ORDER NO. KMS0307792C3

Digital Proprietary Telephone

KX-T7665AL

KX-T7665X

(for Australia, Asia, Middle Near East, Africa and Latin

America)

IMPORTANT INFORMATION ABOUT LEAD FREE, (PbF), SOLDERING

If lead free solder was used in the manufacture of this product the printed circuit boards will be marked PbF.

Standard leaded, (Pb), solder can be used as usual on boards without the PbF mark.

When this mark does appear please read and follow the special instructions described in this manual on the use of PbF and how

it might be permissible to use Pb solder during service and repair work.

© 2003 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

KX-T7665AL / KX-T7665X

CONTENTS

Page Page

1 ABOUT LEAD FREE SOLDER (PbF: Pb free) 3

1.1. SUGGESTED PbF SOLDER

1.2. HOW TO RECOGNIZE THAT Pb FREE SOLDER IS

USED

2 FOR SERVICE TECHNICIANS

3 SPECIFICATIONS

4 LOCATION OF CONTROLS

5 CONNECTION

6 DISASSEMBLY INSTRUCTIONS

7 HOW TO REPLACE A FLAT PACKAGE IC

7.1. PREPARATION

7.2. PROCEDURE

7.3. REMOVING SOLDER FROM BETWEEN PINS

8 TROUBLESHOOTING GUIDE

8.1. NO OPERATION

8.2. LCD DOES NOT OPERATE

8.3. HANDSET DOES NOT WORK

8.4. SPEAKER-PHONE TROUBLE

8.5. DXDP-DPT DOES NOT WORK

9 BLOCK DIAGRAM

10 CIRCUIT OPERATIONS

10.1. KEY INPUT CONTROL CIRCUIT

10.2. LCD CONTROL CIRCUIT

10

11

12

13

14

15

15

16

3

4

5

5

5

6

7

8

8

8

8

9

9

10.3. LED CIRCUIT

10.4. RESET CIRCUIT

10.5. POWER SUPPLY CIRCUIT

10.6. DATA COMMUNICATION

10.7. DXDP COMMUNICATION

10.8. ANALOG CIRCUIT

11 IC DATA

11.1. IC2

11.2. IC6

12 TER MINAL GUIDE OF ICs, TRANSISTORS AND DIODES

13 CABINET AND ELECTRICAL PARTS LOCATION

14 ACCESSORIES AND PACKING MATERIALS

15 REPLACEMENT PARTS LIST

15.1. CABINET AND ELECTRICAL PARTS

15.2. ACCESSORIES AND PACKING MATERIALS

15.3. MAIN BOARD PARTS

16 FOR THE SCHEMATIC DIAGRAM

17 SC HEMATIC DIAGRAM

18 WAVEFORM

19 PRINTED CIRCUIT BOARD (MAIN BOARD)

19.1. COMPONENT VIEW

19.2. BOTTOM VIEW

17

18

18

19

20

21

23

23

25

26

27

28

29

29

29

29

31

32

34

37

37

38

2

KX-T7665AL / KX-T7665X

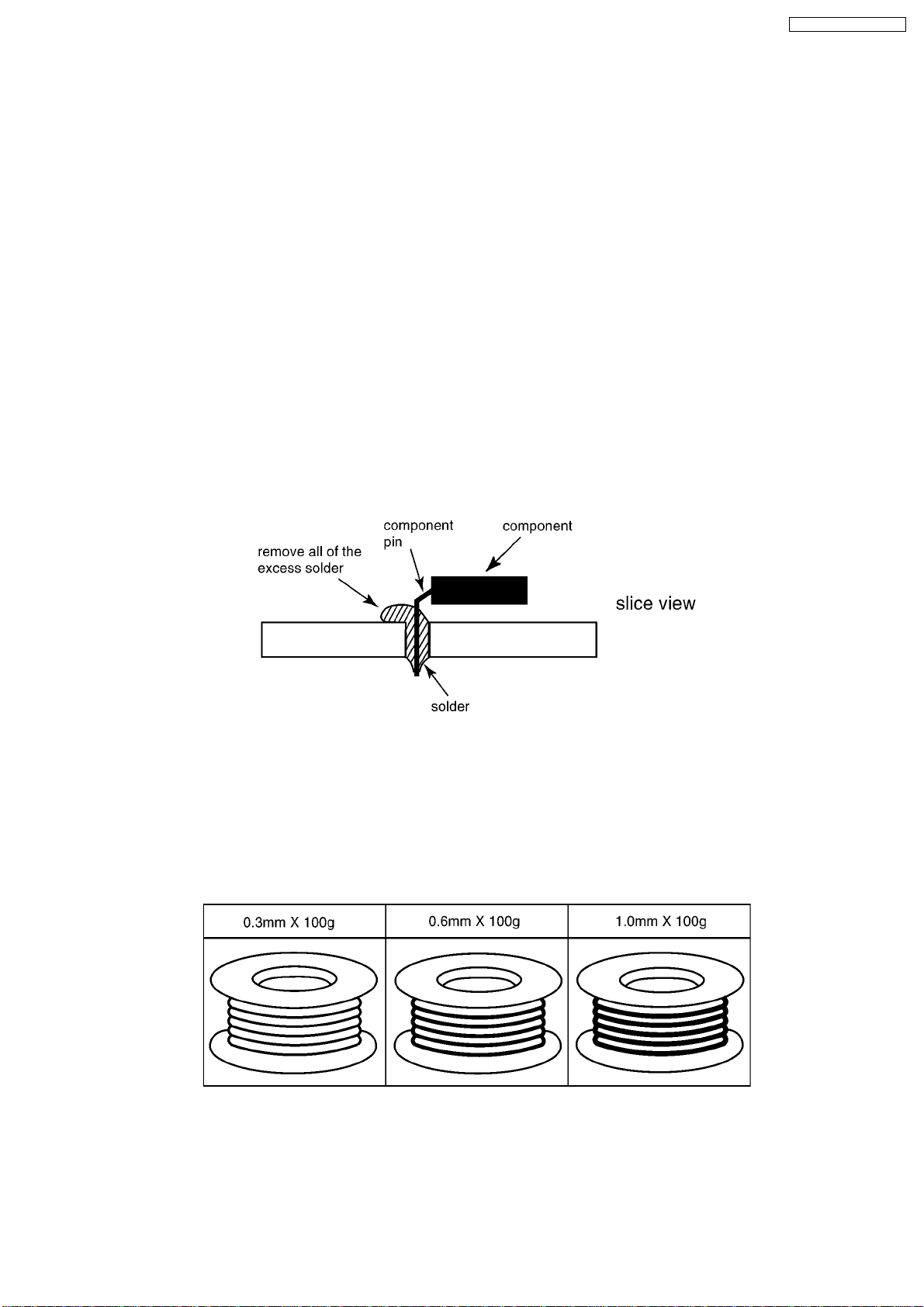

1 ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin, (Sn),

Silver, (Ag), and Copper, (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

· PbF solder has a melting point that is 50° ~ 70° F, (30° ~ 40°C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700° ± 20° F, (370° ± 10°C). In case of using high temperature soldering iron, please

be careful not to heat too long.

· PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F, (600°C).

· If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

and be sure that any remaining is melted prior to applying the Pb solder.

· When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See figure, below).

1.1. SUGGESTED PbF SOLDER

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper,

(Sn+Ag+Cu), you can also use Tin and Copper, (Sn+Cu), or Tin, Zinc, and Bismuth, (Sn+Zn+Bi).

Please check the manufacturer’s specific instructions for the melting points of their products and any precautions for using their

product with other materials.

The following lead free (PbF) solder wire gauges are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

3

KX-T7665AL / KX-T7665X

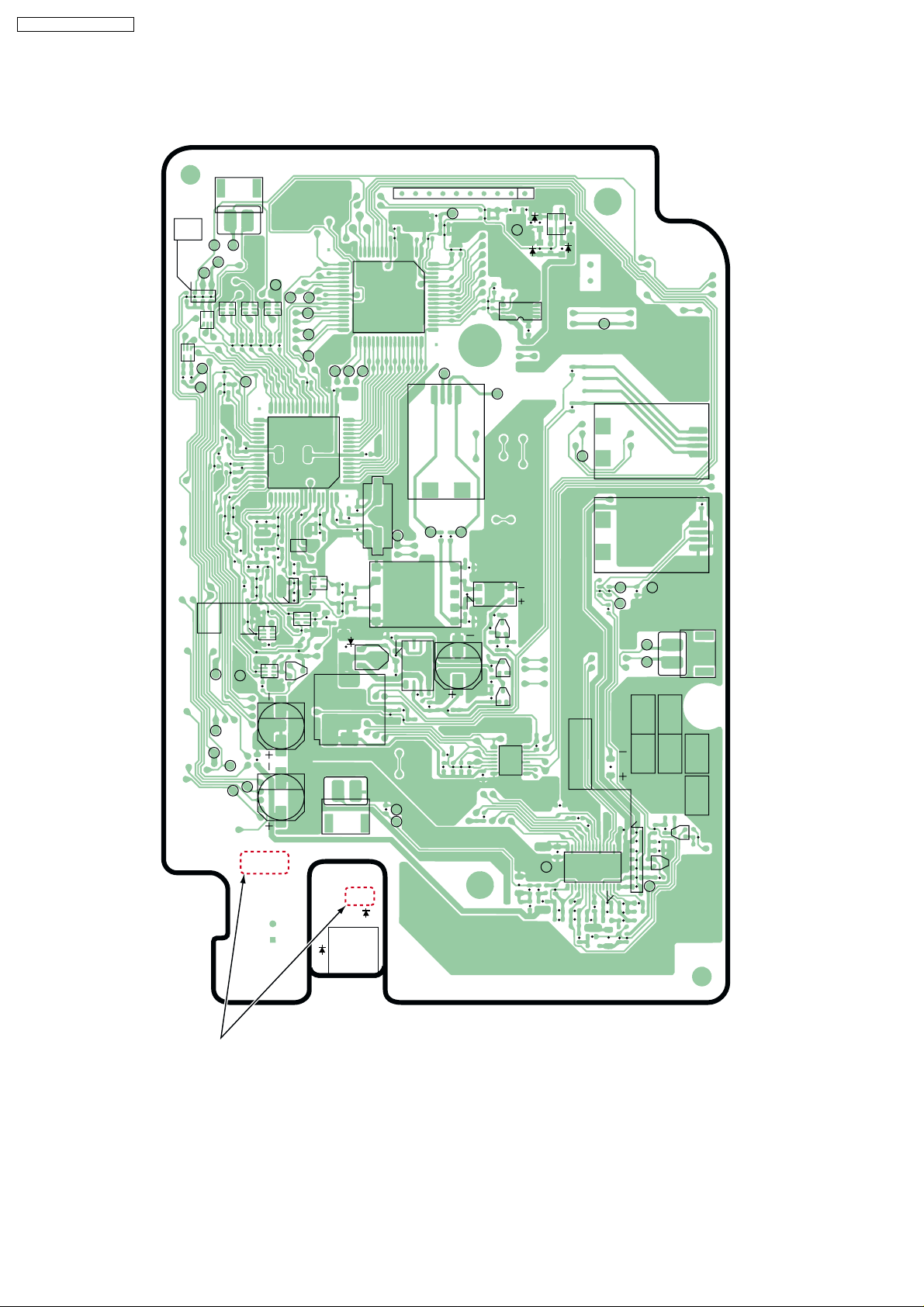

1.2. HOW TO RECOGNIZE THAT Pb FREE SOLDER IS USED

PbF is stamped to show that Pb free solder is used. (See the figure below.)

R

W

R306

A1

R310

Q32

R308

R309

R311

A6

Q31

A3

R307

A4

R516

C104

C103

R100

B3

B2

B1

2

R519

R520

R119

C107

R112

R115

A5

1

B6

A2

Q33 Q34 Q35

R305

R302

R301

R303

R402

PN9

17

R521

R517

R406

R129

C401

32

R116

R114

C101

R113

C108

R110

C105

R109

R111

R117

C106

C114

C120

Q3

R136

R135

Q5

D3V

C117

R200

F5

F7

PSUP1439Z-A

PbF

CN3

B5

E2

R304

R300

R407

16

IC2

33 48

C407

R103

R102

C100

C406

R101

R106

R105

IC7

R108

C102

R107

R104

C113

Q2

R134

R133

R139

R138

Q6

R137

C204

C205

C607

C606

16

17

E1

F8

32 49

F6

33 48

F4

F2

F1

F3

C400

1

64

C403

49

R403

R132

C115

R401

R130

D21

Q21

L21

CN2

R400

C111

C109

C404

C405

R131

5

21

X1

C201

W

C402

Q1

C116

R

PSUP1439Z-B

PbF

D43

10

IC6

D44

B4

R202

R201

C200

C505

R610

1

T1

IC1

R208

R204

AG2

MIC2

R601

C602

64

H

R209

R518

G1

R602

JK1

L1

C203

C202

R526

CN5

C605

T

L

L2

101

9

R206

R515

R604

R603

R611

R609

R608

C118

C112

R524

C110

R207

R525

R600

D5V

D1

R140

R119

R203

R205

C522

R513

R607

R

R114

IC3

C601

IC5

Q4

R142

Q22

Q23

C524

1

C600

C609

GND

R506

R512

C514

R505

D63

D62

C523

C528

C516

C506

R511

IC8

C603

D61

E3

R514

C515

R507

C604

L3

L4

R605

C608

R606

R503

C503

C510

C521

C508

C507

C517

IC4

C519

C502

R502

E4

L51

R527

C518

C511

C520

C512

L52

MIC1

C525

R510

C526

SP1

SPN

SPP

C509

R509

R500

R501

JK2

JK3

C501

RU CNGen

C513

AG1

W

R

R523

R504

C504

R508

A3V

2

1

C527

Q51

C500

CN1

GRA

DB

Q52

R522

Marked PbF

A

KX-T7665AL / KX-T7665X : MAIN BOARD

4

2 FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover the plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not touch IC or LSI pins with bare fingers.

3 SPECIFICATIONS

Station Loop Limit: 90 ohms

Calling Method: 2 pair wire

Jacks: Handset Jack, TEL Jack

Dimensions: Low Angle:

High Angle:

Weight: 0.7 kg

213 (D)mm × 177 (W)mm × 107 (H)mm

201 (D)mm × 177 (W)mm × 127 (H)mm

KX-T7665AL / KX-T7665X

Design and specifications are subject to change without notice.

4 LOCATION OF CONTROLS

5

KX-T7665AL / KX-T7665X

5 CONNECTION

Caution:

The availability of D-XDP function depends on the software version of the connected Business Telephone System.

Consult your dealer for more details about D-XDP.

6

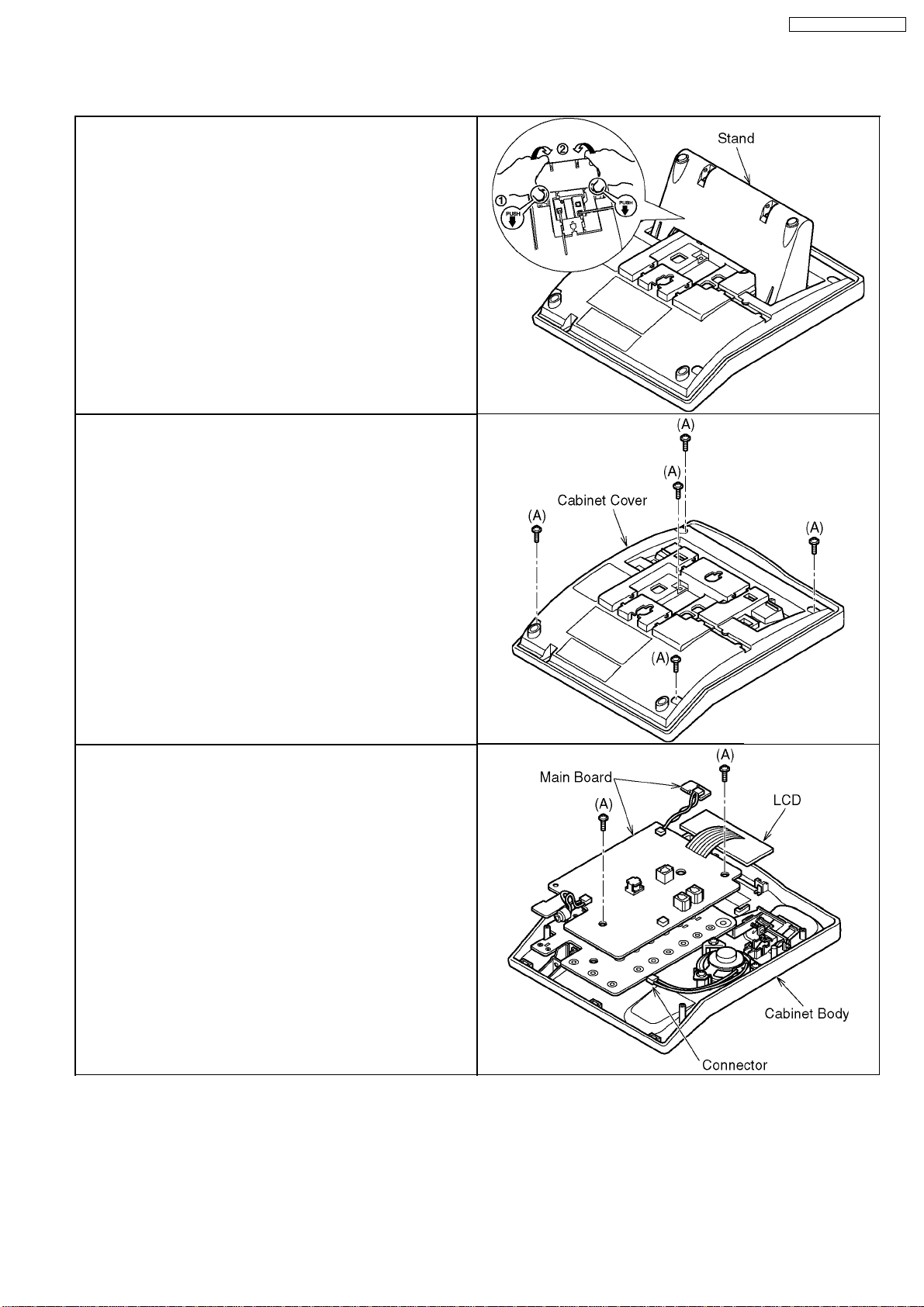

6 DISASSEMBLY INSTRUCTIONS

1. Remove the Stand.

2. Remove 5 Screws (A).

3. Remove the Cabinet Cover.

KX-T7665AL / KX-T7665X

4. Remove the Connector from the Main Board.

5. Remove 2 Screws (A).

6. Remove the Main Board and the LCD from the Cabinet Body.

7

KX-T7665AL / KX-T7665X

7 HOW TO REPLACE A FLAT PACKAGE IC

7.1. PREPARATION

· PbF (: Pb free) Solder

· Soldering Iron

Tip Temperature of 700°F±20°F (370°C±10°C)

Note: We recommend a 30 to 40 Watt soldering iron. An

expert may be able to use a 60 to 80 Watt iron where

someone with less experience could overheat and damage

the PCB foil.

· Flux

Recommended Flux: Specific Gravity → 0.82.

Type → RMA (lower residue, non-cleaning type)

Note: See ABOUT LEAD FREE SOLDER (PbF: Pb free)

(P.3).

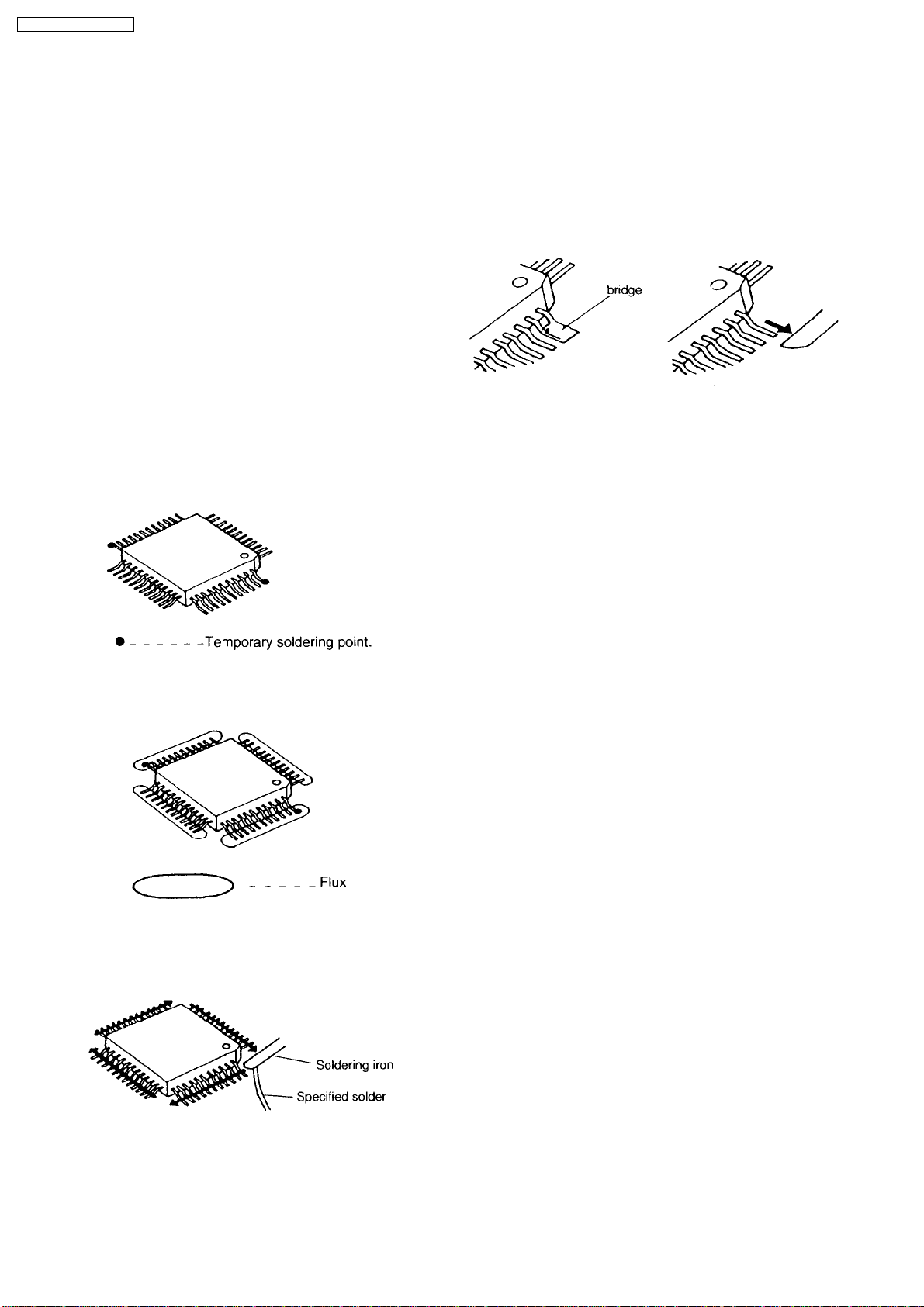

7.2. PROCEDURE

1. Tack the flat pack IC to the PCB by temporarily soldering

two diagonally opposite pins in the correct positions on the

PCB.

7.3. REMOVING SOLDER FROM

BETWEEN PINS

1. Add a small amount of solder to the bridged pins.

2. With a hot iron, use a sweeping motion along the flat part of

the pin to draw the solder from between the adjacent pads.

Be certain each pin is located over the

correct pad on the PCB.

2. Apply flux to all of the pins on the IC.

3. Being careful to not unsolder the tack points, slide the

soldering iron along the tips of the pins while feeding

enough solder to the tip so that it flows under the pins as

they are heated.

8

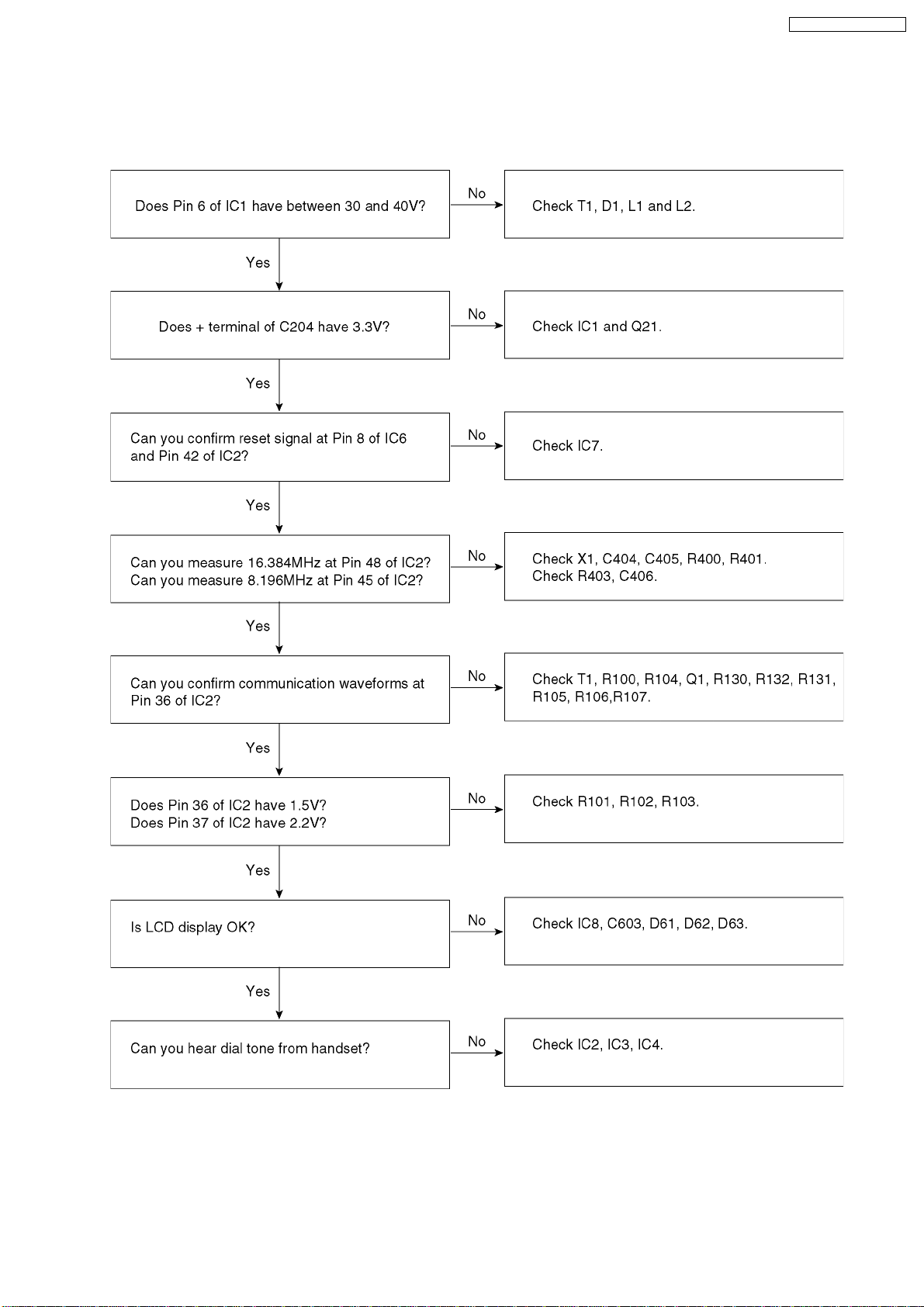

8 TROUBLESHOOTING GUIDE

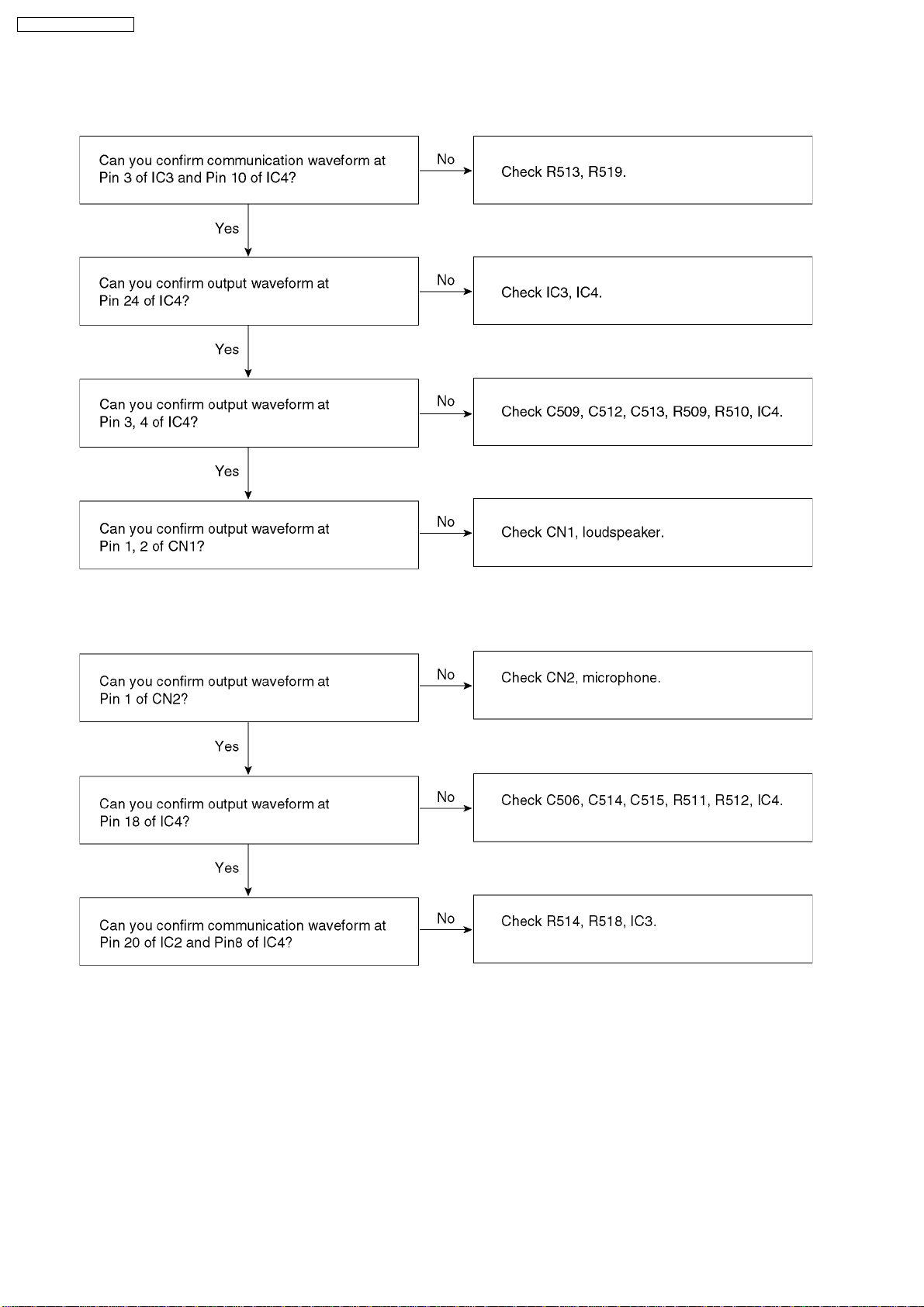

8.1. NO OPERATION

KX-T7665AL / KX-T7665X

Note:

Refer to (1)~(4) of WAVEFORM (P.34) for waveform.

9

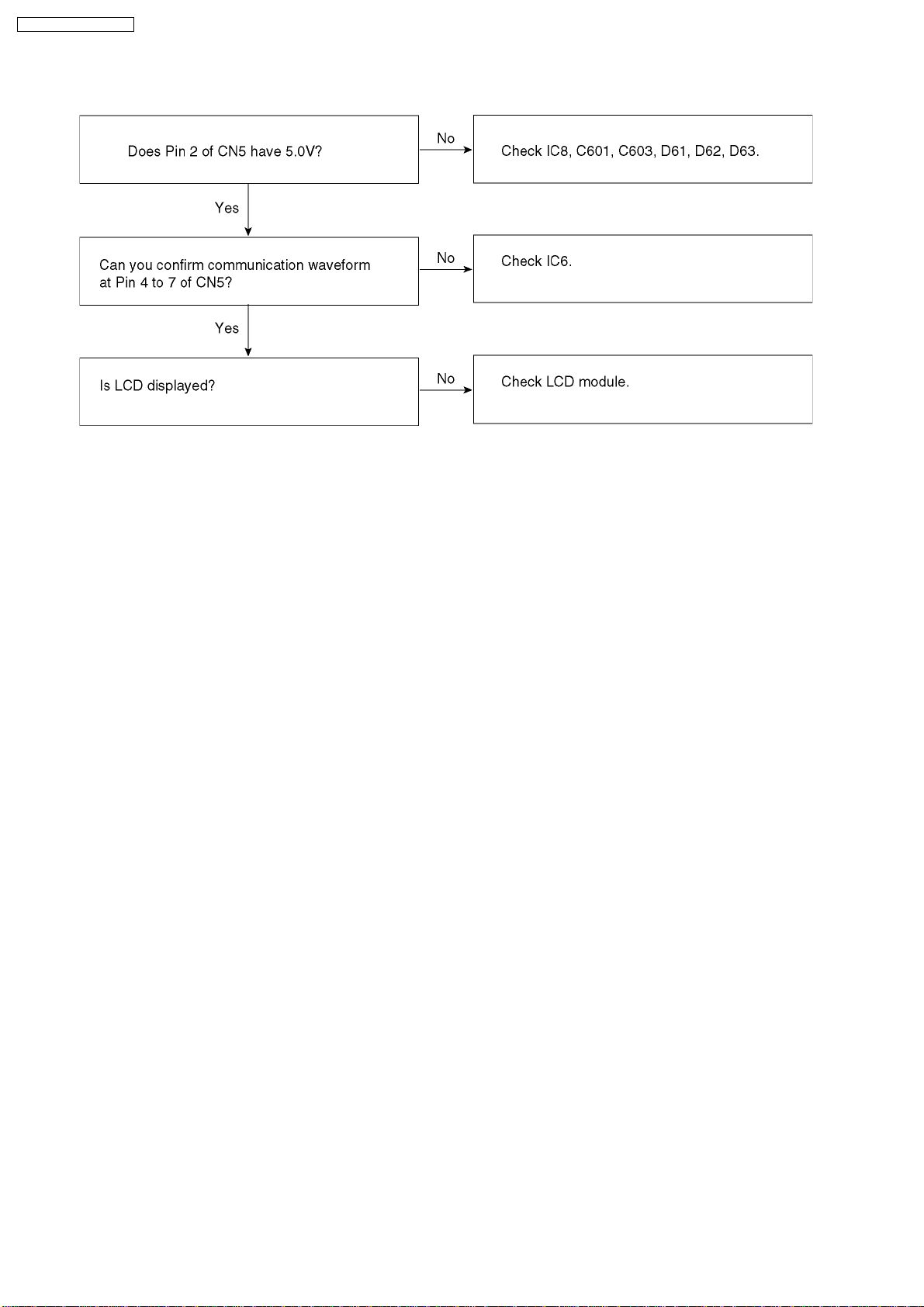

KX-T7665AL / KX-T7665X

8.2. LCD DOES NOT OPERATE

Note:

Refer to (5)ofWAVEFORM(P.34) for waveform.

10

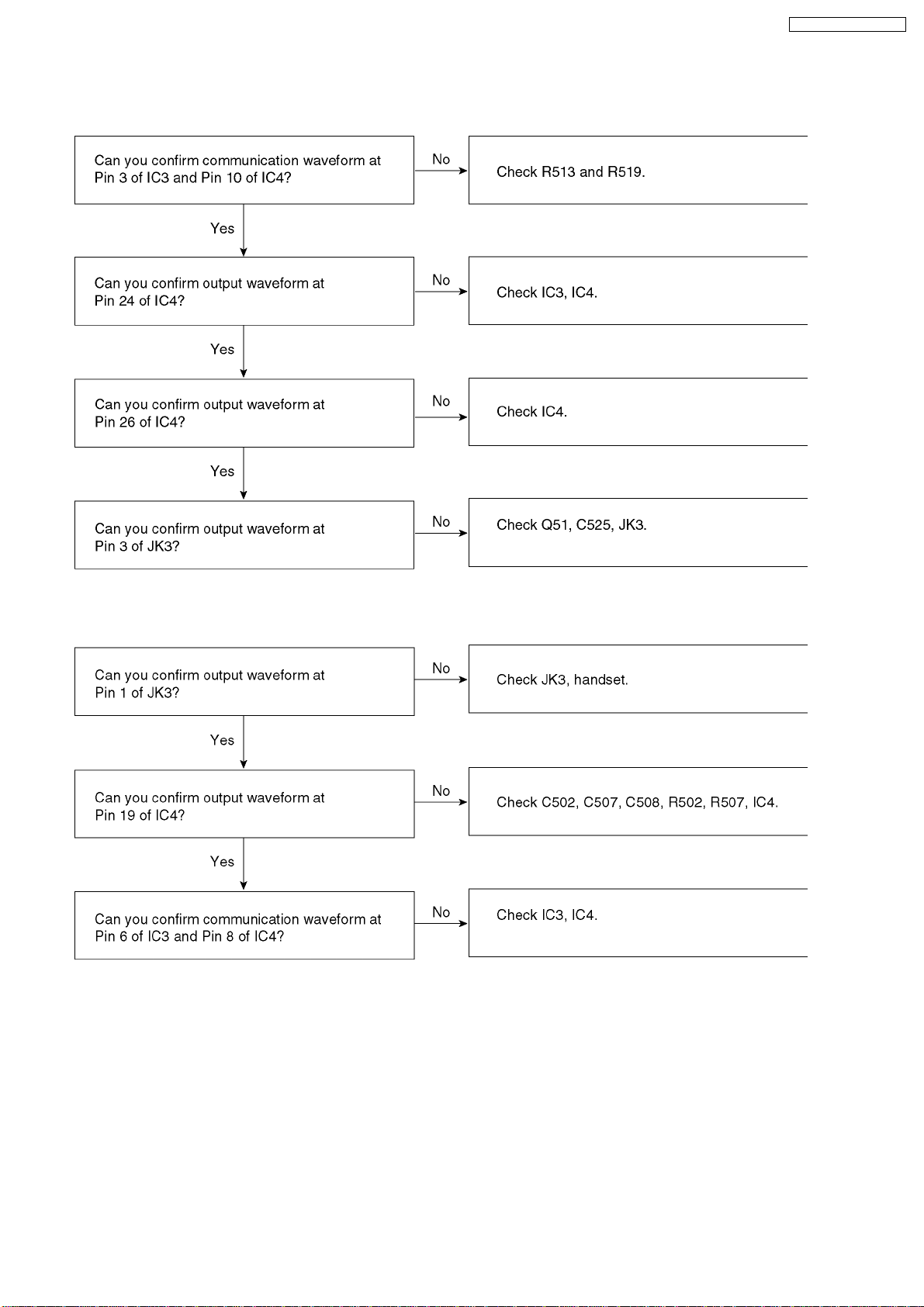

8.3. HANDSET DOES NOT WORK

Receive

KX-T7665AL / KX-T7665X

Send

Note:

Refer to (6)~(7) of WAVEFORM (P.34) for waveform.

11

KX-T7665AL / KX-T7665X

8.4. SPEAKER-PHONE TROUBLE

Receive

Send

Note:

Refer to (6)~(7) of WAVEFORM (P.34) for waveform.

12

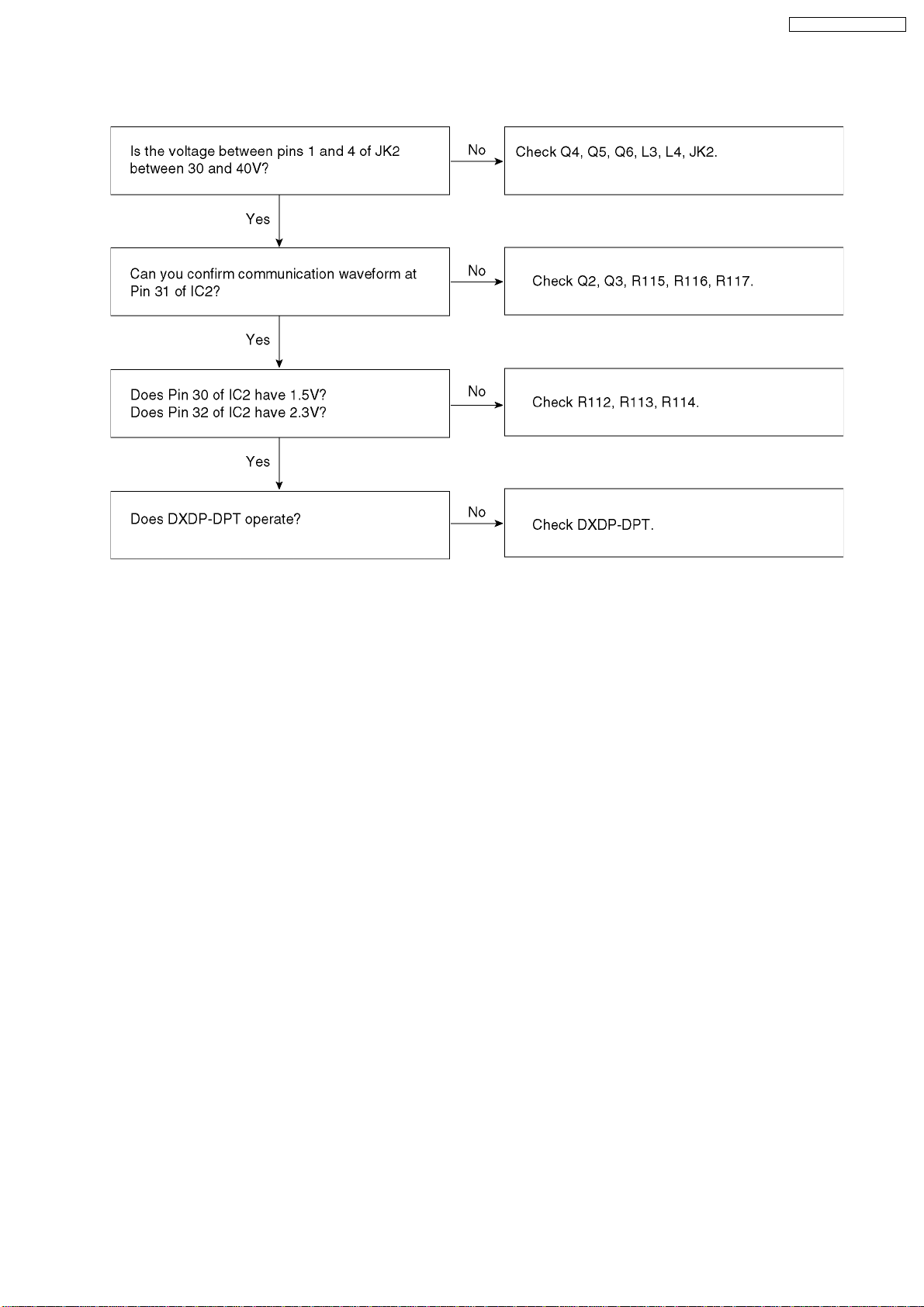

8.5. DXDP-DPT DOES NOT WORK

KX-T7665AL / KX-T7665X

Note:

Refer to (8)ofWAVEFORM(P.34) for waveform.

13

KX-T7665AL / KX-T7665X

JK1

TEL Jack

T1

Q1

Data

Communication

PDX1

PDX0

PDR

JK2

Q4

Q2

Q3

Data

Communication

DDX1

DDX0

DXDP Jack

Q6

Q5

DDR

Power

D3V

IC1

A3V

Q21,L21

LED

D43

CN3-CN4

D44

LED

3

~

5

~

CLM0

NROW0

D32~D42

Q31~Q35

KX-T7665AL / KX-T7665X : BLOCK DIAGRAM

OSR

OSX

DXDRBCLK

OEP0

OCK

Phone

Speaker

FS

IC4

CODEC

IC3

X1

SCK,DATA

Tone

ASIC

Reset

SCL,SDA

IC2

IC7

5

7

~

~

DB0

ADR0

IC6

CPU

7

~

E,W,RS

LCD-D4

WEN,REN,INTN

5.0V

IC8,D63

3.3V

Hook SW

Key

SW1~32

9 BLOCK DIAGRAM

JK3

H/S Jack

SP

CN1

MIC

CN2

IC5

EEPROM

14

TO

LCD

MAIN P. C. Board

(CN5)

10 CIRCUIT OPERATIONS

10.1. KEY INPUT CONTROL CIRCUIT

The key data is under the matrix control by 20 to 23(KEYOUT) and 28 to 35(KEYIN) of IC6.

The key information outputted from KEYOUT is inputted into KEYIN, when the key is pressed.

KX-T7665AL / KX-T7665X

15

KX-T7665AL / KX-T7665X

10.2. LCD CONTROL CIRCUIT

The LCD data is output from pins 52 to 58 of IC6.

LCD contrast adjustment is performed by the circuit composed of R603 and R604.

The contrast is determined only by the voltage level between pin 2 and pin 3 of CN5. Higher potential makes the contrast high.

CONTRAST IC6 Pin 59 IC6 Pin19

HIGH L L

MIDDLE Z L

LOW Z Z

LCD Contrast Control

16

10.3. LED CIRCUIT

The lighting of the LED is controlled by pin 14 to 18 (Row) and pin 8 to 13 (Colum) of IC2.

The LED lights up in a dynamic lighting system.

The duty ratio is 1/8 (ON time 1.5ms).

KX-T7665AL / KX-T7665X

17

KX-T7665AL / KX-T7665X

10.4. RESET CIRCUIT

Reset Signal is outputted from IC7 and inputted into IC2, IC3 and IC6 at the connection of TEL cord.

10.5. POWER SUPPLY CIRCUIT

This circuit converts the voltage supplied from PBX into the power supply voltage of +3.3V by IC1 (Switching Regulator IC).

Q22 and Q23 control the power supply circuit as below to turn IC1 on in low consumption current at starting up.

· Input Voltage approx. 26V or less →Q23 OFF →Q22 ON →IC1-pin 3 H →IC1 OFF

· Input Voltage approx. 26V or more →Q23 ON →Q22 OFF →IC1 ON

18

KX-T7665AL / KX-T7665X

10.6. DATA COMMUNICATION

Function

The data communication circuit serves the following functions:

Information exchanger between PBX and proprietary telephone, key input information as well as data for the LED control, LCD

control, voice data, etc. This information is continuously exchanged at all times.

Circuit Operation

The data received from PBX is inputted to the comparator (pin 36) built in IC2 through Pulse Trans T1. The threshold voltage

of the comparator is determined by R101 to 103 and inputted to pin 37 and 35 of IC2.

The data to PBX is outputted from pin 38 and 39 of IC2, drives T1 by Transistor Q1 and transmitted.

19

KX-T7665AL / KX-T7665X

10.7. DXDP COMMUNICATION

Function

This circuit performs the same communication as DXDP-compatible DPT and PBX communication connected with DXDP port.

Circuit Operation

The data to Slave DPT is outputted from pin 33 and 34 of IC2 and sent by Transistor Q2 and Q3.

The data from Slave DPT is inputted to the comparator (pin 31) built in IC2.

The threshold voltage of the comparator is determined by R112 to 114 and inputted to pin 30 and 32 of IC2.

Also, the supplying power to Slave DPT is controlled by a constant current circuit of Q16 as below.

· IC2-pin 28 as H : Constant current circuit ON

· IC2-pin 28 as L : Constant current circuit OFF

· IC2-pin 29 as H : 40mA Feeding (Slave DPT usually)

· IC2-pin 29 as L : 20mA Feeding (Slave DPT at starting up only)

20

10.8. ANALOG CIRCUIT

This circuit performs the setting of the call path/vol. adjustment in each call mode by IC4.

The audio gain of each call is determined by download data from PBX.

· IC2 sends each audio data to IC3 by PCM interface.

· IC2 receives each audio data from IC3 by PCM interface.

1. Handset Call

Transmitting signal is inputted from handset microphone and amplified by IC4 built-in Amp → A/D conversion →Gain

adjustment by IC4 →inputted to IC3 and IC2 in PCM data →then sent to PBX.

Receiving signal is inputted from PBX →IC2→IC3→D/A conversion after the input to IC4 in PCM data→Gain adjustment by

DSP of IC4→Pin 26 of IC4→ outputted from Q51 to handset.

2. Speakerphone Call

The speakerphone mode can only provide a one-way communication path.

IC3 compares transmitting signal and receiving signal during speakerphone mode, then provide a one-way communication

path.

Transmitting signal is inputted from SP phone mic. and amplified by IC4 built-in Amp→ A/D conversion→inputted to IC3 in

PCM data→Gain adjustment by IC3→inputtedtoIC2→ then sent to PBX.

KX-T7665AL / KX-T7665X

Receiving signal is inputted from PBX is →IC2→Gain adjustment by IC3 →inputted to IC4 in PCM data→D/A

conversion→pin24ofIC4→pin 27 of IC4→pin 28 of IC4→pin29ofIC4→ outputted from pin 3 and 4 of IC4 to speaker.

21

KX-T7665AL / KX-T7665X

IC2

PCM TX DATA

PCM RX DATA

HANDSET TX

HANDSET RX

D3V

SP PHONE RX

SP PHONE TX

R406

OSYNC

26

D3V

D3V

D3V

IC3

7

VDD

C522

8

VSS

OSR20OSX21OEPO22OCK

R515

R526

R518

DG

3

6

RIN

TOUT

TIN

ROUT

4

5

R525

R524

R513

R519

BCLK

1

25

R520

FS

2

R521

R517

R516

C523

12

TEST2

DG

16

RST

DG

DG

10

TxON

SCLK

DG

9

RxON

DATA11SCLK13CSN

DATA

15

TEST1

14

SP_CSN

DG

DATA

SCLK

CSN

C516

A3V

15

2

AVSS

AVDD

IC4

ANALOG CIRCUIT

E

Q52

R522

B

A3V

HANDT3

HANDT1

19

20

C508

C

C527

R523

C526

R501

R500

AG

21

R502

C502

L51

MIC1

A3V

5

DVDD

HANDT2

C507 R507

AG

A3V

C500

C517

6

C

DVSS

HANDR

26

C510

R508

B

Q51

C525

R527

L52

SP1

R514

AG

HANDI25DAOUT

R504 C504

E

C501

8

DX

C511

10FS7

DR

24

C512

R503

C503

AG

AG1

9

BCLK

NC

RAI

27

R509

AG

AG

1

R510

C509

C518

PLLCAP

RAO28SPI

29

C513

C519

22

VREF

SPP

CN1

C520

23

RAGND

SPOP

4

1

SPON

3

2

AG

AG

C521

14

13

11

12

CSN

DATA

TEST

SCLK

A3V

SPN

MIC3

18

C515

R505

MIC1

17

R506

C524

C514

MIC2

CN2

TONE 30

16

AG

MIC2

1

R512R511C506

2

AG

AG2

JK3

1

MIC

2

3SP4

SP

MIC

TO HANDSET

22

11 IC DATA

11.1. IC2

KX-T7665AL / KX-T7665X

Pin No. I/O Setting Pull-up

Processing

1 VDD - - Vdd

2 CSN in Built-in chip select

3 REN in Built-in Read

4 WEN in Built-in Write

5 WAITN tri - Wait

6 INTN out - Interrupt out

7 VSS - - GND

8 CLM5 out - LED column 5

9 CLM4 out - LED column 4

10 CLM3 out - LED column 3

11 CLM2 out - LED column 2

12 CLM1 out - LED column 1

13 CLM0 out - LED column 0

14 NROW3 out - LED Row 3

15 NROW2 out - LED Row 2

16 NROW1 out - LED Row 1

17 VSS - - GND

18 NROW0 out - LED Row 0

19 OEP1/PN9/CK512K tri - enable pulse

20 OSR in Built-in 2.048MHz serial data input

21 OSX tri 2.048MHz serial data output

22 OEP0 tri - enable pulse

23 VSS - - GND

24 VDD - - Vdd

25 OCLK bi - 2.048MHz serial clock

26 OSYNC bi - 8Khz FS

27 GOP0 out - DXDP1 H:40mA L:20mA

28 GOP1 out - DXDP2 H:ON L:OFF

29 TEST in - TEST

Contents of Control Remark

23

KX-T7665AL / KX-T7665X

Pin No. I/O Setting Pull-up

Contents of Control Remark

Processing

30 DVRL in - Comp. Ref.

31 DDR in - Comp. Input

32 DVRH in - Comp. Ref.

33 DDX0 out - Tx DATA OUT0

34 DDX1 tri - Tx DATA OUT1

35 PVRL in - Comp. Ref.

36 PDR in - Comp. Input

37 PVRH in - Comp. Ref.

38 PDX0 out - Tx DATA OUT0

39 PDX1 out - Tx DATA OUT1

40 MMODE in - Mode

41 SCAN in Pull Down scan

42 RSTN in - Reset

43 SCANE in Pull Down scan test

44 VDD - - Vdd

45 CK8_16 tri - 8MHz clock out

46 VSS - - GND

47 OSI in - OSC

48 OSO out - OSC

49 VSS - - GND

50 ADR5 in Built-in Add.5

51 ADR4 in Built-in Add.4

52 ADR3 in Built-in Add.3

53 ADR2 in Built-in Add.2

54 ADR1 in Built-in Add.1

55 ADR0 in Built-in Add.0

56 VDD - - Vdd

57 DB7 bi Built-in Data 7

58 DB6 bi Built-in Data 6

59 DB5 bi Built-in Data 5

60 DB4 bi Built-in Data 4

61 DB3 bi Built-in Data 3

62 DB2 bi Built-in Data 2

63 DB1 bi Built-in Data 1

64 DB0 bi Built-in Data 0

24

11.2. IC6

KX-T7665AL / KX-T7665X

Pin No. I/O Setting Pull-up

Processing

1 X1 I - not in use

2 X2 O - not in use

3 Vss - GND

4 OSC2 O - not in use

5 OSC1 I - 8.192MHz clock from IC2

6 TEST I - not in use

7 Vcc - Vcc

8 Reset/ I - Reset input

9 P20/IRQ4 O - CODEC chip select

10 P21/SCK1 O - SCLK

11 P22/SI1 O - Sp Phone chip select

12 P23/SO1 O - DATA

13 P24/SCK3 O - not in use

14 P25/RxD I Built-in not in use

15 P26/TxD O - not in use

16 P27/IRQ0 I - not in use

17 P17/IRQ3 I Built-in Hook SW L:OFF-HOOK

18 P16/IRQ2 I Built-in ASIC INT/ Low active

19 P15/IRQ1 I/O - LCD contrast 2 Cont.H/M:L Cont.L:High"Z"

20 P14 I/O Built-in KEYOUT3 L output

21 P13/TMIG I/O Built-in KEYOUT2 L output

22 P12/TMOFH I/O Built-in KEYOUT1 L output

23 P11/TMOFL I/O Built-in KEYOUT0 L output

24 P10/TMOW O - OSC for LCD Power 128kHz(4.096MHz/32)

25 PA3 O - side tone Cont. H:side tone ON

26 PA2 O - ASIC REN/ Low active

27 PA1 O - ASIC WEN/ Low active

28 P50/WKP0 I Built-in KEYIN0

29 P51/WKP1 I Built-in KEYIN1

30 P52/WKP2 I Built-in KEYIN2

31 P53/WKP3 I Built-in KEYIN3

32 P54/WKP4 I Built-in KEYIN4

33 P55/WKP5 I Built-in KEYIN5

34 P56/WKP6 I Built-in KEYIN6

35 P57/WKP7 I Built-in KEYIN7

36 P60 I/O Built-in DB0

37 P61 I/O Built-in DB1

38 P62 I/O Built-in DB2

39 P63 I/O Built-in DB3

40 P64 I/O Built-in DB4

41 P65 I/O Built-in DB5

42 P66 I/O Built-in DB6

Contents of Control Remark

25

KX-T7665AL / KX-T7665X

Pin No. I/O Setting Pull-up

Processing

43 P67 I/O Built-in DB7

44 P70 O - ADR0

45 P71 O - ADR1

46 P72 O - ADR2

47 P73 O - ADR3

48 P74 O - ADR4

49 P75 O - ADR5

50 P76 O - EEPROM CLK

51 P77 I/O - EEPROM DATA

52 P80 O - LCD_D7

53 P81 O - LCD_D6

54 P82 O - LCD_D5

55 P83 O - LCD_D4

56 P84 O - LCD_E

57 P85 O - LCD_W

58 P86 O - LCD_RS register select

59 P87 O - LCD contrast 1 Cont.H:L Cont.M/L:High"Z"

60 TONED O - DTMF/Tone Tone out

61 VTref I - Tone reference

62 PB7/AN7 I - for Test MODE connect D3V for Sp phone

63 PB6/AN6 I - not in use

64 CVcc I - internal power source

Contents of Control Remark

test

12 TERMINAL GUIDE OF ICs, TRANSISTORS AND DIODES

26

13 CABINET AND ELECTRICAL PARTS LOCATION

KX-T7665AL / KX-T7665X

27

KX-T7665AL / KX-T7665X

14 ACCESSORIES AND PACKING MATERIALS

28

15 REPLACEMENT PARTS LIST

KX-T7665AL / KX-T7665X

1. RTL (Retention Time Limited)

Note:

The marking (RTL) indicates that the Retention Time is

limited for this item.

After the discontinuation of this assembly in production, the

item will continue to be available for a specific period of

time. The retention period of availability is dependent on the

type of assembly, and in accordance with the laws

governing parts and product retention.

After the end of this period, the assembly will no longer be

available.

2. Important safety notice

Components identified by

mark have special

characteristics important for safety. When replacing any of

these components, use only manufacture´s specified parts.

3. The S mark means the part is one of some identical parts.

For that reason, it may be different from the installed part.

4. ISO code (Example: ABS-HB) of the remarks column

shows quality of the material and a flame resisting grade

about plastics.

5. RESISTORS & CAPACITORS

Unless otherwise specified;

All resistors are in ohms (Ω) K=1000Ω, M=1000kΩ

All capacitors are in MICRO FARADS (µF) P=µµF

*Type & Wattage of Resistor

Ref.

No.

7 PQAS57P03Z SPEAKER

8 PSJS02P15Z CONNECTOR, 2 PIN

9 PSUS1026Z TORSION SPRING

10 PSBH1007Z1 PUSH BUTTON, HOOK PC+ABS-

11 PSHG1122Z RUBBER PARTS, MIC COVER

12 RJM142Z BUILTIN-MICROPHONE S

13 PSJS02Q35Y CONNECTOR, 2 PIN

14 PSBX1116Z1 PUSH BUTTON, FUNCTION ABS-HB,

15 PSBX1089Z1 PUSH BUTTON, 12 KEY ABS-HB,

16 PSBX1117Z1 PUSH BUTTON, CO LINE ABS-HB,

17 PSSX1030Z1 KEYBOARD SWITCH S

18 PSJS02P10Z CONNECTOR, 2 PIN

19 PSYF1047Z1 CABINET COVER ASS´Y PS-HB,

19-1 PSHA1002Z RUBBER PARTS, FOOT

20 PSYET7665AL NAME PLATE

20 PSYET7665X NAME PLATE

21 ECUV1H102KBV CERAMIC CAPACITOR (0.001)

Part No. Part Name & Description Remarks

HB, S

S

S

S

S

(for KX-T7665AL)

(for KX-T7665X)

15.2. ACCESSORIES AND PACKING

MATERIALS

Ref.

No.

A1 PSJA1082Z CORD, TELEPHONE

A1 PSJA1068Z CORD, TELEPHONE

A2 PSJA1084Z CORD, HANDSET

A3 PQJXF0202Z HANDSET

A4 PSYL1002Z3 STAND ASS´Y PS-HB

A5 PSQW2035Z LEAFLET (STAND) S

A6 PSQX2962Z INSTRUCTION BOOK

A6 PSQX2963Z INSTRUCTION BOOK

A7 PSQX2964Z INSTRUCTION BOOK (Spanish)

Part No. Part Name & Description Remarks

(for KX-T7665AL)

(for KX-T7665X)

(QUICK REFERENCE GUIDE)

(for KX-T7665AL)

(QUICK REFERENCE GUIDE)

(for KX-T7665X)

(QUICK REFERENCE GUIDE)

(for KX-T7665X)

S

S

S

S

S

15.1. CABINET AND ELECTRICAL

PARTS

Ref.

No.

1 PSKM1110Z1 CABINET BODY ABS-HB,

2 PQKE10070Z3 HANGER ABS-HB,

3 PSGD1073Z TEL. CARD

4 PSHR1305Z TRANSPARENT PLATE PC-HB

5 PSGP1101Z1 PANEL, LCD PC-HB,

6 PSGP1100Z OPTIC CONDUCTIVE PARTS, LED

Part No. Part Name & Description Remarks

S

S

S

LENS

ABS-HB

P1 PSZKT7665AL GIFT BOX ASS´Y

P1 PSZKT7665X GIFT BOX ASS´Y

P2 PQPP170Z PROTECTION COVER

(for KX-T7665AL)

(for KX-T7665X)

15.3. MAIN BOARD PARTS

Ref.

No.

PCB1 PSWPT7665AL MAIN BOARD ASS´Y (RTL)

IC1 PQVIMC34063M IC S

IC2 C1CB00001612 IC

IC3 C1CB00001623 IC

IC4 C1CB00001622 IC

IC5 C3EBCC000052 IC

IC6 C2BBGF000486 IC

IC7 C0EBF0000123 IC

IC8 PQVITC7SH04F IC S

29

Part No. Part Name & Description Remarks

(ICs)

KX-T7665AL / KX-T7665X

Ref.

No.

Q1 PSVTUMS1NTR TRANSISTOR(SI) S

Q2 B1HFCFA00008 TRANSISTOR(SI)

Q3 XP4601 TRANSISTOR(SI) S

Q4 2SC4081R TRANSISTOR(SI) S

Q5 PSVTUMX1NTN TRANSISTOR(SI)

Q6 B1ABMF000004 TRANSISTOR(SI)

Q21 2SA1900 TRANSISTOR(SI) S

Q22 2SA1576R TRANSISTOR(SI)

Q23 2SA1576R TRANSISTOR(SI)

Q31 B1GHCFCJ0001 TRANSISTOR(SI)

Q32 B1GHCFCJ0001 TRANSISTOR(SI)

Q33 PSVTUMX1NTN TRANSISTOR(SI)

Q34 PSVTUMX1NTN TRANSISTOR(SI)

Q35 PSVTUMX1NTN TRANSISTOR(SI)

Q51 2SC4081R TRANSISTOR(SI) S

Q52 2SC4081R TRANSISTOR(SI) S

D1 PQVDS1ZB60F1 DIODE(SI) S

D21 B0JCME000035 DIODE(SI)

D31 PSVD1SRCT DIODE(SI) S

D32 PQVDBRPY1204 DIODE(SI) S

D33 PQVDBRPY1204 DIODE(SI) S

D34 PQVDBRPY1204 DIODE(SI) S

D35 PQVDBRPY1204 DIODE(SI) S

D36 PQVDBRPY1204 DIODE(SI) S

D37 PQVDBRPY1204 DIODE(SI) S

D38 PQVDBRPY1204 DIODE(SI) S

D39 PQVDBRPY1204 DIODE(SI) S

D40 PSVD1SRCT DIODE(SI) S

D41 PSVD1VGCT DIODE(SI) S

D42 PSVD1SRCT DIODE(SI) S

D44 PSVD1SRCT DIODE(SI) S

D61 MA729 DIODE(SI) S

D62 MA729 DIODE(SI) S

D63 B0BC5R000009 DIODE(SI)

CN1 PSJP02A05Z CONNECTOR, 2 PIN S

CN2 PSJP02A05Z CONNECTOR, 2 PIN S

CN3 PSJP02A05Z CONNECTOR, 2 PIN S

CN4 PSJP02A05Z CONNECTOR, 2 PIN S

JK1 PSJJ1T011Z JACK, TELEPHONE LINE S

JK2 PSJJ1T011Z JACK, DXDP S

JK3 PSJJ1T012Z JACK, HANDSET S

L1 PFVF1B601ST CERAMIC FILTER S

L2 PFVF1B601ST CERAMIC FILTER S

L3 PFVF1B601ST CERAMIC FILTER S

L4 PFVF1B601ST CERAMIC FILTER S

L51 PFVF1B601ST CERAMIC FILTER S

L52 PFVF1B601ST CERAMIC FILTER S

L21 G1A331D00005 COIL

R100 ERJ3GEYJ182 1.8K

R101 ERJ3GEYJ822 8.2K

R102 ERJ3GEYJ562 5.6K

R103 ERJ3GEYJ123 12K

R104 ERJ3GEYJ182 1.8K

R105 ERJ3GEYJ122 1.2K

R106 ERJ3GEYJ121 120

R107 ERJ3GEYJ182 1.8K

R108 ERJ3GEYJ101 100

R109 ERJ3GEYJ101 100

R110 ERJ3GEYJ122 1.2K

R111 ERJ3GEYJ122 1.2K

Part No. Part Name & Description Remarks

(TRANSISTORS)

(DIODES)

(CONNECTORS)

(JACKS)

(CERAMIC FILTERS)

(COIL)

(RESISTORS)

Ref.

No.

R112 ERJ3GEYJ562 5.6K

R113 ERJ3GEYJ682 6.8K

R114 ERJ3GEYJ103 10K

R115 ERJ3GEYJ472 4.7K

R116 ERJ3GEYJ153 15K

R117 ERJ3GEYJ472 4.7K

R119 ERJ3GEYJ822 8.2K

R129 ERJ3GEYJ123 12K

R130 ERJ3GEYJ220 22

R131 ERJ3GEYJ271 270

R132 ERJ3GEYJ220 22

R133 ERJ3GEYJ561 560

R134 ERJ3GEYJ331 330

R135 ERJ3GEYJ561 560

R136 ERJ3GEYJ331 330

R137 ERJ3GEYJ102 1K

R138 ERJ3GEYJ270 27

R139 ERJ3GEYJ180 18

R140 ERJ3GEYJ562 5.6K

R141 ERJ3GEYJ330 33

R142 ERJ3GEYJ100 10

R200 ERJ6GEYJ3R3 3.3

R201 ERJ3GEYJ221 220

R202 PQ4R10XJ562 5.6K S

R203 ERJ3GEYJ153 15K

R204 ERJ3GEYJ392 3.9K

R205 ERJ3GEYJ104 100K

R206 ERJ3GEYJ472 4.7K

R207 ERJ3GEYJ224 220K

R208 ERJ3GEYJ242 2.4K

R209 ERJ3GEYJ1R2 1.2

R300 ERJ3GEYJ102 1K

R301 ERJ3GEYJ102 1K

R302 ERJ3GEYJ102 1K

R303 ERJ3GEYJ102 1K

R304 ERJ3GEYJ102 1K

R305 ERJ3GEYJ102 1K

R306 ERJ3GEYJ181 180

R307 ERJ3GEYJ121 120

R308 ERJ3GEYJ120 12

R309 ERJ3GEYJ121 120

R310 ERJ3GEYJ121 120

R311 ERJ3GEYJ120 12

R313 ERJ3GEYJ4R7 4.7

R400 ERJ3GEYJ821 820

R401 ERJ3GEYJ105 1M

R402 ERJ3GEYJ473 47K

R403 ERJ3GEYJ181 180

R406 ERJ3GEYJ473 47K

R407 ERJ3GEYJ473 47K

R500 ERJ3GEYJ102 1K

R501 ERJ3GEYJ222 2.2K

R502 ERJ3GEYJ103 10K

R503 ERJ3GEYJ102 1K

R504 ERJ3GEYJ103 10K

R505 ERJ3GEYJ102 1K

R506 ERJ3GEYJ222 2.2K

R507 ERJ3GEYJ563 56K

R508 ERJ3GEYJ822 8.2K

R509 ERJ3GEYJ333 33K

R510 ERJ3GEYJ473 47K

R511 ERJ3GEYJ223 22K

R512 ERJ3GEYJ274 270K

R513 ERJ3GEY0R00 0

R514 ERJ3GEY0R00 0

R515 ERJ3GEYJ473 47K

R516 ERJ3GEYJ473 47K

R517 ERJ3GEYJ473 47K

R518 ERJ3GEYJ102 1K

R519 ERJ3GEYJ102 1K

R520 ERJ3GEYJ102 1K

R521 ERJ3GEYJ102 1K

R522 ERJ3GEYJ124 120K

Part No. Part Name & Description Remarks

30

KX-T7665AL / KX-T7665X

Ref.

No.

R523 ERJ3GEYJ473 47K

R524 ERJ3GEYJ473 47K

R525 ERJ3GEYJ473 47K

R526 ERJ3GEYJ473 47K

R527 ERJ3GEYJ100 10

R600 ERJ3GEYJ822 8.2K

R602 ERJ3GEYJ473 47K

R603 ERJ3GEYJ822 8.2K

R604 ERJ3GEYJ183 18K

R605 ERJ3GEYJ682 6.8K

R606 ERJ3GEYJ472 4.7K

R607 ERJ3GEYJ182 1.8K

R608 ERJ3GEYJ181 180

R609 ERJ3GEYJ181 180

R611 ERJ3GEYJ473 47K

C100 ECUV1C104ZFV 0.1

C101 ECUV1C104ZFV 0.1

C102 ECUV1H102KBV 0.001

C103 ECUV1H102KBV 0.001

C104 ECUV1C104ZFV 0.1

C105 ECUV1H102KBV 0.001

C106 ECUV1H102KBV 0.001

C107 ECUV1C104ZFV 0.1

C108 ECUV1C104ZFV 0.1

C109 ECUV1A105ZFV 1

C110 ECUV1H101JCV 100P

C111 ECUV1A105ZFV 1

C112 ECUV1H101JCV 100P

C113 ECUV1C104ZFV 0.1

C114 ECUV1C104ZFV 0.1

C115 PQCUV1C105ZF 1 S

C116 PQCUV1C105ZF 1 S

C117 ECUV1A105ZFV 1

C118 PQCUV1C105ZF 1 S

C119 ECUV1A105ZFV 1

C200 ECUV1C104ZFV 0.1

C201 ECUV1H181JCV 180P S

C202 ECUV1H104ZFV 0.1 S

C203 F2G1H3300004 33

C204 EEEFK0J471P 470

C205 EEEFK0J471P 470

C400 ECUV1C104ZFV 0.1

C401 ECUV1C104ZFV 0.1

C402 ECUV1C104ZFV 0.1

Part No. Part Name & Description Remarks

(CAPACITORS)

Ref.

No.

C403 ECUV1C104ZFV 0.1

C404 ECUV1H120JCV 12P

C405 ECUV1H120JCV 12P

C406 ECUV1H120JCV 12P

C407 ECUV1C104ZFV 0.1

C500 ECUV1H222KBV 0.0022

C501 ECUV1H102KBV 0.001

C502 ECUV1C104KBV 0.1

C504 ECUV1E103KBV 0.01

C506 ECUV1H333KBV 0.033 S

C507 ECUV1H152KBV 0.0015

C508 ECUV1C104KBV 0.1

C509 ECUV1H152KBV 0.0015

C510 ECUV1H223KBV 0.022 S

C511 ECUV1C104KBV 0.1

C512 ECUV1E103KBV 0.01

C513 ECUV1C104KBV 0.1

C514 ECUV1H181JCV 180P S

C515 ECUV1C104KBV 0.1

C516 PQCUV1C105ZF 1

C517 ECUV1C104ZFV 0.1

C518 ECUV1A105ZFV 1

C519 ECUV1A105ZFV 1

C520 ECUV1A105ZFV 1

C521 ECUV1C104KBV 0.1

C522 ECUV1A105ZFV 1

C523 ECUV1C104ZFV 0.1

C524 ECST0JY106 10

C525 ECST0JY106 10

C526 ECST0JY106 10

C527 ECUV1C104KBV 0.1

C528 ECUV1H103KBV 0.01 S

C600 ECUV1C104ZFV 0.1

C601 ECUV1C104ZFV 0.1

C603 ECUV1C104ZFV 0.1

C604 ECUV1C104ZFV 0.1

C605 ECUV1C104ZFV 0.1

C606 ECUV1C104ZFV 0.1

C607 ECUV1C104ZFV 0.1

E1 L5DAAGB00001 LIQUID CRYSTAL DISPLAY

T1 ETJS13ZA14AB TRANSFORMER

X1 PSVCC0025GT CRYSTAL OSCILLATOR S

Part No. Part Name & Description Remarks

(OTHERS)

16 FOR THE SCHEMATIC DIAGRAM

Note:

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagrams and circuit board may be modified at any time with the development of new technology.

31

KX-T7665AL / KX-T7665X

17 SCHEMATIC DIAGRAM

JK3

TO LCD

CN5

2D5V

3V0

1GND

4RS

5R/W

6E

7D4

8D5

9D6

10D7

MIC

SP

TO HANDSET

SP

MIC

C600

Z0.1

LCD_RS

LCD_D4

LCD_D5

LCD_D6

LCD_D7

(5)

F1

CO7

SW1

E1

CO8

SW2

E2

MES

SW3

E3

V/DWN

SW4

E4

1

2

3

4

R600

8.2K

LCD_W

LCD_E

F2

SW5

SW6

AT/ST

SW7

SW8

MIC1

SP1

AG1

DG

D63

CO6

PRO

V/UP

L51

C500

2200P

L52

R527

C501

1000P

SPP

CN1

1

2

SPN

MIC2

CN2

1

C505

2

NC

AG2

AG

D61

D5V

D62

C601

Z0.1

DG DG

F3 F4 F5 F6 F7

CO4

CO5

SW13

SW9

3

TRANS

SW14

SW10

2

AT/MT

SW15

SW11

INCOM

1

SW12

SW16

C525

10

AG

C604

Z0.1

D3V

C603

Z0.1

CO3

SW17

6

SW18

5

SW19

4

SW20

R500

R501

2.2K

SCLK

DATA

1K

Z10

C503

CO2

SW21

SW22

SW23

SW24

A3V

NC

R505

R506

9

8

7

A3V

Q51

AG

1K

2.2K

D3V

5

3

DG

IC8

R522

120K

C526

Z10

C502

K0.1

AG

C

B

R504

E

10K

R503

1K

AG

A3V

C524

Z10

AG

NC

R601

47K

R602

DG

DG

CSN

SP_CSN

1

IC8

24

CO1

SW25

#

SW26

0

SW27

SW28*SW32

C504

C506

K0.033

NC

C602

R604

18K

F8

SP

SW29

FLASH

SW30

HOLD

SW31

REDIAL

R502

K0.01

D3VD3V

Q52

B

C527

K0.1

R523

10K

R610

R611

47K

E

C

R511

22K

NC

47K

DG

(1)

KOUT[0]

KOUT[1]

KOUT[2]

KOUT[3]

DG

C606

C509

1500P

C607

Z0.1

Z0.1

C507

1500P

R508

8.2K

C514

180P

C511

C512

R509

DG

IC4

19

HANDT3

20

HANDT1

21

HANDT2

56K

26

HANDR

25

HANDI

24

DAOUT

27

RAI

28

RAO

29

SPI

4

SPOP

3

SPON

18

MIC3

17

MIC1

16

MIC2

R603

8.2K

G1

64

63

PB662PB7

CVcc

X1

X2

Vss

OSC2

OSC1

TEST

Vcc

RES

P20

SCK

SI1

SO1

P24

P25

P26

P27

P1718P1619P1520P1421P1322P1223P1124P1025PA326PA227PA128P5029P5130P5231P5332P54

17

INTN

SW33

DG

KIN[0]

KIN[1]

KIN[2]

KIN[3]

KIN[4]

KIN[5]

KIN[6]

KIN[7]

A3V

15

AVDD

2

AVSS

AG

A3V

5

DVDD

6

DVSS

AG

8

DX

10

DR

9

BCLK

7

FS

1

PLLCAP

22

VREF

23

RAGND

11

DATA

12

SCLK

13

CSN

14

TEST

AG

TONE 30

C521

K0.1

C608

NC

AG

R606

R605

4.7K

AG

6.8K

LCD_W

LCD_RS

61

60

59

P8758P8657P8556P8455P8354P8253P8152P8051P7750P7649P75

VTref

TONED

IC6

KOUT[0]

KOUT[2]

KOUT[1]

KOUT[3]

KX-T7665AL / KX-T7665X : MAIN BOARD (1/2)

K0.01

33K

R510

47K

C513

K0.1

C605

DG

R507

C510

K0.1

C515

K0.1

R512

10

11

12

13

14

15

16

C508

K0.1

K0.022

270K

Z0.1

1

2

3

4

5

6

7

8

9

C516

Z1

2125

C517

Z0.1

R514

0

C518

C519

C520

AG

LCD_E

Z1

Z1

Z1

LCD_D4

REN

C528

Z0.01

AG DG

Between IC3 and IC4

(7)

SCLK

DATA

SP_CSN

DATA

SCLK

CSN

LCD_D5

LCD_D6

LCD_D7

P74

P73

P72

P71

P70

P67

P66

P65

P64

P63

P62

P61

P60

P57

P56

P55

WEN

KIN[3]

KIN[1]

KIN[4]

KIN[2]

KIN[0]

R524

R513

DG

47K

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

0

D3V

1

A0

2

A1

3

A2

4

GND5SDA

IC5

R525

13

11

47K

4

5

1

2

SCL

Vcc

WP

IC3

VDD

VSS

TIN

TOUT

ROUT

BCLK

FS

TEST2

RST

TxON

SCLK

RxON

DATA

CSN14TEST1

D3V

8

7

R607

6

DG

R608

180

R609

180

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

KIN[7]

KIN[6]

KIN[5]

DG

RIN

1.8K

ADR5

ADR4

ADR3

ADR2

ADR1

ADR0

3

4

NC

Vss

DG

7

8

6

3

12

16

10

9

15

IC7

Vout

Vin

D3V

DG

DG

C609

C522

Z1

R518 1K

(6)

DG

NC

2

1

C523

Z0.1

D3V

(1)

(2)

(3)

DG

(4)

(5)

(6)

(7)

(8)

(9)

(10)

32

KX-T7665AL / KX-T7665X

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

R526

47K

(3)

D3V

DG

PN9

(1)

R515

47K

R516

47K

Z0.1

C400

C404

12P

X1

16.384MHz

C405

12P

WEN

REN

INTN

DG

Z0.1

C401

C406

R517

47K

R402

47K

12P

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

ADR5

ADR4

ADR3

ADR2

ADR1

ADR0

C402

R406

47K

R519 1K

R520 1K

R521 1K

Z0.1

Z0.1

C403

R400

820

R403

DG

R407

DG

D3V

D3V

D3V

180

C407

Z0.1

47k

DG

R401

DG

26

OSYNC

20

OSR

21

OSX

22

OEPO

25

OCK

44

VDD

56

VDD

24

VDD

1

VDD

7

GND

2

CSN

23

GND

17

GND

49

GND

46

GND

48

OSO

1M

47

OSI

19

OEP1/PN9/CK512K

45

CK8M/16M

57

DB7

58

DB6

59

DB5

60

DB4

61

DB3

62

DB2

63

DB1

64

DB0

50

ADR5

51

ADR4

52

ADR3

53

ADR2

54

ADR1

55

ADR0

4

WEN

3

REN

6

INTN

42

RSTN

41

SCAN

43

SCANE

5

WAITN

29

TEST

40

MMODE

IC2

(2)

GOP1/DRE

GOP0/DR

NROW3

NROW2

NROW1

NROW0

PDX0

PDX1

PVRH

PDR

PVRL

DDX0

DDX1

DVRH

DDR

DVRL

CLM5

CLM4

CLM3

CLM2

CLM1

CLM0

C110

4

2

5

C201

180P

B1

D34

D33

6

1

D3V

DG

R136

C117

DG

R135

Z1

Q33

100P

4

10

59

T1

1

7

26

100P

C112

C113

Z0.1

560

R133

DG

C115

Z1/50V

330

R134

DG

C114

560

Z0.1

DG

C116

Z1/50V

C120

330

NC

DG

DG

R137

1K

5

6

DG

Q5

143

2

R138

27

DG

Q22

R203

15K

IC1

1

OUT

DrvC

2

E

Ipk

DG

3

Ct

Vcc

4

GND5IN-

R204

R208

3.9k

2.4K

CO8

CO7

D35

R

R

G

G

D36

R

R

GG

G

CO3

CO2

2

3

5

4

C118

Z1/50V

DG

R139

18

Q23

8

7

6

D40

D41

INTERCOM

D37

6

1

R209

Q34

R140

5.6K

C119

Z1

DG

1.2

C202

CO4

B

Q6

B

R205

100K

50V0.1

MUTE

R

G

R

5

D1

C

E

E

C203

B4 B5B3B2

2143

DG

R141

33

Q4

R142

10

C

50V33

D42

D38

3

4

DG

STORE

CO5

R206

4.7K

R207

220K

L4

R

R

2

Z1C109

R130 22

4

R131

5

180R306

120R309

120R310

12R311

120R307

12R308

270

R132 22

Z1C111

Q2

3

1

D3V

5

6

Q3

1234

DG

Q21L21

R201

220

R202

5.6K(2125)

D21

A5 A6

SP

D31

R

D32

R

GGG

CO1

2

C100

Z0.1

DG

C101

Z0.1

DG

C107

DG

C108

DG

D3V

A3V

1000PC103

R100 1.8K

1000PC102

R104 1.8K

(4)

Z0.1

(8)

Z0.1

R119

R129

D3V

A3V

GND

AG

1k

R300

1kR304

1kR301

1kR305

1k

R302

R303

1k

D3V

DG

R111 1.2K

D3V

DG

8.2K

12K

D3V

R101

8.2K

R102

5.6K

R103

12K

R108

R109

R110

R112

5.6K

R113

6.8K

R114

10K

R200

3.3(2125)

C205

6.3V470u

1

2

3

1

2

3

100

Q31

Q32

100

J200

Q1

D3V

3

2

C104

1

Z0.1

DG

D3V

R105

1.2K

R106

120

R107

1.8K

1000PC106

1.2K

1000PC105

R115

4.7K

R117

4.7K

R116

15K

DG

330µ

Z0.1

C204

6.3V470u

C200

DG

5

4

5

4

38

39

37

36

35

33

34

32

31

30

28

27

14

15

16

18

8

9

10

11

12

13

H

L2

L

L1

L3

CN3

D39

R

CO6

5

Q35

6

1

T

R

CN4

2+

1+

1-

2B6

3

4

DG

JK1

TO PBX

1

H

2

R

3

T

4

L

TO DPT/SLT

JK2

1

H

2

R

3

T

4

L

MSG / RINGER LAMP

BOARD-B

B9B10

B7B8

D43

NCR312

R313

4.7

D44

A1

A2

A3

A4

NC

MW2

KX-T7665AL / KX-T7665X : MAIN BOARD (2/2)

33

KX-T7665AL / KX-T7665X

18 WAVEFORM

(1)

Pin42 of IC2 and Pin8 of IC6

Rest signal

Pin42 of IC2 and Pin8 of IC6

(2)

Pin48 of IC2 16.384MHz

(3)

Pin45 of IC2 8.196MHz

34

(4)

Pin36 of IC2

Communication waveform

(5)

Pin4 to 7 of CN5

Communication waveform

KX-T7665AL / KX-T7665X

(6)

Pin3 and 6 of IC3

PCM interface waveform between IC3 and IC2

35

KX-T7665AL / KX-T7665X

(7)

Pin8 and 10 of IC4

PCM interface waveform between IC4 and IC3

(8)

Pin31 of IC2

Communication waveform

36

19 PRINTED CIRCUIT BOARD (MAIN BOARD)

19.1. COMPONENT VIEW

KX-T7665AL / KX-T7665X

W

R

CN3

R306

A1

R310

Q32

R308

R309

R311

A6

A3

R307

A4

R516

C104

C103

R100

B3

B2

B1

2

Q31

R519

R520

R119

C107

R112

R115

A5

1

B6

A2

Q33 Q34 Q35

R303

R305

R302

R301

R402

PN9

17

R521

R517

R406

R129

C401

32

R116

R114

C101

R113

C108

R110

C105

R109

R111

R117

C106

C114

C120

Q3

R136

R135

Q5

D3V

C117

R200

F5

F7

PSUP1439Z-A

PbF

B5

E2

R304

R300

R407

16

IC2

33 48

C407

R103

R102

C100

C406

R101

R106

R105

IC7

R108

C102

R107

R104

C113

Q2

R134

R133

R139

R138

Q6

R137

C204

C205

16

17

E1

F8

32 49

F6

33 48

F4

F1

F2

F3

C400

1

64

49

Q1

1

B8

B10

R401

R403

R132

C115

2

R130

D21

Q21

L21

CN2

R313

R400

C111

C109

CN4

C404

C405

5

RW

C402

C116

R

C403

R131

C201

21

R312

B9

10

C607

C606

IC6

X1

W

B7

B4

R202

R201

C200

C505

R610

1

T1

IC1

R208

R204

AG2

MIC2

R601

C602

64

H

R209

R518

G1

R602

JK1

L1

C203

C202

R526

CN5

C605

T

L

L2

101

9

R206

R515

R604

R603

R611

R609

R608

C118

C112

R524

C110

R207

R525

R600

D5V

D1

R140

R119

R203

R205

C522

R513

R607

R

R114

IC3

C601

IC5

Q4

R142

Q22

Q23

1

C600

GND

C524

R506

D63

D62

C609

C523

C528

C506

R512

C514

R505

IC8

C603

C516

R511

D61

E3

R514

C515

R507

C604

L3

L4

R605

C608

R606

R503

C503

C510

C521

C508

C507

C517

IC4

C519

C502

R502

E4

L51

R527

C518

C511

C520

C512

L52

MIC1

C525

R510

C526

SP1

SPN

SPP

C509

R509

R501

JK2

C501

C513

R500

JK3

RU CNGen

AG1

W

2

R

1

R523

R504

C504

R508

A3V

GRA

C527

Q51

C500

CN1

DB

Q52

R522

A

KX-T7665AL / KX-T7665X : MAIN BOARD : COMPONENT VIEW

37

KX-T7665AL / KX-T7665X

19.2. BOTTOM VIEW

SW33

110

SW6

SW3

HOOK-SW

SW8

V/UP

SW4

V/DWN

SW16

SW20

SW24

PRO

D41

D40

1

4

7

SW12

INCOM

SW11

AT/MT

SW15

2

SW19

5

SW23

8

D42

SW10

TPANS

SW7

AT/ST

SW14

3

SW18

6

SW22

9

MES

D35

D33

D39

D38

D37

D36

D34

SW2

CO8

SW1

CO7

SW5

CO6

SW9

CO5

SW13

CO4

SW17

CO3

SW21

SW28

SW32

REDIAL

SW27

0

SW26

#

D32

PSUP1439Z-B

PbF

D44

SW30

FLASH

SW31

HOLD

D43

D31

SW29

SP

KX-T7665AL / KX-T7665X : MAIN BOARD : BOTTOM VIEW

CO2

SW25

CO1

38

NT1

KXT7665AL

KXT7665X

Loading...

Loading...