Page 1

Order No:

Room Air Conditioner

CS-A28BKP5/CU-A28BKP5

CONTENTS

Page Page

1 Features 2

2 Functions

3 Product Specifications

4 Dimensions

5 Refrigeration Cycle Diagram

6 Block Diagram

7 Wiring Diagram

8 Operation Details

9 Operating Instructions

10 Installation Instructions

11 3-way Valve 51

3

12 Servicing Information

6

13 Troubleshooting Guide

14 Technical Data

8

9

15 Exploded View

16 Replacemen t Parts List

10

11

17 Exploded View

12

18 Replacemen t Parts List

19 Electronic Parts List

22

42

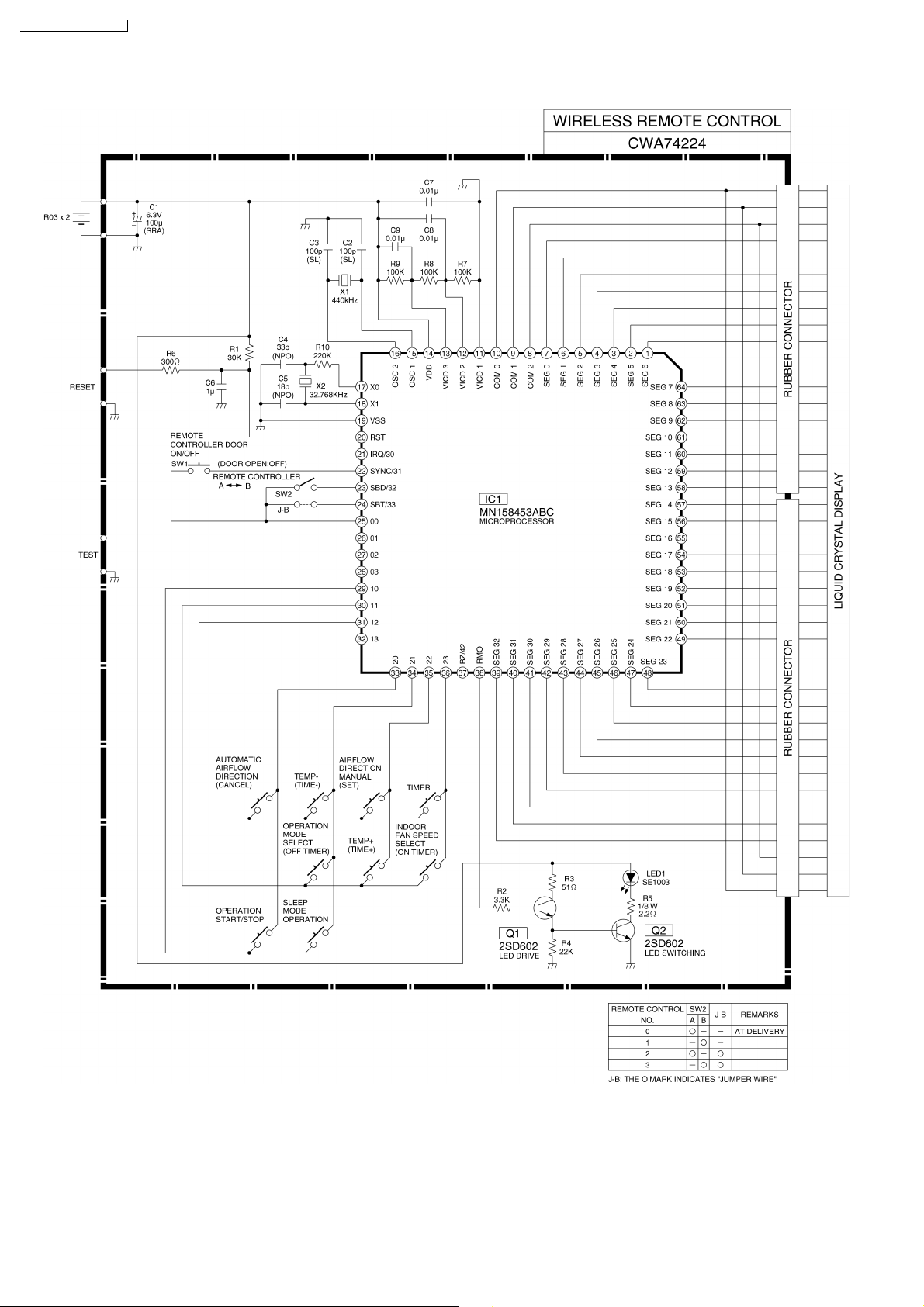

20 Electronic Circuit Diagram

© 2002 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D) All rights reserved. Unauthorized copying

and distribution is a violation of law.

58

62

64

67

68

69

70

71

72

Page 2

CS-A28BKP5/CU-A28BKP5

1 Features

• High Efficiency

High Efficiency Airflow Circuit

•

Compact Design

•

Auto Restart after Power Failure

•

Long Piping up to 30m

•

• Catechin Deodorizing Air Filter

Deodorizing Control during operation

•

Cold draught Control

•

2

Page 3

2 Functions

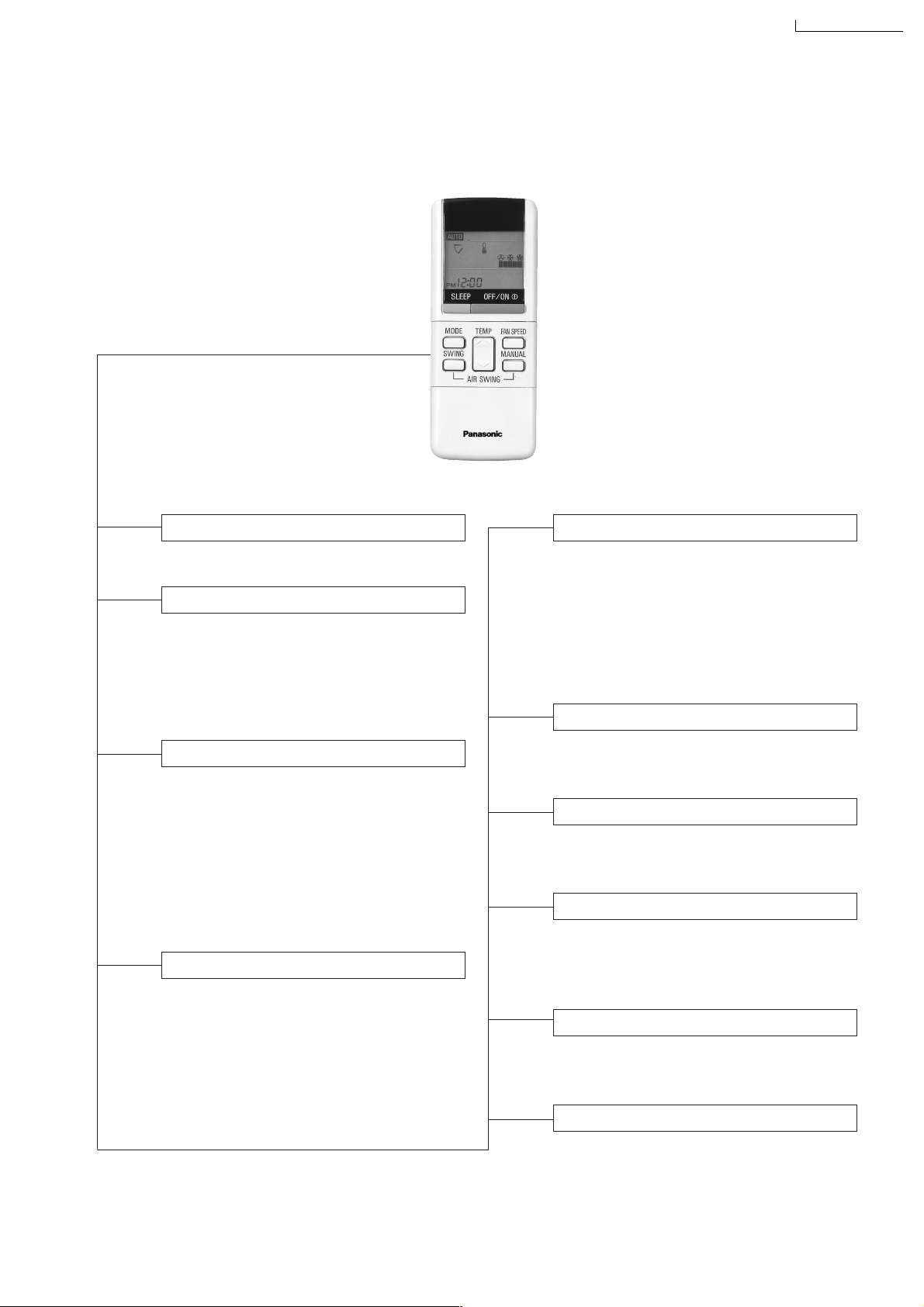

Remote Control

CS-A28BKP5/CU-A28BKP5

OFF / ON I

MODE

FAN SPEED

AIR SWING

Operation OFF / ON

Operation Mode Selection

•

•

•

•

AUTO

HEAT

COOL

DRY

Automatic Operation Mode

Heating Operation Mode

Cooling Operation Mode

Soft Dry Operation Mode

Indoor Fan Speed Selection

• h j k Low Speed

l

• h j k Medium Speed

lll

• h j k High Speed

lllll

•

AUTOFAN

Automatic Fan Speed

Airflow Direction Control

•

SWING

•

MANUAL

Automatic Airflow Direction

Control

Airflow Direction Manual

Control

TEMP.

ON-TIMER

OFF-TIMER

TIME

SET

CANCEL

CLOCK

(q)

Room Temperature Setting

• Temperature Setting (16˚C to 30˚C)

• Automatic Operation

m / n

n

n - o

2˚C lower than standard

Standard

2˚C higher than standard

Timer Operation Selection

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

Timer Operation Set / Cancel

• ON Timer and OFF Timer setting and

cancellation.

Clock Setting

• Current time setting.

3

SLEEP

Sleep Mode Operation OFF / ON

Page 4

CS-A28BKP5/CU-A28BKP5

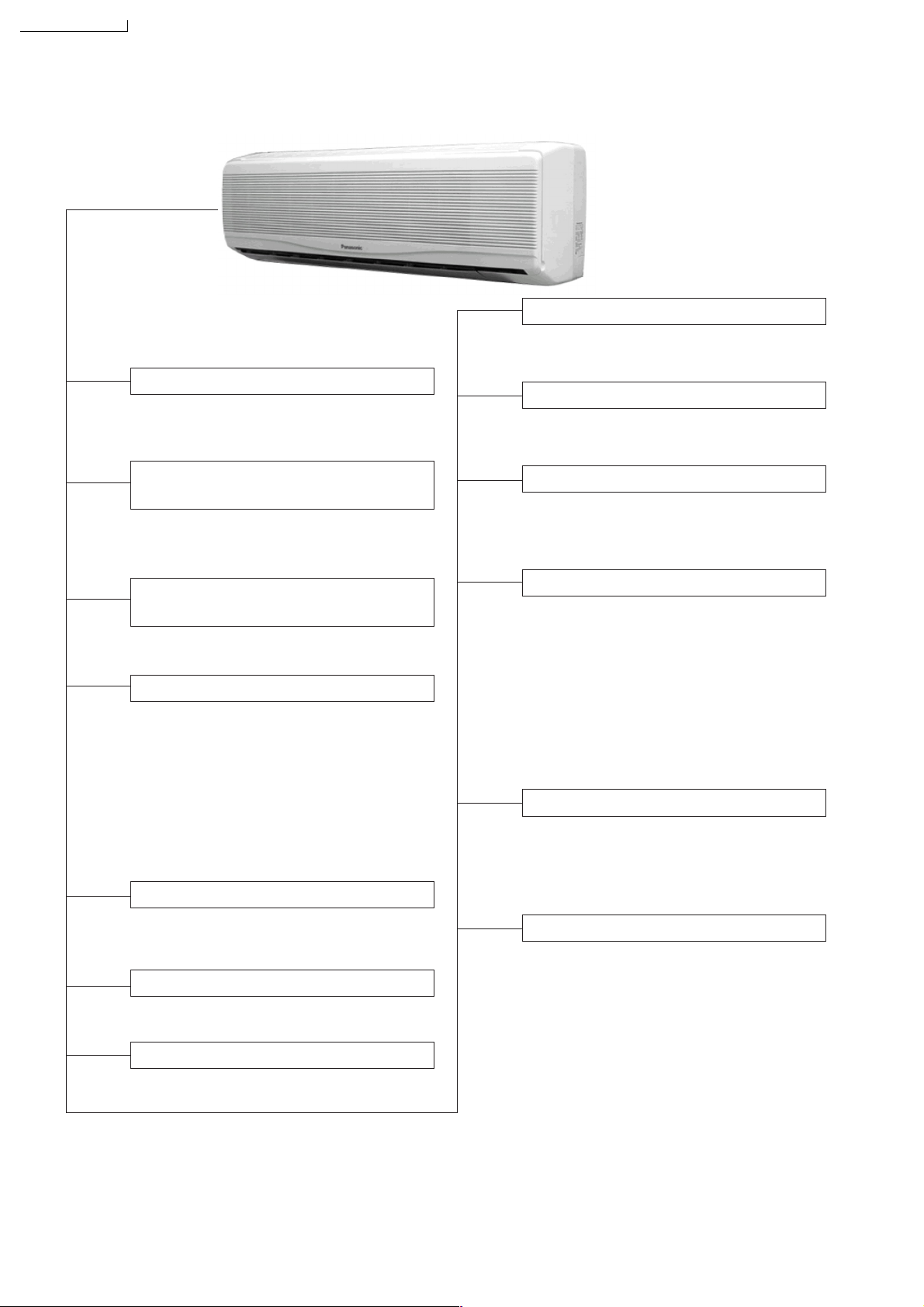

Indoor Unit

AUTO

OFF / ON

Auto Operation Switch

• Used when the remote control cannot be

used.

Auto Restart Control

• Operation is restarted after power failure

at previous setting mode.

Anti-Freezing Control

• Anti-Freezing control for indoor heat

exchanger. (Cooling and Soft Dry)

TEST RUN

OFF / ON

Remote Control Signal Receiving

Sound Control

• It can be controlled by pressing Auto

Operation Switch for 10 seconds.

Operation Test Running / Pump

Down Switch

• Used when test running or servicing.

Operation Indication Lamps (LED)

•

POWER

(Red)........ Lights up in operation,

blinks in Automatic

Operation Mode judging

and Hot Start operation.

•

SLEEP

(Orange).... Lights up in Sleep

Mode Operation.

•

TIMER

(Orange).... Lights up in Timer

Setting.

Operation Mode

• Heating, Cooling, Soft Dry, and Automatic

Mode.

Time Delay Safety Control

• Restarting is inhibited for appro. 3 minutes.

7 Minutes Time Save Control

• Cooling Operation only.

Sleep Mode Auto Control

• Indoor Fan operates at Low fan

speed.

• Operation stops after 8 hours.

Indoor Fan Speed Control

• High, Medium and Low.

• Automatic Fan Speed Mode

– Heating : Fan speed varies from Hi

➝

SLo in accordance with

indoor heat exchanger.

– Cooling : Fan rotates at Hi and Me

speed. Deodorizing control

is available.

– Soft Dry: Fan rotates at Lo speed.

Airflow Direction Control

• Automatic air swing and manual adjusted

by remote control for vertical airflow.

• Manually adjusted by hand for horizontal

airflow.

Hot-Start Control

• The indoor fan stops until the indoor heat

exchanger temperature over 30°C.

• The indoor fan operates at SLo and Lo

when indoor heat exchanger temperature

reaches 30°C ~ 42°C.

• Hot start is completed when indoor heat

exchanger reaches 42°C.

4

Page 5

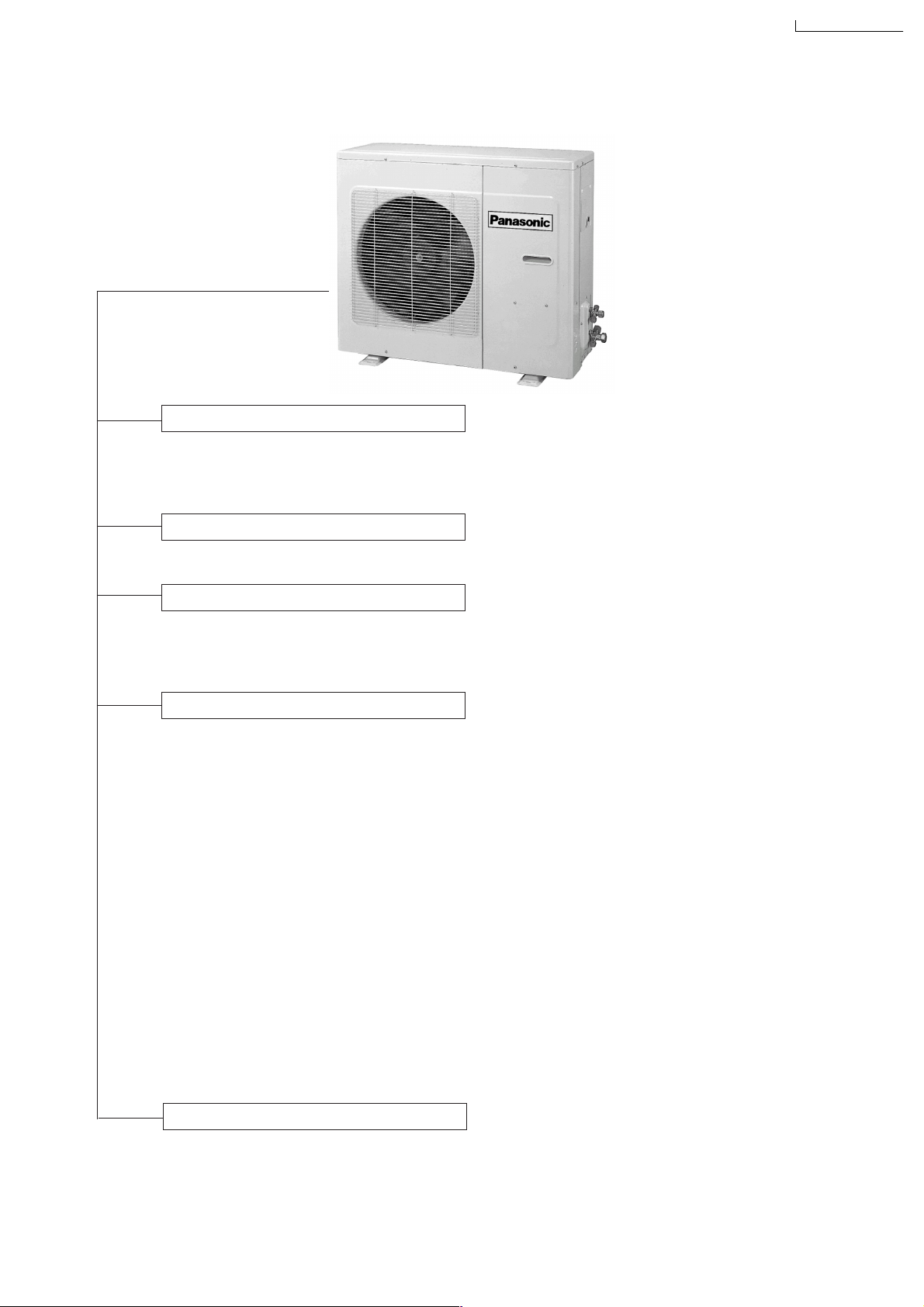

Outdoor Unit

4-Way Valve Control

• When the unit is switched to “OFF”

during Heating operation, 4-way valve

stays at Heating Position for 5 minutes.

CS-A28BKP5/CU-A28BKP5

Overload Protector

• Inner protector (Compressor, Fan Motor).

60 Secs. Forced Operation Control

• Once the compressor is activated, it

does not stop for 60 secs. (Stops immediately with remote control stop signal.)

Outdoor Fan Operation Control

•

4-pole induction motor (2-speed)

• For Cooling or Soft Dry Operation

Hi-speed … when outdoor temperature

reaches to 31°C

Lo-speed … when outdoor temperature

reaches to 29°C

• For Heating Operation

Hi-speed ... when outdoor temperature

reaches to 13.5°C.

Lo-speed ... when outdoor temperature

reaches to 15.5°C.

• For Over-heating Protection, the Fan is

switched ON or OFF depending on the

piping temperature and the outdoor

temperature.

Deice Control

•

To prevent frosting at outdoor heat

exchanger during Heating Operation.

5

Page 6

CS-A28BKP5/CU-A28BKP5

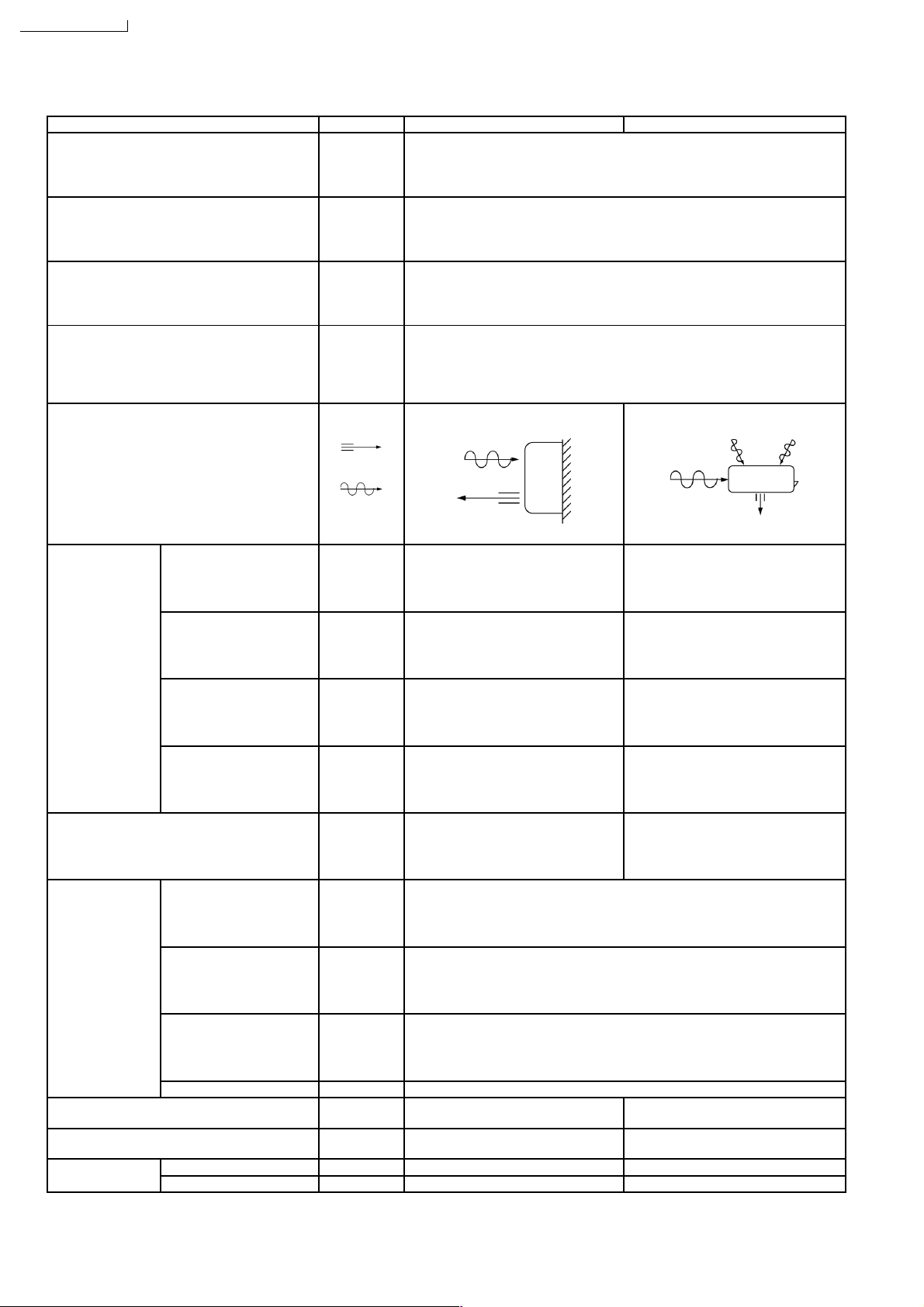

3 Product Specifications

Unit CS-A28BKP5 CU-A28BKP5

Cooling Capacity kW

Heating Capacity kW

Moisture Removal l/h

Power Source Phase

Airflow Method OUTLET

Air Volume Indoor Air (Lo) m3/min (cfm) Cooling; 14.2 (501) —

Btu/h

Btu/h

Pint/h

V

Cycle

SIDE VIEW TOP VIEW

INTAKE

Heating; 15.6 (551)

7.92 - 7.80

27,000 - 26,600

8.35 - 8.25

28,500 - 28,200

4.6

9.7

Single

230 - 220

50

Indoor Air (Me) m3/min (cfm) Cooling; 15.0 (530) —

Heating; 16.4 (579)

Indoor Air (Hi) m3/min (cfm) Cooling; 16.3 (575) —

Heating; 17.7 (625)

Outdoor Air m3/min (cfm) — Cooling; 59.0 (2,083)

Heating; 59.2 (2,090)

Noise Level dB (A) Cooling; 48/46/44 Cooling; 63/55

Heating; 48/44 Heating; 63/55

Electrical Data Input kW Cooling; 2.62 -2.60

Heating; 2.88 - 2.85

Running Current A Cooling; 12.2 - 12.5

Heating; 13.2 - 13..5

COP W/W Cooling; 3.0 - 3.0

Heating; 2.9 - 2.9

Starting Current A 76

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Inner diameter mm 14 —

Length m 0.73 —

inch

inch

inch

inch

G ; Half Union 5/8”

L ; Half Union 1/4”

G (gas side); 5/8”

L (liquid side); 1/4”

6

G ; 3-way valve 5/8”

L ; 3-way valve 1/4”

G (gas side); 5/8”

L (liquid side); 1/4”

Page 7

CS-A28BKP5/CU-A28BKP5

Power Cord Length

Number of core-wire

m 2.1

3 (2.5 mm

2

)

—

—

Dimensions Height inch (mm) 14 - 9/16 (370) 26 - 31/32 (685)

Width inch (mm) 48 - 1/32 (1,220) 34 - 21/32 (880)

Depth inch (mm) 8 - 21/32 (220) 13 - 19/32 (345)

Net Weight lb (kg) 40 (18) 150 (68)

Compressor Type — Scroll type

Motor Type — Induction (2-poles)

Rated Output kW — 2.11

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 30% AS + Glass Fiber 20%

Motor Type Induction (4-poles) Induction (4-poles)

Input W — —

Rated Output W 40 100

Fan Speed Low rpm Cooling; 1,262 Heating; 1,250 920 - 880

Medium rpm Cooling; 1,322 Heating; 1,328 —

High rpm Cooling; 1,418 Heating; 1,420 1,200 - 1,170

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Louver Louver

Row / Stage (Plate fin configuration, forced draft)

2×10 2×26

FPI 18 18

Size (W × H × L) mm 966.5 × 254 × 44 826 × 663.9 × 44

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (cm3) — SONTEX

200 LT (1,242)

Refrigerant (R-22) g (oz) — 1,800 (63.5)

Thermostat Electronic Control Electronic Control

Protection Device Inner Protector Inner Protector

Capillary Tube Length mm — Cooling; 850, Heating; 1,200

Flow Rate l/min — Cooling; 21.8, Heating; 23 (1/2 ATM)

Inner Diameter mm — Cooling; 2.0, Heating; 2.4

Air Filter Material

Style

A.B.S

Honeycomb

—

Compressor Capacitor µF, VAC — 50 µF, 370VAC

Fan Motor Capacitor µF, VAC 2.0 µF, 450VAC 3.0 µF, 450VAC

•

Specifications are subject to change without notice for further improvement.

7

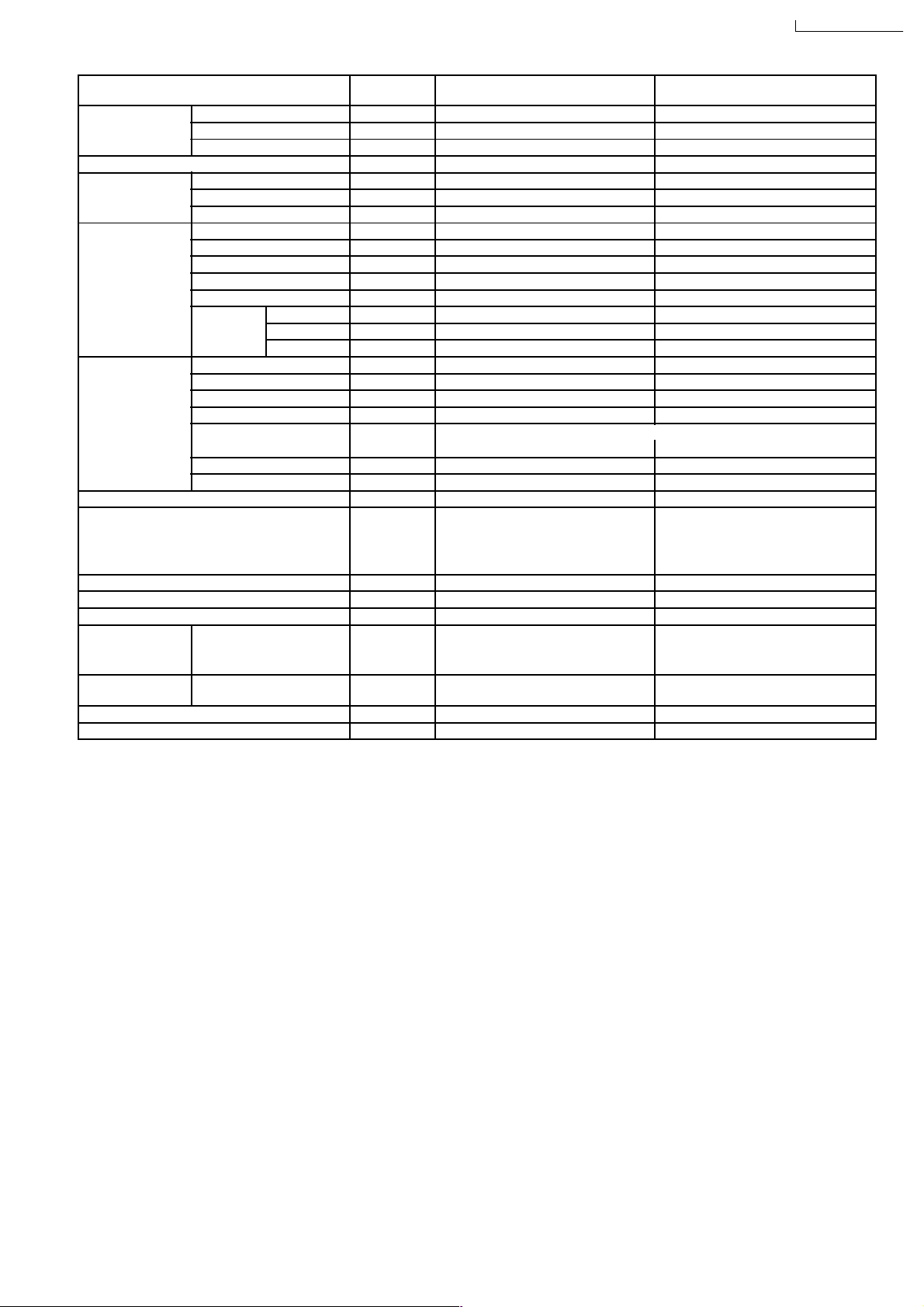

Page 8

CS-A28BKP5/CU-A28BKP5

4 Dimensions

CS-A28BKP5/ CU-A28BKP5

8

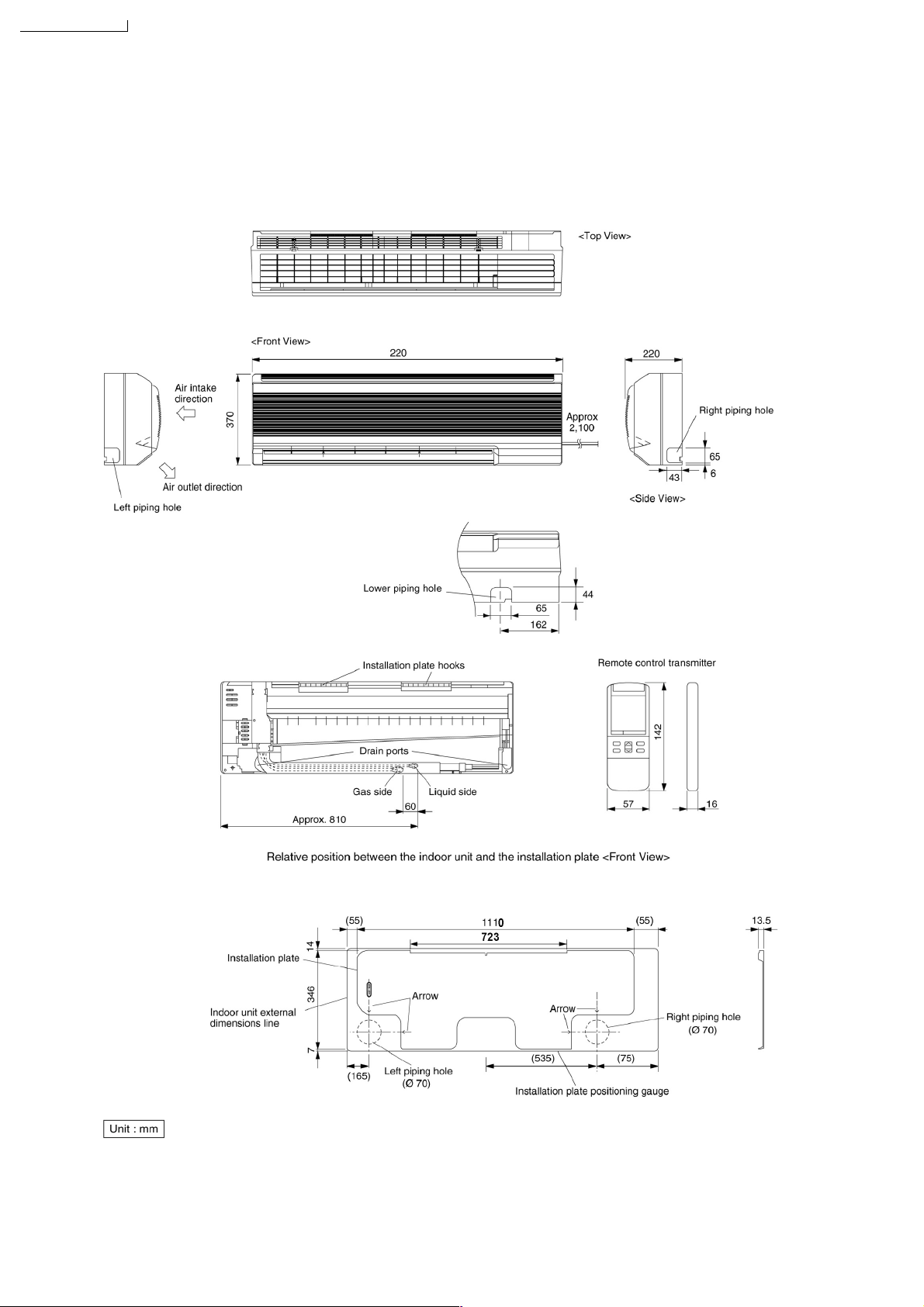

Page 9

Dimensions

CS-A28BKP5/CU-A28BKP5

CS-A28BKP5/CU-A28BKP5

5 Refrigeration Cycle Diagram

CS-A28BKP5/CU-A28BKP5

CS-A28BKP5/CU-A28BKP5

9

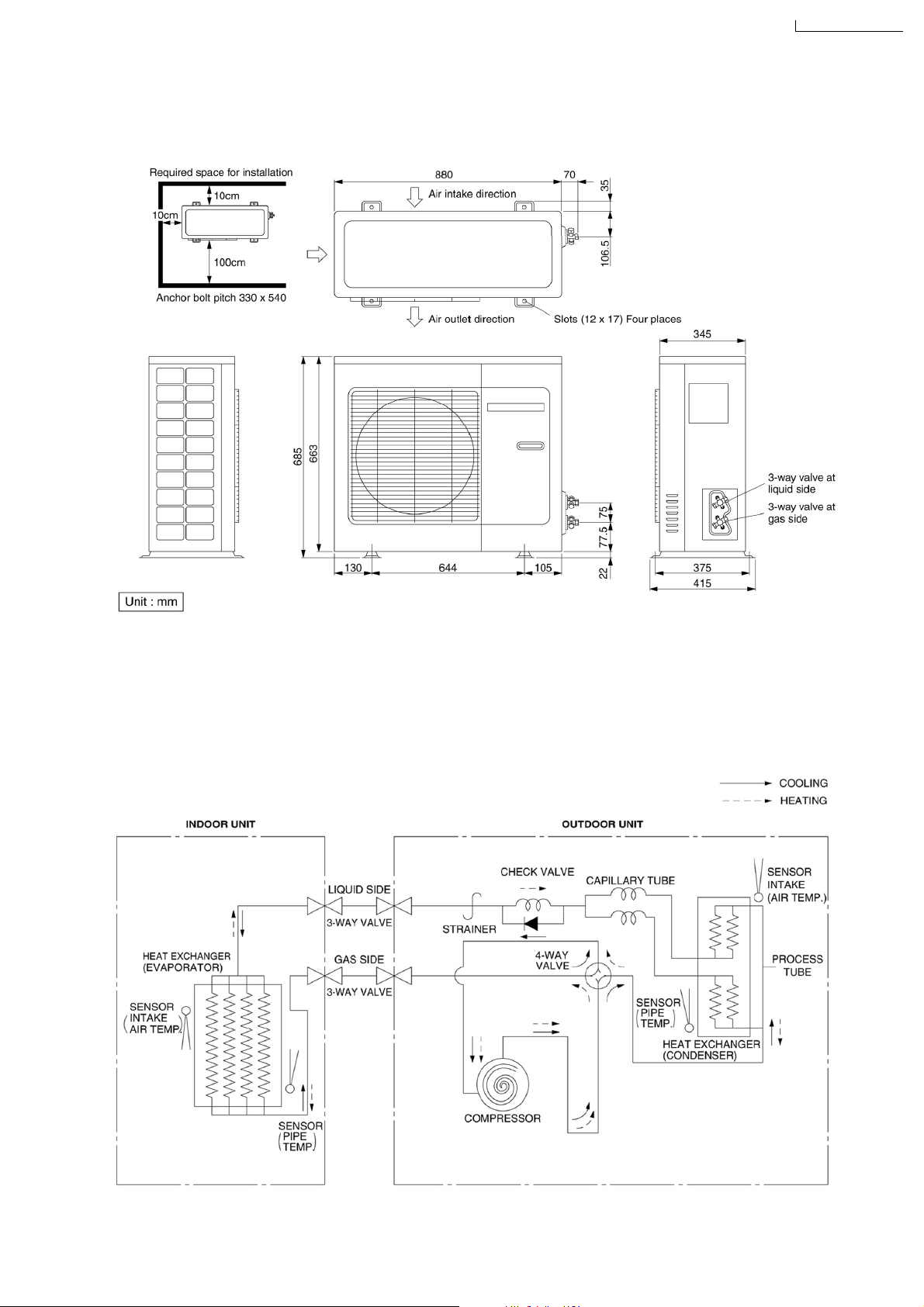

Page 10

CS-A28BKP5/CU-A28BKP5

6 Block Diagram

CS-A28BKP5/CU-A28BKP5

10

Page 11

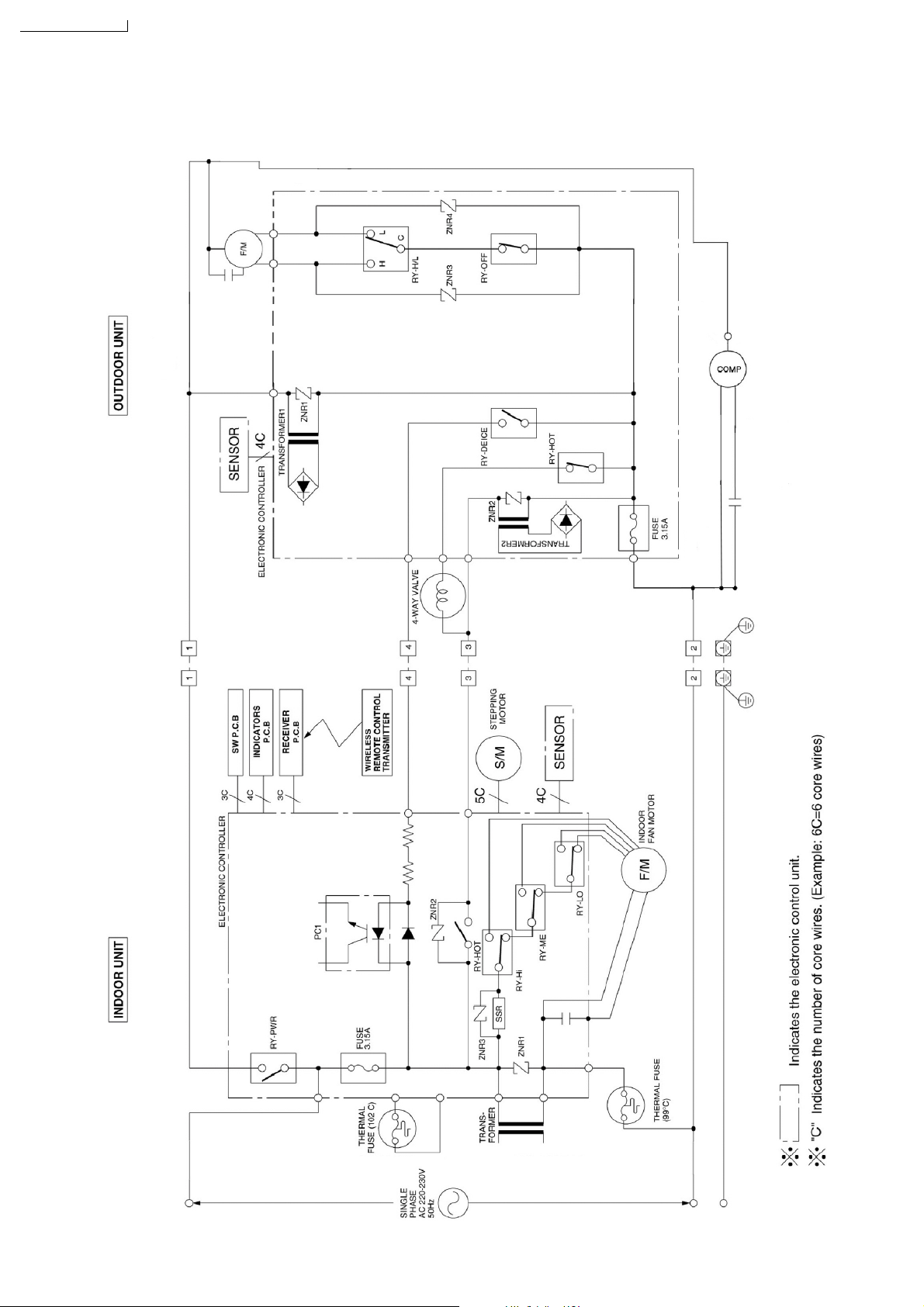

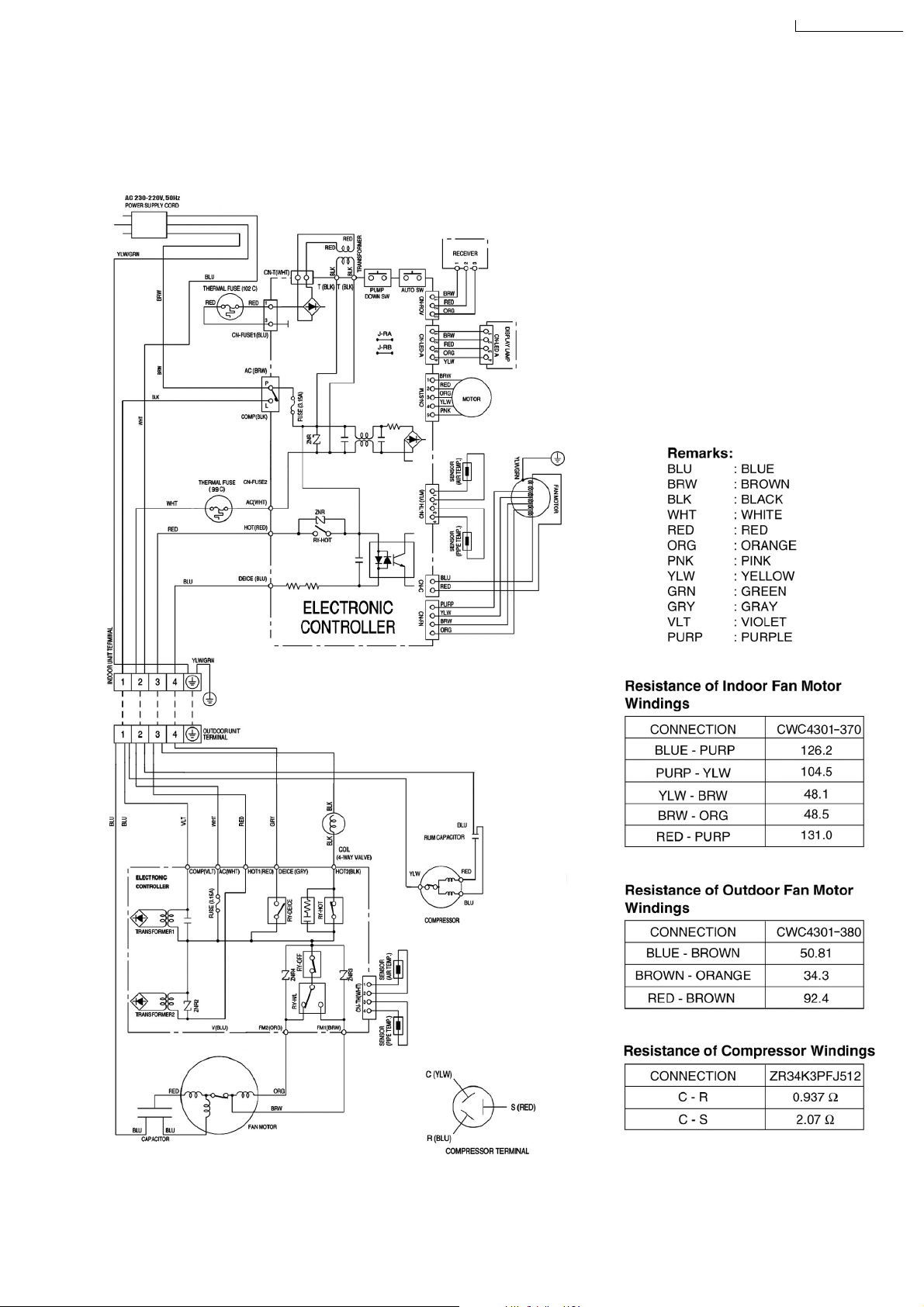

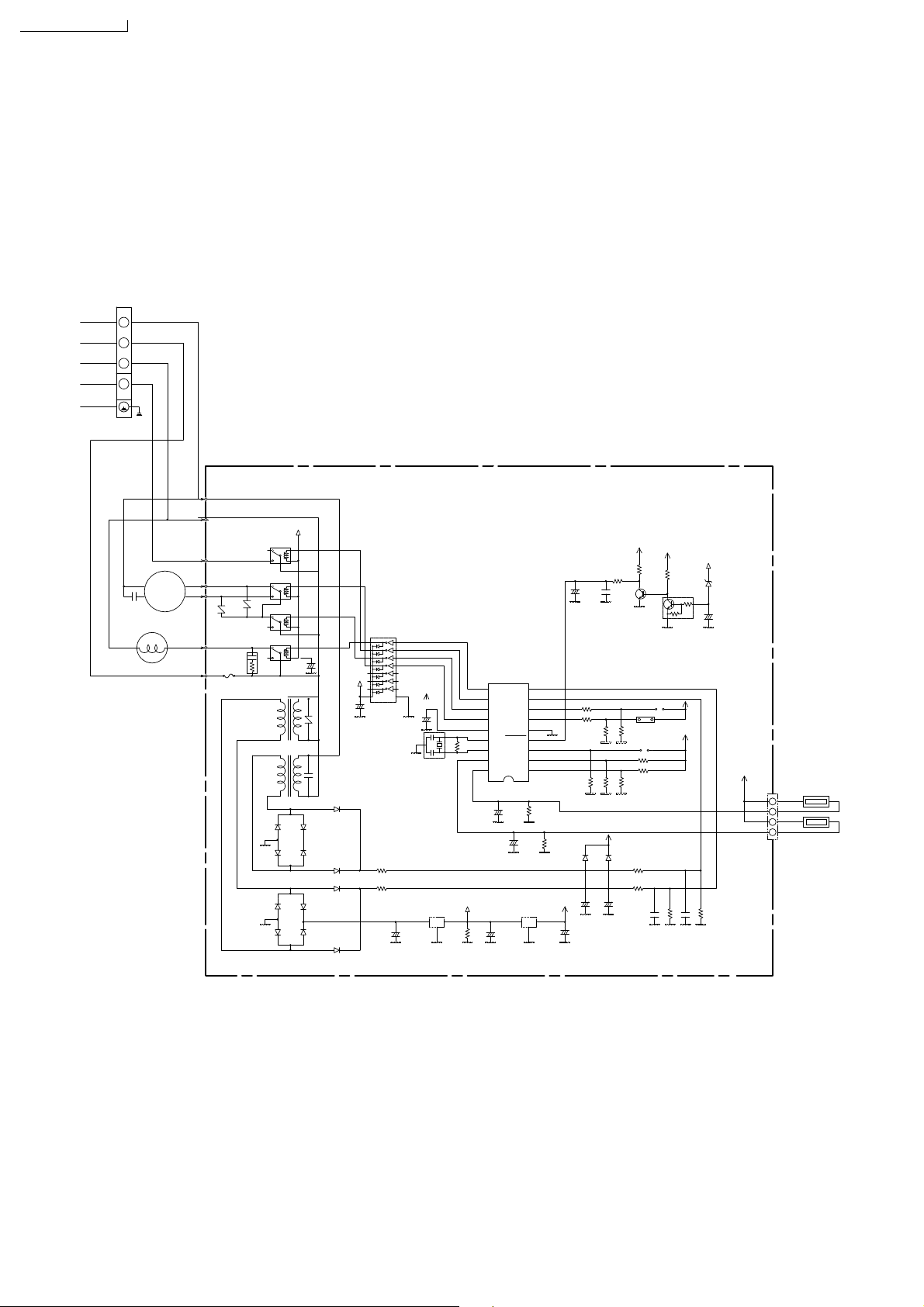

7 Wiring Diagram

CS-A28BKP5 / CU-A28BKP5

CS-A28BKP5/CU-A28BKP5

11

Page 12

CS-A28BKP5/CU-A28BKP5

8 Operation Details

8.1. Cooling Mode Operation

Cooling in operation according to Remote Control setting.

Time Delay Safety Control (3 minutes)

When the compressor is stopped by Power Switch, Remote Control or there is a power failure, it restarts after 3 minutes when

•

the Power Switch, Remote Control is turned ON or the power supply is resumed.

When the setting temperature is reached during cooling operation, the compressor stops and it will not start for 3 minutes.

•

7 minutes Time Saved Control

The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is below the compressor

•

ON temperature.

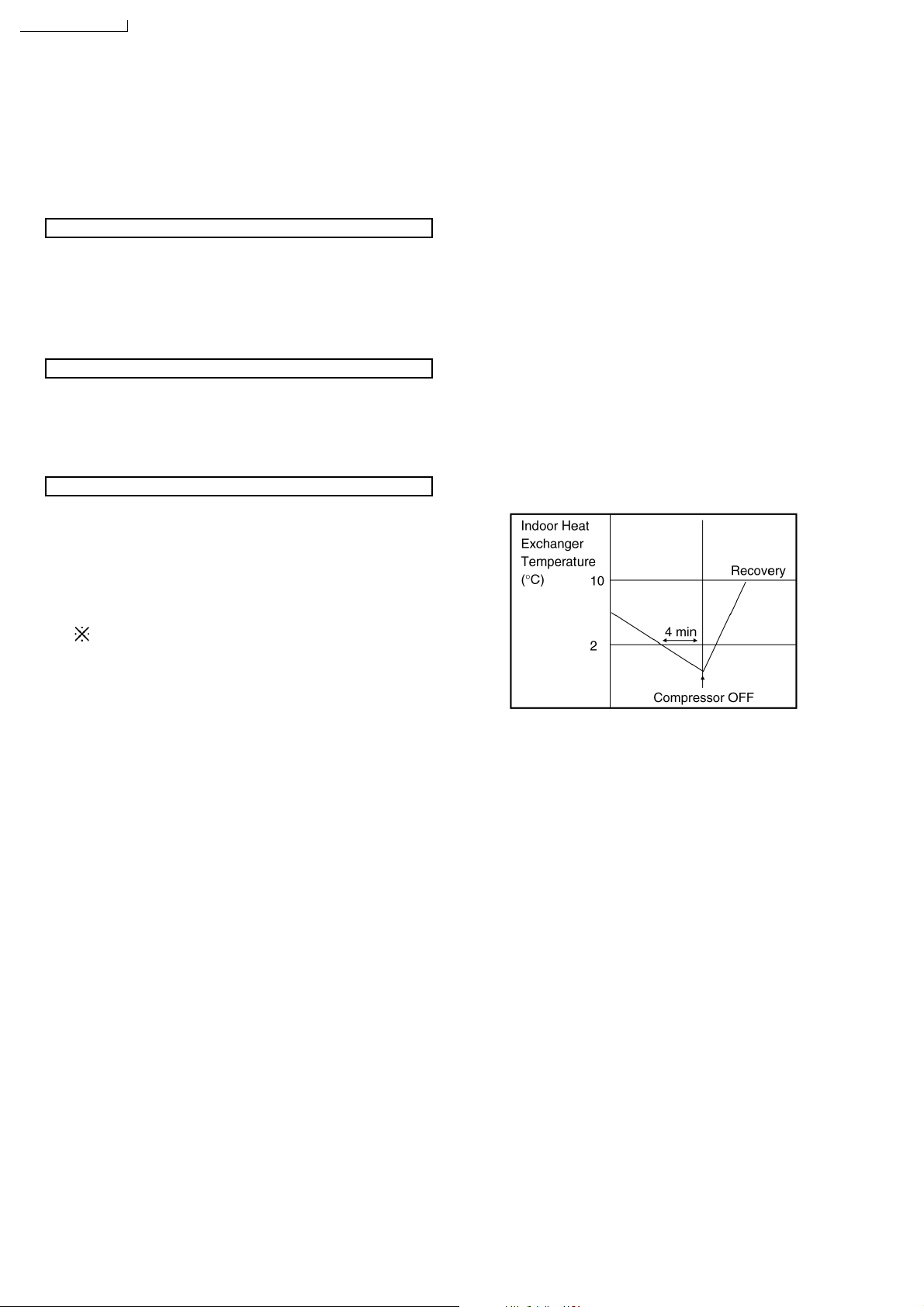

Anti-Freezing Control

If the temperature of the indoor heat exchanger falls

•

continuously below 2°C for 4 minutes, the compressor turns

off to protect the indoor heat exchanger from freezing. The

fan speed setting remains the same.

Compressor recommences when the indoor heat

•

exchanger temperature rises to 10°C (Recovery).

3 minutes waiting of Time Delay Safety Control is

valid for Cooling Operation.

12

Page 13

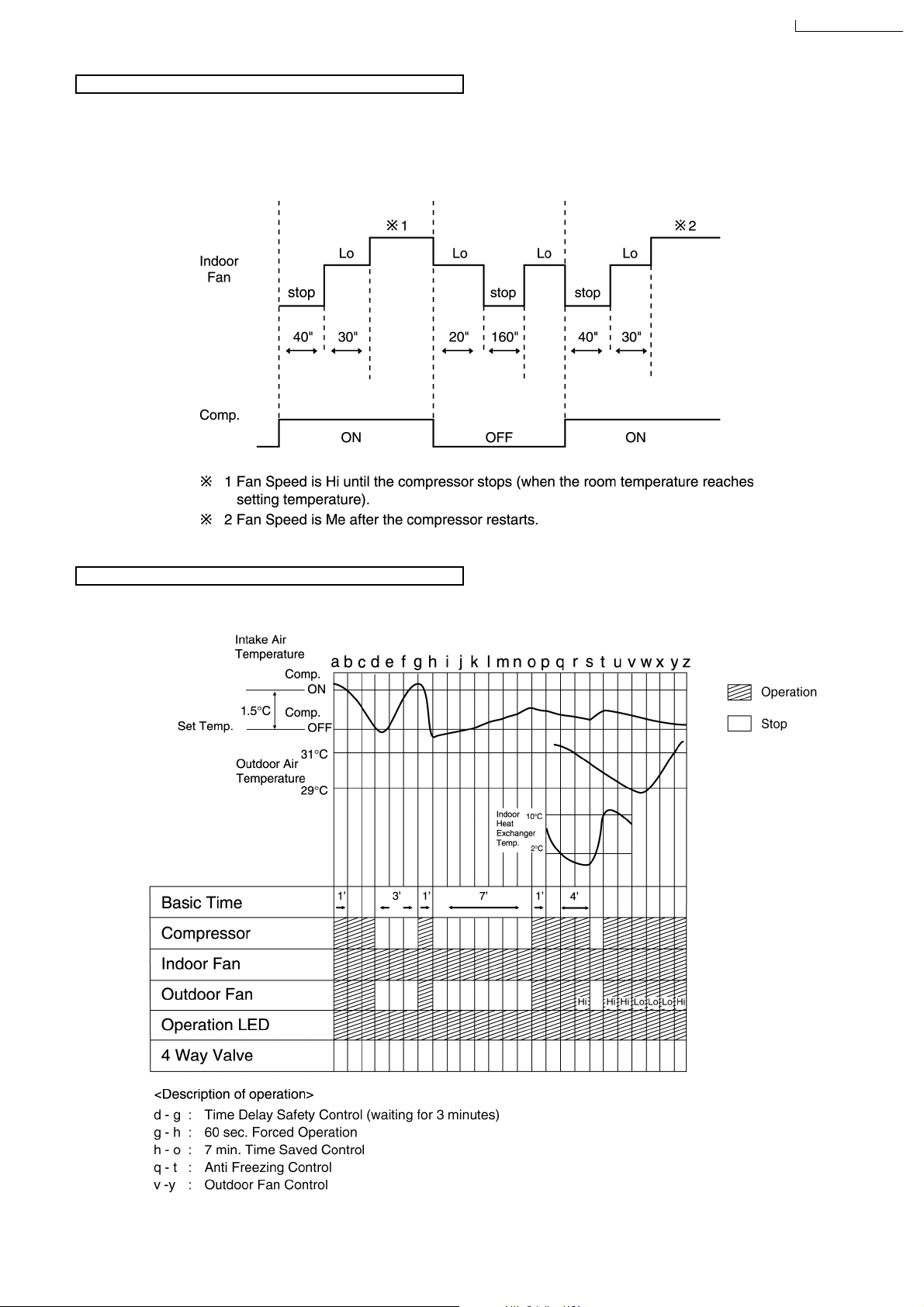

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during cooling operation.

Fan speed rotates in the range of Hi to Me.

•

Deodorizing Control.

•

CS-A28BKP5/CU-A28BKP5

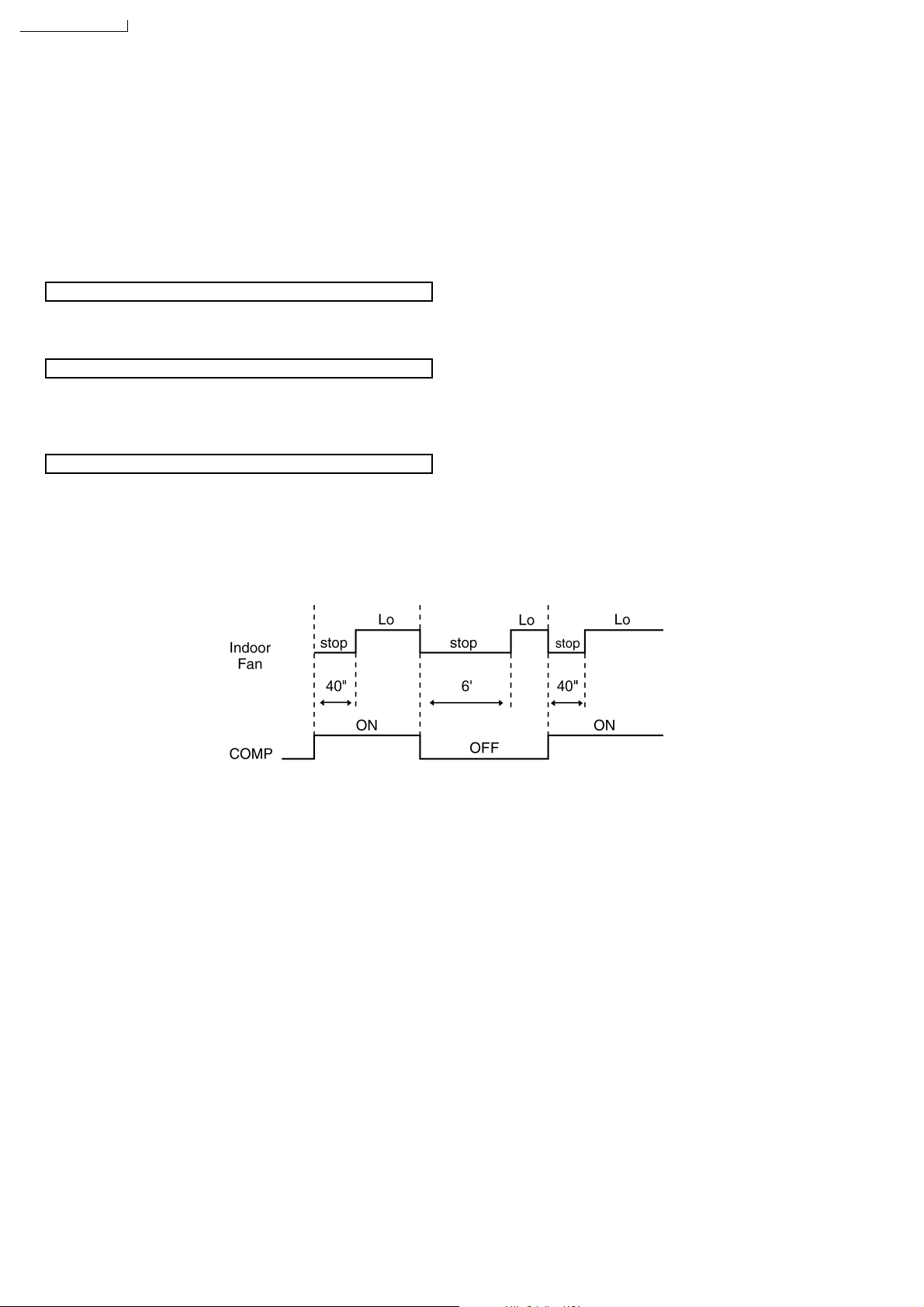

Cooling Operation Time Diagram

13

Page 14

CS-A28BKP5/CU-A28BKP5

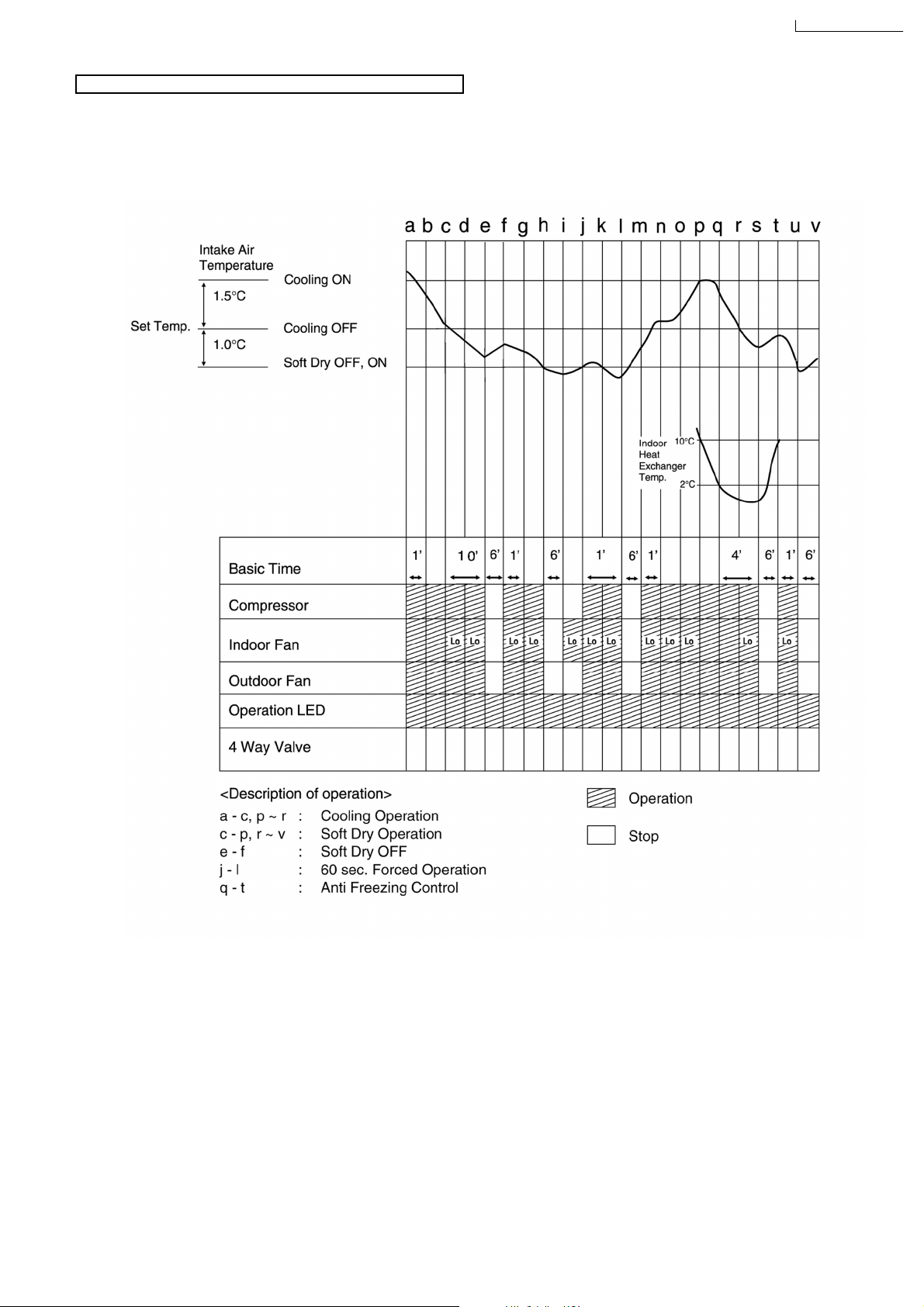

8.2. Soft Dry Mode Operation

The unit starts cooling operation until the room temperature reaches the setting temperature set on the Remote Control, and

•

then Soft Dry operation will start.

During Soft Dry operation, the Indoor Fan operates with Lo speed.

•

Once room temperature reaches below Soft Dry OFF temperature, Indoor Fan, Compressor and Outdoor Fan Stop for 6

•

minutes.

Time Delay Safety Control

Once the compressor stops, it will not start for 3 minutes during Cooling operation.

•

Anti-Freezing Control

Same as Anti-Freezing Control for Cooling Mode operation. (For Soft Dry region, 6 minutes waiting is valid during compressor

•

stops.)

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during Soft Dry operation.

Fan speed rotates at Lo speed.

•

Deodorizing Control.

•

14

Page 15

Soft Dry Operation Time Diagram

CS-A28BKP5/CU-A28BKP5

15

Page 16

CS-A28BKP5/CU-A28BKP5

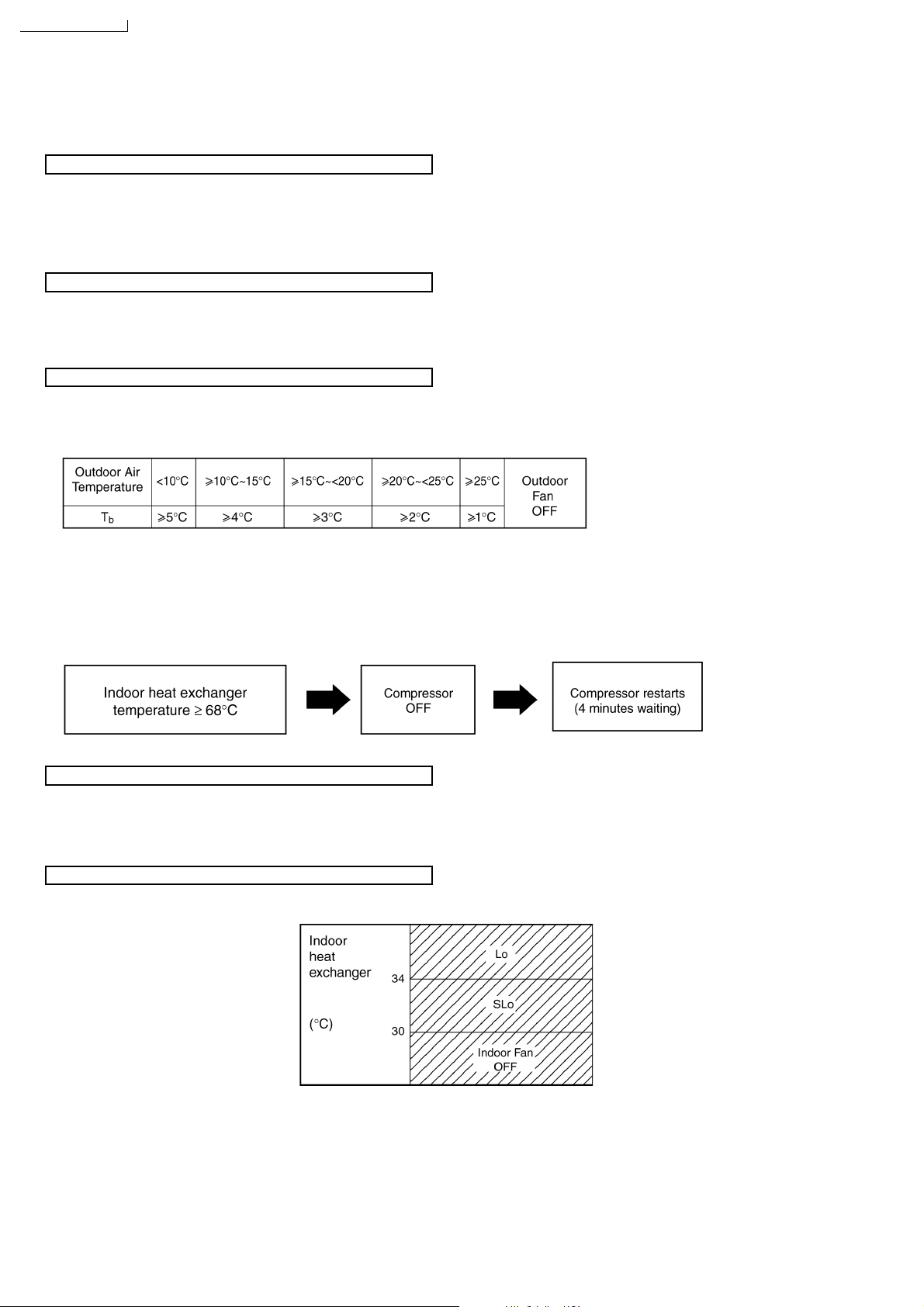

8.3. Heating Mode Operation

Heating in operation according to Remote Control setting.

•

Time Delay Safety Control

When the compressor is stopped by Power Switch, Remote Control or there is a power failure, it restarts after 3 minutes when

•

the Power Switch, Remote Control is turned ON or the power supply is resumed.

When the setting temperature is reached during heating operation, the compressor stops and it will not start for 4 minutes.

•

30 minutes Time Saved Control

The compressor will start automatically if it has stopped for 30 minutes even if the room temperature is below the compre ssor

•

OFF temperature.

Overload Protection Control

If the temperature of the Outdoor Heat Exchanger less than -3°C, Outdoor Fan is ON. The Outdoor Fan stop, when Outdoor

•

Heat Exchanger temperature is T

or more according to Outdoor Air Temperature region as table below:

b

During starting of Heating mode and after deice, Outdoor Fan ON for 90 sec. (Hi).

If the Indoor heat exchanger becomes 68°C or more, the compressor will stop and restart automatically.

•

(Time Delay Safety Control - 4 minutes waiting)

4-way Valve Control

4-way valve ON during Heating operation, except deicing operation.

•

When the unit is switched to “OFF” during Heating operation, 4-way valve stay at Heating position for 5 minutes.

•

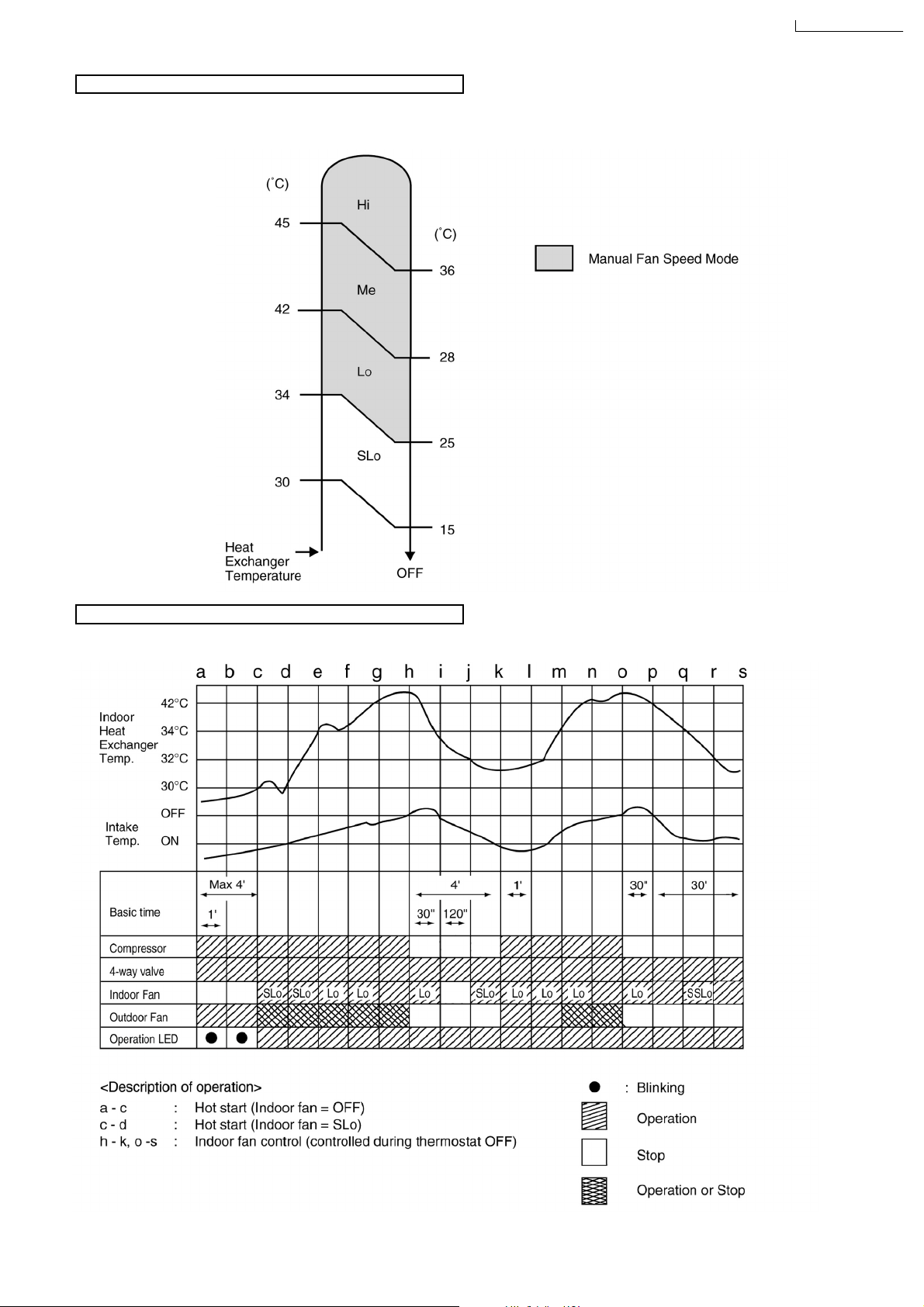

Hot Start Control

When Heating operation starts, Indoor Fan will not start until the indoor heat exchanger reaches 30°C as diagram shown.

Hot Start is completed when indoor heat exchanger reaches

42°C.

Maximum Hot start duration = 4 minutes. After 4 minutes, Hot

start operation will be shifted to normal Heating operation.

16

Page 17

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during heating operation.

Fan speed rotates in the range of Hi→SLo according to the heat exchanger temperature.

•

CS-A28BKP5/CU-A28BKP5

Heating Operating Time Diagram

17

Page 18

CS-A28BKP5/CU-A28BKP5

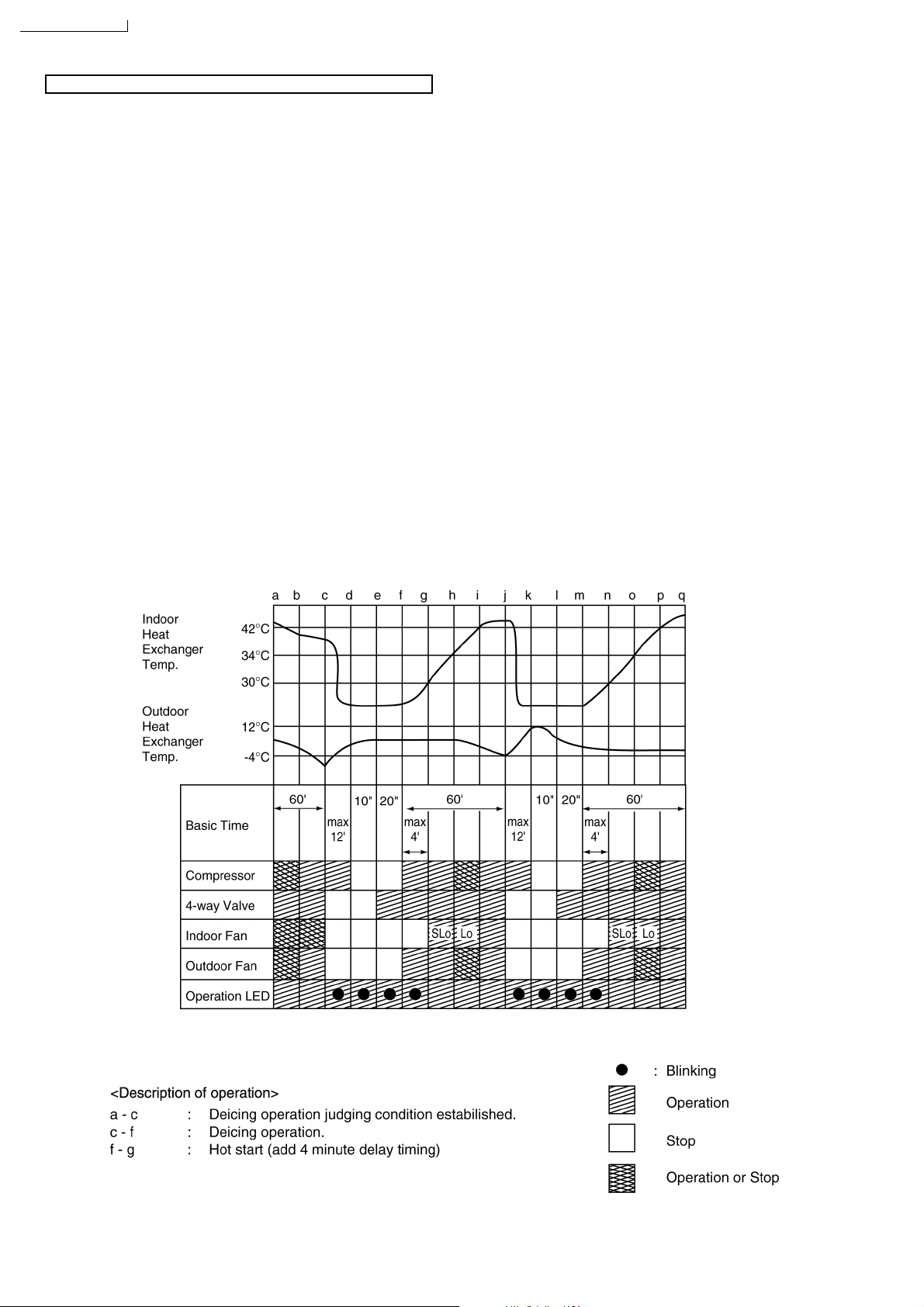

Deicing Control

Deice starts to prevent frosting at outdoor heat exchanger.

Normal Deicing

•

Deice operations detection commences in Heating operation starts or 60 minutes after previous deice operation. If the

outdoor piping temperature drops to -4°C for 50 sec. continuously during compressor is in operation, deice will start.

(There is no detection during Outdoor Fan stops.)

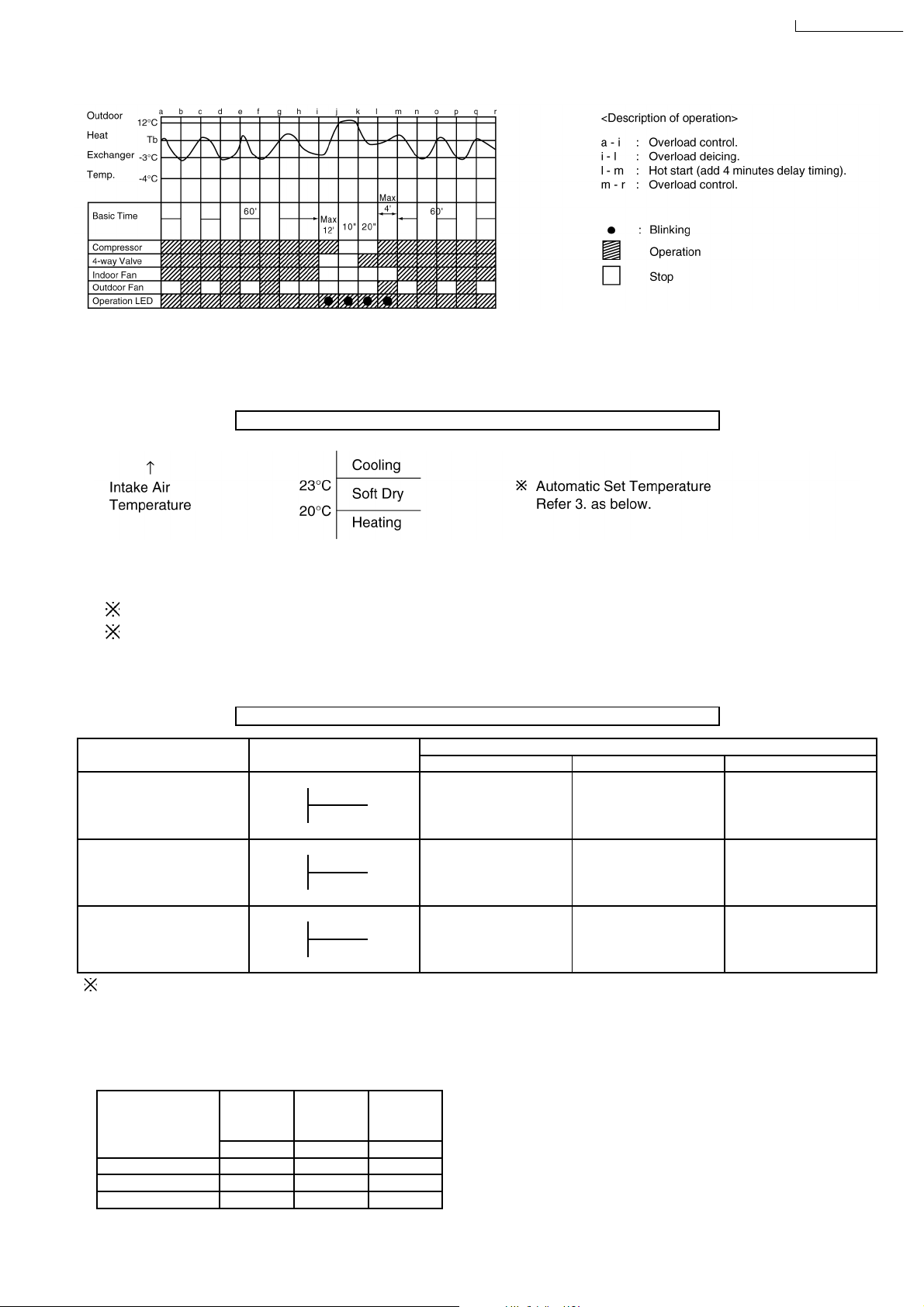

Overload Deicing

•

During heating operation, if the outdoor Fan OFF duration (due to overload control) is accumulated up to 60 minutes and

after compressor starts for 1 minute, deicing starts.

Deicing ends when

•

(a) 12 minutes after deicing operation starts;

(b) The outdoor piping temperature rises to about 12°C.

After deicing operation, compressor stops for 30 seconds and 4-way valve stays at cooling position for 10 seconds.

•

a) Normal Deicing Time Diagram

18

Page 19

CS-A28BKP5/CU-A28BKP5

b) Overload Deicing Time Diagram

8.4. Automatic Mode Operation

1. When the Automatic Mode Operation is selected, the indoor fan operates at SLo fan speed for 20 seconds to sense intake air

temperature and determine the 1st operation mode.

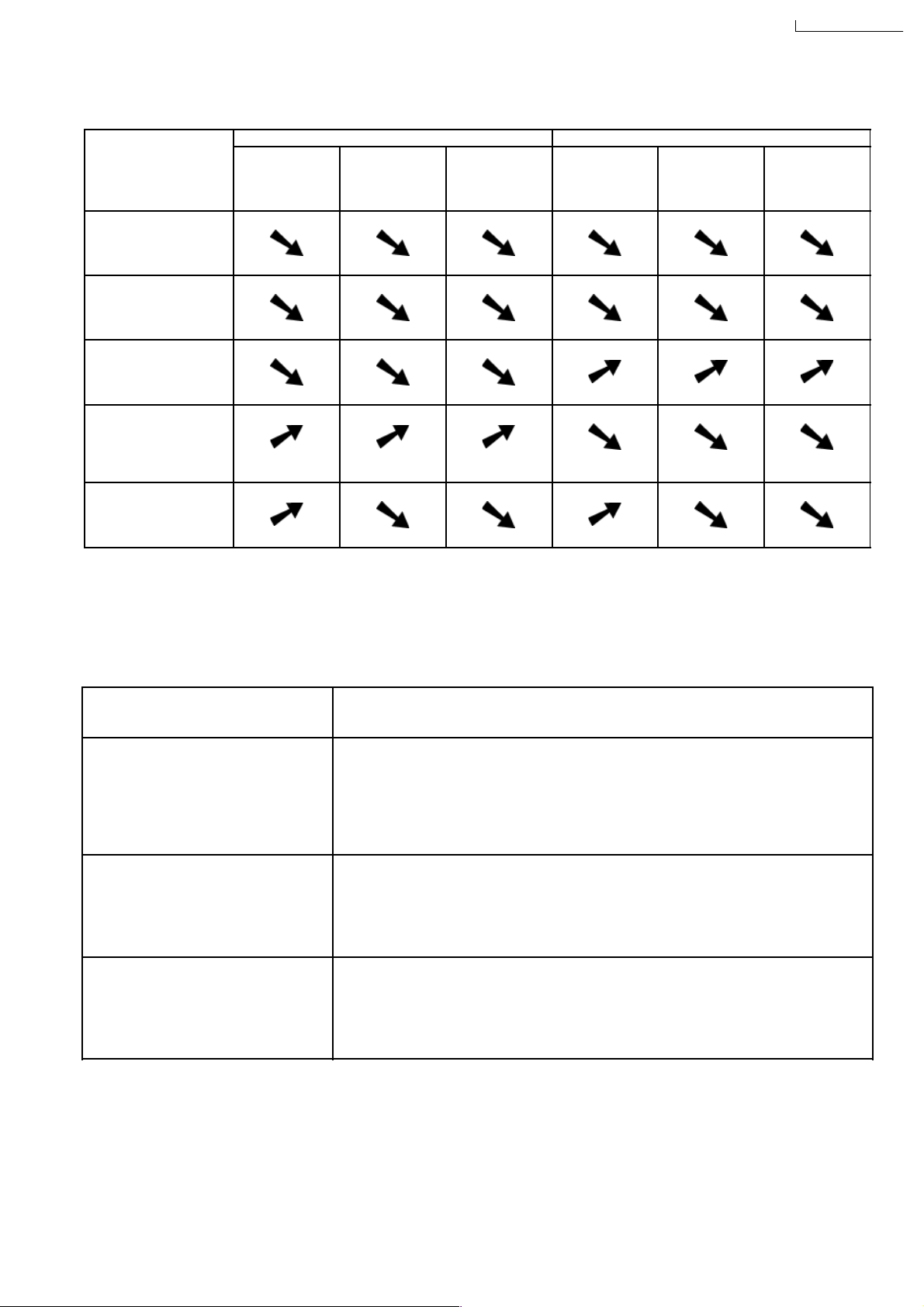

Standard for Determining Operation Mode 1st Judgement

2. Operation mode will be determine again after 1 hour of operation, if the room temperature reaches to set temperature and

compressor off time is over 7 minutes 30 seconds continuously.

Indoor intake air is less than 16°C, Heating mode will immediate operate. (only in the first time judgement)

The present operation mode will be continued, if the room temperature does not reach to set temperature (Compressor

keeps running) eventhough after 1 hour from automatic operation mode started.

For 2nd judgement onwards, indoor fan will operate for 20 seconds to sense the intake air temperature for determining

operation mode.

Standard for Determining Operation Mode 2nd Judgement onwards

Present Judgement Next Mode

Mode Cooling Soft Dry Heating

O O

Cooling 23°C Cooling (Judgement: Not Applicable (Judgement:

Heating 23°C & Above) Below 23°C)

O O

Soft Dry 20°C Soft Dry Not Applicable (Judgement: (Judgement:

Heating 20°C & Above) Below 20°C)

O O

Heating Cooling (Judgement: Not Applicable (Judgement:

25°C Heating 25°C & Above) Below 25°C)

Automatic Set Temperature Refer 3. as below.

3. Automatic Set Temperature

For each operation, set temperature will automatically set as shown below.

However it can be selected 2°C higher or 2°C lower from standard set temperature by pressing the “Room Temperature Setting

button”.

Operation Higher Standard Lower

Mode

(+2°C) (±0°C) (-2°C)

Cooling 27°C 25°C 23°C

Soft Dry 24°C 22°C 20°C

Heating 23°C 21°C 19°C

19

Page 20

CS-A28BKP5/CU-A28BKP5

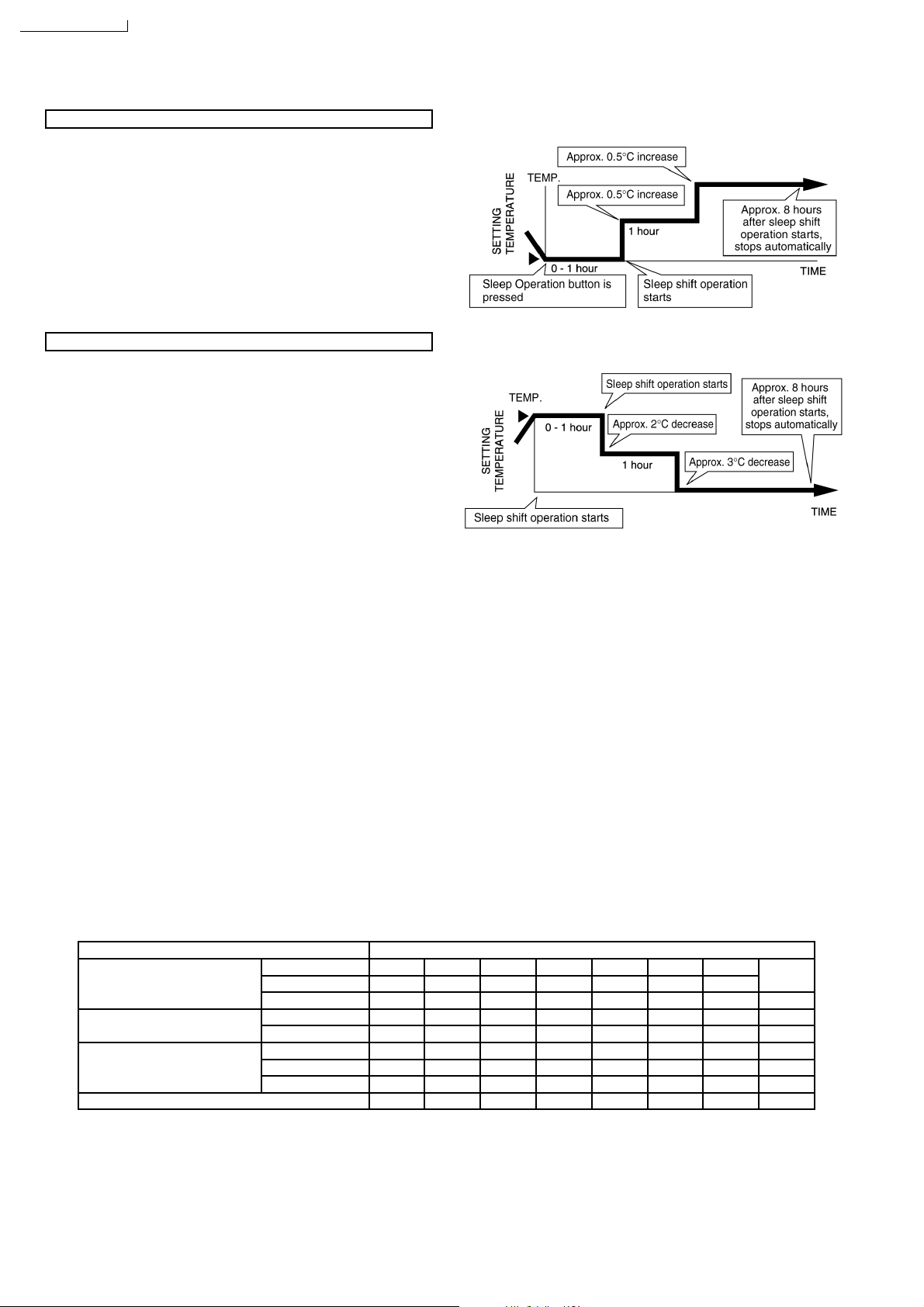

8.5. Sleep Mode Auto Operation

Cooling or Soft Dry Operation

When you press the SLEEP Mode, the following movement will

start to avoid overcooling.

The fan speed refer to Indoor Fan Motor Control.

•

The setting temperature will be risen by

•

operation and by

The operation will stop after8hours.

•

When using together with the Timer, the ON-Timer has

•

0.5

°C one hour later.

priority.

Heating Operation

When you press the SLEEP Mode, the following movement will

start to avoid overheating.

The fan speed refer to Indoor Fan Motor Control.

•

The setting temperature will be descented by 2°C at the start

•

of operation and by 3°C one hour later.

The operation will stop after8hours.

•

When using together with the Timer, the ON-Timer has

•

priority.

0.5

°C at the start of

8.6. Auto Restart Control

If there is a power failure, operation will be automatically restarted when the power is resumed.

•

It will start with previous operation mode and airflow direction.

(Time Delay Safety Control is valid)

Auto Restart Control is not available when Timer or Sleep Mode is set.

•

This control can be omitted by cutting the jumper wire J2. (Refer Circuit Diagram)

•

8.7. Indoor Fan Speed Control

Auto Fan Speed Control

•

When set to Auto Fan Speed, the fan speed is adjusted between maximum and minimum setting as shown in the table.

Manual Fan Speed Control

•

Basic fan speed adjustment (3 settings, from Lo to Hi) can be carried out by using the Fan Speed selection button.

Fan Speed High Speed

Manual O O O

Cooling Auto O O O O

Sleep O

Soft Dry Manual, Auto O

Sleep O

Manual O O O

Heating Auto O O O O O O

Sleep O O O

Hi Me Lo SLo SSLo STOP

O

←→

Low Speed

20

Page 21

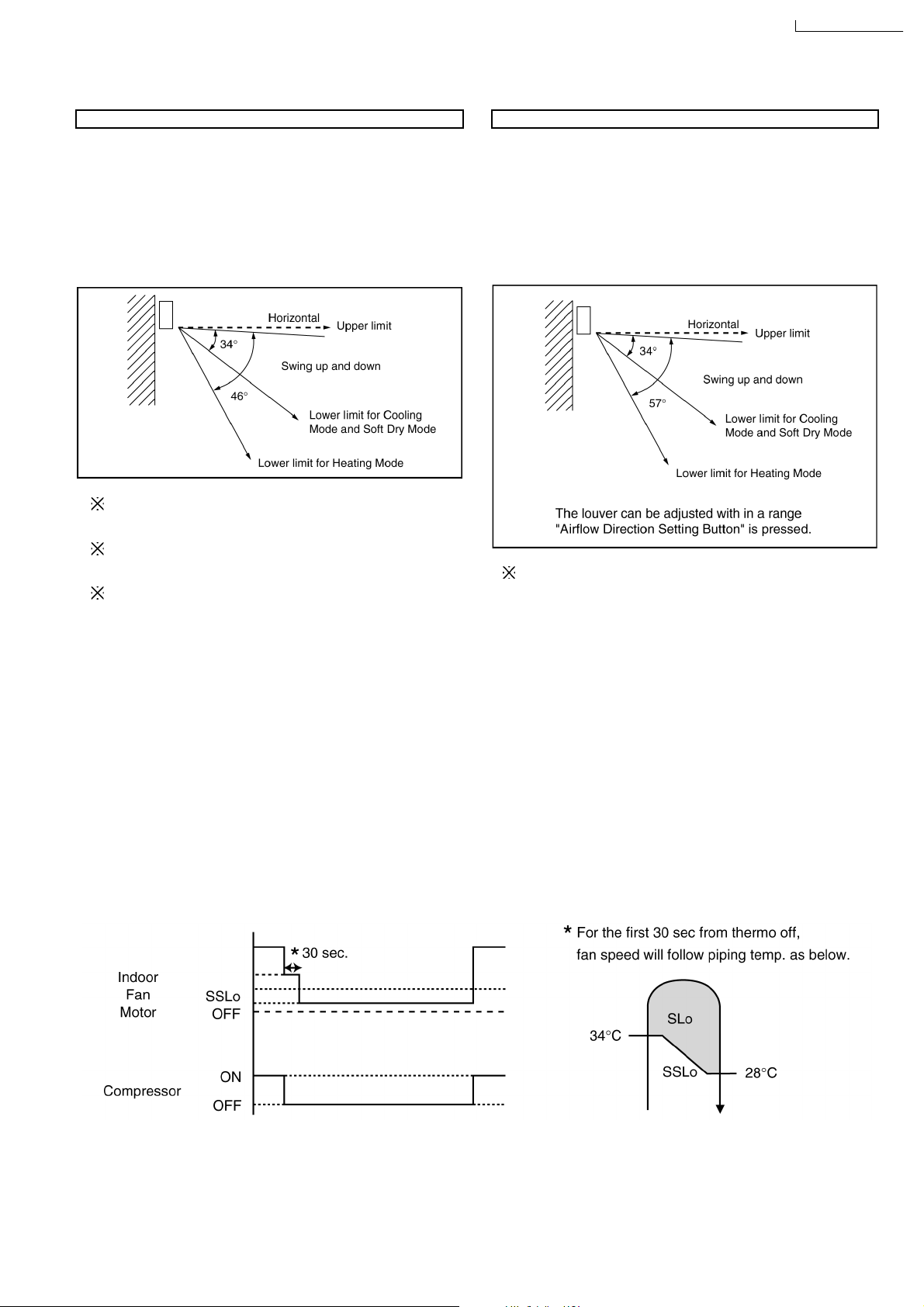

8.8. Airflow Direction Control

CS-A28BKP5/CU-A28BKP5

Airflow Direction Auto-Control

When set a Airflow Direction Auto-Control with remote

•

control, the louver swings up and down as shown in the

diagram.

The louver does not swing when the Indoor Fan stops

•

during operation.

When stopped with remote control, the discharge vent is

•

closed with the louver.

The left and right airflow direction louvers can be adjusted

manually.

1 There is no swinging while indoor fan is stopped during

Cooling and Soft Dry operation.

2 In Heating operation, when the indoor heat exchanger

temperature rises to 38°C, the airflow direction is changed

from upper limit to lower limit. When the indoor heat

exchanger temperature falls to 35°C, the air flow direction

is changed from lower limit to upper limit.

Airflow Direction Manual Control

When the airflow direction set button is pressed, the

•

automatic airflow is released and the airflow direction louver

move up and down in the range shown in the diagram.

The louver can be stopped by releasing the button at the

desired louver position.

When the remote control is used to stop the operation, the

•

discharge vent is closed with airflow direction louver.

The left and right airflow direction louvers can be adjusted

manually.

8.9. Delay ON Timer Control

When the Delayed ON Timer is set by using the remote control, the unit will start operate slightly before the set time, so that

•

the room will reach nearly to the set temperature by the desired time.

For Cooling and Soft Dry mode, the operation will start 15 minutes before the set time.

•

For Heating mode, the operation will start 30 minutes before the set time.

•

For Automatic mode, the indoor fan will operate at SLo speed for 20 seconds, 30 minutes before the set time to detect the

•

intake air temperature to determine the operation mode. The operation indication lamp will blink at this time.

8.10. Cold Draught Control

When COMP = Thermal OFF, indoor fan speed immediately changed to SLo for 30 sec., followed by SSLo speed until COMP

•

= ON.

During cold draft c/m operation, fan speed will be SSLo only.

SSLo: Fan will be running at Lo speed with SSR ON for 0.6 sec. and OFF for 5.0 sec.

21

Page 22

CS-A28BKP5/CU-A28BKP5

9 Operating Instructions

Safety Precautions

Before operating, please read the following “Safety Precautions” carefully.

To prevent personal injury, injury to others and property damage, the following instructions must be followed.

■ Incorrect operation due to ignoring of instructions will cause harm or damage, the seriousness of which is

classified as follows :

Warning

:

This sign warns of death or serious injury.

!

!

■ The instructions to be followed are classified by the following symbols :

Caution

OFF

This sign warns of injury or damage to property only.

:

This symbol (with a white background) denotes an action that is

PROHIBITED.

These symbols (with a black background) denote an action that is

COMPULSORY.

Installation precautions

Warning

!

■ Do not install, remove and reinstall the unit yourself.

Improper installation will cause leakage, electric shock or fire. Please consult an authorized dealer or

specialist for the installation work.

!

■ This room air conditioner must be

earthed.

Improper grounding could cause

electric shock.

■ Do not install the unit in a place where

there may be explosive gas leaks.

Gas leaks near the unit could

cause fires.

Caution

■ Ensure that drainage piping is connected

properly.

Otherwise, water will leak out.

22

Page 23

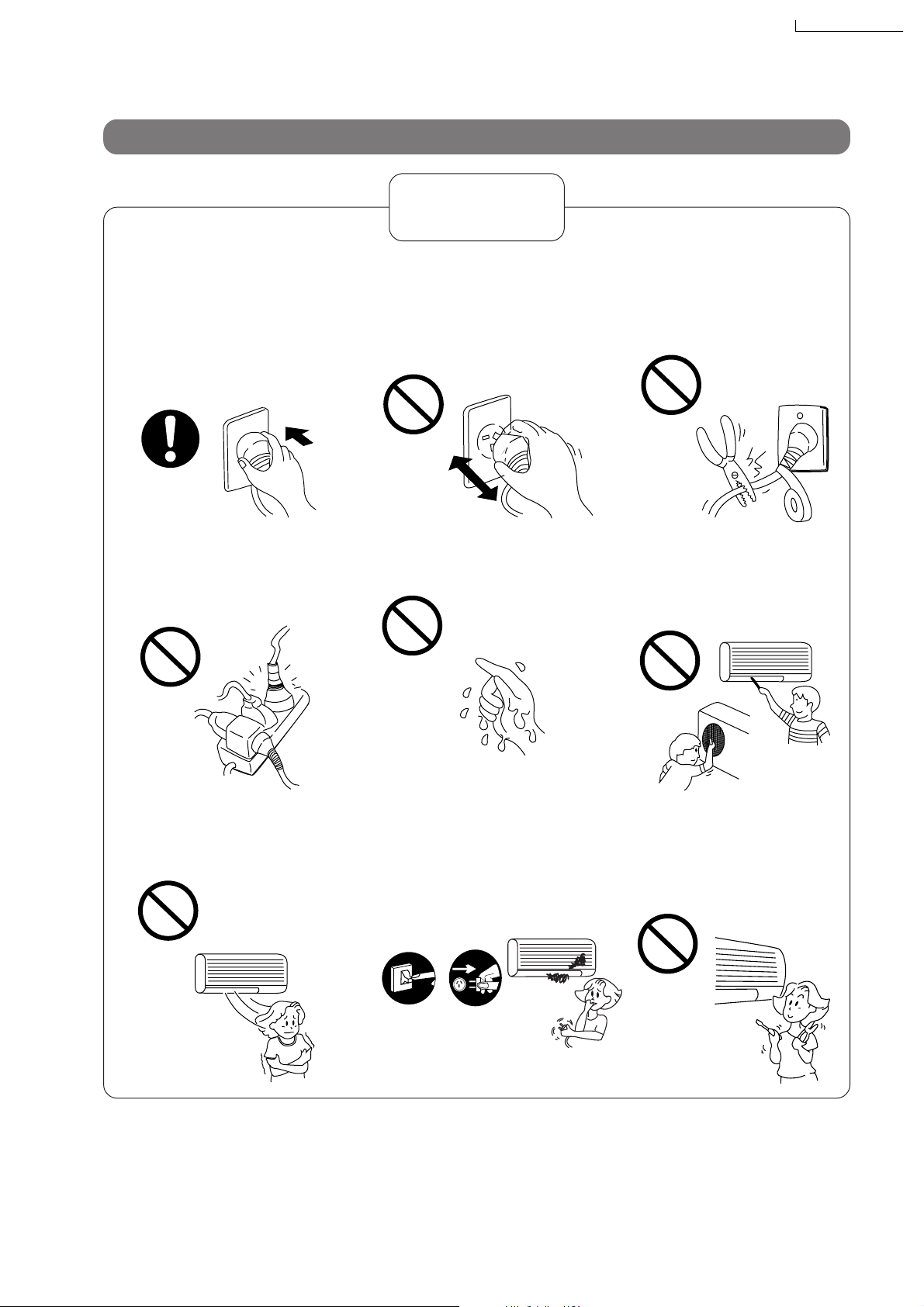

Operation precautions

Warning

!

CS-A28BKP5/CU-A28BKP5

■ Insert the power plug

properly.

Heat generated by a loose

power plug could cause electric

shock or fire.

Electrical outlet and power plug

shall be easily accessible.

■ Do not modify the length of

the power cord or use an

extension cord.

It could cause electric shock or

fire.

■ Do not operate or stop the

unit by inserting or pulling

out the power plug.

It could cause electric shock or

fire.

■ Do not operate the unit with

wet hands.

It could cause an electric shock.

■ Do not damage or use an

unspecified power cord.

It will cause electrical shock or

fire.

■ Do not insert finger, sticks

or other objects into the

units.

It could lead to physical injury

and cause damage to the units.

■ Do not be directly exposed

to the cold airstream for

too long.

It could lead to health problems.

■

If there is a smell of burning,

stop the air conditioner and

disconnect the power supply.

The heat generated could cause

electric shock or fire. Please consult an authorized dealer or service centre.

F

F

O

Switch off

the breaker.

Disconnect

the power

plug.

23

■ Do not try to repair the unit

yourself.

It could lead to fire or cause an

electric shock. Please call an

authorized dealer or service

centre.

Page 24

CS-A28BKP5/CU-A28BKP5

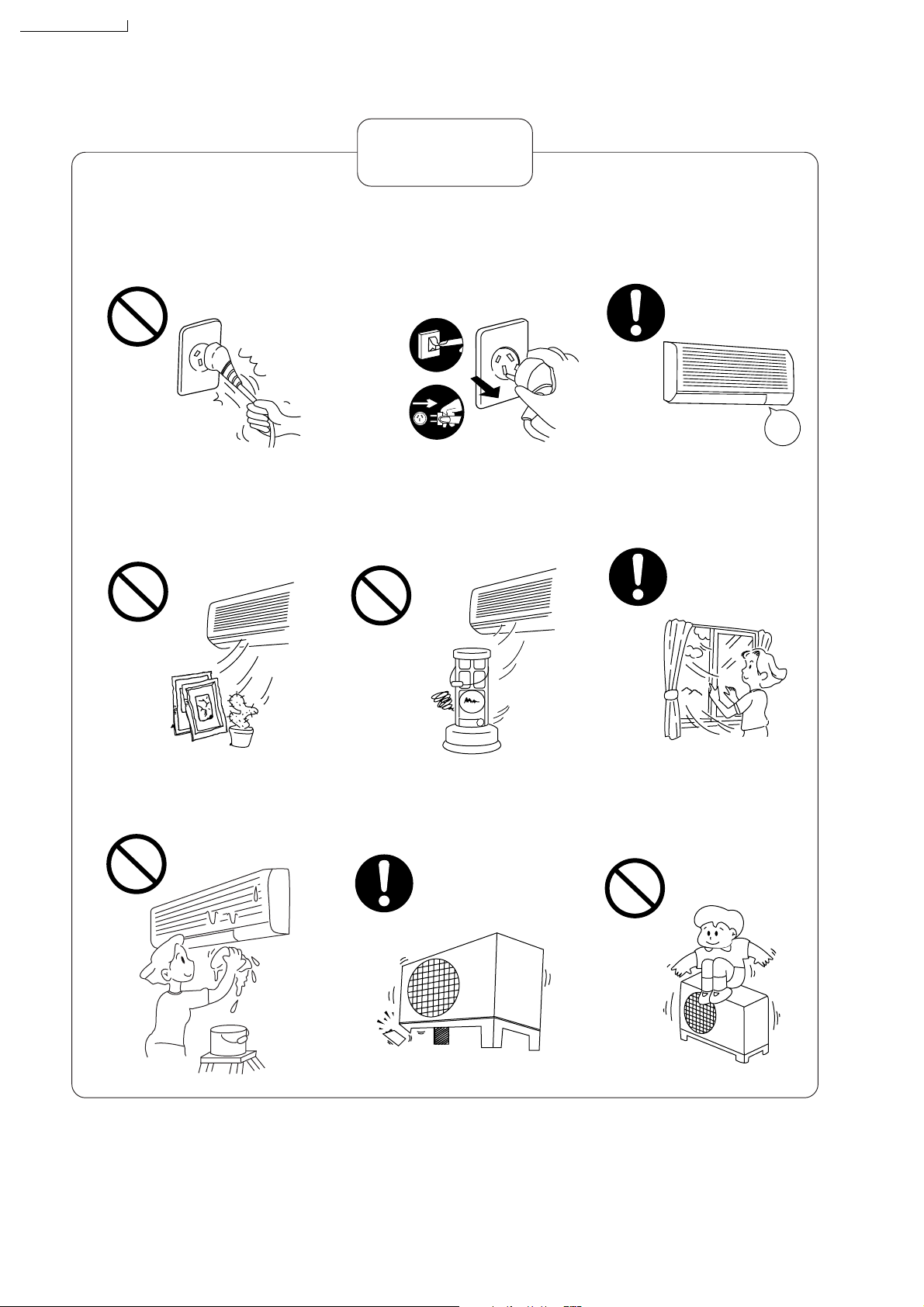

Caution

!

■ Do not remove the power

plug by pulling the cord.

Hold the plug when disconnecting the plug from the wall outlet.

■ Do not use for other pur-

poses.

Do not use for preservation purposes. It will affect food quality,

animals or plants.

■

Switch off the power supply if

the unit is not going to be

used for a long period of time.

If dust accumulates on the plug, it

will generate heat and this could

cause a fire.

Switch off

the breaker.

Disconnect

the power

plug.

OFF

■ Do not place combustor in

the path of the airflow from

the unit.

Incomplete combustion could

cause toxic gas (CO) poisoning.

■ When cleaning the unit, re-

move the plug.

This is to prevent injury due to

the rotating fan in the unit.

OFF

■

Ventilate the room regularly.

If not ventilated regularly, the

lack of oxygen could cause

headaches.

■ Do not wash the unit with

water.

It could cause an electric shock.

■ Inspect the unit for any

damage.

Ensure that the necessary repairs

are carried out.

■ Do not sit or place any-

thing on the outdoor unit.

You might fall off or the unit

might collapse.

24

Page 25

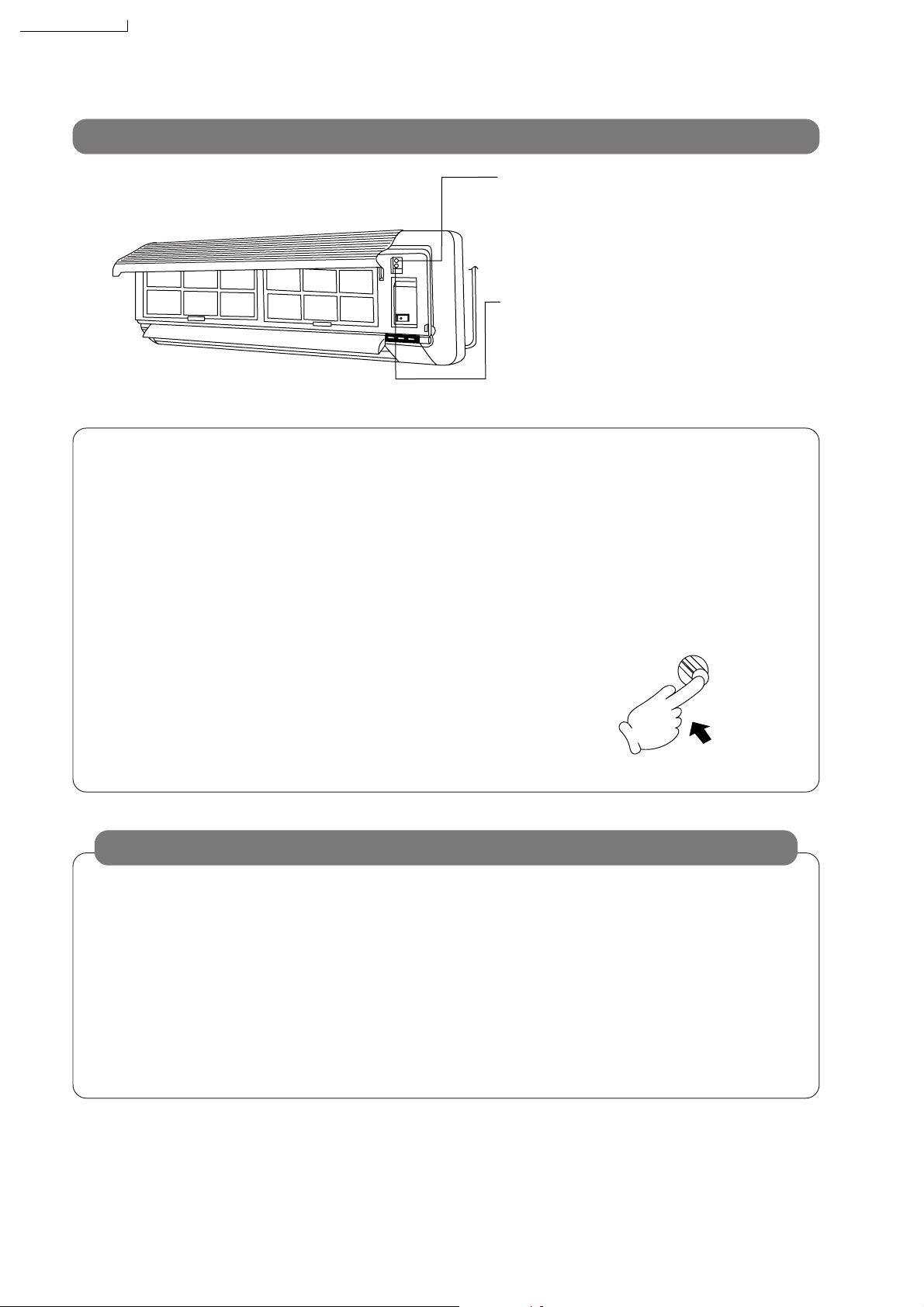

Name of Each Part

CS-A28BKP5/CU-A28BKP5

Indoor unit

Air Intake Vent

Panel Opener

Vertical Airflow

Direction Louver

Air Outlet Vent

Front Panel

Signal Receptor

Power Sleep Timer

Red Orange Orange

Operation Indication

Lamps (LED)

Airflow Direction Louver

Horizontal

(Manually adjusted)

Outdoor unit

Air Intake Vents

Air Outlet Vents

(Side)

(Rear)

Ground Terminal

(Inside Cover)

Piping

Drain Hose

25

Page 26

CS-A28BKP5/CU-A28BKP5

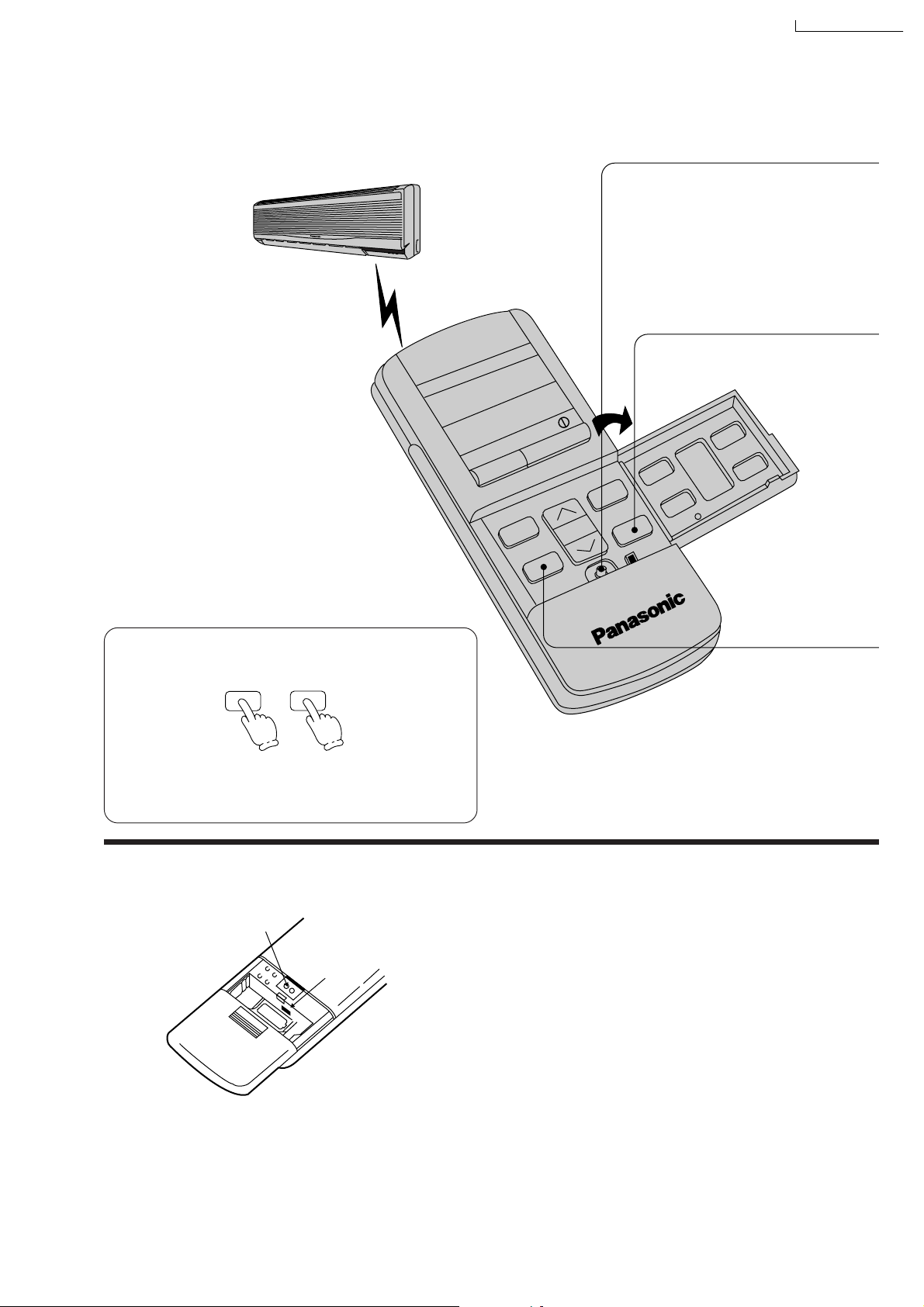

Remote control

Signal Transmitter

Operation Display

Accessories

Remote Control Two R03 dry-cell

DRY

AUTO FAN

h j k

ER

COOLHEAT

ON-TIM

°C

m n o

N

R

E

/O

AM

M

I

F

T

-

F

F

F

AUTO

O

O

c

P

E

FAN SPEED

PM

E

L

S

ANUAL

P.

M

TEM

ODE

ING

M

AIR SW

ING

SW

batteries or equivalent

Air Purifying Filters

(with deodorizing function)

Sleep Mode

Operation Button

AUTO

c

HEAT

COOL

m n o

DRY

AUTO FAN

°C

ER

OFF-TIM

PM

j

h

SLEEP

OFF/ON Button

k

ER

N-TIM

O

AM

OFF/ON

TEMP.

MODE

SWING

Airflow Volume

Selection Button

FAN SPEED

MANUAL

AIR SWING

Airflow Direction Manual

Control Button

Room Temperature

Setting Button

Operation Mode

Selection Button

Airflow Direction Auto Control Button

Separate displays and functions are available when the door is opened.

ON-Timer Button

Door

OFF-Timer Button

Time

Button

Door

OFF-TIMER ON-TIMER

CANCEL SET

q

Cancellation Button

Clock Button

26

TIME

Set Button

Page 27

Preparation Before Operation

Before operating the unit

CS-A28BKP5/CU-A28BKP5

1

■ Connect the power

supply cord to an

independent power

supply.

23

■ Open the front panel.

Hold the panel openers at both

sides and pull up the front panel.

<Note>

Use under the following conditions :

■ Remove air filter.

Air

filter

Hold the tab to raise up

slightly and then pull down.

■ Insert air purifying filter.

Insert the air filters.

Be careful not to

hurt your hands by

metal parts.

Air purifying

filter

(Unit in °C)

DBT : Dry Bulb Temperature

WBT : Wet Bulb Temperature

Maximum Temperature

Minimum T emper ature

Cooling

Indoor Outdoor

DBT WBT DBT WBT

32 23 43 26

16 11 16 11

27

Heating

Indoor Outdoor

DBT WBT DBT WBT

30

16

_

_

24 18

-5

-6

Page 28

12

CS-A28BKP5/CU-A28BKP5

How to insert batteries

Gently press the

OPEN

place marked

[OPEN] and slide

the cover toward

you.

Make sure that the

signal path is

obstructed.

r

e

O

P

E

N

e

(Two R03 dry-cell

batteries or equivalent)

Operating the remote control

not

r

■ Fix the cover to the back of the remote

control (“PM 12:00” will flash in the operation display.)

er Be sure

that the (+) and

(–) directions

are correct.

PM

12

:

00

If the display does not appear when the batteries

are inserted, remove the batteries and

insert them once more.

■ Aim at the signal receptor on the room air conditioner when operating.

■ Do not drop or throw the remote control.

■ Do not place the remote control in a location that

is exposed to direct sunlight or next to a heating

unit or other heat source.

The maximum distance at which signals

can be received is

about 10 m.

Pull out the power plug or turn off the

power breaker when:

■ The air conditioner is not going to be used

for an extended period of time.

If the power switch is left at “I” (ON), approximately

3.25 watts of electric power are used even if the

main unit is turned off by remote control.

■ There is a danger of lightning.

The air conditioner is provided with a built-in protec-

tive device, but the control equipment may be adversely affected depending on the extent of lightning activity.

■ Signal received sound:

One short beep or one long beep.

Regarding the batteries.

■

The batteries can be used for approximately one

year.

■

Do not use rechargeable (Ni-Cd) batteries,

because such batteries differ from standard

dry-cell batteries in shape, dimensions and

performance.

■

Be sure to replace the batteries with two new

batteries of the same type.

■

Do not dispose of empty batteries in household

waste. Take them to special local collection sites.

28

Page 29

How to Operate

Auto Restart Control.

■ If there is a power failure, operation will be

automatically restarted after 3 minutes when

the power is resumed with previous operation

mode and airflow direction.

(When the operation is not stopped by remote control.)

■ If you do not intend to continue the operation

when the power is resumed, pull out the

power plug at main unit or power supply.

When you switch on the power switch, the

operation will be automatically restarted

with previous operation mode and airflow

direction.

Note: 1. If you do not require Auto Restart

Control, please consult your dealer.

2. Auto Restart Control is not available

when Timer or Sleep Mode is set.

AUTO

m

AUTO FAN

SLEEP

OFF/ON

MODE

TEMP.

SWING

CS-A28BKP5/CU-A28BKP5

FAN SPEED

MANUAL

AIR SWING

Recommended temperature for health

and comfort.

For Heating : 20°C – 24°C

For Cooling : 26°C – 28°C

For Soft Dry : 1°C – 02°C lower than

room temperature.

<Operation Details>

AUTO – Automatic Operation.

■ Once the Automatic Operation is selected, the

indoor temperature sensor operates automatically to select the desired operation mode with

Cooling, Soft Dry or Heating.

■ The operation mode changes every hour,

when necessary.

DRY – Soft Dry Operation.

■ Soft Dry is a very gentle Cooling Operation

consisting primarily of dehumidifying. It does

not lower the room temperature very much.

Cooling Operation

until room temperature reach

the setting tem

ature

Setting

Temperature

When room temperature reaches the setting temperature, operation will switch to Soft Dry.

per-

es

Super Low airflow amount

29

Page 30

CS-A28BKP5/CU-A28BKP5

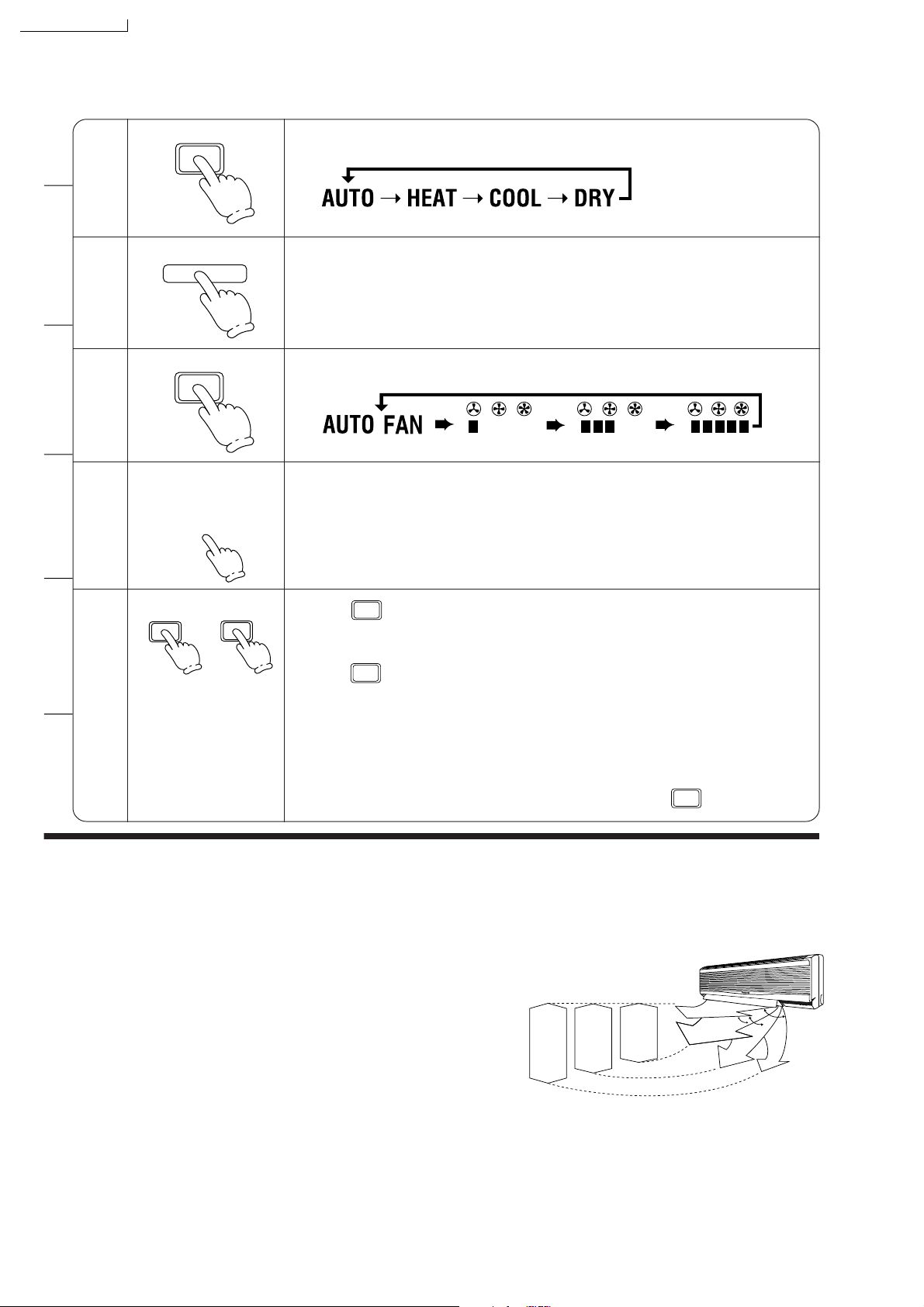

1

2

3

4

MODE

OFF/ON I

FAN SPEED

TEMP.

i

Press to select operation mode.

■ The display changes in the order

each time the button is pressed.

Press to start the operation.

■ Operation indication lamp (RED) will light up.

■ Press once more, to stop the operation.

Press to select airflow volume.

■ The display changes in the order.

Automatic Low Medium High

Press to select room temperature.

■ Heating, Cooling, Soft Dry – Select temperature as desired.

(16°C ~ 30°C)

■ Automatic.

▼

m n

2°C lower than

standard

n

standard

▼

n o

2°C higher than

standard

SWING

MANUAL

5

HEAT – Heating Operation

■ Defrosting Operation

Depend on the outdoor temperature, the operation occasionally stops to melt the frost on the

outdoor unit.

■ Heat is obtained from outdoor air to warm up the

room. When the outdoor ambient air temperature

falls, the heating capacity of the unit might be

reduced.

We recommend that you use an additional heating device when the outdoor ambient air temperature is low.

Press continuously.

■ The vertical airflow direction louver will move up and down. Release the

Press .

■

MANUAL

button when the louver is at the desired position.

SWING

Cooling & Soft Dry – The vertical airflow direction louver will swing up and

Heating – When the discharge air temperature is low such as at the start of

heating operation, the cold air blows at horizontal level.

As the temperature rises, the hot air blows in a downwards

direction.

To stop the automatic airflow direction operation, press button.

down automatically.

MANUAL

Automatic Airflow Volume

■ The speed of the indoor fan is adjusted automatically according to the operation. The indoor fan

stops occasionally during cooling operation.

Range of louver adjustment

34°

46°

(Airflow

Heating

Heating

Direction Manual)

(Airflow

Cooling/Soft Dry

(Airflow Direction

Manual and Auto)

Direction Auto)

57°

30

Page 31

Setting the Timer

PM

11:30

SLEEP

CS-A28BKP5/CU-A28BKP5

OFF/ON

If there is a power failure.

To reset the Timer.

(Example) If the OFF Timer has been set.

OFF-TIMER

SET

➡

■ Even if there is a power failure, the setting time

is still stored in the memory because the remote control is a battery operated type.

<Note>

Regarding remote control.

[RESET] points

[B ↔ A] switch

ON-TIMER

OFF-TIMER TIME

CANCEL

q

SET

■ If the current time is not set correctly, correct

Timer setting will not be possible.

■ When the Timer is set, the current time display

will vanish.

OPEN

■ [RESET] points will clear the memory once

they are shorted.

■ [B ↔ A] switch is used when two air

conditioners units have been installed in one

room. Please consult your dealer.

31

Page 32

q

q

CS-A28BKP5/CU-A28BKP5

To set the current time.

■ Set hours and minutes

To set the Timer.

■ OFF Timer Set hours and minutes

The “

■ ON Timer Set hours and minutes

The “

To cancel the Timer.

■ OFF Timer

OFF-TIMER

OFF-TIMER

” will blink.

0N-TIMER

ON-TIMER

” will blink.

OFF-TIMER

TIME

TIME

TIME

CANCEL

.... to advance the time

.... to reverse the time

.... to increase 10 minutes

each step.

.

... to decrease 10 minutes

each step.

.... to increase 10 minutes

each step.

.

... to decrease 10 minutes

each step.

SET

The Timer indication lamp at main

unit will light up. LED colour: Orange.

SET

The Timer indication lamp at main

unit will light up. LED colour: Orange.

● The Timer indication lamp at

main unit will go off.

● To cancel the ON Timer, follow

the same procedure.

To change the Timer setting time.

■ (Example) To change the ON Timer setting time.

0N-TIMER

Change hours and minutes setting

TIME

Timer

■ The ON Timer and OFF Timer can only be

set once during a day.

■ The operation will start before the actual

setting time with ON Timer setting.

Cooling and Soft Dry : 15 minutes before

Heating and Automatic: 30 minutes before

This is to allow time to attain your desired

set temperature.

.

... to increase 10 minutes

each step.

.

... to decrease 10 minutes

each step.

■ Setting the OFF Timer.

This is useful for saving electricity costs in-

curred by forgetting to turn off the air conditioner.

■ Setting the ON Timer.

If the air conditioner is set before you go out,

the room temperature will be close to your

desired temperature when you return.

SET

32

Page 33

Convenient Operation

Sleep Mode

This is to gain a comfortable room temperature while sleeping.

CS-A28BKP5/CU-A28BKP5

To set Sleep Mode.

■ Press

SLEEP

(The sleep indication lamp on the

main unit will light up.)

k

j

h

°C

c

27

PM

11:30

SLEEP

OFF/ON

TEMP.

FAN SPEED

MANUAL

AUTO

MODE

SWING

AIR SWING

<Information>

■ Cooling or Soft Dry Operation for Sleep Mode

movement will start to avoid overcooling.

Approx. 0.5°C increase

TEMP.

Approx. 0.5°C increase

Approx. 8 hours after sleep

shift operation starts, stops

automatically

SETTING

TEMPERATURE

Sleep Operation button is pressed

0 – 1 hour

1 hour

Sleep shift operation

starts

TIME

To cancel Sleep Mode.

■ Press once more

SLEEP

(The sleep indication lamp on the

main unit will switch off.)

Sleep Mode Operation.

■ When the room temperature reaches

the setting temperature or after 1

hour of operation, sleep shift

operation starts and the airflow

volume will automatically change to

low.

■ Sleep Mode Operation time is 8

hours.

■ When using together with the Timer,

the Timer has priority.

■ Heating Operation for Sleep Mode movement will start to avoid overheating.

TEMP.

0 – 1 hour

SETTING

TEMPERATURE

Sleep Operation button is pressed

Sleep shift operation starts

Approx. 2°C decrease

1 hour

Approx. 3°C decrease

Approx. 8 hours

after sleep shift

operation starts,

stops

automatically

TIME

33

Page 34

CS-A28BKP5/CU-A28BKP5

When the remote control cannot be used

Test Run Button.

(Use when installing and moving)

Auto Operation Button.

■ When the remote control cannot be

used, press Auto Operation Button to run

Automatic Operation.

(Airflow direction setting will be automatic.)

■ Press Auto Operation Button.

(The operation indication lamp will blink for 20

seconds, and then light up)

● If the button is pressed once more, the

air conditioner will stop.

(The operation indication lamp will switch

off.)

OFF/ON remote control signal receiving sound

AUTO

OFF/ON

■ The Remote Control Signal receiving sound can be omitted as desired.

■ To switch OFF the signal receiving sound, press Auto Operation Button for 10 seconds or more. At

the same time, Automatic Operation starts.

(To switch ON, press Auto Operation Button once more for 10 seconds or more.)

34

Page 35

Operation Hints

CS-A28BKP5/CU-A28BKP5

Adjust room temperature properly. Set the

■

temperature 1°C higher (Cooling Operation)

or 2°C lower (Heating Operation) than actu

ally desired. Approximately 10% of electricity

costs can be saved.

1°C higher

2°C lower

Clean the air filter regularly. Blockage in the

■

air filter reduces the airflow and lowers the

cooling or heating. Clean at least once every

2 weeks. Otherwise, about 6% of electricity

cost will be wasted.

Prevent wastage with the Timer. Use Timer

■

when sleeping or going out to save electricity

cost.

Do not block the air outlet vents at outdoor

■

unit. Otherwise, it will lower the cooling or

heating performance.

35

Page 36

CS-A28BKP5/CU-A28BKP5

Make sure that the doors and windows are

■

shut. Otherwise, cooling and heating per

formance will be reduced and electricity cost

is wasted.

Proper airflow direction adjustment. Set the

■

airflow direction louvers horizontal for Cool

ing Operation and downwards for Heating

Operation. Operation result will be better.

Keep blinds or curtains closed. Do not let sun

■

shine enter the room directly. About 5% of

electricity cost can be saved.

Use insulating material for better

■

performance. Use insulating material during

construction or renovations. It will save

electricity cost.

Cooling

Heating

36

Page 37

CS-A28BKP5/CU-A28BKP5

Better Care and Maintenance

Regular care and maintenance will extend the life of the air conditioner and prevent wastage of electricity.

Before performing any maintenance procedure, be sure to switch off the main power supply.

Caution

Do not use water or volatile liquids.

■ Do not make air conditioner wet, as there is the danger that it could cause

■ Using water above 40°C could cause deformation and/or discolouration.

■ Volatile liquids such as thinner or benzene may damage the air condi-

Cleaning the air conditioner and air filters

Once every 2 weeks is recommended.

■ Clean the air conditioner.

Wipe gently with a soft, dry cloth.

electric shocks.

Be sure not to apply water when cleaning or at any other time.

tioner.

■Clean the air filters.

■ To remove the dust adhering to the filters,

either use a vacuum cleaner, or wash them in

water and dry in the shade.

■ Re-insert the filters correctly at the left and right,

with the side marked [FRONT] facing forward.

■ Purchase replacement filters from your air conditioner dealer if the air filters become damage.

Air Filter No. CWD4209540 (right)

CWD4209550 (left)

37

Page 38

Replacement of air purifying filters

Remove the air filters.

2

Air filter

<Note>

■ Solar Refreshing Deodorizing Filter

• Used to remove unpleasant odour and deodorize the air in the room.

• Reusable.

• Vacuum, place under direct sunlight for 6 hours and fit it back in place.

(Recommended : every 6 months)

■ Catechin Air Purifying Filter

• The filter is coated with catechin to prevent growth of bacteria and viruses.

• Reusable.

• Vacuum and fit it back in place

(Recommended : every 6 months)

Remove the air purifying filters.

Catechin Air

Purifying Filter

Solar Refreshing

Deodorizing Filter

! Caution

Be careful not to

hurt your hands on

metal parts.

31

■ Recommended to change these filters every 3 years.

Do not reuse damaged filters.

Consult the nearest authorized dealer to purchase a new filter.

Catechin Air Purifying Filter No.: CZ-SF71P

Solar Refreshing Deodorizing Filter No.: CZ-SFD71P

If you operate the air conditioner with dirty filters:– Air is not purified

– Cooling capacity decreases

– Foul odour is emitted

Remove the filters

from the filter frame.

Filters

When not using the air conditioner for a long period

Operate the air conditioner for 2 to 3 hours.

■ Type of operation: Cooling.

1

■ Temperature setting: 30°C.

In order to dry out the

internal mechanisms

For air conditioners with

a power plug, stop operation by remote control and

2

pull out the power plug.

Note: If the unit is not off by

remote control, the unit

will operate when you

plug in (because

of Auto-restart

Control is provided).

Remove the batteries

from the remote control.

3

Pre-season inspection (The earlier the better)

■ Is the discharge air

cold (warm)?

Operation is normal if, 15 minutes after the start of operation,

the temperature difference between the air intake vent and

outlet vent is 8°C or above for

cooling and 14°C or above for

heating.

Is cool (warm) air

coming out?

■ Are the air outlet

vents and air intake

vents obstructed?

If they are, cooling

performance will drop and

cause problems.

■ Is the drain hose

cracked or crushed?

If it is, leaks will

result.

38

■ Are the remote

control batteries in

good condition?

If display is faint or

no display is visible,

the batteries should

be replaced.

Page 39

Troubleshooting

Q

Is it okay?

Normal operation

A

This is the answer.

CS-A28BKP5/CU-A28BKP5

Sight

?

Air conditioner has been restarted, but does not

operate for 3 minutes.

During Soft Dry Mode

Operation, the air conditioner stops.

Airflow does not begin

immediately during Heating Operation.

The room has a peculiar

odour.

A sound like water flowing

can be heard. A noise that

sounds like the compressed air releasing into

atmosphere

This is to protect the air conditioner. Wait until

the air conditioner begins operating.

Soft Dry Mode Operation is a very gentle cooling

operation consisting primarily of dehumidifying.

The air conditioner may stop for approximately 6

minutes in order to prevent overcooling.

If the room temperature rises again, the operation will recommence.

If the airflow begins before its temperature become warm, it will cause an undesired cooling

effect. In order to prevent this, the airflow will not

begin until it is sufficiently warm.

(The operation lamp will blink until the airflow

begins.)

This may be a damp smell exuded by the walls,

carpet, furniture or clothing in the room.

This is the sound of refrigerant flowing inside the

air conditioner unit.

This is the sound of reversing the freon flow inside the unit at the starting and finishing the defrosting during Heating operation.

z

z

z

Stop for 12 minutes.

Blinks

It seems that fog is coming

out from the air

conditioner.

Operation stops for about

12 minutes during heating.

(The operation lamp

blinks.)

During Automatic Airflow

Volume setting, indoor fan

stops occasionally.

Condensation occurs when the airflow from the

air conditioner cools the room air.

This is to melt the frost which has accumulated on the outdoor unit (Defrosting Operation). This will take no longer than

about 12 minutes, so wait for operation. (Frost accumulates

on the outdoor unit when the outdoor temperature is low and

the humidity is high.) Water comes out from the outdoor unit.

This is to remove the smell exuded by the

surroundings.

39

Page 40

CS-A28BKP5/CU-A28BKP5

The air conditioner

does not operate.

The air conditioner

does not cool effectively.

Abnormal operation

■ Has the circuit breaker been tripped?

■ Has the power plug been removed from the

wall outlet?

■ Is the Timer being used correctly?

■ Has the REMOTE CONTROLLER B ↔ A

switch been set to “B”?

■ Has the temperature been set incorrectly?

■ Are the filters dirty?

■ Are the intake or outlet vents of the outdoor

unit obstructed?

■ Are all windows and doors closed?

Air conditioner operation

noise too loud.

■ Is the installation work slanted?

■ Is the front grille closed properly?

Call the dealer immediately

If the following conditions occur, immediately turn the power plug or turn off the power breaker.

■ Abnormal noise is heard during

operation.

■ Water or foreign material

gets into the remote control by mistake.

■ Switches or buttons do not

operate properly.

■ The circuit breaker switch-

es off frequently.

■ Water leaks from the indoor unit.

■ Power supply cord and plug

become unusually warm.

40

Page 41

CS-A28BKP5/CU-A28BKP5

!

WARNING

(1) REMOVE POWER PLUG OR DISCONNECT FROM THE MAINS BEFORE SERVICING THIS APPLIANCE.

(2) THIS APPLIANCE MUST BE EARTHED.

(3) THE APPLIANCE IS NOT INTENDED FOR USE BY YOUNG CHILDREN OR INFIRM PERSONS WITHOUT

SUPERVISION

(4) YOUNG CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY DO NOT PLAY WITH THE

APPLIANCE.

IMPORTANT

Replacement or installation of power plugs shall be performed only by authorised/qualified personnels.

1. WHEN THE POWER CORD IS CONNECTED TO THE MAINS THROUGH A MULTI POLAR SWITCH

THERE MUST BE A MULTI POLAR SWITCH (DISCONNECTING MEANS) WITH A MINIMUM 3 mm

CONTACT GAP IN THE FIXED INSTALLATION CIRCUIT.

2. WHEN THE POWER PLUG IS CONNECTED TO THE RECEPTACLE

The wires in this main lead are coloured in accordance with the following code :

Green-and-yellow : Earth

Blue : Neutral

Brown : Live

If the colours of the wires in the main lead of this appliance do not correspond with the coloured markings

indentifying the terminals in your plug, proceed as follows :

The green-and-yellow wire must be connected to the terminal in the plug which is marked with letter E or by

!

the earth symbol

The blue wire must be connected to the terminal which is marked with the letter N or coloured black.

The brown wire must be connected to the terminal which is marked with the letter L or coloured red.

Fuse Specifications

or coloured green or green-and-yellow.

Indoor

T3.15(A), L250(V)

T3.15(A), L250(V)

Outdoor

NOTE

IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED WITH A SPECIAL CORD OR ASSEMBLY

AVAILABLE FROM THE MANUFACTURER OR IT’S SERVICE AGENT.

41

Page 42

CS-A28BKP5/CU-A28BKP5

10 Installation Instructions

Required tools for Installation Works

1. Phillips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter

2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench

3. Electric drill, hole core drill

(ø70 mm)

4. Hexagonal wrench (4 mm) 8. Knife 12. Megameter 16. Gauge manifold

7. Reamer 11. Thermometer 15. Vacuum pump

10.1. Safety Precautions

•

Read this following “SAFETY PRECAUTIONS” carefully before installation.

•

Electrical work must be installed by all licensed electrician. Be sure to use the correct rating of the power plug and main circuit

for the model to be installed.

•

The caution items stated here must be followed because these important contents are related to safety. The meaning of each

indication used is as below.

Incorrect installation due to ignoring of the instruction will cause harm or damage, and the seriousness is classified by the

following indication.

18 N.m (1.8 kgf.m)

65 N.m (6.5 kgf.m)

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties only.

The items to be followed are classified by the symbols:

Symbol with white background denotes item that is PROHBITED from doing.

•

Carry out test running to confirm that no abnormality occurs after the installation. Then, explain to user the operation, care and

maintenance as stated in instruction. Please remind the customer to keep the operating instructions for future reference.

1. Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage, electrical shock or

fire.

2. Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical shock or fire.

3. Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage, fire or

electrical shock.

4. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly

done, the set will drop and cause injury.

5. For electrical work, follow the local national wiring standard, regulation and this installation instruction. An independent circuit and single

outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

6. Use the specified cable (2.5 mm2) and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable so that no

external force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection.

7. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will

cause heat-up at connection point of terminal, fire or electrical shock.

8. When carrying out piping connection, take care not to let air or other substances other than the specified refrigerant go into refrigeration

cycle. Otherwise, it will cause lower capacity, abnormal high pressure in the refrigerant cycle, explosion and injury.

9. Do not damage or use unspecified power supply cord. Otherwise, it will cause fire or electrical shock.

10. Do not modify the length of the power supply cord or use of the extension cord, and do not share the single outlet with

other electrical appliances. Otherwise, it will cause fire or electrical shock.

42

Page 43

CS-A28BKP5/CU-A28BKP5

1. Grounding is necessary. It may cause electrical shock if grounding is not perfect.

2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at

surrounding of the unit, it may cause fire.

3. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the

furniture.

1. Selection of the installation location.

Select a installation location which is rigid and strong enough to support or hold the unit, and select a location for easy maintenance.

2. Power supply connection to the room air conditioner.

Connect the power supply cord of the room air conditioner to the mains using one of the following method.

Power supply point shall be the place where there is ease for access for the power disconnection in case of emergency.In some

countries, permanent connection of this room air conditioner to the power supply is prohibited.

1. Power supply connection to the receptacle using a power plug. Use an approved 20A power plug with earth pin for the connection to

the receptacle.

2. Power supply connection to a circuit breaker for the permanent connection. Use an approved circuit breaker as shown in the table

below for the permanent connection. It must be a double pole switch with a minimum 3 mm contact gap.

CS/CU-A28BKP5

20 A

Circuit Breaker

CS/CU-W28BKP5

30 A

3. Do not release refrigerant.

Do not release refrigerant during piping work for installation, re-installation and during repairing a refrigeration parts. Take care of the

liquid refrigerant, it may cause frostbite.

4. Installation work.

It may need two people to carry out the installation work.

5. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

43

Page 44

CS-A28BKP5/CU-A28BKP5

Attached accessories

Piping length and the elevation

Pipe size Max.

Model Gas Liquid Length Elevation

W28BKP5 5/8”

A28BKP5 5/8”

Example:

If the unit will be installed at a 12 m distance, the quantity of

additional refrigerant should be 80 g...(12-10 m) × 40 g/m = 80g

Piping

Length

A (m)

1/4”

1/4”

Max.

Elevation

B (m)

30 25 7.5 5 40

30

25

Rated Additional

Refrigerant

7.5 5 40

Indoor/Outdoor unit installation diagram

(g/m)

Applicable: Flaring piping kit CZ-52F

SELECT THE BEST LOCATION

INDOOR UNIT

There should not be any heat source or steam near the

•

unit.

There should not be any obstacles blocking the air

•

circulation.

A place where air circulation in the room is good.

•

A place where air drainage can be easily done.

•

A place where noise prevention is taken into

•

consideration.

Do not install the unit near the door way.

•

Ensure the spaces indicated by arrows from the wall,

•

ceiling, or other obstacles.

Indoor unit of this room air conditioner shall be installed

•

on the wall in a height of at least 2.5 m.

OUTDOOR UNIT

If an awning is built over the unit to prevent direct

•

sunlight or rain, be careful that heat radiation from the

condenser is not obstructed.

There should not be any animal or plant which could be

•

affected by hot discharged air.

Keep the spaces indicated by arrows from wall, ceiling,

•

fence or other obstacles.

Do not place any obstacles which may cause a short

•

circuit of the discharged air.

If piping length is over 10 m, additional refrigerant

•

should be added as shown in the table.

This illustration is for explanation purposes only.

•

The indoor unit will actually face a different way.

44

Page 45

10.2. INDOOR UNIT

CS-A28BKP5/CU-A28BKP5

10.2.1. SELECT THE BEST LOCATION

(Refer to “Select the best location”

section)

10.2.2. HOW TO FIX INSTALLATION

PLATE

The mounting wall is strong and solid enough to prevent it from

the vibration.

10.2.3. TO DRILL A HOLE IN THE WALL

AND INSTALL A SLEEVE OF

PIPING

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about 15 mm from the wall.

Caution

When the wall is hollow, please be sure to use the

sleeve for tube ass’y to prevent dangers caused by

mice biting the indoor/outdoor connecting cable.

4. Finish by sealing the sleeve with putty or caulking

compound at the final stage.

: Unit centre should be at more than 700 mm at right and left

of the wall.

The height should be more than 250 mm from the ceiling.

: From installation plate end to unit left side end is 55 mm.

: From installation plate end to unit right side end is 55 mm.

: Indoor outdoor connecting cable should be about 1100 mm

from this line. (Only for left rear piping)

1. Mount the installation plate on the wall with 6 screws.

(If mounting the unit on the concrete wall, consider using

anchor bolts.)

Always mount the installation plate horizontally by

•

aligning the marking-off line with the thread and using a

level gauge.

2. Drill the piping plate hole with ø70 mm hole-core drill.

Line according to the arrows marked on the lower left

•

and right side of the installation plate. The meeting point

of the extended line is the centre of the hole.

Drill the piping hole at either the right or the left and the

•

hole should be slightly slant to the outdoor side.

10.2.4. INDOOR UNIT INSTALLATION

For the right rear piping

1.

For the right and right bottom piping

2.

For the embedded piping

3.

45

Page 46

CS-A28BKP5/CU-A28BKP5

(This can be used for left rear piping and left bottom piping

also.)

46

Page 47

CS-A28BKP5/CU-A28BKP5

10.2.5. CONNECT THE CABLE TO THE

INDOOR UNIT

1. The inside and outside indoor/outdoor connecting cable can

be connected without removing the front grille.

2. Indoor/outdoor connecting cable between indoor unit and

outdoor unit shall be approved polychorprene sheathed 5 ×

2.5 mm

or heavier cord.

•

2

flexible cord 245 IEC 57 ,type designation H05 RN-F

Secure the cable onto the control board with the holder

(clamper).

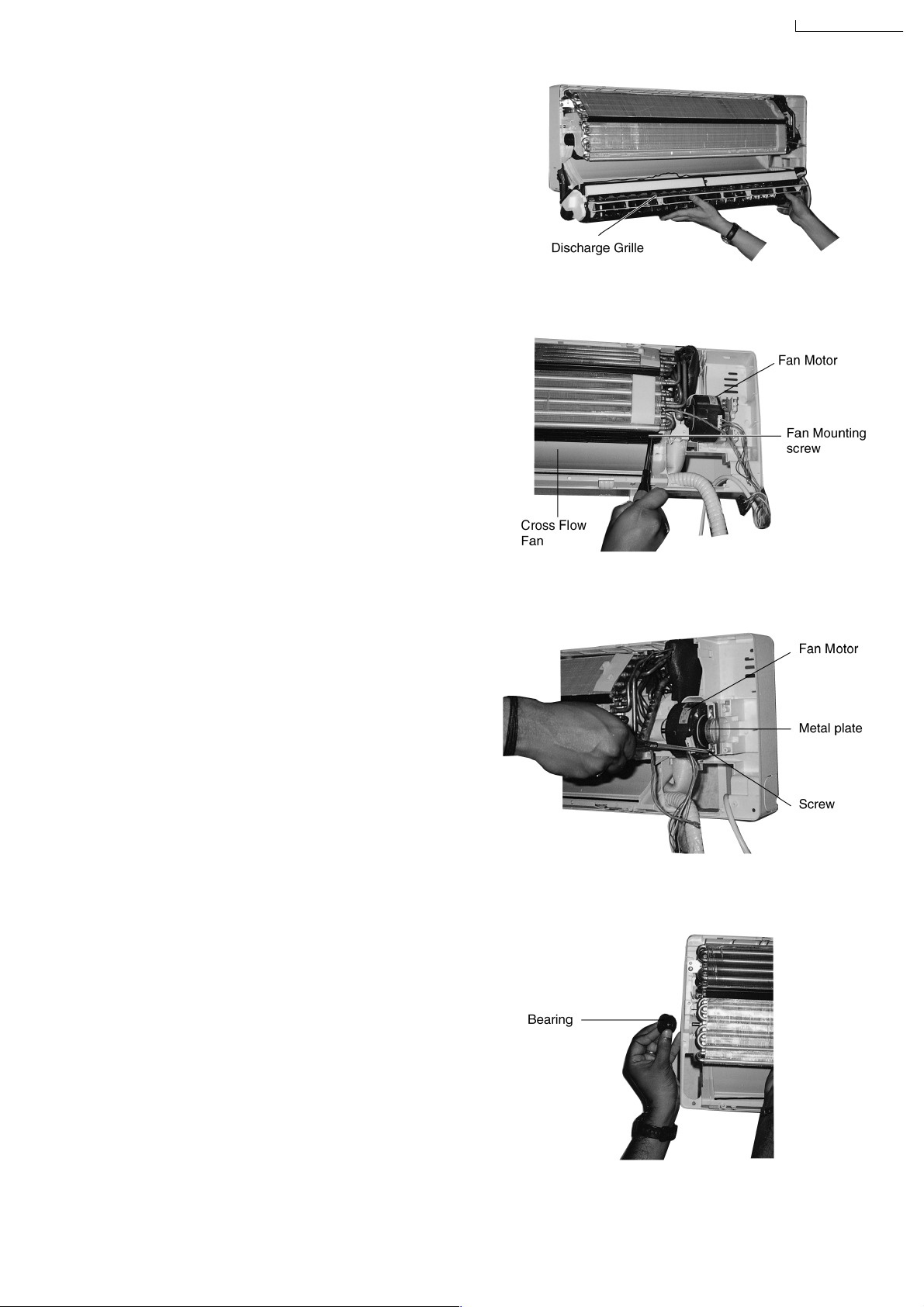

INSTALLATION OF AIR PURIFYING FILTERS

1. Open the front panel.

2. Remove the air filters.

3. Hold the catechin filters by their tabs and install as shown in

the illustration at below.

47

Page 48

CS-A28BKP5/CU-A28BKP5

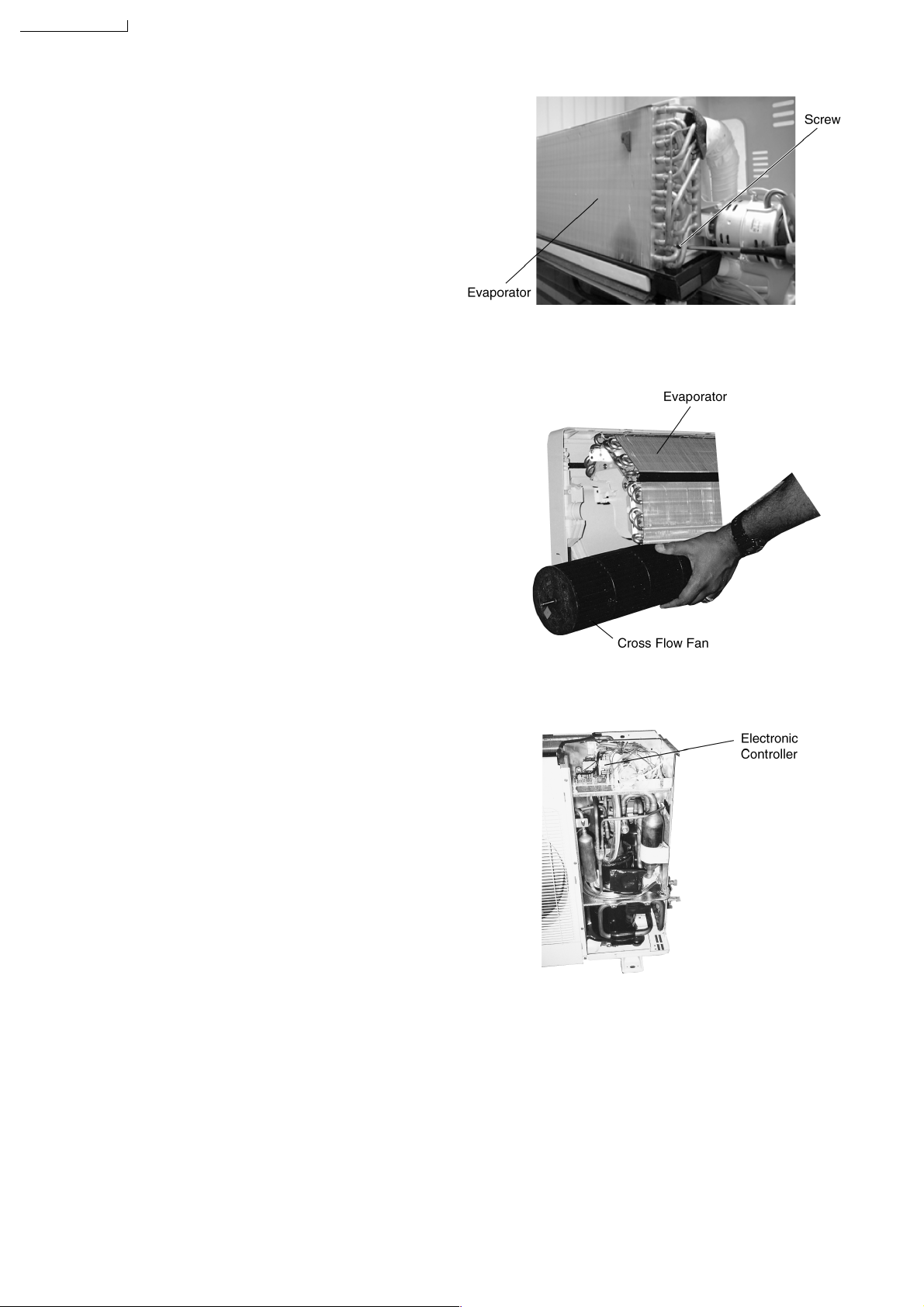

HOW TO TAKE OUT FRONT GRILLE

Please follow below steps to take out front grille if necessary

such as when servicing.

Remove the Grille from the chassis.

1. Set the up-and-down air direction louver to open position

(horizontally) by finger pressure.

2. Open the three screw covers as shown in the illustration

below.

3. Remove the five mounting screws.

4. Open the front panel and remove a mounting screw at the

centre.

(Refer Diagram below)

5. To remove the Grille, pull the lower left and right side of the

grille towards you (slightly tilted) and lift it straight upwards

(Two tabs on the top inside edge of the grille are clear of

their slots).

10.3. OUTDOOR UNIT

10.3.1. SELECT THE BEST LOCATION

(Refer to “Select the best location”

section)

10.3.2. INSTALL THE OUTDOOR UNIT

After selecting the best location, start installation according

•

to Indoor/Outdoor Unit Installation Diagram.

1. Fix the unit on concrete or rigid frame firmly and horizontally

by bolt nut. (ø10 mm).

2. When installing at roof, please consider strong wind and

earthquake. Please fasten the installation stand firmly with

bolt or nails.

10.3.3. CONNECTING THE PIPING

Connect Piping to Indoor

Please make flare after inserting flare nut (locate at joint portion

of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten the flare

•

nut with fingers.

Further tighten the flare nut with torque wrench in specified

•

torque as stated in the table.

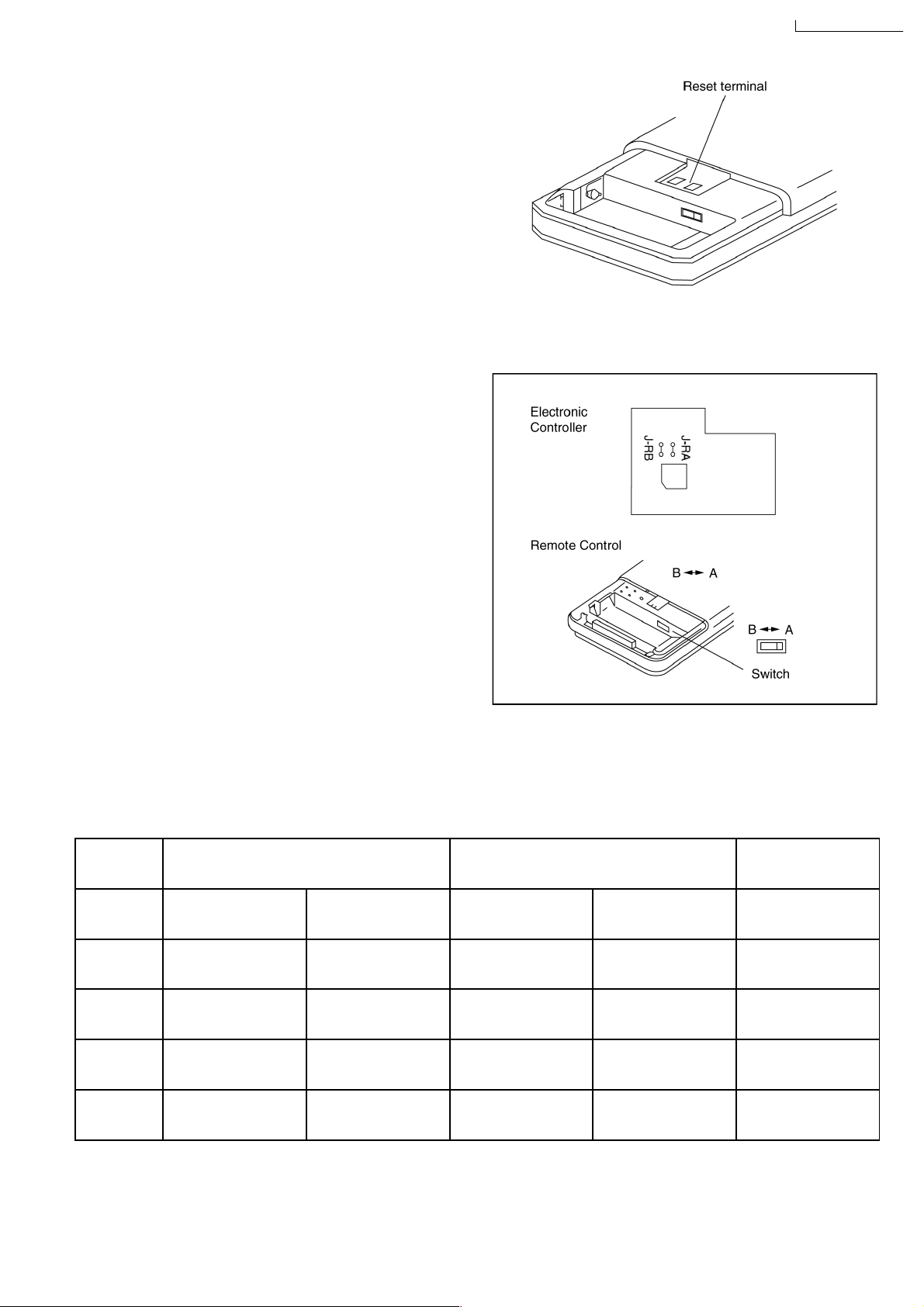

REMOTE CONTROL NO. SWITCH

1. When installing two air conditioners in one room, each air

conditioner can be synchronized to the remote controller.

2. In order tooperate separately, open the rear cover ofone of

the remote controller and set the switch to “B”.

3. Also, set the remote control No. switch to “B” in the

corresponding indoor unit.

(The switch is located in the control box-sub. of the indoor

unit.)

Connect the Piping to Outdoor Unit

1. Align the center of the piping and sufficiently tighten the

flare nut with fingers.

2. Finally, tighten the flare nut with torque wrench until the

wrench clicks.

When tightening the flare nut with torque wrench,

•

ensure the direction for tightening follows the arrow on

the wrench.

48

Page 49

CS-A28BKP5/CU-A28BKP5

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not

removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder

entering the pipe.

3. Please make flare after inserting the flare nut onto the

copper pipes.

10.3.4. EVACUATION OF THE EQUIPMENT

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO

EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES

in the following procedure.

If air remains in the indoor unit and refrigeration pipes, it will

affect the compressor, reduce to cooling capacity, and could

lead to a malfunction.

2. Connect the center hose of the charging set to a vacuum

pump.

3. Turn on the power switch of the vacuum pump and make

sure that the needle in the gauge moves from 0 cmHg (0

MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air

approximately ten minutes.

4. Close the valve of both the Low and High sides of the

charging set and turn off the vacuum pump. Make sure that

the needle in the gauge does not move after approximately

five minutes.

Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER

TO AVOID REFRIGERANT GAS LEAKAGE.

5. Disconnect the charging hose from the vacuum pump and

from the service port of the 3-way valve.

6. Tighten the service port caps of the 3-way valve attorque of

18 N.m with a torque wrench.

7. Remove the valve caps of both the 3-way valve. Position

both of the valves to “OPEN” using a hexagonal wrench (4

mm).

8. Mount valve caps both of the 3-way valves.

Be sure to check for gas leakage.

•

CAUTION

If gauge needle does not move from 0 cmHg (0

•

MPa) to -76 cmHg (-0.1 MPa), in step 3 above take

the following measure:

If the leak stops when the piping connections are

•

tightened further, continue working from step 3.

If the leak does not stop when the connections are

•

retightened, repair the location of leak.

SERVICE PORT CAP

Be sure, using a torque wrench to tighten the service port cap

(after using the service port), so that it prevents the gas

leakage from the refrigeration cycle.

Procedure:

1. Connect a charging hose with a push pin to the Low and

High sides of a charging set and the service port of the 3way valve.

Be sure to connect the end of the charging hose with the

•

push pin to the service port.

10.3.5. CONNECT THE CABLE TO THE

OUTDOOR UNIT

(FOR DETAIL REFER TIO WIRING DIAGRAM AT UNIT)

1. Remove the control board cover from the unit by loosening

the screw.

2. Indoor/outdoor connecting cable between indoor unit and

outdoor unit shall be approved polychorprene sheathed 5 ×

2.5 mm

RN-F or heavier cord.

3. Secure the cable onto the control board with the holder

(clamper).

4. Attach the control board cover to the original position with

the screw.

2

flexible cord 245 IEC 57 ,type designation HO5

49

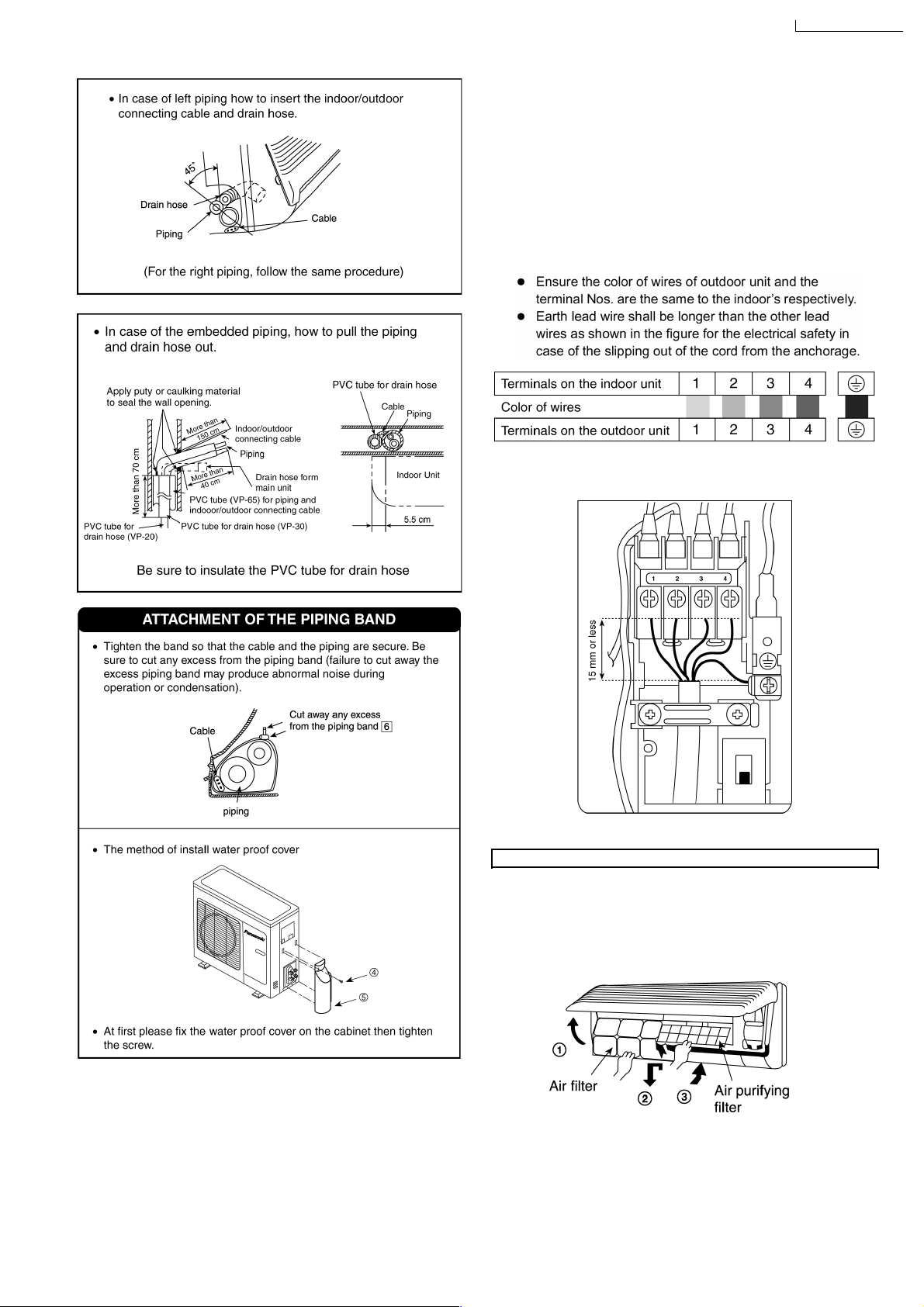

Page 50

CS-A28BKP5/CU-A28BKP5

10.3.6. PIPE INSULATION

1. Please carry out insulation at pipe connection portion as

mentioned in Indoor/Outdoor Unit Installation Diagram.

Please wrap the insulated piping end to prevent water from

going inside the piping.

2. If drain hose or connecting piping is in the room (where dew

may form), please increase the insulation by using POLY-E

FOAM with thickness 6 mm or above.

CHECK THE DRAINAGE

1. Pour a glass of water into the drain tray-styrofoam.

2. Ensure if water flows out from drain hose of indoor unit.

EVALUATION OF THE PERFORMANCE

1. Operate the unit at cooling operation mode for fifteen

minutes or more.

2. Measure the temperature of the intake and discharge air.

3. Ensure the difference between the intake temperature and

the discharge is more than 8°C.

CHECK ITEMS

Is there any gas leakage at flare nut connections?

Has the heat insulation been carried out at flare nut

connection?

DISPOSAL OF OUTDOOR UNIT DRAIN WATER

If a drain elbow is used, the unit should be placed on a

•

stand which is taller than 3 cm.

If the unit is used in an area where temperature falls below

•

0°C for 2 or 3 days in succession, it is recommended not to

use a drain elbow, for the drain water freezes and the fan

will not rotate.

Is the indoor/outdoor connecting cable being fixed to terminal

board firmly?

Is the indoor/outdoor connecting cable being clamped firmly?

Is the drainage OK?

(Refer to “Check the drainage” section)

Is the earth wire connection properly done?

Is the indoor unit properly hooked to the installation plate?

Is the power supply voltage complied with rated value?

Is there any abnormal sound?

Is the cooling operation normal?

Is the thermostat operation normal?

Is the remote control’s LCD operation normal?

Is the air purifying filter installed?

50

Page 51

11 3-way Valve

CS-A28BKP5/CU-A28BKP5

3-way Valve (Liquid Side) 3-way Valve (Gas Side)

Works Shaft Position Service Port Shaft Position Service Port

Shipping Close Closed Closed Closed

(With valve cap) (With cap) (With valve cap) (With cap)

Evacuation Closed Open Closed Open

(Installation and (Clockwise) (Connected manifold (Clockwise) (Push-pin)

Re-installation) gauge w/charging

cylinder)

Operation Open Closed Open Closed

(With valve cap) (With cap) (With valve cap) (With cap)

Pumping down Closed Closed Open Open

(Transferring) (Clockwise) (With cap) (Counter-Clockwise) (Connected manifold

Evacuation Open Open Open Open

(Servicing) (Counter-Clockwise) (Connected manifold (Counter-Clockwise) (Connected manifold

gauge) gauge)

Gas charging Open Open Open Open

(Servicing) (Counter-Clockwise) (Connected manifold (Counter-Clockwise) (Connected manifold

gauge) gauge)

gauge)

Pressure check Open Open Open Open

(Servicing) (Counter-Clockwise) (Connected manifold (Counter-Clockwise) (Connected manifold

gauge) gauge)

Gas releasing Open Open Open Open

(Servicing) (Counter-Clockwise) (Connected manifold (Counter-Clockwise) (Connected manifold

gauge) gauge)

51

Page 52

CS-A28BKP5/CU-A28BKP5

11.1. Evacuation of Installation

When installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure.

Required tools: hexagonal wrench, adjustable wrench,

torque wrenches, wrench to hold the

joints, gas leak detector, and charging

set.

The air in the indoor unit and in the piping must be purged. If air

remains in the refrigeration pipings, it will affect the

compressor, reduce the cooling capacity, and could lead to a

malfunction.

Service port cap

Be sure, using a torque wrench to tighten the service port cap (after using the service port), so that it prevents the gas leakage from the

refrigeration cycle

Procedure:

Connect a charging hose with a push pin to the Low

1.

and High sides of a charging set and the service ports

of a 3-way valve.

Be sure to connect the end of the charging hose with the

•

push pin to the service port.

Connect the centre hose of the charging set to a

2.

vacuum pump.

Turn on the power switch of the vacuum pump and

3.

Tighten the service port caps of both the 3-way valves

6.

at a torque of 18 N.m with a torque wrench.

Remove the valve caps of the 3-way valves. Position

7.

both of the valves to “open” using a hexagonal wrench

(4 mm).

Mount the valve caps onto both of the 3-way valves.

8.

Be sure to check for gas leakage.

•

make sure that the needle in the gauge moves from 0

cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate

the air for approximately 10 minutes.

Close the valve of both the Low and High sides of the

4.

charging set and turn off the vacuum pump. Make sure

that the needle in the gauge does not move after

approximately 5 minutes.

BE SURE TO TAKE THIS PROCEDURE IN ORDER TO

Caution

If gauge needle does not move from 0 cmHg (0 MPa)

to -76 cmHg (-0.1 MPa) in step (3) above, take the

following measures:

If the leaks stop when the piping connections are

tightened further, continue working from step (3).

If the leaks do not stop when the connections are

retightened, repair the location of the leak.

AVOID REFRIGERANT GAS LEAKAGE.

Disconnect the charging hose from the vacuum pump

5.

and from the service port of the 3-way valve.

52

Page 53

11.2. Pumping down

CS-A28BKP5/CU-A28BKP5

Procedure:

Confirm that both the 3-way valves are set to the open

1.

position.

Remove the valve stem caps and confirm that the valve

•

stems are in the open position.

Be sure to use a hexagonal wrench to operate the valve

•

stems.

Operate the unit for 10 to 15 minutes.

2.

Stop operation and wait for 3 minutes, then connect the

3.

charge set to the service port of the 3-way valve.

Connect the charge hose with the push pin to the Gas

•

side service port.

Air purging of the charge hose.

4.

Open the low-pressure valve on the charge set slightly

•

to purge air from the charge hose.

Set the Liquid side 3-way valve to the close position.

5.

Operate the air conditioner at the cooling cycle and

6.

stop it when the gauge indicates 0 kg/cm

If the unit cannot be operated at the cool condition

•

2

G (0 MPa).

(weather is rather cool), press the Pump Down Switch

on the Indoor unit.

So that the unit can be operated.

•

Immediately set the gas side 3-way valve to the close

7.

position.

Do this quickly so that the gauge ends up indicating 1 to

•

3 kg/cm

Use refrigerant reclaiming equipment to collect

8.

2

G (0.1 MPa to 0.3 MPa).

refrigerant from indoor unit and pipes.

Disconnect the charge set, and mount both the 3-way

9.

valve’s stem nuts and the service port caps.

Use a torque wrench to tighten the service port cap to a

•

torque of 18 N.m.

Be sure to check for gas leakage.

•

Disconnect pipes from indoor unit and outdoor unit.

10.

53

Page 54

CS-A28BKP5/CU-A28BKP5

11.3. Evacuation of Re-installation

WHEN REINSTALLING AN AIR CONDITIONER, BE SURE TO

EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES

in the following procedure.

If air remain in the indoor unit and refrigeration pipes, it will

affect the compressor, reduce to cooling capacity, and could

lead to a malfunction.

Procedure: