Panasonic DMP-BDT165EB, DMP-BDT165EF, DMP-BDT165EG, DMP-BDT166EB, DMP-BDT166EG Service Manual

Page 1

ORDER NO.CHM1501004CE

Blu-ray Disc Player

Model No. DMP-BDT165EB

DMP-BDT165EF

DMP-BDT165EG

DMP-BDT166EB

DMP-BDT166EG

Colour

(K).......................Black Type (DMP-BDT165EG/EB/EF)

(S).......................Silver Type (DMP-BDT166EG/EB)

Panasonic Corporation © 2015.

Unauthorized copying and distribution is a violation

of law.

Page 2

234

Page 3

Page 4

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------5

1.1. General guidelines -----------------------------------------5

2Warning--------------------------------------------------------------6

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatic Sensitive (ES) Devices---------------6

2.2. Precaution of Laser Diode -------------------------------7

2.3. Service caution based on legal restrictions----------8

2.4. Static Electricity Protection Measures ----------------9

2.5. Ground for electrostatic breakdown

prevention----------------------------------------------------9

3 Service Navigation---------------------------------------------- 10

3.1. Combination of Multiple Pressing on the

Remote Control------------------------------------------- 10

3.2. The display position of TV ----------------------------- 10

3.3. Entering Special Modes with Combination of

Multiple Pressing on the Remote Control ---------- 10

3.4. How to Update Firmware------------------------------- 12

4 Specifications ---------------------------------------------------- 15

5 Location of Controls and Components------------------ 16

6 Operating Instructions ---------------------------------------- 17

6.1. Taking out the Disc from BD-Drive Unit when

the Disc cannot be ejected by OPEN/CLOSE

button-------------------------------------------------------- 17

7 Service Mode ----------------------------------------------------- 18

7.1. Special Mode Setting and Service mode----------- 18

8 Service Fixture & Tools --------------------------------------- 30

9 Disassembly and Assembly Instructions --------------- 31

9.1. Unit----------------------------------------------------------- 31

9.2. Drive Unit--------------------------------------------------- 34

9.3. Disassembly from the traverse unit, assembly

of the optical pick-up unit, and precautions on

ESD-preventive------------------------------------------- 39

9.4. Adjustment of BD Drive--------------------------------- 44

10 Measurements and Adjustments -------------------------- 47

10.1. Service Positions -----------------------------------------47

10.2. Caution for Replacing Parts ---------------------------48

11 Block Diagra m --------------------------------------------------- 49

11.1. Overall Block Diagram ----------------------------------49

11.2. Digital P.C.B. Regulator Block Diagram ------------ 50

11.3. Digital (Back End Section) Block Diagram --------- 51

11.4. Digital (Front End Section) Block Diagram -------- 52

12 Wiring Connection Diagram --------------------------------- 53

12.1. Interconnection Schematic Diagram ---------------- 53

Page 5

1 Safety Precautions

1.1. General guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage current cold check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be .

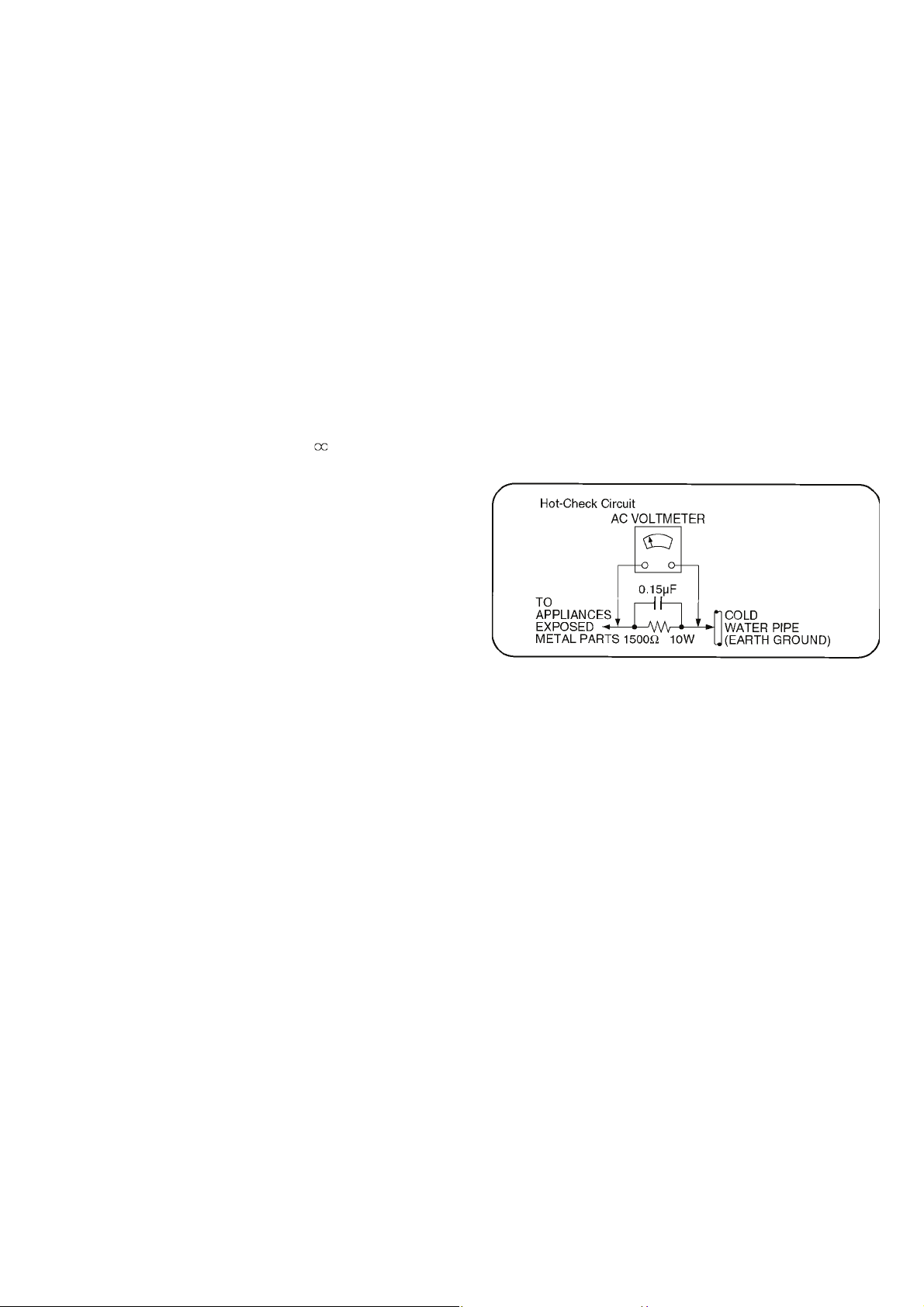

1.1.2. Leakage current hot check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliampere. In case a measurement is outside of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

5

Page 6

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatic Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatic Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ES device).

6

Page 7

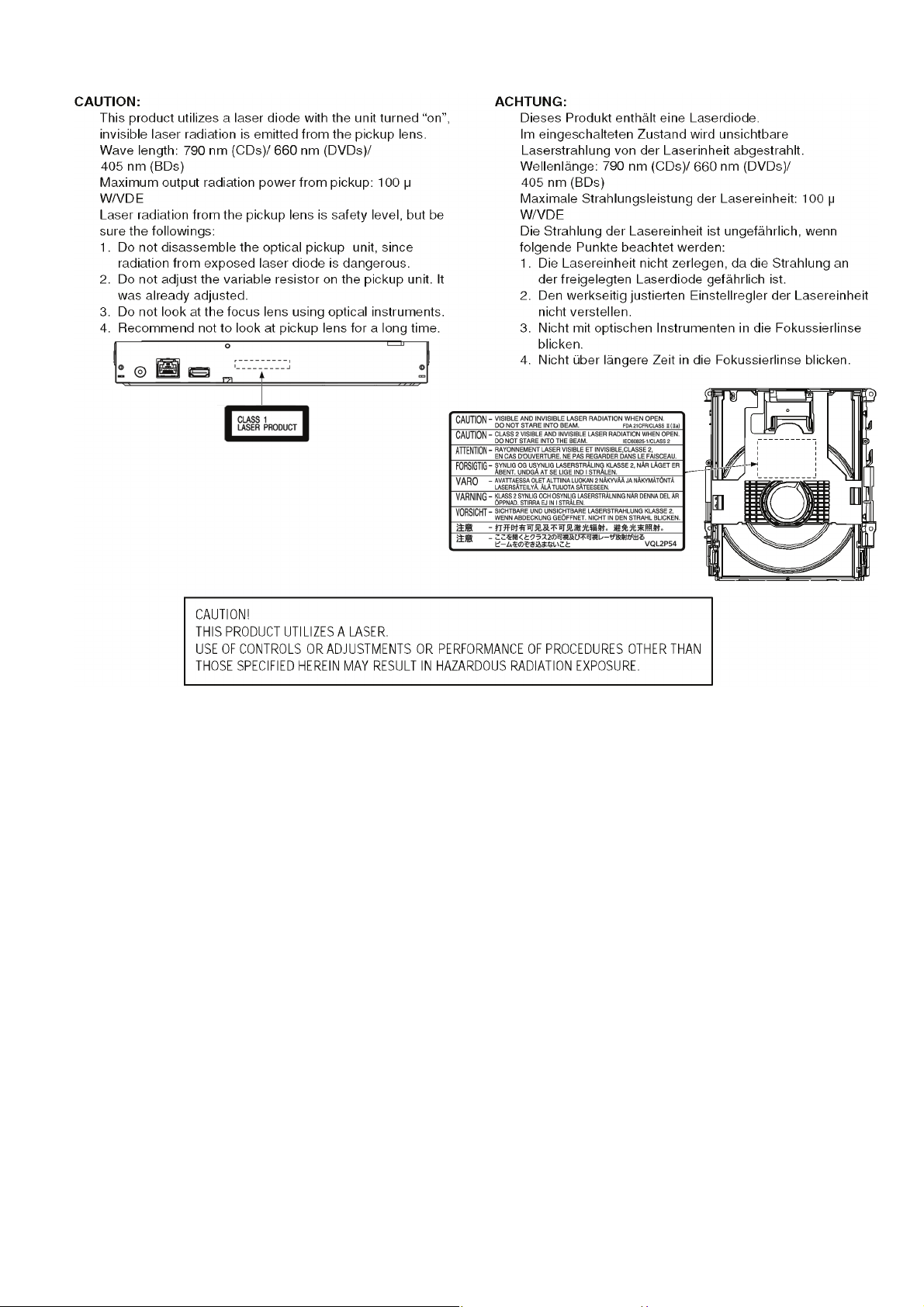

2.2. Precaution of Laser Diode

7

Page 8

2.3. Service caution based on legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

SVKZ000001-----------(0.3mm 100g Reel)

SVKZ000002-----------(0.6mm 100g Reel)

SVKZ000003-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn) 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%. (Flux cored)

8

Page 9

2.4. Static Electricity Protection Measures

• The laser diode in the traverse unit (optical pick-up) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse unit (optical pick-up).

2.5. Ground for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.5.1. Work table grounding

• Put a conductive material (sheet) or steel sheet on the area where the traverse unit (optical pick-up) is placed, and ground the

sheet.

2.5.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity from your body.

2.5.3. When exchange the BDP Drive

• Before remove the ESD prevention bag, make sure to use the anti-static wrist strap to discharge the static electricity when

replace the BDP Drive.

Note:

The ESD prevention bag is used to replace the original short-circuit point.

It can be removed while placing the BDP Drive.

9

Page 10

3 Service Navigation

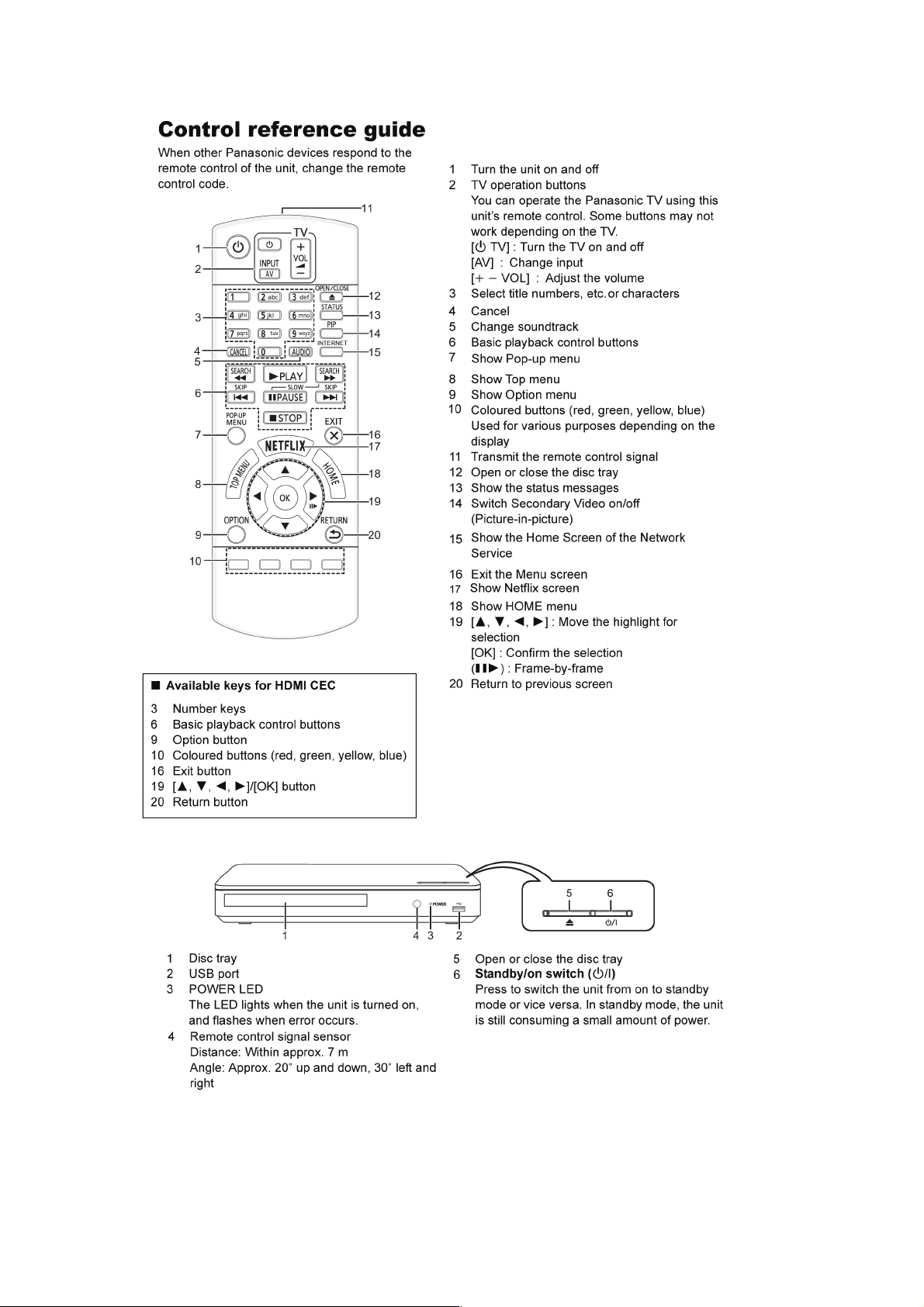

3.1. Combination of Multiple Pressing on the Remote Control

Press multi-buttons (in combination) on the remote control simultaneously for operations, such as initialization or service mode, etc.

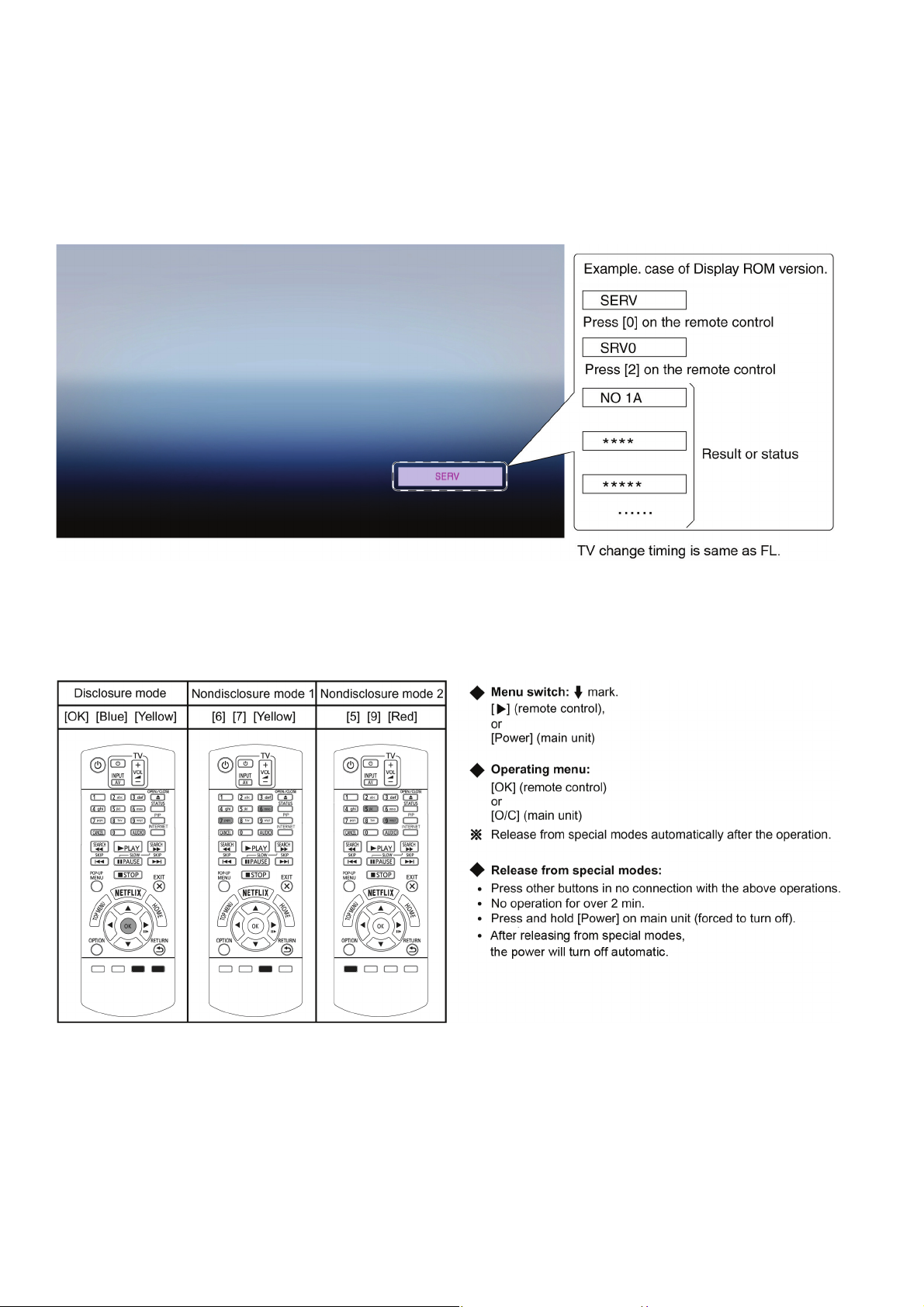

3.2. The display position of TV

Special modes display of this unit changes to TV display from the original FL display.

3.3. Entering Special Modes with Combination of Multiple Pressing on the Remote Control

Enter the following special modes by multiple pressing functions on the supplied remote control.

After entering each mode, switch to the desired menus for operation.

10

Page 11

3.3.1. Disclosure mode (Combination of multiple pressing: [OK] [Blue] [Yellow])

Press and hold [OK] [Blue] [Yellow] on the remote control simultaneously for 5 sec., then "00RET" is displayed on TV display

window.

3.3.2. Nondisclosure mode 1 (Combination of multiple pressing: [6] [7] [Yellow])

Press and hold [6] [7] [Yellow] on the remote control simultaneously for about 5 sec., then "50RET" is displayed on TV display

window.

3.3.3. Nondisclosure mode 2 (Combination of multiple pressing: [5] [9] [Red])

Press and hold [5] [9] [Red] on the remote control simultaneously for about 5 sec., then "70RET" is displayed on TV display

window.

11

Page 12

3.4. How to Update Firmware

The firmware of the unit may be renewed to improve the quality including operational performance and playability.

Make sure to refer the following procedure when performing version-up.

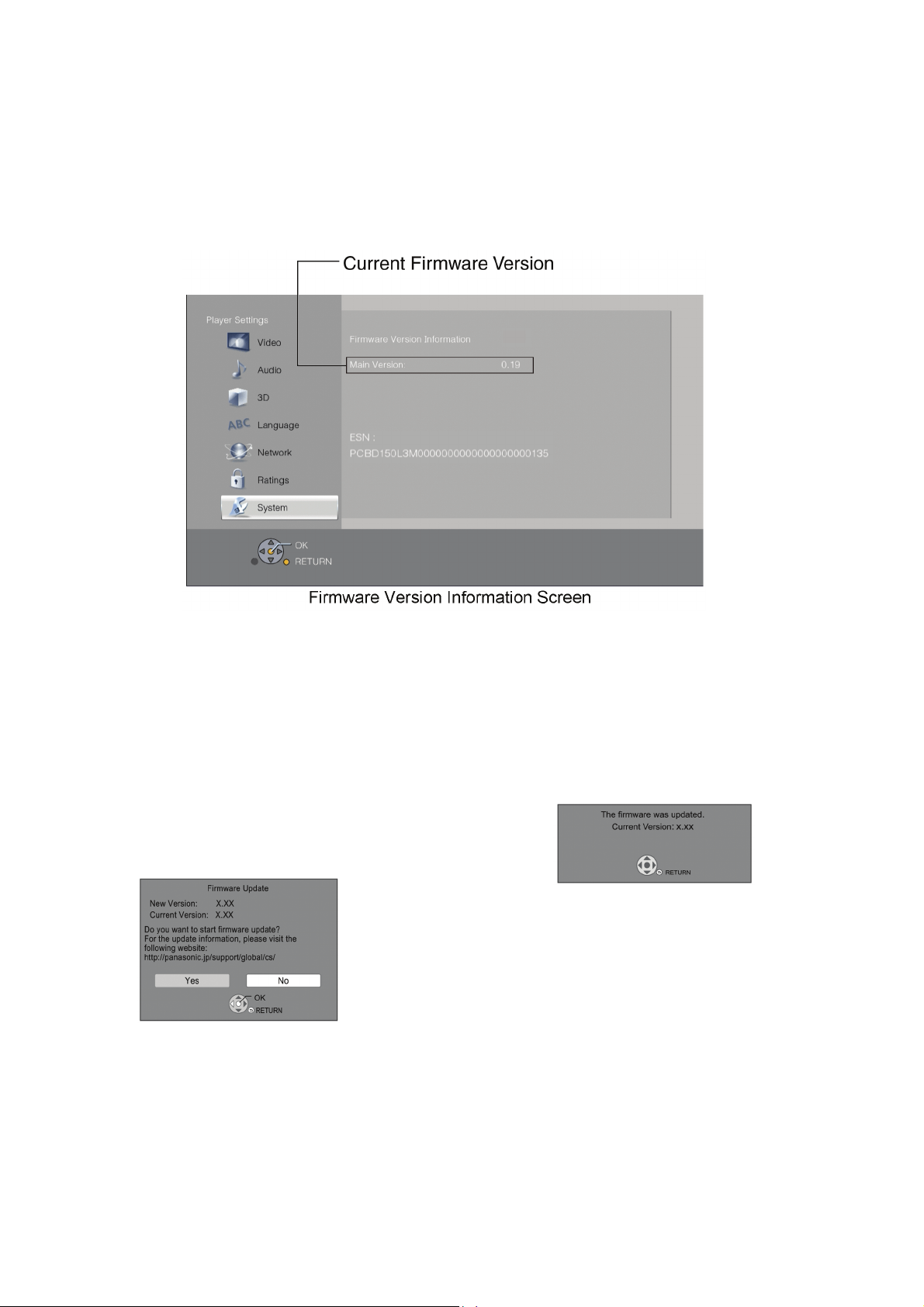

3.4.1. Confirmation of the Firmware Version

Perform following steps to checking the firmware version currently installed in the unit.

1. Turn the unit on and wait the Home screen is displayed.

2. Select [Setup] → [Player Settings] → [System] → [System Information] → [Firmware Version Information].

3. Firmware Version Information screen is displayed.

3.4.2. Updating Firmware

This unit has 2 updating method, one way to update via the internet, the other way to update using CD-R or USB device which is

stored pre-downloaded firmware update file.

3.4.2.1. Updating firmware via the internet

Occasionally, Panasonic may release updated firmware for this

unit that may add or improve the way a feature operates. These

updates are available free of charge.

This unit is capable of checking the firmware automatically

when connected to the Internet via a broadband connection.*

When a new firmware version is available, the following

message is displayed.

You can also download the latest firmware from the following

website and store it to a USB device to update the firmware.

http://panasonic.jp/support/global/cs/

(This site is in English only.)

DO NOT DISCONNECT the unit from the AC power or perform

any operation while the update takes place.

After the firmware is installed, unit will restart and the following

screen will be displayed.

12

Page 13

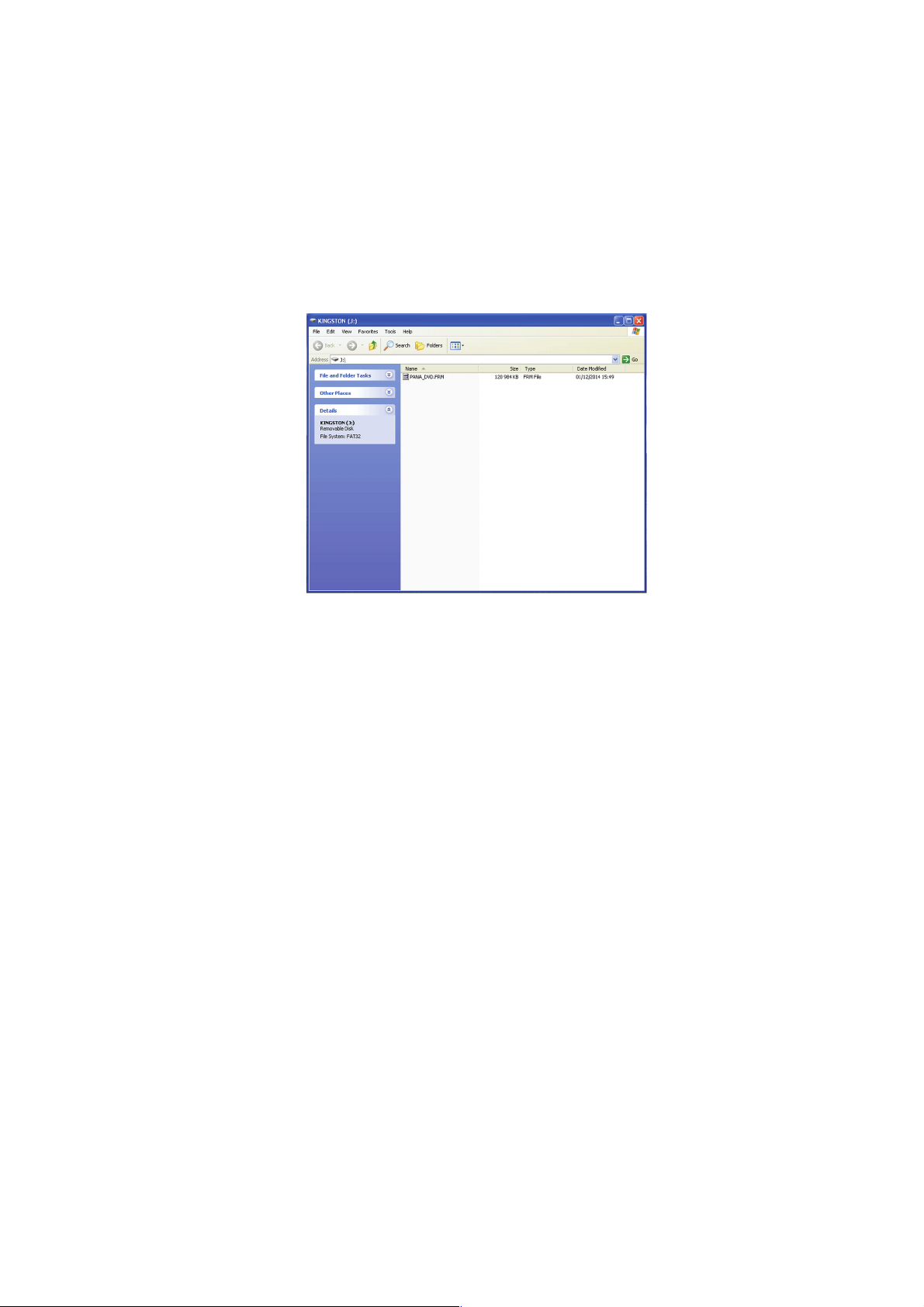

3.4.2.2. Updating firmware using the USB device

When updating firmware using USB device, perform following procedures.

(When using CD-R instead of USB device, perform same procedures)

1. Download the latest firmware file of the unit

The latest firmware required for version-up can be downloaded from "Support Information from AVC"

web-site in "TSN system".

Click file name to download.

After download, click file to decompress.

2. Decompress the downloaded file.

The decompressed file will be named as "PANA_DVD.FRM".

Copy the file to root folder of the USB device.

(If using CD-R instead of USB device, burn the file to a blank CD-R by writing software.)

13

Page 14

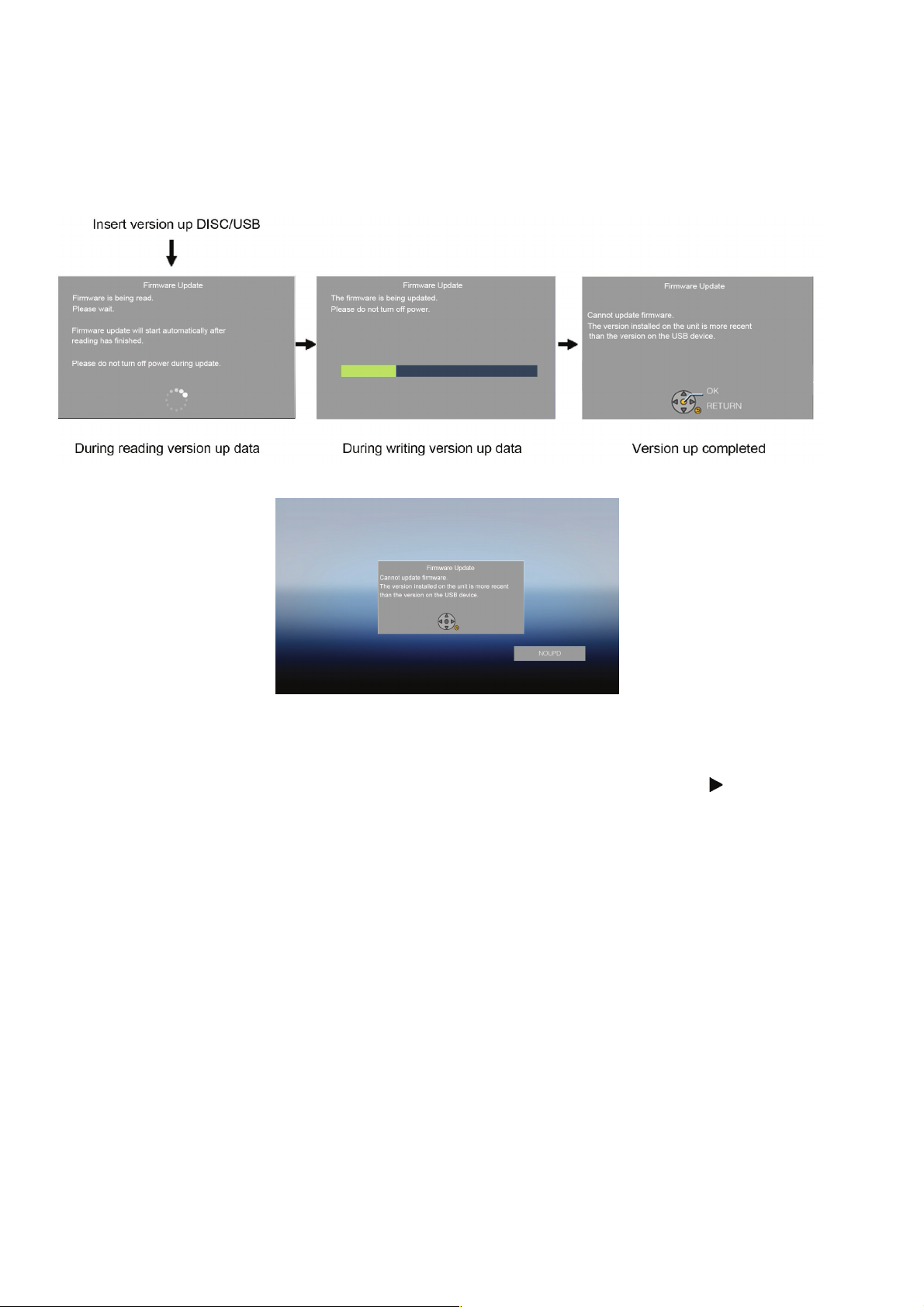

3. Update the unit

(1)Turn the unit power on.

(2)After the home screen is displayed, insert the USB device stored downloaded latest firmware file to front USB port of the

unit.(or set the CD-R into the unit and playback it.)

(3)The screens are displayed as below.

[Screen transition]

(if the following screen is displayed, the unit has already been update the latest version of firmware.)

Firmware update is not needed

(4)Remove the USB device (or the CD-R) and press the [POWER] button to turn the unit off.

(5)Turn the unit on and home screen is displayed, the firmware update is completed.

NOTE:

After updating finishing, press [Y] [B] [OK] into Disclosure mode and hold the right button of remote control [ ]

displayed, then long press [OK] and make factory setting. (Refer to "3.3.1".)

until [08FIN] is

14

Page 15

4 Specifications

Power supply: DC12V, 0.8A(DC IN terminal)

Power consumption: Approx. 11W

in standby mode: Approx. 0.5W

in Network standby mode: Approx. 3.5W

Operating temperature range: +5°C to +35°C (+41 to +95°F)

Operating humidity range: 10% to 80%RH (no condensation)

Signal system: PAL /NTSC

HDMI AV output:

Output connector: TypeA (19pin)

1 system

USB slot:

USB2.0: 1 system

Ethernet:

10BASE-T/100BASE-TX: 1 system

Media:

Playable disc:

BD-Video

(Blu-ray 3D, BD-LIVE,

BONUSVIEW):

BD-RE: Version3 (Single Layer/Dual Layer),

BD-R: Version2 (Single Layer/ Dual

DVD-R:

DVD-R DL:

DVD-RW: DVD-Video format(*1), DVD Video

+R: Video(*1), AVCHD format(*1)

+R DL: Video(*1), AVCHD format(*1)

+RW: Video(*1), AVCHD format(*1)

DVD-Video: DVD-Video format

CD-Audio: CD-DA

CD-R/CD-RW:

*1: Finalizing is necessary.

*2: ISO9660 level 1 or 2 (except for extended formats), Joliet.

This unit is compatible with multi-session.

This unit is not compatible with packet writing.

*3: UDF1.02 without ISO9660, UDF1.5 with ISO9660.

*4: UDF2.5.

*5: MPEG-4 ASP Level 4.

MPEG2 Video, AAC-LC, MP3, Dolby Digital audio, DTS,

PCM, FLAC and Vorbis can be decoded.

*6: Subtitle text support.

SD card: no SD card slot

USB device:

USB Standard: USB2.0 High Speed

Format:

Contents:

BD-ROM Part3 Version 2.4

JPEG, MPO:MP3, FLAC,

WAV, AAC, WMA, DSD, ALAC

Layer), MKV(*4,*5,*6),

:MP3, FLAC, WAV, AAC, WMA,

DSD, ALAC

DVD-Video format(*1), DVD Video

Recording format(*1), AVCHD

format(*1), JPEG(*2), MPO(*2),

MP3(*2), WAV(*2), FLAC(*2),

AAC(*2), WMA(*2),

MKV(*2,*3,*5,*6), Xvid(*6), DSD,

ALAC

DVD-Video format(*1), DVD Video

Recording format(*1), AVCHD

format(*1), JPEG(*2), MPO(*2),

MP3(*2), WAV(*2), FLAC(*2),

AAC(*2), WMA(*2),

MKV(*2,*3,*5,*6), Xvid(*6), DSD,

ALAC

Recording format(*1), AVCHD

format(*1)

CD-DA, JPEG(*2),

WAV(*2), FLAC(*2), AAC(*2),

WMA(*2), MKV(*2,*5,*6), Xvid(*6),

ALAC

FAT12, FAT16, FAT32, NTFS

Xvid(*6)

MPO(*2),

MP3(*2),

JPEG:

CD-R/RW, BD-RE, DVD-R, USB device:

Pixcels: 34x34~8172x8172

Sub Sampling: 4:2:2, 4:2:0

Motion JPEG not supported

MP3:

BD-R/RE, CD-R, CD-RW, DVD-R, USB device:

Compression rate: 32kbps~320kbps

Sampling rate: 44.1kHz, 48kHz

AVCHD (H.264):

DVD: AVCHD format V1.0

HDMI: 480p(525p)/1080i(1125i)/

720p(750p)/1080p(1125p)

HDMI (V.1.4a with 3D, Content

Type)

This unit supports “HDMI-CEC”

function.

Playable disc:

BD-ROM (SL/DL): Compliant Ver. 1.3

(SL: Single Layer/DL: Dual Layer)

BD-RE (SL/DL): BD-MV

(SL: Single Layer/DL: Dual Layer)

BD-R (SL/DL): BD-MV

(SL: Single Layer/DL: Dual Layer)

DVD-ROM (SL/DL): DVD-Video

(SL: Single Layer/DL: Dual Layer)

DVD-R: DVD-Video, DVD-VR

DVD-R(DL): DVD-Video, DVD-VR

DVD-RW: DVD-Video, DVD-VR

+R: Video

+R(DL): Video

+RW: Video

CD: CD-DA, CD-R/RW

Optical pick-up:

Wave length: System with 1 lenses

790 nm (CDs)/660 nm (DVDs)/

405 nm (BDs)

LASER Specification:

Class I LASER Product

Wave length: 790nm (CDs)/660 nm (DVDs)/405

nm (BDs)

Laser power: No hazardous radiation is emitted

with the safety protection

Regional Code: DVD: #2

BD: Region B

Dimensions:

245mm(W) [Approx. 9 10/16''(W)]

38.5mm(H) [Approx. 1 8/16''(H)]

175mm(D) [Approx. 6 14/16''(D)]

Mass: Approx. 0.8 kg ( 1.7 lbs)

Solder: This model uses lead free

solder(PbF).

Note: Specifications are subject to

change without notice.

15

Page 16

5 Location of Controls and Components

16

Page 17

6 Operating Instructions

6.1. Taking out the Disc from BD-Drive Unit when the Disc cannot be ejected by OPEN/CLOSE button

6.1.1. Forcible Disc Eject

1. Turn on the power, press and hold [OK], [B] and [Y] on the remote control at the same time for more than 5 seconds.

"00RET" is displayed on the TV.

2. Repeatedly press [ ] on the remote control or [POWER] on the unit until "06FT0" is displayed on the TV.

3. Press [OK] on the remote control or [OPEN/CLOSE] on the unit.

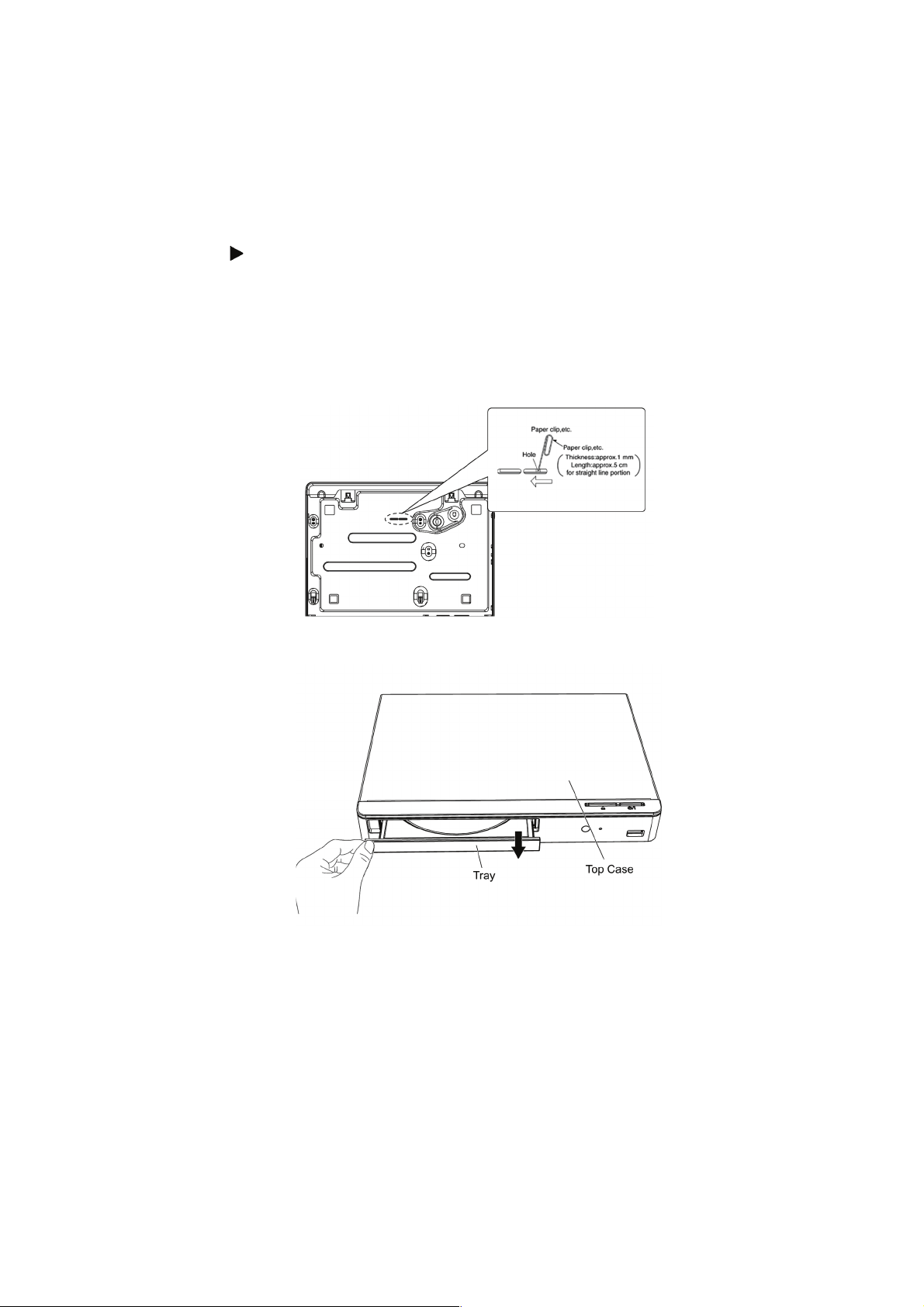

6.1.2. When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Put deck so that bottom can be seen.

3. Insert the Paper clip, etc. into the hole on the bottom of BD Drive and slide the Paper clips, etc. in the direction of the arrow to

eject tray slightly.

4. Put deck upward, and pick out Tray by finger.

17

Page 18

7 Service Mode

7.1. Special Mode Setting and Service mode

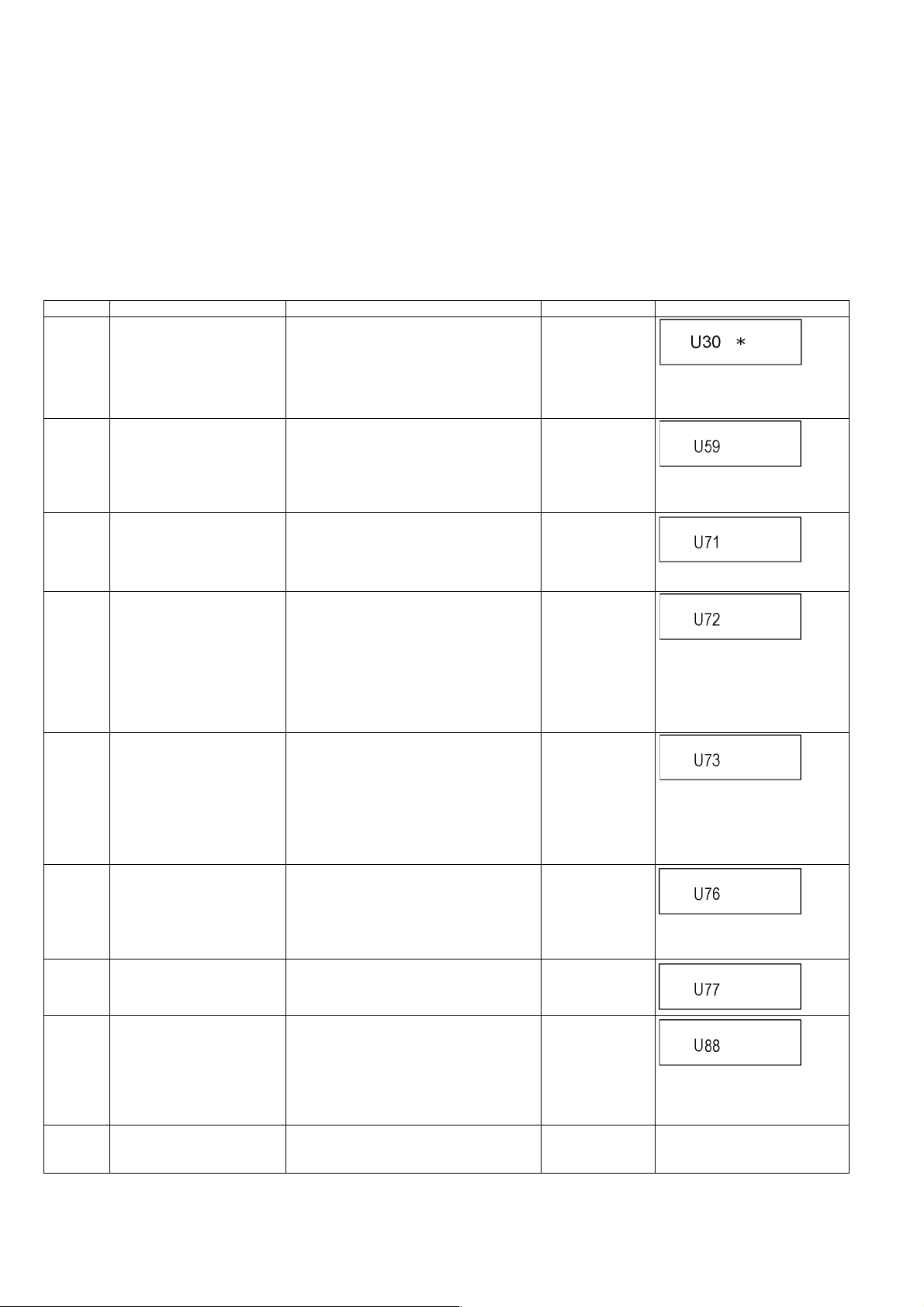

7.1.1. Self-Diagnosis Functions

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U**

and F** are stored in memory and held.

You can check latest error code by transmitting [0] [1] of Remote Controller in Service Mode.

Automatic Display on TV will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

Error Code Diagnosis contents Description Monitor Display Automatic TV display

U30 Remote control code error Display appears when main unit and remote

controller codes are not matched.

U59 Abnormal inner temperature

detected

U71 HDMI incompatible error

(HDMI incompatible)

U72 HDMI connection error

(communication error)

U73 HDMI connection error

(authentication error)

U76 Connection error This error is displayed when equipment such

U77 Illegal disc error This error is displayed when it becomes

U88 Restoration is operation.

(When the disc is in the disc

tray)

F00 No error information Initial setting for error code in memory (Error

Display appears when the drive temperature

exceeds 70°C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled.

The event is saved in memory as well.

Display this error when the equipment (compatible with DVI such as TV, amplifier etc.)

connected to the unit by HDMI is incompatible

with HDCP (High-bandwidth Digital Content

Protection).

Display this error when there are any communication problems with the unit and the equipments (TV, amplifier ect.) connected to the

unit by HDMI. (or when there is a problem

with the HDMI cable).

The display disappears only when the

connection is released. Neither the button

operation nor the passage of the fixed time

disappear the display.

When authentication error occurs while the

equipments (TV, amplifier etc.) are connected

by HDMI. (or when there is a problem with the

HDMI cable)

The display disappears only when the connection is released. Neither the button operation nor the passage of the fixed time

disappear the display.

as TVs or amplifiers connected to the unit

with the HDMI cable do not correspond to the

copyright protection. (The BD/DVD video

where the copyright is protected cannot be

played.)

impossible to reproduce because of copyright

illegal information.

This error is displayed when there is a disc in

the disc tray or abnormality is confirmed

during playback. It is shown that the

restoration to return the main unit operation

normally is operating. It becomes possible to

use as soon as not the breakdown but the

U88 display disappears.

code Initialization is possible with error code

initialization and main unit initialization).

No display

* is remote controller code of the

main unit.

Display for 5 seconds.

No display

"U59" is displayed for 30 minutes.

No display

No display

"U72" display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

No display

"U73" display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

No display

No display

No display

Display for 30 seconds.

No display No display

18

Page 19

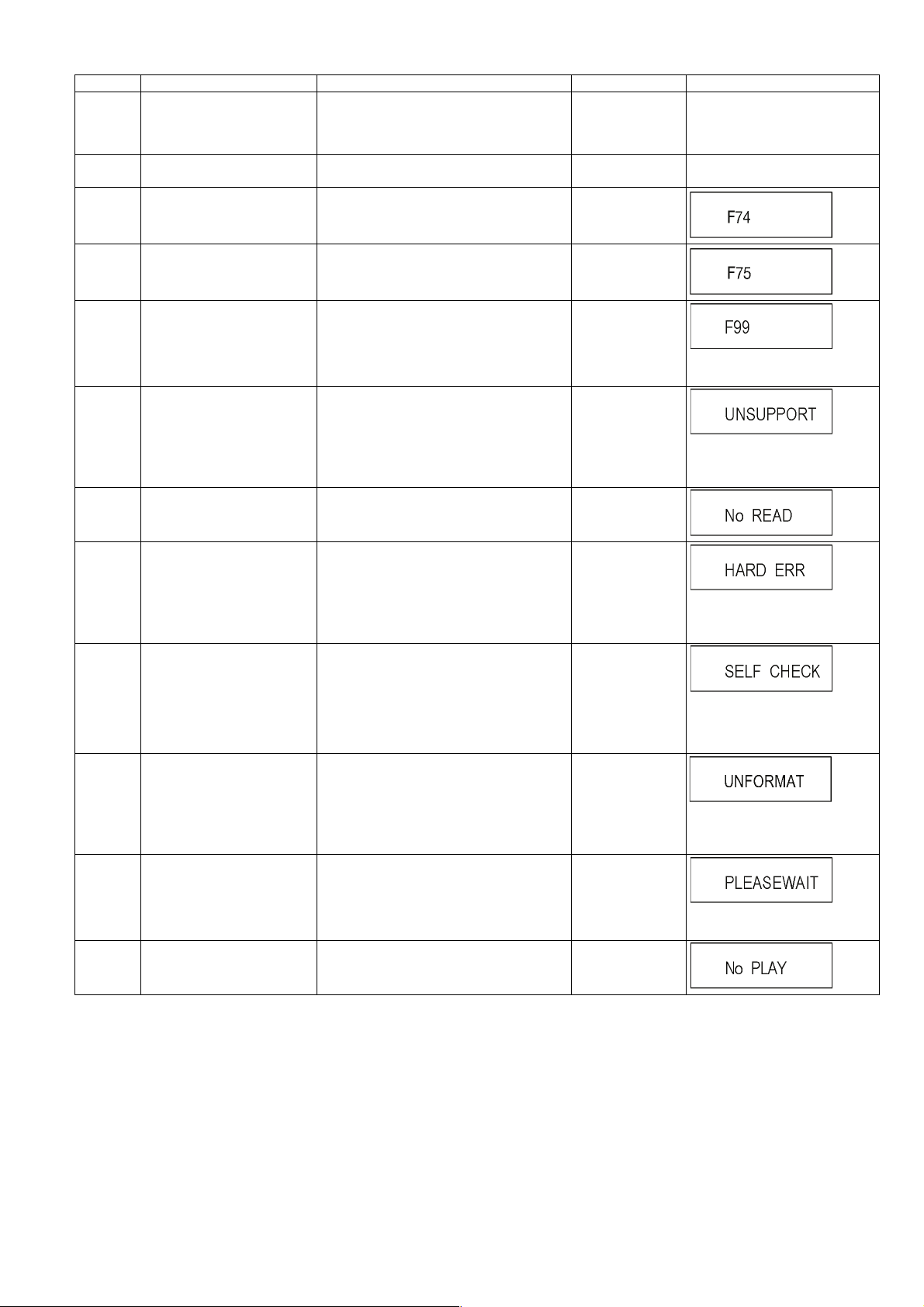

Error Code Diagnosis contents Description Monitor Display Automatic TV display

F34 Initialization error When initialization error is detected after start-

ing up main microprocessor, the power is

turned off automatically. The event is saved in

memory.

F58 Drive hardware error When drive unit error is detected, the event is

saved in memory.

F74 HDMI Device Key Communica-

tion error

This error is displayed when the information

error is occurred at HDMI device key loading.

No display No display

No display No display

No display

F75 HDMI Device Key Loading

error

F99 Hang-up Displayed when communication error has

UNSUPPORT

NO READ Disc read error *A disc is flawed or dirty.

HARD

ERR

SELF

CHECK

UNFORMAT

PLEASE

WAIT

No PLAY When there is a viewing restric-

Unsupported disc error *An unsupported format disc was played,

Drive error The drive detected a hard error. “BD drive error.”

Restoration operation Since the power cord fell out during a power

Unformatted disc error This error is displayed when the unformatted

Unit is in termination process Unit is in termination process now.

tion on a BD-Video or

DVD-Video.

This error is displayed when the key of loaded

is illegal at HDMI device key loading.

occurred between Main microprocessor and

Timer microprocessor.

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears automatically. If a display does not disappear, there is

the possibility that defective Digital P.C.B. /

BD Drive.

DVD-RAM/DVD-RW or the DVD-RW

recorded by another make of recorder is

inserted.

[BYE] is displayed and power will be turned

off.

Rating password is set. No display

No display

No display

"F99" is displayed utill the

[POWER] key is pressed.

“This disc is

incompatible.”

It is displayed for 5 seconds.

The character indication flows

sideways.

“Cannot read.

Please check the

disc.”

It is display for 5 seconds.

The character indication flows

sideways.

No display

The character indication flows

sideways.

No display

This disc is not formatted properly.

Format the disc in DISC

MANAGEMENT?

No display

The character indication flows

sideways.

19

Page 20

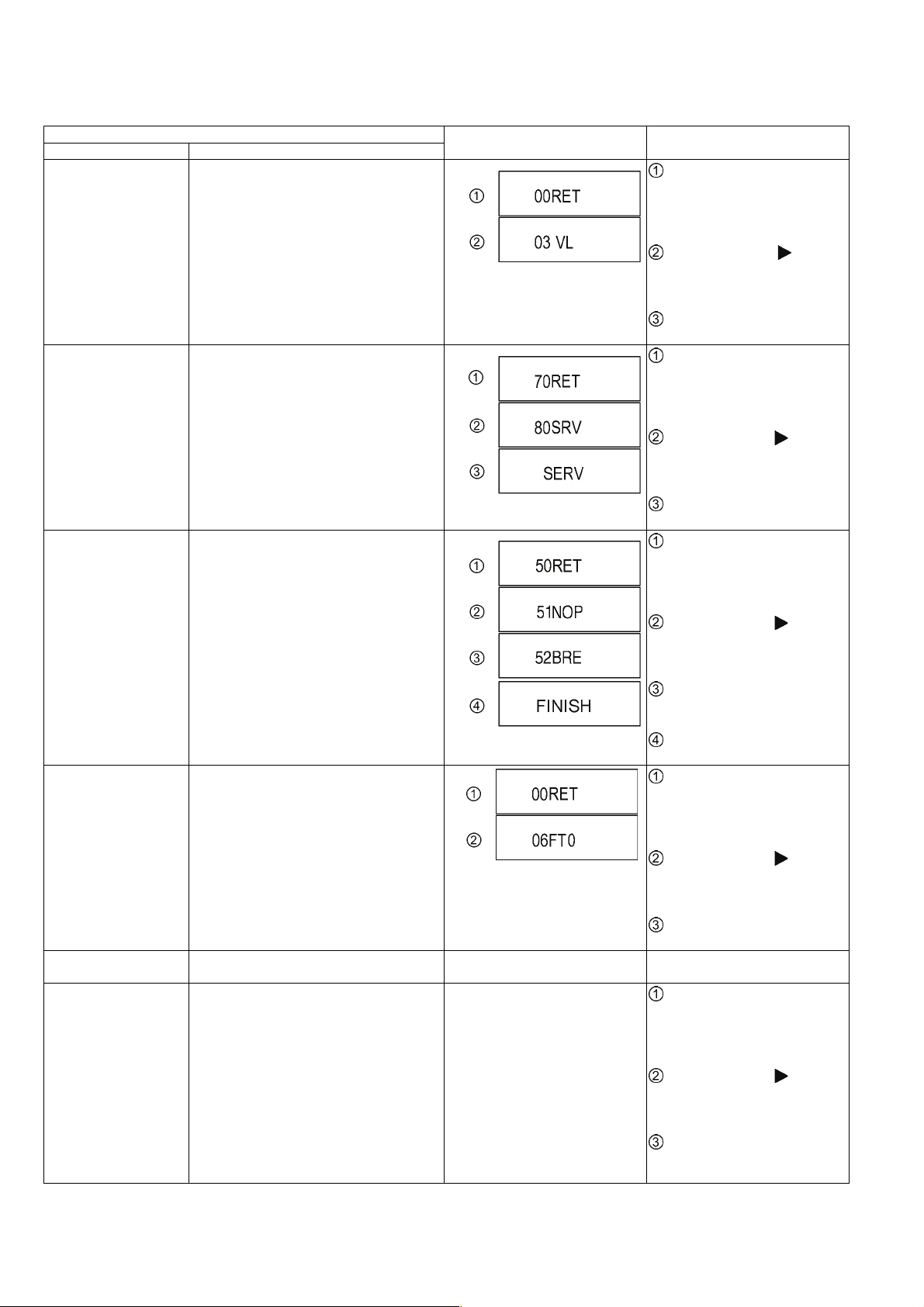

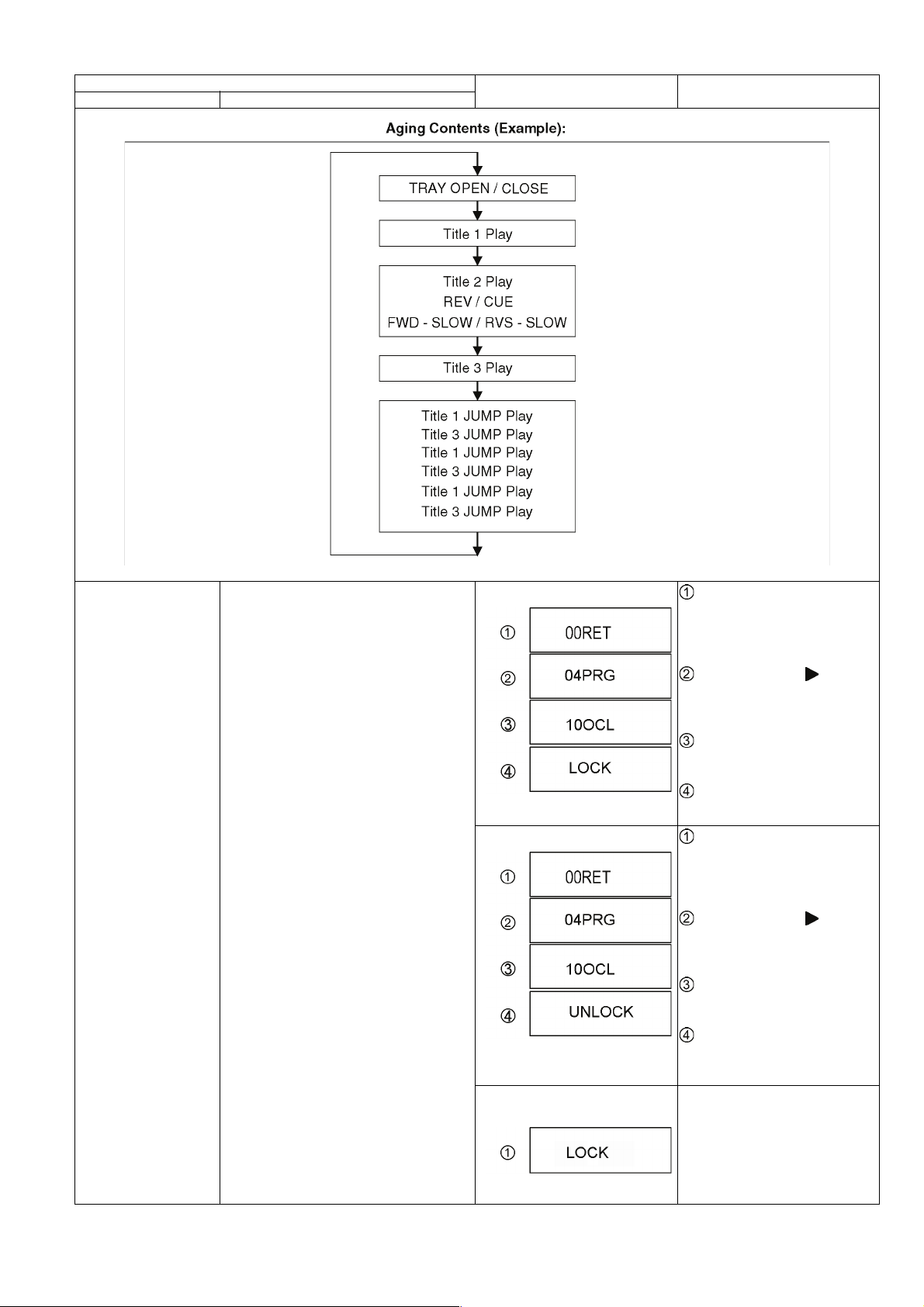

7.1.2. Special Modes Setting

Item

Mode name Description

Rating password The audiovisual level setting password is

initialized to Level 8.

Service Mode Setting every kind of modes for servicing.

*Details are described in 7.1.3. Service Mode

at a glance.

BD-ROM history cleaning <Persistent Storage> of BD-ROM standard is

cleaned.

Forced disc eject Removing a disc that cannot be ejected.

The tray will open and unit will shift to P-off

mode.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

Forced power-off When the power button is not effective while

power is ON, turn off the power forcibly.

Aging Perform sequence of modes as * Aging

Description shown below continually.

TV display Key operation

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "03 VL" is displayed on the

TV.

Press [OK] on the remote control

or [OPEN/CLOSE] on the unit.

While the unit is on, press and

hold [5], [9] and [R] on the remote

control at the same time for more

than 5 seconds.

-"70RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "80SRV" is displayed on

the TV.

Press [OK] on the remote control

or [OPEN/CLOSE] on the unit.

While the unit is on, press and

hold [6], [7] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"50RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "51NOP" is displayed on

the TV.

Press and hold [STOP] on the

remote control until "52BRE" is displayed on the TV.

Press [OK] on the remote con-

trol or [OPEN/CLOSE] on the unit.

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "06FT0" is displayed on

the TV.

Press [OK] on the remote control

or [OPEN/CLOSE] on the unit.

Display in P-off mode. Press [POWER] key over than 10

Display following the then mode.

seconds.

While the unit is on, press and

hold [5], [9] and [R] on the remote

control at the same time for more

than 5 seconds.

-"70RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "81AIG" is displayed on the

TV.

Press [OK] on the remote control

or [OPEN/CLOSE] on the unit for at

least 3 seconds.

[ ] on the

[ ] on the

[ ] on the

[ ] on the

[ ] on the

20

Page 21

Item

Mode name Description

TV display Key operation

Demonstration

lock / unlock

Ejection of the disc is prohibited.

The lock setting is effective until unlocking the

tray and not released by Main unit initialization of service mode.

*When lock the tray.

"LOCK" is displayed for 3 seconds.

*When lock the tray.

"UNLOCK" is displayed for 3 seconds.

*When press [OPEN/CLOSE] key

while the tray being locked.

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "04PRG" is displayed on

the TV.

Press and hold [STOP] on the

remote control until "10OCL" is displayed on the TV.

Press [OK] on the remote con-

trol or [OPEN/CLOSE] on the unit.

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "04PRG" is displayed on

the TV.

Press and hold [STOP] on the

remote control until "10OCL" is displayed on the TV.

Press [OK] on the remote con-

trol or [OPEN/CLOSE] on the unit.

Press [OPEN/CLOSE] key while the

tray is being locked.

[ ] on the

[ ] on the

Display "LOCK" on the screen.

21

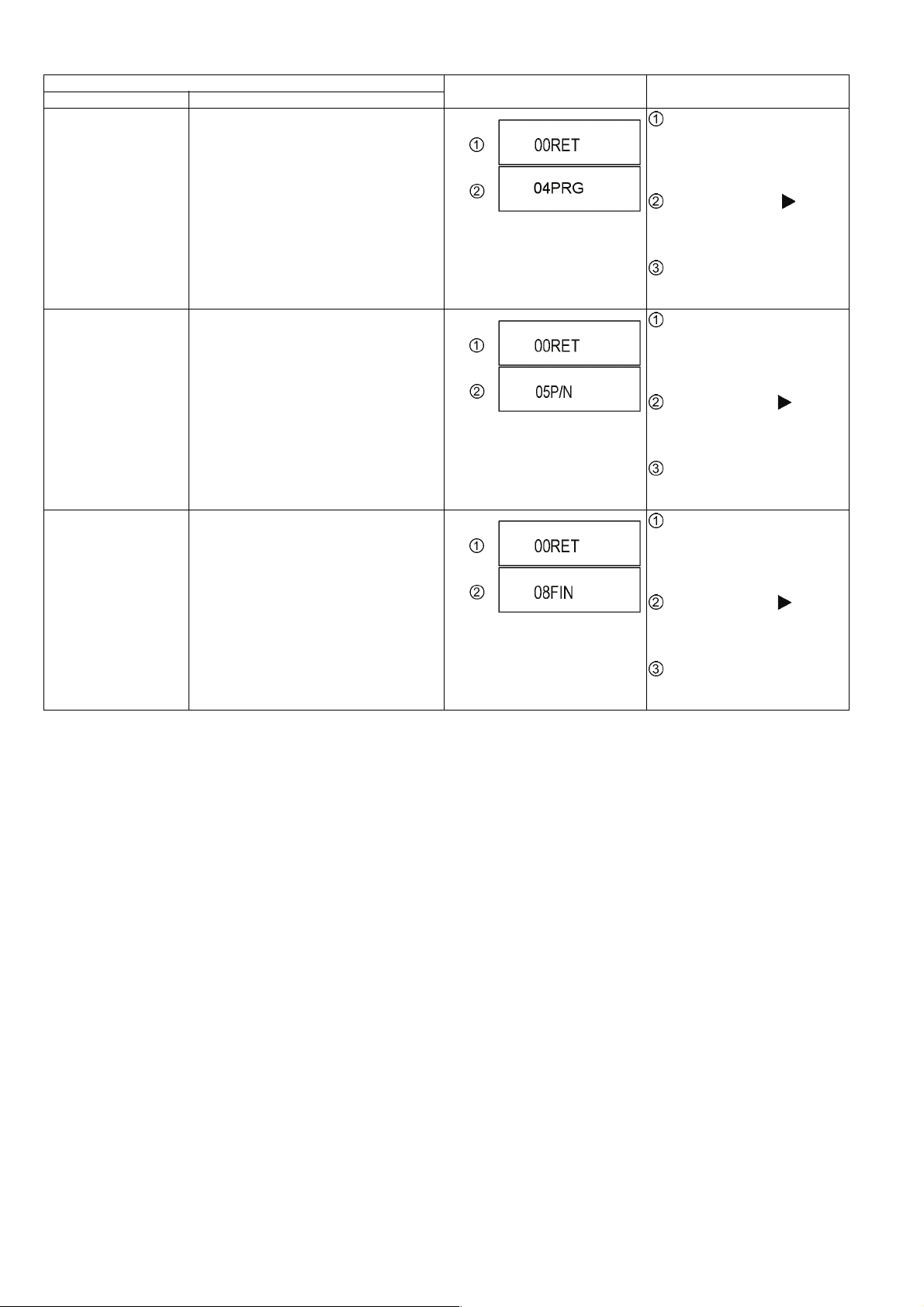

Page 22

Item

Mode name Description

Progressive initialization The progressive setting is initialized to inter-

lace.

PAL/NTSC switch The signal system is switched to PAL or

NTSC.

Default setting The date of Menu, Mode and EEPROM set-

ting, etc. is set to the default condition in factory.

TV display Key operation

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "04PRG" is displayed on

the TV.

Press and hold [OK] on the

remote control or [OPEN/CLOSE]

on the unit for at least 3 seconds.

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "05P/N" is displayed on the

TV.

Press and hold [OK] on the

remote control or [OPEN/CLOSE]

on the unit for at least 3 seconds.

While the unit is on, press and

hold [OK], [B] and [Y] on the remote

control at the same time for more

than 5 seconds.

-"00RET" is displayed on the TV.

Repeatedly press

remote control or [POWER] on the

unit until "08FIN" is displayed on the

TV.

Press and hold [OK] on the

remote control or [OPEN/CLOSE]

on the unit for at least 3 seconds.

[ ] on the

[ ] on the

[ ] on the

22

Page 23

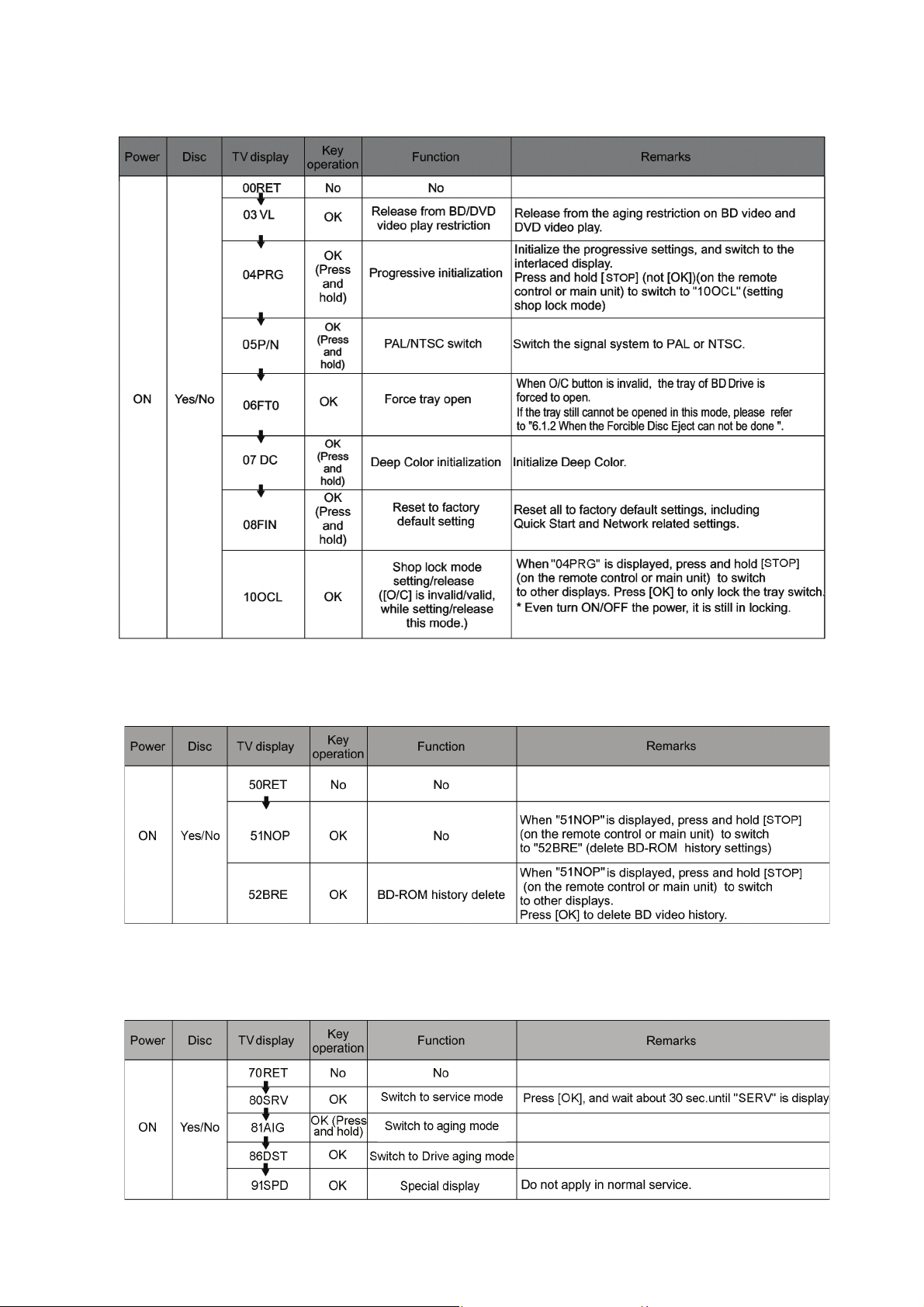

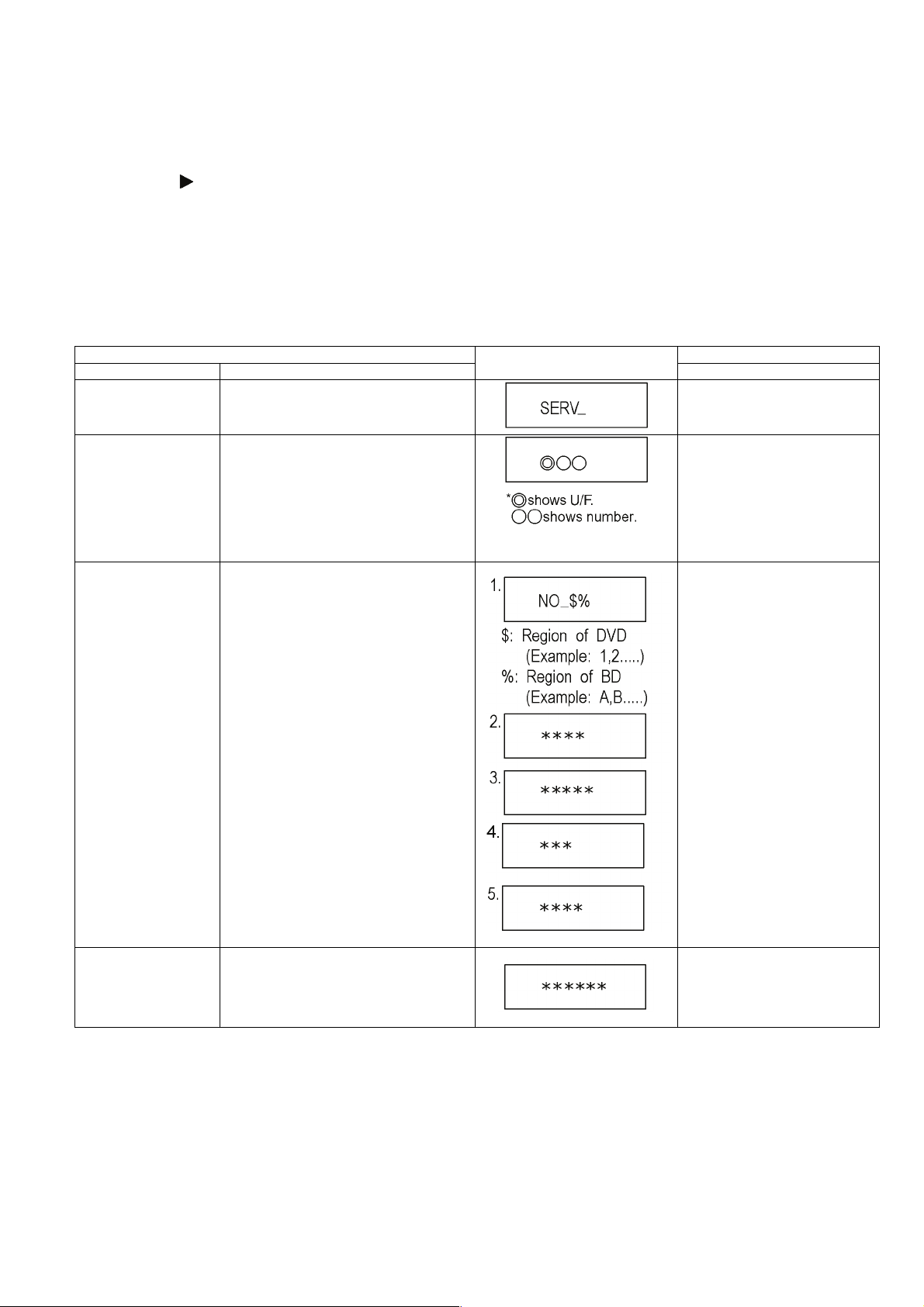

7.1.3. Service Mode at a glance

Information necessary for service can be displayed.

Service mode setting:

1. Turn the power on.

2. Press the [5] [9] and [R] button simultaneously for five seconds, then [70RET] is displayed on TV.

3. Press the

4. Press the [OK] button.

5. It is displayed on TV as [SERV]: It is shown to have entered the service mode.

6. The command is transmitted by attached remote control.

Method of making clear service mode: Press the power button (power off).

The display of information to each command is as follows.

NOTE:

Do not use it excluding the designated command.

[ ] button to select until [80SRV] is displayed on TV.

Item

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

Error Code Display Last Error Code of U/F held by Timer is dis-

played on TV.

*Details are described in

7.1.1. Self-Diagnosis Functions.

If any error history does not exist,

[F00] is displayed.

ROM Version Display The display contents are switched over every

5 seconds.

1. Region code

2. Main firm version

3. Boot View version

4. Timer firm version

5. Drive firm version

TV display

mode.

Press [0] [1] in service mode

Press [0] [2] in service mode

Key operation

Display Engineering

Adjusted Value

Displays the Engineering Adjusted Value. Press [0] [9] in service mode.

23

Page 24

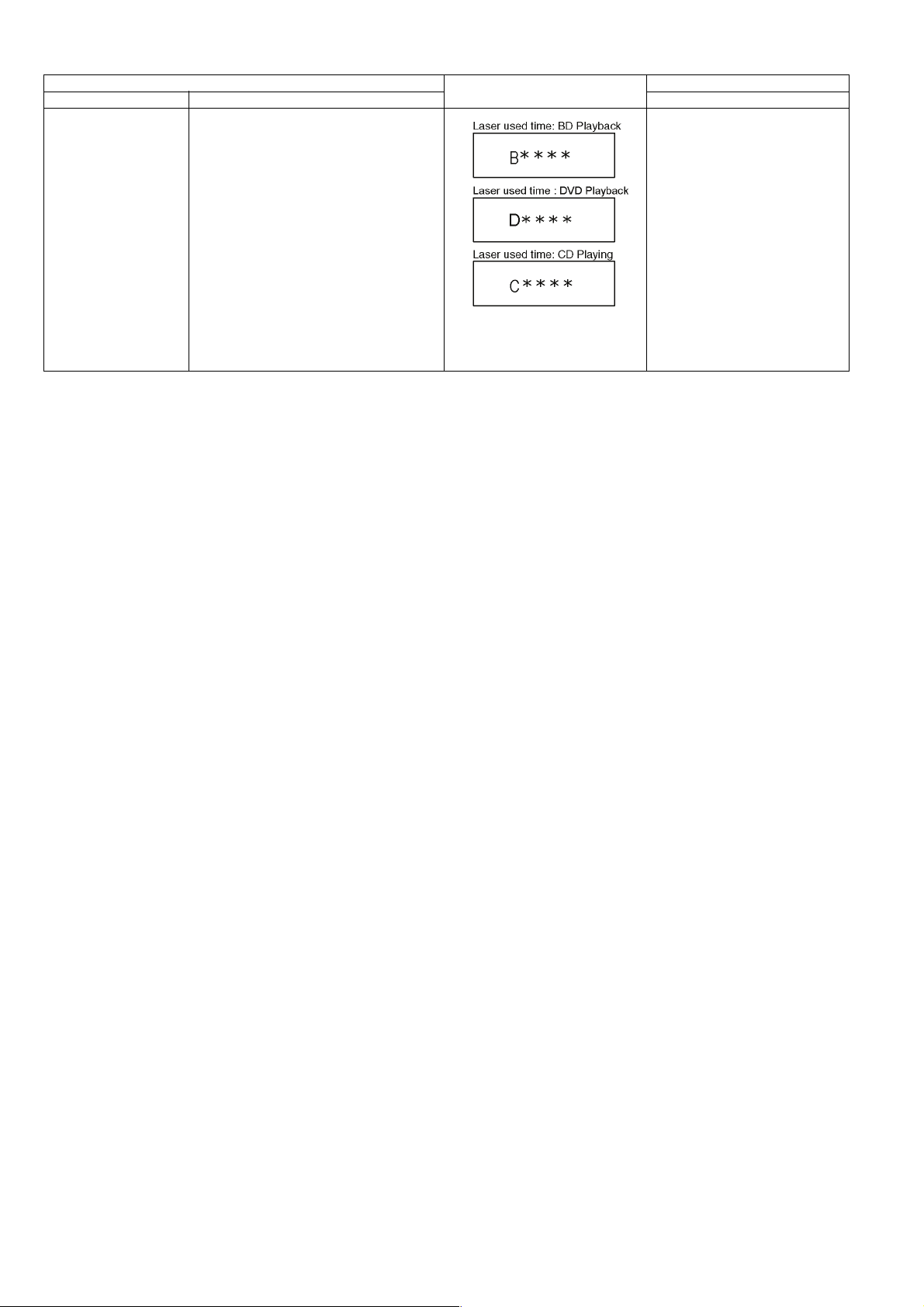

Item

Mode name Description (Remote controller key)

Laser Used Time

Indication

Check laser used time (hours) of drive.

(****) is the used time display in

hour. Laser used time of BD/DVD/

CD in Playback mode is counted.

TV display

Press [4] [1] in service mode.

Key operation

24

Page 25

Item

Mode name Description (Remote controller key)

BD Drive last error BD Drive error code display. 1. Error Number is displayed for 5

seconds.

2. Time when the error has occurred

is display for 5 seconds.

YY: Year

MM: Month

DD: Date

3. Last drive error (1/2) is displayed

for 5 seconds.

00 : Bad disc

03 : Bad disc

04 : Bad disc or drive malfunction

4. Last drive error (2/2) is displayed

for five seconds.

TV display

Press [4] [2] in service mode.

Key operation

5. Error occurring disc type is displayed for 5 seconds.

25

Page 26

Item

Mode name Description (Remote controller key)

TV display

Key operation

6. Disc maker ID is displayed for 5

seconds.

26

In case that the maker cannot be

identified, display is blackout.

Page 27

Item

Mode name Description (Remote controller key)

7. Factor of drive error (hexadecimal) occurring is left displayed.

TV display

Key operation

8. When the last error doesn't exist .

PD Balance Measuring the PD balance.

Formalize FE (0~99999)

FE symmetry (0~99999)

Number of reflection surface (0~2)

Measurements failure

CEC (H) Output The CEC terminal high output of HDMI. Press [5] [5] in service mode.

1.Insert the Panasonic BD-VIDEO

SL Disc(Ver 1.0/Ver 2.0) into the

tray.

(Incompatible with other media)

2.Press [4] [8].

27

Page 28

Item

Mode name Description (Remote controller key)

CEC (L) Output The CEC terminal low output of HDMI. Press [5] [6] in service mode.

TV display

Key operation

Manufacturing Date Read out the manufacturing date of the unit.

Save the error history to

USB storage device

Update Engineering

Adjusted value

The error and user operation history of the

remote control are saved to the USB storage

device.

NANDFlash is updated with the 6-figure input

value of a remote control.

YY: Year

MM: Month

DD: Date

The USB storage device cannot be

recognized

During saving

Save end

Press [6] [1] in service mode.

Press [6] [9] in service mode.

Press [7] [2] in service mode.

Tray OPEN/CLOSE Test The BD Drive tray is opened and closed

repeatedly.

Delete the Laser Used

Time

Laser used time information stored in the

memory of the unit is deleted.

Input the 6 digits adjust value, that

is in the Drive or OPU replacement

part,with the remote control's number keys in the service mode.

When register successful:

When register fail:

Press [9] [1] in service mode.

*When releasing this mode, pull out

AC cord.

"*" is number of open/ close cycle

times.

Press [9] [5] in service mode.

Delete the Last Drive

Error

Laser Drive Error information stored on the

BD Drive is deleted.

Press [9] [6] in service mode.

28

Page 29

Item

Mode name Description (Remote controller key)

Delete the Error History Error History information stored on the unit is

deleted.

TV display

Press [9] [7] in service mode.

Key operation

Initialization of Error code Last Error Code information stored by timer is

deleted. (Write in F00)

Initialization of the

Service Mode

Release Service Mode Release Service Mode and turns the Power

Last Drive Error, Error History and Error code

information stored on the unit are initialized to

factory setting.

Off.

Press [9] [8] in service mode.

Press [9] [9] in service mode.

Display in STOP (SS) mode. Press [POWER] button on the front

panel or Remote controller in service mode.

29

Page 30

8 Service Fixture & Tools

Part Number Description Pcs Compatibility

SVKZ000001 Lead Free Solder (0.3mm/100g Reel) New

SVKZ000002 Lead Free Solder (0.6mm/100g Reel) New

SVKZ000003 Lead Free Solder (1.0mm/100g Reel)) New

RFKZ0316 Solder Remover (Lead free low temperature Solder/50g) Same as BDT360 Series

RFKZ0328 Flux Same as BDT360 Series

* The above parts are supplied by AVC-CSC-SPC.

30

Page 31

9 Disassembly and Assembly Instructions

9.1. Unit

9.1.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

9.1.2. P.C.B. Positions

31

Page 32

9.1.3. Top Case

1. Remove the 3 Screws (A).

2. Slide the Top Case rearward and open the both ends at

rear side of the Top Case a little and lift the Top Case in

the direction of the arrows.

9.1.4. Front Panel Ass'y

9.1.4.1. Tray Top

1. Put deck so that bottom can be seen.

2. Insert the Paper clip, etc. into the hole on the bottom of

BD Drive and slide the Paper clips, etc. in the direction of

the arrow to eject tray slightly.

3. Unlock 2 tabs to remove the tray top from the tray section.

32

Page 33

9.1.4.2. Front Panel

1. Unlock 6 tabs (A)-(E) turn. Pull with the Front Panel in the

direction of your side.

NOTE:

1. The LED SHEET is easy to fall off when removing the

front panel, please be careful when disassembling.

9.1.5. BD Drive

1. Remove the OPU FFC, and isolate it with an ESD prevention bag (RPFC0114) to prevent the laser diode from

the ESD damage.

2. Remove the FFC(A), FFC(B), FFC(C).

3. Remove the 2 Screws (A), remove 2 tabs (B) of BD Drive

in the direction of the arrow, to remove BD Drive.

2. When installing the FUNCTION BUTTON, insert the front

half part of FUNCTION BUTTON into the front hole

obliquely, and then press down till claw, snaps in to place.

NOTE:

The metal side of the FFC(C) should be inserted in the

direction of the Front Panel during installation as shown.

33

Page 34

9.1.6. Digital and Operation P.C.B.

1. Remove the 2 Screws (A) to remove Digital and Operation P.C.B..

2. Desoldering the Digital P.C.B. end of solder joint, and

then removing the Operation P.C.B..

9.2. Drive Unit

9.2.1. Tray Unit

1. Insert the Paper clips, etc. into the hole of the bottom

side, and slide it to the direction of arrow until it can be.

2. Pull the Tray Unit to the direction of arrow until it can be.

NOTE:

After removing the digiboard and Front Panel, do not

bend the cable repeatedly shown in the illustration, in

case of breaking off.

3. Insert the paper clips, screw drivers, etc. to open the 2

tabs, and pull the Tray Unit.

34

Page 35

Notes when attaching the tray:

• Push Slide cam to the left side slightly, and make sure

the tray band is between the two posts of Slide cam

when attaching the tray.

3. Remove the Pulley Gear and Belt.

9.2.3. Slide Cam, Traverse Base

1. Perform the step "9. 2. 2. Pulley Gear, Belt".

2. Open the connector lock, and disconnect the FFC.

9.2.2. Pulley Gear, Belt

1. Perform the step "9. 2. 1. Tray Unit".

2. Push the Post to the direction of arrow by using the slotted screwdriver.

3. Turn over the drive unit then unlock the 2 tabs.

35

Page 36

4. Slide the FFC and remove it.

5. Slide the Slide Cam to right, then lift up the Traverse

base.

6. Remove the Traverse base with spreading the 2 hooks to

direction of arrows.

7. Slide the Slide Cam to right, then open the 2 tabs and

remove the Slide Cam.

9.2.4. Drive Gear and Loading Motor Unit

1. Perform the step "9. 2. 3. Slide Cam, Traverse Base".

2. Remove the Drive Gear.

3. Turn over the Drive Unit, then remove the Loading Motor

unit with spreading the 2 tabs.

36

Page 37

4. Pull out the SW FFC.

5. Push the tab to the direction of arrow by using the slotted

screwdriver and slide the SW Ass'y to remove.

37

Page 38

9.2.5. Grease

38

Page 39

9.3. Disassembly from the traverse unit, assembly of the optical pick-up unit, and precautions on ESD-preventive

9.3.1. Disassemly

1. Before removing the optical pick-up unit, please apply an

ESD prevention bag(RPFC0114) to the OPU FFC, and

weld the short-circuit solder.

a. Set the temperature of iron is 350°C.

b. When using the iron head,do not apply a force more

than 1N to the pad. Do not touch any other components around the welding spot.

c. Welding should be applied less than 3 seconds.

2. Remove the connector, and take out the OPU FFC.

4. Unlock 2 Damper Springs of the Screw Shaft side.

5. Slightly lift up the Drive Shaft (A) by the end, pull it out of

the Damper Spring, and remove the Drive Shaft (A) as

well as the Optical Pick-Up Unit with the Nut Piece Unit.

3. Slide the Middle Base horizontal and remove the Middle

Base from the Traverse Unit.

39

Page 40

6. Remove 1 screw (A), and remove the Nut Piece Unit.

9.3.2. Assembly

1. Attach the Nut Piece Unit sufficiently onto the Optical

pickup Unit, and tighten 1 screw (A).

NOTE:

1. In this action, finger stab needs to be put on. Do not

touch any parts other than the positions marked in the

Figure 1.

40

Page 41

2. After applying a small amount of lubricants to the both

ends of Drive Shaft (A), insert the Optical Pick-Up Unit

into the Drive Shaft (A), then insert them into shaft hole of

the base.

Attach the other side of Optical Pick-Up on the Drive

Shaft (B), then set 2 damper springs and lock the drive

shaft (A) to the base.

4. Insert FFC, and desolder the solder spot.

a. Use the iron head with an angle as shown in

Fig,remove the solder in the direction as shown.

b. Set the temperature of iron below 350° C.

c. When using the iron head,do not apply a force more

than 1N to the pad. Do not touch any other compo-

nents around the welding spot.

d. Welding should be applied less than 3 seconds.

Caution:

Do not stick any foreign bodies to the shaft duringassembly.

3. Attach the Middle Base to the traverse unit.

41

Page 42

9.3.3. How to Clean the Lens of Optical Pick-UP

After performing the step "9. 2. 3. Slide Cam, Traverse Base", clean the lens of the Optical Pick-UP.

42

Page 43

9.3.4. How to Clean up the Turntable

When "NoREAD" is displayed in TV display, after performing the step "9. 2. 3. Slide Cam, Traverse Base", clean up the Turntable

according to the following steps.

1. Blow the dust from the Turntable in the blower.

(Do not strongly blow it.)

2. Put one drop of isopropyl or ethyl alcohol to clean cotton swab.

(Using a fresh cotton swab does not use chemicals or additives.)

3. Using the cotton swab, wipe out the dust on the Turntable.

(Be careful not touching the surface of Turntable directly.)

43

Page 44

9.4. Adjustment of BD Drive

9.4.1. Repair Flowchart

44

Page 45

9.4.2. Adjustment

9.4.2.1. The adjustment value setting of Drive Unit/OPU replacement

1. Power ON

2. Press and hold [5] [9] [Red] button on the remote control concurrently for 5 sec.

3. Display "70RET"

4. Press

5. It reboots automatically.

6. Display "SERV" (Service Mode)

7. Input the number of 6 sdigits adjust value that is wrote on

8. Input [7] [2] in "SERV" then display "DQR" total 6 digits

9. It will be OK if "DQR OK"is displayed.

10. Input [0] [0],return to "SERV".

11. Input [0] [9],the adjustment value is confirmed.

[ ] button on the remote control then display "80SRV". Press [OK] button.

Drive Unit/OPU replacement part.

that is the adjustment value write-in state.

---The confirmation method ---

If the same as the inputted adjustment value of 6 digits, it

is write-in OK.

45

Page 46

9.4.2.2. The Drive Unit's adjustment value setting while Digital PCB/Drive replacement without 6-digit adjustment value.

1. Power ON

2. Press and hold [5] [9] [Red] button on the remote control concurrently for 5 sec.

3. Display "70RET"

4. Press

5. It reboots automatically.

6. Display "SERV" (Service Mode)

7. Input [7] [2] in "SERV" then display "DQR" that is the

8. Input the 6 digits "999999".

9. Take the Power OFF(Exit service mode)

10. Take the Power ON.

11. BD-VIDEO SL Disc

12. Repeat 1-6 procedures and then enter into service mode

13. Input [0] [9],the adjustment value is confirmed.

[ ] button on the remote control then display "80SRV". Press [OK] button.

adjustment value write-in mode.

"DQR OK"is displayed.

(The normal press disc product saled in market)

Play the disc then reproduction is carried out.

(Several seconds may be sufficient)

(Adjustment is completed by reproducing)

Reference:

(The confirmation method of 1 layer's BD Disc)

7. Operate the above-mentioned 1-6.

Insert the BD-VIDEO SL Disc.

(BD-R and BD-RE can't be used)

8. Input [4] [8] in "SERV"(Service Mode)

Display the following three kinds of content.

A

B

C1 OR C2 C1: 1 layer's Disc/C2: 2 layers' Disc

---The confirmation method ---

again.

9.4.2.3. In the Case of Necessity the Adjustment

1. When the OPU is replaced.

2. When the Drive unit is replaced.

3. When the Digital PCB is replaced.

46

Page 47

10 Measurements and Adjustments

10.1. Service Positions

NOTE:

For description of the disassembling procedure, see the section 9.

10.1.1. Checking and Repairing of BD Drive and Digital P.C.B.

47

Page 48

10.2. Caution for Replacing Parts

10.2.1. Items that should be done after replacing parts

Note 1:

About the details of updating firmware,please see the chapter 3.4. How to Update Firmware.

10.2.2. Standard Inspection Specifications after Making Repairs

After making repairs, we recommend performing the following inspection, to check normal operation.

No. Procedure Item to Check

1 Turn on the power, and confirm items pointed out. Items pointed out should reappear.

2 Insert RAM disc. The Panasonic RAM disc should be recognized.

3 Perform playback for one minute using the RAM disc. No abnormality should be seen in the picture, sound or operation.

*Panasonic DVD-RAM disc should be used when recording and

playback.

4 Perform playback for one minute using the BD-Video disc. No abnormality should be seen in the picture, sound or operation.

5 If a problem is caused by a BD-Video disc, VCD, DVD-R,

DVD-Video, Audio-CD, or MP3, playback the test disc.

6 After checking and making repairs, upgrade the firmware to the

latest version.

7 Transfer [9][9] in the service mode setting, and initialize the service

settings (return various settings and error information to their

default values. The laser time is not included in this initialization).

8 After replacing the Drive Unit, transfer [9][5] in the service mode

setting, and initialize the laser used time.

Use the following checklist to establish the judgement criteria for the picture and sound.

No abnormality should be seen in the picture, sound or operation.

Make sure that [FIN] appears in the TV displays.

*[NO UPD] display means the unit is already updated to

newest same version. Then version up is not necessary.

Make sure that [CLR] appears in the TV display.

After checking it, turn the power off.

Make sure that [CLR] appears on the FL display. After checking it,

turn the power off.

Item Contents Check Item Contents Check

Picture

Block noise

Crosscut noise Noise (static, background noise, etc.)

Dot noise The sound level is too low.

Picture disruption The sound level is too high.

Not bright enough The sound level changes.

Too bright

Flickering colour

Colour fading

Sound

Distorted sound

48

Page 49

11 Block Diagram

TRAVERSE MECHANISM UNIT

OPTIACL

PICK-UP

UNIT

X5001

IC8001

IC4001

SERVO CONTROLLER/

AV DECODER/

SYSTEM CONTROLLER

OPTICAL DISC CONTROLLER/

OVERALL BLOCK DIAGRAM

KEY

USB PORT

JK2001

LED

LASER DIODE

MOTOR DRIVE

FOCUS COIL

BEAM EXPANDER

TRACKING COIL

TRAVERSE

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

IC7201

ETHERNET

ISOLATION

TRANSFORMER

IC6001

ETHERNET

PORT

JK7201

NAND FLASH

ROM/2Gb

REMOTE

SENSOR

HDMI

JK5001

TERMINAL

)TUOV/A(

SDRAM

2Gb

IC4002

DMP-BDT166EG/EB

DMP-BDT165EG/EB/EF

11.1. Overall Block Diagram

49

Page 50

11.2. Digital P.C.B. Regulator Block Diagram

DIGITAL P.C.B. REGULATOR BLOCK DIAGRAM

PW_12V

PW_5V

(REG.5V)

IC3101

Vin

EN

1

8

SW

6

PW_1.5V

IC4002-VDDQ,VDD

(REG.1.5V)

IC3201

Vin

EN

1

8

SW

6

IC4001-

PW_1.2V

(REG.1.2V)

IC3301

Vin

EN

1

8

SW

6

JK3001

DDRVCCIO_01-09

IC4001-

B18

F16

A18 C7

,DVCC12_K

/

//

(REG.3.3V)

IC3501

Vin

EN

1

4

Vo

5

P_ON_H

IC3601-

FROM MTK

SECTION

(REG.3.3V)

IC3601

VDD

CE

1

4

Vout

3

(REG.5V)

IC3701

VI

EN

3

1

Vo

6

(REG.5V)

IC5001

VDD

CE

1

4

VOUT

3

PW_3.3V

STD_3.3V

(REG.3.3V)

IC3602

VDD

CD

1

2

OUT

4

USB_5V

IC3701-

4

IC4001-

V23

IC6001-

19

12

/

37

/

7

/

/

B19

/

E20

/

D10

/

A19

/

V22

P7001-

7

IC4001-

J20

/

G19

/

G21

/

N17

/

P17

/

R21

/

J21

B5

/

M19

IC4001-

P18

P7001-

4

JK5001-

HDMI_VCC

RESET

18

DMP-BDT166EG/EB

DMP-BDT165EG/EB/EF

3

50

Page 51

11.3. Digital (Back End Section) Block Diagram

IC4001

(MT8563)

DIGITAL BLOCK DIAGRAM

(BACK END SECTION)

HDMISCK

HDMISD

HTPLG

1

3

4

6

7

9

10

12

16

15

LB5001

LB5002

JK5001

HDMI JACK

TX2+

TX2TX1+

TX1-

TX0+

CLK+

TX0-

CLK-

HDMISDA

HDMISCL

13

CEC

19

HTPLG

CH2_P

CH2_M

CH1_P

CH1_M

CH0_P

CH0_M

CLK_P

CLK_M

CEC

F15

D15

C15

D16

B17

A17

B16

A16

B15

A15

B14

A14

S2002

POWER

GPIO3

R21

P2001P7001

8

OPEN/CLOSE_SW

S2001

GPIO0

N20

P2001P7001

6

P2001P7001

9

P21

IR

OPERATION P.C.B.

IR2001

JK2001

(USB PORT)

SENSOR

REMOTE CTL.

2

1

STD_3.3V

G_REMOCON

4

3

USB_DM_P1

2

USB_DP_P1

IC6001

(8bit NAND)

IC4002

DDR SDRAM

2Gbit

64M X 8bit NAND

FLASH MEMORY

IC4001-C:NFD0-7

IC4001-A: RDQ0-15, 1_RA0-13

DDR3_I/F

HOST I/F

J7

K7

CK

CK#

RCLK0

RCLK0_

JK7201

(ETHERNET PORT)

IC7201

(ETHERNET ISOLATION TRANSFORMER)

G23

TXVN_0

TXVP_0

H21

TXVP_1

H22

TXVN_1

1

2

3

6

1

3

6

8

16

14

11

9

RX-

RX+

TX-

TX+

RX-

RX+

TX-

TX+

RD-

RD+

TD-

TD+

1 VBUS

DM

DP

DM

USB_5V

DP

P2001

D2001

YELLOW GREEN

POWER

P7001

Q6001

LED DRIVE

5

N23

VSTB

2

3

G22

AB15

AC15

T21

T22

P2001

P2001

P2001

P7001

P7001

P7001

DMP-BDT166EG/EB

DMP-BDT165EG/EB/EF

51

Page 52

11.4. Digital (Front End Section) Block Diagram

IC4001

(OPTICAL DISC CONTROLLER)

RFIN

RFIP

INA

INB

INC

IND

INE

INF

ING

INH

VWDC2O

FEGIO4

FETRAYPWM

FEFMO

FEFMO2

SODC

G1

G2

A1

B2

B1

C3

D2

D3

C2

C3

C4

P1

P3

L6

L5

G_VWDC2O

FEGIO4

FETRAYPWM

FEFMO

FEFMO2

3.3V

IC8001

(MOTOR/PWM/DRIVER)

VLDDIN

21

SSZ

14

SCLK

15

SIMO

16

SIOV

SIMO

17

18

SIOV

SOMI_HIZ

LD

select

SPI I/F

Digital core

V/I

V/I

V/I

LDD_MSEL

LDD_AMODE

DAC

STP_ENA

TLT_ENA

DAC

PWM

DAC

PWM

DAC

PWM

DAC

PWM

F/B

F/B

ENDDET

V

pre-

driver

pre-

driver

V

pre-

driver

V

pre-

driver

PUMP2

PUMP2

PUMP2

V

PUMP2

V

DD

power

FET

DD

V

power

FET

STEP END

detection

V

DD

power

FET

V

DD

power

FET

ILDD_DVD

ILDD_CD

ILDD_BD

STP1+

STP1-

STP2+

STP2-

TLT+

TLT-

FCS+

FCS-

G_LDI_DVD

27

G_LDI_CD

26

G_LDI_BD

25

G_SA+

52

G_SA-

53

G_SB+

54

G_SB-

55

G_FO1+

36

G_FO1-

35

G_FO2+

39

G_FO2-

40

LD CONTROL SIGNAL

BEAM EXPANDER

OPTICAL PICK-UP/TRAVERSE

J8001

BD/DVD

RF SIGNAL

DVD FOCUS AND TRACKING SIGNAL

BD FOCUS AND TRACKING SIGNAL

CD MAIN AND SUB SIGNAL

LASER DIODE

DRIVE(LDD)

FOCUS/TRACKING ACTUATOR

LASER

DETECTOR

LASER

DETECTOR

LASER

DETECTOR

DVD

CD

BD

FO/TR

ACTUATOR

SPINDLE

MOTOR

RF SIGNALMOTOR DRIVE SIGNALTRACKING ERROR SIGNALFOCUS ERROR SIGNAL

FEGIO0

FEFG

V

PUMP2

V

M2

XRSTINFEGIO0

19

F/B

DAC

TRK_ENA

PWM

LOAD_ENA

F/B

RDY

power

13

monitor

P3.3V

P12V

P5V

DAC

PWM

SLD_ENA

SLD_ENA

DAC

PWM

SIOV

P4

FEFG

XFG

12

XSLEEP

SPM Logic

DAC PWM

ENDDET

F/B

ENDDET

F/B

pre-

driver

V

pre-

driver

V

pre-

driver

V

pre-

driver

V

pre-

driver

PUMP1

PUMP

PUMP1

PUMP1

DD

power

FET

V

DD

power

FET

TRAY Lock

detection

V

DD

power

FET

SLED END

detection

DD

V

power

FET

V

DD

power

FET

BEMF

detector

TRK+

TRK-

LOAD+

LOAD-

SLED1+

SLED1-

SLED2+

SLED2-

MCOM

G_TR+

37

G_TR-

38

29

30

G_LDM+

G_LDM-

J8003

J8003

1

2

LOADING

MOTOR

J8002

G_TRVA+

1

G_TRVA-

2

STEPPING

MOTOR

G_TRVB+

4

G_TRVB-

5

STEPPING MOTOR DRIVE

J8004

49

G_U

U

47

G_V

V

45

G_W

W

43

SPINDLE MOTOR DRIVE

DMP-BDT165EG/EB/EF

DMP-BDT166EG/EB

DIGITAL BLOCK DIAGRAM

(FRONT END SECTION)

52

Page 53

12 Wiring Connection Diagram

DIGITAL P.C.B.

BD DRIVE

OPERATION P.C.B.

J8001

JK3001

INTERCONNECTION SCHEMATIC DIAGRAM

F

E

D

1

C

B

A

98765432

40

39

38

37

36

45

44

43

42

41

35

34

33

32

31

30

29

28

27

26

25

24

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2

1

3

4

40

39

38

37

36

45

44

43

42

41

35

34

33

32

31

30

29

28

27

26

25

24

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2

1

3

4

J8004

2

1

3

4

2

1

3

4

P1102

5

6

7

8

9

2

1

3

4

GND1

TEMP

VCC(HFM)

LDI_CD

RF-

SWB2(BD)

SWB1(BD)

B

D

SA

C

A

SC

SD

SB

RF+

GND_CLSFT

SW3(BD)

GND_PD

GND1

LDI_BD

LDI_DVD

SEL_HFA_DVD

NC

GND1

SEL_HFA_CD

MON_CD/DVD

MON_BD

SEL_CD

SEL_DVD

VREF_PD

SW(DVD/CD)

VCC_+5PD

FCS1+

TRK-

FCS2+

TRK+

FCS2-

VCC_CLSFT

SIG_P0

BA-

B+

A+

FCS1-

GND1

TEMP

VCC(HFM)

LDI_CD

RF-

SWB2(BD)

SWB1(BD)

B

D

SA

C

A

SC

SD

SB

RF+

GND_CLSFT

SW3(BD)

GND_PD

GND1

LDI_BD

LDI_DVD

SEL_HFA_DVD

NC

GND1

SEL_HFA_CD

MON_CD/DVD

MON_BD

SEL_CD

SEL_DVD

VREF_PD

SW(DVD/CD)

VCC_+5PD

FCS1+

TRK-

FCS2+

TRK+

FCS2-

VCC_CLSFT

SIG_P0

BA-

B+

A+

FCS1-

TPIC_B-

TPIC_A+

TPIC_A+

TPIC_B+

J8002

2

1

3

4

5

2

1

3

4

5

TPIC_V

TPIC_U

TPIC_W

TPIC_COMMON

GND

J8003

2

1

3

4

5

2

1

3

4

5

GND

TRAYIN#

TPIC_LOAD

TRAYIN#

TPIC_LOAD+

TPIC_B-

TPIC_A+

TPIC_A+

TPIC_B+

TPIC_V

TPIC_U

TPIC_W

TPIC_COMMON

GND

GND

TRAYIN#

TPIC_LOAD

TRAYIN#

TPIC_LOAD+

DP

DM

USB_5V

GND

STD_3R3V

O/C_KEY

PW_LED

PW_KEY

REMOCON

DMP-BDT166EG/EB

DMP-BDT165EG/EB/EF

1

2

3

4

5

6

7

8

9

DP

DM

USB_5V

GND

STD_3R3V

O/C_KEY

PW_LED

PW_KEY

REMOCON

12.1. Interconnection Schematic Diagram

53

Page 54

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Schematic Diagram Notice

Page 55

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG PartList Notice

Page 56

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Abbreviation

Page 57

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG OPERATION SECTION(OPERATION P.C.B.)

Page 58

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG DIGITAL POWER SECTION(DIGITAL P.C.B.)

Page 59

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG FE SECTION(DIGITAL P.C.B.)

Page 60

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG FLASH POWER SECTION(DIGITAL P.C.B.)

Page 61

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG HDMI TX/PLL POWER SECTION(DIGITAL P.C.B.)

Page 62

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG DDR SECTION(DIGITAL P.C.B.)

Page 63

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG WiFi ETHER SECTION(DIGITAL P.C.B.)

Page 64

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG OPERATION P.C.B.(COMPONENT SIDE)

Page 65

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG OPERATION P.C.B.(FOIL SIDE)

Page 66

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG DIGITAL P.C.B.(COMPONENT SIDE)

Page 67

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG DIGITAL P.C.B.(FOIL SIDE)

Page 68

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

■ SEP0405AA OPERATION P.C.B. (RTL) E.S.D.

C2001 F1H1A105A143 10V 1U 1

D2001 B3AAA0001018 DIODE 1 E.S.D.

IR2001 PNJ4881M02VT REMOTE SENSOR 1

JK2001 K1FY104B0104 JACK USB 1

P2001 SEE0157 FFC 1

R2001 D0GD911JA052 1/8W 910 1

R2002 D0GB330JA065 1/16W 33 1

S2001 EVQ11A05R OPEN/CLOSE KEY 1

S2002 EVQ11A05R POWER KEY 1

ZA2001 K9ZZ00002324 EARTH PLATE 1

■ SUKB0404AGGT DIGITAL P.C.B. E.S.D. ADJ BDT165EG/BDT166EG

■ SUKB0404AGBT DIGITAL P.C.B. E.S.D. ADJ BDT166EB/BDT165EB

■ SUKB0404AGFT DIGITAL P.C.B. E.S.D. ADJ BDT165EF

C3001 F1H1E105A153 25V 1U 1

C3101 F1J1C106A269 16V 10U 1

C3102 F1H1A105A143 10V 1U 1

C3103 F1H0J1060006 6.3V 10U 1

C3104 F1G1E682A134 25V 6800P 1

C3105 F1H0J1060006 6.3V 10U 1

C3106 F1H1C104A209 16V 0.1U 1

C3201 F1J1C106A269 16V 10U 1

C3202 F1H1A105A143 10V 1U 1

C3203 F1J0J2260004 6.3V 22U 1

C3204 F1G1E682A134 25V 6800P 1

C3205 F1J0J2260004 6.3V 22U 1

C3206 F1H1C104A209 16V 0.1U 1

C3301 F1J1C106A269 16V 10U 1

C3302 F1H1A105A143 10V 1U 1

C3303 F1J0J2260004 6.3V 22U 1

C3304 F1G1E682A134 25V 6800P 1

C3305 F1J0J2260004 6.3V 22U 1

C3306 F1H1C104A209 16V 0.1U 1

C3501 F1J1A2250011 10V 2.2U 1

C3502 F1J1A2250011 10V 2.2U 1

C3503 F1G1C103A127 16V 0.01U 1

C3601 F1H1E223A050 25V 0.022U 1

C3602 F1H1A105A143 10V 1U 1

C3603 F1H1A105A143 10V 1U 1

C3604 F1H1C104A209 16V 0.1U 1

C3605 F1H1C104A209 16V 0.1U 1

C3701 F1J0J106A098 6.3V 10U 1

C3702 F1J0J106A098 6.3V 10U 1

C3801 F1H1A105A143 10V 1U 1

C4001 F1G0J105A030 6.3V 1U 1

C4002 F1G1C104A124 16V 0.1U 1

C4003 F1G1C104A124 16V 0.1U 1

C4004 F1G1C104A124 16V 0.1U 1

C4005 F1G1C104A124 16V 0.1U 1

C4006 F1G1C104A124 16V 0.1U 1

C4007 F1G0J105A030 6.3V 1U 1

C4008 F1G1C104A124 16V 0.1U 1

C4009 F1G1C104A124 16V 0.1U 1

C4010 F1G1C104A124 16V 0.1U 1

C4011 F1G1C104A124 16V 0.1U 1

C4012 F1J0J2260004 6.3V 22U 1

C4022 F1H1A4750004 10V 4.7U 1

C4024 F1G0J105A030 6.3V 1U 1

C4025 F1G1C104A124 16V 0.1U 1

C4026 F1G1C104A124 16V 0.1U 1

C4027 F1G1C104A124 16V 0.1U 1

C4028 F1G1C104A124 16V 0.1U 1

Part No. Part Name & Description Q'ty Remarks

Page 69

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

C4029 F1G1C104A124 16V 0.1U 1

C4030 F1G1C104A124 16V 0.1U 1

C4032 F1G1C104A124 16V 0.1U 1

C4033 F1G1C104A124 16V 0.1U 1

C4034 F1G1C104A124 16V 0.1U 1

C4035 F1G1C104A124 16V 0.1U 1

C4036 F1H0J1060006 6.3V 10U 1

C4037 F1G0J105A030 6.3V 1U 1

C4038 F1G1C104A124 16V 0.1U 1

C4039 F1G1C104A124 16V 0.1U 1

C4040 F1G1C104A124 16V 0.1U 1

C4041 F1G1C104A124 16V 0.1U 1

C4042 F1G1C104A124 16V 0.1U 1

C4043 F1G1C104A124 16V 0.1U 1

C4044 F1G1C104A124 16V 0.1U 1

C4045 F1H0J1060006 6.3V 10U 1

C4046 F1J0J2260004 6.3V 22U 1

C4047 F1G1C104A124 16V 0.1U 1

C4048 F1H1A4750004 10V 4.7U 1

C5003 F1G1C104A124 16V 0.1U 1

C5005 F1G1C104A124 16V 0.1U 1

C5006 F1H1A4750004 10V 4.7U 1

C5007 F1G0J105A030 6.3V 1U 1

C5008 F1G1C104A124 16V 0.1U 1

C5009 F1G0J4750005 6.3V 4.7U 1

C5011 F1G1H220A774 50V 22P 1

C5012 F1G1C104A124 16V 0.1U 1

C5013 F1G1H220A774 50V 22P 1

C5016 F1G1C104A124 16V 0.1U 1

C5017 F1G1C104A124 16V 0.1U 1

C5018 F1G0J105A030 6.3V 1U 1

C5019 F1G1C104A124 16V 0.1U 1

C5021 F1G1C104A124 16V 0.1U 1

C5022 F1G0J105A030 6.3V 1U 1

C5028 F1G1C104A124 16V 0.1U 1

C6002 F1G1C104A124 16V 0.1U 1

C6003 F1G0J105A030 6.3V 1U 1

C6004 F1G1C104A124 16V 0.1U 1

C6005 F1G1C104A124 16V 0.1U 1

C6006 F1G1C104A124 16V 0.1U 1

C6007 F1G0J105A030 6.3V 1U 1

C6012 F1G1C104A124 16V 0.1U 1

C6013 F1G1C104A124 16V 0.1U 1

C6014 F1G1C104A124 16V 0.1U 1

C6015 F1G1C104A124 16V 0.1U 1

C6016 F1G0J105A030 6.3V 1U 1

C6017 F1G1C104A124 16V 0.1U 1

C7201 F1G1C104A124 16V 0.1U 1

C7204 F1G1C104A124 16V 0.1U 1

C8001 F1J1A106A024 10V 10U 1

C8002 F1H0J225A085 6.3V 2.2U 1

C8003 F1H1A4750004 10V 4.7U 1

C8004 F1G1A104A058 10V 0.1U 1

C8005 F1H1A4750004 10V 4.7U 1

C8006 F1G1E102A134 25V 0.001U 1

C8008 F1J1A106A024 10V 10U 1

C8009 F1H0J225A085 6.3V 2.2U 1

C8010 F1G1C104A124 16V 0.1U 1

C8011 F1G1C104A124 16V 0.1U 1

C8014 F1G1A104A058 10V 0.1U 1

C8023 F1G1E1040001 25V 0.1U 1

C8024 F1J1A106A145 10V 10U 1

Part No. Part Name & Description Q'ty Remarks

Page 70

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

C8026 F1K1E1060001 25V 10U 1

C8027 F1G1E1040001 25V 0.1U 1

C8029 F1G1E1040001 25V 0.1U 1

C8030 F1G1E1040001 25V 0.1U 1

C8031 F1G1E102A134 25V 0.001U 1

C8032 F1G1E102A134 25V 0.001U 1

C8034 F1G1A104A058 10V 0.1U 1

C8036 F1J0J2260004 6.3V 22U 1

C8037 F2G0J221A065 6.3V 220U 1

C8038 F1G1E1040001 25V 0.1U 1

C8039 F1G1E102A134 25V 0.001U 1

C8040 F1G1C104A124 16V 0.1U 1

C8041 F1G1E102A134 25V 0.001U 1

C8044 F1G0J105A030 6.3V 1U 1

C8045 F1G1A104A058 10V 0.1U 1

C8047 F1K1E1060001 25V 10U 1

C8048 F1G1E1040001 25V 10U 1

C8049 F2G1E470A066 25V 47U 1

C8051 F1G1E1040001 25V 0.1U 1

C8052 F1G1E1040001 25V 0.1U 1

C8053 F1J1A106A024 10V 10U 1

C8054 F1G1C104A124 16V 0.1U 1

C8055 F1G1A104A058 10V 0.1U 1

C8056 F1H1H682B153 50V 0.0068U 1

C8057 F1G1E103A134 25V 0.01U 1

C8058 F1G1E103A134 25V 0.01U 1

C8065 F1G1E102A134 25V 0.001U 1

C8066 F1J1C106A269 16V 10U 1

C8068 F1K1E105A029 25V 1U 1

C8069 F1K1E1060001 25V 10U 1

C8070 F1G1A104A058 10V 0.1U 1

C8078 F1H1A225A051 10V 2.2U 1

C8079 F1J1C106A269 16V 10U 1

C8080 F1J1C106A269 16V 10U 1

FB8000 G1C100KA0101 COIL 1

FB8001 G1C100KA0101 COIL 1

FB8002 G1C220MA0291 COIL 1

FB8003 J0JYC0000743 COIL 1

FB8004 J0JYC0000743 COIL 1

IC3101 C0DBAYY02083 IC 1 E.S.D.

IC3201 C0DBAYY02083 IC 1 E.S.D.

IC3301 C0DBAYY02083 IC 1 E.S.D.

IC3501 C0DBGYY03592 IC 1 E.S.D.

IC3601 C0DBGYY03975 IC 1 E.S.D.

IC3602 C0EBY0000679 IC 1 E.S.D.

IC3701 C0DBZYY00723 IC 1 E.S.D.

IC4001 SUKB0404AGGT IC 1 E.S.D. ADJ BDT165EG/BDT166EG

IC4001 SUKB0404AGBT IC 1 E.S.D. ADJ BDT166EB/BDT165EB

IC4001 SUKB0404AGFT IC 1 E.S.D. ADJ BDT165EF

IC4002 C3ABVY000026 IC 1 E.S.D.

IC5001 C0DBGYY03992 IC 1 E.S.D.

IC6001 SUKB0404AGGT IC 1 E.S.D. ADJ BDT165EG/BDT166EG

IC6001 SUKB0404AGBT IC 1 E.S.D. ADJ BDT166EB/BDT165EB

IC6001 SUKB0404AGFT IC 1 E.S.D. ADJ BDT165EF

IC7201 G5BYC0000040 IC 1 E.S.D.

IC8001 C0GBY0000130 IC 1 E.S.D.

IC8002 C0DBGYY02449 IC 1 E.S.D.

IP3001 K5H252Z00003 SURFACE MOUNTING FUSE 1

J8001 K1MY45AA0310 CONNECTOR(45P) 1

J8002 K1MN05AA0046 CONNECTOR(5P) 1

J8003 K1MN05AA0046 CONNECTOR(5P) 1

J8004 K1MN04AA0046 CONNECTOR(4P) 1

Part No. Part Name & Description Q'ty Remarks

Page 71

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

JK3001 K2EDYB000005 JACK DC 1

JK5001 K1FY119E0067 JACK HDMI 1

JK7201 K2LC108E0016 JACK LAN 1

L3101 G1C4R7MA0654 COIL 1

L3201 G1C3R3ZA0367 COIL 1

L3301 G1C3R3ZA0367 COIL 1

LB5001 J0ZZB0000194 COIL 1

LB5002 J0ZZB0000194 COIL 1

LB5003 J0JCC0000287 COIL 1

P5002 K1KY06AA1485 CONNECTOR(6P) 1

Q3801 B1CHRD000092 TRANSISTOR 1 E.S.D.

Q5001 B1GBCFJN0039 TRANSISTOR 1 E.S.D.

Q6001 B1GDCFEJ0010 TRANSISTOR 1 E.S.D.

QR3801 B1GBCFNN0041 TRANSISTOR 1 E.S.D.

R3101 D0GB220JA065 1/16W 22 1

R3102 D1BA1203A022 1/32W 120K 1

R3103 D1BA2202A022 1/32W 22K 1

R3104 D1BA1801A022 1/32W 1.8K 1

R3105 D0GA103JA023 1/16W 10K 1

R3201 D0GB220JA065 1/16W 22 1

R3202 D1BA2202A022 1/32W 22K 1

R3203 D1BA2202A022 1/32W 22K 1

R3301 D1BA2202A022 1/32W 22K 1

R3302 D0GB470JA065 1/10W 47 1

R3303 D1BA1002A022 1/32W 10K 1

R3304 D1BA2701A022 1/16W 2.7K 1

R3601 D0GA103JA023 1/16W 10K 1

R3701 D0GA474JA023 1/16W 470K 1

R3702 D0GA183JA023 1/16W 18K 1

R3703 D0GBR00J0004 1/16W 0 1

R3704 D0GA103JA023 1/16W 10K 1

R3705 D0GA103JA023 1/16W 10K 1

R3801 D0GA473JA023 1/16W 47K 1

R3802 D0GA103JA023 1/16W 10K 1

R3803 D0GDR00J0004 1/8W 0 1

R4001 D0GAR00J0005 1/16W 0 1

R4004 D1BA4992A022 1/32W 49.9K 1

R4006 D0GA241JA023 1/16W 240 1

R4007 D1BA4992A022 1/32W 49.9K 1

R4011 D0GAR00J0005 1/16W 0 1

R4015 D1BA1001A022 1/32W 1K 1

R4016 D1BA1000A022 1/32W 100 1

R4018 D1BA1001A022 1/32W 1K 1

R4019 D1BA1200A022 1/32W 120K 1

R4020 D1BA1001A022 1/32W 1K 1

R4021 D0GAR00J0005 1/16W 0 1

R4023 ERJ2RKD510X 1/16W 51 1

R5001 D0GA105JA023 1/16W 1000K 1

R5002 D0GA100JA023 1/16W 10 1

R5004 D0GA182JA023 1/16W 1.8K 1

R5005 D0GA182JA023 1/16W 1.8K 1

R5006 D0GAR00J0005 1/16W 0 1

R5010 D0GA103JA023 1/16W 10K 1

R5011 D0GA103JA023 1/16W 10K 1

R5013 D0GA472JA023 1/16W 4.7K 1

R5016 D0GA472JA023 1/16W 4.7K 1

R5019 D0GA330JA023 1/16W 33 1

R5029 D0GA103JA023 1/16W 10K 1

R5030 D0GA103JA023 1/16W 10K 1

R5031 D0GA103JA023 1/16W 10K 1

R5032 D0GA103JA023 1/16W 10K 1

R5033 D0GA182JA023 1/16W 1.8K 1

Part No. Part Name & Description Q'ty Remarks

Page 72

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

R5034 D0GA103JA023 1/16W 10K 1

R6001 D1BA5101A022 1/16W 5.1K 1

R6002 D1BA5101A022 1/16W 5.1K 1

R6003 D1BA2402A022 1/32W 24K 1

R6004 D0GA472JA023 1/16W 4.7K 1

R6005 D0GAR00J0005 1/16W 0 1

R6006 D0GA472JA023 1/16W 4.7K 1

R6008 D0GA103JA023 1/16W 10K 1

R6009 D0GA103JA023 1/16W 10K 1

R6010 D0GA103JA023 1/16W 10K 1

R6011 D1BA5101A022 1/16W 5.1K 1

R6012 D0GA103JA023 1/16W 10K 1

R6013 D0GA153JA023 1/16W 15K 1

R6014 D0GA153JA023 1/16W 15K 1

R6015 D0GA153JA023 1/16W 15K 1

R6016 D0GA153JA023 1/16W 15K 1

R6017 D0GA103JA023 1/16W 10K 1

R7201 D0GA750JA023 1/16W 75 1

R7202 D0GA750JA023 1/16W 75 1

R7203 D0GA750JA023 1/16W 75 1

R7204 D0GA750JA023 1/16W 75 1

R8002 D0GA121JA023 1/16W 120 1

R8004 D0GA121JA023 1/16W 120 1

R8005 D0GA121JA023 1/16W 120 1

R8013 D0GFR39ZA043 1/2W 0.39 1

R8014 D0GA103JA023 1/16W 10K 1

R8015 D0GFR39ZA043 1/2W 0.39 1

R8019 D0GA103JA023 1/16W 10K 1

R8023 D0GB913JA065 1/10W 91K 1

RX8000 D1H81024A042 RESISTOR-RESISTOR 1

X5001 H0J270500185 OSCILLATOR 1

Part No. Part Name & Description Q'ty Remarks

Page 73

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Exploded View

Page 74

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Mechanism View

Page 75

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Packing View

Page 76

Model No. : DMP-BDT165EB/DMP-BDT165EF/DMP-BDT165EG/DMP-BDT166EB/DMPBDT166EG Parts List

Change Safety

Ref.

No.

1 SXY0013T BD DRIVE 1 ADJ

2 SEP0405AA OPERATION P.C.B. 1 (RTL) E.S.D.

3 SUKB0404AGGT DIGITAL P.C.B. 1 E.S.D. ADJ BDT165EG/BDT166EG