Page 1

INSTALLATION INSTRUCTIONS

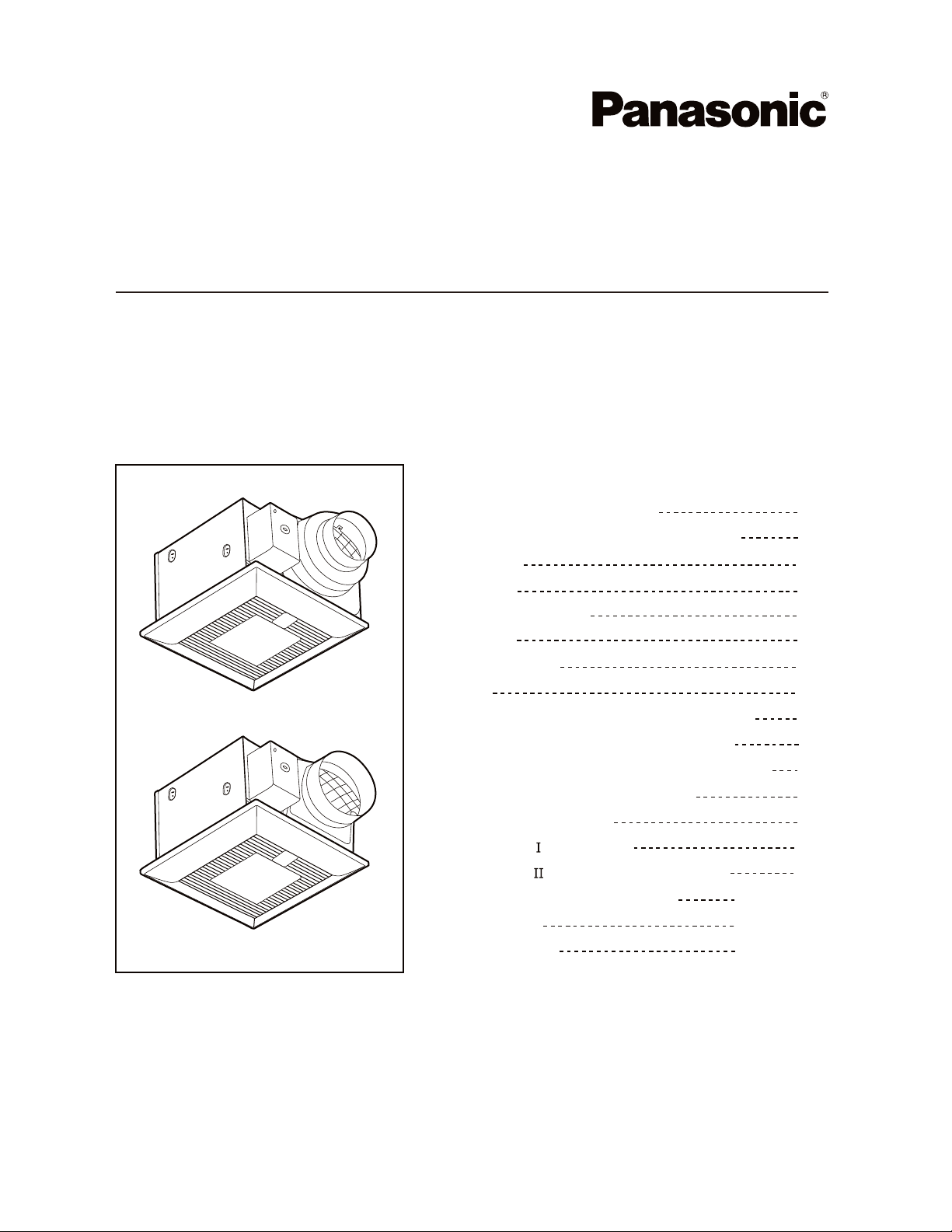

Ventilating Fan

Representative models:

FV-05-11VKSL1 FV-05-11VKL1

FV-11-15VKL1

Model No.

FV-05-11VKSL1

FV-05-11VKL1

FV-11-15VKL1

Contents

GENERAL SAFETY INFORMATION

PLEASE READ PRIOR TO INSTALLING THIS FAN

DESCRIPTION

UNPACKING

SUPPLIED ACCESSORIES

DIMENSIONS

WIRING DIAGRAM

FEATURE

INDICATION (PLUG ‘N PLAY FUNCTION DEVICES)

MOTION (PLUG ‘N PLAY FUNCTION DEVICES)

INSTALLATION (PLUG ‘N PLAY FUNCTION DEVICES)

INSTALLATION (NEW CONSTRUCTION)

INSTALLATION (RETROFIT)

MAINTENANCE (CLEANING)

MAINTENANCE (REPLACEMENT OF LAMP)

PRACTICAL GUIDE TO INSTALLATION

SPECIFICATIONS

PRODUCT SERVICE

BACK COVER

BACK COVER

BACK COVER

2-3

3-4

4

4

5

5

5

6

6-7

7

8

8-10

10

11

11

READ AND SAVE THESE INSTRUCTIONS

Thank you for purchasing this Panasonic product.

Please read these instructions carefully before attempting to install, operate or service

the Panasonic product. Failure to comply with instructions could result in personal injury

or property damage. Please explain to users how to operate and maintain the product

after installation, and this booklet should be presented to users.

Please retain this booklet for future reference.

Page 2

GENERAL SAFETY INFORMATION

For Your Safety

To reduce the risk of injury, loss of life, electric shock, fire, malfunction, and damage to

equipment or property, always observe the following safety precautions.

Explanation of symbol word panels

The following symbol word panels are used to classify and describe the level of hazard, injury, and

property damage caused when the denotation is disregarded and improper use is performed.

WARNING

CAUTION

The following symbols are used to classify and describe the type of instructions to be observed.

This symbol is used to alert users to a specific operating procedure that must be followed

in order to operate the unit safely.

This symbol is used to alert users to a specific operating procedure that must not be

performed.

This symbol is used to alert users not to disassemble the equipment.

This symbol is used to alert users to make sure of grounding when using the equipment

with the grounding terminal.

WARNING

WARNING

To reduce the risk of fire, electric shock or injury to persons, observe the following :

Use this unit only in the manner intended by the manufacturer. If you have any questions,

contact the manufacturer.

Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

Installation work and electrical wiring must be done by qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction.

Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney)

of fuel burning equipment to prevent back drafting. Follow the heating equipment manufacturer's

guideline and safety standards such as those published by the National Fire Protection Association

(NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

Ducted fans must always be vented to the outdoors.

Denotes a potential hazard that could result in serious

injury or death.

Denotes a hazard that could result in minor injury.

If this unit is to be installed over a tub or shower, it must be marked as appropriate for the

application and be connected to a GFCI(Ground Fault Circuit Interrupter) - protected branch

circuit.

These models are UL listed for tub and shower enclosures.

Canada only: Not to be installed in a ceiling thermally insulated to a value greater than R40.

Do not disassemble the unit for reconstruction.

2

Page 3

GENERAL SAFETY INFORMATION CONTINUED

WARNING

When this product is no longer being operated, please remove the product to prevent the

possibility of falling.

Ceiling joist must be subjected to static load more than five times the weight of the product.

Do not install with a method which is not approved in the instructions.

Do not use this fan with any solid-state speed control device. Solid state controls may cause

harmonic distortion which can cause motor humming noise.

This product must be properly grounded.

CAUTION

Do not install this ventilating fan where interior room temperature may

exceed 104°F(40°C).

Make sure that the electric service supply voltage is AC 120V, 60Hz.

Prohibited

Follow all local electrical and safety codes, as well as the National

Electrical Code (NEC) and the Occupation Safety and Health Act (OSHA).

Always disconnect the power source before working on or near the fan,

motor, light fixture or junction box.

Protect the supply wiring from sharp edges, oil, grease, hot surfaces,

chemicals or other objects.

Do not kink the supply wiring.

Provide make up air for proper ventilation.

For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

Do not install the unit where ducts are configured as shown

in Fig.A.

Not for use in cooking area. (Fig.B)

The special-purpose or dedicated parts, such as mounting

fixtures, must be used if such parts are provided.

Prohibited

Prohibited

Prohibited

(Cooking area)

Do not install above or

inside this area

45

equipment

45

Cooking

Fig. B

Adaptor

Floor

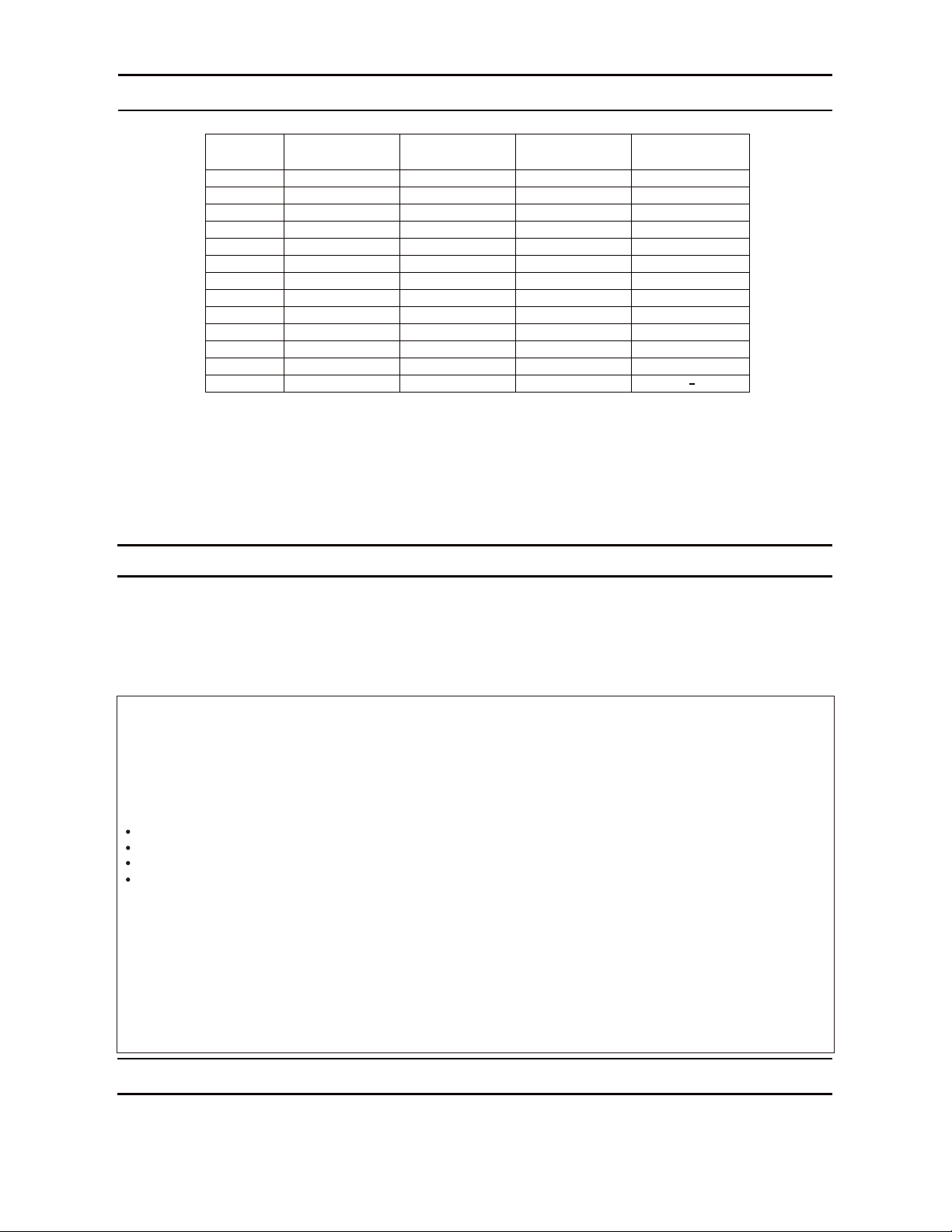

PLEASE READ PRIOR TO INSTALLING THIS FAN

Spot and Continuous Ventilation: These fans are designed to run continuously ensuring a healthy

environment at low CFM levels 24 hours a day. By utilizing the optional CustomVent Multi-Speed module

the fans are built to run continuously at a pre-set lower level (FV-05-11VKSL1 and FV-05-11VKL1: 0, 30,

40, 50, 60, 70, 80, 90, 100 CFM; FV-11-15VKL1: 0, 50, 60, 70, 80, 90, 100, 110, 120 CFM). The setting is

dependent on the size of the house and the individual wishes of the homeowner. It is crucial that the

installer pre-set the lower setting during the installation. Please refer to the chart below and the

switch indication on page 6.

3

Page 4

PLEASE READ PRIOR TO INSTALLING THIS FAN CONTINUED

CustomVent Multi-Speed module (Lower Setting). ASHRAE 62.2-2010

(sq.feet)

<1,000

1,500

2,000

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

7,000

These fans are also built to take care of the homeowner’s spot ventilation needs when the room is

occupied. The basic fan models allow a choice of three speeds. When fans are equipped with the optional

Multi-Speed module, these models kick up to a maximum level of 150 CFM for the FV-11-15VKL1 and 110

CFM for the FV-05-11VKSL1 and FV-05-11VKL1 either when the switch is turned on or activated by the

optional Condensation Sensor module or the optional Motion Sensor module.

A High/Low Delay Timer, located inside the fan unit, is utilized to return the fan back to the pre-set

Continuous ventilation mode. The installer needs to consult with the homeowner for the desired

setting on the timer (0 - 60 minutes) and make the adjustments during the installation.

Two Bedrooms

33

38

43

48

53

58

63

68

73

78

83

88

93

Three Bedrooms

40

45

50

55

60

65

70

75

80

85

90

95

100

Four Bedrooms

48

53

58

63

68

73

78

83

88

93

98

103

108

Five Bedrooms

55

60

65

70

75

80

85

90

95

100

105

110

DESCRIPTION

These products are listed by UL under UL file No. E78414.

These products use a sirocco fan driven by a DC motor powered by an integral transformer. The motor is

designed to have long operating life, high dynamic response, higher speed ranges with saving energy.

The grille covering the fan body is a spring-loaded, quick remove type. A damper for preventing air counter

flow is provided. The blower uses a high-capacity sirocco fan developed to reduce the noise level.

The lighting unit is an energy-saving LED lighting device that uses two 7W LED lamps and produces almost

the same illumination as a standard 60W incandescent lamp.

FCC Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning this product on and off, the user is encouraged to try to correct the

interference by one of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect equipment into outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Warning: This equipment must be installed by qualified person in accordance with the provided installation

instructions; and all applicable codes and standards. Also, any changes or modifications not expressly

approved by the party responsible for compliance could void the user’s authority to operate this equipment.

DoC Responsible Party:

Customer Call Support:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Risk of Fire: Type IC-Inherently Protected, Only Use LED Lamp, Max 7W, Type GU24.

Panasonic Corporation of North America

Two Riverfront Plaza, Newark, NJ 07102

1-866-292-7299

UNPACKING

Unpack and carefully remove the unit from carton.

Refer to the Supplied Accessories list to verify that all parts are present.

4

Page 5

SUPPLIED ACCESSORIES

Part name Part name

Appearance AppearanceQuantity Quantity

Installation

Grille

1

instructions

Warranty

Flex-Z Fast

bracket

TM

1

Tapping screw

(ST4.2X20)

7W

LED lamp

2

Self-drilling

screw

DIMENSIONS

1 1/2 (38)

FV-05-11VKL1

FV-11-15VKL1

12 1/8 (307)

10 1/4 (260)

FV-05-11VKSL1

13 (330)

10 1/4 (260)

3 7/8 (100)

3 7/8 (98)

5 7/8 (148)

3 7/8 (100)

5 7/8 (148)

FV-11-15VKL1

No. No.

3

4

5

6

7

13 (330)

Blade

Grille

Lens

Motion sensor location

(FV-MSVK1 not included)

Junction box

Adaptor

Multi-Speed module

(FV-05-11VKSL1 only,

other models not included)

sheet

1 (26)

15

7 3/8 (190)

Part name

4 5/8 (116)

Unit: inches (mm)

13

FV-11-15VKL1

3 1/4 (81)

14

14

Part name

81

Connector cover

92

Base PCB box

10

Pick-A-Flow switch

Lighting

11

12

LED lamp

13

Fan

14

Damper

Flex-Z Fast bracket

15

unit

body

2

1

4

4

3 1/2 (88)

6 3/8 (163)

TM

WIRING

Fan body

DC-Motor

Multi-Speed module

(FV-05-11VKSL1

only, other models

not included)

Plug ‘N Play module slot

Plug ‘N Play module slot

Green

LED

lamp

DIAGRAM

Junction box

(114°C Fuse)

Thermally

protected

Black

White

Red

Red

Green

Black

White

Switch for power

Switch for power

Live (Fan)

Neutral

Hi/Low switch: When plug in

Multi-Speed module;

switch: When plug in

On/Off

other Plug ‘N Play modules.

(Non-powered control wires)

Earth ground

Live (Light)

Neutral

(Power supply)

AC120V 60Hz

(Power supply)

AC120V 60Hz

55

Page 6

FEATURE

[For models of: FV-05-11VKSL1, FV-05-11VKL1, FV-11-15VKL1.]

The WhisperGreen Select Line of ventilation fans employs innovative, state-of-the-art technologies that

provide a number of customizable unique features that lead to improved indoor air quality. Please

read the installation manual first in order to realize the benefits of this customizable, modular fan.

Optimum Ventilation Performance:

Duct length, elbows and other factors increase static pressure which can hinder the performance of most

ventilation fans. This fan utilizes SmartFlow microchip technology that monitors the static pressure in the

system and speeds up or slows down the rpm of the fan depending upon the amount of resistance within

the ducts. This feature allows the fan to perform as rated and avoid potential installation issues.

Outstanding Energy Savings:

The WhisperGreen Select Line of fans are built using DC motor technology. The DC motor is 30% - 70%

more energy efficient than the minimum ENERGY STAR requirements.

Pick-A-Flow Feature

11080

( )

130

50

110 150

MODEL

MODEL

05-11

11-15

AIR VOLUME CFM

All the WhisperGreen Select base models of fans come with Pick-A-Flow

speed options. The Pick-A-Flow switch on the face of all WhisperGreen

Select fans allows the option to choose 50 – 80 – 110 CFM for the

FV-05-11VKL1, FV-05-11VKSL1 or 110 – 130 – 150 CFM for the

FV-11-15VKL1. These fans can run continuously or intermittently,

depending upon the needs of the owner.

Pick-A-Flow

switch

AIR VOLUME CFM

05-11

MODEL

11-15

MODEL

( )

50

11080

130

110 15 0

Air volume type (CFM)

FV-05-11VKSL1

FV-05-11VKL1

FV-11-15VKL1

50

11080130

Factory setting

110 80 CFM

150 130 CFM

INDICATION (PLUG ‘N PLAY FUNCTION DEVICES)

PLUG ‘N PLAY Modular Component Accessories

Sold Separately, Not Included With Base Model Fan

AIR VOLUME CFM

MODEL

MODEL

05-11

11-15

110 150

50

130

( )

11080

Note that there is ONLY ONE

Plug ‘N Play slot to insert the

Multi-Speed module within the

base model fan. There are TWO

interchangeable Plug ‘N Play

slots to insert the Condensation

Sensor module, Motion Sensor

module or Nite-Glo LED Night

TM

Light module within the base

model fan.

FV-VS15VK1 Multi-Speed module allows the fan to run continuously

at lower speeds to maintain ventilation standards to meet Indoor

Air Quality and then boost up to high speed to meet intermittent

needs for ‘Spot’ or ‘Point Source’ exhaust needs. The FV-VS15VK1

Modular Component will operate for both the FV-05-11VKL1 and the

FV-11-15VKL1 matching the appropriate Multi-Speed setting shown

below. The FV-05-11VKSL1 comes with the FV-VS15VK1 Multi-Speed

module. It is not necessary to purchase this component.

Note the options on the face of the FV-VS15VK1 Multi-Speed module

to choose appropriate levels of airflow (CFM) and time delay before

returning back to low speed (TIME). Choosing the Pick-A-Flow setting

automatically adjusts the Multi-Speed setting accordingly. As an

example, if the Pick-A-Flow Multi-speed setting is 80 CFM, the

Multi-Speed settings adjust automatically to be 0, 30, 40, 50, 60 or 70

CFM at the lower speeds. The fan will ‘boost’ to the 80 CFM speed as

the high speed setting. Selecting a particular TIME option will cause

the fan to run for the selected amount of time before returning to

the lower speed setting chosen on the CFM dial.

Pick-A-Flow (CFM)

FV-05-11VKSL1,

FV-05-11VKL1

(plug-in FV-VS15VK1)

FV-11-15VKL1

(plug-in FV-VS15VK1)

50

80

110

110

130

150

Multi-Speed Air volume (CFM)

0

0

0

0

0

0

30

30

30

50

50

50

40

40

40

60

60

60

40

50

50

70

70

70

40

60

60

80

80

80

40

70

70

90

90

90

40

70

80

100

100

100

40

70

90

100

110

110

40

70

100

100

110

120

Delay Time (min)

45

Factory setting: 20 minutes.

Delay Time position “0“ : Manual wall switch control is 0 minute;

without manual wall switch control is 0.5 minute.

6

Page 7

INDICATION (PLUG ‘N PLAY FUNCTION DEVICES) CONTINUED

PLUG ‘N PLAY Modular Component Accessories

Sold Separately, Not Included With Base Model Fan

FV-CSVK1 Condensation Sensor module turns the base fan on or

boosts to higher speed when humidity is detected when used in

combination with the FV-VS15VK1. The Condensation Sensor works

based on calculations from the Psychrometric Chart, or combination

of Relative Humidity (RH) and Temperature. This allows the fan to

anticipate the formation of condensation and automatically turn on

when needed to expel humid air. The Condensation Sensor is pre-set

to run for 20 minutes; it will then check the RH and Temperature to

detect if the fan needs to run for another 20 minutes cycle.

FV-MSVK1 Motion Sensor module turns the base fan on or boosts

to higher speed when motion is detected when using in combination

with the FV-VS15VK1. The Motion Sensor is pre-set to run for 20

minutes; it will then re-check for movement; if detected the fan will

run for another 20 minutes cycle. The Motion Sensor detects within

the range shown below.

The distance that motion

can be detected is limited

to 10 feet (3m). The field

of view of the sensor is 90°.

(Room temperature is 25 C).

FV-NLVK1 Nite-Glo LED Night Light module automatically turns on

TM

when ambient light levels are met. Turning the dial on the Modular

Nite-Glo Component to ‘DARK’ is ideal if the fan is in an isolated room

with little ambient light from nearby rooms. Turning the dial to

‘BRIGHT’ is ideal if there is light spill from nearby rooms. (Note that it is

necessary to connect wall switch when only plug in FV-NLVK1, fan can

operate on high speed with wall switch control, fan can also operate

on low speed when used in combination with the FV-VS15VK1.)

MOTION (PLUG ‘N PLAY FUNCTION DEVICES)

PLUG ‘N PLAY Modular

Components used in

Combinations

Human

active

Fan

active

Module FV-MSVK1,

FV-CSVK1 (Not

included)

INSIDE

At low

speed

When motion or

excess humidity is

detected, fan runs

at high speed.

PLUG ‘N PLAY Modular Component Accessories

Sold Separately, Not Included With Base Model Fan

FV-CSVK1 + FV-MSVK1

Turns the fan on for 20 minutes when either

motion or excess humidity is detected.

FV-CSVK1 + FV-VS15VK1

Cycles the fan to high speed from low speed

for the amount of time selected on the Control

Dial based upon detection of excess humidity.

FV-MSVK1 + FV-VS15VK1

Cycles the fan to high speed from low speed

for the amount of time selected on the Control

Dial based upon motion within the room.

Motion

OUTSIDE

Remains running

at high speed until

the delay time has

passed.

FV-CSVK1 only

FV-MSVK1 only

FV-CSVK1 + FV-VS15VK1

FV-MSVK1 + FV-VS15VK1

Fan

operation

Fan

ON/OFF

Fan

Hi/Low speed

Time delay

operation

20 minutes

time delay

Depend on

FV-VS15VK1 Time

delay setting

7

Page 8

INSTALLATION (PLUG ‘N PLAY FUNCTION DEVICES)

You can purchase the specified Plug ‘N Play devices that are explained on page 6-7 and install them in positions

2

, and . Position can only be used with Multi-Speed module (model FV-05-11VKSL1 already have

this control installed), position and can be used for any of the other optional control modules.

1. Remove the connector cover

3

2

3

2

from position , or .

3

2. Plug in the specified devices to Base PCB box and fix to the slot, till hear the sound installed in place.

Connector

cover

2

3

Base PCB box

Slot

2

3

Clasp

Squeeze tabs on the Clasp to

remove. Squeeze, insert and

release the tabs on Clasp to replace.

INSTALLATION (NEW CONSTRUCTION)

The fan position between joists from 16" to 24"

on center can be adjusted flexibly.

CAUTION

Please wear gloves during the installation

work as follow.

1. Disconnet plug connector from receptacle and

remove adaptor from fan body by removing the

machine screw (M4X6) before installation. (Fig.1)

IMPORTANT:

Remove the tape from damper and adaptor

before installation. As shown below:

Adaptor

2. Bend down 4 tabs for positioning, install the

Flex-Z Fast bracket to joists by using 2 tapping

screws (ST4.2X20) (Please prepare the screws and

put on Flex-Z Fast bracket before Flex-Z Fast

TM

TM TM

bracket is installed on joist). (Fig.2)

3.

Adjust the length of Flex-Z Fast bracket as the

spacing between joists, and install to joists by

using 2 tapping screws (ST4.2X20). (Fig.3)

4. Remove junction box cover and secure conduit

or stress relief to junction box knock-out hole.

(Fig.4)

5. Install a circular duct and secure it with clamps,

or ties and seal it with mastic or approved foil tape.

4 inch 6 inch circular duct is needed to connect to

relevant part of common adaptor. (Fig.4)

6. Install the adaptor to Flex-Z Fast bracket by

using 2 self-drilling screws. (Fig.4)

8

Damper

Tape

TM

TM

Machine screw

(M4X6)

Joist

2 Tapping screws

(ST4.2X20)

Knock-out

hole

Junction box

cover

Fan body

2 Tapping screws

(ST4.2X20)

Conduit

2 Self-drilling screws

Adaptor

Circular duct

Fig.1

Bend down

4 tabs

Fig.2

Joist

Fig.3

Mastic or

approved

foil tape

Fig.4

Page 9

INSTALLATION (NEW CONSTRUCTION) CONTINUED

7. Refer to wiring diagram on page 5.

Follow all the local electrical safety codes as well

as the National Electrical Code (NEC).

Using UL approved wire nuts, connect house

power wires to ventilating fan wires. (Fig.5)

CAUTION

Mount junction box cover carefully so that

lead wires are not pinched.

8. Insert fan body and slide into adaptor assy with some

strength, untill the flange overlaps the Flex-Z Fast

bracket. Secure the fan body to Flex-Z Fast bracket

TM

TM

by using 2 self-drilling screws, plug connector to

receptacle and secure the fan body to adaptor by

using machine screw (M4X6). (Fig.6)

CAUTION

Secure machine screw (M4X6) to

hole and not touch the Flex-Z Fast bracket.

Please fix the screw carefully to avoid screw

slip teeth.

9. Finish ceiling work. Ceiling hole should be aligned

with the inside edge of the flange. (Fig.7)

10. Remove the tapes from louver and springs before

installation. Remove screw (M4X8) and light cover.

(Fig.8)

IMPORTANT:

Replace the sensor cover before the installation

(only for plug-in Motion sensor module FV-MSVK1).

As shown below:

Keep on pressing the clasps when removing the ornamental cover.

Gloves

the suitable

TM

FV-05-11VKSL1

FV-05-11VKL1

FV-11-15VKL1

Junction

box

Netural to

white

Live to black

(Light)

Joist

Plug connector

Receptacle

(270)

10 1/2

After finishing the ceiling job, fill gap between flange

and ceillng with caulk or other sealant to prevent air

leakage

Conduit

Machine

screw

(M4X6)

Ceiling

10 1/2

(270)

Earth ground to green

Wire nut

Live to black

(Fan)

Netural to white

Two red wires (Connect

to a general manual

wall switch)

2 Self-drilling

screws

Unit: inches (mm)

Fig.5

Fig.6

Fig.7

Ornamental

cover

Insert the sensor cover (attachment for FV-MSVK1) into slot.

Sensor

cover

11. Install the LED lamps. (Fig.9)

12. Install light cover. (Fig.10)

13. Insert the grille mounting spring on the wiring side

into the slot and insert the plug connector into the

housing of the lighting unit. (Fig.11 of page 10)

Tapes

Remove screw

(M4X8)

Light cover

LED lamp

Light cover

Fig.8

Fig.9

Secure

screw

(M4X8)

Fig.10

9

Page 10

INSTALLATION (NEW CONSTRUCTION) CONTINUED

CAUTION

Before turn on the light, make sure the

connector at the correct position. If not,

the lighting can’t work.

The claw of connector must latch the rib

completely.

14. Plug in the specified devices as your choice

(refer to installation on page 8). Insert the

motion sensor (FV-MSVK1 only) or LED night

light (FV-NLVK1 only) into slot of the grille.

Fix the lead wire into the clasp (Fig.11).

15. Adjust Pick-A-Flow switch; if used, adjust the

FV-VS15VK1 Multi-Speed module. (Fig.12)

Refer to indication on page 6.

16. Insert the other mounting spring into the slot

as shown and mount grille to fan body. (Fig.13)

CAUTION

Mount grille carefully so that lead wire of

lighting unit is not pinched.

INSTALLATION (RETROFIT)

WARNING

Disconnect power source before working

on unit.

1. Remove the existing fan and cut ceiling openning.

Secure the Flex-Z Fast bracket to joists by using 4

tapping screws (ST4.2x20) (Please prepare the

screws and put on Flex-Z Fast bracket before

Flex-Z Fast bracket is installed on joist).

TM

Existing ductwork and wiring left in place. (Fig.14)

2. Follow the step 1, 4, 5 on page 8 and step 7 on

page 9. (Before connect the circular duct to the

adaptor, should pull down the circular duct from

the ceiling)

3. Install the adaptor to Flex-Z Fast bracket by using

2 self-drilling screws. (Fig.15)

4. Secure the fan body to Flex-Z Fast bracket by

using 2 self-drilling screws, plug connector to

receptacle and secure the fan body to adaptor

by using machine screw (M4X6). (Fig.16)

TM

TM

TM

TM

Ceiling

Plug

connector

Lighting

unit

Rib

Ceiling (already existed)

Knock-out

hole

Gloves

Claw

Junction box

cover

Ceiling

Joist

Inser plug

connector

Ceiling

Grille

Conduit

Conduit

Circular duct

4 Tapping

screws (ST4.2x20)

10 7/8

Circular duct

2 Self-drilling screws

Mounting spring

Mounting spring

(275)

Motion sensor

(FV-MSVK1 only)

Clasp

LED night light

(FV-NLVK1 only)

Fig.11

Ceiling

Grille

Fig.12

Gloves

Fig.13

Unit: inches (mm)

Joist

10 7/8

(275)

Fig.14

Mastic or

approved

foil tape

Joist

Fig.15

CAUTION

Secure machine screw (M4X6) to the suitable

hole and not touch the Flex-Z Fast bracket.

Please fix the screw carefully to avoid screw

slip teeth.

5. Follow the step 10 to 16 on page 9 to 10.

10

TM

Ceiling

Machine screw (M4X6)

2 Self-drilling screws (Fix the

flange and Flex-Z Fast bracket through the ceiling)

TM

Flange

Fig.16

Page 11

MAINTENANCE (CLEANING)

WARNING

Disconnect power source before working on unit.

CAUTION

Routine maintenance must be done every year.

Please wear gloves during the cleaning work.

Never use gasoline, benzene, thinner or any other

such chemicals for cleaning the ventilating fan.

Do not immerse motor in water when cleaning.

Do not soak resin parts in water over 140 F (60 C).

1. Clean grille. (Don’t put into hot water. Use non-abrasive

kitchen detergent, wipe dry with clean cloth) (Fig.17)

2. The grille should be dry after cleaning.

3. Remove dust and dirt from fan body using a vacuum

cleaner. (Fig.18)

4. Using a cloth dampened with kitchen detergent, remove

any dirt from fan body. Wipe dry with clean cloth. (Fig.19)

5. Reinstall grille.

Gloves

Fig.17

Ceiling

Vacuum

cleaner

Fig.18

Ceiling

Gloves

Fig.19

MAINTENANCE (REPLACEMENT OF LAMP)

WARNING

Disconnect power source before working on unit.

The lamp’s glass is fragile, be careful when the lamp

is replaced.

Make sure the temperature of lens and lighting

unit has cooled down before maintenance

(cleaning) or replacement of lamp.

CAUTION

Remove dust and dirt from light cover and lens,

before replace the lamps.

The LED lamps should be replaced as the specified

type. The supplied LED lamps are not intended for

other use.

1. Remove grille by pulling down one mounting spring

(Fig.20). Remove plug connector then pull down the other.

(For models plug-in FV-MSVK1 or FV-NLVK1: Pull down the

mounting spring that without lead wire passed side, and

remove motion sensor or LED night light as shown in Fig.20)

(Squeeze mounting spring and pull down carefully)

2. Remove the screw as shown in step of Fig.21.

Remove the light cover as shown in step of Fig.21.

3. Replace the LED lamps (CX-GU24-H-B, 7W) as shown in

step 1 and step 2 of Fig.22.

4. Install the

step 1 and step 2 of Fig.9 (Page 9).

5. Install light cover. (Fig.10 of page 9)

LED lamps (CX-GU24-H-B, 7W) as shown in

Ceiling

Plug

connector

Gloves

Rib

Claw

Lens

Remove

plug

connector

Lighting

unit

Remove screw

(M4X8)

Light cover

LED lamp

Mounting spring

Motion sensor

(FV-MSVK1 only)

Clasp

LED night light

(FV-NLVK1 only)

Grille

Fig.20

Fig.21

Fig.22

11

Page 12

PRACTICAL GUIDE TO INSTALLATION

Properly insulate the area around the fan to

minimize building heat loss and gain. (Fig.23)

Loose fill or batt insulation can be placed

directly over the fan housing in the attic.

Our fans and fan/light combination units do

not create excessive heat that is a common

problem with recessed light fixtures or some

4 inches or 6 inches roof jack, wall cap,

or soffit vent with backdraft damper

Mechanically connect duct to termination

and seal with mastic or approved foil

faced tape

2-3 ft straight run before elbow

In attic installation,

caulk box to drywall

competitor’s fan/light combination. Our

efficient, cool-running motors and our LED

lighting unit do not create enough ambient

heat to be subjected to these limitations.

Short piece of flexible duct helps

alignment and absorbs sound.

Clamps plus mastic or approved

foil faced tape at all flex joints

Foil tape tightly covers all metal

duct joints (glue PVC joints)

SPECIFICATIONS

Specifications for Base Model fans

Duct

diameter

(inches)

4 or 6

Model No.

FV-05-11VKSL1

FV-05-11VKL1

FV-11-15VKL1

Air

direction

Exhaust

Exhaust

Voltage

(V)

Frequency

(Hz)

HVI Certified performance based on HVI Procedures 915, 916, and 920.

Specifications for Multi Speed fans

Model No.

FV-05-11VKSL1,

FV-05-11VKL1

(Plug-in

FV-VS15VK1)

FV-11-15VKL1

(Plug-in

FV-VS15VK1)

Air

direction

Exhaust

Exhaust

Voltage

(V)

Frequency

(Hz)

Duct

diameter

(inches)

Reference performance based on HVI Procedures 915, 916, and 920. [( ) Standby wattage.]

Air volume

at 0.1"WG

(CFM)

50

80

110

110 <0.3

130

150

Air volume

at 0.1"WG

(CFM)

100

90

80

70

60

50

40

30

0

120

110

100

90

80

70

60

50

0

Noise

(sones)

<0.3

<0.3

0.4

<0.3

0.6

Noise

(sones)

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

<0.3

Speed

(rpm)

750

825

965

650

680

730

Speed

(rpm)

915

865

825

795

770

750

730

725

665

650

645

640

635

630

625

620

*

Power (W)

Fan

3.6

6.0

11.0

8.5

12.0

16.5

Power (W)

Fan

8.7

7.0

6.0

4.7

3.9

3.6

2.8

2.5

9.5

8.5

6.9

5.7

5.0

4.3

4.0

3.2

Lighting

unit

Lighting

14

14

unit

14

14

Insulation

3

Weight

lb.

11.5(5.2)

11.7(5.3)

Weight

lb.

11.5(5.2)

11.7(5.3)

PRODUCT

SERVICE

Warning Concerning Removal of Covers. The unit should be serviced by qualified technicians only.

Your product is designed and manufactured to ensure a minimum of maintenance. Should your unit

require service or parts, call Panasonic Call Center at 1-866-292-7299 (USA) or 1-800-669-5165 (Canada).

Panasonic Corporation of North America

Two Riverfront Plaza, Newark, NJ 07102

www.panasonic.com

Panasonic Canada lnc.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3

www.panasonic.ca

Panasonic corporation 2014

Printed in China

X0114-2024 11KSL1420B

Loading...

Loading...