Page 1

Order No: PAPAMY1604052CE

Installation Manual

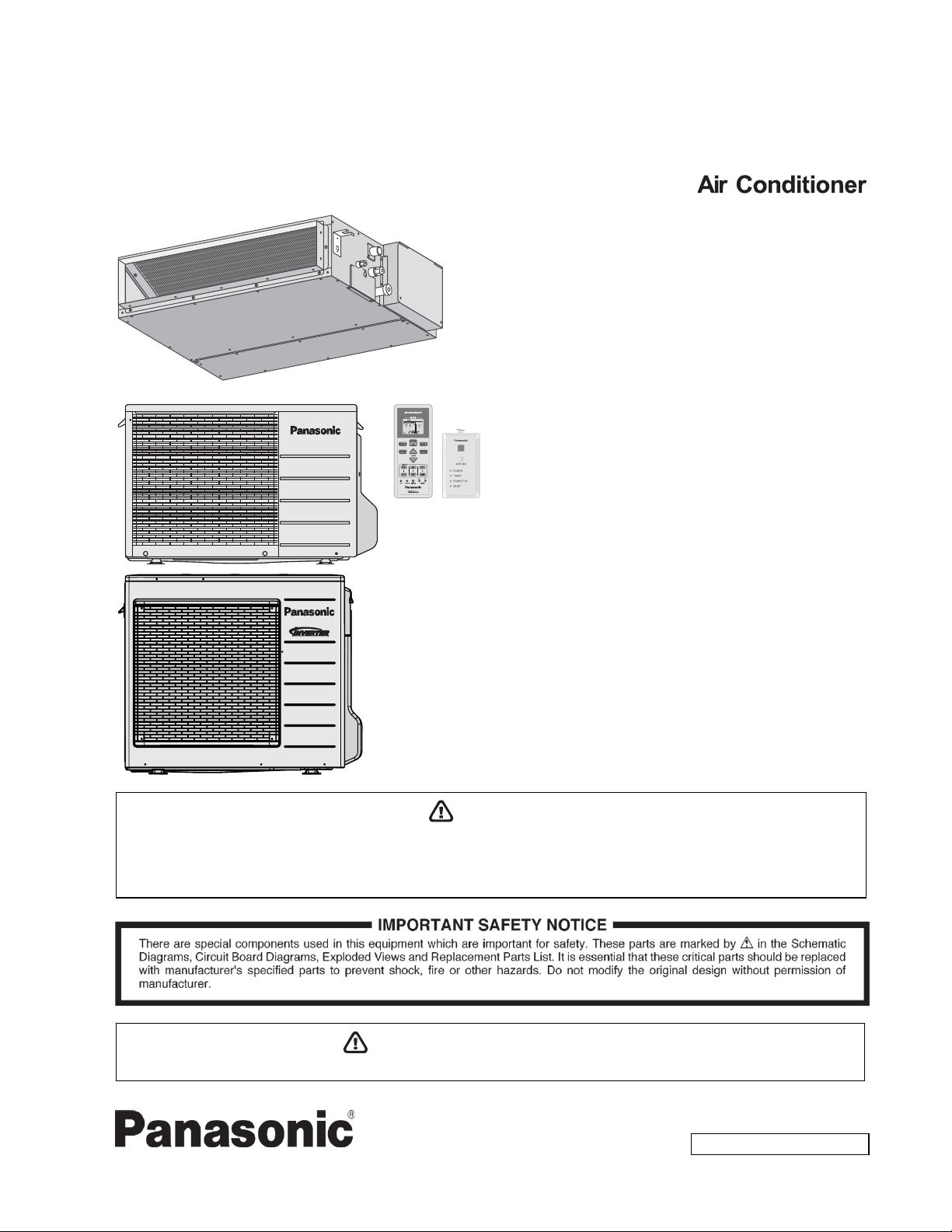

Indoor Unit Outdoor Unit

CS-E9SD3UAW

CS-E12SD3UAW

CS-E18SD3UAW

CU-E9SD3UA

CU-E12SD3UA

CU-E18SD3UA

Destination

USA

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2016

Page 2

11. Installation Instruction

x IMPORTANT (ONLY FOR E9SD3UAW AND E12SD3UAW)

This product has been designed and manufactured to meet ENERGY STAR

matche

achive rated

cha

efficiency and shorten equipment life.

Attached Accessories

d with appropriate coil components. However, proper refrigerant charge and proper air flow are critic

capacity and efficiency. Installation of this product should follow the manufacturer’s refri

rging and air flow instructions. Failure to confirm proper charge and airflow may reduce energy

®

criteria for energy efficiency when

al to

gerant

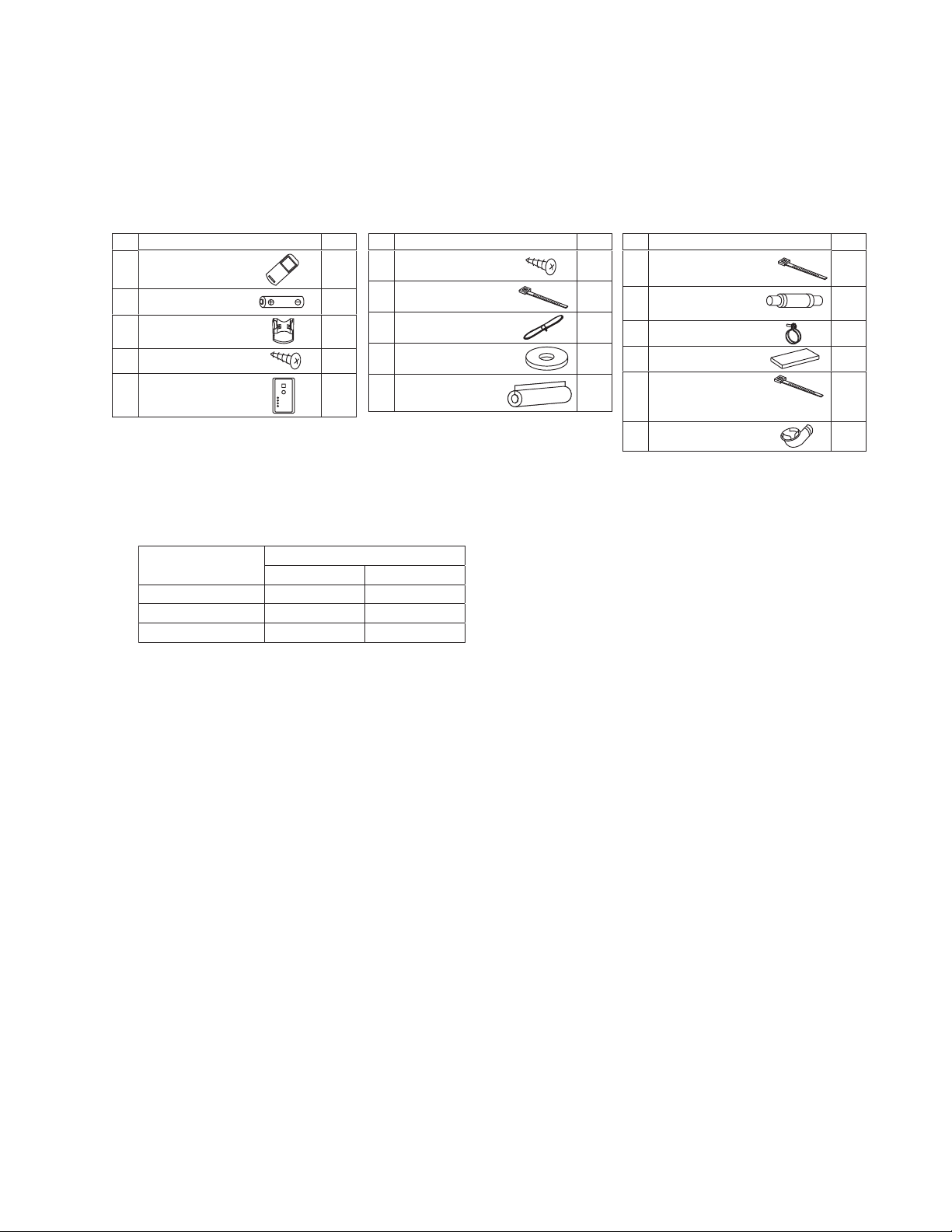

No. Accessory part Qty.

Remote control

1

Battery

2

Remote control holder

3

Remote control holder

4

fi xing screw

Remote control receiver

5

Ŷ

Requir

ed Materials

No. Accessory part Qty.

Receiver fi xing screw

(M4 x 39/64" (15.5 mm))

6

1

Clamper (band)

(for receiver cable fi xing)

7

2

1

2

1

Receiver cable

(6.56 ft (2 m))

8

Washer

(for suspension fi tting)

9

Flare insulator

(for gas pipe / liquid pipe

0

connection)

No. Accessory part Qty.

Clamper (band)

2

1

1

8

2

(for fl are & drain insulating

!

connection)

Drain hose

(for unit & PVC pipe

@

connection)

Hose band

#

(for drain hose connection)

Drain hose insulation

$

(for drain pipe connection)

Clamper (band)

(for power supply cord)

%

* Be sure to fi x the power supply cord

with clamper (band).

Drain elbow

¥

x Read the catalog and other technical materials and prepare the required materials.

x Applicable piping kit

Applicable piping kit

CZ-3F5, 7BP 3/8" (9.52 mm) 1/4" (6.35 mm)

CZ-4F5, 7, 10BP 1/2" (12.7 mm) 1/4" (6.35 mm)

CZ-52F5, 7, 10BP 5/8" (15.88 mm) 1/4" (6.35 mm)

x

Pipe size reducer (CZ-MA1P) for outdoor Multi connection CS-E12SD3UAW, CS-E18SD3UA

Piping size

Gas Liquid

W

L=131

4

1

1

2

1

1

33

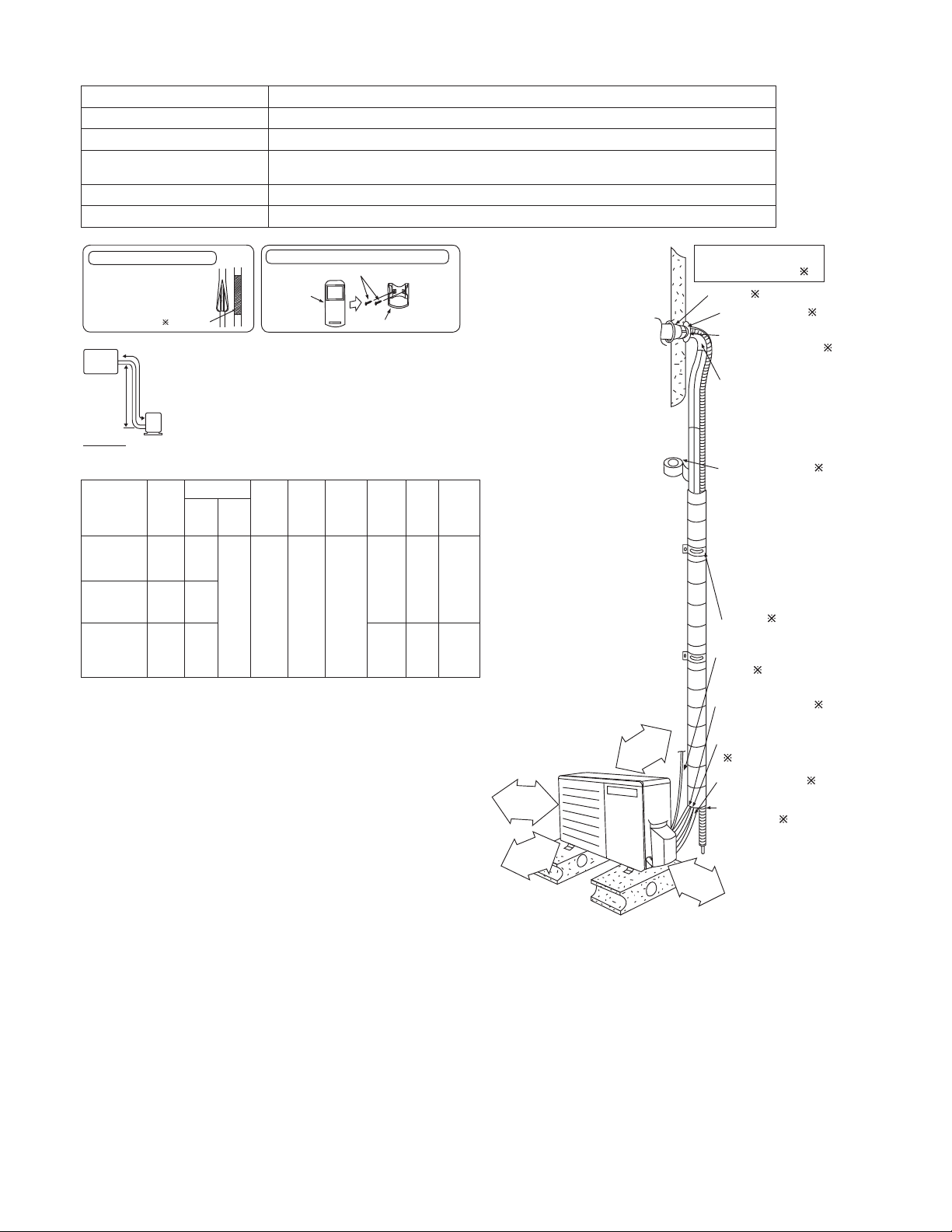

Page 3

Ŷ

Other Items to be Prepared (Locally Purchased)

Product name Remarks

Rigid PVC pipe VP20 (outer diameter ø1 1/32" (ø26); also sockets, elbows and other parts as necessary

Adhesive PVC adhesive

Insulation

For refrigerant piping insulation: foamed polyethylene with a thickness of 5/16" (8 mm) or more.

For drain piping insulation: foamed polyethylene with a thickness of 13/32" (10 mm) or more.

Indoor/outdoor connecting cable UL listed or CSA approved 4 conductor wires minimum AWG16

Hanging bolt related parts Hanging bolts (M10) (4) and nuts (12), (when hanging the indoor unit)

Insulation of piping connections

• Carry out insulation after

checking for gas leaks and

secure with vinyl tape.

Vinyl tape

Indoor unit

A

B

Outdoor

unit

IMPORTANT

Begin the installation job from

the “Indoor Unit” installation.

Piping size

Model

E9SD3UAW 9000

E12SD3UAW 11500

E18SD3UAW 17200

Capa-

city

(Btu/h)

Gas Liquid

3/8"

(9.52

mm)

1/2"

1/4"

(12.7

(6.35

mm)

mm)

1/2"

(12.7

mm)

Example: For E9SD3UA

Attaching the remote control holder to the wall

Remote control holder fi xing screws

Remote

control

1

Remote control holder

Min.

Max

Std.

Length

24.6 ft

(7.5 m)

Eleva-

tion

49.2 ft

(15 m)

Piping

Length

9.8 ft

(3 m)

W

Max.

Piping

Length

65.6 ft

(20 m)

100.0 ft

(30.5 m)

If the unit is installed at 32.8 ft (10 m) distance, the

quantity of additional refrigerant should be 1.64 oz

(50 g) …. (32.8 - 24.6) ft x 0.2 oz/ft = 1.64 oz.

((10 - 7.5) m x 20 g/m = 50 g).

4

Additional

Refri-

gerant

0.2

oz/ft

(20

g/m)

0.3

oz/ft

(25

g/m)

3

Piping

Length

for add.

gas

24.6 ft

(7.5 m)

32.8 ft

(10 m)

15

3

/16"

(100 mm)

or more

/16"

15

3

(100 mm)

or more

Installation parts you

should purchase (

Sleeve (

)

Bushing-Sleeve (

Putty

(Gum Type Sealer) (

Bend the pipe as

closely on the wall

as possible, but

be careful that it

doesn’t break.

Vinyl tape (Wide) (

• Apply after carrying

ainage test.

out a dr

To carr

•

y out the

drainage test,

remove the air

fi lters and pour

water into the heat

exchanger.

Saddle (

)

Power supply

cable (

)

Connection cable (

1/4" (6.35 mm)

Liquid side piping

)

(

Gas side piping (

Additional

drain hose (

)

)

)

)

)

)

)

3

/8"

39

(1000 mm)

or more

It is advisable

to avoid more than 2 blockage

11

13

(300 mm)

/16"

or more

directions. For better ventilation & multiple-outdoor

installation, please consult authorized dealer/specialist.

Or

x This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

34

Page 4

11.1 Indoor Unit

11.1.1 Selecting the Installation Location

Take into consideration the following contents when creating the blueprint.

Ŷ

Indoor unit installation location

x Do not install the unit in excessive oil fume area such as kitchen, workshop an

x

The location should be strong enough to support the main unit without vibration.

x There should not be any heat or steam source ne

x

Drainage should be easy. Avoid locating the drain port close to ditches (domestic wastew

Avoid locations above entrances and ex

x

its.

arby.

x Do not block the air intake and discharge passages.

x

Select the location that enables the cool and warm air to spread out

Locate the indoor unit at least 3.28 ft (1 m) or more away from a TV, radio, wireless appliance, antenna cabl

x

fluore

scent light, and 6.56 ft (2 m) or more away from a telephone.

to the entire room.

x Recommended installation height for indoor unit shall be at least 8.27 ft (2.5 m) from floor.

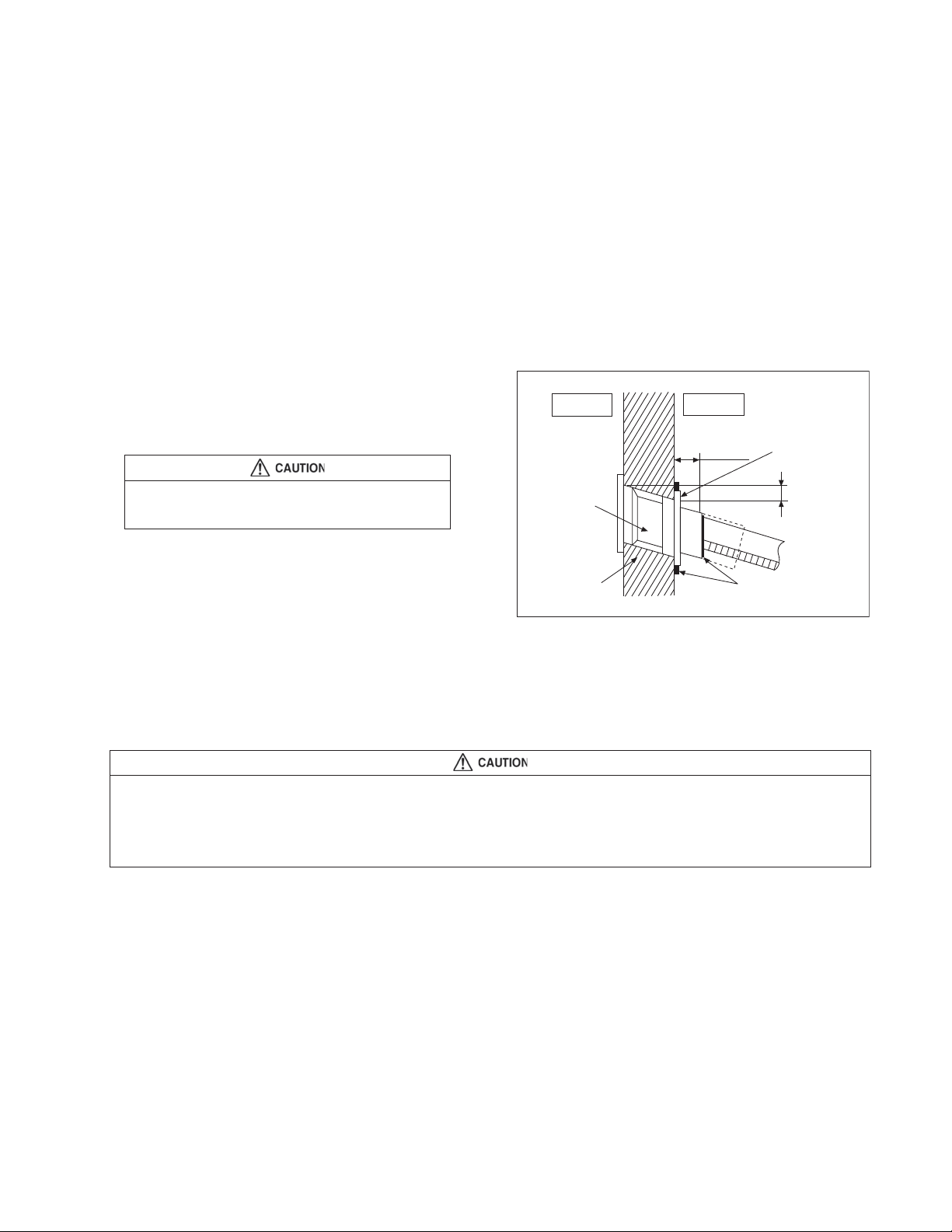

11.1.2 To Drill a Hole in the Wall and Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32"

(15 mm) from the wall.

When the wall is hollow, be sure to use the sleeve for tube

assembly to prevent pests from damaging the cables, e.g.

mice biting the connection cable.

4

Finish by sealing the sleeve with putty or

caulking compound at the final stage.

Indoor

Sleeve

for tube

assembly

3

ø

/4

2

"

(ø70 mm)

through hole

d etc.

Wall

ater).

Outdoor

Bushing for

19

/32"

(15 mm)

Putty or caulking compound

tube assembly

e and

Approx.

7

/32

" -

9/32

(5 - 7 mm)

"

11.1.3 Installing the Indoor Unit (Installation Embedded in the Ceiling)

11.1.3.1 Preparation Before Installation

x Always provide sufficient entry and exit space to allow installation work, inspection and unit replacement.

x Waterproof the rear surface of the ceiling below the unit in consideration of water droplets forming and dropping.

When cooling operation is performed for an extended period under the following conditions, water droplets may form and drop. Attach locally

purchased insulation (foamed polyethylene with a thickness of 7/32" (5 mm) or more) to the outside of the indoor unit before installing into the

ceiling to improve heat insulation.

x Locations with a dew point inside the ceiling of 73.4°F (23°C) or more

x Kitchens and other locations that produce large amounts of heat a

x

Locations where the inside of the ceiling serves as

x When ins

air to spre

talling into a ceiling, select the unit position and airflow direction that enable the cool and wa

ad out to the w

hole room.

an outside air intake passage

x Do not place objects that might obstruct the airflow

nd steam

rm

within 3.28 ft (1 m) below the intake grill.

35

Page 5

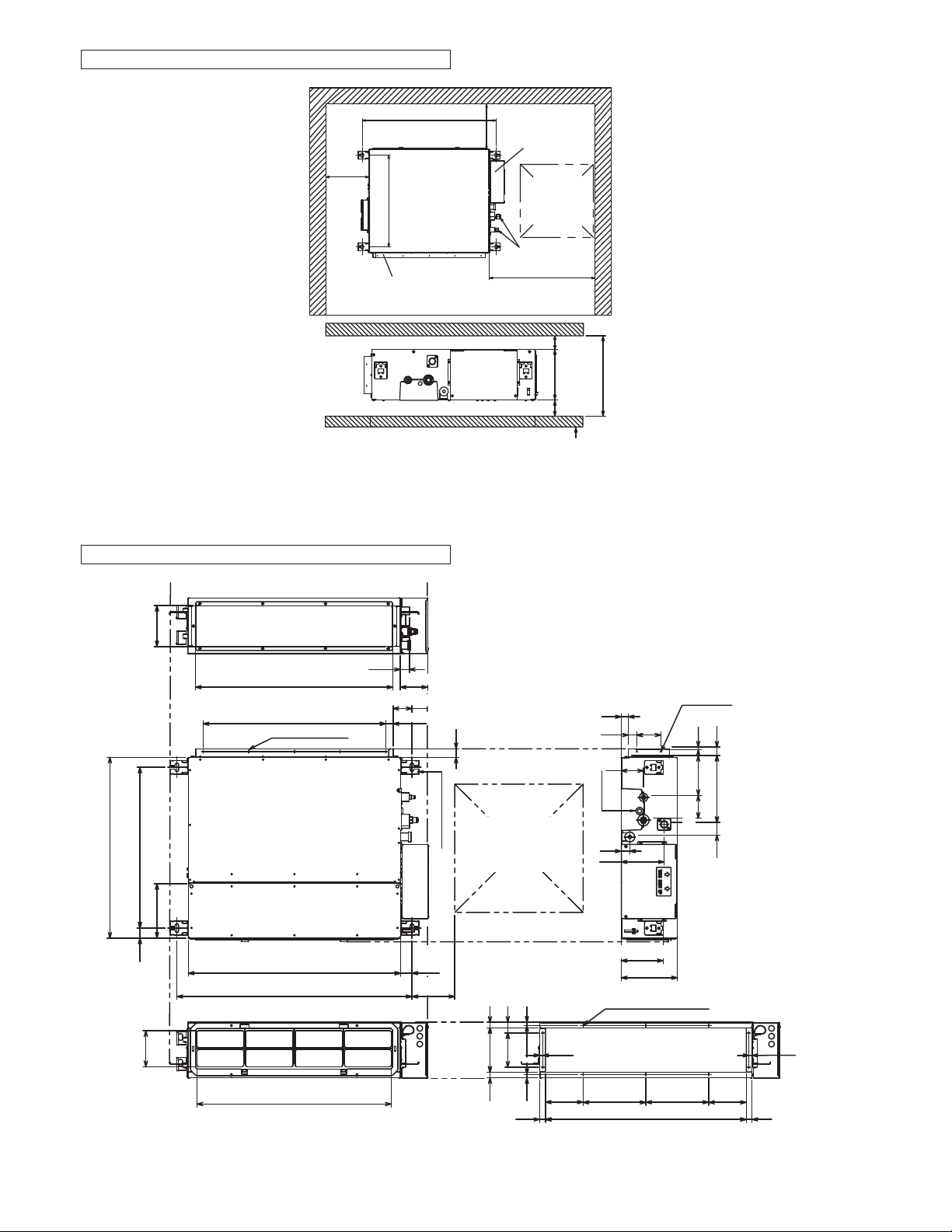

Required Minimum Space for Installation and Service

7

/16" (

824) (Suspension bolt pitch)

32

7

/8"

Min. 7

(

200) or

more

Min 3 15/

564)

(

"

/32

7

22

Flange for air outlet duct

" (100 mm) or more for bottom

16

air intake

x

H dimension means the minimum height of the unit installation space.

"

/8

7

or

200)

Min.

more

(

7

Min. 25/32" (20) or more

Min. 25/32" (20) or more

Electrical

component box

Inspection

access

23

/32

17

23

/32

17

(

450 x 450)

Refrigerant tubing

19

/32

Min. 25

(

650) or more

" (200)

/8

7

7

Ceiling

x

"

"

"

" (240)

/16

*H=Min.

7

9

x Select H dimension such that a downward slope of at least 1/100 is ensured. Refer to 11.1.4 “Connecting

drain pi

ping

”

Dimension of the Indoor Unit

the

" (145)

/32

23

5

27

(640)

"

/16

3

25

194)

" (564) (Suspension bolt pitch)

" (

/32

/8

7

5

7

22

(38)

"

/2

1

1

(126)

"

/32

31

4

1

/4

"

(692) (Flange for air outlet duct)

3

/16

" (640) (6

25

7

/16

32

" (824) (Suspension bolt pitch)

5-ø

29

26

1

"

/8

17

/32

25

/32

"

5

/16

" (160) x 4)

(ø3.1)(Hole)

" (750)

(680)

5

/32

" (29)

1

25

/32

" (96)

3

5

/8

2

" (66)

1

/32

1

1 15/32

5 29/32"

"

(37)

(150)

(26)

1

(27)

1

/16"

Inspection access

23

17

Suspension lug

/32" X

(450x450)

(Field supply)

"

(22)

"

/8

7

"

/32

3

(155)

6

(23)

"

/32

29

(40)

"

/16

9

1

"

/32

23

4

29

19

"

/32

/32

9

(120)

(15)

17

(14)

"

/16

(23)

"

23/32"

9

/16

5

(132)

3

" (28)

/32

1

3

1

/16

" (30)

3

/16

3

1

(33)

6

(153)

"

(14)

3

/16

"

3

(84)

" (81)

Water inlet

5

"

/16

1

"

/32

29

5

" (150)

/32

7

/8

7

1

10-ø

"

/8

21

/32

8

"

(220)

23

/32

27

* Filter Uninstalled

1

2-ø

(Hole)

5

"

/16

"

/32

13

"

/8

5

5

"

/32

5

3

" (200)

(ø3.1)(Hole)

21

8

"

/32

(220)

" (704)

"

/8

(10)

(ø3.1)

"

/16

3

1

(143)

(80)

" (44)

/32

23

1

3

/16

5

(132)

(30)

" (238)

/8

3

9

"

29

/32

"

(23)

9

/16

" (14)

36

Page 6

In Case of Bottom Intake

1

Remove the frame filter assy as shown in

diagram 1

2 Remove cover plate as shown in diagram 1

3 Fix frame filter assy as shown in diagram 2

4 Fix cover plate as shown in diagram 2 with

the dummy hole downward.

Fixing Frame Filter Assy

Filter Assy

In case of bottom side

Ceiling Opening

* Attach the frame fi lter assy to

the main unit while pushing the

tip of the latches in the direction

of the arrow.

Main unit

1

Air

discharge

Air intake

Cover plate

Dummy hole

In case of back side

Frame Filter

Assy

Cover plate

2

Air discharge

Air intake

Dummy hole

Frame

Filter

Assy

x

Install inspection opening 17 23/32" x 17 23/32" (450 mm x 450 mm) on the control box side where maintenan

spection of the control box and drain pump are easy. Install another inspection opening

and in

31 1/2" x 27 9/16"

(800 mm x 700 mm) also at the lower part of the unit.

9

27

" (700)

/16

700

Hanging

bolt M10

(2

" (800)

800

/2

1

31

Reinforcing materials

3

17

3

/8

/32

" to

" (144)

/2

1

Approx.

4

") (60 to 90 mm)

Roof beam

Ceiling surface

Securing the Hanging Bolts

Reinforced concrete

Hanging

bolt M10

/2" (114)

1

Approx.

4

discharge

Insert hole-in

anchor, etc.

”

Ceiling surface

Air intakeAir

A

Ceiling

Wooden of other structure

9

/16

" (40)

1

3

/32

t =

3

" (30)

/16

1

(Hanging bolt pitch)

Hanging bolt

C channel

Hanging fi xture

" (2)

Allow view A

Inspection access

(Field supply)

ce

x

Secure the hanging bolts (M10, locally purchased) firmly in a manner capable of supporting the unit weight

Consult your construction or interior contractor for details on finishing the ceiling opening

x

.

37

.

Page 7

Installing an Intake and Discharge Duct Type

Ensure the range of unit external static pressure is not exceeded. Refer technical manual for the rang

x

external stati

x

Connect the duct as sh

When attaching duct to the intake side, remove the product filter frame assy and replace with locally purcha

x

c pressure se

own.

tting.

intake-side flange by using flange by using 10 - Ø 1/8" (Ø 3.1)(hole) screws.

x Wrap the flange and duct connection area with aluminium tape or similar to prevent air leak.

e of

se

Flange

(locally purchase)

Connection screw (x10)

Rectangular solic duct

When attaching a duct to the intake-side, be sure to attach

an air filter inside the air passage on the intake-side.

(Use an air filter with dust collecting efficiency at least 50%

in a gravimetric technique.)

Installation into the Ceiling

Attach the nuts and washers to the hanging bolts, then lift up and hook the main unit onto the hanging fixtures.

x

Main unit

Flange

Insulation material

(locally purchased)

Air outlet sideAir inlet side

x Check if the unit is leveled using a level or a vinyl hose filled partially with water.

Hanging bolt (M10)

(locally purchased)

Washer

9

Hexagonal nut (M10)

(locally purchased)

Level

38

Page 8

Mounting Remote Controller Receiver

Install the remote controller receiver cable at least 1 31/32" (50 mm) away from electric wires of other appliances to avoid miss-operation

(electromagnetic noise).

1

Remove the bottom case.

Insert the driver

and slightly turn.

tention

At

Mounting the bottom case

x Tighten the screws securely until the screw head

touch the b

head

when mounting the top ca

Do not over-tighten the screws. (The bottom ca

x

may be deformed, re

ottom case. (Otherwise, loose scre

s may hit the PCB and cause malfunction

se.)

g in fall of the unit.)

sultin

w

se

Bottom

case

s

Flat-blade

screwdriver

Screws

6

necting the remote control wiring

Con

x Arrange the wires as shown in the illustration for 2 as in diagram below, avoiding unnecessary wires bei

store

d in the case. (Caught wires ma

Avoid wires touching parts on the PCB. (Caught wires may destro

x

Mount to the wall.

2

EXPOSED TYPE

Prepara

tion: Make 2 holes for screws using a driver.

Mount the top case.

• Align the claws of the

top case and then align

the claws of the bottom

case.

Cut here with

a nipper and

remove the burr

le.

with a fi

Claw (2 places)

Claw

Wood screw (supplied)

Connect the remote control wiring.

• Arrange the wires along the groove of the case.

Mount the bottom case

to the wall.

Hole for screw

Wall to fi x the

receiver

y destroy the PCB.)

Prepara

y the PCB.)

EMBEDDED TYPE

tion: Make 2 holes for screws using a driver.

Mount the top case.

• Align the claws of the

top case and then

align the claws of the

bottom case.

Avoid the wire

being caught.

Claw (2 places)

Wood screw (supplied)

Connect the remote control wiring.

Mount the bottom case to the wall.

• Pass the wire through the hole in

the centre of the bottom case.

Claw

Hole for screw

ng

Top case

(Back side)

Bottom case (Back side)

Clamper 7

(supplied)

Pass

through

the hole

39

Top case

(Back side)

Bottom case (Back side)

Terminal board

Page 9

x Connect the indoor unit and the remote control receiver 5. (Refer to the illustrati

Fix the green wire from receiver cable 8 to the grounding location provided inside control

x

Receiver cable 8

Control box

Remote control

receiver

on.)

board.

5

11.1.4 Connecting the Drain Piping

x Lay the drain piping so as to ensure drainage.

x Use a locally purchased VP20 general rigid PVC pipe (outer diameter ø1 1/32" (ø26)) for the drain piping a

connect the indoor unit and the drain piping using supplied hose band to ensure that no leakag

firmly

occurs.

x Drain piping located indoor should always be insulated by wrapping with locally purchased insulation (foa

polyethylene

x

The drain piping should have a downward gradient (1/100 or more) and should be secured by using pipe ha

equipm

with a thickness of 13/32" (10 mm) or more

ent to avoid creating hills or traps partway.

).

x Should there be any obstacle preventing the drain piping from being extended smoothly, the drain piping can be

raised out

side of the main unit as shown in the illustration below.

nd

e

med

nging

Drain hose

1

/32

1

1

"

/8

(130)

#

Hard PVC pipe (VP20)

@

Adhere with

PVC adhesive.

$

"

(26)

Rise

At least 1/100

Good

Hill

13

" (300 mm) or less

11

/16

(not a downward gradient)

11

/16

" (500 mm) or less

19

Tr ap

Unit drain port

Do not use adhesive.

x Strictly do not install and extend the drain piping from the main unit drain water outlet horizontally or upward or raised it 19 11/16" (500 mm)

or more.

Doing so ma

x Do not use drain hose bent at 90° angle. (The maximum permissible bend is 45°.)

Hose band

Drain hose insulation

1

/32" (26)

1

5

y result in poor drainage or drain motor failure.

11.1.5 Insulating the Refrigerant Piping

x After the piping is connected, insulate. (Refer to the illustration)

Clamper

!

Wrap fi rmly

with vinyl tape,

leaving no gaps.

Unit side

40

Wrap fi rmly

with vinyl tape,

leaving no gaps.

Flare insulator

0

Page 10

11.1.6 Connect the Cable to the Indoor Unit

x Remove control box cover.

Remove

x

Fix the conduit connections to the knockout holes

x

the plug

together with lock nuts, then secure them against

the cont

rol box side pan

x Receiver cable wires 8 must pass through the

uppe

r conduit

Make

sure the receiver cable is inserted

inside of the control box.

Connect receiver cable connector to control box

wire

connector and fix it to the power su

r as shown in the diagram.

holde

Insert firmly the connector of receiver cable 8

con

nector at control box of indoor un

Connection cable between indoor un

x

outdoo

r unit should be UL listed or

ductor wires minimu

4 con

accordan

ce with local electric codes.

o Ensure that the terminal numbers on

indoo

r unit are connec

terminal n

right coloured wires as shown in the diagram.

o Earth lead wire should be longer than th

other lea

electri

out from the anchorage.

Secure the cable onto the control board

o

the holde

s.

el.

hole.

from

pply cord

it.

it and

CSA approved

m AWG16 in

the

ted to the same

umbers on the outdoor un

it by the

d wires as shown in the diagram

cal safety purpose in case the cord

r (clamper).

to

e

for

slips

with

Control Box

Control Box cover

Lock Nuts

Plugs

Connectors

Knockout holes

Screws

Fix the receiver cable to the holderFix receiver cable connector

Terminals on the indoor unit 1 2 3

Colour of wires

Terminals on the outdoor unit 1 2 3

When the wall is hollow, please be sure to use the sleeve

for tube ass’y to prevent dangers caused by mice biting the

connection cable.

Earth wire

(connection cable)

Indoor/outdoor connection terminal

This equipment must be properly earthed.

x

Ensure the colour of wires of outdoor un

terminal

Holder for

connection cable

WARNING

Earth wire

(receiver cable)

Indoor/outdoor

connection cable

Nos. are the same to the indoor’s

respectively.

x

Earth wire shall be Yellow/Green (Y/G) in colo

and lon

ger than other AC wires for safety reason.

it and the

ur

41

Page 11

11.1.6.1 Wire Stripping and Connecting Requirement

Wire stripping

Indoor/outdoor

connection

terminal board

7

10 ± 1 mm

13/32" ± 1/32"

No loose strand when inserted

/32" (5 mm)

or more

(gap between wires)

Do not joint wires

WARNING

RISK OF FIRE

JOINING OF WIRES MAY CAUSE

OVERHEATING AND FIRE.

Use complete wire without joining.

Use approved socket and plug with earth pin.

Wire connection in this area must follow to national wiring rules.

OR

Conductor

fully inserted

ACCEPT

Conductor

over inserted

PROHIBITED

OR

Conductor not

fully inserted

PROHIBITED

OR

42

Page 12

11.2 Outdoor Unit

11.2.1 Select the Best Location

11.2.2 Install the Outdoor Unit

x After selecting the best location, start installation to Indoor/Outdoor Unit Installation Diagram.

1

Fix the unit on concrete or rigid frame firmly and horizontally with a bolt nut (ø 13/32" (ø10 mm)).

2 When installing at roof, please consider strong wind and earthqua

Please fa

sten the installation stand firmly with bolt or nails.

ke.

AB

C

D

11.2.3 Connect the Piping

11.2.3.1 Connecting the Piping to

Indoor

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

x Align the center of piping and suffici

the flare nut

with fingers.

x Further tighten the flare nut with torque wren

cified torque as stated in

spe

the table.

ently tighten

ch in

11.2.3.2 Connecting the Piping to

Outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

Model A B C D

E9SD3UAW,

E12SD3UAW

E18SD3UAW

Do not over tighten, overtightening may cause gas leakage.

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf•ft [18 N•m (1.8 kgf•m)]

3/8" (9.52 mm) 31.0 Ibf•ft [42 N•m (4.3 kgf•m)]

1/2" (12.7 mm) 40.6 Ibf•ft [55 N•m (5.6 kgf•m)]

5/8" (15.88 mm) 47.9 Ibf•ft [65 N•m (6.6 kgf•m)]

3/4" (19.05 mm) 73.8 Ibf•ft [100 N•m (10.2 kgf•m)]

22 7/16"

(570 mm)

24 1/8"

(613 mm)

4 1/8"

(105 mm)

5 5/32"

(131 mm)

23/32"

(18.5 mm)

5/8"

(16 mm)

Spanner

or Wrench

To r qu e

wrench

12 19/32"

(320 mm)

14 3/16"

(360.5 mm)

11.2.3.3 Connecting the Piping to

Outdoor Multi

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

Male side

(Auxiliary pipe)

Wrench

(Adjustable Wrench)

Male side

(Auxiliary pipe)

Wrench

(Adjustable Wrench)

Torque Wrench for Flare

Nut and Pipe Size Reducer

Hall Union

Hall Union

Flare Nut

Packing

(Connection pipe)

Torque Wrench

for Flare Nut

Pipe Size

Reducer

Female side

Applicable to

Liquid and Gas side of

CS-E9SD3UAW

Liquid side of

CS-E12SD3UAW

CS-E18SD3UAW

Flare Nut

(Connection pipe)

Applicable to

Gas side of

CS-E12SD3UAW

CS-E18SD3UAW

Female side

11.2.3.4 Gas Leak Checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system. If the pressure

holds, release the nitrogen and proceed to section 4.

43

Page 13

11.2.4 Evacuation of the Equipment

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedure.

Indoor unit

Vacuum

pump

1

Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

Liquid side

Gas side

Two-way valve

Close

Three-way valve

Close

Outdoor unit

valve.

2 Connect the micron gauge between vacuum pump and service port of outdoor units.

3 Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge and to pull

down to a value of 500 microns.

4 To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn off

the vacuum pump.

5 Disconnect the vacuum pump house from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf•ft (18 N•m) with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Open”

using a hexagonal wrench (5/32" (4 mm)).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o Be sure to check for gas leakage.

x If micron gauge value does not descend 500 microns, take the following measures:

If the leak stops when the piping connections are tightened further, continue working from step 3

-

-

If the leak does not stop when the connections are retightened, re

-

Do not release refrigerant during piping work for installation and reinstallation.

Be careful with the liquid refrigerant, it may cause fr

-

ostbite.

pair location of leak.

.

44

Page 14

11.2.5 Connect the cable to the Outdoor Unit

x For model E9SD3UAW, E12SD3UAW

1 Remove

2 Remove Control Board Cover (Resin and

Metal).

3 Remove Plugs.

4 Fix the conduit connectors to the knockout

holes with lock-nuts, then secure them against

the side panel.

5 All wires pass through conduits.

6 Connection cable between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

7 Wire connection to the power supply

(208/230V 60Hz) through circuit breaker.

o Connect the UL liste

Connect the power supply cord and connection cable between indoor unit and outdoor unit according to the

8

diagram below.

Top panel.

s minimum AWG14 to

wire

board, and co

ct the other end of the

nne

wires to ELCB / GFCI.

d or CSA approved

the terminal

Control Board

Metal Cover

Control Board

Cover (Resin)

To p Pa n e l

Powe r

Supply

Wires

Lock Nuts

Knockout

Holes

Plugs

Side Panel

Connectors

Indoor Unit

Outdoor Unit

lanimreTlanimreT

1

2

3

9

Secure the wire onto the control board with the holder (clamper).

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

Grounding wire min AWG16

* Ensure all connecting wire

between indoor unit and

outdoor unit and power supply

cord are installed in individual

conduit.

1

2

3

L1

L2

Disconnect

Switch

Field supply

Grounding wire

ower Supply

P

Single Phase

208/230V 60Hz

min AWG14

10 After completing wiring connections, reattach the control board cover (Metal and Resin) and the top panel to

the original position with the screws.

11 For wire stripping and connection requirement, refer to instruction 11.1.6 of indoor unit.

Terminal

Board

Earth

wire

longer

than

other AC

wires for

safety

reasons

Earth

wire

longer

than

other AC

wires for

safety

reasons

Holder

Powe r

supply cord

This equipment must be properly earthed.

x

Earth lead wire shall be Yellow/Green (Y/G) in colour and should be longer than other lead wires as shown in

figure for el

ectrical safety in case of slippi

ng.

Indoor & outdoor

connection cable

WARNING

45

the

Page 15

x For model E18SD3

Remove control board cover (Resin and

1

UAW

Metal).

2 Remove particular plate.

3 Remove plugs.

4 Fix the conduit connectors to the knockout

holes with lock-nuts, then secure them against

the side panel.

5 All wires pass through conduits & particular

plate’s opening hole.

6 Connecting wire between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

7 Wire connection to the power supply

(208/230V 60Hz) through circuit breaker.

o Connect the UL liste

s minimum AWG12 to

wire

board, and co

d or CSA approved

the terminal

nne

ct the other end of the

wires to ELCB / GFCI.

Connect the power supply cord and connecting wire between indoor unit and outdoor unit according to the

8

diagram below.

Front Panel

Particular

Plate

Lock Nuts

Knockout

Holes

Connecting Wires

Particular Plate’s

opening holes

Control Board

Cover (Metal)

Plugs

Connectors

Control Board

Cover (Resin)

Indoor Unit

Outdoor Unit

TerminalTerminal

1

2

3

9

Secure the wire onto the control board with the holder (clamper).

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

Grounding wire min AWG16

* Ensure all connecting wire

between indoor unit and

outdoor unit and power supply

cord are installed in individual

conduit.

1

2

3

L1

L2

Disconnect

Switch

Field supply

Grounding wire

Power Supply

Single Phase

208/230V 60Hz

min AWG12

10 After completing wiring connections, reattach the particular plate and control board cover (metal and resin) to

the original position with the screws.

11 For wire stripping and connection requirement, refer to instruction 11.1.6 of indoor unit.

Terminal

Board

Earth

wire

longer

than

others

AC wires

for safety

reasons

Holder

Terminal

Board

Earth

wire

longer

than

others

AC wires

for safety

reasons

Holder

Power

supply cord

This equipment must be properly earthed.

x

Earth lead wire shall be Yellow/Green (Y/G) in colour and longer than other lead wires for el

Indoor & outdoor

connection cable

WARNING

of the slipping.

46

ectrical safety in case

Page 16

11.2.6 Piping Insulation

1 Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 1/4" (6 mm) or above.

Switching the High State Switch (SW2)

x To increase the air volume, open the control box and on the control board, switch the FAN switch (SW2) to “HI”.

x See the diagram for “Connecting the Indoor/Outdoor Connection Cable”.

Note: Enabling Long-range Remote Control

x To maintain EMC emission limits, cabling interconnecting the HA terminal and subsequent opto-coupler, must be

no more than 6.2 ft (1.9 m) length.

x Loop four turns of this cable through a suitable small EMC ferrite toroid, and protect with a short length of large

diameter heat-shrink tube.

x There is no similar length limit for cable following on from the opto-coupler isolation.

DISPOSAL OF OUTDOOR UNIT DRAIN WATER

x If a drain elbow is used, the unit should be placed

on a stand which is taller than 1 3/16" (30 mm).

x If the unit is used in an area where temperature

falls below 32°F (0°C) for 2 or 3 days in

succession, it is recommended not to use a drain

elbow, for the drain water freezes and the fan will

not rotate.

CHECK THE DRAINAGE

Check after connecting the power supply.

x Pour approximately 600 cc of water into the drain

pan of the main unit using a squeeze bottle, etc.

x Press the drain test run switch on the control

board in the control box to start the drain motor

and check whether the water drains normally.

(The drain motor operates for approximately

5 minutes and then stops automatically.)

(See the diagram for “Connecting the

Indoor/Outdoor Connection Cable”.)

¥

Install the hose at an angle so that the water smoothly flows out.

Heat

exchanger

Drain pan

HoseDrain elbow

Squeeze bottle

Approximately

600 cc of water

47

Loading...

Loading...