Panasonic FX-400 Installation Manual

INSTRUCTION MANUAL

Photoelectric Sensor

Digital Fiber Sensor

FX-400 Series

Thank you very much for using SUNX products. Please read this Instruction Manual

carefully and thoroughly for the correct and optimum use of this product. Kindly keep

this manual in a convenient place for quick reference.

WARNING

٨

Never use this product as a sensing device for personnel protection.

٨

In case of using sensing devices for personnel protection, use products which

meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

1

PART DESCRIPTION

Operation indicator (Orange)

Digital display (Green)

Threshold value (RUN condition)

2

MOUNTING

Make sure that the power supply is off while connecting disconnecting the amplifiers and the quick-connection cables.

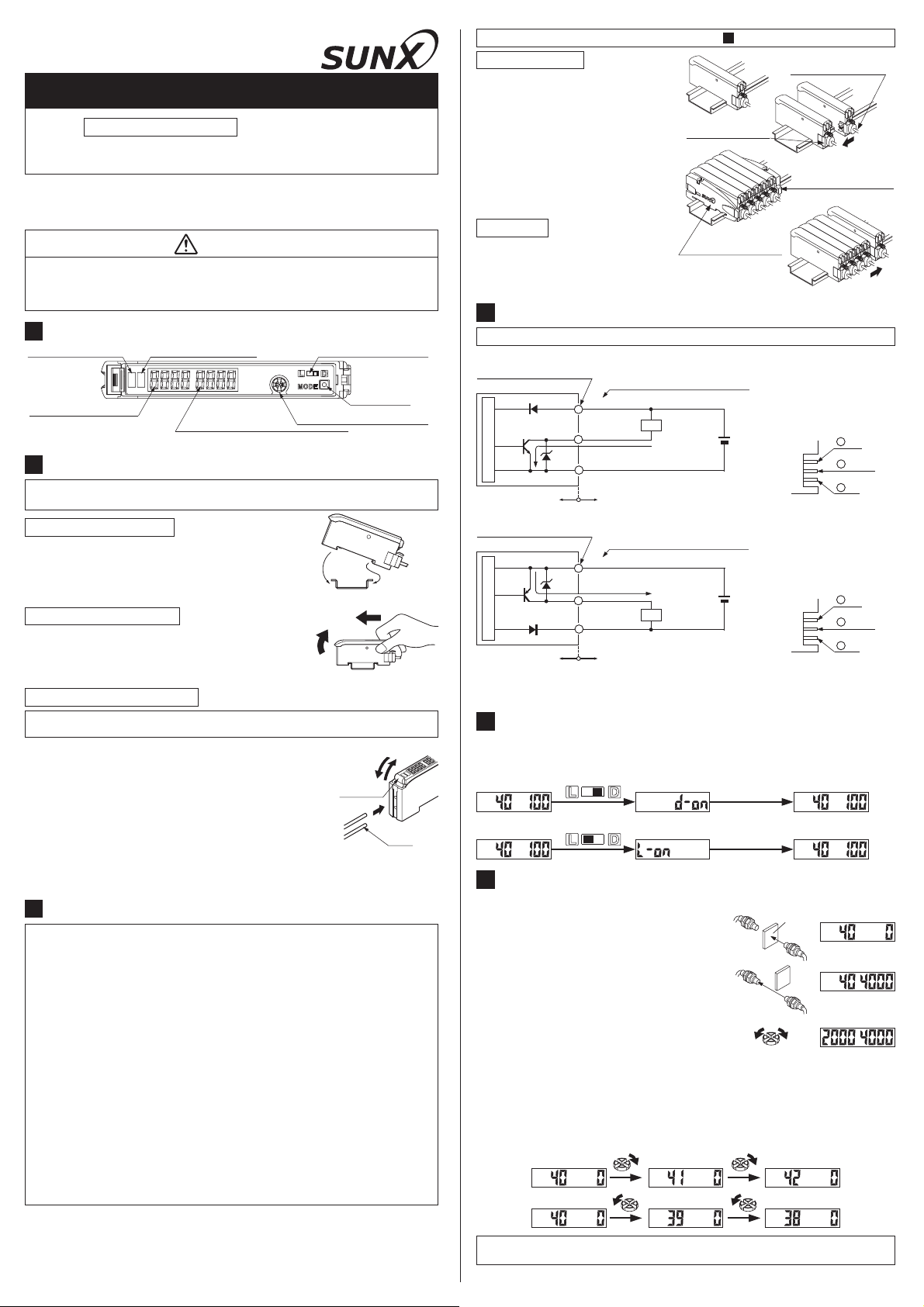

How to mount the amplifier

ԘԙFit the rear part of the mounting section of the amplifier

on a DIN rail.

Press down the rear part of the mounting section of the

unit on the DIN rail and fit the front part of the mounting

section to the DIN rail.

How to remove the amplifier

ԘԙPush the amplifier forward.

Lift up the front part of the amplifier to remove it.

Take care that if the front part is lifted without pushing the

Note:

amplifier forward, the hook on the rear portion of the mounting section is likely to break.

How to connect the fiber cables

Be sure to fit the attachment to the fibers first before inserting the fibers to the

amplifier. For details, refer to the instruction manual enclosed with the fibers.

Ԙ

Snap the fiber lock lever down.

ԙ

Insert the fiber cables slowly into the inlets until they

stop. (Note 1)

Ԛ

Return the fiber lock lever to the original position, till it

stops.

Notes: 1) 2)In case the fiber cables are not inserted to a position where

they stop, the sensing range reduces. In case of a flexible

fiber, take care that it may bend inside the amplifier, during

insertion.

With the coaxial reflective type fiber, such as, FD-G4 or FD-FM2, insert the single-core fiber cable into the beam-emitting inlet and the multi-core fiber cable into the beam-receiving inlet. If they are inserted in reverse, the sensing accuracy will deteriorate.

3

CASCADING

٨

Make sure that the power supply is off while adding or removing the amplifiers.

٨

Make sure to check the allowable ambient temperature, as it depends on the

number of amplifiers connected in cascade.

٨

In case two, or more, amplifiers are connected in cascade, make sure to mount

them on a DIN rail.

٨

When the amplifiers move on the DIN rail depending on the attaching condition

or the amplifiers are mounted close to each other in cascade, fit them between

the optional end plates (MS-DIN-E) mounted at the two ends.

Up to maximum 15 amplifiers can be added (total 16 amplifiers connected in cascade.)

٨

When connecting more than two amplifiers in cascade, use the sub cable

٨

(CN-71-Cغ) as the quick-connection cable for the second amplifier onwards.

٨

When connecting amplifiers not close to each other in parallel, be sure to mount

the optional end plate (MS-DIN-E) at both sides of each amplifier or affix the

communication window seal of the optional amplifier protection seal (FX-MB1) to

the communication windows. For details, refer to the instruction manual enclosed

with the FX-MB1.

٨

When the connector type and the cable type or different LED (red / blue / green)

types are connected in cascade, mount the identical models together.

٨

When this product is used with the other digital fiber amplifiers, be sure to place

this product to the left most position (When you look from the connector side). If

this product is not placed to the leftmost position, this product may not operate

properly.

Stability indicator (Green)

Digital display (Red)

Incident light intensity (RUN condition)

Operation selection switch

Setting switch

Threshold value adjuster (Note)

ԙ

Ԙ

Ԙ

Fiber

lock lever

Ԙ

Ԛ

ԙ

Fiber

35mm width DIN rail

ԙ

For mounting and removing the amplifier, refer to ' MOUNTING'.

Cascading method

Ԙ

Mount the amplifiers, one by one,

on the DIN rail.

ԙ

Slide the amplifiers next to each

other, and connect the quick-connection cables.

Ԛ

Mount the optional end plates

(MS-DIN-E) at both the ends to

hold the amplifiers between their

flat sides.

ԛ

Tighten the screws to fix the end

plates.

Dismantling

Loosen the screws of the end plates.

Ԙ

Remove the end plates.

ԙ

Slide the amplifiers and remove

Ԛ

them one by one.

4

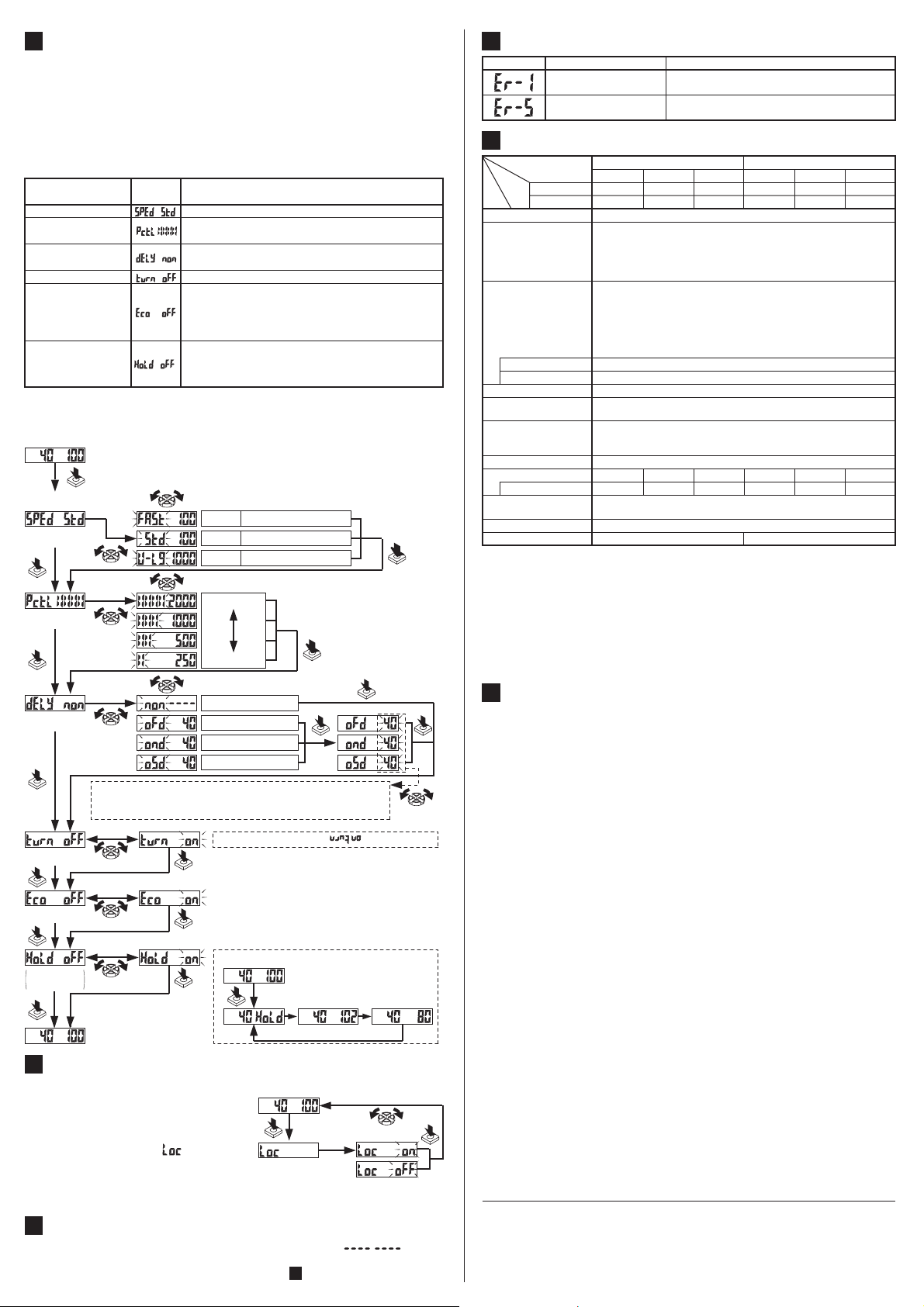

I/O CIRCUIT DIAGRAMS

2

Main cable (CN-73-Cغ)

(optional)

End plates (MS-DIN-E)

(optional)

Sub cable (CN-71-Cغ)

(optional)

End plates (MS-DIN-E)

(optional)

Make sure that the power supply is off while wiring.

٨ NPN output type

Terminal No. of connector type

Sensor circuit

Cable type / Color code of quickconnection cable

(Brown) +V (Note 1)

1

100mA max.

Users' circuitInternal circuit

Load

(Note 2)

(Black) Output

3

(Blue) 0V (Note 1)

2

+

12 to 24V DC

r10%

-

Terminal arrangement diagram of the

connector type

1

+V

3

Output

2

0V

٨ PNP output type

Terminal No. of connector type

Sensor circuit

Notes: 1) 2)The quick-connection sub cable does not have +V (brown) and 0V (blue).

The power is supplied from the connector of the main cable.

50mA max., if five, or more, the connector type amplifiers are connected in cascade.

5

SWITCHING OUTPUT OPERATION

The operation selection switch can be used to display different output operations

٨

(L-ON / D-ON) on the digital display.

<When se

<When se

6

t to Dark-ON (D-ON)>

t to Light-ON (L-ON)>

THRESHOLD VALUE (SENSITIVITY) AD-

Cable type / Color code of quickconnection cable

(Brown) +V (Note 1)

1

100mA max.

3

(Black) Output

2

(Blue) 0V (Note 1)

Users' circuitInternal circuit

(Note 2)

Load

Terminal arrangement diagram of the

+

12 to 24V DC

r10%

-

Disappears automatically

after 2 seconds.

Disappears automatically

after 2 seconds.

connector type

1

+V

3

Output

2

0V

JUSTMENT

Ԙ Check the incident light intensity [in the digital

display (red)] when a sensing object is placed

in the sensing position.

ԙ Check the incident light intensity [in the digital

display (red)] when the sensing object is

removed from the sensing position.

Ԛ Turn the threshold value adjuster to the

threshold value [in the digital display (green)]

that is the value in between Ԙ and ԙ. (The

threshold value is automatically written to the

EEPROM.)

<Threshold value setting method>

When the threshold value adjuster is turned clockwise, the threshold value

٨

increases. When the threshold value adjuster is turned counterclockwise, the

threshold value decreases.

(Threshold value)

(Threshold value)

Sensing

object

(Incident light intensity)

(Incident light intensity)

(Threshold value)

Slide

Slide

If there is a sufficient level of margin in the incident light intensity, the stability indicator (green) will light up.

7

MODE SELECTION

٨

When the setting switch is pressed and held for 2 sec. or more, 'SET' mode (mode

setting screen) is activated.

٨

If the setting switch is pressed while in 'SET' mode, the mode will change.

٨

If the threshold value adjuster is turned while a mode is active, the setting item will change and blink.

٨

When the setting switch is pressed at the item you would like to set, it blinks 3

times and then the setting is confirmed and the mode switches to the next mode.

٨

If the setting switch is pressed and held for 2 sec. or more or do not press any key for

15 sec. while 'SET' mode is active, the mode will switch automatically to 'RUN' mode.

10

11

٨ Mode table

Mode Description

Response time change mode

Emitting intensity selection mode (Note 1)

Timer setting mode

Digital display inversion mode

Eco mode (Note 2)

Peak / Bottom hold mode

Notes: 1) This mode is not incorporated in the blue LED type and green LED type.

2) While the peak / bottom hold mode is ON, the digital display is not turned off even if the

Eco mode is set to ON.

Factory

setting

The response time can be set.

The light emitting intensity can be switched among four levels.

Timer settings can be select ed; Without timer / OFF-delay timer /

ON-delay timer / ONE-SHOT timer. Also the timer period can be set.

The display on the digital display can be inverted.

If no key is pressed for approximately 20 sec. while in 'RUN' mode, the

digital display turns off automatically. Press the setting switch or move

the operation selection switch to make the display light up again. The

digital display will light up when the threshold value adjuster is turned,

but note that this will also cause the threshold value to change.

If the setting switch is pressed while 'RUN' mode is active, the display

will alternate between the peak hold value and the bottom hold value.

(The display will refresh every 2 sec.) The display will return to normal if any operation other than threshold value setting is carried out.

<RUN condition>

Press and hold for 2 seconds or more

<SET condition>

High speed

Response time

(

change mode

Emitting intensity

(

selection mode

(Note 1)

)

)

Response time: 150Ǵs or less

Standard

Response time: 500Ǵs or less

Long-range

Response time: 4.5ms or less

Emitting power Hi

Emitting power Lo

Note:

This mode is not incorporated

in the blue LED type and

green LED type.

Notes: 1)

ERROR DISPLAY INDICATOR READINGS

Display

Error description Measures

The load has short-circuited

and excess current is flowing.

Communication error has occurred at time of connection.

Turn off the power, then check the load.

Check if the mounted amplifiers are in close contact

with each other.

SPECIFICATIONS

Type

Model

NPN output (Note 1)

No.

Item

Power consumption

Output

Response time

Ambient temperature

Ambient humidity

Emitting element

Material

Cable

Weight

PNP output

Short-circuit protection

Interference prevention

function

Peak emission wavelength

FX-412غ, with the sensitivity adjuster shaped so that it can be turned manually using

fingers, is also available. However, the cable type is not available for FX-412غ.

2)

50mA, the connector type five, or more, amplifiers are connected in cascade.

3)

When the power supply is switched on, the light emission timing is automatically set for

interference prevention.

4)

The cable for amplifier connection is not supplied as an accessory. Make sure to use the

optional quick-connection cables given below.

Main cable (3-core): CN-73-C1 (cable length 1m), CN-73-C2 (cable length 2m)

Sub cable (1-core) : CN-71-C1 (cable length 1m), CN-71-C2 (cable length 2m)

Connector type Cable type

Red LED Blue LED

FX-411 FX-411B FX-411G

FX-411P

<Red LED type>

Normal operation: 960mW or less

ECO mode: 840mW or less

<NPN output type>

NPN open-collector transistor

FAST: 150Ǵs or less, STD: 500Ǵs or less, U-LG: 4.5ms or less selectable with switch

Incorporated [up to four fibers can be mounted adjacently (However,

U-LG mode is eight fibers)

Red LED Blue LED

Enclosure: Heat-resistant ABS, Transparent cover: Polycarbonate

Setting switch: Heat-resistant ABS, Threshold value adjuster: Polycarbonate

FX-411BP

(Current consumption 40mA or less at 24V supply voltage)

(Current consumption 35mA or less at 24V supply voltage)

Maximum sink current: 100mA (Note 2)

Applied voltage: 30V DC or less

(between output and 0V)

Residual voltage: 1.5V or less

[at 100mA (Note 2) sink current]

-10 to +55 (If 4 to 7 units are connected in cascade: -10 to +50,

if 8 to 16 units are connected in cascade: -10 to +45)

(No dew condensation or icing allowed), Storage: -20 to +70

650nm 470nm 525nm 650nm 470nm 525nm

0.3mm

20g approx. 60g approx.

CN-73-C5 (cable length 5m)

CN-71-C5 (cable length 5m)

Green LED

FX-411GP

12 to 24V DCr10% Ripple P-P 10% or lessSupply voltage

Light-ON or Dark-ON, selectable with switchOutput operation

35 to 85% RH, Storage: 35 to 85% RH

Green LED

2

3-core cabtyre cable, 2m long (Cable type only)

Red LED Blue LED

FX-411-C2

FX-411P-C2

<Blue LED type / Green LED type>

Normal operation: 720mW or less

<PNP output type>

PNP open-collector transistor

Applied voltage: 30V DC or less

Residual voltage: 1.5V or less

Incorporated

Red LED Blue LED

FX-411B-C2

FX-411BP-C2

(Current consumption 30mA or less at 24V supply voltage)

ECO mode: 580mW or less

(Current consumption 24mA or less at 24V supply voltage)

Maximum source current: 100mA (Note 2)

(between output and +V)

[at 100mA (Note 2) source current]

Green LED

FX-411G-C2

FX-411GP-C2

Green LED

Without timer

Timer setting

(

mode

Digital display

(

inversion mode

(Eco mode)

Peak / Bottom

hold mode

)

The timer period can be set within the following ranges:

1 to 10 ms: 1 ms units; 10 to 100 ms: 10 ms units; 100 to 500 ms: 50 ms units

500 to 1000 ms: 100 ms units; 1000 to 3000 ms: 500 ms units

)

OFF-delay

ON-delay

ONE-SHOT

(The actual display will be ' '.)

<RUN condition>

(Peak value)

(Bottom value)

<RUN condition>

8

KEY LOCK FUNCTION

٨

When the setting switch is pressed and

hold for 5 sec. while in 'RUN' mode, the

key lock function can be set / canceled.

٨

When the key lock function is set to ON,

even if the threshold value adjuster or the

setting switch is operated, ' ' is displayed

and the key operation cannot be carried out.

Note:

Although the display changes to the indication of 'SET'

condition 2 sec. after pressing the setting switch, keep

pressing the switch. Furthermore, the sensor does not go into the key lock setting from 'SET' condition.

9

FACTORY SETTING

٨

When the setting switch is pressed and held for 10 sec., until ' ' is displayed while in 'RUN' mode, the all settings are returned to the factory setting.

(For the factory setting, refer to '٨Mode table'in ' MODE SELECTION'.)

<RUN condition>

Press and hold

for 5 sec. (Note)

7

(Set to ON)

(Set to OFF)

12

CAUTIONS

٨

Take care that wrong wiring will damage the sensor.

٨

Make sure that the power supply is off while wiring.

٨

Verify that the supply voltage variation is within the rating.

٨

Take care that if a voltage exceeding the rated range is applied, or if an AC power supply is directly connected, the sensor may get burnt or damaged.

٨

In case noise generating equipment (switching regulator, inverter motor, etc.) is

used in the vicinity of this product, connect the frame ground (F.G.) terminal of

the equipment to an actual ground.

٨

If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

٨

Do not use during the initial transient time (0.5 sec.) after the power supply is

switched on.

٨

Take care that short-circuit of the load or wrong wiring may burn or damage the

sensor.

٨

Do not run the wires together with high-voltage lines or power lines or put them

in the same raceway. This can cause malfunction due to induction.

٨

Extension up to total 100m (if 5 to 8 units are connected in cascade: 50m, if 9 to

16 units are connected in cascade: 20m) is possible with 0.3mm

ble. However, in order to reduce noise, make the wiring as short as possible.

٨

Take care that cable extension increases the residual voltage.

٨

This sensor is suitable for indoor use only.

٨

Avoid dust, dirt, and steam.

٨

Take care that the product does not come in direct contact with water, oil,

grease, organic solvents, such as, thinner, etc., strong acid or alkaline.

٨

This sensor cannot be used in an environment containing inflammable or explosive gases.

٨

Never disassemble or modify the sensor.

٨

The changes to the settings are written to the EEPROM, but because the EEPROM has a limited service life, you should avoid changing the settings any

more than 1 million times.

SUNX Limited

2

, or more, ca-

http://www.sunx.co.jp/

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN