Panasonic CS-V9BKPG, CU-2V14BKP5G, CU-2V18BKP5G, CU-3V20BKP5G, CS-V7BKPG Service Manual

...

Order No. MAC0205021C2

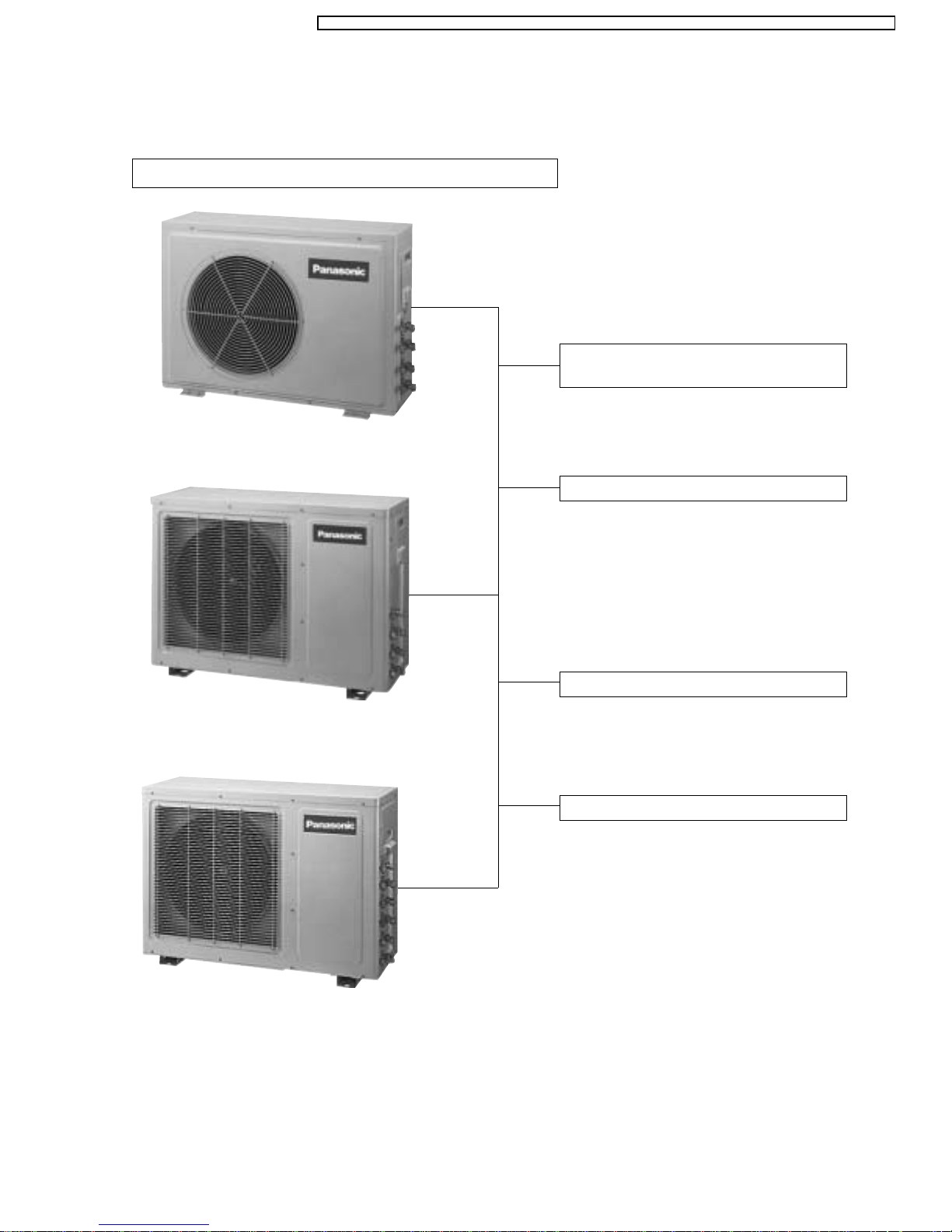

Multi-Split Air Conditioner

CS-V9BKPG CU-2V14BKP5G

CS-V9BKPG CU-2V18BKP5G

CS-V9BKPG CU-3V20BKP5G

CS-V7BKPG CU-2V19BKP5G

CS-V12BKPG

CONTENTS

Page Page

1 Features 2

2 Functions

3 Product Specifications

4 Dimensions

5 Refrigeration Cycle Diagram

6 Block Diagram

7 Wiring Diagram

8 Operation Details

9 Operating Instructions

10 Installation Instructions

11 Installation and Servicing Air Conditioner Using R410A 49

3

12 Servicing Information

6

13 Troubleshooting Guide

14

14 Technical Data

16

15 Exploded View

18

16 Replacement Parts List

22

17 Exploded View

26

18 Replacement Parts List

34

19 Exploded View

39

20 Replacement Parts List

© 2002 Matsushita Industrial Corp. Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

60

64

66

72

73

74

75

76

77

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

21 Exploded View 78

22 Replacement Parts List

23 Exploded View

79

80

1 Features

• High Efficiency

• Compact Design

• Comfort Environment

− 8 hours of sleep mode operation

− Air filter with function to reduce dust and smoke

− Wider range of horizontal discharge air

• Auto Restart

− Random auto restart after power failure for safety restart

operation

• Removable and Washable Front Panel

• Remote Control Self-illuminating Button

24 Replacement Parts List 81

25 Electronic Parts List

26 Electronic Circuit Diagram

82

83

• Quality Improvement

− Gas leakage protection

− Prevent compressor reverse cycle

− 2-stage OLP to protect compressor

− Noise prevention during soft dry operation.

− Anti-dew Formation Control (Cooling & Soft Dry)

• Operation Improvement

− Economy mode to reduce electrical power consumption

− Powerful mode to reach the desired room temperature

quickly

• Long Installation Piping

− Long piping up to 15 meter

• 24-hour Timer Setting

• Catechin Air Purifying Filter

− Trap dust, tobacco smoke and tiny particles

− Prevent the growth of bacteria and viruses trapped

• Solar Refreshing Deodorizing Filter

− Remove unpleasant odour from the air

• Environmental Friendly

− R410A, which does not contain chlorine, is used as its

refrigerant, so there is no danger of damage to the

ozone layer in stratosphere.

2

2 Functions

Remote Control

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Self illuminating

button

OFF / ON I

MODE

FAN SPEED

AIR SWING

POWERFUL

Operation OFF / ON

Operation Mode Selection

•

AUTO

•

COOL

•

DRY

•

FAN

Automatic Operation Mode

Cooling Operation Mode

Soft Dry Operation Mode

Air Circulation Mode

Indoor Fan Speed Selection

•

FAN

•

FAN

•

FAN

•

AUTO

FAN

Low Fan Speed

Medium Fan Speed

High Fan Speed

Automatic Fan Speed

Vertical Airflow Direction Control

•

AUTO

Automatic Vertical Airflow

Direction Control

•

MANUAL

Vertical Airflow Direction

Manual Control (5 stages of

adjustment)

Powerful Mode Operation OFF/ON

TEMP.

ON-TIMER

OFF-TIMER

TIME

SET

CANCEL

CLOCK

Room Temperature Setting

Cooling, Soft Dry, Air Circulation Operation.

• Temperature Setting (16°C to 30°C)

Automatic Operation

•

Operation with 2°C higher than

standard temperature.

• Operation with standard temperature.

•

Operation with 2°C lower than

standard temperature.

Timer Operation Selection

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

Timer Operation Set / Cancel

• ON Timer and OFF Timer setting and

cancellation.

Clock Setting

• Current time setting.

ECONOMY

Economy Mode Operation OFF/ON

3

SLEEP

Sleep Mode Operation OFF / ON

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Indoor Unit

AUTO

OFF / ON

Automatic Operation Button

• Press for < 5s to operate Automatic

operation mode.

(Used when the remote control cannot be used.)

• Press continuously for 5s or < 10s to

operate Test Run/Pump down. “Beep”

sound will be heard at the 5th second.

(Used when test running or servicing.)

• Press continuously for 10s and above to

omit or resume the remote control signal

receiving sound. “Beep, beep” sound will

be heard at the 10th second.

Random Auto Restart Control

• Operation is restarted randomly after

power failure at previous setting mode.

Anti-Freezing Control

• Anti-Freezing control for indoor heat

exchanger. (Cooling and Soft Dry)

Sleep Mode Auto Control

• Indoor Fan operates at Low speed.

• Operation stops after 8 hours.

Operation Indication Lamps (LED)

•

POWER

(Green) ........ Lights up in operation,

blinks in Automatic

Operation Mode

judging.

•

SLEEP

(Orange) ........ Lights up in Sleep

Mode Operation.

•

TIMER

(Orange) ....... Lights up in Timer

Setting.

•

POWERFUL

(Orange) .. Lights up in Powerful

Mode Operation.

•

ECONOMY

(Green) ..... Lights up in Economy

Mode Operation.

Operation Mode

• Cooling, Soft Dry, Air Circulation and

Automatic Mode.

Powerful Operation

• Reaches the desired room temperature

quickly.

Economy Operation

• To reduce electrical power consumption.

Indoor Fan Speed Control

• High, Medium and Low.

• Automatic Fan Speed Mode

– Cooling : Fan rotates at Hi, Me and

SLo speed. Deodorizing

control is available.

– Soft Dry: Fan rotates at SLo speed.

Deodorizing control

is available.

Airflow Direction Control

• Automatic air swing and manual adjusted

by remote control for vertical airflow.

Manually adjusted by hand for horizontal airflow.

•

Starting Current Control

• Fan motor is delayed for 1.6 seconds

when compressor starts simultaneously.

Time Delay Safety Control

•

Restarting is inhibited for appro. 3 minutes.

7 Minutes Time Save Control

• Cooling Operation only.

Anti-Dew Formation Control

• Anti-Dew Formation Control for indoor

unit discharge area.

4

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Outdoor Unit

CU-2V14BK, CU-2V18BK, CU-2V19BK & CU-3V20BK

Compressor Reverse Rotation

Protection Control

• To protect compressor from reverse

rotation when there is a instantaneous

power failure.

Overload Protector

• 2-Stage OLP to protect the compressor.

Overload Protector will trip when

– Temperature of compressor increases

to 120°C.

– High temperature or high current flows

to compressor.

(Refer circuit diagram for OLP

characteristic)

60 Secs. Forced Operation Control

• Once the compressor is activated, it

does not stop within the first 60 secs.

However, it stops immediately with

remote control stop signal.

Outdoor Fan Operation Control

• Temperature Fuse.

5

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

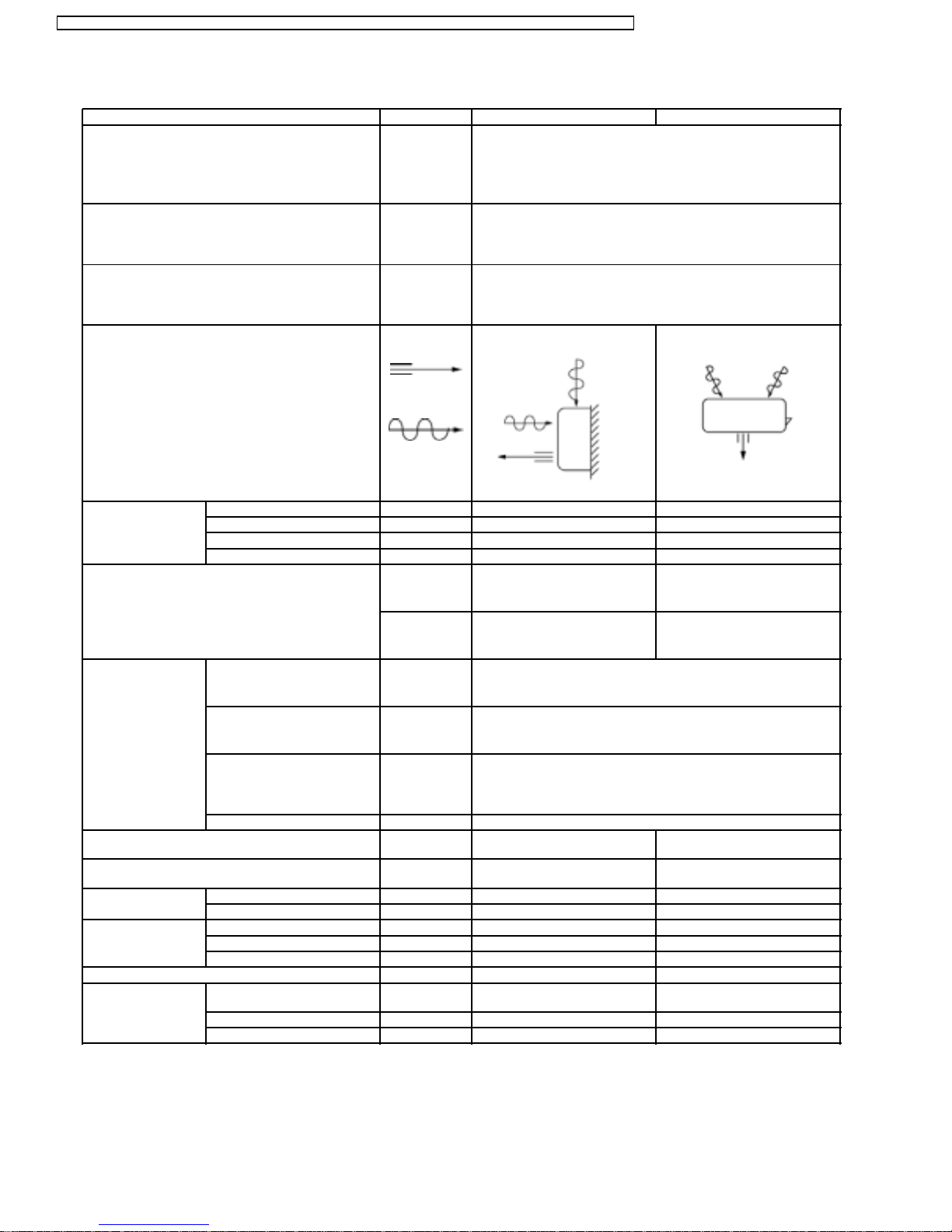

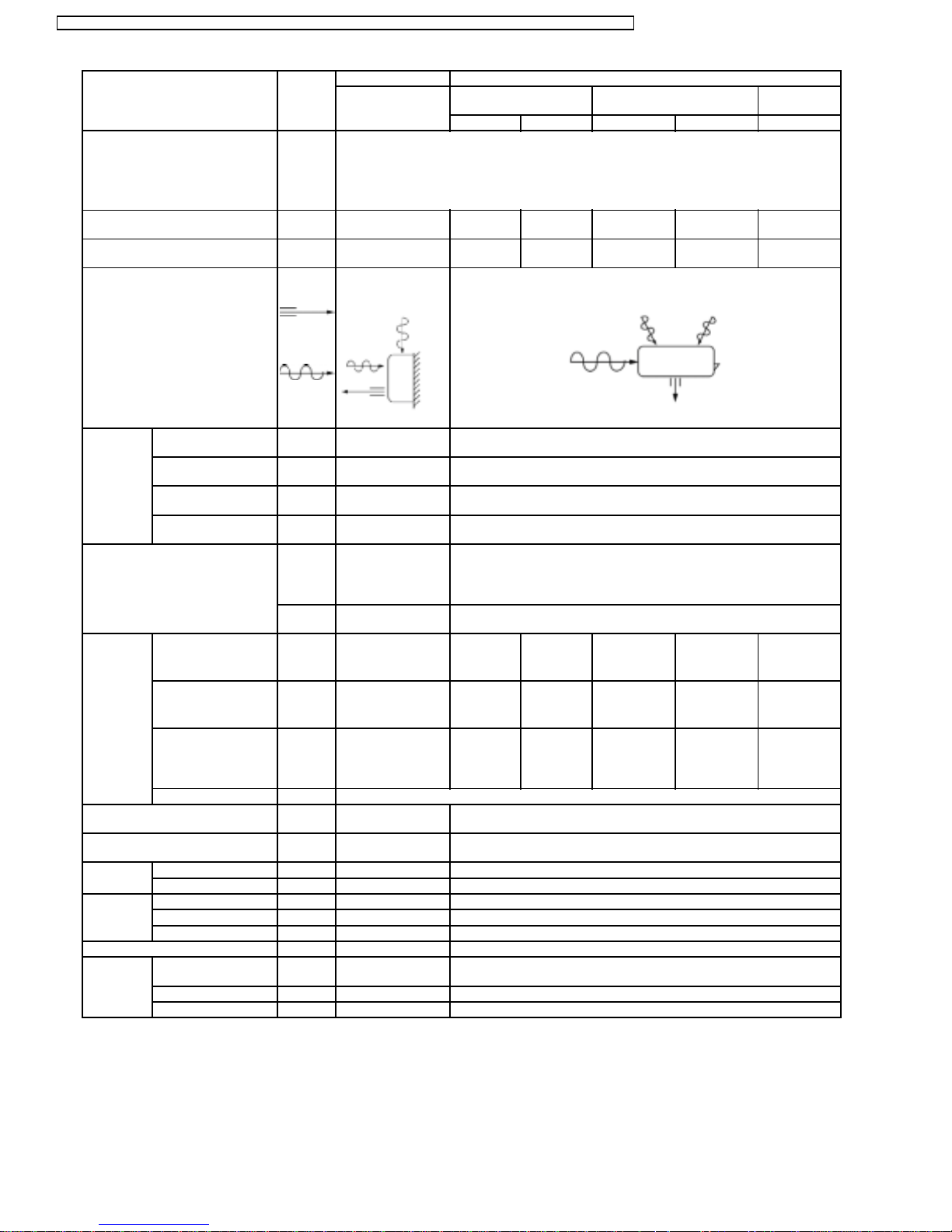

3 Product Specifications

Unit CS-V9BKPG CU-2V14BKP5G

Power Source Phase Single

V 230

Cycle 50

Cooling Capacity kW

kcal/h

Moisture Removal l/h

Pint/h

Airflow Method OUTLET

INTAKE

Air Volume Indoor Air (Lo) m3/min (cfm) 6.8 (240) —

Indoor Air (Me) m3/min (cfm) 8.0 (280) —

Indoor Air (Hi) m3/min (cfm) 9.9 (350) —

Indoor Air (SHi) m3/min (cfm) 10.9 (380) —

Noise Level dB (A) High 36, Low 26 High 47

Power level dB High 49 High 62

(1 unit) 3.00

2,580

(1 unit) 1.7

3.6

SIDE VIEW TOP VIEW

(2 units) 3.70

(2 units) 2.2

3,180

4.6

Electrical Data Input W (1 unit) 1,180 (2 units) 1,240

Running Current A (1 unit) 5.3 (2 units) 5.6

EER W/W

Starting Current A 17.8

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Dimensions Height inch (mm) 10 - 13/16 (275) 21 - 1/4 (540)

Net Weight lb (kg) 20 (9.0) 75 (34.0)

Compressor Type — Rota r y (1 cylinder)

Inner diameter mm 12 —

Length m 0.7 —

Width inch (mm) 31 - 15/32 (799) 29 - 15/16 (760)

Depth inch (mm) 8 - 9/32 (210) 9 - 7/8 (250)

Motor Type — Induction (2-poles)

Rated Output W — 830

kcal/hW

inch

inch

inch

inch

(1 unit) 2.54

2.19

G ; Half Union 3/8”

L ; Half Union 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

(2 units) 2.98

2.56

G ; 3-way valve 3/8”

L ; 3-way valve 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

rolling piston type

6

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 20% AS + Glass Fiber 20%

Motor Type Induction (4-poles) Induction (6-poles)

Input W 29.3 39.4

Rated Output W 15 15

Fan Speed Low rpm 800 —

Medium rpm 940 —

High rpm 1,160 795

SuperHigh rpm 1,250 —

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Louver Fin

Row / Stage (Plate fin configuration, forced draft)

2×15 1×20

FPI 19 17

Size (W × H × L) mm 610 × 315 × 25.4 687 × 508 × 22

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS M60

Refrigerant (R410A) g(oz) — 970 (34.2)

Thermostat Electronic Control —

Protection Device — Overload Protector

Capillary Tube Length mm — 615

Flow Rate l/min — 14.4

Inner Diameter mm — 1.6

Air Filter Material

Style

Capacity Control Capillary Tube

Compressor Capacitor µF, VAC — 35 µF, 400 VAC

Fan Motor Capacitor µF, VAC 1.5 µF, 400 VAC 1.0 µF, 430 VAC

(c.c) P.P.

Honeycomb

(330)

—

• Specifications are subject to change without notice for further improvement.

7

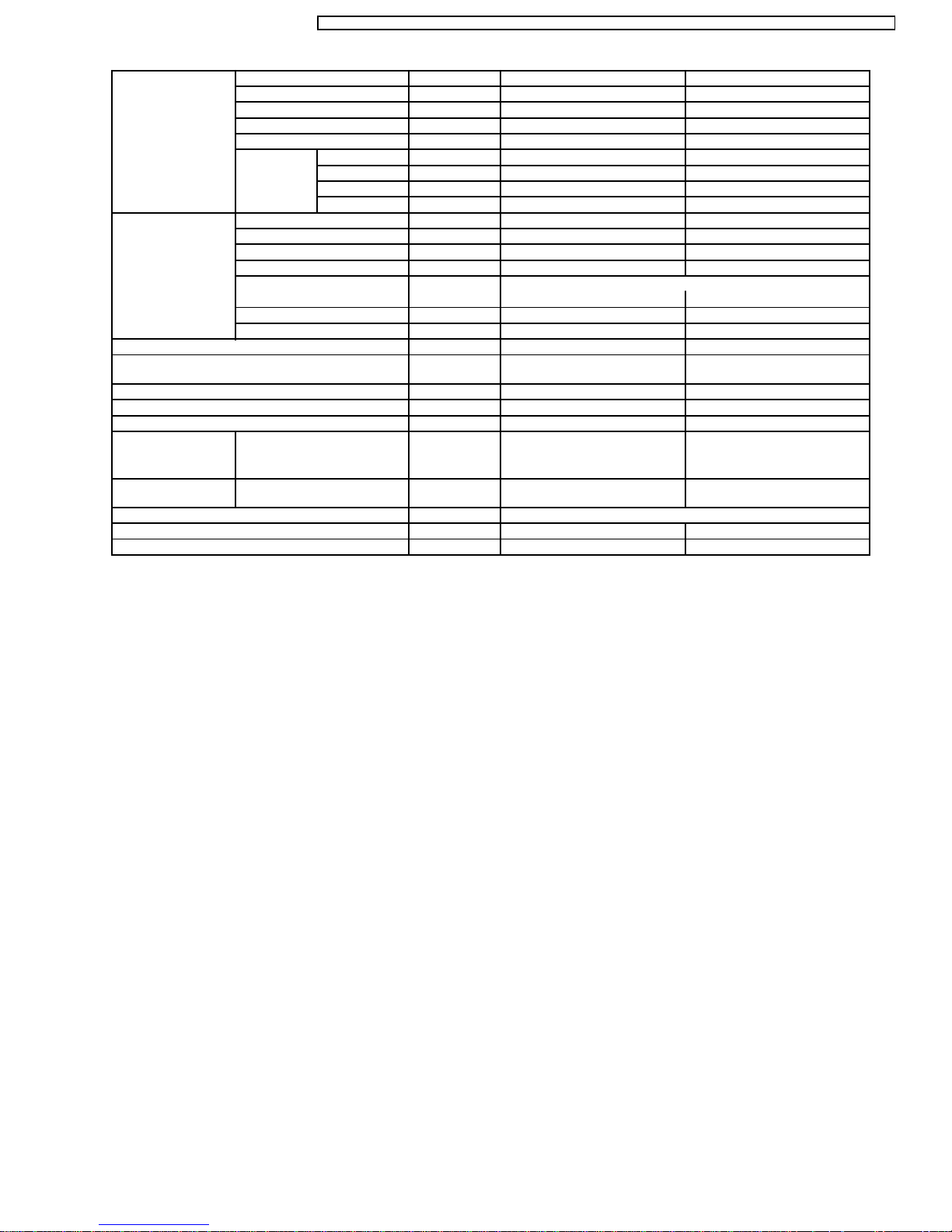

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

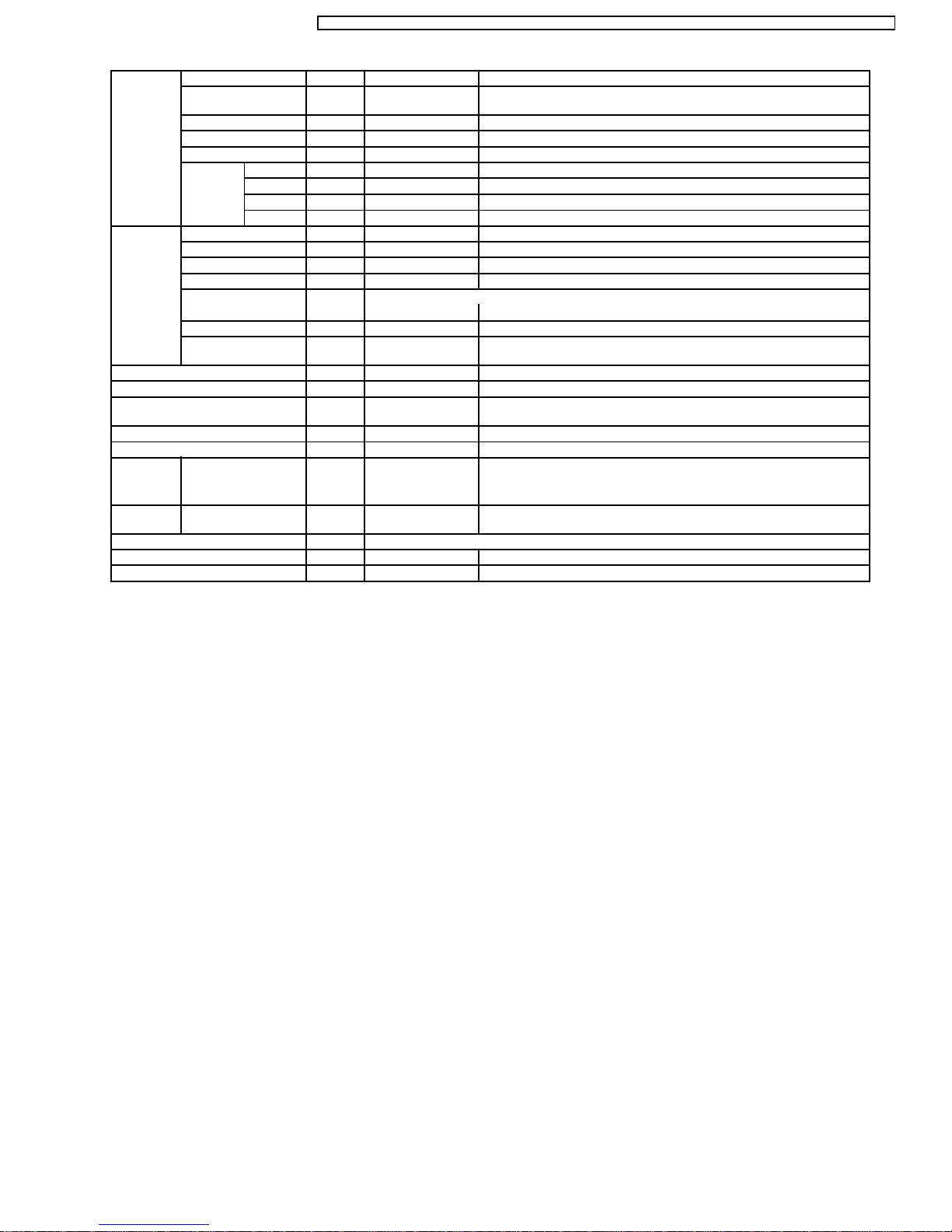

Unit CS-V9BKPG CU-2V18BKP5G

Power Source Phase Single

V 230

Cycle 50

Cooling Capacity kW

kcal/h

Moisture Removal l/h

Pint/h

Airflow Method OUTLET

(1 unit) 2.73

(2 units) 5.46

2,350

(1 unit) 1.6

(2 units) 3.0

3.4

SIDE VIEW TOP VIEW

4,700

6.3

INTAKE

Air Volume Indoor Air (Lo) m3/min (cfm) 6.8 (240) —

Indoor Air (Me) m3/min (cfm) 8.0 (280) —

Indoor Air (Hi) m3/min (cfm) 9.9 (350) —

Indoor Air (SHi) m3/min (cfm) 10.9 (380) —

Noise Level dB (A) High 36, Low 26 High 55

Power level dB High 49 High 70

Electrical Data Input W (1 unit)

860

Running Current A (1 unit)

3.9

(2 units)

1,720

(2 units)

7.8

EER W/W (kcal/hW) 3.17 (2.73)

Starting Current A 15.9

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Inner diameter mm 12 —

Length m 0.7 —

inch

inch

inch

inch

G ; Half Union 3/8”

L ; Half Union 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

G ; 3-way valve 3/8”

L ; 3-way valve 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

Dimensions Height inch (mm) 10 - 13/16 (275) 25 - 21/32 (651)

Width inch (mm) 31 - 15/32 (799) 35 - 3/16 (893)

Depth inch (mm) 8 - 9/32 (210) 13 - 19/32 (345)

Net Weight lb (kg) 20 (9.0) 141 (64)

Compressor Type — Rotary (1 cylinder)

rolling piston type

Motor Type — Induction (2-poles)

Rated Output W — 780

8

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 20% AS + Glass Fiber 20%

Motor Type Induction (4-poles) Induction (6-poles)

Input W 29.3 123.0

Rated Output W 15 50

Fan Speed Low rpm 800 —

Medium rpm 940 —

High rpm 1,160 760

SuperHigh rpm 1,250 —

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Louver Fin

Row / Stage (Plate fin configuration, forced draft)

2×15 2×24

FPI 19 14

Size (W × H × L) mm 610 × 315 × 25.4 560 × 609.6 × 44

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS M60

Refrigerant (R410A) g(oz) — 880 × 2 (31.0 × 2)

Thermostat Electronic Control —

Protection Device — Overload Protector

Capillary Tube Length mm — 1,160

Flow Rate l/min — 7.0

Inner Diameter mm — 1.4

Air Filter Material

Style

Capacity Control Capillary Tube

Compressor Capacitor µF, VAC — 30 µF, 370 VAC

Fan Motor Capacitor µF, VAC 1.5 µF, 400 VAC 3.0 µF, 450 VAC

(c.c) P.P.

Honeycomb

(330)

—

• Specifications are subject to change without notice for further improvement.

9

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

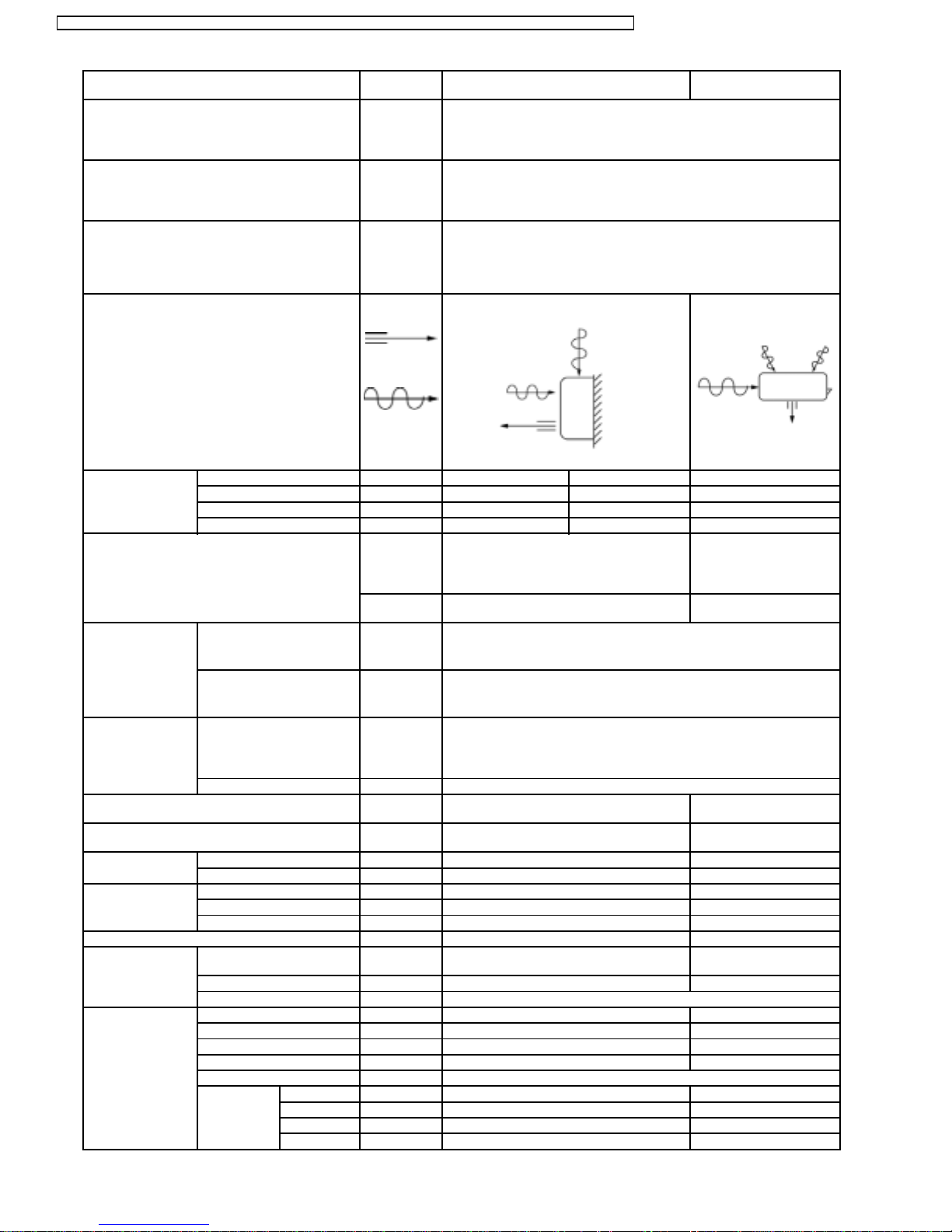

CS-V9BKPG CU-3V20BKP5G

Unit Single Operation

Single Operation Double Operation Triple

(A, B1, B2)

(A) (B1 or B2) (B1 + B2) (A + B1 or B2) (A + B1 + B2)

Power Source Phase Single

V 230

Cycle 50

Operation

Cooling Capacity Per Unit kW

— 2.73

kcal/h

Moisture Removal l/h

— 1.6

Pint/h

Airflow Method OUTLET

SIDE VIEW TOP VIEW

INTAKE

Air Volume Indoor Air (Lo) m3/min

(cfm)

Indoor Air (Me) m3/min

(cfm)

Indoor Air (Hi) m3/min

(cfm)

Indoor Air (SHi) m3/min

(cfm)

6.8

(240)

8.0

(280)

9.9

(350)

10.9

(380)

Noise Level dB (A) High 36,

Low 26

Power

High 49 High 71

level dB

Electrical

Input W 50 910 1,120 1,200 1,940 1,990

Data

2,350

3.4

2.95

2,540

1.7

3.6

3.82

3,290

2.2

4.6

—

—

—

—

High 56

5.68

4,890

3.1

6.6

6.55

5,630

3.7

7.8

Running Current A 0.23 4.1 5.0 5.3 8.6 8.9

EER W/W

(kcal/hW)

— 3.00

2.58

2.63

2.27

3.18

2.74

Starting Current A (A unit) 15.9 (B unit) 17.8

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Inner diameter mm 12 —

Length m 0.7 —

inch

inch

inch

inch

G ; Half Union 3/8”

L ; Half Union 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

G ; 3-way valve 3/8”

L ; 3-way valve 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

Dimensions Height inch (mm) 10 - 13/16 (275) 25 - 21/32 (651)

Width inch (mm) 31 - 15/32 (799) 35 - 3/16 (893)

Depth inch (mm) 8 - 9/32 (210) 13 - 19/32 (345)

Net Weight lb (kg) 20 (9.0) 146 (66)

Compressor Type — Rotary (1 cylinder)

rolling piston type

Motor Type — Induction (2-poles)

Rated Output W — (A unit) 780 (B unit) 830

2.93

2.52

3.29

2.83

10

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Air

Circulation

Motor Type Induction (4-poles) Induction (6-poles)

Rated Output W 15 50

Fan Speed Low rpm 800 —

Heat

Exchanger

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS M60 (330, 330)

Refrigerant (R410A) g(oz) — (A unit) 780 (27.5)

Thermostat Electronic Control —

Protection Device — Overload Protector

Capillary

Tube

Air Filter Material

Capacity Control Capillary Tube

Compressor Capacitor µF, VAC — 30/35 µF, 370 VAC

Fan Motor Capacitor µF, VAC 1.5 µF, 400 VAC 3.0 µF, 450 VAC

Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Louver Fin

Row / Stage (Plate fin configuration, forced draft)

FPI 19 14

Size (W × H × L) mm 610 × 315 × 25.4 756.0

Length mm — 780, 645, 950

Flow Rate l/min — 16.2/13.5, 8.0

Inner Diameter mm — 1.8, 1.6, 1.4

Style

Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber

20%

Input W 29.3 123.0

Medium rpm 940 —

High rpm 1,160 760

SuperHigh rpm 1,250 —

2×15 2×24

P.P.

Honeycomb

AS + Glass Fiber 20%

× 609.6 × 44

719.5

(B unit) 1,000 (35.3)

—

• Specifications are subject to change without notice for further improvement.

11

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Unit

Cooling Capacity kW

kcal/h

Moisture Removal l/h

Pint/h

Power Source Phase

V

Cycle

Airflow Method OUTLET

One Unit (A)

CS-V12BKPG

(A) 3.55

(A) 3,050

(A) 2.1

4.4

SIDE VIEW TOP VIEW

One Unit (B)

CS-V7BKPG

(B) 2.10

(B) 1,810

(B) 1.4

3.0

Single

230

50

CU-2V19BKP5G

(A+B) 5.65

(A+B) 4,860

(A+B) 3.1

6.6

INTAKE

Air Volume Indoor Air (Lo) m3/min (cfm) 7.3 (260) 6.4 (230) —

Indoor Air (Me) m3/min (cfm) 8.7 (310) 7.4 (260) —

Indoor Air (Hi) m3/min (cfm) 10.2 (360) 8.5 (300) —

Indoor Air (SHi) m3/min (cfm) 10.5 (370) 9.4 (330) —

Noise Level dB (A) (A) High 39

Low 29

Power level

(A) High 52 (B) High 46 High 70

(B) High 33

Low 26

High 55

dB

Electrical Data Input W (A) 1,230 (B) 720 (A+B) 1,850

Running Current A (A) 5.5 (B) 3.2 (A+B) 8.3

EER W/W

(kcal/hW)

(A) 2.89

(2.48)

(B) 2.92

(2.51)

(A+B) 3.05

(2.63)

Starting Current A (A) 17.8 (B) 12.5 (A+B) 30.3

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Inner diameter mm 12 —

Length m 0.7 —

inch

inch

inch

inch

G ; Half Union 1/2”, 3/8”

L ; Half Union 1/4”, 1/4”

G (gas side) ; 1/2”, 3/8”

L (liquid side) ; 1/4”, 1/4”

G ; 3-way valve 1/2”, 3/8”

L ; 3-way valve 1/4”, 1/4”

G (gas side) ; 1/2”, 3/8”

L (liquid side) ; 1/4”, 1/4”

Dimensions Height inch (mm) 10 - 13/16 (275) 25 - 21/32 (651)

Width inch (mm) 31 - 15/32 (799) 35 - 3/16 (893)

Depth inch (mm) 8 - 9/32 (210) 13 - 19/32 (345)

Net Weight lb (kg) 20 (9.0) 146 (66)

Compressor Type — Rotary (1 cylinder)

rolling piston type

Motor Type — Induction (2-poles)

Rated Output W (A) 830 (B) 670 (A+B) 1,500

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 20% AS + Glass Fiber 20%

Motor Type Induction (4-poles) Induction (6-poles)

Input W (A) 28.7 (B) 20.6 123.0

Rated Output W 15 50

Fan Speed Low rpm (A) 900 (B) 800 —

Medium rpm (A) 1,080 (B) 920 —

High rpm (A) 1,260 (B) 1,050 760

SuperHigh rpm (A) 1,300 (B) 1,140 —

12

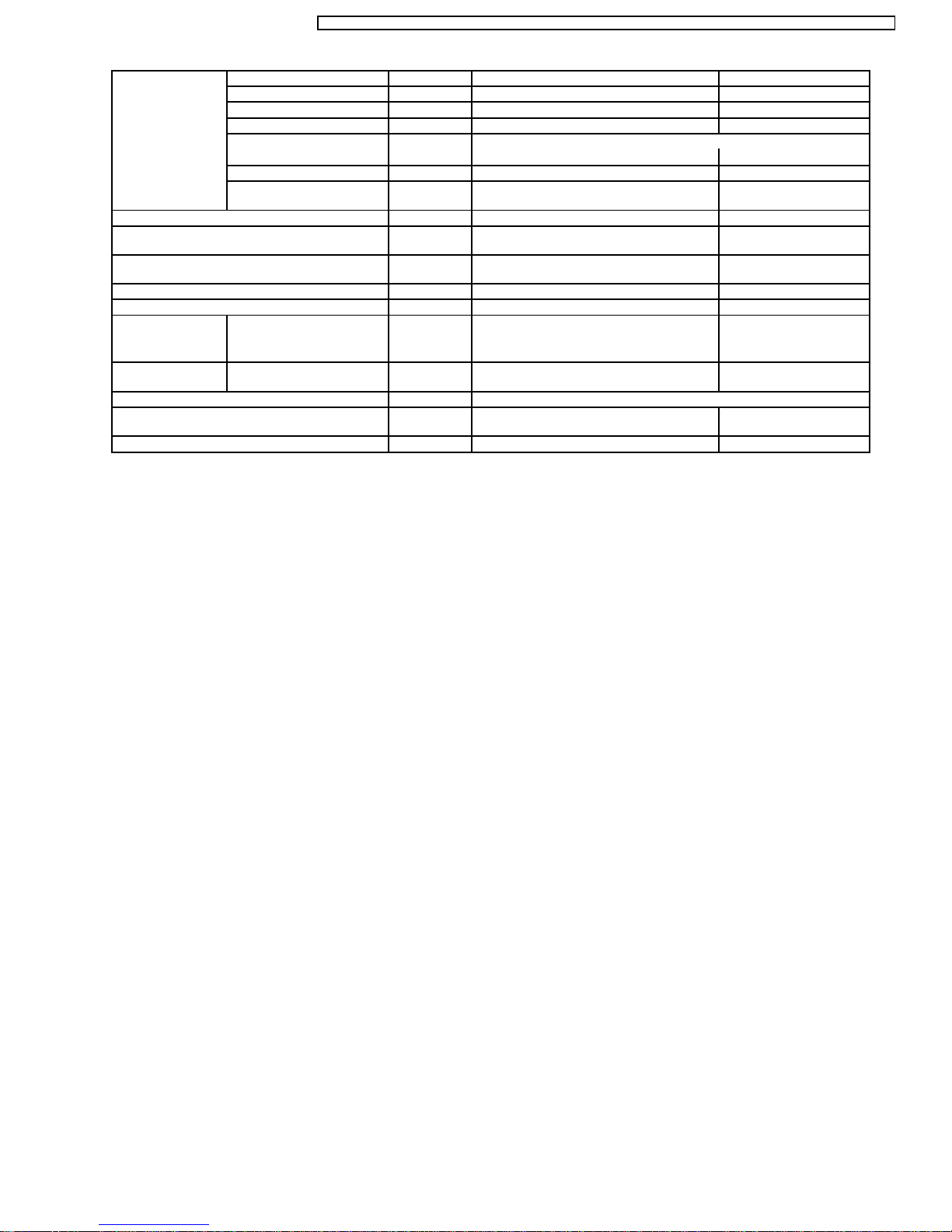

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Louver Fin

Row / Stage (Plate fin configuration, forced draft)

(A) 2 × 15 (B) 2 × 15 2×24

FPI 21 19 14

Size (W × H × L) mm 610 × 315 × 25.4 756

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS

Refrigerant (R410A) g(oz) — (A) 1,050 (37.0)

Thermostat Electronic Control —

Protection Device — Overload Protector

Capillary Tube Length mm — (A) 1,160 (B) 810

Flow Rate l/min — (A) 10.5 (B) 7.0

Inner Diameter mm — (A) 1.6 (B) 1.3

Air Filter Material

Style

Capacity Control Capillary Tube

Compressor Capacitor µF, VAC — (A) 35 µF, 370 VAC

Fan Motor Capacitor µF, VAC 1.5 µF, 400 VAC 3.0 µF, 450 VAC

(c.c) P.P.

Honeycomb

× 609.6 × 44

719.5

M60 (330, 330)

(B) 860 (30.3)

—

(B) 25 µF, 370 VAC

• Specifications are subject to change without notice for further improvement.

13

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

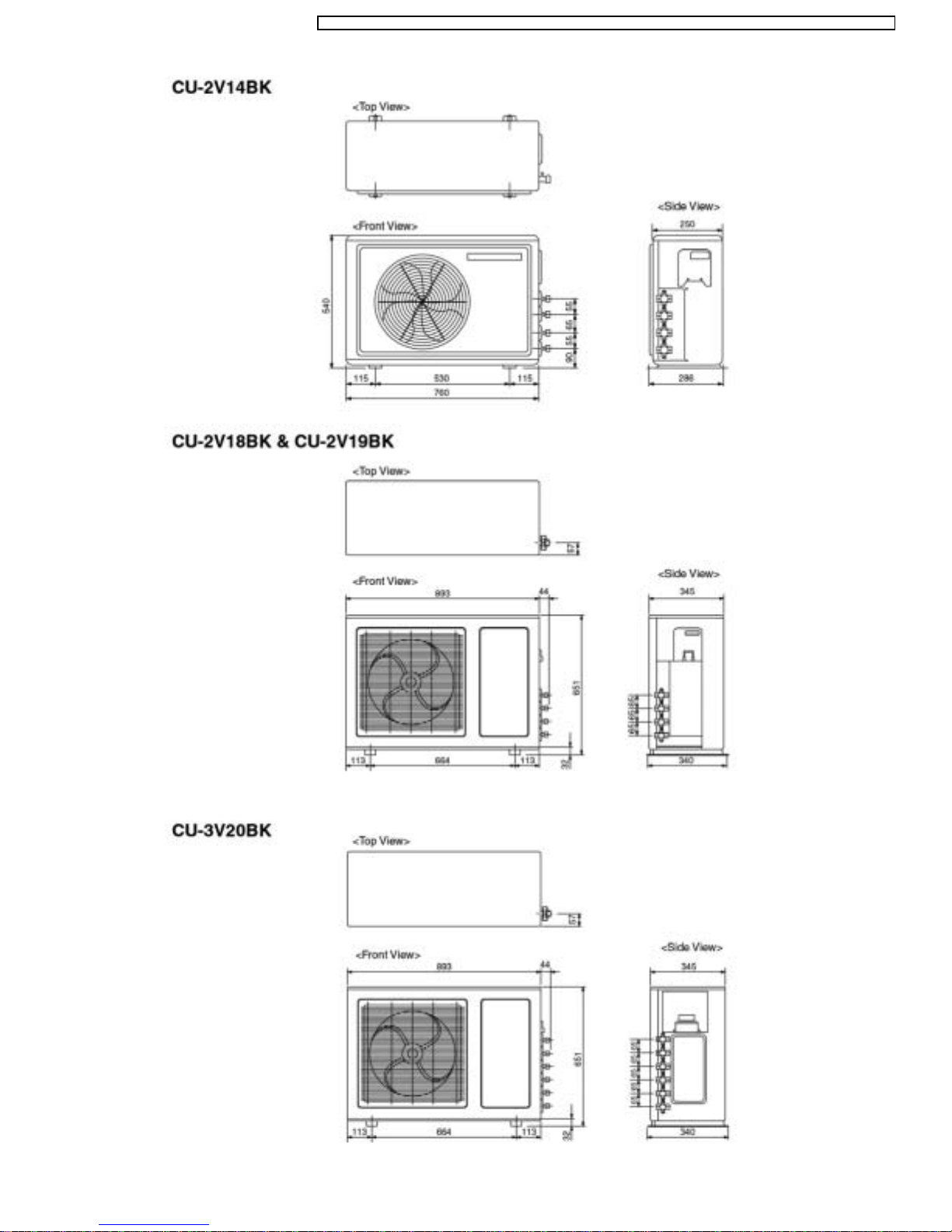

4 Dimensions

14

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

15

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

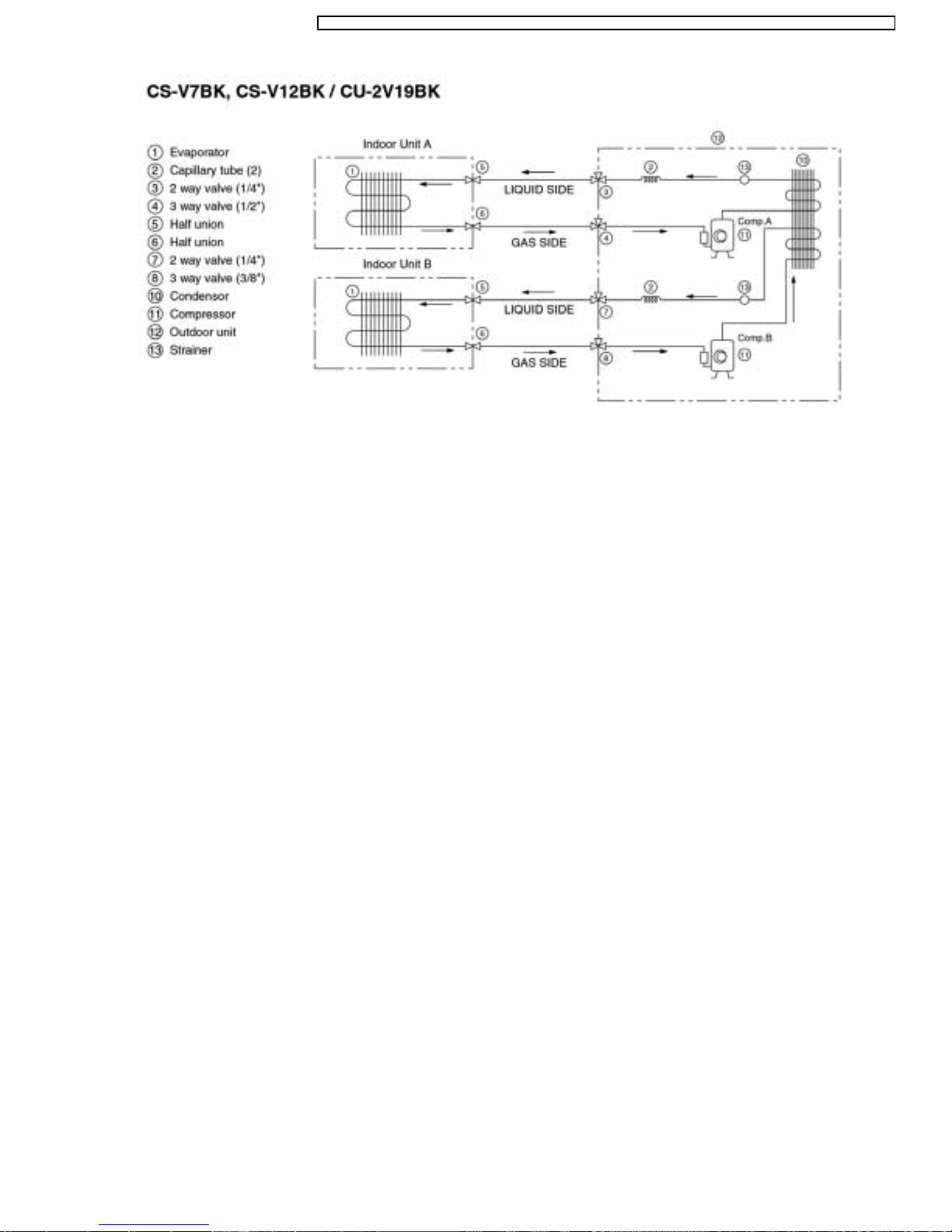

5 Refrigeration Cycle Diagram

16

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

17

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

6 Block Diagram

18

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

19

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

20

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

21

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

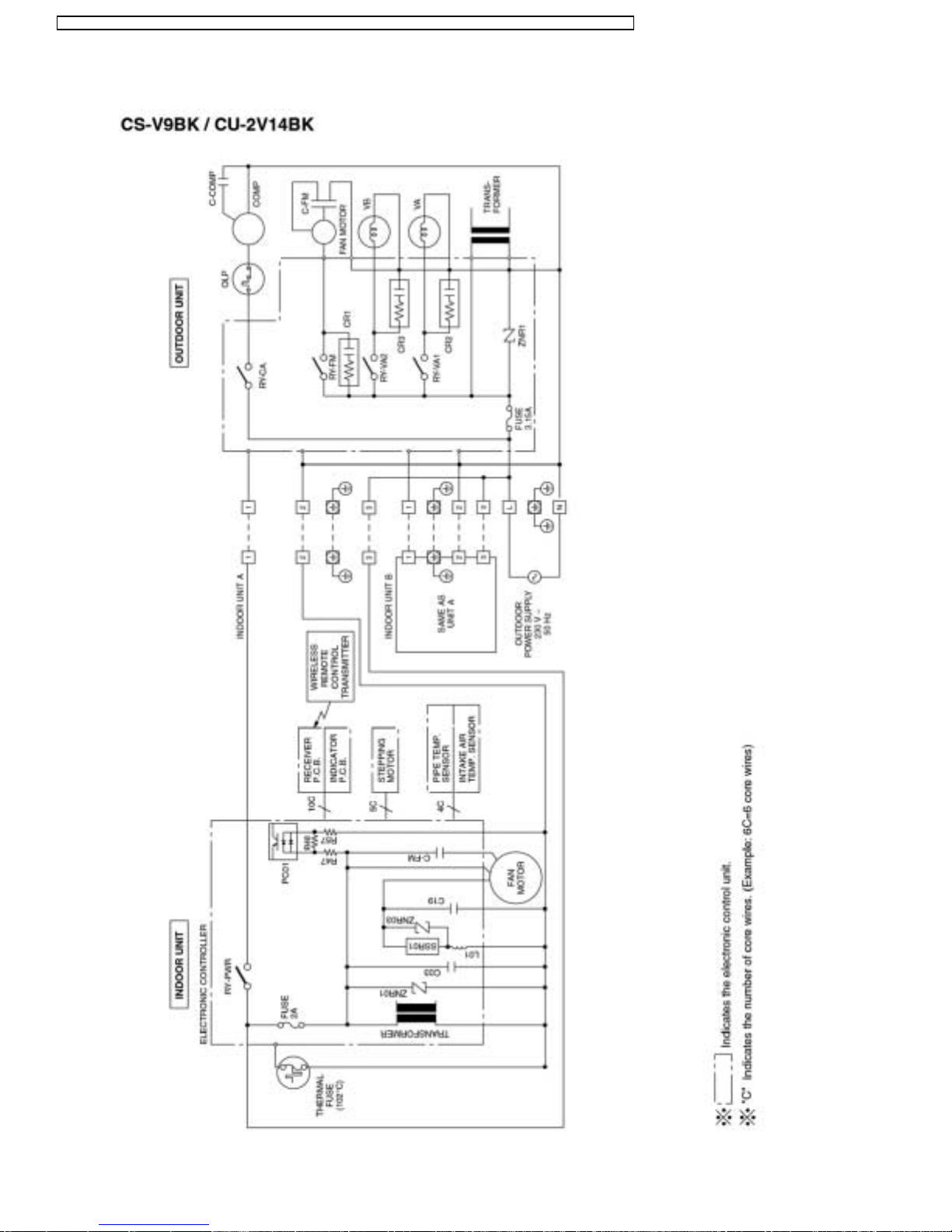

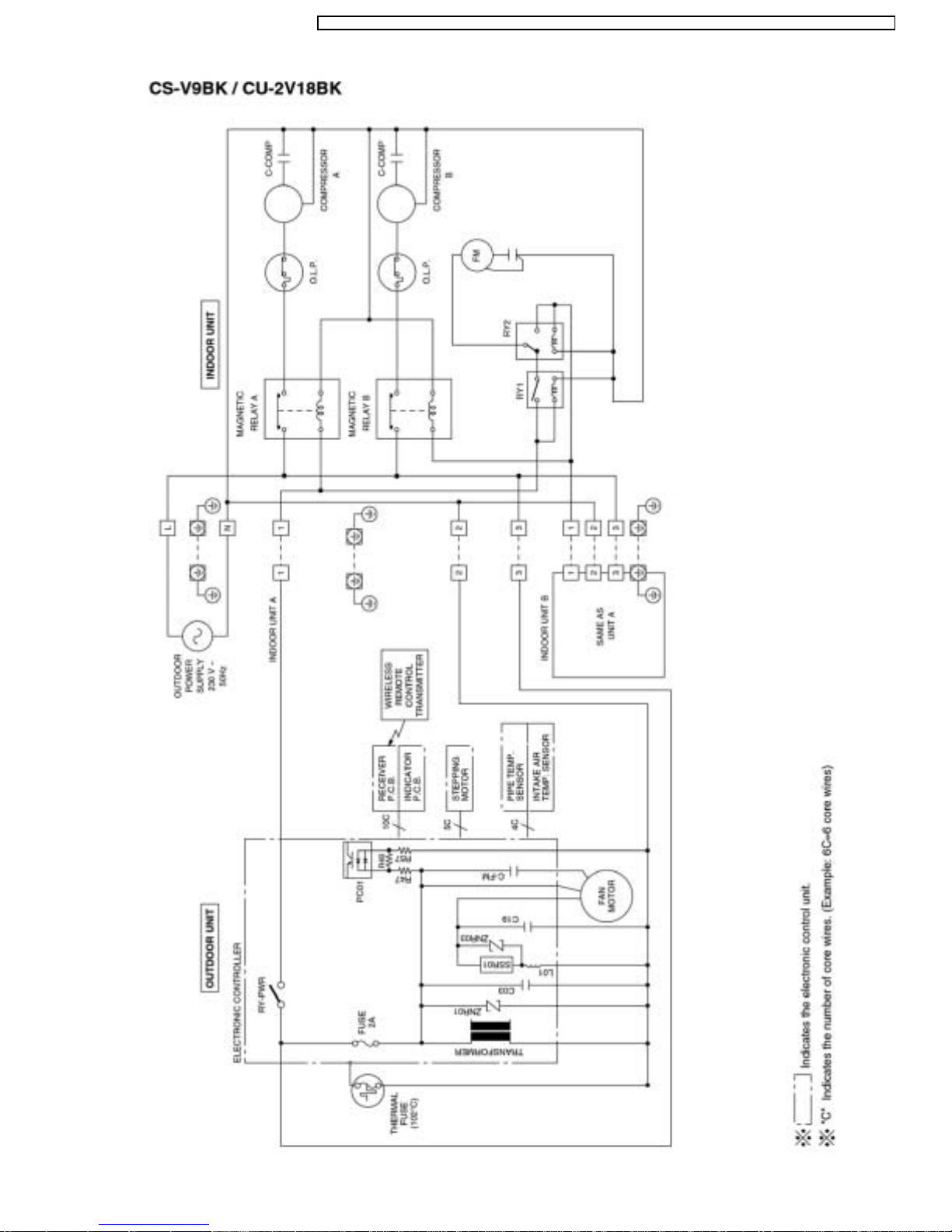

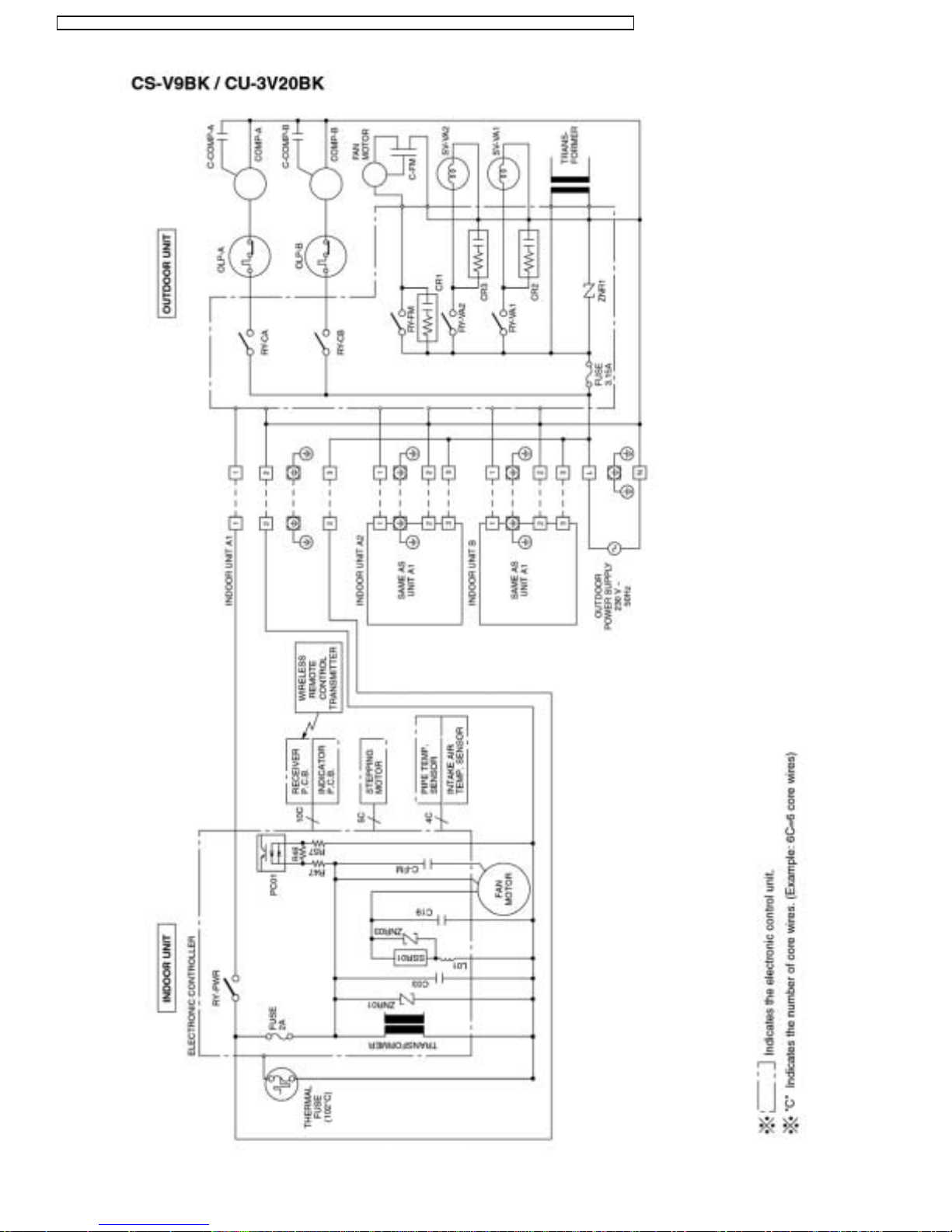

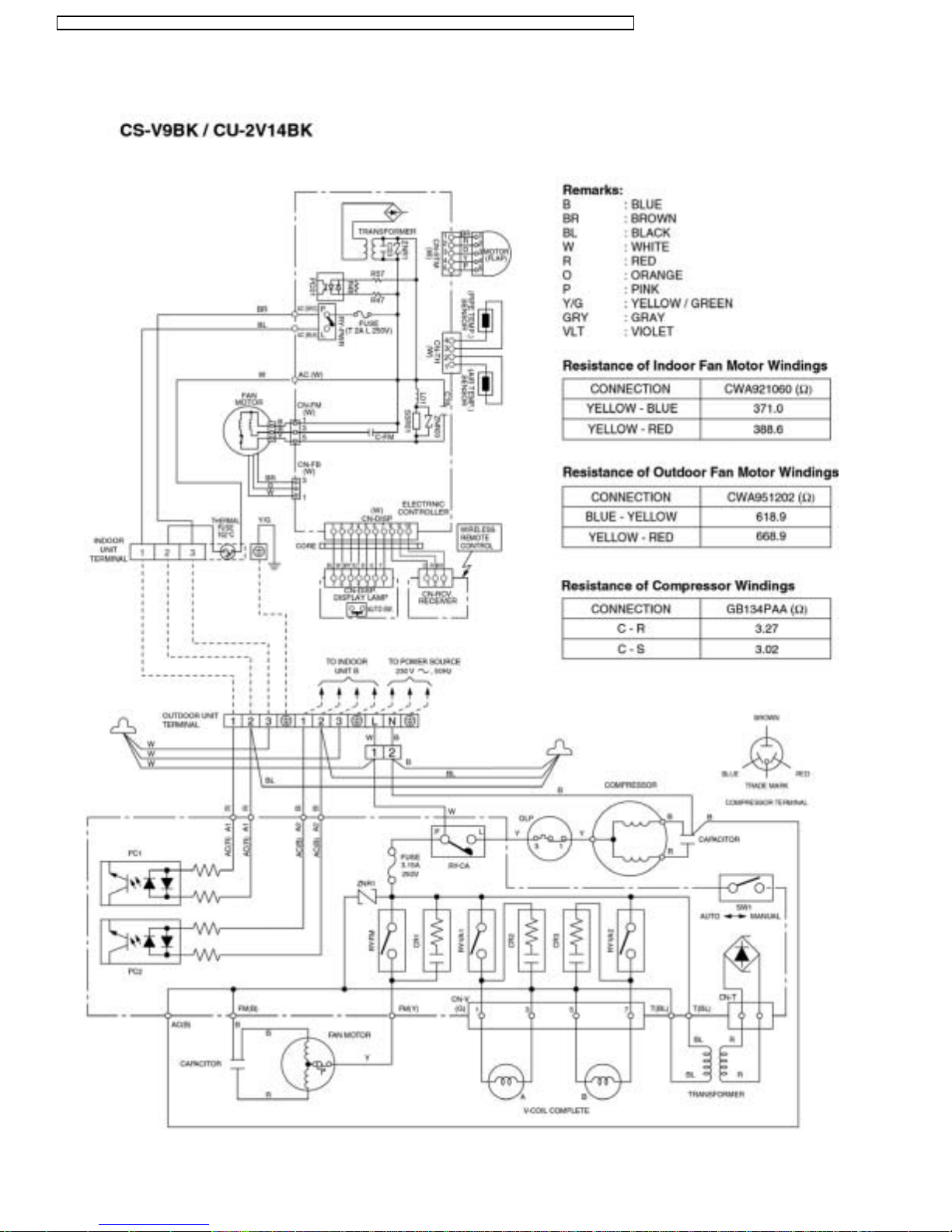

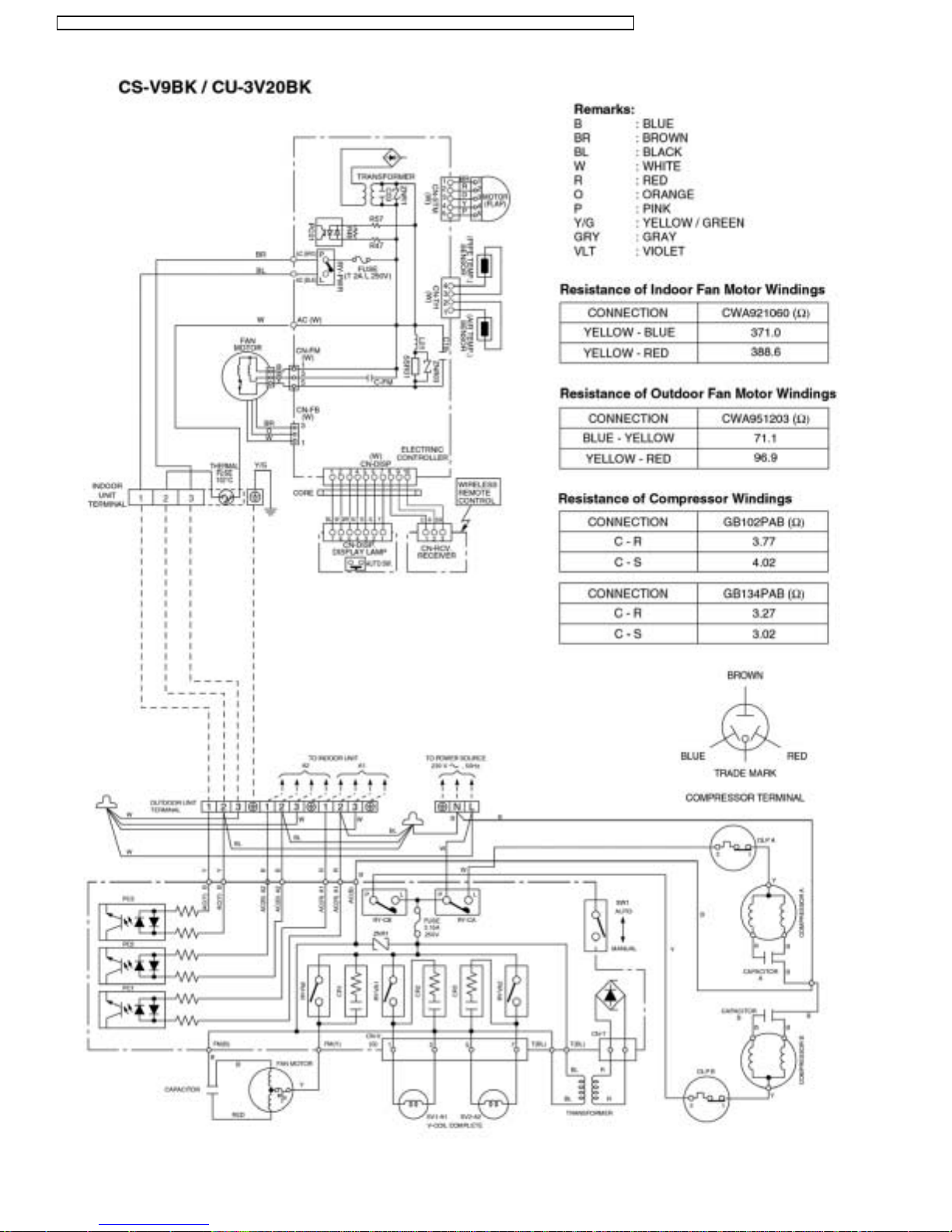

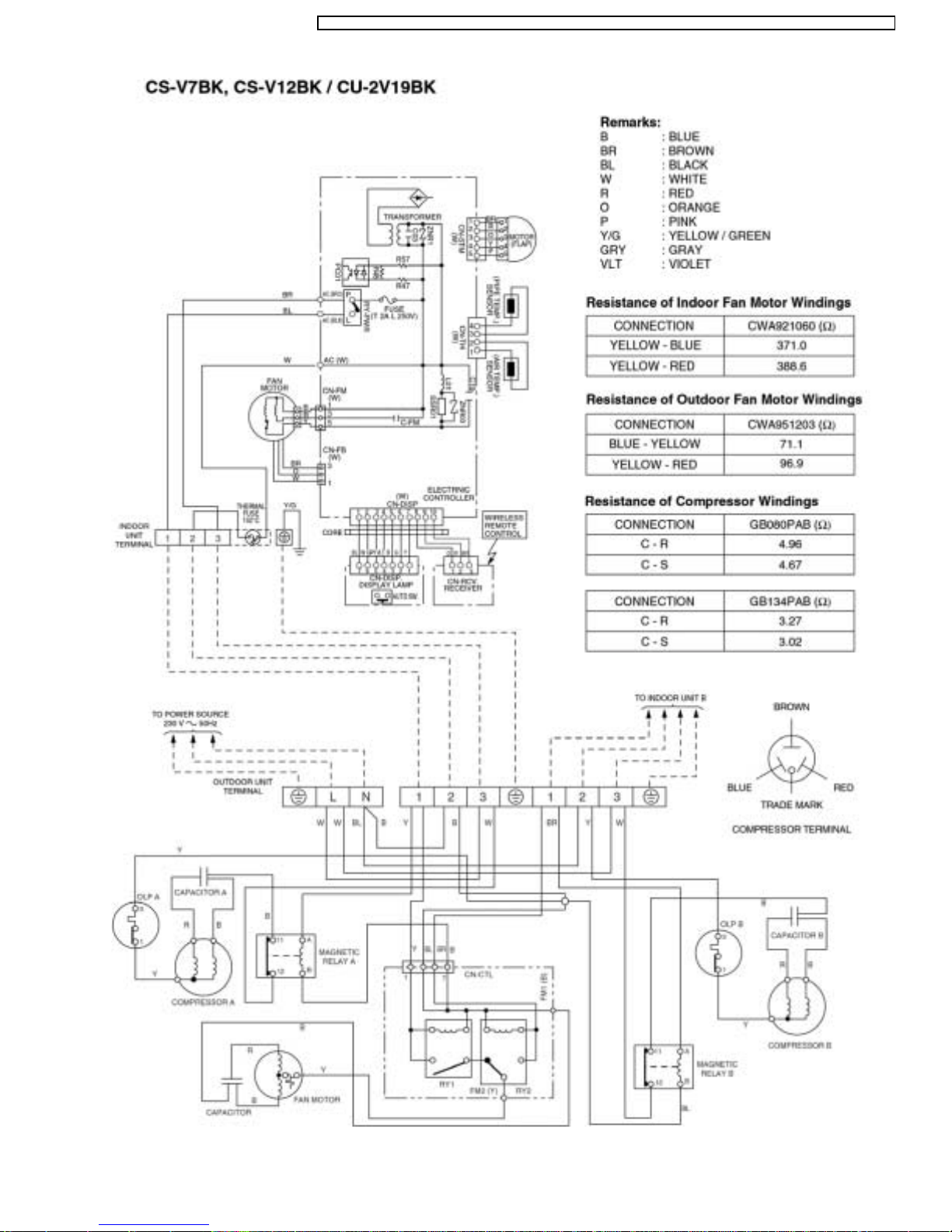

7 Wiring Diagram

22

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

23

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

24

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

25

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

8 Operation Details

8.1. Cooling Mode Operation

Cooling in operation according to Remote Control setting.

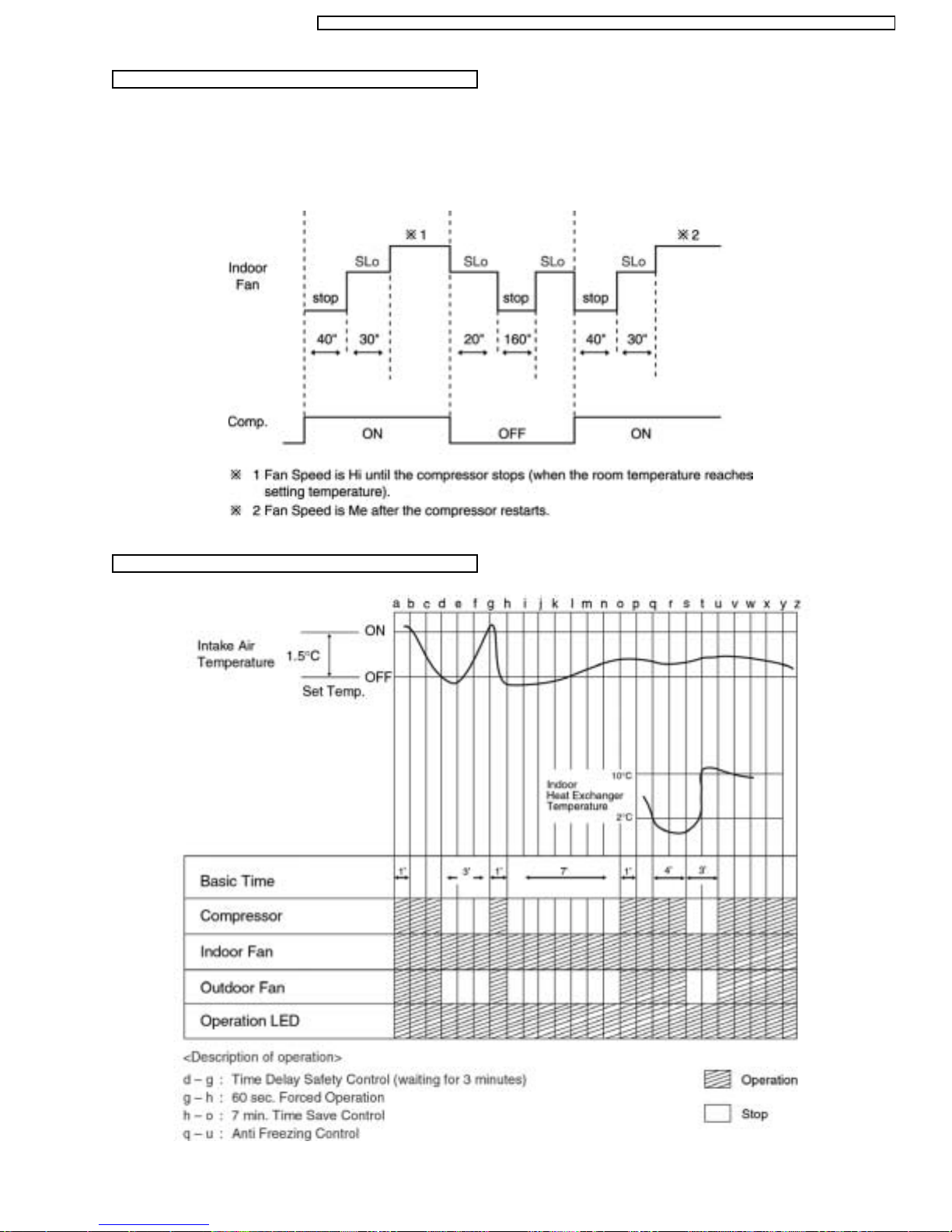

Time Delay Safety Control (3 minutes)

• When the compressor is stopped by Remote Control, it restarts after 3 minutes when the Remote Control is turned ON.

• When the setting temperature is reached during cooling operation, the compressor stops and it will not start for 3 minutes.

7 minutes Time Save Control

• The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is between the compressor

ON temperature and OFF temperature.

Starting Current Control

• When the compressor outdoor fan motor and indoor fan motor are simultaneously started, the indoor fan motor will operate 1.6

second later.

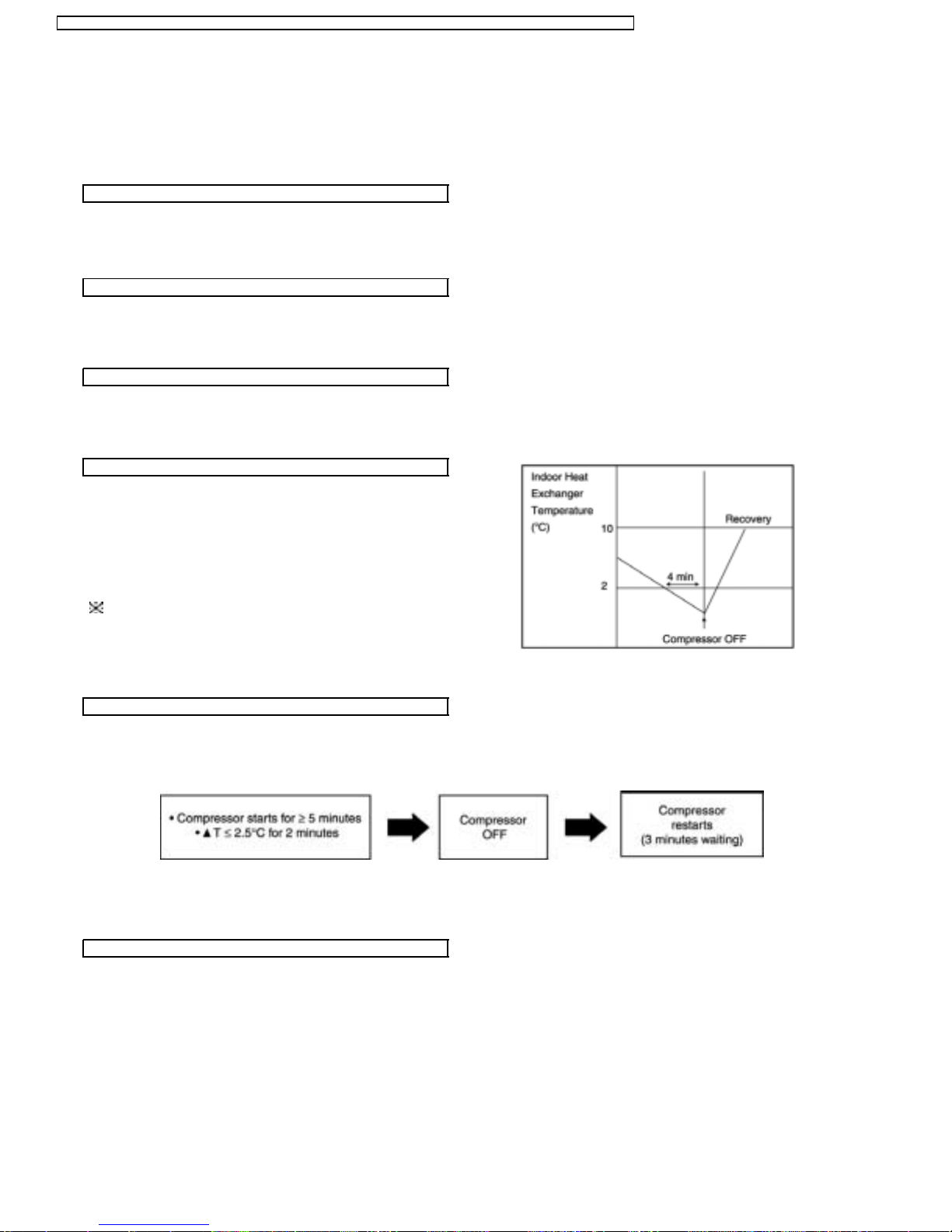

Anti-Freezing Control

• If the temperature of the indoor heat exchanger falls

continuously below 2°C for 4 minutes or more, the

compressor turns off to protect the indoor heat exchanger

from freezing. The fan speed setting remains the same.

• Compressor will restart again when the indoor heat

exchanger temperature rises to 10°C (Recovery).

3 minutes waiting of Time Delay Safety Control is valid for

Cooling Operation.

Compressor Reverse Rotation Protection Control

• If the compressor is operating continuously for 5 minutes or longer and the temperature difference between intake air and

indoor heat exchanger is 2.5°C or less for 2 minutes, compressor will stop and restart automatically.

(Time Delay Safety Control is valid)

▲ T = Intake air temperature - Indoor heat exchanger temperature

This is to protect reverse rotation of the compressor when there is a instantaneous power failure.

Anti-Dew Formation Control

• Purpose is to prevent dew formation on indoor unit air discharge area.

• When the following conditions accur for 30 minutes continuously, anti-dew formation is controlled by indoor fan speed shift to

low (CLo to HLo):

− Indoor intake air temperature is more than 24°C and less than 30°C.

− Remote Control setting temperature is less than 25°C.

− Compressor is on.

− Cooling operation mode.

− Indoor Fan motor operate at Low fan speed.

• This control is cancelled immediately when above condition is changed.

26

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during cooling operation.

• Fan speed rotates in the range of Hi to Me.

• Deodorizing Control.

Cooling Operation Time Diagram

27

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

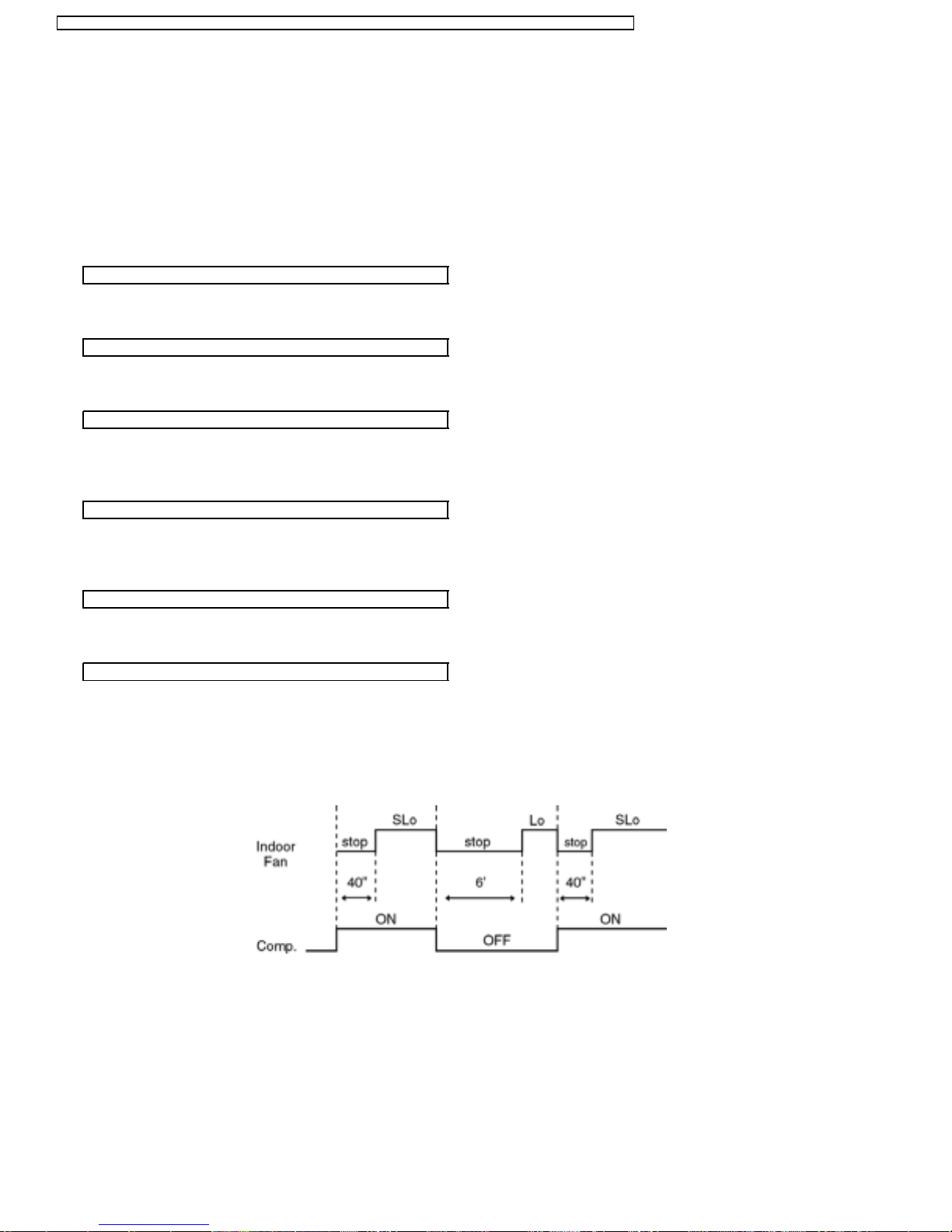

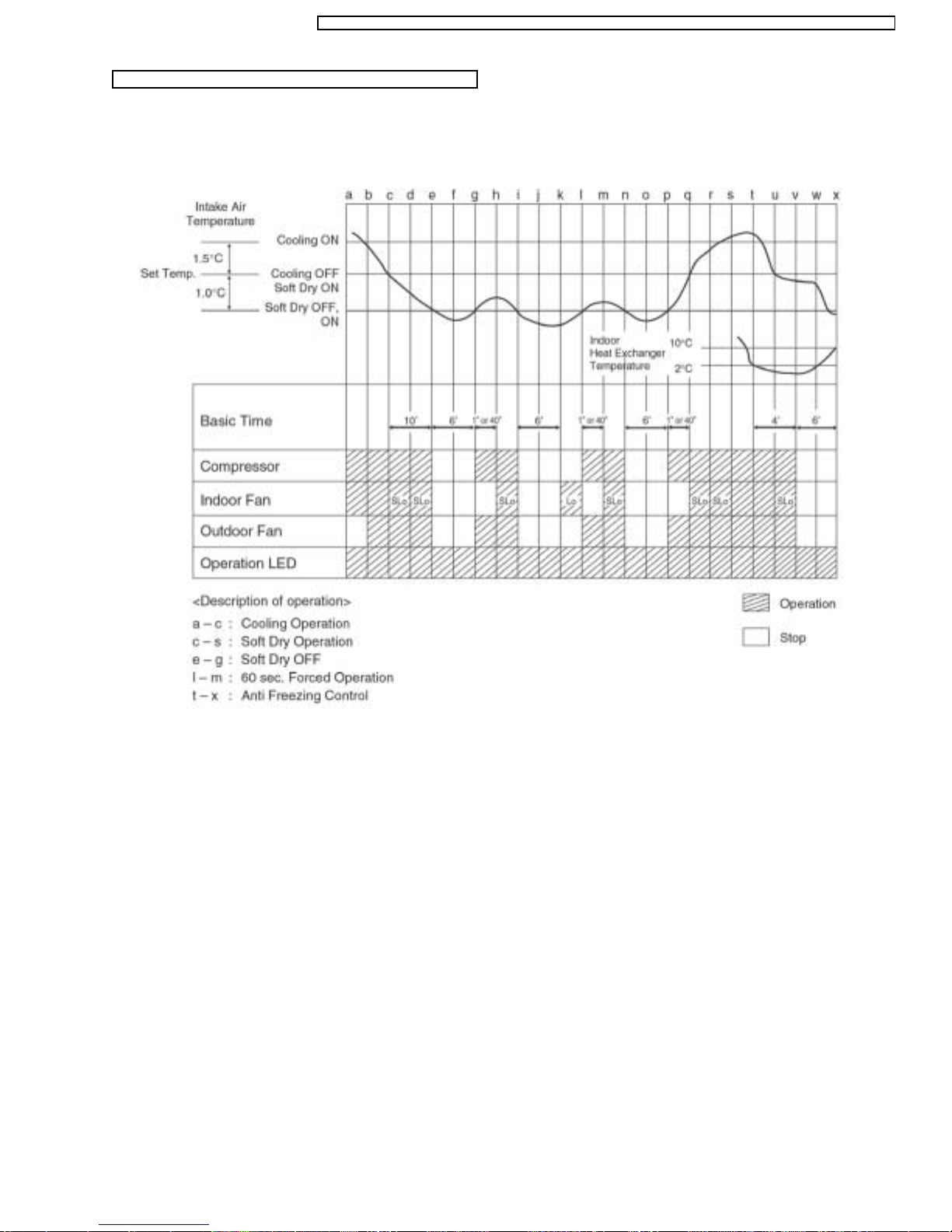

8.2. Soft Dry Mode Operation

• The unit starts cooling operation until the room temperature reaches the setting temperature set on the Remote Control, and

then Soft Dry operation will start.

• During Soft Dry operation, the Indoor Fan will operate at SLo speed.

• The operation will be switched on and off for up to 10 minutes “ON” and 6 minutes “OFF”. Once Soft Dry operation is turned

off, it stops for 6 minutes.

Time Delay Safety Control

• Once the compressor stops, it will not start for 3 minutes during Cooling operation.

Starting Current Control

• Same as Starting Current Control for Cooling Mode operation.

Anti-Freezing Control

• Same as Anti-Freezing Control for Cooling Mode operation. (For Soft Dry region, 6 minutes waiting is valid during compressor

stops.)

Compressor Reverse Rotation Protection Control

• Same as Compressor Reverse Rotation Protection Control for Cooling Mode Operation. (For Soft Dry region, 6 minutes waiting

is valid during compressor stops.)

Anti-Dew Formation Control

• Same as Anti-Dew Formation Control for Cooling Mode operation.

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during Soft Dry operation.

• Fan speed off and on at SLo speed.

• Deodorizing Control.

28

CS-V9BKPG CU-2V14BKP5G / CS-V9BKP G CU-2V18BKP5G / CS-V9BKP G CU-3V20BKP5G / CS-V7BKP G CU-2V19BKP5G / CS-V12BKPG

Soft Dry Operation Time Diagram

29

Loading...

Loading...