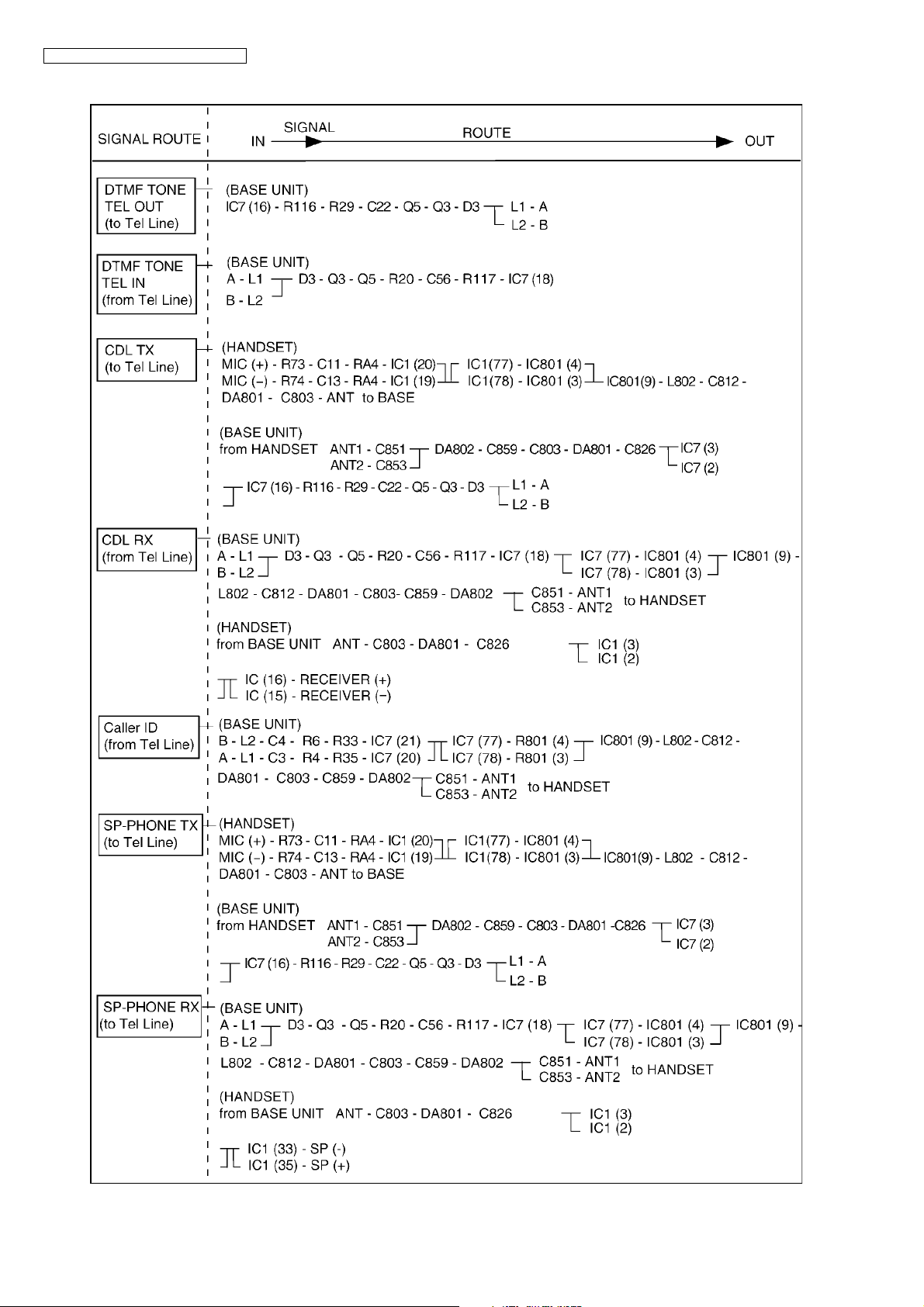

4.6. Signal Route

14

Page 15

5 Location of Controls and Components

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

6 Installation Instructions

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

7 Operating Instructions

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

7.1. For Service Hint

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

15

Page 16

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

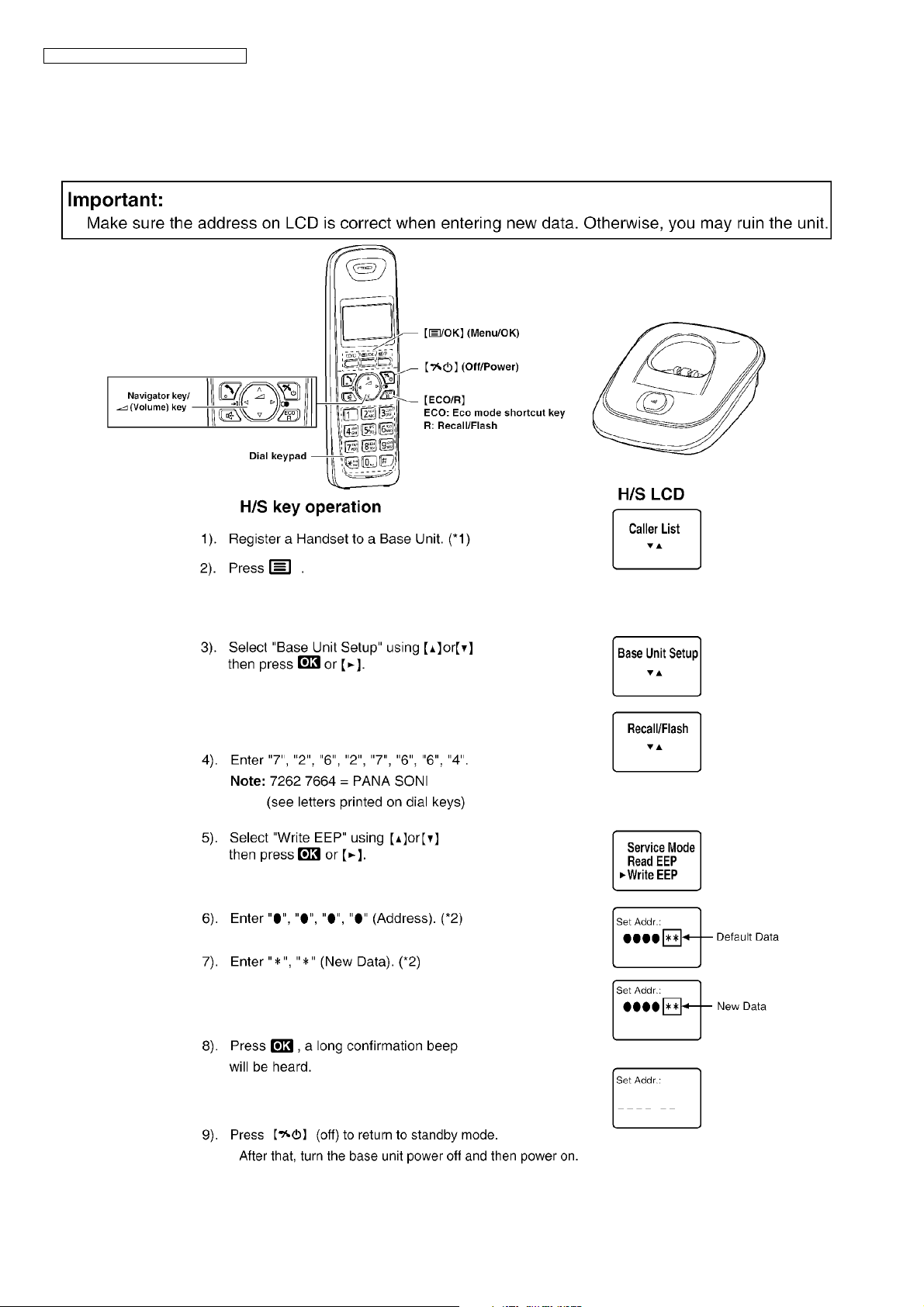

8 Service Mode

8.1. Engineering Mode

8.1.1. Base Unit

16

Page 17

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Frequently Used Items (Base Unit)

ex.)

Items Address Default Data New Data Remarks

C-ID (FSK) sensitivity 04 8B 00 01 (6 dB up) 02 (12 dB up) When hex changes from “00” to “01” or “02”,

Frequency 00 08/00 07 02/70 - - Use these items in a READ-ONLY mode to

ID 00 02~00 06 Given value - -

Bell length 02 18 32 (5sec) (*3) 1E (3 sec) 14 (2 sec) This is time until bell stops ringing.

PULSE Dial speed

(10PPS -> 20PPS)

01 F8 28 (40msec)

(*3)

01 F9 3C (60msec)

(*3)

02 07 57 (870msec)

(*3)

14 (20msec) - This is pulse make time. (Unit:1 ms)

1E (30msec) - This is pulse break time. (Unit:1 ms)

2C (440msec) - This is inter-digit time in pulse mode.

gain increases by 6 dB or 12 dB.

confirm the contents. Careless rewriting may

cause serious damage to the computer system.

(Unit: 100 ms)

(Unit:10 ms)

Note:

(*1) Refer to Registering a Handset to a Base Unit in the Operating Instructions.

(*2) When you enter the address or New Data, please refer to the table below.

Desired Number (hex) Input Keys Desired Number (hex) Input Keys

00 A[R] + 0

11 B[R] + 1

.. C[R] + 2

.. D[R] + 3

.. E[R] + 4

99 F[R] + 5

(*3)

Bell length 32(hex) = 50(dec) → 50 × 100 msec = 5000 msec (5 sec)

PULSE Dial speed

(10PPS -> 20PPS)

28(hex) = 40(dec) → 40 × 1msec = 40msec

3C(hex) = 60(dec) → 60 × 1msec = 60msec

57(hex) = 87(dec) → 87 × 10msec = 870msec

17

Page 18

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

8.1.2. Handset

18

Page 19

Frequently Used Items (Handset)

ex.)

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Address Default Data New Data Possible Adjusted

Value MAX (hex)

Sending level 03 17 Adjusted value Given value F3 F3 (*2)

Receiving level 03 18 Adjusted value Given value DB DB (*3)

Battery Low 00 04 70 - - -

Frequency 00 02/00 01 02/70 - - -

ID 00 10~00 14 Given value - - -

Possible Adjusted

Value MIN (hex)

Note:

(*1) When you enter the address or New Data, please refer to the table below.

Desired Number (hex.) Input Keys Desired Number (hex.) Input Keys

00 A[R] + 0

11 B[R] + 1

.. C[R] + 2

.. D[R] + 3

.. E[R] + 4

99 F[R] + 5

(*2) When adding “01” (hex) to default value, sending level increases by 0.25 dB.

ex.)

Item Default Data New Data

E7 EB E3

Sending level -2.5dBm -1.5dBm -3.5dBm

(*3) When reducing “01” (hex) from default value, receiving level increases by 0.25 dB.

ex.)

Remarks

(*4)

Item Default Data New Data

E7 EB E3

Receiving level -23dBm -22dBm -24dBm

(*4) Use these items in a READ-ONLY mode to confirm the contents. Careless rewriting may cause serious damage to the

handset.

19

Page 20

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

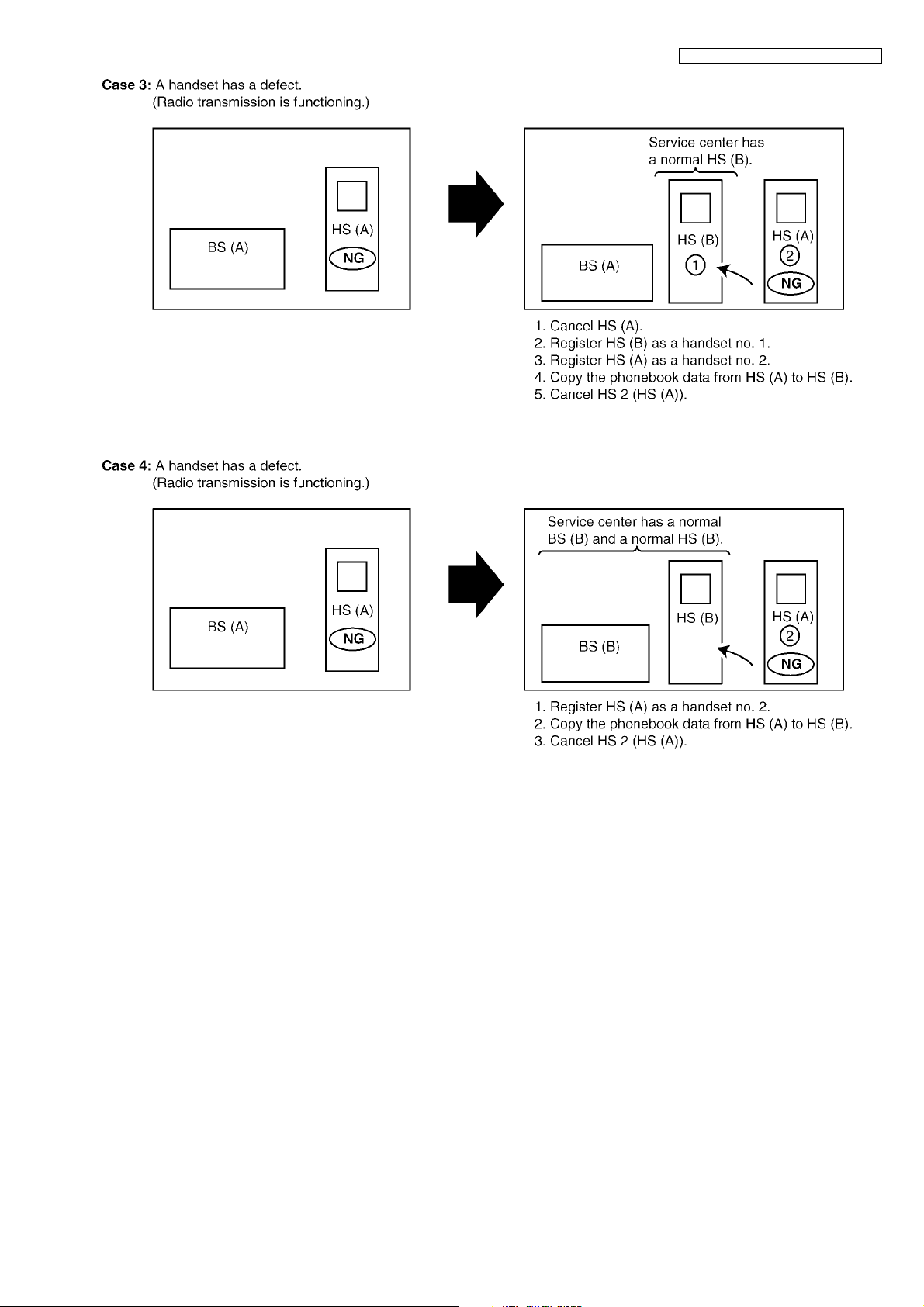

8.2. Copying Phonebook Items when Repairing

You can copy the handset phonebook to another (compatible Panasonic) handset. This will help to save the original phonebook

data which the customer has registered.

Available models: KX-TG2511/KX-TG2512

Refer to the following procedures.

Note:

• BS=Base Unit, HS=Handset

• If the max number of handsets are already registered to the base unit, a new handset cannot be registered.

• To register the handset, refer to Registering a Handset to a Base Unit in the Operating Instructions.

• To cancel the handset, refer to Deregistering a Handset in the Operating Instructions.

• To copy the handset phonebook, refer to Copying Phonebook Entries in the Operating Instructions.

20

Page 21

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Note:

• BS=Base Unit, HS=Handset

• If the max number of handsets are already registered to the base unit, a new handset cannot be registered.

• To register the handset, refer to Registering a Handset to a Base Unit in the Operating Instructions.

• To cancel the handset, refer to Deregistering a Handset in the Operating Instructions.

• To copy the handset phonebook, refer to Copying Phonebook Entries in the Operating Instructions.

21

Page 22

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

8.3. How to Clear User Setting

Units are reset to the Factory settings by this operation (Erase stored Phone numbers, Caller list and etc.)

Note:

• Some menus are not reset. Refer to Operating Instructions (P.15).

• The reset menus differ depending on the following operations.

• This operation should not be performed for a usual repair.

8.3.1. Resetting both base unit and handset

Both the base unit and the registered handset which you did the following steps to are reset. Other registered handsets

will not be reset.

Note:

(*1) Refer to Registering a Handset to a Base Unit in the Operating Instructions.

8.3.2. Resetting only handset

The only handset is reset by doing the following steps to .

Note: (*2)

• The handset registration to the base unit is cancelled.

• If the handset needs to be registered to the base unit, refer to Registering a Handset to a Base Unit in the Operating

Instructions.

• If users do not bring the base unit with them, the registration procedure has to be done by users themselves.

22

Page 23

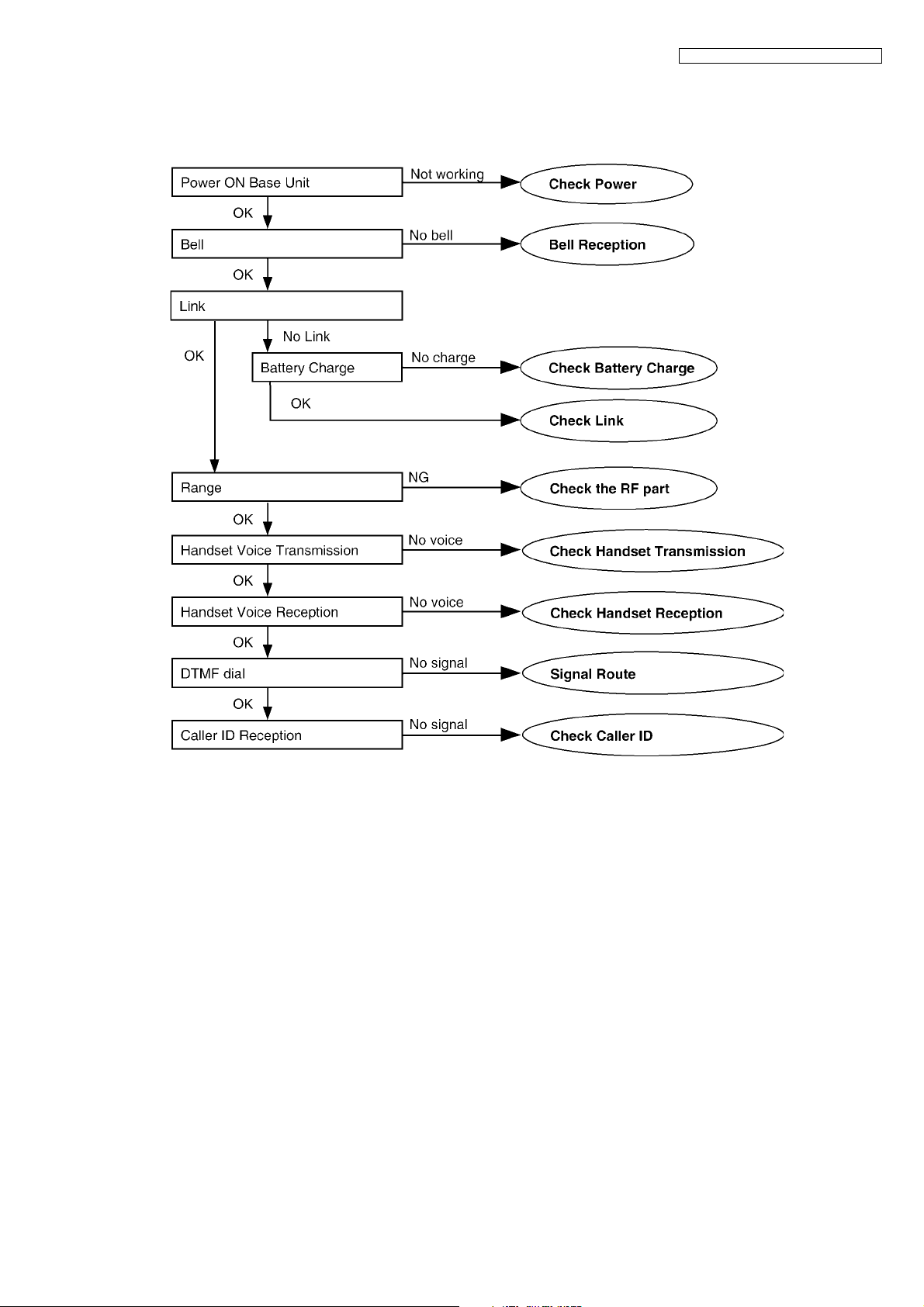

9 Troubleshooting Guide

9.1. Troubleshooting Flowchart

Flow Chart

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Cross Reference:

Check Power (P.24)

Bell Reception (P.34)

Check Battery Charge (P.25)

Check Link (P.26)

Check the RF part (P.30)

Check Handset Transmission (P.33)

Check Handset Reception (P.33)

Signal Route (P.14)

Check Caller ID (P.33)

23

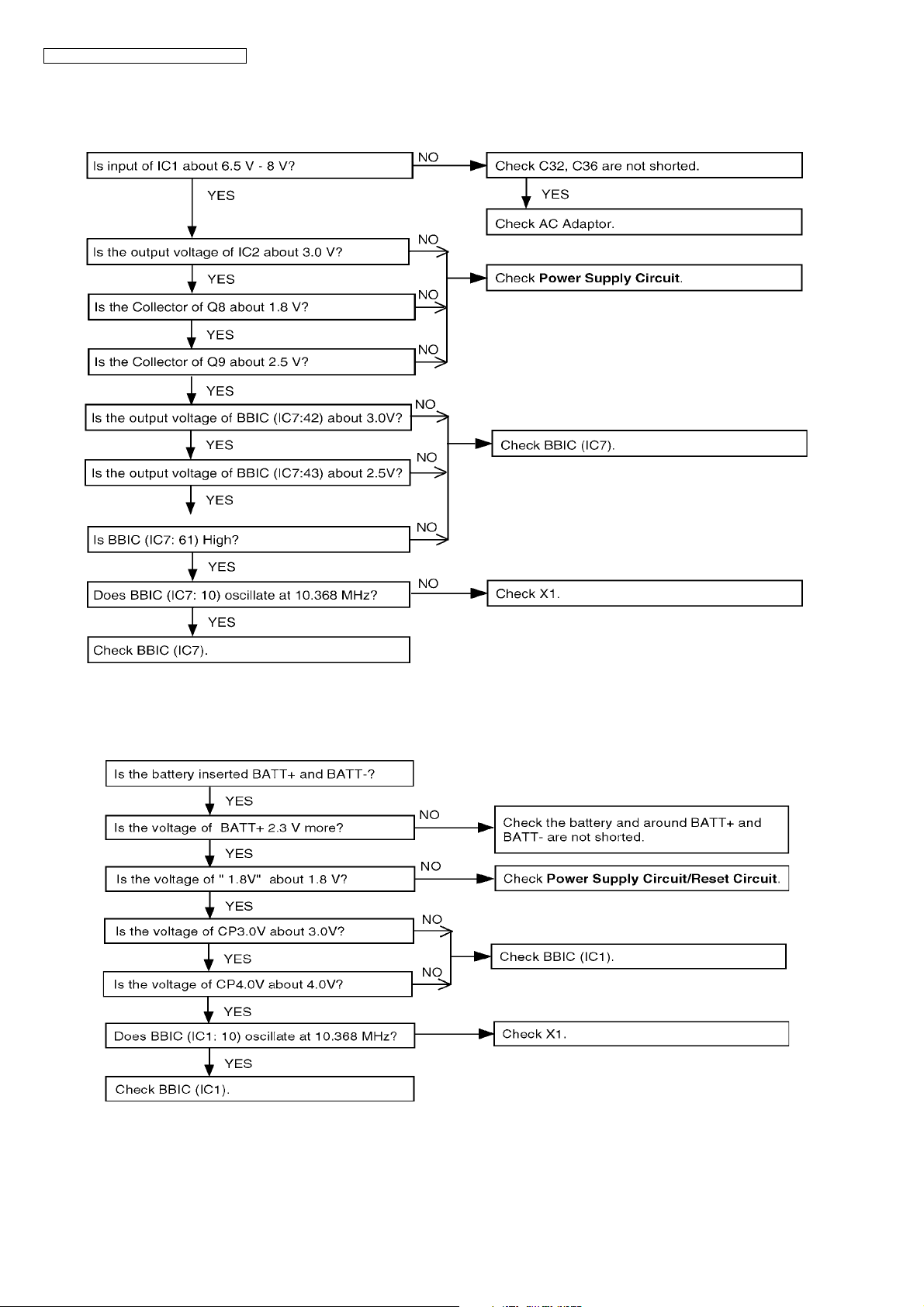

Page 24

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.1. Check Power

9.1.1.1. Base Unit

Is the AC Adaptor inserted into AC outlet? (*1)

Cross Reference:

Power Supply Circuit (P.9)

9.1.1.2. Handset

Cross Reference:

Power Supply Circuit/Reset Circuit (P.12)

Note:

(*1) Refer to Specifications (P.6) for part number and

supply voltage of AC Adaptor.

24

Page 25

9.1.2. Check Battery Charge

9.1.2.1. Base Unit

Cross Reference:

Charge Circuit (P.12)

9.1.2.2. Handset

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Cross Reference:

Check Power (P.24)

Charge Circuit (P.12)

9.1.2.3. Charger Unit

Cross Reference:

Charge Circuit (P.12)

25

Page 26

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.3. Check Link

9.1.3.1. Base Unit

Note:

(*1) Refer to Troubleshooting by Symptom (Base Unit and Charger Unit) (P.35)

Cross Reference:

Check Point (Base Unit) (P.35)

Power Supply Circuit (P.9)

26

Page 27

Cross Reference:

Check Point (Base Unit) (P.35)

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

27

Page 28

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.3.2. Handset

Note:

(*1) Refer to Troubleshooting by Symptom (Handset) (P.39)

Cross Reference:

Check Point (Handset) (P.39)

Power Supply Circuit/Reset Circuit (P.12)

28

Page 29

Cross Reference:

Check Point (Handset) (P.39)

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

29

Page 30

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.4. Check the RF part

9.1.4.1. Finding out the Defective part

After All the Checkings or Repairing

1. Re-register the checked Handset to the checked Base Unit, and Regular HS to Regular BU.

Note:

If you need to register a handset, refer to Registering a Handset to a Base Unit in the Operating Instructions.

30

Page 31

9.1.4.2. RF Check Flowchart

Each item (1 ~ 3) of RF Check Flowchart corresponds to Check Table for RF part (P.32).

Please refer to the each item.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Note:

(*1) Base unit - refer to (G) of Check Point (Base Unit) (P.35)

Handset - refer to (H) of Check Point (Handset) (P.39)

31

Page 32

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.4.3. Check Table for RF part

No. Item BU (Base Unit) Check HS (Handset) Check

1 Link Confirmation Normal

HS, BU Mode: [Normal mode]

2 X’tal Frequency confirmation 1. Check X’tal Frequency. (*1)

3 Range Confirmation Normal

HS, BU Mode: [Normal mode]

Note:

(*1) Refer to Adjustment Standard (Base Unit) (P.49)

(*2) Refer to Adjustment Standard (Handset) (P.53)

1. Register Regular HS to BU (to be

checked).

2. Press [Talk] key of the Regular HS to

establish link.

(10.368 MHz ± 100 Hz)

1. Register Regular HS to BU (to be

checked).

2. Press [Talk] key of the Regular HS to

establish link.

3. Compare the range of the BU (being

checked) with that of the Regular BU.

1. Register HS (to be checked) to Regular

BU.

2. Press [Talk] key of the HS to establish link.

1. Check X’tal Frequency. (*2)

(10.368 MHz ±100Hz)

1. Register HS (to be checked) to Regular

BU.

2. Press [Talk] key of the HS to establish link.

3. Compare the range of the HS (being

checked) with that of the Regular HS.

32

Page 33

9.1.5. Check Handset Transmission

Cross Reference:

Signal Route (P.14)

9.1.6. Check Handset Reception

Cross Reference:

How to Check the Handset Speaker or Receiver (P.57).

Signal Route (P.14)

9.1.7. Check Caller ID

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Cross Reference:

Signal Route (P.14)

33

Page 34

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.1.8. Bell Reception

9.1.8.1. Base Unit

9.1.8.2. Handset

Cross Reference:

Telephone Line Interface (P.10)

Check Link (P.26)

How to Check the Handset Speaker or Receiver (P.57)

34

Page 35

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.2. Troubleshooting by Symptom (Base Unit and Charger Unit)

If your unit has below symptoms, follow the instructions in remedy column. Remedies depend on whether you have DECT tester

(*1) or not.

Note:

(*1) A general repair is possible even if you don’t have the DECT tester because it is for confirming the levels, such as Acoustic

level in detail.

(*2) Refer to Check Point (Base Unit) (P.35)

9.2.1. Check Point (Base Unit)

Please follow the items below when BBIC or EEPROM or FLASH is replaced.

Note:

After the measuring, suck up the solder of TP.

*: The Setting Method of JIG (Base Unit) (P.47) is required beforehand.

The connections of simulator equipment are as shown in Adjustment Standard (Base Unit) (P.49).

Items Check

(A) 3.0 V Supply Confirma-

tion

(B) 1.8 V Supply Confirma-

tion

(C) Charge Pump

2.5V Supply Confirmation

(D) Charge Pump

3.0V Supply Confirmation

(E)* BBIC Confirmation - 1. BBIC Confirmation (Execute the command “getchk”).

Point

VDD3 1. Confirm that the voltage between test point VDD3 and GND is 3.0 V ± 0.2 V. IC2, IC3, C32,

VDD1 1. Confirm that the voltage between test point VDD1 and GND is 1.8 V ± 0.02 V.

2. Execute the command “VDD”, then check the current value.

3. Adjust the 1.8V voltage of VDD1 executing command “VDD XX“(XX is the

value).

VDD5 1. Confirm that the voltage between test point VDD5 and GND is 2.5 V ± 0.3 V. IC7,C625,C631

VDD4 1. Confirm that the voltage between test point VDD4 and GND is 3.0 V ± 0.2 V. IC7,C616,C630

2. Confirm the returned checksum value.

Connection of checksum value and program number is shown below.

Procedure Check or

Replace Parts

C36, C86, C87,

C88, R91, R92,

R93, R95, D10,

Q10, L3

Q8, C75, C614,

C61, IC7

IC7, X1, R77,

RA80

(F)* EEPROM Confirmation - 1. EEP-ROM Confirmation (Execute the command "sendchar EPV").

2. Confirm the returned Value(Value for reference is written at "EEPROM C/

SUM” in Software_Version_Table.xls).

(G)* BBIC Clock Adjustment CLK 1. Input Command “ sendchar WWD ff 48 IC 8006”

2. Confirm that the voltage between testpoint VDD4 and GND is less than 1.0 V.

3. Input Command “ sendchar sfr”, then you can confirm the current value.

4. Check X’tal Frequency. (10.368 MHz ± 100 Hz).

5. If the frequency is not 10.368MHz ± 100Hz, adjust the frequency of CLK executing the command “sendchar sfr xx xx (where xx is the value)” so that the

reading of the frequency counter is 10.368000 MHz ± 5 Hz.

35

IC7, RA402,

C51, R657,

IC401

X1, IC7, R430,

C305

Page 36

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Check

Procedure Check or

Point

(H)* Hookswitch Check with

DC Characteristics

- 1. Connect Telephone Socket to Tel-simulator which is connected with 600 Ω.

2. Set line voltage to 48 V and line current to 40mA at off-hook condition of normal telephone.

3. Execute the command “hookoff”

4. Confirm that the line current is 40 mA ± 5 mA.

5. Execute the command “hookon”.

6. Confirm that the line current is less than + 0.8 mA.

(I) DTMF Generator Check - 1. Connect Telephone Socket to DTMF tester. (Load=600 Ω)

2. Link Handset and push dial key.

3. Confirm DTMF character.

4. Confirm that the high Group is -3.0 ± 2.

5. Confirm that the low Group is -6.0 ± 2.

(J)* Transmitted Power Con-

firmation

-

ANTI_TP

Remove the Antenna before starting step from 1 to 7.

1. Configure the DECT tester (CMD60) as follows;

<Setting>

• Test mode: FP

• Traffic Carrier: 5

•Traffic Slot: 4

• Mode: Loopback

• PMID: 00000

• RF LEVEL = -70 dBm.

2. Execute the command ”sendchar TST”.

3. Execute the command “sendchar dmv 2 2”.

4. Check that “Signalling Status” has been set to “Locked”, then press “ACCEPT

RFPI”.

5. Initiate connection from Dect tester (“set up connect”)

6. Execute the command “ANT1”.

7. Confirm that the NTP value at ANT is 19.0 dBm ~ 25.0 dBm.

(K)* Modulation Check -

ANTI_TP

Follow steps 1 to 6 of (J).

7.Confirm that the B-Field Modulation is -370 ± 30/ +370± 30 kHz/div & Modulated width 690 kHz using data type Fig31.

(L)* Frequency Offset Check -

ANTI_TP

Follow steps 1 to 6 of (J).

7.Confirm that the frequency offset is < ± 50 kHz.

Replace Parts

L1, L2, Q3, R14,

R15, Q4, R16,

R17, D3,

R18~R24,

C15~C17, D21,

Q5, R27, IC7

IC7, R116,

C141, R29, C22,

C23, Q5, D21

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

36

Page 37

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Check

Point

(M)* Frequency Drift Confir-

mation

ANTI_TP

(N)* Sensitivity Receiver

Confirmation

ANTI_TP

(O)* Timing Confirmation -

ANTI_TP

(P)* Power RAMP Confirma-

tion

-

Follow steps 1 to 6 of (J).

7.Confirm that the frequency drift is < ± 35 kHz/ms.

-

Follow steps 1 to 6 of (J).

7.Set DECT tester power to -90 dBm.

8.Confirm that the BER is < 1000 ppm.

Follow steps 1 to 6 of (J).

7.Confirm that the Timing accuracy is

• ± 5.0 ppm (When adjust the frequency of CLK in item (G)).

• ± 15 ppm (When do not adjust the frequency of CLK in item (G)).

- Follow steps 1 to 6 of (J).

7.Confirm that Power RAMP is matching.

Procedure Check or

Replace Parts

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

IC7,

C802~C806,

C808~C814,

C820, C819,

C822, C823,

C825, C827,

C826, C834,

C851, C853,

C859~C861,

DA801, DA802,

IC801,

L801~L803,

C855~C858,

R801~R807,

R106, R109,

Q9, C617

37

Page 38

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Check

Point

(Q) Audio Check - 1. Link with Handset which is connected to Line Simulator.

(R) Charging Check - 1. Connect Charge Contact 12 Ω/2 W resistor between charge+ and charge-.

(S) 2.4V Supply Confirma-

tion VDD2

VDD2 1. Confirm that the voltage between test point VDD2 and GND is 2.5V ± 0.2V. IC7, Q9, C617

2. Set line voltage to 48V and line current to 50mA.

3. Input -45dBm(600.)/1kHz to MIC of Handset. Measure the Level at Line I/F

and distortion level.

4. Confirm that the level is -2.5dBm ± 2 dBm and that the distortion level is <5%

at TEL Line (600. Load).

5. Input -23dBm(600.)/1kHz to Line I/F. Measure the Level at Receiver of Handset and distortion level (Receive volume set to second position from minimum).

6. Confirm that the level is -22 dBm ± 2 dBm and that the distortion level is < 5%

at Receiver (150. Load).

2. Measure and confirm voltage across the resistor is 3.3V ± 0.3V.

Procedure Check or

9.2.2. Check Point (Charger Unit)

Replace Parts

IC7, SA1, L1,

L2, D3, Q3, Q4,

R14, R15, R16,

R17, D21, Q5,

R19, R20, C14,

C56, R117,

R116, C141, R9,

C22, C23

R55, R56, D22,

D23, D24, C623,

C624

Items Check

Point

(A) Charging Check - 1. Connect Charge Contact 12Ω/2 W resistor between charge+ and charge-.

2. Measure and confirm voltage across the resistor is 3.1 V ± 0.3 V.

Procedure Check or

Note:

After the measuring, suck up the solder of TP.

The connection of adjustment equipment is as shown in Adjustment Standard (Charger Unit) (P.50).

Replace Parts

R1, F1

38

Page 39

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.3. Troubleshooting by Symptom (Handset)

If your unit has below symptoms, follow the instructions in remedy column. Remedies depend on whether you have DECT tester

(*1) or not.

Note:

(*1) A general repair is possible even if you don’t have the DECT tester because it is for confirming the levels, such as Acoustic

level in detail.

(*2) Refer to Check Point (Handset) (P.39)

9.3.1. Check Point (Handset)

Please follow the items below when BBIC or EEPROM is replaced.

Note:

After the measuring, suck up the solder of TP.

*: Connections (P.51) is required beforehand.

The connections of adjustment equipment are as shown in Adjustment Standard (Handset) (P.53).

Items Check

Point

(A)* 1.8 V Supply Adjustment VDD1 1. Confirm that the voltage between test point VDD1 and GND is 1.8 V ± 0.02 V.

(B)* BBIC Confirmation - 1. BBIC Confirmation (Execute the command “getchk”).

(C)* EEP-ROM Confirmation - 1. EEP-ROM Confirmation (Execute the command "sendchar EPV").

(D) Charge Control Check &

Charge Current Monitor

Check

(E)* Charge Detection (OFF)

Check

- 1. Apply 3.5 V between CHG(+) and CHG(-) with DC power supply and set cur-

- 1. Stop supplying 3.5 V to CHG (+) and CHG (-).

2. Execute the command “VDD”, then check the current value.

3. Adjust the 1.8V voltage of VDD1 executing command “VDD XX“(XX is the

value).

2. Confirm the returned checksum value.

Connection of checksum value and program number is shown below.

2. Confirm the returned Value (Value for reference is written at "EEPROM C/

SUM” in Software_Version_Table.xls).

rent limit to 250 mA.

Confirm the indication of “charging” on LCD.

2. Confirm that the current limit LED of DC power supply is ON/OFF.

Confirm it after waiting over 1 minute at least.

3. Decrease current limit of DC power supply to 100 mA.

4. Confirm that the current limit LED of DC power supply is stable. (Current limiter

is ON.)

(If charge control cannot be confirmed by this procedure, please use battery to handset power supply and try again.)

2. Confirm the indication of “charging” has been cleared.

Procedure Check or

Replace Parts

IC1, Q2, C48,

D1, C1, C44,

R45, C40,

C45, F1

IC1, X1, RA61,

R64, R66

IC1, IC3,

RA40, C172

IC1, Q4 Q9,

D7, R6, R7,

F1, C1, R2,

R30, R31, R8,

R45

IC1, Q4 Q9,

D7, R6, R7,

F1, C1, R2,

R30, R31, R8,

R45

39

Page 40

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Check

Point

(F)* Battery Monitor Check - 1. Apply 2.25 V between BATT+ and BATT-.

2. Execute the command

sendchar PAD

sendchar LED 0

sendchar CRX 0 1

sendchar AD1

It assumes that the return value is XX.

a) 6c XX 71: No need to adjust

b) XX: 6A ~ 6B: Need to adjust

XX: 72 ~ 74: Need to adjust

Write AD value of 2.25 V to EEPROM.

ex) read data: XX = 6A, write data: YY = 6A

read data: XX = 73, write data: YY = 73

EEPROM = 0009(Low Voltage) write “YY”

Execute the command “wreeprom 00 09 01 YY”.

EEPROM = 000A(No Voltage) write ‘’YY - 1D’’

Execute the command “×wreeprom 00 0A 01 ZZ”.

Procedure Check or

Note:

ZZ = YY - 1D

No Voltage writing data limit is ‘00’.

c) XX: 00 ~ 69: Reject

XX: 75 ~ FF: Reject

(G) Battery Low Confirma-

tion

(H)* BBIC Clock Adjustment CLK 1. Apply 2.6 V between BATT+ and BATT- with DC power.

(I)* Transmitted Power Con-

firmation

(J)* Modulation Check - Follow steps 1 to 3 of (K).

- 1. Apply 2.40 V between BATT+ and BATT-.

2. Confirm that there is no flashing of Battery Icon.

3. Apply 2.25 V ± 0.08 V between BATT+ and BATT-.

4. Confirm that there is flashing of Battery Icon.

2. Input Command “sendchar sfr”, then you can confirm the current value.

3. Check X’tal Frequency. (10.368 MHz ± 100 Hz).

4. If the frequency is not 10.368 MHz ± 100 Hz, adjust the frequency of CLK executing the command “sendchar sfr xx xx (where xx is the value)” so that the

reading of the frequency counter is 10.368000 MHz ± 5 Hz.

Note:

Clear the registered information for Base Unit before measurement, because the

Frequency will not possibly get stable due to the registered information.

Pressing the button of "3" "5" "7" "#" clears the registration.

Register to it on Base Unit after measurement.

- Remove the Antenna before starting step from 1 to 4.

1. Configure the DECT tester (CMD60) as follows;

<Setting>

• Test mode: PP

• RFPI: 0102030405

• Traffic Carrier: 5

•Traffic Slot: 4

• Mode: Loopback

• RF LEVEL = -70 dBm

• PACKET: PP32Z

2. Execute the command “sendchar TST 01 02 03 04 05".

3. Initiate connection from DECT tester.

4. Confirm that the NTP value at ANT is 19 dBm ~ 25 dBm.

4.Confirm that the B-Field Modulation is -370±30/ +370±30 kHz/div & Modulated

width 690 kHz using data type Fig 31.

Replace Parts

IC1, F1, C1,

R45

IC1, F1, C1,

R45

IC1, X1, C47

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

40

Page 41

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Items Check

(K)* Frequency Offset Confir-

mation

(L)* Frequency Drift Confir-

mation

(M)* Sensitivity Receiver

Confirmation

(N)* Power RAMP Confirma-

tion

(O) Audio Check and Confir-

mation

(P) SP phone Audio Check

and Confirmation

(Q) Charge Pump 3.0V

Supply Confirmation

(R) Charge Pump 4.0V

Supply Confirmation

Procedure Check or

Point

- Follow steps 1 to 3 of (I).

4.Confirm that the frequency Offset is < ± 50 kHz.

Replace Parts

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

- Follow steps 1 to 3 of (I).

4.Confirm that the frequency Drift is < ± 35 kHz/ms.

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

- Follow steps 1 to 3 of (I).

4.Set DECT tester power to -88 dBm.

5.Confirm that the BER is < 1000 ppm.

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

- Follow steps 1 to 3 of (I).

4.Confirm that Power RAMP is matching.

IC1,

C802~C806,

C808~C814,

C819~C820,

C822,

C825~C827,

C834,

C860~C864,

L801~L804,

DA801,

R801~R808

- 1. Link to BASE which is connected to Line Simulator.

2. Set line voltage to 48V and line current to 50mA.

3. Input -45dBm(600.)/1kHz to MIC of Handset. Measure the Level at Line I/F and

distortion level.

4. Confirm that the level is -2.5dBm ± 2 dBm and that the distortion level is <5% at

TEL Line (600. Load).

IC1, C12, C96,

C97, R215,

R27, RA4,

C11, C13,

R28, D3, D4,

MIC, R73, R74

5. Input -23dBm(600.)/1kHz to Line I/F. Measure the Level at Receiver of Handset

and distortion level (Receive volume set to second position from minimum).

6. Confirm that the level is -22dBm ± 2 dBm and that the distortion level is <5% at

Receiver (150. Load).

- 1. Link to Base which is connected to Line Simulator.

2. Set line voltage to 48V and line current to 50mA.

3. Set the handset off-hook using SP-Phone key.

4. Input -23 dBm(600.)/1KHz to Line I/F and measure Receiving level at SP+ and

SP-.

5. Confirm that the level is -11.0 dBm ± 2 dBm and that the distortion level is <

5%. (vol = 3)

IC1, C12, C73,

D13, D14,

R73, R74,

MIC, C11,

C13, RA4,

R27, R28,

C96, C97,

R215, C72

CP3.0V 1. Confirm that the voltage between testpoint CP3.0V and GND is 3.0 ± 0.3. C49, C52~C54

CP4.0V 1. Confirm that the voltage between testpoint CP4.0V and GND is 4.0V ± 0.3V. C50, C51, C55

41

Page 42

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

9.3.2. Troubleshooting for Speakerphone

When the customer’s telephone line corresponds to the following conditions, and the transmission signal of SP-Phone is

interrupted, performing the next set up to a cordless handset will improve it to some extent.

Conditions

1. When customer’s line has less line loss.

ex.) The customer is using optical fiber, ISDN terminal adaptor, or PBX.

In this case, receiving signal is strong and it may affect transmission signal.

2. When the other party is talking from noisy place.

ex.) The other party is using cellular phone. The background noise is very loud.

In this case, the noise from the other party (i.e. surrounding noise) may affect transmission signal.

Setting Method

• Change the handset address of EEPROM (0129) from 00 to 01 by Engineering Mode.

42

Page 43

10 Disassembly and Assembly Instructions

10.1. Disassembly Instructions

10.1.1. Base Unit

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

43

Page 44

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

10.1.2. Handset

44

Page 45

10.1.3. Charger Unit

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

45

Page 46

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

10.2. How to Replace the Handset LCD

Note:

The illustrations are simplified in this page.

They may differ from the actual product.

46

Page 47

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11 Measurements and Adjustments

This chapter explains the measuring equipment, the JIG connection, and the PC setting method necessary for the measurement in

Troubleshooting Guide (P.23)

11.1. Equipment Required

• Digital multi-meter (DMM): it must be able to measure voltage and current.

• Oscilloscope.

• Frequency counter: It must be precise enough to measure intervals of 1 Hz (precision; ±4 ppm)

Hewlett Packard, 53131A is recommended.

• DECT tester: Rohde & Schwarz, CMD 60 is recommended.

This equipment may be useful in order to precisely adjust like a mass production.

11.2. The Setting Method of JIG (Base Unit)

This section explains the PC setting to use command required in Check Point (Base Unit)(P.35).

<Preparation>

• Serial JIG cable: PQZZ1CD300E*

• PC which runs in DOS mode

• Batch file CD-ROM for setting: PNZZTG2511CA

Note:

*: If you have the JIG Cable for TCD500 series

11.2.1. Connections

Connect the AC adaptor to DC-JACK (base unit).

Connect the JIG Cable GND (black) to GND.

Connect the JIG Cable RX (red) to URX and TX (yellow) to UTX.

(PQZZ1CD505E), change the following values of

resistance. Then you can use it as a JIG Cable for both

TCD300 and TCD500 series. (It is an upper compatible JIG

Cable.)

Resistor Old value (kΩ) New value (kΩ)

R2 22 3.3

R3 22 3.3

R4 22 4.7

R7 4.7 10

Note:

*: COM port names may vary depending on what your PC calls it.

47

Page 48

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.2.2. How to install Batch file into P.C.

Note:

• “*****” varies depending on the country or models.

11.2.3. Commands

See the table below for frequently used commands.

Command name Function Example

rdeeprom Read the data of EEPROM Type “rdeeprom 00 00 FF”, and the data from address

readid Read ID (RFPI) Type “readid”, and the registered ID is read out.

writeid Write ID (RFPI) Type “writeid 00 18 E0 0E 98”, and the ID “0018 E0 0E

hookoff Off-hook mode on Base Type “hookoff”.

hookon On-hook mode on Base Type “hookon”.

getchk Read checksum Type “getchk”.

wreeprom Write the data of EEPROM Type “wreeprom 01 23 45”. “01 23” is address and “45”

“00 00” to “FF” is read out.

98” is written.

is data to be written.

48

Page 49

11.3. Adjustment Standard (Base Unit)

PNLB1732Z

PbF

A

C23

C24

C57

C141

C305

C614

C61

C168

C820

C826

C65

C814

C90

C72

C422

C625

C631

C617

C421

C84

C55

C53

C137

C423

C54

R615

R2

R57

R117

R29

TP9

R12

R77

R78

DC_IN

R36

R34

R37

R33

R81

IC7

D10

Q9

Q421

DCP

SPp

SPm

DCM

C624

C637

C19

C22

C56

C14

C18

C155

CL2

C857

C855

C167

C623

C626

C856

C858

C837

C169

C170

C136

C171

C52

CL1

C146

C150

C149

C145

C615

C75

C74

CLK

C616

C630

C60

ANT2_TP

ANT1_TP

R24

R23

R20

R19

R18

R116

R87 R86

R429

R425

R424

R430

R426

R76

R40

R13

R35

R32

R75

R428

R427

LINE_DC

CHG

RED BLK

RED

RED WHT RED

BLK

BLK

GRN

YLW

CHG

SPDC

L2RL1RL1TL2T

IC421

TP10

TP15

TP15-sub

TP16

TP16-sub

RA80

JTAG

RA1

D21

D27

D15

D16

D26

D24

D23

Q5

Q2

Q8

Q10

E

E

14

GND_C

GND2

UTX2

URX2

GNDJ101

VDD5

VDD3

VDD1

VDD2

VDD4

URXUTX

GND GND

CHARGE+

CHARGE-

GND

RX

TX

GNDANT

CP+2.5V

+3.0V

+2.4V

+1.8V

VDD5

CP+3.0VVDD4

VDD3

VDD2

VDD1

Digital

Volt Meter

Digital

Volt Meter

DC Power

6.5V

DECT Tester

CTS60

PC

U-ART

Digital

Volt Meter

GND

Frequency

Counter

50

Terminal

12

2W

(G)

(A),(B),(C),(D),(T)

(J),(K),(L),(M),

(N),(O),(P)

(E),(F),(G),(H),

(I),(J),(K),(S)

(R)

When connecting the simulator equipment for checking, please refer to below.

11.3.1. Bottom View

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Note:

(A) - (S) is referred to Check Point (Base Unit) (P.35)

49

Page 50

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.4. Adjustment Standard (Charger Unit)

When connecting the simulator equipment for checking, please refer to below.

11.4.1. Bottom View

TP4

PbF

PNLP1029YA

TP4 (GND)

DC POWER

Digital

Volt Meter

Charge-

12 /2 W

DC 6.5 V

F1

TP3

TP3

(A)

Charge+

PQUP11532Y

J1

1

2

A

Note:

(A) is referred to Check Point (Charger Unit) (P.38)

50

Page 51

11.5. The Setting Method of JIG (Handset)

This section explains the PC setting to use command required in Check Point (Handset)(P. 3 9 ) .

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

<Preparation>

• Serial JIG cable: PQZZ1CD300E*

• PC which runs in DOS mode

• Batch file CD-ROM for setting: PNZZTG2511CA

Note:

*: If you have the JIG Cable for TCD500 series

11.5.1. Connections

Connect the DC Power or Battery to BATT+ and BATT-.

Connect the JIG cable GND (black) to GND.

Connect the JIG cable UTX (yellow) to UTX and URX (red) to URX.

(PQZZ1CD505E), change the following values of

resistance. Then you can use it as a JIG Cable for both

TCD300 and TCD500 series. (It is an upper compatible JIG

Cable.)

Resistor Old value (kΩ) New value (kΩ)

R2 22 3.3

R3 22 3.3

R4 22 4.7

R7 4.7 10

Note:

*: COM port names may vary depending on what your PC calls it.

51

Page 52

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.5.2. How to install Batch file into P.C.

Note:

• “*****” varies depending on the country or models.

11.5.3. Commands

See the table below for frequently used commands.

Command name Function Example

rdeeprom Read the data of EEPROM Type “rdeeprom 00 00 FF”, and the data from address

readid Read ID (RFPI) Type “readid”, and the registered ID is read out.

writeid Write ID (RFPI) Type “writeid 00 18 E0 0E 98”, and the ID “0018 E0 0E

getchk Read checksum Type “getchk”.

wreeprom Write the data of EEPROM Type “wreeprom 01 23 45”. “01 23” is address and “45”

“00 00” to “FF” is read out.

98” is written.

is data to be written.

52

Page 53

11.6. Adjustment Standard (Handset)

When connecting the simulator equipment for checking, please refer to below.

11.6.1. Component View

KX-TGA650XX

KX-TGA651XX

KX-TGA250XX

KX-TGA251XX

KX-TGA403XX

PNLB1734Y

PbF

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Oscilloscope

Probe

Current

DC 6.5V

GND

CMD60

DECT Tester

(I),(J),(K),(L),(M),(N)

ANT

(at battery low)

DC POWER

2.00~2.25V

Power Key

GND

TP_ANT1

C182

R401

R402

R407

C1C2

BATT+

C860

X1

D400

Q400

R400

C38

R406

POWER

C802

Q12

TGA650XX

TGA651XX

TGA250XX

TGA251XX

TGA403XX

C104

C103

C811

C804

C803

C813

C812

L802

C810

DA801

C827

L801

C837

C826

C822

C47

Q2

C10

1.8V

RA4

C13

C11

C400

R27

R403

R404

Q401

C332

R332

R331

Q11

C331

R330

C342

D1

C341

C340

D7

C3

F1

R30

C147

CHG(+)

C5

C580

C106

C107

R53

C806

L803

C805

C861

C809

C825

C820

R807

R203

C43

C48

R215

C96

C18

R28

C12

R2

Q4

R7

D3

MIC+ MIC-

C17

R50

C808

R73

IC801

R806

1

C97

R23

C74

C113

R805

R6

C187

C204

R31

R233

21

C75

R231

R236

C814

R802

C834

Q9

R74

C186

C819

C150

R4

D4

R232

CLK

MIC

C175

R578

C201

C206

RA800

C46

IC1

L47

RA30

RA31

R8

R3

C121

CHG(-)

C203

R880

L46

C39

C200

Q880

C45

RECEIVER

C70

R55

C105

R54

C138

D14

C864C863

R801

R808

C880

STM

R405

C44

C50

C188

R37

R36

C30

R20

C172

Q7

RCV-

RCV+

RA61

BAT

C35

RED

C152

D22D21

BLK

SPEAKER

C139

RED

C73

C881

JTAG

R63

R66

R225

R64

RA1

C49

C55

C51

R249

R248

Q10

85

IC3

14

E

URX

R45

BATT-

BLK

C71

C72

RA32

C40

C54

C52

C53

CP4.0V

CP3.0V

RA40

D13

MIC+

MIC-

UTX

GND

A

150

8

CP 4.0V

CP 3.0V

1.8V

56

56

CLK

1 F

1

100

+

RX

TX

GND

+

2.7 V

Zener

AF Volt Meter

22pF

Frequency

Digital

AF

PC

DC Power

(H)

Counter

GND GND

Volt Meter

(A),(Q),(R)

(O)

Generator

URX

(A),(B),(C),(F),

(G),(H),(I)

2.30~2.60V

(D),(E),(F),(G)

(O),(P)

Oscilloscope

Note:

(A) - (R) is referred to Check Point (Handset) (P.39)

53

Page 54

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.7. Things to Do after Replacing IC or X'tal

If repairing or replacing BBIC (FLASH type), EEPROM and X'tal, it is necessary to download the required data such as

Programming data or adjustment data, etc in memory.

The set doesn't operate if it is not executed.

11.7.1. How to download the data

11.7.1.1. Base Unit

First, operate the PC setting according to The Setting Method of JIG (Base Unit)(P.47).

Then download the appropriate data according to the following procedures.

Items How to download/Required adjustment

BBIC (FLASH type)

(IC7)

EEPROM (IC401) Adjusted parameter data is stored in memory.

X'tal (X1) System clock Clock adjustment data is in EEPROM, adjust the data again

Note:

(*1) XX: country code, YY: revision number, ZZ: Voice Prompt

“XX”, “YY” and “ZZ” vary depending on the country version. You can find them in the batch file, PNZZ- mentioned in The Setting

Method of JIG (Base Unit) (P.47).

(*2) Refer to Check Point (Base Unit) (P.35)

Programming data is stored in memory. 1) Make sure to connect the JIG cable, then disconnect the DC

(country version batch file, default batch file,

etc.)

Power in order to download the data.

2) Execute the command “flw480 *********.hex”.

3) Connect the DC Power.

4) Press the PC Enter key once.

5) After a few minutes, “Successful upgrade” is displayed on the

PC indicating downloading has finished.

6) Detach the JIG cable, then disconnect the DC Power.

7) Connect the DC Power.

8) Connect the JIG cable again, and execute the command

“getchk”, then confirm the checksum value is correct.

• If the downloading fails, start again from step 1).

9) Default batch file: Execute the command “default.bat”.

10) Country version batch file: Execute the command

“TG2511EUXXrevYY.bat”. (*1)

11) Clock adjustment: Refer to Check Point (G). (*2)

1) Change the address “0001” of EEPROM to “00” to download

the data.

2) Default batch file: Execute the command “default.bat”.

3) Country version batch file: Execute the command

“TG2511EUXXrevYY.bat”. (*1)

4) Clock adjustment: Refer to Check Point (G). (*2)

after replacing it.

1) Refer to Check Point (F). (*2)

54

Page 55

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.7.1.2. Handset

First, operate the PC setting according to The Setting Method of JIG (Handset)(P. 5 1 ) .

Then download the appropriate data according to the following procedures.

Items How to download/Required adjustment

BBIC (FLASH type)

(IC1)

EEPROM (IC3) Adjusted parameter data is stored in memory.

X'tal (X1) System clock Clock adjustment data is in EEPROM, adjust the data again

Note:

(*3) XX: country code, YY: revision number

“XX” and “YY” vary depending on the country version. You can find them in the batch file, PNZZ- mentioned in The Setting

Method of JIG (Handset) (P.51).

(*4) Refer to Check Point (Handset) (P.39)

Programming data is stored in memory.

(country version batch file, default batch file,

etc.)

1) Make sure to connect the JIG cable, then disconnect the DC

Power in order to download the data.

2) Execute the command “flw480 *********.hex”.

3) Connect the DC Power.

4) Press and hold the handset Power key.

5) While holding down the handset Power key, press the PC

Enter key once.

6) After a few minutes, “Successful upgrade” is displayed on

the PC indicating downloading has finished.

7) Detach the JIG cable, then press the handset Power key to

turn it on.

8) Connect the JIG cable again, and execute the command

"getchk”, then confirm the checksum value is correct.

• If the downloading fails, start again from step 1).

10) Default batch file: Execute the command “default.bat”.

11) Default batch file (remaining): Execute the command

“TGA250RUDEFrevYY.bat”. (*3).

12) Country version batch file: Execute the command

“TGA250RUXXrevYY.bat”. (*3).

13) Clock adjustment: Refer to Check Point (H). (*4).

14) 1.8 V setting and battery low detection: Refer to Check

Point (A), (F) and (G). (*4).

1) Default batch file: Execute the command “default.bat”.

2) Default batch file (remaining): Execute the command

“TGA250RUDEFrevYY.bat”. (*3)

3) Country version batch file: Execute the command

“TGA250RUXXrevYY.bat”. (*3)

4) Clock adjustment: Refer to Check Point (H). (*4)

5) 1.8 V setting and battery low detection: Refer to Check Point

(A), (F) and (G). (*4)

after replacing it.

1) Refer to Check Point (C). (*4)

55

Page 56

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.8. RF Specification

11.8.1. Base Unit

Item Value Refer to -. *

TX Power 19 dBm ~ 25 dBm Check Point (Base Unit) (J)

Modulation -370±30/+370±30 kHz/div & Modulated

width 690 kHz

Frequency Offset -50 kHz ~ +50 kHz Check Point (Base Unit) (L)

Frequency Drift < ± 35 kHz / ms Check Point (Base Unit) (M)

RX Sensitivity < 1000 ppm Check Point (Base Unit) (N)

Timing Accuracy < ± 5.0 ppm/<±15.0ppm Check Point (Base Unit) (O)

Power RAMP Power RAMP is matching Check Point (Base Unit) (P)

*: Refer to Check Point (Base Unit) (P.35)

11.8.2. Handset

Item Value Refer to -. **

TX Power 19 dBm ~ 25 dBm Check Point (Handset) (I)

Modulation -370±30/+370±30 kHz/div & Modulated

width 690 kHz

Frequency Offset -50 kHz ~ +50 kHz Check Point (Handset) (K)

Frequency Drift < ± 35 kHz / ms Check Point (Handset) (L)

RX Sensitivity < 1000 ppm Check Point (Handset) (M)

Power RAMP Power RAMP is matching Check Point (Handset) (N)

Check Point (Base Unit) (K)

Check Point (Handset) (J)

**: Refer to Check Point (Handset) (P.39)

56

Page 57

11.9. How to Check the Handset Speaker or Receiver

1. Prepare the digital voltmeter, and set the selector knob to ohm meter.

2. Put the probes at the speaker terminals as shown below.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

11.10. Frequency Table (MHz)

BASE UNIT HANDSET

Channel No Transmit Frequency Receive Frequency Transmit Frequency Receive Frequency

1 1897.344 1897.344 1897.344 1897.344

2 1895.616 1895.616 1895.616 1895.616

3 1893.888 1893.888 1893.888 1893.888

4 1892.160 1892.160 1892.160 1892.160

5 1890.432 1890.432 1890.432 1890.432

6 1888.704 1888.704 1888.704 1888.704

7 1886.976 1886.976 1886.976 1886.976

8 1885.248 1885.248 1885.248 1885.248

9 1883.520 1883.520 1883.520 1883.520

10 1881.792 1881.792 1881.792 1881.792

Note:

Channel No. 10: In the Test Mode on Base Unit and Handset.

57

Page 58

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

12 Miscellaneous

12.1. How to Replace the Flat Package IC

Even if you do not have the special tools (for example, a spot heater) to remove the Flat IC, with some solder (large amount), a

soldering iron and a cutter knife, you can easily remove the ICs that have more than 100 pins.

12.1.1. Preparation

• PbF (: Pb free) Solder

• Soldering Iron

Tip Temperature of 700 °F ± 20 °F (370 °C ± 10 °C)

Note: We recommend a 30 to 40 Watt soldering iron. An expert may be able to use a 60 to 80 Watt iron where someone with

less experience could overheat and damage the PCB foil.

•Flux

Recommended Flux: Specific Gravity → 0.82.

Type → RMA (lower residue, non-cleaning type)

Note: See About Lead Free Solder (Pbf: Pb free) (P.4)

12.1.2. How to Remove the IC

1. Put plenty of solder on the IC pins so that the pins can be completely covered.

Note:

If the IC pins are not soldered enough, you may give pressure to the P.C. board when cutting the pins with a cutter.

2. Make a few cuts into the joint (between the IC and its pins) first and then cut off the pins thoroughly.

3. While the solder melts, remove it together with the IC pins.

When you attach a new IC to the board, remove all solder left on the board with some tools like a soldering wire. If some solder is

left at the joint on the board, the new IC will not be attached properly.

58

Page 59

12.1.3. How to Install the IC

1. Temporarily fix the FLAT PACKAGE IC, soldering the two marked pins.

*Check the accuracy of the IC setting with the corresponding soldering foil.

2. Apply flux to all pins of the FLAT PACKAGE IC.

3. Solder the pins, sliding the soldering iron in the direction of the arrow.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

12.1.4. How to Remove a Solder Bridge

1. Lightly resolder the bridged portion.

2. Remove the remaining solder along the pins using a soldering iron as shown in the figure below.

59

Page 60

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

12.2. How to Replace the Shield Case

12.2.1. Preparation

• PbF (: Pb free) Solder

• Soldering Iron

Tip Temperature of 700°F ± 20°F (370°C ± 10°C)

Note:

We recommend a 30 to 40 Watt soldering iron. An expert may be able to use a 60 to 80 Watt iron where someone with less

experience could overheat and damage the PCB foil.

• Hot Air Desoldering Tool

Temperature: 608°F ± 68°F (320°C ± 20°C)

12.2.2. Caution

• To replace the IC efficiently, choose the right sized nozzle of the hot air desoldering tool that matches the IC package.

• Be careful about the temperature of the hot air desoldering tool not to damage the PCB and/or IC.

12.2.3. How to Remove the Shield Case

Note:

If you don’t have special tools (ex. Hot air disordering tool), conduct the following operations.

1. Cut the case along perforation.

2. Remove the cut part.

3. Cut the four corners along perforation.

4. Remove the reminds by melting solder.

60

Page 61

12.2.4. How to Install the Shield Case

Note:

• If you don’t have special tools (ex. Hot air disordering tool), conduct the following operations.

• Shield case’s No. : PNMC1013Z

1. Put the shield case.

2. Solder the surroundings.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

61

Page 62

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

12.3. Terminal Guide of the ICs, Transistors and Diodes and Electrolytic

Capacitors

12.3.1. Base Unit

12.3.2. Handset

62

Page 63

13 Schematic Diagram

13.1. For Schematic Diagram

13.1.1. Base Unit (Schematic Diagram (Base Unit))

Notes:

1. DC voltage measurements are taken with voltmeter from the negative voltage line.

2. The schematic diagrams may be modified at any time with the development of new technology.

13.1.2. Handset (Schematic Diagram (Handset))

Notes:

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagram may be modified at any time with the development of new technology.

13.1.3. Charger Unit (Schematic Diagram (Charger Unit))

Notes:

1. DC voltage measurements are taken with voltmeter from the negative voltage line.

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

2. The schematic diagram may be modified at any time with the development of new technology.

63

Page 64

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

13.2. Schematic Diagram (Base Unit)

ANT_1

CL1

C850

*CN5

.

PARALLEL WIRE

AP1

CN5-10

CN5-9

CN5-8

CN5-7

C517 NC

CN5-6

CN5-5

CN5-4

CN5-3

CN5-2

CN5-1

*C516 NC

ANT1_TP

NC

GND

GND

L804

C862

GND

C518 NC

*C515 NC

GND

10p

C857

C858

GND

W 0.15mm

L 20+/-1mm

3rd layer

C809

GND

C812

10p

NC

TX _RF

NC

W 0.15mm

L 20+/-2mm

3rd layer

+3.0V

C519 NC

GND

*C513 NC

*C514 NC

W 0.15mm

L 22+/-4mm

1st or 4th layer

100p

ANT1

GND

W 0.15mm

L 5.0mm

1st layer

10p

GND

*C511 NC

*C512 NC

GND

C825

C804

GND

L803

R806

10p

ANT2_TP

ANT_2

L801

27n

DA801

3

+3.0V

C860

GND

W 0.15mm

L 22+/-4mm

1st or 4th layer

100p

C856

GND

GND

ANT2

C827

10p

1

2

3p

11

10

9

8

7

6

R803

1k

R804

1k

LED1

LED2

ROW0

ROW1

ROW2

KEY0

KEY1

KEY2

VCC

PO

POX

PSEL

PAON

GND

C855

10p

C837

GND

GND

IC801

GND

PSEL

PON

*C421

GND

C854

GND

W 0.15mm

L 20+/-2mm

3rd layer

NC

PSET

VCCS

PRAMP

NC

CL2

NC

PI

PIX

1

*CE

2

SO

3

*WP

4

VSS5SI

*IC421

*C826

1

2

3

4

5

Shield

*Q421

NC

0.9p

C814

GND

GND

GND

R801 22k

GND

45

*R424

NC

*HOLD

C822

3.3n

6

VDD

SCK

R807

220

3p

GND

GND

NC

GND

Q24

R808 NC

GND

*R802

W 0.15mm

L 4.0mm x2

1st layer

3

*R425

NC

NC

C423

8

7

6

NC

100p

C823

GND

C820

W 0.125mm

L 7.6mm

Gap 0.125mm

1st layer

Pow_Adj

+1.8V

C861

560

*R132

R135

C163

GND

GND

120

10p

C819

GND

12

CP_OUT1=3.0V

*C422

NC

GND

RX _RF

0.5p

R133

10k

NC

1p

*C834

47R805

3.0V

VDD4

*R426 NC

RXON

1.5k

Q25

GND

eco_mode

Low_Rad

TX _RF

VDD_PADRV

GND

*R427 NC

*R428 NC

RF_RXn

RF_RXp

TXn

TXp

C521

C522

NC

NC

TAM_WP

*R429 NC

SPI_CLK

TAM_CSn

SPm

SPp

URX2

UTX2

GND2

SPI_DO

SPI_DI

CKM

R430

TAM_WP

NC

*C146

GND

GND

10

CHARGE

TAM_WP

ROW2

ROW1

ROW0

KEY1

KEY0

KEY2

SPI_DI

SPI_DO

SPI_CLK

TAM_CSn

SCL2

SDA2

URX

UTX

JTAG

GND

GND

NC

*C145

GND_C

*R511

0

ROW0

C520

for TG6511/2511/2521

TG7511/8511/5511

*SW1

Beep

Bell Signal

*R86 NC

*R87 NC

NC

NC

*C149

*C150

2.5V

GND

VDD5

GND

*C501

1n

GND

1234

220RA80

R75

100

NC

GND

12

GND

C616

+2.5_CP

C625

C60

100n

(1)

(2)

(3)

(4)

1u

10p

C630

GND

1u

10p

C631

GND

10

GND

(5)

(6)

1k

R76

(7)

(8)

(9)

C851

C853

7p

7p

1

2

3

DA802

W 0.15mm

L 22+/-4mm

1st or 4th layer

GND

C859

10p

C803

1.5p

1.8p

1.8p

C802

GND

GND

BPF

W 0.15mm

L 5.0mm

1st layer

100n

C808

10p

C811

GND

3n

L802

C813

Balun

220

3n

2.2p

C810

GND

Pre-matching

TXON

GND

3.3p

2.2p

C805

GND

3.3p

C806

GND

*RA501

45

3

6

2

7

1

8

NC

*R516

NC

NC: No Components

64

Page 65

KX-TG2511CA/KX-TG2512CA/KX-TGA250RU

Loop Current

*C14

C15

C167

0.039u

NC

NC

TP9

C56

3.3kR117

LINE_DC

D27 NC

*D26 NC

GND

GND

K0.1u

C57

GND

*R30

330

1.8k

R116

*R31

C27

0.1u

*C28

R29

+1.8V

0

GND

GND

C24

D9

50 10u

NC

C23

GND

NC

AK

GND

GND

TP10

0

NC

C141

GND

NC

C22