Page 1

Order No: PAPAMY1604017CE

Installation Manual

Outdoor Unit

CU-2E18SBU

Please file and use this manual together with the service manual for Model No. CS-ME5RKUA CS-ME7RKUA, CS-E9RKUA

CS-E12RKUA, CS-ME9SB4U, CS-E12RB4UW, CS-ME5SD3UA CS-ME7SD3UA, CS-E9SD3UAW CS-E12SD3UAW, Order No.

PAPAMY1503085CE, PAPAMY1501049CE, PAPAMY1604059CE, PAPAMY1503095CE, PAPAMY1604056CE,

PAPAMY1604052CE.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2016

Page 2

Item Unit OUTDOOR UNIT

Air Volume High m3/min (ft3/min) 41.0 (1447)

Refrigerant Control Device Expansion Valve

Refrigerant Oil cm3 FV50S (900)

Refrigerant (R410A) g (oz) 2.23k (78.7)

Dry Bulb Wet Bulb

Cooling

Indoor Operation Range

Heating

Cooling

Outdoor Operation Range

Heating

Maximum °C (°F) 32 (89.6) 23 (73.4)

Minimum °C (°F) 16 (60.8) 11 (51.8)

Maximum °C (°F) 30 (86.0) —

Minimum °C (°F) 16 (60.8) —

Maximum °C (°F) 46 (114.8) 26 (78.8)

Minimum °C (°F) -10 (14.0) — / —

Maximum °C (°F) 24 (75.2) 18 (64.4)

Minimum °C (°F) -15 (5.0) -16 (3.2)

Note

x Specifications are subject to change without notice for further improvement.

x Multi split combination possibility:

o A single outdoor unit enables air conditioning of up to two separate rooms for CU-2E18SBU.

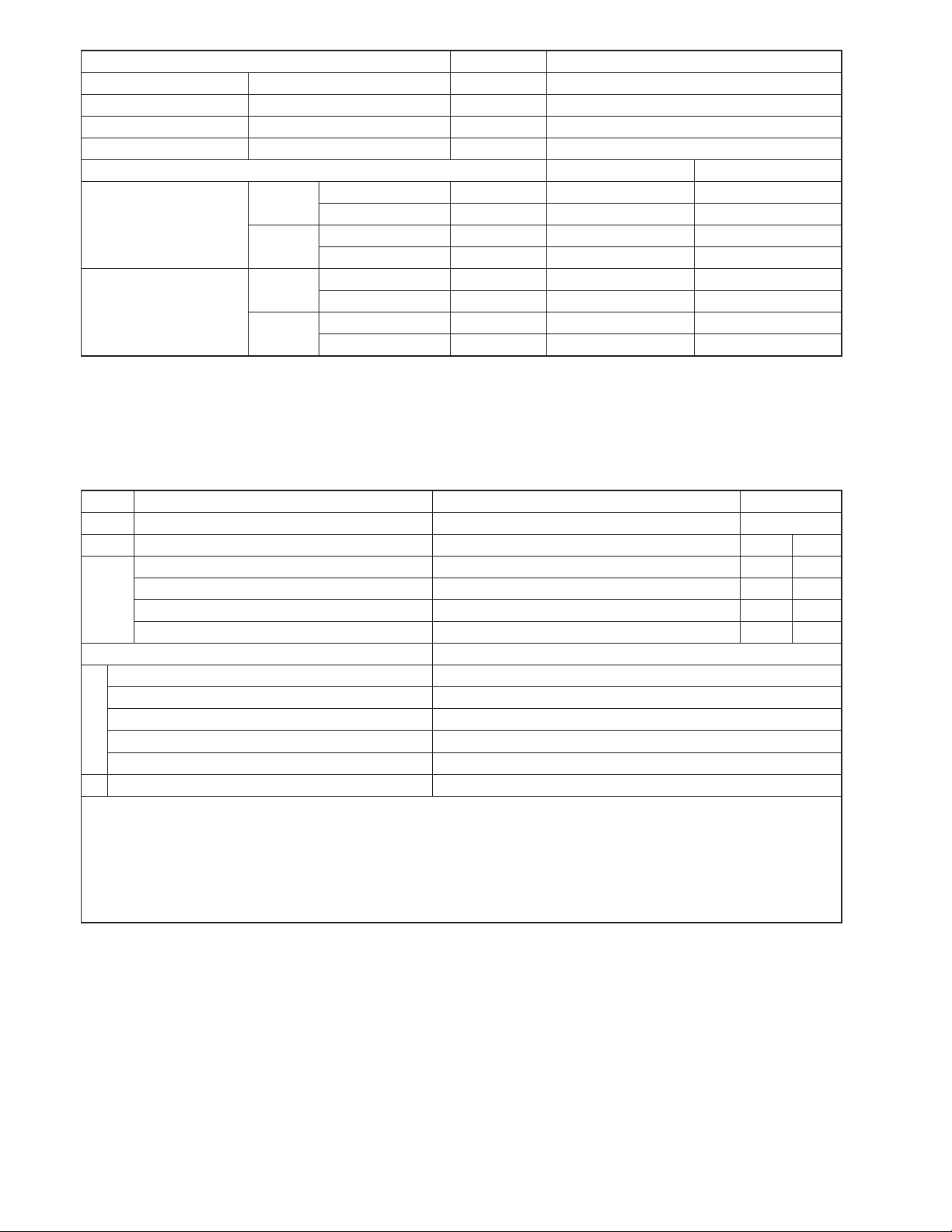

Outdoor Unit

CU-2E18SBU

A B

1.6 kW CS-ME5RKUA, CS-ME5SD3UA

2.0 kW CS-ME7RKUA, CS-ME7SD3UA

Wall

Capacity range of connectable indoor units From 3.2 kW to 6.4 kW

1 room maximum pipe length (m (ft)) 25 (82.0)

Allowable elevation (m (ft)) 15 (49.2)

Total allowable pipe length (m (ft)) 50 (164.0)

Total pipe length for maximum chargeless length (m (ft)) 20 (65.6)

Piping Length

Additional gas amount over chargeless length (g/m (oz/ft)) 20 (0.2)

Remarks for CU-2E18SBU

1. At least two indoor units must be connected.

2. The total nominal cooling capacity of indoor units that will be connected to outdoor unit must be within connectable capacity range of

indoor unit.

(as shown in the table above)

Example: The indoor units’ combination below is possible to connect to CU-2E18SBU. (Total nominal capacity of indoor units is between

3.2 kW to 6.4 kW)

1) Two CS-E9RKUAW only. (Total nominal cooling capacity is 5.0 kW)

2) One CS-E9RKUAW and one CS-E12RKUAW. (Total nominal cooling capacity is 5.7 kW)

x Specifications are subject to change without notice for further improvement.

2.5 kW CS-E9RKUAW, CS-ME9SB4U, CS-E9SD3UAW

3.2 kW CS-E12RKUAW, CS-E12RB4UW, CS-E12SD3UAW

Note: “

• •

• •

• •

• •

•” : Available

6

Page 3

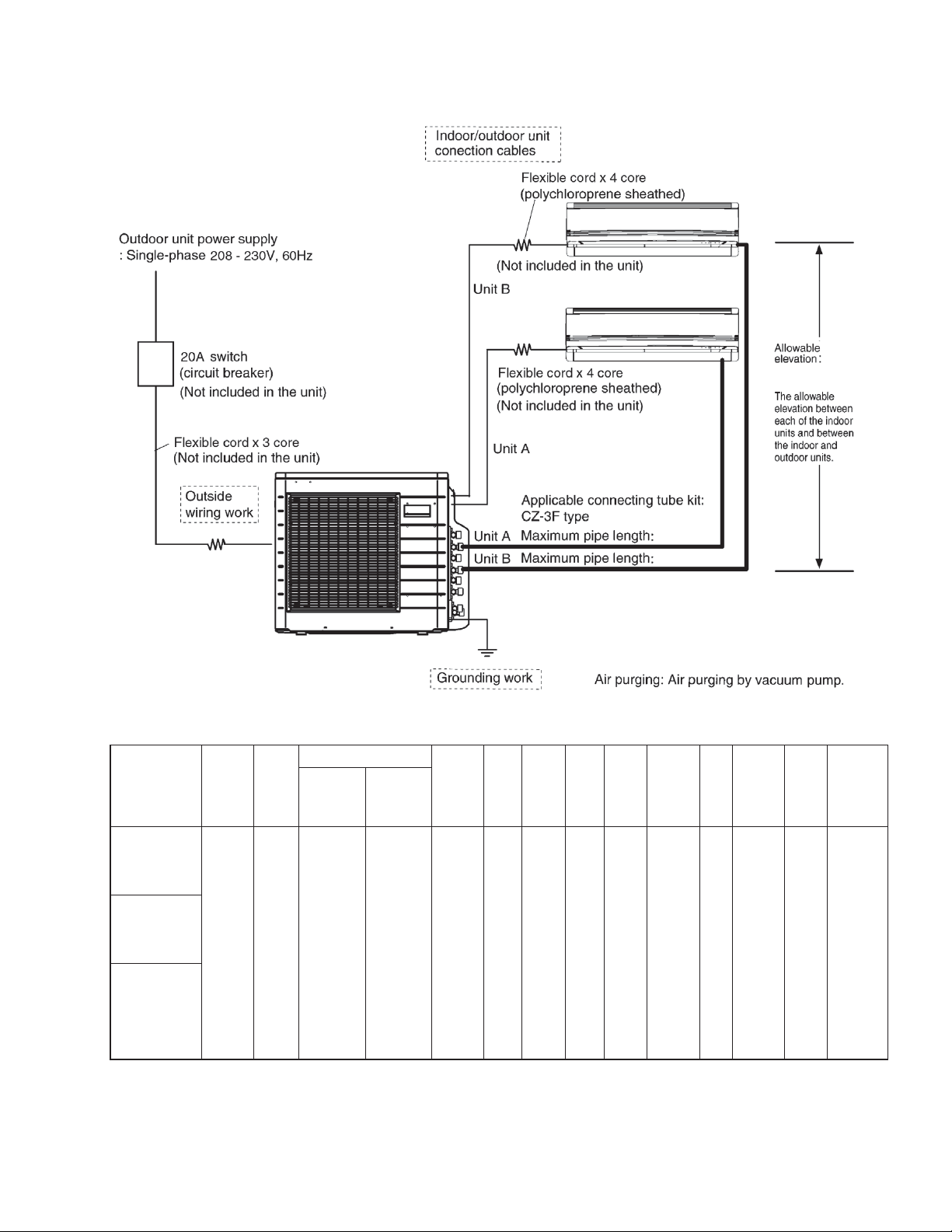

9. Installation Information

9.1 Check Points

49.2 ft max.

82 ft

82 ft

Total maximum pipe length: 164 ft

QUICK GUIDE PIPING AND ELECTRICAL SPECIFICATION

Indoor (ID) &

Outdoor (OD)

units: Possible

Combination

Patterns

Outdoor (OD):

CU-2E18SBU

Indoor (ID): 2

UNITS OF CSE9RKUAW

Outdoor (OD):

CU-2E18SBU

Indoor (ID): 2

UNITS OF CSE12RKUAW

Outdoor (OD):

CU-2E18SBU

Indoor (ID): 1

UNIT OF CSE9RKUAW +

1 UNIT OF

CS-E12RKUAW

Capacity

Refrige-

(Btu/h)

16700 R410A

rant

Piping size

Gas Liquid

Ø3/8”

(Ø9.52mm)

Ø1/4”

(Ø6.35mm)

Standard

pipe

length

24.6 ft

Min.

Max.

pipe

Max.

Eleva-

tion

See

Step 1

each ID

from

length

OD to

for

each

ID unit

unit

9.8 ft 82.0 ft 164.0 ft 65.6 ft

Max.

total

length

Min. total

pipe

length

for

additional

gas

Additional

refri-

ge-

rant

0.2

oz / ft

Power

supply

208/230V

60 Hz

MCA 20A

MOP

25A

Power

supply

AWG12 AWFG16

wire

size

OD-ID

connection

wire size

Example:

If total piping length of all installed indoor units is at 68.6 ft, the quantity of additional refrigerant should be 0.6 oz ......

(68.6 - 65.6) ft x 0.2 oz/ft = 0.6 oz.

15

Page 4

10. Installation Instruction

x IMPORTANT

This product has been designed and manufactured to meet ENERGY STAR

matched with appropriate coil components. However, proper refrigerant charge and proper air flow are critical to

achieve rated capacity and efficiency. Installation of this product should follow the manufacturer’s refrigerant charging

and air flow instructions. Failure to confirm proper charge and airflow may reduce energy efficiency and

shorten equipment life.

10.1 Accessories Supplied with Outdoor Unit

x The following parts are supplied as accessories with each outdoor unit.

Check that all accessory parts are present before installing the outdoor unit.

HEAT PUMP-TYPES ONLY

Part name Qty. Diagram Application

®

criteria for energy efficiency when

Drain elbow 1

For connecting the drain pipe

10.2 Cutting and Flaring the Piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

1. To cut

Point down

2. To remove burrs

Pipe

Reamer

Bar

Clamp handle

3. To fl are

Handle

Yo k e

Core

Red arrow mark

Bar

1

0 –

/32"

(0-0.5 mm)

Copper pipe

When properly fl ared, the internal surface

of the fl are will evenly shine and be of

even thickness. Since the flare part

comes into contact with the connections,

carefully check the fl are fi nish.

Improper fl aring

Inclined Surface

damaged

Cracked Uneven

thickness

16

Page 5

10.3 Select the Best Location

10.3.1 Outdoor Unit

x If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from

the condenser is not obstructed.

x There should not be any animal or plant which

could be affected by hot air discharged.

x Keep the spaces indicated by arrows from wall,

ceiling, fence or other obstacles.

x Do not place any obstacles which may cause a

short circuit of the discharged air.

x Recommended installation height for outdoor unit

should be above the seasonal snow level.

Refrigerant piping size

Outdoor Unit CU-2E18**

Liquid - side ø1/4" (ø6.35 mm) thickness 1/32" (t0.8 mm)

Gas - side ø3/8" (ø9.52 mm) thickness 1/32" (t0.8 mm)

Outdoor Unit CU-2E18**

Min. total piping length for additional gas 65.6 ft (20 m)

x If total piping length of all indoor units exceeds the

minimum length listed above, additionally charge

with 0.2 oz (20 g) of refrigerant (R410A) for each

additional feet (meter) of piping.

Allowable piping length

Outdoor Unit CU-2E18***

Allowable piping length of each indoor unit (min. ~ max.) 9.8 ft ~ 82.0 ft (3 m ~ 25 m)

Allowable total piping length of all indoor units 164.0 ft (50 m) or less

Height difference between indoor and outdoor units

Height difference between indoor units

Outdoor unit located on upper side

Outdoor unit located otherwise

Outdoor unit located on upper side

Outdoor unit located otherwise

Outdoor unit located

on upper side

Outdoor Unit Installation Diagram

x This illustration is for explanation purposes only.

* Note:

Respective indoor unit installation procedure shall

refer to instruction manual provided in the indoor

unit packaging.

a

b

c

d

Outdoor unit located

otherwise

Indoor unit

Installation parts you

should purchase (

It is advisable to avoid more

than 2 blockage directions.

For better ventilation &

multiple-outdoor installation,

please consult authorized

dealer/specialist.

Power supply cord (

(Conduit)

Connection cable (

(Conduit)

Additional drain hose (

1

4

" (6.35 mm)

/

Liquid side piping (

3

/8" (9.52 mm)

Gas side piping (

49.2 ft (15 m) or less

24.6 ft (7.5 m) or less

24.6 ft (7.5 m) or less

49.2 ft (15 m) or less

)

)

)

)

)

)

a

c

Outdoor unit

d

Outdoor unit

d

b

b

roodnItinu roodn

I

tinu

17

Outdoor unit

Page 6

Outdoor Unit Installation Guidelines

f

x Where a wall or other obstacle is in the path of outdoor unit’s intake or exhaust airflow, follow the installation

guidelines below.

x For any of the below installation patterns, the wall height on the exhaust side should be 47 1/4" (1200 mm) or

less.

Wall facing one side

More than 3 15/16" (100)

47

1

/4" (1200)

or less

More than

3

" (1000)

39

/

8

Walls facing two side Walls facing three side

More than

15

/16" (100)

3

More than

15

/16" (100)

3

weiv poTweiv ediS

More than

3

/

8

39

" (1000)

More than

13

/

11

16

" (300)

More

than

3

(100)

More than

15

3

" (100)

/

16

15

/16"

More than

3

/8" (1000)

39

Top view

Unit : inch (mm)

10.4 Install the Outdoor Unit

x After selecting the best location, start installation

to Indoor/Outdoor Unit Installation Diagram.

1 Fix the unit on concrete or rigid frame firmly

and horizontally with bolt nut (ø13/32"

(ø10 mm)).

2 When installing on a roof, please consider

strong winds and earthquakes.

3 Please fasten the installation stand firmly with

bolt or nails.

10.5 Connect the Piping

x Remove the control board cover (resin) from the

outdoor unit by loosening three screws.

Connecting the Piping to Outdoor Unit

Decide piping length and then cut by using pipe

cutter.

Remove burrs from cut edge. Make flare after

inserting the flare nut (locate at valve) onto the

copper pipe.

Align center of piping to valves and then tighten

with torque wrench to the specified torque as

stated in the table.

Screws

Control Board Cover (Resin)

Liquid side

Gas side

AB

C

D

Model A B C D

CU-2E18***

24 1/8"

(613 mm)

5 5/32"

(131 mm)

5/8"

(16 mm)

14 3/16"

(360.5 mm)

Do not overtighten, over tightening may cause gas leakage.

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf•ft [18 N•m (1.8 kgf•m)]

3/8" (9.52 mm) 31.0 Ibf•ft [42 N•m (4.3 kgf•m)]

1/2" (12.7 mm) 40.6 Ibf•ft [55 N•m (5.6 kgf•m)]

5/8" (15.88 mm) 47.9 Ibf•ft [65 N•m (6.6 kgf•m)]

3/4" (19.05 mm) 73.8 Ibf•ft [100 N•m (10.2 kgf•m)]

Flare Nut

(Connection Pipe)

Torque Wrench for Flare Nut

Flare Nut

(Connection Pipe)

Female side

Applicable to

Liquid and Gas side o

CS-E9***

CS-E12***

CS-ME5***

CS-ME7***

CS-ME9***

Male side

Screw

Torque Wrench for Flare Nut

Gas Leak Checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 10.7.

18

Page 7

10.6 Evacuation of the Equipment

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedure.

1 Connect a charging hose with a push pin to

the Low side of a charging set and the service

Indoor Unit

port of the gas side 3-way valve.

2 Connect the micron gauge between vacuum

pump and service port of outdoor units.

3 Turn on the power switch of the vacuum pump

and make sure that connect digital micron

gauge and to pull down to a value of

500 microns.

Indoor Unit

4 To make sure micron gauge a value

500 microns and close the low side valve of

the charging set and turn off the vacuum

pump.

5 Disconnect the vacuum pump house from the

service port of the 3-way valve.

6 Tighten the service port caps of gas side

3-way valve at a torque of 13.3 Ibf•ft (18 N•m)

with a torque wrench.

7 Remove the valve caps of both of the 2-way

Vacuum

pump

valve and 3-way valve. Position both of the

valves to “Open” using a hexagonal wrench

(5/32" (4 mm)).

8 Mount valve caps onto the 2-way valve and

3-way valve.

o Be sure to check for gas leakage.

x If micron gauge value does not descend 500 microns, take the following measures:

- If the leak stops when the piping connections are tightened further, continue working from step 3.

- If the leak does not stop when the connections are retightened, repair location of leak.

- Do not release refrigerant during piping work for installation and reinstallation.

- Take care when handling the liquid refrigerant, it may cause frostbite.

Tube connector

Liquid side

Tube connector

Gas

side

Tube connector

Liquid side

Tube connector

Gas

side

Liquid side 3-way valve

Gas side 3-way valve

Close

Close

Outdoor unit

19

Page 8

10.7 Connect the Cable to the Outdoor Unit

1 Remove Control Board Cover (Metal) by

loosening 2 screws.

2 Remove Valve Cover (Metal) by loosening

2 screws.

3 Remove Plugs.

4 Fix the conduit connectors to the knock out

holes with lock-nuts, then secure them.

5 Connecting wire between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

6 Wire Connection to the power supply

(208/230V 60Hz) through circuit breaker.

o Connect the UL listed or CSA approved

wires minimum AWG12 to the terminal

board, and connect to other end of the

wires to circuit breaker.

7 Connect the power supply cord and

connecting wires between indoor unit and

outdoor unit according to the diagram as

shown.

Indoor

Unit A

Terminal

1

2

3

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

Grounding wire min AWG16

Outdoor Unit

Terminal

1

2

Unit A

3

Screws

Valve Cover

Screws

Lock Nuts

(Metal)

Side Panel

To p Pa ne l

Control Board Cover

(Metal)

Connectors

Plugs

Knock Out Holes

Unit A Unit B

Indoor

Unit B

Terminal

1

2

3

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

Grounding wire min AWG16

1

2

Unit B

3

L1

L2

Disconnect

Switch

Field supply

Grounding wire

Power Supply

Single Phase

208/230V 60Hz

min AWG12

Power Supply

Cord

Indoor & outdoor

connection wire

Indoor

Unit A

8 For wire stripping and connection requirement, refer to the diagram below.

9 Secure the power supply cord and connection cables onto the control board with the holder.

10 Attach the control board cover (metal and resin) and valve cover back to the original position with screw.

WIRE STRIPPING AND CONNECTING REQUIREMENT

Wire stripping

"

16

/

1

" ±

32

(10±1 mm)

/

13

No loose strand when inserted

Indoor/outdoor

connecting

terminal board

7

/32" (5 mm)

or more

(gap between

wires)

Conductor fully

inserted

ACCEPT PROHIBITED PROHIBITED

Conductor over

inserted

Conductor not

fully inserted

This equipment must be properly earthed.

o Earth wire must be Yellow/Green (Y/G) in colour and longer than other AC wires for safety reasons.

Indoor

Unit B

10.8 Heat Insulation

Use a material with good heat-resistant properties as the heat insulation for the

pipes. Be sure to insulate both the gas-side and liquid-side pipes. If the pipes are

not adequately insulated, condensation or water leakages may occur.

20

Liquid-side pipes

Gas-side pipes

Material shall

withstand 248°F

(120°C) or

higher

Loading...

Loading...