Page 1

ORDER NO. MAC0509070C2

Air Conditioner

CS-F24DD3E5 CU-B24DBE5

CS-F28DD3E5 CU-B28DBE5

CS-F28DD3E5 CU-B28DBE8

CS-F34DD3E5 CU-B34DBE5

CS-F34DD3E5 CU-B34DBE8

CS-F43DD3E5 CU-B43DBE8

CS-F50DD3E5 CU-B50DBE8

CONTENTS

Page Page

1 SERVICE INFORMATION 3

1.1. Example of trouble at test operation

1.2. Caution of test operation

1.3. Caution during automatic address setting

1.4. Operation range

2 FEATURES

3

3

3

3

4

2.1. Hide-away type 4

2.2. Outdoor unit

2.3. A brand-new control method using the latest in technology

3 SPECIFICATION

© 2005 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

4

5

6

Page 2

3.1. CS-F24DD3E5 CU-B24DBE5 6

3.2. CS-F28DD3E5 CU-B28DBE5

3.3. CS-F28DD3E5 CU-B28DBE8

3.4. CS-F34DD3E5 CU-B34DBE5

3.5. CS-F34DD3E5 CU-B34DBE8

3.6. CS-F43DD3E5 CU-B43DBE8

3.7. CS-F50DD3E5 CU-B50DBE8

4 DIMENSIONS

4.1. CS-F24DD3E5 CS-F28DD3E5

4.2. CS-F34DD3E5 CS-F43DD3E5 CS-F50DD3E5

4.3. CU-B24DBE5 CU-B28DBE5 CU-B28DBE8

4.4. CU-B34DBE5 CU-B34DBE8 CU-B43DBE8 CUB50DBE8

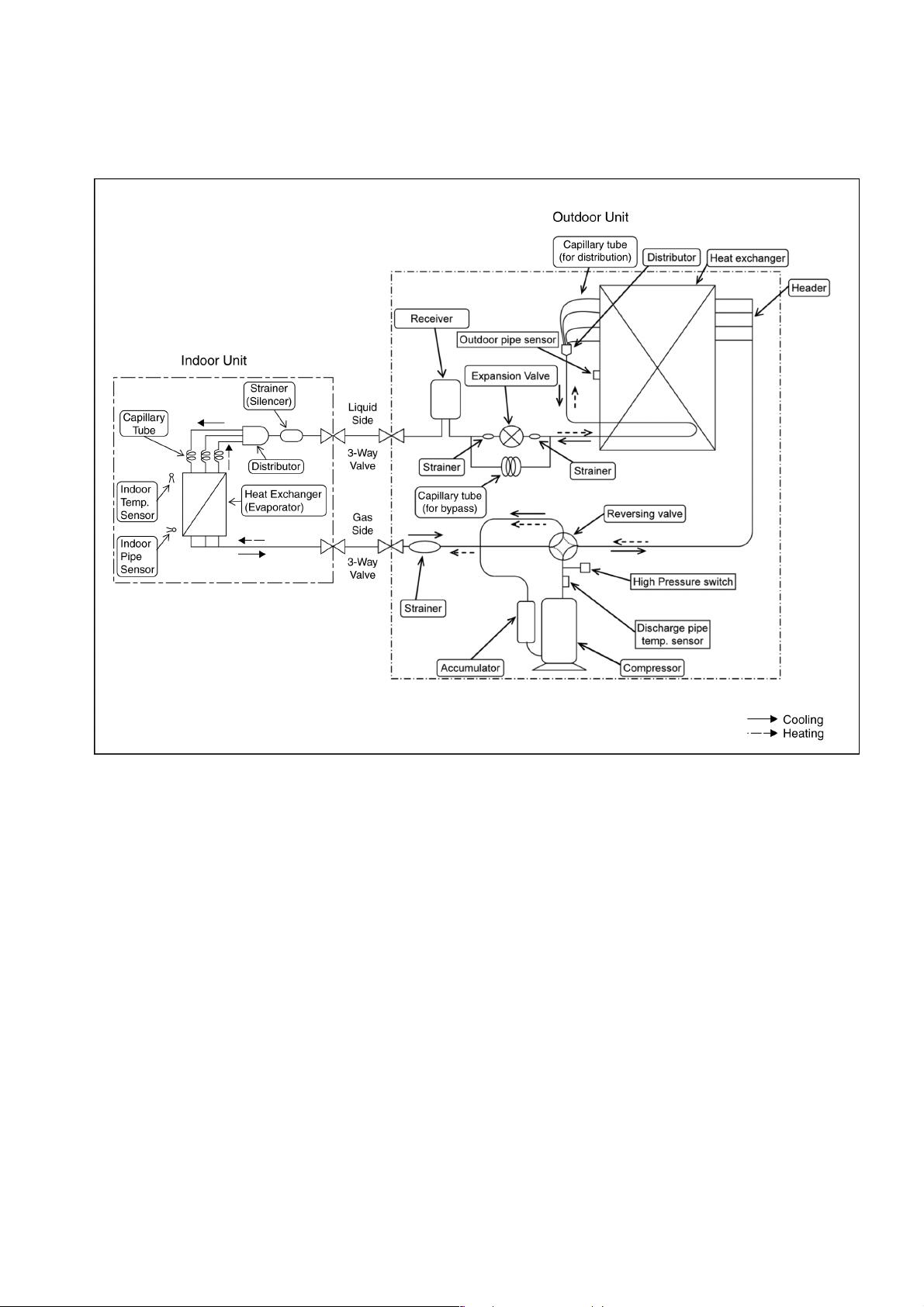

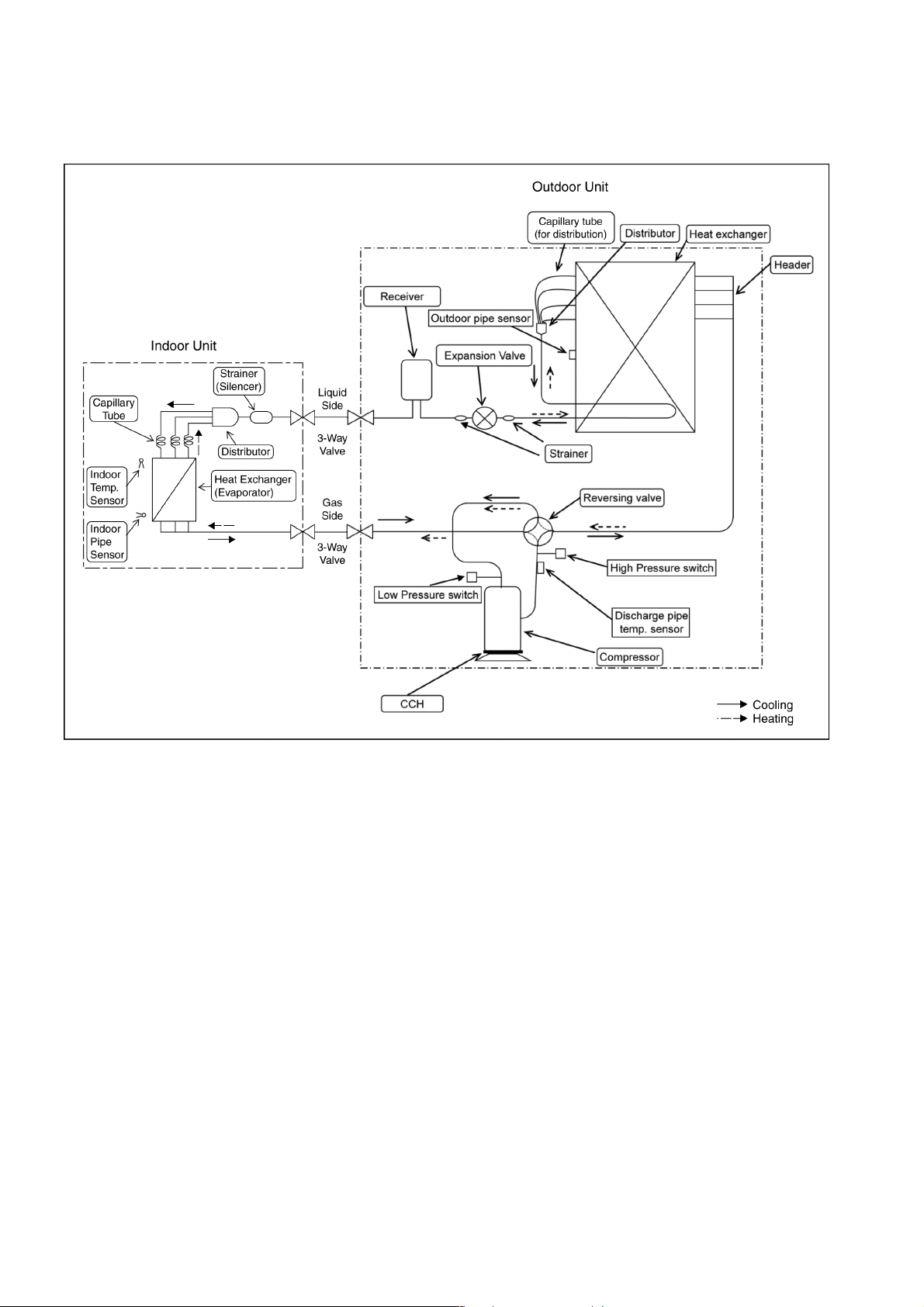

5 REFRIGERATION CYCLE

5.1. CS-F24DD3E5 CU-B24DBE5 CS-F28DD3E5 CUB28DBE5 CU-B28DBE8

5.2. CS-F34DD3E5 CU-B34DBE5 CU-B34DBE8 CSF43DD3E5 CU-B43DBE8 CS-F50DD3E5 CU-B50DBE8

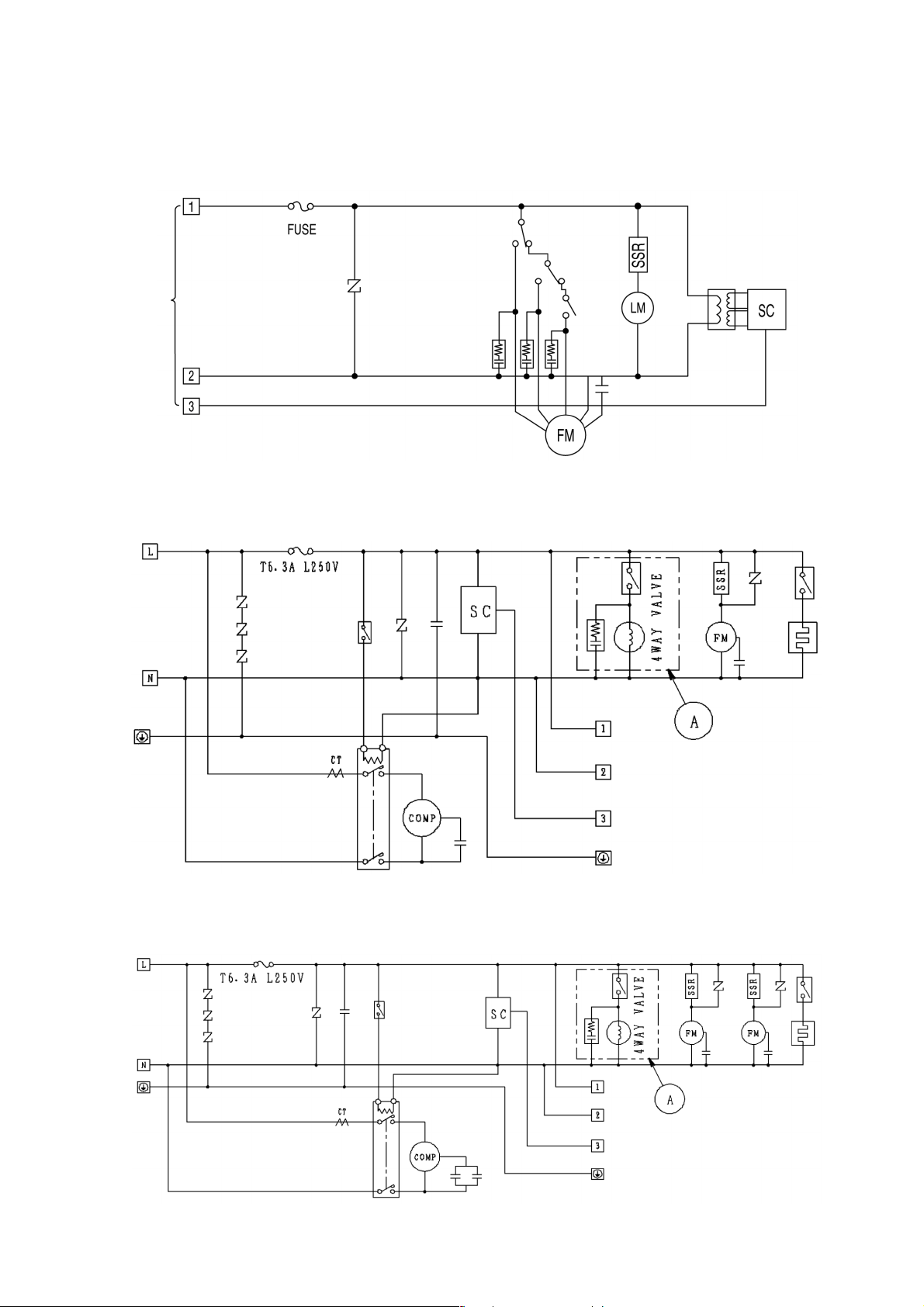

6 BLOCK DIAGRAM

6.1. CS-F24DD3E5 CS-F28DD3E5 CS-F34DD3E5 CSF43DD3E5 CS-F50DD3E5

6.2. CU-B24DBE5 CU-B28DBE5

6.3. CU-B34DBE5

6.4. CU-B28DBE8

6.5. CU-B34DBE8 CU-B43DBE8 CU-B50DBE8

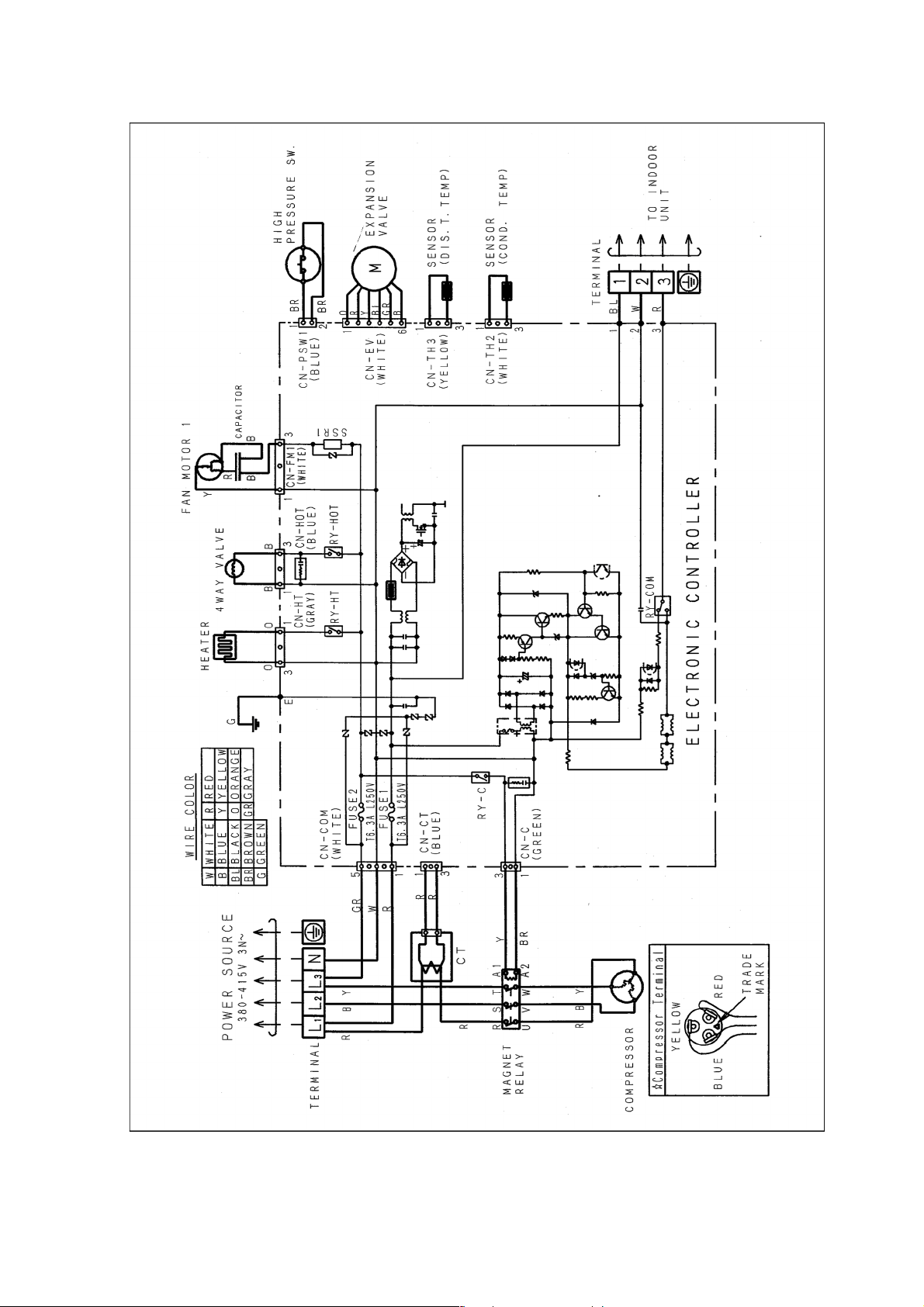

7 WIRING DIAGRAM

7.1. CS-F24DD3E5 CS-F28DD3E5 CS-F34DD3E5 CSF43DD3E5 CS-F50DD3E5

7.2. CU-B24DBE5 CU-B28DBE5

7.3. CU-B28DBE8

7.4. CU-B34DBE5

7.5. CU-B34DBE8 CU-B43DBE8 CU-B50DBE8

8 WIRED REMOTE CONTROL OPERATING INSTRUCTIONS

8.1. Name and function of each part

8.2. Remote control - display

8.3. Remote control - panel

8.4. How to set remote control day and time

8.5. How to select the timer

8.6. Daily timer setting

8.7. Weekly timer setting

9 OPERATION DETAIL

9.1. Cooling operation

7

8

9

10

11

12

13

13

14

15

16

17

17

18

19

19

19

19

20

20

21

21

22

23

24

25

26

26

27

28

29

29

30

31

33

9.2. Heating operation

9.3. Soft dry operation

9.4. Auto operation

9.5. Fan operation

9.6. Normal control

9.7. Operation control

9.8. Protection control

9.9. Test run

10 INSTALLATION INSTRUCTION

10.1. Pipe length

10.2. Position of the centre gravity

10.3. Indoor unit installation

10.4. Outdoor unit installation

10.5. Wired remote controller installation

10.6. Twin systems installation

11 INSTALLATION & SERVICING AIR CONDITIONER

11.1. Outline

11.2. Tools for installing/servicing refrigerant piping

11.3. Refrigerant piping work

11.4. Installation, transferring, servicing

12 TROUBLE SHOOTING GUIDE

12.1. For standard installation

12.2. During twin operation

12.3. During group control operation

12.4. Test operation and self diagnosis

12.5. Emergency operation

12.6. Self-diagnosis error code table

13 TECHNICAL DATA

13.1. Sound data

13.2. Sound measurement point

13.3. Discharge and suction pressure

13.4. Capacity and power consumption

13.5. Fan performance

13.6. Safety device

13.7. Operating characteristics

14 REPLACEMENT PARTS

14.1. Indoor unit

14.2. Outdoor unit

15 PRINT PATTERN

15.1. Indoor unit

15.2. Outdoor unit

33

34

34

34

34

35

36

39

41

42

42

44

45

56

67

74

75

75

76

80

82

86

86

88

90

91

94

95

97

97

103

104

106

129

134

135

136

136

140

147

147

148

2

Page 3

1 SERVICE INFORMATION

Notice of Address setting for NEW Duct / NEW Outdoor Unit.

The new Duct Type / New Outdoor models are possible to have address setting for twin control by automatic when main

power supply is switched on.

(Manual address setting is also possible by using Dip switch on Indoor unit P.C. board.) However,

possible when made proper wiring connection and also Indoor unit should be original virgin unit

1.1. Example of trouble at test operation

If found out as following phenomenon at test operation on site, it may have possibility of wrong address setting.

Therefore, please ensure of the address setting.

1. LCD display of wired remote control had not illuminate although the main power supply switch is ‘on’.

2. LCD display had indicated as normal illumination when power supply switch is ‘on’, however outdoor unit cannot be operated.

(But, it is necessary to take 3 to 5 minutes for outdoor unit to start from the timing of remote control ON/OFF switch is ‘on’.)

3. P.C. board had memorized wrong setting information.

a. If main power supply is switched ‘on’ with the wrong connection.

b. When changing the connection or combination of units due to re-installation etc.

• When changing the system from twin control to normal one to one system.

• When making the replacement of units as master and slave etc.

this address setting is only

.

1.2. Caution of test operation

Do not touch the remote control switch and do not change any wirings for one minute when the main power supply switch is ‘on’.

(Because the unit is having automatic address setting during the first one minute.)

1.3. Caution during automatic address setting

When main power supply switch is ‘on’, the P.C. board will automatically memorized the connecting system.

Consequently, when initial power supply is ‘on’, there will not be interchangeability of units even of the same type and same

capacity unit. Therefore unable to connect the unit to another system.

1.4. Operation range

The applicable voltage range for each unit is given in “the following table”. The working voltage among the three phases must be

balanced within 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the

rated voltage.

1.4.1. Power Supply

Model

CU-

B24DBE5

B28DBE5

B34DBE5

B28DBE8

B34DBE8

B43DBE8

B50DBE8

Unit Main Power Applicable Voltage

Phase, Volts Hz Maximum Minimum

1~220 50 242 198

1~230 50 253 207

1~240 50 264 216

3N~380 50 418 342

3N~400 50 440 360

3N~415 50 457 374

1.4.2. Indoor and Outdoor Temperature

Model 50Hz ... B24DBE5, B28DBE5, B28DBE8, B34DBE5, B34DBE8, B43DBE8, B50DBE8

Operating Hz Indoor Temp. (D.B./W.B.) (°C) Outdoor Temp. (D.B./W.B.) (°C)

Maximum Minimum Maximum Minimum

Cooling 50 32/23 21/15 43/- -10/Heating 50 27/- 16/- 24/18 -10/-

3

Page 4

2 FEATURES

2.1. Hide-away type

2.1.1. Compact design

• The height has been reduced to 25 cm, the equipment can

be installed in limited spaces.

2.1.2. Versatile installation

• The indoor unit is designed in order that air will also enter

from below, for easier installation under different conditions.

2.2. Outdoor unit

2.2.1. Flexible installation in smaller

spaces

• Space-saving outdoor unit with the improvement of the

outdoor unit fan makes it possible to install the outdoor unit

into a smaller space where the conventional model cannot

be installed.

• Long pipe design with a maximum piping length of 50m.

• Additional charging of refrigerant are not required for 30m

of pipe length.

• Flexible 4-way piping.

• The equipment has two drain outlets on the right and left

side for adoption to the installation conditions in the

building.

2.1.3. Easy maintenance

• Equipped with a filter as standard. The filter can be

removed in three directions for easier maintenance.

• Centralized drain method gather multiple outdoor units’

drain pipes into a single drain pipe to make installation

easier and also improve appearance.

• Side-by-side continuous installation is possible even for

outdoor units with different capacities.

4

Page 5

2.2.2. Quiet, efficient design

• A host of silencing technologies achieves super-quiet

operation.

• The noise-suppressing winglet fan is a result of new

research into vane design theory. The unique curved shape

suppresses the generation of vortexes, thus reduces air

flows noise.

• Operating efficiency is improved and energy consumption is

reduced.

2.2.3. Low ambient cooling operation

• The unit can set for cooling even when the outdoor

temperature drops to -10°C. This is ideal for locations that

require cooling even in winter.

2.3. A brand-new control method using the latest in technology

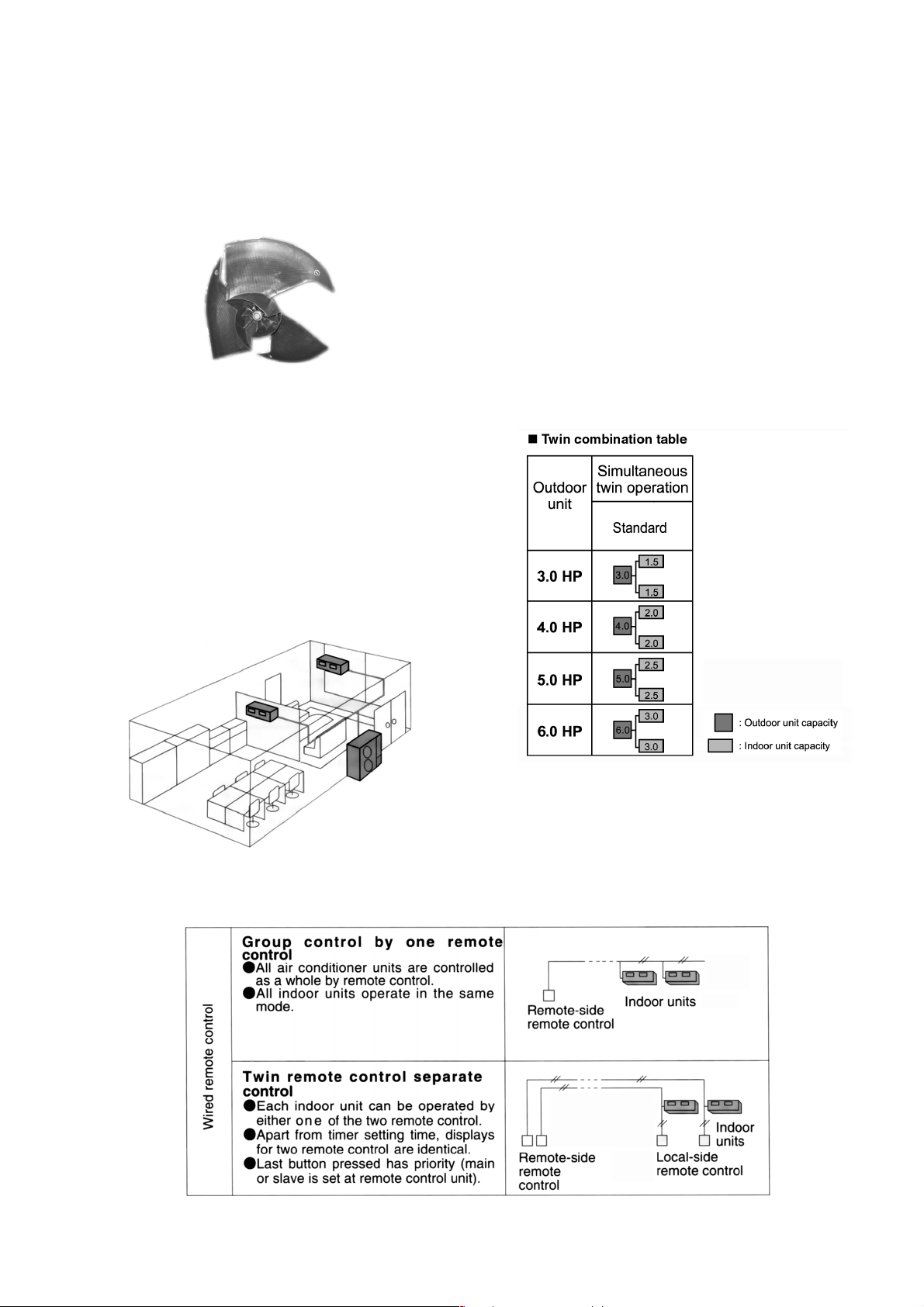

2.3.1. Twin operation

• Simultaneous air conditioning of wide spaces and corners is

possible. Indoor units of same horsepowers and models

can even be used in combination.

• Master unit and slave-units can be set automatically in twin

systems. No address setting is necessary.

• Multiple indoor units can be operated simultaneously with a

single remote control. Note that individual operation is not

possible.

2.3.2. Group control equipment

5

Page 6

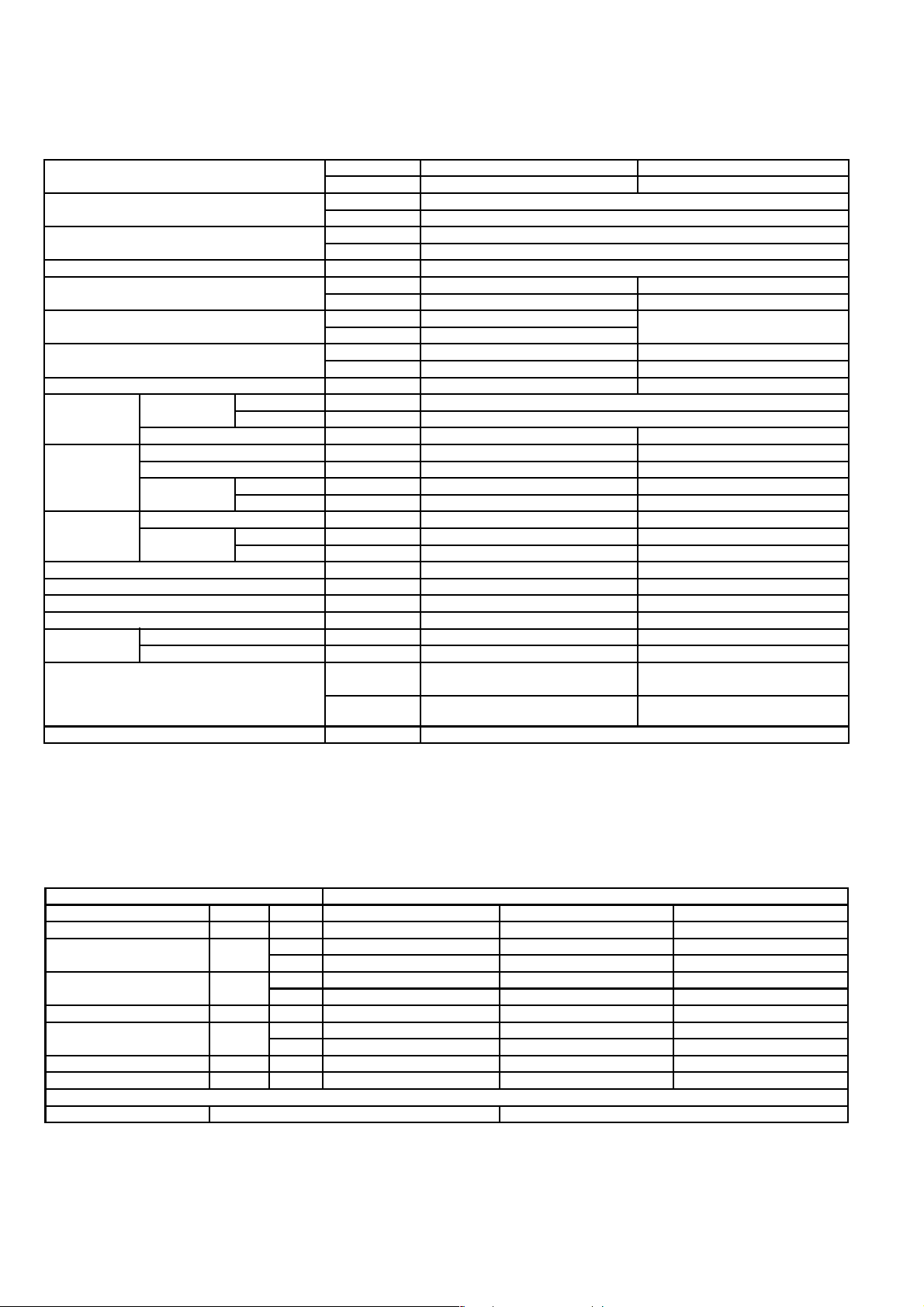

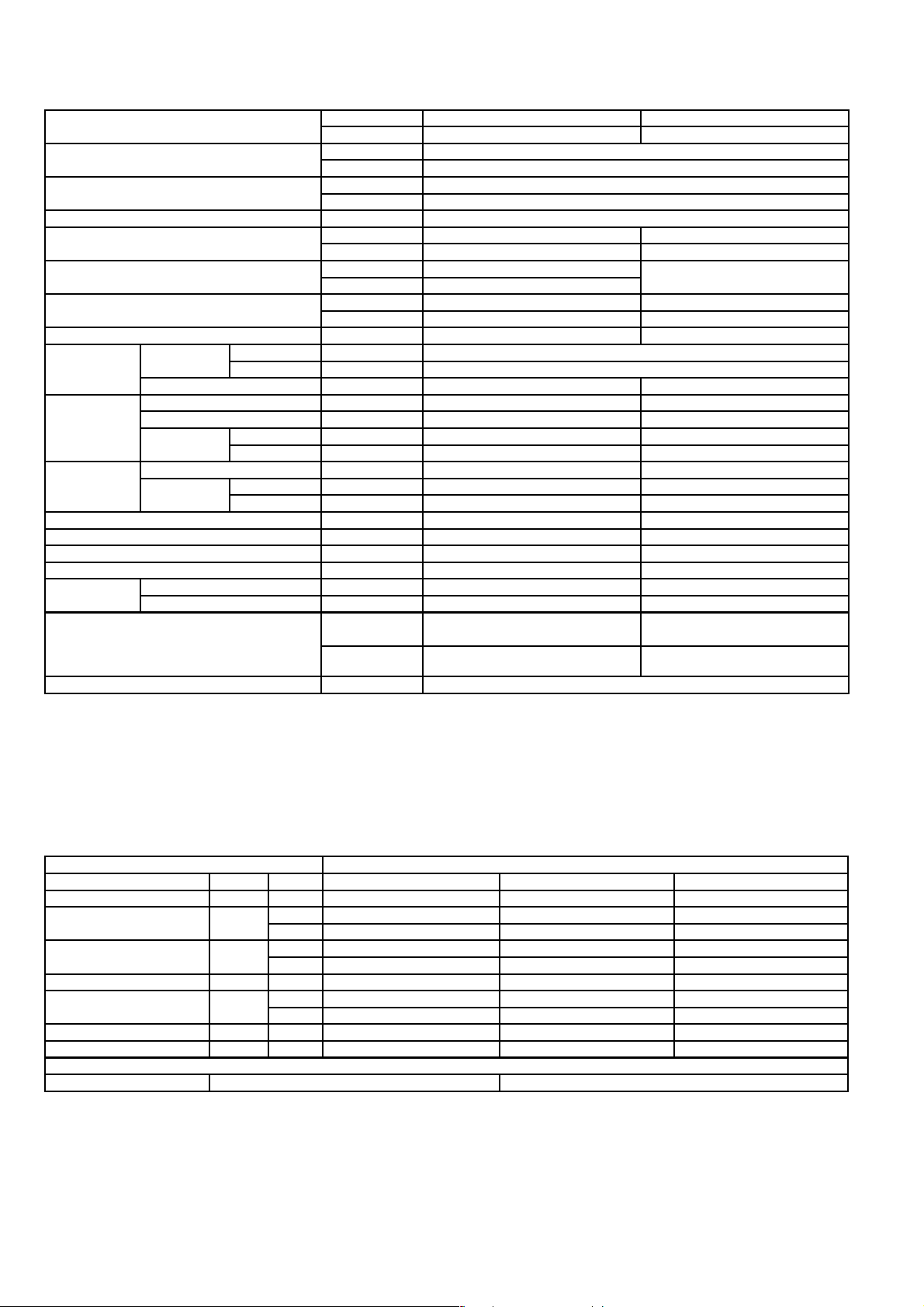

3 SPECIFICATION

3.1. CS-F24DD3E5 CU-B24DBE5

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F24DD3E5 CU-B24DBE5

Cooling Capacity kW 6.6

BTU/h 22,500

Heating Capacity kW 7.1

BTU/h 24,200

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 22 Hi 60

cfm Hi 777 Hi 2120

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1000 x 650 795 x 900 x 320

inch 9-26/32 x 39-5/16 x 25-18/32 31-5/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 41 (91) 69 (152)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco fan, 2 Mix flow fan - 1

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 12 x 15) Corrugate-fin type (2 x 36 x 19)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 1.7 (60)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 43 Lo 39 Cooling 50, Heating 51

Moisture Removal L/h (Pt/h) 3.8 (8.0)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 2.2

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.085 0.07

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 43 Lo 39

Power level dB Cooling : Hi 59 Lo 55

Heating : Hi 59 Lo 55

- FV50S (1130)

Cooling 66, Heating 67

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 220 230 240

Phase Single Single Single

Power Consumption kW Cool 2.56 2.59 2.64

Heat 2.4 2.47 2.56

Running Current A Cool 12.7 12.9 13.1

Heat 11.5 11.8 12.3

Starting Current A 59 62 65

Power Factor % Cool 92 87 84

Heat 95 91 87

EER W/W 2.58 2.55 2.50

COP W/W 2.96 2.87 2.77

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~220V, 230V, 240V 50Hz

6

Page 7

3.2. CS-F28DD3E5 CU-B28DBE5

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F28DD3E5 CU-B28DBE5

Cooling Capacity kW 7.3

BTU/h 24,900

Heating Capacity kW 8.0

BTU/h 27,300

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 22 Hi 63

cfm Hi 777 Hi 2226

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1000 x 650 795 x 900 x 320

inch 9-26/32 x 39-5/16 x 25-18/32 31-5/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 41 (91) 69 (152)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco Fan, 2 Mix flow fan - 1

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 12 x 15) Corrugate-fin type (2 x 36 x 19)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 2.05 (72)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 43 Lo 39 Cooling 52, Heating 53

Moisture Removal L/h (Pt/h) 4.3 (9.0)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 2.2

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.085 0.07

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 43 Lo 39

Power level dB Cooling : Hi 59 Lo 55

Heating : Hi 59 Lo 55

- FV50S (1130)

Cooling 67, Heating 68

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 220 230 240

Phase Single Single Single

Power Consumption kW Cool 2.78 2.84 2.89

Heat 2.61 2.69 2.78

Running Current A Cool 13.3 13.5 13.7

Heat 12.5 12.6 13.1

Starting Current A 62 65 68

Power Factor % Cool 95 91 88

Heat 95 93 88

EER W/W 2.63 2.57 2.53

COP W/W 3.07 2.97 2.88

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~220V, 230V, 240V 50Hz

7

Page 8

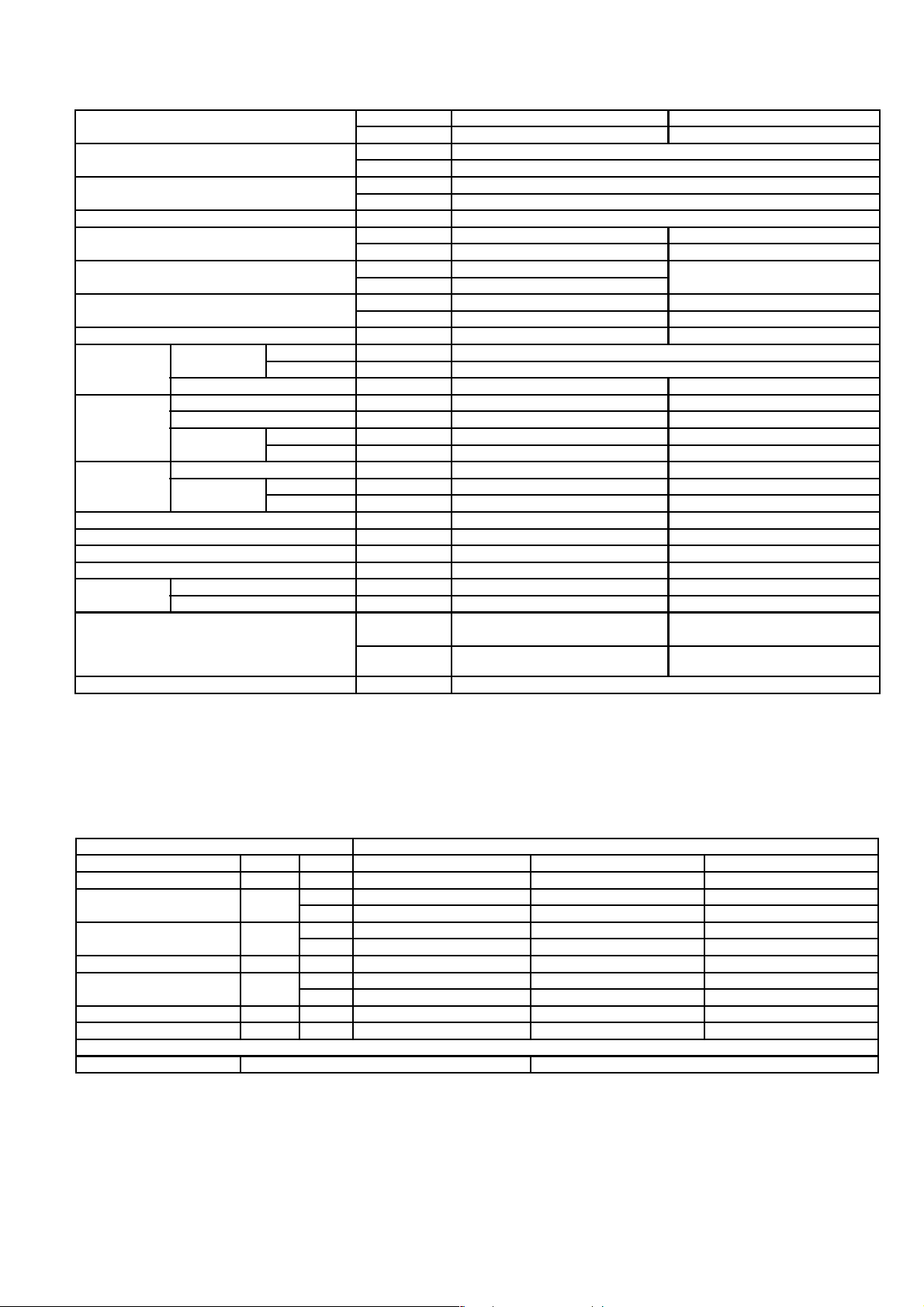

3.3. CS-F28DD3E5 CU-B28DBE8

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F28DD3E5 CU-B28DBE8

Cooling Capacity kW 7.3

BTU/h 24,900

Heating Capacity kW 8.0

BTU/h 27,300

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 22 Hi 63

cfm Hi 777 Hi 2226

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1000 x 650 795 x 900 x 320

inch 9-26/32 x 39-5/16 x 25-18/32 31-5/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 41 (91) 69 (152)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco Fan, 2 Mix flow fan - 1

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 12 x 15) Corrugate-fin type (2 x 36 x 19)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 2.05 (72)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 43 Lo 39 Cooling 52, Heating 53

Moisture Removal L/h (Pt/h) 4.3 (9.0)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 2.2

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.085 0.07

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 43 Lo 39

Power level dB Cooling : Hi 59 Lo 55

Heating : Hi 59 Lo 55

- FV50S (1130)

Cooling 67, Heating 68

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 380 400 415

Phase 3N 3N 3N

Power Consumption kW Cool 2.78 2.84 2.89

Heat 2.61 2.69 2.78

Running Current A Cool 4.85 4.9 4.95

Heat 4.65 4.7 4.75

Starting Current A 23 25 27

Power Factor % Cool 87 84 81

Heat 85 83 82

EER W/W 2.63 2.57 2.53

COP W/W 3.07 2.97 2.88

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 3N~380V, 400V, 415V 50Hz

8

Page 9

3.4. CS-F34DD3E5 CU-B34DBE5

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F34DD3E5 CU-B34DBE5

Cooling Capacity kW 10.0

BTU/h 34,100

Heating Capacity kW 11.2

BTU/h 38,200

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 36 Hi 94

cfm Hi 1271 Hi 3316

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1200 x 650 1170 x 900 x 320

inch 9-27/32 x 47-7/32 x 25-19/32 46-1/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 47 (104) 102 (225)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco fan, 3 Mix flow fan - 2

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 16 x 15) Corrugate-fin type (2 x 44 x 20)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 2.7 (95)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 45 Lo 41 Cooling 55, Heating 56

Moisture Removal L/h (Pt/h) 6.0 (12.6)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 3.0

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.185 0.07 x 2

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 44 Lo 40

Power level dB Cooling : Hi 60 Lo 56

Heating : Hi 59 Lo 55

- FV68D (1500)

Cooling 69, Heating 70

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 220 230 240

Phase Single Single Single

Power Consumption kW Cool 3.83 3.88 4.05

Heat 3.86 3.94 4.0

Running Current A Cool 18.4 18.6 18.8

Heat 18.5 18.6 18.9

Starting Current A 92 95 98

Power Factor % Cool 95 91 90

Heat 95 92 88

EER W/W 2.61 2.58 2.47

COP W/W 2.9 2.84 2.8

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~220V, 230V, 240V 50Hz

9

Page 10

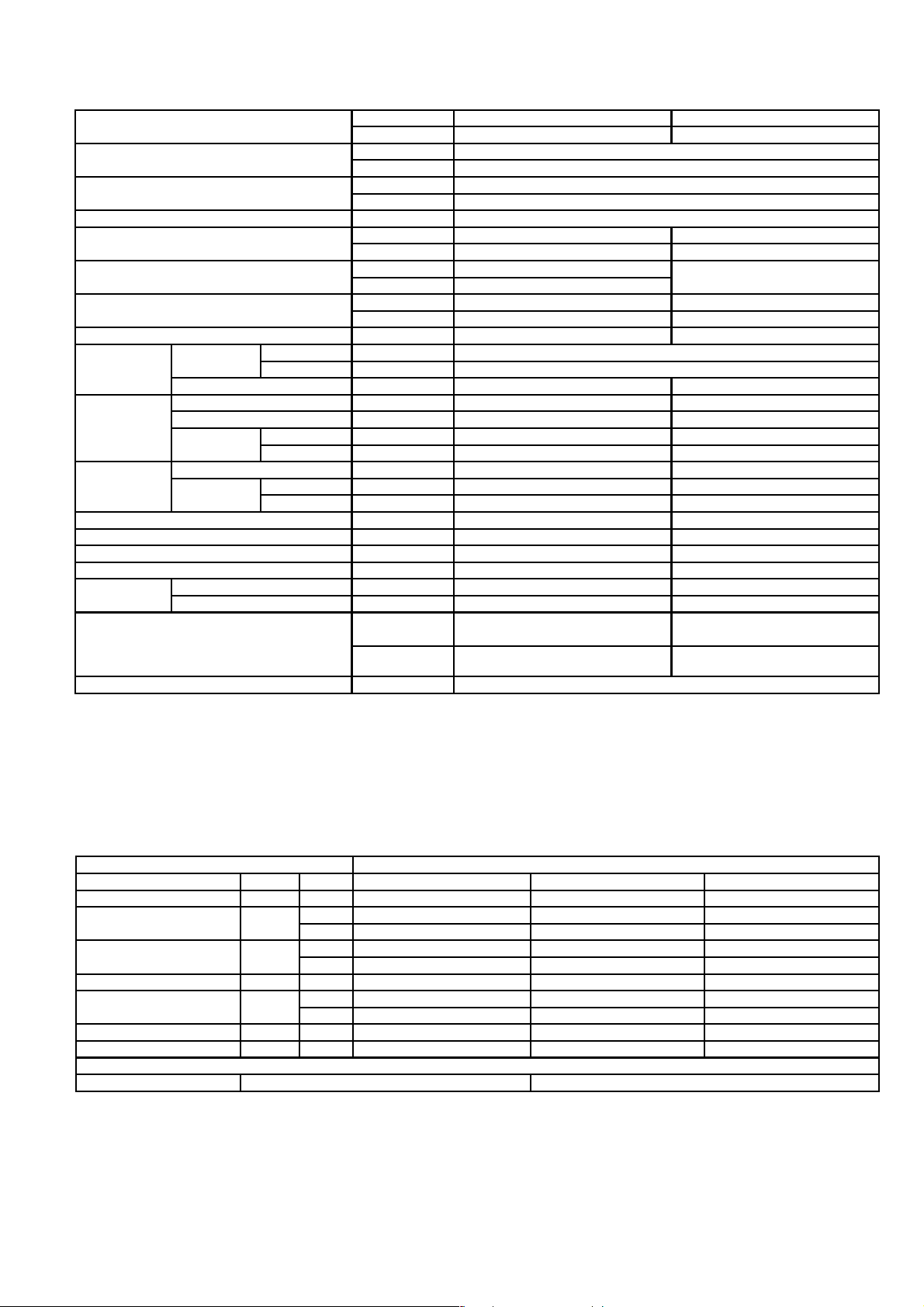

3.5. CS-F34DD3E5 CU-B34DBE8

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F34DD3E5 CU-B34DBE8

Cooling Capacity kW 10.0

BTU/h 34,100

Heating Capacity kW 11.2

BTU/h 38,200

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 36 Hi 94

cfm Hi 1271 Hi 3316

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1200 x 650 1170 x 900 x 320

inch 9-27/32 x 47-7/32 x 25-19/32 46-1/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 47 (104) 100 (221)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco fan, 3 Mix flow fan - 2

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 16 x 15) Corrugate-fin type (2 x 44 x 20)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 2.7 (95)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 45 Lo 41 Cooling 55, Heating 56

Moisture Removal L/h (Pt/h) 6.0 (12.6)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 3.0

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.185 0.07 x 2

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 44 Lo 40

Power level dB Cooling : Hi 60 Lo 56

Heating : Hi 59 Lo 55

- FV68D (1500)

Cooling 69, Heating 70

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 380 400 415

Phase 3N 3N 3N

Power Consumption kW Cool 3.7 3.75 3.8

Heat 3.54 3.58 3.64

Running Current A Cool 6.35 6.45 6.55

Heat 6.10 6.20 6.30

Starting Current A 41 44 47

Power Factor % Cool 89 84 81

Heat 88 83 80

EER W/W 2.70 2.67 2.63

COP W/W 3.16 3.13 3.08

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 3N~380V, 400V, 415V 50Hz

10

Page 11

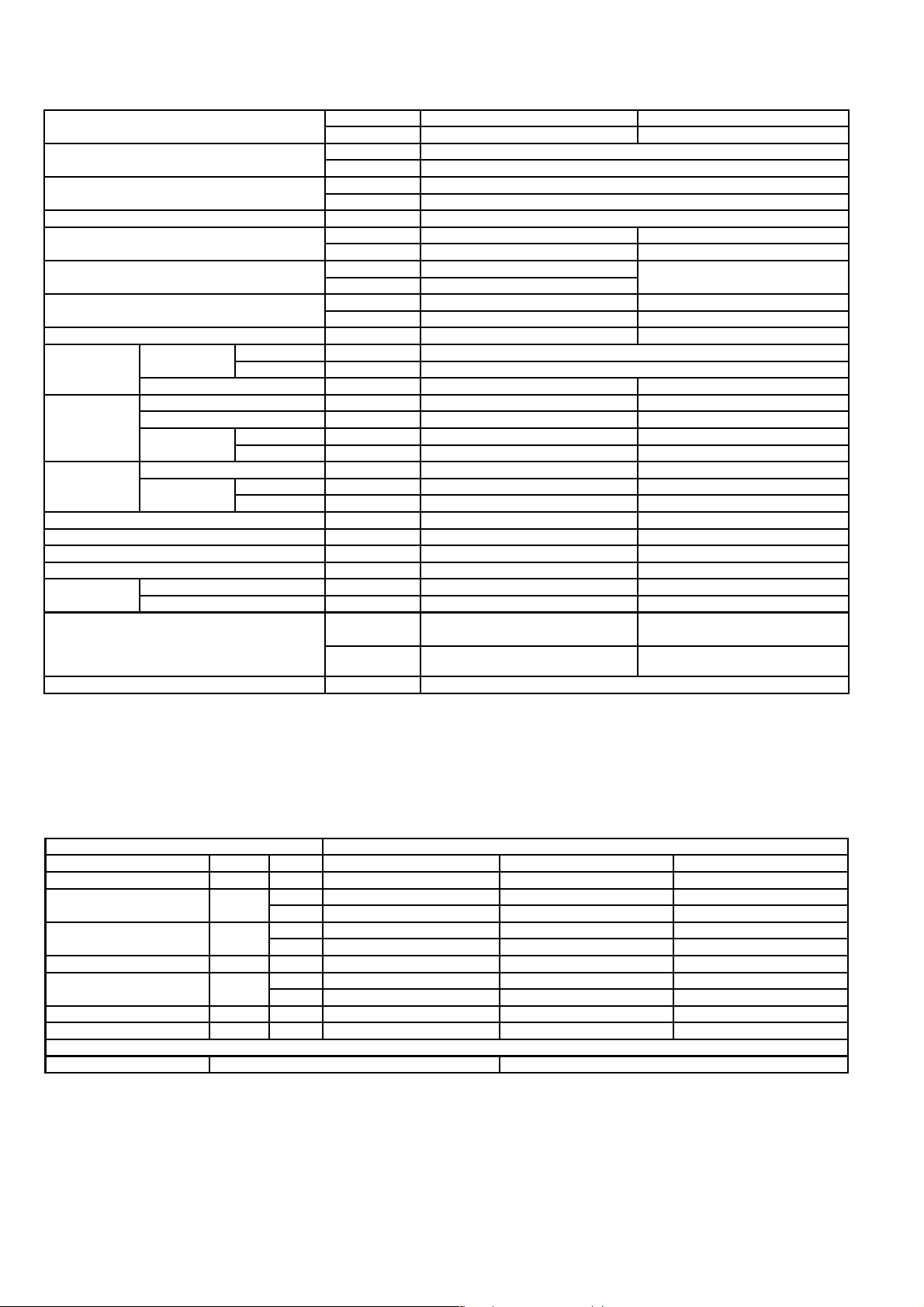

3.6. CS-F43DD3E5 CU-B43DBE8

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F43DD3E5 CU-B43DBE8

Cooling Capacity kW 12.5

BTU/h 42,600

Heating Capacity kW 14.0

BTU/h 47,700

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 40 Hi 94

cfm Hi 1413 Hi 3316

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1200 x 650 1170 x 900 x 320

inch 9-27/32 x 47-7/32 x 25-19/32 46-1/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 47 (104) 102 (225)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco Fan, 3 Mix flow fan - 2

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 16 x 15) Corrugate-fin type (2 x 44 x 20)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 3.10 (109)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 45 Lo 41 Cooling 56, Heating 57

Moisture Removal L/h (Pt/h) 7.9 (16.6)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 3.75

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.185 0.07 x 2

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 44 Lo 40

Power level dB Cooling : Hi 60 Lo 56

Heating : Hi 59 Lo 55

- FV68D (1500)

Cooling 70, Heating 71

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 380 400 415

Phase 3N 3N 3N

Power Consumption kW Cool 4.75 4.8 4.87

Heat 4.61 4.68 4.78

Running Current A Cool 8.0 8.1 8.2

Heat 7.8 7.9 8.0

Starting Current A 54 57 60

Power Factor % Cool 90 86 83

Heat 90 86 83

EER W/W 2.63 2.60 2.57

COP W/W 3.04 2.99 2.93

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 3N~380V, 400V, 415V 50Hz

11

Page 12

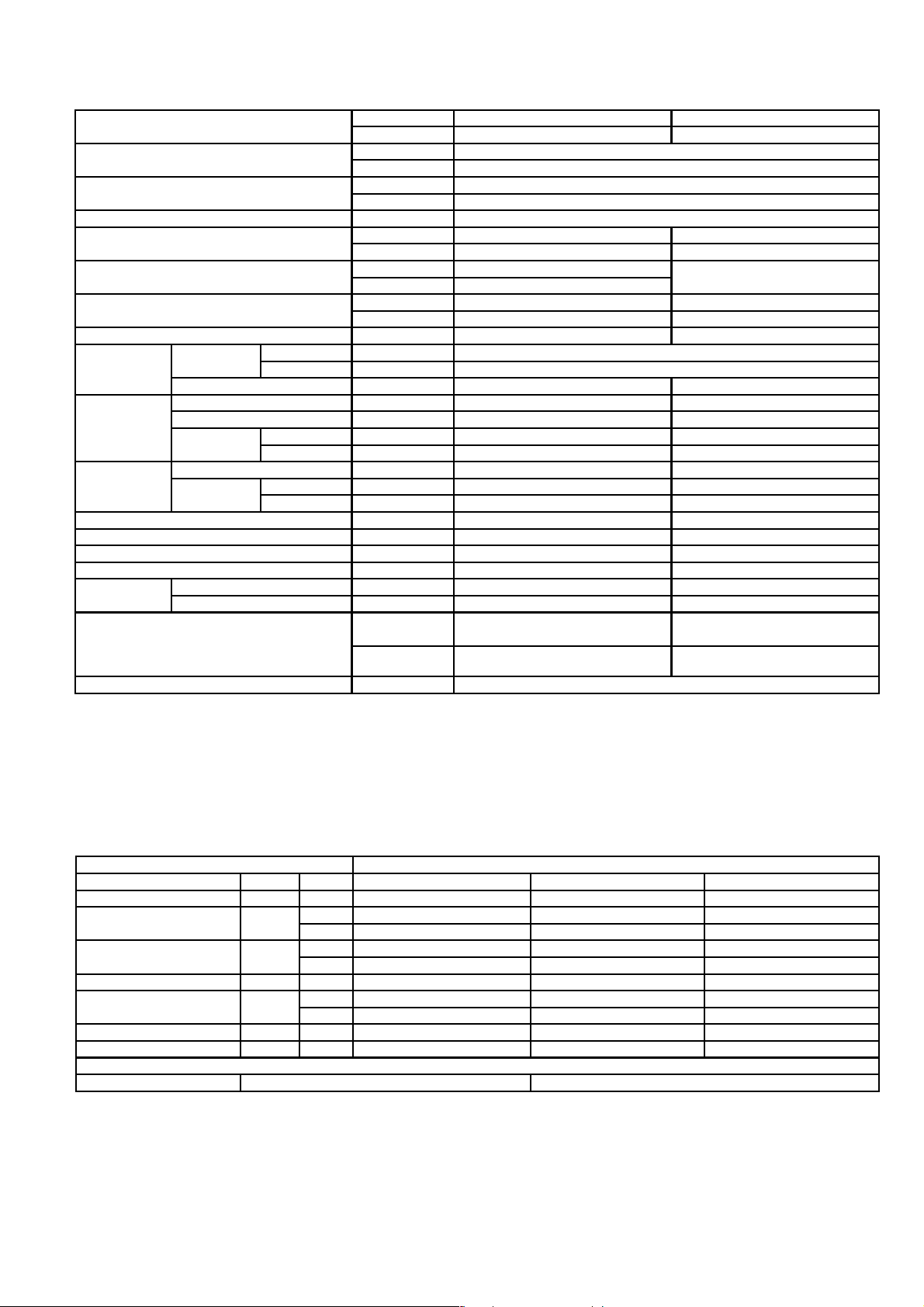

3.7. CS-F50DD3E5 CU-B50DBE8

ITEM / MODEL Indoor Unit Outdoor Unit

Main Body CS-F50DD3E5 CU-B50DBE8

Cooling Capacity kW 13.5

BTU/h 46,000

Heating Capacity kW 15.0

BTU/h 51,100

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min Hi 44 Hi 96

cfm Hi 1555 Hi 3387

External Static Pressure Pa Hi 50 -

mmAq Hi 5.1

Outside Dimension (H x W x D) mm 250 x 1200 x 650 1170 x 900 x 320

inch 9-27/32 x 47-7/32 x 25-19/32 46-1/16 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 47 (104) 102 (225)

Piping

Connection

Compressor Type, Number of Set - Hermetic, 1

Fan Type, Number of Set Sirocco Fan, 3 Mix flow fan - 2

Air-heat Exchanger (Row x Stage x FPI) Louvre-fin type (3 x 16 x 15) Corrugate-fin type (2 x 44 x 20)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged) cm

Refrigerant (Charged) R410A kg (oz) - 3.4 (120)

Running

Adjustment

Noise Level dB (A) Cooling : Hi 46 Lo 42 Cooling 56, Heating 57

Moisture Removal L/h (Pt/h) 8.6 (18.1)

Refrigerant Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm Female screw RC1 (PT1) I.D Ø 20 x 1

Starting Method - Permanent Split Capacitor

Motor Type - 2-pole single phase brushless motor

Rated Output kW - 4.5

Motor Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.185 0.07 x 2

3

Control Switch Wired Remote Control Room Temperature Thermostat -

Heating : Hi 45 Lo 41

Power level dB Cooling : Hi 61 Lo 57

Heating : Hi 60 Lo 56

- FV68D (1500)

Cooling 70, Heating 71

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL Condition by ISO5151

Volts V 380 400 415

Phase 3N 3N 3N

Power Consumption kW Cool 5.26 5.31 5.46

Heat 5.03 5.08 5.13

Running Current A Cool 8.7 8.8 9.1

Heat 8.2 8.4 8.7

Starting Current A 55 58 61

Power Factor % Cool 92 87 83

Heat 93 87 82

EER W/W 2.57 2.54 2.47

COP W/W 2.98 2.95 2.92

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 3N~380V, 400V, 415V 50Hz

12

Page 13

4 DIMENSIONS

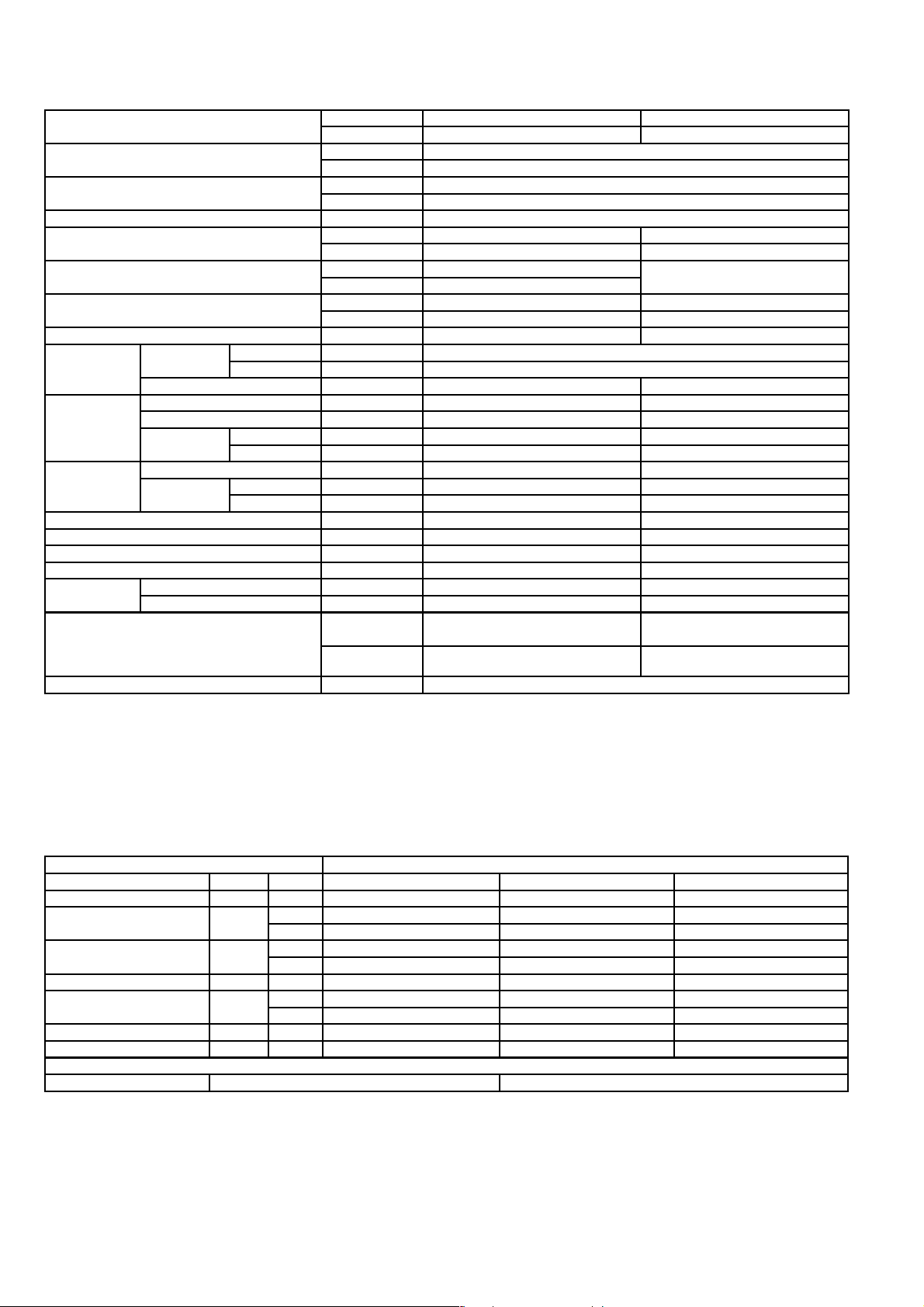

4.1. CS-F24DD3E5 CS-F28DD3E5

13

Page 14

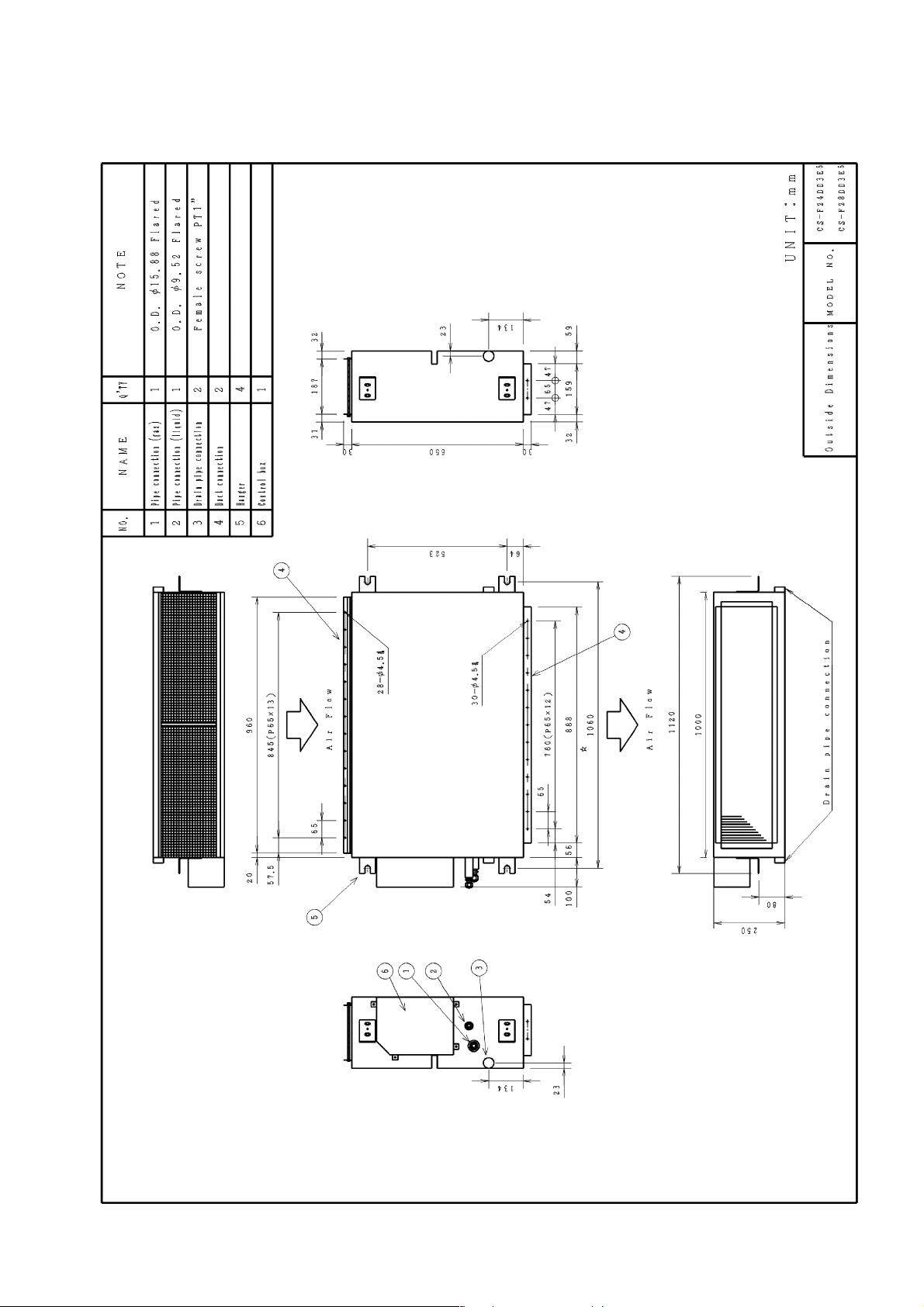

4.2. CS-F34DD3E5 CS-F43DD3E5 CS-F50DD3E5

14

Page 15

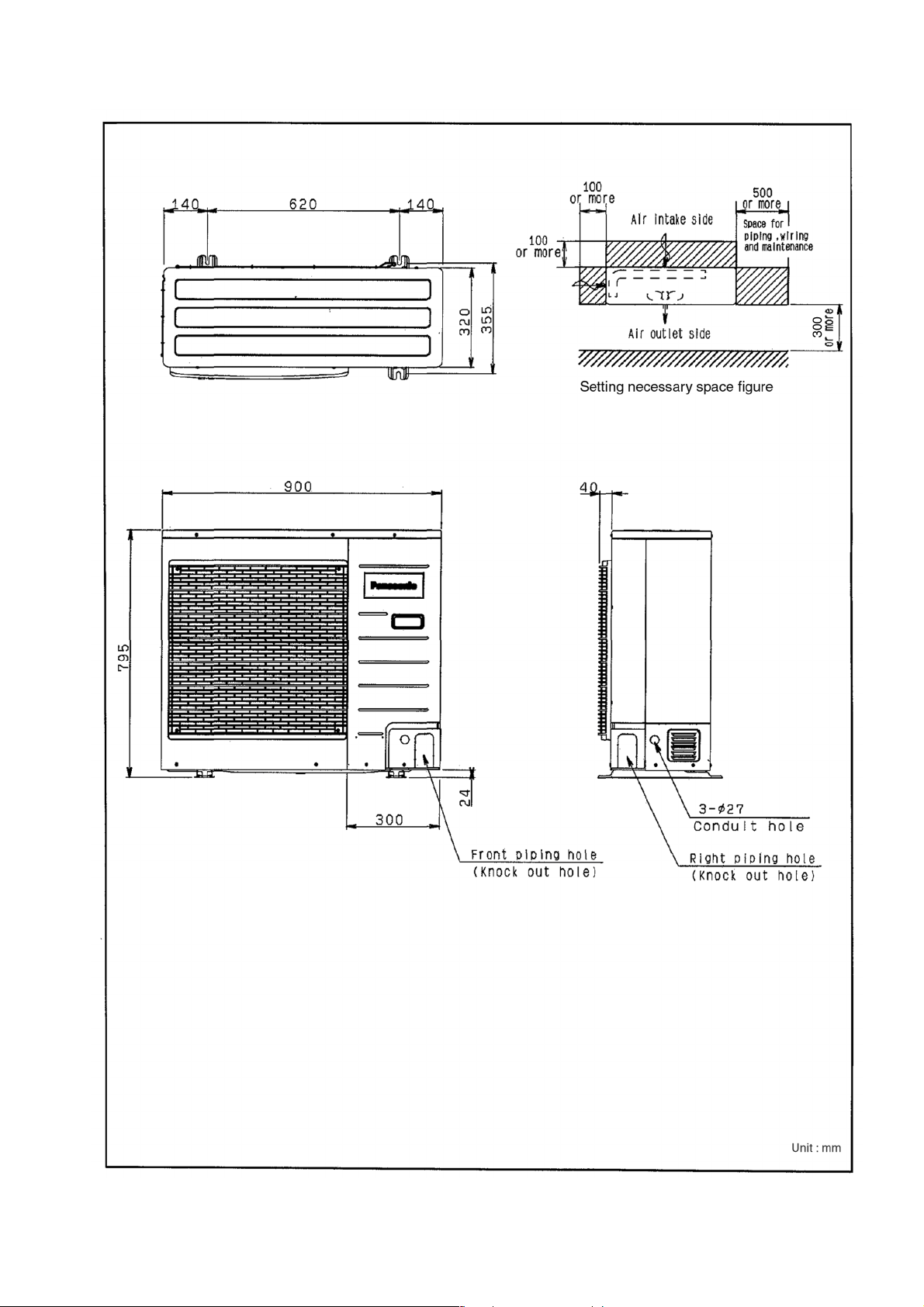

4.3. CU-B24DBE5 CU-B28DBE5 CU-B28DBE8

15

Page 16

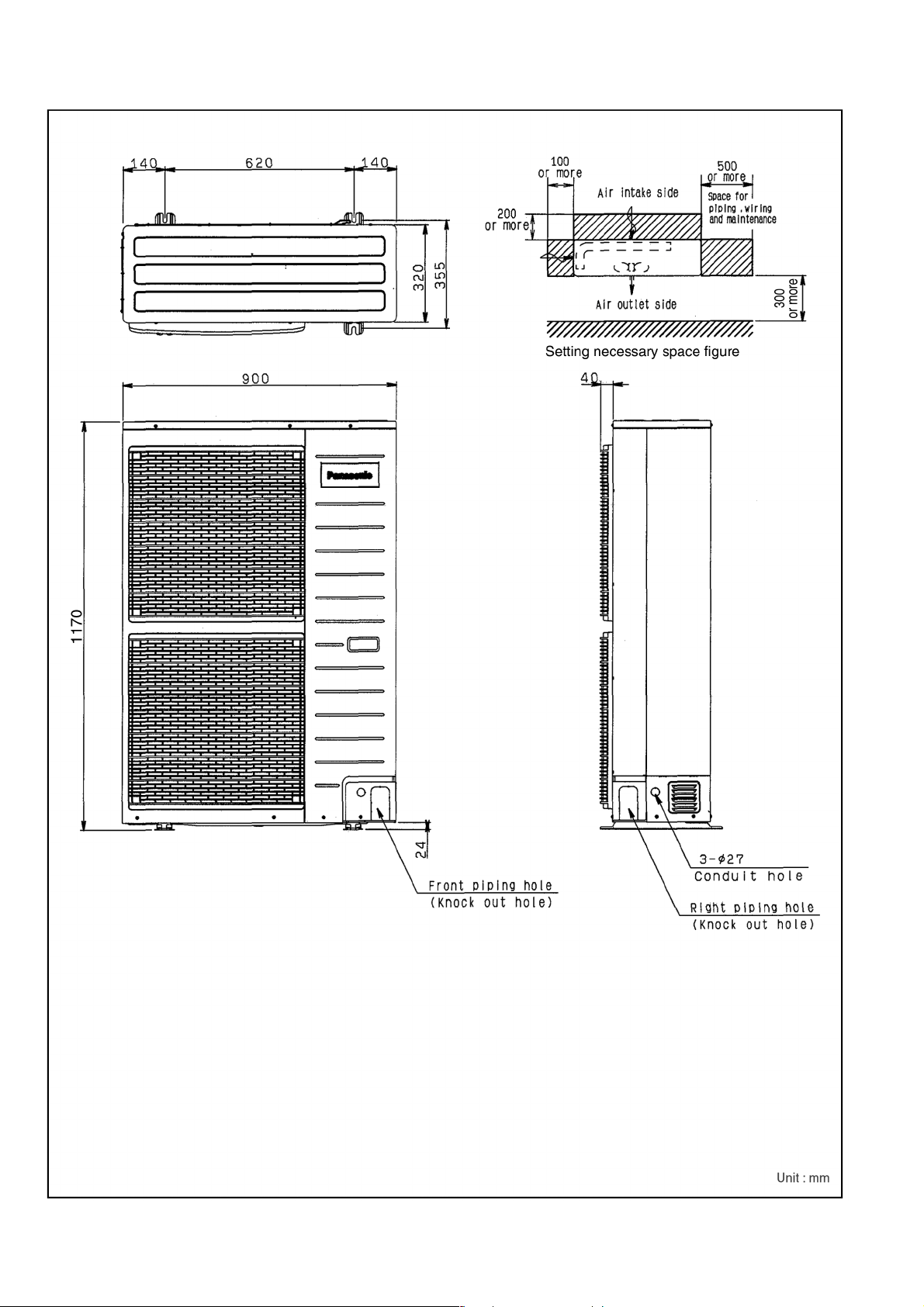

4.4. CU-B34DBE5 CU-B34DBE8 CU-B43DBE8 CU-B50DBE8

16

Page 17

5 REFRIGERATION CYCLE

5.1. CS-F24DD3E5 CU-B24DBE5

CS-F28DD3E5 CU-B28DBE5 CU-B28DBE8

17

Page 18

5.2. CS-F34DD3E5 CU-B34DBE5 CU-B34DBE8

CS-F43DD3E5 CU-B43DBE8

CS-F50DD3E5 CU-B50DBE8

18

Page 19

6 BLOCK DIAGRAM

6.1. CS-F24DD3E5 CS-F28DD3E5 CS-F34DD3E5 CS-F43DD3E5

CS-F50DD3E5

6.2. CU-B24DBE5 CU-B28DBE5

6.3. CU-B34DBE5

19

Page 20

6.4. CU-B28DBE8

6.5. CU-B34DBE8 CU-B43DBE8 CU-B50DBE8

20

Page 21

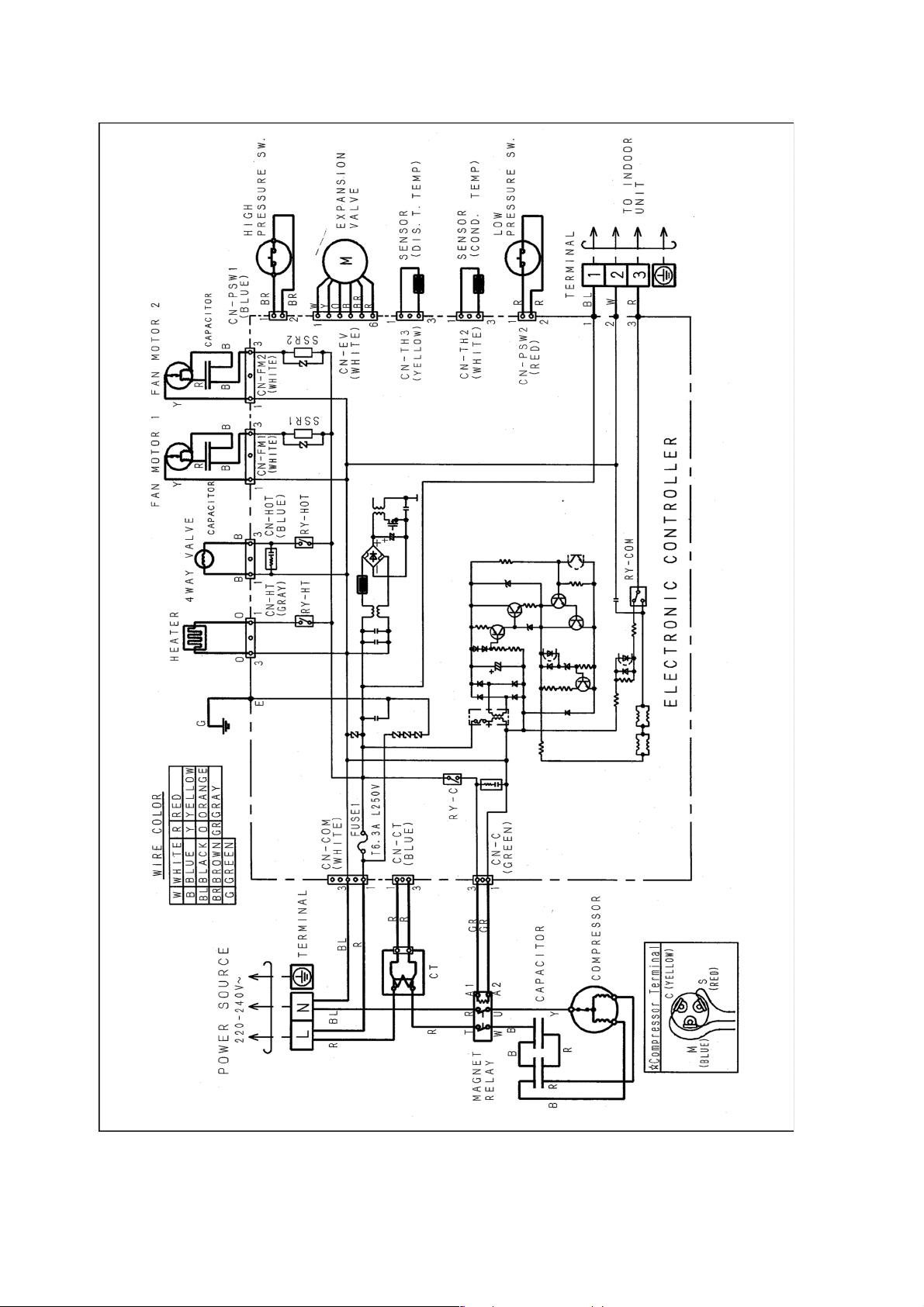

7 WIRING DIAGRAM

7.1. CS-F24DD3E5 CS-F28DD3E5 CS-F34DD3E5 CS-F43DD3E5

CS-F50DD3E5

21

Page 22

7.2. CU-B24DBE5 CU-B28DBE5

22

Page 23

7.3. CU-B28DBE8

23

Page 24

7.4. CU-B34DBE5

24

Page 25

7.5. CU-B34DBE8 CU-B43DBE8 CU-B50DBE8

25

Page 26

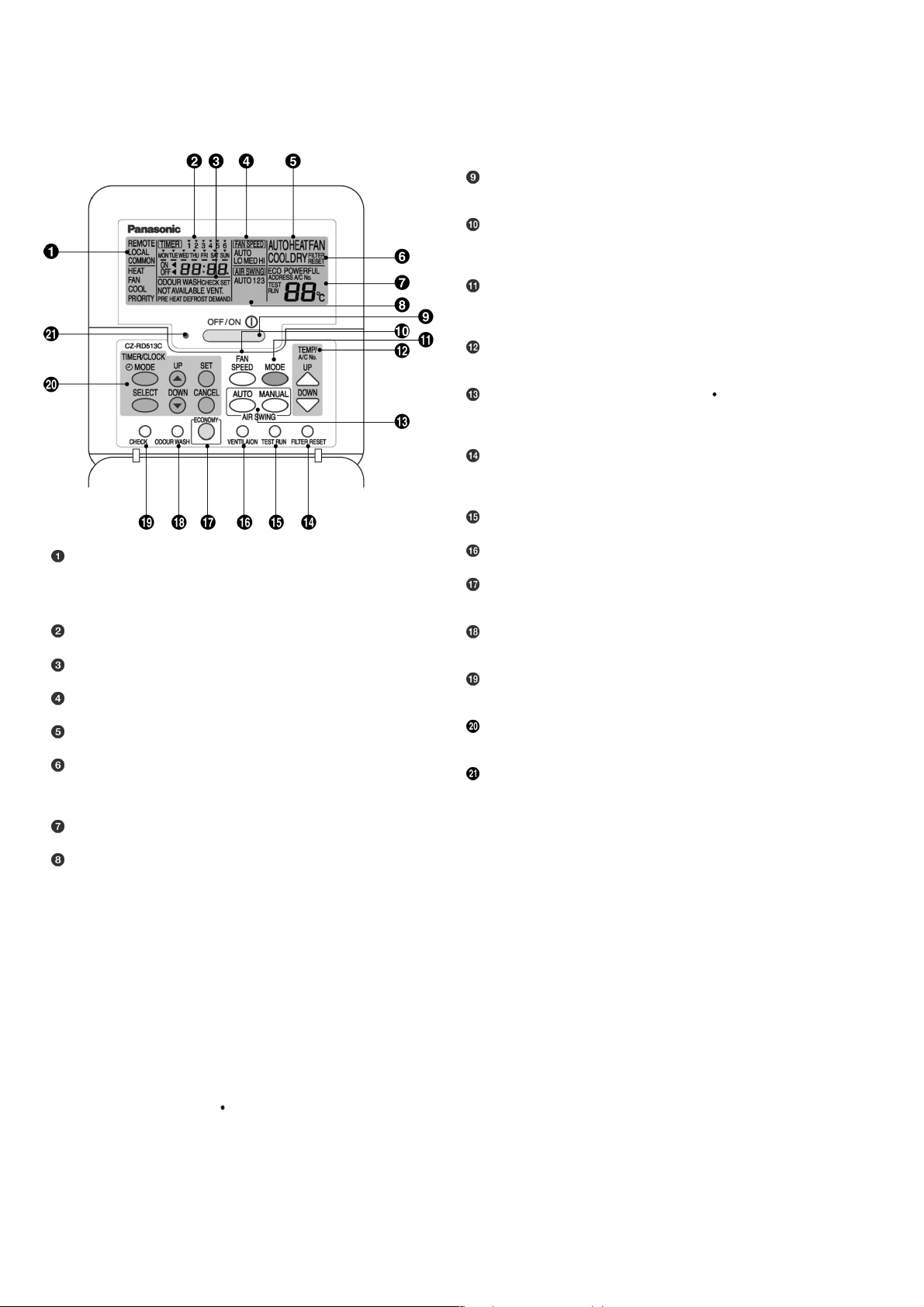

8 WIRED REMOTE CONTROL OPERATING INSTRUCTIONS

8.1. Name and function of each part

OFF/ON button

Used to start and stop the operation.

FAN SPEED button

Used to select the fan speed of high (HI), medium (MED), low

(LO) or auto (AUTO).

MODE button

Used to select the operation of AUTO, HEAT, FAN, COOL, or

DRY.

TEMP (UP/DOWN) buttons

Used to select the desired temperature.

AIR SWING (AUTO/MANUAL) buttons

Used to determined the air swing condition, either auto or

manual.

FILTER RESET button

Press to reset the “FILTER RESET” display after washing the

filter.

TEST RUN button*

REMOTE

The OFF/ON button cannot be used.

LOCAL

All wired remote control buttons can be used.

Time/time setting display

Check display

Fan speed display

Operation mode selection display

FILTER RESET display

(Appears after the cumulative running time reaches

approximately 2,500 hours of operation.)

Temperature setting display (16°C - 31°C)

Airflow direction setting display

VENTILATION button*

ECONOMY operation button

Provides Energy saving function

ODOUR WASH button

Provides deodorizing function.

CHECK button

Press this button if the check display is flashing.

TIMER/CLOCK SET buttons

Used to set the timer operation and the current time.

Operation indicator

Lights up when the unit in operation.

NOTES

Ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct.

•

The illustration above is for explanatory purposes only. The appearance will be different during actual operation.

•

Do not operate the remote control with wet hands. Otherwise, electric shock or malfunction may occur.

•

Do not press the remote control buttons with sharp object as this may damage the remote control.

•

Buttons marked with * are not needed for normal operation. If one of these buttons is pressed by mistake, press the same

•

button once more to cancel the operation.

When the power resumed after power failure, the unit will restart automatically with all the previous settings preserved by

•

the memory function. (Auto restart function)

Buttons marked with

•

are not available for operation. If one of these buttons is pressed function will not be available.

26

Page 27

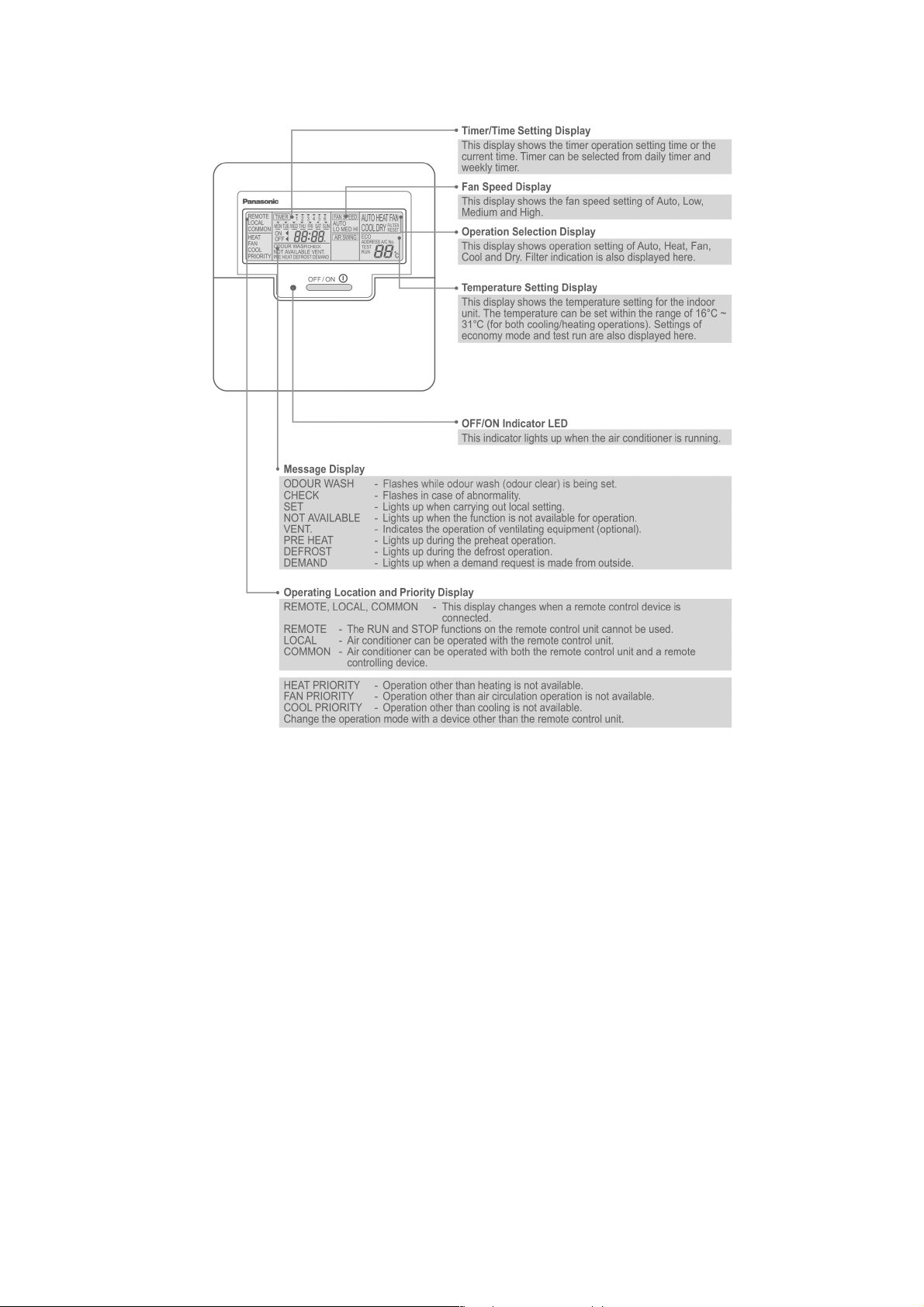

8.2. Remote control - display

27

Page 28

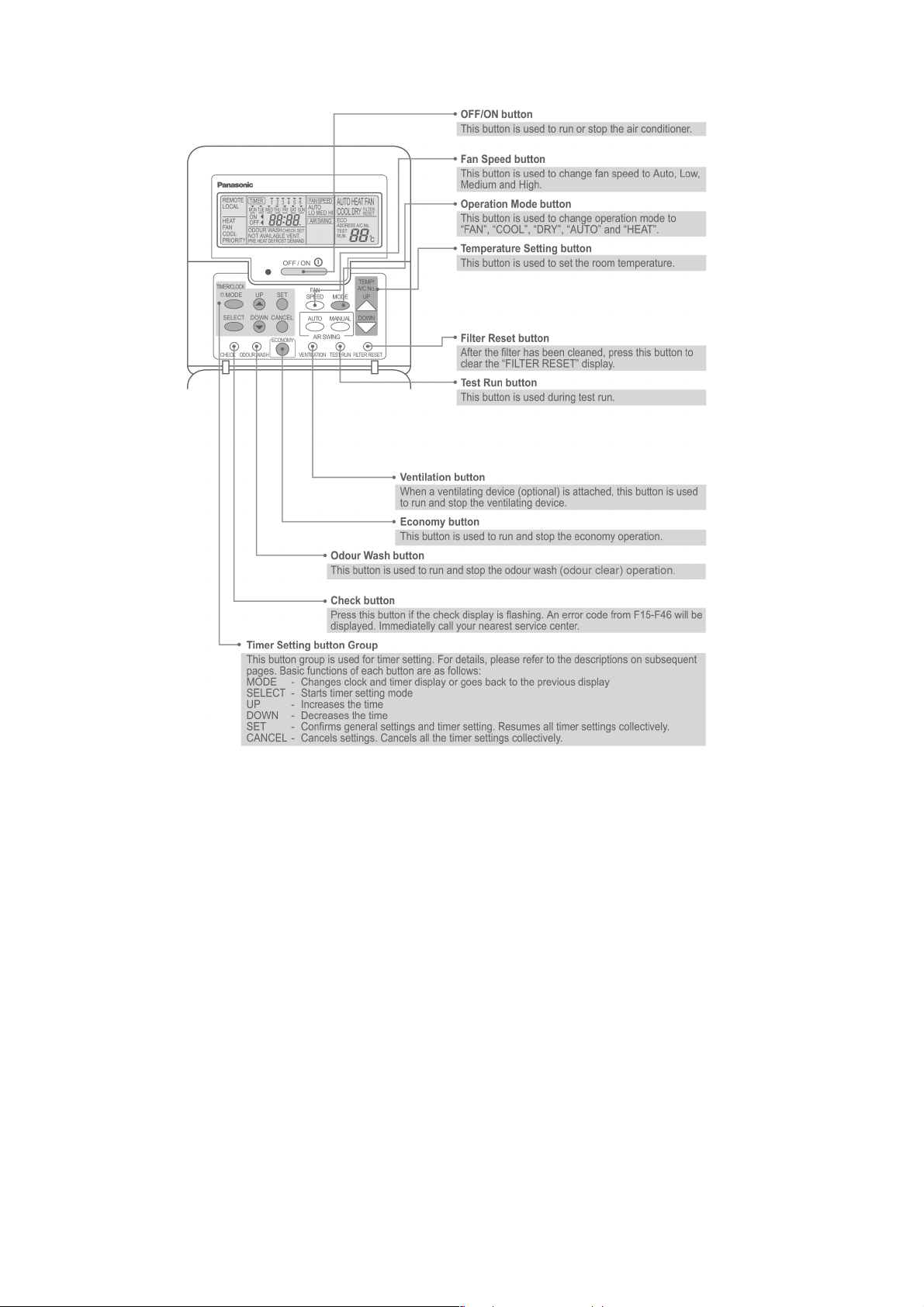

8.3. Remote control - panel

28

Page 29

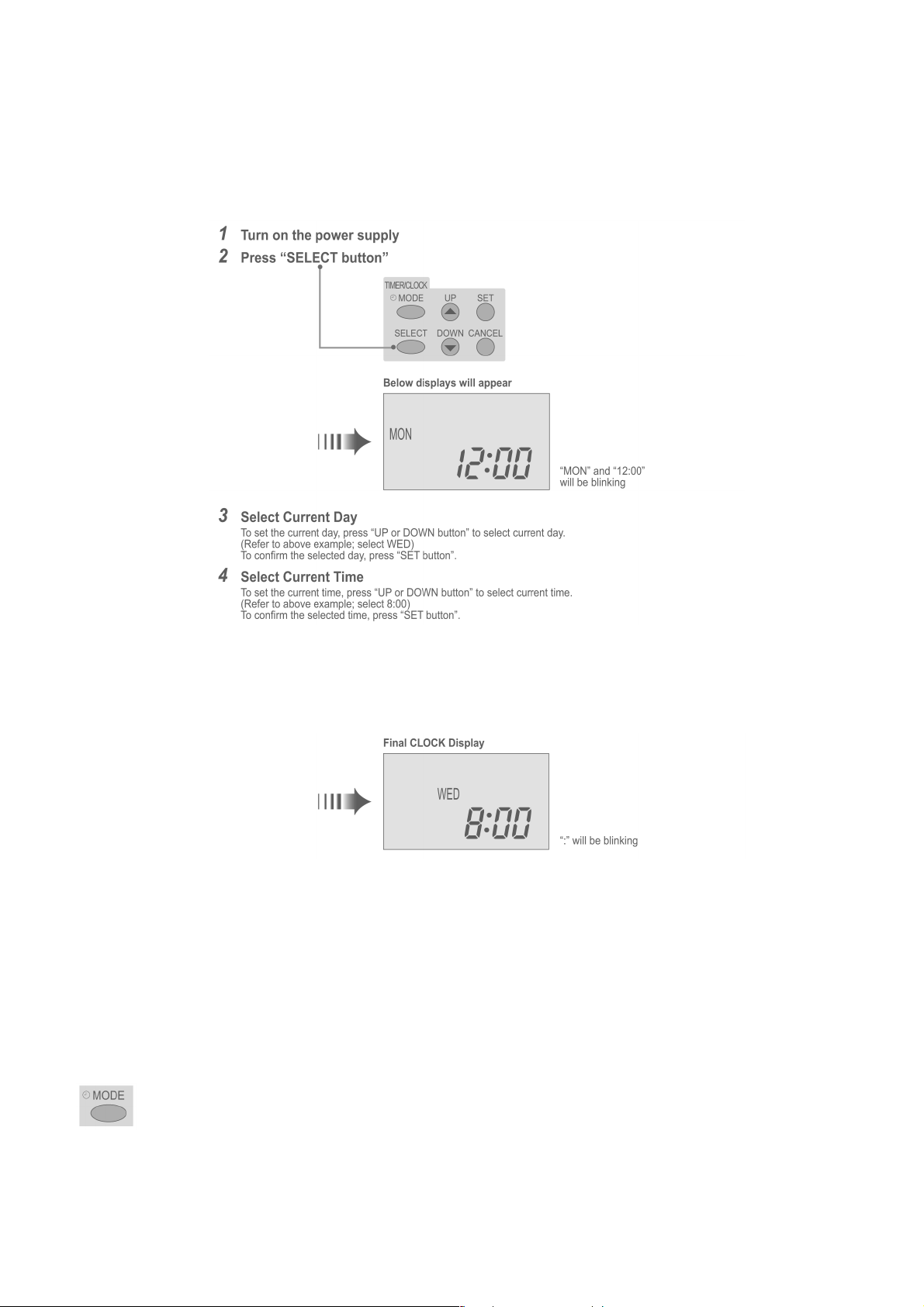

8.4. How to set remote control day and time

• The day and time need to be set when you turn on the power for the first time or after a long time has elapsed since the power

was last turned on.

• The day and time become the standard time for all the Timer operations.

• Set the day and time accurately.

• Example : Current Day is Wednesday and Current Time is 8:00.

Note:

• Press “UP button” to increase or “DOWN button” to decrease (interval 1 minute) or hold the button to change the time faster.

• If the “UP or DOWN button” is not pressed for 30 seconds during the day or time setting or if the “SELECT button” is

pressed, the setting at that moment is confirmed and setting will end.

8.5. How to select the timer

• 2 types of Timer mode can be selected on the remote control.

− Daily Timer

− Weekly Timer

• These timers cannot be operated simultaneously.

• Select one of these Timers for your convenience.

How to Change the Display

• Press once to change the display from CLOCK to Timer or vice-versa.

• Press more than 3 seconds to change the display from Daily Timer to Weekly Timer or vice-versa.

29

Page 30

CLOCK Display (To set current Day and Time)

Note:

• The above display is shown if no valid timer setting is made.

• If valid timer setting is made.

− Timer

and setting will be displayed.

− If you want to check the current time and day, press “MODE button” once.

(However, after a few seconds, the display will change back to Timer

8.6. Daily timer setting

and the setting)

• Display

• How to Set Daily Timer

− You can set only “ON” or only “OFF” or “ON” and “OFF” in a day.

1. Change Display

Press “MODE button” to change the display to daily timer.

2. ON-Timer, OFF-Timer and select Time

Press “SELECT button”; ON-Timer setting will be displayed.

Press “UP or DOWN button” to select the desired time, (Example: ON 9:00), then press “SET button” to confirm

the selected desired time.

Or press “CANCEL button” if you do not want any setting for ON-Timer.

Then OFF-Timer setting will be displayed.

Press “UP or DOWN button” to select the desired time, (Example: OFF 18:30), then press “SET button” to

confirm the selected desired time.

Or press “CANCEL button” if you do not want any setting for OFF-Timer.

Note:

• The setting timer will be activated everyday.

• Timer nearer to the current time will be activated first.

30

Page 31

Final Display of Daily Timer:

8.7. Weekly timer setting

• Display

• How to Set Weekly Timer

− You can set the Timer for 1 week (Monday to Sunday) with 6 programs per day.

− ON-Timer can be set together with your desired temperature. However, this temperature will be used continuously.

− Cannot set 2 programs with same time setting in a day.

− You also may select Collective - many days with same time setting or Individual

− single/one day setting.

1. Change Display

Press “MODE button” to change the display to weekly timer.

2. Select Day (please refer to next page for example of setting)

You may select Collective or Individual day setting.

•

Collective day setting.

Press “SELECT button”: display will show day selection setting.

Press “UP or DOWN button” to select the day. Then press “SET button” to delete triangle mark

(deselect) or add triangle mark (select).

(Triangle mark on top of each day indicates the day to be selected).

Repeat these steps if you want to deselect or select many days.

To confirm the selected days, press the “SELECT button”.

•

Individual day setting.

Press “UP or DOWN button” to select the day.

Then press “SELECT button”.

3. Select Time (please refer to next page for example of setting)

For 1st program setting.

Press “UP or DOWN button” to select ON or OFF.

Then press “SET button” to confirm.

Press “UP or DOWN button” again to select the desired time.

(If you want to set them together with your desired temperature, press “TEMP UP/DOWN button” to

select the temperature).

Then press “SET button” to confirm.

Or press “CANCEL button” if you do not want to set any time.

For 2nd ~ 6th program you may refer to the above step.

31

Page 32

For example, if you want to set:

A - Monday to Friday: Same time, 1st program ON 9:00 & 2nd program OFF 16:00.

B - Only Wednesday: Additional 3rd program OFF 12:30 & 4th program ON 13:30.

C - Only Saturday: 1st program ON 10:00 with 20°C & 2nd program OFF 14:00.

D - Sunday: Holiday. No need to set any Timer.

•

To set A (Monday to Friday - Collective day setting)

Press “SELECT button”

To select Monday to Friday, deselect Saturday and Sunday by pressing “UP or DOWN button” to Saturday, press

“SET button” (triangle mark on top of Saturday will disappear)

Follow the same step to deselect Sunday.

Ensure triangle mark appears on top of Monday ~ Friday.

−

To confirm the selected days, press “SELECT button”.

To set the time, please refer to step 3.

−

1st program - select ON and desired time to 9:00.

2nd program - select OFF and desired time to 16:00.

3rd ~ 6th program - press “CANCEL button”.

•

To set B (Wednesday - Individual day setting)

−

Press “UP or DOWN button” to select WED (Wednesday).

Then press “SELECT button”.

To set the time, please refer to step 3.

−

1st program - press “SET button” twice (confirm ON and 9:00)

2nd program - also press “SET button” twice. (Confirm OFF and 16:00)

3rd program - select OFF and desired time to 12:30

4th program - select ON and desired time to 13:30

5th ~6th program - press “CANCEL button”

•

To set C (Saturday - Individual day setting)

−

Follow the same step as above.

To set the time, please refer to step 3.

−

1st program - select ON, desired time to 10:00 and desired temperature to 20°C.

2nd program - select OFF and desired time to 14:00.

3rd ~ 6th program - press “CANCEL button”.

−

Final Display for Weekly timer may show as:

(Display is showing, 9:00 ON - Timer on Wednesday will be activated next because it is nearest the current

day/time.)

Note:

• Timer that has setting nearest to current time and day will be activated first.

• To check the setting timer, press “SELECT button”, then “UP or DOWN button” to select day. The display will show each

program for the selected day.

• To reset the setting for all, press “SELECT button”, then ensure all day setting with triangle mark. Then press “CANCEL

button” for all the programs.

32

Page 33

9 OPERATION DETAIL

9.1. Cooling operation

• Cooling operation can be set using remote control.

• This operation is applied to cool down the room temperature reaches the setting temperature set on the remote control.

• Cooling Operation Time Diagram.

33

Page 34

9.2. Heating operation

• Heating operation can be set using remote control.

• This operation is applied to warm up the room temperature reaches the setting temperature set on the remote control.

• Heating Operation Time Diagram.

9.3. Soft dry operation

• Soft Dry Operation can be set using remote control.

• Soft Dry operation is applied to dehumidify the room.

• When operation begins, the fan speed is fixed at Low speed while cooling operation is running until reaches the remote control

setting temperature.

9.4. Auto operation

• Automatic Mode can be set using remote control.

• This operation starts to judge the intake air temperature, setting temperature, and outdoor piping temperature. Then the unit

starts to operate at determined operation mode.

9.5. Fan operation

• Fan operation can be set using remote control.

• The indoor fan is operated at High, Medium or Low speed according to remote control setting.

34

Page 35

9.6. Normal control

9.6.1. Cooling Indoor Fan Control

• Manual Fan Speed

Operation starts at High, Medium or Low speed set by remote control.

• Auto Fan Speed

When operation starts, or shifting to thermostat ON condition from thermostat OFF condition, indoor fan operates as below.

Thermostat &

Compressor ON/OFF

Time 40 sec. 50 sec. - 20 sec. 120 sec. 20 sec. 40 sec. 50 sec. -

Cool Auto Off Lo Hi Lo Off Lo Off Lo Me

Soft Dry Auto Off Lo Lo Lo Off Lo Off Lo Lo

9.6.2. Heating Indoor Fan Control

• Manual Fan Speed

Operation starts at High, Medium or Low speed set by remote control.

However, when operation start, or during operation, fan speed control is limited due to prevent a cold draft, for example, when

heating operation start.

Thermostat & Compressor ON Thermostat & Compressor OFF Thermostat & Compressor ON

• Auto Fan Speed

When operation start, or during operation, fan speed control by detecting indoor heat exchanger as follows:

• If thermostat is off, indoor fan fixed low speed.

35

Page 36

9.6.3. Cooling Outdoor Fan Control

• During cooling operation, outdoor fan speed changes according to outdoor pipe temperature.

• The fan speed is controlled by the timing of turning the outdoor fan ON and OFF within an interval.

• When outdoor pipe temperature increases, internal timing also increases.

• Outdoor fan ON time is a variable with the range of 200ms to 2000ms.

• After 2 minutes, the outdoor pipe temperature is detected and the outdoor unit fan speed is changed automatically.

9.6.4. Heating Outdoor Fan Control

• During heating operation, the fan speed is controlled by indoor heat exchanger temperature.

• In case of twin operation, the higher indoor heat exchanger temperature is used to control the fan speed. During heating

operation, the fan speed is controlled by indoor heat exchanger temperature.

9.7. Operation control

9.7.1. Thermostat Control

• Depending on differences between room temperature and setting temperature, compressor operation is decided and starts

operation.

• If temperature difference matches values shown below, thermostat switches off.

Cool Mode -1.5°C

Soft Dry Mode -2.5°C

Heat Mode 3.5°C

9.7.2. Odour Cut Control

• Odour cut operation removes the odour generated at indoor heat exchanger by using drain water come out from indoor heat

exchanger.

• Press “Odour” button at remote control to enable odour cut operation.

• Odour cut operation starts when compressor or thermostat is on.

Thermostat &

Compressor ON/OFF

Time 40 sec. 50 sec. - 20 sec. 120 sec. 20 sec. 40 sec. 50 sec. -

Cool Off Lo Normal

Soft Dry Off Lo Lo Lo Off Lo Off Lo Lo

Thermostat & Compressor ON Thermostat & Compressor OFF Thermostat & Compressor ON

Operation

Lo Off Lo Off Lo Normal

Operation

36

Page 37

9.7.3. Powerful Control

• To achieve setting temperature quickly.

• Cooling powerful operation:

− Setting temperature and thermostat shifting temperature are decrease by 2°C (lower limit 16°C).

− Airflow direction is optimized regardless the air flow setting at remote control.

− Fan speed is optimized at Hi regardless the fan speed setting at remote control.

• Drying powerful operation:

− Setting temperature and thermostat shifting temperature are decrease by 2°C (lower limit 16°C).

− Airflow direction follows remote control setting.

• Heating powerful operation:

− Setting temperature and thermostat shifting temperature are increase by 2°C (upper limit 31°C).

− Airflow direction is optimized regardless the air flow setting at remote control.

− Fan speed is optimized at Hi regardless the fan speed setting at remote control.

• During powerful operation, the powerful indicator lights on.

• Powerful operation cancel when:

− Powerful operates for more than 15 minutes.

− Powerful button is pressed again.

− Operation mode changed.

− Operation stopped by remote control or emergency button.

− OFF timer is activated.

9.7.4. Hot Start Control

• Hot start control operates at the starting of heating operation, where [PREHEAT] displayed at wired remote control.

• Indoor fan stops until hot start control ends (indoor heat exchanger temperature increases or 4 minutes past heating operation

starts), fan control resume.

9.7.5. Energy Save Control

• During Cooling Operation, press "Economy" button at remote control to enable Energy Saving Operation.

• The air conditioner judges the stable condition, where the different between indoor suction temperature and setting temperature

is 1°C for 30 minutes and moderately shifts the set temperature in 0.5°C steps (Maximum 2°C) to control energy saving

operation.

• If temperature different is out of range, energy save operation will not start.

• Energy Save Operation is canceled by pressing the "Economy" button again.

Energy save control time chart

37

Page 38

9.7.6. Dew Form Prevention Control

• During cool or dry operation, if outdoor temperature is less than 30°C, and indoor fan speed is low or auto setting, indoor heat

exchanger temperature become lower, dew form prevention control start to prevent dew form at indoor discharge grill.

• When indoor pipe temperature decrease, cooling capacity will be reduced.

9.7.7. Freeze Prevention Control

• During Cooling or Dry operation, after compressor starts operation for 4 minutes, the outdoor unit will stop its operation if indoor

pipe temperature falls below 0ºC for 6 minutes.

• After 3 minutes stops, compressor restarts operation if indoor pipe temperature is 6ºC or more.

• This phenomenon is to protect the indoor heat exchanger from freezing and to prevent higher volume of refrigerant in liquid from

returning to the compressor.

9.7.8. Deice Control

• During heating operation at low outdoor temperature, deice operation start timely to melt the ice formed on outdoor heat

exchanger.

• During deice operation, in spite of any changes of remote control, indoor fan stop.

• During deice operation, [DEFROST] is displayed at wired remote control, hot start operate after deice operation finish.

• Deice operation start when accumulative heating operation time or after previous deice end reaches 45 minutes, the outdoor

fan maintains Hi status and the outdoor heat exchanger maintains -2°C for 5 minutes.

38

Page 39

9.7.9. Time Delay Safe Control

• The compressor will not start for three minutes after stop of operation.

9.7.10. Outdoor Fan Remaining Heat Removal Control

• When compressor stops, outdoor fan operates at High speed for 1 minute to remove the remaining heat.

9.7.11. Crank Case Heater Control

• Crank case heater ON when the compressor is shutdown and discharge temperature is 20°C to prevents the refrigerant solving

into compressor oil inside the compressor shell at cold condition.

9.7.12. Pump Down

• To enable pump down operation, at outdoor PCB, set the DS1 and DS2 to OFF position.

• Press Test Run button for 1 second. SW1 located at outdoor printed circuit board.

• During Pump Down operation, push the Test Run button again for 1 second to stop the pump down operation.

• The pump down operation runs for 10 minutes.

9.8. Protection control

9.8.1. Outdoor Low-pressure Protection Control

• The purpose of low-pressure protection control is gas leakage detection control.

• The low-pressure protection control starts when low-pressure switch is activated less than 15 minutes after compressor startup.

During heating operation or deice control low-pressure detection does not start.

• During this protection control, compressor is shut down, indoor unit is set to thermo-off status.

• After 6 occasions, suction pressure error is displayed; all operations stopped except outdoor fan remaining heat removal

control.

39

Page 40

9.8.2. Outdoor High-pressure Protection Control

• The high-pressure protection control starts when high-pressure switch is activated less than 15 minutes after compressor

startup.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 6 occasions, high-pressure protection error is displayed; all operations stopped except outdoor fan remaining heat removal

control.

9.8.3. Discharge Temperature Protection Control

• The discharge temperature protection control starts when abnormal compressor temperature 115°C is detected when outdoor

unit is operating in cooling or heating operation.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 6 occasions, high-pressure protection error is displayed; all operations stopped except outdoor fan remaining heat removal

control.

9.8.4. Over Current Protection Control

• The purpose of over current protection control is to protect the air conditioner from over current.

• The over current protection control starts when input current from CT is maintained at 20A or more for 2 seconds when the

outdoor unit is starting up or during cooling or heating operation.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 4 occasions, over current protection error is displayed; all operations stopped except outdoor fan remaining heat removal

control.

9.8.5. CT Disconnection Detection Control

• CT disconnection detection control detects if the CT sensor works normally.

• The CT disconnection detection activates when:

− CT input value is maintained at compressor shutdown status (1.5A or less) consecutively for 2 seconds when the

compressor is operating; except deice mode.

− During this condition, compressor is shut down and indoor unit is set to thermo-off status.

− After 4 occasions, CT sensor error is displayed; all operations stopped except outdoo r fan remaining heat removal

control.

− CT input value is maintained at compressor operation status (5A or more) consecutively for a period of 60 seconds when

the compressor is shut down.

− During this condition, CT sensor error is displayed.

9.8.6. Connection Capacity Protection Control

• The purpose of connection capacity protection control is to ensure the total capacity of connected indoor units is within

acceptable range.

Model Number Min Capacity (kW) Max Capacity (kW) Model Number Min Capacity (kW) Max Capacity (kW)

CU-B14DBE5 5.3 6.9 CU-B28DBE8 6.3 9.8

CU-B18DBE5 5.3 6.9 CU-B34DBE8 7.3 12.3

CU-B24DBE5 6.3 9.8 CU-B43DBE8 10.2 13.8

CU-B28DBE5 7.3 12.3 CU-B50DBE8 12.7 15.8

• During this protection control, connection capacity error is displayed; all operations stopped.

9.8.7. Sensor Disconnection Detection Control

• The sensor disconnection detection control activates when the following condition comply:

Sensor Detection Threshold Duration (Sec) Detection condition

Discharge Temperature < -4.5°C or 201.8°C 5 Other than compressor start control

Outdoor heat exchange < -50.5°C or 103.7°C 5 Regularly

• During sensor disconnection, sensor error is displayed; all operations stops except outdoor fan remaining heat removal control.

40

and compressor ON

Page 41

9.8.8. Four-way Valve Error Detection Control

• The four-way valve error detection control starts when:

− During cooling operation, when indoor heat exchanger temperature exceeds 45°C in 5 minutes after compressor starts.

− During heating operation, when indoor heat exchanger temperature is below 5°C in 5 minutes after compressor starts.

• During four-way valve error, compressor is shut down and indoor unit is set to thermo-off status.

• After 3 occasions, four-way valve error is displayed; all operations stopped except outdoor fan remaining heat removal control.

9.8.9. Valve Error Detection Control

• This control is to protect the compressor.

• Valve error is detected if comply with condition below:

− Power is on for the first time and within 5 minutes from compressor starts (However, the unit is considered power on for first

time when compressor starts operating continuously for 7 minutes).

− Indoor heat exchanger temperature at compressor start -3°C < current heat exchanger temperature for 1 minute.

• During this error, four-way valve error is displayed; compressor is shutdown.

9.8.10. High-pressure Switch Disconnection Error Detection Control

• High-pressure switch disconnection is detected when high-pressure switch input continuously open for 1 minute while the

compressor shutdown.

• During this error, high-pressure switch error is displayed.

9.8.11. Low-pressure Switch Disconnection Error Detection Control

• Low-pressure switch disconnection is detected when low-pressure switch input continuously open for 1 minute while

compressor shutdown.

• During this error, low-pressure switch error is displayed.

9.9. Test run

• Test run is necessary after installation is completed.

• To enable forced cooling test run, at outdoor PCB, set the DS1 to ON position and DS2 to OFF position.

• To enable forced heating test run, at outdoor PCB, set the DS1 to ON position and DS2 to ON position.

• Press Test Run button for 1 second. SW1 located at outdoor printed circuit board.

41

Page 42

10 INSTALLATION INSTRUCTION

10.1. Pipe length

10.1.1. Correction of capacities

Correction of capacities according to the connecting pipe length.

The data of rated capacities (marked on the name plate) are based on 7.5 metres connecting pipe and horizontal

installation.

Piping Size / Length & Elevation

Model No. Piping size Piping

length (A)

Liquid/High Valve Gas/Low Valve Max (m) Max (m) Max (m) Max (m) (g/m)

R CS-F24DD3E5

HIDE 4 CS-F28DD3E5

AWAY 1 (Lo) CS-F34DD3E5 9.52 3-ways 15.88 3-ways 50 30 20 30 50

TYPE 0 CS-F43DD3E5

A CS-F50DD3E5

Piping

elevation

(B)

Piping

elevation

(C)

Piping

Chargeless

Add

Refrigerant

Note :

Piping elevation B = outdoor unit installed at top

Piping elevation C = outdoor unit installed at bottom

Calculation 1

•

In case of CU-B28DBE5, B28DBE8, B34DBE5, B34DBE8

When pipe length exceed 30m calculated by formula 1, adding refrigerant amount should be calculated by formula 2. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + (branch pipe La + branch pipe Lb)/2.78...formula 1

Add refrigerant = (main pipe + (branch pipe La + branch pipe Lb)/2.78-30) * 50...formula 2

Calculation 2

•

In case of CU-B43DBE8, B50DBE8

When pipe length exceed 30m calculated by formula 3, adding refrigerant amount should be calculated by formula 4. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + branch pipe La + branch pipe Lb...formula 3

Add refrigerant = (main pipe + branch pipe La + branch pipe Lb-30) * 50...formula 4

42

Page 43

43

Page 44

10.1.2. Refrigerant additional charge

• The piping length exceeds 30 metres.

APPLICABLE FOR ALL MODELS

Before shipment, this air conditioner is filled with the rated amount of refrigerant subject to 30m piping length. (The rated

amount of refrigerant is indicated on the name plate.) But when the piping length exceeds 30m, additional charge is required

according to the following table.

Example :

CS-F24DD3E5

In case of 31m long pipe (one-way), the amount of refrigerant to be replenished is: (31 - 30) x 50 = 50g

Model Name Standard piping specification

Liquid piping

(dia. mm)

CU-B24DBE5 9.52 15.88 30 50

CU-B28DBE5 9.52 15.88 30 50

CU-B28DBE8 9.52 15.88 30 50

CU-B34DBE5 9.52 15.88 30 50

CU-B34DBE8 9.52 15.88 30 50

CU-B43DBE8 9.52 15.88 30 50

CU-B50DBE8 9.52 15.88 30 50

Gas piping

(dia. mm)

Gas charge-

less length

(m)

Additional

gas volume

(g/m)

10.2. Position of the centre gravity

MODEL NAME OUTSIDE DIMENSIONS NET WEIGHT CENTRE OF GRAVITY

WIDTH (mm) DEPTH (mm) HEIGHT (mm) kg X (mm) Y (mm) Z (mm)

CU-B24DBE5 900 320 795 69 560 150 320

CU-B28DBE5 900 320 795 69 560 150 320

CU-B28DBE8 900 320 795 69 560 150 320

CU-B34DBE5 900 320 1170 102 560 150 450

CU-B34DBE8 900 320 1170 100 560 150 450

CU-B43DBE8 900 320 1170 102 560 150 450

CU-B50DBE8 900 320 1170 102 560 150 450

44

Page 45

10.3. Indoor unit installation

DUCT TYPE AIR CONDITIONERS INSTALLATION INSTRUCTIONS

Carry out installation work with reliability after thorough reading of this “Precautions in terms of safety”.

Precautions in terms of safety

Precautions shown here are differentiated between

•

Warnings and Cautions . Those that have much chances for

leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling

them especially into the column of

However, even in the case of items which are listed in the column of

Warnings .

Cautions , such items also have a chance for leading

to significant result depending on the situations.

In either case, important descriptions regarding the safety are listed, then observe them without fail.

As to indications with illustration

•

This mark means “Caution” or “Warning”. This mark means “Earth”.

After installation work has been completed, do not only make sure that the unit is free from any abnormal condition through the

•

execution of trial run but also explain how to use and how to perform maintenance of this unit to the customer according to the

instruction manual.

In addition, request the customer to keep this manual for installation work together with the instruction manual.

Warnings

The appliance must be installed by technician, who takes into

account the requirements given by ISO5149 or eventual

equivalent requirements.

As to installation, request the distributor or vendor to perform it.

Imperfection in installation caused by that having been carried

out by the customer himself may lead to water leakage, electric

shock, fire, etc.

Carry out the installation work with reliability according to this

manual for installation work.

Imperfection in installation leads to water leakage, electric

shock, fire, etc.

Carry out the installation work with reliability on the place that

can bear the weight of this unit sufficiently. Insufficient strength

leads to injury due to falling of the unit.

Carry out predetermined installation work in preparation for

strong wind such as typhoon, earthquake.

Imperfection in installation work may lead to accidents arisen

from overturn, etc.

The unit must be installed in accordance with applicable national

and local regulations.

Any electrical work should only be carried out by qualified

technician and use exclusive circuits without fail.

Presence of insufficient capacity in power circuit or imperfection

in execution leads to electric shock, fire, etc.

If installing inside a small room, measures should be taken to

prevent refrigerant levels from building up to critical

concentrations in the event of a refrigerant leak occurring.

Please discuss with the place of purchase for advice on what

measures may be necessary to prevent critical concentrations

being exceeded. If the refrigerant leaks and reaches critical

concentration levels, there is the danger that death from

suffocation may result.

Securely attach the protective covers for the outdoor unit

connection cables and power cord so that they do not lift up

after installation. If the covers are not properly attached and

installed, the terminal connections may overheat, and fire or

electric shock may result.

Switch off all supplies before accessing any electrical part.

If refrigerant gas escapes during installation, ventilate the

affected area. If the refrigerant gas comes into contact with

sparks or naked flames, it will cause toxic gases to be

generated.

Once installation work is completed, check that there are no

refrigerant gas in the room that can come into contact with

sparks or flames from a fan heater, stove or kitchen range,

which will cause toxic gases to be generated.

When performing piping work do not mix air except for specified

refrigerant (R410A) in refrigeration cycle. It causes capacity

down, and risk of explosion and injury due to high tension inside

the refrigerant cycle.

45

Page 46

Warnings

Wiring shall be connected securely using specified cables and

fix them securely so that external force of the cables may not

transfer to the terminal connection section.

Imperfect connection and fixing leads to fire, etc.

Cautions

Carry out Earthing work.

Do not connect the Earth return to the gas pipe,

water line pipe, lightning rod and telephone lines.

Imperfection in Earth return may lead to electric

shock.

Do not install the unit at the place where the possibility of

inflammable gas leakage exists. If such gas leakage should arise

and the gas builds up around the unit, such situation may lead to

ignition.

Mounting of the earth leakage circuit breaker is required.

Omission in mounting of the earth leakage circuit breaker may

lead to electric shock.

Drain piping should be made to ensure secure drainage

according to the manual for installation work and carry out the

thermal insulation to prevent the occurrence of condensation.

Imperfection in piping work leads to water leakage and may

cause the house and property, etc. to become wet.

Position the indoor unit, outdoor unit, power cords and

indoor/outdoor unit connection cables in a way so that they are

at least 1 meter away from televisions and radios.

This is to avoid problem such as interference with picture and/or

sound. (However, note that depending on the electromagnetic

wave conditions, interference may still occur even if the

separation distance is more than 1 meter.)

10.3.1. Accessories packed in the indoor unit container

NO. Parts name Q’ty

1 Thermal insulator for refrigerant pipe 2

2 Hose clip for thermal insulator 5

3 M10 Flange washer 4

4 M10 Flat washer 4

5 Thermal insulator for drainage hole 1

6 Duct flange R 1

7 Duct flange L 1

8 Screws 4

(6) and (7) should be installed when the duct will be

•

installed at the return hole.

10.3.2. Selecting the location for the indoor unit

Provide a check port on the piping side ceiling for repair and maintenance.

Install the indoor unit once the following conditions are satisfied and after receiving the customer approval.

•

1. The indoor unit must be within a maintenance space.

2. The indoor unit must be free from anyobstacles in pathof the airinlet and outlet, and must allowspreading of air throughout

the room.

*If the height from the floor to ceiling exceeds three meters, air flow distribution deteriorates and the effect is decreased.

3. The installation position must be able to support a load four times the indoor unit weight.

4. The indoor unit must be away from heat and steam sources, but avoid installing it near an entrance.

5. The indoor unit must allow easy draining.

6. The indoor unit must allow easy connection to the outdoor unit.

7. Place the indoor unit easy water drainage. (Suitable dimension “H” is necessary to get slop to drain as figure.)

Warnings

46

Page 47

8. The indoor unit must be from at least 3m away from any noise-generating equipment. The electrical wiringmust be shielded

with a steel conduit.

9. If the power supply is subject to noise generation, add a suppressor.

10. Do not install the indoor unit in a laundry. Electric shocks may result.

Note

• Thoroughly study the following installation locations.

1. In such places as restaurants and kitchens, considerable amount of oil steam and flour adhere to the turbo fan, the fin

of the heat exchanger and the drain pump, resulting in heat exchange reduction, spraying, dispersing of water drops,

drain pump malfunction, etc.

In these cases, take the following actions:

− Make sure that the ventilation fan for smoke-collecting hood on a cooking table has sufficient capacity so that it draws

oily steam which should not flow into the suction of the air conditioner.

− Make enough distance from the cooking room to install the air conditioner in such place where it may not suck in oily

steam.

2. Avoid installing the air conditioner in such circumstances where cutting oil mist or iron powder exist especially in

factories, etc.

3. Avoid places where inflammable gas is generated, flows-in, contaminated, or leaked.

4. Avoid places where sulphurous acid gas or corrosive gas can be generated.

5. Avoid places near high frequency generators.

47

Page 48

10.3.3. Installation of indoor unit

POSITION OF SUPENSION BOLT

• Apply a joint-canvas between the unit and duct to absorb unnecessary vibration.

• Install the unit learning to a drainage hole side as a figure for easy water drainage.

INSTALLATION OF DUCT

1. The duct of the air inlet could be installed by the three situations as shown in the illustration below (a) ~ (c).

Setting the filter:

Case of (a): Reverse the filter and not install the duct of the air inlet.

Case of (b): Remove the filter (local arrangement) and install the duct of the air inlet.

Case of (c): Change the panel bottom to install the duct of the air inlet.

48

Page 49

2. The panel bottom could be changed into the air inlet (case of (c)) as shown in the illustration below.

3. When the duct of air inlet will be installed, install the duct flange side R & L to the air inlet with accessories as shown in the

illustration.

4. The filter could be removed from any one of three directions as shown in the illustration below.

49

Page 50

10.3.4. Refrigerant piping

• Refrigerant is charged to the outdoor unit. For details, see the manual for installation work of outdoor unit. (Additional charging,

etc.)

1. Brazing for piping.

a. Execute brazing before tightening the flare nut.

b. Brazing must be executed while blowing nitrogen gas.

(This prevents generation of oxidized scale in copper

pipe.)

2. When there is a lot of brazings for long piping, install a

strainer midway of the piping. (The strainer is locally

supplied.)

3. Use clean copper pipe with inner wallsurface free from mist

and dust. Blow nitrogen gas or air to blow off dust in the

pipe before connection.

4. Form the piping according to its routing. Avoid bending and

bending back the same piping point more than three times.

(This will result in hardening of the pipe).

5. After deforming the pipe, align centers of the union fitting of

the indoor unit and the piping, and tighten them firmly with

wrenches.

6. Connect pipe to the service valve or ball valve which is

located below the outdoor unit.

7. After completed the piping connection, be sure to check if

there is gas leakage in indoor and outdoor connection.

Vaccum drying

After completing the piping connection, execute vacuum drying for the connecting piping and the indoor unit.

The vacuum drying must be carried out by using the service ports of both the liquid and gas side valves.

CAUTION Use two wrenches and tighten with regular torque.

• Confirm the red mark of the union (thin side) is always at

lower direction after connecting piping.

Flare nut fastening torque N.m (kgf.cm)

ø6.35 mm 18 (180) ø12.7 mm 55 (560) ø19.05 mm 100

ø9.52 mm 42 (430) ø15.88 mm 65 (660)

(1020)

10.3.5. Indoor unit drain piping

•

The unit has two drainage holes at both side.

The drainage hole without connection needs seal and thermal

insulation with accessories.

•

Always lay the drain with downward inclination (1/50 to 1/100).

Prevent any upward flow or reverse flow in any part.

•

5mm or thicker formed thermal insulator shall always be

provided for the drain pipe.

Liquid side piping Gas side piping

ø9.52 mm ø15.88 mm

50

Page 51

10.3.6. Heat Insulation

Caution Be sure to perform heat insulation on the drain, liquid and gas piping. Imperfection in heat insulation work leads to water leakage.

1. Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over 120°C).

2. Precautions in high humidity circumstance.

This air conditioner has been tested according to the “JIS Standard Conditions with Mist” and have been confirmed that there

are no faults. However, if it is operated for a long time in high humid atmosphere (dew point temperature: more than 23°C),

water drops are liable to fall. In this case, add heat insulation material according to the following procedure:

Heat insulation material to be prepared... Adiabatic glass wool with thickness 10 to 20mm.

•

Stick glass wool on all air conditioners that are located in ceiling atmosphere.

•

In addition to the normal heat insulation (thickness: more than 8mm) for refrigerant piping (gas piping: thick piping) and drain

•

piping, add a further of 10mm to 30mm thickness material.

Wall seal

When the outdoor unit is installed on a higher position than the indoor unit, install the trap so as not to instill rain water into

•

the wall by transmitting in piping.

Stuff the space among piping, the electric wire, and the drain hose with “Putty” and seal the penetration wall hole.

•

Make sure that rain water do not instill into the wall.

*Put the incision at the trap part of the heat insulator (for water drain)

3. The duct connection of the air outlet needs thermal insulation.

51

Page 52

10.3.7. Electrical wiring

As to main power source and cable size of outdoor unit, read the installation manual attached to the outdoor unit.

The units must be installed in accordance with applicable national and local regulations.

Warning The units installed by a professional installer must be supplied from a dedicated electrical circuit.

All electrical work must be carried out by a qualified technician according to proper technical standards for electrical work and

according to installation manual for installation work.

If circuit with insufficient capacity are used, or if electrical work is not carried out properly, electric shocks or fire may result.

Caution Be sure to install a current leakage breaker or circuit breaker to the main power supply, otherwise electric shocks may result.

Caution Be sure to connect the unit to secure earth connection. (with an earth resistance of 100 Ω or less)

If the earthing work is not carried out properly, electric shocks may result.

Warning Wiring shall be connected securely using specified cables and fix them securely so that external force of the cables may not

1. Select a power source that is capable of supplying the current required by the air conditioner.

2. Feed the power source to the unit via a distribution switch board designed for this purpose, the switch should disconnected all

poles with a contact separation of at least 3 mm.

3. Always ground the air conditioner with a grounding wire and screw to meet the LOCAL REGULATIONS.

4. Be sure to connect the wires correctly to terminal board with connecting the crimp type ring terminal to the wires.

5. Be sure to turn off the main power before installing and connecting the remote controller.

Note If momentarily turning on the power supply for both the indoor and outdoor units, do not turn the power off after at least 1 minute has

Use the standard power cord for Europe (such as H05RN-F or H07RN-F which conforms to CENELEC (HAR) rating

•

specifications) or use the cables based on IEC standard. (245IEC57, 245IEC66)

transfer to the terminal connection section. Imperfect connection and fixing leads to fire, etc.

passed. (For the system’s automatic setting.)

Turning off the power supply on the way may cause an abnormal operation.

52

Page 53

CONNECTING THE WIRES TO THE CONTROL BOX

• Remove two screws

, remove the control box cover, and

then connect the wires by following the procedure given in

the illustration.

<INDOOR UNIT>

• Remove the control box for electrical connection between

the indoor and outdoor unit. (Remove two screws

).

• Use the cord clamper to fix the cord.

Caution

Make sure that screws of the terminal are free from Looseness.

Fastening torque

M4... 118N.cm (12kgf.cm)

M5... 196N.cm (20kgf.cm)

10.3.8. Settings

*Do not operate the remote controller within 1 minute after turning on the power of the indoor unit.

*When using group control with the standard type, at least 1 unit must be set at No.1 at the indoor unit.

*Check the settings of the indoor unit in a case where there are no display at remote controller. If there is no problem to the settings,

either group control or standard type should be set at No.16 at the indoor unit before turning the power on again.

• All sets in the group which uses the same remote controller thermistor settings can be controlled by the same remote controller

thermistor.

• Up to a maximum of 16 indoor units can be connected at the time of group control. (Do not connect heat pump unit with cooling

only unit.)

• Indoor unit No. will be set automatically at the time of group control. However, which indoor unit uses which number is unknown.

Indoor unit No. is also possible to be set manually with DIP switches. Since manual address setting has priority to automatic

address setting. To perform automatic address setting after doing manual setting, turn off all DIP switches from No.1 to No.4,

and then stop the operation. Then press three switches such as [AIR SWING AUTO]

(Do not use manual address setting and automatic address setting together.)

• Centralized control is possible for master unit and slave unit at the time of group control.

[MODE] [A/C No.] at the same time.

53

Page 54

(Remote Controller address setting)

(Refer to the Installation Manual which is provided with the remote controller for details.)

• Two remote controllers (including the wireless remote controller) can be connected. However, remote control thermistor setting is not

possible.

• As for [master/slave] setting of remote controller, the automatic setting and manual setting are possible. Since manual setting is priority.

• Two remote controllers, which both are wireless, cannot be connected.

10.3.9. As for timer output

Connect the timer cord to connector (CN-TIMER) on print circuit board.

•

10.3.10. Precautions in test run

The initial power supply must provide at least 90% of the rated voltage. Otherwise, the air conditioner may not operate.

•

Test operation can be carried out using the remote control unit or at the outdoor unit. (If carrying out test operation at the

•

outdoor unit, refer to “TEST OPERATION” in the outdoor unit installation manual.)

If using the remote control unit to carry out test operation, follow the procedure given below.

•

• First, press the OFF/ON ( ) button.

• Then press the TEST RUN button within 1 minute of pressing the OFF/ON (

• Next, select the operation modes.

• The temperature of the indoor unit pipes will be shown on the temperature setting display. (At the start of the test

operation, it may take up to 1 minute for air conditioner number, switching time and other displays to appear.)

• After operation modes have been selected, stop the compressor for a moment.

• Press the OFF/ON (