Page 1

ORDER NO.KM69307470C8

Service Manual

Printer

Dot Matrix Printer

SPECIFICATIONS\TEXHM4ECKME ХАРАКТЕРИСТИКИ

OPERATOR CONTROLS/INDICATORS\УПРАBЛEHИE И ИНДИКАТОРЫ

REMOVAL AND REPLACEMENT PROCEDURES\METОДИKА ЗАМЕНЫ И

РАЗБОРКИ

ADJUSTMENT\HАCTРОЙKА

MECHANICAL FUNCTIONS\МEXАHИЧECKИE ФУНКЦИИ

ELECTRONIC CIRCUIT BLOCK DIAGRAM\БЛОK-CXEМА ЭЛЕКТРИЧЕСКОЙ

ЦЕПИ

ELECTRONIC CIRCUIT DESCRIPTIONS\ОПИCАHИE ЭЛЕКТРИЧЕСКОЙ ЦЕПИ

PARTS LIST AND LUBRICATION\CПИCОK ЗАПАСНЫХ ЧАСТЕЙ И СМАЗКА

PACKING MATERIALS\УПАKОBОЧHЫE МАТЕРИАЛЫ

KX-P1150

Panasonic

Page 2

KX-P1150

1. Specifications

Power requirements:

Current:

Power consumption:

Interface:

Print mode:

Character sets:

Buffer: 4K (standard), additional 32K (optional KX-P44)

Dot configuration:

Character size

Normal characters:

Character per line (cpI)

(per inch (25.4mm) (cpi)):

AC220-240V, 50/60Hz

Idle: 0.1A; Maximum 0.7A

Max

------

60 W

Standby 5W

Self Test

Centronics parallel

Draft, Near Letter Quality (Courier, Bold PS, Times Roman, Sans Serif)

96 ASCII characters, 33 International characters (14 countries + LEGAL Set no

science), 158 IBM-PC special characters, 38 Multilingual characters

Dot Diameter: 1/84 inch (0.3mm)

Dot Alignment (HxV)

Dot Pitch

0.074(W) X 0.097(H) inch (1.89 x 2.46 mm)

Pica

Elite 96 cpi (12cpi) 48 cpi (6cpi)

Micron

Compressed 137 cpi (17cpi)

Elite compressed 160 cpi (20cpi) 80 cpi (lOcpi)

-----

35 W

(H)

(V)

Draft NLQ

9x9

1/120"

1/72"

Draft, LQ

80 cpi (lOcpi) 40 cpi (5cpi)

120 cpi (15cpi)

18x18

1/240"

1/144"

Elongated

60 cpi (7.5cpi)

68 cpi (8.5cpi)

Print speed:

Print direction:

New line time:

Paper feed:

Paper used:

Paper thickness:

Number of copies:

Printer emulation:

Micron

Draft

Letter Quality

Text printing: Bi-Directional

Bit Image printing: Uni-Directional & Bi-Directional

Approx. 100 msec [with 1/6 inch (4.2 mm) line feeding]

Friction and Push Tractor

Fanfold paper

Single sheet

Envelopes

Total thickness of sheets must be less than 0.013 inch (0.32 mm).

Original -(- 3 non-carbon copies

EPSON

IBM

(102-254mm1

(102-297mm)

FX-850

Proprinter 111

240 cps 192 cps

32 cps

Width

4-10 in

4-11.7 in

Standard business envelopes ie: #6, #10 size

16-24lbs.

14-24 lbs.

Elite

38 cps 32 cps

Weight

(127-363mm)

Height

5-14.3 in

Pica

160 cps

Page 3

KX-P1150

Storage environment:

Temperature: -4°F to 140°F (-20°C to + 60°C)

Humidity: 10-90%RH

Operating environment: Temperature: 50°F to 95°F (+10°C + 35°C)

Humidity: 30-80%RH

Head service life:

Approx. 200 million strokes in draft mode

Ribbon: Cassette seamless fabric ribbon

Black ribbon cassette KX-P115/KX-P115i:

Life expectancy (in Draft mode) (rolling ASCII)

Approx. 4 million characters

Optional accessories: Auto Cut Sheet Feeder (single bin) (KX-PT12)

32K Buffer Chip (KX-P44)

Ribbon Cassette (black) (KX-P115/KX-P115i)

Dimensions:

17.1" (W) X 12.4" (D) X 5.3" (H) in. (434 x 314 x 134.5 mm)

Weight: Approx. 10.6 lbs. (4.8 kg)

Printing area: Fanfold paper

J^i

_________

A

B

C 0.33" (8.38 mm)

■ 1st character

D

A; Value A indicates the area near the paper

Printing area

---------------------

i— Paper perforations

Printing area

-

To-i:

perforations where the quaiity may not be

optimum.

B

Vaiue B indicates the maximum distance

between the sprockets and first printabie

character. (When the ieft tractor is set on the

left end and the margin is set to 0.)

C: Value C indicates the area from the top edge

of the paper to the top of the first printed

character.

D: Value D indicates the position where paper out

is detected and printing may not be optimum.

Single sheets and Envelopes

B

C

D

»*

B

arc

B: Value B indicates the minimum distance

' 1 St character

Printing area

Id

between the edge of the paper and the first

printable character.

C: Value C indicates the area from the top edge

of the paper to the top of the first printed

character.

D: Value D indicates the position where paper out

is detected and printing may not be optimum.

(When printing on envelopes, do not print on

area where edges overlap. Print quality may

not be optimum.)

Fanfold Paper

1" (25.4 mm)

0.7" (17.8 mm)

1" (25.4 mm)

Single sheets and Envelopes

1.5" (38 mm)

0.33" (8.38 mm)

1" (25.4 mm)

Specifications are subject to change without notice.

Page 4

KX-P1150

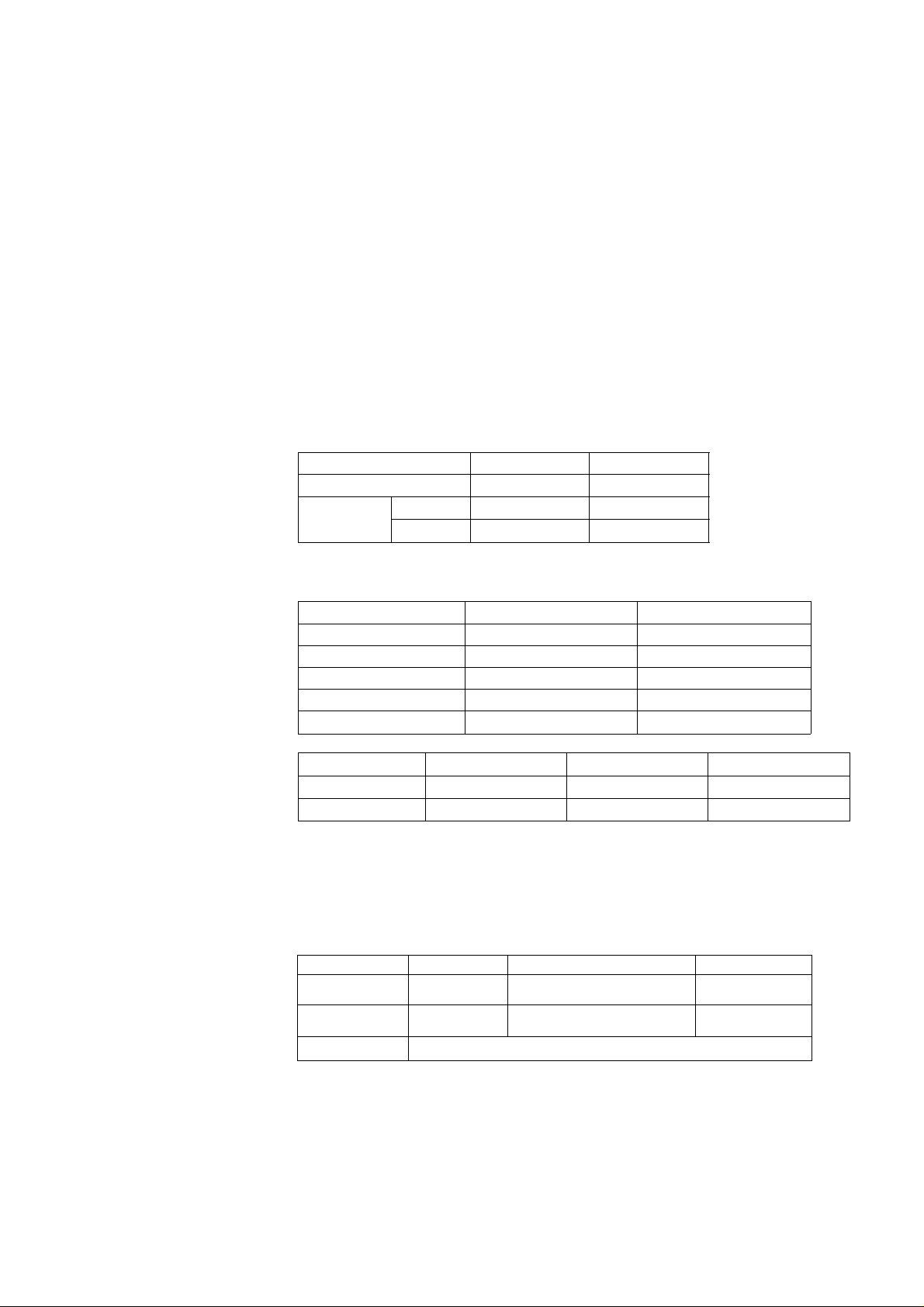

2. Operator Controls/Indicators

■ON LINE Switch

■TEAR OFF Switch

-LF/FF Switch

■LOAD PARK Switch

-ON LINE Indicator

•POWER/PAPER OUT

Indicator

Page 5

KX-PllSQ

3. Setting of Controls

This section covers the basic operation of the printer. For more detailed operation, refer to the operator's

manual.

3.1 Print Mode

®® PROGRAM

Courier

@®

®@

Rom an O O

Bold PS POWER

Sans Serif

^®"

FONT

ON LINE

o

PAP ER OUT

ON LINE

TEAR

OFF

LF/FF

LOAD

PARK

FONT switch:

ON LINE switch:

LF/FF switch:

TEAR OFF switch:

LOAD/PARK switch:

FONT indicators:

ON LINE indicator:

POWER/PAPER OUT indicator:

Pressing this switch will select the font style.

This switch opens and closes the communication line with the computer.

Pressing this switch advances the paper one line at a time. Holding this

switch advances the paper to the first print line of the next page.

Pressing this switch will advance or reverse the paper for tearing off.

Pressing this switch will load or park the paper.

These indicators identify which Font has been selected.

This indicator is lit when the printer is in the ON LINE mode and is out in the

OFF LINE mode.

This indicator is lit when the power is on and paper is installed. It blinks

when paper is not installed.

Page 6

KX-P1150

3.2 Service Operation

The following service functions can be executed when checking, adjusting or testing the printer.

Operating Switch Function Name Description

LF/FF switch + Power switch

ON LINE switch, LF/FF switch +

Power switch

ON LINE switch + Power switch

FONT switch + Power switch

TEAR OFF switch + Power switch

Self. Printing Test

Print Timing

Head Aging

Hex-Dump

Demonstration

Printing

All characters stored in the FONT ROM are printed

for 20 minutes.

When adjusting the Print Timing, use this function.

For more detailed information please refer to Section

5.2 Print Timing

After installing the new printhead, use this function to

check the movement of the printhead pins. Do not

use this function more than 30 minutes.

This function is for analyzing the data being

printed by the printer. When the function is

activated, all data received by the printer is printed

in hexadecimal code.

The printer will perform Demonstration Printing.

Note: After completing each of the above checks, turn the power switch off to reset the unit.

Page 7

KX-P1150

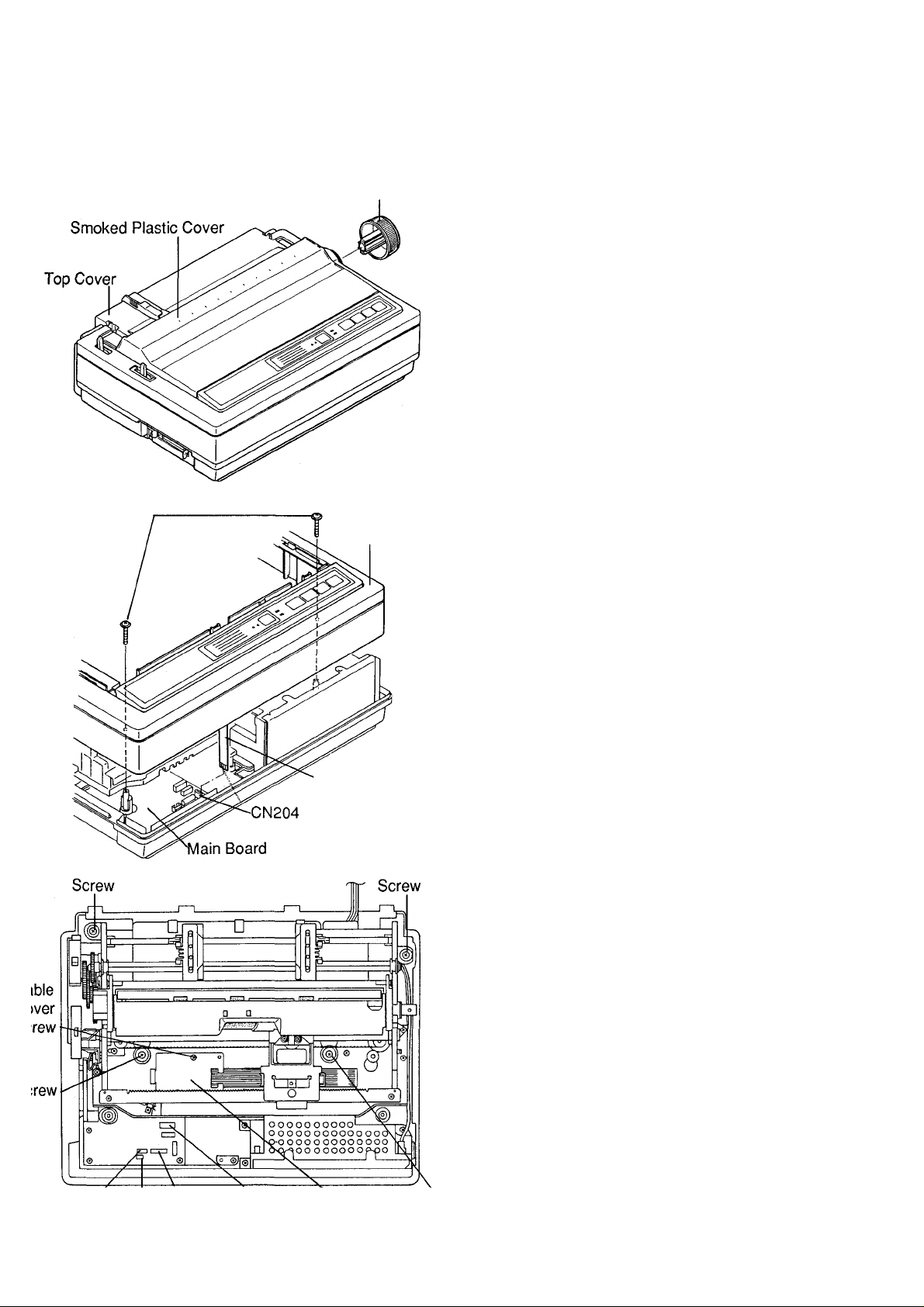

4. Removal and Replacement Procedures

For safety and to avoid possible damage to electronic components, the AC line cord must be unplugged before

disassembly.

Platen Knob

4.1 Covers

Caution: The control panel board is installed on the

upper cabinet. The control panel cable is

attached to connector CN300 on the

control panel board and connector CN204

on the main board.

When lifting off the upper cabinet from the

machine, be careful not to damage the

connectors and control panel cable.

1. Remove the paper stand and smoked plastic

cover.

Screws

2. Remove the platen knob.

Upper Cabinet

3. Remove the screws (2) from the upper cabinet.

4. Lift off the upper cabinet.

5. Unplug the control panel cable from connector

(CN204) on the main board.

6. Remove the Upper Cabinet.

Control Panel Cable

4.2 Printing Mechanism

1. Unplug connectors CN201, CN202, CN206 and

CN207.

2. Position the carriage on the right side.

CN206 CN201 CN202 Cable Cover Screw

CN207

3. Remove the cable cover screw and cover.

4. Unplug the printhead flat cable from connector

(CN203) on the main board.

5. Remove the screws (4) from the chassis.

6. Lift off the printing mechanism.

Note: Use care when removing the cable cover to

avoid damaging the print head flat cable.

Page 8

KX-P1150

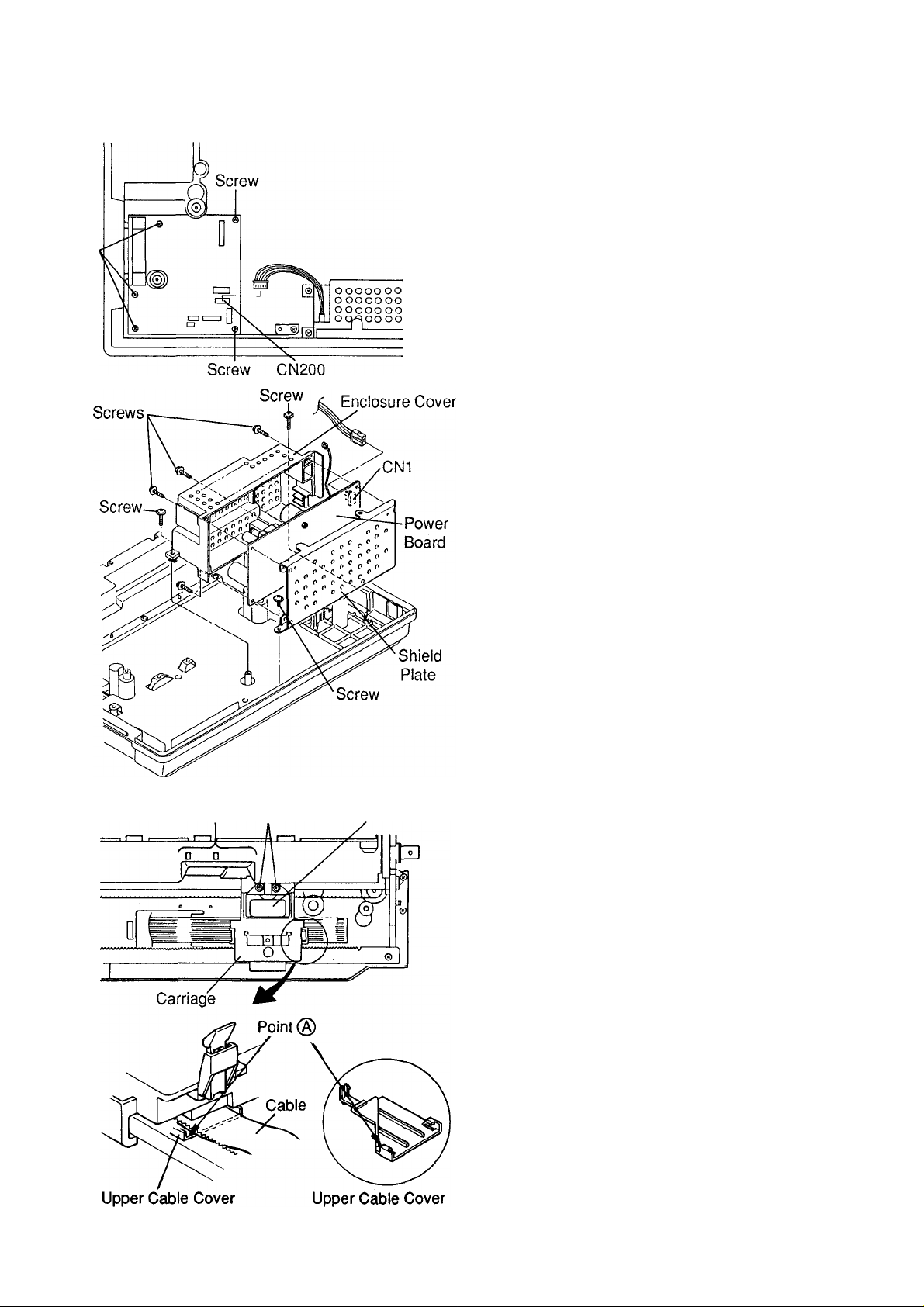

Screws

4.3 Main Board

1. Unplug connector (CN200) on Main Board.

2. Remove the screws (5) from the Main Board.

The Main Board can now be removed.

4.4 Power Board

1. Unplug connector CN1 on the power board.

2. Remove the screws (3) from the power supply

unit.

Opening Screws Printhead

3. Remove the screws (4) from the enclosure cover.

4. The enclosure cover, shield plate and power

board can now be separated.

4.5 Printhead

1. Position the carriage at the opening.

2. Remove the screws (2) from the printhead.

3. Release the upper cable cover from the carriage

by pushing down on the upper cable cover at

point (A).

4. Remove the printhead by lifting the printhead and

unplugging the printhead flat cable.

Note: When reinstalling the upper cable cover,

ensure that the print head cable is not pinched

by the cable cover latches.

Note: When the printhead is installed, ensure that

the head gap is correct.

Refer to section 5.1.

Page 9

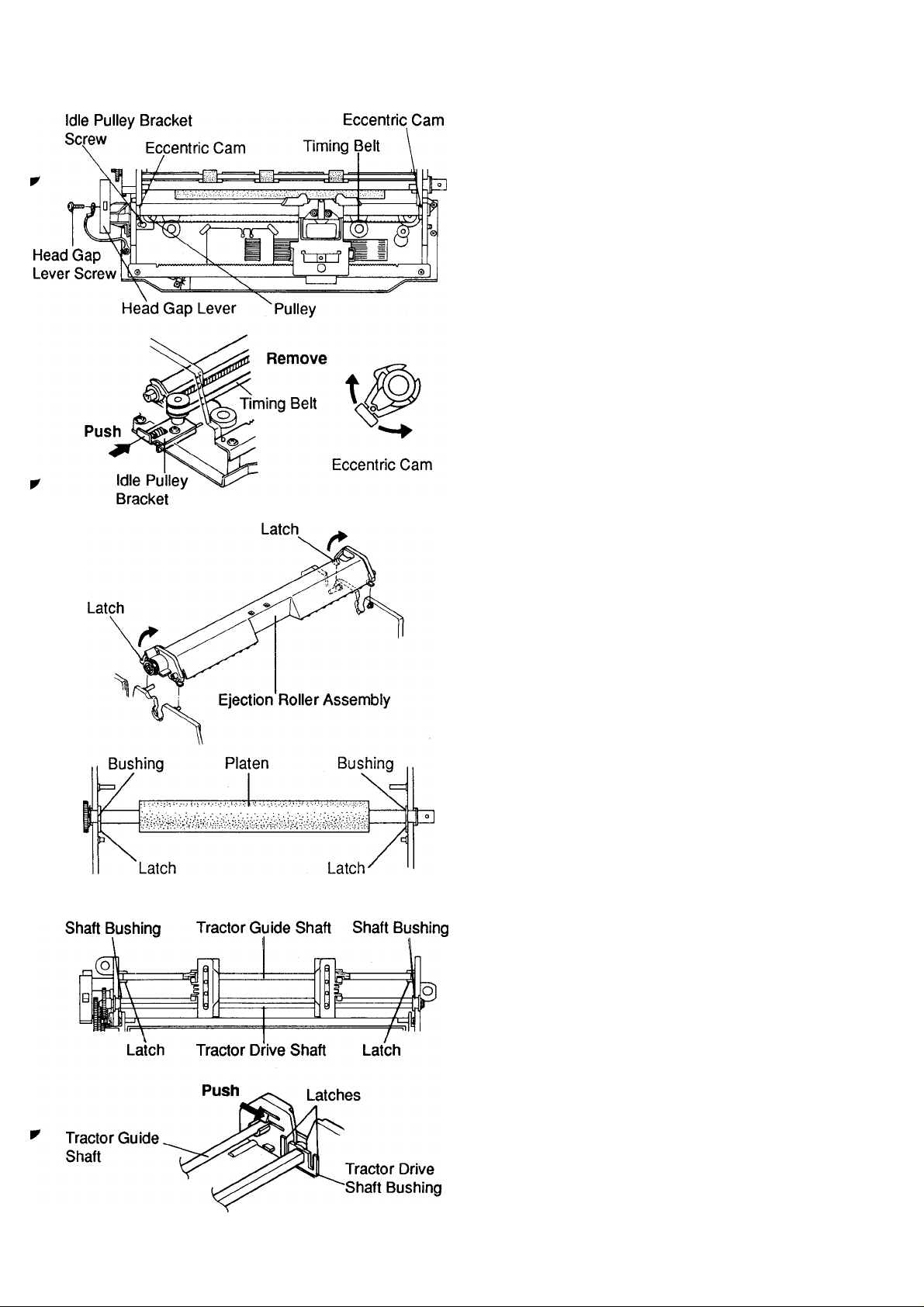

KX-P1150

4.6 Carriage Assembly

1. Loosen the idle pulley bracket screw (1) and

release the timing belt from the pulley.

2. Remove the head gap lever screw, and Ground

Wire. Remove the head gap lever.

3. Remove the carriage shaft eccentric cams from

the right and left side frames by turning either

clockwise or counter clockwise.

4. Slide the carriage shaft out from the left side and

remove the carriage shaft.

Note: When installing the carriage assembly and its

shaft, ensure that the head gap is properly

adjusted. (Refer to section 5.1).

Tractor Drive

4.7 Platen Assembly

1. Release the latches on the ejection roller

assembly.

2. Rotate the ejection roller assembly forward.

3. Remove the ejection roller assembly by lifting

straight up.

4. Release the latch of the platen bushings from the

left and right side frame. Rotate the bushings

toward the rear of the machine.

5. Slide both platen bushings out of the frame by

pushing them inward.

6. Lift off the platen assembly.

Tractor Drive

4.8 Tractor Assembly

1. Release the tractor guide shaft from the left and

right side frame by pushing the iatches.

2. Release the latches of the left and right tractor

drive shaft bushings.

3. Lift off the tractor assembly.

Page 10

KX-P1150

5. Adjustment

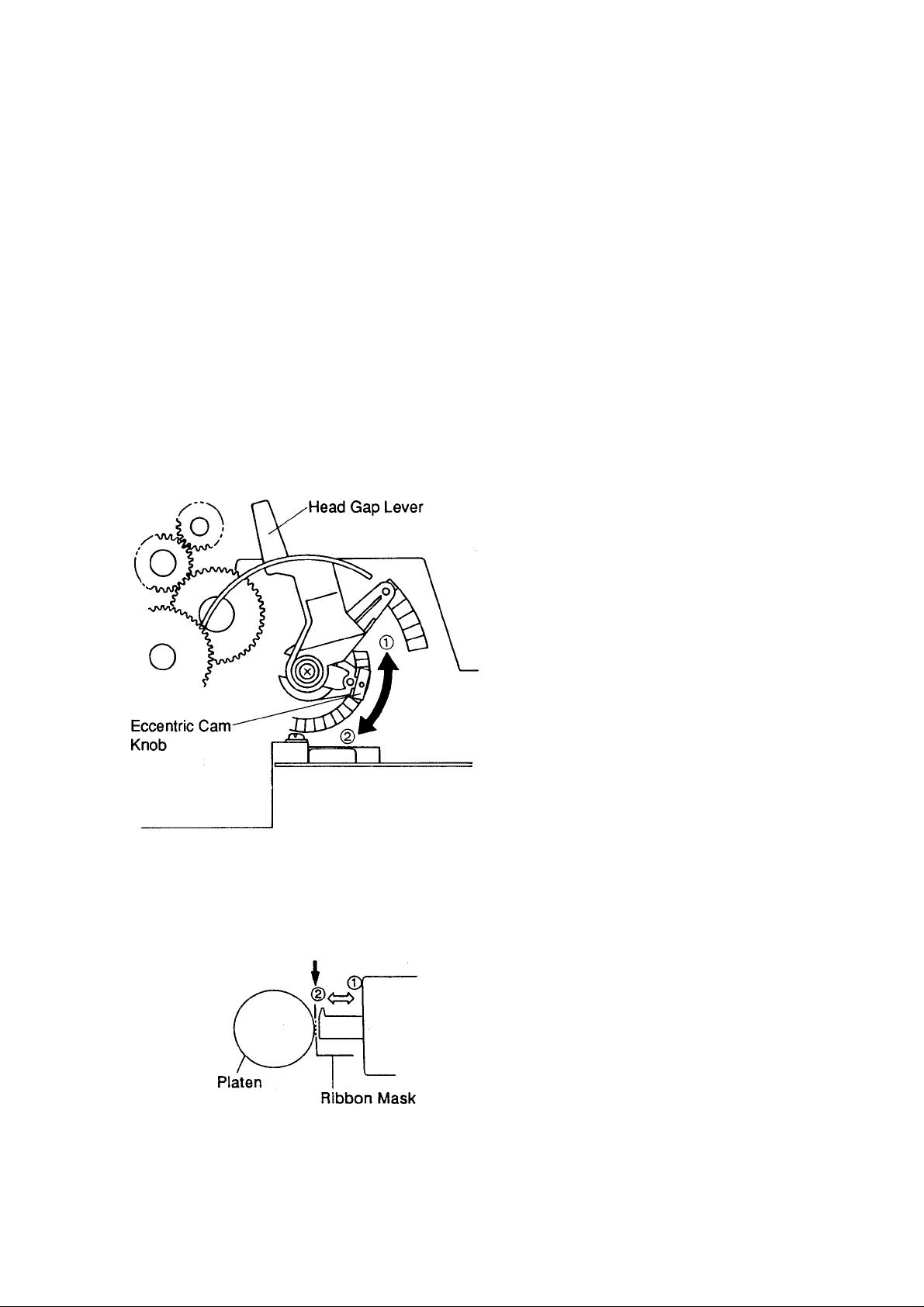

(Head Gap Lever)

Ac

H

E

A

D

G

A

P

V c

+

Single

Sheet

Position

(Paper Feed Selector)

□

5.1 Head Gap

1. Set the head gap lever to the single sheet

position.

2. Set the paper feed selector to the position.

3. Ensure the printhead is firmly secured with 2

screws.

4. Move the carriage to the left side and adjust the

head gap between the platen and the printhead

for a clearance of 0.35mm-0.4mm by turning the

left eccentric cam.

0.45 mm Gauge^,^^ n

(does not pass)

0.40 mm Gauge\^ n

(does pass)

5. Move the carriage to the right side and adjust the

gap as per step 4 above by turning the right

eccentric cam.

Note: The projection on the eccentric cam is

released from the adjustment hole by pulling

the knob. Turning the eccentric cam one step

causes 0.037mm ± 0.052mm head movement.

Note: Use only a round wire feeler gauge of the

specified dimension for this adjustment.

Note: The head gap adjustment is required when

replacing the head, platen, carriage, carriage

shaft or eccentric cams.

Note: Moving the head gap lever towards the®

position increases the head gap clearance,

and moving toward the(2)position decreases

the clearance.

Page 11

KX-P1150

5.2 Print Timing

This adjustment is used for adjusting the print timing.

There are 6 different speeds at which the print timing

can be adjusted.

abnormal

H H H

normal

The print timing is adjusted using the following

procedure:

1. Turn on the power while holding the ON LINE

and LF/FF switches.

2. Press the FONT switch to print the "H" pattern.

The "H" pattern will be printed for 4 full lines.

3. Check the print timing comparing the "H" pattern

from line to line.

4. If the print timing is misaligned, adjust it by using

the LF/FF (Move to right) and ON LINE (Move to

left) switches and retry the printing for a final

check.

Note: Pressing the LF/FF or ON LINE switch moves

the line in 1/1440 inch increments.

5. Press the TEAR OFF switch to select the next

print speed.

6. Repeat steps 2-4 for each print speed.

7. Press the LOAD/PARK switch to save the print

timing in memory. The printer will return to the

normal print mode.

Note: If the second line of the "H" pattern is shifted

by more than half of an "H" character, be sure

the printing mechanism is normal before

starting adjustment.

Page 12

KX-P1150

6. Mechanical Function

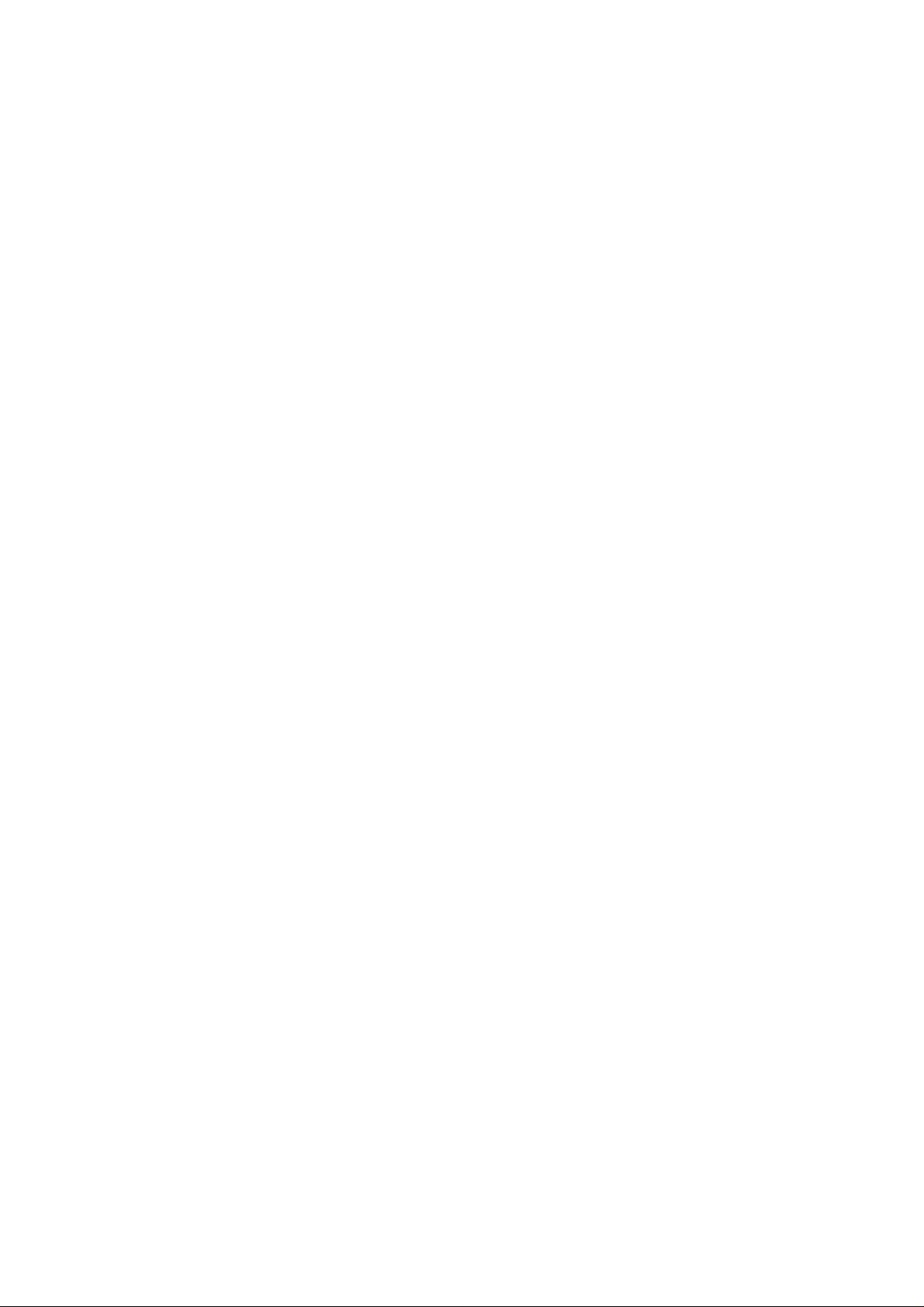

6.1 Carriage Drive System

Carriage Drive Gear

The Carriage Drive System uses a pulse motor to

move the carriage 1/60 inch per single drive pulse.

The carriage slides on the carriage guide plate and

carriage shaft when spacing to the right and left.

6.1.1 Power Transmission Mechanism

The rotation of the carriage motor is transmitted to the

carriage through the carriage drive gear. The timing

belt fixed under the carriage is looped around the idle

pulley and carriage drive gear. This causes the

carriage to move left and right along the carriage

shaft. The timing belt is given proper tension by the

idle pulley tension spring hooked between the pulley

bracket and chassis.

Leaf Switch

Barrier Tab

6.1.2 Print Timing

Print timing for pica (1/60 inch) and elite (1/72 inch) is

generated by a software operated timer. Refer to

"Carriage Motor Drive Block" page 33.

6.1.3 Home Position Detector Mechanism

The home switch is a leaf switch located at the far left

of the printer. Its function is to notify the CPU of the

carriage reference position. During spacing operation,

when the carriage approaches the left margin, the

barrier tab, mounted under the carriage, actuates the

home switch, generating the signal and indicating

carriage position to the CPU.

Page 13

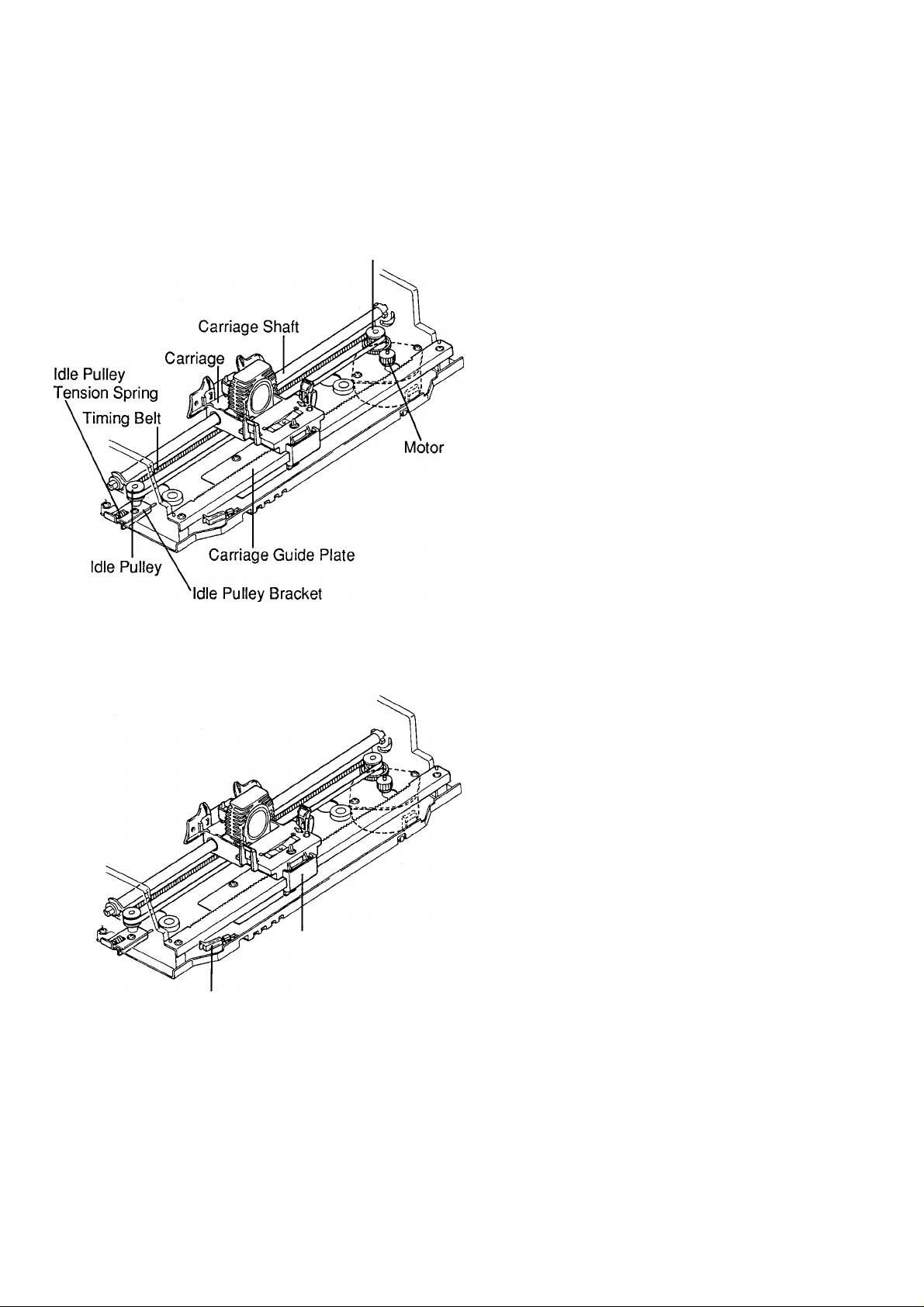

Fig,1 (Bottom View)

KX-P1150

6.1.4 Ribbon Cassette Drive Mechanism

This function performs the ribbon feed operation in

accordance with the movement of the carriage. The

ribbon cassette drive mechanism is shown in Figures

1 and 2.

This mechanism gives uniform ribbon feed

regardless of the direction of the carriage movement.

It consists of the rack gear 0 , ribbon drive gear (§)

with the ribbon feed hub and 3 gears.

When the carriage moves to the right (Fig.1), rack

gear 0 turns the neutral gear ® counter-clockwise.

The neutral gear 0 then engages with gear ® via

the gear (5) which turns the ribbon drive gear 0

clockwise with the hub.

When the carriage moves to the left (Fig.2), rack

gear 0 turns neutral gear @ clockwise. Neutral

gear ® then engages with gear 0 which turns

ribbon drive gear 0 clockwise with the hub.

6.2 Paper Thickness Selection

Selection for the number of copies is made by

changing the distance between the platen and the

printhead nose tip. When the head gap lever is

operated, the carriage shaft revolves on the

eccentric cams, moving the carriage forward or

backward.

Page 14

KX-P1150

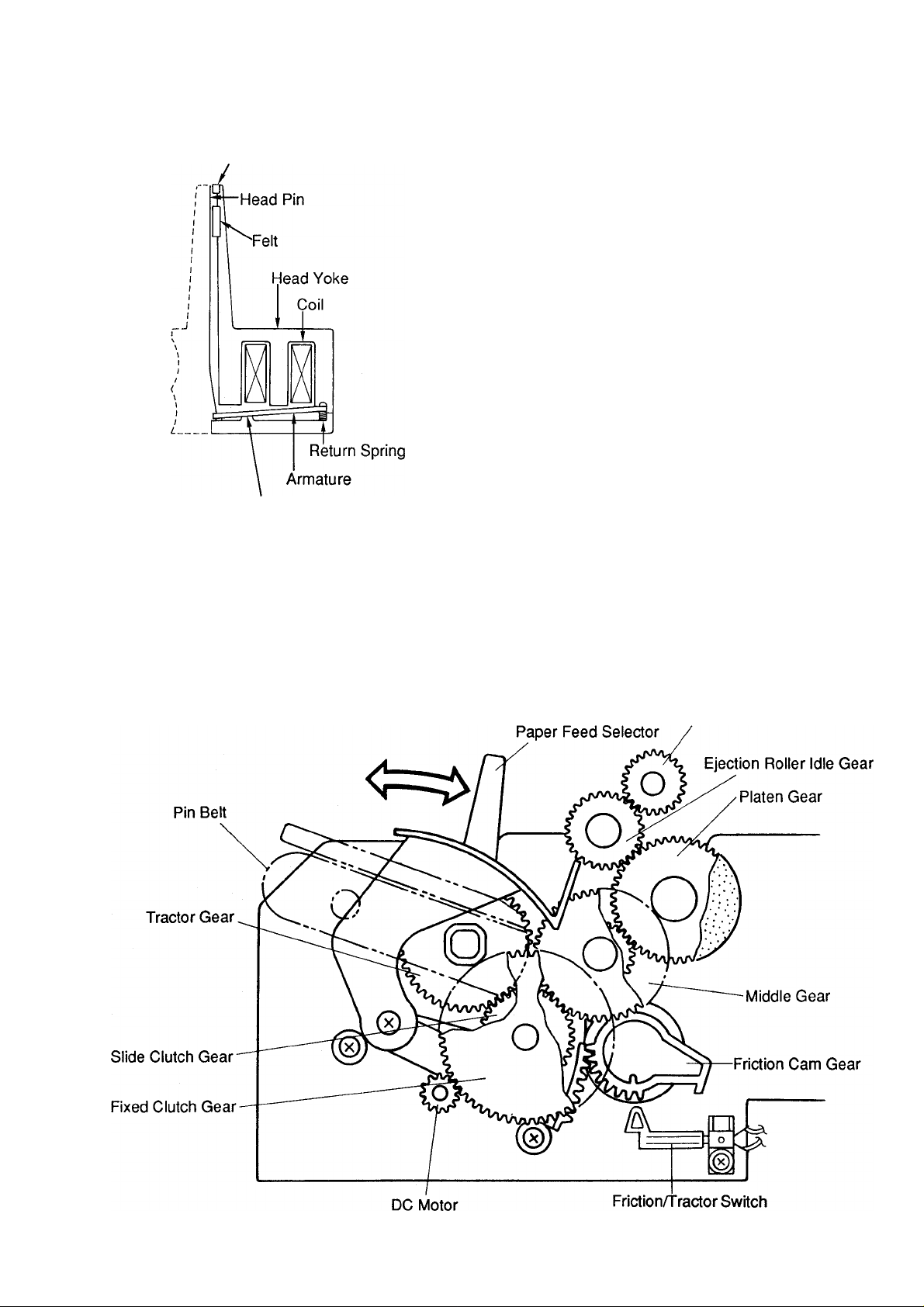

6.3 Printhead

Pin Guide

Stopper

6.4 Paper Feed Mechanism

The printhead utilizes 9 electromagnets as a driving

source, which causes the pins to strike the ink ribbon

against the platen and onto the typing paper for

matrix printing. The construction of the printhead is

shown at the left.

6.3.1 Power Transmission Mechanism

The set of 9 electromagnets consists of a one piece

yoke and 9 coils. The armature which secures the

pins is supported by this yoke.

6.3.2 Printhead Pin Operation

When the coil assembly is excited by a print signal,

the armature is drawn in, and the pin secured by the

armature is guided by the various guides to move in

the direction of the platen. The pin strikes the ribbon

to the paper. Next, the return spring moves the

armature and pin from the platen back to the rest

position.

A DC pulse motor is used as a paper feed motot. Both continuous paper and single sheet can be fed by

operating the paper feed selector. Continuous paper is loaded on both left and right sides of the pin belt on the

tractor drive device. Continuous paper is fed from the rear of the printer. Single sheet is fed from the top of the

printer. The paper feed mechanism is shown below.

Ejection Roller Gear

Page 15

KX-P1150

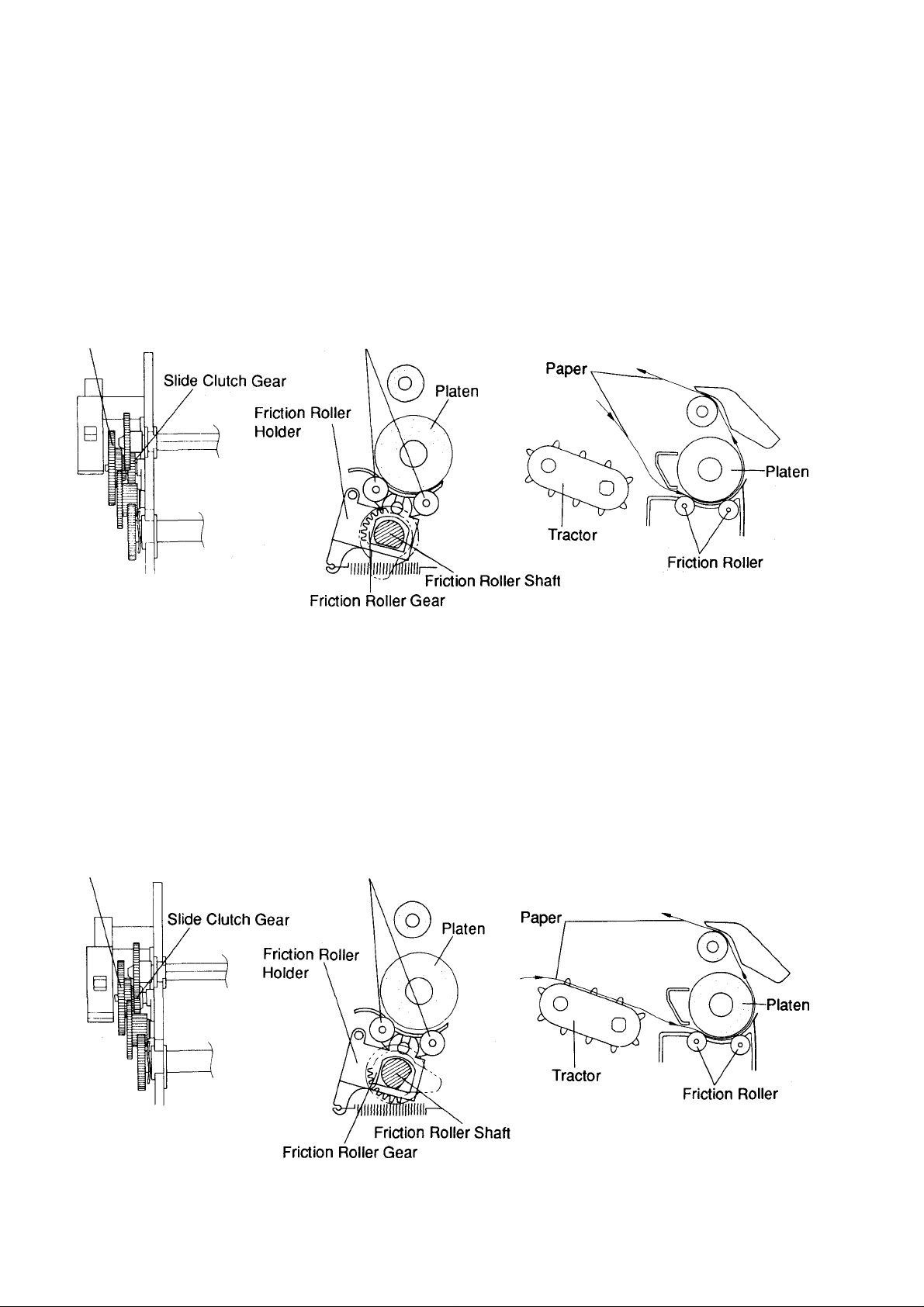

6.4.1 Friction Paper Feed Mode

This mode is for feeding single sheet paper from the top of the printer in the friction paper feed position. By

operating the paper feed selector, the fixed Clutch Gear is disengaged from the Slide Clutch Gear. As a result,

the Tractor Gear is released from its power transmission mechanism.

When setting the paper feed selector at single sheet paper position, the Friction Roller Gear rotates in a

clockwise direction. As a result, the Friction Roller Shaft revolves, allowing the Friction Rollers to contact the

platen for gripping the paper when feeding. The Friction Roller Gear also pushes the leaf switch to notify the

CPU that the selector is in the" Q " Friction position.

Fixed Clutch Gear

6.4.2 Tractor Paper Feed Mode

This mode is for feeding continuous paper from the rear of the printer. By moving the paper feed selector to the

" ini" Tractor position, the Slide Clutch Gear is engaged with the Fixed Clutch Gear. This enables turning of the

tractor drive mechanism for push mode. When the paper feed selector moves to the" 0" Tractor position the

Friction Roller Gear is rotated in a counterclockwise direction. As a result, the Friction Roller Shaft revolves and

moves the Friction Rollers away from the platen. This enables free paper passage from the rear of the

machine. The Friction Roller Gear also breaks contact with the leaf switch to notify the CPU that the selector is

in the" p]" Tractor position.

Friction Roller

Fixed Clutch Gear

Friction Roller

Page 16

KX-P1150

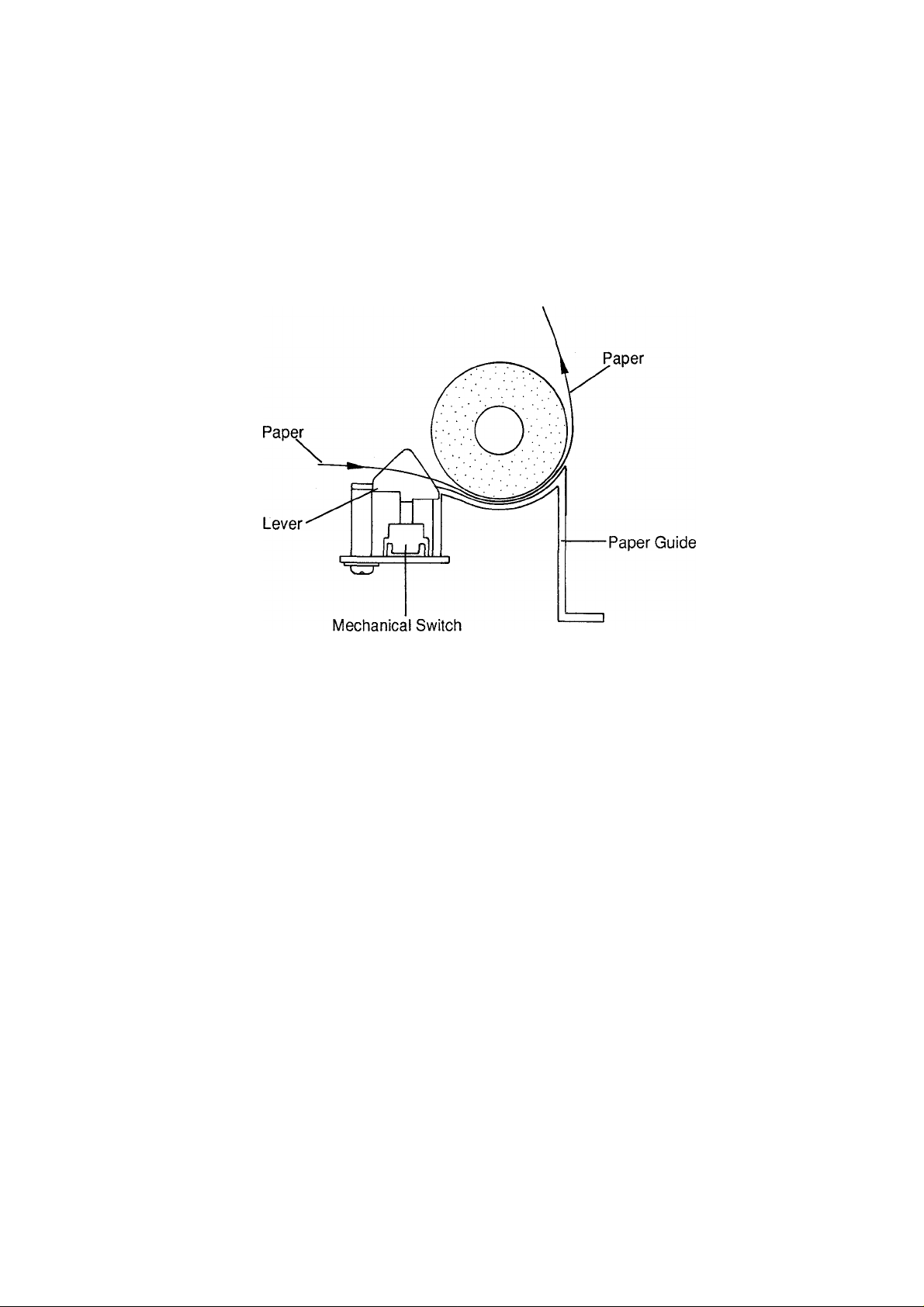

6.5 End of Paper Detector

The printer uses a mechanical switch for detecting paper out with continuous or single sheet paper. When

paper is loaded In the printer, the lever is down, and the condition of the mechanical switch is on. This sends a

signal to the CPU indicating paper loaded in the printer. When paper is out, the lever is up, and the condition of

the mechanical switch is off. This removes the signai from the CPU indicating no paper is in the printer.

Page 17

тз

g

Page 18

KX-P1150

8. Electronic Circuit Descriptions

8.1 Principle of Operation

The KX-P1150 has three Micro switches. The home position switch sets a reference for the carriage and is

necessary for aligning the first print position. The Friction/Tractor switch detects the selected method of

paperfeed (Friction or Tractor).

The paper out switch detects paper end and prevents printing when the printer is out of paper.

The printer has three drive circuits: carriage spacing motor, paper feed motor and printhead.

The control panel is composed of switches and LEDs that indicate the various states of the printer.

Logic Diagram

Printer

Page 19

8.2 Circuitry

8.2.1 Power Supply Block

(1) Block Diagram and Schematic Diagram

KX-P1150

l-J

C-D VOLTAGE WAVE E-F VOLTAGE WAVE

Ml

w

Page 20

KX-P1150

(2) Description

(a)

Input Circuit

This circuit decreases RF and eliminates transient line noise. After the AC line voltage is filtered, it is

supplied to the rectifier circuit. Fuse F001 protects the power supply from external power surges and

internal current overloads.

C006

(b) Rectifier Circuit

The AC power is rectified by D001, then supplied to the converter circuit and provides the Kick-on

voltage for control circuit (MC001) through R008-R013. Over current protection in this circuit is

provided by TH001.

Page 21

(c) Converter Circuit

This power supply produces 2 output voltages (+36VDC and +5VDC). The output voltages are stabilized

by controlling the on and off period of Transformer T001, which is controlled by MC001 monitoring the

+36VDC output and then turning Q001 on and off. +8VDC is input to IC101, a three pin regulator that

regulates the +5VDC output.

KX-P1150

+36V

GND

+ BV

(d) Control Circuit and Error Detection Circuit

When the +36VDC output voltage increases, the current of photocoupler PC001 increases, MC001

monitors this current level and controls on and off time of Q001. The turning on and off of Q001 controls

the oscillation frequency of T001 which regulates the +36VDC output.

(e) Over Current Limiter

IC101 has built in over current protection and protects the +5VDC circuit from current overload. Control

circuit MC001 provides over current protection for the +36VDC circuit by controlling Q001 turn on time

by an internal limiter circuit.

Page 22

KX-P1150

8.2.2 CPU and Peripheral Circuit Block

(1) This block diagram consists of the CPU (IC200), Gate Array (IC205), ROM (IC202), RAM (IC203) and

optional RAM (IC204). It receives the data from the host computer, processes the input from the printhead

overheat sensor and operation switches, and controls the carriage, paper feed motors, and the printhead.

ROM contains the operation program, which controls data processing and mechanical functions and the

character generator, which determines the appearance of the characters.

IC202 IC203 IC204

Page 23

(2) CPU Functions

Block Diagram

KX-P1150

(b) Timer / Counter

(16bitx2, 8bitx4)

(c) A / D Converter

(a) CPU

This block mainly consists of the Program Counter, Arithmetic Logical Unit, and Instruction Decoder. This

block fetches the program from the ROM, decodes the instructions, and processes it accordingly.

(b) Timer/Counter

This block consists of two 16-bit timers and four 8-bit timers. They are used for generating the timing for

the printhead and carriage motor.

(c) A/D Converter

In this circuit, 8 bits/4 channel A/D Converters are prepared. One channel is used for sensing the overheat

of the printhead and other channels are used for sensing the input of control panel switches.

(d) Watch Dog Timer

(e) I/O PORTS

(d) Watch Dog Timer

When a program does not run properly, the CPU is reset.

(e) I/O PORTS

These ports are used for sensing the input of Paper End, Friction/Tractor, Home switches and driving the

LEDs in the control panel.

Page 24

K5C-P1150

(3) CPU Pin Functions

The CPU has total of 64 pins and an 12MHz clock. It controls a 128KB ROM, 8KB RAM and 32KB optional

RAM. These RAMs are used as an input buffer, line buffer, bit image buffer, and download area. The CPU

pin functions are as follows.

CPU

12MHz Clock

IC205 Addressing

Address Bus

Address/Data Bus

Address Latch -------------

3.7 MHz

HTRG

CRTRG**

Interrupt 0

Interrupt 2

-----------

-------------

-------------

--------------

------------

------------

-----------

OSC (XI ,2)

►

l/OCS (A22)

A8-A19

AD0-AD7

ALE

CLK ANO

T04

T01

INTO

►

INT2

P31-P34

AN2

AN3

AN1

P70-P73

Reset

RD

WR

•*

----------

-----------

-----------

-----------

^

-----------

-----------

EEPROM DI/0

Head Temprature

FONT, LF/FF

TEAR OFF, LOAD PARK

ON LINE

LEDs

Reset

► OE (for ROM, RAM, GA)

-► WR

Page 25

(4) Gate Array

The gate array (IC205) is a 100 pin Flat Package, which consists of seven blocks.

(a) Head Drive Controller

The 9 Print Head Pins are controlled by a Head pin group controller. The Head Pin Trigger Pulse

triggers generation of the Head Pin Signal from each group.

(b) Decoder

It is used for accessing ROM and RAMs, and used for refreshing RAMs.

(c) Handshake Interface

In this gate array, the Centronics Parallel Interface (usually called Handshake Interface) is prepared.

The busy signal to the host computer is generated automatically when receiving the DSTB (data

strobe) signal. The ACK (acknowledge) signal is also generated automatically when the busy signal

turns to L level (Ready state).

(d) Pulse Generator for Stepper Motor

In this gate array the pulse generator for the stepper motor is prepared. This function is used for the

carriage spacing motor and line feed motor. The motor driving pattern is generated automatically

when the generator receives the starting signal. This pattern is synchronized with the output of the

timer which determines motor pulse rate.

KX-P1150

Page 26

KX-P1150

(5) Gate Array Pin Function

The pin functions are as follows.

CPU

lOCSi

A19

GATE ARRAY

Address

Head Pin Data (Sink Tr)

MEMORY

CPU

CPU

IC202^

IC203^

IC204^

LF Motor Enable

LF Motor Phase

A15

A7

AO J

AD7n

ADO

RESET

ALE

CLK

RD

WR

CRTRG

HTRG

ROM1

RAM1

RAM2

LFEN

LFA

LFNA

LFB

LFNB

Address

Address/Data

H9

HTD

INTO

INT2

HSO

HS7

STB

ACK

BUSY

PE

ERROR

SELECT

AFXT

PRIME

CRA

CRNA

CRB

CRNB

CRCNTO

CRCNT1

CRCNT2

-► Head Pin Data

(Common Tr)

Carriage

Counter,

PRIME

-►STB

Parallel Data

— Strobe

-► Acknowledge

Busy

-► Paper End

-► Error

-*■

Select

— Auto Feed XT

— Prime

CR Motor Phase

CR Motor

Power

Control

to CPU

Interrupt

output

Page 27

KX-P1150

8.2.3 Parallel Interface Circuit

The Interface Block receives data from the host computer and generates the appropriate status signals.

The handshake method is described in the following steps.

Process

(1) A STROBE signal is sent from the host computer and is used to set the internal latch of the Gate Array. At

the same time Gate Array pin (3) sends a BUSY signal to the host computer.

(2) The CPU checks the internal latch of the Gate Array periodically and checks whether a STROBE is sent or

not

_______

(3) If a STROBE signal has been sent, the CPU reads the data through HS ports (HS0-HS7) of the Gate Array.

(4) When the BUSY signal disappears, an ACK (Acknowledge) signal is sent to the host computer

automatically during the time determined by software.

(5) The CPU then determines from the received data as to wheter it is a character code, control code or bit

image data and processes the data accordingly.

(6) The CPU processes another command (for instance: operation swtich state check, motor drive during

print).

_______

Thus the data received by handshake is accomplished.

Timing Chart

Data 1-8 from HOST —

STROBE from HOST

BUSY to HOST (pin (1^ )

ACK to HOST (pin ^ )

CN205

-T5V

EXPRM O-

R1NF0 OR1NF2 O

AFXT/1 a

PRIME0STROBE

ERROR a

SELECT

P.E. O-

ACK O-

BUSY

OATAB a

DATA? ODATAS O

DATAS a

DATA4 a

DATAS

DATA20DATAI

GND

FG

0

O-

0

0

0

0

0

0

-

-

-

«

Printer HOST

Handshake

r

j

IC20S

AFXT

PRIME

STB

ERROR

SELECT

PE

ACK

BUSY

Hb /

HS6

HS5

HS4

HS3

HS2

HS1

HS0

GATE

ARRAY

RA205

Page 28

KX-P1150

8.2.4 Carriage Motor Drive Biock

The Carriage motor is driven by the four signals from CRA, CRB, CRNA and CRNB, and is driven by 1-2 phase

driving system.

The time interval is determined by the CPU's interval counter clock as generated from the CPU's clock.

This circuit is a chopper drive circuit for fixing the amount of the current through the motor during stepping and

has two threshold voltages

proportion to the current through the motor. For example, when the voltage drop across R212 (R213) is larger

than

Vsh,

IC207 is turned off and Q202 (Q203) is turned off, then Q200 (Q201) is turned off. At the same time, the

current through the motor decreases, because the voltage drop across R212 (R213) decreases. When this

voltage drop is smaller than

The amount of current through the motor is fixed during stepping by repeating this process.

(Vsh, Vsl).

Vsl,

IC207 is turned on, and the current through the motor increases.

IC207 compares the voltage drop across R212 (R213) which is in

These threshold voltage

(Vsh, Vsl)

are able to be changed by IC205

pin

95 H or L signal duty Ratio according to

Timing Chart

CRA

CRB

CRNA

CRNB

Carriage Motor Coil Resistance Value

Pin No.

(CN202)

6-5

4-5

1-2

3-2

Resistance Value

9.5 ± 0.7 ohms

9.5 ± 0.7 ohms

9.5 ± 0.7 ohms

9.5 ± 0.7 ohms

Page 29

Pulse Rate Chart

Relation between the printing mode and the pulse rate is shown in the chart.

Printing Mode

Holdinq State 0

10CPI

DRAFT

LQ

12CPI

15CPI

17CPI

20CPI

10CPI

12CPI

15CPI

17CPI

20CPI

Pulse Rate(PPS)

1953

1953

1953

977

977

977

977 6/128

651 6/128

488

488

Current Control

CRCNTO OUTPUT PULSE DUTY

20/128

10/128

10/128

10/128

6/128

6/128

6/128

6/128

6/128

Note: The CRCNTO Output Pulse Duty Cycle is determined by dividing the on time

of the pulse (b) by the total time of the pulse (a), measured at point A of the

carriage motor drive circuit.

b/a=CRCNTO Output Pulse Duty Cycle

8.2.5 Paper Feed Motor Drive Block

KX-P1150

POINT A

b

During paper feed, IC205 sets LFEN (pin @ ) at the H level and turns on Q204 and 0205. +39V is then fed to

the motor.

The driving method by LFA, LFNA, LFB, LFNB is a 2-2 driving system and the pulse rate is 400 pulses per

second. When paper feed is not active, 0205 is turned off by LFEN (pin @) L level signal and then a holding

voltage (about 2V) is applied to the motor through R214.

The Line Feed Motor is protected from current overload by setting LFA, LFNA, LFB, LFNB and LFEN to a L

level. This is controlled by the Dip-SW Port of IC205 (pin @ ) detecting the collector voltage of 0205 through

R221-R223 and R260.

Timing Chart

R222 R221 R260

Paper Feed Motor

LFA _

LFB

LFNA

LFNB

Pin No.

(CN203)

1-2

3-2

4-5

6-5

Resistance Value

140 ± 10 ohms

140 ± 10 ohms

140 ± 10 ohms

140 ± 10 ohms

Page 30

KX-P1150

8.2.6 Head Drive Block

This block consists of Q208-216 and Q206, Q207. Q208-216 control each pin and Q206, Q207 control the

power supplied to the printhead.

The CPU (IC200) sends the printhead trigger pulses from terminal T04 to the Gate Array. During this time, the

head pin solenoids are fired by Q206-216 according to the data received from the Gate Array as H1-H9. IC205

and Q206, Q207 control the current used to drive the pin solenoids. A thermistor is attached in the printhead

and is used to detect overheating.

Timing Chart

Print Data ^

Trigger Pulse

Print Pulse

Print Pulse Time

Print Mode Td

Draft

Bit Image

about 280 |i sec

about 280 sec

Tp

about 492 p. sec

about 492 ц sec

X

Printhead

Pin No.

CN203

1-5

2-5

3-5

4-5

9-7.8

11-7.8

13-7.8

14-7.8

15-7.8

10-12

6

Resistance Value

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

24.9 ±0.5 ohms

24.9 ± 0.5 ohms

24.9 ± 0.5 ohms

Less than

37K±8 Kohms (at25t:)

OPEN

Page 31

о

сЗ

с

ш

(О

S

3

Л

ф

tu

о.

о

<■

ф

X

•о

Page 32

KX-P1150

8.2.7 Switch Circuits

(1) The purpose of the home position switch is to move the carriage to a reference position (home position) at

the left end of the carriage when the power switch is turned on or when a Reset signal is generated.

When the carriage comes to the home position, P60 (pin @ ) changes from H to L level.

(2) The paper out switch detects if the paper is in or out of the machine. When this switch detects paper out,

P63 (pin @ ) changes from H to L and the Power/Paper Out LED flashes to indicate paper out status.

(3) The paper feed selector switch detects if the paper feed selector is in the friction or tractor position.

If the paper feed selector switch is set to the friction position, P61 (pin @ ) is L and if set to the tractor

position, P61 (pin @ ) is H.

Page 33

8.2.8 Control Panel

The control panel is composed of 5 switches and 4 LEDs.

(1) The ON LINE switch, switches between on-line and off-line and is input to IC200 (pin @). This switch is

also used to change the current setting in the initial setup mode.

(2) The LF/FF switch is for one-line or one page-feed paper feed and is input to IC200 (pin @)).

(3) The Font switch selects the character fonts and is input to the CPU (pin @ ). This switch is also used to

select the item in the initial setup mode.

(4) The TEAR OFF switch enables paper feeding to the tear off position and is input to the CPU (pin @ ).

(5) The LOAD PARK switch enables automatic loading and feeding back of the fanfold paper and is input to

the CPU (pin @ ).

(6) The power/paper out LED lights when power is turned on and blinks when paper out is detected.

(7) The ON LINE LED lights when at the on-line status.

KX-P1150

(8) Two Font LEDs display Font Type.

IC200

CPU

P70 (Ml 01

(Mil)

P71

P72 (Ml 2)

P73 (M13)

AN0

AN1

AN3

R245.

Tw:

R247'

RA214.-:^

b

U

CN204

L

JT

0302 R303

----Nt----

D300 FONT

—nr-

0301

D303 POWER R302

E

8

7

l

3

7

S

1

ON LINE

V

CN500

L

X“

^

R300

-V*i—

R301

-w»—

'8300

, nS)q301

----

,, Vd^Q302

FONT

f—O O—-I

SW300

TEAR

OFF

p-O

SW302

LF/FF

rC O—J

SV303

LOAD

PARK0NLINE

-O 0—1

SW304

Page 34

KX-P1150

8.2.9 Reset, EEP ROM

(1) Reset Circuit

The reset circuit is provided to initialize the gate array (IC205) and CPU (IC200). Approximately 8msec after the

voltage at IC206 pin(D reaches approximately 4.3V, the reset terminal RES (pin0) changes from L to H.

IC206 PIN ®

IC206 PIN ©

5V

4.3V

GND

5V

GND

Power ON

--------

-------

Power OFF

8 msec

IC20B

(2) EEP ROM

This IC memorizes the setting such as printer mode character set, etc.

IC200

Page 35

8.2.10 Logic Board Connection Diagram

KX-P1150

Page 36

KX-Ptt50

8.3 Explanation of Connectors

8.3.1 Name of Connectors

Connector applications are shown below. For details, refer to

CN1

CN2

CN200

CN201

CN202

CN203

: AC Power Supply

: Power Supply (+36V,+5V,GND)

: Power Supply (+36V,+5V,GND)

: Paper Feed Motor

: Carriage Motor

: Printhead

CN204

CN205

CN206 : Friction/Tractor Switch,

CN207 : Home Switch

CN300

8.3.2 Pin Assignment

CN1 (AC Power Supply)

Pin

Signal

No.

Name

AC

1

2

AC

CN2 ,CN200 (Power Supply +36V,+5V,GND)

Pin

No,

v-rtNiiuo [ rriouüM/1 raulur owiiori.raper uui owiicri;

Pin

No.

CN207 (Home Switch)

Pin

No.

CN201 (Paper Feed Motor)

Pin

No.

Signal

Name

1

DC +36V

2

DC +36V

GND

3

GND

4

5 DC +5V

Signal

Name

1

2

3

4

1 SW

2

1

2

3

4

5

6

SW Paper Out Switch

SG Signal Ground

SW

SG Signal Ground

Signal

Name

SG

,

Signal

Name

LFA Line Feed Motor Phase A

SLF

LFNA

LFB

SLF

LFNB

AC 220-240V —

AC 220-240V

For Printhead,Motor

For Printhead,Motor

Ground

Ground

For Main Board Logic Circuit —

Friction/Tractor Switch

Home Switch

Signal Ground

Line Feed Motor Power Supply

Line Feed Motor Phase A

Line Feed Motor Phase B

Line Feed Motor Power Supply Out

Line Feed Motor Phase B In

Description

Description

Description

Description

Description

In/

Out

— 2 SCR

In/

Out

— 6 CRA

—

—

In/

Out

In

Out 6 24

In

Out

In/

Out

In

Out

In/

Out

In

Out

In

In

CN205 (Centronics I/O)

—

tables.

: Control Panel (LED, KEY)

: Centronics I/O

Paper Out Switch

: Control Panel

CN202 (Carriage Motor)

Pin

Signal

No.

Name

1 CRB

3 CRB

4 CRA

5 SCR

Pin

Return Side

No.

19-30

Pin No.

1

2 20

3 21 DATA2

4 22 DATA3

5 23

7 25

8 26

9

10 28 ACk

11 29 BUSY

12

13

14

15

16

17

18 +5V

31

32 ERROR

33

34

35

36

19 STB

27 DATA8

30

Carriage Motor Phase B

Carriage Motor Power Supply

Carriage Motor Phase B

Carriage Motor Phase A

Carriage Motor Power Supply

Carriage Motor Phase A

Signal

Name

DATAI Handshake Data 1

DATA4

DATA5 Handshake Data 5

DATA6

DATA7

PE

SLCT

AFXT/1

SG Signal Ground

FG

PRIME Prime

SG Signal Ground

SG Signal Ground

Description

Description

Strobe

Handshake Data 2

Handshake Data 3

Handshake Data 4

Handshake Data 6

Handshake Data 7 In

Handshake Data 8

Acknowledge

Busy

Paper End

Select

Auto Feed XT

Frame Ground

+5V

Error

In/

Out

In

Out

In

In

Out

In

In/

Out

In

In

In

In

In

In

In

In

Out

Out

Out

Out

In

—

—

—

Out

In

Out

—

—

—

—

—

Page 37

KX-P1150

CN203 (Print Head)

Pin

Signal

No.

Name

1 H6

2 H4

3 H8

H2 Head Pin 2 Drive Out

4

5 COMMON

6

NC Not Used

COMMON

7

COMMON

8

H9

9

10 PTH

11

12 PTH

13

14 HI Head Pin 1 Drive Out

15 H3 Head Pin 3 Drive Out

H7 Head Pin 7 Drive Out

H5 Head Pin 5 Drive Out

Head Pin 6 Drive Out

Head Pin 4 Drive Out

Head Pin 8 Drive Out

H2. H4, H6, H8 Out

HI, H3, H5, H7, H9

HI, H3, H5, H7, H9

Head Pin 9 Drive

Connected to Signal Ground

Connected to Signal Detect

Description

In/

Out

—

Out

Out

Out

Out

In

CN204, CN300 (LED, Switches)

Pin

Signal

No.

Name

1 SG Signal Ground Out

LED

2

LED

3

LED

4

LED

5

6 SW On Line Switch In

SW

7

8 SW

9 +5V +5V Out

Font Out

Font

Power Out

ON LINE Out

Font, Tear Off Switches

LF/FF, Load Park Switches

Description

In/

Out

Out

In

In

Page 38

KX-P1150

8.4 IC Pin Configuration

8.4.1 Logic Symbol Chart

Positiva Logic

NOT

!-[>-(

BUFFER

A-l C

AND

so-

8.4.2 Pin Configuration

S5i!~::°8So8^

FK2SSSSS2SJ;]

v-OCOCSJv-OOC>J»-Qf/>rr.-v^«’'^COCVIv-

'4-Trr»r>.r'.h»LDy3<DSU)£Cl«jT-v-»-t-,-

a.Q.0.a.Q.CL0.Q.Q.Q.CCSCCO4S<<<<

C = A

C = A

C-AB

Negative Logic

A^[^C

INVERT-NOR

C = A + B

C = A

C = A

Truth Table

A

c

L H

H

L

A

C

L

L

H

H

A

B C

L L L

L H

H

L L

H H H

L

Positive Logic

NANO

OR

A

B

O-

NOR

Si><

Negativa Logic

INVERT-OR

SO-

c = XB C = *+B

INVERT-NAND

A

B

i>=

C = A + B

INVERT-AND

c=>rrB

Truth Table

c=/fS

C = A6

IC200 CPU

TMP90C845F

□ AIO

A8

X2

□ XI

3 Vss(GND)

D ALE

□ AD7

□ AD6

A04

□ AD3

PJVIGP0901

Page 39

KX-P115Q

NC [T

A16 [T

A15 [T

A12 [T

A7 [X

A6 nr

A5 [T

A4 [T

A3 [T

A2 Qo

A1 QT

AO 01

DO 01

D1 Ol

D2 01

GND fiS

IC202 Mask ROM

■V^

1Mbit

HI VDD

H] NC

30] NC

29l A14

28l A13

2T| A8

HI A9

m A11

24] OE

m A10

22) CE

m D7

H] D6

OH D5

Tsl D4

TtI D3

VPP [T

A16 HE

A15 [F

A12 [T

A7 CE

A6 CE

AS [T

A4

CE

A3 [E

A2 01

A1 QT

AO OE

DO Ol

D1 Ol

D2 Ol

GND nr

IC202 ROM

1M bit (D27C010«150)

32] VDD

3i1 PGM

30l NC

m A14

28l A13

2t1 A8

26] A9

25] A11

24l OE

HI A10

22l CE

iO D7

20] D6

IFI D5

Ts] D4

V7l D3

AU [T

A12 [F

A7

CE

A6 E

AS E

A4 E

A3

E

A2

E

A1 E

AO E

DO E

D1 E

D2 E

GND E

IC204 RAM (Option)

(TC51832)

in VDD

27l RAW

in A13

25] A8

24l A9

in A11

m OE/RFSH

in A10

in cE

El D7

E D6

E DS

E DA

E D3

A 4

A-

A+“

GND (V)

(S8054HN)

■E

-E

-E

E

IC207

(LM393)

3^

3-

v+

’ B

• B-

■ B+

NC

E

A12

E

A7

E

A6

E E

AS

E

A4

E

A3

E

A2

E

A1

E E

AO

E

DO

E E

D1

E

D2

E

GND

E

IC203 RAM

(LC3664)

E

VDD

17 ]

WE

26] VCC

A8

E

A9

E

E

OE/R^

E

A10

CE

E

D7

D6

17 1 D5

E

04

E

D3

Page 40

KX-P1150

7

V

Printhead Driver

BCE

Q208-216

(2SD2170)

12

QA201

(MP4303)

QA200

(STA471A)

Paper Feed Motor Driver

Line Feed Motor Driver

Memory Array

64x16

^

___

Address

Decoder

Vcc

GND

8 Pin SOP

Top View

IC201

(S2914AIF)

Dl -

CS .

SK-

I

Data Register

^ Mode Decode

* Logic

^ Clock Generator

BLOCK DIAGRAM Of IC201

Output Buffer

-» DO

Page 41

8.4.3 Pin Assignment

IC200 CPU (TMP90C845F)

Pin

Symbol

No.

1 P30

2 P31

P32

3

4 P33

5 P34

6 RXD

Not Used

EEPROM DATA OUT

EEPROM DATA IN

EEPROM Clock

EEPROM Chip Select

Not Used

7 P36 Not Used —

8 TXD

9 A16

A17 Address Bus 17

10

11 A18

12 A19

13 A20

14 A21

15 IOCS

16 WAIT

17 ADO

18 ADI

19 AD2

20 AD3

AD4 Address Bus 4

21

22 AD5

23 AD6

24 AD7

25 ALE

Not Used

Address Bus 16

Address Bus 18 Out

Address Bus 19 Out

Not Used

Not Used

G.A. Chip Select

No Wait In

Address Bus 0

Address Bus 1

Address Bus 2 In/Out

Address Bus 3 In/Out

Address Bus 5 In/Out

Address Bus 6 In/Out

Address Bus 7 In/Out

Address Latch Enable Out

26 GND GND

27 XI OSC In

28 X2 OSC Out

29 EA

30 A8

A9

31

32 A10

Extend Address (GND) In

Address Bus 8 Out

Address Bus 9 Out

Address Bus 10 Out

Function

In/

Out

—

Out

in

Out

Out

—

—

Out

Out

—

—

Out

In/Out

In/Out

In/Out

In

In

Out

Pin

No.

33 All

Symbol

Function

Address Bus 11 Out

In/

Out

34 A12 Address Bus 12 Out

35 A13

36 A14

Address Bus 13 Out

Address Bus 14 Out

37 A15 Address Bus 15 Out

38 CLK System Clock Out

39 RD

40 WR Write Enable

41 RESET

42

MOO

M01 Friction/Tractor Switch In

43

M02

44

45

M03

46 M10

Mil Power LED Out

47

48 M12

49 M13

50 T01

T03 Timer 3 Out Out

51

52 T04

Read Enable Out

Out

Reset In In

Home Switch In

Not Used

Paper End Sensor In

On Line LED

Font LED (Right)

Font LED (Left)

CR Trigger Out

Head PIN Trigger

Out

Out

Out

Out

Out

53 T05 Not Used

TIO Timer 1 In In

54

55 INTO Interrupt 0 In In

56 T14 Timer 4 In In

57 INT2 Interrupt 2 In In

58 VCC +5V In

59 VREF

+5V In

60 AGND GND In

61

62

ANO

AN1

On Line Key

Tear off .Load park Key

63 AN2 Overheat Protector

64 AN3

Font.LF/FF Kev

KX-P115Q

In

—

In

In

In

In

Page 42

KX-P1150

IC205 GA (PJVIGP2404)

Pin

Symbol

No.

CRNB

1

GND

2

VDD

3

4 HTD

HTP1

5

6

HTP9

HTP7

7

8

TEST

GND Ground

9

10

HTP8

11 HTP5

HTP6

12

13

HTP3

14 HTP4

15 GND

16

HTP2

17

SELECT

18 PE

19 BUSY

20 NC Not Used

21 VDD

ACK

22

23 AFXT

ERROR

24

VDD

25

26 VDD

27 GND

28

GND

29 PRIME Prime

30

STB

HS7

31

HS6

32

33 HS5

34

HS4

35 HS3

36 HS2

37 HS1

38

HSO

GND

39

VDD

40

GND

41

A7 Address Bus A7

42

A6

43

A5 Address Bus A5

44

A4

45

A3 Address Bus A3

46

A2 Address Bus A2

47

48 A1 Address Bus A1

AO

49

RAMCS1

50

Function

CR Motor B

Ground

+5V in

Head Common

Head Pin 1

Head Pin 9

Head Pin 7

G.A.Test pin

Head Pin 8

Head Pin 5

Head Pin 6

Head Pin 3

Head Pin 4

Ground

Head Pin 2

SELECT

PE

Busy to Host

+5V

ACK to Host

AFXT

ERROR

+5V In

+5V

Ground

Ground

STB from Host

Centronics Data 7 Out

Centronics Data 6 Out

Centronics Data 5

Centronics Data 4

Centronics Data 3

Centronics Data 2

Centronics Data 1 Out

Centronics Data 0

Ground

+5V

Ground In

Address Bus A6

Address Bus A4

Address Bus AO

RAMI Chip Enable Out

In/

Out

Out

In

Out

Out

Out

Out

In

In

Out

Out

Out

Out

Out

In

Out

In

Out

Out

—

In

Out

In

Out

In

In

In

Out

Out

Out

Out

Out

Out

Out

In

In

Out

Out

In

In

In

In

Pin

Symbol

No.

NC

51

GND

52

VDD

53

RAMCS2

54

ROMCS1

55

AD7

56

AD6

57

ADO

58

GND

59

AD5

60

ADI

61

AD4

62

AD2

63

AD3

64

ALE

65

GND Ground In

66

CLK

67

WR Write Enable

68

RESET

69

RD

70

VDD

71

CRTRG

72

HTRG

73

INTO

74

VDD

75

VDD

76

GND

77

GND

78

INT2

79

IOCS

80

A19

81

A18

82

A17

83

A16

84

A15

85

LFEN

86

LFA

87

LFNA

88

GND

89

VDD +5V

90

GND

91

LFB

92

LFNB

93

DIP

94

CRCNTO

In

In

95

96

97

98

99

100

CRCNT2

CRCNT1

CRNA

CRA

CRB

Not Used

Ground In

+5V

RAM2 Chip Enable Out

ROM1 Chip Enable

Address Data Bus 7 In/Out

Address Data Bus 6 In/Out

Address Data Bus 0 In/Out

Ground

Address Data Bus 5 In/Out

Address Data Bus 1

Address Data Bus 4

Address Data Bus 2

Address Data Bus 3 In/Out

Address Latch Enable

System clock

RESET

Read Enable

+5V In

Carriage Trigger In

Head Pin Trigger In

Interrupt Request 0

+5V In

+5V In

Ground In

Ground In

Interrupt Request 2 Out

G.A. Chip Select In

Address Bus A19

Address Bus A18 In

Address Bus A17

Address Bus A16

Address Bus A15

LF Enable Out

LF Motor A

LF Motor A

Ground In

Ground In

LF Motor B

LF Motor B

Dip Switch In

CR Power Control 0

CR Power Control 2

CR Power Control 1 Out

CR Motor A

CR Motor A Out

CR Motor B Out

Function

In/

Out

—

In

Out

In

In/Out

In/Out

In/Out

In

In

In

in

In

Out

In

In

In

In

Out

Out

In

Out

Out

In

Out

Out

Out

Page 43

8.6 Schematic Diagram

[Main Baoard]

0.4 V

Page 44

“V

"V^

CRACRB-

CRNA-

CRNB-

yu

RA2AS

\

2.2K

iger

4V

0 V

Rotate Trigger

"1 4 V

!

CN20B

+5V

EXPRM

RINFB O-

R1NF2 O

AFXT/1

PRIME

STROBE O

ERROR O

SELECT O

P.E.

ACK O

BUSY O

DATAS

DATAT O-

DATAS O-

DATAS

DATA4 O

DATAS O

DATA2

DATAI

GND O

FG

-----

0 V

O

c>

(y

O

O

O-

<>

l>

O

O

_2L

-2J<

fliit

1C203(8K)

DB

D1

02

DÎ

04

00

00

07

CE2

m

№

SF

C2B4,^|.

««““l.BK

AB

A1

A2

A3

A4

AB

AB

A7

A6

A9

A1B

A11

_2

A12

B.lu

RA201 RA202i >

2-7K 2.7K

TW

*

m;

m

1C204

D8 AB

Dt

D2

03

04 A4

DB

DB

D7 A7

R224^1BK

_21

m

22,

R/W

CF

5F/R5B

C2BB,

O o

o

A1B

A11

A12

A13

A14

/

/

_

/

_

/

✓

A1

J

A2

_

/

A3

B /

5 /

AB

A

_

/

AS

A8

A9

_2

[__/

__

/

/

/

№

sH

Si.

IC20B

A19 CRA

A1S CRNA

A17 CRB

A16 CRNB

A1B CRCNT1

A7 CRCNT0

A6 CRCNT2

AB VDD

A4 VDD

A3

A2 VDD

A1 VDD

A0 VDD

AD7 VDD

AD6 VDD

ADB VDD

AD4 VDD

AD3 GND

AD2 GND

AD1 GND

AD0 GND

RAMCS2 GND

RAMCS1 GND

R0MCS1

RD

»R

ALE

CLK HTP1

[NT0 HTP2

[NT2 HTP3

HTRG

CRTRG HTPB

AFXT HTP6

PRIME

STB HTP8

ERROR HTP9

SELECT

PE DIP-SW

ACK LFEN

BUSY LFA

HS7 LFNA

H3S LFB

MSB LFNB

HS4 NC

HS3 NC

HS2 NC

HS1

HS0 NC

IOCS NC

RESET GA-TEST

VDD

GND

GND

GND

GND

HTP4

HTP7

HTD

NC

j

TP

TD=280

TP=*492

Page 45

Page 46

—rr-|p

>- -O

O

K> O

r* lo

r

H

O

_ o_

»^d

- O-

r

Ui

- fO-

r N"

ts

•>s4

L»J

Lsl

l>J

LMlMLM

S

7^ '

iM ; :

vo :

Q X

J ISJ

lO

J s;

hj

CN20B

O

+5V

EXPRM O

O

RINFB

RINF2

(>

AFXT/1 O

PRIME O-

STROBE O

O

ERROR

SELECT O

O

R.E.

O

ACK

a

BUSY

DATAS

(>

DATAT

O

DATAS O-

DATAS O

DATA4

a

DATAS i>

DATA2 O

DATAI O

GND O

FG O

T» t a

__

M_Lr»

0.

DATA

STB

BUSY

ACK

Page 47

Page 48

Page 49

9. Parts List and Lubrication

KX-P1150

Notes: 1.

9.1 Cabinet

Important safety notice.

Components identified by Amark have special characteristics important for safety.

When replacing any of these components, use only manufacturer's specified parts.

2.

The S mark is for service standard parts and may differ form production parts.

3.

The marking (RTL) indicates that the Retention Time is limited for this item. After

the discontinuation of this assembly in production, the item will continue to be

available for a specific period of time. The retention period of availability is

dependent on the type of assembly, and in accordance with the laws governing

part and product retention. After the end of this period, the assembly will no longer

be available.

=Lubrication=

A PJOL-SG3451

Page 50

9.2 Tractor and Carriage

KX-P1150

A PJOL-SG3451

Page 51

9.3 Chassis

KX-P1150

A PJOL-SG3451

Page 52

KX-P1150

9.5 Control Panel Board

Ref.No.

D300-302

D303 PJVDSLR40VRM

Q300-303 PJVIDTC143ES

Part No. Part Name and Description

PJVDSLR40MGF

Diode

Diode 1

Transistor

R300.301 ERDS2FJ151 150K

R302

R303

ERDS2FJ471 470K

ERDS2FJ151 150

R304.305 ERDS2FJ472 4.7K

SW300-304

EVQQS205K Switch

CN300 PJJS459Z Connector

PB2

1

PJWP1P1121M

PJUP583Z

Control Panel Board Complete

Control Panel Board Bare PCB 1

9.6 Switch Board

1/4W Carbon

1/4W Carbon

1/4W

Carbon

1/4W Carbon

(Parts Side View)

Per Set

3

4

2

1

1

2

5

1

1

Remarks

S

S

s

s

RTL

Ref.No.

SW402

1

Part No. Part Name and Description

PJSH1A47Z

PE Switch

Per Set

PJUP625Z Switch Board Bare PCB 1

Remarks

1

Loading...

Loading...