Page 1

Installation and Operating Instructions

In-Line Fan

Model No.

CONTENTS

GENERAL SAFETY INFORMATION

DESCRIPTION

UNPACKING

SUPPLIED ACCESSORIES

DIMENSIONS

INSTALLATION

OPERATION

MAINTENANCE

PRACTICAL GUIDE TO INSTALLATION

SPECIFICATIONS

PRODUCT SERVICE

FV-15NLFS1

2~4

4

4

5

5

6~8

9~10

10~11

11

12

12

READ AND SAVE THESE INSTRUCTIONS

Thank you for purchasing this Panasonic product.

Please read these instructions carefully before attempting to install, operate or service the

Panasonic product. Please carefully read the “GENERAL SAFETY INFORMATION” (P.2~4) of

this manual before use. Failure to comply with instructions could result in personal injury or

property damage. Please explain to users how to operate and maintain the product after

installation, and this booklet should be presented to users.

Please retain this booklet for future reference.

Page 2

GENERAL SAFETY INFORMATION

For Your Safety

To reduce the risk of injury, loss of life, electric shock, fire, malfunction, and damage to

equipment or property, always observe the following safety precautions.

Explanation of symbol word panels

The following symbol word panels are used to classify and describe the level of hazard, injury,

and property damage caused when the denotation is disregarded and improper use is

performed.

Denotes a potential hazard that could result in death or

WARNING

serious injury.

CAUTION

NOTICE

The following symbols are used to classify and describe the type of instructions to be

observed.

This symbol is used to alert users to a specific operating procedure that must not be

performed.

This symbol is used to alert users to a specific operating procedure that must be

followed in order to operate the product safely.

This symbol is used to alert users not to disassemble the equipment.

This symbol is used to alert users to make sure of grounding when using the

equipment with the grounding terminal.

Denotes a hazard that could result in minor injury.

Denotes a hazard that could result in property damage.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR PERSONAL INJURY, OBSERVE THE

FOLLOWING :

Do not use this product with any solid-state control device. Solid-state controls may

cause harmonic distortion which can cause motor humming noise.

Do not install with a method which is not approved in the instructions.

Do not disassemble the product for reconstruction. It may cause fire or electric shock.

Use this unit only in the manner intended by the manufacturer. If you have any

questions, contact the manufacturer.

Before servicing or cleaning product, switch power off in control box and lock the

service disconnecting means to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated construction.

2

Page 3

GENERAL SAFETY INFORMATION

Sufficient air is needed for proper combustion and exhausting of gases through the

flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating

equipment manufacturer’s guideline and safety standards such as those published by

the National Fire Protection Association (NFPA), and the American Society for Heating

Refrigeration and Air Conditioning Engineers (ASHRAE) and the local code authorities.

When cutting or drilling into ceiling, do not to damage metal objects, electrical

wiring and other hidden utilities.

Ducted fans must always be vented to the outdoors.

Ceiling must be subjected to static load more than five times the weight of the product.

A statement to the effect that when the product is to no longer be used, it must

not be left in place but remove, to prevent it from possibly falling.

Never place a switch where it can be reached from a tub or shower.

The product must be properly grounded.

CAUTION

Do not kink the power cord.

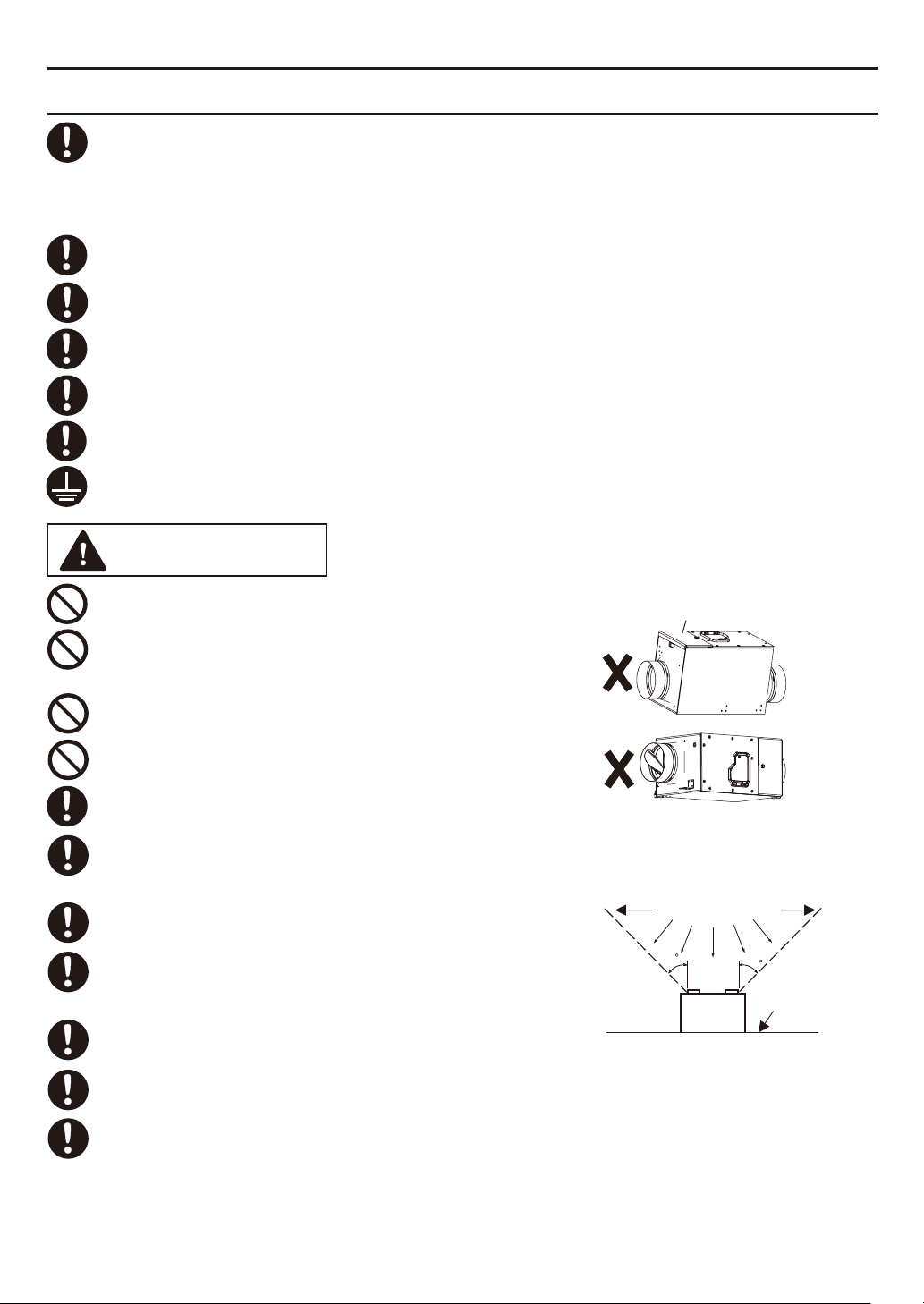

Do not install the product as the directions

shown in right. Otherwise, it may cause electric

shock.

(Fig.A)

Not for use in cooking area. (Fig.B)

This fan shall not be installed behind a suspended floor/

ceiling or a structural wall, ceiling, or floor.

Install this product in the area where the temperature

is between14 °F (-10 °C)~104 °F (40 °C).

The special-purpose or dedicated parts, such as

mounting fixtures, must be used if suchparts are

provided.

Make certain that the electric service supply voltage

is AC 120 V, 60 Hz.

Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

Always disconnect the power source before working

on or near the fan or motor.

Protect the power cord from sharp edges, oil, grease,

hot surfaces, chemicals or other objects.

Put the product on the hanger securely. Otherwise, it

may drop.

Maintenance board

to be upside

Fig. A

(Cooking area)

Do not install above or

inside this area

4

5

4

Cooking

equipment

5

Floor

Fig. B

3

Page 4

GENERAL SAFETY INFORMATION

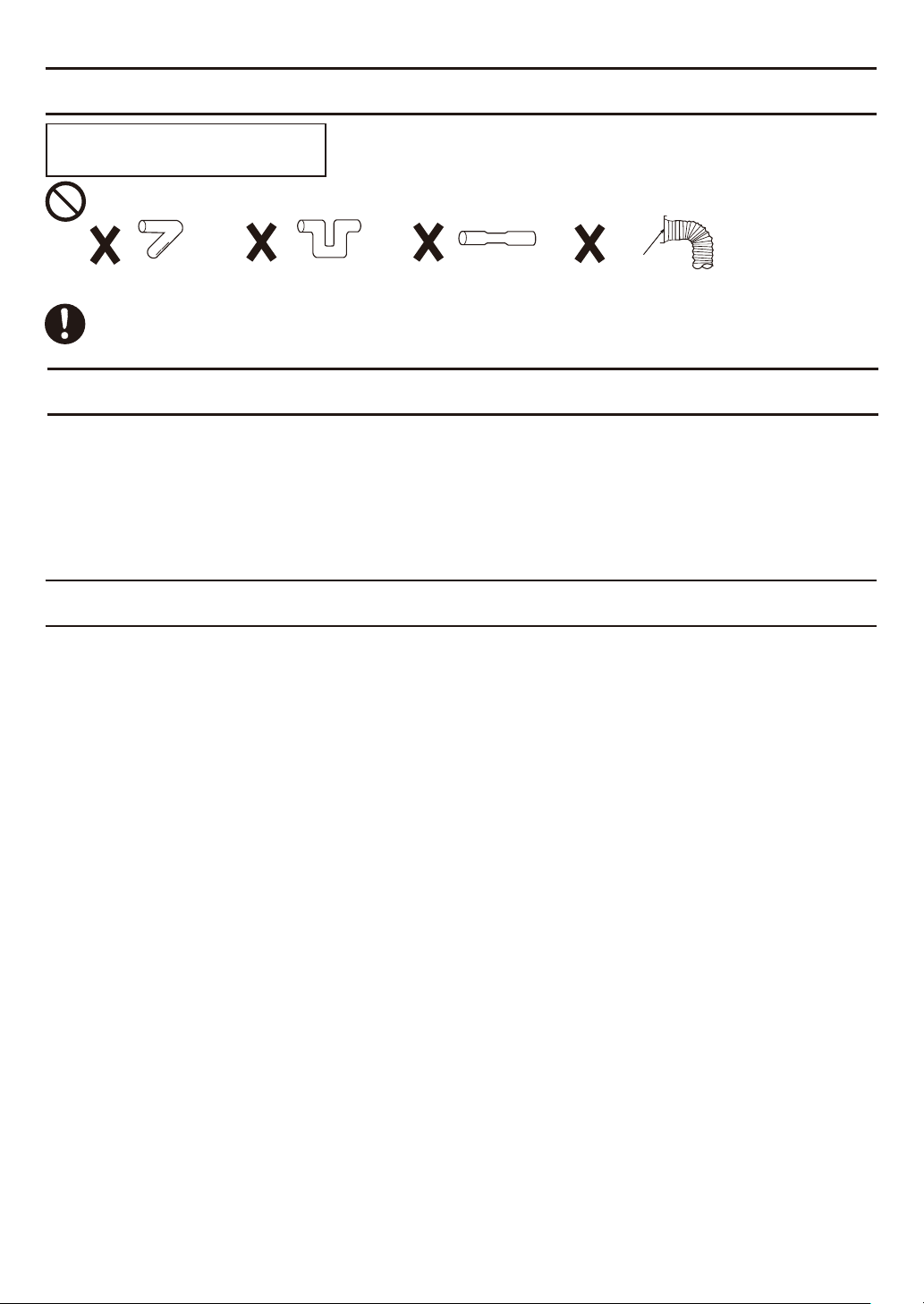

NOTICE

Do not install the product where ducts are configured as shown below.

Adaptor

Excessive bending Successive bending Squeezed duct Bend close to duct adaptor

Please install the tube cover or similar items at the air inlet, otherwise it may cause the

entry of foreign matter or rain, affecting product performance.

DESCRIPTION

This product uses a sirocco fan driven by a DC motor powered by an integral transformer.

The motor is designed to have long operating life, high dynamic response, higher speed

ranges with saving energy. The blower uses a high-capacity sirocco fan developed to reduce

the noise level.

UNPACKING

Unpack and remove product carefully from carton.

Refer to the supplied accessories list to verify that all parts are present.

4

Page 5

SUPPLIED ACCESSORIES

Part name

Hanger

Screw

(M4X8)

Installation and

operating instructions

Limited warranty

DIMENSIONS

3 3/4 (97)

4 3/8 (112)

Air

flow

23 3/8 (594 )

15 3/4 (399)

Appearance

Quantity

3

10

1

1

Unit : inch (mm)

8 3/4 (223)

3 3/4 (97)

Φ5 7/8 (148)

4 3/8 (112)

Part nameNo. Part nameNo.

1

Pre-filter

Sub-efficient filter

2

Main PCB

3

Motor

4

5

Sirocco fan

1 2

3

910

Damper

6

7

Power cord

Adaptor

8

Control box cover

9

10

Maintenance board

Φ5 7/8 (148)

5

4

8

4 5/8 (119)

6

11 (282)

7

5

Page 6

INSTALLATION

Before installing please choose the installation direction.

You can install the product with maintenance board towards down or towards side. (Fig.1,

Fig.2) If there are joists on ceiling, you should install it with the maintenance board towards

down, otherwise you may can not to maintain filter.

Maintenance board towards down

Maintenance board towards side

(Not applicable for ceiling with joists)

Maintenance

board

Fig.1

Maintenance

board

1-1 Install with the maintenance board towards down

1. Fix the hangers (3 pcs) on fan body by screws.

(Fig.3)

2.Install hanger bolts on ceiling, and put washers

and nuts on bolts. (Hanger bolt, nut and washer

should be M8-M10 and no provided.) (Fig.4)

6 3/8 (162)

3 1/2 (90)

Unit : inch (mm)

Hanger

(Fix by 4

screws)

Fig.2

Hanger (Fix

by 3 screws)

Hanger (Fix by 3 screws)

Ceiling

Fig.3

10 1/2 (267)

7 (182)

2 7/8 (74)

7/8 (22) 7/8 (22)

1/2 (12)

3.Install the product on hanger bolts and fix the

nuts tightly. (Fig.5)

Note

Please use the spirit level to adjust the body, to

ensure that the height of the three hangers

within ± 2 mm.

6

1 (25)

3-Hanger

bolts

Hanger

Nut

Washer

Nut

Fig.4

Fig.5

Page 7

INSTALLATION

4.Install Φ6 inch ducts.

(1) Connect the circular duct (suggest using

the insulated flexible duct) to adaptor by

mastic or approved foil tape.

Place/wrap insulation around duct and/or

fan in order to minimize possible

condensation buildup within the duct.

(Fig.6)

Note

Install the exterior duct with a declining

slope toward outer side at least 1/100.

Install the interior duct with a declining

slope toward inner side at least 1/100.

(Fig.6)

5.Set an square inspection hole

of 450 mm or more under the

maintenance board. (Fig.7)

Interior duct

Mastic or

approved foil

tape

Adaptor

Exterior duct

Hanger

Adaptor

Fiberglass insulation

Unit : inch (mm)

Mastic or

approved foil

tape

Fig.6

17 3/4 (450)

Square inspection hole

>1 1/4 (30)

CeilingCeiling

17 3/4 (450)

Square inspection hole

1 5/8 (40)

Fig.7

6.Twist hand screw open maintenance board and pull out the sub-efficient filter,

fill in beginning time on sub-efficient filter, then install back. (Refer Fig.13~15 on P.10~11)

7

Page 8

INSTALLATION

1-2 Install with the maintenance board towards side

Note

This method can not applicable for ceiling

with joists.

1. Fix the hangers (3 pcs) on fan body by screws.

(Fig.8)

2.Install hanger bolts on ceiling, and put washers

and nuts on bolts. (Hanger bolt, nut and washer

should be M8-M10 and no provided.) (Fig.9)

Unit : inch (mm)

2 1/2 (65)

1/2 (12)

17 1/2 (443)

4 3/8 (110)

8 7/8 (224)

3 1/2 (90)

1/2 (12)

3 (78)

3.Install the product on hanger bolts and fix the

nuts tightly. (Fig.10)

3-Hanger

bolts

1 (25)

Hanger (Fix

by 3 screws)

Hanger (Fix by

3 screws)

Hanger (Fix by

4 screws)

Fig.8

Ceiling

Nut

Washer

Nut

Fig.9

Note

Please use the spirit level to adjust the body, to

Hanger

ensure that the height of the three spreaders

within ± 2 mm.

4.Install the ducts. (It is same with step 4 in P.7)

5.Set an square

Unit : inch (mm)

inspection hole of

450 mm or more

beside and below the

Maintenance

board

maintenance board.

(Fig.11)

17 3/4 (450)

Square inspection hole Ceiling

17 3/4 (450)

Square inspection hole Ceiling

6.Twist hand screw open maintenance board and pull out the sub-efficient filter, fill in

beginning time on sub-efficient filter, then install back. (Refer Fig.13~15 on P.10~11)

Fig.10

Fig.11

8

Page 9

OPERATION

Insert power cord plug into

power socket, then open

Control box cover

”I” is on

“O” is off

the control box cover and turn

on the main switch. (Fig.12)

I

O

Main switch

Port receptacle for add-on Module provides additional

features. (Module sold separately)

For details, please consult Panasonic Call Center

Control panel

1

Running indicator

Telephone : 1-866-292-7299 (USA)

1-800-669-5165 (Canada)

When the indicator is on green, indicates the product is running.

2

Filter indicator

The indicator will light on red when the accumulated running

time is up to 90 days. When the indicator is on (with buzzer

1

sound), indicates need to maintain filters.

Note

2

(1)The indicator will be on when the product accumulated

running time reaches to 90 days. The buzzer will sound

every hour and 10 seconds in an hour.

4

(2)If you want to turn off the indication of buzzer, please

press filter reset button about 3 seconds until there is the

sound of a long beep. Press filter reset button about 3

seconds again until there is sound of two quick beeps, the

buzzer indication will be turned on again.

5

(3)If you want to cancel buzzer sound when sleeping, you

just need to turn off the wall switch. The buzzer will

continue to sound when the product is turned back on and

will not stop until the filter has been maintained and the

filter alarm has been reset.

6

(4)When the the running indicator or filter indicator blinks, means

the product failure.

3

Filter reset button

Press the button after filter maintenance for resetting accumulated running time and the

filter indicator will light off, the buzzer will turn off.

4

Air volume dial switch

Adjusting the product air volume by this dial switch, you can choose 50, 60, 70,

80, 90, 100, 110, 130, 150 CFM.

Default setting : 80 CFM

5

Humidity dial switch

Adjusting the humidity protection value of the product by this dial switch, you can choose

from 30 %RH~80 %RH (stepless) or turned to OFF position.

Default setting : 80 %RH

If the product inside humidity detected by sensor is over than setting value, the fan will

stop for 60 minutes, then according to the detected value to determine whether to

operate.

If the switch is turned to OFF position, the humidity sensor detection function will be

disabled.

Fig.12

3

9

Page 10

OPERATION

6

Temperature dial switch

Adjusting the temperature protection value of the product by this dial switch, you can

choose 15 °F~40 °F (stepless) or turned to OFF position.

Default setting : 15 °F

If the product inside temperature detected by sensor is lower than setting value, the fan

will stop for 60 minutes, then according to the detected value to determine whether to

operate.

If the product inside temperature detected by sensor is higher than 95 °F (35 °C), the fan

will stop for 60 minutes, then according to the detected value to determine whether to

operate.

If the switch is turned to OFF position , the temperature sensor detection function will

be disabled.

Note

The humidity and temperature value detected by sensor may be different from outside.

MAINTENANCE

CAUTION

To avoid injury or electric shock, turn off the main switch in control box to stop the fan

before checking, cleaning or replacing filter.

To ensure product running normally, routine maintenance must be performed every

3 months.

Please wear gloves to avoid pinching fingers during maintenance.

When cleaning or replacing filters, dust, insects, etc. attached on the filters may fall.

Please pay attention to the protection of eyes and so on.

Open the control box cover by twist hand

1

1.

screw. (Fig.13)

2

Turn off main switch. (Fig.13)

3

Twist hand screw open maintenance board.

(Fig.13)

2.Pull out the pre-filter, clean it with water once in

3 months when filter indicator lights on with

buzzer sound “Pi-Pi-Pi-

...

”. (Fig.14)

3

Pre-filter

1

2

Fig.13

Fig.14

10

Page 11

MAINTENANCE

3.Pull out the sub-efficient filter, clean it with

vacuum cleaner once in 3 months when filter

indicator lights on with buzzer sound “Pi-Pi-Pi Replace it once in 6 months when filter indicator

lights on with buzzer sound “Pi-Pi-Pi-

...

”. (Fig.15)

Please fill in beginning time on

new filter before replacing.

...

”.

Sub-efficient

filter

BEGINNING TIME:

Note

AIR FLOW

Please replace sub-efficient filter by Panasonic

Model FV-FL0815NL1or FV-FL1315NL1. If you do

not use the Panasonic filter will result in poor

Fig.15

performance.

4.Install back the filters and close the maintenance

board by twist hand screw. Please make sure that

the arrow direction on sub–efficient filter is same

as the “Air flow” mark on name plate. (Fig.15)

5.Turn on main switch, press filter reset button with

sound of “Pi-”, then filter indicator and buzzer

sound will be off. Close the control box cover by

Fig.16

twist hand screw.(Fig.16)

PRACTICAL GUIDE TO INSTALLATION

Properly insulate the area around the fan to

minimize building heat loss and gain. (Fig.17)

Loose fill or batt insulation can be placed directly

over the fan housing in the attic. Our fans

and fan/light combination units do not create

excessive heat that is a common problem with

recessed light fixtures or some competitor’s fan/

light combination. Our efficient, cool-running

motors and our fluorescent lamps do not create

enough ambient heat to be subjected to these

limitations. The ducting from this fan to the

outside of the building has a strong effect on the

air flow, noise and energy use of the fan. Use

the shortest, straightest duct routing possible for

best performance, and avoid installing the fan with smaller ducts than recommended.

Insulation around the ducts can reduce energy loss and inhibit mold growth. Fans installed

with existing ducts may not achieve their rated air flow.

6 inch roof jack,

wall cap, or soffit vent

with backdraft damper

Mechanically connect duct to

termination and seal with mastic

or approved foil faced tape

2-3 ft straight run before elbow

In attic installation,

caulk box to drywall

A short piece of flexible

duct helps alignment

and absorbs sound.

Use clamps plus mastic

or approved foil faced

tape at all flex joints.

Foil tape tightly

covers all metal

duct joints.

(Glue PVC joints)

Insulation

Fig.17

11

Page 12

SPECIFICATIONS

Air

direction

Supply

Voltage

(V)

Frequency

(Hz)

60

Duct

(inch)

6 0.2”WG120

Static

pressure

Air volume

(CFM)

50/50*

60/60*

70/70*

80/80*

90/90*

100/100*

110/110*

130/130*

150/150*

Power

consumption

(W)

8/8.2* 969/989*

9/9.3*

10/10*

12/12.4*

13/13.5*

15/15.3*

16/16.7*

21.5/22.6*

27.1/27.3*

992/1012*

1022/1033*

1030/1067*

1056/1086*

1101/1121*

1122/1152*

1202/1235*

1296/1314*

Speed

(rpm)

Weight

kg)

Ib.(

13.4

(6.1)

Performance based on the MERV8 filter (FV-FL0815NL1), and data with “*” is a reference

datas when using the MERV13 filter (FV-FL1315NL1).

Air volume performance based on HVI Procedures 916 and 920.

PRODUCT SERVICE

Warning Concerning Removal of Covers.

The unit should be serviced by qualified technicians only.

Your product is designed and manufactured to ensure a minimum of maintenance.

Should your unit require service or parts, call Panasonic Call Center at 1-866-292-7299 (USA)

or 1-800-669-5165 (Canada).

Two Riverfront Plaza, Newark, NJ 07102

www.panasonic.com

Panasonic Corporation 2018

12

5770 Ambler Drive, Mississauga, Ontario L4W 2T3

www.panasonic.com

Printed in China

Issue date:01/2018

P0118-0 15NLF4051

Loading...

Loading...